Patents

Literature

222 results about "Laser ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser ignition is an alternative method for igniting mixtures of fuel and oxidiser. The phase of the mixture can be gaseous or liquid. The method is based on laser ignition devices that produce short but powerful flashes regardless of the pressure in the combustion chamber. Usually, high voltage spark plugs are good enough for automotive use, as the typical compression ratio of an otto cycle internal combustion engine is around 10:1 and in some rare cases reach 14:1. However, fuels such as natural gas or methanol can withstand high compression without self ignition. This allows higher compression ratios, because it is economically reasonable, as the fuel efficiency of such engines is high. Using high compression ratio and high pressure requires special spark plugs that are expensive and their electrodes still wear out. Thus, even expensive laser ignition systems could be economical, because they would last longer.

Laser ignition

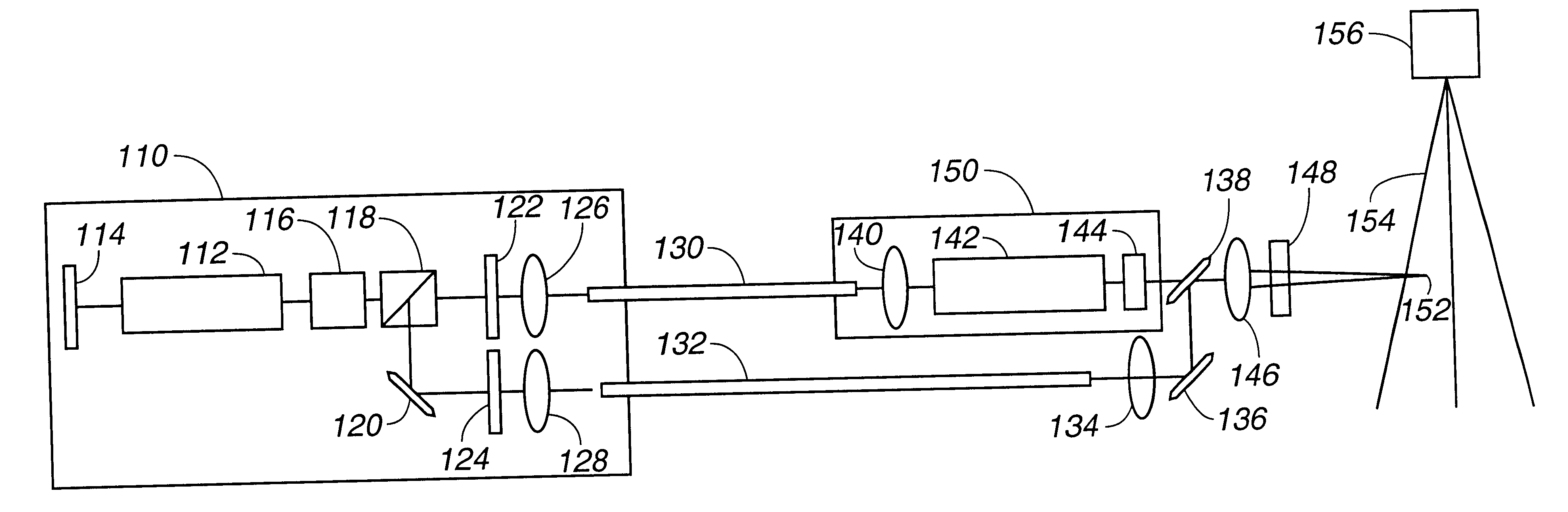

InactiveUS6676402B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionResonant cavityLight beam

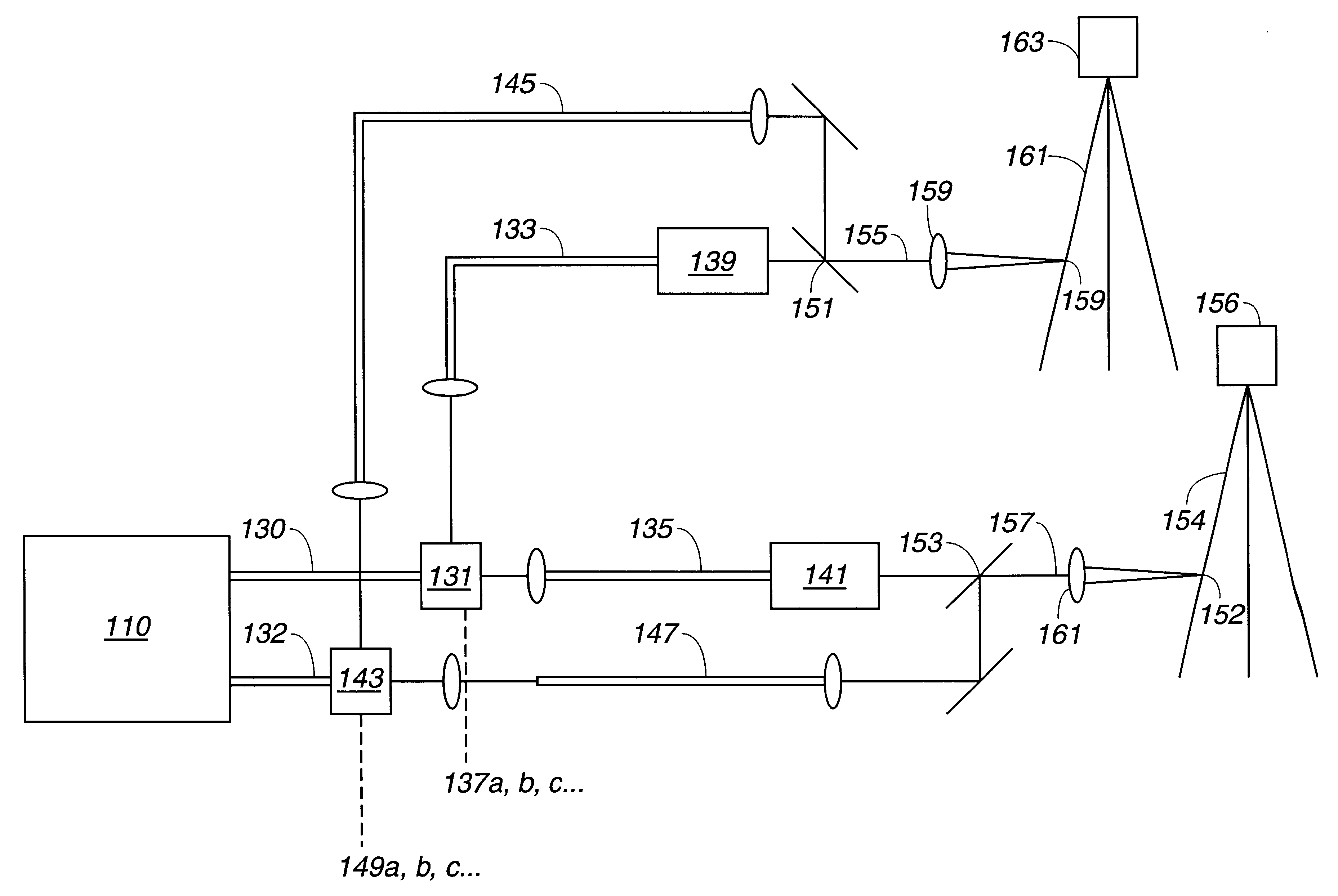

Sequenced pulses of light from an excitation laser with at least two resonator cavities with separate output couplers are directed through a light modulator and a first polarzing analyzer. A portion of the light not rejected by the first polarizing analyzer is transported through a first optical fiber into a first ignitor laser rod in an ignitor laser. Another portion of the light is rejected by the first polarizing analyzer and directed through a halfwave plate into a second polarization analyzer. A first portion of the output of the second polarization analyzer passes through the second polarization analyzer to a second, oscillator, laser rod in the ignitor laser. A second portion of the output of the second polarization analyzer is redirected by the second polarization analyzer to a second optical fiber which delays the beam before the beam is combined with output of the first ignitor laser rod. Output of the second laser rod in the ignitor laser is directed into the first ignitor laser rod which was energized by light passing through the first polarizing analyzer. Combined output of the first ignitor laser rod and output of the second optical fiber is focused into a combustible fuel where the first short duration, high peak power pulse from the ignitor laser ignites the fuel and the second long duration, low peak power pulse directly from the excitation laser sustains the combustion.

Owner:LOS ALAMOS NATIONAL SECURITY

Laser ignition for gas mixtures

ActiveUS20100147259A1Reduce riskReliable ignitionCombustion enginesIgnition sparking plugsCombustion chamberInternal combustion engine

Owner:MULTIFLASHLIGHT

Laser ignition

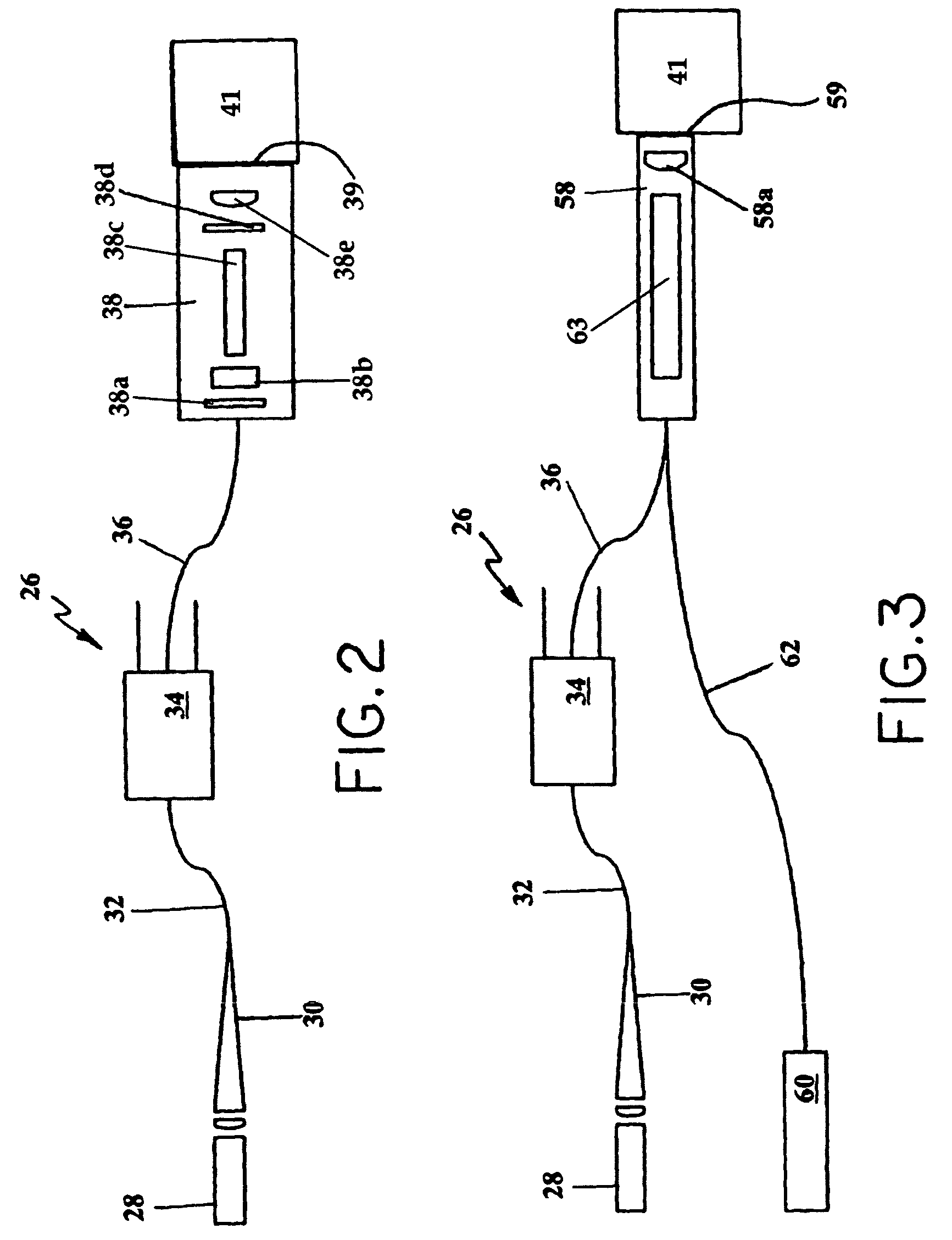

InactiveUS6382957B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionLight beamEngineering

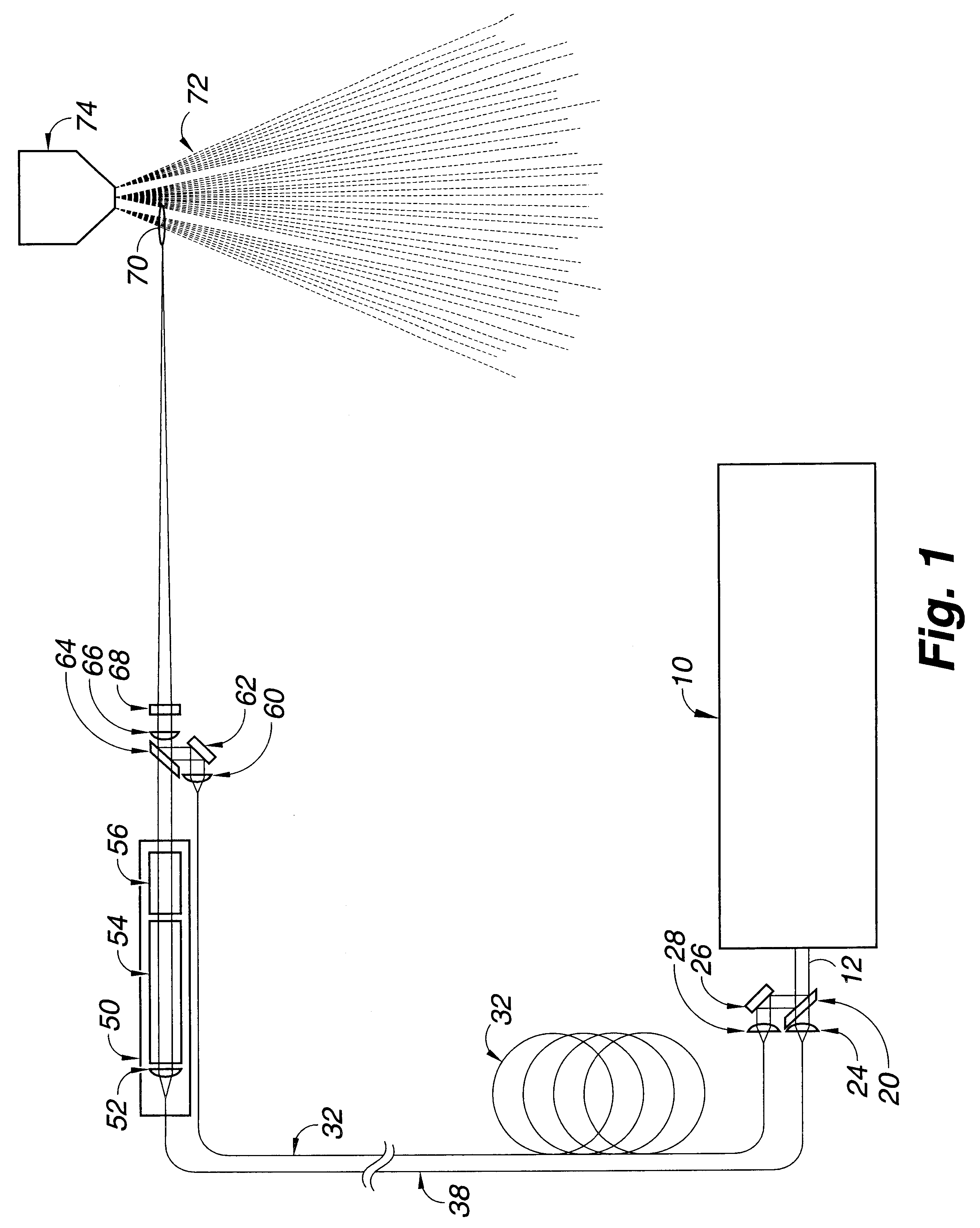

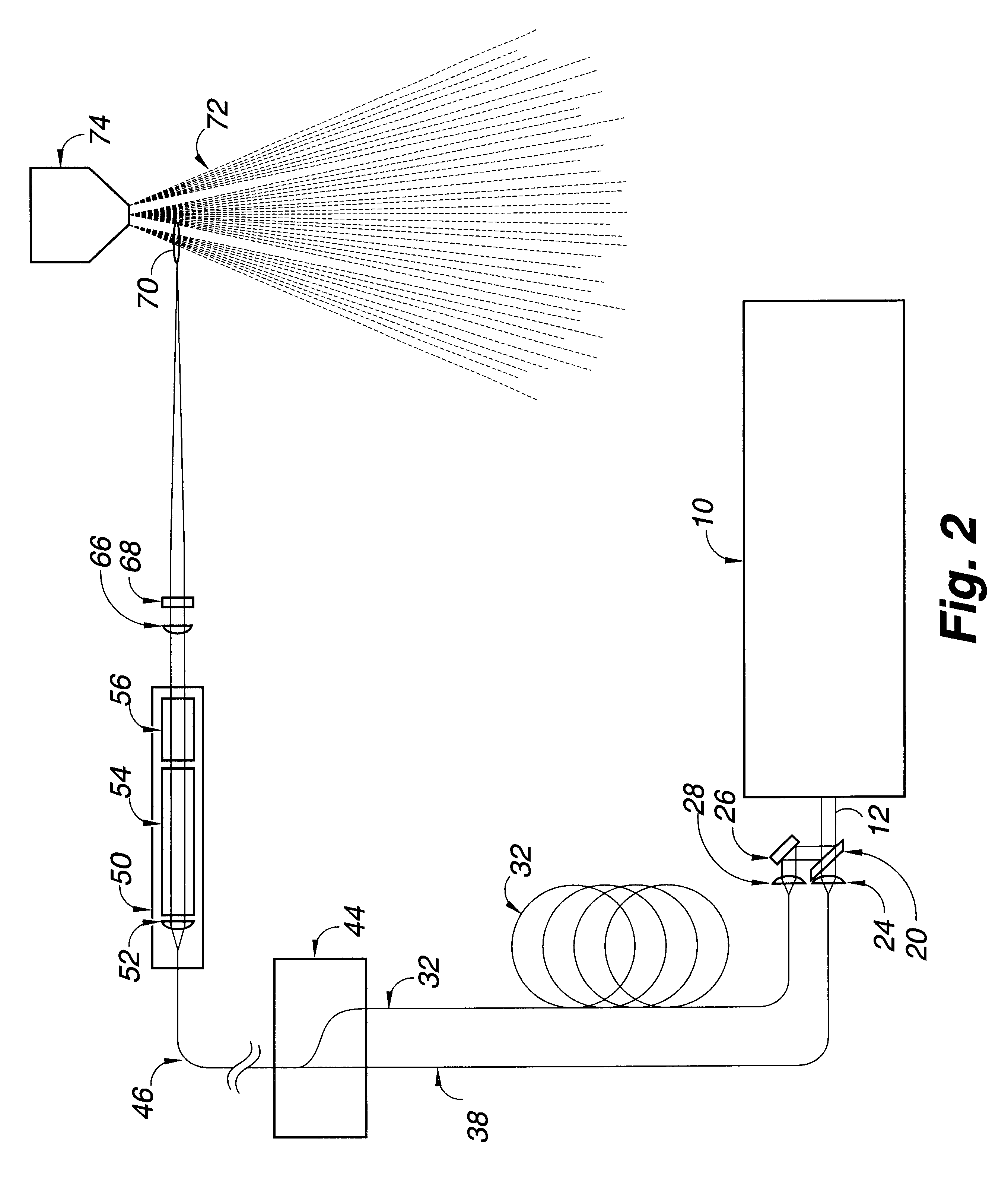

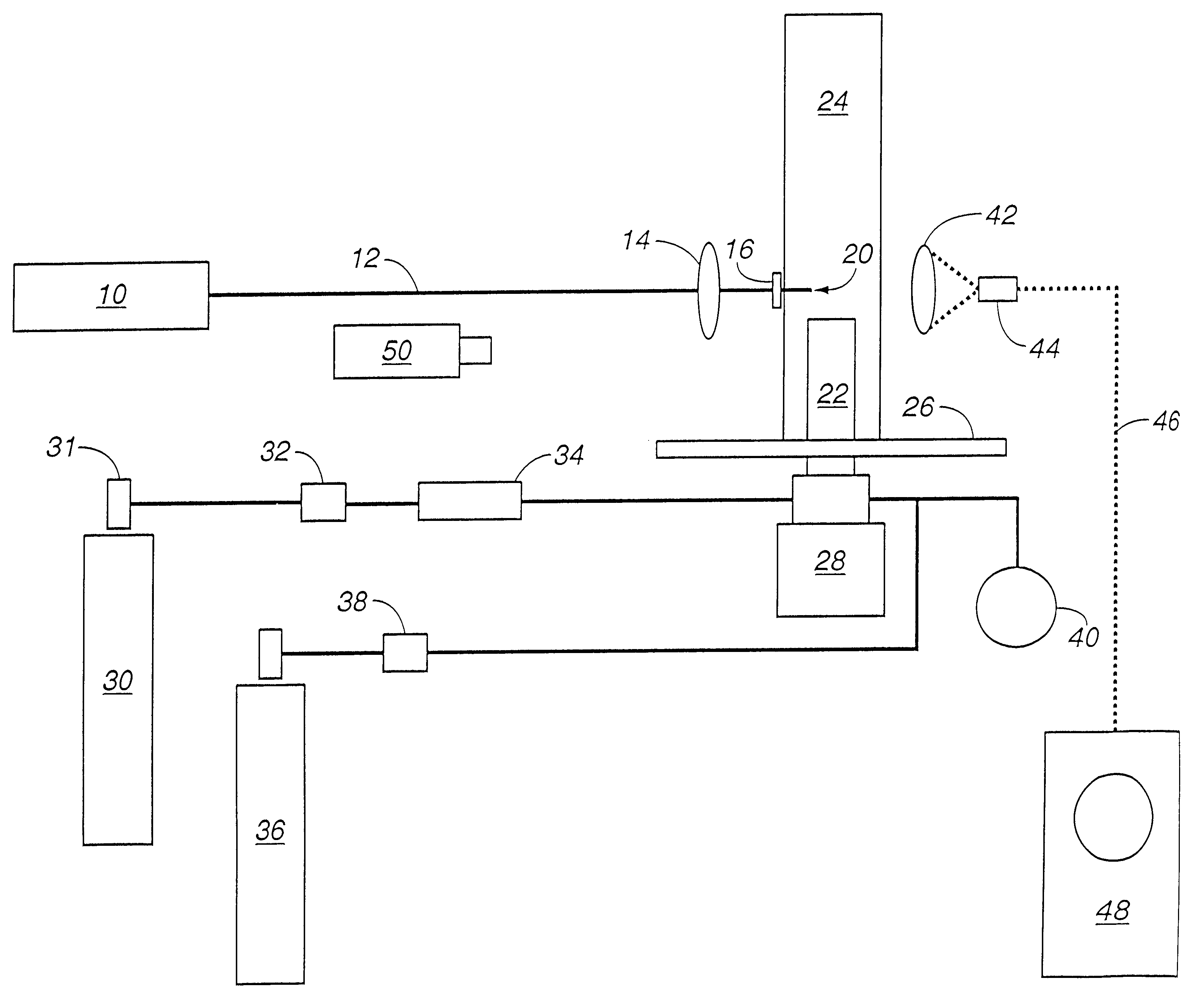

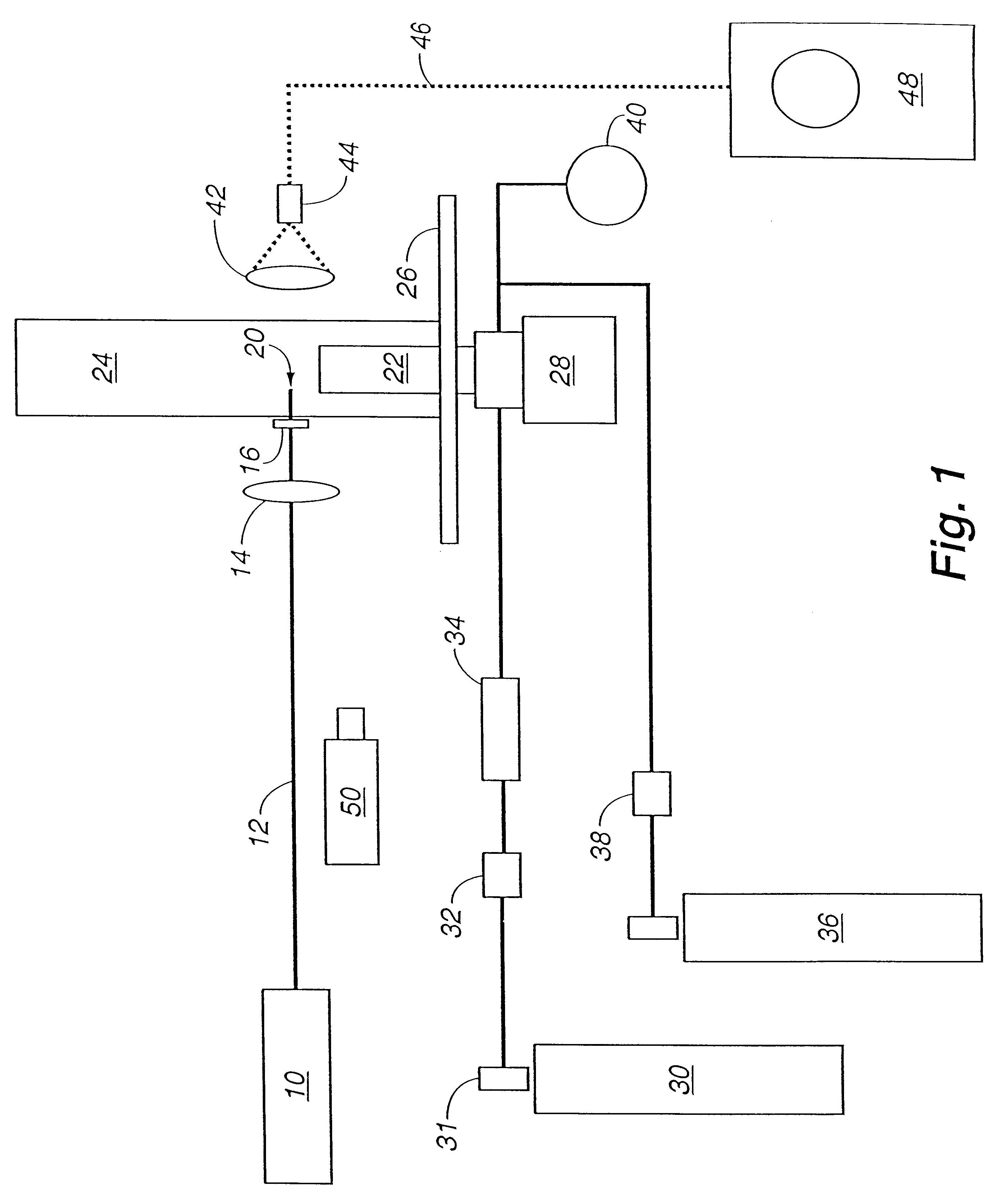

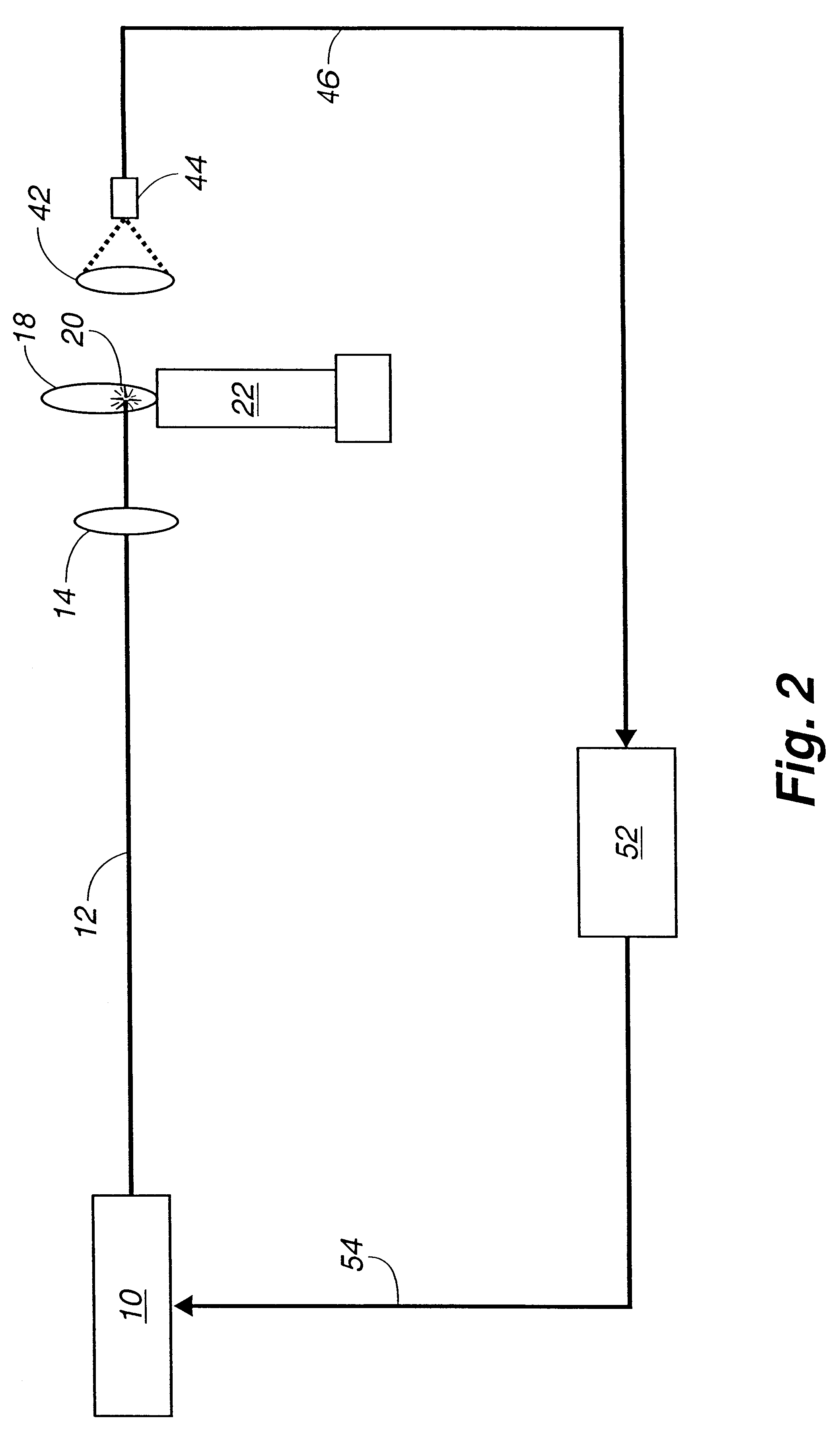

In the apparatus of the invention, a first excitation laser or other excitation light source is used in tandem with an ignitor laser to provide a compact, durable, engine deployable fuel ignition laser system. Reliable fuel ignition is provided over a wide range of fuel conditions by using a single remote excitation light source for one or more small lasers located proximate to one or more fuel combustion zones.In the embodiment of the invention claimed herein, the beam from the excitation light source is split with a portion of it going to the ignitor laser and a second portion of it being combined with either the first portion after a delay before injection into the ignitor laser.

Owner:LOS ALAMOS NATIONAL SECURITY

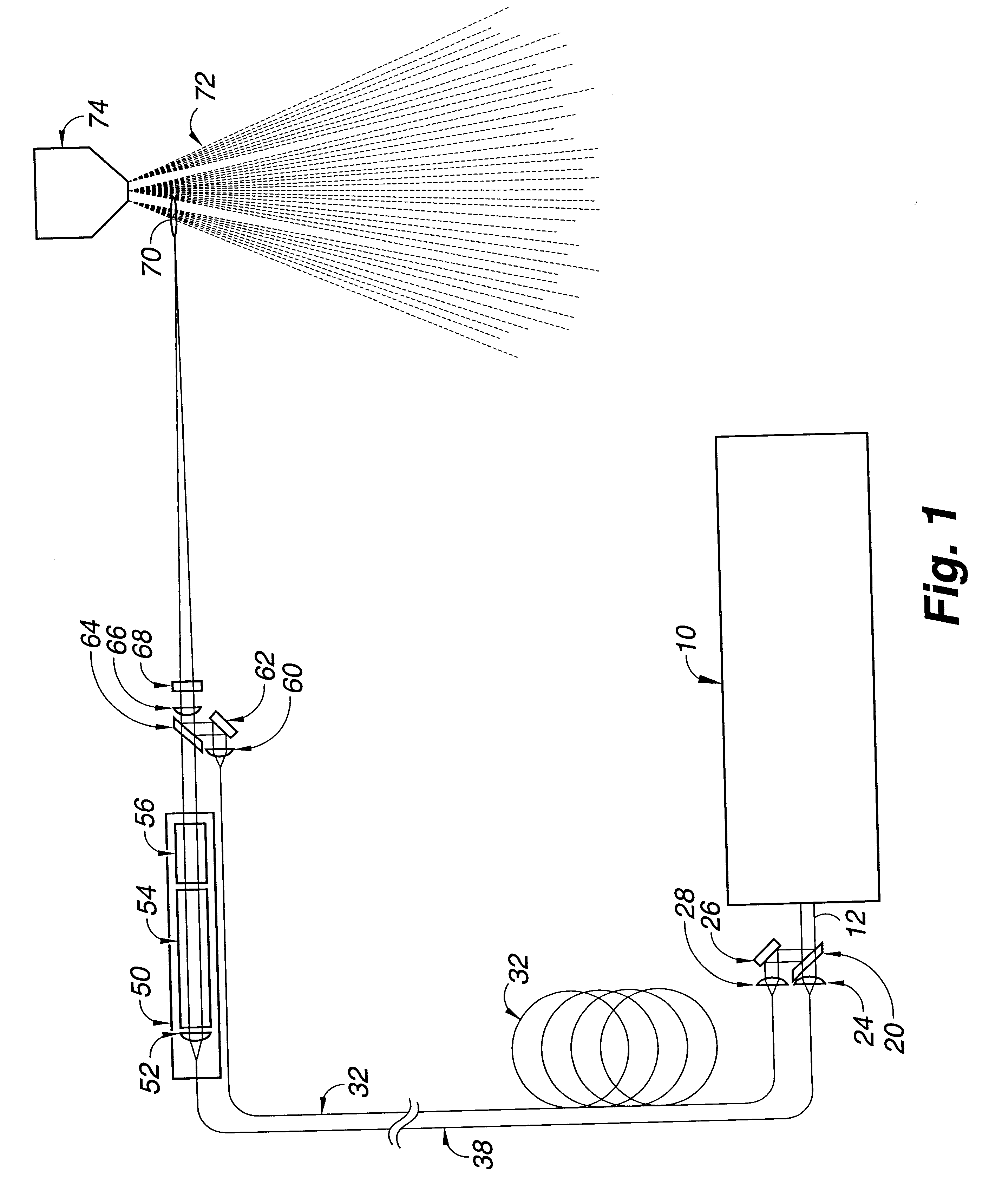

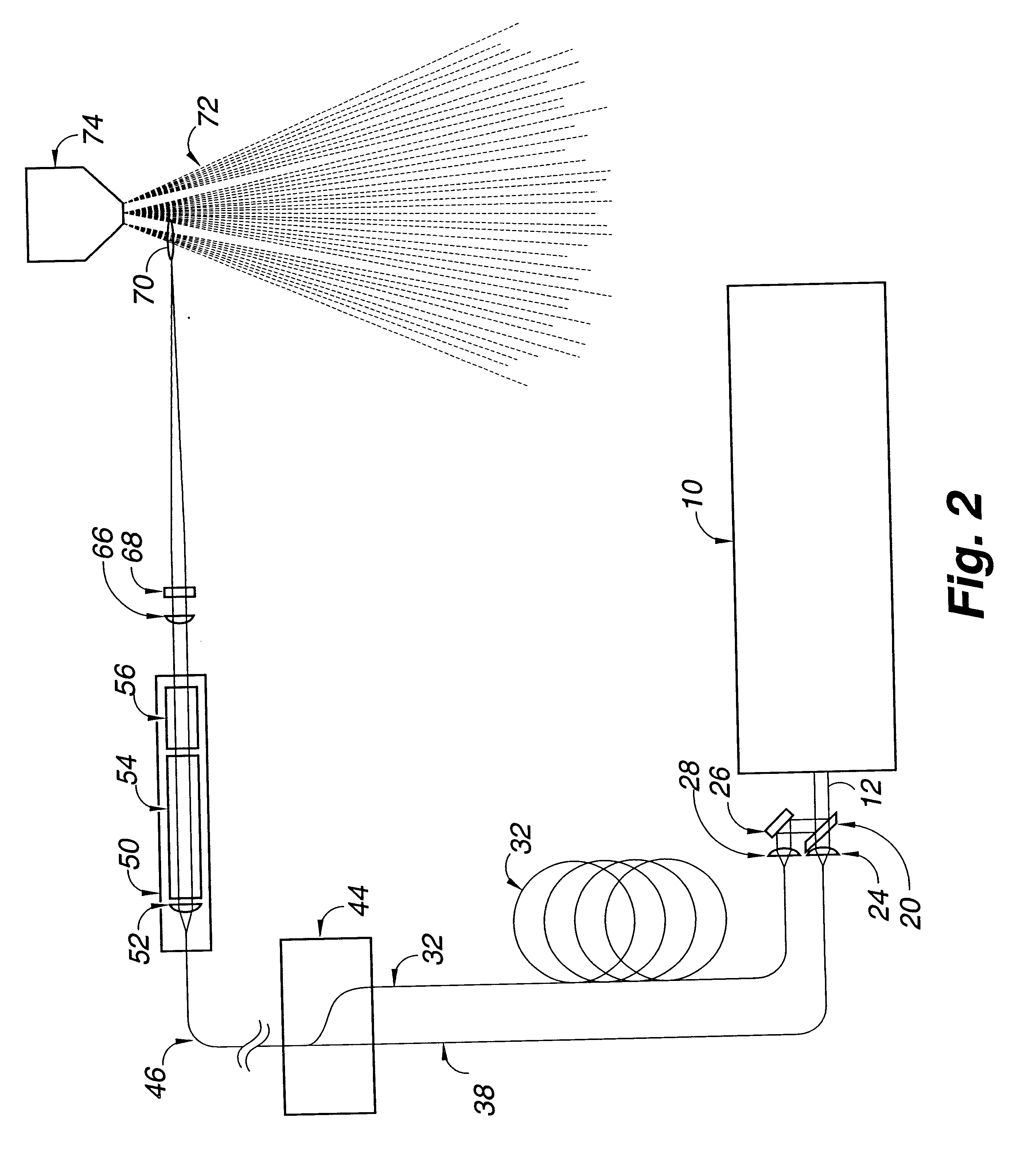

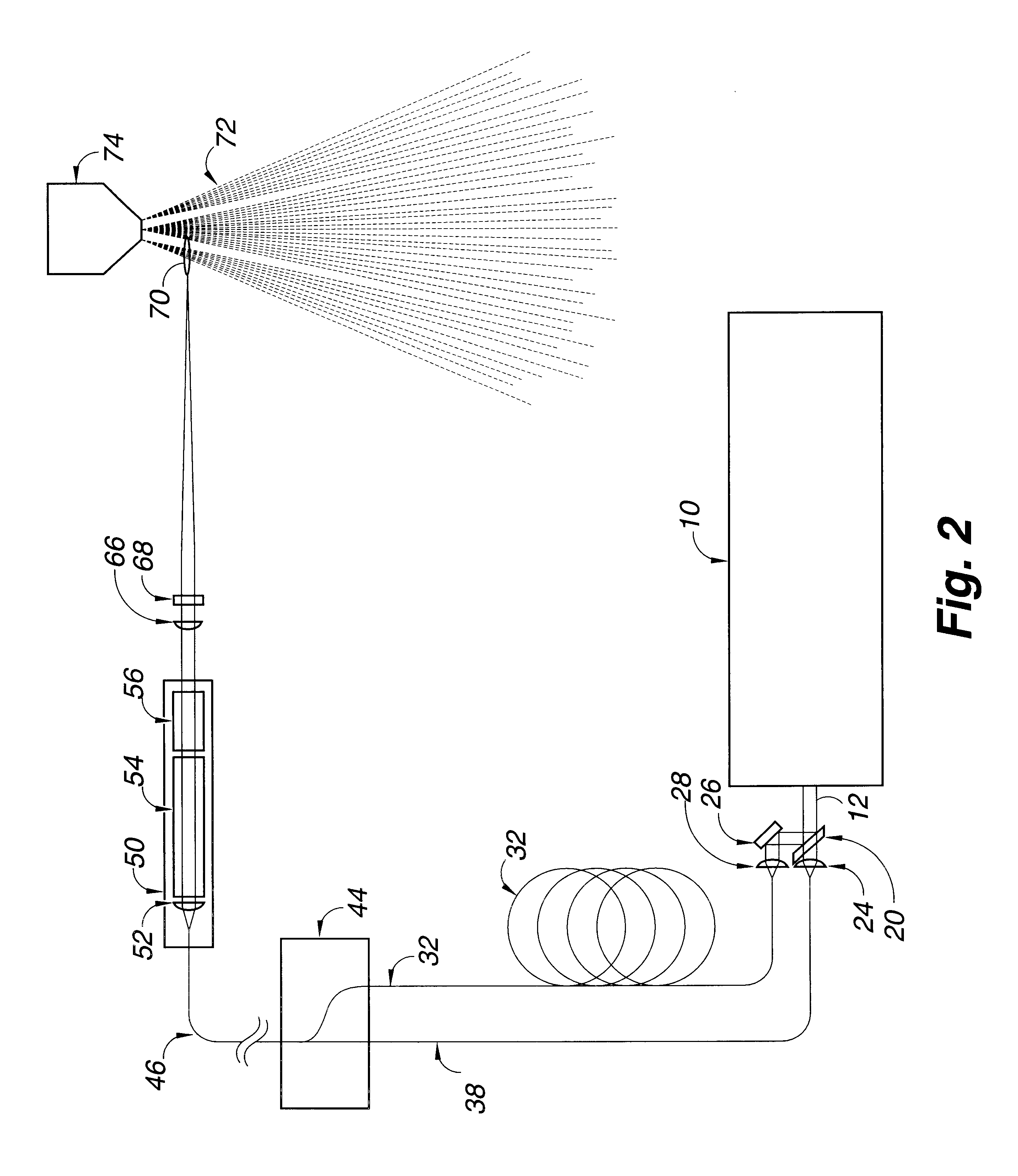

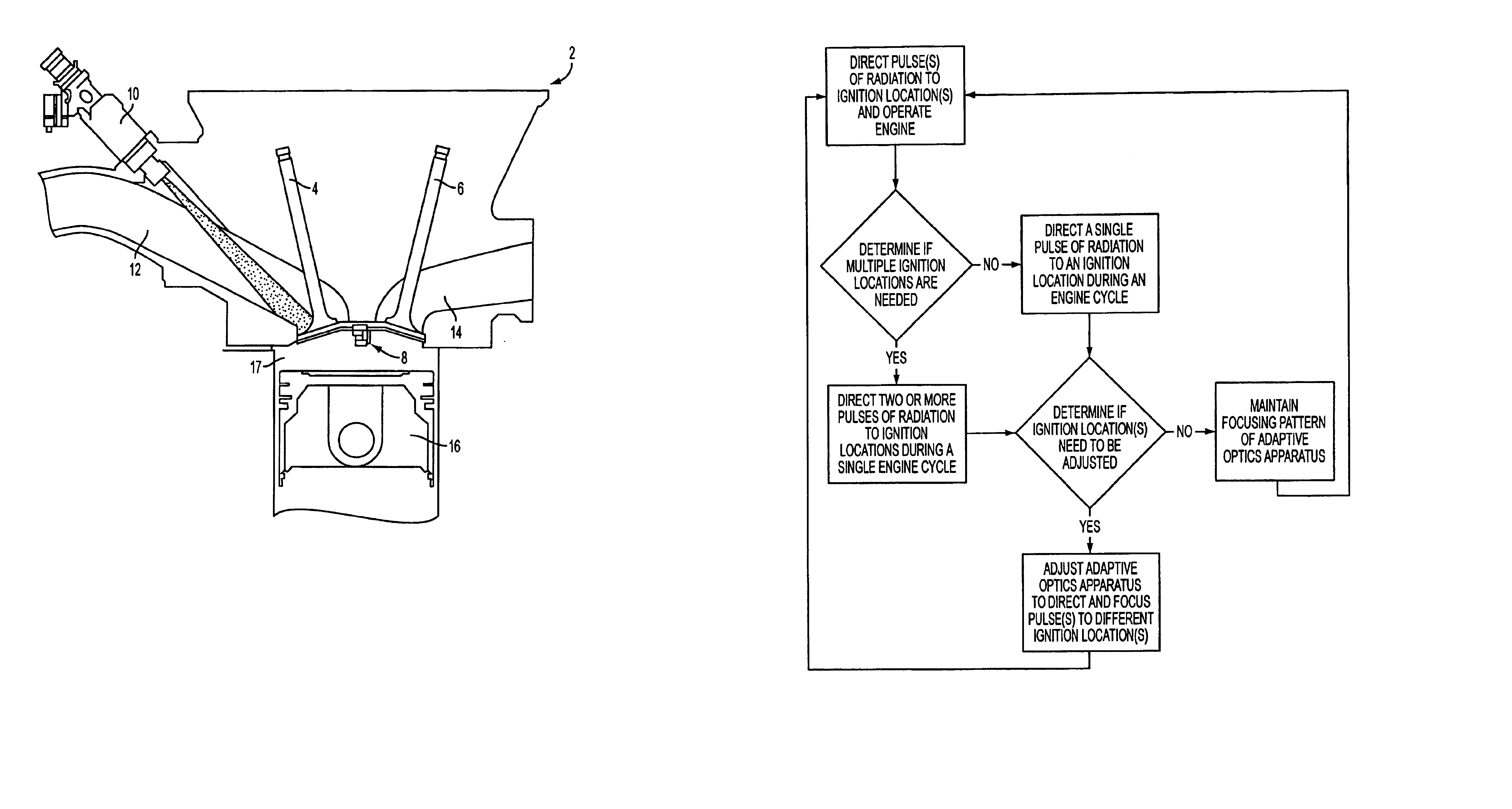

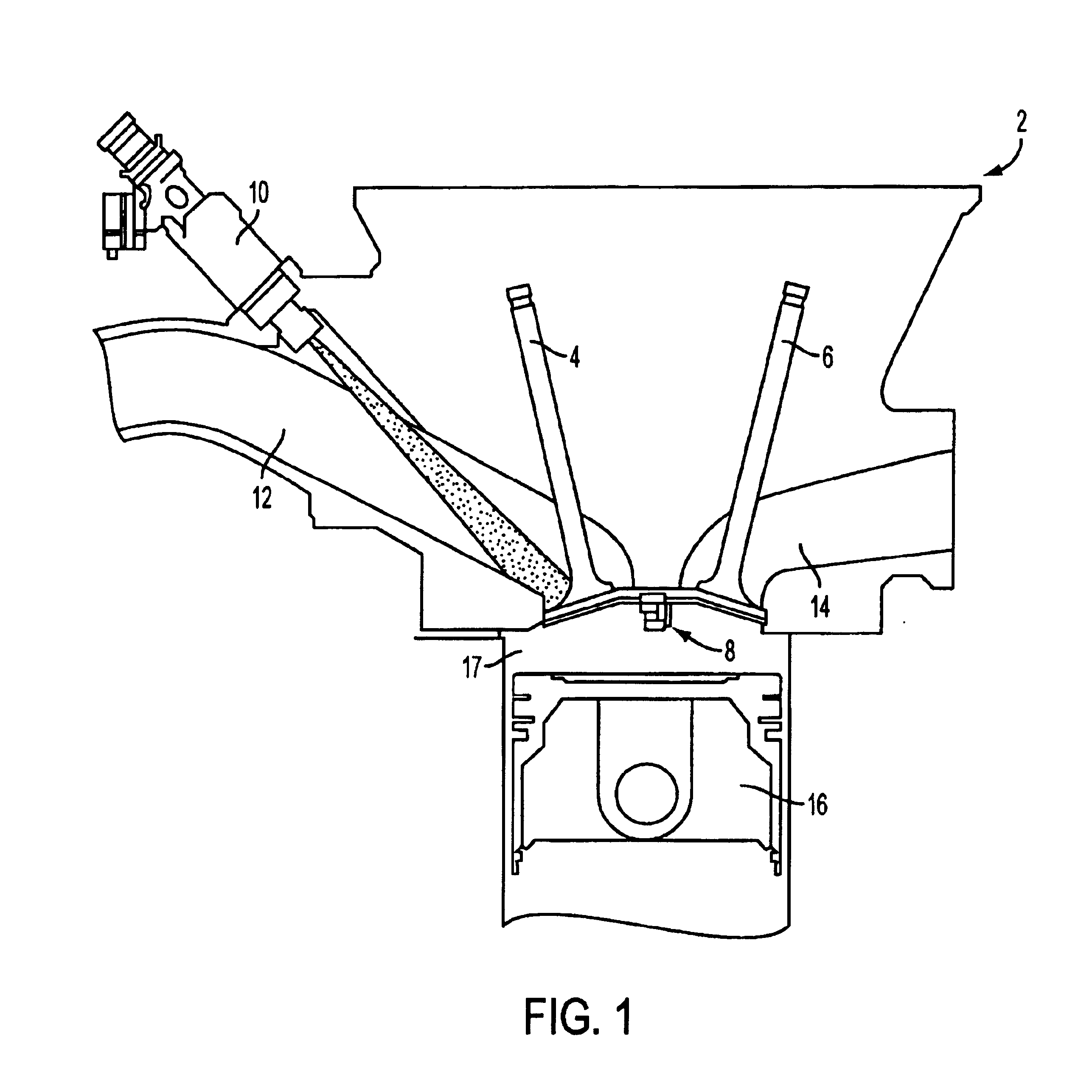

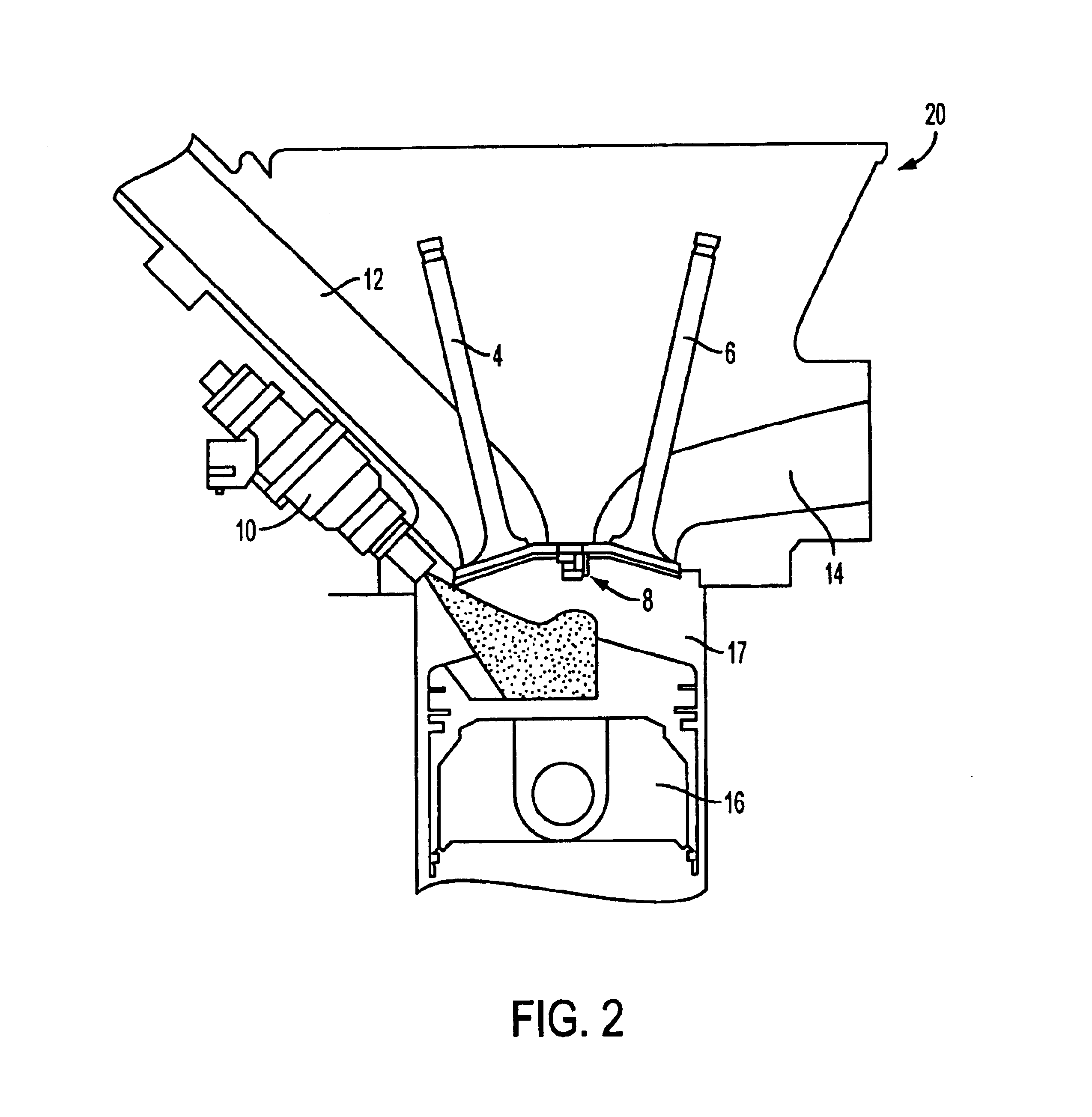

Methods and apparatuses for laser ignited engines

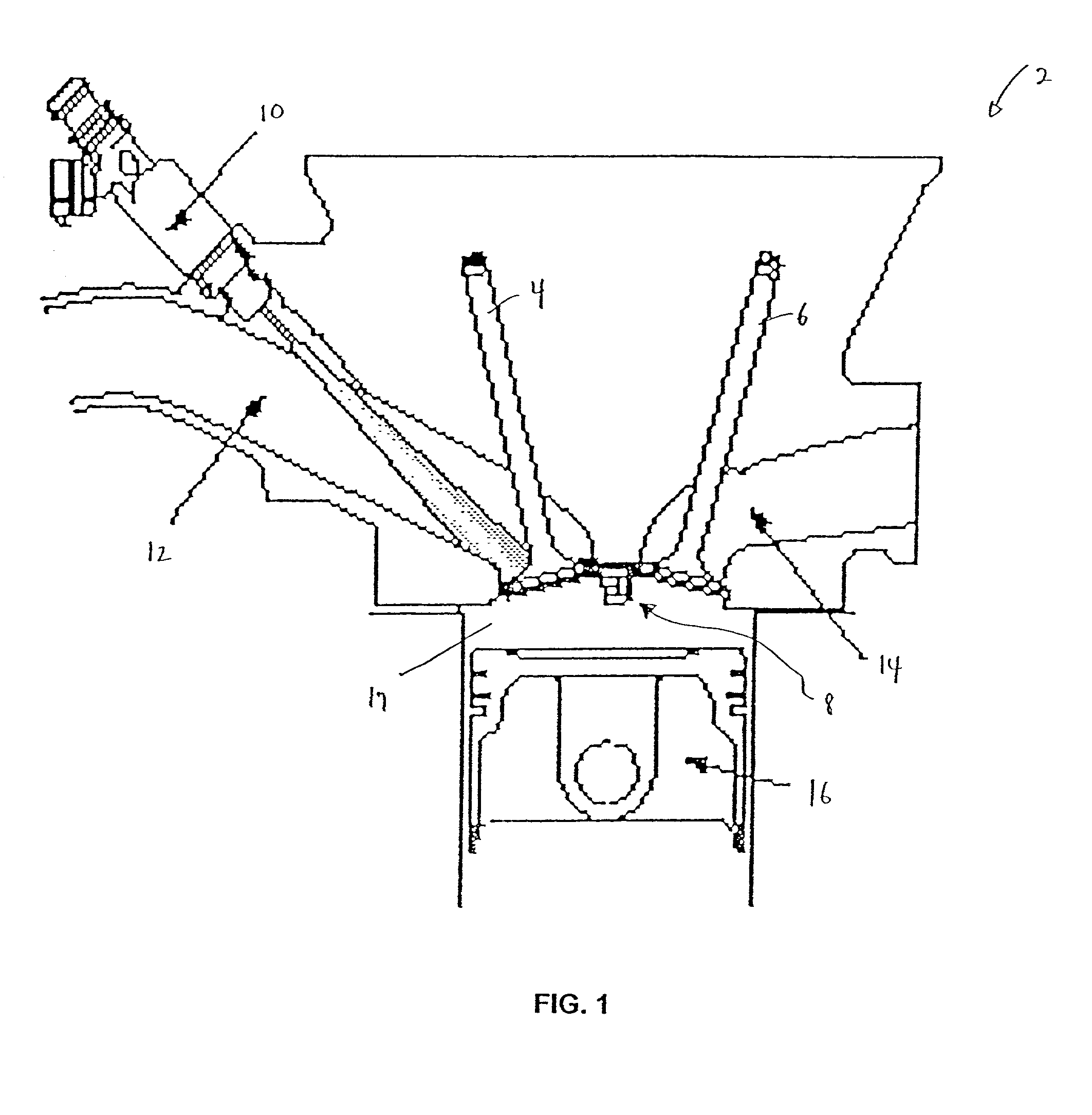

InactiveUS6796278B2Electrical controlInternal combustion piston enginesCombustion chamberEngineering

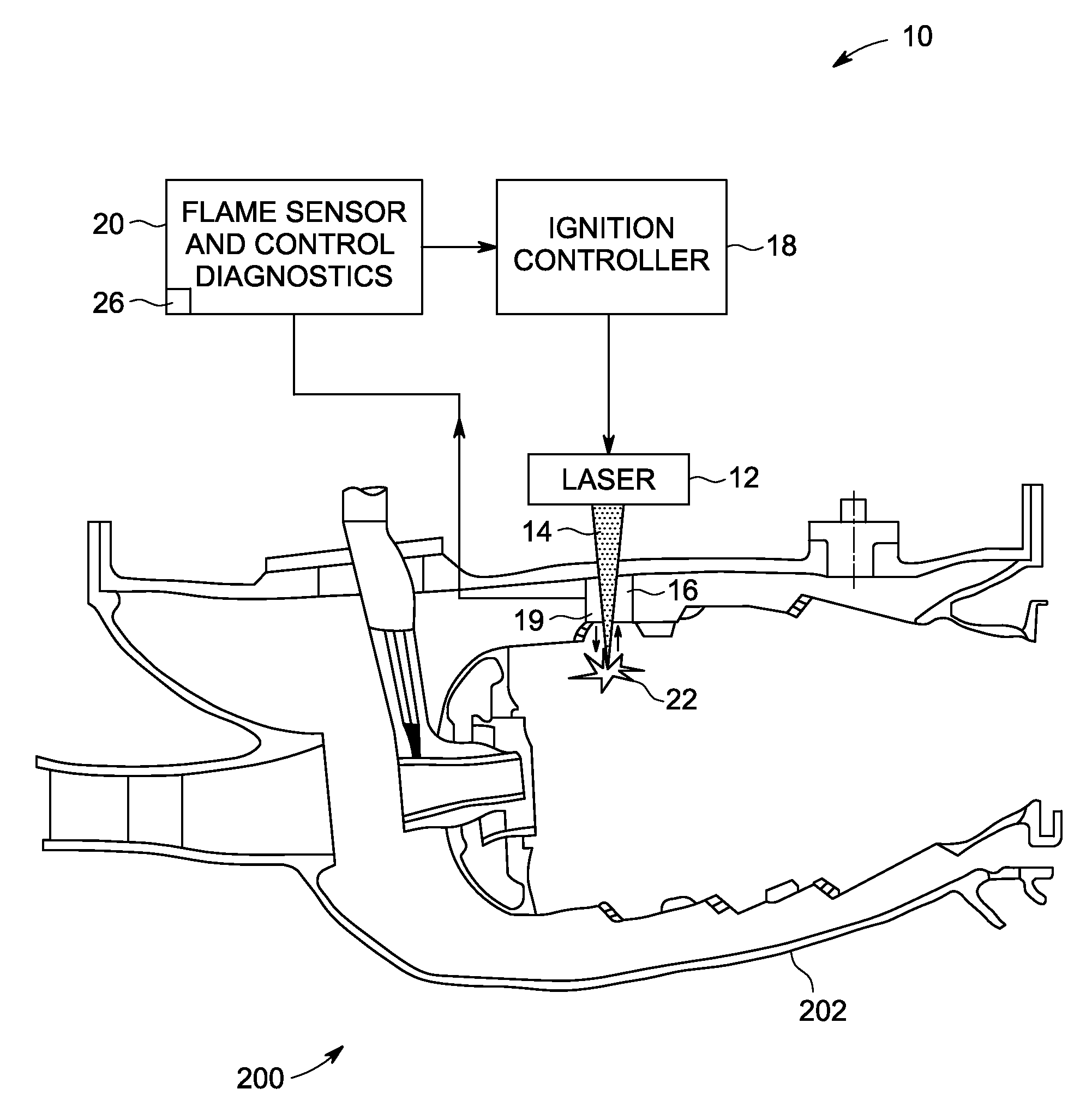

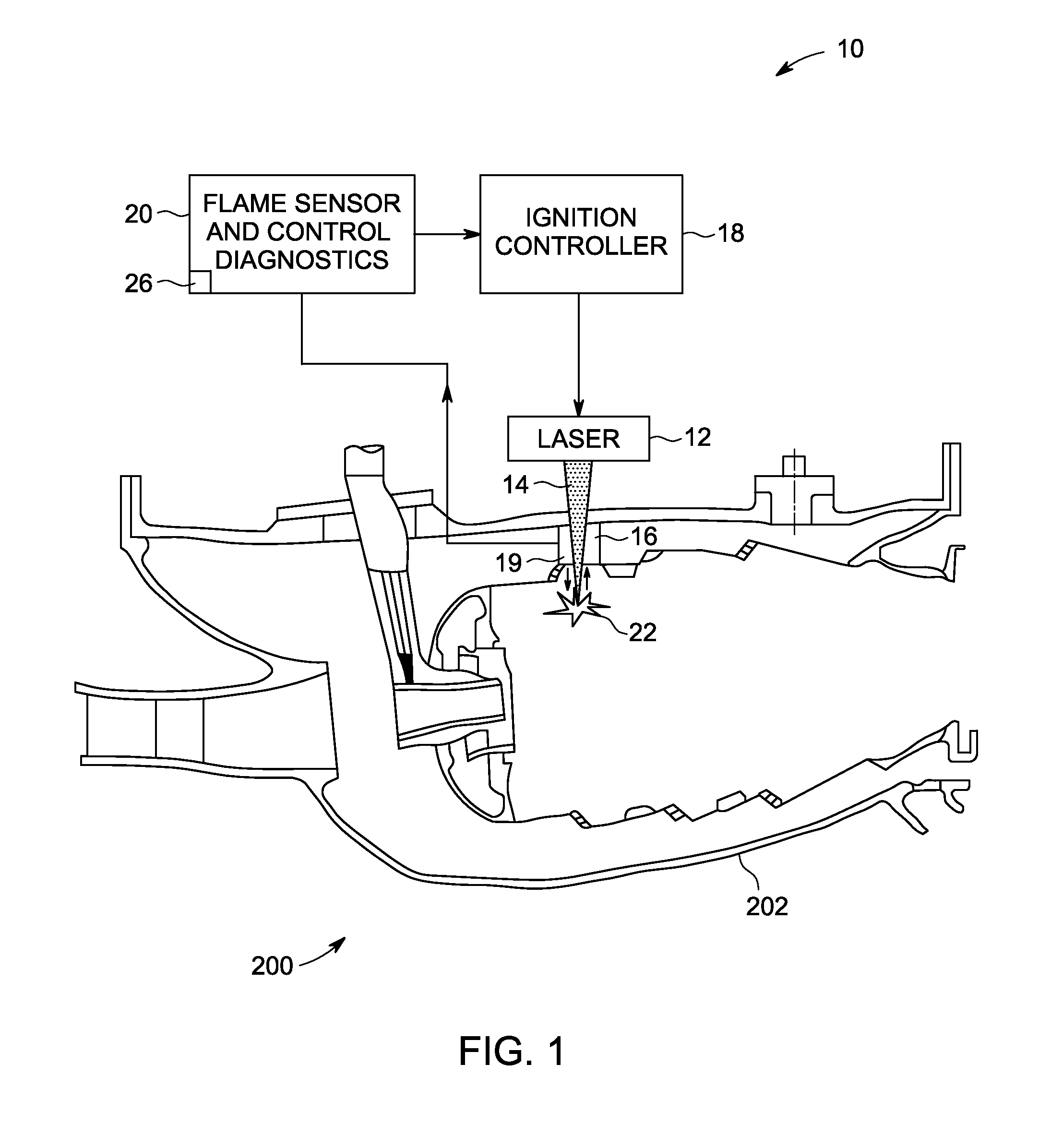

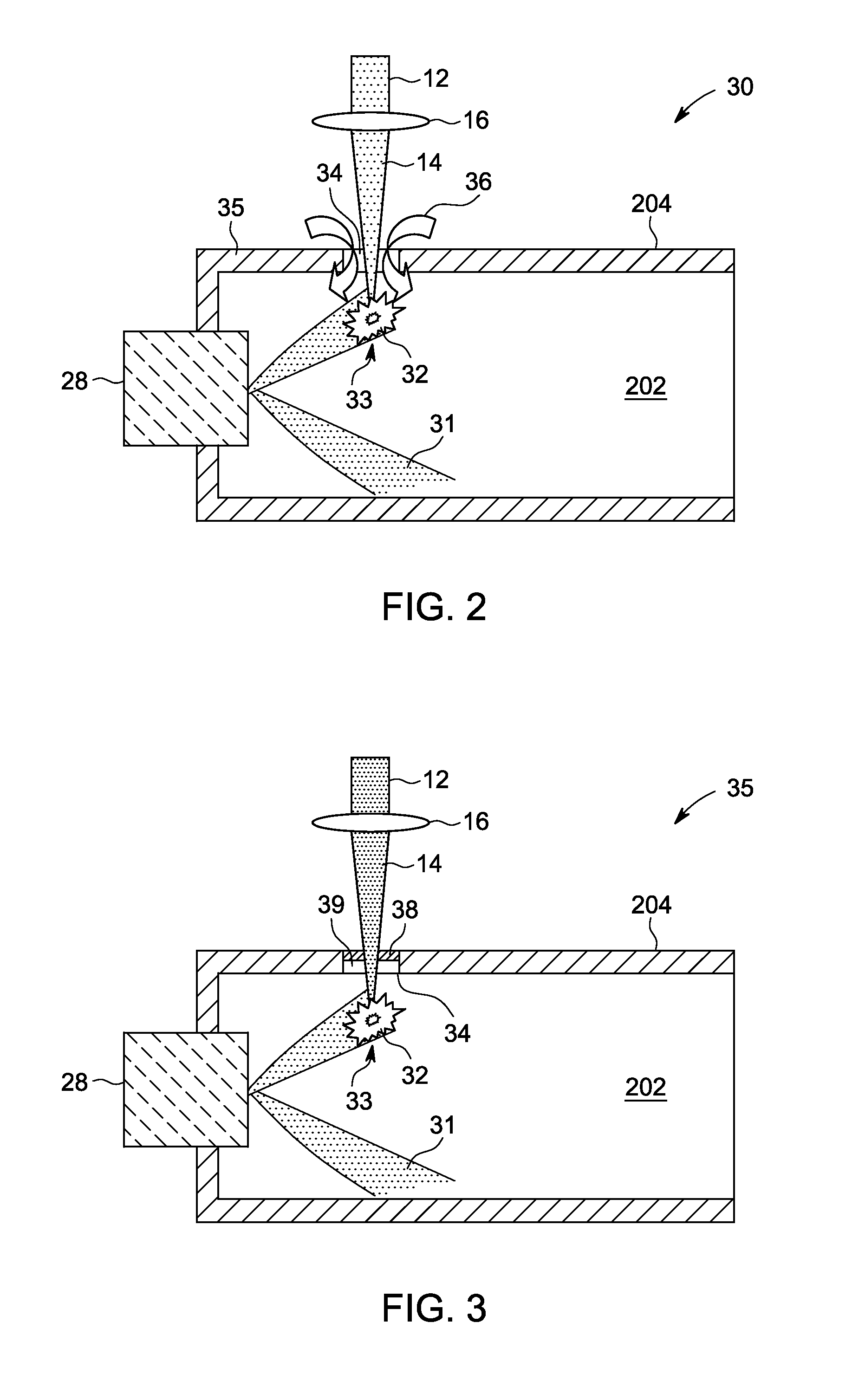

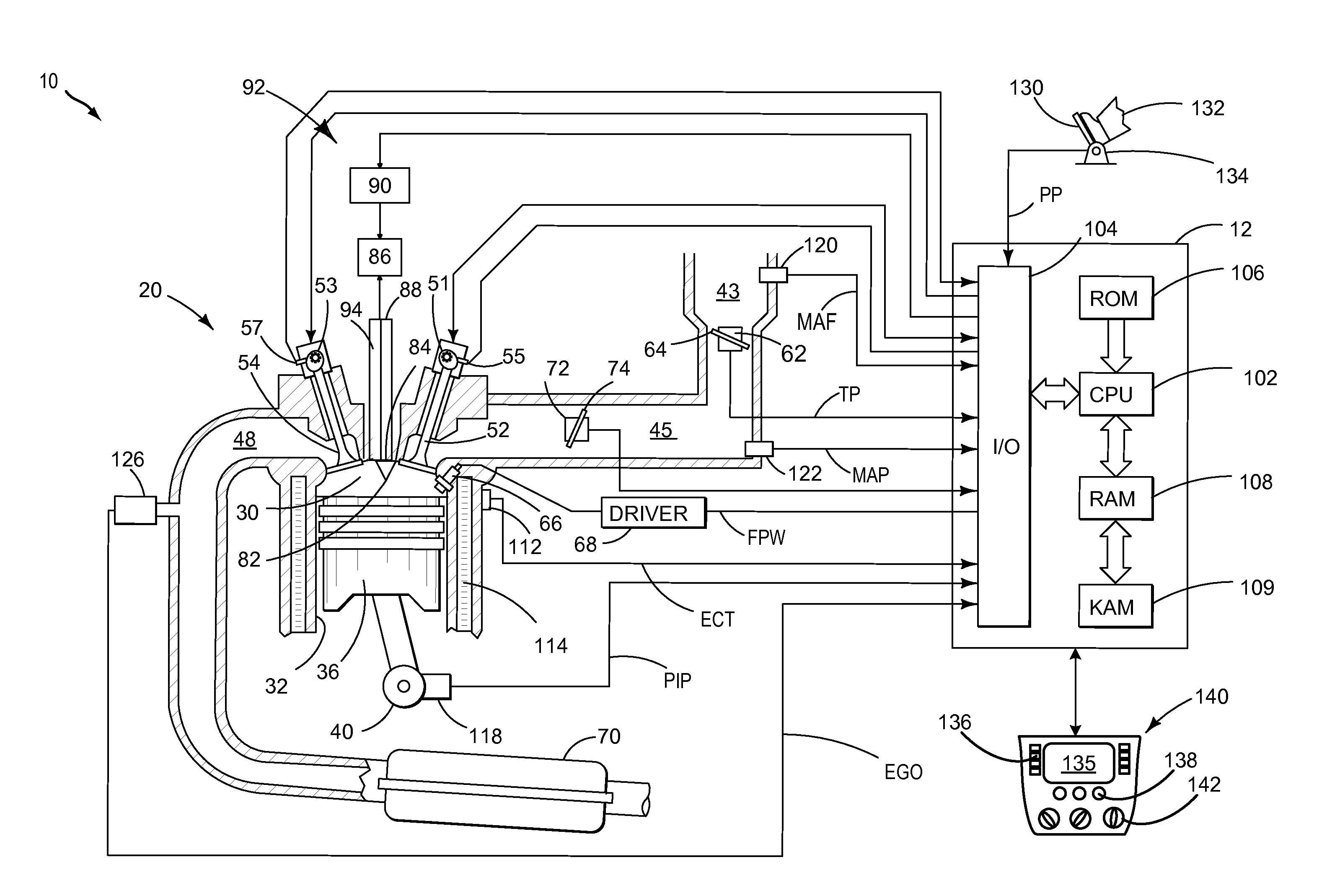

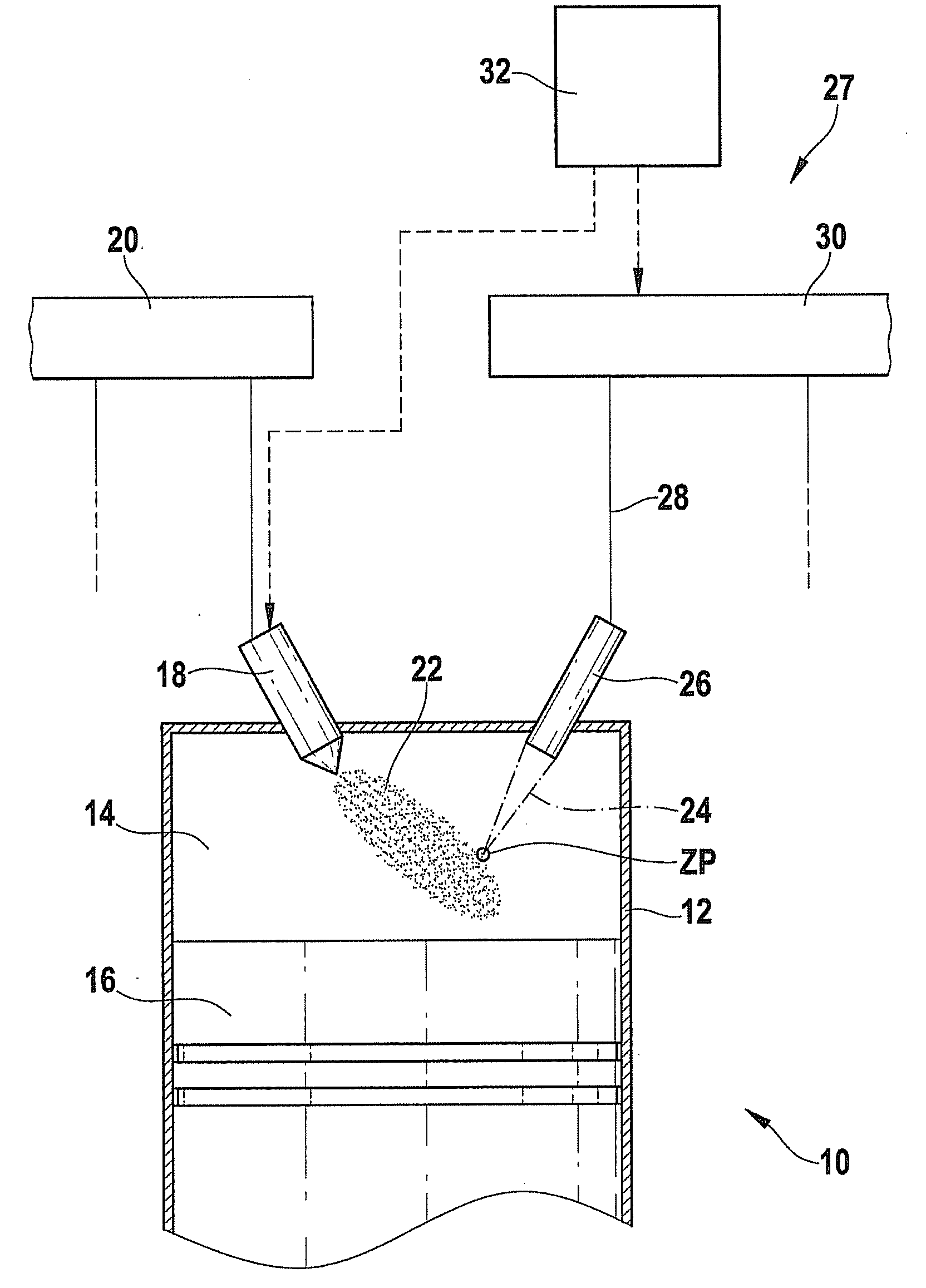

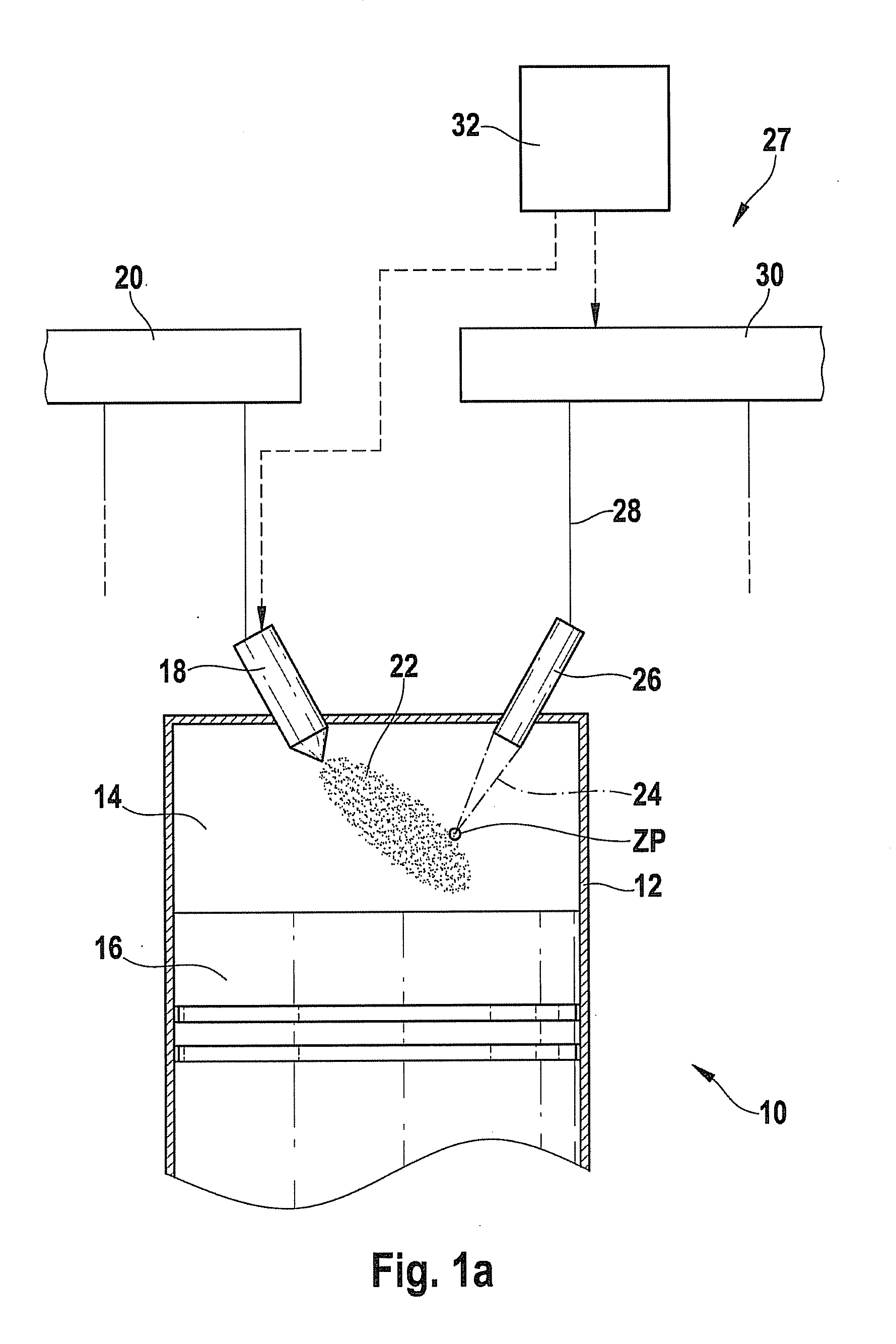

Methods and apparatuses for laser ignition in an internal combustion engine. Laser radiation is directed to an ignition location within a combustion chamber with adaptive optics, and the position of the ignition location is adaptively adjusted during operation of the engine using the adaptive optics. Multiple ignition locations may be provided during a cycle of an internal combustion engine. A first pulse of laser radiation is directed to a first ignition location within a combustion chamber with adaptive optics, and a second pulse of laser radiation is directed to a second ignition location within the combustion chamber using the adaptive optics.

Owner:III HLDG 1

Laser ignition for gas mixtures

ActiveUS8181617B2Emission reductionReduce torque fluctuationCombustion enginesIgnition sparking plugsExternal combustion engineEngineering

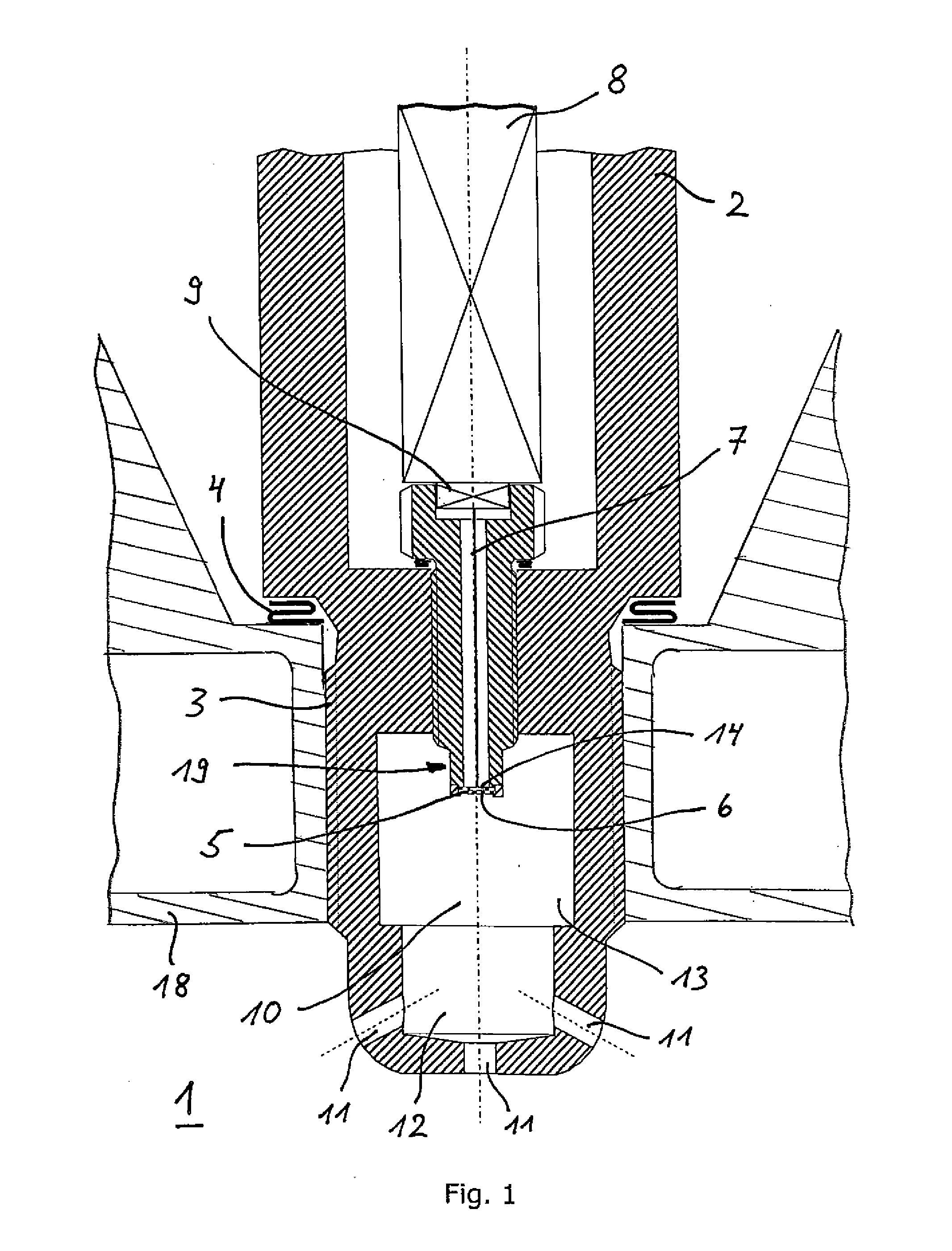

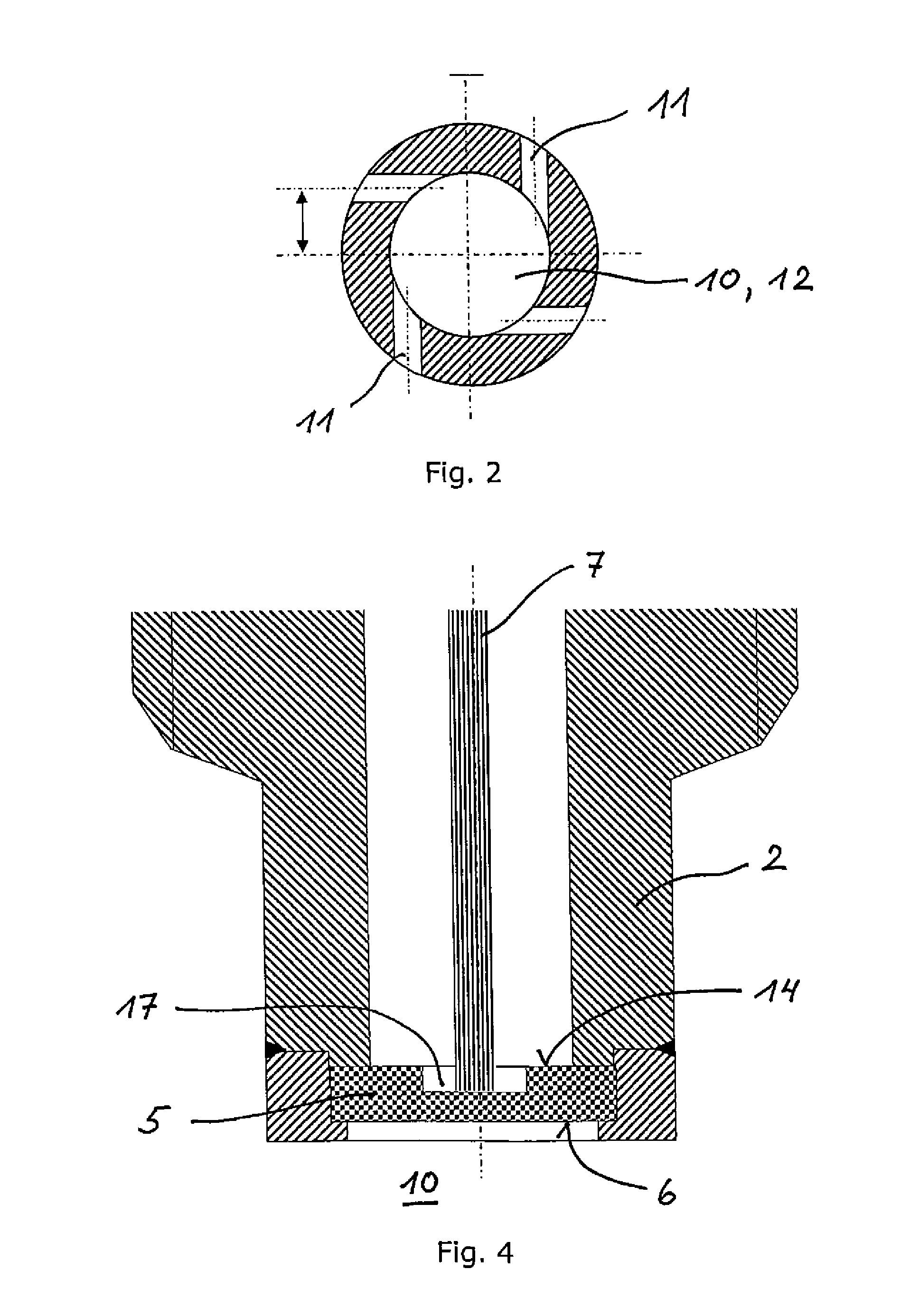

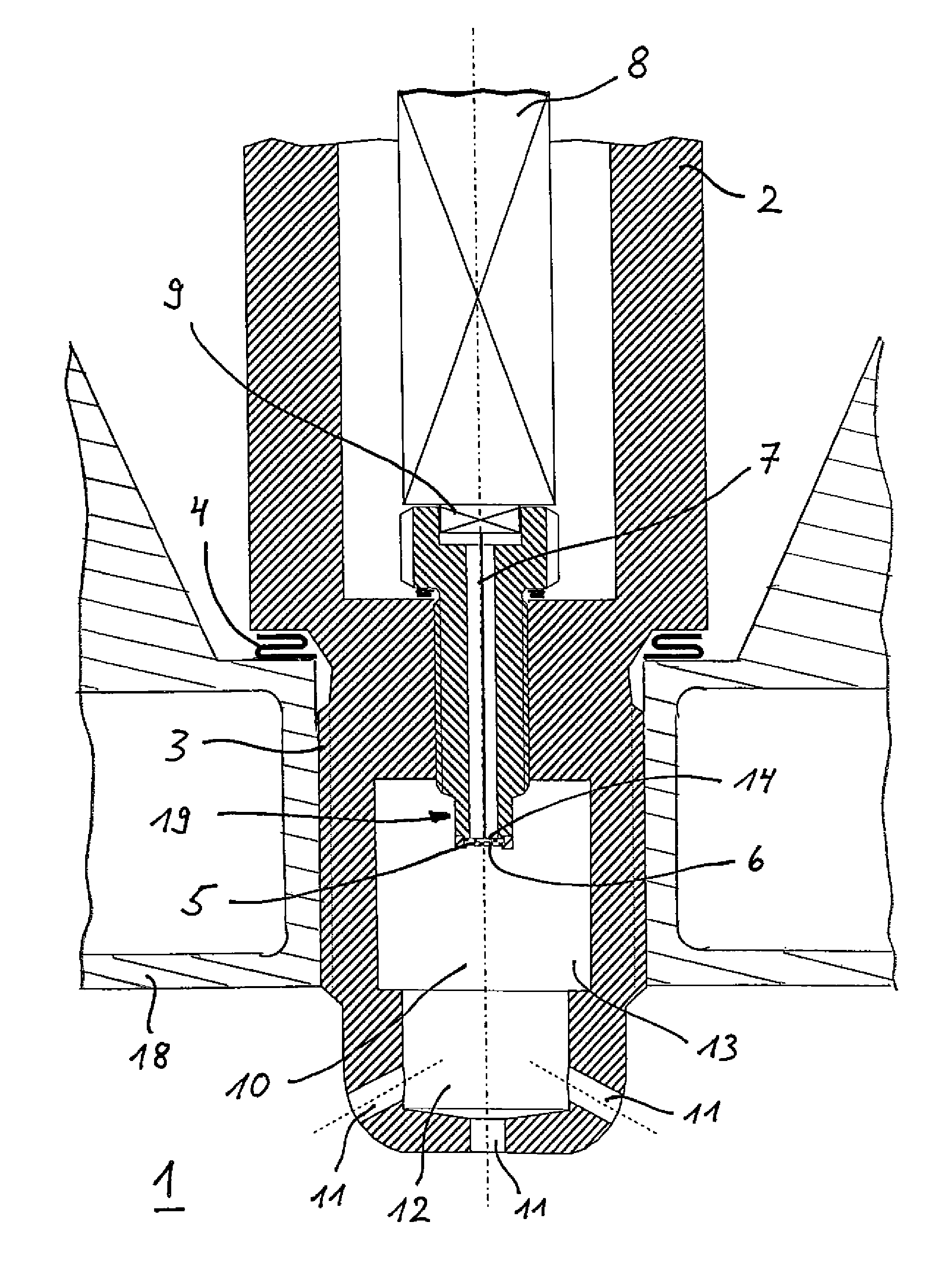

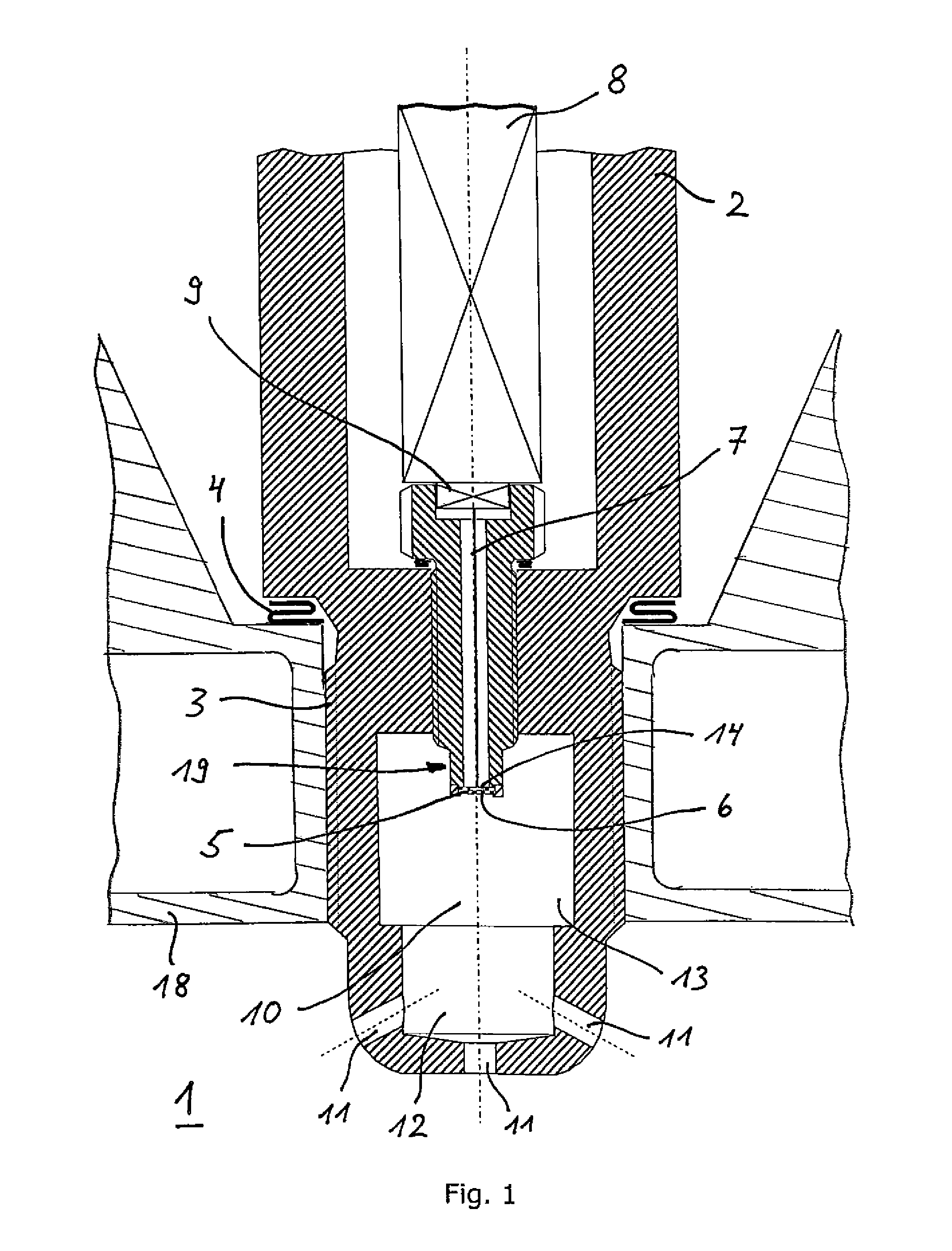

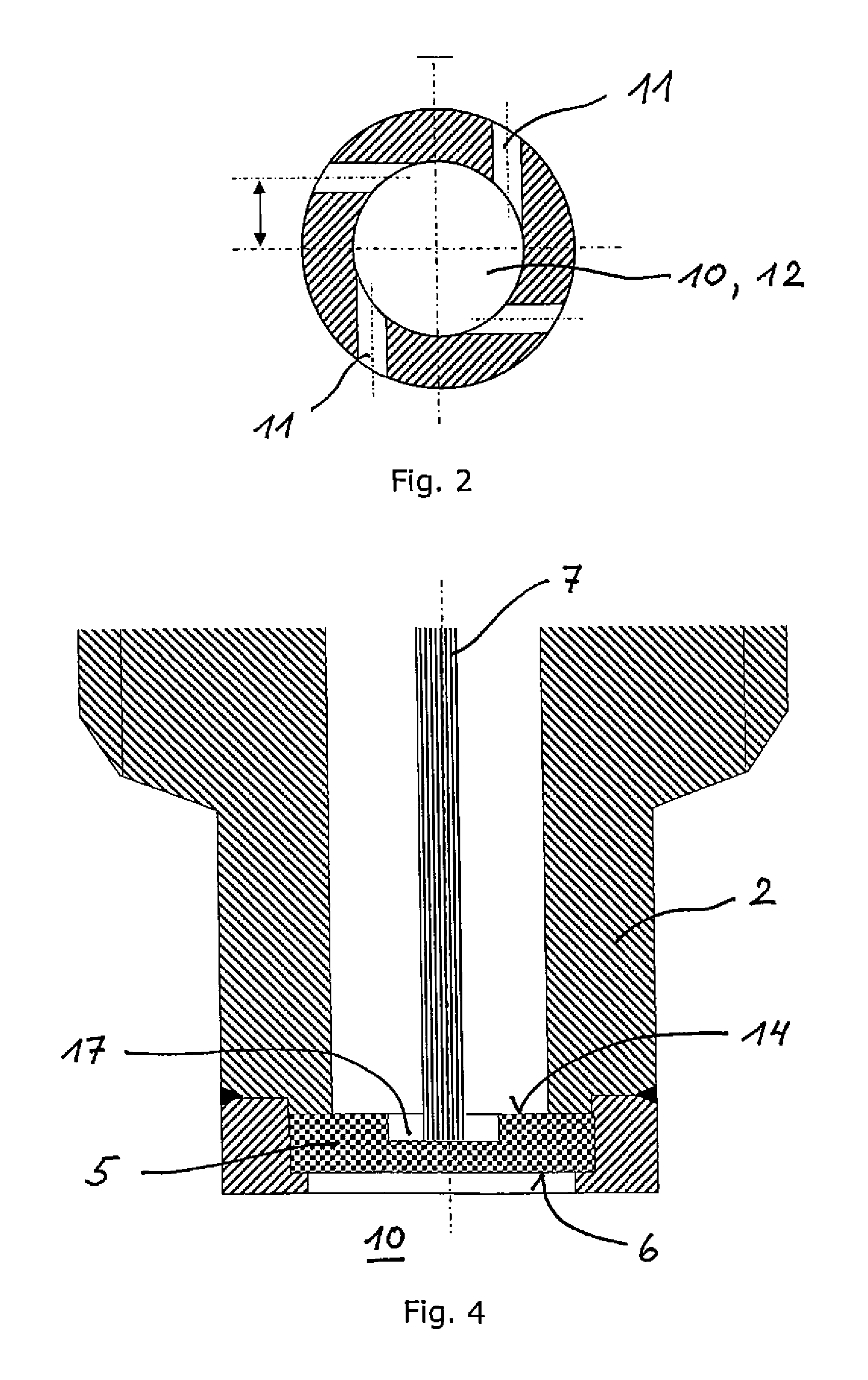

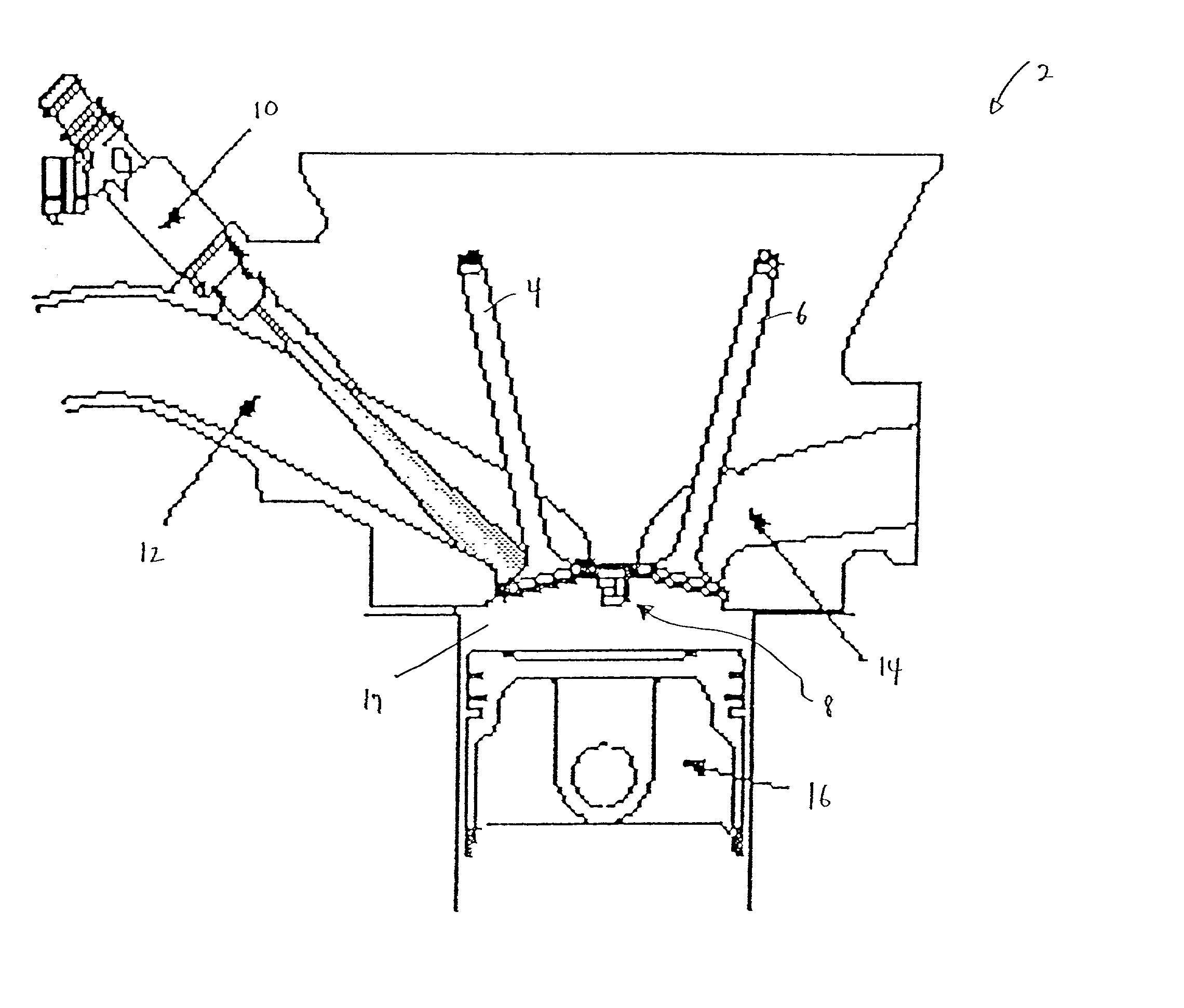

An ignition device for the ignition of a gas mixture in a main combustion chamber (1), in particular of an internal combustion engine, is proposed, wherein the absorber body (5) is heated by means of a laser (8). A prechamber (10) is located upstream of the absorber body (5) on the combustion chamber inner side (6) in order to improve the ignition behavior.

Owner:MULTIFLASHLIGHT

Methods and apparatuses for laser ignited engines

InactiveUS20020185097A1Electrical controlInternal combustion piston enginesCombustion chamberEngineering

Methods and apparatuses for laser ignition in an internal combustion engine. Laser radiation is directed to an ignition location within a combustion chamber with adaptive optics, and the position of the ignition location is adaptively adjusted during operation of the engine using the adaptive optics. Multiple ignition locations may be provided during a cycle of an internal combustion engine. A first pulse of laser radiation is directed to a first ignition location within a combustion chamber with adaptive optics, and a second pulse of laser radiation is directed to a second ignition location within the combustion chamber using the adaptive optics.

Owner:III HLDG 1

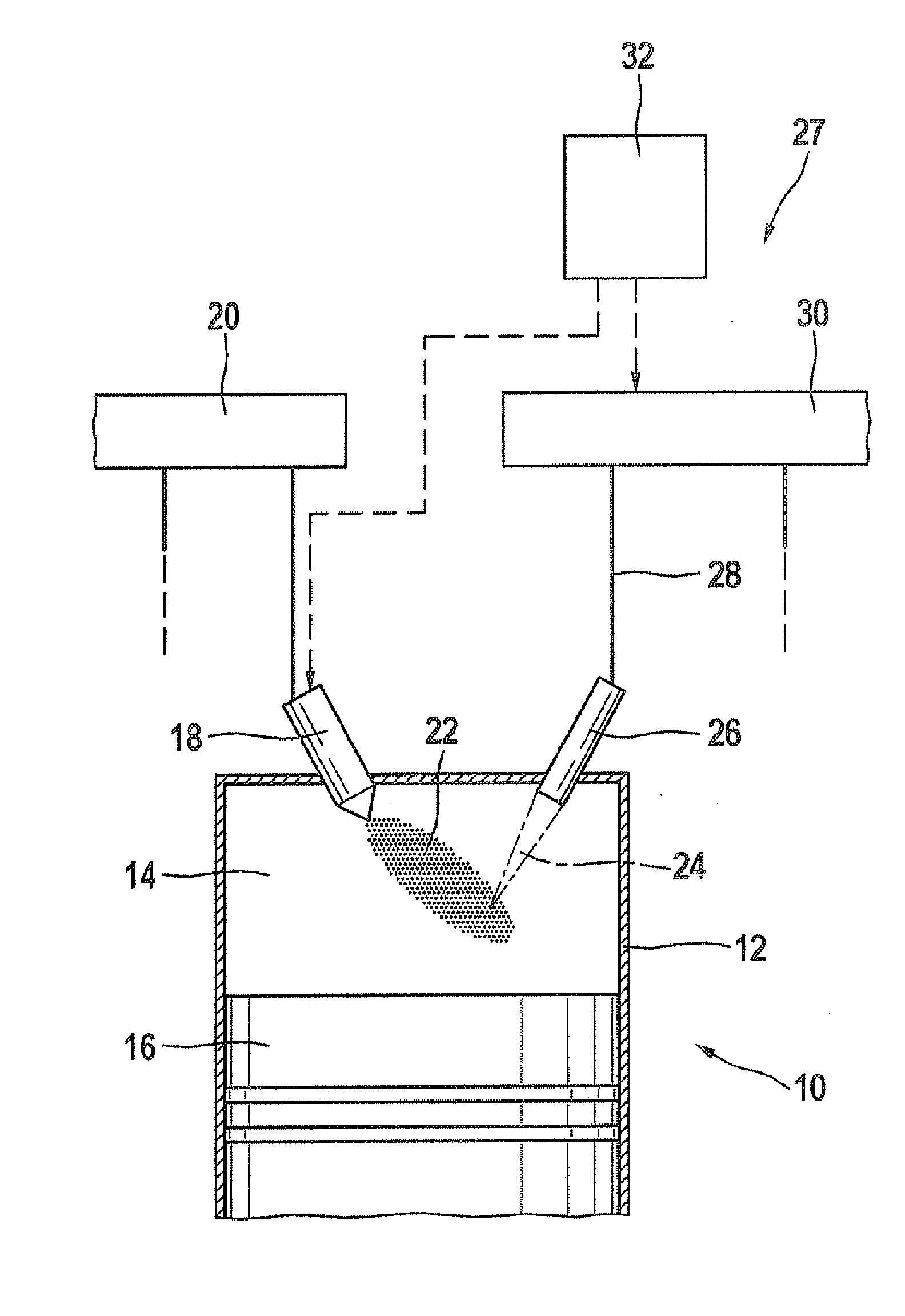

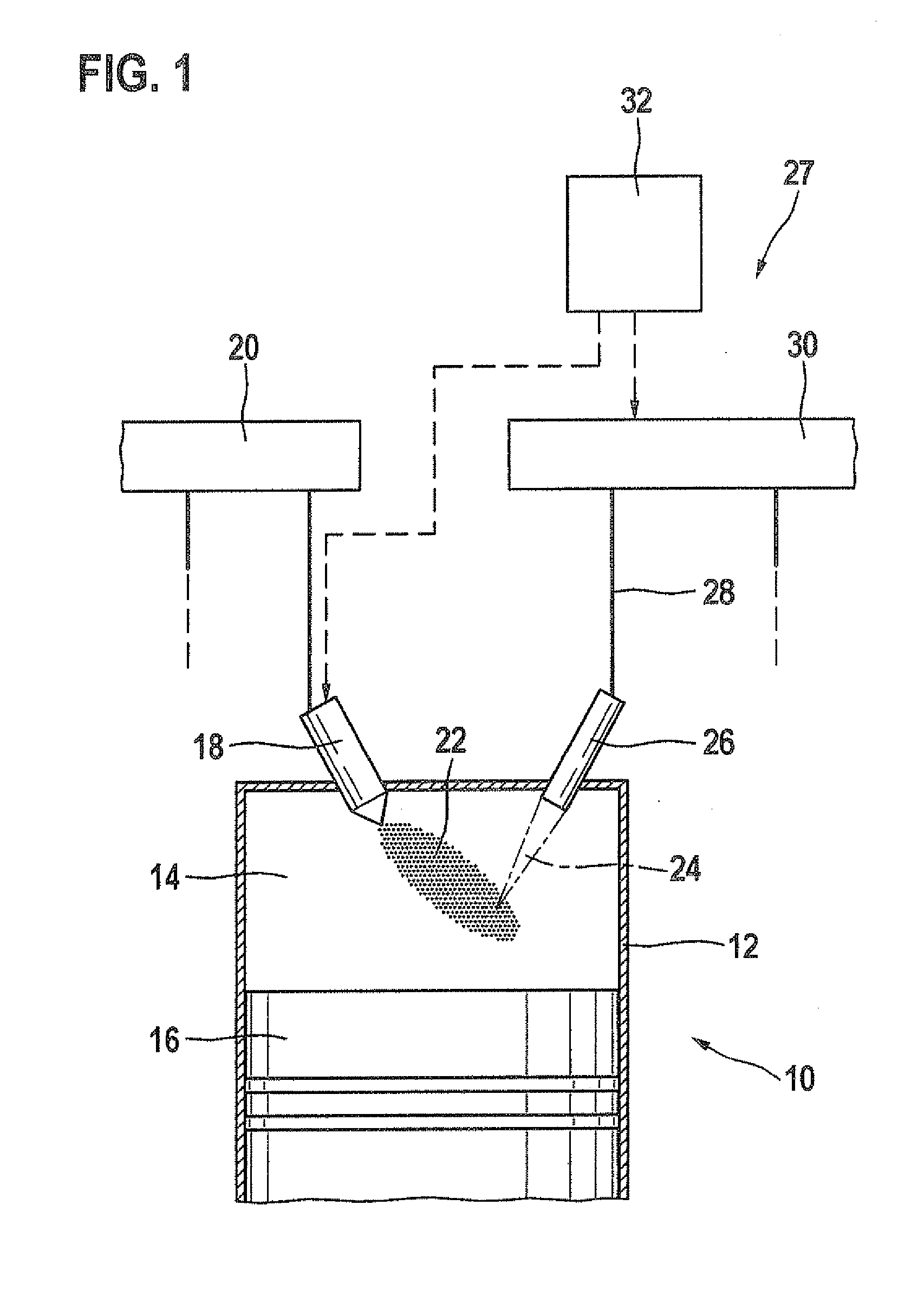

Laser ignition apparatus

InactiveUS7806094B2Reduce disadvantagesReduce depositionLaser detailsIncandescent ignitionCombustion chamberInlet valve

An apparatus is provided for the ignition of a fuel / air mixture in the combustion chamber of a combustion machine, wherein the combustion chamber has at least one inlet valve and at least one outlet valve. There are further provided a laser light generating device for giving off laser light and a combustion chamber window for coupling the laser light into a combustion chamber of the combustion machine. There is provided at least one fluid feed means which is separate from the inlet valve or valves and with which a fluid can be caused to flow at least on to regions of the surface of the combustion chamber window or between the combustion chamber window and the focal point of the laser light.

Owner:GE JENBACHER

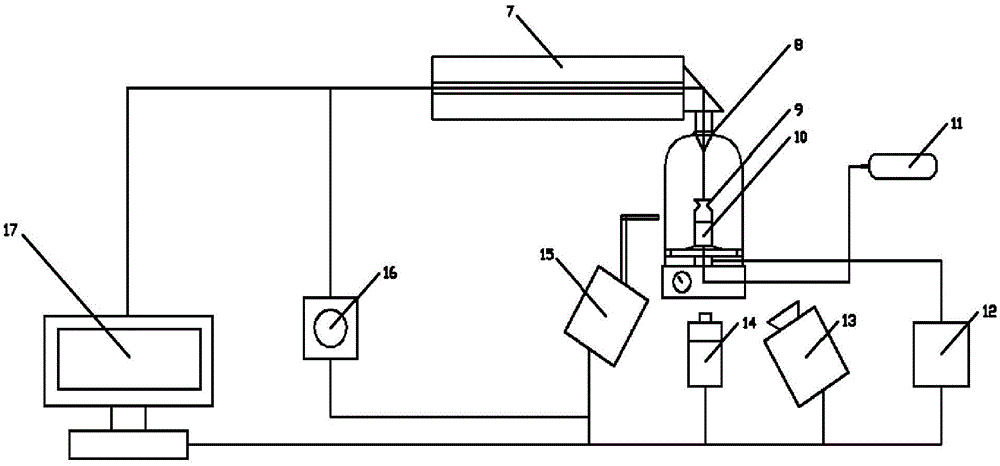

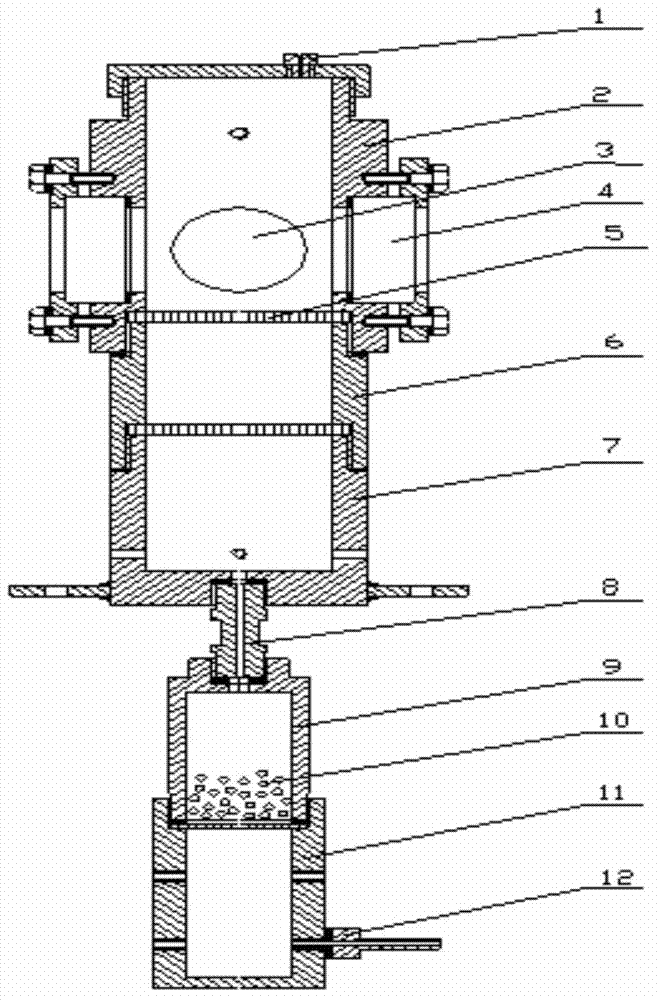

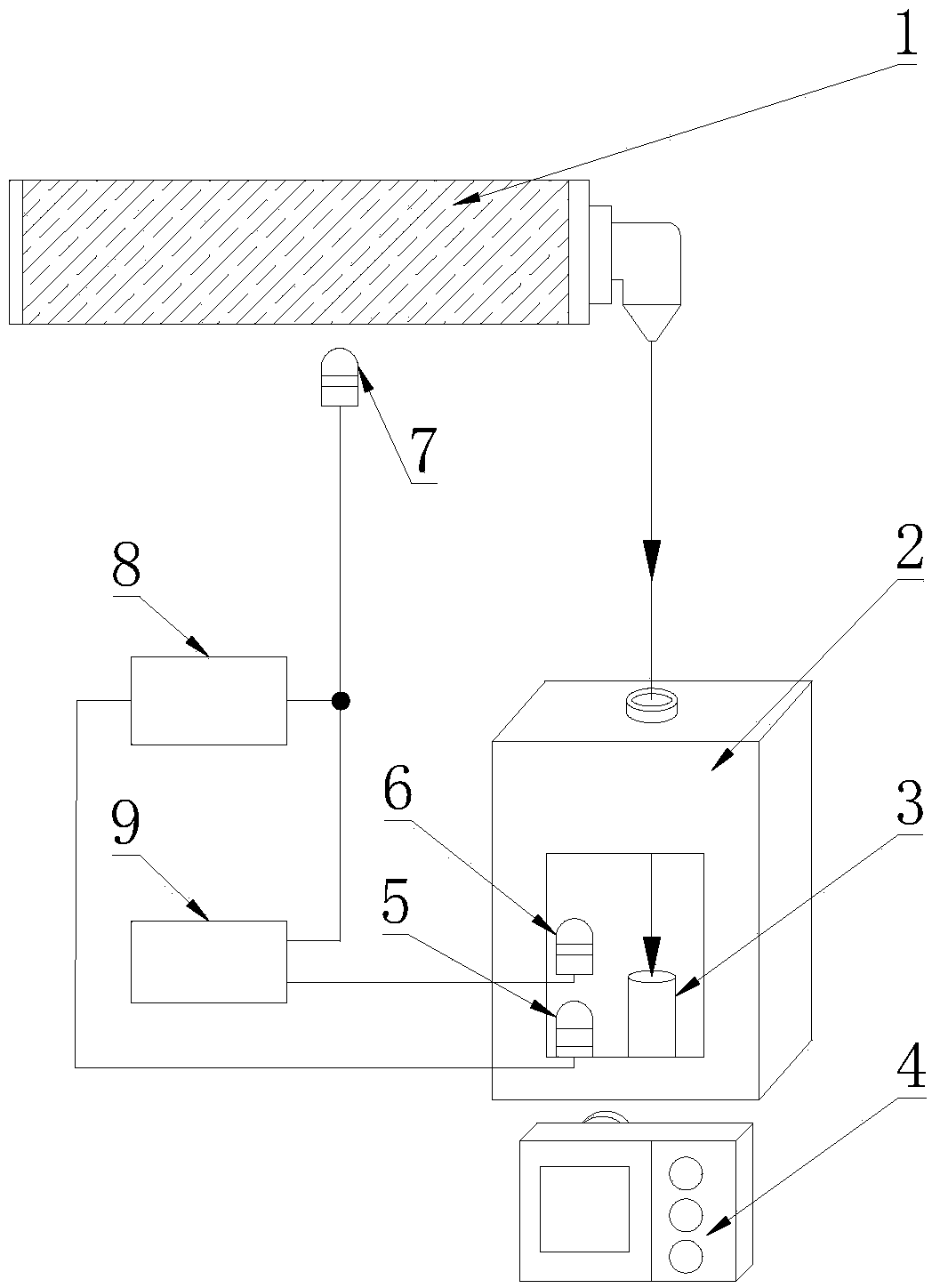

Device for testing ignition combustion characteristics and propulsive performance of solid fuel micro-thruster

The invention relates to a testing device for testing ignition combustion characteristics and propulsive performance and is to disclose a device for testing ignition combustion characteristics and propulsive performance of a solid fuel micro-thruster. The device comprises a laser, a reactor, a vacuum pump, a high-speed camera, a high-speed temperature detector, a fiber optic spectrometer, a data acquisition card, a synchronous trigger switch and a computer, wherein the reactor comprises a pressure-resistant glass cover, a micro-thruster fixing rack, a sealing ring, a pedestal, a pressure gauge and a high-sensitivity pressure sensor. The device is characterized in that a propulsive agent in the thruster is ignited by a laser ignition method; the ignition energy, the ignition temperature and the heating rate are basically the same as these of the actual resistance wire, but the cost is greatly reduced, the process is greatly simplified, and the working stability is better; thus the testing device is very suitable for test and research in a laboratory.

Owner:ZHEJIANG UNIV

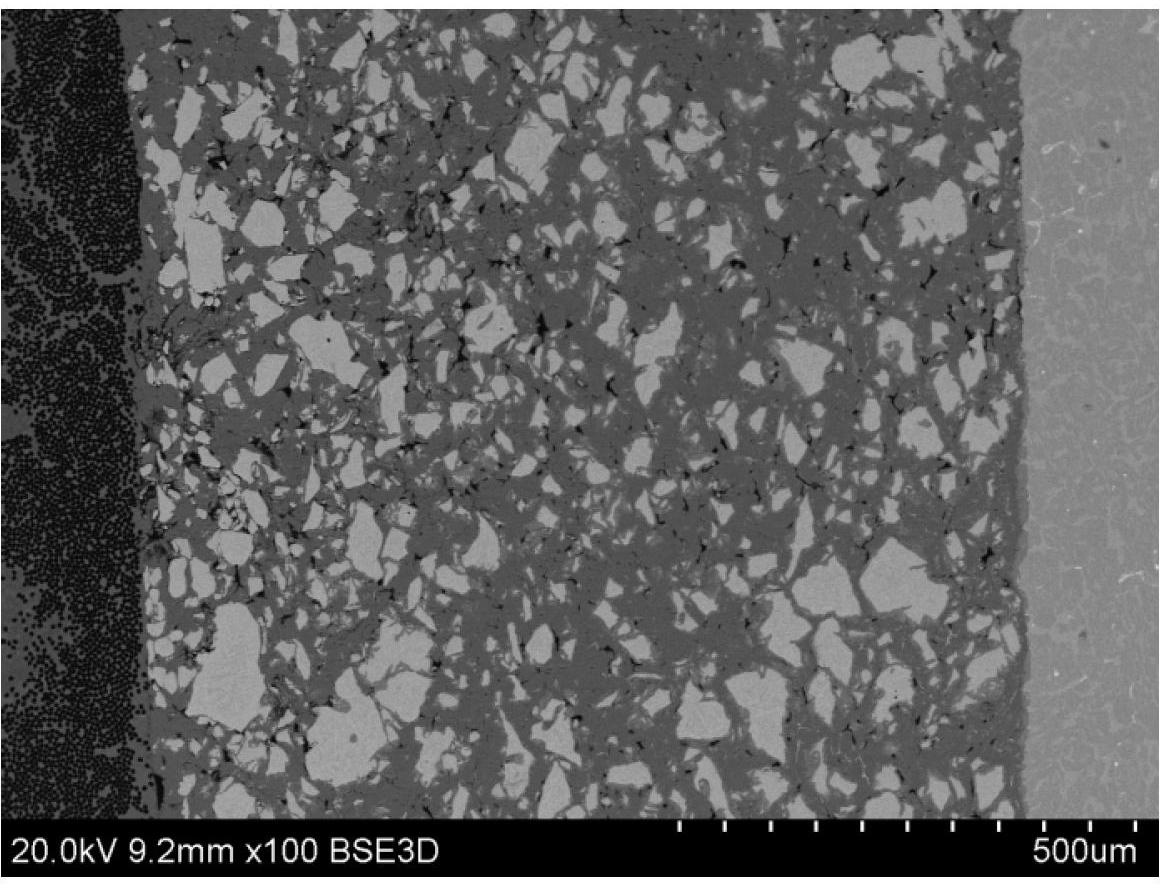

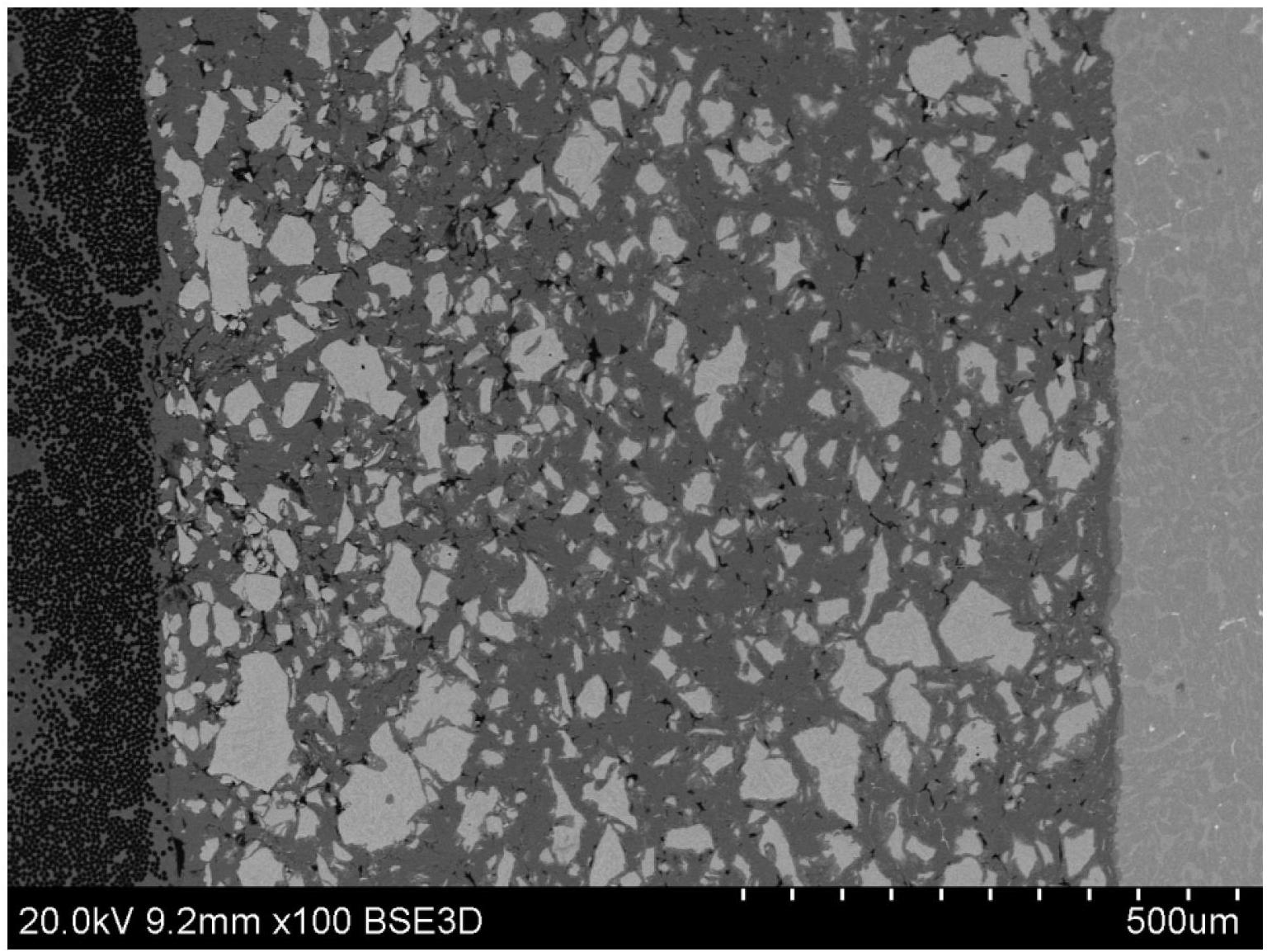

Method for laser-induced self-propagating connection between carbon fiber reinforced aluminum-based composite and metal

InactiveCN102689096APerformance is not affectedMaintain good propertiesWelding/cutting media/materialsWelding/soldering/cutting articlesCarbon fibersLaser ignition

The invention discloses a method for laser-induced self-propagating connection between carbon fiber reinforced aluminum-based composite and metal, relates to a method for connecting aluminum-based composite and the metal, and aims to solve the problems of serious interface reaction between reinforced phase carbon fibers and aluminum and parent metal performance deterioration caused by overall high heating temperature in the conventional welding method. The method comprises the following steps of: 1, uniformly mixing and ball-milling titanium powder, aluminum powder and nano-carbon powder to obtain mixed powder; 2, pressing the mixed powder into an intermediate layer compact with relative density of 60 to 80 percent and thickness of 1 to 3mm, and sealing and storing the intermediate layer compact; and 3, placing the intermediate layer compact between the carbon fiber reinforced aluminum-based composite and the metal to obtain a sandwich, igniting the intermediate layer compact by using laser, and stopping a laser to finish the laser-induced self-propagating connection. The self-propagating heating intermediate layer compact is used for realizing the connection by adopting a laser ignition technology, and the joint strength reaches 30.5MPa. The method is applied to the field of connection between the carbon fiber reinforced aluminum-based composite and the metal.

Owner:HARBIN INST OF TECH

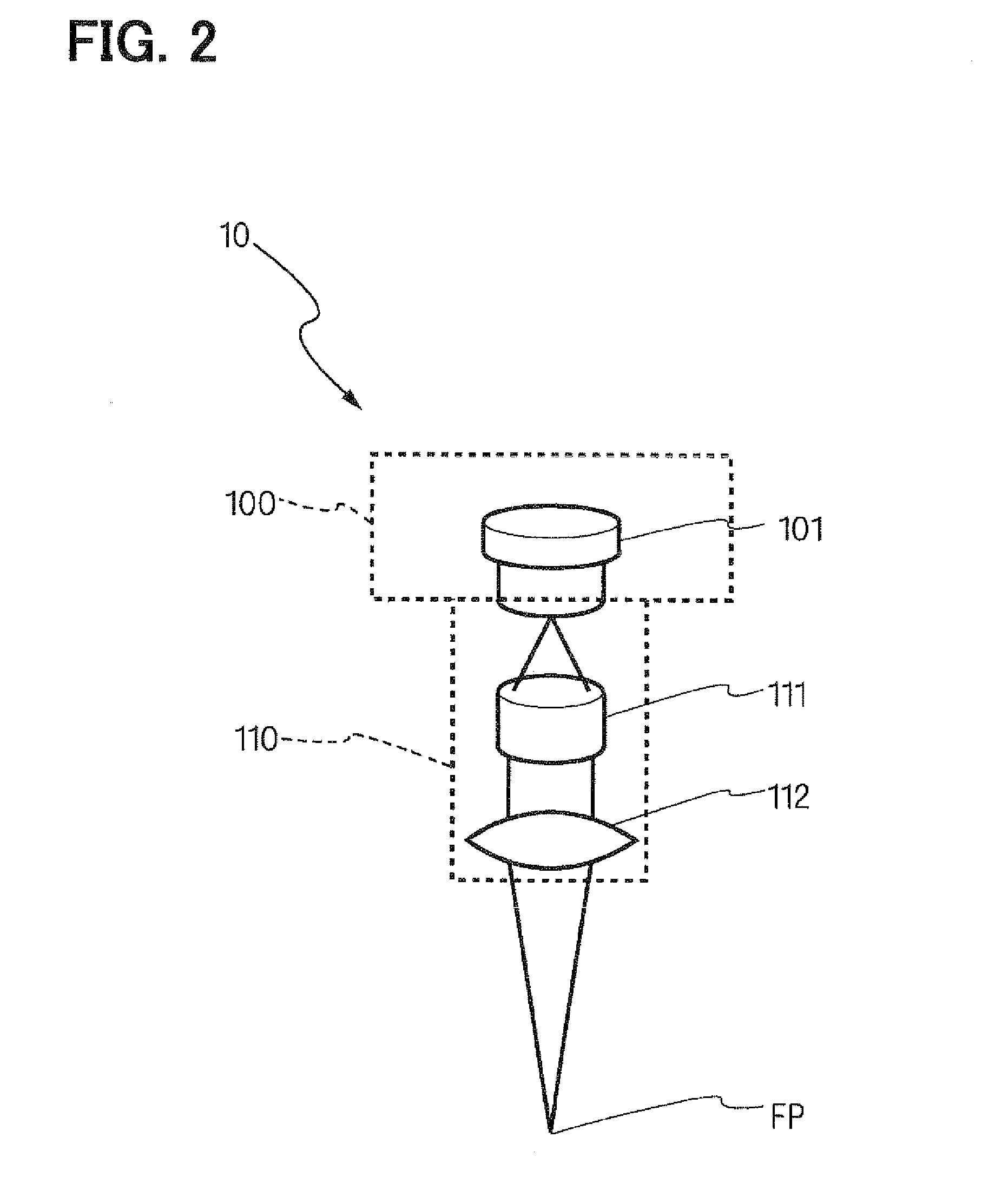

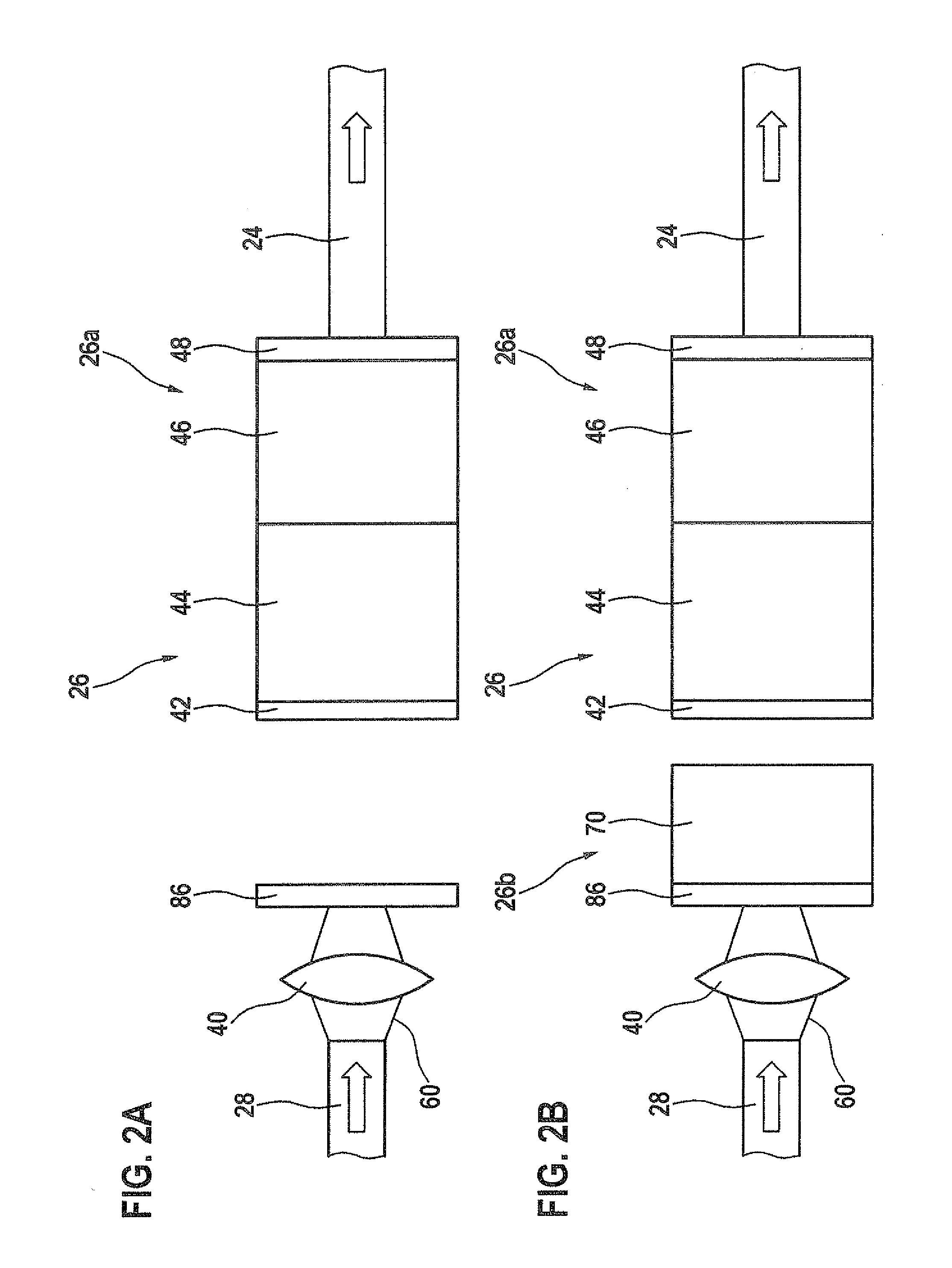

Laser ignition apparatus

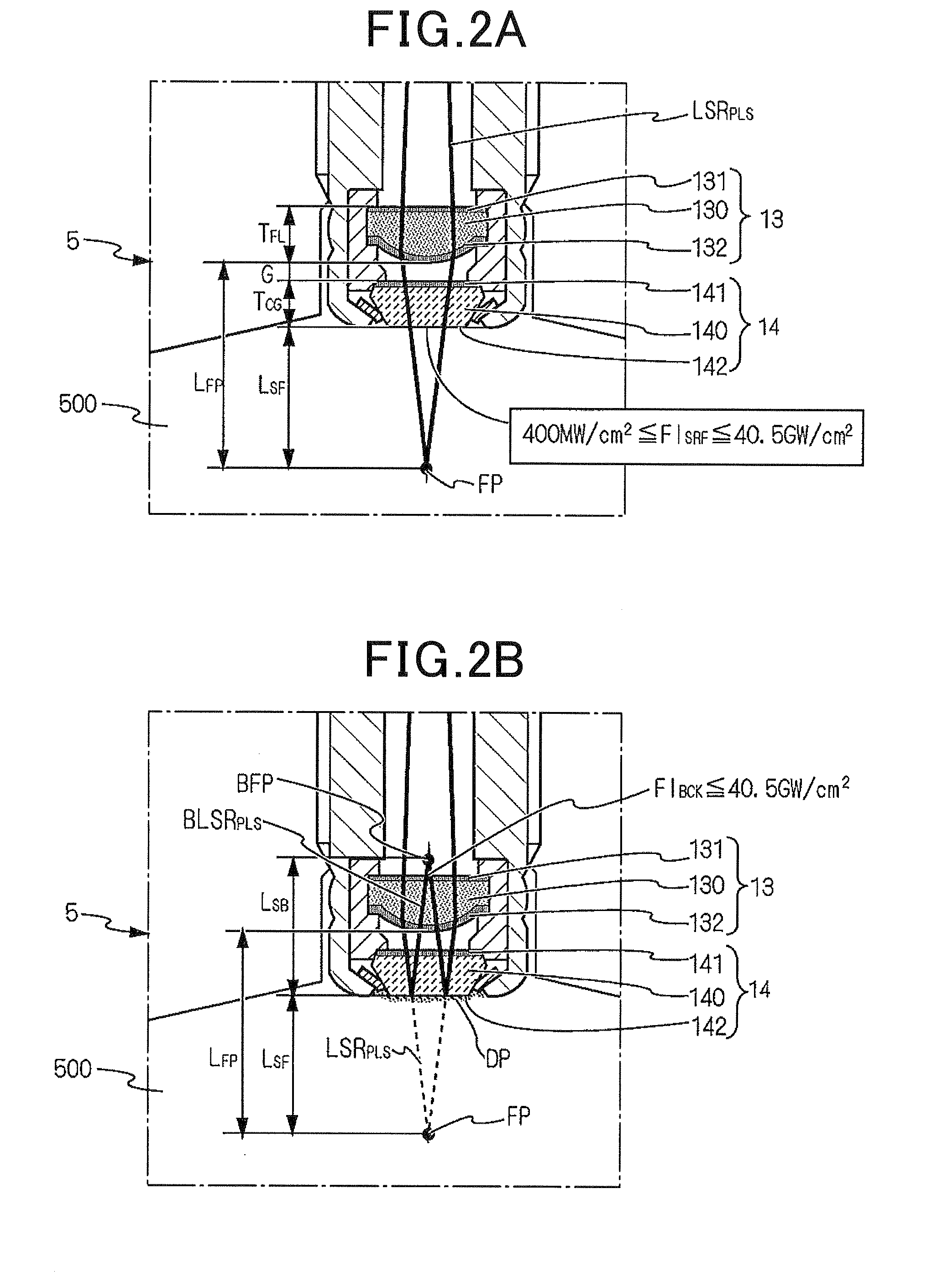

ActiveUS20130206091A1Stable ignitionImprove power densitySparking plugsCombustion enginesCombustion chamberOptoelectronics

In a laser ignition apparatus, a focusing optical element is configured to focus a pulsed laser light to a predetermined focal point in a combustion chamber of an engine. An optical window member is arranged on the combustion chamber side of the focusing optical element so as to separate the focusing optical element from the combustion chamber. A catoptric-light focal point, at which a catoptric light is to be focused, is positioned on the anti-combustion chamber side of a combustion chamber-side end surface of the optical window member. The catoptric light results from the reflection of the pulsed laser light by a pseudo mirror that is formed by the optical window member when the combustion chamber-side end surface thereof is fouled with contaminants. Further, the catoptric-light focal point falls in a region where no solid material forming either the focusing optical element or the optical window member exists.

Owner:NIPPON SOKEN +1

Laser ignition

InactiveUS6394788B1Durable and reliable and economical ignitionEliminate needLaser detailsPulsating combustionResonant cavityLight beam

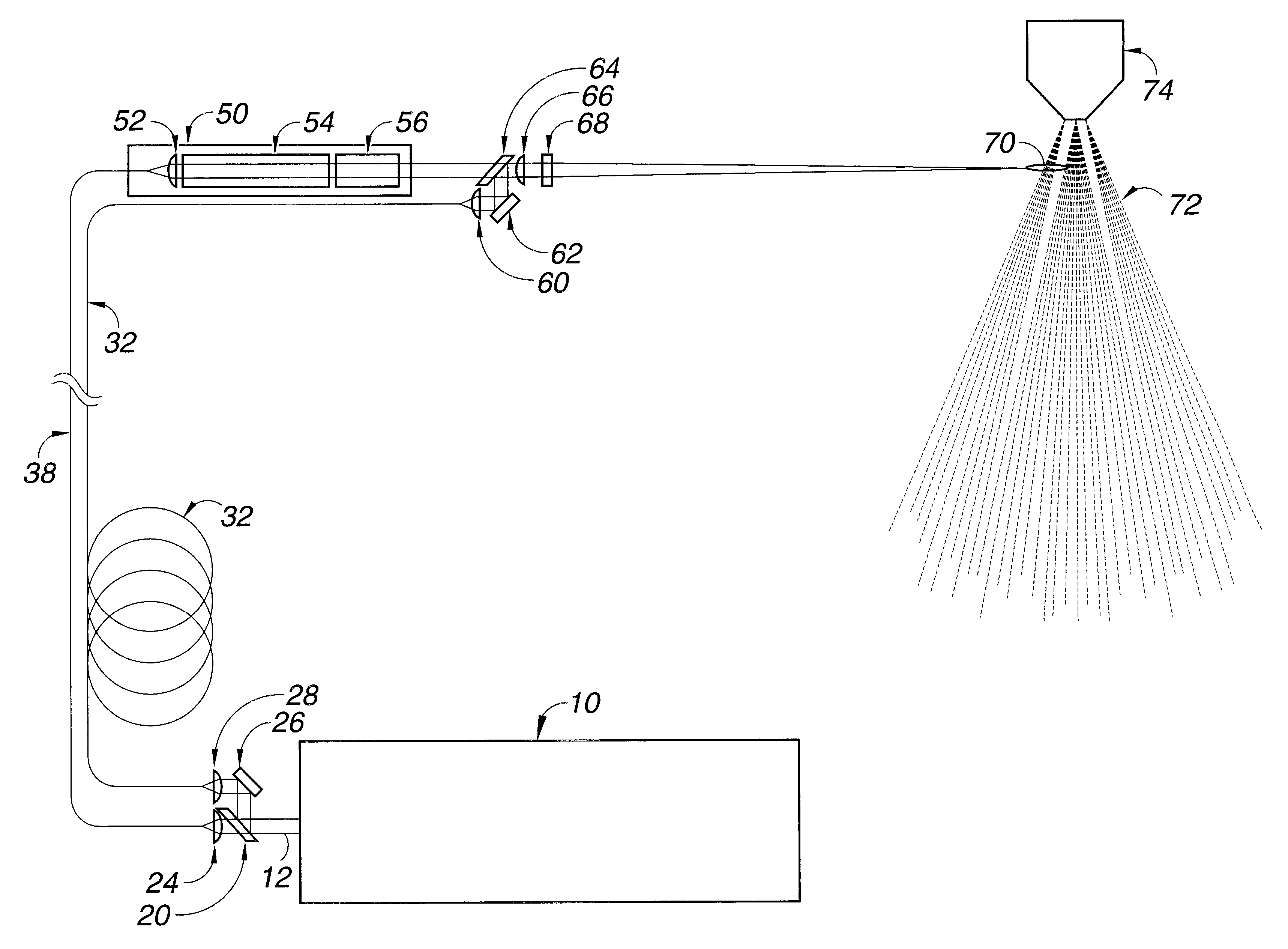

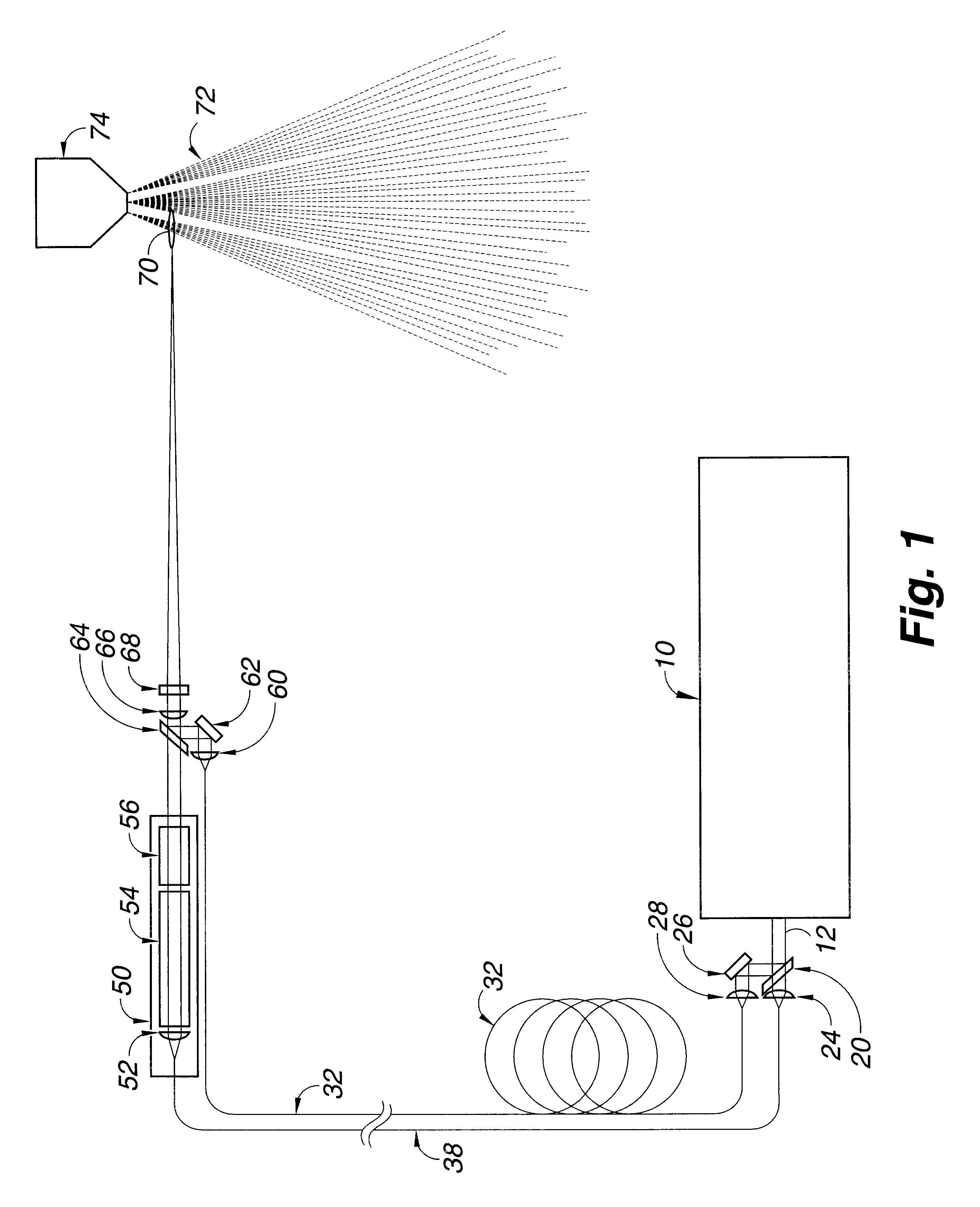

In the apparatus of the invention, a first excitation laser or other excitation light source is used in tandem with an ignitor laser to provide a compact, durable, engine deployable fuel ignition laser system. Reliable fuel ignition is provided over a wide range of fuel conditions by using a single remote excitation light source for one or more small lasers located proximate to one or more fuel combustion zones.In two embodiments the beam from the excitation light source is split with a portion of it going to the ignitor laser and a second portion of it being combined with either the first portion after a delay before injection into the ignitor laser or combined with the output of the ignitor laser. In another embodiment alternating short and long pulses of light from the excitation light source are directed into the ignitor laser. In a fourth embodiment the excitation light source is a laser with more than one resonating cavity; beams from one resonating cavity are directed into an ignitor laser and beams from the other resonating cavity are directed into a beam combiner where they are combined with the output of the ignitor laser. In a fifth embodiment an excitation light source capable of producing alternating beams of light having different wavelengths is used to pump the ignitor laser.

Owner:LOS ALAMOS NATIONAL SECURITY

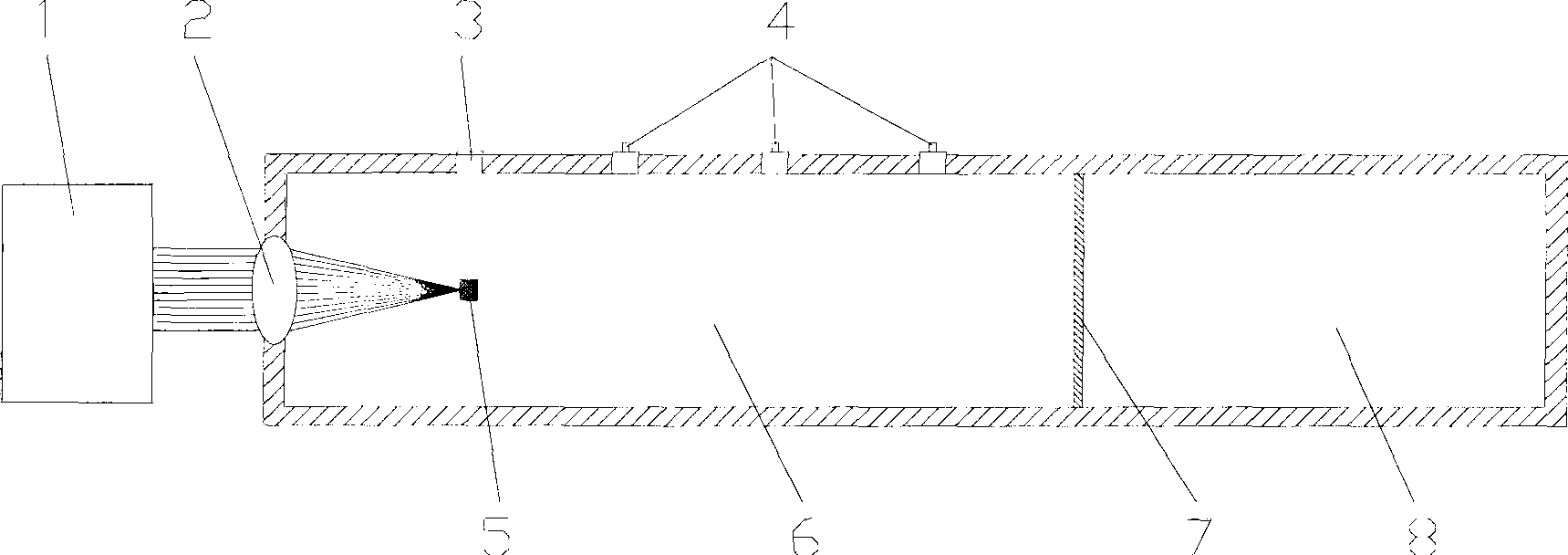

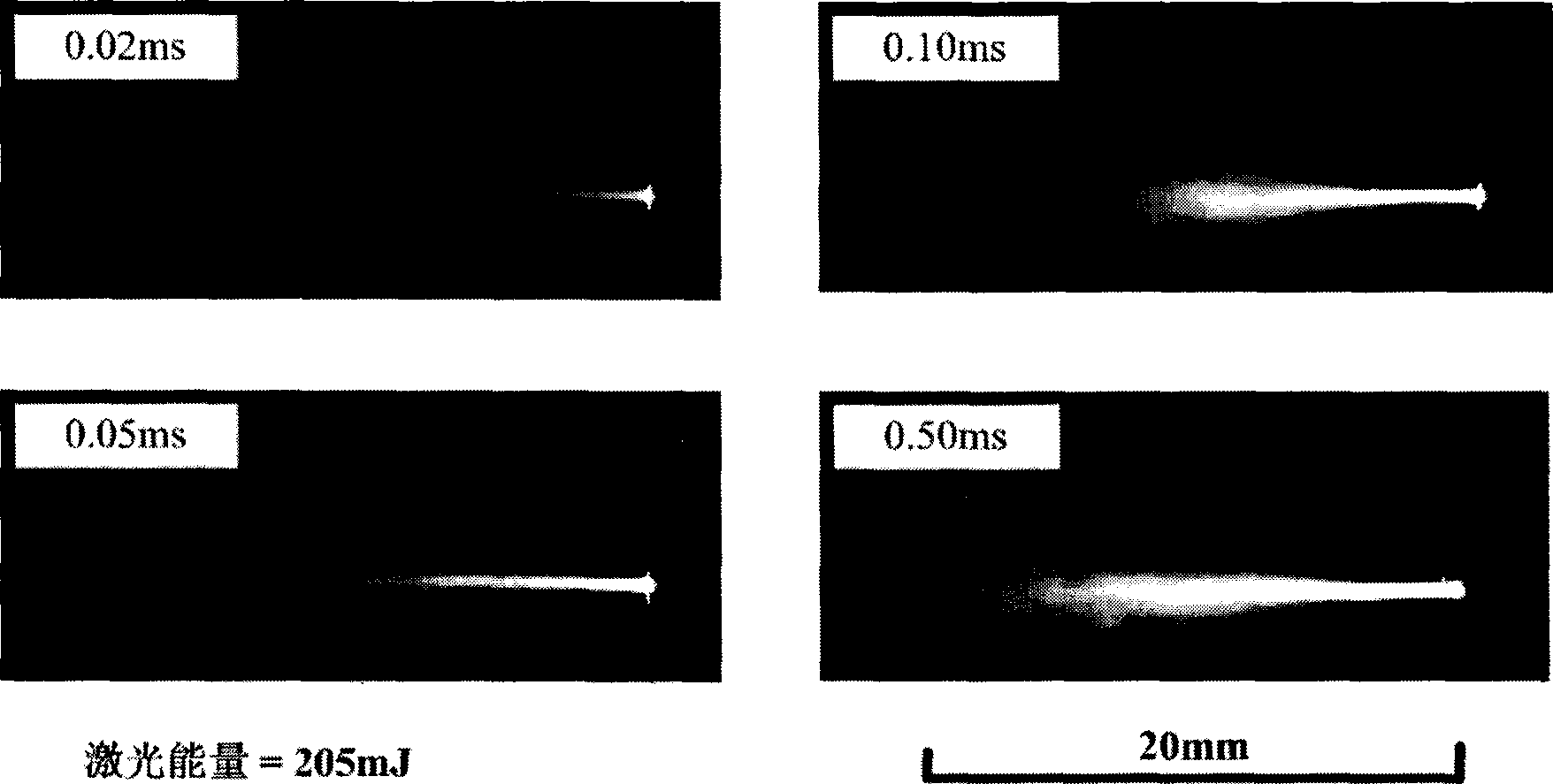

Particle airflow suspension laser ignition experiment device

InactiveCN104330519ATo achieve the purpose of the ignition processChemical analysis using combustionCombustorShoot

The invention discloses a particle airflow suspension laser ignition experiment device belonging to the technical field of solid rocket engines. The particle airflow suspension laser ignition experiment device enables particles to suspend in space in a combustor by means of tiny airflow, and the particles are not in contact with a metal wall plate, and are continuously heated and ignited by using a high-energy laser igniter. A gas environment is adjustable, single gas can be fed or different kinds of gases are simultaneously fed so that the purpose of testing particle ignition processes under different gas environments is achieved. Four transparent windows are arranged on the combustor, wherein two windows are observation windows and two windows are germanium glass windows; a working process is observed and tested by means of the two observation windows, laser generated by the laser igniter shoots into the combustor by means of the two germanium glass windows, the power of the laser igniter is regulated, and the particles suspending in the combustor are heated and ignited; a detailed process of particle ignition combustion are shot by means of the observation windows by using a high-speed photography system. The experiment device can be used for researching ignition and combustion characteristics of metal particles and nonmetal particles.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

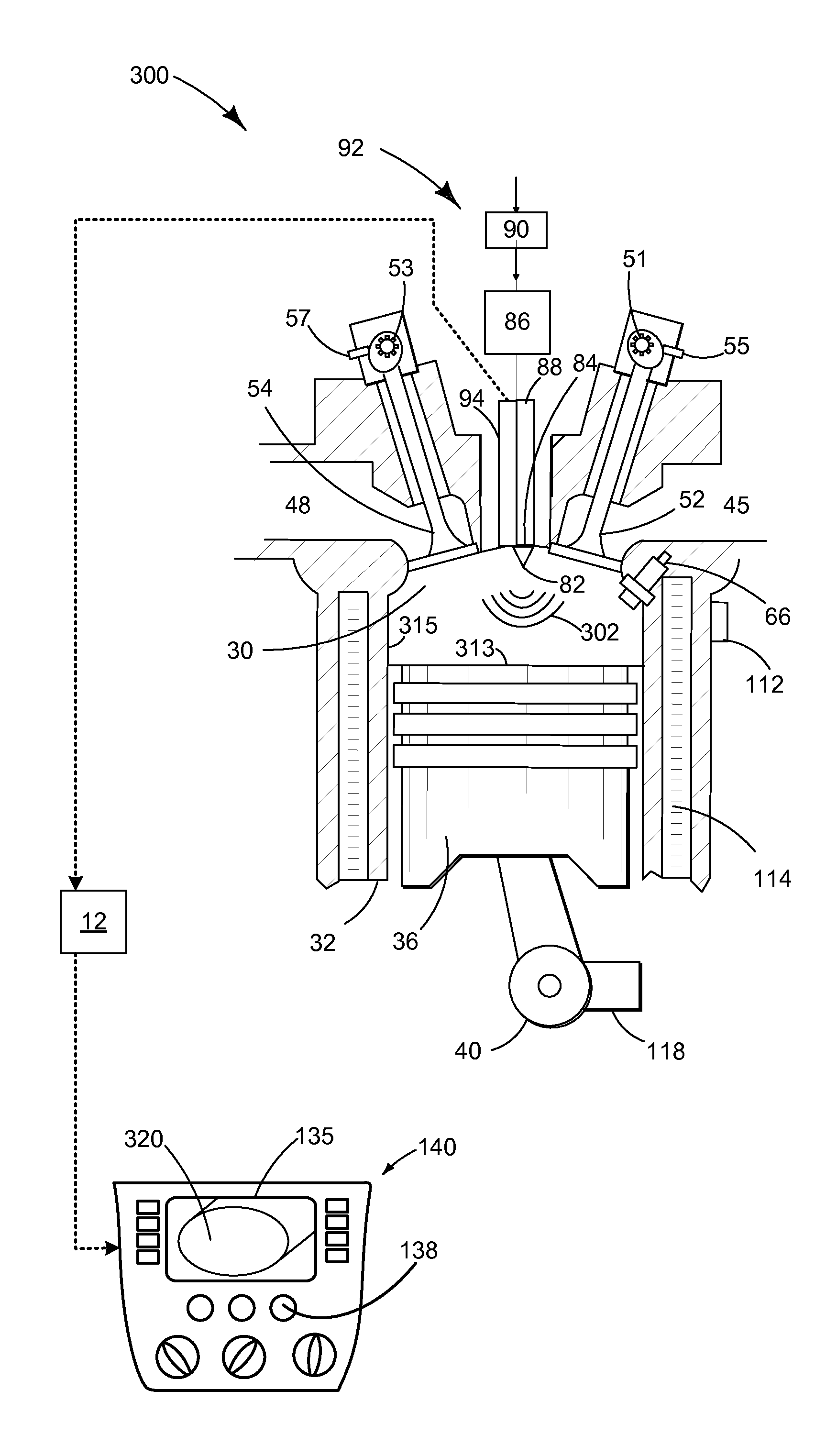

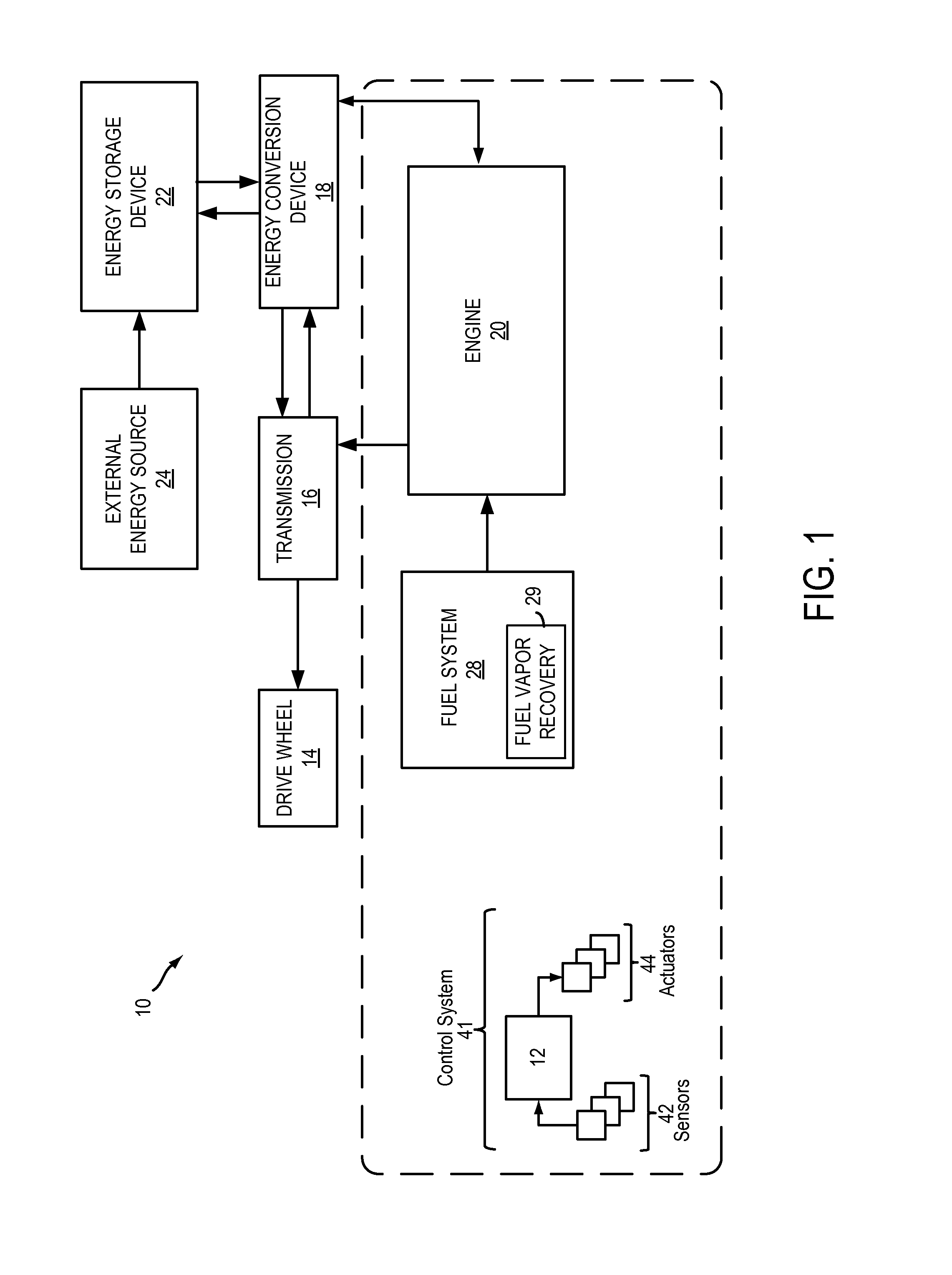

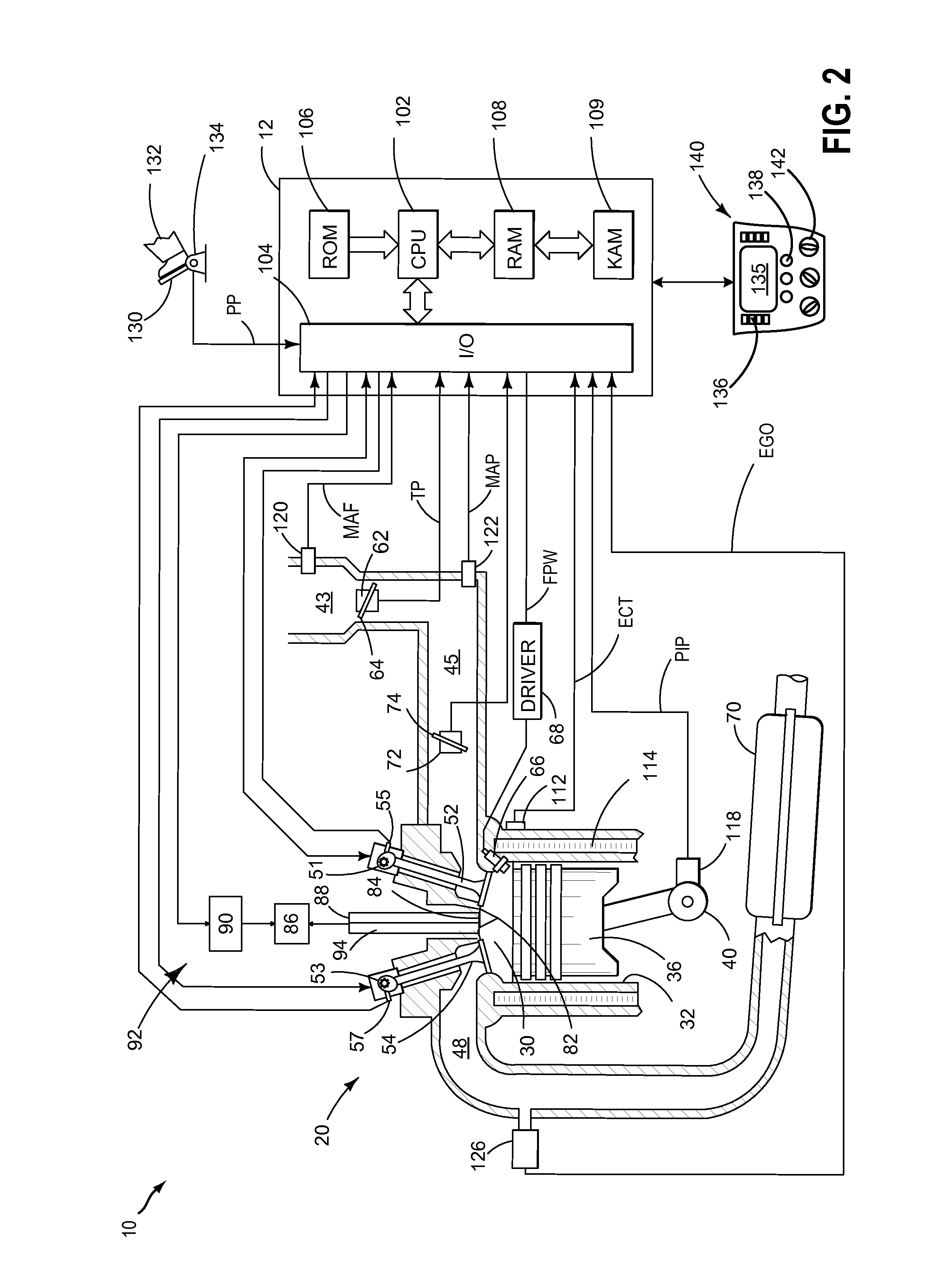

Laser ignition system based diagnostics

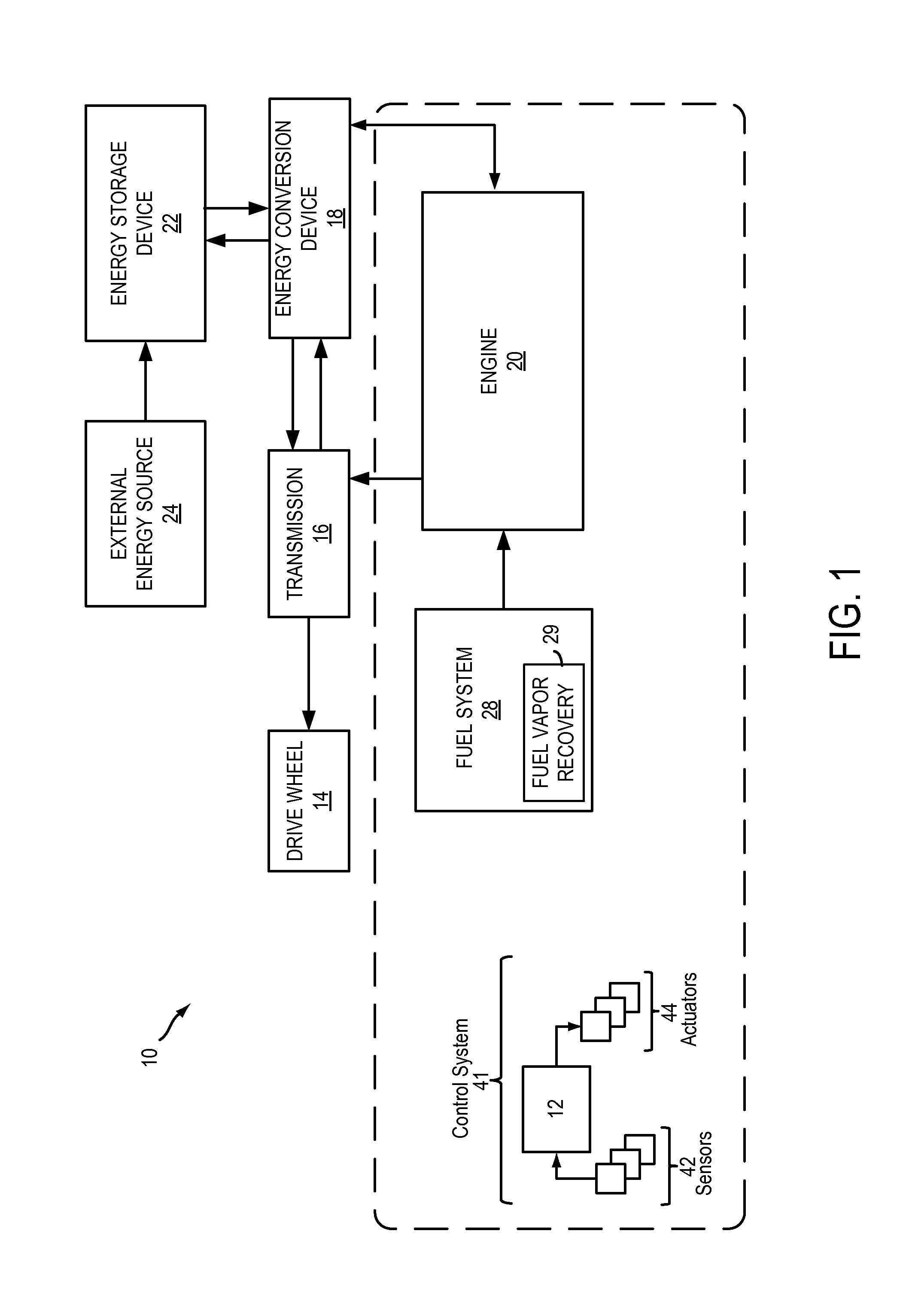

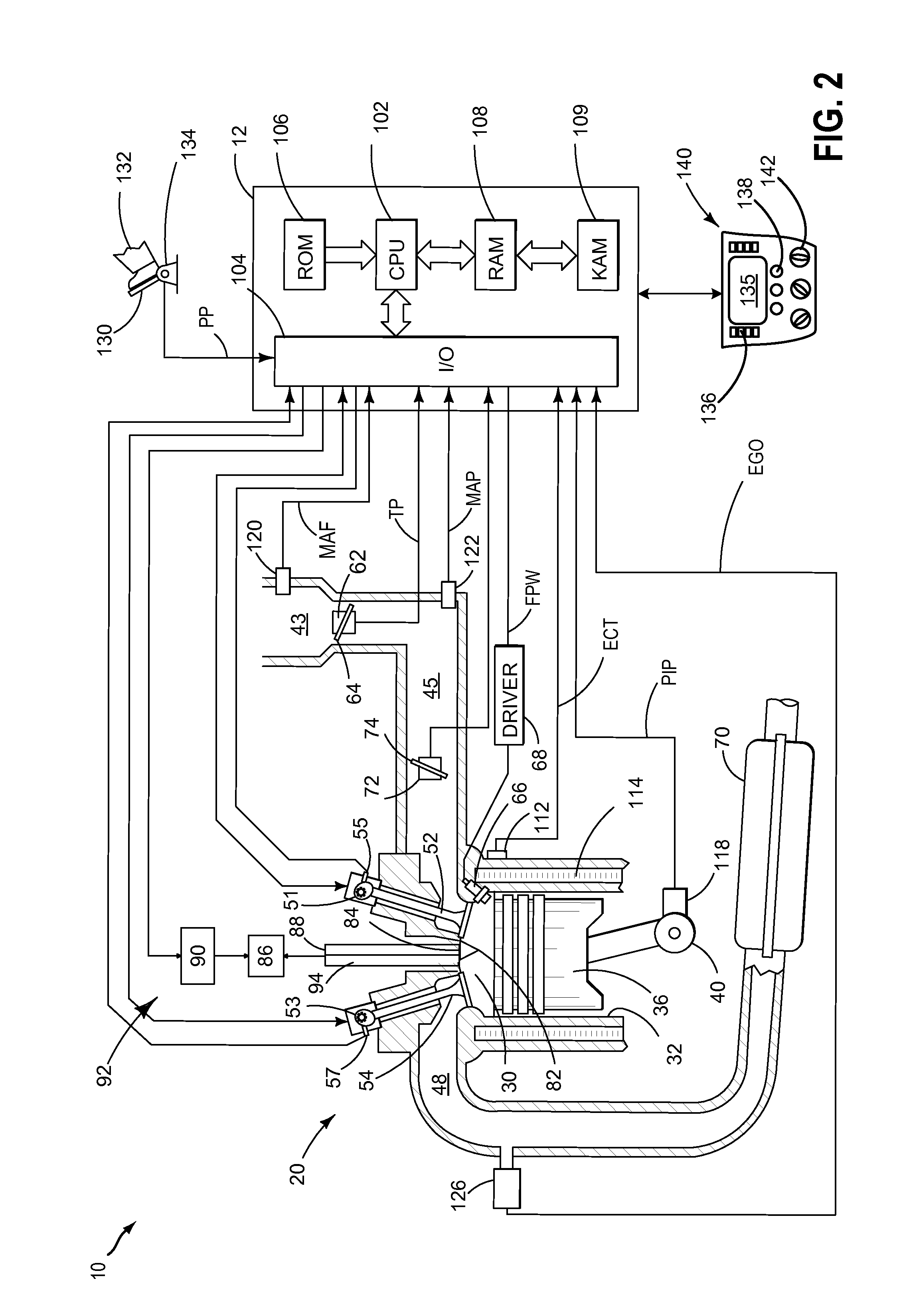

ActiveUS20140316621A1Inspection is accurateShorten the timeHybrid vehiclesAnalogue computers for vehiclesPhotovoltaic detectorsPhotodetector

Methods and systems are provided for enabling engine diagnostics, including visual inspections of an engine cylinder, using existing hardware from a laser ignition system. Light pulses from a laser ignition device are received at a photodetector during non-combusting conditions and used to generate images of an inside of the cylinder that can be assessed by a service technician. An electric motor of the vehicle system can be used during a service mode of the vehicle to rotate the engine to, and hold the engine at, specified engine positions that enable the technician to perform selected diagnostic tests.

Owner:FORD GLOBAL TECH LLC

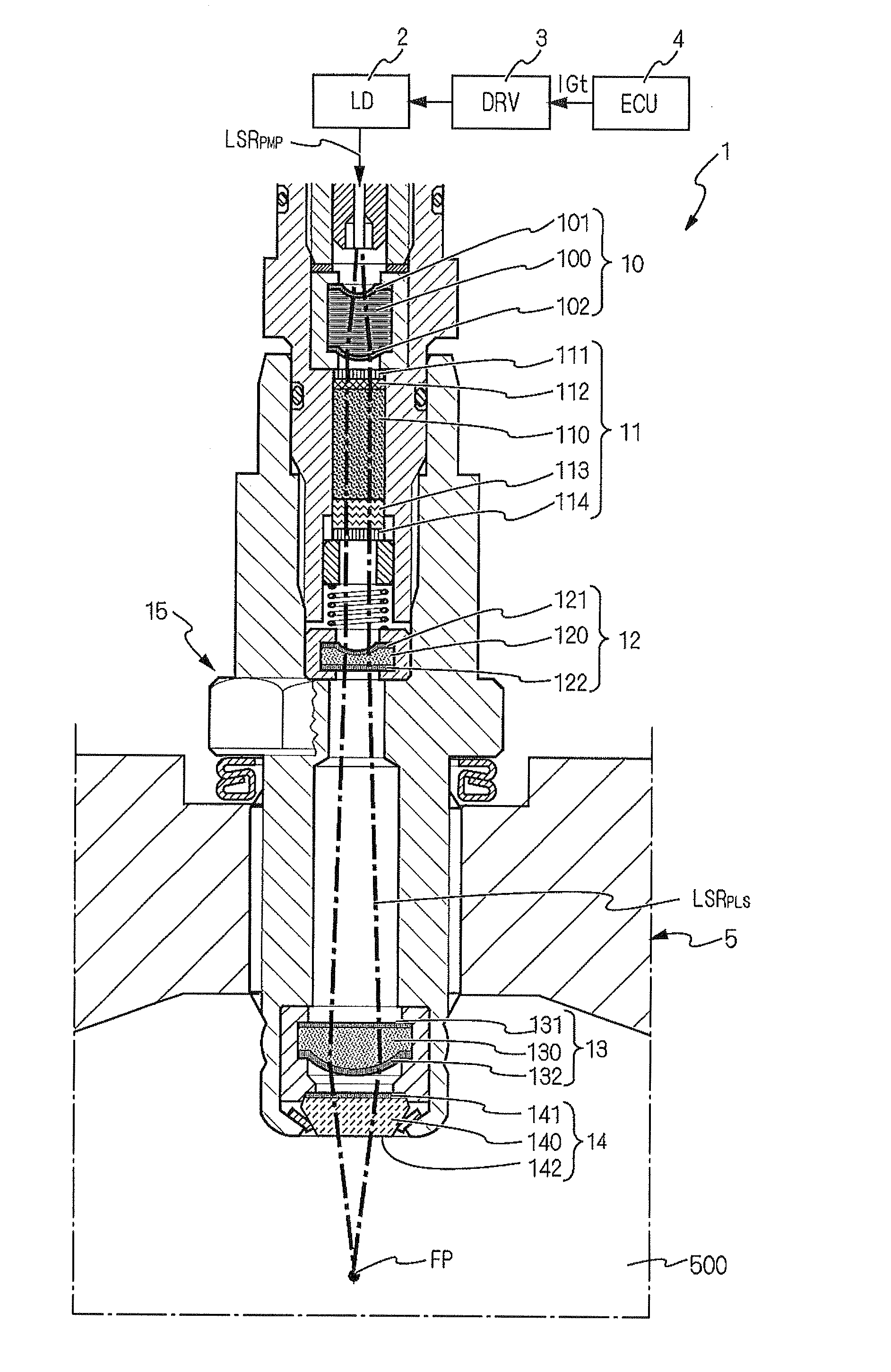

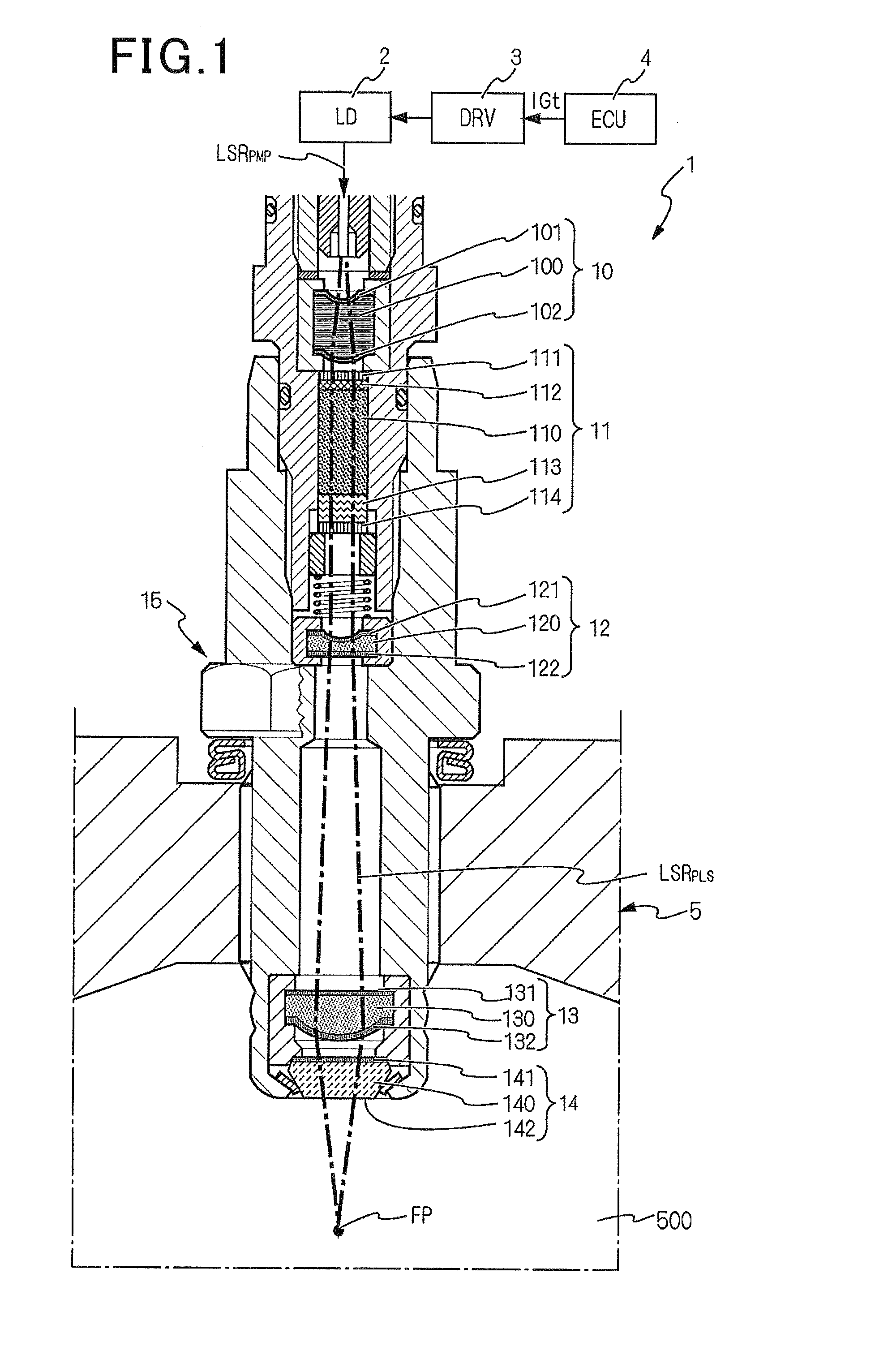

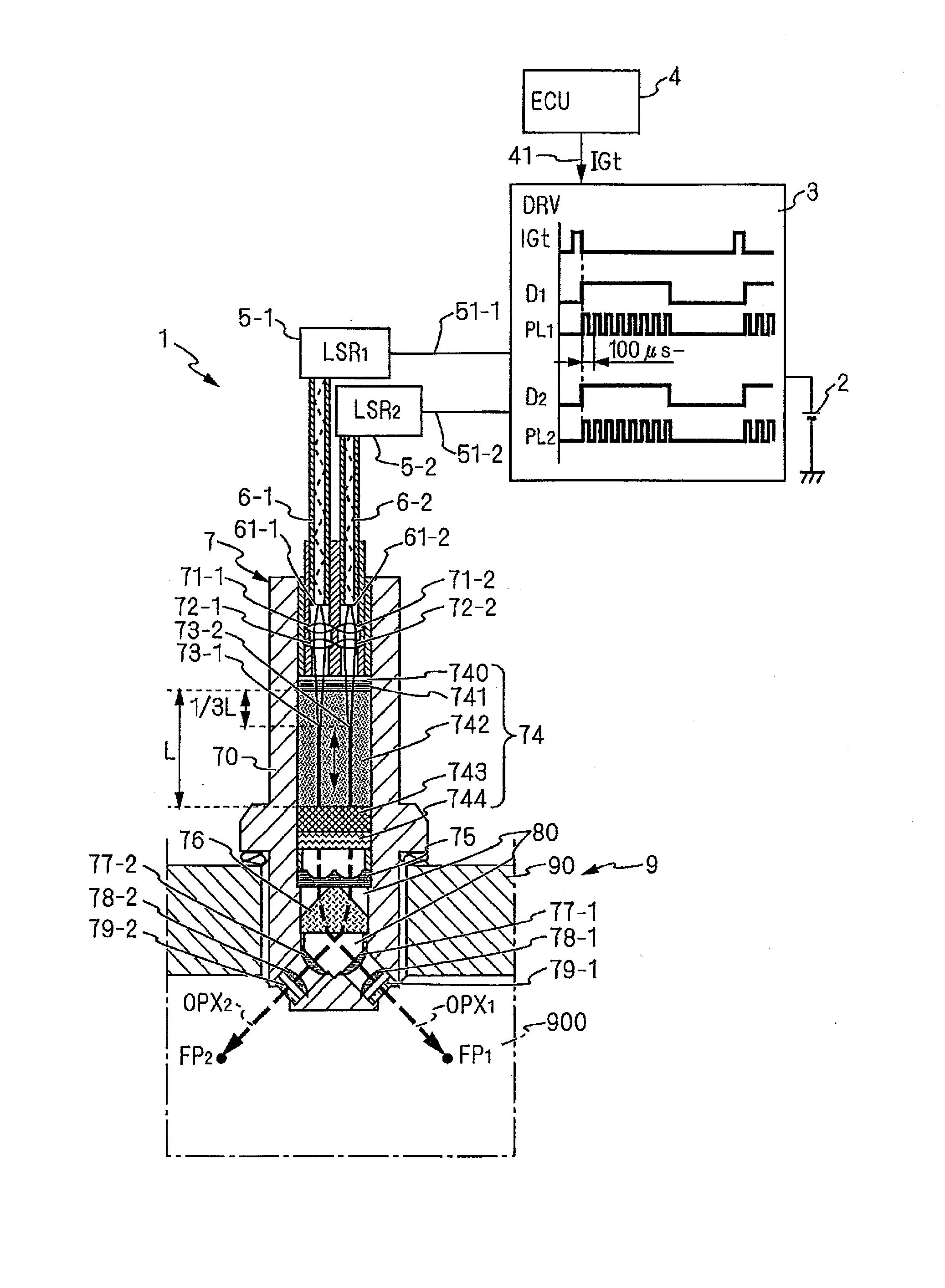

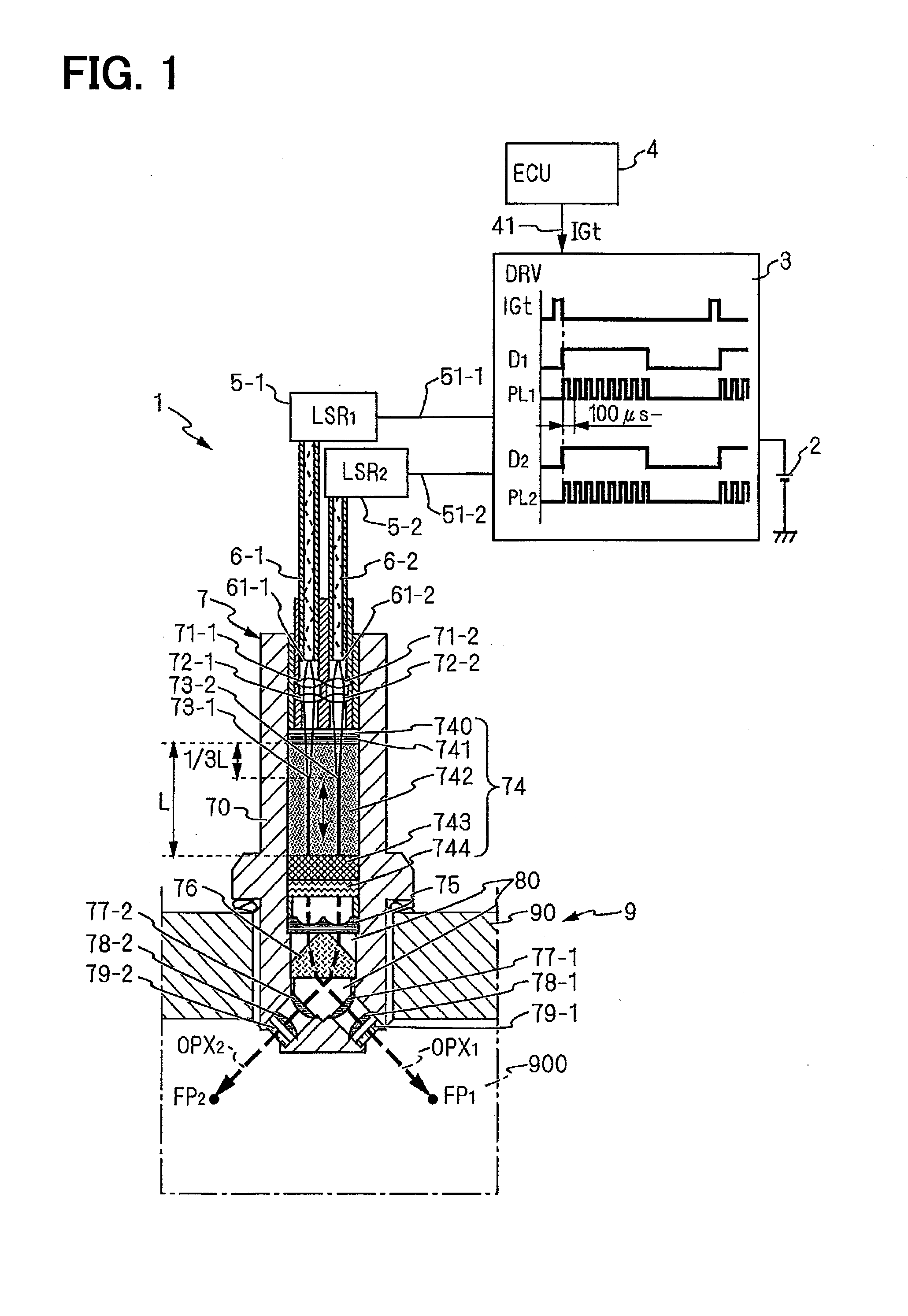

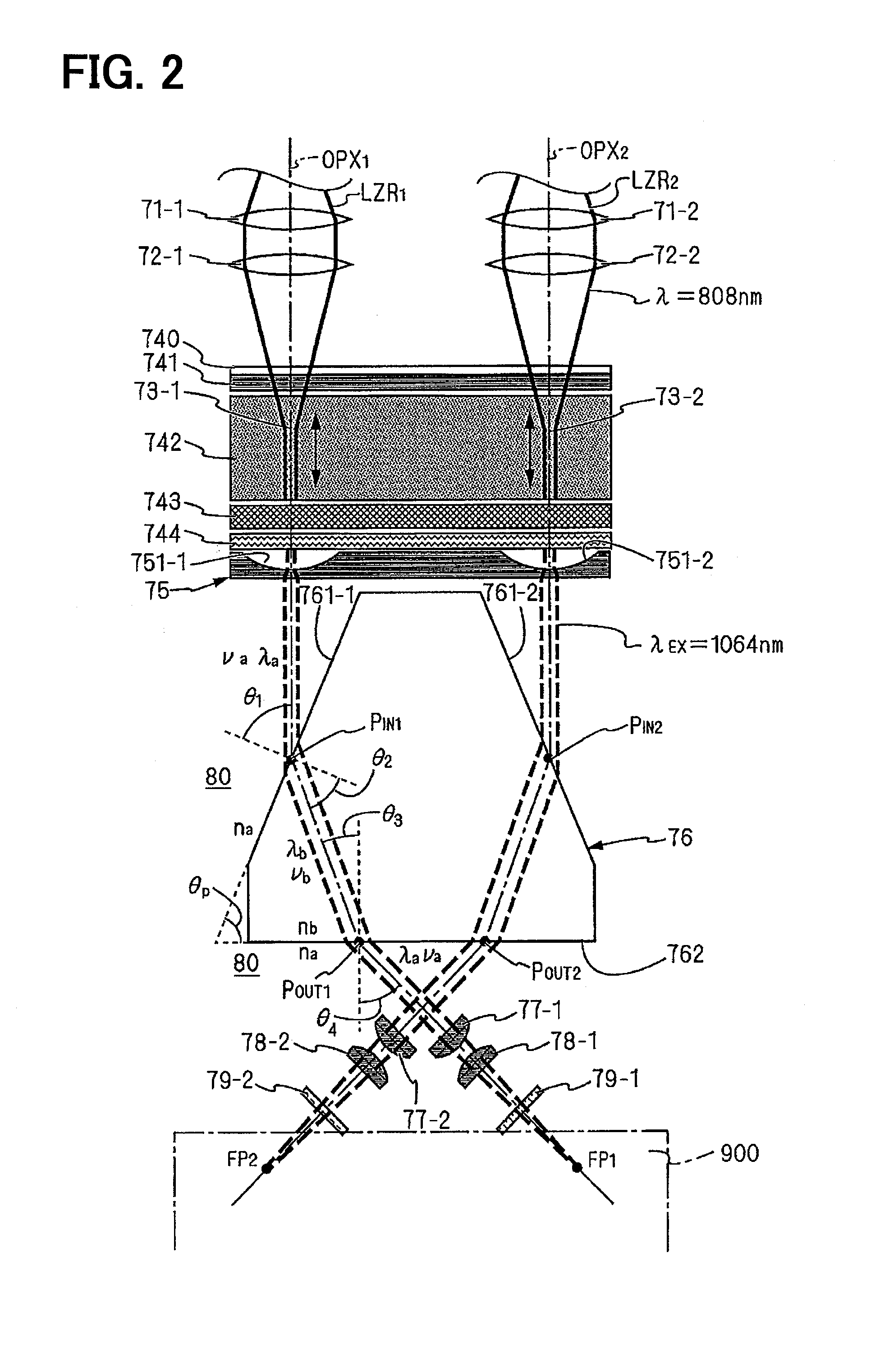

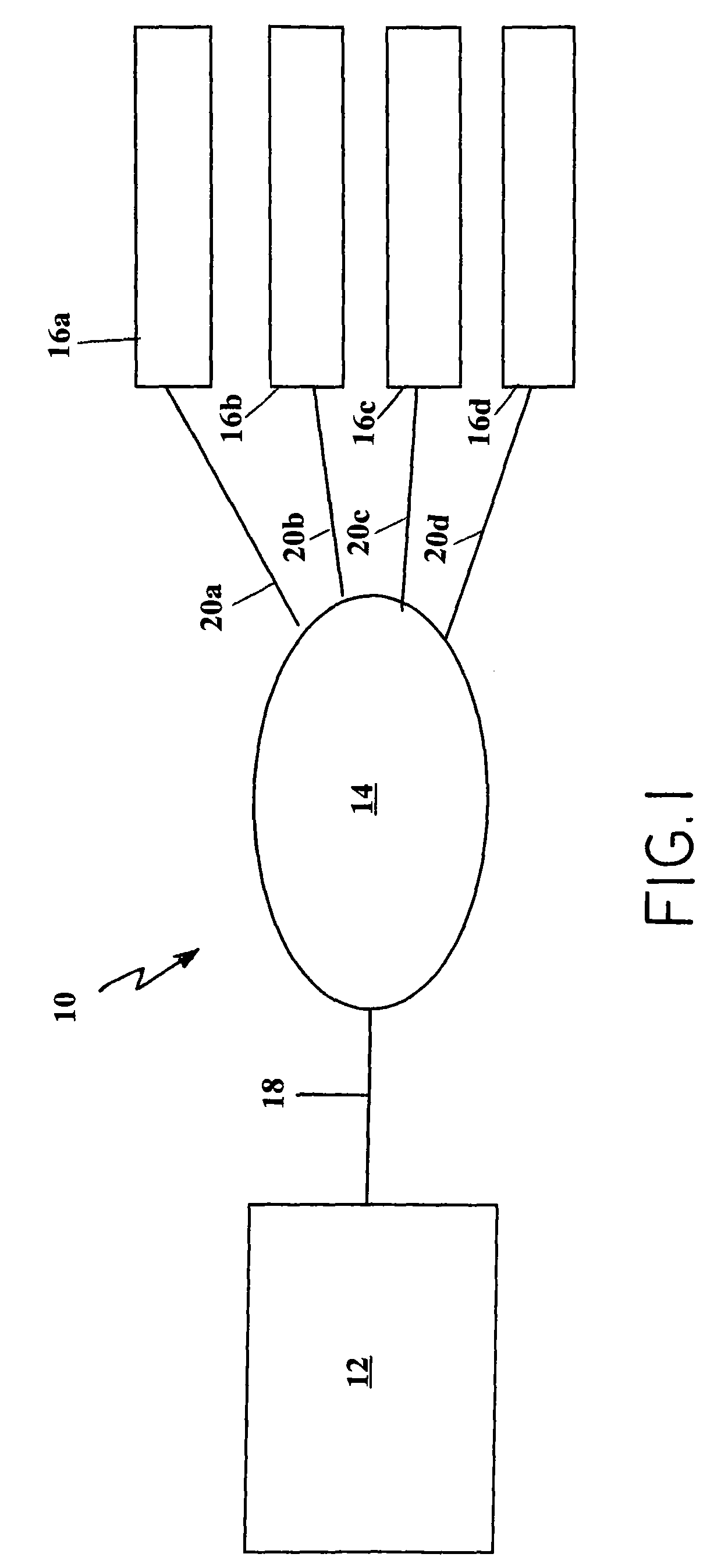

Laser ignition system

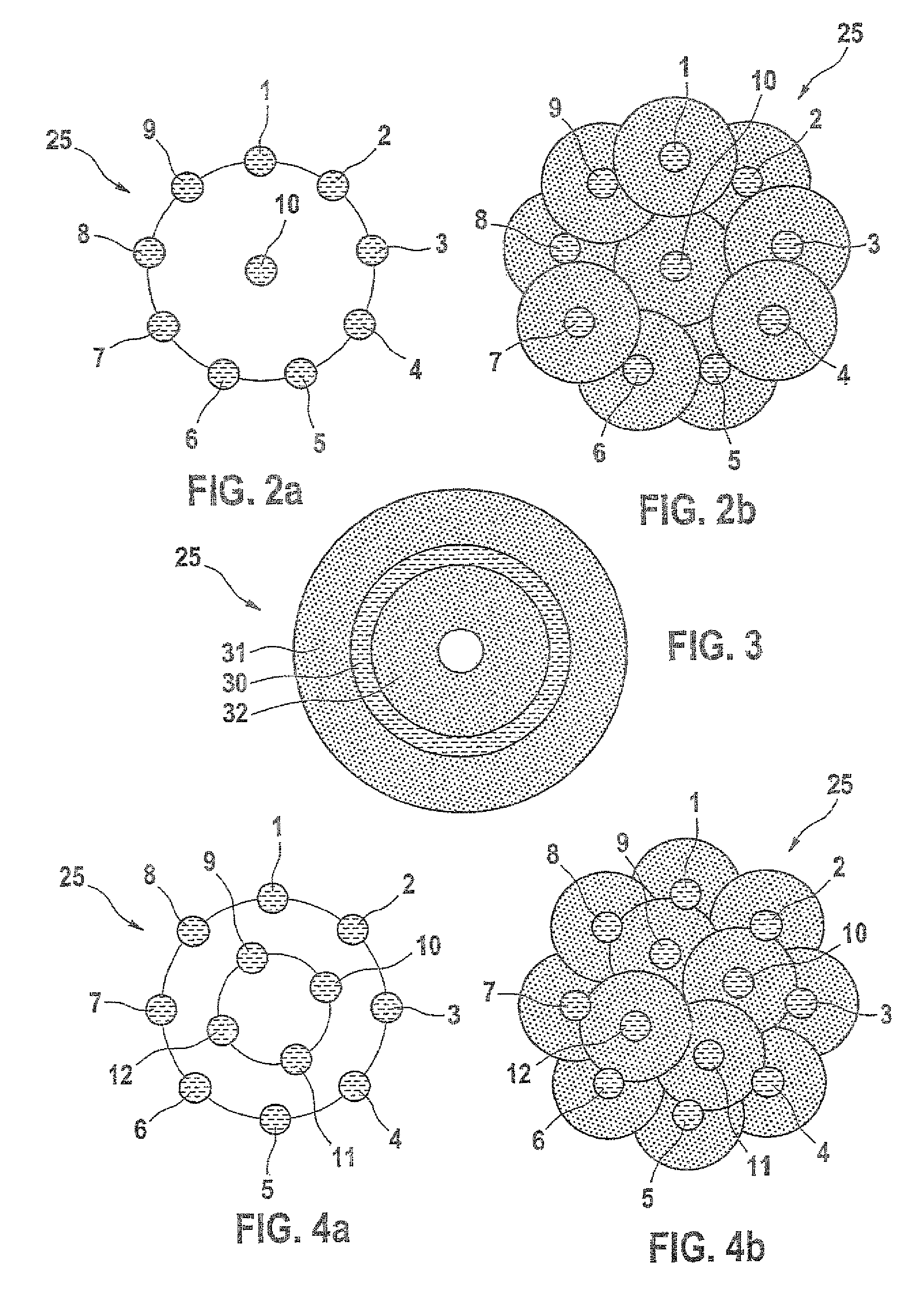

A laser ignition system that is mounted on an internal combustion engine and that condenses a laser beam oscillated from a laser oscillator into an engine combustion chamber by using a condenser lens to generate a flame kernel with high energy and to perform ignition includes at least a highly-refractive optical element that refracts optical axes OPX1 to OPXn of plural laser beams oscillated from plural semiconductor lasers 5-1 to 5-n through a resonator to change traveling directions of the laser beams and a condenser device that condenses the laser beams refracted by the highly-refractive optical element on plural positions FP1 to FPn in the engine combustion chamber.

Owner:NIPPON SOKEN +1

Laser-ignition unit

InactiveCN101463790AAchieve pre-ignitionImprove operational safetyElectric ignition installationMachines/enginesCombustion chamberOptoelectronics

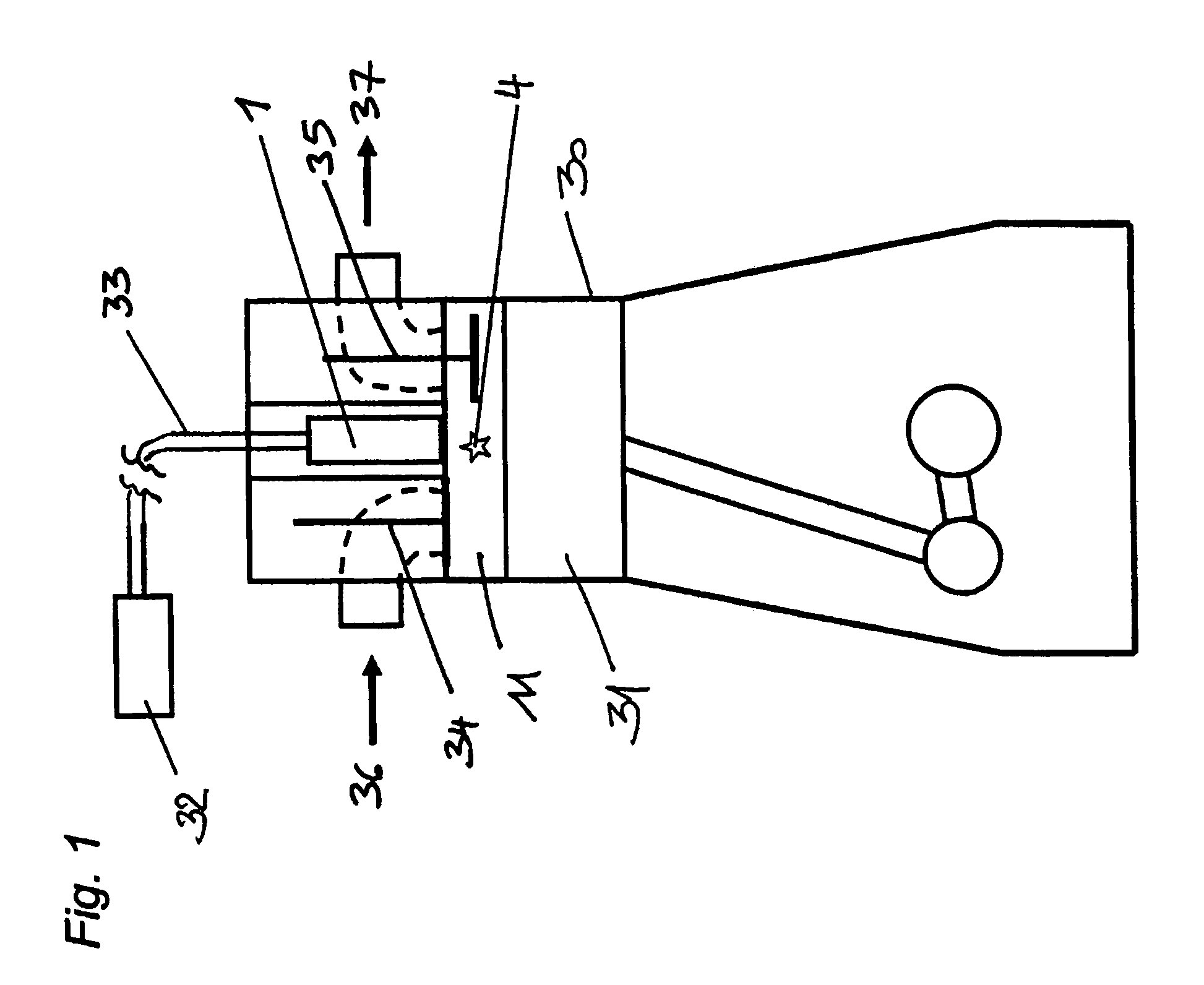

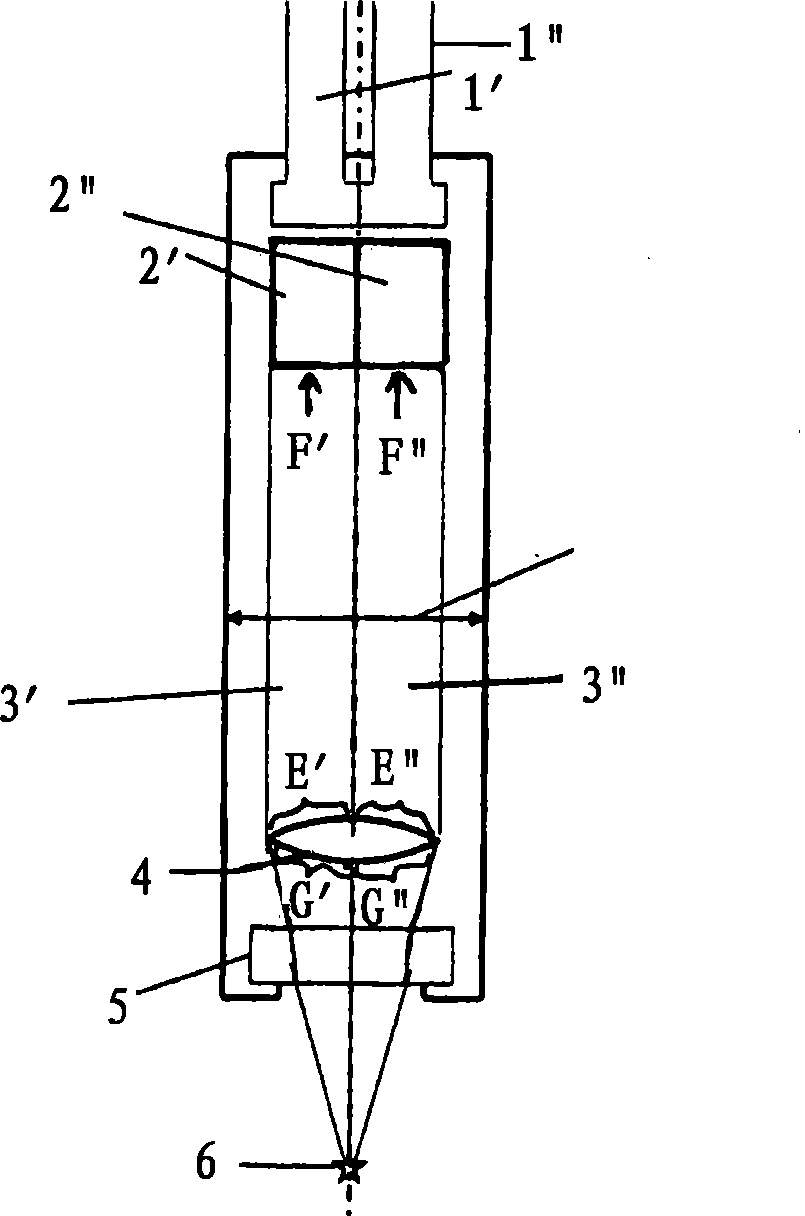

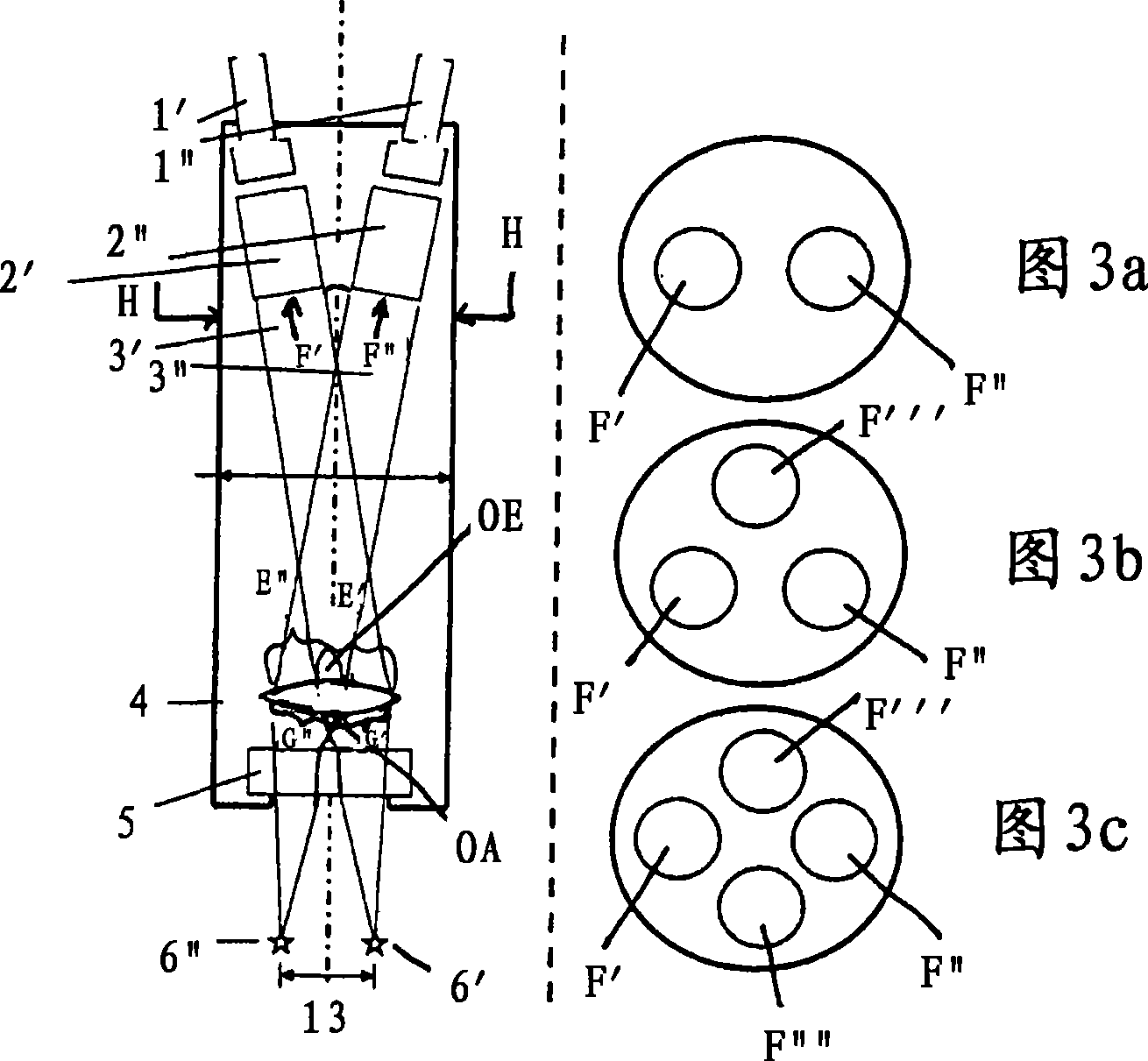

The present invention relates to a laser ignition apparatus (10), including at least two laser light generating devices (2', 2'') and a common optical coupling-in means (4) for coupling laser light (3', 3'') from the at least two laser light generating devices into a combustion chamber (11) of a combustion machine, wherein the at least two laser light generating devices are so arranged that laser light given off by the laser light generating devices in the operating condition impinges on the optical coupling-in means and / or issues from the optical coupling-in means (4) in parallel displaced relationship or at an angle to each other. There are provided laser light steering elements between the laser light generating devices and the optical coupling-in means, at least two laser light generating devices are so arranged that the ejection surface of the laser light of the first laser light generating device and the ejection surface of the laser light of the second laser light generating device are arranged at an angle different from 0. The present invention also relate to a method of igniting a fuel / air mixture in a combustion chamber of a combustion machine.

Owner:GE JENBACHER

Laser controlled flame stabilization

A method and apparatus is provided for initiating and stabilizing fuel combustion in applications such as gas turbine electrical power generating engines and jet turbine engines where it is desired to burn lean fuel / air mixtures which produce lower amounts of NOx. A laser induced spark is propagated at a distance from the fuel nozzle with the laser ignitor being remotely located from the high temperature environment of the combustion chamber. A laser initiating spark generated by focusing high peak power laser light to a sufficiently tight laser spot within the fuel to cause the ionization of air and fuel into a plasma is unobtrusive to the flow dynamics of the combustion chamber of a fuel injector, thereby facilitating whatever advantage can be taken of flow dynamics in the design of the fuel injector.

Owner:LOS ALAMOS NATIONAL SECURITY

Advanced Optics and Optical Access for Laser Ignition for Gas Turbines Including Aircraft Engines

ActiveUS20120131927A1Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion chamberEngineering

A laser ignition system for an internal combustion engine, and more specifically a gas turbine engine, is provided. The system including a laser light source configured to generate a laser beam, an ignition port configured to provide optimized optical access of the laser beam to a combustion chamber and an optical beam guidance component disposed between the laser light source and the ignition port. The optical beam guidance component is configured to include optimized optic components to transmit the laser beam to irradiate on a fuel mixture supplied into the combustion chamber to generate a combustor flame in a flame region. A method for igniting a fuel mixture in an internal combustion engine is also presented.

Owner:GENERAL ELECTRIC CO

Aerospace laser ignition/ablation variable high precision thruster

InactiveUS9021782B1Cosmonautic vehiclesCosmonautic propulsion system apparatusAviationLaser ignition

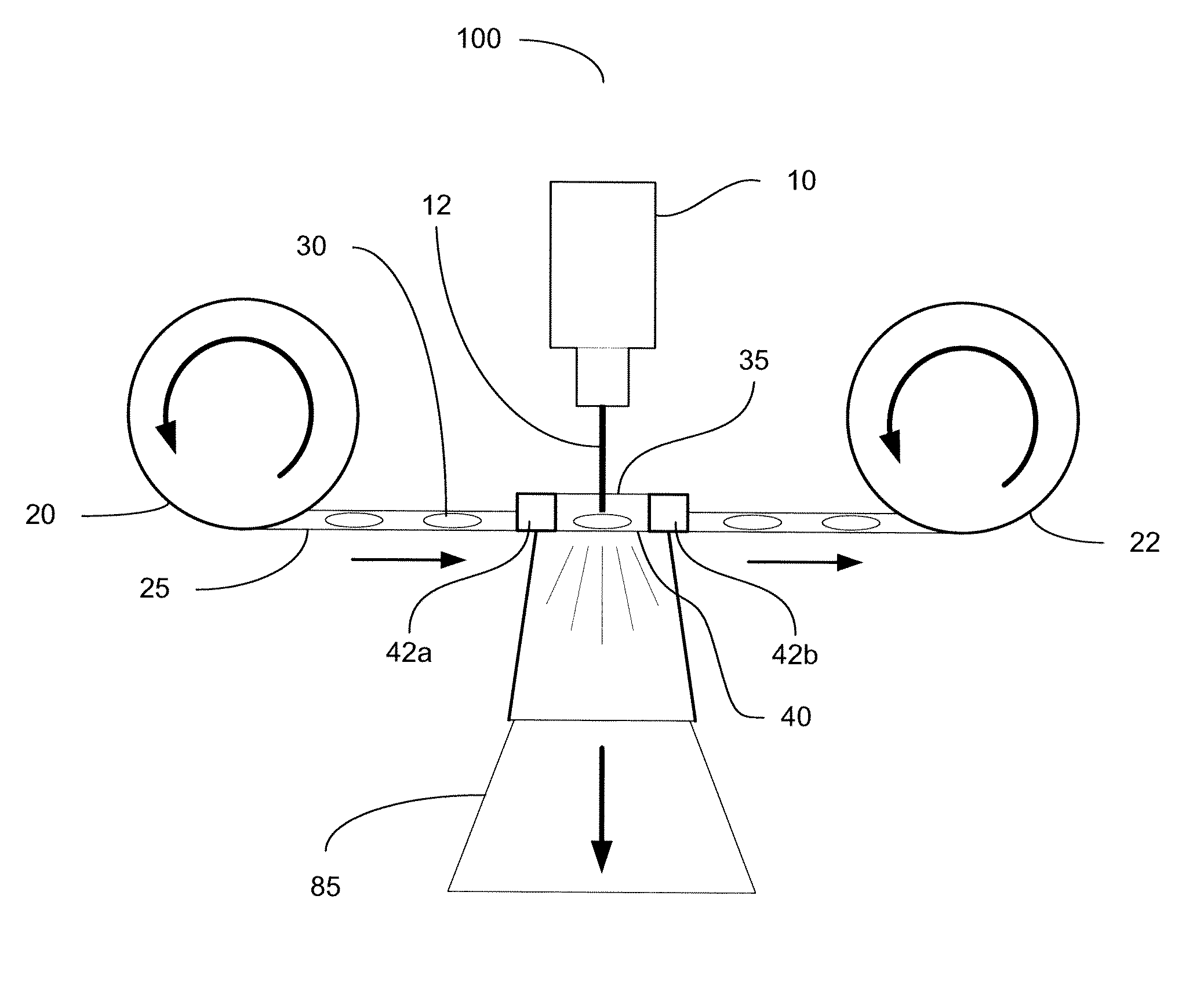

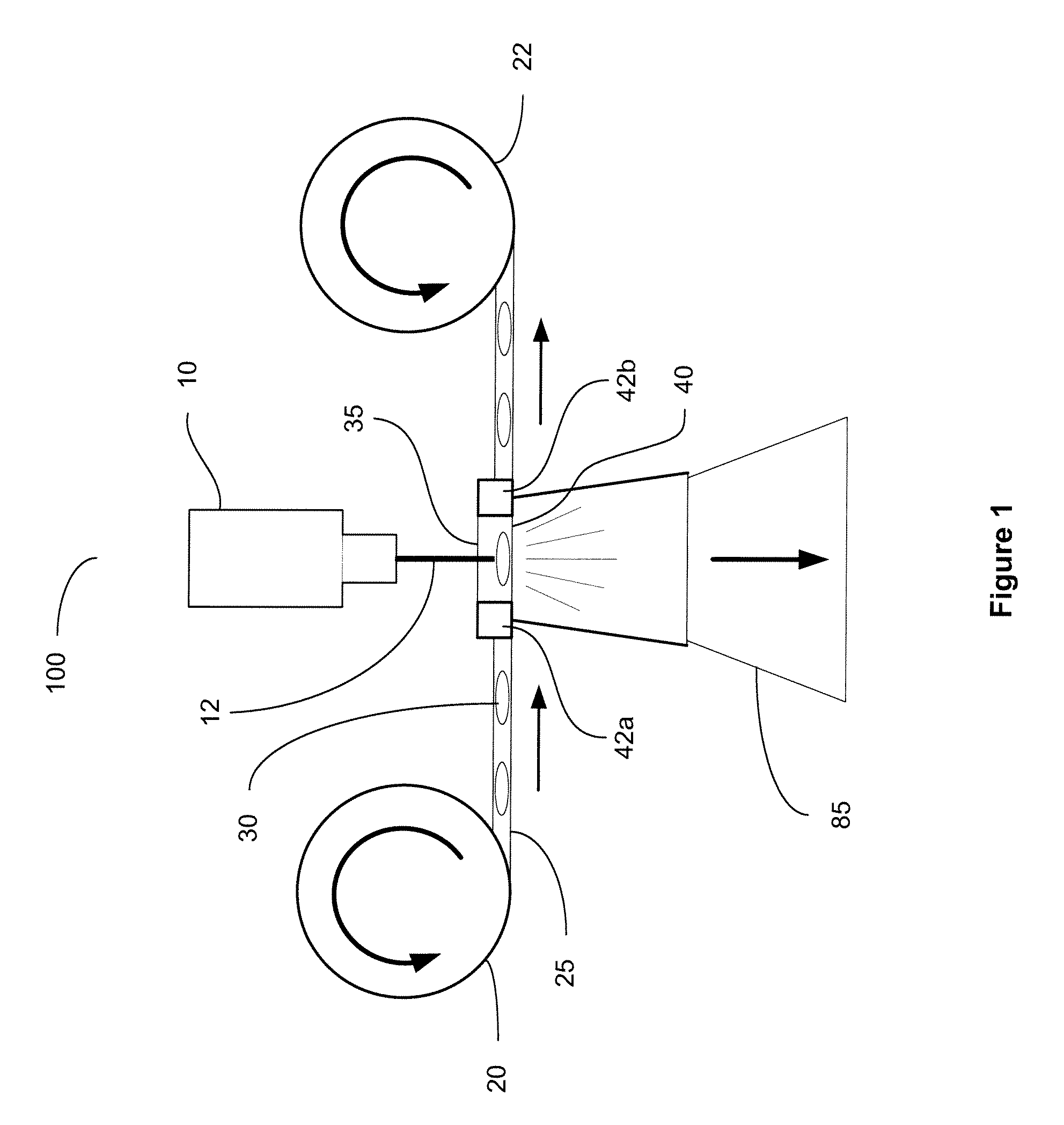

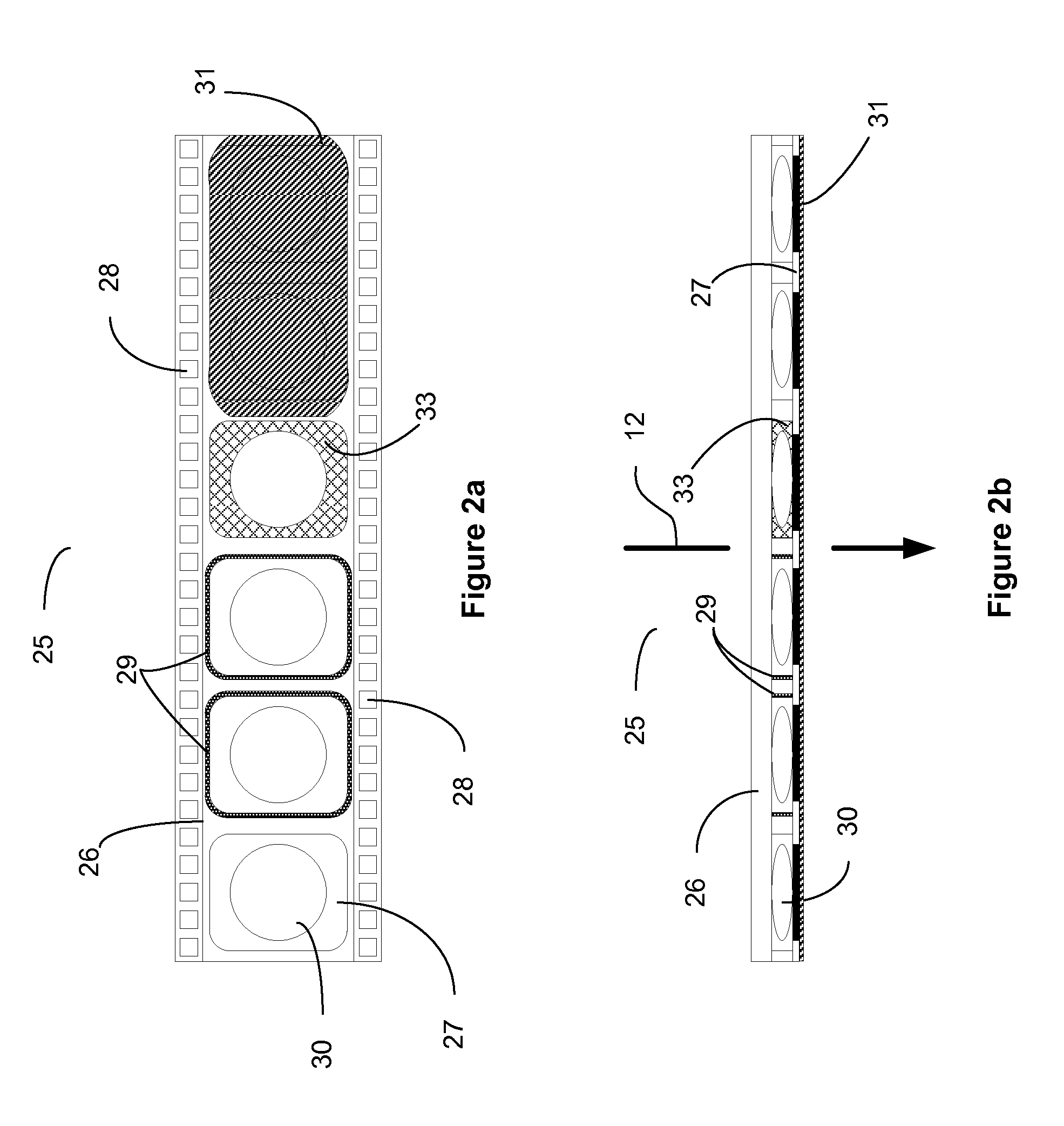

A laser ignition / ablation propulsion system that captures the advantages of both liquid and solid propulsion. A reel system is used to move a propellant tape containing a plurality of propellant material targets through an ignition chamber. When a propellant target is in the ignition chamber, a laser beam from a laser positioned above the ignition chamber strikes the propellant target, igniting the propellant material and resulting in a thrust impulse. The propellant tape is advanced, carrying another propellant target into the ignition chamber. The propellant tape and ignition chamber are designed to ensure that each ignition event is isolated from the remaining propellant targets. Thrust and specific impulse may by precisely controlled by varying the synchronized propellant tape / laser speed. The laser ignition / ablation propulsion system may be scaled for use in small and large applications.

Owner:NASA

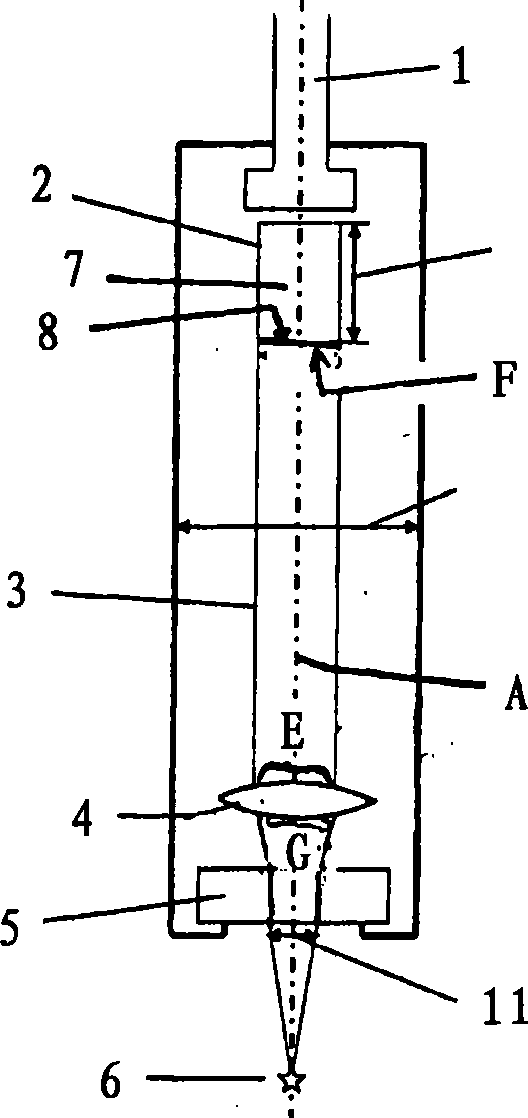

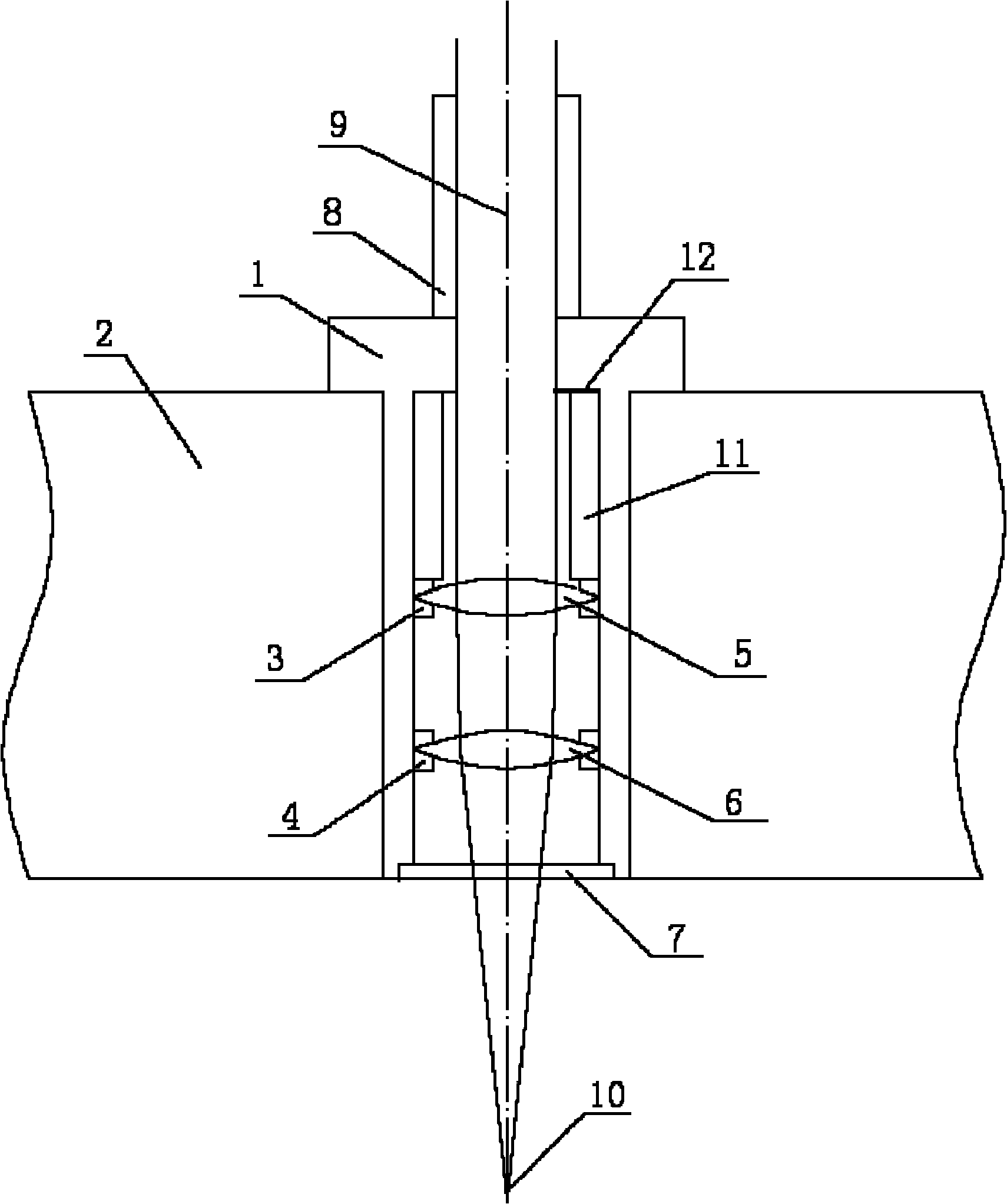

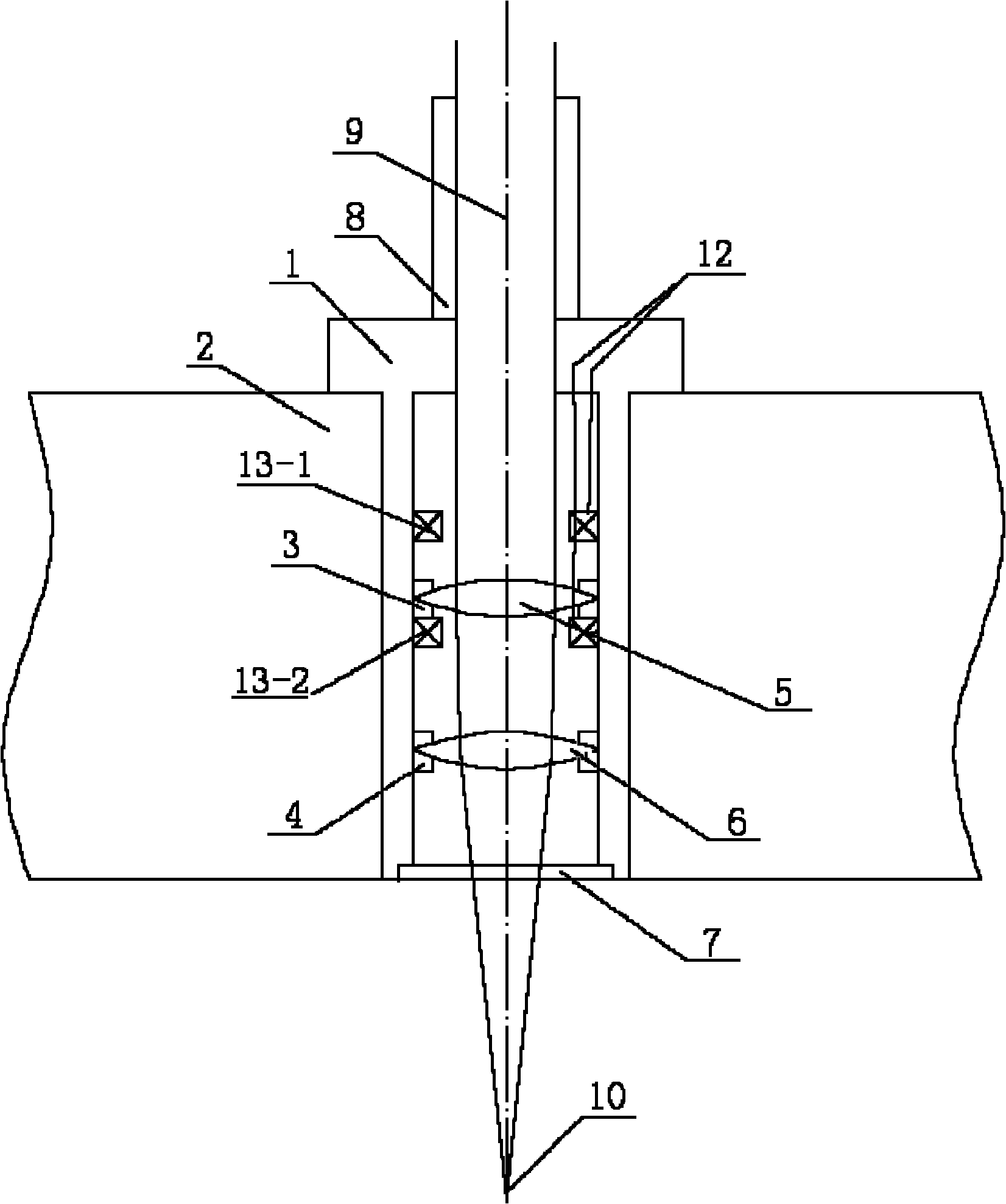

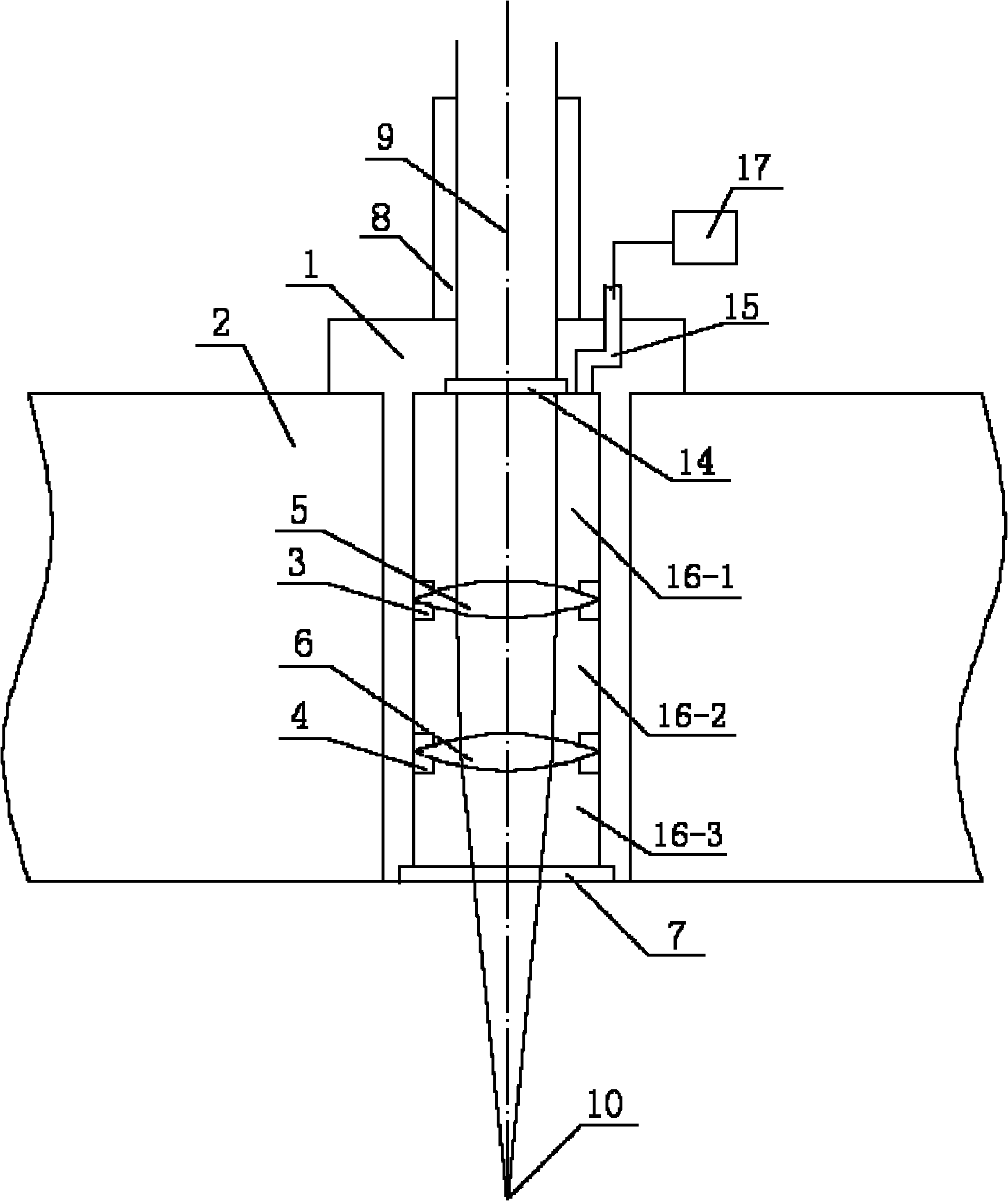

Variable-focus engine laser ignition device

The invention discloses a variable-focus engine laser ignition device, wherein the specific structure is that an optical fiber is fixed to a cylinder cover through a laser igniter shell; a primary lens fixing seat and a secondary lens fixing seat are arranged in the laser igniter shell; and a primary lens and a secondary lens are horizontally embedded in the lens fixing seats respectively. The lower end of the secondary lens fixing seat is provided with a protection mirror; a laser beam is emitted into a cylinder through the optical fiber, the primary lens, the secondary lens and the protection mirror and converged on a focus point. Drive mechanisms of three manners are arranged above or below the primary lens fixing seat so that the primary lens generates displacement. According to the invention, the relative position of the laser focus in the cylinder can be adjusted according to the requirements of different work conditions. The laser igniter has a small volume about 1 / 10 that of a spark plug, and one end of the laser igniter connected into an air cylinder only consists of an optical fiber and a lens. Compared with the spark plug, the laser igniter has the characteristics of small energy consumption and high reliability. The laser igniter is in a non-contact ignition manner, thereby avoiding the problem of carbon deposition close to the spark plug electrode.

Owner:TIANJIN UNIV

Laser spark distribution and ignition system

InactiveUS7421166B1High energyHigh energy sparkSparking plugsElectric ignition installationCombustion chamberLaser-induced breakdown spectroscopy

A laser spark distribution and ignition system that reduces the high power optical requirements for use in a laser ignition and distribution system allowing for the use of optical fibers for delivering the low peak energy pumping pulses to a laser amplifier or laser oscillator. An optical distributor distributes and delivers optical pumping energy from an optical pumping source to multiple combustion chambers incorporating laser oscillators or laser amplifiers for inducing a laser spark within a combustion chamber. The optical distributor preferably includes a single rotating mirror or lens which deflects the optical pumping energy from the axis of rotation and into a plurality of distinct optical fibers each connected to a respective laser media or amplifier coupled to an associated combustion chamber. The laser spark generators preferably produce a high peak power laser spark, from a single low power pulse. The laser spark distribution and ignition system has application in natural gas fueled reciprocating engines, turbine combustors, explosives and laser induced breakdown spectroscopy diagnostic sensors.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

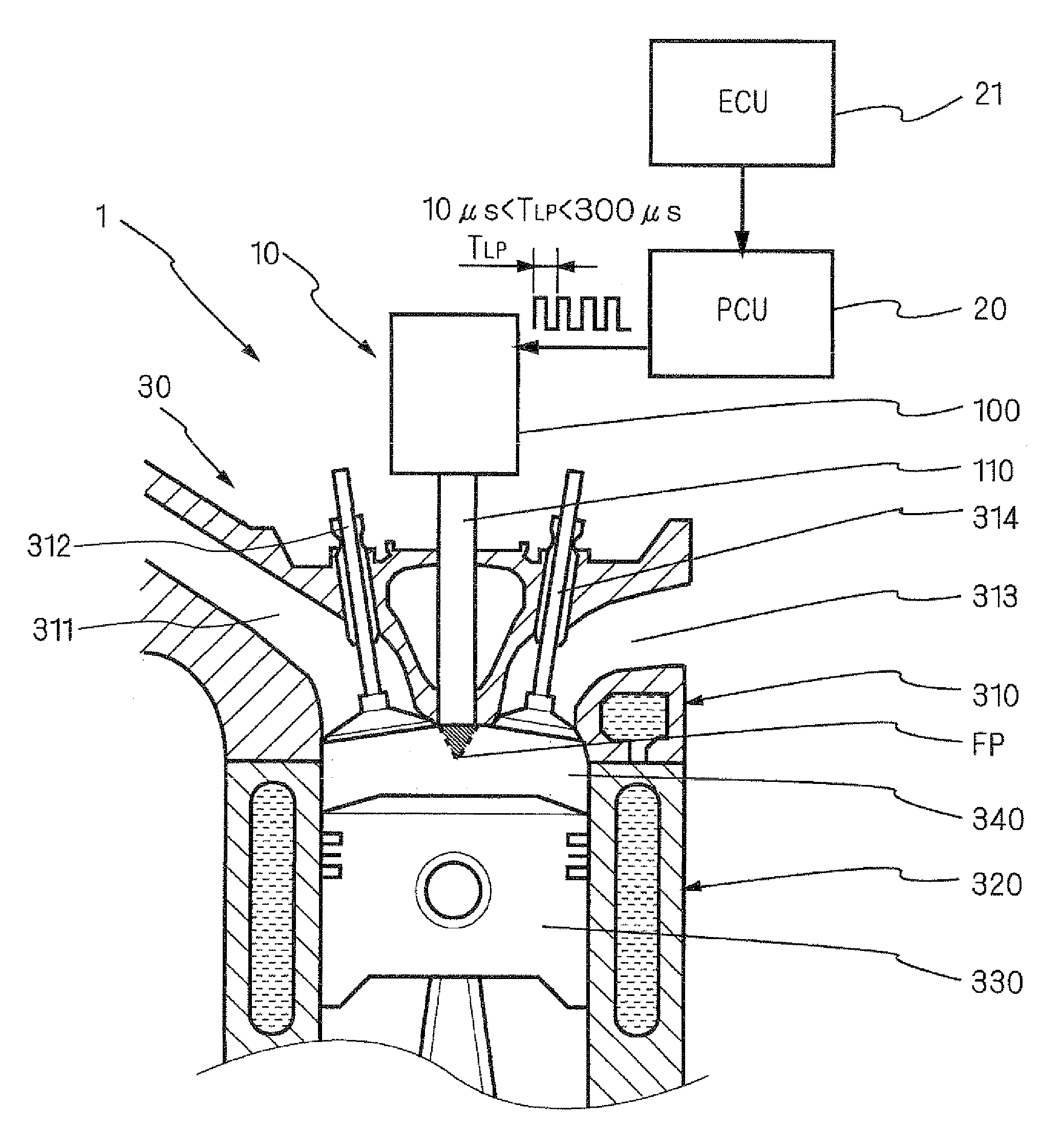

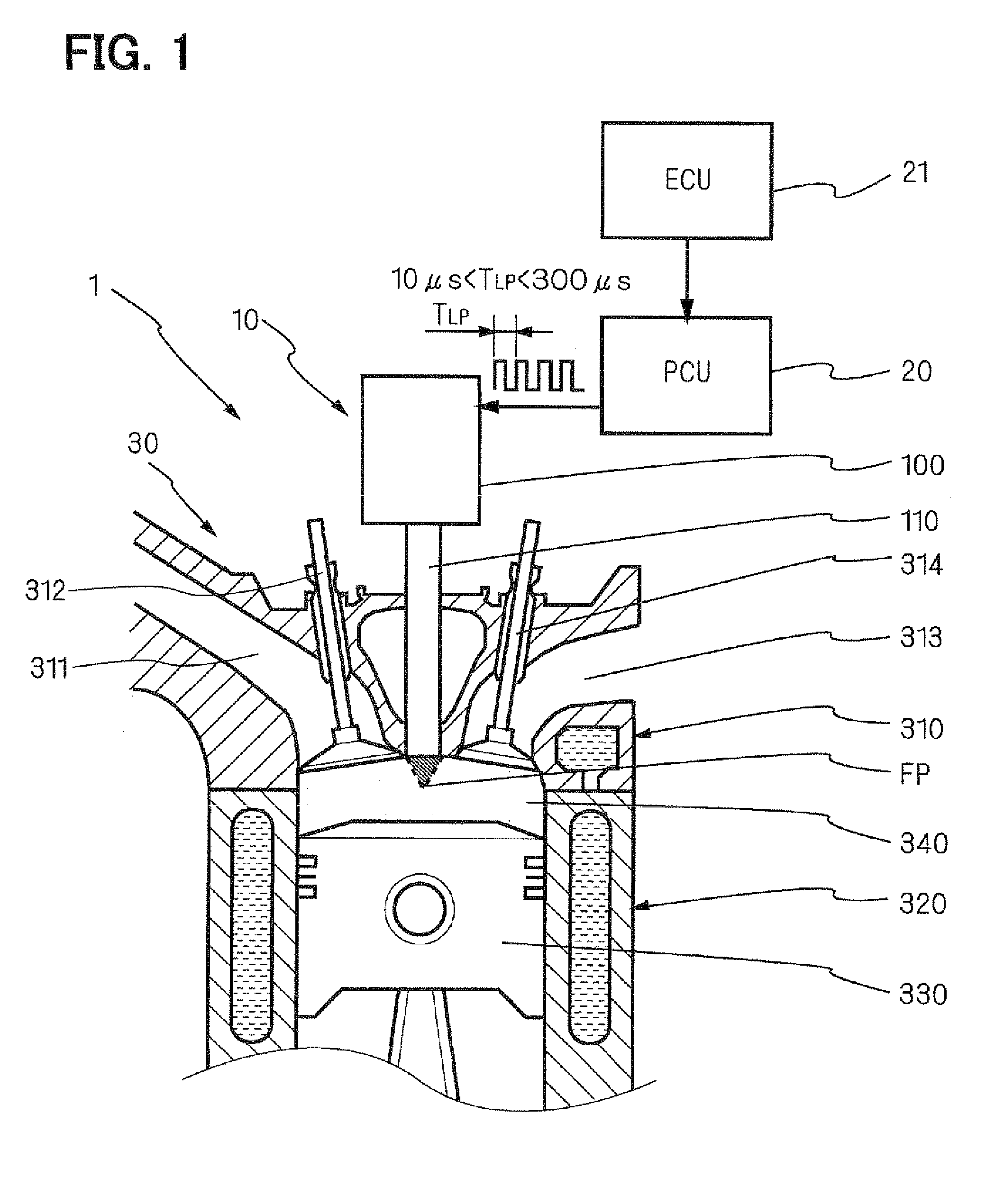

Laser ignition system

A laser ignition system includes a laser oscillator and an oscillation controller. The laser oscillator is configured to generate laser light into a combustion chamber of an engine. The oscillation controller is configured to cause the laser oscillator to generate a plurality of laser pulses into the combustion chamber in order to ignite the engine. The oscillation controller causes the laser oscillator to generate each of the plurality of laser pulses at a laser oscillation period that is longer than 10 μs and shorter than 300 μs.

Owner:DENSO CORP +1

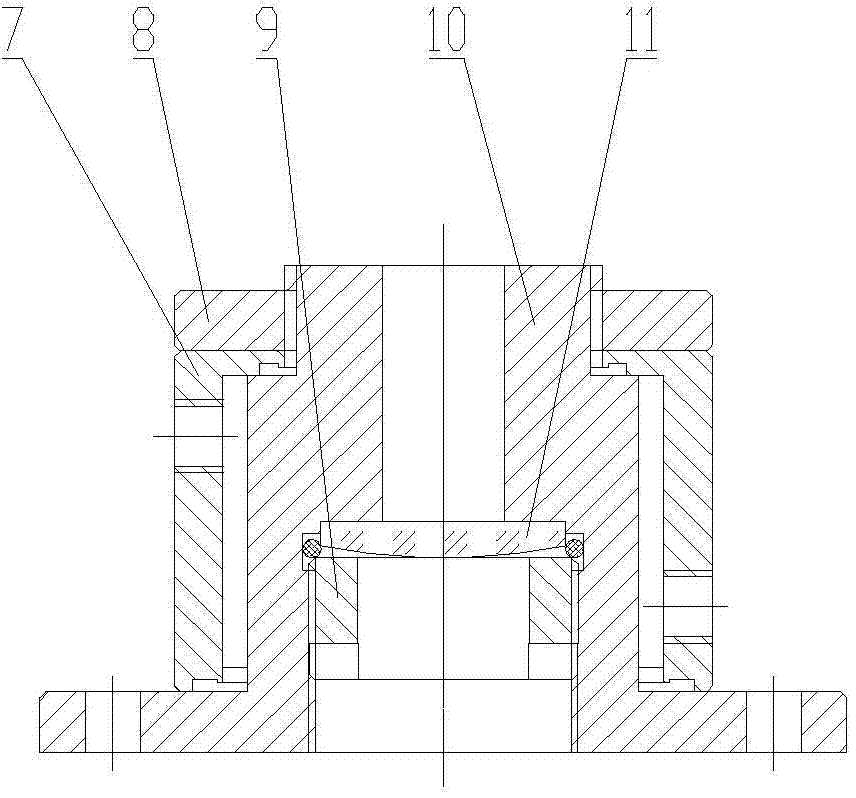

Signal acquisition device based on experiments of laser-induced ignition of solid propellants

ActiveCN104181160AHigh measurement accuracyError ignoreMaterial analysis by optical meansCombustion chamberData acquisition

The invention discloses a signal acquisition device based on experiments of laser-induced ignition of solid propellants. The signal acquisition device comprises image recording equipment, a light-emitting diode, a flame photodiode, a laser photodiode, an amplifying circuit and a data acquisition card, wherein the laser photodiode is close to the wall of a laser tube; the flame photodiode is arranged outside a view window of a combustion chamber and is in positional correspondence with the view window; an input end of the amplifying circuit is connected with the laser photodiode, and an output end of the amplifying circuit is connected with the light-emitting diode; the light-emitting diode is arranged in a photographable visual angle of the image recording equipment, and the image recording equipment is arranged outside the view window of the combustion chamber and is in positional correspondence with the view window; a signal input end of the data acquisition card is connected with the laser photodiode and the flame photodiode. The signal acquisition device is simple in principle, high in precision and reasonable in cost and is convenient to operate.

Owner:NANJING UNIV OF SCI & TECH

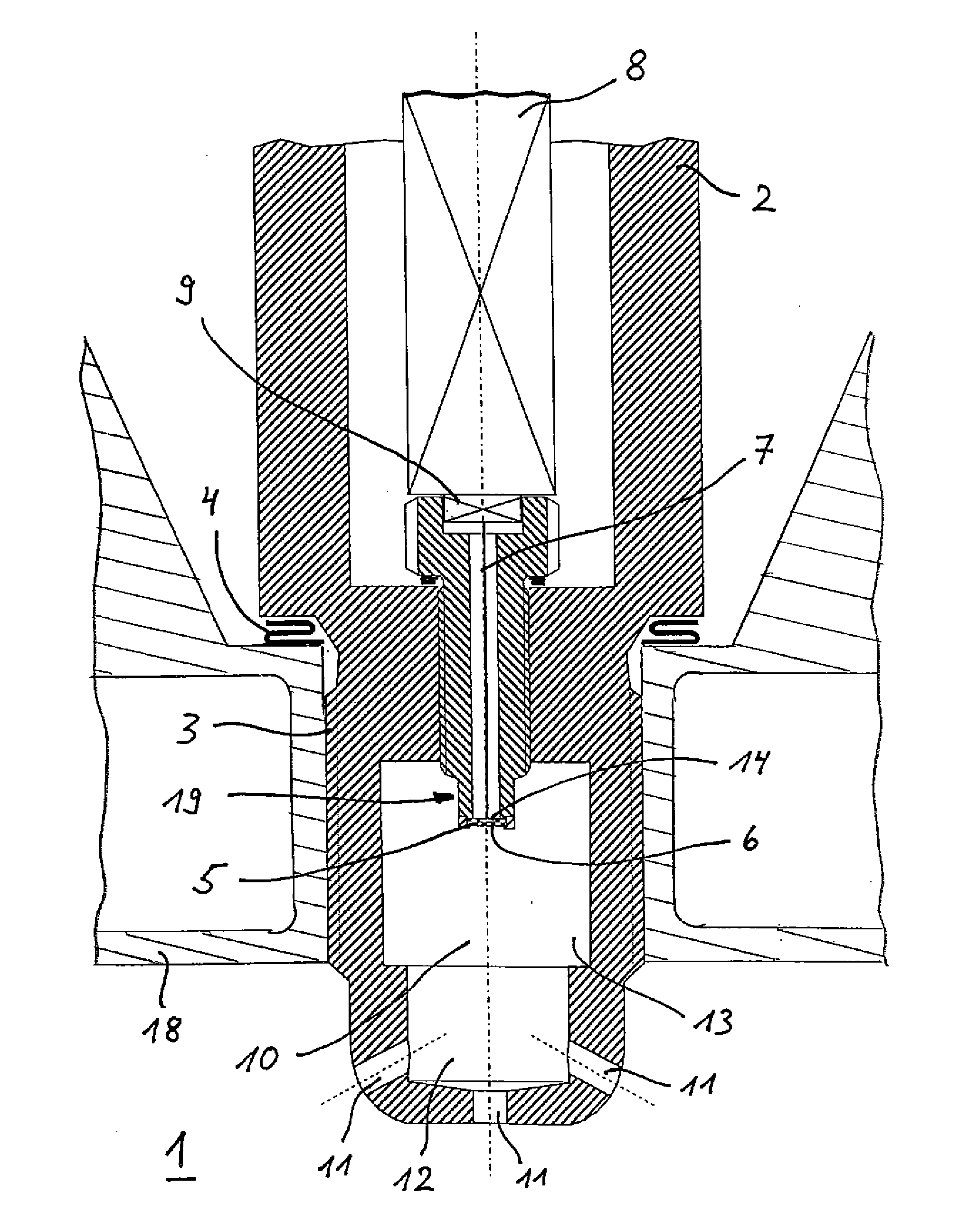

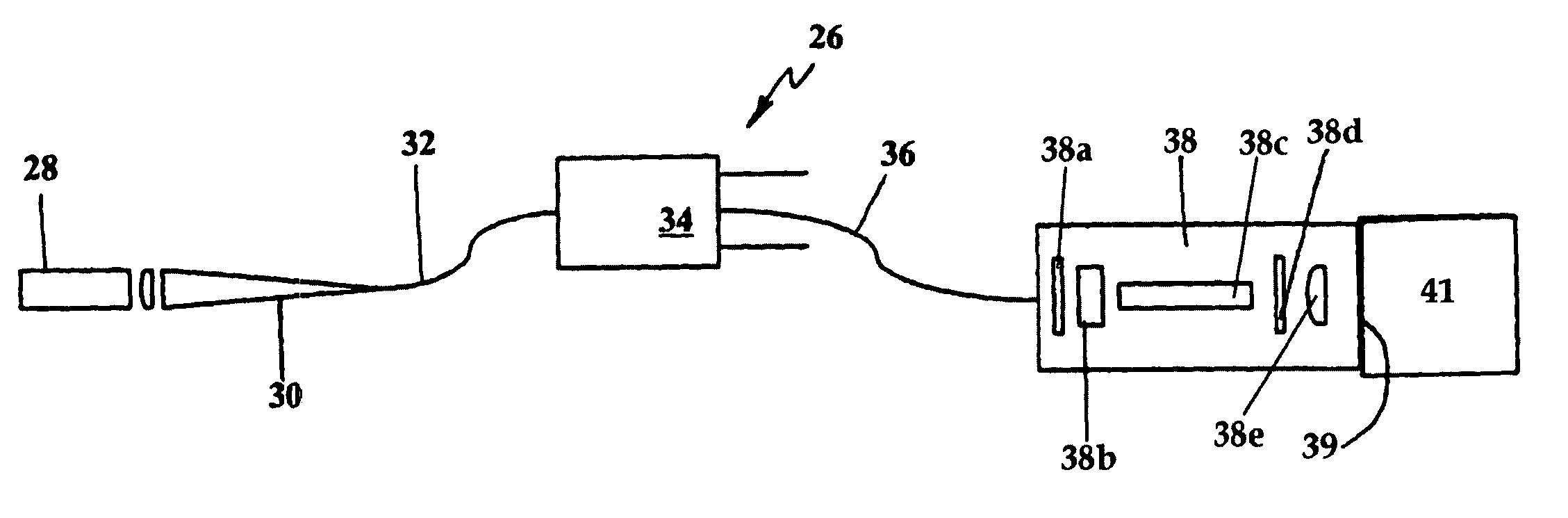

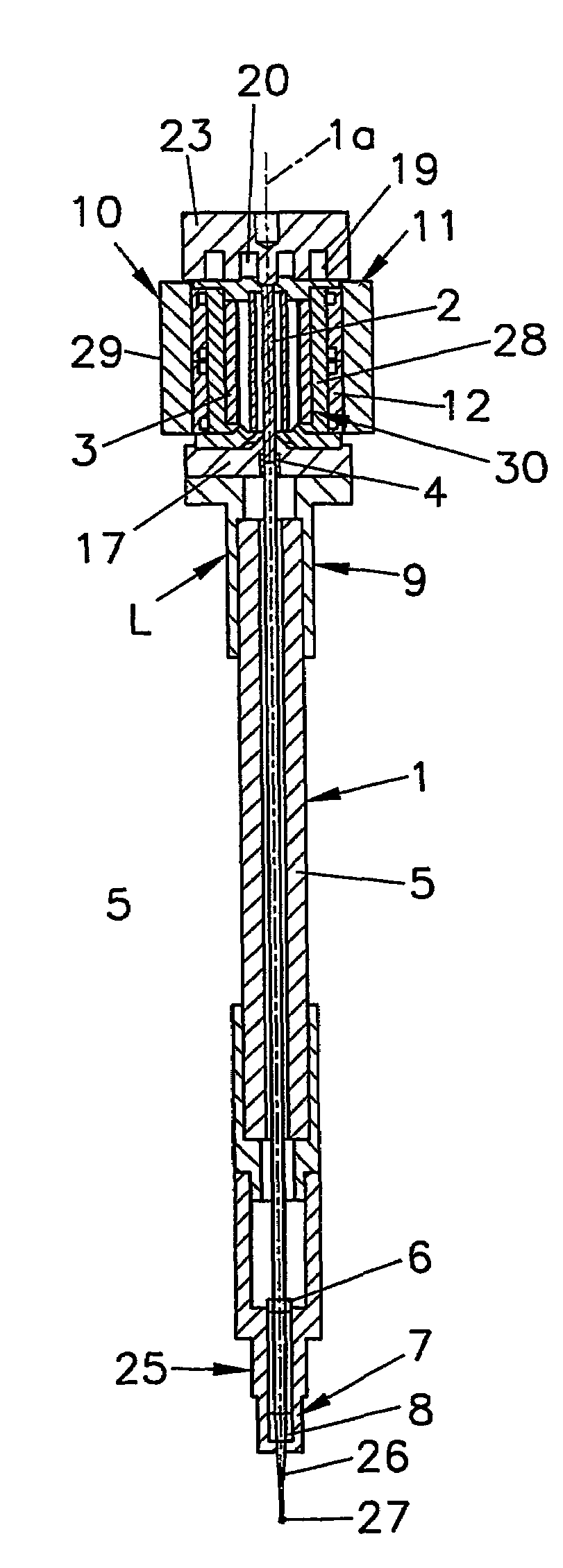

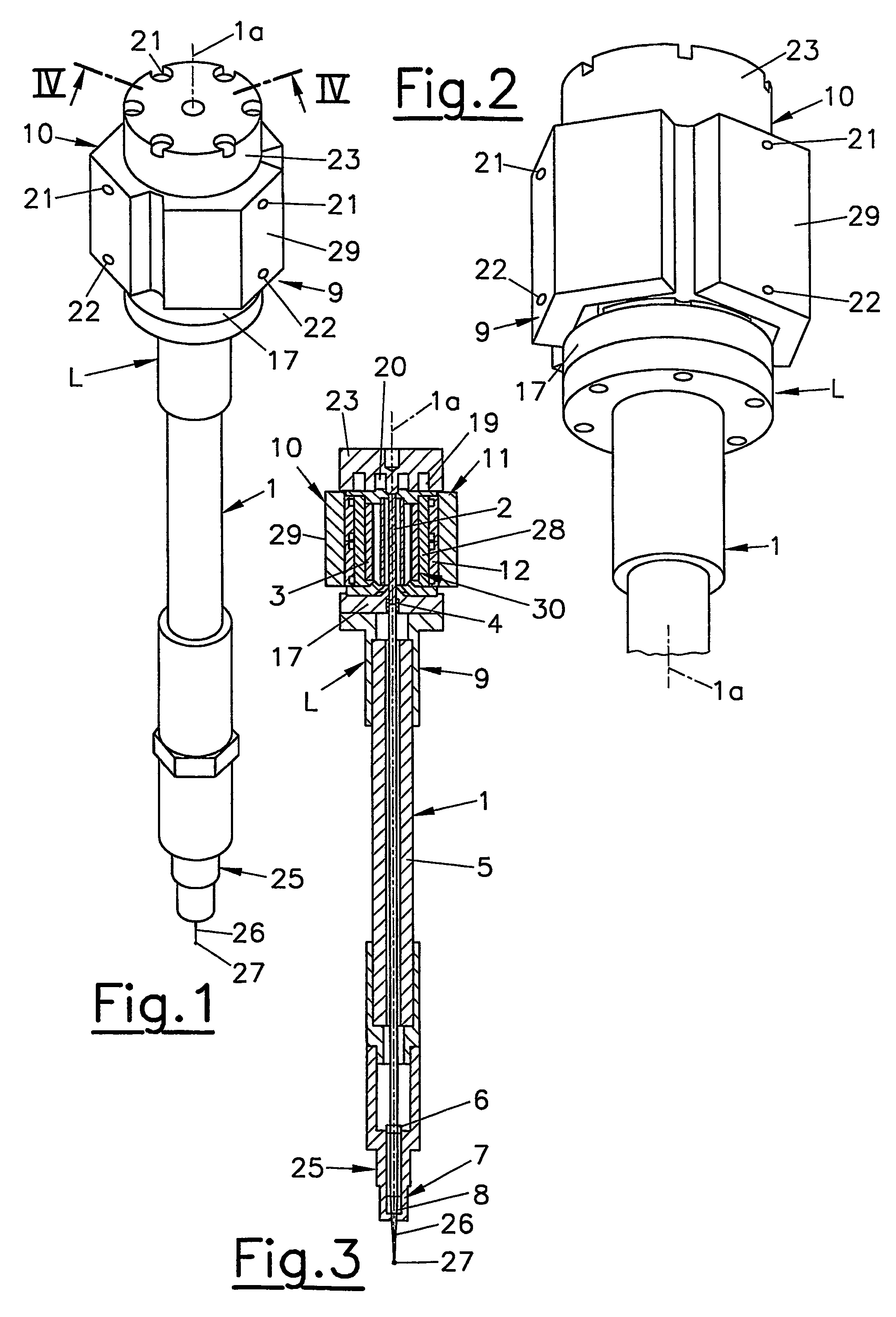

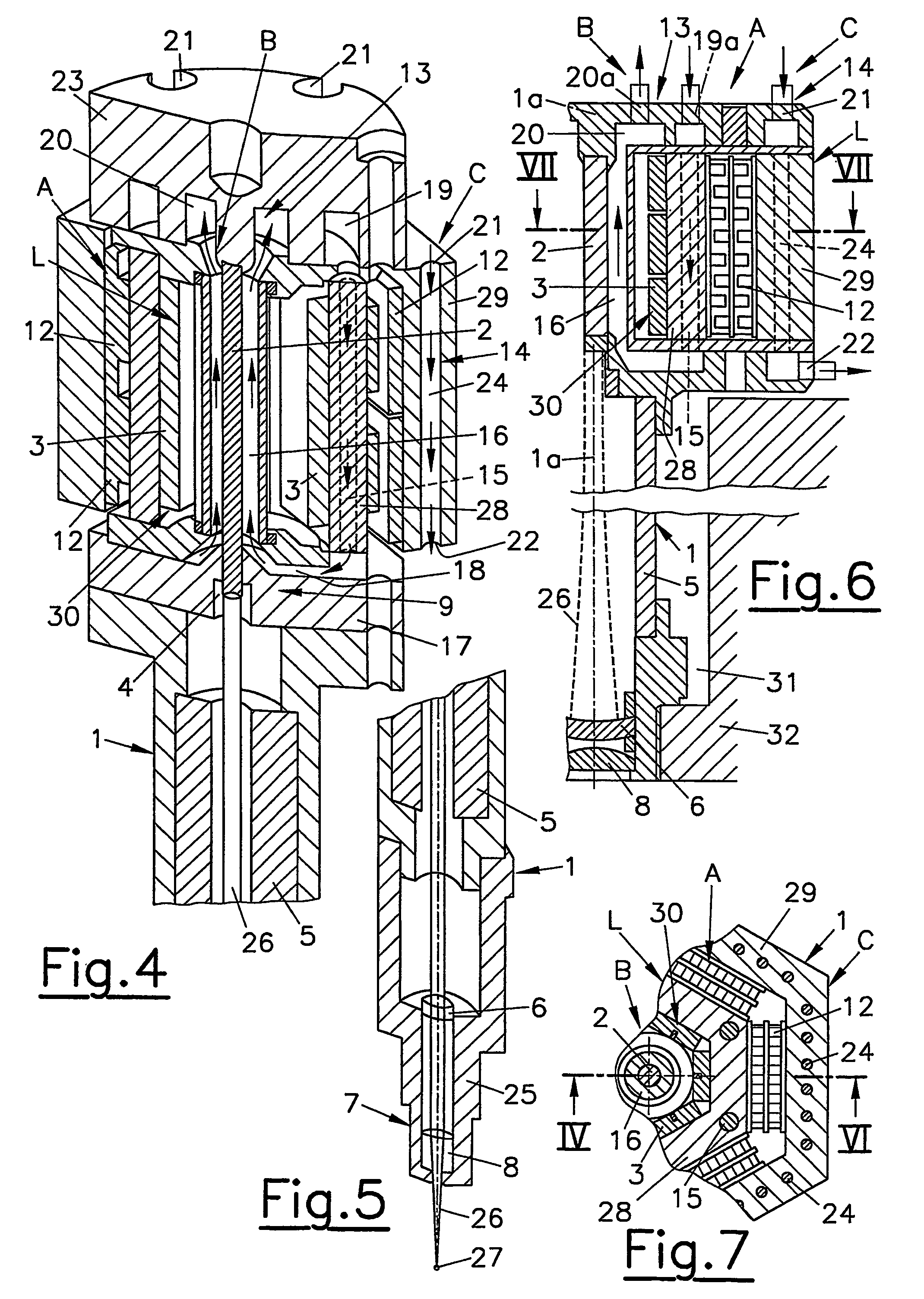

Internal combustion engine

InactiveUS7499477B2High magnificationQuality improvementEngine ignitionMachines/enginesCombustion chamberEngineering

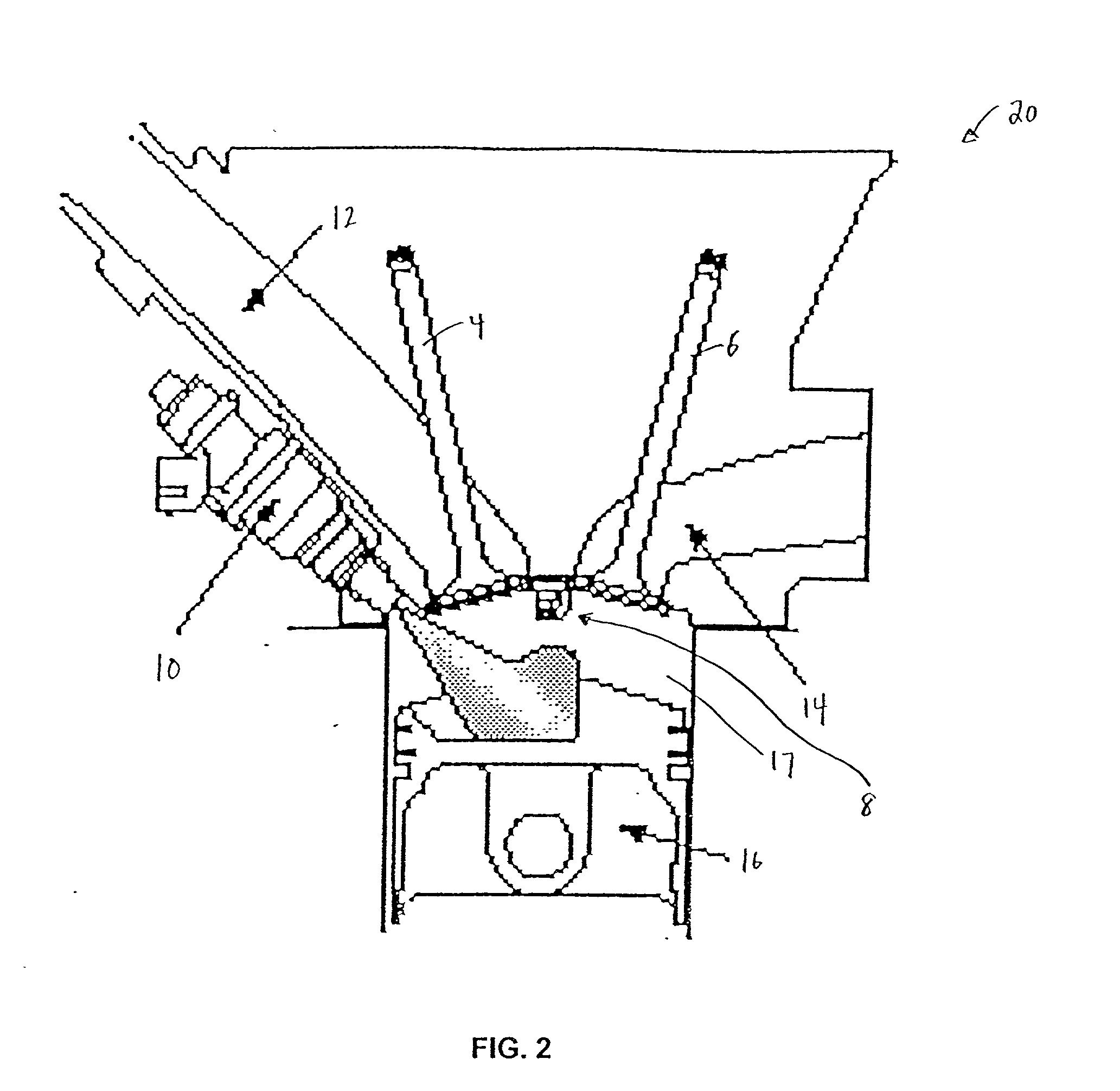

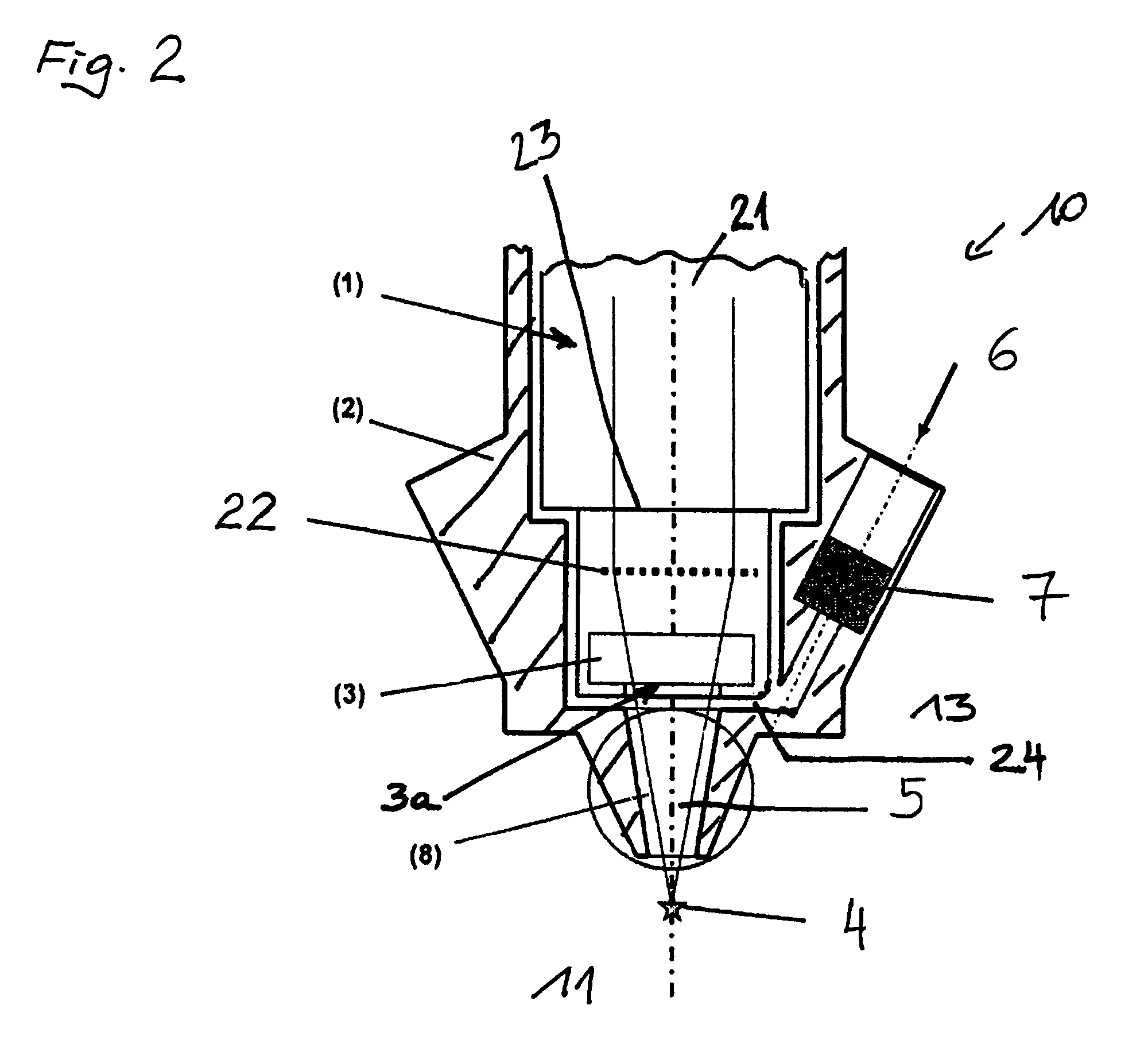

The invention relates to an internal combustion engine with a laser ignition device (1), Q-switched, pumped solid-state laser with a pulsed pumped light source (30), a solid laser crystal (2), enclosed in a resonator, a Q-switch (4), for increasing the power density, at least one output mirror (6) and a focussing device (7), by means of which the laser beam (26) may be focussed in a combustion chamber.

Owner:AVL LIST GMBH

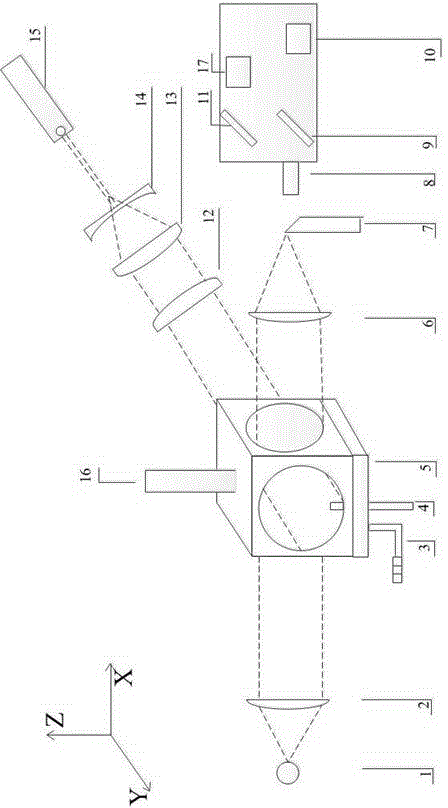

Device and method used for observing air flow field structure in environment of different degrees of vacuum

ActiveCN104931224AImprove the odds of successImprove reliabilityAerodynamic testingCcd cameraHigh reflectivity

The invention discloses a device and a method used for observing an air flow field structure in environment of different degrees of vacuum. The device is composed of a light source, a collimating lens, a pressure transmitter, a gas nozzle, a vacuum chamber, a focusing lens, a cut, a camera, a high reflectivity and high transmittance lens, a first CCD camera, a second CCD camera, a totally reflecting mirror, a focusing convex cylindrical lens, a collimating convex cylindrical lens, a plano-concave lens, a laser, a vacuum pump, a gas nozzle and a vacuum pump. According to the invention, a schlieren method and acetone PLIF are used to simultaneously observe the air flow field structure in environment of different degrees of vacuum; through the contrast correction of information acquired in two observing manners at the same time, a real air flow field structure is acquired; the success probability and the reliability of high altitude and space laser ignition are improved; the device and the method focus on observing the air flow field structure under different degrees of vacuum; and the air flow field structure information acquired through the device and the method can effectively help to choose the best ignition location for the laser ignition scheme of an engine in different environments.

Owner:HARBIN INST OF TECH

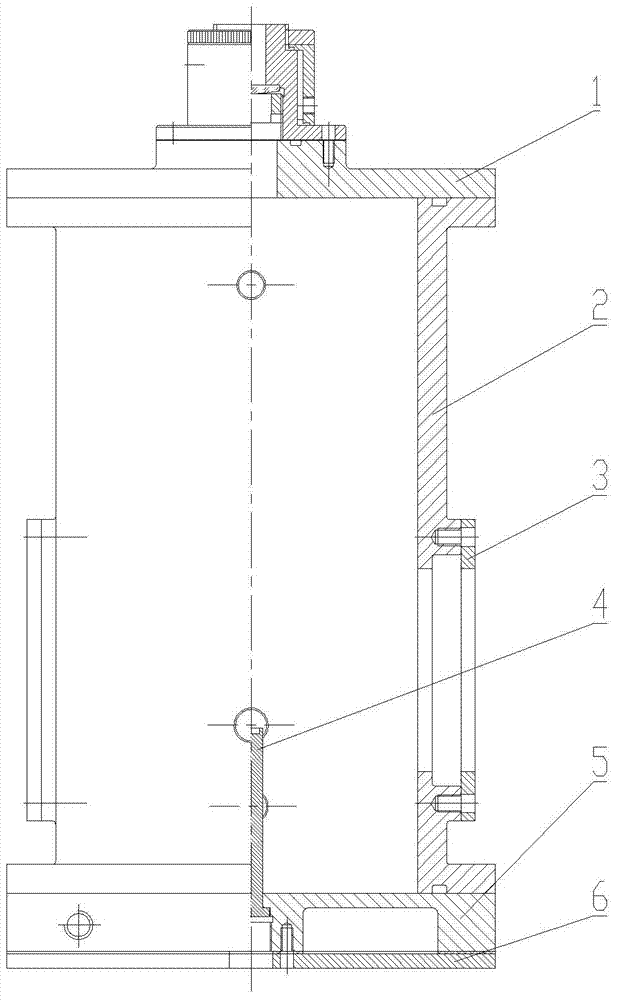

High-pressure adjustable-temperature laser ignition experimental device

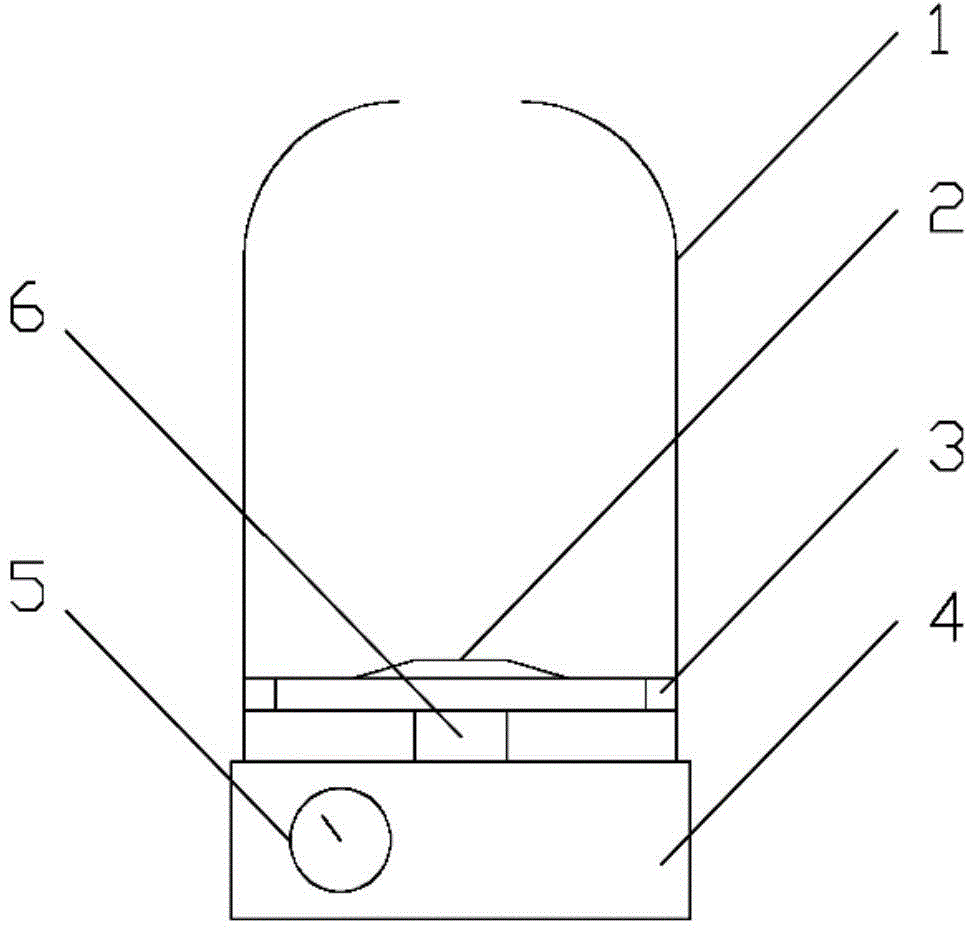

InactiveCN104215736ASolve the adjustmentSolve temperature problemsChemical analysis using combustionCombustion chamberGas composition

The invention discloses a high-pressure adjustable-temperature laser ignition experimental device, comprising a laser lens cooling device and an adjustable-temperature combustion chamber; the adjustable-temperature combustion chamber comprises a combustion chamber top cover, a combustion chamber shell, a glass gland, a test piece support seat, a combustion chamber bottom cover and a cavity sealing plate; the laser lens cooling device comprises a water cooler outer shell, a lens clamp ring, a water cooler inner shell and a laser focus lens; according to the high-pressure adjustable-temperature laser ignition experimental device, the sealed combustion chamber and the combustion chamber bottom cover with a cavity are used for solving the problem that the laser ignition experimental device cannot achieve adjustment on pressure, temperature and gas composition; due to the structure that a laser lens, an O-shaped ring and the lens clamping ring are respectively arranged at the two-stage stepped hole section and the threaded hole section at the center of the water cooler inner shell, the problem that detachability and leakproofness of the laser lens cannot be achieved at the same time; different environmental parameters are provided for laser irradiation experiments, experimental cost is saved, and experimental contents are enriched.

Owner:NANJING UNIV OF SCI & TECH

Laser ignition system based diagnostics

ActiveUS20140316622A1Improve accuracyImprove reliabilityHybrid vehiclesElectrical controlPhotovoltaic detectorsPhotodetector

Methods and systems are provided for enabling engine diagnostics, including visual inspections of an engine cylinder, using existing hardware from a laser ignition system. Light pulses from a laser ignition device are received at a photodetector during non-combusting conditions and used to generate images of an inside of the cylinder that can be assessed by a service technician. An electric motor of the vehicle system can be used during a service mode of the vehicle to rotate the engine to, and hold the engine at, specified engine positions that enable the technician to perform selected diagnostic tests.

Owner:FORD GLOBAL TECH LLC

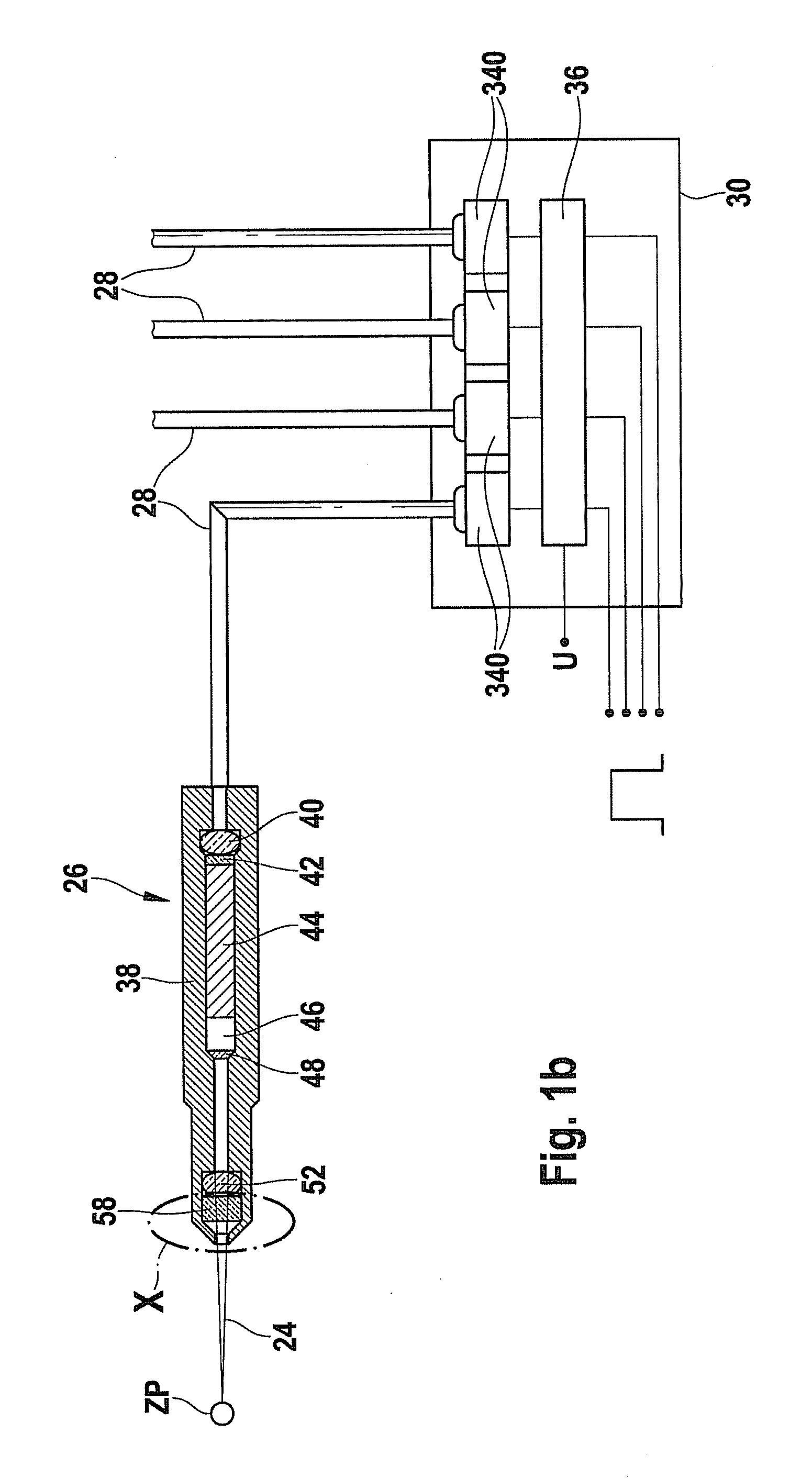

Ignition device for a laser ignition system of an internal combustion engine

InactiveUS20100263615A1Ensure sealing performanceCombustion enginesEngine ignitionCombustion chamberInternal combustion engine

An ignition laser for an internal combustion engine is provided, wherein the combustion chamber window is connected to a housing of the ignition laser in a gas-, pressure-, and temperature-resistant manner.

Owner:ROBERT BOSCH GMBH

Laser ignition system

InactiveUS20120312267A1Easy to igniteHigh mechanical strengthCombustion enginesEngine ignitionOptoelectronicsInternal combustion engine

A laser device for a laser ignition system for an internal combustion engine, in particular of a motor vehicle or a stationary engine, including a laser oscillator, the laser oscillator having a first laser-active solid, an optical Q-switch, and an output mirror which is partially reflective for a light to be generated by the laser device, in which the laser oscillator has another mirror which is partially reflective for the light to be generated by the laser device.

Owner:ROBERT BOSCH GMBH

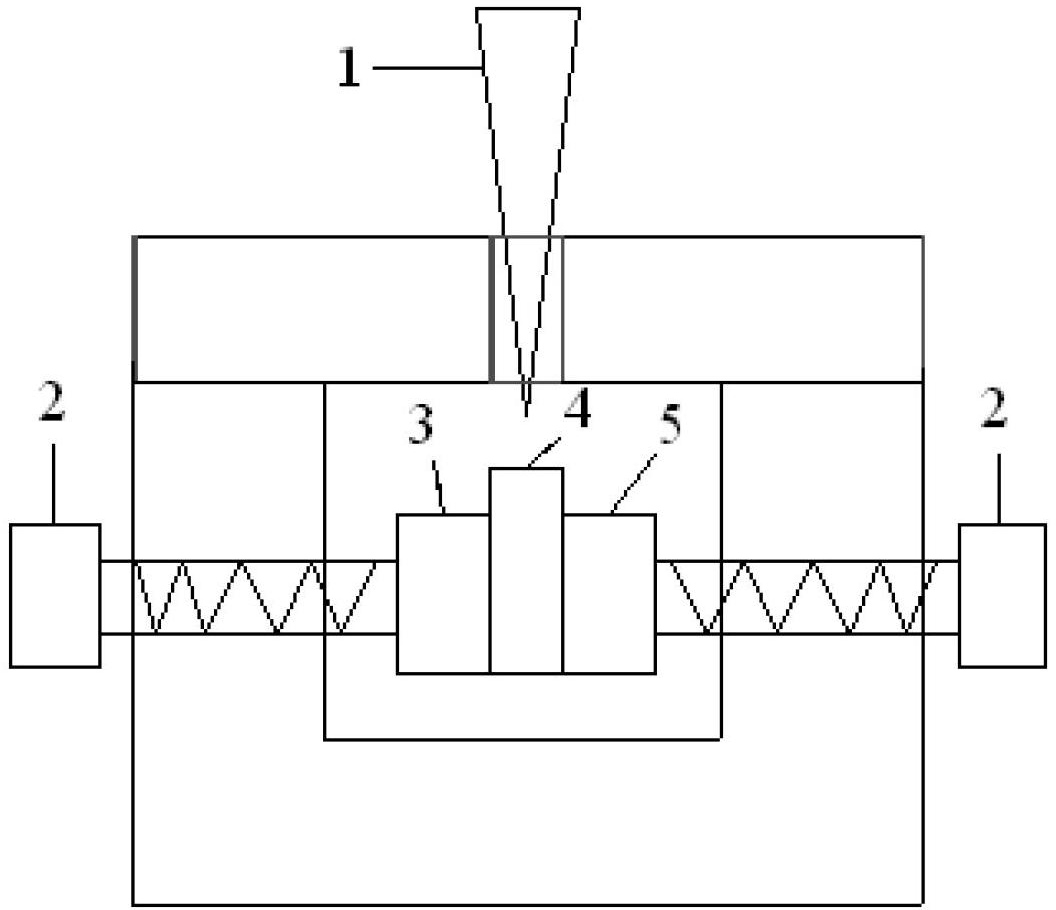

Laser-induced microparticle jetting ignition method

InactiveCN101363391AImprove convenienceImprove continuityEngine ignitionMachines/enginesCombustion chamberHigh power lasers

The invention discloses a laser-induced particle jet ignition method; the method is as follows: laser pulses are led into a combustion chamber of an engine through a focusing lens in a common way; the focal position of the focusing lens in the combustion chamber is provided with an absorbing target; the hot particle jet which is generated after the absorbing target is intensively heated by laser is used for starting the combustion or the detonation of flammable mixture in the combustion chamber. The laser ignition method of the invention avoids the use of high-power laser, and increases the convenience for selecting ignition positions and the probability of high-frequency continuous ignition. In addition, the ignition mode is suitable for the ignition of different types of engines.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

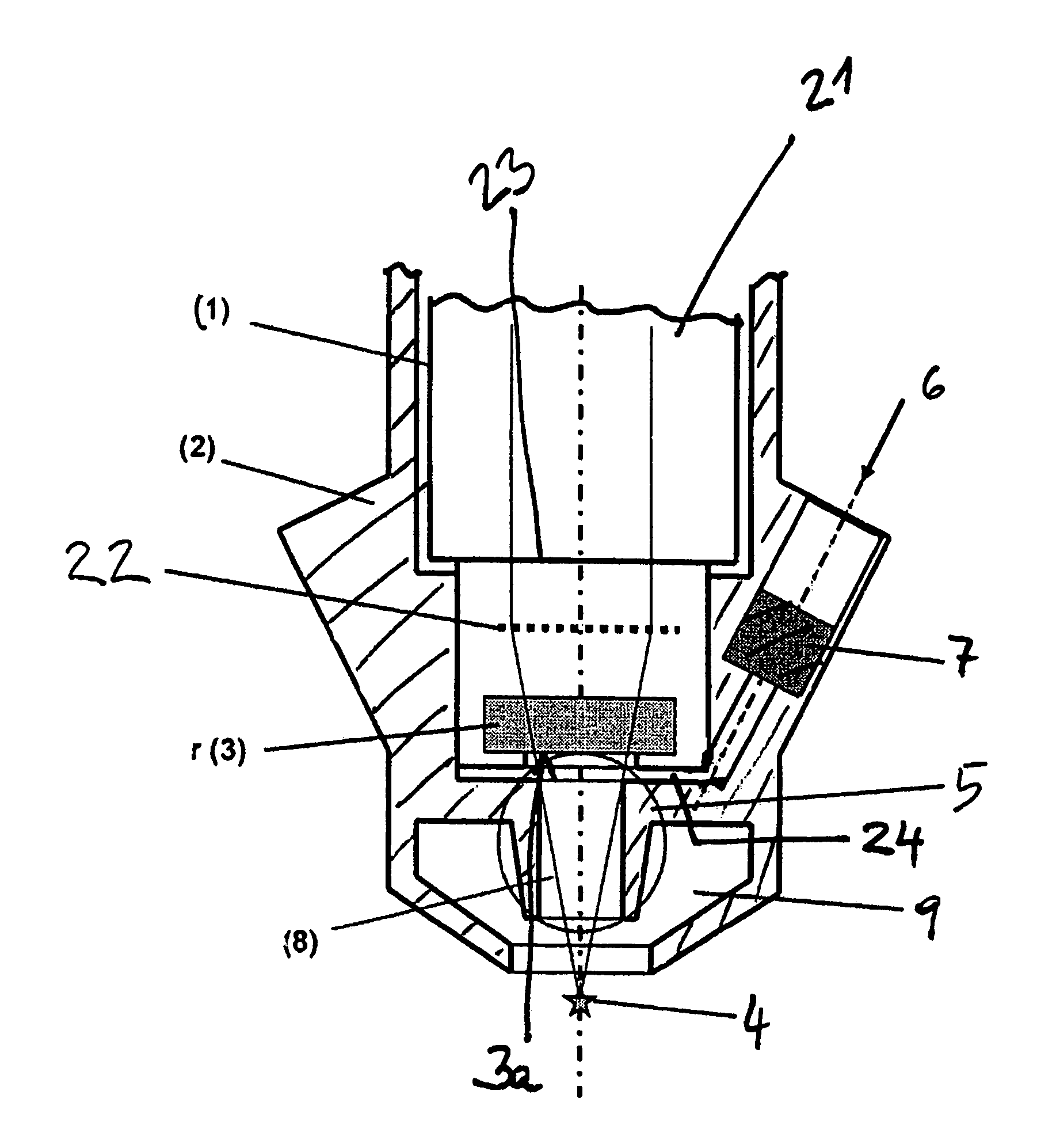

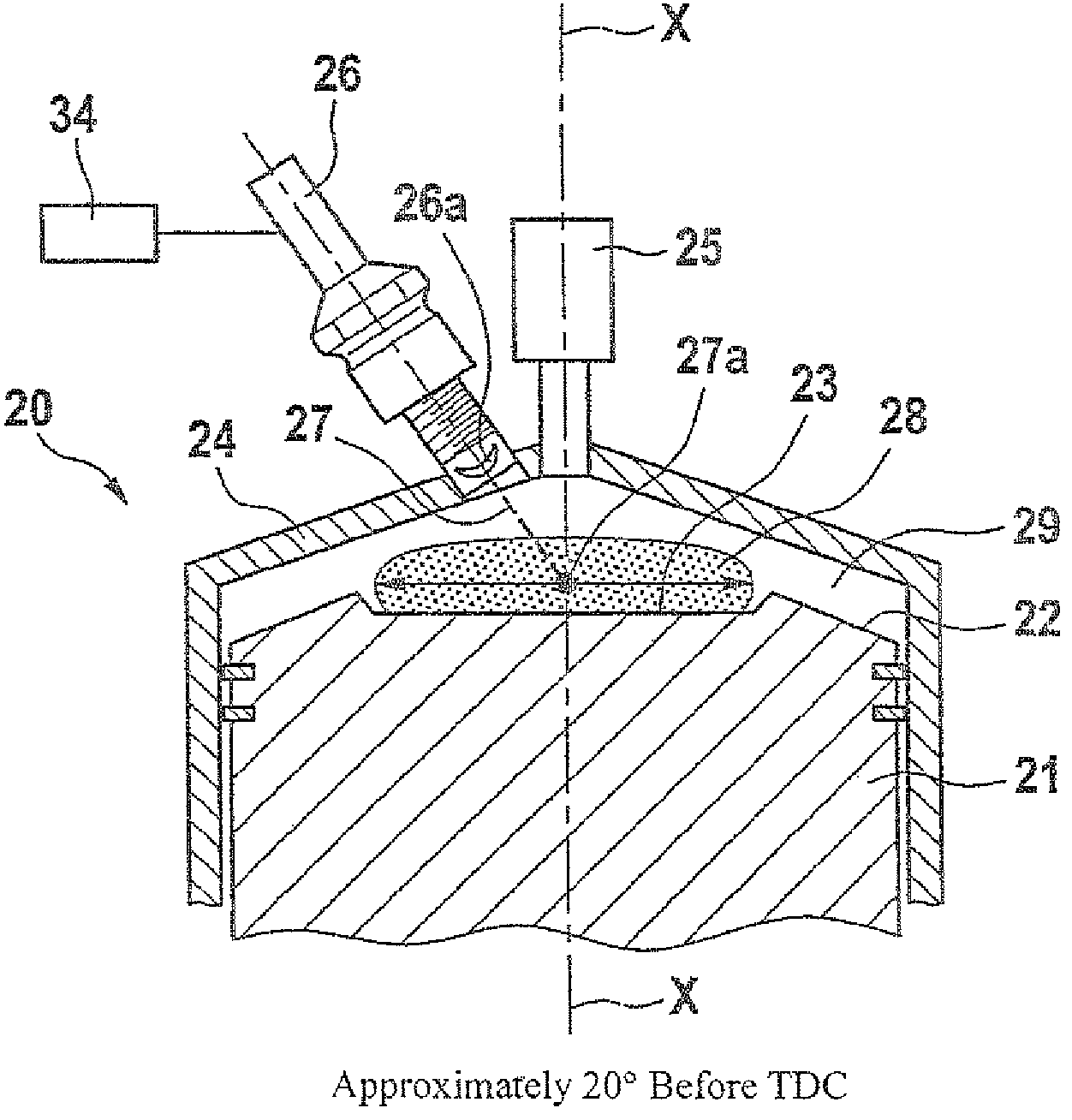

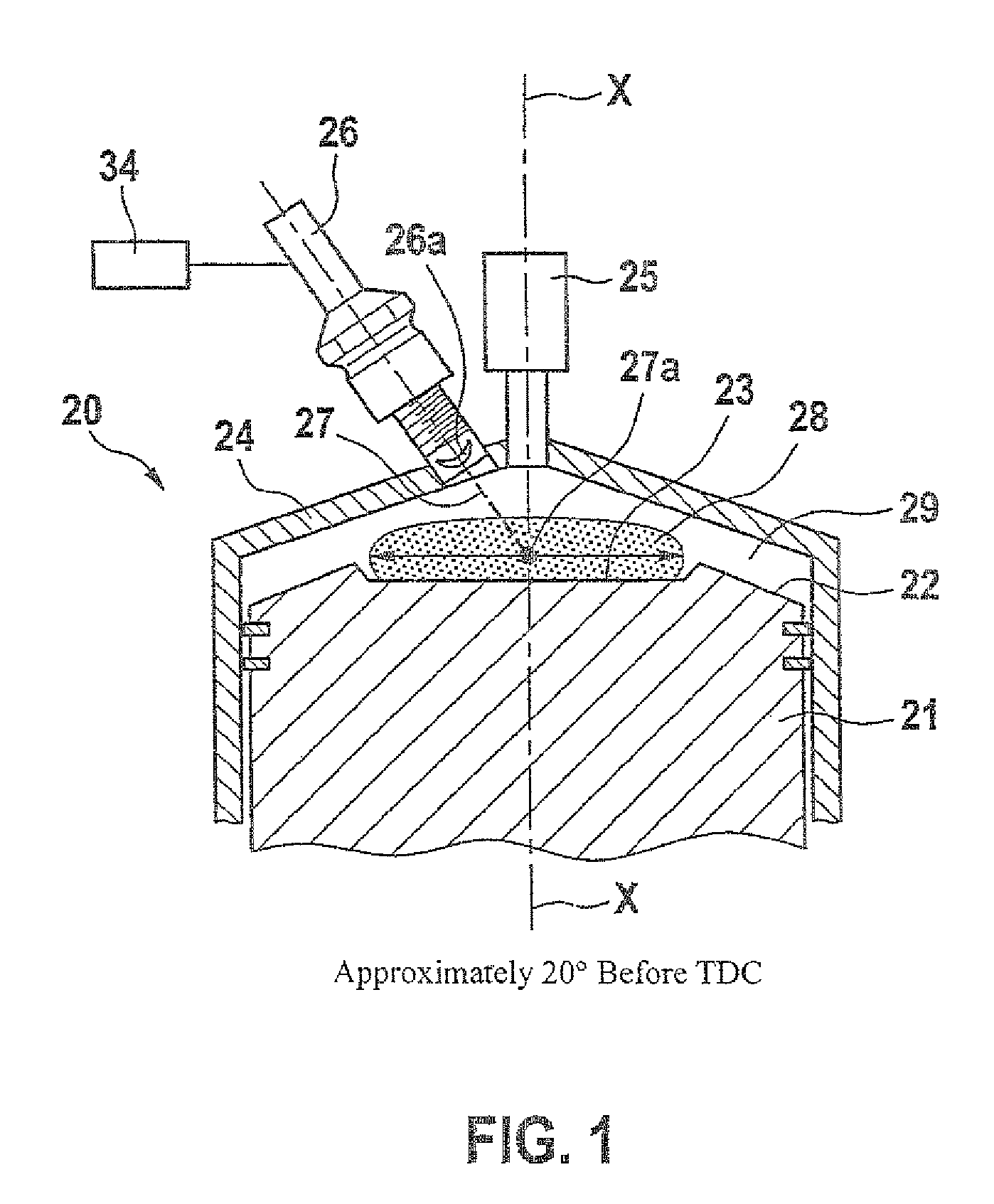

Internal combustion engine and method for operating an internal combustion engine by means of a laser ignition unit

InactiveUS7765980B2Promote rapid formationHigh proportionCombustion using gaseous and pulverulent fuelElectrical controlExternal combustion engineInternal combustion engine

The invention relates to a method for operating an internal combustion engine including a fuel-injection unit and a laser ignition-unit. According to the invention, during a compression cycle of the internal combustion engine, fuel is injected into the combustion chamber by means of the fuel-injection unit in such a way that an ignitable, round, flat mixed region of fuel and air forms on a plunger and a predetermined period elapses between the end of the fuel injection and the start of ignition in order to form the round flat mixed region. Ignition then takes place within the flat round mixed region by means of the laser-ignition unit.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com