Patents

Literature

168results about How to "Reduce the amount of sewage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

Method for processing sewage from industrial cycle water

InactiveCN101172724AIncrease the concentration factorImprove running qualityScale removal and water softeningMultistage water/sewage treatmentFilter systemEnvironmental engineering

The invention relates to a method for treating industrial circulating water and sewage through the technology of a nano filter film. The invention is characterized in that one part of the sewage is used as the supplementing water of a circulating water system, while the other part is reused after being processed through a nano filter system after the sewage of the industrial circulating cooling water system is flocculated and precipitated and filtered; one part and the other part are added into the circulating water system after being mixed with a certain proportion so as to achieve the reuse of the industrial circulating water, thereby increasing the condensation times of the whole system, decreasing the water implementing quantity and the sewage discharge quantity of the system, and increasing the economic effect of the whole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

One bath super dark dyeing technology of polyester-cotton fabric disperse and reactive dyes

InactiveCN101392462AHigh color yieldGood color yieldDyeing processLiquid/gas/vapor textile treatmentReactive dyeColour fastness

The invention provides a super-dark dyeing technology by dispersing the polyester-cotton fabrics and one bath of the reactive dye, which belongs to a dyeing technology of the fabrics. The technology comprises the following steps: selecting the WW series disperse dyes and C series reactive dyes to soak the pure cotton fabrics into the dyeing solution for one time, then rolling with a squeezer for one time, then pre-baking and baking the cloth, then steaming in a steaming chamber, then washing with water after the steaming, then washing with soap after the water washing, then washing the cloth with water again and drying to finish the dyeing process. The disperse dyes and reactive dyes selected by the dyeing technology has high color yield and good color fastness and the loose color on the fabrics can be completely washed during the soap washing process, therefore, the loose color can not dye the surface of the fabrics, which basically solves the color transfer fastness and wet grinding fastness of the super-dark color. The design of the baking temperature is reasonable, which improves the color yield of the disperse dyes and the color fastness of the dye; the adopted one-bath dyeing process is simple in process flow and low in production cost and the amount of the sewage is few and the dyeing quality is stable.

Owner:HUAFANG

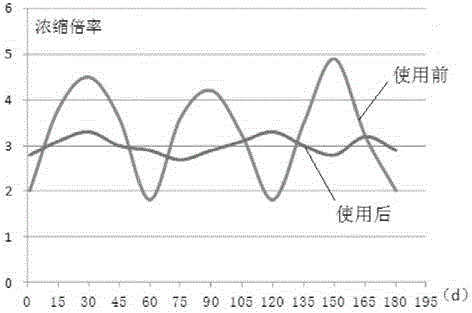

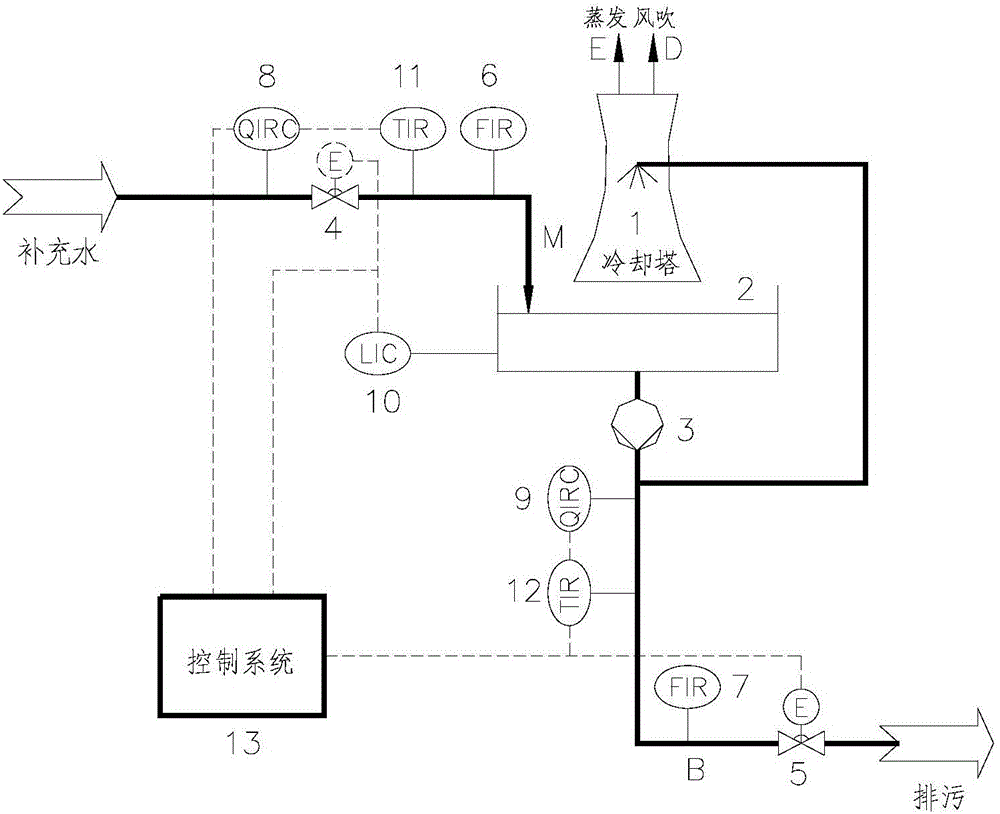

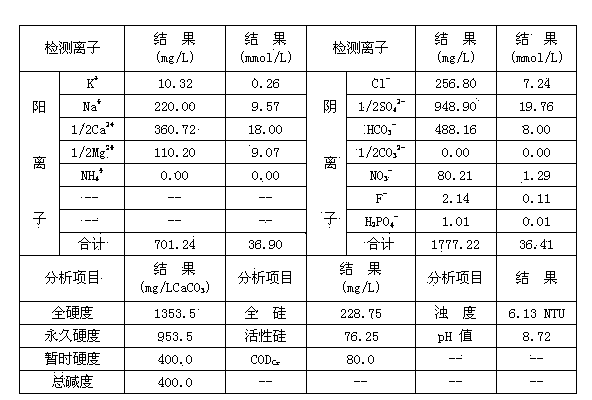

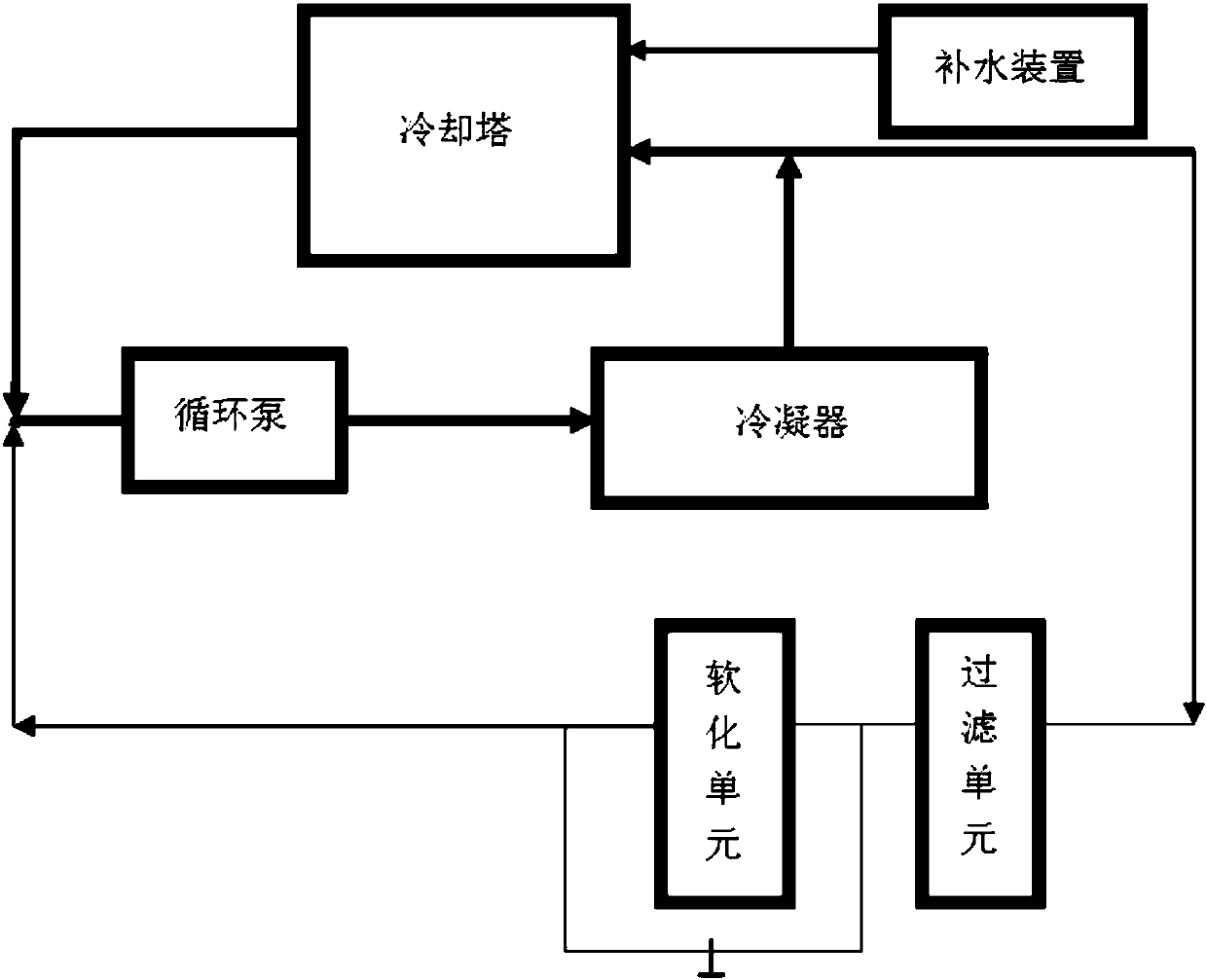

System and method for controlling concentration ratio of open type circulating cooling water system

InactiveCN104991579AReduced manual effortHigh degree of automationControlling ratio of multiple fluid flowsCooling towerControl system

The invention relates to a system and method for controlling the concentration ratio of an open type circulating cooling water system. The system for controlling the concentration ratio of the open type circulating cooling water system includes a control system and a cooling tower; a cooling tower water tank with a cooling tower water tank liquidometer is arranged below the cooling tower; the bottom of the cooling tower water tank is provided with a pollution discharge pipeline; the pollution discharge pipeline is provided with a circulating water conductivity meter, a circulating water temperature gauge, a pollution discharge electric control valve and a pollution discharge flowmeter; a water entering pipeline used for supplementing the cooling tower water tank with water is arranged above the cooling tower water tank; and the water entering pipeline is provided with a water supplementation flowmeter, a water supplementation conductivity meter, a water supplementation electric control valve and a water supplementation temperature gauge, wherein the water supplementation electric control valve is connected with the cooling tower water tank liquidometer. With the system and method of the invention adopted, automatic continuous and stable water supplementation and pollution discharge of the open type circulating cooling water system can be realized; automatic continuous on-line monitoring on the concentration ratio of circulating water can be realized; and concentration ratio fluctuation which is caused by intermittent water supplementation and pollution discharge of the circulating cooling water system can be avoided, so that the quality of the circulating water can be stabilized.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

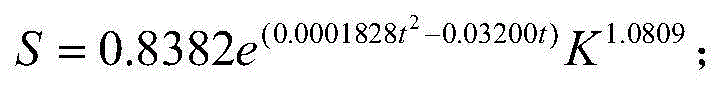

Open industrial circulating-cooling water concentrating ratio and drug concentration balance control method

InactiveCN101071053AReduce consumptionImprove protectionHeat exchange apparatusSimultaneous control of multiple variablesWater sourceWater resources

The invention provides a kind lf balance control way of open style industry recycling cooling water's weight concentration and pharmacy concentration .And weight concentration balance control way mainly controls the amount of water and salt of the industry recycling cooling water system ,according to the weight concentration N to control the add water and sewage water effectively to realize the balance control over the weight concentration of the industry recycling cooling water .And the pharmacy concentration balance control way is carried out on the basis of the weight concentration balance control way ,on the basis of weight concentration no change ,through adjusting and controlling the add water amount and dosing amount's proportion ,making the add dosage equal to the losing dosage in the same time of the system ,so realizing the pharmacy concentration keeping no change in the recycling water .The invention's advantages are saving water source ,keeping water quality stable ,etc.

Owner:任广兴

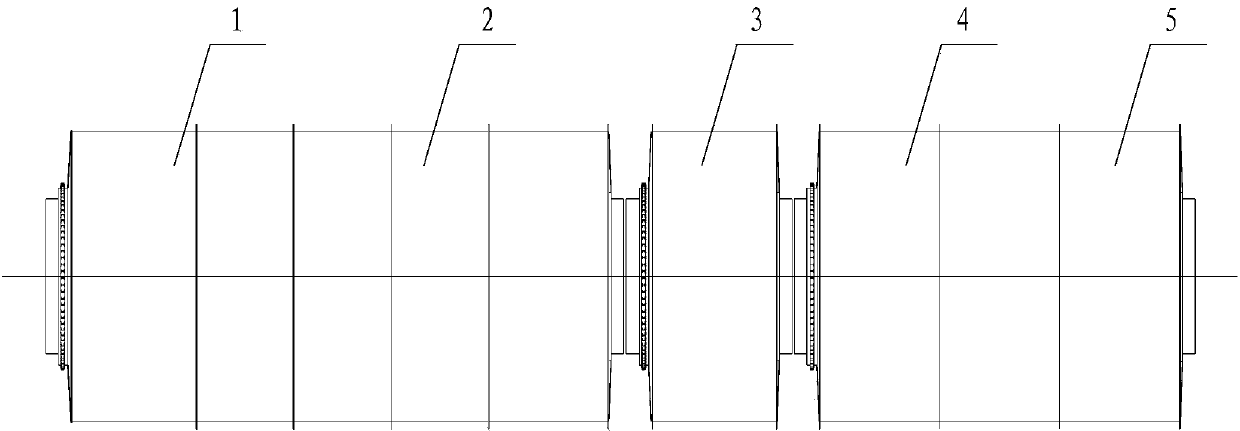

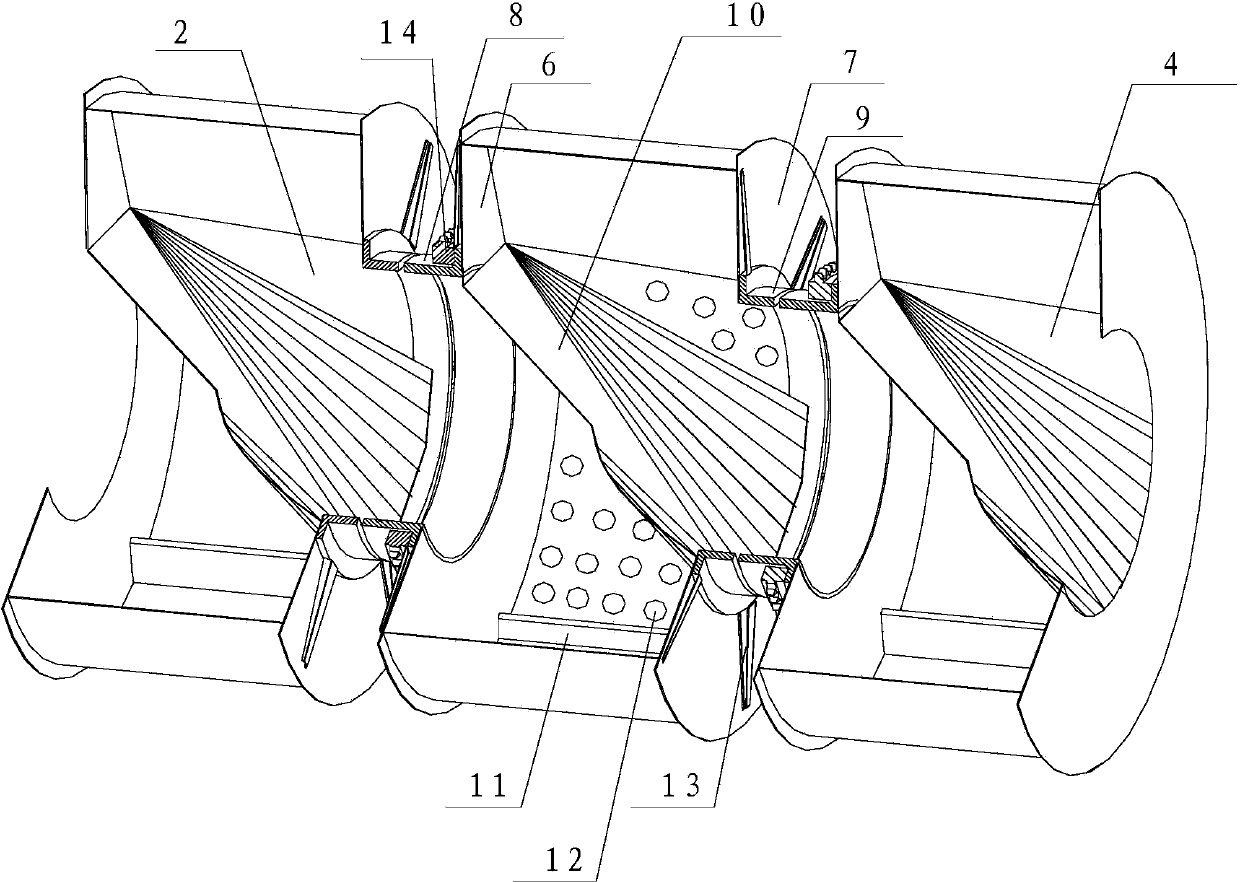

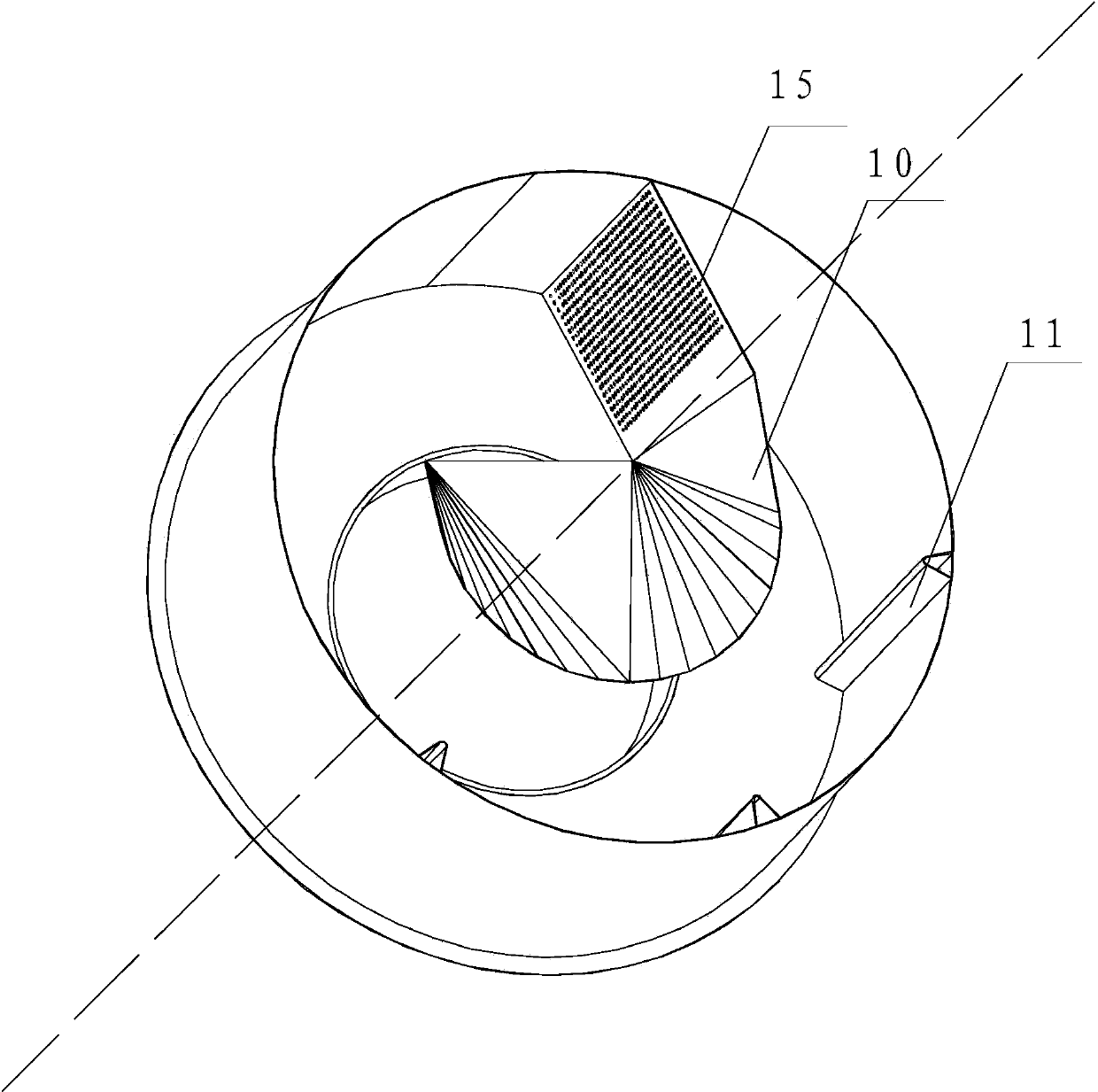

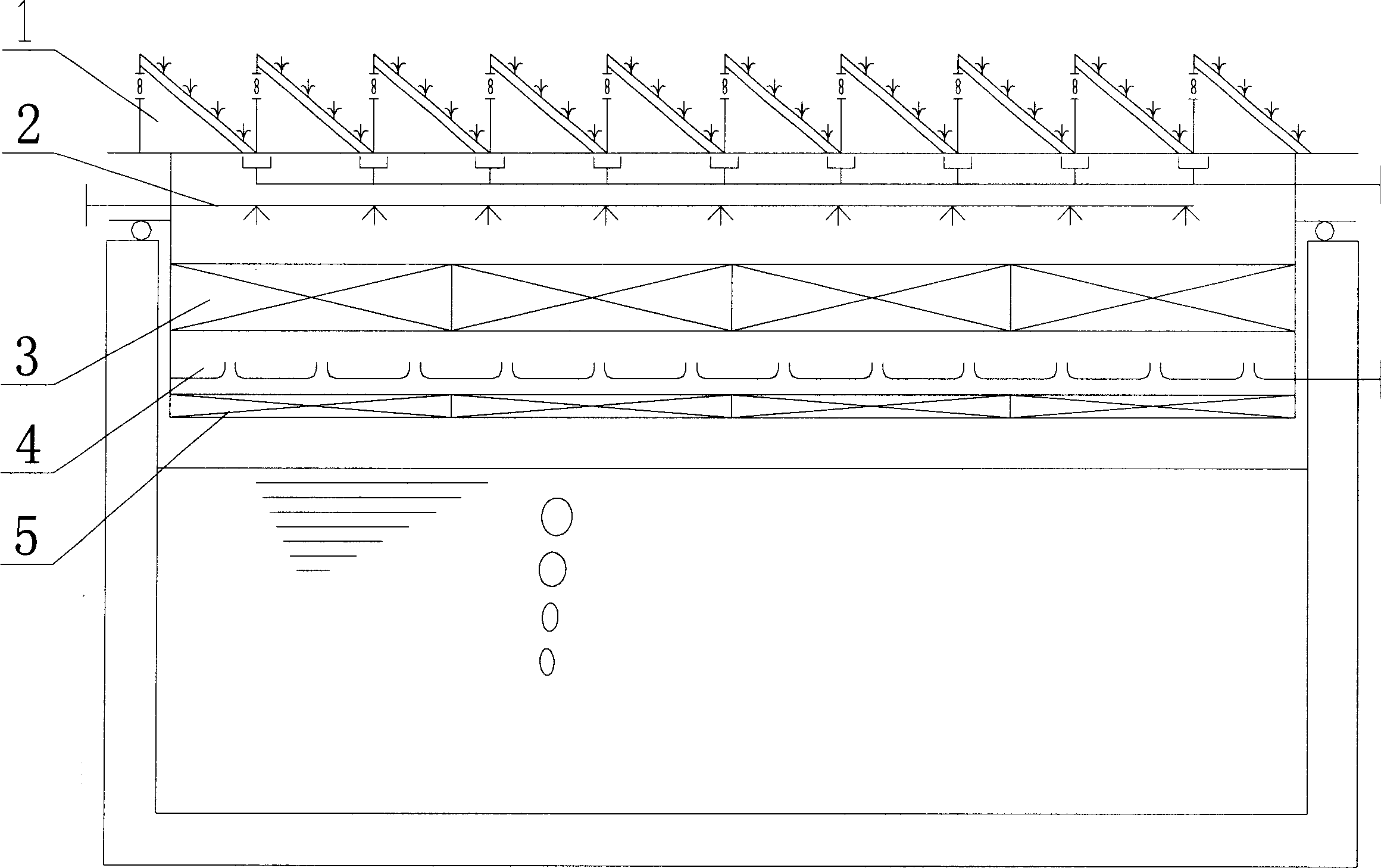

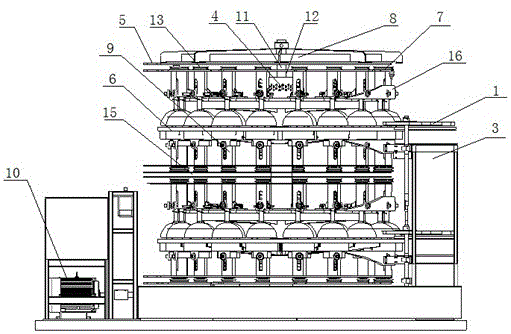

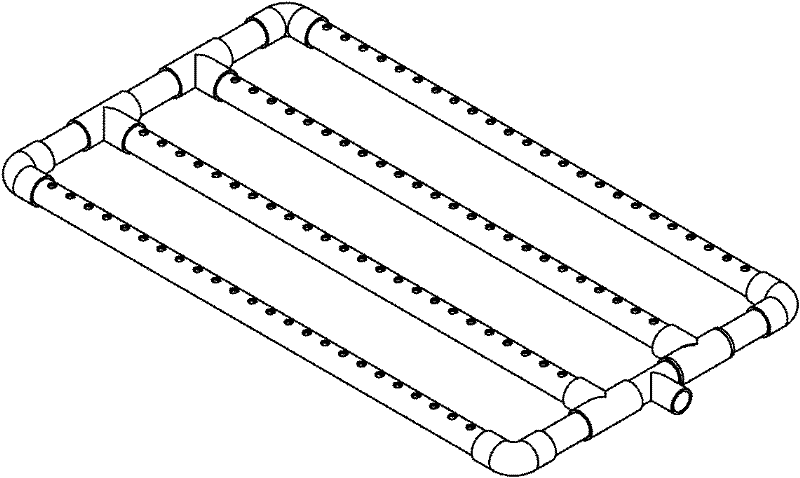

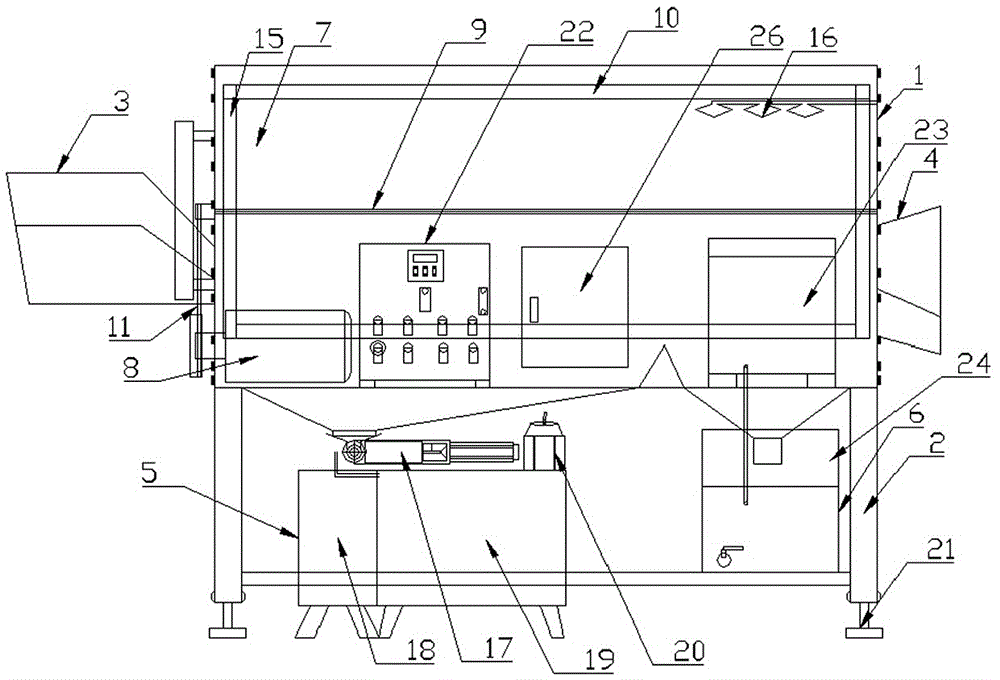

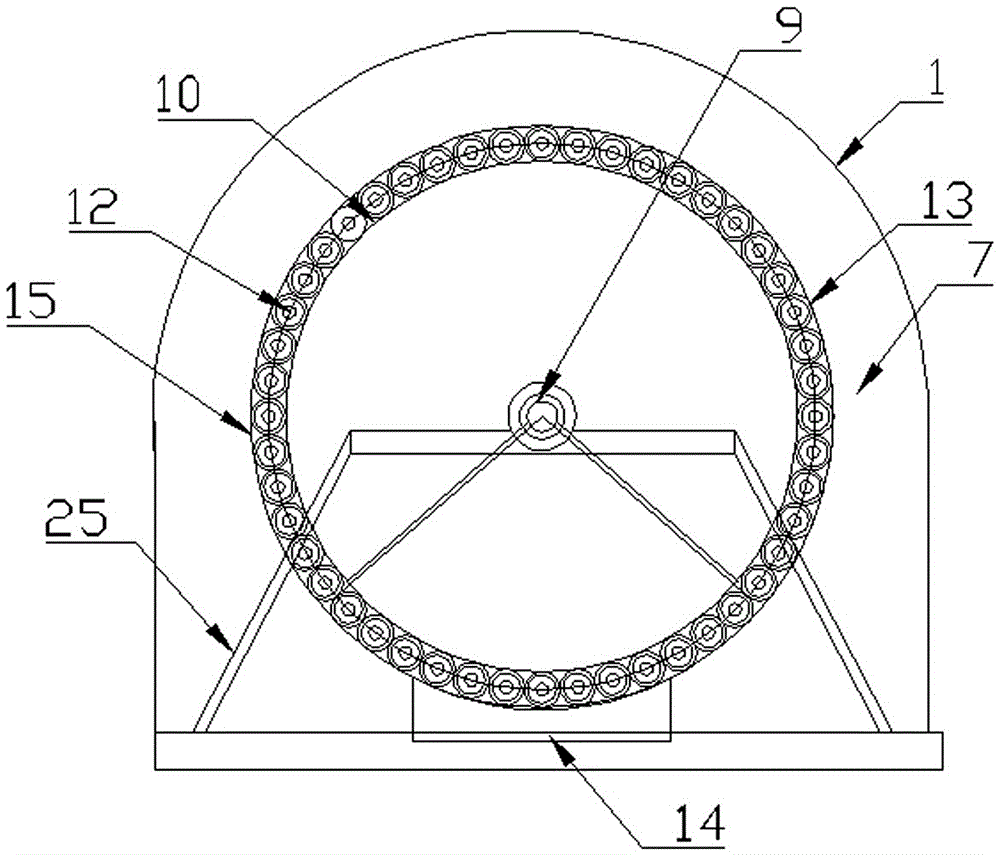

Tunnel type continuous washing machine

InactiveCN103726256AReduce the amount of sewageImprove washing effectOther washing machinesTextiles and paperAfter treatmentEngineering

The invention relates to a tunnel type continuous washing machine, and belongs to the field of washing equipment. The tunnel type continuous washing machine comprises a pre-washing area, a main washing area, a rinsing area and an after-treatment area, wherein a dewatering area is inserted between the main washing area and the rinsing area and comprises an inner barrel and an outer barrel; two panels are respectively fixed at an inlet and an outlet of the inner barrel; an inlet supporting steel ring and an outlet supporting steel ring are respectively fixed on surfaces, which are not fixed on the inner barrel, of the inlet panel and the outlet panel; the inlet supporting steel ring, the outlet supporting steel ring and the inner barrel are integrated; an optional one of the inlet supporting steel ring and the outlet supporting steel ring is connected with an external driving device; a conveying screw plate is fixed in the inner barrel; a through hole is formed in the inner wall of the inner barrel; and the inner barrel of the dewatering area is driven by an independent motor to rotate. By using the tunnel type continuous washing machine, the rinsing efficiency can be effectively improved; water consumed during rinsing is reduced; resources are saved; dewatered cloth grasses are easily rinsed cleanly; and a washing effect is obviously improved.

Owner:SHANGHAI WEISHI MACHINERY

High-efficiency acylation production method of L-methionine nonaqueous solution

InactiveCN102051401AComprehensive cycle process is reasonable and feasiblePurify the environmentFermentationMethionine biosynthesisChemistry

The invention relates to a high-efficiency acylation production method of an L-methionine nonaqueous solution. The novel process is bold in innovation and is mainly a bold reformation to an acylation process. The method comprises the following steps of: directly dripping acetic anhydride into DL-methionine for carrying out an acylation reaction by using acetic acid as a reaction solution, and after the reaction ends, evaporating to recover the acetic acid; directly adding water to acetyl DL-methionine to regulate the pH value without crystallizing; adding biological catalysis enzyme, inorganic catalysis enzyme, and the like; and entering a split procedure. The method is characterized in that the yield of the L-methionine nonaqueous solution reaches 126-128 percent, the sewage discharge quantity is reduced by 2 / 3, and the total yield of the L-methionine nonaqueous solution is improved to 60 percent. The process has reasonable and feasible comprehensive cycle process, conforms to a green and environmental protection idea, purifies the environment, promotes the ecological balance, reduces the production cost and enhances the social and economic benefits.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

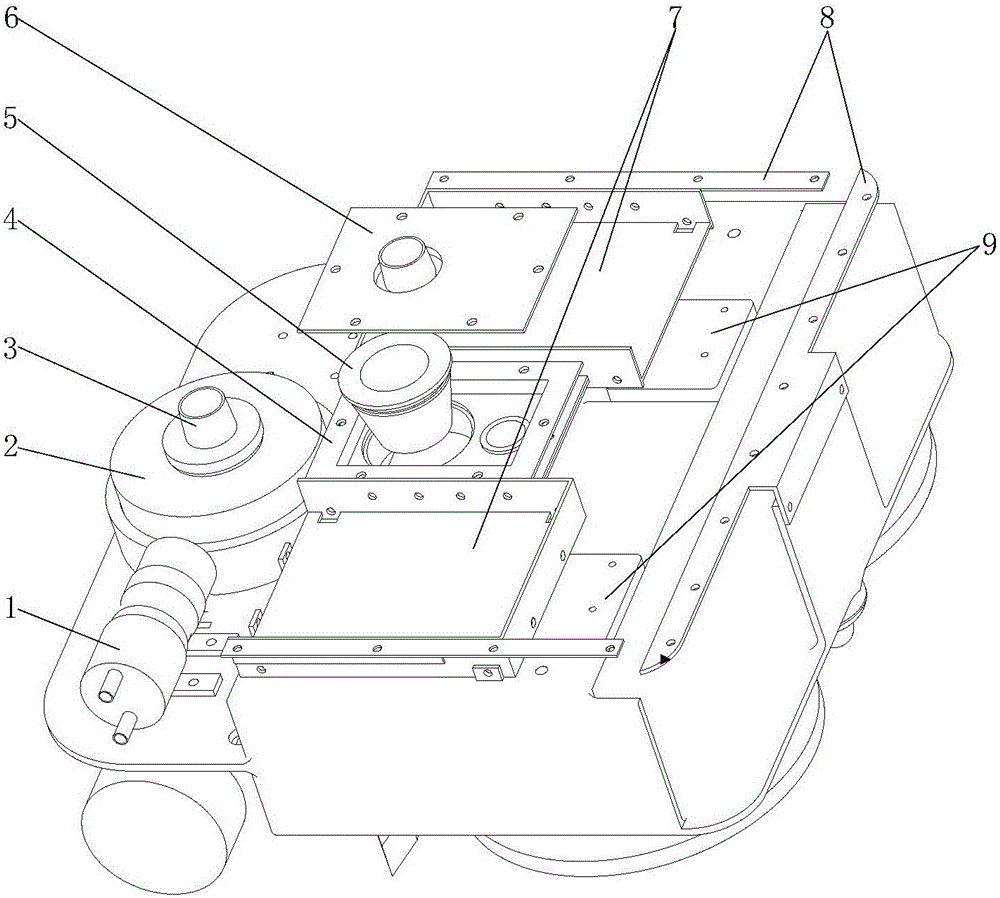

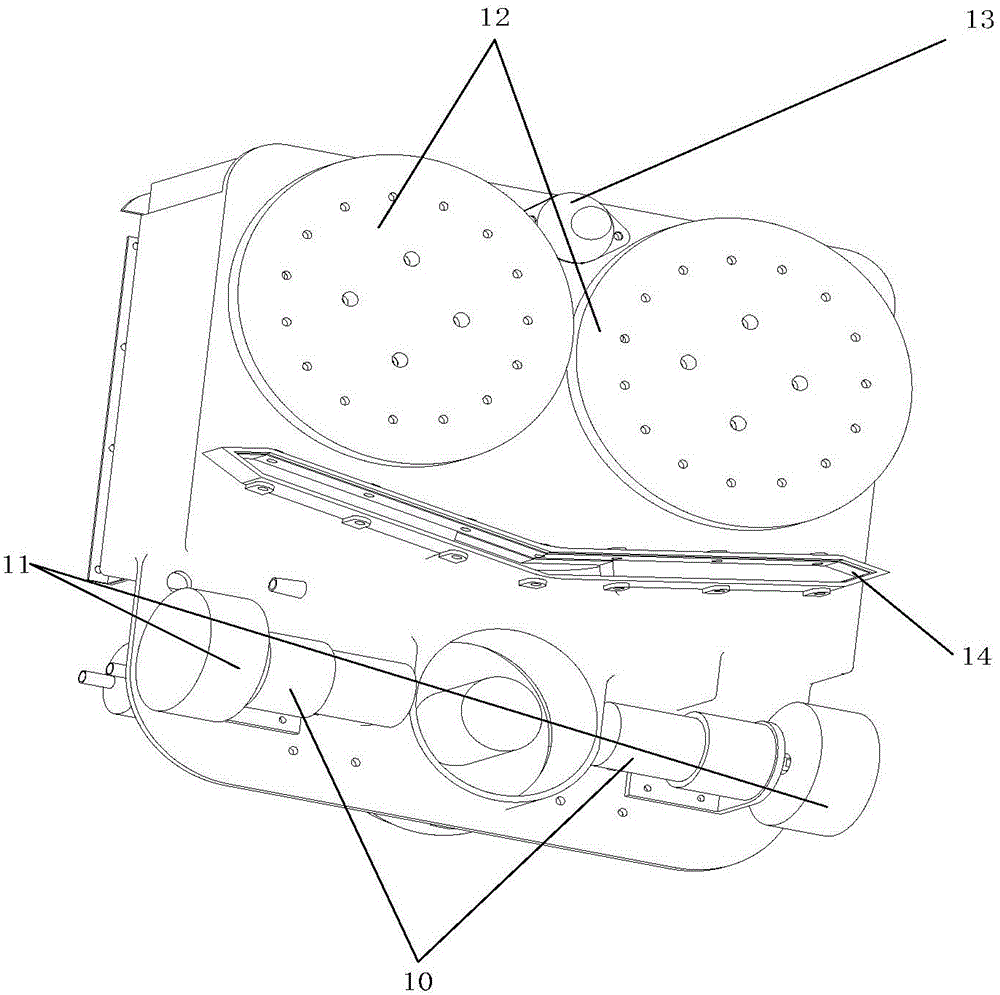

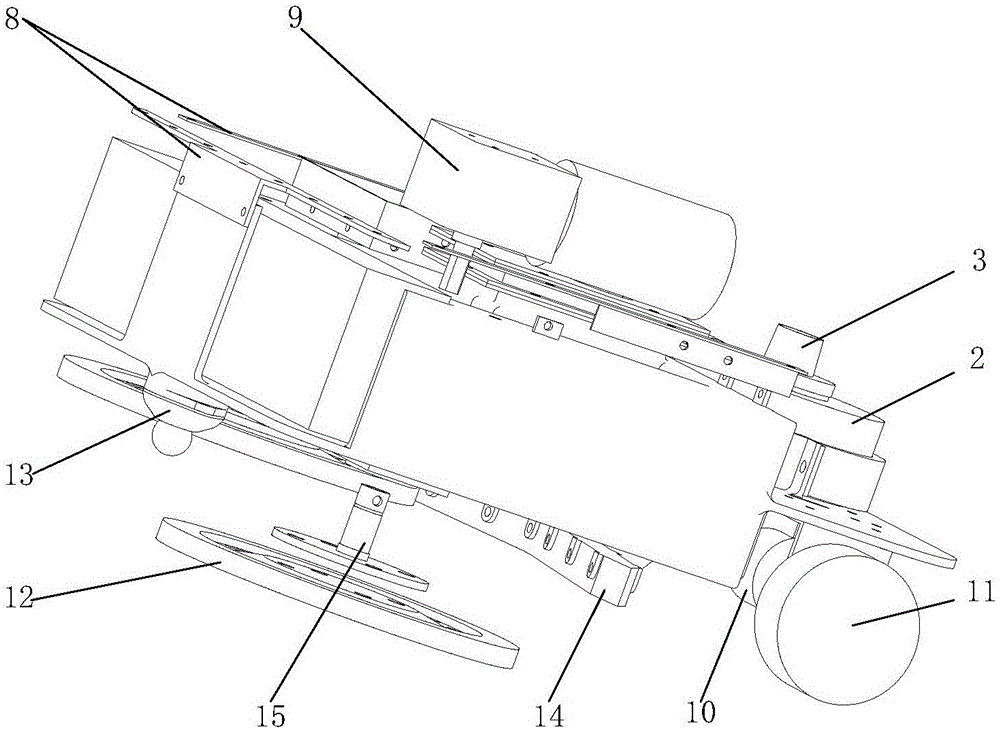

Novel floor mopping robot

InactiveCN106037596ASolve the problem that too much residue affects the cleaning effectSimplify processing and assembly complexityCarpet cleanersFloor cleanersSewageEngineering

The invention discloses a novel floor mopping robot, which comprises a skeleton, wherein a water tank is arranged in the middle of the skeleton; an upper sealing gland and a lower sealing gland are arranged at the upper part of the water tank; a water pump and a fan are fixed to the skeleton of the floor mopping robot by virtue of bolt groups; a fan connecting piece is arranged on the fan; a filter cup is embedded in the middle of the lower sealing gland; sensor fixing brackets are arranged on the sidewalls of the skeleton; distance measuring sensors are arranged on the sensor fixing brackets; a brush disc driving motor is arranged on each of two sides of the water tank; and brush disc driving motor cover plates are arranged on the tops of the brush disc driving motors. According to the robot disclosed by the invention, since the main body structure of the robot is integrally molded, the sealing performance of the structure is guaranteed and the complexity of processing and assembling is simplified; the robot is small and beautiful in form and flexible to move, and the robot is capable of automatically avoiding obstacles; and in addition, sewage, which is generated in a cleaning process, can be recovered, processed and recycled, so that the robot is quite high in environmental protection value and is suitable for commercial popularization and for development and application.

Owner:NANJING UNIV OF SCI & TECH

By-pass flow treatment method for circulating water from power plant

ActiveCN104030498AIncrease available chlorine productionGood removal effectMultistage water/sewage treatmentElectrolytic agentMicroorganism

The invention discloses a by-pass flow treatment method for circulating water from a power plant, which sequentially comprises the following steps: feeding circulating water into a multimedia filter, and filtering; then performing ultrafiltration treatment; feeding ultrafiltered effluent water into a nanofilter, and treating; feeding the obtained nanofilter produced water having zero hardness and serving as electrolyte into an electrolytic bath, and electrolyzing to prepare sodium hypochlorite, wherein the available chlorine content of the produced water after electrolysis is controlled to reach 100 mg / L or above by regulating the flow rate of the electrolyte and electrolysis voltage; and finally feeding back the obtained water solution containing sodium hypochlorite and having zero hardness to the circulating water. According to the method disclosed by the invention, based on the characteristics of the circulating water such as high water temperature, high salt content and the like, the circulating water is electrolyzed to prepare the sodium hypochlorite, both the high temperature and the high salt content are beneficial to increase the yield of the available chlorine generated by electrolysis, the circulating water enriched with the sodium hypochlorite is fed back to the circulating water system without the introduction of foreign impurities, the continuous sterilization treatment of the circulating water is realized, and the influence of microorganism growth on the circulating water system is effectively reduced.

Owner:STATE GRID CORP OF CHINA +2

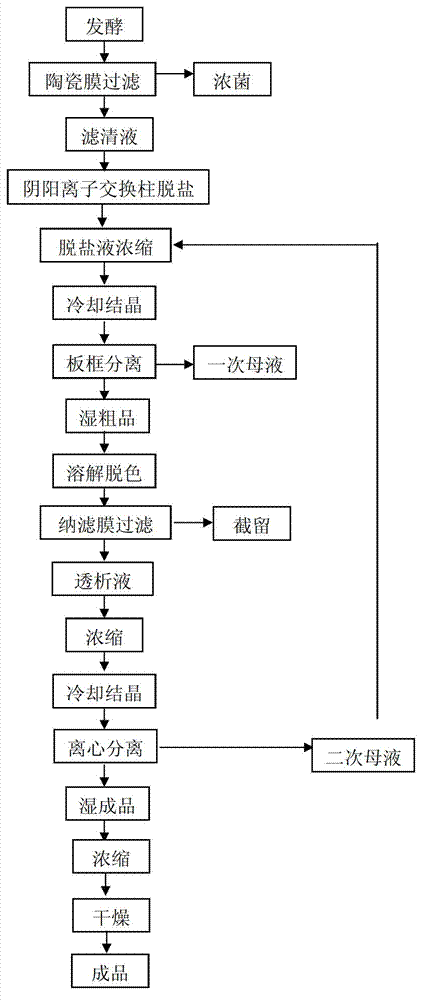

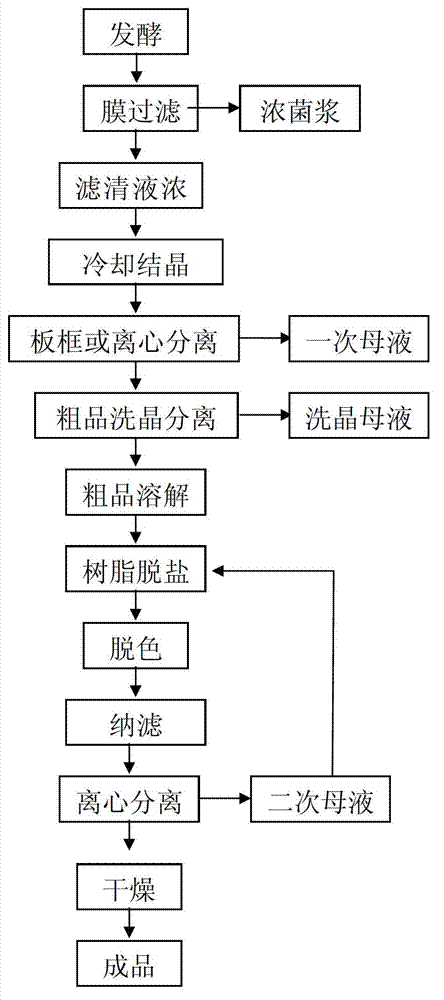

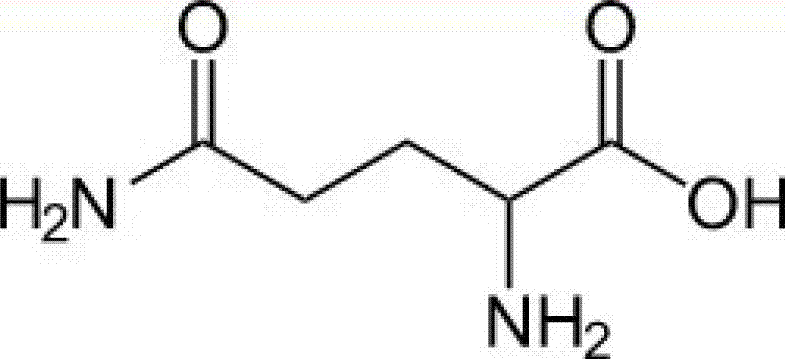

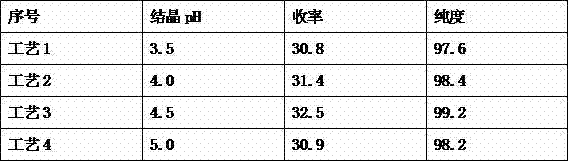

Method for extracting glutamine from fermentation liquor

ActiveCN102924321AHigh purityReduce lossesCarboxylic acid amide separation/purificationSewageIon-exchange resin

The invention belongs to the technical field of fermentation and discloses a method for extracting glutamine from fermentation liquor. The method comprises the following steps of: cooling and filtering glutamine fermentation liquor, concentrating, cooling and crystallizing the obtained filtrate, and separating to obtain a crystallized crude product; adding 30-60 weight percent of water for washing the crystal, and separating to obtain a crude product in which the crystal is washed; and adding water for dissolving, sequentially adding a cation exchange resin and an anion exchange resin for removing salt, and filtering to obtain desalted liquid; performing nanofiltration to obtain nanofiltration liquid, decolorizing and filtering to obtain decolorized solution, concentrating, cooling, crystallizing, separating and drying to obtain glutamine. According to the method, the crude product is washed and crystallized, most of impurities on the surface of the crystallized crude product are removed, and the amount of the desalted resin is reduced, so that the sewage quantity is reduced, the energy consumption is reduced, and the pollution is reduced; and meanwhile, the method of sequentially adding the cation exchange resin and the anion exchange resin into the feed liquid is used for desalting, the glutamine loss caused by long desalting period is greatly reduced, and the yield of the glutamine is improved.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

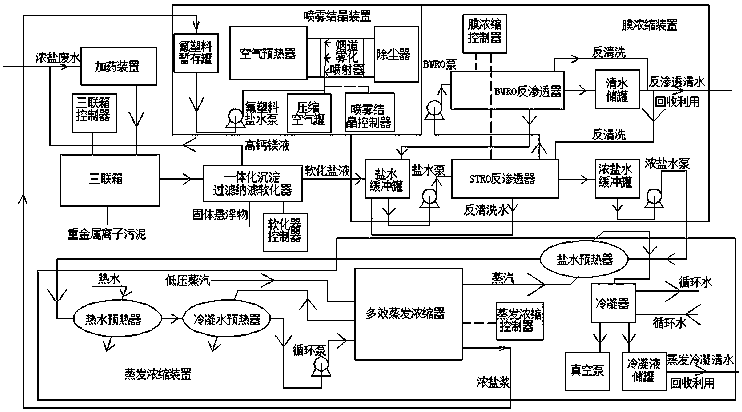

Concentrated salt waste water composite zero discharge system and process

PendingCN108275823AReduce energy consumptionLess investmentTreatment involving filtrationMultistage water/sewage treatmentSalt-wastingSoft water

The invention belongs to the technical field of water treatment and particularly relates to a concentrated salt waste water composite zero discharge system and a concentrated salt waste water composite zero discharge process. The concentrated salt waste water composite zero discharge process is characterized by comprising the following steps: (1) reducing the hardness of calcium and magnesium ionsof to-be-treated concentrated salt waste water; (2) performing softening treatment on the concentrated salt waste water; (3) performing twice membrane concentration crystallization treatment on the soft water part of the treated water; (4) performing evaporation crystallization treatment on the concentrated salt water subjected to the first-time membrane concentration crystallization treatment; and (5) performing spraying crystallization on concentrate salt slurry and recovering the crystal salt after spraying crystallization into smoke. The system and the process have the following beneficial effects: the system is low in energy consumption, low in system investment, reliable in operation, low in treatment cost and small in sewage quantity, the operation of the subsequent dust-removing equipment is not influenced, mixed salt products are not generated, the crystal salt does not need to be subjected to one-step treatment, and the operation stability of the whole system is guaranteed.

Owner:SHANDONG AONENG ELECTRIC POWER SCI & TECH

Method for producing aluminum fluoride and co-produced high-molecular ratio cryolite

ActiveCN105502451AReduce concentrationStable concentrationAluminium fluoridesAluminum fluorideAluminium hydroxide

The invention discloses a method for producing aluminum fluoride and co-produced high-molecular ratio cryolite. The method comprises the following steps: (1) preparation of aluminum fluoride: heating fluosilicic acid of which the concentration is 13 to 14 percent to be 65 to 75 DEG C through a heat exchanger, and carrying out a stirring reaction on the fluosilicic acid and aluminum hydroxide under 70 to 80 DEG C for 12 to 16 minutes; then obtaining the aluminum fluoride through filtering and desiliconizing, crystallizing, drying, calcining and cooling; (2) preparation of the high-molecular ratio cryolite: carrying out the stirring reaction on a filtered aluminum fluoride mother solution and sodium fluoride under 80 to 90 DEG C for 50 to 60 minutes, filtering a reactant after the reaction is completed, feeding filtrate in a sewage pool for being treated, carrying out flash drying on a filter cake under 120 to 150 DEG C, and obtaining the high-molecular ratio cryolite. The aluminum fluoride prepared by the invention is low in concentration, is stable and is high in yield; the co-produced high-molecular ratio cryolite is high in quality and also high in yield; meanwhile, only the aluminum fluoride mother solution is brought in sewage during a production process, so compared with other production technologies, the method disclosed by the invention has the advantages of less sewage quantity and easiness in treatment.

Owner:湖北祥福化工科技有限公司

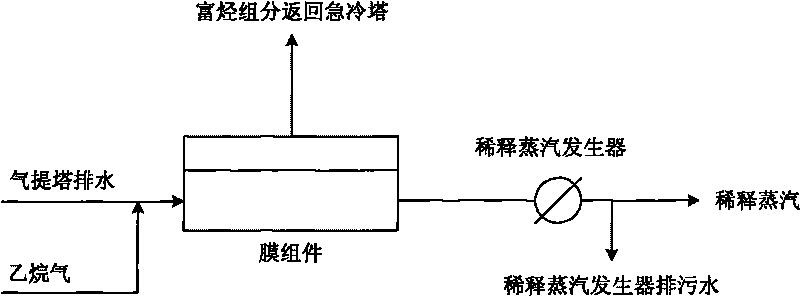

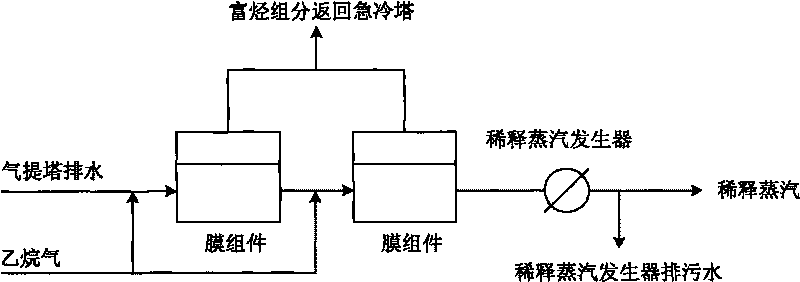

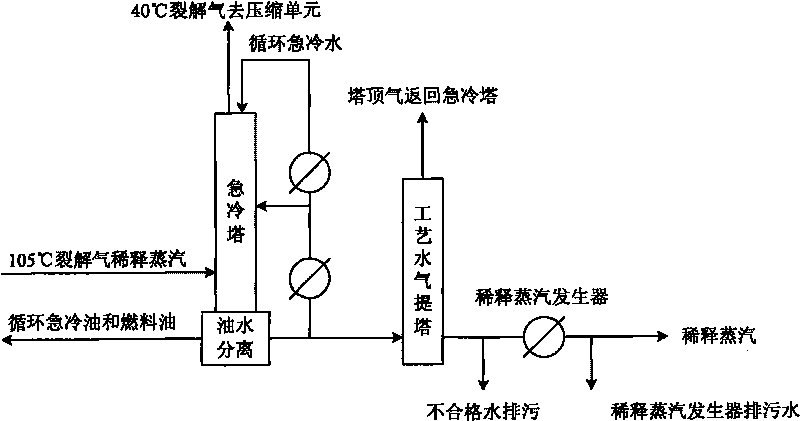

Processing method of water flowing out of technological water stripper of ethylene unit

ActiveCN101734737AImprove water qualityGood removal effectWater/sewage treatment by heatingSaline waterWater quality

The invention provides a processing method of water flowing out of a technological water stripper of an ethylene unit. In the invention, hydrocarbon and acid gas dissolved in water flowing out of the technological water stripper is removed by a vacuum membrane distillation method which mixes inert gas in inflowing water, so as to improve water quality of inflowing water of a diluting vapor generation system. The method not only further lowers content of hydrocarbon and acid gas in water flowing out of the technological water stripper, avoids scaling of the diluting vapor generation system, prolongs running period of the device, and reduces sewage water discharge amount of the diluting vapor generation system, usage of desalted water of ethylene unit and usage of system corrosion inhibitor.

Owner:CHINA PETROLEUM & CHEM CORP +1

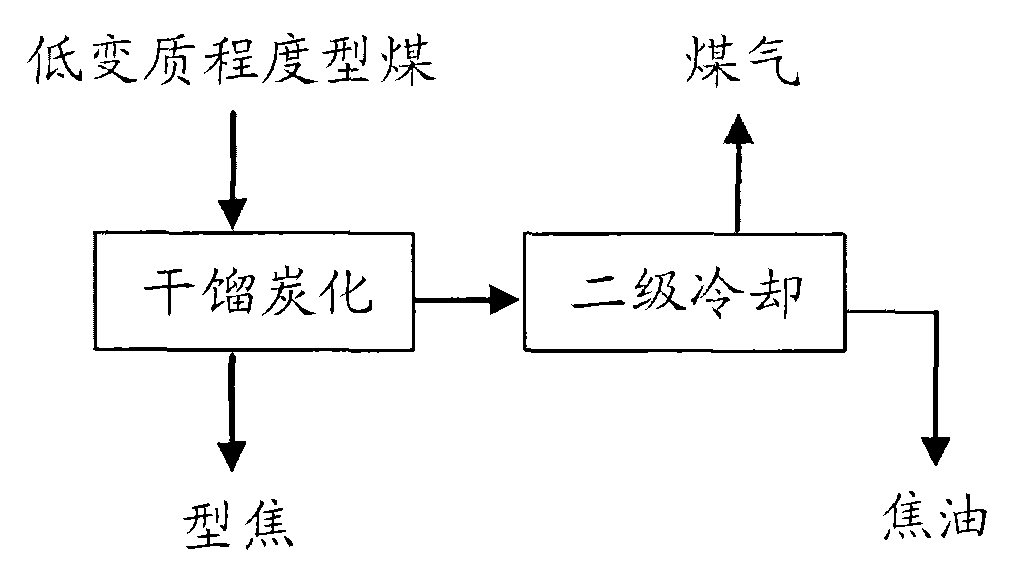

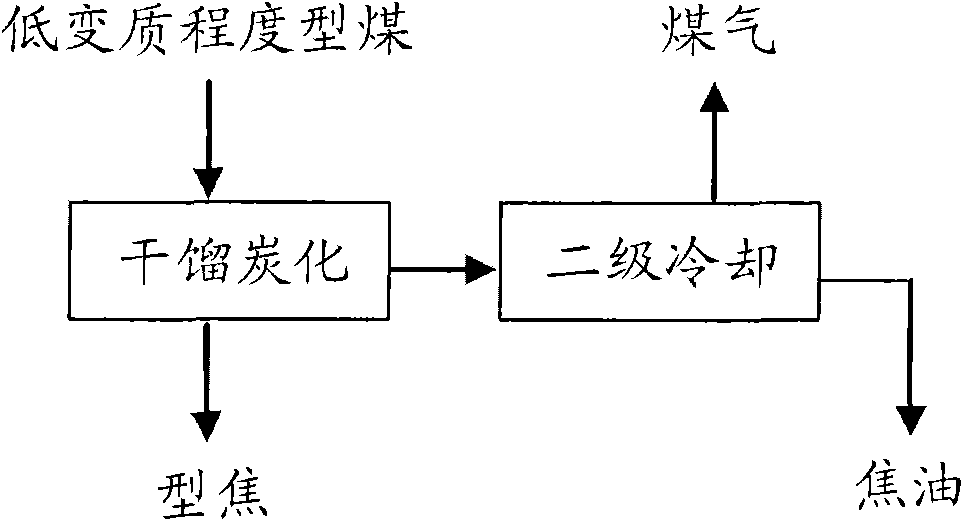

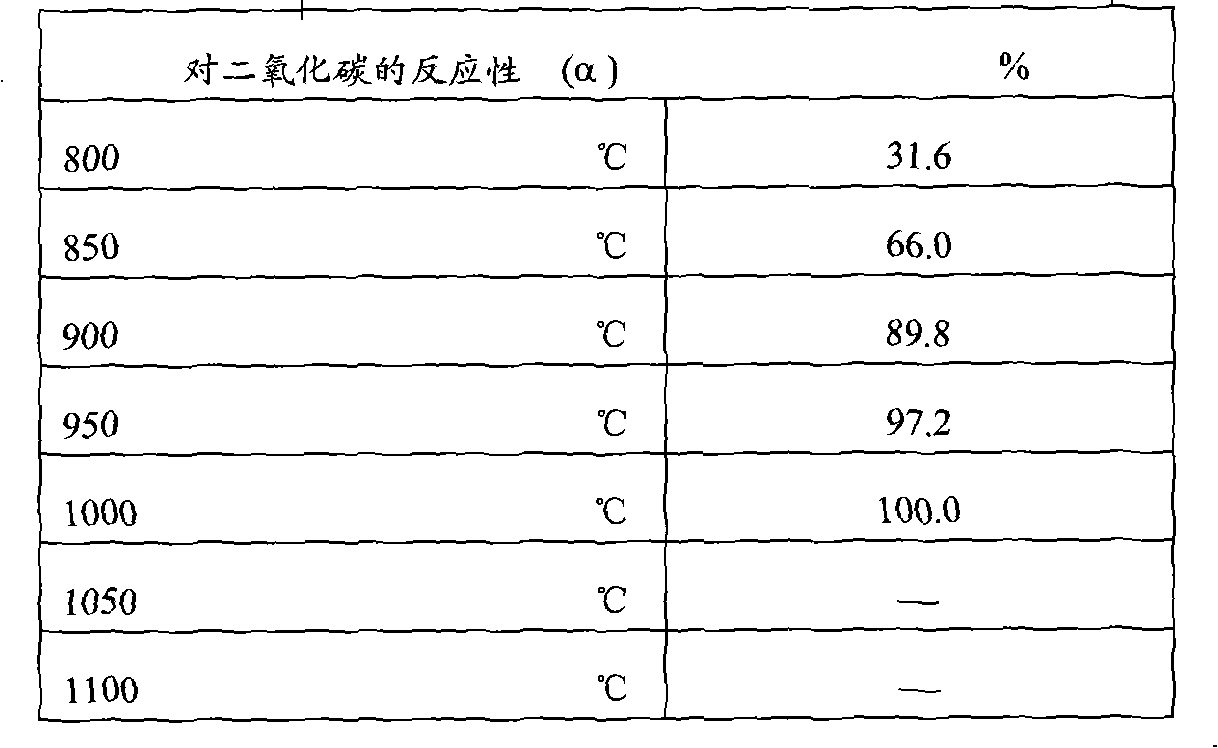

Formed coke and production method of formed coke, coal gas and tar

ActiveCN101775321AHigh calorific valueHigh strengthSolid fuelsIndirect heating destructive distillationTarThermal stability

The invention relates to formed coke and a production method of formed coke, coal gas and tar. The mass percent of dry base volatile components of the formed coke is lower than 10 percent, the mass percent of the dry base fixed carbon content is more than 70 percent, the cold pressure intensity is higher than 400 N / ball, the thermal stability is higher than 90 percent, and the dry base high-position heat generation quantity is more than 6000 cal / g. The production method comprises the following steps: using binderless hot pressing moulded coal of low-deterioration dgree coal as raw materials to carry out dry distillation in an external heating type dry distillation device at the temperature between 550 and 1000 DEG C for obtaining the formed coke; and then, obtaining the coal gas and the tar through indirectly cooling and separating obtained gaseous products. The formed coke produced by the method of the invention has low production cost and good reactive activity, and the production process is simple and effective.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Waste gas purifier and application

ActiveCN1768908AReduce the amount of sewageReduce power consumptionDispersed particle separationAir quality improvementSmall footprintEnvironmental engineering

The invention discloses a device for purifying the industrial waste gas and relative application, especially providing a waste gas purifying device which can be directly used in waste gas generating area to purify and remove fetor. The invention comprises a biological packed layer component and a spray component above the biological packed layer component. Wherein, the biological packed layer component comprises: one or several parallel packed beds, inside which there is the stuff for carrying microbes, to form the integration continuous biological purify reaction area, which takes 30-150% area of waste gas generator. Compared to present technique, said invention has simple structure, smaller accommodation area, reliable operation, lower power consumption, lower cost, and environment-friendly, which can apply the industrial waste gas purify treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

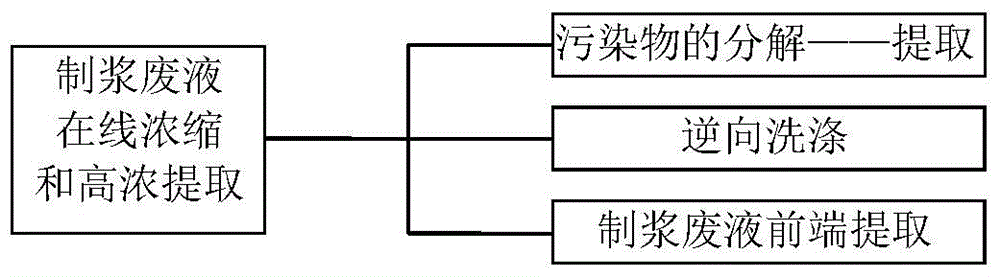

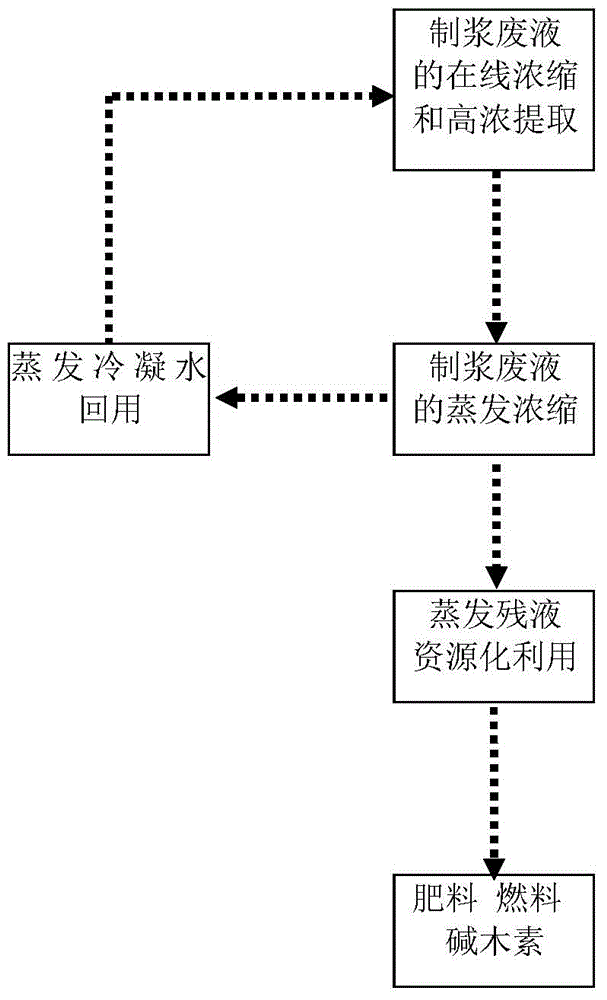

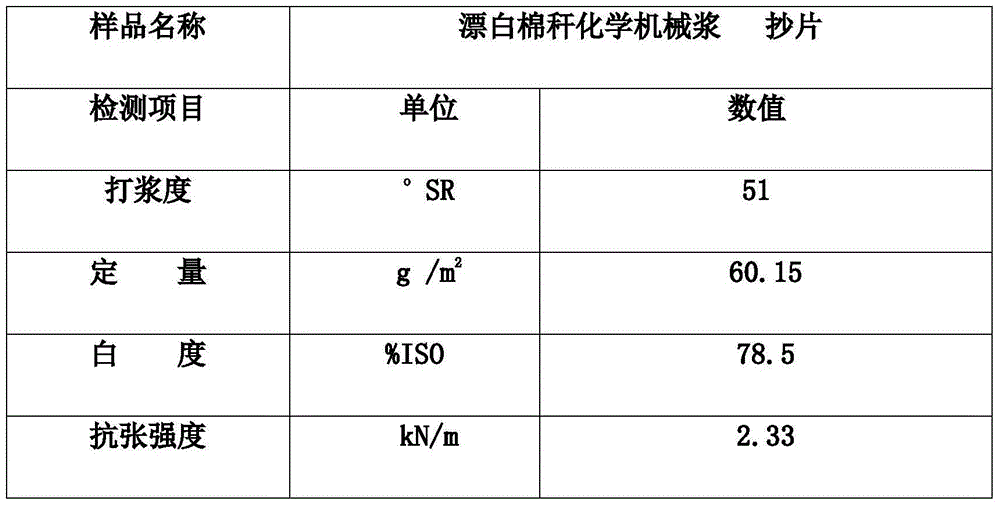

Zero-discharge online high concentration extraction process for chemimechamical pulp pulping waste liquid

ActiveCN104928963AReduce the amount of sewageGood for evaporation and concentrationWashing/displacing pulp-treating liquorsPulp bleachingFertilizerChemistry

The invention discloses a zero-discharge online high concentration extraction process for a chemimechamical pulp pulping waste liquid. Online high concentration extraction is carried out on the pulping waste liquid and the high concentration waste liquid is evaporated and concentrated. Evaporated condensate water is recycled to a pulping production process and resource utilization of an evaporated residual liquid is carried out so as to realize zero discharge of the pulping waste liquid. Online high concentration extraction of the pulping waste liquid comprises the process links: decomposition-separation of pollutants; counter flow washing; and front-section extraction; the evaporated condensate water is recycled to material washing and dosing to impregnate and bleach; resource utilization of the evaporated residual liquid comprises production of fertilizers and alkali lignin and alkali recovery. On the basis, a conventional chemimechamical pulp process is redesigned.

Owner:白博

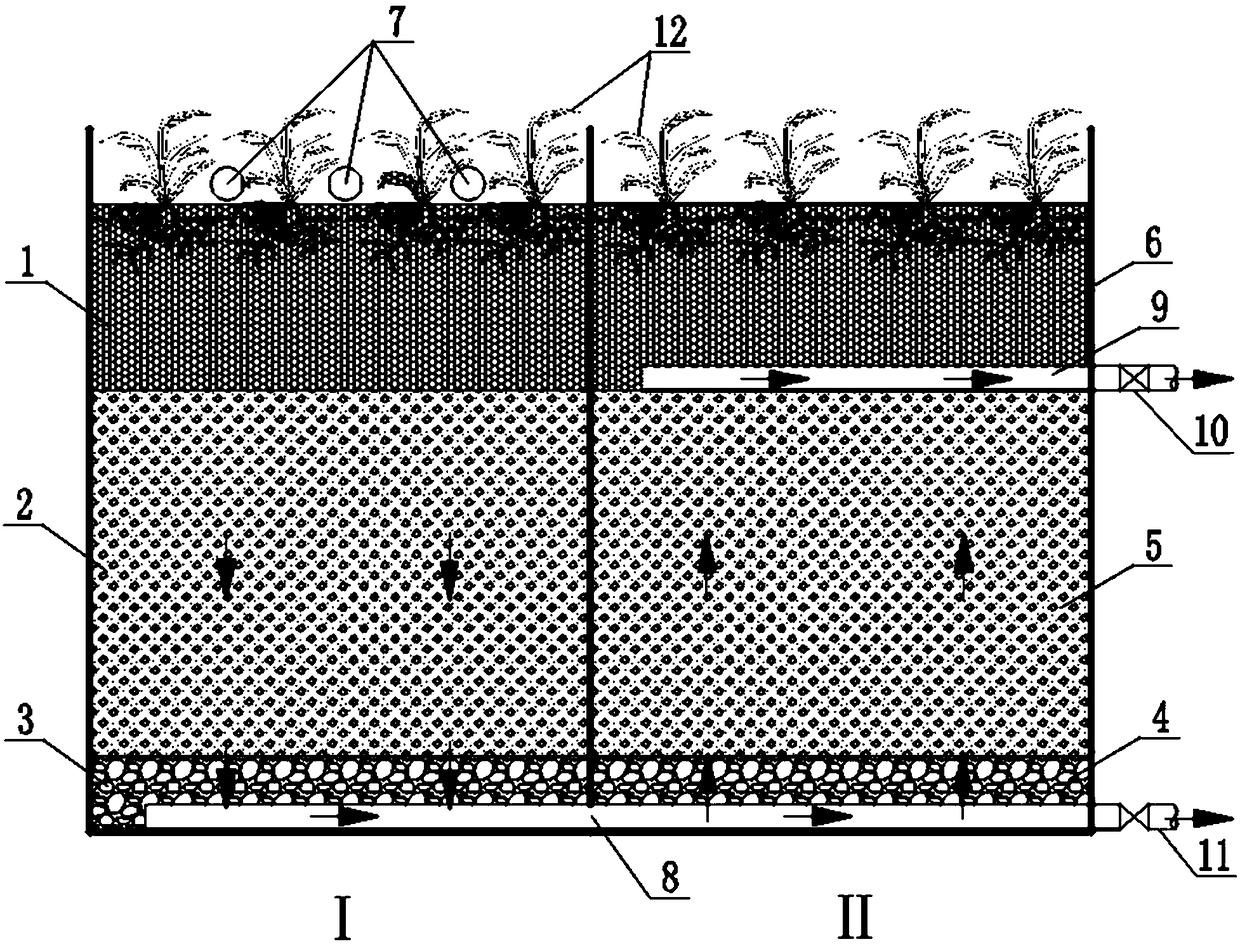

High-load artificial wetland system with enhanced nitrogen and phosphorus removal function

ActiveCN109384315AGuaranteed treatment effectReduce operating expensesWater contaminantsTreatment with aerobic and anaerobic processesConstructed wetlandDraining tube

The invention discloses a high-load artificial wetland system with an enhanced nitrogen and phosphorus removal function. The system comprises a wetland I and a wetland II which are communicated at thebottom, wherein the wetland I comprises water sprinkling devices, a first packing layer, a second packing layer and a first broken rubble layer which are laid from top to bottom; the wetland II comprises a second broken rubble layer, a third packing layer and a fourth packing layer which are laid from bottom to top; the artificial wetland system further comprises a water collecting and distributing pipe and a drain pipe, the water collecting and distributing pipe is arranged in the first broken rubble layer and the second broken rubble layer and used for communicating the bottoms of the wetlands on the left side and the right side; the water collecting and distributing pipe is connected with the drain pipe; a water collecting and draining pipe is arranged at the bottom of the fourth packing layer of the wetland II and provided with an electrically operated valve which is used for controlling draining time of the system. The system is simple in structure, high in integration level, high in hydraulic loading, good in nitrogen and phosphorus removal effect and lower in investment and operating cost, consumes no energy during oxygen supply and is not prone to blocking.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI +1

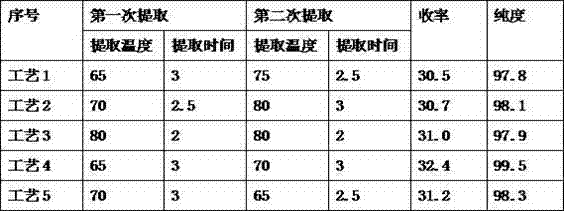

Method for preparing high-purity hesperidin

InactiveCN104119411AReduce the amount of sewageMeet the requirements of energy saving and emission reductionSugar derivativesSugar derivatives preparationIndustrial scaleChemistry

The invention relates to a method for preparing high-purity hesperidin, which belongs to the technical field of traditional Chinese medicine extraction and is used overcoming the technical defects that the purity of hesperidin prepared by using a conventional preparation process is relatively low and the energy consumption is large and the environment is severely polluted in the preparation process. The method for preparing high-purity hesperidin comprises the steps of impurity removal, gradient extraction, crystallization separation and the like. Not only is a product prepared by using the method high in purity, but also the energy consumption is low and the environment pollution is low in the preparation process, so that the method is applicable to popularization and application on industrial scale.

Owner:四川天予植物药业有限公司

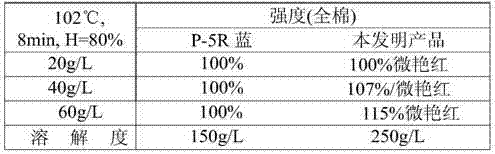

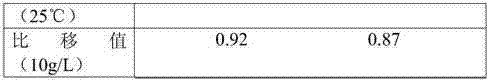

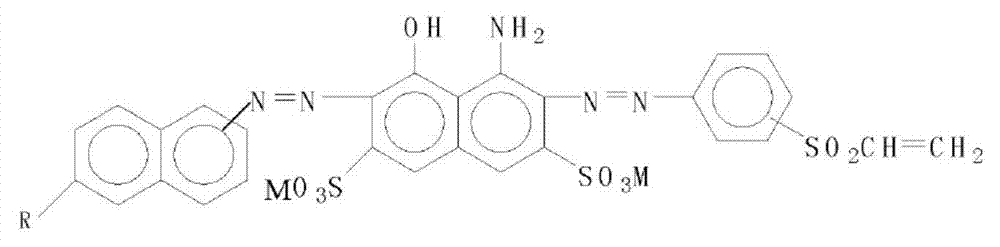

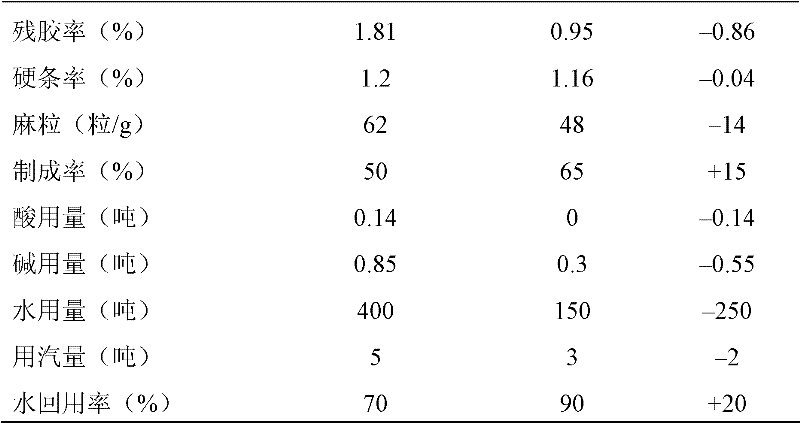

Blue reactive dye for printing, and preparation methods thereof

InactiveCN103709784ABright colorExcellent fastness performanceReactive dyesDyeing processColour fastnessStructural formula

The invention discloses a blue reactive dye for printing, and preparation methods thereof. The blue reactive dye has a structural formula shown as formula (1). The invention also discloses three different preparation methods of the blue reactive dye. The reactive dyes prepared by the three methods all blue printing reactive dyes with excellent color fastness such as washing durability, rub resistance and sunlight fastness, and meet the requirements of various indexes.

Owner:ZHEJIANG JINGGUANG IND

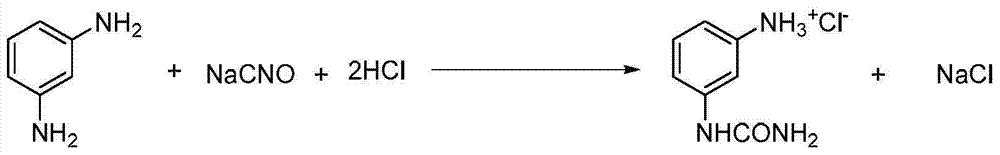

Clean production process of m-carbamidoaniline hydrochloride

ActiveCN103539705AEmission reductionAvoid reactionUrea derivatives preparationOrganic compound preparationReaction temperatureSodium cyanate

The invention discloses a clean production process of m-carbamidoaniline hydrochloride. The clean production process comprises the following steps of: dissolving m-phenylenediamine into a sodium chloride salt water reaction system; adding an auxiliary agent into the reaction system; controlling a reaction temperature at -5 DEG C to 25 DEG C; then adding sodium cyanate and hydrochloric acid for reaction; and after the reaction is completed, carrying out post-treatment on a resulting substance to obtain m-carbamidoaniline hydrochloride, wherein the auxiliary agent is nitric acid or nitrate. According to the clean production process, salt water, instead of pure water, is used as base water, m-carbamidoaniline hydrochloride produced in the reaction can be separated out in time by using salt precipitation effects of sodium chloride, a byproduct diurea is not generated, the purity of the obtained m-carbamidoaniline hydrochloride is more than 98%, the yield is more than 95%, the content is 75%-80%, the sewage quantity is reduced by 50%, and the process is simple and high in automation degree.

Owner:ZHEJIANG RUNTU INST

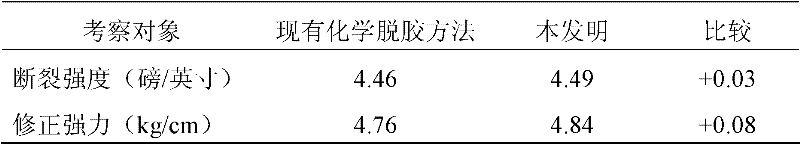

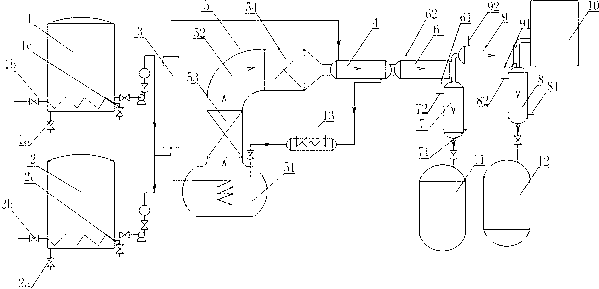

Manufacturing method of ramie based on sectioned circulation

ActiveCN101624727BGet rid of dependenceReduce dosageMechanical treatmentBacteriological rettingChemical treatmentCarding

The invention discloses a manufacturing method of ramie based on sectioned circulation, belonging to the manufacturing method of textile fibre and solving the problems that the prior method has a large quantity of waste water, serious pollution and high cost. The method comprises following steps: pretreatment of primary ramie, chemical treatment, biological treatment and post treatment; the pretreatment improves the degree of looseness of the primary ramie through beating, ultrasound or extraction; the biological treatment degrades pectin, hemicellulose and others impurities through bio-enzyme or microbial fermentation; the chemical treatment further degrades residual pectin and others impurities through alkali boil-off; the post treatment obtains refined dry ramie by beating, whitening, water scrubbing, dehydration, oil feeding, drying, carding and baking. The quality of the product meets the requirements of first-class GB / T 20793-2006, the degumming yield rate is improved by 15%, the water consumption is reduced by at least 60%, the method is free from using acid, the alkali charge is reduced by 65%; water, the alkali and the bio-enzyme used in each step are recyclable; the byproducts can be recycled in time, the sewage quantity is small and the pollution level is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Device and method for producing biodiesel with illegal cooking oil and waste engine oil

InactiveCN103013554AGood choiceReduce sulfur contentBiofuelsLiquid hydrocarbon mixture productionFixed bedGasoline

The invention provides a device and a method for producing biodiesel with illegal cooking oil and waste engine oil. The device comprises an illegal cooking oil settling tank, a waste engine oil settling tank, a mixer, a heat exchanger, a tower-type fixed bed reactor, a condensing system, a gas storage tank, a diesel tank and a gasoline tank, wherein the mixer is connected with the heat exchanger; the heat exchanger is connected with the lower part of the tower-type fixed bed reactor through a preheater; and the condensing system is connected with the heat exchanger. The method comprises the following steps: pretreating, performing catalytic cracking reaction and collecting a product. The produced biodiesel is light yellow in color, has the condensing point of about minus 5 DEG C, has good low temperature fluidity, has a heat value far higher than that of the conventional biodiesel, and has stable product quality; environment pollution is reduced, and a decoloring step is not required; the tower-type fixed bed reactor is applied to the catalytic cracking reaction, so that the method has the advantages of convenience in heating, small investment, easiness in control of treatment amount and low operating cost; and a catalyst can be recycled, so that the device and the method are suitable to be popularized and applied.

Owner:青岛福瑞斯生物能源科技开发有限公司

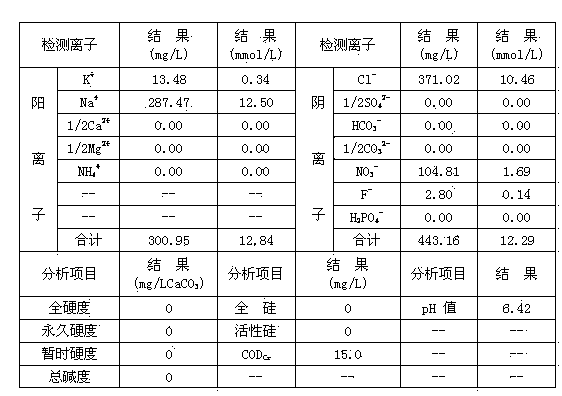

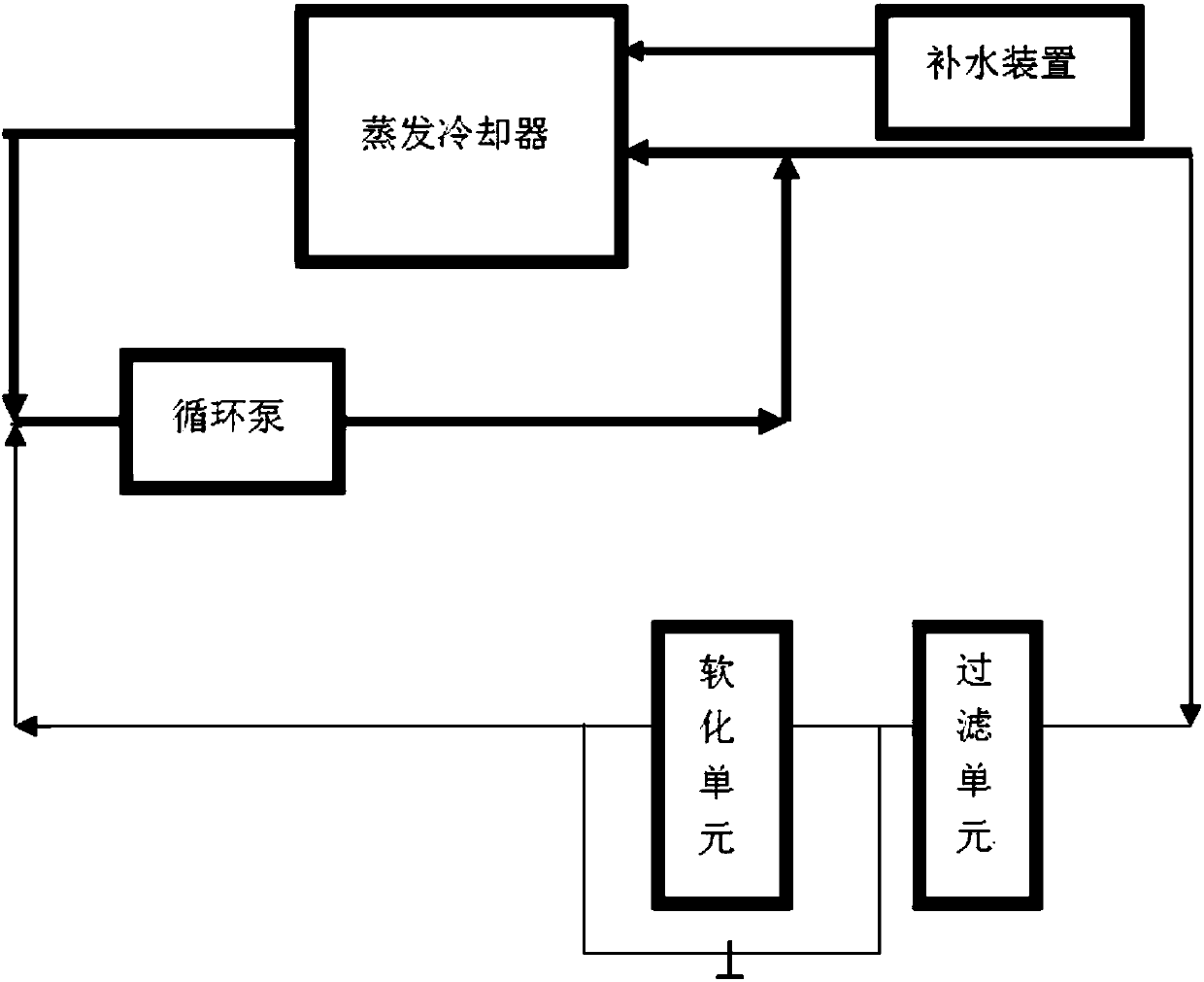

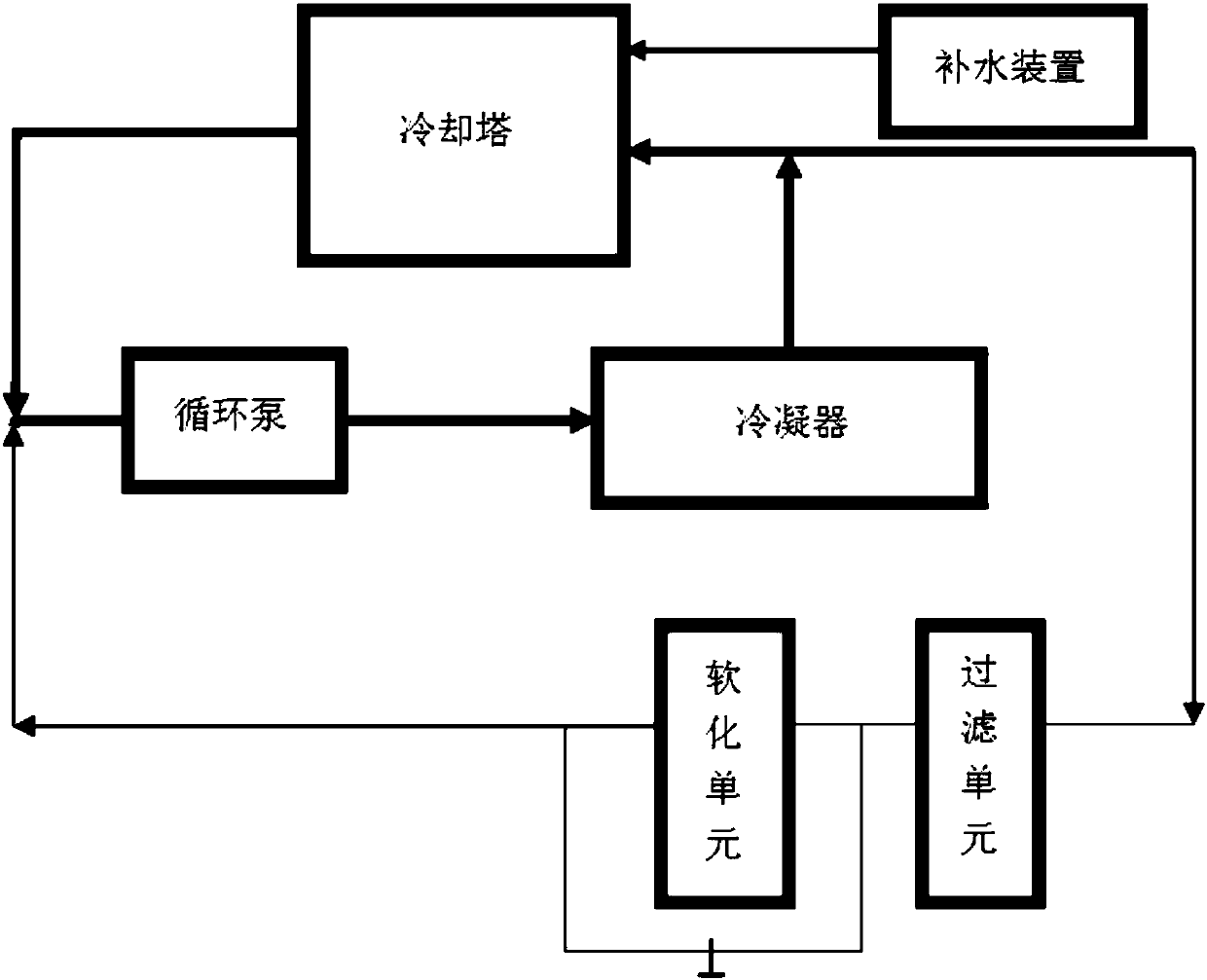

Ultrahigh-concentration-multiple circulating cooling water treatment system and circulating cooling water treatment method

InactiveCN106698774ASolve the special requirements of water qualitySolve the rise of thermal resistanceTreatment involving filtrationWater/sewage treatment by ion-exchangeWater savingWater treatment system

The invention discloses an ultrahigh-concentration-multiple circulating cooling water treatment system. The ultrahigh-concentration-multiple circulating cooling water treatment system comprises a circulating cooling water system and a bypath treatment system which is circularly connected with the circulating cooling water system, wherein the bypath treatment system comprises a filtering unit and a softening unit which are connected in sequence. The invention discloses a circulating cooling water treatment method. The circulating cooling water treatment method comprises the following steps: (1) concentrating circulating cooling water into ultrahigh-concentration-multiple circulating cooling water through the circulating cooling water system, wherein the concentration multiple reaches 20 to 1000 times; (2) filtering the ultrahigh-concentration-multiple circulating cooling water by adopting a bypass filtering method; and (3) softening the filtered ultrahigh-concentration-multiple circulating cooling water obtained by the step (2) by adopting an ion exchange method. According to the ultrahigh-concentration-multiple circulating cooling water treatment system and the circulating cooling water treatment method, the circulating cooling water is filtered and softened online through the bypath treatment system, and normal operation is realized under the condition of the ultrahigh-concentration-multiple circulating cooling water (with the concentration multiple of 20 to 1000 times); the water saving rate reaches 85 percent or more; and the corrosion prevention and microorganism inhibition effects, low cost, environment friendliness and feasibility are realized.

Owner:汪传发

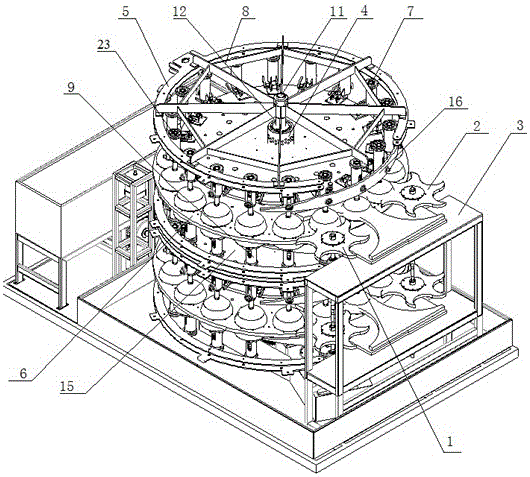

Automatic tableware washing machine

PendingCN105686775ARealize automatic deliveryAchieve cleaningTableware washing/rinsing machine detailsHome appliance efficiency improvementBrush deviceEngineering

The invention discloses an automatic tableware washing machine. The automatic tableware washing machine comprises a tableware rotating washing rack, a driving mechanism used for driving the tableware rotating washing rack to perform washing operation of tableware and a tableware conveying mechanism arranged on one side of the tableware rotating washing rack. The tableware rotating washing rack comprises a large stand column connected with an output shaft of the driving mechanism; a top rotating plate and a bottom rotating plate which are parallel to each other are fixedly arranged on the large stand column; tableware stations are distributed on the top rotating plate; lower brush devices used for cleaning the inner wall of tableware are arranged at the positions, corresponding to the tableware stations on the top rotating plate, of the bottom rotating plate; the lower brush devices rotate under the action of the driving mechanism. The automatic tableware washing machine is simple in structure, reasonable in design, high in cleaning efficiency, good in effect, capable of saving time and labor, less in water for washing and more environmentally friendly, washing cost is saved, and the sewage amount is reduced.

Owner:李振华

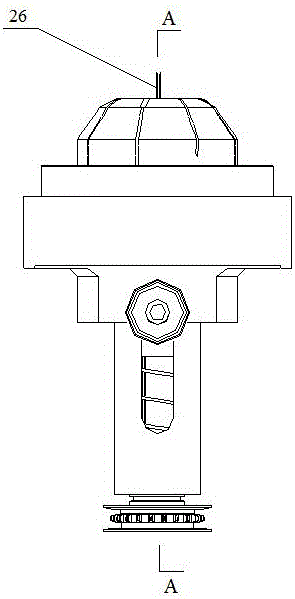

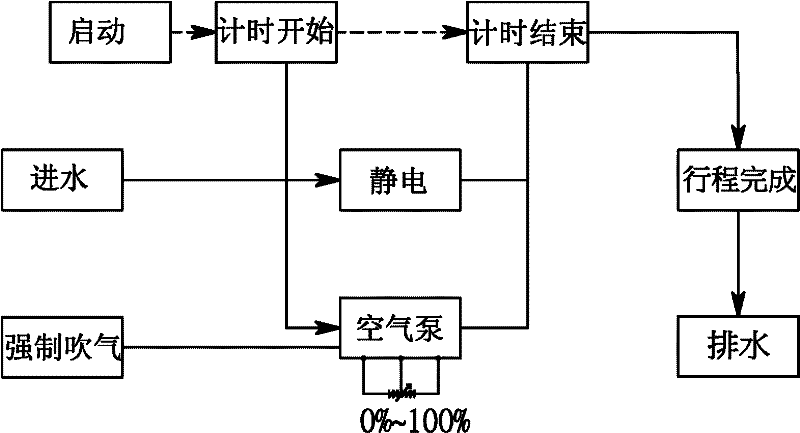

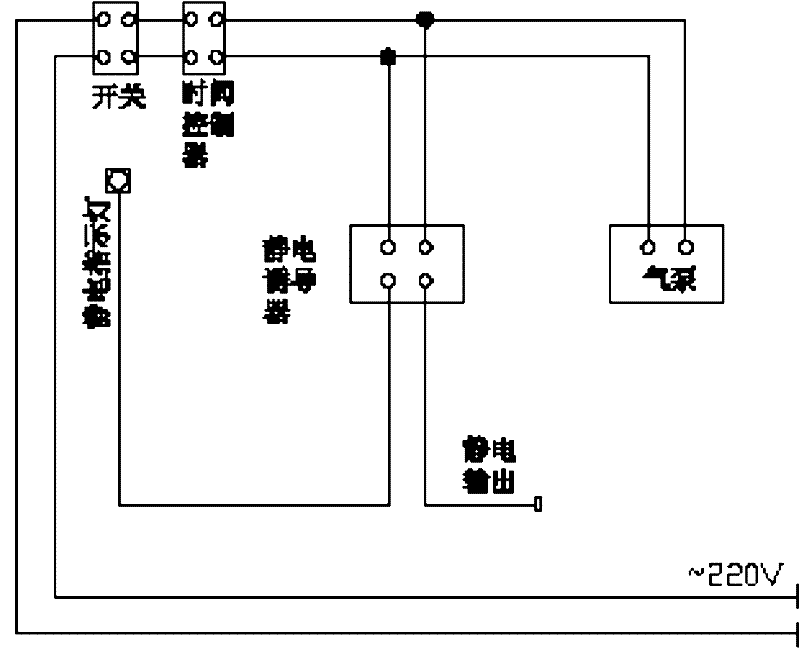

Electrostatic induced water unfreezing method and device for food

The invention discloses an electrostatic induced water unfreezing method and an electrostatic induced water unfreezing device for food. The device is characterized in that: a storage net made of conductive material is arranged in a water tank which is full of water and made of conductive material; the water tank is connected with a body shell through an insulated support seat arranged at the bottom of the body shell and made of insulating material and / or an insulated support frame arranged at the upper part of the water tank, and a proper blocking distance is kept between the side wall of the water tank and the side wall of the body shell, so that the water tank is insulated with the body shell; an electrostatic induction device capable of generating a high-voltage electrostatic field is connected to the water tank through a lead; and an air pump is connected with an air injection pipe arranged at the bottom of the water tank and provided with air injection holes through an air inlet pipe, and the air pump is used for pumping air to form bubbles.

Owner:NEW DEFROST TECH

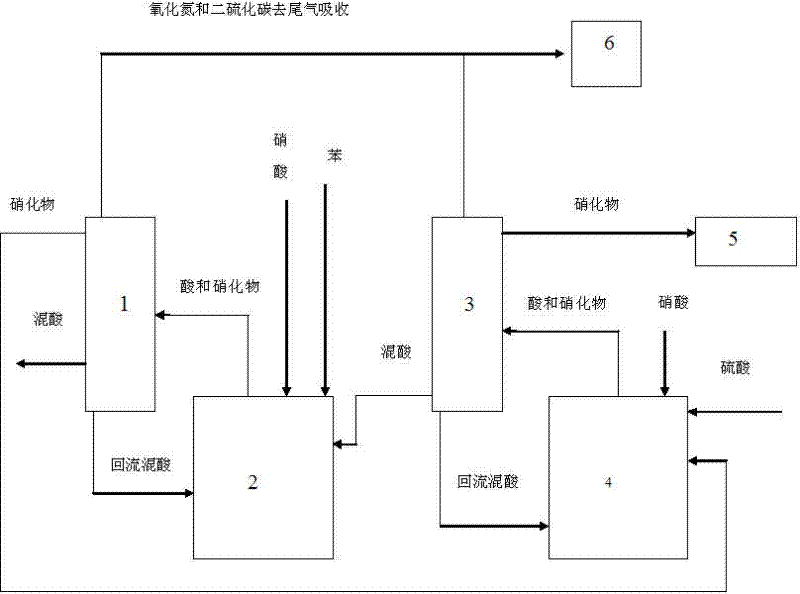

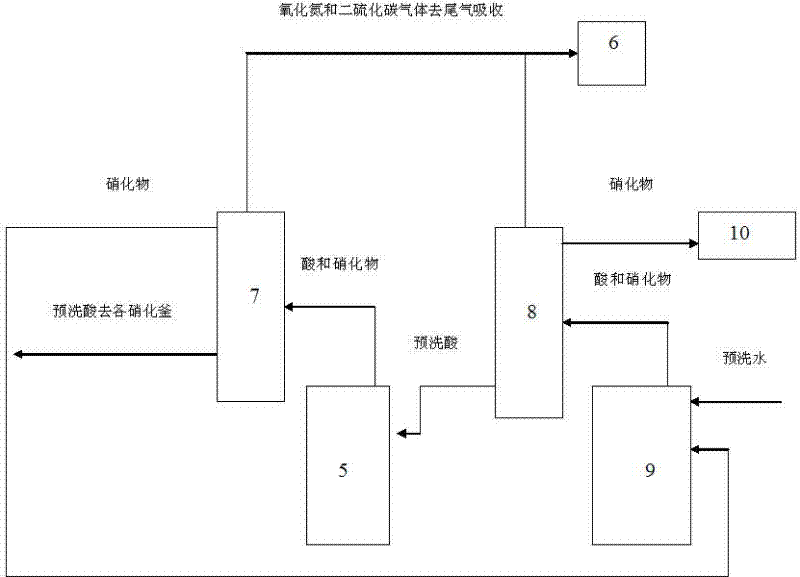

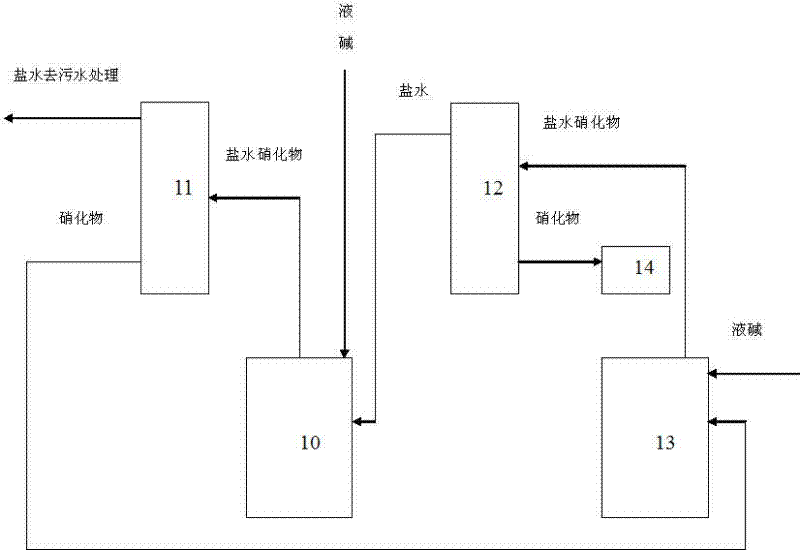

Device and method for continuously producing mixed dinitrobenzene by using coking benzene

ActiveCN102311347AReduce desulfurization costHigh reaction conversion rateNitro compound preparationNitrationPre washing

The invention discloses a device and method for continuously producing mixed dinitrobenzenes by using coking benzene. The production device is composed of nitrating kettles, pre-washing kettles, neutralization kettles and washing kettles which are reversely connected in series, wherein the number of the nitrating kettles is 5-7, the number of the pre-washing kettles is 1-2, the number of the neutralization kettles is 2-4, the number of the washing kettles is 2-4, and an oil-water separator is connected in front of each kettle. The method disclosed by the invention comprises the following steps: nitrating coking benzene into dinitrobenzene in the nitrating kettles by using mixed acid consisting of sulfuric acid and nitric acid, and simultaneously carrying out ring-opening oxidation on thiophene so as to obtain carbon disulfide; then, sequentially processing a mixture by using the pre-washing kettles, the neutralization kettles and the washing kettles so as to obtain hetero-dinitrobenzene. In the invention, based on the characteristics of a benzene nitration process and the reaction characteristics of thiophene and the mixed acid, the mixed dinitrobenzene production process is a reverse continuous nitration process; the sulfur-free mixed dinitrobenzene is produced directly by using coking benzene, therefore, the energy consumption and material consumption of the traditional coking benzene desulfurization process are reduuced; because the step of pre-desulfurization is not required, the desulfurization cost is low, and the nitrification is safe; meanwhile, because the whole system is in reverse series connection, the conversion rate of the nitration reaction is high, the consumption of the sulfuric acid is low, and less wastewater is generated.

Owner:JIANGSU KESHENG CHEM EQUIP ENG

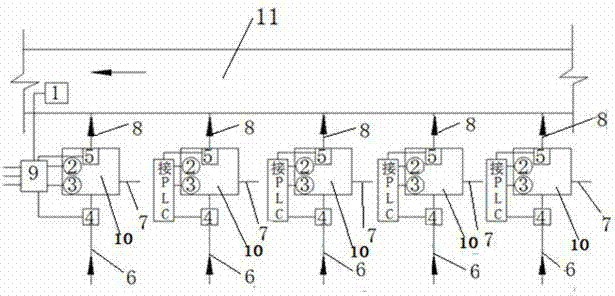

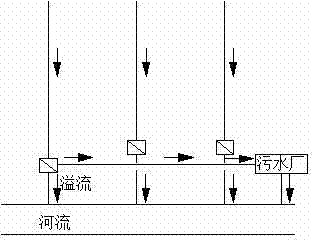

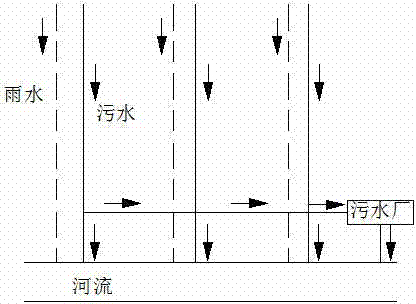

Non-point source pollution control-based arterial drainage water quality regulation and control system and arterial drainage water quality regulation and control method

ActiveCN104234171ASimple structureEasy to implementSewerage structuresSewage drainingControl systemPollutant flux

The invention relates to a non-point source pollution control-based arterial drainage water quality regulation and control system and an arterial drainage water quality regulation and control method. The system comprises an arterial drainage which is divided into a plurality of control sections, a controller and a plurality of switching wells, wherein each control section has a most unfavorable control point provided with a liquid level instrument; the arterial drainage is provided with a plurality of water outlet pipes; all the switching wells are respectively communicated with the water outlet pipes in a way of one-to-one correspondence; each switching well is provided with a water inlet pipe and an overflow pipe, and is internally provided with a turbidity meter, a conductivity meter and an electric flashboard; each water inlet pipe is provided with a Doppler ultrasonic flow meter; the liquid level instruments, the turbidity meters, the conductivity meters, the electric flashboards and the Doppler ultrasonic flow meters are respectively connected with the controller. The system is simple in structure, convenient in implementation and low in engineering cost. According to the arterial drainage water quality regulation and control method, the system is utilized to calculate the flux of pollutant in the switching wells, and regulation and control are performed according to the principle that water in the switching wells with high flux of pollutant firstly enters the arterial drainage firstly and water in the switching wells with low flux of pollutant waits, so that the double-staggering peak adjustment of water quality and water quantity of the arterial drainage can be realized, and risk of waterlogging is reduced.

Owner:CHONGQING UNIV

Pulp and peel separator

InactiveCN106387941AEasy to separateImprove peeling efficiencyVegetable peelingSewageWater treatment

The invention discloses a pulp and peel separator, and belongs to the technical field of deep processing of fruits. The pulp and peel separator comprises a machine body and supporting legs, wherein a feed opening is formed in the front end of the machine body, and a discharge opening is formed in the rear end of the machine body; a solid-liquid separation device is arranged at the front end at the bottom of the machine body, and a waste water treatment device is arranged at the rear end at the bottom of the machine body; a peel and pulp separation barrel is arranged in the machine body; and the solid-liquid separation device and the waste water treatment device are connected with the machine body through collection hoppers. The pulp and peel separator provided by the invention is high in peeling efficiency, the sewage production quantity is greatly reduced, caustic wash water can be in cyclic utilization, and the pulp and peel separator is energy-saving and environmental-friendly, and high in automation control degree.

Owner:大连渴望科技发展有限公司

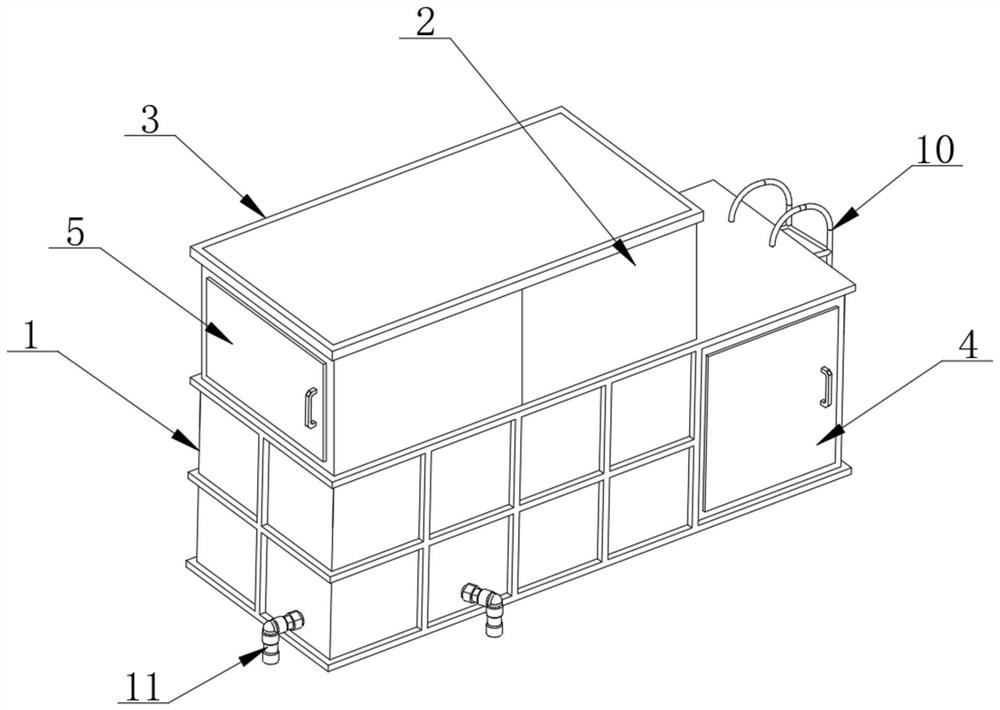

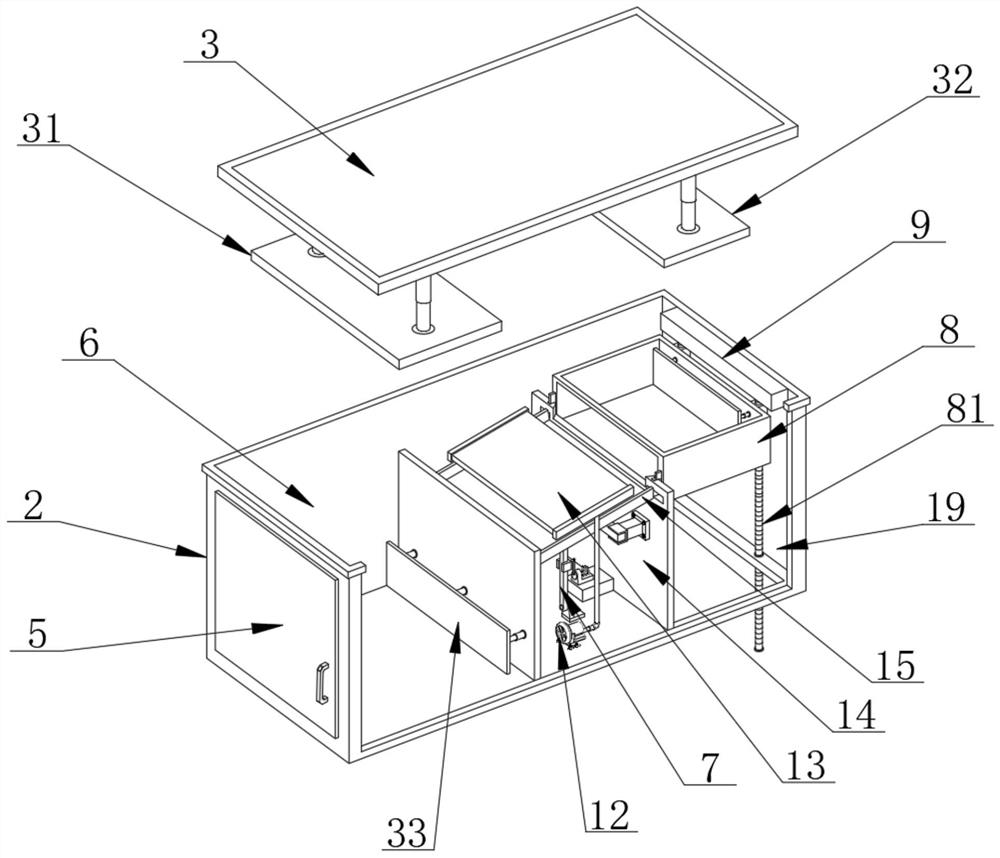

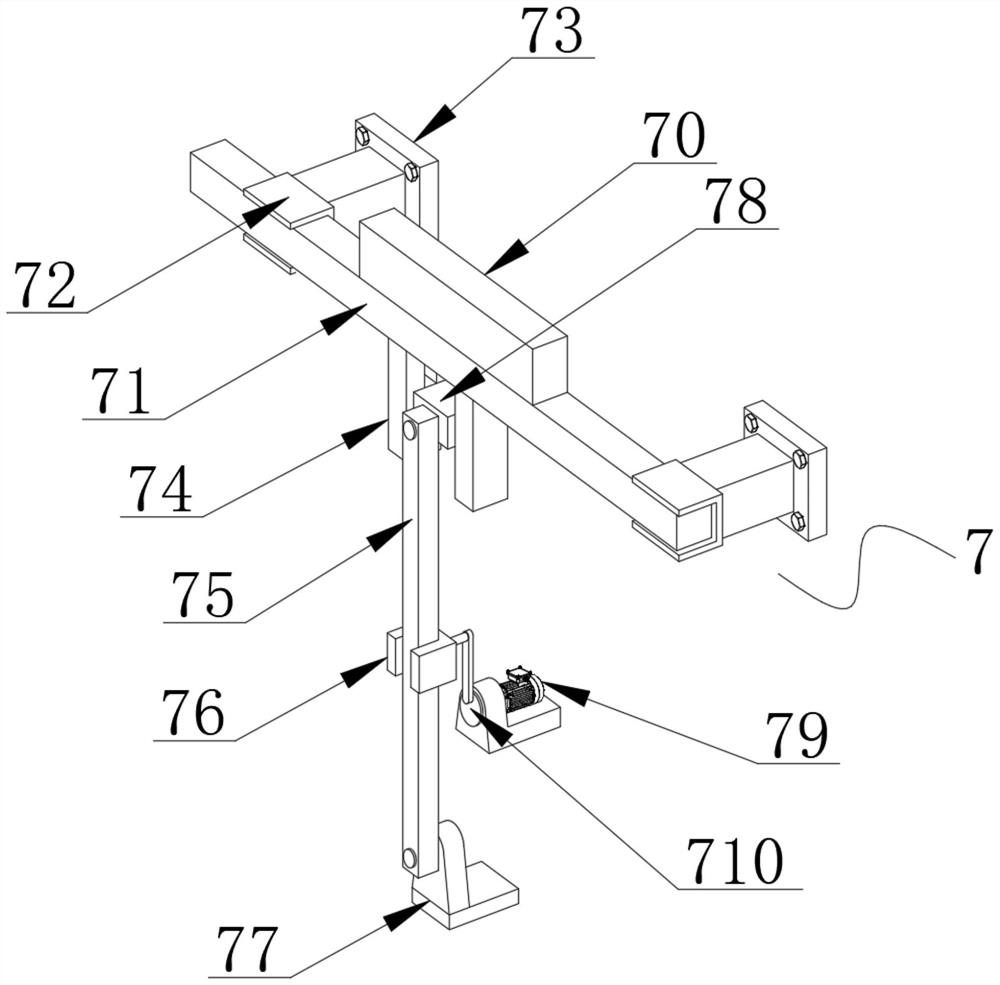

Container type environment-friendly sewage treatment device

ActiveCN112830591AAchieve extrusionRealize moving up and downSludge treatment by de-watering/drying/thickeningTreatment involving filtrationSewage treatmentMechanical engineering

The invention relates to the technical field of sewage treatment, and discloses a container type environment-friendly sewage treatment device. The device comprises a sewage treatment mechanism and a solid treatment mechanism, wherein the interior of the solid treatment mechanism is divided into a compression chamber, a drying chamber and a separation chamber; a lifting screw rod is correspondingly mounted on one inner side wall of the separation chamber; a driving mechanism is connected to the top end of the lifting screw rod; a solid-liquid separation mechanism is connected to the position, located on the outer surface of the lifting screw rod, in the separation chamber; a discharging plate is arranged at the inner upper end of the drying chamber; a swing mechanism is connected to the lower surface of the discharging plate; and an air plate is mounted over the discharging plate. A container type sewage treatment design is adopted in the invention, and sewage and solid impurities are separated and treated independently, so integrated treatment of the sewage and the solid impurities is achieved, treatment is easy and convenient, efficiency is high, and the sewage discharge efficiency of navy during offshore operation is improved.

Owner:ANHUI HUAJING MACHINERY

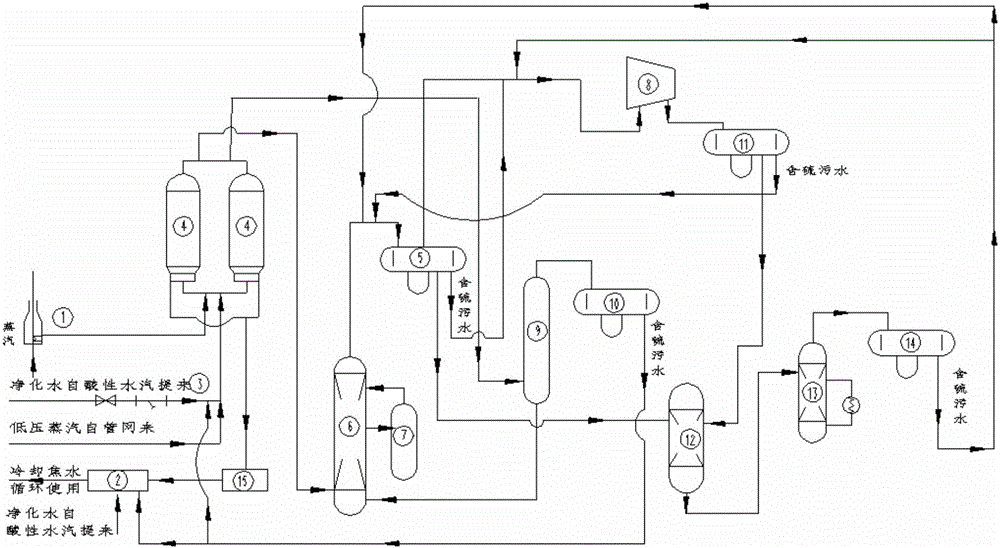

Method for reducing and reusing sulfur-bearing waste water of coking unit

ActiveCN105776695AReduce steam and water consumptionIncrease dosageMultistage water/sewage treatmentNature of treatment waterSource waterWater use

The invention provides a method for reducing and reusing sulfur-bearing waste water of a coking unit.The water use link and the drainage link of the coking unit are subjected to systematic optimization, consumption of steam and water resources is reduced, the sulfur-bearing waste water is used in a cascading mode, the amount of the generated sulfur-bearing waste water is reduced from the source, the amount of the sulfur-bearing waste water entering a subsequent acidic water steam stripping device is reduced, the water is purified after multi-path reusing and steam stripping, and the mount of the waste water entering a tail end treatment device of a sewage farm is reduced; the pressure of the acidic water steam stripping device and the tail end sewage farm is reduced, natural clean production and source water saving and emission reducing are achieved, and double win of economic benefits and environmental benefits can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com