Patents

Literature

851results about How to "Falling smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

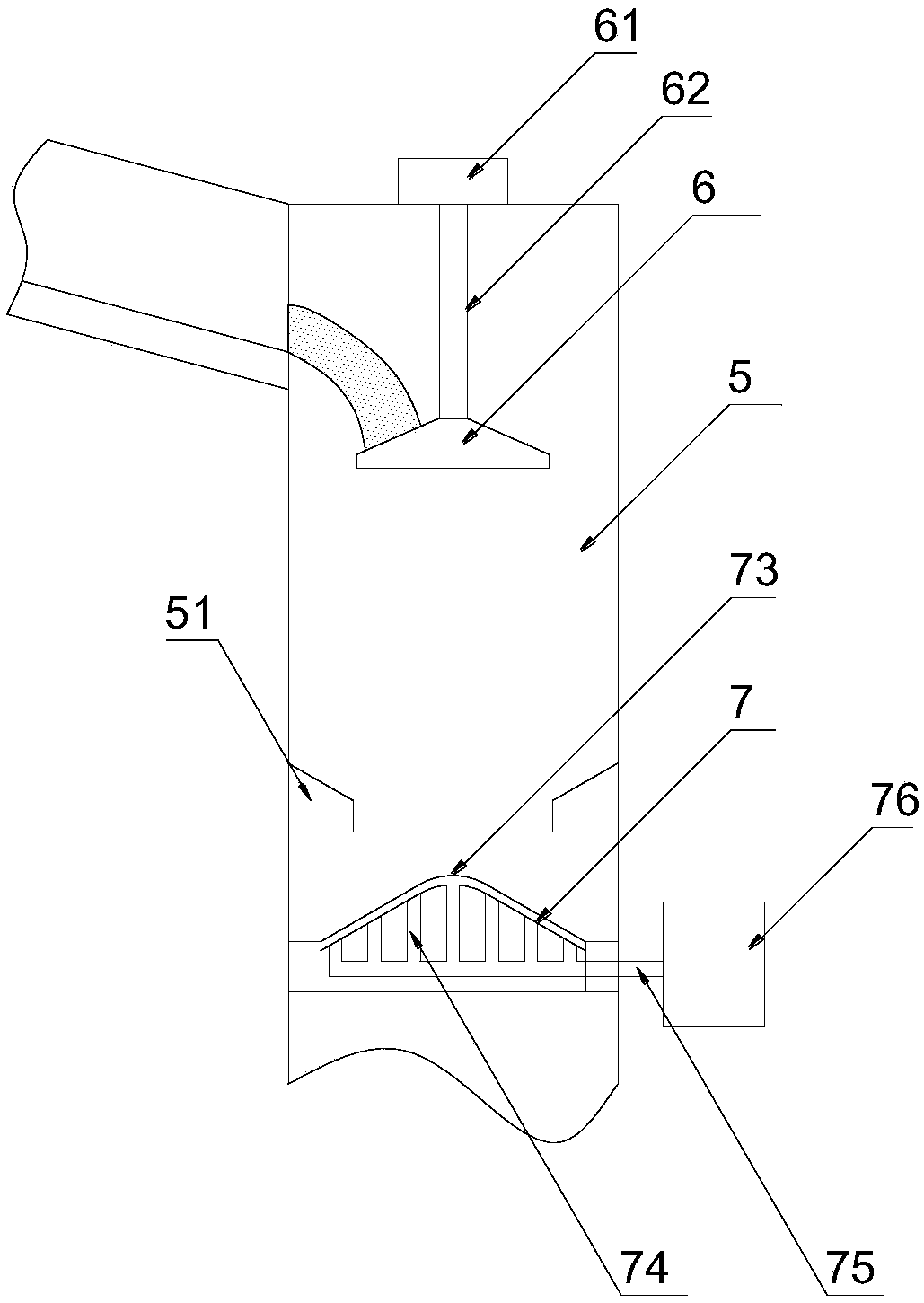

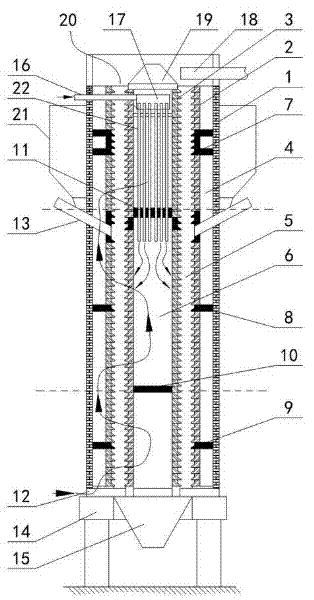

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

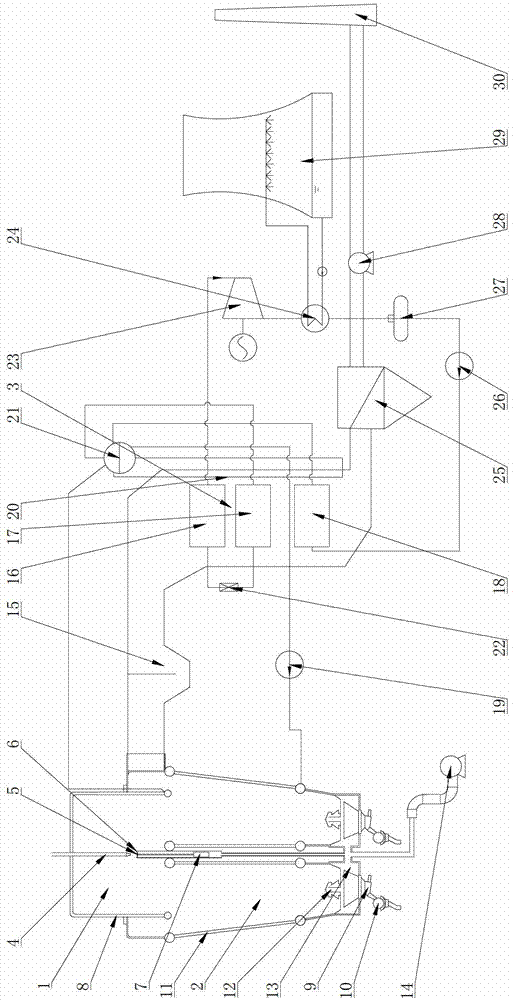

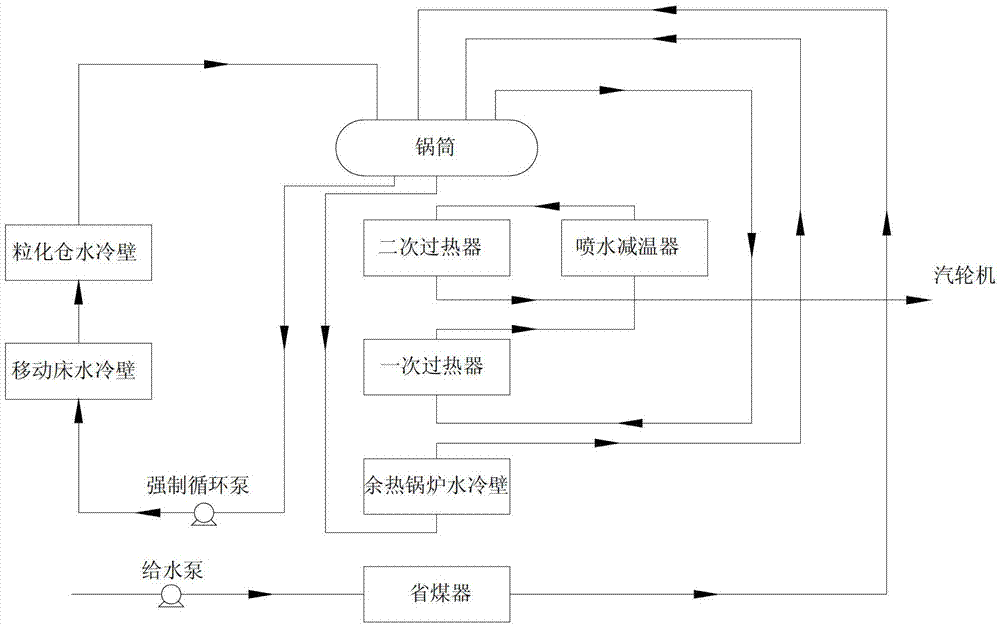

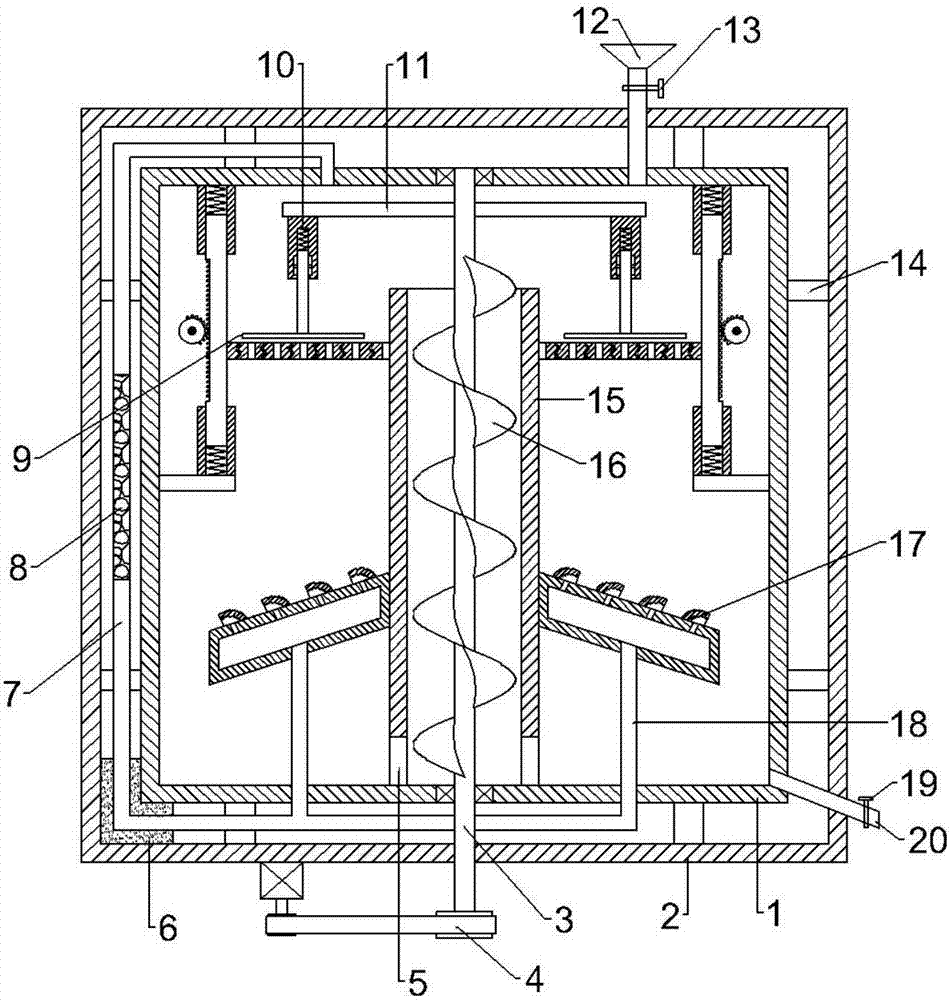

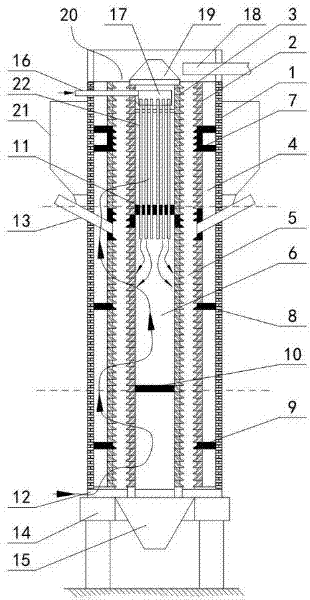

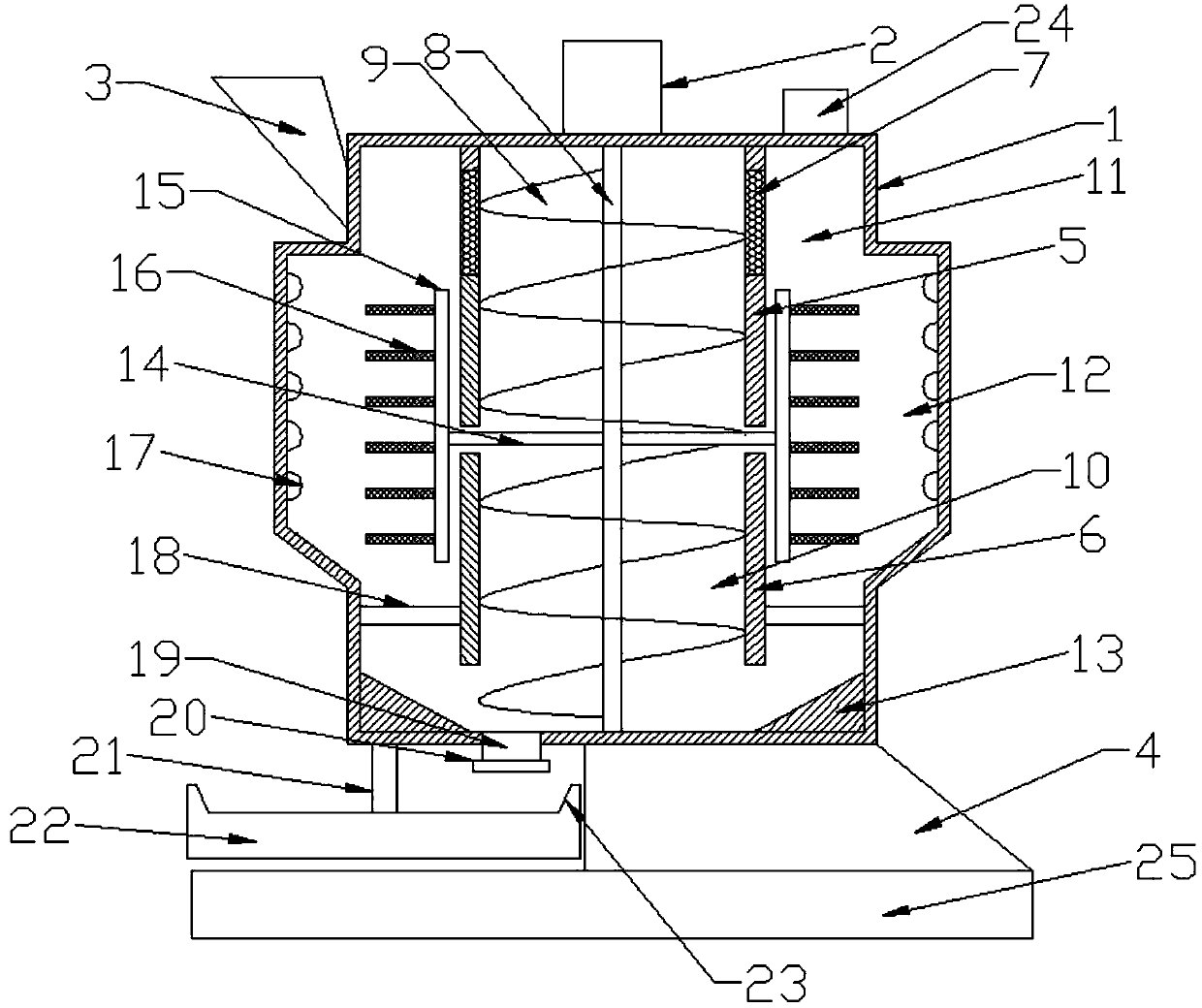

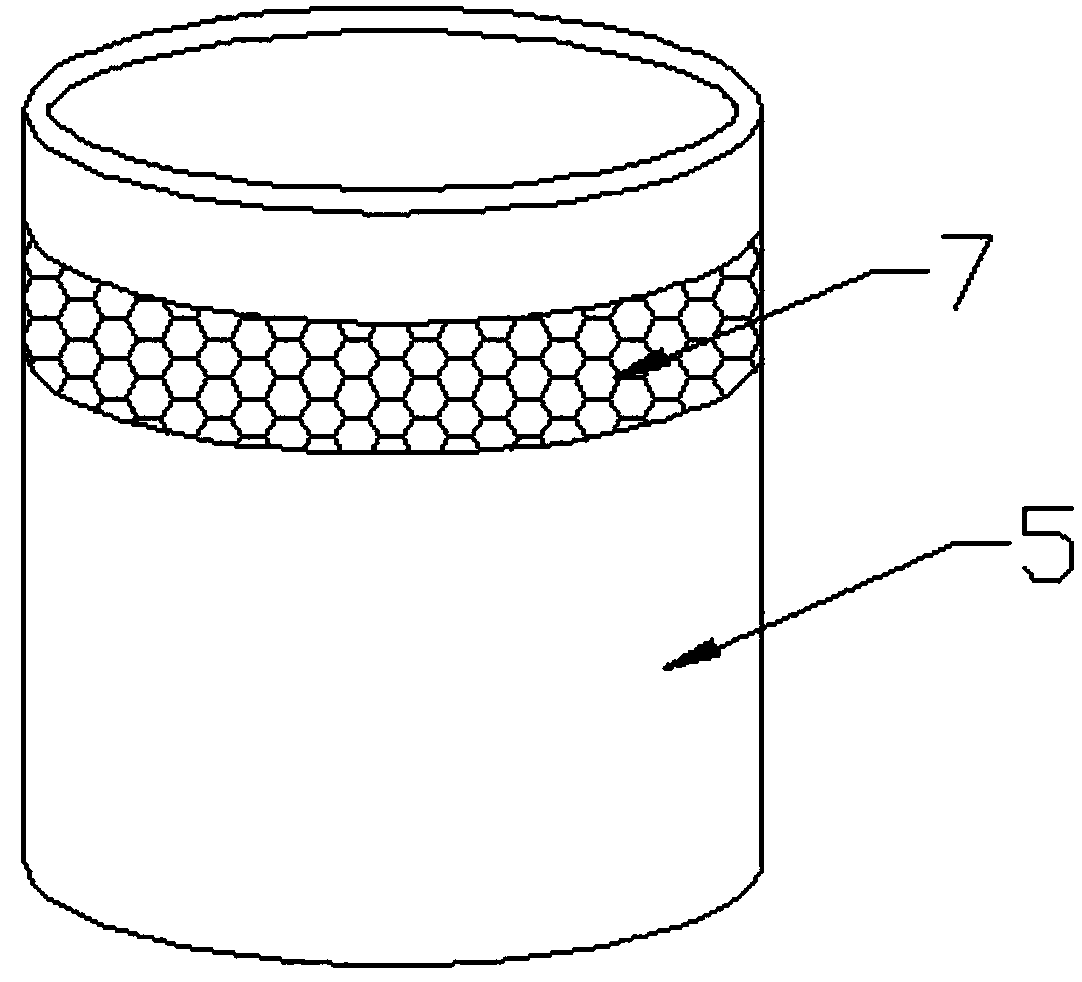

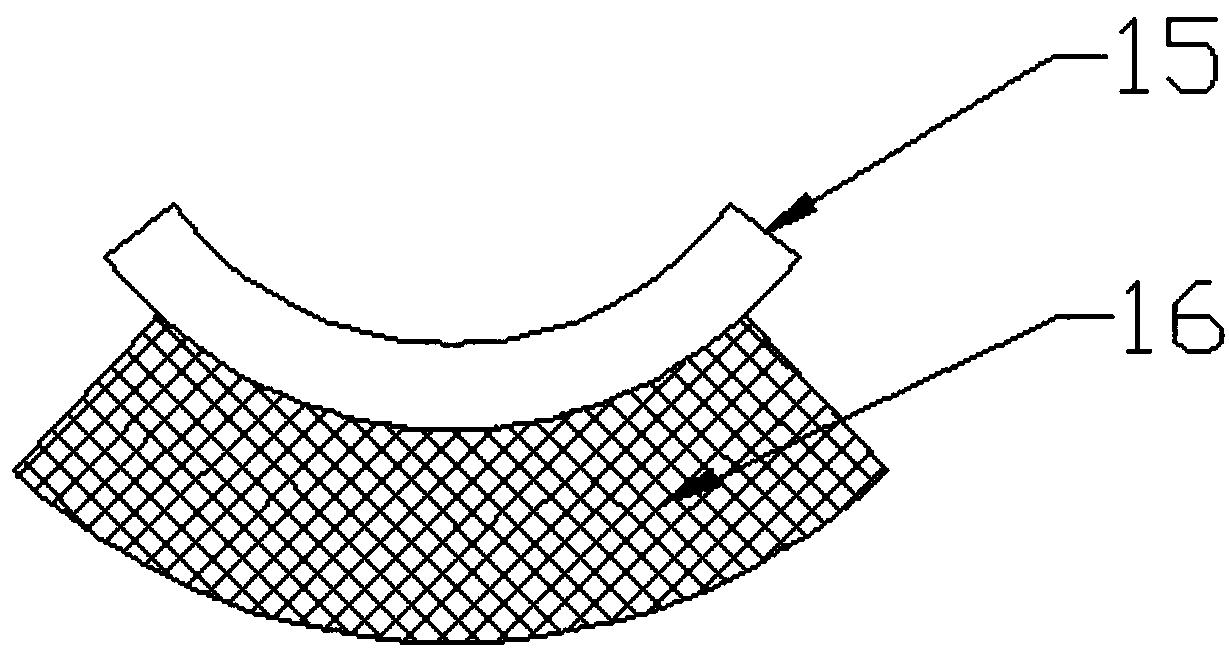

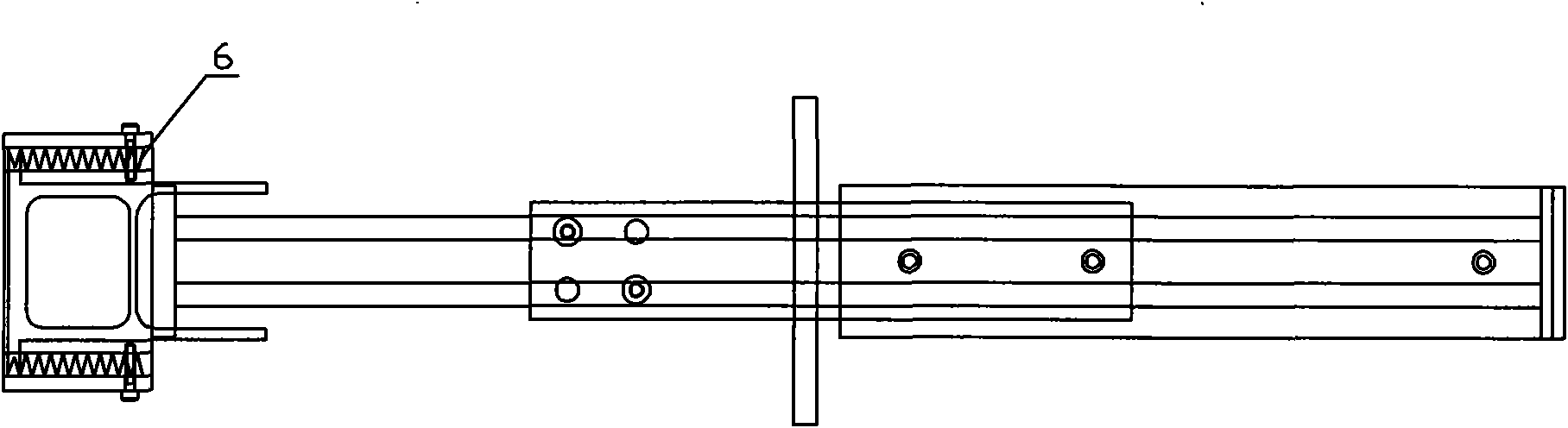

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

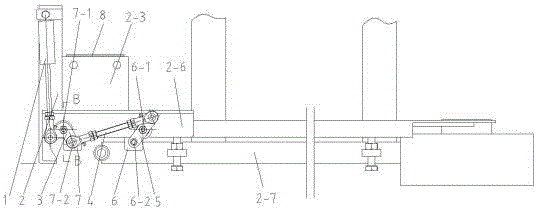

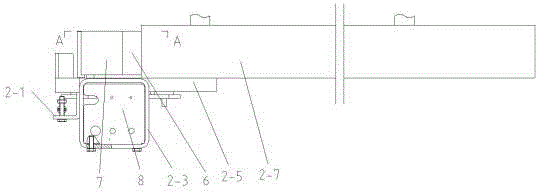

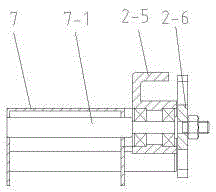

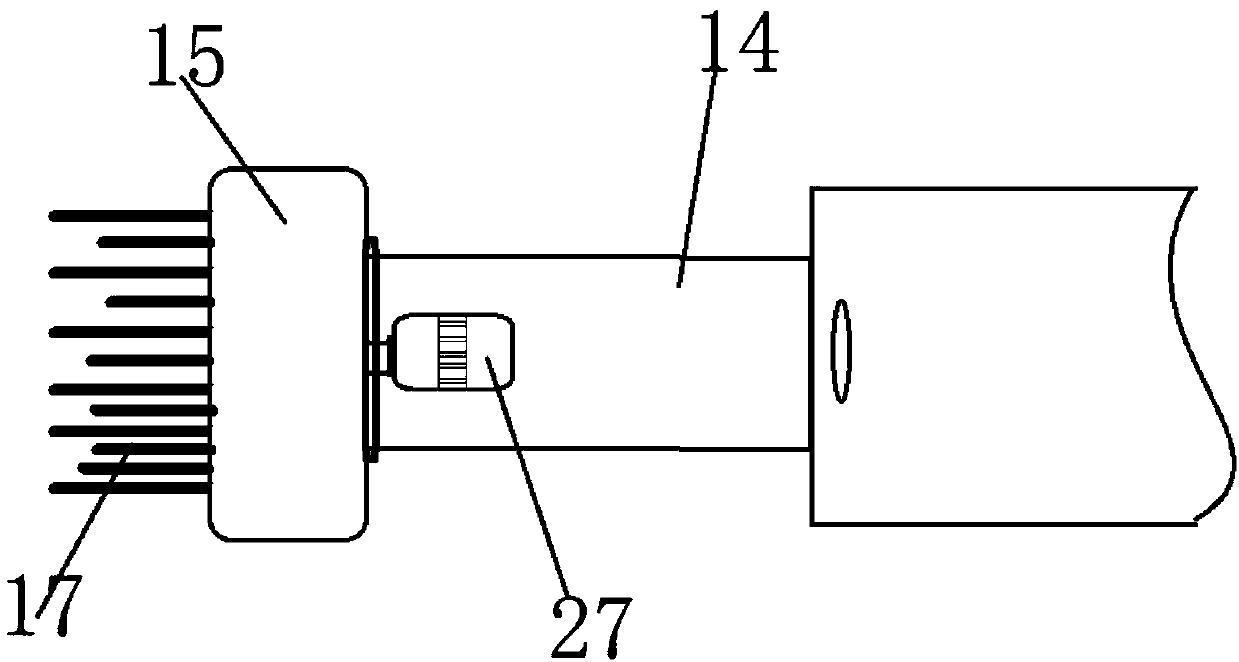

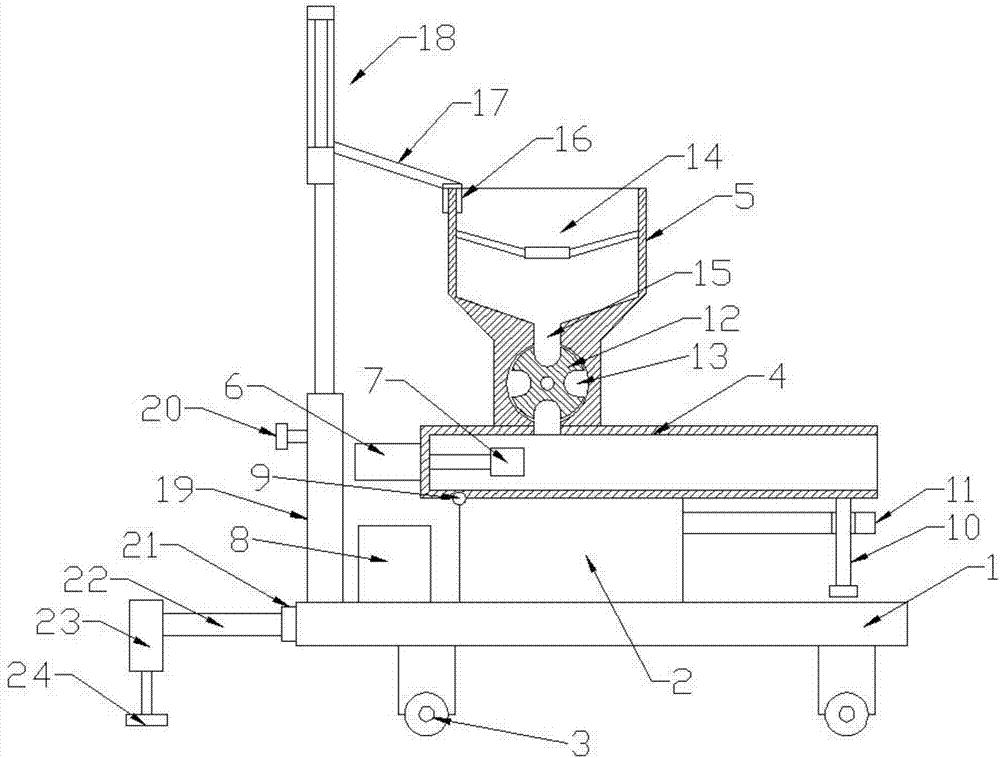

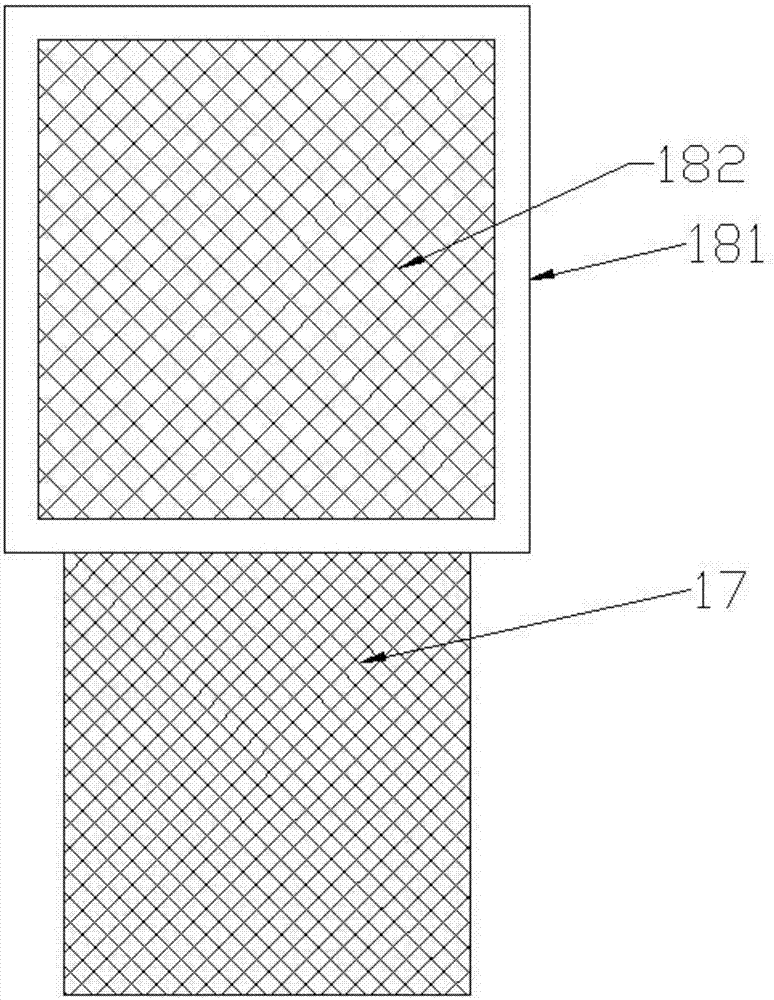

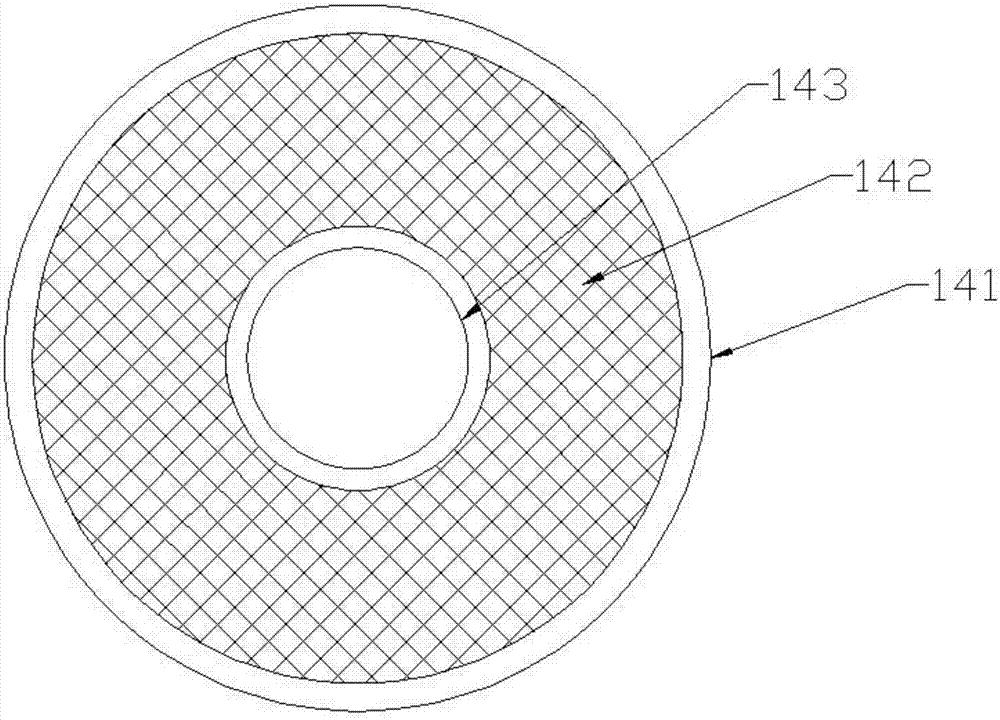

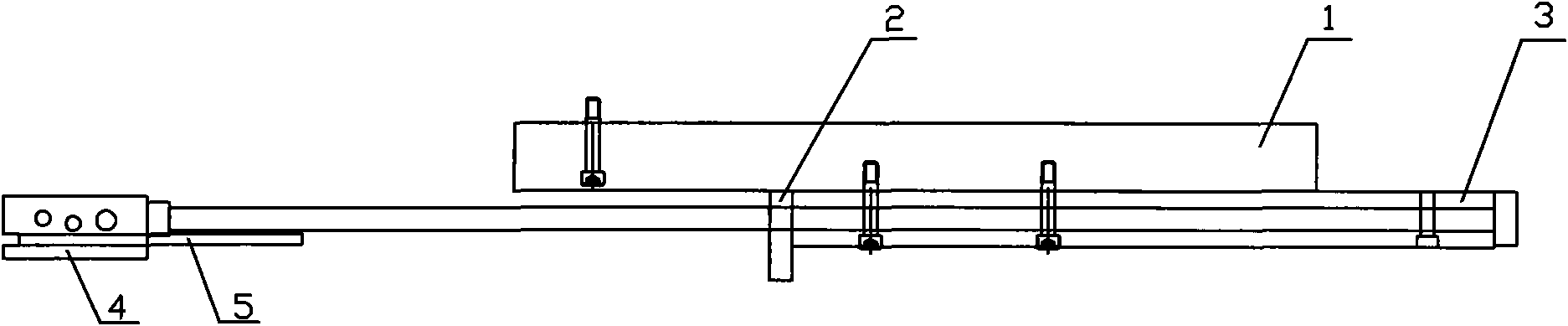

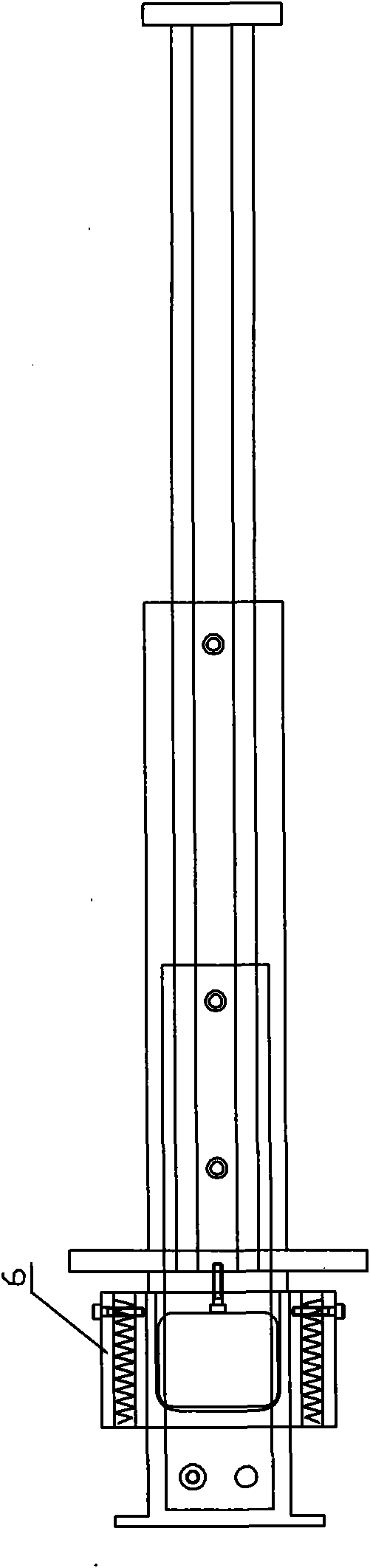

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

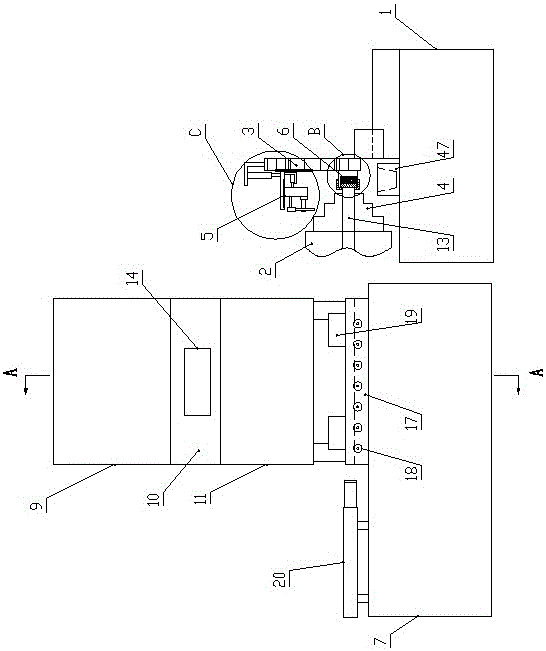

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

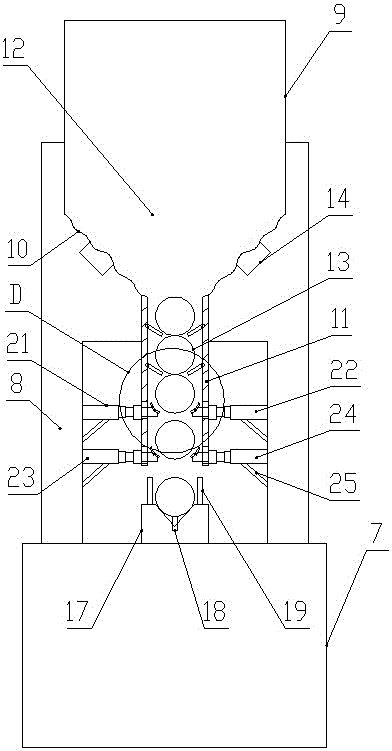

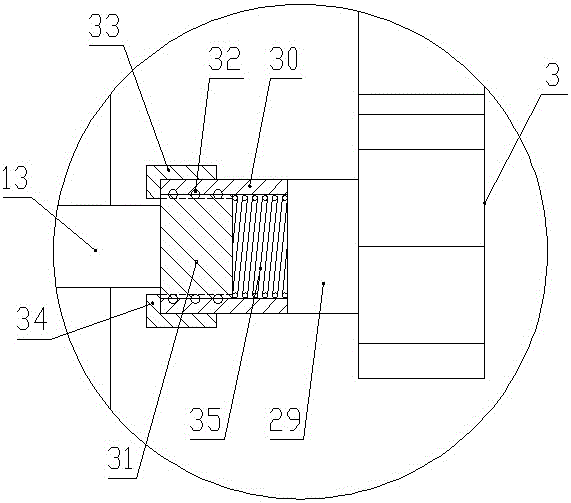

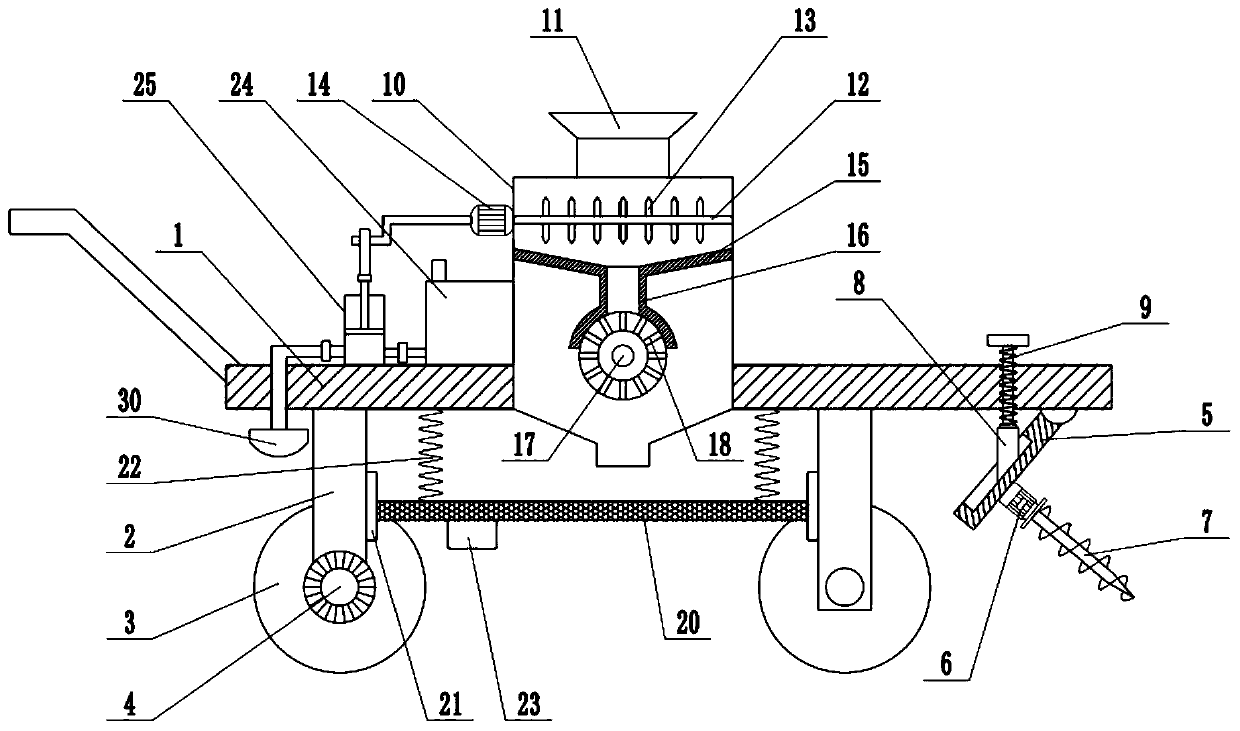

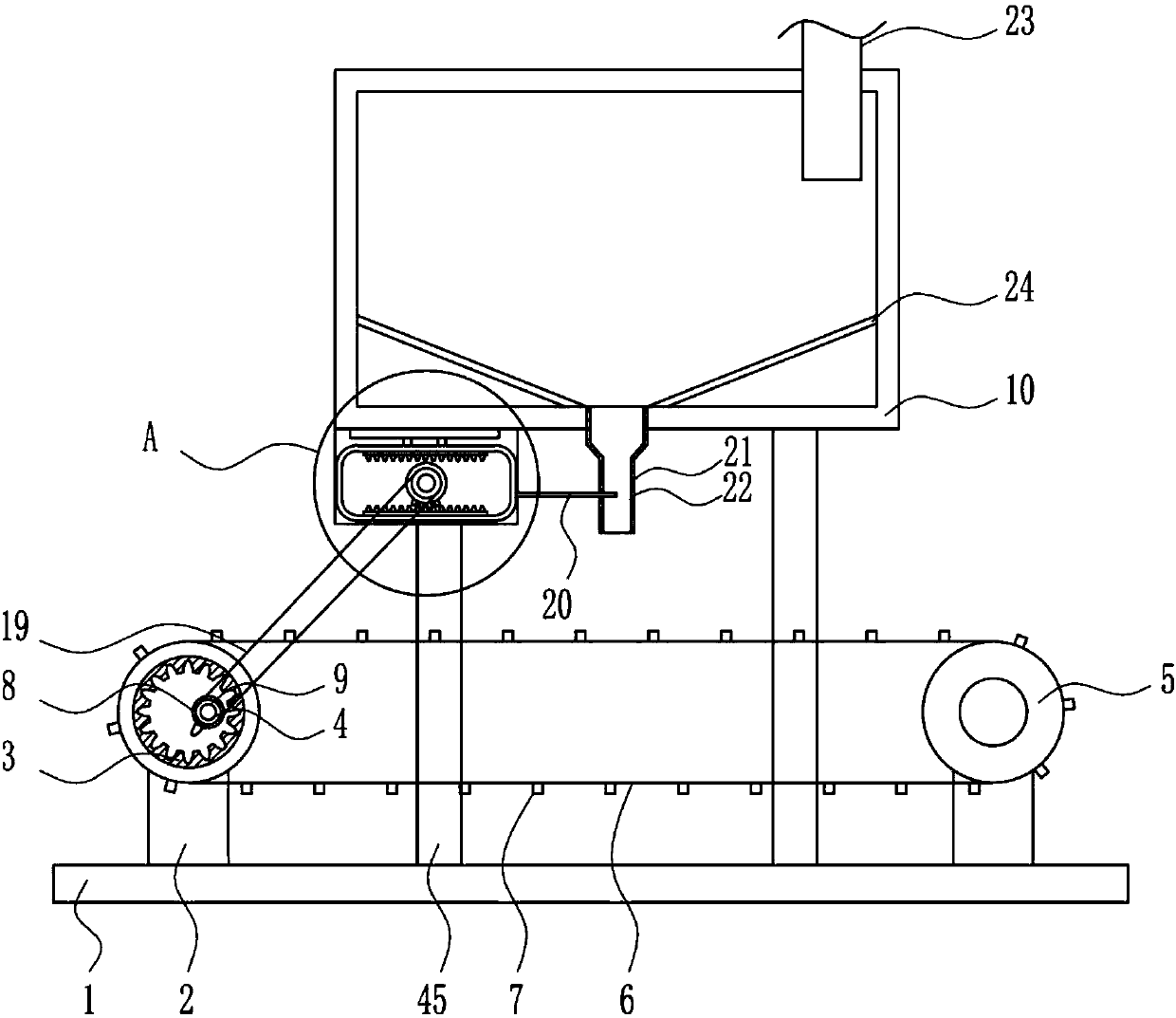

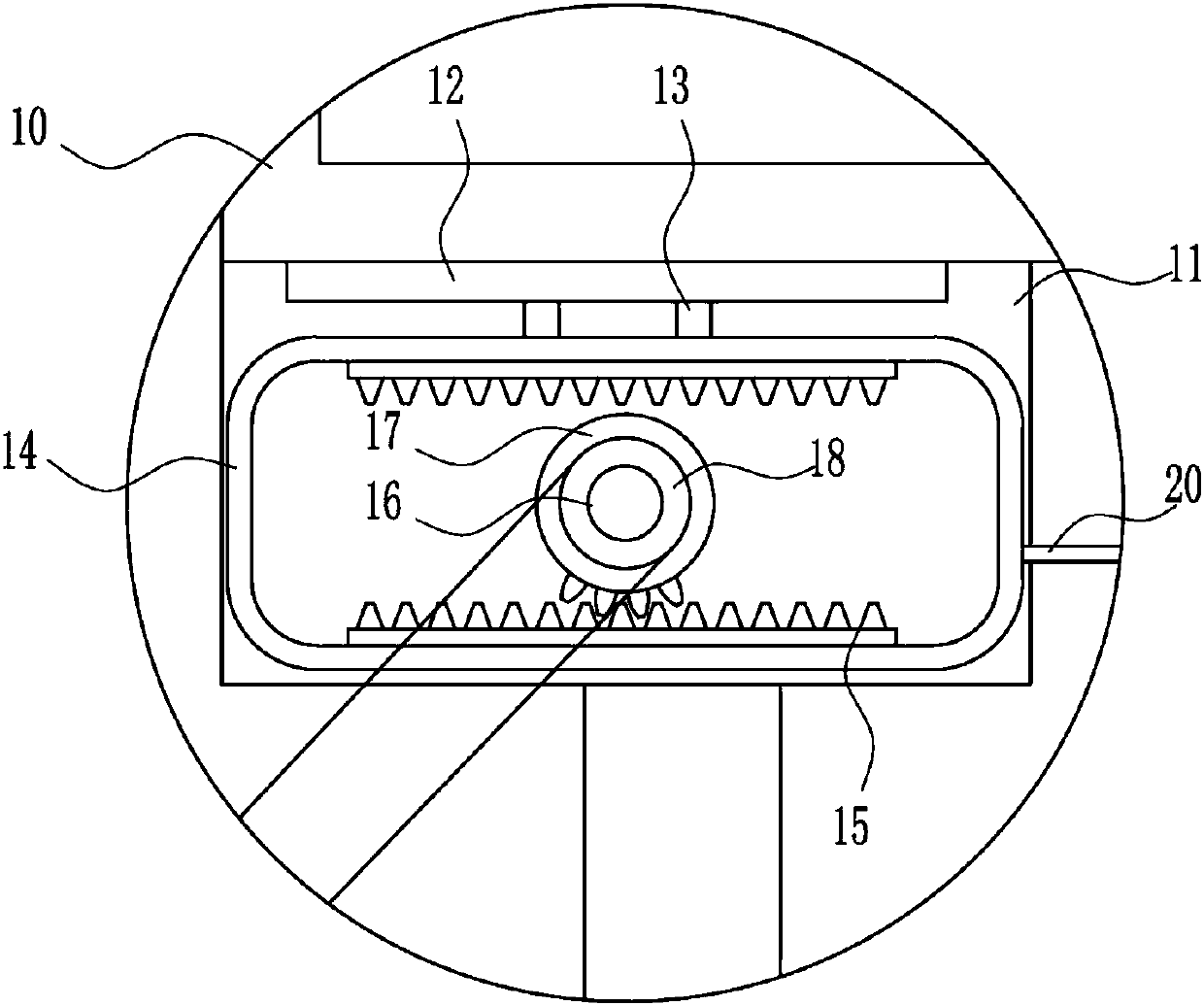

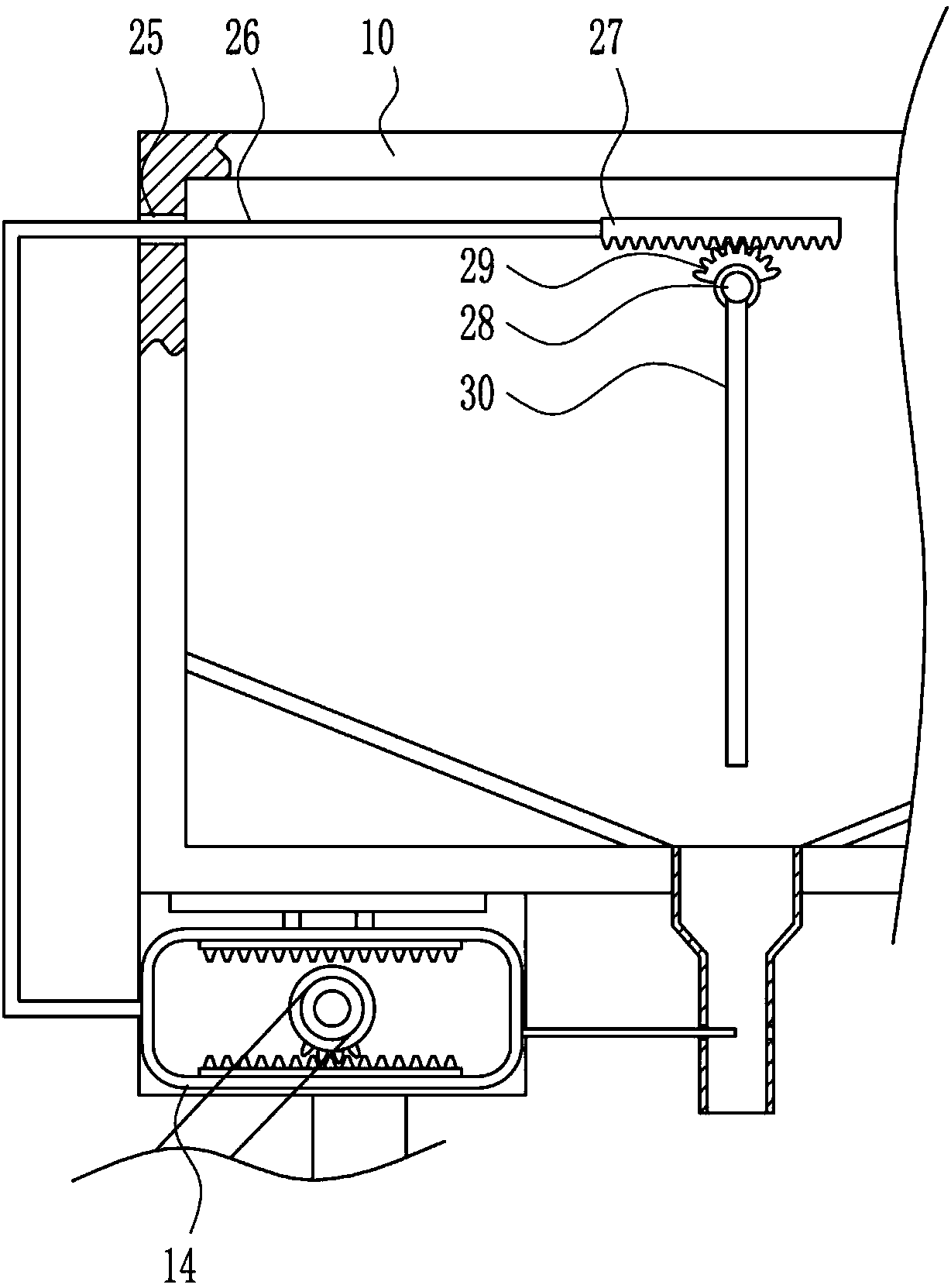

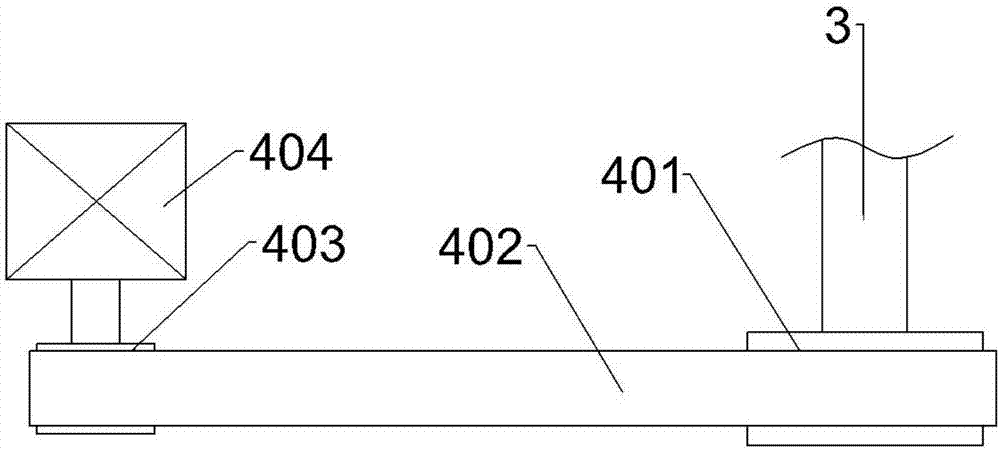

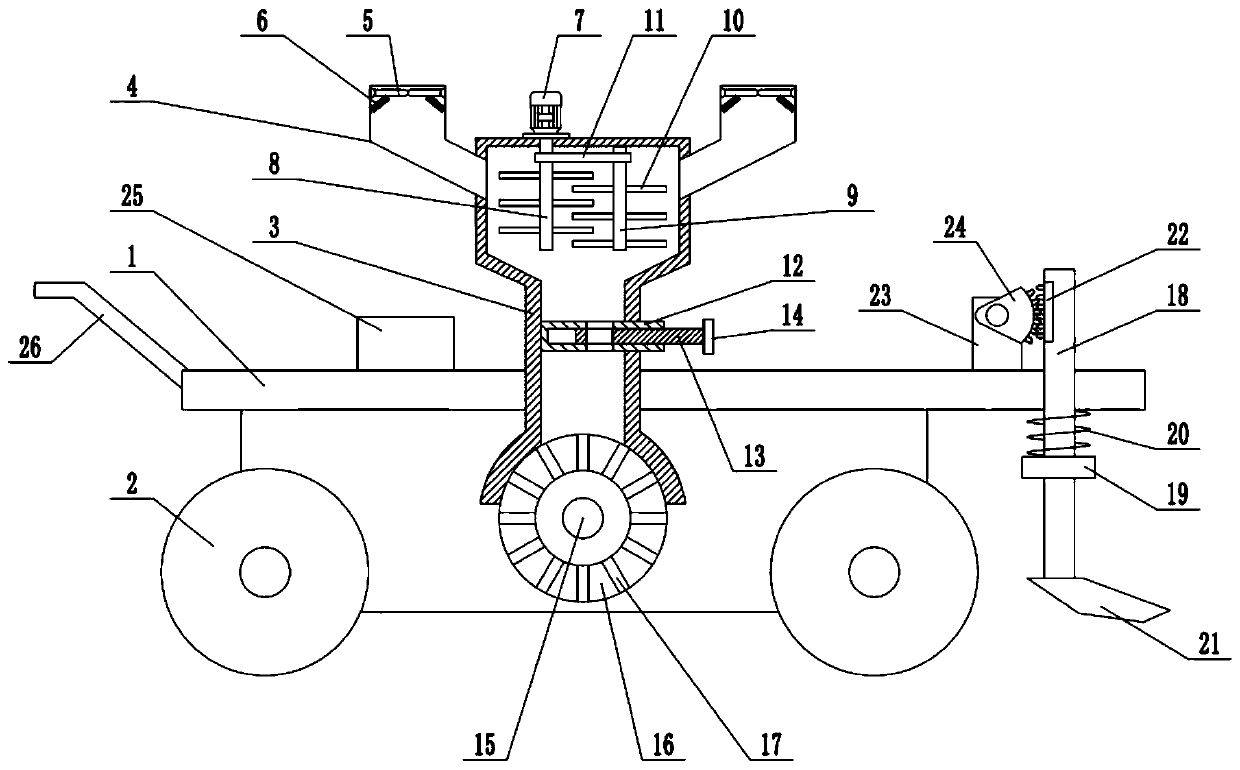

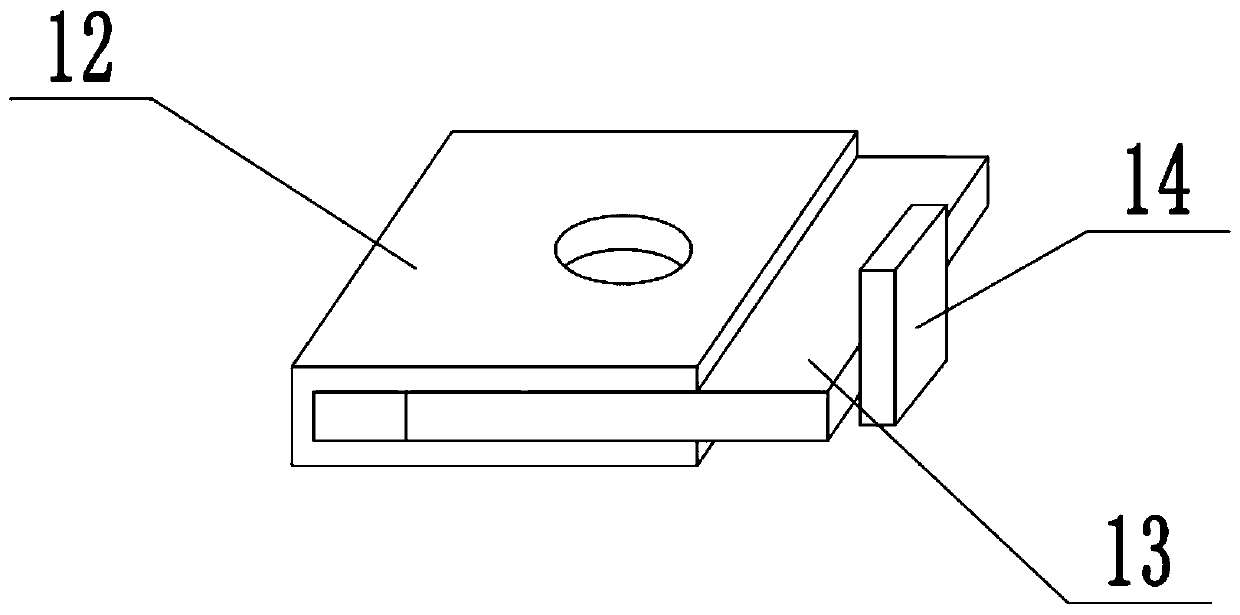

Crop fertilization equipment with uniform fertilization effect

InactiveCN110226376AAvoid cloggingFalling smoothlySpadesWatering devicesEngineeringAgricultural machinery

The invention relates to the field of agricultural machinery equipment, in particular to crop fertilization equipment with a uniform fertilization effect. The crop fertilization equipment comprises arack, a support, rollers and a fertilization bin, wherein the support is mounted at the bottom of the rack, the rollers are mounted at the lower end of the support, a soil turning mechanism is mountedon the lower surface of the rack, the fertilization bin is fixedly connected with the middle of the rack, a double-shaft motor is fixedly connected with the side wall of the fertilization bin, a distributing mechanism is mounted in the rack, a sieve plate is arranged below the fertilization bin, sliding rails are mounted on the side walls of the support, springs are fixedly connected with the upper surface of the sieve plate, a vibration motor is mounted at the lower end of the sieve plate, and a water sprinkling mechanism is mounted on the upper surface of the rack. By means of the soil turning mechanism, fertilizer can be contacted with soil sufficiently, and the fertilization effect is improved; uniform dropping of the fertilizer is realized by the distributing mechanism, the fertilizer is enabled to be dispersed and drop by means of the sieve plate, so that the fertilizer is scattered on the soil more uniformly, and fertilization and water sprinkling work are performed synchronously by means of the water sprinkling mechanism.

Owner:唐玉祥

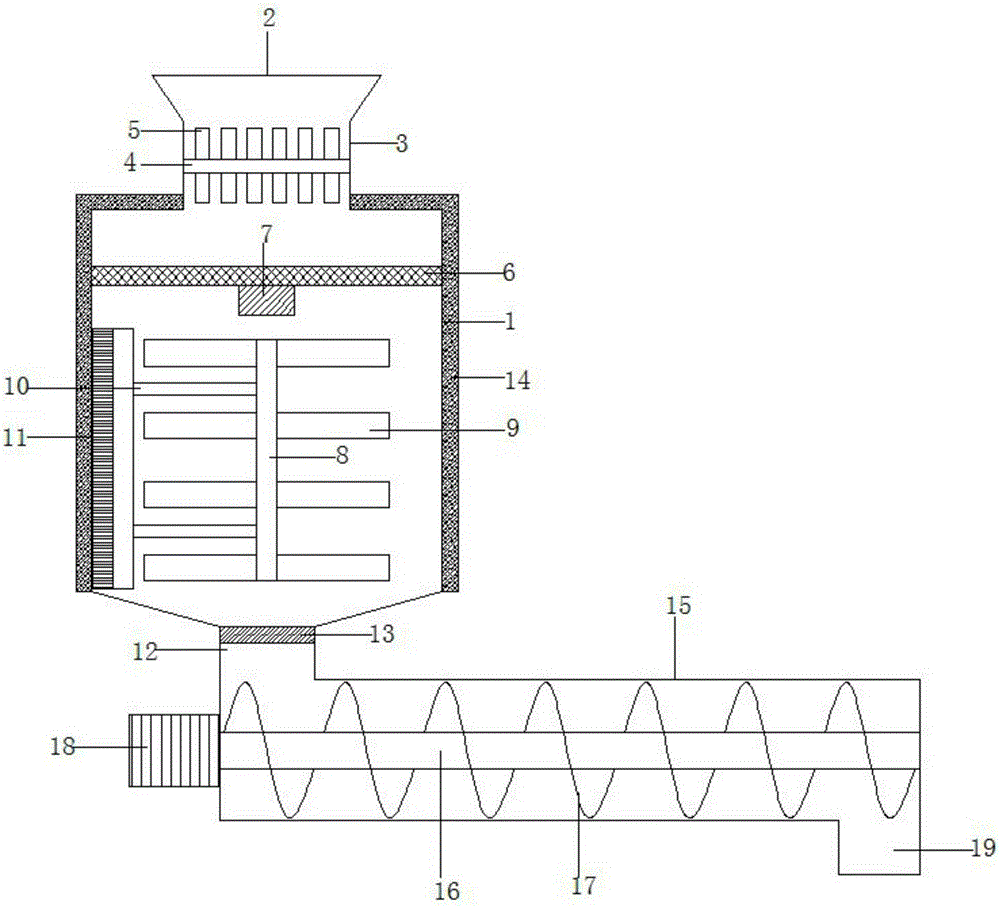

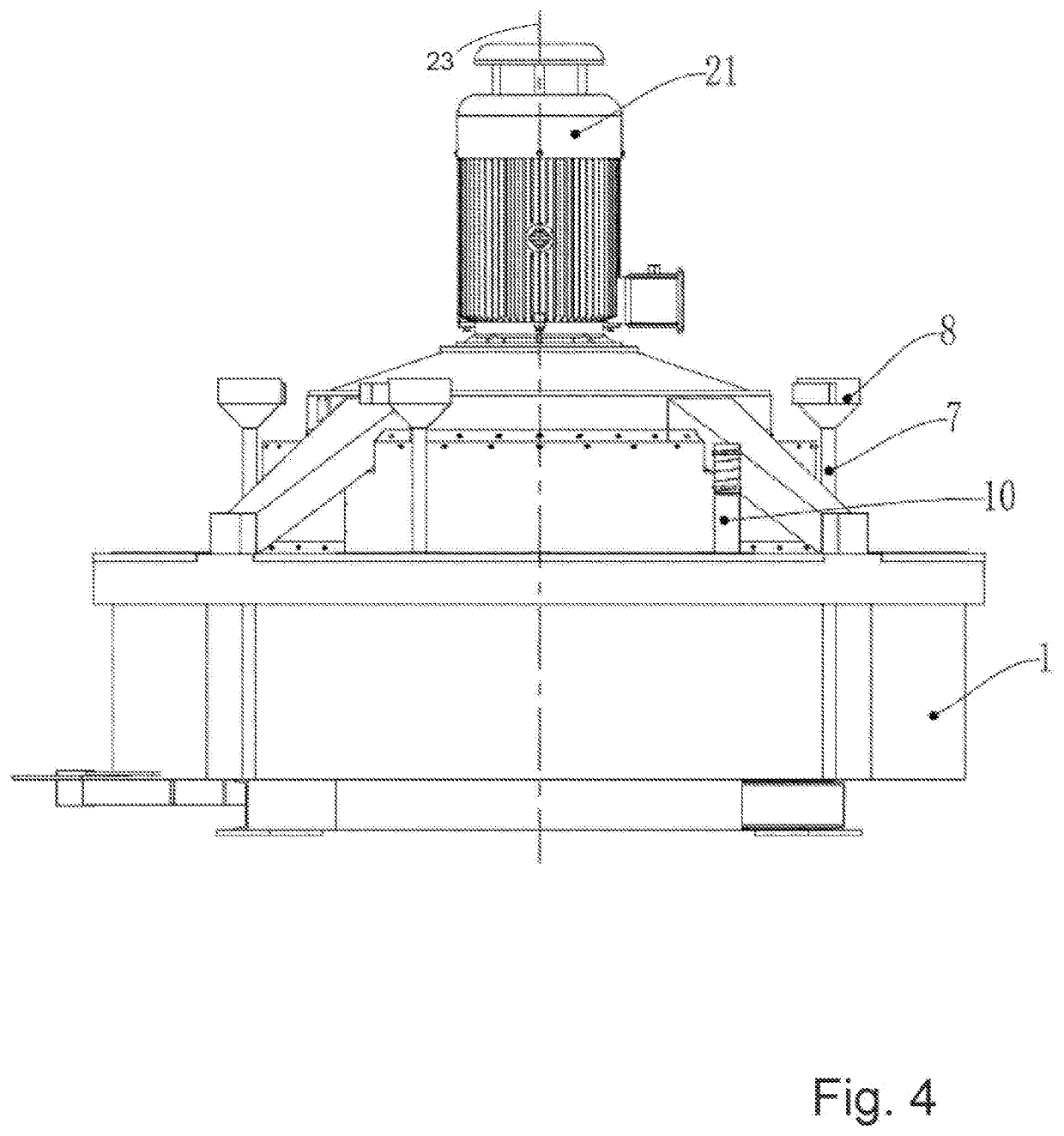

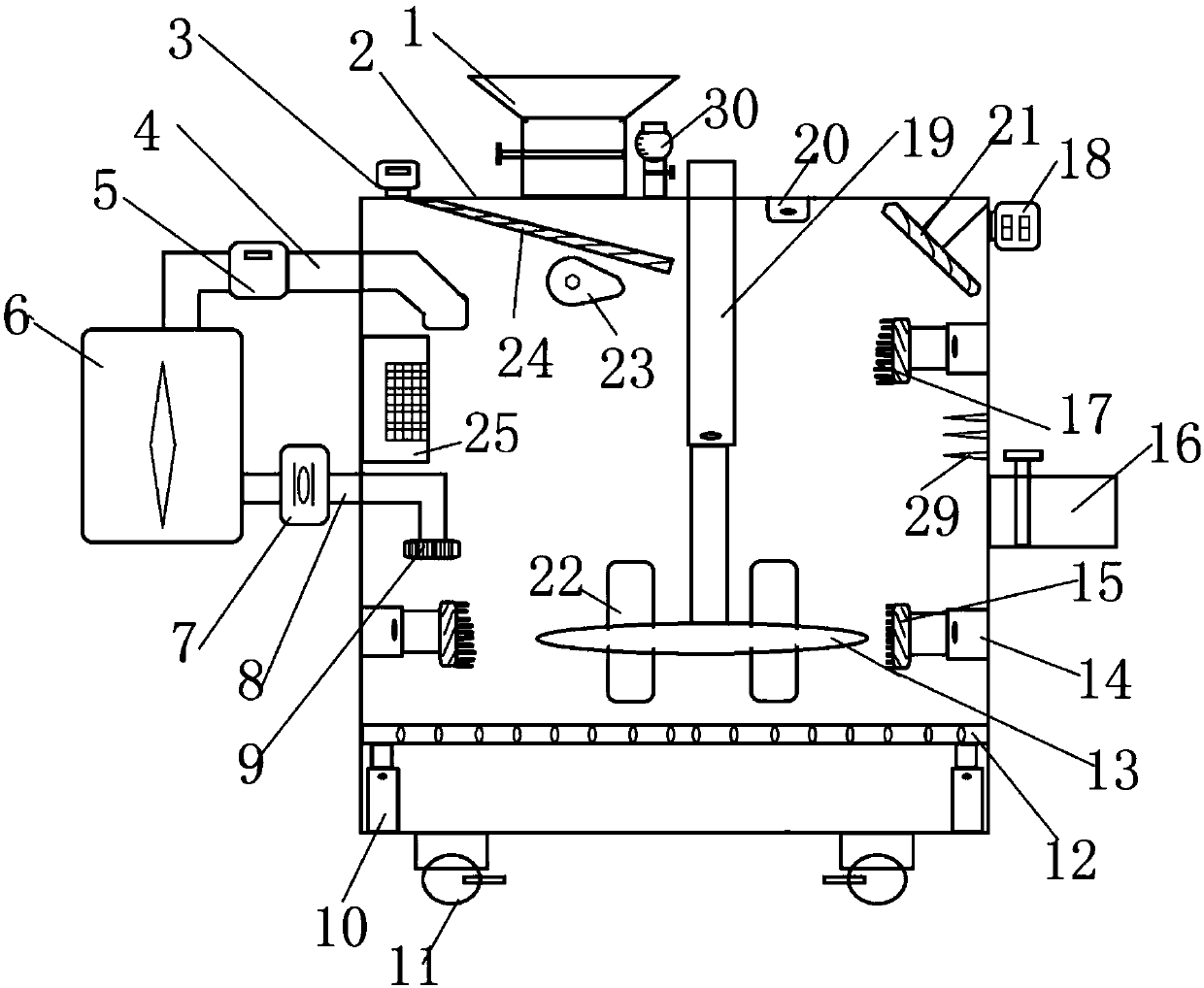

Efficient energy-saving feedstuff stirring machine

InactiveCN105169993AFalling smoothlyDrop savingsRotary stirring mixersMixer accessoriesBristleEngineering

The invention discloses an efficient energy-saving feedstuff stirring machine. The efficient energy-saving feedstuff stirring machine comprises a stirring barrel, an iron removing cavity and a spiral conveying barrel. A feeding hopper is arranged on the upper side of the stirring barrel, the lower side of the feeding hopper is connected with the iron removing cavity, a rotating shaft is horizontally arranged inside the iron removing cavity, magnetic iron pieces are symmetrically arranged on the outer wall of the rotating shaft in the vertical direction, and the seven pairs of magnetic iron pieces are arranged in the left-right direction. The bottom end of the iron removing cavity is connected with a feeding port in the lower side of the stirring barrel, a sieve is horizontally arranged on the upper side inside the stirring barrel, and the periphery of the sieve is installed on the inner wall of the stirring barrel through bolts. The magnetic iron pieces are rotated to remove iron of feedstuff sufficiently, the vibration sieve can make the feedstuff evenly fall, and therefore the stirring effect and efficiency are improved; a scraping cleaning bristle brush can scrap off the feedstuff adhering to the inner wall, waste of the feedstuff is avoided, a solar cell panel converts solar energy into electric energy so that the electric energy can be used for the stirring machine, in this way, energy is saved, continuous and even automatic discharging can be achieved, and the working efficiency of the stirring machine is improved.

Owner:林桂清

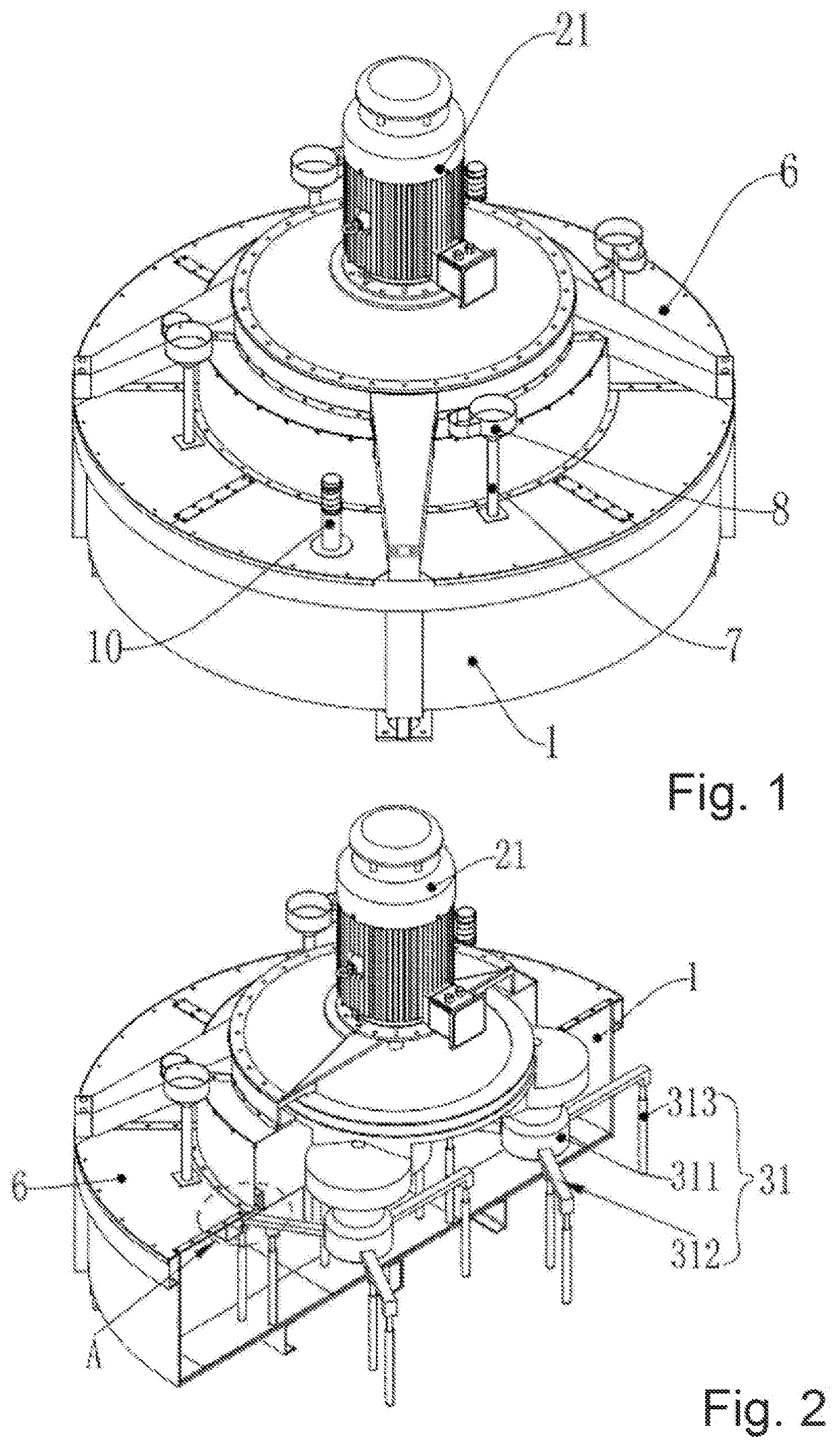

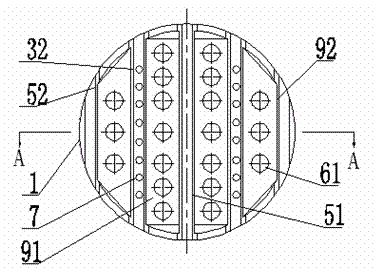

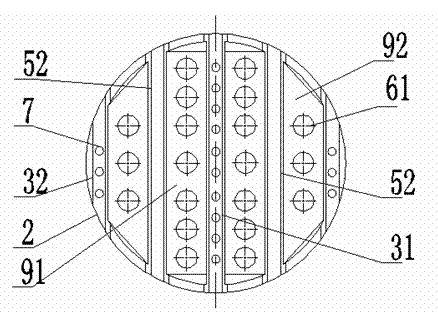

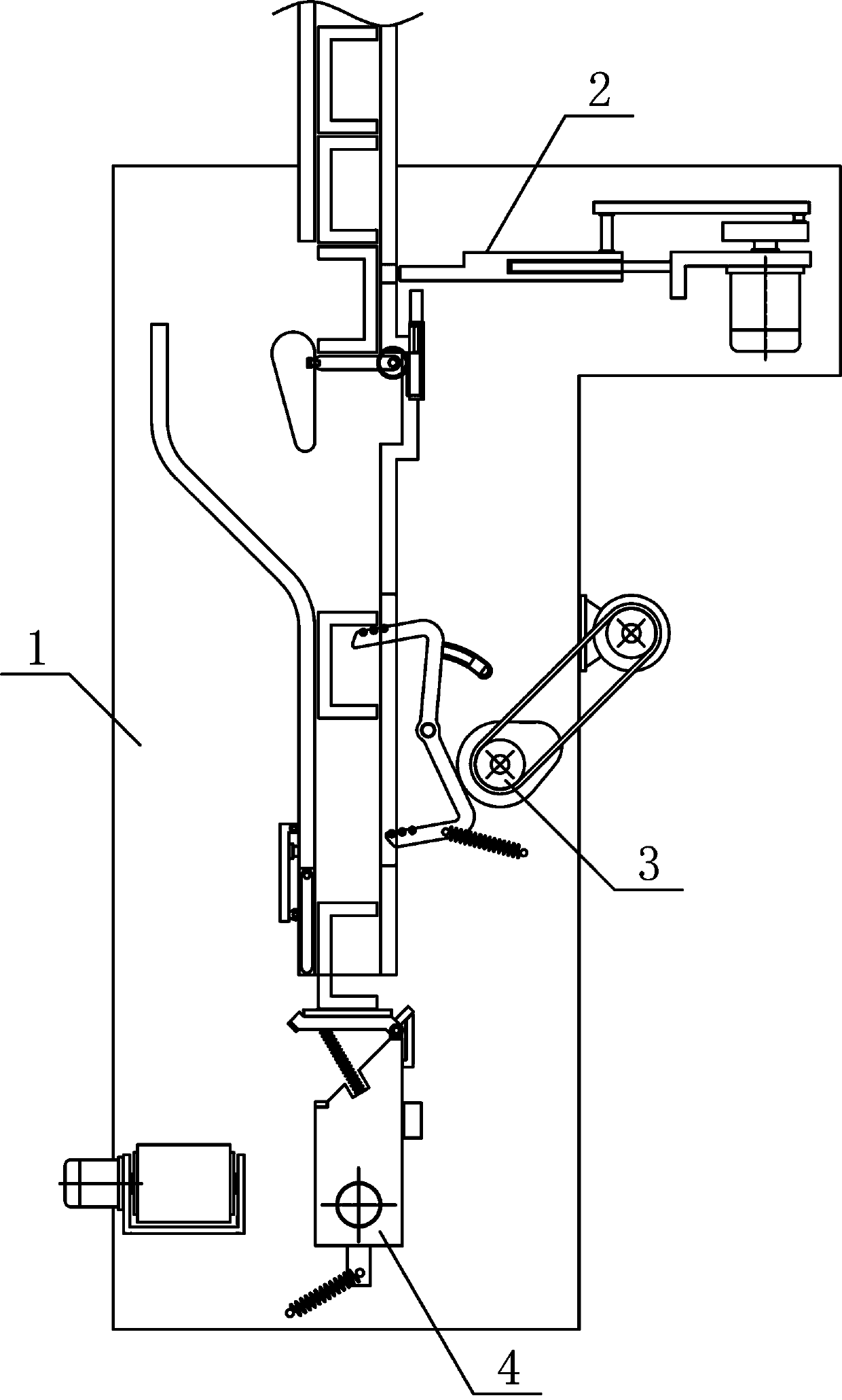

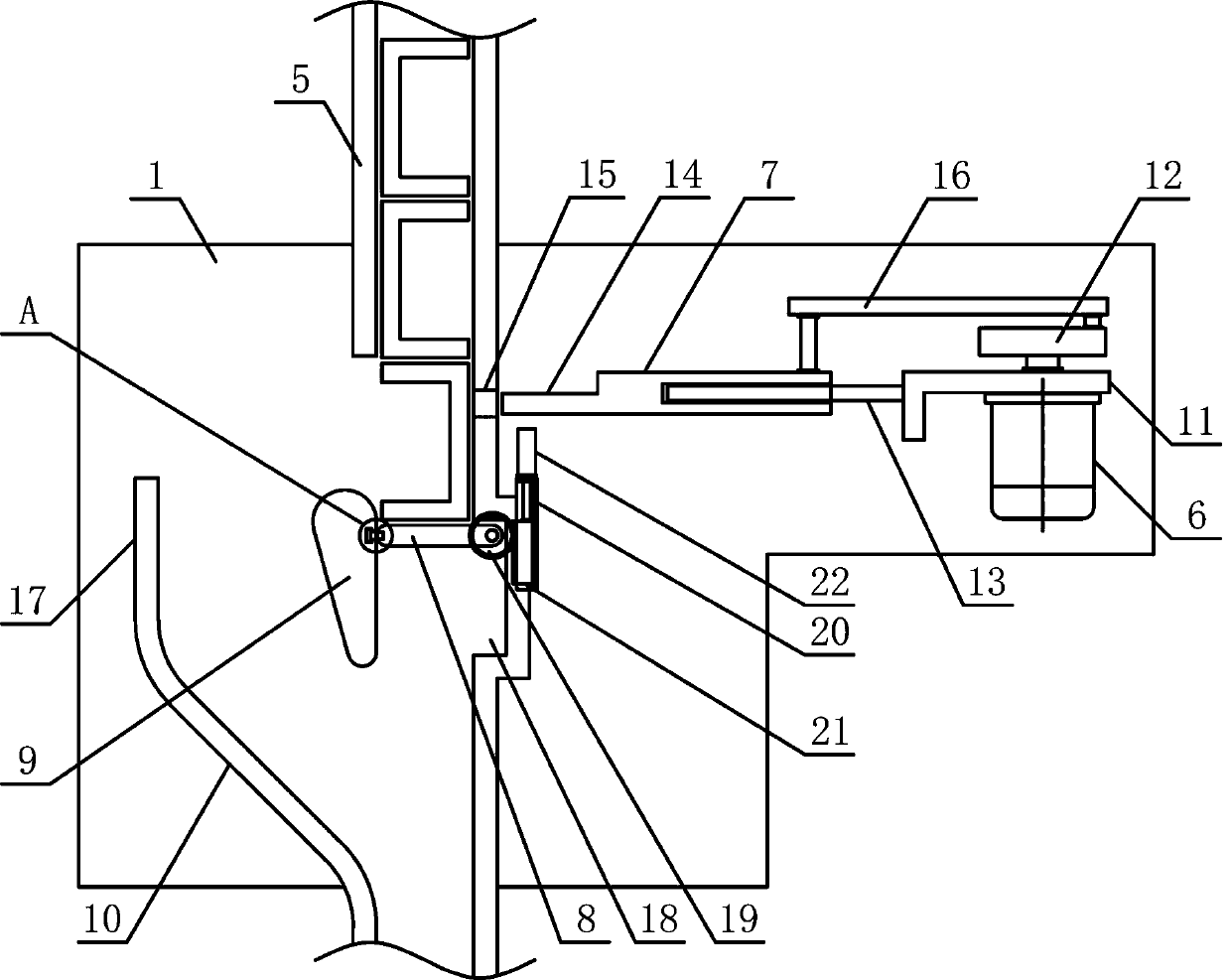

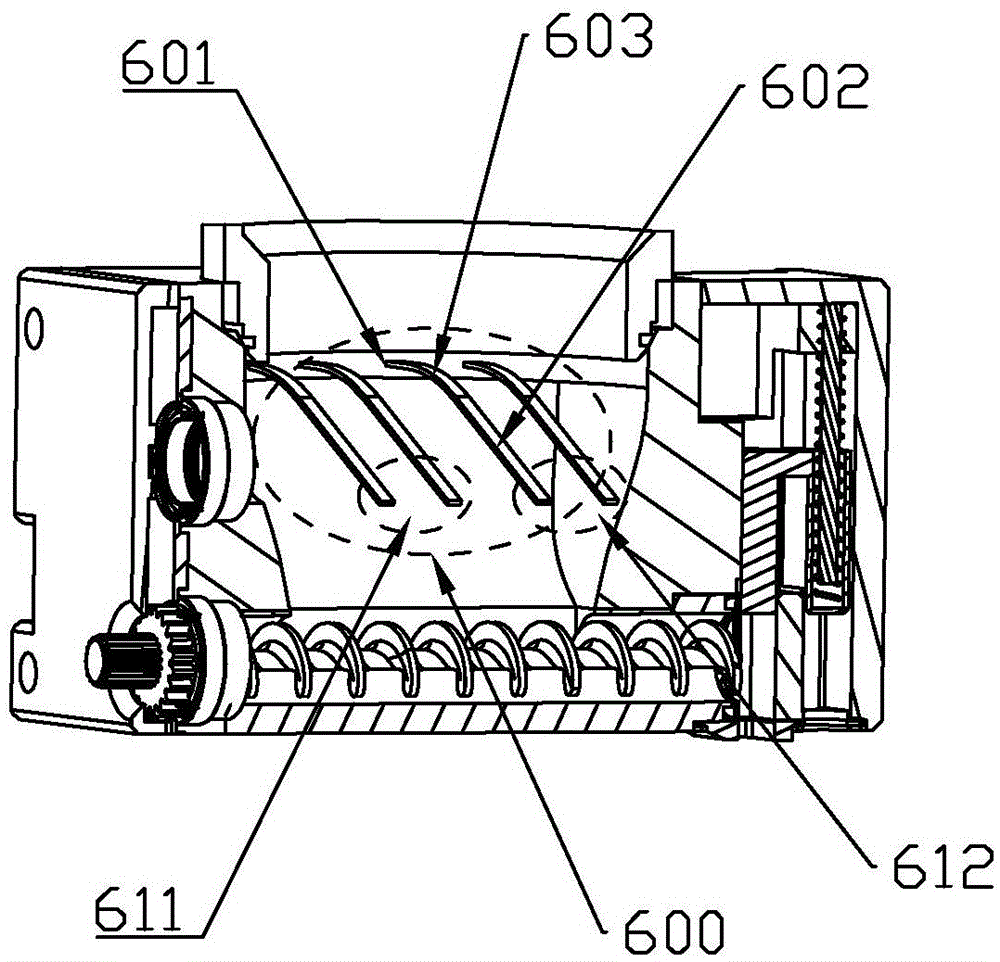

Mixer for synthetic quartz

InactiveUS20200261871A1Easy to cleanSmall flow resistanceRotary stirring mixersMixing operation control apparatusEngineeringMixing tank

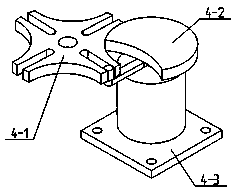

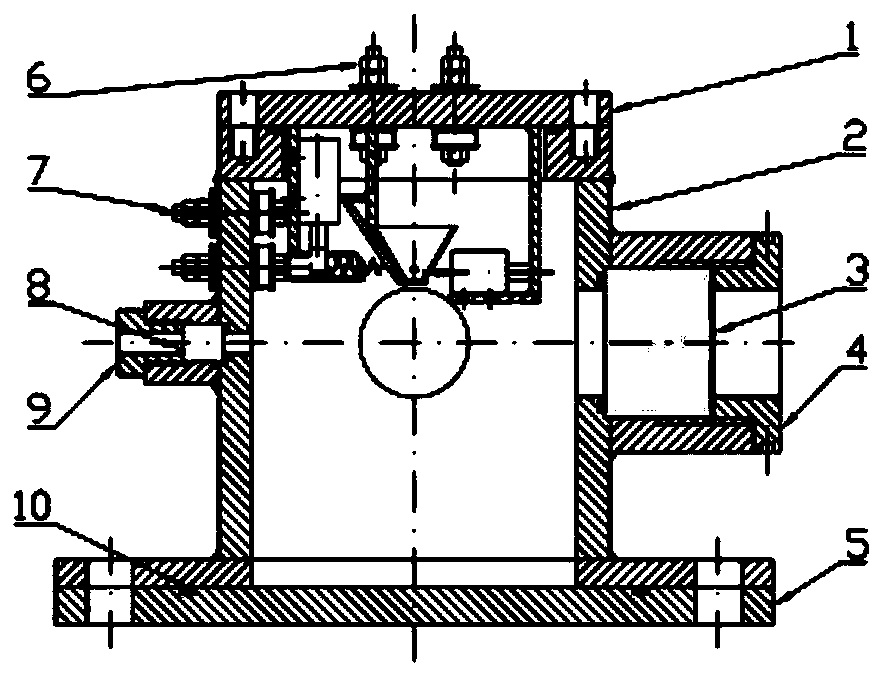

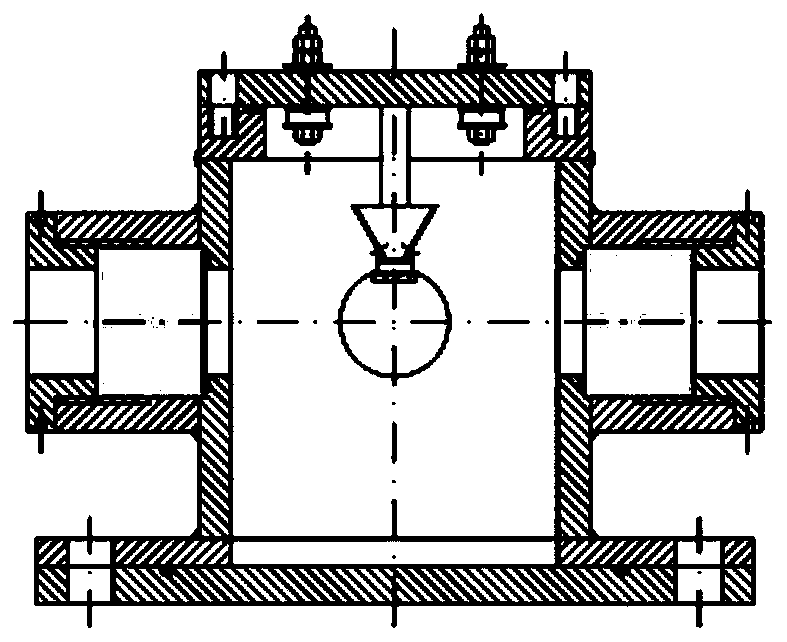

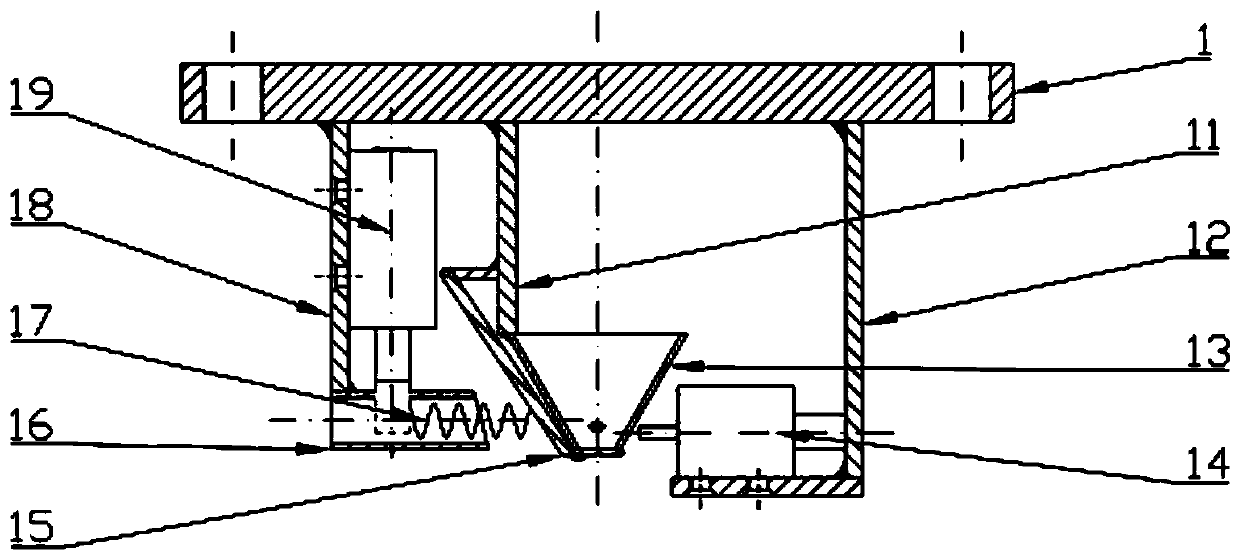

A mixer for synthetic quartz includes a mixing barrel (1), a power transmission system (2), a mixing system (3), and multiple material receiving receptacles (4). The power transmission system is provided above the mixing tank. The mixing system is provided inside the mixing tank. The power transmission system is used to drive the mixing system to move. An opening is arranged at each of two ends of the material receiving receptacle. The multiple material receiving receptacles (4) are arranged at a top portion of the mixing tank, and end portions of two adjacent material receiving receptacles are spaced apart from each other without contact there between. A resin experiences low flow resistance in the material receiving receptacle, and thus can fall smoothly without accumulating in the material receiving receptacle. Moreover, the material receiving receptacle can be cleaned easily.

Owner:VEEGOO TECH CO LTD

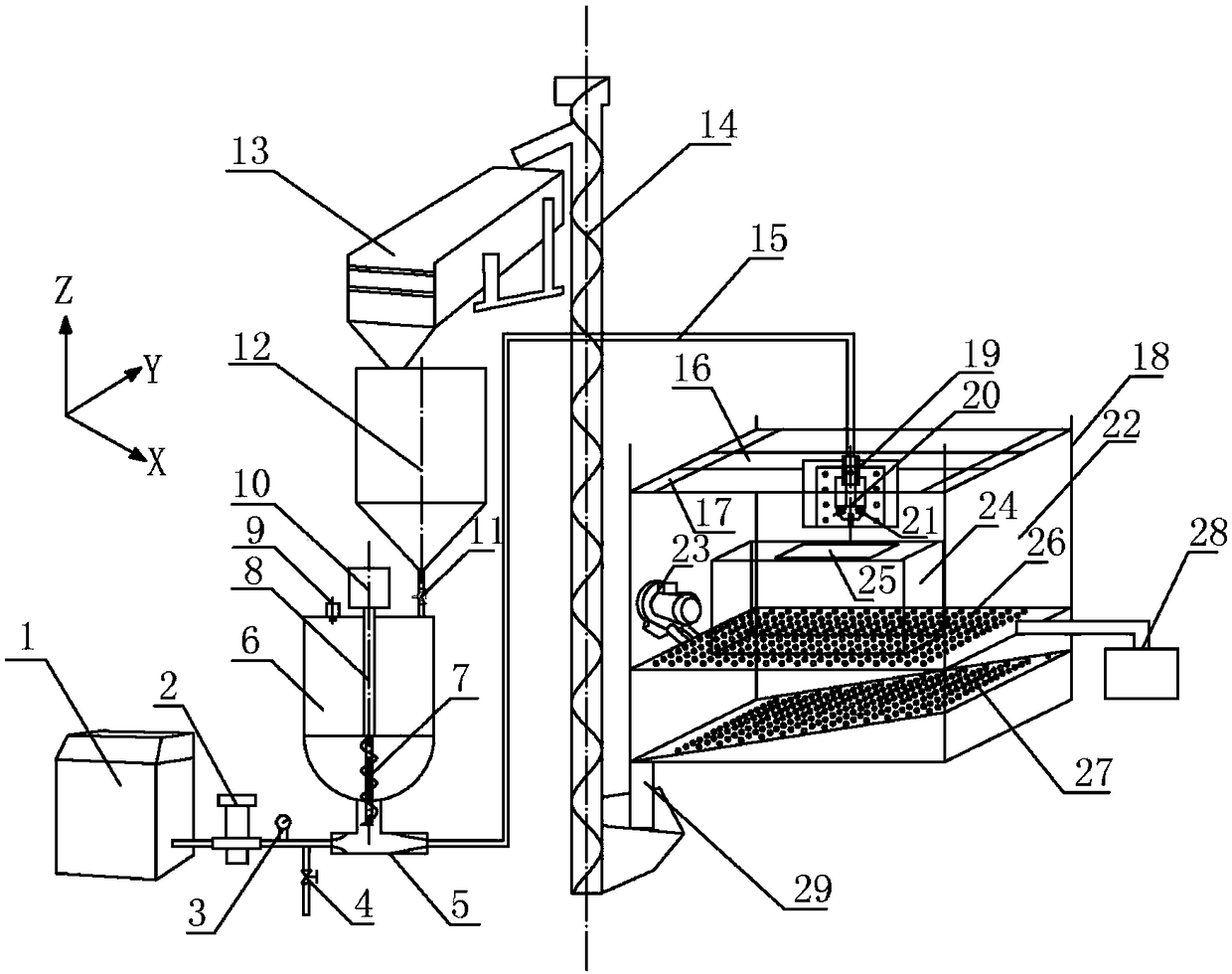

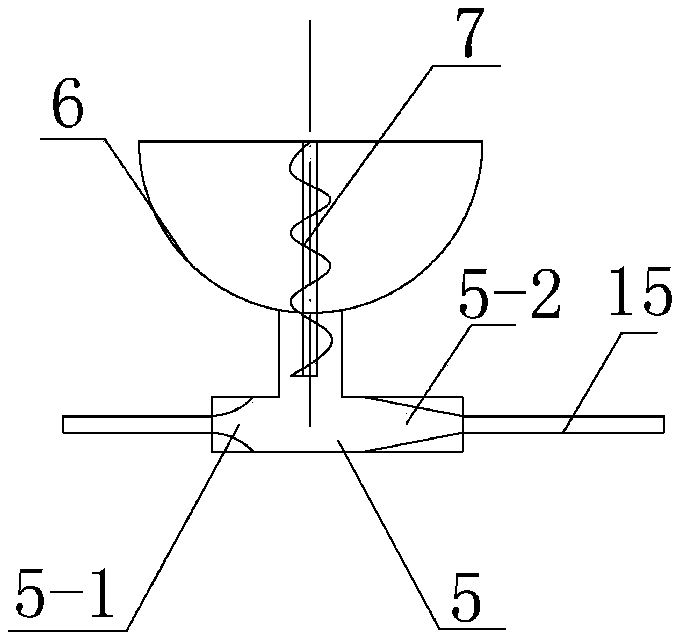

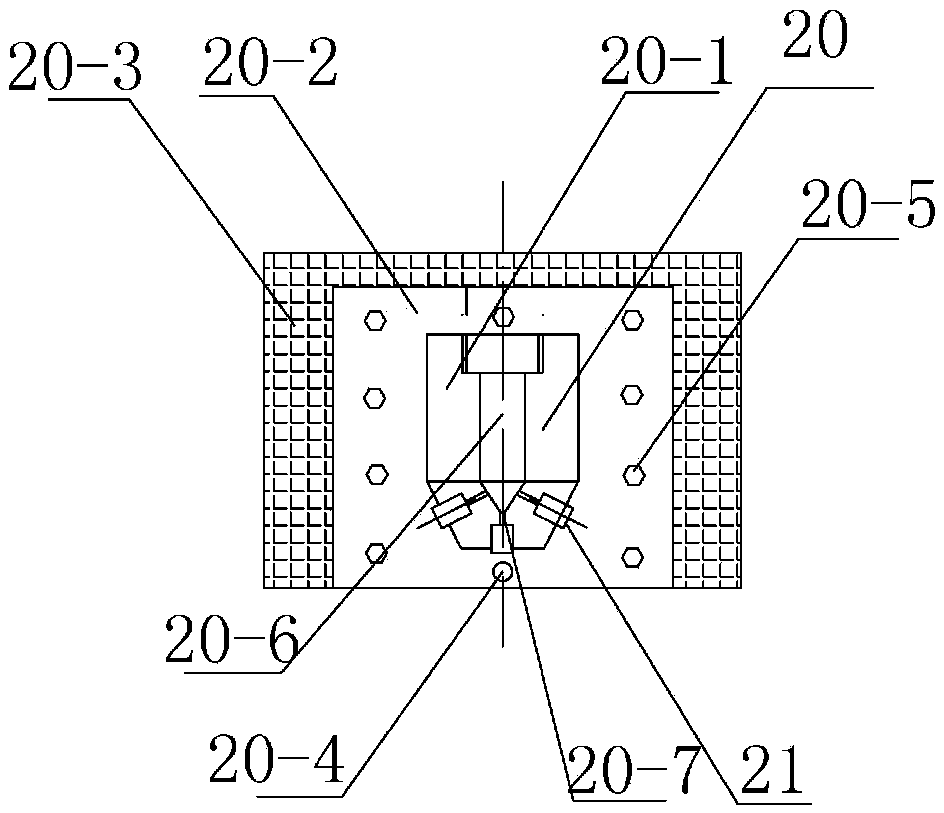

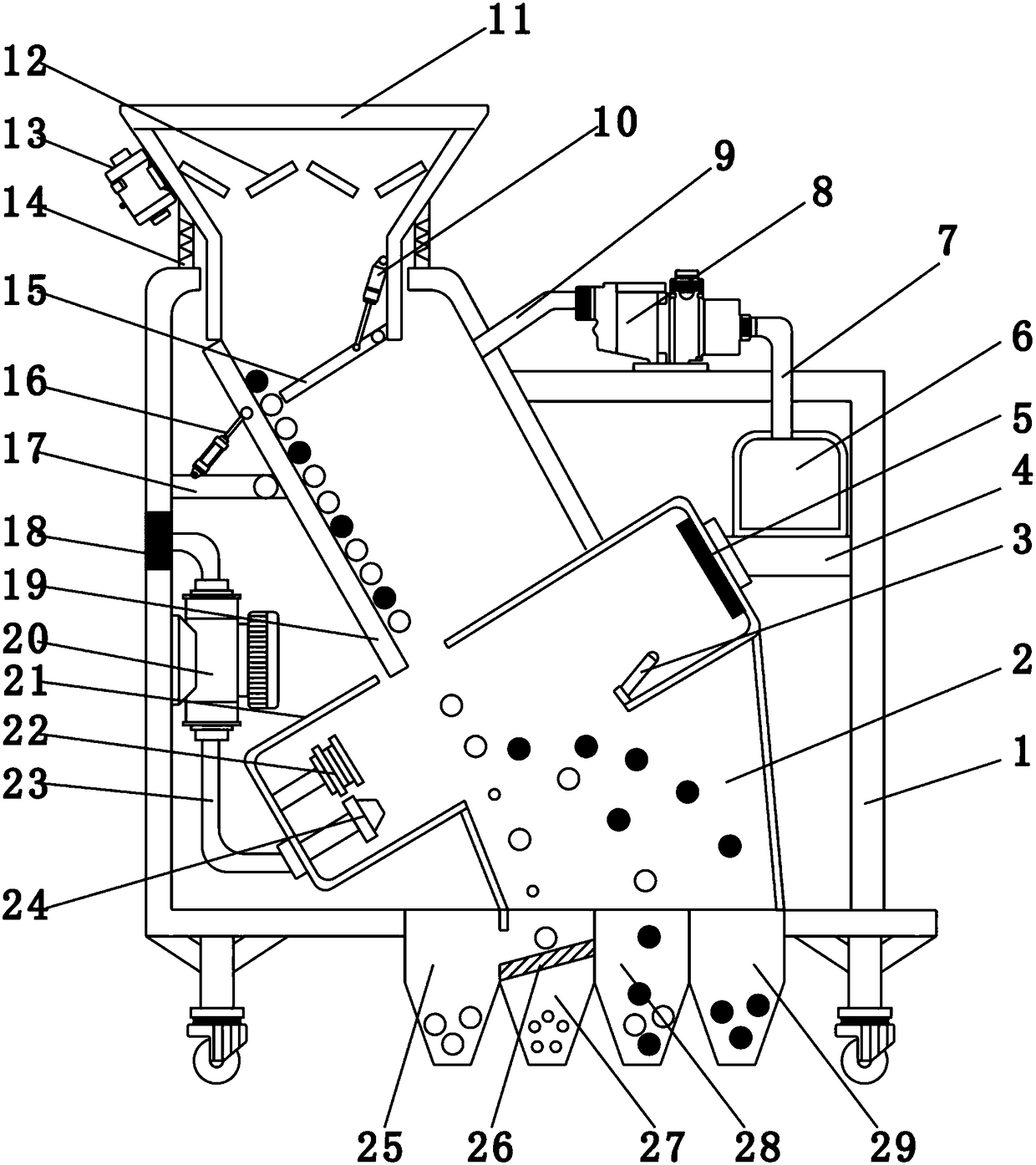

Recyclable particle jet descaling device

ActiveCN108772784AEfficient recyclingImprove rust removal efficiencyAbrasive machine appurtenancesGas solidEngineering

The invention belongs to the field of rust surface treatment, in particular relates to a recyclable particle jet descaling device comprising an air compressor, a pressure dividing valve, a mixing chamber, a high pressure particle tank, a screw, a 3D particle amount detector, a speed regulating motor, a particle storage tank, a double-layer vibrating screen, a vertical screw conveyor, an X-direction rail, a Y-direction rail, a Z-direction rail, a nozzle assembly, a nozzle, a dust cover, a blower, a horizontal filter pore plate, an inclined filter pore plate, a dust removal cloth bag, and the like. The recyclable particle jet descaling device can realize rapid particle addition, real-time particle amount monitoring, uniform, stable and controllable gas-solid mixing, injection position three-dimensional movement and angle adjustment, multi-stage particle separation and recycling, effective dust recovery, significant improvement of part surface rust removal efficiency, and enhancing of part surface strength.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

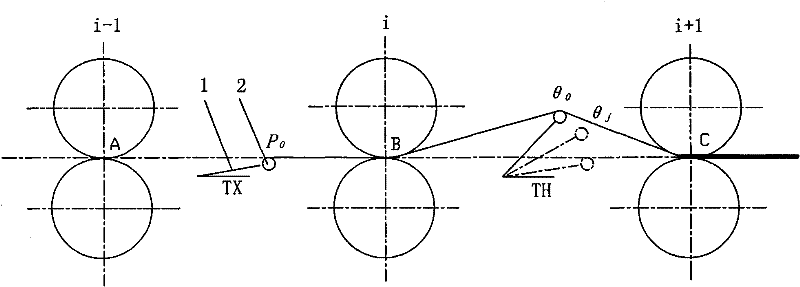

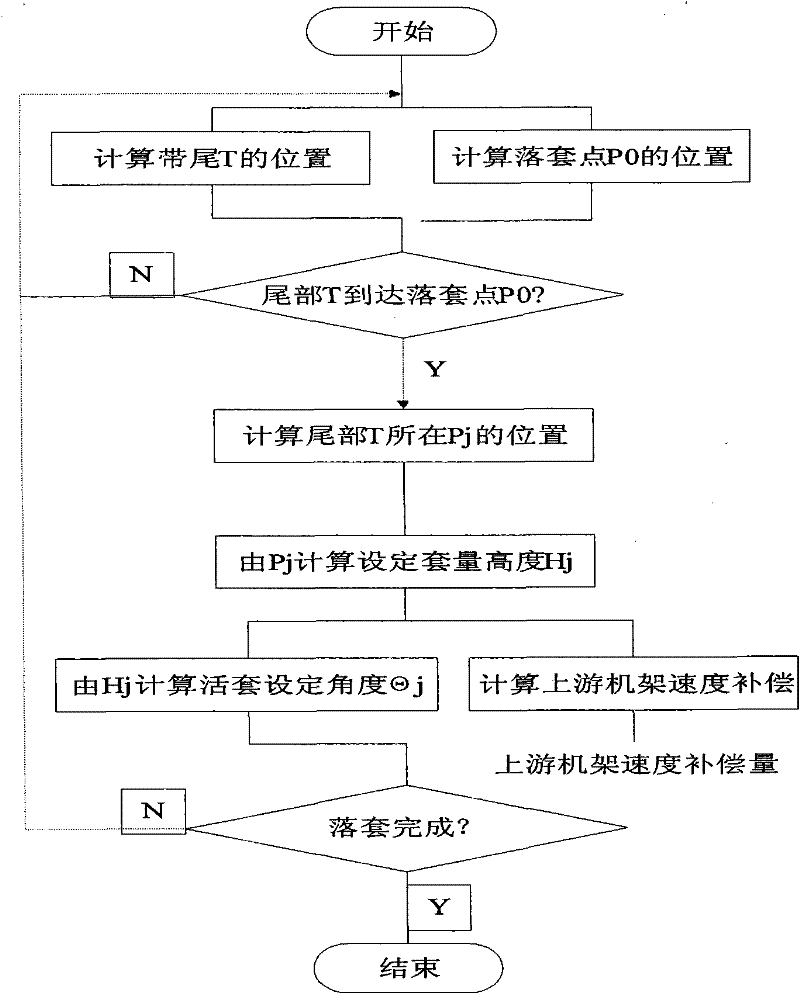

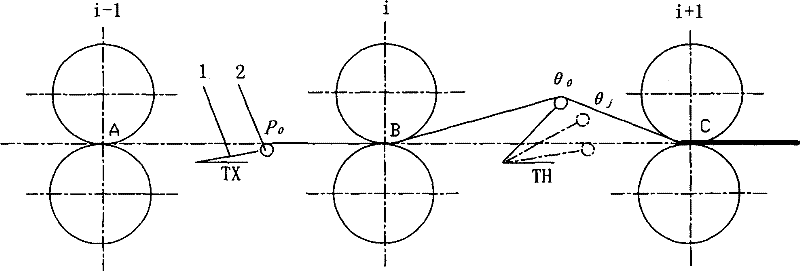

Stable sleeve-dropping method for moveable sleeve of hot milling machine

InactiveCN102205349AClear logical relationshipAvoid flickFlexible work arrangmentsMetal rolling arrangementsControl functionMovement control

The invention relates to a stable sleeve-dropping method for a moveable sleeve of a hot milling machine and belongs to the technical field of steel rolling. According to the method, a sleeve-dropping controller controls a sleeve-dropping process of a rear moveable sleeve according to the following steps: tracking the position of a strip steel tail; confirming a sleeve-dropping position; establishing a sleeve-dropping angle control function; and lastly, after detecting and confirming that the strip steel tail reaches the confirmed sleeve-dropping position, starting a moveable sleeve rod and simultaneously controlling a sleeve-dropping angle of the moveable sleeve rod according to the sleeve-dropping angle control function till the moveable sleeve drops to the position as high as a rolling level. According to the method, by organically considering a frame driving transmission speed together with the moveable sleeve motion control, in the process of slowly digesting the sleeve quantity, a moveable sleeve roller keeps a tensile force on the strip steel till the moveable sleeve completely drops off, and the drifting phenomenon in a throwing process is prevented while a hollow sleeve isprevented from being formed, thereby achieving the purpose of stably dropping the sleeve.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Rice color sorter

The invention discloses a rice color sorter which comprises a machine bin, a feeding opening, a sliding plate and an induction region branch bin, wherein the feeding opening is mounted above the machine bin; material distributing plates are uniformly mounted inside the feeding opening; a vibrating motor is mounted on one side of the feeding opening; a telescopic rod is hinged below one side insidethe feeding opening remote from the vibrating motor; a discharging plate is hinged to the feeding opening below the telescopic rod; an output end of the telescopic rod is hinged to the discharging plate. The rice color sorter provided by the invention is provided with the feeding opening which is equipped with the vibrating motor and the material distributing plates; the discharging plate is hinged in the feeding opening; an angle of the discharging plate can be adjusted according to the type of rice, so that the rice fall more uniformly and cannot be stacked together, and a color sorting effect is better; the sliding plate is mounted in a hinging manner, so that the angle of the sliding plate can be adjusted to control a falling speed of the rice; the sliding plate has a groove-shaped surface which is adaptive to the shape of the rice and allows the rice to fall, so that the color sorting effect is better.

Owner:陈坤荣

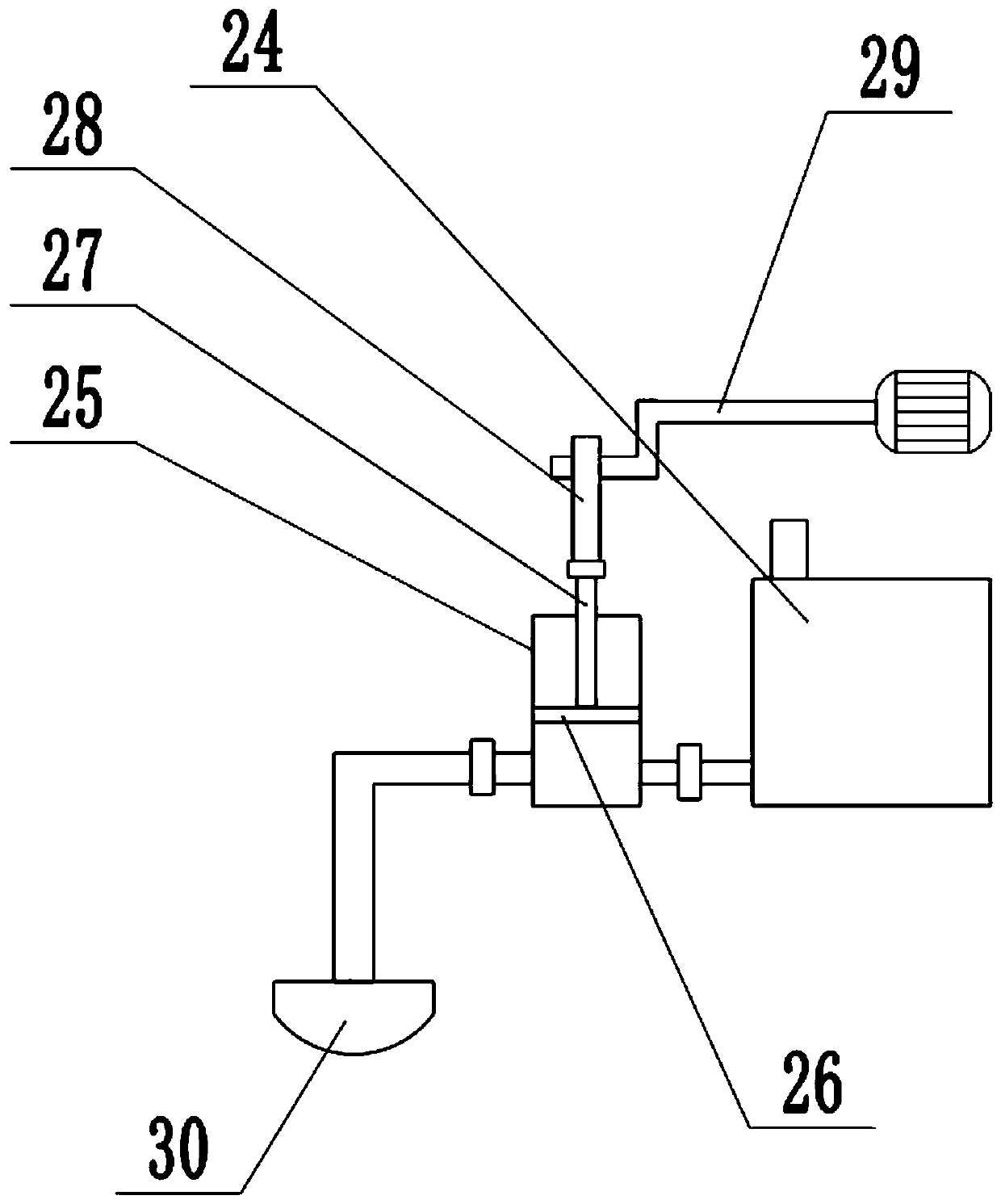

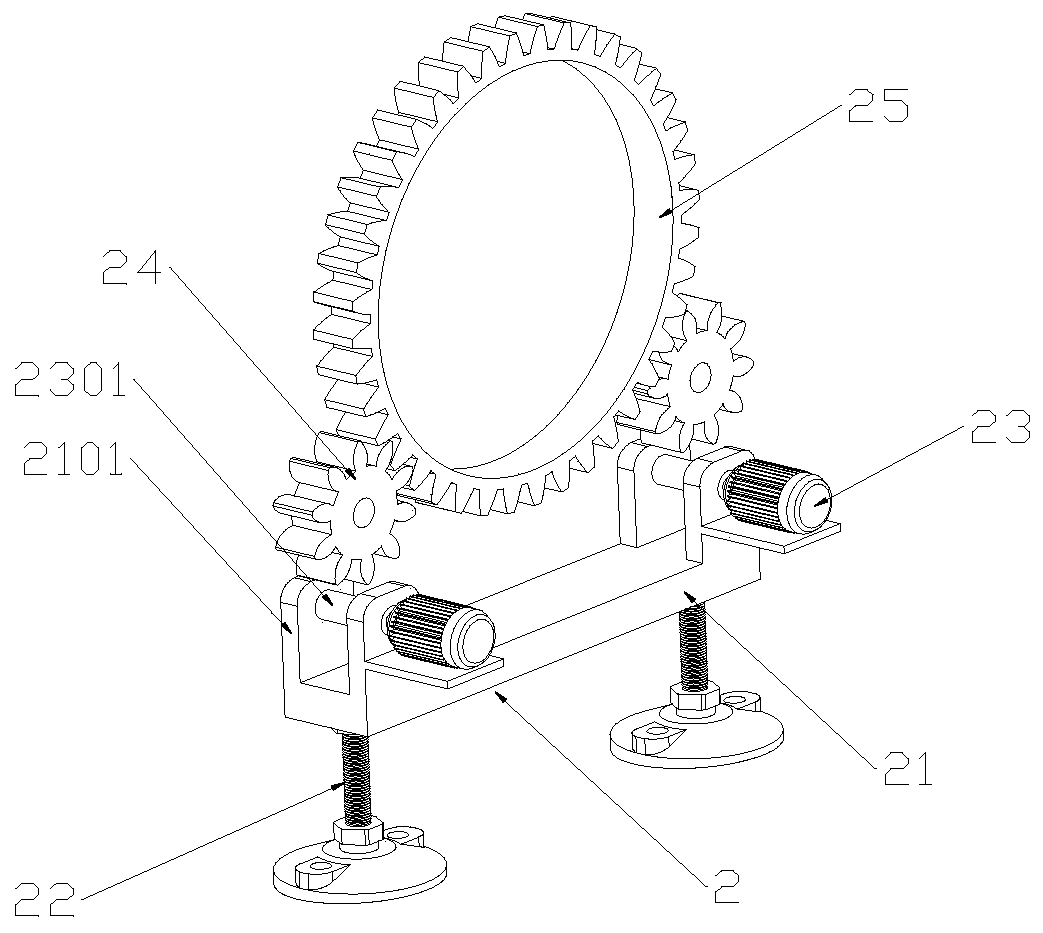

Quantified tinning device for colorful candies

The invention relates to a tinning device, in particular to a quantified tinning device for colorful candies. The quantified tinning device for colorful candies achieves technical purposes. In order to achieve the technical purposes, the quantified tinning device for colorful candies comprises a base plate, a first support, an inner gear ring and the like; the first support and a third support arearranged on the top of the base plate, the inner gear ring is rotationally connected to the front portion of the first support, a first rotating shaft is arranged at the front portion of the first support and located inside the inner gear ring, the inner gear ring and the right first support are each provided with a first belt wheel, and a first flat belt is wound around the first belt wheels. The tinning device has the effects that during quantified tinning, the number of candies of each tin is small, and operation is easy and convenient; knocking balls continuously knock a guiding plate, candy falling is more smooth, the deviation of the numbers of candies discharged every time is lowered, the quantified precision of the device is improved, and the device is reliable and stable, and high in generalizability.

Owner:南通北外滩建设工程有限公司

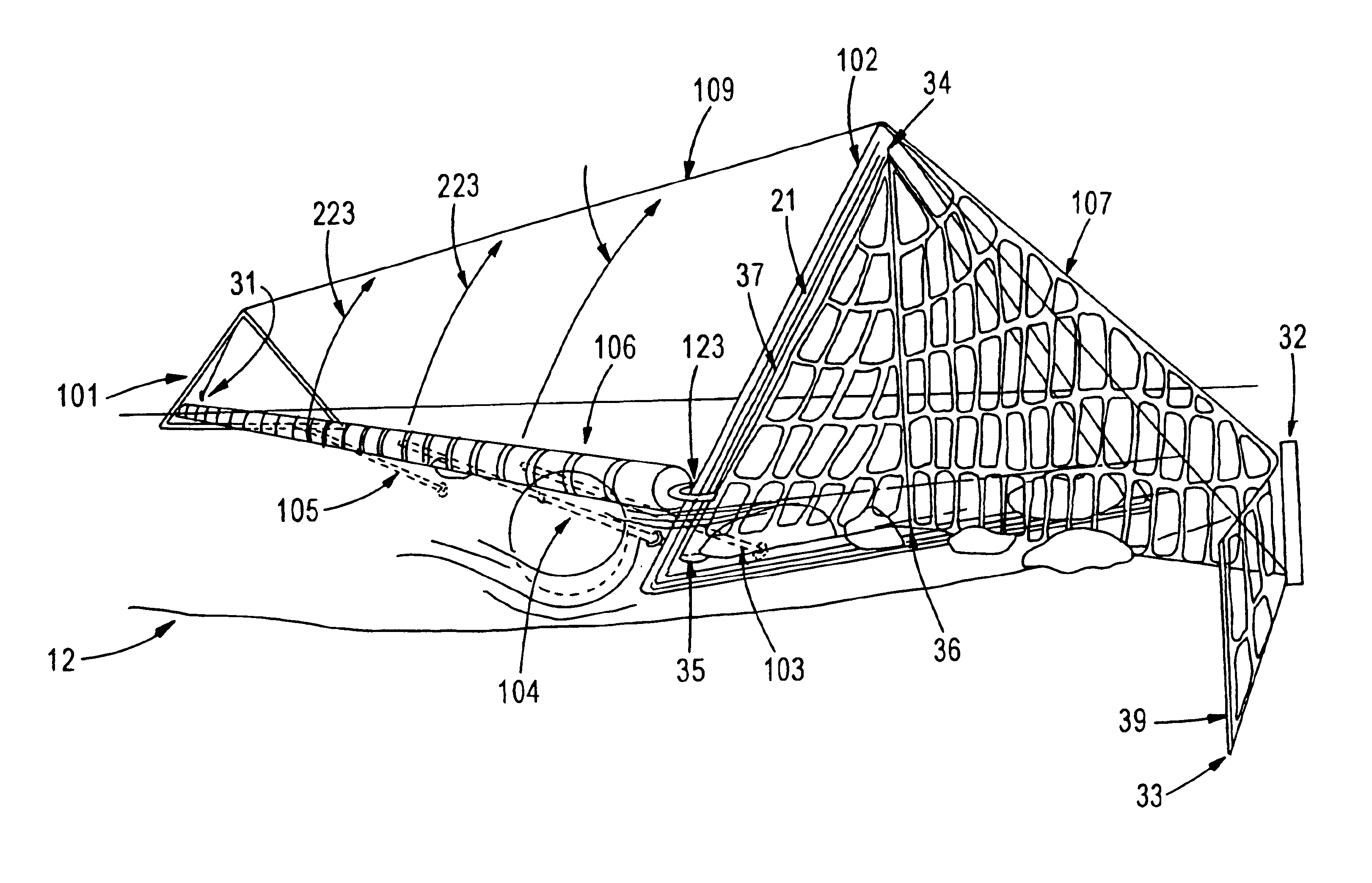

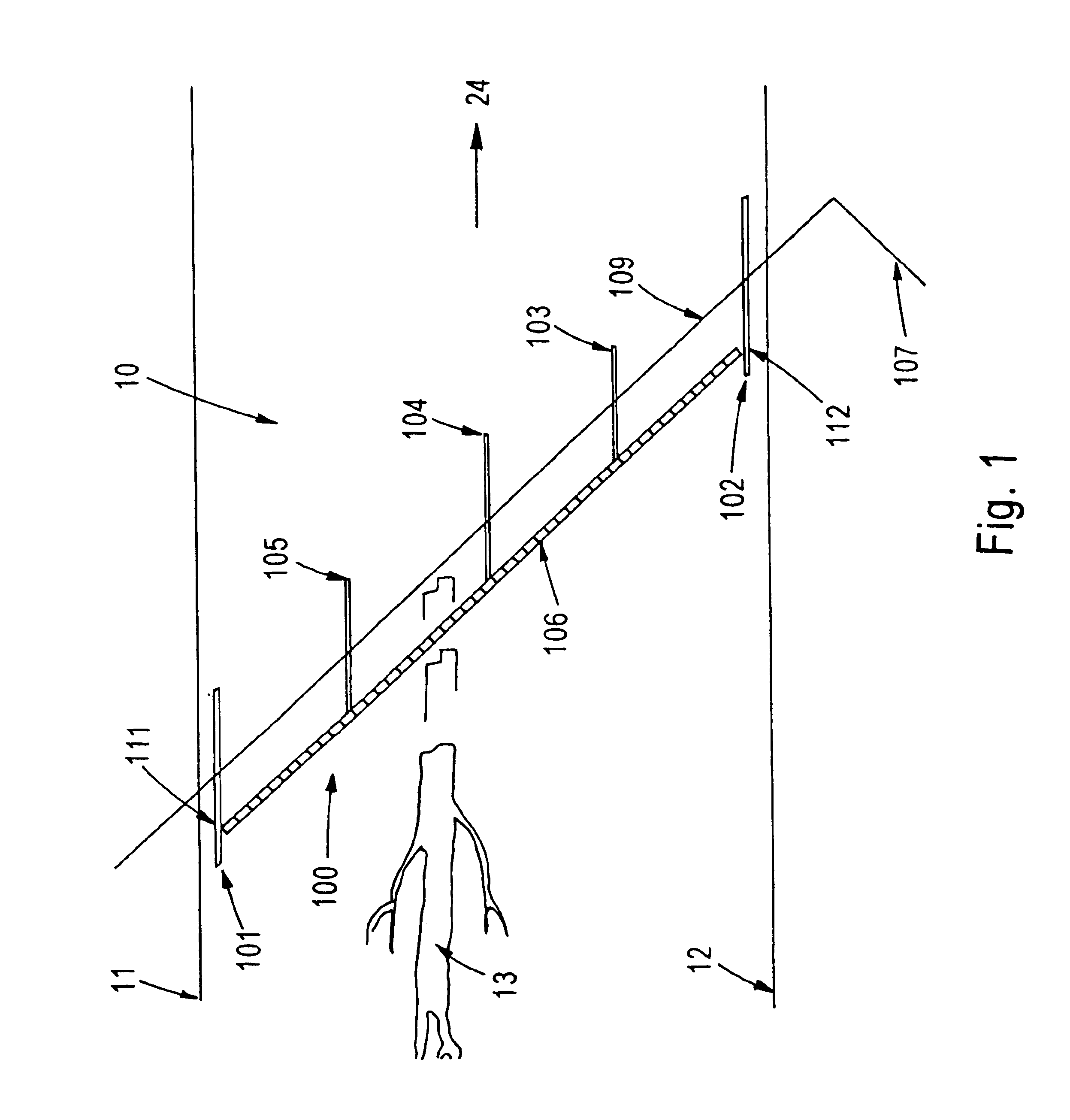

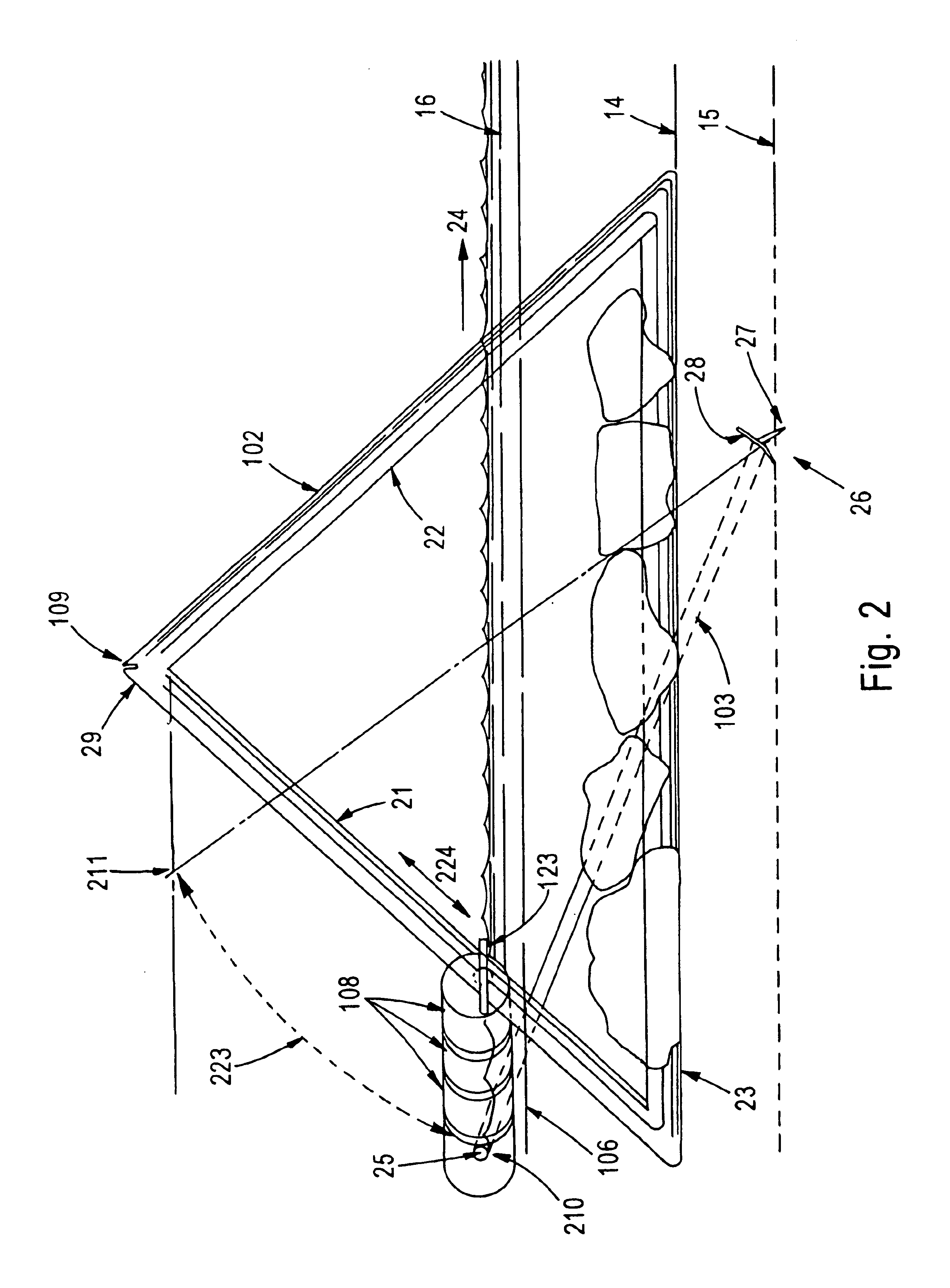

Floating river debris skimmer

InactiveUS6860677B2Minimal distractionFalling smoothlyBarrages/weirsWater cleaningFluvialEnvironmental engineering

A skimmer for removing debris off the surface of a river includes a float line installed across the river at an angle with respect to the river current, and a collecting net installed at the downstream end of the float line. The ends of the line are slidable upwards, along inclined supports, to unsnag the line when a heavy object hooks onto the line. A second mechanism, assisting in raising the line, is a series of rods which swivel in a pole-vaulted fashion from their leverage at the bottom of the river to lift the line out of the water and allow the heavy object to pass underneath. If the object hits the line with an excessive force, the line will reliably break at a desired weak point. The rods may have elbow joints that would provide better leverage in shallow water.

Owner:JOHNSTON BARRY

Energy-saving environment-friendly material drying equipment with disturbance drying function

ActiveCN107328190AKeep drySave energyDrying gas arrangementsDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention provides energy-saving environment-friendly material drying equipment with a disturbance drying function. The energy-saving environment-friendly material drying equipment comprises an inner shell. An outer shell covers the inner shell. The outer shell is fixedly connected with the inner shell through a plurality of fixing blocks. The center of the bottom in the inner shell is fixedly connected with a first sleeve. A plurality of through holes are uniformly formed in the side wall of the bottom of the first sleeve. A first rotary shaft is arranged in the first sleeve. The bottom end of the first rotary shaft extends to the outside of the outer shell, and the bottom end of the first rotary shaft is connected with a driving device. A spiral auger is arranged on the side wall of the first rotary shaft. The energy-saving environment-friendly material drying equipment has the following beneficial effects that firstly, materials can be lifted through the spiral auger so that the materials can be dried circularly and repeatedly, and the drying effect is improved; and secondly, a vertical vibrating device drives the materials on a vibrating plate to be vibrated up and down, the situation that the materials are in contact with the vibrating plate for a long time, and consequently, the materials are excessively dried is avoided, and the drying effect is improved.

Owner:江苏龙鑫智能干燥科技有限公司

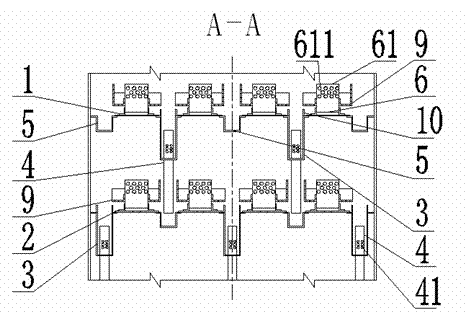

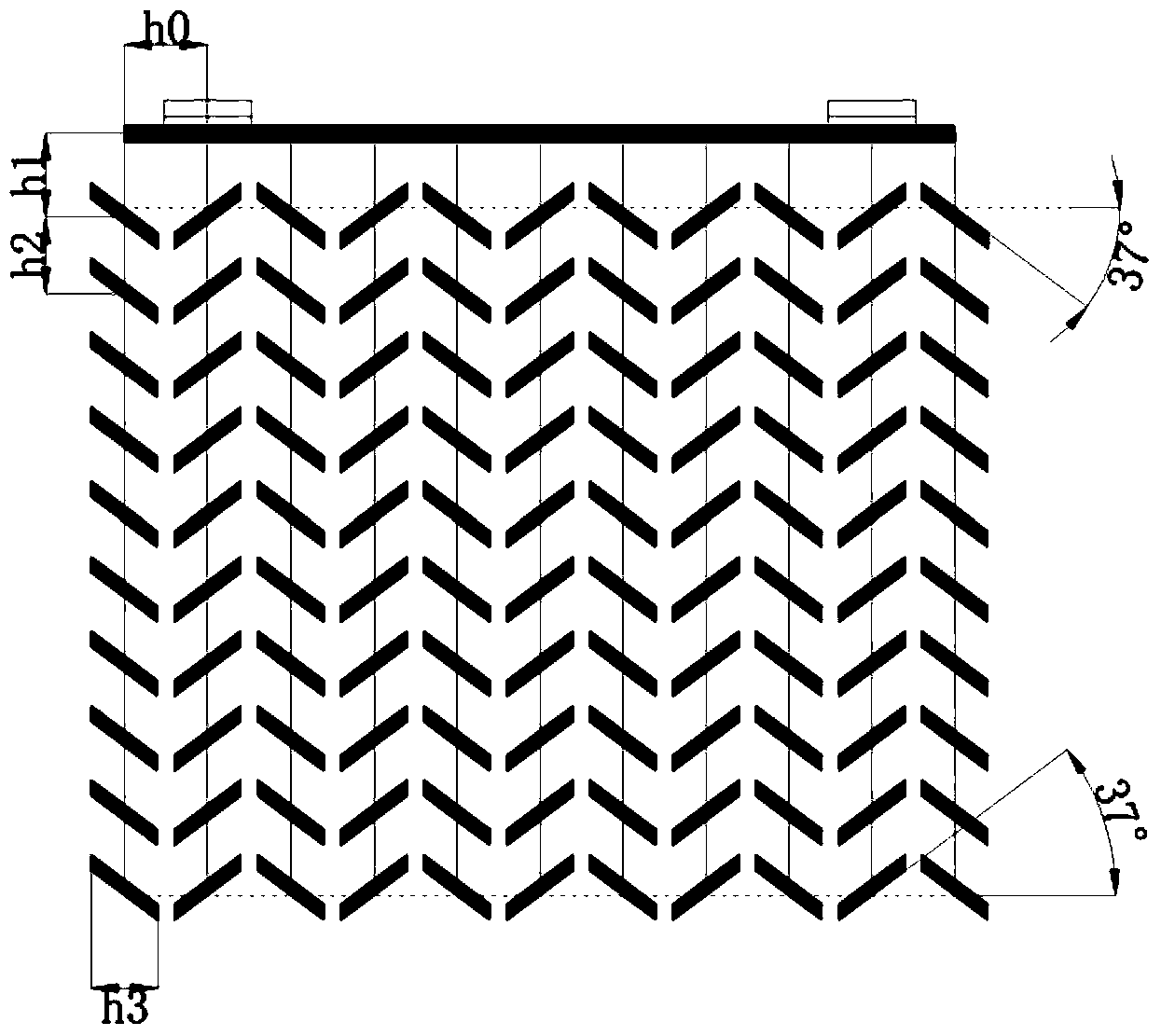

Flow-separation back-mixing-free spraying tower disc

ActiveCN102961888AStrong anti-blockingLess foamingDispersed particle separationDistillation separationSpray towerMechanical engineering

The invention discloses a flow-separation back-mixing-free spraying tower disc. The tower disc is formed by combining an upper-layer tower disc and a lower-layer tower disc; and each tower disc comprises liquid descending grooves, liquid descending pipes, liquid accepting grooves, three-dimensional spraying and mass transferring units and liquid guide grooves. The flow-separation back-mixing-free spraying tower disc is characterized in that the long-strip-shaped liquid accepting grooves are formed in the horizontal position of the center of the tower disc; each long-strip-shaped liquid descending groove is arranged between each two adjacent liquid accepting grooves; liquid descending openings are designed in the bottoms of the liquid descending grooves; each liquid descending opening corresponds to one liquid descending pipe, and each liquid descending pipe stretches and is fixed in each liquid descending groove; the three-dimensional spraying and mass transferring units are arranged among the liquid descending grooves and the liquid accepting grooves; the liquid guide grooves, which are flow-separation-plate-type liquid guide grooves, are arranged on the peripheries of cap covers of the three-dimensional spraying and mass transferring units; one liquid guide groove corresponds to one three-dimensional spraying and mass transferring unit; the shapes and the structures of the upper and lower tower discs are the same basically; and one set of liquid descending pipes on the lower edge of one liquid descending groove of the upper-layer tower disc correspond to one liquid accepting groove of the lower-layer tower disc in a staggered manner, so that the upper-layer tower disc and the lower-layer tower disc are combined into the double-layer flow-separation back-mixing-free spraying tower disc.

Owner:TIANJIN CHUANGJU TECHNOLGOY

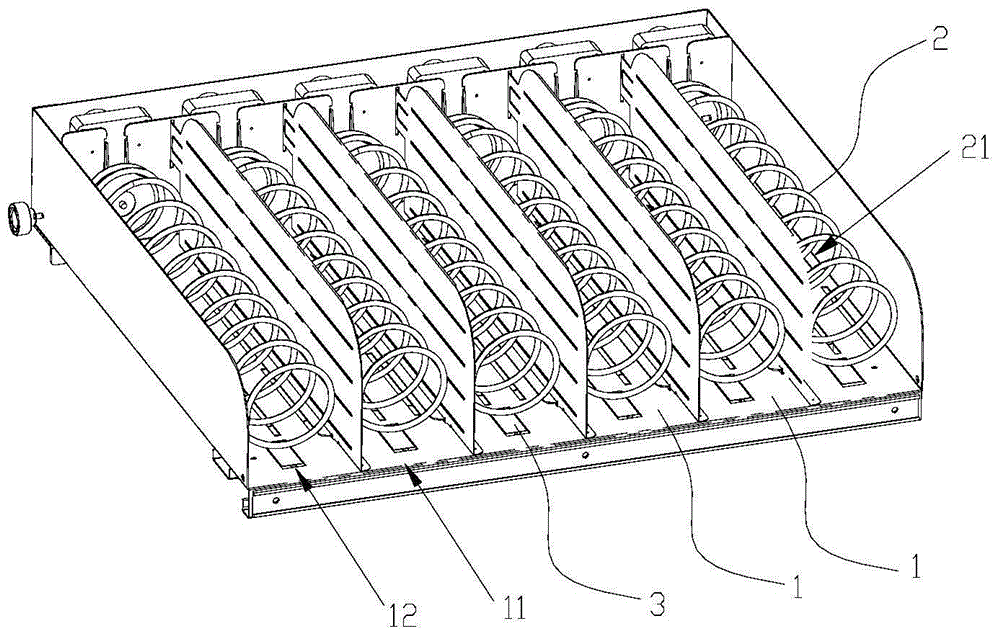

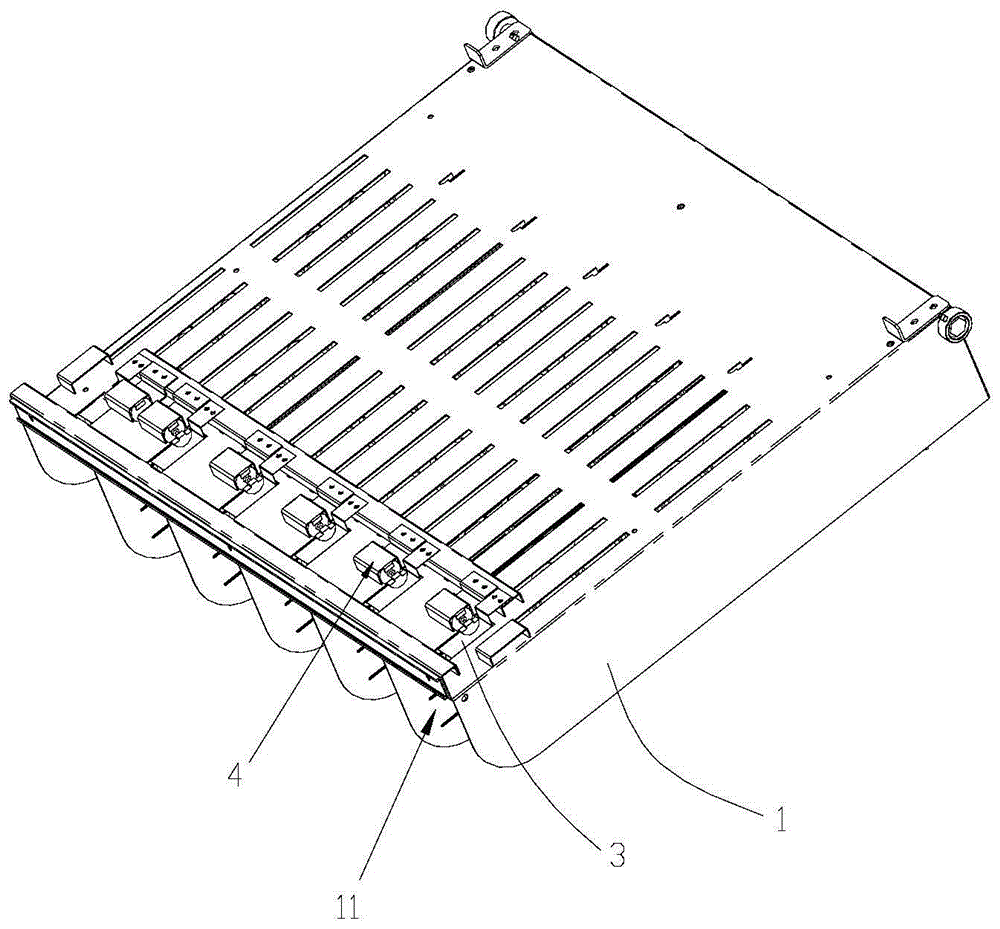

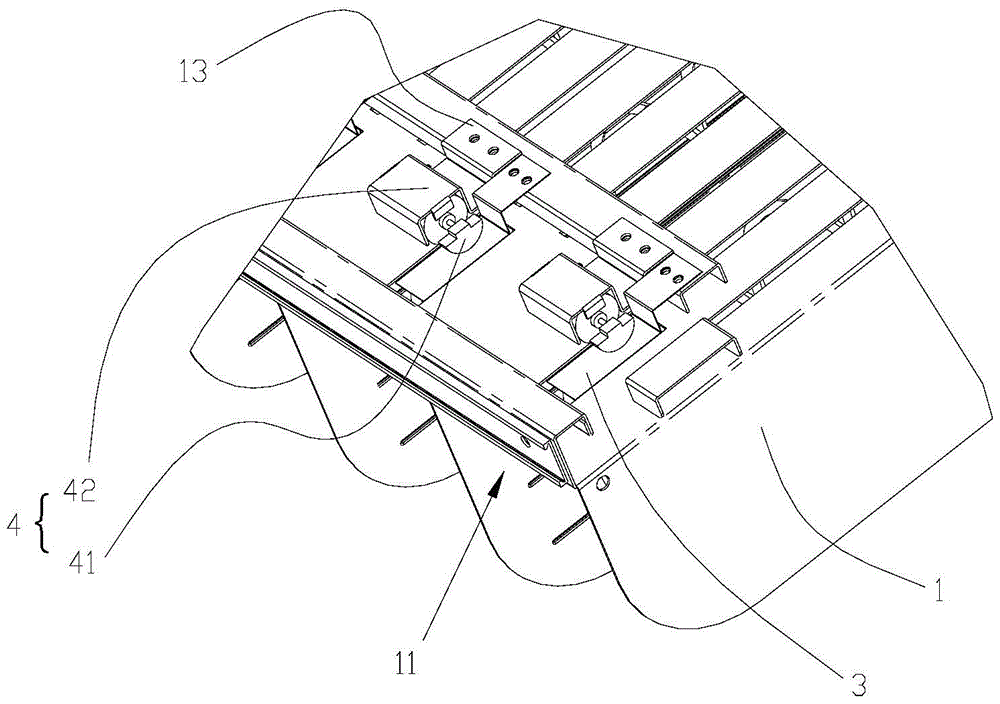

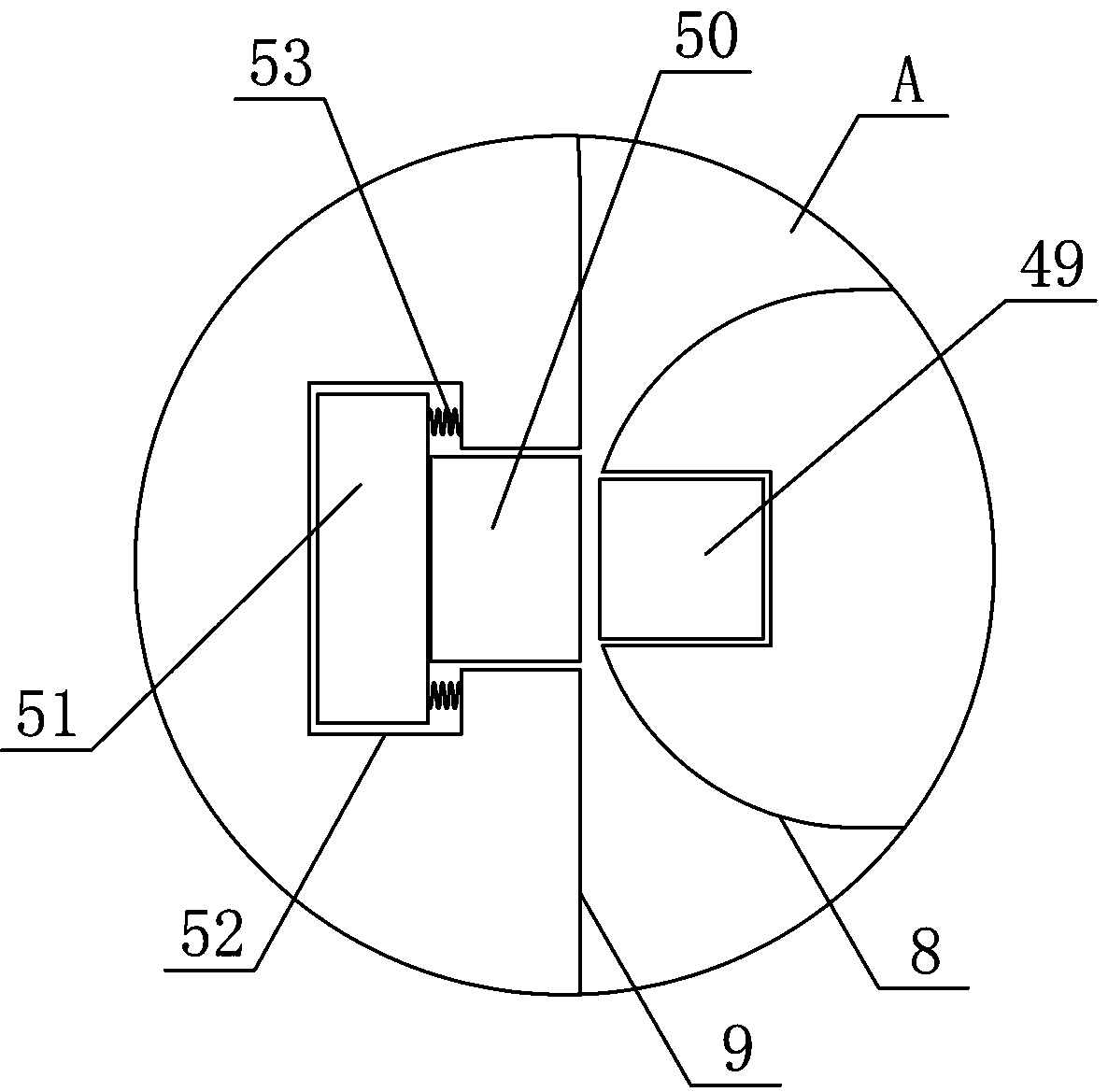

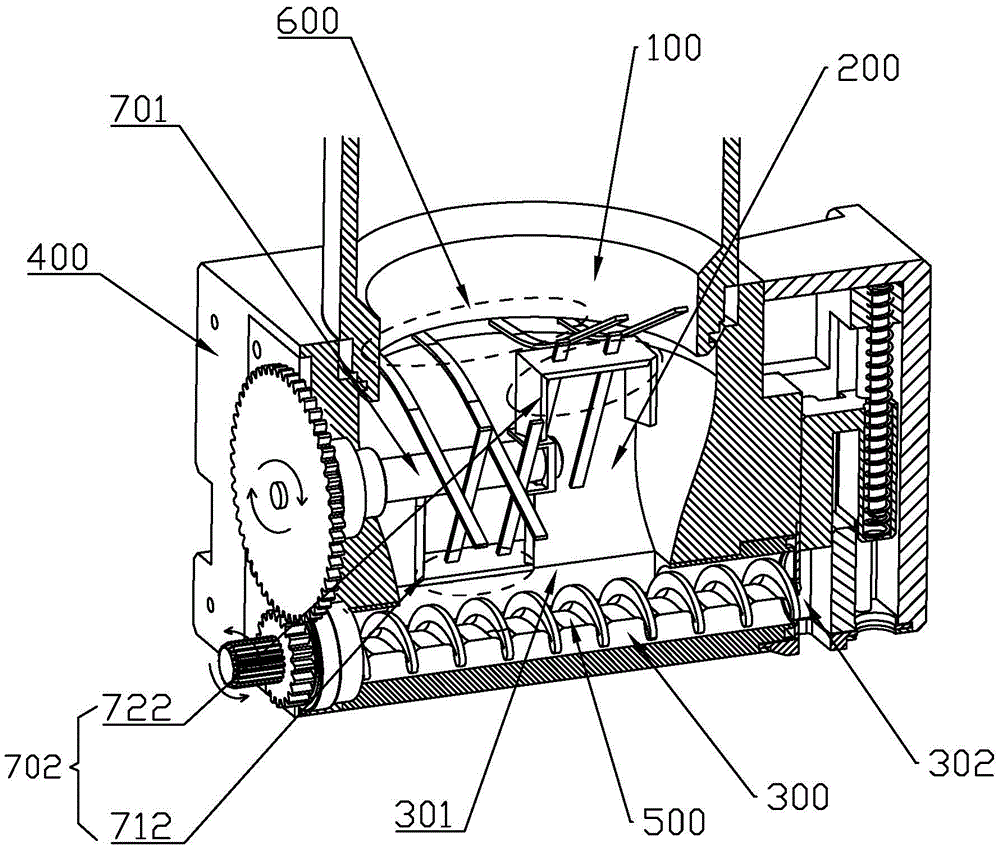

Spring-type vending machine, cargo outlet device thereof and cargo blocking preventing mechanism

ActiveCN105046819AFalling smoothlySales impactCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringMechanical engineering

The invention provides a spring-type vending machine, a cargo outlet device thereof and a cargo blocking preventing mechanism. Cargo blocking can be prevented in the cargo vending process, and continuous and stable vending of cargoes is achieved. The cargo blocking preventing mechanism is used for the cargo outlet device of the spring-type vending machine. The cargo outlet device comprises material channels with cargo outlets in the front ends and cargo outlet springs extending along the material channels. Cargo containing space is formed between adjacent rings of the cargo outlet springs. The cargo blocking preventing mechanism comprises a vibration piece and a power source for driving the vibration piece to vibrate. The vibration piece is arranged at the position corresponding to the corresponding cargo outlet spring and can be in contact with the corresponding cargo outlet spring to drive the cargo outlet spring to vibrate to vibrate the cargoes blocked at the front end of the cargo outlet spring down. The vibration piece of the cargo blocking preventing mechanism can vibrate the cargoes blocked at the front end of the corresponding cargo outlet spring down by driving the cargo outlet spring to vibrate so that cargo blocking can be prevented; meanwhile, vending of the next cargoes can not be influenced, and continuous and stable vending of the cargoes can be achieved.

Owner:青岛澳柯玛自动售货机股份有限公司

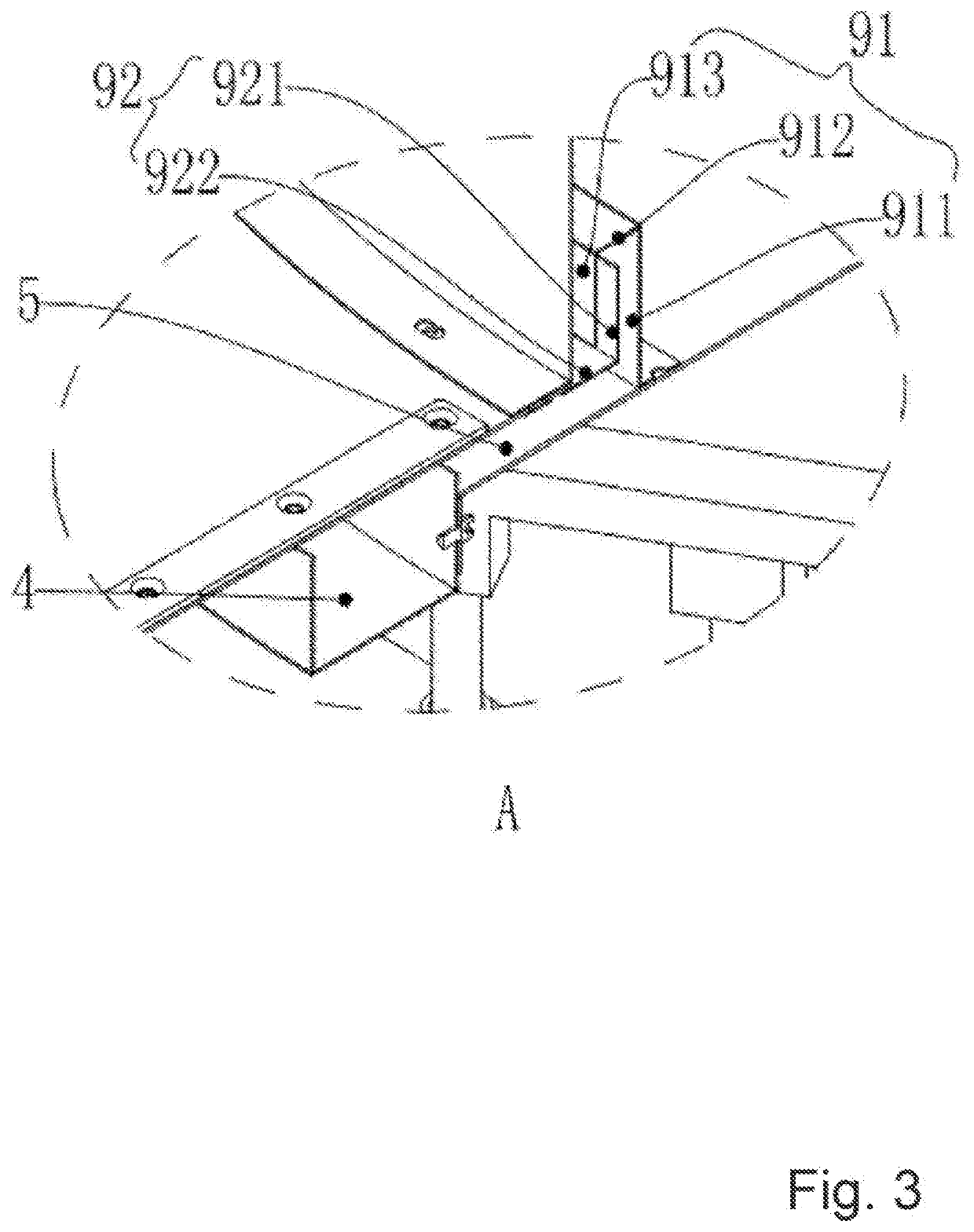

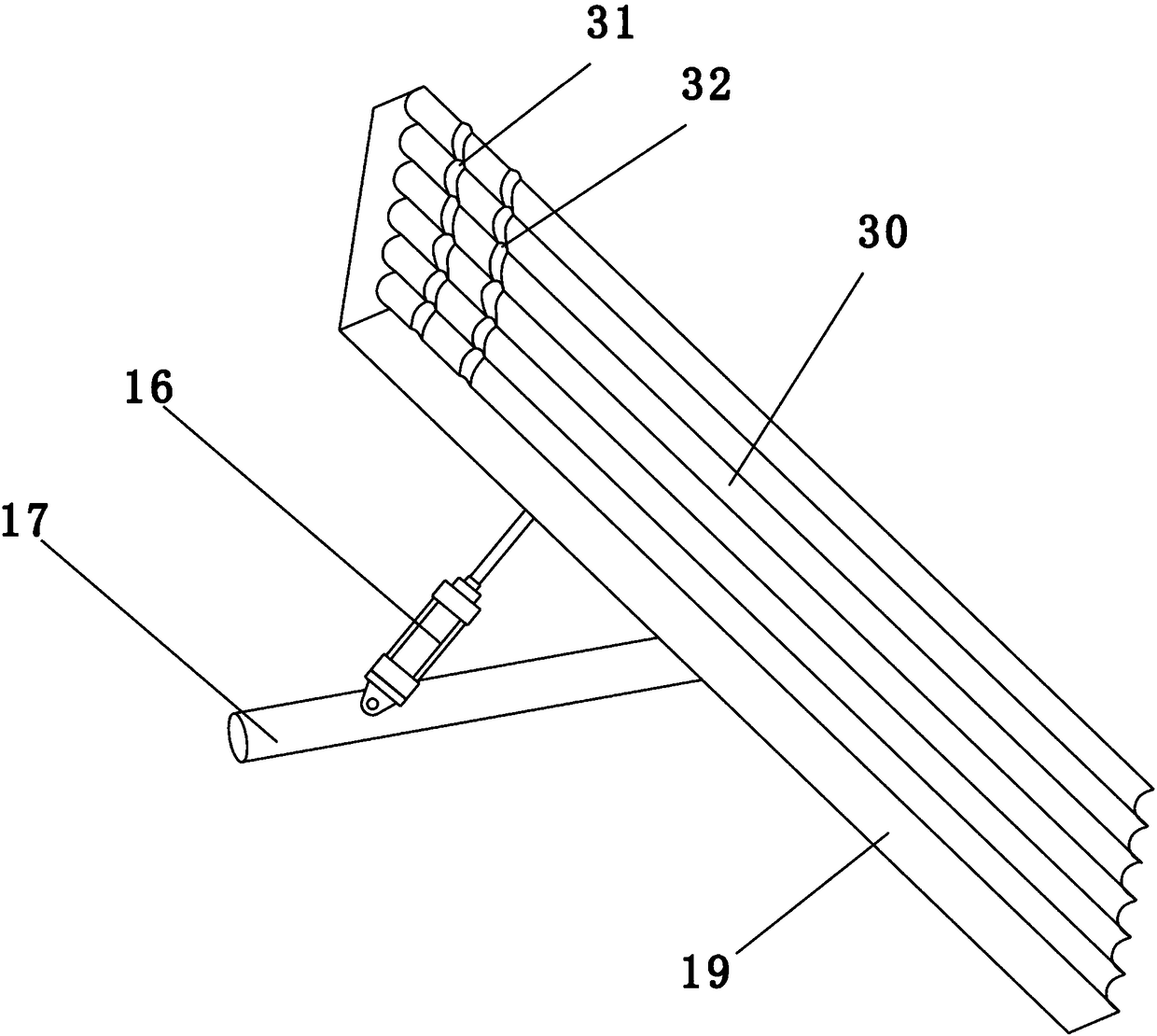

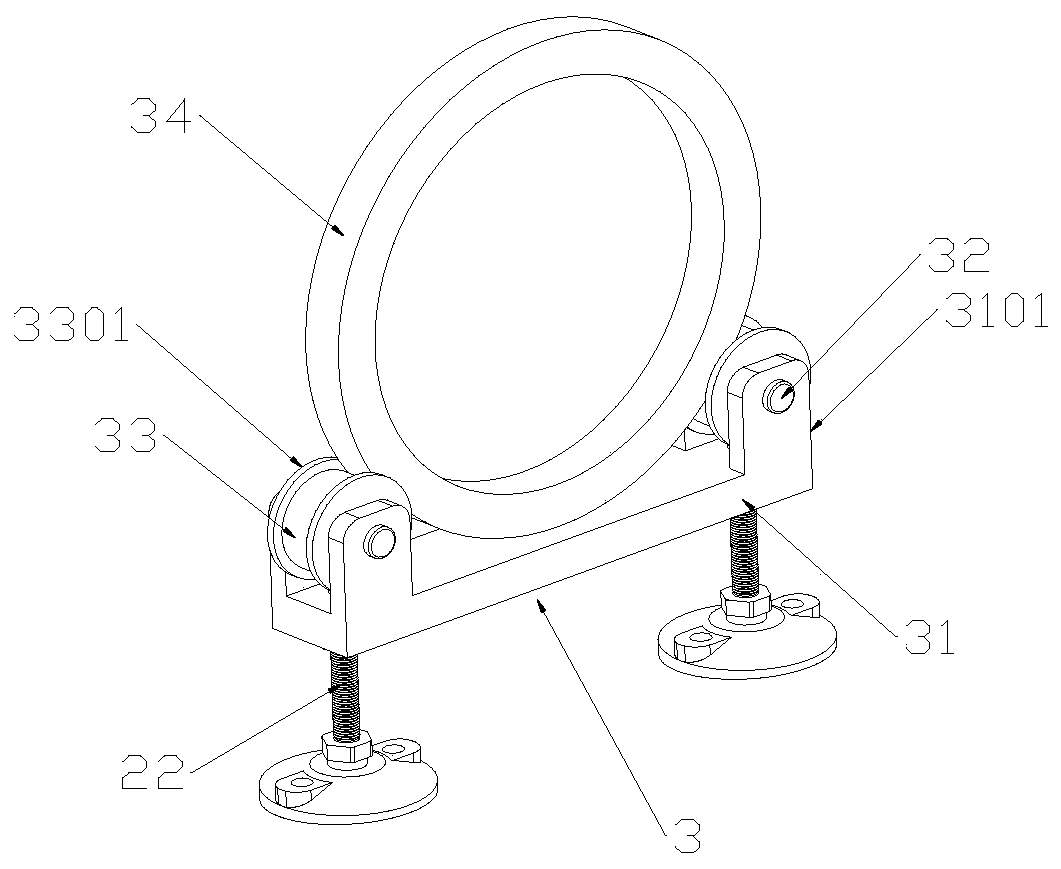

Seedling falling control mechanism of potted seedling transplanting machine

ActiveCN104855013AFalling smoothlyConvenient seedling timeTransplantingAgricultural engineeringSeedling

The invention relates to a seedling falling control mechanism of a potted seedling transplanting machine and belongs to the technical field of agricultural machinery. The seedling falling control mechanism comprises a front opening and closing plate, a rear opening and closing plate and a seedling falling frame; the front opening and closing plate and the rear opening and closing plate are arranged at an output end of a seedling conveying barrel base plate and comprise a folded horizontal plane respectively; the seedling falling frame extends upward from the front end of the seedling conveying barrel base plate; the upper portion of the outer side of the front opening and closing plate and the upper portion of the outer side of the rear opening and closing plate and the middle of an inverted V-shaped lever piece and the middle of a straight lever piece are supported on a fixing plate through a horizontal pin shaft in a hinged mode respectively, wherein the fixing plate is arranged at the front end of the seedling conveying barrel base plate; the lower portion of the folded horizontal plane of the front opening and closing plate is hinged to the inner lower end of the inverted V-shaped lever piece and the lower portion of the folded horizontal plane of the rear opening and closing plate is hinged to the lower end of the straight lever piece; the upper end of the straight lever piece and the inner lower end of the inverted V-shaped lever piece are hinged to two ends of a connecting rod respectively; the upper portion of the seedling falling frame is hinged to a cylinder body of a cylinder; the lower end of a piston rod of the cylinder, which extends downward, is hinged to an outer lower end of the inverted V-shaped lever piece. According to the seedling falling control mechanism of the potted seedling transplanting machine, the accurate control on the seedling falling time of potted seedlings can be facilitated and meanwhile a seedling falling opening is gradually opened, the opening speed can be convenient to control, and accordingly the potted seedlings can reliably fall down and the seedling injury rate and the seedling fall rate are significantly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

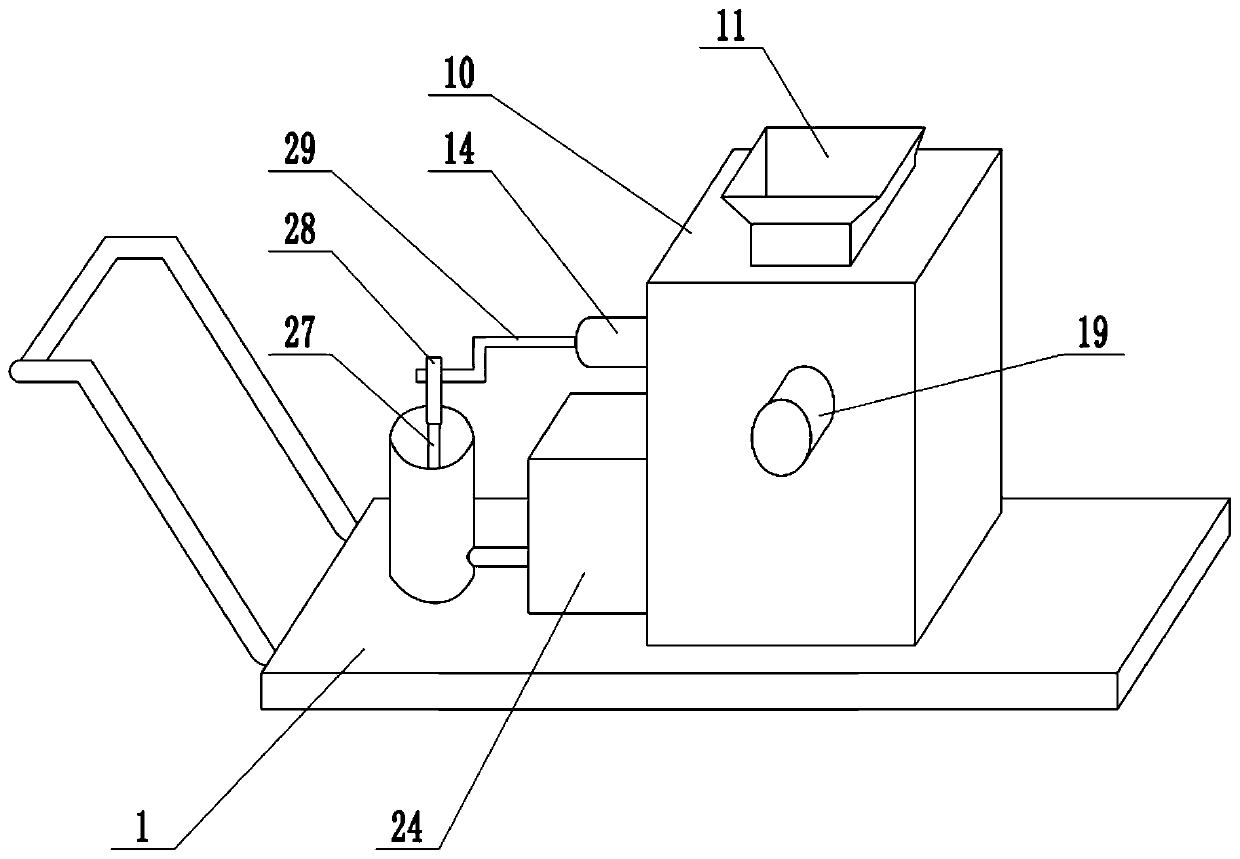

Rationed fertilizing device with fertilizer mixing function

InactiveCN110149865APrevent escapePrevent splashFertiliser distributersAgricultural engineeringAgricultural machinery

The invention relates to the field of agricultural machinery and equipment, in particular to a rationed fertilizing device with a fertilizer mixing function. The rationed fertilizing device comprisesa frame, wheels and a mixing chamber. The mixing chamber is mounted on the frame, a stirring mechanism is mounted in the mixing chamber, an arc-shaped discharge outlet is arranged at the bottom of themixing chamber, a rotating shaft is mount in the discharge outlet, a discharge motor for driving the rotating shaft to rotate is mounted on the frame, the rotating shaft is sleeved with a dispensingdisc, and dispensing plates are radially distributed in the dispensing disc. The rationed fertilizing device has the advantages that different types of fertilizer can be fed into the mixing chamber atthe same time; a moving plate prevents the fertilizer from overflowing and scattering; the two types of fertilizer are stirred by the stirring mechanism to be mixed evenly; the fertilizer is enabledto drop evenly through the dispensing disc and the dispensing plates to achieve rationed fertilization; through a coulter capable of moving up and down, soil is stirred to make the fertilizer fully contact with the soil.

Owner:张媛

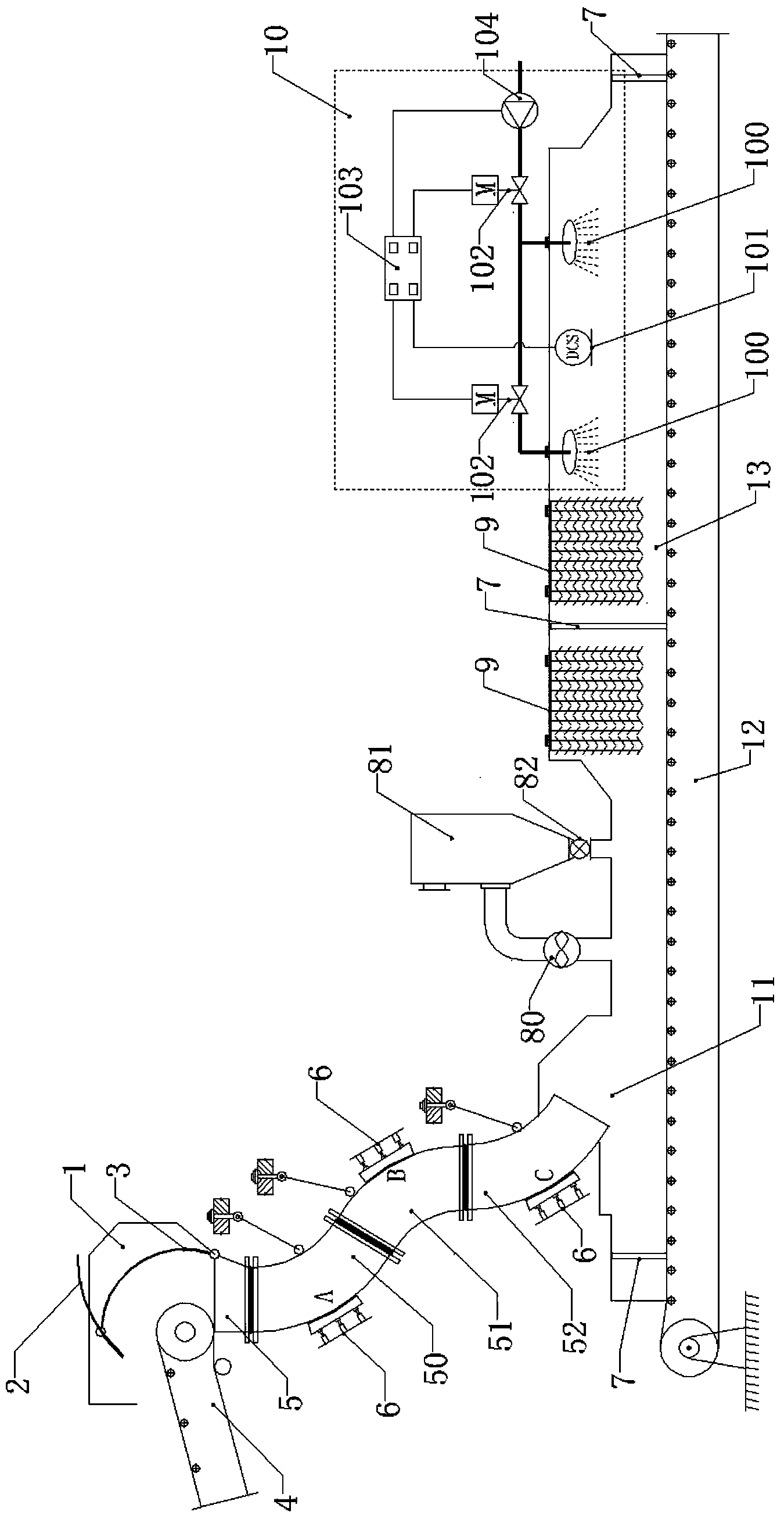

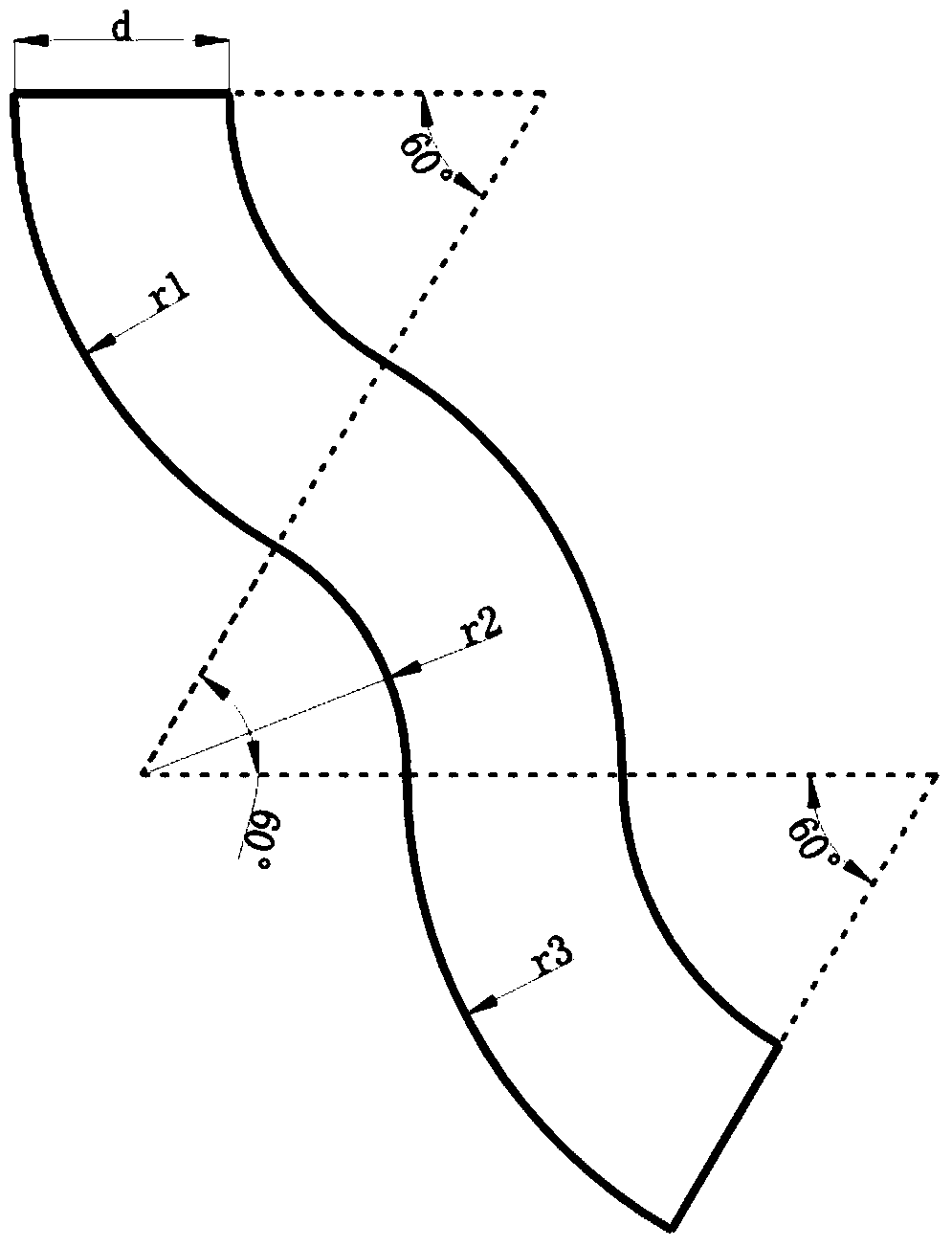

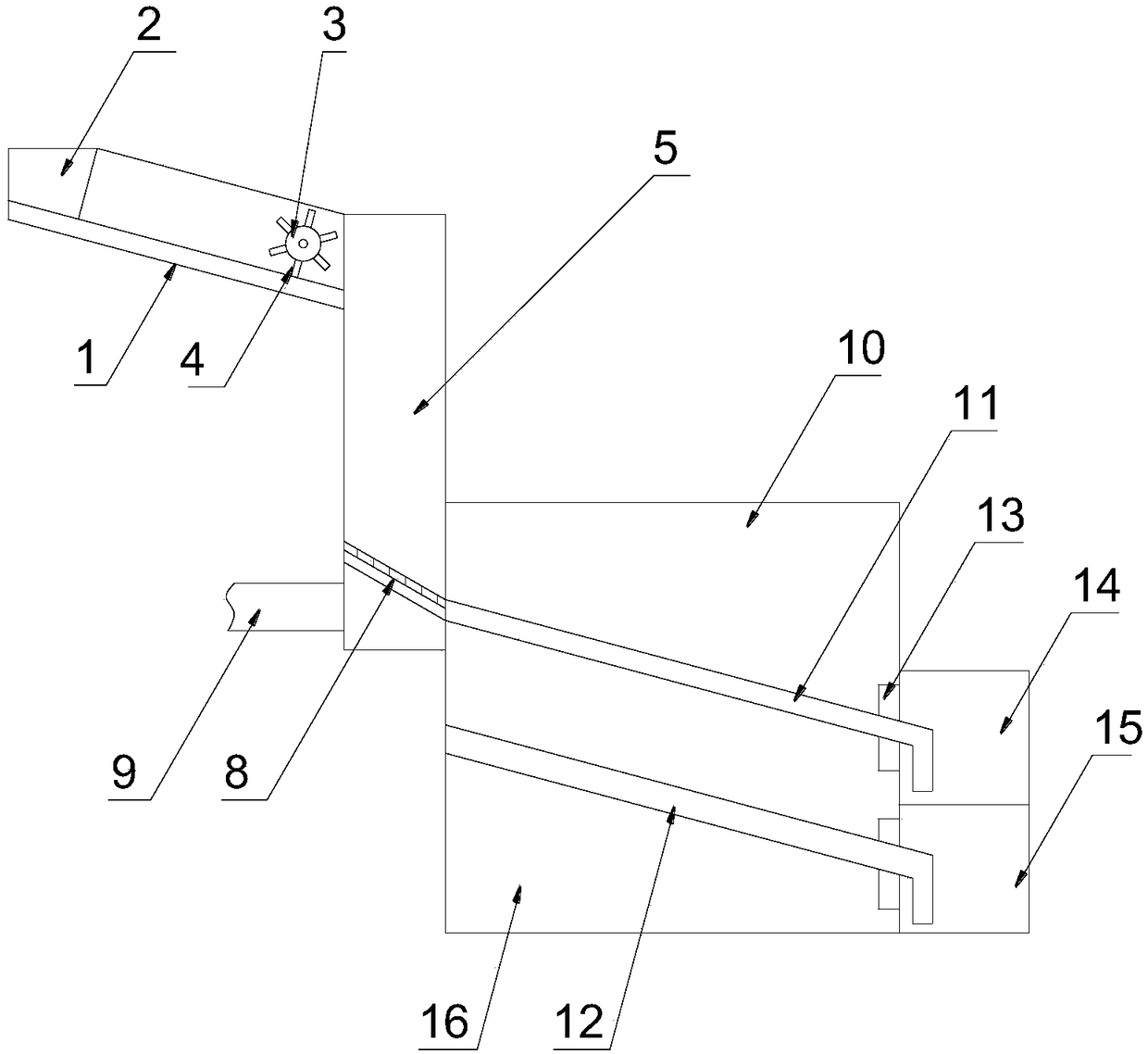

Anti-blockage, dust suppression and noise reduction coal transport system for power plant

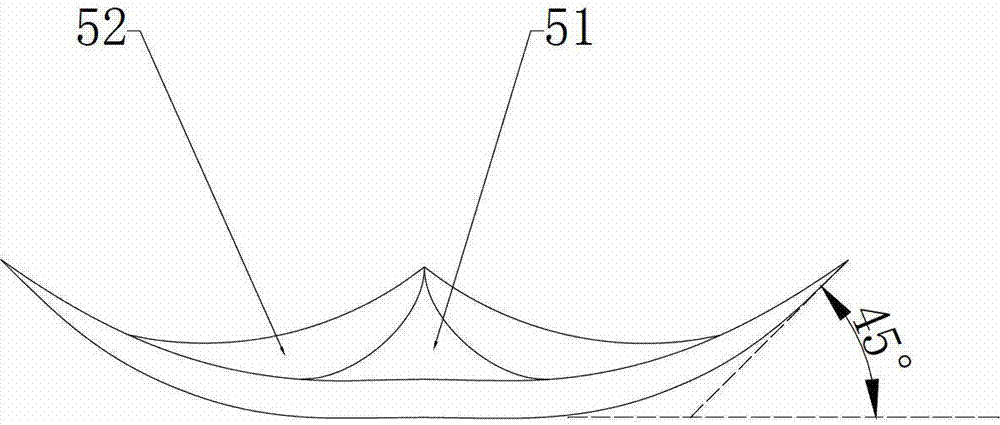

ActiveCN104386470AGood dust removal effectEasy to remove cloth bagCleaningDiscrete element simulationThroat

The invention discloses an anti-blockage, dust suppression and noise reduction coal transport system for a power plant. The coal transport system comprises an upstream conveying device, a coal falling pipe and a downstream conveying device, wherein the discharging end of the upstream conveying device is used for feeding materials into the feeding hole of the coal falling pipe; the discharging hole of the coal falling pipe is used for feeding the materials to the feeding end of the downstream conveying device; the coal falling pipe comprises a throat hopper and a three-arc-segment coal falling pipe. The three-arc-segment coal falling pipe is designed on the basis of discrete element simulation EDEM, and has high coal type adaptability. By adopting a flow channel, the blockage of coal particles can be well prevented; meanwhile, the collision angles of the coal particles and a pipeline are reduced, and the advantage of reducing noise is realized. The three-segment coal falling pipe is spliced by adopting a deflection way, and a hydraulic damping device is arranged on a bend collision point, so that wear of the pipeline can be reduced effectively. Meanwhile, the speed of the coal particles is limited, soft landing of the coal particles and a downstream conveying belt is realized, impact on the conveying belt is reduced, and the production of dust is reduced.

Owner:SOUTHEAST UNIV

Sorting and conveying mechanism for groove workpieces

ActiveCN110451228AReasonable structural designHigh degree of automationConveyor partsEngineeringMechanical equipment

The invention discloses a sorting and conveying mechanism for groove workpieces, and belongs to the field of workpiece conveying and machining mechanical equipment. A material transferring pipe is vertically and fixedly arranged in the middle of the upper side of a material transferring support, a horizontal moving push plate is horizontally and fixedly provided with a material pushing pressing rod along the side of the material transferring material pipe, a material guide inclined plate is obliquely and downwards fixedly arranged on one side below the material transferring material pipe, anda material bearing baffle is arranged on one side of a turnover baffle; a material guiding pipe is vertically and fixedly arranged on the material transferring support at the lower side of the material transferring pipe, a material guiding rotating plate is arranged on the material transferring support on one side of the material guiding pipe, the end part the lower side of a transferring guide plate is rotationally connected to the material transferring support, a material bearing rotating plate is arranged on the upper side of the transferring guide plate, and a material transferring belt ishorizontally arranged on the upper side of a conveying base. The sorting and conveying mechanism has the advantages that the structural design is reasonable, the groove workpieces can be convenientlyand efficiently subjected to directional arrangement in the discharging process, automatic overturning and conveying of the groove workpieces can be realized, the workpiece feeding and conveying automation degree is improved, and the requirements of production and use are met.

Owner:泰州市宠友宠物服务有限公司

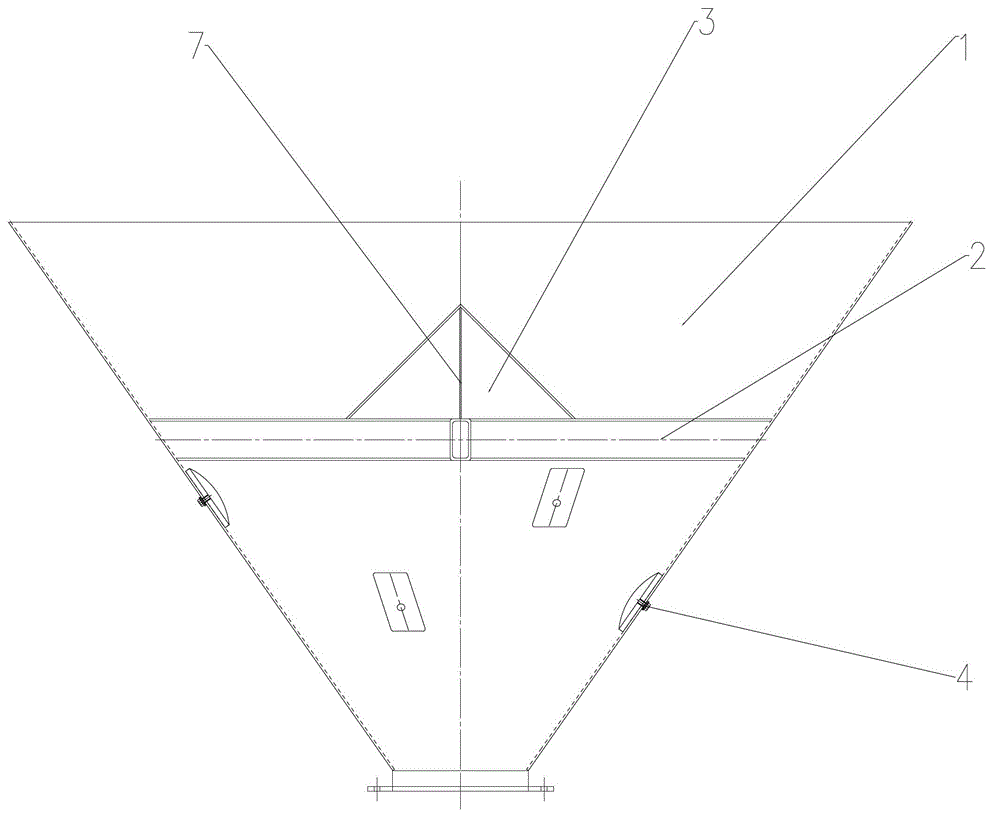

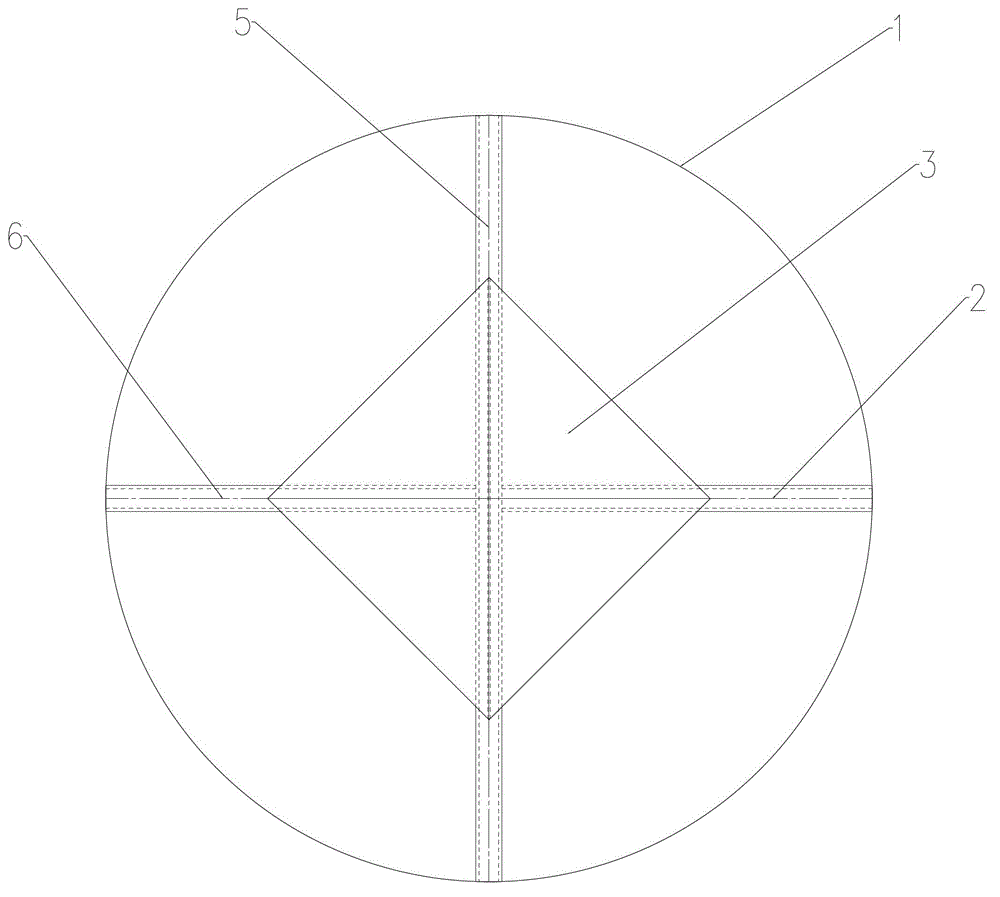

Buffering and flow assisting powder cabin

The invention relates to a buffering and flow assisting powder cabin, which is particularly used for making mineral powder flow out smoothly. The buffering and flow assisting powder cabin comprises a crossed reinforcement tube, a coaming and flow assisting air cushions, wherein the crossed reinforcement tube is positioned in a cabin body; the four ends of the crossed reinforcement tube are connected with the inner wall of the cabin body by welding; the bottom of the coaming is welded on the crossed reinforcement tube; and the inner surface of the cabin body on the lower part of the crossed reinforcement tube is connected with a plurality of flow assisting air cushions through bolts. The buffering and flow assisting powder cabin is simple, compact and reasonable in structure, contributes to successful falling of mineral powder from the outlet of the powder cabin, and is low in cost; and mineral powder is prevented from blocking the cabin body.

Owner:WUXI XITONG ENG MACHINERY

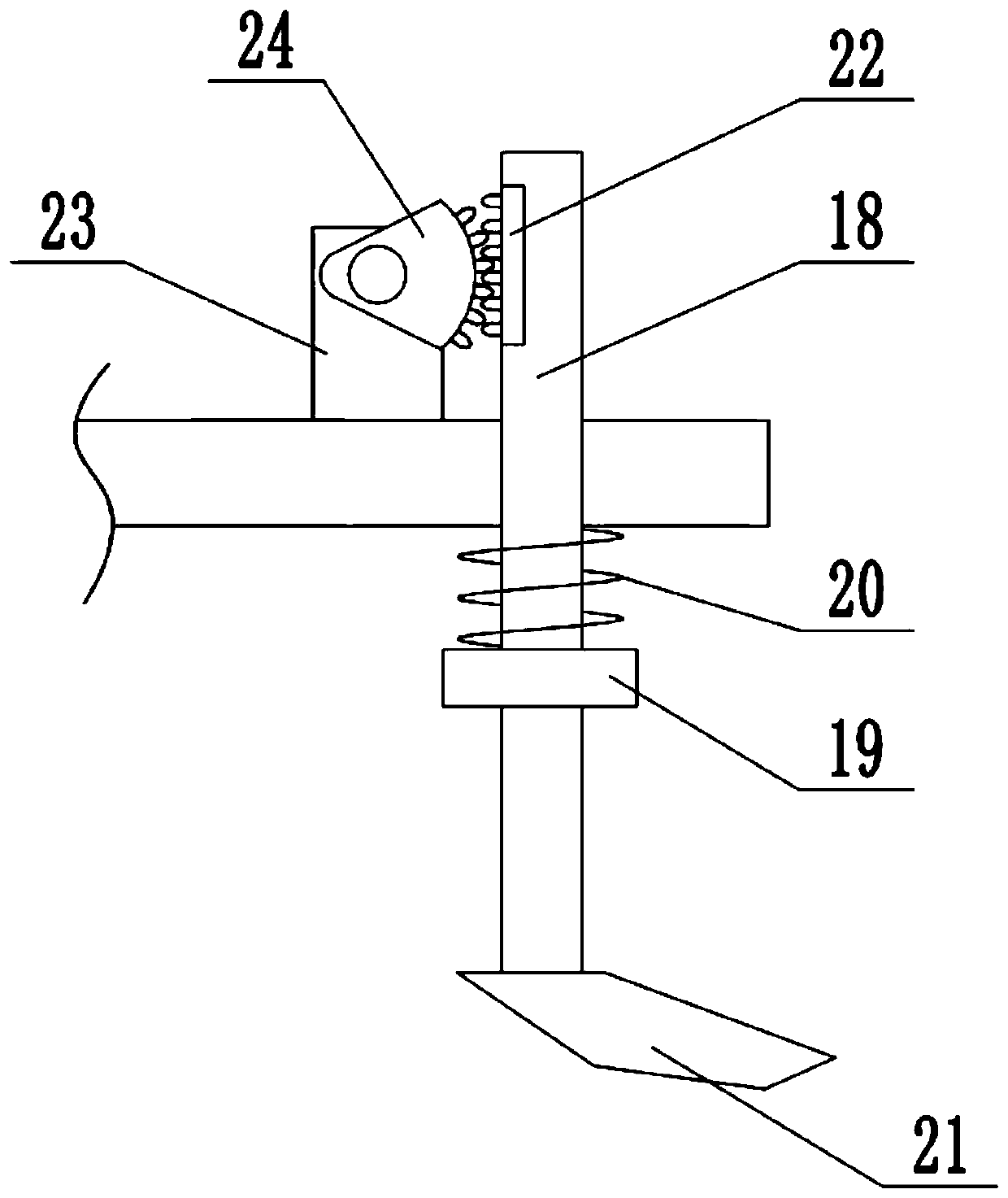

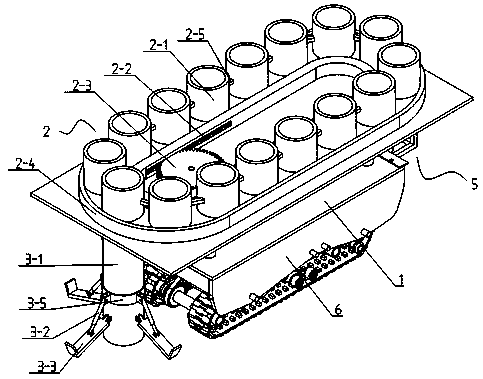

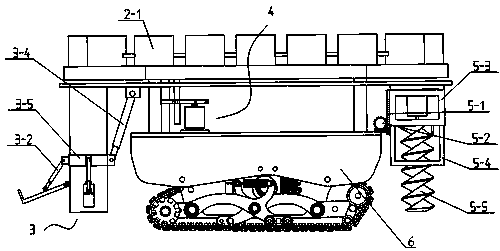

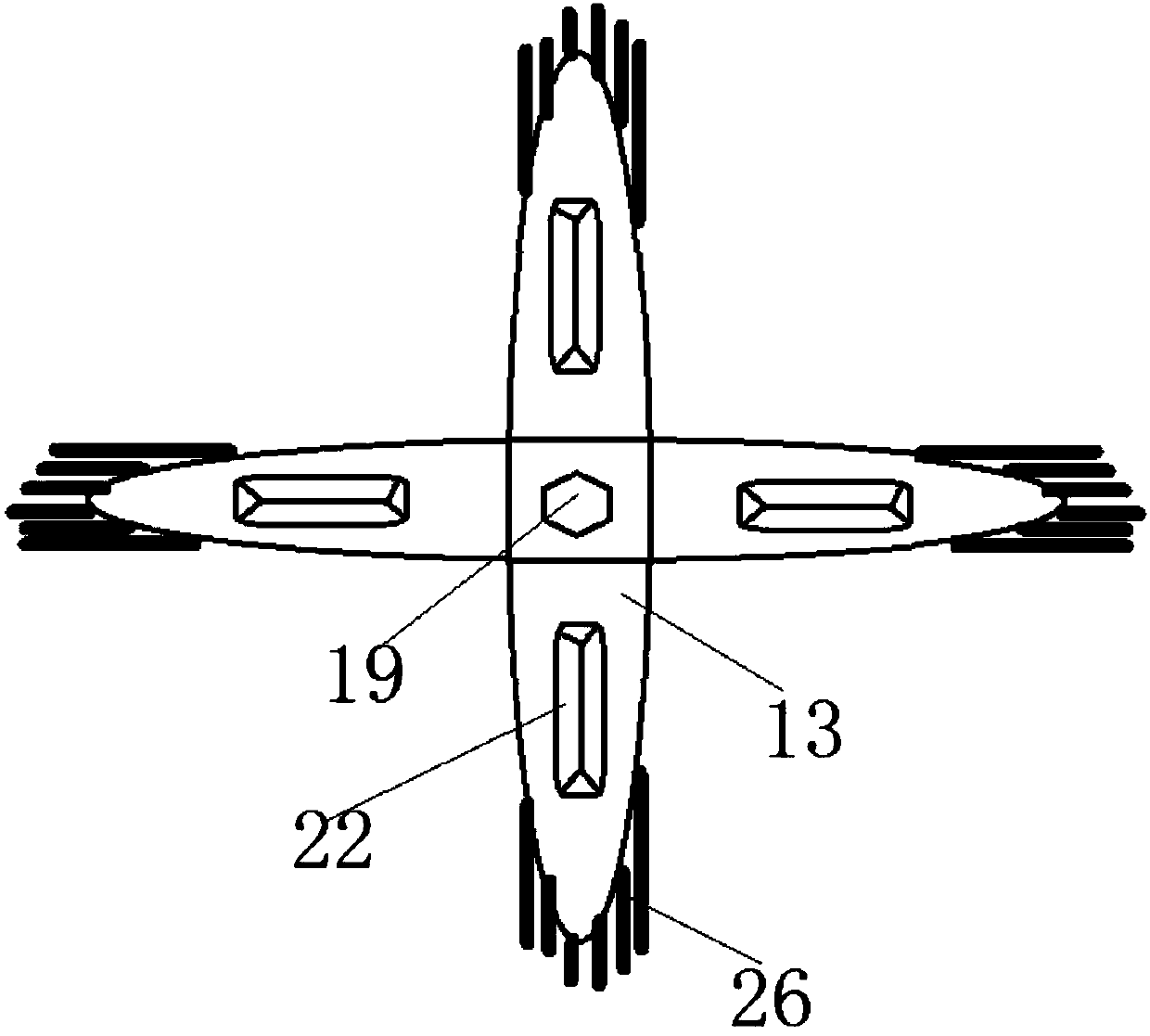

Device applicable to multi-terrain automatic tree planting

ActiveCN111480547AAccurate transmissionSimple structurePlantingFurrow making/coveringAgricultural scienceAgricultural engineering

The invention provides a device suitable for multi-terrain automatic tree planting, and belongs to the technical field of tree planting devices. According to the technical scheme, the device applicable to multi-terrain automatic tree planting comprises a frame, a walking component arranged at the bottom of the frame, an earth cutting and drilling mechanism arranged at the front end of the frame, aseedling preparation component arranged at the top of the frame, a seedling preparation driving assembly arranged on the frame and used for controlling the seedling preparation component, and a treeplanting assembly arranged on the rear end of the frame and matched with the output end of the seedling preparation component. The device has the beneficial effects that the device suitable for multi-terrain automatic tree planting is high in automation degree, high in tree planting operation efficiency, high in planting quality, accurate in conveying, good in continuity and high in sapling survival rate.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

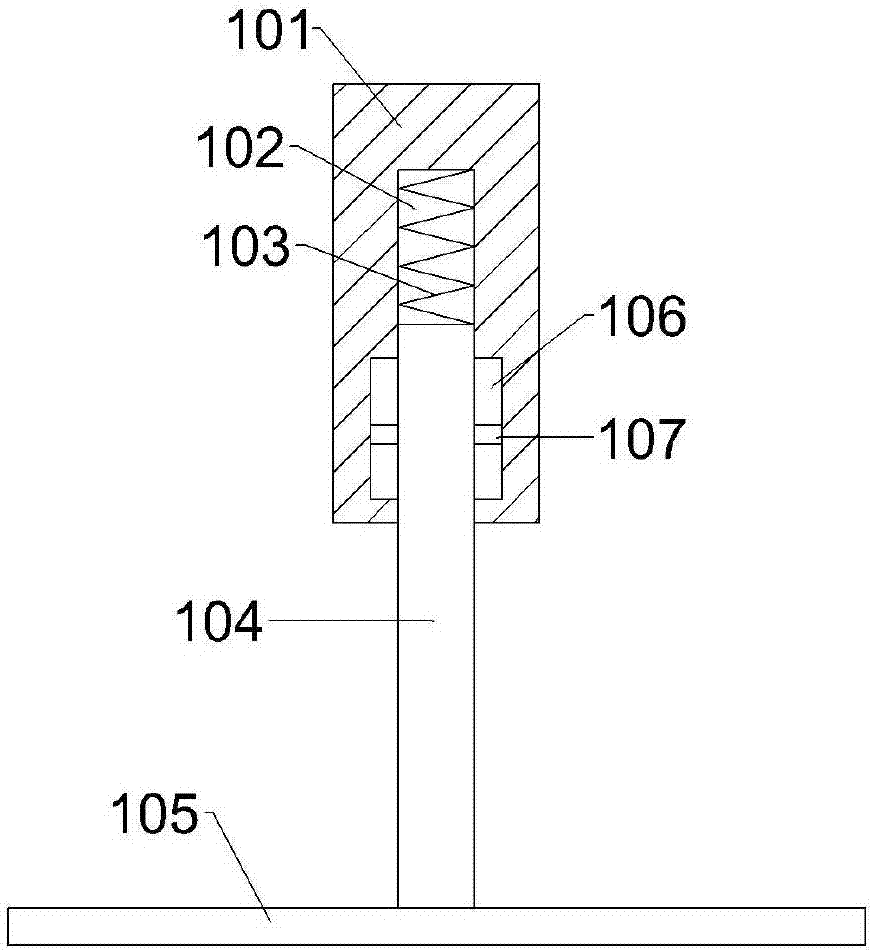

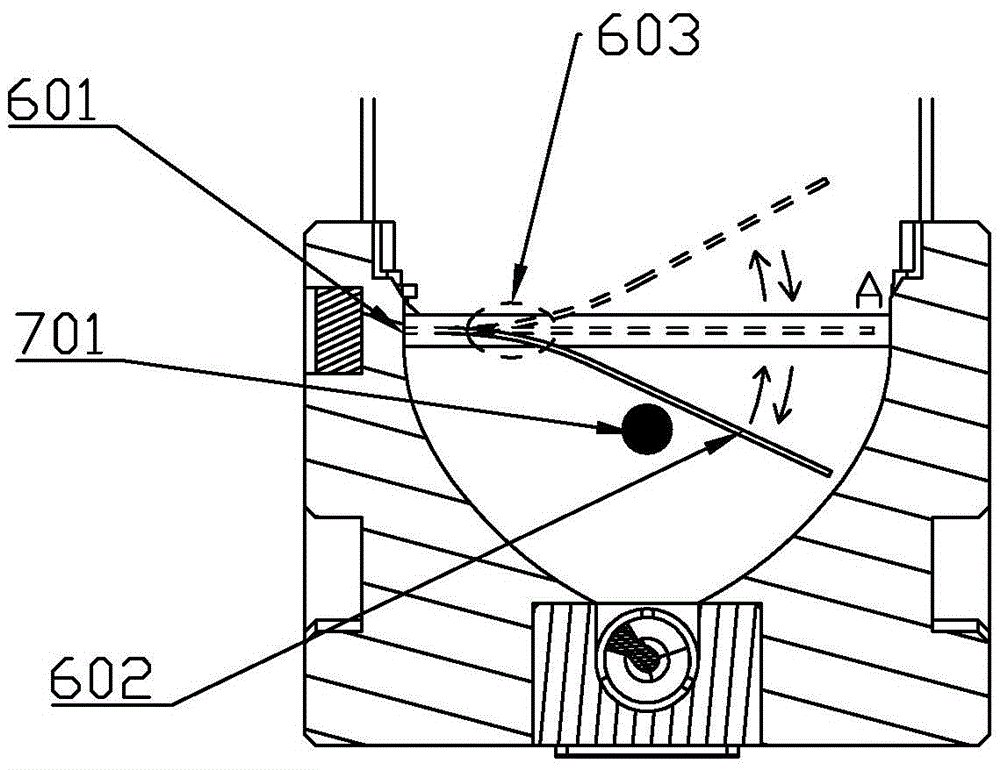

Boron particle laser ignition burning experiment device and experiment method

ActiveCN110333317ASimple structureStable structureChemical analysis using combustionMaterial analysis by optical meansEngineeringDrug Storage

The invention discloses a boron particle laser ignition and burning experiment device and an experiment method and relates to the technical field of a solid engine experiment. The experiment device and a high speed camera are mounted at calibration locations. According to the experiment device, electromagnet of an automatic drug feeding mechanism matches with a drug storage hopper; boron particlesin the drug storage hopper are controlled to drop uniformly in a discrete state according to preset time through utilization of an external voltage signal; in shrinkage of the electromagnet of the drug feeding mechanism, the boron particles drop and pass through laser beams; laser ignition of the boron particles in a movement process under a state of sufficiently contacting with atmosphere is realized; the high speed camera is powered on to start collecting an image; and synchronization of a laser ignition process of the boron particles and an image collection process of the high speed camerais ensured. The experiment device is simple and reliable in structure. The experiment method is rapid and convenient. Laser ignition and burning of the boron particles in the movement are realized under the state of sufficiently contacting with the atmosphere. Image information collection and recording can be carried out on a whole experiment process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

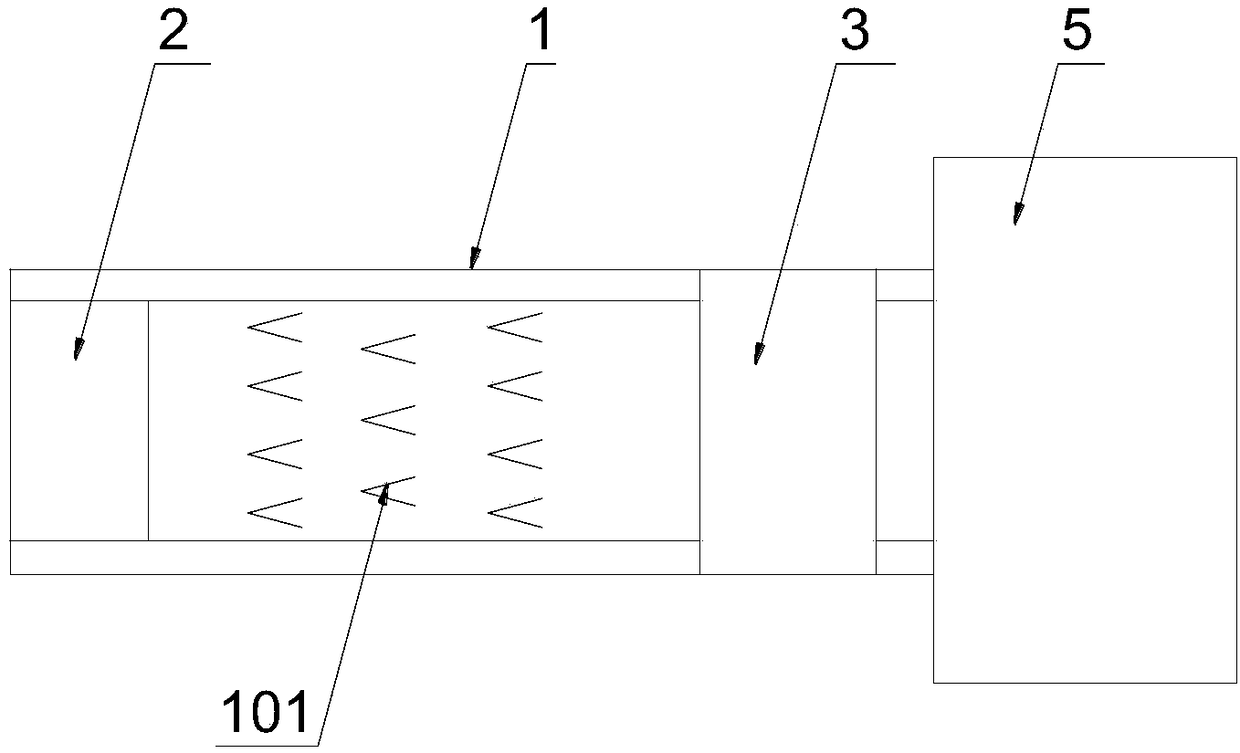

Uniform-feeding rice impurity removing equipment

InactiveCN108339751AGood dust removal effectAvoid reprocessingSievingGas current separationEngineeringWaste management

The invention discloses uniform-feeding rice impurity removing equipment. The uniform-feeding rice impurity removing equipment comprises a feeding plate, a discharging channel, a dust removing assembly, a case, a first vibration screen, a second vibration screen, a recovery box, a rice box and a waste box. The feeding plate is provided with a rotating roller, and pushing plates are uniformly arranged on the periphery of the rotating roller. A motor is installed on the outer side of the top of the discharging channel and drives a scattering disc through a rotating shaft, and the scattering discis located below a feeding inlet of the discharging channel. The dust removing assembly is installed on the lower portion of the discharging channel and comprises a dust removing disc, a filtering net, an air suction pipe and a total air pipe. A discharging outlet of the discharging channel is connected with a feeding inlet of the case, and the discharging channel is arranged close to the case sothat a partition plate can be connected with the first vibration screen. The waste box is placed on the bottom of the case and located below the second vibration screen. According to the uniform-feeding rice impurity removing equipment, rice is fed uniformly, impurities such as sand grains and dust in the rice are removed effectively, and the stone removing effect is good.

Owner:滁州广洋湖米业有限公司

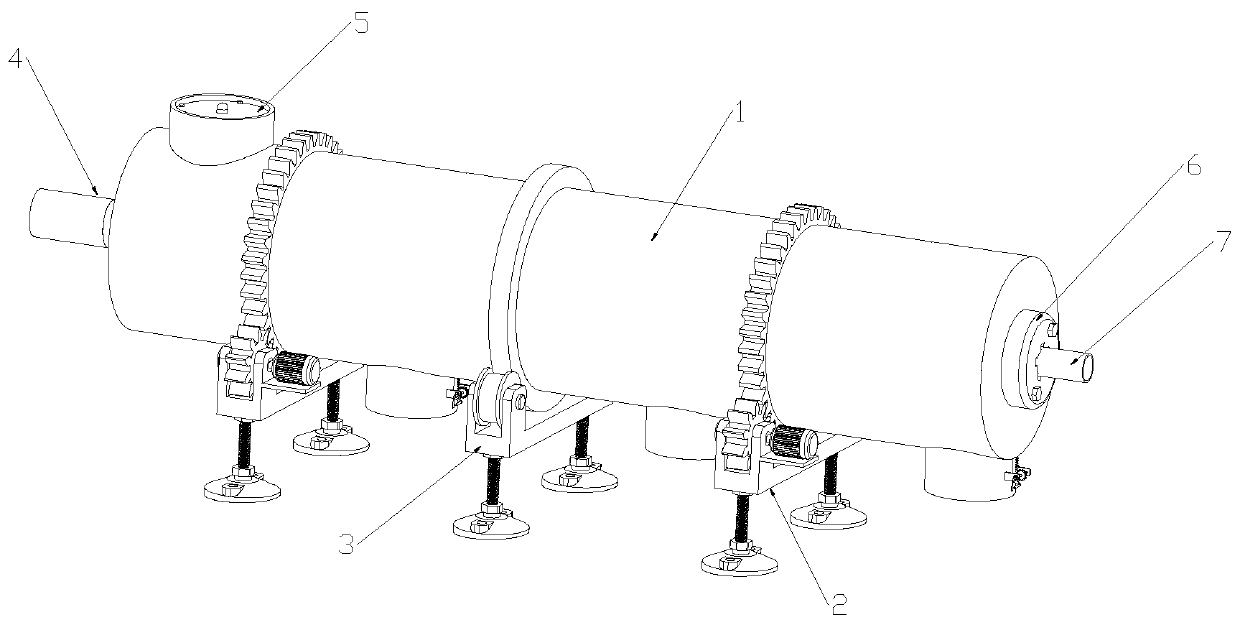

Energy-saving and environment-friendly coal slime drying machine and use method thereof

ActiveCN110030810ASimple structureReduce volumeSievingGas current separationPulp and paper industryCoal

The invention discloses an energy-saving and environment-friendly coal slime drying machine and a use method thereof. The energy-saving and environment-friendly coal slime drying machine comprises a roller arranged obliquely, and driving mechanisms and a limiting mechanism are arranged at the bottom end of the roller; an air inlet mechanism is arranged at a side end of the roller, and a feeding mechanism is fixed to the top of one end of the roller; a fixing disc is welded to one end of the inner wall of the roller, a drainage mechanism is rotatably arranged at the middle position of the fixing disc, the drainage mechanism comprises a drainage rod, a first limiting plate is arranged at one end of the drainage rod, and a second limiting plate is arranged at the other end of the drainage rod; an air outlet pipe connected to tail gas treatment equipment is arranged at the side end of the second limiting plate; and discharging mechanisms distributed parallelly are arranged at the bottom ofthe roller, and the discharging mechanisms are arranged right below drainage paddles. According to the energy-saving and environment-friendly coal slime drying machine and the use method thereof, through the transmission of third gears and racks, and under the action of gravity and spiral material leading paddles, materials with small particle sizes can be obtained, and the purpose of screening in the roller is finally realized; and the structure is simple, the manufacturing cost is reduced, and the energy-saving and environment-friendly coal slime drying machine and the use method thereof are suitable for small-scale production and have good popularization practicability.

Owner:ANHUI UNIV OF SCI & TECH

Safe environmental-protection ore cleaning device

InactiveCN107671061AGuaranteed cleaning effectFalling smoothlyCleaning using toolsCleaning using liquidsWater storageImpeller

The invention discloses a safe environmental-protection ore cleaning device. The safe environmental-protection ore cleaning device comprises a feeding pipe, a box, a water inlet pipe, a pressing device, a water storage tank, a water pumping pipe, an extension rod, a filter plate, an impeller, cleaning shafts, turntables, a discharge pipe, brushes, a timer and a rotating shaft; the feeding pipe isarranged at the top end of the box; the box is provided with a liquid level meter; the water storage box communicates with the box through the water inlet pipe; the pressing device is mounted on the water inlet pipe; the rotating shaft is arranged in the box; the impeller is mounted on the rotating shaft; multiple cleaning shafts are arranged on the inner wall of the box; the turntables are arranged on the cleaning shafts; the brushes are arranged on the surfaces of the turntables; the filter plate is arranged in the box; the bottom surface of the filter plate is connected with the bottom endof the box through the extension rod; one end of the water pumping pipe is connected with the water storage tank, and a water filter screen is arranged at the other end of the water pumping pipe; thedischarge pipe is arranged on the side wall of the box; and a ultraviolet ray lamp is arranged in the box. The safe environmental-protection ore cleaning device accelerates the cleaning speed, improves the working efficiency, saves resources, realizes disinfection and sterilization, prevents wastes, is simple in structure and convenient to use, and facilitates popularization.

Owner:徐继传

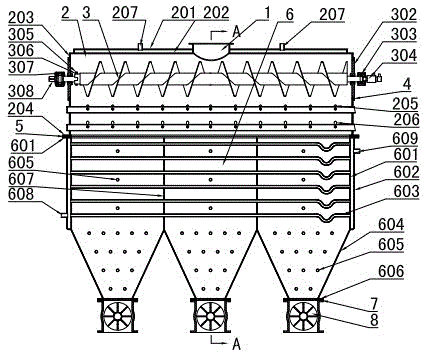

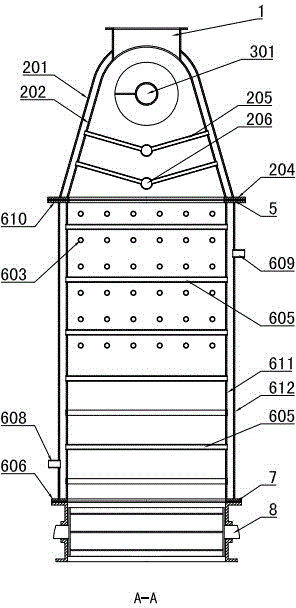

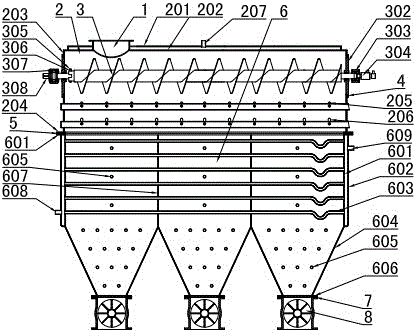

Large box type high-temperature material heat exchanger

ActiveCN104697371ALarge flow cross-sectional areaLarge cooling capacityMoving conduit heat exchangersImpellerEngineering

The invention provides a large box type high-temperature material heat exchanger, and belongs to the field of high-temperature solid material cooling equipment. The large box type high-temperature material heat exchanger is characterized by sequentially comprising a water cooling box cover (2), a heat exchanging box (6) and necking-down type hoppers from top to bottom, wherein a water cooling jacket is arranged on a wall of the water cooling box cover (2); end water cavities and / or side water cavities are formed in the wall of the heat exchanging box (6) and the walls of the necking-down hoppers; a plurality of heat exchanging pipelines are respectively arranged in the water cooling box cover (2), the heat exchanging box (6) and cavities of the necking-down type hoppers; a feeding opening (1) is formed in the upper portion of the water cooling box cover (2); a water cooling spiral distributor (3) which can convey and cool down materials is arranged in the water cooling box cover (2); the necking-down type hoppers are arranged side by side; and an impeller discharging valve (8) is arranged at an outlet of the bottom of each necking-down type hopper. The large box type high-temperature material heat exchanger is large in material cooling amount, low in energy consumption and long in service life; and abrasion of heat exchanging components is small.

Owner:SHANDONG UNIV OF TECH

Volleyball sports trainer with angle capable of being conveniently adjusted

The invention discloses a volleyball sports trainer with an angle capable of being conveniently adjusted. The volleyball sports trainer comprises a rack, a supporting base, a trigger sleeve, a ball hopper and a storage battery; rolling wheels are installed on the lower side of the rack, a supporting mechanism comprises a hinge, a supporting arm, a hydraulic mechanism and a ground foot, a horizontal rotating shaft is installed at the left end of the top of the supporting base, and an adjusting bolt is located under the trigger sleeve; a rotating wheel is installed in a sealing cavity, and ball grooves which are concaved towards the center axis are formed in the rotating wheel; and a buffering device comprises an installation ring, a buffering net and a guide ring, and a ball blocking device is fixed to the upper end of a lifting rod and comprises an installation frame and a ball blocking net. According to the volleyball sports trainer with the angle capable of being conveniently adjusted, volleyballs are sequentially sent into the trigger sleeve through the ball grooves formed in the rotating wheel, the volleyballs cannot interact with one another and fall smoothly, blocking is not prone to occur, no other person is needed for throwing the balls, the flying speed and direction of the volleyballs are kept constant, and the accuracy of training is guaranteed.

Owner:SHANDONG JIAOTONG UNIV

Sleeve type continuous calcining vertical kiln

ActiveCN102230726APrevent burning phenomenonReduce consumptionVertical furnacesEngineeringCalcination

The invention discloses a sleeve type continuous calcining vertical kiln. An annular kiln cavity is formed by the encircling of an inner barrel and an outer barrel which are sleeved together in a kiln body; the annular kiln cavity is provided with a preheating area, a calcining area and a cooling area in sequence from top to bottom; the barrel wall of the inner barrel is provided with a pluralityof ventilation holes for communicating the annular kiln cavity with the inner cavity of the inner barrel; the periphery of the outer barrel is covered with a barrel-shaped kiln shell; a peripheral air channel is arranged between the inner wall face of the barrel-shaped kiln shell and the outer wall face of the outer barrel in an encircling manner; ventilation holes for communicating the annular kiln cavity with the peripheral air channel are distributed on the barrel wall of the outer barrel; radial isolation structures are distributed at intervals in the inner cavity of the inner barrel and the periphery air channel in a staggered way along the axial direction of the kiln body; and a fuel feeding device communicated with the calcining area in the annular kiln cavity is arranged on the upper part of the kiln shell. The vertical kiln has a simple structure and a good energy-saving effect; and calcination of powdery or particulate small-diameter stone raw materials is realized, waste ofraw materials is avoided, meanwhile, the operation of the kiln is simplified, and the fuel consumption is lowered.

Owner:ZHEJIANG DEYAO ENERGY SAVING TECH CO LTD

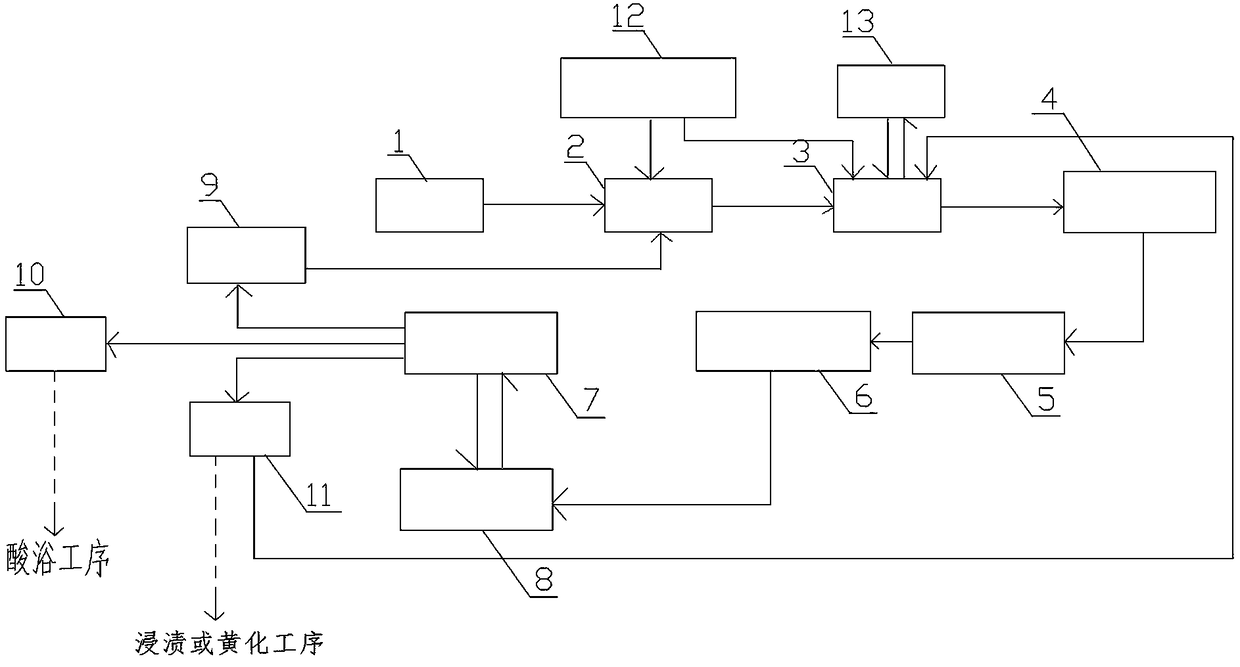

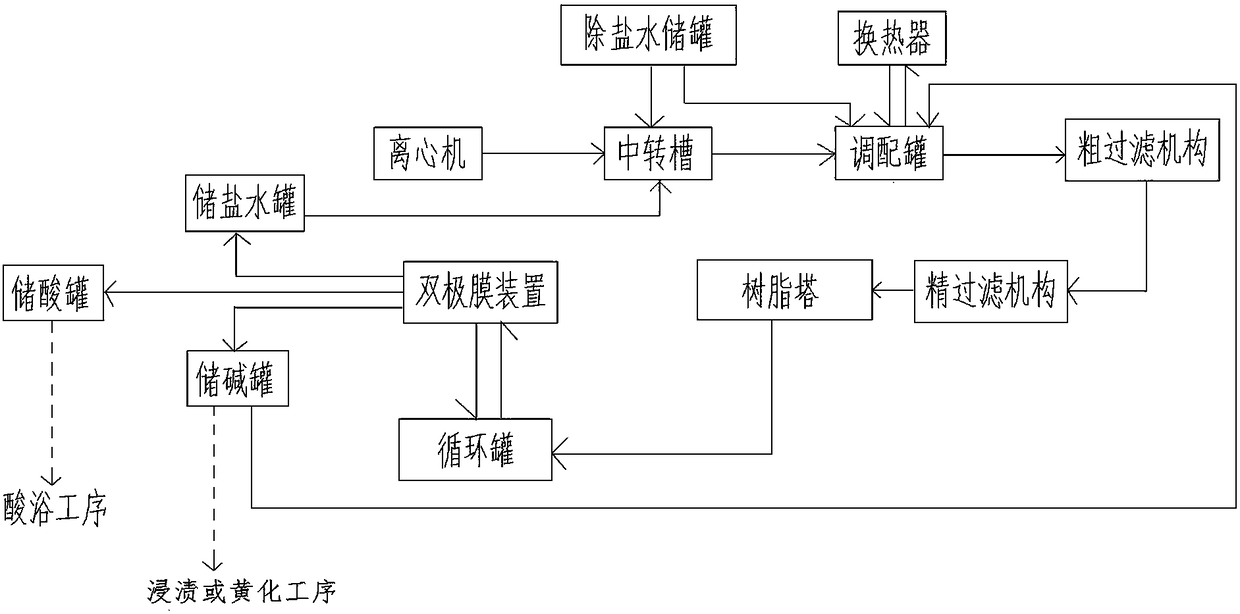

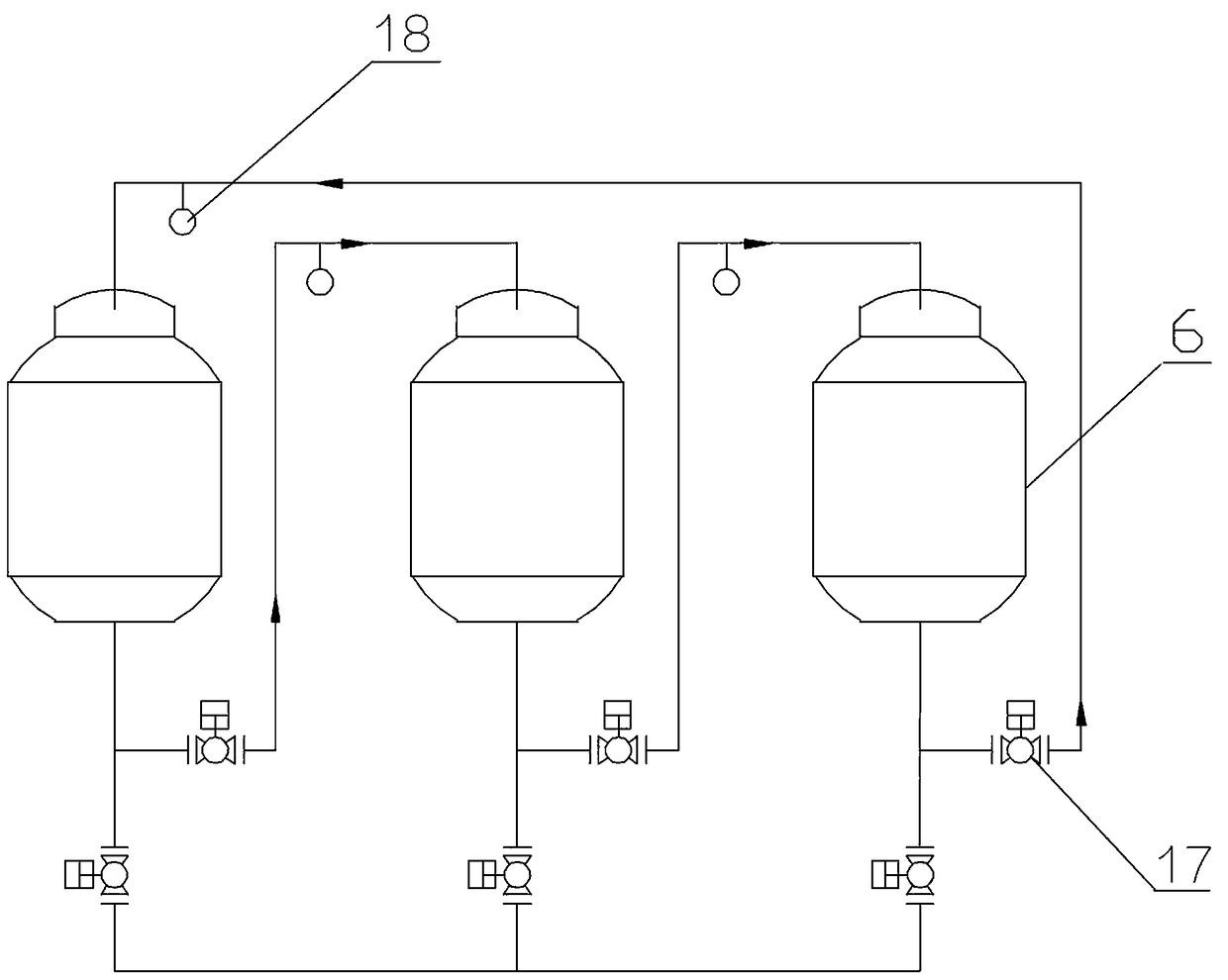

Circulating environment-friendly treatment process and circulating environment-friendly treatment system for waste viscose liquid

PendingCN109133448AGuaranteed purityGuaranteed concentrationWater/sewage treatment by centrifugal separationGeneral water supply conservationLiquid wasteFiltration

Owner:YIBIN HIEST FIBER +2

Mixing equipment for circulating feed processing

InactiveCN107694405AWell mixedGuarantee product qualityFlow mixersFeeding-stuffDrive shaftEngineering

The invention discloses mixing equipment for circulating feed processing. The mixing equipment comprises a shell, a motor, a feed hopper, a base and a bottom plate, wherein the lower end of an outputshaft of the motor is fixedly connected with a vertical transmission shaft; a first cylinder and a second cylinder which are vertical are coaxially fixed in the shell; a screw auger is fixedly arranged on the transmission shaft; an extrusion section is embedded into a side wall at the upper end of the first cylinder; the middle of a blanking cavity is communicated with an outward expansion cavity;a plurality of screen boards are uniformly fixed on the outer side wall of a fixing plate; a horizontal collecting tray is arranged below a feed opening; and a vertical rotating shaft is fixed on a central shaft of the horizontal collecting tray. According to the mixing equipment disclosed by the invention, the interior of the shell is partitioned into two parts by the cylinders, and the feed inthe two parts have opposite moving directions, so that the feed circulates in the shell and is moved to be mixed. The feed dropping from the blanking cavity is in contact with the rotary screen boards, and due to the lateral force effect, the feed is outwards scattered.

Owner:伍超群

Automatic discharging device of cold-punching mold

InactiveCN102133606ASmooth and simple outputFalling smoothlyEjection devicesPunchingAgricultural engineering

Owner:无锡晶心精密机械有限公司

Feeding device

ActiveCN105620952AGood arch breaking strengthImprove arch breaking effectLarge containersNatural stateEngineering

The invention provides a feeding device. The feeding device comprises a feeding inlet, a stirring cavity and a feeding cavity, wherein the stirring cavity is arranged between the feeding inlet and the feeding cavity; a feeding threaded rod penetrates through the feeding cavity; an arc breaking elastic piece is arranged in the stirring cavity, one end of the arc breaking elastic piece is fixedly installed in the combination position of the stirring cavity and the feeding inlet, and the other end of the arc breaking elastic piece is suspended; a stirring mechanism matched with the arc breaking elastic piece is further arranged in the stirring cavity and comprises a rotary shaft and a stirring paddle; in the rotation process of the stirring mechanism, the stirring paddle periodically makes contact with the arc breaking elastic piece, and the contact position of the arc breaking elastic piece deforms elastically, so that the suspended end of the arc breaking elastic piece is driven to swing, and arc breaking is carried out on materials; when the stirring paddle and the arc breaking elastic piece are separated, the arc breaking elastic piece recovers the natural state. According to the feeding device, the arc breaking elastic piece is triggered by the stirring mechanism to swing vertically, arc breaking is carried out on the materials within a large range, the effect that the feeding threaded rod receives materials uniformly is guaranteed, and the discharging precision is effectively improved.

Owner:ZHUHAI YOUTE SMART KITCHEN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com