Complex enzyme preparation and technique for preparing dissolving pulp by using same

A compound enzyme preparation and dissolving pulp technology, which is applied in textiles, papermaking, fiber raw material treatment, etc., can solve the problems of increased difficulty in sewage treatment, large steam energy consumption, and inappropriateness, so as to reduce costs and environmental pollution , beating energy consumption reduction, enhance the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

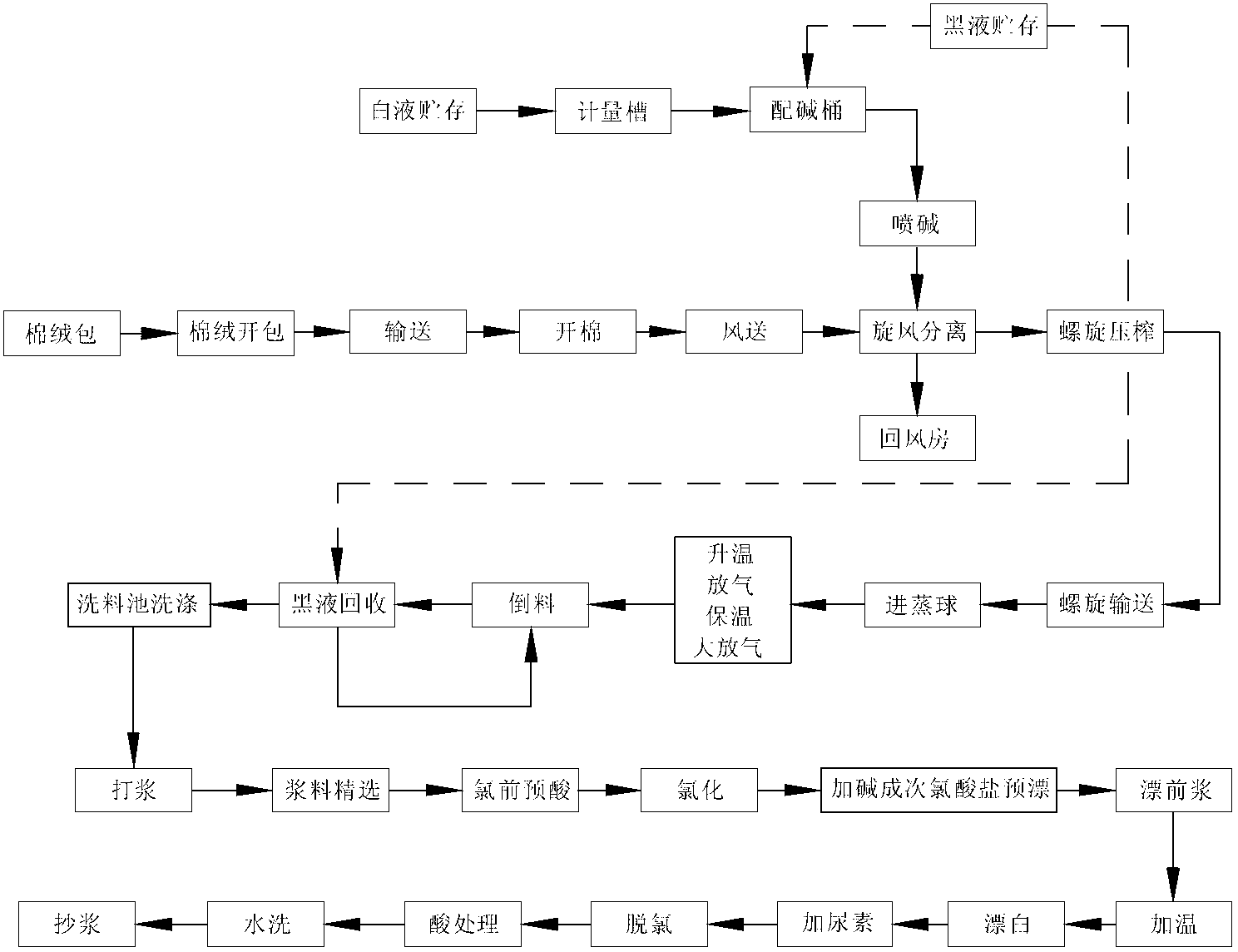

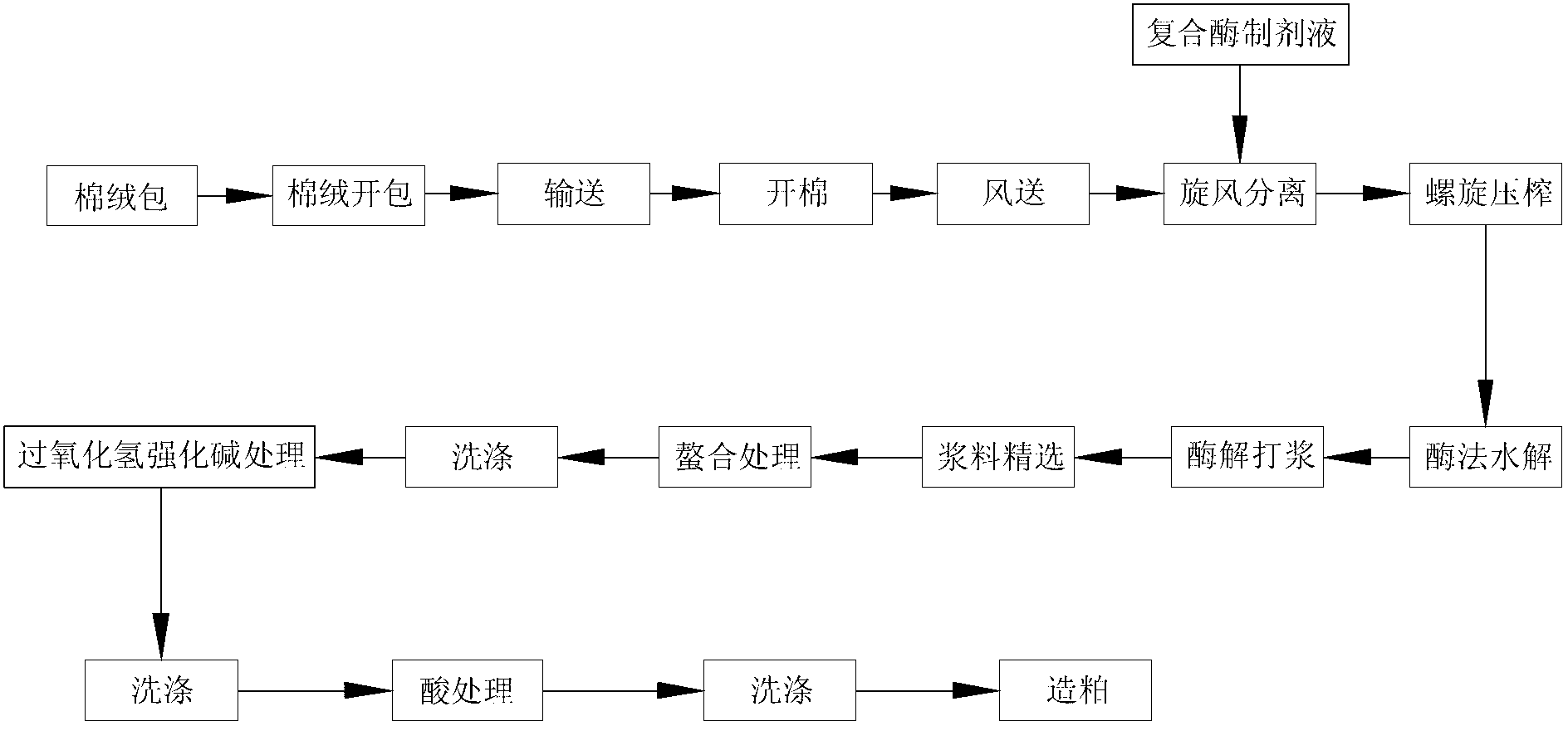

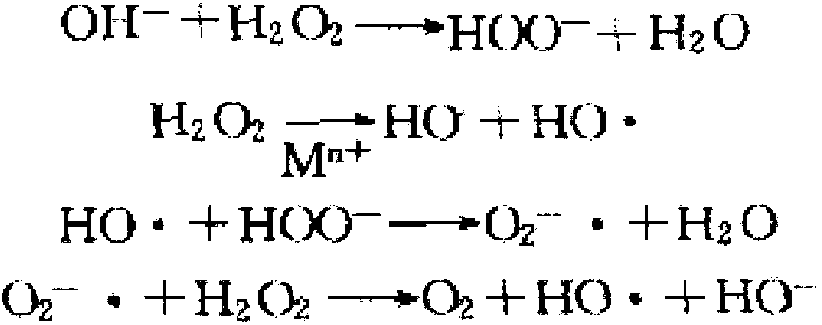

Method used

Image

Examples

Embodiment 1

[0063] A compound enzyme preparation, consisting of compound enzyme preparation I and compound enzyme preparation II, wherein the components and mass percentages of the compound enzyme preparation I are: 0.3% of ferulic acid esterase, 1% of lipase, and 1% of pectinase , laccase 1%, antioxidant 0.5%, antifungal agent 0.5%, insect repellant 0.1%, and the rest is soluble starch;

[0064] The composition and mass percentage of compound enzyme preparation II are: xylanase 5%, cellulase 2%, dextranase 3%, arabinase 4%, antioxidant 0.5%, antifungal agent 0.5%, Insect repellent 0.1%, the rest is soluble starch;

[0065] The dissolving pulp production process using the above-mentioned compound enzyme preparation specifically includes the following steps:

[0066] After preliminary manual dust removal, 6 tons of cotton linters were removed, the slurry concentration was adjusted to 10%, the pH of the solution was adjusted to 6.5, 12kg of compound enzyme preparation I agent was added, an...

Embodiment 2

[0071] A compound enzyme preparation, consisting of compound enzyme preparation I and compound enzyme preparation II, wherein the components and mass percentages of the compound enzyme preparation I are: ferulic acid esterase 0.5%, lipase 2%, pectinase 1% , laccase 3%, antioxidant 2%, antifungal agent 1.5%, insect repellent 0.3%, and the rest is dextrin;

[0072] The composition and mass percentage of compound enzyme preparation II are: xylanase 4%, cellulase 1%, glucanase 2%, arabinase 1%, antioxidant 2%, antifungal agent 2%, Insect repellent 0.5%, the rest is soluble starch;

[0073] The dissolving pulp production process using the above-mentioned compound enzyme preparation specifically includes the following steps:

[0074] Take 6 tons of cotton linters of the third type and second grade after preliminary manual dust removal, adjust the pulp concentration to 8%, adjust the pH of the solution to 5.5, add 24kg of compound enzyme preparation I, and treat at 50°C for 24h. Ad...

Embodiment 3

[0080] A compound enzyme preparation, which is composed of compound enzyme preparation I and compound enzyme preparation II, wherein the composition and mass percentage content of the compound enzyme preparation I are: 2% ferulic acid esterase, 1% lipase, and 5% pectinase , laccase 3%, antioxidant 1%, antifungal agent 1%, insect repellent 0.2%, soluble starch 80%, dextrin 6.8%;

[0081] The composition and mass percentage of compound enzyme preparation II are: xylanase 3%, cellulase 5%, dextranase 5%, arabinase 1%, antioxidant 1%, antifungal agent 1.5%, Insect repellent 0.2%, the rest is soluble starch;

[0082] The dissolving pulp production process using the above-mentioned compound enzyme preparation specifically includes the following steps:

[0083] Take 6 tons of second-class and third-class cotton linters after preliminary manual dust removal, adjust the pulp concentration to 12%, adjust the pH of the solution to 6.5, add 30kg of compound enzyme preparation I, and trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com