Patents

Literature

109results about How to "Reduce secondary processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

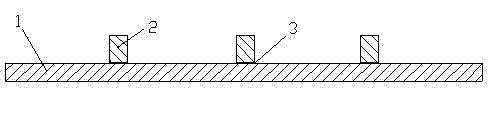

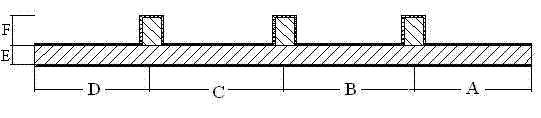

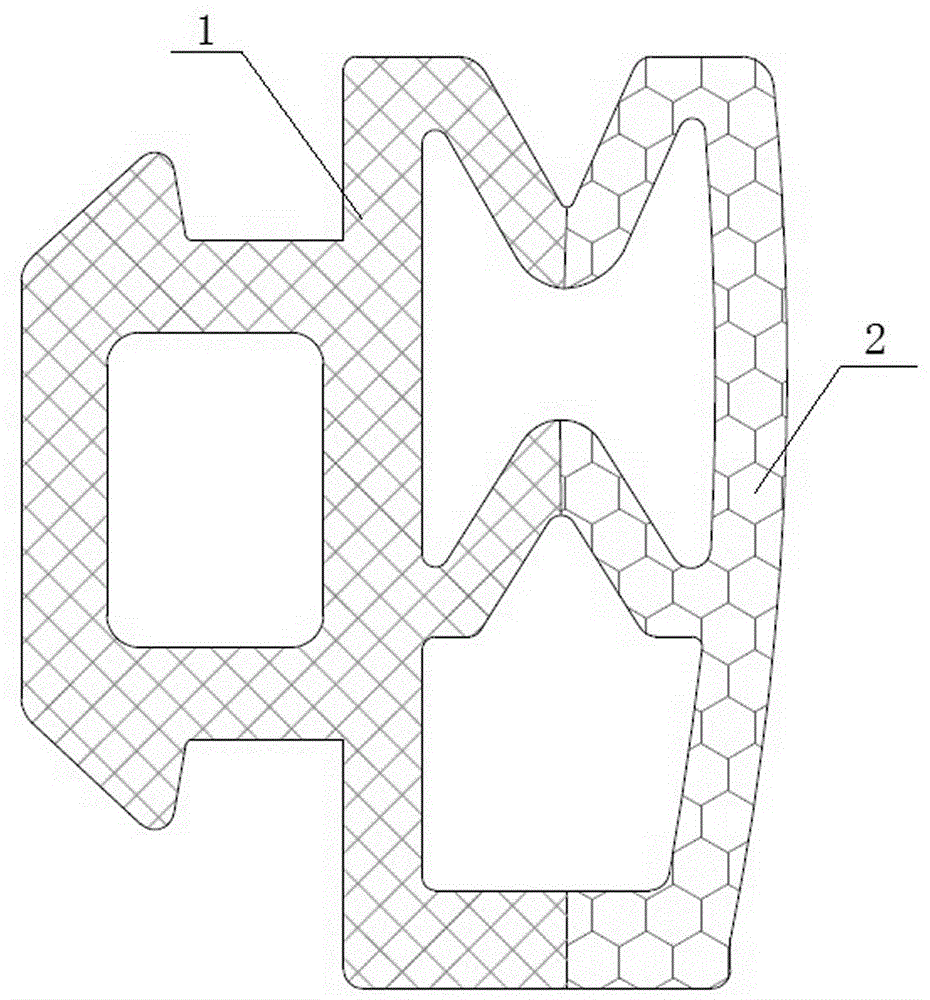

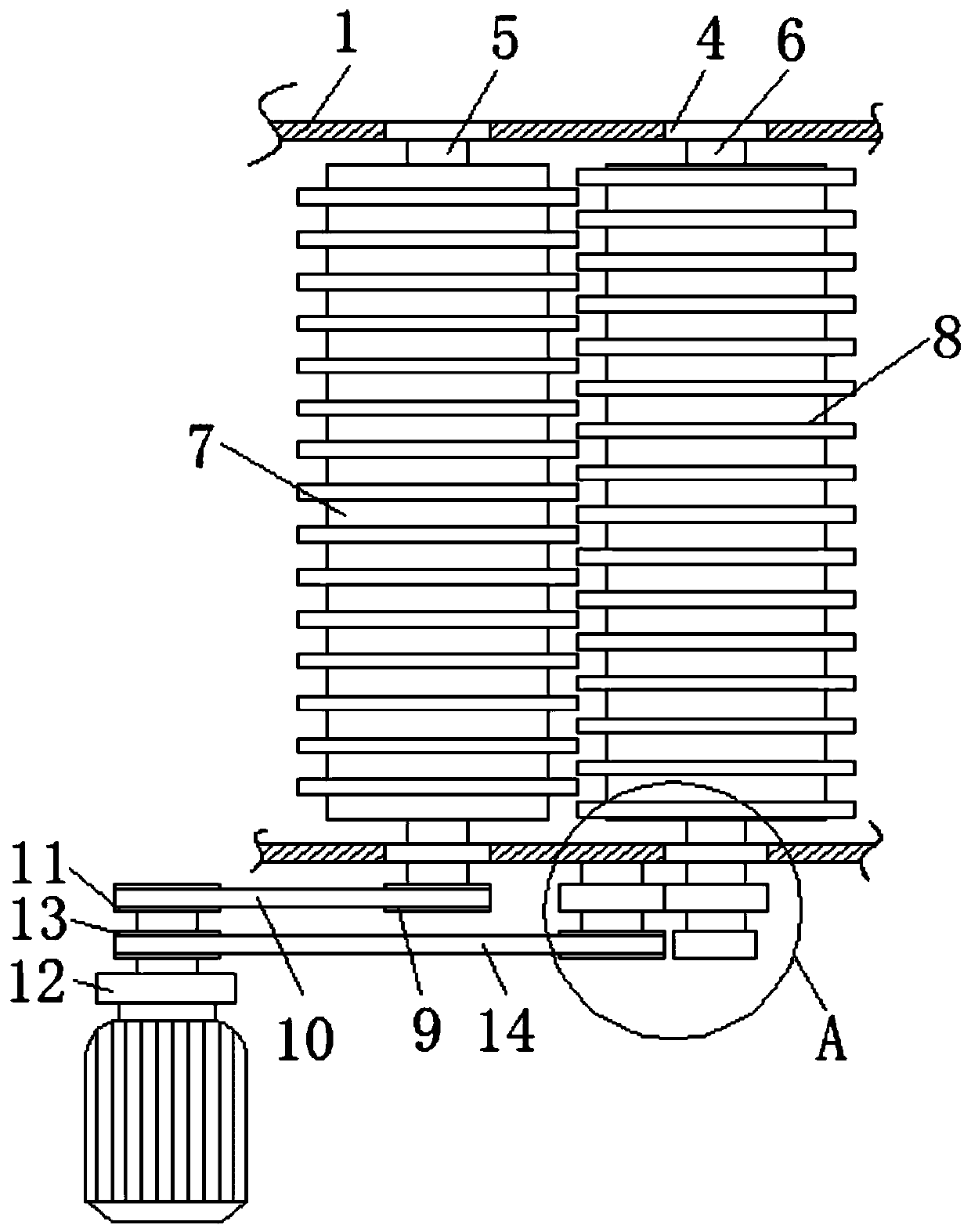

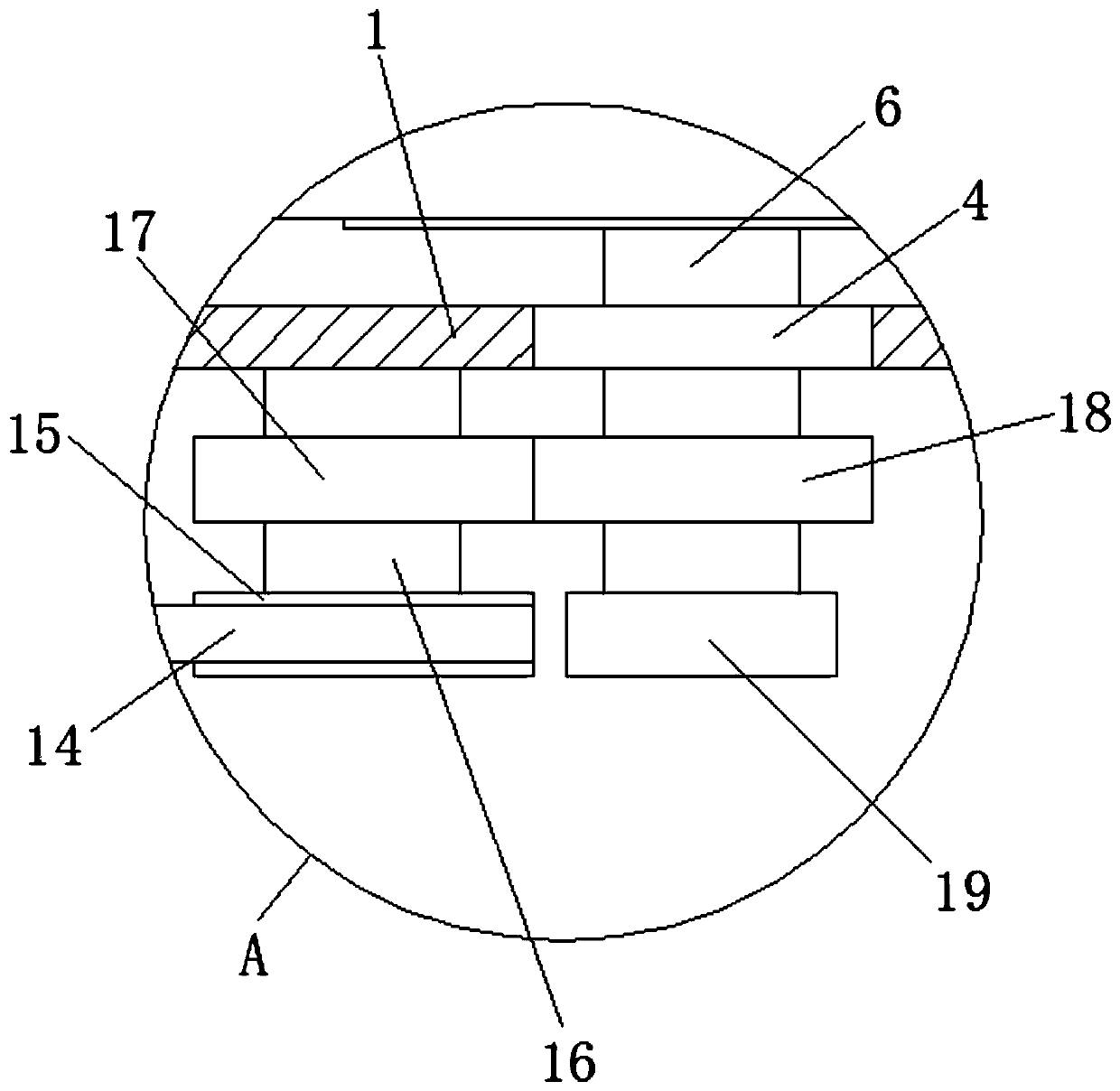

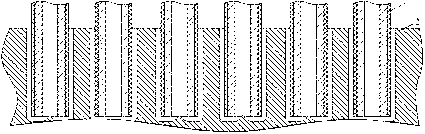

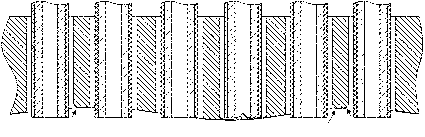

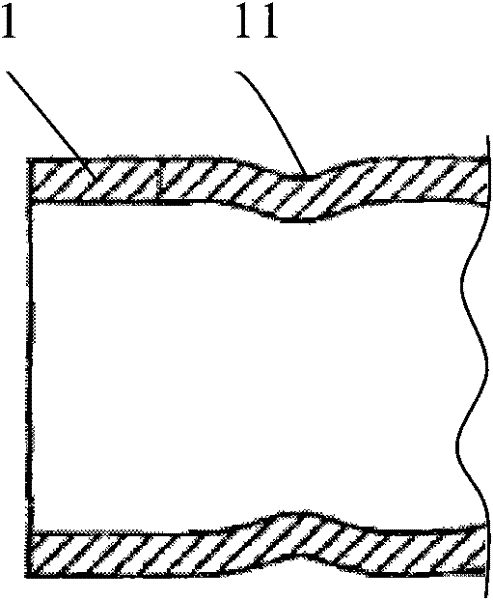

Reinforcing ribs contained sandwich structure composite material and its making method

The invention discloses a reinforcing ribs contained sandwich structure composite material and its making method. The composite material is composed of an internal core material, reinforcing ribs, and a one-time-formed fiber fabric reinforced resin composite material layer, wherein the internal core material is a lightweight buoyancy material having a compressive strength of above 0.5MPa; each of the reinforcing ribs is formed by a lightweight material internal model connected with the internal core material through an adhesive, and a fiber fabric layer coated on the external surface of the lightweight material internal model; the fiber fabric is a glass fiber, a carbon fiber, a Kevlar fiber, an ultrahigh molecular weight polyethylene fiber or a basalt fiber; and a resin is a cured substance of a polyester resin, a vinyl resin, an epoxy resin, a phenolic resin and the like. The making method has the advantages of one-time-forming of a product having the reinforcing ribs and the sandwich structure, increase of the rigidity design space of the composite material, reduction of sequent secondary processing, reduction of the defect appearance possibility, scarce generation of the volatilization of harmful gases, and personnel health protection.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

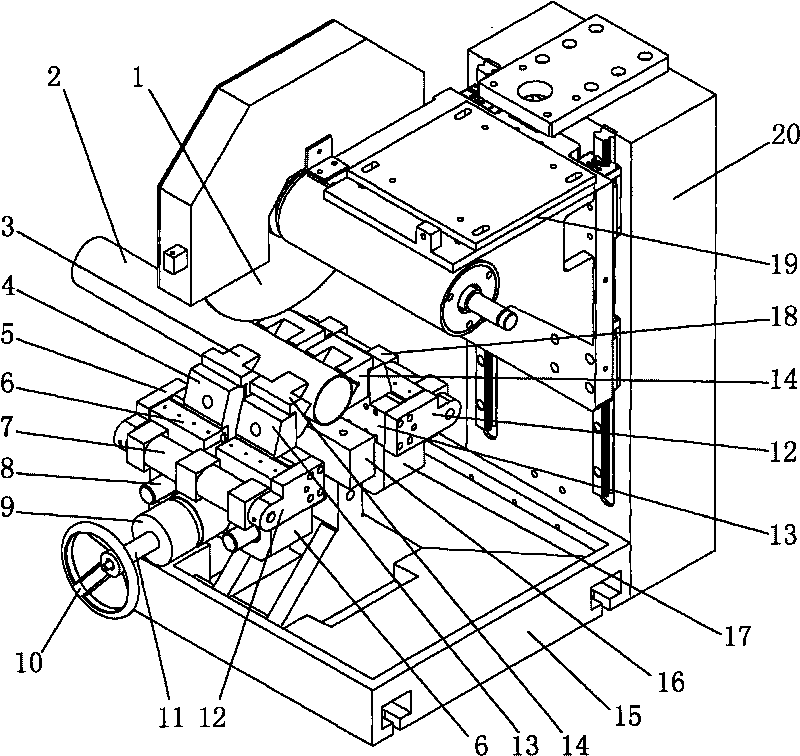

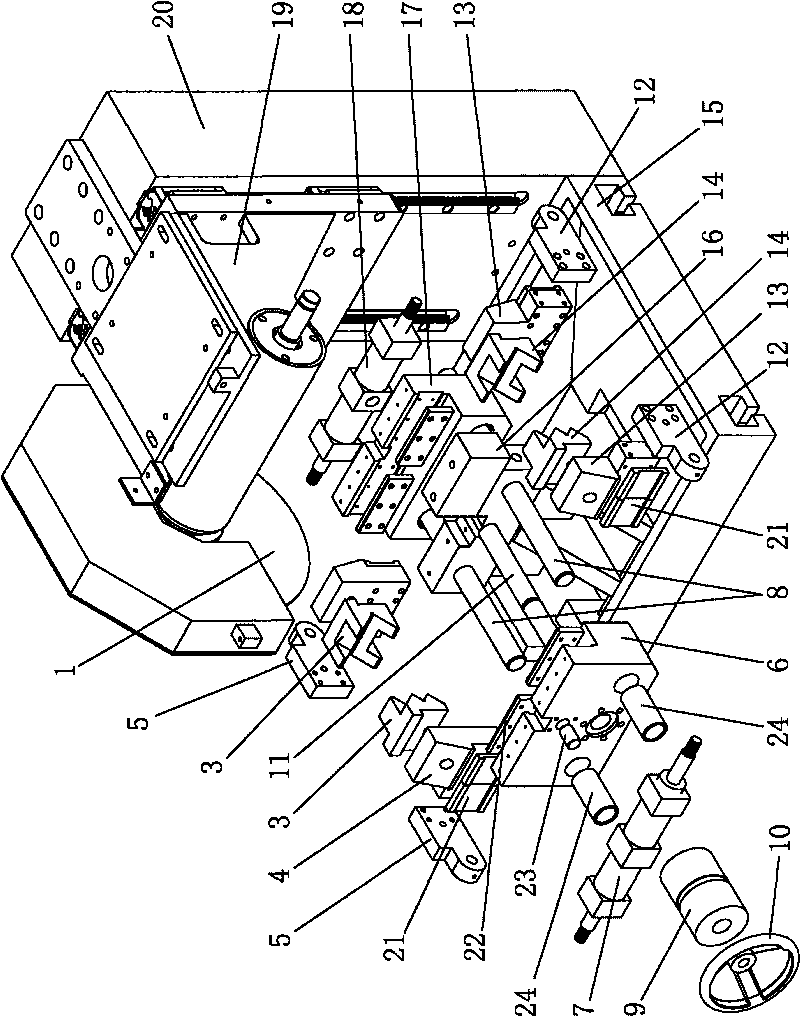

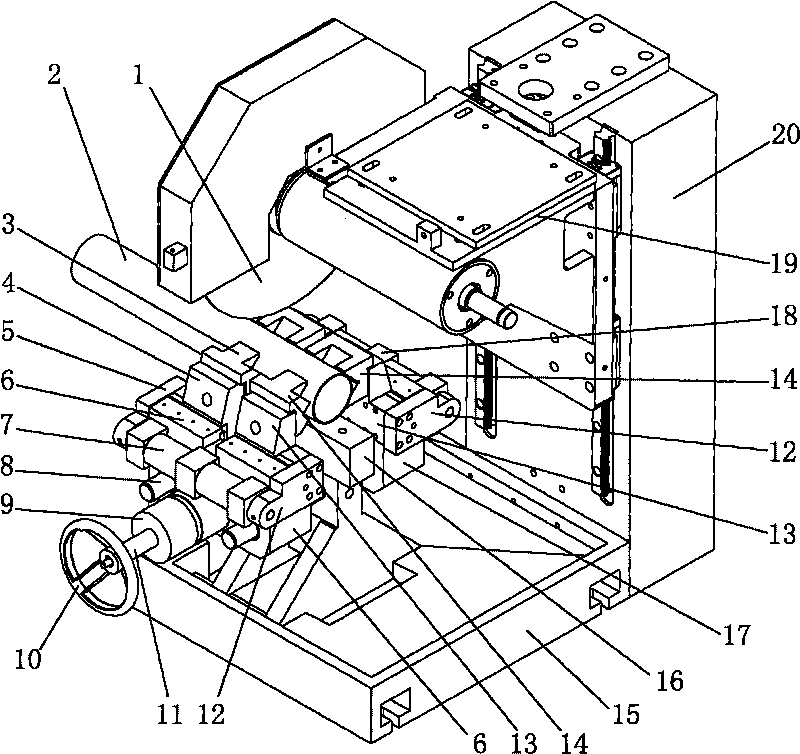

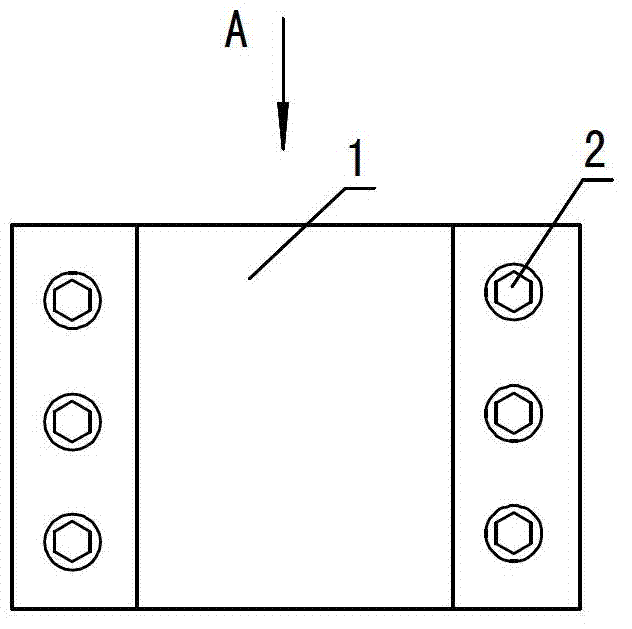

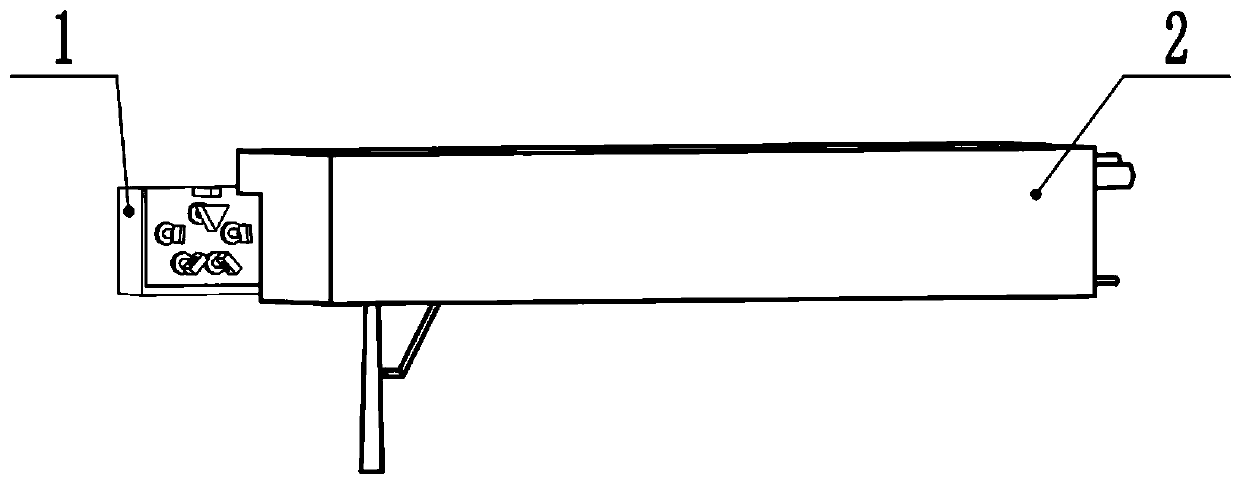

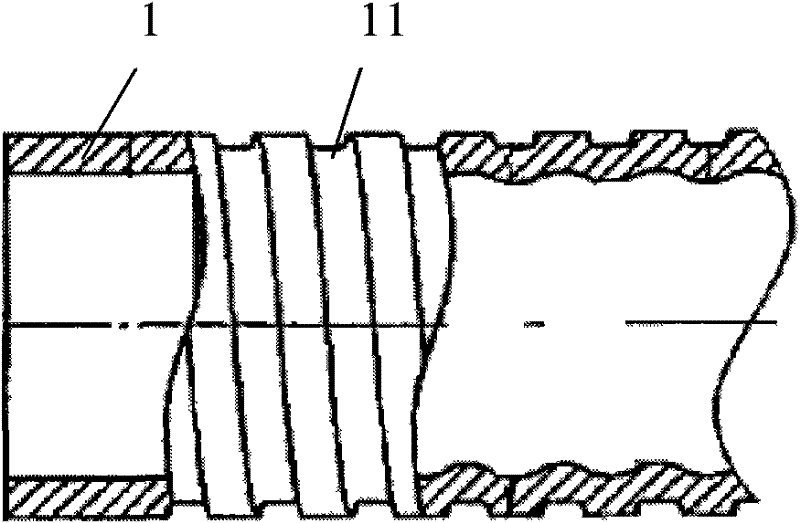

Automatic cutter relieving mechanism

InactiveCN101704130AReduce secondary processingExtended service lifeMetal sawing devicesEngineeringMachining

The invention discloses an automatic cutter relieving mechanism, which comprises a main clamp screw, a front main clamp body, a rear main clamp body, a clamping cylinder, a left clamp claw and a right clamp claw, wherein a front single claw and a rear single claw of the left clamp claw and the right clamp claw are slidingly connected with the front main clamp body and the rear main clamp body; and the left clamp claw and the right clamp claw are driven to move by driving mechanisms fixed on the front main clamp body and the rear main clamp body. The automatic cutter relieving mechanism comprises the technical scheme that: the driving mechanisms automatically move away two part materials which are cut off leftwards and rightwards, and leave a left gap and a right gap for making a saw blade lift or transverse and the like to retreat from a material position so as to avoid the saw blade contacting the materials and scratching (or galling) the fracture surfaces of the materials in the process of leaving the materials, to improve surface accuracy of a cut-off surface, to omit secondary machining of the fracture surfaces of the cut-off materials, and to improve the service life of the saw blade. The automatic cutter relieving mechanism has the advantages of reasonable structure, high machining accuracy, good stability, reliable operation, convenient adjustment and the like.

Owner:ZHEJIANG KING MAZON MACHINERY

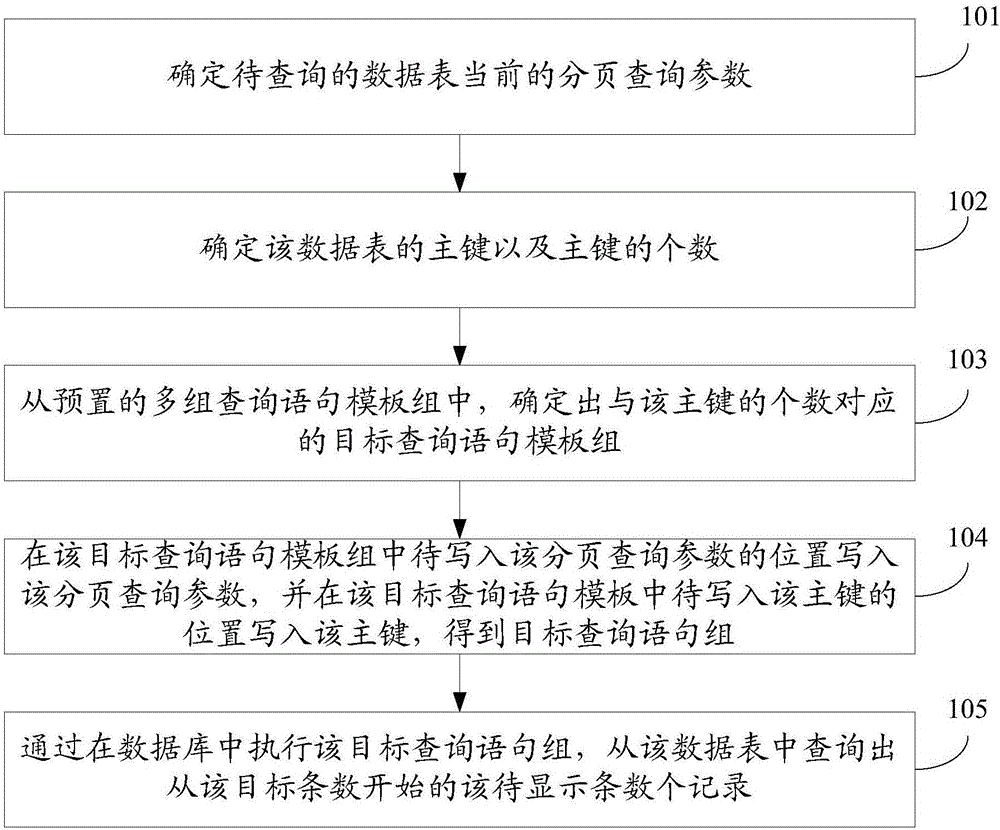

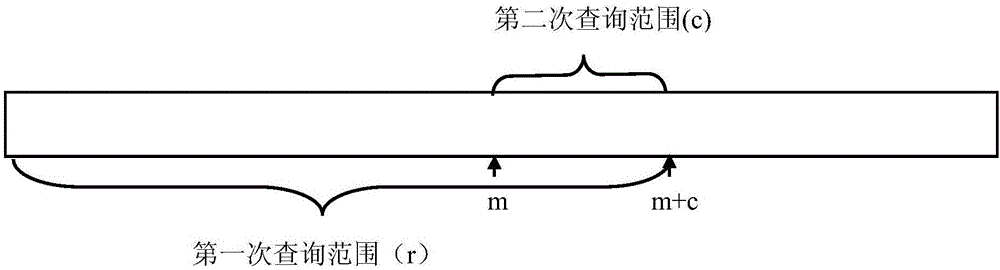

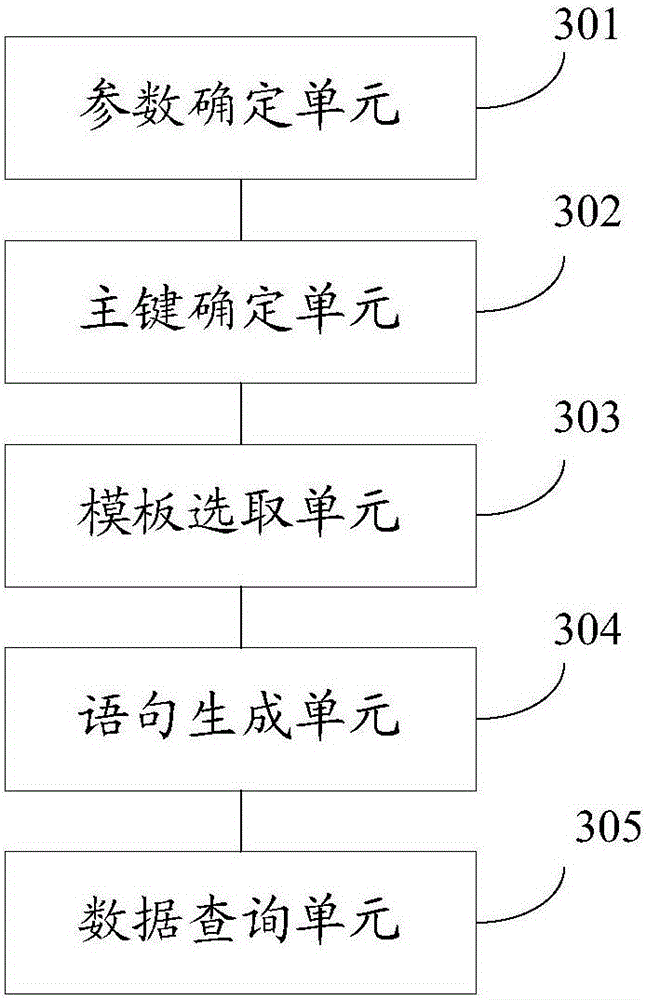

Data paging query method and device

ActiveCN106227894AReduce data volumeAvoid secondary processingRelational databasesSpecial data processing applicationsPagingQuery statement

The invention provides a data paging query method and device. The method includes the steps: determining current paging query parameters of a data table to be queried; determining main keys and the number of the main keys of the data table; determining target query statement template groups corresponding to the number of the main keys from preset multi-group query statement template groups; writing the paging query parameters at the positions with the paging query parameters to be written in the target query statement template groups, writing the main keys at the positions with the main keys to be written in target query statement templates to obtain target query statement groups; executing the target query statement groups in a database and querying a plurality of entry records to be displayed from target entry records in the data table. The paging query parameters comprise current paging number of branches to be displayed, query conditions and of target number of branches of initial query. By the method and the device, network resources and data processing resources consumed by data paging can be reduced.

Owner:AGRICULTURAL BANK OF CHINA

Cosolidation with sludge dredging and water draining

InactiveCN1818222AEasy constructionEasy to operateFoundation engineeringLand reclamationSoil treatmentSludge

This is a quick damming method suitable for yielding soil treatment composed by several layers of sullage and sand. At building, a layer of sullage is dumped then a layer of sand. Sand will sink into sullage by gravity to increase sullage penetrability. The procedure is repeated till reach the designed height. Put loading, like water bag, to the dam top to move out water and solidify.

Owner:SOUTHEAST UNIV

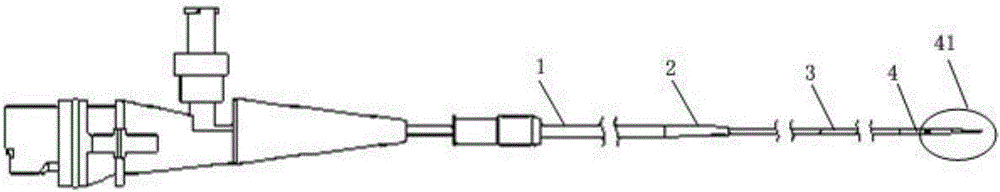

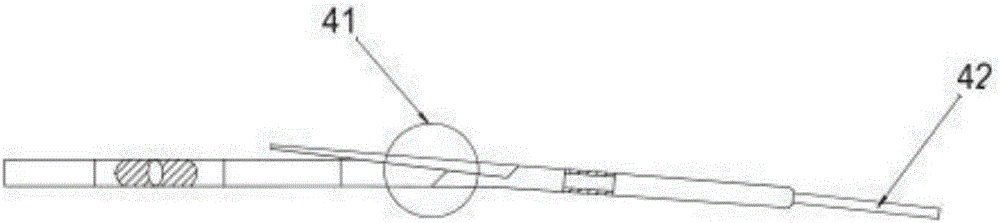

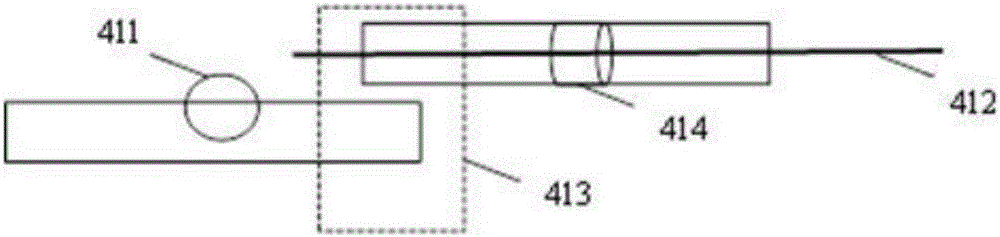

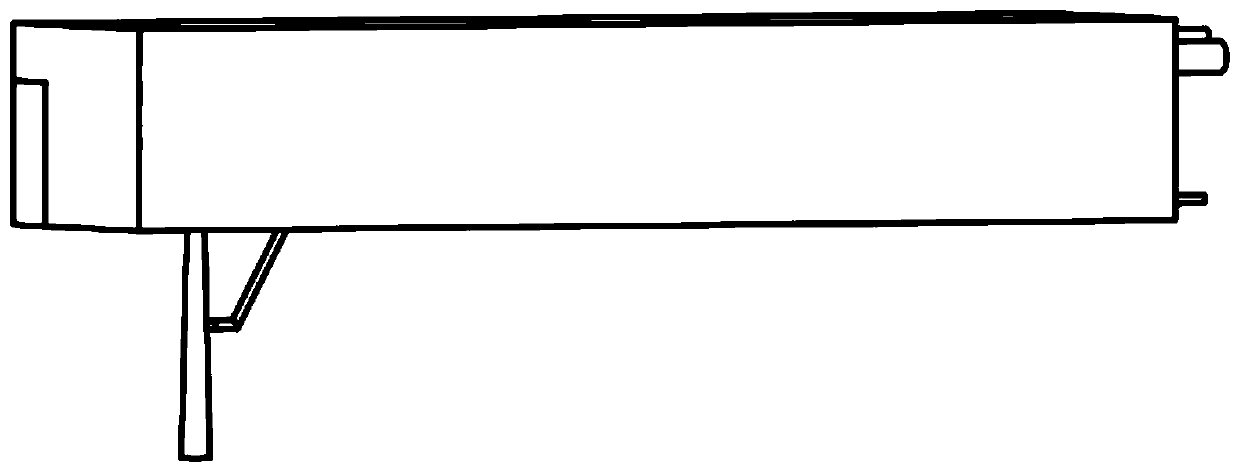

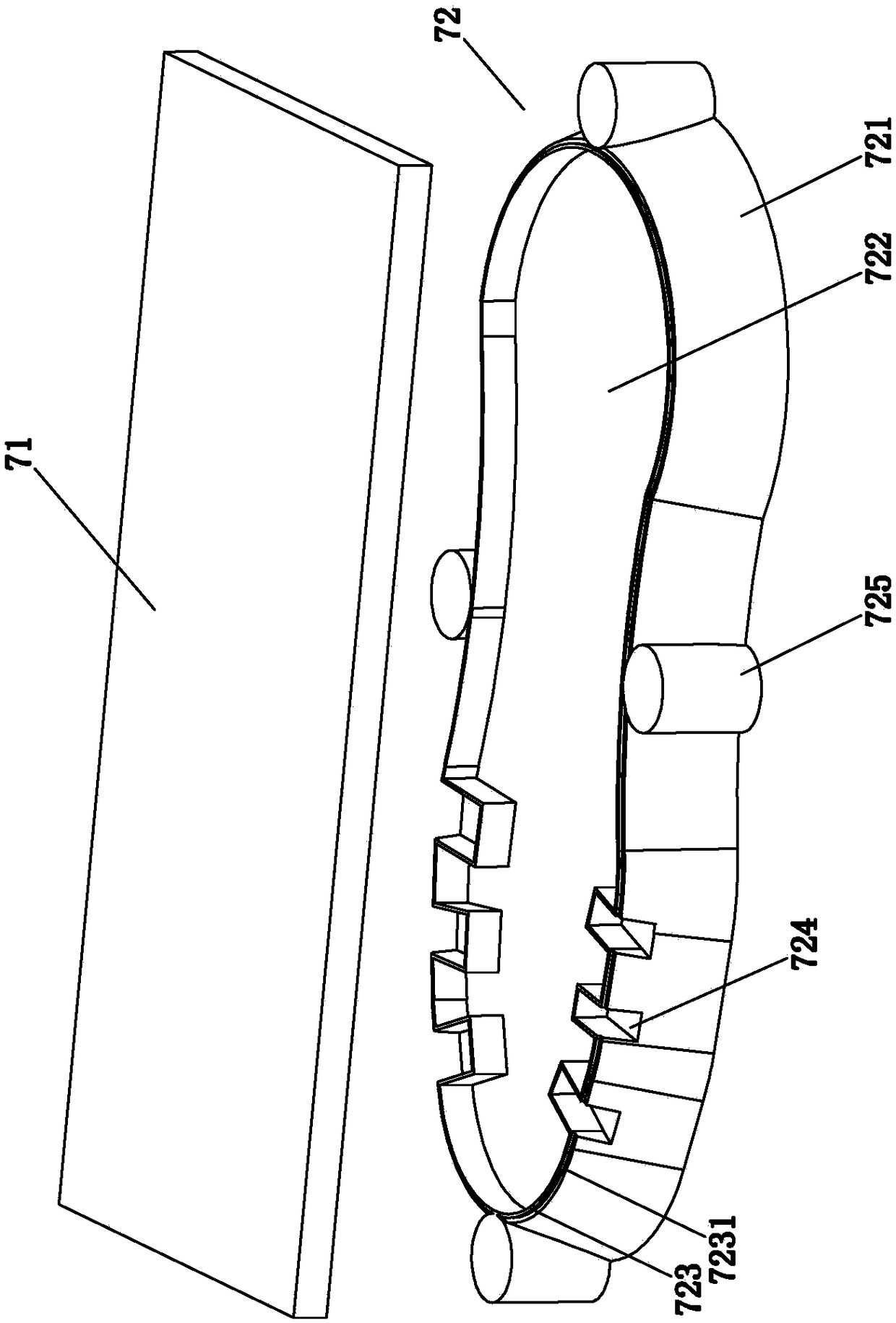

Intravascular ultrasound catheter and rapid forming method thereof

ActiveCN105147336AEasy to produceIncrease productivityOrgan movement/changes detectionSurgerySurgical riskTransducer

The invention discloses an intravascular ultrasound catheter and a rapid forming method thereof. The catheter comprises a sleeve tube which is of a one-time formed structure. A transducer with a rotation driving wire is arranged at the far end of the sleeve tube, and the near end of the sleeve tube is connected with a driving / retreating device. A wire guide opening is formed in the far end of the sleeve tube. The method includes the steps that the sleeve tube is formed through a one-time forming method; the wire guide opening is formed in the far end of the sleeve tube. According to the intravascular ultrasound catheter and the rapid forming method thereof, the one-time forming method is used for forming the sleeve tube, production efficiency is greatly optimized, production cost is lowered, no connecting section exists, the reliability of the catheter is improved, and surgical risks are reduced.

Owner:上海爱声生物医疗科技有限公司 +1

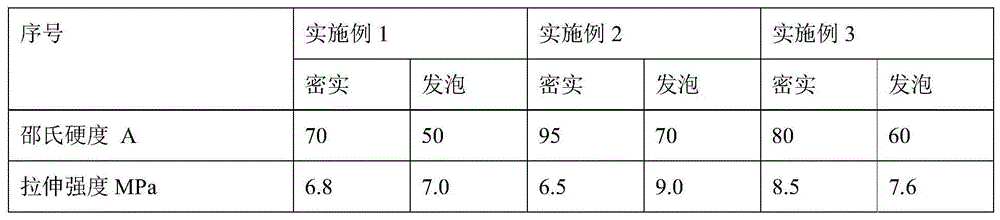

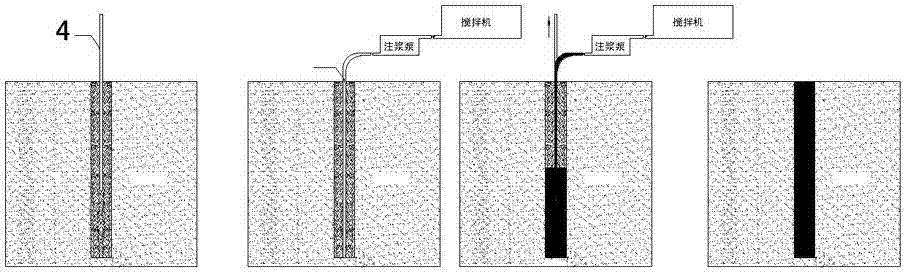

Soft-hard co-extrusion composite silicone rubber strip

The invention discloses a soft-hard co-extrusion composite silicone rubber strip, the composite silicone rubber strip is composited by dense mixed stock film and foaming mixed stock film; the dense mixed stock film comprises the following components by weight part: 100 parts of dense mixed stock, 1-3 parts of vulcanizing agent and 0.5-1.5 parts of masterbatch; the foaming mixed stock film comprises the following components by weight part: 100 parts of foaming mixed stock, 2-5 parts of vulcanizing agent, 1-3 parts of masterbatch and 1-4 parts of foaming agent. The installation part of the soft-hard co-extrusion composite silicone rubber strip is dense glue with high hardness and fixed size, fixing is convenient, and installation is easy, the sealing part is foaming glue with good elasticity and rapid rebound performance, and has advantages of high compression ratio and good sealing performance, and sealing performance of door and window can be increased.

Owner:浙江凌志新材料有限公司

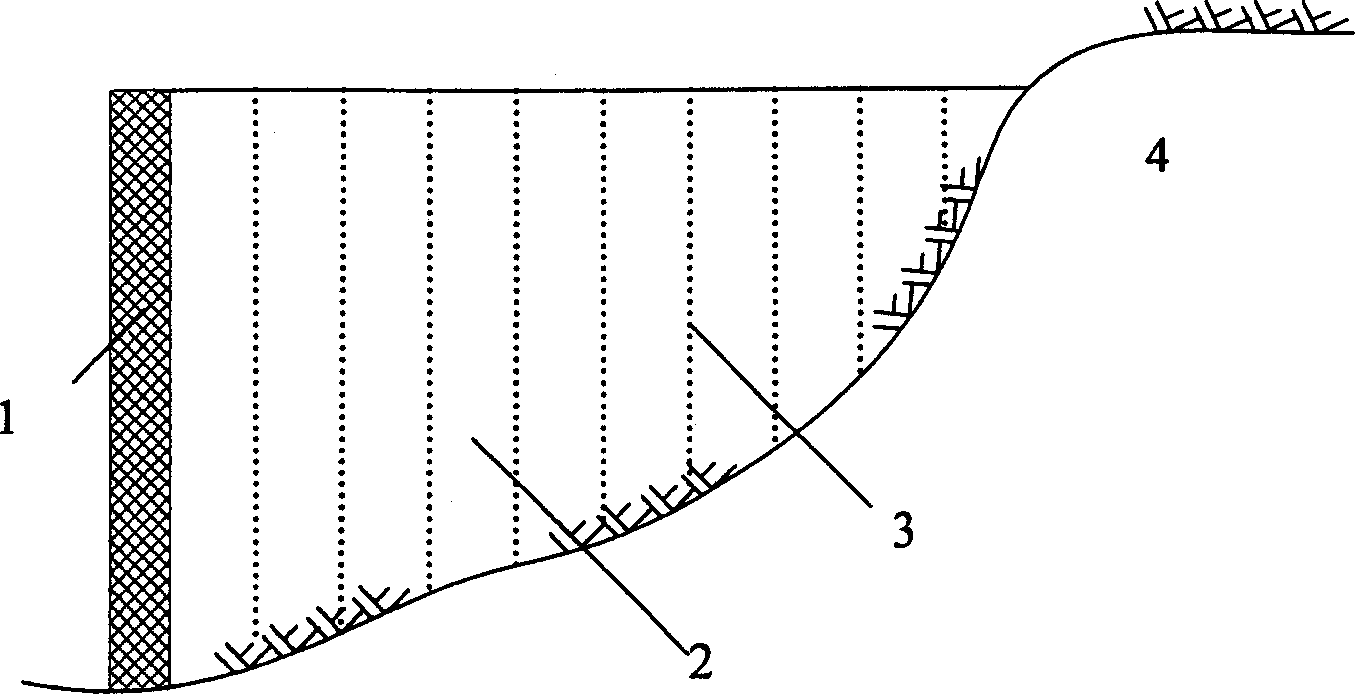

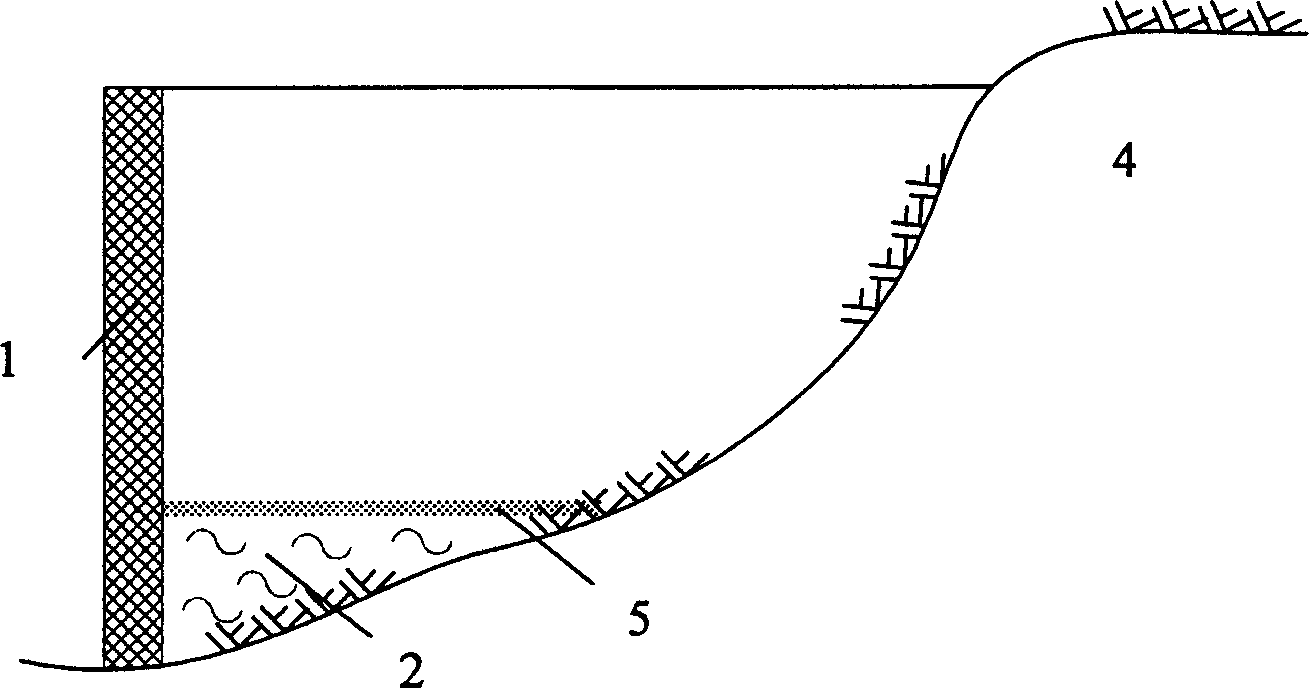

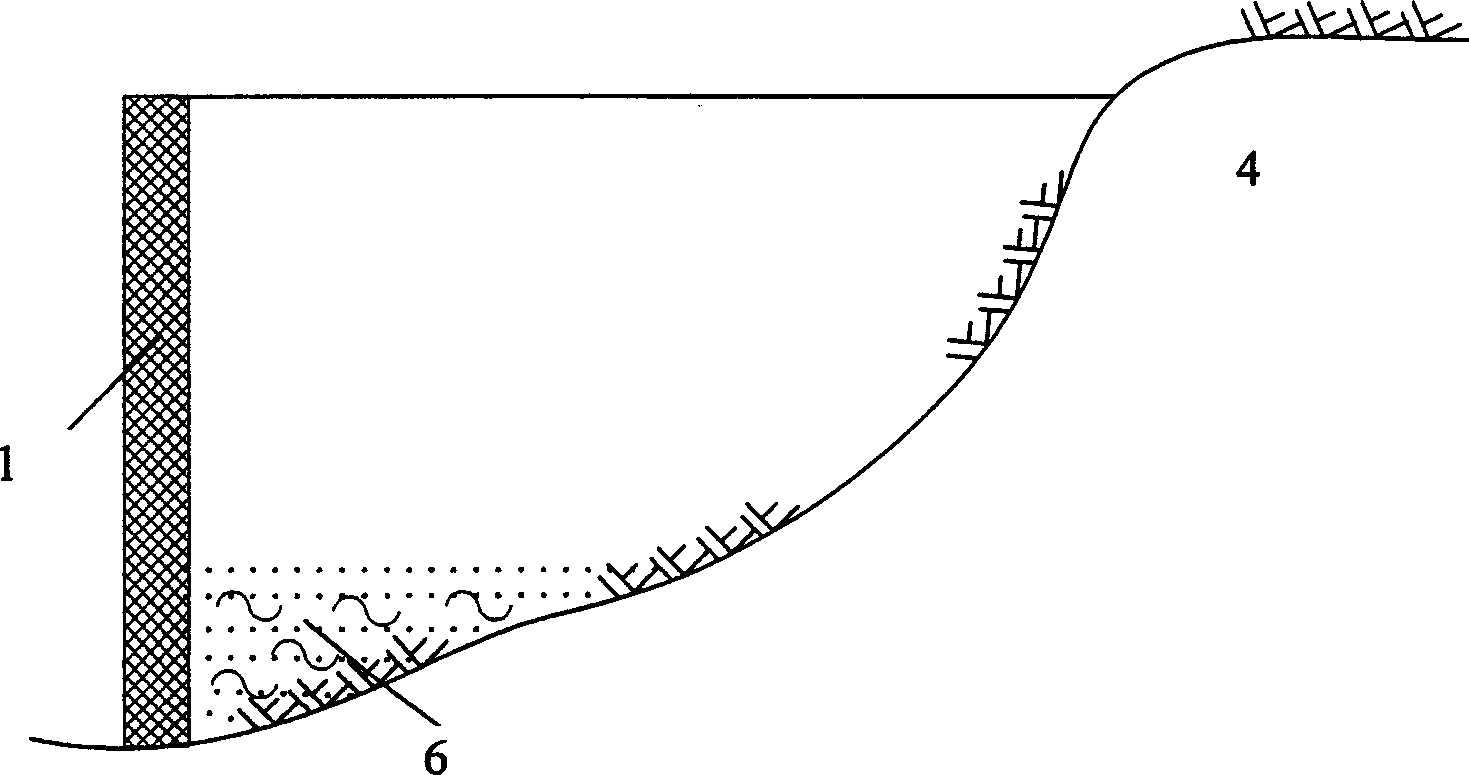

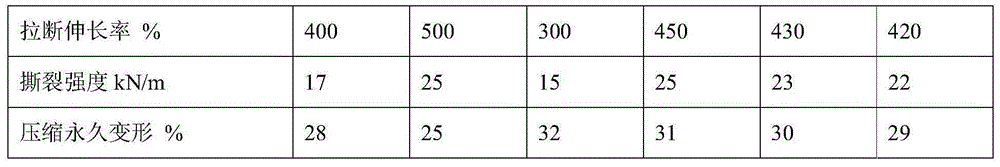

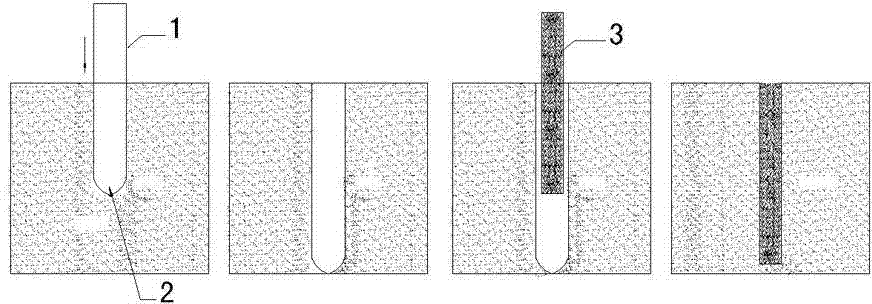

Formation method of straw solidifying and blow-filling sludge pile

InactiveCN104762949AImprove bearing capacityLow costBulkheads/pilesSoil preservationSludgeEngineering

The invention relates to a formation method of a straw solidifying and blow-filling sludge pile. The method comprises the steps of 1) downwards vertically inserting a bottom cover of a hollow metal pipe with the bottom cover into sludge, filling straws into the hollow metal pipe, and drawing out the hollow metal pipe from the sludge to enable the straws to form lengthways-arranged straw draining body in the sludge; 2) arranging a transverse draining body in the sludge; 3) paving a layer of sealing films on the surface of the sludge, and then pre-pressing in vacuum and solidifying; 4) inserting a hollow metal grouting pipe into each straw draining body, pumping solidifying material agitating mortar into each hollow metal grouting pipe until the solidifying material agitating mortar overflows out of a straw pile, and then drawing out each hollow metal grouting pipe from each straw draining body to form the sludge pile. According to the method, the vertical straw draining bodies for solidifying and blowing-filling sludge are utilized and grouted to form a pile body, so that the blow-filling sludge bearing capacity can be further improved after the solidifying and blowing-filling of the sludge, and the purpose of reinforcing a blow-filling sludge foundation is achieved.

Owner:江苏禾吉新材料科技有限公司

Composite casting technology

The composite casting process includes the following steps: 1. designing twice or more than twice pouring casting size; 2. casting out primary poured casting; 3. making pattern for secondary pouring on the primary poured casting surface of surface of damaged metal component; 4. moulding sand mould for pouring; 5. using primary poured casting or damaged metal component and secondary pouring sand mould to form mould cavity for secondary pouring; 6. feeding them into drying kiln and drying sand mould; 7. after the sand mould is heated, taking out the sand mould from kiln, maing secondary pouring; and 8. cleaning sand mould material from casting system.

Owner:国成军

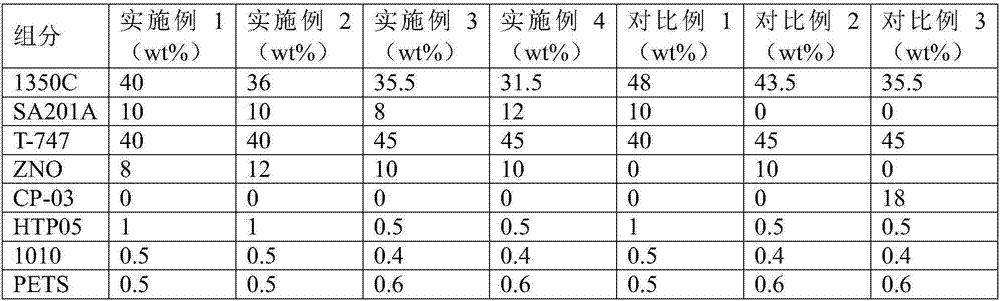

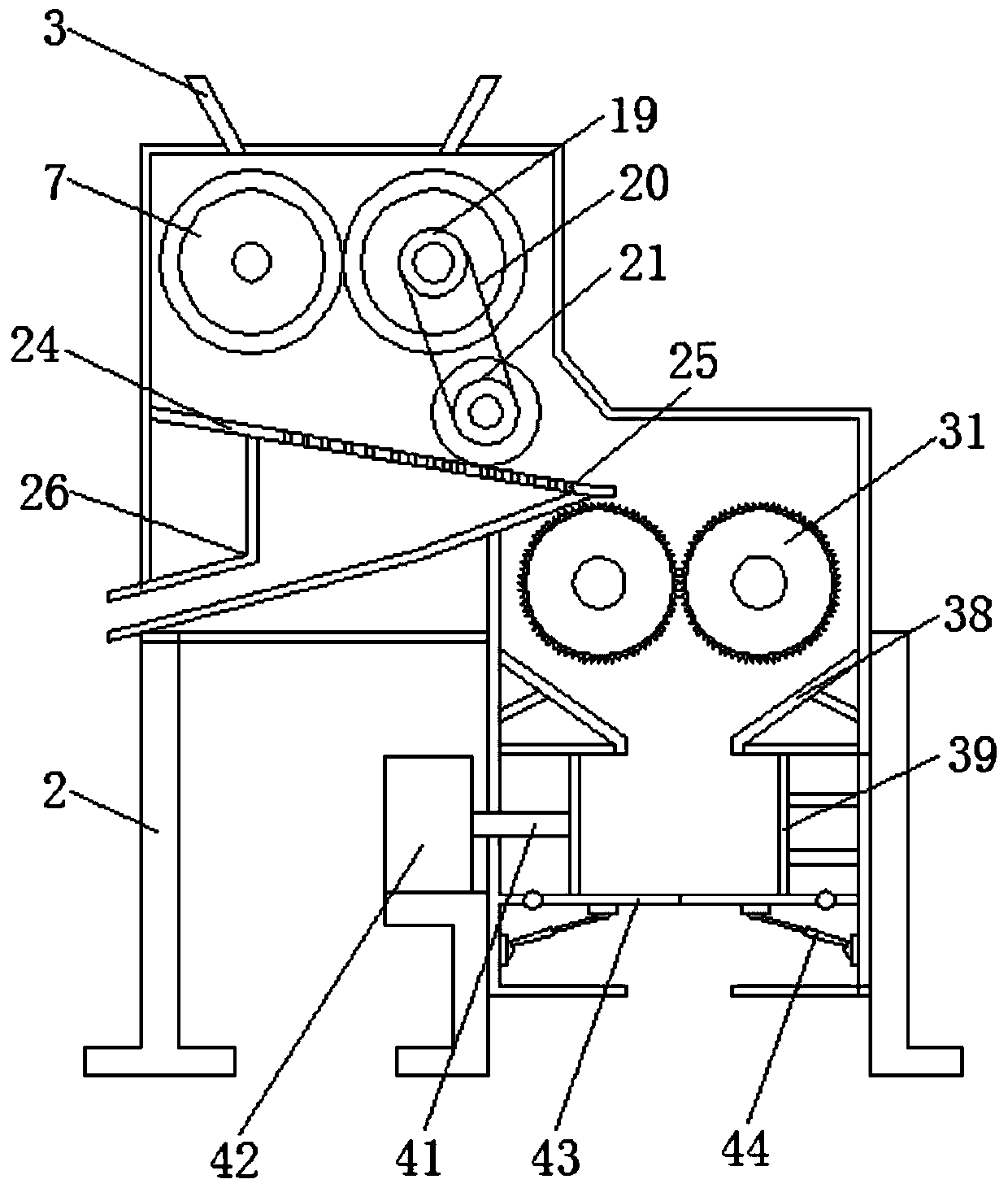

Antimicrobial low-warpage low-flash PPS composite material and preparation method thereof

The invention discloses an antimicrobial low-warpage low-flash PPS composite material and a preparation method thereof. The material is prepared from, by weight, 31.5-48% of PPS resin, 6-12% of PPE resin, 40-45% of glass fibers, 8-12% of antimicrobial agent, 0.5-1% of nucleating agent, 0.4-0.5% of antioxidant and 0.5-0.6% of lubricating agent. An engineering plastic, namely PPS, serves as a main body, the PPE resin, the glass fibers, the antimicrobial agent, the nucleating agent the antioxidant and the lubricating agent are added, the raw materials are mixed together and melted through a double-screw extruder, and then the antimicrobial low-warpage low-flash PPS composite material which is capable of meeting the antimicrobial requirements of household appliances is prepared. The material has the advantages of being antimicrobial, low in warpage and low in flash on the basis of ensuring the original excellent mechanical performance, heat resistance, fire resistance and electrical performance of PPS.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

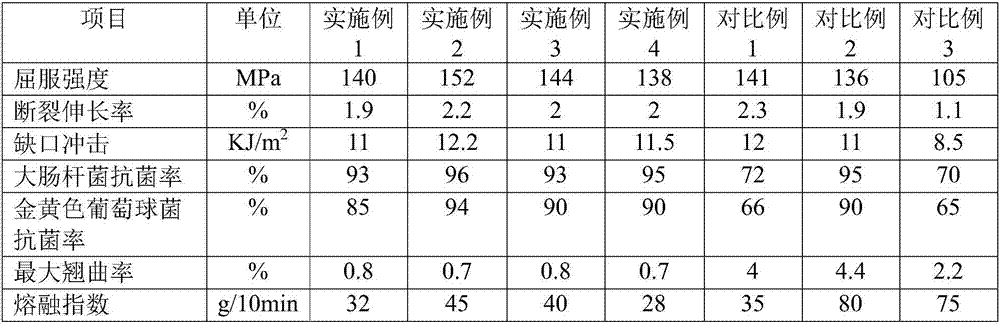

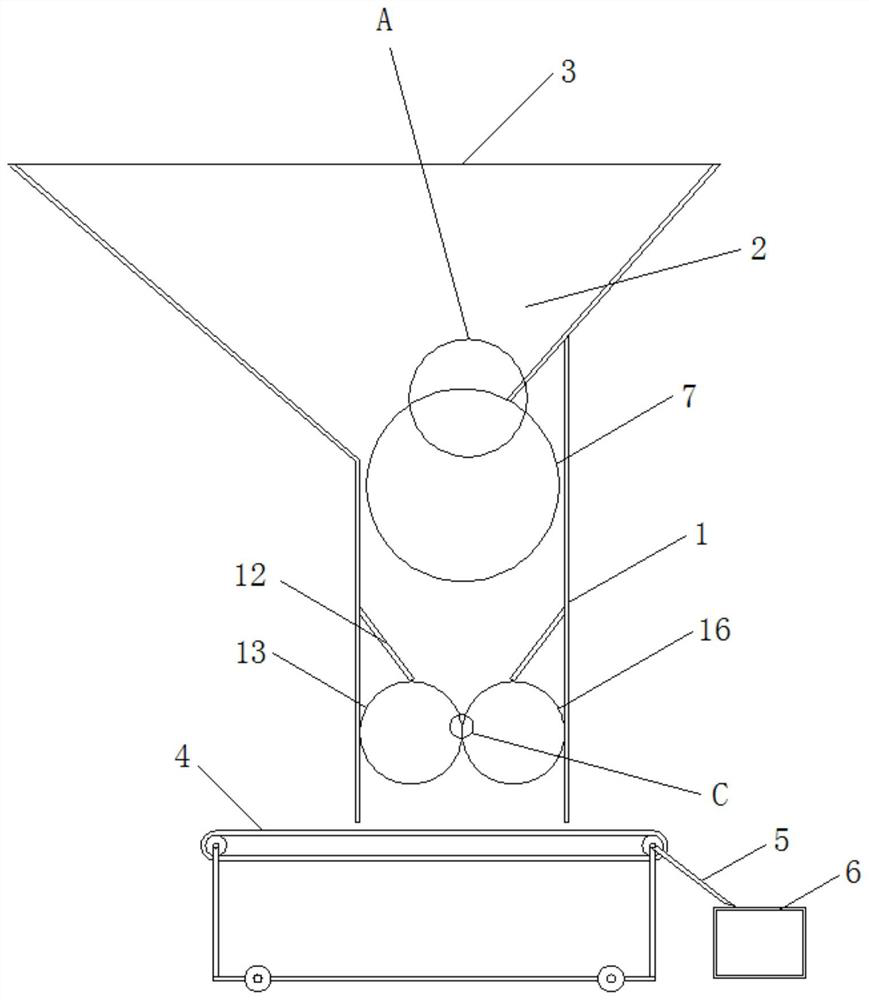

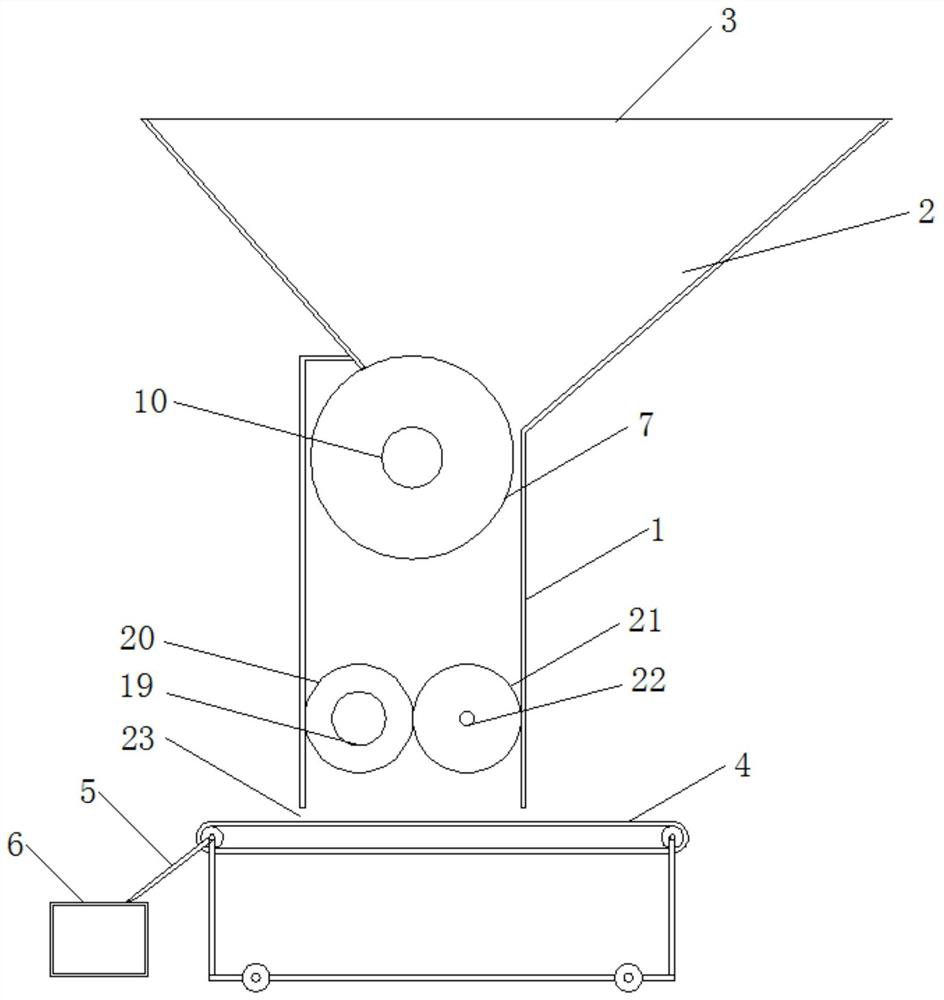

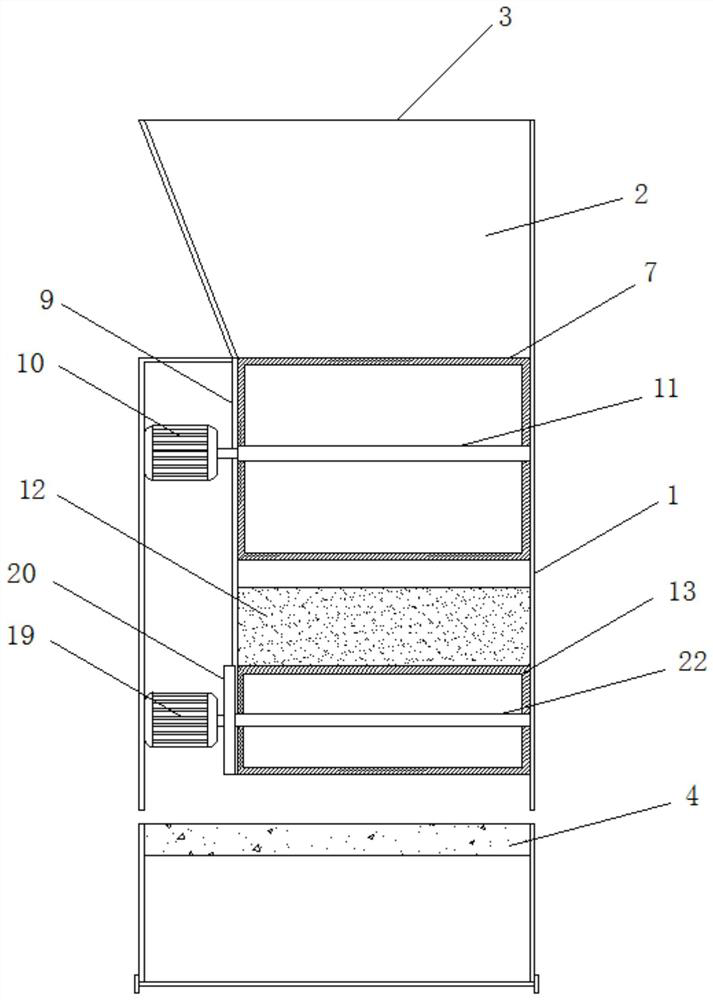

Waste plastic crushing and compressing recovery device based on sprocket driving principle

InactiveCN110625859AReduce storage and transportation spaceSmall footprintPlastic recyclingMechanical material recoveryEngineeringSprocket

The invention relates to the technical field of plastic recovery, and discloses a waste plastic crushing and compressing recovery device based on a sprocket driving principle. The device comprises a shell, wherein a support frame is fixedly welded to the outer portion of the shell, the top of the shell is fixedly connected with a feeding hopper, the inside of the shell is fixedly connected with acutting wheel bearing, the interior of the cutting wheel bearing is movably connected with a first cutting wheel shaft and a second cutting wheel shaft, the outer portions of the first cutting wheel shaft and the second cutting wheel shaft are fixedly connected with a first cutting wheel and a second cutting wheel respectively, the outer portion of the first cutting wheel shaft is fixedly connected with a first transmission wheel, through cooperation between the first cutting wheel and the second cutting wheel, the effect of primarily waste plastic crushing is achieved, the storage transportation space of bottles is reduced, the storage transportation cost is reduced, residual liquid in the bottles can be discharged, the space occupied by the liquid is reduced, the pollution of the liquidis avoided, the storage transportation cost is reduced, and the recovery degradation cost is recycled.

Owner:毛思静

Surface treatment process for aluminum plate

InactiveCN105951150AImprove corrosion resistanceImprove flatnessAnodisationMetallic material coating processesElectrolysisStain

The invention discloses a surface treatment process for an aluminum plate. The surface treatment process comprises the following steps: (1) putting the surface of the aluminum plate in a soaking tank, performing 2 minute soaking treatment by using a soaking agent of 32 DEG C, thoroughly washing the soaked surface of the aluminum plate by using clear water, and then gently wiping the washed surface of the aluminum plate by using clean soft cloth; (2) putting the aluminum plate treated in step (1) in an electrolyte, and performing electrolysis with iron as a cathode and the treated aluminum plate as an anode; (3) cleaning the aluminum plate treated in step (2) by using deionized water of 18 DEG C, and then gently wiping up water stains on the surface of the treated aluminum plate by using the clean soft cloth; (4) putting the aluminum plate treated in step (3) in a passivating solution of 22 DEG C for 82-88 second passivating treatment; (5) thoroughly washing the aluminum plate subjected to the passivating treatment by using deionized water; and (6) spraying paint. In the same using environment, the service life of the aluminum plate subjected to the surface treatment process provided by the invention is 1.2 times longer than that of a common aluminum plate. By adoption of the surface treatment process, the service life of a coating formed by the paint can reach 7-9 years.

Owner:JINYU METAL MATERIALS CO LTD

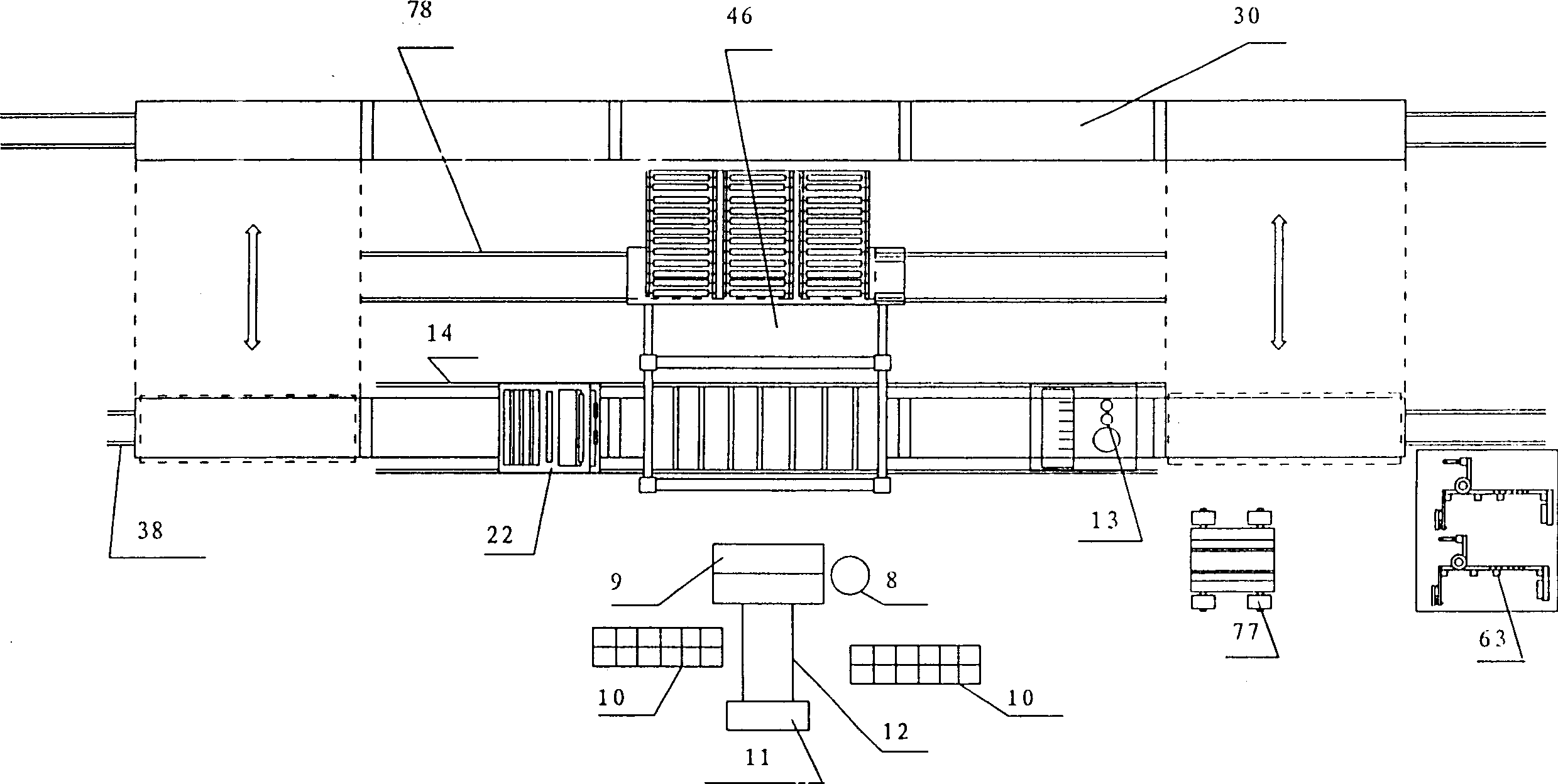

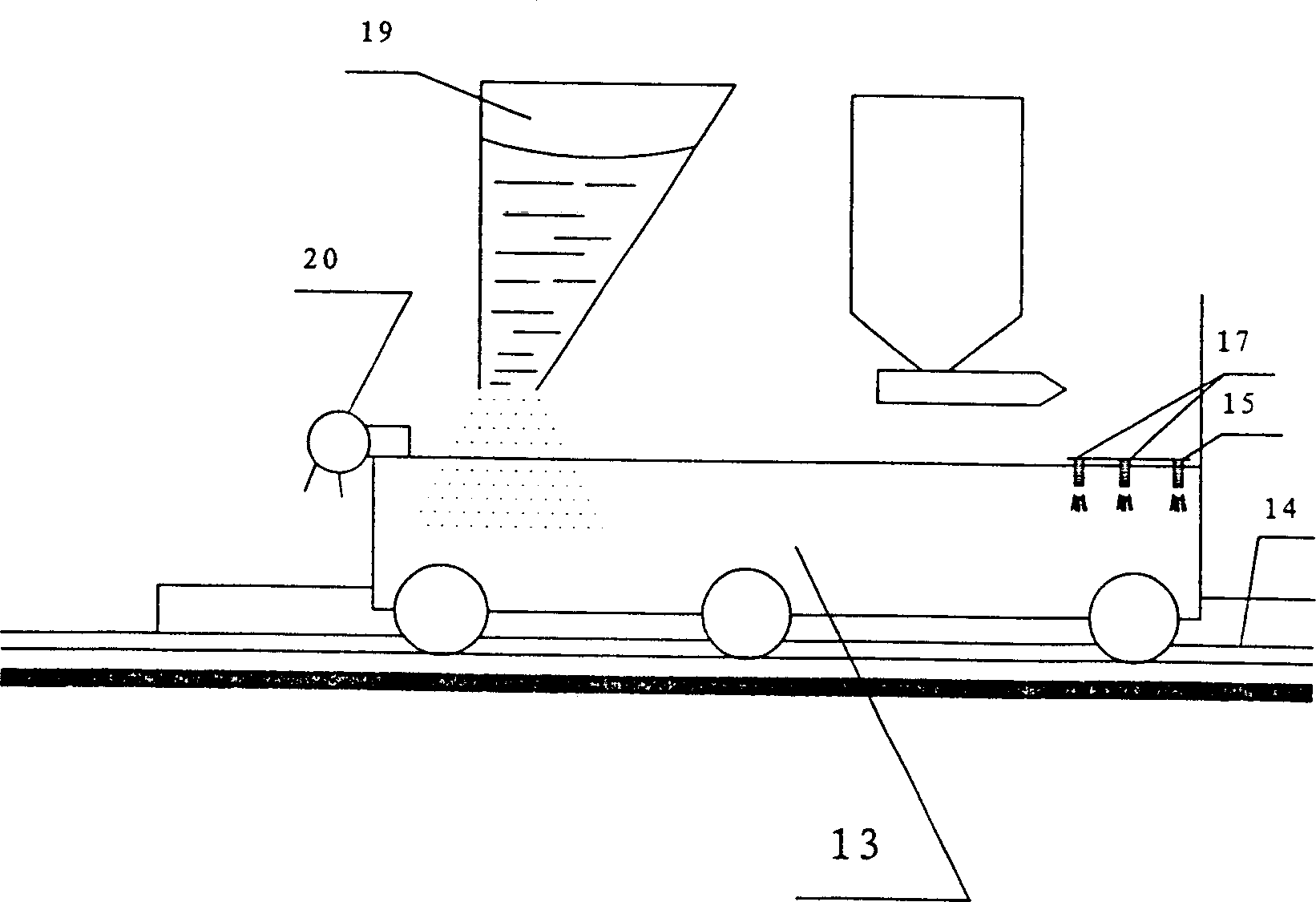

Apparatus and technology for producing integrally splicing hollow boards for building

InactiveCN1381343APrecise positioningSimple structureCeramic shaping apparatusGlass fiberReinforced concrete

A large hollow building slab of glass fibre-reinforced concrete (GRC) material, is made up through spraying adhesive to the working surface of a mould, spreading decorative particles, spraying decorative slurry, spreading reinforcing material, spraying premixed slurry, installing mandrel mould, spraying premixed slurry over mandrel mould, inserting reinforcing material coated with premixed slurryat the reinforming rib-position between mandrel moulds, spreading reinforcing material, spraying premixed slurry, compacting, plastering, solidifying and removing mandrel mould and other shutterings.Its apparatus is composed of slurry mixing station, decorative layer assembling car, structural layer assembling car, mould carriage, mandrel mould, mandrel mould detaching car, and lifting jaws.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

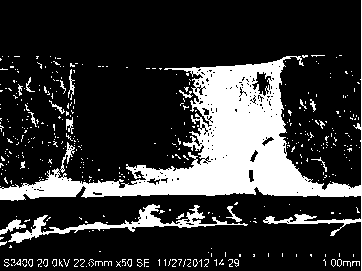

Hole processing method for which low-melting-point alloy sacrificial layer is adopted

ActiveCN103128525AImprove processing stabilityAvoid phenomena that damage processing stabilityElectrolysisAlloy

The invention relates to a hole processing method for which a low-melting-point alloy sacrificial layer is adopted and belongs to the technical field of electrochemical machining. The hole processing method comprises a first step of coating molten low-melting-point alloy at the position of an outlet of a predetermined processing hole of a workpiece in a spray method, cooling the low-melting-point alloy in the air, and forming the low-melting-point alloy layer; a second step of performing tube electrode electrochemical machining; a third step of removing the low-melting-point alloy layer after processing is finished; and a fourth step of cleaning a part. The method is of great significance for improving process stability and processing accuracy of the tube electrode electrochemical machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

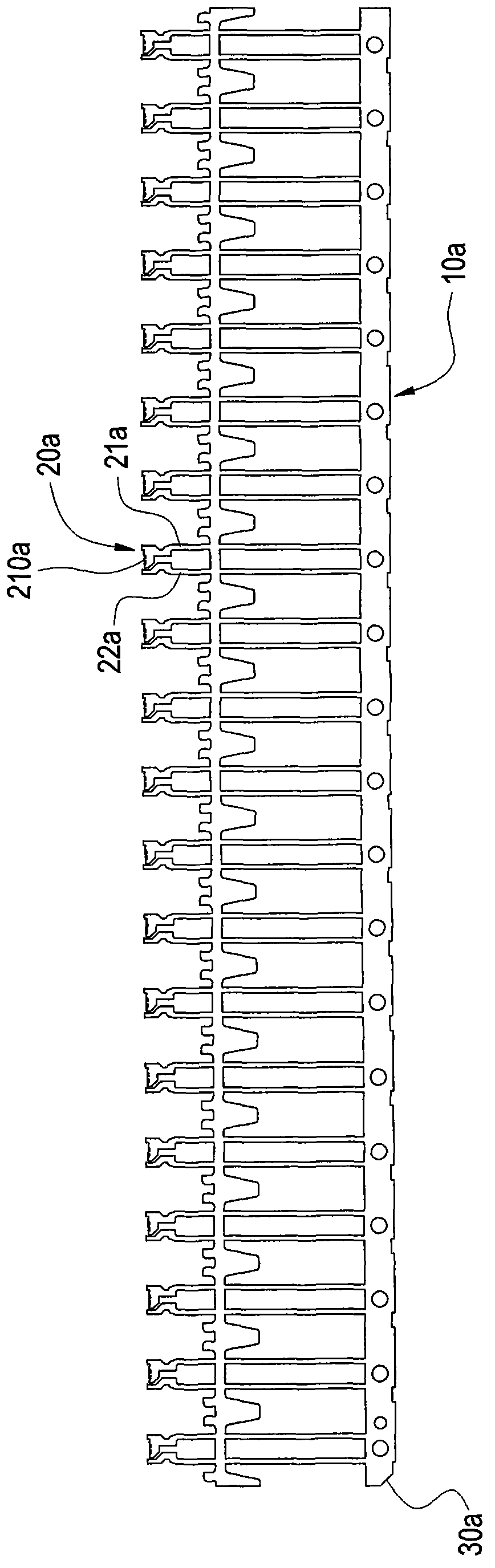

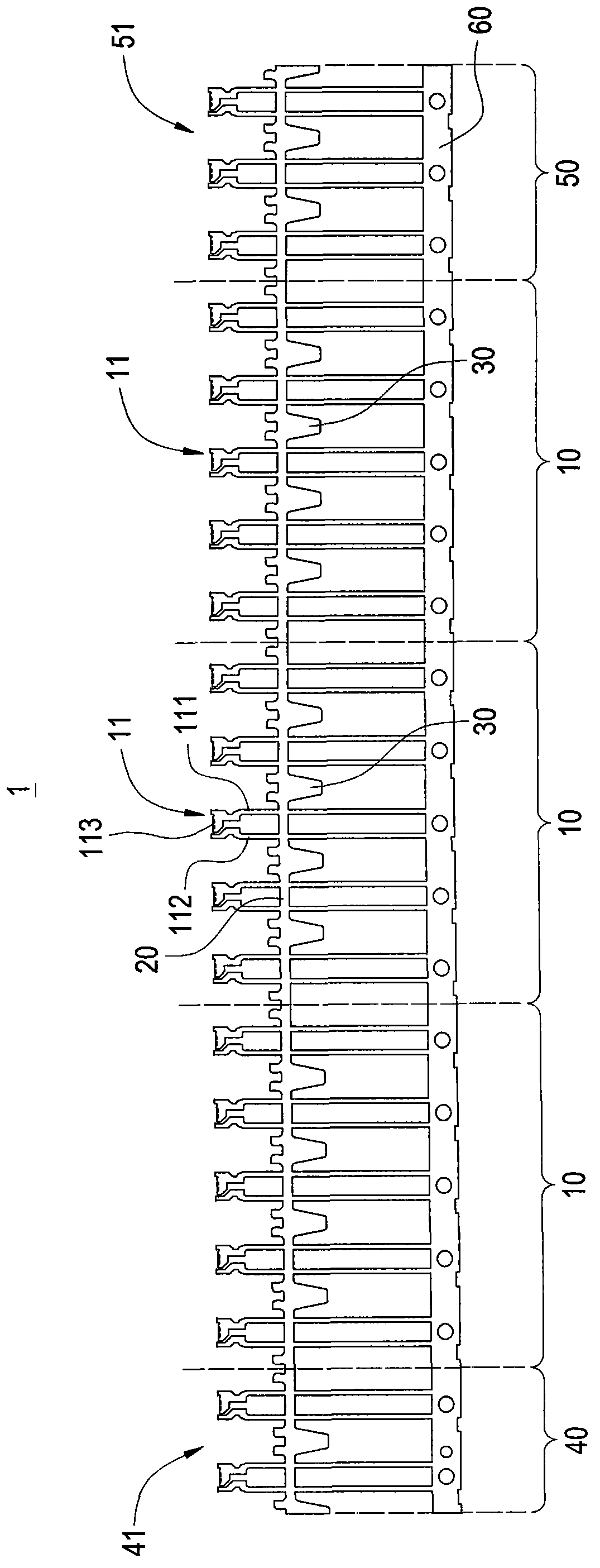

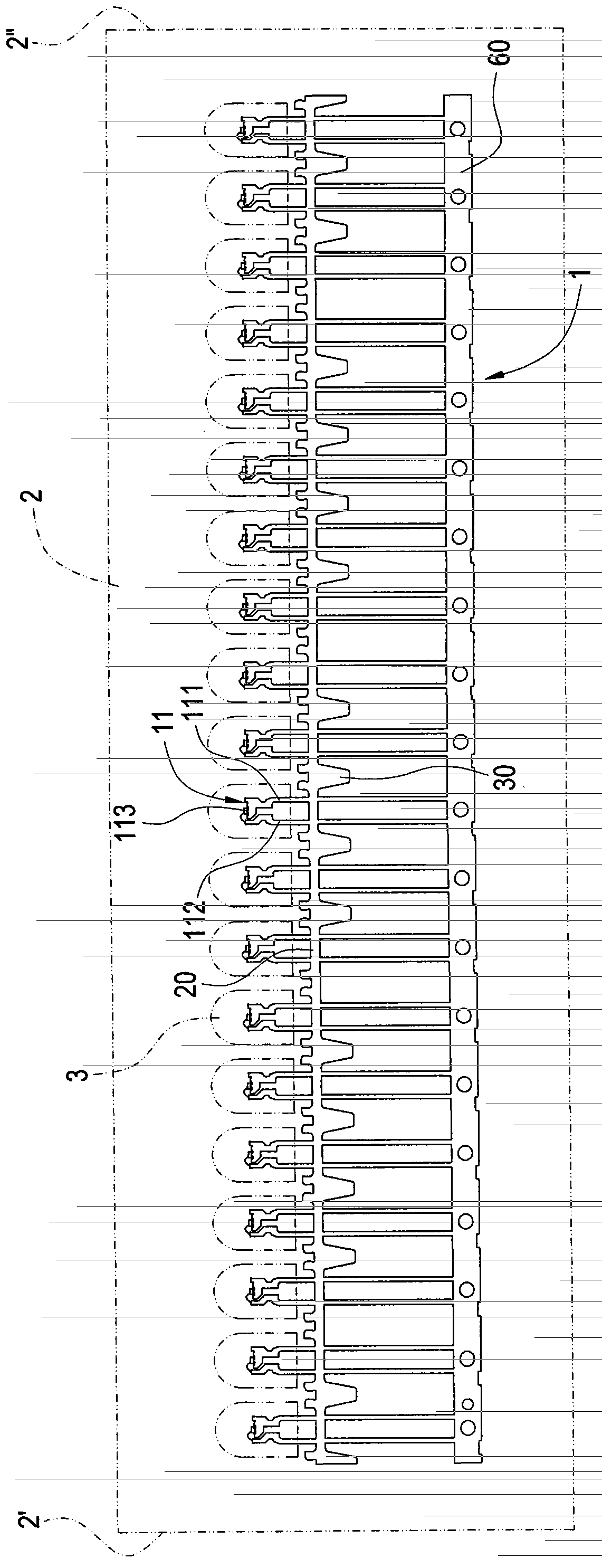

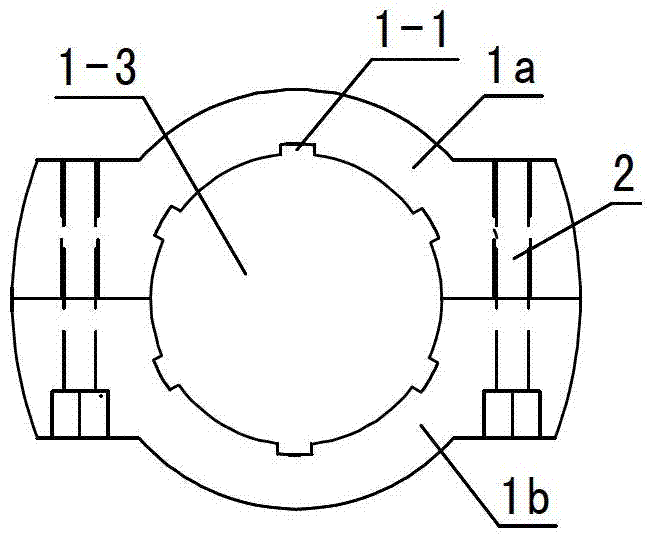

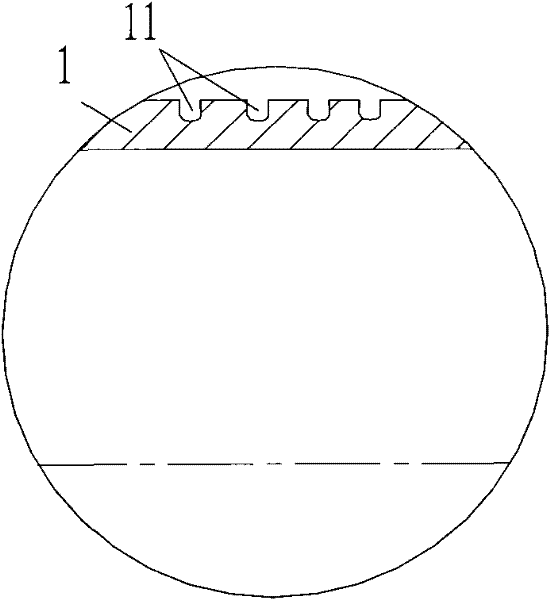

LED material strap with identification structure

InactiveCN103579449ALow costReduce secondary processingSemiconductor/solid-state device testing/measurementSemiconductor devicesEngineeringLead frame

The invention discloses an LED material strap with an identification structure. The LED material strap comprises a plurality of lead frame sets, main joint sections, a plurality of clamping sheets, first support units and second support units, the lead frame sets are connected in an equal-distance mode and arranged linearly, each lead frame set comprises support units in a certain number, the main joint sections are connected with the support units in series and are in extending connection with the adjacent lead frame sets, the clamping sheets are arranged between the adjacent support units and protrude and extend out of one lateral sides of the main joint sections, the first support units and the second support units are arranged on two outer sides of the lead frame sets respectively, the number of the first support units is not equal to that of the second support units, and the total of the number of the first support units and the number of the second support units is equal to the number of the support units included in each lead frame set. The direction of the LED material strap is judged through the structure.

Owner:I-CHIUN PRECISION IND CO LTD +1

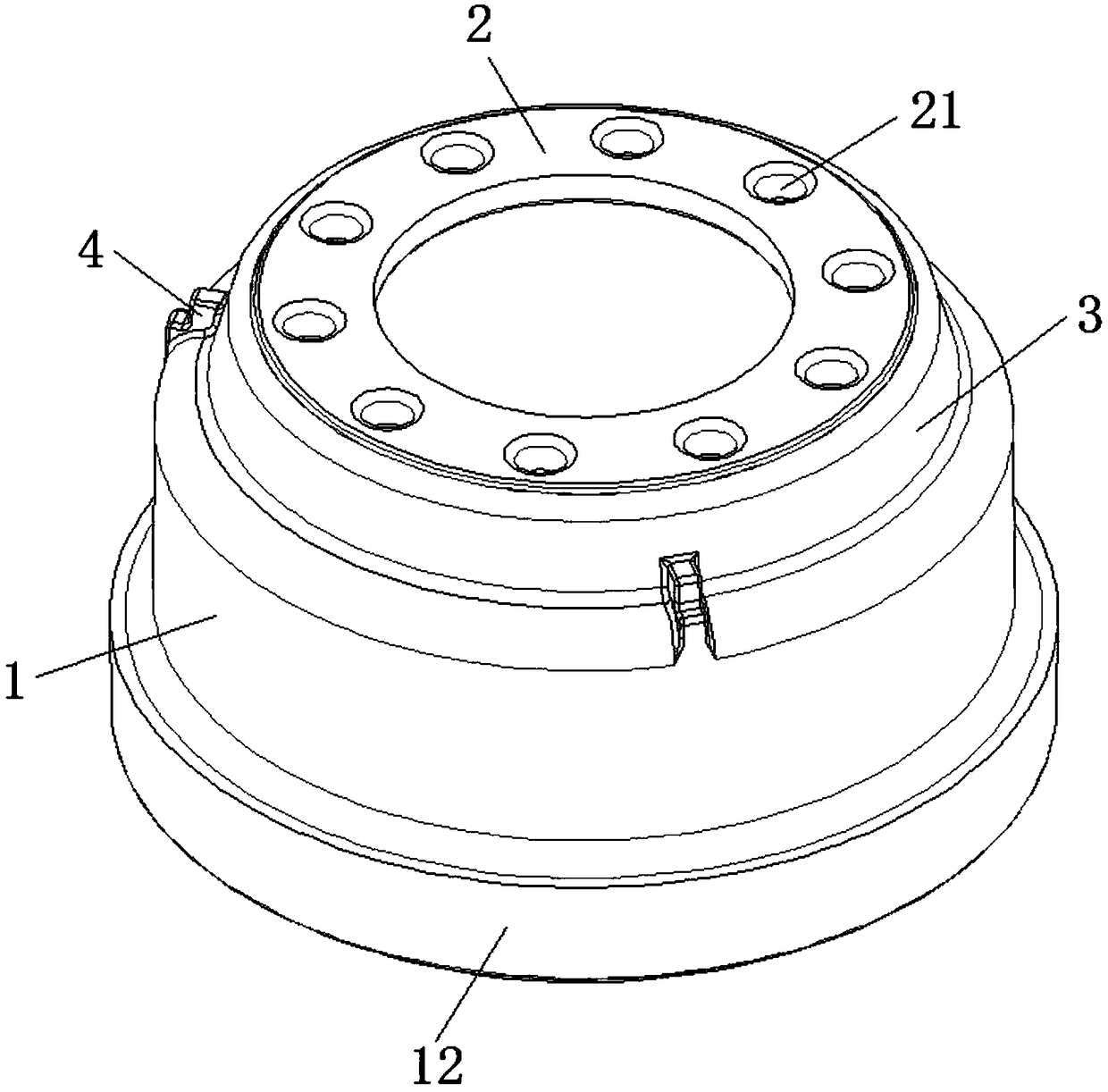

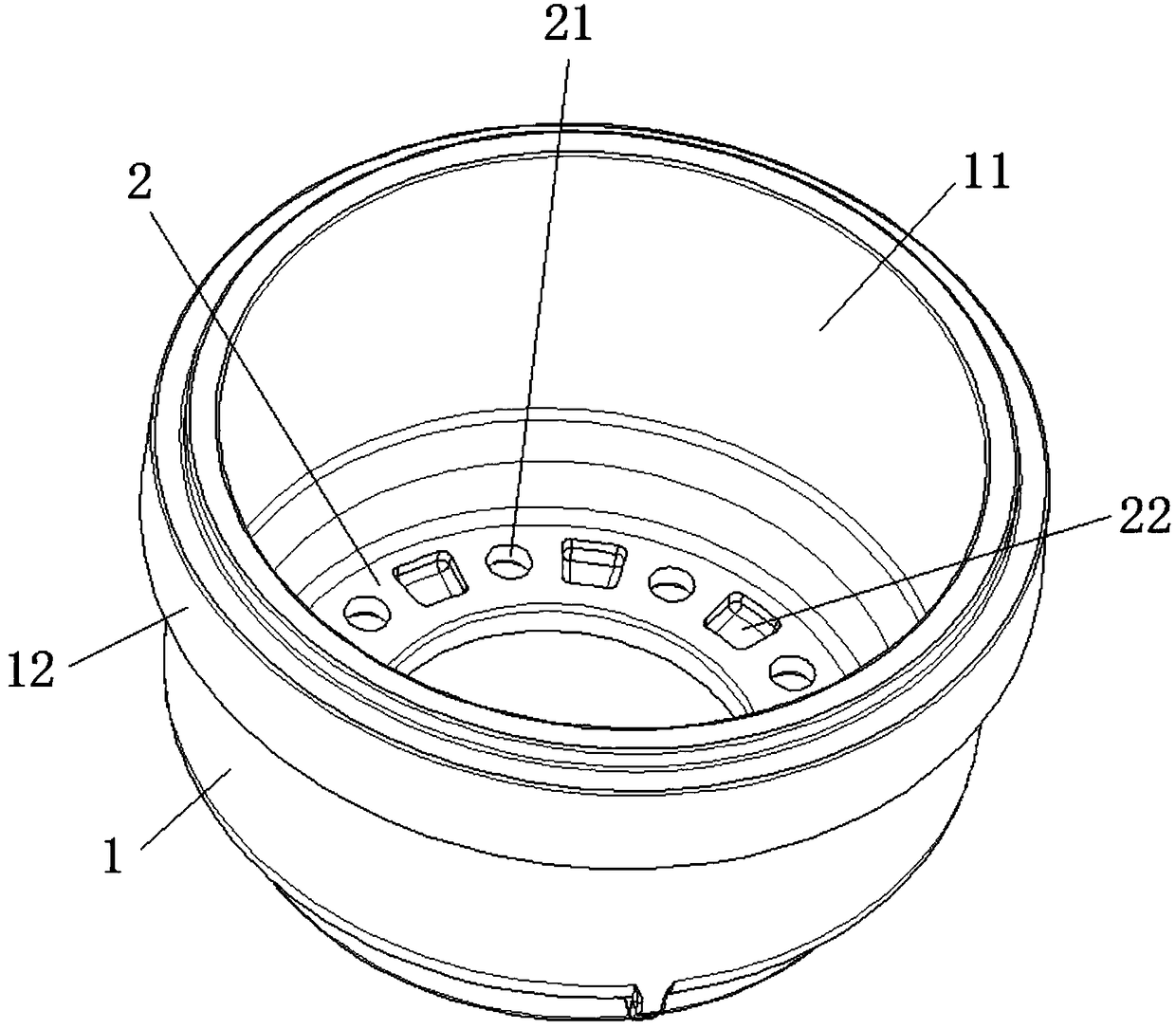

Manufacturing method of brake drum, and brake drum

PendingCN108220751AReduce secondary processingReduce processing steps and costsBraking drumsFoundry mouldsEngineeringSmelting

The invention relates to a manufacturing method of a brake drum. The manufacturing method comprises the following steps: step (S1) preparing raw materials; step (S2) smelting; step (S3) performing vermicularizing treatment; step (S4) pouring; and step (S5) performing cooling formation. According to the manufacturing method of the brake drum provided by the invention adopts integrated casting for the brake drum, reduces secondary machining, reduces machining procedures and lowers the machining cost; compared with a gray pig iron brake drum having the same structure, the brake drum manufacturedby the manufacturing method can be prolonged by 50% to 100% in service life. The invention also discloses the brake drum; the brake drum comprises a brake drum body and a mounting part; the mounting part is annular and is arranged at one end of the brake drum body; the mounting part is provided with a plurality of mounting holes which are in circumferential array distribution; lightening holes areformed in a spaced manner among the plurality of mounting holes; a friction part is arranged at the inner wall of the brake drum body; and an annular reinforcing ring is arranged at the outer wall ofthe brake drum body. The brake drum provided by the invention has the advantages of being simple in structure, light in weight, high in strength and the like.

Owner:GUANGDONG FUHUA CASTING

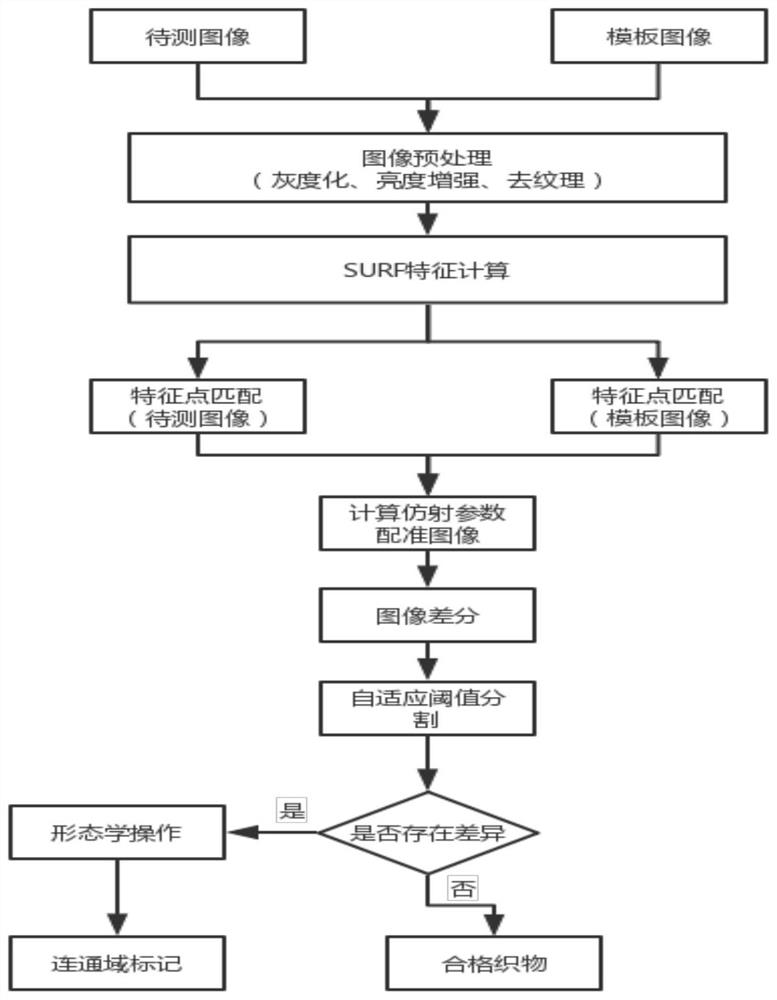

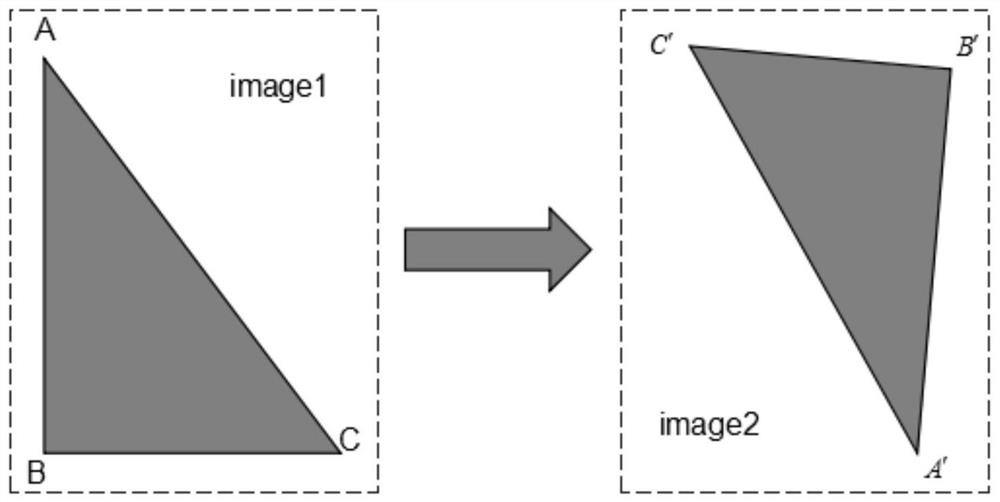

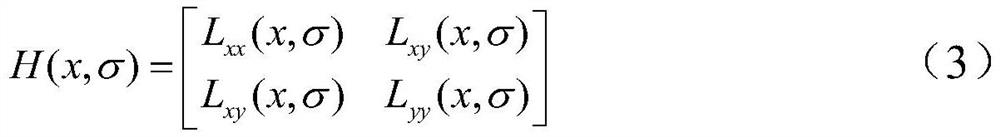

Printed fabric surface defect detection method based on image processing

PendingCN112288734ADefects in timeTimely defect detectionImage enhancementImage analysisTextile printerImaging processing

The invention discloses a printed fabric surface defect detection method based on image processing, and the method comprises the steps: collecting a template image and a to-be-detected cloth image, carrying out the same preprocessing of the images, calculating the SURF features of the images, and determining feature points; taking the to-be-detected cloth image as a template image, taking the template image as a reference image, carrying out bidirectional feature point matching, obtaining registered feature point information, carrying out affine transformation, image registration and image difference, and extracting a difference region in the image to obtain a difference image; and performing threshold segmentation, opening operation and connected domain marking operation on the differential image to obtain an image marked with defects. The detection method provided by the invention solves the problems of non-uniform detection standards and low accuracy in the existing defect detectionmethod.

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

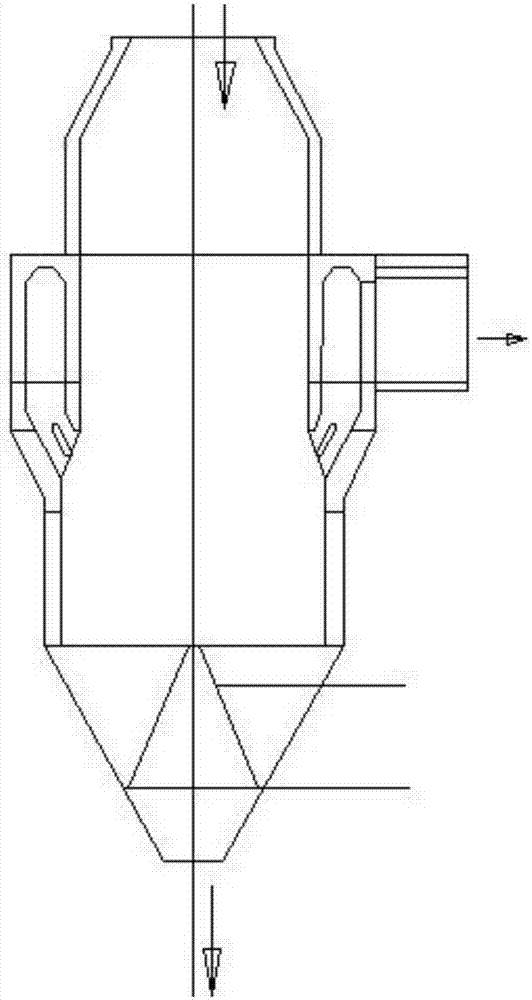

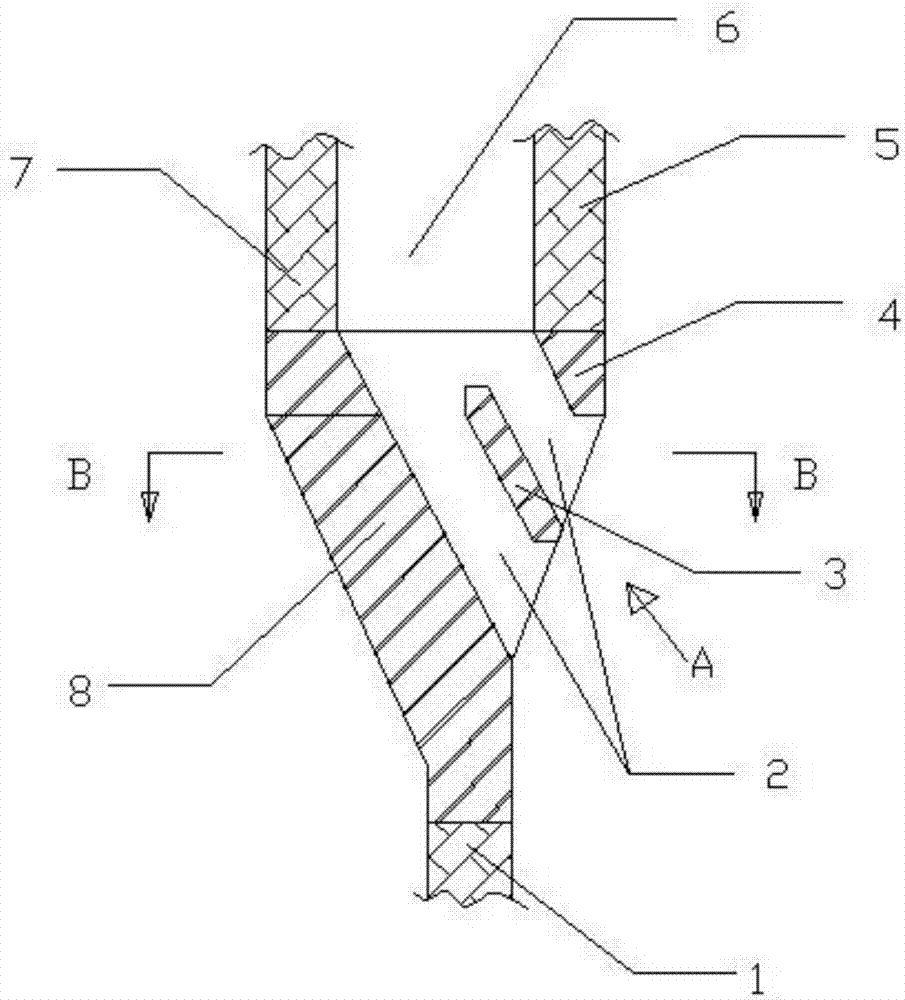

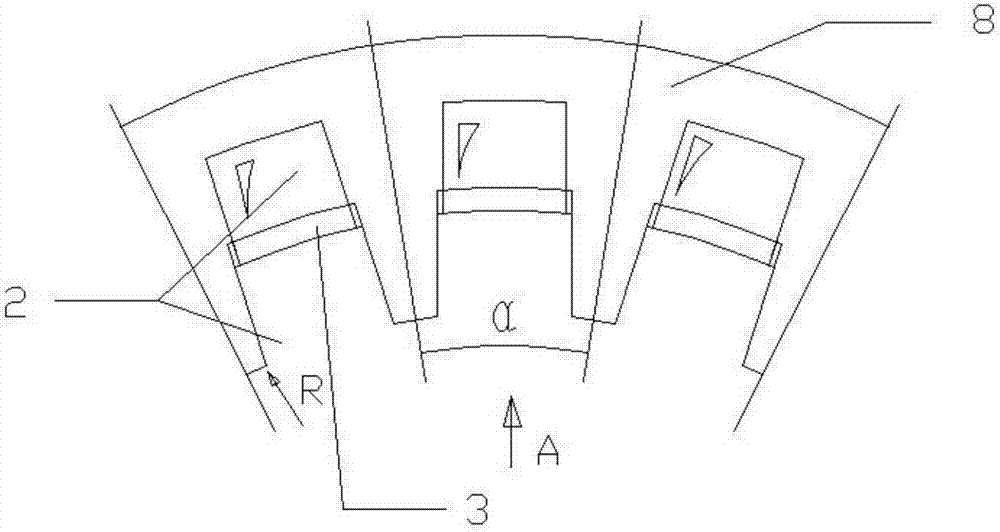

Refractory lining dual-chute of dry quenching furnace and technique method of building thereof

PendingCN107129814AReduce secondary processingEliminate errorsCoke quenchingCoke oven brickworkFire brickCoke burner

The invention discloses a technique method of building a refractory lining dual-chute of a dry quenching furnace, and belongs to the building construction field of metallurgical equipment. The technique method is mainly used for solving the problems that the construction difficulty of the refractory lining dual-chute of the dry quenching furnace is big, and the dimension accuracy is hard to control. The technique method includes the first step, selecting proper refractory bricks and pre-practicing mating objects according to equipment requirement; the second step, manufacturing standard fixtures with corresponding dimensions; the third step, confirming position of every supporting wall by a tool; the fourth step, timely detecting bias of corresponding dimension and making adjustment during the building process according to corresponding reference line. Specific to bracket brick expansion or rupture of a single-chute bracket supporting wall in the prior art, the technique method reduces the safety problem of the dry quenching production; the method applies a technique of 'pre-practicing for many times and selecting bricks to form a complete set' and a control method of 'measuring every brick while adjusting every layer', so that the supporting wall stability of a chute zone is improved, and the service life of the dry quenching furnace is prolonged.

Owner:ANHUI MASTEEL ENG & TECH GRP

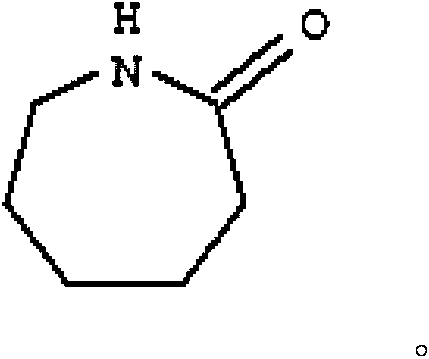

LED (Light-Emitting Diode) heat radiator and preparation method thereof

ActiveCN103013102AEasy to manufactureReduce productionPoint-like light sourceLighting heating/cooling arrangementsMaterials preparationPolyamide

The invention discloses a preparation method of an LED (Light-Emitting Diode) heat radiator, comprising the following steps of: (a) providing a raw material mixture, wherein the mixture contains epsilon-caprolactam, graphite powder, a catalyst, an auxiliary catalyst, a lubricant and a coupling agent; (b) polymerizing the epsilon-caprolactam in the raw material mixture to form a fused mixture containing polyamide 6; and (c) injecting the fused mixture containing the polyamide 6 into a mould for preparing the LED heat radiator so as to be injected to form the LED heat radiator. According to the preparation method, the LED heat radiator is molded by one step through reaction and injection molding from a monomer, so that a material preparation process is saved, the production efficiency is high and the energy consumption is small; and the heat radiation performance of the prepared heat radiator is excellent.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

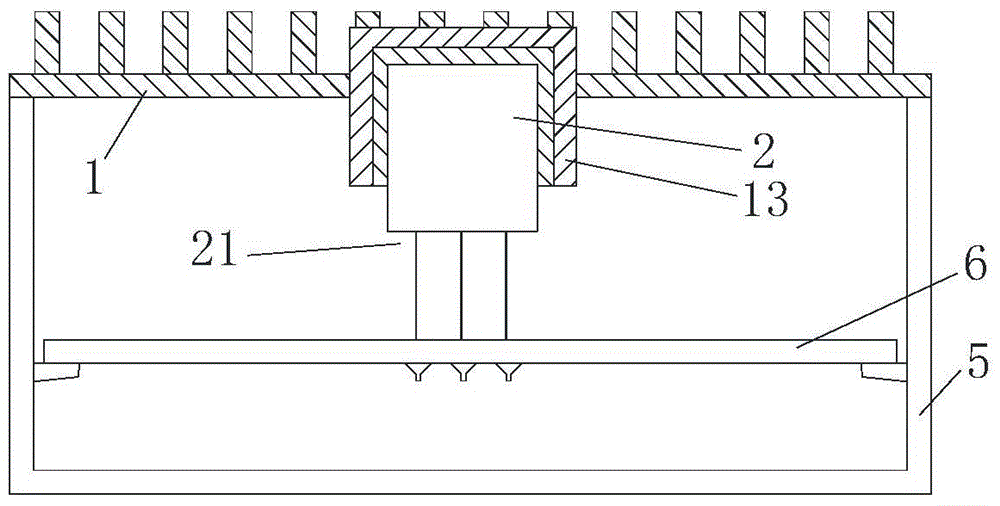

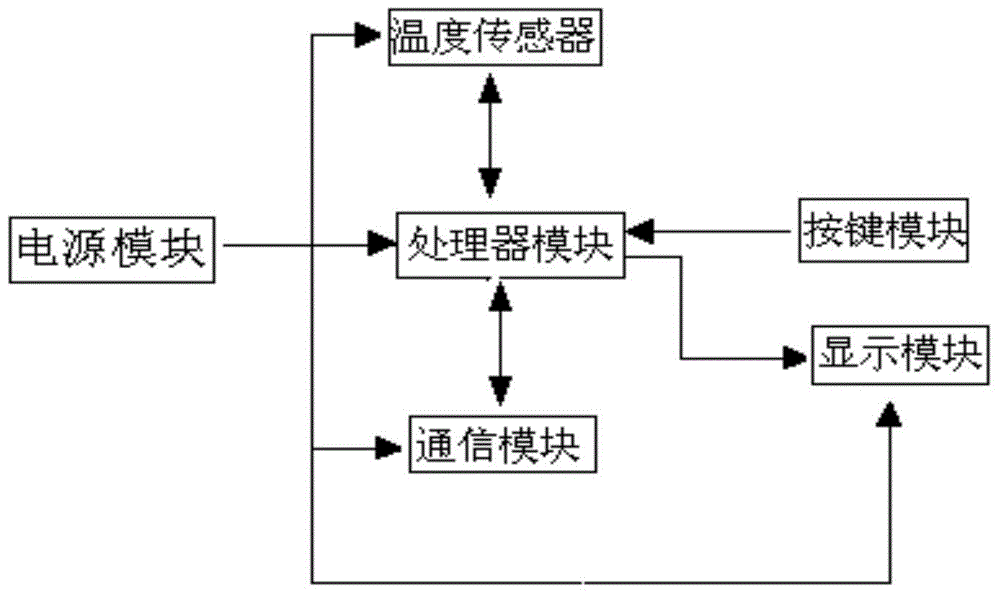

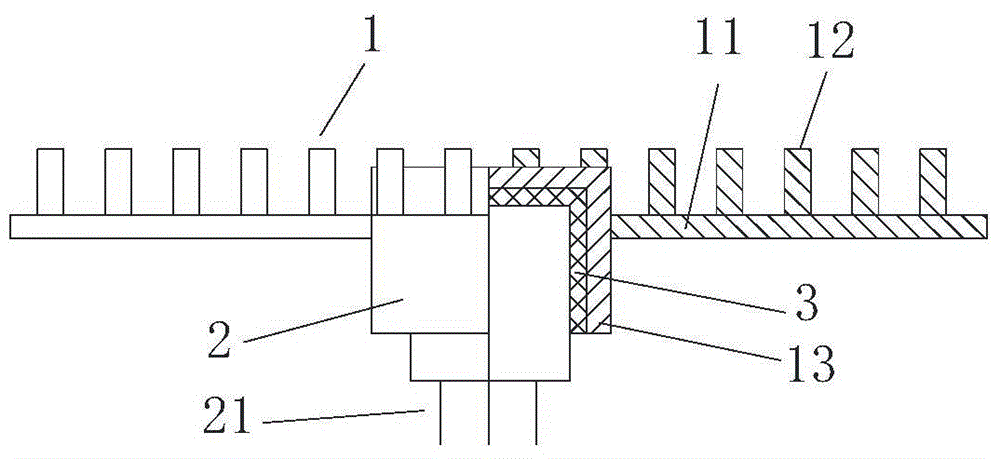

Temperature controller capable of restraining fluctuation of detection temperature

ActiveCN105068578AShort response timeReduce thermal resistanceSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlControl system

The invention discloses a temperature controller capable of restraining fluctuation of detection temperature, which comprises a power supply module, a processor module, a display module, a communication module, a temperature sensor, a key module and a sensible heat module, wherein the processor module carries out calculation processing on signals from the temperature sensor, the key module and the communication module and then transmits the signals to the display module for display; the processor module transmits control signals acquired after calculation processing to an air conditioning control system; the sensible heat module comprises a tubular measurement part with one end sealed capable of accommodating the temperature sensor and a plate heat integration part, the sealed end of the measurement part passes through and protrudes against the plate heat integration part, and the plate heat integration part is opposite to a temperature measurement part of the temperature sensor arranged in the measurement part. The sensible heat module has a large heat transfer area, is contacted with to-be-measured air, has a large detection area, and is high in heat transfer efficiency, room temperature detection precision is improved, room temperature fluctuation is reduced, and temperature control response delay is further shortened.

Owner:南京西笛电器有限公司

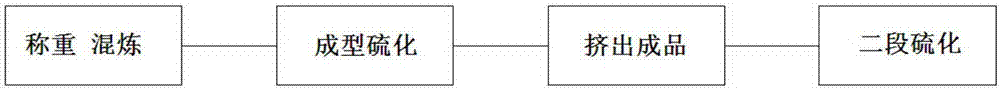

Transparent bloomless silicone rubber mixed compound and preparation method

The invention discloses a transparent bloomless silicone rubber mixed compound and a preparation method. The transparent bloomless silicone rubber mixed compound is prepared from the following components: 100 parts of methyl vinyl silicone rubber mixed compound, 0.5 to 1.0 part of DCBP and 0.3 to 1.0 part of alkyl peroxide. The preparation method comprises the following steps: measuring various components according to a ratio, uniformly dispersing the components into 100 parts of silicone rubber mixed compound, extruding molding by virtue of a rubber extruder, shaping and vulcanizing at a temperature of 500 to 600 DEG C for 5 to 30 s, wherein a temperature of a horizontal drying passage is 200 to 300 DEG C, and the time is 1 to 10 min; and preparing an extruded product corresponding to themold. Compared with the product in the prior art, the product disclosed by the invention has the advantages that on the premise of hardly changing the physical mechanical performance, and in the production, 1 to 2 months with blooming are prolonged to 2 years or more without blooming, so that the extruded product can be stored for a long time, the appearance is not changed, the secondary treatment of the product is reduced, and the product security is improved. In addition, the secondary vulcanizing time can also be reduced, the energy consumption can be saved, and the production cost can bedecreased.

Owner:JINAN CHENSHENG MEDICAL SILICONE RUBBER PROD

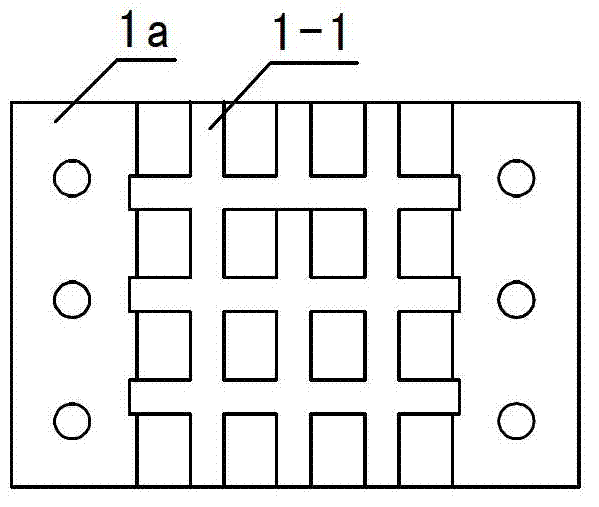

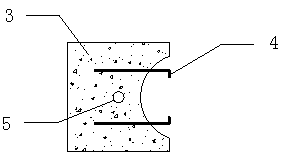

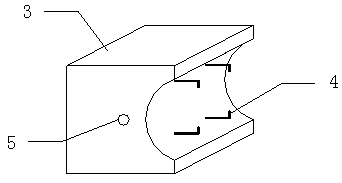

Combined metal shrink ring for lateral restricted expansion test for rock

ActiveCN102830059AGood removal effectInhibit swellingUsing mechanical meansMaterial analysisRock coreTest requirements

The invention discloses a combined metal shrink ring for a lateral restricted expansion test for a rock. The combined metal shrink ring comprises a split cavity and an open cutting ring. The split cavity is composed of two butted semicircular molds and bolts by connection. A central inner circle of the split cavity is provided with the open cutting ring. The open cutting ring is a stainless steel cylinder provided with a longitudinal opening. The split cavity is graded according to differences of central inner circle diameters. Different grades of the split cavities having the different central inner circle diameters are provided with the corresponding open cutting rings having different wall thickness values. The combined metal shrink ring can satisfy requirements of lateral restriction of rock samples having different diameters in a lateral-restricted rock expansion test, can satisfy lateral-restricted expansion test requirements and can be directly used for rock core drilling in the field. The combined metal shrink ring for a lateral-restricted rock expansion test has structural features equivalent to the existing metal shrink ring and can satisfy technical conditions required by the existing railway rock test standard.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Soft and hard plastic co-extrusion method

The invention relates to a hard plastic co-extrusion method, using two extrusion machines with soft hard plastic on a streamline to extrude to one mold to make it melt inside the mold, controlling the hard plastic in 175deg.C-185deg.C and the soft plastic in 155deg.C-165deg.C, extracting the air from the mold on the vacuum cooling working platform, allowing the plastic part sticking close to the mold cavity to get away the heat, cooling and shaping the product, with the plastic part close to the mold cavity tightly and converting from fuse state to glass state, using extractor to drag the shaping mold in the power of 2-5kw, extraction force hundreds of thousands N, the extruded part being cut synchronically by the cutter, using one mold to stick the soft and hard plastic directly, reducing secondary processing, labor cost and material cost.

Owner:SHANGHAI CANAAN PLASTIC CO LTD

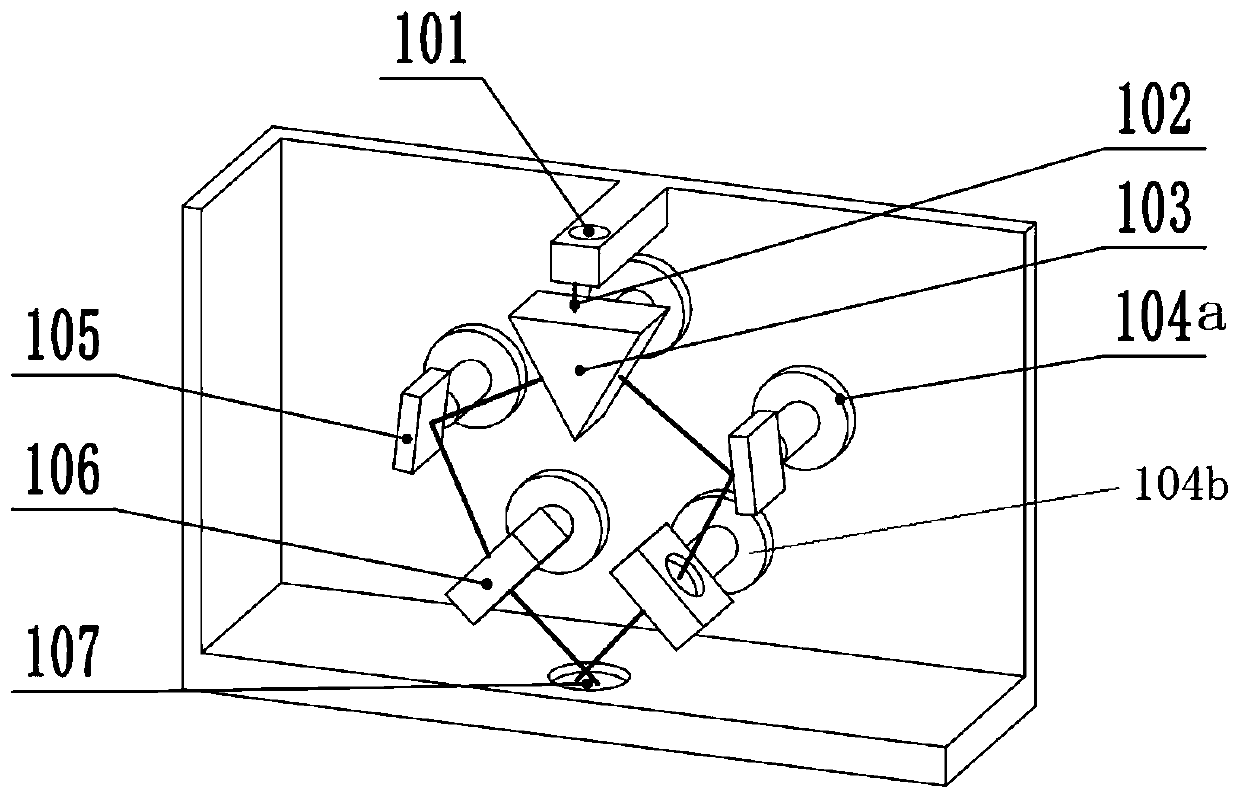

Inner wall supersonic laser composite deposition device

PendingCN110904447AAchieve fixAchieve remanufacturingPressure inorganic powder coatingMetal coatingGalvanometer

The invention discloses an inner wall supersonic laser composite deposition device. The device comprises a galvanometer scanning unit, wherein the galvanometer scanning unit comprises a mounting framebody and a galvanometer scanning device, the mounting frame body is mounted on an inner wall supersonic laser deposition unit, an upper portion of the mounting frame body is provided with a light transmitting opening allowing laser beams to penetrate through, and the bottom of the mounting frame body is provided with a laser outlet allowing the laser beams to penetrate through, the inner wall supersonic laser deposition unit comprises a cylinder body, a nozzle, a laser path, an air supply pipe and a powder supply pipe, the nozzle, the laser path, the air supply pipe and the powder supply pipeare all installed in the cylinder body, a light outlet of the laser path is divided into two parts through an optical splitter, a first path extends to the light transmitting opening of the mountingframe body, and a second path communicates with the upper portion of the nozzle, and a light outlet of a laser device is aligned with a light inlet of the laser path. The device is advantaged in thatpreparation of a metal coating or a composite coating on an inner wall of a hole part is achieved, repairing and remanufacturing of the inner wall can further be achieved, and surface performance of the inner wall is improved.

Owner:ZHEJIANG UNIV OF TECH

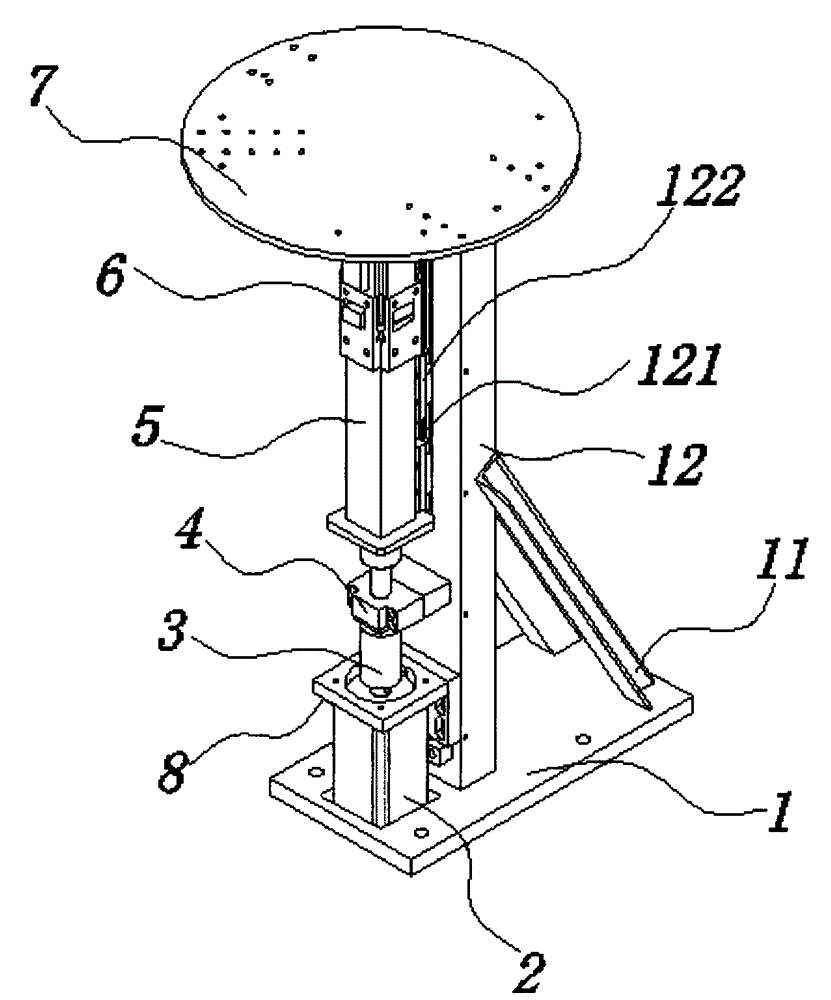

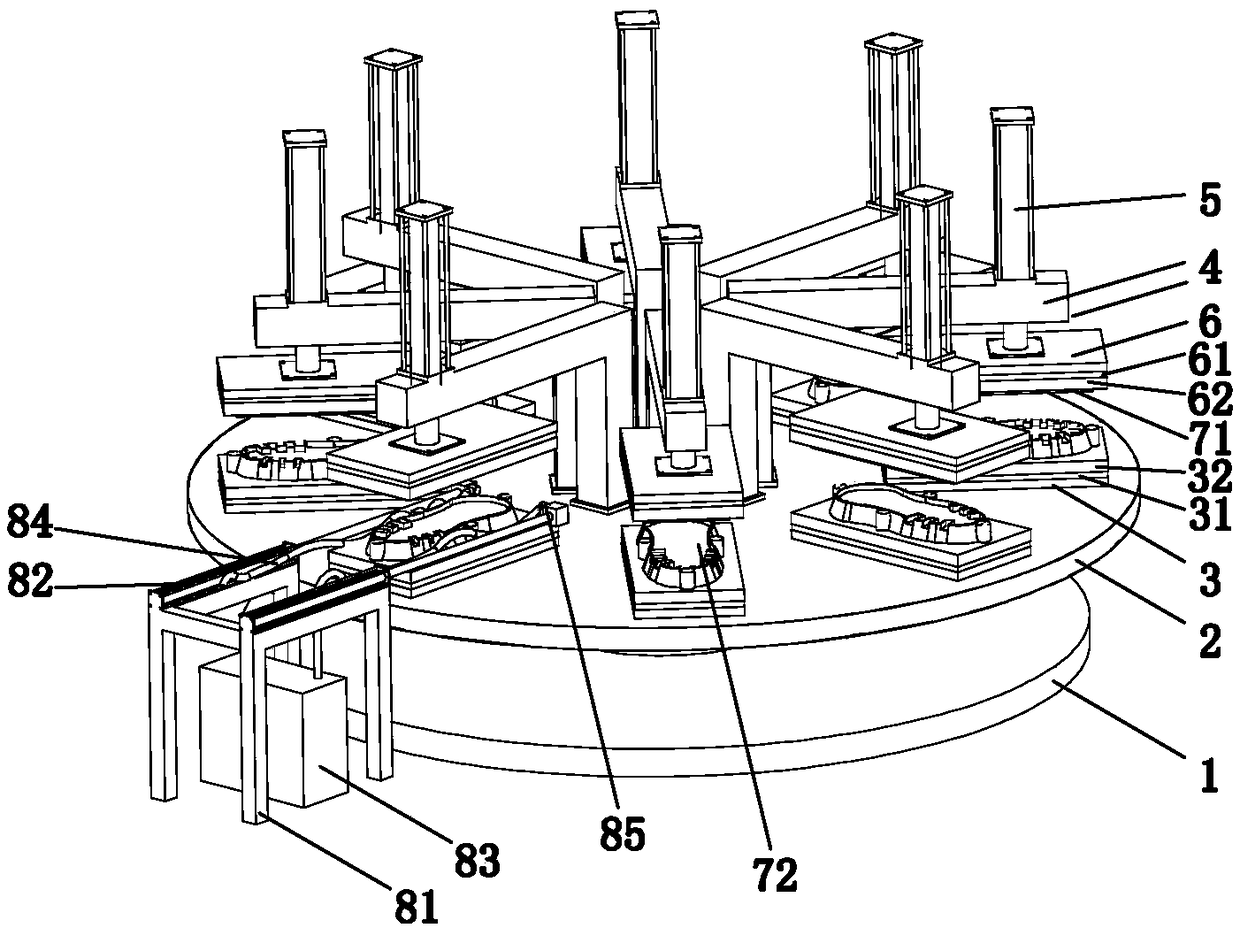

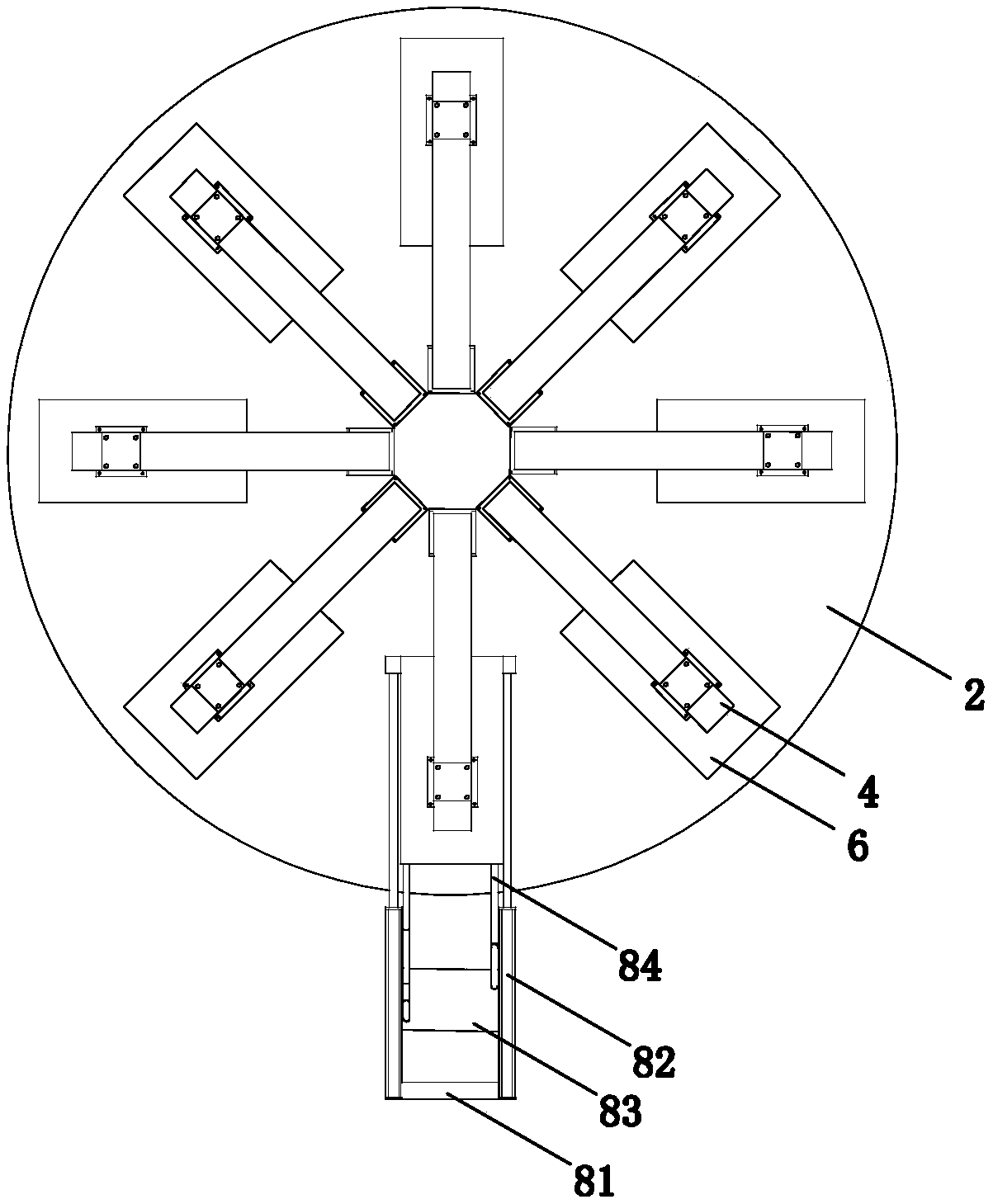

Three-spot welding device

InactiveCN104646871AReduce harmAchieve diversificationWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingMachining process

The invention relates to the technical field of welding and particularly relates to a three-spot welding device. The device comprises a fixing bottom plate, a lifting servo motor, a coupler, a bearing block, a lifting unit, a rotation servo motor and a working rotation disc. A square column is formed integrally on the fixing bottom plate, the working rotation disc is arranged at the top end of the square column, the lifting unit is arranged on one side of the square column below the working rotation disc, the rotation servo motor is arranged on the lifting unit, the bearing block is fixed on one side of the square column below the lifting unit, and the lifting servo motor is arranged on the fixing bottom plate. By means of the device, an automatic position searching function of the servo motor is used, so that product diversification can be achieved, the device is applicable to production of multi-model products, the product quality is guaranteed, the production efficiency is high, welding splashes are few, the secondary machining process is reduced, the labor intensity and the production cost are reduced, and hurt to human bodies caused by harmful substances is reduced to the largest degree.

Owner:NINGBO SONGYA WELDING TECH

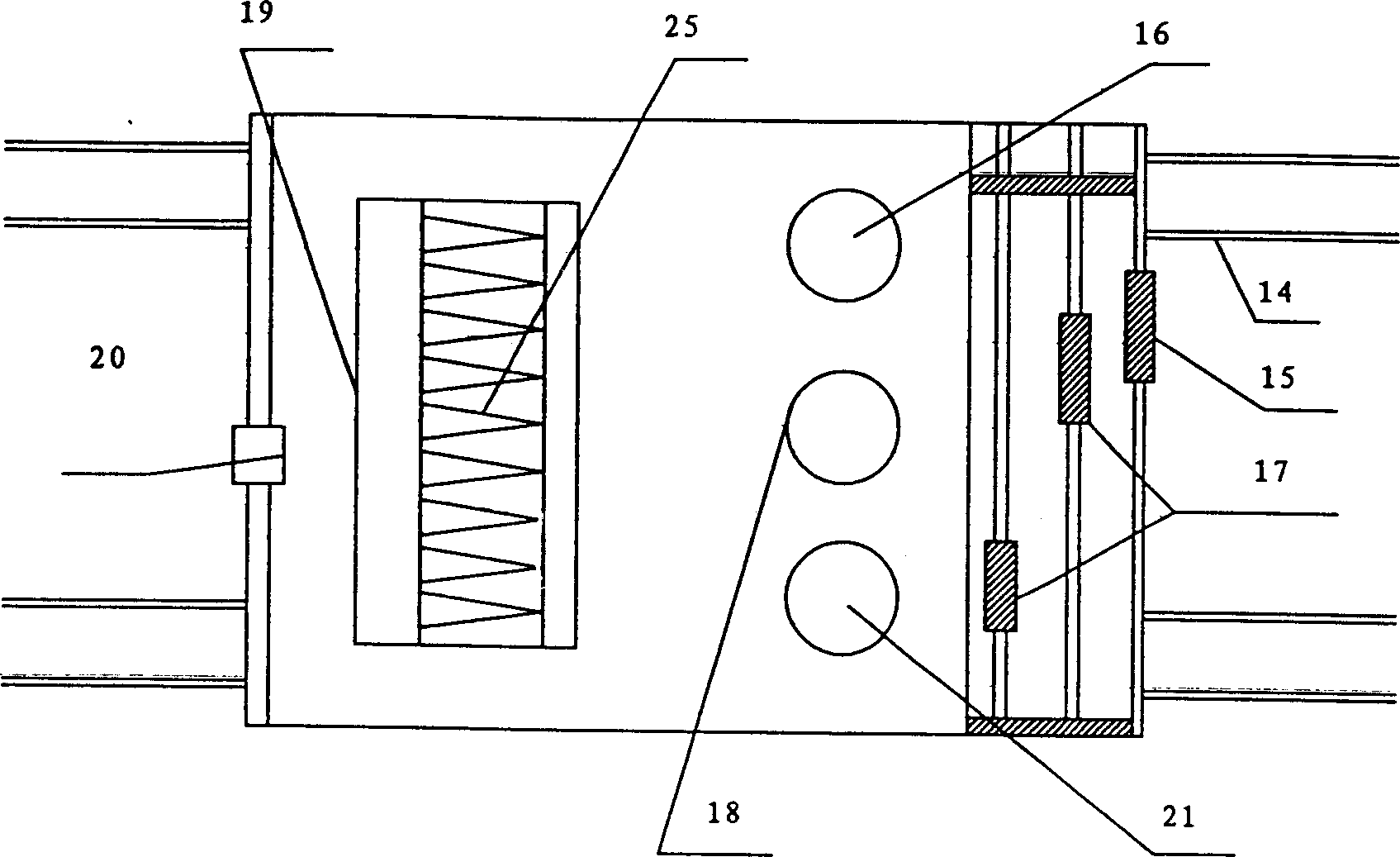

Heat exchange pipe and on-line pipe-making processing technique thereof

InactiveCN102230754AIncrease the heat exchange areaLow costChemical industryTubular elementsThermal energyNuclear power

The invention discloses a heat exchange pipe, which comprises an outer pipe at least. The interior of the outer pipe serves as a medium passage. A heat exchange element is configured inside the medium passage. The heat exchange element divides the medium passage into a direct heat exchange zone which exchange heat with the outer pipe and an indirect heat exchange zone which exchange heat with the heat exchange element. The heat exchange medium inside the indirect heat exchange zone exchanges heat with the heat exchange medium inside the direct heat exchange zone via the heat exchange element. In addition, the invention provides an on-line pipe-making processing technique of the pipe, which is adopted to overlap the outer pipe with the heat exchange element by means of an on-line welding technique. Because the heat exchange element is configured inside the outer pipe, the heat exchange area of the heat exchange pipe provided by the invention is increased, which greatly improves the heat exchange efficiency of the indirect heat exchange zone so that the heat exchange pipe provided by the invention is superior to the current heat exchange pipes in terms of the overall heat exchange efficiency. In addition, the invention has low cost and is convenient for manufacturing, and the heat exchange pipe provided by the invention can be applied to high-efficiency heat exchangers or heat exchanging equipment of multiple industries like petroleum, chemicals, fertilizer, boilers, pharmacy, foodstuff, electric power, nuclear power, environmental protection, heat supply and the like.

Owner:SHANGHAI KEMI STEEL TUBE

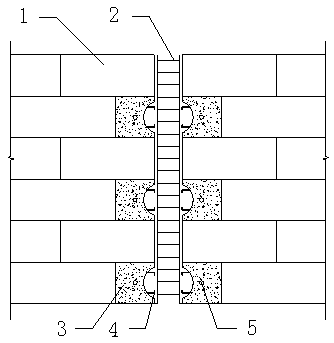

Construction method of constructional column prefabricated dent joint concrete module

ActiveCN110761441ASimple structureEasy to manufactureWallsForms/shuttering/falseworksBrickArchitectural engineering

The invention discloses a construction method of a constructional column prefabricated dent joint concrete module. The method is characterized by comprising the following steps of: a, prefabricating aplurality of dent joint concrete modules, b, building a wall, c, binding constructional column steel bars and arranging a constructional column pouring concrete template, and d, pouring constructional column concrete. The construction method of the constructional column prefabricated dent joint concrete module has the advantages that the dent joint concrete module is simple in structure, convenient to manufacture, guaranteed in factory prefabricated quality, and safe and reliable in engineering quality, the construction quality of a constructional column is effectively guaranteed, the integrity of a masonry structure is enhanced, the secondary processing of brick blocks is reduced, the construction is simple and convenient, the construction progress is accelerated, and the engineering cost is reduced.

Owner:CHINA MCC20 GRP CORP

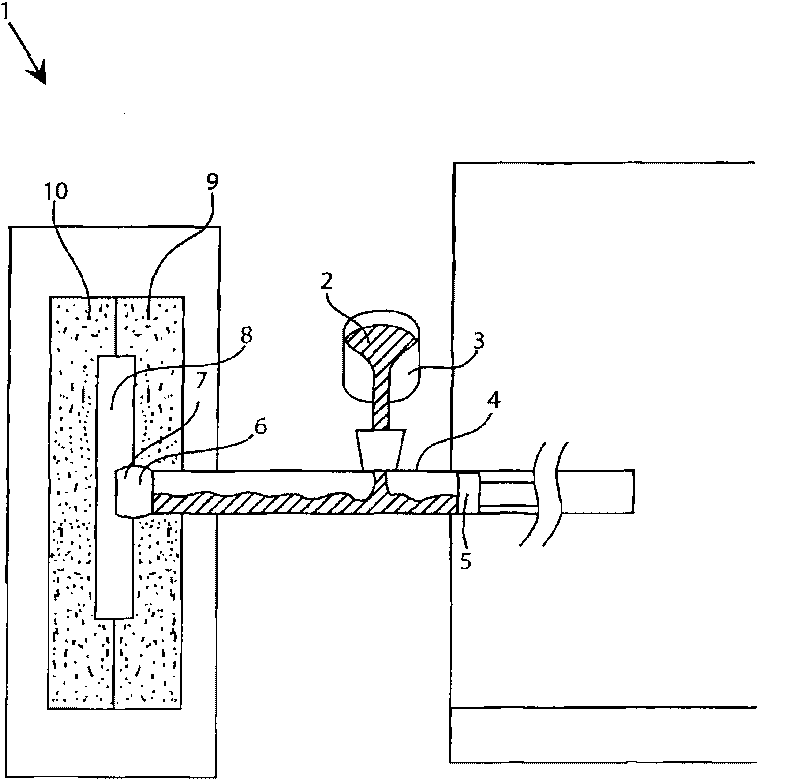

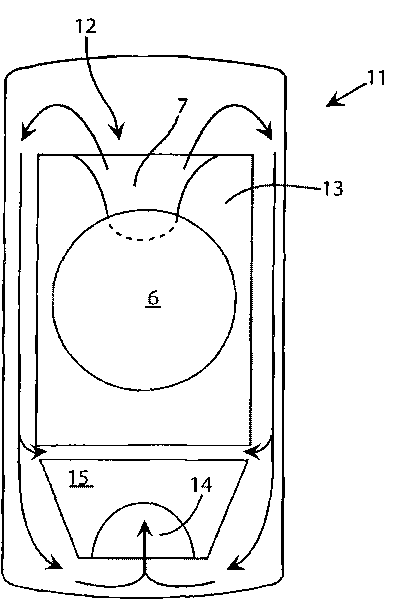

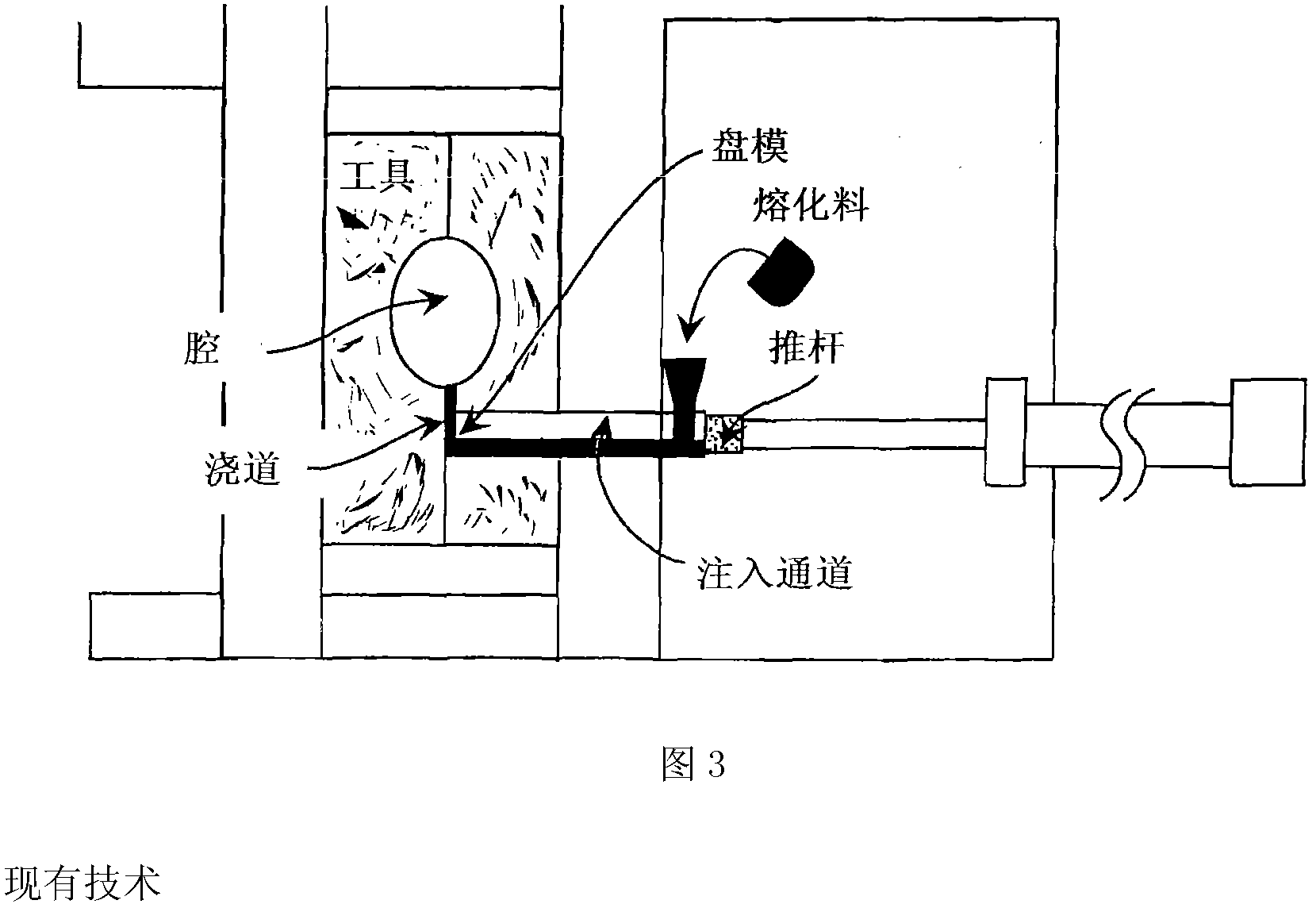

Method and apparatus for die casting of parts

InactiveCN101730600APrevent leakageExtend your lifeThin material handlingDie castingMaterials science

Owner:INTERPLEX IND

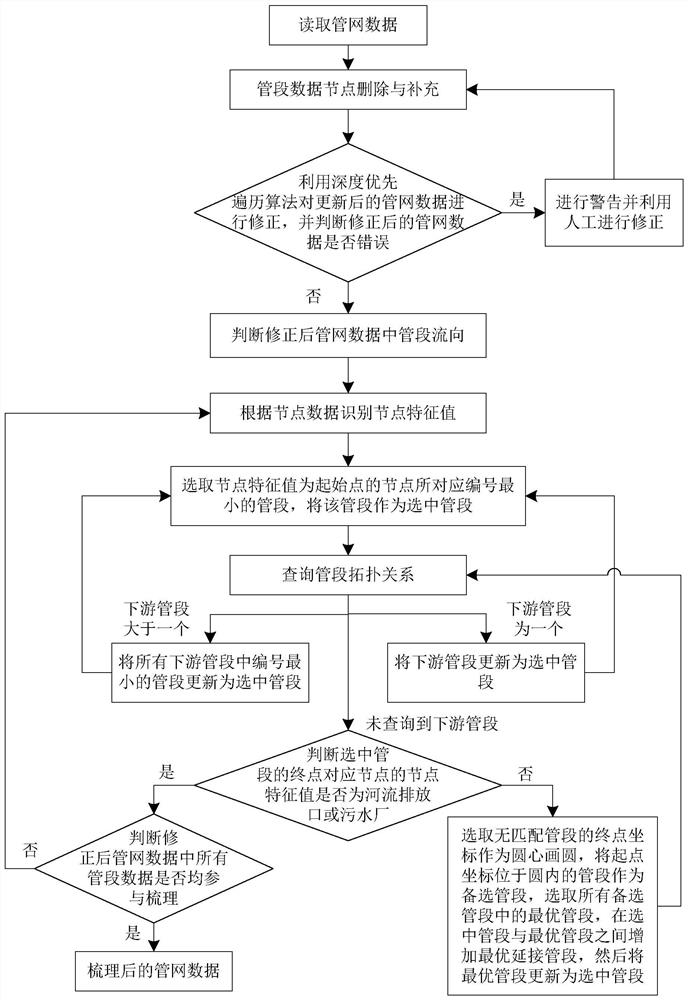

Automatic sorting method for urban plant-network-river topological relation

ActiveCN112712441AReduce secondary processingShorten inspection timeData processing applicationsOther databases queryingEnvironmental systemsSewage

The invention discloses an automatic sorting method for urban plant-network-river topological relations, and relates to the technical field of environmental system simulation and prediction. The objective of the invention is to solve the problems of long time consumption, low efficiency and high error rate caused by manual sorting of a plant network river topological relation in the prior art. According to the invention, the complex connection relationship of the urbanplant-network-riverwater system is abstracted into a two-dimensional point-line topological structure, data rationality check is realized by using a depth-first traversal algorithm, topological structure check and extension are achieved by using a breadth-first traversal algorithm, and efficient automation of the conversion process is achieved by using an intelligent automation technology. According to the invention, automatic construction of a flow direction relationship of a pipe network-sewage plant-river discharge port-river is achieved, flow direction errors, pipeline breakpoints, river discharge port omission and the like are automatically identified and corrected, and a hydrodynamic path of an urban'plant network river 'is intelligently penetrated, so that modeling and operation management services are provided for the urban'plant-network-river'.

Owner:HARBIN INST OF TECH

Sole production process

PendingCN109130271AReduce manufacturing costReduce secondary processingDomestic footwearRubber materialEngineering

The invention relates to a sole production process. The sole production process includes the steps of firstly, discharging a rubber material piece according to standard thickness, cooling, and cuttingoff with a cutting die for standby; secondly, arranging the upper die of a forming die on the upper heating plate of a sole forming device, and arranging the lower die of the forming die on the lowerheating plate of the sole forming device, wherein the sole forming device is provided with a burr cleaning device; thirdly, preheating the upper die and the lower die for 10-15 minutes; fourthly, after the heating, placing a first raw material in the lower die, covering the upper die and pressurizing for 3-5 seconds, placing a second raw material on the first raw material, and covering the upperdie and pressurizing for 3-5 seconds; fifthly, using the burr cleaning device to clean burrs; sixthly, covering the upper die and pressurizing, and vulcanizing the material in the forming die.

Owner:晋江市星仕明鞋材有限责任公司

Cutting and crushing system for plastic processing

InactiveCN111873255AReduce configurationReduce labor costsPlastic recyclingMechanical material recoveryElectric machinerySlide plate

The invention relates to the technical field of plastic processing, and discloses a cutting and crushing system for plastic processing. The system involves a box body, the upper portion of the box body is provided with a feeding box, the upper portion of the feeding box is provided with a feeding port, the lower portion of the box body is provided with a conveyor belt, one end in the rotating direction of the conveyor belt is provided with a sliding plate, a receiving box is arranged on the lower portion of the sliding plate, an extrusion wheel is arranged in the box body, barbs are arranged on the surface of the extrusion wheel, a partition plate is arranged on the side face of the extrusion wheel, and a first motor is arranged on the side face of the partition plate. According to the cutting and crushing system for plastic processing, the feeding box is matched with the box body, the box body is matched with the conveyor belt, and the conveyor belt and the receiving box are matched for use, so that in the whole working process, the labor force and personnel allocation are greatly reduced, the labor cost is reduced, and meanwhile, the working efficiency is improved, and the mechanical production in the working process is improved.

Owner:刘春喻

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com