Patents

Literature

132results about How to "Improve beating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

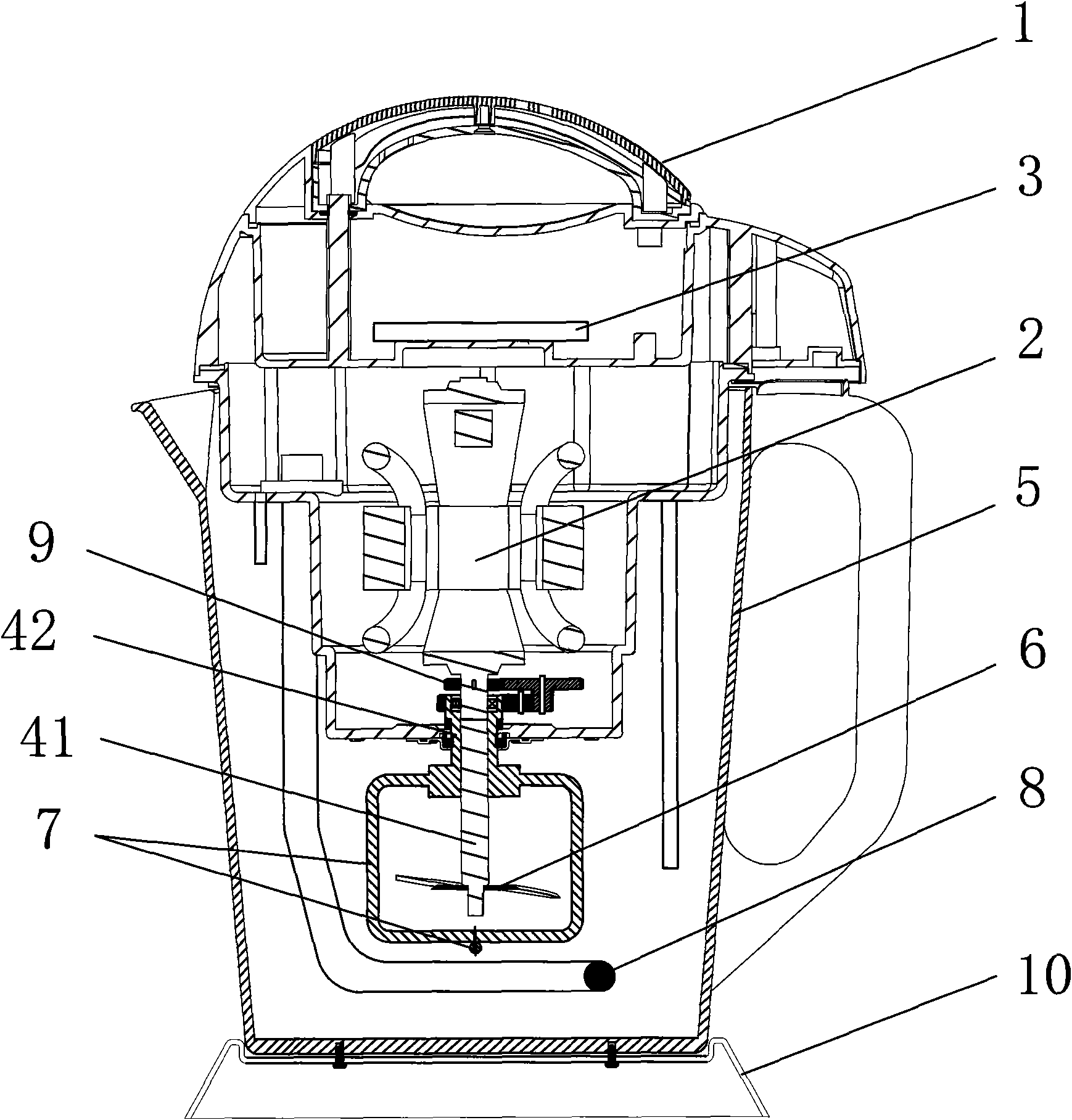

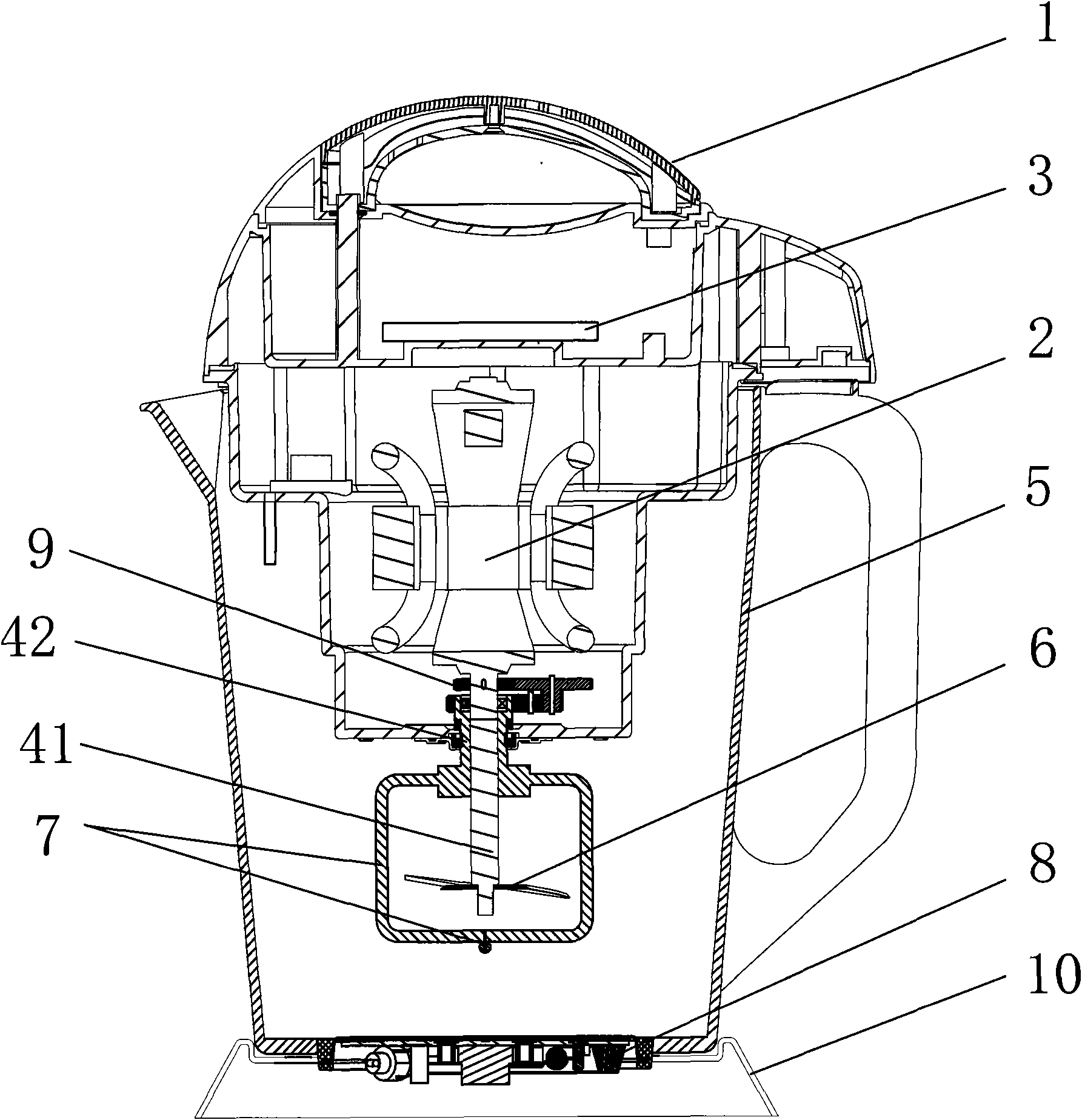

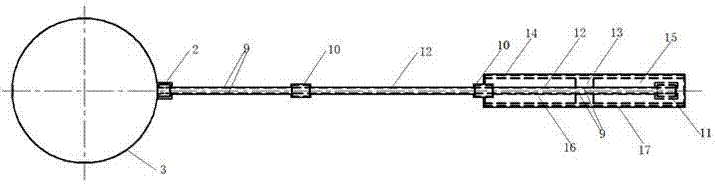

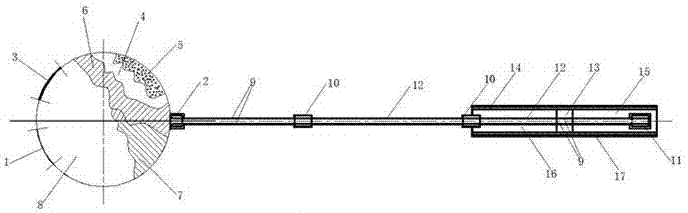

Soybean milk machine capable of completely smashing pulping materials

InactiveCN101647535AImprove beating efficiencyAvoid the problem of sticking the bottom of the tubeBeverage vesselsFood preparationEngineeringMotor shaft

The invention relates to a soybean milk machine capable of smashing pulping materials, comprising a pedestal, a nose, an electric motor arranged in the nose, a control device, a cup body and a heatingdevice. The soybean milk machine is characterized in that an inner shaft and an outer shaft extend from the downside of the nose to the interior of the cup body, one end of the inner shaft is connected with a smashing device, one end of the outer shaft is connected with a stirring frame, and the inner shaft and the outer shaft are connected with the electrical motor output shaft by a transmissiondevice. The invention adopts the electric motor to connect the outer and inner shafts, and the smashing device and the stirring frame are respectively fixed on the inner and outer shafts, when the soybean milk machine is in operation, the stirring frame and the smashing device synchronously operate in inverse direction, beans are smashed by collision with the smashing device under the rotating driving of the stirring frame and further smashed by collision with the stirring frame, thus not only pulping efficiency of the soybean milk machine is improved but also the problem of tube and bottom pasting is avoided. Besides, no flow disturbing rib or device is required to be arranged in the cup body of the soybean milk machine, so that the cleaning of the soybean milk machine is more convenientand simper.

Owner:MIDEA GRP CO LTD

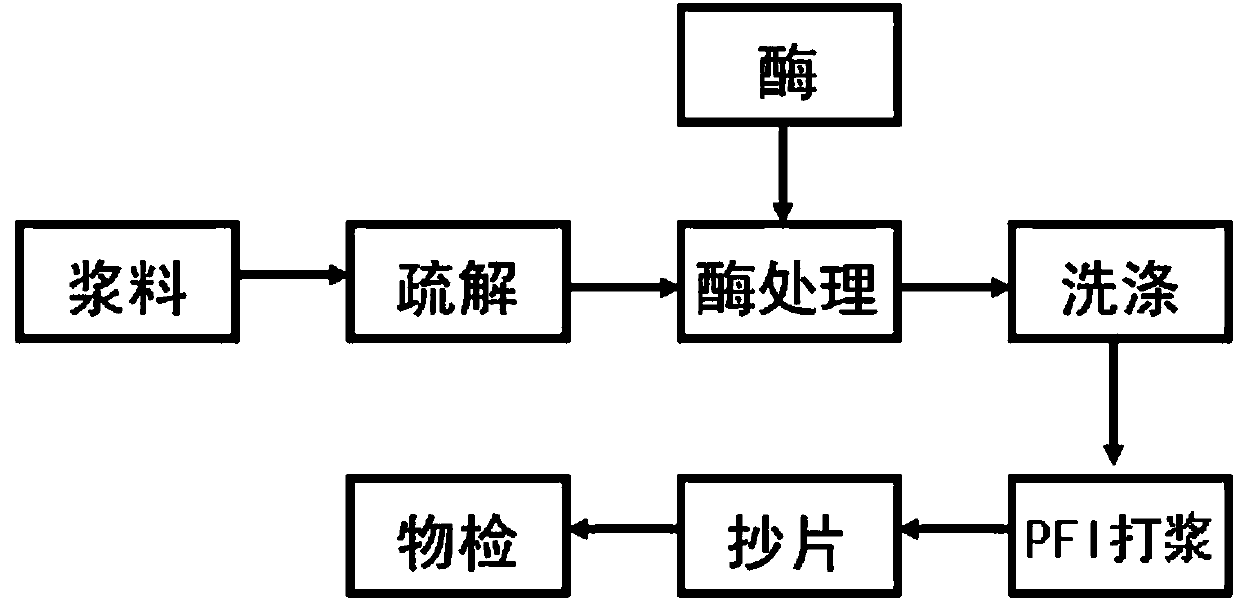

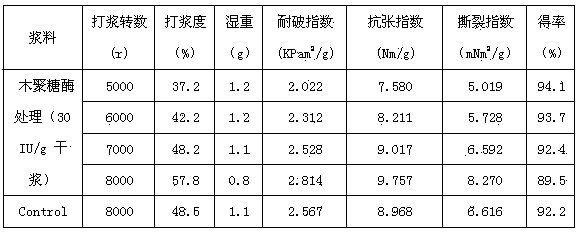

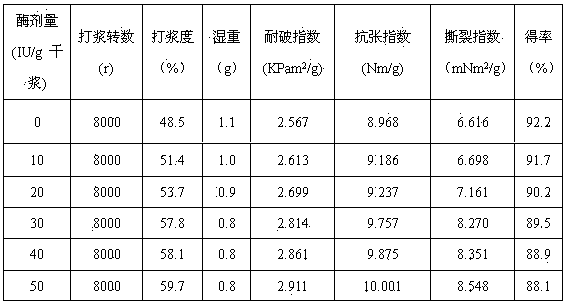

Enzymatic beating process for natural-color bagasse pulp

The invention discloses an enzymatic beating process for natural-color bagasse pulp. Xylanase is used in the enzymatic beating process for the natural-color bagasse pulp. The process comprises the steps of sizing agent defibering, enzyme treatment, washing, PFI beating, sheet making and physical detection. By adopting the process, the beating energy consumption of the natural-color bagasse pulp can be lowered effectively; the beating degree can be increased greatly up to 19.2 percent when enzyme treatment is performed on the xylanase at the dry pulp dosage of 30IU / g; meanwhile bagasse pulp cellulase can be protected from being damaged, and the process has important significance to the production of industrial paper from bagasse pulp.

Owner:GUANGXI UNIV

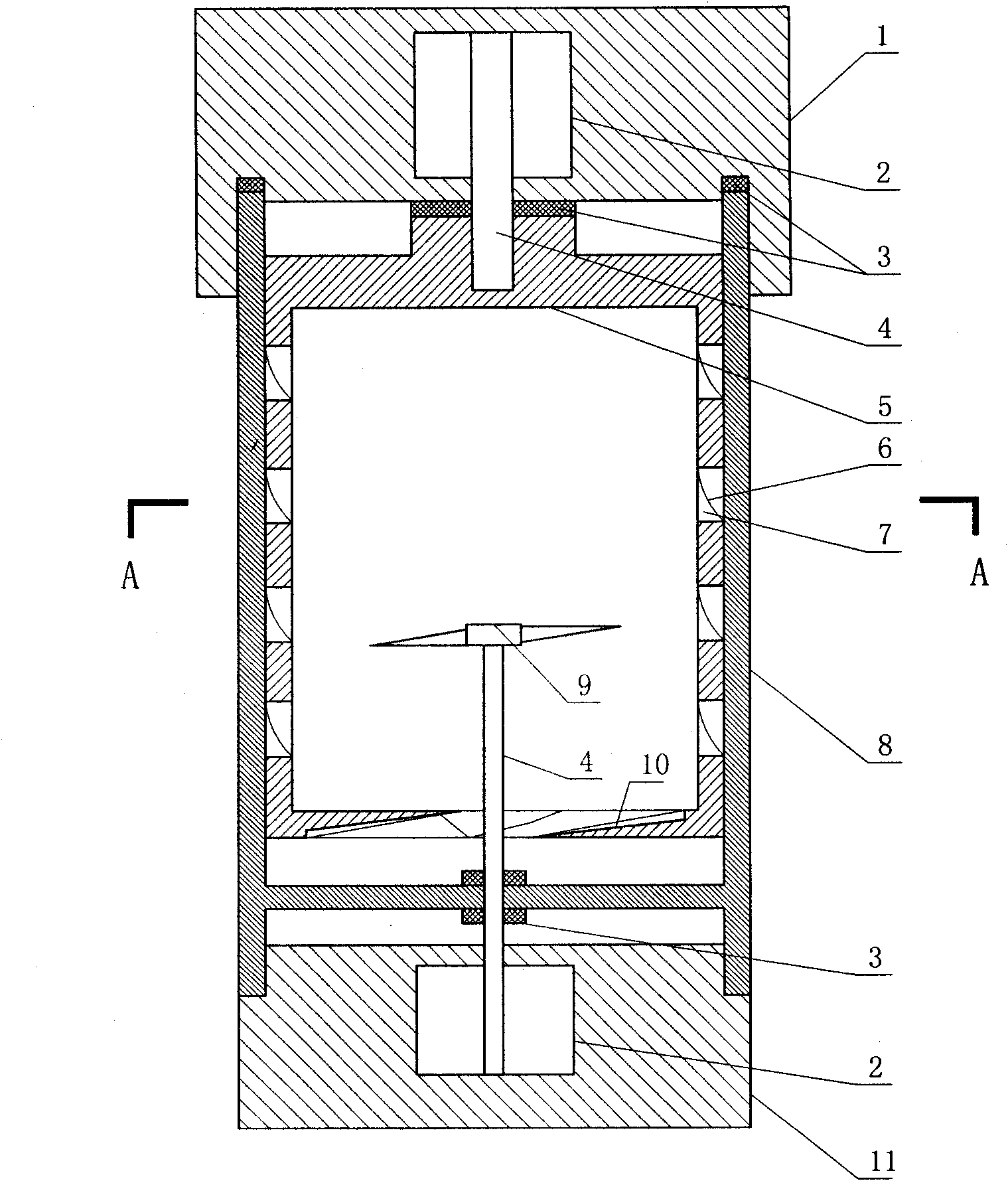

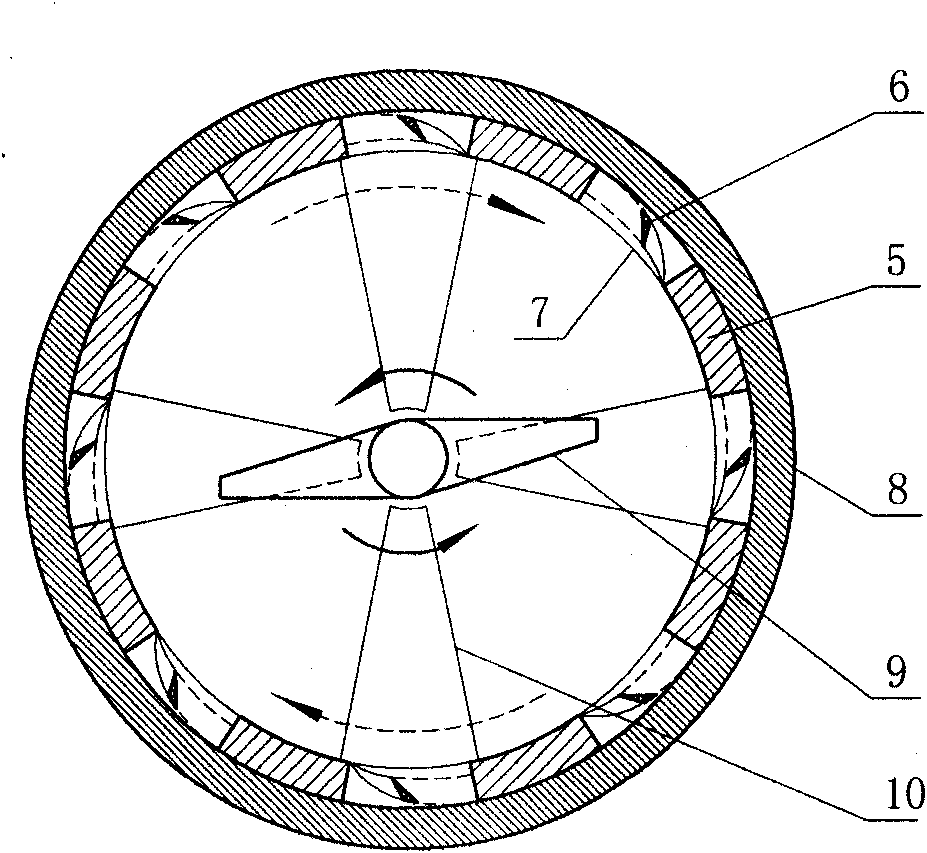

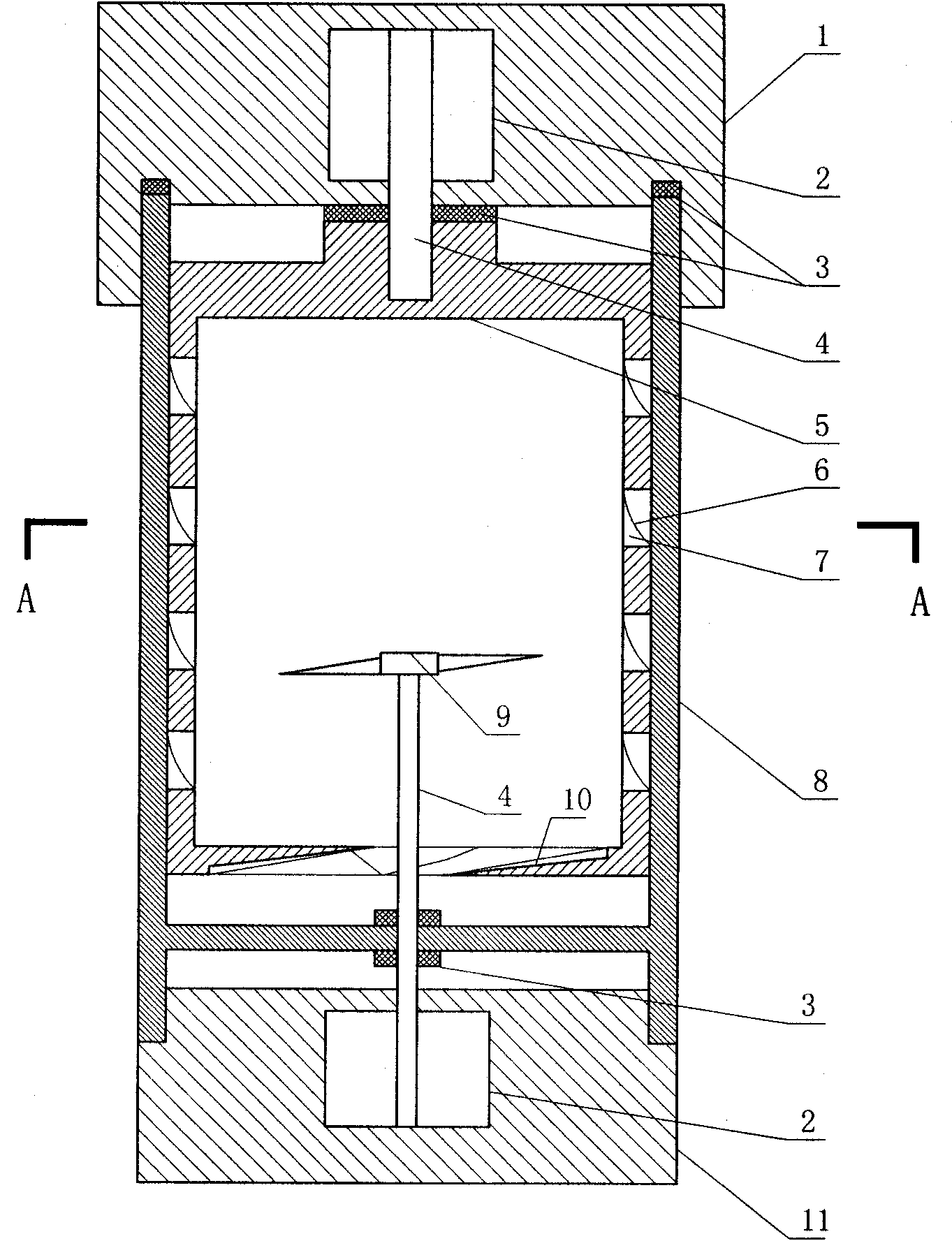

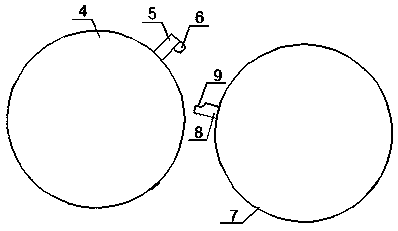

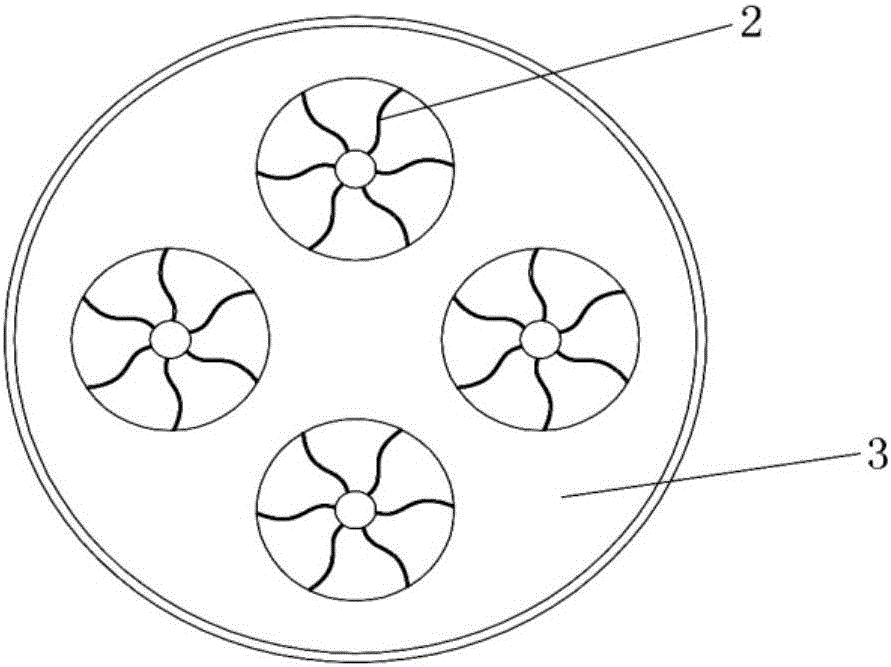

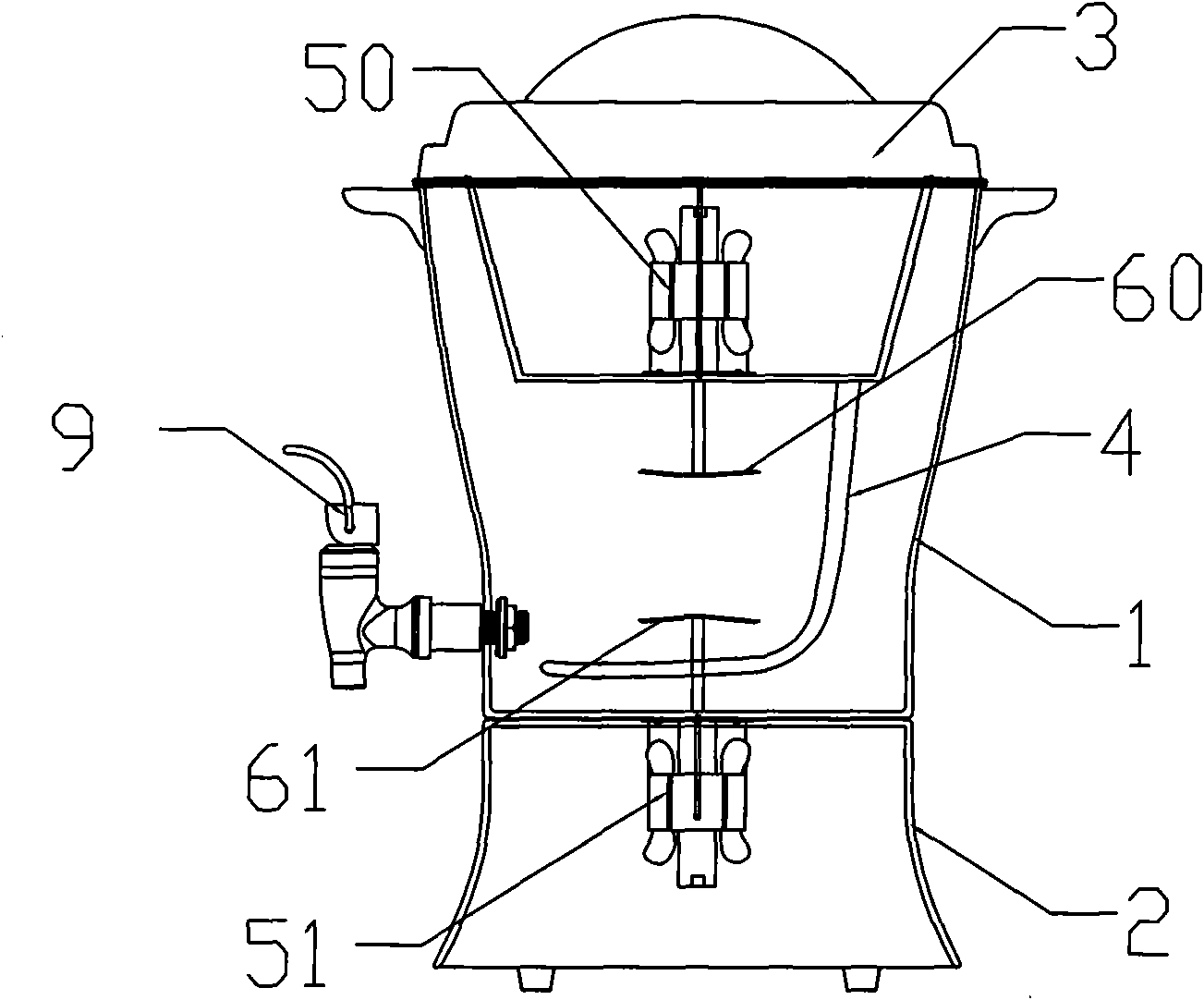

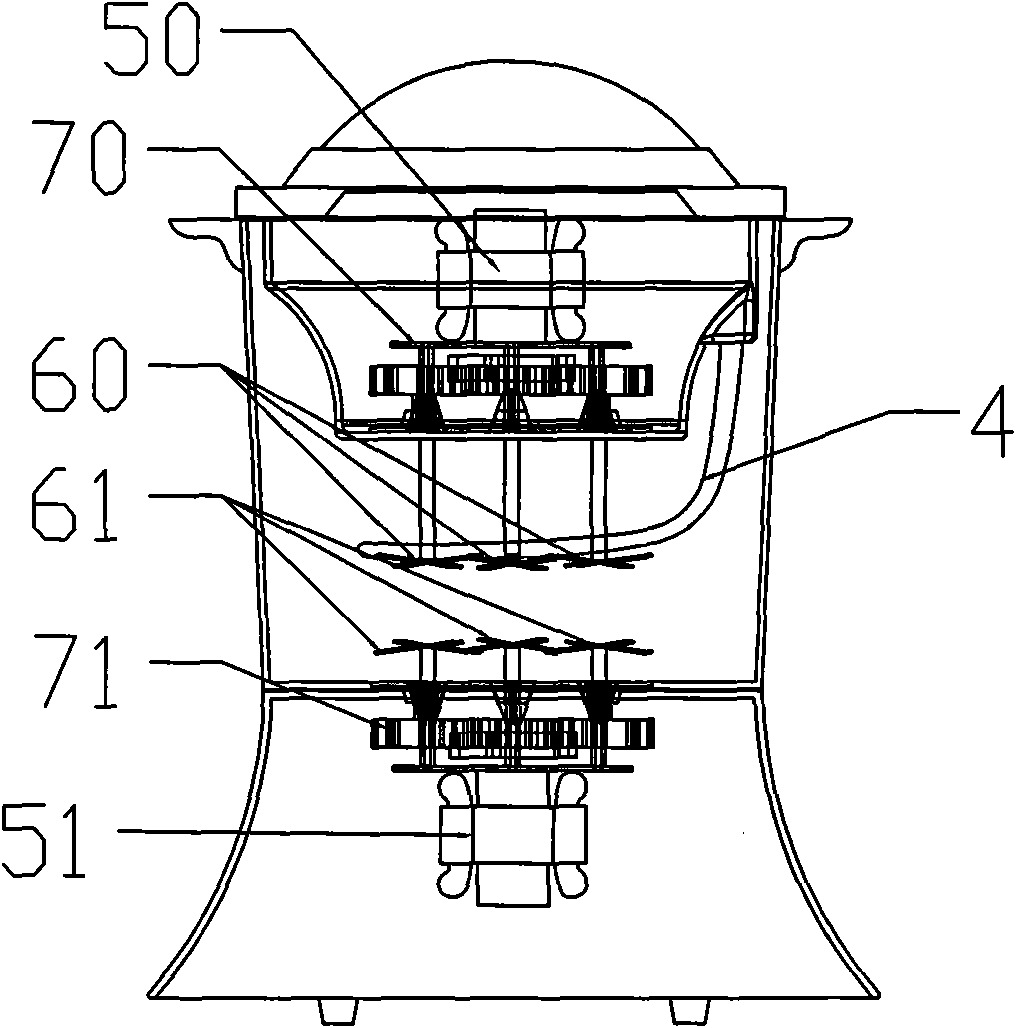

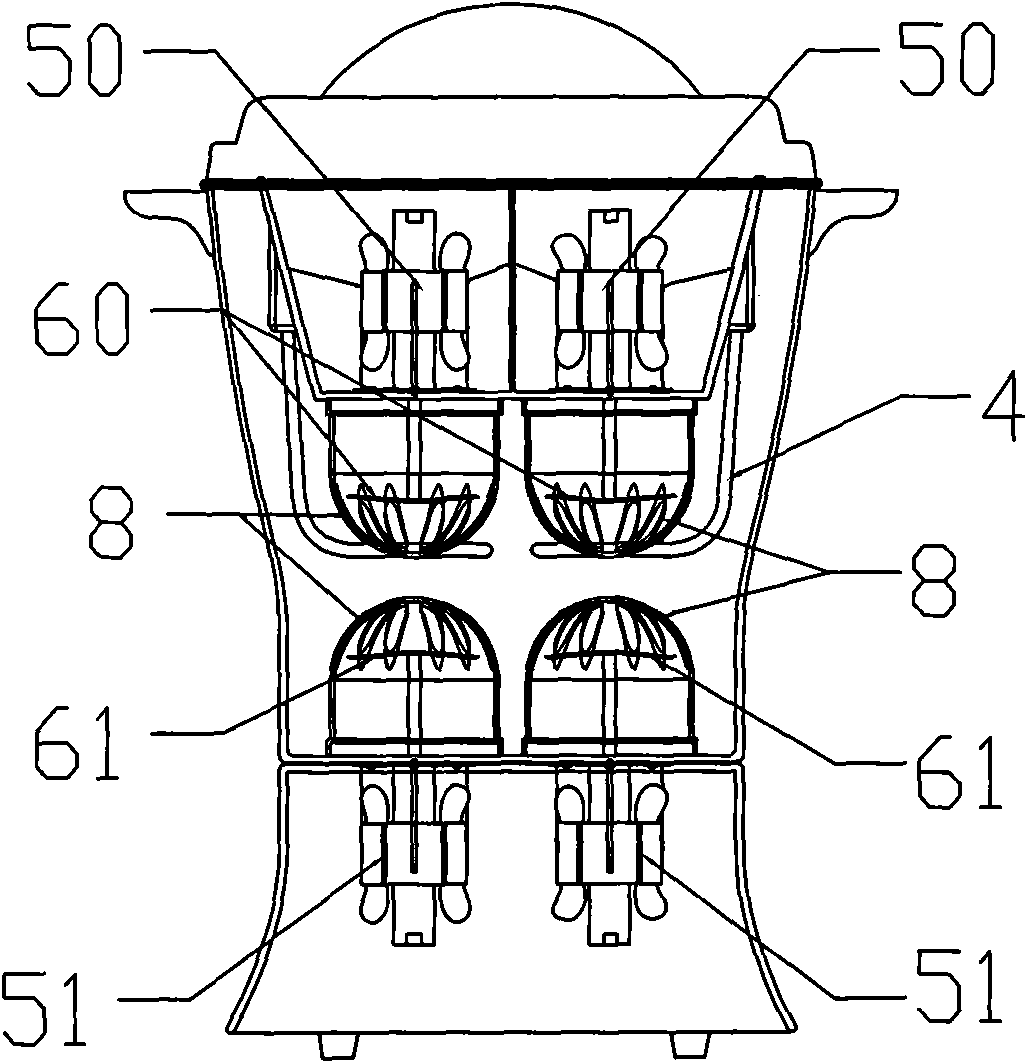

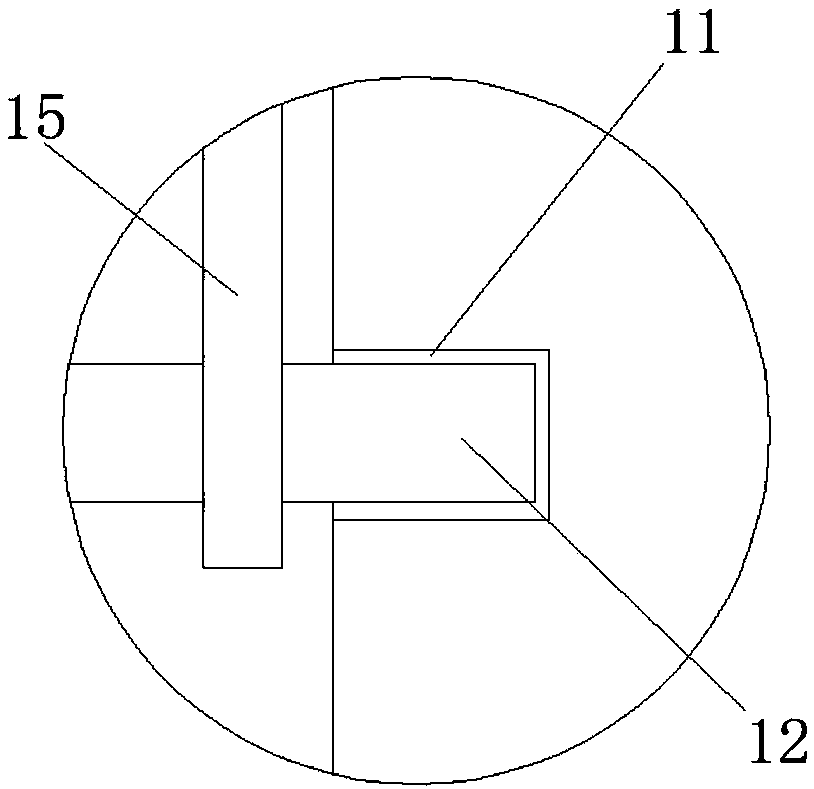

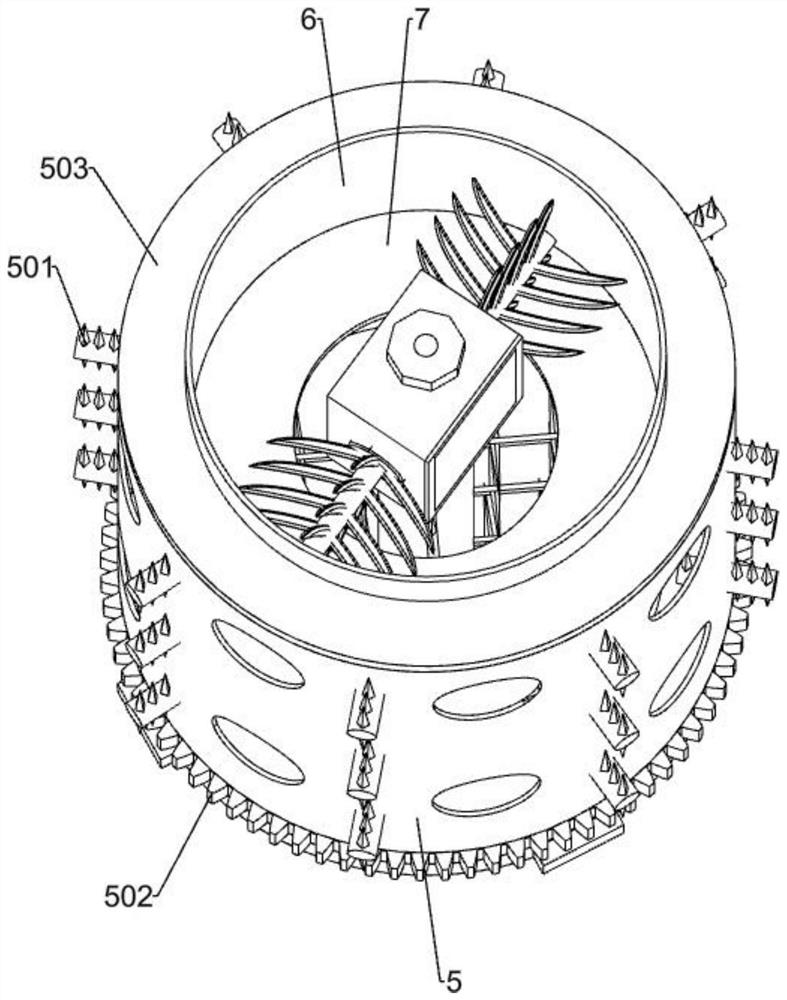

Dual-rotation direction blade hole-blade soybean milk machine

ActiveCN101953400AThe effect is thoroughIncrease momentumBeverage vesselsGrain treatmentsSlurryEngineering

The invention relates to a soybean milk machine, in particular to a dual-rotation direction blade hole-blade soybean milk machine, comprising a top cover, a motor, a sealing ring, a rotation shaft, a sleeve, a hole blade, a grinding hole, a material cylinder, a main blade, a cylinder bottom blade and a base. The top cover and the base are respectively arranged at the top part and the bottom part of the material cylinder; the sleeve is a cylinder with the upper end closed and the lower end opened; the lower end of the sleeve is provided with four cylinder bottom blades integrated with the sleeve and evenly distributed along the circumference of the sleeve; the top cover and the base are respectively provided with a motor; the rotation shaft of the motor of the base penetrates an axial hole at the bottom part of the material cylinder and the upper end thereof is connected with the main blade which is integrated with the rotation shaft. Compared with the traditional soybean milk machine, the dual-rotation direction blade hole-blade soybean milk machine of the invention greatly improves the speed of beating the slurry particles by the blades, and increases the rate that the blades collide with the slurry particles, thereby greatly enhancing the working efficiency of the soybean milk machine.

Owner:JIANGSU LUSHI DIAMOND TOOLS CO LTD

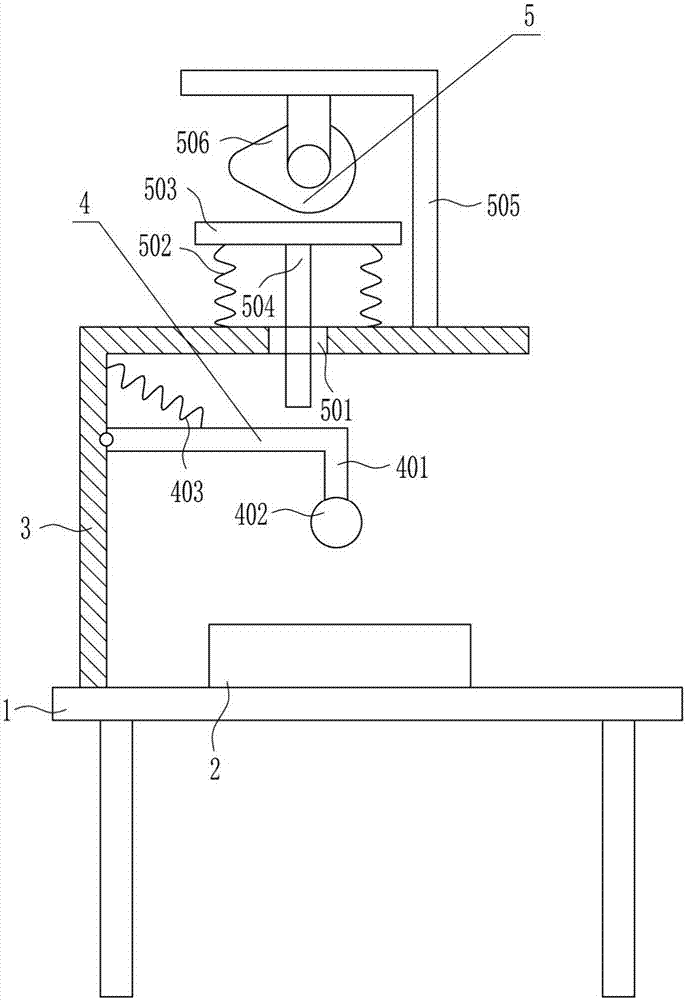

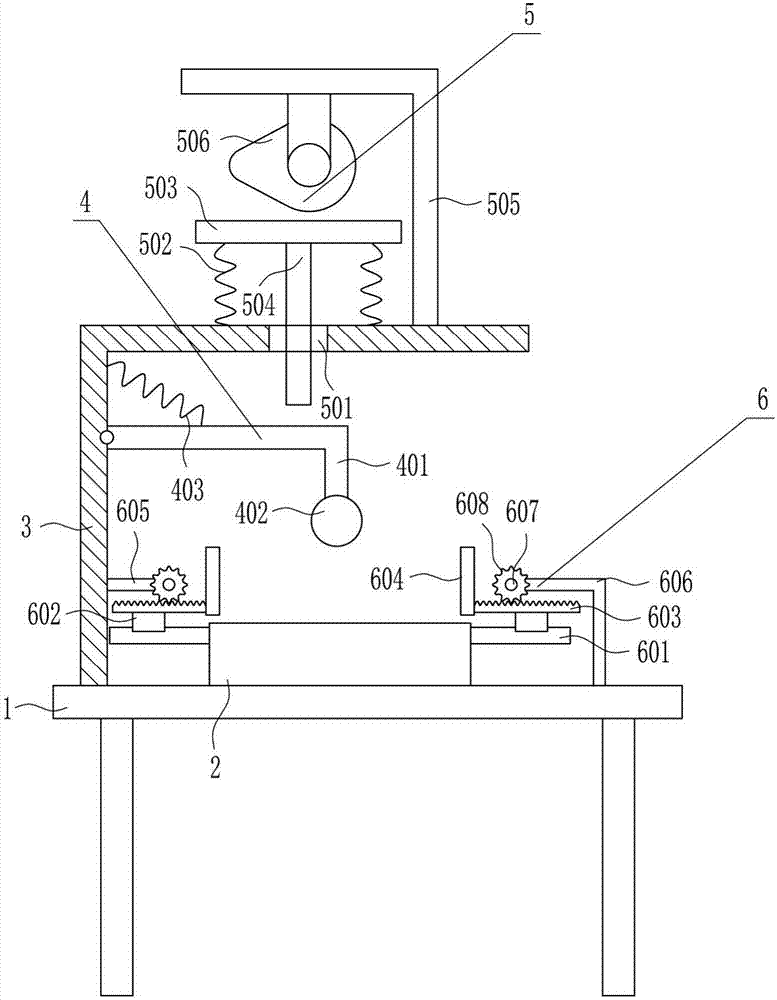

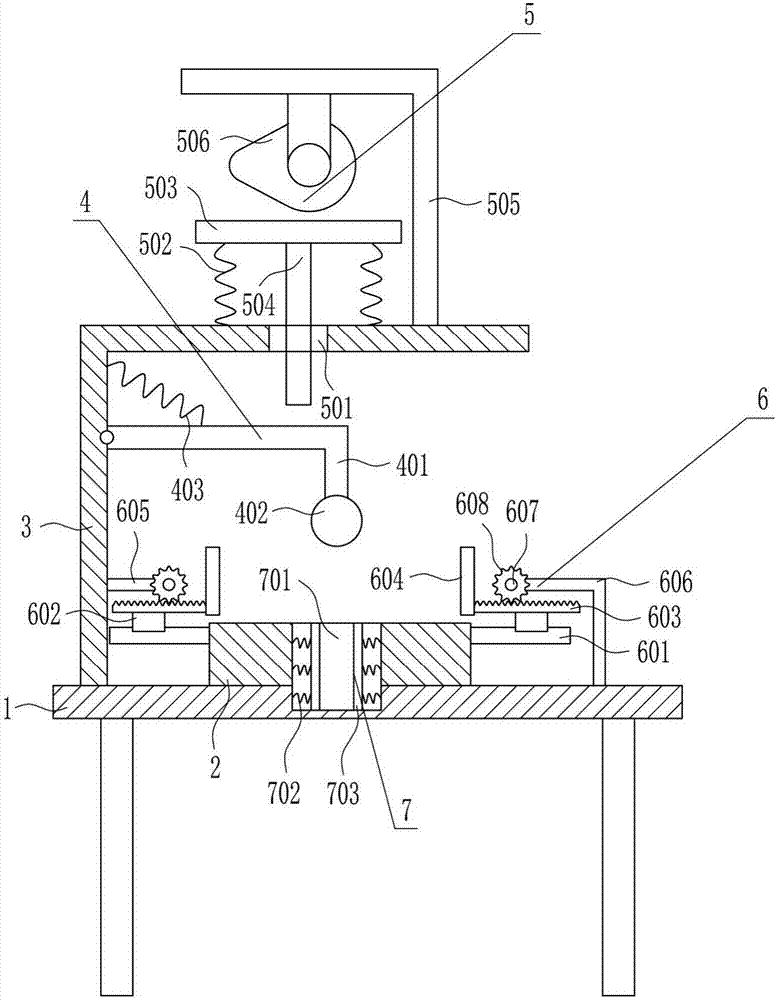

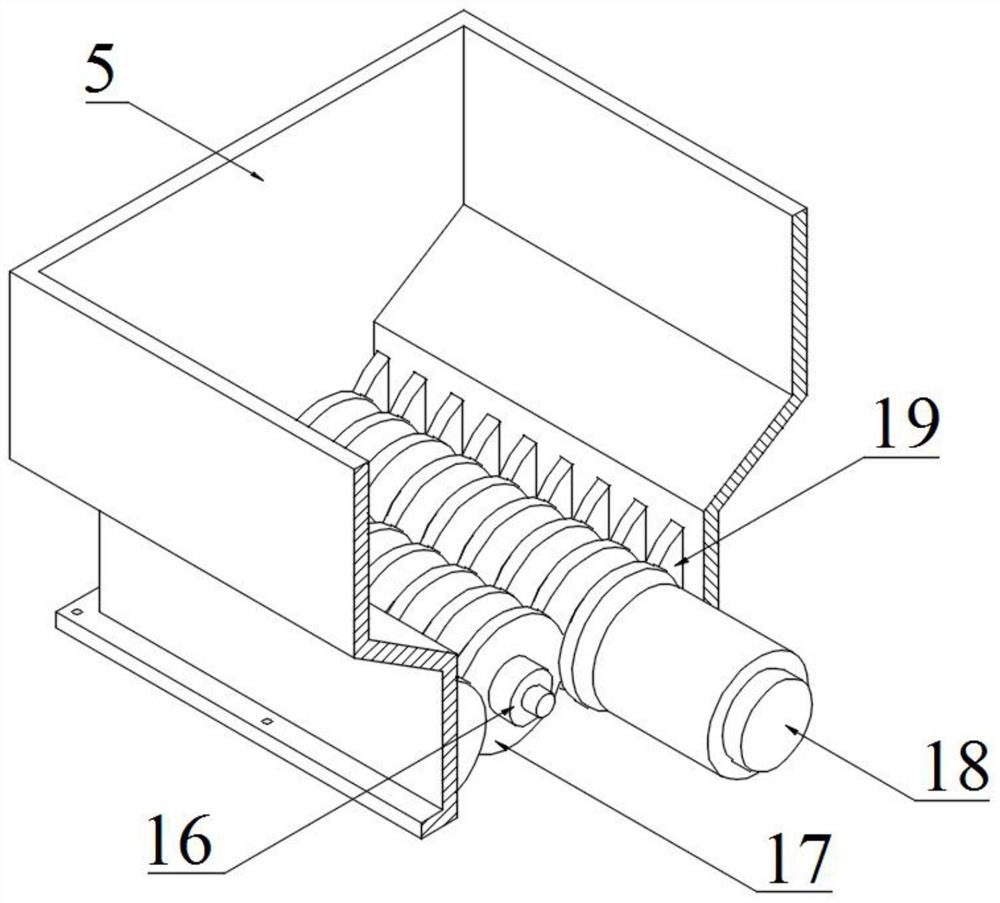

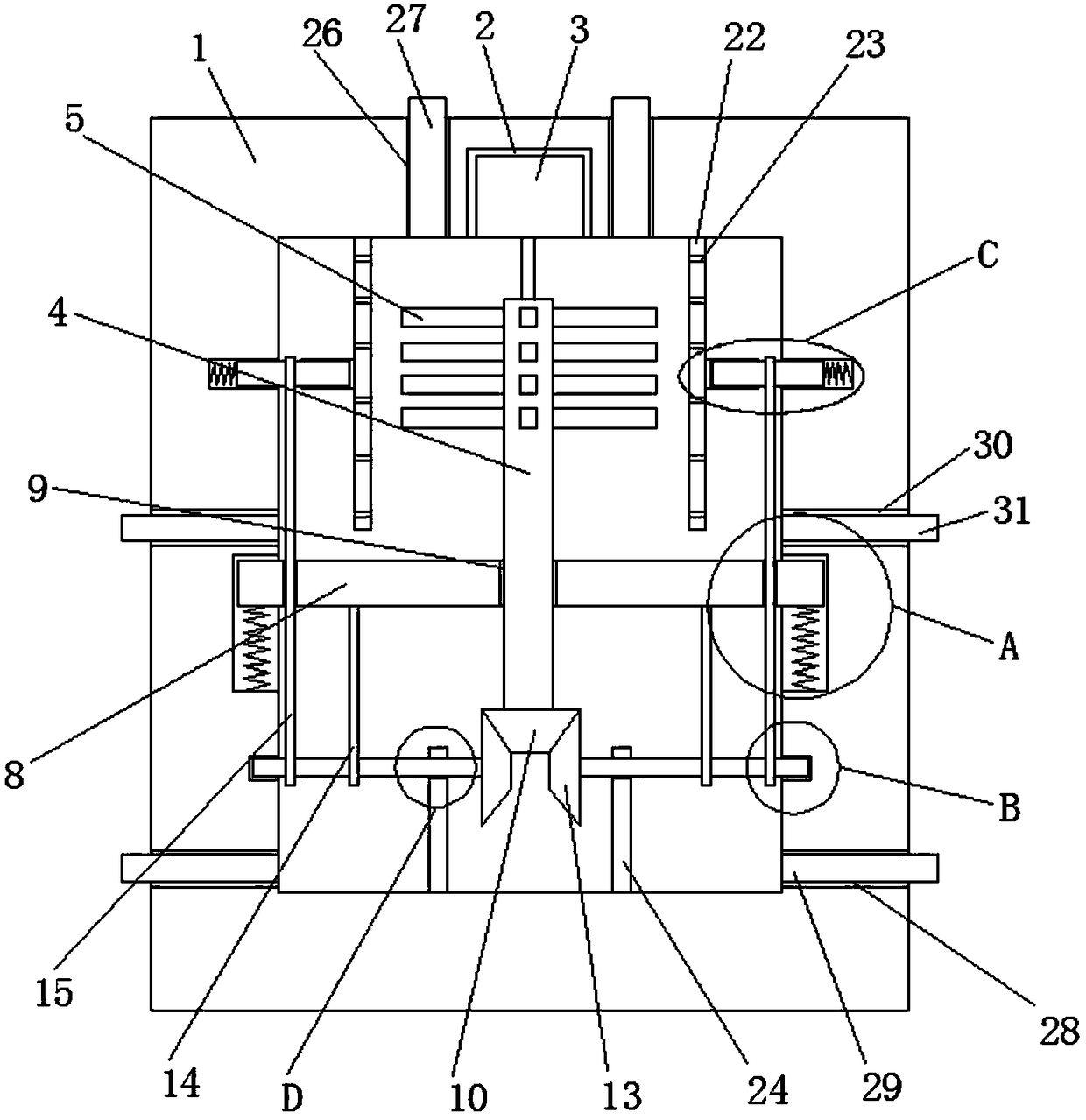

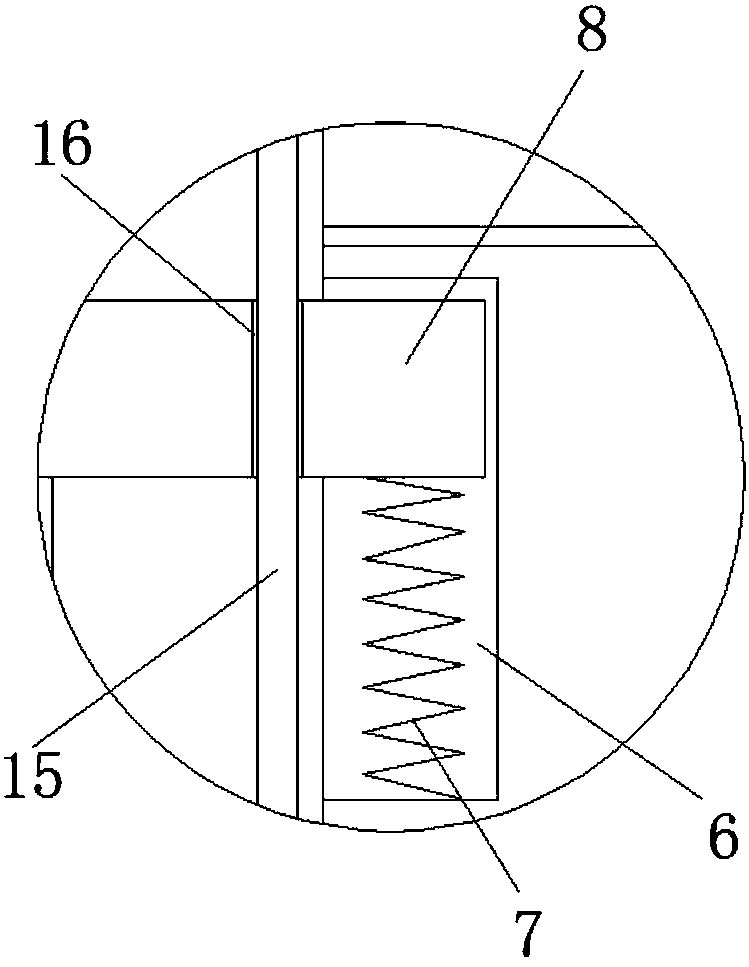

Pork hammering device

InactiveCN107821554AImprove beating efficiencyReduce labor intensityBeating-based meat tenderisingEngineeringUltimate tensile strength

The invention discloses a pork hammering device which includes a machine frame, a circuit controller, a servo motor, a main rotary disk, a plurality of first baffle rods, a plurality of baffle balls,a sub-rotary disk, a secondary baffle rod, a position-limiting groove, an iron hammer, a stone hammer trough, a material trough, a side door, a support frame, an air-cylinder and a pushing plate. Themain rotary disk is rotatably installed on the left end of the machine frame and is connected to an output shaft of the servo motor via a gear. There are eight first baffle rods uniformly arranged onthe side surface of the main rotary disk at equal interval, each first baffle rod being fixedly provided with one baffle ball. The sub-rotary disk is rotatably installed on the right end of the machine frame. A second baffle rod is fixedly installed on the left upper end of the side wall of the sub-rotary disk. The position-limiting groove is formed in the second baffle rod. The iron hammer is fixedly installed on the right lower end of the sub-rotary disk. The pork hammering device is convenient to use, is improved in hammering efficiency and reduces labor intensity of workers.

Owner:ANHUI FURUN MEAT PROCESSING

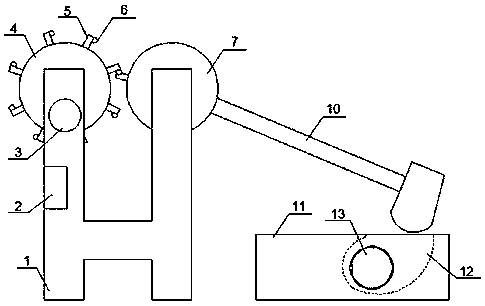

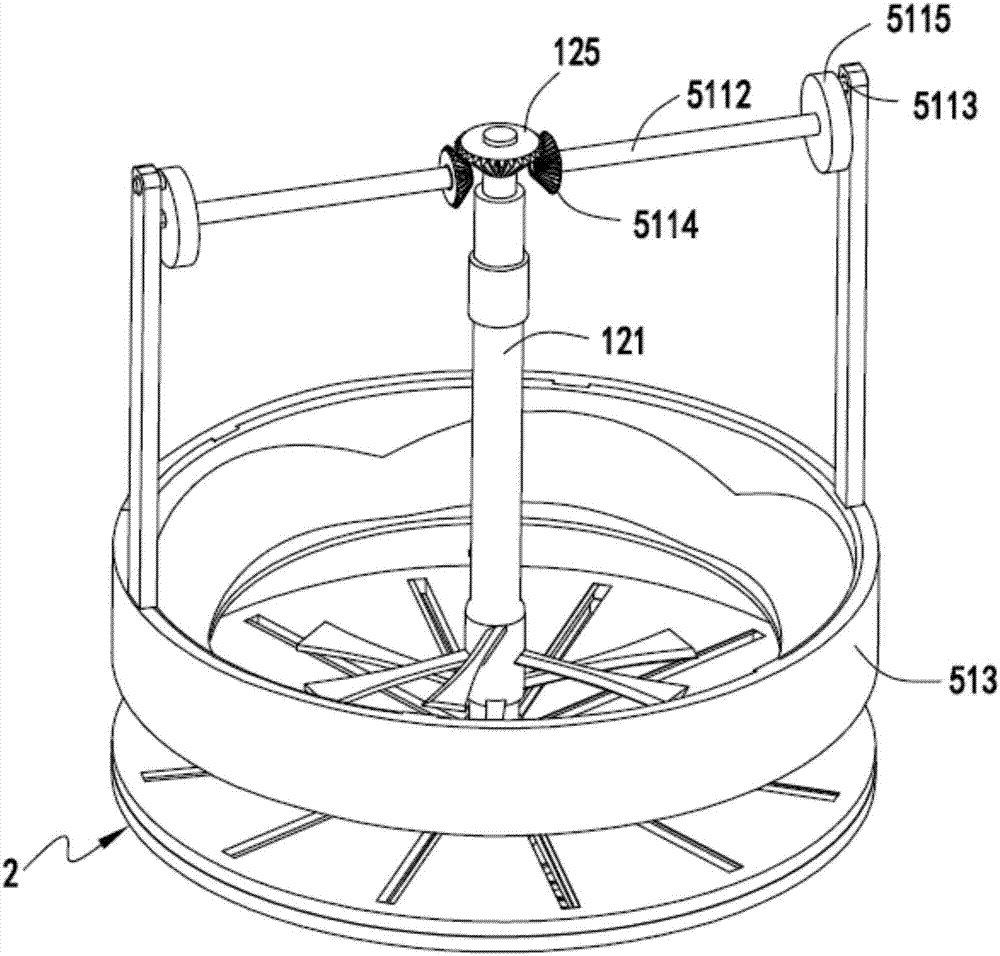

Multi-stage size beating device for textile size

The invention relates to a multi-stage beating equipment for textile pulp, which includes a crushing part, the crushing part includes a power mechanism and a crushing mechanism for crushing the pulp in the beating barrel driven by the power mechanism; the cross-cutting part, The cross-cutting part is arranged below the crushing part, and the cross-cutting part includes a cross-cutting mechanism and a control mechanism arranged under the cross-cutting mechanism, and the cross-cutting mechanism divides the beating bucket into primary pulp from top to bottom. The material area and the qualified pulp area, the control mechanism is used to control the slurry in the primary pulp area to flow to the qualified pulp area, and the cross-cutting mechanism is used to control the slurry flowing from the primary pulp area to the qualified pulp area Chopping; the present invention overcomes the problems of insufficient beating of the slurry and inability to connect well between the two beating processes before and after, and cannot give full play to the effects of the two beating processes.

Owner:SUZHOU RUIRI TEXTILE SCI & TECH

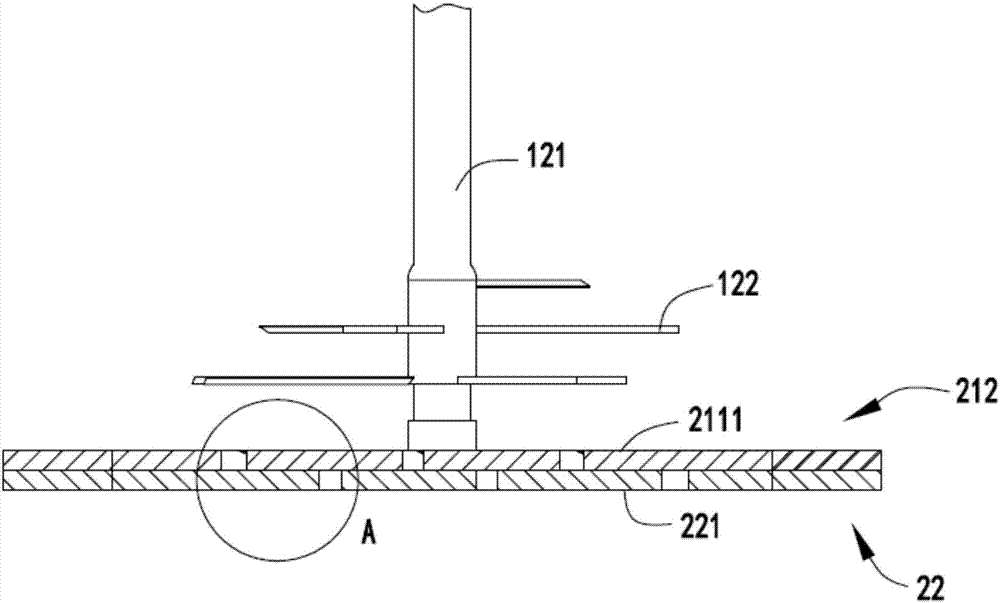

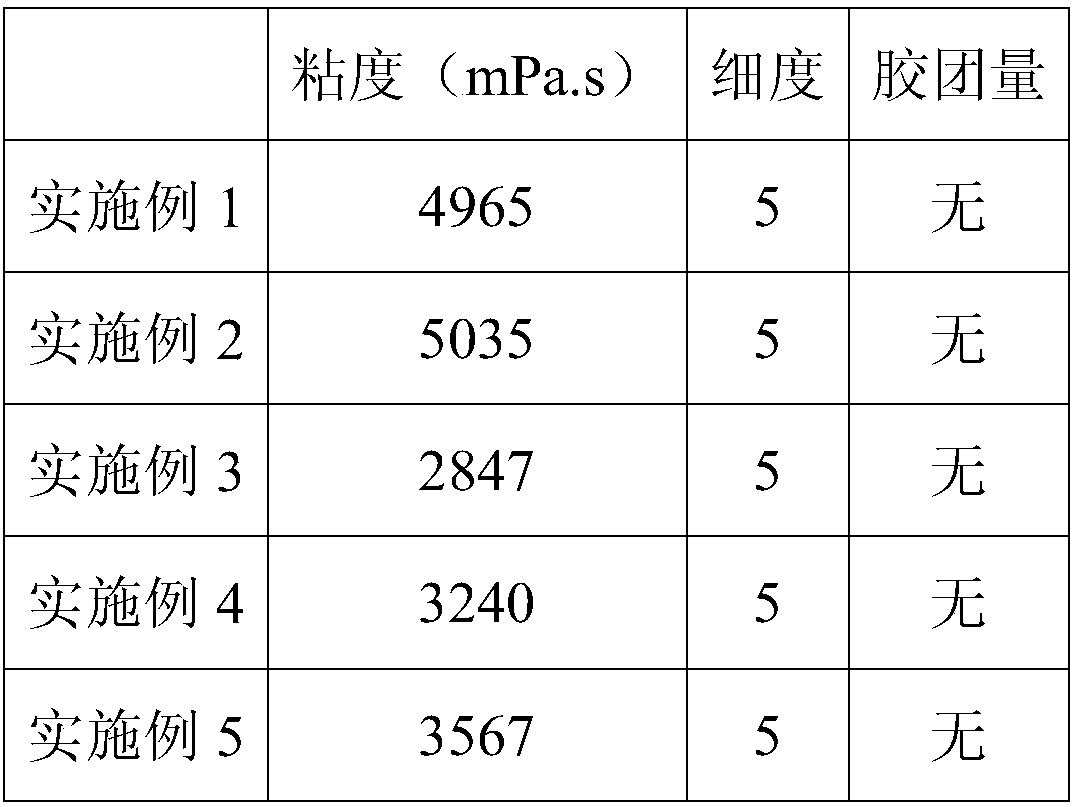

Method for preparing lithium ion battery electrode slurry by using vibration-mechanical stirring combination

InactiveCN108400287AImprove dispersion uniformityEvenly dispersedElectrode manufacturing processesSlurrySolvent

The invention discloses a method for preparing lithium ion battery electrode slurry by using vibration-mechanical stirring combination, comprising the following steps of: S1: mixing active materials,binders and conductive agents for vibration stirring for 0.5 to 1h, and continuously adding the solvent by spraying during the vibration stirring process; S2: continuing the vibration stirring for 0.5to 1hour after the solvent is added; and S3: finally performing the vacuum mechanical stirring for 0.5 to 2 hours to obtain the lithium ion battery electrode slurry. The method has simple operation steps, improves production efficiency and reduces energy consumption. The obtained lithium ion battery electrode slurry has suitable viscosity, good dispersibility and fineness, and the prepared lithium ion battery has excellent performance.

Owner:安徽益佳通电池有限公司

Paper pulp of paper logistics tray

InactiveCN102199895AHigh strengthImprove beating efficiencyNatural cellulose pulp/paperReinforcing agents additionPolyvinyl alcoholPulp and paper industry

The invention discloses paper pulp of a paper logistics tray. Raw materials of the paper pulp comprise waste corrugated paper, a raw bamboo pulp board, a wood pulp board, auxiliaries and a packing material, wherein the auxiliaries comprises a AKD (Alkyl Ketene Dimer) waterproof agent, a twice-modified polyacrylamide derivative strengthening agent, a PAE (polyarylether) wet strengthening agent, formaldehyde, paranitrophenol, polyacrylamide and polyvinyl alcohol, and the packing material is calcium carbonate; the formula of the paper pulp of the paper logistics tray comprises the following components in percentage by mass: 77% to 80% of waste corrugated paper, 6% to 9% of raw bamboo pulp board, 4 % to 7% of wood pulp board, 1.2% to 2.1 % of AKD waterproof agent, 1.2% to 2.1 % of twice-modified polyacrylamide derivative strengthening agent, 0.8% to 1.5% of PAE wet strengthening agent, 0.6 to 1.2% of formaldehyde, 0.4% to 0.8 % of paranitrophenol, 1.78% to 3.67% of polyacrylamide, 0.12% to 0.28% of polyvinyl alcohol and 4 % to 7 % of calcium carbonate. The formula of the paper pulp of the paper logistics tray has the advantages of low cost, high beating efficiency, high strength of products, good moisture resistance, high permeability and little pollution to environments.

Owner:HANGZHOU LVBAO PAPER PROD

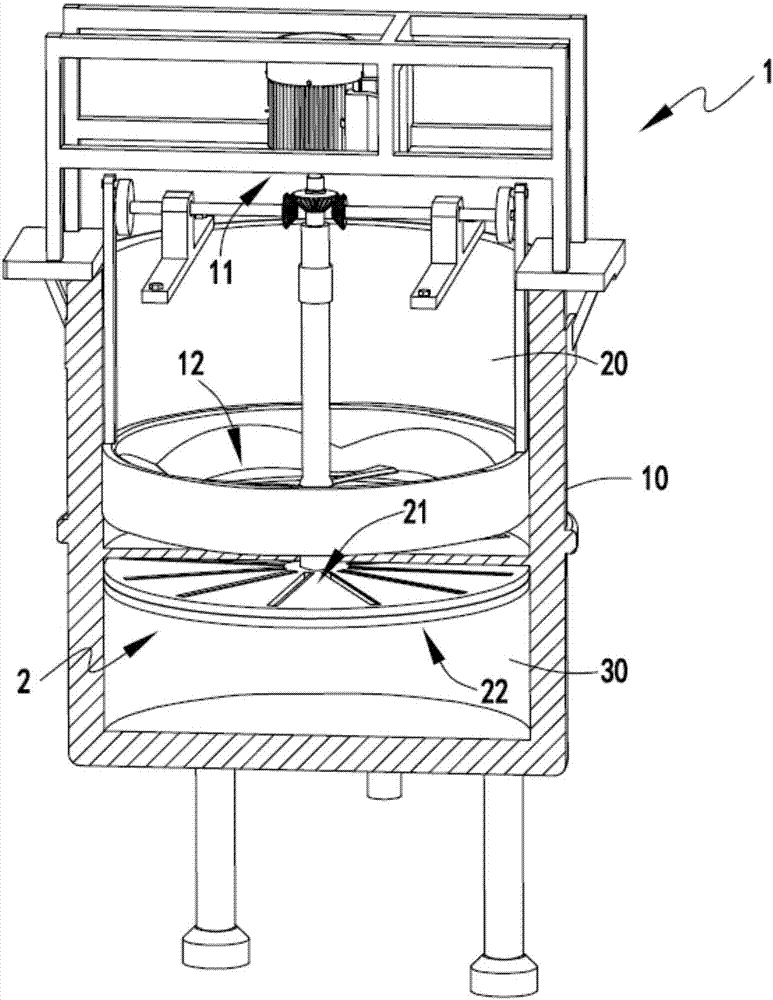

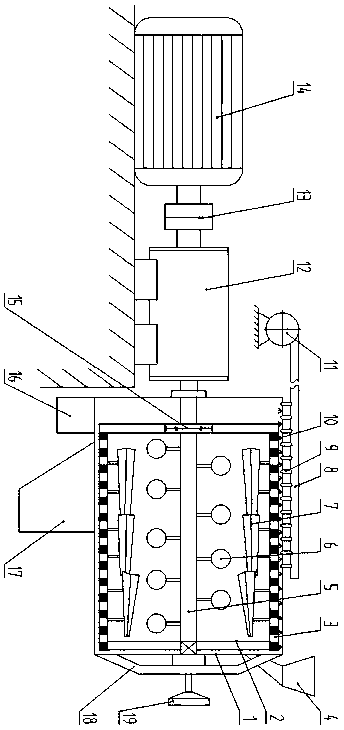

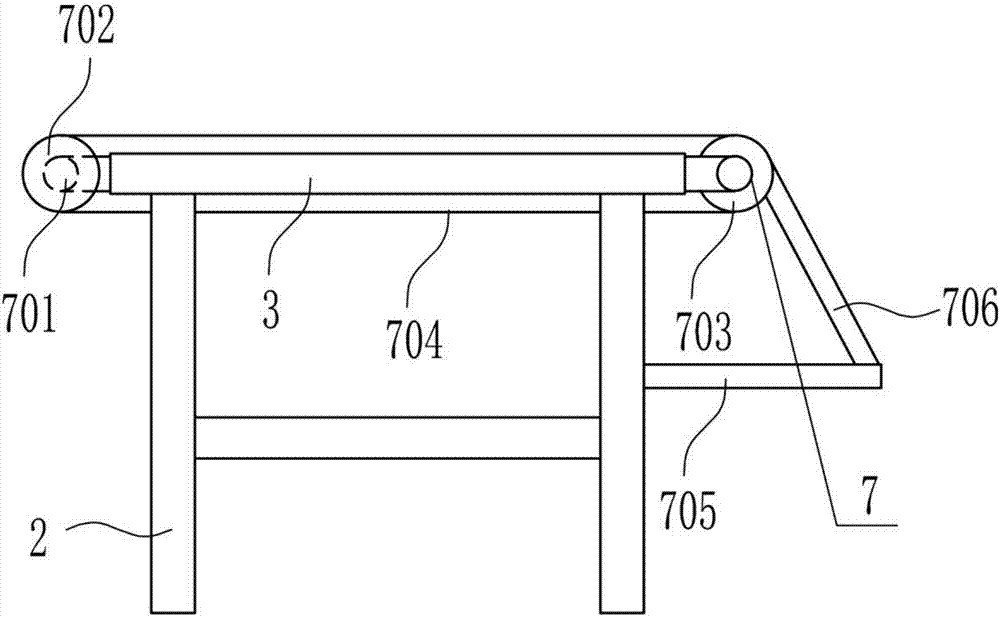

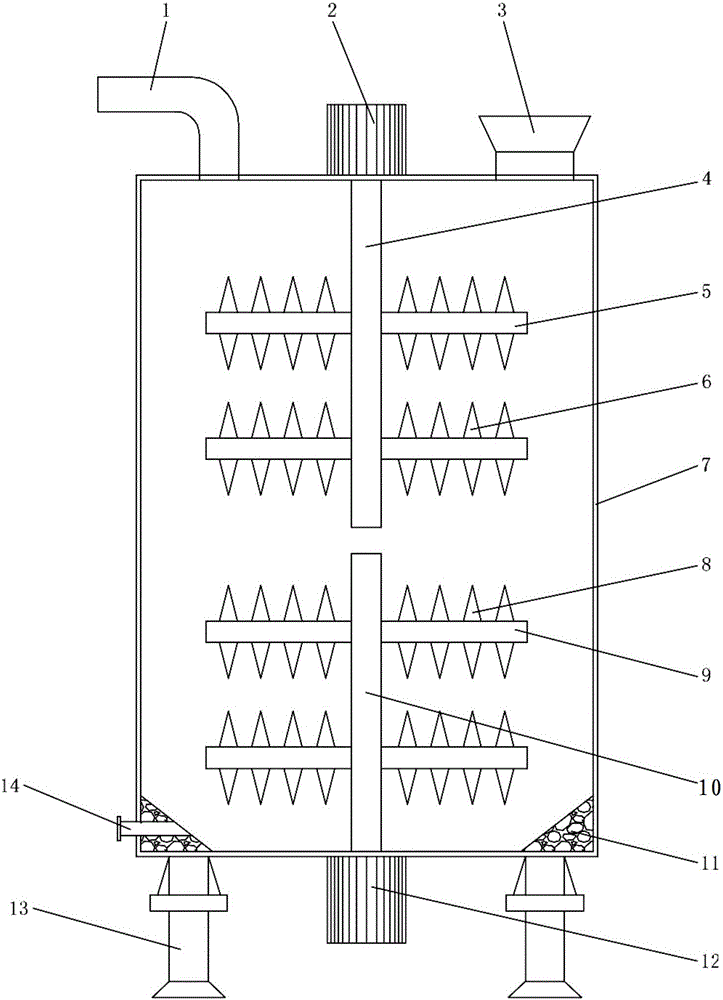

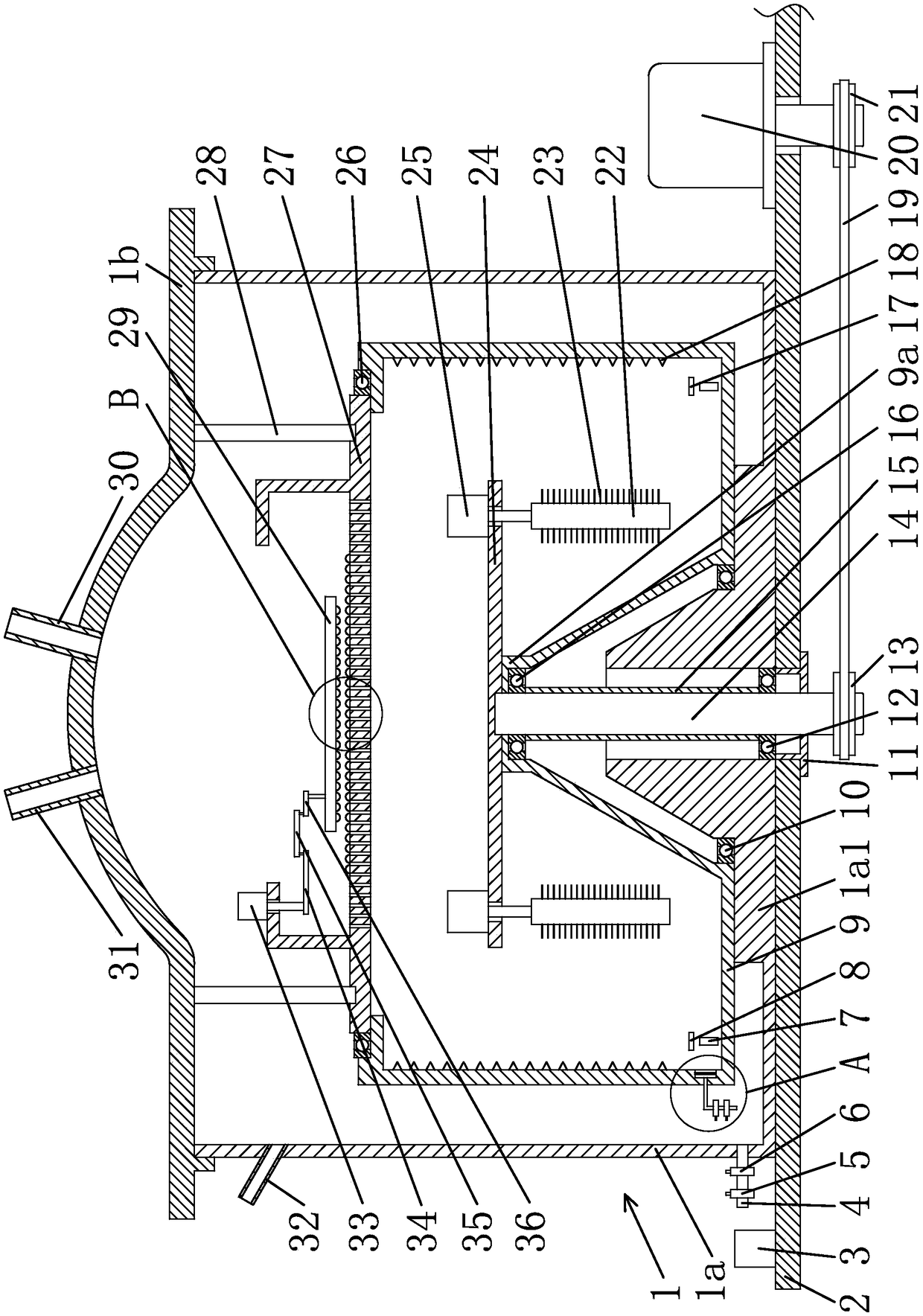

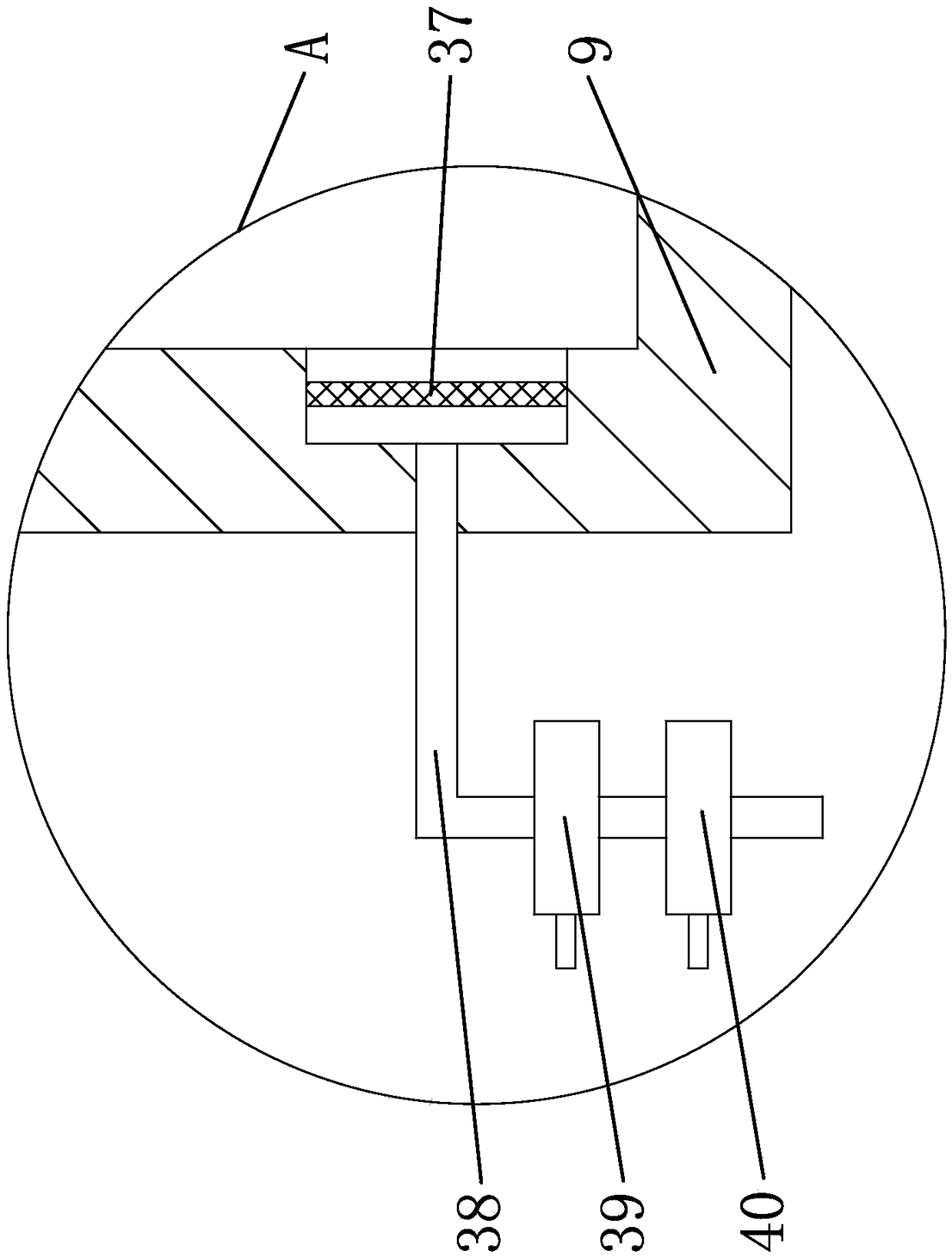

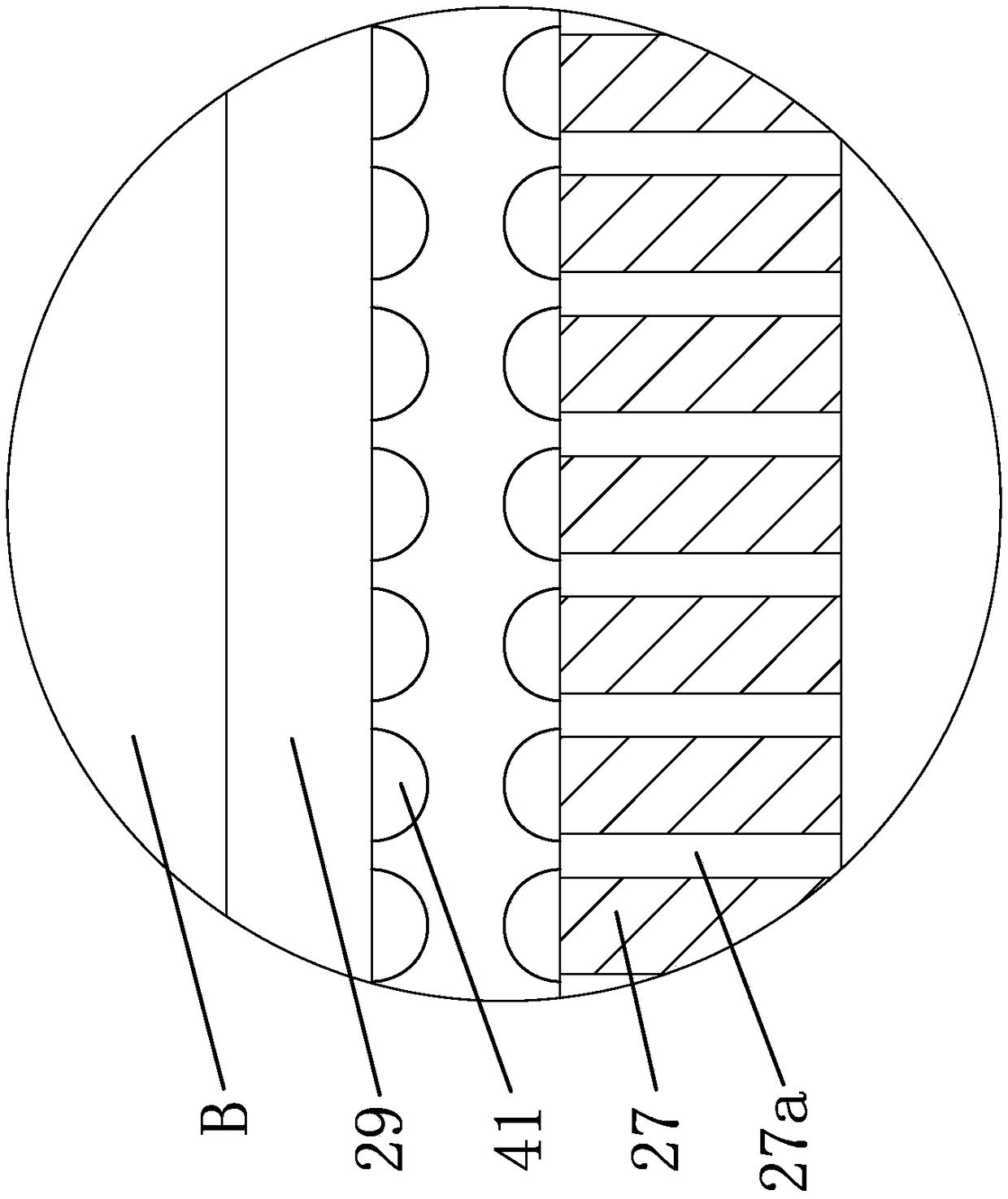

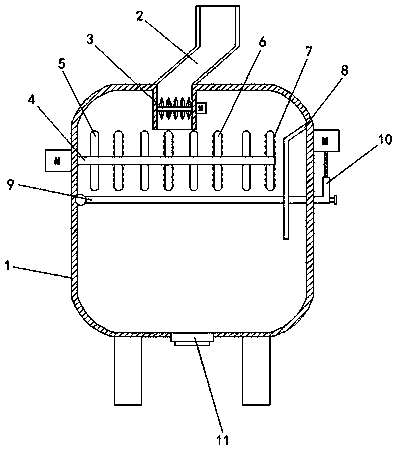

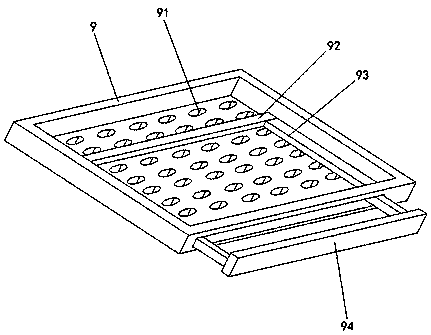

Waste paper stirrer

InactiveCN106351045AImprove beating efficiencyAvoid stickingPaper recyclingRaw material divisionImpellerPulp and paper industry

The invention belongs to the technical field of waste paper recycling and pulping, and discloses a waste paper stirrer. According to the waste paper stirrer, a motor is arranged at the outer side of a stirring barrel, an output shaft of the motor is connected with a rotating shaft, the rotating shaft is sleeved by a stirring plate, a plurality of groups of blade knives are assembled on the stirring plate, and an impeller is assembled under the stirring plate. When the rotating shaft is driven to push the stirring plate to rotate by the motor, the blade knives are utilized and the blade knives can cut up paper pulp on one hand, so that a waste paper pulping effect can be improved; on the other hand, the paper pulp at the bottom in the stirring barrel is rotated by the impeller, so that the phenomenon of bonding at the bottom of the stirring barrel is prevented, the fluidity is improved, and a later papermaking technology is high in quality.

Owner:ZHONGSHAN WEIKE PACKAGE PROD CO LTD

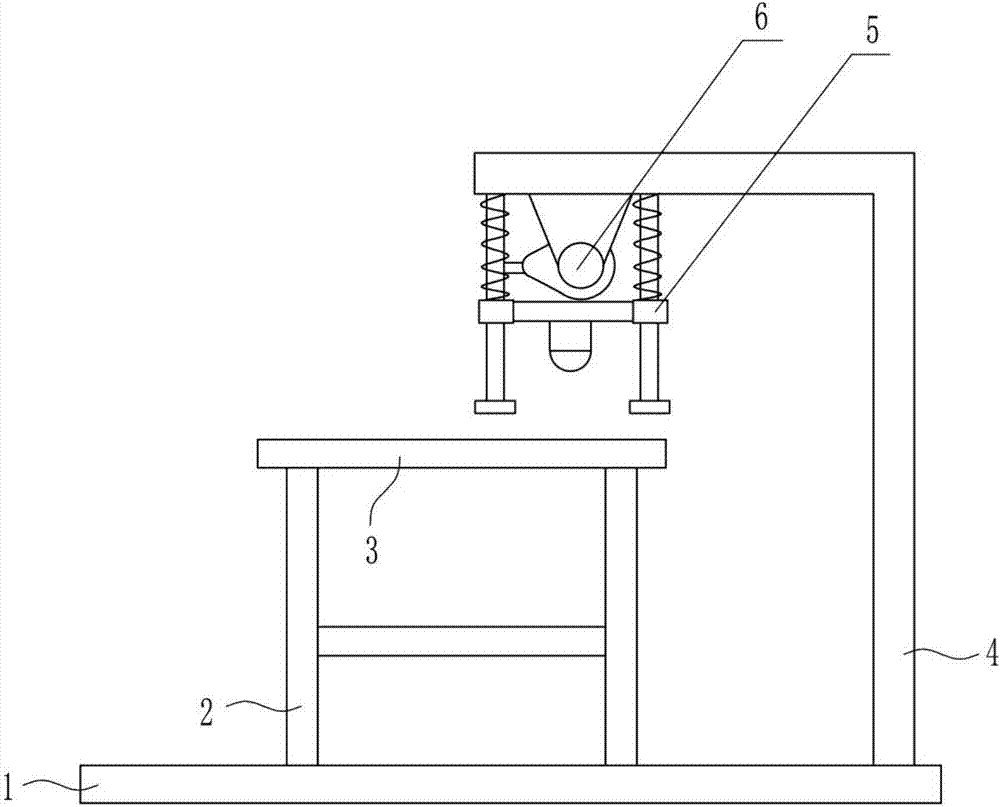

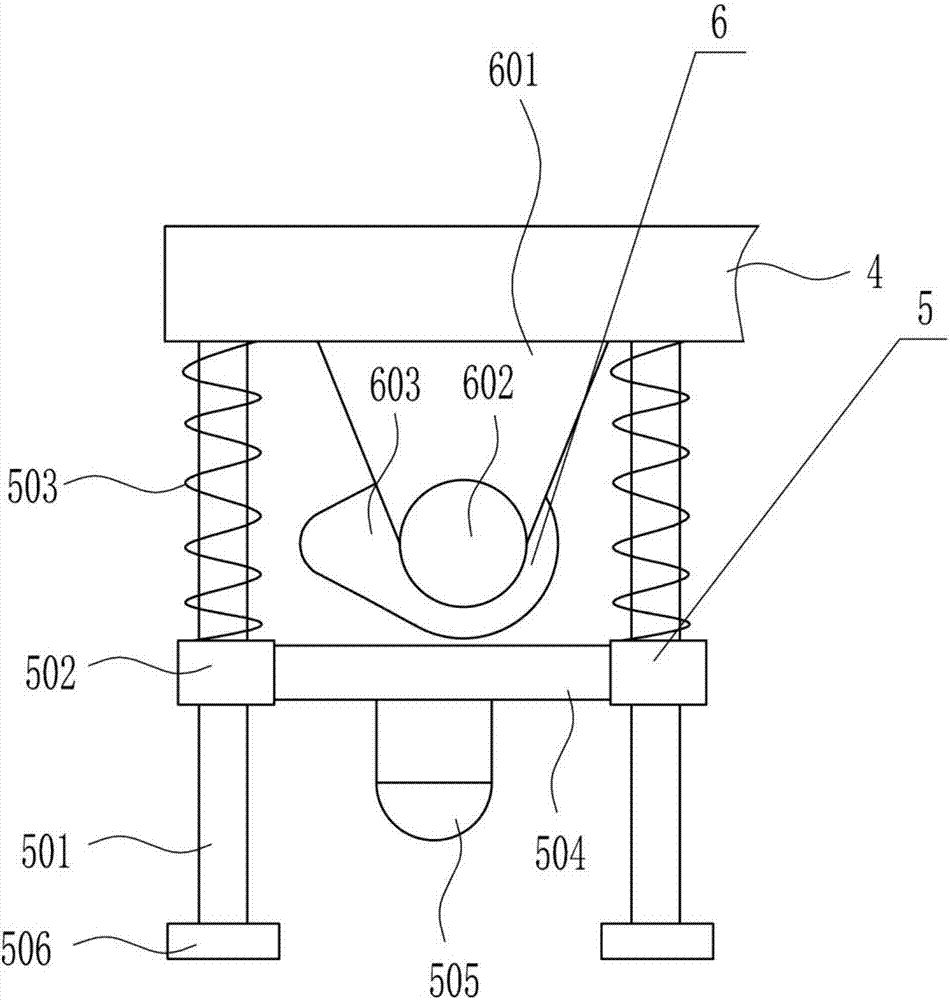

Shoe upper beating device for shoemaking

ActiveCN106963043AImprove beating efficiencyImprove beating effectPoundingEngineeringUltimate tensile strength

The invention relates to a shoemaking device, in particular to a shoe upper beating device for shoemaking. The shoe upper beating device for shoemaking achieves the technical purposes that the labor intensity of workers can be lowered, the beating efficiency can be improved, and the two hands can be protected. In order to achieve the technical purposes, the shoe upper beating device for shoemaking comprises a workbench and the like; a placement table is connected to the top of the workbench through a bolt, a first 7-shaped plate is connected to the top of the workbench on the left side of the placement table through a bolt, a beating device is arranged on the inner side face of the first 7-shaped plate, and a driving device is arranged on the top of the first 7-shaped plate. The driving device drives the beating device for rapidly beating a shoe, so that a worker does not need to beat the shoe with a smaller hammer.

Owner:浙江名将鞋业有限公司

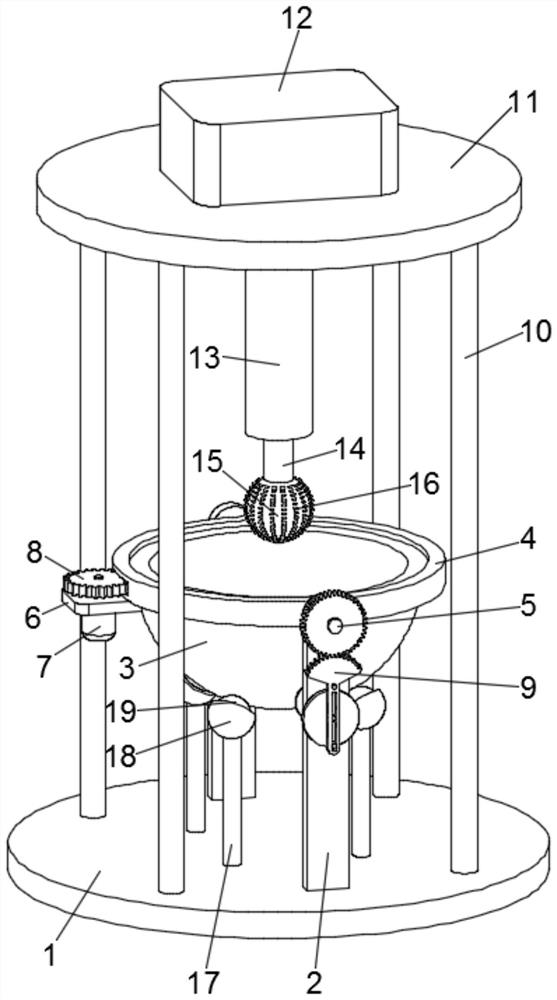

Beating machine for preparing mixed mango jam

InactiveCN107692246ASimple structureEasy to useJuice extractionHollow article cleaningFiberMotor drive

The invention discloses a beating machine for preparing assorted mango jam, which comprises an outer shell, a beating mechanism and a cleaning device; an inner shell is arranged in the outer shell, and a screen layer is arranged between the inner outer shells; a cleaning device is also installed on the outer shell A beating mechanism is arranged in the inner shell; the beating mechanism includes a beating rotating shaft, a beating stirring ball and a beating blade; the beating and stirring ball is fixedly connected with the beating rotating shaft through a connecting rod, and rotates at a high speed under the rotation of the beating rotating shaft; the beating blade is arranged on the On the inner side wall of the inner shell, the beating blade is arranged around the outside of the beating and stirring ball; the beating shaft is connected with the external drive motor; the beating efficiency is high after the mango is peeled, which can ensure the quality of the mango jam, and can solve the problem of multi-fiber mango. It solves the problems that the mango jam can be quickly made into jam, the mango fiber is easy to wrap around the beating blade and the beating machine is difficult to clean; the problem that the fiber in mango jam may affect its taste is solved; the problem of low beating efficiency and high beating cost of the beating machine is solved.

Owner:黄浩

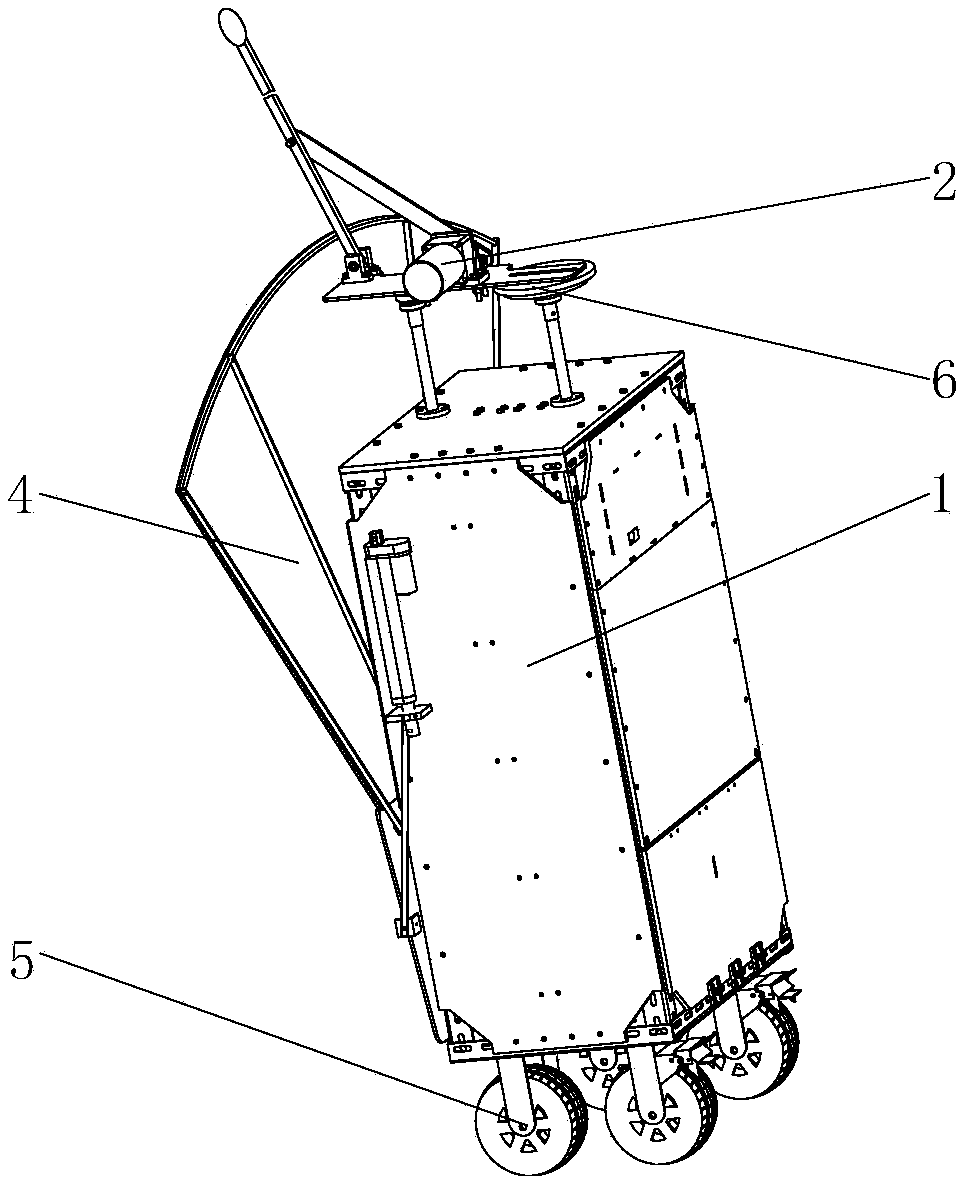

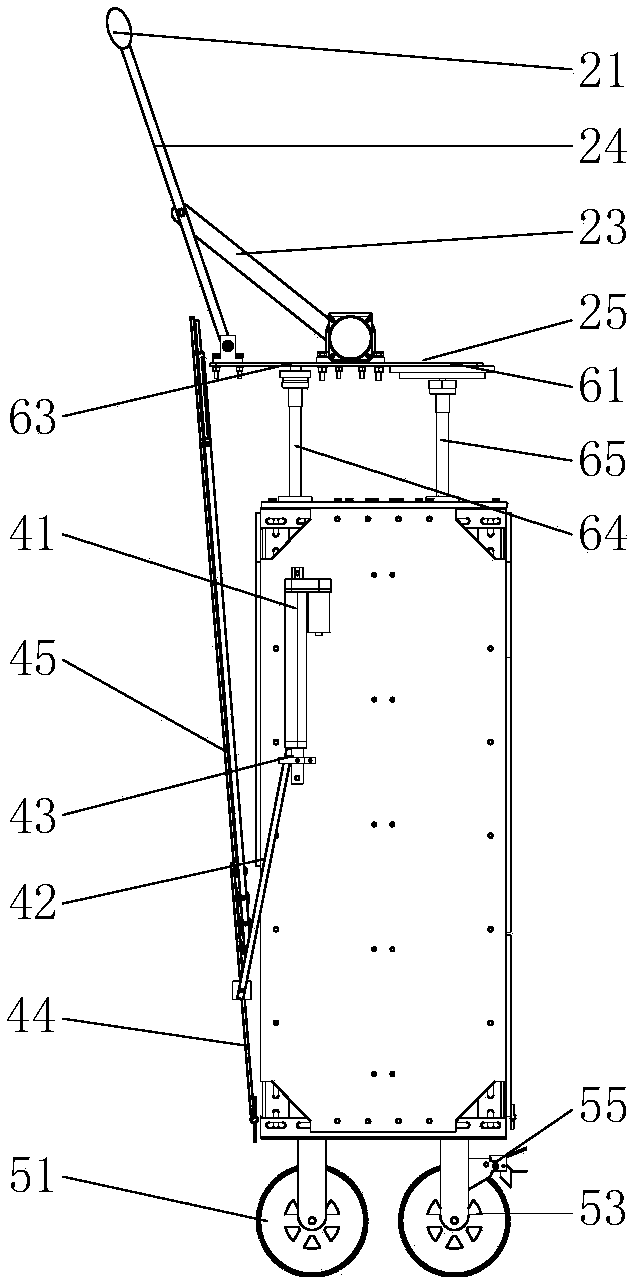

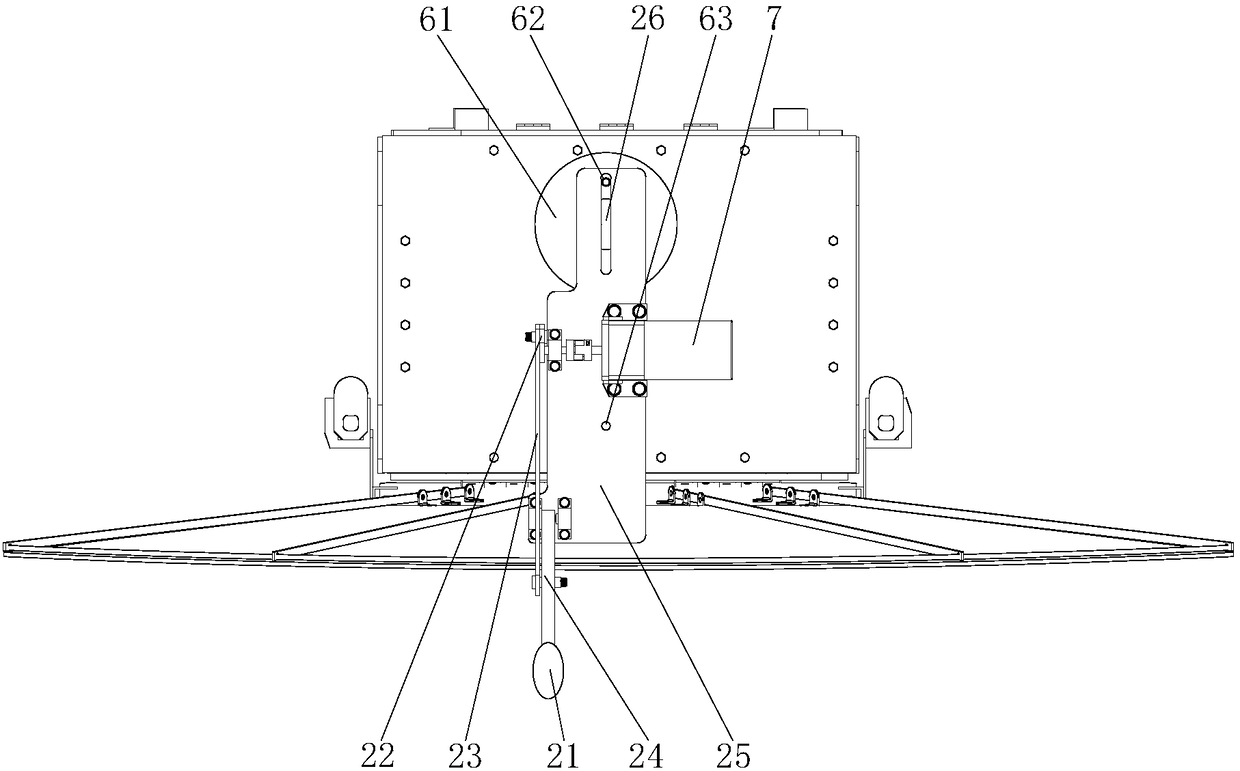

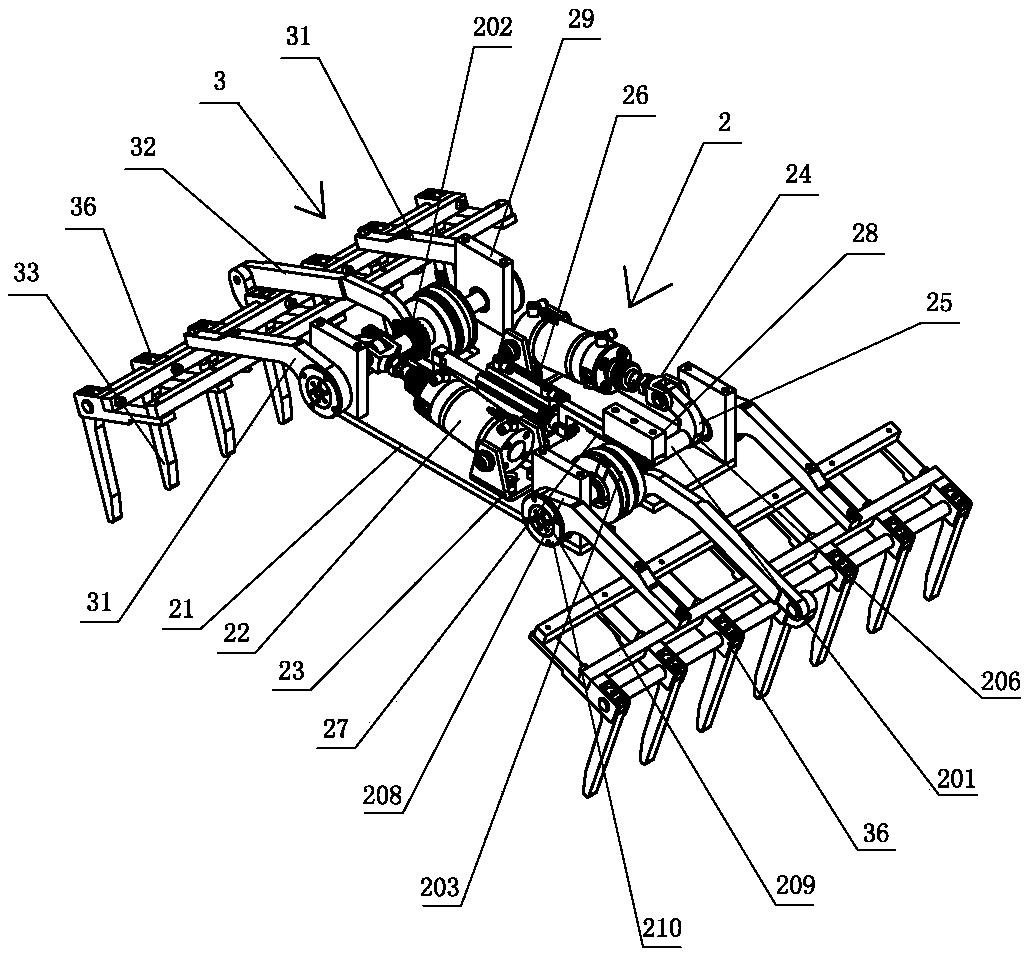

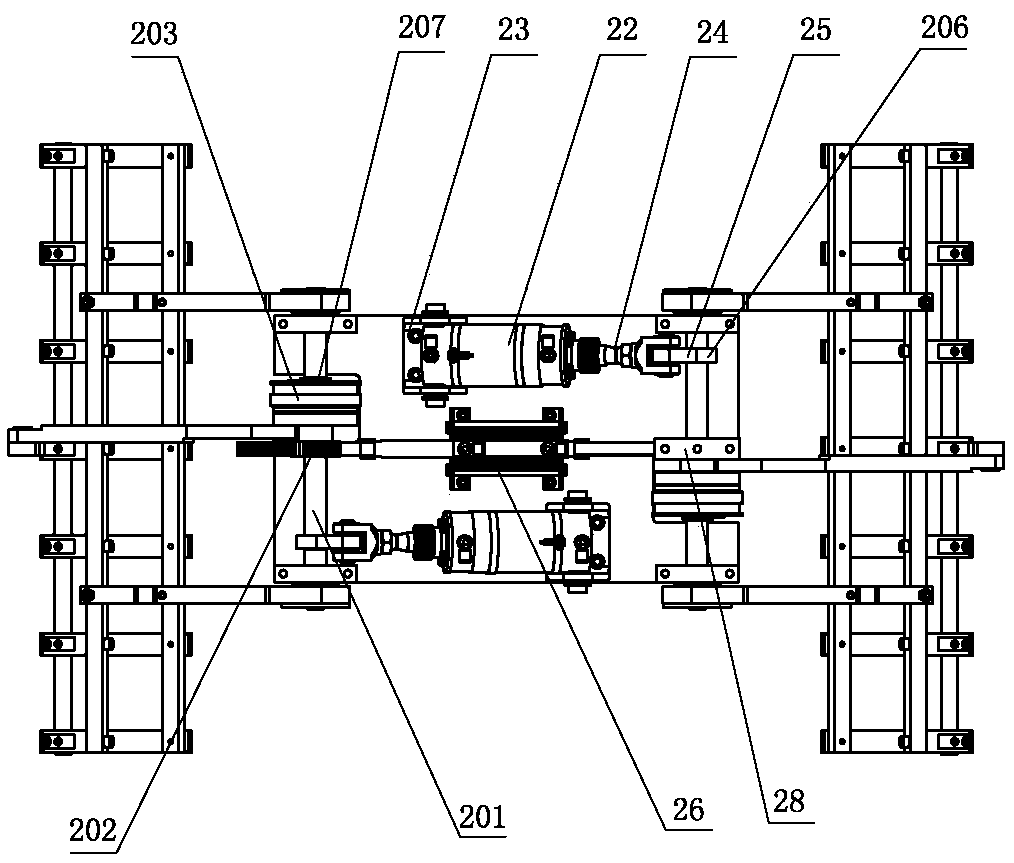

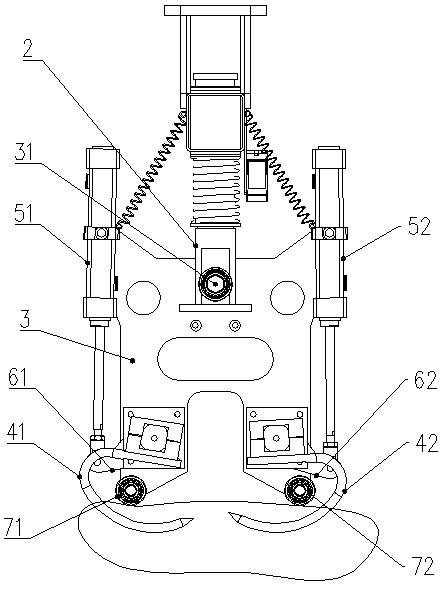

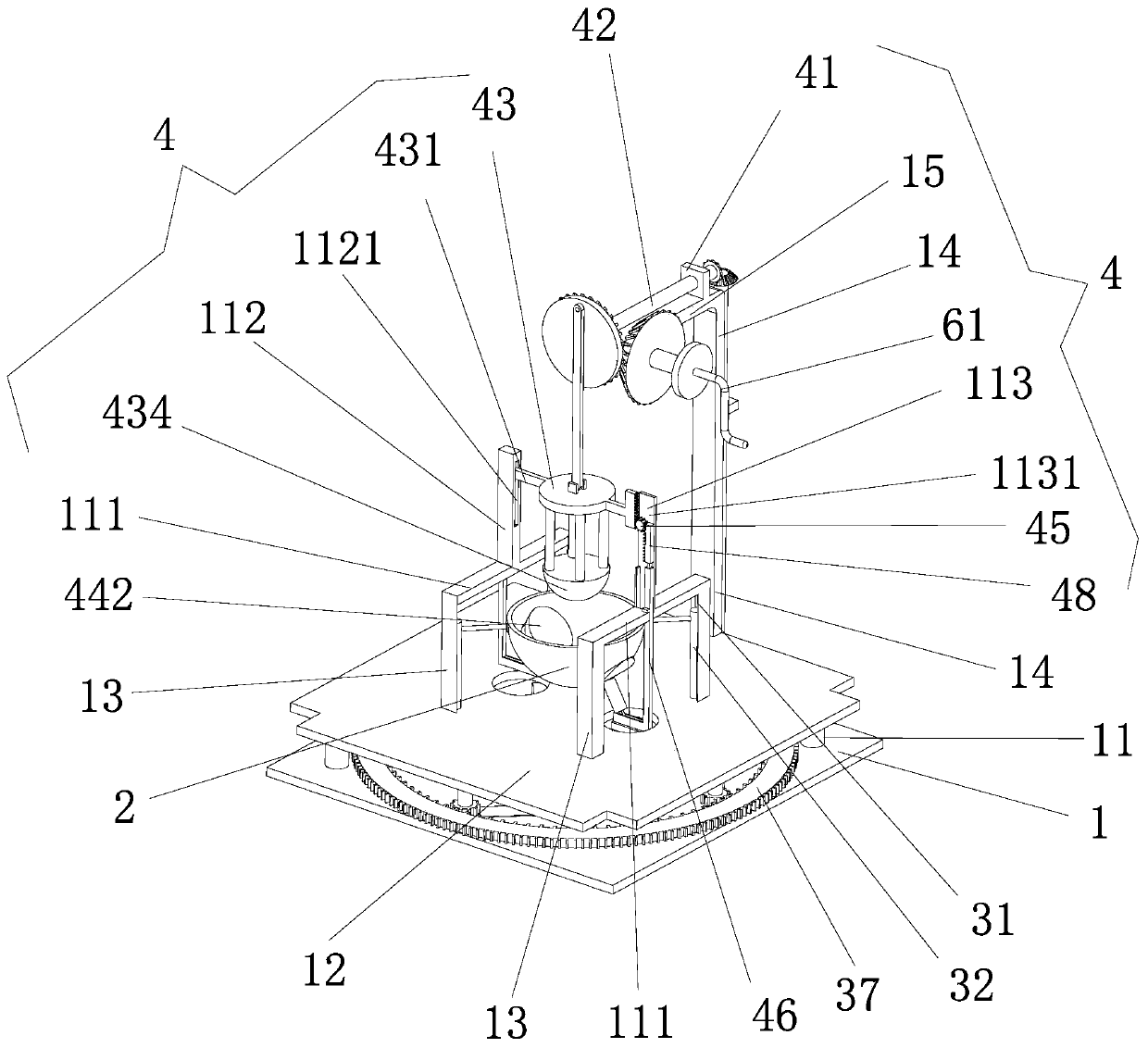

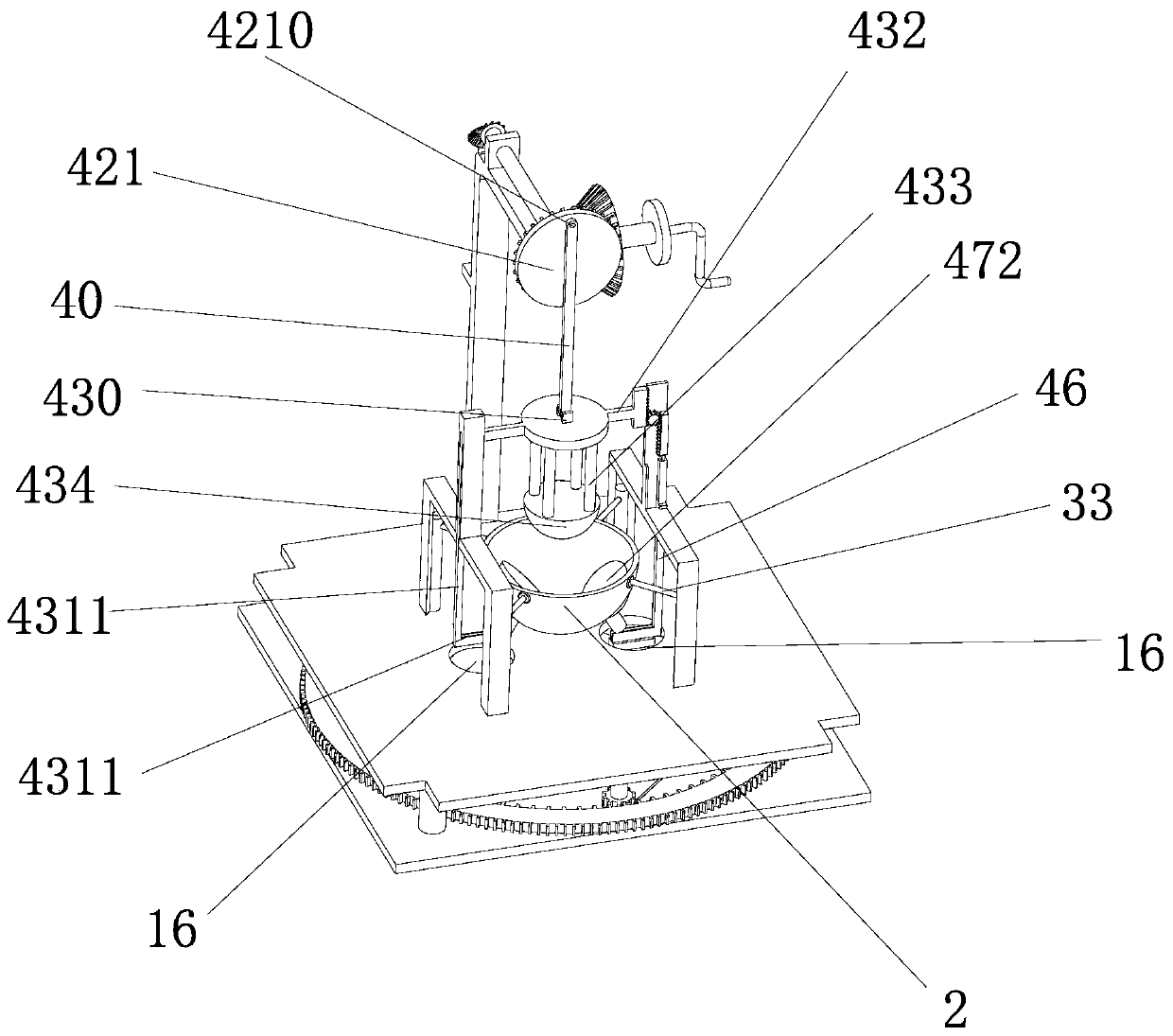

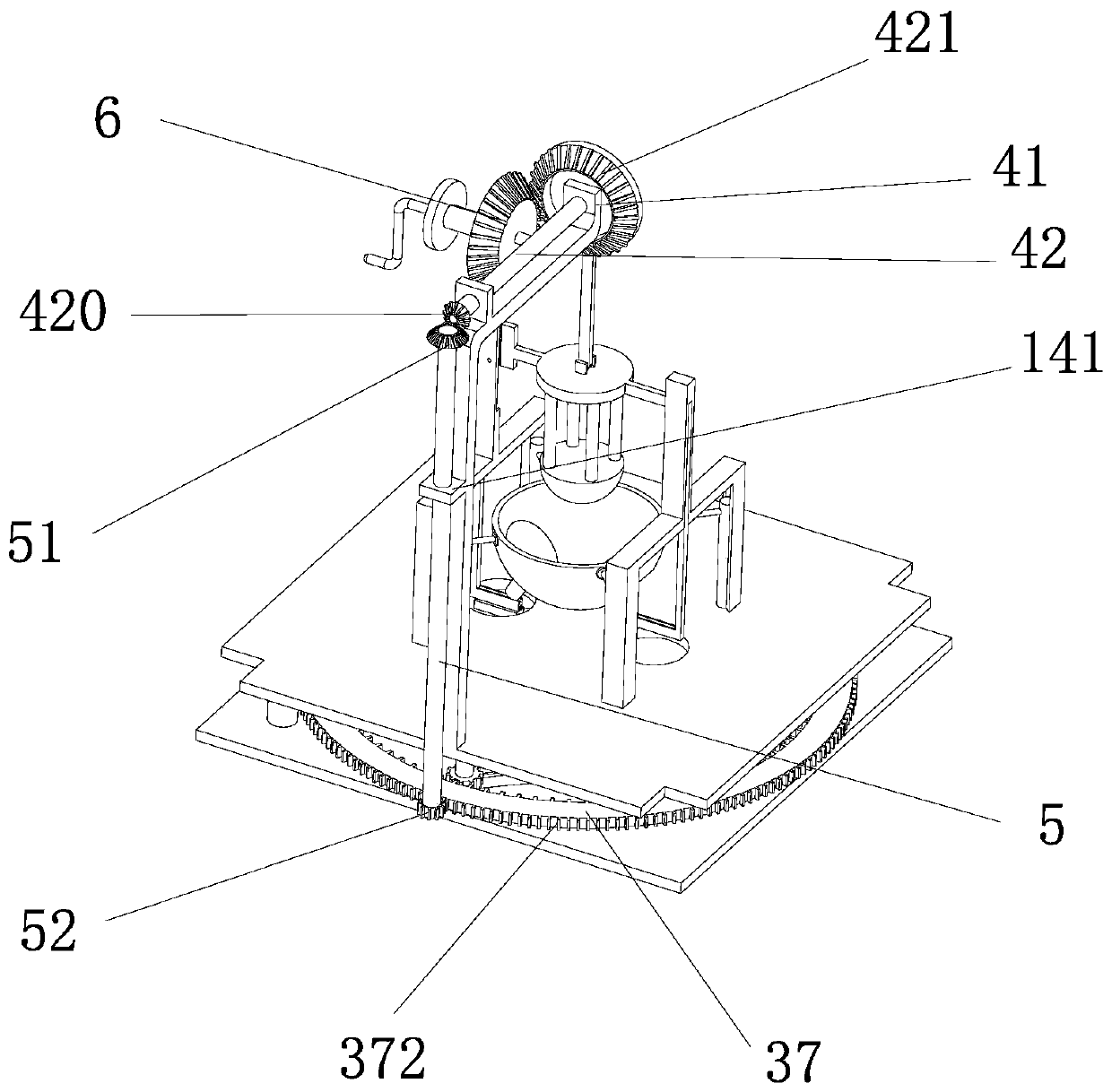

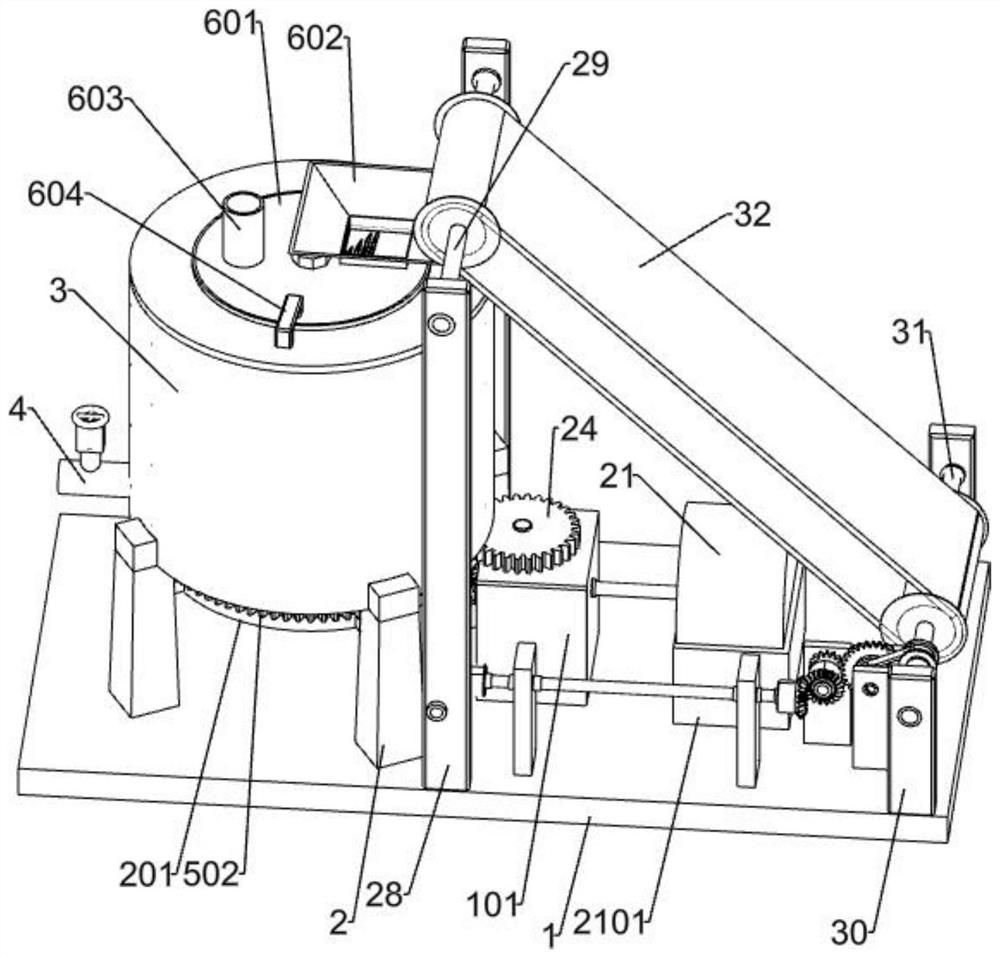

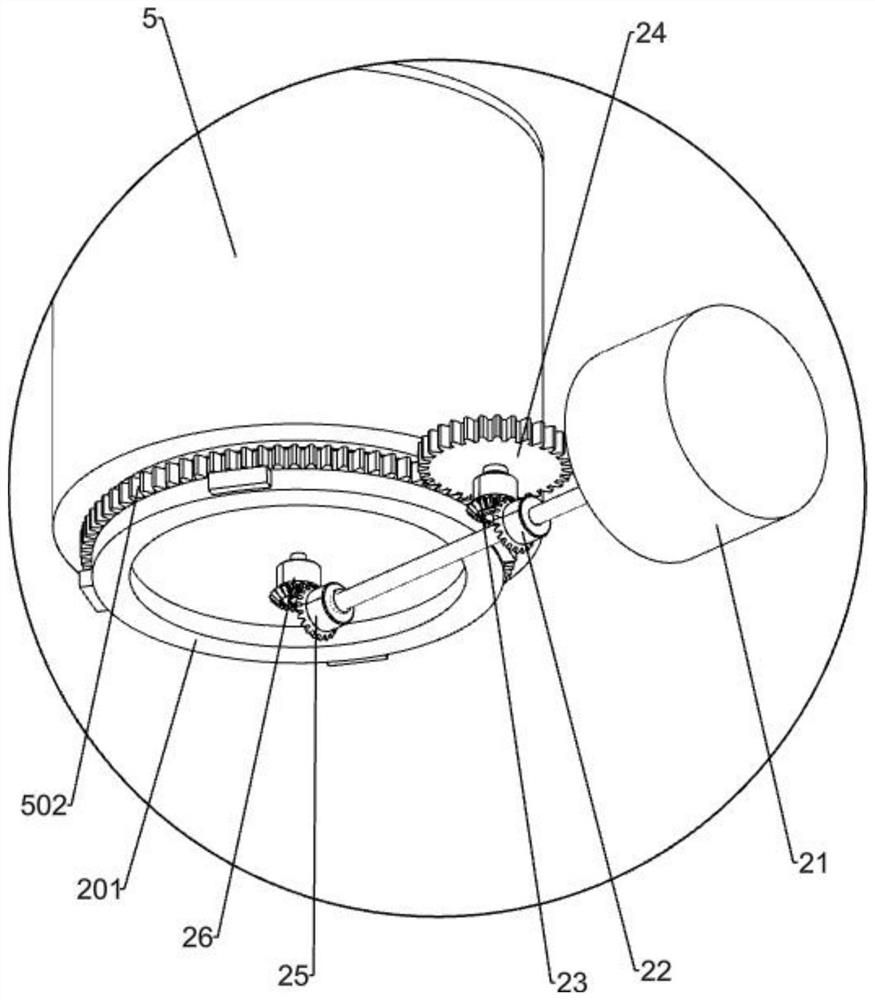

Multi-degree-of-freedom imitating manual beating and collecting jujube device

PendingCN108575312ABeat evenlyImprove beating efficiencyPicking devicesRenewable energy machinesMulti degree of freedomZiziphus jujuba

Owner:周逸伦

High-efficiency pulping soy milk grinder

InactiveCN101991360AIncrease the number ofIncrease chance of contactBeverage vesselsMotor driveEngineering

The invention relates to a high-efficiency pulping soy milk grinder, which comprises a stirring cup, a base, a machine head and a heating device. An upper motor is arranged on the machine head; upper crushing knifes are arranged at the lower end of an output shaft of the upper motor; a lower motor is arranged on the base; and lower crushing knifes are arranged at the upper end of an output shaft of the lower motor. More than two upper crushing knifes are arranged; the upper motor drives the upper crushing knifes to work through an upper transmission mechanism; the more than two upper crushing knifes are respectively driven by the independent upper motor which is arranged on the machine head. More than two lower crushing knifes are arranged; the lower motor drives the lower crushing knifes to work through a lower transmission mechanism; the more than two lower crushing knifes are respectively driven by the independent lower motor which is arranged on the base. By adopting the structure, the soy milk grinder has high pulping efficiency and good effect of crushing beans.

Owner:刘伟文

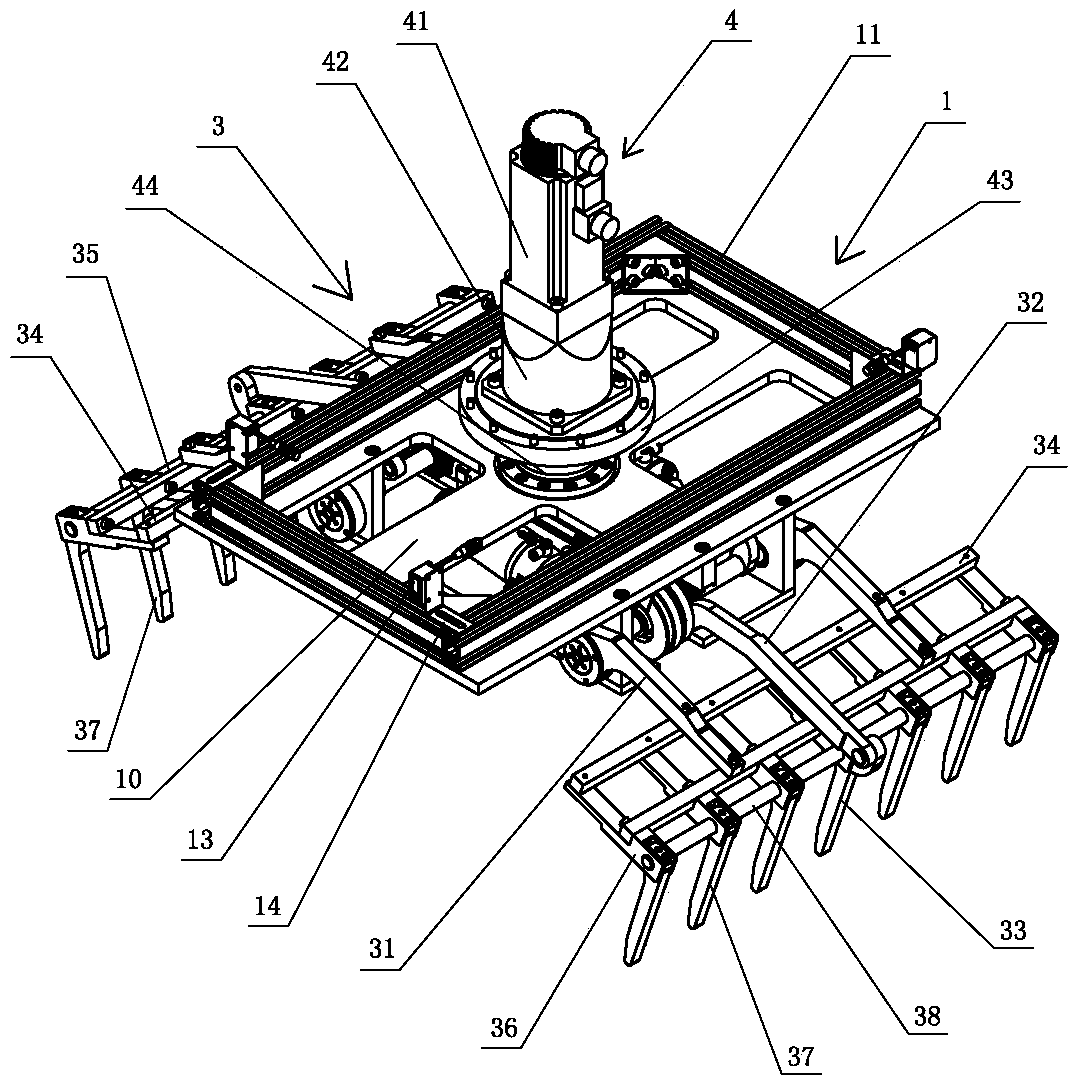

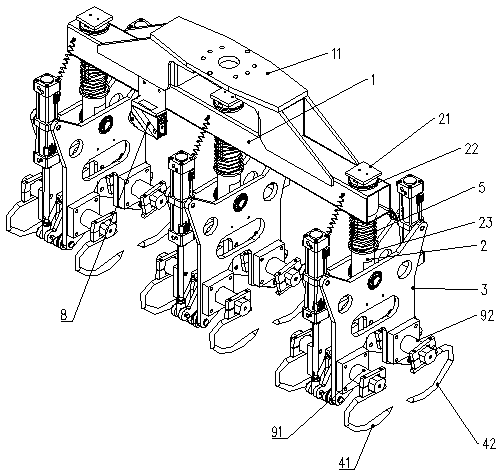

Robot end effector suitable for conveying compact-space bagged materials

PendingCN108100659AImprove beating efficiencyHigh degree of automationConveyorsGripping headsDrive shaftRobot end effector

The invention discloses a robot end executor suitable for conveying compact-space bagged materials. The robot end executor comprises a frame body assembly, a swinging assembly, grabbing assemblies anda servo assembly; the frame body assembly is used for supporting the swinging assembly, the grabbing assemblies and the servo assembly; the servo assembly and the swinging assembly drive the grabbingassemblies to carry out grabbing and putting actions; the frame body assembly comprises an upper fixing plate and a distance sensor; the servo assembly comprises a servo motor and a connecting shaft;the swinging set comprises a supporting plate, air cylinders, a rack, a winding arm shaft and a clutch gear; and each grabbing assembly comprises swing rods, a connecting rod, a connecting rod grabbing tooth, vertical plate grabbing teeth and a grabbing tooth transmission shaft. The robot end executor has the advantages that the problems that the labor is intensive, the space is small, the equipment adaptability is poor, the occupied space is large, the structure is complex, the efficiency is low and the like in the fields of bagged material producing, conveying, stacking and the like can besolved, and automation in the bagged material conveying process can be realized; the production efficiency can be improved, and the production cost can be lowered; and the whole process is safe, reliable, fast and efficient, and the robot end executor can be widely popularized in the industries with narrow carrying space and heavy work.

Owner:青岛宝佳智能装备股份有限公司

Leather watchstrap beating device for watch manufacturing

InactiveCN107322535AReduce labor intensityImprove production efficiencyPortable percussive toolsArabic numeralsEngineering

The invention relates to a beating device for watch manufacturing, in particular to a leather watchstrap beating device for watch manufacturing. The leather watchstrap beating device for watch manufacturing aims to achieve the technical effects that the labor intensity of workers can be reduced, the beating efficiency can be improved, the watchstrap manufacturing efficiency can be improved, and the watch manufacturing efficiency can be improved. In order to achieve the technical effects, the leather watchstrap beating device for watch manufacturing comprises a bottom plate and the like. A support is connected to the middle of the top of the bottom plate through a bolt, a transverse plate is arranged on the top of the support, a first plate shaped like the Arabic numeral seven is connected to the right side of the top of the bottom plate through a bolt, and the left side of the top of the inner side of the first plate shaped like the Arabic numeral seven is provided with a beating device and a driving device. The leather watchstrap beating device achieves the effects that the labor intensity of workers can be reduced, the beating efficiency can be improved, the watchstrap manufacturing efficiency can be improved, and the watch manufacturing efficiency can be improved.

Owner:王思洁

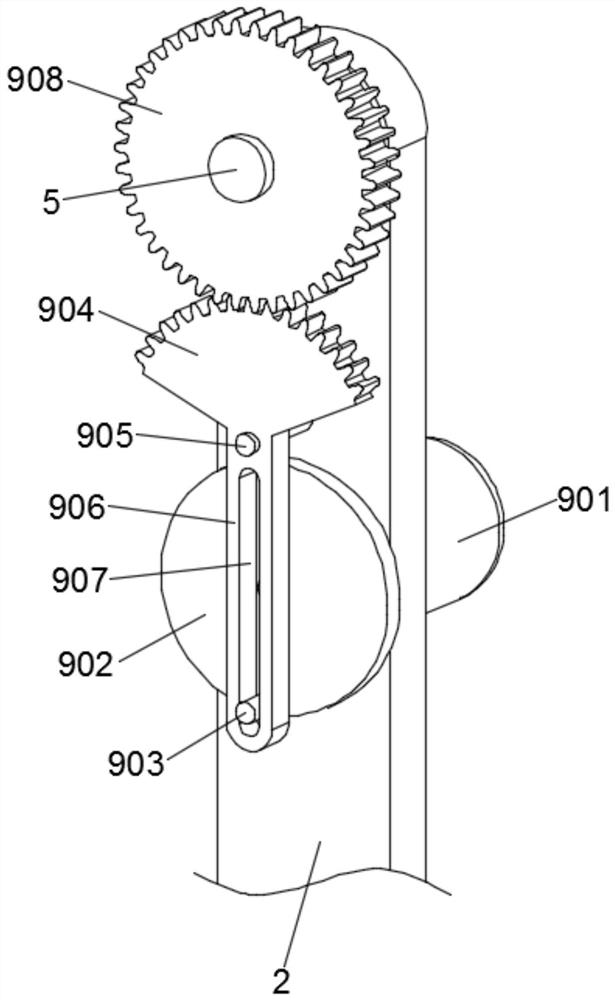

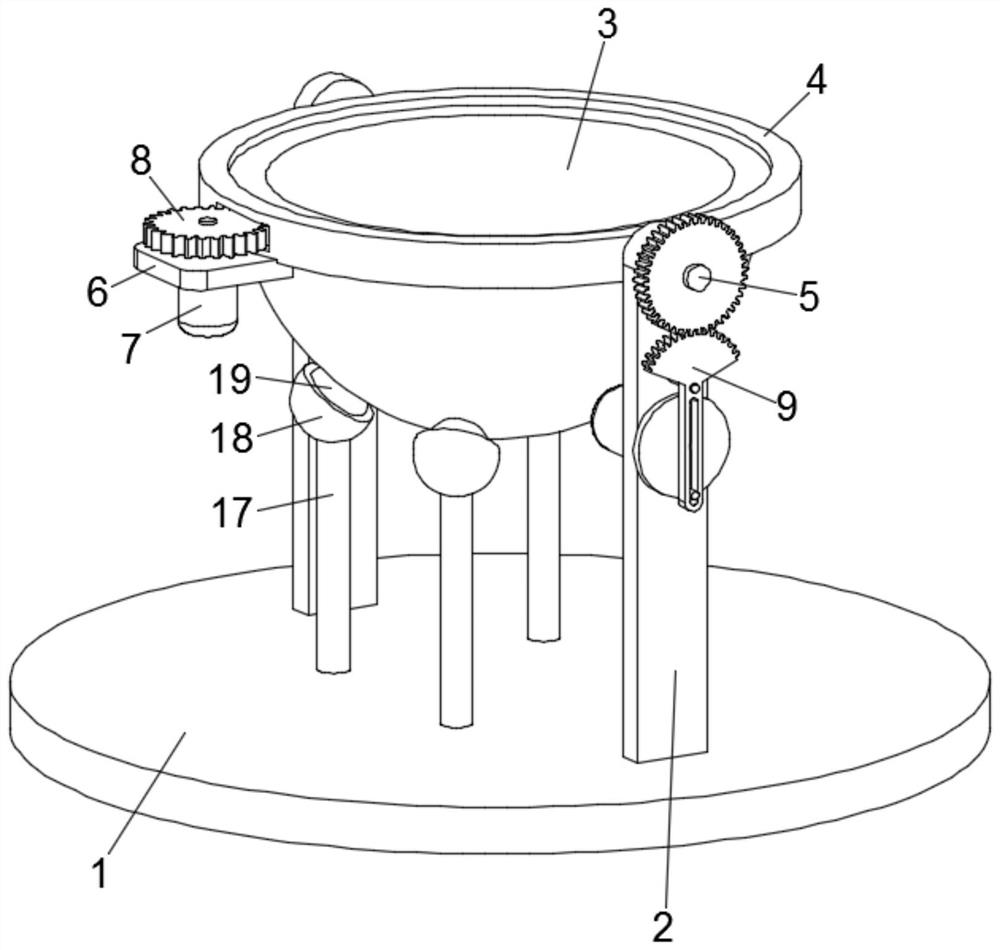

Beating device for food processing

InactiveCN112042696AFully artificialNo resistanceMeat processingFood shapingReciprocating motionElectric machine

The invention discloses a beating device for food processing. The beating device comprises a base, supporting frames and a material containing groove, wherein the two supporting frames are verticallyfixed on the base; an annular sleeve is rotationally arranged outside the edge of the upper end of the material containing groove in a sleeving mode; the annular sleeve is rotationally installed at the upper ends of the supporting frames; a rotating motor is arranged on the annular sleeve; a first gear is rotationally installed on the rotating motor; an annular gear ring is arranged on the edge ofthe upper end of the material containing groove; a swinging mechanism for driving the annular sleeve to swing in a reciprocating mode is further arranged on the supporting frame on one side; and a plurality of supporting assemblies are uniformly distributed on the base in the circumferential direction. According to the beating device for food processing, the material containing groove is driven to rotate in the circumferential direction and swing in a left-right reciprocating mode through the rotating motor and the swinging mechanism, meanwhile, a hammer head is driven by a press machine to move up and down in a reciprocating mode, food in the material containing groove is repeatedly beaten, so that the hammer head can act on each area on the inner wall of the material containing groove,the food in each area is beaten, dead angles are avoided, shutdown operation is not needed, the processing beat is not delayed, and the beating efficiency is high.

Owner:吕瑞雪

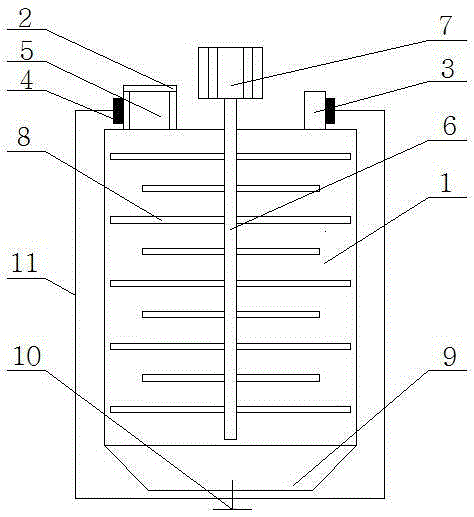

Paper making beater

InactiveCN106638097ALarge reserved spaceImprove beating effectPulp beating methodsProduction ratePulp and paper industry

The invention belongs to a paper making machinery and discloses a paper making beater. The upper portion of a machine body and the lower portion of the machine body are each provided with a beating assembly. Each beating assembly comprises a motor, a cutter shaft, cutter rests and cutter blades. An output shaft of each motor is connected with the corresponding cutter shaft, the cutter rests are uniformly distributed on the periphery of the outer wall of the corresponding cutter shaft and the cutter blades are arranged on the cutter rests. The output shaft of the motor on the upper portion of the machine body and the output shaft of the motor on the lower portion of the machine body are oppositely arranged. Two sets of cutter blade components in the machine body are axially opposite, during beating, the rotational direction of the upper cutter rests is opposite to that of the lower cutter rests, pulp and water are formed into two steams of pulp flows, crushing and beating are sufficiently conducted on materials, the beating effect is good, the pulp production rate is high and uniform beating is achieved. Because the reserved space between the beating assemblies and the machine body is large, the beating bulk is great, and the beating efficiency is improved.

Owner:ZHONGSHAN WEIKE PACKAGE PROD CO LTD

High-efficiency fruit and vegetable pulping machine

InactiveCN105341954AGuaranteed uptimeEasy to adjustJuice extractionPressure sensePulp and paper industry

The invention provides a high-efficiency fruit and vegetable pulping machine. The high-efficiency fruit and vegetable pulping machine comprises a cavity, wherein a feed opening and a liquid inlet are correspondingly formed at the two sides of the top part of the cavity; a guide hole is formed in the inner wall of the feed opening, and a V-shaped pulp outlet is formed in the bottom of the cavity; a pressure sensing valve is arranged at the bottom of the V-shaped pulp outlet; flow controllers are arranged on the outer wall of the feed opening and the outer wall of the liquid inlet and are connected with the pressure sensing valve through wires; a rotating shaft is arranged in the center of the cavity, one end of the rotating shaft extends into the bottom of the cavity, and the other end of the rotating shaft is connected with a motor; a plurality of stirring vanes are arranged on the outer wall of the rotating shaft, and stirring teeth are arranged on the surfaces of the stirring vanes. According to the high-efficiency fruit and vegetable pulping machine disclosed by the invention, the number of the stirring vanes is increased, so that the pulping is uniform and thorough and the pulping efficiency is high, and besides, the pulping machine is also provided with the flow controllers and the pressure sensing valve, so that when the pressure sensing valve senses that the pulp-out flow from the pulp outlet is too high or insufficient, the pressure sensing valve can timely feedback the information to the flow controllers; therefore, the adjustment of the feed opening and the liquid inlet can be conveniently realized so as to ensure the normal and stable running of the pulping machine.

Owner:徐浩

Moisture-proof and corrosion-proof corrugated paper production process and device

InactiveCN112813728AHigh strengthImprove water resistanceWater-repelling agents additionNon-macromolecular organic additionCardboardFiber

The invention discloses a moisture-proof and corrosion-proof corrugated paper production process and device, the moisture-proof and corrosion-proof corrugated paper is formed by bonding at least one layer of core paper and cardboard paper, the core paper is made of corrugated base paper through machining, the corrugated base paper is divided into a surface layer and a bottom layer, the surface layer is made of long fiber pulp, short fiber pulp and broken pulp of waste paper pulp, the bottom layer is made of short fiber pulp and waste paper pulp of waste paper pulp, and the preparation method of the corrugated base paper comprises the following steps: S1, pulping waste paper; s2, performing internal sizing treatment on the raw material slurry; s3, performing net feeding, squeezing and drying treatment on the raw material paper pulp, and then obtaining a base paper blank; and S4, sizing the surface of the base paper blank, and drying to obtain the corrugated base paper. According to the moisture-proof and corrosion-proof corrugated paper, the corrugated base paper of the moisture-proof and corrosion-proof corrugated paper is prepared from the waste paper pulp through a dual sizing process, and then the core paper machined from the corrugated base paper is bonded with the cardboard paper so that the prepared moisture-proof and corrosion-proof corrugated paper is high in machine strength and has good water resistance and corrosion resistance.

Owner:ANHUI UNIV OF SCI & TECH

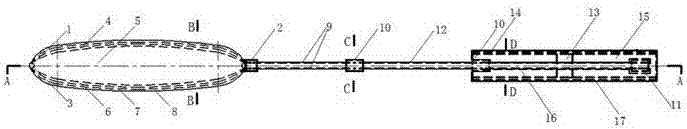

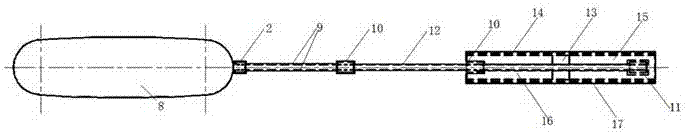

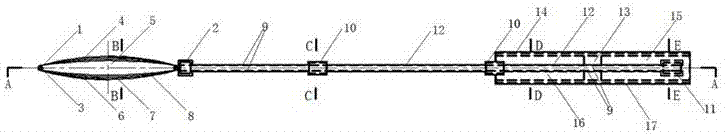

Swatter for meridian dredging and detoxification of four limbs of human body and use method of swatter

InactiveCN107569378AReduce volumeIncrease contact areaDevices for heating/cooling reflex pointsDevices for pressing relfex pointsHuman bodySurface layer

The invention relates to a swatter for meridian dredging and detoxification of the four limbs of the human body and a use method of the swatter, belonging to the field of meridian health. The swattercomprises a swatter head, a swatter rod and a handle which are connected, wherein two ends of the swatter rod are connected with the swatter head and the handle, respectively. The swatter is pure handmade, according to the principle that the four limbs of the human body are in the shapes of straight lines relatively, the oblong swatter head is researched, so that the swatter head can well tally with the lines of the legs and the arms, the compactness between the swatter head and the swatted meridians is increased, and finally, the optimal swatting effect is achieved; the optimal force arm swatter rod length is researched from the angle of mechanics; the diameter and length of the handle are researched from the holding force of the hand for the handle; mung beans are placed in the swatter head, and pure cotton cloth free of toxic and side effects to the human body is adopted as the outer package of the swatter head. The swatter is mainly used for meridian dredging and detoxification ofthe four limbs of the human body, eruptive toxins in deep layers existing on the four limbs of the human body are rapped to the surface layer of the skin, and the toxins are expelled out of the humanbody through microcirculation; the meridians of the four limbs are dredged, so that the meridians are smooth, thus a major part of meridian dredging for the whole body is completed, and finally, a foundation is laid for the body health.

Owner:SHENYANG JIANZHU UNIVERSITY

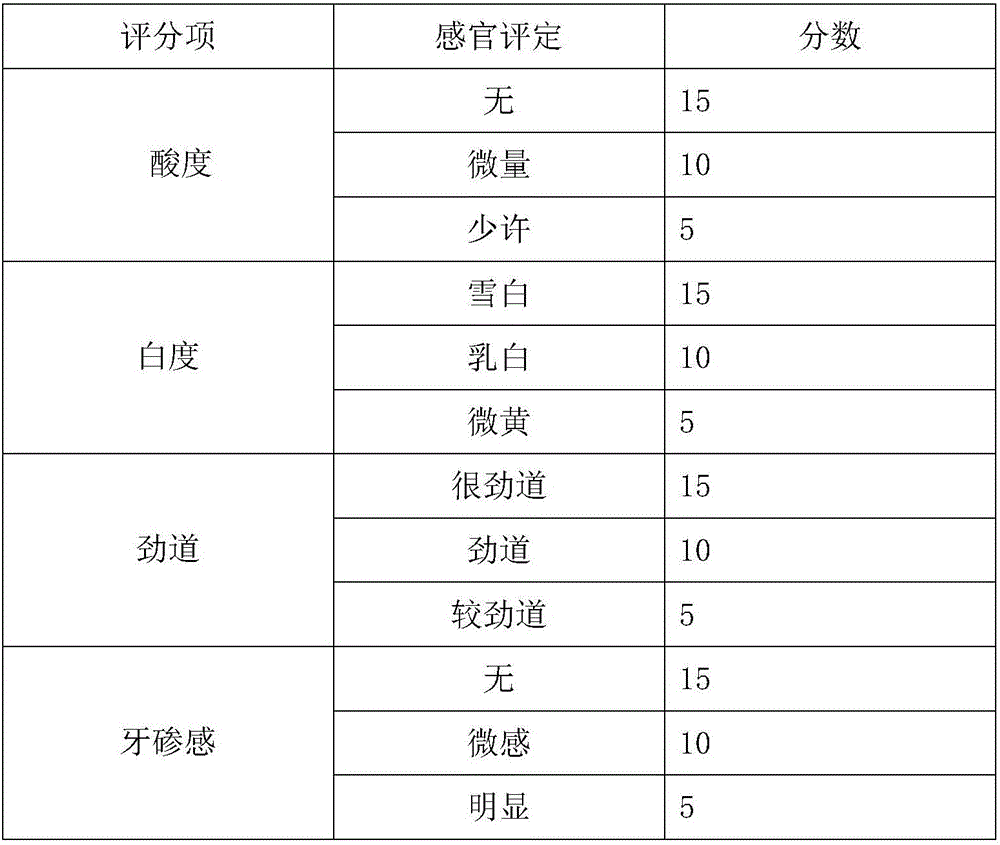

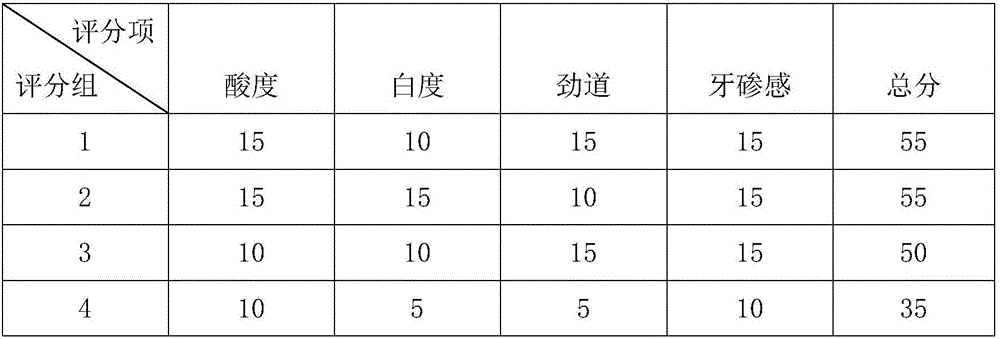

Glue pudding preparation technology

The invention relates to the technical field of glue pudding preparation and discloses a glue pudding dough preparation technology. The glue pudding preparation technology includes the steps of (1), cleaning; (2), soaking glutinous rice in water in a volume ratio of 1-2:4 for 3-3.5 hours in spring and autumn, for 2.5-3.5 hours in summer and for 3.5-4 hours in winter, wherein the temperature of the water is as same as that of the environment; if the glutinous rice turns sour during soaking, adding new glutinous rice soaked for 0.5-1 hour at 70-80 DEG C into a soaking vat, wherein the volume ratio of the new glutinous rice to the original glutinous rice is 1-1.5:3; (3), mashing by mixing the soaked glutinous rice with pre-gelatinized starch according to a volume ratio of 20:0.5-0.8; (4), drying by pressing; (5), mixing and stirring glutinous rice flour with water at 15-20 DEG C to form a glue pudding dough, wherein the volume ratio of the glutinous rice flour to the water is 200:93-96 in spring and autumn, 200:85-90 in summer and 200:98-100 in winter; (6), keeping the whole preparation time for 9-10 hours. The glue pudding preparation technology is capable of improving stickiness of the glue pudding dough and reducing granularity of the glue pudding dough, thereby making prepared glue pudding smooth in surface.

Owner:CHONGQING QIGE FOOD CO LTD

Preparation method of packaging paper for vegetable-based safe and environment-friendly food

InactiveCN107216674AHigh strengthImprove mechanical propertiesFlexible coversWrappersPotato starchAntibacterial activity

The invention discloses a preparation method of packaging paper for a vegetable-based safe and environment-friendly food. The preparation method comprises the following steps: smashing fresh cabbage and fresh celery, and adding water while stirring to prepare pulp; adding a proper amount of sweet potato starch, konjac gum and the like; performing ultrasonic oscillation to form paper-making pulp. Compared with an ordinary mechanical stirring manner, the preparation method has the advantages that an ultrasonic technical process is simple and is convenient to operate, the pulping efficiency is increased, the production energy consumption is lowered, and meanwhile the prepared pulp has superior strength and mechanical performance. Cinnamyl aldehyde and chitosan are complexed into mixed filler through a series of treatment methods, and the mixed filler is added into paper pulp, so that the antibacterial activity of paper can be improved remarkably; moreover, all components are pure natural components, so that the paper is safe and reliable. The packaging paper produced by the method is made from safe and reliable components, is solid and durable, has high strength, is safe to human body, and can be directly applied to packages of foods.

Owner:CHUZHOU HAICHUAN PRINTING PACKAGING CO LTD

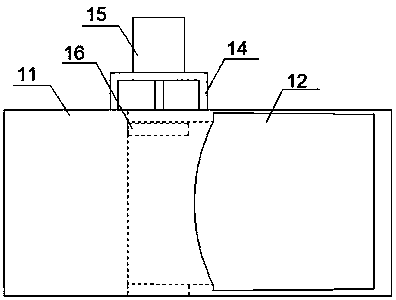

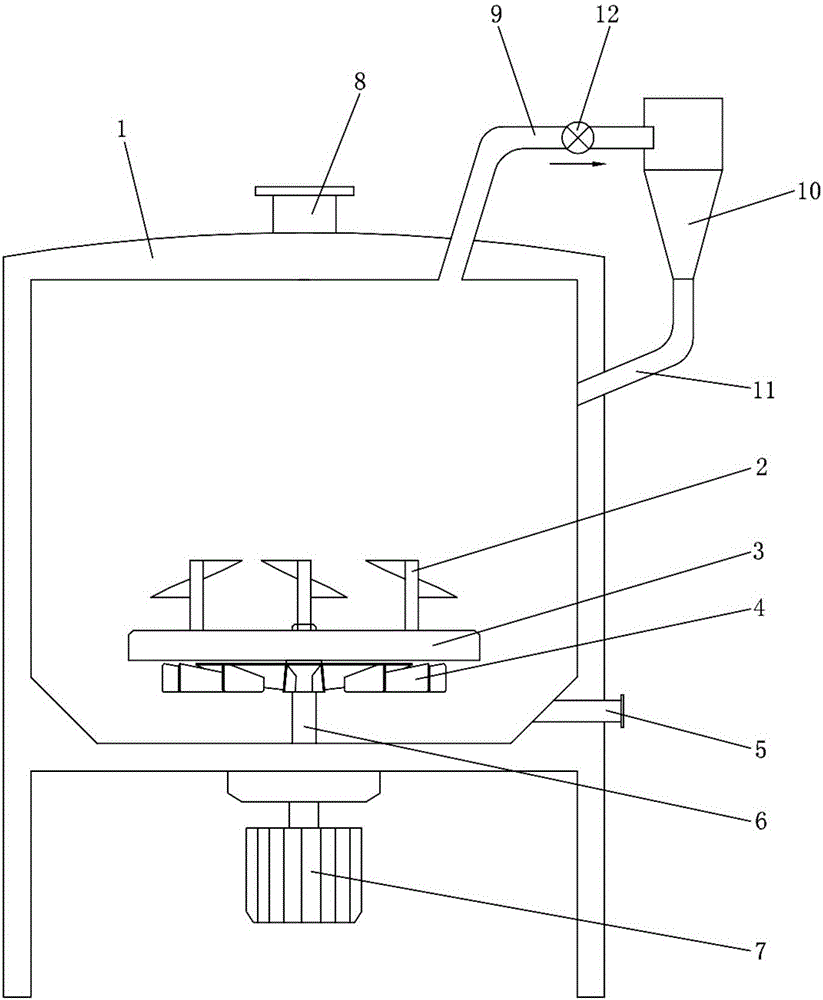

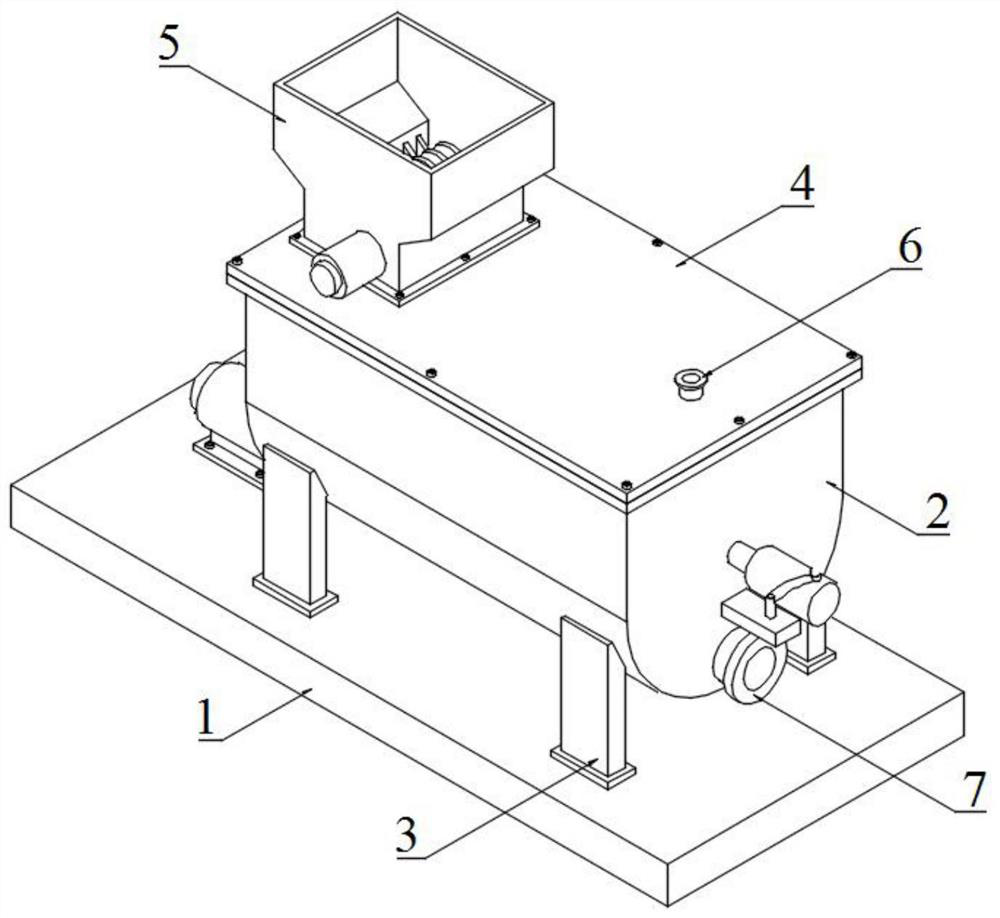

Beating device for toilet paper machine

InactiveCN108425264AAvoid cloggingImprove beating efficiencyPulp beating methodsToilet paperPulp and paper industry

The invention discloses a beating device for a toilet paper machine. The beating device comprises a processing box, the top inner wall of the processing box is provided with a mounting groove, a stepping motor is mounted in the mounting groove, a first rotating shaft is welded to an output shaft of the stepping motor, a plurality of groups of stirring shafts are fixedly mounted on the outer side of the first rotating shaft, the inner walls of the two sides of the processing box are provided with sliding grooves, and returning springs are welded to the bottom inner walls of the sliding grooves.An identical filter plate is welded to the top ends of the two returning springs, a first vertical plate is formed at the center of the top of the filter plate, a first vertical hole is formed in thecentral position of the top of the filter plate, the plurality of groups of stirring shafts are located above the filter plate, the bottom end of the first rotating shaft passes through the first vertical hole, a first bevel gear is welded to the first rotating shaft, and the inner walls of the two sides of the processing box are provided with first rotating grooves located below the sliding groove. The beating device is high in practicality; through a second rotating shaft and a first drawn wire, the blockage of the filter plate is effectively prevented; and the beating efficiency is effectively improved through a vertical plate and the stirring shafts.

Owner:罗厚镇

Process for preparing low-sugar mixed jam

The invention discloses a process for preparing low-sugar mixed jam, which comprises, by mass, 20-25 parts of pawpaw, 10-15 parts of grapefruit, 10-15 parts of xylitol, 2-5 parts of pectin, 3-5 partsof lemon juice, 1-2 parts of potassium sorbate and 100-150 parts of water. According to the invention, the jam is prepared from fruits with extremely low sugar contents, the peel of the fruits can befully utilized, pectin is extracted to be used in preparing the jam, and xylitol is utilized to replace white sugar, so that the jam can be used for people with hyperglycemia and even diabetes while the original sweetness is kept; and a beating device in the process drives four peripheral slave rotating shafts provided with beating blades to rotate at a high speed together to beat the fruits through a main rotating shaft provided with beating blades, so that the beating efficiency is high, the beating time is greatly reduced, and the beating thinning degree of the fruits is high; meanwhile, after the beating is finished, the peel and the seeds are filtered and separated, and the fruit pulp which is mixed with the skin and the seeds is completely separated through a spin-drying mechanism, so that resources are saved; the whole device is convenient to move through a support moving mechanism which is convenient to operate.

Owner:江川

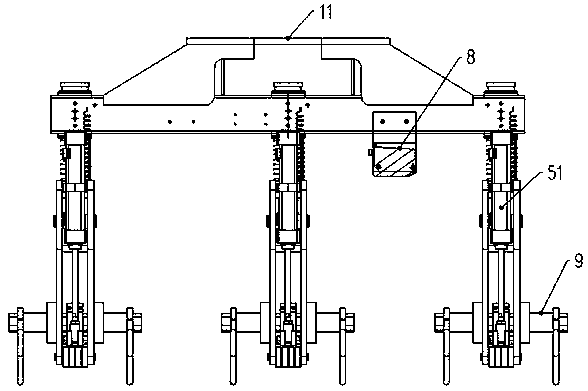

Flexible and efficient unstacking robot system for bagged material

PendingCN110642027AImprove beating efficiencyAdaptableGripping headsStacking articlesRobotic systemsProduction line

The invention discloses a flexible and efficient unstacking robot system for a bagged material. The flexible and efficient unstacking robot system for the bagged material comprises a robot base, a robot, a feeding box, a bag-breaking saw blade, a terminal actuator, two pallet positioning blocks and a waste bag collecting box, the robot is mounted on the robot base, the terminal actuator is mountedat the terminal of the mechanical arm of the robot, each pallet positioning block is in an L shape, and the two pallet positioning blocks are used in pairs and mounted in a left-right symmetry and used for positioning a pallet of storing the material. The flexible and efficient unstacking robot system has the beneficial effects that the problems of low equipment adaptability and compatibility andefficiency in labor-intensive fields such as unstacking, transporting, bag breaking and waste bag managing of the bagged material needing to be broken can be overcome, self adapting of the bagged material needing to be broken and the automation of unstacking, bag breaking and waste bag recovering processes are achieved, and the flexible and efficient unstacking robot system can be directly used for self adapting, unstacking, bag breaking, waste bag recovering of the bagged material needing to be broken in a production line and not limited by the shape, quantity and arraying manner of the bag.

Owner:青岛宝佳智能装备股份有限公司

Method for treating leather leftover materials

InactiveCN108708205AEasy to sortImprove efficiencyPulp beating methodsRaw material divisionTreatment effectEngineering

The invention provides a method for treating leather leftover materials. The method solves the technical problems of complexity, excessive processes and poor treatment effects of existing methods. Themethod for treating the leather leftover materials comprises the following steps of S1, preparing the leather leftover materials, removing impurities, then conducting screening and sorting, and saving the obtained materials as standby materials; S2, placing the standby materials in S1 into a crushing mechanism of a beating system to obtain short-fiber-shaped standby materials; S3, placing the short-fiber-shaped standby materials in S2 into a cleaning liquid for soaking treatment, conducting heating to raise the temperature to 30-50 DEG C, and conducting heat preservation for 2-3 h; S4, placing the soaked standby materials in S3 into a beating barrel of the beating system, conducting grinding for 15-30 min to obtain fine-fiber-shaped initial slurry, and then placing treatment liquid into the beating barrel of the beating system to obtain finished slurry. The method has the advantage that the treatment effect is good.

Owner:海宁市丁桥镇永畅知识产权服务部

High efficiency mulberry pulping machine

The invention discloses a high efficiency mulberry pulping machine. The pulping machine includes a stirring shell; a feeding pipe is inserted in the top end of the stirring shell; the middle part of the feeding pipe is an inclined channel; the upper side wall of the stirring shell is provided with a communicating pipe communicating with the outlet of the feeding pipe; the internal of the communicating pipe is provided with a cutting device; the cutting device includes a first rotating shaft and cutting knives; the first rotating shaft is connected to the inner wall of the communicating pipe; multiple cutting knives are equidistantly arranged on the first rotating shaft; a first rotating motor is arranged on the outer side wall of the communicating pipe; the driving end of the first rotating motor is connected to the first rotating shaft through a coupling; the internal of the stirring shell is provided with a second rotating shaft; and multiple first crushing rods are equidistantly arranged on the second rotating shaft in a surrounded manner. The pulping machine is simple in structure and convenient in operation, and can perform good smashing and separating on mulberries without crushing fruit stones, so that pulping efficiency can be enhanced.

Owner:斯录萍

Food processing device

InactiveCN111011710AMeet the needs of useSimple structureFood shapingAgricultural engineeringStructural engineering

The invention discloses a food processing device. The device comprises a supporting bottom plate, wherein supporting main columns are arranged at the opposite corners of the front end and the rear endof the upper surface of the supporting bottom plate; the upper end faces of the supporting main columns are connected with a supporting base plate; small supporting rods corresponding to the front, back, left and right corners are arranged at the center of the upper surface of the supporting base plate; large supporting rods arranged on the supporting base plate and behind the small supporting rods; supporting cross rods extending to the upper parts of the small supporting rods are arranged at the upper ends of the large supporting rods; a jolting semicircular box used for containing rice cakes is arranged among the small supporting rods; a jolting mechanism is arranged on the supporting bottom plate and is used for controlling the jolting semicircular box to rotate and jolt so as to hammer the rice cakes more sufficiently; a hammering mechanism used for overturning and hammering the jolting semicircular box is arranged on the supporting cross rods; and the hammering mechanism is in driving connection with the jolting mechanism.

Owner:中山美味来食品科技有限公司

Human-body-meridian-collateral dredging and toxin expelling racket and applying method thereof

InactiveCN107468504ANo side effectsWide range of magnetic field diffusionDevices for pressing relfex pointsVibration massageEngineeringHardness

The invention discloses a human-body-meridian-collateral dredging and toxin expelling racket. The human-body-meridian-collateral dredging and toxin expelling racket comprises a racket head, a racket rod and a handle; the two ends of the racket rod are connected with the racket head and the handle respectively, the racket head is a ring defined by a spring steel wire, a flapping material is arranged inside the ring, the racket head is connected with the racket rod through a first hard copper tube, the racket rod is made of two straight spring steel wires, and the two straight spring steel wires are sleeved with a first colorful heat shrink tube; the handle is of a hollow cylinder structure, one end of the racket rod is inserted into the handle and connected with the handle through a second hard copper tube, and the handle is filled with an environment-friendly transparent rubber stick. The human-body-meridian-collateral dredging and toxin expelling racket has the advantages that the toxin expelling racket is small in size, convenient to take along, firm and durable; elastic force is sufficient, and force is saved during flapping; the toxin expelling racket is attached to the skin, and measles is deeply and thoroughly generated; the body sense is comfortable; muscles and bones are not injured; deep permeation is achieved, and pain is not generated in the skin; all the measles can be removed; the hardness is moderate, the measles generating rate is high, the flapping vibration range is deep and wide, the radiation range of vibration of the racket head is wide, the flapping frequency is high, time and labor are saved, the whole connecting quality of the flapping racket is good, manual manufacturing is convenient, and the manufacturing cost is low.

Owner:SHENYANG JIANZHU UNIVERSITY

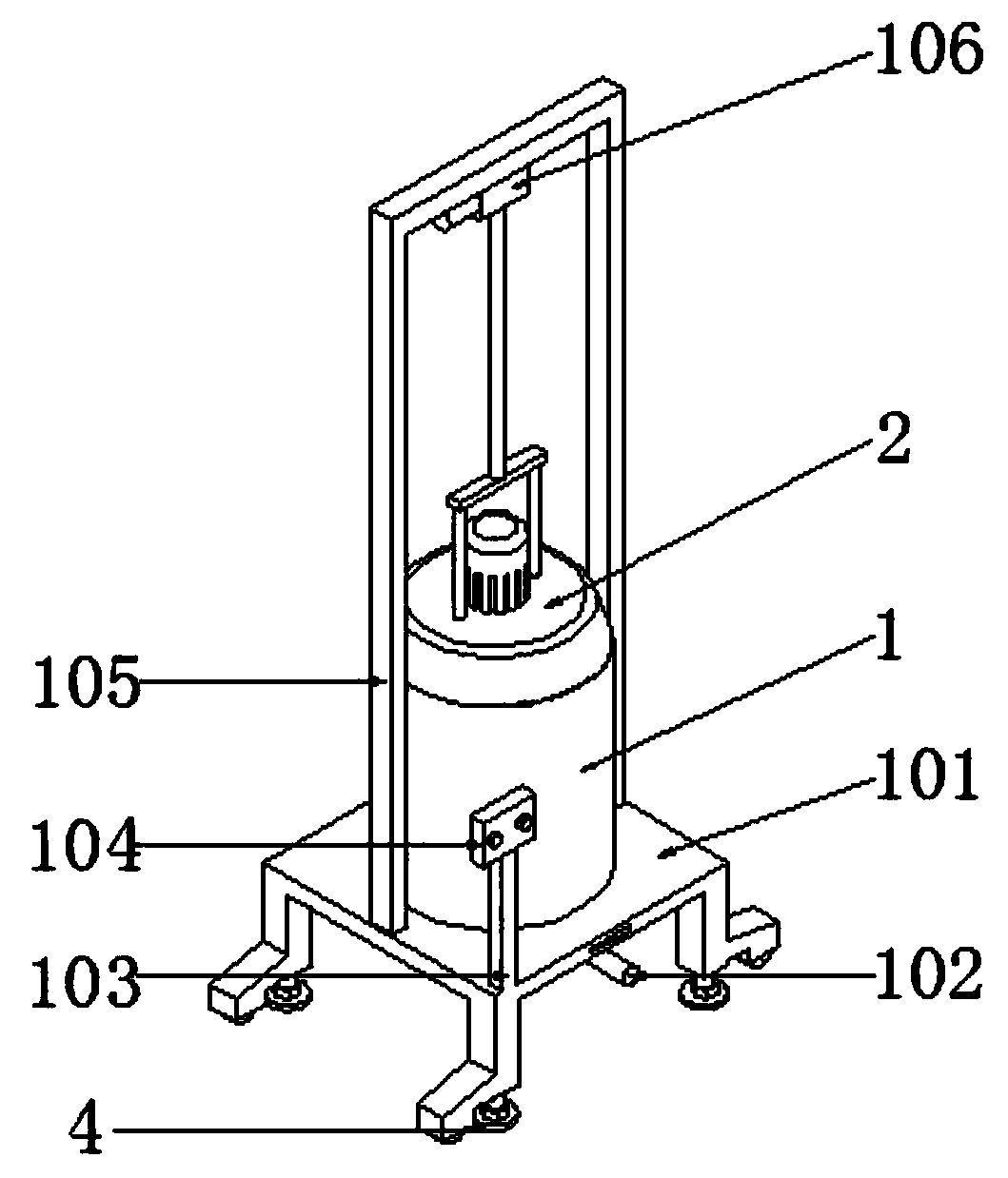

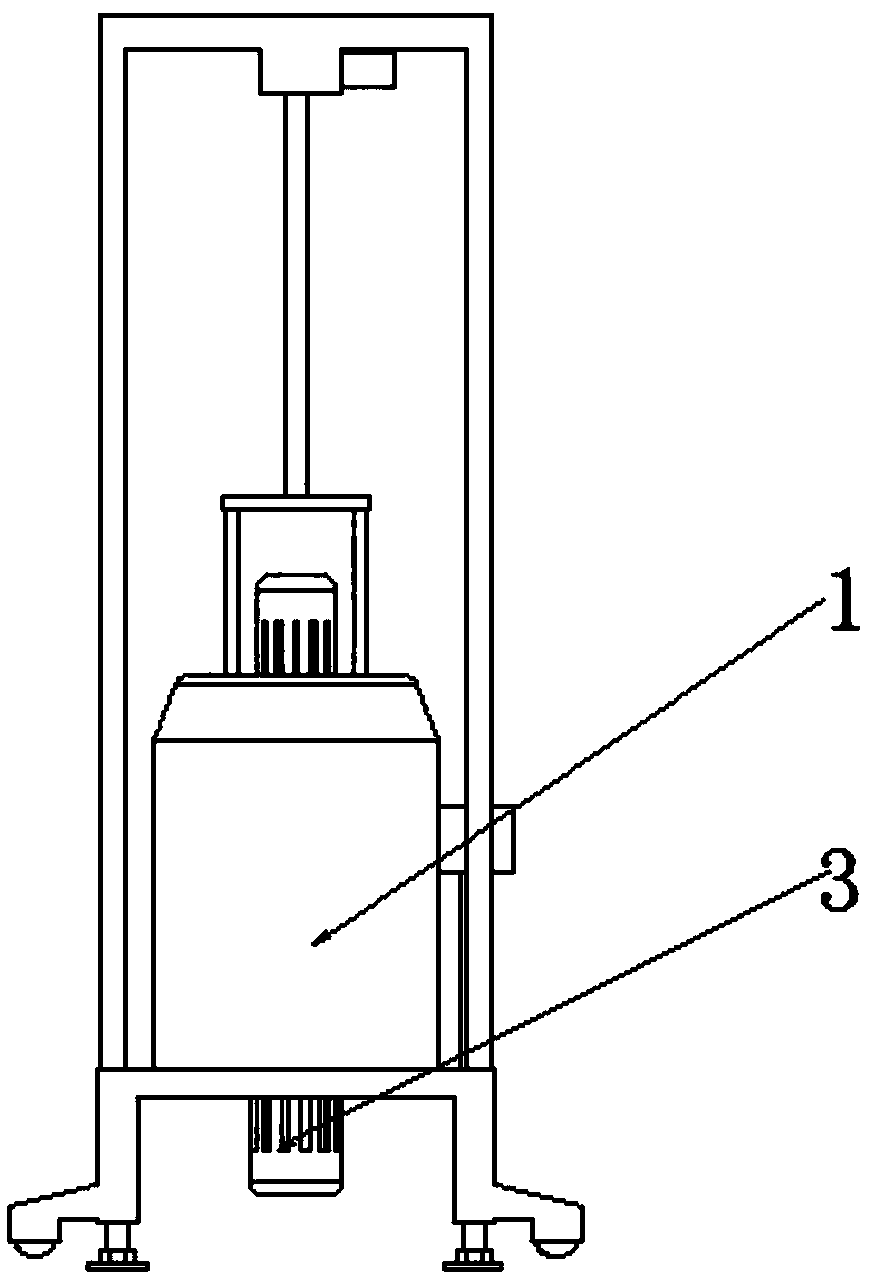

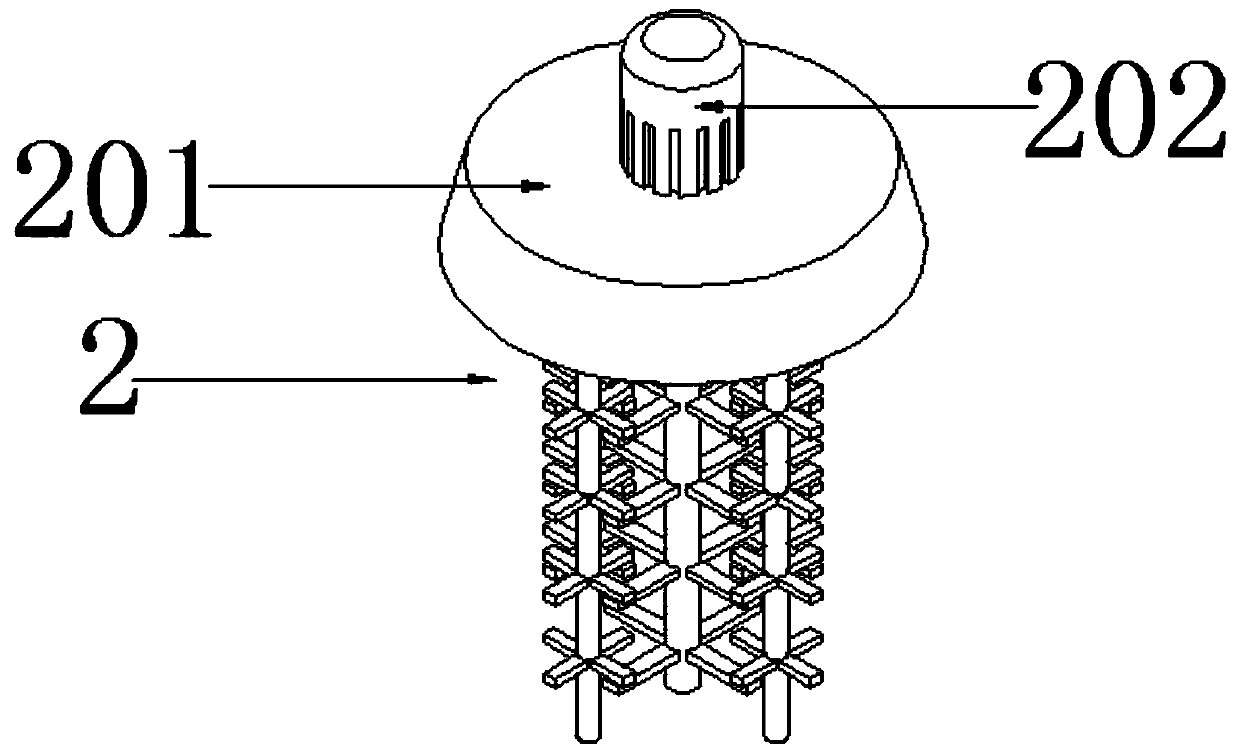

Pulping device for papermaking

InactiveCN112359632AImprove beating efficiencyBig impactPulp beating methodsRaw material divisionPapermakingProcess engineering

The invention relates to a pulping device, in particular to a pulping device for papermaking. The invention aims to provide the pulping device for papermaking, which can be used for thoroughly crushing raw materials, improving the working efficiency and saving resources. According to the technical scheme, the pulping device for papermaking comprises a bottom plate, supporting blocks, a base, an outer box body, a discharging opening, an upper cover plate, a feeding opening and the like; four supporting blocks are fixedly installed on the bottom plate, the base is fixedly installed on the innerside walls of the four supporting blocks, the outer box body is fixedly installed above the base, the discharging port is fixedly installed on the outer side wall of the outer box body, and the feeding port is fixedly installed above the upper cover plate. The pulping device is provided with a shredding device, materials entering from the feeding opening can be shredded, the shredded materials canfall down from the middle of the center circular plate, and therefore the pulping efficiency can be improved.

Owner:程新钟

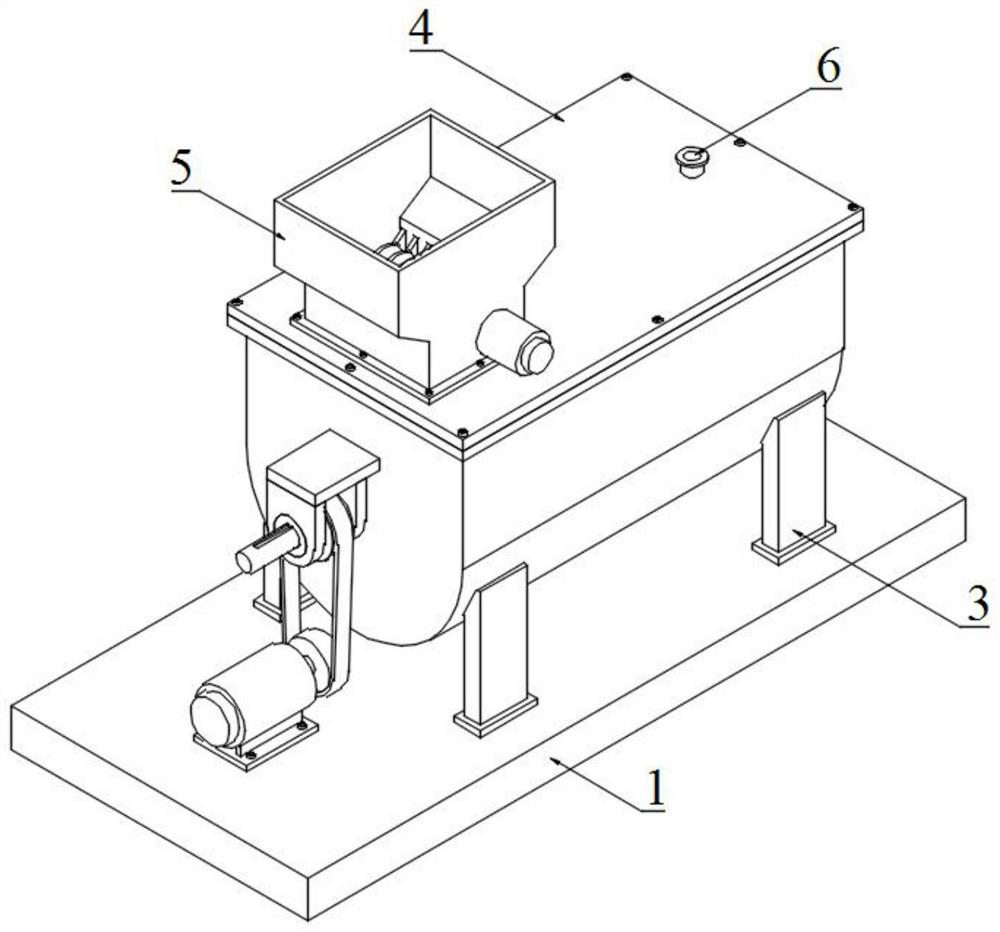

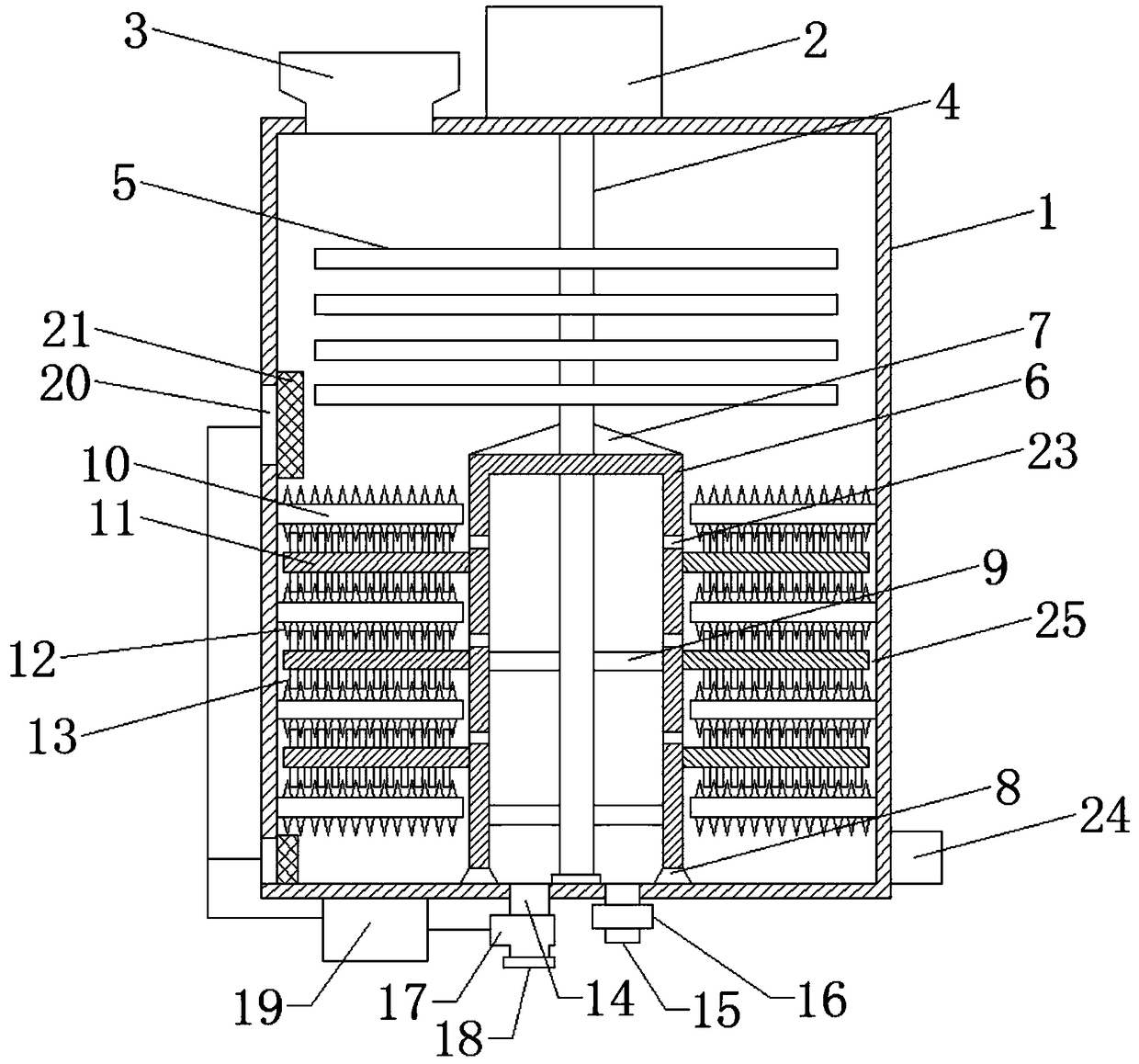

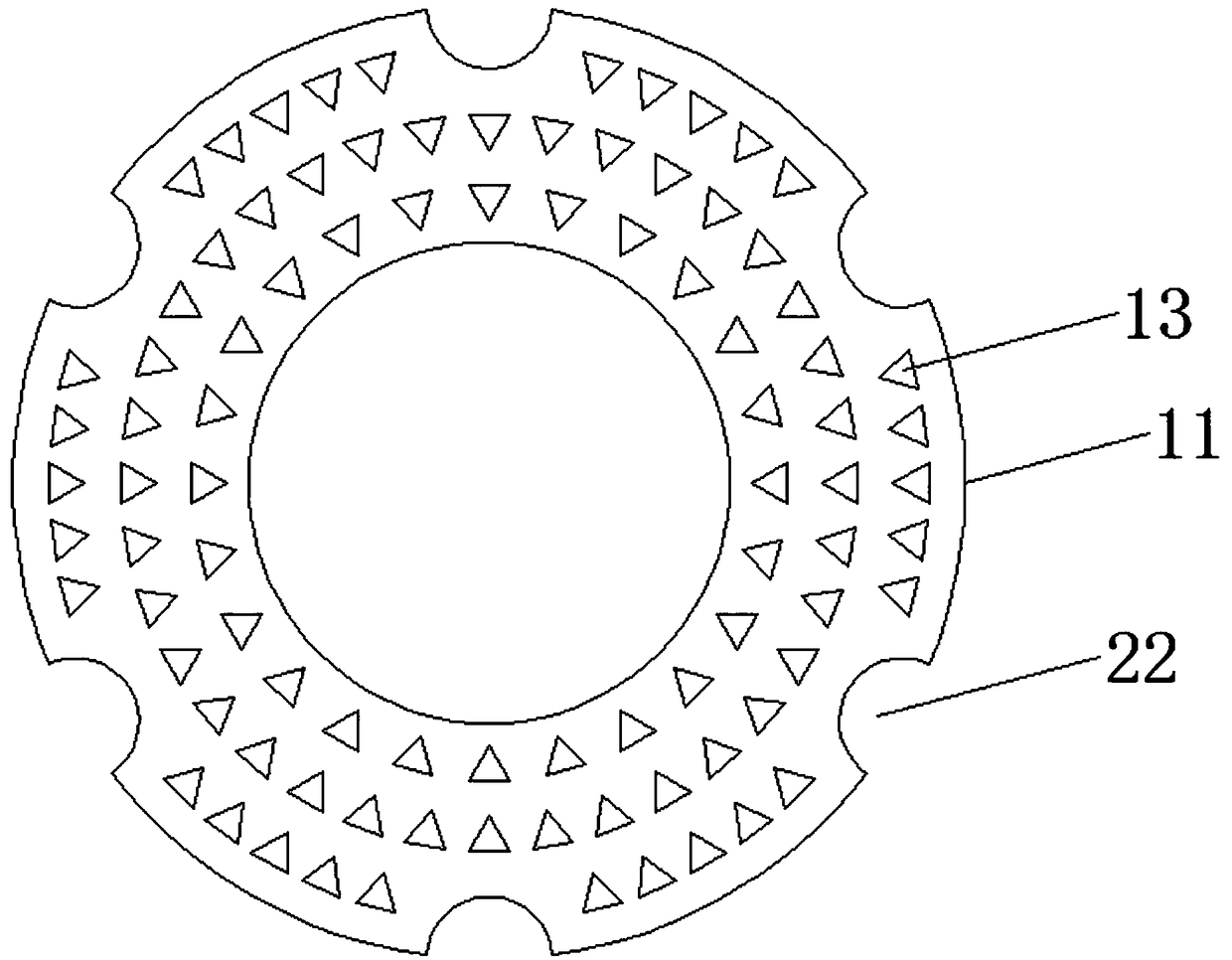

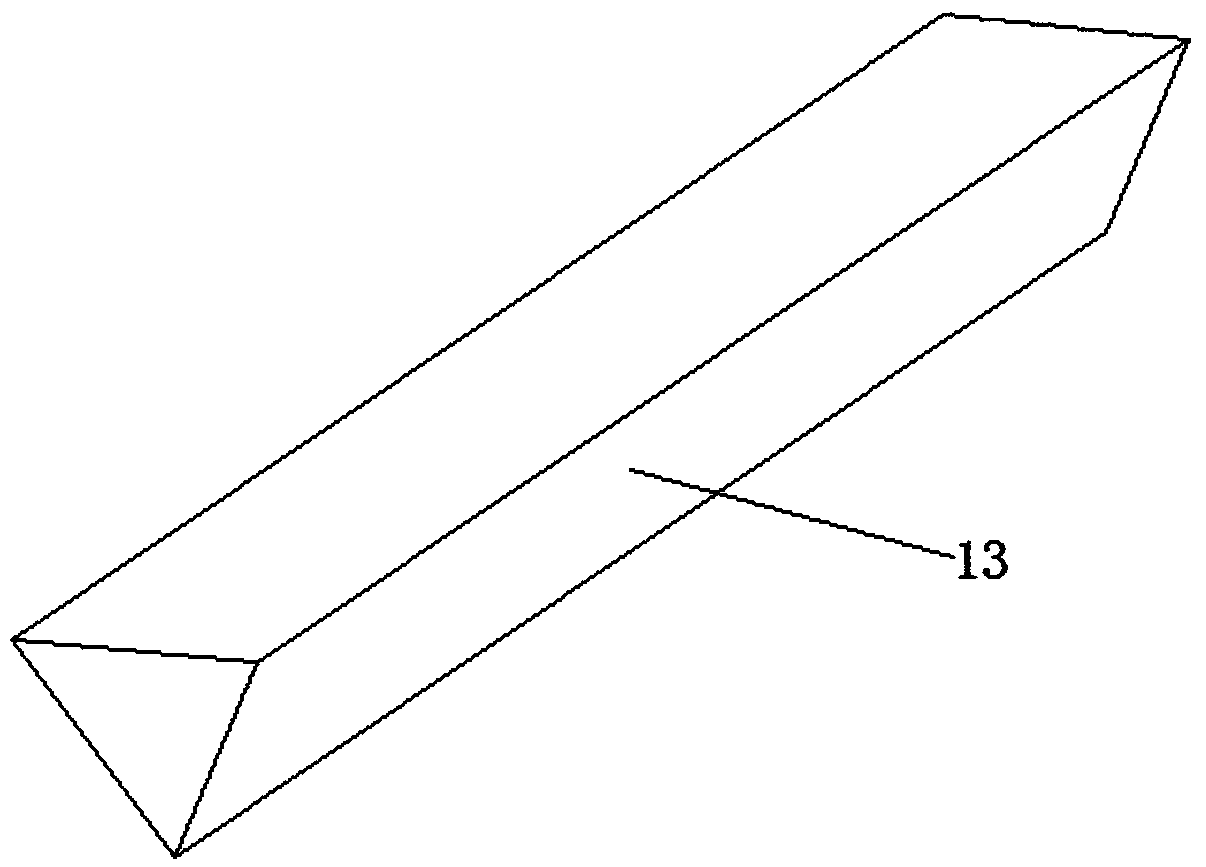

Layered-pulverizing beater for paper making

InactiveCN108951258ABeat thoroughlyAvoid residuePulp beating methodsMachining timeMechanical engineering

The invention discloses a layered-pulverizing beater for paper making. The beater comprises a housing, a motor, a feeding hopper, a rotary shaft, beating blades and a rotary tube, the rotary tube is coaxially and vertically fixed to the rotary shaft arranged below the beating blades, multiple horizontal layering plates are uniformly distributed from top to bottom of the outer side wall of the rotary tube, the upper and lower portions of the layering plates are provided with a plurality of fixing rods which are fixed to the inner wall of the housing, a plurality of beating teeth are fixed to the side walls of the fixing rods, squeezing strips are fixed to the corresponding layering plates located between the adjacent beating teeth, and water spraying holes are formed in the parts located onthe side wall of the rotary tube corresponding to the upper layers of the layering plates. By arranging the rotary tube to drive the layering plates on the outer side of the rotary tube to rotate andmatching with the beating teeth and the squeezing strips to perform pulverizing, raw materials are allowed to be pulverized by the beating teeth and the squeezing strips for multiple times when the raw materials flow downwards, the beating efficiency is improved, and the processing time is shortened.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com