Method for treating leather leftover materials

A processing method and technology for leftover materials, applied in the processing field, can solve the problems of poor processing effect, complicated methods and too many processes, and achieve the effect of convenient sorting and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

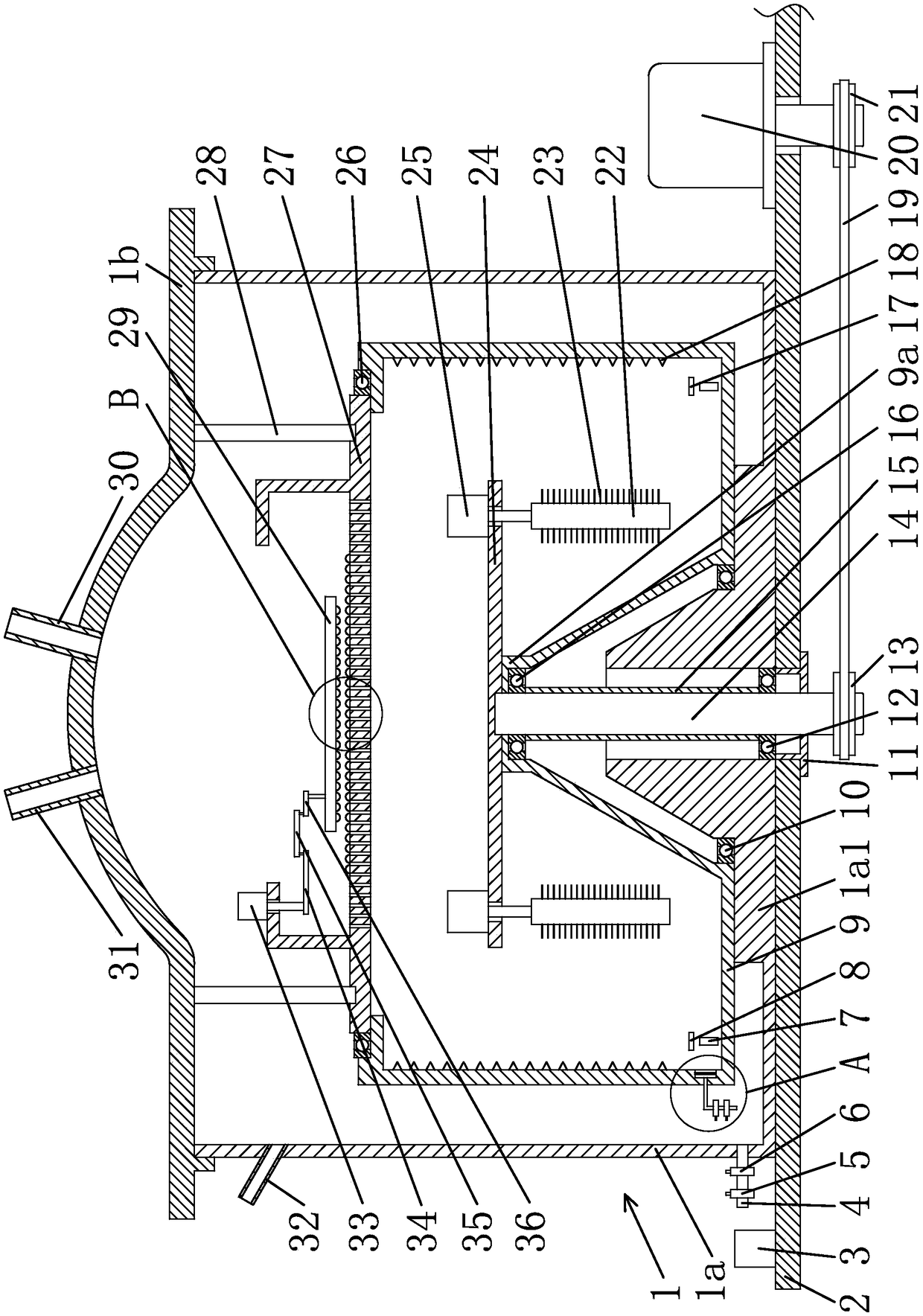

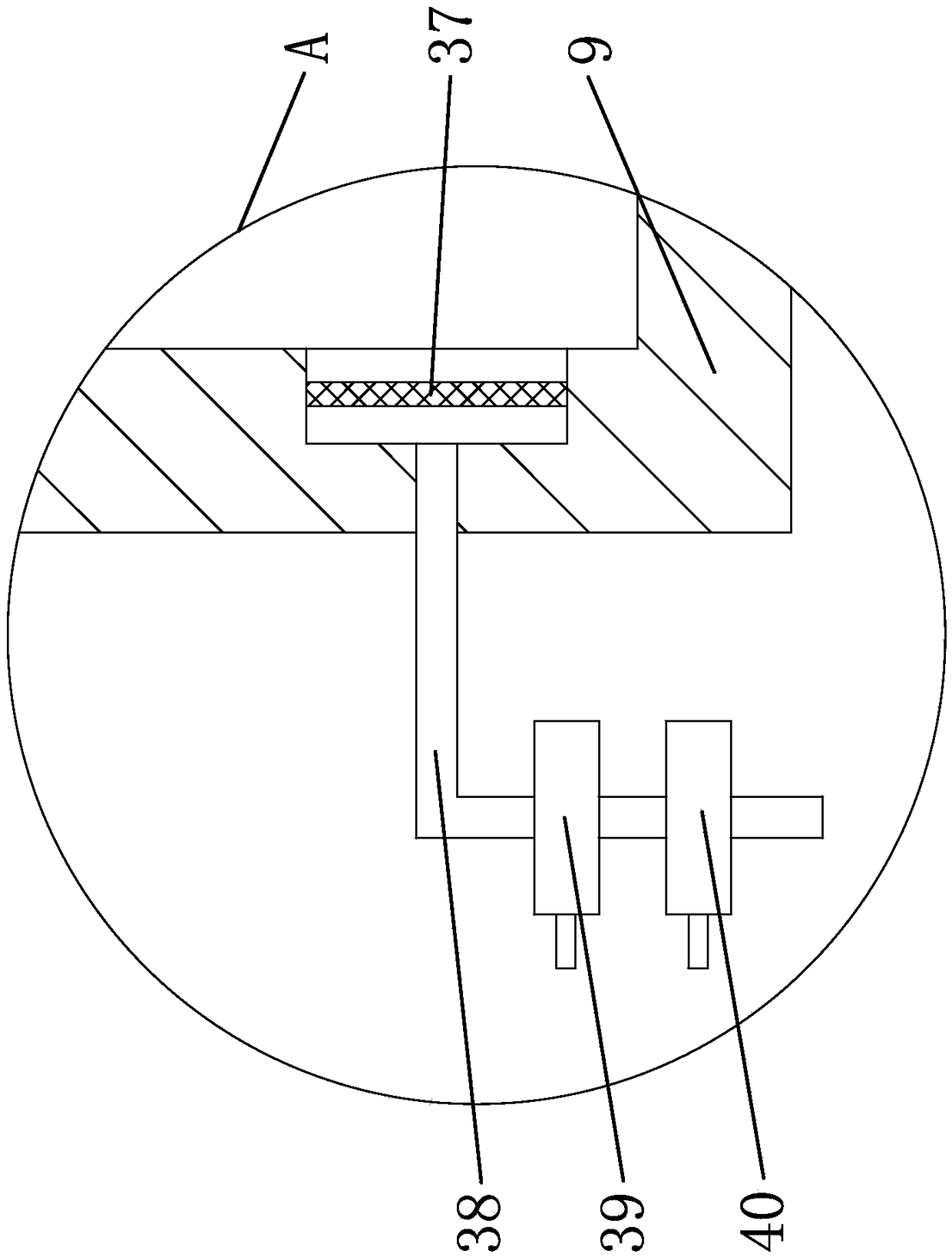

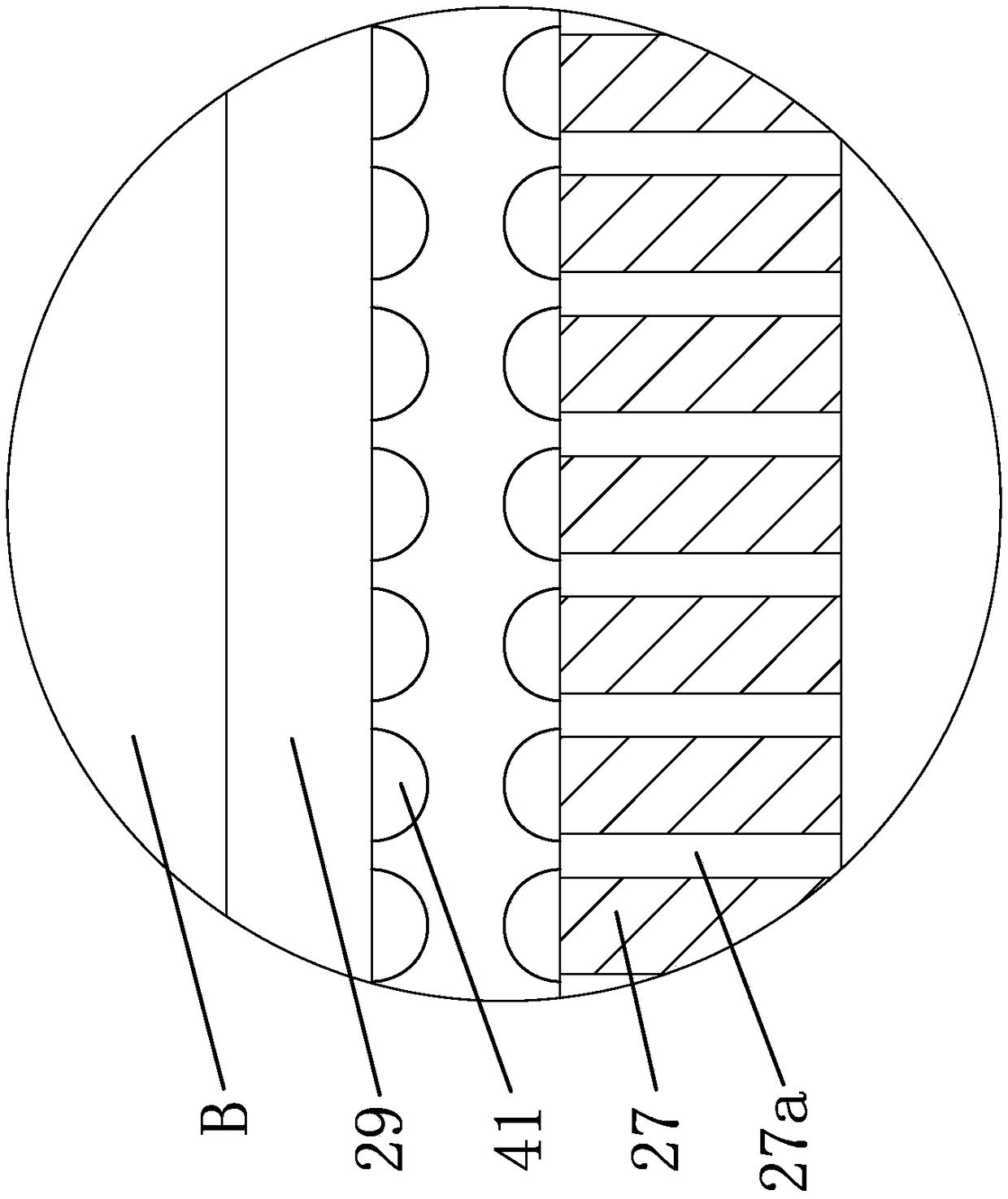

[0061] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0062] A method for processing leather leftovers, the processing method comprising the following steps:

[0063] S1. Prepare leather leftovers, remove impurities, then screen and classify them, and store them as spare materials;

[0064] S2, putting the standby material in S1 into the crushing mechanism of the beating system to obtain the short fiber-shaped standby material;

[0065] S3. Put the short-fibrous spare material in S2 into the cleaning solution for soaking treatment, heat the temperature to 30-50°C, and keep it warm for 2-3h; in this embodiment, heat it up to 40°C, and keep it warm for 2.5h;

[0066] S4, first put the spare material soaked in S3 into the beating barrel of the beating system, and the grinding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com