High-pressure adjustable-temperature laser ignition experimental device

A technology of laser ignition and experimental equipment, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems that the ambient temperature cannot be adjusted, the temperature adjustment cannot be realized, and the experimental effect is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

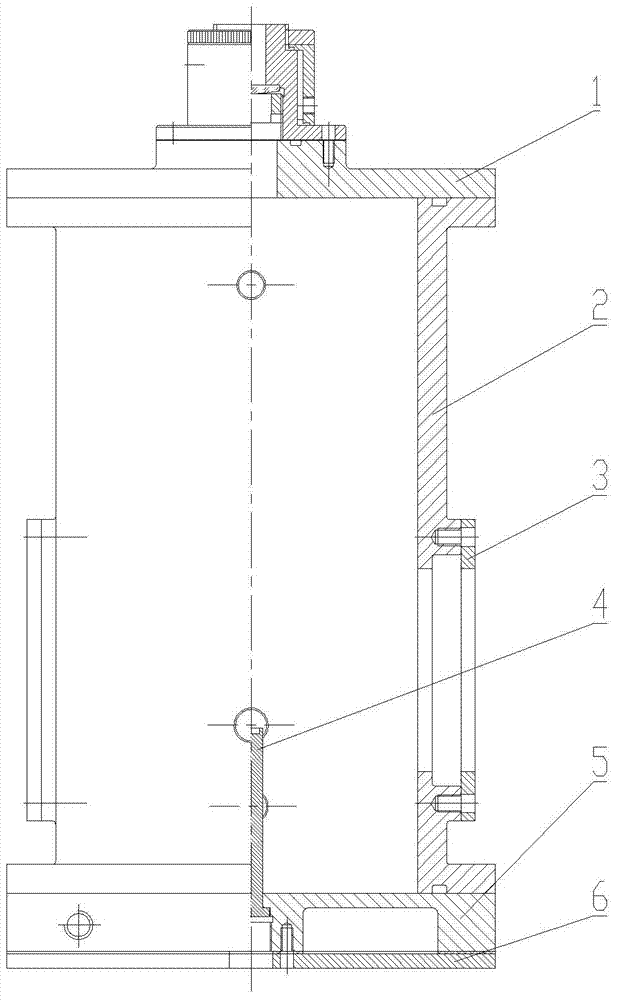

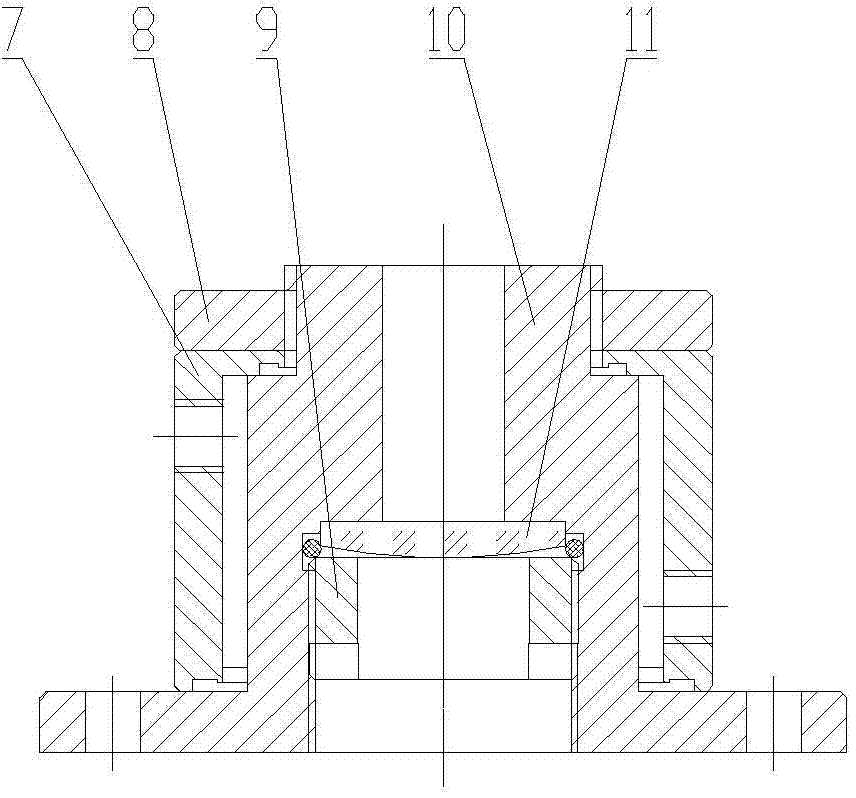

[0025]A high-pressure resistant and temperature-adjustable laser ignition experimental device includes a laser lens cooling device and a temperature-adjustable combustion chamber, and the laser lens cooling device is located at the top of the temperature-adjustable combustion chamber. The temperature-adjustable combustion chamber includes a combustion chamber top cover 1, a combustion chamber shell 2, a see-through window glass cover 3, a specimen support seat 4, a combustion chamber bottom cover 5 and a cavity sealing plate 6, and the combustion chamber shell 2 side walls There are two pairs of threaded holes and two perspective windows, the perspective window is sealed with a transparent window glass cover, the positions of the threaded holes and the perspective window are staggered; the top of the combustion chamber shell 2 and the combustion chamber top cover 1 pass through Bolt connection, the top of the combustion chamber housing 2 is provided with an annular groove, and ...

Embodiment 2

[0027] combine Figure 1 ~ Figure 2 :

[0028] A high-pressure resistant and temperature-adjustable laser ignition experimental device includes a laser lens cooling device and a temperature-adjustable combustion chamber, and the laser lens cooling device is located at the top of the temperature-adjustable combustion chamber. The temperature-adjustable combustion chamber includes a combustion chamber top cover 1, a combustion chamber shell 2, a see-through window glass cover 3, a specimen support seat 4, a combustion chamber bottom cover 5 and a cavity sealing plate 6, and the combustion chamber shell 2 side walls There are three pairs of threaded holes and two perspective windows on the top. The threaded holes are used to install external equipment such as thermometers, pressure gauges, and intake pipes. When not in use, the threaded holes are plugged with screw plugs for backup, and the perspective windows are sealed. There is a transparent window glass gland, and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com