Patents

Literature

164results about How to "Solve molding problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

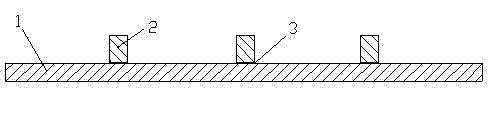

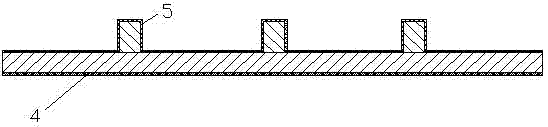

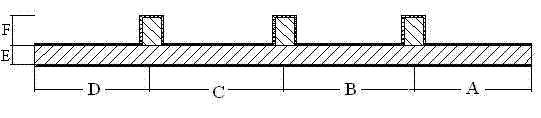

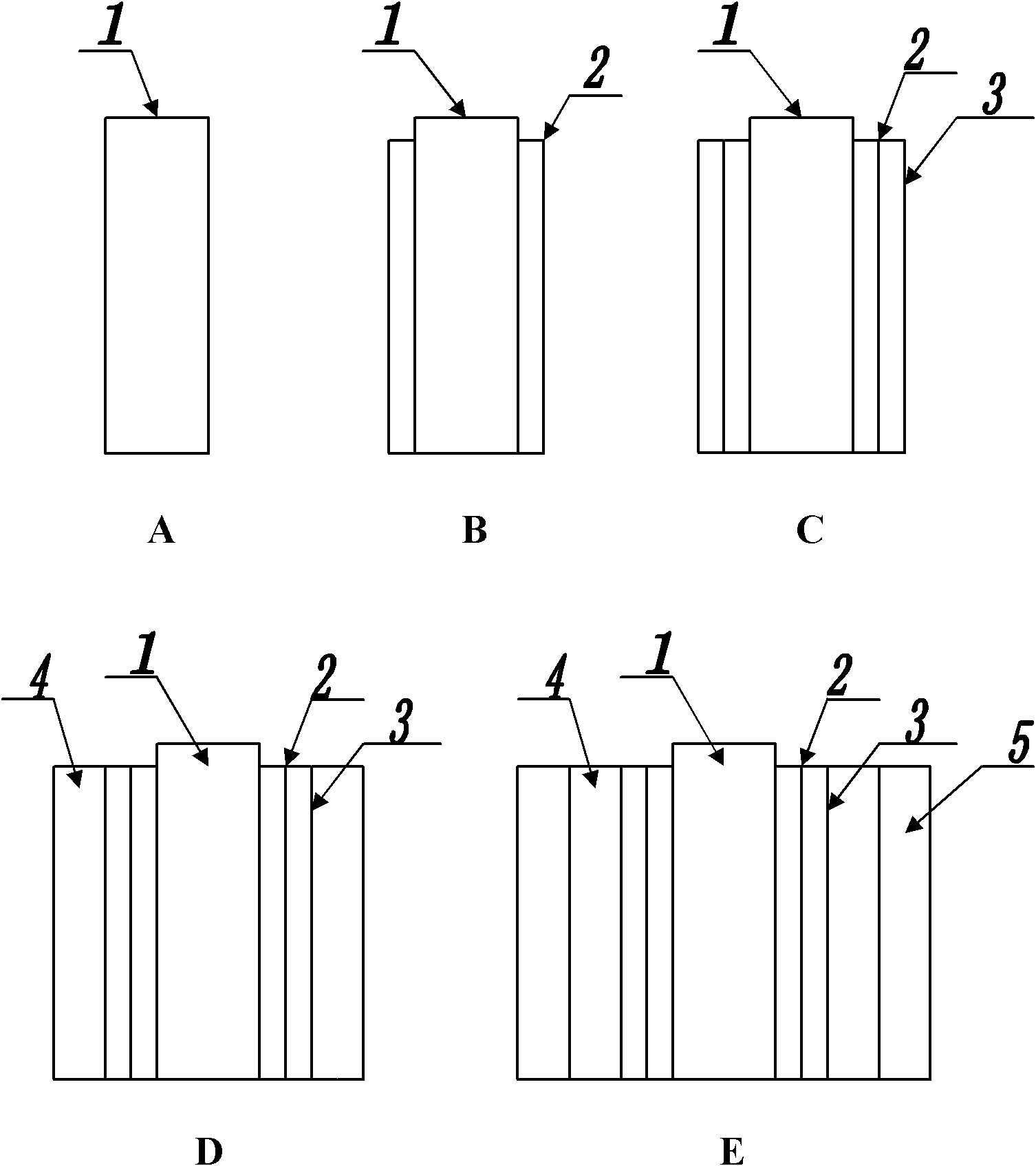

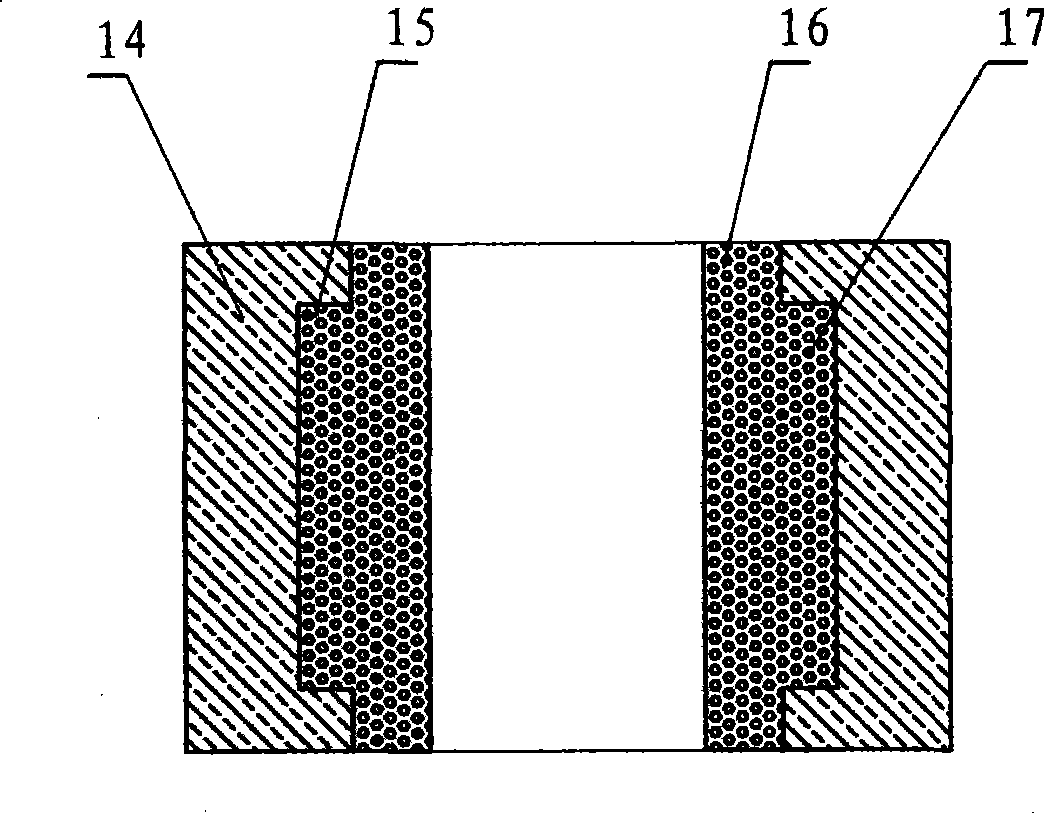

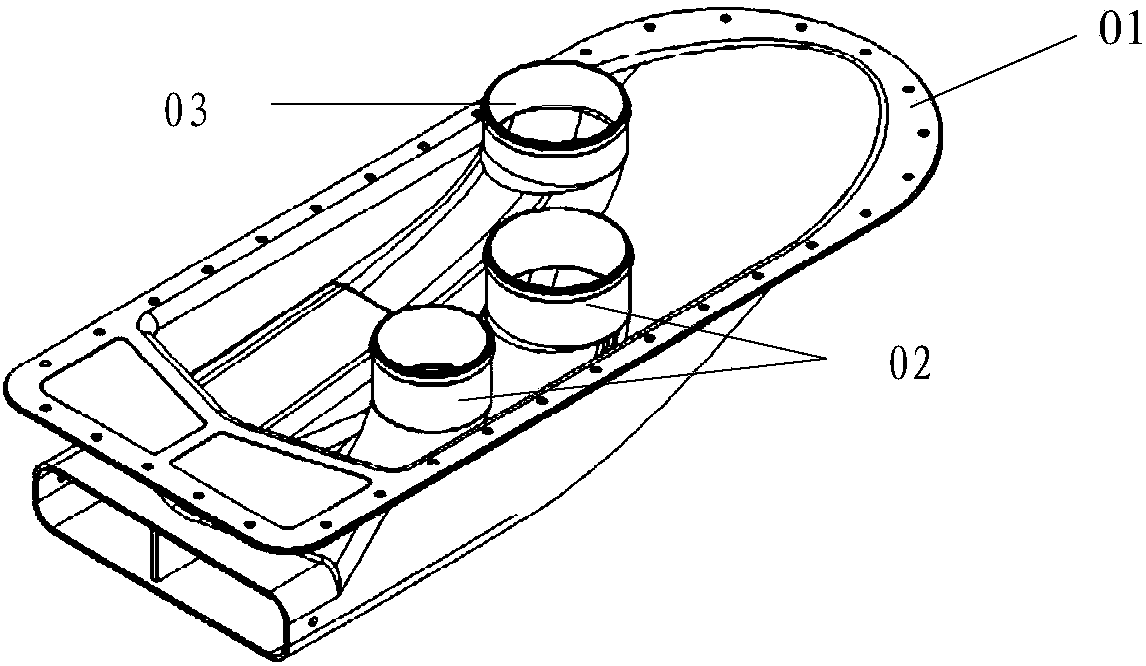

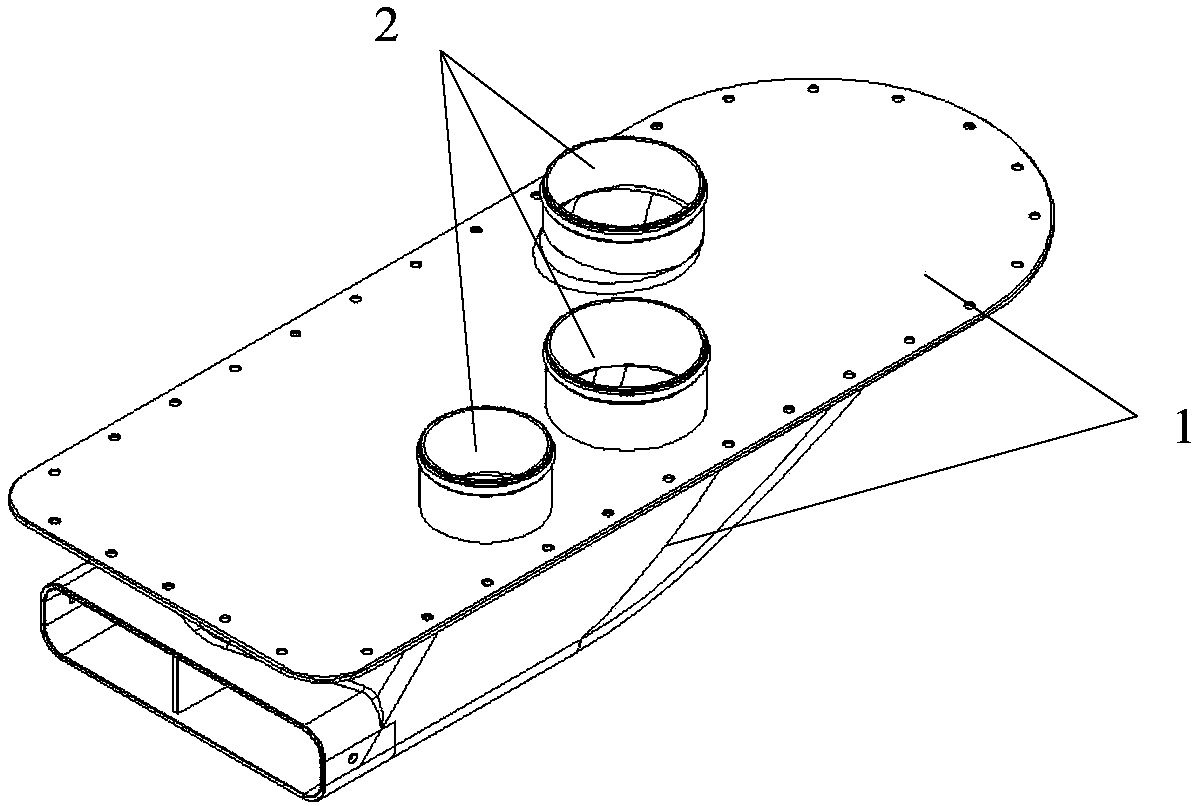

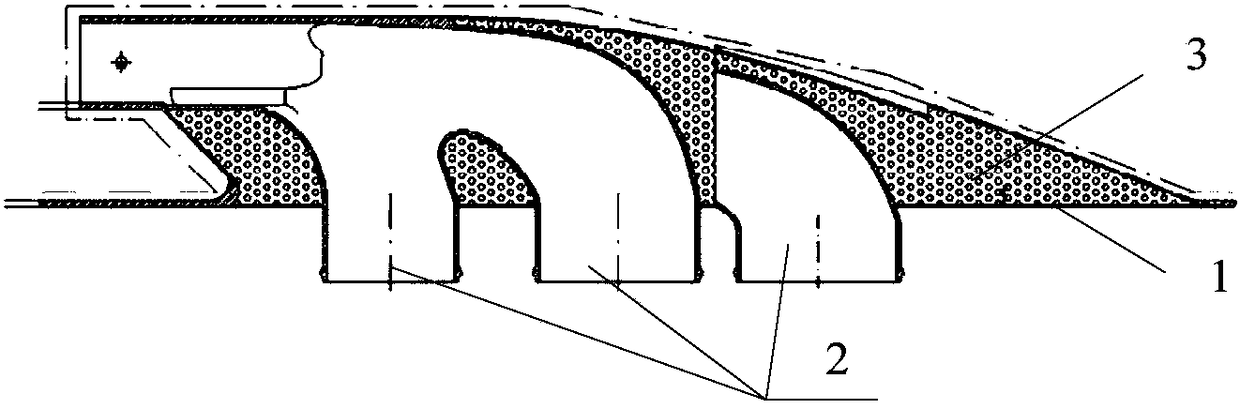

Reinforcing ribs contained sandwich structure composite material and its making method

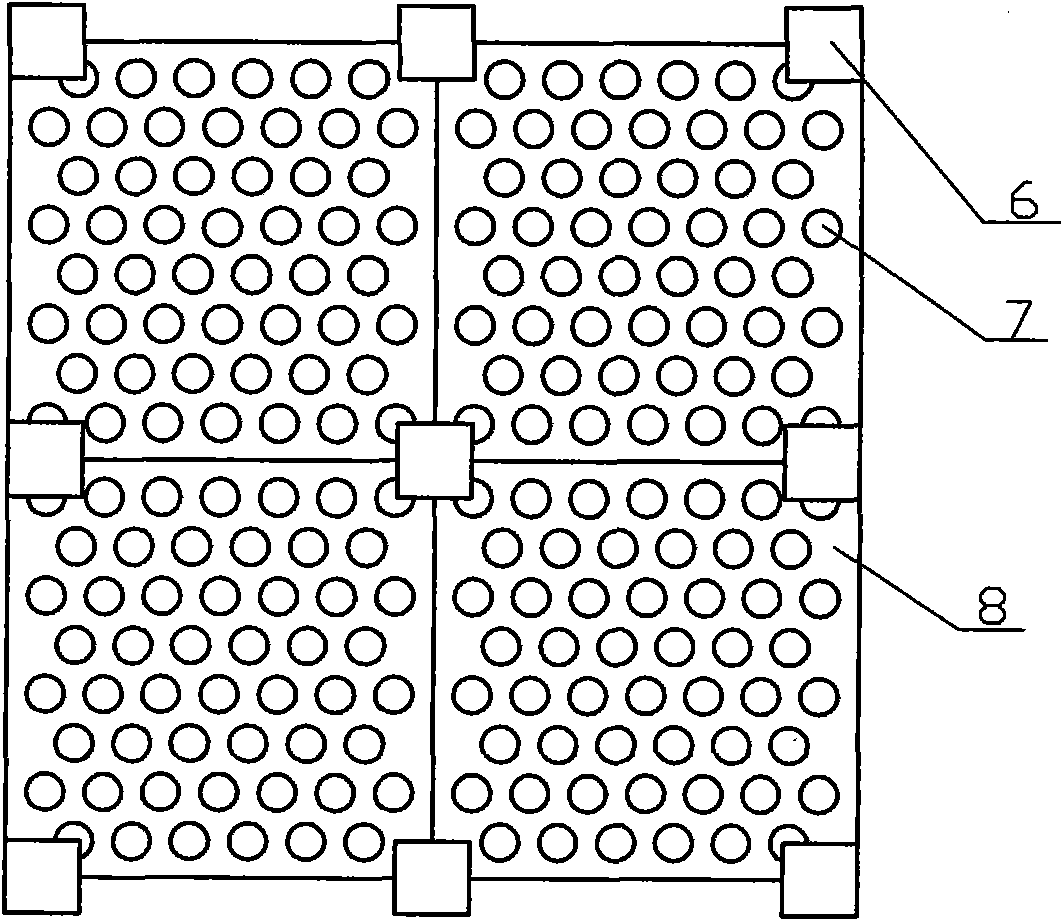

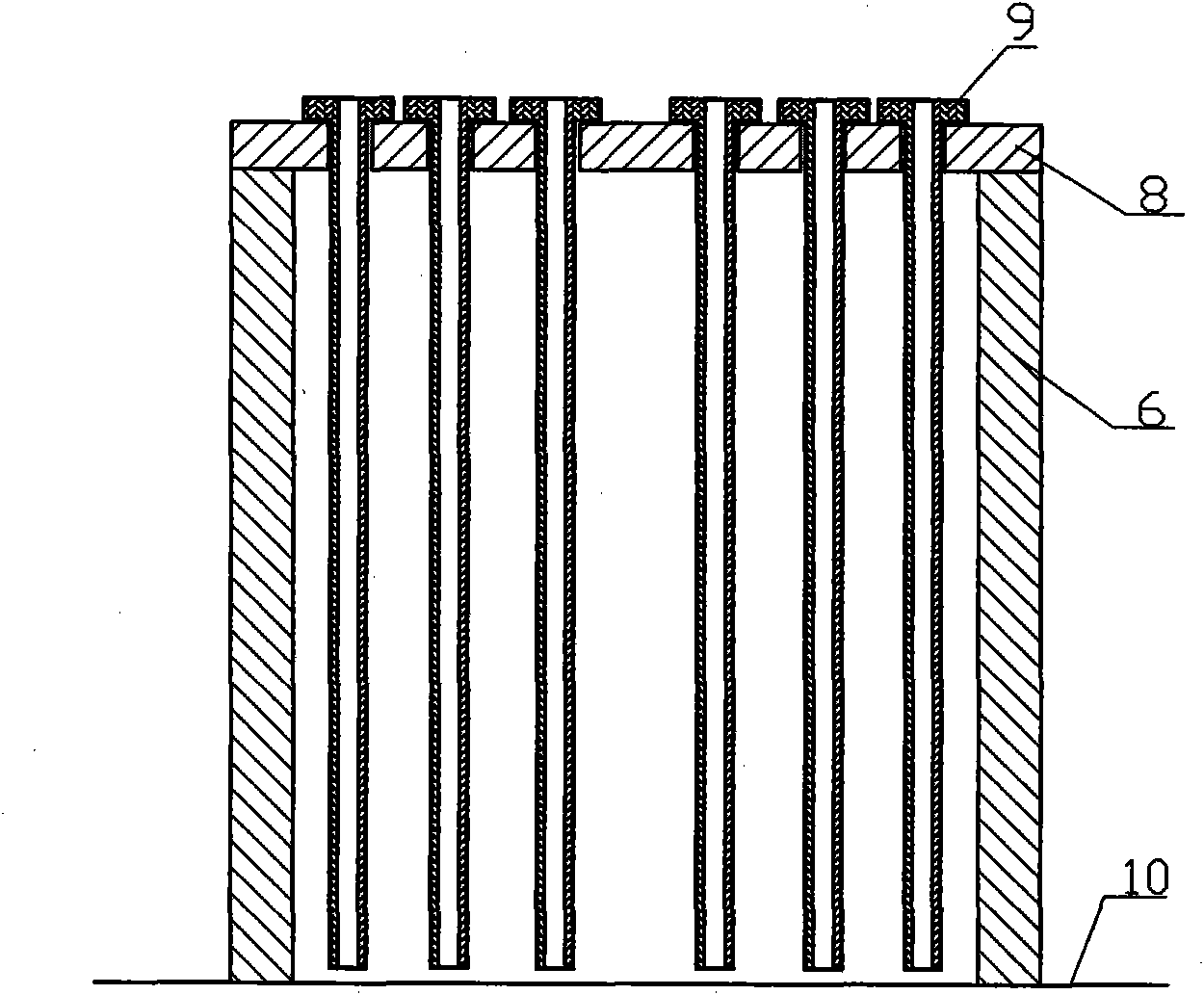

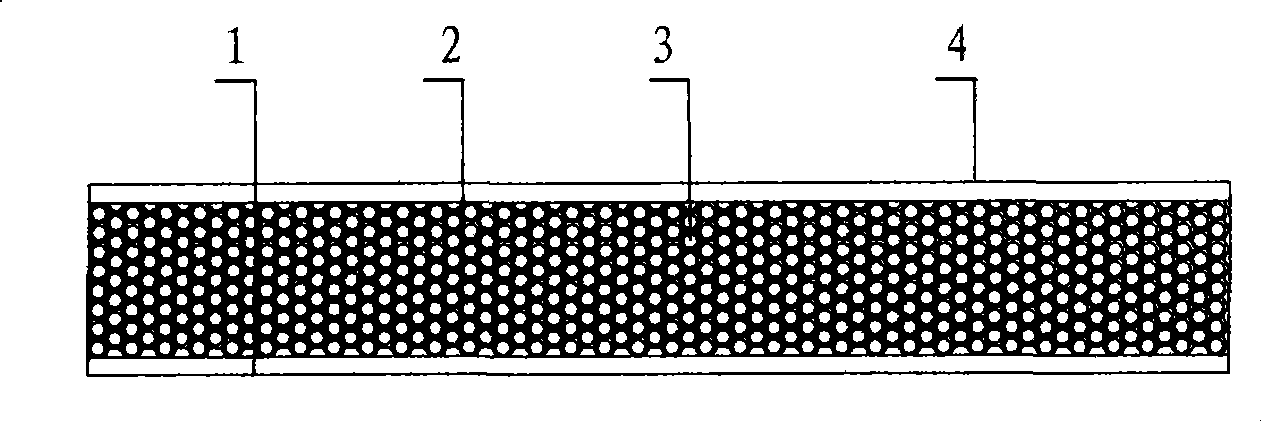

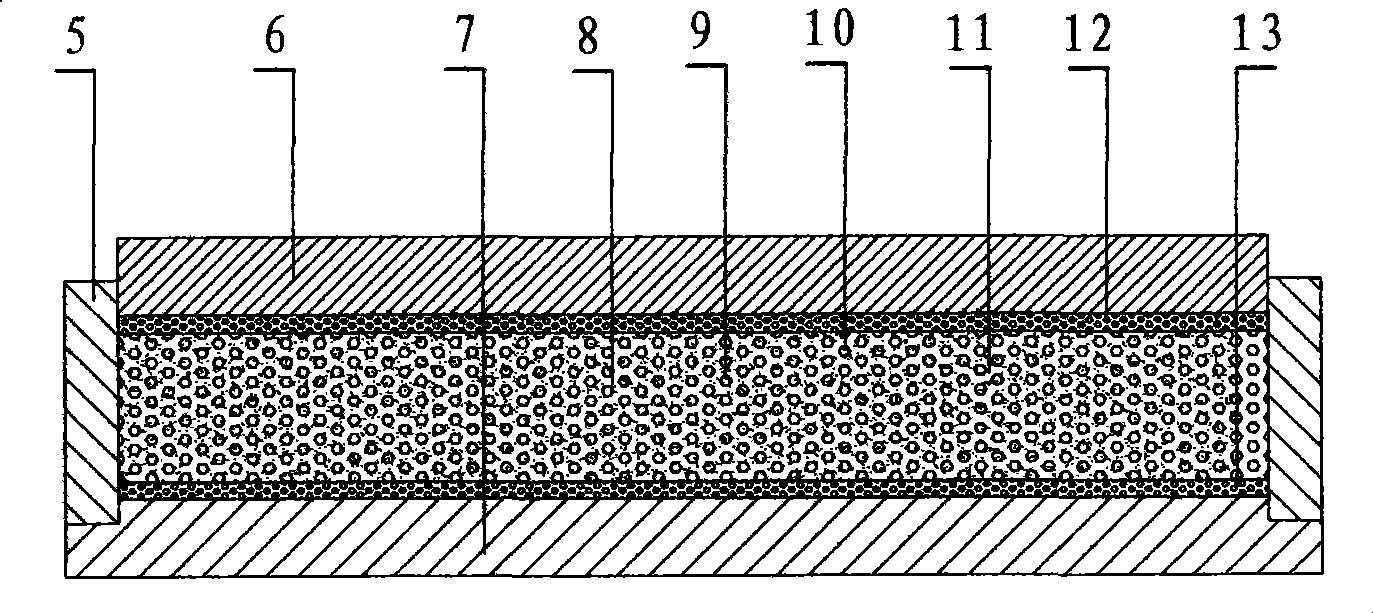

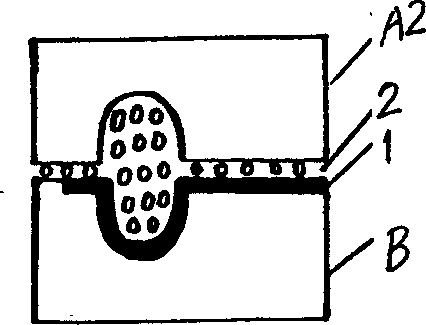

The invention discloses a reinforcing ribs contained sandwich structure composite material and its making method. The composite material is composed of an internal core material, reinforcing ribs, and a one-time-formed fiber fabric reinforced resin composite material layer, wherein the internal core material is a lightweight buoyancy material having a compressive strength of above 0.5MPa; each of the reinforcing ribs is formed by a lightweight material internal model connected with the internal core material through an adhesive, and a fiber fabric layer coated on the external surface of the lightweight material internal model; the fiber fabric is a glass fiber, a carbon fiber, a Kevlar fiber, an ultrahigh molecular weight polyethylene fiber or a basalt fiber; and a resin is a cured substance of a polyester resin, a vinyl resin, an epoxy resin, a phenolic resin and the like. The making method has the advantages of one-time-forming of a product having the reinforcing ribs and the sandwich structure, increase of the rigidity design space of the composite material, reduction of sequent secondary processing, reduction of the defect appearance possibility, scarce generation of the volatilization of harmful gases, and personnel health protection.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Preparation method for high purity fructo-oligosaccharide

ActiveCN101368195AImprove performanceSuitable for useOn/in organic carrierFermentationSucrosePeroxidase

The invention relates to a preparation method of high purified fructo-oligosaccharide, in particular to a method for preparing the high purified fructo-oligosaccharide by using immobilized enzyme. The preparation method of the invention prepares immobilized fructosyltransferase, immobilized glucose oxidase and immobilized mimic hydrogen peroxidase; then prepared enzymes are used to prepare the high purified fructo-oligosaccharide through an interrupted or continuous production method. In the preparation method, cheap metalporphyrin compounds are used as the mimic hydrogen peroxidase to replace expansive catalase; the fructosyltransferase, the glucose oxidase and the mimic hydrogen peroxidase are all immobilized and all can be recycled and reused; the stability and the operating factor of the enzymes are improved; the production cost for preparing the high purified fructo-oligosaccharide is greatly reduced. The preparation method can use one step method to directly produce the high purified fructo-oligosaccharide from cane sugar.

Owner:量子高科(广东)生物有限公司

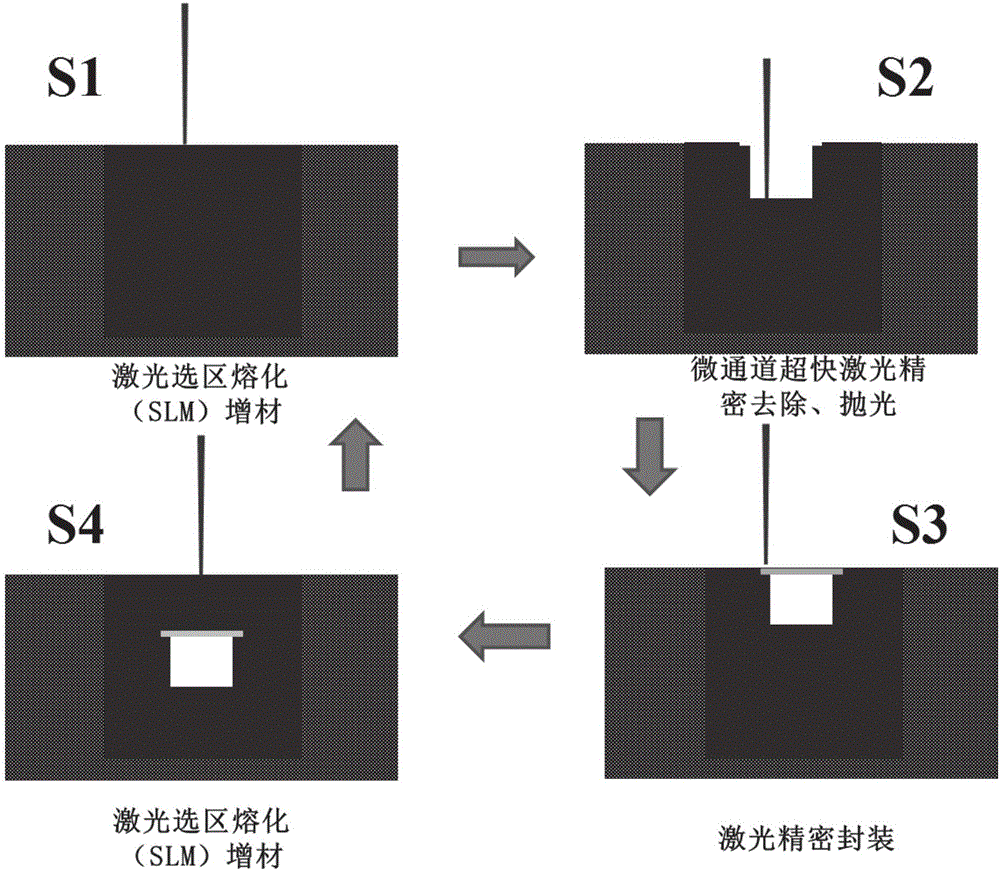

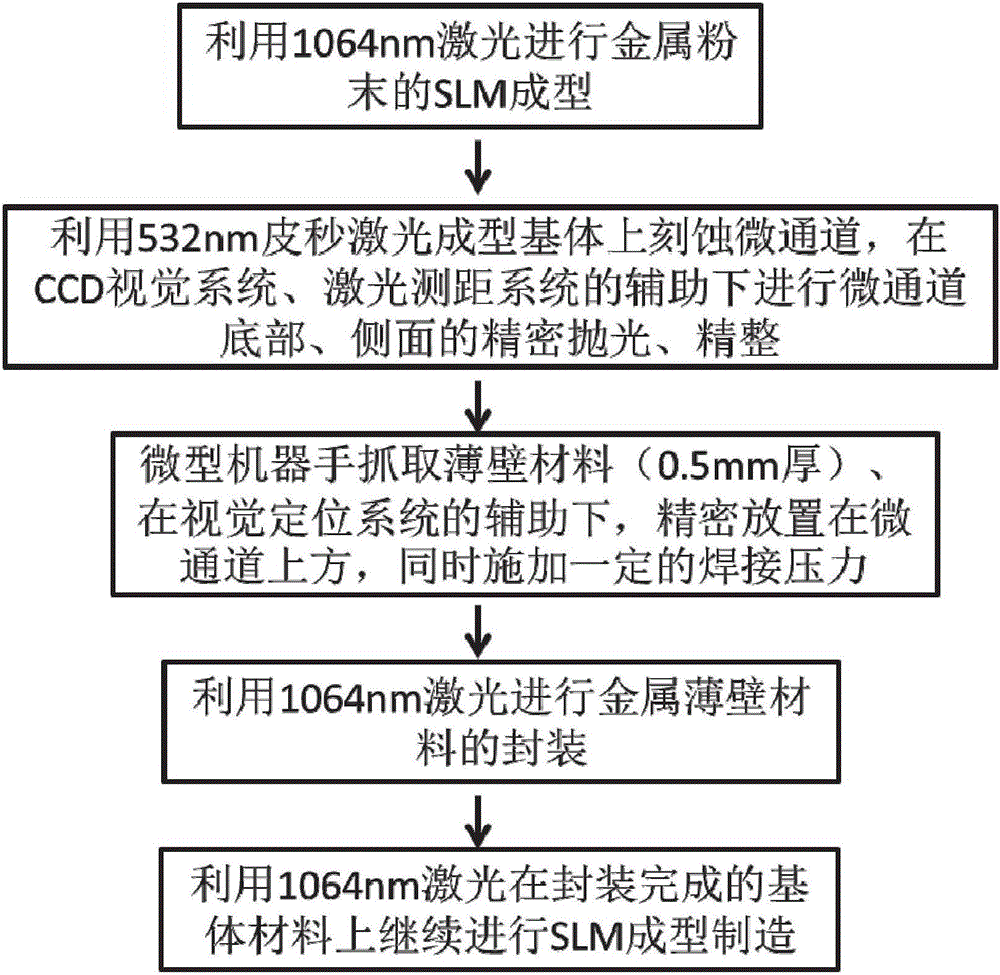

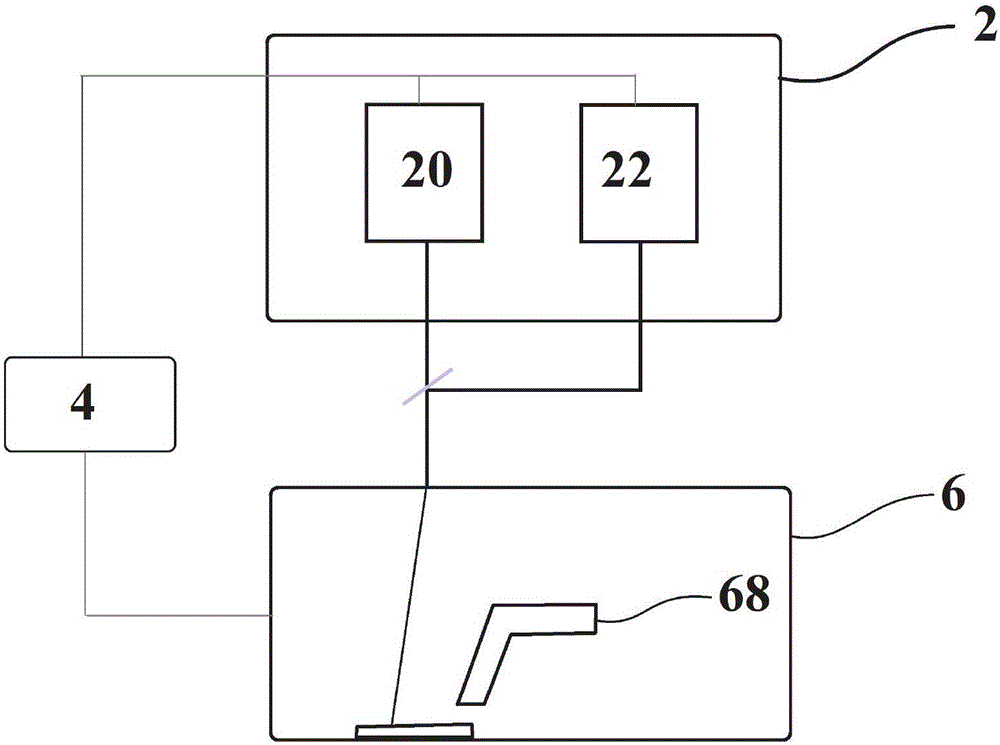

Full-laser hybrid additive manufacturing method and device

ActiveCN106513996ASolve molding problemsSolve the problem of powder residueAdditive manufacturing apparatusLaser detailsEngineeringLaser light

The invention discloses a full-laser hybrid additive manufacturing method. Based on select laser melting, a laser precise packaging method is adopted to solve the problem of forming of an overhung surface and solve the problem that powder remains on micro-channels, and therefore the requirements for high precision, high finish degree and high cleanness degree of machining of aerospace key parts are met. According to the full-laser hybrid additive manufacturing method, after a matrix is obtained through select laser melting forming, subtractive forming is conducted on the matrix through pulse laser, so that a cavity is formed, packaging is conducted on the laser, and then a formed material provided with an inner cavity structure is obtained. The invention discloses a device applied to the full-laser hybrid additive manufacturing method. The device comprises a laser portion, a control portion and a forming portion. The laser portion is in light path connection with the forming portion. The control portion is electrically connected with the laser portion and the forming portion. The laser portion comprises a first laser light source and a second laser light source. The forming portion comprises a welding portion. The welding portion is in cooperation with the laser portion to conduct additive manufacturing in the manner that the welding portion is controlled by the control portion.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

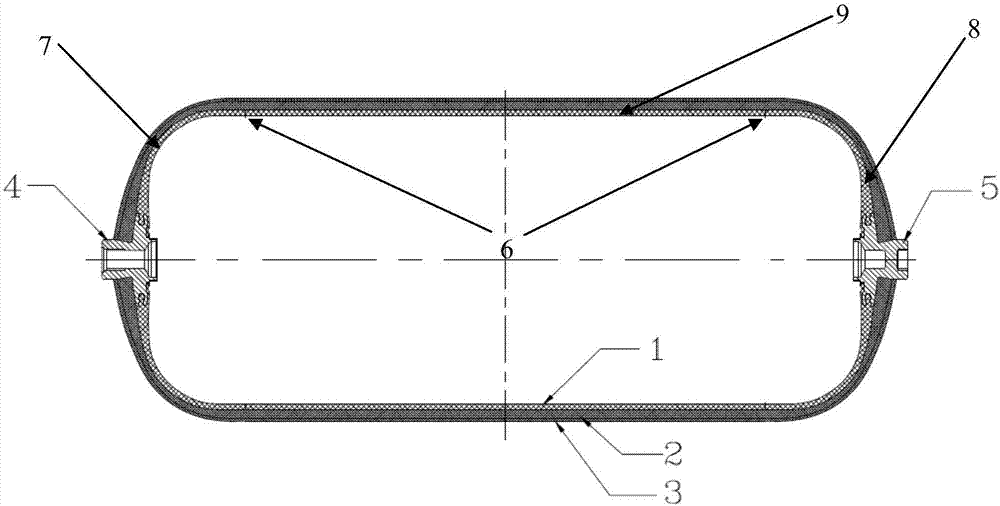

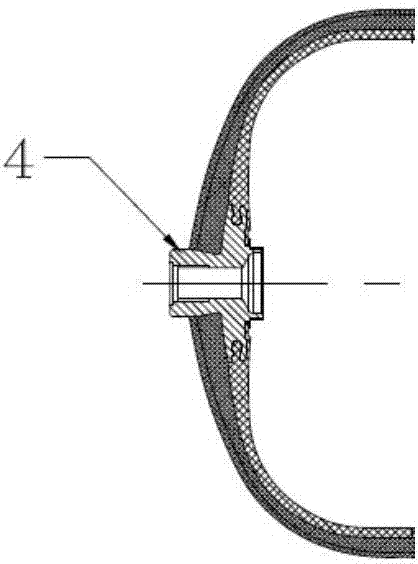

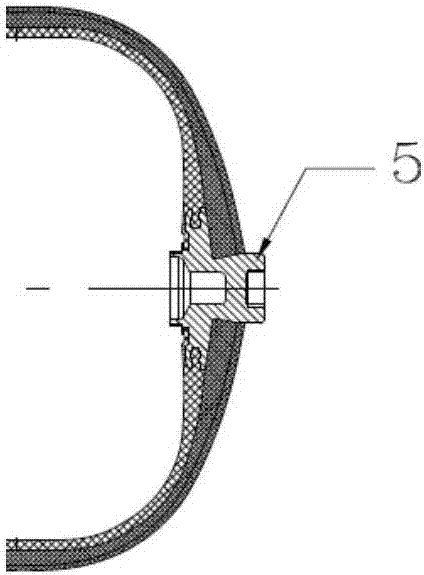

Manufacturing method of fiber full winding plastic liner composite gas cylinder

InactiveCN106863863ASolve molding problemsSolve the sealing problemHollow articlesGas cylinderConductor Coil

The invention discloses a manufacturing method of a fiber full winding plastic liner composite gas cylinder. The method comprises the steps of plastic liner forming, plastic liner outer surface treatment and fiber winding and solidification. The liner is formed by welding a head in the opening position and a head in the plug position with a straight line section of a cylinder body. The head in the opening position is formed by injection molding of a metal joint with a through hole thread and plastic. The head in the plug position is formed by injection molding of a metal joint with a non through hole thread and plastic.

Owner:安徽绿动能源有限公司

Precision casting method of double-layer thin-wall bent pipe casting

InactiveCN102078919ASolve molding problemsQuality improvementFoundry mouldsFoundry coresWaxEconomic benefits

The invention discloses a precision casting method of a double-layer thin-wall bent pipe casting. Aimed at the shortcomings of the prior art, the method comprises the following steps: preparing a wax rod; pressing a soluble carbonyl core by taking the wax rod as a core rod; pressing an inner pipe wax mould by taking the soluble carbonyl core as a core rod; dissolving the soluble carbonyl core with hydrochloric acid to obtain the inner pipe wax mould; performing sand hanging, dewaxing, roasting of a mould shell and the pouring to obtain an inner pipe casting; performing quality inspection; if the inner pipe casting is qualified according to the inspection, preparing a resin sand core by taking the inner pipe casting as a core rod; preparing an integral resin sand casting mould of an exhaust pipe by taking an aluminum alloy metal sample of the exhaust pipe; and putting the resin sand core in the integral resin sand casting mould and performing preheating and pressure-regulation pouring to obtain the exhaust pipe casting. According to the invention, the problem in formation of a double-layer exhaust pipe is solved, and a reliable technical scheme is provided for the casting production. Meanwhile, the production cost is greatly reduced by using a casting formation method, the manufacturing period is shortened, the product quality is improved, and great economic benefits can be gained.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

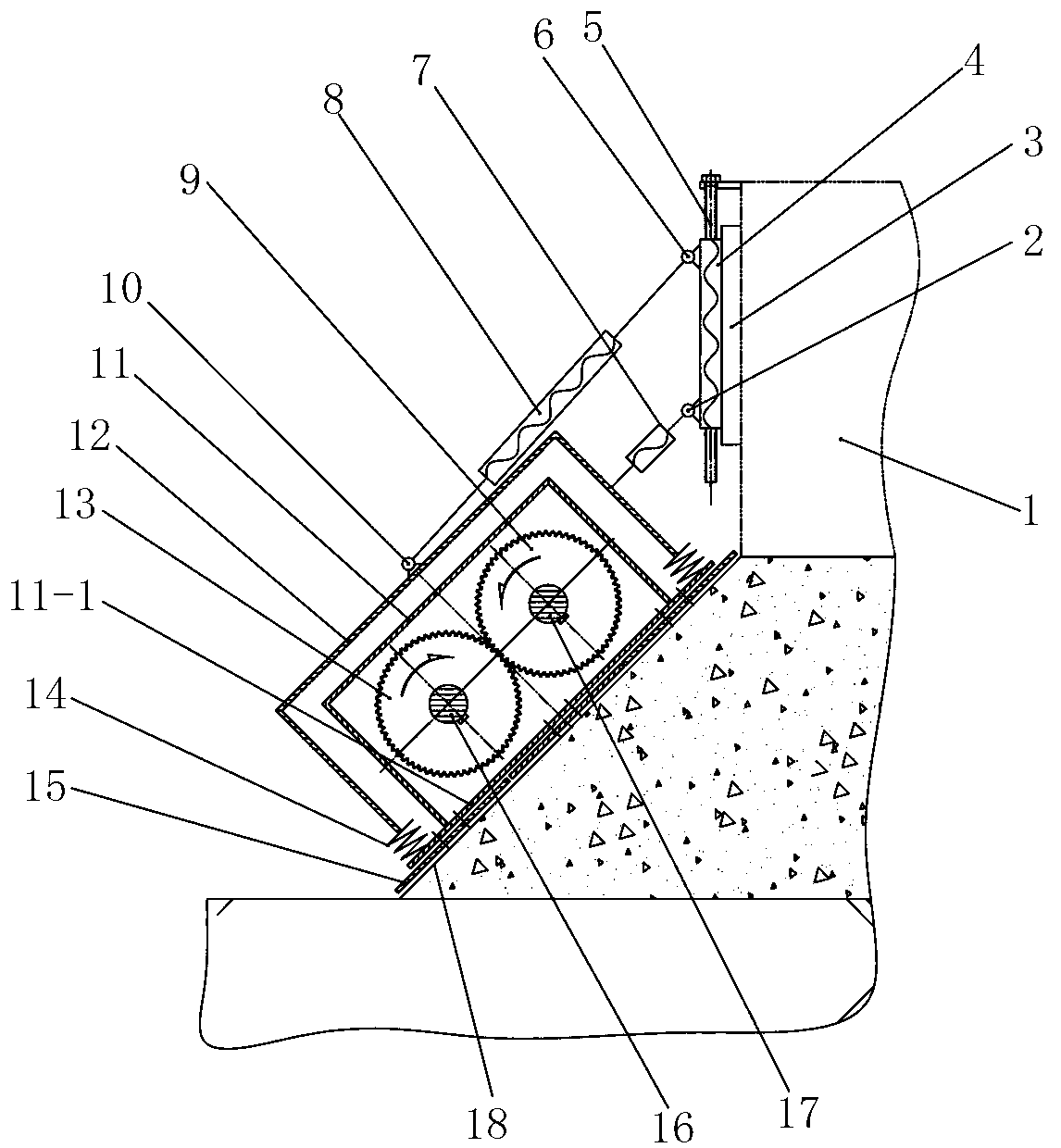

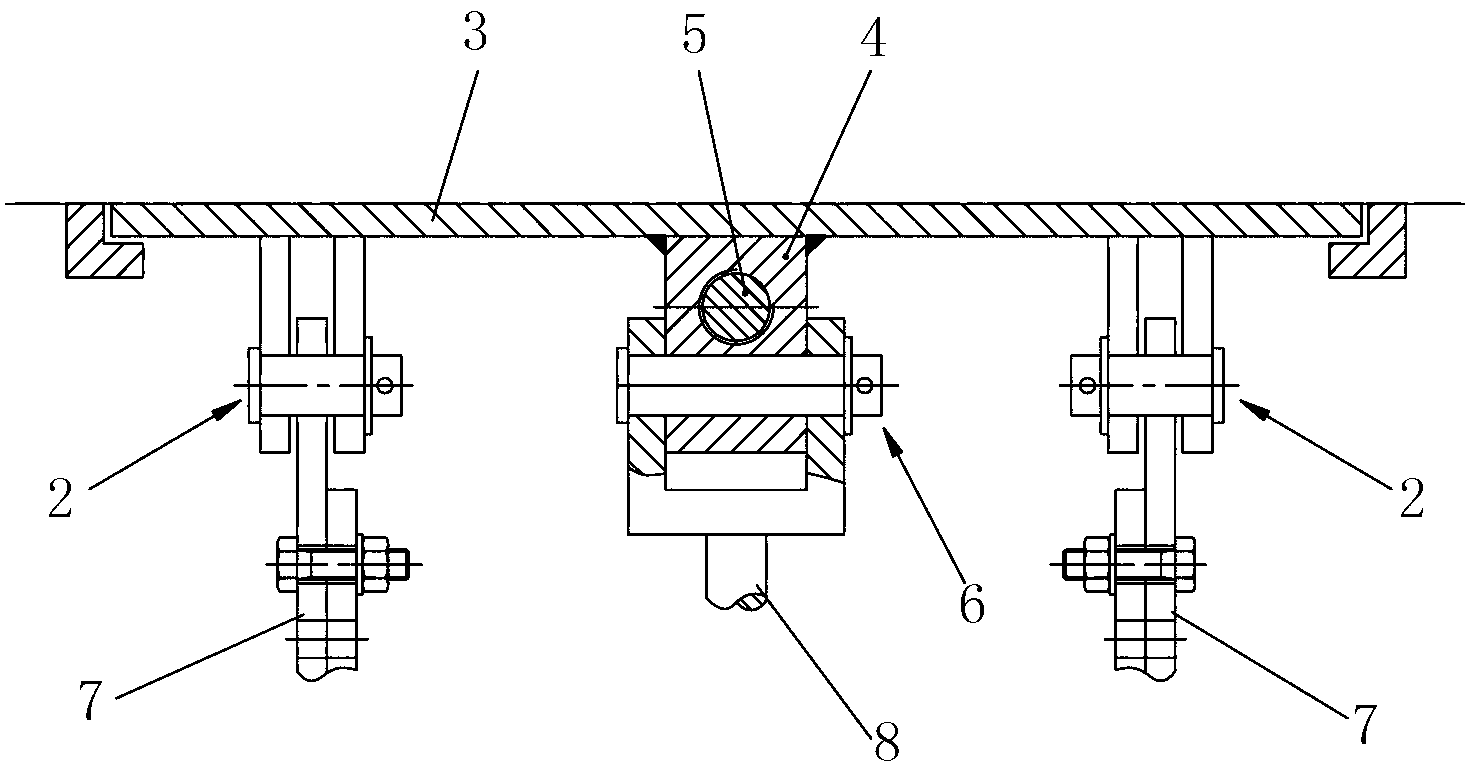

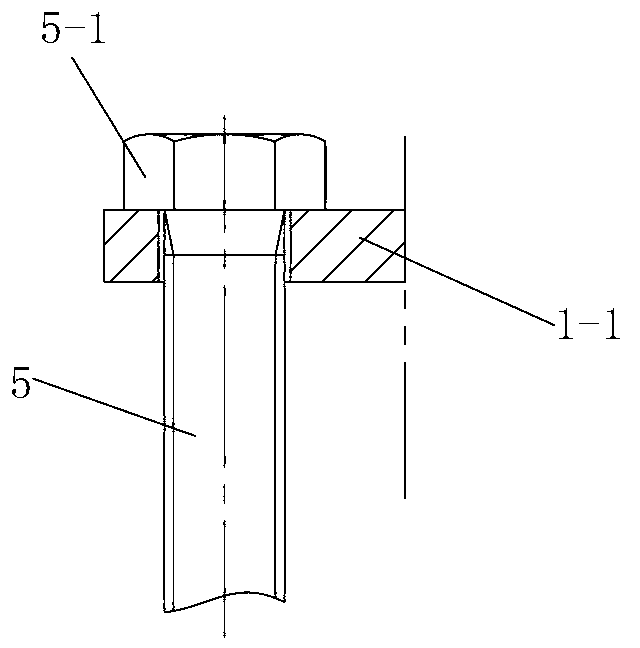

Roadbed slop vertical vibrating compacting device

The invention discloses a roadbed slop vertical vibrating compacting device which comprises a vertical vibrating mechanism aslant connected to the side wall of a working device, wherein the vertical vibrating mechanism comprises a vibrating box body, a rotating shaft I and a rotating shaft II which are mutually parallel are rotatably connected into the vibrating box body, a synchronizing wheel I is arranged on the rotating shaft I, a synchronizing gear II meshed with the synchronizing gear I is arranged on the rotating shaft II, an eccentric block I is arranged on the rotating shaft I, an eccentric block II is arranged on the rotating shaft II, a tamping plate supporting against a roadbed slope is connected to a bottom plate of the vibrating box body, and a drive device used for driving the rotating shaft I or rotating shaft II to rotate is arranged on the tamping plate. The roadbed slop vertical vibrating compacting device is capable of carrying out effective vibrating compaction on the roadbed slope, and is good in use effect, easy to operate and convenient to popularize and use.

Owner:SHAANXI JOINTARK MASCH GRP CO LTD

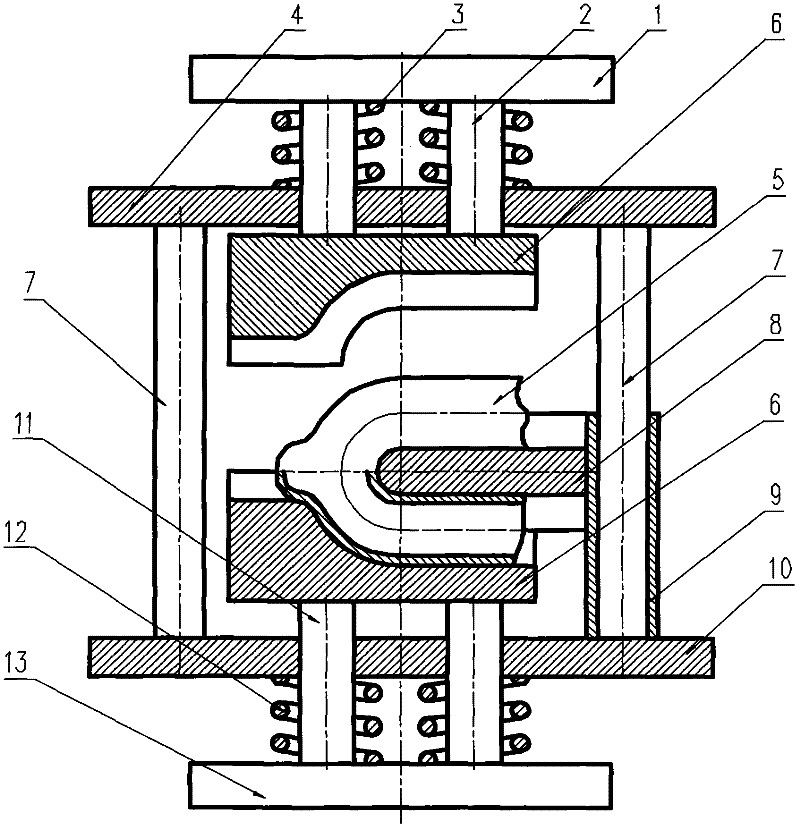

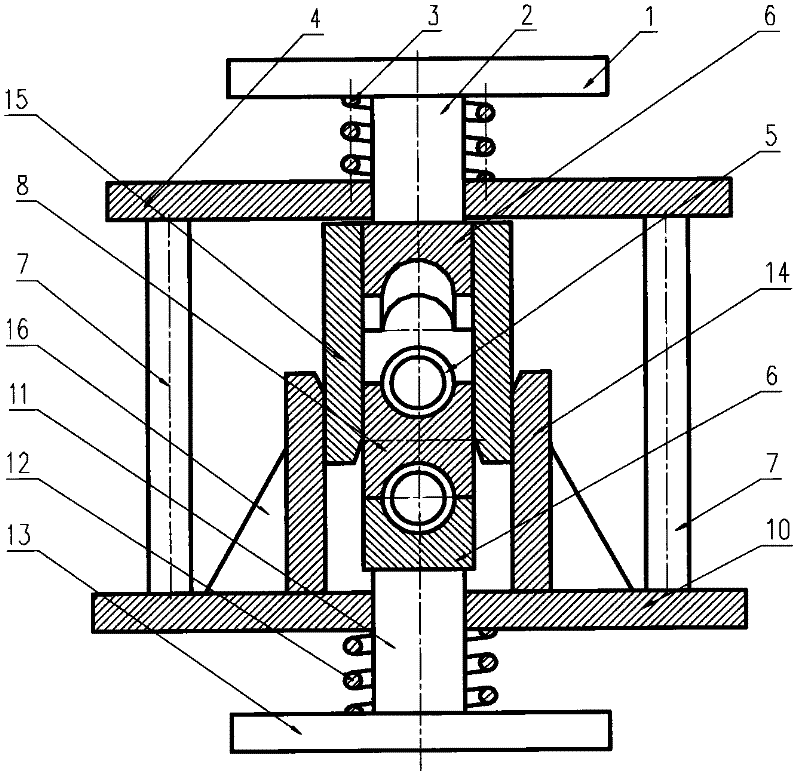

Seamless fork-shaped tube forming process and forming die

ActiveCN102266876ASolve molding problemsReduce production processExtrusion diesIntermediate frequencyEngineering

The invention discloses a forming process of a seamless fork-shaped pipe, comprising the following steps of: (1) bending, heating a seamless fork-shaped steel pipe via middle frequency and manufacturing an elbow in 160-200 degrees; (2) shaping the manufactured elbow and enabling the center distance of the elbow to basically accord with the size of the centre distance of the fork-shaped pipe; (3) flattening the shaped blanks and enabling the pipe diameter B of two branch pipes to be greater than or equal to the outer diameter of the branch pipe of the fork-shaped pipe by 1-2 mm; (4) extruding and forming, placing the heated pipe blanks into a forming mould for extruding and forming, enabling the outer diameter and the length of two branch pipes of the fork-shaped pipe to accord with the design demand, and forming bulges on the outer arc at the same time; and (5) turning and processing, cutting a cover protruding from the circular arc at the upper end part of the fork-shaped pipe and forming a main pipe interface. The seamless steel pipe is used as the raw material, and the mould is used for forming, thus the difficulty of forming the fork-shaped pipe is solved. The invention has the advantages of improving the forming quality and the finished product ratio of the fork-shaped pipe, effectively reducing the manufacture procedures, saving materials, and reducing the manufacture cost.

Owner:YANSHI HUAKE PIPE FITTINGS

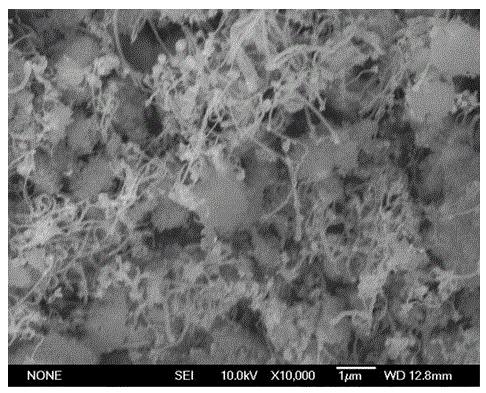

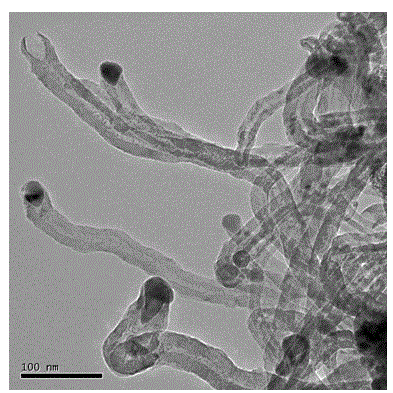

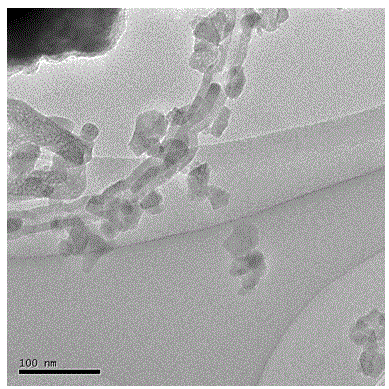

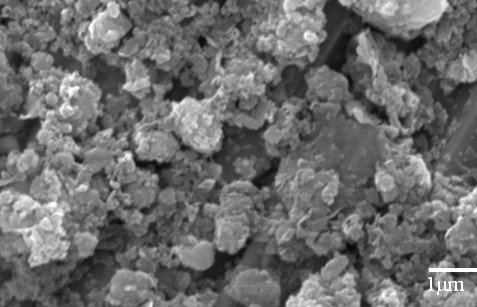

Preparation method of carbon nanotube reinforced hydroxyapatite composite material

The invention discloses a preparation method of a carbon nanotube reinforced hydroxyapatite composite material, relating to a composite material for prosthesis materials. According to the preparation method, a carbon nanotube is synthesized in hydroxyapatite powder, the carbon nanotube is subjected to surface modification by using hydroxyapatite, and the carbon nanotube reinforced hydroxyapatite composite material is further prepared. The preparation method comprises the following steps of: firstly preparing carbon nanotube-hydroxyapatite powder from nickel carbonate and the hydroxyapatite powder, then preparing hydroxyapatite-modified carbon nanotube-hydroxyapatite powder, and finally preparing the carbon nanotube reinforced hydroxyapatite composite material. The preparation method disclosed by the invention overcomes the defects that the carbon nanotube is difficult to disperse in a hydroxyapatite matrix, the wettability and the interfacial strength between the carbon nanotube and the hydroxyapatite matrix are low, the hydroxyapatite powder of which the surface is loaded with the carbon nanotube is difficult to form and the biocompatibility of the composite material is poorer in the prior art.

Owner:HEBEI UNIV OF TECH

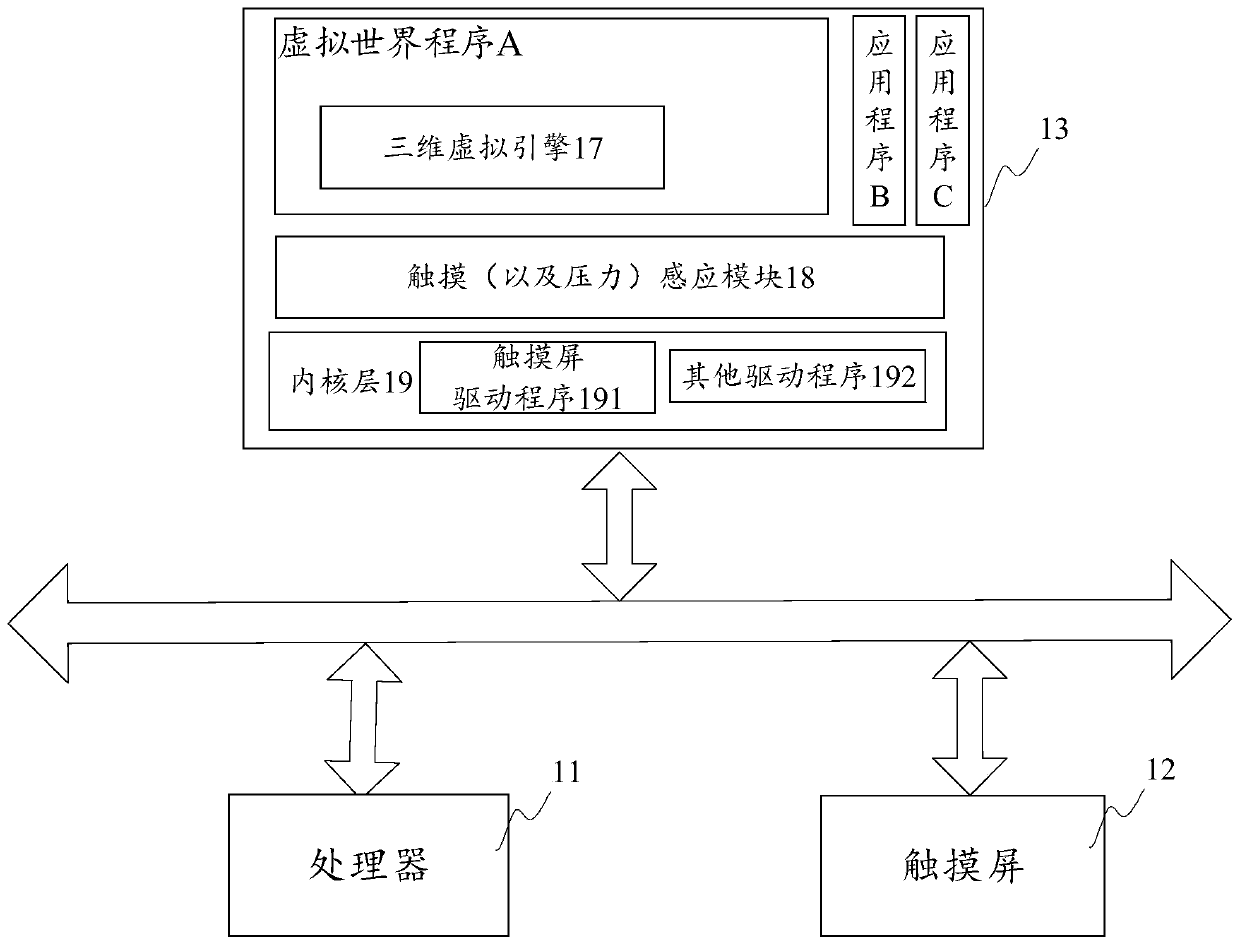

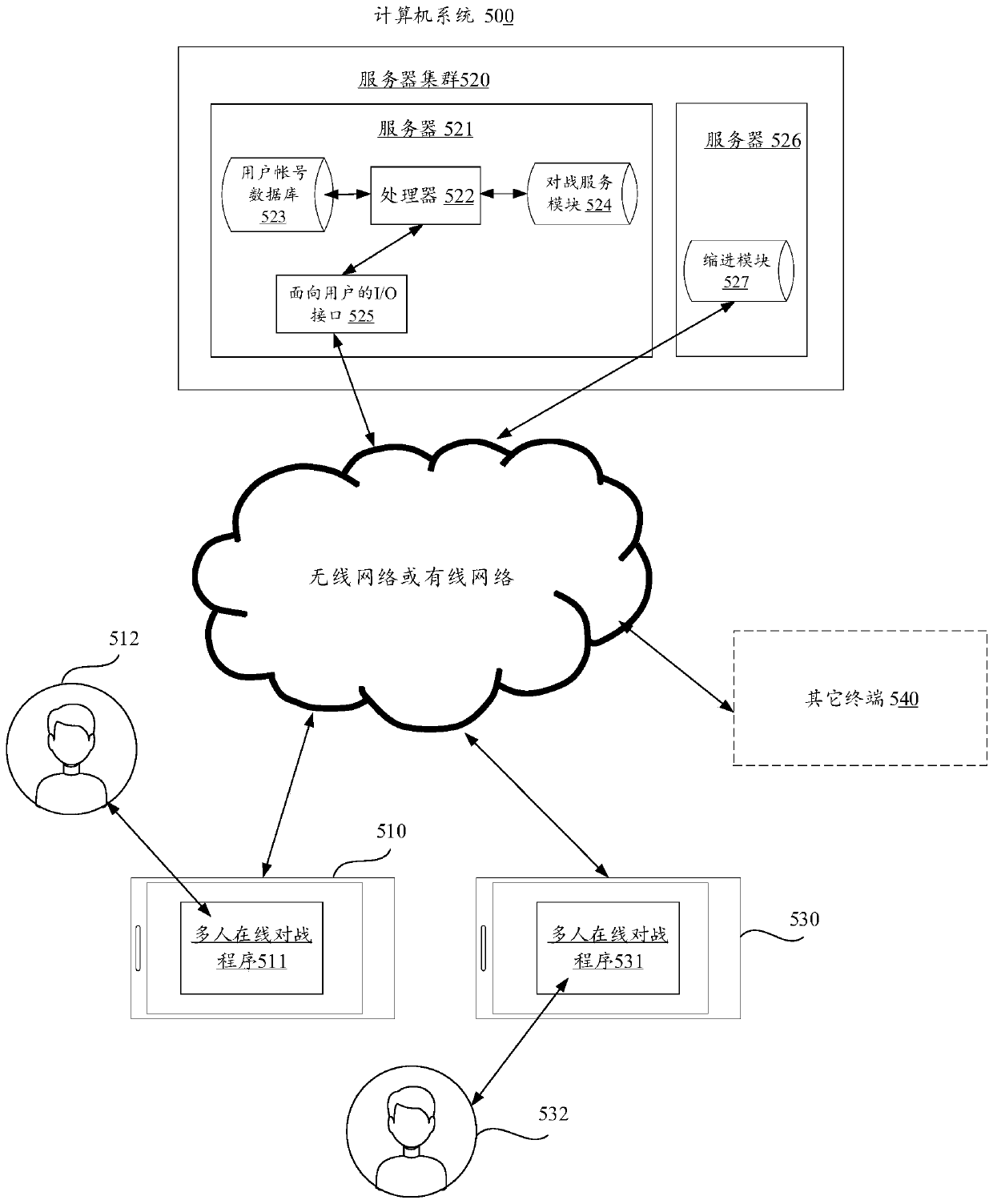

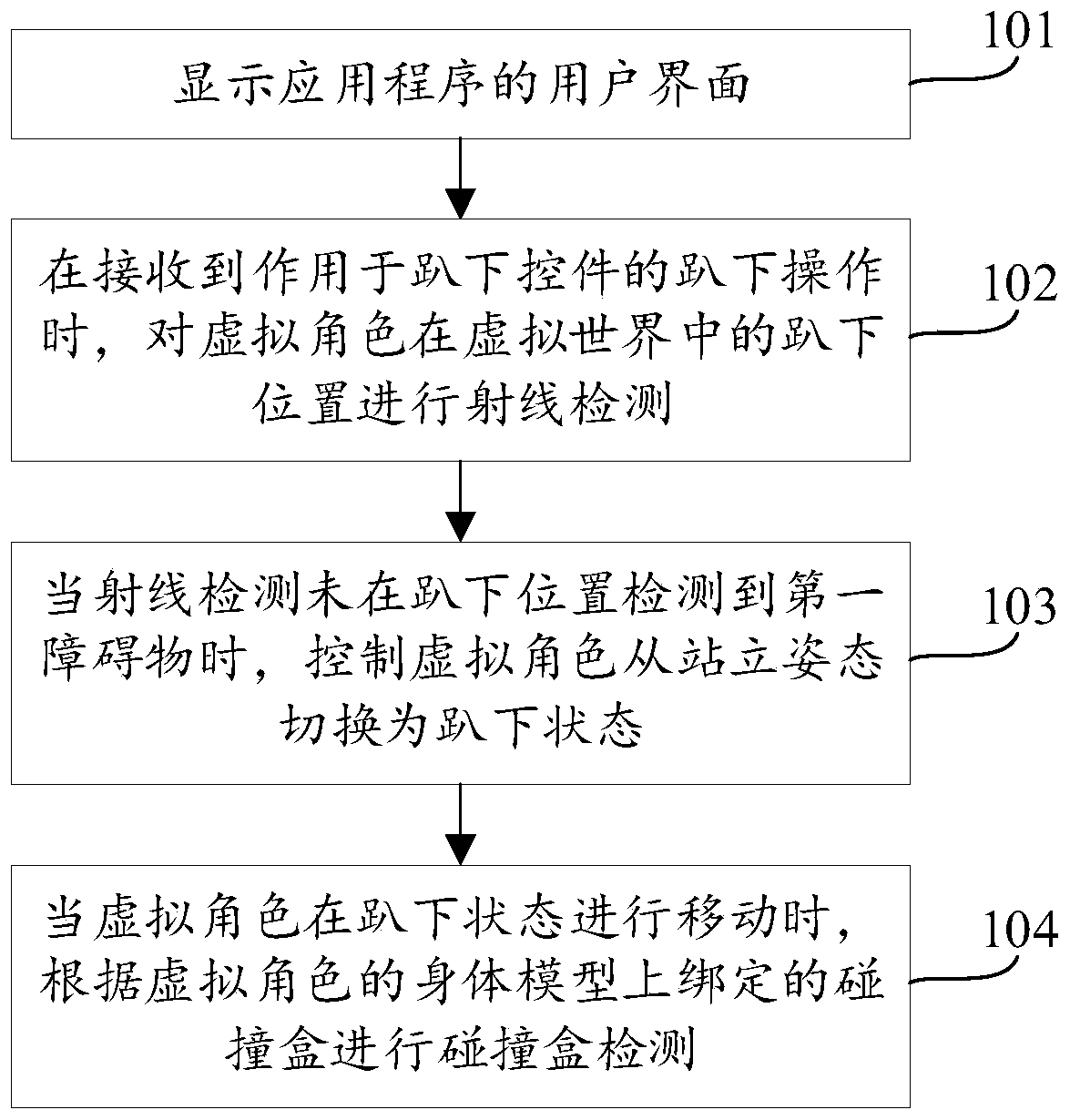

Virtual character control method and device for virtual world, equipment and medium

ActiveCN110665230AAvoid situations where obstacles cannot be detectedSolve molding problemsVideo gamesComputer graphics (images)Engineering

The invention discloses a virtual character control method and device for a virtual world, equipment and a medium, and relates to the field of virtual world. The method comprises the following steps of displaying a user interface of an application, wherein the user interface includes a virtual world picture and a get-down control, and the virtual world picture refers to a picture acquired by observing the virtual world from the viewing angle of the virtual character; carrying out ray detection on the get-down position of the virtual character in the virtual world when a get-down operation acting on the get-down control is received; controlling the virtual character to switch from a standing posture to a get-down state when a first barrier is not detected at the get-down position by the raydetection; and carrying out collision box detection according to a collision box bound to a body model of the virtual character when the virtual character moves in the get-down state, wherein the collision box detection is used for detecting a second barrier met by the virtual character in the moving process. Through the adoption of the method, the problem of interpenetration of the virtual character after getting down is solved by the collision box detection.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Aluminum oxide ceramic slender tube and manufacture method thereof

The invention relates to an aluminum oxide ceramic slender tube for a high-voltage fuse and a manufacture method thereof. The raw materials comprise 90 to 96% of alpha-Al2O3 powder, 0.2 to 1% of SiO2, 0.2 to 1% of calcined talcum, 1 to 5% of CaCO3, 1 to 5% of Su Zhou clay, and also comprise 0.04 to 0.1% of polyvinyl alcohol, 0.1 to 0.5% of dispersant and 80 to 85% of water. The manufacture method comprises the steps of: ball-milling and prilling; isostatic-pressing at the pressure of 120 MPa; drying; lathing with vacuum rubber expansion fixture; and setting and firing at the temperature of 1680 DEG C with the hanging method. The aluminum oxide ceramic slender tube of the invention has the diameter phi of 25 to 40 mm, the wall thickness of 2.5 to 3.5 mm, the length of more than 600 mm, and the straightness of less than 0.3 mm, and the properties of the tube are better than those of the similar products. The technology of the invention uses the isostatic-pressing and the vacuum rubber expansion fixture, thereby achieving the purpose that the small-bore thin walled tube can be molded and lathed, and solving the problem of easy deformation during the firing of the products, and effectively controlling the product quality. The products can be widely used in the high-voltage fuses as well as in the fields of electronics, machinery, chemical industry, metallurgy, textile industry, electric power industry and the like.

Owner:河南车材企业孵化器有限公司

Mixed powder alloy with high melting point particles or fibers and low melting point particles as well as method for preparing same

The invention relates to a mixed powder alloy with high melting point particles or fibers and low melting point particles, which comprises the high melting point particles or fibers made up of one material or various materials, the low melting point particles made up of one material or various materials, an auxiliary agent and a cast die, wherein the high melting point particles or the fibers and the low melting point particles are mixed together evenly and then are pressurized, heated and melted into a liquid state low melting point material which is filled into gaps of adjacent high melting point particles or the fibers so as to form an alloy structure which is formed by enwrapping the high melting point particles or the fibers by a three-dimensional netlike framework of the low melting point material, or a new alloy material which is formed on an interface by the three-dimensional netlike framework of the low melting point material and an enwrapped high melting point material.

Owner:王广武

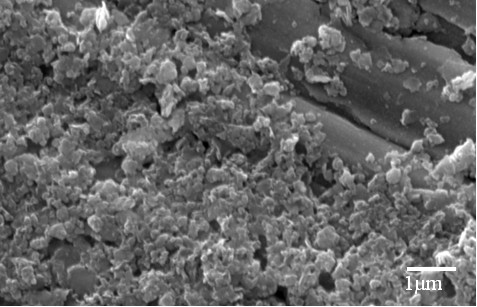

Preparation method and application of ball-milling organic modified bentonite for retention and filter aids in papermaking

InactiveCN102182110AReduce pollution loadEasy to prepareSilicon compoundsRetention agents additionActive agentSurface-active agents

The invention relates to a preparation method and application of ball-milling organic modified bentonite for retention and filter aids in papermaking. The preparation method comprises the steps of: dispersing the bentonite in water, stirring and ultrasonically dispersing to form a bentonite suspension; adding octodecyl trimethyl ammonium bromide as a surface active agent into the bentonite suspension, stirring and undergoing a water bath reaction to obtain a reaction liquid; and washing the reaction liquid by utilizing distilled water, carrying out pumping filtration till the filtrate has no white precipitate under the AgNO3 titration, drying the obtained filter cake and carrying out ball-milling to obtain the ball-milling organic modified bentonite. The prepared ball-milling organic modified bentonite has smaller particle size, the particles are basically in submicron to nanometer scale and the size distribution is more uniform; and when the prepared ball-milling organic modified bentonite is cooperated with other retention aids such as cationic polyacrylamide (CPAM), phenolic resin polymer and the like to be applied to paper pulp retention and filter systems, the problems of paper stock molding and shearing can be more effectively solved, the pulp drainage property can be enhanced, the retention effect can be improved, the speed of a paper machine can be enhanced, and therefore, the production efficiency can be increased.

Owner:SOUTH CHINA UNIV OF TECH

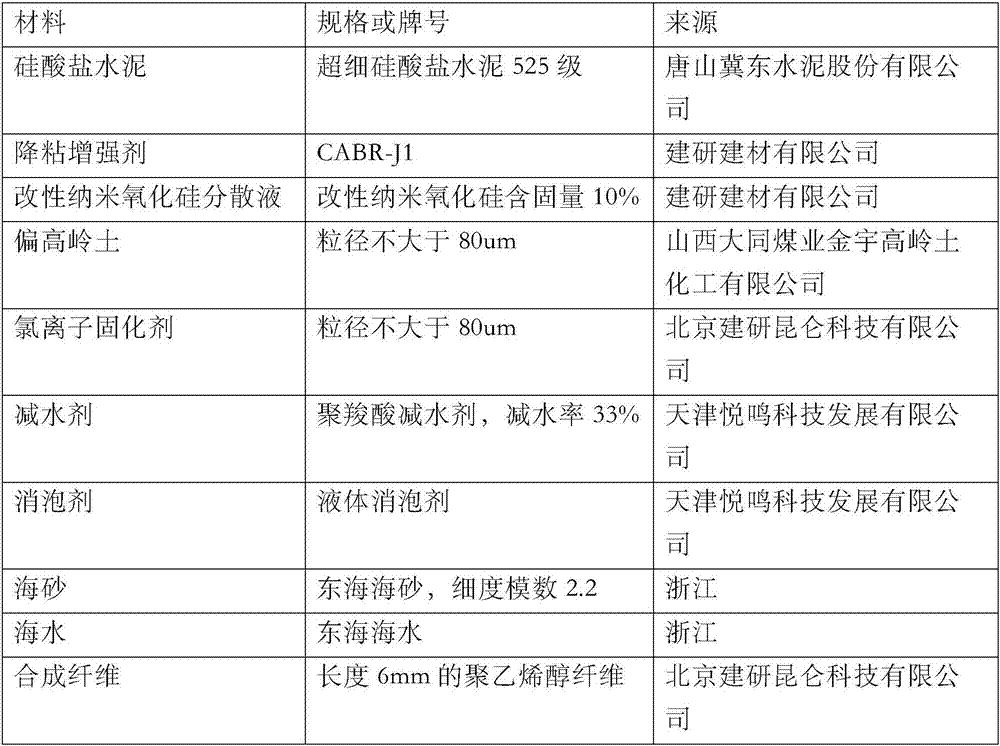

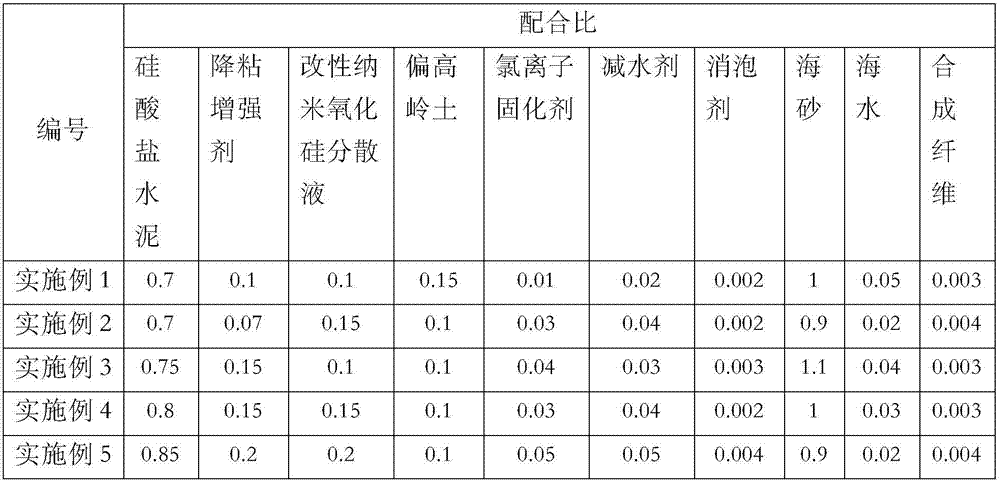

Ultrahigh performance sea sand concrete and preparation method thereof

The invention belongs to the technical field of a novel construction material and specifically relates to an ultrahigh performance sea sand concrete and a preparation method thereof. The ultrahigh performance sea sand concrete is prepared from cement, viscosity-reducing reinforcing agent, modified nanometer silicon dioxide dispersing solution, metakaolin, chloride ion curing agent, water reducingagent, de-foaming agent, sea sand, seawater and synthetic fiber at certain ratio. According to the invention, the viscosity-reducing reinforcing agent is adopted, so that the ultrahigh performance concrete still has better working property under the condition of lower water binder ratio; the modified nanometer silicon dioxide dispersing solution and the chloride ion curing agent are respectively adopted, so that the strength and durability of the ultrahigh performance concrete under normal temperature curing condition are greatly higher than those of the ultrahigh performance concrete at traditional silicon fume ratio; according to the invention, the sea sand and the seawater are used as some raw materials and are used for preparing the ultrahigh performance concrete, higher mechanical property and durability can be uniquely achieved in the manner of normal temperature moisturizing curing, the technical method is novel, the cost is lowered and the engineering can be practically popularized.

Owner:CHINA ACAD OF BUILDING RES +1

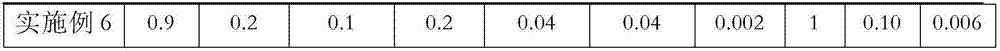

Preparation method for total-degradation layer-structured rice seedling-growing tray

InactiveCN105165466AAchieve recyclingSolve irreversible problemsGrowth substratesCulture mediaFiberCompost

A Preparation method for total-degradation layer-structured rice seedling-growing tray relates to the preparation method for the rice seedling-growing tray. The preparation method settles the following problems in existing rice seedling growing: degrading incapability of plastic seedling-growing tray, low moldability of a degradable seedling-growing matrix, requirement for matched use of the seedling-growing tray, and incapability of realizing soilless cultivation. The preparation method of the invention comprises seven steps: a first step, preparing rice straw biological carbon; a second step, performing nitriding modification processing on the rice straw biological carbon; a third step, processing compost; a fourth step, preparing a seedling growing main material; a fifth step, performing acid treatment and drying treatment; a sixth step, performing laying operation by means of a seedling-growing tray mold; and a seventh step, laying a lower-layer fiber felt, the seedling growing main material and an upper-layer fiber felt. According to the preparation method, the waste material of a crop is sufficiently utilized, and total degradation of a rice seedling growing matrix is realized. The seedling growing matrix which is prepared according to the invention can improve the condition of a farmland soil year by year. The preparation method is used for preparing the total-degradation rice seedling-growing tray.

Owner:JIAMUSI UNIVERSITY

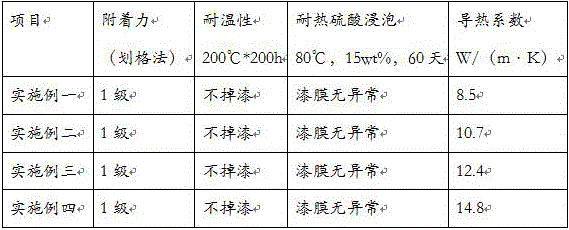

Graphene coating for corrosion prevention of thermal power plant desulfurization chimney, and preparation method of graphene coating

ActiveCN106366928AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsFiberMetallurgy

The invention discloses graphene coating for corrosion prevention of a thermal power plant desulfurization chimney. The graphene coating consists of the following raw materials in parts by weight: 90 to 100 parts of film-forming resin, 0.5 to 3 parts of graphene, 0.5 to 2 parts of reinforced fibers, 10 to 20 parts of fillers, 10 to 20 parts of a curing agent, 15 to 30 parts of a diluents, 1 to 5 parts of polyacrylic acid, 1 to 5 parts of a polyethylenimin crosslinking agent, 1 to 3 parts of stearate and 2 to 6 parts of aids. By the mode of adding the raw materials, such as the reinforced fibers, the fillers, the polyethylenimin crosslinking agent and the polyacrylic acid, the defect that the existing corrosion-resistant coating has low durability and heat stability is overcome, the problem that the corrosion-resistant coating layer is easy to pollute and difficult to clean is solved, the developed graphene corrosion-resistant coating can completely adapt to the high-temperature strong-acid environment, the manufacturing process is simple, the practicability is high and the graphene coating is particularly suitable for thermal power plant desulfurization chimneys and flues.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

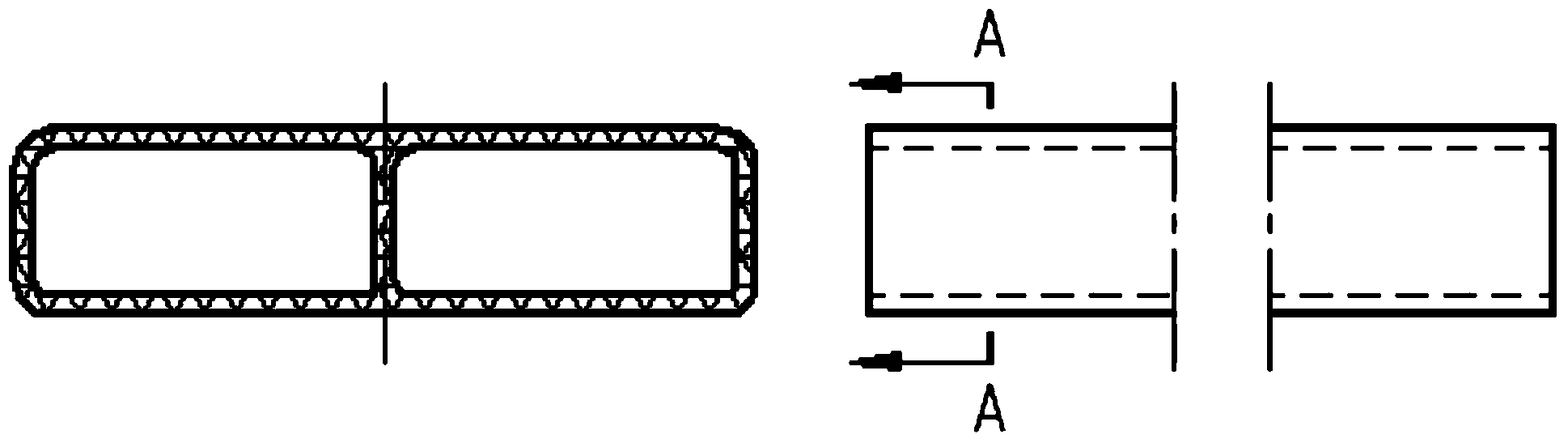

Forming method for rectangular carbon fiber composite reinforced pipe fitting

The invention belongs to the technical field of forming of carbon fiber reinforced resin matrix composite structures, and relates to a forming method for a rectangular carbon fiber composite reinforced pipe fitting. The reinforcing ribs of the rectangular carbon fiber reinforced resin matrix composite reinforced pipe fitting prepared by adopting the method cannot generate distortion deformation; inner-cavity round corners and an outline round corner of the pipe fitting are relatively regular, and stress concentration points are reduced, so that the mechanical properties of products are ensured; in addition, the method is simple to operate, and the reliability in quality of the products is high. The forming method has the advantages that wound mandrels are rigid molds, winding equipment can be fully utilized, and efficiency is higher; mold-filling and demolding are simple and easy to operate, and forming pressure is stable and controllable.

Owner:BEIJING SATELLITE MFG FACTORY

Novel reinforced bar type ultra-high-performance concrete pipeline and preparing method thereof

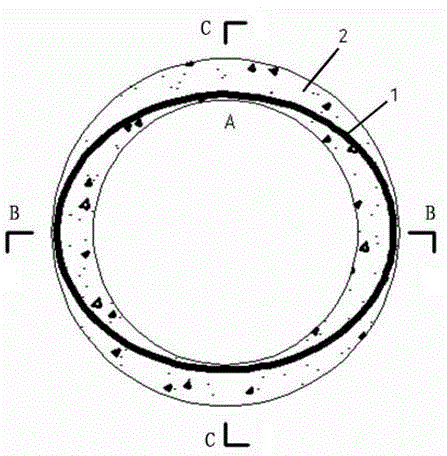

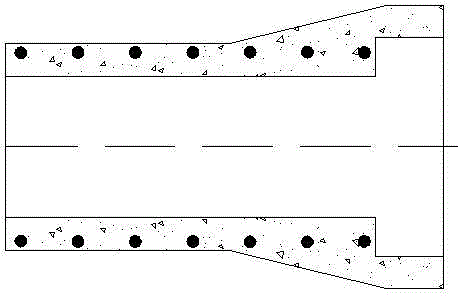

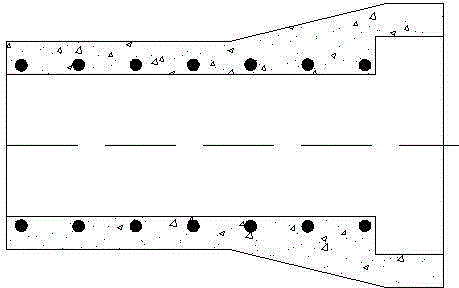

InactiveCN104832720AEfficient use ofIncrease breaking loadShaping reinforcementsRigid pipesArchitectural engineeringRebar

The invention discloses a preparing method of a novel reinforced bar type ultra-high-performance concrete pipeline. An adopted pipeline forming mold comprises a steel outer mold and an inner mold. The method comprises the following steps that (1) a steel bar framework is welded, a longitudinal bar of the framework is unchanged, and an annular bar is processed into an oval shape; (2) the mold is assembled, a steel bar framework is fixed, a pumping machine is connected with the mold, and the sealing performance is checked; (3) an ultra-high-performance concrete mixture is prepared; (4) the ultra-high-performance concrete mixture is added into the pumping machine, and a pumping jacking process is adopted for forming a pipeline; (5) after the pumping is completed, a closed grouting opening of the mold is sealed in time; (6) a pipeline with the mold is subjected to integral maintenance; (7) the mold is dismounted; (8) hydrothermal maintenance or natural maintenance is carried out after the pipeline mold dismounting. The invention also discloses the novel reinforced bar type ultra-high-performance concrete pipeline. The pipeline annular bar prepared by the method provided by the invention is in an oval shape, so that the strength of a reinforced bar is effectively utilized, and the pipeline strength is improved.

Owner:SOUTH CHINA UNIV OF TECH

Compound immobilization method for fructosyl transferase

InactiveCN104560936ANovel cracking methodNovel methodMicroorganism based processesOn/in organic carrierCalcium alginateBatch reaction

The invention discloses a compound immobilization method for fructosyl transferase, and belongs to the field of biotechnologies. The technology has the advantages that fructosyl transferase extraction technological equipment is simple; the fructosyl transferase is embedded by calcium alginate after chitosan covalence immobilization; the problems of forming and integer of chitosan covalence immobilized enzyme can be solved; the immobilization efficiency of the enzyme is high (enzyme activity recovery rate reaches above 70%); the enzyme can be used repeatedly for more than 85 times during batch reaction.

Owner:BAOLINGBAO BIOLOGY

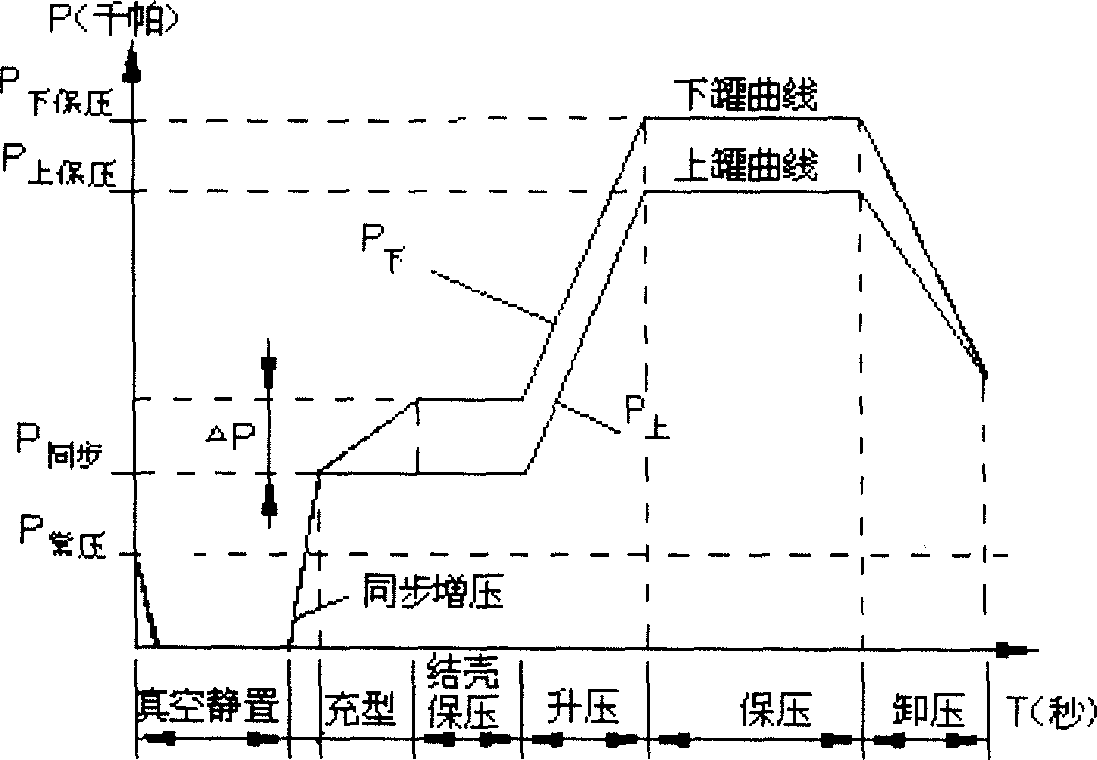

Pressure difference casting process of preparing in-situ aluminium base composite material

The pressure difference casting process of preparing in-situ aluminum base composite material in casting technology field includes the following steps: re-melting liquid metal, introducing inert gas for protection and stirring; setting cast mold and crucible separately inside the upper and the lower mold cavity, sealing and vacuum refining to deair; increasing the pressure of the upper and the lower mold cavity to initial pressure, pressure difference casting via liquid raising and filling, i. e., increasing the pressure of the lower mold cavity to pressurize the metal liquid into mold cavity in antigravity direction; and pressurizing the upper and the lower mold cavity simultaneously while maintaining the pressure difference in between for high pressure solidification and feeding until complete solidification. The present invention applies pressure difference casting technology in preparing in-situ aluminum base composite material and can form thin wall complicated and high precision casting of in-situ aluminum base composite material.

Owner:SHANGHAI JIAO TONG UNIV

Low pressure casting process of preparing in-situ aluminium-base composite material

InactiveCN1739887ASolve molding problemsSolve the problem of serious oxidationPressure castingCrucible

The low pressure casting process of preparing in-situ aluminum-base composite material includes the following steps: melting and stirring the composite material under the protection of inert gas; sealing liquid metal inside sealing crucible with middle partition and installing the cast mold on the middle partition; deairing the composite material in vacuum environment; pressurizing the sealed crucible to pressurize liquid composite material into mold cavity in the antigravity direction; maintaining the pressure after crusting for some period; raising the pressure inside the crucible to certain high pressure and maintaining the high pressure until complete solidification of the casting; eliminating pressure and taking out the casting. The present invention applies low pressure casting method in preparing in-situ aluminum-base composite material and can form high performance aluminum-base composite material.

Owner:SHANGHAI JIAO TONG UNIV

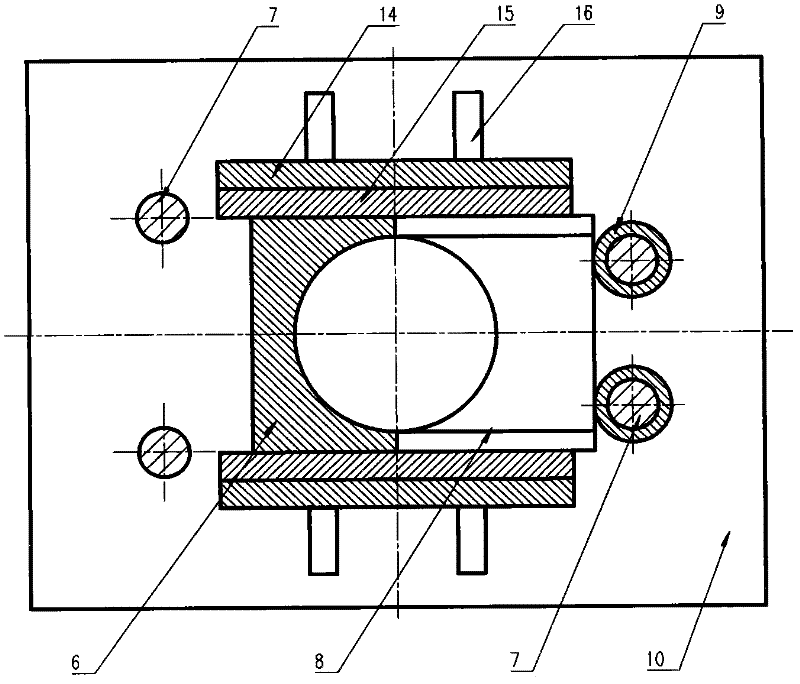

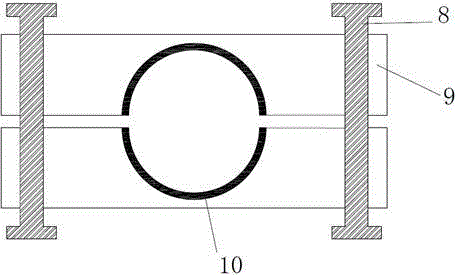

Mould and method for preparing ultra-high performance concrete pipeline

InactiveCN104802301AReduce crackingHigh strengthMouldsCeramic shaping coresShrinkage crackingStructural engineering

The invention discloses a mould for preparing an ultra-high performance concrete pipeline. The mould comprises an outer steel mould and an inner steel mould with grouting holes, wherein a steel wedge block is arranged at a joint of the inner steel mould; the steel wedge block is supported on an inner wall of the inner steel mould through a wedge block; the inner steel mould is formed by splicing two steel components and a rubber part which is connected between the two steel components; fixing devices for clamping and fastening the inner steel mould are arranged at the two ends of the inner steel mould. The invention also discloses a method for preparing the ultra-high performance concrete pipeline by adopting the mould. According to the mould, the steel mould is combined with the rubber, so that the advantages of high rigidity and capability of bearing higher pumping pressure of the steel mould are utilized, the excellent deformability of the rubber is also utilized, and the shrinkage crack phenomenon of the pipeline is effectively eliminated.

Owner:SOUTH CHINA UNIV OF TECH

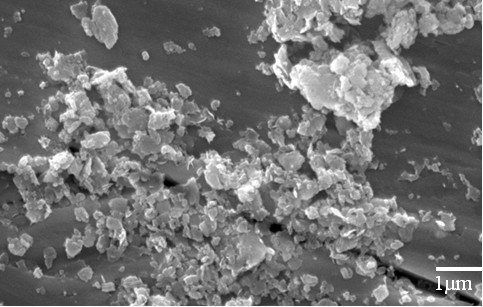

Preparation method of low-temperature co-fired ceramic super-hard abrasive polymer based on 3D printing

InactiveCN111470871ASolve molding problemsIncrease densityAdditive manufacturing apparatus3d printAdhesive

The invention discloses a preparation method of a low-temperature co-fired ceramic super-hard abrasive polymer based on 3D printing, and belongs to the field of additive manufacturing and super-hard material preparation. The method comprises following steps: preparing a 3D printed low-temperature co-fired ceramic bonding agent; step 2, mixing the low-temperature co-fired ceramic bonding agent, a super-hard abrasive and an adhesive, and molding the mixture in 3D printing equipment to obtain a to-be-fired polymer; and step 3, placing the obtained polymer to be sintered in an environment of 700-1000 DEG C at a heating rate of 2-20 DEG C / min, and maintaining the temperature for 0.5-3 hours to prepare the low-temperature co-fired ceramic super-hard abrasive polymer based on 3D printing. The low-temperature co-fired ceramic bonding agent can be reliably connected with a super-hard abrasive, the bonding strength is improved, the microcrystalline glass is formed through high-temperature smelting, and the microcrystalline glass in the low-temperature co-fired ceramic can permeate into gaps between ceramic particles and super-hard abrasive particles in the sintering process, so that the compactness of the prepared polymer is improved.

Owner:江苏新砺河磨具科技有限公司

Bean roll and manufacturing method thereof

InactiveCN103431063AImprove technical levelHigh technical contentCheese manufactureFood scienceFlavorAdditive ingredient

The invention discloses a bean roll and a manufacturing method thereof and aims to overcome the defects that an existing leisure bean product lacks of characteristics and has a single species and has the defects of rough taste, low toughness and low competitiveness. The manufacturing method comprises the main process steps: selecting materials, performing pretreatment, pulping, boiling the pulp, dispensing the pulp, performing first molding, slicing and forming, alkalifying and seasoning, performing secondary molding, and seasoning and packaging. The dried tofu produced from high-quality soybeans under special technical parameter conditions serves as a main ingredient, the dried tofu is coated with fried sandwiches and steamed, the traditional bean product processing technology is effectively combined with the modern food production technology, the processing modes of stirring, frying and steaming are combined together, and the problems of food molding, single taste, retention of nutritional ingredients of soybeans, addition of multiple nutrient substances and the like are solved. The bean roll has the characteristics of golden yellow and attractive color, diversified tastes and flavors, high chewy property, rich and comprehensive nutrition, unique shape, great eating convenience, high safety and sanitation, convenience for carrying and saving and the like, and is suitable for various consumer groups.

Owner:CHENGDU LONGFU FOOD

Manufacturing method of super two-phase stainless steel thick-wall welded pipe

The invention discloses a manufacturing method of a super two-phase stainless steel thick-wall welded pipe. The manufacturing method comprises the steps of edge milling, prebending, JCO forming, innerdie edge pressing, prewelding, outer welding, inner welding, heat treatment, circle finishing, weld joint X-ray detection, static water pressure testing, chamfering, acid pickling passivation and appearance quality examination. According to the thick-wall super two-phase stainless steel welded pipe manufactured through the method, the weld joint structure ratio of ferrite to austenite is reasonable, the excellent mechanical performance and corrosion resistance are formed, and forming and circular degree problems are well solved through a JCO two-die prebending and inner die edge pressing mixed forming method.

Owner:ZHEJIANG JIULI HI TECH METALS

Process for shaping foamed latex product

InactiveCN1373032ASolve molding problemsConvenient and practical molding processEngineeringNATURAL LATEX RUBBER

Owner:郭 赞兴

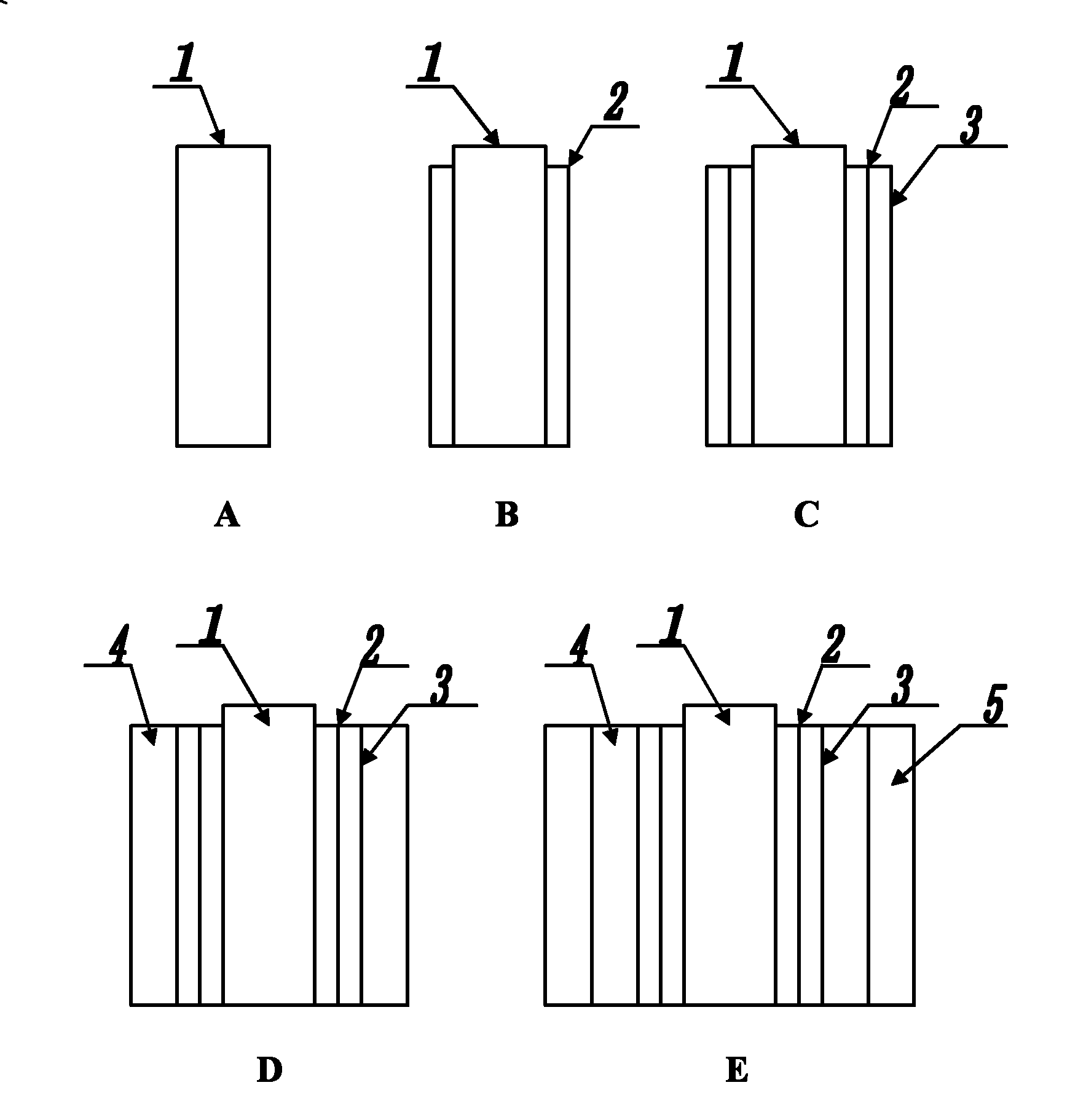

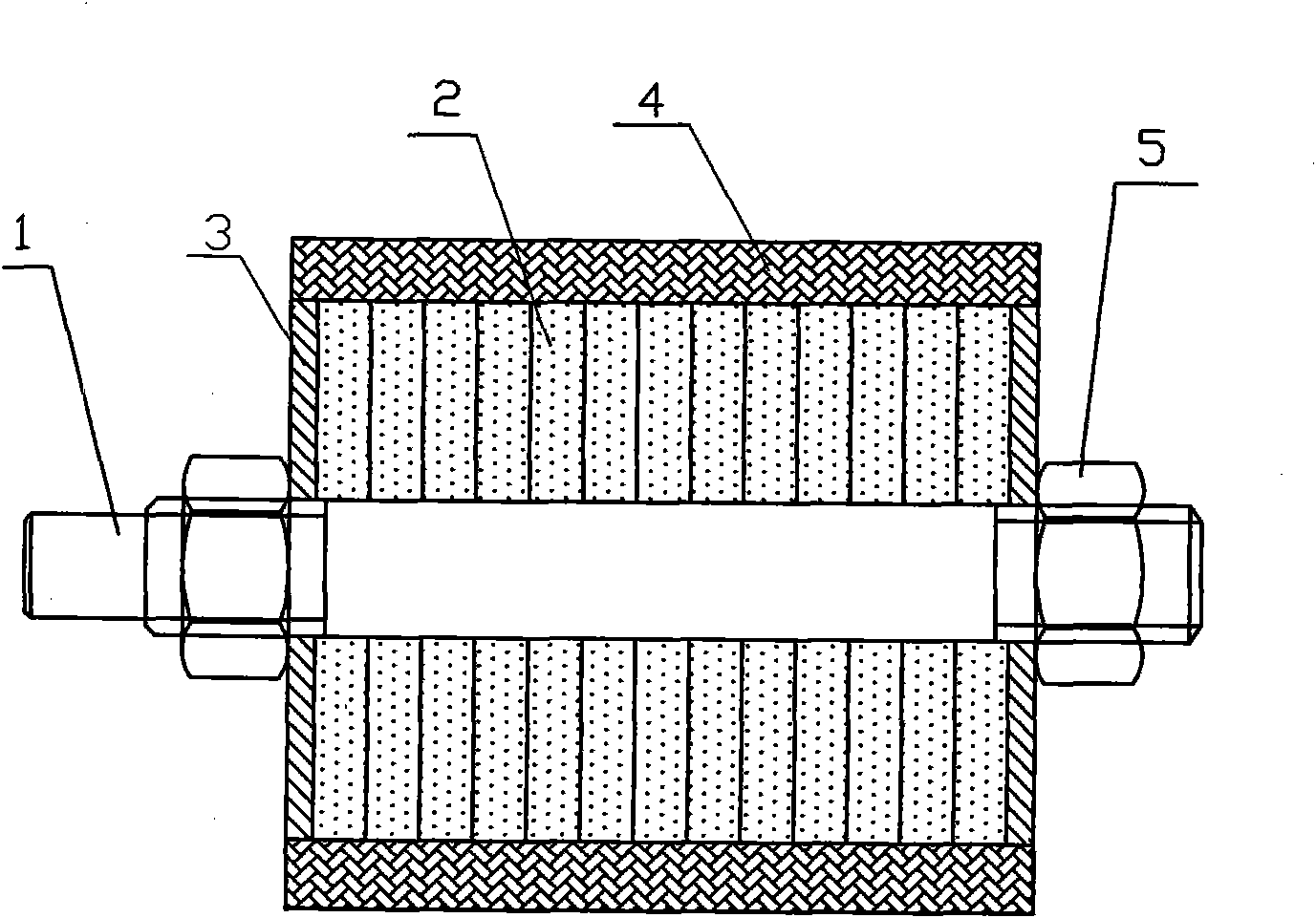

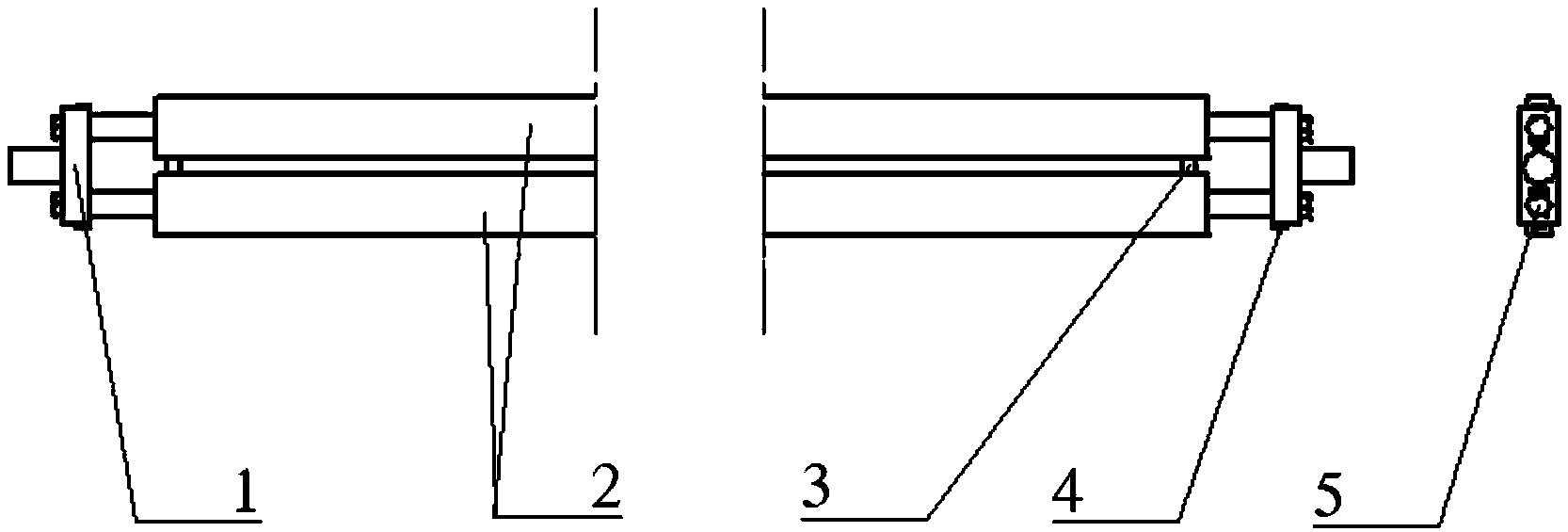

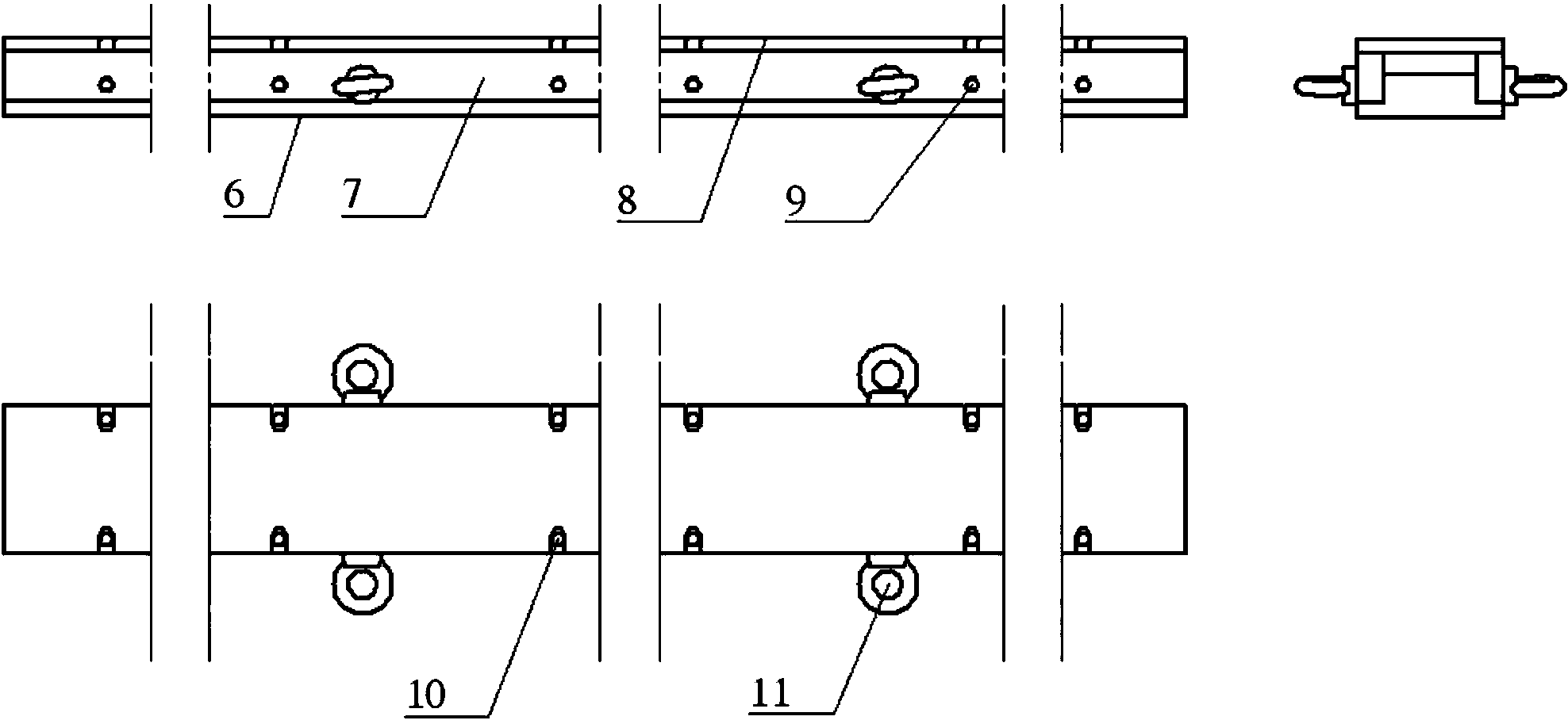

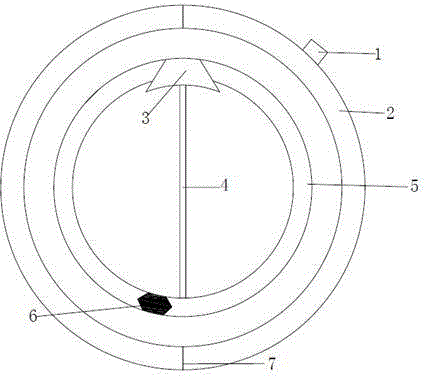

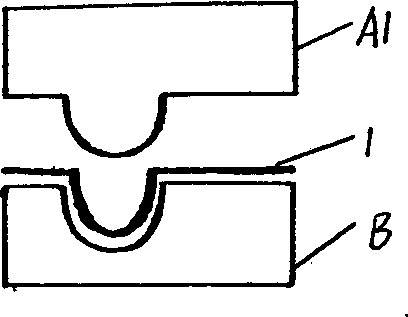

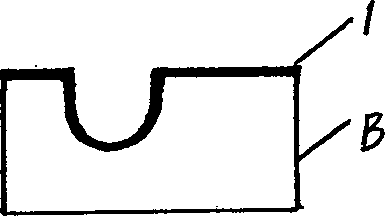

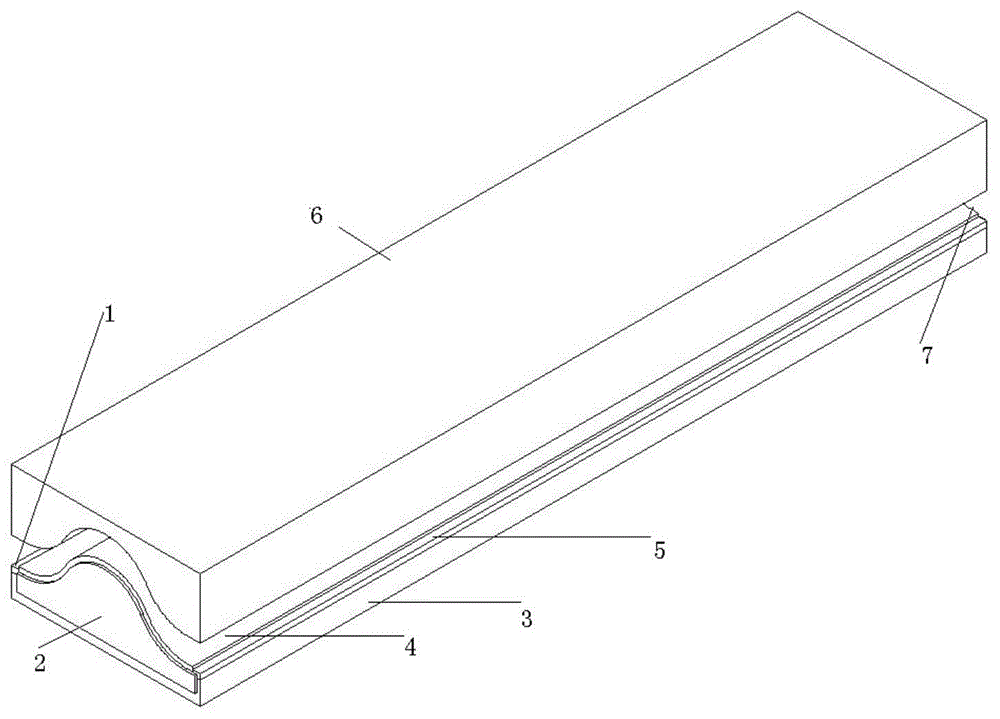

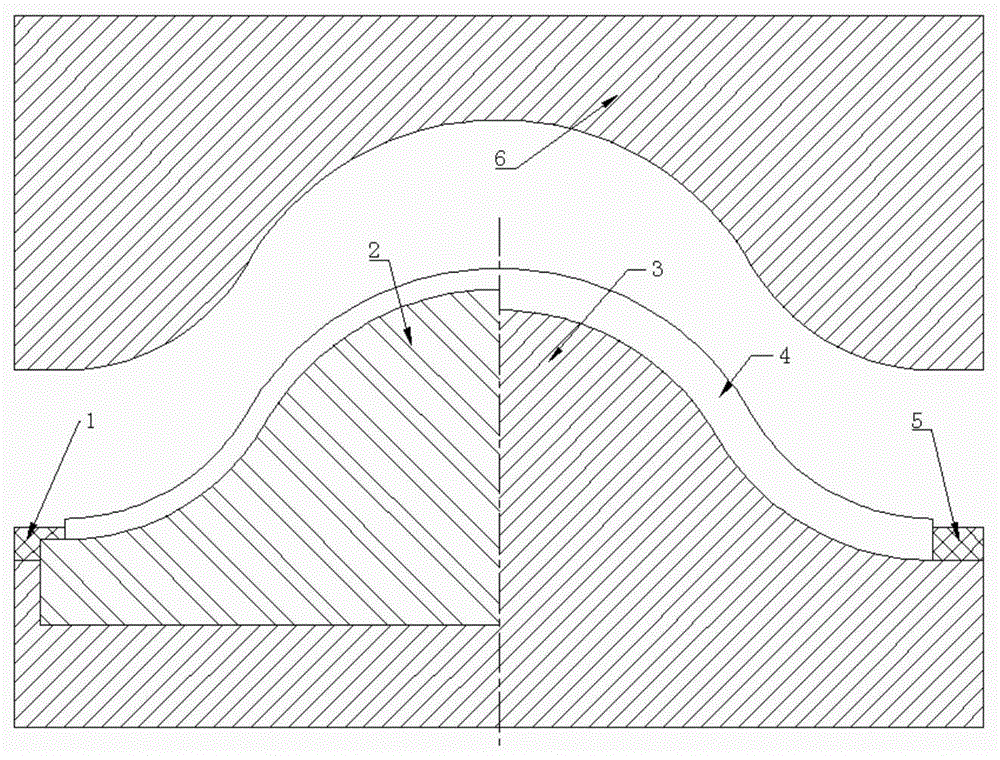

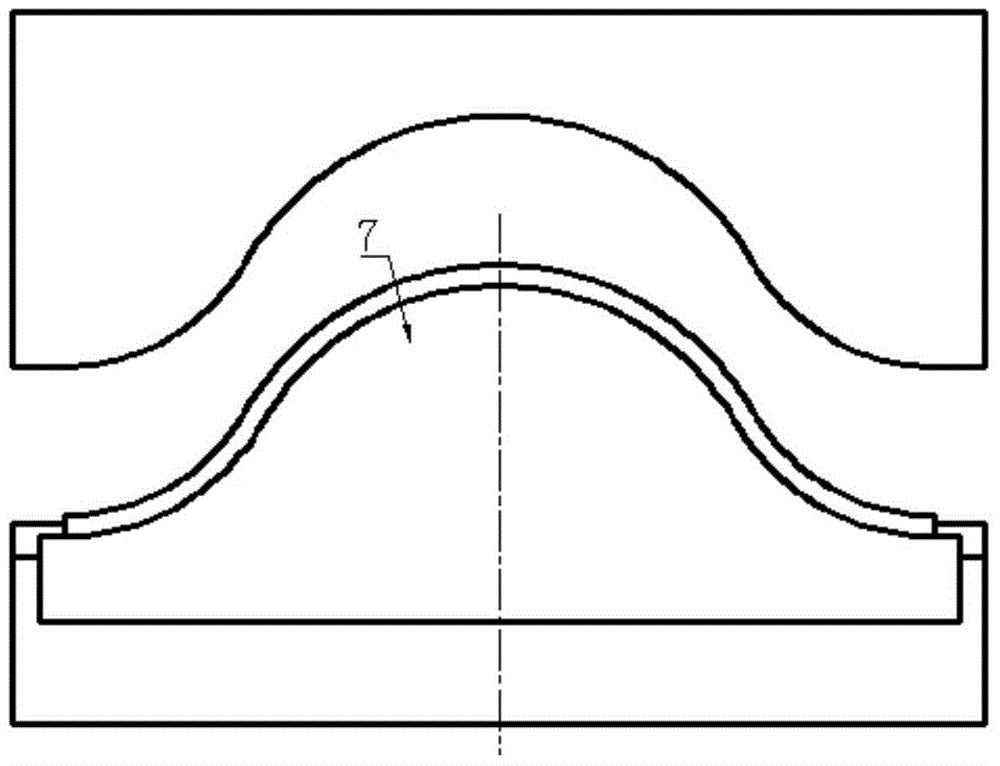

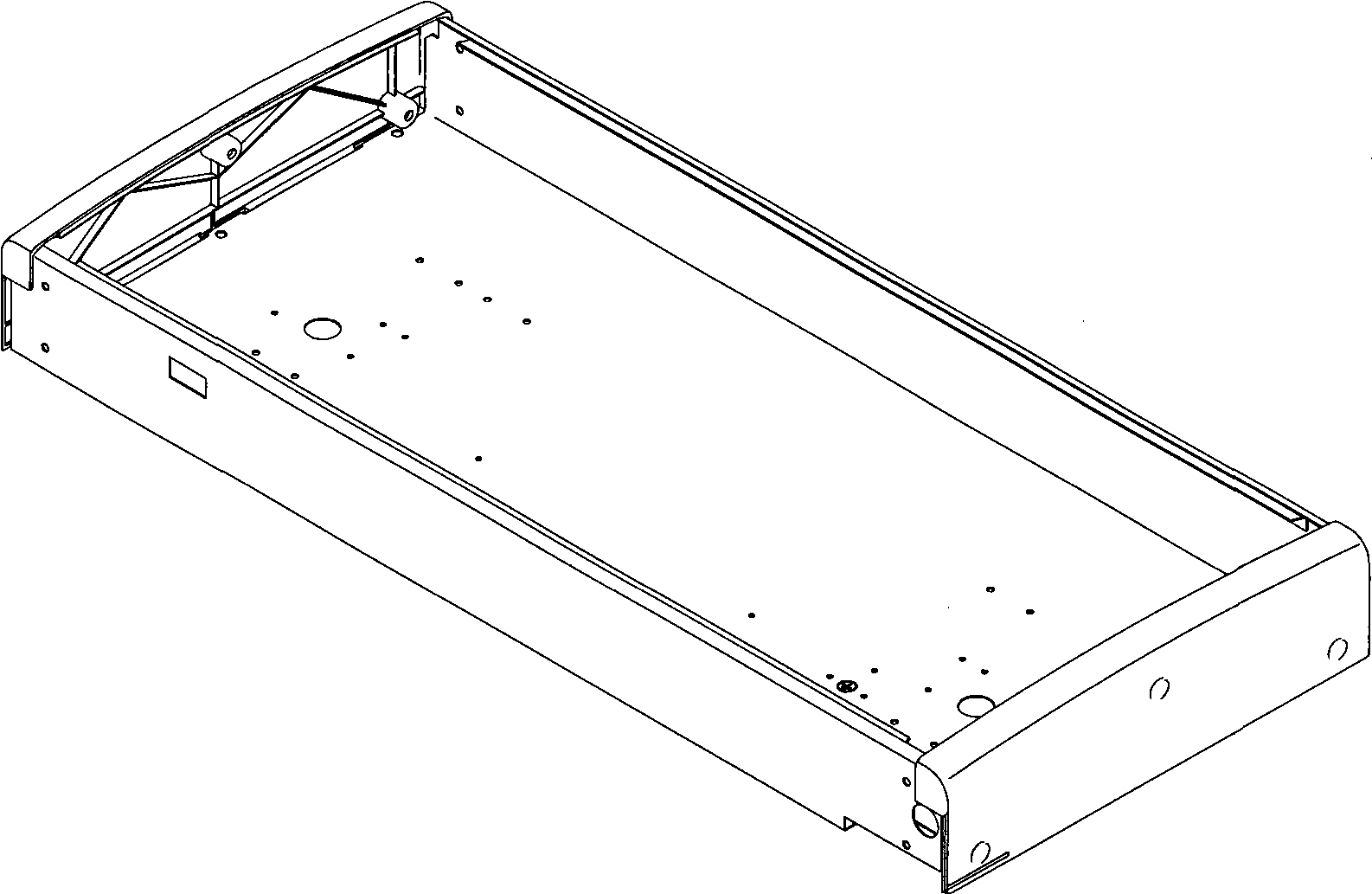

Novel continuous molding mould for ultrathin component

The invention provides a novel continuous molding mould for an ultrathin component. The novel continuous molding mould comprises a left baffle 1, a front baffle 2, a male mould 3, a flexible mould 4, a right baffle 5, a female mould 6 and a rear baffle 7, wherein the male mould 3 has a convex curved surface; the female mould 6 has a concave curved surface at a position corresponding to the convex curved surface; the circular arc radius of the convex curved surface is equal to that of the concave curved surface; the male mould 3 is covered with the flexible mould 4; the left baffle 1, the front baffle 2, the rear baffle 7 and the right baffle 5 are respectively in screw joint to the periphery of the male mould 3 and are used for blocking the flexible mould 4. According to the novel continuous molding mould, the flexible mould and a fixing device of the flexible mould are additionally arranged, so that a composite material component for a large ultrathin non-equal-thickness complex satellite can be prepared with high accuracy; the product is excellent in surface quality, high in accuracy of the molded surface and excellent in performance; the problem of molding of the composite material component for the large ultrathin non-equal-thickness complex satellite can be solved; the problems of poor appearance quality, high porosity and poor accuracy of the molded surface caused by uneven pressure distribution of a metal mould due to the non-equal thickness of the product can be solved.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Mutual-nested topology pipeline type structure and overall forming method

ActiveCN108481767AGuaranteed integritySolve molding problemsBranching pipesTubular articlesEngineeringUltimate tensile strength

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

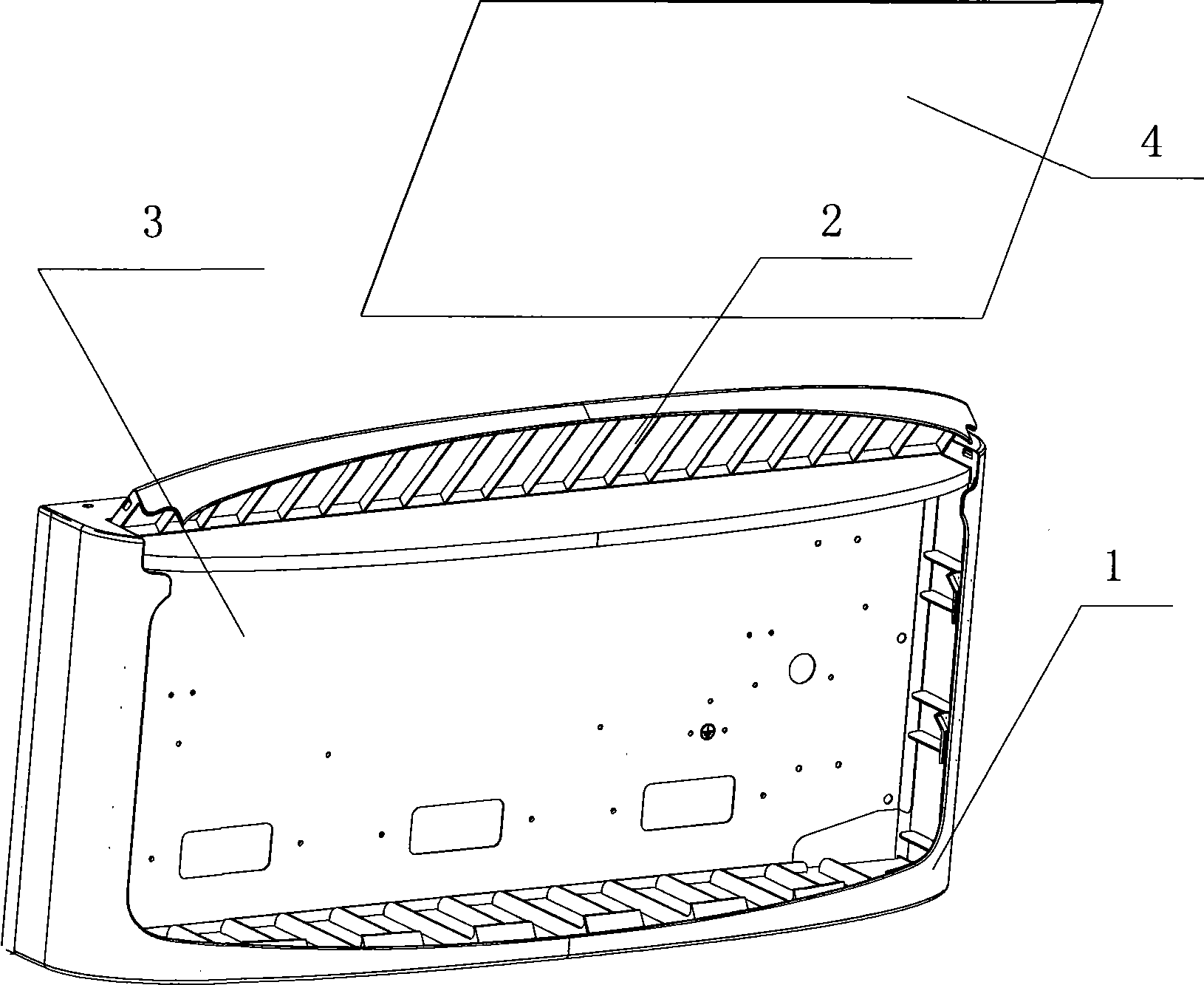

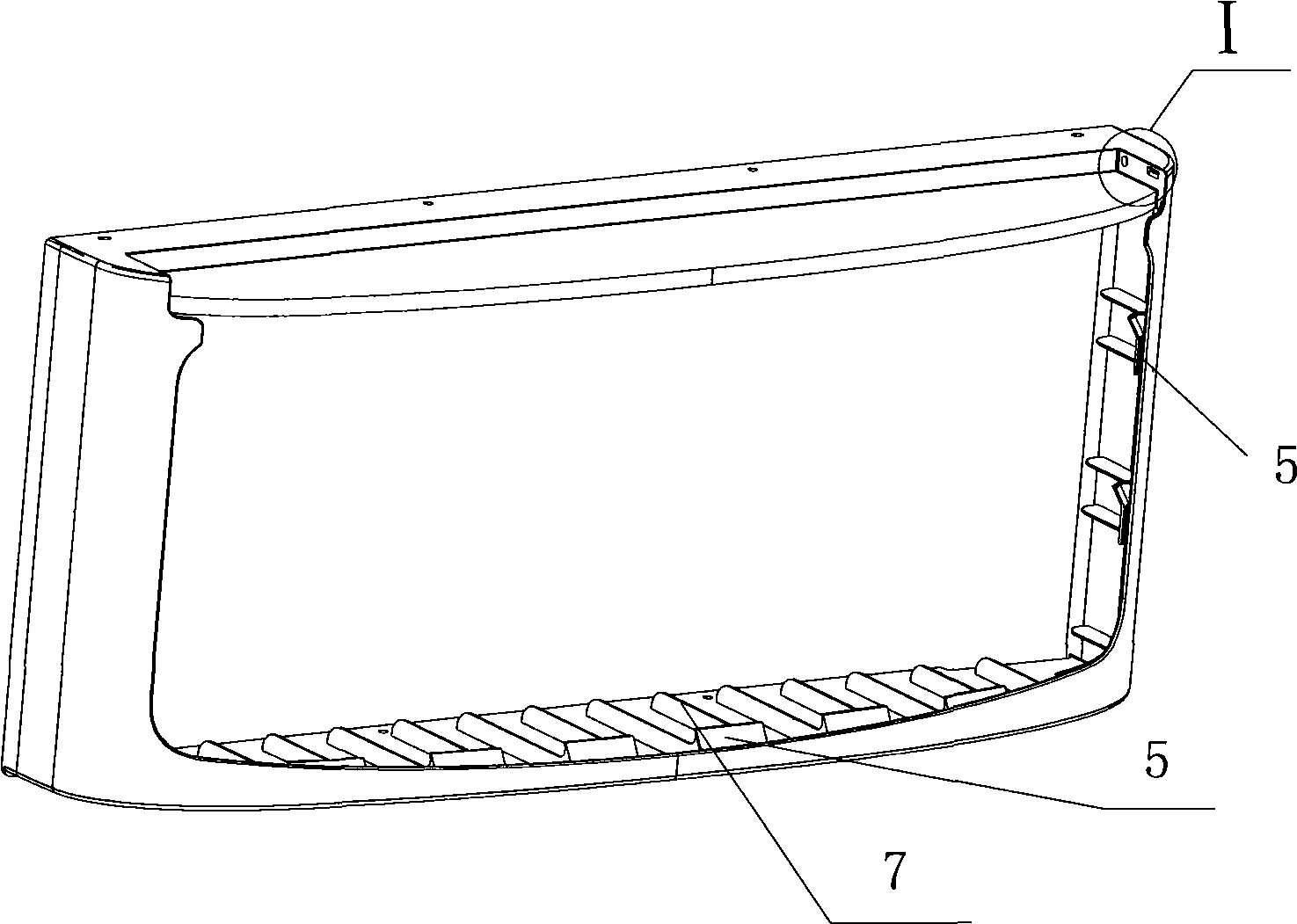

Lamp house apparatus of showcase

ActiveCN101509638AEasy to installImprove fastnessLighting applicationsProtective devices for lightingMechanical engineering

Owner:HISENSE HOME APPLIANCES GRP CO LTD +1

Preparation method of quartz ceramic product with complex structure

The invention discloses a preparation method of a quartz ceramic product with a complex structure. The preparation method comprises the steps that 1, high-purity fused quartz powder is mixed, lactic acid of which the mass accounts for 0.35%-0.42% of the mass of the quartz powder and sodium sesquicarbonate of which the mass accounts for 0.1%-0.2% of the mass of the quartz powder are added into the high-purity fused quartz powder, and the materials are stirred to be uniform to obtain mixed powder; 2, an adhesive of which the mass accounts for 10%-18% of the mass of the quartz powder in the step 1 is weighed and heated to be melted in a water bath, the mixed powder prepared in the step 1 is poured into the adhesive, and the materials are stirred to be uniform to obtain slurry; 3, the slurry prepared in the step 1 is injected into a mold, the slurry is subjected to temperature lowering through a cooling system of the mold to be cooled and solidified, and a molded blank is taken out; 4, the molded blank in the step 3 is heated until polyethylene wax and vaseline in the molded blank are completely evaporated or completely flow out, firing is conducted by increasing the furnace temperature to 1,050 DEG C-1,250 DEG C, heat preservation is conducted for 4-6 h, the molded blank is cooled along with a furnace, and then the needed quartz ceramic product is obtained.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Antigravity vacuum sucking cast process for preparing aluminium base composite material

InactiveCN1739890ASolve molding problemsImprove mechanical propertiesLiquid metalMechanical property

The antigravity vacuum sucking cast process for preparing aluminum base composite material in casting field includes the following steps: 1. heating to melt the composite material in crucible under the protection of inert gas and stirring; 2. shutting off inert gas, closing the middle partition board and vacuum pumping to refine; 3. finishing vacuum refining, introducing inert gas to crucible surface, and installing riser tube, mold cavity and sleeve; 4. vacuum pumping the mold cavity and antigravity filling liquid metal into the mold cavity; and 5. maintaining for crusting before increasing the pressure of inert gas to the lower cavity, feeding and solidifying composite material under the action of both vacuum in the upper cavity and the pressure of the lower cavity. The present invention raises the mechanical performance of aluminum base composite material casting, can form thin wall complicated aluminum base composite material casting, and has high production efficiency and high casting precision.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com