Pulping device for papermaking

The technology of a stirring device and a power device is applied in the field of beating devices for papermaking, which can solve the problems of complex structure, crushing dead ends, single beating blades, etc., and achieve the effects of good beating effect, large impact force and improving beating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

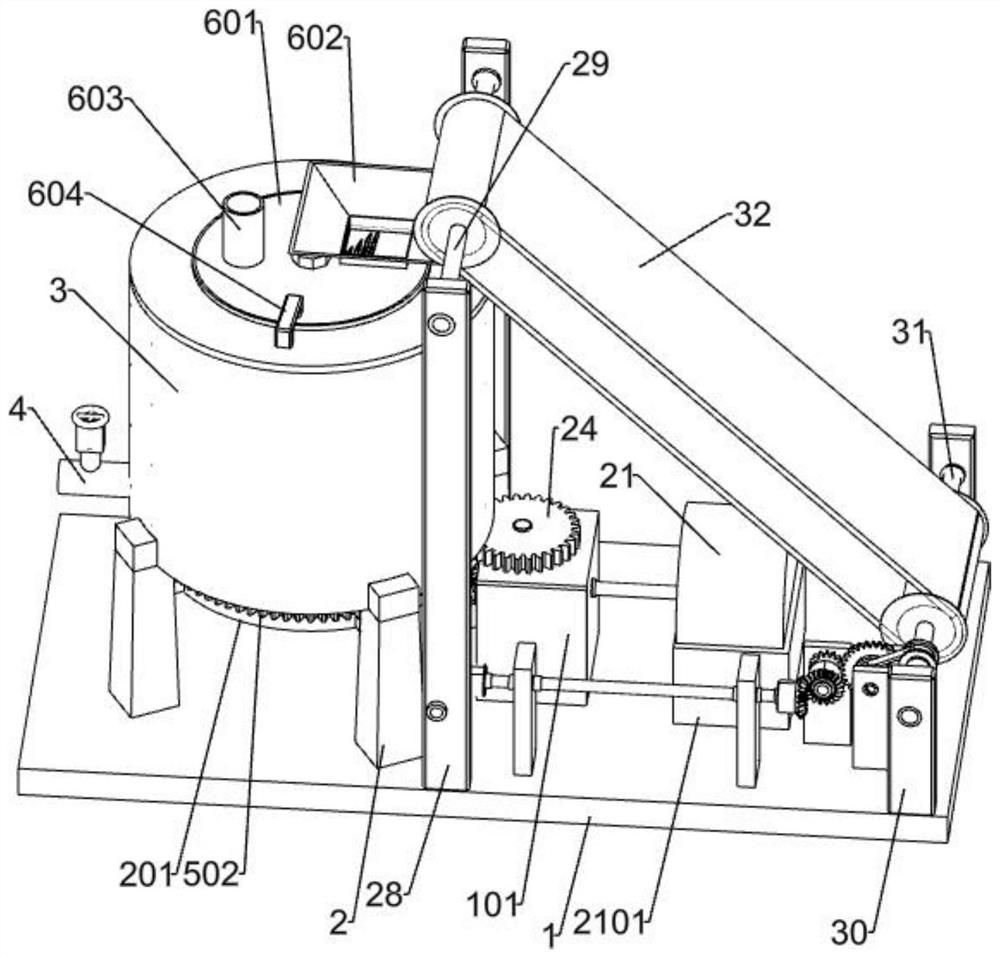

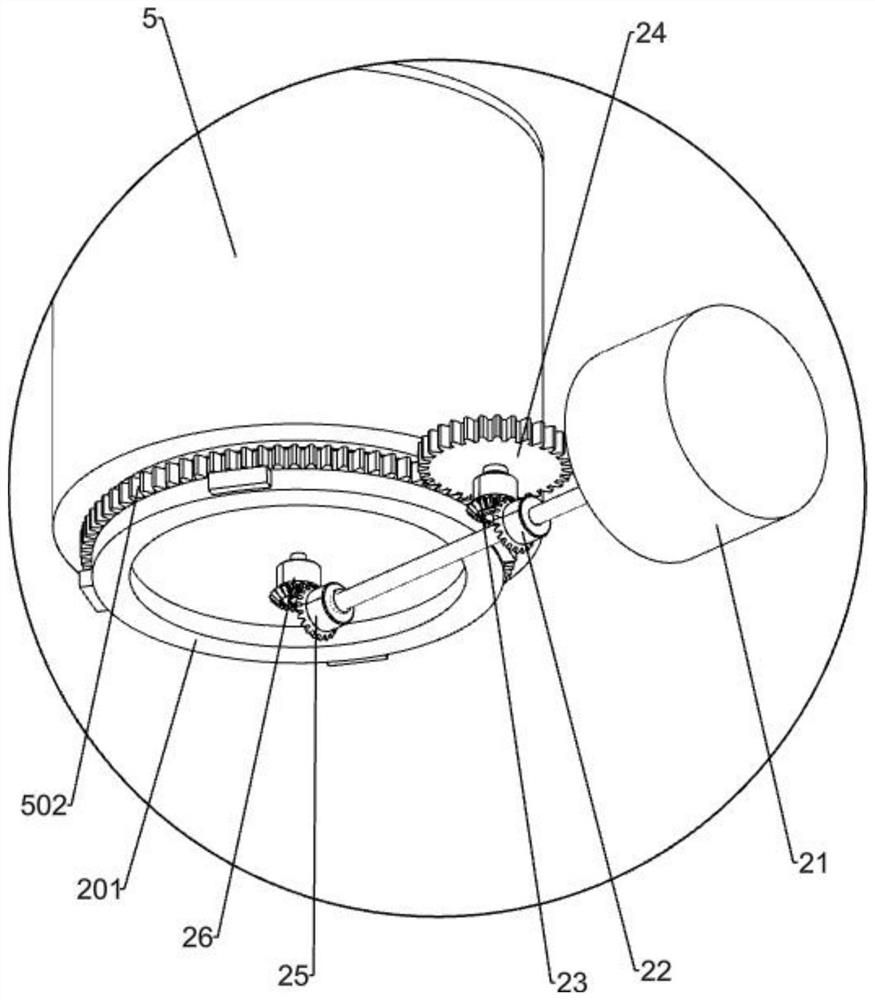

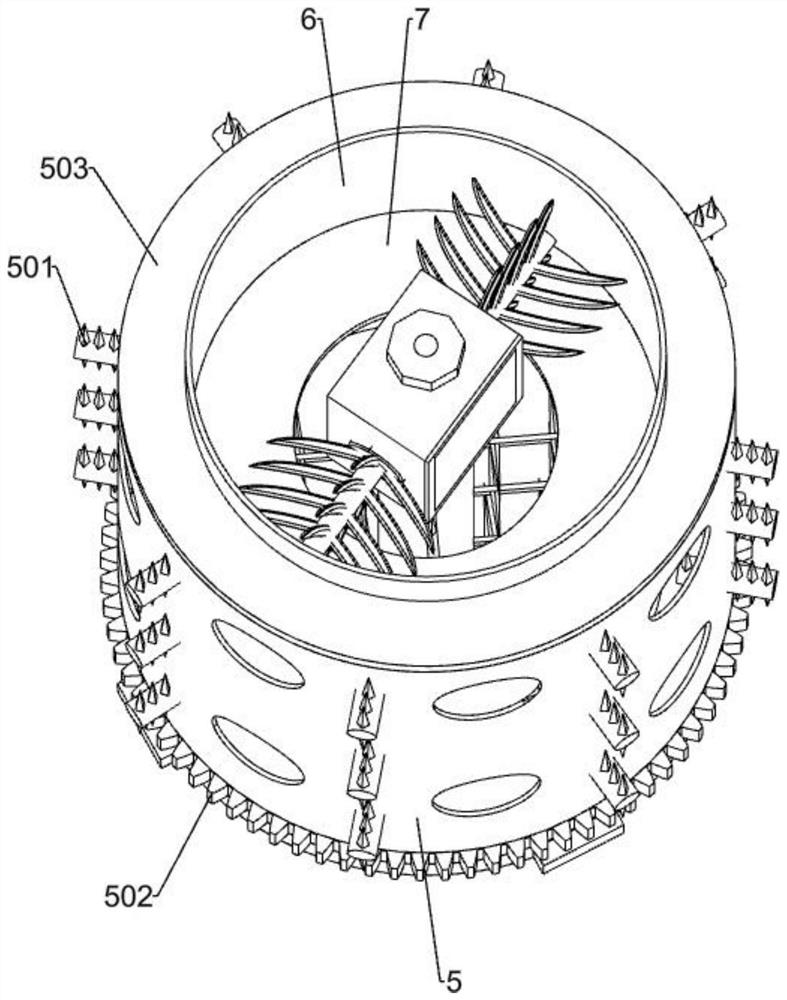

[0028] A pulping device for papermaking, such as Figure 1-7 As shown, it includes a bottom plate 1, a support block 2, a base 201, an outer box 3, a discharge port 4, an upper cover plate 601, a feed port 602, a water injection port 603, a handle 604, a power device, a stirring device and a chopper The device, four support blocks 2 are fixedly installed on the bottom plate 1, a base 201 is fixedly installed on the inner side wall of the four support blocks 2, an outer box 3 is fixedly installed above the base 201, and the left side wall of the outer box 3 is fixedly installed There is a discharge port 4, a handle 604 is symmetrically installed above the upper cover 601, the rear end of the handle 604 is fixedly connected with the upper cover 601, the front end of the handle 604 is in contact with the top of the outer box 3, and a note is installed on the upper left of the upper cover 601. The water port 603 and the feed port 602, the power device is installed on the upper rig...

Embodiment 2

[0039] On the basis of Example 1, as Figure 8-9 Shown, also include 28-large straight column 28,29-the first connecting shaft 29,30-small straight column 30,31-second connecting shaft 31 and 32-conveyor belt 32, two big straight columns 28 are fixedly installed on Above the middle part of the bottom plate 1, a first connecting shaft 29 is installed between the two large straight columns 28, the first connecting shaft 29 is rotationally connected with the two large straight columns 28, and two small straight columns 30 are fixedly installed on the upper right side of the bottom plate 1, A second connecting shaft 31 is installed in the middle of the two small straight columns 30, the second connecting shaft 31 is rotatably connected with the two small straight columns 30, the left end of the conveyor belt 32 is rotatably connected on the first connecting shaft 29, and the right end of the conveyor belt 32 is rotatably connected On the second connecting shaft 31 , the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com