High-efficiency pulping and refining kettle for crude p-phenoxyphenol and use method of high-efficiency pulping and refining kettle

A technology of phenoxyphenol and refining kettle, which is applied in the field of high-efficiency beating and refining kettle for p-phenoxyphenol crude products, which can solve problems such as uneven mixing and inability to beat raw materials, so as to improve the beating effect and efficiency and reduce the risk of uniformity and inconsistency , the effect of increasing the contact range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

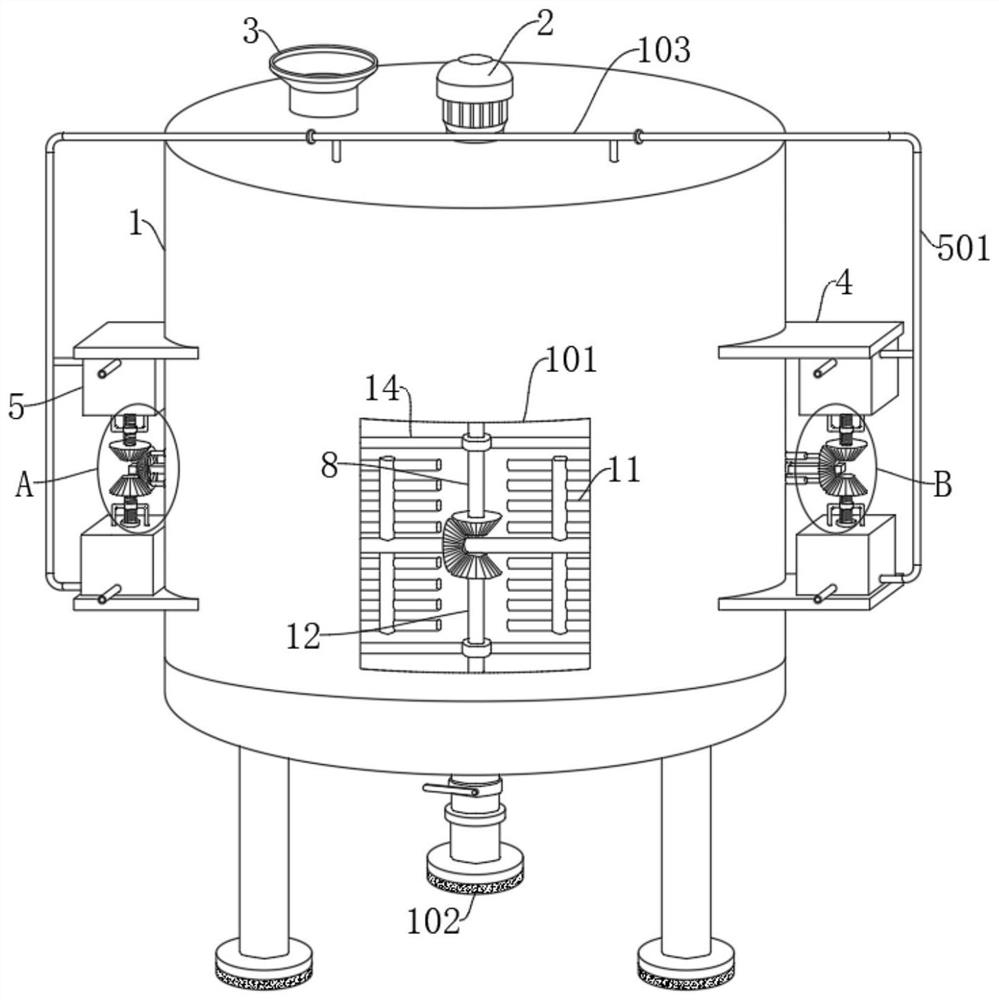

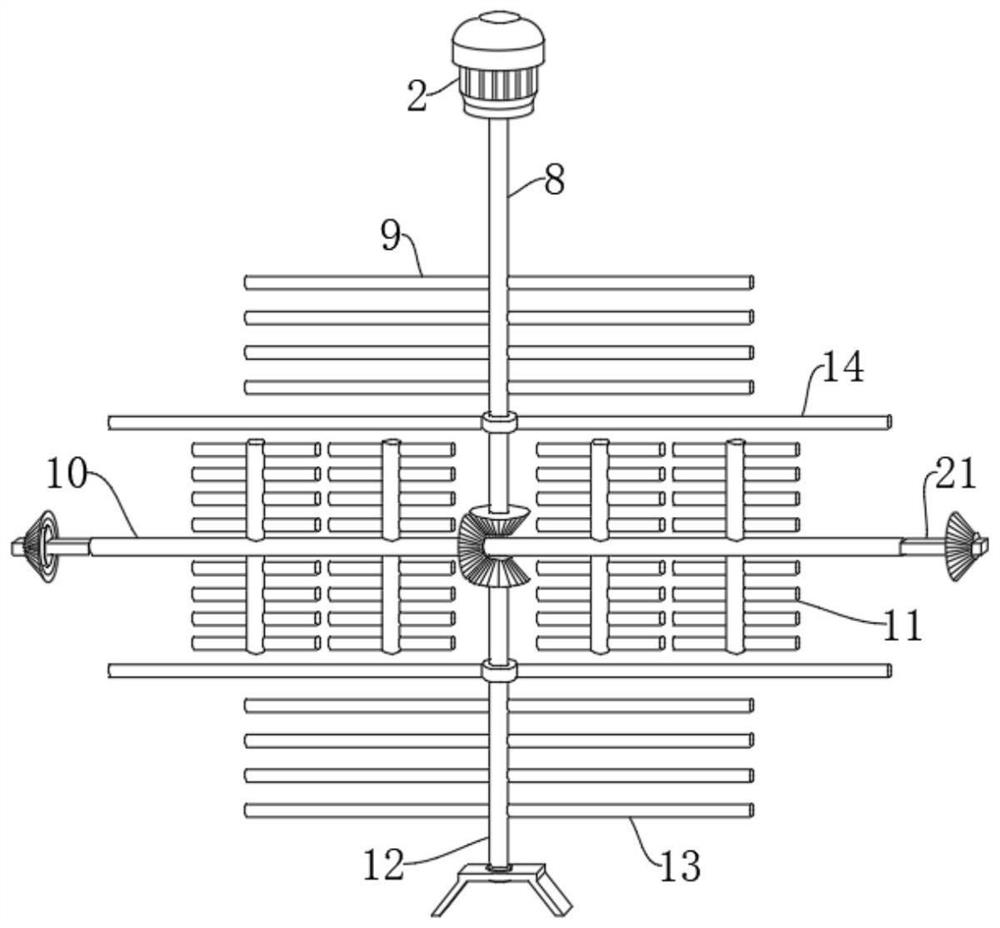

[0038] refer to Figure 1-Figure 9 , a kind of high-efficiency beating and refining kettle of p-phenoxyphenol crude product, comprising a kettle body 1, a feeding funnel 3, and the feeding funnel 3 is fixedly connected at the feeding port of the kettle body 1, and also includes: a motor 2, which is fixedly connected to the kettle body 1. The upper end of the body 1; the first vertical rod 8 is fixedly connected to the telescopic end of the motor 2, and the end away from the motor 2 extends into the kettle body 1; the first horizontal beating column 9 is evenly distributed on the two sides of the first vertical rod 8 side; horizontal bar 10, rotatably connected in the kettle body 1 near the lower end of the first vertical bar 8; vertical beating column 11, evenly distributed on both sides of the horizontal bar 10; The inner lower end of the kettle body 1; the second horizontal beating column 13 is evenly distributed on both sides of the second vertical rod 12, wherein the lower...

Embodiment 2

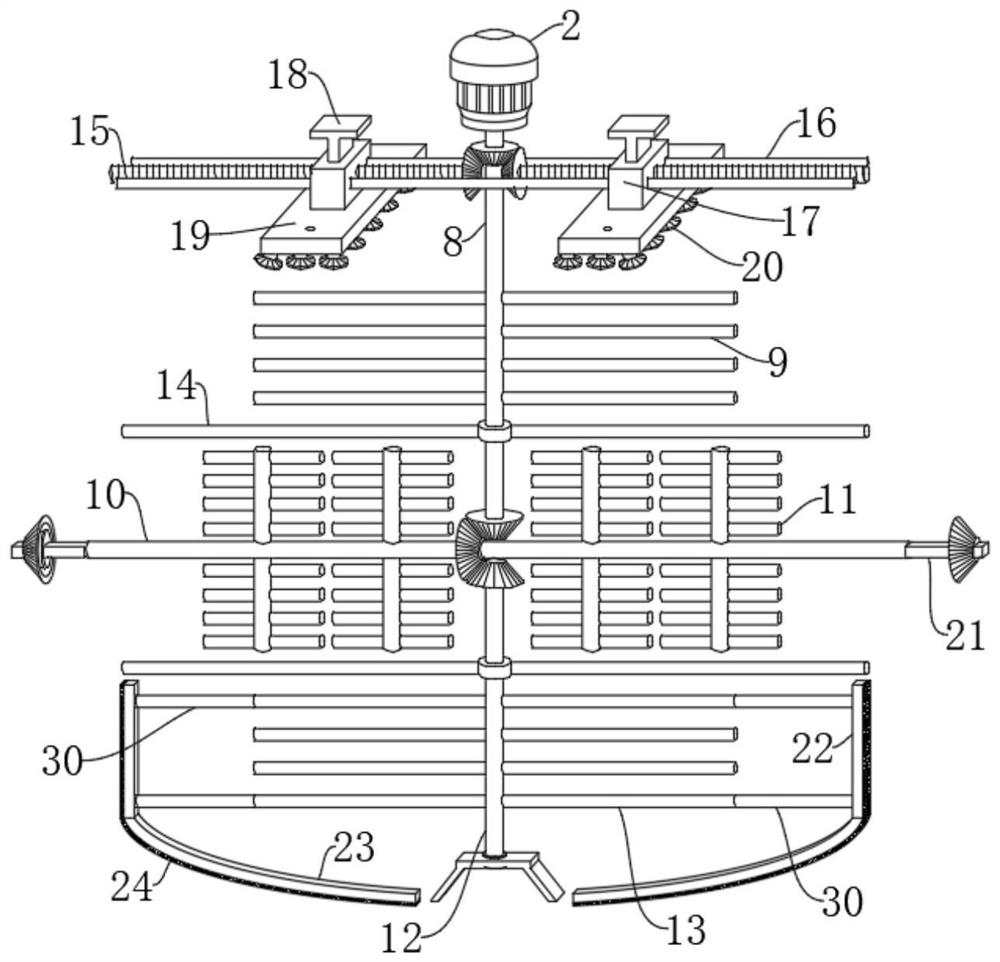

[0041] refer to Figure 1-Figure 9 , a kind of high-efficiency beating and refining kettle of p-phenoxyphenol crude product, which is basically the same as Example 1, and further is: the reciprocating transmission assembly includes the first reciprocating screw rod 15, the slider 17, the T-shaped block 18, the first reciprocating wire rod The rod 15 is symmetrically connected to both sides of the inner upper end of the kettle body 1, and a fourth transmission bevel gear is fixedly connected to the position of the first vertical rod 8 close to the first reciprocating screw rod 15, and the first reciprocating screw rod 15 is close to the first vertical rod 8. A fifth drive bevel gear is fixedly connected to one end of the fuselage, the slider 17 and the first reciprocating screw 15 are threadedly connected, the T-block 18 is fixedly connected to the slider 17, and is slidably connected to the limit set on the top of the kettle body 1 In the track, the jet box 19 is fixedly conne...

Embodiment 3

[0046] refer to Figure 1-Figure 9 , a kind of high-efficiency beating and refining kettle of p-phenoxyphenol crude product, which is basically the same as Example 1, and further is: the end of the second horizontal beating column 13 away from the second vertical rod 12 is fixedly connected with a vertical scraper through the connecting rod 30 Plate 22, the vertical scraper 22 is attached to the side wall of the lower end of the kettle body 1, the lower end of the vertical scraper 22 is fixedly connected with an arc scraper 23 attached to the arc bottom of the kettle body 1, the vertical scraper 22, A rubber strip 24 is fixedly connected to the side of the arc-shaped scraper 23 that is in contact with the inner wall of the kettle body 1 . The setting of the plate 23 can transfer the materials on the arc surface at the bottom of the kettle body 1, so that when discharging, not only can the discharging efficiency be improved, but also the materials attached to the kettle body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com