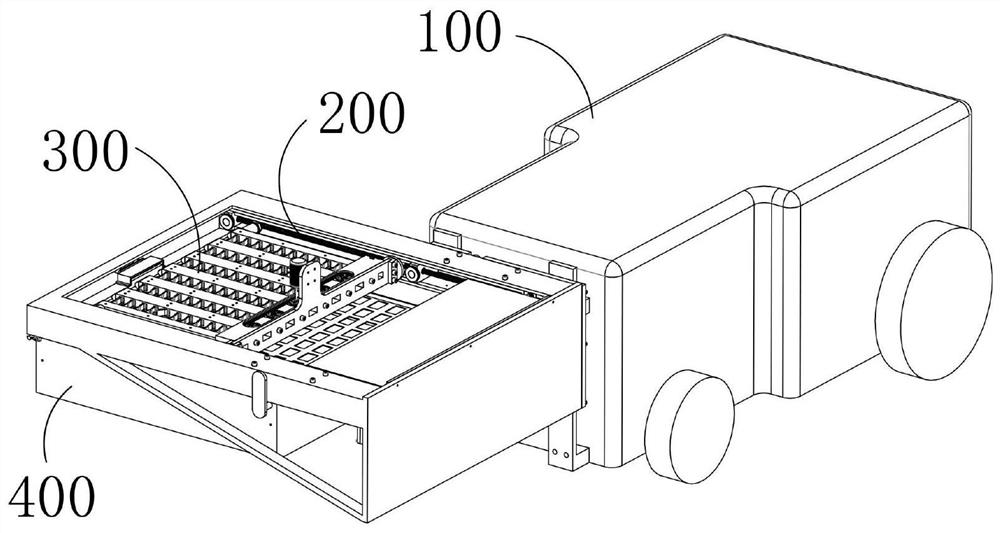

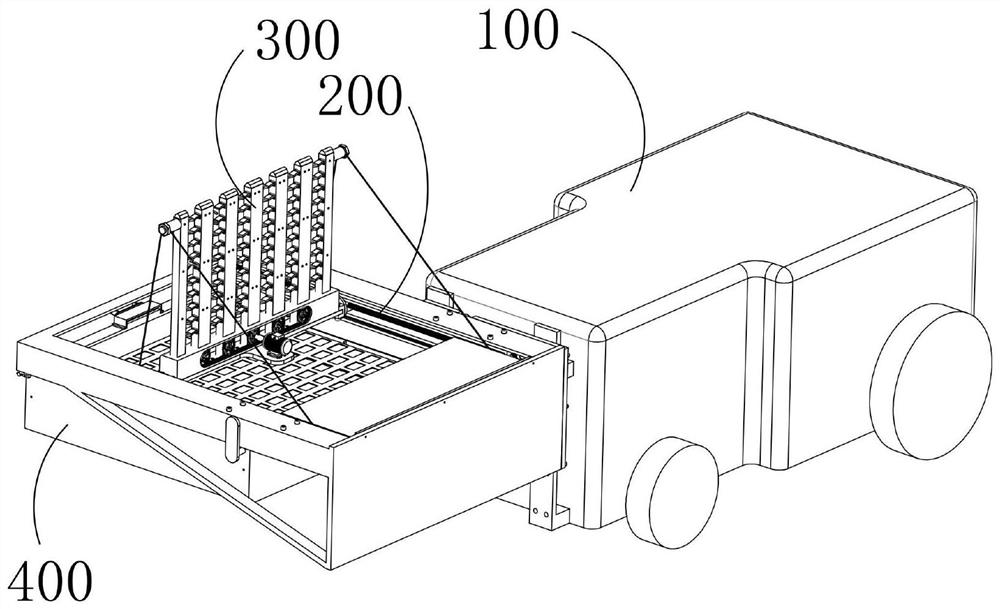

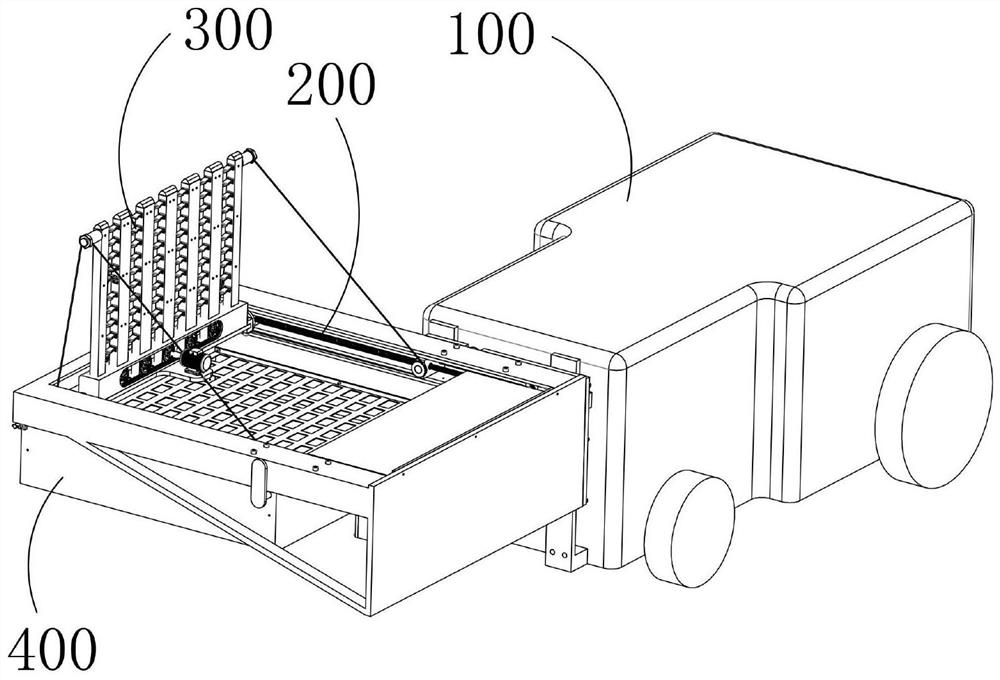

Automatic Preparation System of Lycium Barbarum Slurry

A wolfberry and slurry technology, which is applied in juice extraction, agricultural machinery and implements, picking machines, etc., can solve the problems of high labor intensity, low work efficiency, and high difficulty, and achieve the goal of reducing labor intensity, improving work efficiency, and avoiding injuries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The advantage of using the wolfberry picking machine to pick wolfberry in the present invention is that the wolfberry picking machine adopts a vibration method to make the wolfberry vibrate and fall from the branches and complete the picking. The whole picking process is realized by the picking preparation / driving device controlled by the picker, without picking Workers wear gloves with both hands and use scissors and other tools to pick, which improves work efficiency and reduces labor intensity, and effectively avoids the damage of thorns on the branches of wolfberry to the picking workers. The quality of wolfberry can be guaranteed. In addition, the follow-up wolfberry cleaning device can effectively remove the leaf debris mixed in the wolfberry and the impurities attached to the surface of the wolfberry and make the wolfberry cleaning more thorough. The wolfberry is beaten to make the wolfberry beating more thoroughly, and the slurry filter can filter the particles s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com