Pulse fluidization-based integrated de-ashing and dehydrating method and equipment of brown coal

A technology of pulsating flow and pulsating airflow, applied in the field of integrated method and equipment for deashing and dehydrating lignite based on pulsating fluidization, which can solve the problems of inability to deash and dehydrate lignite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

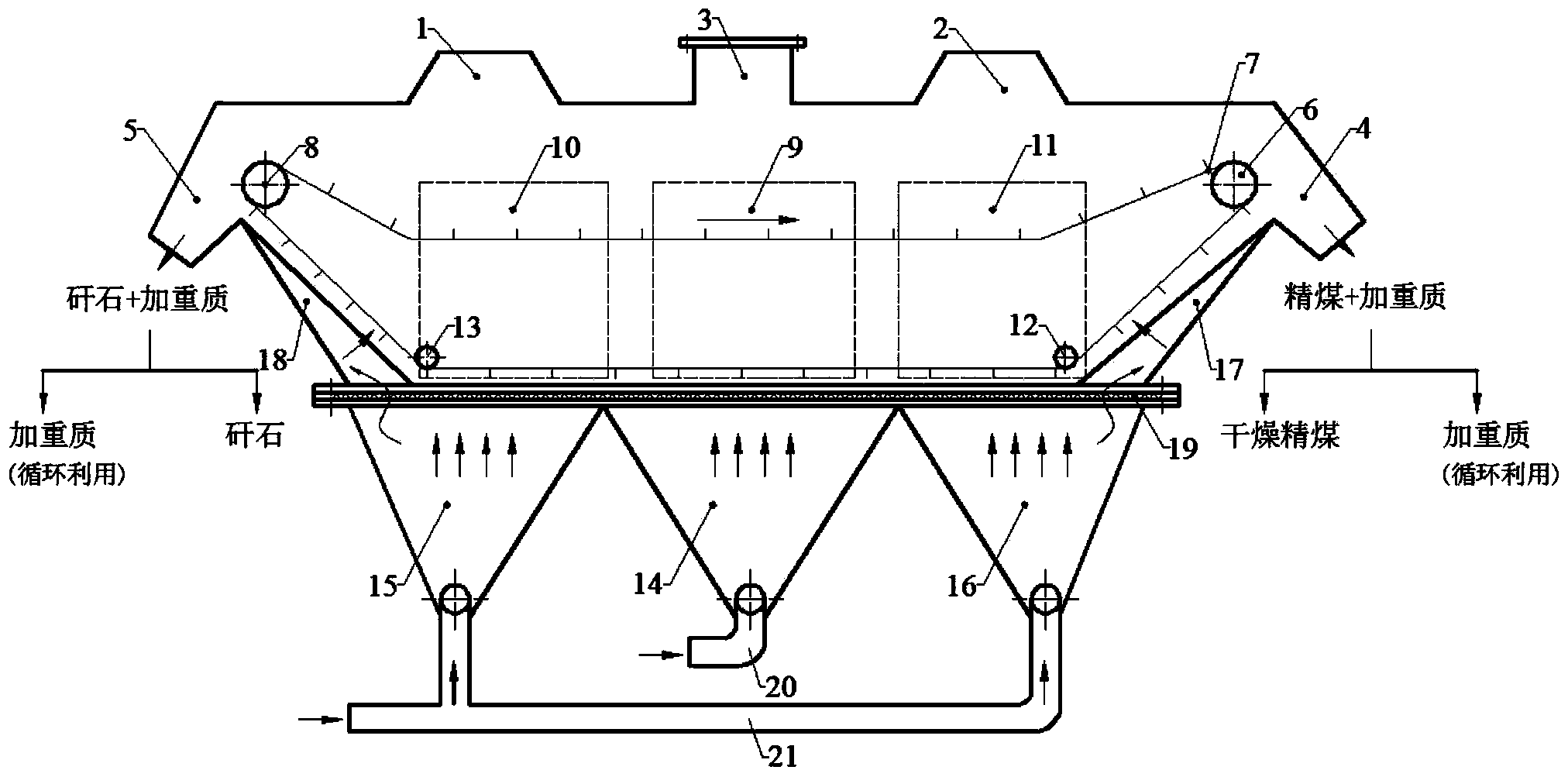

[0016] Embodiment 1: Deashing and dehydration based on pulsating fluidized lignite includes methods and equipment:

[0017] a. The described method is realized by the following steps:

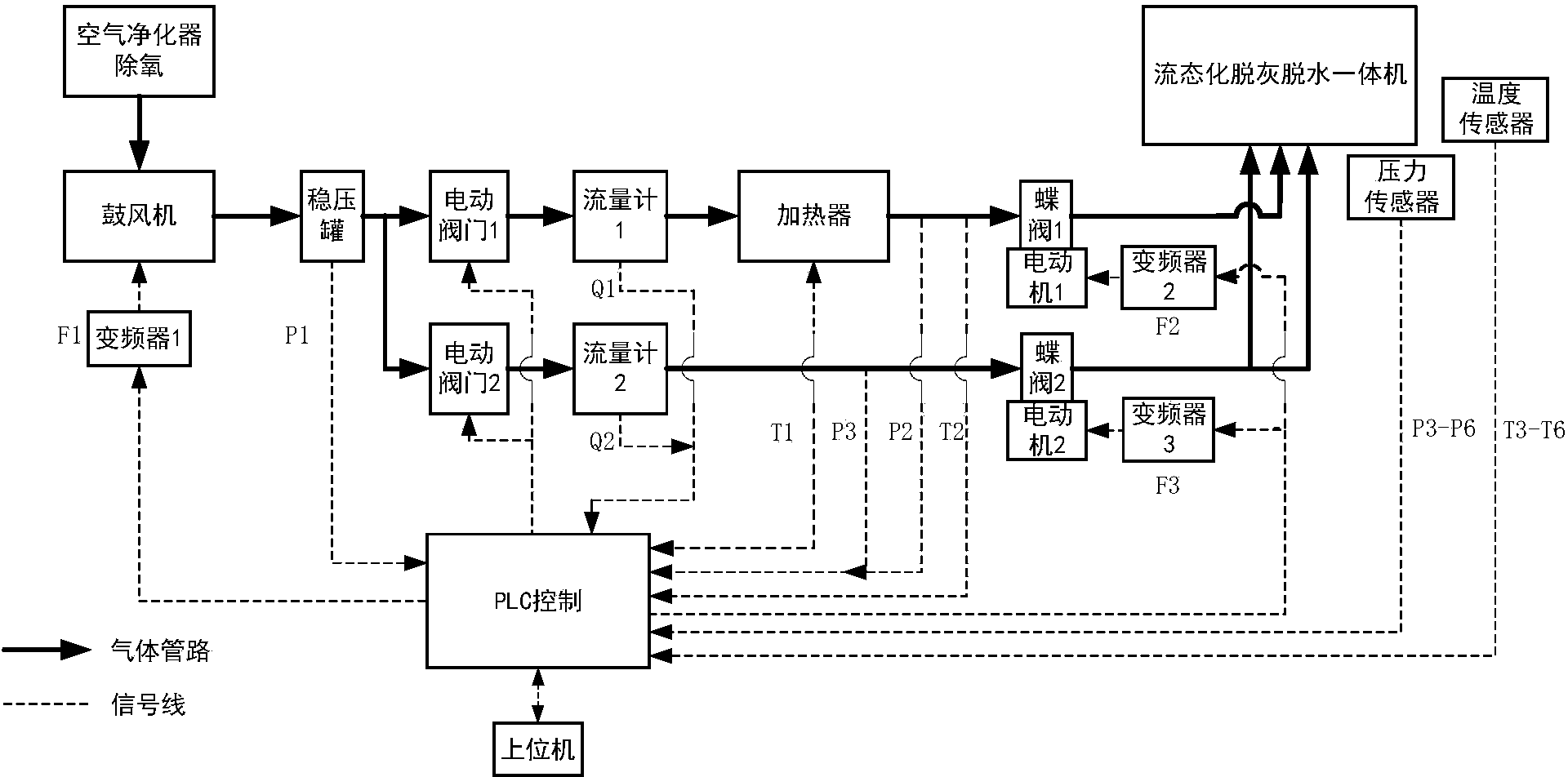

[0018] (1) Generation and control of pulsating airflow: After the air is deoxygenated by the air purifier, it enters the air storage tank under the action of the blower, and the airflow after stabilization is divided into two branches; one of which passes through the first electric valve in turn , the first flowmeter, the air heater, and the first butterfly valve are used as pulsating dry hot air; the second branch is turned into pulsating sorting cold air after passing through the second electric valve, the second flowmeter, and the second butterfly valve; the flow rate of the airflow , temperature, pressure and pulsation frequency through sensors, frequency converters, motors, etc. according to the material properties and product moisture and ash index requirements through PLC to complete rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com