Pulp making device of used paper recycling apparatus and used paper recycling apparatus

A technology for recycling and waste paper pulp, applied in the field of pulping technology, can solve the problem of no longer recycling, and achieve the effects of stable processing capacity, high-efficiency processing capacity, and stable processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

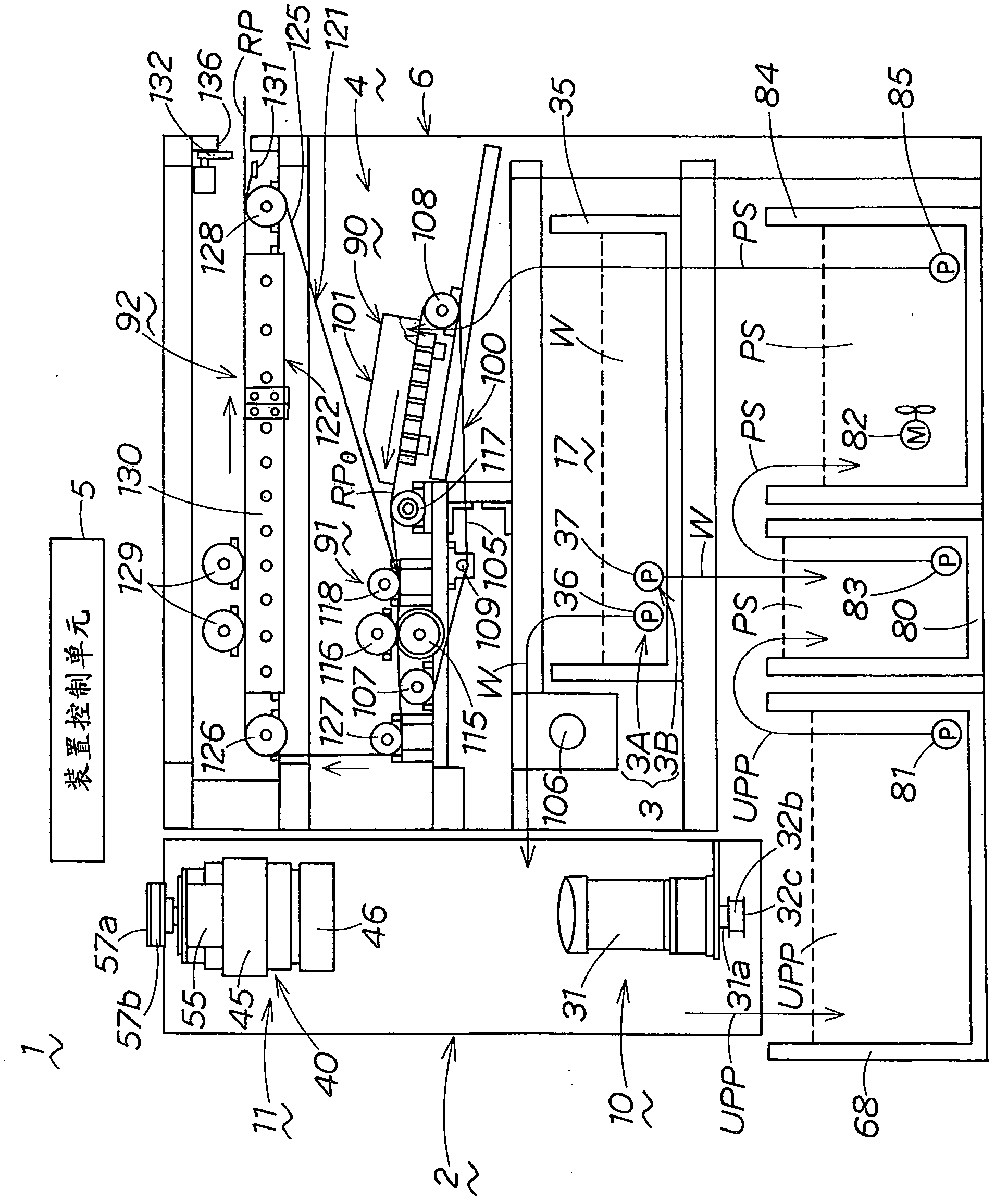

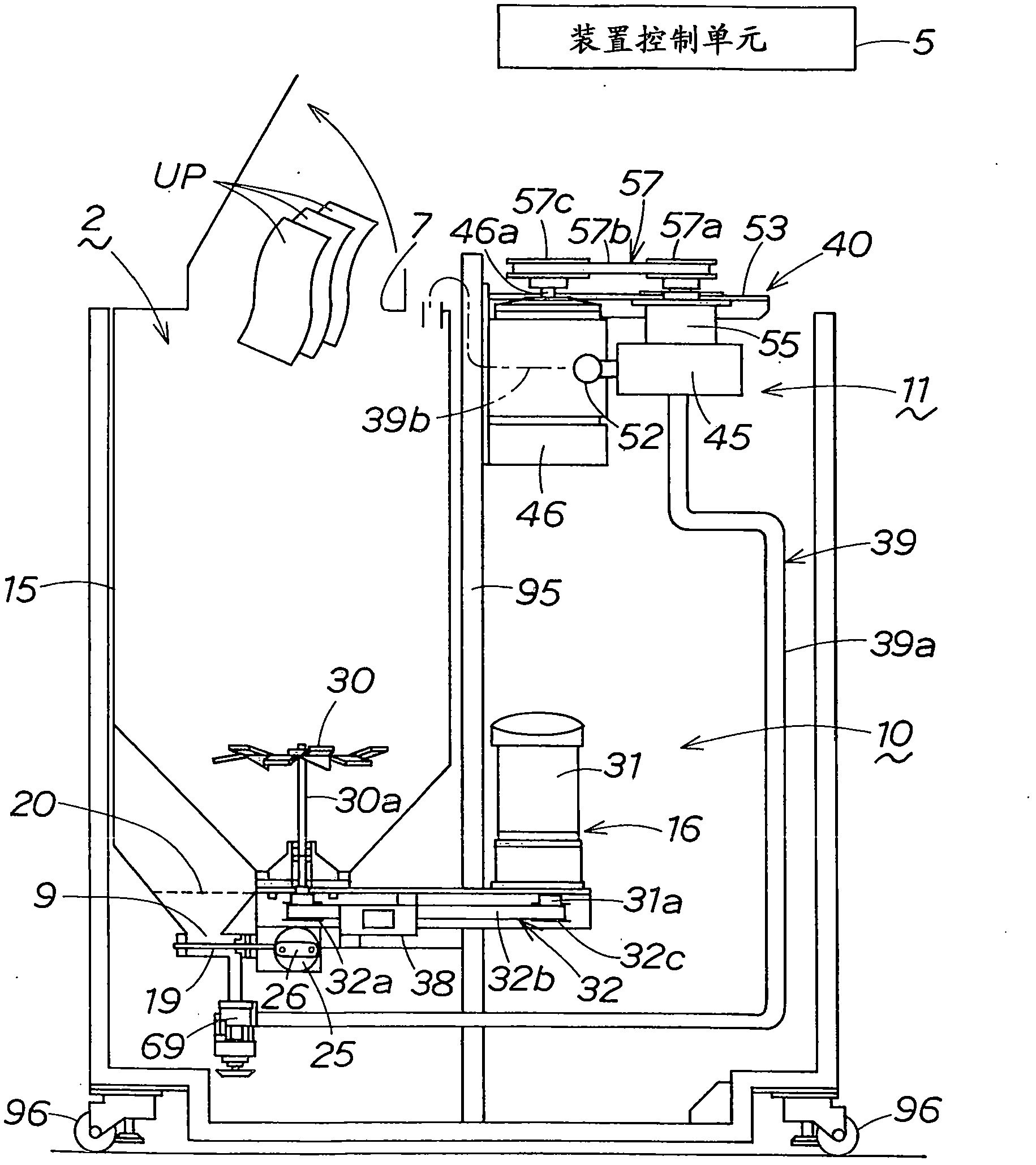

[0064] Figure 1-10 Shown is the waste paper recycling apparatus of the present invention, the waste paper recycling apparatus 1 is specifically installed at the original source of the waste paper, and it is a waste paper UP that is generated without processing or discarding at the same place. Equipment that can be processed into recycled paper, waste paper UP includes confidential documents of government agencies and private companies, private letters of ordinary families and other unnecessary paper.

[0065] Such as Figure 10 As shown, the waste paper recycling apparatus 1 is furniture-sized, that is, it is small and compact, similar to general office furniture, such as bookshelves, lockers, desks, copiers, personal computers, or other furniture such as figure 1 and 2 As shown, the waste paper recycling equipment 1 is mainly composed of a pulping unit 2, a pulp concentration adjustment unit (pulp concentration adjustment device) 3, a papermaking unit 4 and a device contro...

Embodiment 2

[0199] The preferred embodiment consists of Figure 7 The two-dot dash line in indicates that only the structure of the beating unit 11 of the pulping unit 2 in the embodiment 1 is modified.

[0200] That is to say, in the beating unit 11 of this preferred embodiment, the waste paper pulp circulation path 39 is connected to a bypass path 151 through a direction switching valve 152 as a switching device. 40 reserve barrels of beaten wastepaper pulp UPP 150. Specifically, the direction switching valve 152 is an electromagnetic closing valve, which is electrically connected to the beating control unit 142 of the device control unit 5 .

[0201] When performing the beating process of Embodiment 2, the beating control unit 142 drives and controls the direction switch valve 152 to switch and use the maceration tank 15 of the maceration unit 10 and the reserve tank 150 of the bypass path 151 .

[0202] More specifically, in the beating process of Embodiment 2, the waste paper pulp ...

Embodiment 3

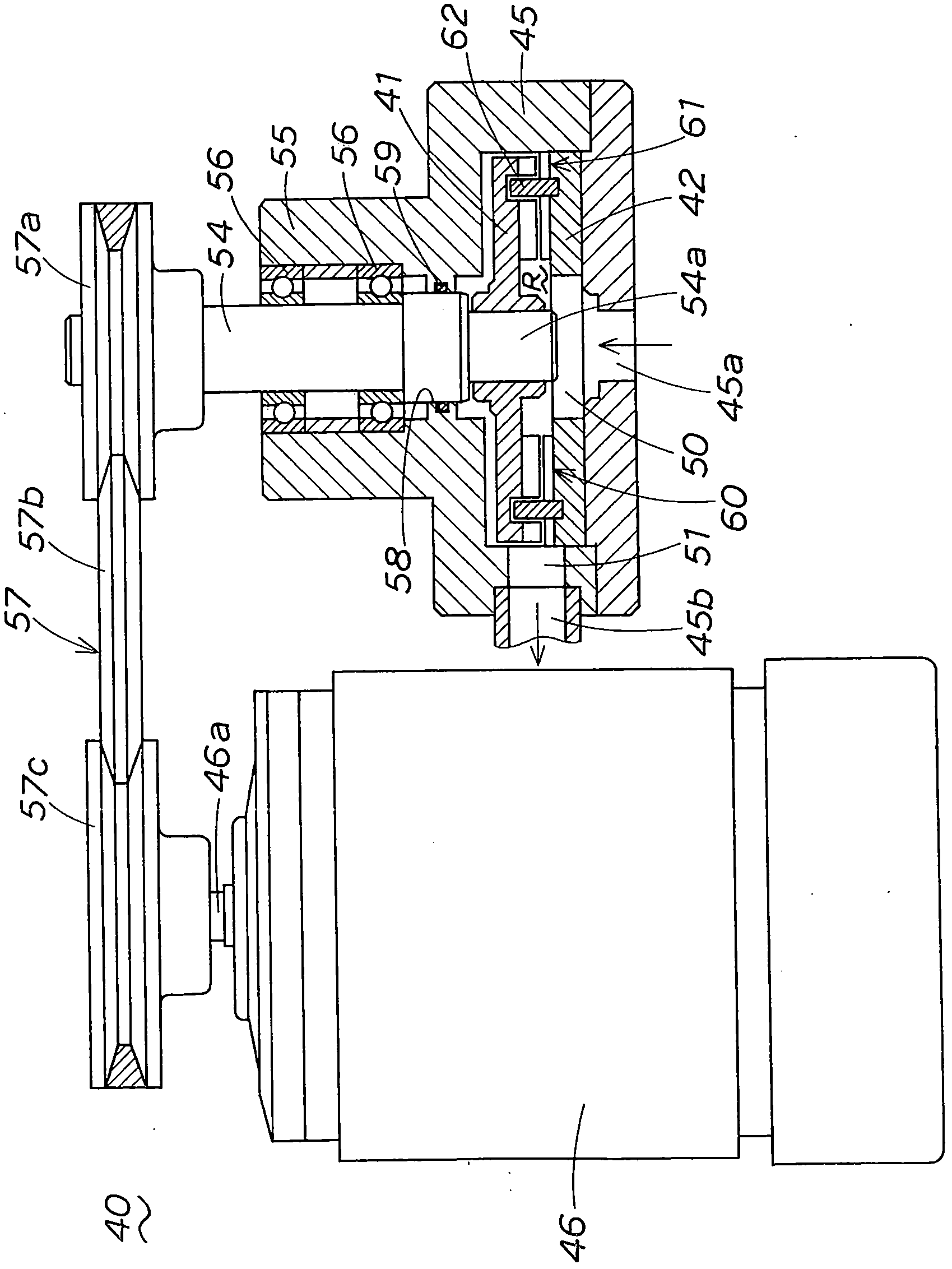

[0206] 11 and 12 show this preferred embodiment, in which only the structure of the beater 40 of the pulping unit 2 in Embodiment 1 is changed.

[0207] That is to say, like Embodiment 1, the beater 40 of this preferred embodiment includes a pair of beating discs 41, 41 that can be driven in relative rotation as main components, and these two beating discs 41, 42 span a small beating gap R They are arranged concentrically and relatively rotatable.

[0208] The beating gap R formed between the opposite sides 41a, 42a of the pair of upper and lower beating discs 41, 42 starts from the supply port 45a formed in the central portion of the fixed side beating disc 42, and ends at the opening between the two beating discs 41, 42. The discharge port 45b formed on the outer periphery of the

[0209] The beating gap R is designed to perform three consecutive beating processes from a rough beating process to a fine beating process.

[0210] More specifically, the beating gap R is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com