Patents

Literature

121results about How to "Easy to change color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

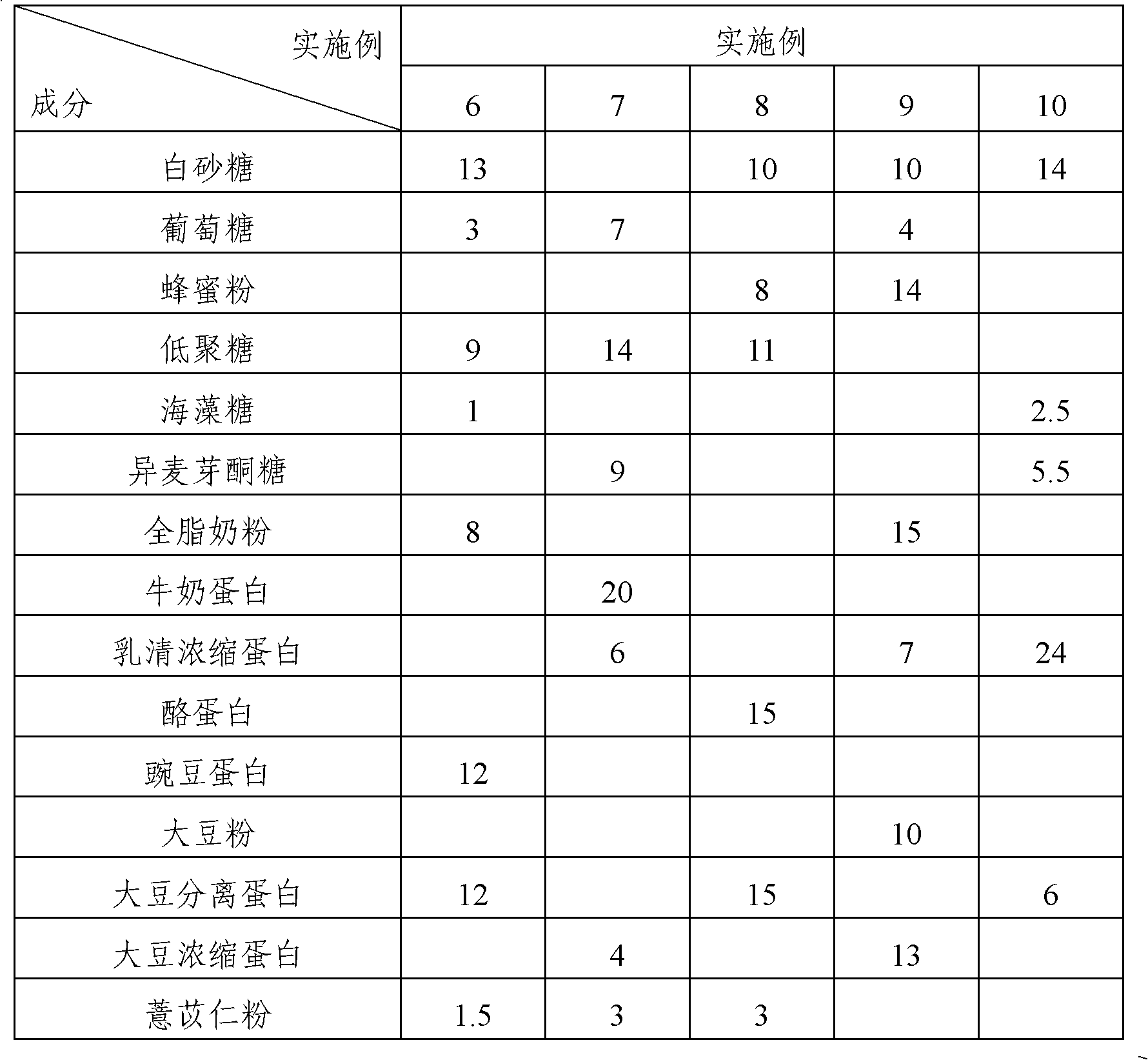

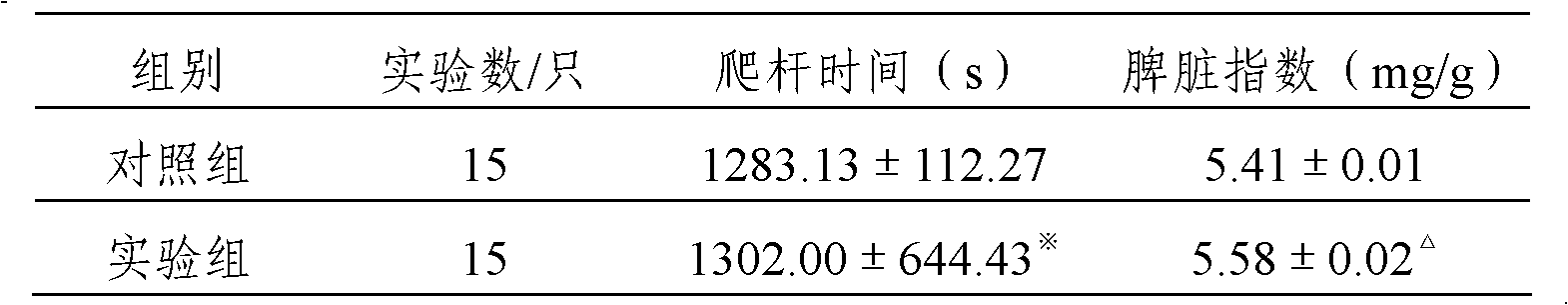

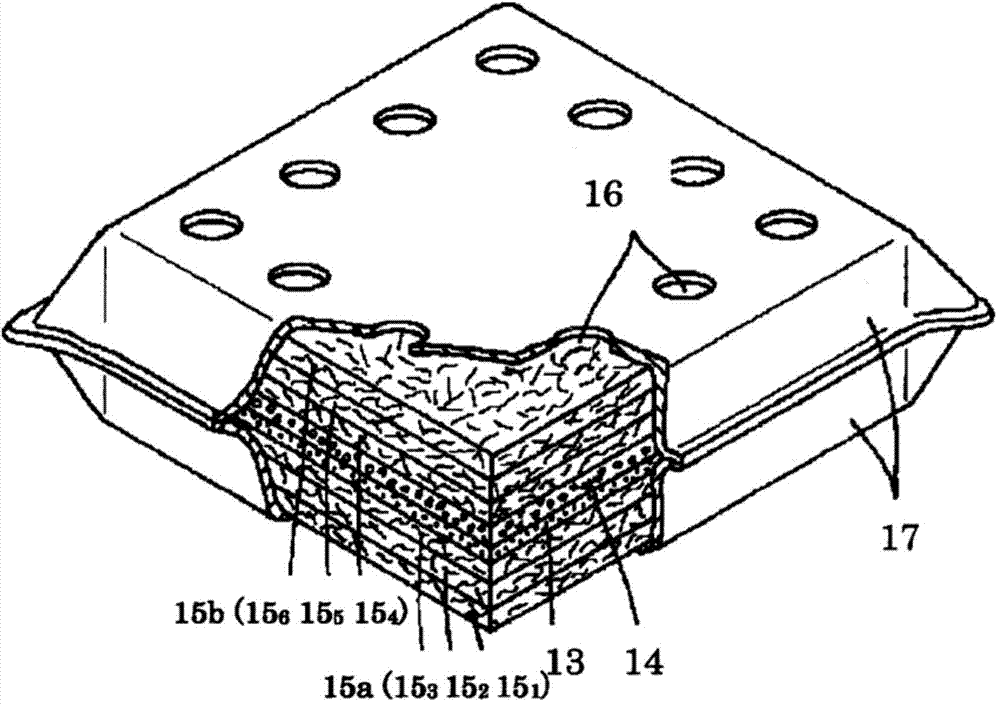

Energy supplement food and preparation method thereof

ActiveCN102178144AImprove immunityHas the effect of invigorating the spleenFood preparationFlavorMeal replacement

The invention provides an energy supplement food and a preparation method thereof. The energy supplement food comprises the following components in percentage by weight: 1 to 30 percent of spleen-reinforcing qi-tonifying component, 20 to 43 percent of sugar or syrup, 25 to 45 percent of protein component, 6 to 10 percent of grease and 8 to 25 percent of flavor component. The food can strengthen the immunity of human bodies, has the effect of tonifying spleen, also has the advantages of good mouthfeel and high stability, and can be taken as an energy supplement food eaten by white collar crowds, sport crowds and fitness crowds when the white collar crowds, the sport crowds and the fitness crowds are hungry, or meal replacement food of weight loss crowds.

Owner:BEIJING TONGRENTANG HEALTH PHARMA

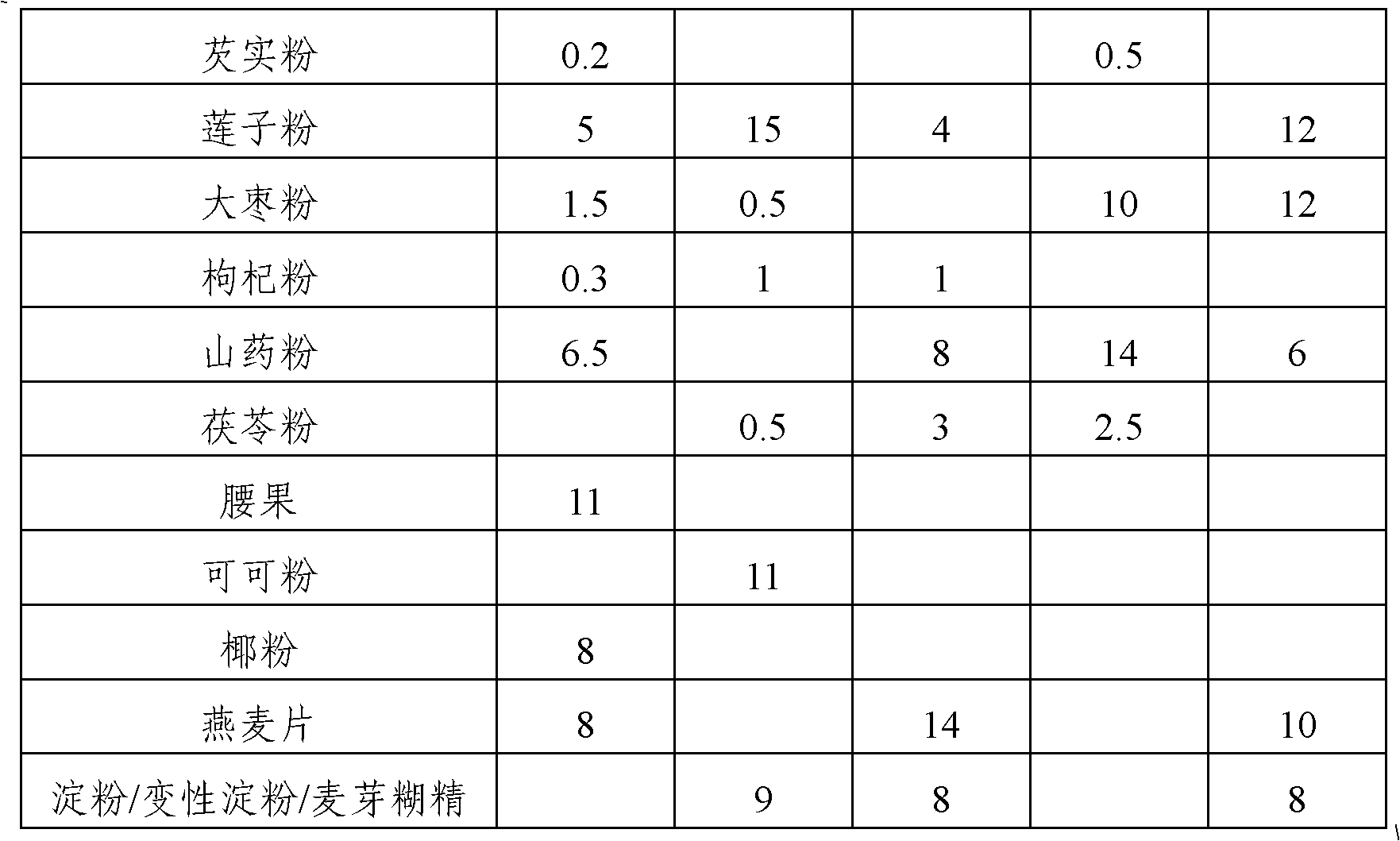

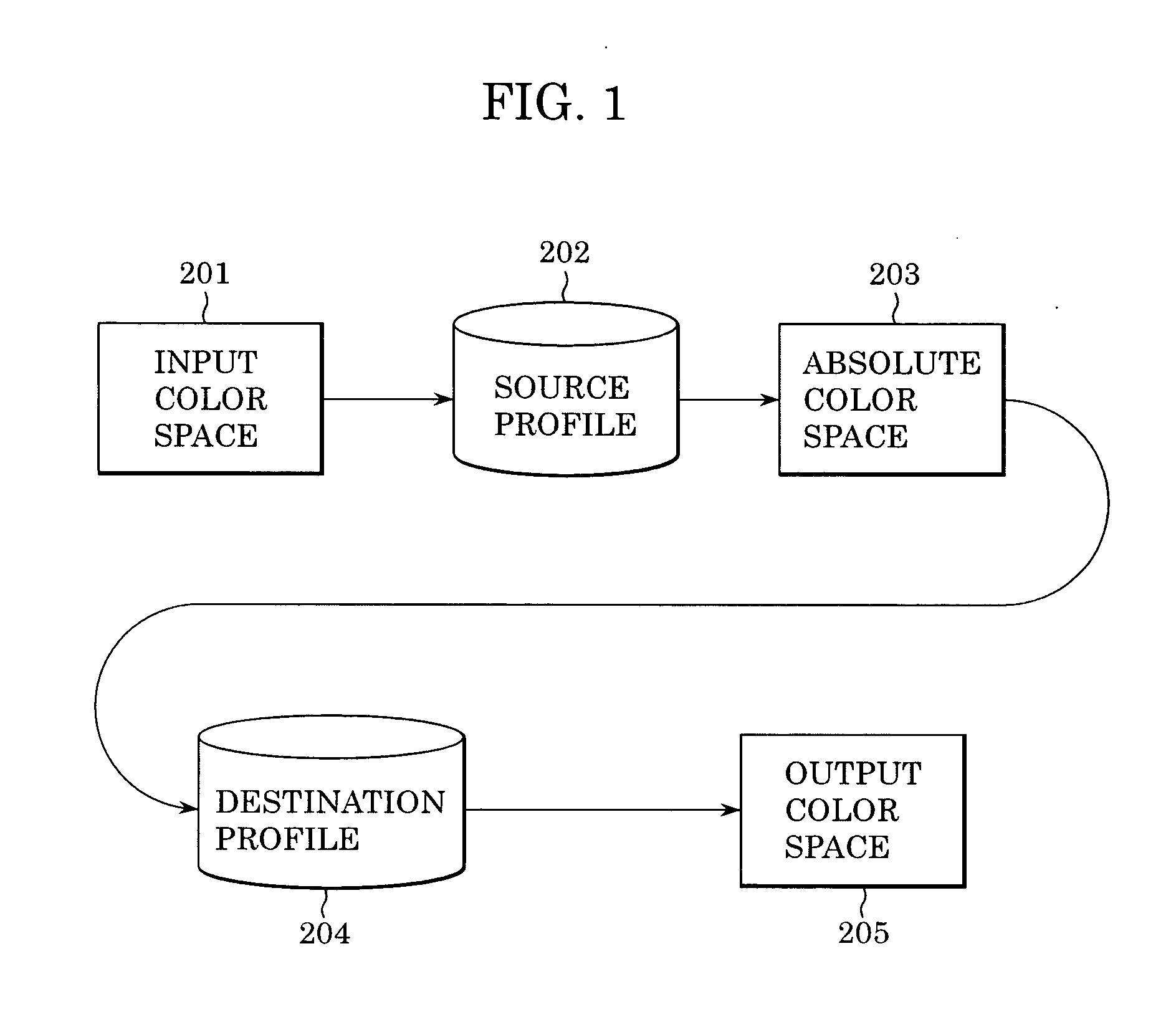

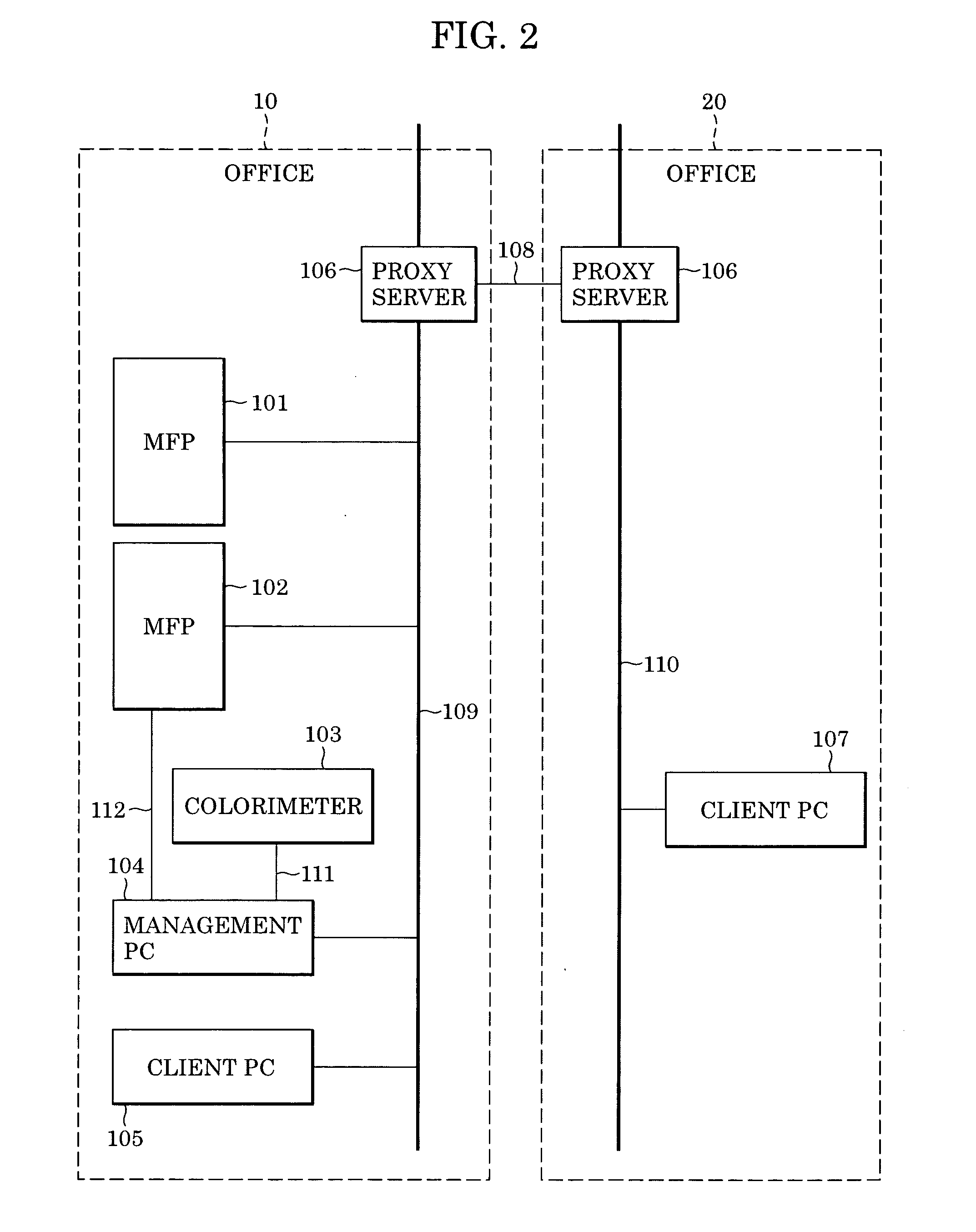

Image processing apparatus and method

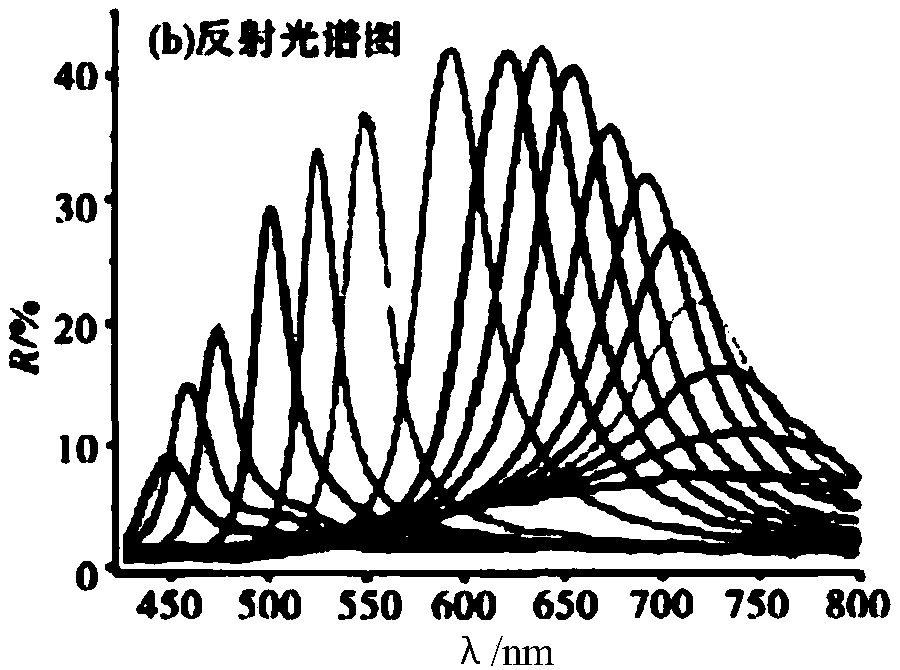

ActiveUS20050128498A1Easy to change colorDesirable colorDigitally marking record carriersDigital computer detailsPattern recognitionImaging processing

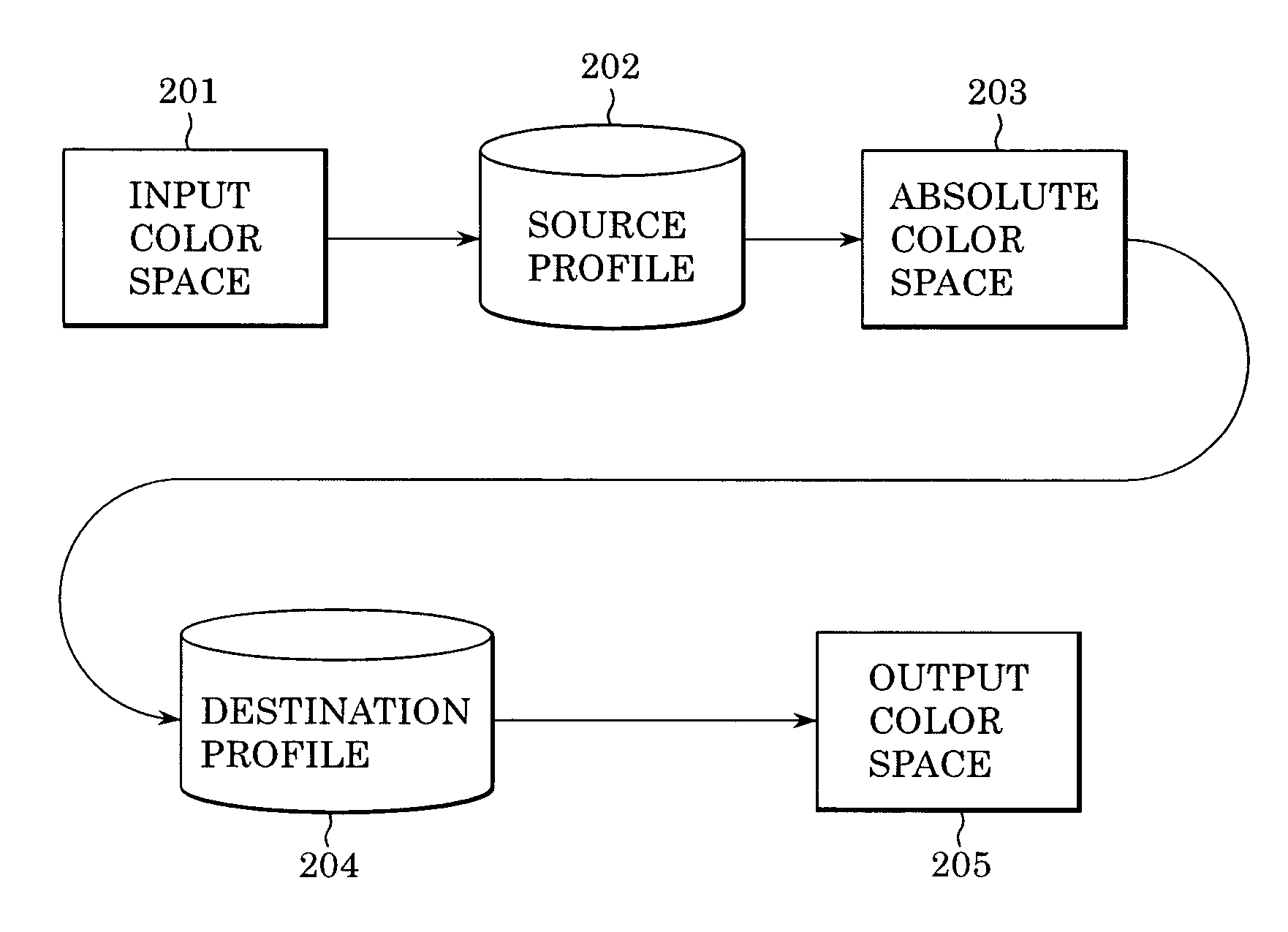

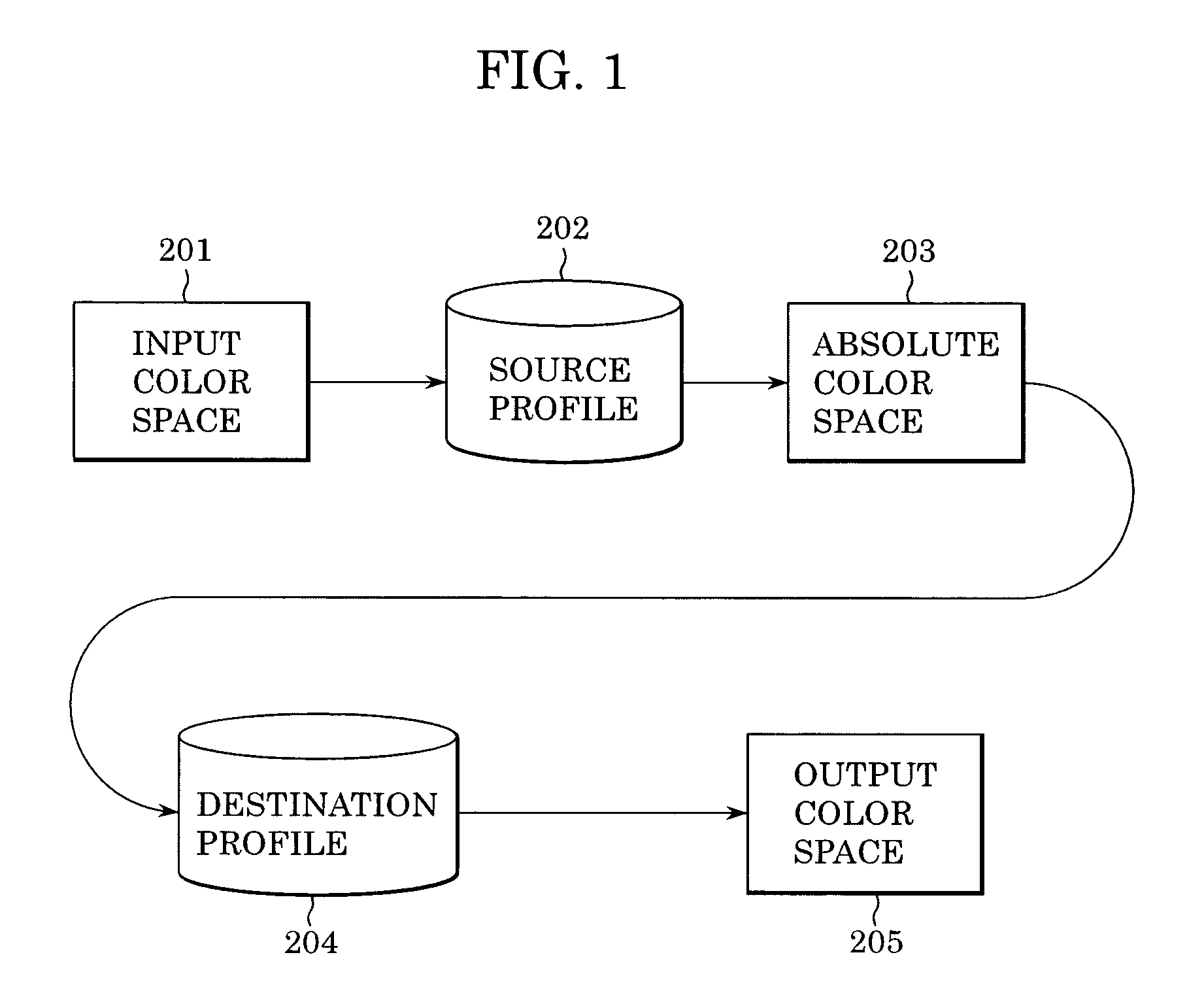

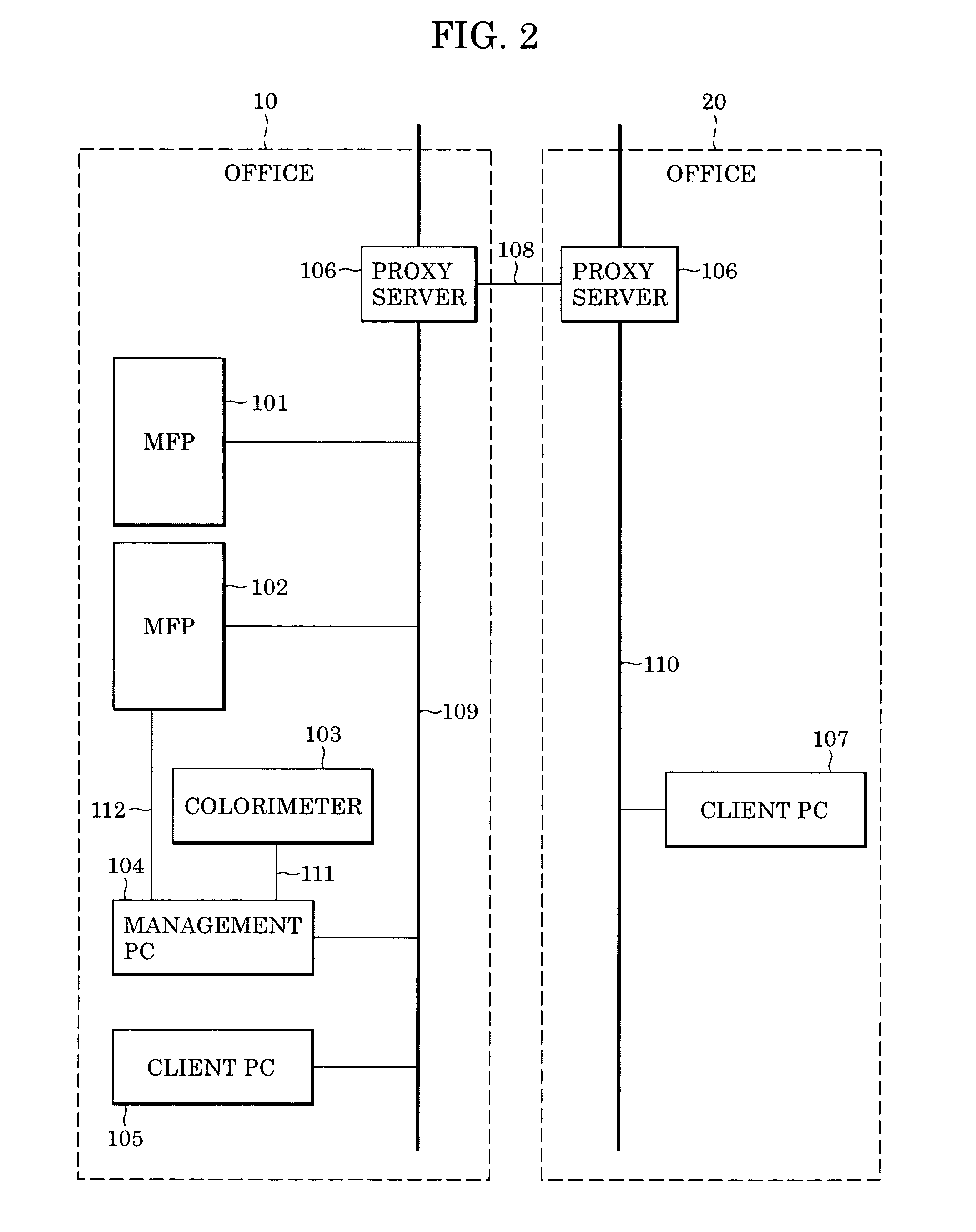

An image processing system and method include allowing an output device to output patch-data items of plural multi-order colors represented by a first color space, measuring the color values, in an absolute color space, of the output patch-data items, calculating reference values by converting the plural multi-order colors represented by the first color space based on a first color conversion table containing correspondence between the first color space and the absolute color space, calculating distances between the color values measured by the color measuring means and the reference values, which correspond thereto, and correcting, based on the calculated distances, a second color conversion table containing correspondence between the absolute color space and an output color space.

Owner:CANON KK

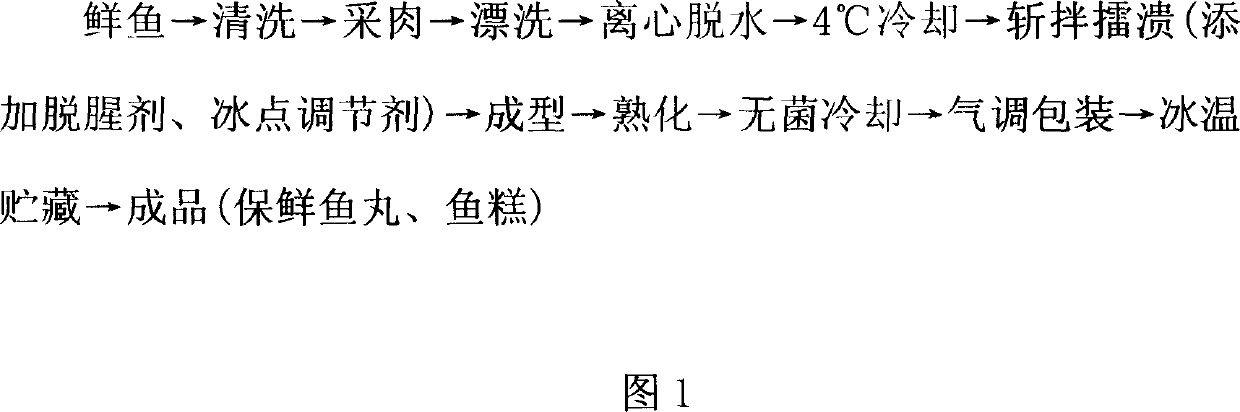

Ice-temperature air adjusting fresh-keeping minced fillet foodstuff and production process thereof

InactiveCN1545931AExtend freshnessGrowth inhibitionFood preservationFood preparationGrass carpChemistry

The invention relates to a process for preparing minced fish food and products by using meat of fresh water fish such as silver carp, grass carp as raw material, and table salt, modified starch, konjac glucomannan, white sugar, smell removing agent as auxiliary material. The preparing process comprises smell removing, freezing point adjustment, germ-free cooling down, air regulation packaging, and ice temperature storage.

Owner:HUAZHONG AGRI UNIV

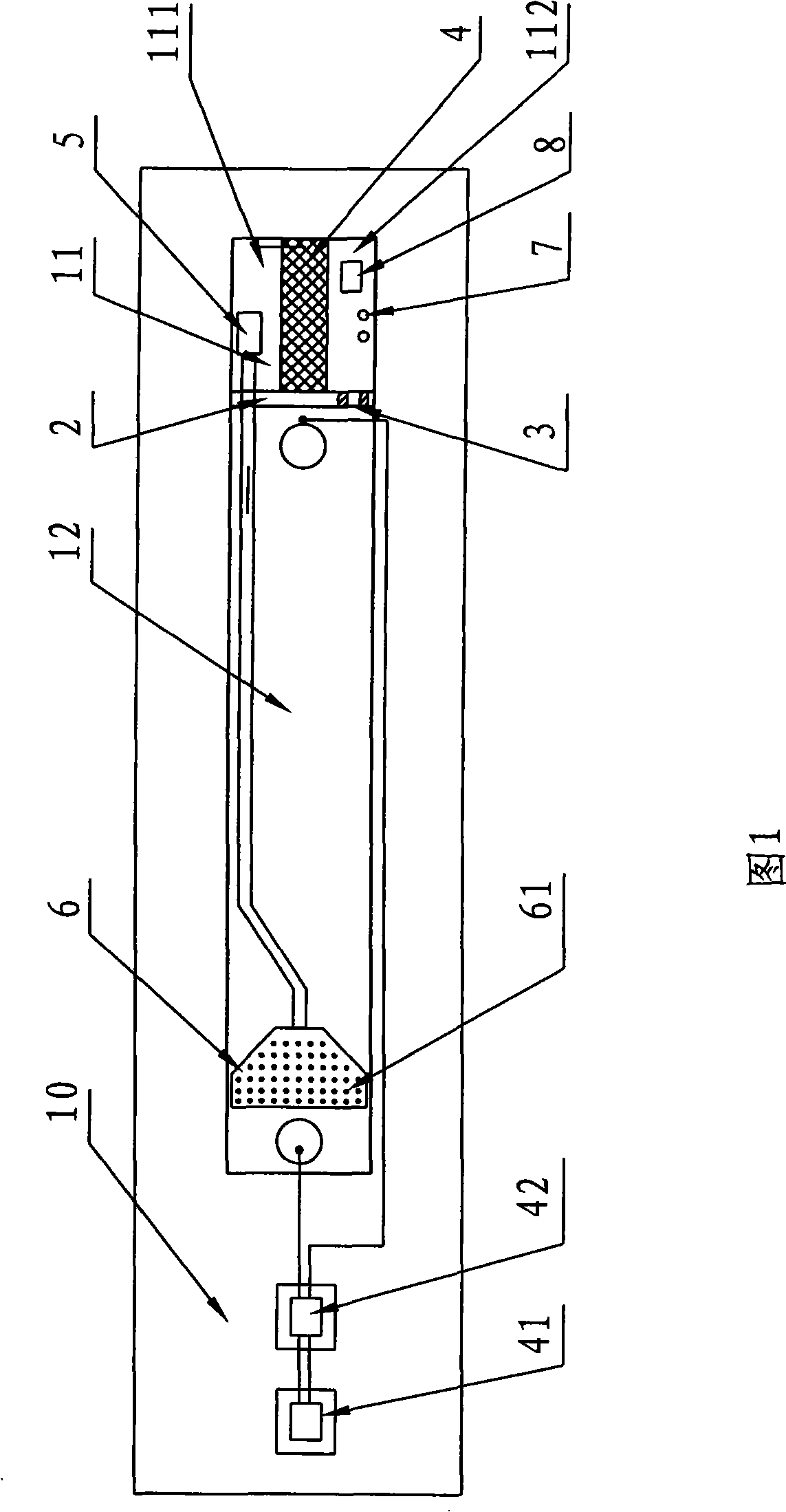

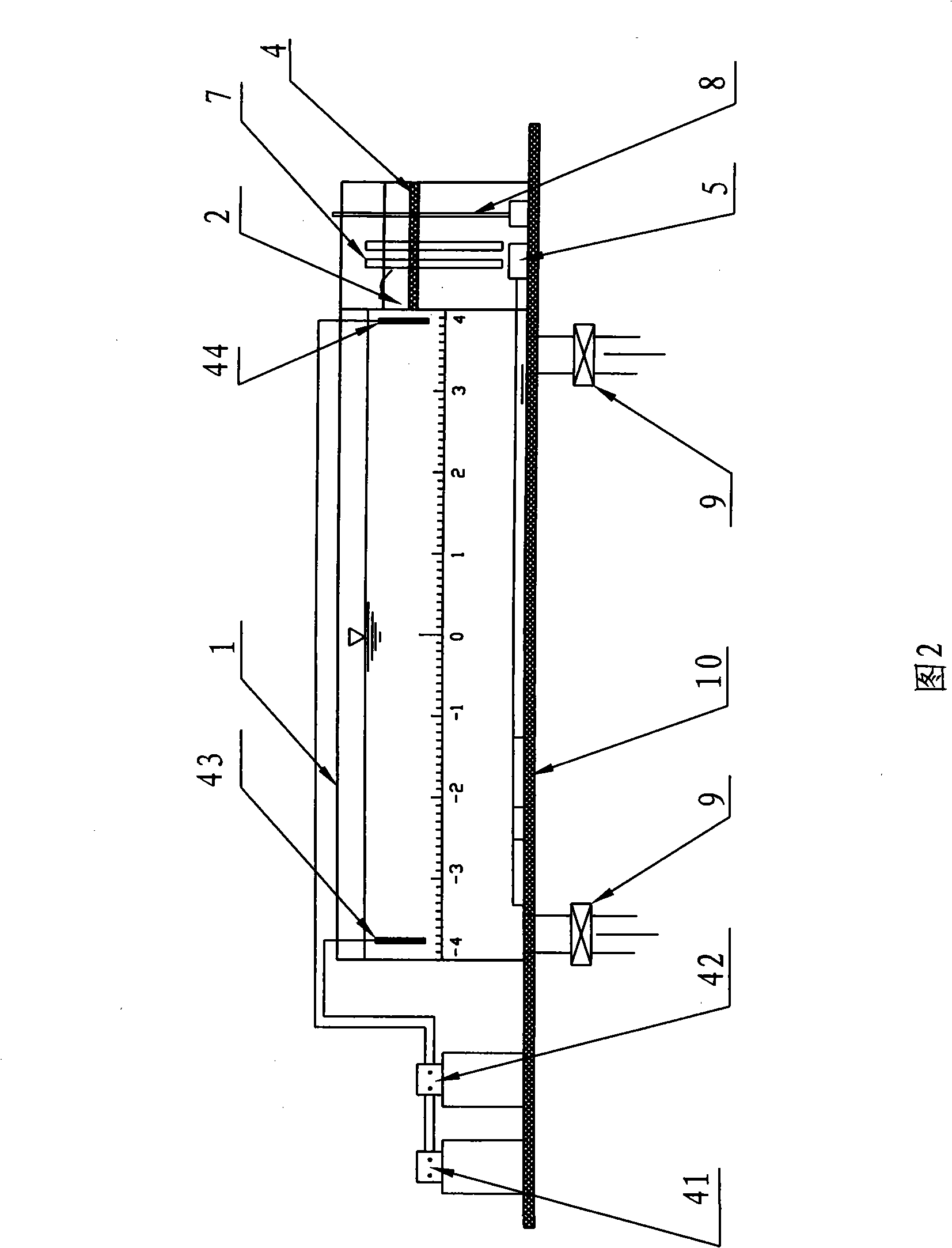

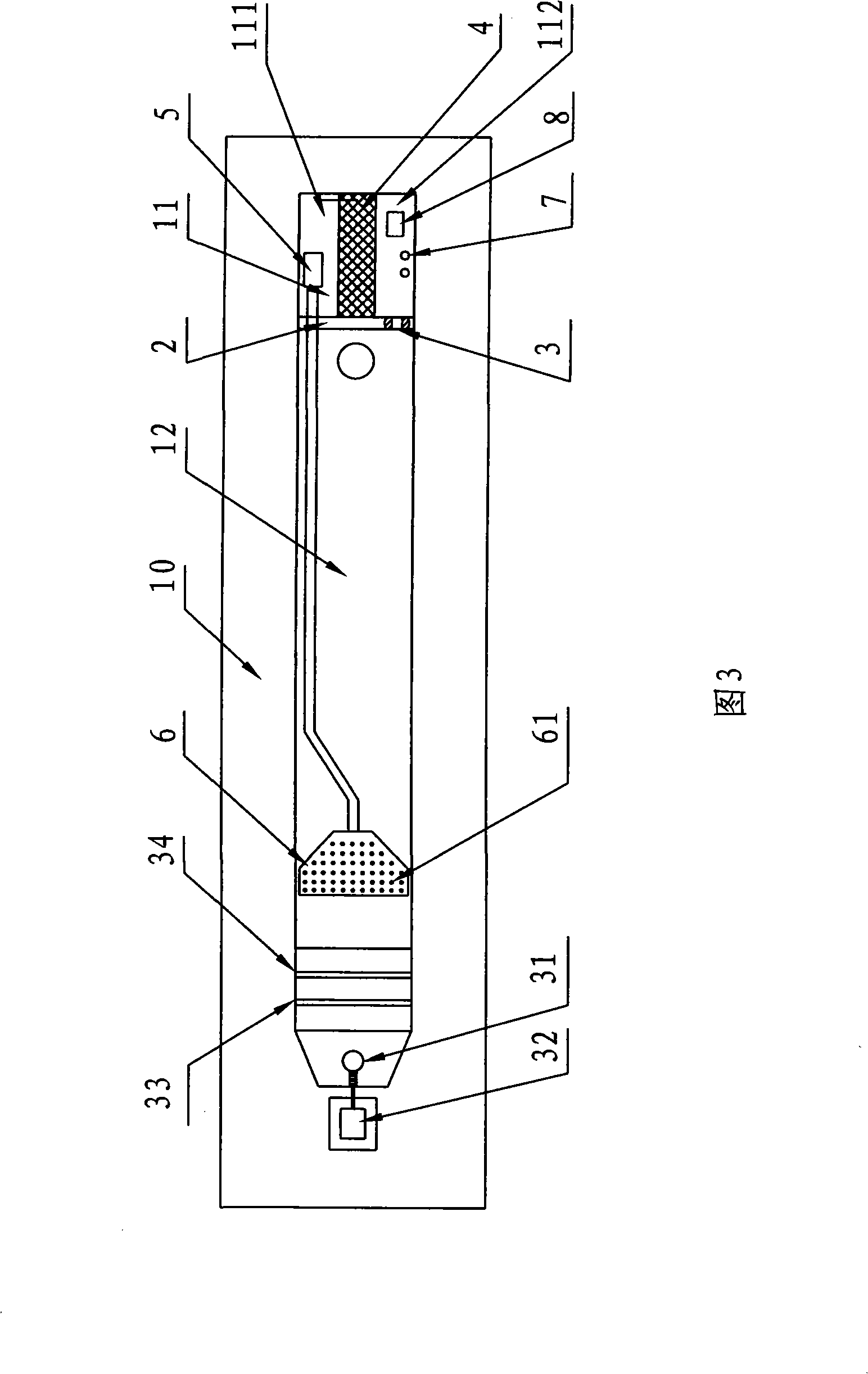

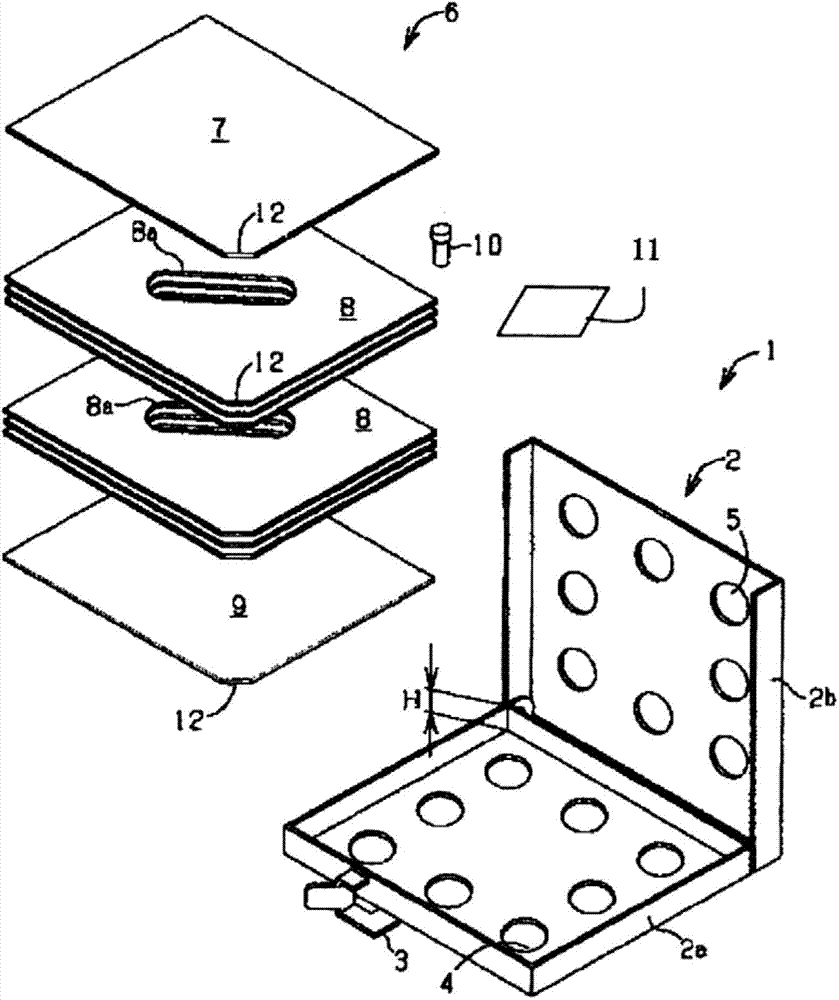

Tester for acousto-optic-electric action of fishes

InactiveCN101317553AEasy to measureEasy to change colorClimate change adaptationPisciculture and aquariaElectricityFiltration

The invention relates to a fish acoustic-photoelectric behavior testing device, comprising an acoustic reaction device, an optical reaction device and an electric reaction device which are independently combined with a circulation water trough to assemble the testing device or combined with each other two by two and then combined with the circulation water trough to assemble a fish behavior testing device or combined together and then combined with the circulation water trough to assemble the fish behavior testing device; the water flows through a plurality of pores on a water outlet device of the circulation water trough, thus leading the circulated water flow inside the trough body to have stable flowing speed; furthermore, high-precision filtration is adopted to lead the water to have high cleanliness, so as to adapt to the long-time fish behavior test. The fish acoustic-photoelectric behavior testing device has the advantages of reasonable structure, easy fabrication, and especially has the beneficial effects of easy controlling the testing acoustic source to simulate various fish sounds, easy changing the colors of testing light, providing various external profile of penetrating light, controllable electric reaction test voltage, easy measuring the test reaction region, carrying out the long-term fish behavior testing, etc.

Owner:ZHEJIANG OCEAN UNIV +2

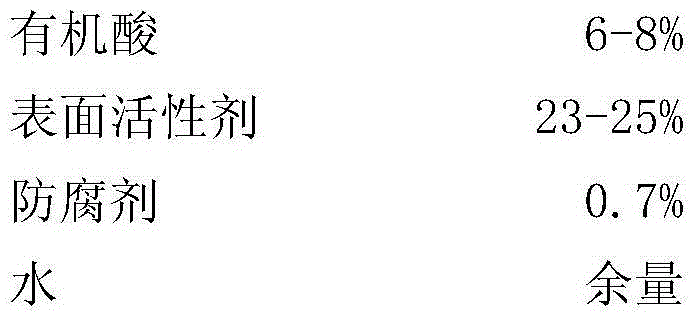

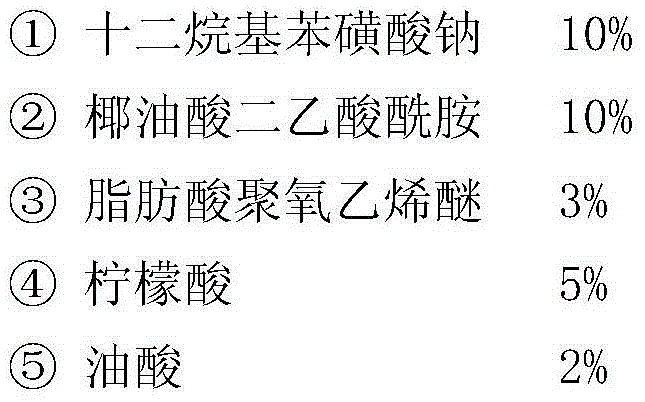

Copper alloy low-temperature cleaning agent

ActiveCN103603001ALow temperature cleaning effect is goodEasy to change colorOrganic acidPreservative

The invention relates to a copper alloy low-temperature cleaning agent which consists of the following raw materials in percent by weight: 6-8 percent of organic acids, 30-35 percent of surfactant, 0.7 percent of preservative and the balance of water, wherein the organic acids are citric acid and oleic acid; the surfactant comprises an anionic surfactant and a nonionic surfactant. According to the cleaning agent, multiple specified anionic surfactants and nonionic surfactants, organic acids and preservatives are compounded, the corresponding ratio is adjusted, and the mixed cleaning agent has the characteristic of low-temperature cleaning effect and is particularly suitable for cleaning a watch shell. Because parts of a watch are high in precision requirements and are generally made of the copper alloy, the copper alloy has the requirement of having a relatively good cleaning effect at the relatively low temperature of less than 45 DEG C on the temperature or the temperature of cleanout fluid, if the temperature is extremely high, the parts easily discolor or are easily corroded, and therefore, the low-temperature cleaning agent is needed.

Owner:TIANJIN ZHENPENG CLEANING TECH DEV

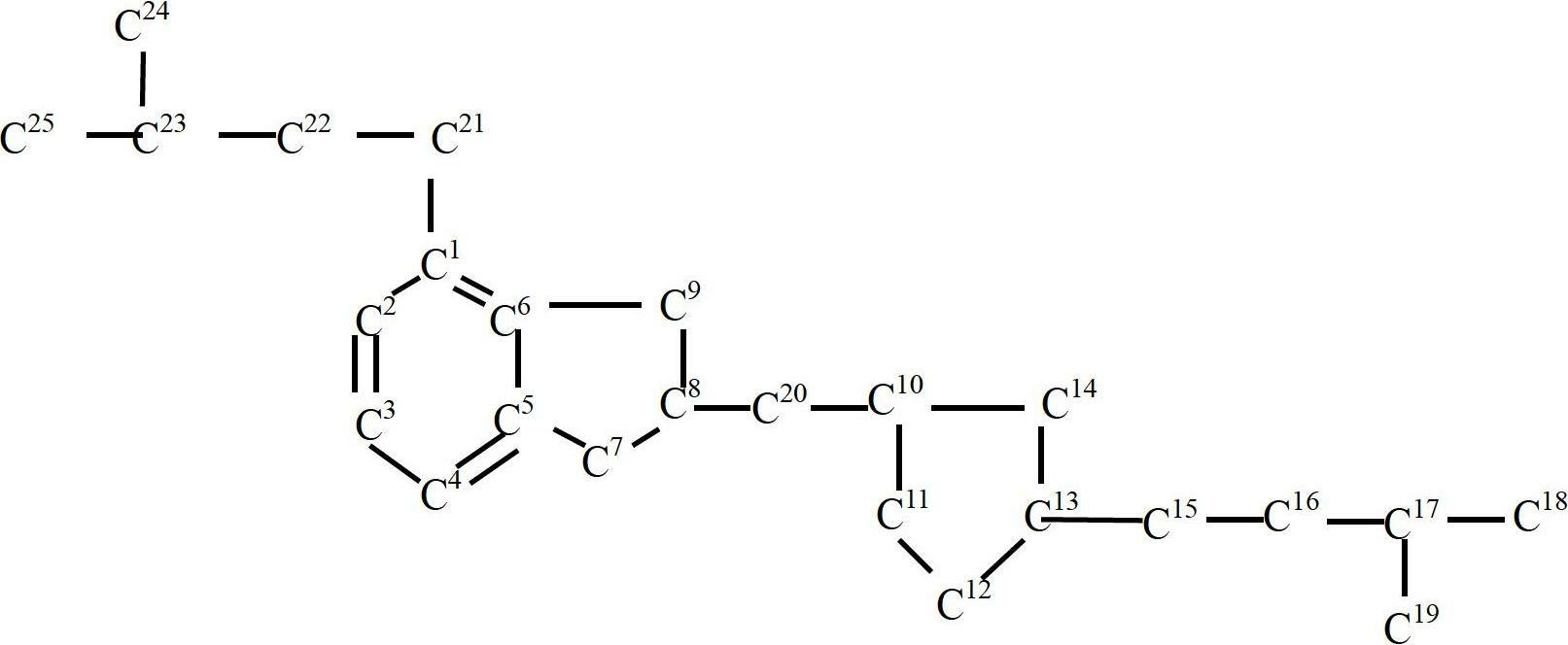

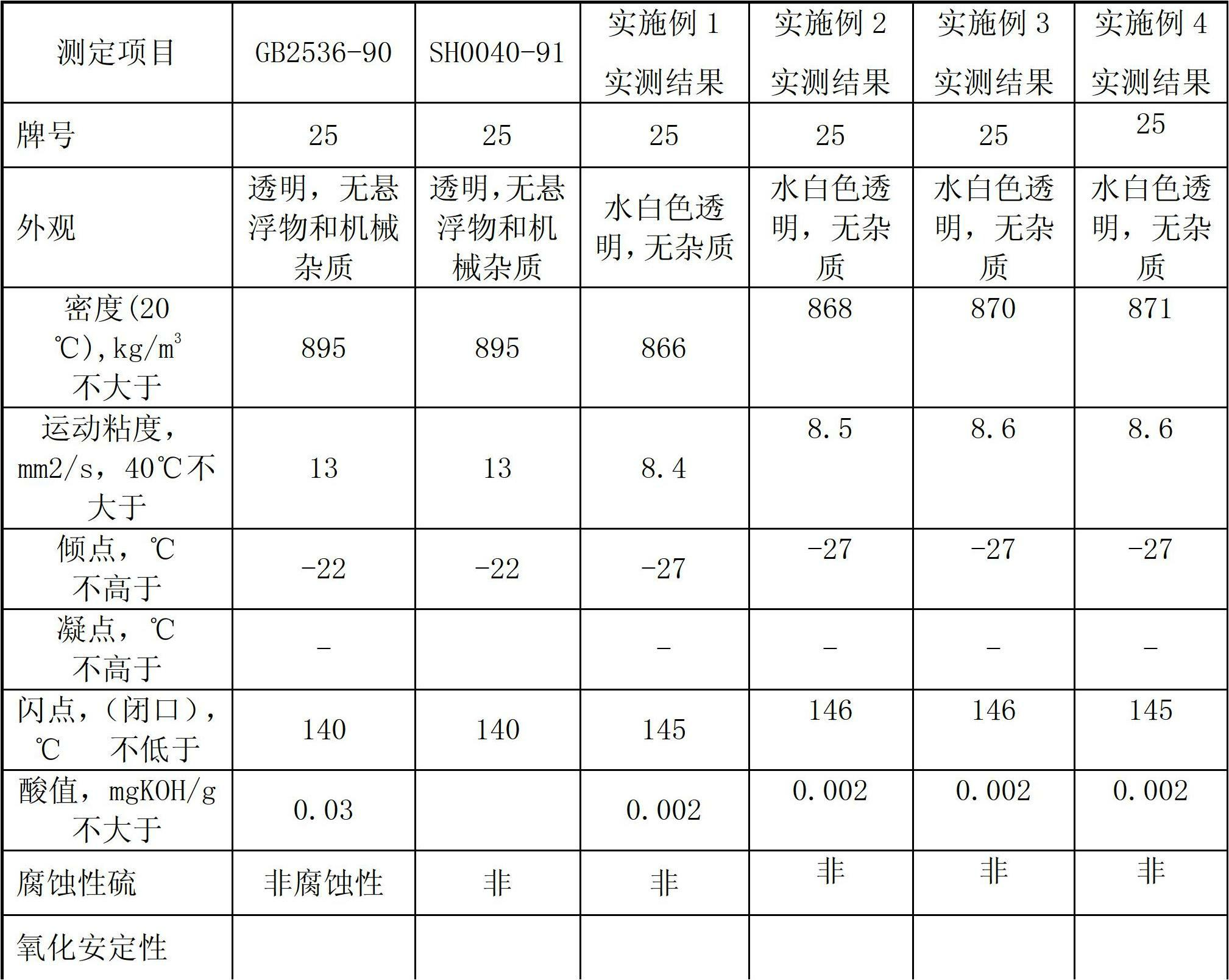

Transformer oil and preparation method thereof

ActiveCN102660363AThe effect is positive and obviousImprove securityLubricant compositionWaxParaffin oils

Transformer oil comprises paraffin base oil fraction, naphthenic base oil, alkyl high boiling substances, antioxidant and photosensitivity resistant agents. In the transformer oil, the weight percentage of the paraffin base oil fraction ranges from 60% to 75%, the weight percentage of the naphthenic base oil ranges from 19.4% to 28.5%, the weight percentage of the alkyl high boiling substances ranges from 5% to 10%, the weight percentage of the antioxidant ranges from 0.5% to 1.0%, and the weight percentage of the photosensitivity resistant agents ranges from 0.1% to 0.5%. The invention further provides a preparation method for the transformer oil, and the preparation method includes adding the paraffin base oil fraction, the naphthenic base oil and the alkyl high boiling substances in a reaction kettle; adding clay in the mixture to refine; performing stirring, refining and adsorbing at high temperature; adding antioxygen additives and photosensitivity agents in the mixture after themixture is filtered; and performing vacuum treatment once to three times in a vacuum pump under negative pressure of 0.8KPa. The kinematic viscosity of the transformer oil is 6.5mm<2> / s-9.5mm<2> / s, and the breakdown voltage reaches 55-80KV / 2.5mm.

Owner:上海中孚油品集团有限公司

Coloring master batches for polyethylene and preparation method thereof

The invention discloses coloring master batches for polyethylene and a preparation method thereof. The coloring master batches for polyethylene disclosed by the invention comprise the following components in percentage by mass: 70%-90% of pigment, 10%-20% of polyethylene resin, 3%-5% of dispersant, 0.1%-1% of antioxidant and 0.1%-1% of antistatic agent. Compared with the prior art, the coloring master batches for polyethylene have the beneficial effects that the prepared coloring master batches for polyethylene are applied to coloring of polyethylene products, have the characteristics of good dispersibility, uniform coloring, high concentration, little dosage and no influence on the mechanical property of the polyethylene products, and are low in cost, easy to color, convenient to use and capable of saving production time and raw materials and the like.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

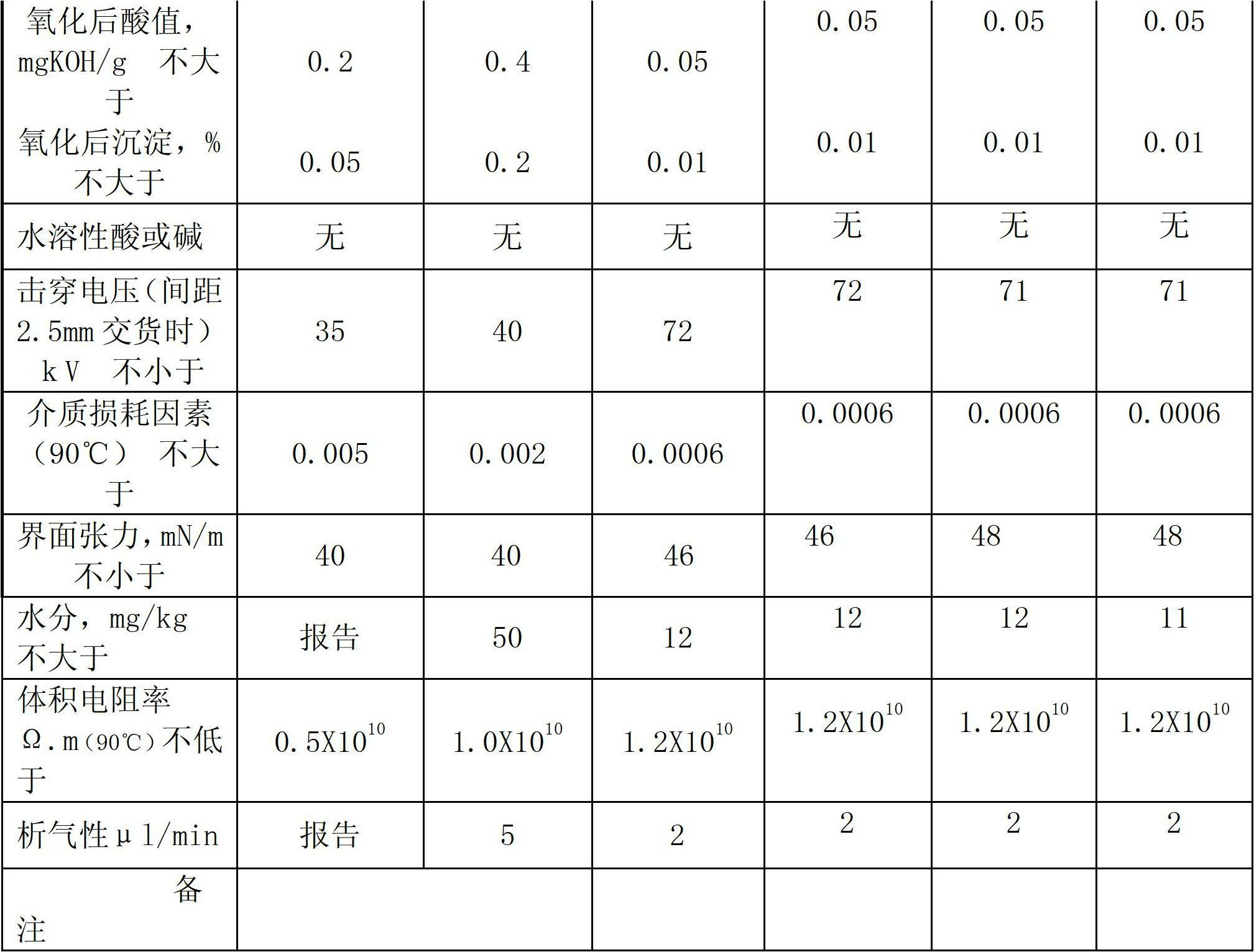

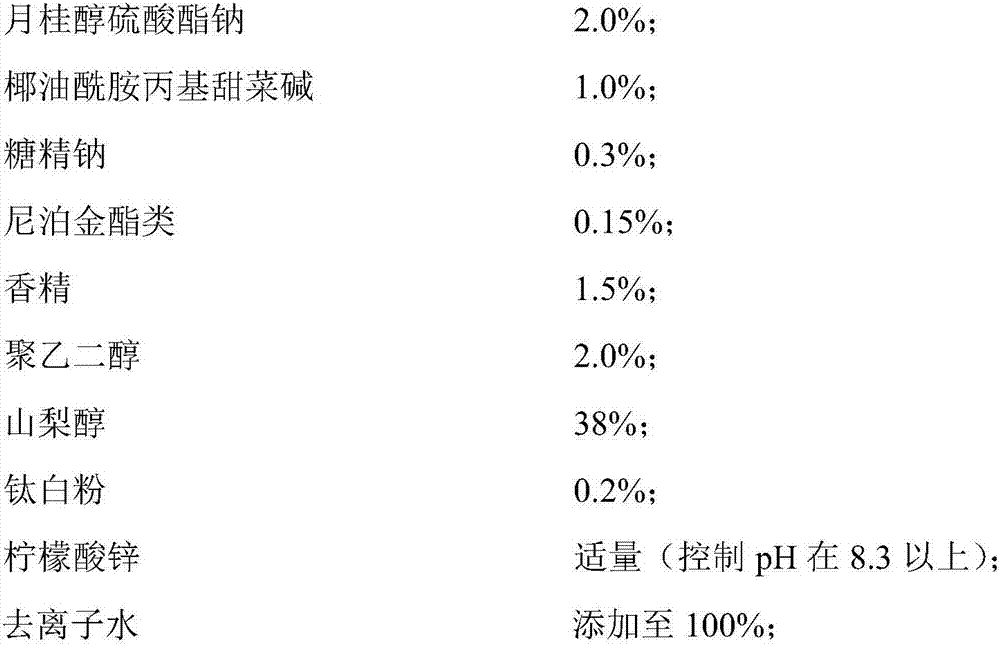

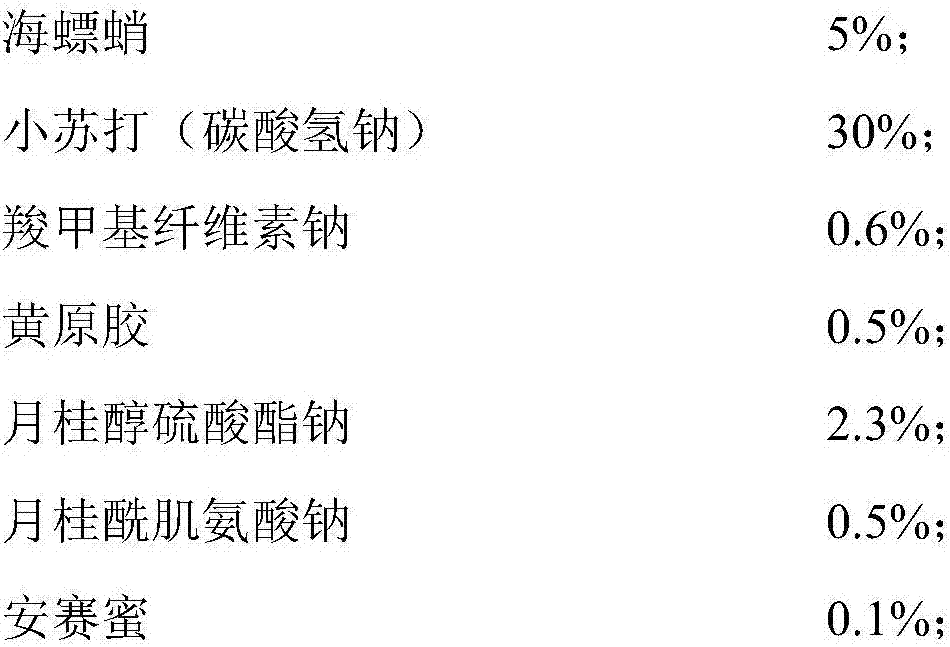

Toothpaste with low abrasion and high tooth cleaning effect

InactiveCN107982185AAvoid wear and tearAvoid the problem of poor cleaning powerCosmetic preparationsToilet preparationsSodium bicarbonatePreservative

The invention discloses toothpaste with low abrasion and a high tooth cleaning effect. The toothpaste is prepared from the following components in percentage by weight: 20 to 40 percent of a frictionagent composition, a humectant, a thickener, a surfactant, a sweetener, a preservative, essence, de-ionized water and the like. The friction agent composition is prepared from 5 to 20 percent of cuttlebone and 10 to 30 percent of baking soda (sodium bicarbonate). According to the toothpaste disclosed by the invention, a natural friction agent is prepared by carrying out degreasing and protein removal treatment on the cuttlebone; then the natural friction agent and the baking soda (sodium bicarbonate) form the friction agent composition and the friction agent composition is added into the toothpaste, so that the low-abrasion and high-tooth-cleaning-effect type toothpaste is provided.

Owner:MINGCHEN HEALTH CO LTD

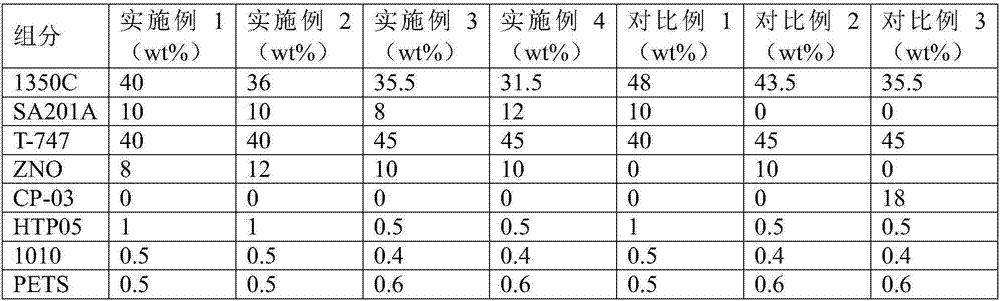

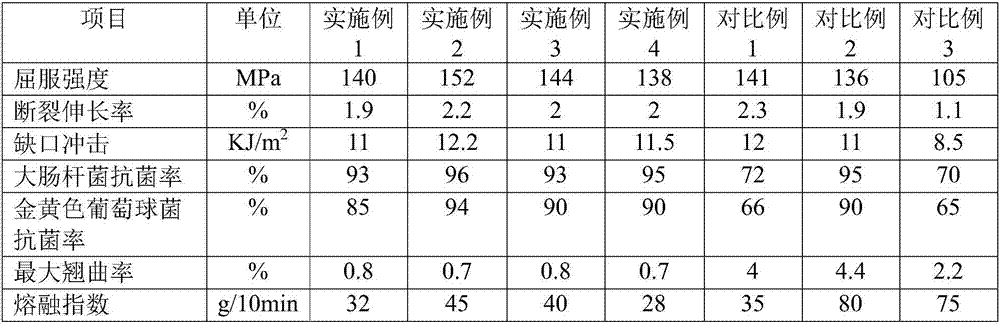

Antimicrobial low-warpage low-flash PPS composite material and preparation method thereof

The invention discloses an antimicrobial low-warpage low-flash PPS composite material and a preparation method thereof. The material is prepared from, by weight, 31.5-48% of PPS resin, 6-12% of PPE resin, 40-45% of glass fibers, 8-12% of antimicrobial agent, 0.5-1% of nucleating agent, 0.4-0.5% of antioxidant and 0.5-0.6% of lubricating agent. An engineering plastic, namely PPS, serves as a main body, the PPE resin, the glass fibers, the antimicrobial agent, the nucleating agent the antioxidant and the lubricating agent are added, the raw materials are mixed together and melted through a double-screw extruder, and then the antimicrobial low-warpage low-flash PPS composite material which is capable of meeting the antimicrobial requirements of household appliances is prepared. The material has the advantages of being antimicrobial, low in warpage and low in flash on the basis of ensuring the original excellent mechanical performance, heat resistance, fire resistance and electrical performance of PPS.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Color-changing method of teak wood floor

ActiveCN101670603AReduce dark streaksReduce spotsWood treatment detailsWood impregnation detailsChange colorEngineering

The invention discloses a color-changing method of a teak wood floor. The color-changing method carries out ultraviolet irradiation with the wavelength of 280 to 400 nanometers to the teak wood floorwith immersed surface so as to achieve color changing of the teak wood floor. The color-changing method is not limited by fields and weather, has time color-changing time, high efficiency and excellent color-changing effect and obviously reduces the black patterns and spots on the surface of the teak wood floor after changing color.

Owner:JIUSHENG WOOD

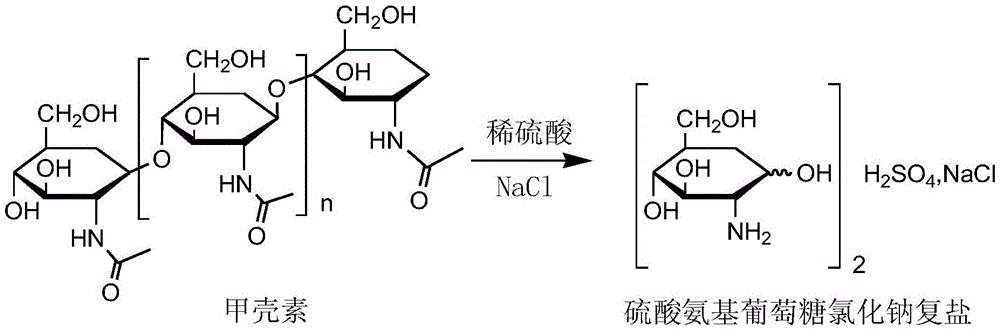

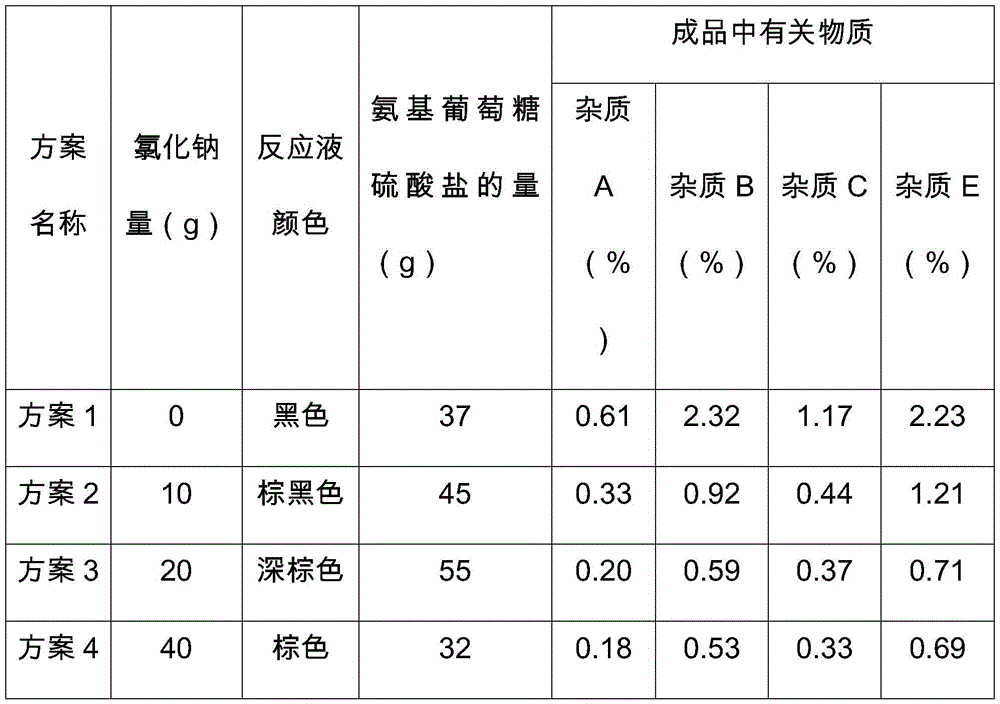

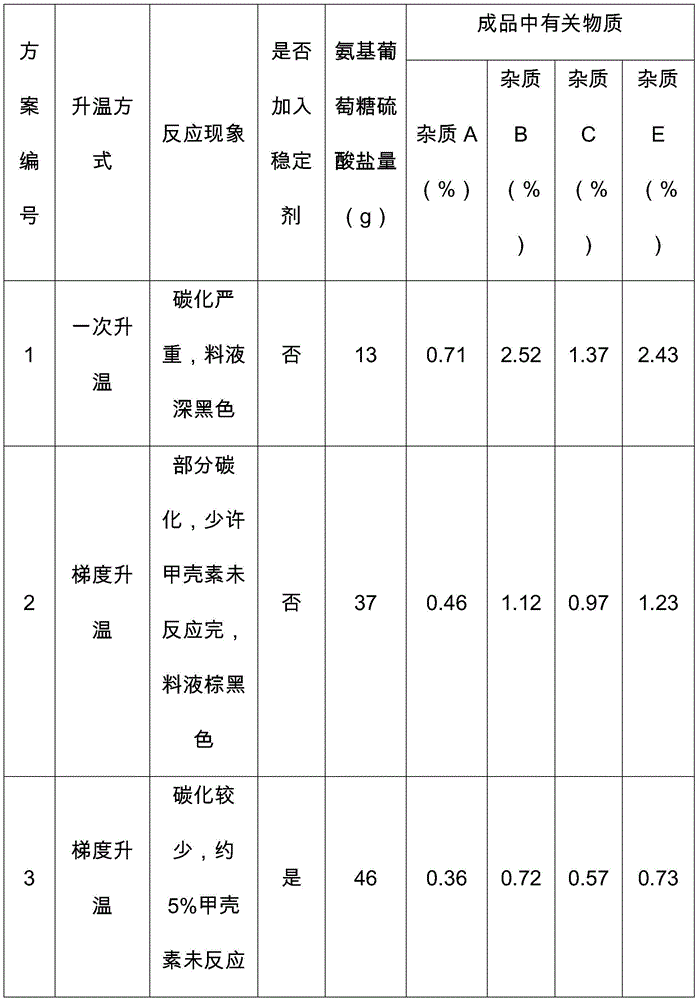

Preparation method of glucosamine sulfate and sodium chloride double salt

ActiveCN106749436AImprove stabilityMild responseSugar derivativesSugar derivatives preparationGlucosamine SulfateMass ratio

The invention discloses a preparation method of glucosamine sulfate and sodium chloride double salt. The preparation method comprises the following steps: adding chitin and dilute sulfuric acid into a reactor, wherein the concentration of the dilute sulfuric acid is 40%-90%, and the mass ratio of the dilute sulfuric acid to the chitin is (3-10):1; performing a fist stage of temperature rise and thermal insulation reaction, wherein the temperature in the fist stage of temperature rise is 40-70 DEG C, and the time in the fist stage of thermal insulation is 2-10 hours; then adding sodium chloride as a reaction stabilizer, wherein the mass ratio of the sodium chloride to the chitin is (0.1-0.5):1; performing a second stage of temperature rise and thermal insulation reaction, wherein the temperature in the second stage of temperature rise is 70-90 DEG C, and the time in the fist stage of thermal insulation is 1-5 hours; after the completion of basic reaction, quickly reducing the temperature of reaction liquid. The preparation method disclosed by the invention is simple in process and low in cost, and facilitates industrial production; an obtained finished product is stable in property, difficult to yellow and moisten, and good in impurity situations; the contents of glucosamine sulphate and sodium chloride conform to the drug requirements; the quality is stable.

Owner:GUANGDONG XIANQIANG PHARMA +1

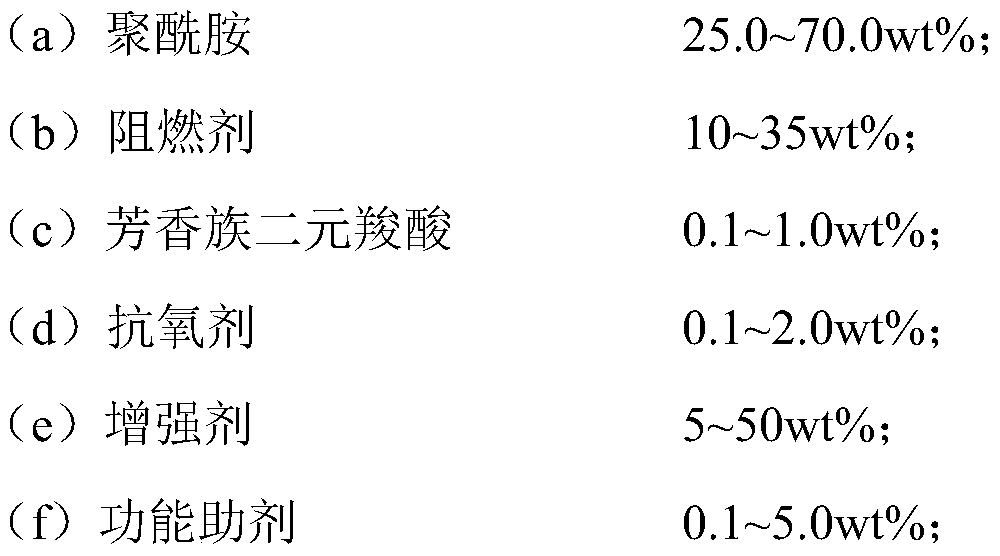

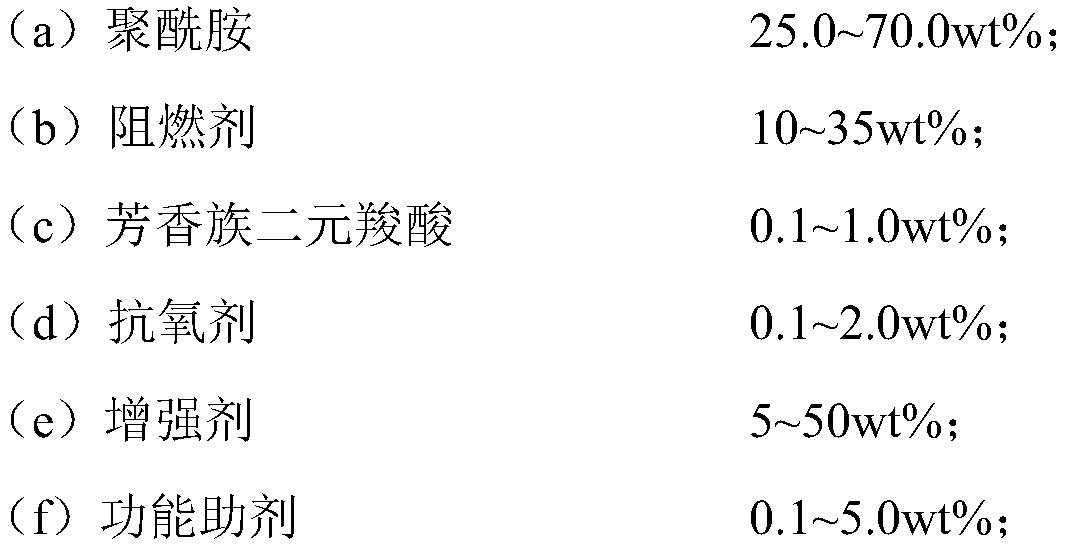

Yellowing-resistant and flame-retardant polyamide composition and preparation method thereof

The invention belongs to the technical field of polymer materials, and concretely relates to a yellowing-resistant and flame-retardant polyamide composition and a preparation method thereof. The polyamide composition comprises 25.0-70.0 wt% of polyamide, 10-35 wt% of a flame retardant, 0.1-1.0 wt% of aromatic dicarboxylic acid, 0.1-2.0 wt% of an antioxidant, 5-50 wt% of a reinforcing agent and 0.1-5.0 wt% of a functional assistant. The polyamide composition is obtained by melt blending, and the preparation method has the advantages of simplicity, low production cost, and facilitation of promotion. The polyamide composition of the present invention meets UL-94V-0 standard with high flame retardancy, does not affect the coloring property, and improves the thermotropic yellowing problem.

Owner:江苏晋伦塑料科技有限公司

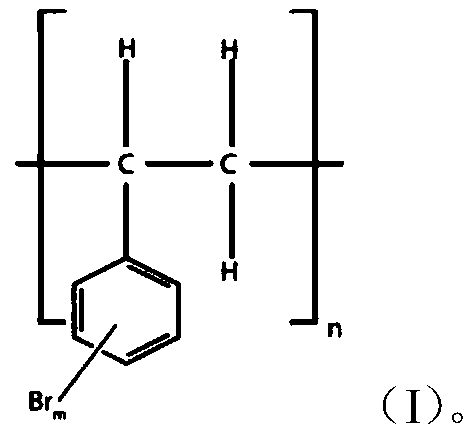

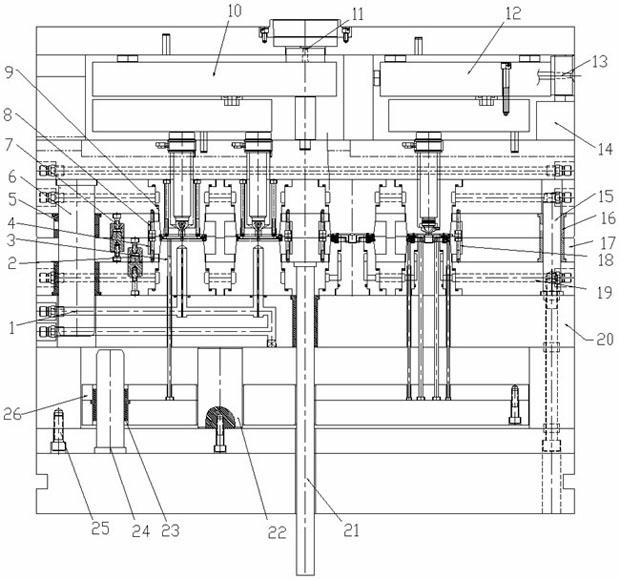

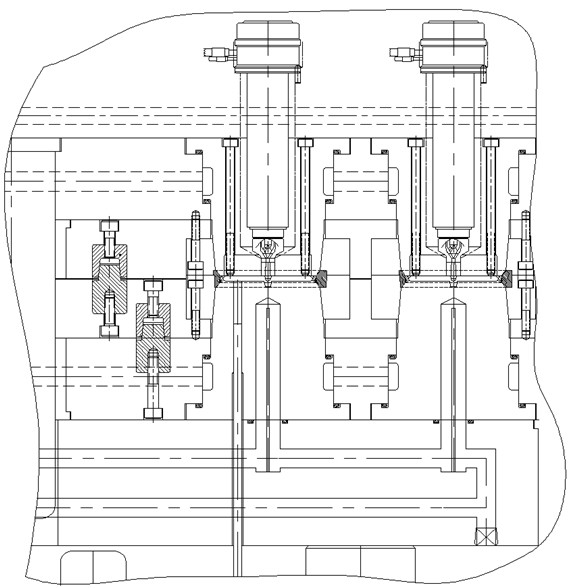

Double-color hot runner die and using method thereof

The invention discloses a double-color hot runner die and a using method thereof. The double-color hot runner die comprises thimbles, a positioning round pin, a rear die insert, a rear die, a guide sleeve, an upper guide post, a front die, a front die insert, a hot runner, a pouring gate, a movable die and a cylinder. A double-color die product is generated by one-time stripping in the hot runnerdie. After the die is closed for casting in use, the die is opened, the runner rest in a semi-finished product is ejected, then the movable die rotates for 180 degrees, the die is closed again for casting, the die is opened, the runner rest and the finished product in the semi-finished product are ejected by the left and right thimbles respectively, and then the die is closed for processing the products of next batch. The double-color hot runner die has the advantages of high automation degree, high production efficiency, low requirement for operators and simplicity in processing; and the cost is reduced due to large production batch, the appearance of the produced product is attractive, the reject rate is reduced, the quality of the product is improved, the plastic raw material is saved,and subsequent processes are not needed.

Owner:南通江海港建设工程有限公司

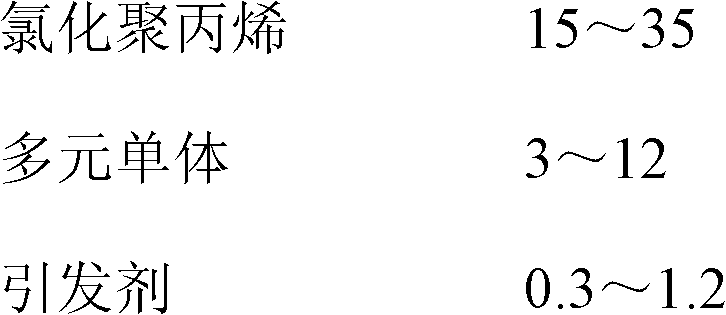

Method for preparing modified chlorinated polypropylene and paint produced by modified chlorinated polypropylene for plastic-steel doors and windows

The invention discloses modification of chlorinated polypropylene and paint prepared by the chlorinated polypropylene for plastic-steel doors and windows. In the modification, the chlorinated polypropylene is modified by adopting composite acrylic monomers by virtue of a heterogeneous graft technology, and a polar group is introduced into the backbone, so that the backbone can be dissolved in an ester solvent. The modified resin has higher hardness and excellent low-temperature usability by regulating the proportion of soft and hard monomers. The finished product paint is prepared by using modified chlorinated polypropylene resin as a main film forming substance, adding dispersant, defoaming agent, flatting agent, ultraviolet absorbent and pigment, preparing materials, dispersing, grinding, stirring and filtering. According to the preparation method and the pain, colorization of plastic-steel doors and windows is realized, the fullness of the paint coating is improved, and color changing is flexible; the paint has excellent adhesive force and weather tolerance, and the service life of doors and windows is prolonged; and the paint is environmentally friendly, has low cost, and can be widely used.

Owner:ANHUI NORMAL UNIV

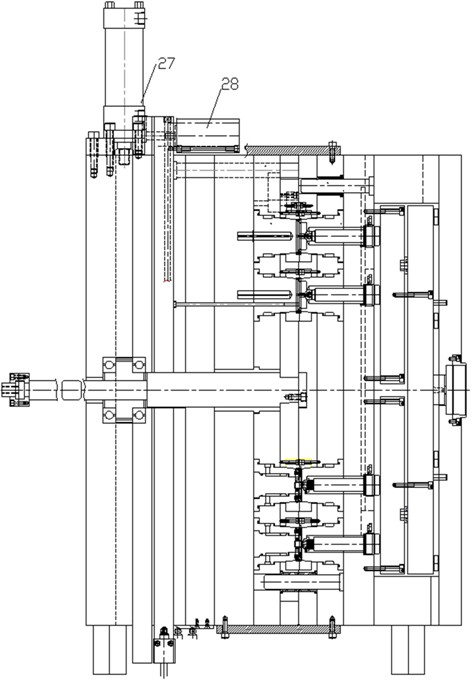

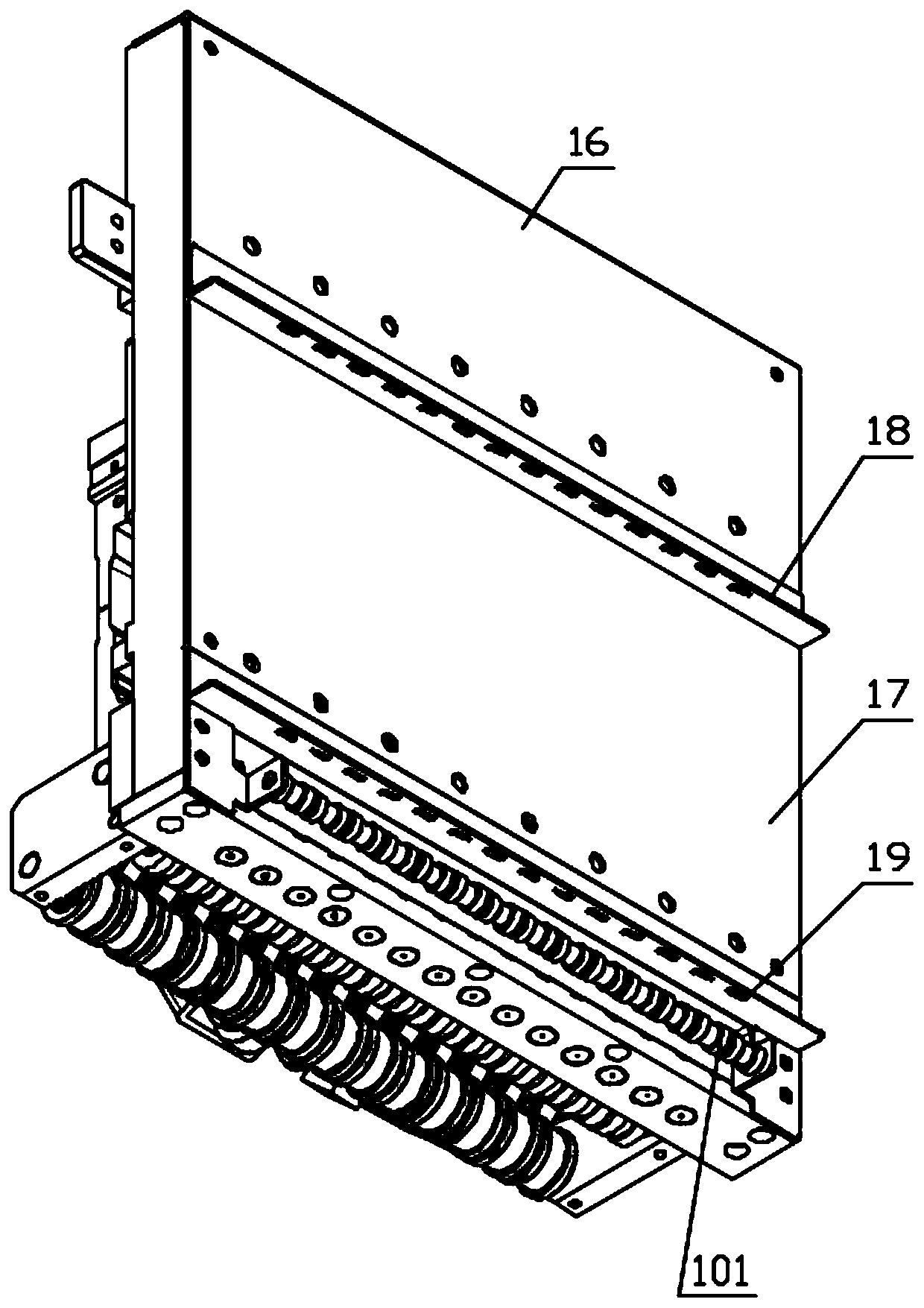

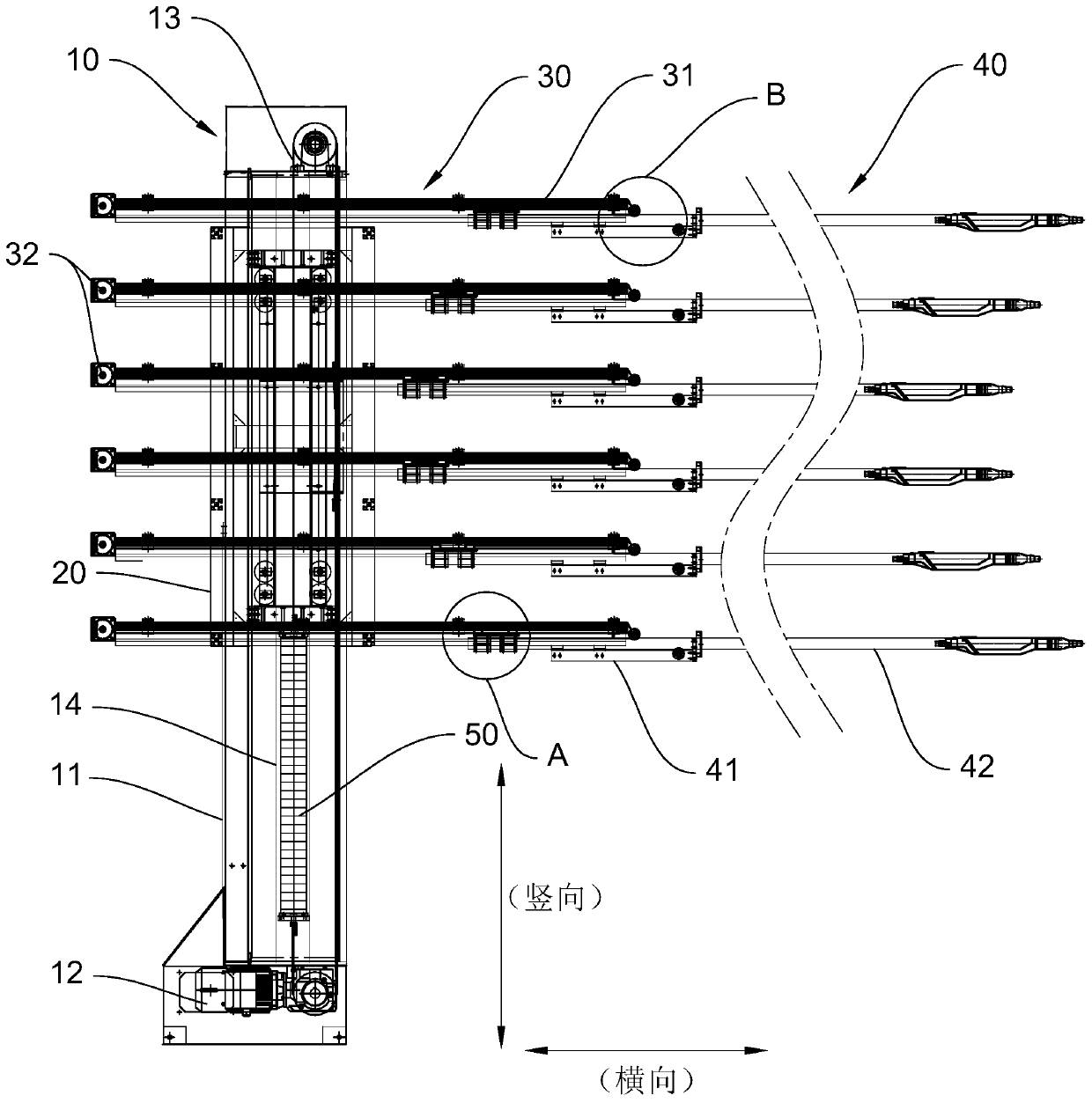

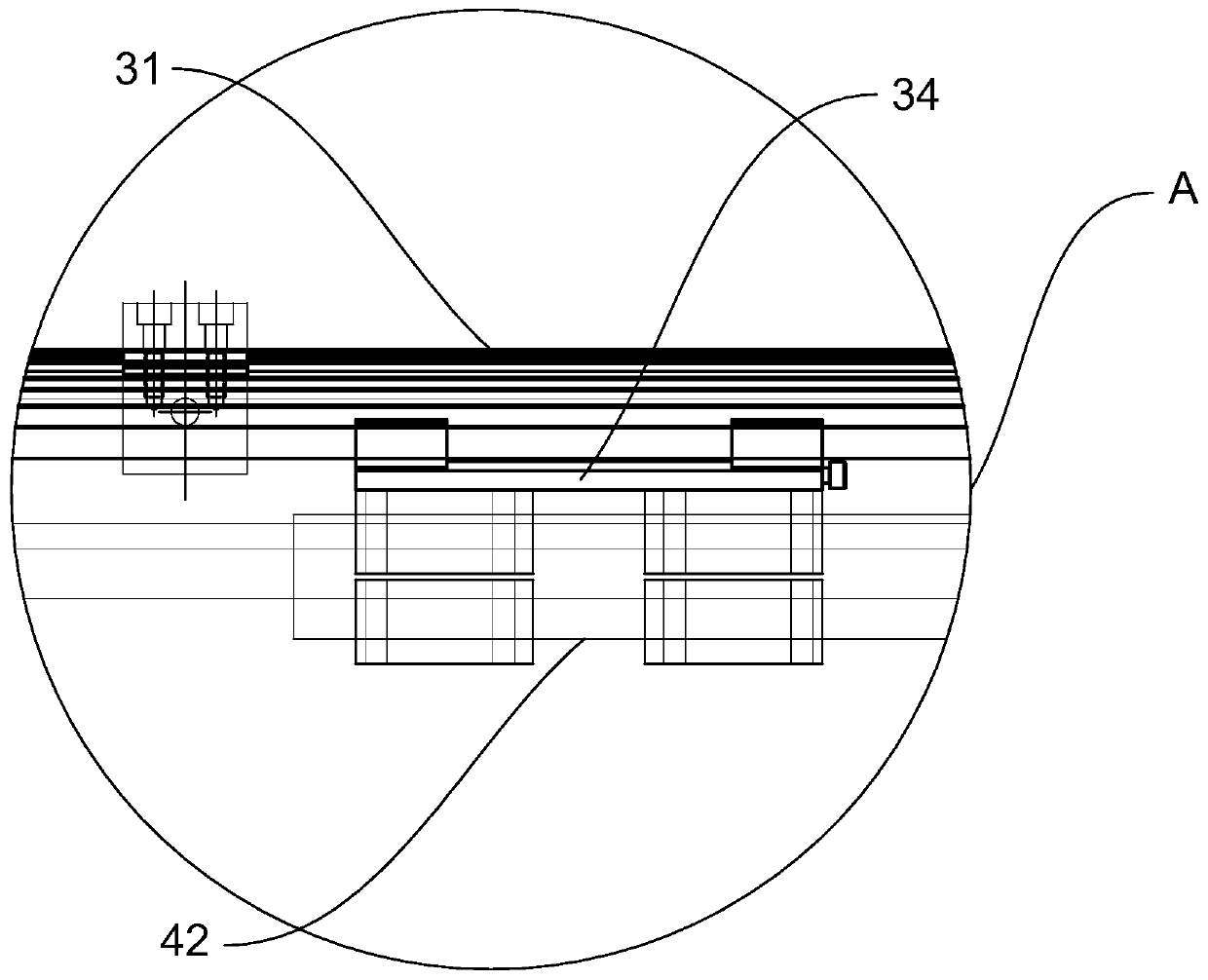

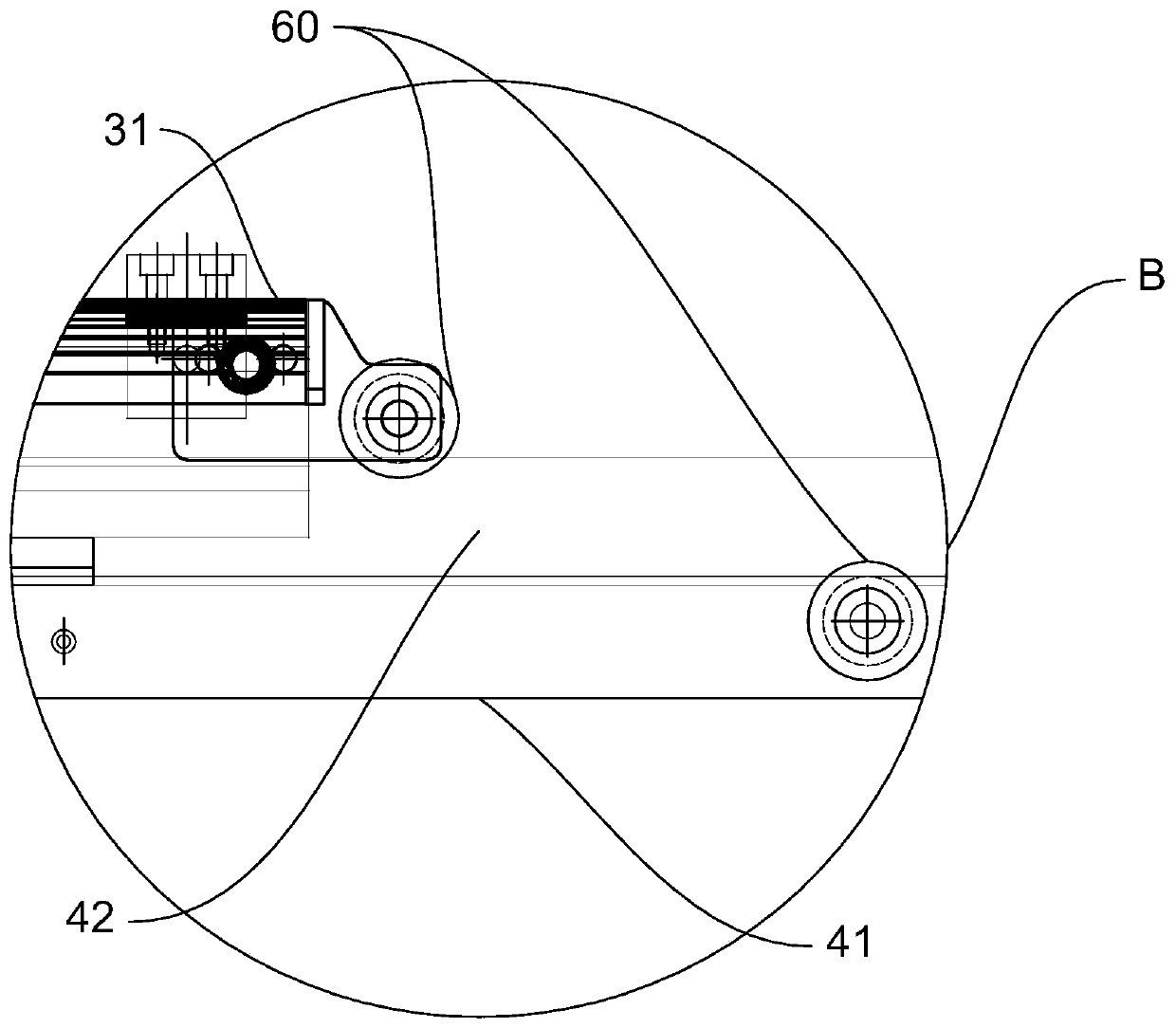

Panel pressing machine handpiece for multicolor panel pressing and panel pressing machine

ActiveCN111575934AReduce spacingCompact structureAutomatic machinesAuxillary devicesEngineeringStructural engineering

The invention discloses a panel pressing machine handpiece for multicolor panel pressing and a panel pressing machine. The handpiece comprises a needle bar frame and a handpiece shell, wherein the needle bar frame is provided with a row of punch needle bar assemblies in the width direction, and a belt performs conveying below the needle bar frame; each punch needle bar assembly comprises a punch needle bar and a punch needle mounted at the bottom of the punch needle bar, and the punch needles punch off pressed panels conveyed on the belt below; and a panel feeding roller assembly is mounted atthe rear side of the bottom of the needle bar frame, and a panel feeding driving assembly is mounted on the handpiece shell. The handpiece further comprises a color changing mechanism, wherein the color changing mechanism comprises a color changing guide rail and a color changing box assembly, the needle bar frame is connected with the color changing guide rail, and during color changing, the color changing box assembly drives the needle bar frame to move along the color changing guide rail to complete color changing. Through the handpiece, the demand for feeding the panels on multiple beltscan be met in a small space, the requirement for normal color changing is met, and the requirement for concentricity of the punch needles, pressed panel discharging holes and the pressed panels in theoperating process is met.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

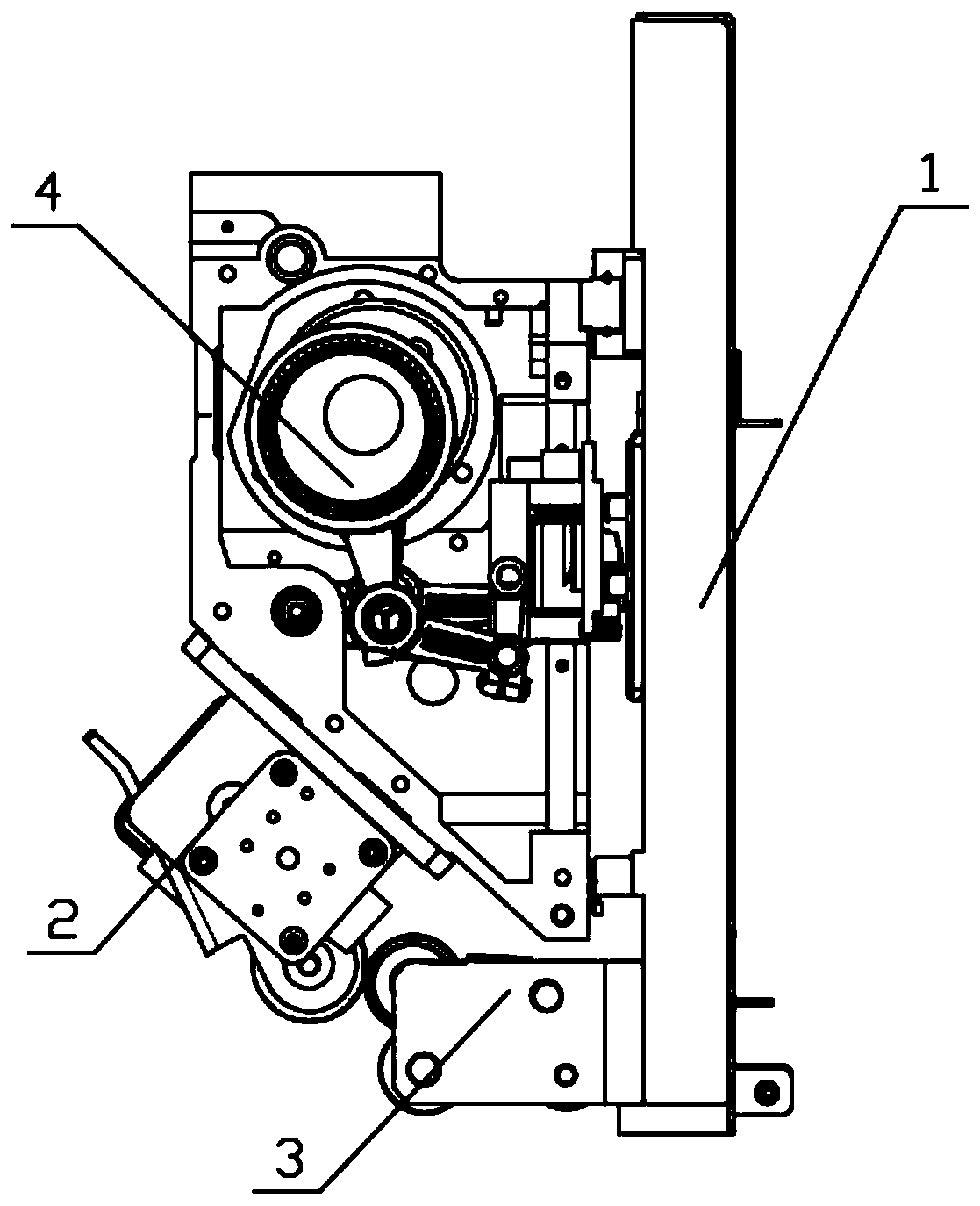

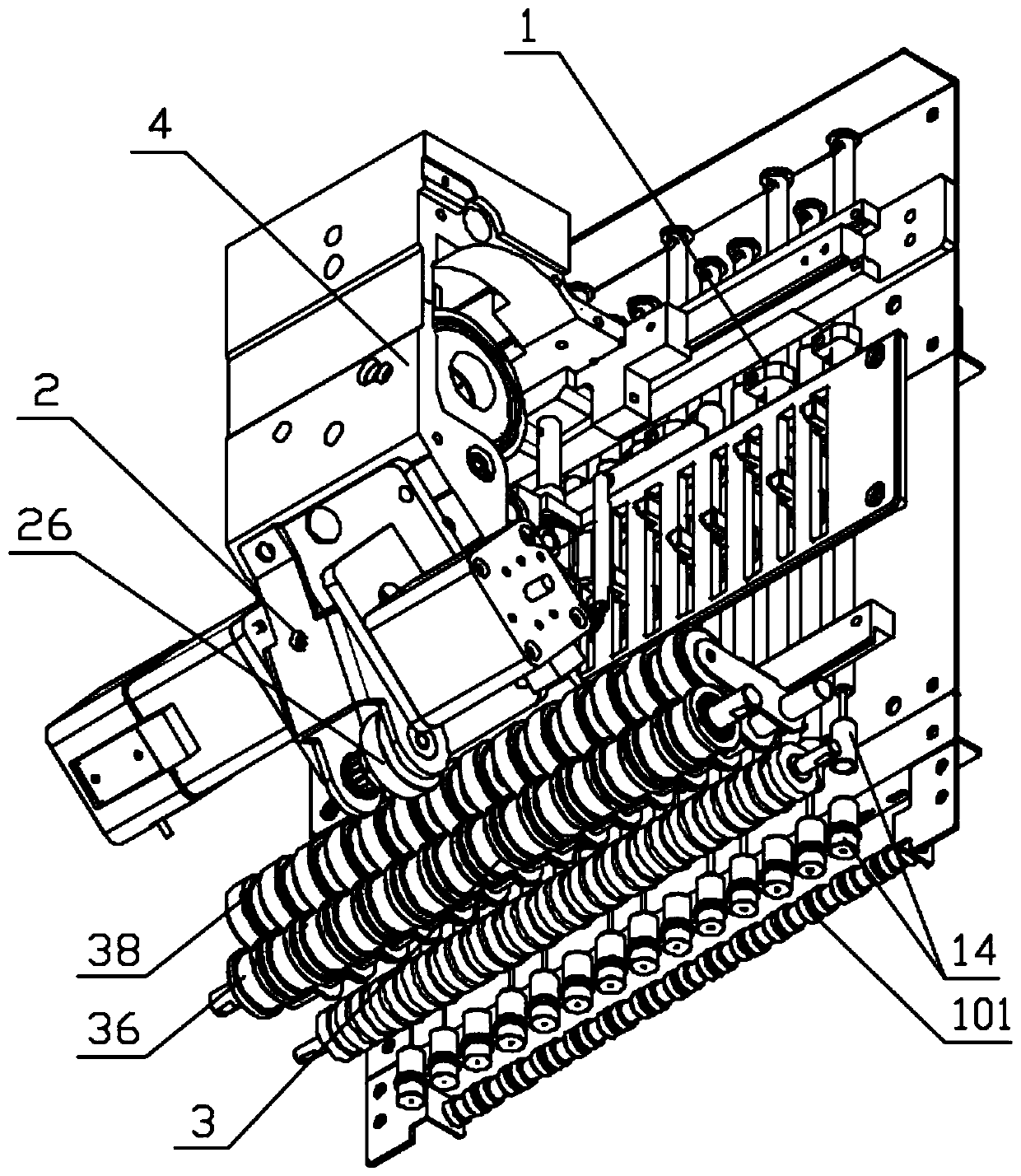

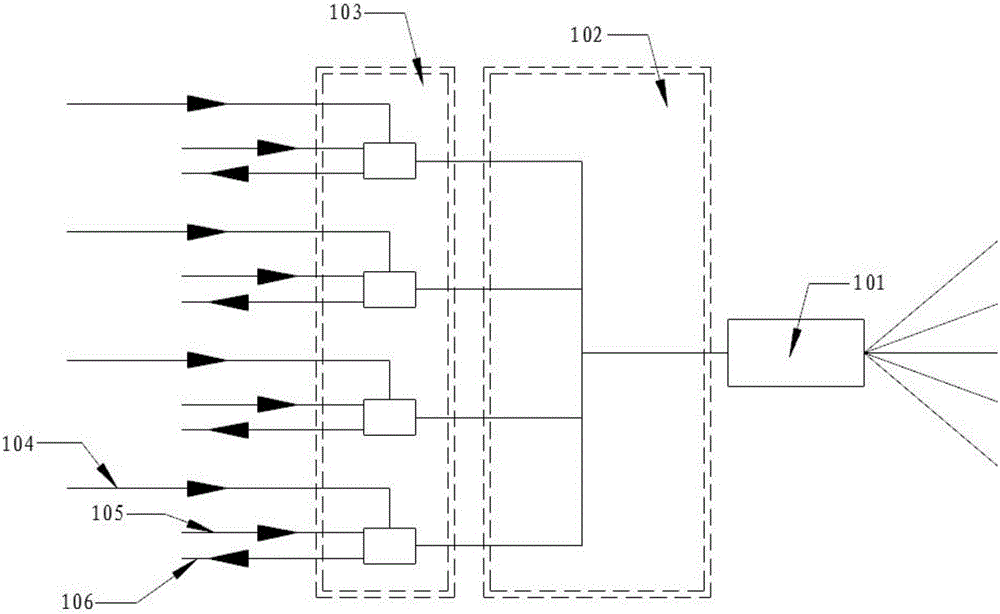

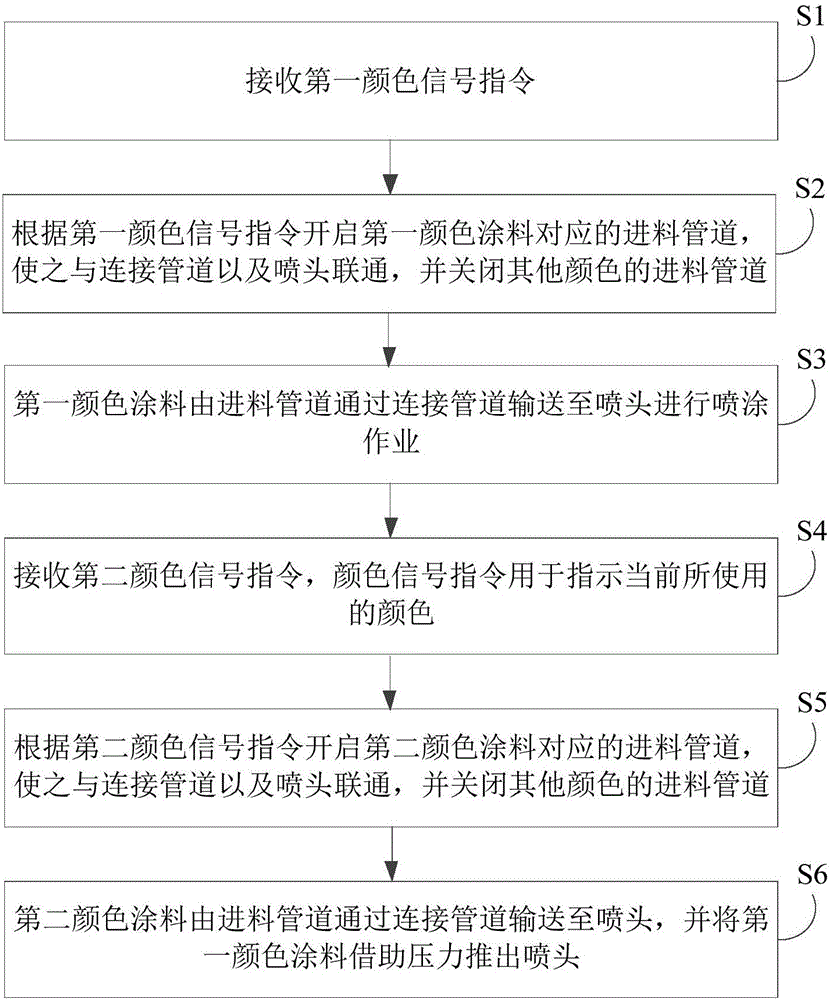

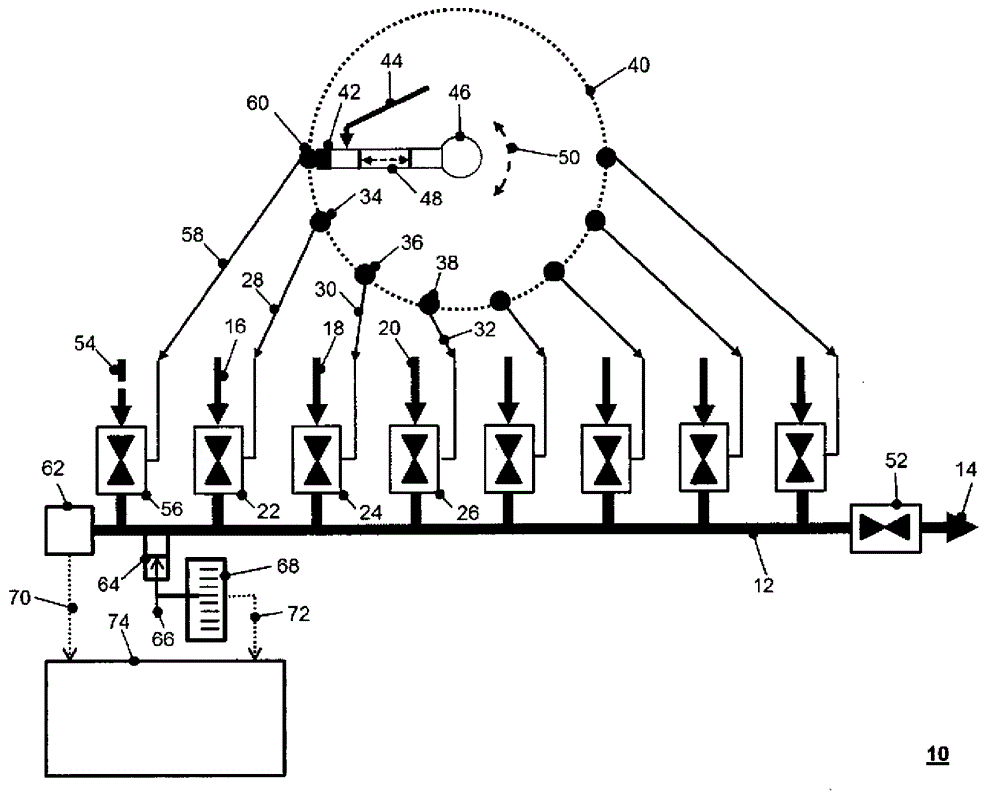

Quick color changing and spraying device and method

InactiveCN105964440AEasy to change colorResidue reductionLiquid surface applicatorsLiquid spraying apparatusAssurance qualityEngineering

The invention discloses a quick color changing and spraying device and method. The quick color changing and spraying device comprises a spray head, a connecting pipeline, color changing equipment and multiple feeding pipelines, wherein one end of the color changing equipment is connected with the feeding pipelines containing coatings of different colors, and the other end of the color changing equipment is connected with the connecting pipeline to switch the communication modes of the feeding pipelines and the connecting pipelines and feed the coating of which the color is changed to the connecting pipeline; one end of the connecting pipeline is connected with the color changing equipment, and the other end of the connecting pipeline is connected with the spray head to deliver the received coating to the spray head; the spray head conducts spraying operation through the coating delivered by the connecting pipeline. According to the quick color changing and spraying device, quick automatic color changing and high-pressure airless spraying can be achieved in a high-pressure state, the color changing pipeline does not need to be cleaned, the colors are not mixed, the coatings and cleaning solvents are saved, the quality is guaranteed, the efficiency is improved, and the cost is reduced.

Owner:QINGDAO JINGUANGHONG INTELLIGENT MACHINERY ELECTRONICS CO LTD

Fresh-keeping processing and packaging process for fresh-cut shredded potatoes

InactiveCN102763721AExtended shelf lifeEasy to change colorFruit and vegetables preservationPackaging under vacuum/special atmospherePolypropyleneCitric acid

The invention discloses a fresh-keeping processing and packaging process for fresh-cut shredded potatoes. The process comprises the following steps: sorting fresh potatoes according to different grades, peeling and shredding (or dicing or slicing) the potatoes, and cleaning the potatoes in a bubbling washing machine for 10min; sterilizing the potatoes in ozone water with O3 concentration of 3ppm, while controlling the ozone water temperature at 10 DEG C and adjusting the pH value of the ozone water at 5, and soaking for 15min; taking out the shredded potatoes, immediately immersing the shredded potatoes into a mixed solution containing 25% of VC and 0.5% of citric acid for 10 minutes, and centrifuging the shredded potatoes in a 1200r centrifuge for 40 s to drain the water; and filling the drained shredded potatoes into a sterile polypropylene box, and packaging the fruits by a controlled atmosphere packaging method. According to the above process provided by the invention, a fresh-keeping period of the fresh-cut shredded potatoes reaches up to 10 days, without loss of section color or taste of the shredded potatoes.

Owner:SUZHOU RENXIANGQUAN PRESERVATION SCI & TECH

Water-based color paste for coloring plastic and preparation method of water-based color paste

InactiveCN112745717AReduce dosageLittle impact on performancePigment pastesDefoaming AgentsCompatibilization

The invention provides water-based color paste for coloring plastics. The water-based color paste for plastic coloring comprises the following raw materials: toner, a resin carrier, a wetting dispersant, a humectant, a defoaming agent, a mildew-proof bactericide, a functional additive and deionized water. The water-based color paste is prepared by fully wetting and uniformly dispersing the toner by using the dispersing agent and then combining with a fine bead milling process. The water-based color paste can be easily combined with plastic resin, toner points and spots on the surface of a plastic product are reduced, the smoothness of the surface of the plastic product is improved, and the use amount of pigment and the adverse effect on the performance of plastic are reduced. The prepared water-based color paste for plastic coloring is high in color concentration, small in particle size, excellent in dispersing performance, high in storage stability, good in compatibility with plastic resin, safe and environmentally friendly.

Owner:ZHEJIANG NAMEI MATERIAL TECH

Image processing apparatus and method

ActiveUS7466450B2Easy to change colorDesirable colorDigitally marking record carriersDigital computer detailsPattern recognitionImaging processing

An image processing system and method include allowing an output device to output patch-data items of plural multi-order colors represented by a first color space, measuring the color values, in an absolute color space, of the output patch-data items, calculating reference values by converting the plural multi-order colors represented by the first color space based on a first color conversion table containing correspondence between the first color space and the absolute color space, calculating distances between the color values measured by the color measuring means and the reference values, which correspond thereto, and correcting, based on the calculated distances, a second color conversion table containing correspondence between the absolute color space and an output color space.

Owner:CANON KK

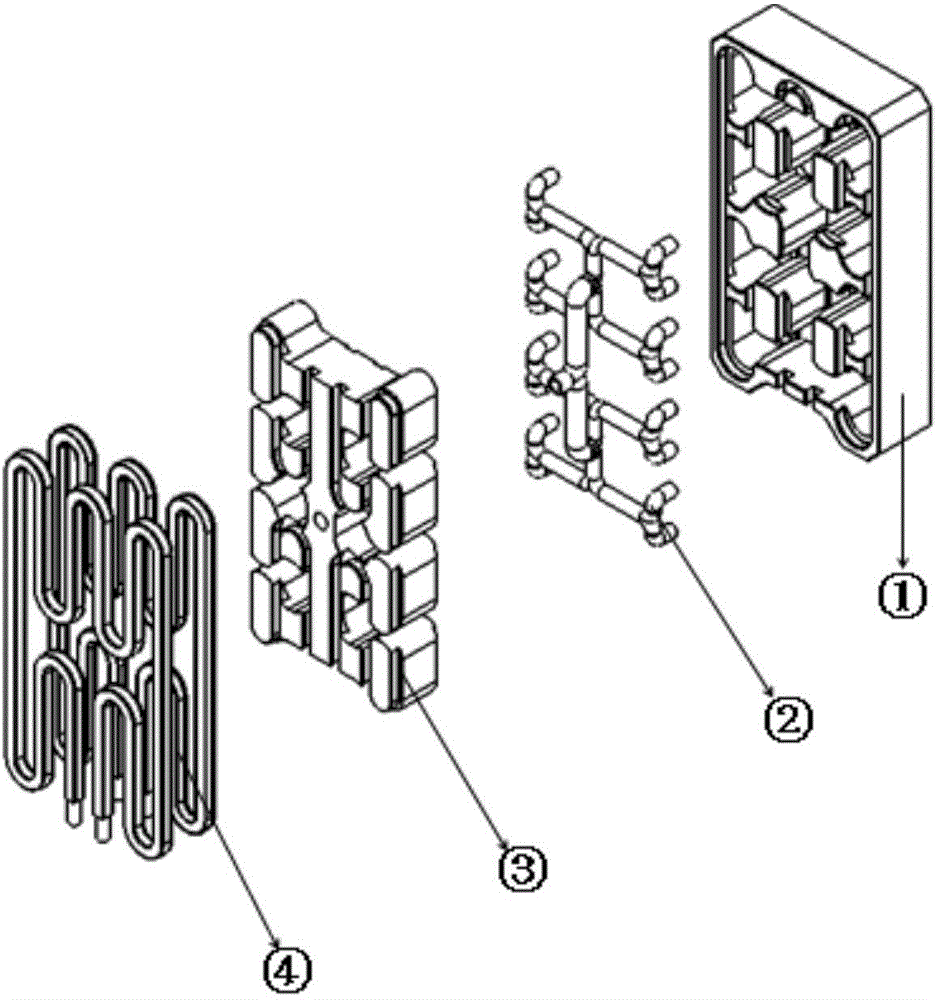

3D printing channel splitter plate processing technology

The invention provides a 3D printing channel splitter plate processing technology. The technology comprises directly printing a metal channel by a 3D printing technology, carrying out metal casting on the metal channel and a splitter plate obtained by preliminary machining molding so that the metal channel and the splitter plate are assembled into an integral body, and carrying out machining molding. A drill gun is used for processing a channel so that processes are simple, the 3D printing channel has any shape so that the 3D printing channel is suitable for complex channel processing, the channel prepared by a 3D printing technology has smooth inner holes and corners with circular arc transition so that pressure loss is small, shearing heat is small and color change in injection molding is fast and convenient.

Owner:YUDO SUZHOU HOT RUNNER SYST

Colour-changer

InactiveCN104619427ACompact layoutChange colorSpraying apparatusFluid-tightness measurementEngineeringMechanical engineering

Owner:ABB (SCHWEIZ) AG

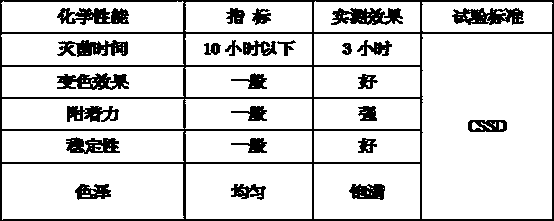

Screen printing ethylene oxide disinfection color shifting printing ink and preparation method

InactiveCN103525198AAchieve sterilization effectEasy to change color shortInksScreen printingEmulsion

The invention discloses a kind of screen printing ethylene oxide disinfection color shifting printing ink and a preparation method. The color shifting printing ink comprises ingredients, by weight, 5-6 parts of formaldehyde red, 100-200 parts of ethene emulsion, 50-70 parts of alcohol with a concentration of 45%-60%, 6-10 parts of citric acid and 8-12 parts of sodium chloride. The monitoring disinfection effects are raised, the disinfection time is shortened, the production cost is low, and the raw material ratio is reasonable.

Owner:ANQING KANGMINGNA PACKAGING

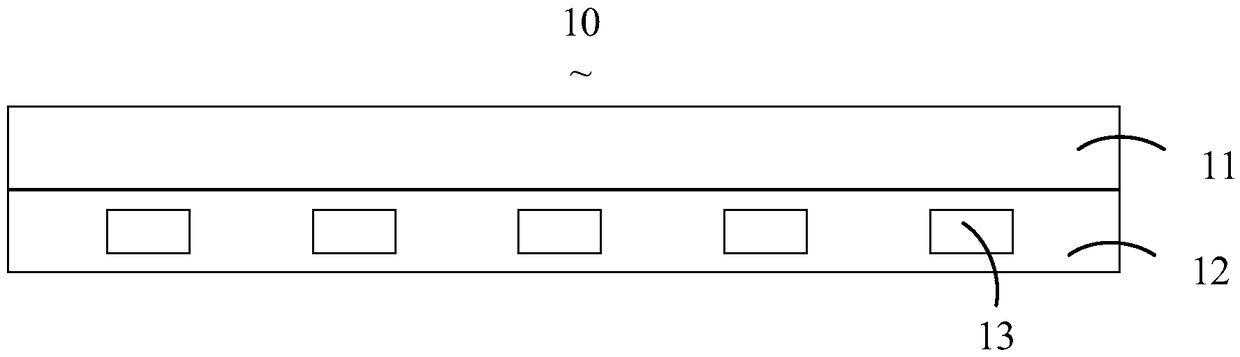

Terminal, housing and color change control method thereof

ActiveCN109040383AEasy to change colorAchieve changeTelephone set constructionsComputational physicsColor changes

The embodiment of the invention provides a terminal, a housing and a color change control method thereof. The housing comprises: a transparent layer, a variable color layer attached to one side of thetransparent layer, the variable color layer having at least one variable color unit, At least one electrical signal load unit corresponding to the at least one variable color unit one by one and usedfor loading an electrical signal to the variable color unit. By the method, the invention can load an electric signal through the electric signal loading unit, so that the color matching with the electric signal is displayed by the variable color unit, thereby realizing the change of the color or the pattern of the housing, making the color or the pattern displayed by the housing more colorful, and the color conversion of the housing is more convenient, and simple and flexible.

Owner:VIVO MOBILE COMM CO LTD

Wear-resistant and crease-resistant fabric

PendingCN112760998AGood oil resistanceImprove wear resistanceTextiles and paperTextile/flexible product manufactureFlax fiberSilicone resin

The invention provides a wear-resistant and crease-resistant fabric, and particularly relates to the technical field of textile fabrics. The wear-resistant and crease-resistant fabric comprises a base cloth layer and a wear-resistant and crease-resistant coating located on the base cloth layer, wherein the base cloth layer is formed by interweaving warp yarn and weft yarn, the warp yarn is formed by blending polyester filament yarn fibers and linen fibers, and the weft yarn is formed by blending polyester fibers, mulberry silk fibers and polyvinyl chloride fibers. The wear-resistant and crease-resistant coating is prepared from the raw materials in parts by weight: 70- 80 parts of polyurethane, 30-50 parts of epoxy resin, 20-35 parts of the polyester fibers, 20 -30 parts of polyamide, 5-10 parts of dispersing agents, 5-10 parts of polytetrahydrofuran, 2-4 parts of butyl acrylate, 5-8 parts of organic silicon resin, 2-4 parts of ethyl cellulose, 1-2 parts of graphene, 2-3 parts of glass fibers, 2-5 parts of pigment, 0.7-1.3 parts of hydroxyl silicone oil, 2-3 parts of carbon fibers, 7-10 parts of curing agents and 50-60 parts of organic solvents. According to the wear-resistant and crease-resistant fabric, the fabric is not easy to wrinkle, and the wear resistance of the fabric is improved.

Owner:东台市恒华织造有限公司

Self-adaptation system for contour of workpiece

PendingCN111330769AReduce labor intensityReduce spray dead angleSpraying apparatusEngineeringSelf adaptive

The invention discloses a self-adaptation system for the contour of a workpiece. The self-adaptation system comprises a lifting mechanism, a mounting frame, multiple linear modules, spraying gun assemblies, a section detecting device and a control device. The mounting frame is arranged on the lifting mechanism, and can drive the mounting frame to ascend and descend. The multiple linear modules arearranged on the mounting frame at intervals in the length direction of the mounting frame. The spraying gun assemblies are arranged on the linear modules, each linear module is correspondingly provided with one spraying gun assembly, and the linear modules can drive the spraying gun assemblies to move towards the workpiece. The section detecting device is used for detecting the outer contour shape of the section, in the conveying direction, of the workpiece. The control device is electrically connected with the lifting mechanism, the linear modules, the spraying gun assemblies and the sectiondetecting device. The outer contour shape of the section, in the conveying direction, of the workpiece is detected through the section detecting device, then detected data are fed back to the controldevice to be analyzed, and the distances between the spraying gun assemblies at different positions and the surface of the workpiece are judged; and then the control device drives the spraying gun assemblies to move towards the workpiece through the linear modules to automatically adapt to workpieces in different shapes.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

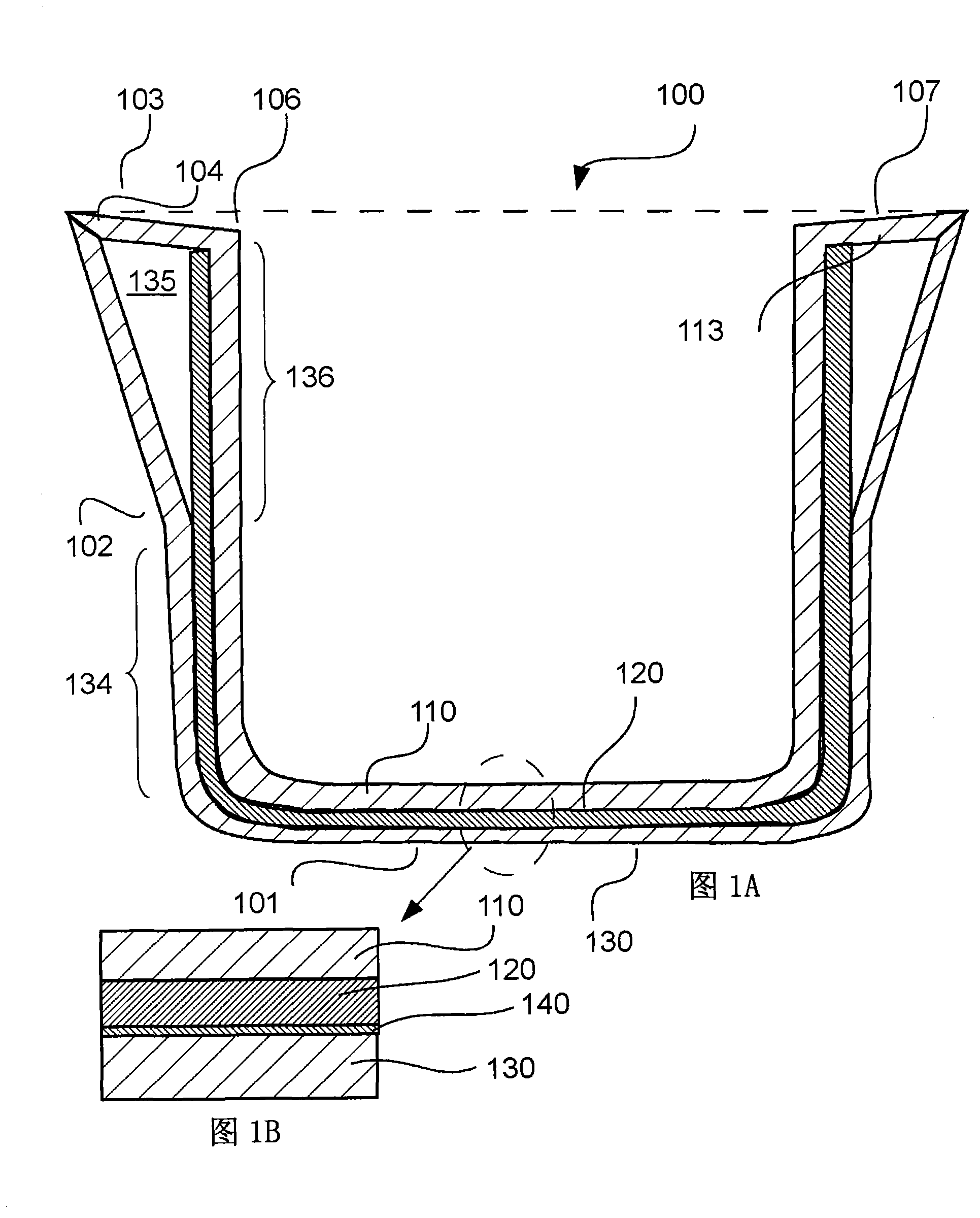

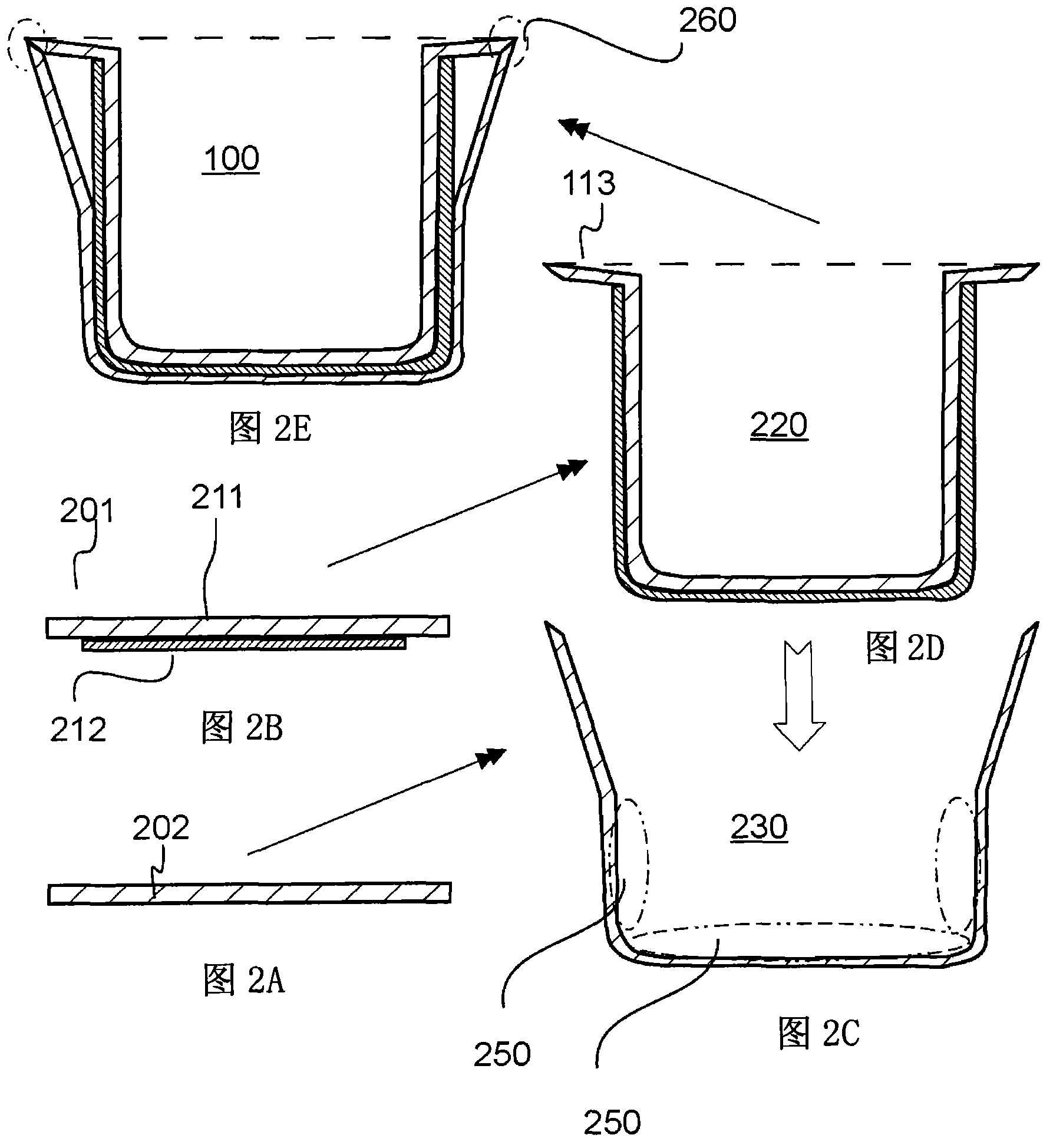

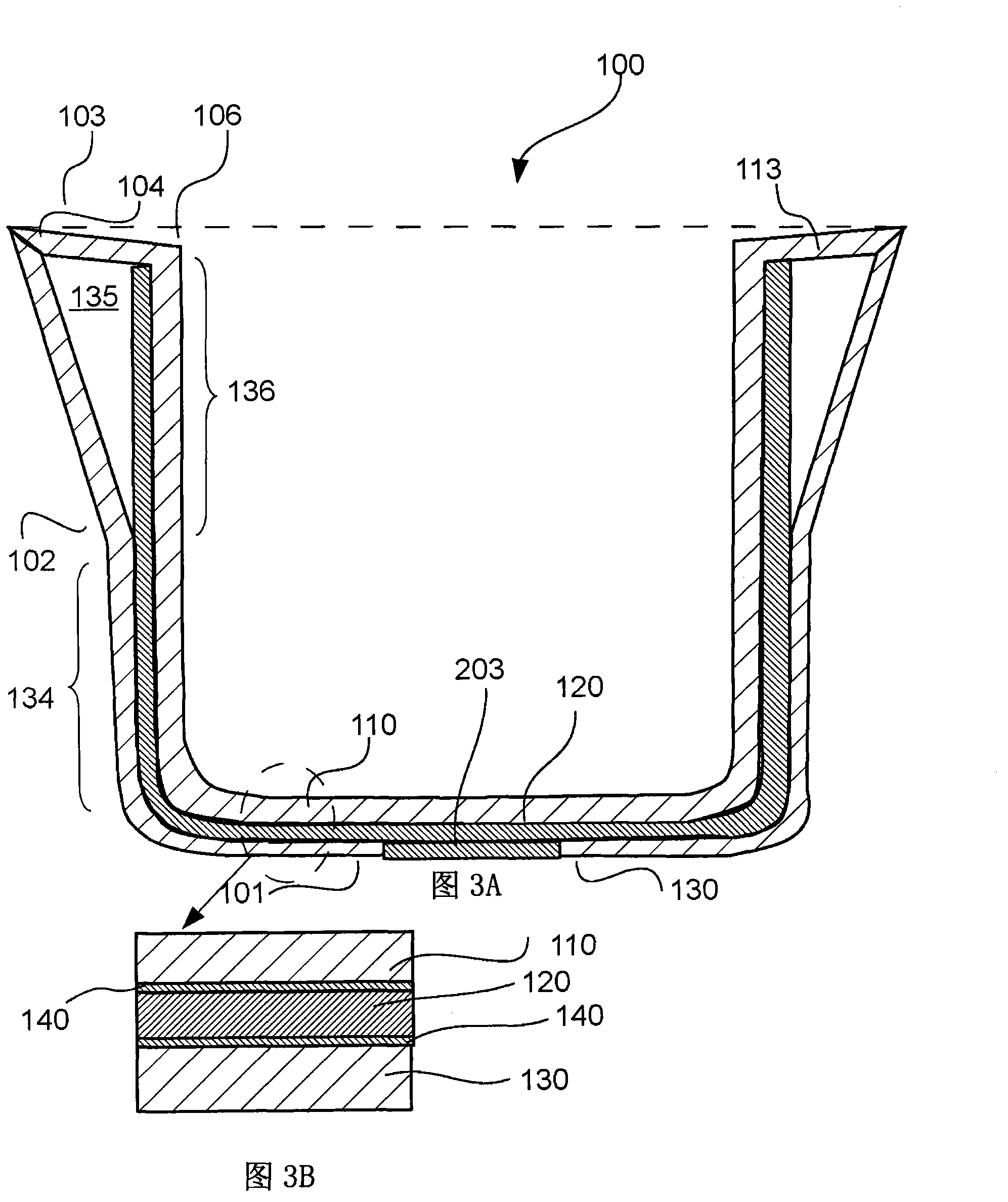

Cooking utensil and method for making the same

InactiveCN103222793ACooking performance impairmentEasy to change colorCooking-vessel materialsSoldering apparatusCombustorEngineering

Owner:MEYER INTPROP

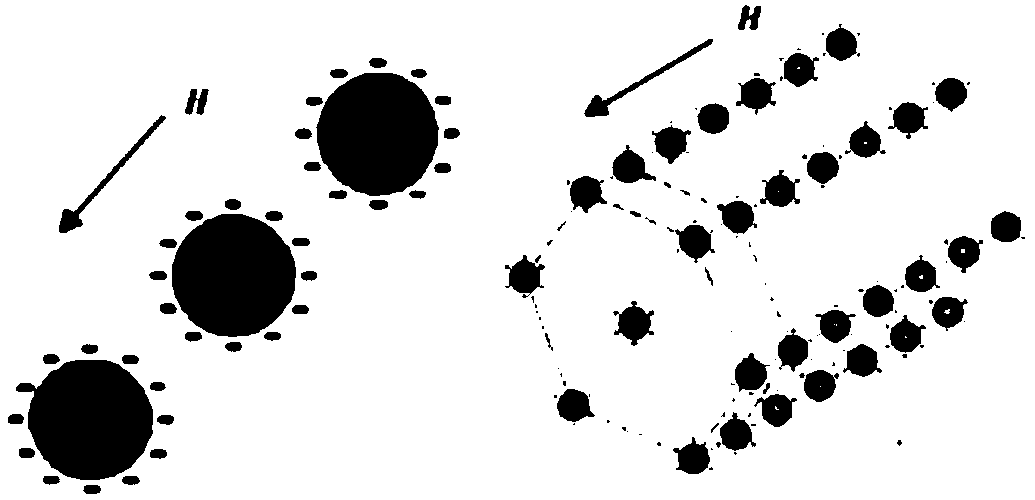

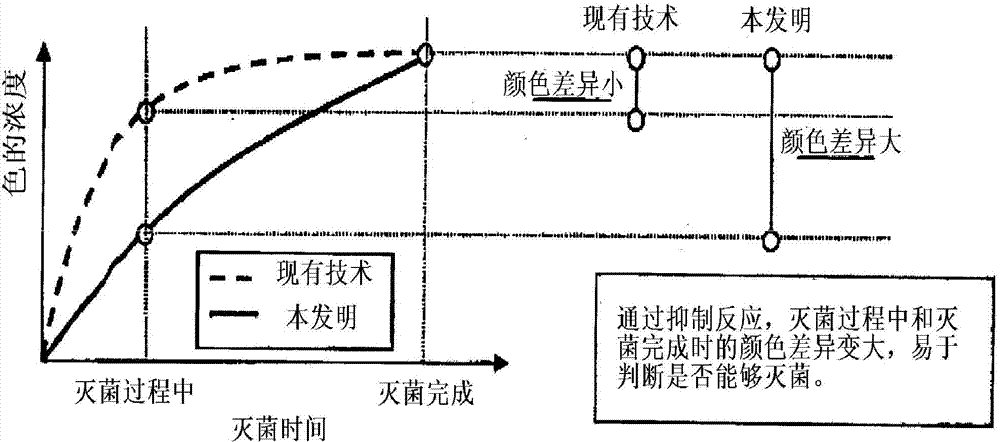

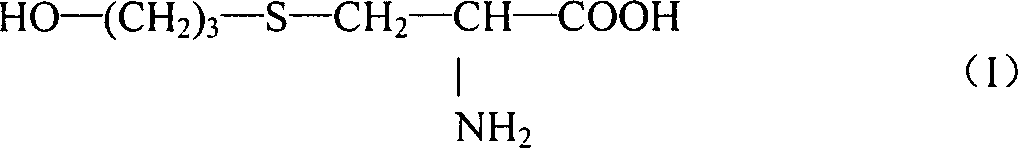

Hygrochromic/thermochromic composition and hygrochromic/thermochromic indicator

InactiveCN103946337AEasy to change colorNot easy to change colorOther chemical processesInksOrganic solventSulfur

The present invention addresses the problem of providing a hygrochromic / thermochromic composition and hygrochromic / thermochromic indicator that are useful for detecting heat and humidity conditions and also make it possible to check for the progress and completion of a sterilization treatment according to the extent of color change. The means by which the invention solves the problem is a hygrochromic / thermochromic composition containing a bismuth compound, a sulfur compound, a binder, and an organic solvent, the hygrochromic / thermochromic composition being characterized in further containing phosphoric acid and / or phosphate ester; and a hygrochromic / thermochromic indicator.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Method for preparing colored meta-aramid

ActiveCN104746366AEasy to change colorReduce manufacturing costDyeing processMonocomponent polyamides artificial filamentSurface layerUltrasonic oscillation

The invention relates to a method for preparing colored meta-aramid. The method comprises the following steps: (1) performing ball-milling on pigments, dispersing, mixing and stirring in water, and performing auxiliary ultrasonic oscillation, thereby obtaining a uniform dye bath solution; (2) performing wet spinning, coagulating and washing on salty polyisophthaloyl metaphenylene diamine spinning solution, performing dyeing treatment in the dye bath solution, drying, performing thermal stretch treatment, curling, and cutting, thereby obtaining the colored meta-aramid. According to the method disclosed by the invention, the fibers are dyed by directly utilizing micro-pores remained in the fibers after spinning coagulation and washing salt removal, the pigments mainly enter the fiber surface layer and can be saved, the dye bath is easy to clean, the pipeline is not polluted by the bath solution, the fiber colors are convenient to replace, the method is suitable for small batch orders, and the production cost of the colored meta-aramid can be greatly saved.

Owner:DONGHUA UNIV

Liquid drug preparations

InactiveCN1511033AEasy to change colorPrevent browningOrganic active ingredientsDispersion deliveryDrugs preparationsAlcohol sugars

Liquid drug preparations characterized by containing fudostein and an acid together with a sweetener such as sugar alcohol, trehalose or a sweetener having a high degree of sweetness. These liquid drug preparations are fudostein-containing liquid drug preparations which are free from color change or sedimentation upon prolonged storage and can be easily taken.

Owner:HISAMITSU PHARM CO INC

Method for preparing meta-aramid colored fiber

InactiveCN109183179ASave pigmentEasy to replacePigment addition to spinning solutionSpinning solutions preparationChemistryBall mill

The invention discloses a method for preparing meta-aramid colored fiber. The invention comprises the following steps: an inorganic pigment is ball-milled and dispersed, and is mixed with an organic solvent and stirred to obtain a dyeing solution, a PMIA spinning solution is prepared, then defoaming is carried out, the meta-aramid fiber is subjected to spinning by a wet method, solidification andwashing with water to prepare mixed liquor of the dyeing solution and a spinning solution, an extruder is connected to a spinneret and directly introduced into coagulation bath, and steps of hot drawing, curling, cutting out and package are carried out to obtain the meta-aramid colored fiber. In the above manner, the method utilizes spinning solidification and the micropores in the fiber after washing to dye the fiber, and the color of the pigment entering a fiber surface layer is easily replaced, and a coloring agent is added at the same time, which saves a path and is easy to alternate color.

Owner:X FIPER NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com