Warp sizing method and application thereof

A warp sizing and foam sizing technology, which is applied in the field of textile dyeing and finishing, can solve problems such as poor application, unstable production, and uneven size, and achieve less chemical and wastewater discharge, low cost, and water consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

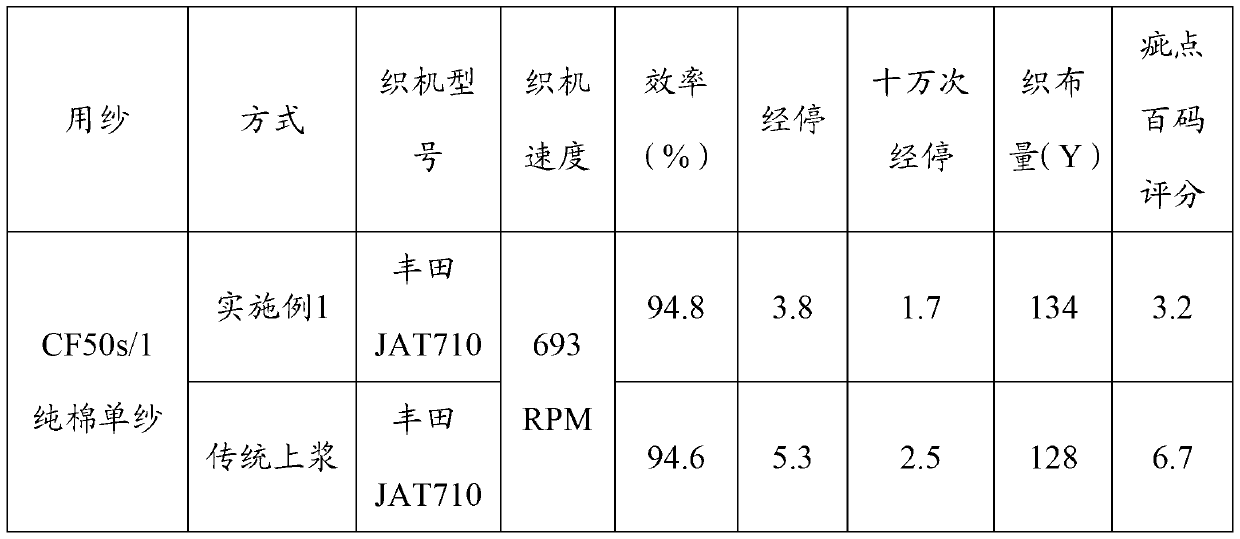

[0045] Take pure cotton CF50 / 1 colored yarn as an example;

[0046] The traditional sizing process is as follows: the warp yarn is dried by a drying cylinder to remove moisture from the yarn and then enters a high temperature storage tank. The yarn passes through the rollers in the storage tank to complete the sizing process, and finally the yarn is dried by the drying cylinder. Sizing process.

[0047] The specific steps of this embodiment 1 are as follows:

[0048] (1) Configure slurry

[0049] 1000g of water;

[0050] Modified starch DM816344g (purchased from Dongmei Company);

[0051] 64g SD propylene slurry (purchased from Sunda Chemical);

[0052] Polyvinyl alcohol (PVA) 35g;

[0053] Wax oil SFO-3016g (purchased from Yixing Junda);

[0054] Antistatic agent TS-656g (purchased from Shanghai Xida);

[0055] Foaming agent FO40005g (purchased from Rudolf Chemical).

[0056] (2) Boiling pulp

[0057] Control the slurry temperature to 80°C.

[0058] (3) Foaming

[0059] The foam generator is u...

Embodiment 2

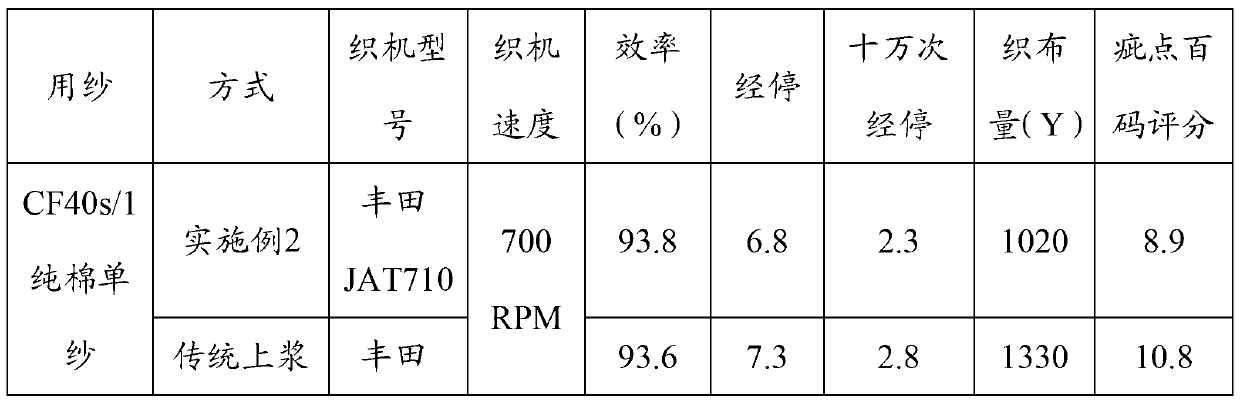

[0073] Taking pure cotton CF40s / 1 colored yarn as an example, the traditional sizing method can be seen in Example 1:

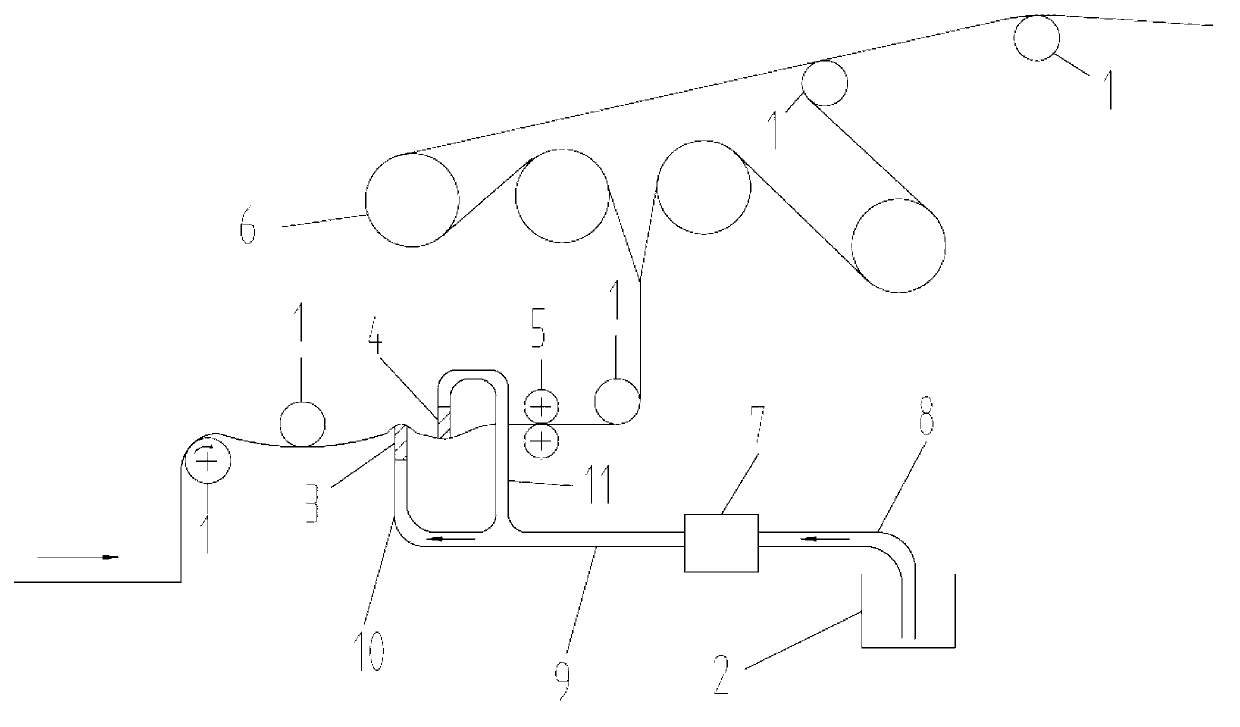

[0074] The warp sizing method of this embodiment is: combining figure 1 , The warp yarn is drawn out from the warp beam, and after passing through the guide roller 1, it is ready for sizing; put the prepared slurry in the slurry tank 2, and the slurry is fed into the slurry tube 8 through the foam generator 7 to form foam. The output tube 9 outputs, and then through the output tube 10 of the lower foam applicator and the output tube 11 of the upper foam applicator respectively, the foam is transported to the lower applicator 3 and the upper applicator 4 of the foam applicator, so that the foam slurry flows from the upper and lower two The direction is applied to the yarn, and then through the pressure of the roller 5, the slurry foam is burst and penetrates into the yarn and fiber. The yarn squeezed by the roller 5 is passed through the guide roller 1 and then ...

Embodiment 3

[0102] Take pure cotton JC40s / 1 colored yarn as an example, the traditional sizing method can refer to Example 1;

[0103] The specific steps of this embodiment 3 are as follows:

[0104] (1) Configure slurry

[0105] Water 1000g

[0106] Modified starch DM816344g (purchased from Dongmei Company);

[0107] 57g SD propylene slurry (purchased from Sunda Chemical);

[0108] Polyvinyl alcohol (PVA) 33g;

[0109] Wax oil SFO-3014g (purchased from Yixing Junda);

[0110] Antistatic agent TS-654g (purchased from Shanghai Xida);

[0111] Amphoteric foaming agent RR20g (purchased from Ningbo Bosite).

[0112] (2) Boiling pulp

[0113] Control the slurry temperature to 85°C.

[0114] (3) Foaming

[0115] The foam generator is used to foam the already configured slurry system. The foaming ratio and application amount can be accurately controlled by the computer control system of the equipment. The foaming ratio is controlled to be 1:3 and the application amount is 40%.

[0116] (4) Foam sizing

[0117] Imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com