Patents

Literature

97results about How to "Reduce the amount of sizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

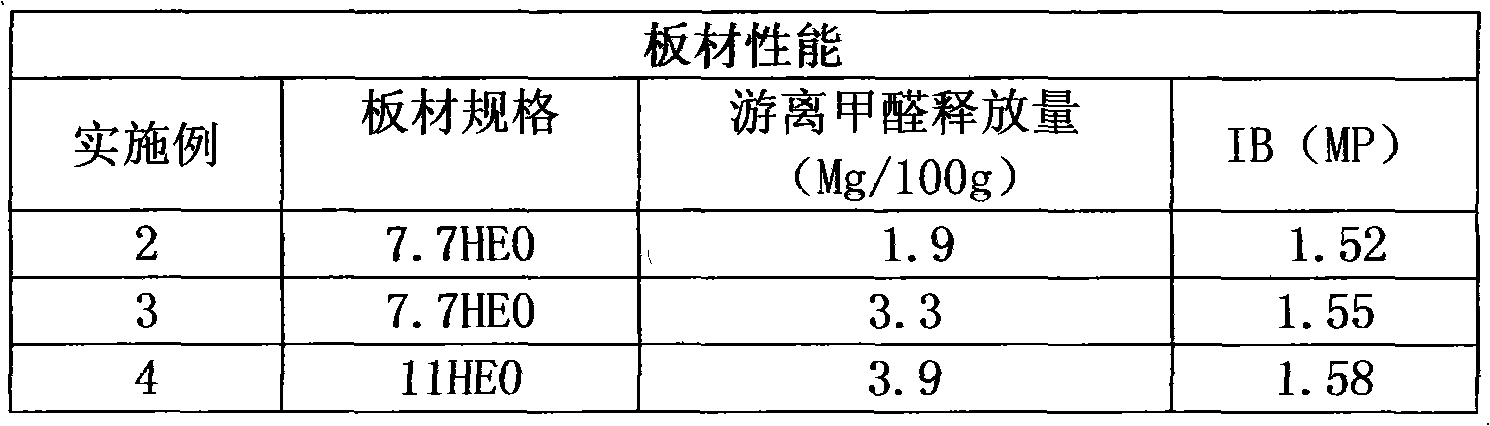

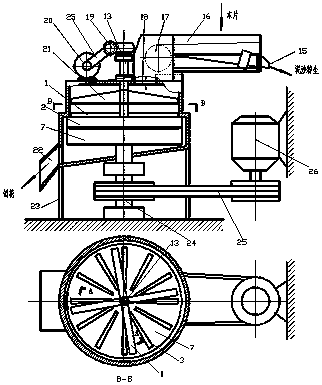

Industrialized production method of wheat straw flakeboard

InactiveCN1631632AHigh yieldMix glue evenlyFlat articlesDomestic articlesMedium density fiberboardCrusher

The invention relates to a crushed aggregate of wheat straw industrial producing techniques. Its technique steps is divided into raw material processing, glue mixing and laying, pavementalize and demoulding , heat pressing, late treatment. The advantages of the invention are: the raw material is crushed by special crusher after processed with heat water or micro wave or plasma, to obtain wheat straw crushed aggregates of better obtaining rate and shape. The glue mixing is finished in a rolling cylinder on cycle type combined glue mixer while ensuring the gluing volume is reduced and uniform. The technique is adopted with combined demoulding techs in which the sheet surface is applied with single-time demoulding agent or sand powder; the surface of the upper pressing plate and the lower bedding plate is applied with semipermanent demoulding agent. The tech solves the problem that after pavementalizing the viscosity between the crushed aggregates of wheat straw and is easily cracked while being transferred, by adopting the plain echoing system. The performance of the crushed aggregates sheets meets the standard requirements inside and outside the nation with a dissociating methanal content of nearly zero which is difficult for the existing wooden shaving board and medium intensity fibre board.

Owner:NANJING FORESTRY UNIV

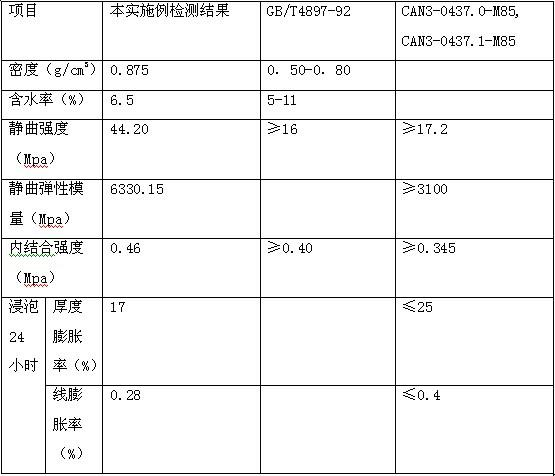

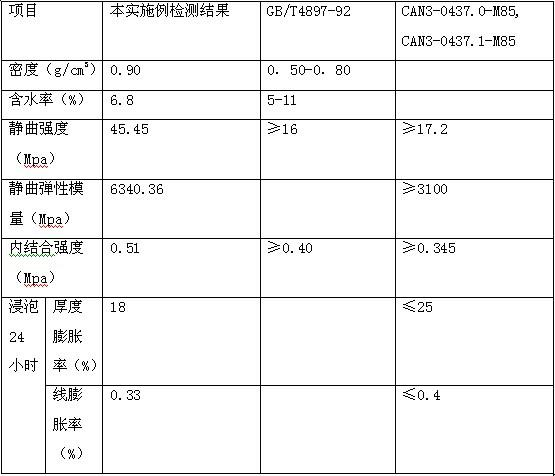

Low glue consumption method for making medium density fiberboard

InactiveCN102514071AGuaranteed mechanical propertiesReduce the amount of sizingWood working apparatusFlat articlesFiberFiberboard

The invention relates to a low glue consumption method for making a medium density fiberboard, which comprises the following steps of: material preparation, i.e. processing the raw materials of small dimension wood, brush wood and the like into wood chips by adopting a drum chipper; fiber preparation, i.e. sending qualified wood chips to a wood chip cooking pot through a belt conveyor, introducing papermaking waste liquid into a boiler to carry out cooking softening treatment after filtering the papermaking waste liquid, sending the wood chips which are cooked and preheated into a thermofiner to carry out mechanical separation through a feeding screw, and filling molten wax before the wood chips enter a grinding chamber body of the thermofiner, so that after the wood chips are separated into the fibers, the wax is uniformly distributed on the surfaces of the fibers; sizing and drying of the fibers, wherein a production process of firstly sizing and then drying is adopted; pavement and formation of a board blank; hot-press forming, i.e. sending the single board blank into a hot press to carry out hot pressing through a loader, so that under the combined action of heat and pressure, moisture in the board blank is gasified and evaporated, the density of the board blank is improved, glue is cured and a waterproof agent is redistributed; and post-processing, i.e. finally, sending the obtained product into a sanding machine to carry out surface processing. The low glue consumption method for making the medium density fiberboard is simple and convenient.

Owner:广西新凯骅实业集团股份有限公司

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

Super-thick bamboo-wood composite board and producing method thereof

ActiveCN101524858ASolve the problem of poor thermal conductivity that is difficult to produce by hot pressingSolve warpingPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesAdhesiveEngineering

The invention provides a super-thick bamboo-wood composite board, which comprises a core board, a surface board and a back board, wherein the core board is a super-thick rotary-cut single board with the thickness of 6-12 mm, the surface board and the back board are made of bamboo, the core board comprises a plurality of super-thick single boards, the contiguous layers of the super-thick single boards are in the combination along the grain, a glue layer is arranged between contiguous single boards, the adhesive of the glue layer is an aqueous macromolecule isocyanate adhesive, the super-thick single boards of the core layer are single boards after the processing of stress degradation, and spot-shape or segment-shape crack grains are formed in the direction along the grain of the loosened surface of every single board. Compared with the prior composite board of the same thickness, the composite board has greatly-reduced glue amount and no deformation or distortion.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Low-density plank, and production technique

InactiveCN101049706ALow adjustabilitySmall adjustabilityDomestic articlesFlat articlesAdhesiveVolumetric Mass Density

A low-density (200-550 Kg / cu.m) board is prepared from rice and wheat straws and the adhesive which is the mixture of isocyanate resin and urealdehyde resin or phenolic resin through pretreating, applying adhesive and hot pressing.

Owner:江苏大盛板业有限公司

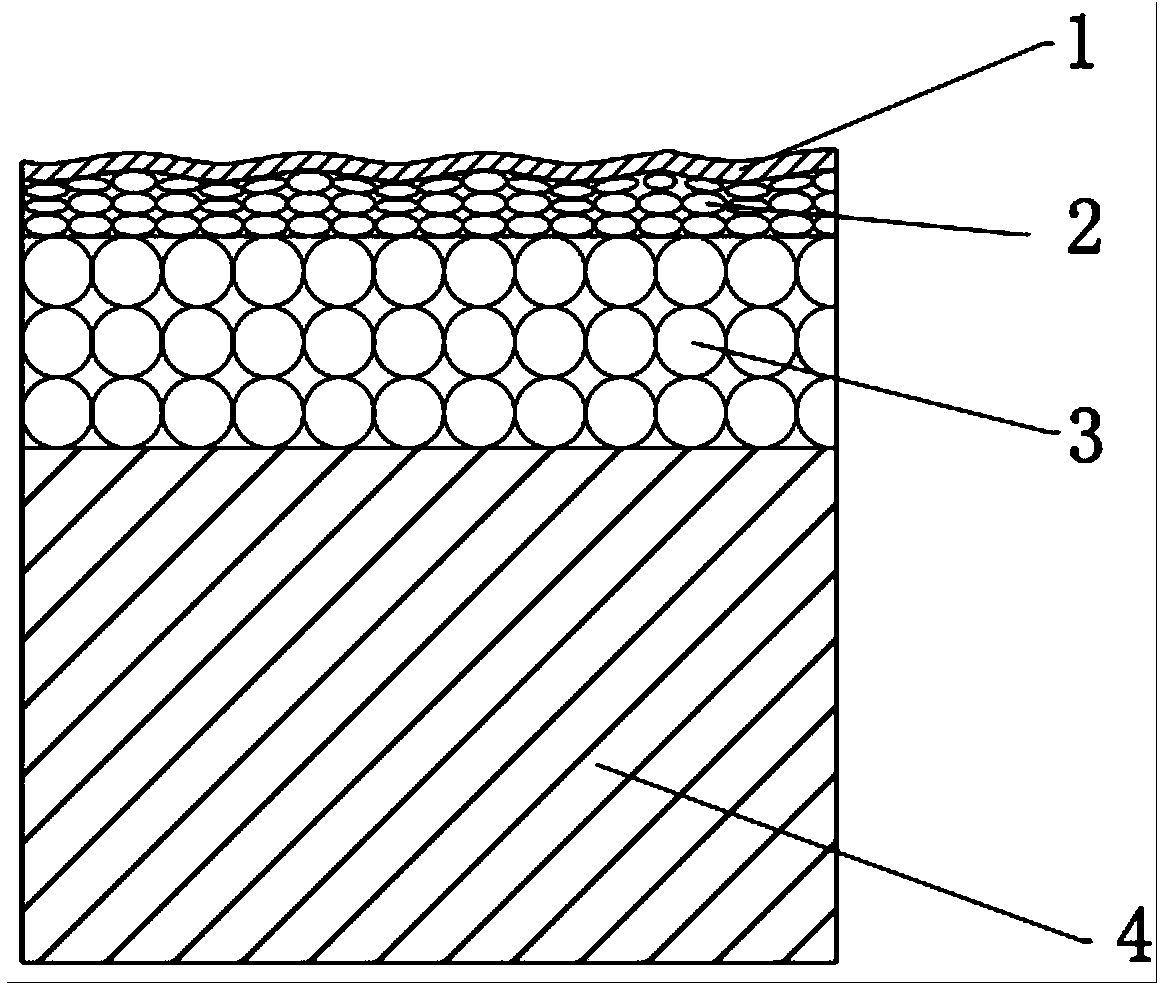

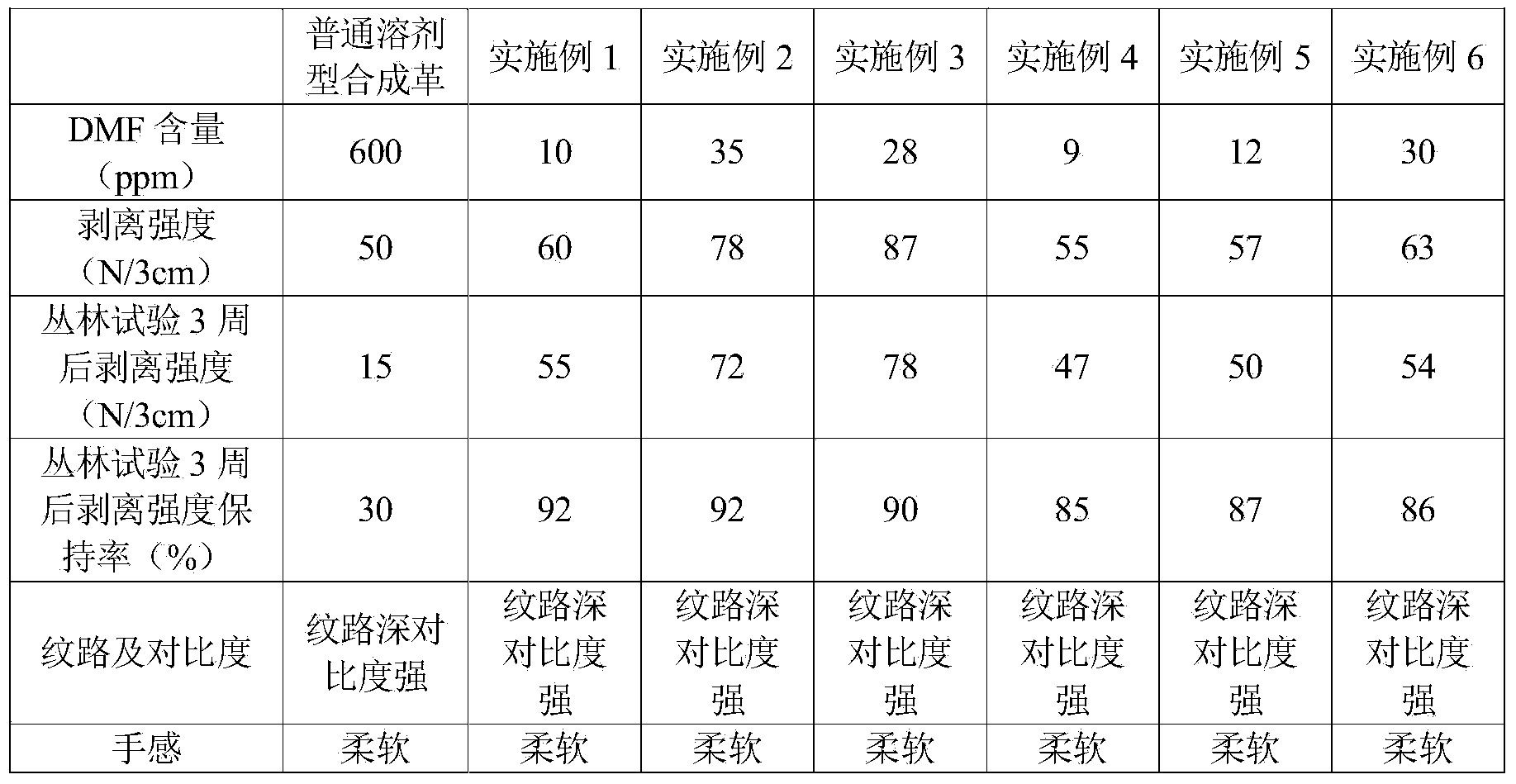

Method for preparing embossable solvent-free synthetic leather

ActiveCN104032587AHigh resistance to aging and hydrolysisReduce the amount of sizingLaminationLamination apparatusProduction linePolymer science

The invention discloses a method for preparing embossable solvent-free synthetic leather. The method comprises the following steps: (a) preparing an embossable solvent-free synthetic leather dry-method half-finished product, namely, uncoiling a piece of release paper, coating a surface layer, drying, cooling, coating a thermoplastic foaming middle layer, drying, cooling, coating a thermoplastic foaming adhesive bottom layer, pre-drying, semi-crosslinking, semi-foaming, adhering to a substrate, cross-linking, solidifying, and peeling off the release paper, so as to obtain an embossable solvent-free synthetic leather dry-method finished product; and (b) embossing and performing aftertreatment, namely, uncoiling the embossable solvent-free synthetic leather dry-method finished product, embossing, and performing other aftertreatment, so as to prepare an embossable solvent-free synthetic leather finished product. The made synthetic leather is of a two-layer foaming structure, the upper layer is a relatively thin thermoplastic foaming middle layer which can be softened, cooled and reformed and deforms at certain temperature, so that the synthetic leather has the characteristic of embossability; the lower layer is a relatively thick thermoplastic foaming bottom layer which can show main physical properties and the hand feeling of the synthetic leather. The synthetic leather can be produced by using an ordinary synthetic leather production line.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

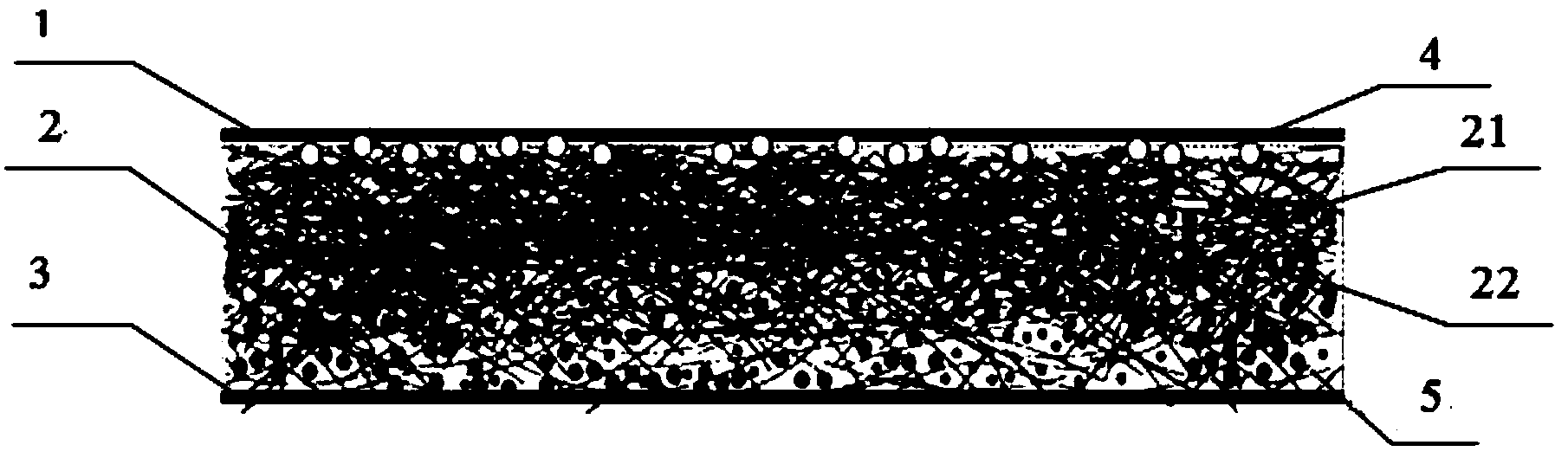

Absorption core with efficient flow guide property and breathability and method for manufacturing absorption core

ActiveCN105919733AReduce the degree of plasticizationIncreased softness and comfortPersonal careSynthetic resin layered productsLiquid diffusionSurface layer

Owner:湖南倍健卫生用品有限公司

Resin glue adhesive for E0 grade fibre board

InactiveCN101307215ALow water resistanceLow aging resistanceAldehyde/ketone condensation polymer adhesivesDomestic articlesFirming agentUltimate tensile strength

The invention discloses a synthetic resin cementing compound used for an EO-stage fiberboard. The synthetic resin cementing compound consists of melamine modified urea resin and a firming agent and is characterized in that the compositions of reaction material of the urea resin by weight percentage are: 4.0 to 6.0 percent of the melamine, 40.0 to 42.0 percent of urea, 52.0 to 56.0 percent of formaldehyde, and 0.4 to 0.6 percent of an accelerating agent; acid and alkali are appropriate and the total mol ratio is between 0.90 and 0.93; and the cementing compound is obtained by the systemization and reaction of the materials. The cementing compound has good cementation strength, appropriate curing time, and the content of 0.06 to 0.08 percent of free formaldehyde, etc. E1 and the E0-stage fiberboard with good quality can be produced stably and have the advantages of low glue feeding amount, strong adaptability to the hot press molding technology and high curing speed in the hot press molding process, etc., thereby meeting the need of the market on products of high environmental performance fiberboards.

Owner:DARE TECH

Method for producing uniform-density bamboo shaving board

InactiveCN102198685ALow costSave on energy costsWood working apparatusFlat articlesEngineeringVolumetric Mass Density

The invention relates to a machining process for an artificial board, in particular to a method for producing a uniform-density bamboo shaving board. The invention is realized through the following technical scheme: the method for producing the uniform-density bamboo shaving board is characterized by sequentially comprising the following steps of: (1) selecting materials; (2) first screening; (3) first drying; (4) second screening; (5) second drying; (6) sizing; (7) hot-pressing; and (8) refrigerating. The uniform-density bamboo shaving board has the advantages of density uniformity, high dimensional stability and high static bending strength.

Owner:浙江安吉强裕人造板有限公司

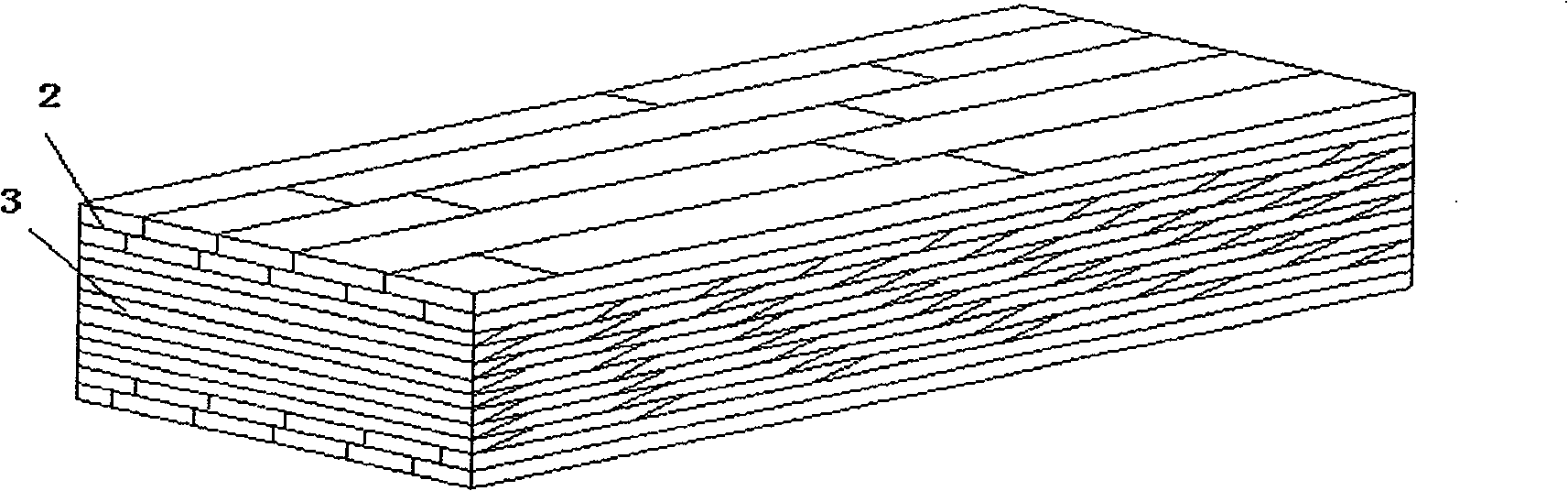

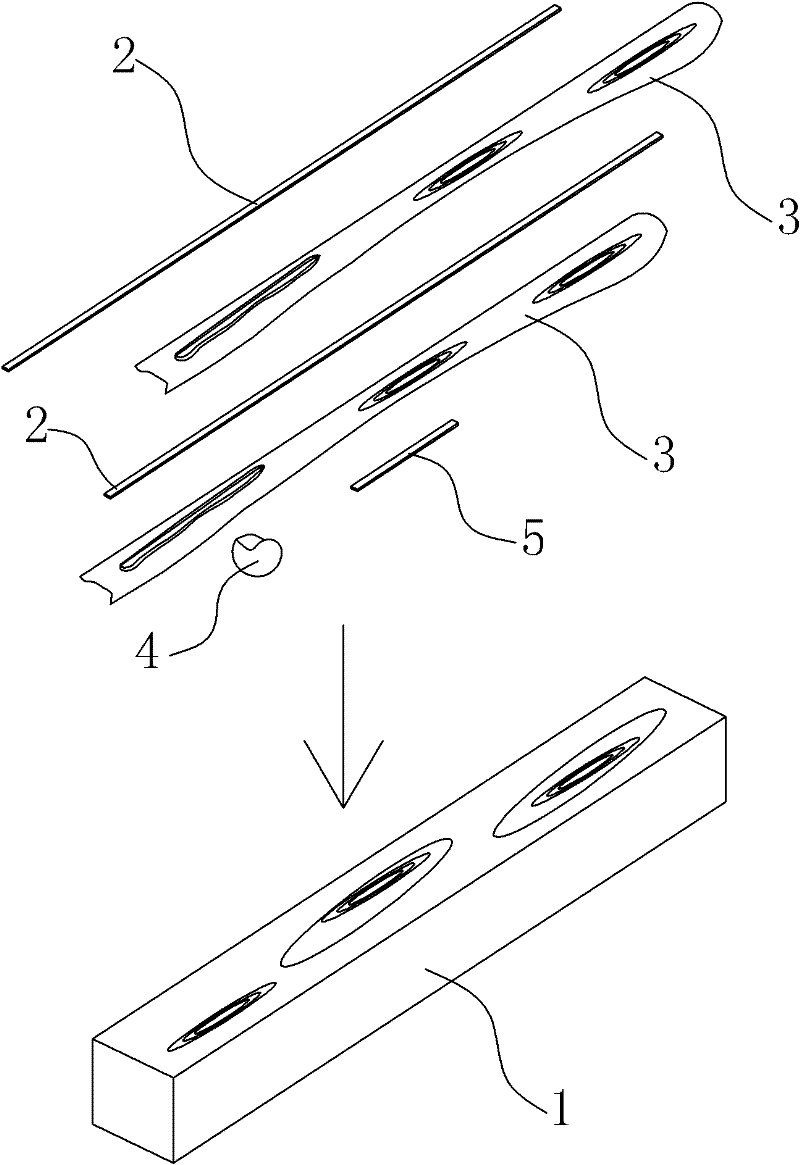

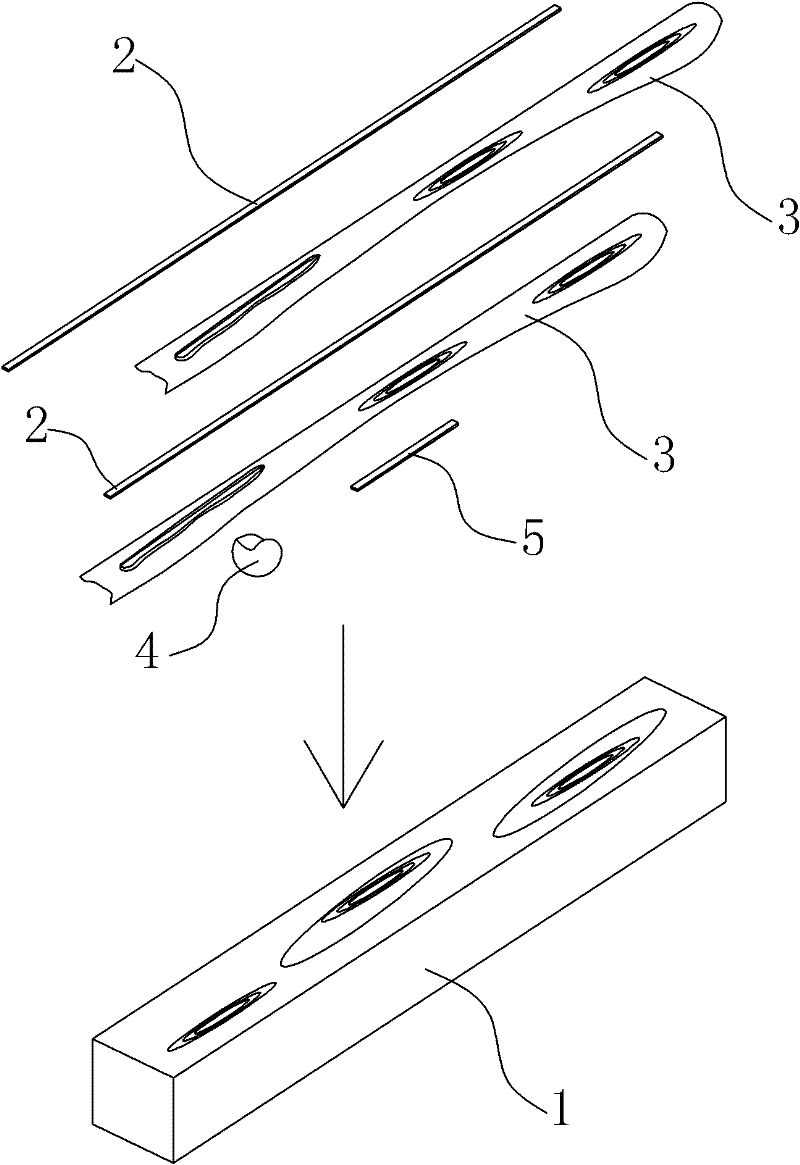

Bamboo-wood mixed reconstituted timber and its processing method

ActiveCN102259371AHigh strengthReduce gapWood working apparatusFlat articlesHigh energyMixed materials

The invention relates to a restructured slab in building boards, in particular to a bamboo-wood mixed restructured lumber and a processing method thereof. Aiming at the technical defects of poor forming texture, uneven material mixing, poor consistency, low strength, difficult manufacturing and high energy consumption existing in the existing single-material pressed slab, the present invention provides a slab with rich texture after forming, uniform and compact material mixing. , high-strength, easy-to-manufacture bamboo-wood mixed recombined wood and its processing method, the bamboo-wood mixed rewood includes bamboo and wood, characterized in that the bamboo and wood are equal in length and in the same direction and are randomly stacked and pressed together. Synthetic profiles. The present invention presses profiles by mixing bamboo and wood. Wood is used to control texture patterns, and bamboo is used to fill holes and reduce gaps. The texture formed by the mixture of the two materials is richer, which is more beautiful than the existing single-material pressed slab, and finally pressed into shape The recombined wood is uniform and dense, with high strength; the two materials are filled and mixed with each other, and the amount of glue required is less than that of single material profiles.

Owner:ZHEJIANG TIANZHEN BAMBOO & WOOD DEV

Manufacturing method for gum wood finger-joined floors

ActiveCN103753661AReduce wasteSolve roughnessWood veneer joiningWood dampingAdhesive glueWood machining

The invention belongs to the technical field of wood processing, and particularly discloses a manufacturing method for gum wood finger-joined floors. The manufacturing method comprises the following steps of drying, selecting, improvement of machining properties, humidifying, connection and combination, treatment of grooves and tongues, sanding, painting and the like. By using the manufacturing method for the gum wood finger-joined floors, the problems that in production of fast-growing gum wood finger-joined floors, sanding cost is high, loss of materials is high, the using amount of glue is high, tree laces crack, the moisture content of a portion between each two gum wood finger-joint floors is not uniform, finger joining is difficult, and the like are solved. The manufacturing method for the gum wood finger-joined floors has the advantages of low production cost, high product quality and the like.

Owner:丰胜(广州)建材有限公司

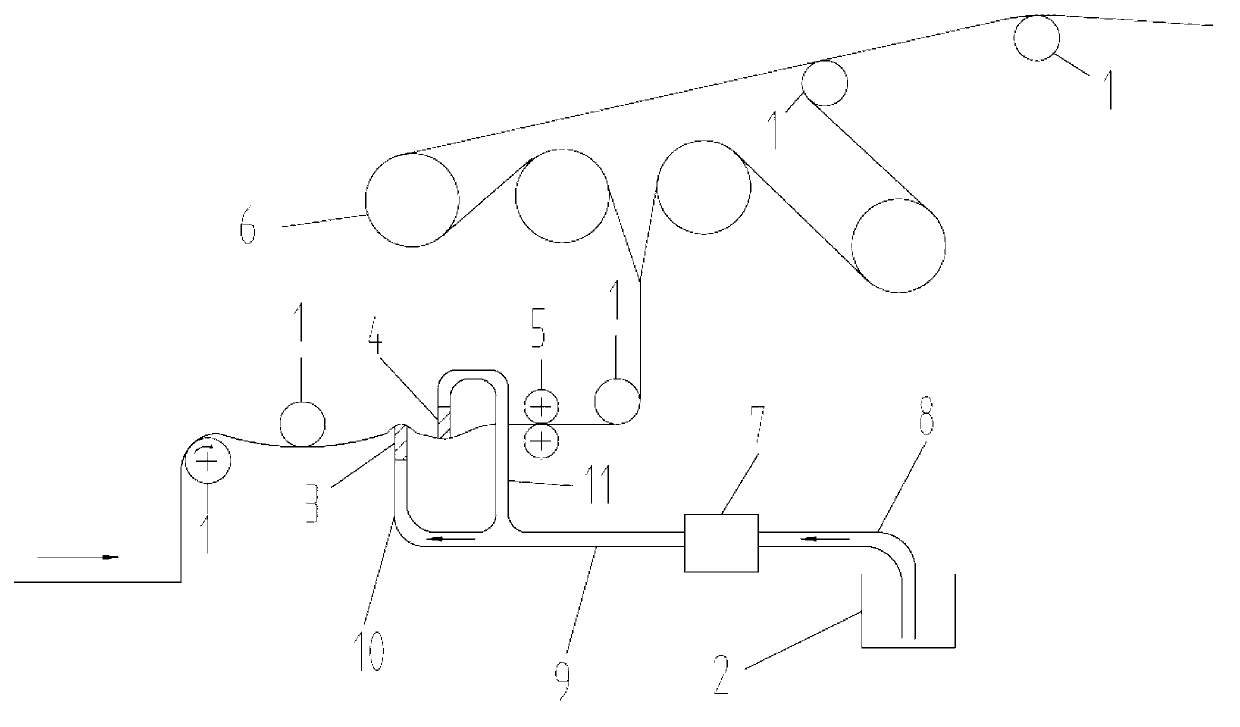

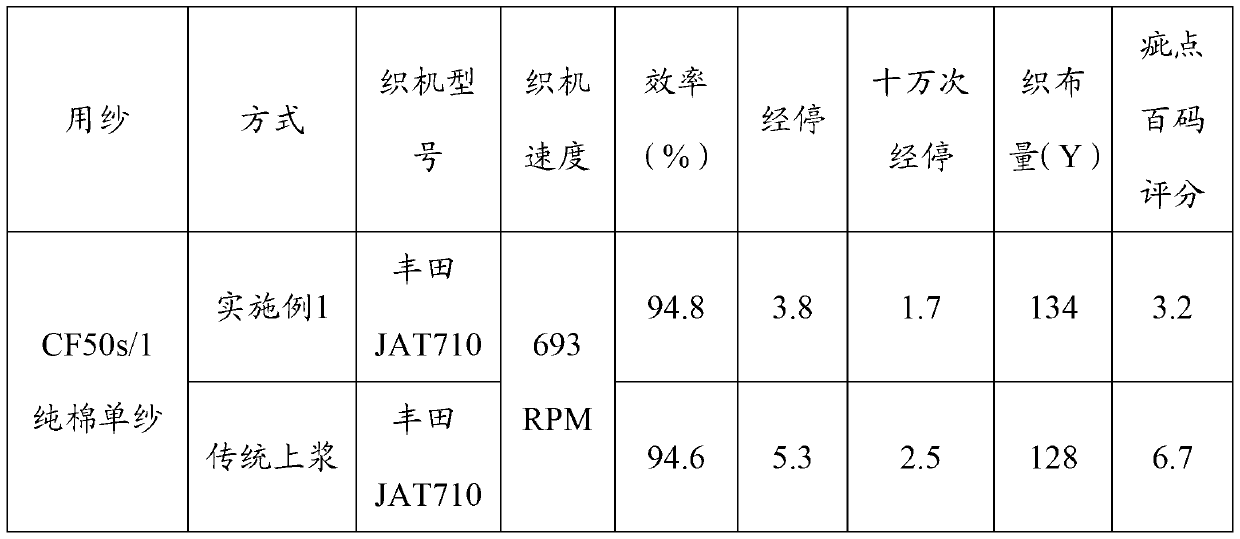

Warp sizing method and application thereof

ActiveCN103103710AEmission reductionReduce water consumptionFibre treatmentLiquid/gas/vapor textile treatmentYarnWastewater

The invention discloses a warp sizing method and an application thereof. The warp sizing method includes the following steps: preparing sizing agents, boiling the sizing agents, foaming, conducting foam sizing, rolling the sizing agents, drying and leasing; foaming ratio and applying amount are controlled by a foam producer in the step of foaming; the foaming ratio is 1:3-30, and the applying amount is 10%-50%; foam formed by the foam producer is instantly and entirely applied to warp yarn through a foam applicator in the step of conducting foam sizing; and the foam applicator is divided into an upper applying head and a lower applying head. The warp sizing method has the advantages of being low in water consumption, little in chemical and wastewater discharge, little in sizing amount, easy to desize, short in yarn drying time, capable of saving energy consumption by 50%-60%, high in production speed, low in cost, continuous in foam applying mode, capable of ensuring uniformity and stability of the applied foam, low in product breakage rate, high in efficiency and good in weaving effect.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

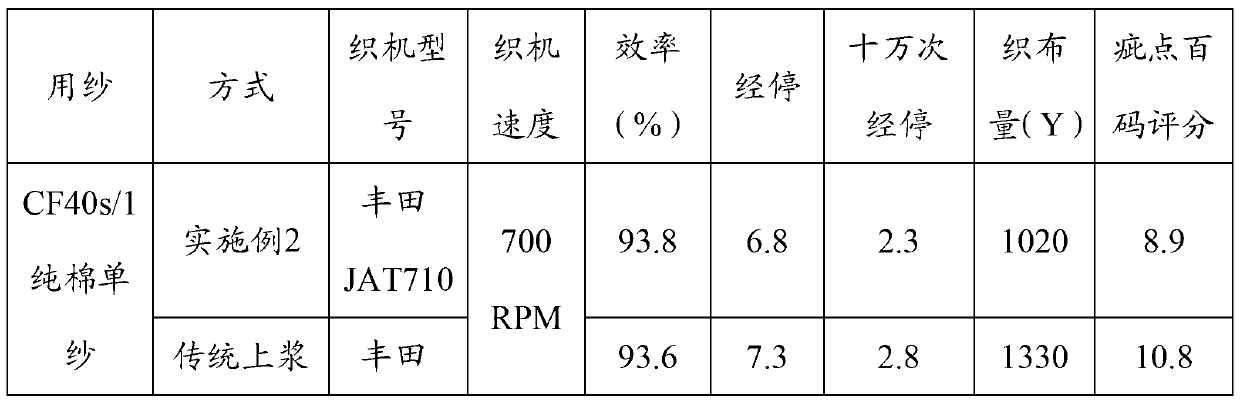

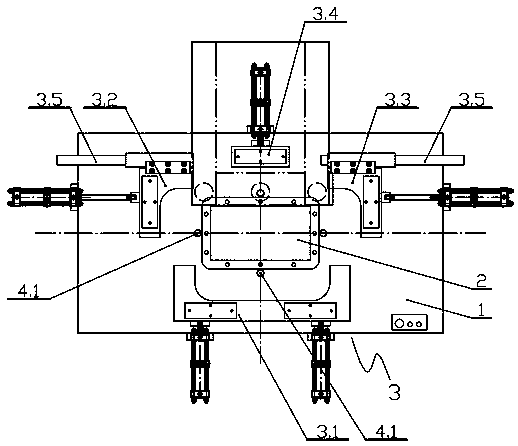

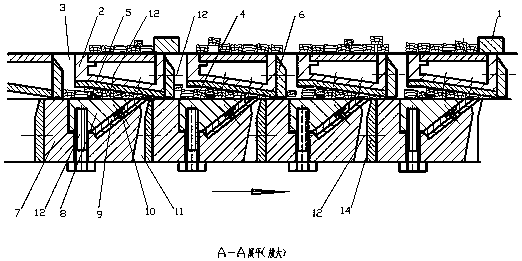

Double-fibre compact spinning device

The invention provides a novel double-fiber close spinning device, consisting of two main parts of a double top roller subassembly and a hollow roller subassembly, wherein in the double top roller subassembly, a top roller(2) and a top roller(4) are arranged on a top roller frame(5), on which an airflow orientation block(11) is arranged by a positioning board(10), a spring(3) is arranged on the top roller frame(5), a permanent magnet(12) is arranged on the airflow orientation block(11); in the hollow roller subassembly, a wide vacuum nozzle(7), an air suction base(9) and a baffle board(6) are jointly assembled in hollow roller rings(8), which are arranged on a main shaft(14) in pairs; the double top roller subassembly is arranged on a cradle(1) and exerts pressure on the hollow roller subassembly. The yarn spun by the device has few hairy feathers and little fly waste and is low in fiber strength.

Owner:陆节 +1

Timber adhesive and preparation method thereof

ActiveCN102443369AAvoid harmImprove plasticityAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholAdhesive

The invention discloses a timber adhesive. The adhesive comprises the following components, by weight, 41-60 parts of an aldehyde compound, 22-45 parts of an amino compound, 2-4 parts of an inorganic silicon compound, 0.2-0.5 parts of an organic silicon compound, 0.8-1.5 parts of a polyvinyl alcohol compound, 0.2-1 part of an acid compound, 0.1-0.3 parts of sodium dodecyl benzene sulfonate and 5-32 parts of water. A preparation method of the adhesive comprises the following steps: 1, taking several components according to corresponding weight parts, heating them to 90DEG C, and maintaining the temperature until the polyvinyl alcohol compound is completely dissolved; 2, cooling to 80-85DEG C, adding the amino compound, adding the inorganic silicon compound to adjust the pH value of the obtained material to 7.0-8.5, reacting for 45-75min, adding the acid compound to adjust the pH value of obtained material to 4.8-6.0, reacting for 45-75min, and adding the residual inorganic silicon compound after the cloud point is 23DEG C; and 3, cooling to 50-60DEG C, adding the organic silicon compound, reacting for 15-30min, heating to about 45DEG C when the pH value reaches 7.5-8.5, and discharging. The adhesive synthesized with the preparation method, which is an inorganic-organic silicon modified non-formaldehyde amino resin, has the advantages of high adhesion strength, good water resistance, no use of formaldehyde as an acetal reactant, and avoiding of the formaldehyde harm.

Owner:东莞市山力高分子材料科研有限公司

High speed cigarette lap adhesive with low temperature quick-drying and high adhesive properties as well as preparation technology thereof

ActiveCN107541160ANo visible foreign objectsNo lumpsMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses high speed cigarette lap adhesive with low temperature quick-drying and high adhesive properties. The cigarette lap adhesive comprises the following components: distilled water, vinyl acetate-ethylene copolymerized emulsion whose solid content is 60%, edible ethanol, an alcoholic solution of polyethylene whose concentration is 19.75%, a sodium hydroxide solution whose concentration is 2.3%, and poly(dimethoxysiloxane); the components are used according to the following weight ratio: 2.2:94.5:1.175:2:0.015:0.11. The invention also discloses preparation technology of theproduct. The product has the beneficial effects that the high speed cigarette lap adhesive with low temperature quick-drying and high adhesive properties has high solid content, good fluidity, low viscosity, low temperature rapid drying, good bonding performance, and other characteristics; the product can be used for greatly reducing hot sealing temperature and glue applying amount of a cigarettemaking machine lap soldering iron; and the product is suitable for various high speed cigarette types with single gun and double guns.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

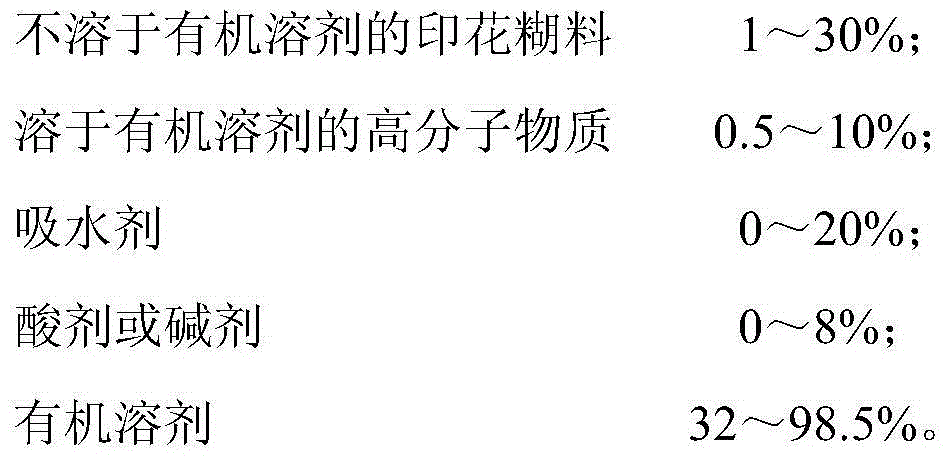

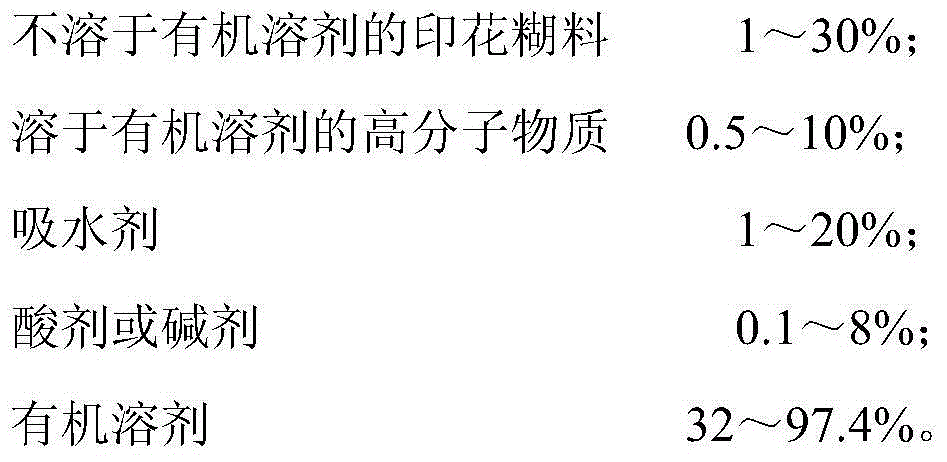

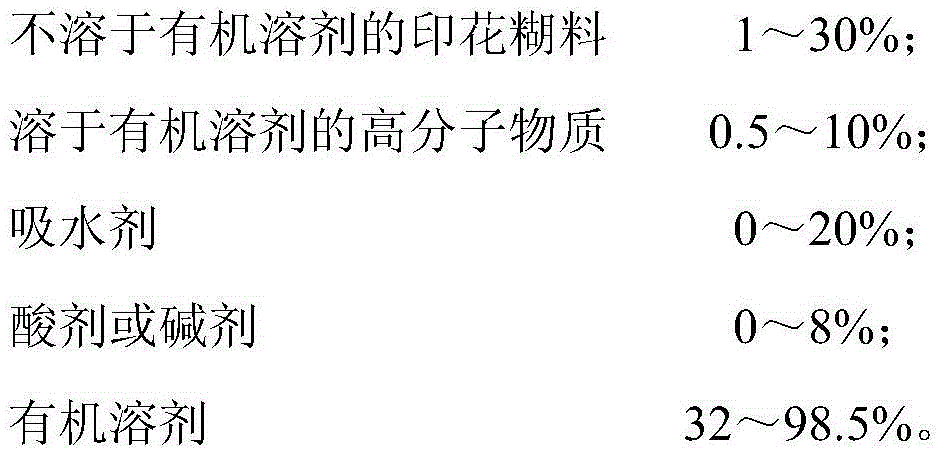

Printing pre-treatment thickener and preparation method thereof

The invention discloses a printing pre-treatment thickener. The pre-treatment thickener comprises the following components in percentage by weight: 1%-30% of printing past which is not dissolved into an organic solvent, 0.5%-10% of macromolecular substances which are dissolved into the organic solvent, 1%-20% of a water absorbent, 0.1%-8% of an acidic agent and 32%-97.4% of the organic solvent. The invention further discloses a preparation method of the thickener. According to the thickener and the method disclosed by the invention, the disadvantages in the prior art that the sizing amount of hydrophilic fiber textiles is great and the discharging amount of wastewater in an later water washing process is not enough are overcome; and furthermore, the disadvantages that hydrophobic textiles can be only printed with shallow colors but not medium and deep colors in a direct injection printing process are overcome.

Owner:苏州汇万色纺织有限公司

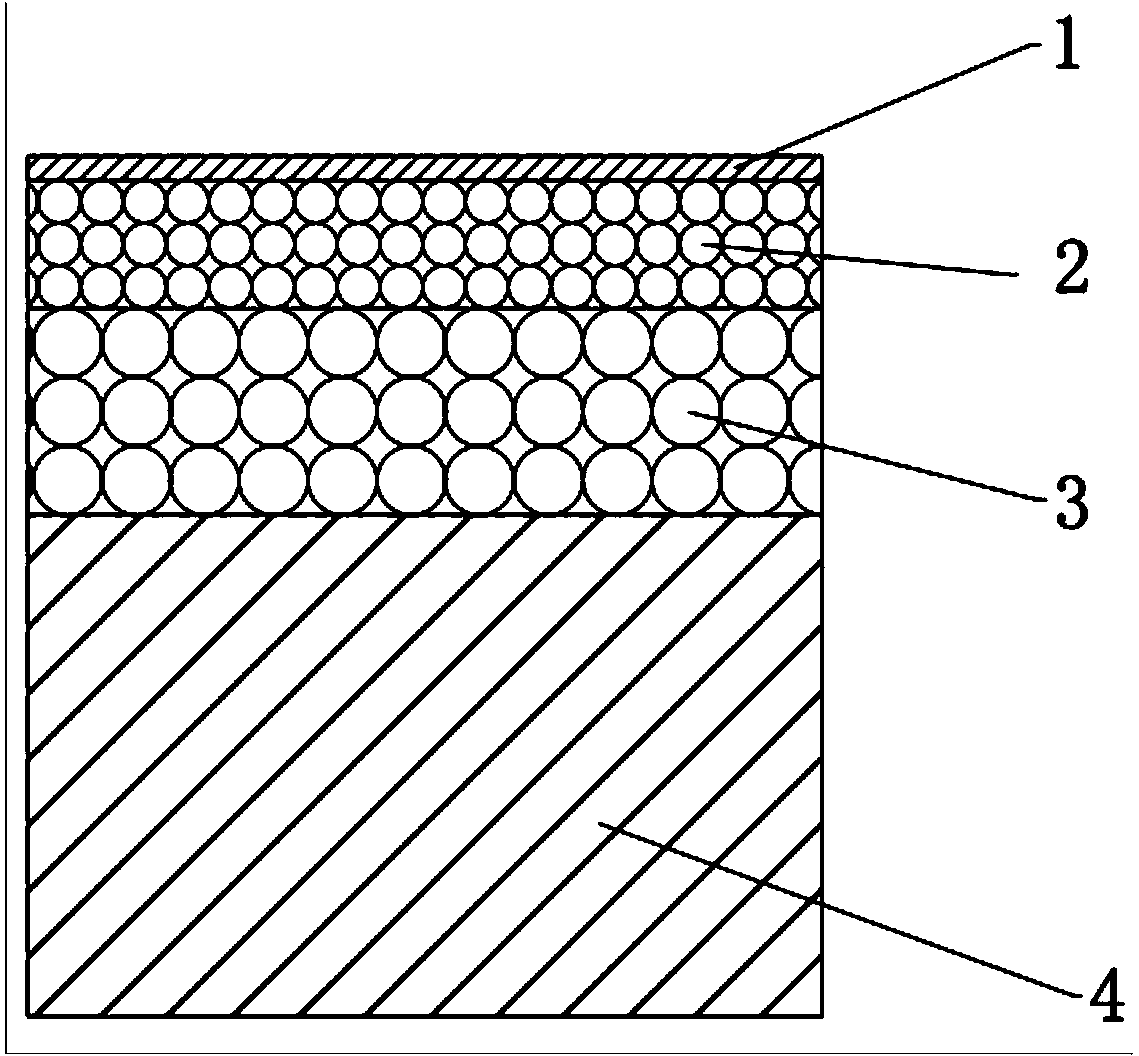

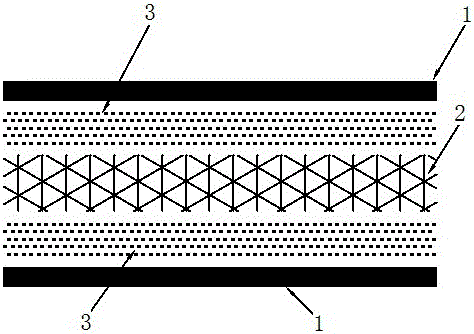

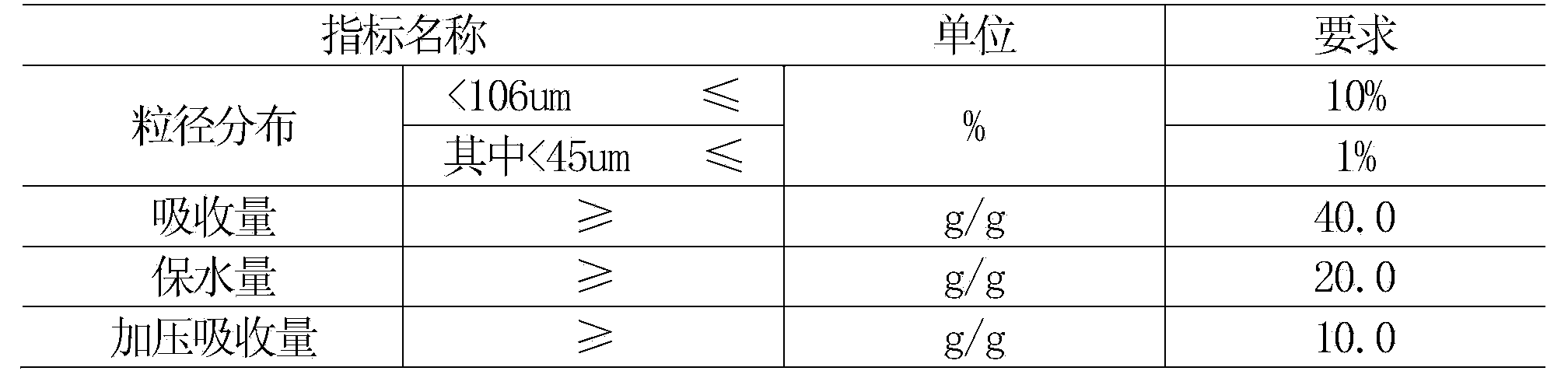

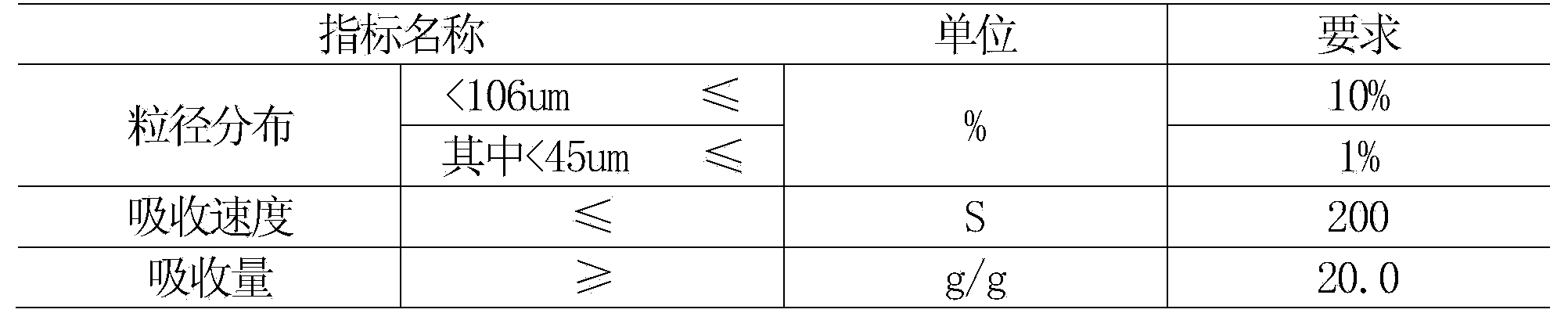

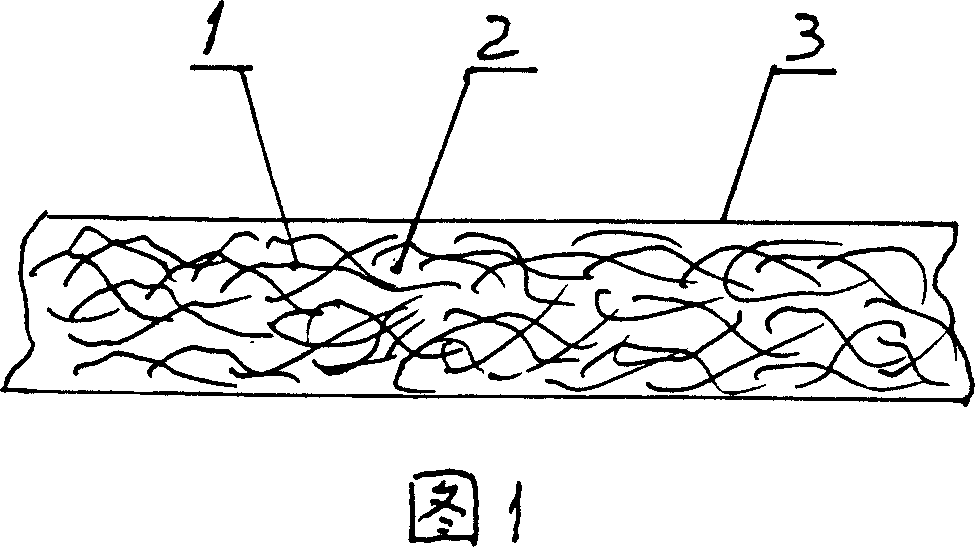

Composite water absorbent paper for absorbent product, preparation method and application of composite water absorbent paper

InactiveCN104382695ALarge particle sizeImprove adhesion strengthAbsorbent padsIsolation layerPulp and paper industry

The invention provides composite water absorbent paper for an absorbent product. The composite water absorbent paper for the absorbent product comprises an upper isolation layer, macromolecular water absorbent resin, a high-fluffy nonwoven fabric and a lower isolation layer, wherein the macromolecular water absorbent resin comprises upper macromolecular water absorbent resin which is distributed between the upper isolation layer and the high-fluffy nonwoven fabric, and lower macromolecular water absorbent resin which is distributed between the high-fluffy nonwoven fabric and the lower isolation layer; the upper isolation layer, the upper macromolecular water absorbent resin, the high-fluffy nonwoven fabric, the lower macromolecular water absorbent resin and the lower isolation layer are combined together in a gluing or heat sealing manner; the composite water absorbent paper is characterized in that the particle size of the upper macromolecular water absorbent resin is different from that of the lower macromolecular water absorbent resin; the particle size of the lower macromolecular water absorbent resin is smaller than that of the upper macromolecular water absorbent resin. According to the composite water absorbent paper for the absorbent product, the absorption performance of the water absorbent paper can be remarkably improved; the utilization rate of macromolecules is improved; the production cost is reduced.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

Method for manufacturing tile by rice/wheat straw

InactiveCN1843719AHigh yieldEasy to shapeDomestic articlesFlat articlesLand resourcesAfter treatment

The invention relates to a method for producing rice / wheat straw tile, which comprises: the raw material treatment; the gluing step; the spreading and demoulding step; the thermal compress step; and after-treatment step. The invention can be used to replace traditional tile, with lower weight and saved land resource. The used straw can be decomposed; therefore, the detached building will not be waste. And it has lower cost, better social and economic benefits, while the water adsorption rate of straw tile can reach 21% which is lower than asbestos cement tile, and its anti-bend strength is significantly higher than the support strengths of sinter tile and asbestos cement tile; and the longitudinal anti-bend strength is reduced to 1400N, and the transverse one is reduced to 2200N.

Owner:NANJING FORESTRY UNIV

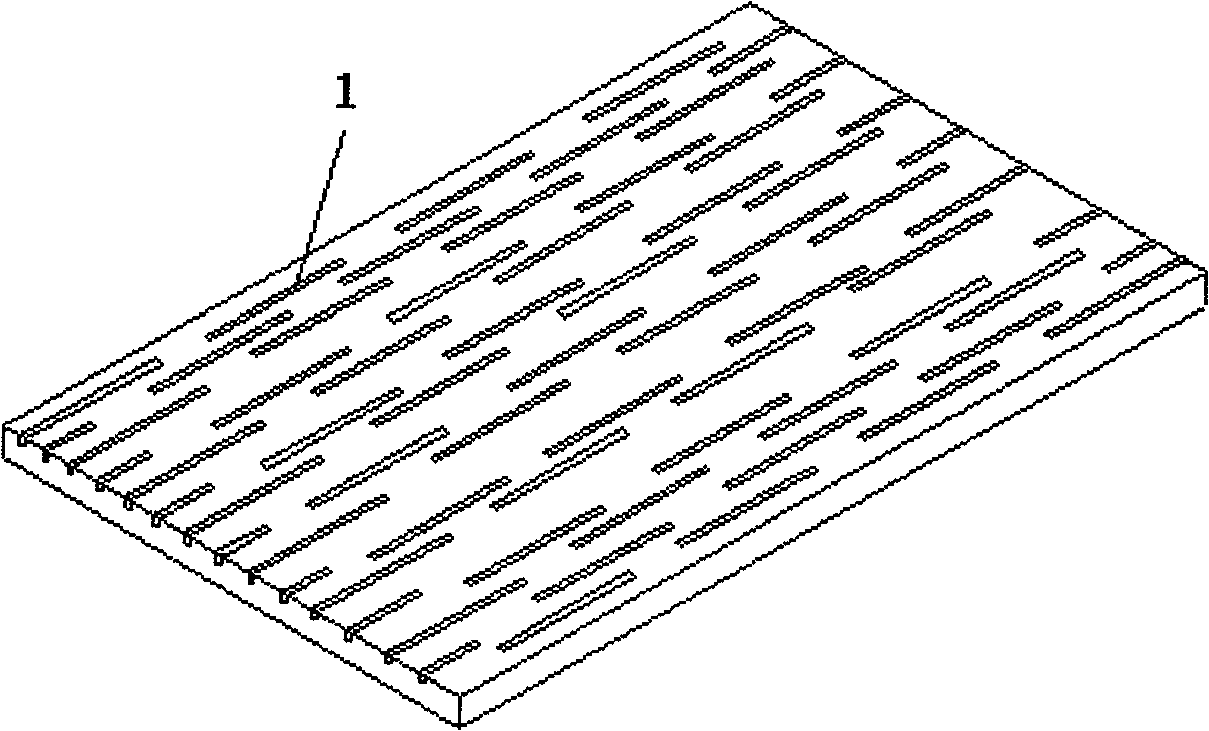

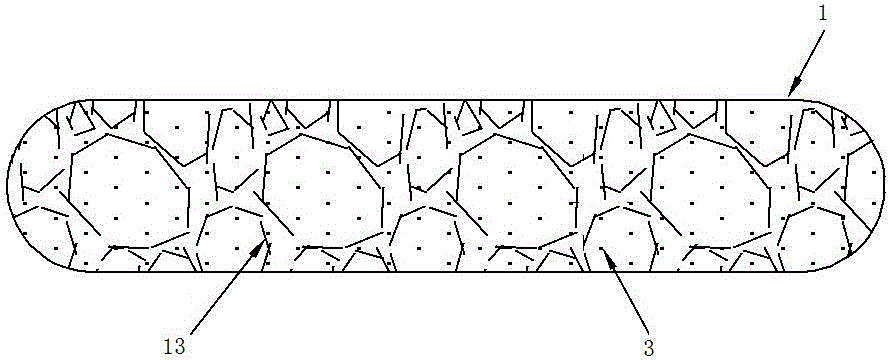

Bamboo filament fibre board and bamboo filament, method for making bamboo filament fibre board

InactiveCN1923481AStrong ability to hold screwsReduce energy consumptionWood working apparatusFlat articlesPolymer scienceMelamine formaldehyde

The invention relates to a bamboo fiber plate, which is made from bamboo fiber at 0.1-0.3mm wide while the length / diameter ratio is 200:1-500:1, to be alternated. Wherein, the bamboo fiber is adhered by melamine- formaldehyde-aquacare resin; it uses explosion method to product bamboo fiber, that cutting bamboo into sheets wide 2-3cm and long 5-7cm; emerging it in 0.5-1% sodium sulfite solution for 10-15h, adding water at 5-10% of total amount, increasing pressure to 101-8kg / cm<2 in 10-15mins, increasing temperature to 106-120Deg. C, keeping said temperature for 18-25min, discharging pressure and exploding into bamboo wires. And the method for producing bamboo fiber plate comprises that mixing the melamine- formaldehyde-aquacare resin with solidifier amchlor at 100:0.5-100:1.0, to be sprayed on bamboo wires; pressurizing it at 4.5-5.5 kg / cm<2, then keeping pressure 3.9N / mm<2 at 160-165Deg. C for 5-10min; and keeping pressure at 1.6N / mm< for 25-30mins, cooling. The invention has low energy consumption and wide application.

Owner:张力新

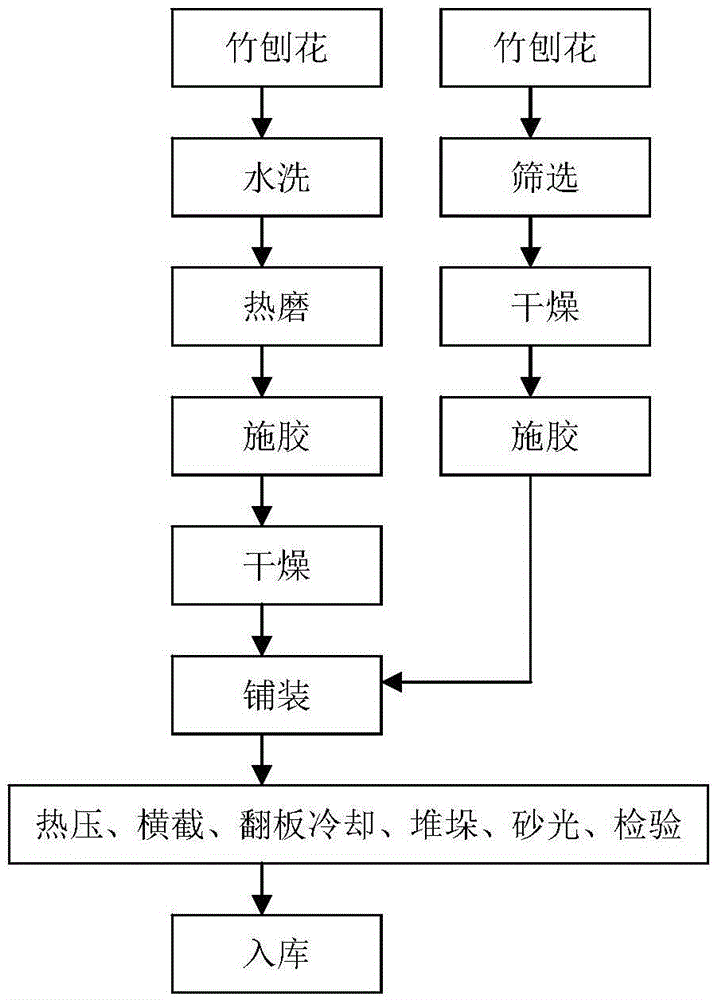

Manufacturing method of bamboo fiber shaving board

InactiveCN105619554AAvoid damageReduce loss and wasteWood veneer joiningPlant material mechanical workingFiberSurface layer

The invention relates to the field of manufacturing of artificial panels, in particular to a manufacturing method of a bamboo fiber shaving board. The manufacturing method comprises the following steps: (1) drying bamboo shaving and then gluing with MDI glue water; (2) cleaning the bamboo shaving, then feeding the bamboo shaving into a defibrater, adding paraffin, adding modified UF glue, drying, and then feeding into a surface layer fiber bin; (3) manufacturing board blanks of which the upper surfaces and the lower surfaces in the thickness direction have surface layer fibers and the middles have the bamboo shaving by using a five-head paver; (4) carrying out pre-pressing forming on the board blanks obtained from the step (3) by using a pre-pressing machine, and then feeding the board blanks to a pressing machine for hot pressing; and (5) cutting, cooling, stacking, sanding and trimming shaving boards subjected to hot-pressing forming in the step (4) so as to obtain the bamboo fiber shaving board. According to the manufacturing method of the bamboo fiber shaving board, the bamboo fiber shaving board is a full-bamboo-structure shaving board of which the surface layers are made of bamboo fibers and the core layer is made of the bamboo shaving, the shaving of the core layer is distributed longitudinally and transversely, loss waste of forest resources is reduced, and various physical performance indexes of the produced shaving board can reach national standards.

Owner:FUREN GRP SHAOWU WOOD CO LTD

Manufacturing method of wide-breadth carbonized board

ActiveCN103317576AImprove structural strengthImprove stabilityWood charring/burningFinger jointUltimate tensile strength

The invention discloses a manufacturing method of a wide-breadth carbonized board, which comprises the following steps: A. material preparing; B. tenoning; C. lengthwise and widthwise splicing; D. sanding and edge cutting on a board blank ; E, hot-press densification treatment on the board blank; F. carbonizing treatment. The manufacturing method of a finger joint laminated board, provided by the invention, is simple in technology; the finger joint laminated board manufactured according to the method has high structural strength, good stability and low adhesive consumption.

Owner:ZHEJIANG LINTAN WOOD SCI & TECH +1

Super-softness non-woven fabric and super-softness hydrophilic non-woven fabric

The invention discloses a super-softness non-woven fabric and a super-softness hydrophilic non-woven fabric. The super-softness non-woven fabric is formed in the mode that a soft layer and a bonding face layer are subjected to hot rolling and solidified, the net forming gram weight ratio of the soft layer is larger than or equal to 70%, and the net forming gram weight ratio of the bonding face layer is smaller than or equal to 30%; as the bonding performance of the bonding face is improved, the glue applying amount is greatly decreased, the light-thin feeling of a non-woven fabric product is improved, the quality of the non-woven fabric product is improved accordingly, and the effect that the production cost is reduced is also achieved.

Owner:FOSHAN NAHAI BEAUTIFUL NONWOVEN CO LTD

Method for preparing high solid content polyacrylate tow cigarette filter rod adhesive in one step

InactiveCN102120923AEasy to produceImprove performanceTobacco smoke filtersEster polymer adhesivesPolymer sciencePolymer

The invention relates to a method for preparing a high solid content polyacrylate tow cigarette filter rod adhesive and belongs to the technical field of adhesives. The preparation method comprises the following steps of: initiating secondary nucleation controllably in situ; and directly preparing acrylic acid or methyl acrylic acid and ester polymer emulsion thereof with solid content of 60 to 75 percent and viscosity of 100 to 300 MPa.s at the temperature of 25 DEG C in one step, wherein water serves as a dispersing medium and an organic solvent is not provided. Compared with the original method, the method has the characteristics of capacity of directly preparing various polymer emulsion with different soft hard section ratio, simple preparation process, low energy consumption, low production cost and the like. The obtained product has the characteristics of no toxicity, noncombustibility, no 'three wastes', convenience of storage and transportation, safety in use and the like. When the product is used for performing adhesive bonding on a polyacrylate tow cigarette filter rod, spicy irritation and tar content of a cigarette can be effectively reduced. The adhesive has the advantages of small using amount, high drying and film-forming speed, capacity of accepting modification of various adhesives and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive

ActiveCN105563571AStress reliefUniform thicknessLaminationLamination apparatusAfter treatmentAdhesive

The invention discloses a method for producing thick-core plywood by using aldehyde-free biomass soy protein adhesive, belongs to the technical field of wood processing, and solves such problems as large back surface cracks, moreburrs, high thickness deviation and easiness in deformation and bending. The production method comprises wood block pretreatment, rotary cutting, drying, plasma treatment, veneer surface scratch treatment, gluing, prepressing, hot pressing and after-treatment. The method is suitable for producing the aldehyde-free thick-core plywood, largely reduces the production cost, and improves the production efficiency.

Owner:SHANDONG XINGANG ENTERPRISE GRP CO LTD

Fiberboard adhesive-reduction manufacturing method

InactiveCN107599109AReduce the amount of sizingReduce manufacturing costDomestic articlesFlat articlesChemical structureFiber

The invention provides a fiberboard adhesive-reduction manufacturing method. The fiberboard adhesive-reduction manufacturing method comprises the following steps of: (1) performing biological pretreatment on a wood fiber raw material, and changing the physical and chemical structures of the wood fibers to generate adhesive substances; (2) uniformly drying the biological pretreated raw material obtained in the step (1) through a rotary barrel type drying method until moisture content is about 10%; (3) uniformly spraying a chemical adhesive into the dried material through a spraying mode; and (4) performing hot-pressing to prepare the fiberboard. According to the fiberboard adhesive-reduction manufacturing method provided by the invention, lignocellulose in the raw material is modified by biologically pre-treating the raw material, and certain adhesive substances are generated; and furthermore, hot-pressing is performed by applying a little chemical adhesive, so that manufacturing of thehigh-strength fiberboard is realized, and therefore, pollution and the production cost of the fiberboard are reduced.

Owner:HUAIYIN TEACHERS COLLEGE

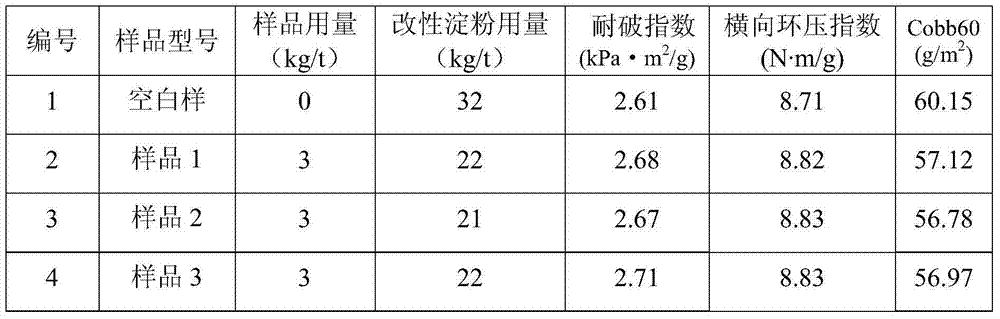

Reinforcing agent for paper surface sizing and preparation method thereof

InactiveCN104499362AReduce product penetrationImprove product utilizationWater-repelling agents additionPaper coatingChemistryEmulsion

The invention relates to a reinforcing agent for paper surface sizing and a preparation method thereof. The preparation method comprises the following steps: modifying part of starch hydroxyl; performing cross-linking reaction for part of a starch modified group and polyvinyl alcohol in the presence of an initiator to obtain a white emulsion cross-linked polymer with a net-shaped structure. The reinforcing agent for surface sizing is low in permeability and high in utilization rate; a complete film can be formed, and thus the breaking resistance, circling pressure and water absorbing performances of paper can be improved; meanwhile; the moisture resistance of the paper can be improved; the use amount of modified starch is obviously decreased under the same strength; the use amount for starch sizing is decreased by about 25%, and use amount for paper surface sizing is decreased by about 40%.

Owner:深圳市瑞成科讯实业有限公司

Bamboo frame molding process

InactiveCN107745425AStress reliefImprove structural stabilityCane mechanical workingReed/straw treatmentEngineeringMoisture

The present invention relates to a bamboo frame molding process, using bamboo frame molding equipment, including the following steps: 1) Bamboo strip production: according to the size of the bamboo frame to be formed, the thickness and length of each layer of bamboo strips are determined to make bamboo strips, And process the butt ends at both ends of the bamboo strips; 2) Pre-setting treatment: arrange the multi-layer bamboo strips and put them into the forming mold of the bamboo frame forming equipment, the forming molds are closed, and the multi-layer bamboo strips are pre-ordered 3) Gluing treatment: Glue the pre-shaped multi-layer bamboo frame; 4) Drying treatment: Dry the multi-layer bamboo frame Dry treatment to make the moisture content meet the requirements; 5) Curing and forming: put it into a forming mold, keep it warm and pressurized for a period of time, make it solidify and form, and make a bamboo frame product. The invention adopts a secondary molding process to ease the stress of the bamboo strips in bending and forming, reduce the amount of glue applied, improve the structural stability of the bamboo frame, and prolong the service life of the bamboo frame.

Owner:FUJIAN SHUANGYI BAMBOO DEV CO LTD

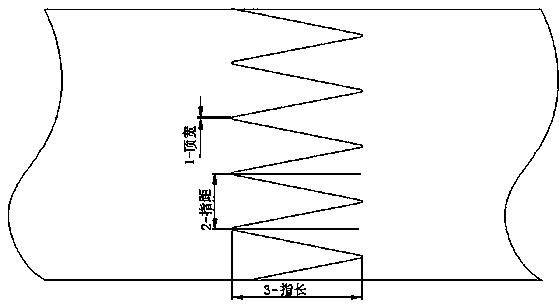

Gluing process of finger joint plate

InactiveCN107571347AQuality improvementReduce the amount of sizingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveFinger joint

The invention discloses a gluing process of a finger joint plate. The finger joint plate is formed in the manner that when 1 / 3-1 / 2 of finger jointing of finger joint wood sheets is finished, an adhesive is sprayed to a gap between sawteeth and grooves of the finger joint wood sheets with high pressure, and finger jointing and bonding are carried out under the hot pressing or cold pressing condition; and the gluing process is characterized in that the adhesive comprises the following raw materials, by weight, including a base stock, a curing agent, a curing promoter, a filler and an ingredientbeing 1:(0.02-0.06): (0.01-0.015): (0.04-0.06): (0.01-0.02). The gluing process technology is based on the environmental protection adhesive, and the aims of reducing adhesive consumption and producing the environmental protection finger joint plate are achieved.

Owner:南宁市森雄木业有限公司

Dry manufacturing method for bagasse fiber board

InactiveCN101745966AImprove surface propertiesImprove mechanical propertiesFlat articlesDomestic articlesFiberPolymer science

The invention discloses a dry manufacturing method for a bagasse fiber board. The method comprises the following steps: thermally grinding bagasse to meet the fiber freeness requirement of between 15 and 24s; adding phenol modified urea resin and paraffin into the bagasse, and mixing the materials to form a board blank, wherein adding amount of the phenol modified urea resin is 3.5 to 5.5 weight percent in the production of a hard fiber board and is 3 to 9 weight percent in the production of a medium-density fiber board, and the adding amount of the paraffin accounts for 1 to 2 percent of the weight of absolute dry fiber; drying the board blank, wherein the water content of the board blank is controlled to be 4 to 8 weight percent in the production of the hard fiber board and 5 to 11 weight percent in the production of the medium-density fiber board; and thermally pressing the board blank to form the bagasse fiber board. The method has the advantages of improving the surface property and physical and mechanical properties of the fiber board, and has no pollution.

Owner:王永

Disc-type wood chip chipper

PendingCN108527585AReduce the amount of scrapLess scrapWood working apparatusWood shavingsEngineering

The invention relates to a disc-type wood chip chipper. The disc-type wood chip chipper comprises a feeding device, a slicing device and a discharging outlet. The feeding device conveys wood chips tobe sliced to the slicing device, and then the wood chips to be sliced are led out through the discharging outlet. The slicing device comprises a horizontally placed feeding disc, and a plurality of slot openings which longitudinally penetrate through are formed in the feeding disc. A discharging rod is arranged above the feeding disc, and a cutter disc is arranged below the feeding disc. The discharging rod is horizontally arranged and moves relative to the feeding disc. The wood chips falling into the feeding disc are scraped down to the slot openings by the discharging rod and drop onto thecutter disc. A plurality of fly cutters are fixed on the cutter disc. The cutter disc and the feeding disc rotate relatively under the action of a driving device. A material guiding slot which is usedfor leading out wood shavings after slicing is formed in the cutter disc, and the material guiding slot communicates with the discharging outlet. The disc-type wood chip chipper realizes transverse slicing of the wood chips, and reduces particle size of the wood shavings.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com