Layered-pulverizing beater for paper making

A technology of beater and layered board, which is applied in the field of papermaking equipment, can solve the problems of extended working time, incomplete processing, and low work efficiency, and achieve the effects of improving beating efficiency, shortening processing time, and thoroughly beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

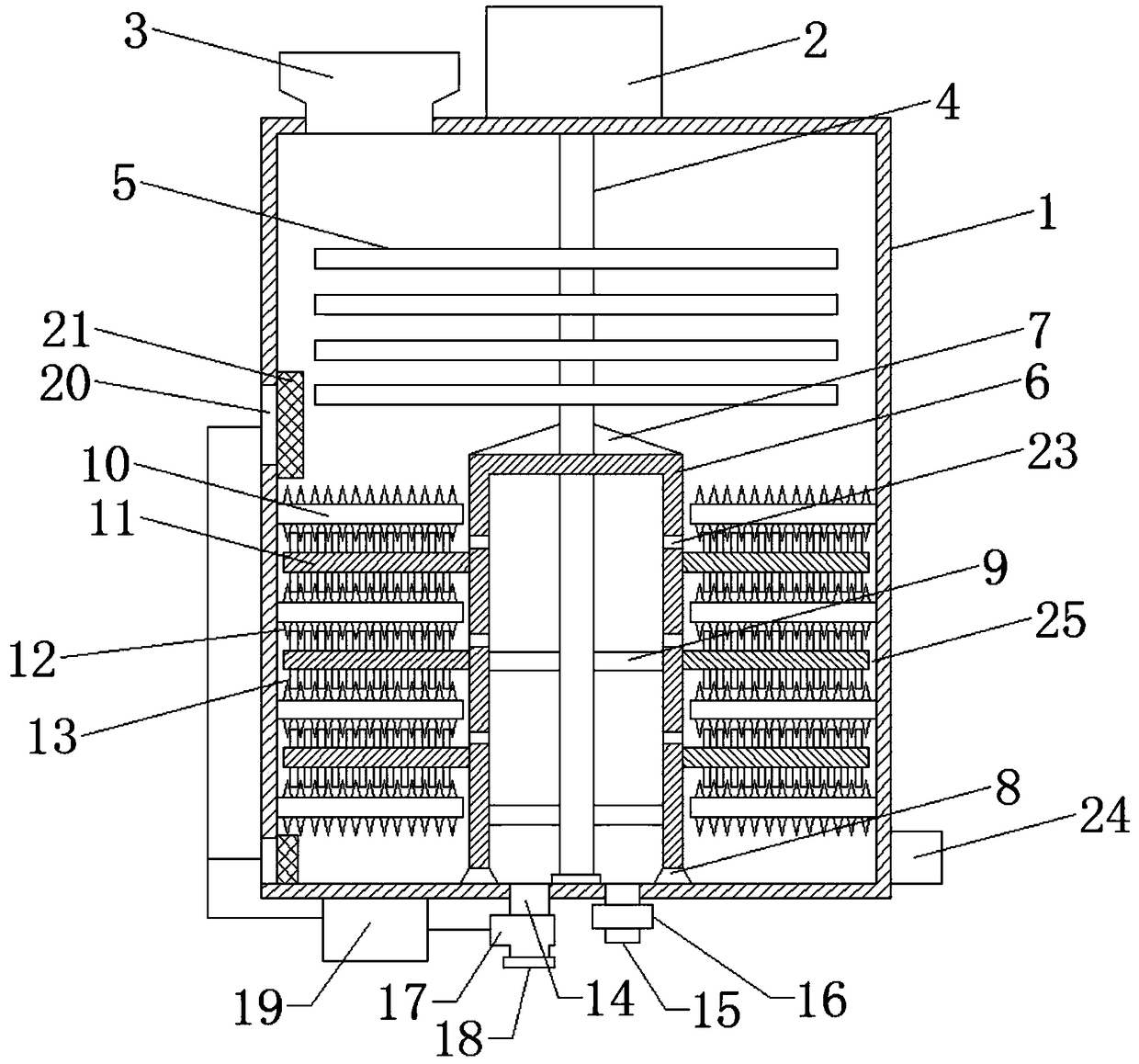

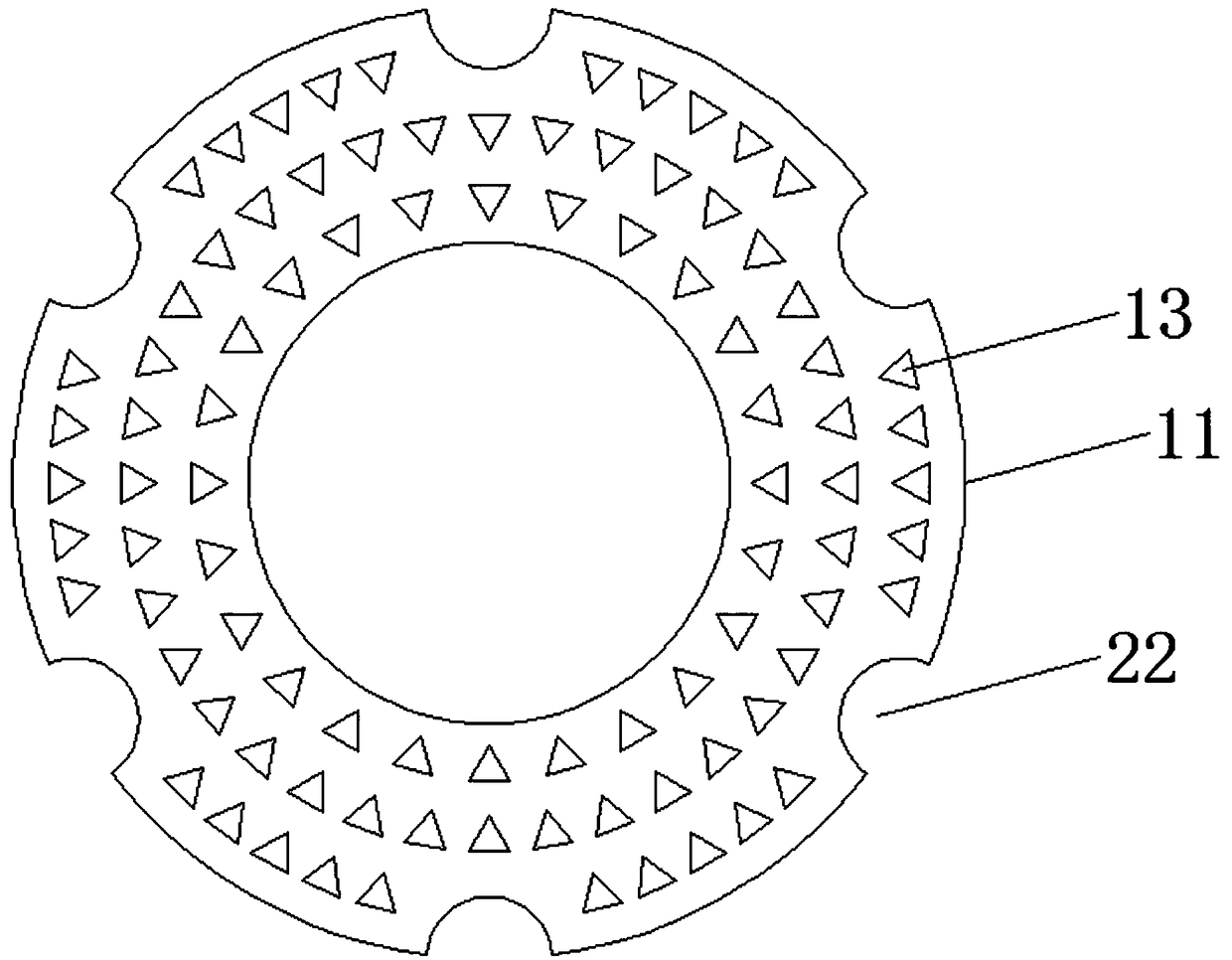

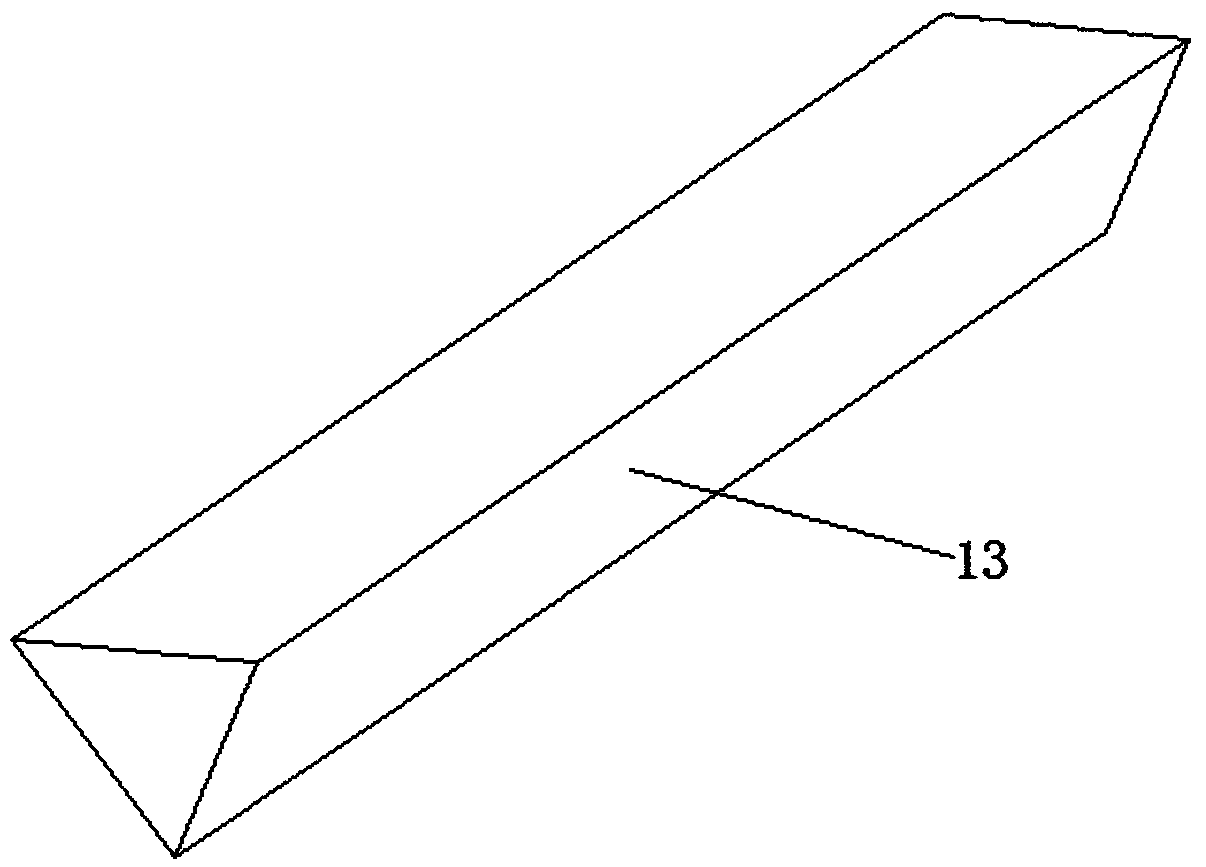

[0020] Please refer to the figure, in an embodiment of the present invention, a papermaking beater for layered pulverization includes a housing 1, a motor 2, a feed hopper 3, a rotating shaft 4, a beating blade 5 and a rotating cylinder 6; the motor 2 is fixed Installed on the top of the housing 1, the output shaft of the motor 2 extends vertically downwards into the housing 1, and the output shaft of the motor 2 coincides with the central axis of the housing 1, and the lower end of the output shaft of the motor 2 is fixedly connected with a vertical A straight rotating shaft 4, the lower end of which is connected to the bottom of the housing 1 through bearings; a plurality of beating blades 5 are fixedly installed on the upper section of the rotating shaft 4, and the raw materials entering the housing 1 are broken, The top of the body 1 communicates with a feed hopper 3 for filling, and raw materials are loaded into the housing 1 from the feed hopper 3 .

[0021] A vertical r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com