Patents

Literature

73results about How to "Reduce take away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

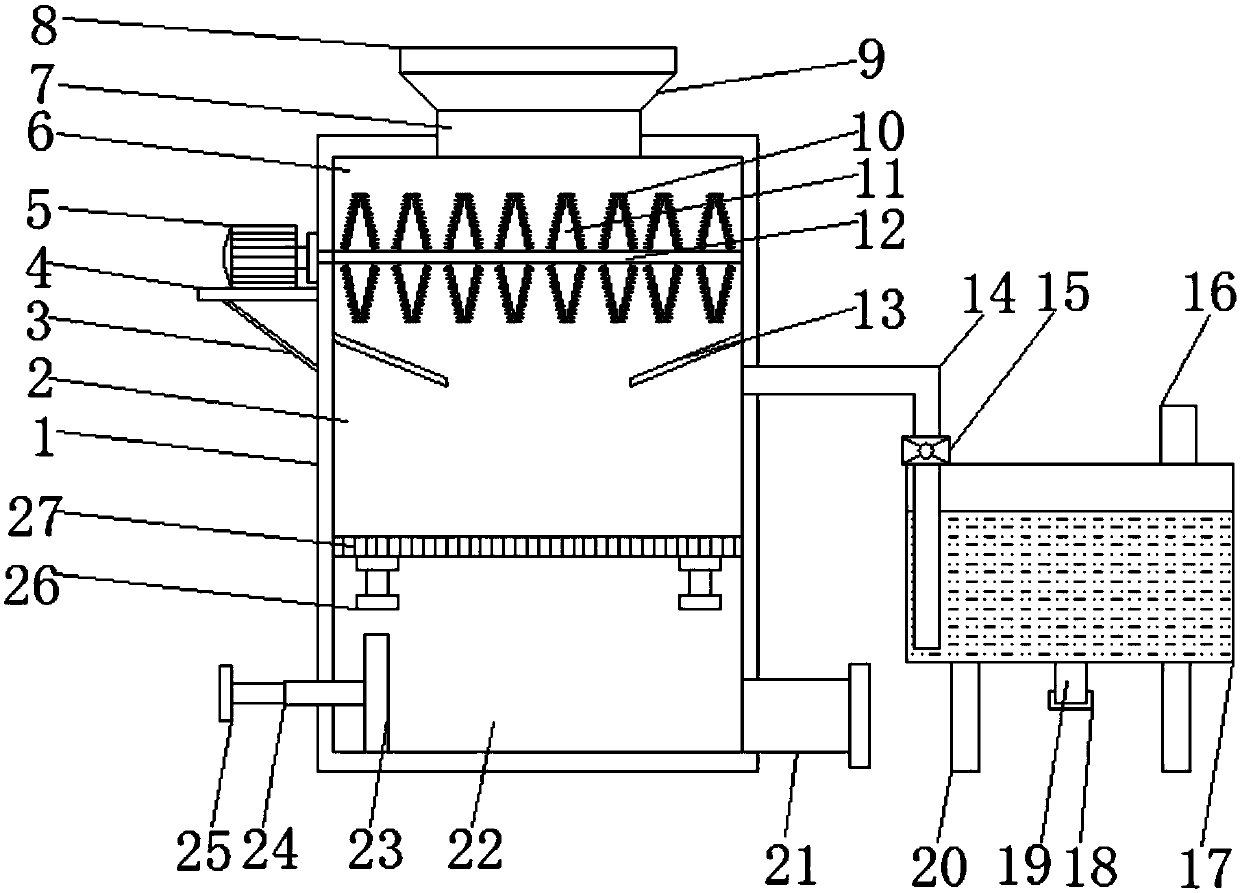

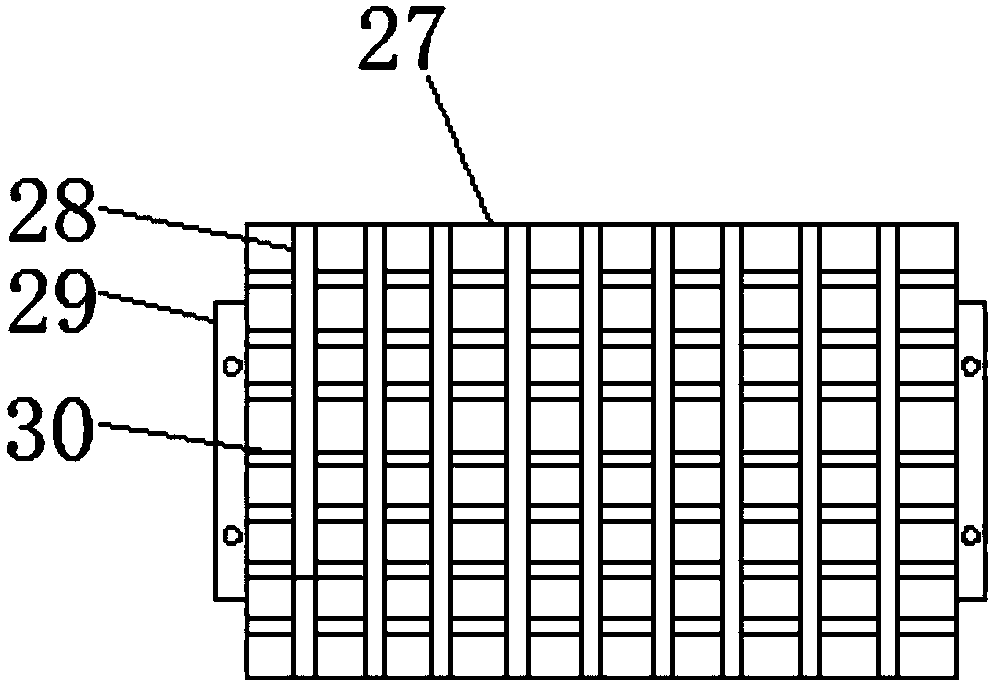

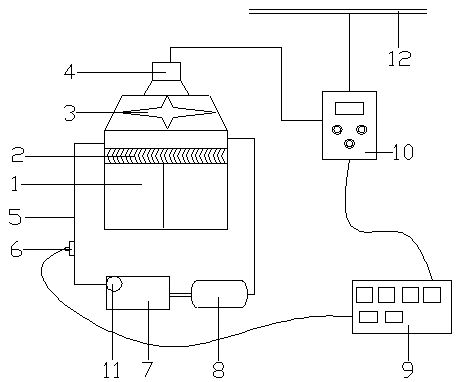

Environment-friendly agricultural straw machining equipment with good machining effect

InactiveCN107830526AImprove incineration efficiencyEasy to sprayCuttersIncinerator apparatusCombustion chamberAgricultural engineering

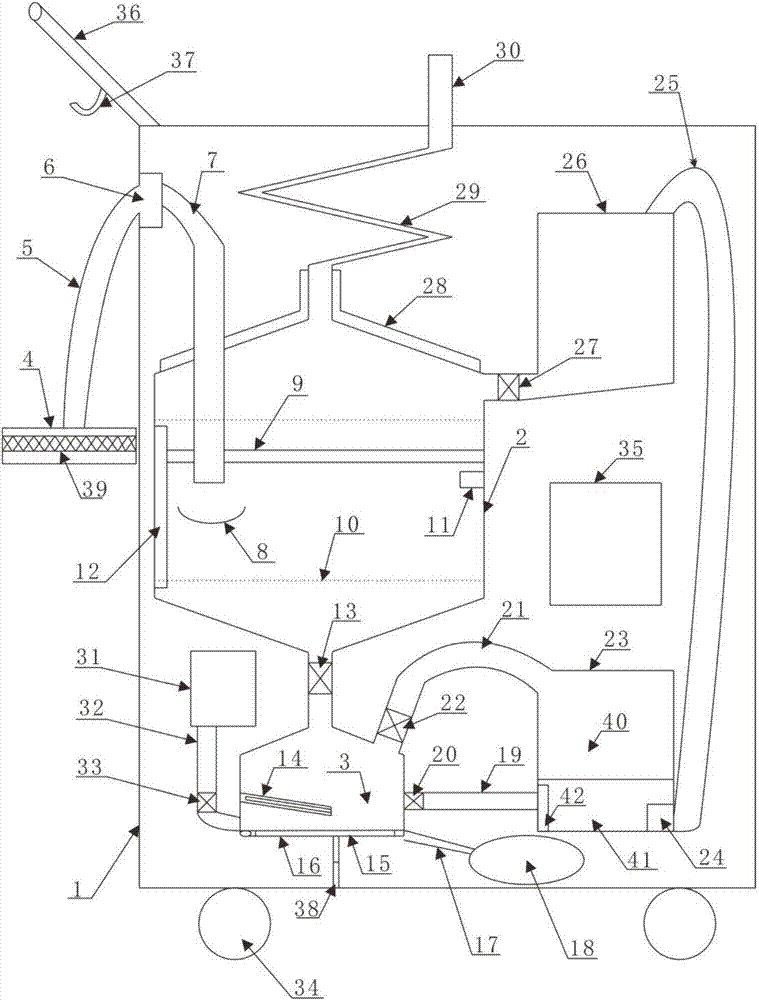

The invention discloses an environment-friendly agricultural straw processing equipment with good processing effect, which comprises a processing main box body. The inner chamber of the processing main box body is sequentially provided with a crushing chamber, a combustion chamber and a material storage chamber from top to bottom. The top of the processing main box is provided with a feed pipe, the middle of the crushing chamber is provided with a rotating shaft, and the outside of the rotating shaft is provided with a crushing blade, and the surface of the crushing blade is provided with crushing teeth. The left side of the shaft is connected with the driving motor, the bottom of the driving motor is provided with a driving motor fixing bracket, the right side of the driving motor fixing bracket is connected with the left side of the processing main box, and the bottom of the driving motor fixing bracket is provided with Reinforcing ribs, the bottom of the reinforcing ribs is connected with the processing main box, and both sides of the bottom of the crushing chamber are provided with baffles. The invention has the advantage of absorbing the nutrients taken away by the thick smoke, and solves the problem of reducing the effect of the straw on the soil.

Owner:江门市新会银洲湖纸业基地投资有限公司

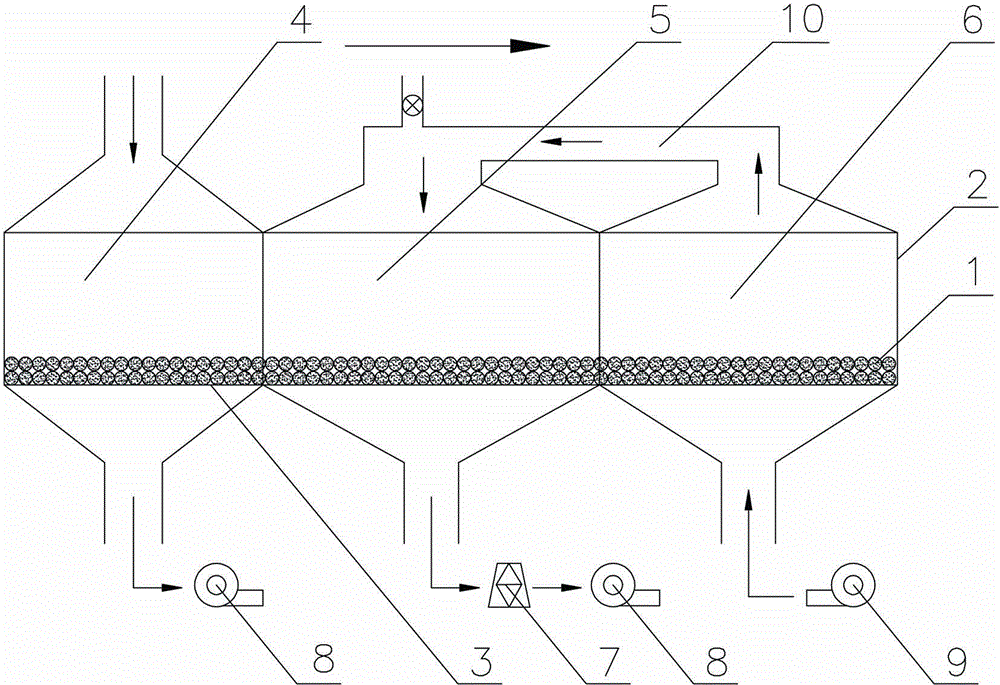

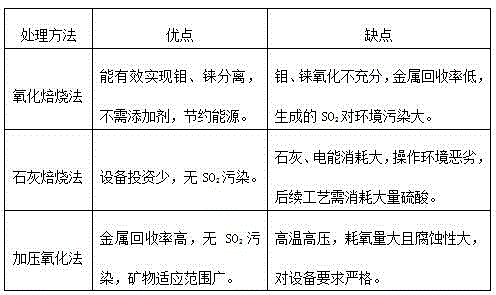

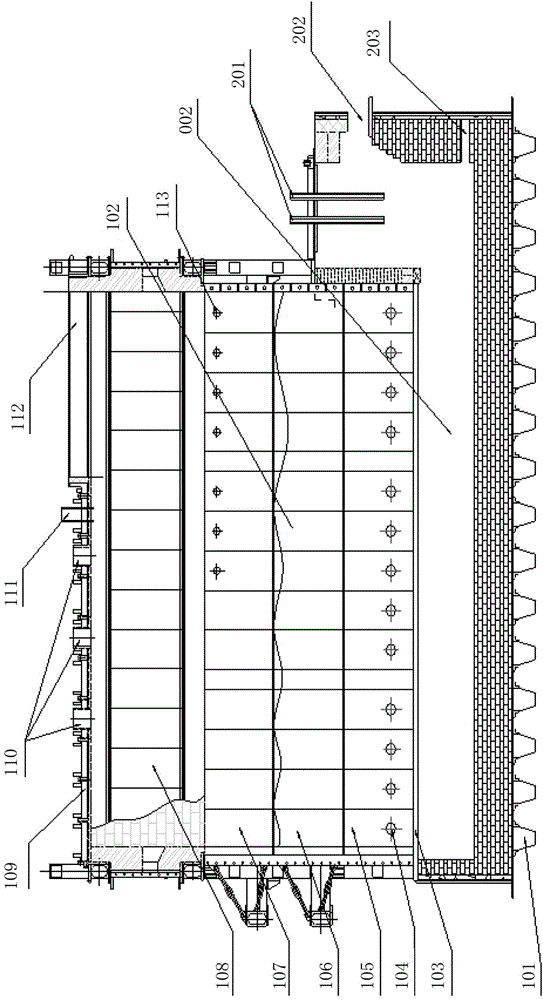

Method for separating molybdenum and rhenium from rhenium and molybdenum-containing concentrate

The invention discloses a method for separating molybdenum and rhenium from rhenium and molybdenum-containing concentrate. The method comprises the following steps: adding an adhesive, an oxidant and water in rhenium and molybdenum-containing concentrate to prepare rhenium and molybdenum-containing concentrate pellets with grain size of 3-6mm and moisture of 8-12%, and distributing the concentrate pellets on a chain grate bed of a chain grate machine to carry out drying, oxidizing roasting and cooling, so that molybdenite in the pellets is oxidized into MoO3, and the rhenite is oxidized into Re2O7, which are volatilized to enter smoke and then are recovered by drip washing with water; in above process, the method of oxidizing roasting at two sections is adopted, the oxidizing efficiency of the molybdenite and the rhenite in the concentrate pellets are improved through different air roasting temperatures and air speeds, the Re2O7 concentration in the smoke is improved by circulating roasting smoke in a roasting chamber II to a roasting chamber I, and the smoke is maintained at 300-400 DEG C to effectively inhibit Re2O7 from being reduced by the SO2 so as to increase the recovery rate of the Re2O7; by adopting the roasting method disclosed by the invention, the volatilization rate of rhenium in the roasting process can be not less than 80%, the content of soluble molybdenum in roasted molybdenum is not less than 90%, the molybdenum and the rhenium are efficiently oxidized and separated.

Owner:DAYE NONFERROUS METALS

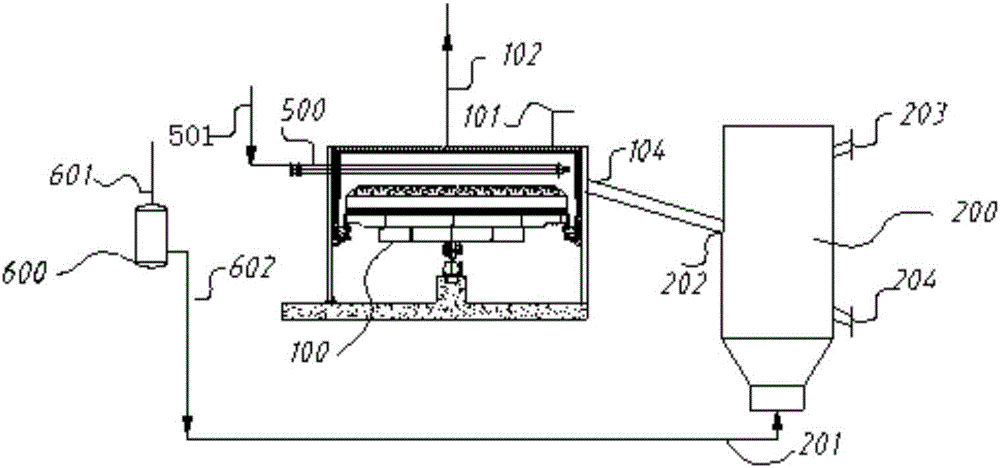

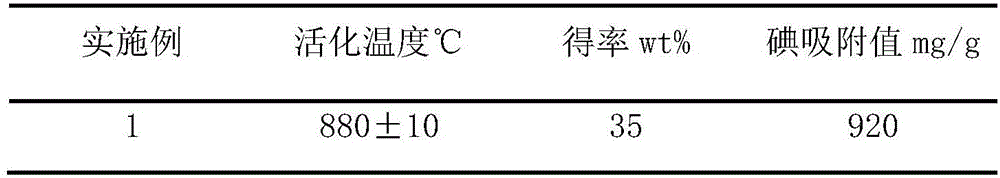

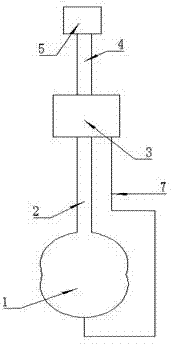

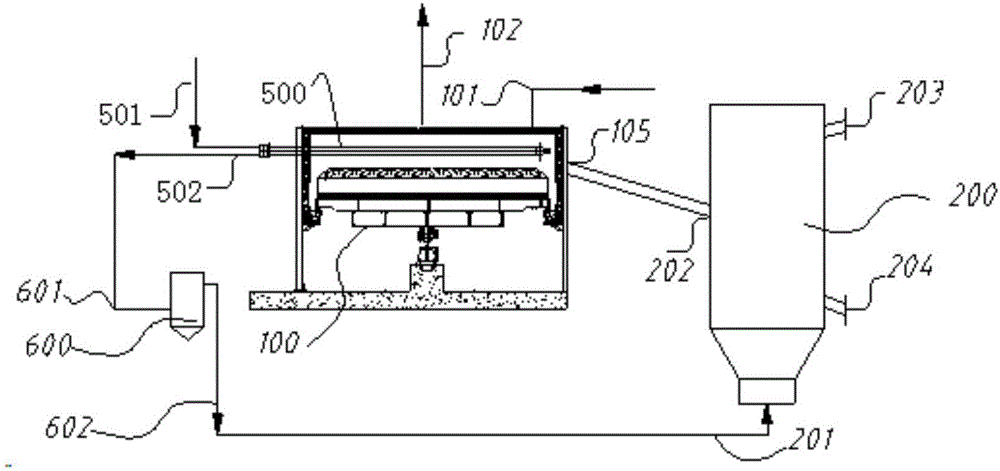

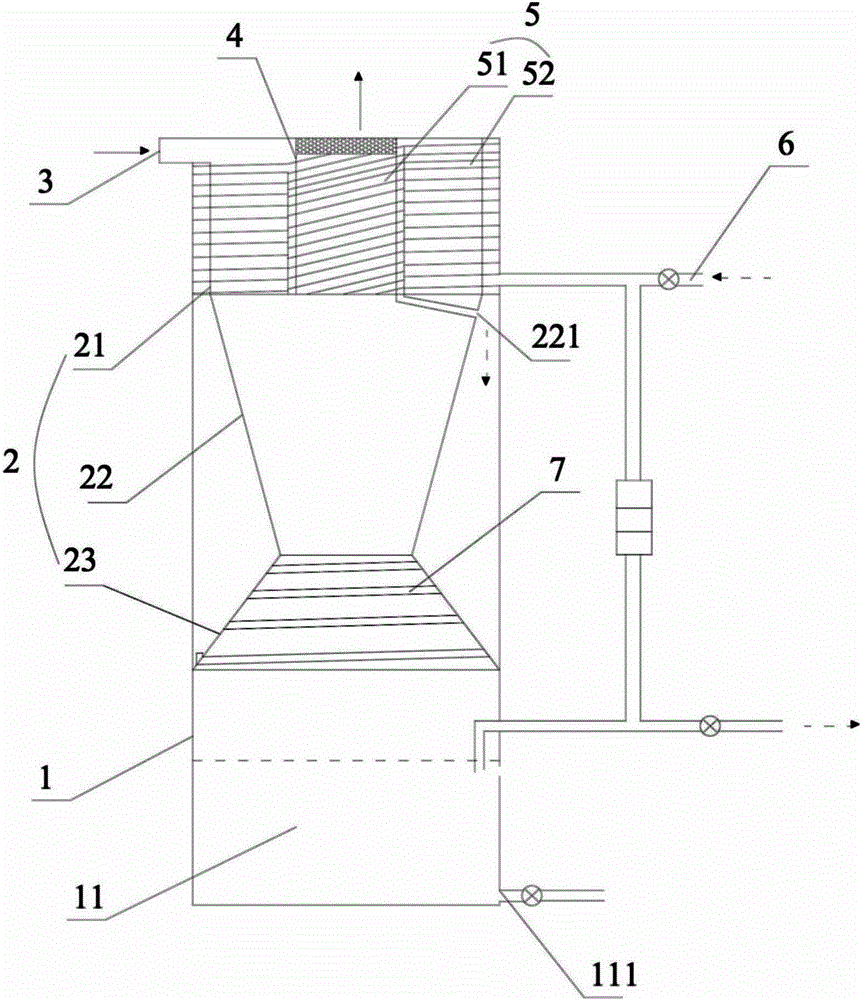

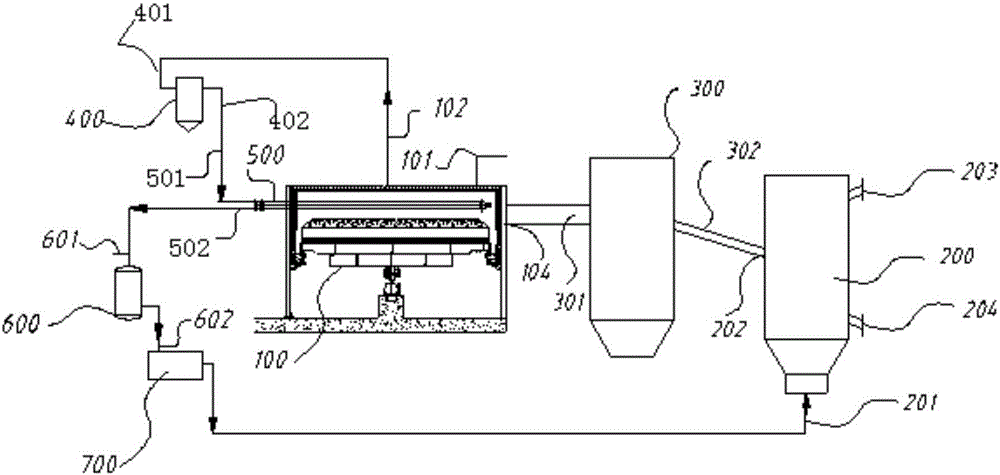

System and method for preparing active carbon by biomass

PendingCN106629715ASolve the blockageSolve heavy dustCarbon compoundsSpecial form destructive distillationCombustorWater vapor

The invention relates to a system and a method for preparing active carbon by biomass. The system comprises a pyrolyzing furnace, a combustor, a steam boiler and a fluidized bed, wherein the pyrolyzing furnace is used for pyrolyzing raw material biomass to generate pyrolyzed oil gas and carbon residue; the combustor is used for heating the raw material biomass to pyrolyze the raw material biomass; the steam boiler is used for heating water to obtain steam; and the fluidized bed is used for activating the carbon residue to generate active carbon. According to the system and the method, the existing fluidized bed does not need to be transformed, heat loss is reduced, energy consumption is reduced, the productivity of the pyrolyzing furnace is improved, and reduction, harmless treatment and resource utilization of the materials is realized.

Owner:SHENWU TECH GRP CO LTD

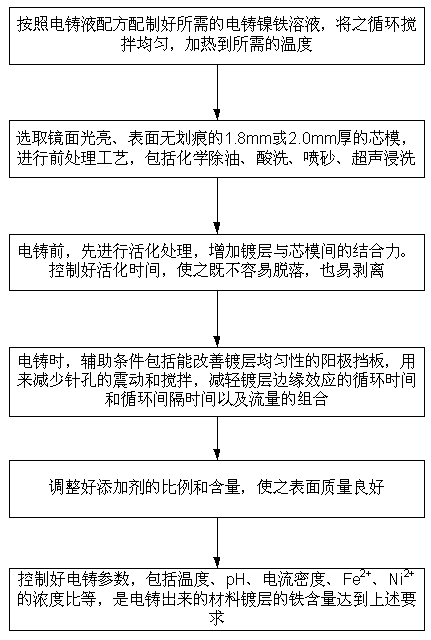

A preparation method for a vapor plating mask plate

InactiveCN103205784AReduce usageGood opening qualityVacuum evaporation coatingSputtering coatingAlloy coatingMetal anode

The invention discloses a preparation method for a vapor plating mask plate. The mask plate is produced from a nickel-iron alloy material by using an electroforming process. The nickel-iron alloy material comprises two elements of nickel and iron, with an iron content being 56%-62%. In a preparation method for the nickel-iron alloy material, an electroforming method is adopted, a sulfate system is used as an electroforming solution, a metal cathode and a metal anode are placed in the electroforming solution, and the nickel-iron alloy is deposited on the cathode; wherein the electroforming solution concretely comprises: 220-260g / L nickel sulfate, 30-50g / L nickel chloride, 40-50g / L boric acid, and 21-25g / L ferrous sulfate. According to the preparation method of the invention, the electroforming process is employed to replace an etching process, openings of obtained products are smooth, have good quality, no blurs, and high accuracy; by employing the process, the use amount of nickel is reduced, the cost is low, the three-waste management burden is alleviated, and an alloy coating with the iron content in the range of 56%-62% can be obtained, which means large flat surface metal mask coatings with different magnetisms can be obtained.

Owner:KUN SHAN POWER STENCIL

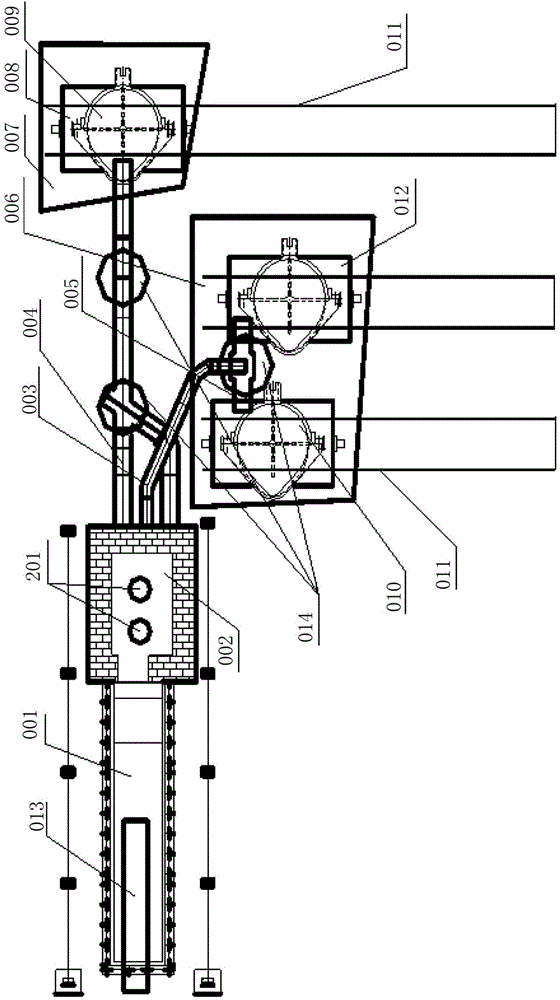

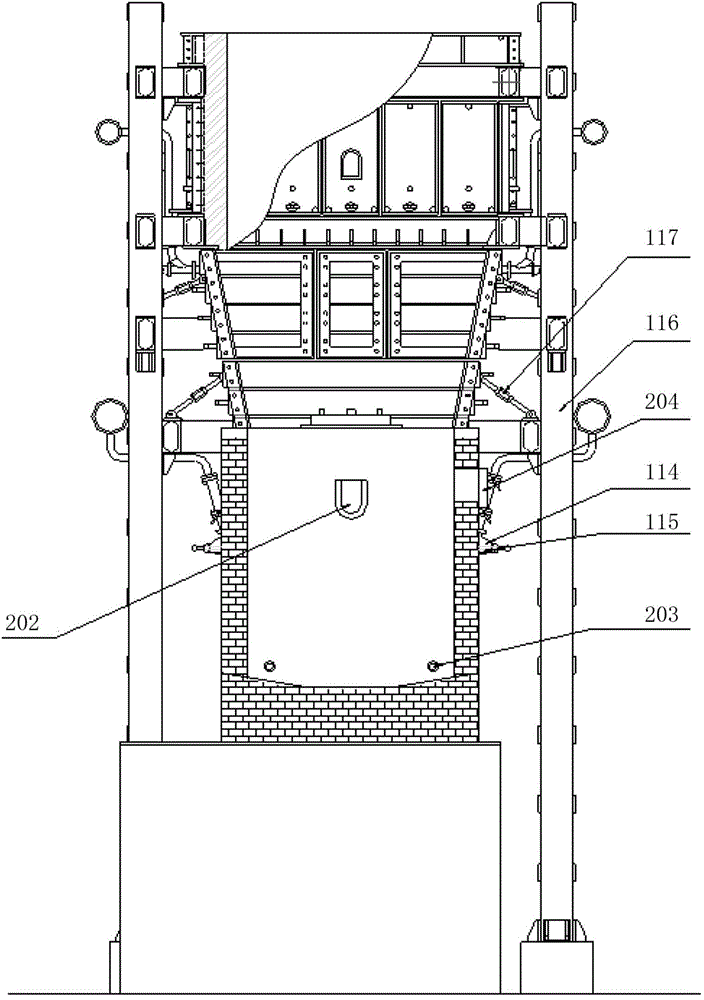

Copper smelting device with high-oxygen-enrichment double-side-blowing melting bat and operation method of copper smelting device

ActiveCN104593617AIncrease useful gas contentReduce take awayRotary drum furnacesCrucible furnacesMelting tankSlag

The invention relates to a copper smelting device with a high-oxygen-enrichment double-side-blowing melting bat and an operation method of the copper smelting device and belongs to the technical field of copper smelting devices and processes. According to the method, a large-volume hearth is used, the continuous production is performed, a single furnace is adopted so as to meet the periodic production of a PS converter, smelting slag continuously overflows from a smelting slag outlet and matte is directly discharged from a matte outlet formed in the bottom end of the hearth. During the smelting slag is discharged, the flowing direction of the smelting slag is controlled by virtue of a switching chute so that the smelting slag can be continuously discharged; the ratio of Fe to SiO2 in the smelting slag is controlled at 1.6-1.8, the ratio of a fuel to input materials is controlled at 2-2.5% and the content of copper in the smelting slag is less than or equal to 0.65%. The method has the characteristics of small construction investment, low production cost, good working environment, high degree of automation, high utilization rate of plant building and the like.

Owner:CHIFENG FUBANG COPPER

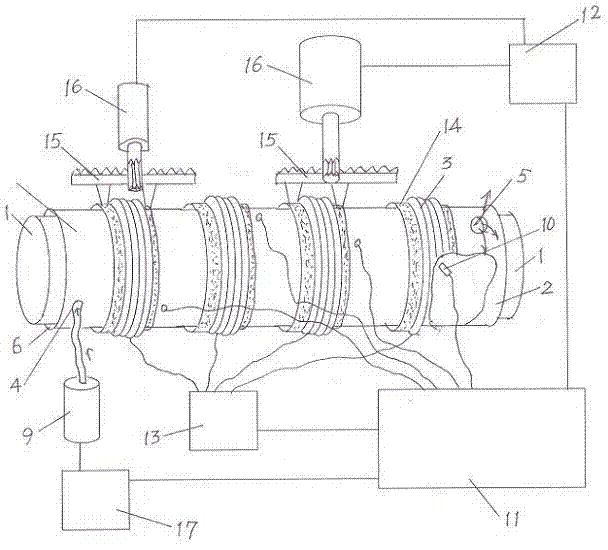

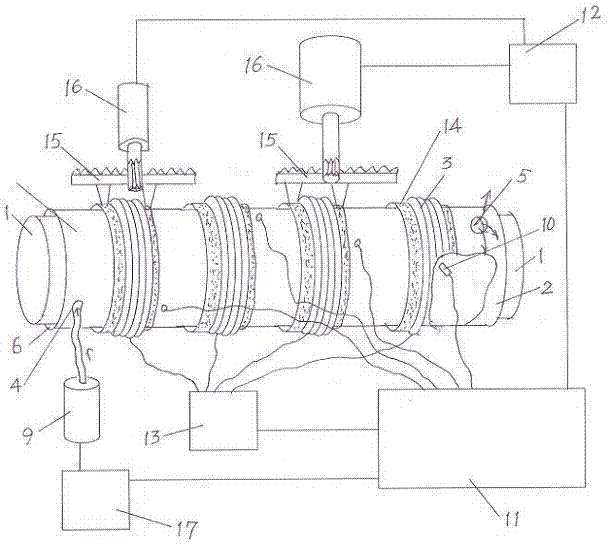

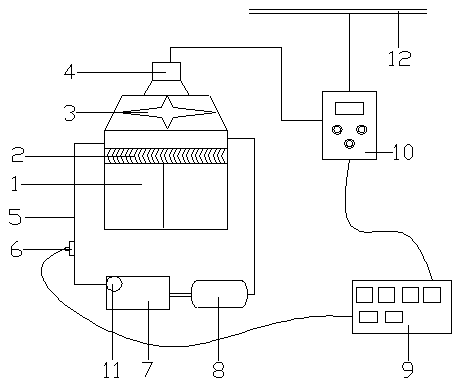

System and method for automatically regulating temperature of interlayer airflow inductive heated material pipe

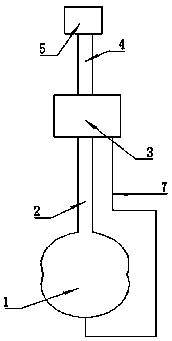

InactiveCN102359694AImprove power utilizationLower heating costsPipe heating/coolingInduction heating controlEngineeringInductance

The invention relates to a system for automatically regulating a temperature of an interlayer airflow inductive heated material pipe and belongs to a material pipe temperature regulating system and a material pipe temperature regulating method for regulating the temperature by ensuring gas in an interlayer of two pipes. An interlayer space is formed between a metal pipe and a non-metallic pipe; at least one group of inductance coils is wound on the outer surface of the non-metallic pipe; the pipe wall of the non-metallic pipe is provided with an air inlet and an air outlet; the air inlet is connected with an air inlet pipe and a blower; a temperature sensor is arranged in the metal pipe; the temperature sensor is connected with a main controller; the main controller is respectively connected with an air quantity controller and an electric conduction quantity controller; the air quantity controller is connected with the blower; and the electric conduction quantity controller is connected with the inductance coils. The material pipe temperature regulating system and the material pipe temperature regulating method have the advantages that the interlayer space has a heat preservation effect on the metal pipe and the utilization rate of electric energy is improved; people around the heated material pipe can be protected by the non-metallic pipe; and fluidity gas can be fed into theinterlayer space, or the temperature of the metal pipe is regulated by regulating a distance between each two adjacent inductance coils.

Owner:唐晓帆

Flower pot soil moisturizing method

The invention relates to the technical field of soil, in particular to a flower pot soil moisturizing method. The flower pot soil moisturizing method comprises the following raw materials: 35-40 parts of super absorbent resin, 35-40 parts of fluff pulp, 10-13 parts of non-woven fabric, 15-20 parts of cotton fiber and 8-10 parts of a compound fertilizer. The raw materials are mixed at a certain ratio and processed according to a certain process to obtain a flower pot soil moisturizing raw material. When the flower pot soil moisturizing raw material is in use, the packaged flower pot soil moisturizing raw material is detached and uniformly mixed and stirred with soil in a flower pot, and the soil mixture is placed at the middle lower part of the flower pot. The flower pot soil moisturizing method has the following benefits: moistness and looseness of soil can be kept for a long time, nutritional ingredients of soil can be supplemented, a favorable growth environment is provided for plants in the flower pot, and troubles caused by manually watering, loosening and fertilizing soil in the flower pot on time are reduced.

Owner:开平市仕冠贸易有限公司

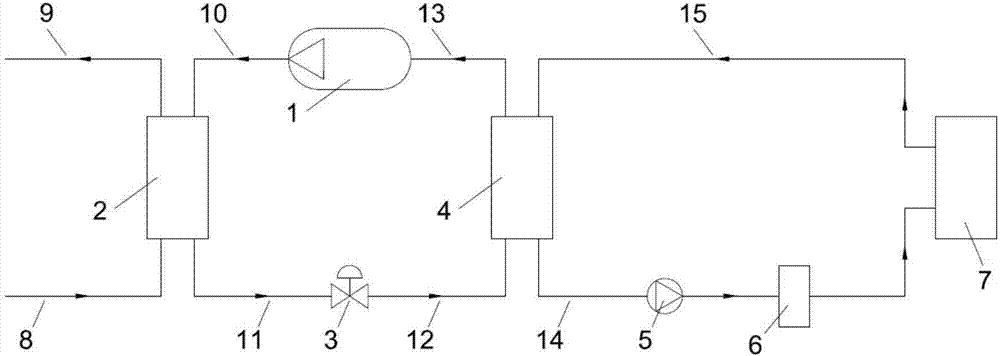

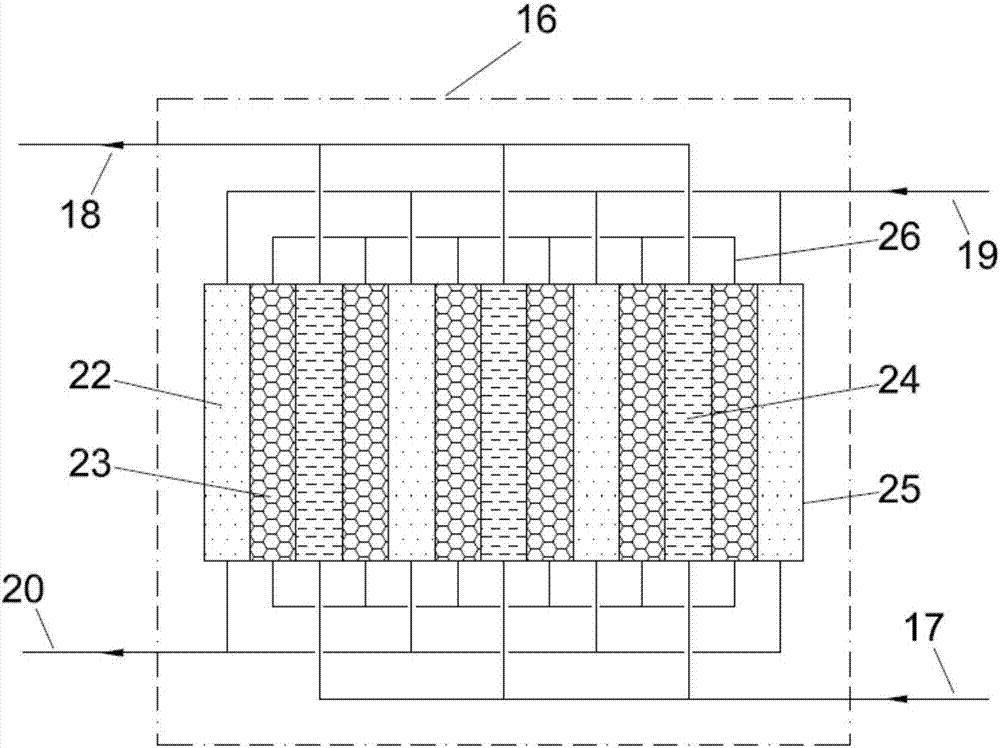

Paraffin phase change heat storage temperature adjusting device for semiconductor technology temperature control equipment

InactiveCN106969532AAvoid excessive temperature riseAvoid the disadvantages of difficult temperature controlMachines using electric/magnetic effectsRefrigeration safety arrangementTemperature controlTwo temperature

The invention provides a paraffin phase change heat storage temperature adjusting device for semiconductor technology temperature control equipment, and belongs to the technical field of temperature control equipment. The paraffin phase change heat storage temperature adjusting device comprises a shell and multiple temperature adjusting units located in the shell. A compressor exhaust heat exchange cavity is formed between every two adjacent temperature adjusting units, and a compressor exhaust heat exchange cavity is formed between each temperature adjusting unit and the shell. Each temperature adjusting unit comprises a refrigerating medium heat exchange cavity in the middle and paraffin heat storage cavities located in the two sides of the refrigerating medium heat exchange cavity. The upper end and the lower end of each paraffin heat storage cavity communicate through a paraffin communicating pipe. The two ends of each refrigerating medium heat exchange cavity are provided with a refrigerating medium liquid outlet pipe connector and a refrigerating medium liquid inlet pipe connector correspondingly. The two ends of each compressor exhaust heat exchange cavity are provided with a compressor exhaust gas inlet pipe connector and a compressor exhaust gas outlet pipe connector correspondingly. According to the device, heat in compressor exhaust waste heat is stored in paraffin, the paraffin achieves heating and temperature adjusting on a refrigerating medium in the phase change process, and the temperature control equipment is more economical and environment-friendly and saves more energy; and loads of a cooling-water machine attached to a semiconductor enterprise can be reduced, and energy consumption is further reduced.

Owner:BEIJING JINGYI AUTOMATION EQUIP CO LTD

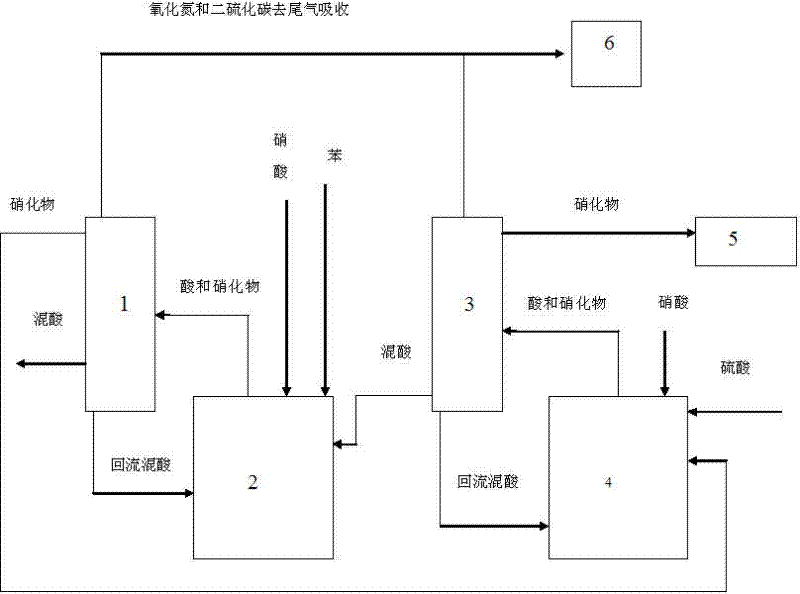

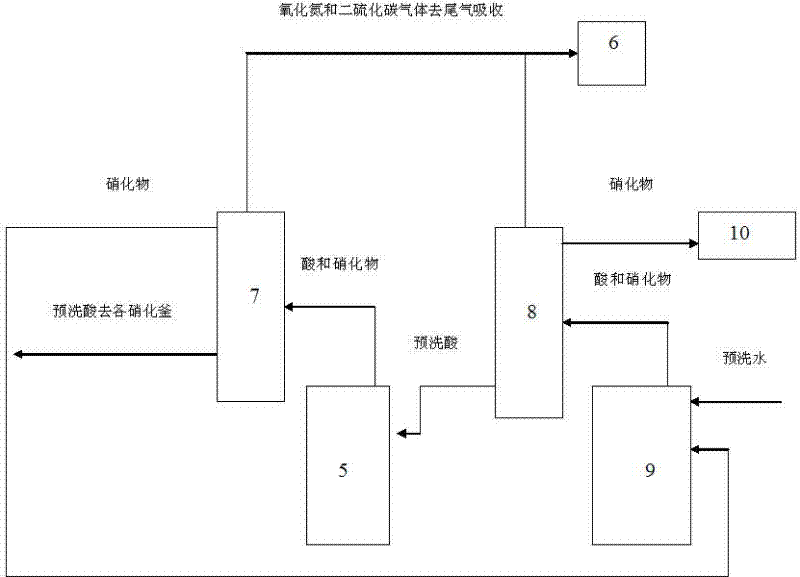

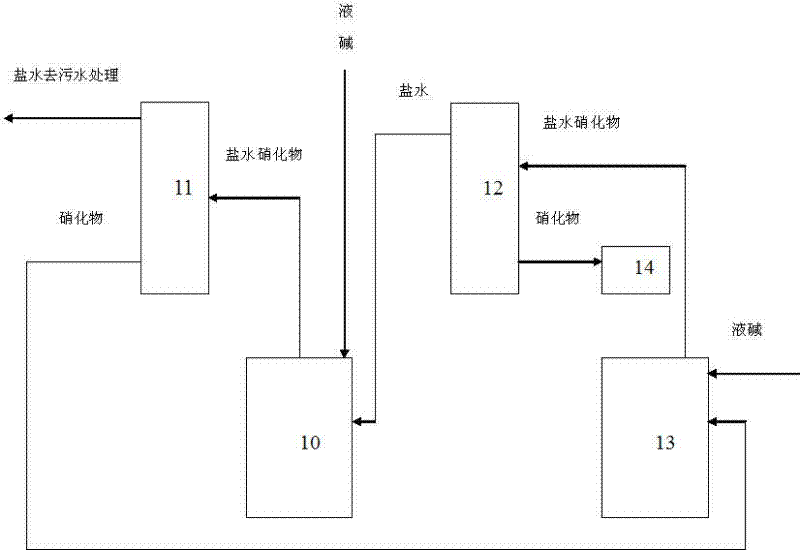

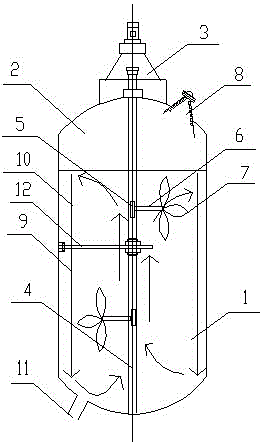

Device and method for continuously producing mixed dinitrobenzene by using coking benzene

ActiveCN102311347AReduce desulfurization costHigh reaction conversion rateNitro compound preparationNitrationPre washing

The invention discloses a device and method for continuously producing mixed dinitrobenzenes by using coking benzene. The production device is composed of nitrating kettles, pre-washing kettles, neutralization kettles and washing kettles which are reversely connected in series, wherein the number of the nitrating kettles is 5-7, the number of the pre-washing kettles is 1-2, the number of the neutralization kettles is 2-4, the number of the washing kettles is 2-4, and an oil-water separator is connected in front of each kettle. The method disclosed by the invention comprises the following steps: nitrating coking benzene into dinitrobenzene in the nitrating kettles by using mixed acid consisting of sulfuric acid and nitric acid, and simultaneously carrying out ring-opening oxidation on thiophene so as to obtain carbon disulfide; then, sequentially processing a mixture by using the pre-washing kettles, the neutralization kettles and the washing kettles so as to obtain hetero-dinitrobenzene. In the invention, based on the characteristics of a benzene nitration process and the reaction characteristics of thiophene and the mixed acid, the mixed dinitrobenzene production process is a reverse continuous nitration process; the sulfur-free mixed dinitrobenzene is produced directly by using coking benzene, therefore, the energy consumption and material consumption of the traditional coking benzene desulfurization process are reduuced; because the step of pre-desulfurization is not required, the desulfurization cost is low, and the nitrification is safe; meanwhile, because the whole system is in reverse series connection, the conversion rate of the nitration reaction is high, the consumption of the sulfuric acid is low, and less wastewater is generated.

Owner:JIANGSU KESHENG CHEM EQUIP ENG

Efficient and practical evaporator

ActiveCN104096369AAchieve hybridEvenly distributedRotary stirring mixersEvaporator accessoriesEngineeringScrew thread

An efficient and practical evaporator comprises a heating chamber and an evaporating chamber, wherein the evaporating chamber is located above the heating chamber; a stirring device is arranged in the heating chamber and comprises a motor and a rotating shaft, a turning block is arranged at each of the upper half part and the lower half part of the rotating shaft and connected with a cross bar, three blades are fixed at the tail end of each cross bar, the tail end of one blade is linearly connected with the cross bar, and the other two blades are vertically and symmetrically arranged and perpendicularly connected with the cross bar, so that a liquid is sufficiently and uniformly mixed, solute is uniformly distributed, and a feed liquid is not easy to escape; and an steam outlet of the evaporating chamber is in a circular truncated cone shape, and zigzag threads are formed in the steam outlet, so that crystal can be effectively prevented from being taken away by steam, the crystal interception effect is good, and the product yield is improved.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

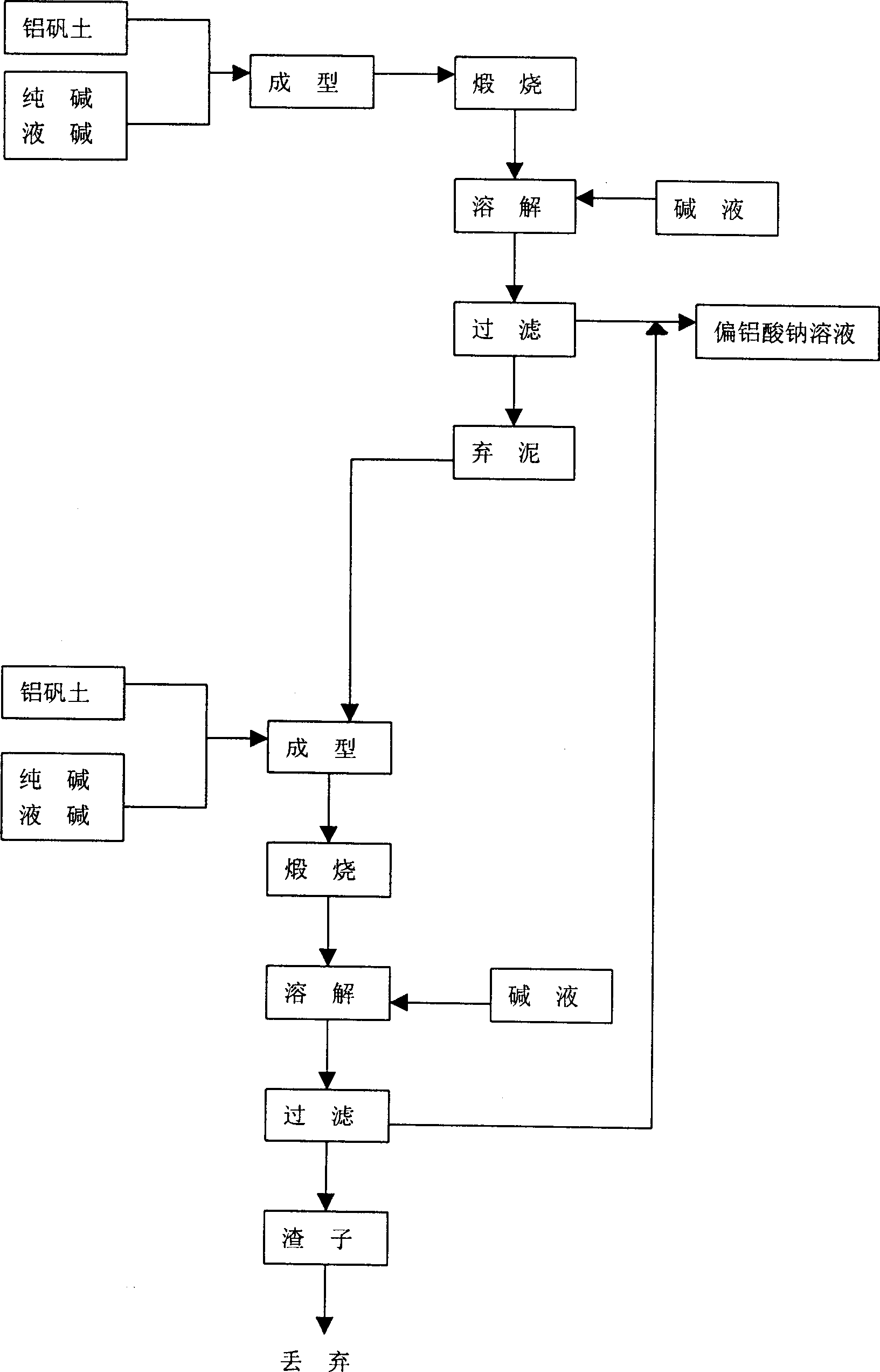

Method for preparing sodium metaaluminate solution for synthesis of zeolite with diasporite

InactiveCN1401577AReduce design requirementsReduce the burden onAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSlagAqueous solution

A process for preparing the solution of sodium metaaluminate used to synthesize zeolite includes mixing bauxite with aqueous solution of alkali; shaping, calcining, cooling, dissolving in alkali solution, stirring, settling separation, and filtering the mother liquid to obtain the solution of sodium metalluminate. Its advantages are lower calcining temp and simple process.

Owner:韩设民

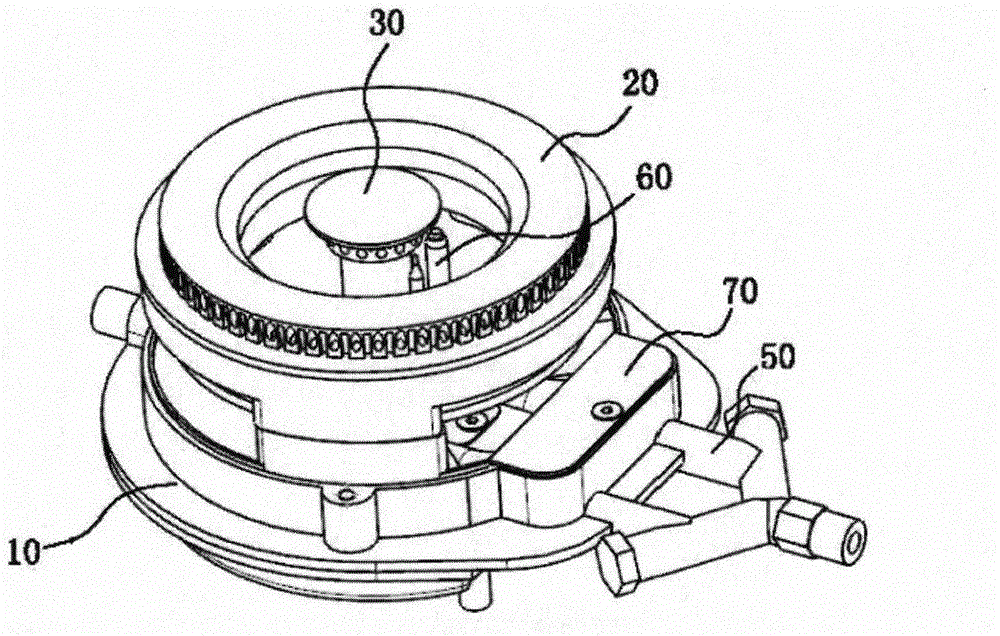

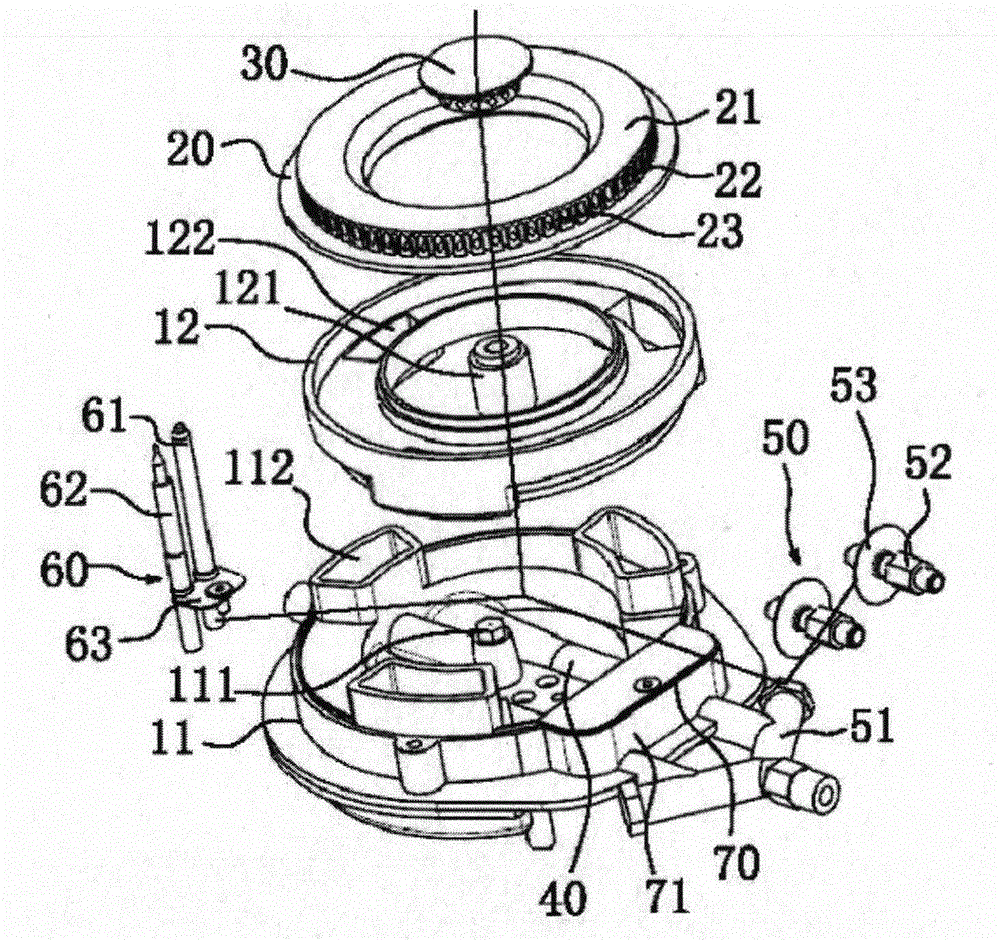

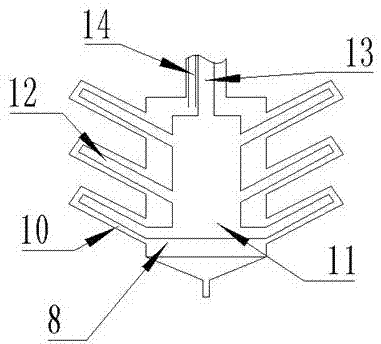

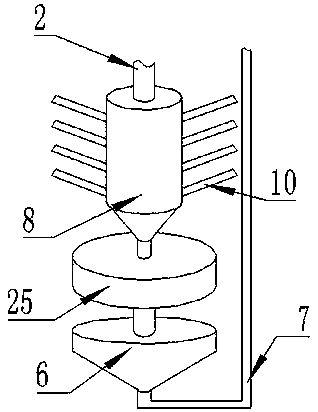

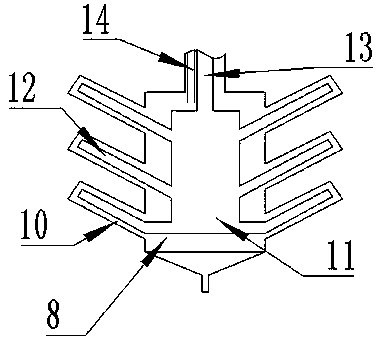

Combustor structure for gas stove

InactiveCN105987383AIncrease heat loadHigh thermal efficiencyGaseous fuel burnerEngineeringThermal efficiency

The invention belongs to the technical field of gas stoves and relates to a combustor structure for a gas stove. According to the combustor structure, the technical problems of low thermal load and efficiency in the prior art are solved. The combustor structure comprises a base, wherein an outer flame cover and an inner flame cover are detachably connected to the base, at least two ejectors are arranged in the base, an air outlet end of each ejector is located in the base and is simultaneously communicated with the outer flame cover and the inner flame cover through the base, and therefore, fuel gas in each ejector can respectively enter the outer flame cover and the inner flame cover to be combusted. The combustor structure is high in thermal efficiency and load, and the combustion is adequate.

Owner:浙江布鲁尼电器科技有限公司

Process and apparatus for separating gas and liquid

A gas-liquid separating method and apparatus based on inertial separation features that a flexible permeable silk screen layer for preventing liquid drop from being broken is arranged between the inner surface of rigid wall and the inertial separation generator to decrease the liquid speed and increase the power to capture liquid drops, and the gas and liquid penetrate said silk screen several times to increase their separation efficiency.

Owner:禹旭方

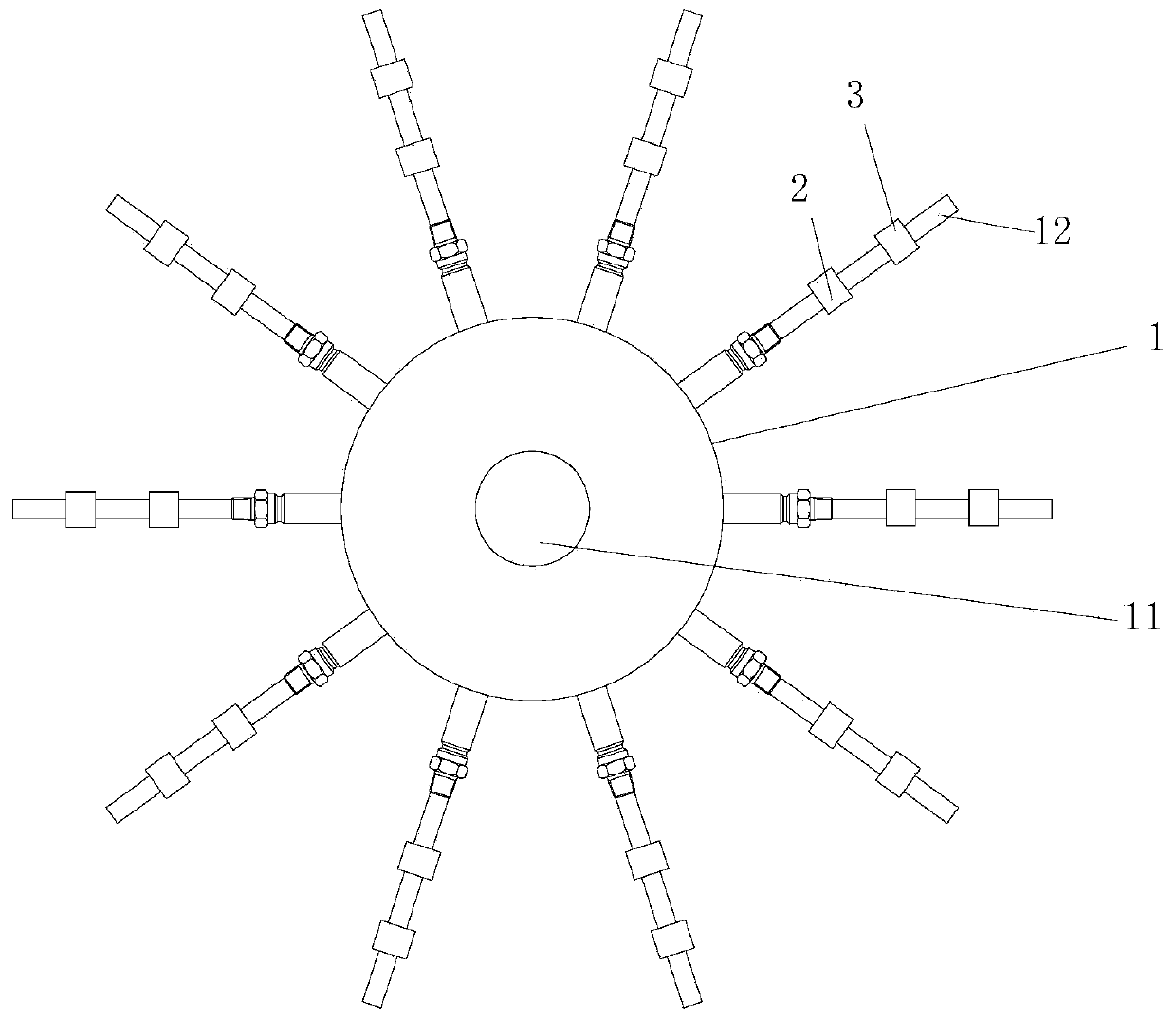

Control device for crystal growth furnace cooling water flow adjustment

InactiveCN103741218AImprove control abilityImprove yieldAfter-treatment apparatusPolycrystalline material growthWater storageWater flow

A control device for crystal growth furnace cooling water flow adjustment is characterized by comprising a water storage body, flow monitoring devices and flow adjustment devices; a water storage cavity is arranged in the water storage body, the water storage body is provided with a total water inlet for communicating with the water storage cavity, and multiple water outlets all communicating with the water storage cavity, wherein each water outlet is provided with a flow monitoring device and a flow adjustment device; and by observing of the surface velocity of an alumina melt in a crystal growth furnace, the flow monitoring device and the flow adjustment device are controlled to achieve precise adjustment of the cooling water flow of each water outlet.

Owner:福建鑫晶精密刚玉科技有限公司

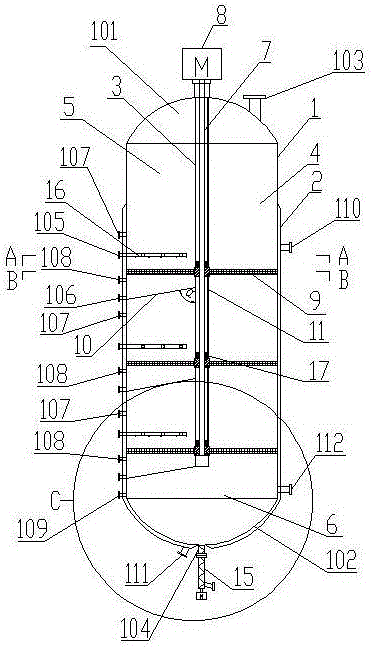

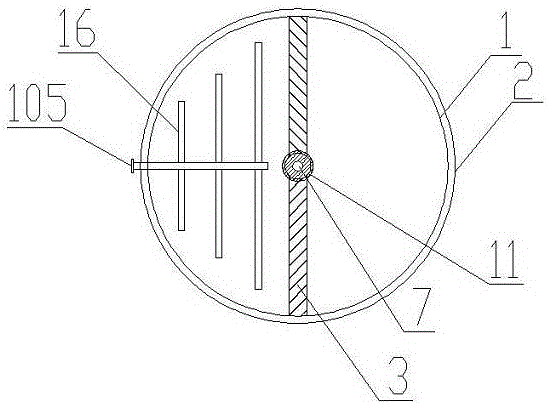

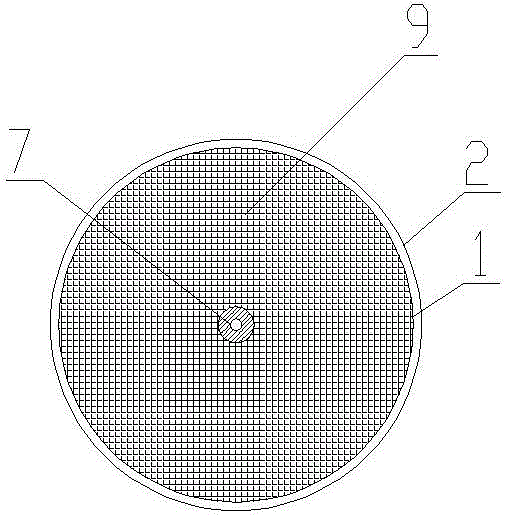

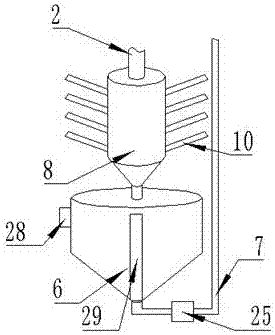

Dust-containing coal tar negative-pressure gasifying filtering device and using method thereof

ActiveCN106621610AHigh yieldDust content is not requiredDispersed particle filtrationTransportation and packagingFiltrationEngineering

The invention discloses a dust-containing coal tar negative-pressure gasifying filtering device and a using method thereof. A partition is longitudinally and fixedly arranged in a separator barrel body for dividing the separator barrel body into a filter cavity and a backwashing cavity; the bottom end of the partition is suspended to form a material input cavity with a lower end enclosure; a rotary shaft is inserted along the axis of the partition; the upper end of the rotary shaft penetrates through an upper end enclosure and is connected with a rotary motor on the outer part of the separator barrel body; a filter disc which is perpendicular to the rotary shaft is fixedly arranged on the rotary shaft; the outer edge of the filter disc clings to the inner side wall of the filter cavity and the inner side wall of the backwashing cavity; a spray liquid input hole, a backwashing liquid output hole, a gas supply hole and a gas extraction hole are formed in the side wall of the backwashing cavity; a spray pipe and a liquid receiving plate which is arranged in an inclined manner are arranged in the backwashing cavity; the spray pipe is positioned above the filter disc and communicates with the spray liquid input hole; and a material input hole is formed in the side wall of the material input cavity. The dust-containing coal tar negative-pressure gasifying filtering device is simple to operate, is low in requirement on dust content of fed coal tar, can perform rotary filtration and backwashing under a negative-pressure condition, and improves the coal tar yield.

Owner:大连市化工设计院有限公司

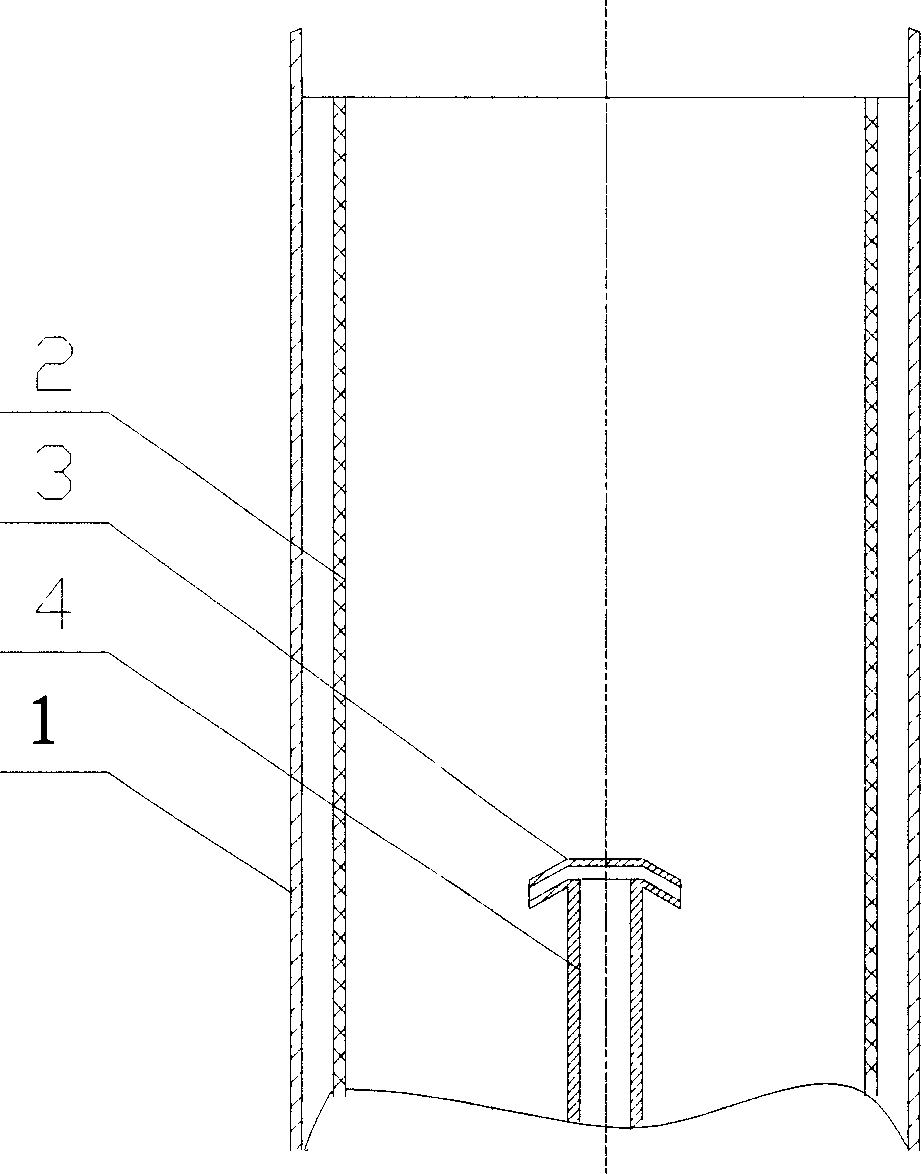

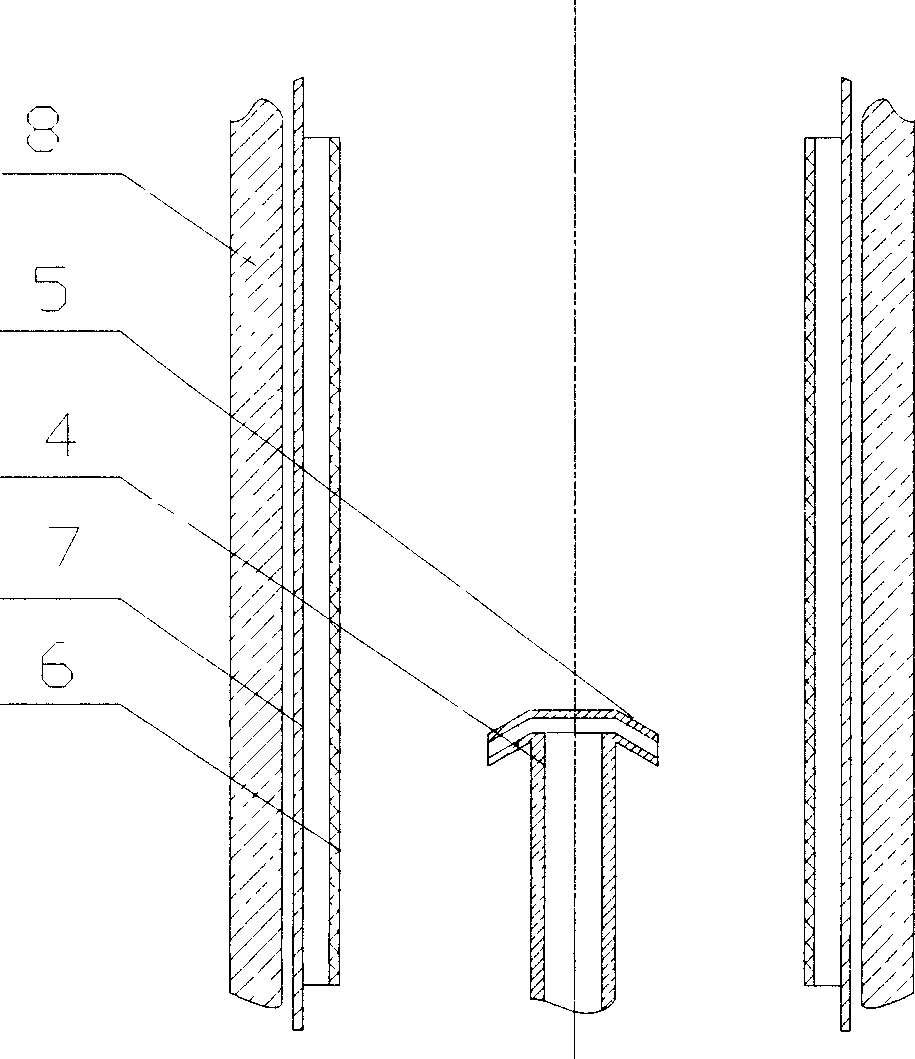

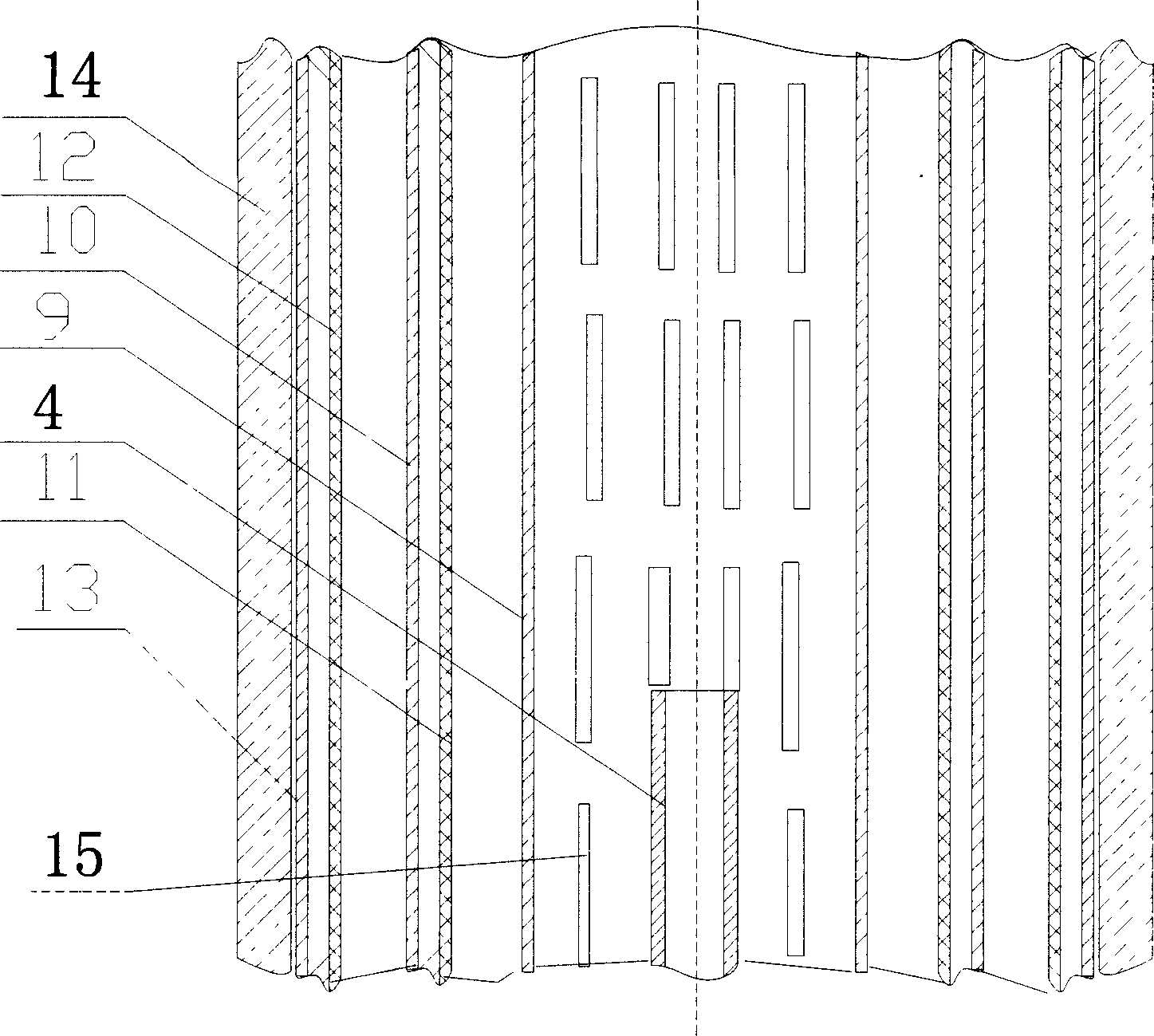

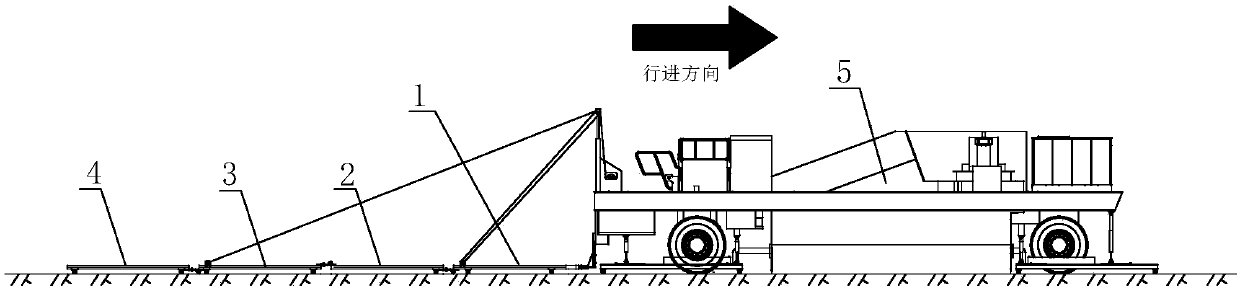

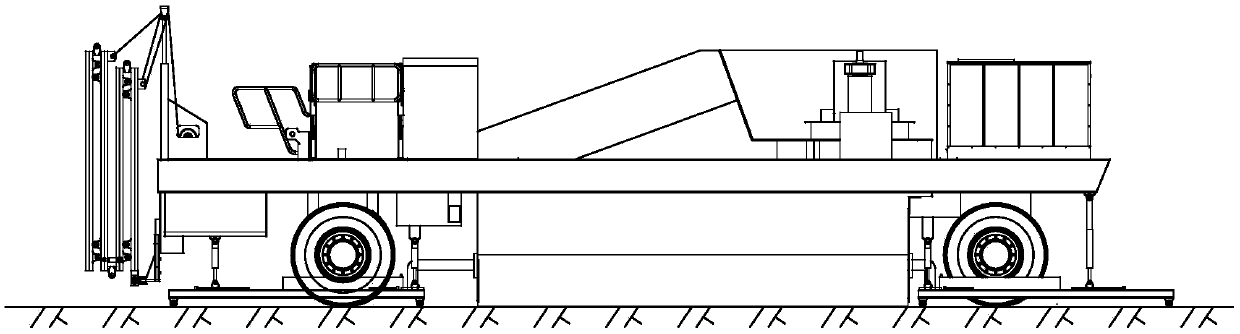

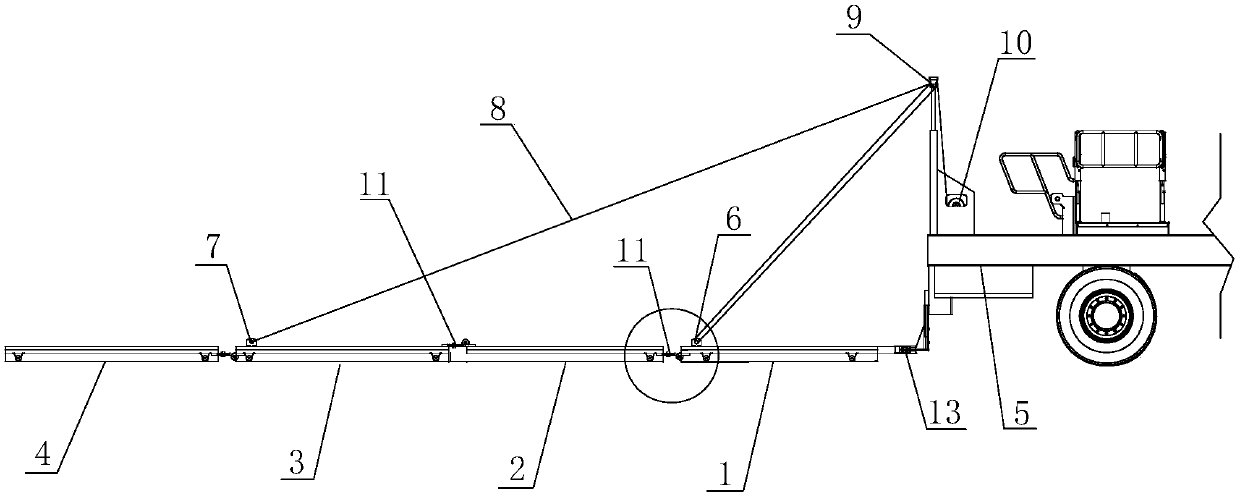

Road pavement heat insulation plate for local heat regeneration unit

The invention discloses a road pavement heat insulation plate for a local heat regeneration unit. The road pavement heat insulation plate comprises a first heat insulation plate, a second heat insulation plate, a third heat insulation plate and a fourth heat insulation plate which are sequentially connected, wherein the first heat insulation plate and the second heat insulation plate form a firstheat insulation unit; the third heat insulation plate and the fourth heat insulation plate form a second heat insulation unit; the first heat insulation plate and the third heat insulation plate are respectively connected with a steel strand line, and the steel strand line penetrates through a pulley block and then is wound on an electric winch; the electric winch is used for retracting and deploying the steel strand line via the pulley block, the first heat insulation unit and the second heat insulation unit are folded or unfolded to the horizontal state, and the heat of the heated asphalt road pavement is insulated. The road pavement heat insulation plate has the advantages that the problem of heat loss of the original road pavement at the heating gap of the heating machine is effectively solved; by covering the heat insulation plate, the coverage heat insulation is performed, so as to reduce the carrying-away of the heat due to air flowing; and the heat efficiency is improved, and the purposes of energy saving and emission reduction are further realized.

Owner:嘉鹏再升科技(深圳)股份有限公司

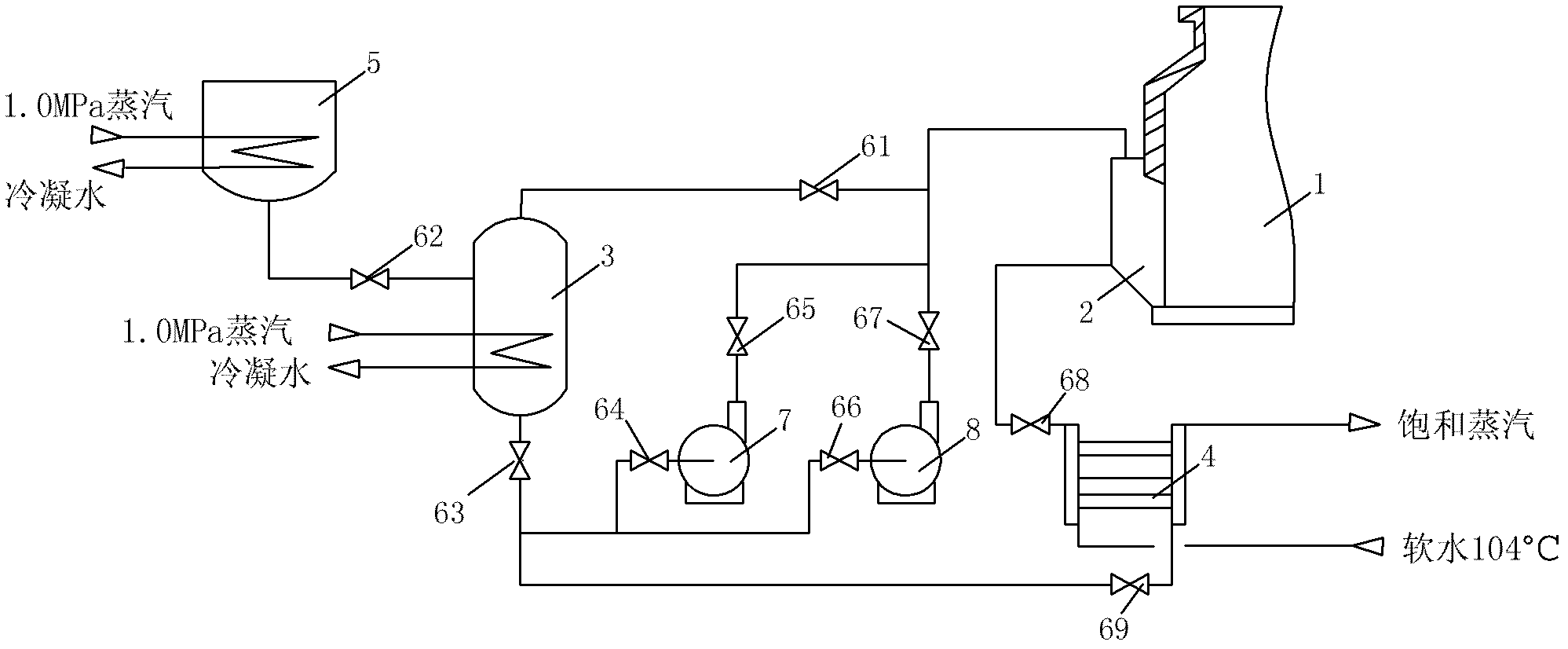

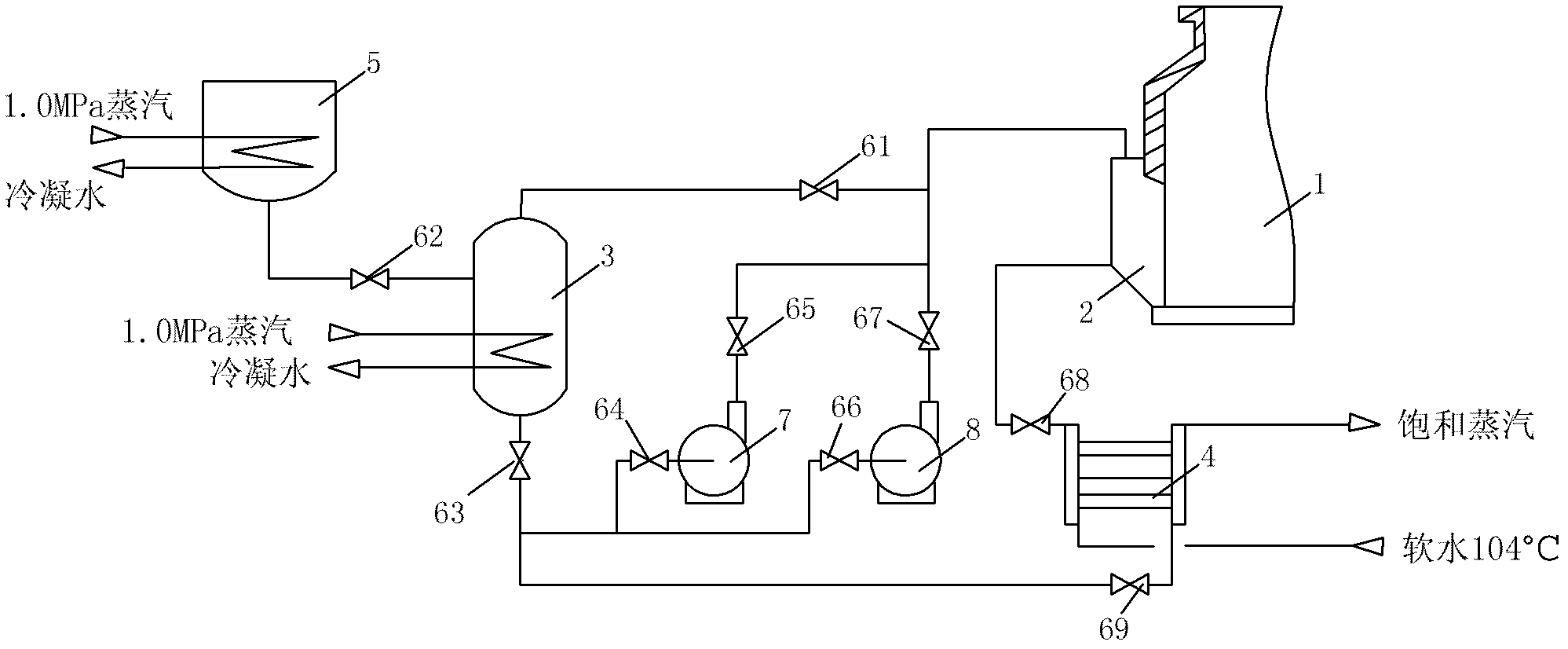

Gas-making furnace jacket fused salt heat exchanging system

InactiveCN102304389AImprove the cold wall effectIncrease productionCombustible gas productionLiquid stateSoftware engineering

The invention relates to a gas-making furnace jacket fused salt heat exchanging system. The system comprises a gas-making furnace and also comprises a fused salt storage tank, wherein the outlet of the fused salt storage tank is connected with the inlet of a fused salt pump; the outlet of the fused salt pump is connected with the inlet of a jacket boiler; the outlet of the jacket boiler is connected with the inlet of a heat exchanger; the outlet of the heat exchanger is connected with the inlet of the fused salt pump; and the medium in the fused salt storage tank is liquid-state fused salt. The technical scheme shows that the liquid-state fused salt in the fused salt storage tank is cycled through the fused salt pump and then fed to the gas-making furnace jacket boiler for further cycle heating, and then heats soft water by the heat exchanger to generate saturated steam, and then the steam is self-used by overheating or externally supplied; and the fused salt is adopted to replace the soft water to be used as a heat-transfer medium, so that the temperature in the jacket boiler is increased, thereby reducing the heat taken away by the heat-transfer medium in the jacket boiler, reducing the loss of sensible heat in the gas-making furnace, improving gasification efficiency and greatly improving the cold wall effect of the gas-making furnace jacket boiler.

Owner:ANHUI HUAIHUA

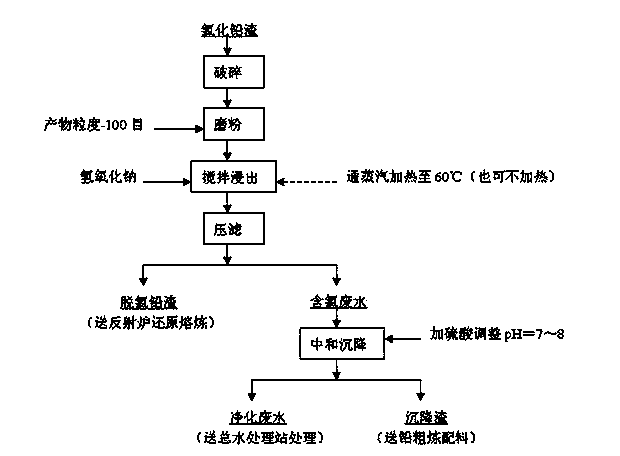

Research on dechloridation process of lead chloride slag

InactiveCN103540757AReduce pollutionImprove direct yieldProcess efficiency improvementSlagNon-ferrous metal

The invention relates to a method for smelting non-ferrous metals, and in particular relates to research on a dechloridation process of lead chloride slag. The shortcomings of the prior art are overcome by the dechloridation process provided by the invention; the novel method, by which chlorine is removed before the lead chloride slag is introduced into a reverberatory smelting step, is provided; the efficient removal of the chlorine inside the lead chloride slag is achieved by means of novel process design; the smelting direct yield rate is increased; the corrosion of a hearth and a steel fume pipe by chlorine gas is reduced; the tail gas exhaust standard can meet the state environmental protection requirements.

Owner:CHENZHOU YUTENG CHEM IND

Water making control device and method for drought regions

InactiveCN107975102ABroaden your optionsLow costDrinking water installationWater storage tankEngineering

The invention discloses a water making control device and method for drought regions. The device comprises a base, a support column is arranged on the top of the base, a vertical axial fan is arrangedon the support column, a connecting pipe is connected to the bottom of the base, a water collector is connected to the tail end of the connecting pipe and arranged in a soil layer below the earth's surface, and the base is arranged on the ground; the water collector comprises a rotary cavity, a water storage tank is connected to the bottom of the rotary cavity, and the bottom of the water storagetank is connected with the base through a drain pipe. The problems that water taking is difficult in the drought regions, water cannot be produced in desert areas, and the water taking cost is high for people living in the drought regions are solved.

Owner:CHENGDU WENDA MAOYUAN TECH

Microemulsion diesel oil and preparation method thereof

InactiveCN102181312AFulfil requirementsSimple production processLiquid carbonaceous fuelsBodies oilExternal combustion engine

The invention relates to microemulsion diesel oil, and main body oil comprises the following raw materials by weight percent: 12-35% of microemulsion, 30-75% of diesel oil and 13-35% of active liquid; 10-25% by weight of solvent is further added into the main body oil for changing flowability and specific gravity, and 0.1-1% by weight of power agent is further added for adjusting heat value. The product has good mutual solubility, no precipitation, no stratification and a wide range of applicable temperature, a production process is simple, the comprehensive cost is low, the stability and thecombustibility are higher, the oil-saving rate can be as high as above 5%, and the tail gas pollution is low. The product is suitable for being used as fuel of diesel vehicles, ships, power generators and other diesel internal combustion engines, when the content of tap water is higher than 18%, the microemulsion diesel oil can be applied in kilns, industry, catering industry and other industries, and the microemulsion diesel oil further has good economic benefits, environment-friendly benefits and social benefits.

Owner:汪青

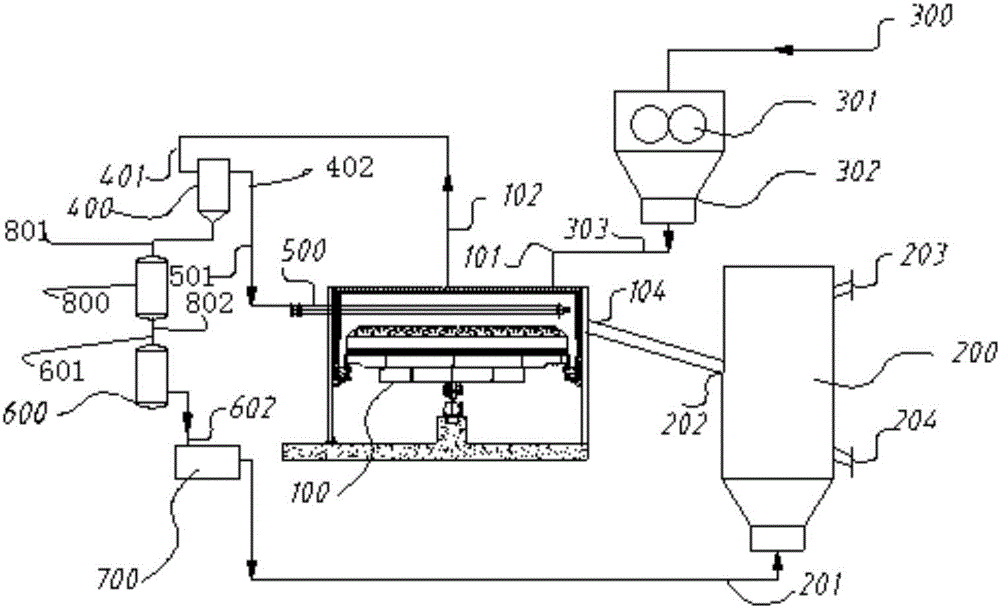

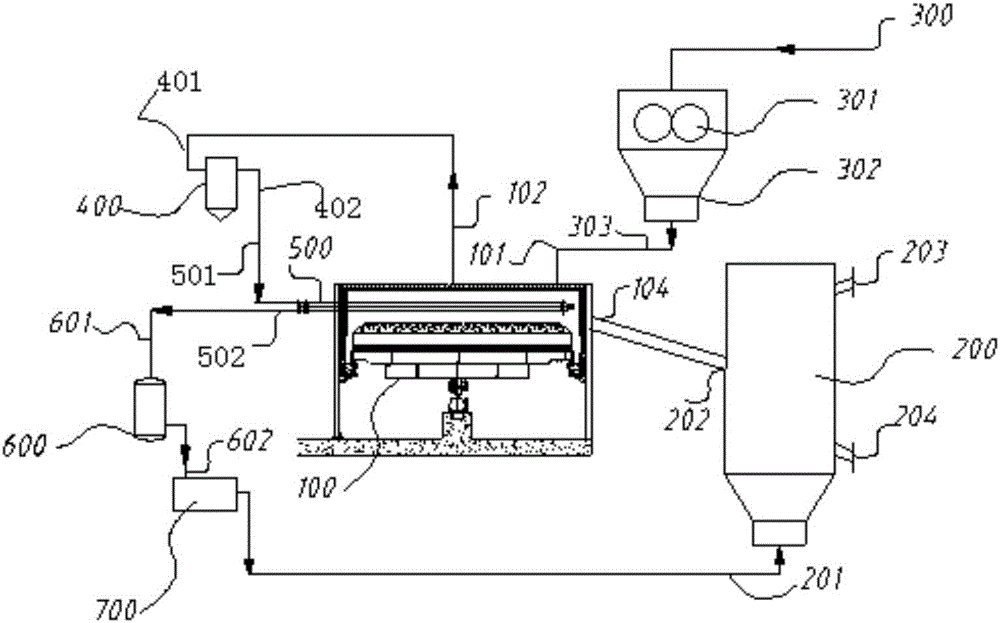

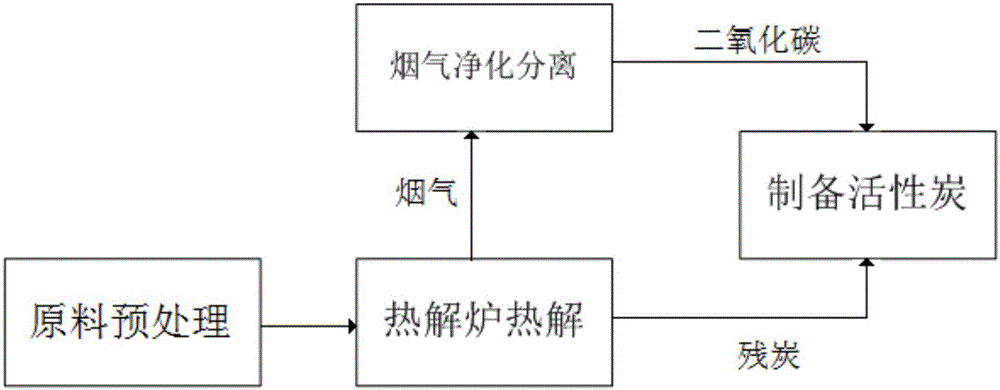

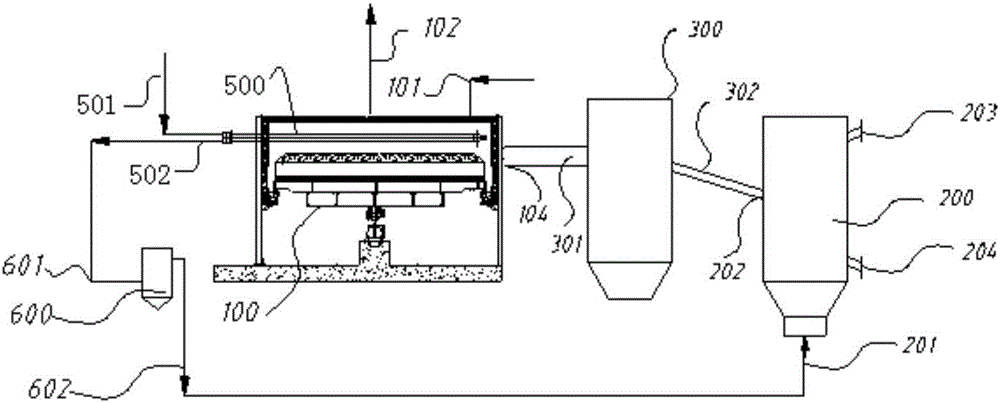

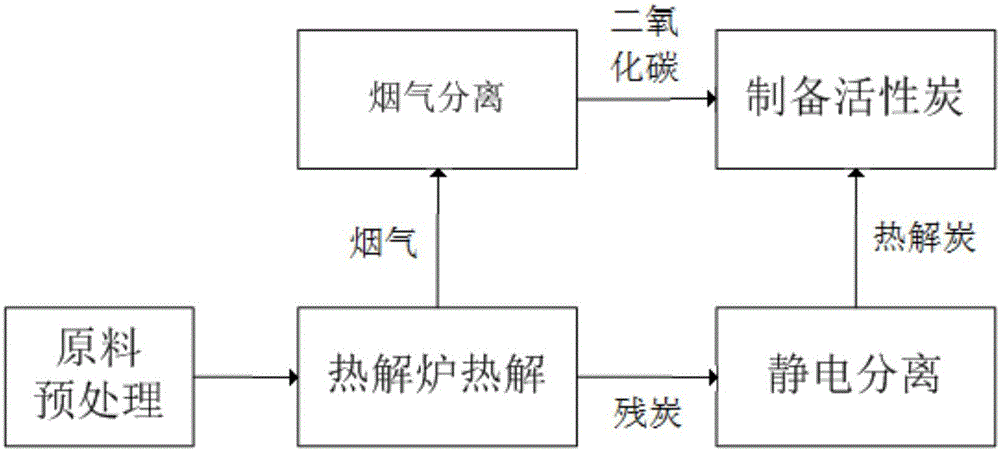

System and method for preparing active carbon by use of coal

InactiveCN106517192AReduce heat lossReduce energy consumptionCarbon compoundsActivated carbonCarbon dioxide

The invention relates to a system and method for preparing active carbon by use of coal. The system comprises a pyrolysis furnace, a combustor, a purifying and separating device and a fluidized bed, wherein the pyrolysis furnace comprises a feed port and a solid outlet and is used for pyrolyzing the raw material coal to generate carbon residue; the combustor is provided with a fuel gas inlet and a combustion flue gas outlet and is used for heating the raw material coal to generate combustion flue gas; the purifying and separating device is provided with a combustion flue gas inlet and a carbon dioxide outlet, the combustion flue gas inlet is connected with the combustion flue gas outlet, and the purifying and separating device is used for purifying and separating the combustion flue gas to obtain carbon dioxide; and the fluidized bed is provided with a solid inlet, an activator inlet, a waste gas outlet and an active carbon outlet, the solid inlet is connected with the solid outlet of the pyrolysis furnace, the activator inlet is connected with the carbon dioxide outlet of the purifying and separating device, and the fluidized bed is used for activating the carbon residue to generate active carbon. In the invention, the existing fluidized bed does not need to be transformed, the heat loss is reduced, the energy consumption is lowered, and the capacity of the pyrolysis furnace is increased.

Owner:SHENWU TECH GRP CO LTD

Surface tension increasing agent for hydrocarbon cleaning agent as well as preparation method and use method of surface tension increasing agent

InactiveCN106350326AWide range of applicationsGood cleanlinessNon-ionic surface-active compoundsOrganic detergent compounding agentsSurface tensionCleanability

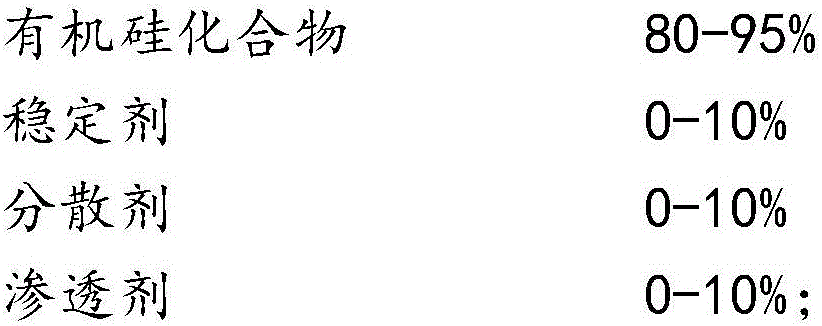

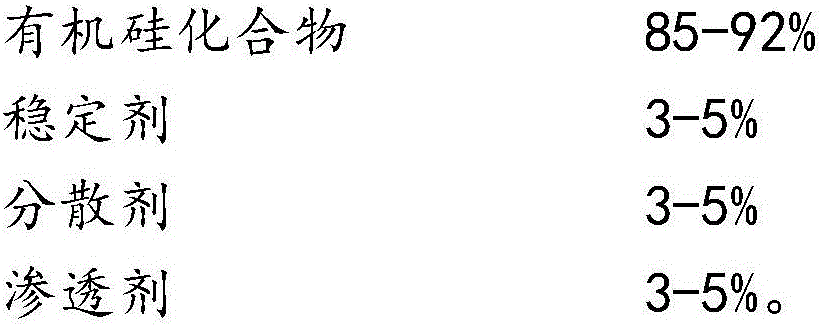

The invention provides a surface tension increasing agent for a hydrocarbon cleaning agent. The surface tension increasing agent is characterized by consisting of or being prepared from the following ingredients in percentage by mass: 80-95% of an organic silicon compound, 0-10% of a stabilizer, 0-10 parts of a dispersant and 0-10% of a penetrant, wherein the ingredients certainty include at least one of the stabilizer, the dispersant and the penetrant. The product provided by the invention is wide in application range, has favorable cleanability, and is capable of effectively preventing secondary pollution of washed-off oil stain. The surface tension increasing agent is also capable of reducing the cleaning agent brought away by workpieces, and reducing losses in a cleaning process.

Owner:诺而曼环保科技(江苏)有限公司

Dust collection system

ActiveCN107158872AAchieve separationEasy to loseCombination devicesWater circulationElectromagnetic valve

The invention discloses a dust collection system. The dust collection system comprises a vehicle, a dust suction component, a control component, a filter component, a dust collection component and a water circulating component, wherein the dust suction component and the control component are arranged on the vehicle; the filter component, the dust collection component and the water circulating component are arranged in the vehicle; the dust suction component, the filter component and the dust collection component are successively connected; the water circulating component is connected with the dust collection component and the filter component; the dust suction component comprises a dust suction head; the dust suction head is connected with a first fan arranged in the vehicle through a hose; the first fan is connected with the filter component through a first pipe; the filter component comprises a filter box for storing water; a second filter is arranged on the upper middle part in the filter box; a port of the first pipe is arranged in the filter box and positioned below the second filter; the top of the filter box is connected with a gas outlet of the vehicle through a gas outlet tube; and a first electromagnetic valve is arranged at the bottom of the filter box and is connected with the dust collection component. Large and small dust in the environment can be collected effectively, the dust collection efficiency is improved, and the environment is also improved.

Owner:四川恒创博联科技有限责任公司

Hot-dip galvanizing method for steel products

ActiveCN101280401BReduce take awayTemperature controlHot-dipping/immersion processesHeat lossesDross

The invention relates to a hot dip galvanizing method for the steel product, which belongs to the hot dip galvanizing engineering in the metallurgy field. The invention mainly solves the technical problem that the hot dip galvanizing method which is utilized for the steel product for directly aiming at the faults of excessive consumption of the zinc and low efficiency utilization of the heating system in the normal hot dip galvanizing process is provided. The heating way of the dip galvanizing kettle of the invention is side surface heating, thus, the temperature of the liquid zinc can be conveniently controlled, the deposition of the zinc dross can be accelerated, and the zinc quantity taken away by the galvanizing piece can be reduced; because the ferric salt content inside the assistant galvanizing tank is controlled, the zinc dross quantity inside the zinc kettle is reduced; simultaneously, the output per hour is controlled to stabilize the heat loss and reduce the increased zinc consumption caused by temperature variation. Through the progress of the process, the zinc consumption is reduced, the heat energy is fully utilized, the faults of excessive zinc consumption and low efficiency utilization coefficient of the heating system caused by normal process are overcome, the quality is ensured, simultaneously, the resources are saved.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

Wind-energy water production equipment

InactiveCN108104201AWiden your optionsLow costWater/sewage treatment by magnetic/electric fieldsDrinking water installationSoil horizonWater storage tank

The invention discloses wind-energy water production equipment. The wind-energy water production equipment comprises a base of which the top is provided with a support column, the support column is provided with a vertical-axis draught fan, the bottom of the base is connected to a connection pipe of which the tail end is connected to a water collection device, the water collection device is arranged in a soil layer under the earth, and the base is arranged on the ground; the water collection device comprises a rotating cavity of which the bottom is connected to a water storage tank, and the bottom of the water storage tank is connected to the base through a water discharge pipe. Through the wind-energy water production equipment, the problems are solved that it is difficult to obtain waterin arid areas, water cannot be produced in desert areas and the water obtaining cost is high for people living in the arid areas.

Owner:CHENGDU WENDA MAOYUAN TECH

Cyclone dust removal device for recycling of high-temperature dust-containing tail gas

The invention discloses a cyclone dust removal device for recycling of high-temperature dust-containing tail gas. The cyclone dust removal device comprises a cylindrical hollow outer cylinder, a hollow inner cylinder, a central air discharging pipe, an inner layer heat exchange pipe, an outer layer heat exchange pipe and a spraying device, wherein the hollow inner cylinder is arranged in the hollow outer cylinder and comprises a first part, a second part and a third part in sequence from top to bottom; the first part is cylindrical, is provided with an air inlet pipe, and forms a first interlayer with the inner wall of the hollow outer cylinder; one end of the air inlet pipe tangentially penetrates through the first part, the other end of the air inlet pipe is communicated with the outside; the second part is conical; an opening is formed in the upper part of the side wall of the second part; the third part is reversely conical; the lower end of the third part props against the hollow outer cylinder so as to form a second interlayer with the second part and the hollow outer cylinder; the central air discharging pipe is arranged in the hollow inner cylinder; the inner layer heat exchange pipe winds along the outer wall of the central air discharging pipe; the lower end of the inner layer heat exchange pipe is communicated with the opening of the second part; the outer layer heat exchange pipe winds along the outer wall of the first part; the lower end of the outer layer heat exchange pipe is communicated with a liquid inlet pipe; the upper end of the outer layer heat exchange pipe is communicated with the upper end of the inner layer heat exchange pipe. The cyclone dust removal device disclosed by the invention has the advantages that both of the dust removal efficient and the heat exchange efficiency are high.

Owner:哈威光电科技(苏州)有限公司

System and method for preparing activated carbon from waste circuit boards

The invention relates to a system and method for preparing activated carbon from waste circuit boards. The system comprises a pyrolysis furnace, a burner, an electrostatic separator, a carbon dioxide separation device and a fluidized bed, wherein the pyrolysis furnace is used for pyrolyzing raw materials, namely the waste circuit boards, and residual carbon is generated; the burner is used for heating the raw materials, namely the waste circuit boards, and combustion flue gas is generated; the electrostatic separator is used for separating metal from non-metal to obtain pyrolytic carbon; the carbon dioxide separation device is used for conducting carbon dioxide separation on the combustion flue gas, and carbon dioxide is obtained; the fluidized bed is used for activating the pyrolytic carbon to generate activated carbon. An existing fluidized bed does not need to be transformed, heat loss is reduced, energy consumption is reduced, productivity of the pyrolysis furnace is improved, and reduction, harmlessness and resource utilization of the materials are achieved.

Owner:SHENWU TECH GRP CO LTD

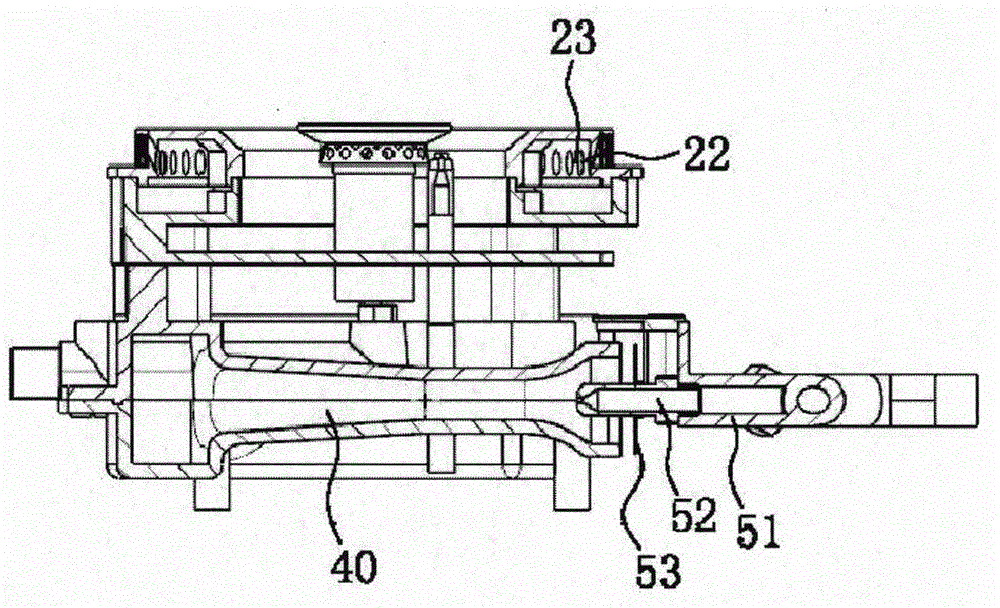

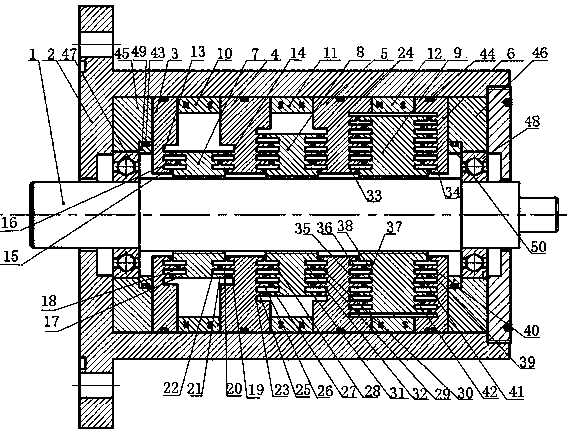

Divergent split-tooth stepped magnetic fluid rotating sealing device

PendingCN110762224AIncrease the number ofIncreased amount under the effect of increasing stress concentrationEngine sealsEngineeringPole piece

The invention aims to provide a divergent split-tooth stepped magnetic fluid rotating sealing device. The device comprises a shaft, a shell, a first pole shoe ring, a second pole shoe ring, a third pole shoe ring, a fourth pole shoe ring, a first sleeve, a second sleeve, a third sleeve, a first permanent magnet ring, a second permanent magnet ring and a third permanent magnet ring. The sealing device has the advantages that the magnetism gathering effect can be improved, so that the pressure resistance of magnetic fluid is improved; meanwhile, the magnetic fluid sealing failure caused by centrifugal force effect can be effectively prevented, the loss of the magnetic fluid is reduced, and the reliability and the service life of the sealing are improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

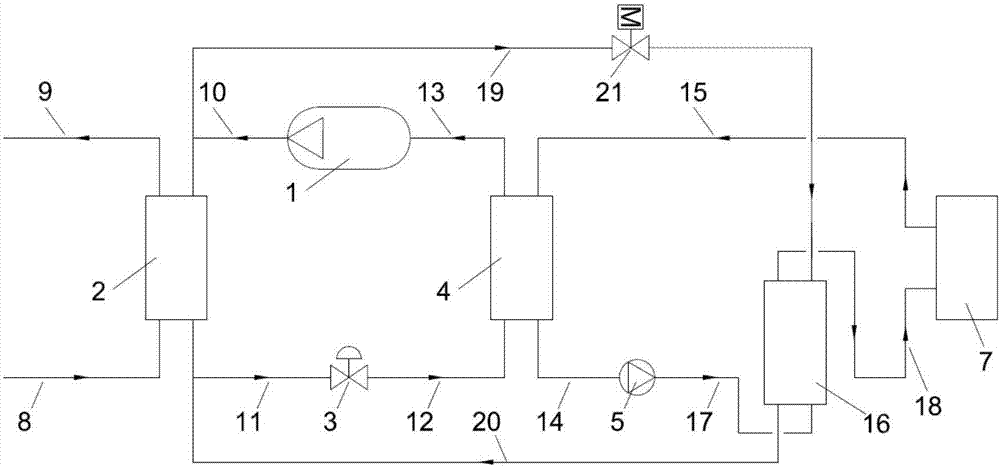

Draft cooling tower ventilation adjusting system

PendingCN110017700AReduce lossesReduce take awayEfficient regulation technologiesHeat exchange apparatusCooling towerBusbar

The invention relates to a draft cooling tower ventilation adjusting system comprising a cooling tower and a water collecting device installed in the cooling tower and arranged to be of a convection angle waveform structure, a fan is arranged at the top of the cooling tower, the fan is provided with a motor with the rotating speed being 0-1480 r / min, a cooling tower water outlet is connected witha circulating water pipe, the circulating water pipe is provided with a temperature detector, a water pump is connected to the tail end of the circulating water pipe, and a water storage tank is connected to the tail end of the circulating water pipe; the water storage tank is connected with a condenser, the condenser is connected with a water inlet in the upper portion of the cooling tower through a water return pipe; the temperature detector is connected with a PLC through a wire, and the PLC is connected with a frequency converter with the frequency range being 0-50 Hz through a control line; and the frequency converter is connected with the motor and communicates with a 380 V power supply busbar. The draft cooling tower ventilation adjusting system effectively adjusts the air flow rate, automatic ventilation control and on-line temperature monitoring are realized, the water separation take-away amount is reduced, the water loss is reduced, a deflector is not prone to being crushed,and the temperature of the cooling water is stabilized.

Owner:嘉峪关大友嘉能精碳科技股份有限公司

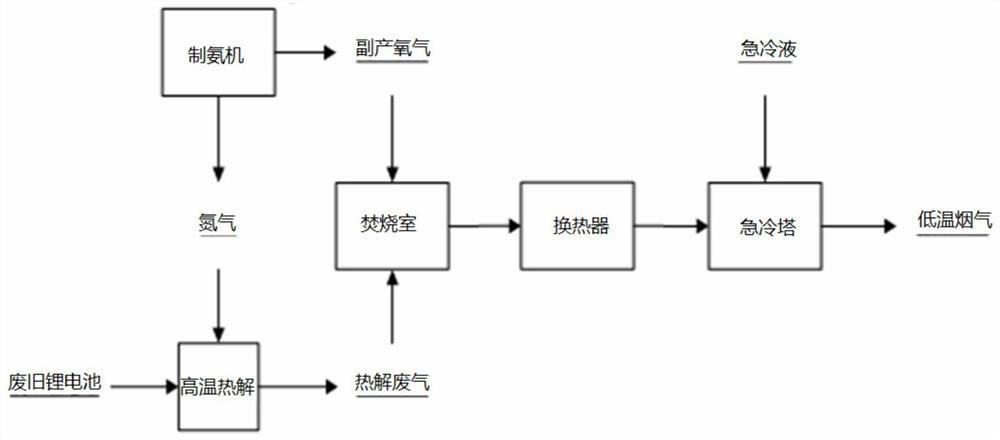

Method for preventing and treating dioxin in waste lithium battery pyrolysis process

PendingCN114353091AInhibitionBreak down toIndirect carbon-dioxide mitigationIncinerator apparatusNitrogen generatorFlue gas

The invention provides a method for preventing and treating dioxin in a waste lithium battery pyrolysis process. In the pyrolysis process of the waste lithium battery, inert gas is introduced to enable the pyrolysis process to be in an oxygen-deficient state, then waste gas generated by pyrolysis is sprayed into an incineration chamber, natural gas is sprayed to support combustion, the combustion temperature is controlled to be 850-1100 DEG C, meanwhile, oxygen-enriched gas is sprayed to form flame vortex with the pyrolysis waste gas, and the oxygen-enriched gas and the pyrolysis waste gas are fully mixed in the incineration chamber to generate oxidation reaction; and dioxin generated by pyrolysis is decomposed. And then flue gas discharged from the incineration chamber passes through a heat exchanger, the temperature is reduced to 600-700 DEG C, then the flue gas is introduced into a quench tower to be quenched, the flue gas is quenched to 200 DEG C or below, the quenching time is shorter than 1 second, and regeneration of dioxin is restrained. According to the method, the nitrogen making machine is used for producing nitrogen, meanwhile, the byproduct oxygen-enriched gas is produced, dioxin generated in the pyrolysis process of the waste lithium batteries is decomposed through oxygen-enriched combustion, the use amount of natural gas is reduced, the cost is relatively low, and the method is suitable for large-scale recycling of the waste lithium batteries.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com