High-efficiency pulping soy milk grinder

A soymilk maker, high-efficiency technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of not achieving ideal effects, difficult to achieve beating effects, etc., and achieve the effects of increasing the number, improving the contact probability, and improving the beating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

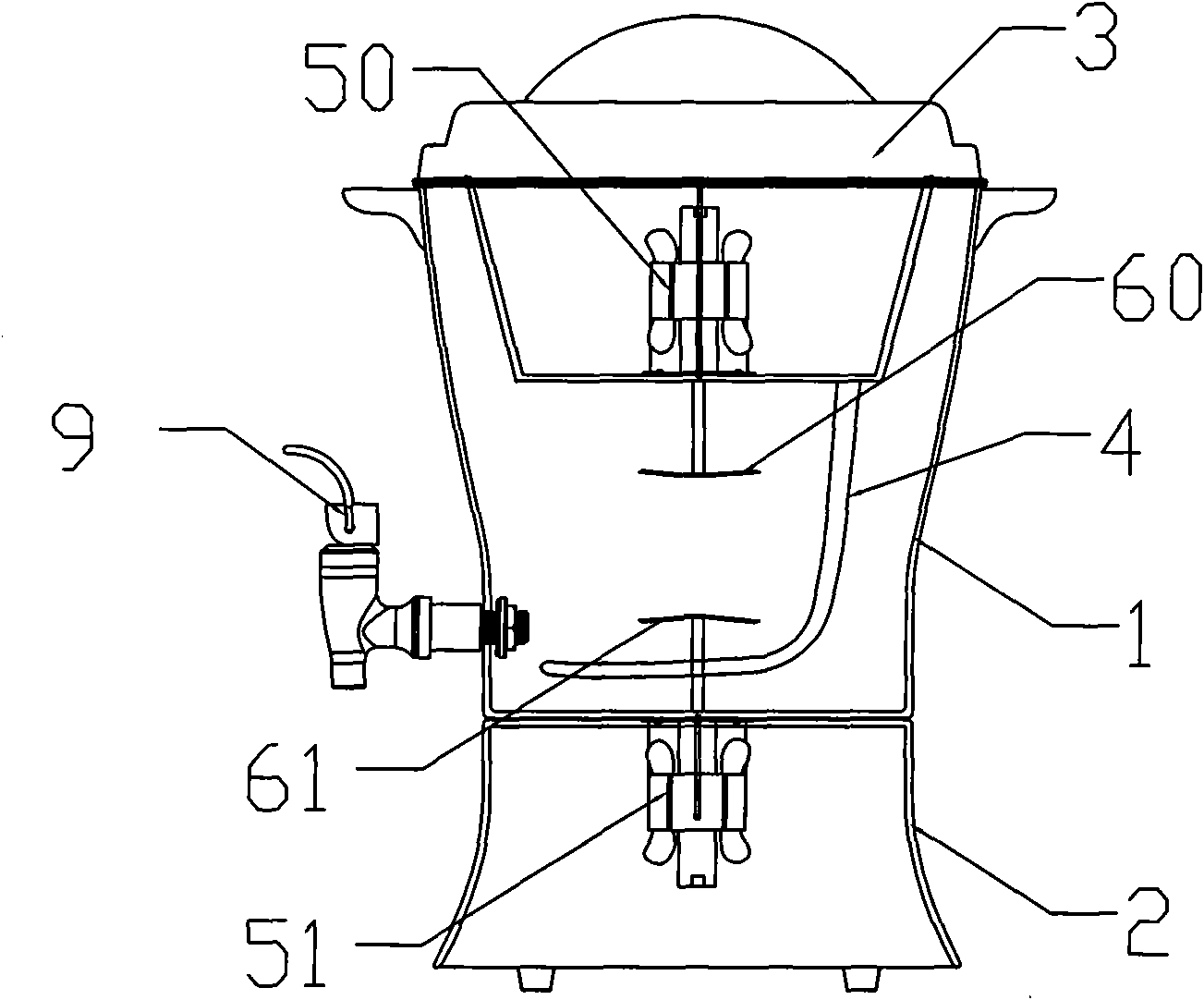

[0022] Embodiment one: if figure 1 As shown, the high-efficiency beating soybean milk machine of this embodiment is mainly composed of a stirring cup 1, a machine base 2, a machine head 3 and a heating device 4. The heating device 4 is an electric heating tube installed on the machine head 3. Of course, it can also be used The heating plate or the electromagnetic heating device installed on the support 2 (the heating technology is the mature technology of soybean milk machine, not shown in the figure). Head 3 is provided with an upper motor 50, the output shaft lower end of upper motor 50 is provided with upper pulverizer 60, and support 2 is provided with a lower motor 51, and the output shaft upper end of lower motor 51 is provided with lower pulverizer 61. In order to facilitate pouring, a slurry discharge valve 9 can be installed on the side wall of the mixing cup 1 .

Embodiment 2

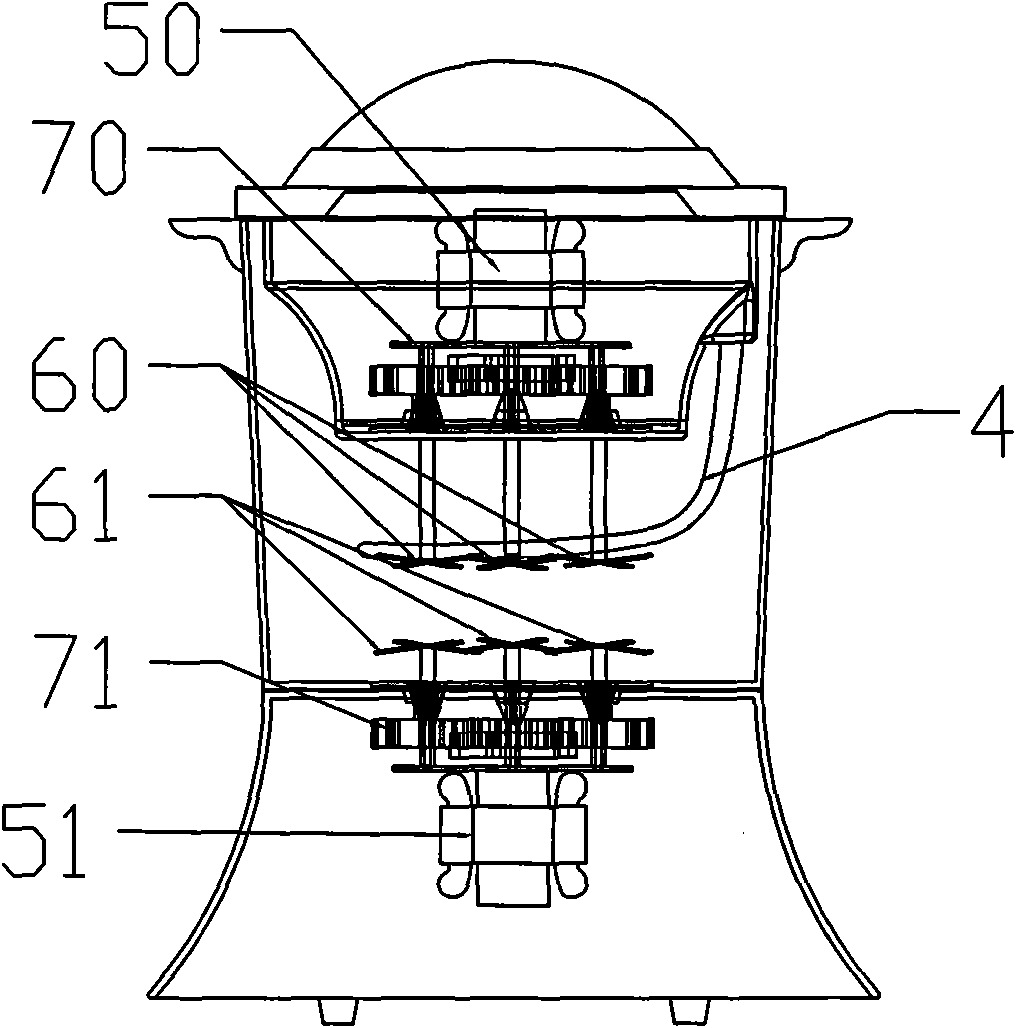

[0023] Embodiment two: if figure 2 As shown, its main structure is basically the same as that of Embodiment 1, the difference is that in the high-efficiency beating soybean milk machine of this embodiment, there are more than two crushing knives 60 on the upper part (three crushing knives are shown in the figure), and the upper motor 50 passes through the upper The gear transmission mechanism 70 drives the upper pulverizer 60 to work; the lower pulverizer 61 has more than two (three pulverizers among the figures), and the lower motor 51 drives the lower pulverizer 61 to work through the lower transmission mechanism 71. The gear transmission mechanism includes a driving gear arranged on the output shaft of the motor and a driven gear equipped with a crushing knife and meshed with the driving gear. Transmission mechanism also can adopt other transmission mechanism except gear transmission mechanism, such as belt transmission mechanism, by being located at the driving wheel on t...

Embodiment 3

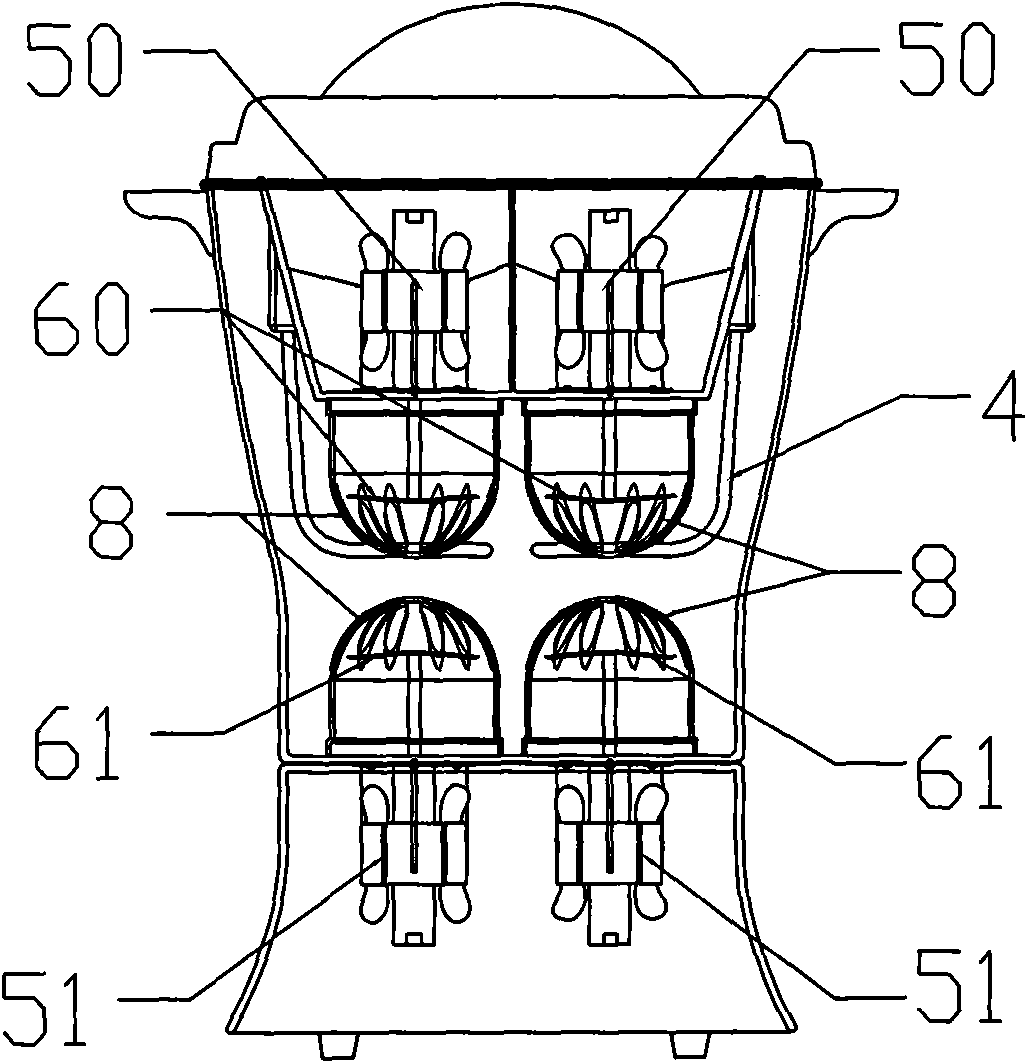

[0024] Embodiment three: as image 3 As shown, its main structure is basically the same as that of Embodiment 1, the difference is that, in the high-efficiency beating soybean milk machine of this embodiment, both the upper pulverizing knife 60 and the lower pulverizing knife have two (certainly also can be more than two), two The upper pulverizing knife 60 is driven by two independent upper motors 50 installed on the machine head 3 respectively, and the two lower pulverizing knives 61 are respectively driven by independent lower motors 51 installed on the machine base 2, and each pulverizing knife is installed There are 8 shrouds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com