Device and method for continuously producing mixed dinitrobenzene by using coking benzene

A technology of mixing dinitrobenzene and coking benzene, which is applied in the application field of coking benzene, can solve the problems of energy consumption, increase process, increase equipment investment, etc., and achieve the effects of reducing consumption, ensuring operating environment, and low desulfurization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

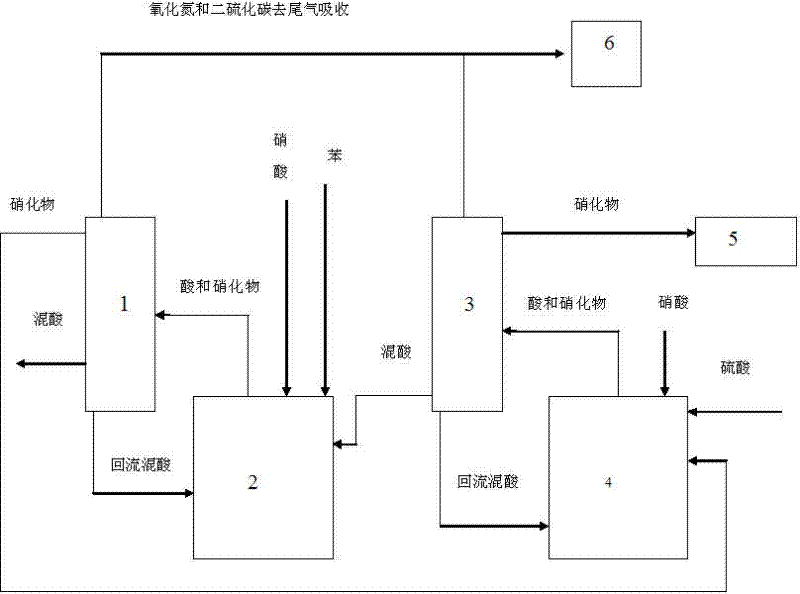

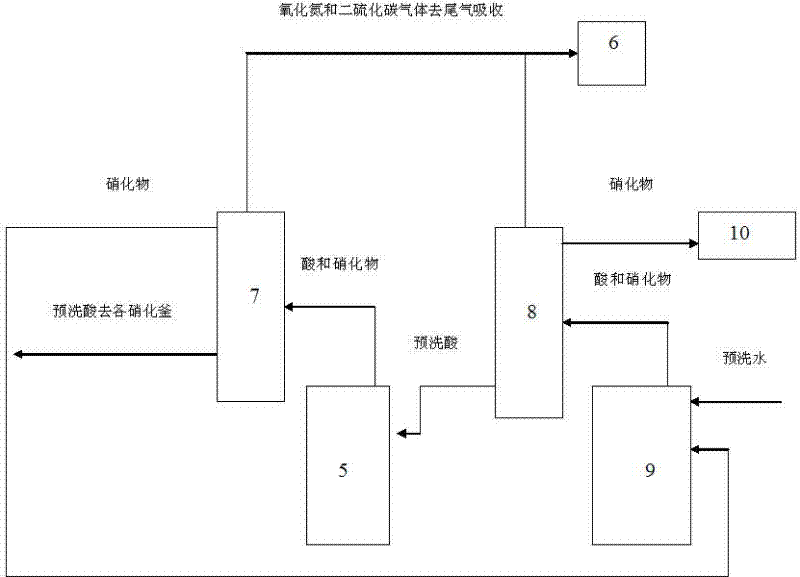

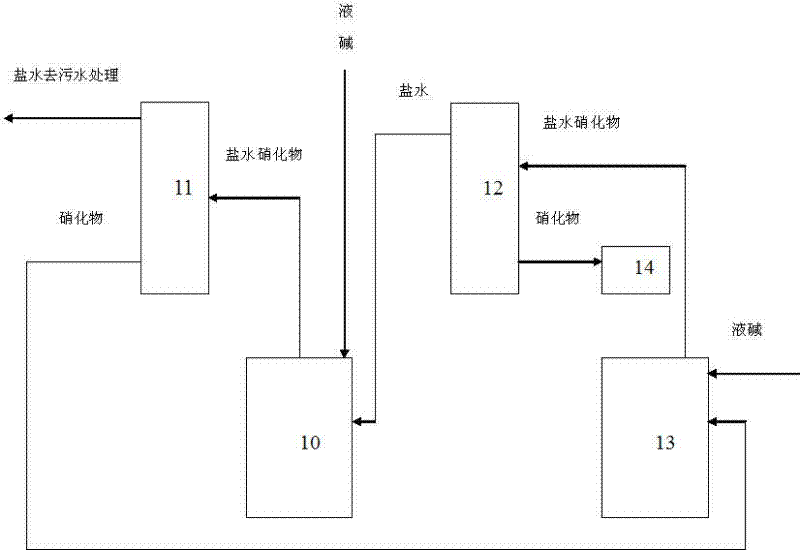

[0043] Example: Mixed dinitrobenzene is produced according to the following steps: the mixed acid composed of sulfuric acid and nitric acid nitrates coked benzene into dinitrobenzene in the nitration tank, and at the same time thiophene is ring-opened and oxidized into carbon disulfide, and then the mixture passes through the pre-washing tank in turn , neutralization kettle, and washing kettle to obtain mixed dinitrobenzene; wherein, sulfuric acid is continuously added to the last nitration kettle by the mixed acid inlet 35, and nitric acid is continuously added to each other than the first nitration kettle by the mixed acid inlet 35 respectively. In the nitration kettle, coking benzene is continuously added to the first nitration kettle 2 through the nitration compound inlet 23, and the reflux acid from the oil-water separator in front of each nitration kettle is also returned to each nitration kettle through the mixed acid inlet 35. The mixed acid from the oil-water separator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com