Patents

Literature

124results about How to "Act as a "catalyst"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mesoporous silicon material as well as preparation method and application thereof

ActiveCN103464140AHigh catalytic activityImprove dispersionHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsIonSol-gel

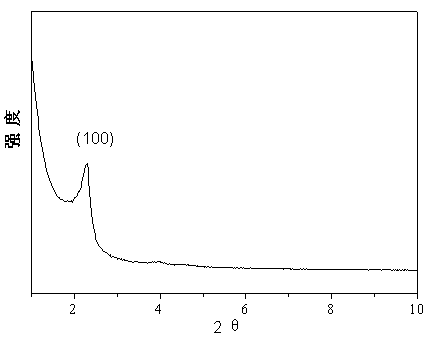

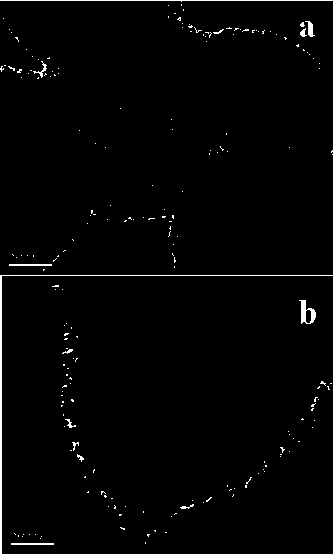

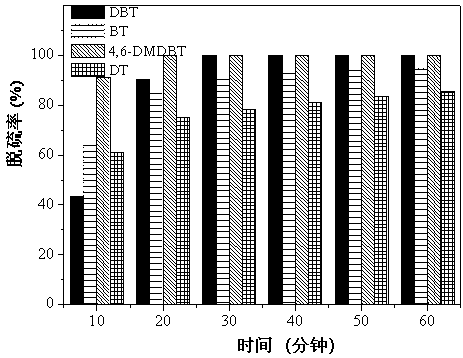

The invention relates to a mesoporous material and particularly relates to a functionalized ordered mesoporous silicon material which is synthesized by taking polyacid-type ionic liquid as a raw material as well as an application of the mesoporous silicon material in oxidation desulfuration of fuel oil. According to the mesoporous silicon material, the polyacid-type ionic liquid is not only used as a template agent of the mesoporous material, but also used as a catalytic activity center, and transition metal is introduced into the mesoporous material structure in situ. A simple and nontoxic synthesis method of the metal-doped green mesoporous material is searched, has a favorable academical research value and also has a wide application prospect in the industrial production. The mesoporous silicon material as well as the preparation method and the application thereof have the advantages that the method is simple in process, and the mesoporous silicon material which is narrow in pore size distribution, regular and ordered in pore duct and good in thermal stability and has the pore size of 2-50nm is self-assembled under the guidance action of inorganic matters and organic matters by adopting a sol-gel method. The purpose of deep desulfuration can be achieved when the mesoporous silicon material is used as a catalyst for an oxidation removing reaction process of organic sulfides.

Owner:泰州市海创新能源研究院有限公司

Synthetic method of phosphorus and nitrogen type fire retardant

The invention relates to a synthetic method of a phosphorus and nitrogen type fire retardant, which comprises the following steps of: reacting an assistant with phosphate materials to remove water out of the phosphate materials; reacting polyhydric alcohols with the phosphate materials with water removed to obtain an intermediate; and reacting the intermediate with melamine in a solvent to obtain the phosphorus and nitrogen type fire retardant, wherein the phosphate materials can be one or more than one of phosphoric acid, pyrophosphoric acid and polyphosphoric acid. Compared with the prior art, the synthetic method provided by the invention has the advantages of shortening the esterification reaction time and increasing yield of the phosphorus and nitrogen type fire retardant, improving the purity of the phosphorus and nitrogen type fire retardant and the production process is simple in process and clean and safe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

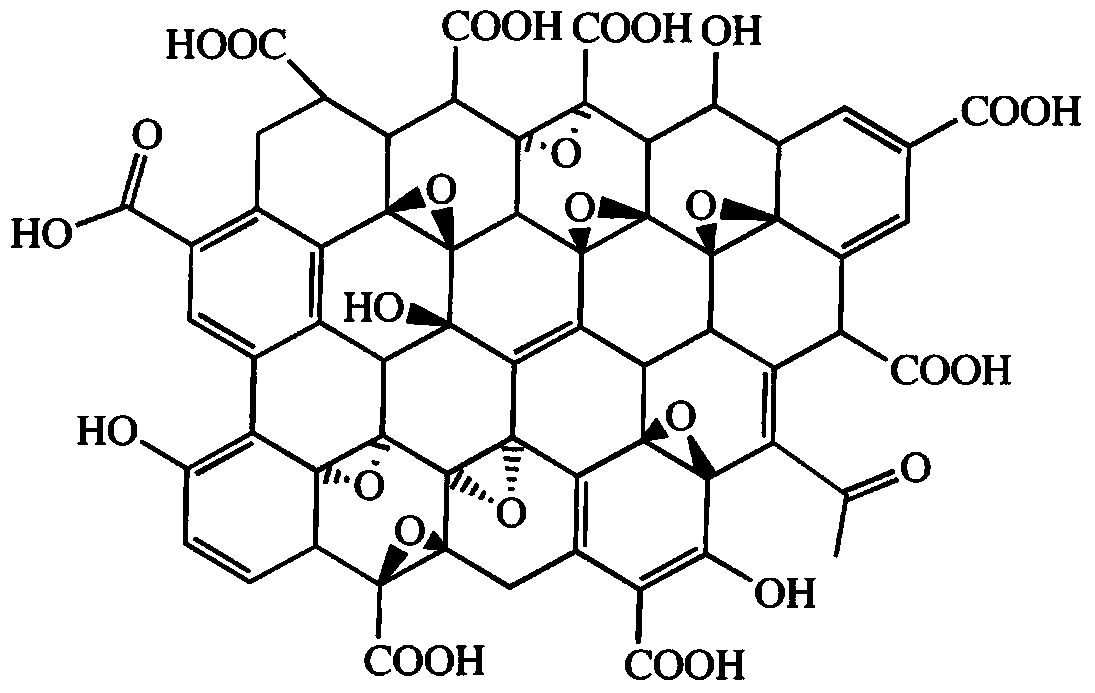

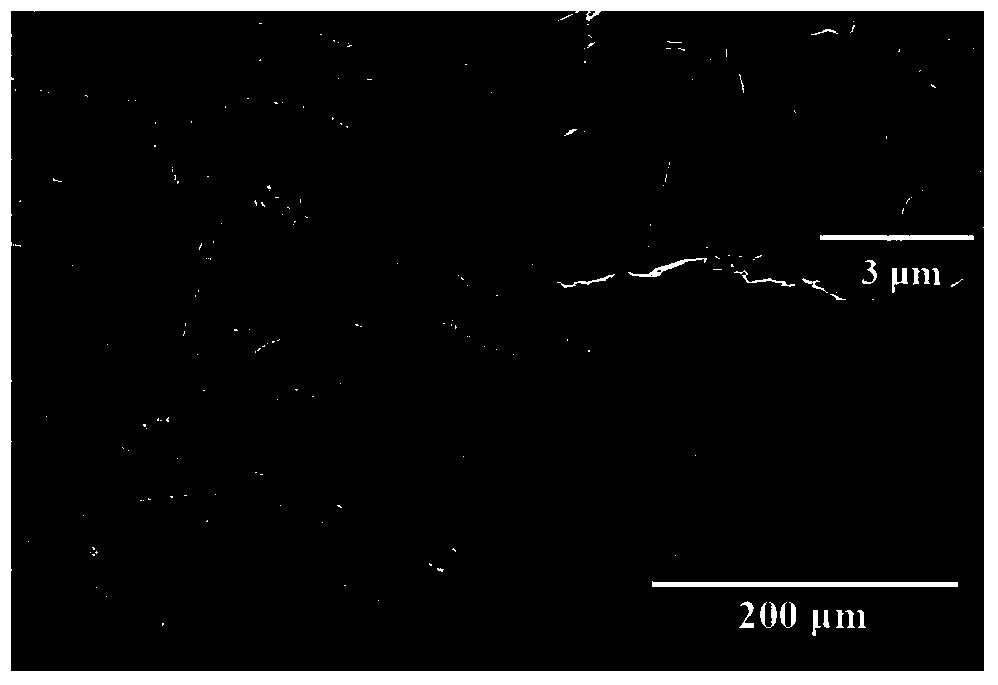

Lithium-air battery based on oxidized graphene-carbon paper gas catalytic electrode

InactiveCN104201438AReduce ohmic voltage dropAvoid corrosionFuel and secondary cellsCell electrodesUltrasonic dispersionReproduction

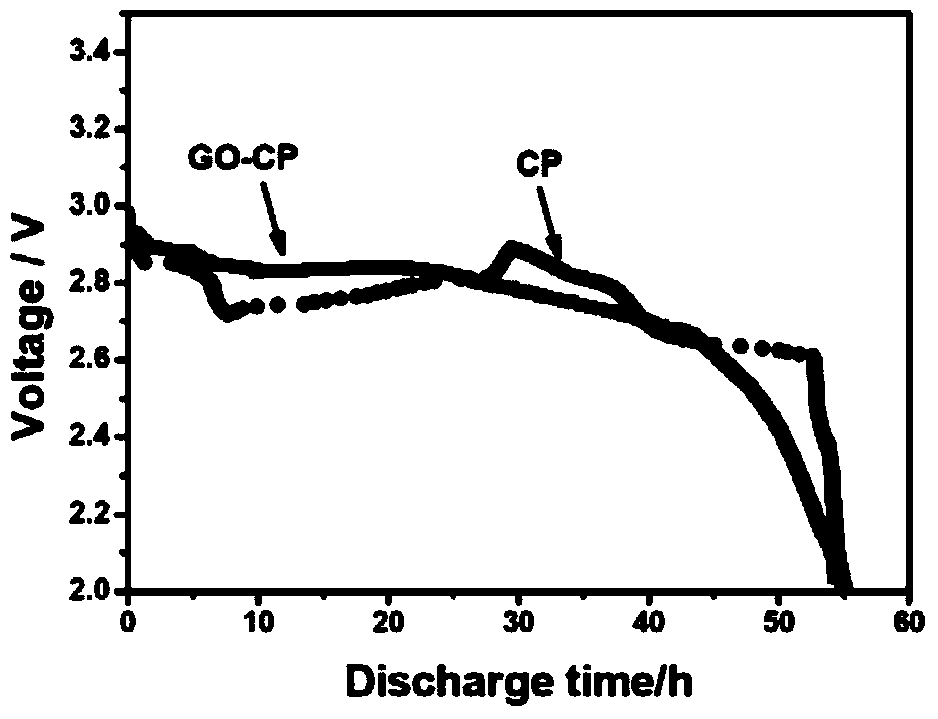

The invention provides a lithium-air battery based on an oxidized graphene-carbon paper gas catalytic electrode. The positive electrode of the battery is an oxidized graphene catalytic electrode which is prepared by the following method and is supported by carbon paper. A preparation method comprises the steps of performing ultrasonic dispersion on oxidized graphene in a phosphate buffering solution to form a suspension state so as to prepare electrolyte; then the carbon paper is used as positive electrode, and a platinum electrode is used as a negative electrode; the voltage of an electrolytic battery is controlled to be 5-20V; under a proper stirring speed and proper temperature, electrophoresis-electrolysis is performed for 5-30 minutes; after electrolytic deposition is ended, oxidized graphene is loaded on the carbon paper; the carbon paper is washed by secondary distilled water and is dried under vacuum; finally a load of the oxidized graphene on the carbon paper is weighed and metered by an analysis balance. The preparation steps are simple; operation parameters are easy to control; the performance of the electrodes is stable, and reproduction is realized; under the current density of 0.1mA / cm<2>, the first discharge capacity is 11,553mAh / g; after the circulating battery runs for 520 hours, the performance is stable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

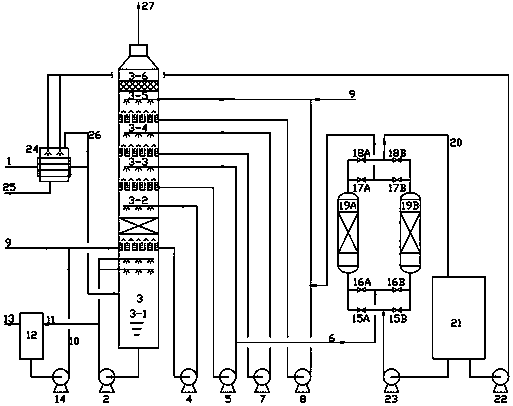

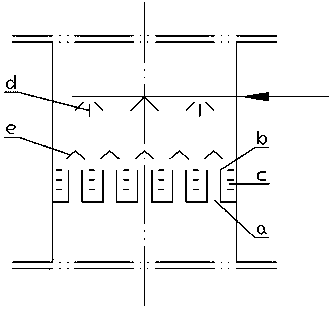

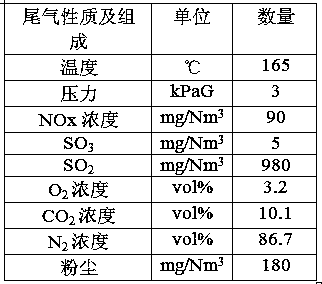

Flue gas desulphurization method and apparatus

ActiveCN107774082ASmall footprintAvoid cloggingCombination devicesGas treatmentHigh concentrationAtmospheric air

The invention relates to a flue gas desulphurization method and apparatus. The method comprises the following steps: after the flue gas is heat exchanged by virtue of a flue gas / sulfuric acid heat exchanger, enabling the flue gas to enter a dust collection desulphurization tower, then enabling the flue gas to successively pass through a pre-dust-collection sudden chilling unit, a further dust removal unit, a desulphurization unit and a mist removal unit from bottom to top, absorbing SO2 in the flue gas, converting the SO2 into the sulfuric acid, and obtaining a rich absorption solution; discharging the flue gas purified by the unit into atmosphere; and enabling a rich absorption solution to enter an absorption solution regeneration tower, removing soluble transitional metal ions, then discharging the solution into a sulfuric acid storage tank, spraying, heat exchanging and concentrating by virtue of the flue gas / sulfuric acid heat exchanger, and then transporting the product. By adopting the method and apparatus, SO2 in the flue gas can be directly oxidized and converted into sulfuric acid; and the sulfuric acid solution with high concentration can be prepared by virtue of the concentration, the purified flue gas can meet the requirements of relevant national or local standard stipulations, and the flue gas desulphurization method and apparatus are suitable for recovering fluegas comprising the sulfur dioxide with various concentrations.

Owner:CHINA PETROLEUM & CHEM CORP +1

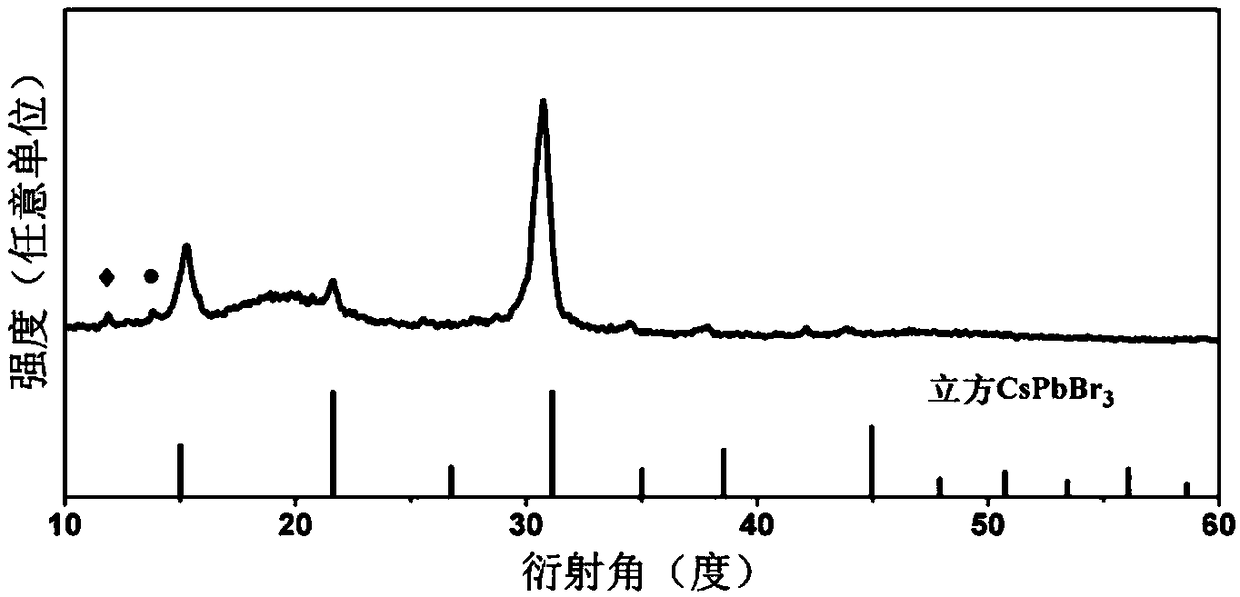

Preparation method of perovskite nanocrystals

ActiveCN108190944AEasy to operateMultiplexable synthesisMaterial nanotechnologyLead compoundsRoom temperatureQuantum dot

The application discloses a method for synthesizing perovskite nanocrystals. The method at least comprises the following steps: S1) obtaining a system I containing organic titanium ester; S2) adding aperovskite precursor to the system I in the step S1) for a reaction under stirring to obtain the perovskite nanocrystalline material. With adoption of the method, the raw materials can be directly mixed at the room temperature, and the method is quick, simple and convenient to operate and is expected to be widely applied to large-scale synthesis of lead halide perovskite quantum dots.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

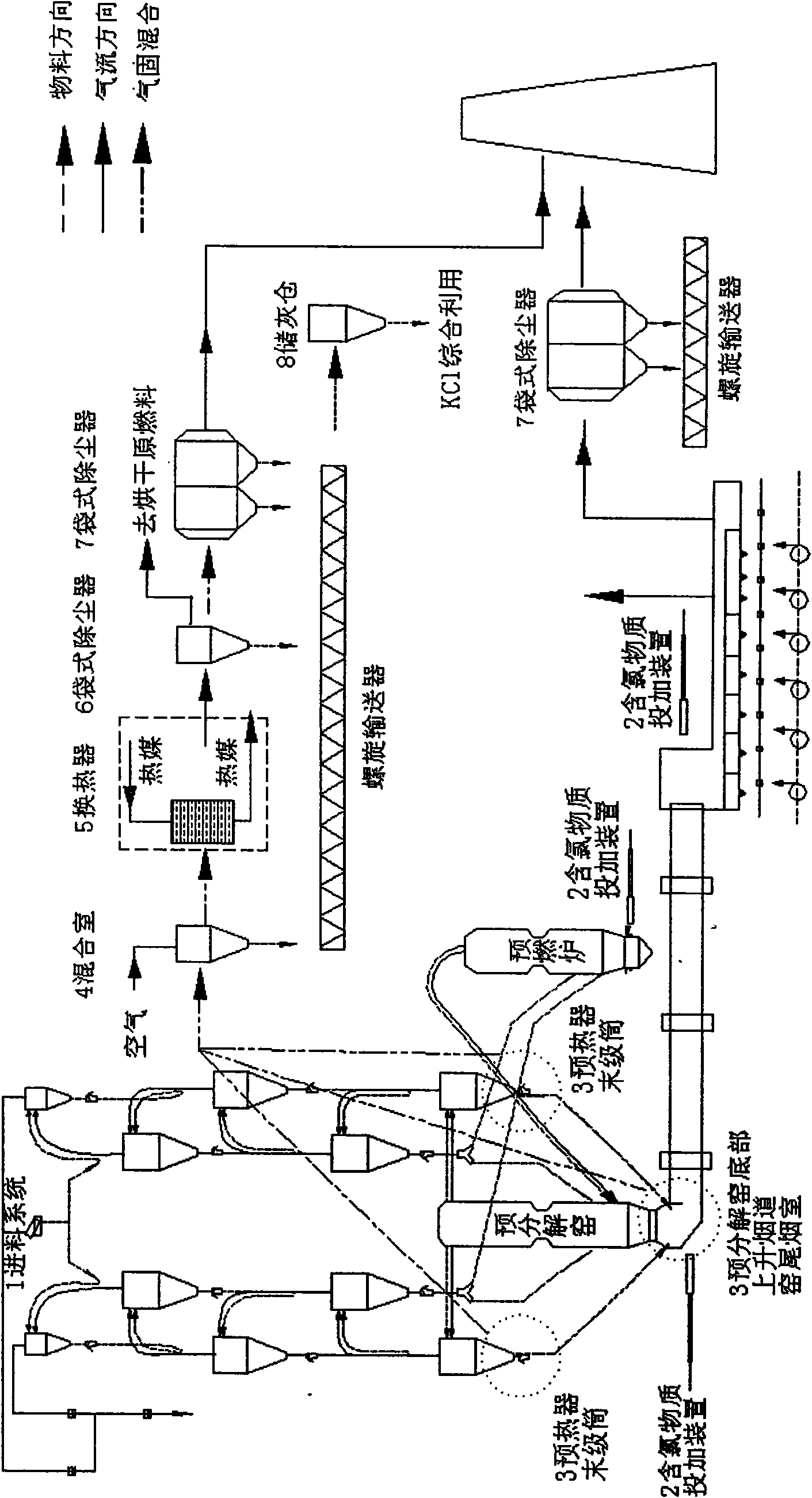

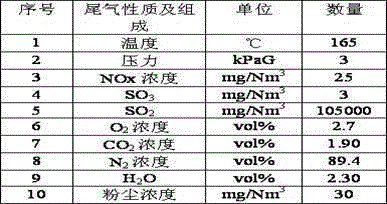

Method for producing low alkali cement by using high alkali raw materials

ActiveCN101607796ASolve environmental problems such as land occupationEfficient removalAlkali metal chloridesDecompositionCement kiln

The invention provides a method for producing low alkali cement by using high alkali raw materials, which includes the steps of: putting the raw material limestone with alkali equivalent about 0.80% into a dry cement rotary kiln through a normal channel for putting the raw material into the kiln; adding chlorine-containing substances into the rotary kiln at the locations of a kiln head, a kiln head fuel burner, a flue chamber at kiln tail end, a pre-decomposition kiln or a pre-burning furnace; opening holes at the positions of the bottom part of the pre-decomposition kiln, an ascending flue channel, the flue chamber at kiln tail end or the tail grade cylinder of a pre-heater and inducting the chlorine-containing smoke gas enriched in the positions into a smoke dust collection system and collecting the smoke dust in the smoke gas. The smoke dust collection system comprises a mixing room. The method for producing low alkali cement by using high alkali raw materials uses the special property that alkali metal ions, chloride ions and sulfate ions mutually affect the melting point temperature under the high temperature coexistence condition, adds the chlorine-containing substances during the production process, and leads the chlorine in wastes to be reacted with the alkali in the raw materials by controlling the proportion between the alkali metal ions, chloride ions and sulfate ions entering the cement kiln, thereby achieving the double effects of reducing the alkali in the cement and processing high-chlorine wastes.

Owner:广灵金隅水泥有限公司

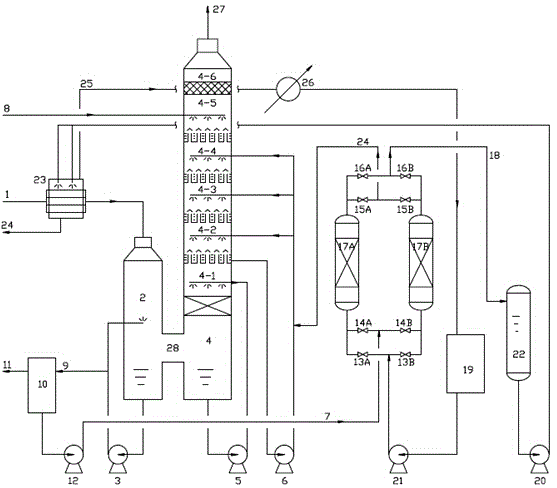

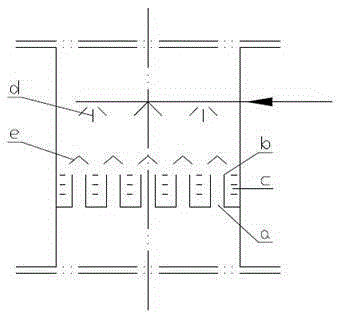

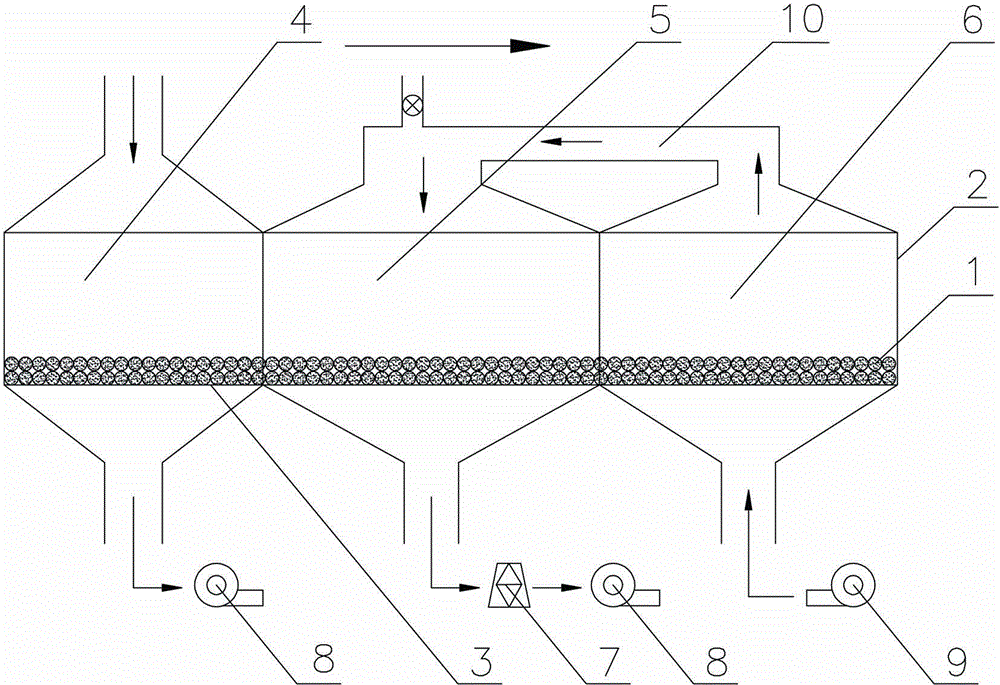

Method for production of sulfuric acid by flue gas desulfurization and for sulfuric acid purification and device thereof

ActiveCN106669361AThe strong absorption effect is fully exertedImprove dissolved oxygen utilizationCombination devicesGas treatmentHigh concentrationGas phase

The invention discloses a method for production of sulfuric acid by flue gas desulfurization and for sulfuric acid purification and a device thereof. The method comprises the following contents: (1) flue gas undergoes heat exchange and then enters a dedusting quench tower for primary dedusting and cooling process; (2) the flue gas enters a desulfurization tower and successively passes through a deep dedusting unit, a desulfurization unit and a washing unit from the bottom to the top; (3) the obtained overflow rich in an absorption liquid successively passes through a desulfurization unit and a deep dedusting unit and then enters a dedusting quench tower for solid-liquid separation, and the residual gas phase is discharged into the atmosphere; and (4) the absorption liquid separated from solid waste enters an absorption liquid regeneration tower, and enters a sulfuric acid storage tank in the form of dilute sulfuric acid after transition metal cations in the absorption liquid are removed through H<+> in resin. By the method and the device, SO2 in the flue gas can be directly converted into sulfuric acid through oxidation, and a sulfuric acid solution with high concentration is prepared by concentration. The purified flue gas can reach the national or local relevant standards. The method and the device are suitable for recovery processing of flue gas containing various concentrations of sulfur dioxide.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

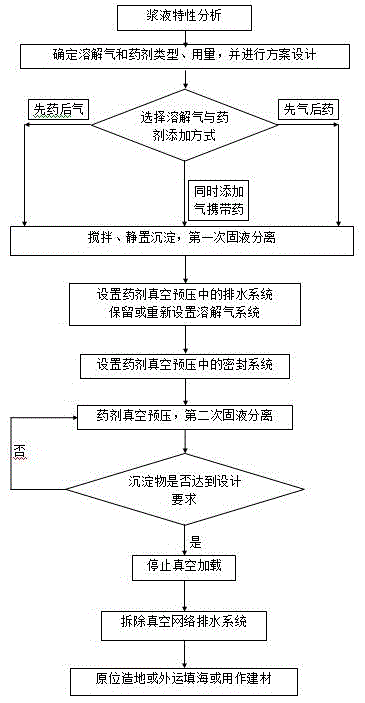

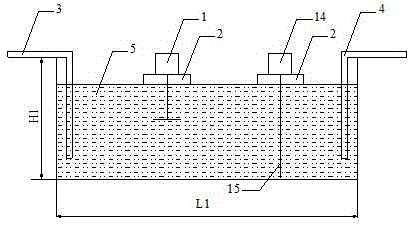

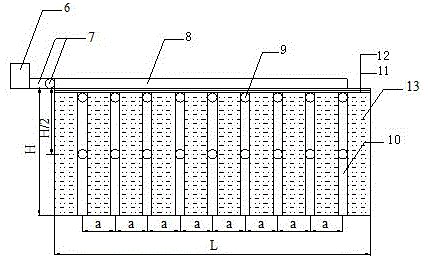

Dissolved gas and reagent integrated vacuum preloading method

ActiveCN105645709AImprove efficiencyWide coverageSludge treatment by de-watering/drying/thickeningPrecipitationSlurry

The invention provides a dissolved gas and reagent integrated vacuum preloading method. The method includes steps: step one, sampling engineering waste slurry on site; step two, determining chemical reagents, dissolved gas and the like according to analysis results acquired at the step one; step three, designing a waste slurry settling tank and the like; step four, feeding the waste slurry into the settling tank to a certain height through a pumping pipe; step five, sequentially feeding the chemical reagents and the like into the settling tank through the pumping pipe; step six, feeding the dissolved gas into the waste slurry through a gas adding device and a gas injection pipe; step seven, standing a waste slurry mixture with the chemical reagents; step eight, arranging transverse drainage pipes and vertical drainage pipes in a separation tank; step nine, using a pump for pumping precipitations into a solid-liquid separation tank with a vacuum network drainage system; step ten, step ten, starting vacuum loading after arrangement is finished; step eleven, stopping vacuum loading; step twelve, demounting the vacuum network drainage system after vacuum loading is finished. By the dissolved gas and reagent integrated vacuum preloading method, thorough solid-liquid separation can be realized.

Owner:SHANGHAI UNIV

High-purity quartz sand purification method

InactiveCN107140647AEfficient removalRemove completelySilicaOXALIC ACID DIHYDRATEPurification methods

The invention provides a high-purity quartz sand purification method, and relates to the technical field of quartz sand purification. The method comprises washing, magnetic separation, acid leaching, vacuumizing, water injection washing and dehydration processes, wherein high-temperature high-pressure water is adopted for washing; magnetic separation is performed in a wet type permanent magnet cylindrical magnetic separator; mixed acid for acid leaching is prepared from oxalic acid, hydrochloric acid, formic acid, citric acid and water; the mixed acid is reutilized for vacuumizing; acid-leached quartz sand is finally washed and dehydrated. The quartz sand purified by the method is high in purity, the SiO2 content is more than 99.99 percent, the process is simple, and the cost is reduced.

Owner:安徽安顺硅基玻璃原料有限公司

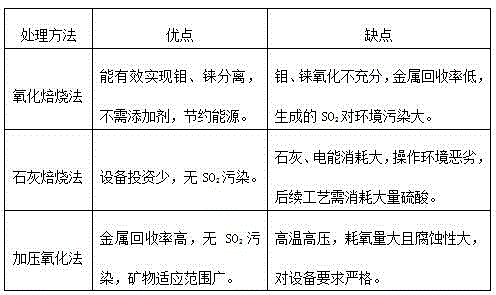

Method for separating molybdenum and rhenium from rhenium and molybdenum-containing concentrate

The invention discloses a method for separating molybdenum and rhenium from rhenium and molybdenum-containing concentrate. The method comprises the following steps: adding an adhesive, an oxidant and water in rhenium and molybdenum-containing concentrate to prepare rhenium and molybdenum-containing concentrate pellets with grain size of 3-6mm and moisture of 8-12%, and distributing the concentrate pellets on a chain grate bed of a chain grate machine to carry out drying, oxidizing roasting and cooling, so that molybdenite in the pellets is oxidized into MoO3, and the rhenite is oxidized into Re2O7, which are volatilized to enter smoke and then are recovered by drip washing with water; in above process, the method of oxidizing roasting at two sections is adopted, the oxidizing efficiency of the molybdenite and the rhenite in the concentrate pellets are improved through different air roasting temperatures and air speeds, the Re2O7 concentration in the smoke is improved by circulating roasting smoke in a roasting chamber II to a roasting chamber I, and the smoke is maintained at 300-400 DEG C to effectively inhibit Re2O7 from being reduced by the SO2 so as to increase the recovery rate of the Re2O7; by adopting the roasting method disclosed by the invention, the volatilization rate of rhenium in the roasting process can be not less than 80%, the content of soluble molybdenum in roasted molybdenum is not less than 90%, the molybdenum and the rhenium are efficiently oxidized and separated.

Owner:DAYE NONFERROUS METALS

Preparation method of special nano calcium carbonate for polyurethane sealant

InactiveCN106277015AAdjust curing speedHigh strengthCalcium/strontium/barium carbonatesMaterial nanotechnologyCarboxylic acidSurface-active agents

The invention discloses a preparation method of special nano calcium carbonate for polyurethane sealant. The preparation method includes the following steps that A, a crystal form control agent is added into a Ca(OH)2 solution, the mixture is stirred and mixed evenly, CO2 gas is injected for a bubbling carbonation reaction until the pH value of the solution is 7-8, and then boiled liquid is obtained; B, the boiled liquid is sieved and heated to 60 DEG C-85 DEG C, a mixture of saturated fatty acid and carboxylic acid bismuth salt is added under a stirring state to serve as a surface active agent, the pH value is regulated to be 7-9, and stirring is continued for 45-60 minutes; C, the stirred boiled liquid in step B is subjected to filter pressing, so that a filter cake is obtained, the filter cake is dried, smashed and further dried, and then the special nano calcium carbonate is obtained. Bonding force between nano calcium carbonate and a polyurethane system is good, the mechanical property of the polyurethane sealant can be obviously improved, and when the nano calcium carbonate is applied to the polyurethane sealant, the tensile strength, elongation at break and tearing strength of the polyurethane sealant can be improved.

Owner:连州市万仕达新材料有限公司

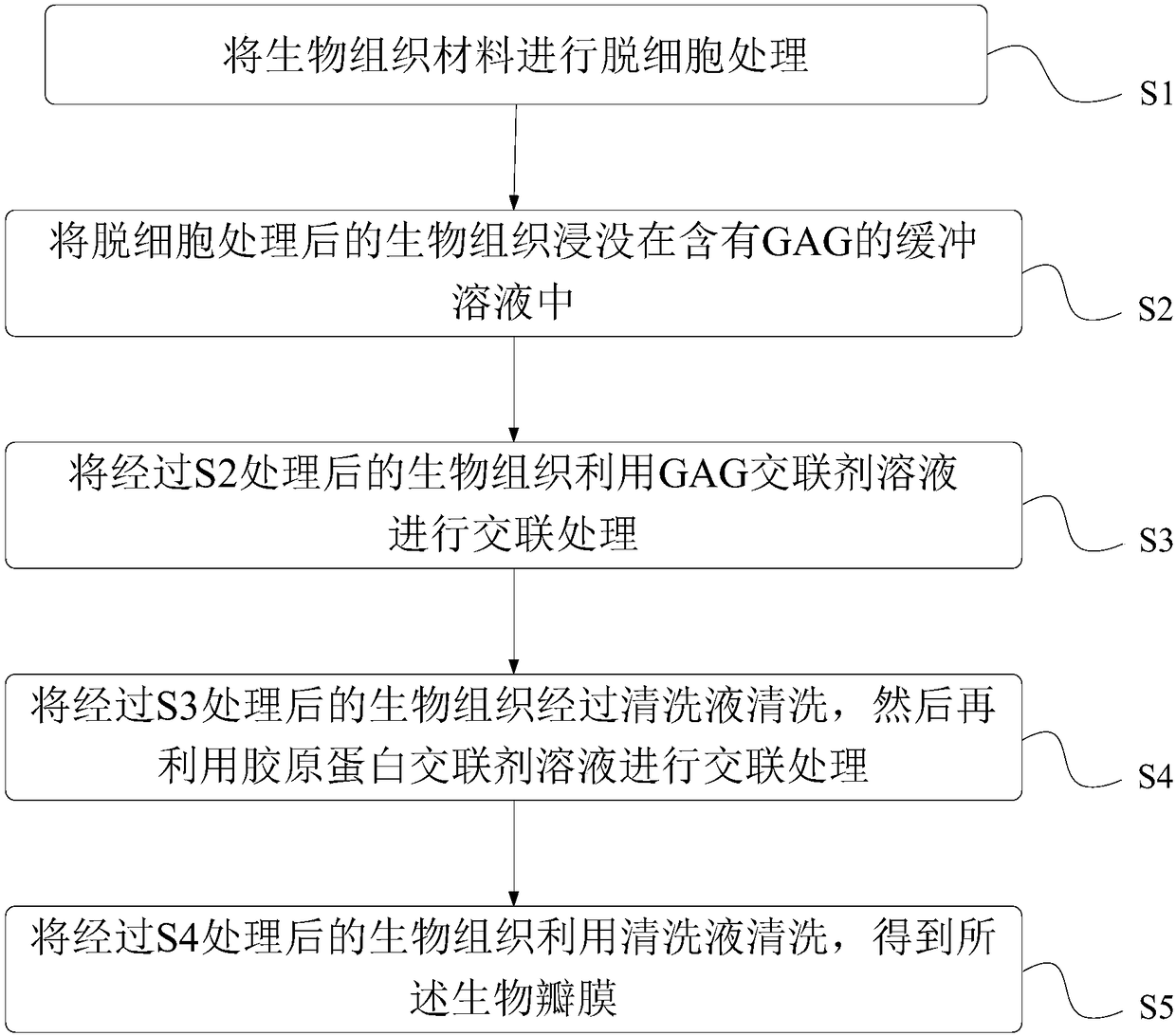

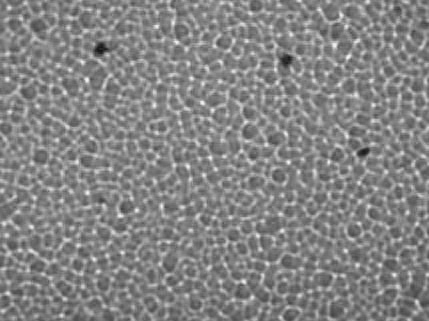

Preparation method of biovalve

InactiveCN109125810AReduce voidsPrevent collapseTissue regenerationProsthesisCross-linkTissue material

The invention provides a preparation method of a biovalve. The method comprises the steps that S1, decellularization is conducted on a biological tissue material to obtain biological tissues on whichdecellularization is conducted; S2, the biological tissues on which decellularization is conducted are immersed in a buffering solution containing GAG; S3, cross-linking treatment is conducted on thebiological tissues treated in S2 by using GAG cross-linking agent solution; S4, the biological tissues treated in S3 are washed by cleaning liquid, and cross-linking treatment is conducted by using collagen protein cross-linking agent; S5, the biological tissues treated in S4 are cleaned by using the cleaning liquid to obtain the biovalve. By means of the biovalve obtained through the treated biological tissues, tissue wrinkling can be significantly relieved or eliminated to reduce stress generated by tissue bending to increase the smoothness of the tissues, improve the using rate of tissue materials and greatly reduce production cost.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

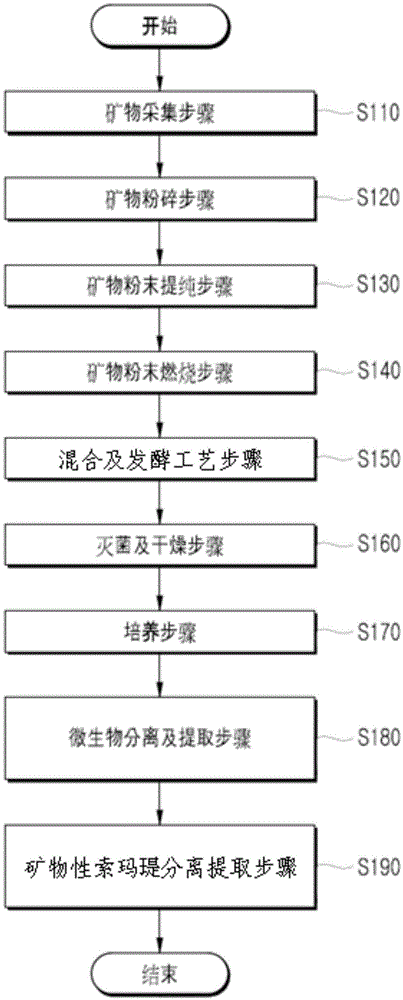

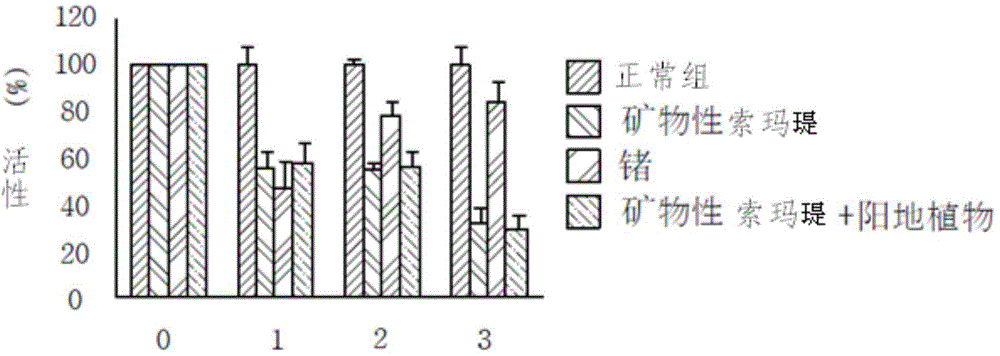

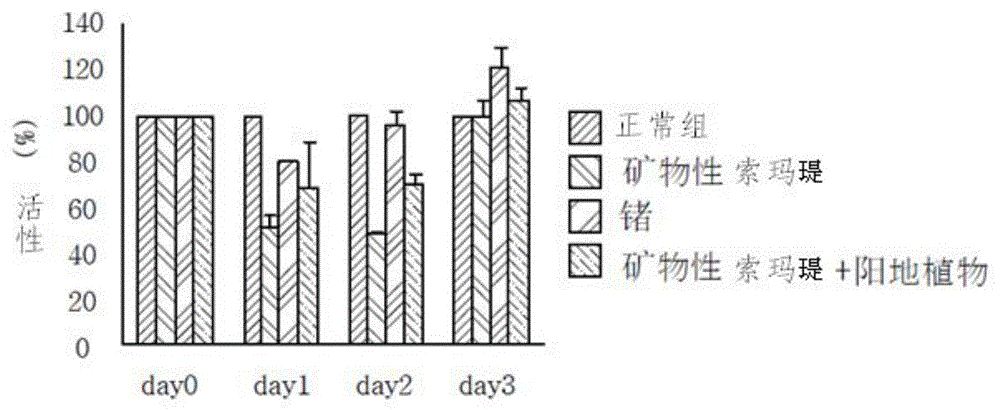

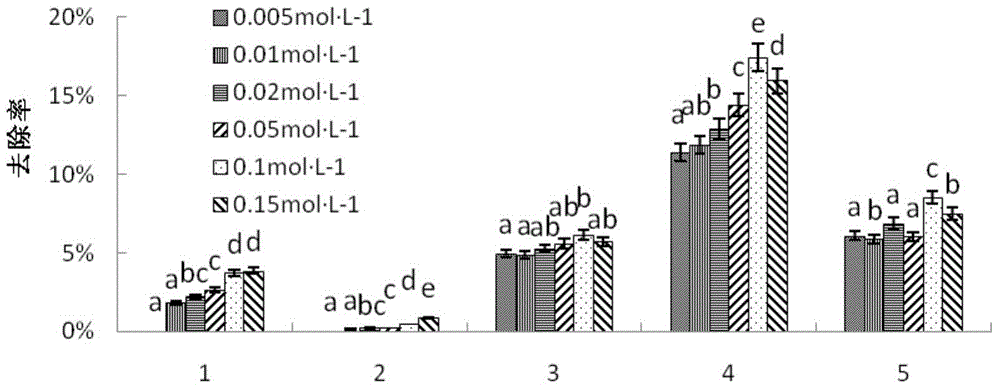

Method for extracting mineral somatid and method for preparing multifunctional advanced materials using same

InactiveCN104364220ANo side effectsSo as not to damageMicroorganismsInanimate material medical ingredientsFlavorBiological body

The present invention relates to a method for preparing a healing and multifunctional natural gel using a mineral-based somatid quantum energy living body (QELBY) extracted from minerals produced in the nature. According to the present invention, the mineral somatid present in the minerals is isolated and cultured, and the cultured mineral somatid is fused with a powder, thereby causing no harm and side effects to the body, enabling inhibition of cancer, reinforcement of immunization, self-heating including skin generation, iced-feeling, VOC deodorization, and shield and absorbance of harmful electromagnetic waves, and enhancing the flavor and useful ingredients through fermenting and aging.

Owner:QUANTUM ENERGY CO LTD

Metal coating for hydraulic cylinder and preparation method of metal coating

The invention discloses a metal coating for a hydraulic cylinder and a preparation method of the metal coating. The metal coating for the hydraulic cylinder includes the following components in mass percent: 0.65-0.67% of carbon, 1.06-1.08% of potassium, 2.95-2.98% of silicon, 1.53-1.55% of vanadium, 9.73-9.75% of nickel, 0.23-0.25% of manganese, 0.42-0.45% of scandium, 0.74-0.76% of molybdenum, 1.56-1.58% of bromine, 1.22-1.24% of tungsten, 3.12-3.15% of titanium, 0.22-0.25% of zirconium, 3.34-3.36% of rare earth, 2.61-2.64% of auxiliaries, and the balance of ferrum.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Safety treatment method for fluorine-containing solid waste

ActiveCN105130346AAvoid pollutionPlay the role of binding the fluorine-containing solid waste residueSolid waste managementWater insolubleFluorine containing

The invention relates to a safety treatment method for fluorine-containing solid waste. According to the method, a calcium compound is added into the fluorine-containing solid waste, and a composition fluorine ions in the fluorine-containing solid waste and calcium ions in the calcium compound form a water-insoluble compound calcium fluoride, so that free fluorine ions in the fluorine-containing solid waste are greatly reduced, and the phenomenon that the fluorine ion content of the fluorine-containing solid waste is large and the fluorine-containing solid waste is easily dissolved in soil and groundwater to cause pollution in the prior art is avoided; a curing agent is added to achieve the effect of bonding the fluorine-containing solid waste, and meanwhile, a layer of low-permeability substance is formed on the surface of the fluorine-containing solid waste to limit the transfer of harmful compositions, mainly the fluorine ions, in the fluorine-containing solid waste, so that soil and underground pollution is also avoided.

Owner:韩素梅

Method for preparing high-purity alumina by virtue of methylamine method

InactiveCN103663525AReduce utilizationAchieve emissionsAluminium oxide/hydroxide preparationAluminium hydroxideFiltration

The invention provides a method for preparing high-purity alumina by virtue of a methylamine method. The method is characterized by preparing methylaminated aluminium through reaction between methylamine and high-purity aluminium, hydrolyzing methylaminated aluminium to generate aluminium hydroxide and methylamine and preparing high-purity alumina by carrying out filtration, washing, drying, calcination, grinding and the like on generated aluminium hydroxide. The method has the prominent advantages of high product purity, simple process, low cost, zero emission and the like. High-purity alumina prepared by the method is suitable for the fields of LED (light emitting diode) long sapphire crystals, laser crystals, transparent ceramics, sodium lamp tubes and the like.

Owner:韩香娟

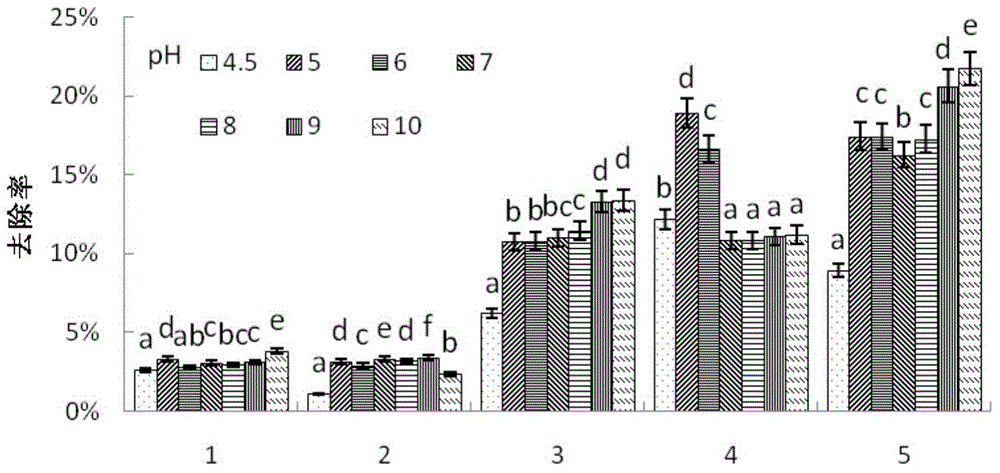

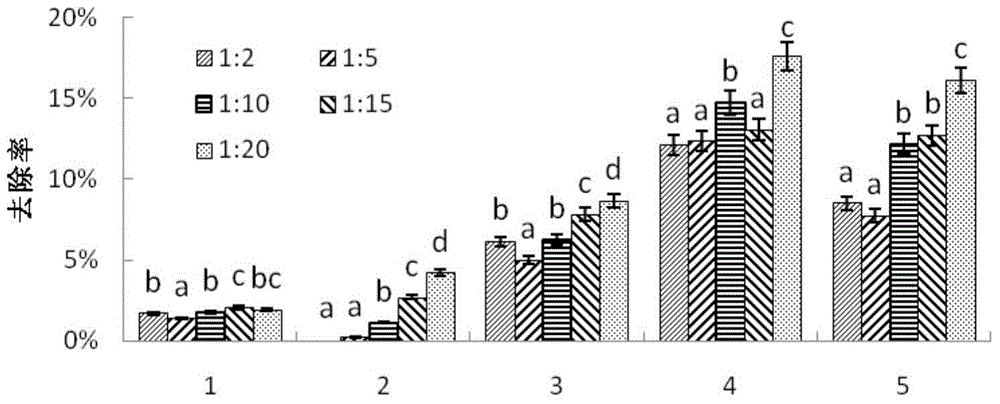

Oxidation-chelation leaching combined remediation method for Cr-contaminated soil

ActiveCN105149334APromote conversionHigh removal rateContaminated soil reclamationMicrowaveAqueous solution

The invention relates to an oxidation-chelation leaching combined remediation method for Cr-contaminated soil. The remediation method comprises the following steps: performing microwave treatment on a H2O2 oxidizing process: uniformly mixing a H2O2 aqueous solution with Cr-contaminated soil for microwave treatment; adding H2O for leaching, and removing leaching liquid; performing chelation leaching, that is, adding a chelating agent for chelation leaching, and removing Cr (VI) and part of Cr (III). Through adoption of the remediation method, Cr in soil can be effectively removed; the remediation method is suitable for Cr-contaminated soil remediation, is relatively high in oxidation efficiency, is a microwave oxidation method without affecting subsequent chelation leaching, and can realize relatively high remediation efficiency through leaching with water or the chelating agent.

Owner:SHANDONG NORMAL UNIV

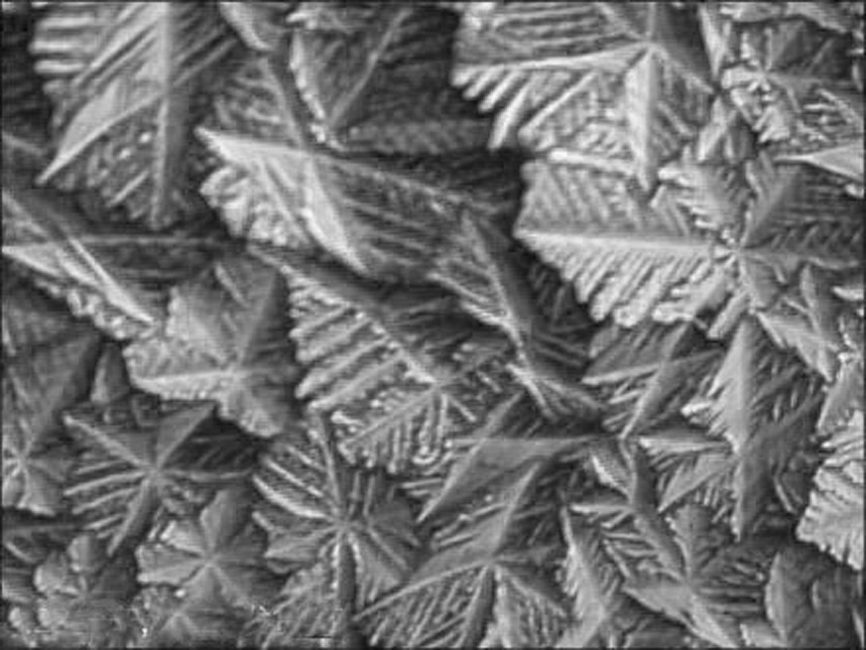

Preparation process of glass with scratch-resistant crystal diamond flash point effect

ActiveCN111847894AEvenly distributedHigh affinitySurface treatment compositionsGlass productionTransmittanceFinger print

The invention belongs to the technical field of etched glass, and in particular, relates to a preparation process of glass with a scratch-resistant crystal diamond flash point effect. The process comprises the following steps: preparing etching liquid and carrying out etching treatment on a raw glass sheet; depending on a fact that fluoride has an etching effect on glass, carrying out multi-stagechemical reaction with the surface of the glass in acid liquor with certain concentration and type; and generating a nanoscale diamond-shaped microcrystalline particle adhesion layer, and uniformly distributing on the whole glass surface. Therefore, the visual effect of glittering in the light facing process is achieved; meanwhile, the excellent properties of reflection light resistance, scratch resistance, dust resistance, fingerprint resistance and the like are realized; the process is simple and practical, easy to operate and low in cost, microcrystalline diamond particles on the surface ofthe prepared scratch-resistant crystal diamond flash point effect glass are uniform in distribution and consistent in size, and the technical indexes such as roughness, glossiness, light transmittance and haze meet the specific requirements of the art decorative glass industry.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

Synergist for assisting wet-process desulphurization of thermal power plant, and application method of synergist

InactiveCN103432894AReduce surface tensionIncrease the speed of diffusionDispersed particle separationOrganic acidGas to liquids

The invention discloses a synergist for assisting wet-process desulphurization of a thermal power plant. The synergist comprises the following components in percentage by mass: 55%-60% of organic acid, 15%-20% of organic acid salt, 10%-15% of oxidized catalyst, and 10%-15% of chelating dispersing agent. The acidity of the organic acid is stronger than that of carbonic acid and weaker than that of sulphurous acid, and the organic acid salt is used for providing organic acid groups. The synergist can reduce the surface tension between gas and liquid and improve the dispersion speed of gas to liquid; the concentration of calcium ions in the liquid solution can be increased, the crystallization speed of sulfate ions can be accelerated, and the desulfurization efficiency of the system and the utilization rate of lime stone can be improved; in addition, the characteristics of calcium sulfate crystals can be changed, so that muddy crystals can be produced, the crystals can be prevented from being deposited at parts, such as a spray nozzle.

Owner:杨子江

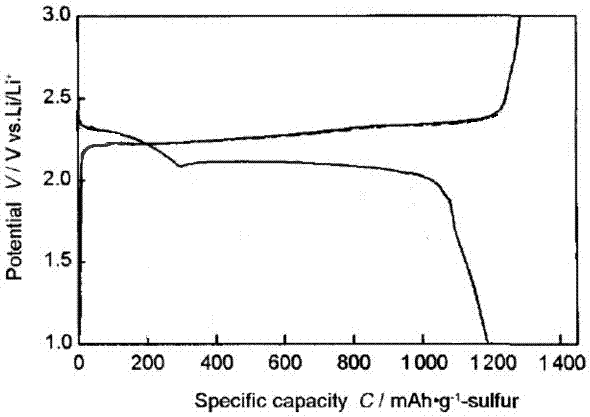

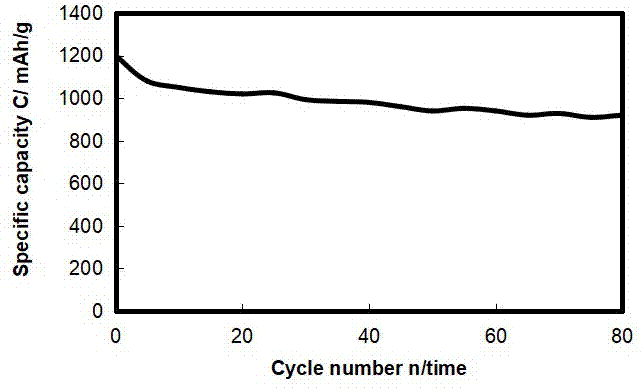

Method for preparing lithium-sulfur battery anode based on catalysis of active MnO2

ActiveCN107887605AEasy accessImprove capacity playElectrode thermal treatmentElectrode collector coatingLithium–sulfur batteryPhysical chemistry

The invention relates to a method for preparing a lithium-sulfur battery anode based on catalysis of active MnO2. The method comprises the following steps: uniformly mixing nano-sulfur simple substance powder, activated manganese dioxide powder, carbon fibers and carbon nano-tubes in a proportion (mass ratio) of (85-90) to (5-10) to 1 to 1, adding absolute ethyl alcohol which has equal mass with the mixture, stirring to obtain a slurry, adding a certain amount of polytetrafluoroethylene (PTFE) emulsion, stirring to obtain paste, uniformly smearing carbon fiber cloth with the paste, heating to120 DEG C under the protection of nitrogen, and heating for 20 minutes, so as to obtain a sulfur electrode. By activating manganese dioxide, the surface of manganese dioxide is adsorbed with particlesof Fe, Ni and the like, and the oxidation reduction of sulfur is integrally catalyzed, so that the charge and discharge electric current densities of the sulfur electrode are increased, high-rate discharging is promoted, more importantly, the unit area capacity of the sulfur electrode can be increased, and a foundation is provided for the preparation of a lithium-sulfur battery with specific energy higher than 700Wh / kg.

Owner:天津赫维科技有限公司

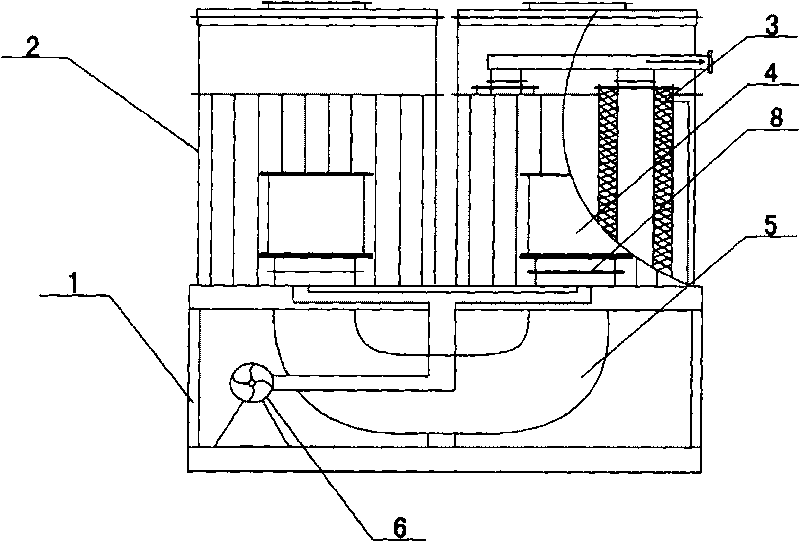

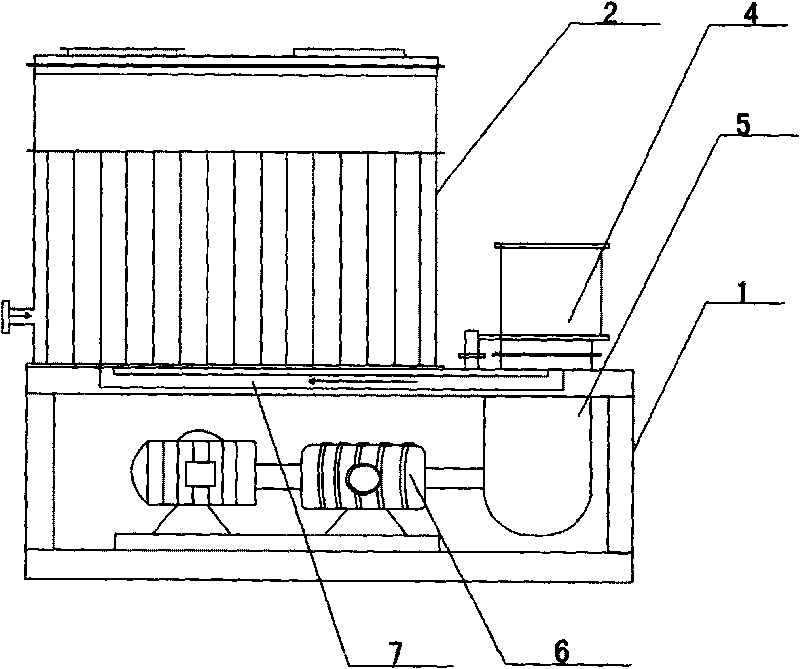

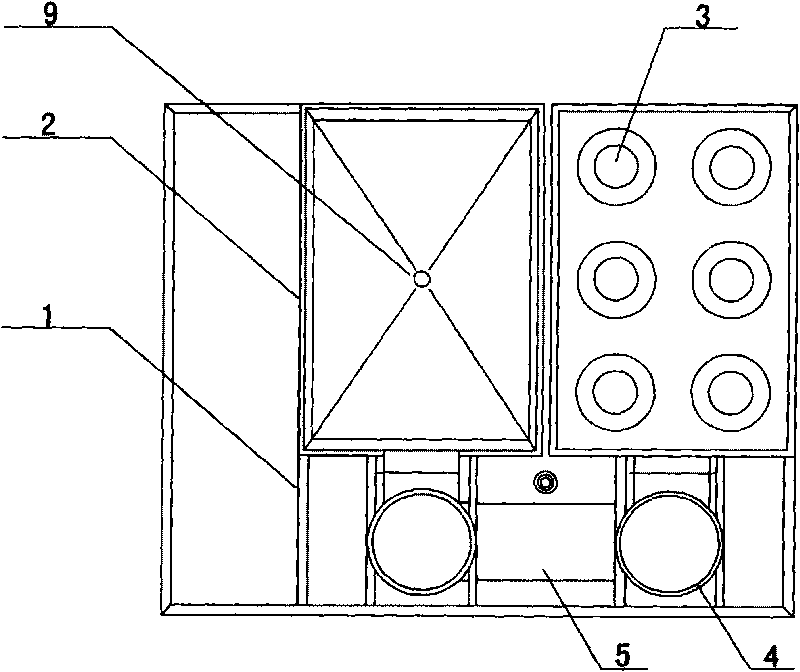

Iron-carbon fiber micro-electrolysis reaction device

InactiveCN101746876AAct as a catalystStrong oxidation abilityWater/sewage treatment by reductionFiberActivated carbon

The invention discloses an iron-carbon fiber micro-electrolysis reaction device, which consists of a machine frame, a reaction device case, a reaction unit, a high-pressure cylinder, a U-shaped wind pipe, a Roots blower, a distribution pipe, a pneumatic sealing valve and a residual liquid discharge opening, wherein the reaction unit is in a cylindrical shape, the inner layer is a hollow pipe, the outer layer is a stainless steel screen, and a hollow filter core made of iron dust and activated carbon fiber is placed between the inner layer and the outer layer to be fixed in the reaction device case, wherein the activated carbon fiber (ACF) has the adsorption, conduction and catalytic oxidation performance, the activated carbon fiber and the micron order pure iron powder are compounded proportionally to be used as a novel water treatment filling material, and the novel water treatment filling material is made into the filter core to be placed into a cylinder of the reaction unit. Under the action of the micro-electrolysis, the strong oxidizability on oxygenous water-soluble organic substances, chlorinous water-soluble organic substances and water-soluble organic substances with benzene rings can be realized. Because ions generated by substances such as salt (NaCl, CaCl2) and the like are needed in the waste water treatment process, the equipment can be used as an effective device for removing CODcr from waste water with high salt content.

Owner:邵志军

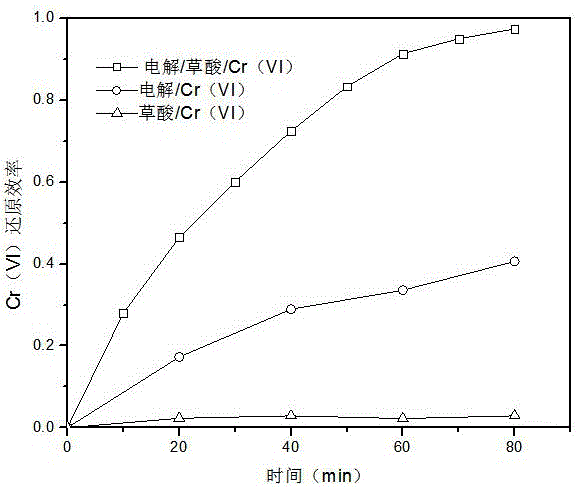

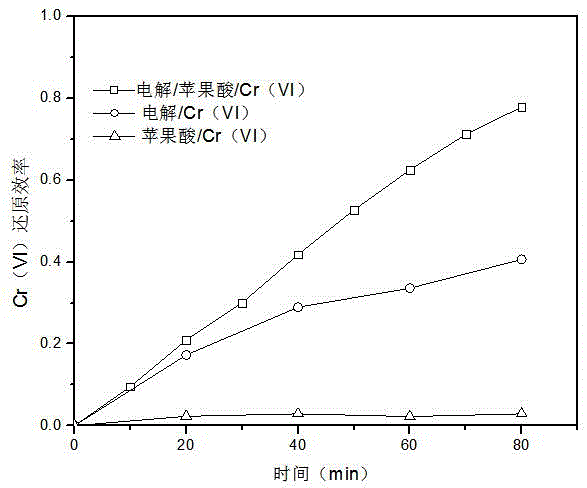

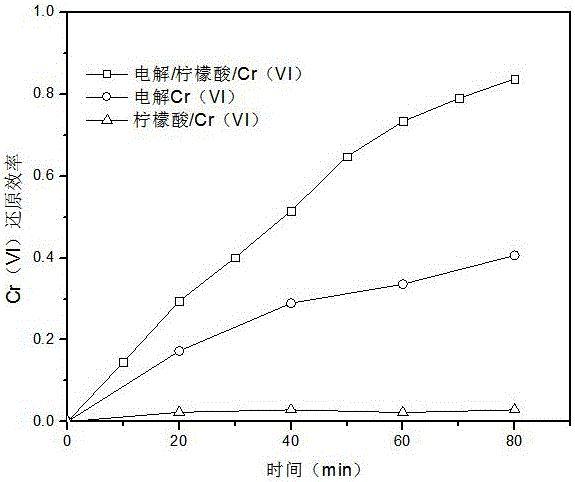

Method for strengthening Cr(VI) electroreduction by virtue of small molecular inorganic acid

InactiveCN105776444AAdd lessFacilitated DiffusionWater contaminantsWater/sewage treatment by substance additionElectrolysisSludge

The invention relates to the field of heavy metal pollution remediation, in particular to a method for strengthening Cr(VI) electroreduction conversion by virtue of an environmentally-compatible small molecular inorganic acid with a specific chemical functional group. The method comprises the following steps: adding the small molecular inorganic acid into a Cr(VI)-containing wastewater solution to be treated under normal temperature and normal pressure, adding an inorganic acid to regulate the pH value, and reducing Cr(VI) into Cr(III) under the action of low-voltage direct current by adopting an electrolytic method. According to the method, hypertoxic Cr(VI) is efficiently and rapidly reduced into Cr(III) under the synergistic effect of the small molecular organic acid and electrolysis, the small molecular organic acid, as a catalyst, can also serve as an electron donor to participate in reductive conversion of Cr(VI) in the process, and in the process, a small amount of chemical reagent is added, no secondary pollution is produced, fewer precipitates and sludge are produced, and the power consumption is low.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

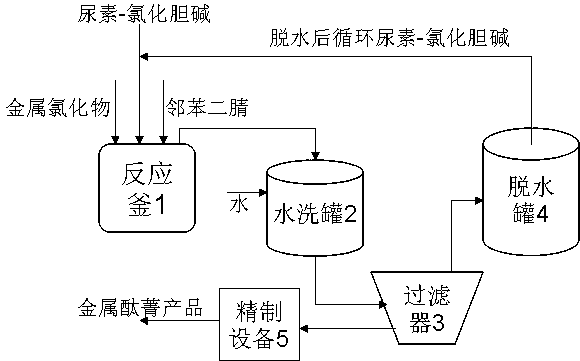

Method for synthesizing metal phthalocyanine from phthalonitrile under catalysis of urea-choline chloride

The invention provides a clean method for synthesizing metal phthalocyanine from phthalonitrile or a phthalonitrile derivative substituted by different functional groups and a metal chloride or nitrate under catalysis of a urea-choline chloride eutecticevaporate green solvent. Multiple functional metal phthalocyanine compounds such as cobalt, copper, zinc, nickel, iron and manganese are synthesized under a gentle condition, the yield is high, and in addition, toxic and organic solvents such as amyl alcohol and expensive DBU (diazabicyclo) organic alkali catalysts which are used in a conventional process are not used. The urea-choline chloride eutecticevaporate solvent DES is adopted as a solvent for dissolving and dispersing reactants, meanwhile, a function of catalyzing formation of a phthalocyanine cycle is also achieved, and the reaction temperature for forming the phthalocyanine cycle is 110-130 DEG C. The low reaction temperature also ensures the uniformity, completeness and highpurity of a phthalocyanine product structure. The synthesis process is green, remarkable environment benefits can be made, the energy can be saved, and meanwhile, environment protection can be achieved.

Owner:石家庄搏澳增塑材料科技有限公司

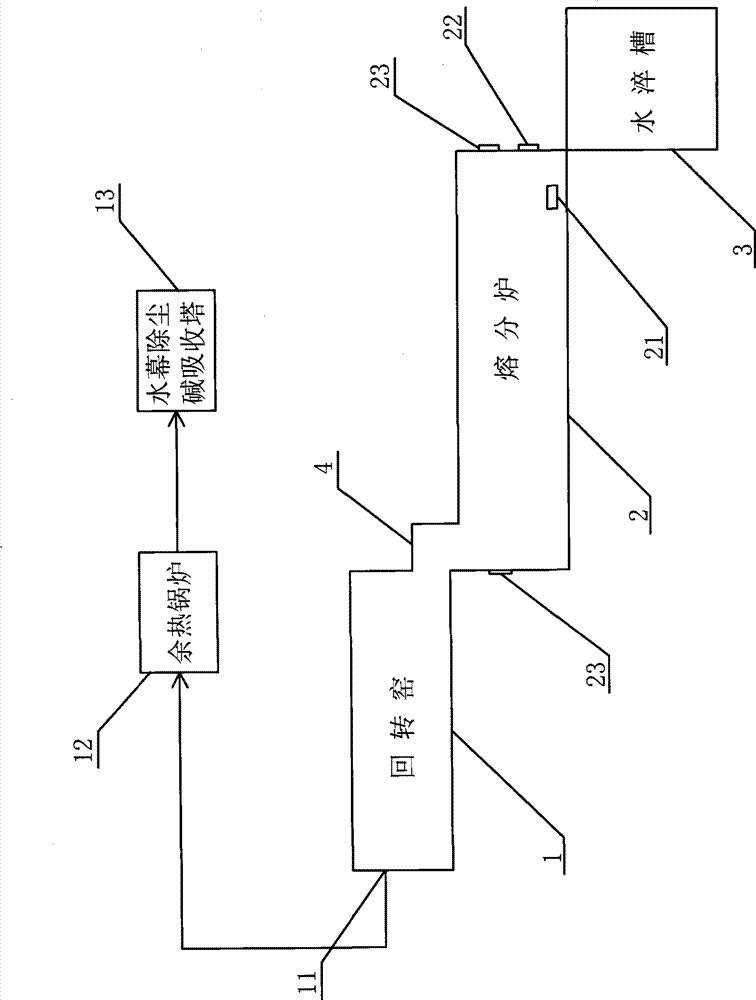

Slag-free combined production process for iron, aluminum and titanium

InactiveCN102766714AEasy to separateAchieve separationIncreasing energy efficiencyWaste heat treatmentSlagRed mud

The invention discloses a slag-free combined production process for iron, aluminum and titanium, which comprises the following steps: a) preparing a mixed raw material by ilmenite, bauxite, coal, alkali, fluorite and lime according to a ratio; b) feeding the mixed raw material into a rotary kiln, drying and pre-reducing to generate a reduced material; c) feeding the reduced raw material into a melting and separating furnace, melting and separating iron from the slag; and d) carrying out water quenching on the discharged high-aluminum titanium clinkers, grinding and acid-leaching to obtain solid light metal oxides of silicon, calcium, magnesium, aluminum and titanium. The production process has the following advantages that alkali and fluorite play a role in catalyzing and fluxing, so that the separation of titanium and iron is fast and thorough; alkali and fluorine are evaporated, recovered and reused under the coal gas effect; furthermore, the production cost is reduced, titanium oxide, iron and aluminum and the like in the ilmenite can be separated and extracted, and no red mud is generated to pollute the environment; and the yields of titanium, iron and aluminum are 99% or more. A new process for a combined production of ilmenite and bauxite is implemented; the energy can be utilized in a stepped way; and the operation cost of the process is low, the economic benefit is high, and the green and environmental protection effect is achieved.

Owner:胡长春 +1

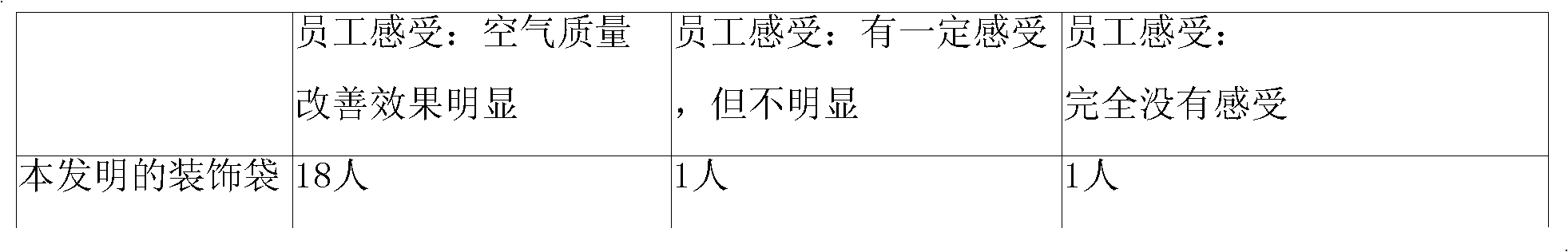

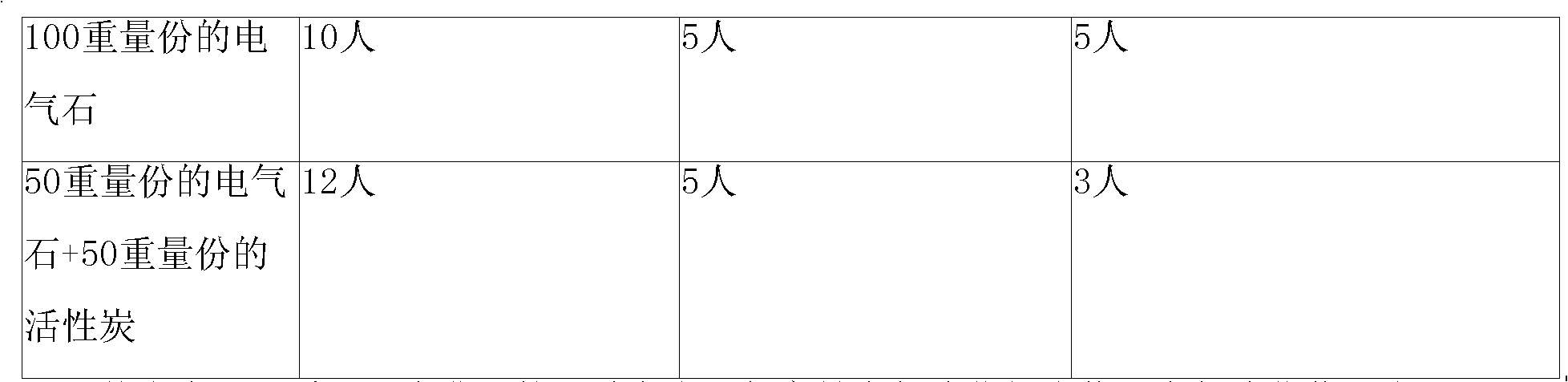

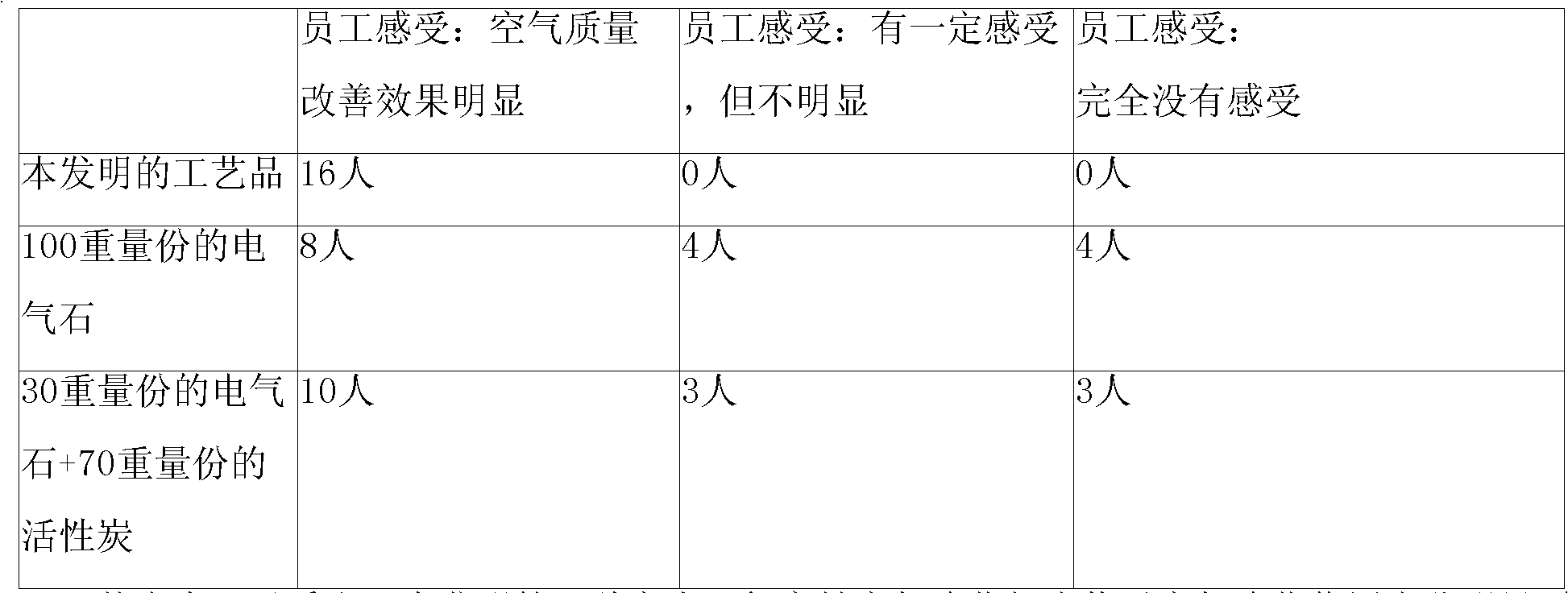

Indoor environmentally-friendly high-efficiency air purification composition and product thereof

InactiveCN101934083AFree from harmPurify indoor airSpecial ornamental structuresDeodrantsEnvironmental resistanceHazardous substance

The invention relates to an indoor environmentally-friendly high-efficiency air purification composition and a product thereof. The composition comprises the following components in part by weight: 5 to 95 percent of tourmaline and 5 to 95 percent of hard charcoal. Compared with the prior art, the composition has the advantage that the tourmaline and hard charcoal are combined to function synergically for absorbing and degrading various harmful matters produced by buildings, decorative materials, furniture, cigarettes and the like, so that the indoor air can be purified to protect people against the various harmful matters.

Owner:洪清盾

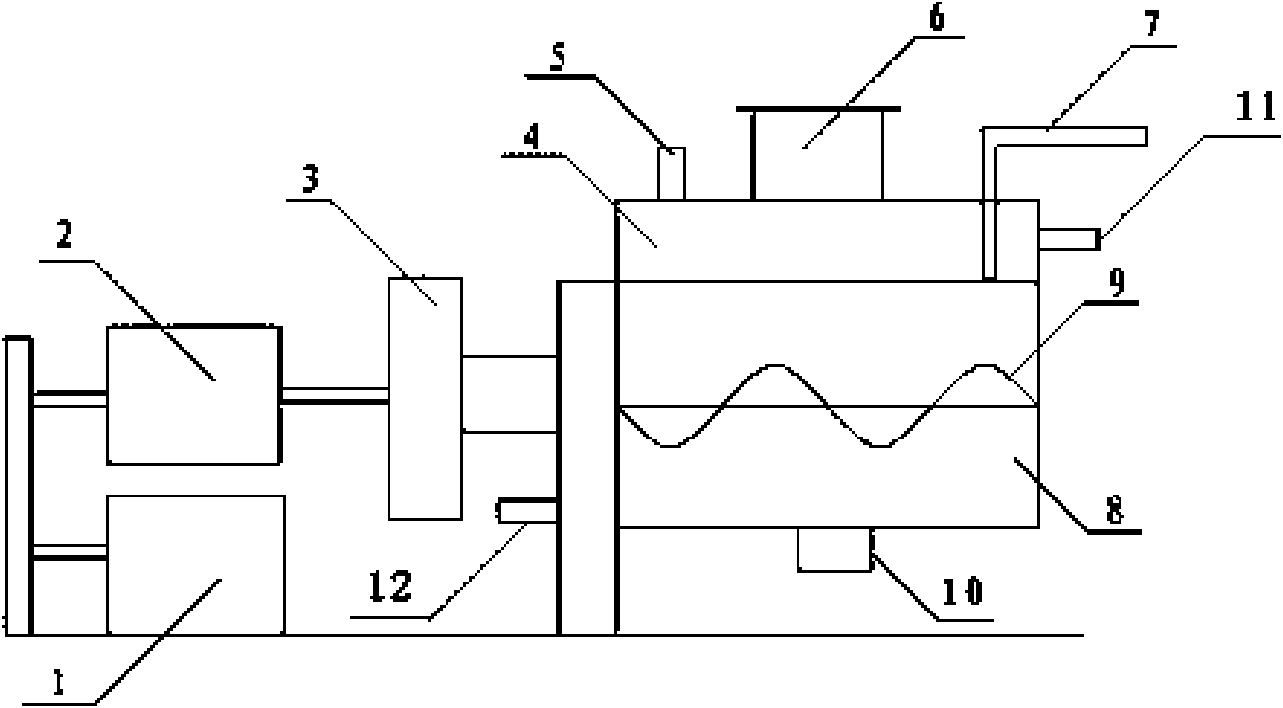

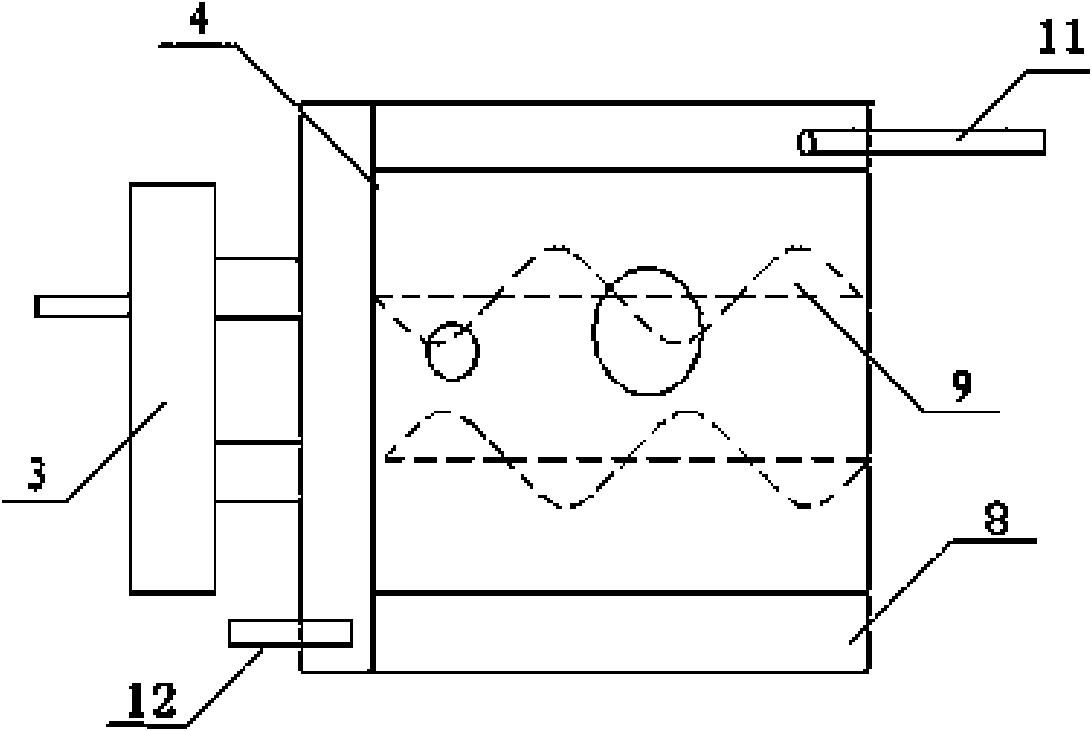

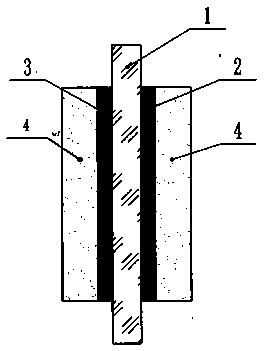

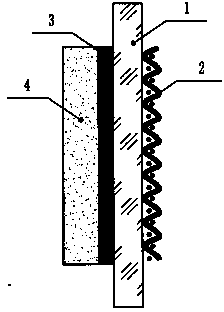

Technique for producing zinc stearate by dry method and device

ActiveCN101607883ASpecial requirements for bactericidal effectPrecipitation particles are smallChemical/physical/physico-chemical stationary reactorsCarboxylic acid salt preparationZinc compoundsWastewater

The invention discloses a technique for producing zinc stearate by a dry method. The technique comprises the following steps of: adding stearate, zinc compound and water in a mass ratio of 82 to 88%:10 to 15%:2 to 5% into a reactor, stirring and reacting for 1 to 5 hours at temperature of 50 to 150 DEG C and pressure of 0 to 0.10 MPa, and then obtaining the zinc stearate. The reaction device is characterized in that a motor (1) is connected with a speed reducer (2) which is connected with a gear transmission (3); the gear transmission (3) is connected with a stirrer (9) arranged in a reaction container (4); and a temperature measuring port (5) and a feeding port (6) are arranged above the reaction container (4) which is externally provided with a clamping sleeve (8), and a discharging port (10) is arranged below the reaction container (4). The invention has simple technique, little equipment investment, short production period, no wastewater discharging, high efficiency and low cost; and compared with a melting method, the technique has lower reaction temperature, low energy consumption and good whiteness and the obtained rough product after the reaction is ended is more loose and easy to be crushed.

Owner:HUZHOU CITY LINGHU XINWANG CHEM CO LTD

Physically foamed porcelain powder aerated concrete and production process thereof

The invention discloses physically foamed porcelain powder aerated concrete and a production process thereof, wherein the physically foamed porcelain powder aerated concrete comprises the following raw materials: water, cement, porcelain powder, a foaming agent and an external additive. According to the present invention, cement is used as the main cementing material while the insufficient calcium-based materials such as lime and gypsum are eliminated, wherein lime and gypsum can produce a large amount of dust during the production, such that the processing process of the concrete of the present invention reduces the environmental pollution and saves the cost; by adding the external additive, the addition of the external additive provides the catalytic action, and can accelerate the coagulation effect of the cement and the remaining aggregate so as to enhance the strength of the product, shorten the curing time and save the cost; and the curing mode adopted by the process is steam curing, and has advantages of natural gas saving and cost reducing compared with the conventional autoclave curing.

Owner:山东铭城环保新材料科技有限公司

Method for simultaneously measuring fatty acid contents in food for special medical purposes

InactiveCN107132296AReduce typesIncrease typeComponent separationRelative standard deviationGas chromatography–mass spectrometry

The invention discloses a method for simultaneously measuring fatty acid contents in food for special medical purposes. The method is characterized by including the steps: 1) performing pretreatment on a sample to be measured of the food for special medical purposes for standby application; 2) placing the sample after pretreatment into a gas chromatograph-mass spectrometer and measuring the sample by selected ion scanning gas chromatography-mass spectrometry; 3) detecting the chromatographic peak area of fatty acid methyl ester by an FID (flame ionization detector). Chromatographic conditions include that the fixed phase of a chromatographic column is poly-dicyan propyl polysiloxane, carrier gas is nitrogen, the flow rate of the carrier gas is 0.4mL-0.6mL / min, the temperature of a sample injection port ranges from 240 DEG C to 260 DEG C, split ratio is (25-35):(1-2), sample injection quantity is 1.0 microliter, the initial temperature of the column is 140 DEG C and kept for 5 minutes, temperature rise rate is 3-5 DEG C / min, and the temperature rises to 240 DEG C and is kept for 30 minutes. By the measuring method, RSD (relative standard deviation) values are effectively reduced, accuracy of sample measuring results is ensured, and measured data are real, stable and reliable.

Owner:HUAREN PHARMACEUTICAL CO LTD

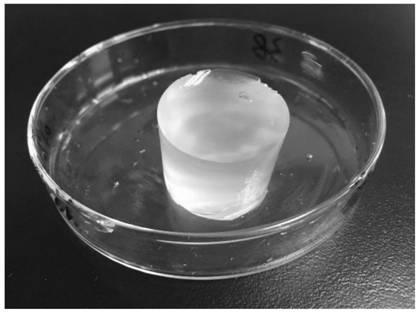

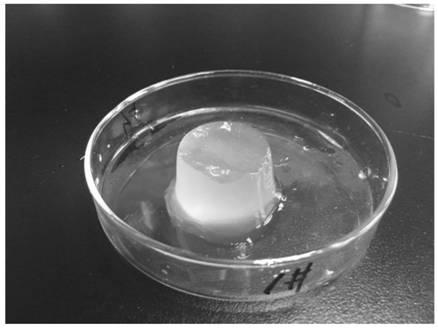

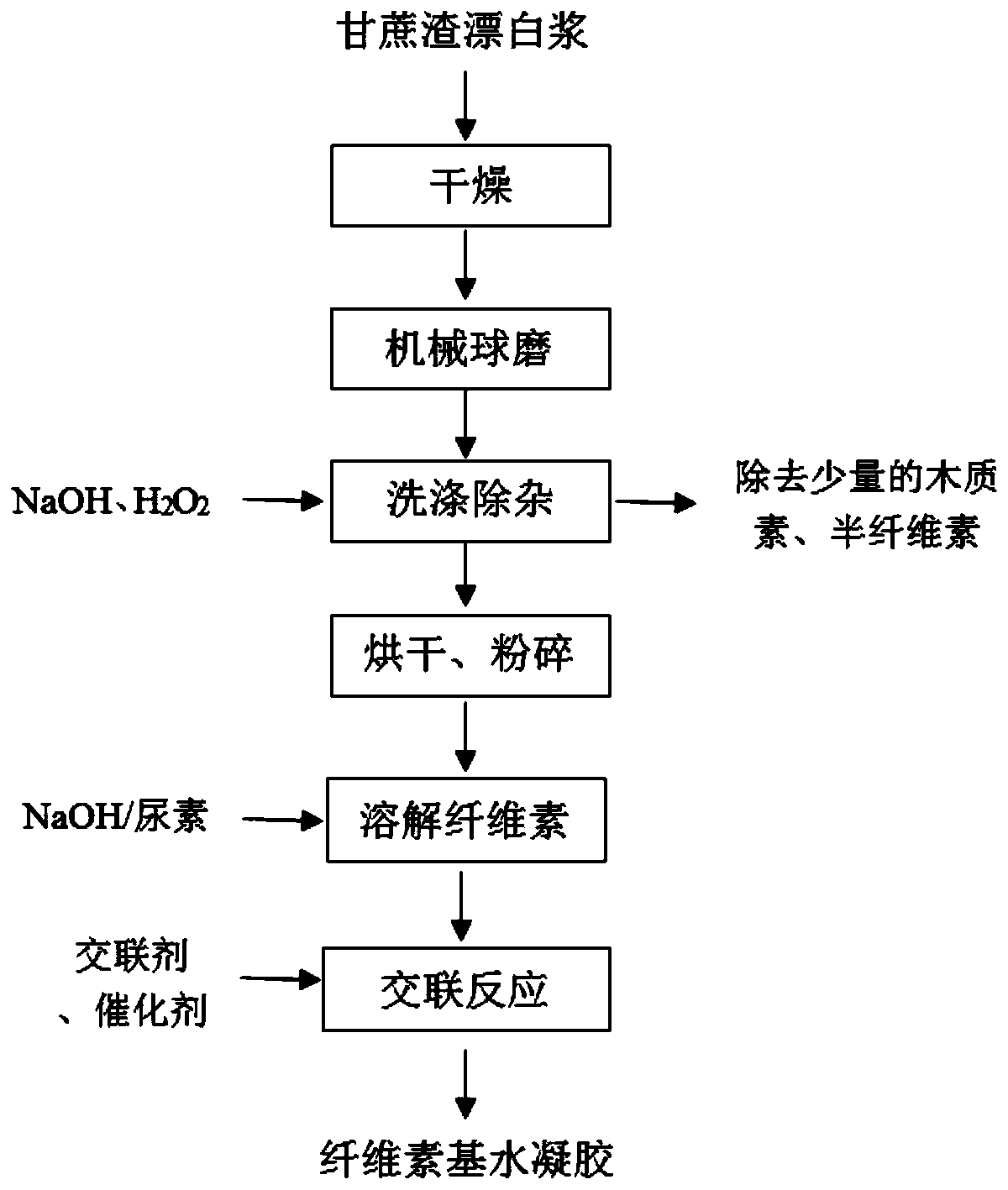

Method for preparing cellulose-based hydrogel by pretreating bagasse bleached pulp through mechanical ball milling

ActiveCN110028682AReduce the degree of polymerizationReduce crystallinityPulp properties modificationCelluloseMaterials science

The invention discloses a method for preparing cellulose-based hydrogel by pretreating bagasse bleached pulp through mechanical ball milling. The method comprises the following steps: (1) pretreatingthe bagasse bleached pulp; (2) dissolving the pretreated bagasse cellulose; (3) conducting chemical crosslinking on cellulose; and (4) gelatinizing cross-linked fibers. Compared with a traditional preparation method for biogasse cellulose-based hydrogel, the preparation method adopts a pretreatment mode of mechanical ball milling, thus the polymerization degree and crystallinity of bagasse bleached pulp cellulose are reduced, the number of active hydroxyl groups in cellulose molecules is increased, the natural bagasse cellulose is directly dissolved in a sodium hydroxide / urea solution, homogeneous chemical crosslinking modification is performed on the bagasse cellulose, and the purpose of preparing the bagasse cellulose-based hydrogel is achieved. The bagasse cellulose-based hydrogel is prepared by taking the bagasse bleached pulp as a raw material and taking mechanical ball milling as a pretreatment reinforcing means, and has the advantages of high efficiency, simplicity in operation,environmental friendliness, mild reaction conditions and the like.

Owner:GUANGXI ACAD OF SCI

Cathode catalyst and cathode structure of membrane electrode electrolysis ozone generator

The invention discloses a cathode catalyst and a cathode structure for a membrane electrode electrolysis ozonator. A ferroalloy containing Mo, Cr, Ni is adopted as the cathode catalyst; the ferroalloy is further processed into a ferroalloy net and directly serves as the cathode structure of the membrane electrode; compared with the prior art, the invention selects acid-proof and cheap ferroalloy net as the catalyst and also serves as a micro-porous current-conducting plate, the cathode catalyst and the micro-porous current-conducting plate are integrated into a whole, the invention is novel in the field either in material or structure; the cathode catalyst and the cathode structure for the membrane electrode electrolysis ozonator has the significant advantages that the cathode catalyzing effect is good, the cathode structure is simple, the cost is reduced greatly and the economic benefit is remarkable.

Owner:胡松 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com