Patents

Literature

41results about How to "Reduce spray dead angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

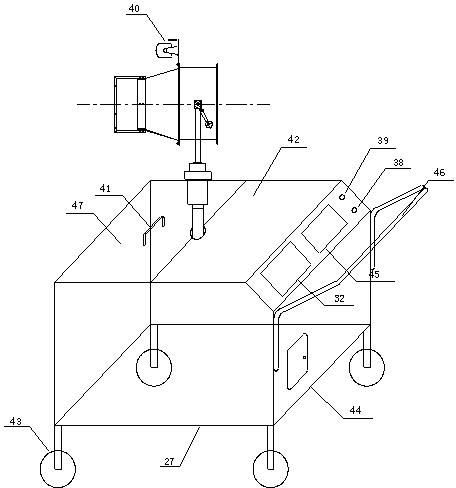

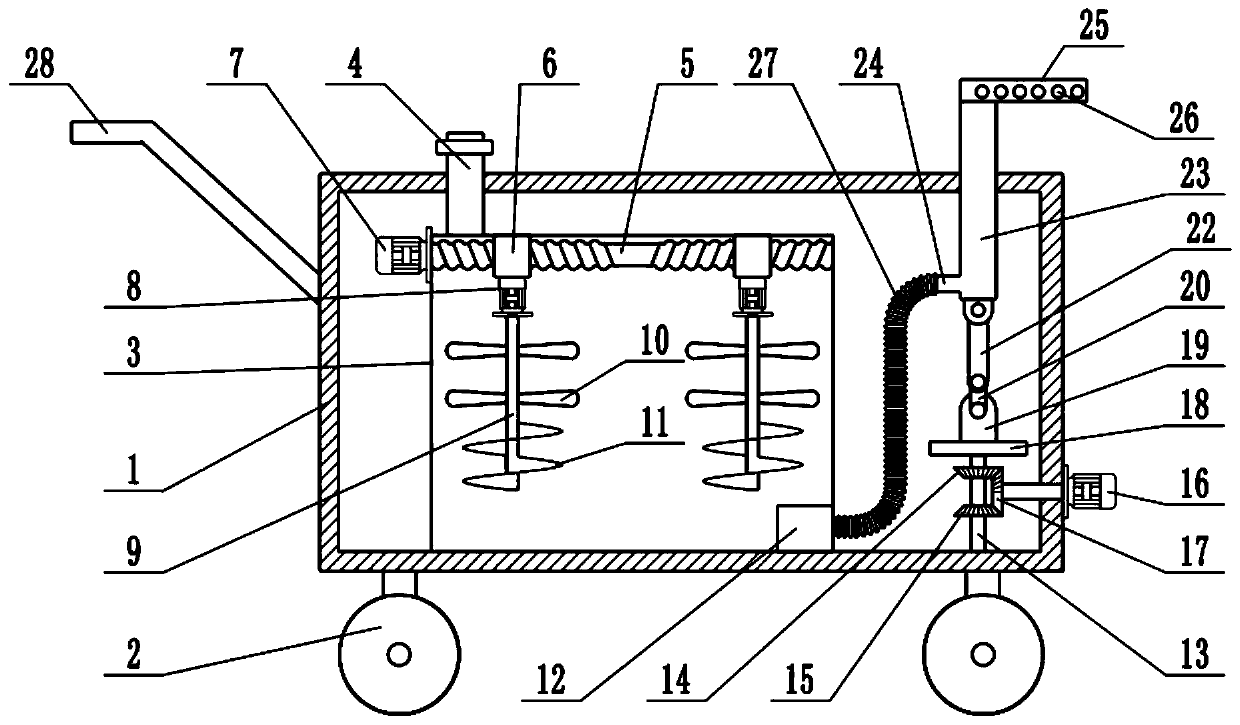

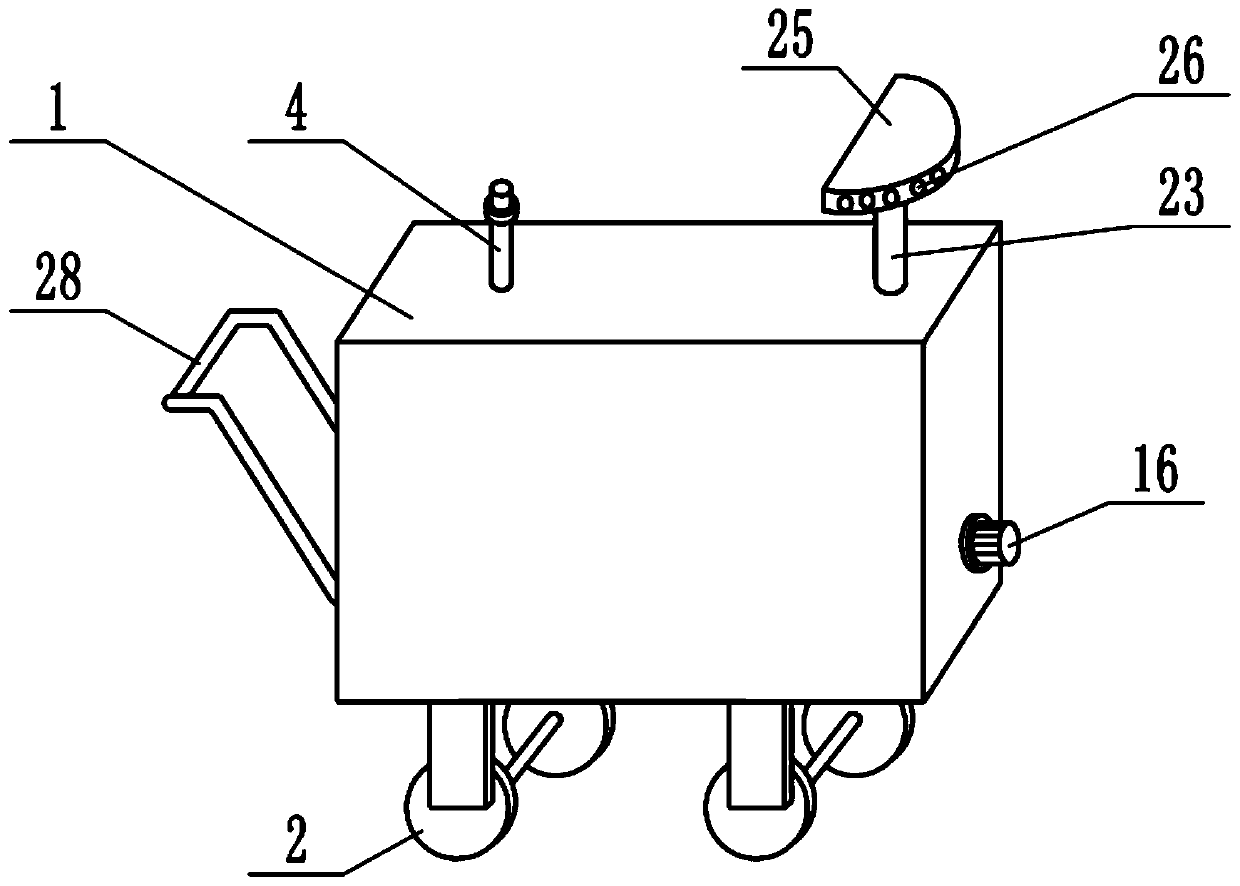

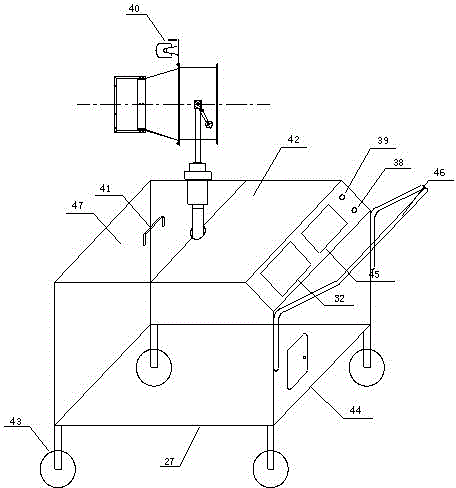

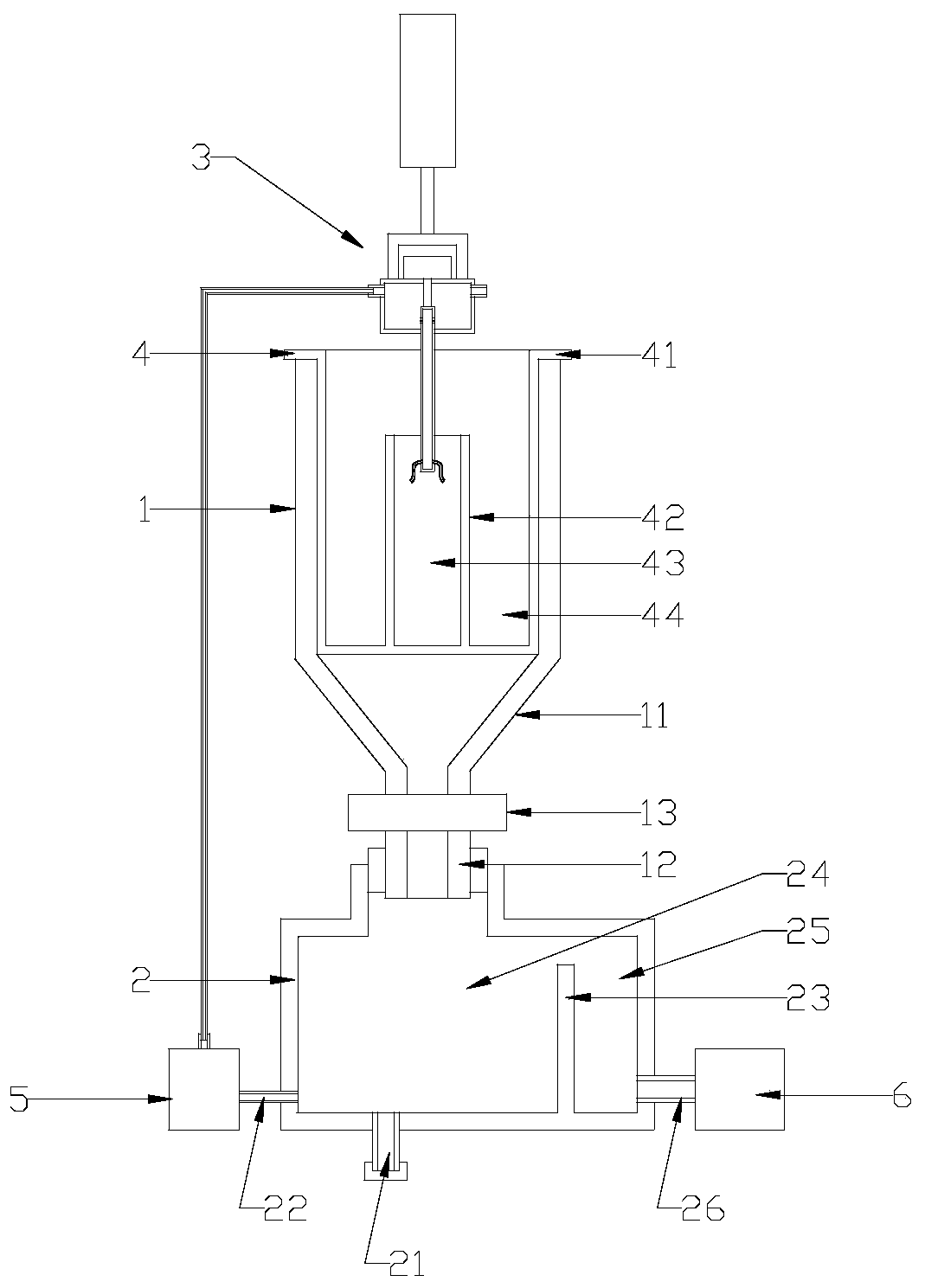

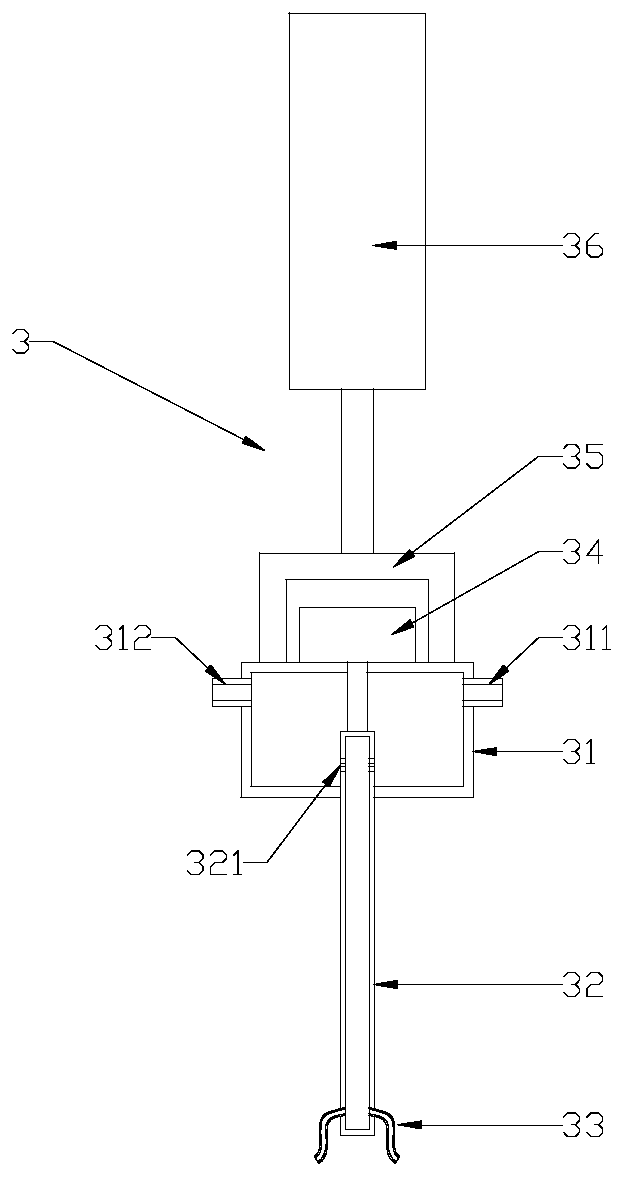

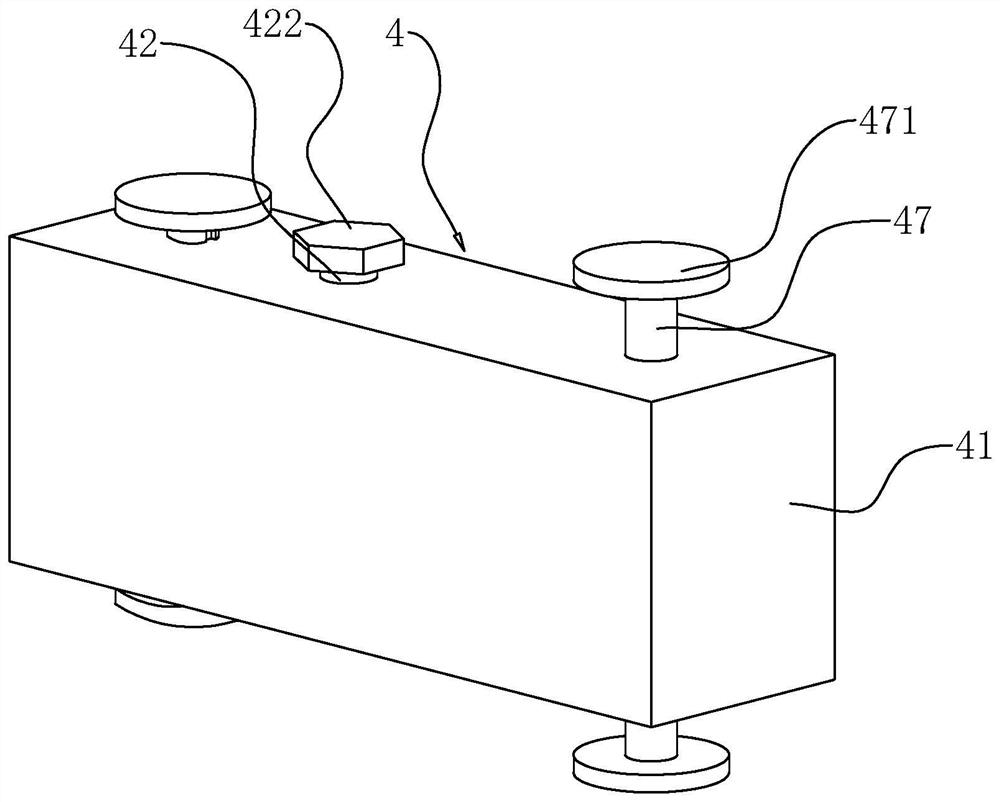

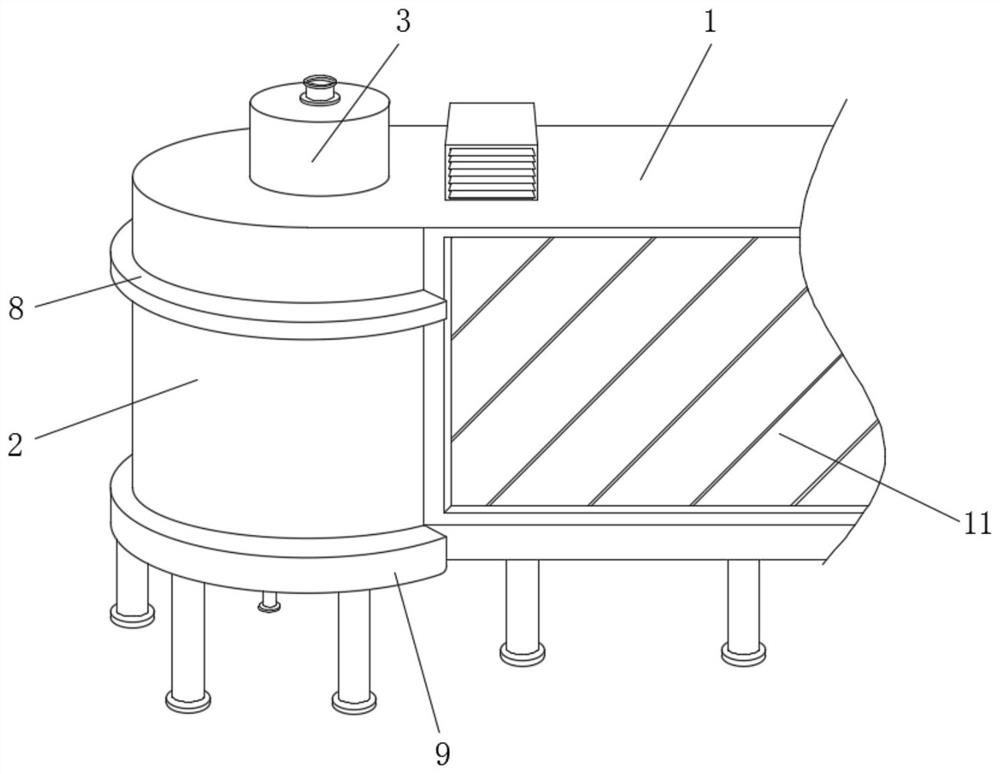

Self-controlled efficient and electrostatic-spraying pesticide application machine for greenhouses

InactiveCN102166548AIncrease profitGuaranteed control effectLiquid spraying apparatusSpray discharge apparatusHuman–machine interfaceEngineering

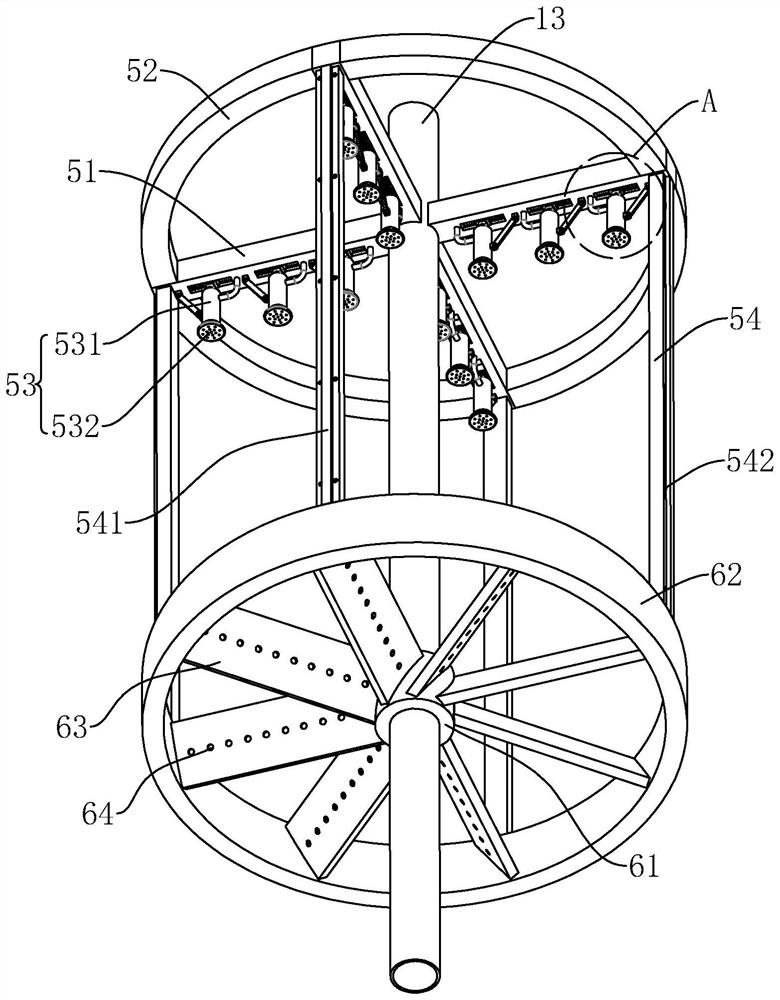

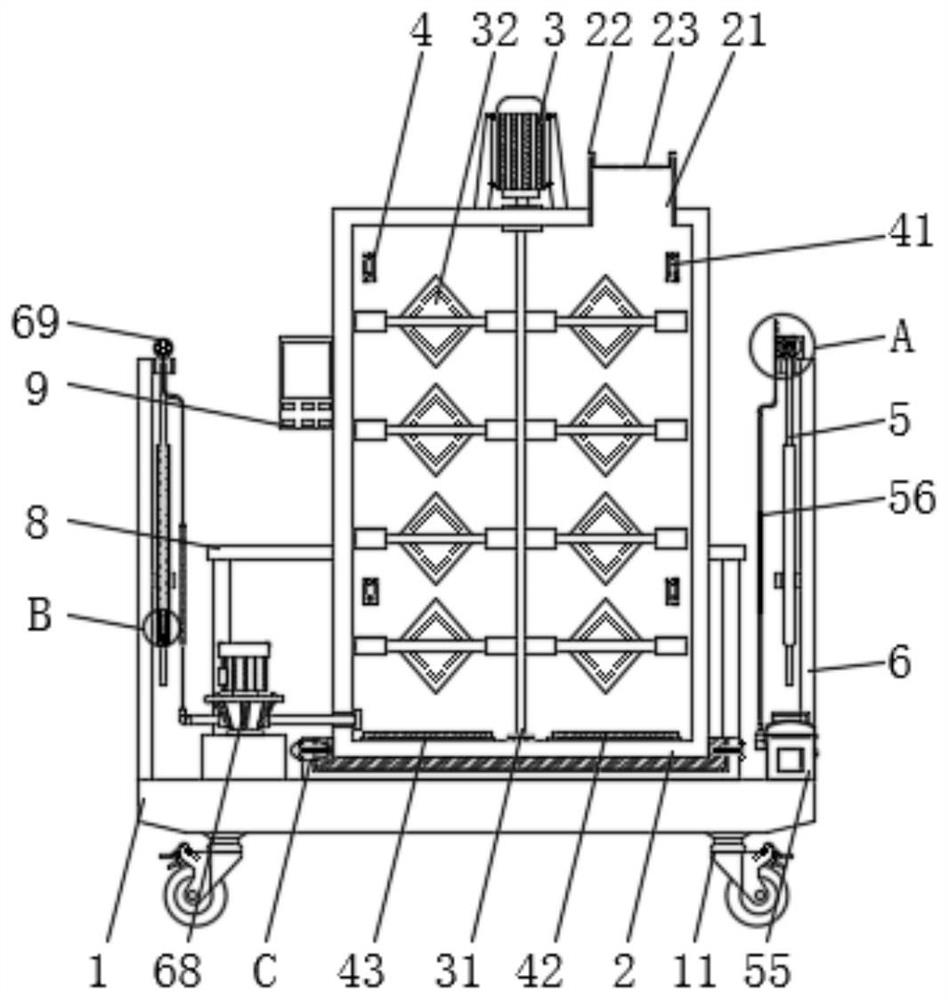

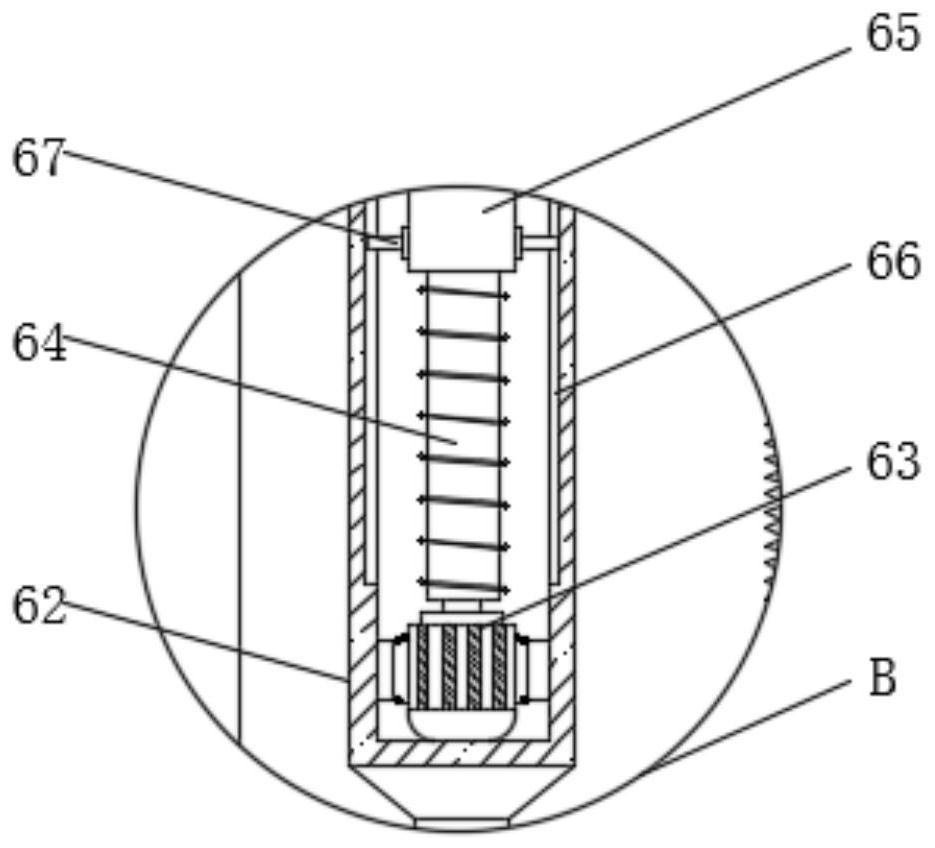

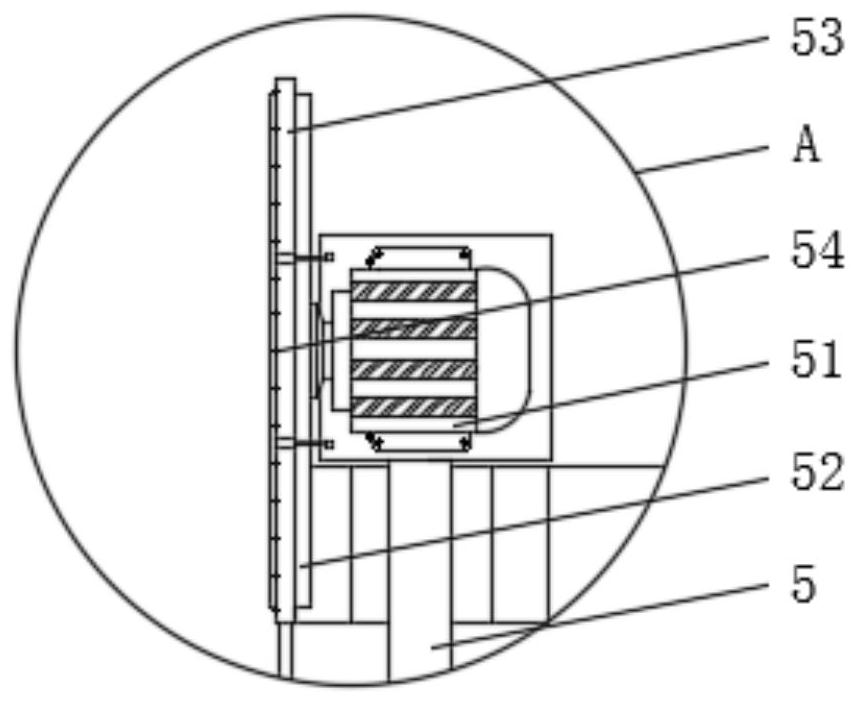

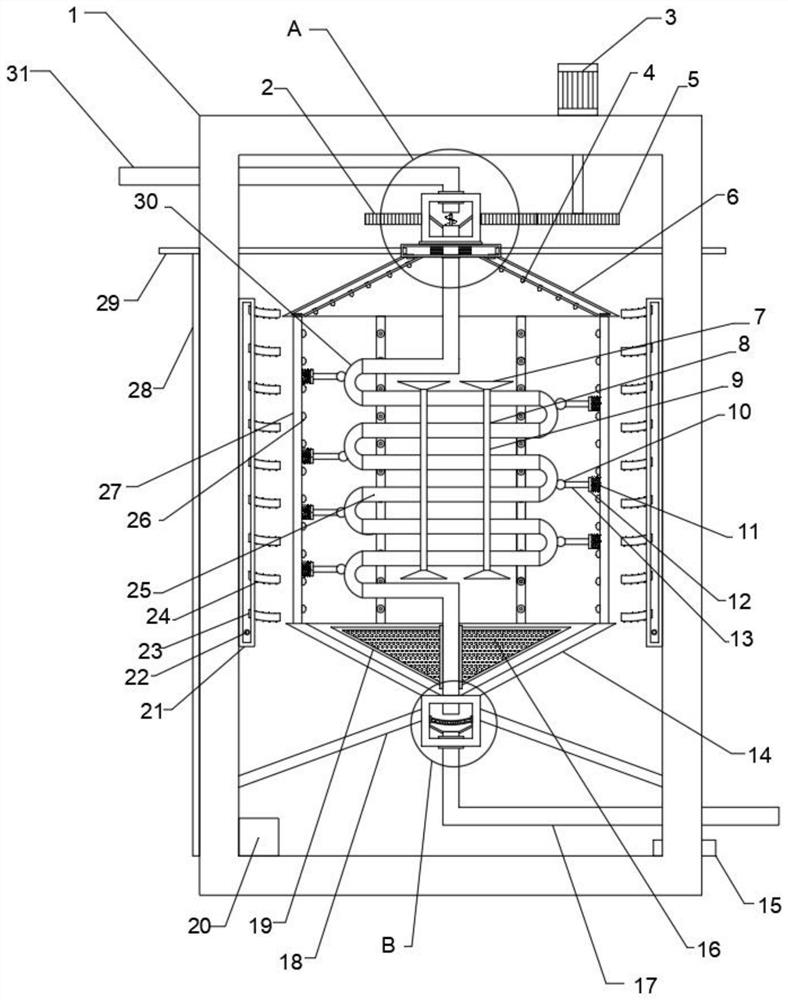

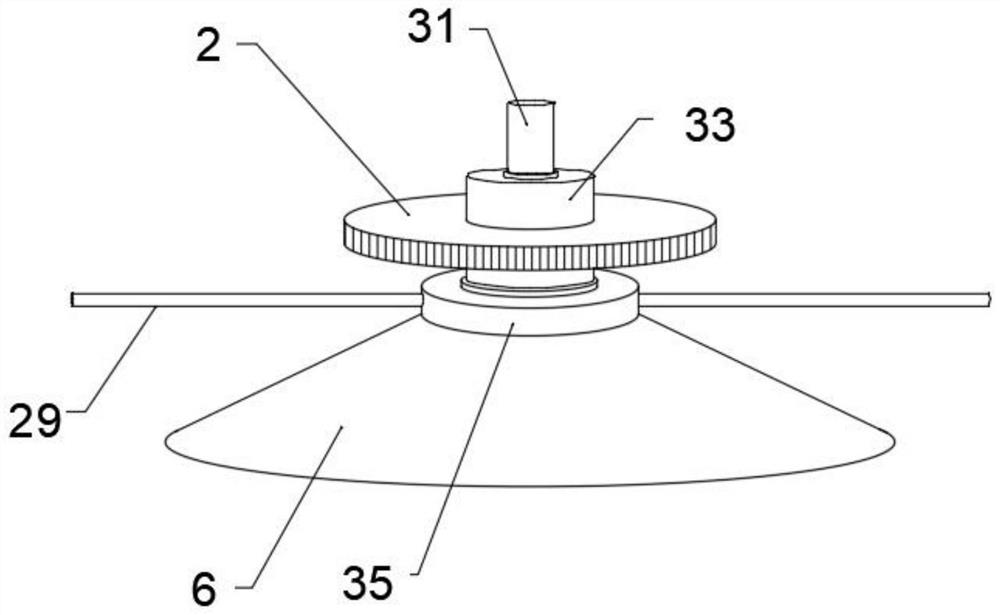

The invention relates to a self-controlled efficient and electrostatic-spraying pesticide application machine for greenhouses, and the machine provided by the invention comprises a spraying dolly, a pesticide supply system, a pressure fluctuation elimination system, an HMI-PLC (human-machine interface-programmable logic controller) human-machine interactive automatic logic control system, a rotating electrostatic spray system, a high-definition mistform vedio monitoring system, a machine frame and a power supply system, wherein the pesticide supply system, the pressure fluctuation elimination system, the HMI-PLC man-machine interactive automatic logic control system, the rotating electrostatic spray system and the power supply system are arranged in a spraying dolly shell (42); the high-definition mistform vedio monitoring system is arranged at the top of the spraying dolly; and the HMI-PLC man-machine interactive automatic logic control system is connected between the pesticide supply system and the rotating electrostatic spray system by virtue of a pipeline. By using the machine provided by the invention, on the premise of ensuring the pest control effect, the utilization rate of pesticides is improved, the pest control cost is reduced, the environmental pollution is reduced, the production efficiency and the social efficiency are improved simultaneously, and the labor intensity is reduced.

Owner:镇江和盛环境科技有限公司 +2

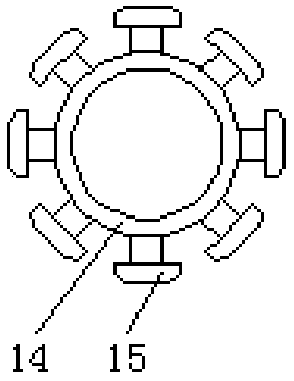

Pipe desilting device for municipal engineering

The invention relates to the field of desilting equipment, in particular to a pipe desilting device for municipal engineering. The pipe desilting device comprises a shell, idler wheels, a brush head and a liquid storage box, wherein electric telescopic rods are mounted at the top and the bottom of the shell; the idler wheels are mounted at the top ends of the electric telescopic rods; a first telescopic mechanism is rotatably connected with the right side wall of the shell; the side wall of the first telescopic mechanism is hinged to a support rod; the brush head is hinged to the free end of the support rod; the liquid storage box is mounted in the shell; a stirring mechanism is mounted in the liquid storage box; a T-shaped water pipe is mounted on the left side wall of the shell; sprayersare mounted at the upper and lower ends of the T-shaped water pipe; and a rotary mechanism is further mounted on the side wall of the shell. Through arranging the angle-adjustable brush head, the brush head better fits the inner wall of a pipeline to clean the inner wall of the pipeline and scrape sludge attached to the inner wall of the pipeline; and through arranging the rotatable sprayers, thespraying range is greatly enlarged, so that the spraying dead angle is reduced to spray cleanout fluid more uniformly.

Owner:陈建

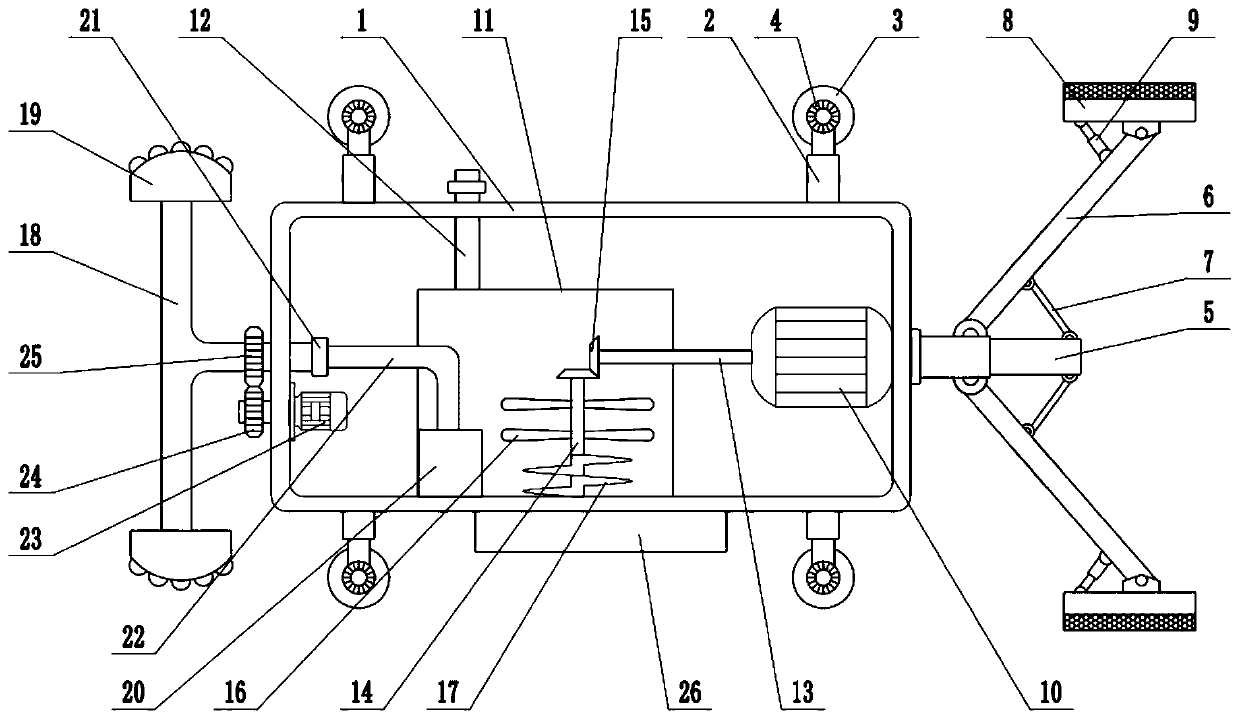

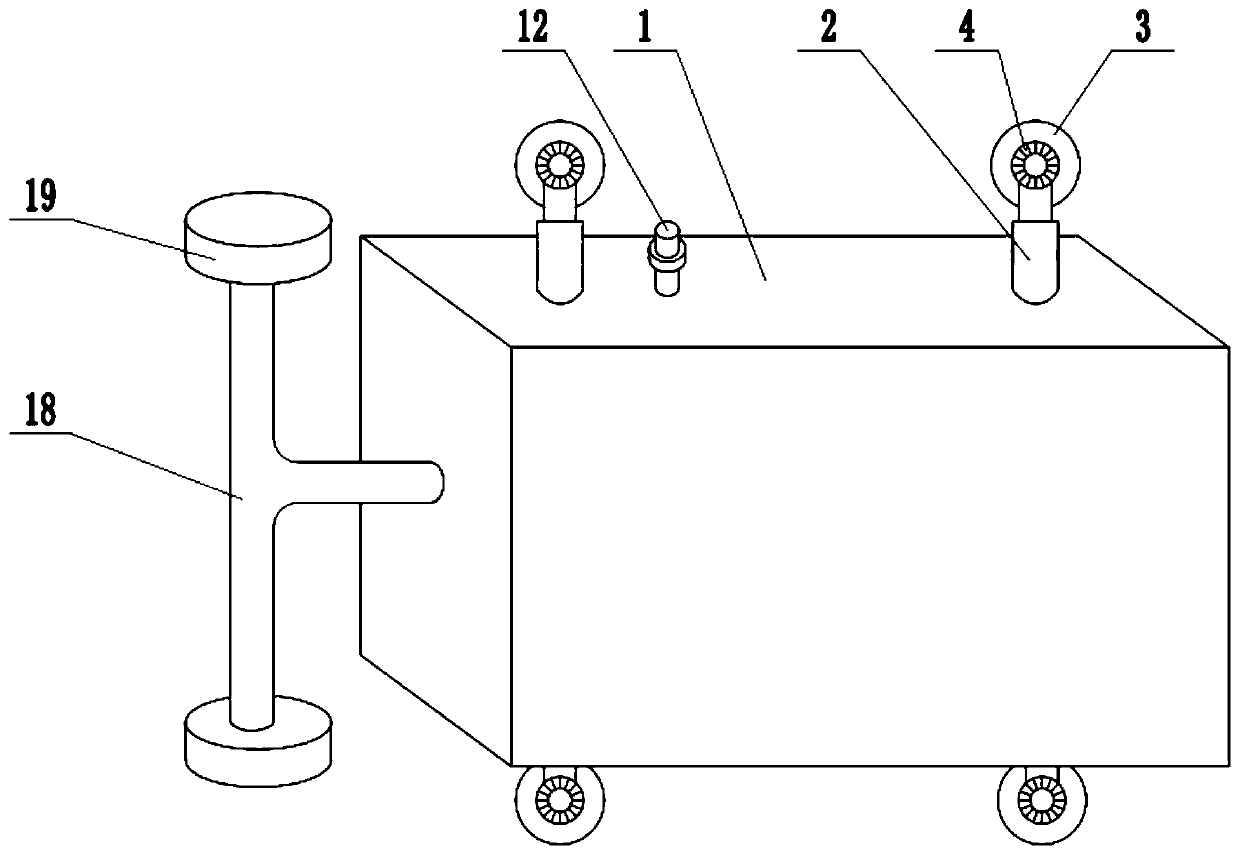

Pesticide spraying vehicle with large spraying range

InactiveCN110226584AExpand the mixing rangeWell mixedRotary stirring mixersTransportation and packagingMotor driveAgricultural engineering

The invention relates to the field of agricultural machinery equipment, in particular to a pesticide spraying vehicle with a large spraying range. The pesticide spraying vehicle comprises a shell, rollers, a liquid storage box, a water pump, a pesticide delivery pipe and a pesticide spraying plate, wherein the rollers are mounted at the bottom of the shell; the liquid storage box is mounted in thecasing; the water pump is mounted at the bottom of the liquid storage box; a rotating shaft is rotationally connected with the bottom of the shell; a rotating table is fixedly connected with the topend of the rotating shaft; a support is fixedly connected with the upper surface of the rotating table; a crank shaft is mounted on the support; a connecting rod is arranged at the shaft neck of the crank shaft in a sleeving manner; the pesticide delivery pipe is hinged with the top end of the connecting rod. In a pesticide spraying process, a pesticide in the liquid storage box is stirred by stirring blades, the pesticide on the bottom layer is stirred by spiral plates, the pesticide is enabled to billow upwards and is prevented from producing sediment, a rotary motor drives the pesticide spraying plate to rotate back and forth in the spraying process, the spraying range is expanded, meanwhile, a driving motor drives the pesticide delivery pipe to move up and down, so that the pesticide spraying plate is driven to move up and down, and the spraying range is further expanded.

Owner:张福明

Self-controlled efficient and electrostatic-spraying pesticide application machine for greenhouses

InactiveCN102166548BIncrease profitGuaranteed control effectLiquid spraying apparatusSpray discharge apparatusHuman–machine interfaceEngineering

Owner:镇江和盛环境科技有限公司 +2

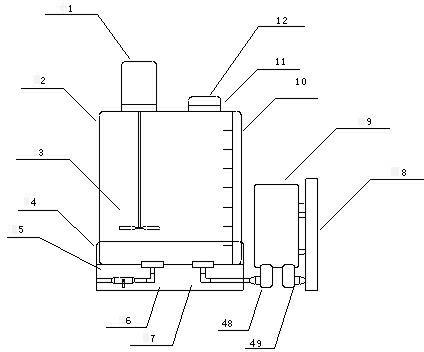

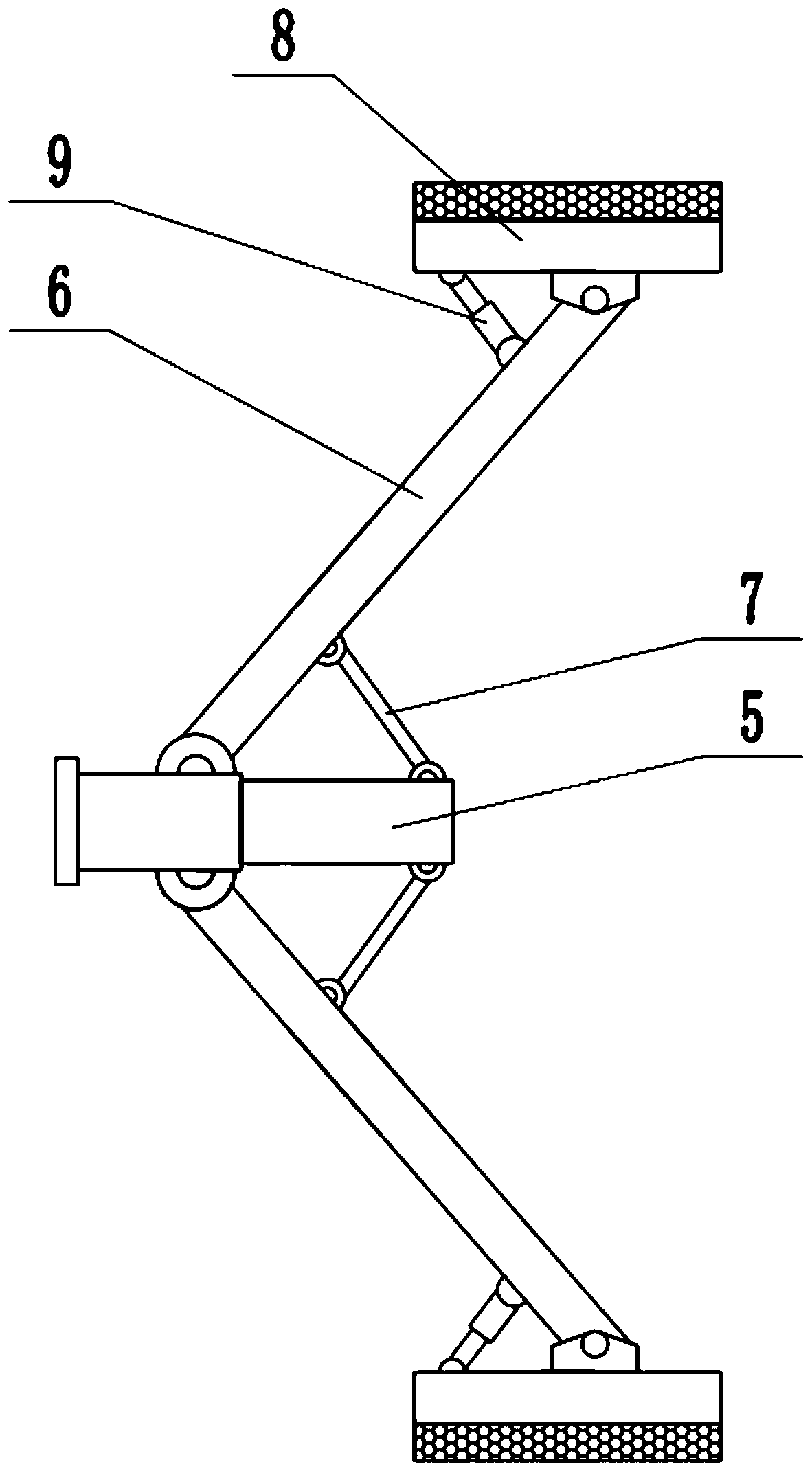

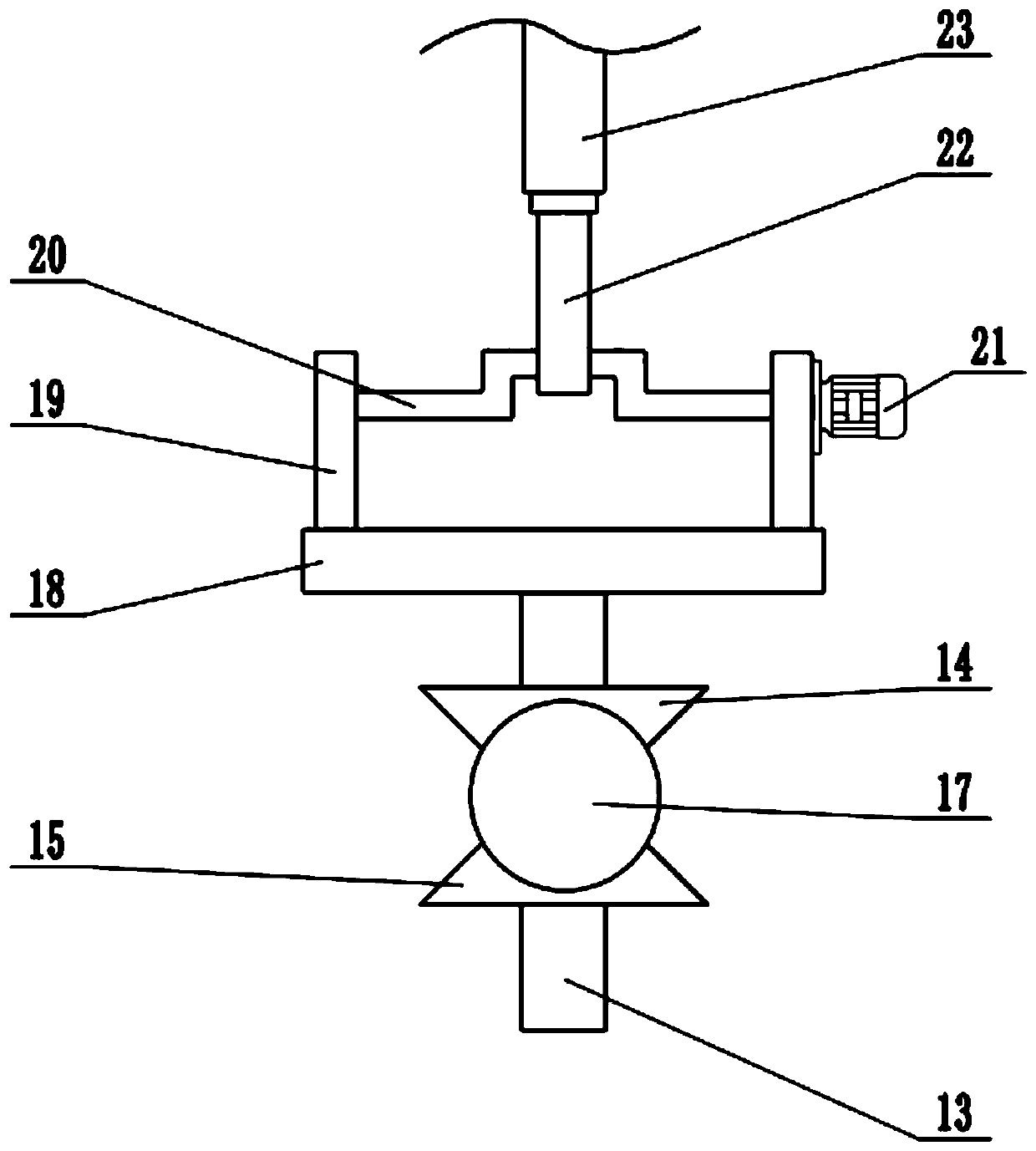

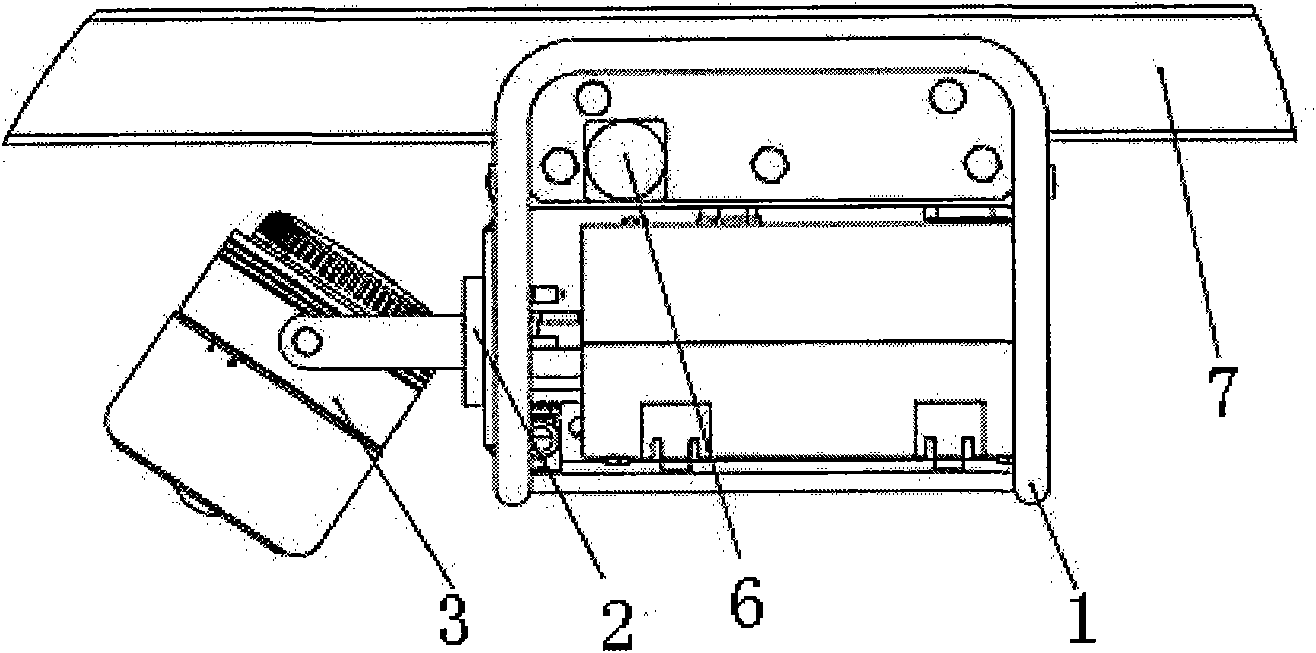

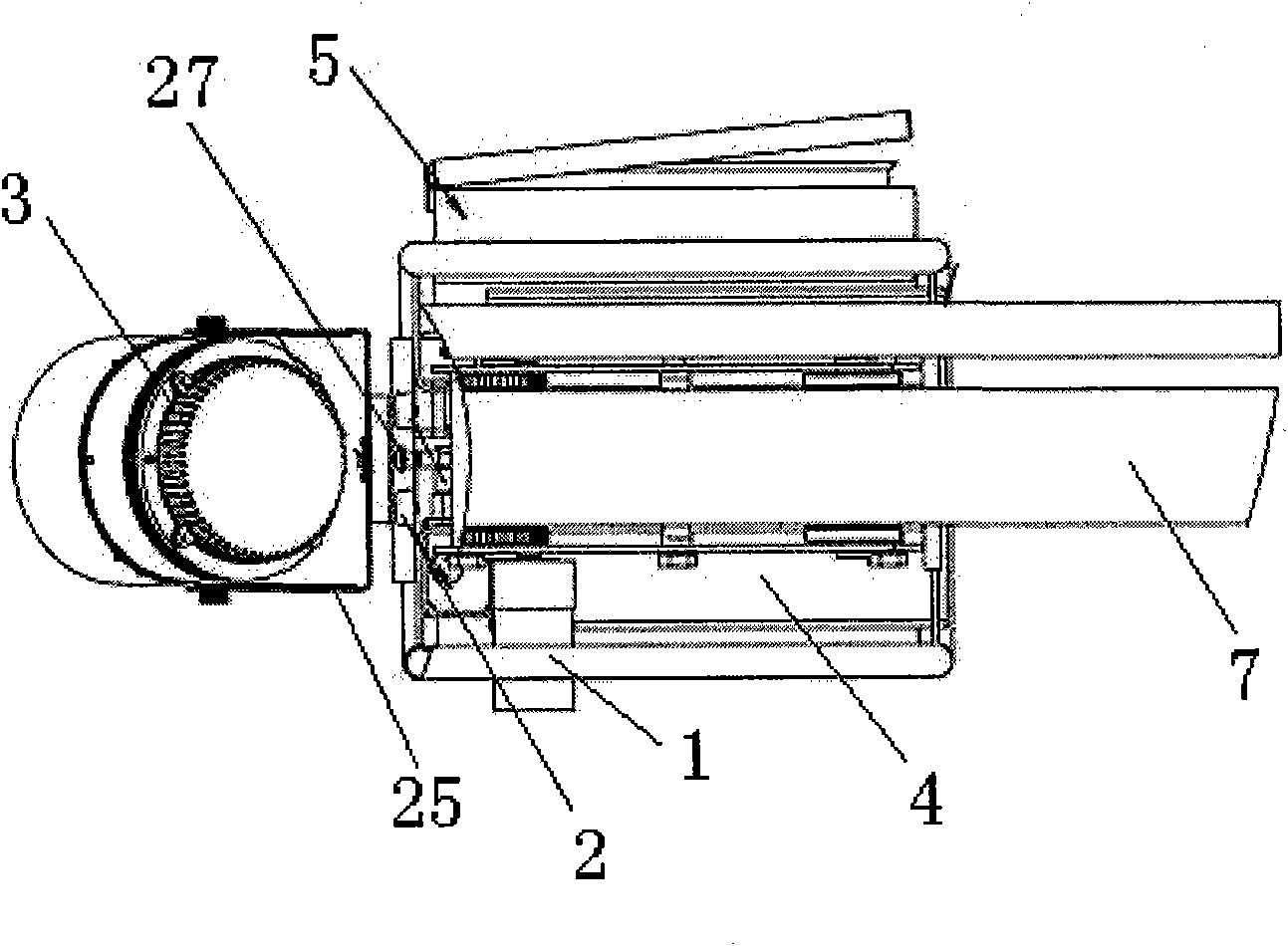

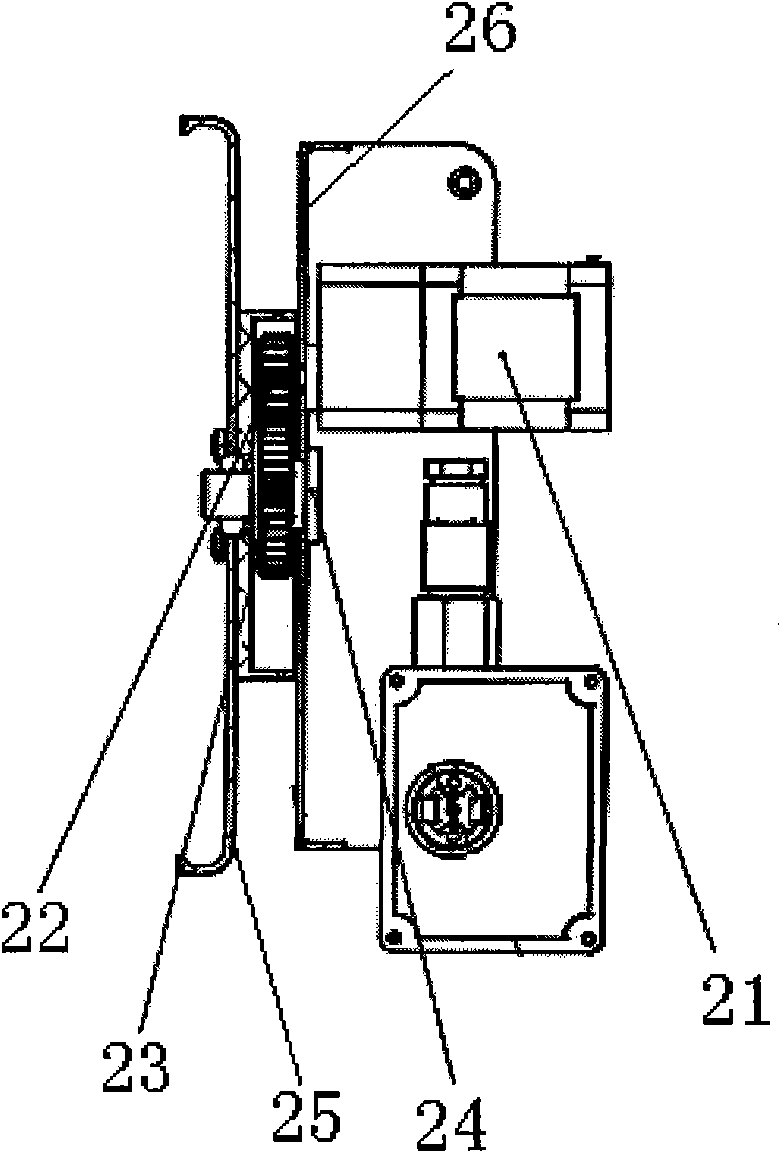

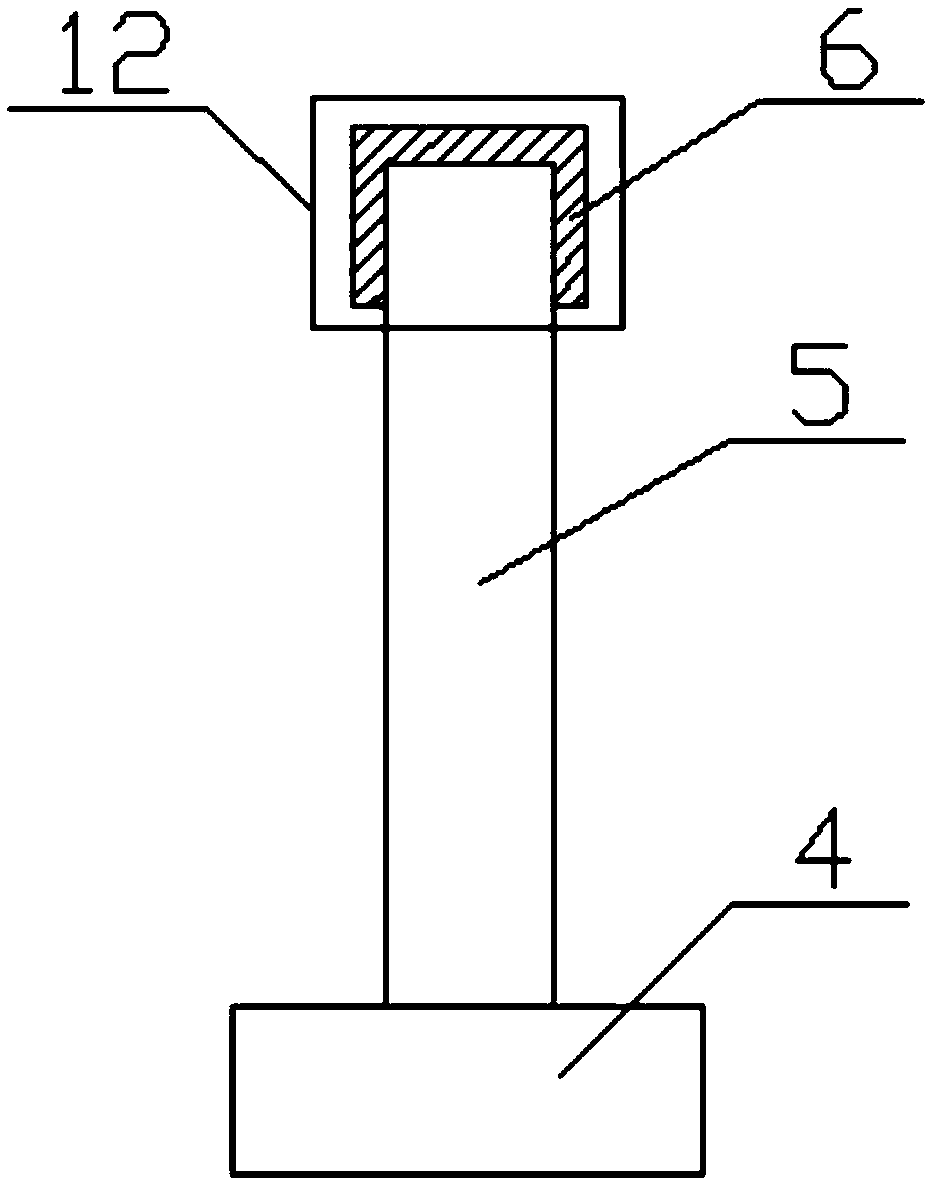

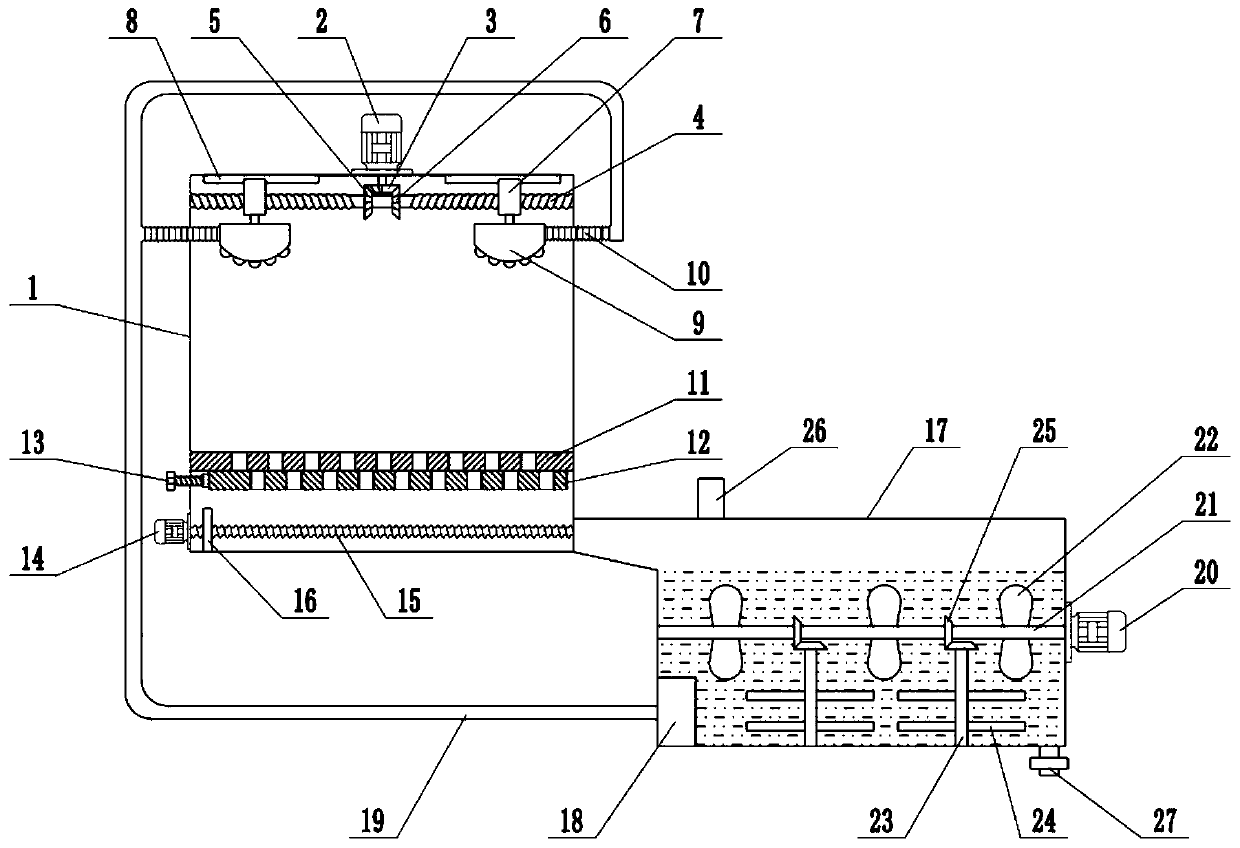

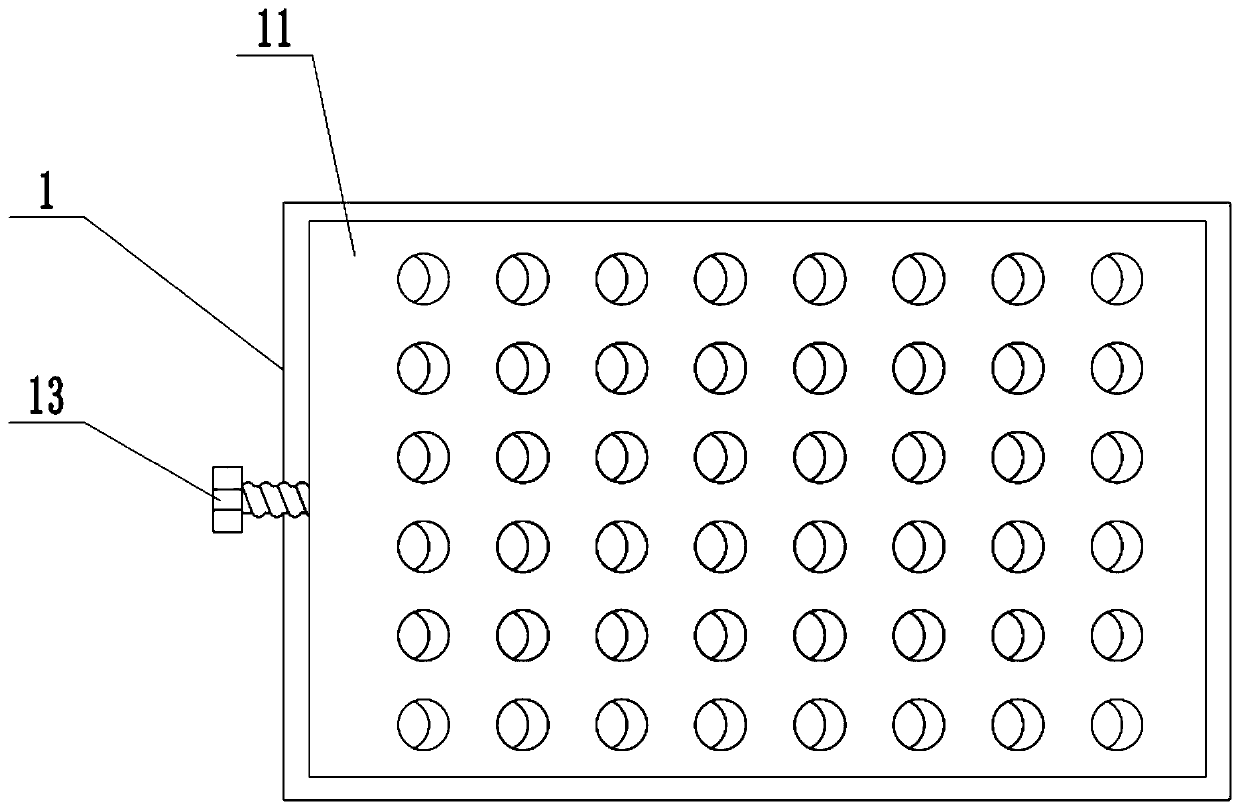

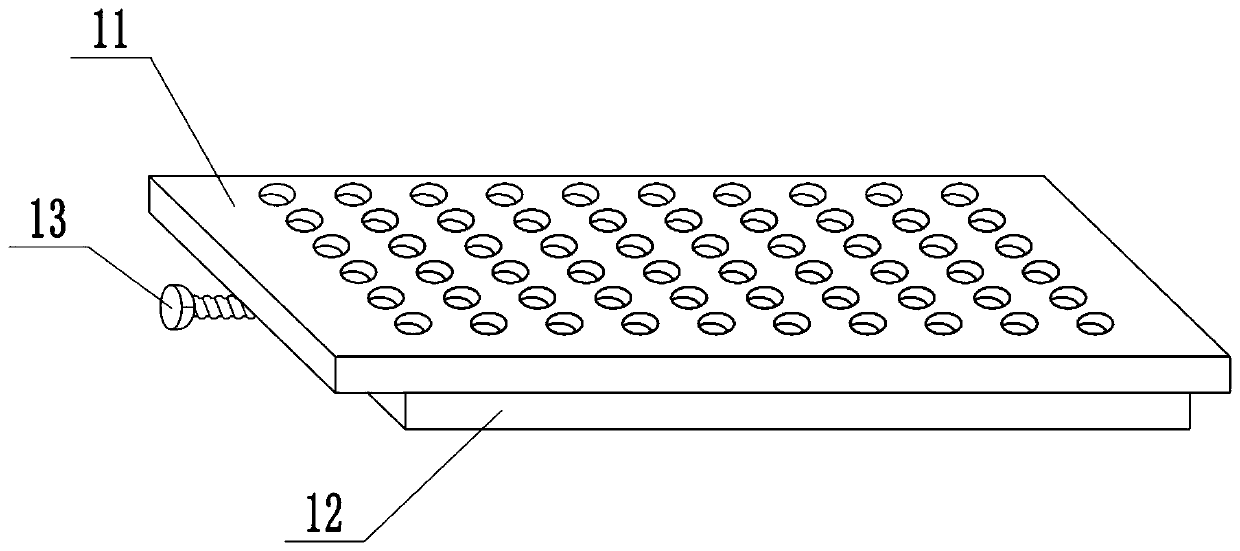

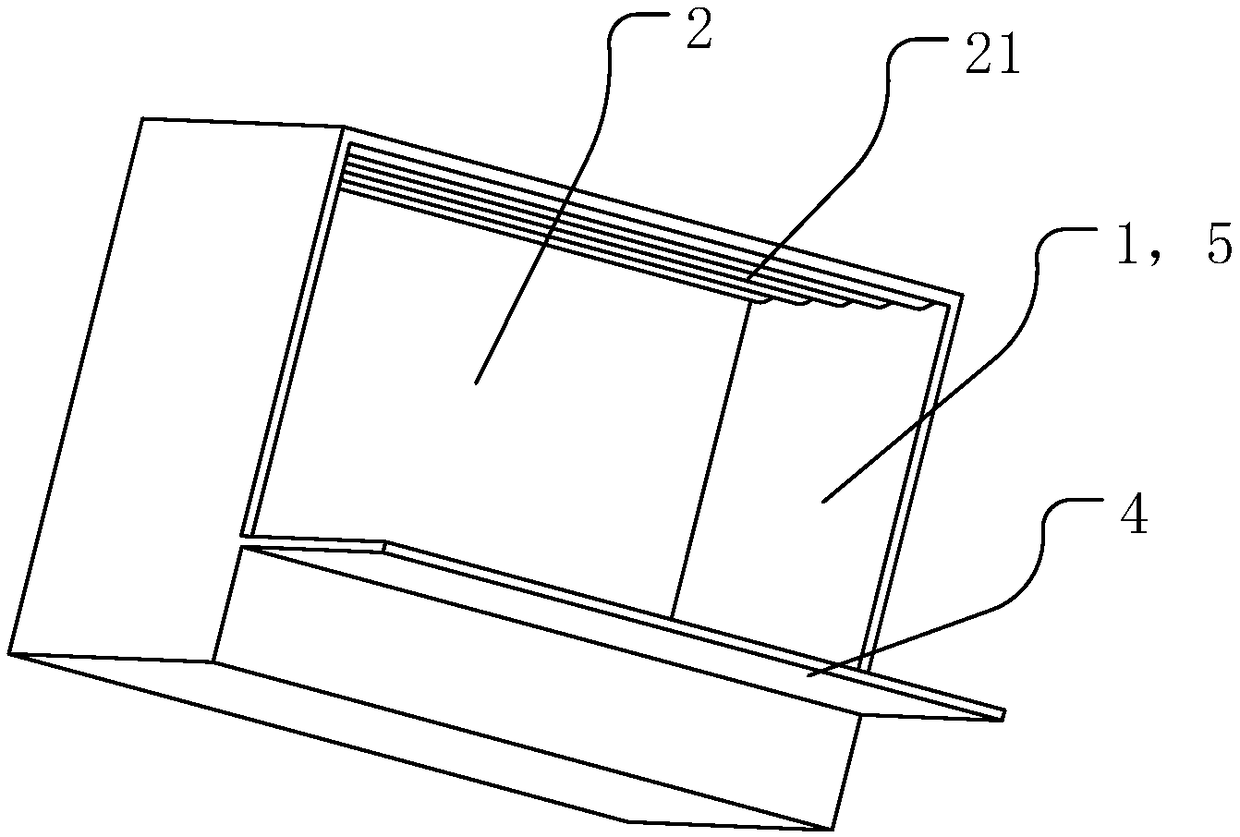

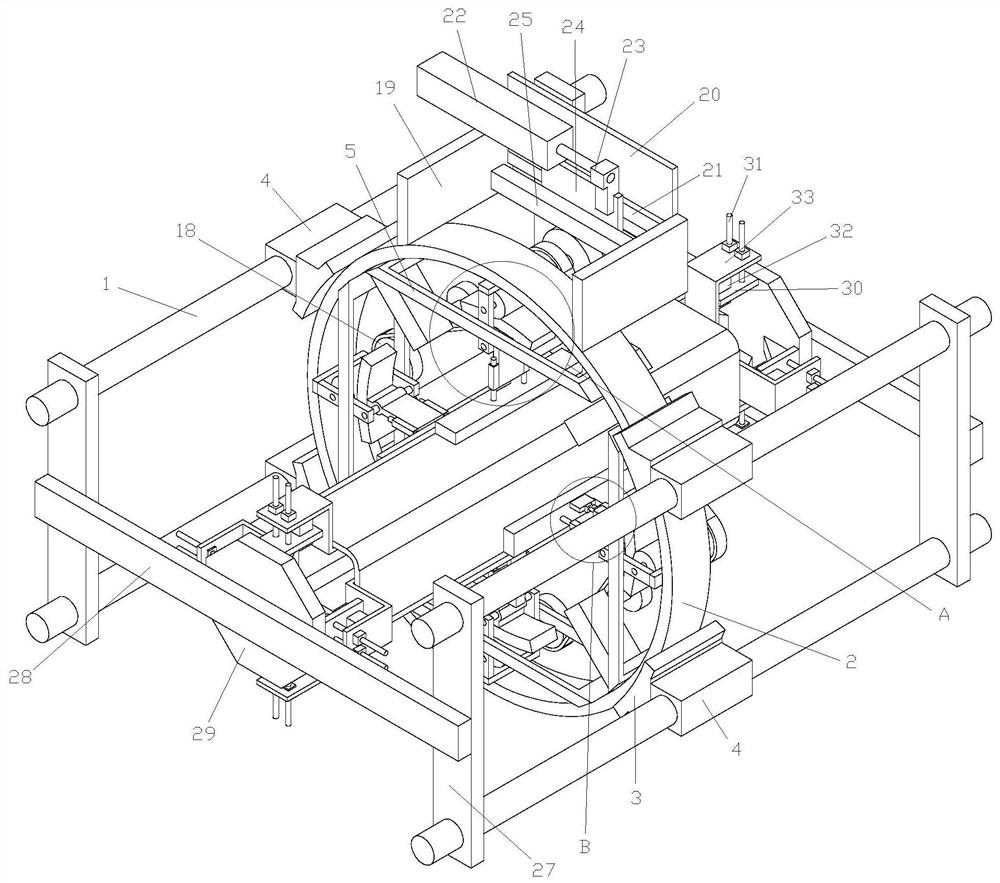

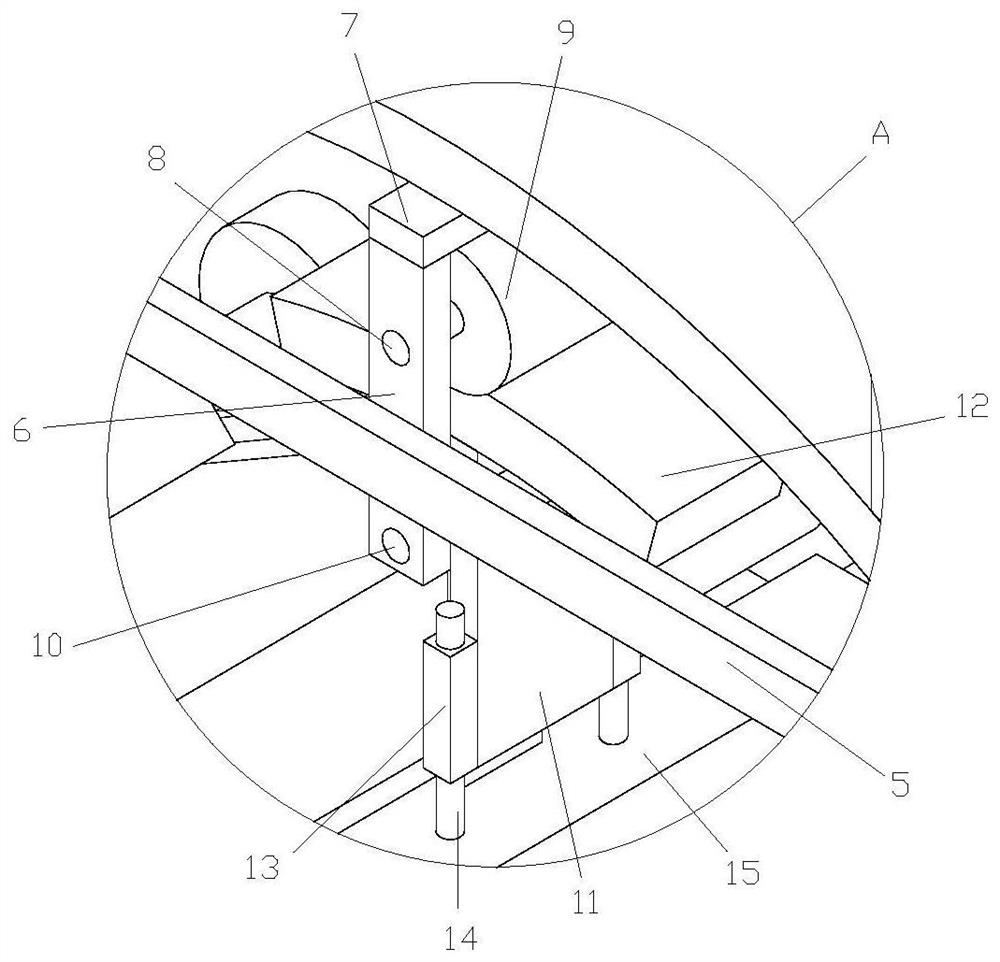

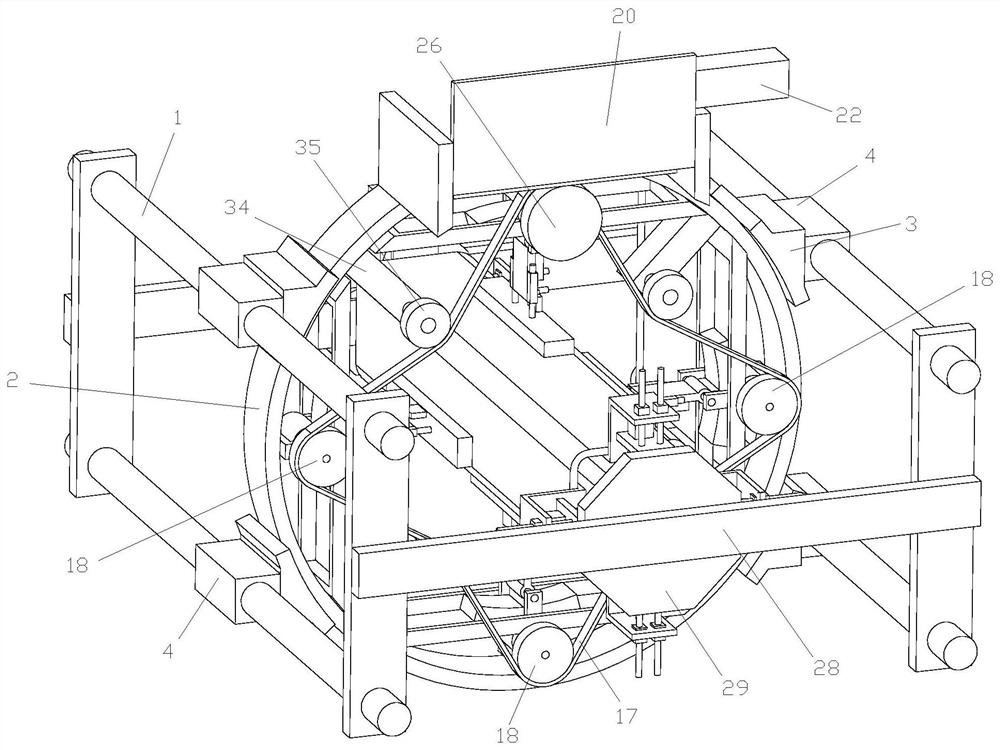

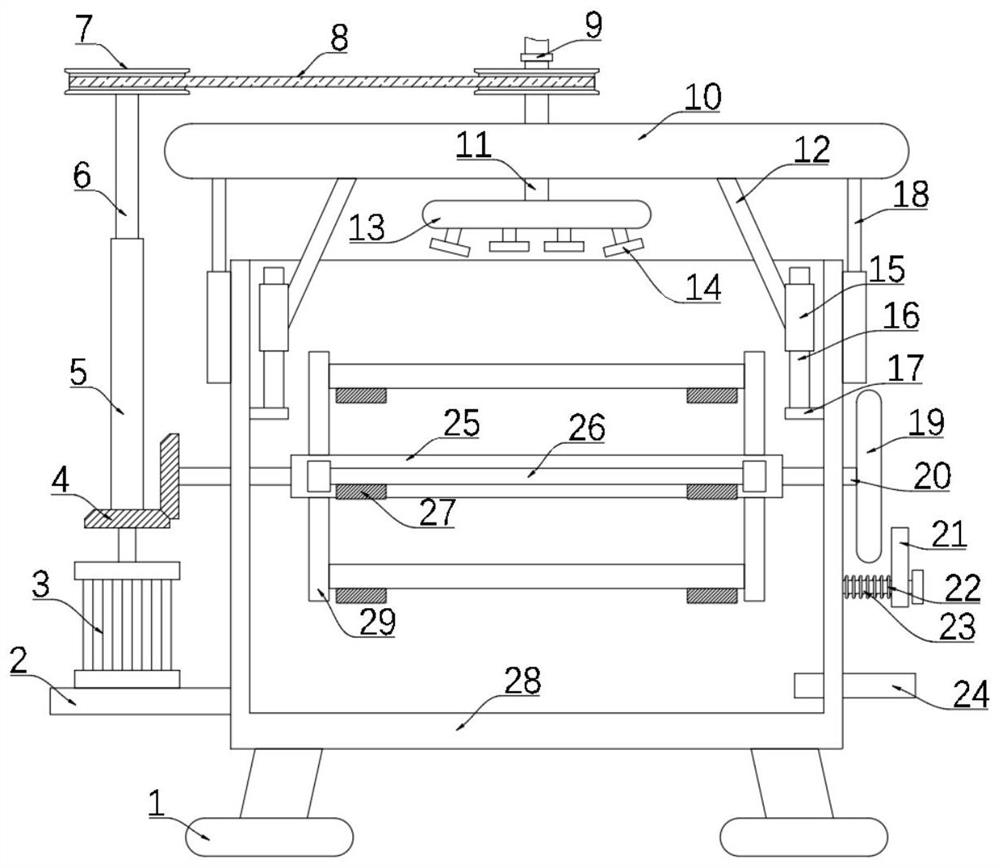

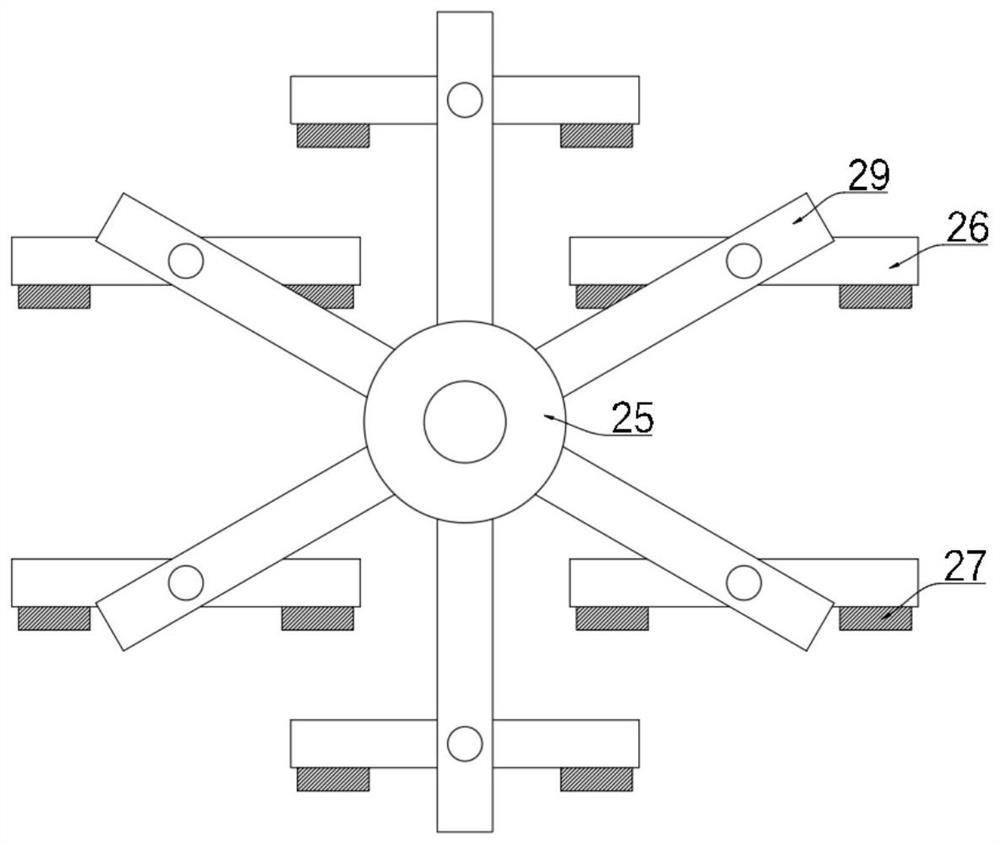

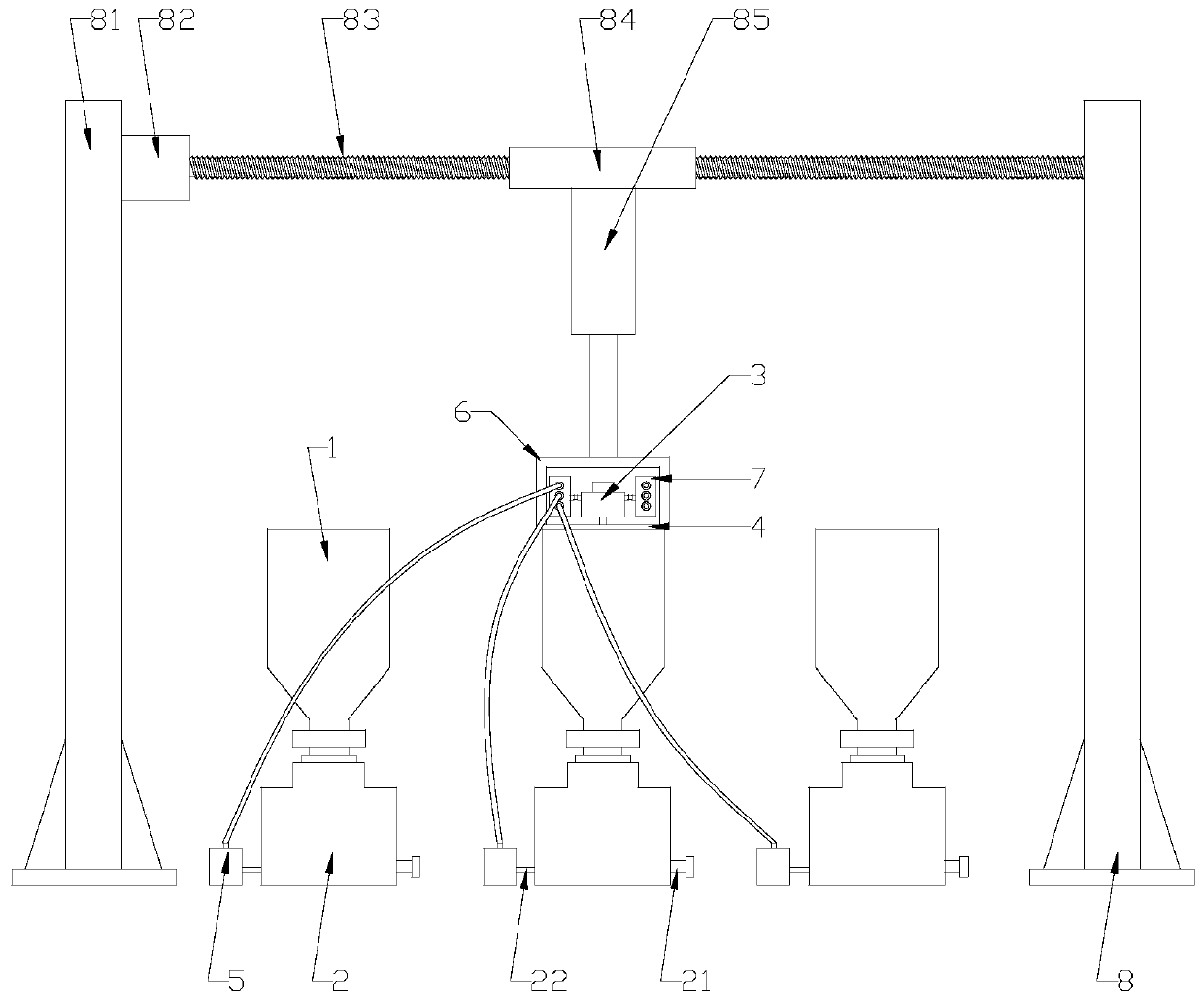

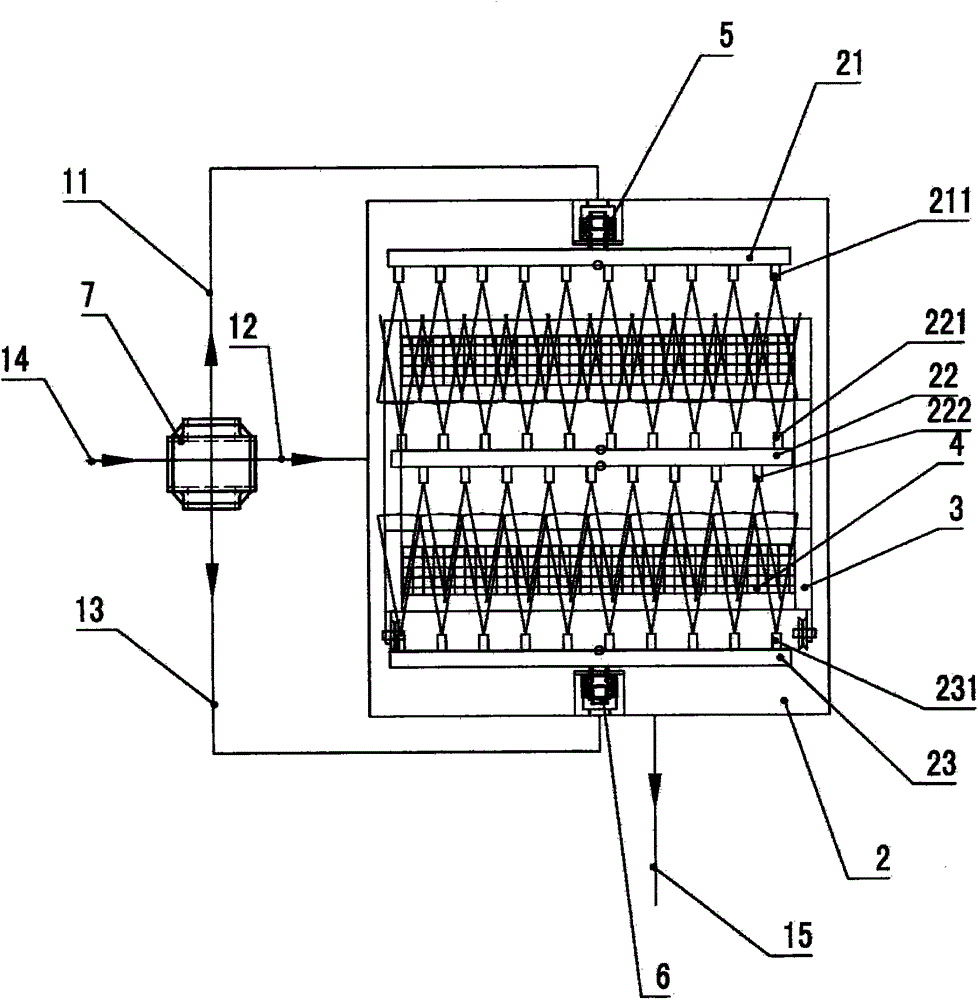

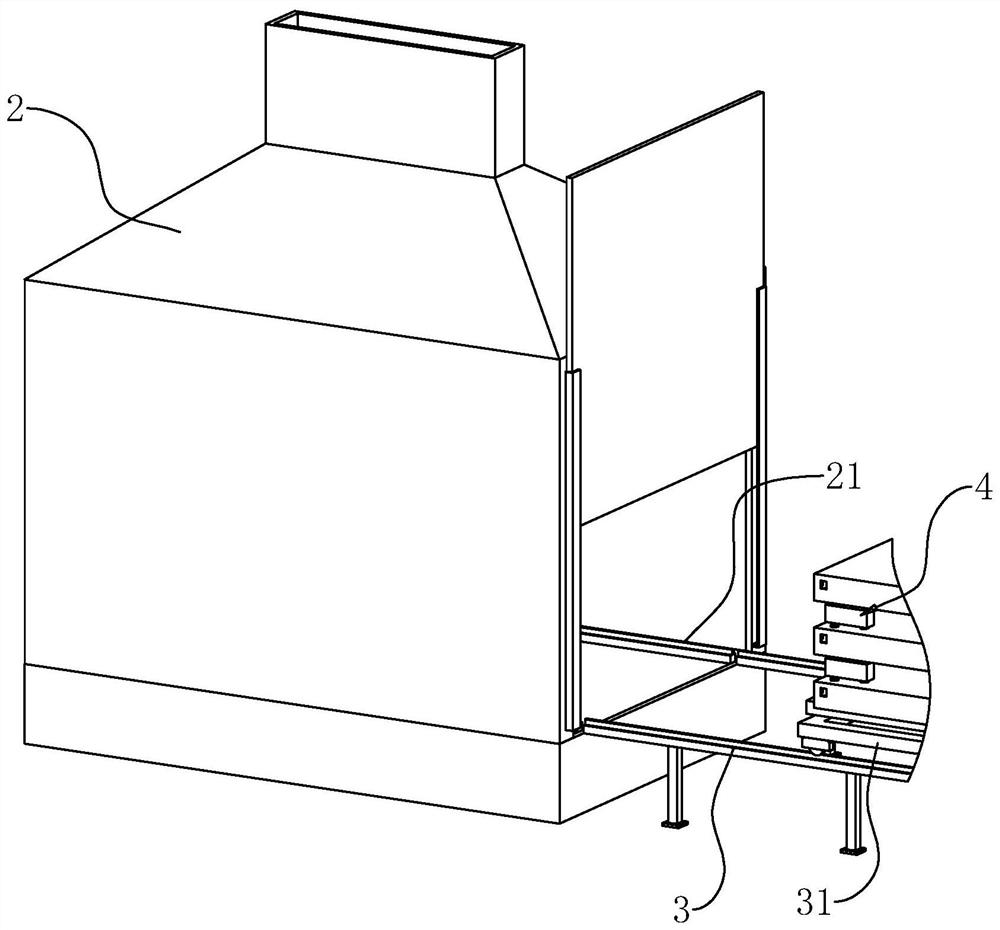

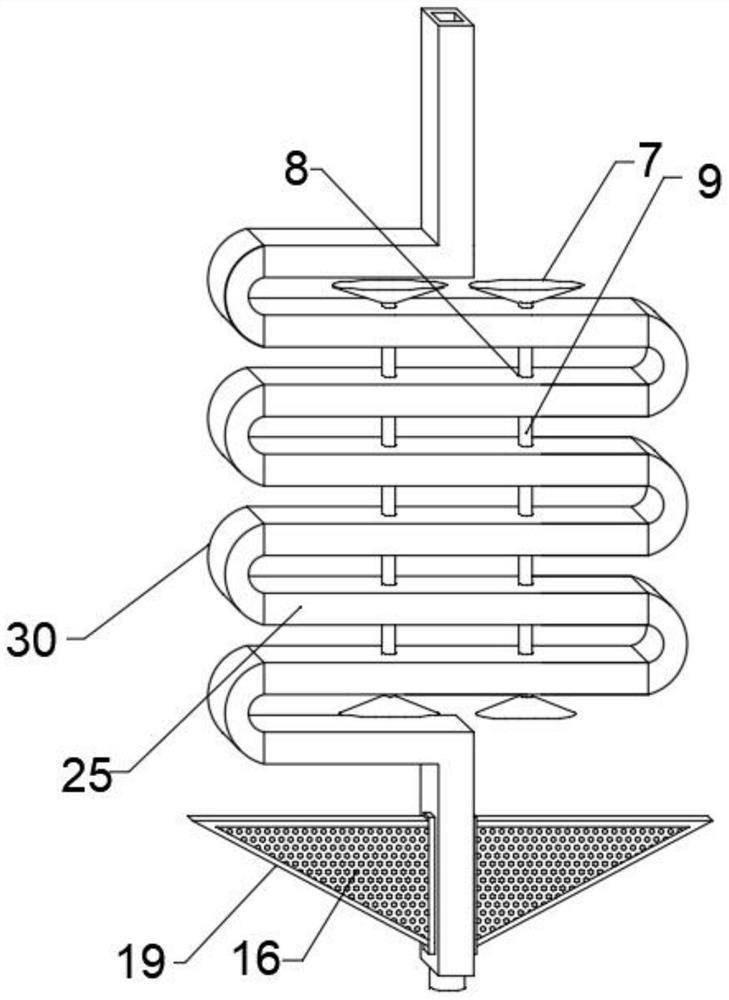

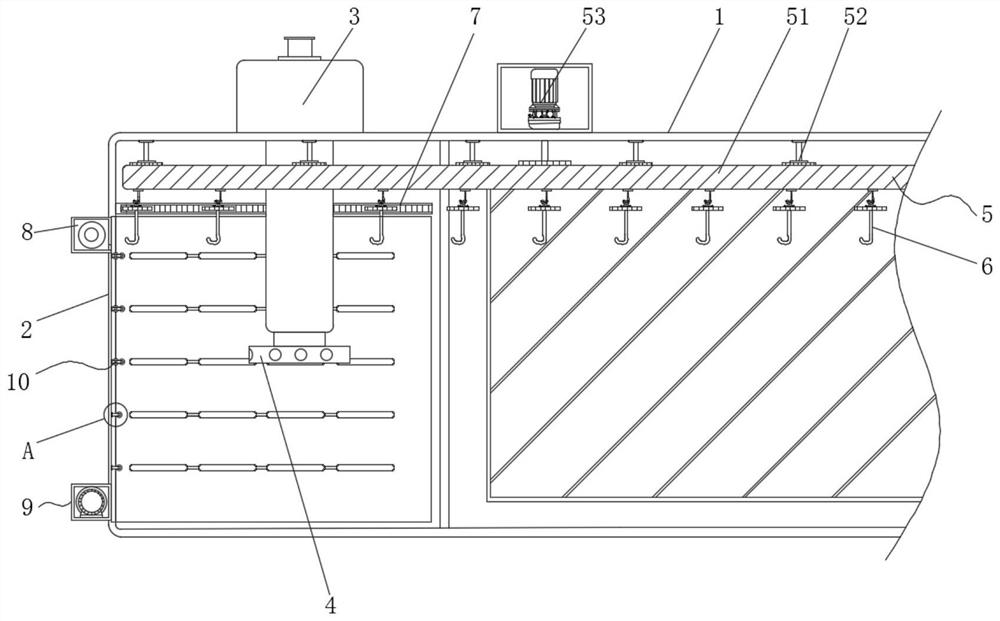

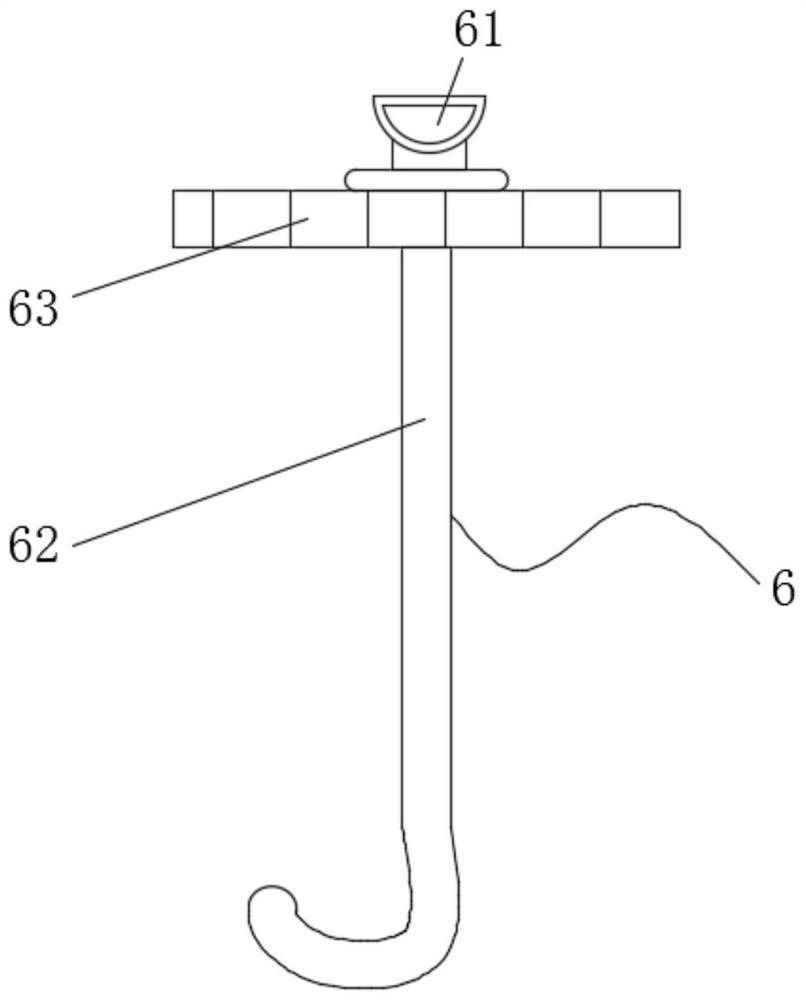

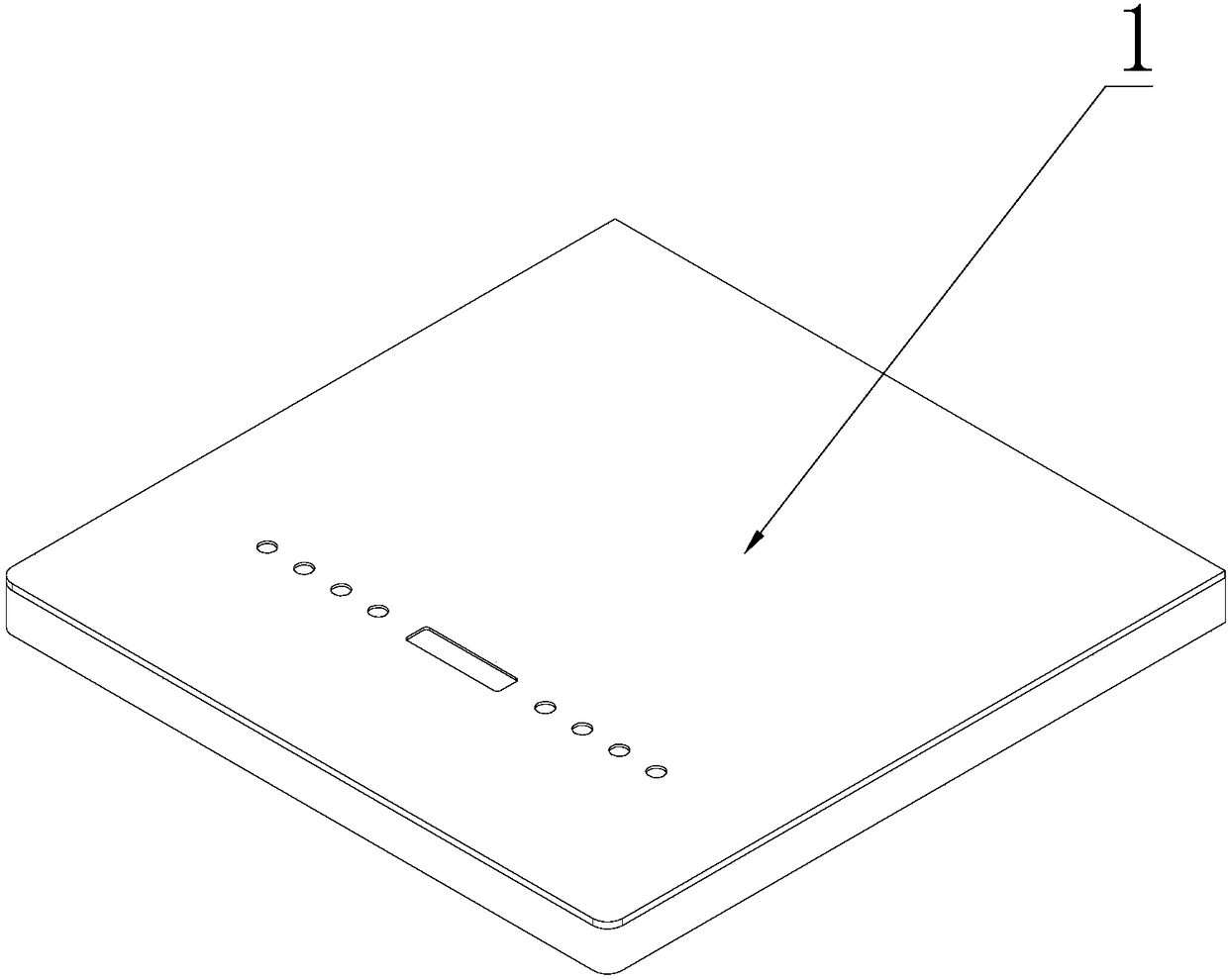

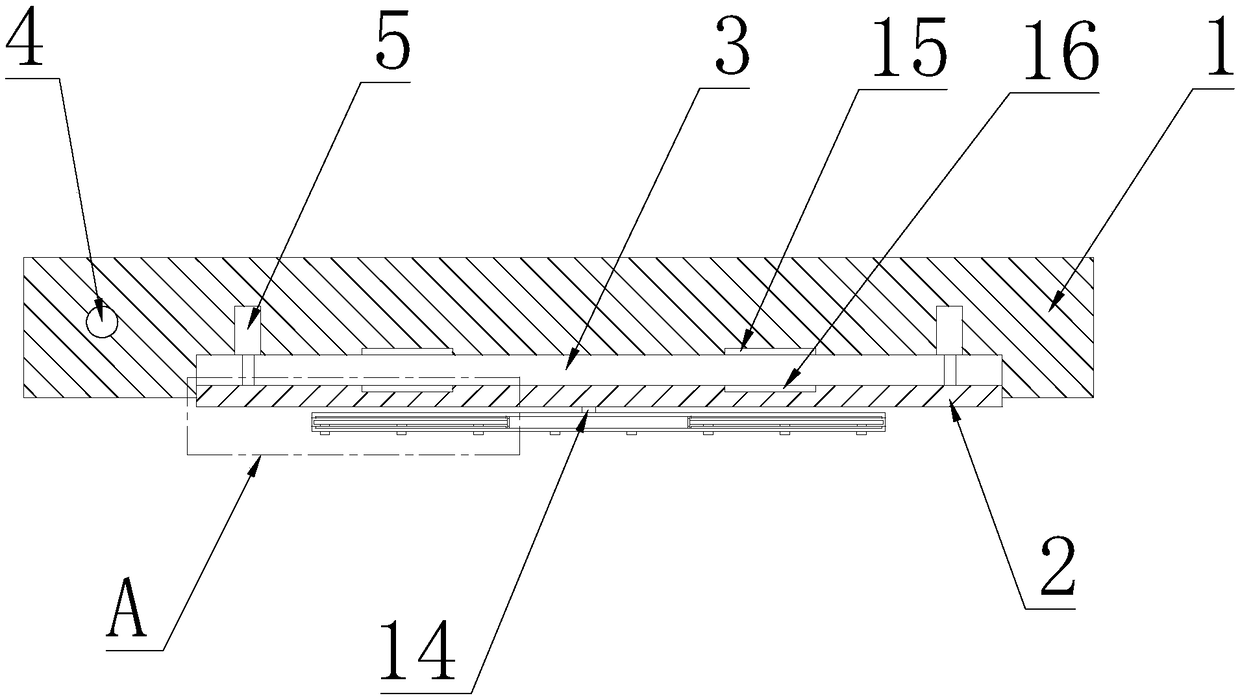

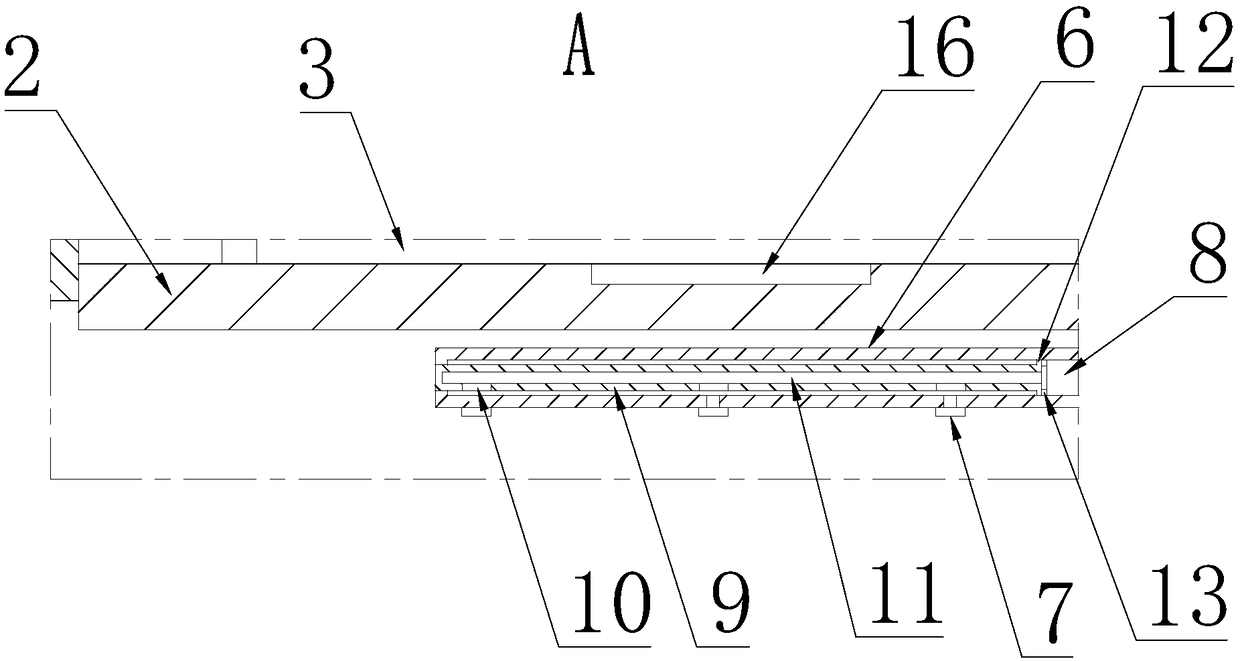

Automatically speed-changing swing type greenhouse spraying device

InactiveCN101926319AReduce spray dead angleImprove the utilization rate of pesticidesSpray nozzlesInsect catchers and killersElectricityEngineering

The invention relates to an automatically speed-changing swing type greenhouse spraying device. The automatically speed-changing swing type greenhouse spraying device is characterized by comprising a machine frame, wherein the machine frame is provided with a swing mechanism which is connected with a spraying mechanism; a medicine-chest is fixed on one side of the machine frame, while an electric cabinet is fixed on the other side of the machine frame; the machine frame is arranged on a guide rail in a sliding mode through a traveling mechanism; the swing mechanism comprises a motor which is connected with the electric cabinet; an output end of the motor is connected with a driving gear which is meshed with a driven gear arranged on an output shaft; one end of the output end is fixedly connected with a U-shaped support, while the other end is rotatablely connected with a fixed plate arranged on the machine frame; the fixed plate is provided with a proximity switch which is electrically connected with the electric cabinet; the spraying mechanism comprises a medicament conveying pipe which is arranged in a spray cap; the medicament conveying pipe is provided with a flow control valve and a flow sensor; the flow sensor and the flow control valve are electrically connected with the electric cabinet; a medicament inlet end of the medicament conveying pipe is connected with the medicine-chest, and a medicament output end is connected with a spray head body through an electric fan and a vortex generator; and the electric fan and the vortex generator are electrically connected with the electric cabinet.

Owner:CHINA AGRI UNIV

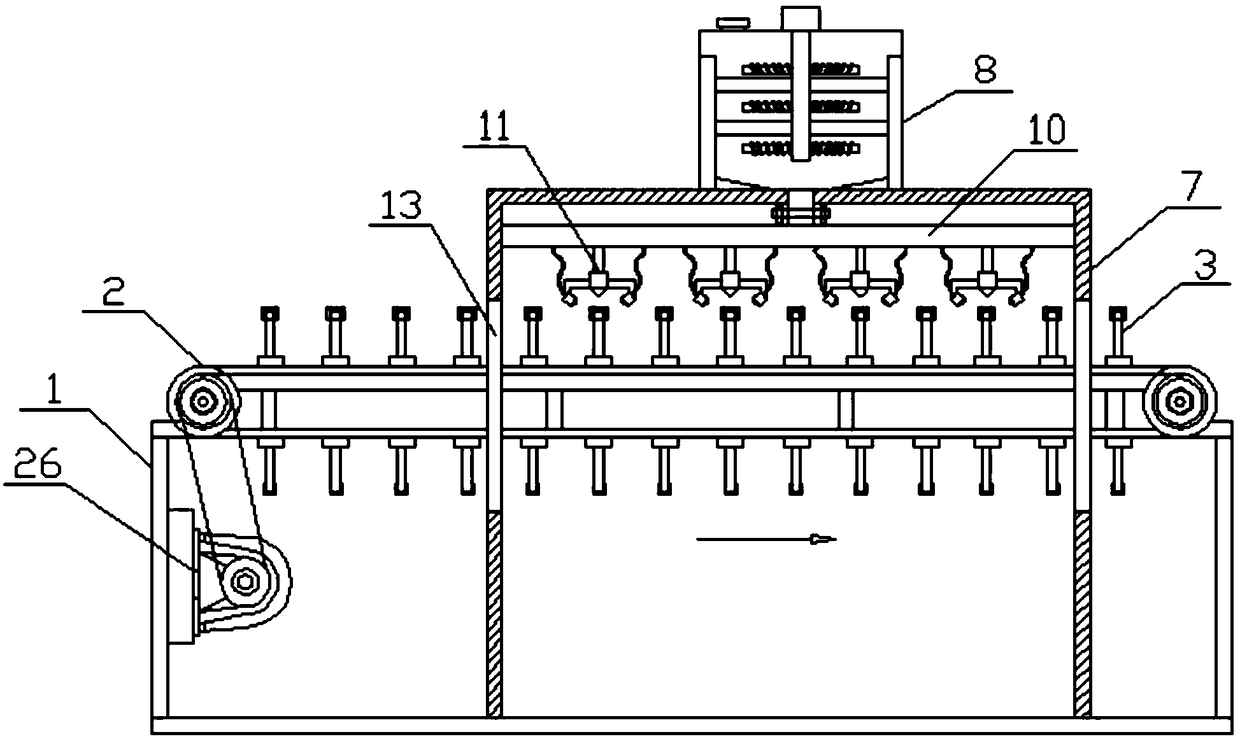

Spraying device for bottle cap production

The invention discloses a spraying device for bottle cap production, and relates to the technical field of bottle cap spraying. The spraying device comprises a rack, a conveyor belt is arranged on theupper surface of the rack, and bottle cap fixing devices are arranged on the outer wall of the conveyor belt at intervals. A spraying room is arranged on the right side of rack, the spraying room isdisposed on the outer side of the rack in a covering mode, and an anti-solidification coating box is arranged on the middle part of the upper surface of the spraying room. A flow-limiting valve is arranged at the middle of the bottom of the anti-solidification coating box in a communicating mode, the flow-limiting valve penetrates through the outer wall of the spraying room to the top end of the inner wall of the spraying room, and a material storage tube is arranged at the upper end of the interior of a cavity of the spraying room. The left and right ends of the outer wall of the material storage tube are fixedly connected with the inner wall of the spraying room, the flow-limiting valve communicates with the middle portion of the upper end of the material storage tube, and spraying device bodies are arranged at the lower end of the material storage tube at intervals. The spraying device for bottle cap production achieves the purposes of looseness preventing, good spraying effect andsolidification preventing, and improves the efficiency of bottle cap spraying.

Owner:连云港翔瑞包装有限公司

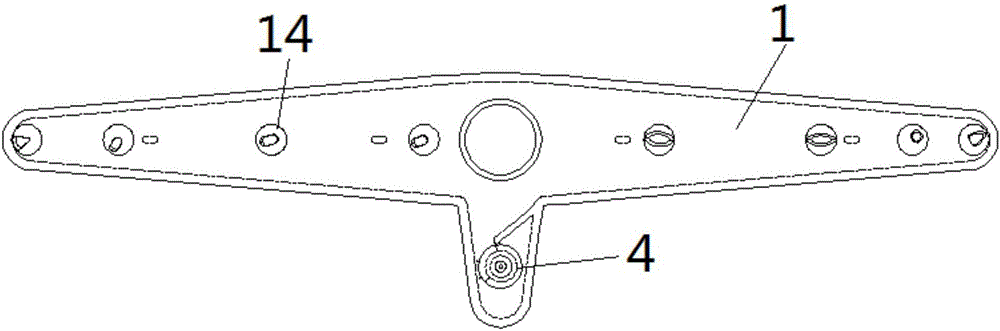

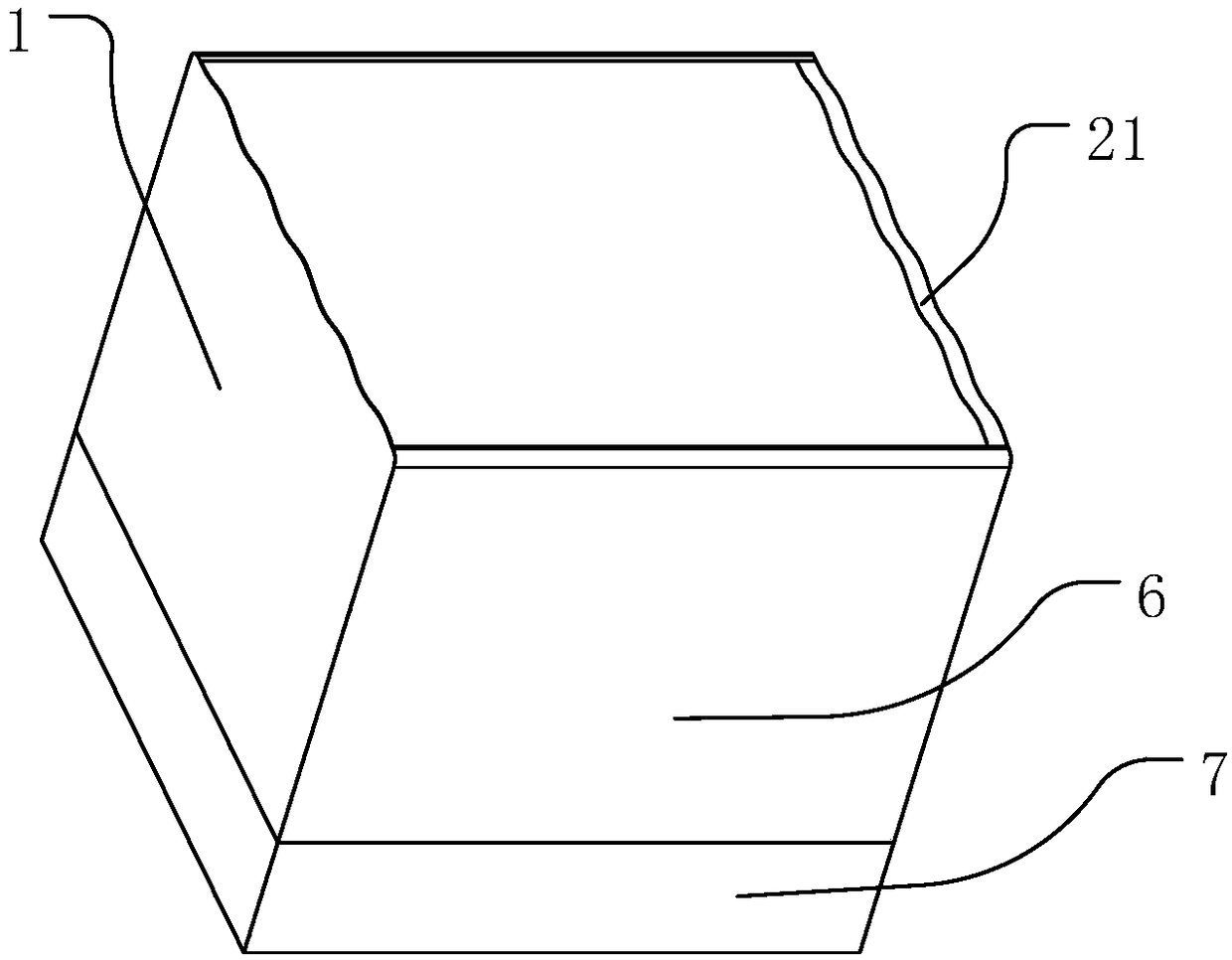

Sprayer structure for dishwasher

InactiveCN106175635AImprove washing effectImprove performanceTableware washing/rinsing machine detailsSprayerEngineering

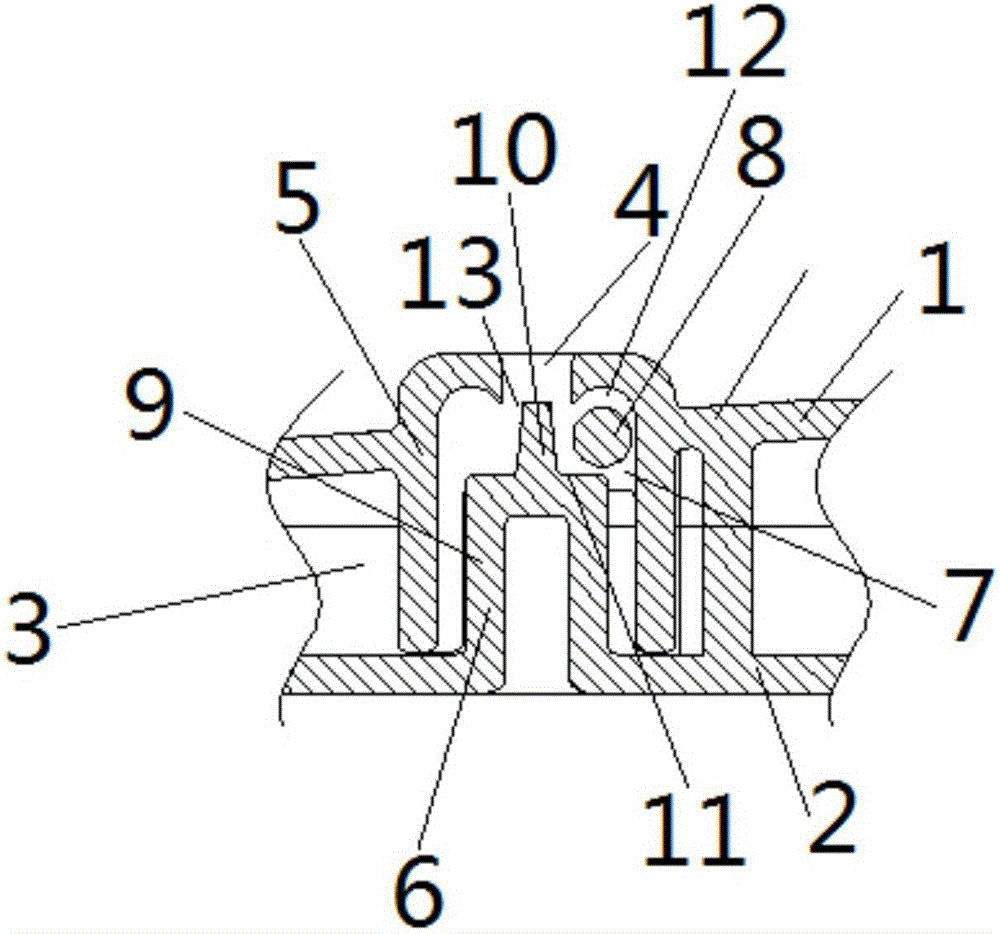

The invention provides a sprayer structure for a dishwasher, applied to the technical field of dishwasher parts. The sprayer structure is characterized in that a spray chamber (3) is formed between a sprayer upper sheet (1) and a sprayer lower sheet (2), the sprayer upper sheet (1) is provided with water spouts (4), the inner wall of the sprayer upper sheet (1) is provided with a circular rib (5), the water spouts (4) are arranged as a structure positioned in the circular rib (5), the sprayer lower sheet (2) below the water spouts (4) is provided with a lower sheet terrace (6), a circular operating chamber (7) is formed between the lower sheet terrace (6) and the circular rib (5), and a moving ball (8) is arranged in the operating chamber (7). The sprayer structure is simple in structure, water spouted from the water spouts may be automatically rotated by 360 degrees while the sprayer structure operates, sweeping area of the water spouts is enlarged, and spouted water provides greater flushing force.

Owner:WUHU GUANGYING IND CO LTD

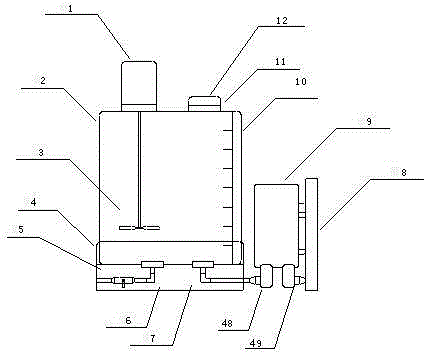

Self-adaptation system for contour of workpiece

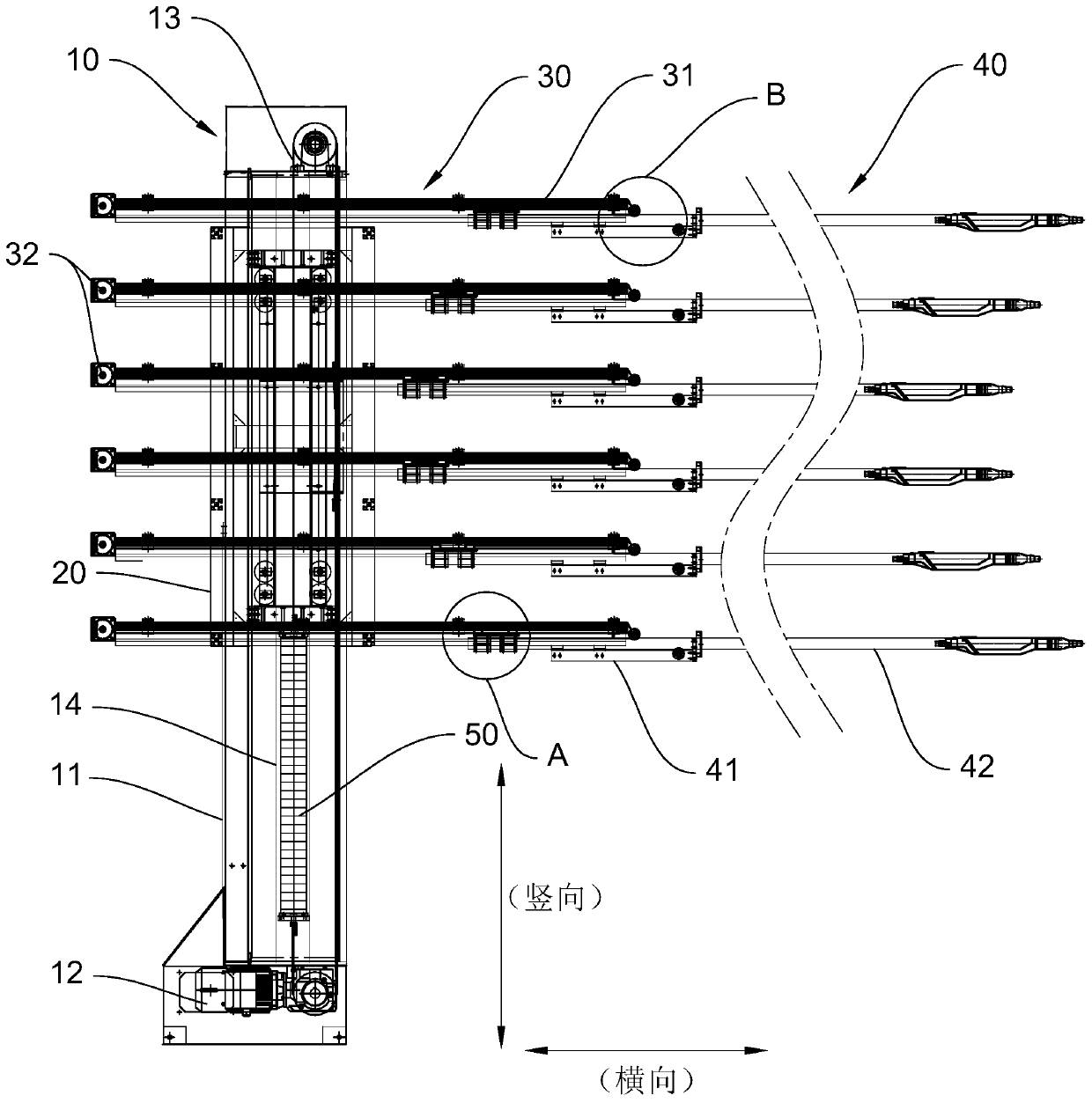

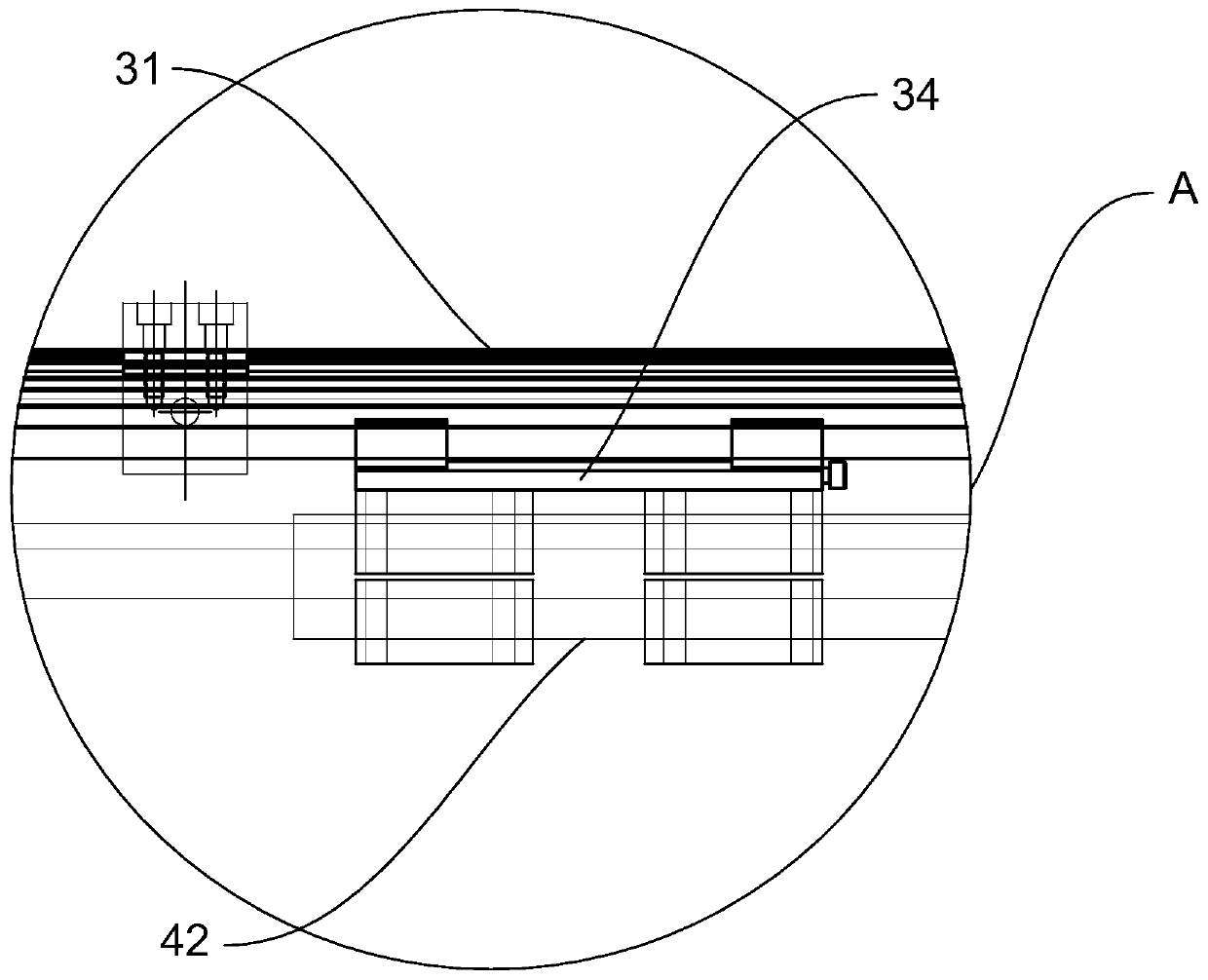

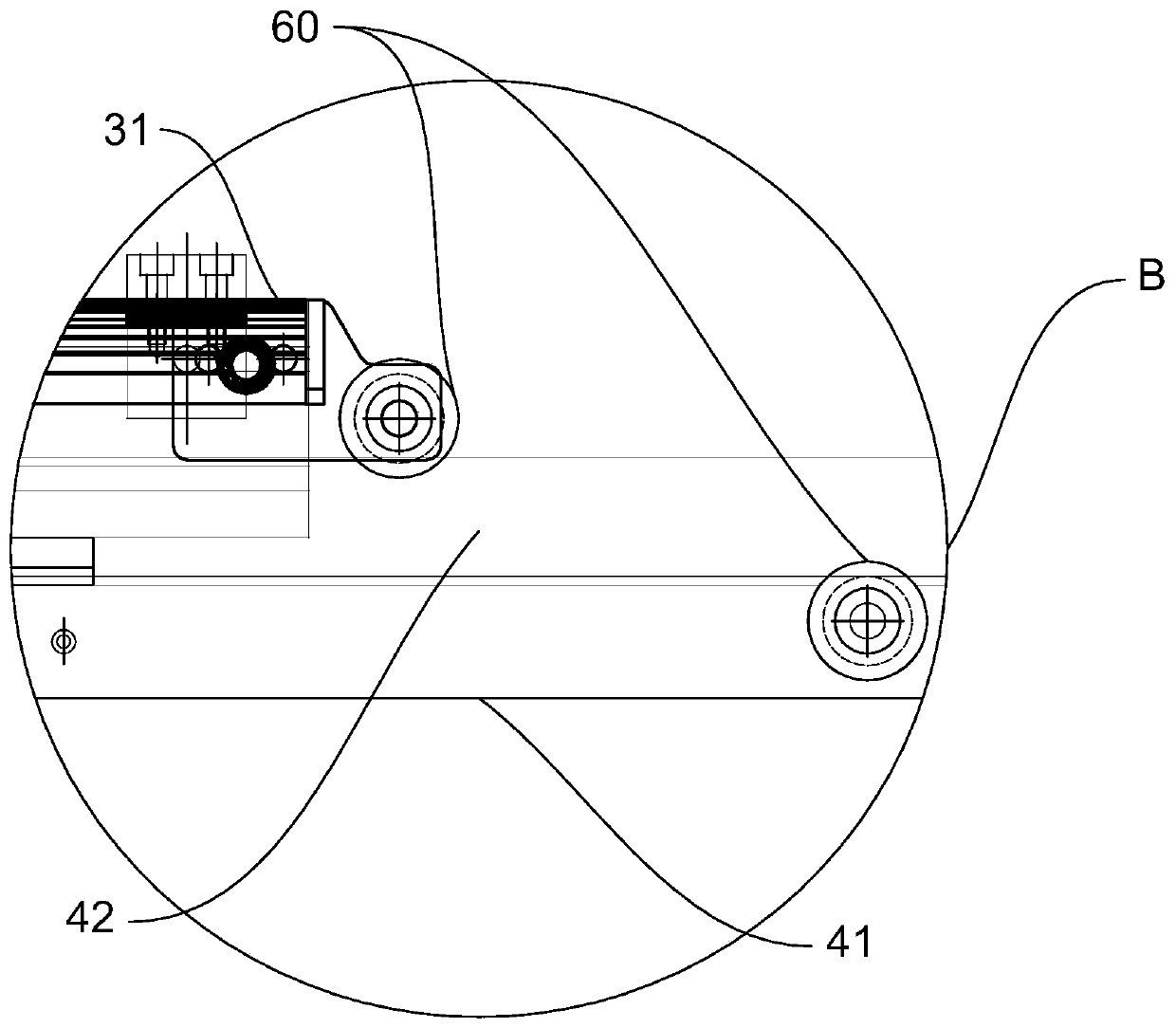

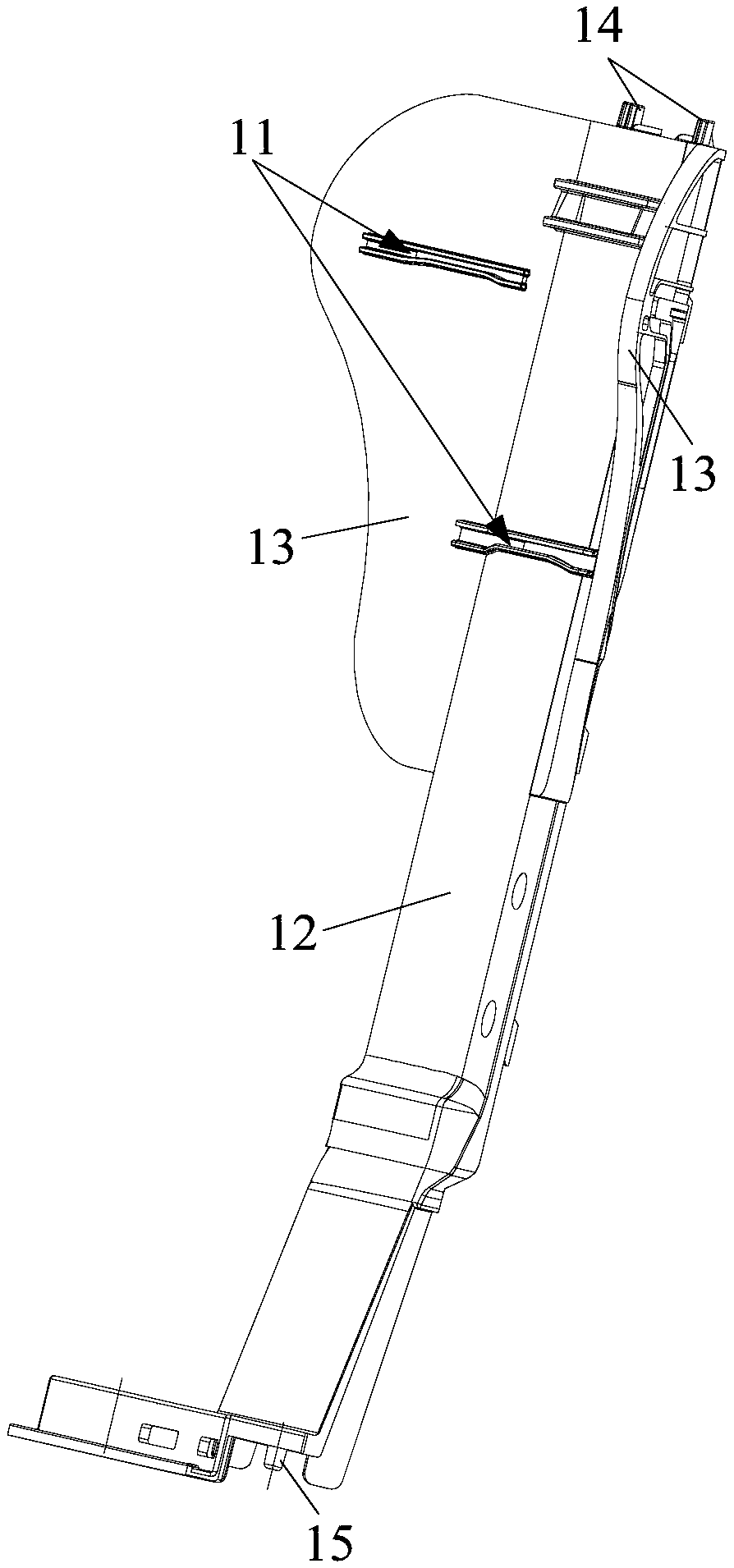

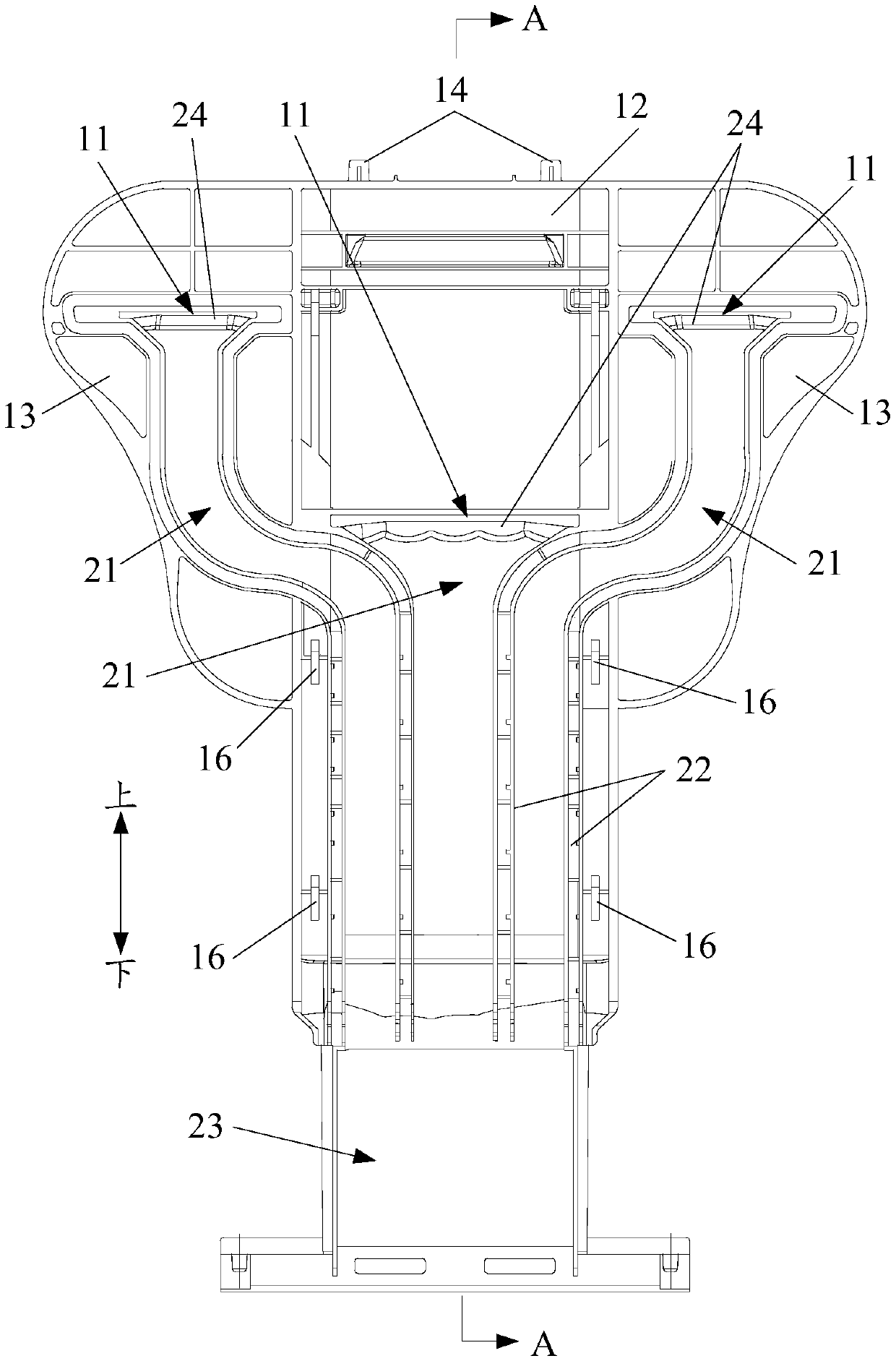

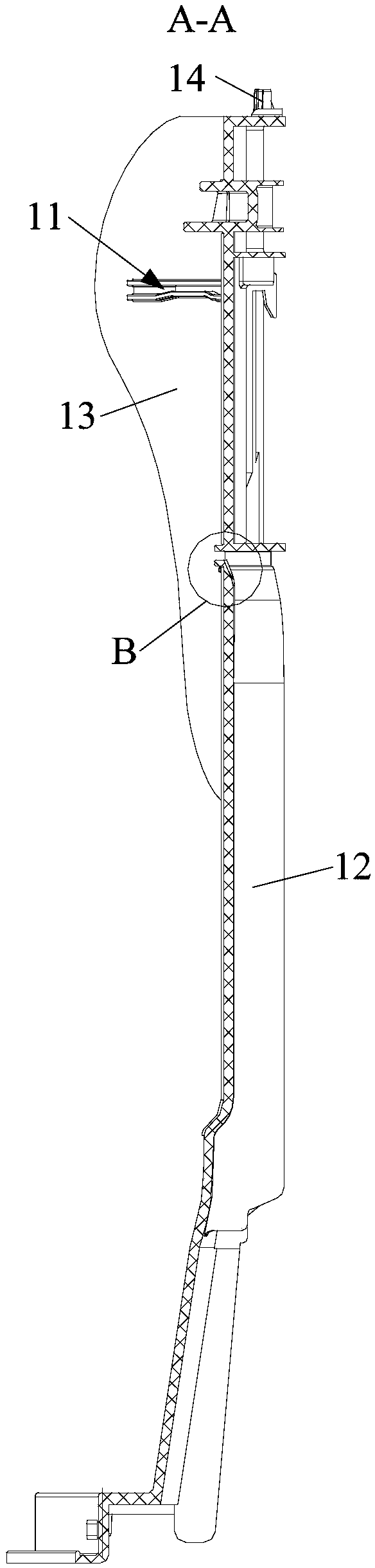

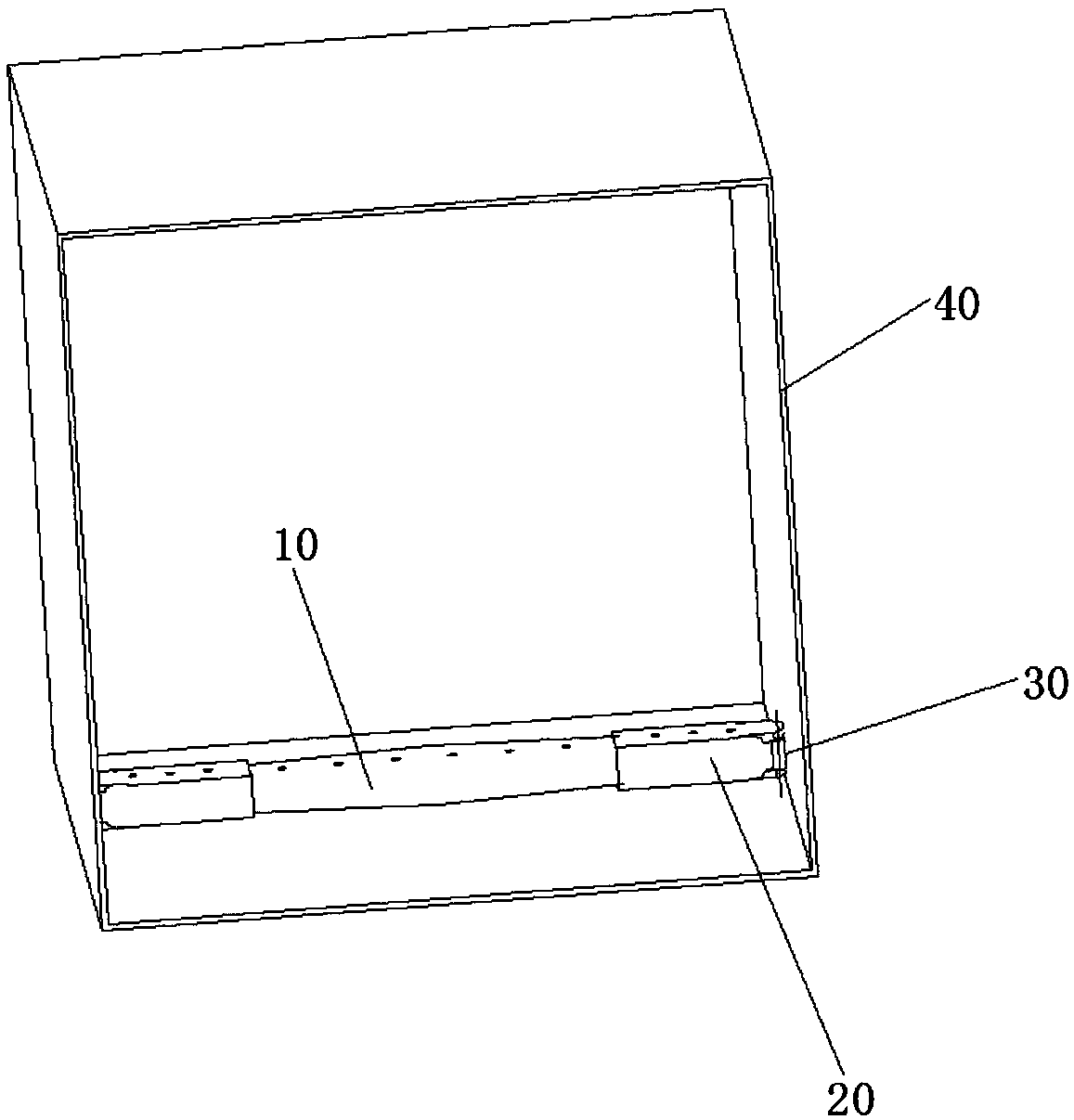

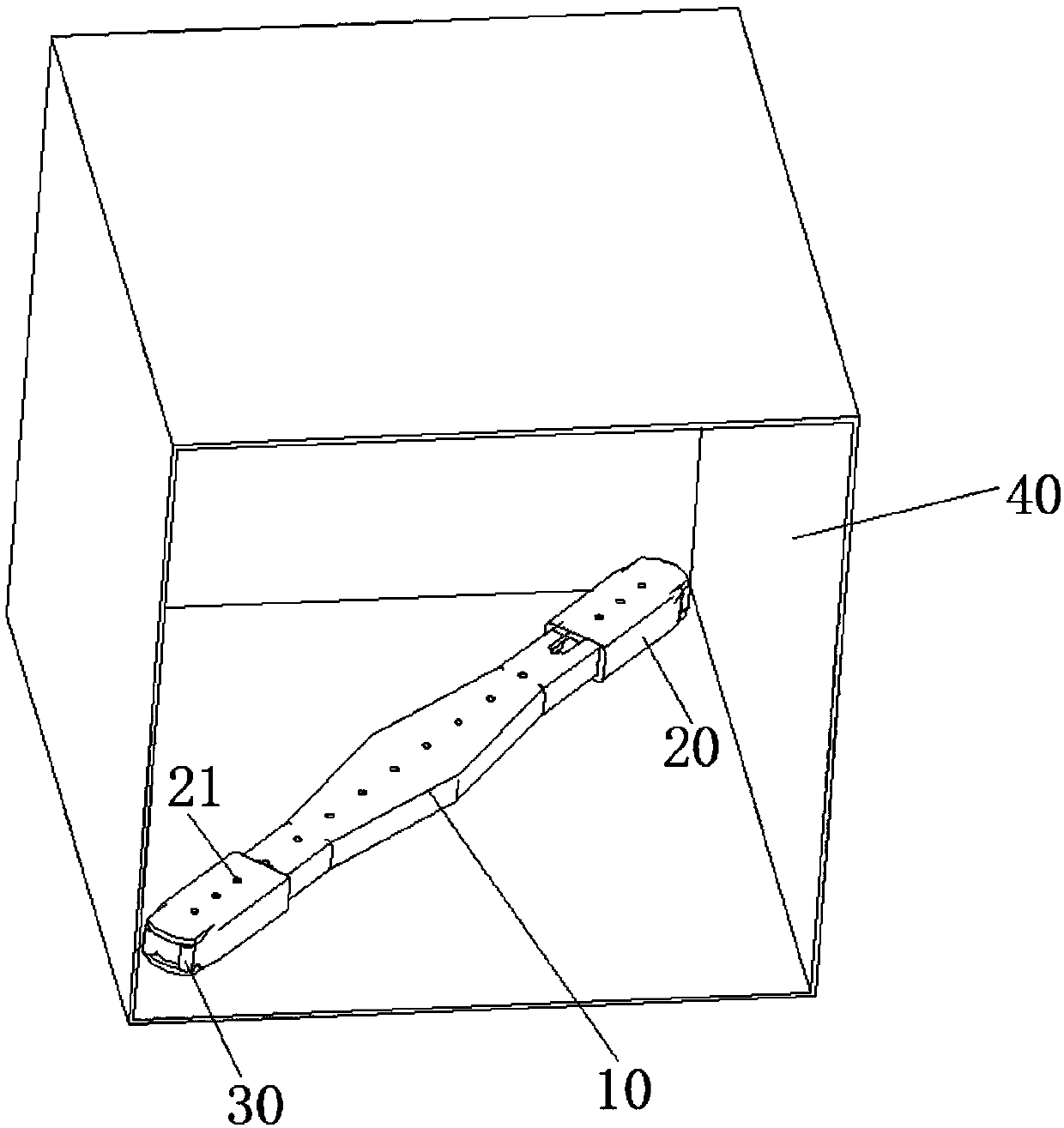

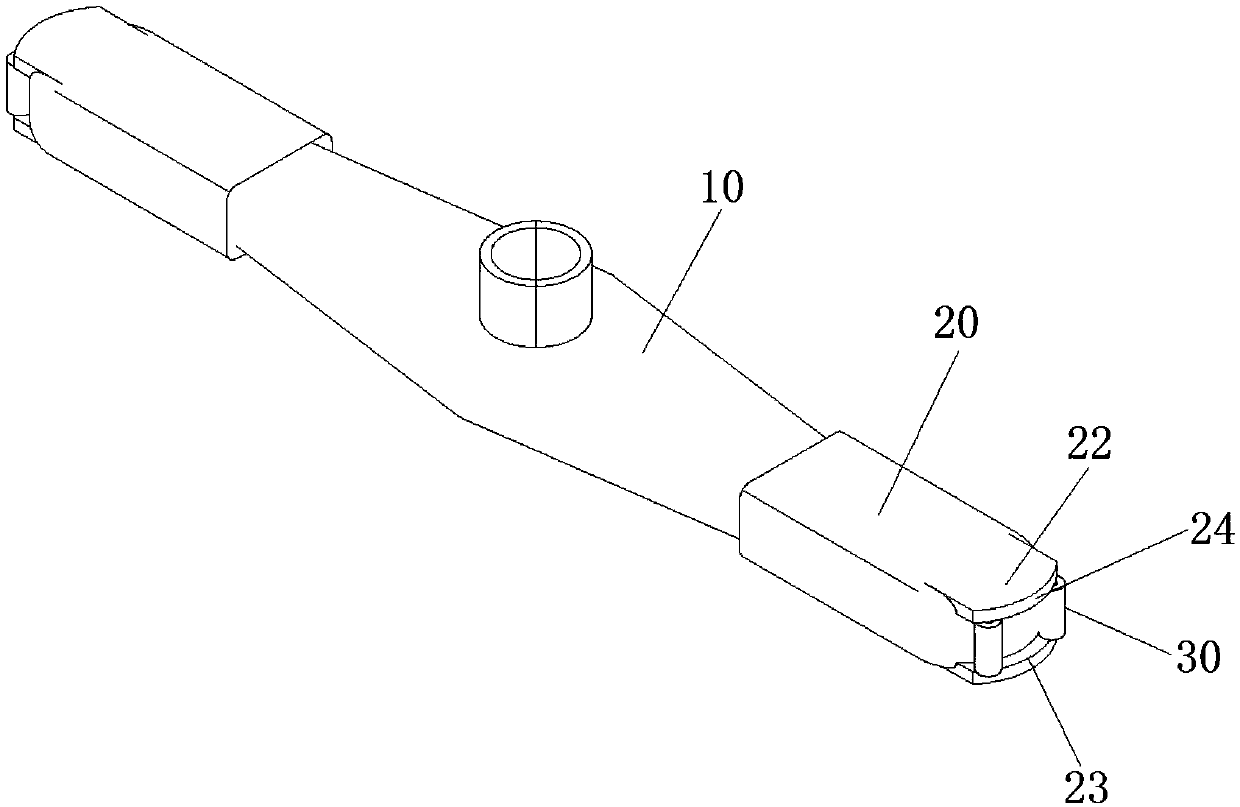

PendingCN111330769AReduce labor intensityReduce spray dead angleSpraying apparatusEngineeringSelf adaptive

The invention discloses a self-adaptation system for the contour of a workpiece. The self-adaptation system comprises a lifting mechanism, a mounting frame, multiple linear modules, spraying gun assemblies, a section detecting device and a control device. The mounting frame is arranged on the lifting mechanism, and can drive the mounting frame to ascend and descend. The multiple linear modules arearranged on the mounting frame at intervals in the length direction of the mounting frame. The spraying gun assemblies are arranged on the linear modules, each linear module is correspondingly provided with one spraying gun assembly, and the linear modules can drive the spraying gun assemblies to move towards the workpiece. The section detecting device is used for detecting the outer contour shape of the section, in the conveying direction, of the workpiece. The control device is electrically connected with the lifting mechanism, the linear modules, the spraying gun assemblies and the sectiondetecting device. The outer contour shape of the section, in the conveying direction, of the workpiece is detected through the section detecting device, then detected data are fed back to the controldevice to be analyzed, and the distances between the spraying gun assemblies at different positions and the surface of the workpiece are judged; and then the control device drives the spraying gun assemblies to move towards the workpiece through the linear modules to automatically adapt to workpieces in different shapes.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

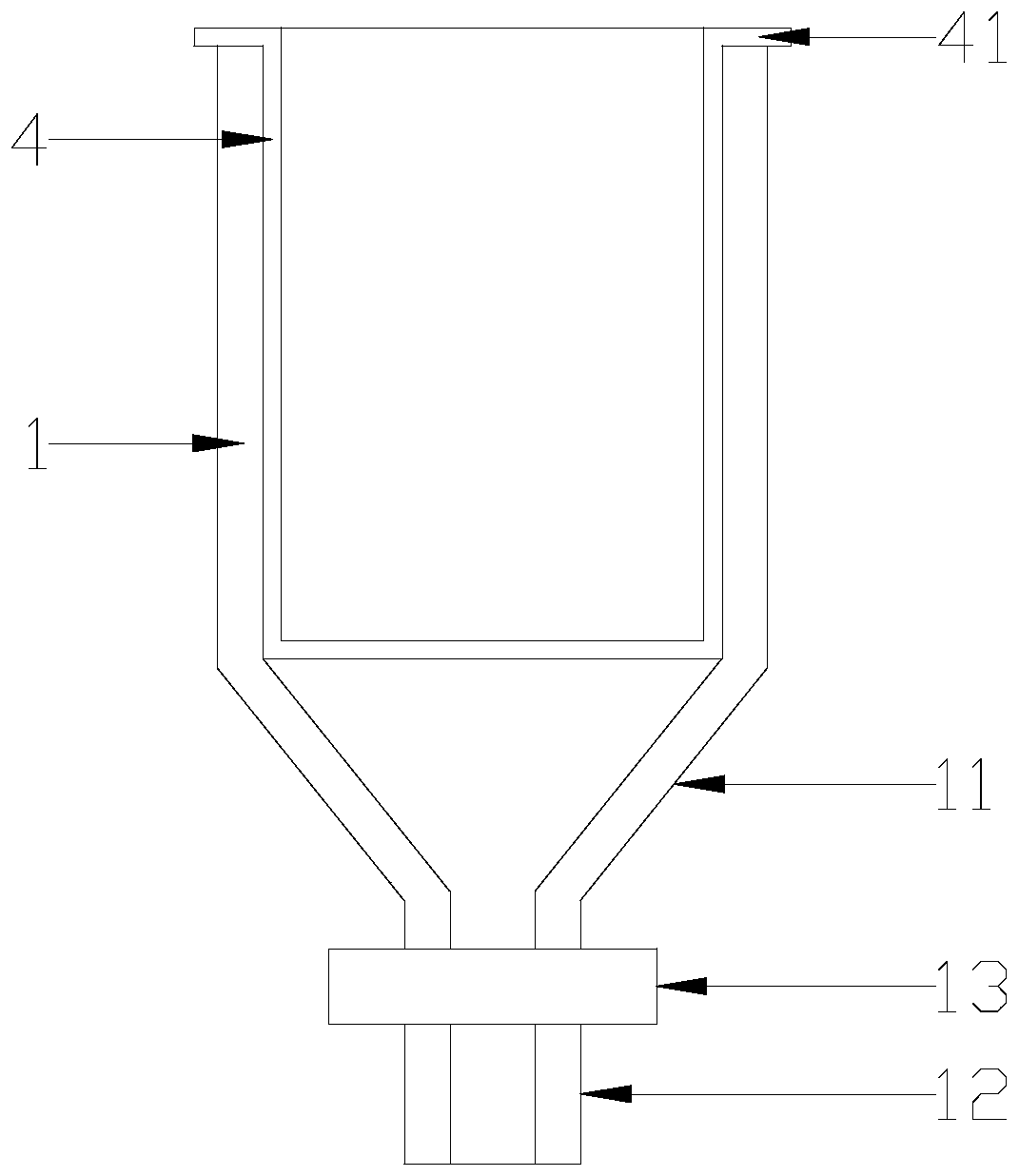

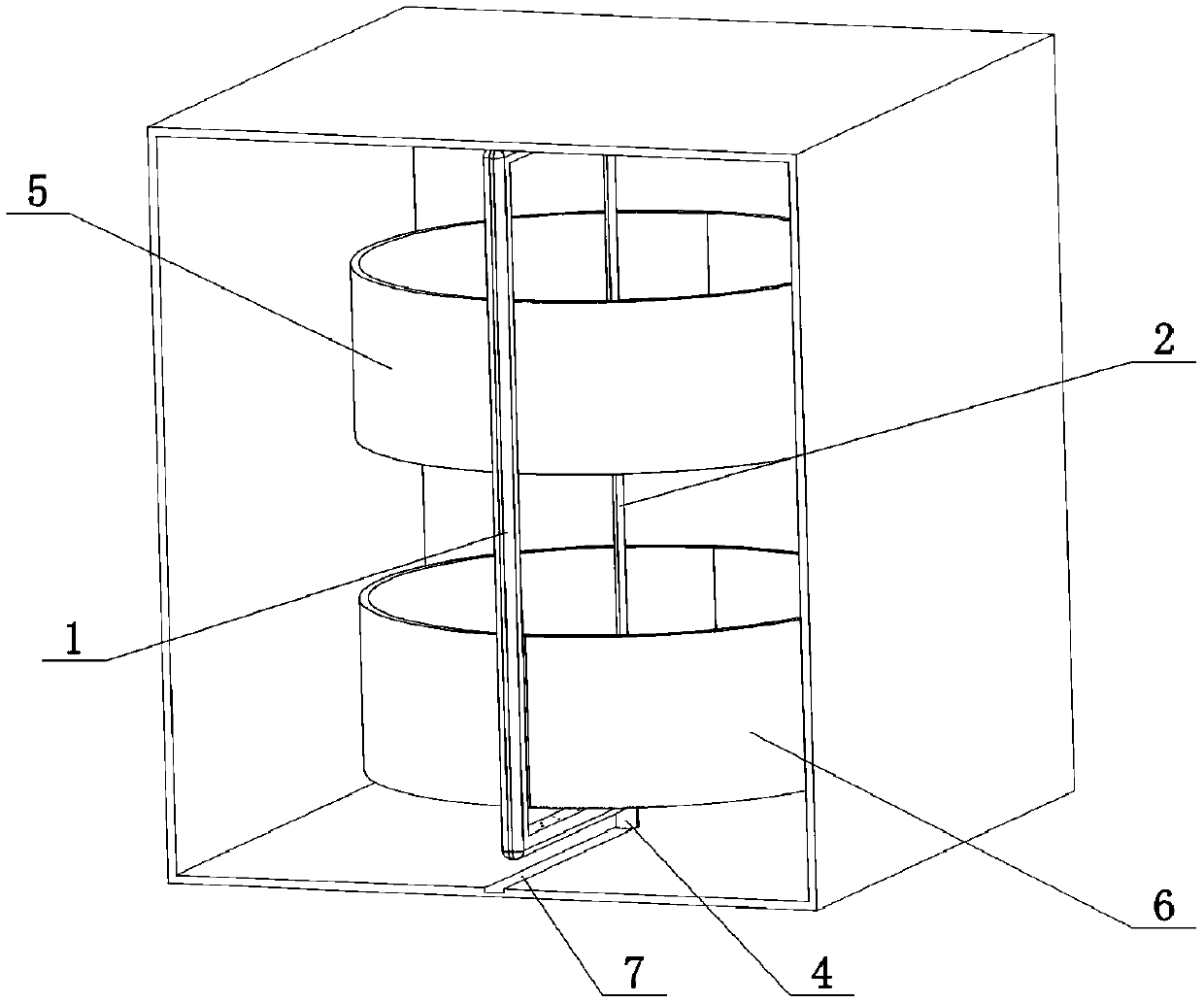

Microbial deodorization device for pig farms

InactiveCN110496524APrevent precipitationAvoid enteringDispersed particle separationAir quality improvementPig farmsMicroorganism

The invention relates to the field of animal husbandry, and concretely relates to a microbial deodorization device for pig farms. The device comprises a pig house, an upper sieve plate, a deodorization bin and a booster pump, a bidirectional screw rod is mounted in the pig house, the bidirectional screw rod is sleeved with sliding blocks, the lower surface of every sliding block is fixedly connected with a nozzle, the upper sieve plate is mounted in the pig house, a lower sieve plate is arranged below the upper sieve plate, the end part of the lower sieve plate is rotationally connected with an adjusting bolt, a cleaning mechanism is mounted at the bottom of the pig house, a deodorization bin is arranged at the right side of the pig house, the bottom of the deodorization bin is fixedly connected with the booster pump, and a stirring mechanism is mounted in the deodorization bin. A microbial solution is sprayed in the pig house through the booster pump, the two nozzles move face to faceor backwards in the spraying process to enlarge the spraying range and improve the deodorization effect, the sewage is treated through the microbial solution to achieve the deodorization purpose, andthe stirring mechanism makes the microbial solution and the sewage fully mixed in order to improve the deodorization efficiency.

Owner:中科元生生物技术(天津)有限公司

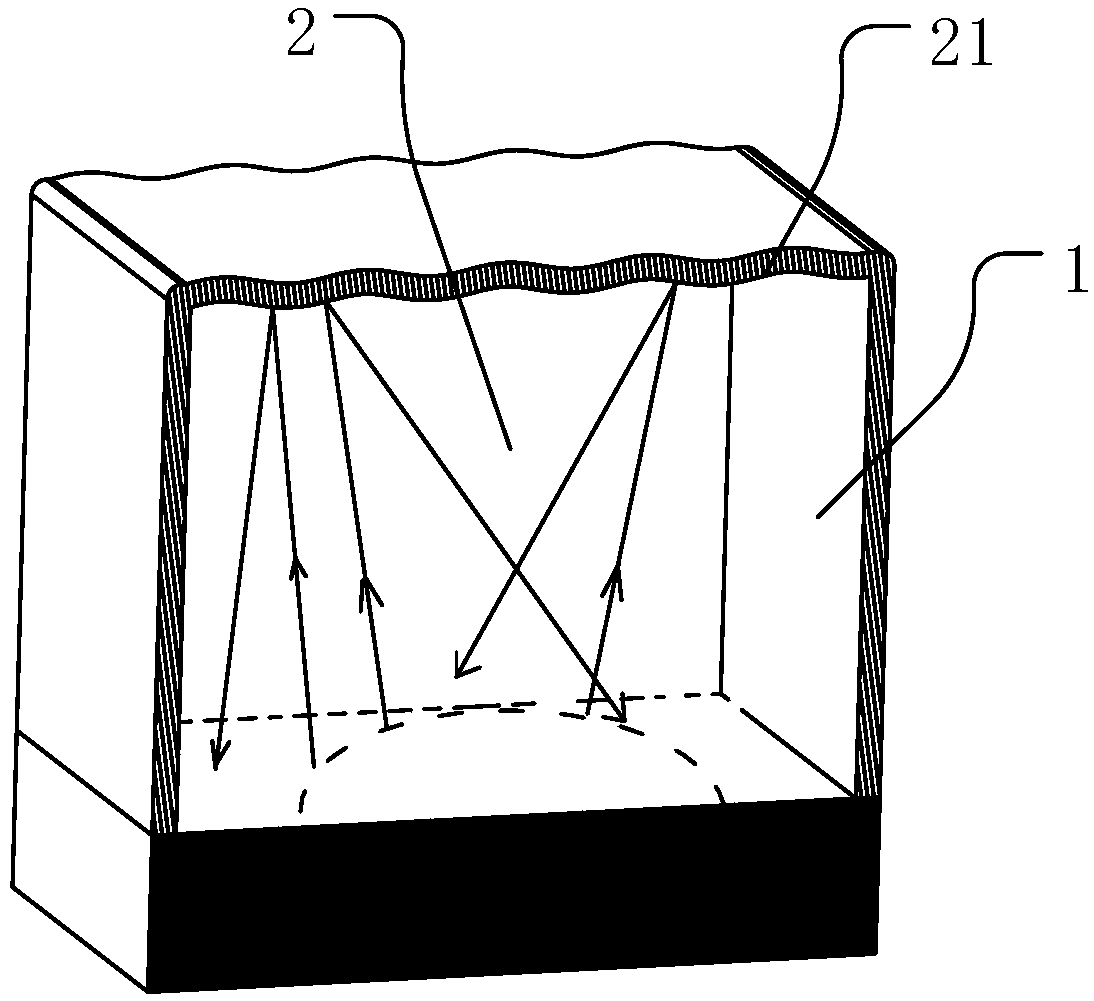

Dish washing machine

PendingCN108814511AEasy to cleanImprove efficiencyTableware washing/rinsing machine detailsEngineeringCavity wall

The invention discloses a dish washing machine, which comprises a main body, wherein an operation cavity for processing tableware is formed in the main body, a spraying structure is arranged in the operation cavity, and the spraying structure is used for spraying washing liquid to the operation cavity, at least part of the cavity wall of the operation cavity is configured as a non-planar surface,so that the washing liquid sprayed to the cavity wall can be reflected in a plurality of directions. The dish washing machine has better reflection effect, can reduce spraying dead angles, achieves better cleaning effect and improves the cleaning capacity and efficiency of the dish washing machine.

Owner:GREE ELECTRIC APPLIANCES INC

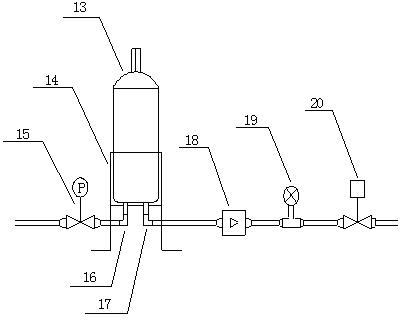

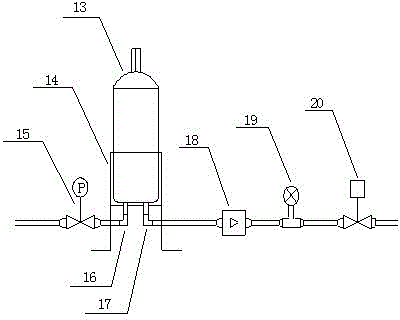

Petrochemical liquid storage device fast to clean

InactiveCN107792554AReduce the temperatureReduce volatilityLarge containersTank wagonsBiochemical engineeringPetrochemical

Disclosed is a petrochemical liquid storage device fast to clean. The petrochemical liquid storage device fast to clean comprises a storage tank body, an inner tank and an outer tank. Supporting legsare symmetrically arranged at the bottom of the storage tank body, the outer tank is welded on the tops of the supporting legs, and a cooling tube is wound around the outer wall of the inner tank in aspiral mode. An oil outlet is formed in the middle of the bottom of the storage tank body, and a spraying pipe is arranged inside the inner tank and located on the vertical axis of the storage tank body. According to the petrochemical liquid storage device fast to clean, the storage tank body is divided into the inner tank and the outer tank, the cooling tube is evenly wound around the outer wallof a tank body of the inner tank in the spiral mode, a cooling device can conduct cooling on water located inside a water tank, cold water can circulate in the cooling tube through the water pumpingeffect of a water pump, and therefore the purpose of lowering the temperature of the inner tank is achieved, the volatilization of petrochemical liquid is reduced, the waste of fuel is reduced, and occurrence of accidents is also avoided.

Owner:CHENGDU KECHUANGCHENG TECH

Steel structure surface paint spraying device

InactiveCN113019775AAchieve vertical movementRealize all-round sprayingSpraying apparatusTransmission beltGear wheel

The invention discloses a steel structure surface paint spraying device, and belongs to the technical field of steel structure equipment. By arranging a first telescopic electric cylinder, extension and retraction of the first telescopic electric cylinder is controlled, the spacing distance between a paint spraying plate and steel in each group of paint spraying assemblies is adjusted, the uniformity of the paint spraying plates during paint spraying is realized, non-uniform paint spraying is prevented, by arranging a second telescopic electric cylinder, extension and retraction of the second telescopic electric cylinder is controlled, a straight rack is driven to transversely move, the transverse movement of the straight rack drives a second rotating gear which is engaged with the straight rack to rotate, due to the fact that the second rotating gear is coaxially connected with a transmission belt wheel, the second rotating gear rotates to drive a first shaft in each paint spraying assembly to rotate through a transmission belt, rotation of a first rotating gear is achieved, rotation of an arc-shaped rack is achieved through rotation of a first rotating gear, so that the paint spraying plates rotate around second shafts, comprehensive paint spraying of the steel is achieved, and spraying dead angles are reduced.

Owner:绍兴三雄钢结构有限公司

Disinfection device with instrument tray and capable of selectively disinfection

InactiveCN112546261AExpand the spraying areaReduce spray dead angleLavatory sanitoryChemicalsPhysicsInstrument tray

The invention discloses a disinfection device with instrument tray and capable of selectively disinfection. The disinfection device comprises a box body, a supporting device is fixedly connected to the lower end of the box body, a top cover is arranged above the box body, electric telescopic rods are fixedly connected to the opposite side walls of the box body, extension ends of the two electric telescopic rods are fixedly connected to the lower end of the top cover, two guiding devices are fixedly connected to the lower end of the top cover, an axis rod is rotationally connected to the side wall of the box body in a penetrating mode, a rotating shaft is fixedly connected to the side wall, located in the box body, of the axis rod, a plurality of bearing devices are fixedly connected to therotating shaft in the circumferential direction of the rotating shaft at equal intervals, a limiting device is fixedly connected to the side wall of the box body, and a fixed plate is fixedly connected to the side wall of the box body. The device is reasonable in structural design and has the advantages of being good in disinfection effect and capable of achieving selectively disinfection.

Owner:湖州一控医疗科技有限公司

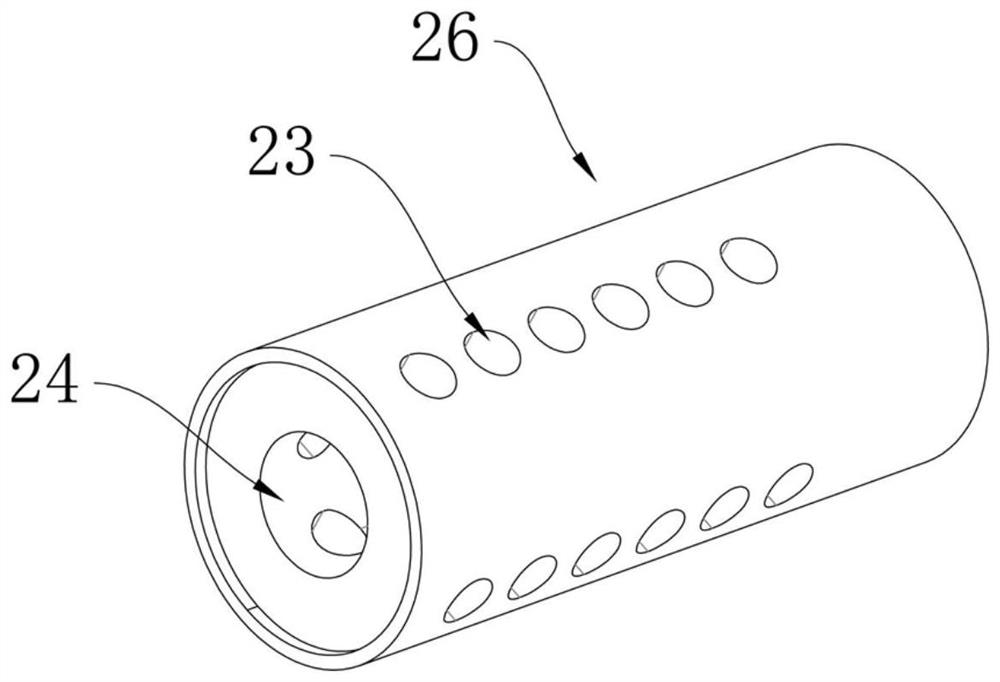

Novel dish-washing machine spraying device

InactiveCN112790712ARealize multi-angle sprayingReduce spray dead angleTableware washing/rinsing machine detailsHome appliance efficiency improvementWater resourcesMechanical engineering

The invention relates to the technical field of dish-washing machines, and particularly relates to a novel dish-washing machine spraying device which comprises a water supply pipe and a spraying rotary drum, wherein the water supply pipe is hollow, one end of the water supply pipe is provided with a water inlet used for introducing a cleaning solution, and the bottom of the water supply pipe is provided with a water outlet hole; the water supply pipe is sleeved with the spraying rotary drum, the spraying rotary drum can rotate on the surface of the water supply pipe, spraying holes are formed in the spraying rotary drum, and the spraying holes are connected with nozzles. The device is sleeved with the rotatable spraying rotary drum, the water outlet hole of the water supply pipe is communicated with the nozzle on the spraying rotary drum, and the nozzle rotates along with the rotary drum, so that multi-angle spraying of tableware is achieved, spraying dead angles are reduced, the spraying cleaning quality is improved, and better washing efficiency is achieved. Besides, the water outlet holes of the water supply pipe are centrally arranged at the bottom of the water supply pipe, and the spraying holes are only communicated with the water outlet holes at the bottom of the water supply pipe in the rotary spraying process, so that intermittent spraying of the nozzle within a certain angle range is realized, and water resources are saved.

Owner:佛山新迈智能科技有限公司

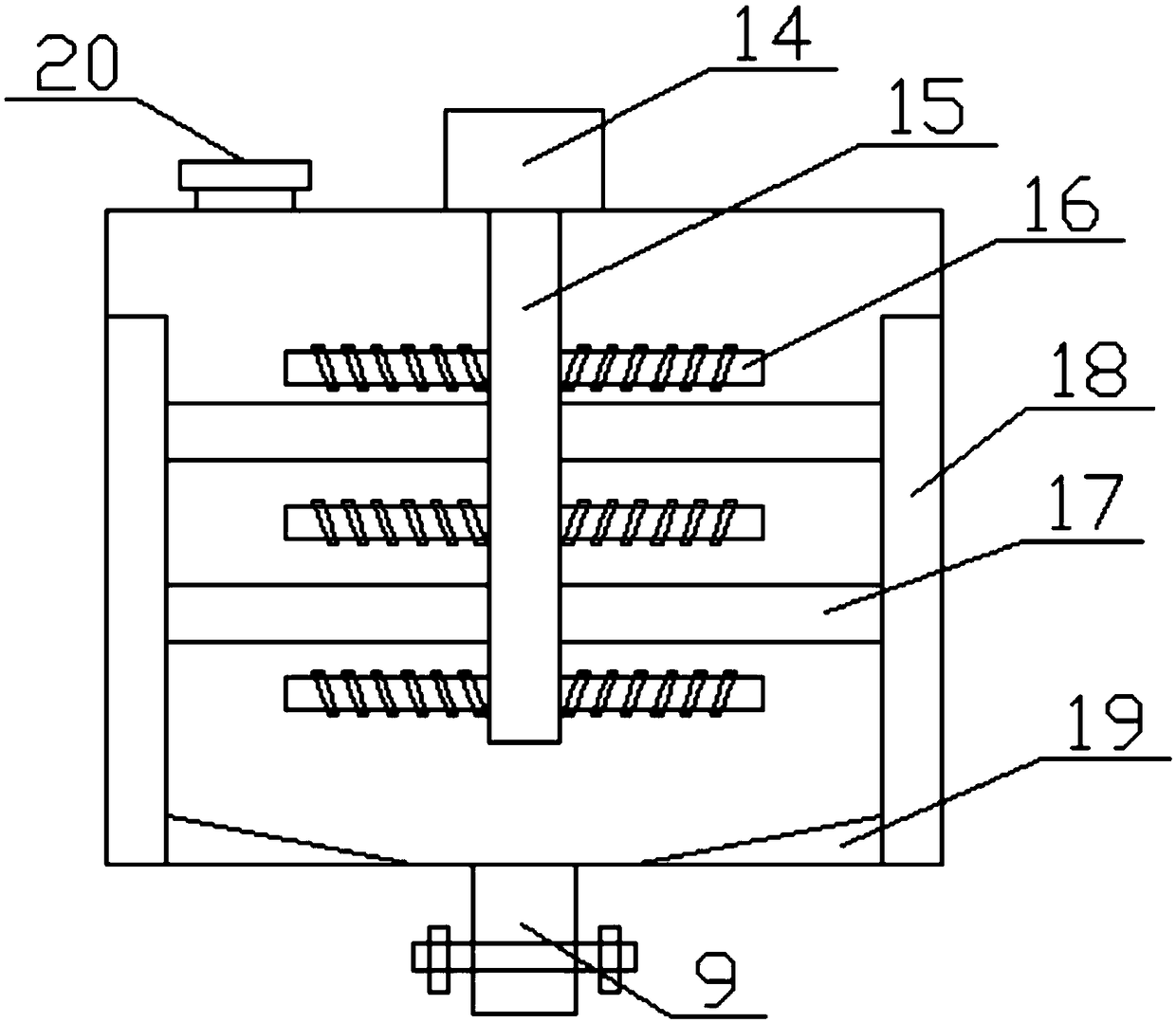

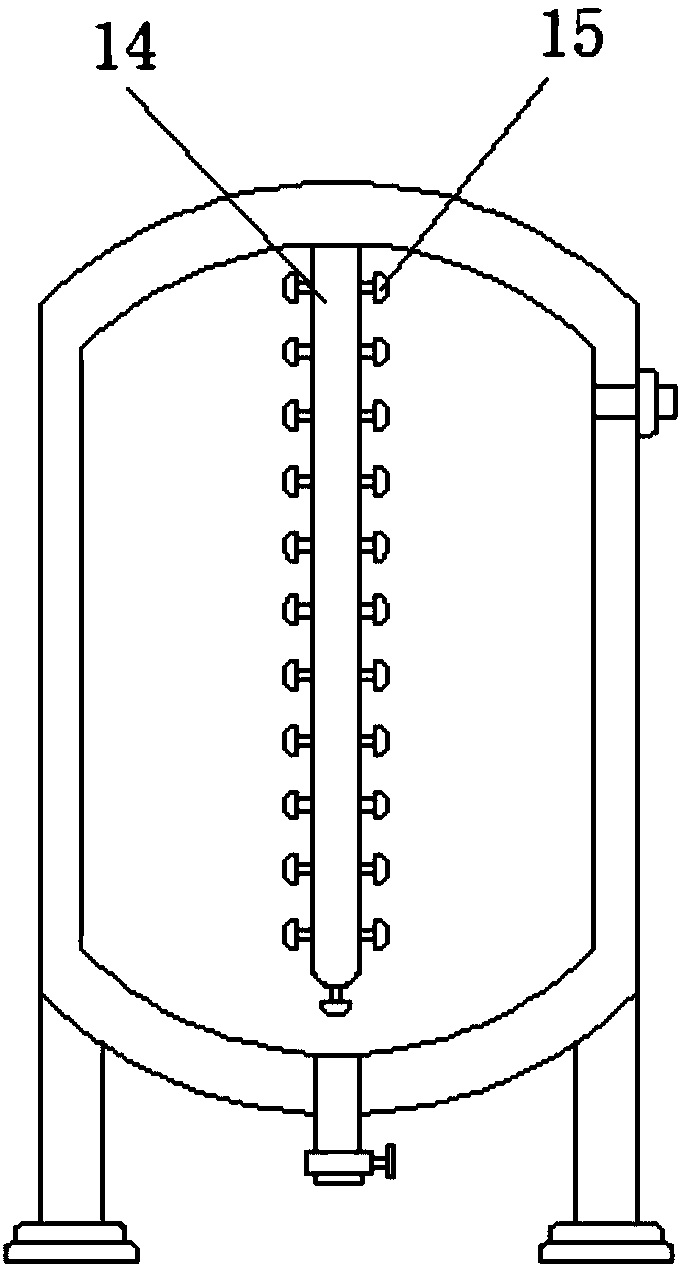

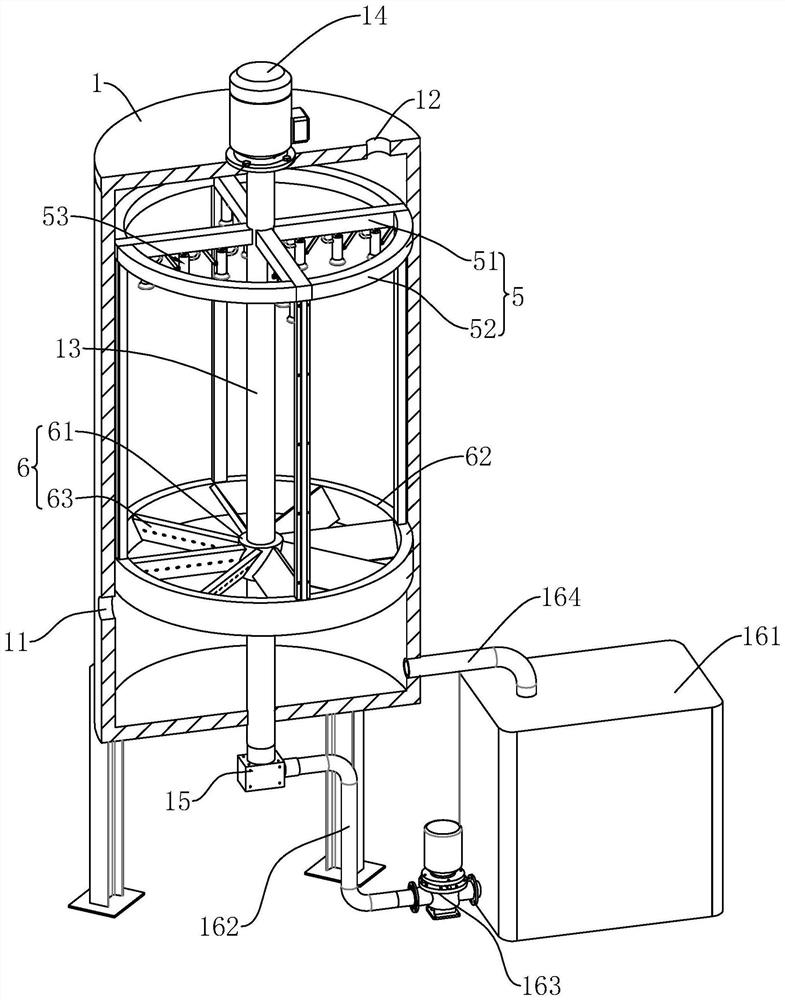

Activated carbon cleaning tank

ActiveCN110508267ALow fluid contentSpray evenlyOther chemical processesCombustible gas purificationActivated carbonLiquid waste

The invention discloses an activated carbon cleaning tank, which comprises a tank body, a filtrate tank, a sprayer, a material frame and a pump, the lower side of the tank body is provided with a conical section with a liquid outlet channel which extends into the filtrate tank and is provided with a first electromagnetic valve; the material frame is placed in the tank body; an annular partition net is arranged in the center of the material frame so as to divide the inner cavity into an inner cylinder cavity and an outer ring cavity; the spray head of the sprayer extends into the inner cylindercavity; and the pump is respectively connected with the sprayer and the filtrate tank through hoses. The sprayer is also connected with a washing liquid bottle through a hose; by placing the materialframe filled with activated carbon in the tank body and spraying a cleaning liquid with the sprayer, impurities in the activated carbon are washed away, and waste liquid can be directly subjected toresource treatment or hazardous waste treatment, the activated carbon cleaning tank is convenient and quick; an air cylinder drives a main liquid pipe to move up and down, and a motor drives the mainliquid pipe to rotate at a variable speed, so that an elastic liquid pipe swings up and down telescopically, the outflow direction of a cleaning liquid is continuously changed, and spray dead angles are further reduced.

Owner:浙江威尔森新材料有限公司

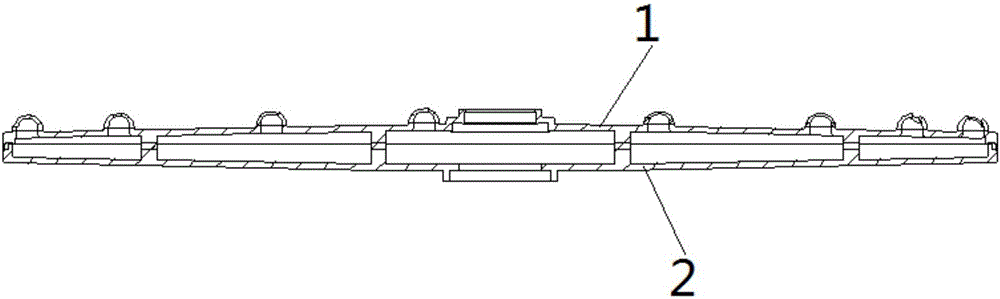

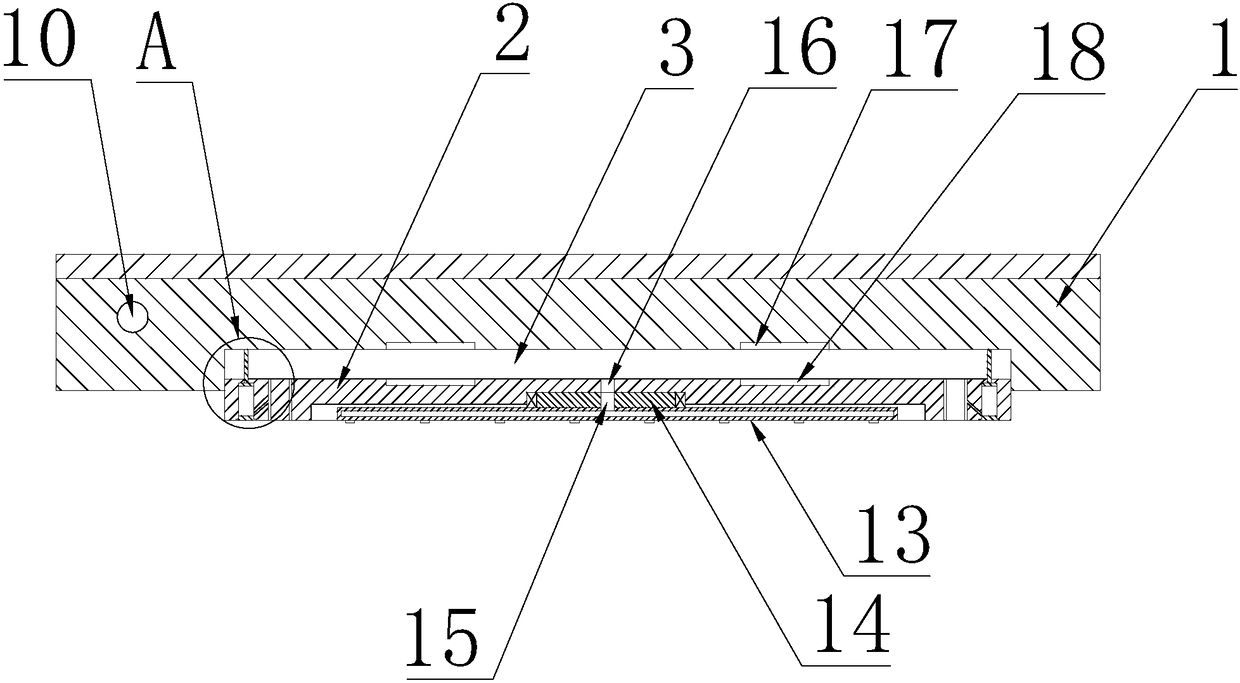

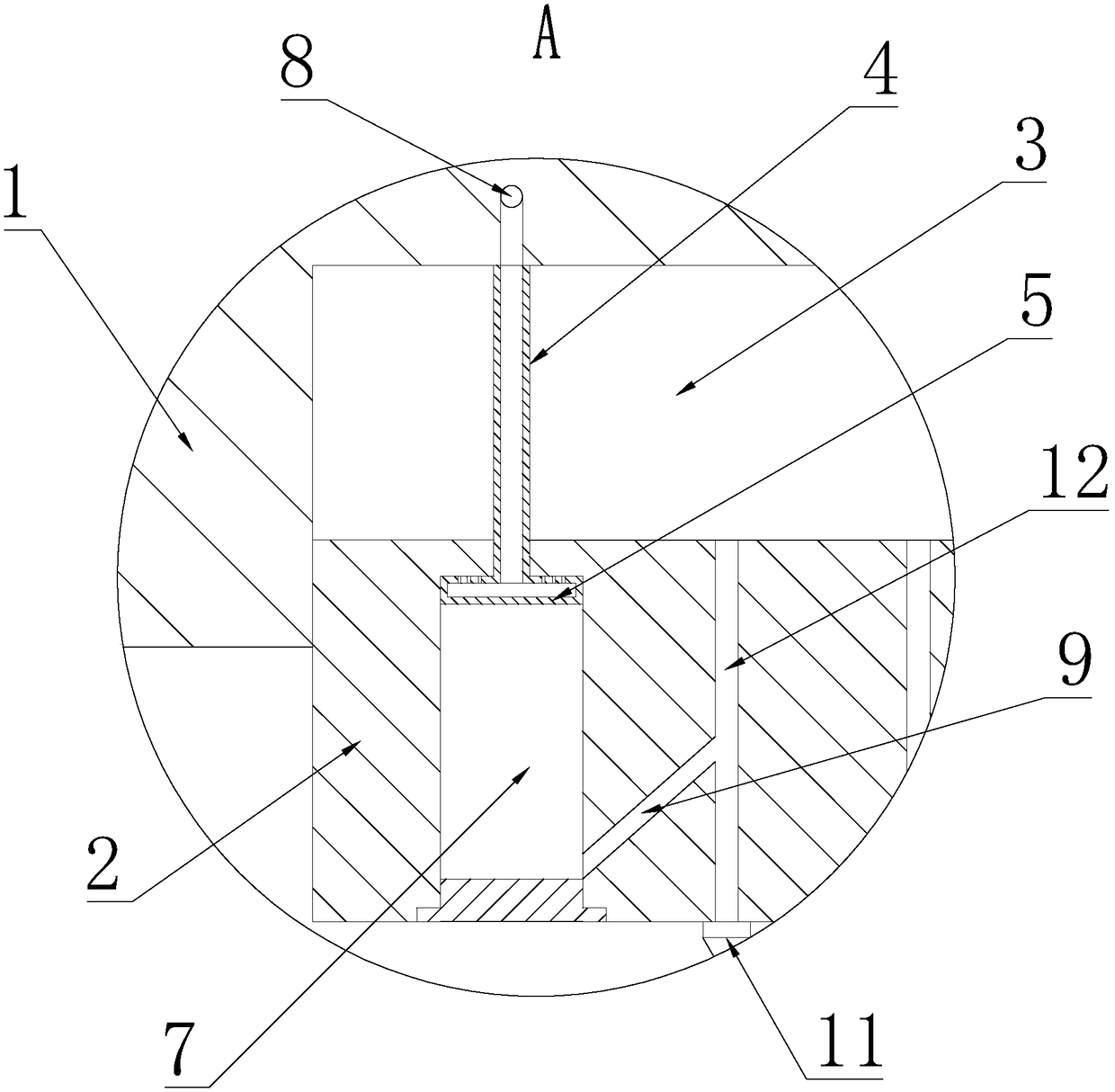

Sink dishwasher panel with spray arms

PendingCN108209812AAvoid damageNot easy to stainTableware washing/rinsing machine detailsEngineeringPiston

The invention discloses a sink dishwasher panel with spray arms. The sink dishwasher panel comprises a panel body, a mounting groove is arranged in the panel body, a main spray arm is accommodated inthe mounting groove and is in sliding match with the same along the vertical direction, the upper end face of the main spray arm is enclosed with the inner surface of the mounting grove to form a hydraulic cavity, a plurality of limit guide rods is arranged in the hydraulic cavity, the guide rods are located in the end of the main spray and expands outwards to form a limit tray, a piston cavity isarranged in the main spray arm and is divided into an upper chamber and a lower chamber through the limit tray, the limit guide rods are hollow inside, and a fluid supply pipe is arranged in the panel body and is communicated with a control pipeline or the hydraulic cavity through an electromagnetic directional valve. By the arrangement that the spray arms are directly mounted on the panel, goodspray effect is achieved, and grease on dishes are not prone to sticking to the spray arms.

Owner:NINGBO MEIGAO KITCHENWARE CO LTD

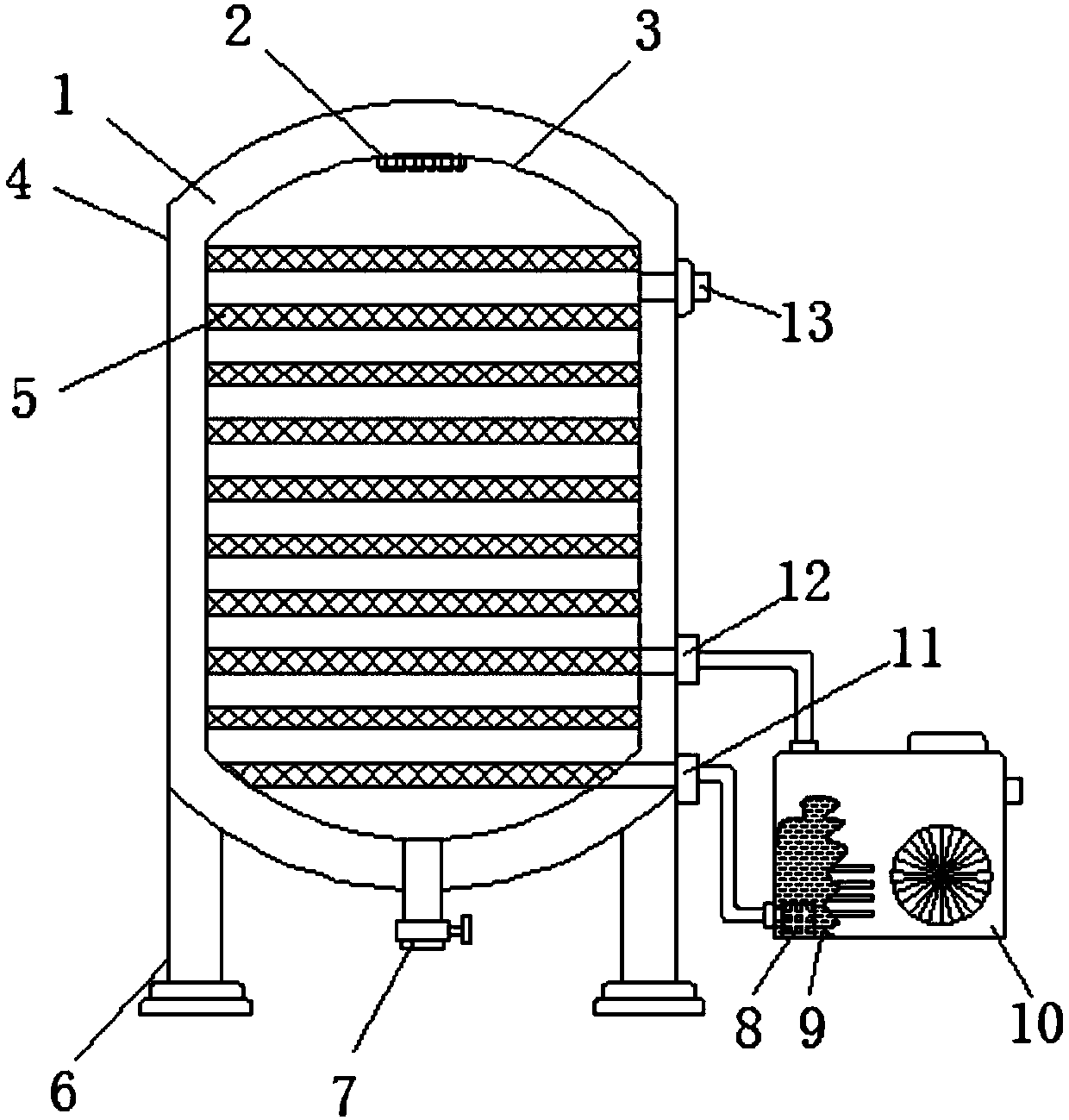

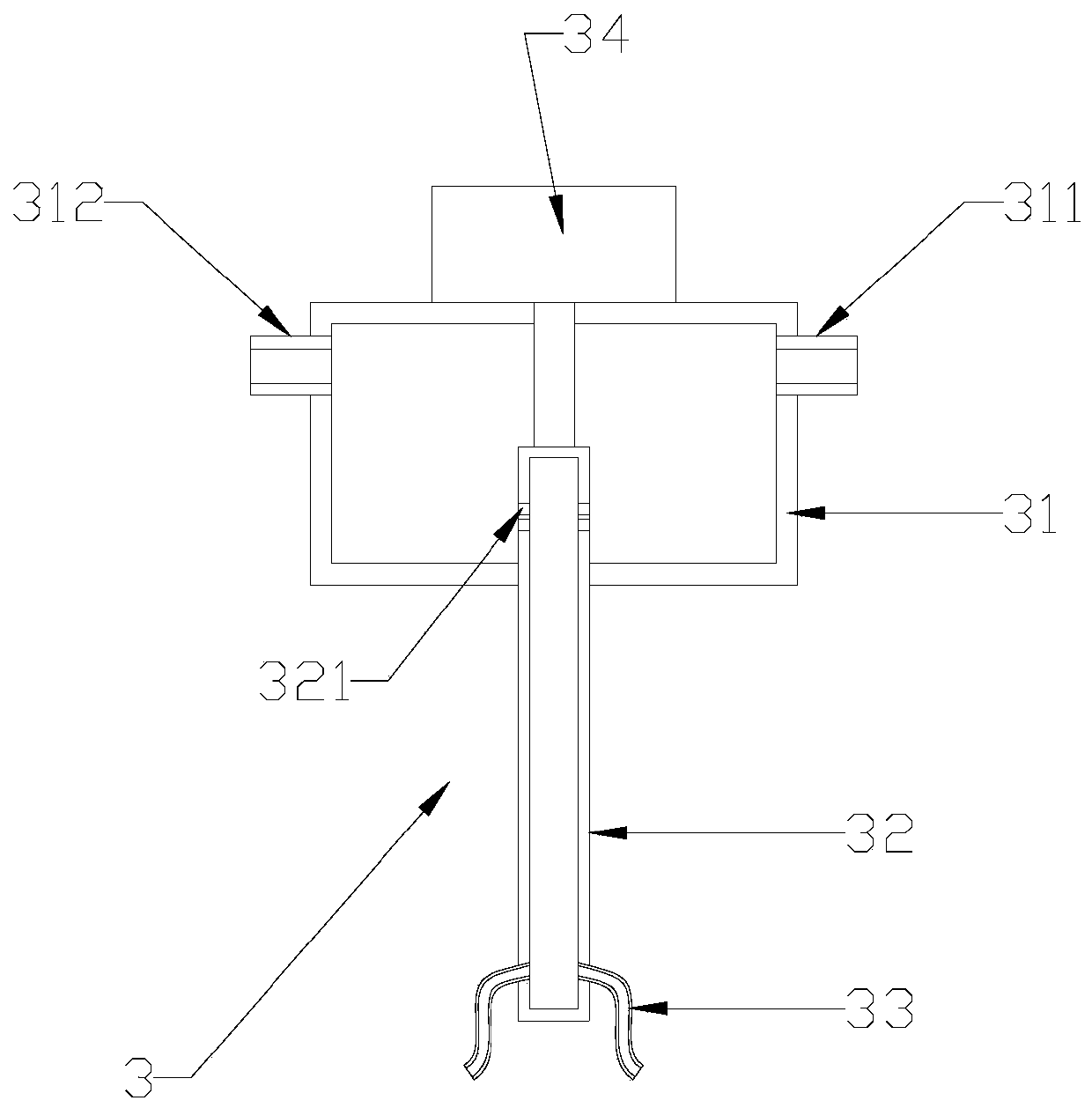

Activated carbon regeneration device

ActiveCN110433786AReduce spray dead angleCombustible gas purificationFilter regenerationActivated carbonSprayer

The invention discloses an activated carbon regeneration device which comprises tank bodies, filtrate tanks, sprayers, a material frame, pumps, a support frame, liquid collectors and a conveying rack,wherein a plurality of tank bodies are sequentially arranged below the conveying rack and are provided with conical sections with liquid outlet channels in lower sides; the liquid outlet channels respectively extend into different filtrate tanks and are provided with first electromagnetic valves; the pumps are respectively arranged on one sides of the filtrate tanks; the conveying rack is used for driving the material frame and the sprayer to transfer among different tank bodies through the support frame; the liquid collectors are respectively connected with both sides of the sprayer throughhoses; the liquid collector on the right side is connected with a plurality of washing liquid bottles through hoses respectively; and the pumps are connected with the liquid collector on the left sidethrough hoses and adjacent filtrate tanks respectively. Different washing liquids are ejected through the sprayer in sequence, and waste liquids can be subjected to resourceful treatment or dangerouswaste treatment directly, thus being convenient and rapid.

Owner:浙江威尔森新材料有限公司

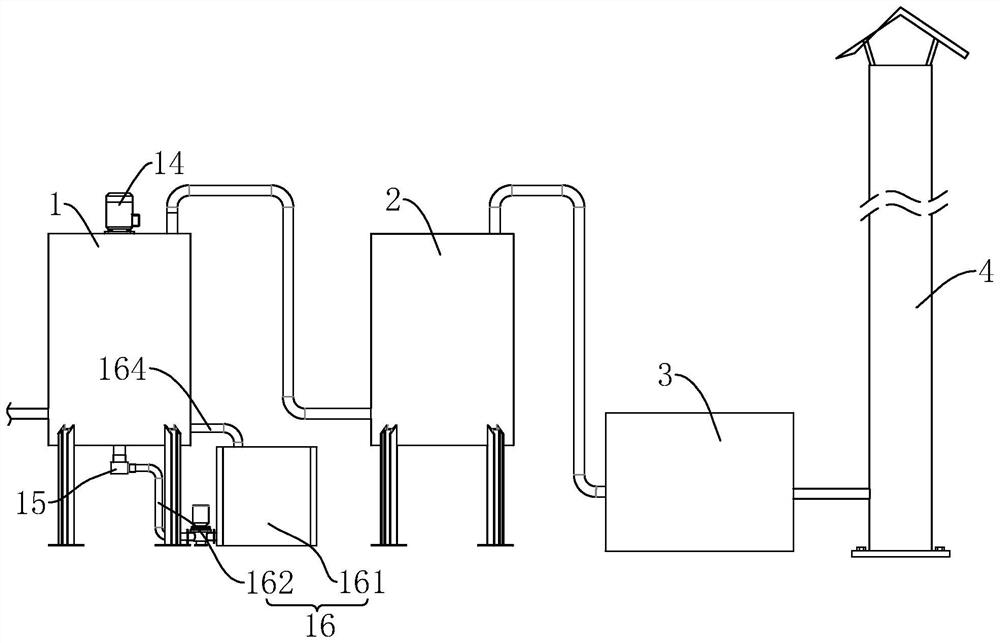

Asphalt waste gas purification system

ActiveCN114028898AImprove settlement performanceImprove thoroughnessCombination devicesParticulatesExhaust fumes

The invention relates to an asphalt waste gas purification system which comprises a spraying tower, the spraying tower is coaxially and rotatably connected with a supporting pipe, a gas inlet is formed in the side wall of the lower portion of the spraying tower, the spraying tower is provided with a driving part for driving the supporting pipe to rotate around the axis of the supporting pipe, and the spraying tower is provided with a liquid supply assembly for supplying liquid to the supporting pipe; the supporting pipe is fixedly connected with a rotary spraying frame; the rotary spraying frame comprises a plurality of mounting rods fixedly connected to the supporting pipe, the mounting rods are distributed in the circumferential direction of the supporting pipe, the supporting pipe and the mounting rods are each provided with a liquid flowing channel and are communicated with one another, and each mounting rod is connected with a plurality of atomizing nozzles; the atomizing nozzles are communicated with the liquid flowing channels of the mounting rods; the atomizing nozzles are distributed in the length direction of the mounting rods; and an air outlet is formed in the top wall of the spraying tower. The device has the advantage of improving the settling effect of particulate matters in the asphalt waste gas.

Owner:HANGZHOU GUANGHUA ROAD & BRIDGE ENG

Efficient spraying equipment for indoor and outdoor decoration construction

InactiveCN114016710AReduced risk of icingReduce harmBuilding constructionsLiquid spraying apparatusCold weatherScrew thread

The invention discloses efficient spraying equipment for indoor and outdoor decoration construction. The equipment comprises a base and a stirring bin, wherein a fixing block is fixedly installed at the center position of a top face of the base, the stirring bin is arranged above the fixing block, threaded grooves are formed in surfaces of the two sides of the fixing block, and handle bolts are in threaded connection with the interiors of the threaded grooves; a feeding hole is fixedly formed in one side of a top surface of the stirring bin, and a mounting shell is arranged on a top surface of the feeding hole. The paint spraying device is advantaged in that the paint can be filtered through a filter screen, the influence of impurities on the spraying effect is reduced, a purpose of heating the paint in severe cold weather can be achieved by arranging a heating plate, the risk that the paint is frozen in the severe cold weather is reduced, and the movable stirring bin is arranged, difficulty of vertical carrying in the multi-storey house is reduced, labor intensity of equipment carrying is relieved, a wall surface can be polished before spraying by arranging a polishing piece, and the friction force between the coating and the wall surface is increased.

Owner:九江立帆科技有限公司

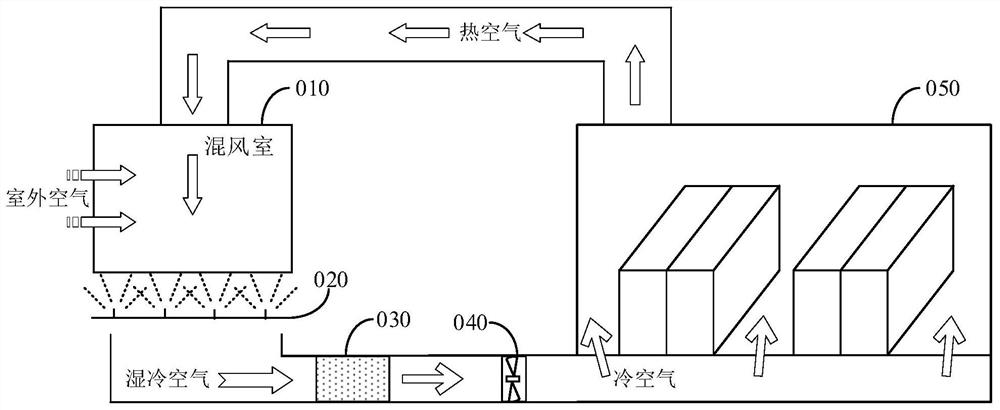

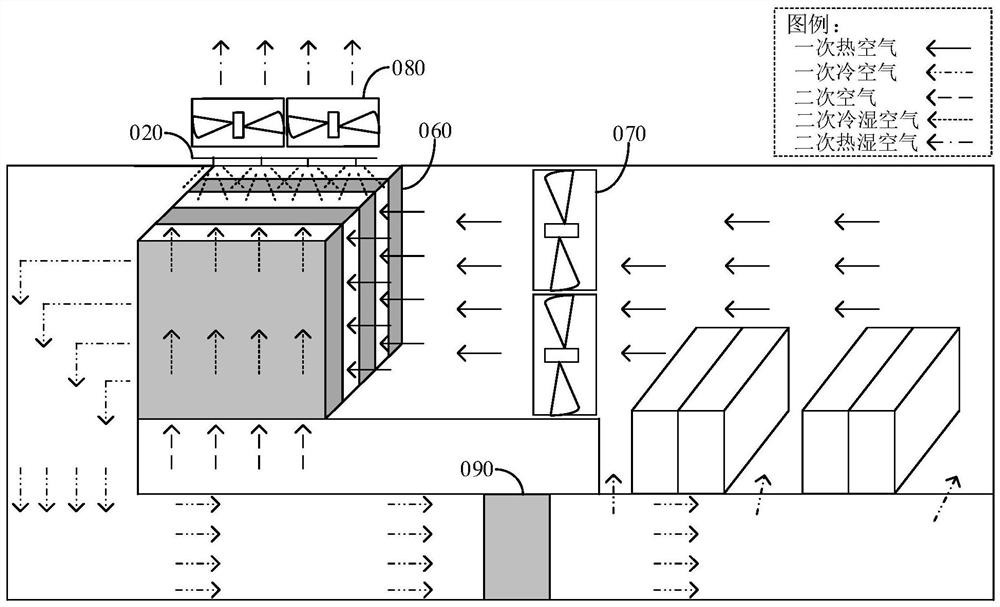

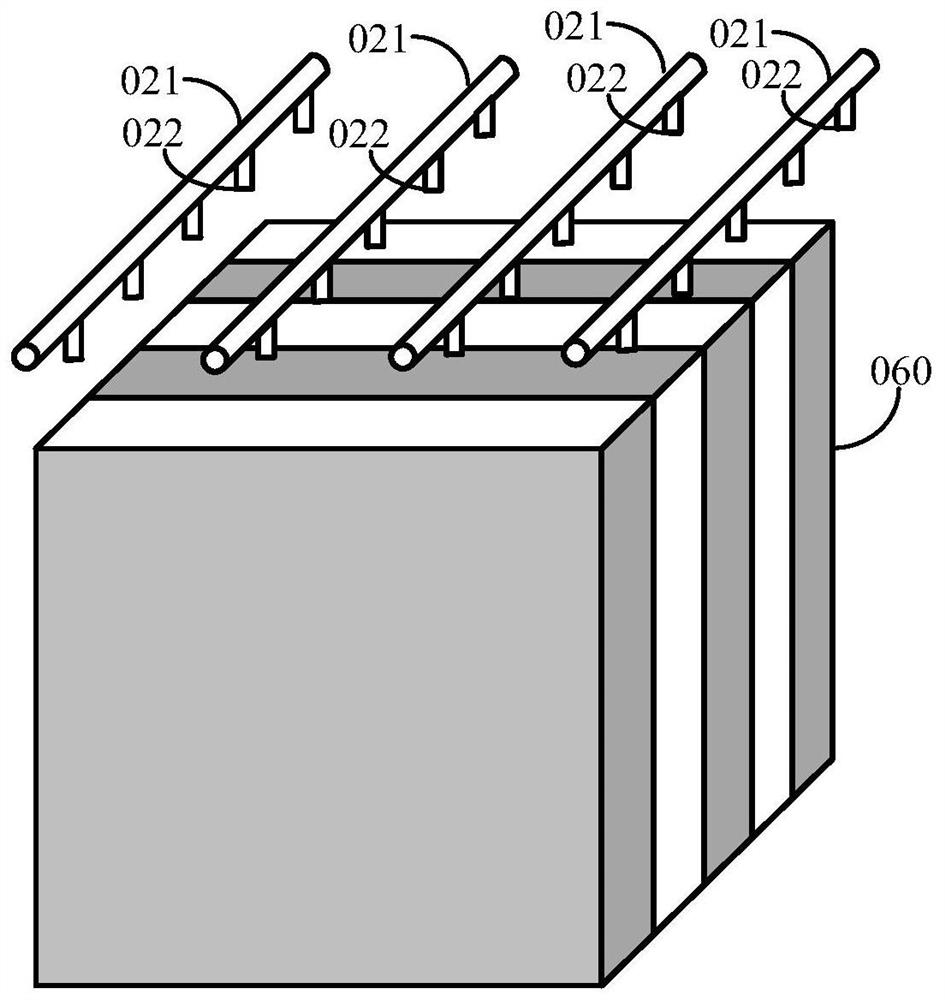

Spraying device and evaporative cooling system

ActiveCN114383226AReduce in quantityReduce spray dead angleLighting and heating apparatusAir conditioning systemsElectric machineryStructural engineering

The embodiment of the invention provides a spraying device and an evaporative cooling system. The spraying device comprises a central pipe which is rotatably arranged by taking the axis of the central pipe as the center; the at least two spraying assemblies are distributed in a circumferential array around the axis of the central pipe; each spraying assembly comprises a spraying pipe and at least one first nozzle arranged on the spraying pipe; one end of the spraying pipe is connected with the water inlet end of the central pipe, and the other end extends away from the axis of the central pipe; the axis of the first nozzle and the axis of the central pipe are located in different planes. According to the structure, the mist sprayed by the first nozzle can generate counter-acting force which is not parallel to the axis of the central pipe, so that the spraying device can rotate under the counter-acting force of the mist. The spraying device can be applied to an evaporative cooling system, the spraying area can be increased on the premise that the number of the nozzles is reduced, spraying dead angles are reduced, mechanical driving structures such as a motor do not need to be used, reliability is high, and cost is low.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

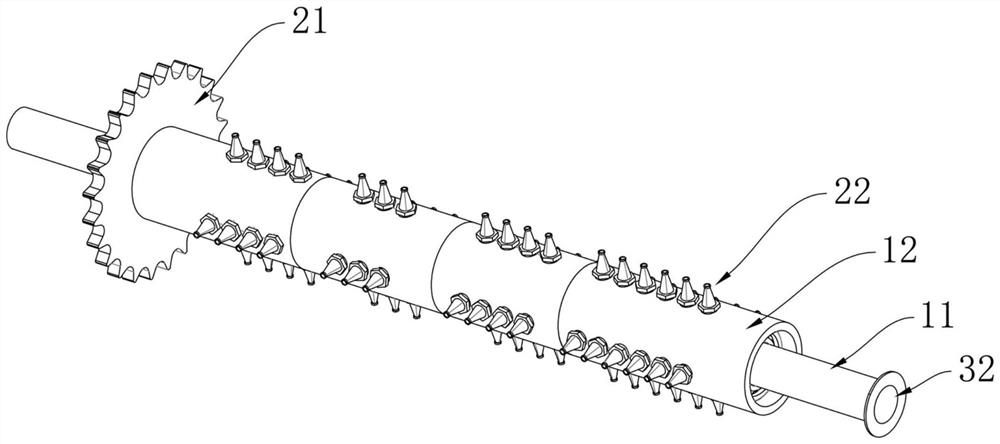

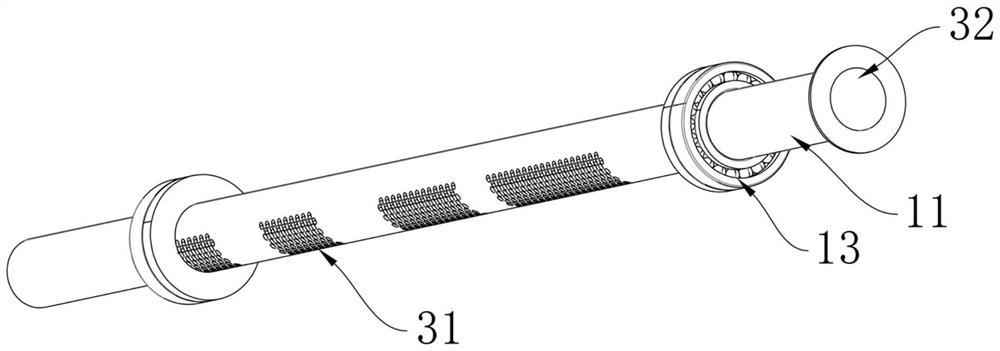

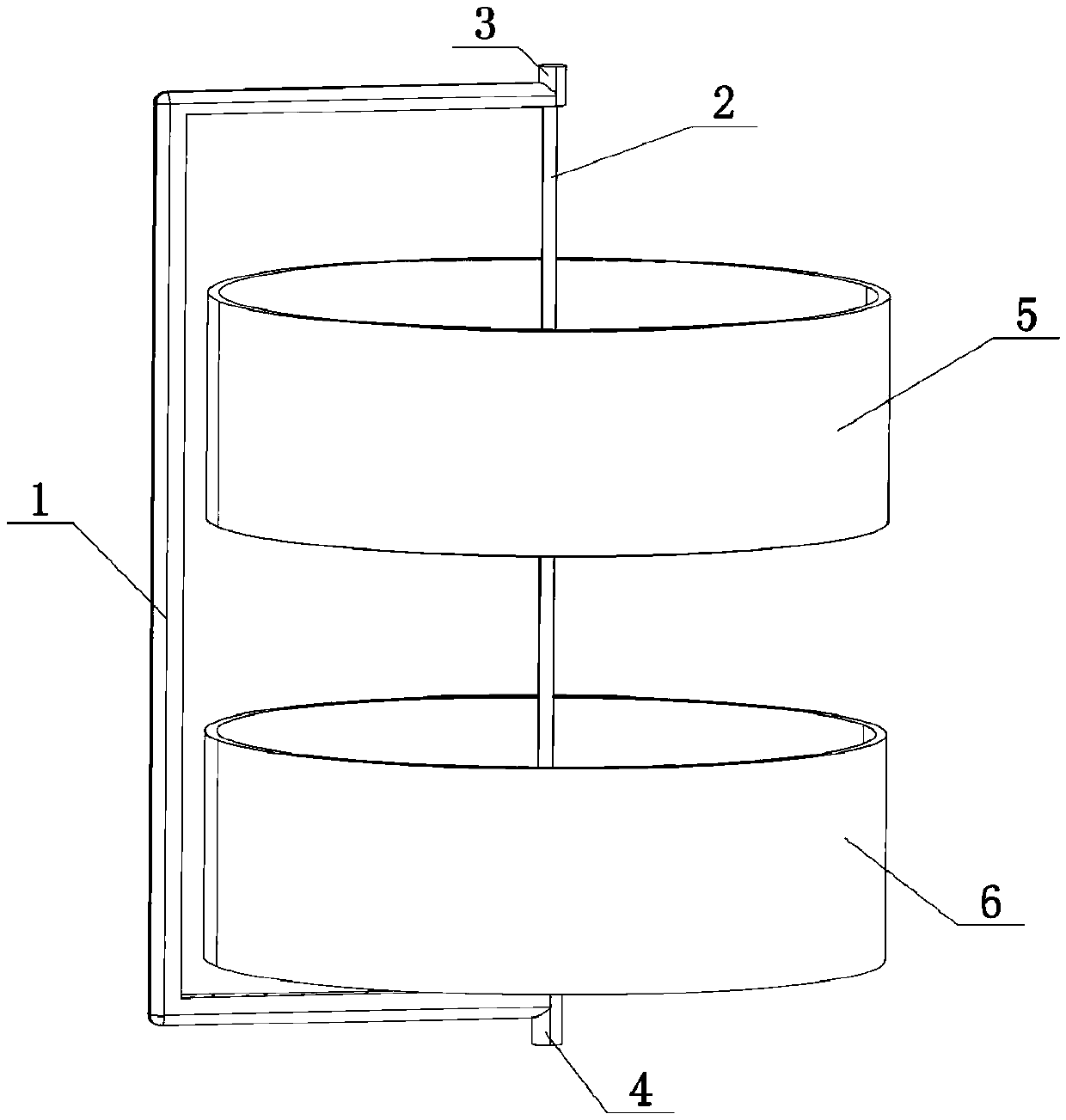

Rotation spraying device for high-efficiency washing

InactiveCN104415934AImprove efficiencyReduce spray dead angleCleaning using liquidsInlet valveEngineering

The invention relates to a spraying device, and in particular relates to a rotation spraying device for the high-efficiency washing. The rotation spraying device comprises a water inlet tube, a water inlet valve, a washing chamber, a support frame, blocking nets, a rotation connector and spraying rods, wherein the water inlet tube is connected with the input end of the rotation connector through the water inlet valve; the spraying rods are in rotation connection with the output end of the rotation connector; the spraying rods are arranged inside a washing chamber; the support frame is arranged inside the washing chamber; the blocking nets are arranged on the support frame. The rotation spraying device for the high-efficiency washing has the beneficial effects that a washing liquid can be fed to spray and wash after passing through the water inlet tube, the water inlet valve, the rotation connector and the spraying rods in sequence, the support frame is arranged inside the washing chamber, the blocking nets are arranged on the support frame, articles to be washed can be put in the nets, and as the spraying rods are in the rotation connection with the rotation connector, the rotation spraying can be achieved, the efficiency can be improved, and the spraying dead angle is reduced.

Owner:SHENZHEN UNICOMP TECH CO LTD

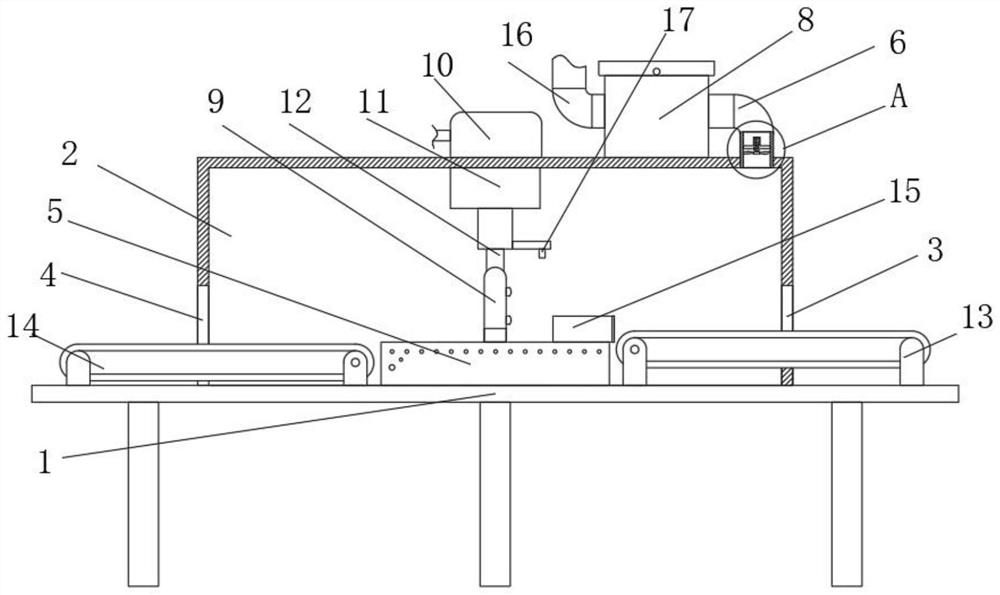

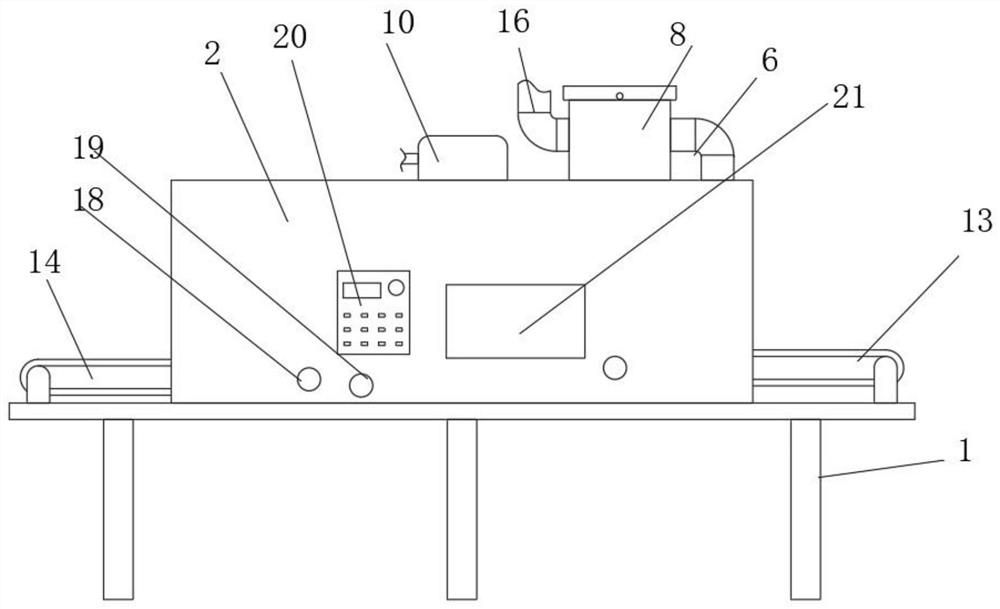

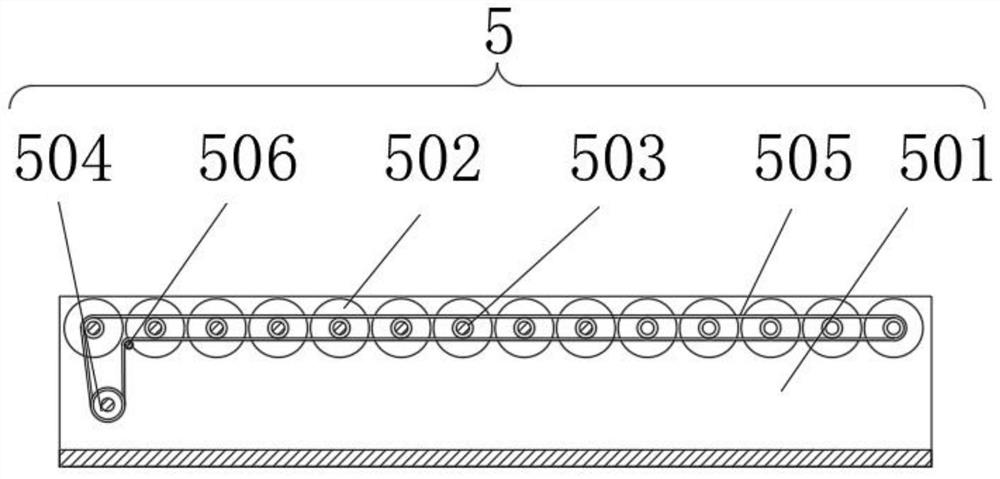

Vamp spraying equipment for shoemaking

InactiveCN112044626ACircumstances to prevent damageReduce spray dead angleShoemaking devicesSpray boothsAssembly lineExhaust pipe

The invention provides vamp spraying equipment for shoemaking, and relates to the field of shoemaking equipment. The vamp spraying equipment for shoemaking comprises a workbench and a box body, wherein the box body is fixedly connected to the middle of the upper part of the workbench; a feeding port is formed in the middle of the lower part of one side of the box body; a discharging port is formedin the middle of the lower part of the side, away from the feeding port, of the box body; a roller conveying mechanism is fixedly connected to the position, below the interior of the box body, of themiddle of the workbench; an exhaust pipe fixedly communicates with the side, close to the feeding port, of the top of the box body; and an exhaust mechanism is arranged in the end, close to the box body, of the exhaust pipe. According to the vamp spraying equipment for shoemaking, the roller conveying mechanism is matched with a spraying mechanism and a splayed limiting plate, automatic sprayingwork can be conducted through cooperation of a controller and a sensor, assembly line type automatic work can be conducted through cooperation of a feeding conveying belt and a discharging conveying belt, so that the work efficiency is improved, and the practicability of the equipment is enhanced.

Owner:湖南日虹科技有限公司

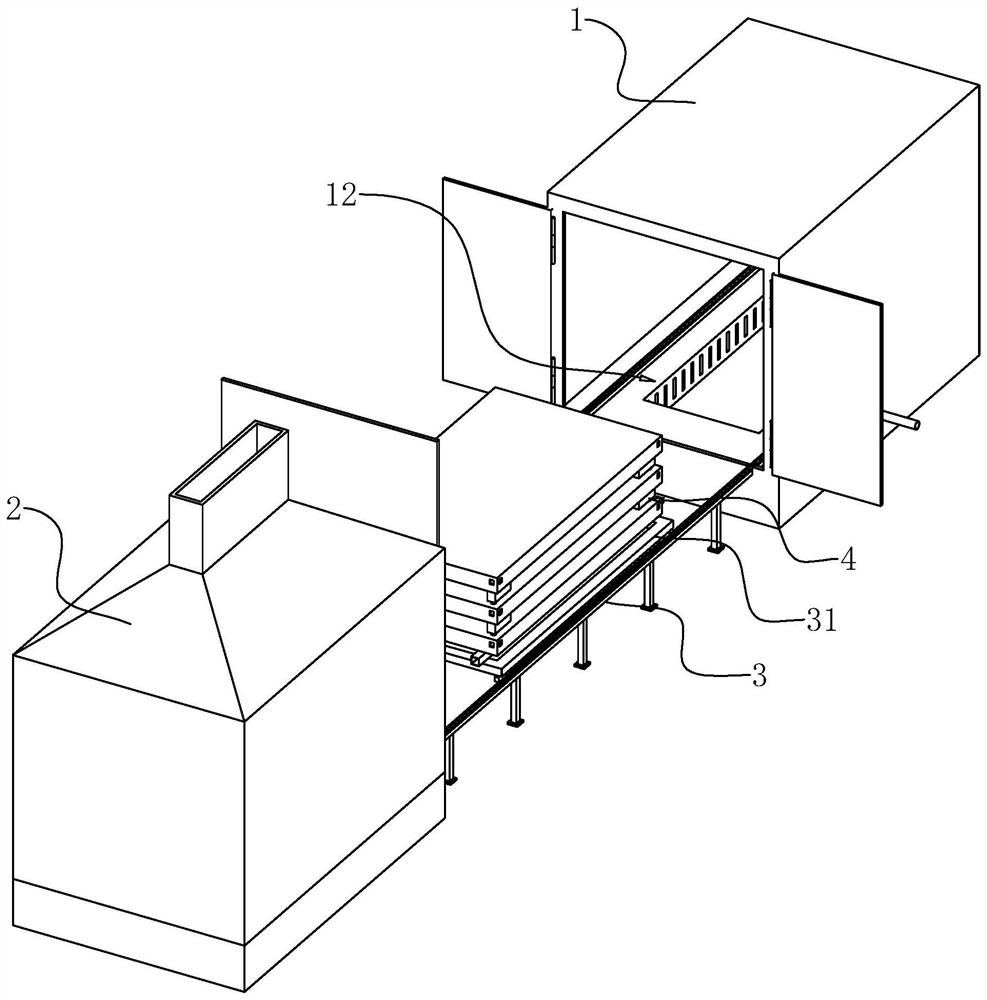

Container spraying process and spraying production line

ActiveCN112044707AReduce pollutionReduced Possibility of ContaminationLiquid spraying plantsPretreated surfacesThermodynamicsContainer tops

The invention relates to a container spraying process and a spraying production line. The container spraying process comprises the steps that S1, all components including a container bottom, a container top, an end wall and a side wall of a container are stacked in a spraying cabin; S2, all the components of the container are sprayed in the spraying cabin until a layer of protective paint is attached to each part of the surface of each component of the container; S3, all the components of the container are taken out of the spraying cabin and conveyed into a baking cabin, all the components ofthe container on a conveying platform are baked through heating equipment in the baking cabin, and the protective paint is made to be attached to and solidified on the surfaces of all the components of the container; and S4, all the components of the container are taken out of the baking cabin and naturally cooled to the room temperature. The container spraying process has the effects that all themain components of the container before assembly are sprayed, so that spraying dead corners are reduced, the spraying quality and efficiency are improved, and meanwhile, due to the fact that sprayingis conducted in the spraying cabin, the possibility of environmental pollution is reduced.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

Spraying system and dish-washing machine

InactiveCN111067452AReduce spray dead angleShorten the timeTableware washing/rinsing machine detailsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of dish-washing machines, and discloses a spraying system and a dish-washing machine. The spraying system comprises a fixed seat and a rotary spraying arm,the fixed seat comprises a water inlet end, the rotary spraying arm is connected to the water inlet end and can rotate around the fixed seat to form a rotary space, a plurality of rotary spraying holes are formed in the rotary spraying arm, the rotary spraying holes are communicated with a water source through the water inlet end, the rotary spraying holes can spray towards the rotary space, andthe dish washing machine comprises the spraying system. According to the dish-washing machine, the rotary spraying arm is matched with the fixed seat, all-around spraying cleaning can be conducted onthe rotary space, spraying dead corners are reduced, compared with a spraying device in an existing dish-washing machine, the spraying cleaning quality is improved, and the spraying cleaning time canbe effectively shortened.

Owner:QINGDAO HAIER DISHWASHER

Washing machine, and dehydration barrel assembly and water spraying cover plate

ActiveCN110924085AIncreased spray coverageImprove spray flushing effectOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention provides a water spraying cover plate, a dehydration barrel assembly and a washing machine. The water spraying cover plate comprises a cover plate body and a flow guide structure, wherein a plurality of water spraying holes distributed at intervals in a circumferential direction of the washing machine are formed in the cover plate body; the flow guide structure is arranged on the cover plate body and comprises a flow guide water passage extending from bottom to top; and the upper end of the flow guide water passage communicates with the plurality of water spraying holes. The water spraying cover plate has the advantages that the plurality of water spraying holes distributed at intervals in the circumferential direction of the washing machine are formed in the cover plate body, so that the spraying coverage range of the waterflow is effectively increased, and the spraying flushing effect on clothes is improved; in a high-speed rotating process of an inner barrel of the washing machine, the waterflow sprayed out from the plurality of water spraying holes in the high-speed rotation process can cover a greater area at the same moment, or even can be connected into a wholeto form 360 degrees, so that the probability of generating a spraying dead corner is greatly reduced; a clothes winding risk in a clothes washing process is further reduced; and the user experience is further improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

A dish-washing machine spraying assembly and a dish-washing machine

ActiveCN110960165AImprove use comfort performanceImprove satisfactionTableware washing/rinsing machine detailsHome appliance efficiency improvementSprayerEngineering

The invention discloses a dish-washing machine spraying assembly and a dish-washing machine, and belongs to the field of kitchenware. The dish-washing machine spraying assembly comprises a sprayer body, sprayer sleeves and a pulley, wherein the sprayer body is rotationally arranged on a bottom plate of the wall of an inner container of the dish washing machine, the sprayer sleeves are arranged atthe two ends of the sprayer in a sleeving mode respectively, and the sprayer sleeves can move at the ends of the sprayer in a telescopic mode; an elastic element is arranged on the sprayer body, the elastic element is connected with the sprayer sleeve, and the elastic element has elastic pulling force on the sprayer sleeve; and the pulley is rotationally arranged at the end part of the sprayer sleeve. According to the scheme, the control mode of telescopic rotation of the sprayer is maintained through the side wall of the inner container and the pulley, the spraying area is increased, sprayingdead corners are reduced, the spraying effect is improved, then the use comfort and satisfaction of customers are improved, and the market competitiveness of products is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

Evaporative condenser for refrigerating system

ActiveCN113758060AEvenly distributedReduce spray dead angleEvaporators/condensersSteam/vapor condensersEngineeringCooling fluid

The invention belongs to the technical field of condensers, particularly relates to an evaporative condenser for a refrigerating system, and aims to solve the problem that water cannot uniformly cover a pipe wall due to the fact that a condensation calandria is complex in structure during spraying in the prior ar. The evaporative condenser comprises a box body, an air inlet pipe is fixedly connected to the outer wall of one end of the box body, a first connecting box is arranged on the inner wall of the box body, and a rotating mechanism is arranged on the outer wall of the first connecting box. Air is finally discharged from a plurality of first spraying pipes at the bottom of a liquid outlet plate, a condensation calandria at the bottom of a liquid collecting box is sprayed, finally, the air is condensed into liquid, the liquid is discharged from a liquid outlet pipe at the bottom, and a rotating mechanism is arranged to drive a first connecting box to rotate, so that the condensation calandria fixedly connected with the bottom of the first connecting box is driven to rotate, the condensation calandria can rotate at the bottom of the liquid outlet plate, cooling liquid can be evenly distributed on the rotating condensation calandria, spraying dead angles are reduced, and the evaporation and condensation effect is guaranteed.

Owner:深圳英创能源环境技术有限公司

Drug coating-spraying method for drug eluting stent and spraying apparatus therefor

Owner:CHONGQING UNIV

Liquid coating production line

ActiveCN113663846AReduce spray dead angleQuality improvementSpray boothsEngineeringManufacturing line

The invention discloses a liquid coating production line, and relates to the technical field of workpiece machining. The liquid coating production line comprises a production box and a cylinder spraying box which are connected, the interior of the cylinder spraying box is fixedly connected with a coating box, the interior of the production box and the interior of the cylinder spraying box are provided with a conveying structure, and the interior of the cylinder spraying box is fixedly connected with a rotating track; and a plurality of self-rotating hanging pieces are hung on the lower side of the conveying structure, a storage box and a storage component are installed on the upper side and the lower side of the cylinder spraying box correspondingly, and a plurality of rows of limiting frames and shielding components penetrating through the limiting frames are installed in the cylinder spraying box and located between the storage box and the storage component. According to the liquid coating production line, the production box used for transferring workpieces and the cylinder praying box used for spraying are arranged, the self-rotating hanging pieces in the conveying structure can rotate in the moving process after making contact with the rotating track, and therefore the direction of the workpieces or products on the lower sides of the self-rotating hanging pieces can be changed.

Owner:SUSONG ANBAO BUSINESS MACHINE

Sink dishwasher panel with spraying arms

PendingCN108451476AAvoid damageNot easy to stainTableware washing/rinsing machine detailsHome appliance efficiency improvementHydraulic cylinderSpray nozzle

The invention discloses a sink dishwasher panel with spraying arms. The panel comprises a panel body, a mounting groove is formed in the lower end face of the panel body, a movable block is containedin the mounting groove, and a working cavity is defined by the upper end face of the movable block and the inner surface of the mounting groove; the panel body is provided with a water inlet pipe, a plurality of hydraulic cylinders are arranged at the portion, located above the movable block, in the panel body in the horizontal direction at intervals, and piston rods of the hydraulic cylinders penetrate through the working cavity and are fixedly connected with the upper end face of the movable block; the main spraying arm is mounted on the lower end face of the movable block, a plurality of spraying nozzles are arranged on the lower end face of the main spraying arm in the horizontal direction at intervals, the main spraying arm is internally provided with a water supply pipeline, and thewater supply pipeline is communicated with the working cavity through a connection pipeline in the movable block. According to the sink dishwasher panel with the spraying arms, the spraying arms are directly mounted on the panel, so that not only is the spraying effect is good, but also oil stains on dishes are not easily attached to the spraying arms.

Owner:NINGBO MEIGAO KITCHENWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com