Patents

Literature

1788results about How to "Solve the sealing problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for butting concrete prefabricated member consisting of prefabricated member connector

ActiveCN101979778AAvoid breakingSolve the sealing problemBuilding constructionsBulkheads/pilesEngineeringArchitectural engineering

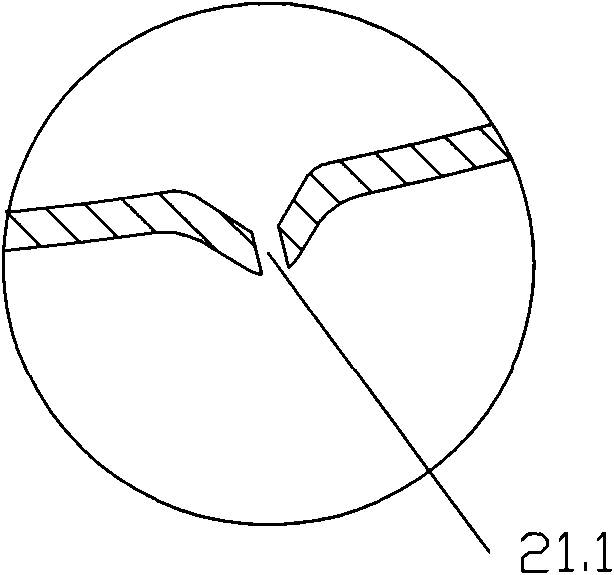

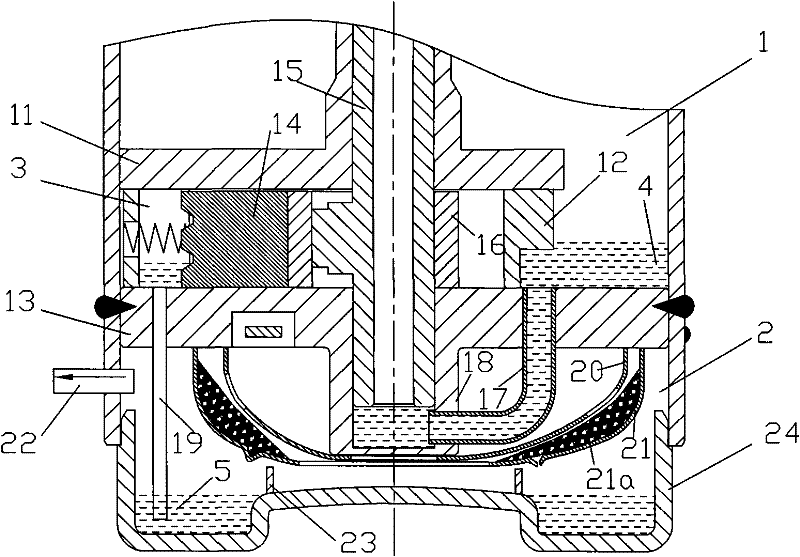

The invention relates to a prefabricated member connector and a method for butting a concrete prefabricated member consisting of the same. The bottom of a large screw cap is provided with a hole, the upset head of a steel bar is blocked in the hole, a spring is positioned in the large screw cap, one end of the spring is contacted with the upset head, the other end of the spring is contacted with a split collar, and a medium hole screw cap is screwed into the large screw cap, wherein the lower end of the medium hole screw cap is elastically matched with the split collar, and the edge of the medium hole screw cap is blocked at the end face of the large screw cap; an insertion rod has an integrated structure consisting of an insertion head, an insertion neck and an insertion body, wherein the circle area of the bottom of the insertion head is greater than the diameter of the insertion neck integrated with the insertion head, and an annular insertion neck clamping table is formed at the bottom of the insertion head; and the insertion body of the insertion rod is screwed with a small screw cap. The invention has the advantages that: 1, the strong tensile strength among insertion pieces greatly exceeds the international standard; 2, breakage of butted pieces is radically solved; and 3, the sealing problem of the insertion pieces is thoroughly solved, the reliability of insertion and connection between the prefabricated members is ensured, and the reliability of a building foundation is ensured.

Owner:周兆弟

Device for reducing friction of guided region when forming high pressure in pipe

InactiveCN101011715ASolve the sealing problemEliminate high pressure contact areasShaping toolsEngineeringHigh pressure

The invention relates to a device for reducing guiding zone friction in high pressure formation of tubular material. It comprises dies, left punch head, right punch head, right round body on the right end face of the left punch head with right guiding ring slot, so does the right punch head, with gaps between the die, left punch head and the right punch head. It can eliminate the high touch pressure zone of the tubular end and the die guiding zone inner wall, reducing the friction resistance to improve production efficiency and die durability, and lowered requirement for tonnage.

Owner:严格集团股份有限公司

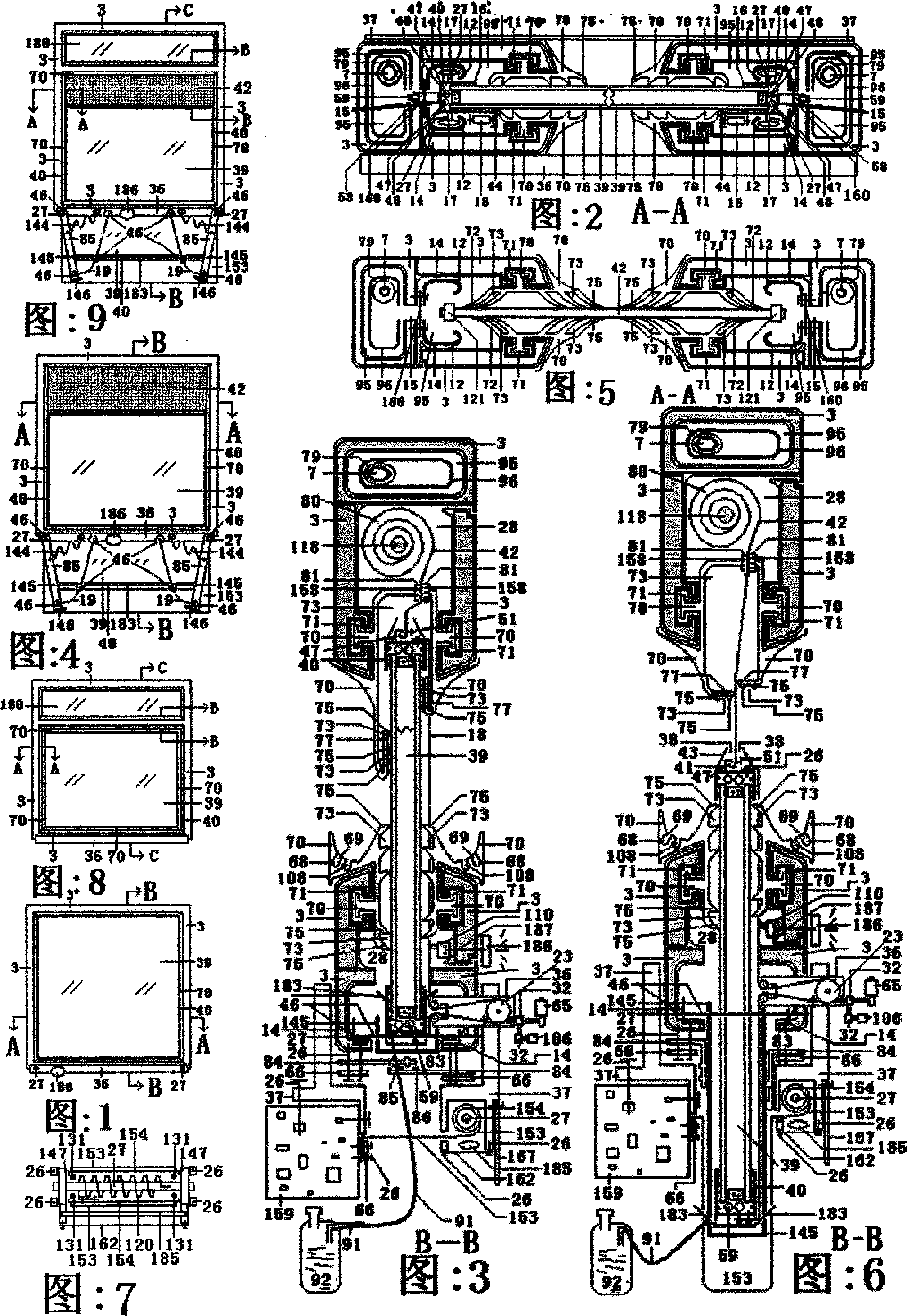

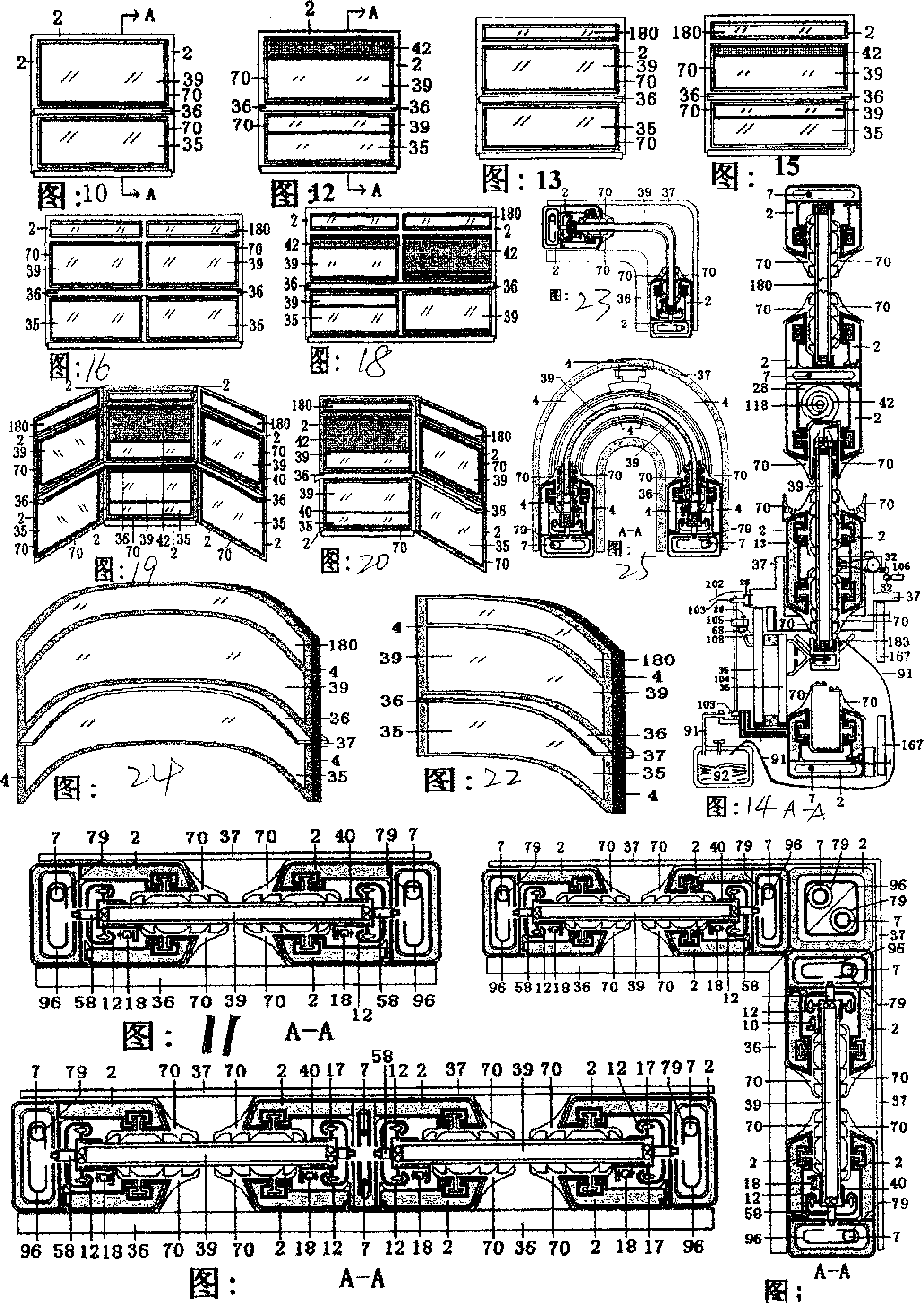

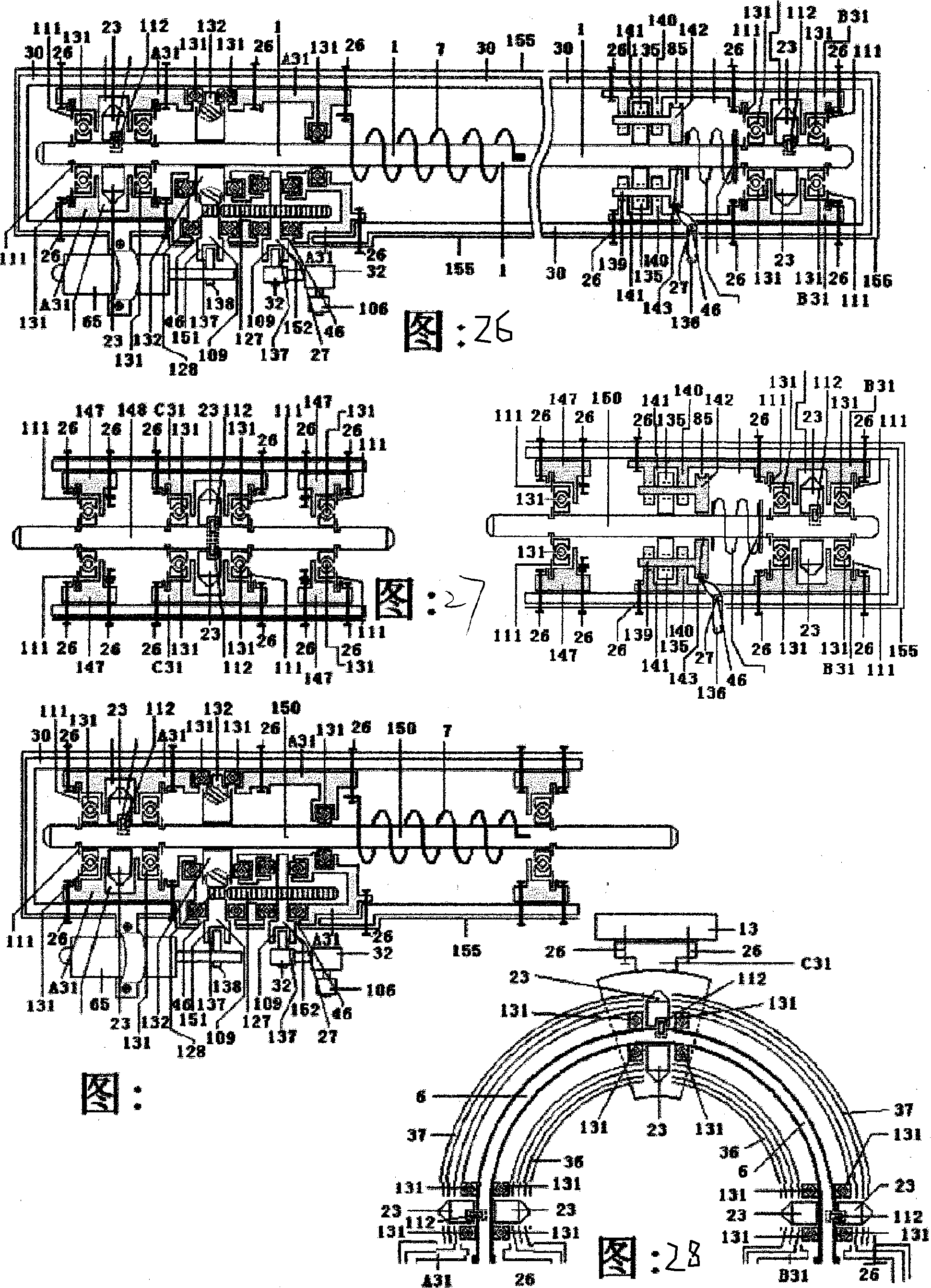

Multi-functional window structure

ActiveCN101298821ASolve potential safety hazardsImprove insurance coverage measuresMan-operated mechanismInsect protectionWindow screenMultiple function

A multifunctional window structure is composed of a window frame sectional material, a primary shaft main body, glass and a protective frame, a clean-free window screen, a primary shaft system, glass for cleaning indoors and outdoors automatically, an electric / manual switching mechanism locking state, an air filtering decompression device, a transparent, insulting, soundproof flexible rolling window which can be rolled up, double-layer flexible transparent curtain, a theft-proof telescopic guard rail, separated glass of the transparent insulating curtain, a transparent, insulating and soundproof flexible rolling door which can be rolled up. Glass (39) with the glass protective frame (40), a gland strip (70), a window sill bracket (36), a music promoting alarm (186) for opening and closingwindow, and a decorative cover (153) are installed in the separated window frame (3). The fully invisible window screen (42) and the glass (39) are connected actively. The steel cable (19) is installed on the glass protective frame (40). The upper bright band (180) is installed on the window frame sectional material (13).

Owner:李京岐

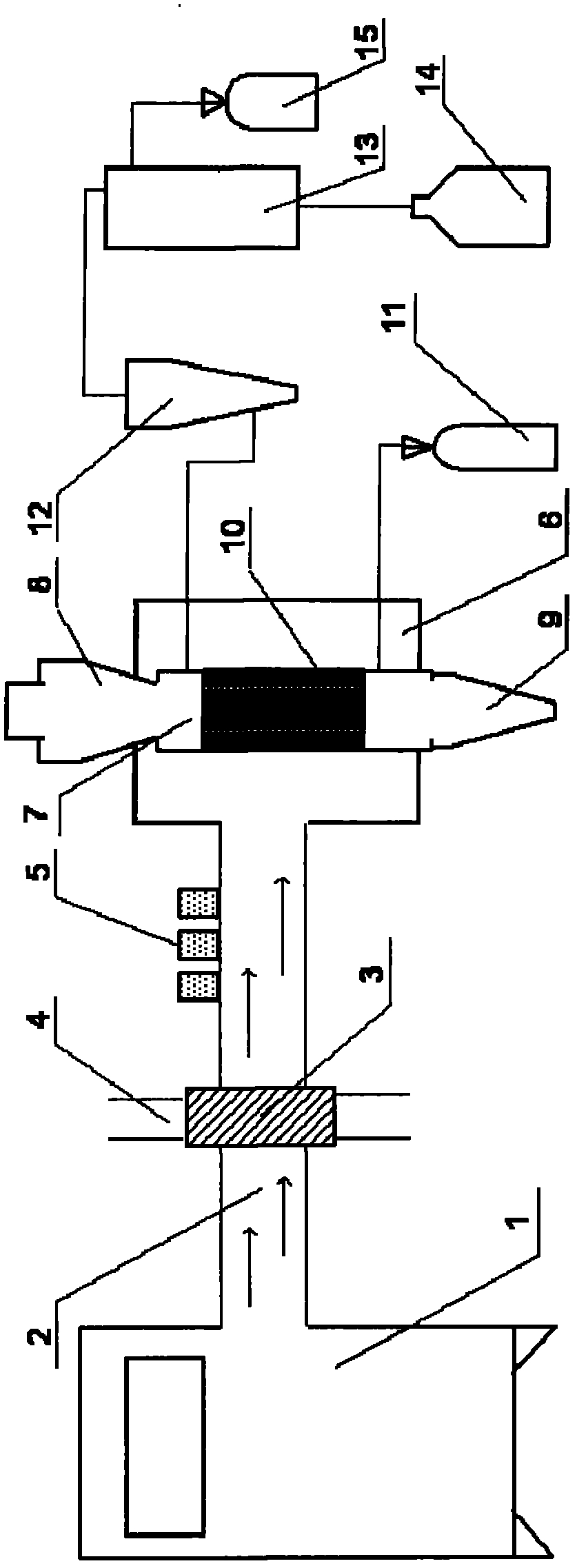

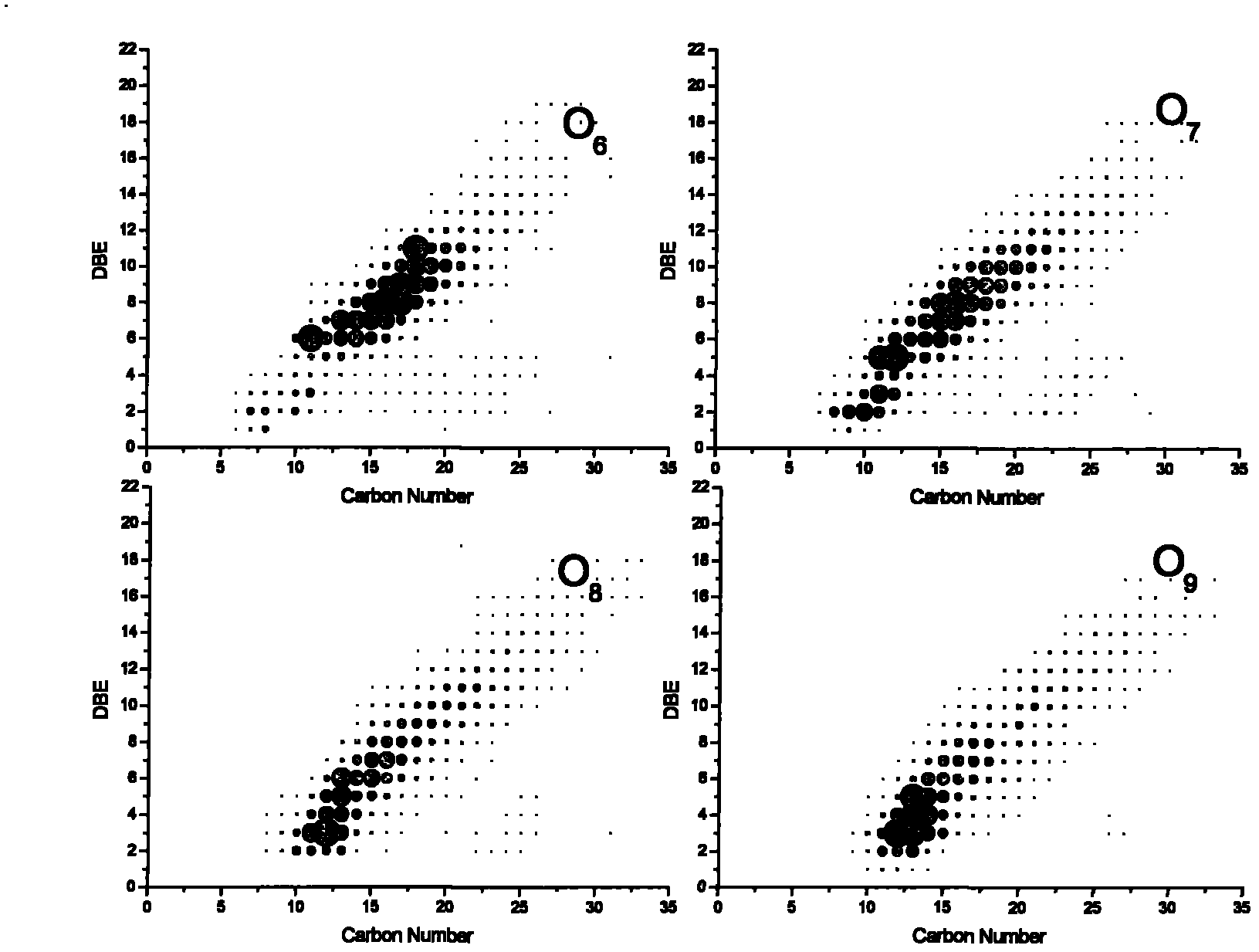

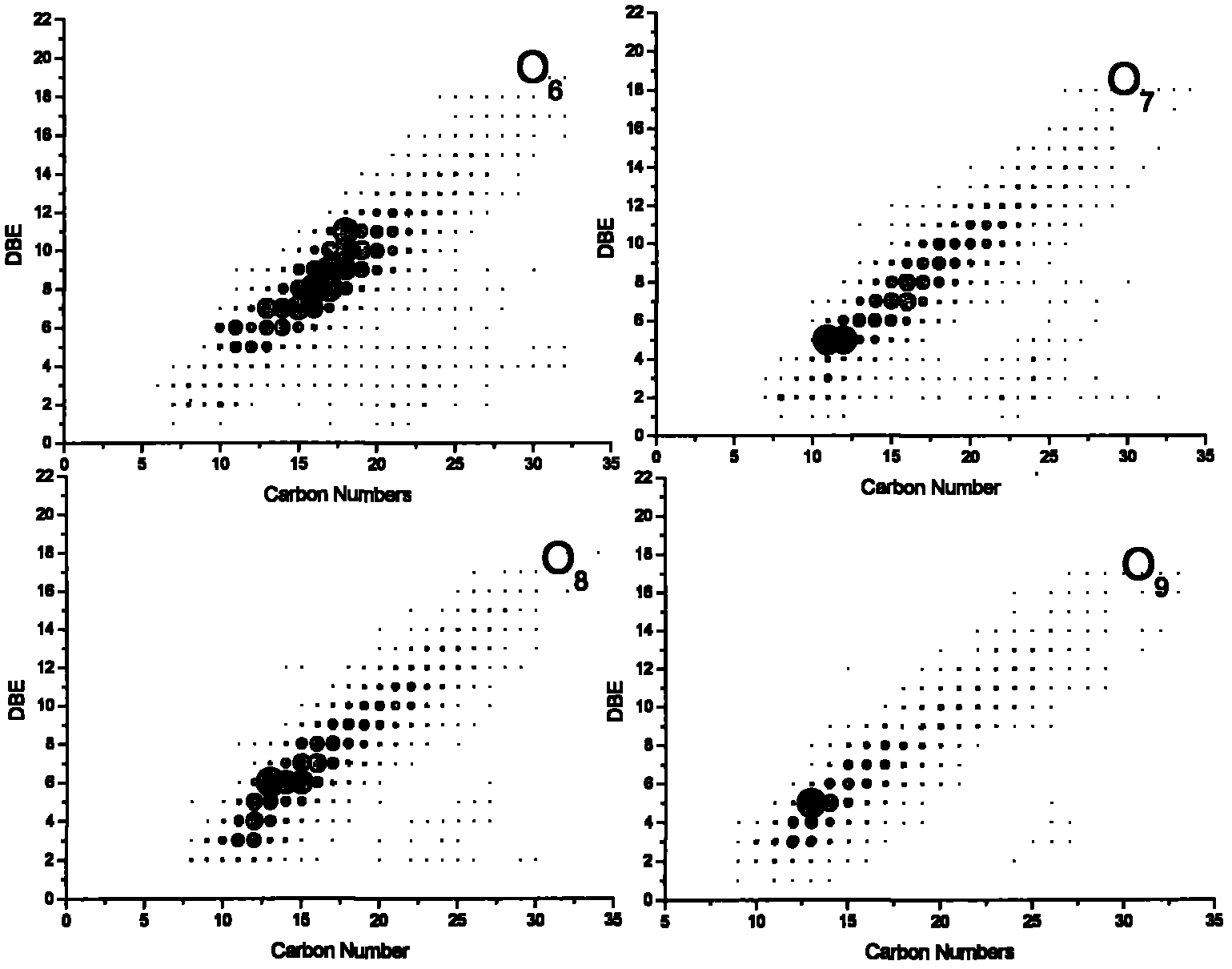

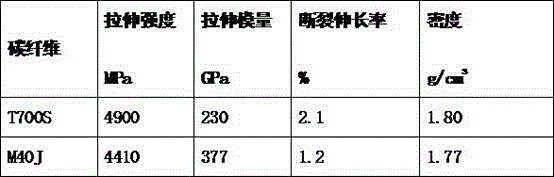

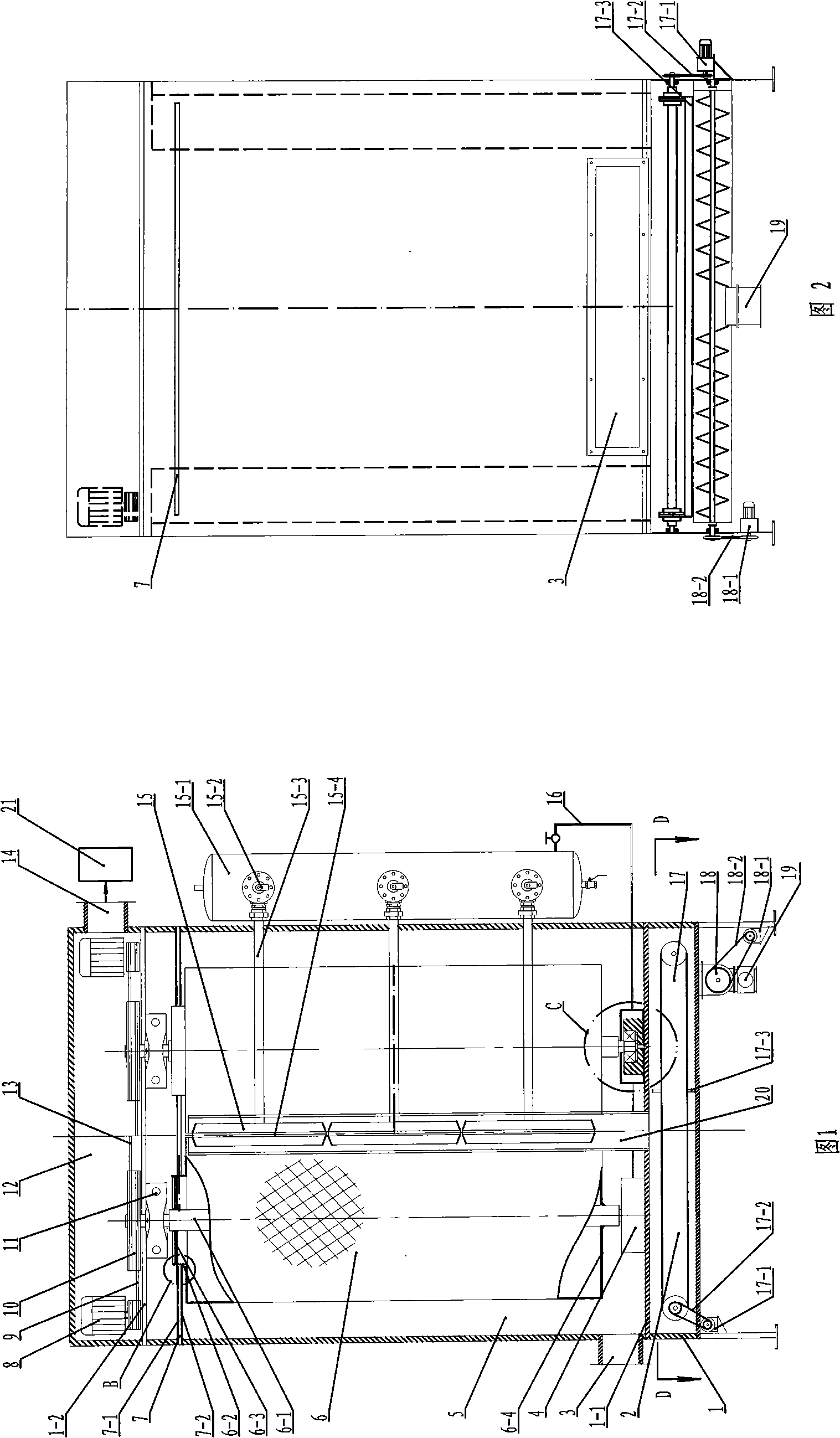

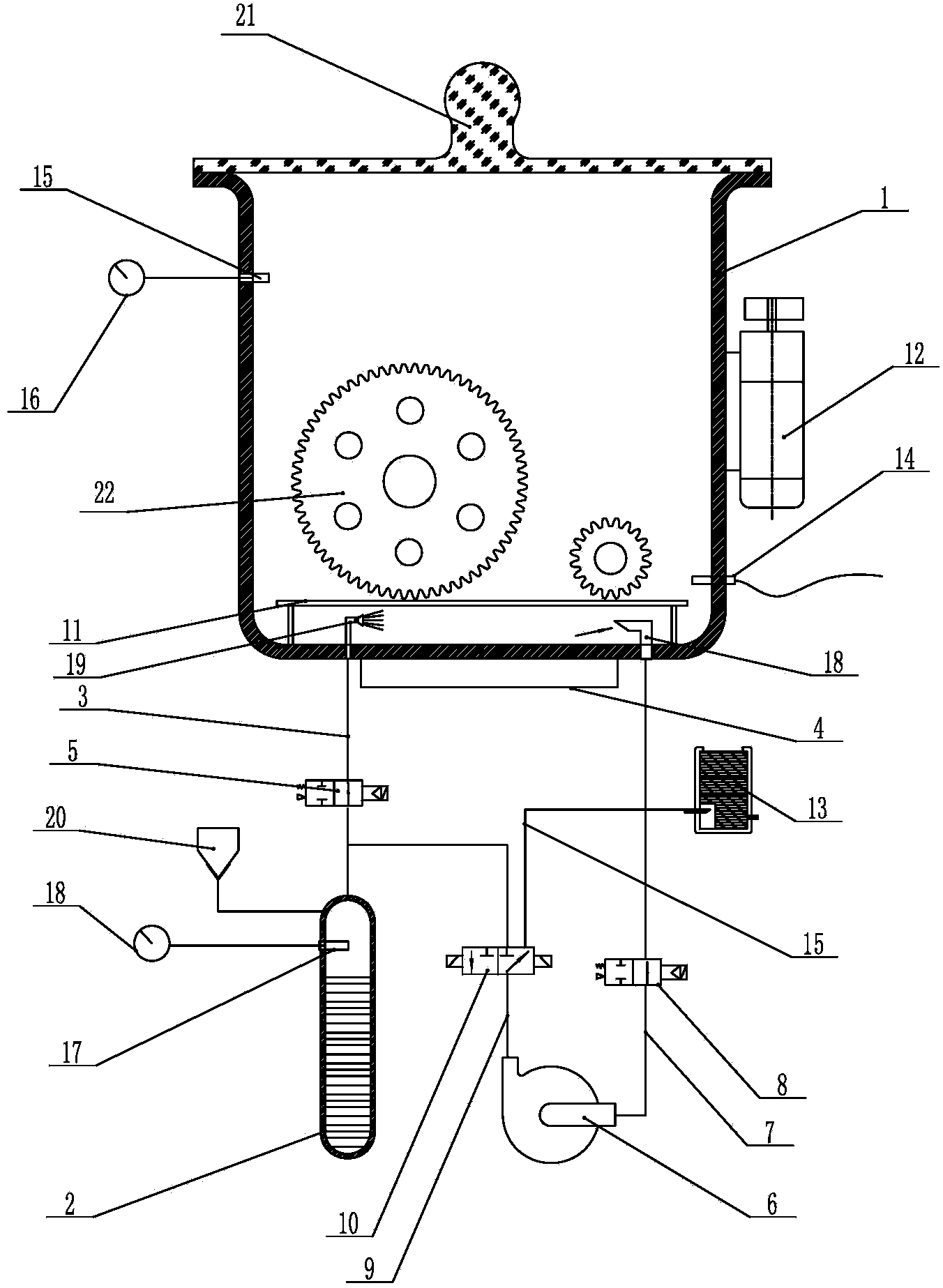

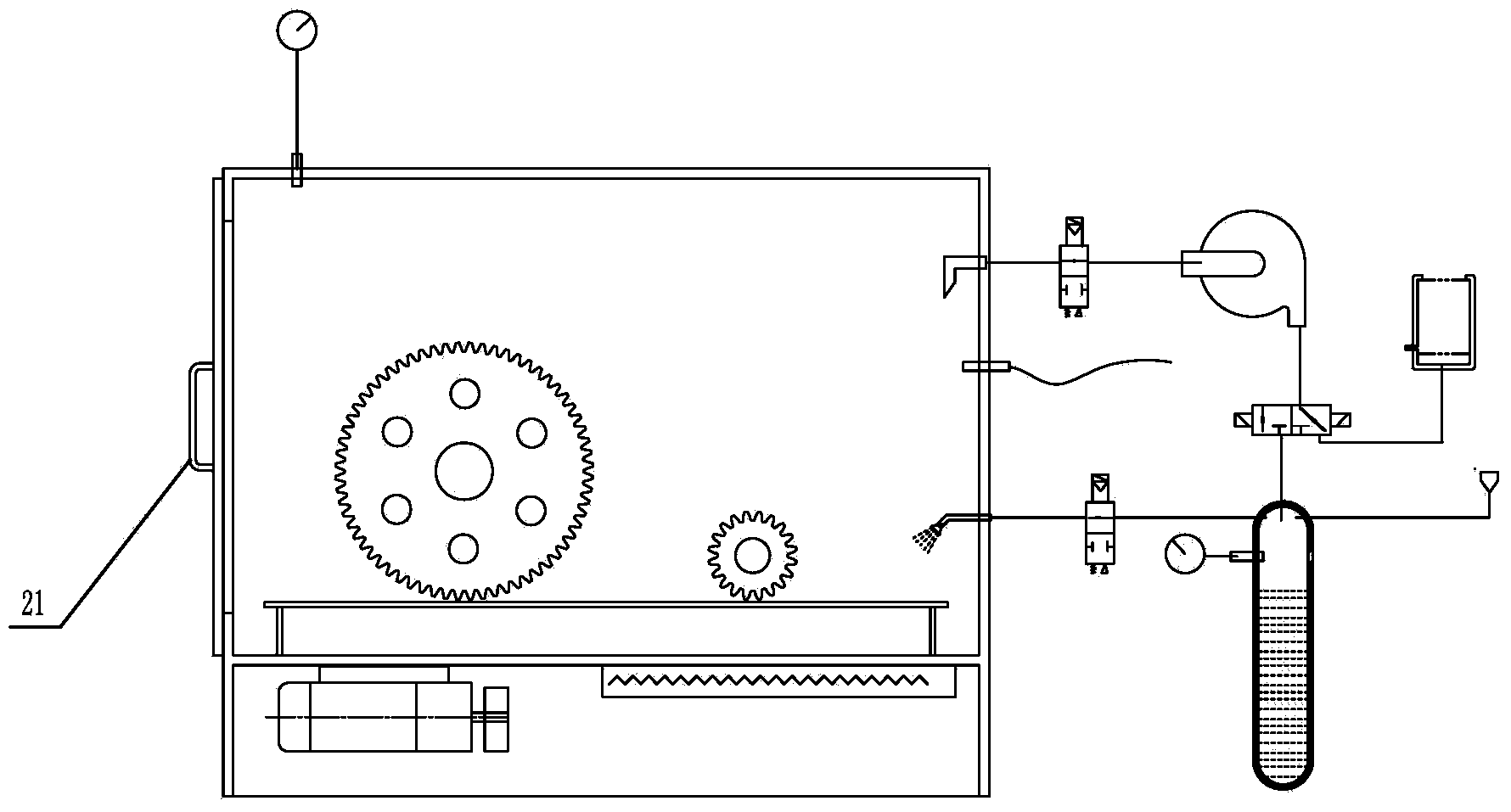

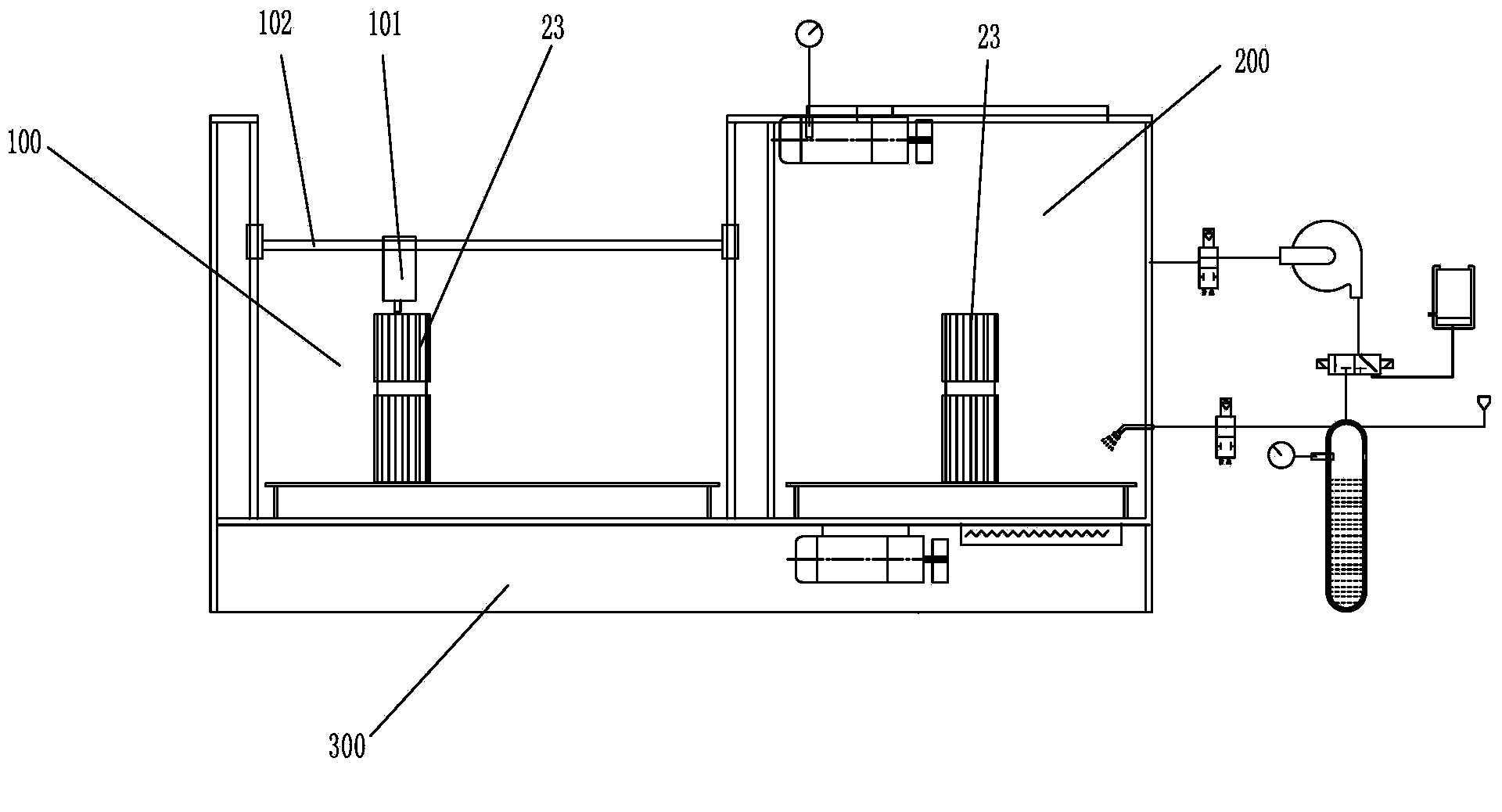

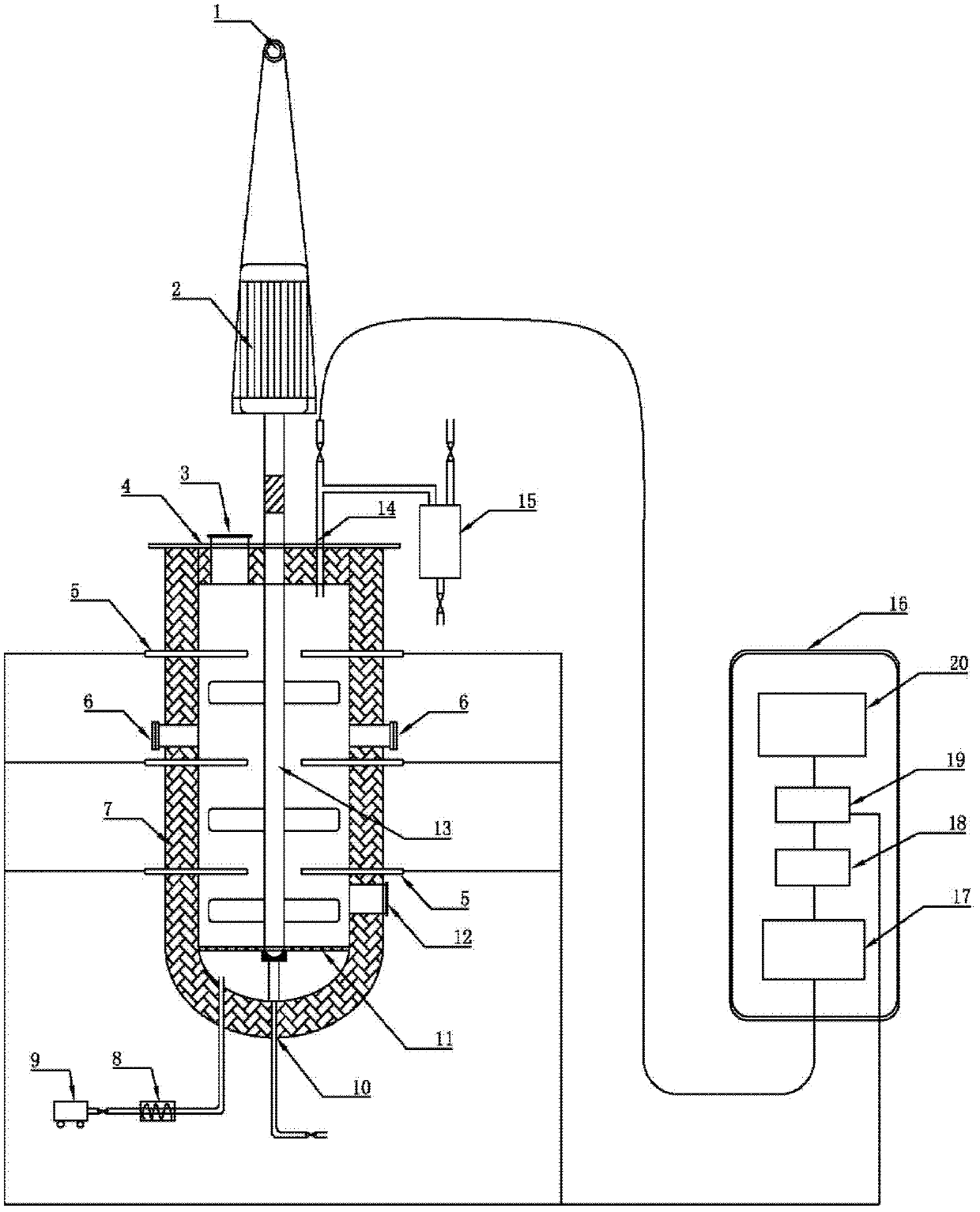

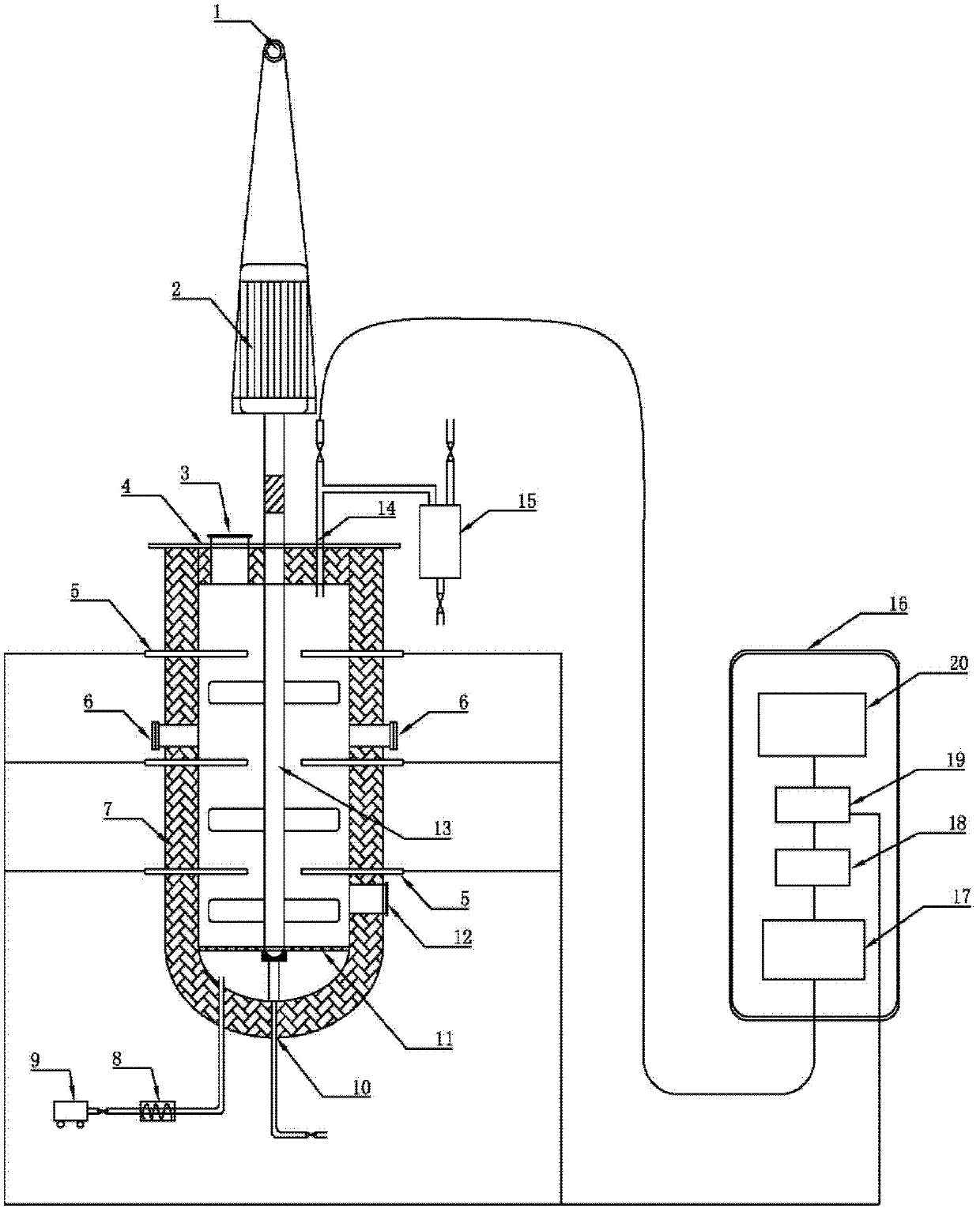

Continuous reaction device and method for microwave biomass pyrolysis

InactiveCN102580650APyrolysis continuous reaction realizedIncrease reaction rateBiofuelsLiquid hydrocarbon mixture productionMicrowaveFuel gas

The invention relates to a continuous reaction device and a method for microwave biomass pyrolysis. The continuous reaction device for the microwave biomass pyrolysis mainly comprises a microwave generator, a reactor and a resultant separating device. The continuous reaction device is a continuous operating system and can process 10-50kg of the biomass every hour. According to the continuous reaction device for the microwave biomass pyrolysis, characteristics of microwave volume heating, transient heating and selective heating are fully utilized, undried biomass is directly pyrolyzed so as toobtain three products of liquid bio-oil, bio-gas and solid coke, the pylolysis efficiency of the biomass is greatly improved, the yield and the quality of the liquid bio-oil are improved, the structure is simple, the design is reasonable, and the achievement of industrial application of the microwave biomass pyrolysis is facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

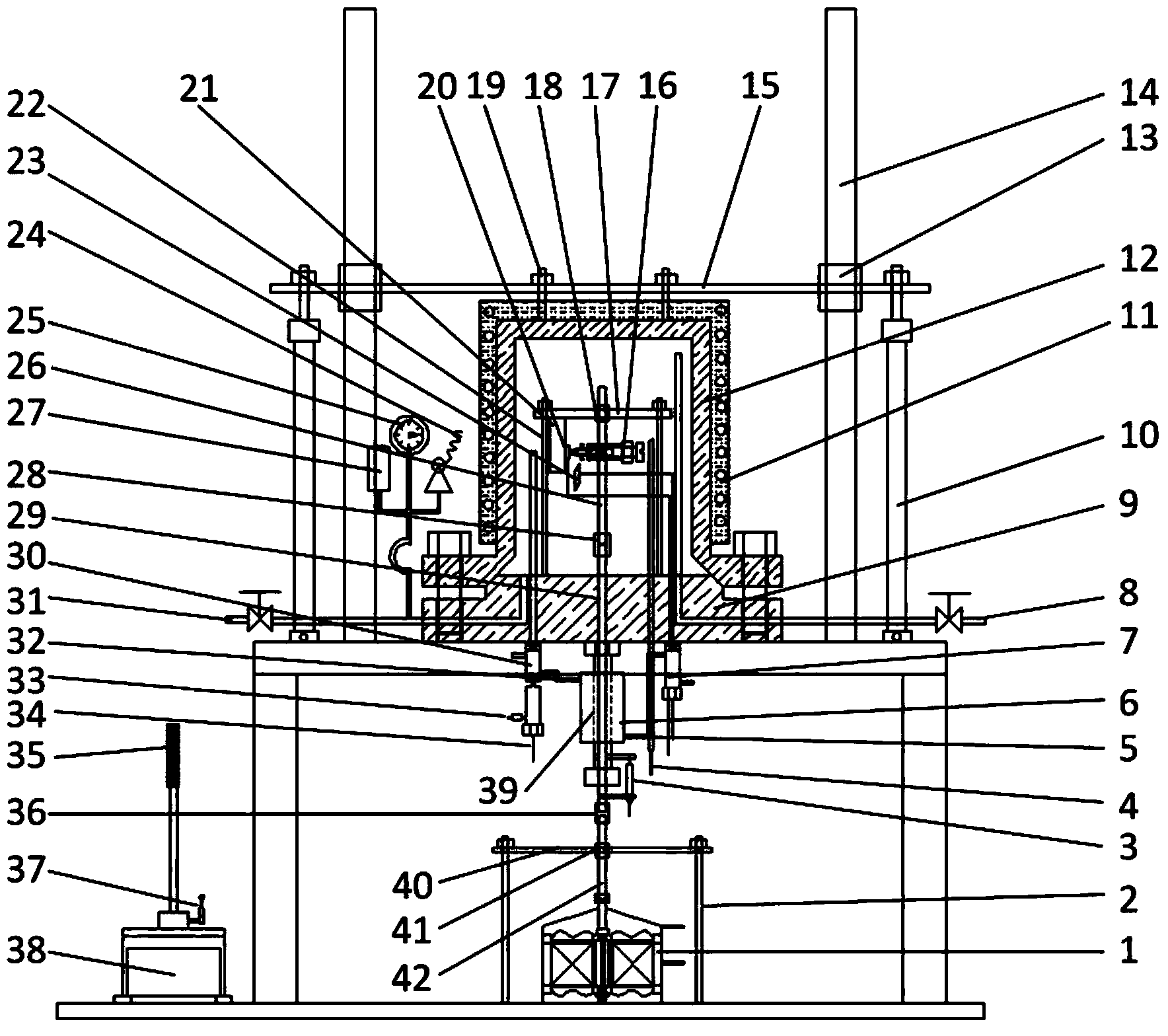

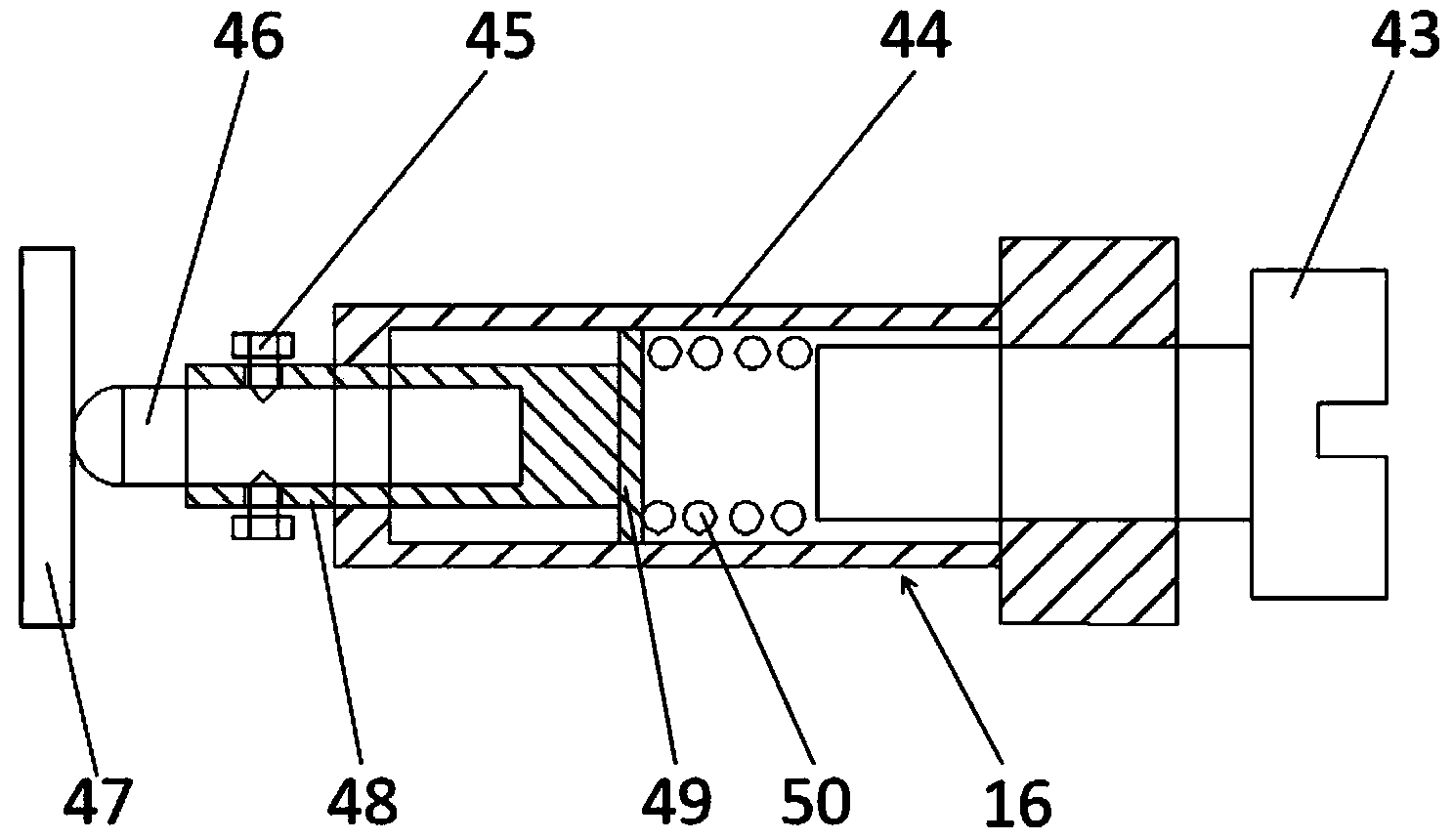

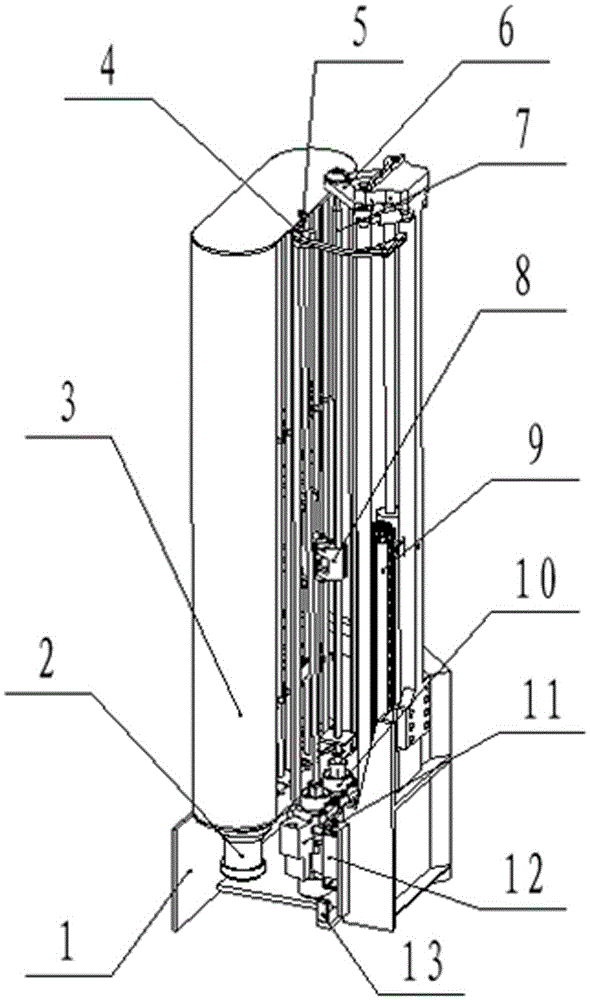

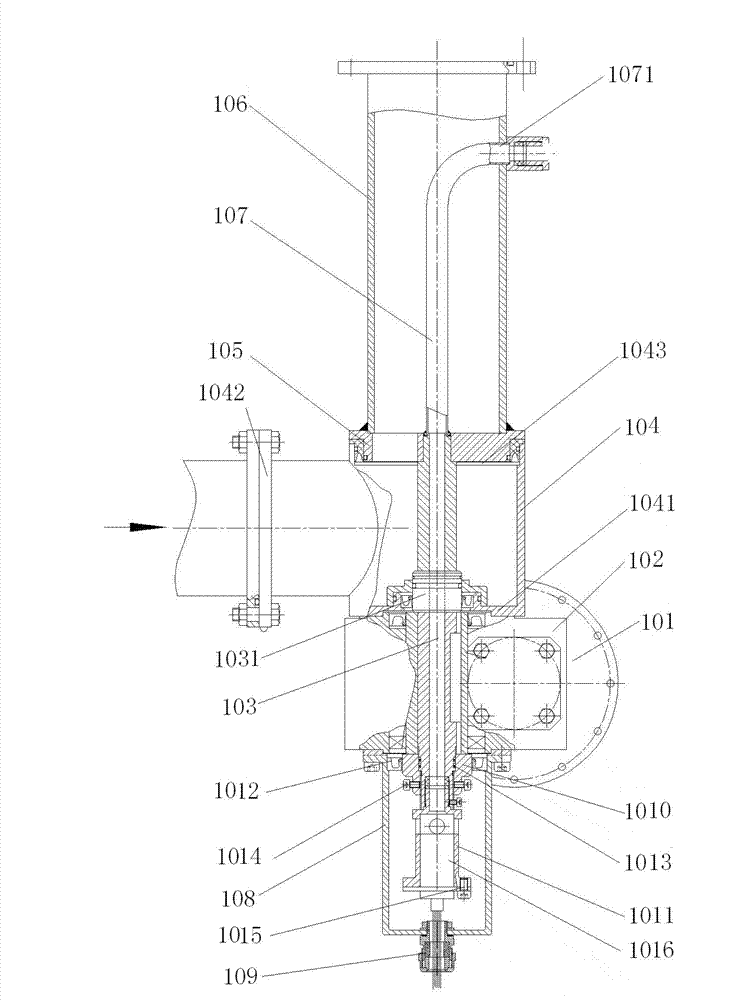

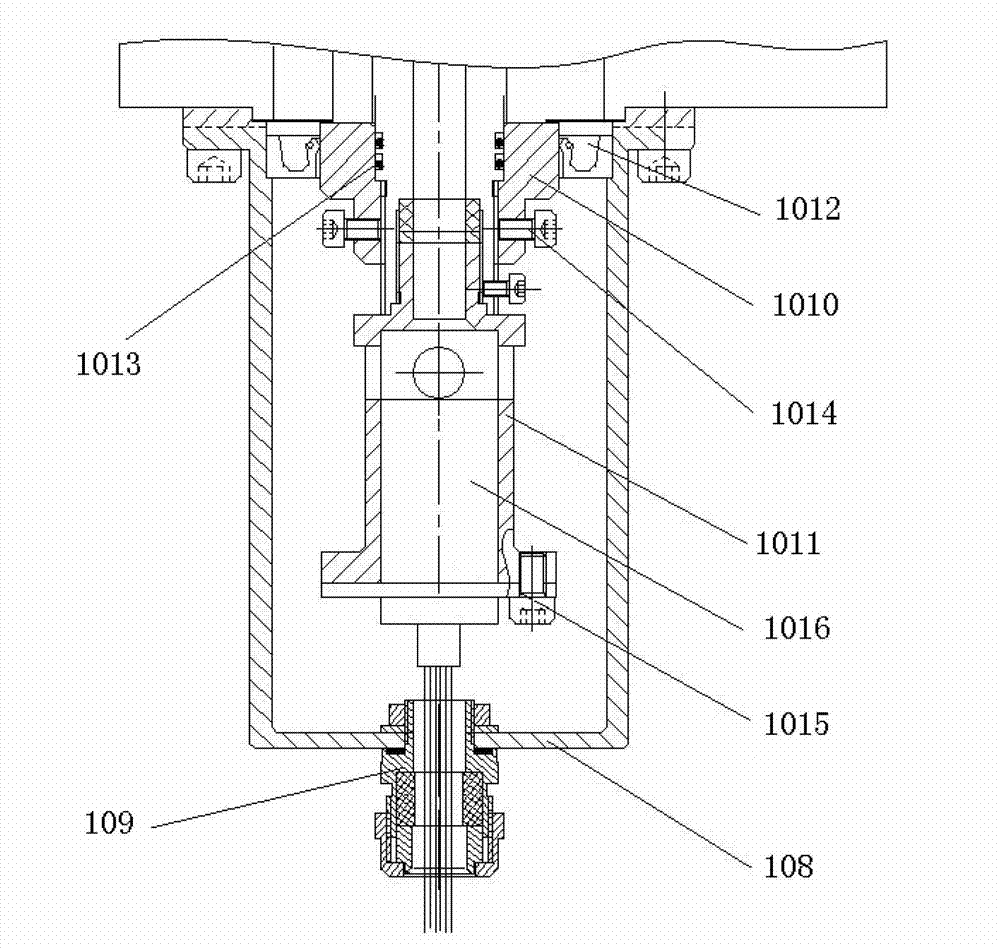

High temperature and high pressure in-situ fretting wear test device

ActiveCN104359778AHigh control precisionReal-time adjustment of micro-motion amplitudeInvestigating abrasion/wear resistanceEngineeringAuxiliary electrode

The invention relates to a fretting wear test device, in particular to a high temperature and high pressure in-situ fretting wear test device, and solves the problems that in-situ fretting wear is difficult to realize at a high temperature and a high pressure; fretting amplitude and frequency are difficult to control accurately; electrochemical signals are hard to measure during fretting wear. The fretting wear test device is provided with a vibration exciter, a thermocouple, a working electrode / auxiliary electrode seat, an autoclave cover, a hydraulic cylinder, an autoclave body, an upright, a positioning plate, a first sample holding and loading device, a moving shaft, an upper linear guideway, a working electrode, a moving shaft guide bracket, an auxiliary electrode, a connecting nut I, a reference electrode seat, a reference electrode, a lower linear guideway, an upper guide platform plate, an upper guide rod, a lower guide rod, a lower guide platform plate and a connecting nut II. The device is capable of performing in-situ fretting wear on the surface of a sample at a high temperature and a high pressure. The reference electrode, the working electrode and the auxiliary electrode mounted on an autoclave work with an electrochemical workstation to detect the electrochemical signals during fretting wear.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

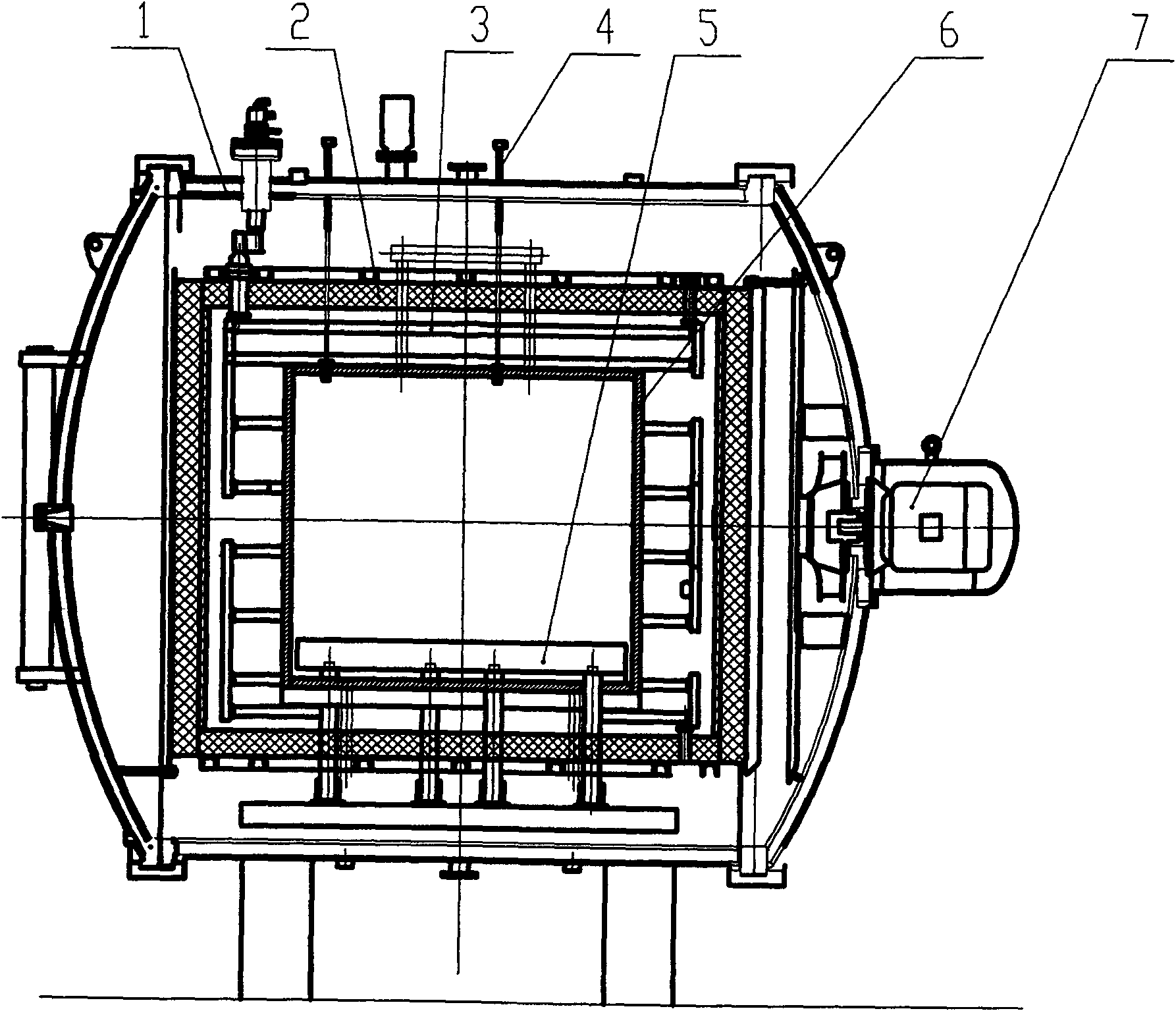

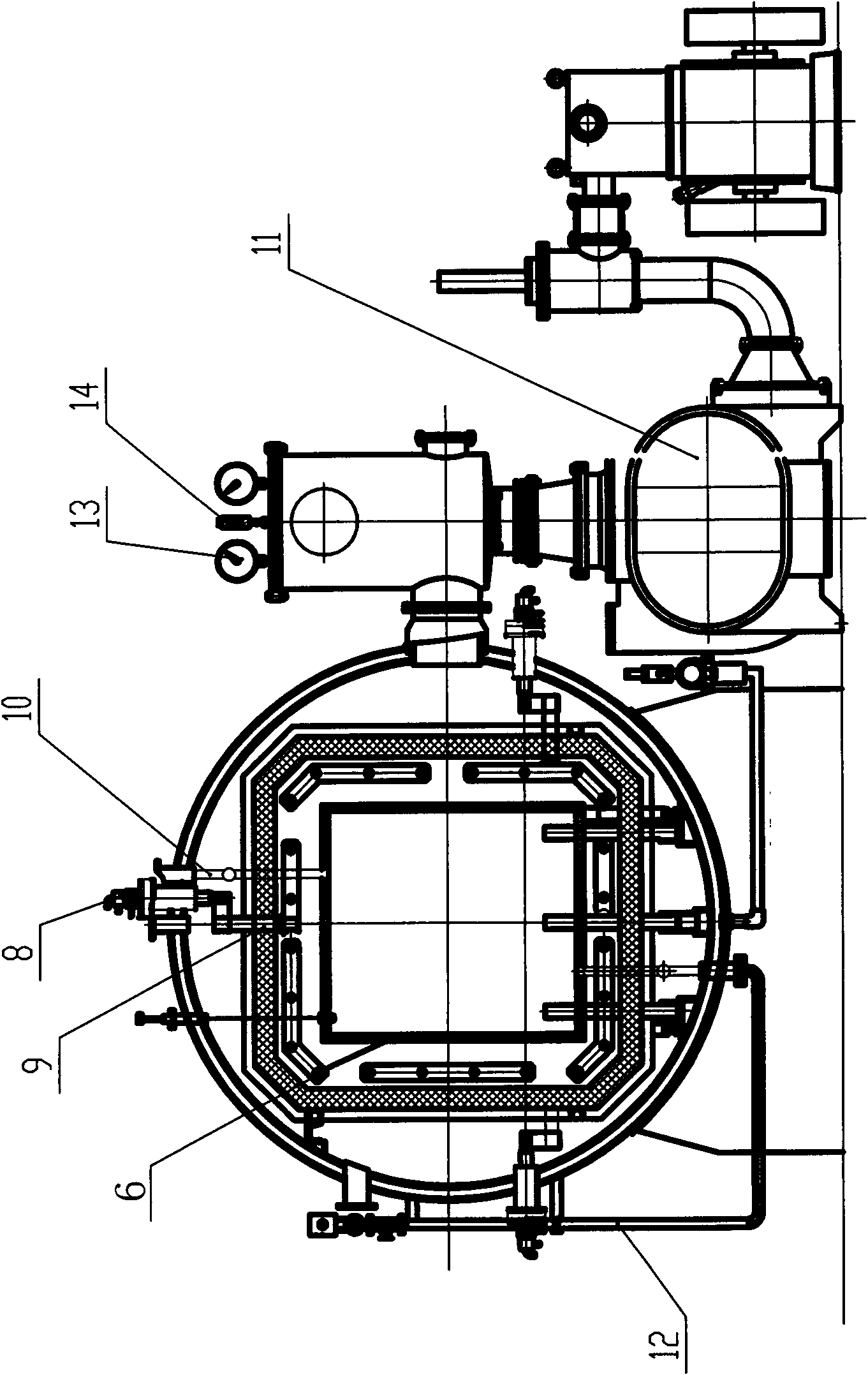

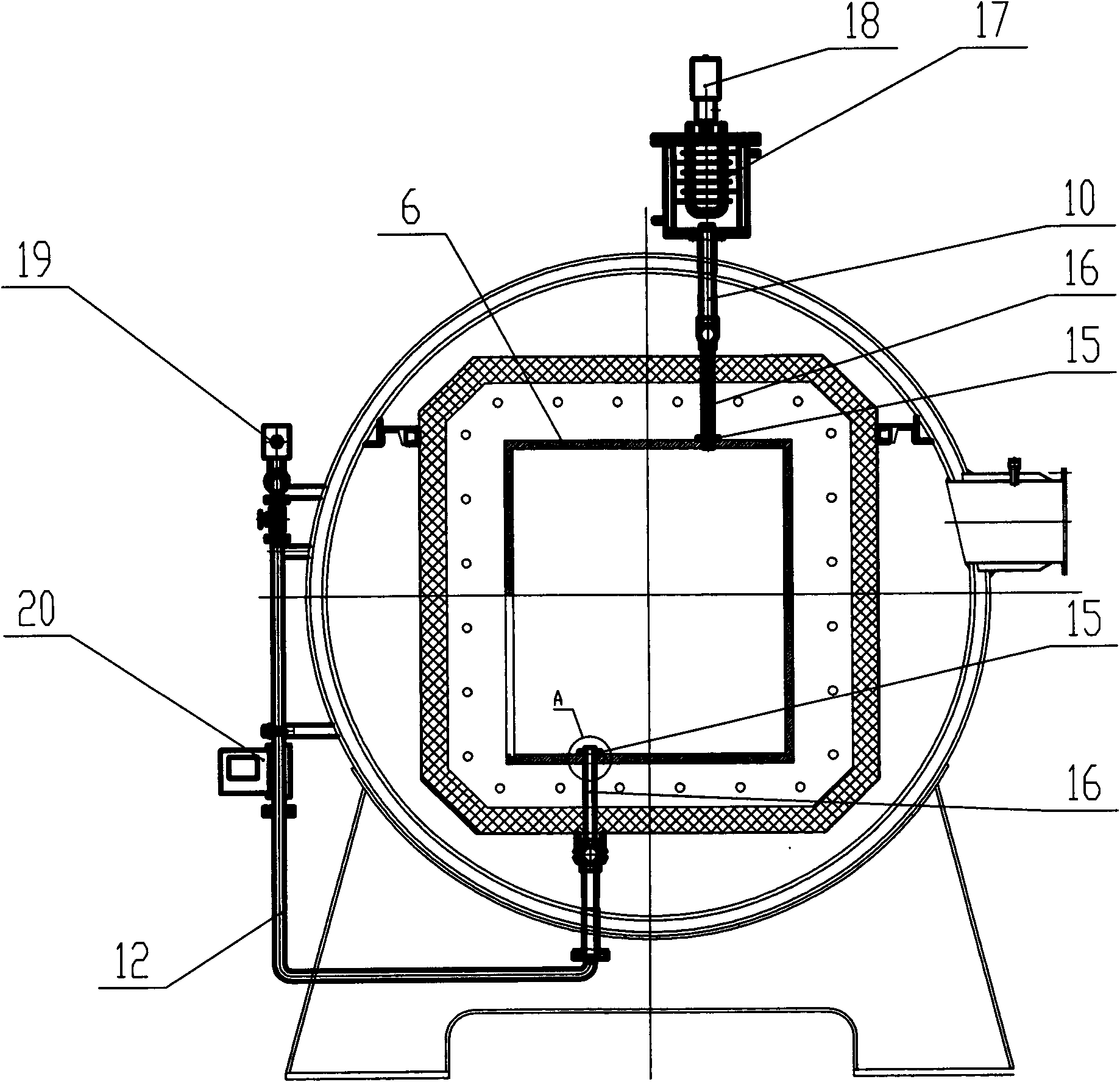

Protective atmosphere vacuum sintering furnace with high temperature of 1800 DEG C

InactiveCN101655310ASolve insulation problemsSolve the sealing problemMuffle furnacesRetort furnacesGraphite electrodeControl system

The invention discloses a protective atmosphere vacuum sintering furnace with high temperature of 1800 DEG C. A control system is connected with an electronically-controlled execution component arranged in an apparatus, a graphite sealing box is arranged in a heating chamber, an air inlet pipeline and an exhaust pipeline of a high-temperature vacuum sintering furnace are connected with the graphite sealing box. The protective atmosphere vacuum sintering furnace is characterized in that the furnace has two techniques of atmosphere sintering and vacuum sintering, and a function conversion measurement is actualized by a control program; a furnace shell is provided with a thermoelectric couple and a copper electrode; the part of a shell column body is provided with a pipe joint communicated with an evacuation unit of a vacuum system; and a square heating chamber is arranged in the furnace shell, heaters are fixed on four walls in the heating chamber, and the heater is internally provided with a sealing box and a support material frame; and the air inlet pipeline and the exhaust pipeline communicated with the sealing box passes through an upper wall and a lower wall of the heating chamber and the sealing box through a graphite pipe to communicate with the inside of the sealing box, one end of the furnace shell is provided with a gas circulating cooling blower, an inner wall of the sealing box is provided with the thermoelectric couple and the copper electrode, and the copper electrode is connected with the heater through a graphite electrode. A volatile substance sealed in the sealing box can not disperse during vacuum sintering, thereby effectively preventing the volatile substance from polluting and damaging the heater, and simultaneously achieving the effect of enabling the protective gas to take the volatile substance away to protect furnace materials, and improving the utilization ratio of the protective gas.

Owner:SHENYANG HENGJIN VACUUM TECH

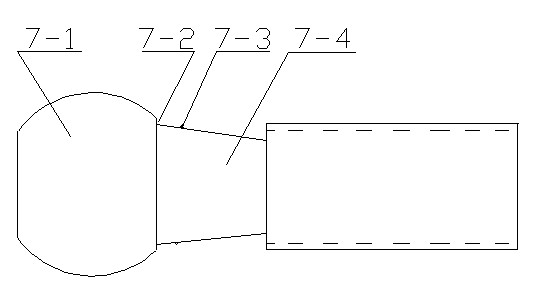

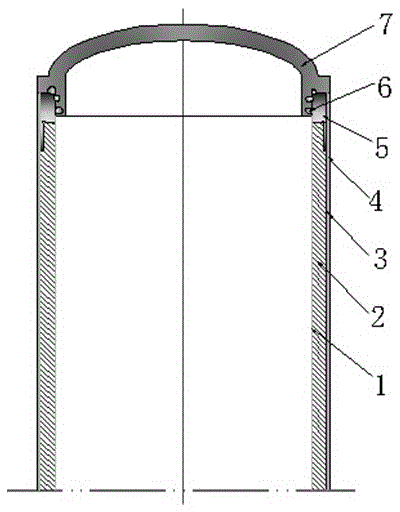

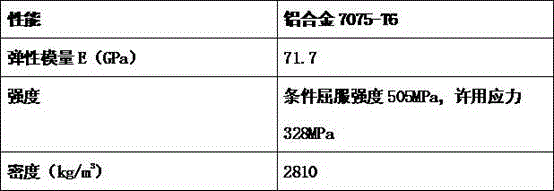

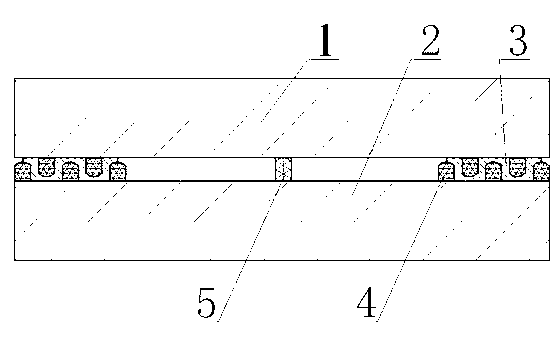

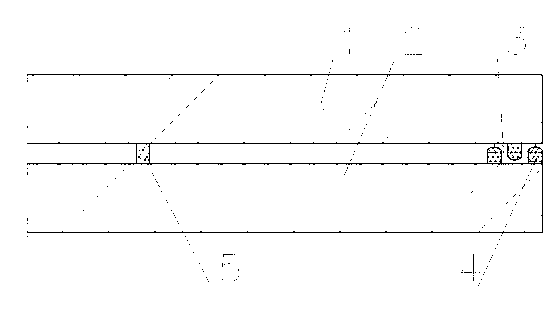

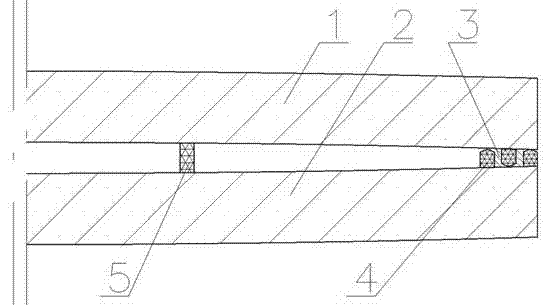

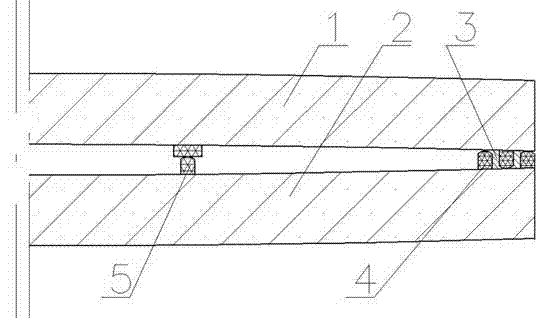

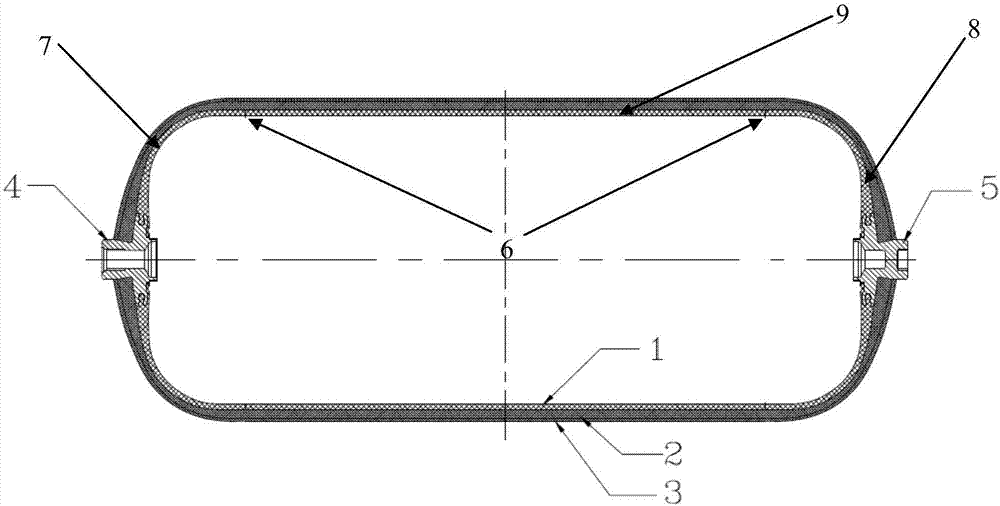

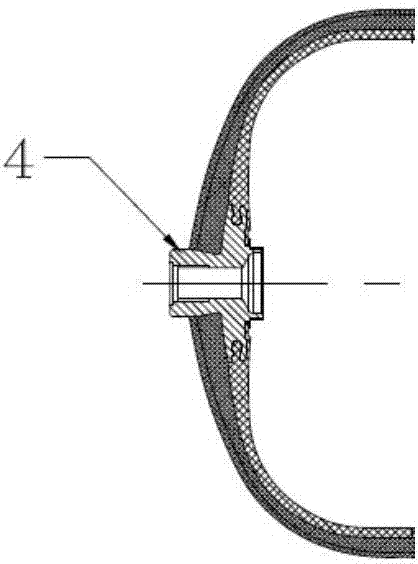

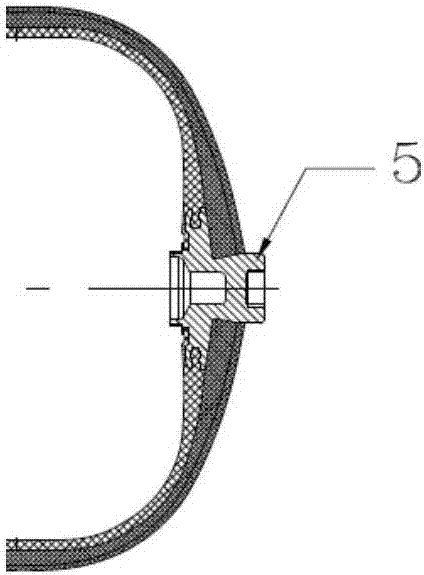

Novel pressure-resistant cabin body made from carbon fiber macromolecular composite materials and manufacturing technology of novel pressure-resistant cabin body

ActiveCN105620693AMeet low temperature resistanceSolve the leakVessel partsUnderwater equipmentFiberManufacturing technology

The invention discloses a novel pressure-resistant cabin body made from carbon fiber macromolecular composite materials. The pressure-resistant cabin body comprises two parts of a cylindric cabin body and end covers 7 positioned at two ends of the cabin body. The pressure-resistant cabin body is characterized in that the cabin body consists of an inner protection layer 1, a carbon fiber barrel body 2, a leak-proof layer 3 and an outer protection layer 4 sequentially from inside to outside, the two ends of the cabin body are in sealed connection with the end covers 7 through connecting fittings 5 and sealing rings 6, and the cabin body and the connecting fittings 5 are in glued joint. The invention further discloses a manufacturing technology of the novel pressure-resistant cabin body made from carbon fiber macromolecular compound materials. The manufacturing technology comprises the following steps of preparation for a mold, compounding of glue stocks, winding of the carbon fiber barrel body, curing of the carbon fiber barrel body, glued joint of the carbon fiber barrel body and the connecting fittings, processing of the leak-proof layer, the processing of the protection layers and the assembling of the end covers. The pressure-resistant cabin body made from carbon fiber macromolecular compound materials can be used in adverse environment with high temperature, low temperature and high pressure in the deep sea, and is high in pressure-resistant intensity, and the problems of leaking and sealing of compound materials under high pressure state are solved.

Owner:山东蓝鲸腾飞海洋科技有限公司

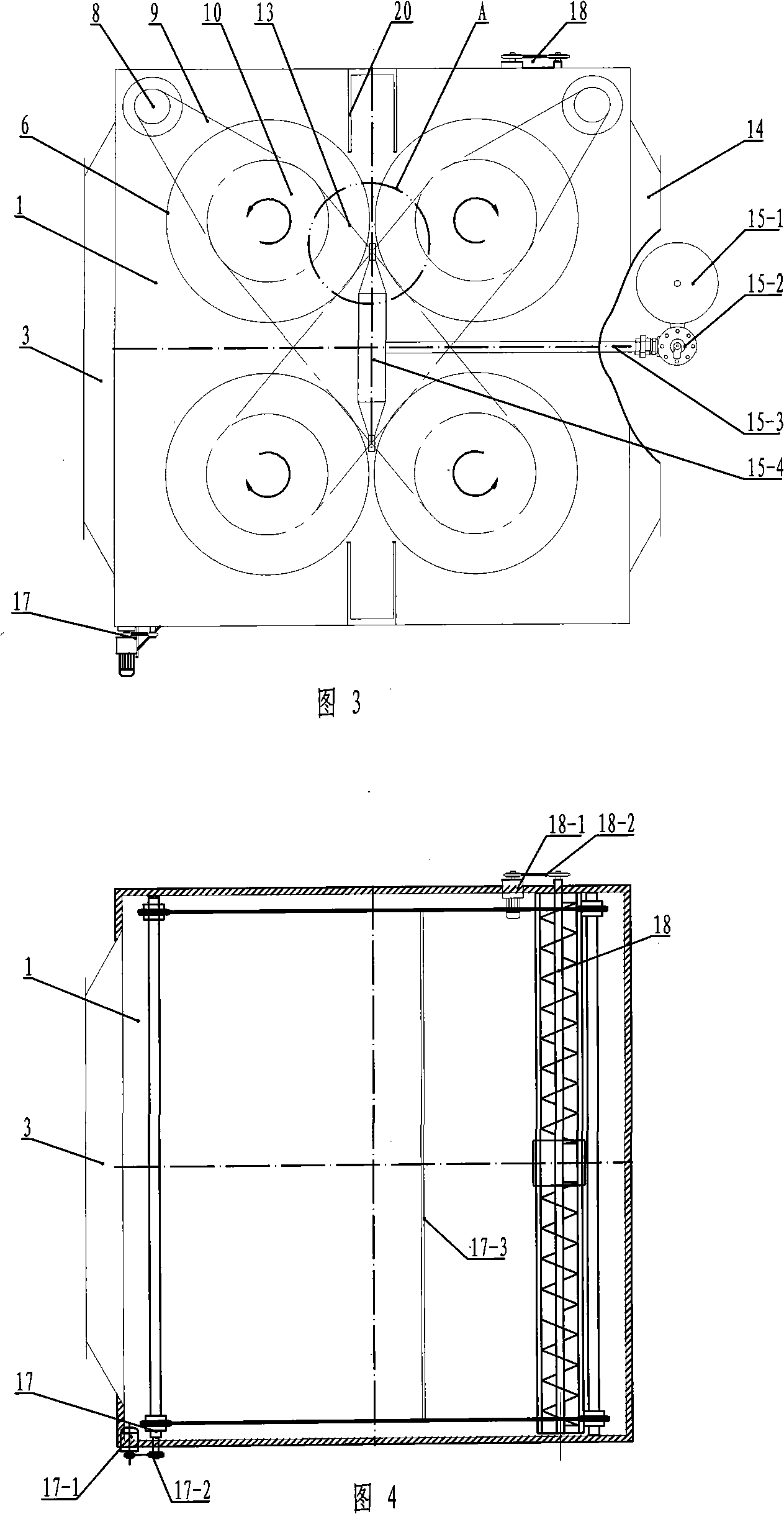

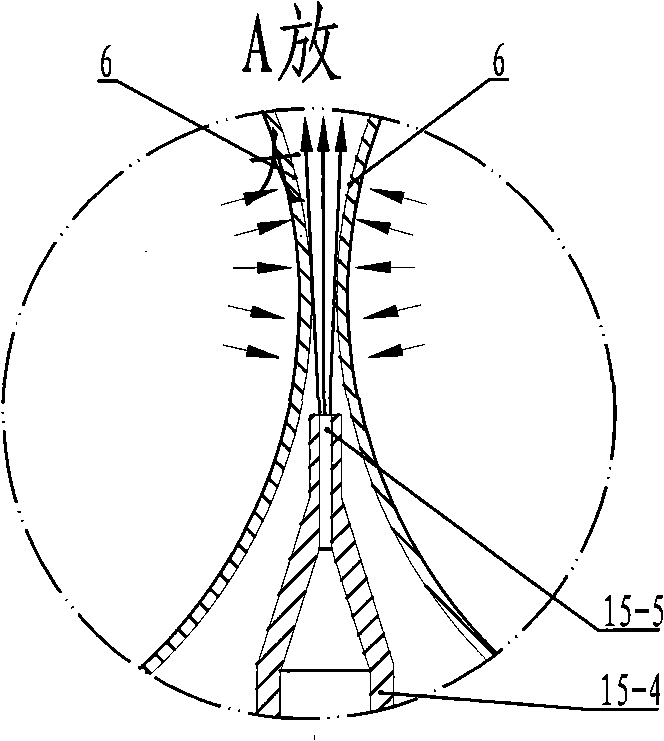

Rotating filter cartridge type air dust remover

InactiveCN101264406AEfficient removalConstant dust removal effectDispersed particle filtrationHigh humidityChain type

The invention discloses a rotary drum type dust remover, comprising a housing, a plurality of filter cylinders arranged in the intracavity of the housing for isolating dust, a main motor for driving filter cylinders, an impulse sweep system for cleaning the deposit dust on the surface of the filter cylinder, a chain typed scraper chain conveyor for cleaning dust, a spiral ash transportor and a dust discharge valve. The dust remover has the advantages of low dust concentration requirement for the air to be purified, ability to remove dust in various environments, and stable dust removal efficiency; and high temperature resistance, high humidity resistance, acid and alkaline corrosion resistance, electrostatic prevention as the filtered cloth material is stainless steel material; and ability to be used independently, also to be used multi-parallelly, and to select the number of single machine in an unit according to different discharge standard.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

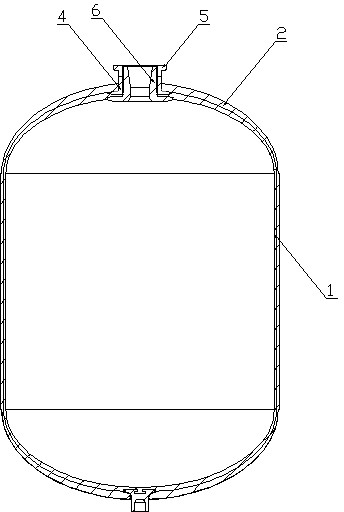

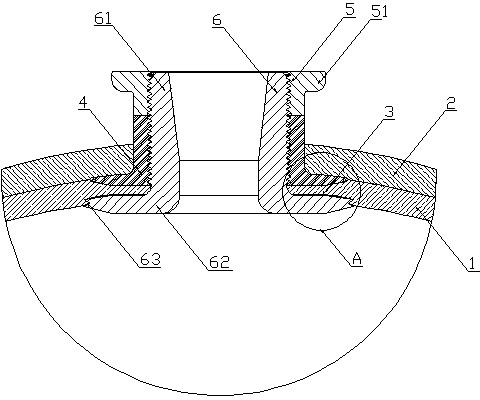

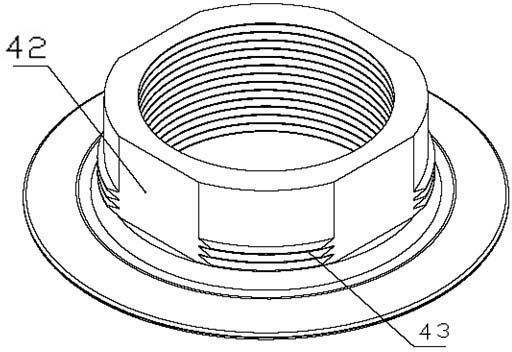

Gas cylinder with fully-wound plastic liner and molding technology thereof

InactiveCN102182910AImprove sealingMeet safety requirementsVessel mounting detailsPressure vesselsGas cylinderShock resistance

The invention relates to a cylinder for storing liquefied petroleum gas and discloses a gas cylinder with a fully-wound plastic liner and a molding technology thereof. The gas cylinder comprises a cylinder body and a cylinder opening, wherein the cylinder body comprises a plastic liner, the liner is wound with a composite material wound layer; the cylinder opening comprises a valve seat which is matched with the liner. According to the invention, a metal flange sealing principle and a unique molding process are adopted, the liner is used as a sealing base surface, a sealing pad is used as a sealing medium, the metal valve base is used as a sealing stressed base, the reliability and tightness of the connection between plastic and metal can be ensured by using a fixing flange to apply a rated sealing force so that the gas cylinder can achieve excellent gas tightness; in addition, a milled opening and a limit boss are arranged on the outer wall of the fixing flange, thereby improving the antitorque performance and shock resistance of the gas cylinder and meeting the technical and safety requirements of a rechargeable gas cylinder.

Owner:杭州余杭獐山钢瓶有限公司

Apparatus and method for polishing three-dimensional printed plastic/resin pieces

The invention provides an apparatus for polishing three-dimensional printed plastic / resin pieces. The apparatus comprises a polishing chamber and a solvent storage tank which are communicated with each other by use of a liquid inlet pipe; the apparatus is characterized in that the polishing chamber is an airtight container, an exhaust opening of the polishing chamber is connected with an air inlet of a vacuum device, an air outlet of the vacuum device is connected to the outside atmosphere and the solvent storage tank, respectively, and a switch is used for controlling the vacuum device to be connected with or disconnected from the polishing chamber, the solvent storage tank and the outside atmosphere, respectively. The apparatus for polishing the three-dimensional printed plastic / resin pieces is environmentally-friendly, capable of effectively polishing to-be-polished pieces with complex structures, and also capable of quickly recovering the hardness of the polished pieces.

Owner:孙韶

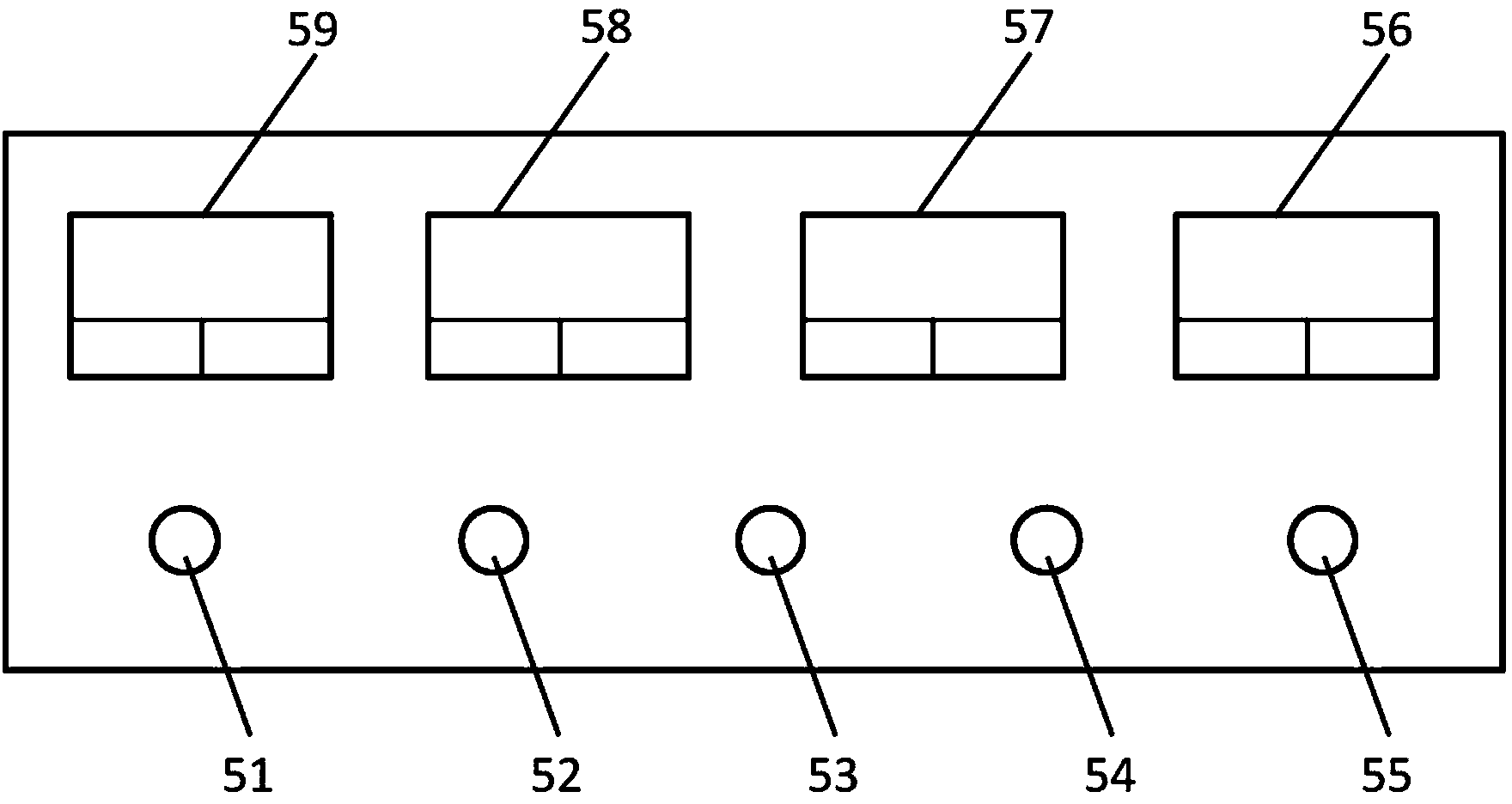

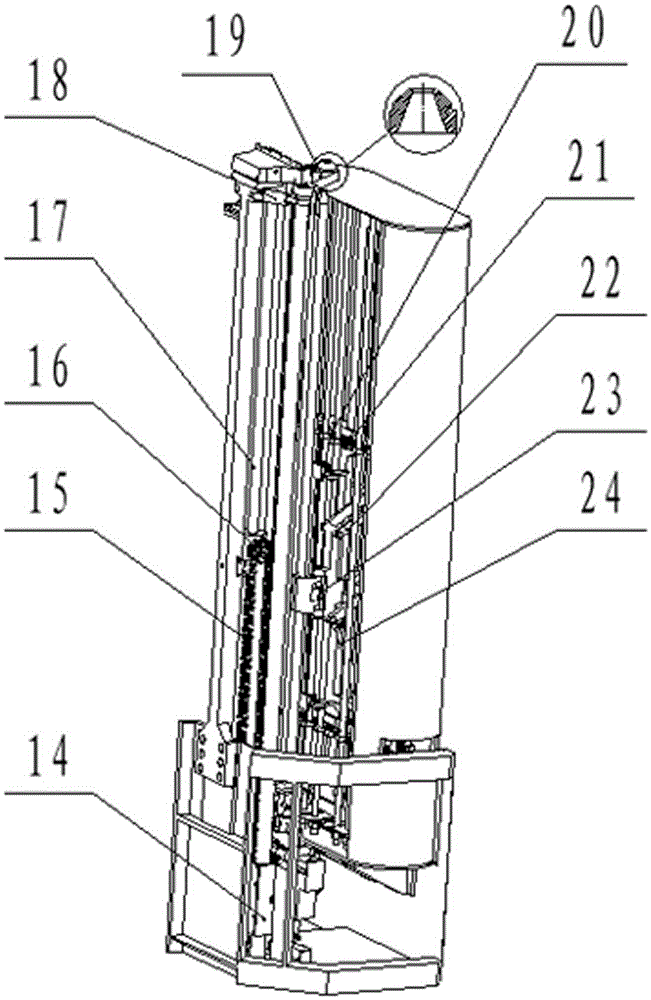

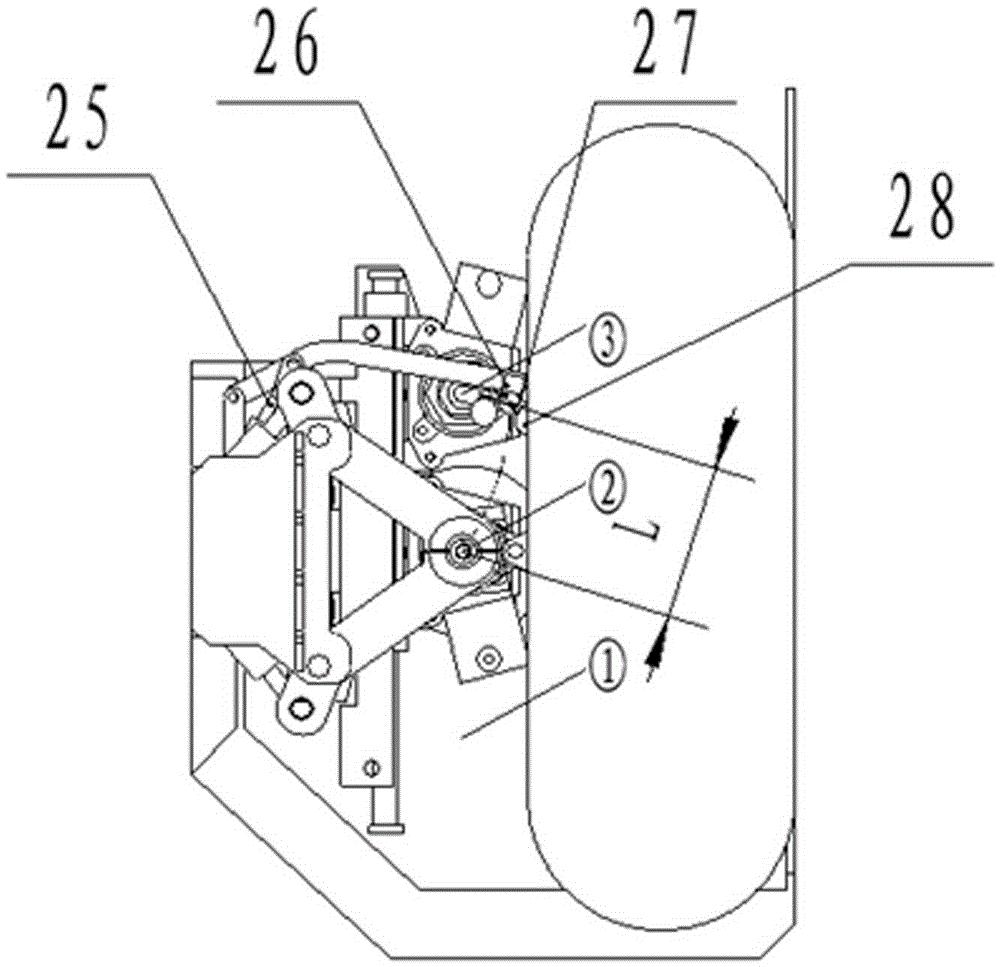

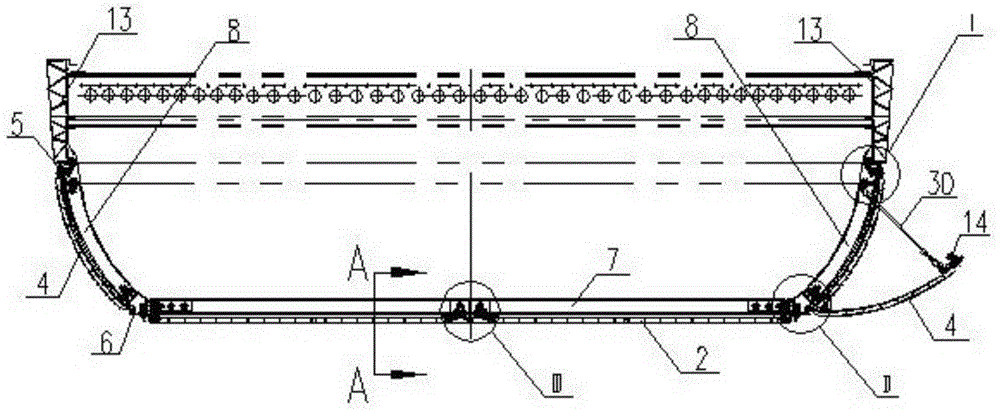

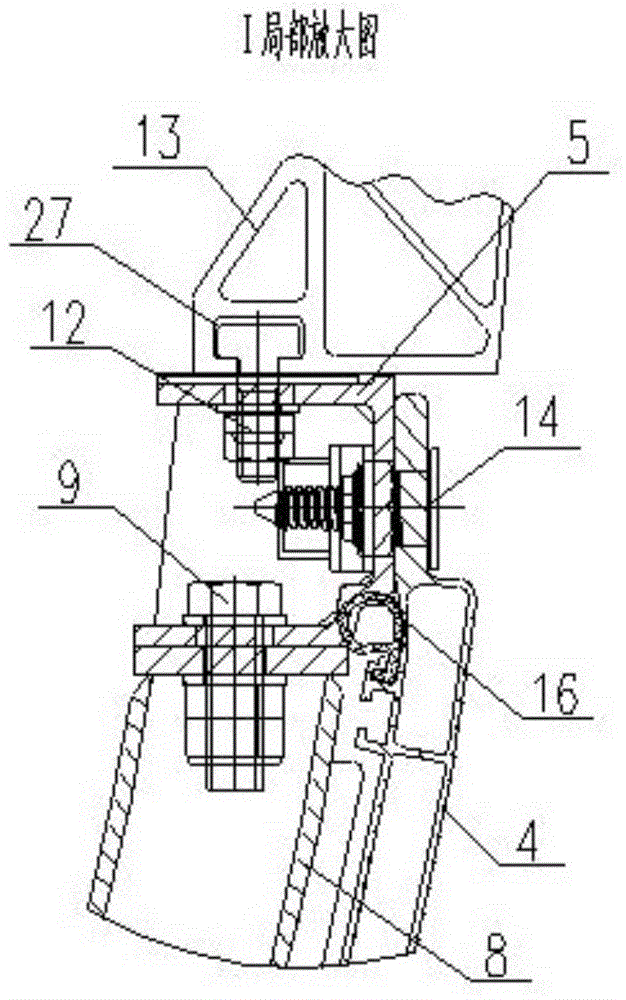

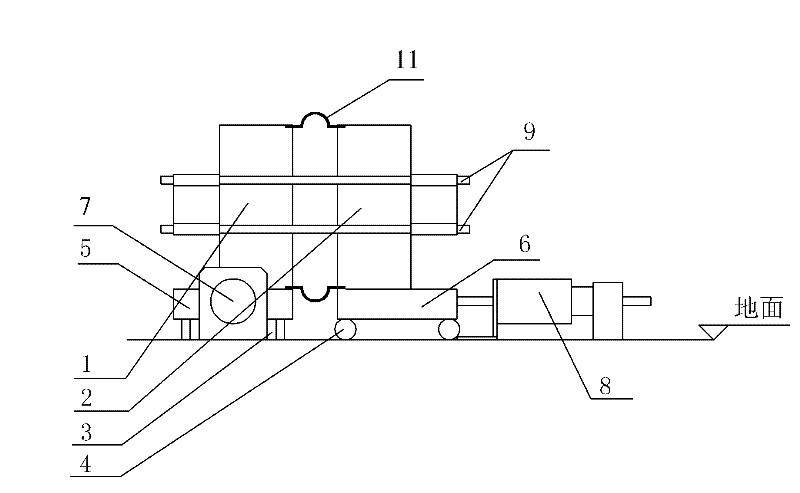

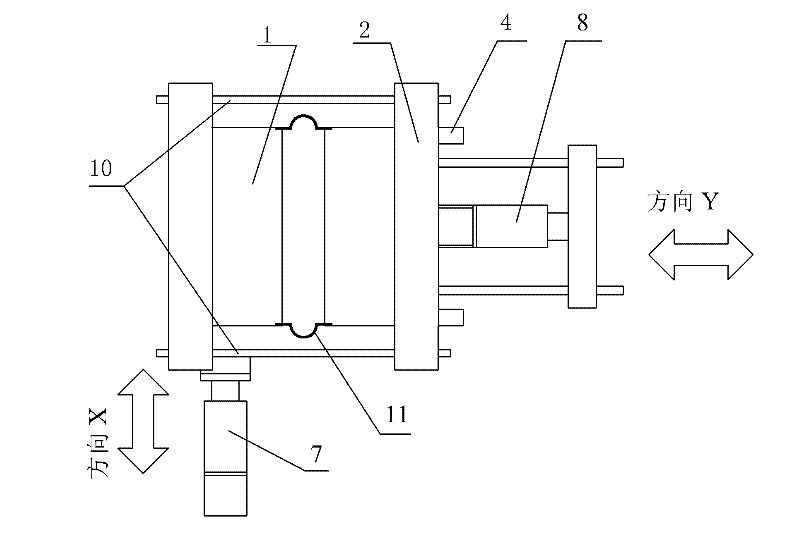

Double drilling-box switching type full-automatic roofbolter

ActiveCN105350992AHigh degree of automationFully automatedAnchoring boltsWorking environmentUltimate tensile strength

The invention belongs to the technical field of rock bolting equipment with the purpose of solving problems arising from a conventional anchor bolting mode such as low automation degree, great labor intensity of workers, a harsh working environment and poor safety. The invention provides a double drilling-box switching type full-automatic roofbolter. The double drilling-box switching type full-automatic roofbolter comprises a frame, a feeding mechanism, a large-capacity rock bolt bin, a drilling box switching mechanism, a drilling box accurate positioning mechanism, a manipulator, a steel pinching mechanism, a drilling rod positioning mechanism, a drilling box and an anchor drilling box. The drilling box and the anchor drilling box achieve drilling, installation and fastening of an anchor rod via the drilling box switching mechanism. The drilling box accurate positioning mechanism is utilized for achieving accurate positioning. The top of the large-capacity rock bolt bin is provided with the steel pinching mechanism and the drilling rod positioning mechanism so that accurate feeding of a drilling rod is ensured and higher drilling positioning is achieved. The roofbolter can be mounted to any equipment needing rock bolting. The double drilling-box switching type full-automatic roofbolter has a compact structure and does not any extra operation space or is protected by staff so that high equipment applicability is achieved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

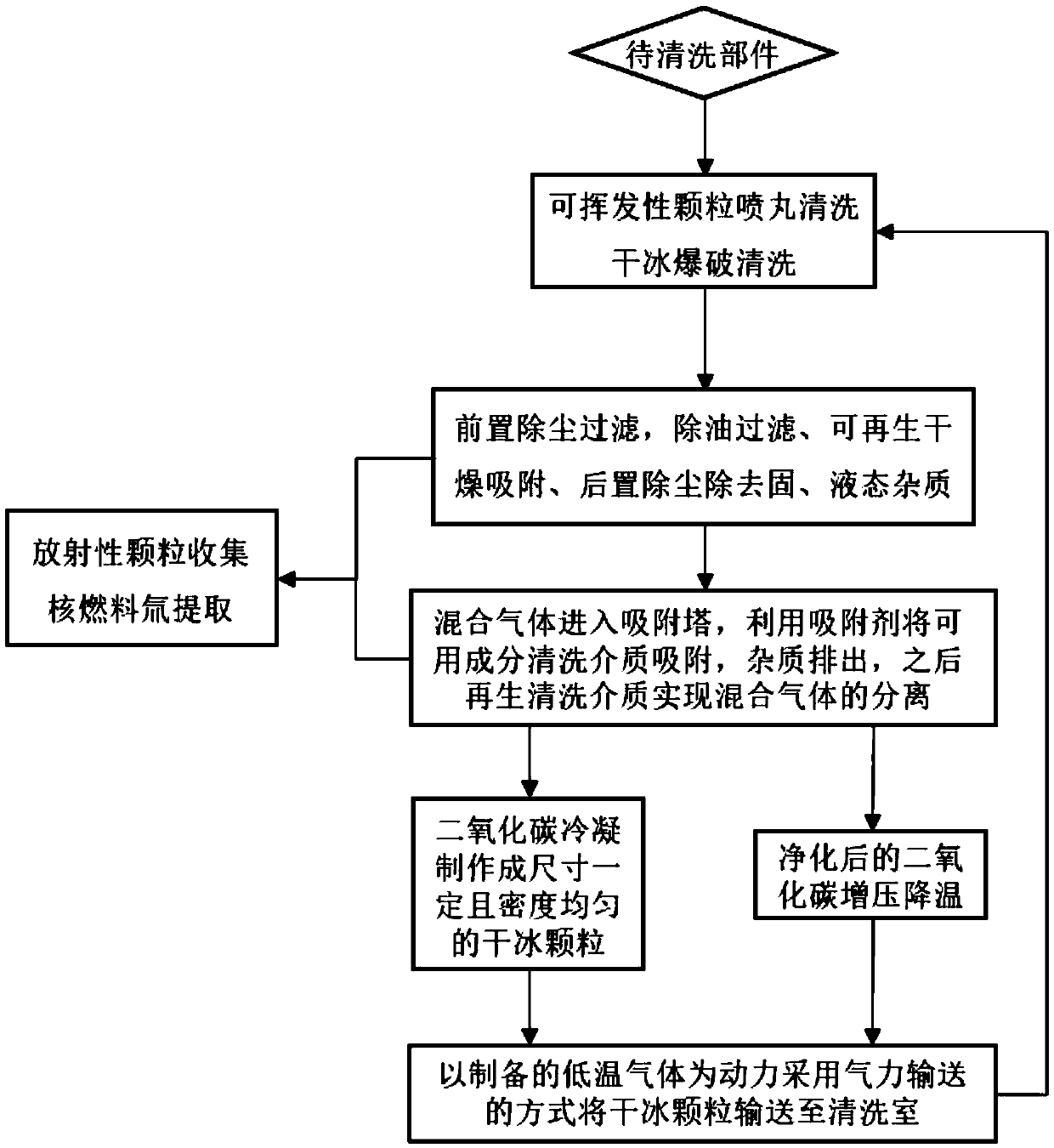

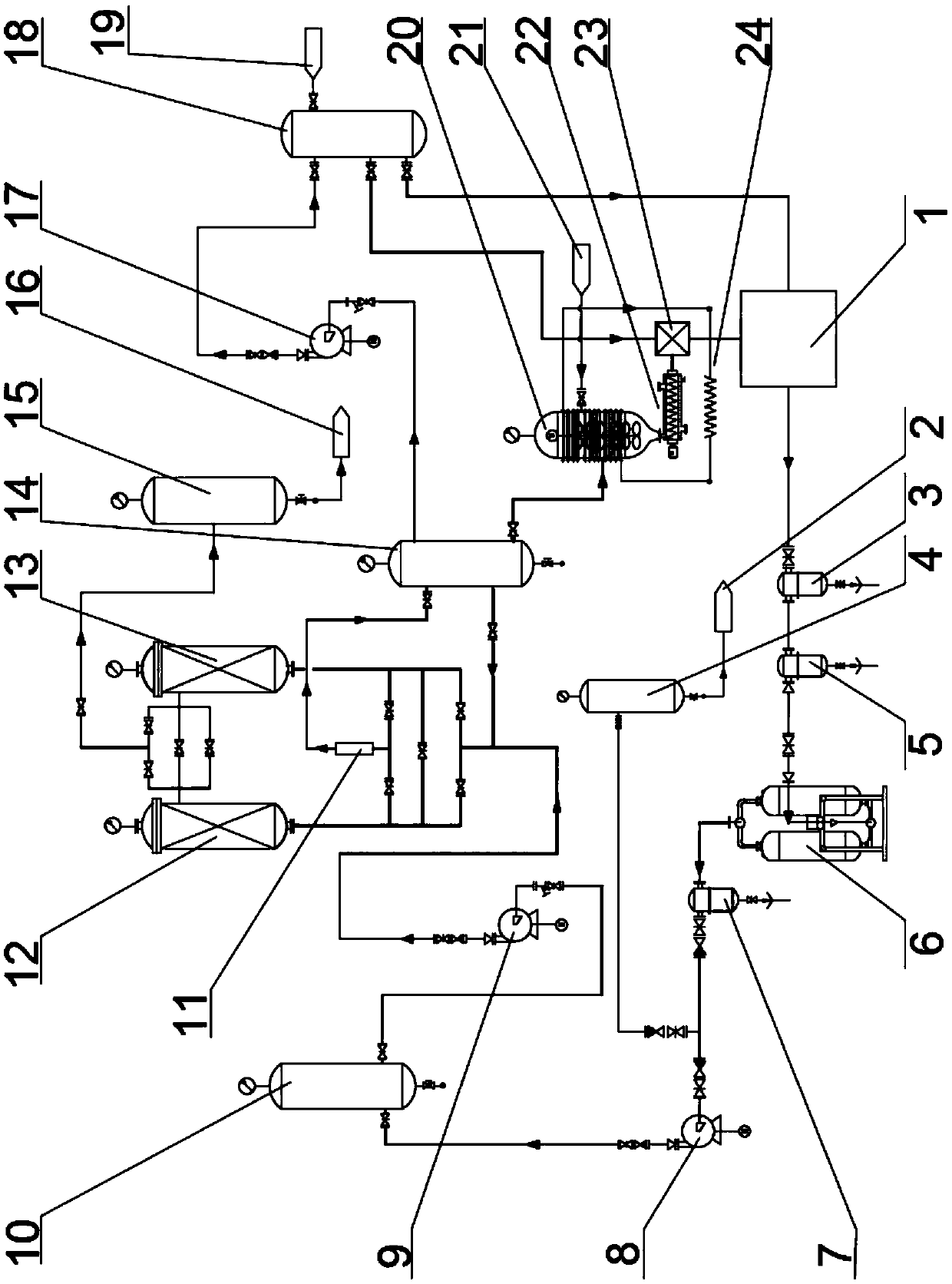

Cleaning waste gas pressure swing adsorption purification and recycling method and device for fusion reactor hot room

ActiveCN105513661AMinimize wasteAchieving classification of by-productsGas treatmentDispersed particle filtrationRadioactive gasCarbon dioxide

The invention relates to a cleaning waste gas pressure swing adsorption purification and recycling method and device for a fusion reactor hot room. The method includes the technological process of cleaning and contaminating, solid and liquid impurity filtration and purification, cleaning medium adsorption separation and regeneration, low-temperature power gas preparation, volatilizable particle regeneration and volatilizable particle remote-distance pneumatic transport. Fusion reactor hot room cleaning waste gas containing radioactive particles and radioactive gas is processed in a low-risk mode through a multiple filtration and pressure swing adsorption method, and separation, classified collection and recycling of radioactive particles, radioactive gas tritium and a cleaning medium carbon dioxide gas are achieved. The purity of regenerated products is high, no external heat source heating is needed, the gas temperature change range is small, the device is more economical and saves more energy, the service life of adsorbent is long, the device maintenance is easy and convenient, automatic production can be completely achieved, and the method and the device are suitable for the hot room environment remotely controlled and operated.

Owner:UNIV OF SCI & TECH OF CHINA

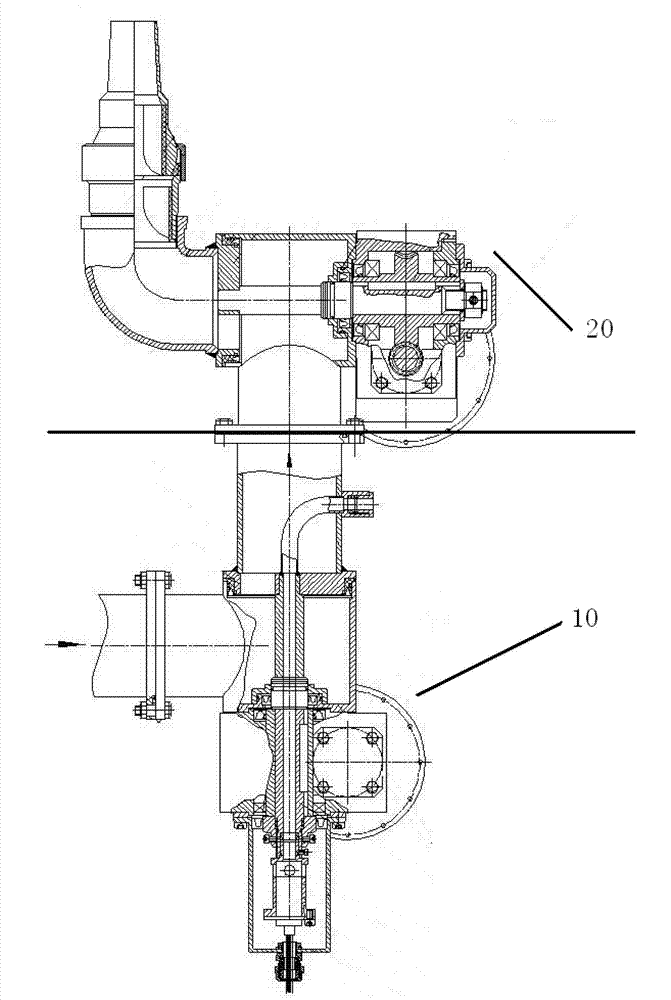

Two-dimension fountain device

ActiveCN102814255ASolve the entanglementSolve the problem of winding on the rotary transmission mechanismEngine sealsMovable spraying apparatusWater flowEngineering

The invention relates to a two-dimension fountain device, which comprises a lower dimension mechanism and an upper dimension mechanism. The lower dimension mechanism and the upper dimension mechanism respectively comprise a motor, a speed reducer, an output shaft, a three-way connector and an overflow support ring. The upper dimension mechanism also comprises a shower nozzle with an elbow pipe. In the lower dimension mechanism, an outlet at the lower end of the shell of the speed reducer is connected with a water-proof tube; the bottom part of the water-proof tube is provided with a cable input connector; the outer wall of the lower end of the output shaft in the water-proof tube is connected with a nut; the inner wall of the lower end of the output shaft in the water-proof tube is connected with a conducting ring seat; and the bottom part of the conducting ring seat is connected with an axial conducting ring inserted into the conducting ring seat. The first ports of the two three-way connectors and the outlet of the shell of the corresponding speed reducer as well as the corresponding input shaft are respectively and hermetically connected through two rubber seal rings, a skeleton seal ring, a seal stop bowl and a stainless steel snap ring. The third ports of the two three-way connectors and the corresponding overflow support ring are hermetically connected through a polytetrafluoroethylene ring. The two-dimension fountain device is good in sealing property under high-pressure water flow, can be used for enabling the shower nozzle to continuously and freely rotate for 360 degrees and can be widely applied to various fountain facilities.

Owner:北京中科恒业中自技术有限公司

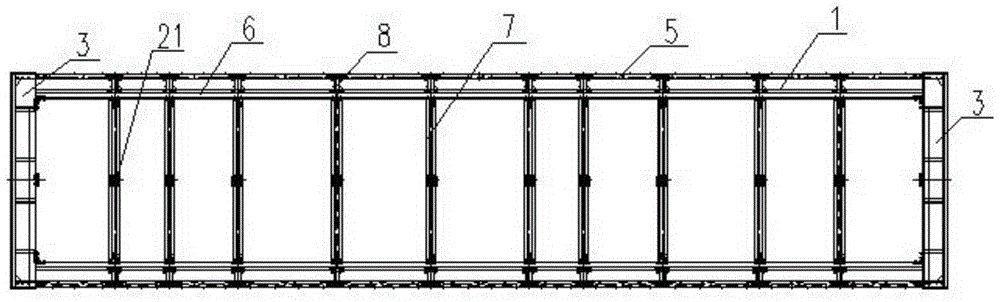

Integral equipment bay

ActiveCN104875760AHigh degree of commercializationShorten the time occupied by the assembly stationAxle-box lubricationRailway bodiesEngineering

The invention relates to an integral equipment bay which comprises a framework, a bottom plate, an end plate and an apron board, wherein the bottom plate, the end plate and the apron board are all fixedly arranged on the framework; the framework consists of an upper edge beam, a lower edge beam, multiple cross beams, multiple camber beams arranged between the upper edge beam and the lower edge beam, and end part brackets arranged at two ends; the upper edge beam and the lower edge beam are arranged along the vehicle length direction, and the multiple cross beams are arranged along the vehicle width direction; the upper edge beam, the camber beams, the lower edge beam, the cross beams and the end part brackets are fixedly connected with one another by virtue of fastening pieces; the upper edge beam is fixedly arranged on a vehicle body edge body by virtue of a fastening piece. <0}{0><}0{>According to the integral equipment bay, an overall equipment bay module can be preassembled by virtue of toolings offline; during entrucking, the overall equipment bay module is connected with the vehicle body edge beam, so that the entire car assembling table bit occupation time is shortened, and the entire car assembly efficiency and the equipment bay commercialization degree are greatly improved.

Owner:CRRC QINGDAO SIFANG CO LTD

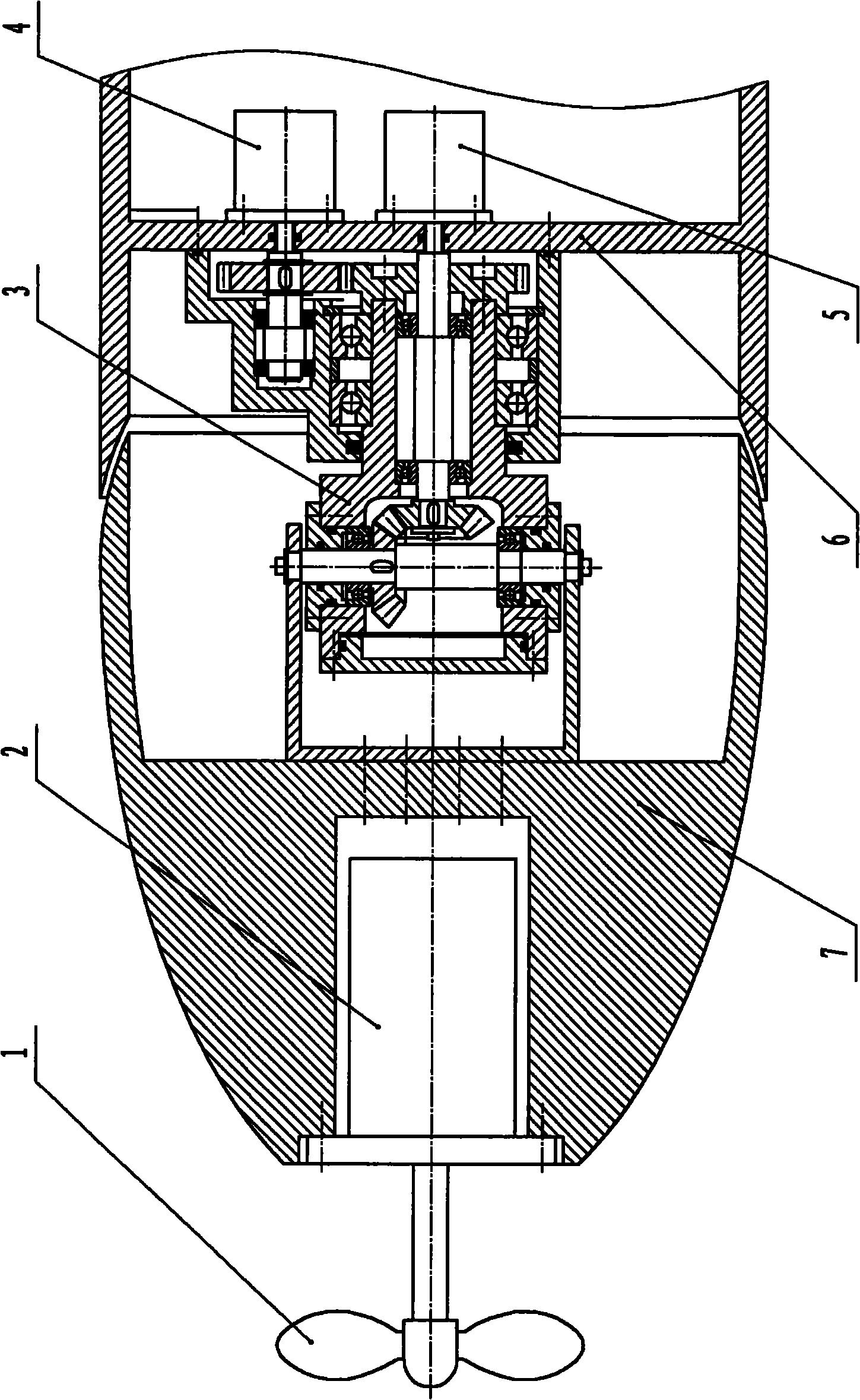

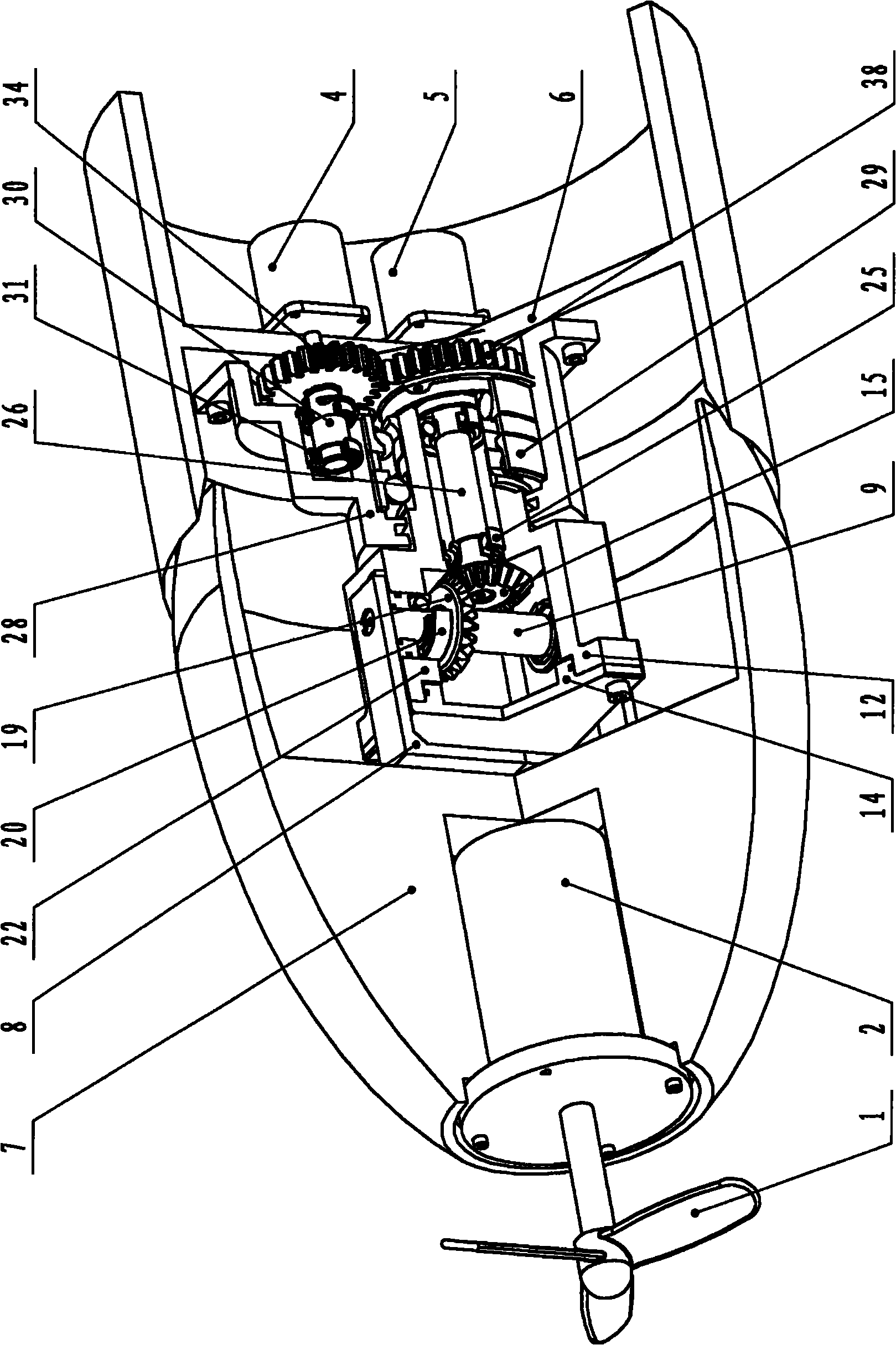

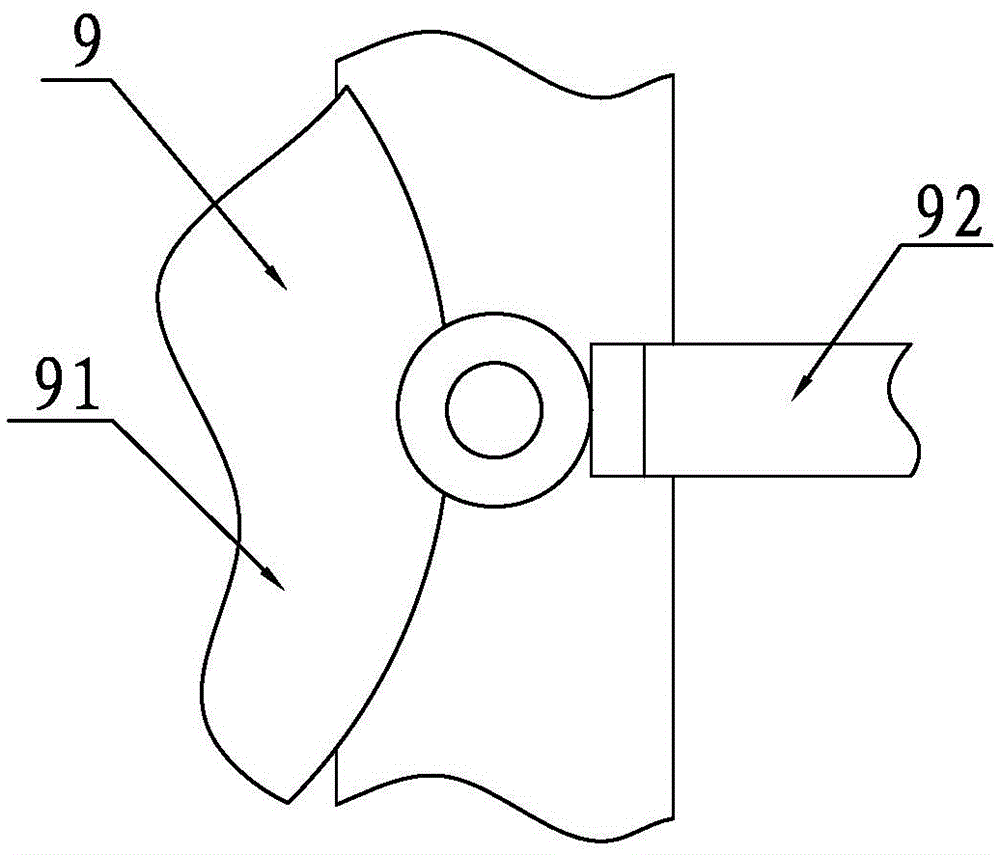

Small oil-filled full-scale deflection vector propeller thruster

InactiveCN102069902ACompact structureReduce volumePropulsion power plantsPropulsive elementsAerospace engineeringCorrosion

The invention discloses a small oil-filled full-scale deflection vector propeller thruster which comprises a propeller, a propulsion motor, a deflection mechanism, a rotary motor, a swing motor, a sealed cabin and a tail tube, wherein the propeller is connected with the propulsion motor so as to form a tail thruster, the rotary motor and the swing motor are respectively connected with the deflection mechanism so as to form a deflection system, the tail thruster and the deflection system are respectively connected with the tail tube of the thruster so as to form the full-scale deflection vector propeller thruster, and the full-scale deflection vector propeller thruster is arranged on a sealed cabin of an underwater vehicle so as to provide a vectored thrust for the underwater vehicle. Under the common driving of the rotary motor and the swing motor, the tail thruster can obtain the swing at a swivel angle of between minus 30 degrees and plus 30 degrees. The inside of the deflection mechanism is filled with oil, which not only solves the seal problem of the deflection mechanism, but also can lubricate the deflection mechanism and prevent mechanical parts in the deflection mechanism from water corrosion. The small oil-filled full-scale deflection vector propeller thruster disclosed by the invention has the advantages of compact structure, small volume, light weight, high efficiency, low cost and the like, and is suitable for providing the vectored thrusts for small underwater vehicles.

Owner:SHENYANG POLYTECHNIC UNIV

Device for conducting electroplating process and electroplate liquid development experiment in high-pressure environment

InactiveCN103173842ASimple structureProcess maintenance control is simpleCellsChemical reactionPolyvinyl chloride

The invention discloses a device for conducting electroplating process and electroplate liquid development experiment in a high-pressure environment. The device comprises a trapezoid reactor, an anode, a cathode, an external power supply, a high-pressure electrochemical reaction kettle, a CO2 conveying system, a pressure control system, a temperature control system and a stirring system, as well as an insulating sealing structure which is applicable to connection of electrodes with reaction containers under high-pressure condition. By utilizing the device, the defect that a normal-pressure Hull cell experiment device cannot meet the high-pressure reaction condition is solved, the problems that insulating materials such as organic glass or rigid polyvinyl chloride and the like generally used by the normal-pressure Hull cell experiment device cannot meet the high-pressure condition, particularly, the materials are easy to swell and degrade and the electrodes are sealed in an insulating manner in supercritical or subcritical CO2, are overcome, an electroplating effect that liquid is plated within a wider current density range can be conveniently achieved in short time, and help is provided for electroplating process research, electroplating liquid formula development and electroplating process control on the presence of high-pressure CO2.

Owner:江苏净视源能源环保研究院有限公司

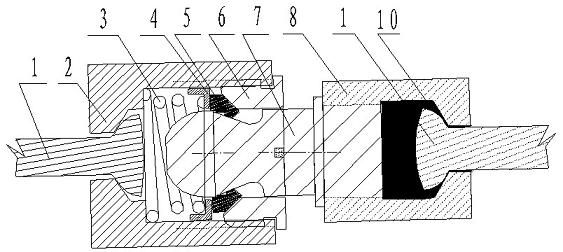

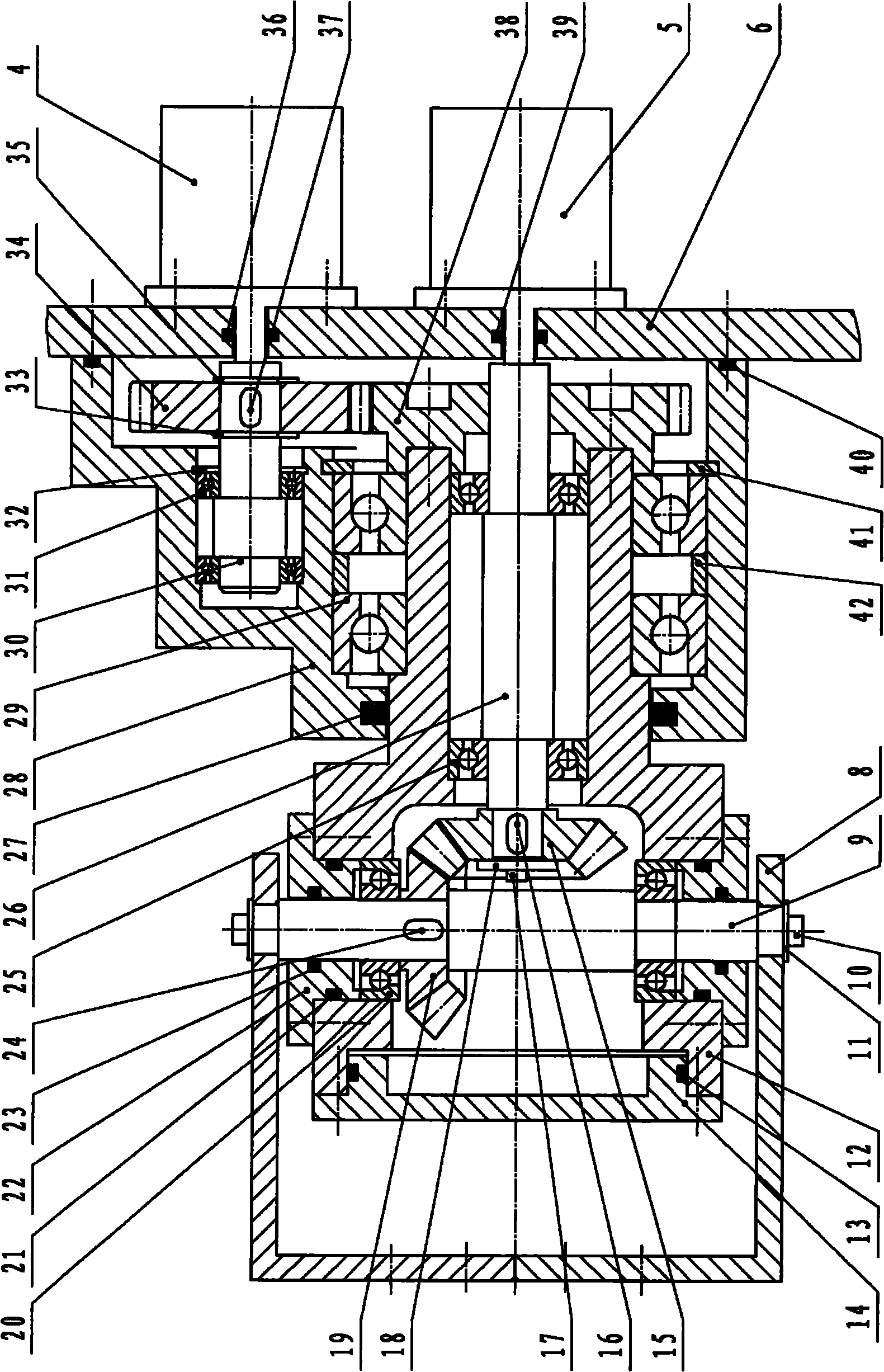

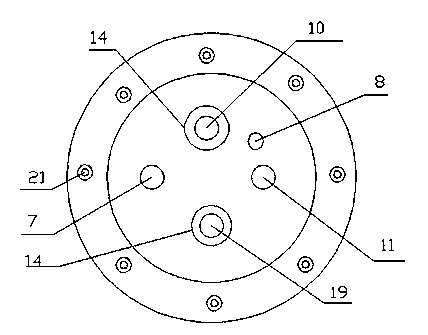

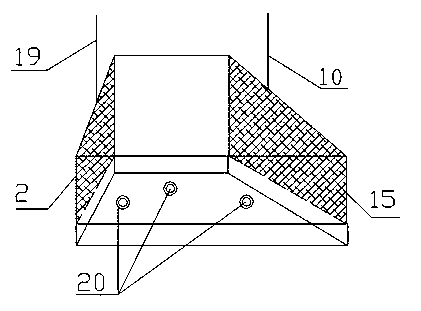

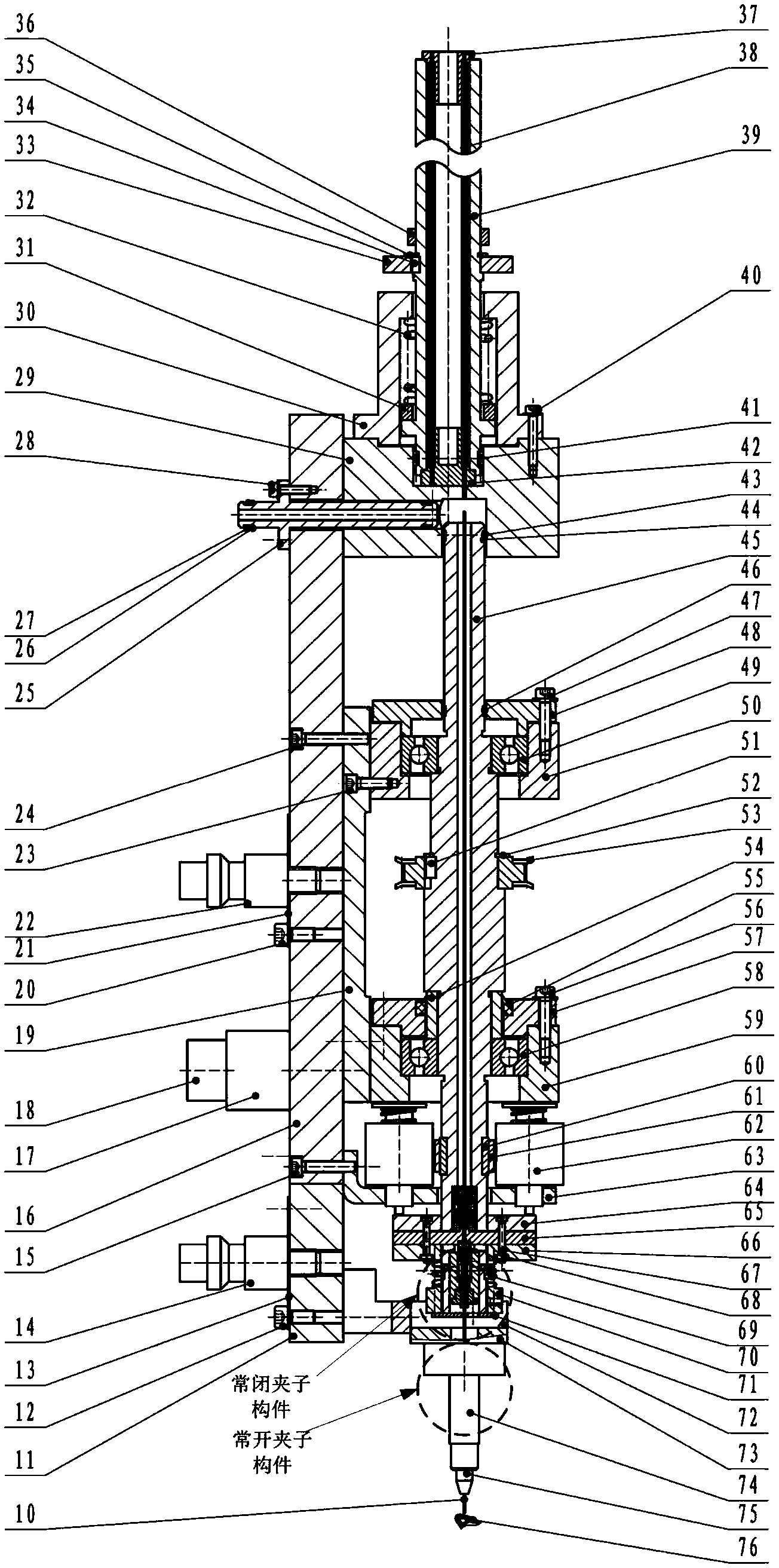

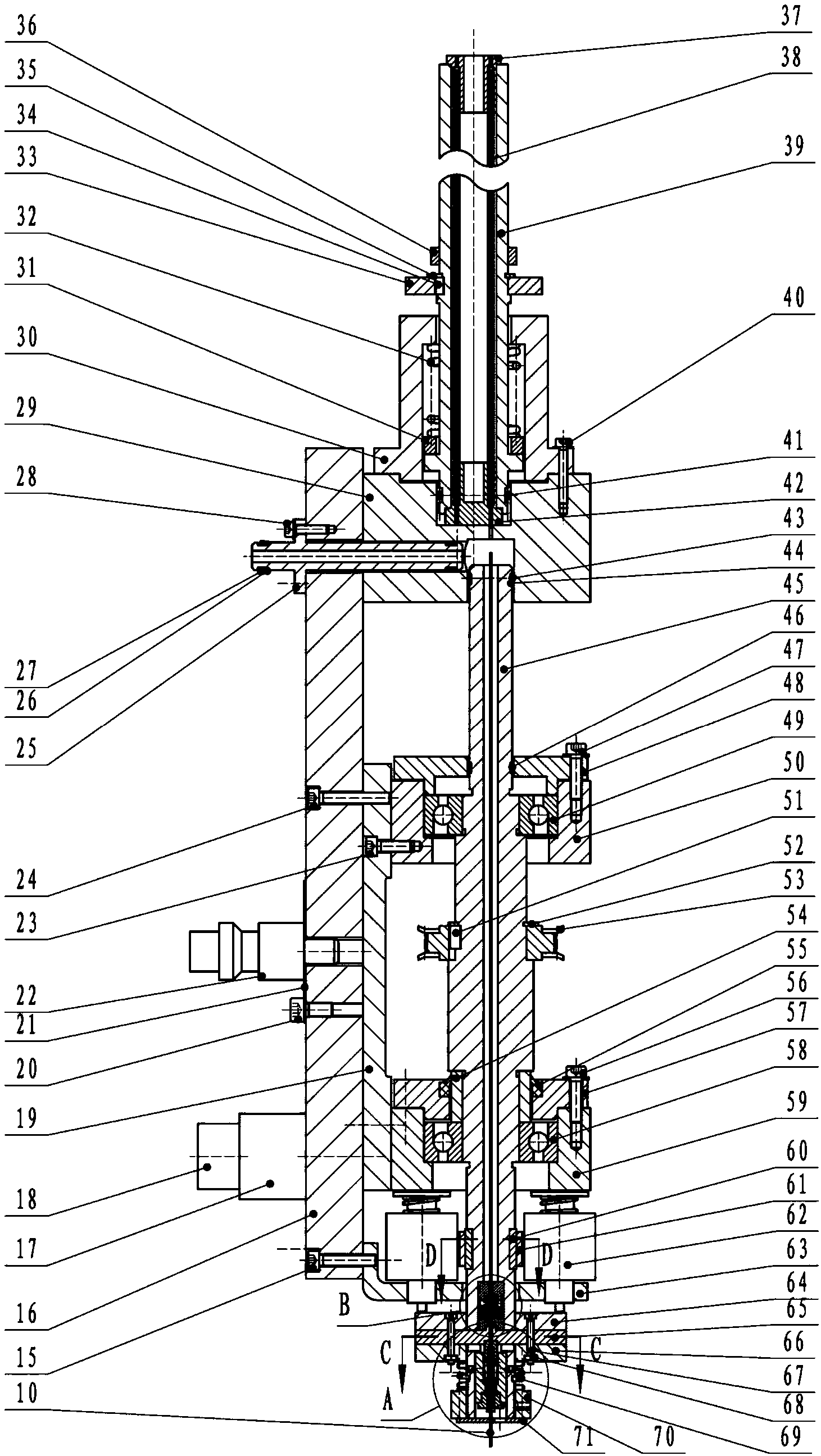

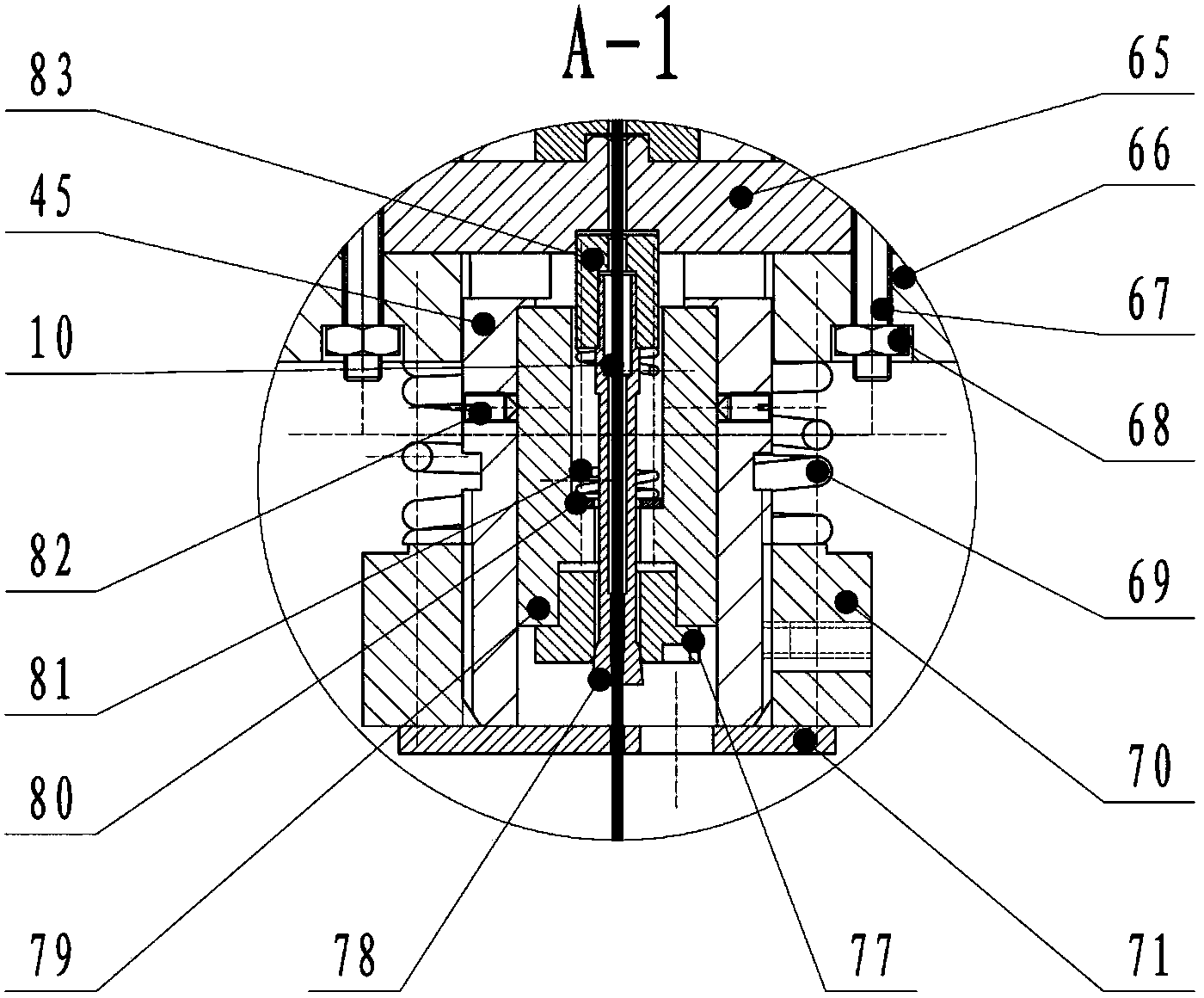

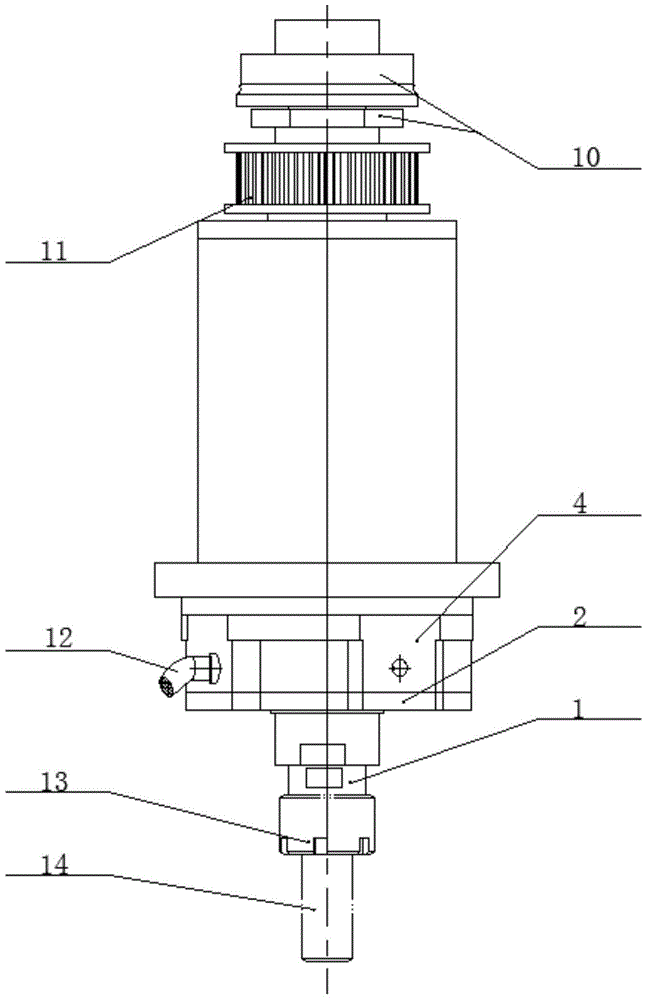

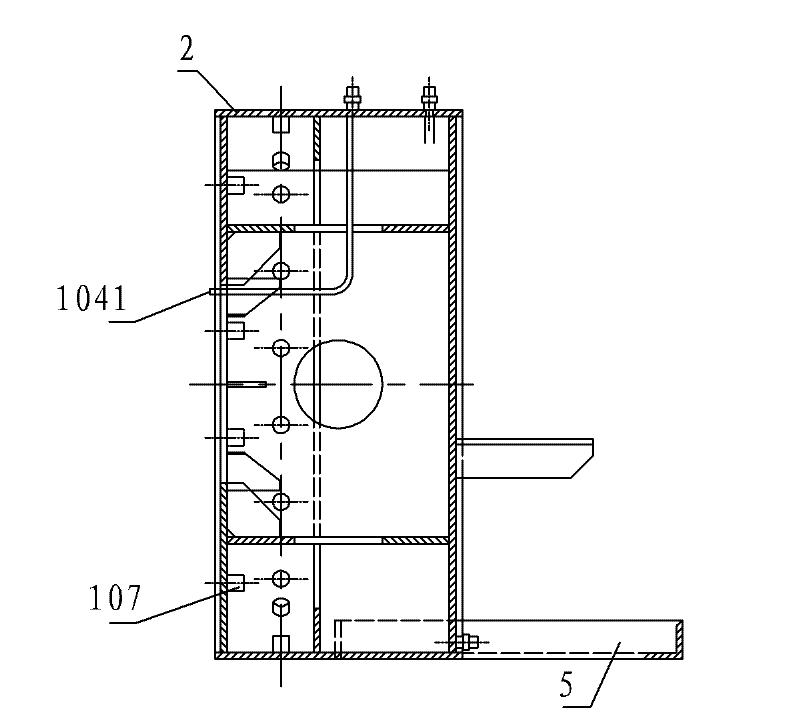

Multi-functional spindle mechanism used for small deep holes electrical discharge machining

InactiveCN103769705AImproved electrode feed stiffness and spindle servo stabilityImproved dimensional accuracy and aspect ratioElectrical-based auxillary apparatusGas turbinesEngineering

The invention discloses a multi-functional spindle mechanism used for the small deep holes electrical discharge machining, belonging to the technical field of micro non-traditional machining. The multi-functional spindle mechanism comprises a rotating spindle mechanism, a transmission mechanism, a normally closed clamp mechanism, a sealing mechanism, an electric brush mechanism, a wire replacing mechanism, a normally opened clamp mechanism, a guide mechanism and a connecting mechanism, wherein the rotating spindle mechanism, the transmission mechanism, the normally closed clamp mechanism, the sealing mechanism, the electric brush mechanism and the wire replacing mechanism are fixedly mounted on an upper mounting plate, and the normally opened clamp mechanism is mounted on a lower mounting plate; the upper mounting plate is connected to the lower mounting plate through the guide mechanism and a degree of freedom of relative movement in the z direction is kept; the upper mounting plate is connected to a z-axis top plate through the connecting mechanism, and the lower mounting plate is connected to a z-axis bottom plate through the connecting mechanism. The mechanism processes the film cooling group holes in the hot components of the aero-engines and the gas turbines, which can realize multiple functions of the forward pushing creep feed, the high precision rotation and the hollow high pressure flushing of the tool electrodes, and the on-line replacement of the electrodes.

Owner:TSINGHUA UNIV

Quasi-solid nano-composite gel electrolyte, its production and use

InactiveCN1941219AImprove performanceSolve the sealing problemIndividual molecule manipulationCapacitor electrolytes/absorbentsIonChemistry

The quasi-solid and nano-multiple gel electrolyte and produce method and application is to equably mix nanograde additive into gelated electrolyte system with polymer coagulant or small molecule coagulant to get the quasi-solid and nano-multiple gel electrolyte. Compared with the common gel electrolyte, it solves the problem about sealing liquid state electrolyte batteries and leaking to enhance charge transmission ability and increase ionic steady pervasion current and apparent diffusion coefficient of redox and improving general capability of quasi-solid gel batteries. This electrolyte is using for dye-sensitized solar cell and fuel cell to enhance photovoltage, short circuit current density, photoelectric conversion efficiency and long time stability to dye-sensitized solar cell.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

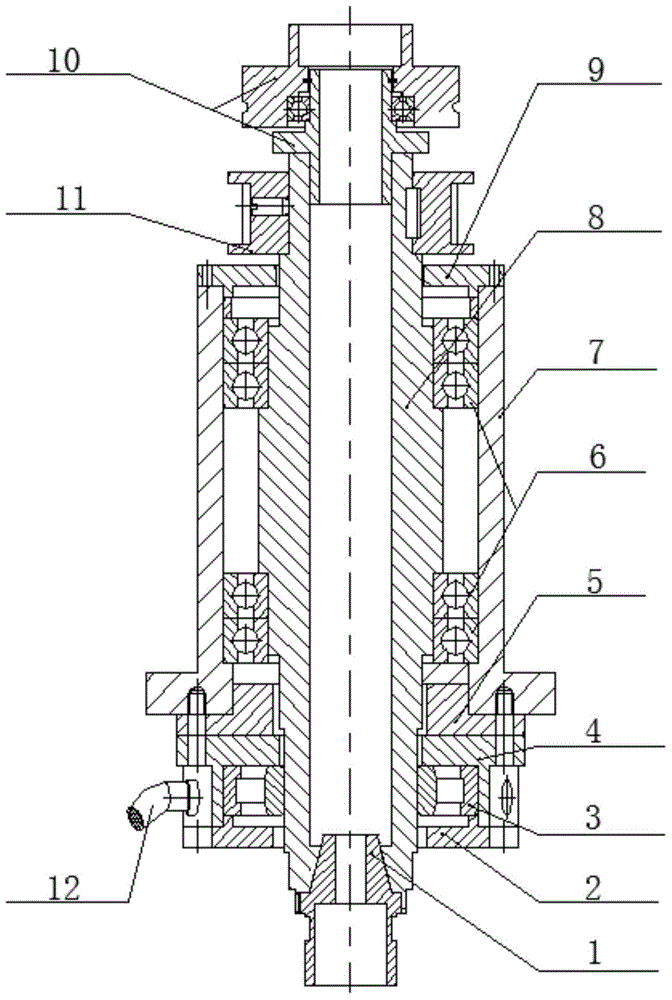

High-speed arc discharge, flushing and rotating main shaft device

ActiveCN104607729AOptimized conductive contact surfaceReduce the difficulty of rotating conductionElectrical-based machining electrodesElectrical-based auxillary apparatusCorrosionElectric arc

The invention discloses a high-speed arc discharge, flushing and rotating main shaft device which comprises a mandrel, a shell, a conductive bearing, a conductive disc, an insulating bearing, an insulating flange, a belt wheel, a rotating connector and the like. A main shaft structure capable of rotating, discharging and flushing is given to achieve the purposes of circulating and supply of high-pressure fluid, rotating and conducting, and the problems of discharge corrosion and the like are solved. According to the high-speed arc discharge, flushing and rotating main shaft device, the light-weight design that the insulating bearing is matched with the mandrel in a supporting mode is adopted, the rotating speed of a main shaft is increased, the accuracy of the main shaft is improved, and the insulating reliability of the main shaft is enhanced; the hollow mandrel structure is combined with the rotating connector to achieve the purposes of high-pressure fluid supply and sealing; the rotating conducting defect that overcurrent capacity of an electric brush is limited, or the rotating speed of a conductive sliding ring is low, or a structure is enormous and complex is overcome; the rotating conducting difficulty is lowered to the maximum degree, and the cost is lowered to the maximum degree. The high-speed arc discharge, flushing and rotating main shaft device is simple in structure, convenient to maintain, low in maintaining cost and capable of being effectively used for various discharging milling including electric arc machining.

Owner:SHANGHAI JIAO TONG UNIV

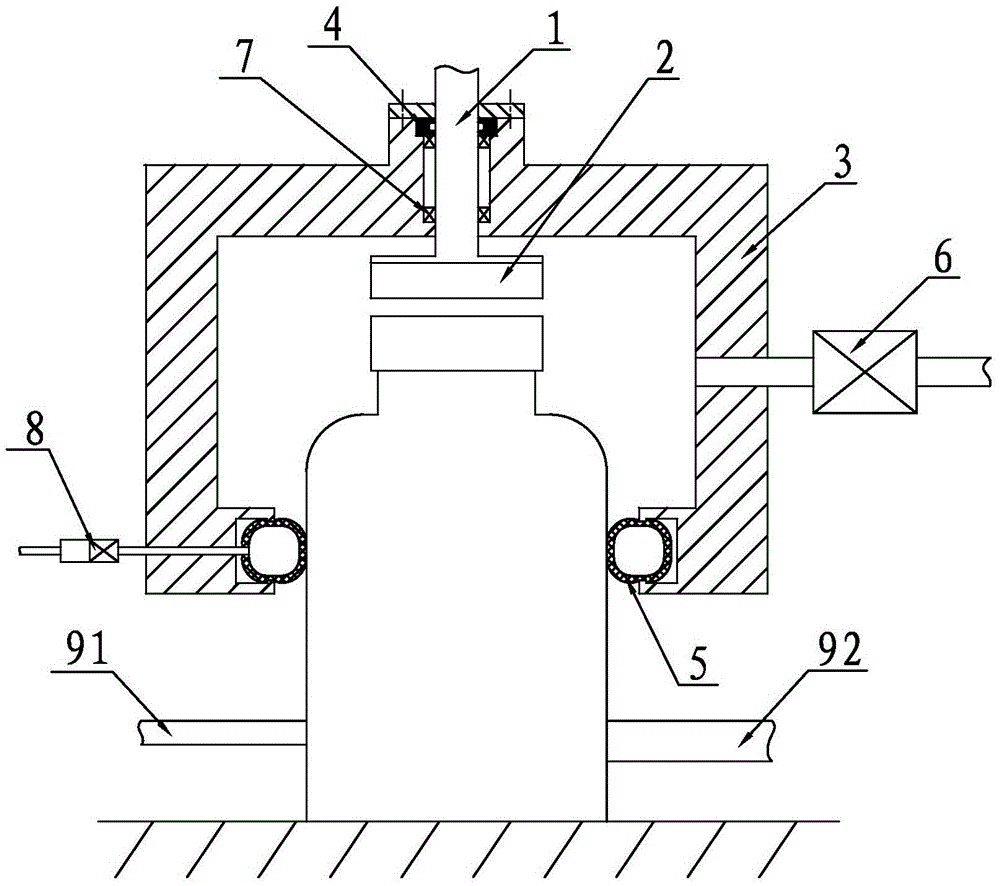

Organic waste aerobic composting test device

InactiveCN102603382AEasy to controlBreak free from the limitations of the seasonsBio-organic fraction processingOrganic fertiliser preparationGas detectorEngineering

An organic waste aerobic composting test device comprises a fermentation tank mounted on a fixed rotary shaft, a stirring motor is arranged above the fermentation tank, a stirring shaft in the fermentation tank penetrates through a sealing cover to be connected with the stirring motor, an exhaust port is disposed on the sealing cover and sequentially communicated with a refrigeration dryer in a detection cabinet and a gas detector, a condensate collector is further communicated with a branch of the exhaust port, a temperature control device and an air compressor are communicated with the bottom of the fermentation tank, a leachate discharge outlet is arranged at the bottom of the fermentation tank, a gas distributing plate is arranged on the inner lower side of the fermentation tank, composting materials are reacted in the fermentation tank, the gas detector realizes an analysis function, most of exhausted gas is exhausted to an outdoor environment after flowing through the condensate collector, and temperature data detected by temperature sensors and gas component data detected by the gas detector are displayed on a computer via a PLC (programmable logic control) module in real time. By the aid of the organic waste aerobic composting test device, the temperature of compost, the content of oxygen and the content of carbon dioxide can be detected in real time in an online manner, the data can be remotely looked up at any time and any places, functions are complete, and effects are remarkable.

Owner:TSINGHUA UNIV

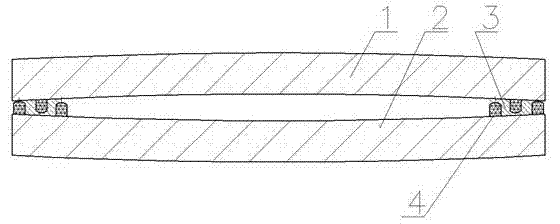

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

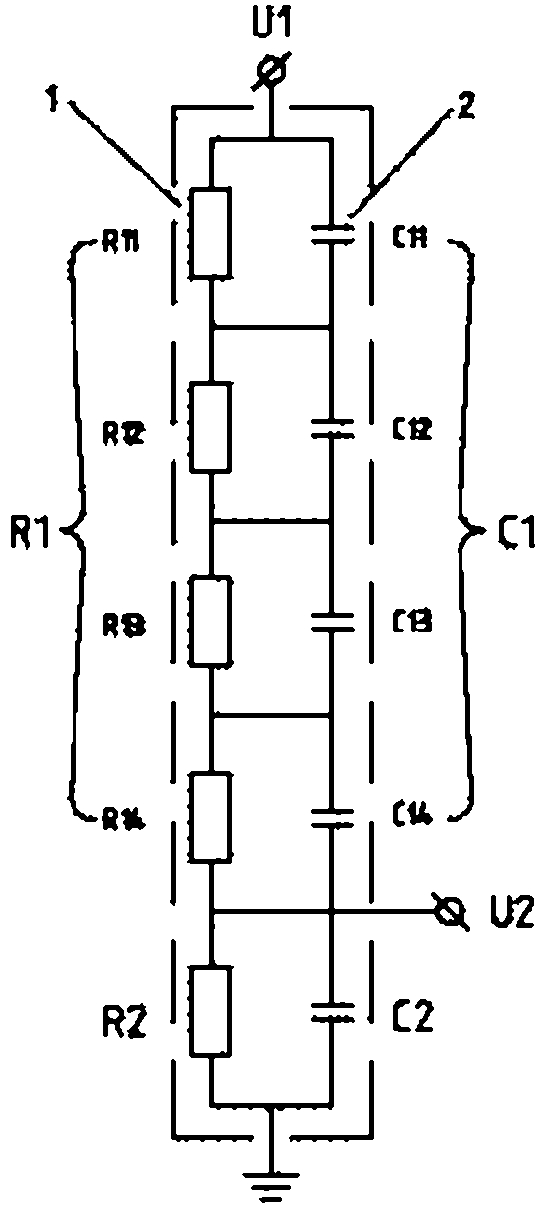

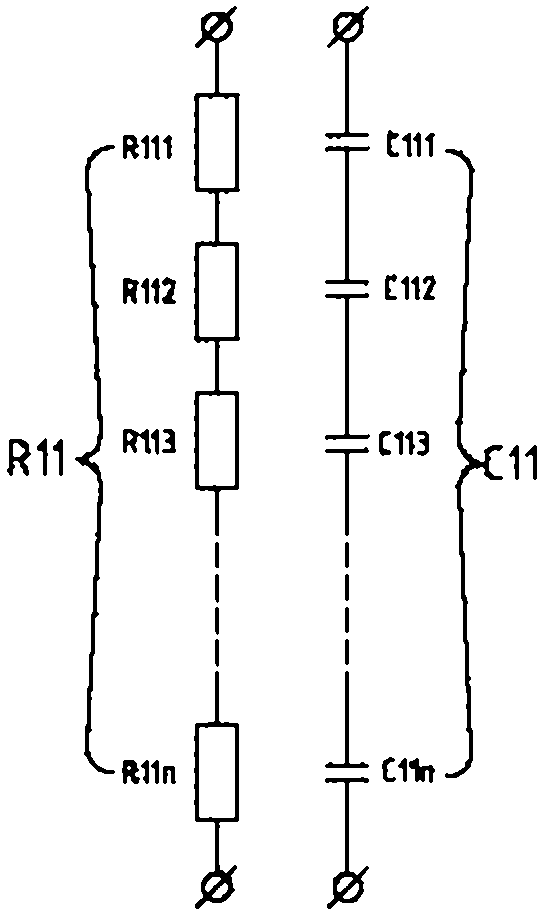

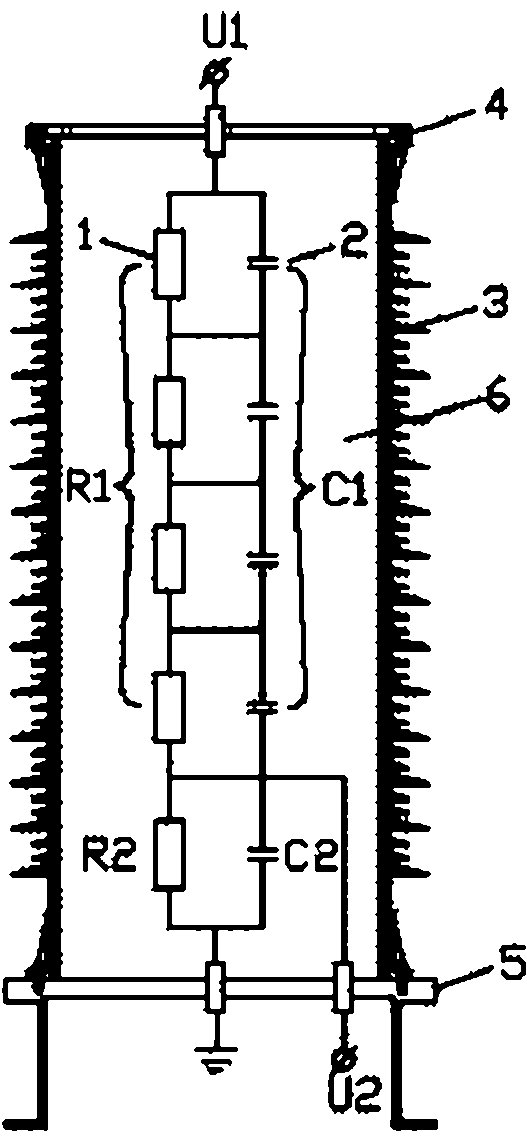

Method for improving pollution flicker-resisting capability of DC voltage transformer

ActiveCN101877275AImproved resistance to filthy flickerLower inner topTransformersInductancesTransformerEngineering

The invention provides a method for improving the pollution flicker-resisting capability of a DC voltage transformer. The method is characterized in that: the internal structure of a hollow insulator of the DC voltage transformer is designed into two coaxial chambers so as to form the heating elements of the DC voltage transformer, namely the resistance elements of a resistance capacitance divider are all arranged in one coaxial chamber, so that the heat generated by the heating elements rises to the top together with an insulating medium, flows downwards from the top of the other coaxial chamber, and forms a fluid-insulating medium circulation loop finally according to a principle that hot air rises. In the method for improving the pollution flicker-resisting capability of the DC voltage transformer, the internal structure of the hollow insulator is designed into the two coaxial chambers, and air pressure difference is generated in the upper and lower parts of each chamber, so that the insulating medium circulates up and down, the temperature gradient of the upper end and the lower end in the insulator is reduced, and the aim of balancing the internal temperature is fulfilled; therefore, the aim of improving the pollution flicker-resisting capability of the DC voltage transformer is fulfilled.

Owner:STATE GRID ELECTRIC POWER RES INST

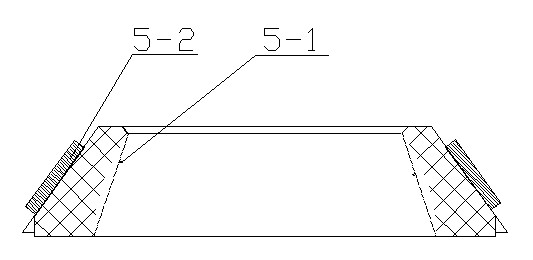

Test system and test method for water tightness test of tunnel deformation joint waterstop

InactiveCN102175406AEnsure safetyConvenient inspectionMeasurement of fluid loss/gain rateEngineeringOmega

The invention discloses a test system for the water tightness test of a tunnel deformation joint waterstop, which comprises two steel tanks mounted, in a sealed manner, at two sides of a waterstop to be tested, a steel structured test bench, an atmospheric pressure test bench, a hydraulic pressure test bench, an air compressor, a remote-distance full-automatic observing and reading apparatus and a safety protection device. The test device of the invention can be used for the water tightness test of a plurality of waterstops, realize random opening displacement and shear displacement accurately, and simulate the stress condition of deformation joint waterstop structure under different working conditions by applying atmospheric pressure in balloon to a tested object through the atmospheric pressure test bench and applying hydraulic pressure to the steel tanks through the hydraulic pressure test bench to simulate seawater pressure. The system and the method are suitable for the test of OMEGA and GINA waterstops as well as expandable waterstop.

Owner:CCCC FOURTH HARBOR ENG INST +2

Manufacturing method of fiber full winding plastic liner composite gas cylinder

InactiveCN106863863ASolve molding problemsSolve the sealing problemHollow articlesGas cylinderConductor Coil

The invention discloses a manufacturing method of a fiber full winding plastic liner composite gas cylinder. The method comprises the steps of plastic liner forming, plastic liner outer surface treatment and fiber winding and solidification. The liner is formed by welding a head in the opening position and a head in the plug position with a straight line section of a cylinder body. The head in the opening position is formed by injection molding of a metal joint with a through hole thread and plastic. The head in the plug position is formed by injection molding of a metal joint with a non through hole thread and plastic.

Owner:安徽绿动能源有限公司

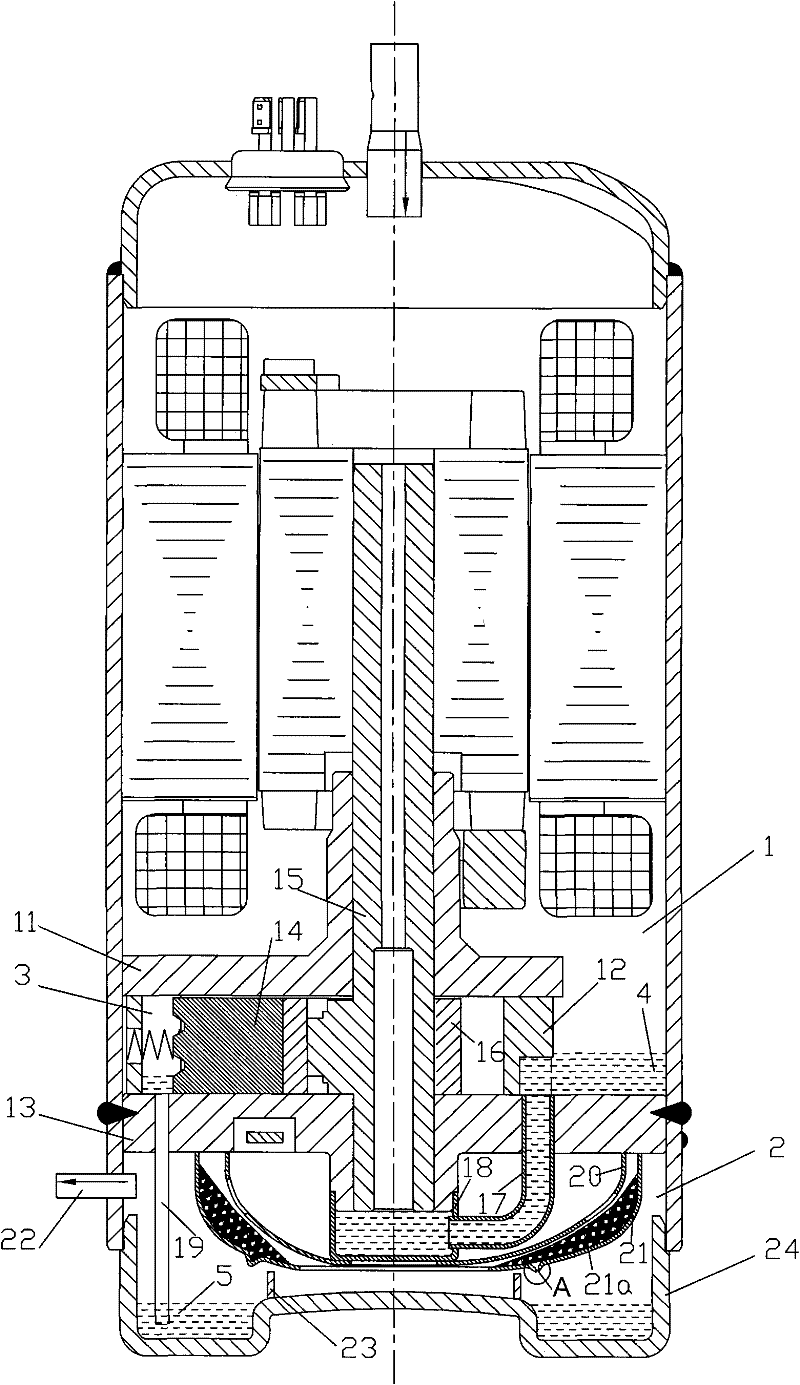

Rotary compressor

ActiveCN102192154AReduce noiseSmall pulsationRotary/oscillating piston pump componentsLiquid fuel engine componentsPistonLubrication

The invention provides a rotary compressor, comprising a compression component and a motor component which are arranged in a shell, wherein the compression component is arranged at the lower part of the shell; the motor component is arranged at the upper part of the shell; the compression component comprises an air cylinder, a piston arranged in the air cylinder and a slip sheet; a long bearing and a short bearing which are used for supporting an eccentric crankshaft are arranged on the air cylinder; the short bearing is used for dividing the inner space of shell into a low-pressure cavity atthe upper part and a high-pressure cavity at the lower part; the short bearing is provided with an upper oil pool, and an oil storage cavity is arranged at the lower end of the short bearing; the oilstorage cavity is communicated with the lubricant channel of the eccentric crankshaft; one end of an oil conduit is communicated with the upper oil pool and the other end of the oil conduit is communicated with the oil storage cavity; an oil conducting cover is arranged at the lower end of the short bearing; and the oil conducting cover, the lower end of the short bearing and the eccentric crankshaft form an oil storage chamber. The rotary compressor is simple and reasonable in structure, flexible in operation, good in lubrication performance, good in oil-gas separation effect, low in oil seal amount and high in safety degree.

Owner:GUANGDONG MEIZHI COMPRESSOR

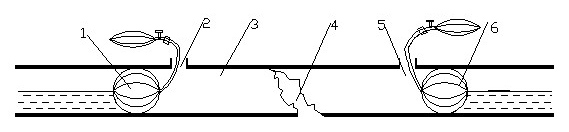

Under-water leakage blocking and repairing method of exterior line pipeline

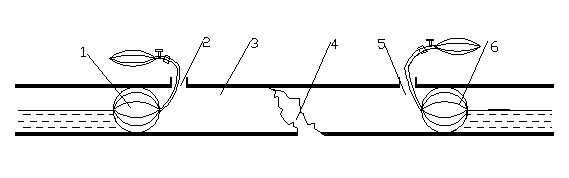

The invention discloses an under-water leakage blocking and repairing method of an exterior line pipeline and belongs to a pipeline repairing method. The method is characterized in that the left position and the right position at the outer side of the damaged position of a pipeline are respectively provided with a threaded hole; the left threaded hole and the right threaded hole are big enough for a contracted rubber ball to be inserted; uninflated rubber balls are respectively plugged into the pipeline from each threaded hole; then, the uninflated rubber balls are inflated to seal the inner cavity of the pipeline so as to block water flow; and then the pipeline is repaired in a welding or bellmouth connecting mode to finish the repair work of the under-water leakage blockage of the pipeline. The under-water leakage blocking and repairing method of the exterior line pipeline is convenient to use and is low in cost, repairing time is shortened, and the working efficiency and the pipeline repairing quality are improved.

Owner:CHINA MCC17 GRP

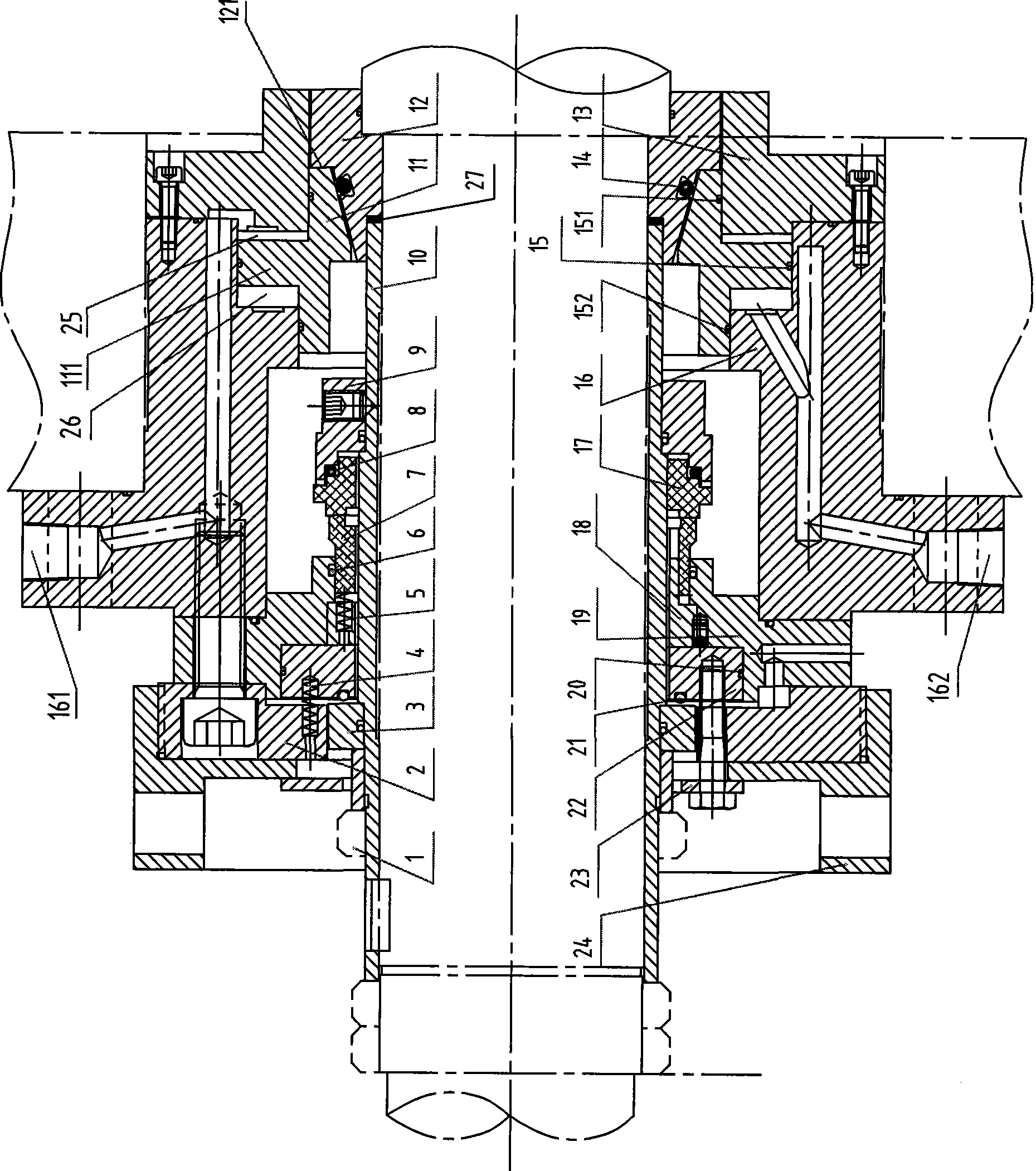

High-pressure controllable slide valve type mechanical combination sealing system

InactiveCN101463903AGuaranteed Replacement RepairAchieving a static sealEngine sealsEngineeringHigh pressure

The invention discloses a high-pressure controllable slide-valve type mechanical combined sealing system. The system comprises a controllable slide valve stationary seal assembly and a rotating mechanical seal assembly; the controllable slide valve stationary seal assemble comprises a slide valve gland (13), a slide valve (11) and a tapered shaft sleeve (12) sheathed on a shaft shoulder, the tapered shaft sleeve (12) is positioned inside the slide valve gland (13), the slide valve (11) which is partially positioned in a flange (16) is hermetically connected with the tapered shaft sleeve (12) in a sliding way, and the flange (16) is provided with a pressure source channel I (161) and a pressure source channel II (162) which are respectively used for controlling the slide valve (11) to slide leftwards or slide rightwards; the rotating mechanical seal assembly comprises a rotating seat (9) which is fixedly connected with a shaft sleeve (10), a rotating ring (17) and a stationary ring (7) which are closely jointed on a seal face and the like. The sealing system can help greatly reduce and avoid leakage of dangerous fluid and serious accidents.

Owner:ZHEJIANG UNIV

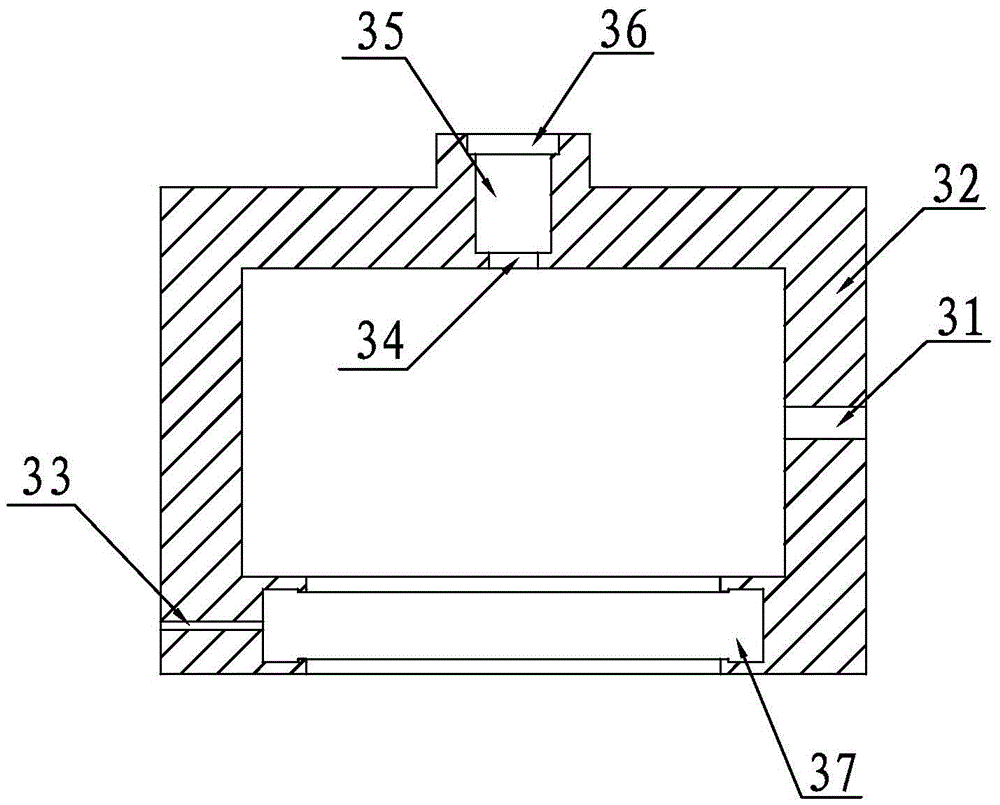

Vacuumizing lid rotating device of hard bottle

PendingCN105564703AAchieve positioningAchieve clampingPackaging under vacuum/special atmosphereEngineeringBottle

The invention discloses a vacuumizing lid rotating device of a hard bottle. The device comprises a lid rotating shaft, a lid rotating head, a vacuum cover, a main shaft sealing ring and an inflation clamping sealing ring; the lid rotating shaft is mounted on the vacuum cover through the main shaft sealing ring; the lid rotating head is fixedly mounted at the lower end of the lid rotating shaft, and is arranged in an inner cavity of the vacuum cover; the inflation clamping sealing ring is peripherally arranged on the side wall of the lower section of the inner cavity of the vacuum cover; the lid rotating head is positioned above the inflation clamping sealing ring; the inflation clamping sealing ring is communicated with a pressure gas source through a pressure gas access control device; and a vacuumizing joint is formed in the vacuum cover above the inflation clamping sealing ring, and is connected with the inner cavity of the vacuum cover and a vacuumizing device. The vacuumizing lid rotating device greatly improves the tightness of the inner cavity of the vacuum cover, largely reduces the vacuumizing energy consumption, shortens the vacuumizing time, is high in production efficiency, is more reliable in clamping of the bottle, and prevents the conditions of fracturing damage of the bottle caused by overhigh inflation pressure and incomplete sealing of a vacuum chamber caused by overlow pressure.

Owner:CHANGZHOU YONGYI PACKAGING TECH

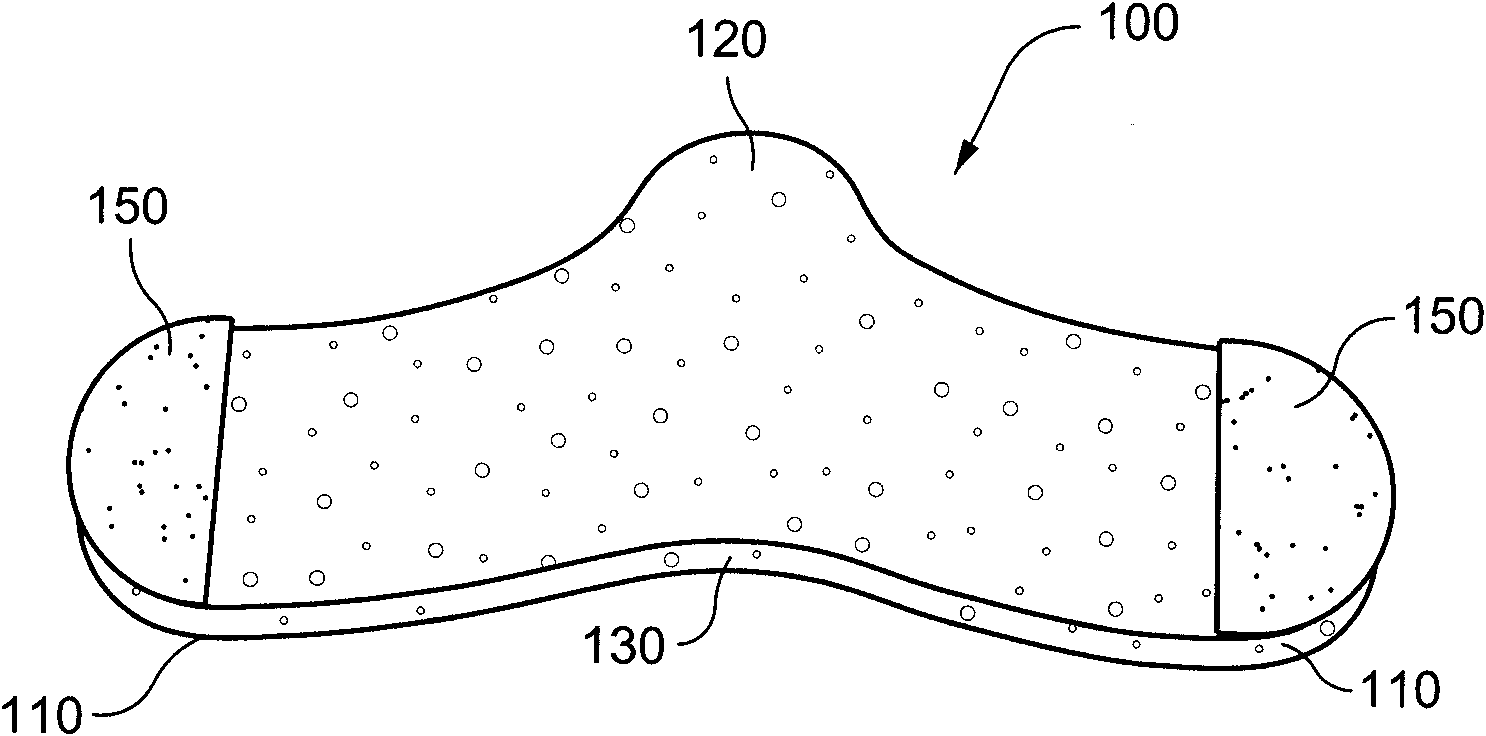

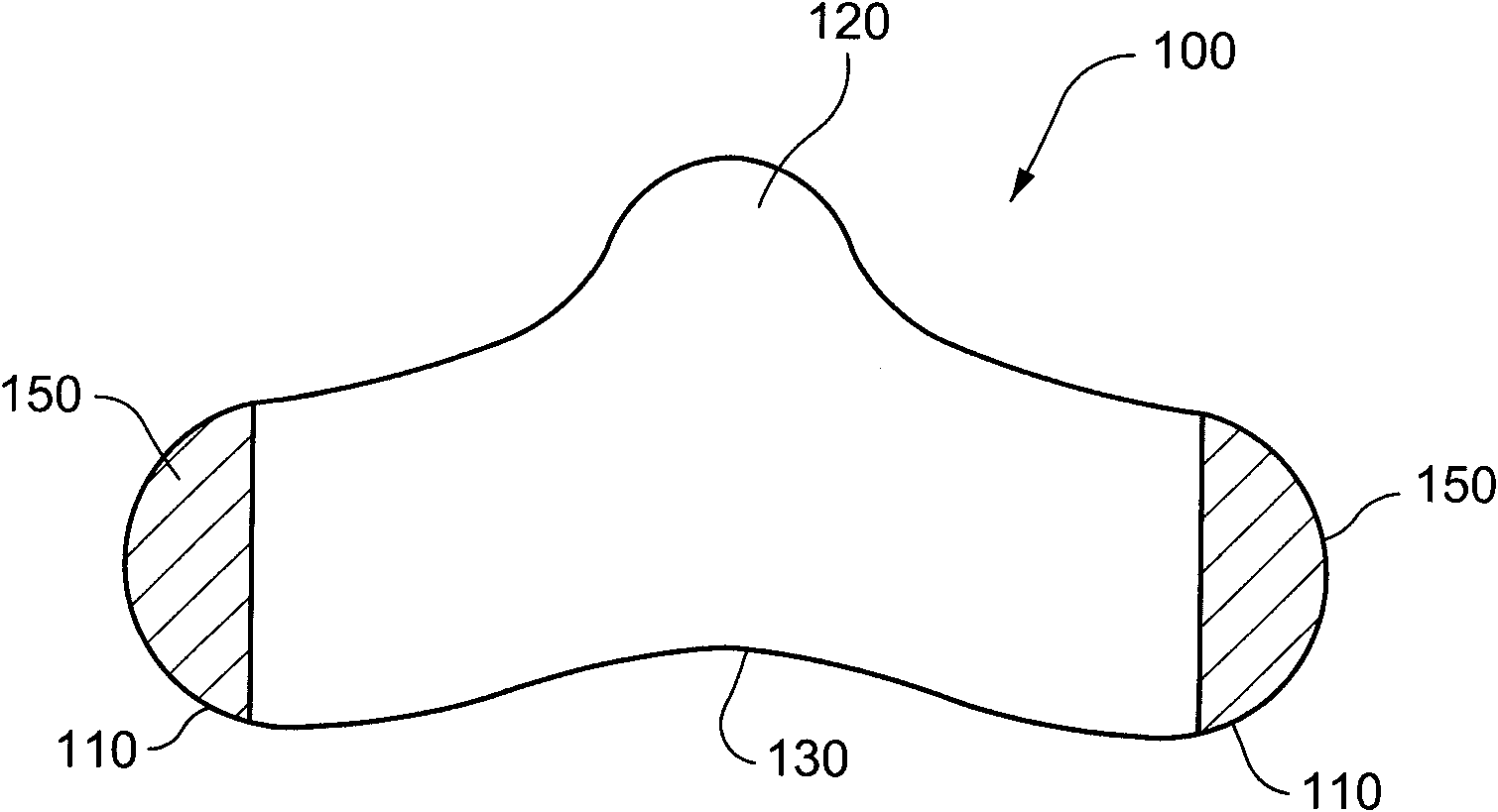

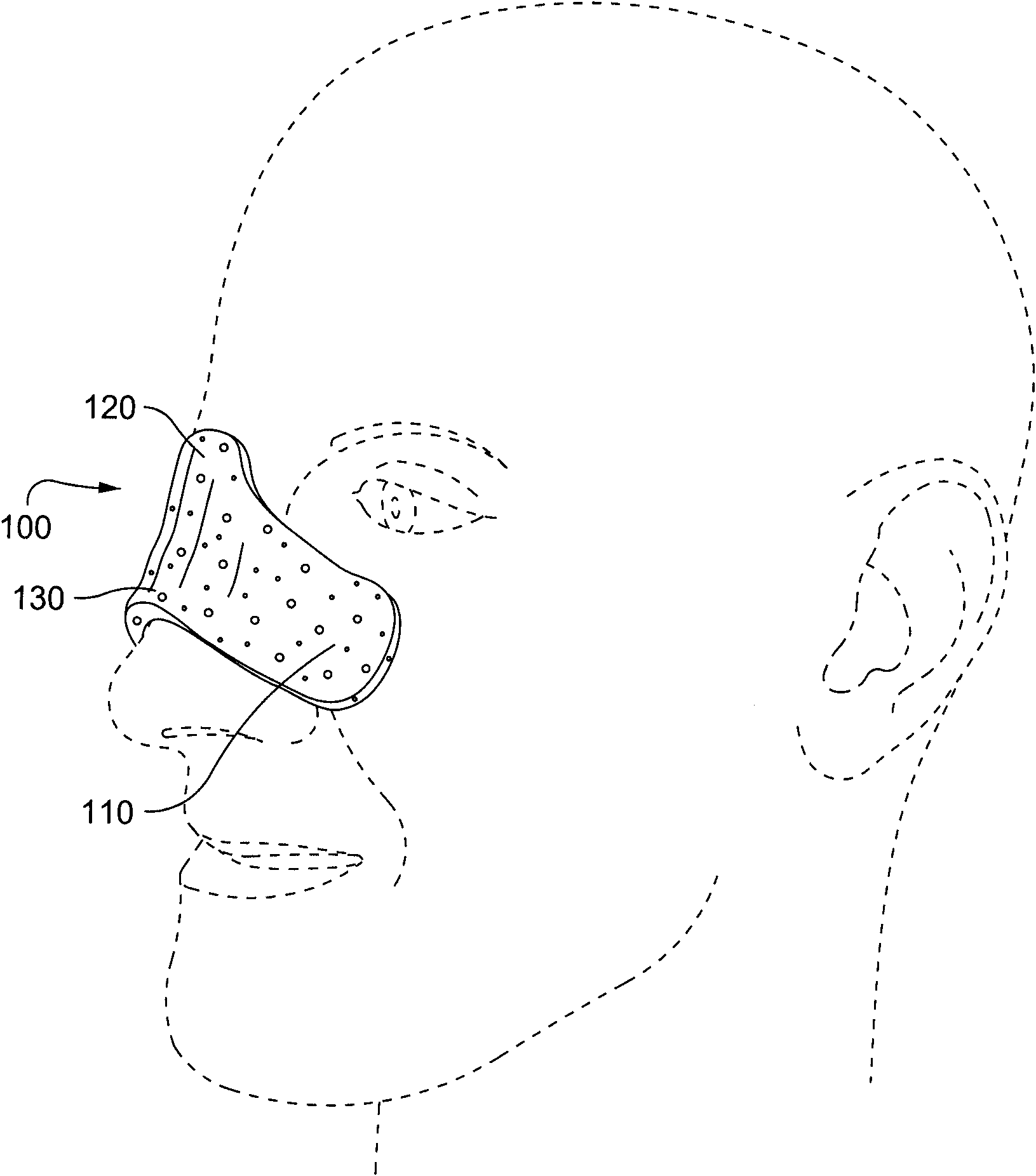

Patient interface systems

A cushion pad for a mask worn by a patient, comprising a first side to contact skin of the patient, and a second side, opposite the first side, to contact or face the mask. The pad has a main body portion having a central portion shaped to cover a portion of the patient's nose extending from above the nose tip to the nasal bridge region without obstructing the patient's line of sight, and lateral side portions to extend downward and terminate along the sides of the nose or on the patient's cheeks. The main body is made of a breathable material, e.g., foam. The pad may include adhesive and / or an attached portion, e.g., a ring, to couple the pad to the patient and / or portion of the mask.

Owner:RESMED LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com