Method for preparing cellulose-based hydrogel by pretreating bagasse bleached pulp through mechanical ball milling

A mechanical ball milling, cellulose-based technology, applied in the field of natural polymers, can solve the problems of large operation loss of materials and complicated process flow, and achieve the effect of reducing the degree of polymerization and crystallinity, and improving the chemical reactivity and the availability of medicines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

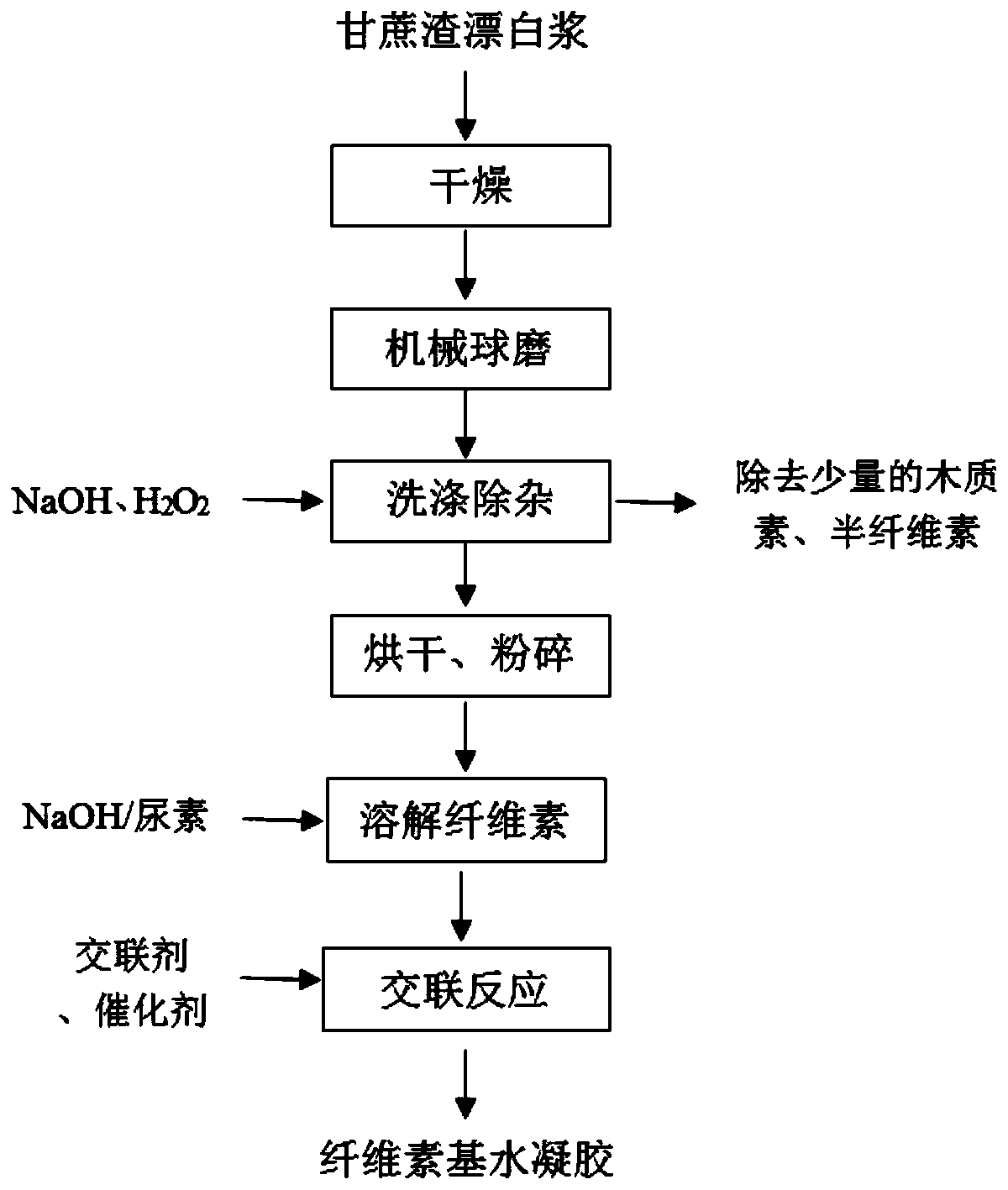

[0034] A method for preparing cellulose-based hydrogel by pretreating bagasse bleached pulp by mechanical ball milling, such as figure 1 Shown is the preparation flow chart of cellulose-based hydrogel. The specific preparation operations are as follows:

[0035] (1) Pretreatment of the bagasse bleached pulp: the water content of the bagasse bleached pulp is dried to below 5%, crushed by a pulverizer, and passed through a 20-mesh sieve. A double planetary ball mill is used to pre-process the bagasse bleached pulp by ball milling. The sieved material and zirconia balls are placed in a 500mL zirconia ball milling tank at a mass ratio of 10:600. The zirconia balls are of two types. Zirconia balls with diameters of 10mm and 5mm respectively, and the mass ratio of 10mm zirconia ball to 5mm zirconia ball is 1:4, the control speed is 300n / min, the ball milling time is 240min, and the ball is taken out after the mechanical ball milling is completed. Material separation. Use NaOH / H 2 O 2 ...

Embodiment 2

[0040] A method for preparing cellulose-based hydrogel by pretreating bagasse bleached pulp by mechanical ball milling, the specific operation is as follows:

[0041] (1) Pretreatment of the bagasse bleached pulp: the water content of the bagasse bleached pulp is dried to below 5%, crushed by a pulverizer, and passed through a 20-mesh sieve. A double planetary ball mill is used to pre-process the bagasse bleached pulp by ball milling. The sieved material and zirconia balls are placed in a 500mL zirconia ball milling tank at a mass ratio of 10:500, and 10mm zirconia balls and 5mm oxidized The mass ratio of the zirconium balls is 1:3, the control speed is 300n / min, and the ball milling time is 360min. After the mechanical ball milling is completed, the balls are taken out and the balls are separated. Use 5%NaOH / 0.7%H 2 O 2 The mixed aqueous solution (mass fraction) is soaked and washed with materials, washed with deionized water to neutrality, dried at 60 DEG C, and crushed to obta...

Embodiment 3

[0046] A method for preparing cellulose-based hydrogel by pretreating bagasse bleached pulp by mechanical ball milling, the specific operation is as follows:

[0047] (1) Pretreatment of the bagasse bleached pulp: the water content of the bagasse bleached pulp is dried to below 5%, crushed by a pulverizer, and passed through a 20-mesh sieve. A double planetary ball mill is used to pre-process the bagasse bleached pulp by ball milling. The sieved material and zirconia balls are placed in a 500mL zirconia ball mill at a mass ratio of 10:700, and 10mm zirconia balls are combined with 5mm oxide The mass ratio of the zirconium balls is 1:2, the control speed is 500n / min, and the ball milling time is 60min. After the mechanical ball milling is completed, the balls are taken out and the balls are separated. Use 5%NaOH / 0.7%H 2 O 2 The mixed aqueous solution (mass fraction) is soaked and washed with materials, washed with deionized water to neutrality, dried at 60 DEG C, and crushed to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com