Reinforcing ribs contained sandwich structure composite material and its making method

A technology of sandwich structure and composite materials, which is applied in the field of composite materials, can solve problems such as structures and molding methods that have not been reported, and achieve the effect of increasing design space and reducing secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

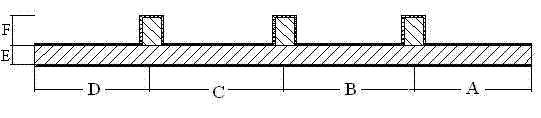

[0047] Below in conjunction with accompanying drawing this patent is further explained and illustrated. But the scope of protection of this patent is not limited to the specific implementation.

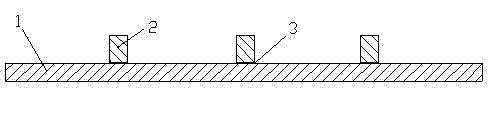

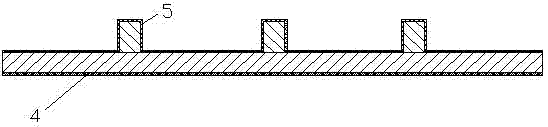

[0048] A sandwich structure composite material plate product containing reinforcing ribs, the cross-sectional dimensions of which are as follows image 3 As shown, the length is 1470mm. The core material of the sandwich structure adopts a density of 200kg / m 3 The polyvinyl chloride foam plastic, the inner mold of the reinforcing rib adopts 80 kg / m 3 polyvinyl chloride foam. Both the sandwich structure panel and the "Π" type reinforcement are made of glass fiber composite materials, the thickness of the sandwich structure panel is 2mm, and the composite material thickness of the "Π" type reinforcement is 6mm. The reinforcement material adopts surface density of 220g / m 2 The S glass fiber satin weave cloth, the matrix resin is vinyl ester resin with a viscosity of 240mPa·s at 25°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com