Beating device and method for filter cakes and application of filter cakes

A filter cake and driving device technology, applied in chemical instruments and methods, transportation and packaging, dissolving, etc., can solve the problems of easy adhesion of beating paddles, inability to continuously beating, poor beating effect of filter cakes, etc., and achieve short pulping time , practical and safe cleaning, improving effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

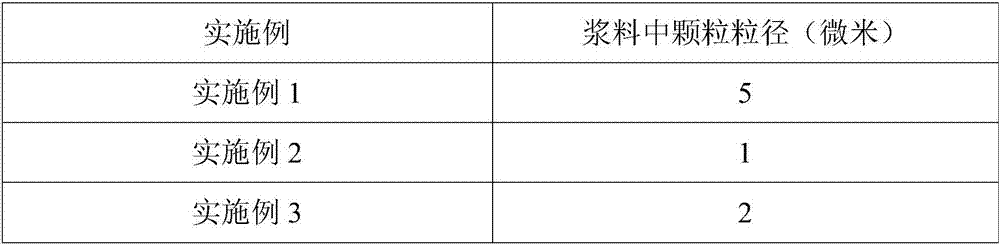

Embodiment 1

[0059] This embodiment is used to illustrate the filter cake continuous beating device and method of the present invention and its application.

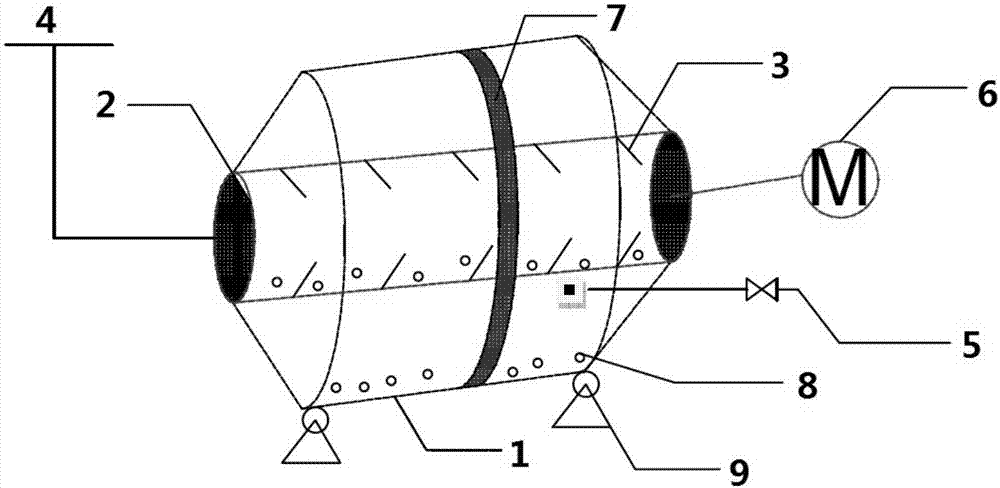

[0060] Such as figure 1 As shown, the filter cake continuous beating device is a horizontal beating device provided with a base 9, wherein the filter cake continuous beating device is provided with a housing 1 and an inner cylinder 2, and the diameter ratio of the inner cylinder 2 and the housing 1 is 1 : 1.2; the inner cylinder 2 is rotatably connected to the housing 1 and is arranged inside the housing 1, and divides the inner cavity of the housing 1 into a first accommodating cavity located inside the inner cylinder 2, and a first accommodating cavity located inside the housing The second accommodating chamber between the body 1 and the inner cylinder 2, the inner cylinder 2 is provided with a material inlet 4 extending to the outside of the housing 1 and communicating with the first accommodating chamber, the side wall of the inn...

Embodiment 2

[0063] This embodiment is used to illustrate the filter cake continuous beating device and method of the present invention and its application.

[0064] Such as figure 1 As shown, the filter cake continuous beating device is a horizontal beating device provided with a base 9, wherein the filter cake continuous beating device is provided with a housing 1 and an inner cylinder 2, and the diameter ratio of the inner cylinder 2 and the housing 1 is 1 : 5; the inner tube 2 is rotatably connected to the housing 1 and is arranged inside the housing 1, and the inner cavity of the housing 1 is divided into a first accommodating chamber located inside the inner tube 2, and a first accommodating cavity located inside the housing The second accommodating chamber between the body 1 and the inner cylinder 2, the inner cylinder 2 is provided with a material inlet 4 extending to the outside of the housing 1 and communicating with the first accommodating chamber, the side wall of the inner cyl...

Embodiment 3

[0067] This embodiment is used to illustrate the filter cake continuous beating device and method of the present invention and its application.

[0068] Such as figure 1 As shown, the filter cake continuous beating device is a horizontal beating device provided with a base 9, wherein the filter cake continuous beating device is provided with a housing 1 and an inner cylinder 2, and the diameter ratio of the inner cylinder 2 and the housing 1 is 1 : 10; the inner cylinder 2 is rotatably connected to the housing 1 and is arranged inside the housing 1, and the inner cavity of the housing 1 is divided into a first accommodating cavity located inside the inner cylinder 2, and a first accommodating cavity located inside the housing The second accommodating chamber between the body 1 and the inner cylinder 2, the inner cylinder 2 is provided with a material inlet 4 extending to the outside of the housing 1 and communicating with the first accommodating chamber, the side wall of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com