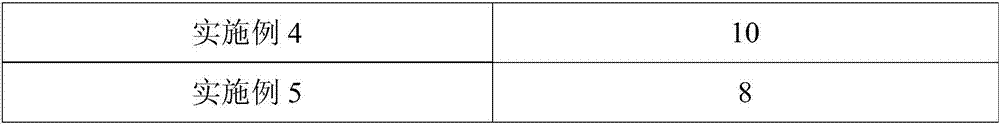

Patents

Literature

161results about How to "Improve beating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

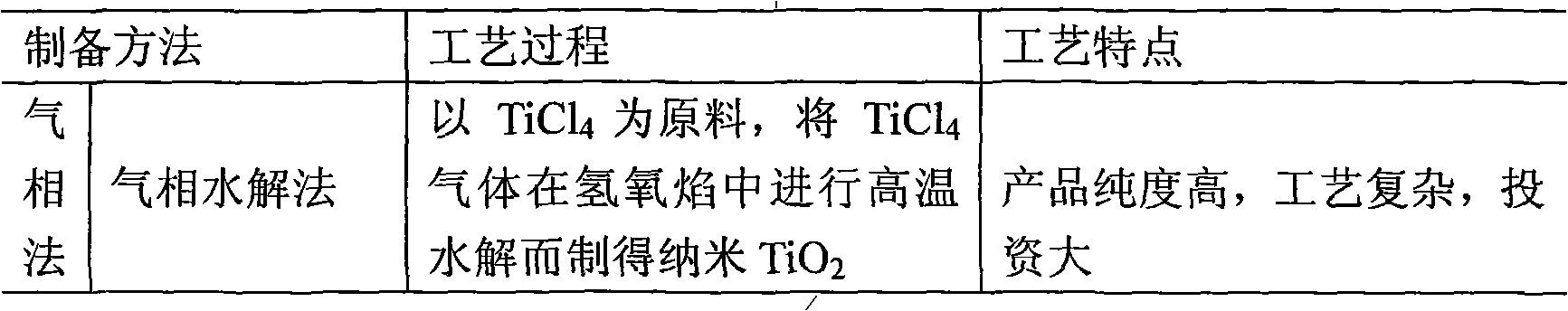

Preparation method for titanium dioxide serving as catalyst carrier

InactiveCN102583522AImprove performanceEasy to processCatalyst carriersTitanium dioxidePtru catalystMaterials science

The invention discloses a preparation method for titanium dioxide serving as a catalyst carrier. The preparation method comprises the following steps of: dispersing metatitanic acid serving as a raw material by pulping, and adjusting until the concentration of the slurry is 12 to 26 mass percent based on titanium dioxide (TiO2); adding ammonia water into the slurry, and adjusting the pH value to be between 6.0 and 9.0; filtering and dehydrating to obtain a blocky filter cake; mechanically crushing the blocky filter cake; drying and calcining the crushed filter cake at 200 to 560 DEG C for 6 hours; and grinding the calcined material in a kiln to obtain a titanium dioxide product which serves as a denitration catalyst carrier. By the preparation method, the manufacturing cost is low, the process is simple, the prepared product has the advantages of large specific area, high surface chemical activity and high processability, and the prepared final product is high in catalytic efficiency.

Owner:四川华铁钒钛科技股份有限公司

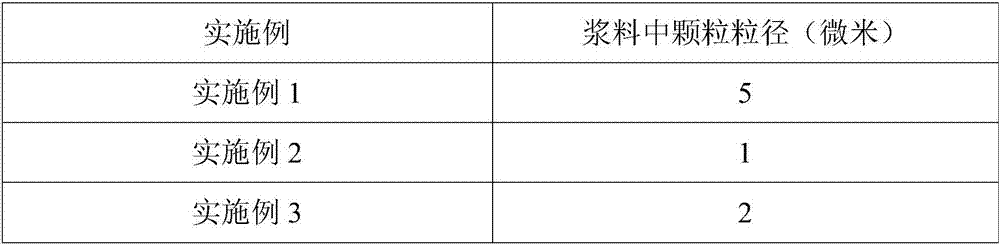

Method for preparing anatase type nano-titanium dioxide

InactiveCN101318698AUniform particle sizeSmall particle sizeTitanium dioxideFiltrationChemical products

The invention relates to a method for preparing anatase nano titania, which relates to the chemical product preparation technical field. The method adopts a metatitanic acid produced by the sulfuric acid method as a raw material; depolymerizing agents are added into the metatitanic acid and reacted with a sulfuric acid in the metatitanic acid so as to depolymerize the metatitanic acid; micron secondary agglomerated particles of the metatitanic acid are depolymerized into nano primary positive particles; and anatase nano titania products are prepared with low cost after subsequent procedure treatments of gel coagulation, filtration, washing, calcination, crushing and so on of the processed metatitanic acid. The method has a simple technique and the anatase nano titania is high in purity; and the three wastes are small in amount and convenient to recover, and no emission of waste gas and liquor can be reached completely, thereby the complete environment-friendly industrial standard can be realized. Moreover, the method can manyfold reduce the manufacturing cost of the nano titania products, thereby having great promotion value and wide market prospect.

Owner:四川华铁钒钛科技股份有限公司

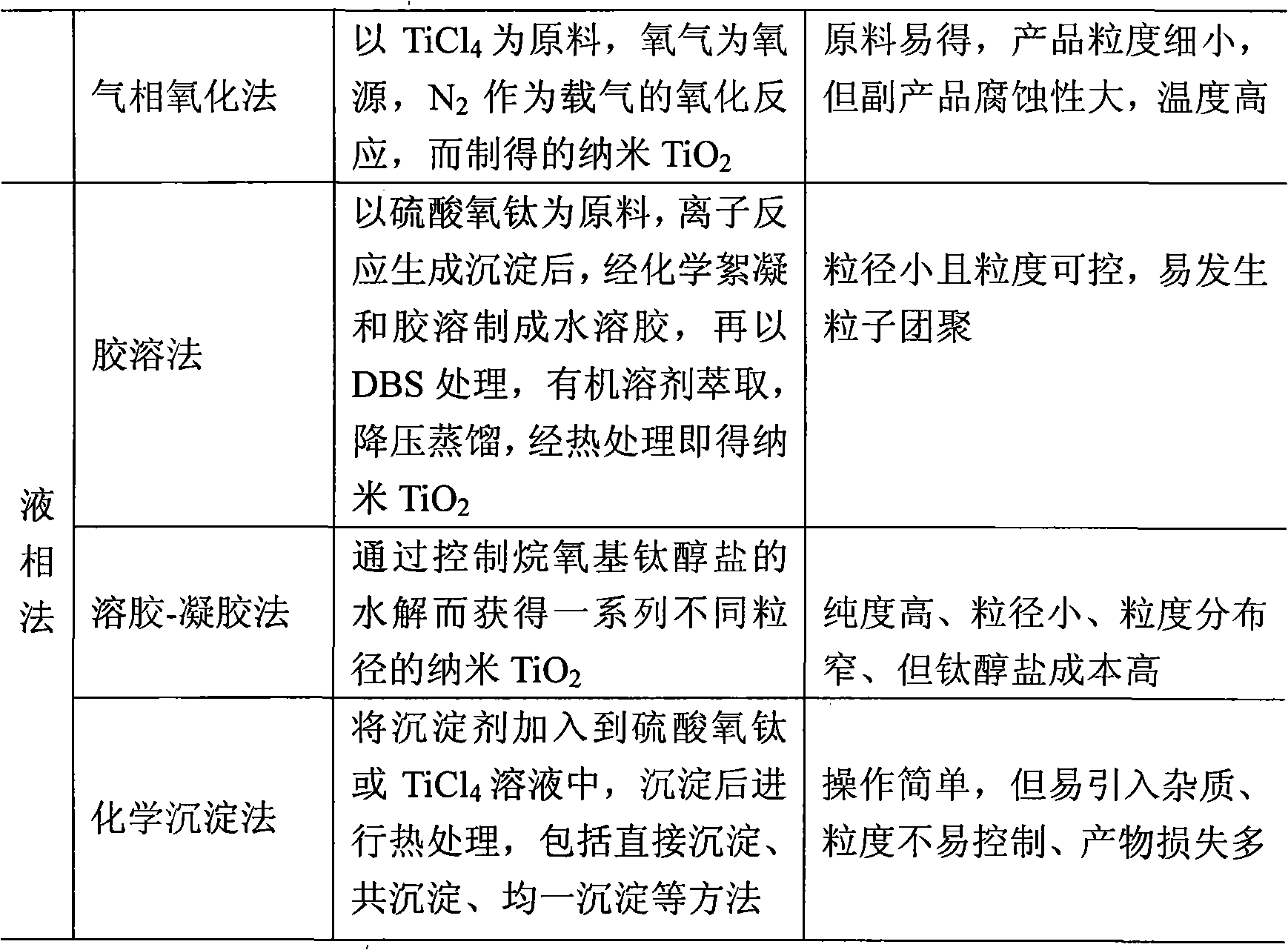

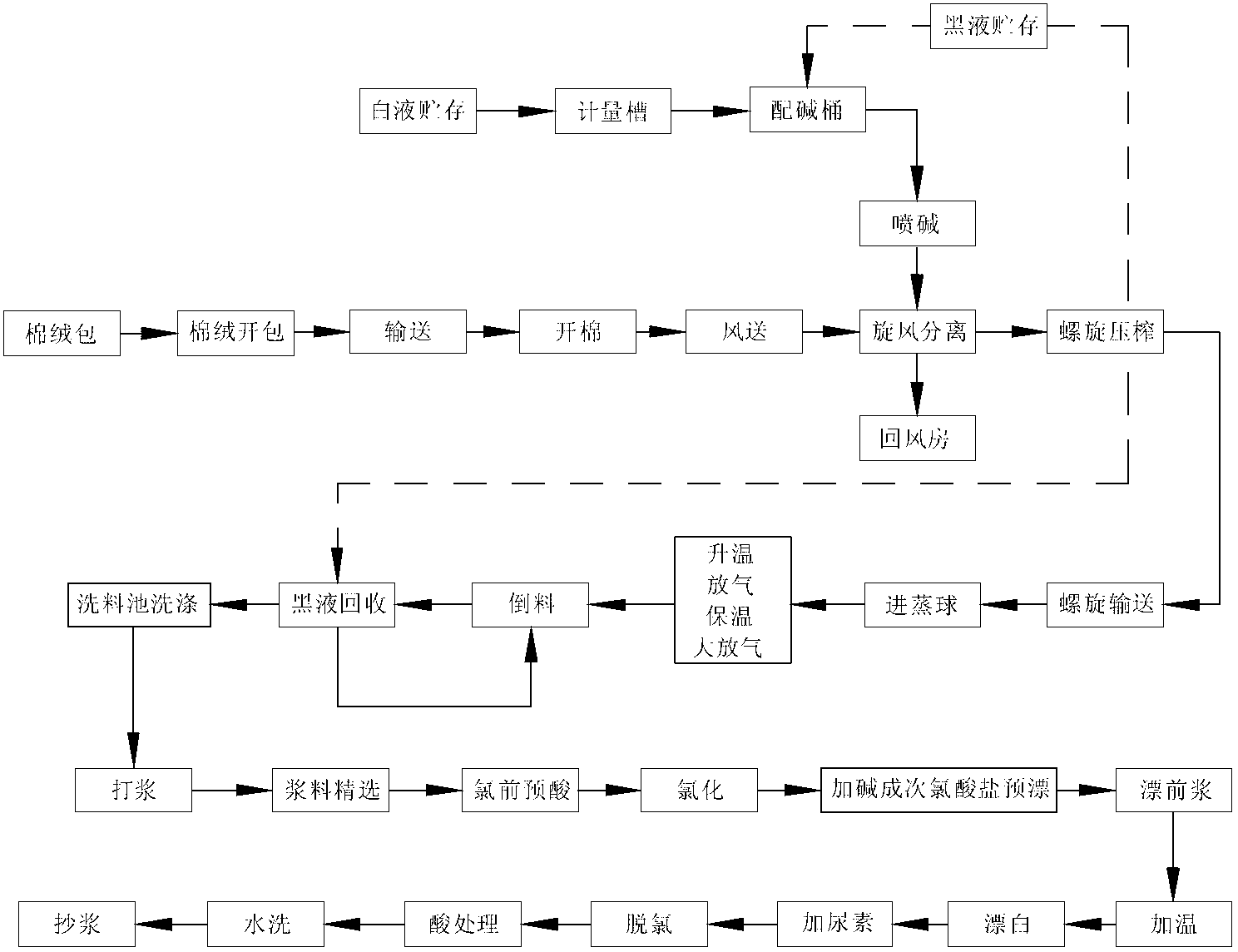

Complex enzyme preparation and technique for preparing dissolving pulp by using same

ActiveCN103061181ALoose structureEnhancement and effectPaper material treatmentChemical oxygen demandCellulose fiber

The invention relates to the technical field of production of regenerated cellulose fiber, in particular discloses a complex enzyme preparation applied in the preparation of dissolving pulp and a technique for preparing the dissolving pulp by using the enzyme preparation. The complex enzyme preparation is divided into a complex enzyme preparation I and a complex enzyme preparation II, wherein the complex enzyme preparation I mainly consists of feruloyl esterase, lipase and the like; and the complex enzyme preparation II mainly consists of xylanase, cellulase and the like. The complex enzyme preparation is applied in the technique for purifying alpha-cellulose and preparing the dissolving pulp; and the technique comprises the following steps of impurity removal for raw materials, enzyme method pretreatment, enzymolysis pulping, chelation treatment, alkali hydroxyl active oxygen cooking, acid treatment, washing, sand removal and pulp mixing. The method has the simple preparation technique, and adopts the complex enzyme preparation to treat the raw material pulp so as to effectively remove lignin, hemicellulose, pectin substance and waxiness and to reduce the degree of polymerization of the alpha-cellulose; the energy consumption is low under the normal pressure condition; the COD (Chemical Oxygen Demand) value of the pulping waste water is low; the yield of the dissolving pulp is high; the alpha-cellulose has high content and uniform degree of polymerization; and the production requirements of viscose can be satisfied.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

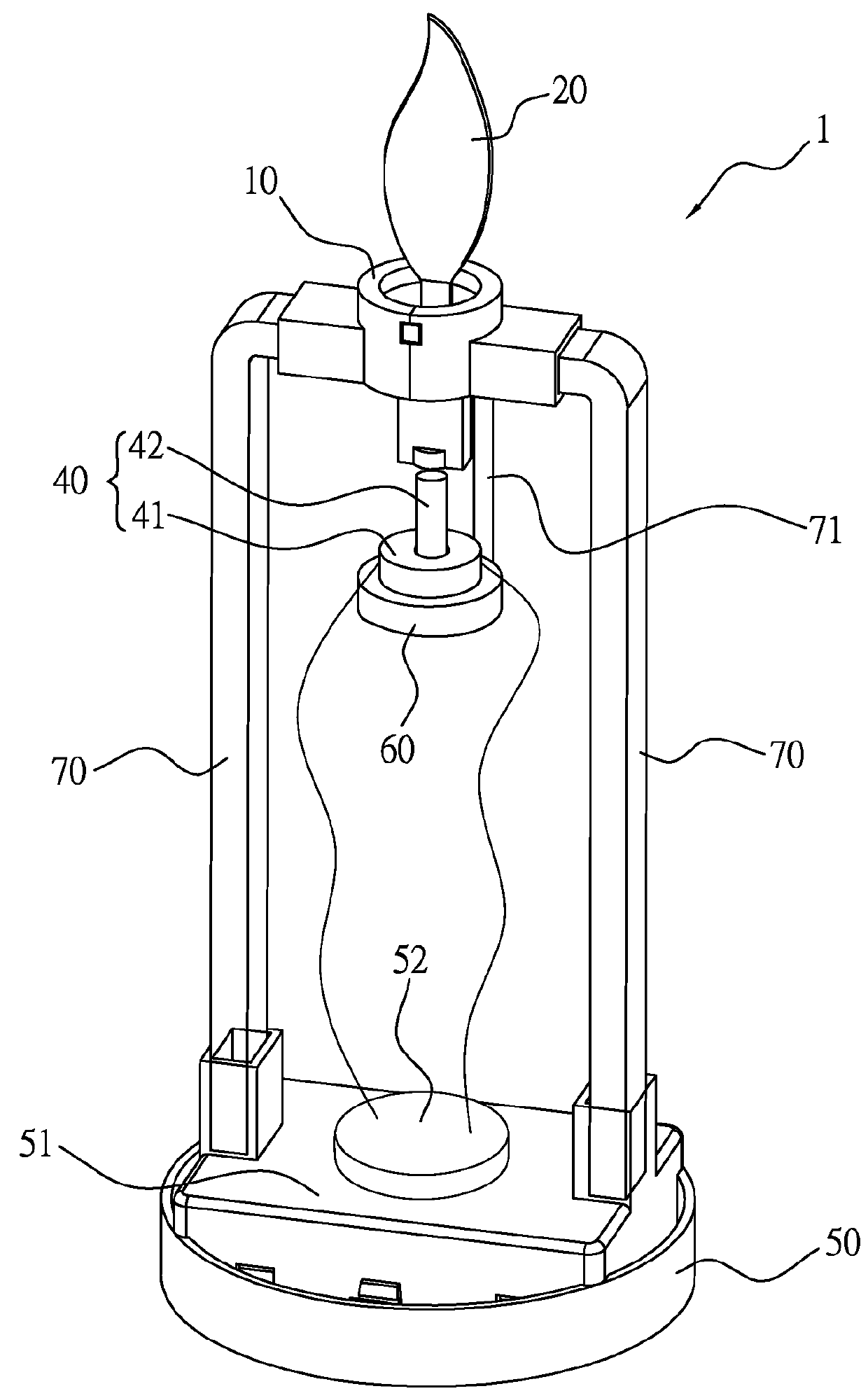

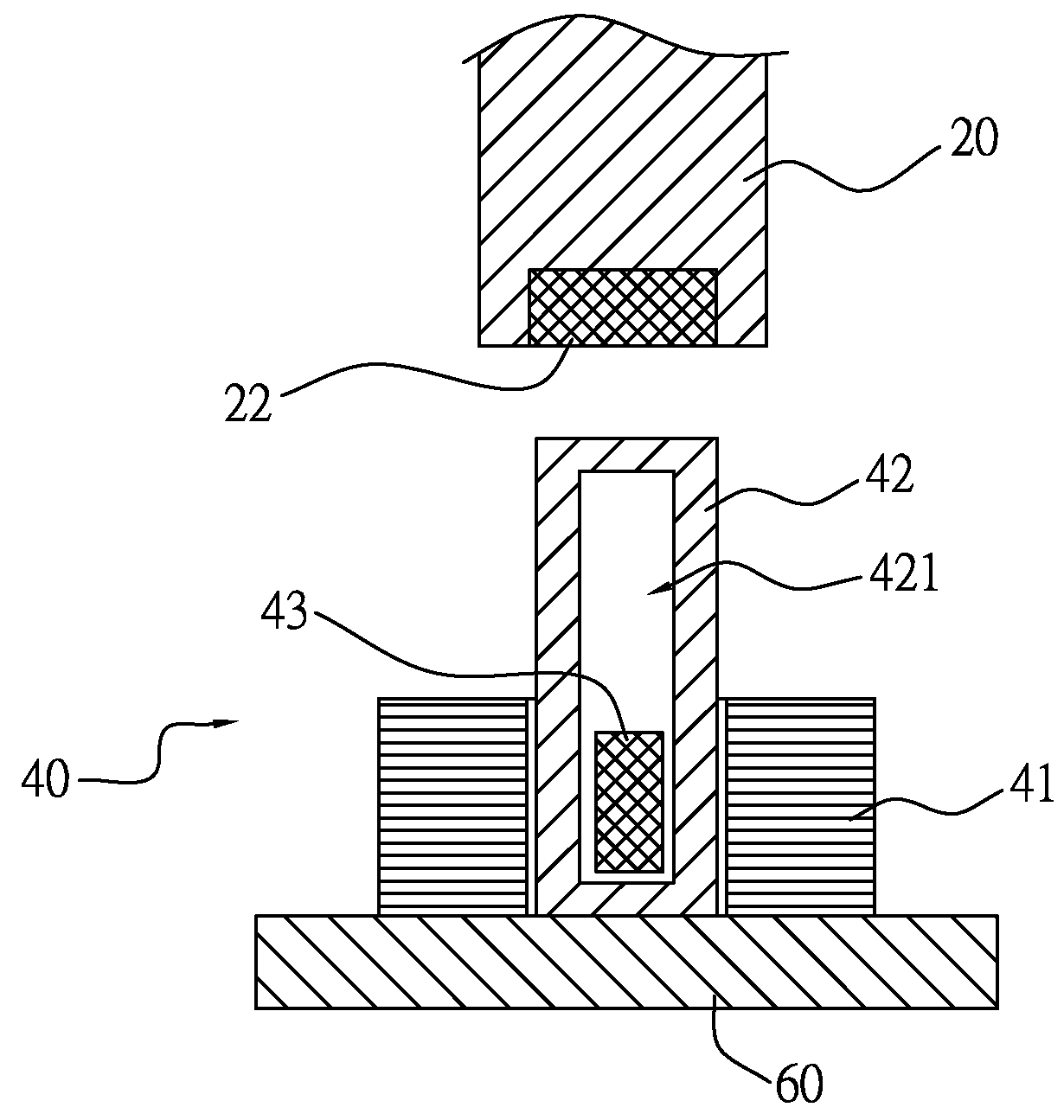

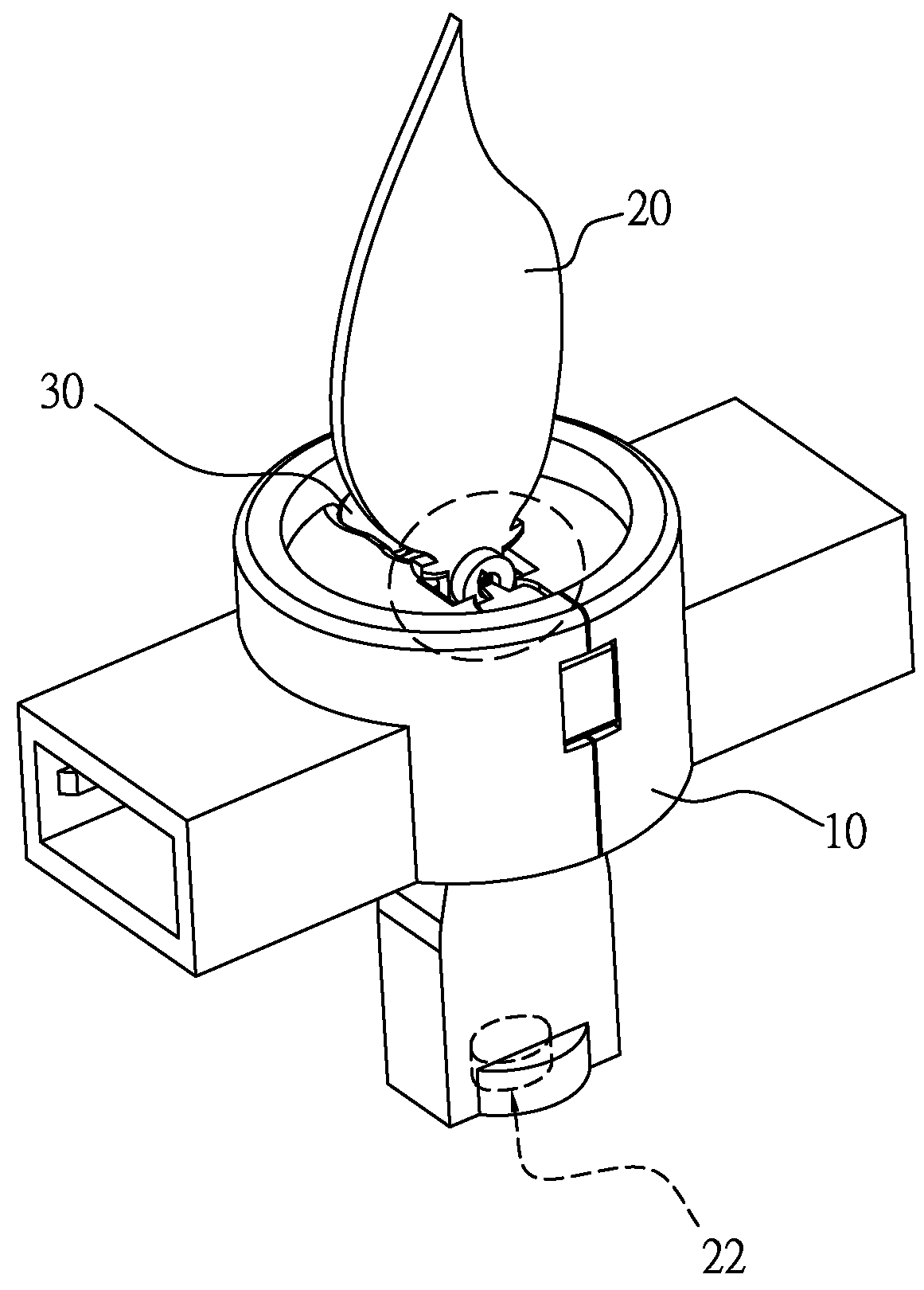

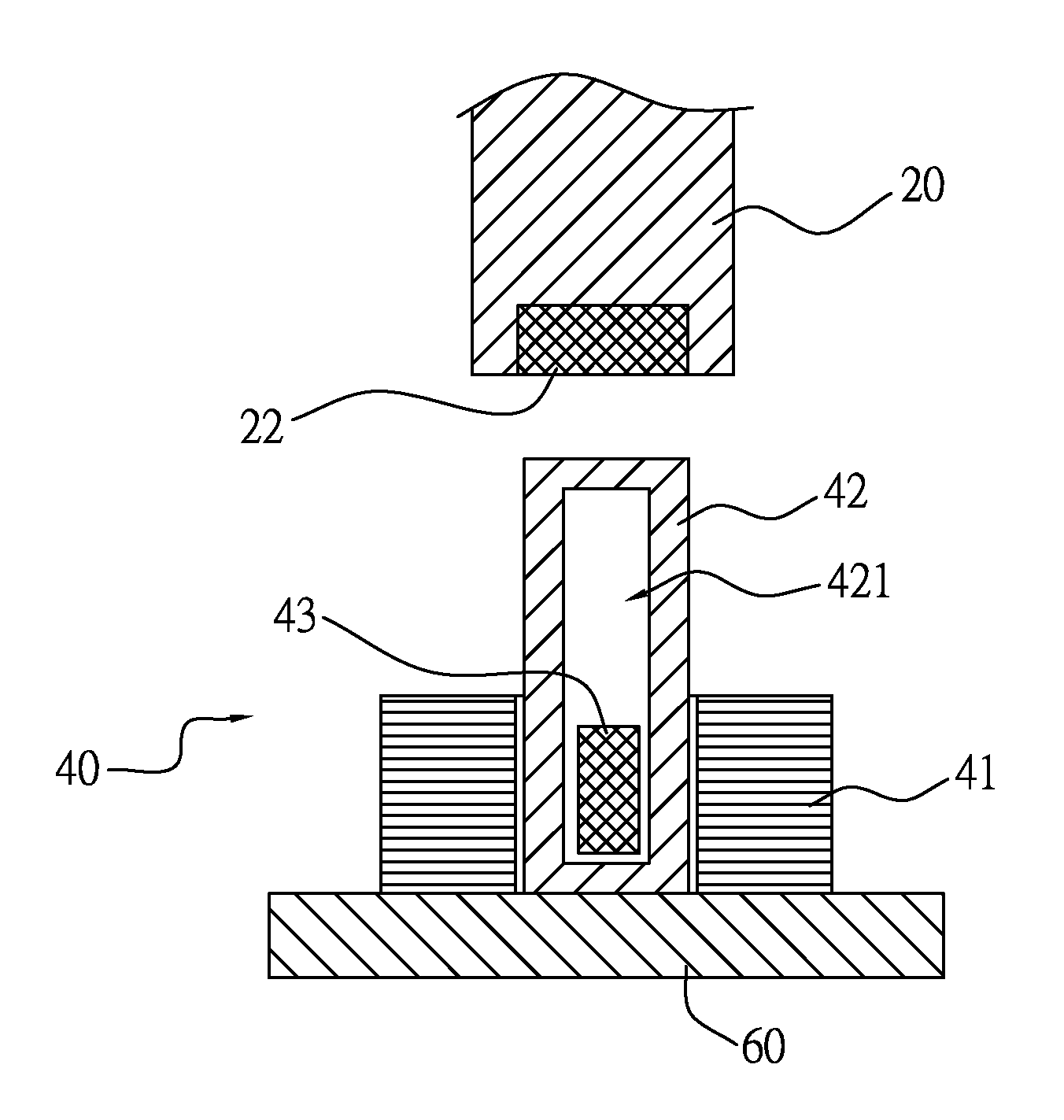

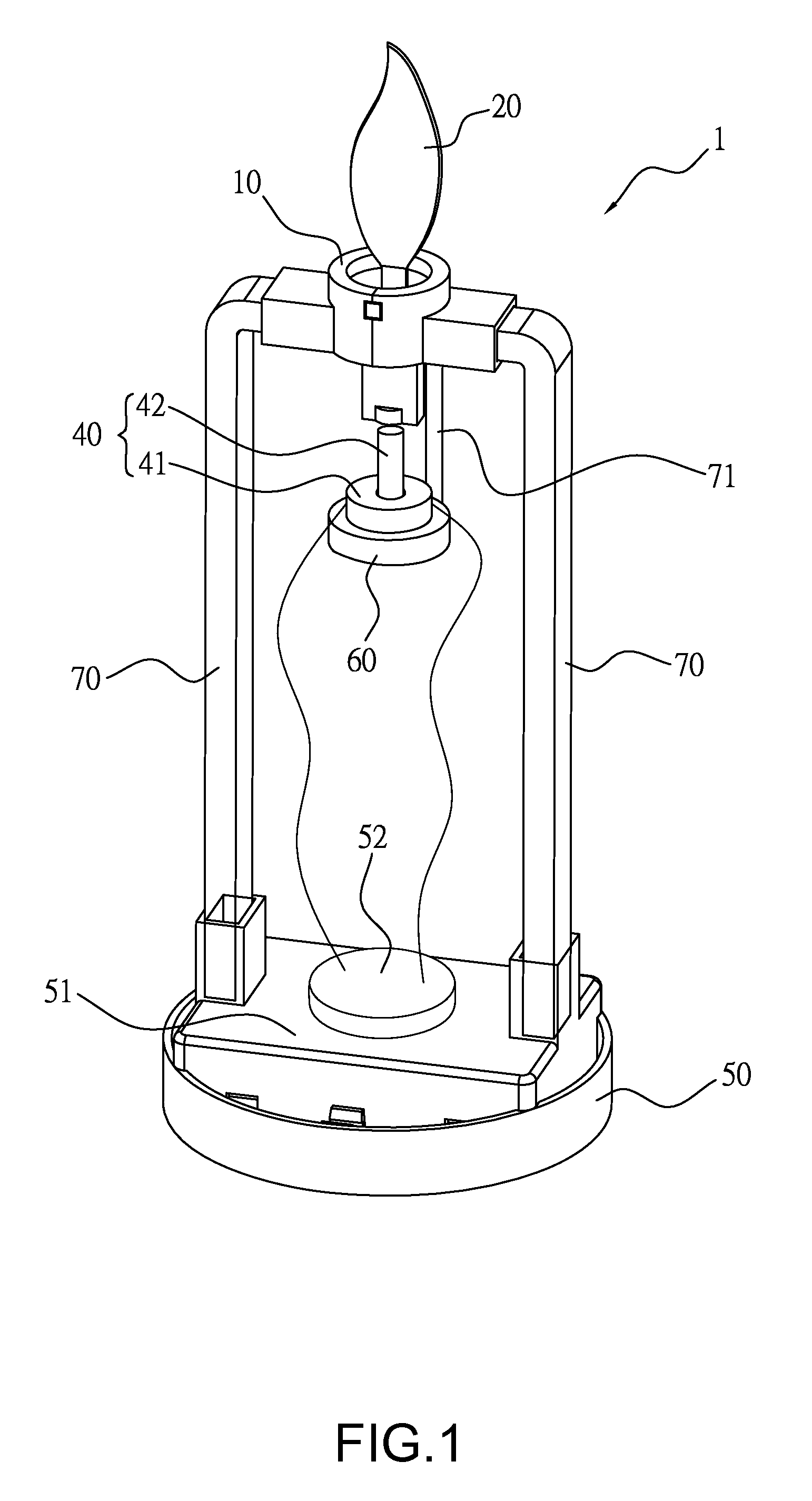

Dynamic flame simulating device

ActiveUS20160053954A1Not be restrictImprove problemElectric circuit arrangementsLight effect designsEngineeringLight source

A dynamic flame simulating device mainly comprises an upper base, a flame element suspended from the upper base, a light source providing light rays, and a driving assembly below the flame element. The driving assembly further comprises an electromagnetic coil and a second magnetic element, wherein the electromagnetic coil is powered on to drive the second magnetic element to bounce toward a first magnetic element on the bottom end of the flame element to generate repellent magnetic acting forces to make the flame element swing naturally and achieve the dynamic visual effect of the natural beating of the burning flame.

Owner:GLOBAL RICH INVESTMENT CO LTD

Cuttlefish ball and preparation method thereof

ActiveCN104664451AQuality improvementThe improvement of quality has two benefits: one is the improvement of adhesionFood preparationIce waterCuttlefish

The invention discloses a cuttlefish ball and a preparation method thereof. The cuttlefish ball is prepared from the raw materials including minced fillet, chicken breast, cassava modified starch, pork fat, cuttlefish flesh, ice water mixture, table salt, phosphate and other seasonings. The preparation method of the cuttlefish ball comprises the following steps of: washing the chicken breast clean, grinding the chicken breast into meat paste particles, and storing the meat paste particles at temperature of -5 to 0 DEG C; mixing the meat paste particles with the minced fillet, the ice water mixture and the phosphate, then, pulping the mixture, and orderly adding other raw materials during the pulping process to form paste; orderly carrying out standing treatment, molding treatment, secondary boiling treatment and freezing treatment for the formed paste, thereby forming the cuttlefish ball.

Owner:HAIXIN FOODS

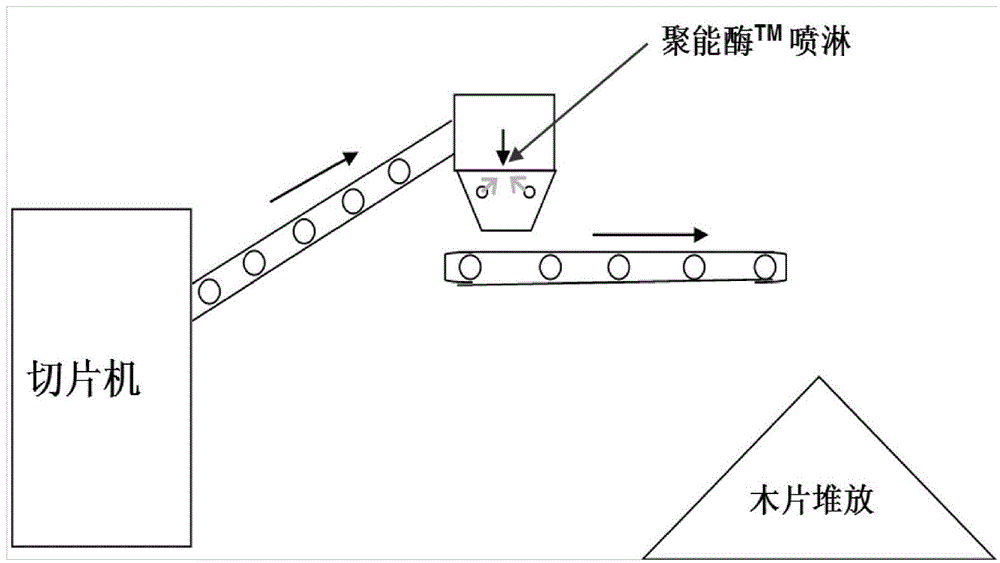

Poplar ultrasonic chemical mechanical pulping technique

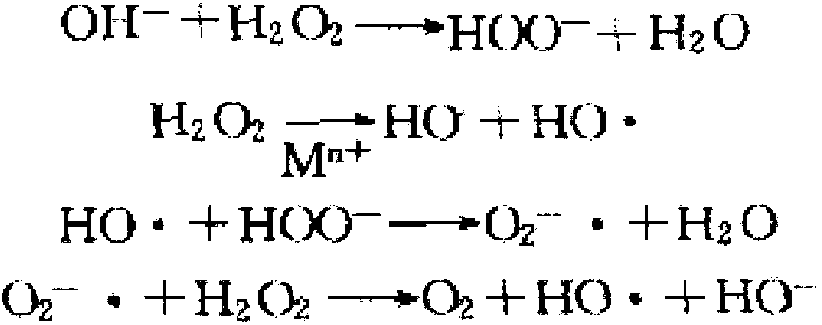

ActiveCN106120418ALarge specific surface areaHigh bonding strengthPulping with organic compoundsMultistage pulping processChemistryPre treatment

The invention relates to a poplar ultrasonic chemical mechanical pulping technique. The pulping technique includes the steps: performing ultrasonic pretreatment on steamed poplar pulp after first stage impressafining; performing xylanase pretreatment on the pulp after the ultrasonic pretreatment; soaking the pulp in soda hydrogen dioxide solution after pretreatment; performing second stage impressafining after soaking; performing second stage soaking on the pulp in the soda hydrogen dioxide solution after the second stage impressafining; performing first stage refining on the pulp with the soaking liquid; performing high concentrated storage and bleaching after the first stage refining; and performing second stage refining to obtain high-brightness high-yield high-strength chemical mechanical pulp. The poplar ultrasonic chemical mechanical pulping technique can improve the mechanical pulping performance of fast-growing poplar, enlarge the application range of poplar high-yield pulp, improve the performance of poplar paper pulp, and improve the use value of the poplar.

Owner:QILU UNIV OF TECH

Dynamic flame simulating device

ActiveUS9388954B2Swinging of the flame element more realistic and naturalSimple structureElectric circuit arrangementsLight effect designsMagnetic tension forceEngineering

Owner:GLOBAL RICH INVESTMENT CO LTD

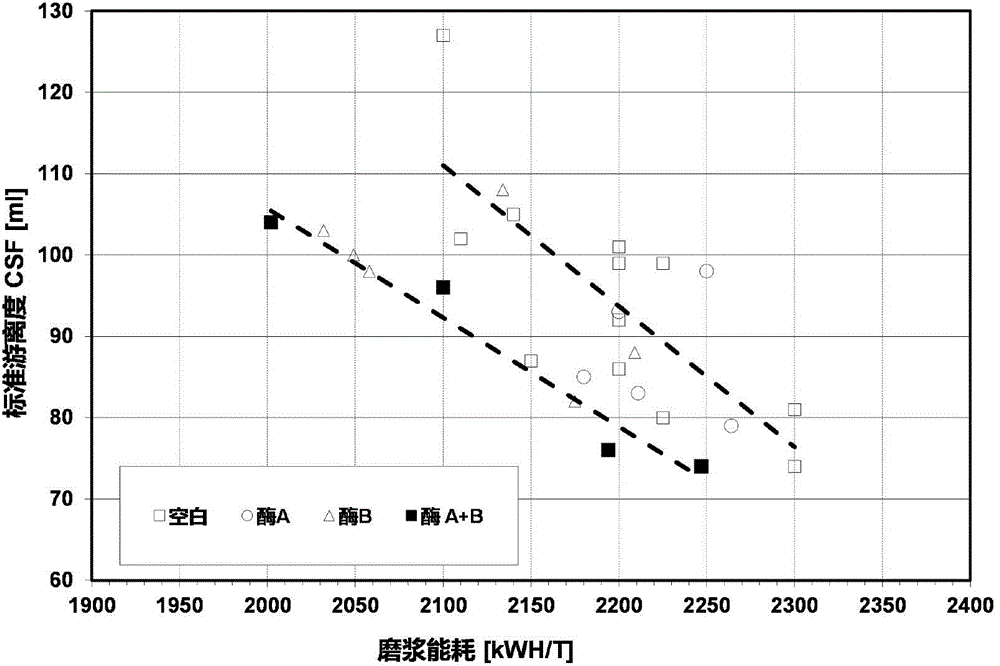

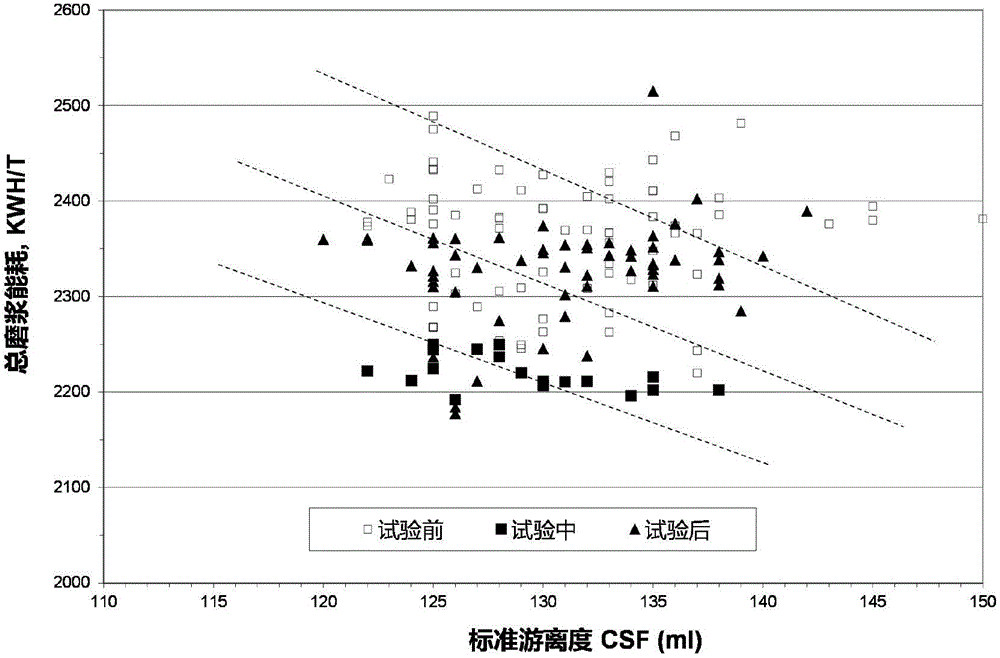

High-strength modified energy-saving biological enzyme paper pulp and pulping process

ActiveCN103898795AImprove performanceImprove percussionDefoamers additionPaper/cardboardEngineeringDefoaming Agents

The invention discloses high-strength modified energy-saving biological enzyme paper pulp and a pulping process thereof. The paper pulp comprises 0.5-5 parts of an antibacterial agent, 1-3 parts of a toughening agent, 1-5 parts of a thickening agent, 40-60 parts of regenerated paper pulp, 10-20 parts of a packing, 1-5 parts of a defoaming agent, 2-8 parts of a stabilizing agent, 1-3 parts of a retention aid, 10-30 parts of fibers and 5-20 parts of biological enzyme. According to the paper pulp, a biological enzyme technique is adopted for beating the pulp, and the biological enzyme with the high pertinence is selected for performing synchronous pulp beating treatment on the pulp, so that not only is the energy consumption reduced and is the yield increased, but also the fibers can be modified, for example, when wood pulp beating enzyme is adopted to be matched with the beating of the wood pulp, the beating degree is improved, the fiber strength is ensured, and the power consumption in beating each ton of the pulp is reduced; when the biological enzyme is adopted for beating OCC pulp, the beating degree is reduced, the fiber strength is improved, the drainability, the pulp beating capability and the flowability of the fibers are improved, and meanwhile, the production energy consumption is reduced, the properties of the pulp are improved, and thus the quality of paper is improved.

Owner:JIANGSU LEE & MAN PAPER MFG

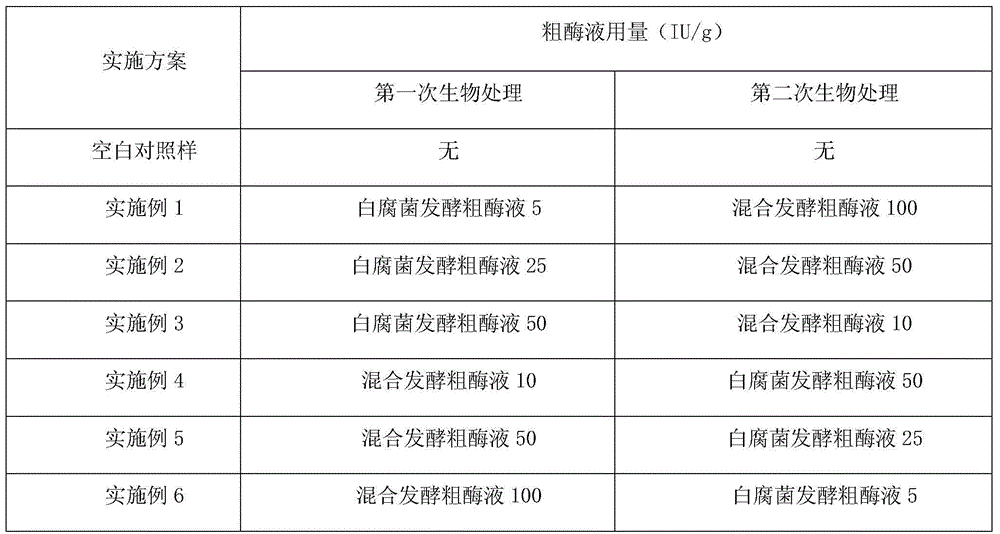

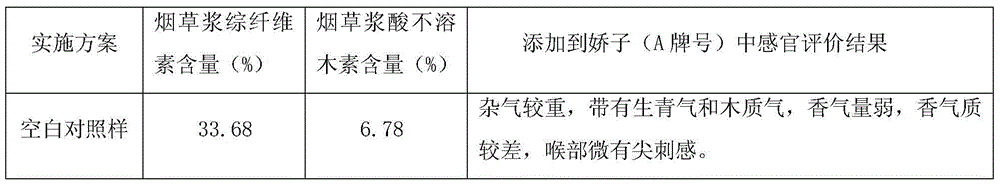

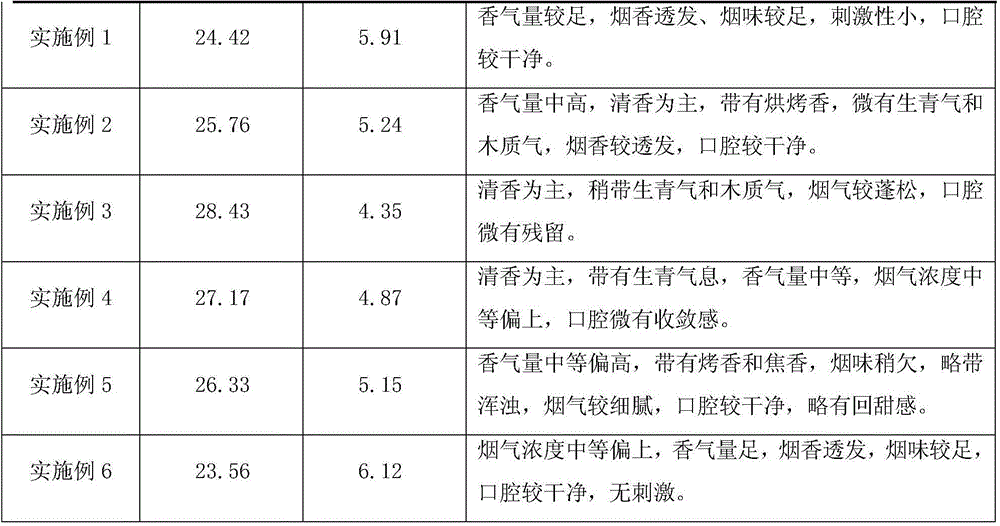

Method for improving sensory quality of tobacco reconstituted through papermaking method

The invention discloses a method for improving the sensory quality tobacco reconstituted through a papermaking method. Biotreatment is conducted twice on raw materials and sizing agents of the tobacco which is reconstituted through the papermaking method through crude enzyme obtained through microbial fermentation, the object of the primary biotreatment is raw materials obtained after extraction and tobacco rod rolling are conducted, biological enzyme penetrates through the surfaces of tobacco stems and shredded tobacco leaves obtained after extraction and tobacco rod rolling are conducted and the surface of tobacco powder and enters cell walls and middle lamella to act on chemical connection among lignin, cellulose and hemicellulose, and enzyme-promoting and defibrination functions are achieved while macromolecule matter is degraded. Secondary biotreatment is conducted in the latency process conducted before low-concentration defibrination and after high-concentration defibrination, the biological enzyme acts on sizing agent fiber, and the lignin, cellulose, hemicellulose, pectin, protein and other macromolecule matter are further degraded effectively. After biotreatment is conducted twice, cell wall matter in raw materials and the sizing agent and undissolved macromolecule matter can be degraded effectively, and the sensory quality of the tobacco reconstituted through the papermaking method is improved remarkably.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +2

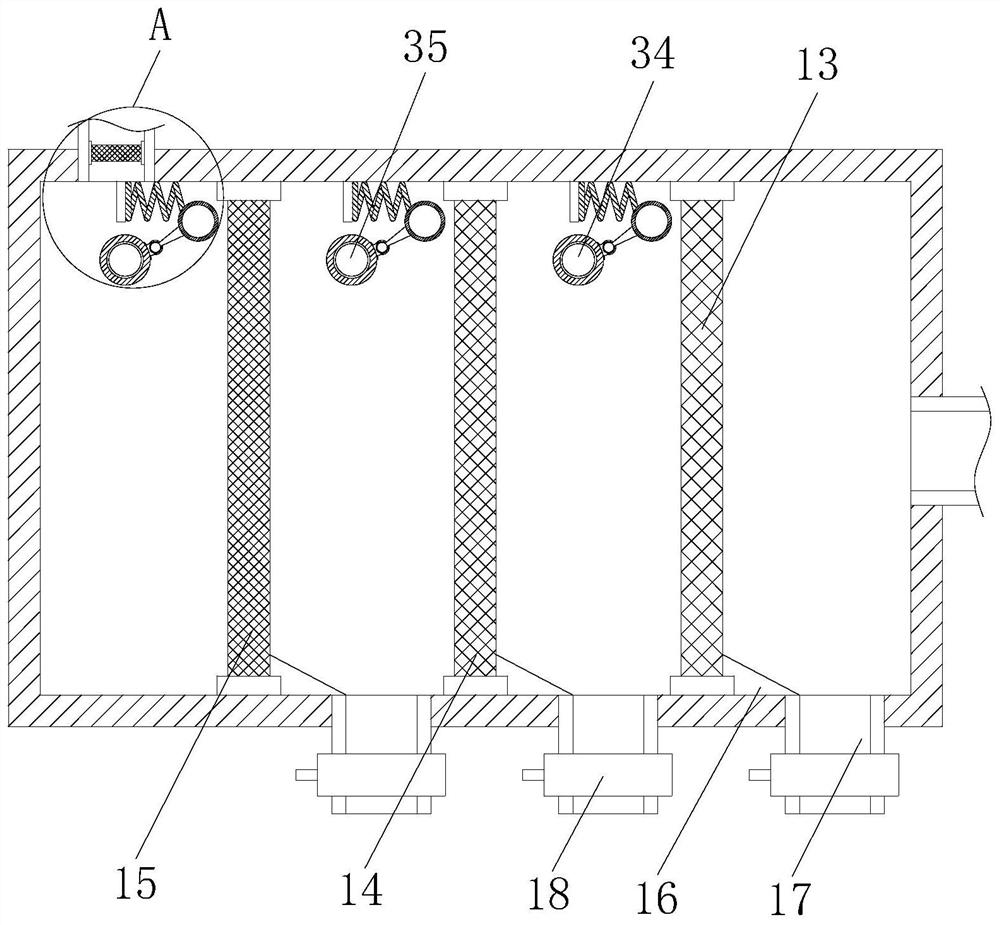

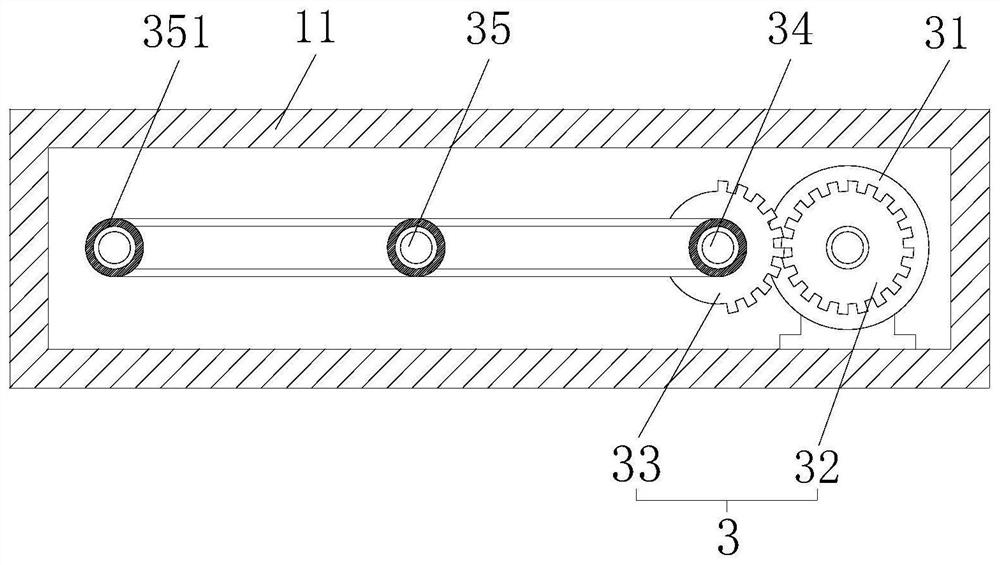

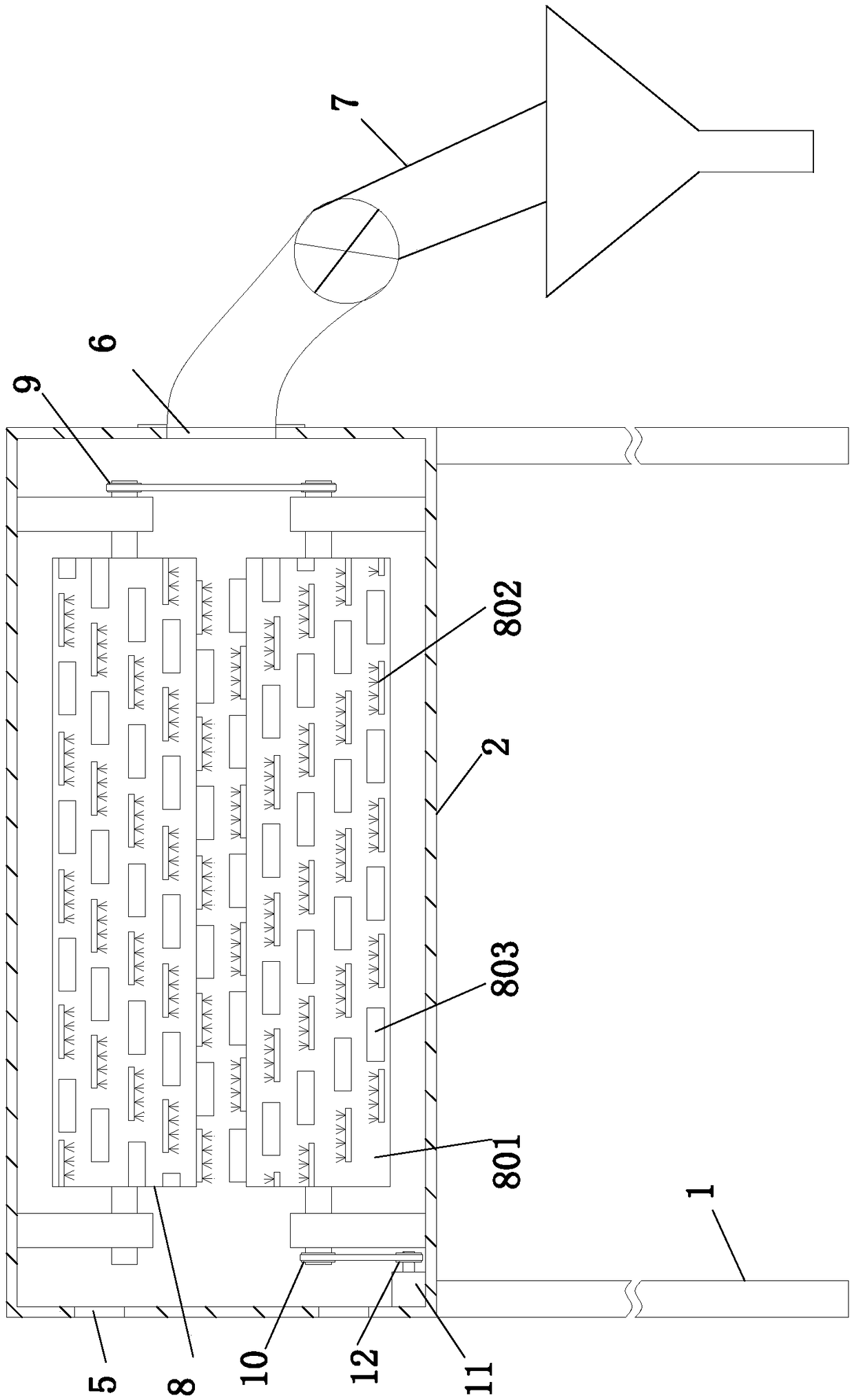

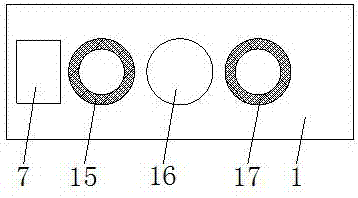

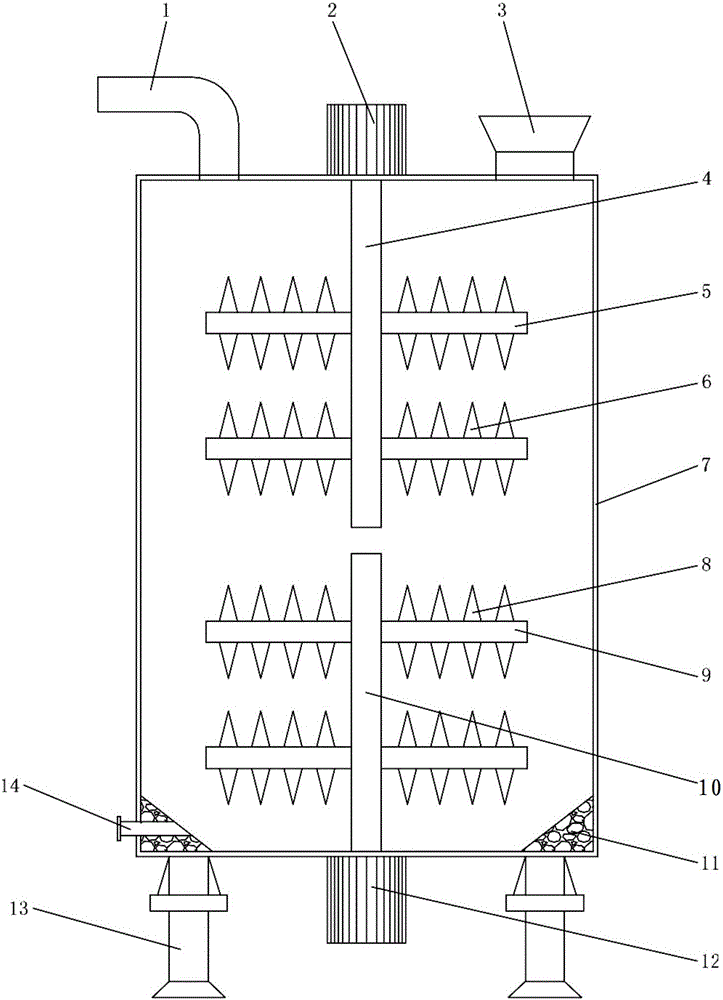

Smoke dust removal equipment for waste incineration

InactiveCN112007449AAchieve vibrationAvoid cloggingDispersed particle filtrationLighting and heating apparatusFiltrationElectric machine

The invention provides smoke dust removal equipment for waste incineration. The smoke dust removal equipment comprises a dust collecting box, a dust suction fan is arranged in front of the dust collection box, a first filter screen, a second filter screen and a third filter screen are arranged on the inner side of the dust collecting box, a protective cover is arranged on one side of the dust collecting box, an anti-blocking assembly is arranged on the inner side of the protective cover, the anti-blocking assembly comprises a driving motor, a straight gear is arranged on an output shaft of thedriving motor, one side of the straight gear is engaged with a sector gear, one side of the sector gear is provided with a first rotating shaft and two second rotating shafts, one end of the first rotating shaft and one ends of the second rotating shafts are each provided with a connecting block, one side of each connecting block is provided with a connecting rod, and one end of each connecting rod is provided with a beating ball. Through the dust suction fan, the first filter screen, the second filter screen and the third filter screen, multi-stage filtration of dusty air is achieved, vibration of the filter screens is achieved through the anti-blocking assembly, the filter screens can be effectively prevented from being blocked, and the dust removal effect is improved.

Owner:浙江万源环保机械科技有限公司

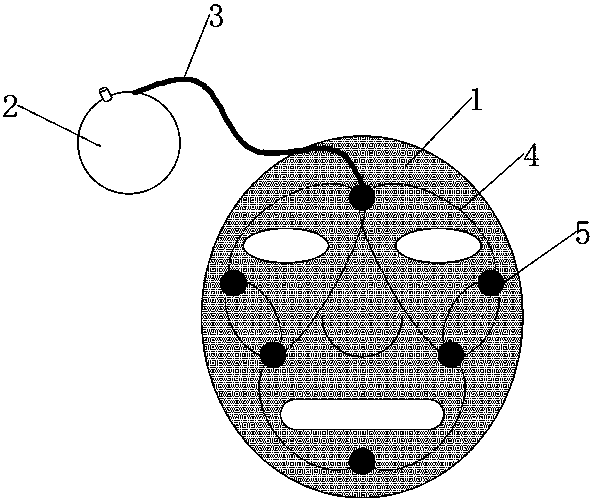

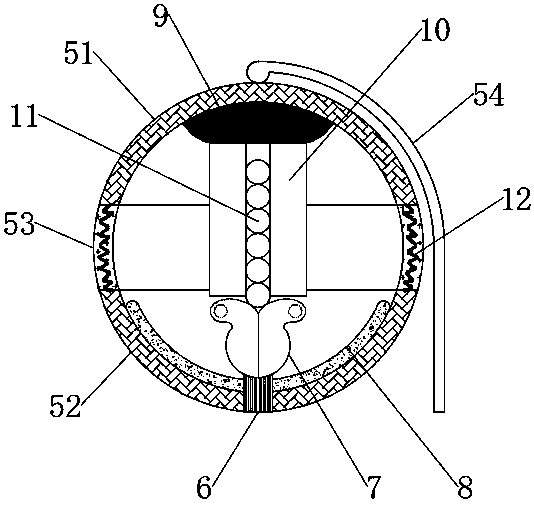

Preparation method of dual-introduction type high-absorbability facial mask

InactiveCN111450037AHigh permeability enhancement efficiencyPromote absorptionCosmetic preparationsToilet preparationsFacial skinHigh absorption

The invention discloses a preparation method of a dual-introduction type high-absorbability facial mask, belongs to the technical field of cosmetics, and aims to extract a natural transdermal introduction agent with high penetration promoting efficiency and good skin compatibility from Chinese herbal medicines after consideration of material selection, and improve the essence absorption effect ofskin; effective components in the essence are promoted to effectively penetrate through epidermis to enter dermis and subcutaneous tissue so as to be absorbed by facial skin to play a role; and meanwhile, the essence is innovatively contained, permeation promoting balls are supplemented to disperse the essence on a facial mask carrier, and the facial skin is slightly heated and flapped based on the internal actions of the permeation promoting balls, so that the absorption of the essence by the skin is promoted from the outside, double introduction from inside to outside is realized, the high absorption of functional components in the essence by the skin of a user is promoted, and the use effect of the facial mask is remarkably improved.

Owner:谢德强

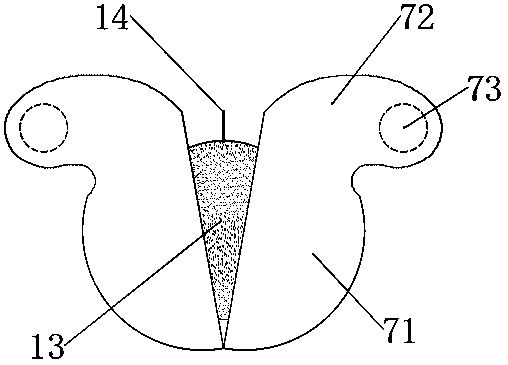

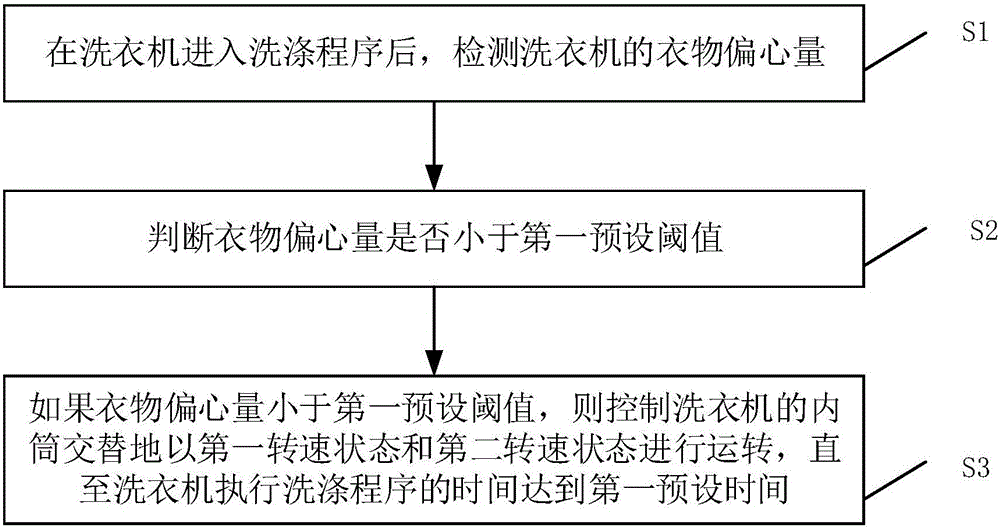

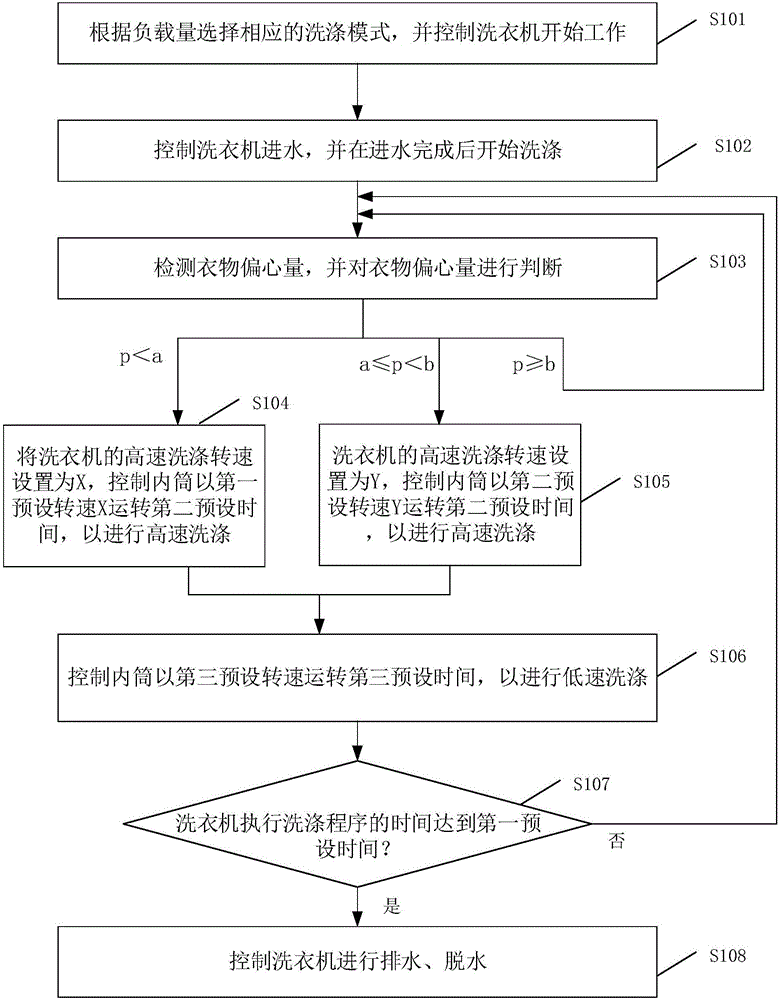

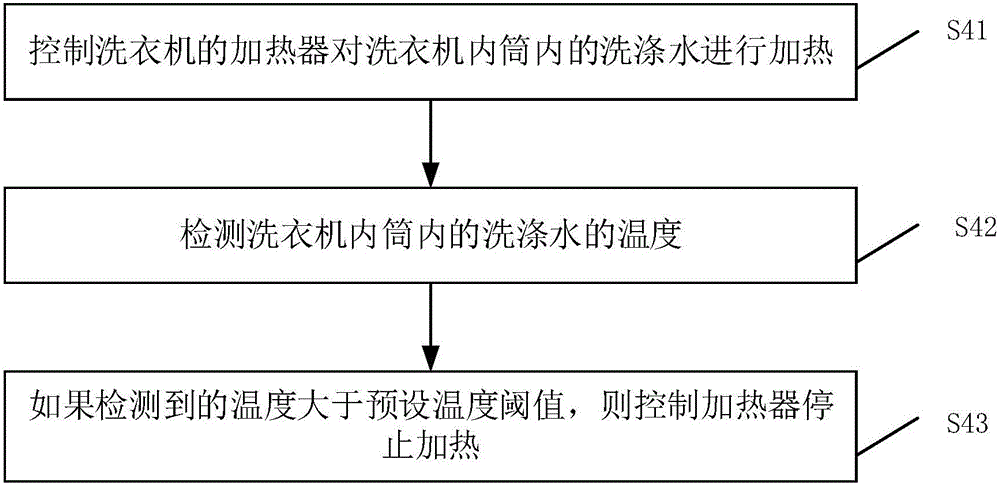

Washing machine as well as control method and control device thereof

ActiveCN105862322AStrengthen the washing machineImprove beating effectControl devices for washing apparatusTextiles and paperProcess engineeringStain removal

The invention discloses a washing machine as well as a control method and a control device thereof. The method comprises the following steps: after the washing machine enters a washing procedure, detecting the clothes eccentric magnitude of the washing machine; judging whether the clothes eccentric magnitude is less than a first preset threshold value nor not; if the clothes eccentric magnitude is less than a first preset threshold value, controlling an inner barrel of the washing machine to alternately operate in a first rotation speed state and a second rotation speed state until the washing machine executes the washing procedure for the first preset time, thereby improving the rotation speed of the inner barrel so as to enhance the mechanical force for washing of the washing machine, increasing the beating effect for clothes, realizing a stain removal effect, and realizing a washing effect with low energy consumption and high cleanness; furthermore, the method is free from cost increase and can be used for reducing the power consumption of procedures and achieving the energy-saving effect as high as 40%.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

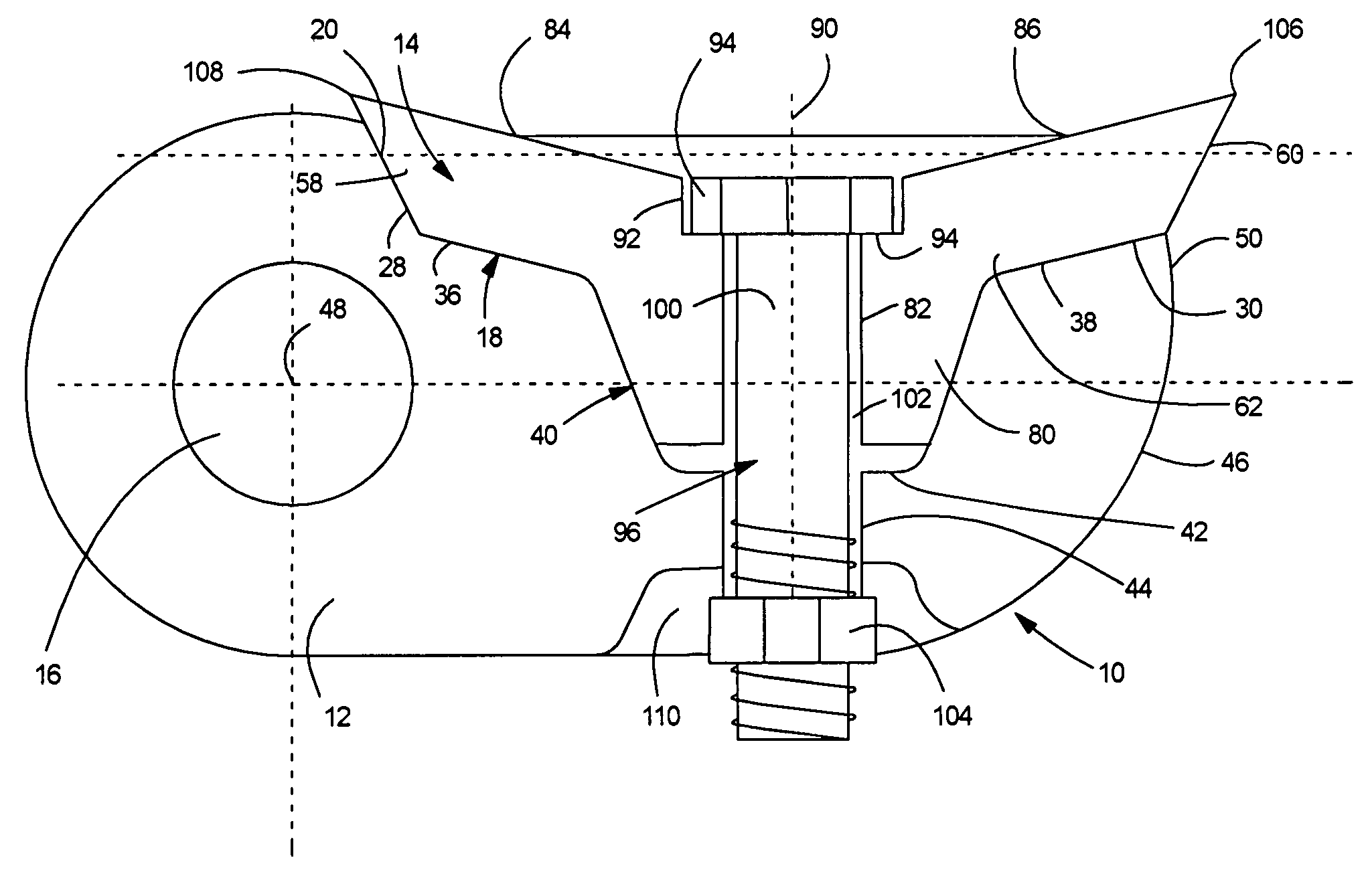

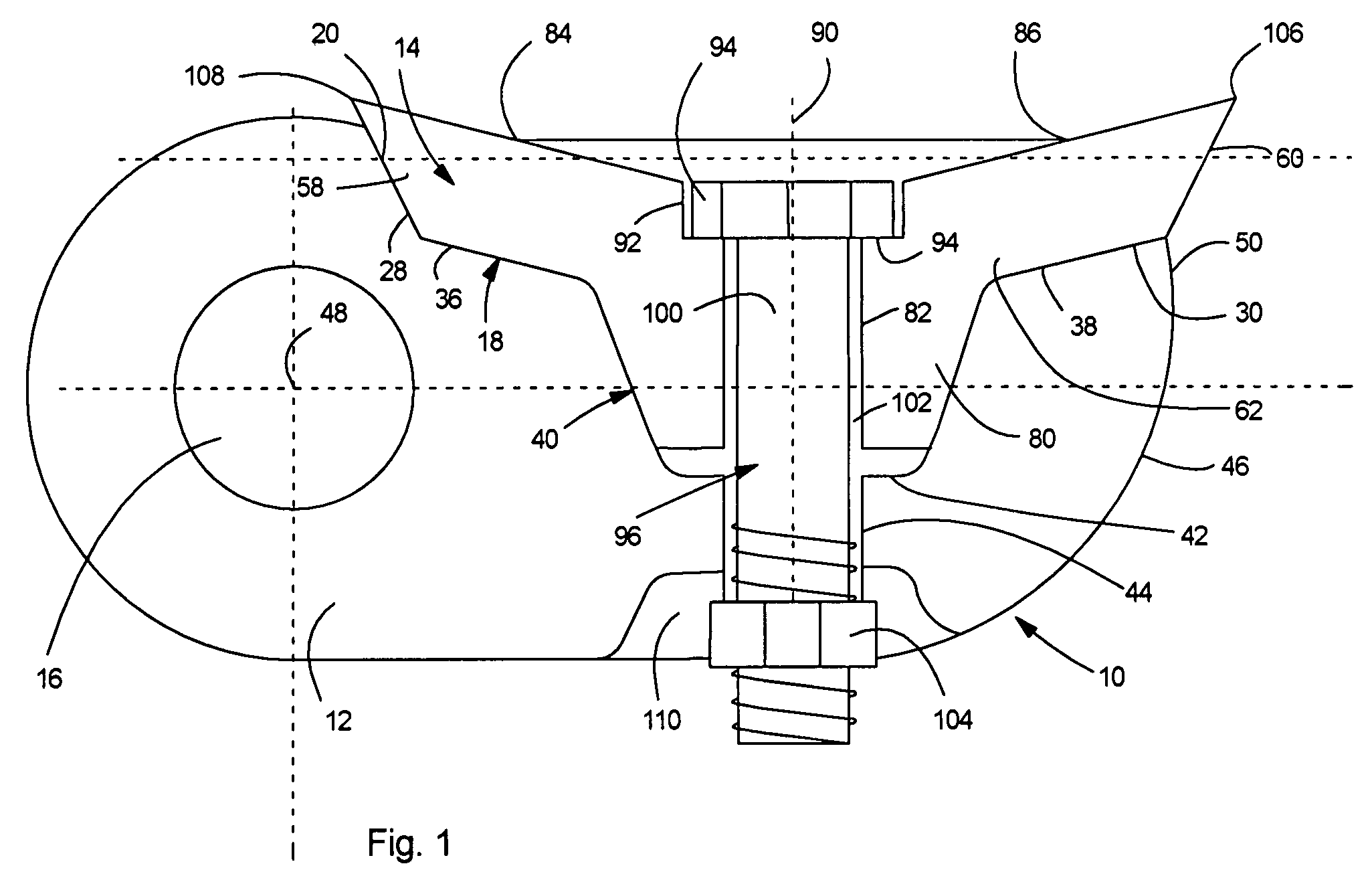

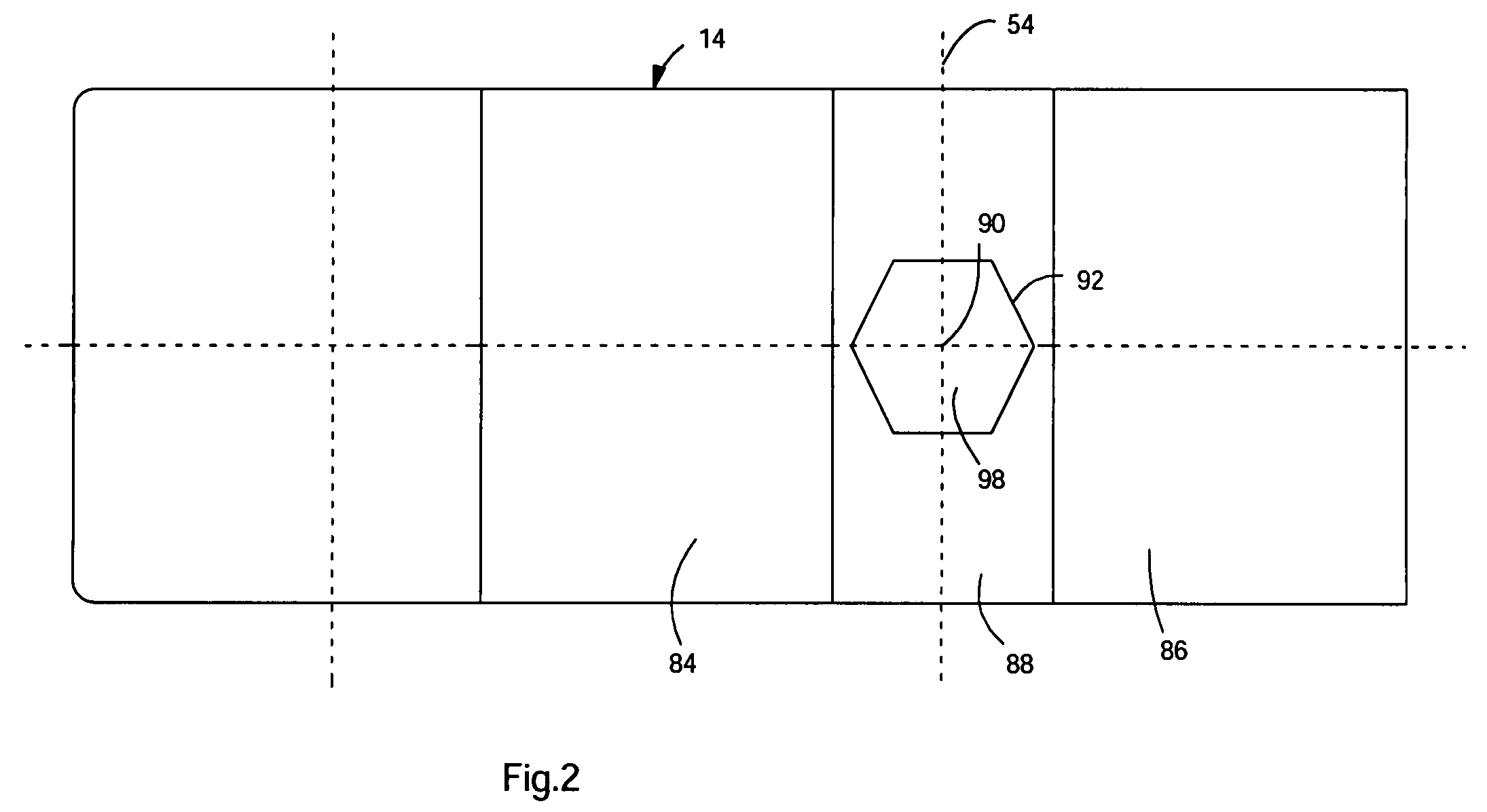

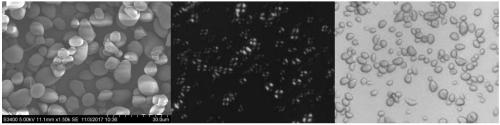

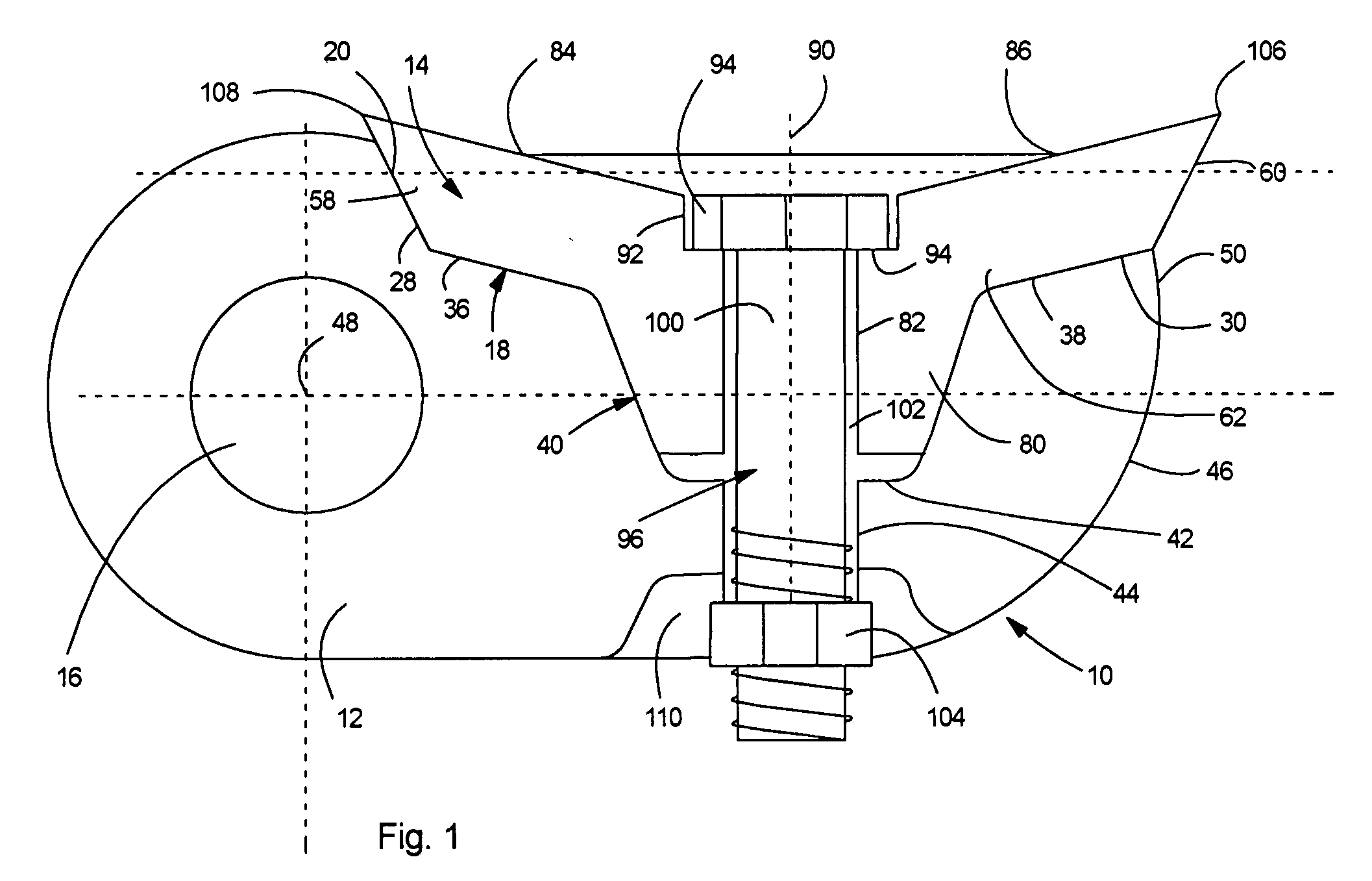

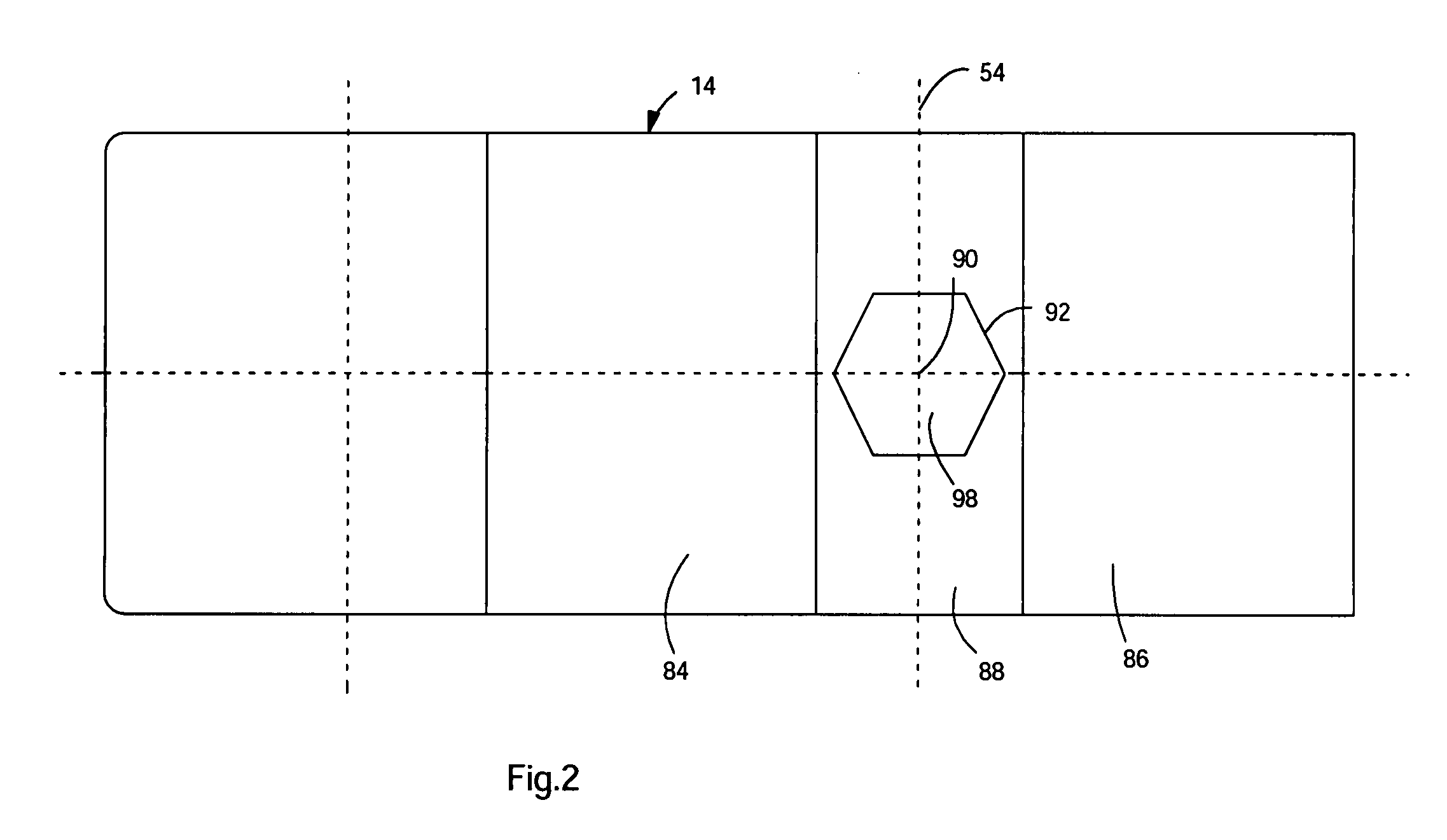

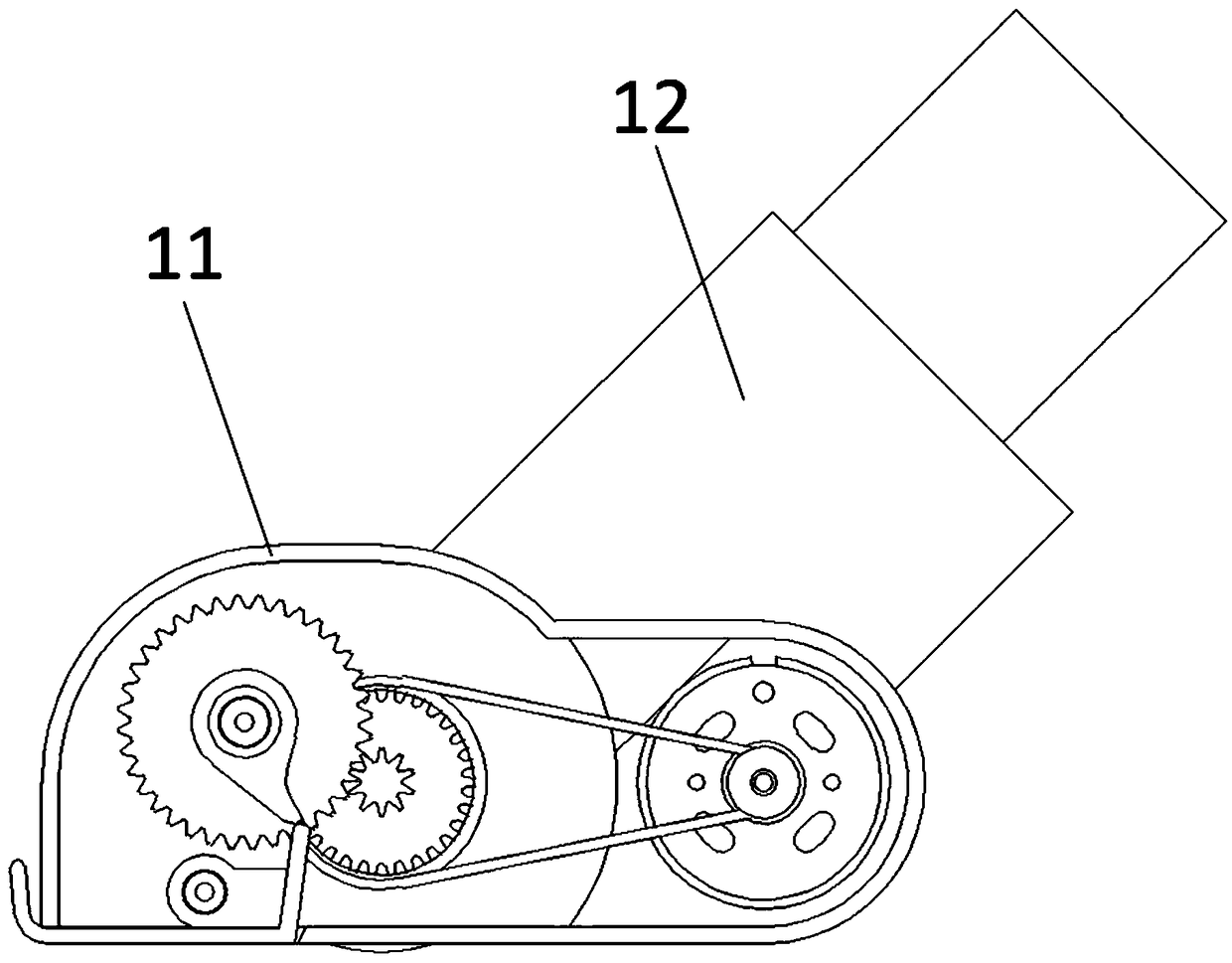

Beater for a rotary shredder

InactiveUS7568645B2Extended service lifePromote absorptionGrain treatmentsEngineeringSupport surface

A beater for a rotary shredder comprises an oblong base body with a pivot bearing adapted for pivotal connection of the beater to a rotor. A cutting head is formed with protruding cutting edges on opposite ends supported by the base body via the support surface. Complementary interlocking structures are provided by the support surface on the support surface and the cutting head. A releasable connection passes through the complementary structures connecting the base body with the cutting head. The complementary structures are provided by a recess formed in the support surface of the base body and a thereto complementary projection of the cutting head.

Owner:DOPPSTADT FAMILIENHOLDING GMBH

Incoming fabric beating de-dusting device of circular screen printer

ActiveCN109228622AImprove dust removal effectEfficient removalMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses an incoming fabric beating de-dusting device of a circular screen printer. The incoming fabric beating de-dusting device comprises a supporting frame, a de-dusting box is arranged on the supporting frame, a beating de-dusting mechanism is arranged in the de-dusting box, the front side and the rear side of the beating de-dusting mechanism are provided with fabric compressionrollers respectively, and a fabric inlet and a fabric outlet are formed in the front side and the rear side of the de-dusting box. Fabric guide rollers are arranged at the fabric inlet and the fabricoutlet respectively, an air inlet and an exhaust inlet are formed in the two ends of the de-dusting box respectively, and the exhaust inlet is connected with a dust collection mechanism. The beatingde-dusting mechanism comprises two beating de-dusting rollers which are arranged up and down, the beating de-dusting rollers comprise roller bodies, and the surfaces of the roller bodies are providedwith two brush assemblies and two beating assemblies, wherein the brush assemblies and the beating assemblies are helically distributed. The incoming fabric beating de-dusting device has the advantages of being capable of effectively improving the de-dusting effect.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

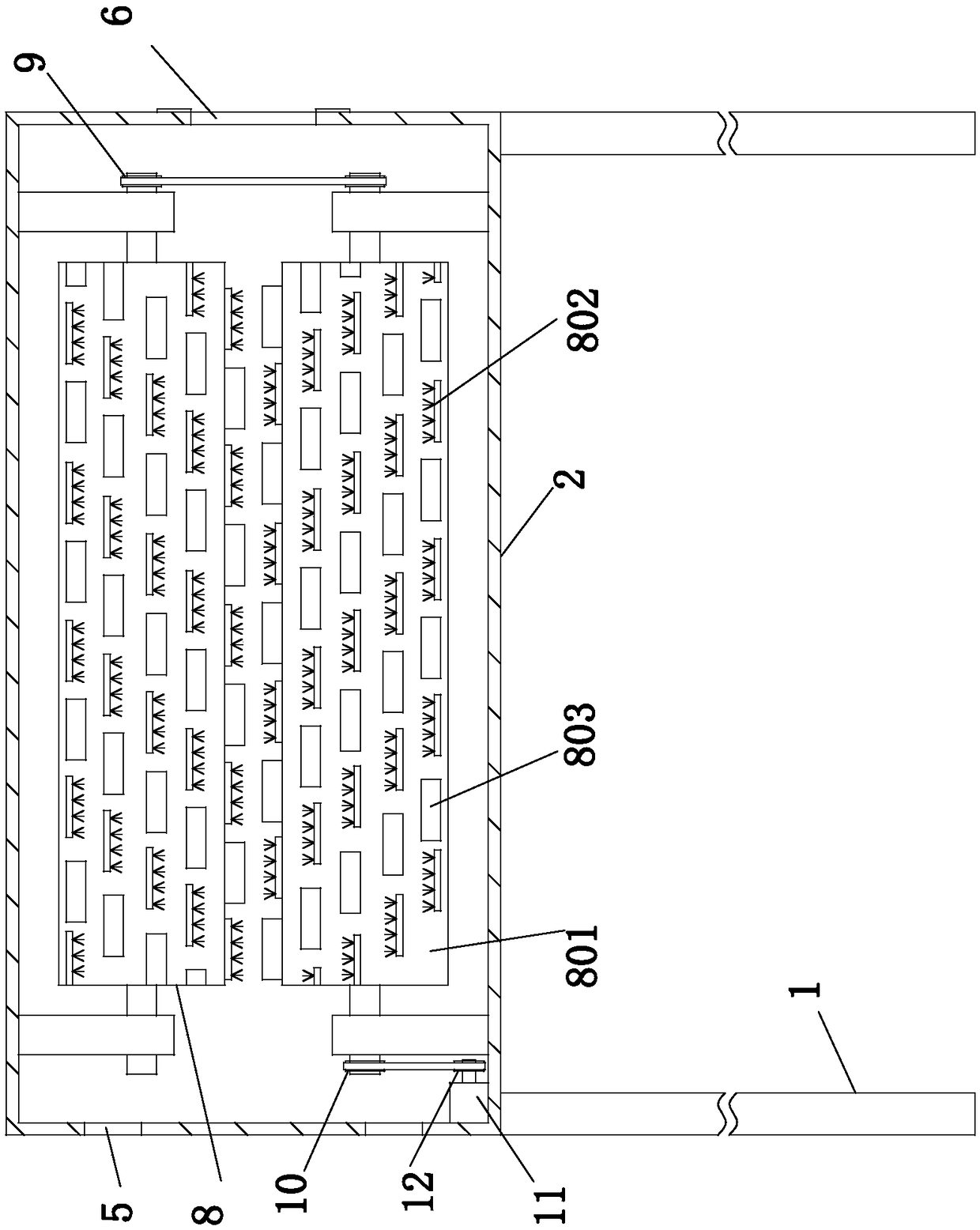

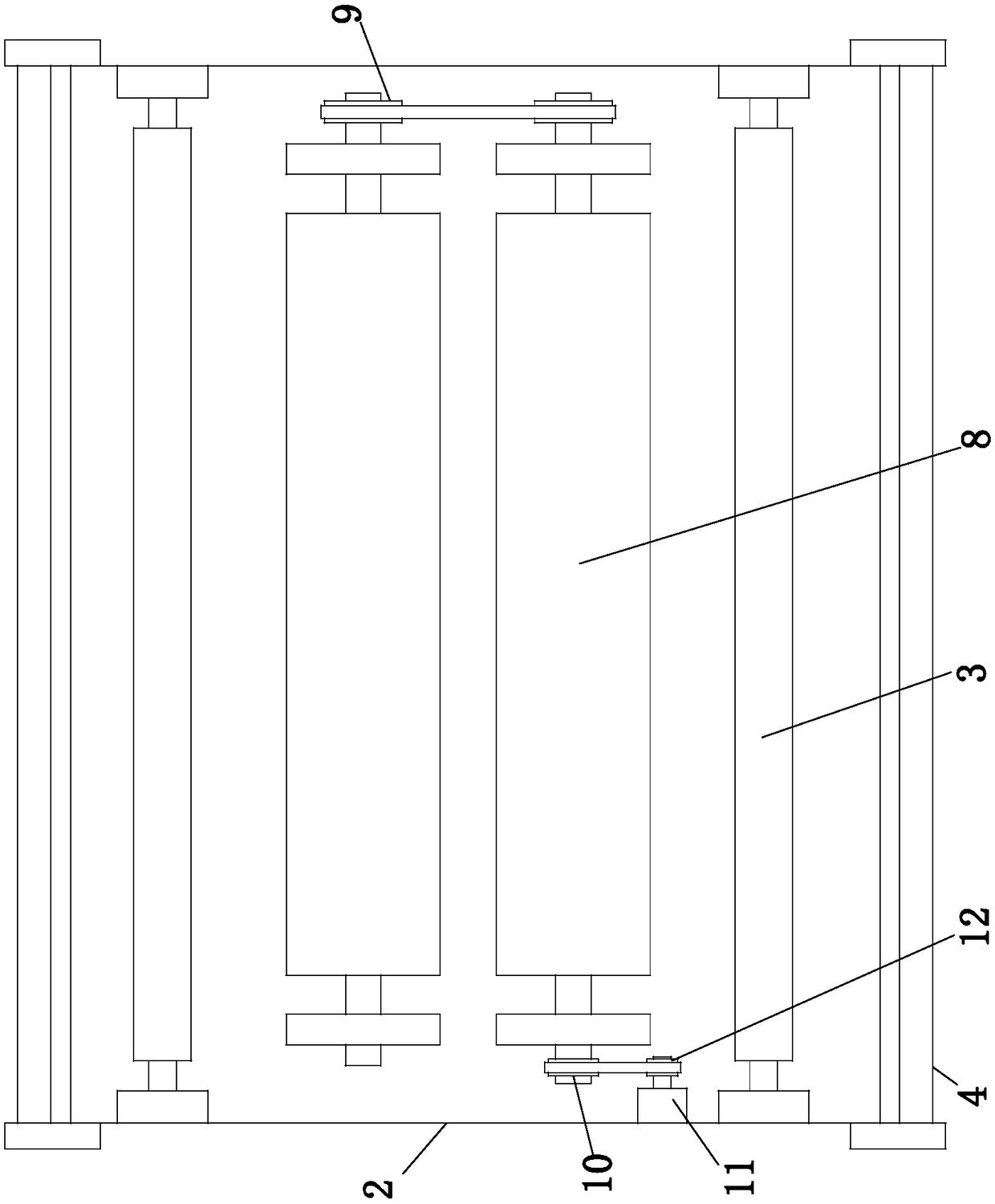

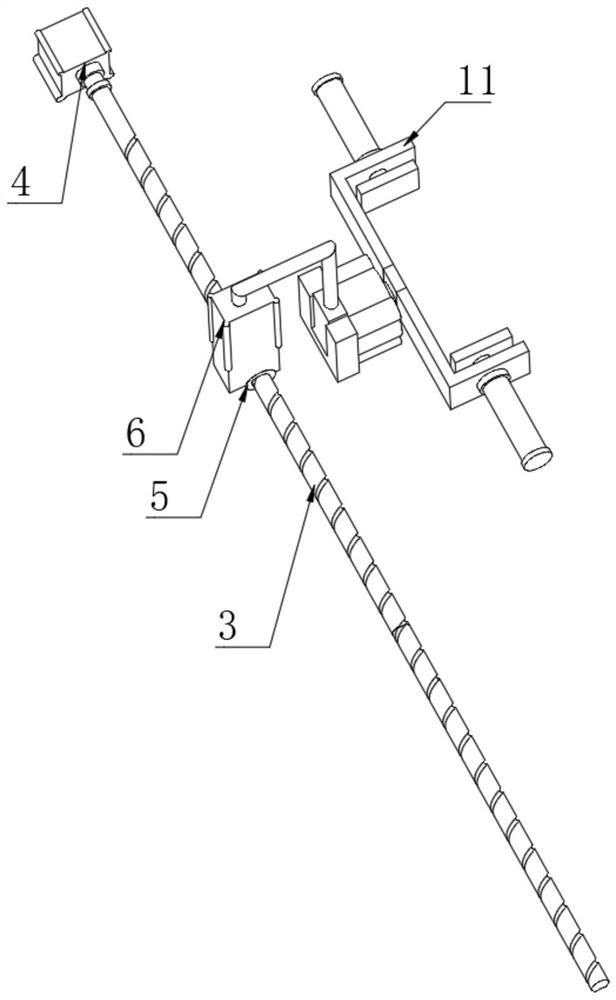

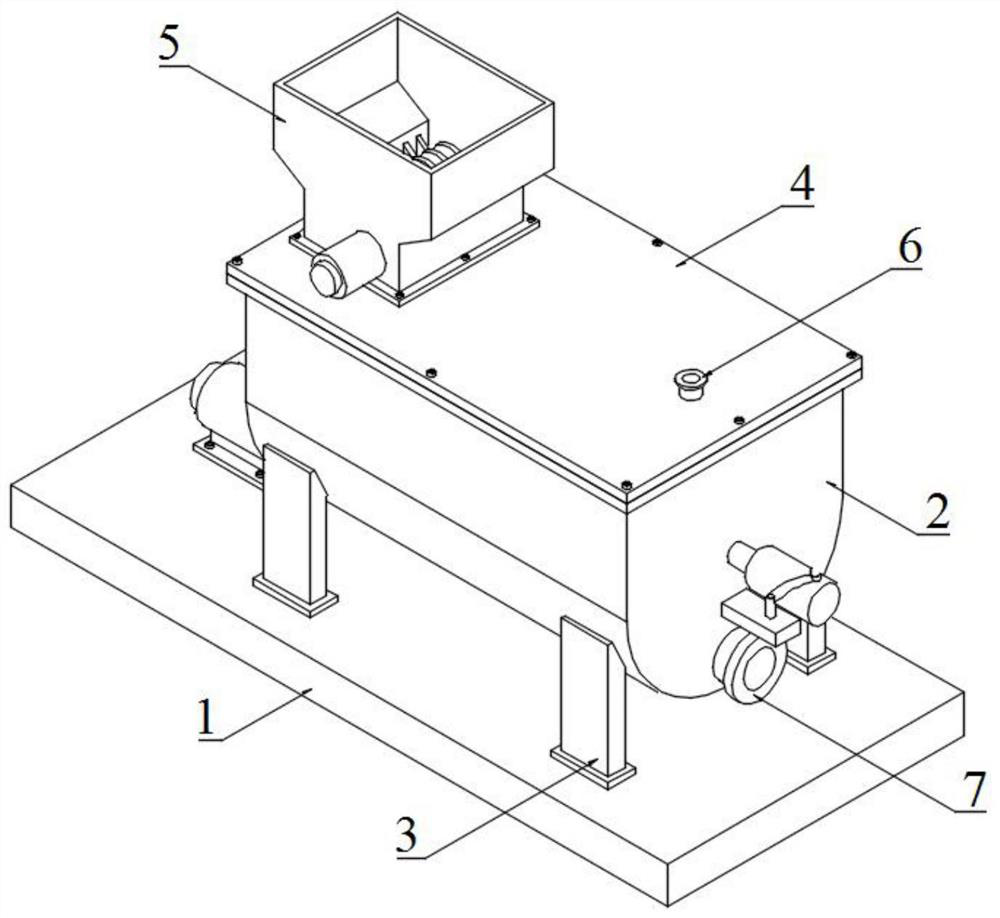

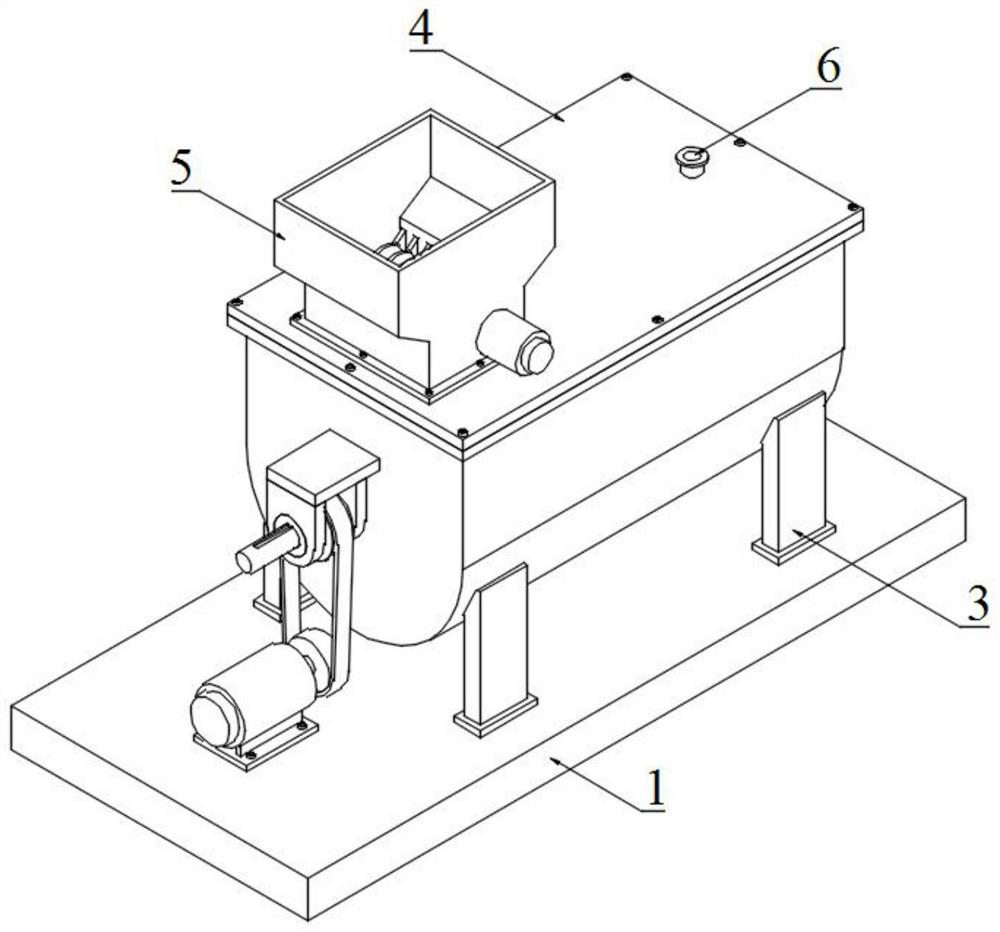

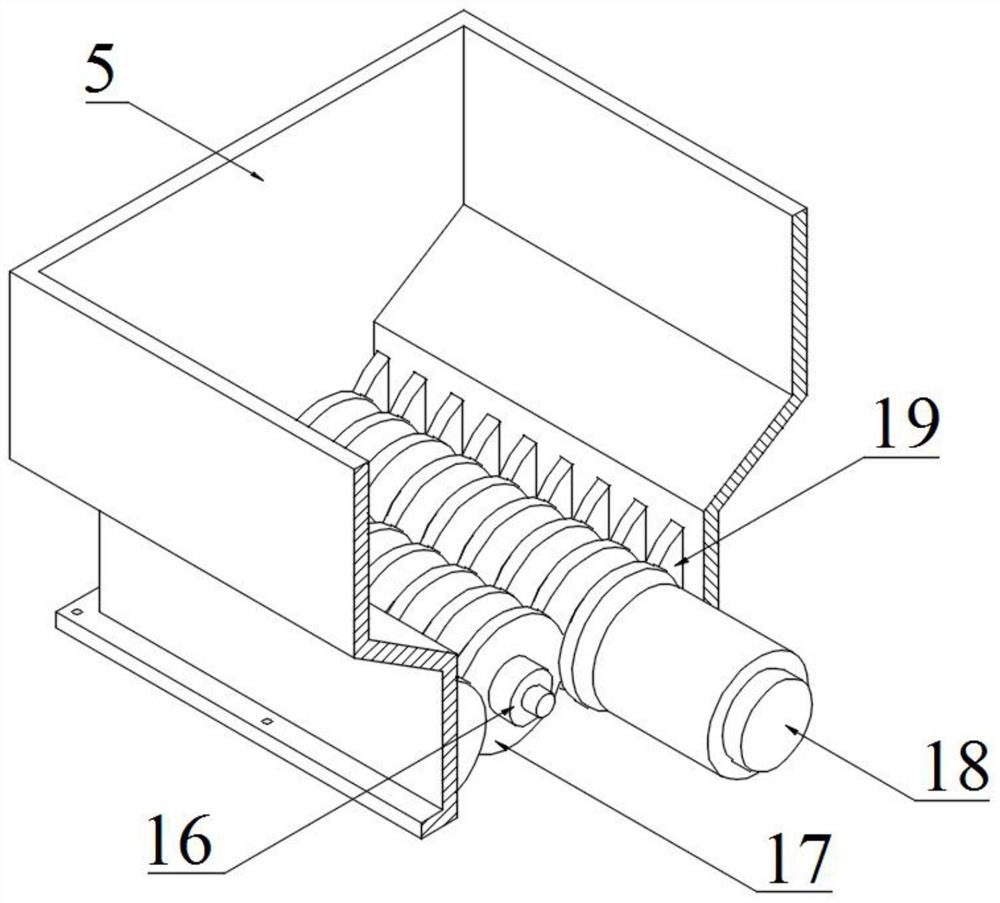

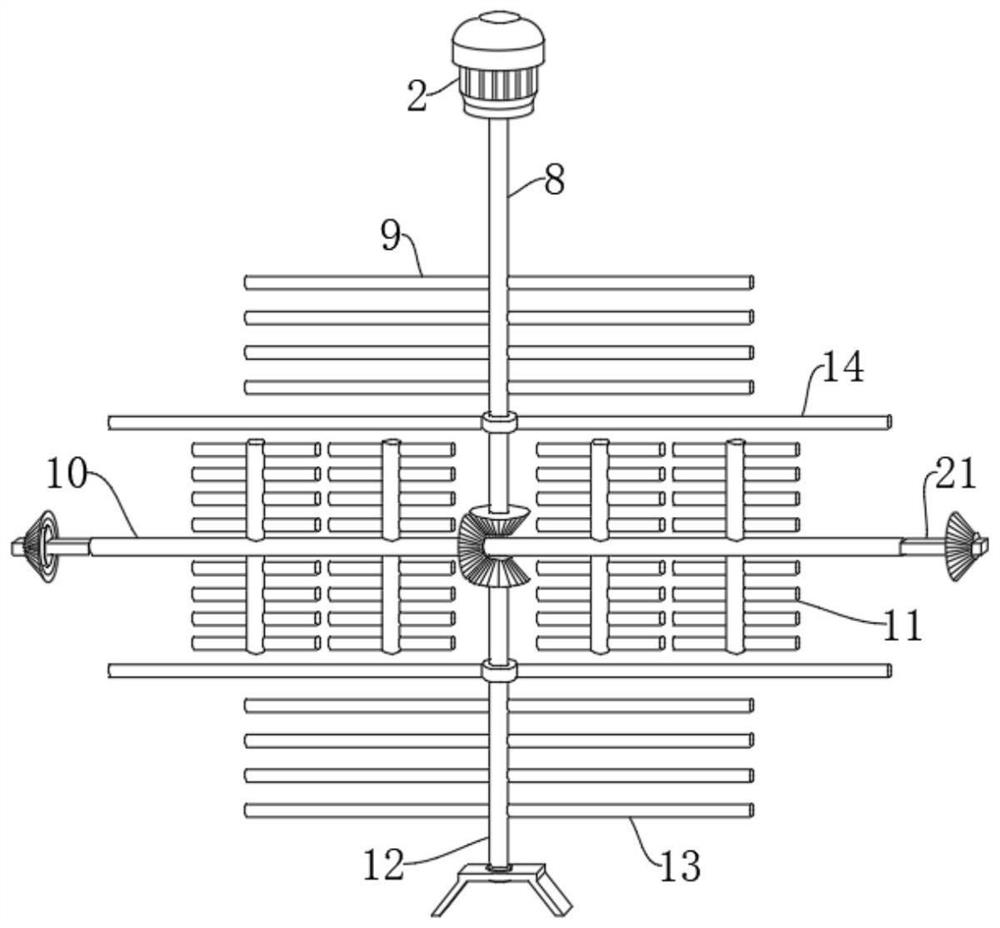

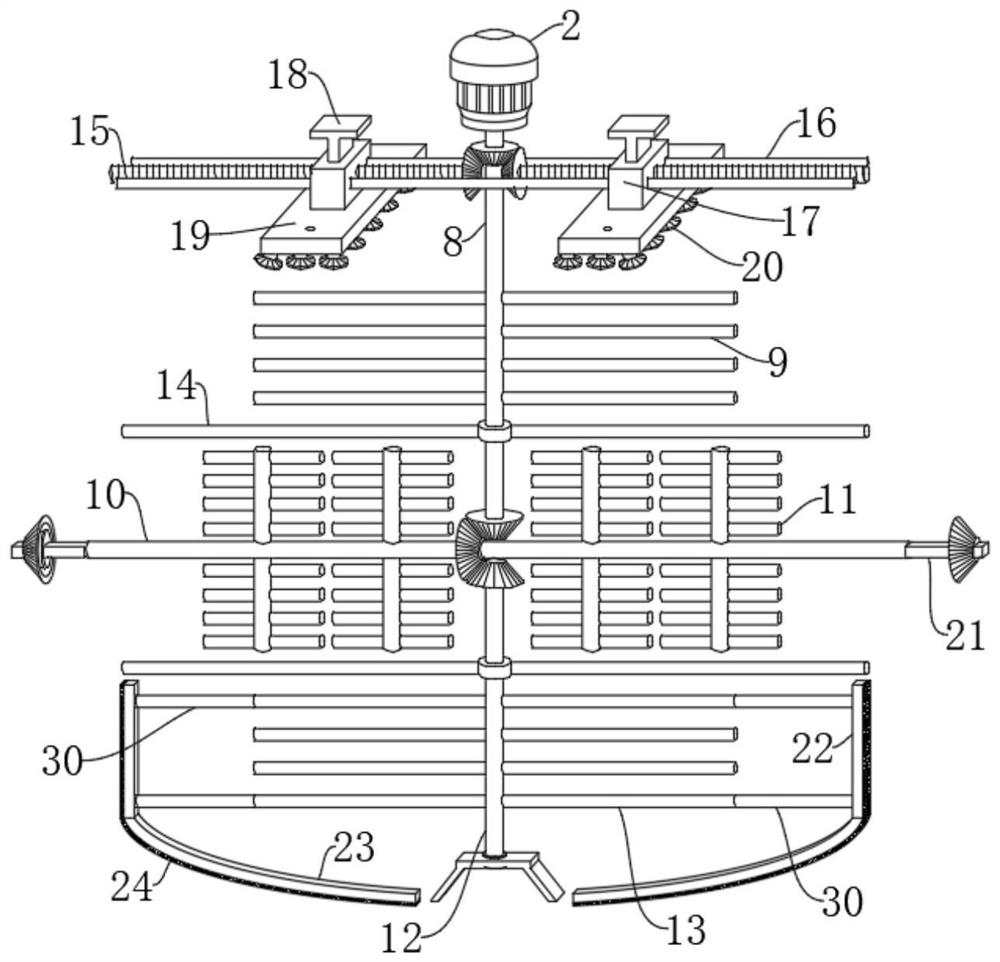

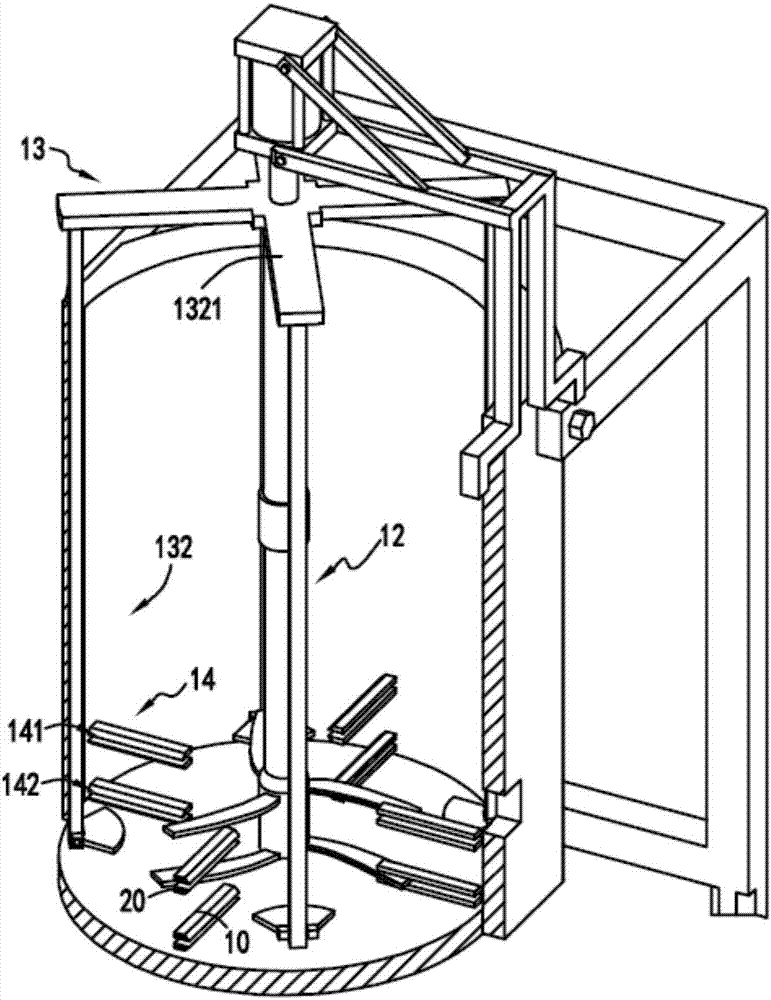

Beating device and method for filter cakes and application of filter cakes

ActiveCN107456905AImprove beating effectImprove efficiencyRotating receptacle mixersTransportation and packagingFilter matingSlurry

The invention relates to the field of chemical engineering and smelting, and discloses a continuous beating device for filter cakes. The device comprises a shell body and an inner cylinder, the inner cylinder is rotatingly connected with the shell body and is arranged in the shell body, and the inner cylinder divides an inner hollow cavity of the shell body into a first containing cavity located in the inner cylinder and a second containing cavity located between the shell body and the inner cylinder, the inner cylinder is provided with a material inlet which extends to the outside of the shell body and communicates with the first containing cavity, the side wall of the inner cylinder is provided with sieve pores which communicate with the first containing cavity and the second containing cavity, the inner wall of the inner cylinder is provided with a plurality of blades or baffles, the shell body is provided with a filter and a material outlet which communicates with the second containing cavity, and a slurry material which flows out from the material outlet is filtered and discharged by cooperation of the material outlet and the filter located near the material outlet. The invention also discloses an application of the beating device for the filter cakes in a catalyst filter cake beating step and the continuous beating device for filter cakes. According to the invention, the beating device for the filter cakes is adopted, beating is continuously performed, and therefore beating effects and efficiency of the filter cakes can be remarkably improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

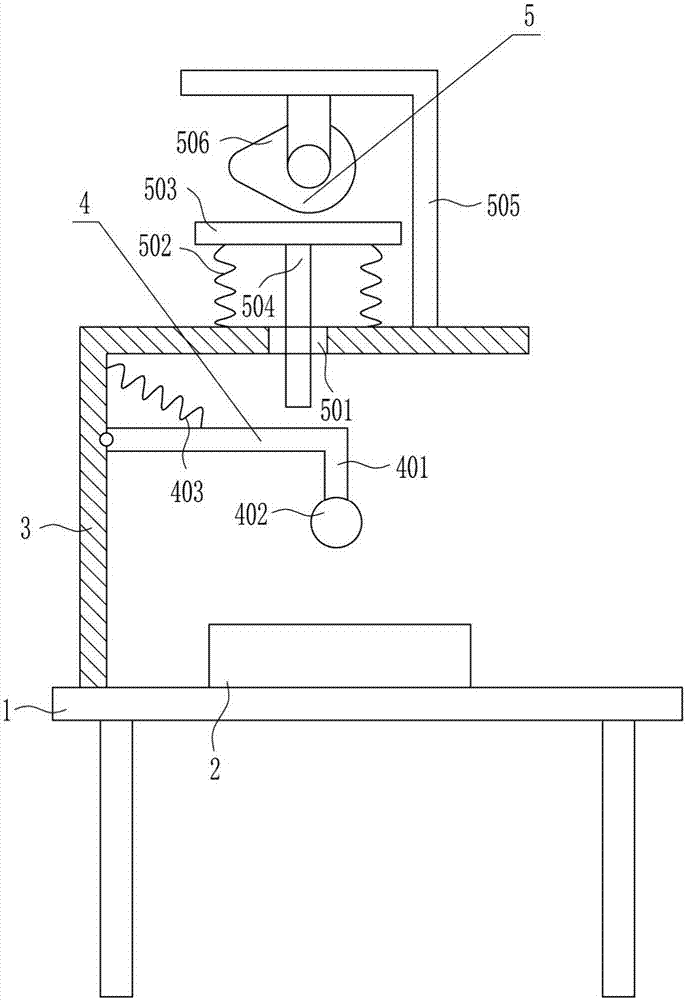

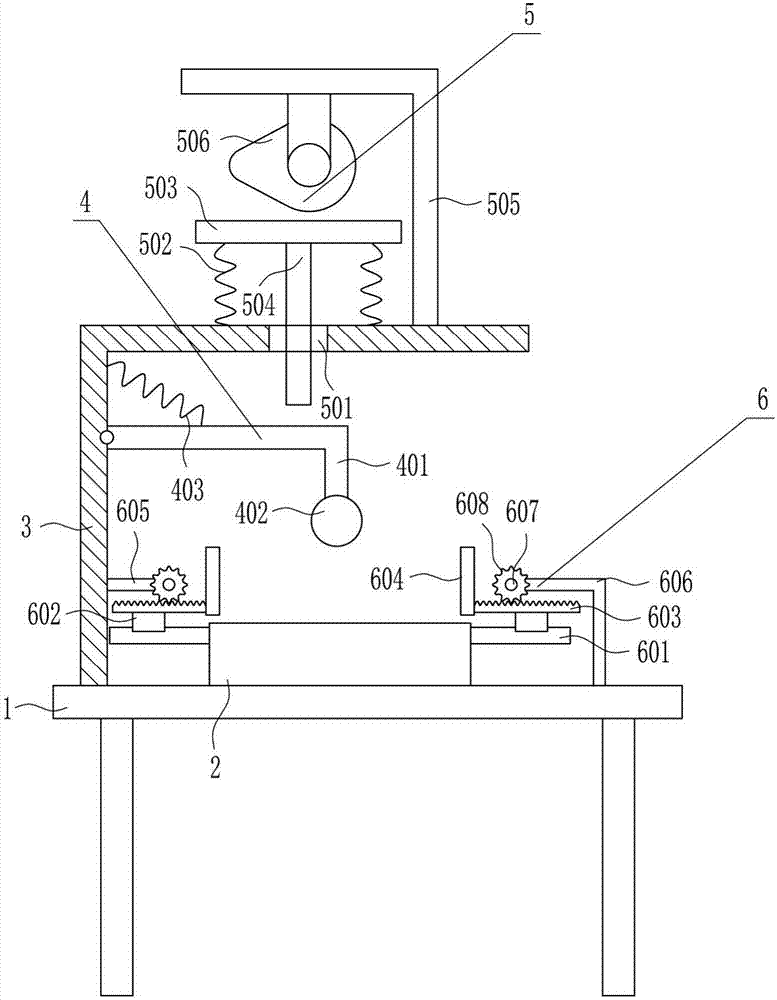

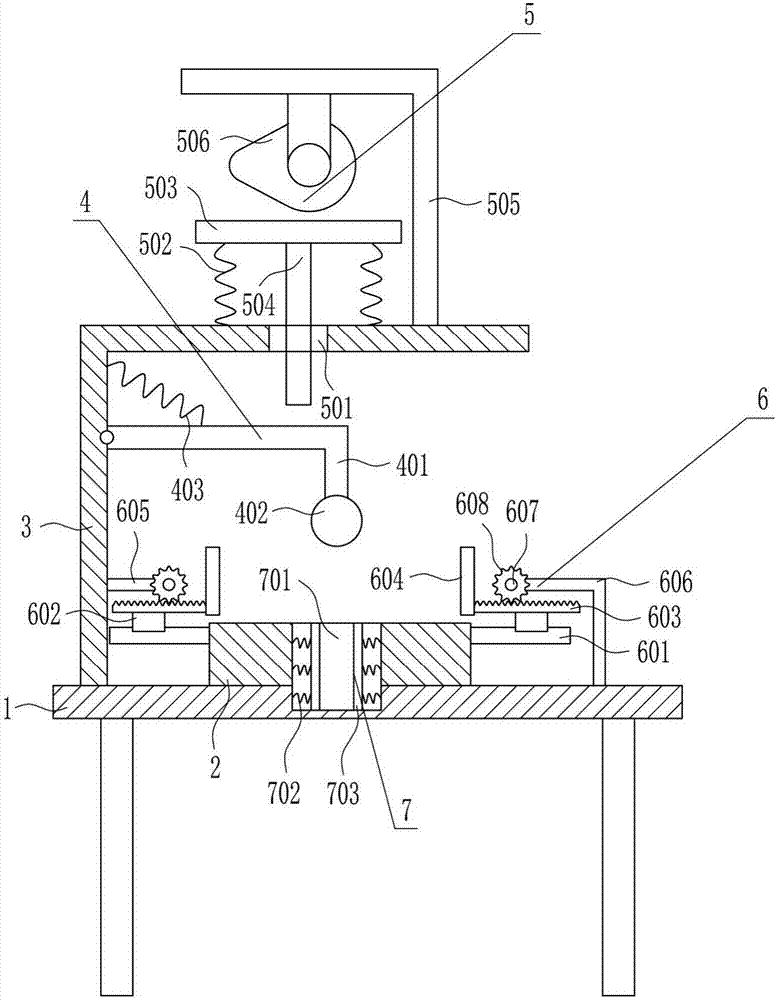

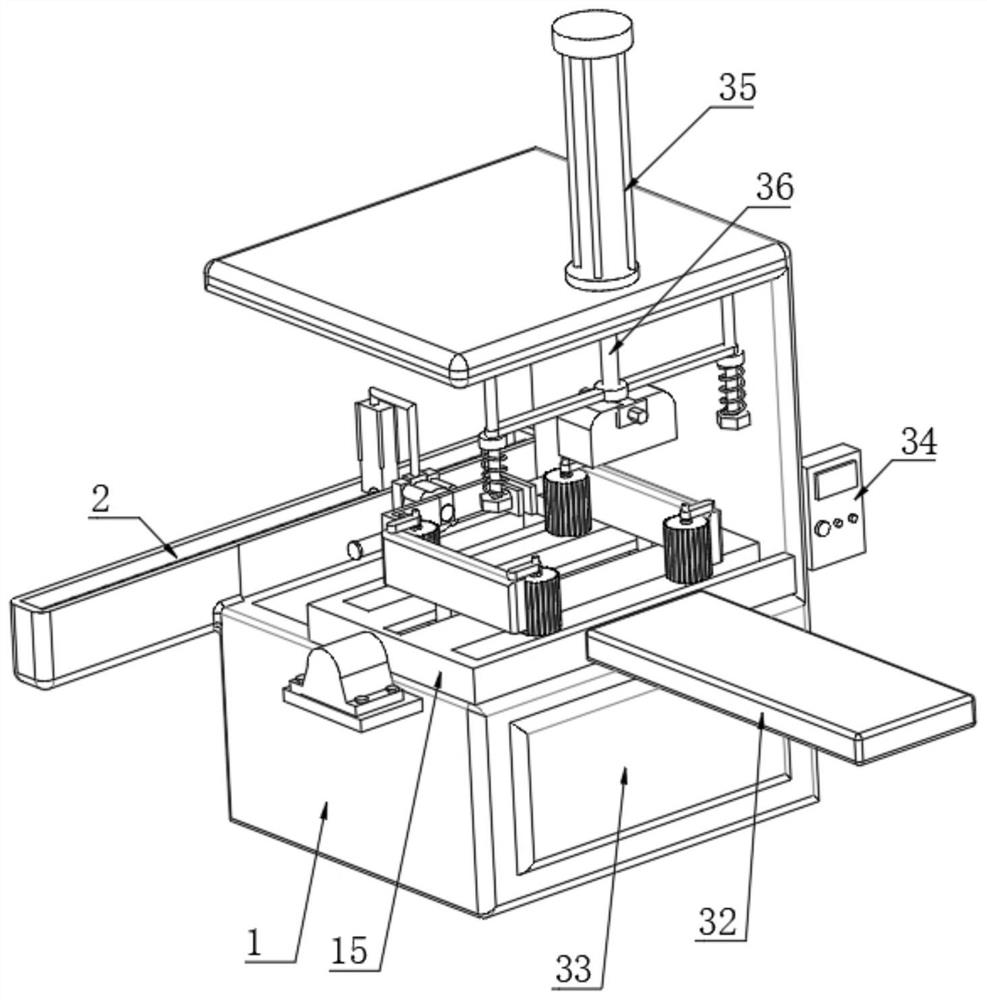

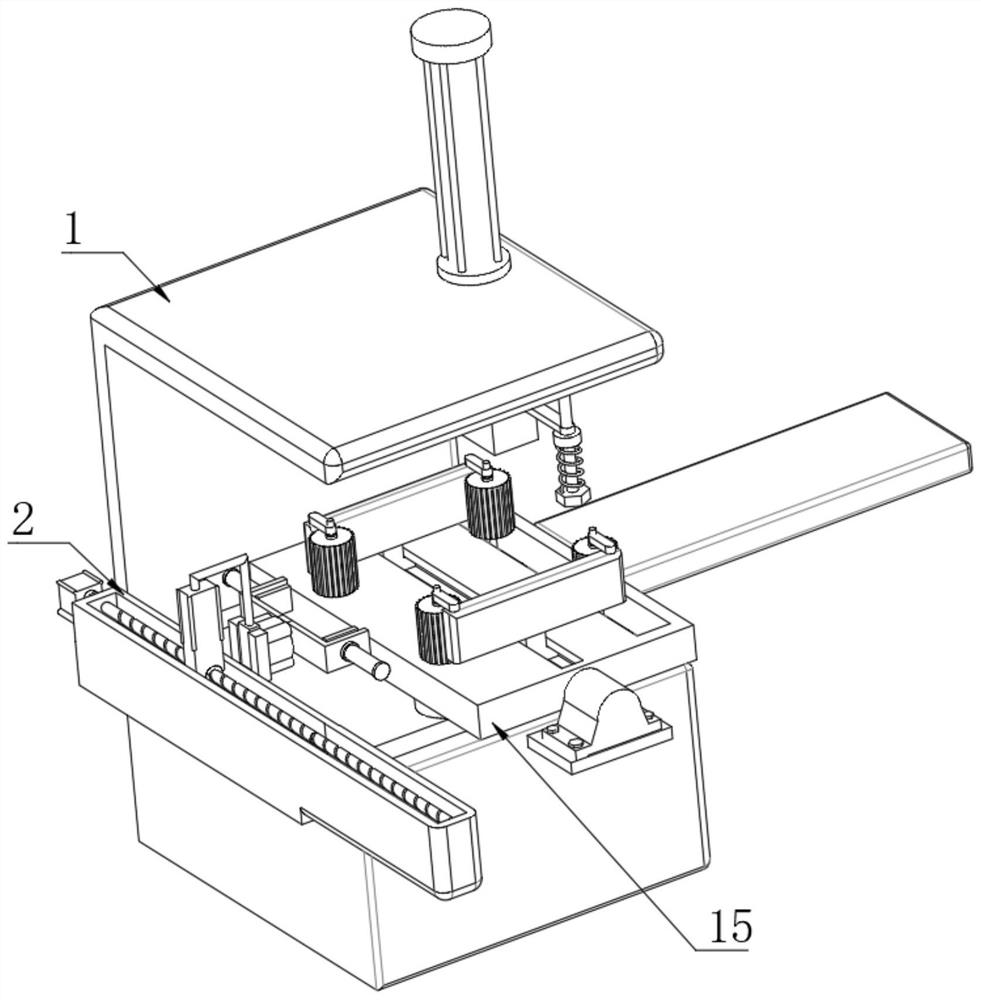

Shoe upper beating device for shoemaking

ActiveCN106963043AImprove beating efficiencyImprove beating effectPoundingEngineeringUltimate tensile strength

The invention relates to a shoemaking device, in particular to a shoe upper beating device for shoemaking. The shoe upper beating device for shoemaking achieves the technical purposes that the labor intensity of workers can be lowered, the beating efficiency can be improved, and the two hands can be protected. In order to achieve the technical purposes, the shoe upper beating device for shoemaking comprises a workbench and the like; a placement table is connected to the top of the workbench through a bolt, a first 7-shaped plate is connected to the top of the workbench on the left side of the placement table through a bolt, a beating device is arranged on the inner side face of the first 7-shaped plate, and a driving device is arranged on the top of the first 7-shaped plate. The driving device drives the beating device for rapidly beating a shoe, so that a worker does not need to beat the shoe with a smaller hammer.

Owner:浙江名将鞋业有限公司

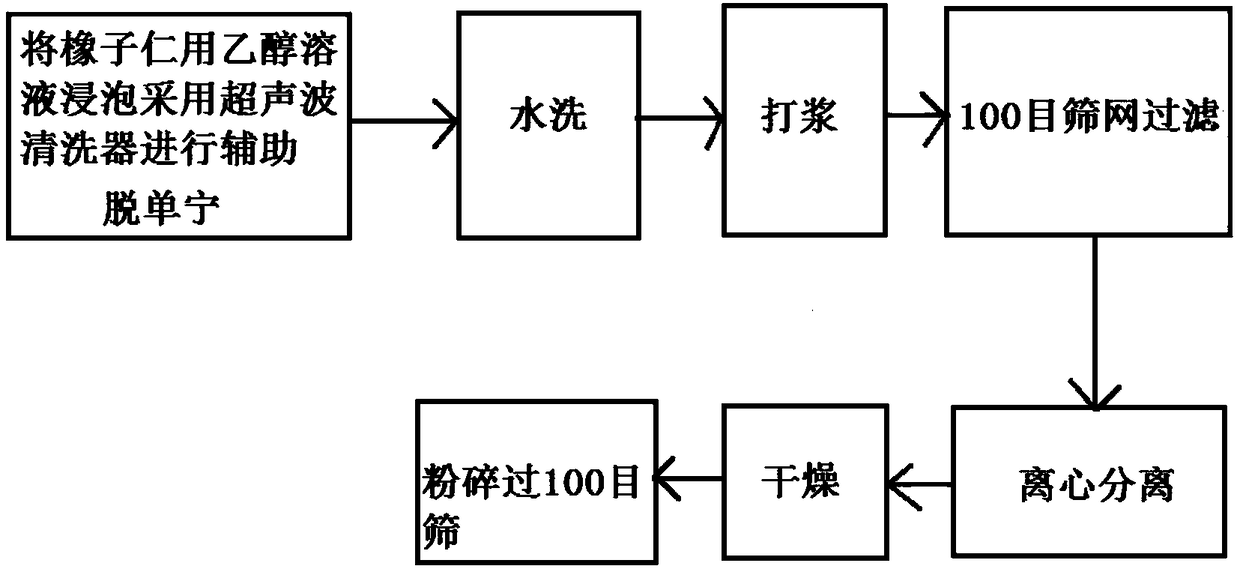

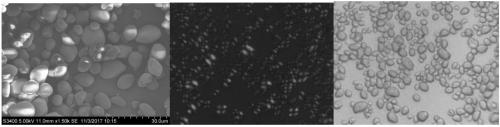

Acorn starch as well as preparation method and application thereof

InactiveCN108976304AImprove efficiencyReduce water consumptionFood ingredientsCheese manufactureFood safetyWater resources

The invention provides a preparation method of acorn starch. The preparation method comprises the following steps: a step of immersing acorn nut kernels with an ethanol solution and carrying out auxiliary tannin removal by adopting an ultrasonic washer, a water washing step, a pulping step, a 100-mesh screen mesh filtering step, a water washing step, a centrifugal separation step, a drying step, and a step of crushing and sieving with a 100-mesh sieve to obtain the acorn starch. The invention further provides the acorn starch and application of the acorn starch. The preparation method of the acorn starch, provided by the invention, has the following beneficial effects that the tannin removal efficiency is high, the water dosage is small and water resources are saved; o toxic and harmful substances are utilized in a production process, so that the requirements on food safety are met.

Owner:YANGLING VOCATIONAL & TECHN COLLEGE

Beater for a rotary shredder

A beater for a rotary shredder comprises an oblong base body with a pivot bearing adapted for pivotal connection of the beater to a rotor. A cutting head is formed with protruding cutting edges on opposite ends supported by the base body via the support surface. Complementary interlocking structures are provided by the support surface on the support surface and the cutting head. A releasable connection passes through the complementary structures connecting the base body with the cutting head. The complementary structures are provided by a recess formed in the support surface of the base body and a thereto complementary projection of the cutting head.

Owner:DOPPSTADT FAMILIENHOLDING GMBH

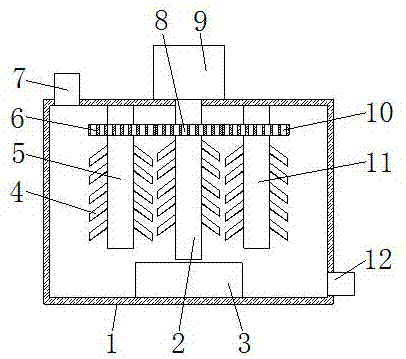

Papermaking beating machine

The invention discloses a papermaking beating machine. The papermaking beating machine comprises a beating machine body, the lower part of the outer side face of the beating machine body is provided with a discharge opening, the top of the beating machine body is provided with a feed inlet and a through hole separately, the top of the beating machine body is further provided with a motor, the output end of the motor is movably connected to a first rotation shaft, one end of the first rotation shaft penetrates through the through hole and extends to the inside of the beating machine body, the inner bottom wall of the beating machine body is fixedly connected to a cylindrical placing block, the inner top wall of the beating machine body is provided with a first clamping groove and a second clamping groove separately, the inside of the beating machine body is provided with a first gear, a second gear, a third gear, a second rotation shaft and a third rotation shaft, and the inner wall of the first gear is fixedly connected to the outer surface of the second rotation shaft. The papermaking beating machine makes beating more even and more thorough, makes the beating speed higher, and saves time and labor, the beating speed is effectively guaranteed, the beating effect is better, and the working efficiency is high.

Owner:保定达亿纸业有限公司

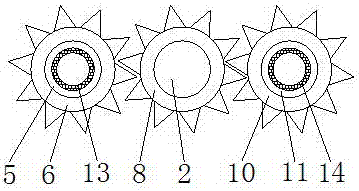

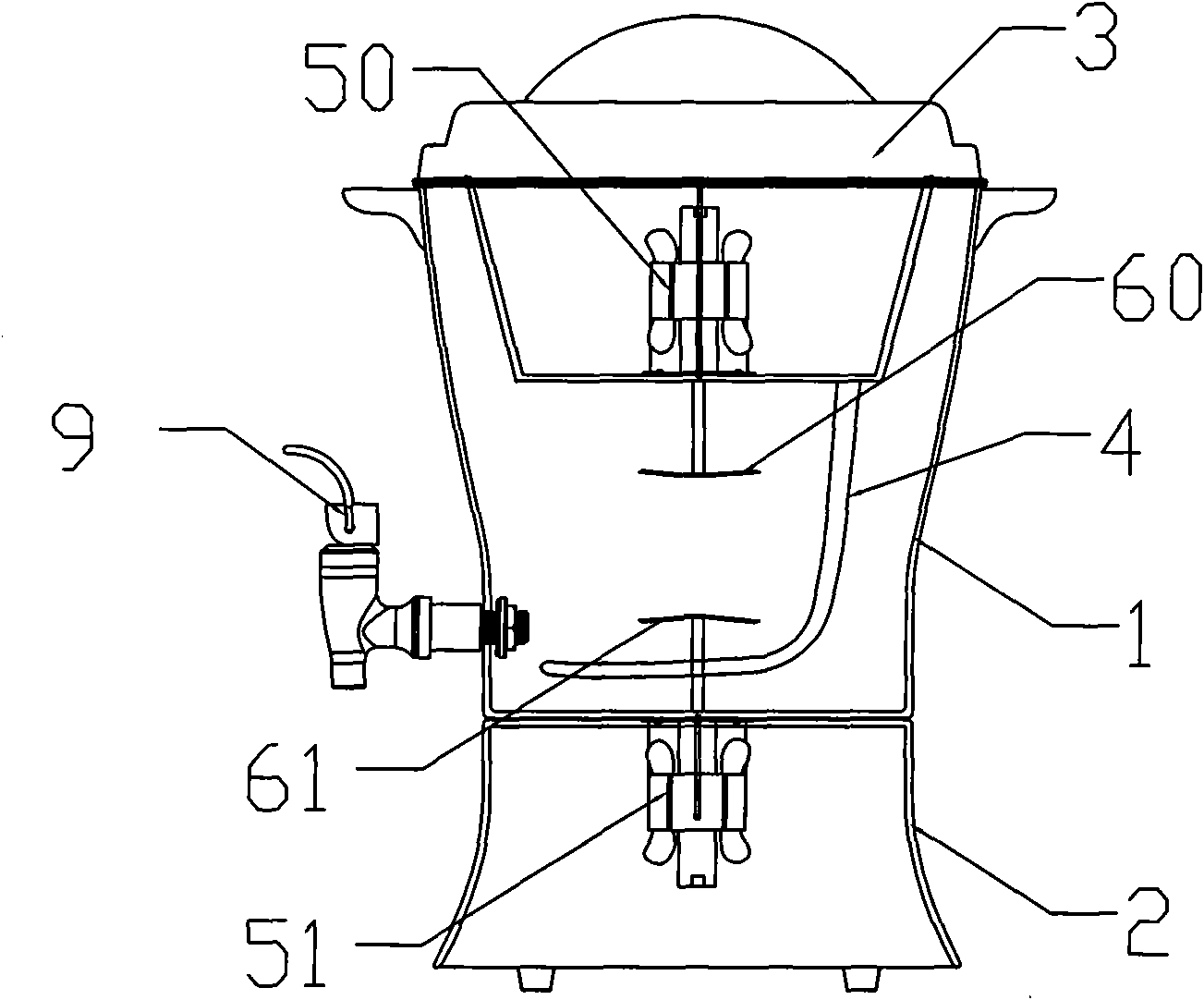

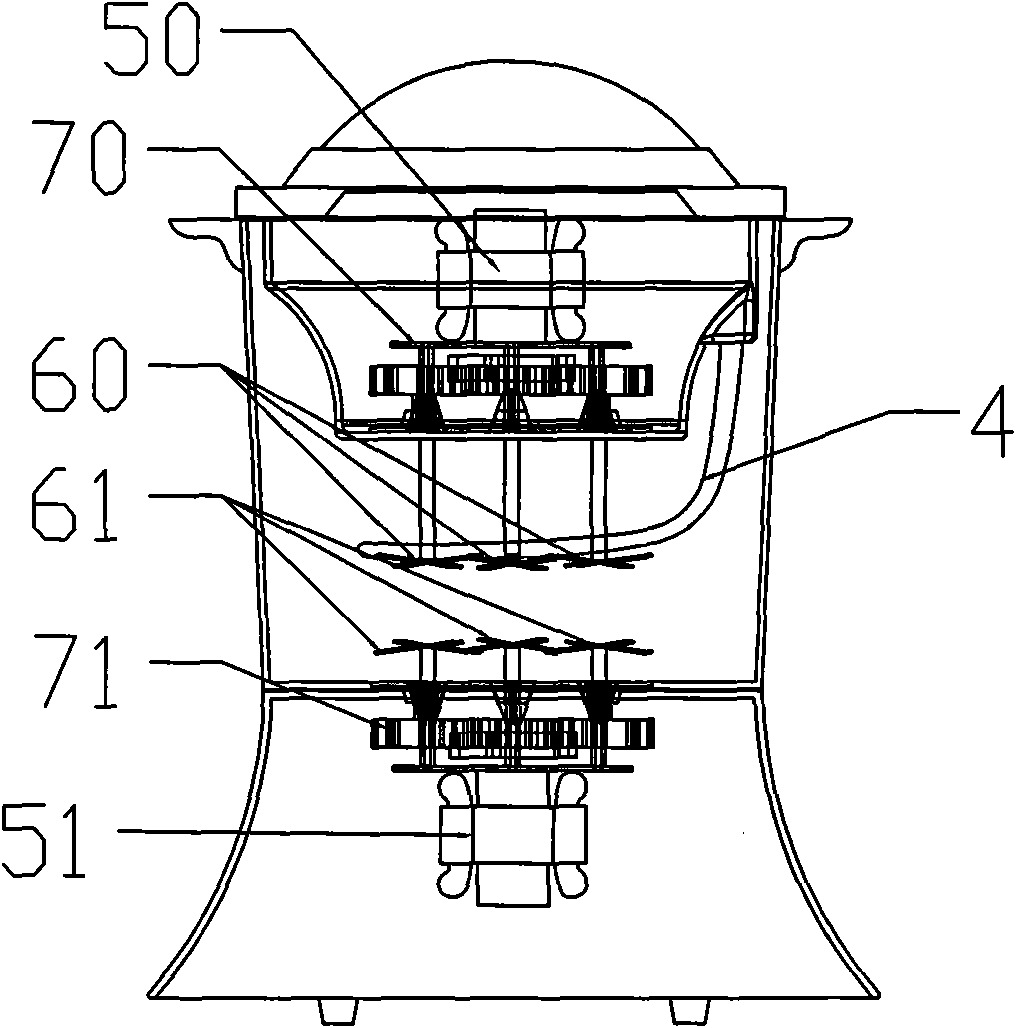

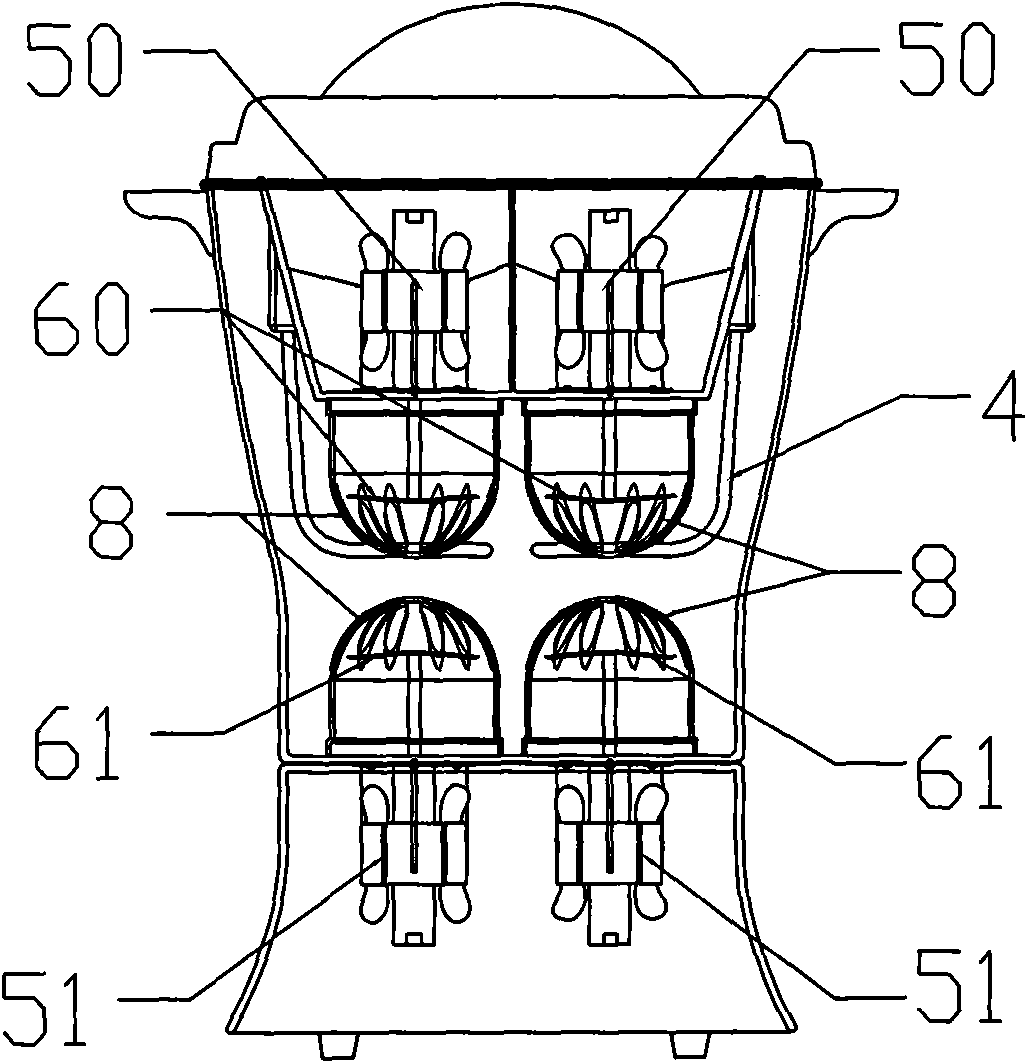

High-efficiency pulping soy milk grinder

InactiveCN101991360AIncrease the number ofIncrease chance of contactBeverage vesselsMotor driveEngineering

The invention relates to a high-efficiency pulping soy milk grinder, which comprises a stirring cup, a base, a machine head and a heating device. An upper motor is arranged on the machine head; upper crushing knifes are arranged at the lower end of an output shaft of the upper motor; a lower motor is arranged on the base; and lower crushing knifes are arranged at the upper end of an output shaft of the lower motor. More than two upper crushing knifes are arranged; the upper motor drives the upper crushing knifes to work through an upper transmission mechanism; the more than two upper crushing knifes are respectively driven by the independent upper motor which is arranged on the machine head. More than two lower crushing knifes are arranged; the lower motor drives the lower crushing knifes to work through a lower transmission mechanism; the more than two lower crushing knifes are respectively driven by the independent lower motor which is arranged on the base. By adopting the structure, the soy milk grinder has high pulping efficiency and good effect of crushing beans.

Owner:刘伟文

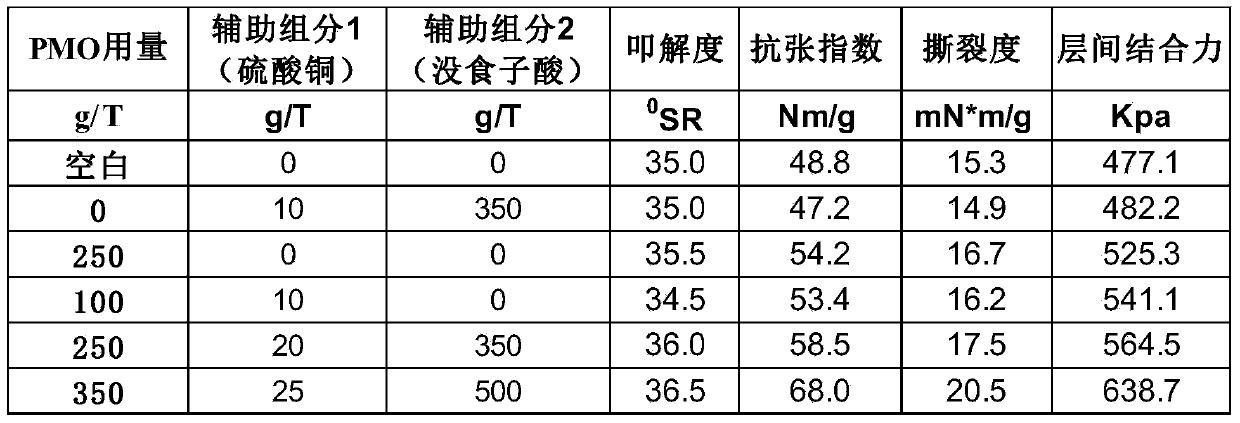

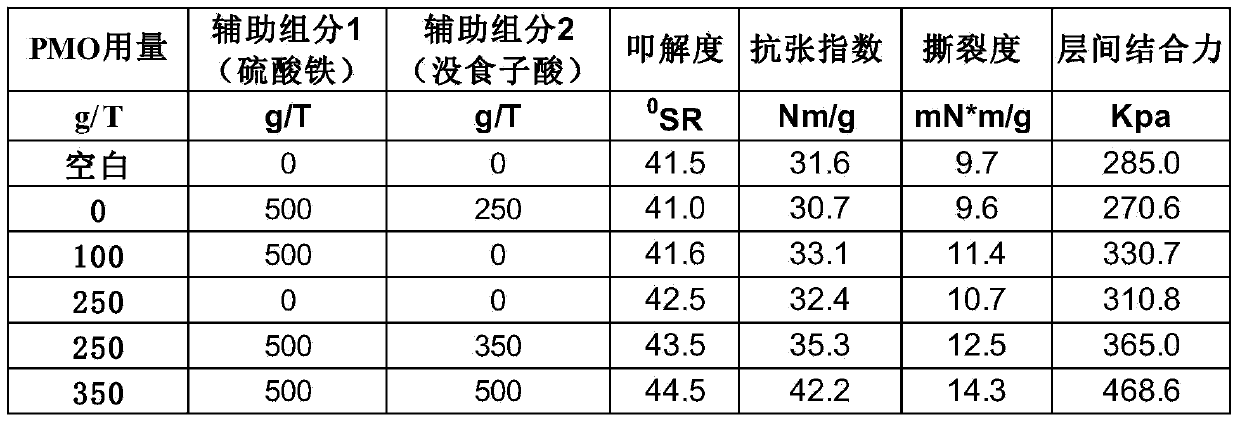

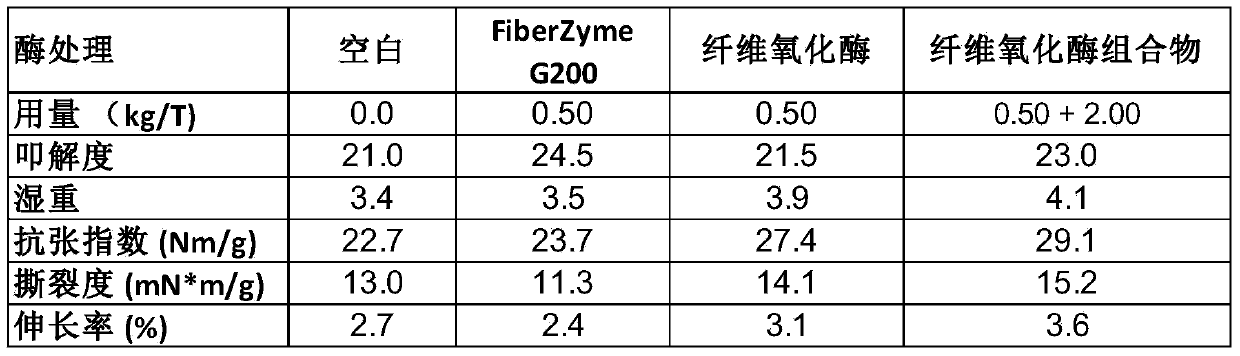

Fiber oxidase composition for changing and improving properties of fibers, paper making method and application

ActiveCN104178474AChange and improve surface propertiesHigh reactivityMicroorganism/enzyme additionLuminescent/fluorescent substance additionFiberScavenger

The invention discloses a fiber oxidase composition for changing and improving the properties of fibers, a paper making method and application. The composition contains the following ingredients: a bio-enzyme ingredient and an auxiliary ingredient, wherein the bio-enzyme ingredient has an oxidation function on the fibers and is fiber oxidase which is used for changing the surface properties of the fibers through redox reaction; the auxiliary ingredient has the function of improving the catalytic activity of the fiber oxidase and is a fiber oxidase reaction product scavenger; the weight ratio of the bio-enzyme ingredient to the auxiliary ingredient is 1: (0.1-50). When the composition is used for treating paper pulp, not only is the strength property of paper remarkably enhanced, but also the draining property of the paper pulp is improved.

Owner:RISINGSTAR BIOTECH GUANGZHOU

Soup-filling meatball wrapper and preparation method thereof

The invention discloses a soup-filling meatball wrapper and a preparation method thereof. The soup-filling meatball wrapper comprises the following raw materials: beef, hind-leg pork, chicken breast, cassava modified starch, soybean isolate protein, fat pork, mixture of ice and water, salt, phosphate and other seasonings. The preparation method comprises the following steps: cleaning up the beef, the hind-leg pork and the chicken breast and then mincing the beef. The hind-leg pork and the chicken breast into mince particles, and storing the mince particles at an environment of -5-0 DEG C; pulping the mince particles and orderly adding the other raw materials during the pulping process to form a paste; performing standing process, shaping process, secondary boiling process and freezing process on the paste, so as to make the soup-filling meatball wrapper. The soup-filling meatball wrapper prepared by the invention is characterized by smooth surface, refreshing and smooth flavor and chewy taste.

Owner:HAIXIN FOODS

Fiber oxidase composition for changing and improving fiber property, and papermaking method and application

ActiveCN104342424AChange and improve surface propertiesHigh reactivityMicroorganism/enzyme additionLuminescent/fluorescent substance additionFiberWAS PROTEIN

The invention discloses a fiber oxidase composition for changing and improving fiber property, and a papermaking method and an application. The composition mainly comprises the following components: a bio-enzyme component with an oxidation function on fibers, and an auxiliary component for increasing catalytic activity on the fiber oxidase, wherein the bio-enzyme component is fiber oxidase for changing the surface property of the fiber by redox reaction; the auxiliary component is protein with catalytic action on the fiber oxidase; and the weight ratio of the bio-enzyme component to the auxiliary component is 1 to (0.4-50). When the composition is used for processing paper pulp, the strength of the prepared paper is significantly enhanced, and the drainage performance of the paper pulp is greatly improved.

Owner:RISINGSTAR BIOTECH GUANGZHOU

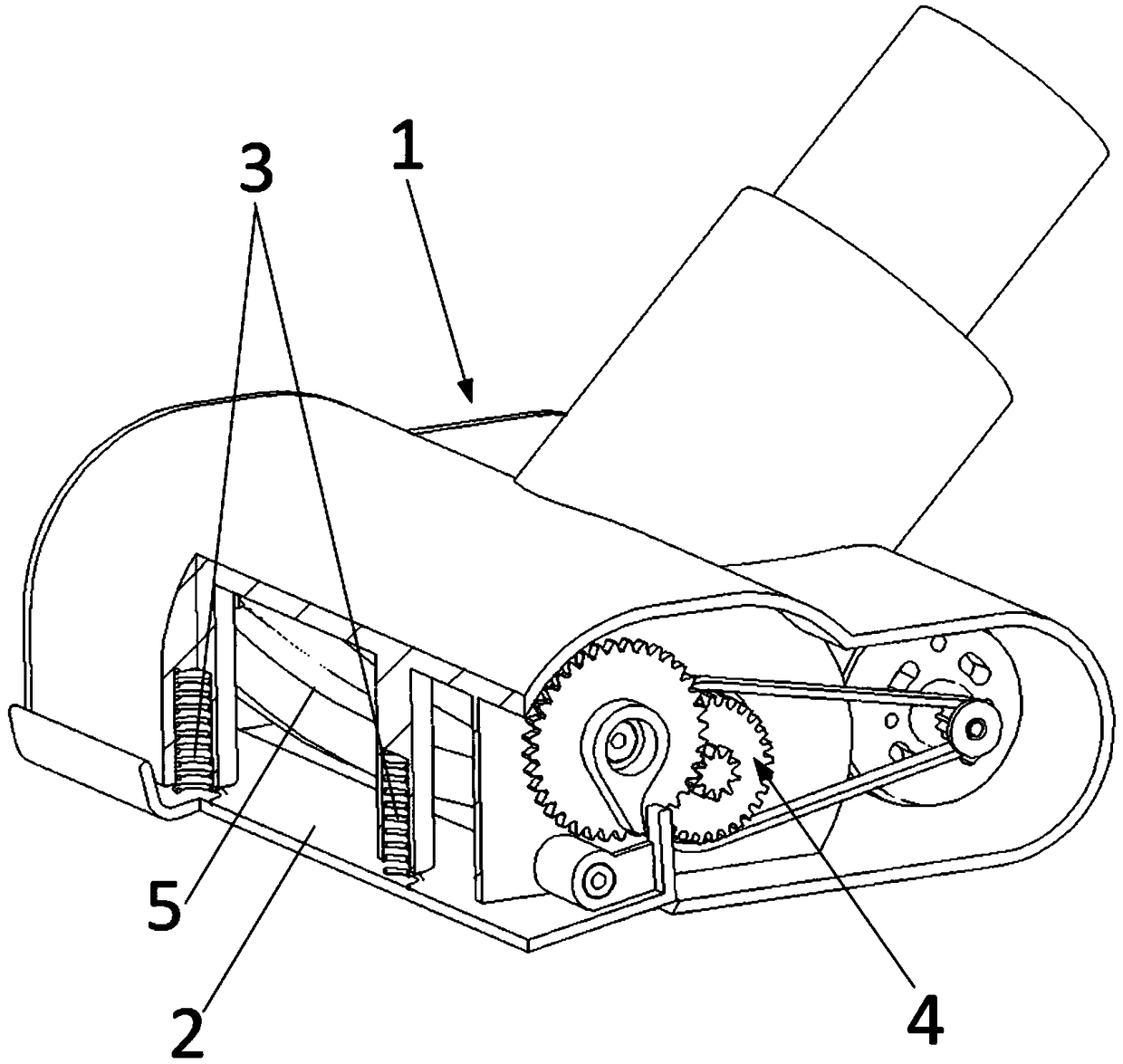

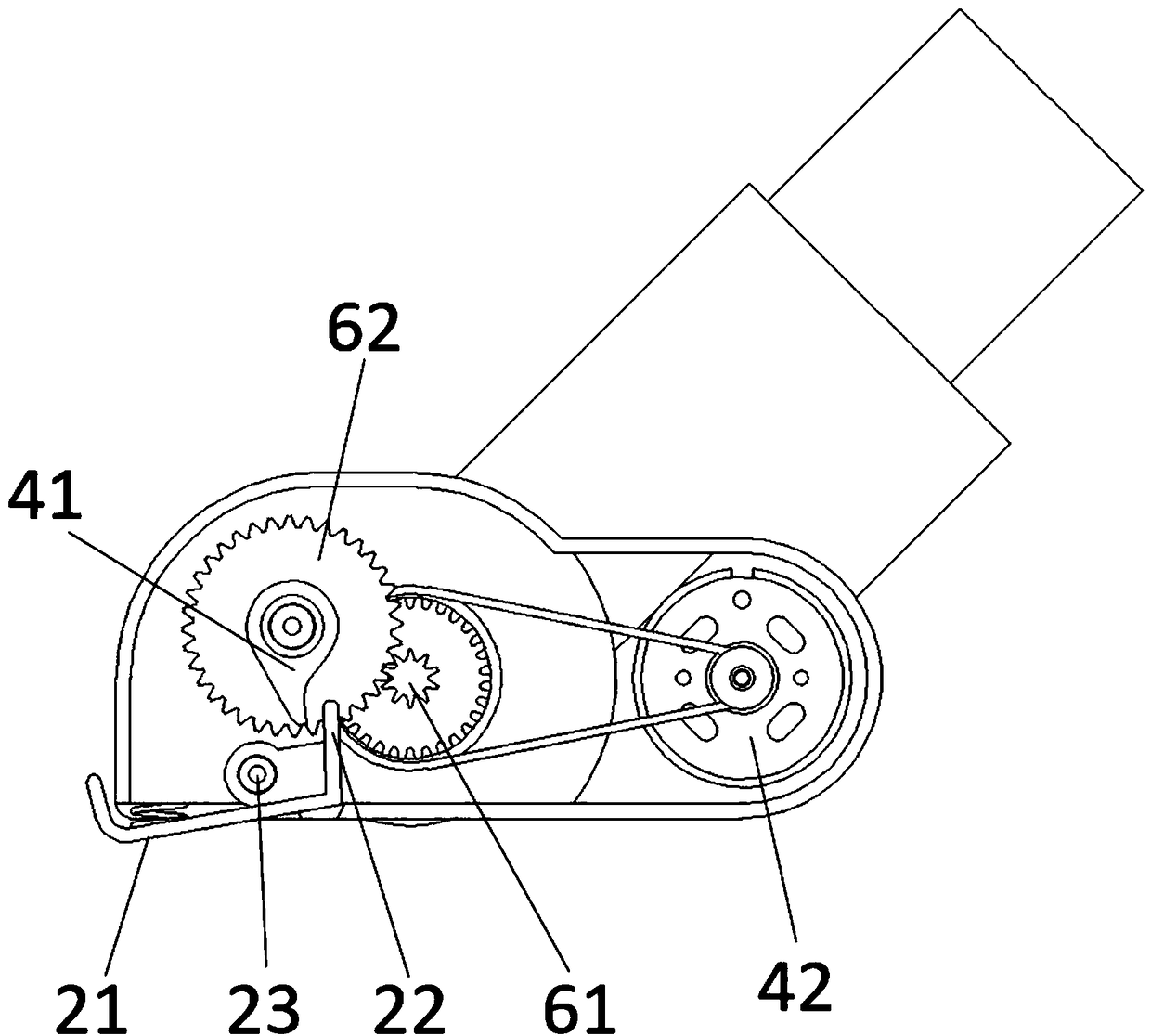

Brush head and vacuum cleaner

PendingCN109349962AImprove the beating effectSimple and reasonable structure settingSuction nozzlesPotential energyEngineering

The invention relates to the field of vacuum cleaners, in particular to a brush head and a vacuum cleaner. The brush head includes: a brush head body, the inner part of which is provided with a suction channel which is communicated with a negative pressure source; a flapping plate, which is arranged on the brush head body and has a flapping part for intermittently making contact with a cleaned object; an elastic reset part, which is arranged between the flapping plate and the brush head body and provides elastic force to drive the intermittent contacting between the flapping part and the cleaned object; and a driving mechanism, which is arranged in the brush head body and is used to provide the driving force that drives the elastic reset part to produce the elastic force. The brush head uses the elastic potential energy of the elastic reset part to drive the flapping plate to work, so that the flapping of the flapping plate is more powerful and the flapping effect is better.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Paper making beater

InactiveCN106638097ALarge reserved spaceImprove beating effectPulp beating methodsProduction ratePulp and paper industry

The invention belongs to a paper making machinery and discloses a paper making beater. The upper portion of a machine body and the lower portion of the machine body are each provided with a beating assembly. Each beating assembly comprises a motor, a cutter shaft, cutter rests and cutter blades. An output shaft of each motor is connected with the corresponding cutter shaft, the cutter rests are uniformly distributed on the periphery of the outer wall of the corresponding cutter shaft and the cutter blades are arranged on the cutter rests. The output shaft of the motor on the upper portion of the machine body and the output shaft of the motor on the lower portion of the machine body are oppositely arranged. Two sets of cutter blade components in the machine body are axially opposite, during beating, the rotational direction of the upper cutter rests is opposite to that of the lower cutter rests, pulp and water are formed into two steams of pulp flows, crushing and beating are sufficiently conducted on materials, the beating effect is good, the pulp production rate is high and uniform beating is achieved. Because the reserved space between the beating assemblies and the machine body is large, the beating bulk is great, and the beating efficiency is improved.

Owner:ZHONGSHAN WEIKE PACKAGE PROD CO LTD

Forging device for casting forming and using method thereof

InactiveCN113894235AEasy to change sidesEasy to operatePower hammersHammer drivesMotor driveElectric machine

The invention discloses a forging device for casting forming and a using method thereof, and particularly relates to the technical field of casting machining. The forging device comprises a device box, an adjusting concave frame is mounted on one side of the device box, and an overturning and removing mechanism is arranged in the adjusting concave frame; and the overturning and removing mechanism comprises a two-way linkage lead screw arranged in the adjusting concave frame, and a first servo motor for driving is installed at one end of the two-way linkage lead screw. According to the forging device, the overturning and removing mechanism is adopted, an adjusting motor drives a rotating rod to clockwise rotate by 90 degrees every time face changing is conducted, the rotating rod can continue to rotate by 90 degrees in the same direction every time, forging operation is conducted on different faces of a forge piece, the forged faces are more uniform, and the forge piece can move to the highest point after forging is completed; and under the action of the two-way linkage lead screw, the forged piece can automatically move to a designated position, so that manual taking-out is avoided, operation is more convenient, the accidental safety problem is avoided, more time and labor are saved, and the safety is higher.

Owner:江苏和昌重工科技有限公司

Moisture-proof and corrosion-proof corrugated paper production process and device

InactiveCN112813728AHigh strengthImprove water resistanceWater-repelling agents additionNon-macromolecular organic additionCardboardFiber

The invention discloses a moisture-proof and corrosion-proof corrugated paper production process and device, the moisture-proof and corrosion-proof corrugated paper is formed by bonding at least one layer of core paper and cardboard paper, the core paper is made of corrugated base paper through machining, the corrugated base paper is divided into a surface layer and a bottom layer, the surface layer is made of long fiber pulp, short fiber pulp and broken pulp of waste paper pulp, the bottom layer is made of short fiber pulp and waste paper pulp of waste paper pulp, and the preparation method of the corrugated base paper comprises the following steps: S1, pulping waste paper; s2, performing internal sizing treatment on the raw material slurry; s3, performing net feeding, squeezing and drying treatment on the raw material paper pulp, and then obtaining a base paper blank; and S4, sizing the surface of the base paper blank, and drying to obtain the corrugated base paper. According to the moisture-proof and corrosion-proof corrugated paper, the corrugated base paper of the moisture-proof and corrosion-proof corrugated paper is prepared from the waste paper pulp through a dual sizing process, and then the core paper machined from the corrugated base paper is bonded with the cardboard paper so that the prepared moisture-proof and corrosion-proof corrugated paper is high in machine strength and has good water resistance and corrosion resistance.

Owner:ANHUI UNIV OF SCI & TECH

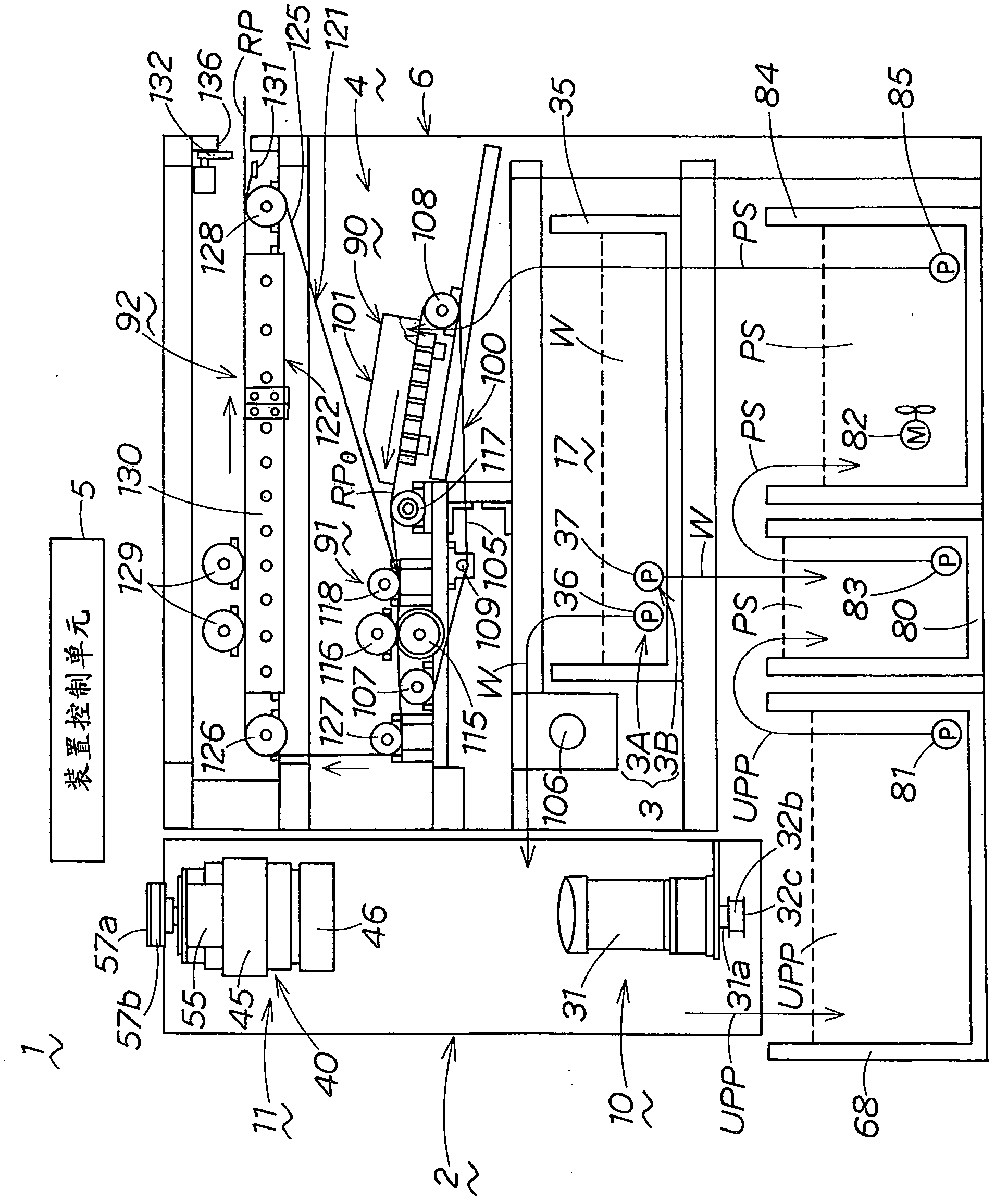

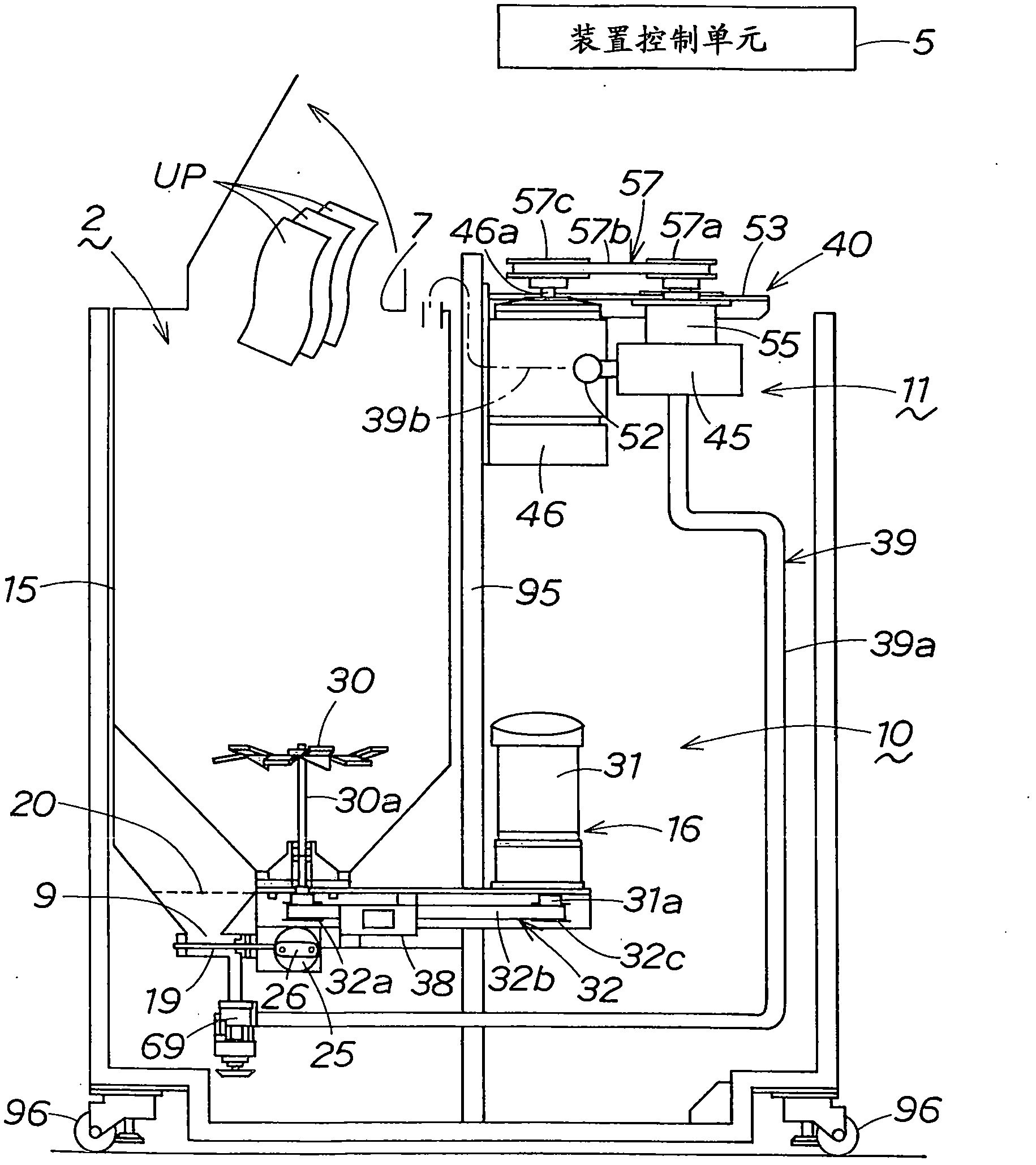

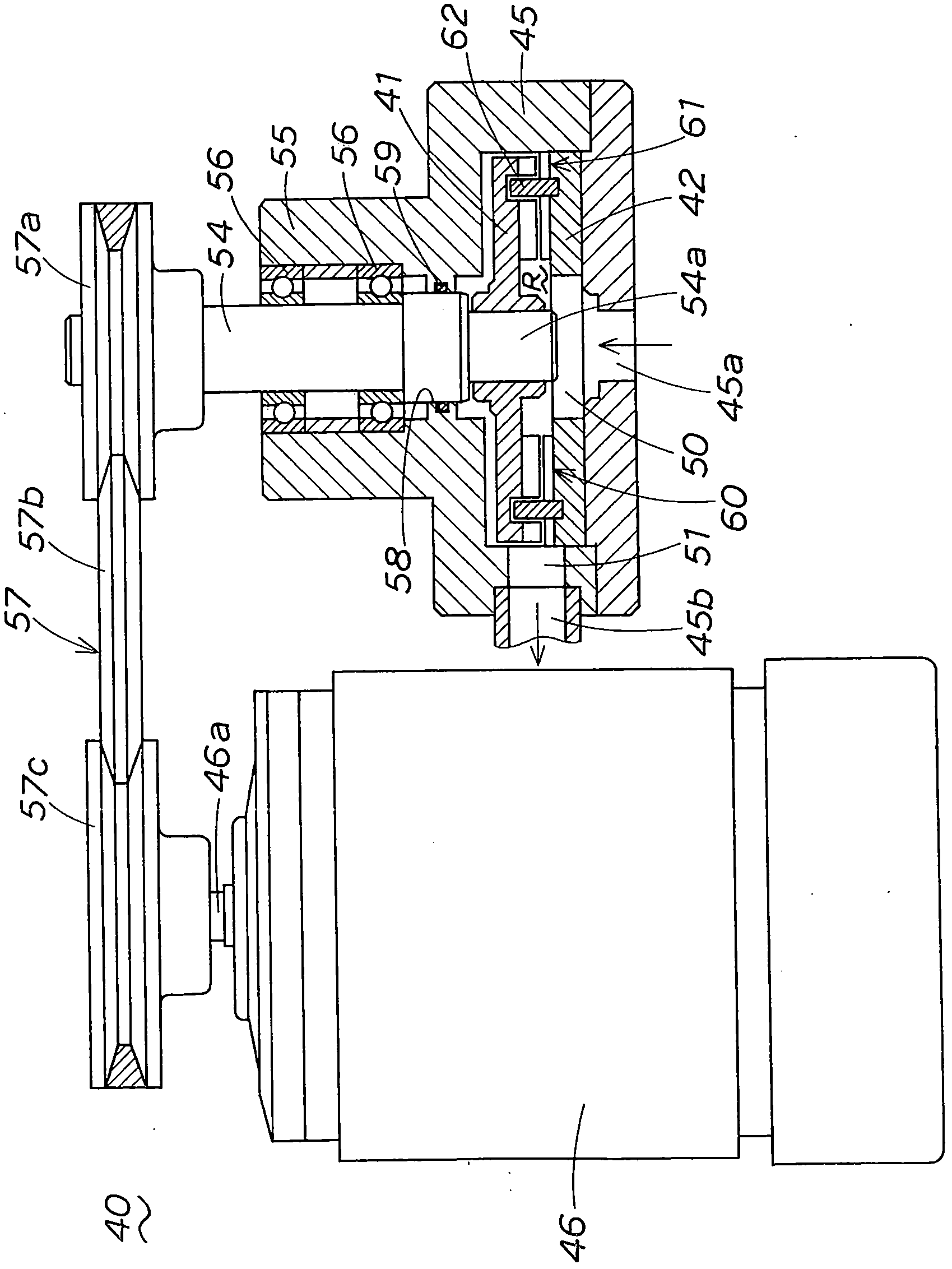

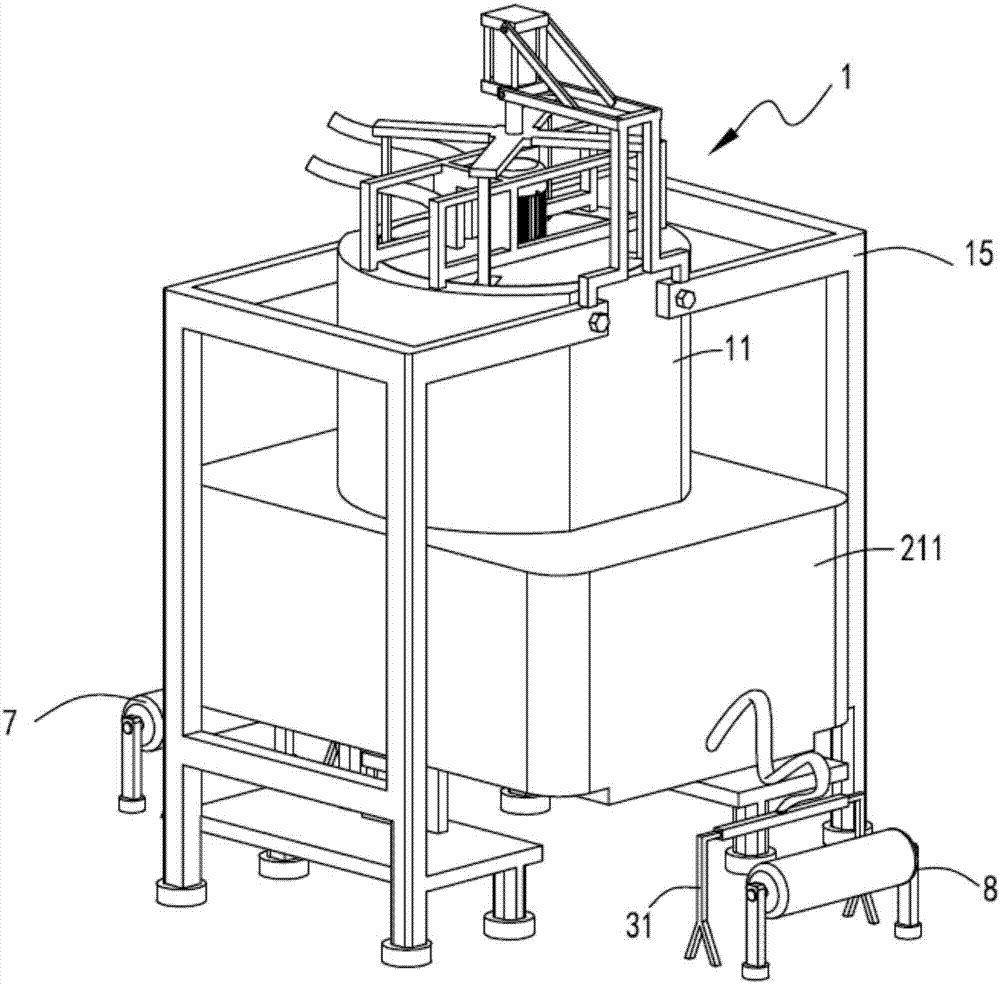

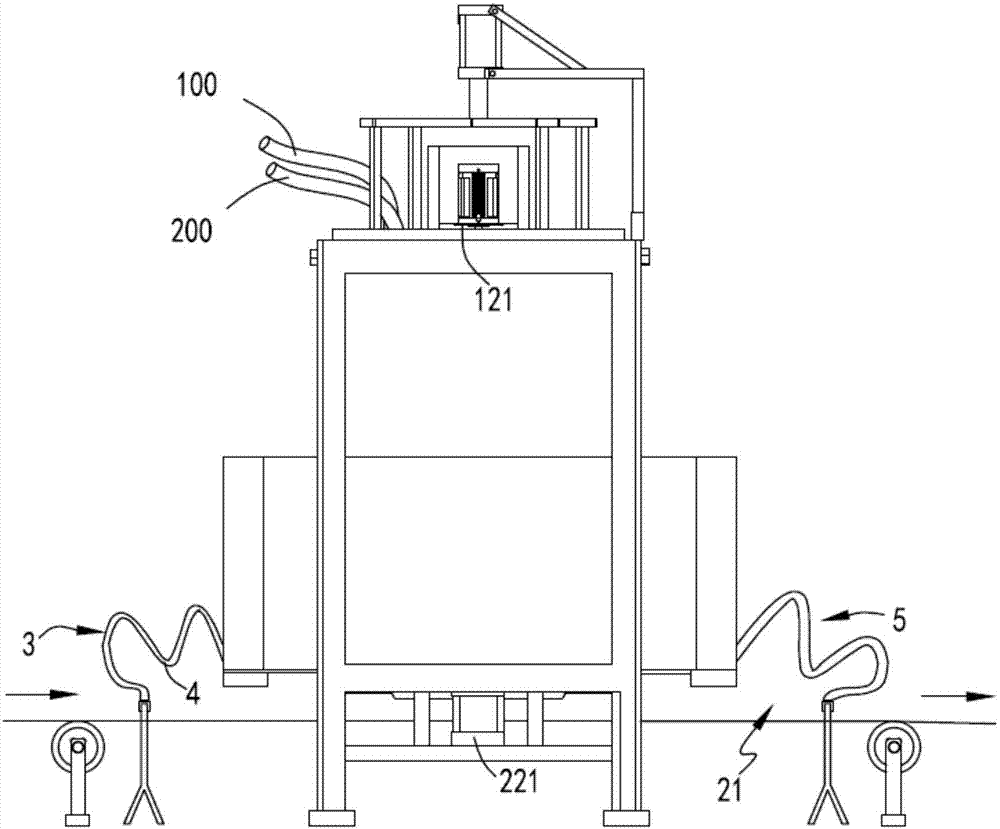

Pulp making device of used paper recycling apparatus and used paper recycling apparatus

InactiveCN102486012AWon't clogSmooth and efficient beatingPulp beating methodsPaper recyclingPaper recyclingEngineering

A pulp making technology for realizing a used paper recycling apparatus of furniture size that can be installed in a small shop, room or the like, having a beating machine provided with a pair of beating disks disposed oppositely to each other in a relatively rotatable manner at a close distance, this beating machine has a tiny beating gap, between the pair of beating disks, for executing the beating process of at least two continuous stages from a rough beating process to a finish beating process, and the beating gap starts at a supply port formed in a central part of the fixed side beating disk, and ends at a discharge port formed on the outer peripheral edge of the beating disks. Therefore, even in a very small beating process space contained in an apparatus space of furniture size, smooth and highly efficient beating of high processing capacity is realized without causing clogging of used paper.

Owner:SEED RUBBER CO LTD

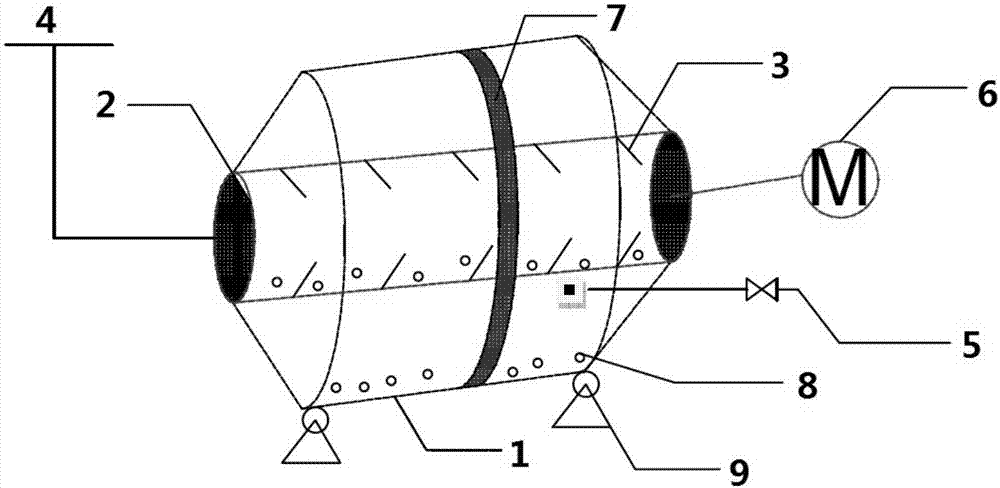

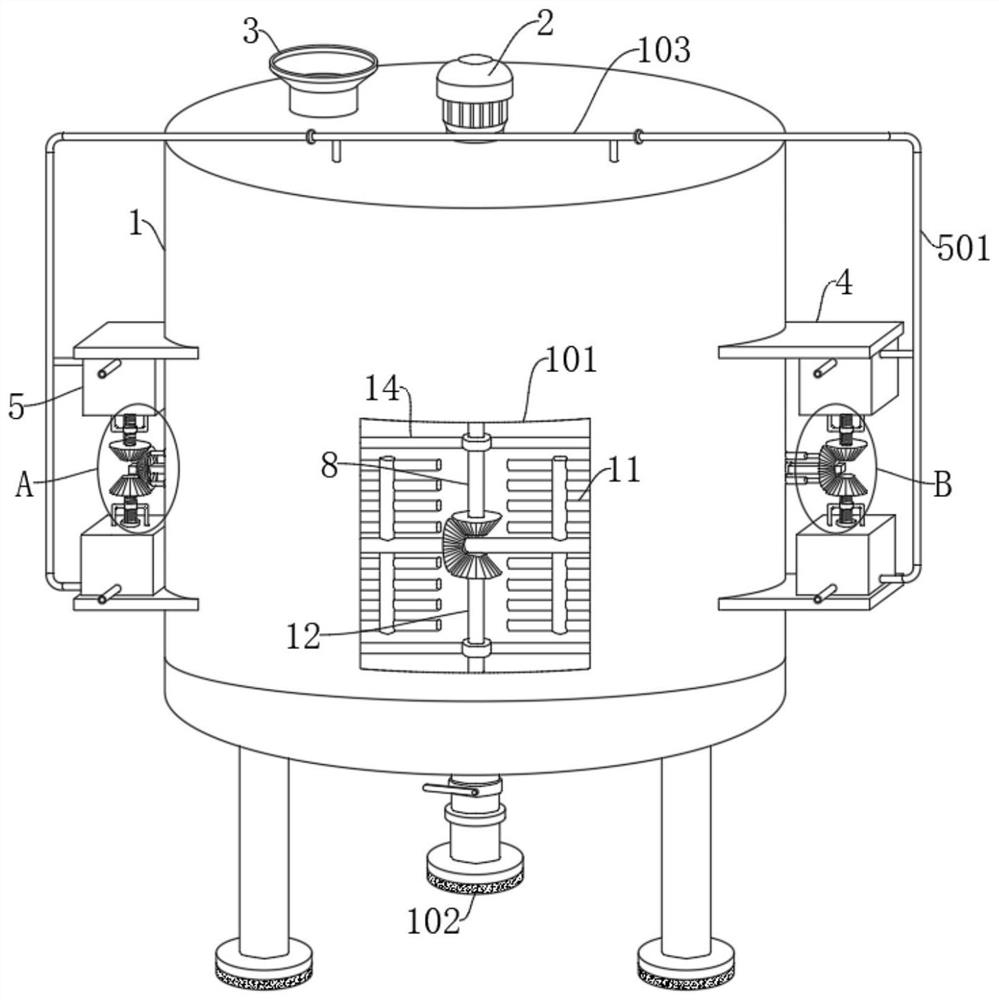

High-efficiency pulping and refining kettle for crude p-phenoxyphenol and use method of high-efficiency pulping and refining kettle

PendingCN114749135ASpray evenlyIncrease reachChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical nozzle-type rreactorsProcess engineeringPhenol

The invention discloses a high-efficiency pulping refining kettle for a crude product of p-phenoxyphenol and a use method of the high-efficiency pulping refining kettle, and belongs to the technical field of production of p-phenoxyphenol. A high-efficiency pulping refining kettle for crude p-phenoxyphenol comprises a kettle body and a feeding funnel fixedly connected to a feeding port of the kettle body, and further comprises a motor fixedly connected to the upper end of the kettle body; the first vertical rod is fixedly connected to the telescopic end of the motor, and one end, far away from the motor, of the first vertical rod extends into the kettle body; the first transverse pulping columns are uniformly distributed on two sides of the first vertical rod; according to the device, the jet box can uniformly spray a solvent into the kettle body, so that the mixing uniformity of a p-phenoxyphenol crude product raw material and the solvent is effectively improved, the p-phenoxyphenol crude product raw material and the solvent can be fully stirred and mixed, the mixing is uniform, the pulping effect and efficiency are improved, and the device is suitable for popularization and application.

Owner:山东亚科环保科技有限公司

Automatic dosing and beating system

InactiveCN107366103AImprove chopping effectGood beating effectTextile treatment machine arrangementsTextile treatment by spraying/projectingTextile fiberPulp and paper industry

The invention relates to an automatic batching and beating system, comprising a beating part, the beating part includes a beating barrel, a rotating chopping mechanism and an agitating mechanism, the beating barrel is fixed on a bracket, and the inner wall of the beating barrel is provided with several cutter mechanisms along its circumferential direction , during the rotation of the rotating shredding mechanism, cooperate with the cutter mechanism to cut the fibers in the slurry, the stirring mechanism is arranged on one side of the cutter mechanism, and the stirring mechanism is used to stir the slurry up and down; the sizing part The sizing part includes a sizing mechanism arranged under the beating barrel and a control mechanism arranged under the sizing mechanism. The sizing mechanism is used to accept the slurry flowing out of the beating barrel and transmit it from the front and rear ends under the action of the control mechanism. Spraying the sizing solution twice on the textile fiber; the invention overcomes the problems of insufficient beating of the sizing material, poor fineness of the sizing material and uneven sizing of the sizing material.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com