Boron particle laser ignition burning experiment device and experiment method

A technology of laser ignition and experimental equipment, which is applied in measuring equipment, chemical analysis by means of combustion, material analysis by optical means, etc. It can solve problems such as weak flame brightness, large particle size, and unreliable observation of the ignition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

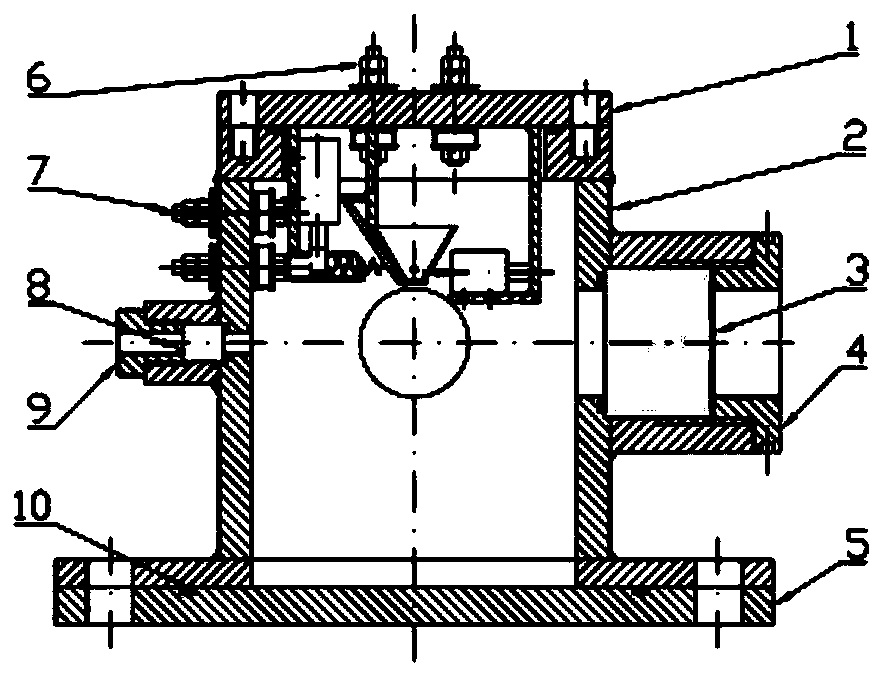

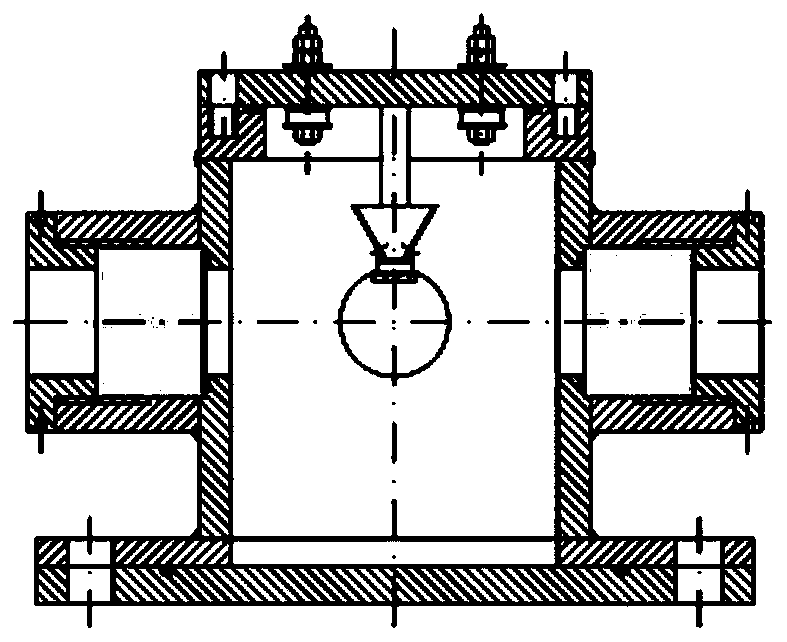

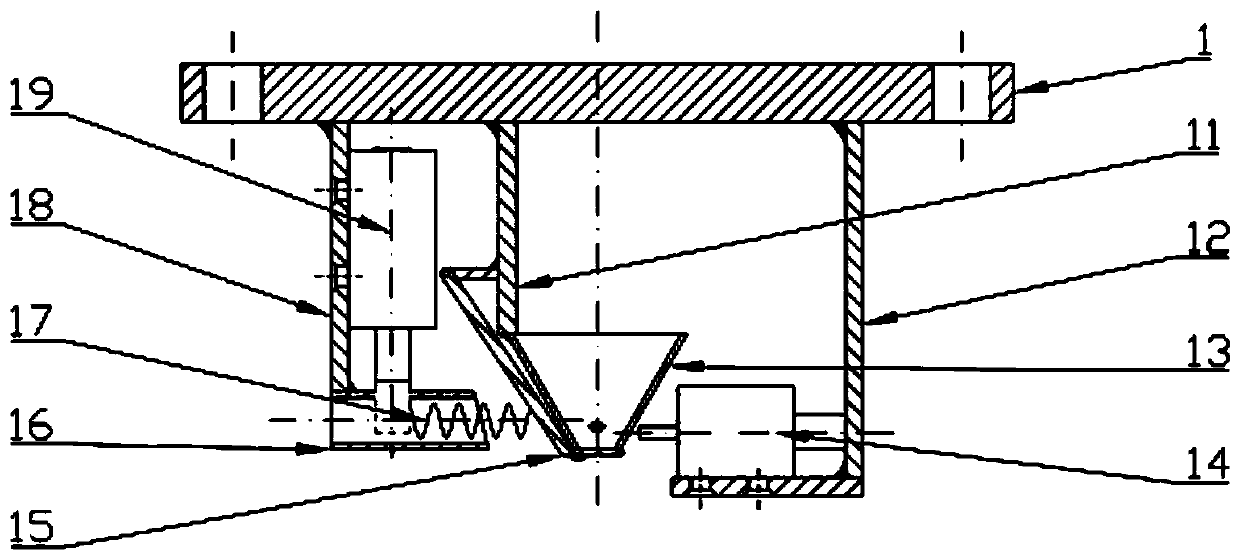

[0026] This embodiment is a boron particle laser ignition combustion experimental device and experimental method.

[0027] See Figure 1(a) Figure 1(b) ~ Figure 3 , In this embodiment, a boron particle laser ignition combustion experiment device includes a burner top plate 1, plexiglass 3, a window pressure screw 4, a burner bottom plate 5, a sealing electrode 6, a spare electrode 7, germanium glass 8, germanium glass window pressure Screw 9, sealing ring 10, burner 2 and burner feeding mechanism; wherein, burner 2 and burner top plate 1, burner bottom plate 5 are fastened by bolts, burner 2 and burner top plate 1, burner bottom plate 5 A sealing ring 10 is embedded between them, and the opposite parts of the side wall of the burner 2 are provided with a germanium glass laser incident window and a plexiglass observation window, which are respectively embedded in the germanium glass 8 and plexiglass 3, and screwed into the corresponding germanium glass window pressing screw 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com