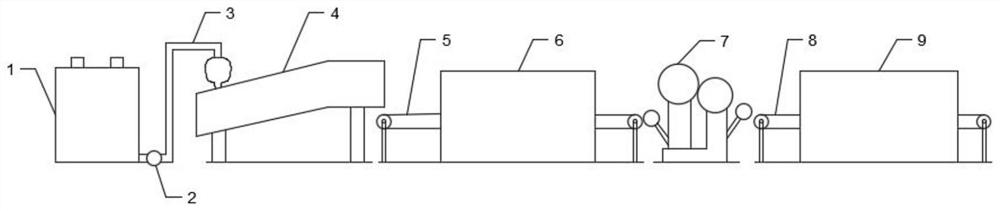

A kind of production equipment and process of plastic-free tableware wrapping paper

A technology of production equipment and production process, applied in the field of production equipment and process of plastic-free tableware wrapping paper, can solve the problems of difficult disposal of plastic waste, waste of resources, and refractory plastic degradation, achieve a wide range of PH values, and optimize products. Structure, the effect of high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

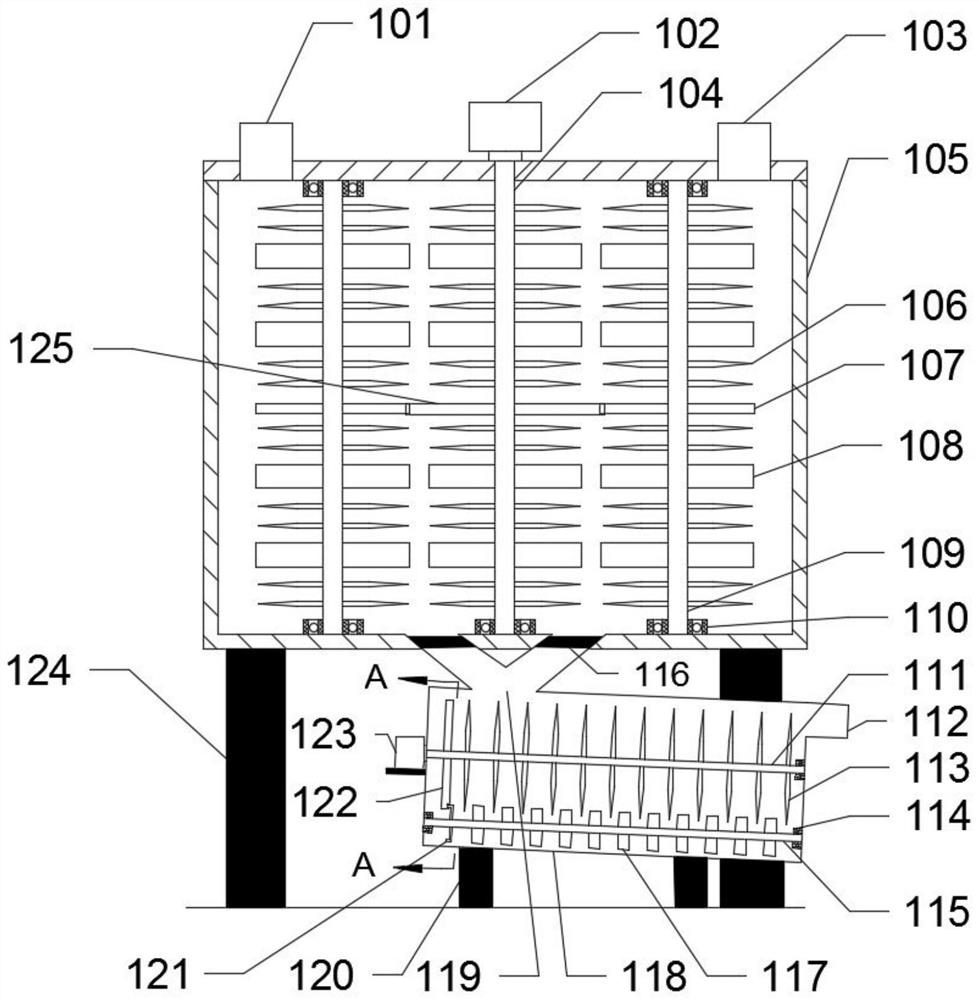

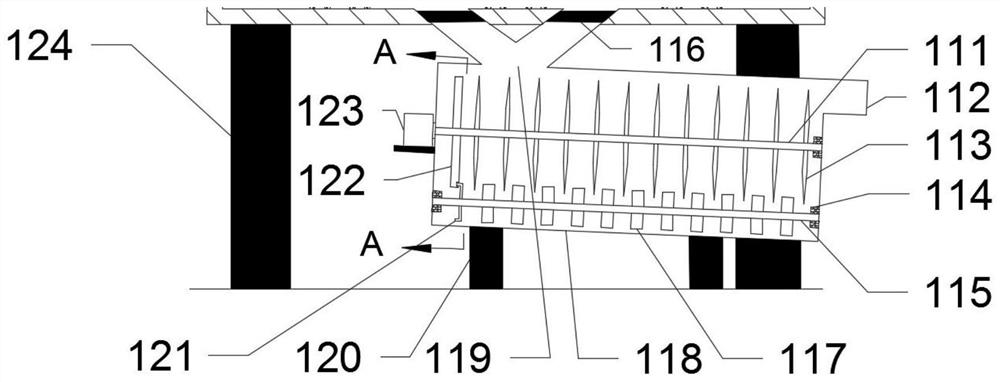

Method used

Image

Examples

Embodiment 1

[0052] Example 1: 40 grams of plastic-free tableware wrapping paper

[0053] Mix softwood pulp and hardwood pulp at a ratio of 40%:60% (the beating degree is controlled at 54-55°SR), add 10-12Kg / ton paper AKD sizing agent, add 8- 10Kg / ton cationic starch in pulp, add 0.3-0.4Kg / ton paper retention aid, add wet strength agent 8-10Kg / ton paper, add light calcium 120-150Kg / ton paper, prepare cost-white diluted pulp and go online , through the dehydration of the wire part to ensure uniform fiber dispersion, orderly and uniform distribution of vertical and horizontal fibers, wet paper sheets enter the press section after compound pressing; paper sheets dried to 95% before entering the sizing section, using film transfer Surface sizing treatment for paper (the main component of the front sizing material is PVA, and the reverse side is PVA+water repellent); the total amount of PVA sizing on the front side is controlled at 20-30Kg / ton of paper, and the amount of sizing on the back side...

Embodiment 2

[0054] Example 2: 52 grams of plastic-free tableware wrapping paper

[0055] Mix softwood pulp, hardwood pulp, and bleached bamboo pulp at a ratio of 30%: 62%: 8% (the degree of beating is controlled at 50-51°SR), and add 14-15Kg / ton of paper AKD Sizing agent, adding 8-10Kg / ton cationic starch in pulp, adding 0.2-0.3Kg / ton paper retention aid, adding wet strength agent 8-10Kg / ton paper, adding light calcium 150-180Kg / ton paper, the preparation cost The white diluted pulp is netted, dehydrated through the wire section to ensure uniform fiber dispersion, orderly and uniform distribution of vertical and horizontal fibers, wet paper sheets enter the press section after compound pressing; paper sheets that are dried to a dryness of 95% enter the In the sizing department, the surface sizing treatment of paper is carried out by film transfer method (the main component of the front sizing material is PVA, and the reverse side is PVA+water-resistant agent); the total amount of PVA sizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com