Waste paper stirrer

A technology of agitator and waste paper, which is applied in papermaking, paper recycling, textiles and papermaking, etc. It can solve the problems of low stirring efficiency, easy slagging and deposition in dead corners at the bottom of the barrel, and insufficient pulp shredding, so as to improve fluidity , prevent sticking, and high-quality workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

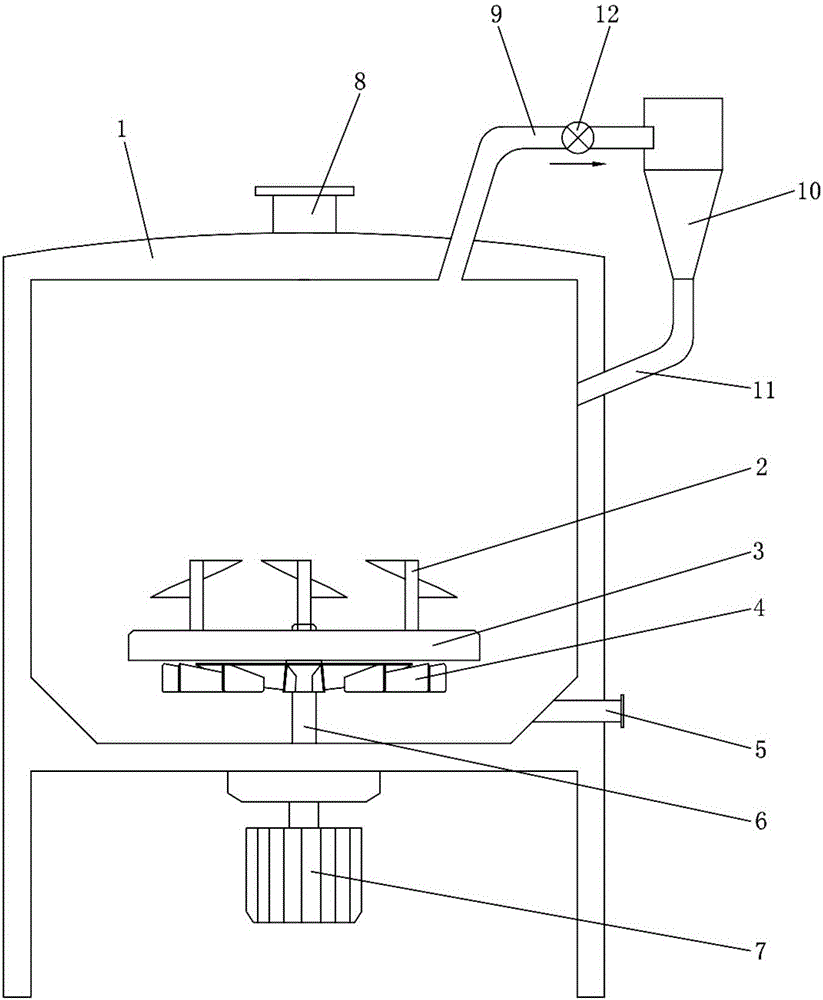

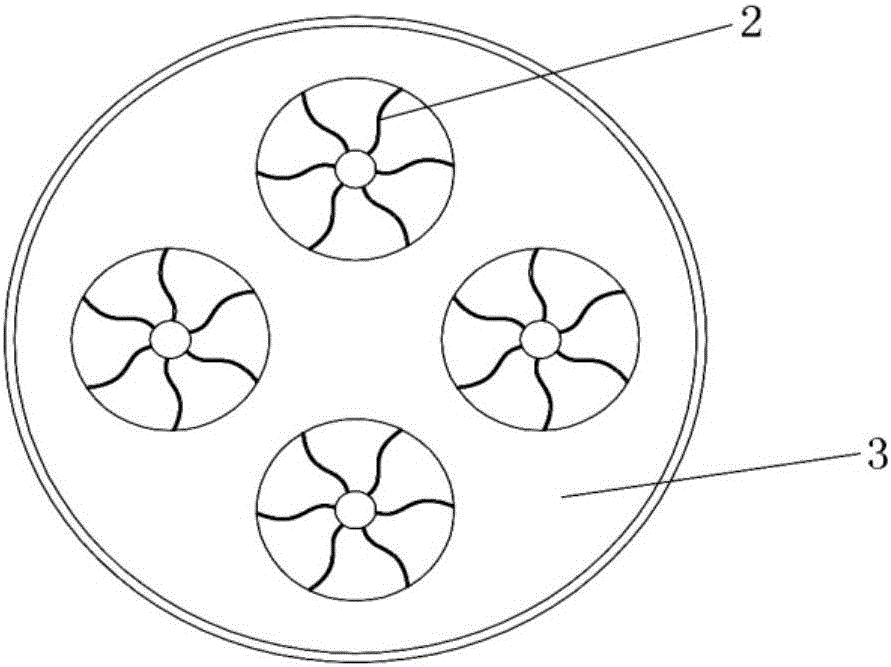

[0008] like figure 1 As shown, the waste paper mixer is mainly composed of a mixing tank 1, a blade knife 2 and an impeller 4.

[0009] The upper end of the mixing tank 1 is provided with a slurry inlet 8, and the inner bottom of the mixing tank 1 is provided with a slurry outlet 5. A motor 7 is installed outside the bottom of the mixing bucket 1 , the output shaft of the motor 7 is connected to the rotating shaft 6 , and the stirring disc 3 is installed on the rotating shaft 6 . A blade knife 2 is installed above the stirring plate 3, and the blade knife is used for chopping the slurry. The impeller 4 is installed under the stirring plate 3, and the impeller can stir the pulp at the bottom of the mixing tank evenly without sedimentation, thereby improving the quality of the papermaking process in the later stage.

[0010] The upper side of the mixing tank 1 is connected to the air outlet pipe 9, and an induced draft fan 12 is arranged on the air outlet pipe 9, and the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com