Mine dust concentration sensor based on electrostatic induction

A technology of dust concentration and electrostatic induction, which is applied in the field of detection, can solve the problem of sensor sensitivity reduction and achieve the effect of simple structure, strong anti-interference ability and maintenance-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

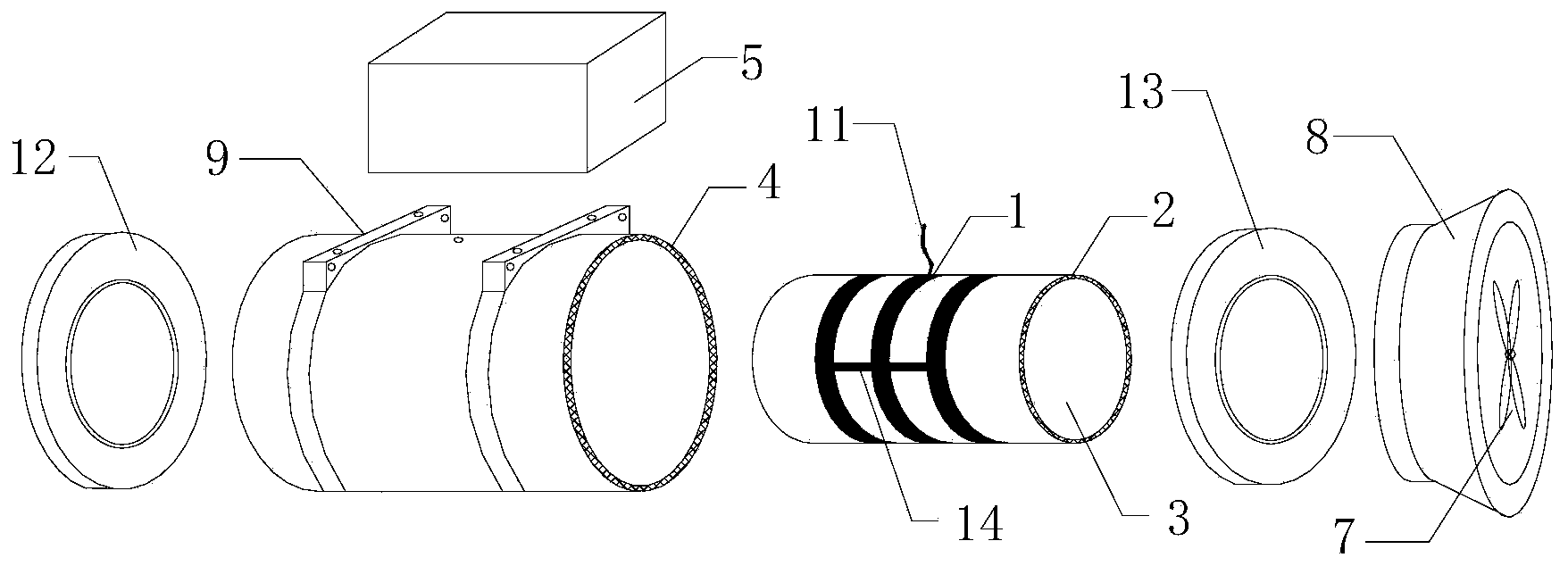

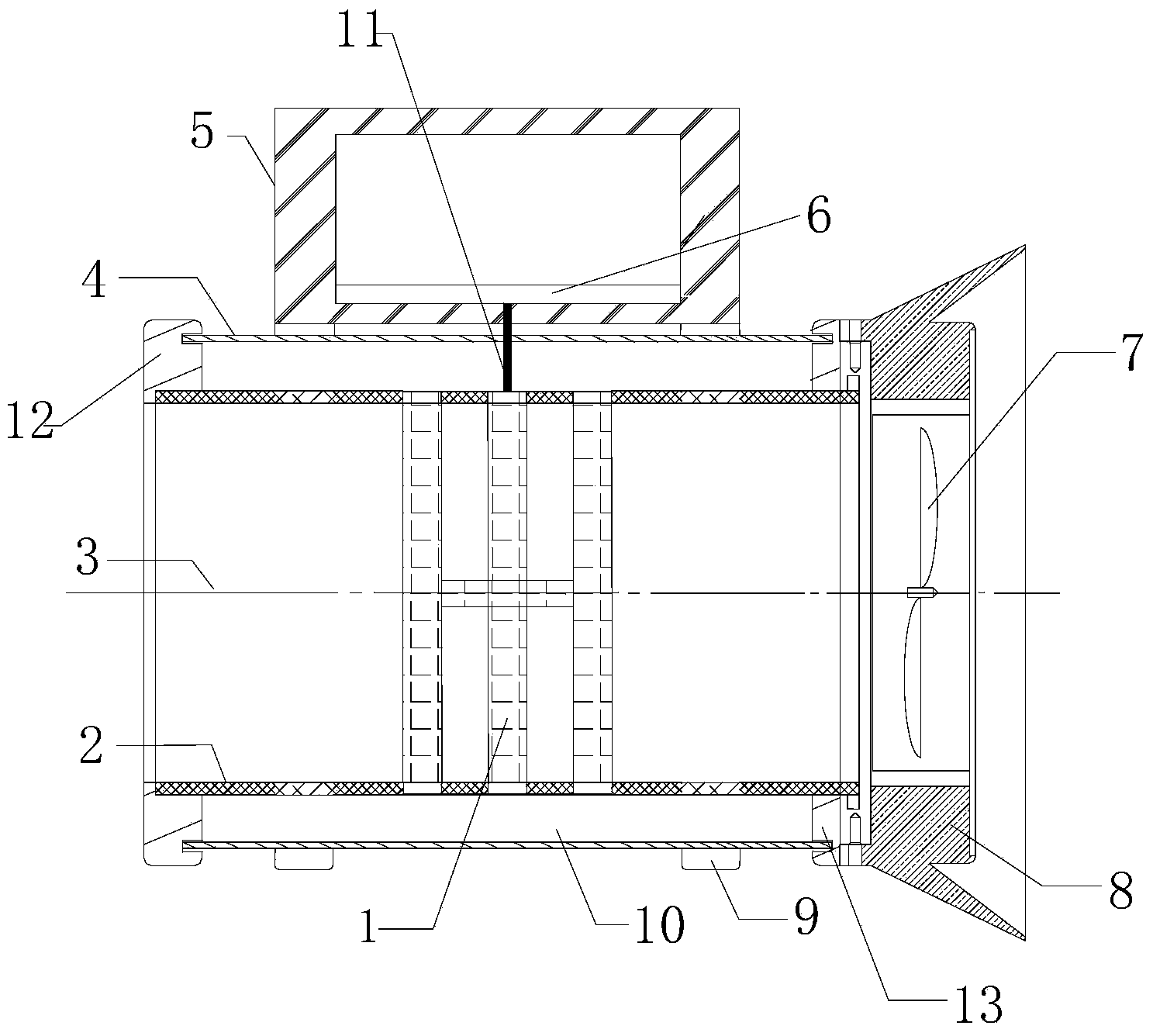

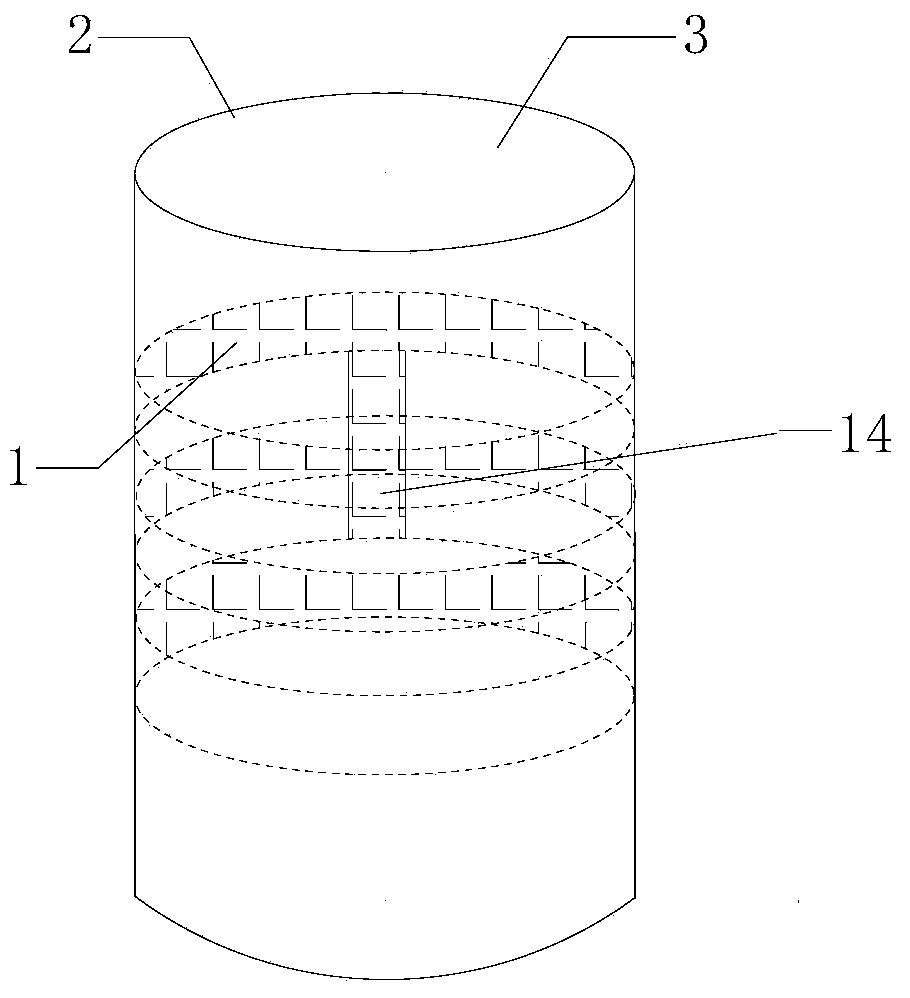

[0016] see figure 1 with figure 2 , the mine dust concentration sensor based on electrostatic induction in the present invention comprises metal support 9, metal shield 4, insulating pipe 2, left sealing ring 12, right sealing ring 13, metal electrode 1, fan outer cover 8, fan 7 and circuit box 5. Wherein: the metal electrode 1 is made of copper sheet, the metal shield 4 and the metal bracket 9 are made of aluminum. The insulating pipe and fan cover are made of polytetrafluoroethylene, and the fan is made of DC motor.

[0017] Both the metal shielding cover 4 and the insulating tube 2 are cylindrical, the left end of the metal shielding cover 4 and the left end of the insulating tube 2 are fastened and connected by the left sealing ring 12, the right end of the metal shielding cover 4 and the right end of the insulating tube 2 are connected through the right The sealing ring 13 is fastened and connected, and an airtight shielding space 10 is formed between the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com