Compound large-resistance wind-tunnel strain balance

A strain balance and composite technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of insufficient resistance bearing capacity, difficult installation of the balance, and insufficient use of the inner cavity space of the model, so as to improve the bearing capacity. , Conducive to the effect of structure and layout optimization design, good practicability and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

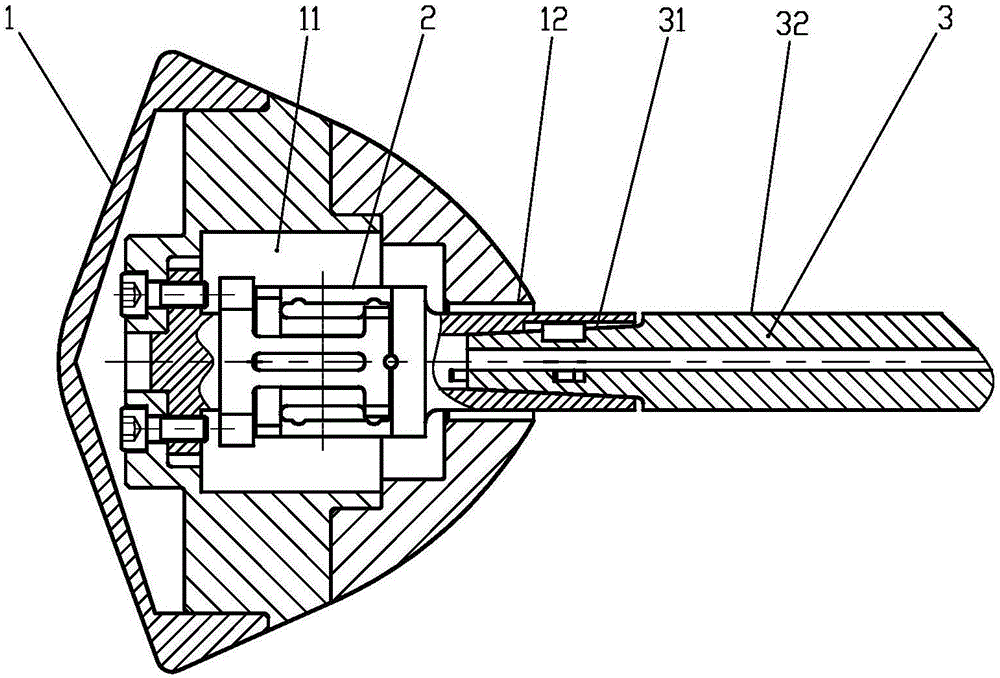

[0014] figure 1 It is an assembly schematic diagram of a compound large resistance wind tunnel strain balance of the present invention. A compound large-resistance wind tunnel strain balance of the present invention mainly includes a compound circuit balance 2 and a support rod 3. The compound circuit balance 2 is connected to the model 1 through a flange, and the square column is positioned. The large-resistance wind tunnel strain balance is matched with the strut through the taper surface, and the wedge is tensioned. The maximum diameter of the strain balance strut of the composite large-resistance wind tunnel is smaller than the minimum diameter inside the model cavity.

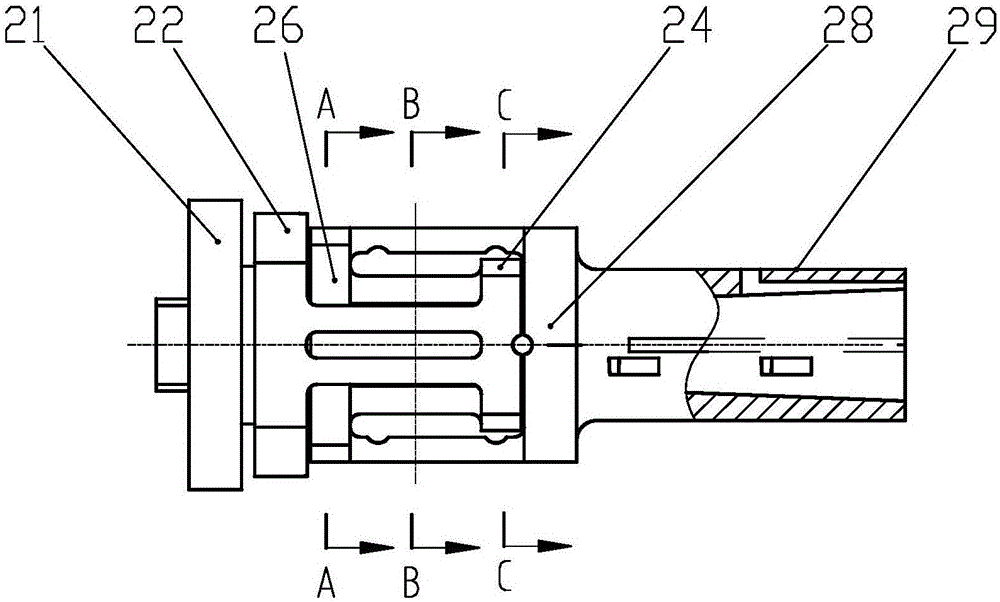

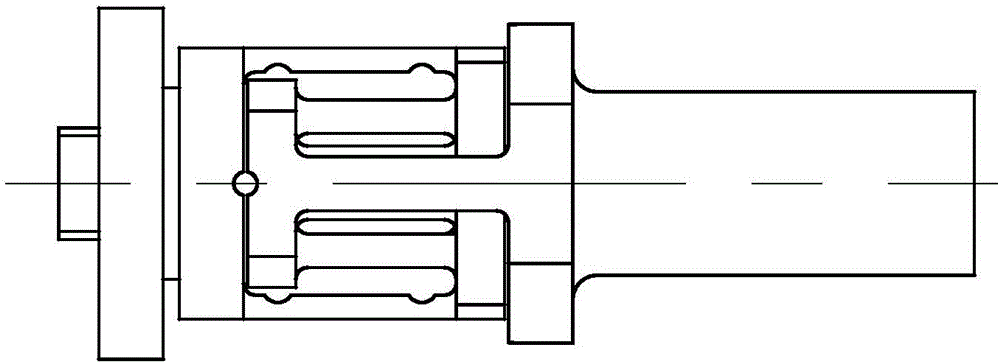

[0015] figure 2 It is a structural schematic diagram of the composite large-resistance wind tunnel strain balance of the present invention. image 3 yes figure 2 The top view of the composite large-resistance wind tunnel strain balance element is placed in the cavity 11 of the model, and six componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com