Patents

Literature

61results about How to "Increased spray coverage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

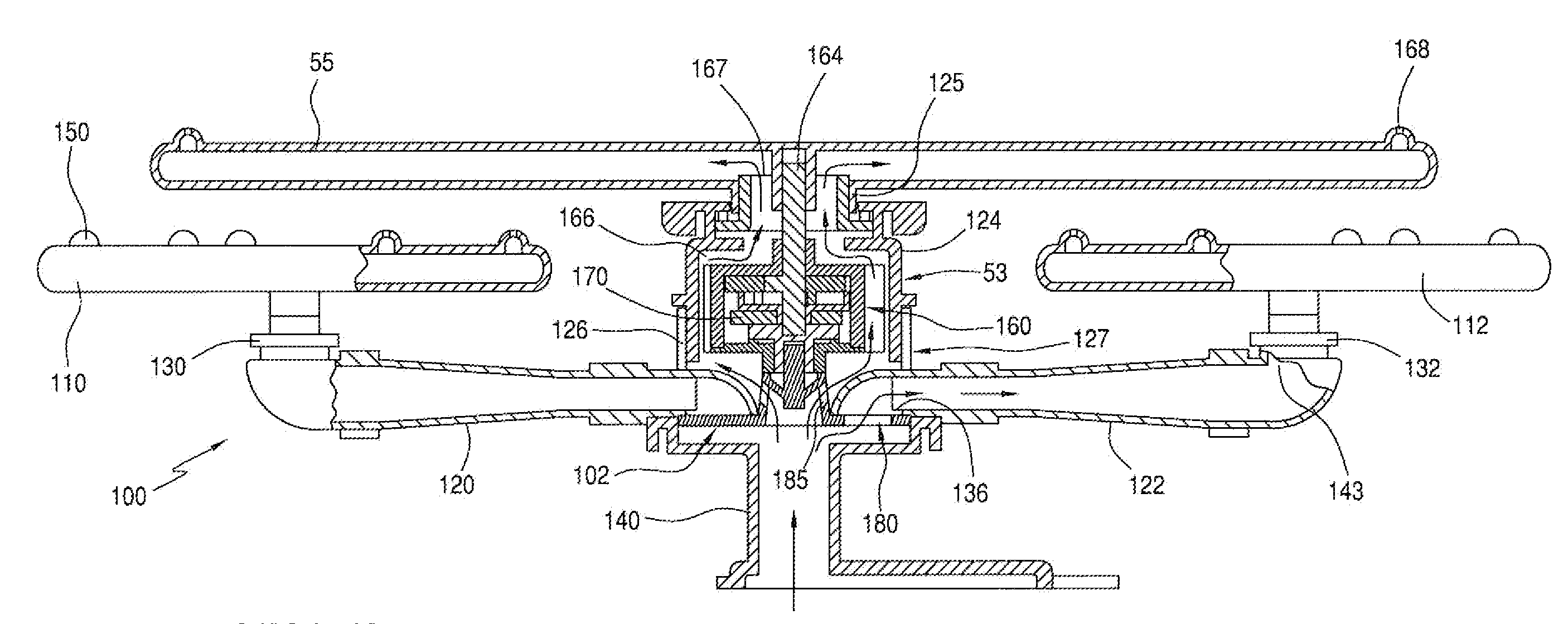

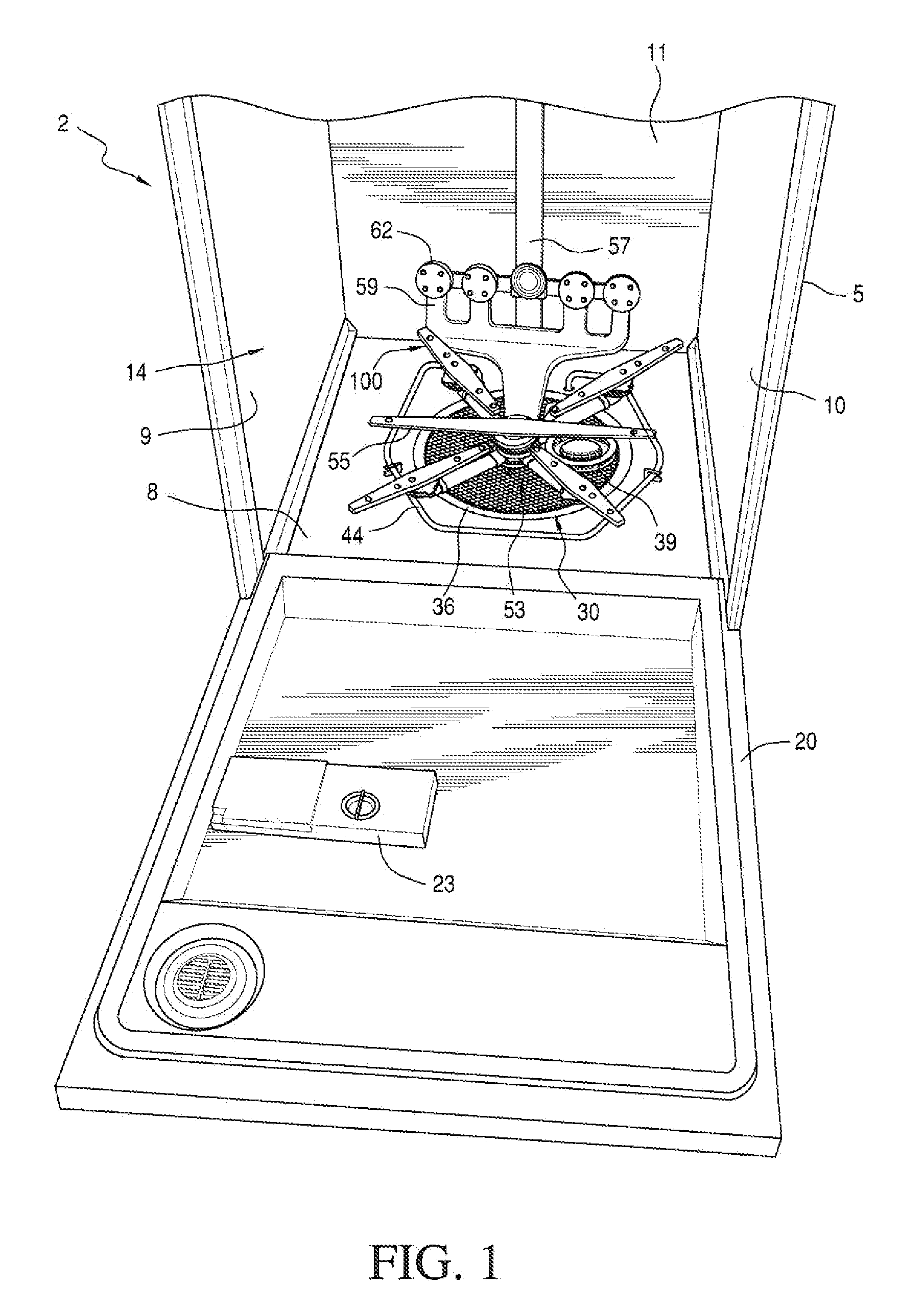

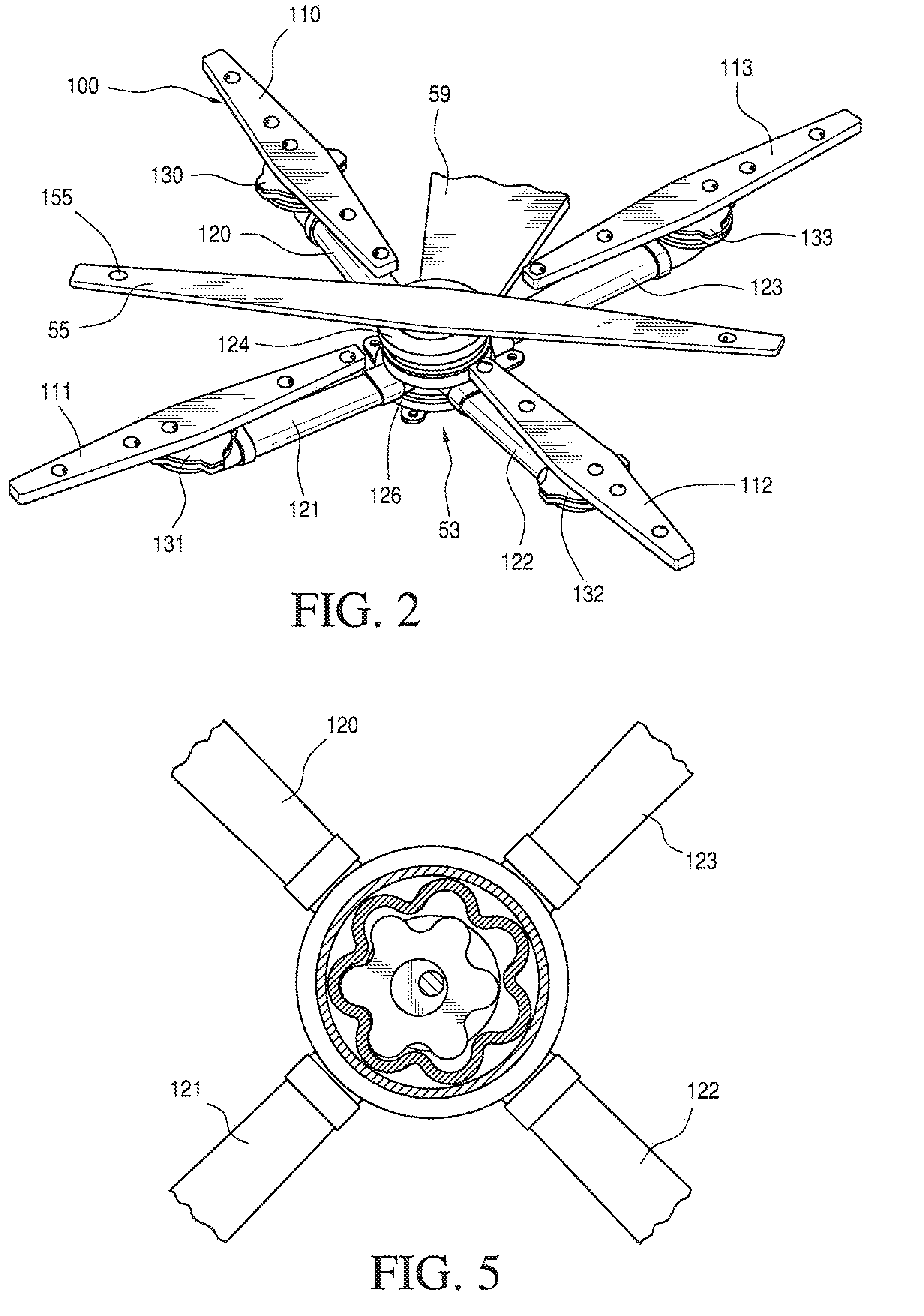

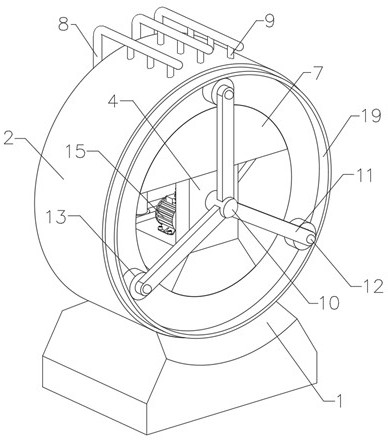

Sequencing spray arm assembly for a dishwasher

InactiveUS8282741B2Sacrificing dwell timeImprove washing effectTableware washing/rinsing machine detailsElectrostatic cleaningEngineeringVALVE PORT

A sequencing spray arm assembly includes a plurality fluid spray arms rotatably mounted on respective radially spaced carrier arms. The rotating fluid spray arms are in fluid communication with a fluid distribution manifold and adapted to distribute washing fluid throughout a washing chamber of the appliance. A sequencing diverter valve system enables delivery of washing fluid from the fluid distribution manifold to one or more of the plurality of rotating fluid spray arms. A fluid responsive rotating drive arm drives the rotation of a sequencing disk in the valve system between discrete positions and enables delivery of fluid to one or more of the plurality of rotating fluid spray arms in a sequential manner such that, for each discrete position, less than the total number of spray arms are supplied with washing fluid at a time.

Owner:WHIRLPOOL CORP

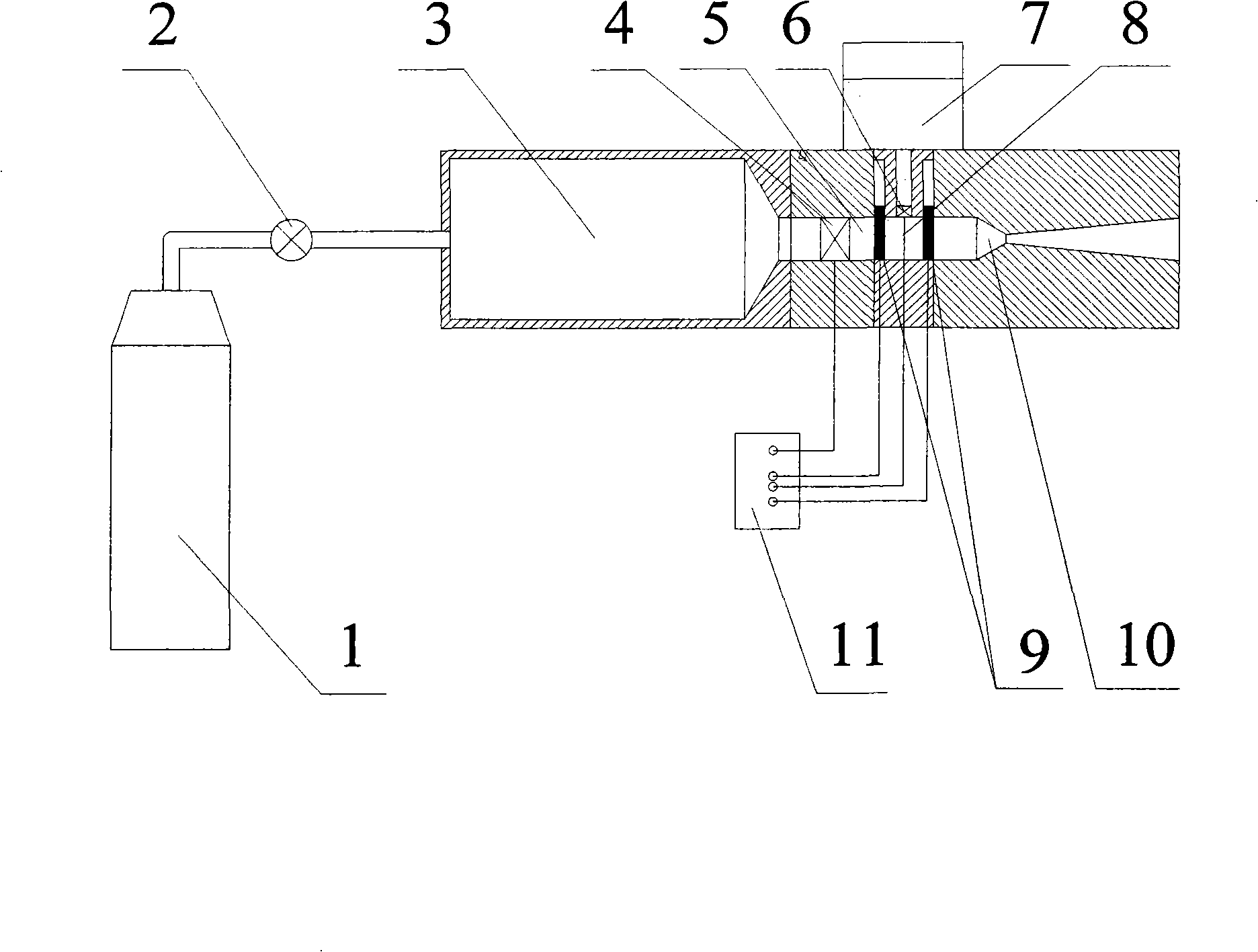

Solid particle group accelerating device for shock tube-Laval nozzle

InactiveCN101274710ALong rangeIncreased spray coverageSpray nozzlesFire rescueParticle injectionSolid particle

The invention discloses a shock wave tube-Laval nozzle accelerating device of a solid particle group. A compressed gas source is connected with a high pressure gas chamber of a shock wave tube by a compressed gas check valve, a powder storage chamber is surrounded by tube walls and movable clapboards at the two ends of the powder storage chamber, one of the movable clapboard separates a low pressure air chamber and the powder storage chamber and the other moveable clapboard separates the powder storage chamber and the Laval nozzle; a particle injection hole is cut on the side wall of the powder storage chamber to be connected with a powder supply source; a powder supply switch valve is arranged in the particle injection hole to separate the powder supply source and the powder particle in the powder storage chamber; a control circuit board is respectively connected with a transient switch valve, the powder supply switch valve and the two movable clapboards. As a chemical powder extinguisher, since the shock wave tube and the Laval nozzle function synchronously to accelerate the solid particle group to cause the shooting range of extinguisher to be sufficiently far off and an ejection covering area can be appropriately enlarged by enlarging the expansion angle of the gradual-widening section of the Laval nozzle, the shock wave tube-Laval nozzle accelerating device has high extinguishing efficiency, good effect, long shooting range and energy conservation; as an ultrasonic cool spraying device, the particle adhesive strength and the coating strength are great.

Owner:ZHEJIANG SCI-TECH UNIV

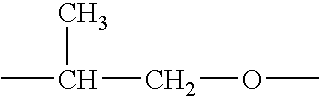

High-efficiency fungicide and method of preparing the same

The invention relates to a highly effective bactericidal agent, which is composed of preparation which is made from triazole-type medicament and auxiliary agent ethoxyl group modified poly trisiloxane which is filled in the agent, wherein the triazole-type medicament takes up 1%-70% of the weight of the preparation, and auxiliary agent ethoxyl group modified poly trisiloxane takes up 0.001-1% of the weight of the preparation. Because triazole-type bactericidal agent has excellent prevention and cure effect to pest diseases of various plants and crops, and further ethoxyl group modified poly trisiloxane is a novel organosilicon-type agricultural chemical auxiliary agent, which can improve the ductility of surfaces of plants which are difficult to be moistened and increase sprayed covering, and can evidently improve the penetration effect of the bactericidal agent.

Owner:HENAN AGRICULTURAL UNIVERSITY

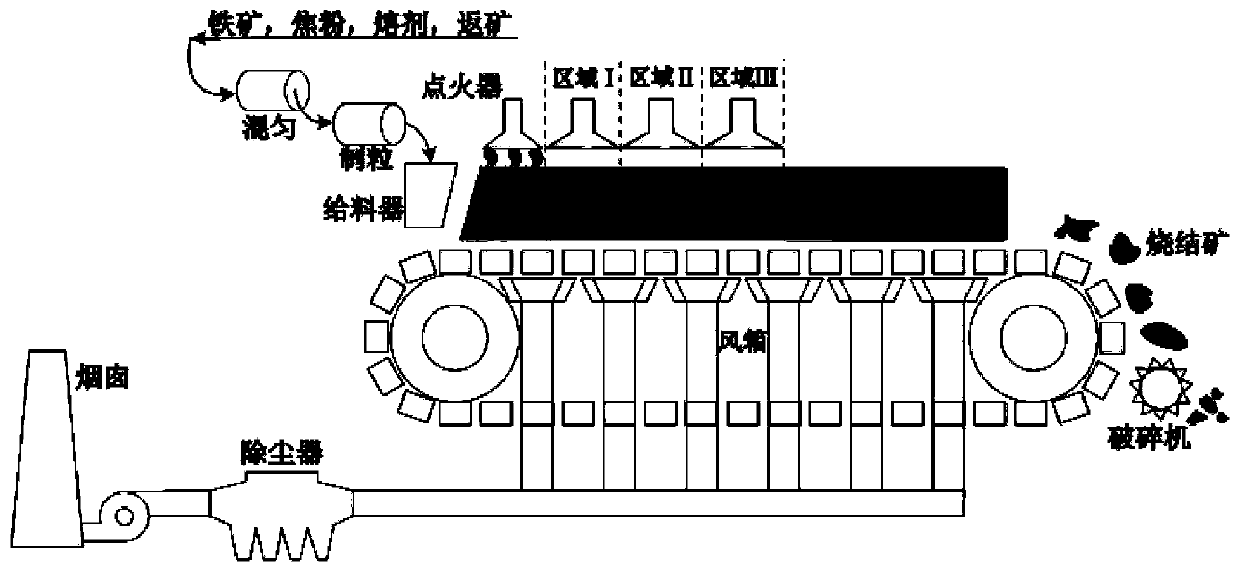

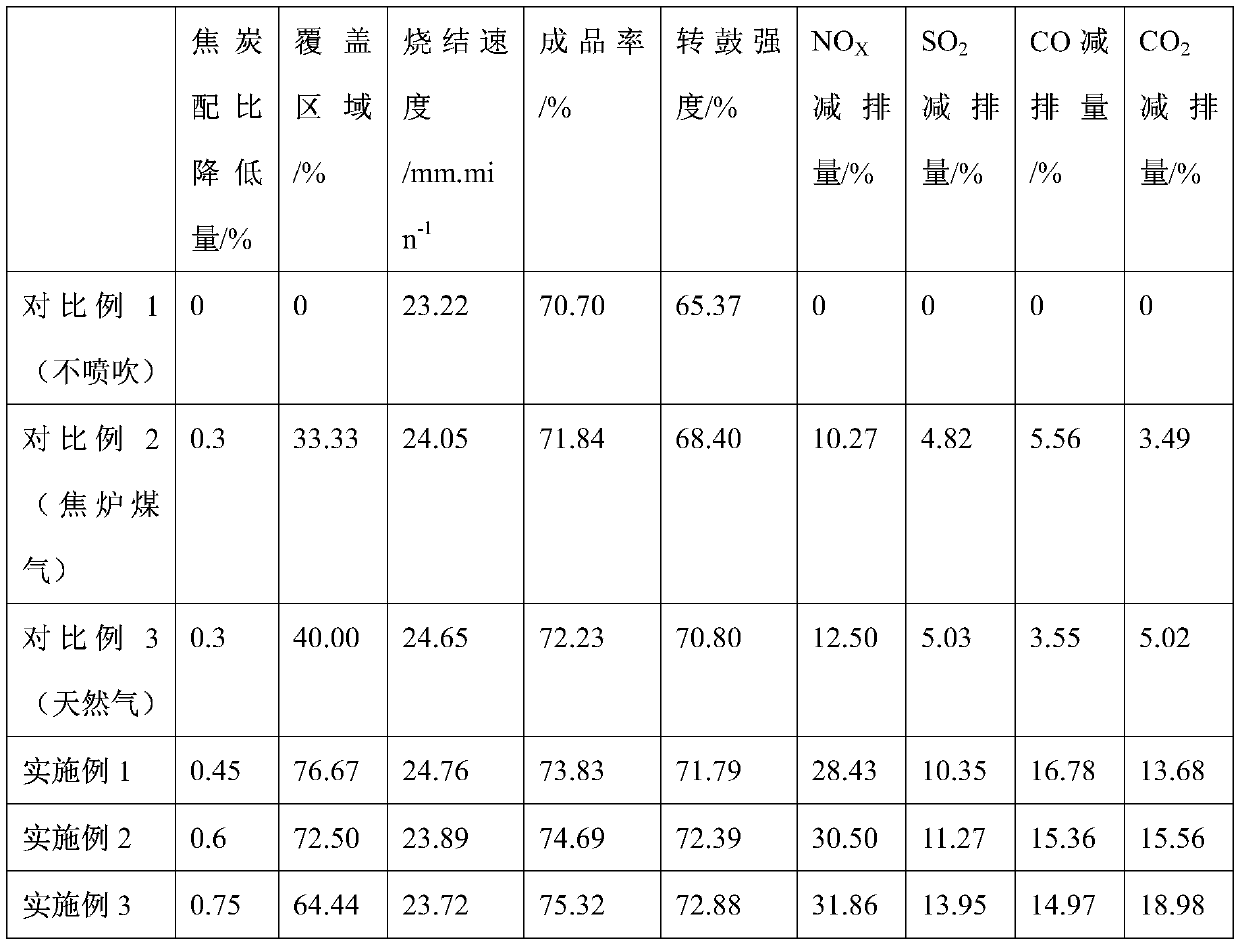

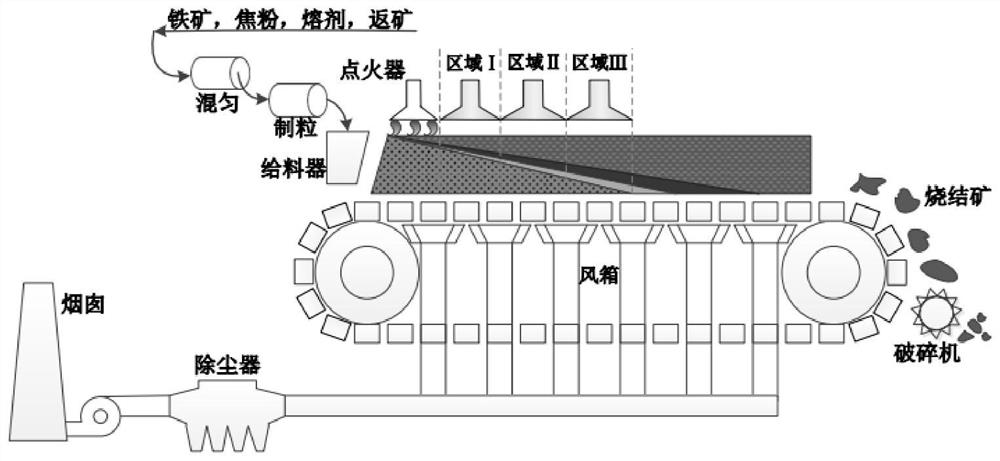

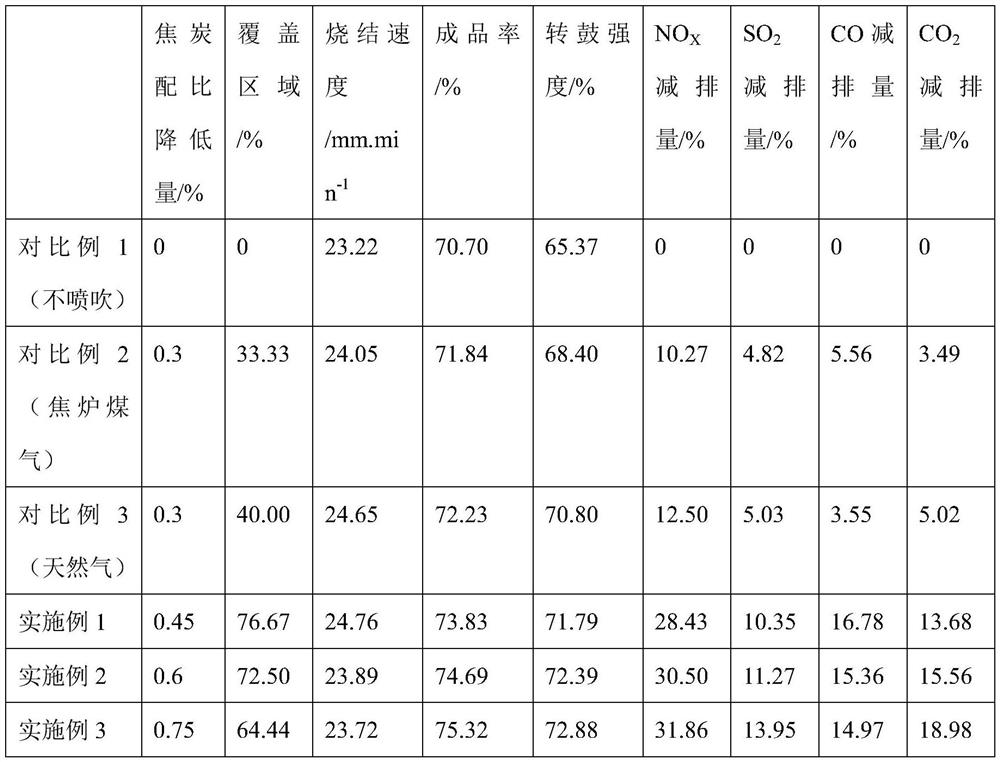

Low-carbon low-emission sintering method based on coupled injection of multiple gases

The invention discloses a low-carbon low-emission sintering method based on coupled injection of multiple gases. Based on the difference of heat storage capacities of parts at the heights of differentmaterial layers, areas from thermal insulation completion to a waste gas temperature rising point of a material surface of a sintering machine are sequentially divided into a low heat storage capacity area, an intermediate heat storage capacity area and a high heat storage capacity area according to the temperature intervals smaller than 1250 DEG C, 1250-1300 DEG C and 1300-1350 DEG C, and high heating value gas with the injection heating value being larger than 30 MJ / Nm<3>, an intermediate heating value gas with the injection heating value being 15-30 MJ / Nm<3> and low heating value gas withthe injection heating value being smaller than 15 MJ / Nm<3> are separately injected to the three areas. The low-carbon low-emission sintering method effectively couples the differences between the heating capacity requirements and the gas quality of different areas of the sintering material layer, realizes heating capacity balanced distribution of the material layers at different heights, forms a beneficial ore-forming condition, greatly improves the sintering quality and the quality index, meanwhile, effectively expands the coverage area of gas injection, further reduces the solid fuel consumption, increases the emission reduction ratio of pollutants such as NOX, SO2 and COX, and realizes the low-carbon low-emission sintering.

Owner:CENT SOUTH UNIV

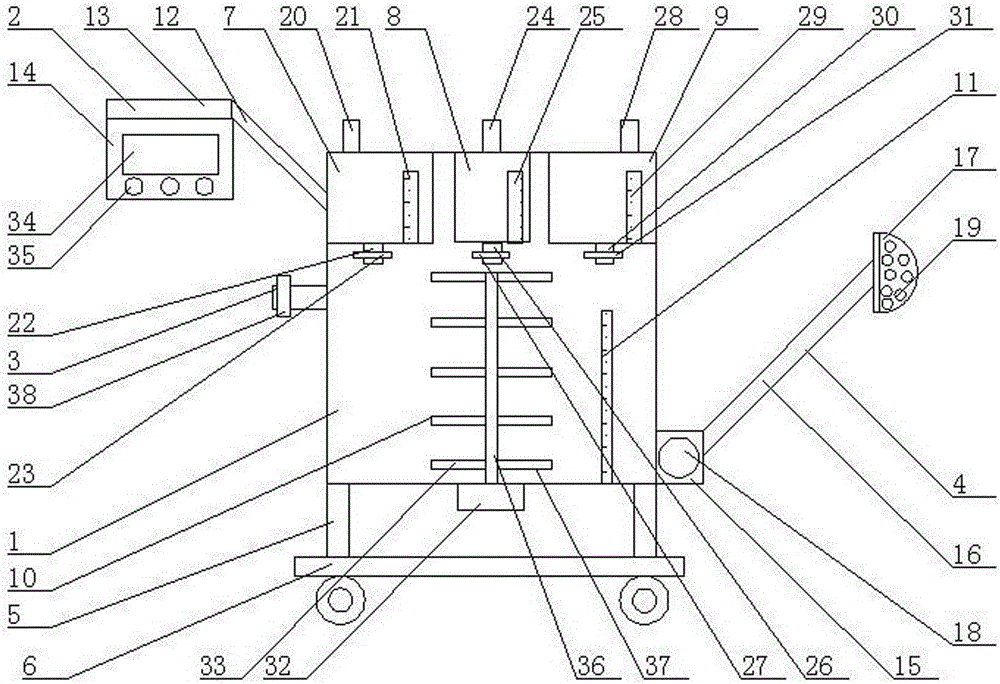

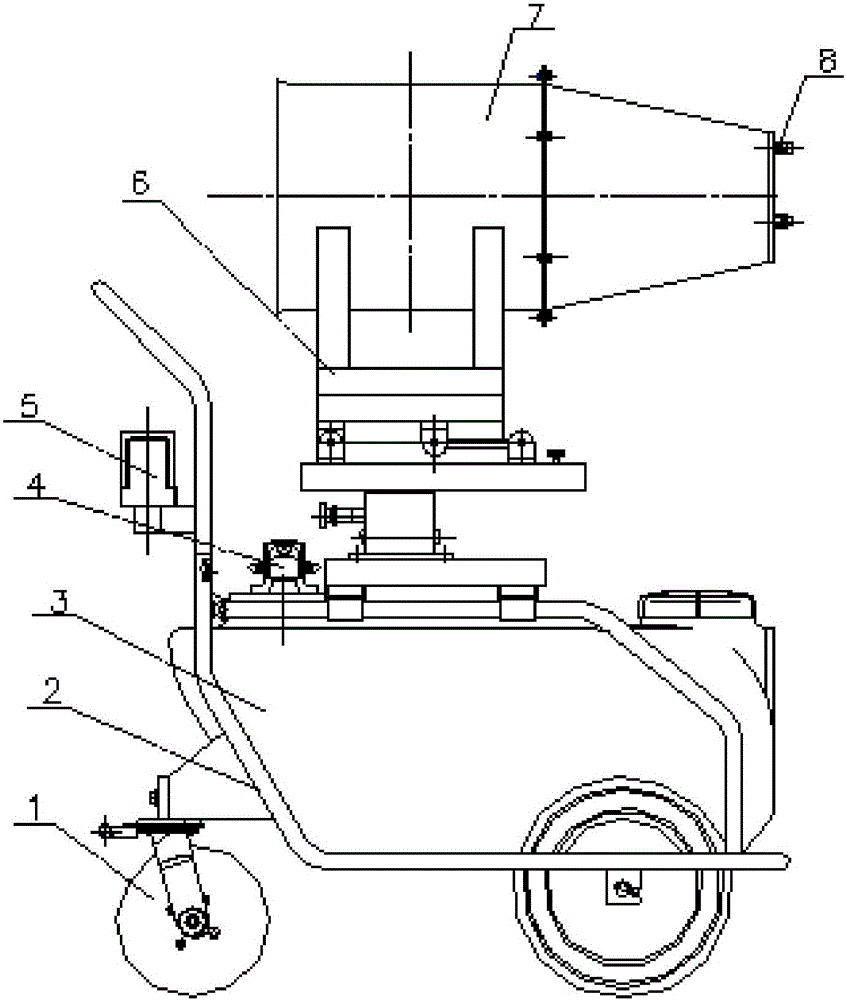

Hand push type agricultural pesticide spraying device

InactiveCN105994236AEasy to viewAccurately grasp the proportionInsect catchers and killersAgricultural scienceAgricultural engineering

The invention provides a hand push type agricultural pesticide spraying device which comprises a box body. The upper end of the left side of the box body is provided with a pushing hand, the lower end of the pushing hand is provided with a water inlet pipe, the lower end of the right side of the box body is provided with a spraying device body, the bottom end of the box body is connected with a walking base through a bracket, the upper end in the box body is provided with a first pesticide liquid box, a second pesticide liquid box and a third pesticide liquid box from left to right in sequence, the middle of the bottom end in the box body is provided with a mixing device, and the right side of the bottom end in the box body is provided with a first liquidometer. The hand push type agricultural pesticide spraying device is high in spraying efficiency, wide in spraying coverage range, convenient to move, easy to operate and convenient to use, the design of the multiple pesticide liquid boxes and the mixing device is adopted, and mixing is uniform and convenient.

Owner:哈尔滨尼亚农业有限公司

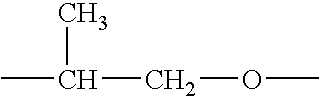

Surface Active Organosilicone Compounds

InactiveUS20080242743A1High retention rateEasy to spreadCosmetic preparationsGroup 4/14 element organic compoundsSurface-active agentsMedicinal chemistry

The present invention relates to new organodisilanes or carbodisilanes, a process for manufacturing the same and their use, in particular, as surface active agents, especially as spreading agents.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

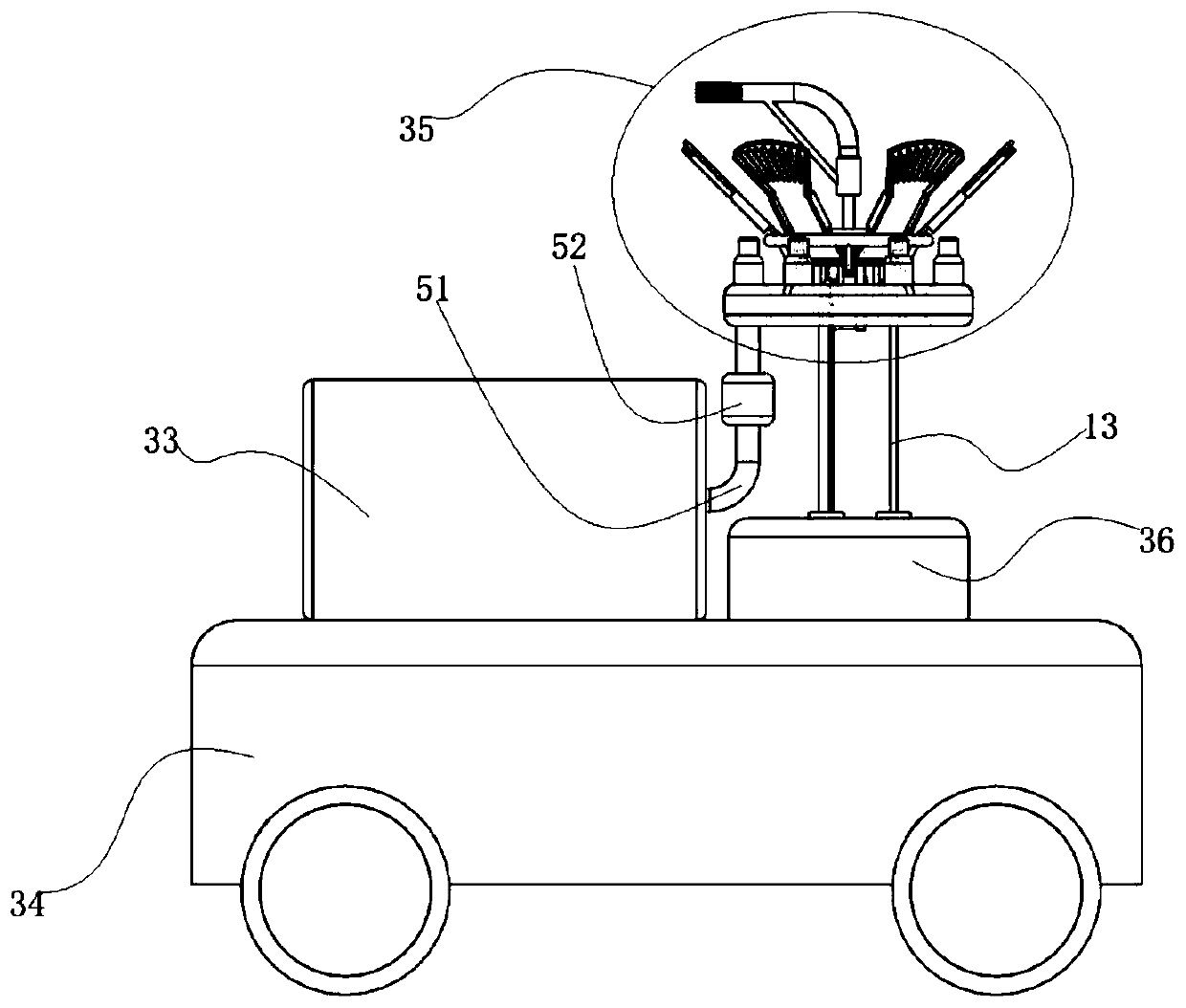

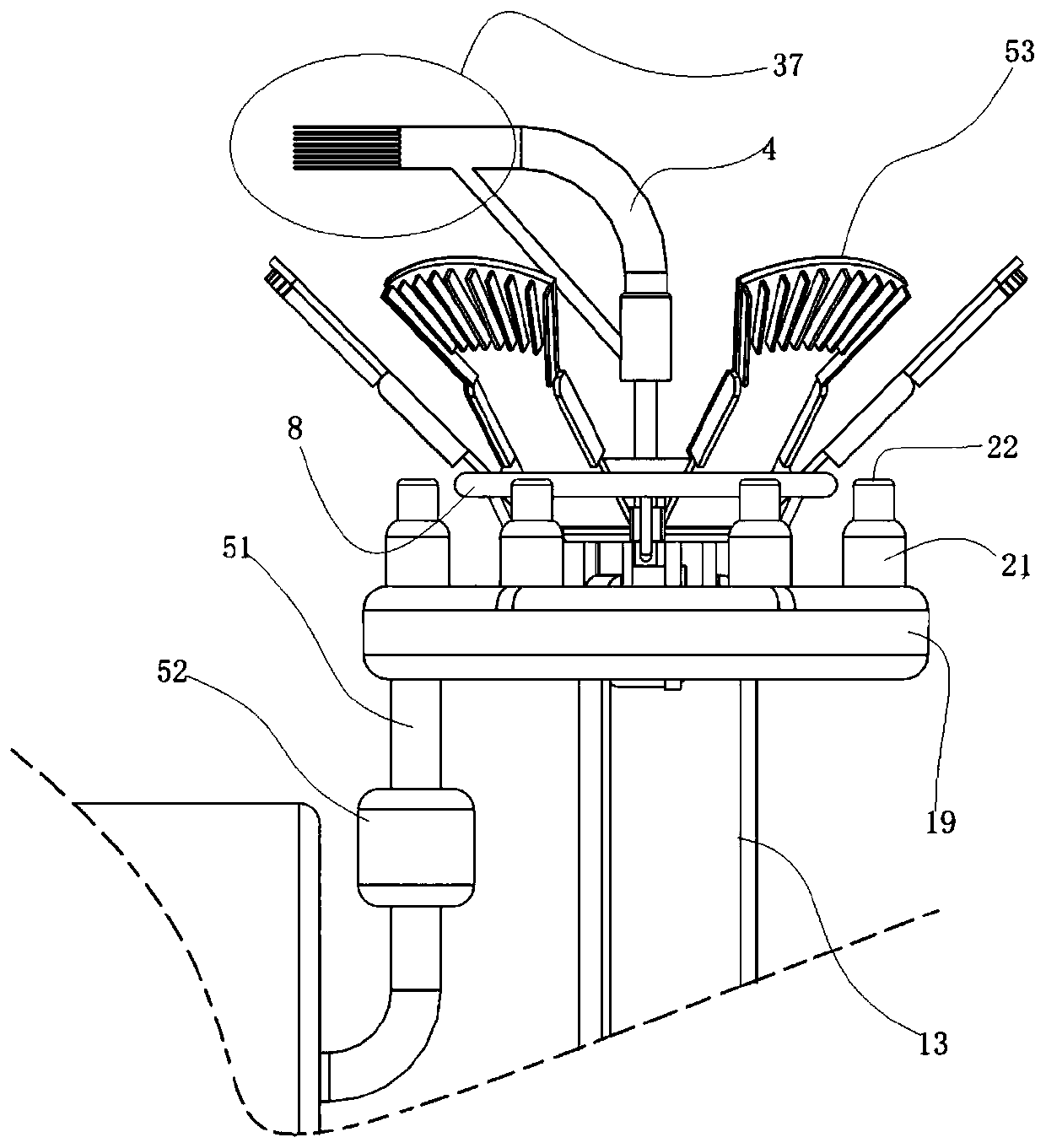

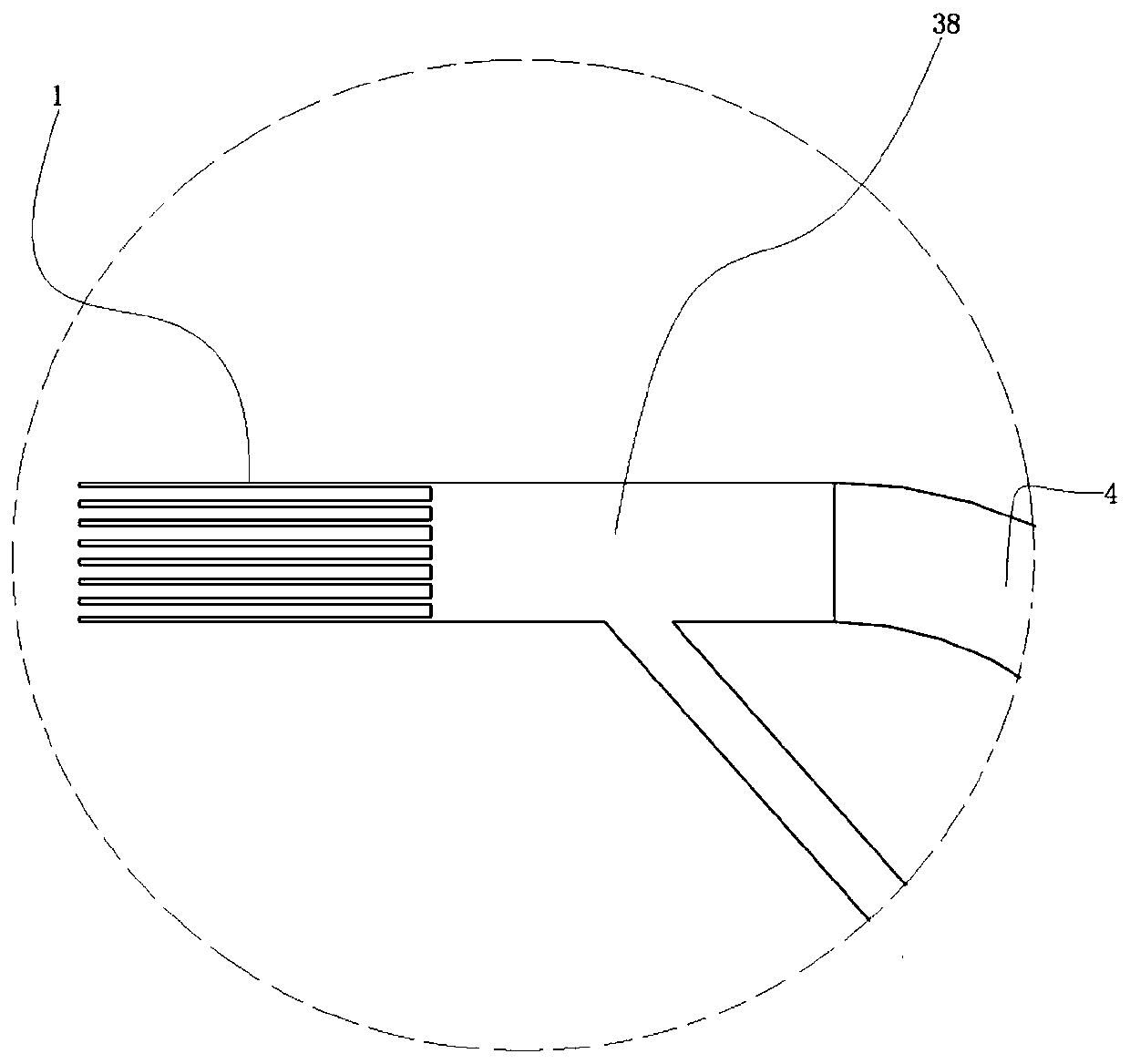

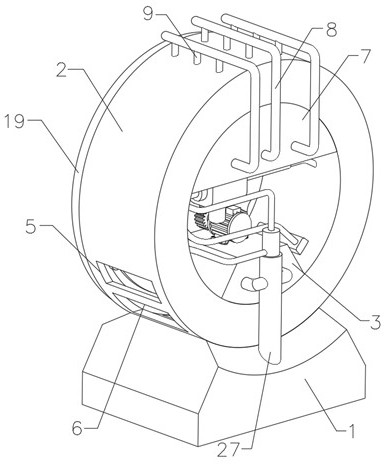

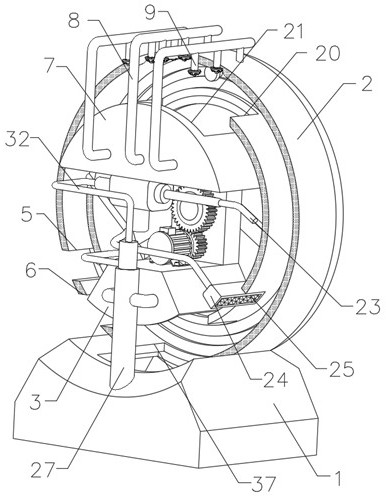

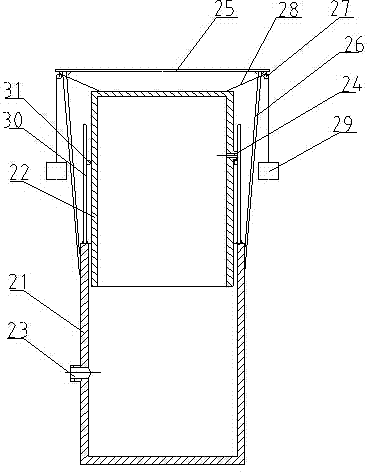

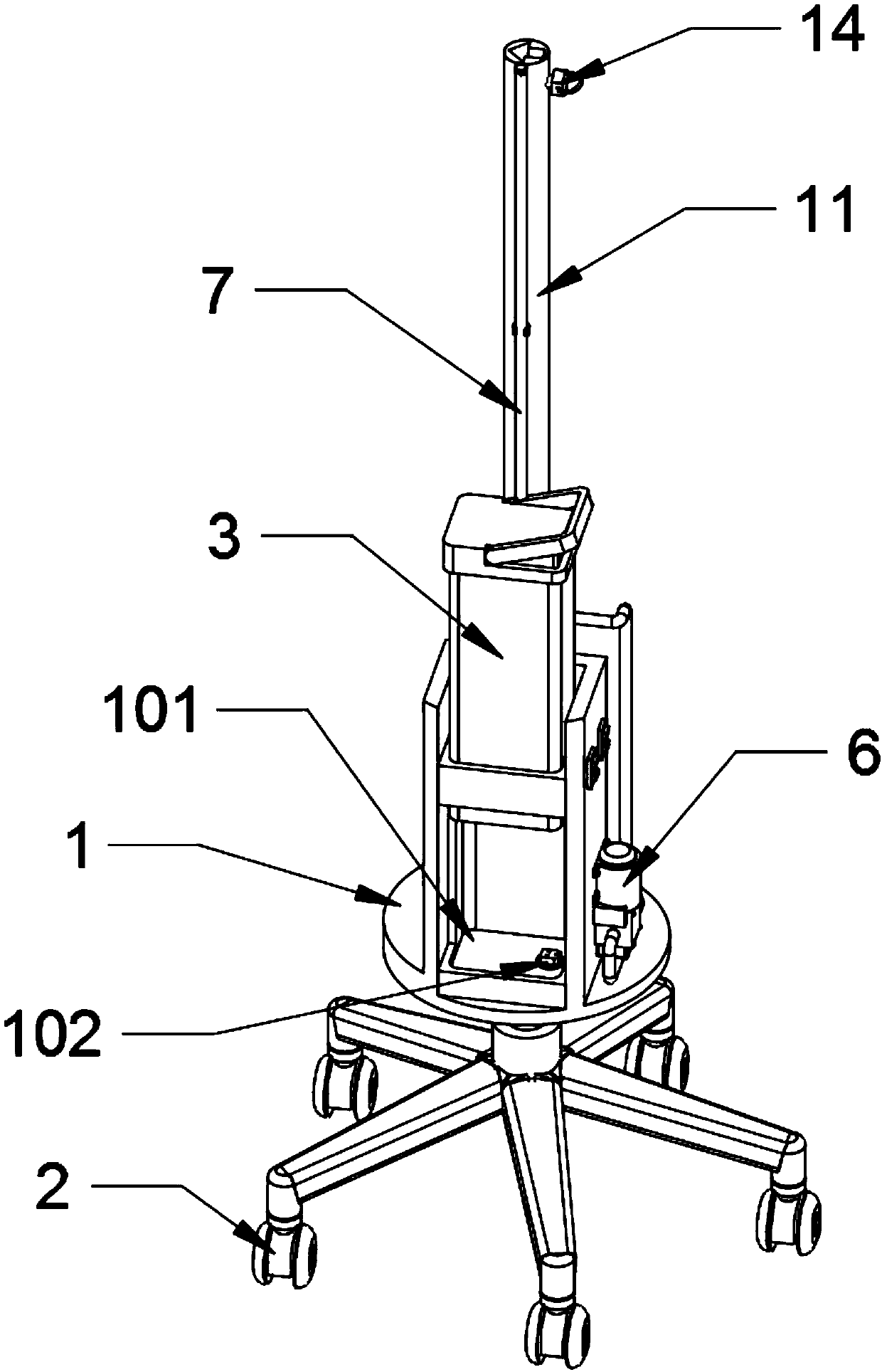

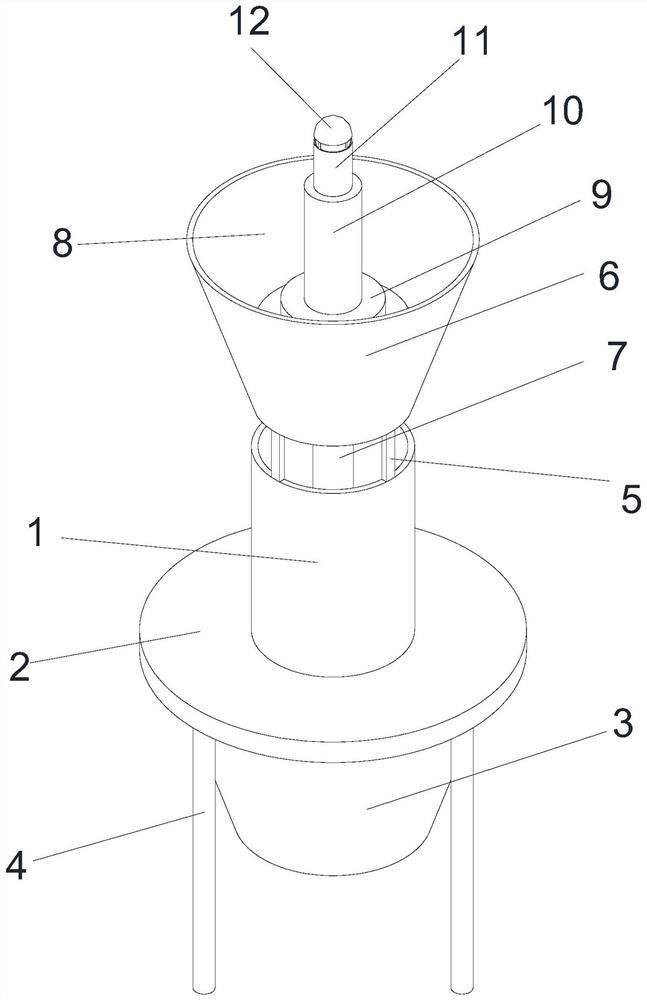

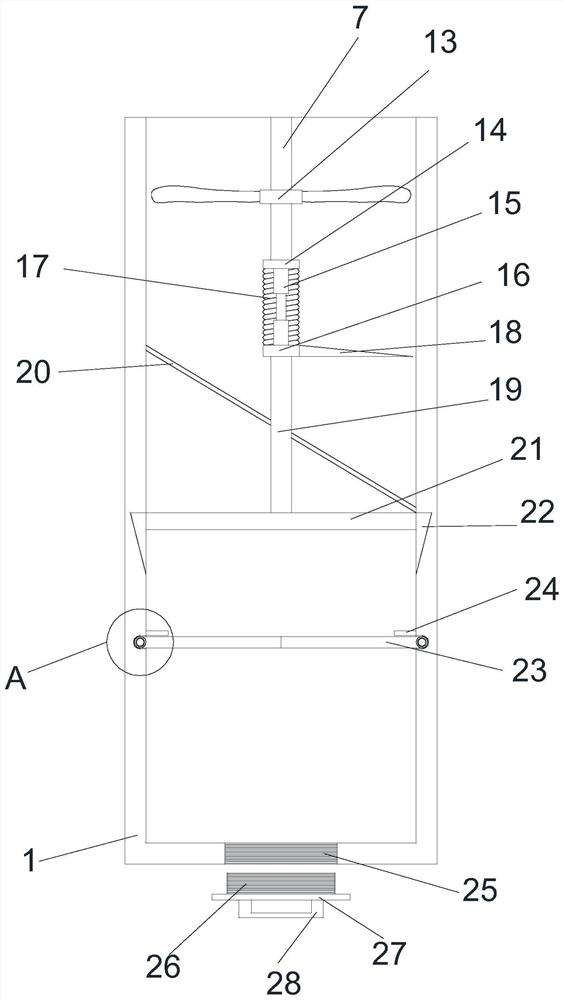

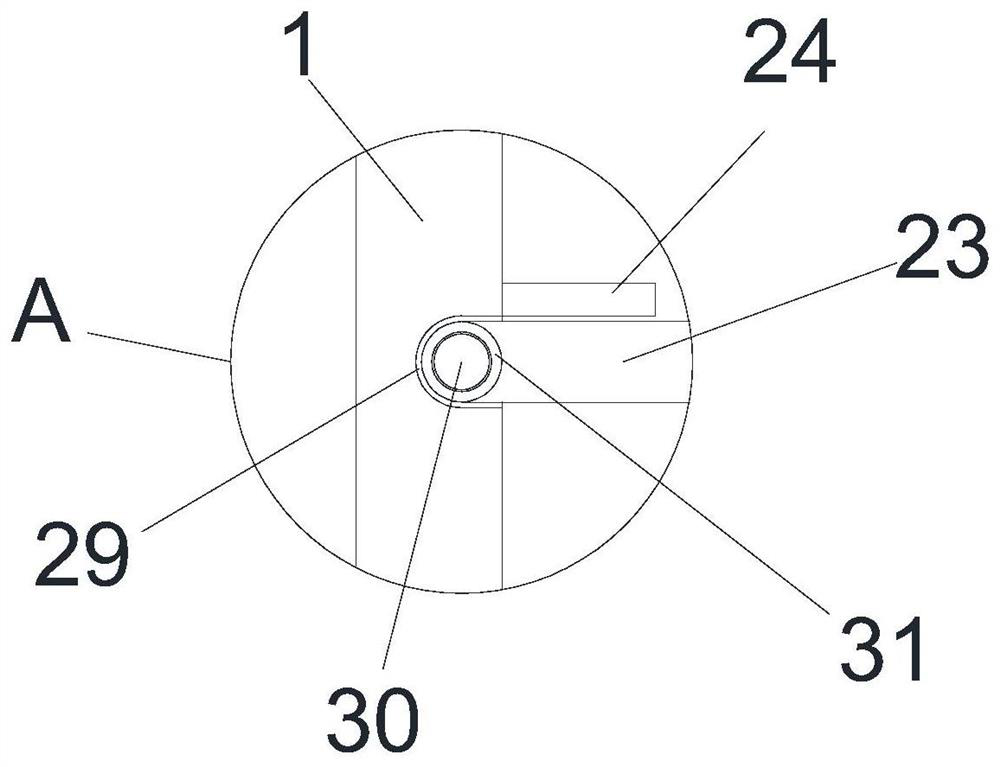

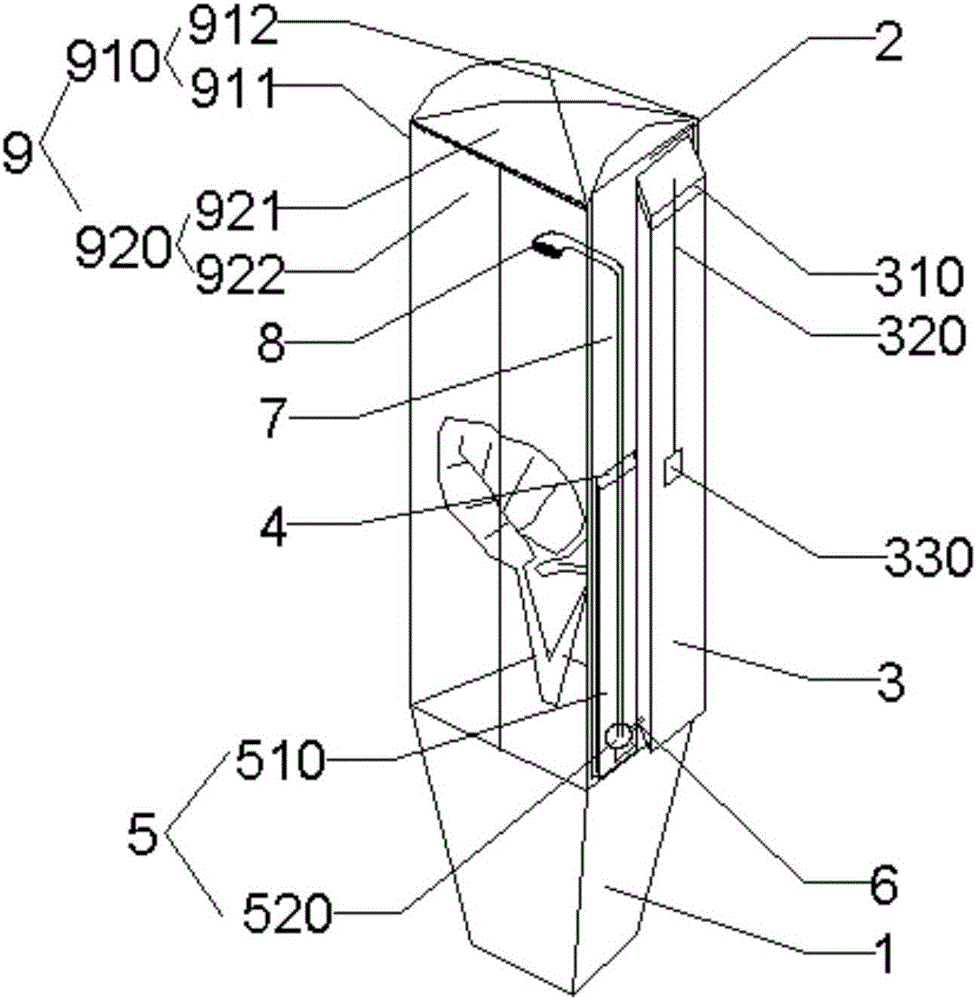

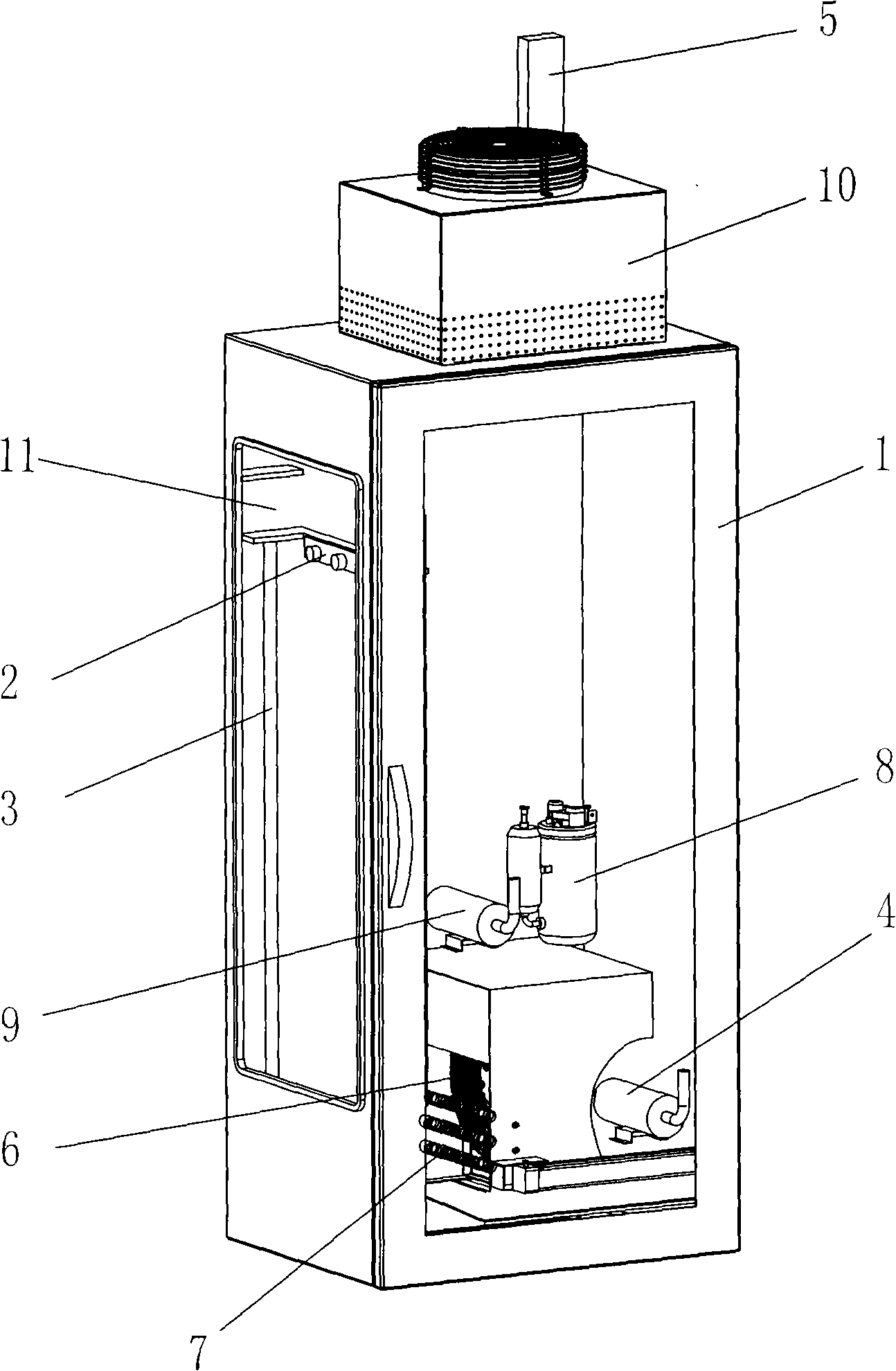

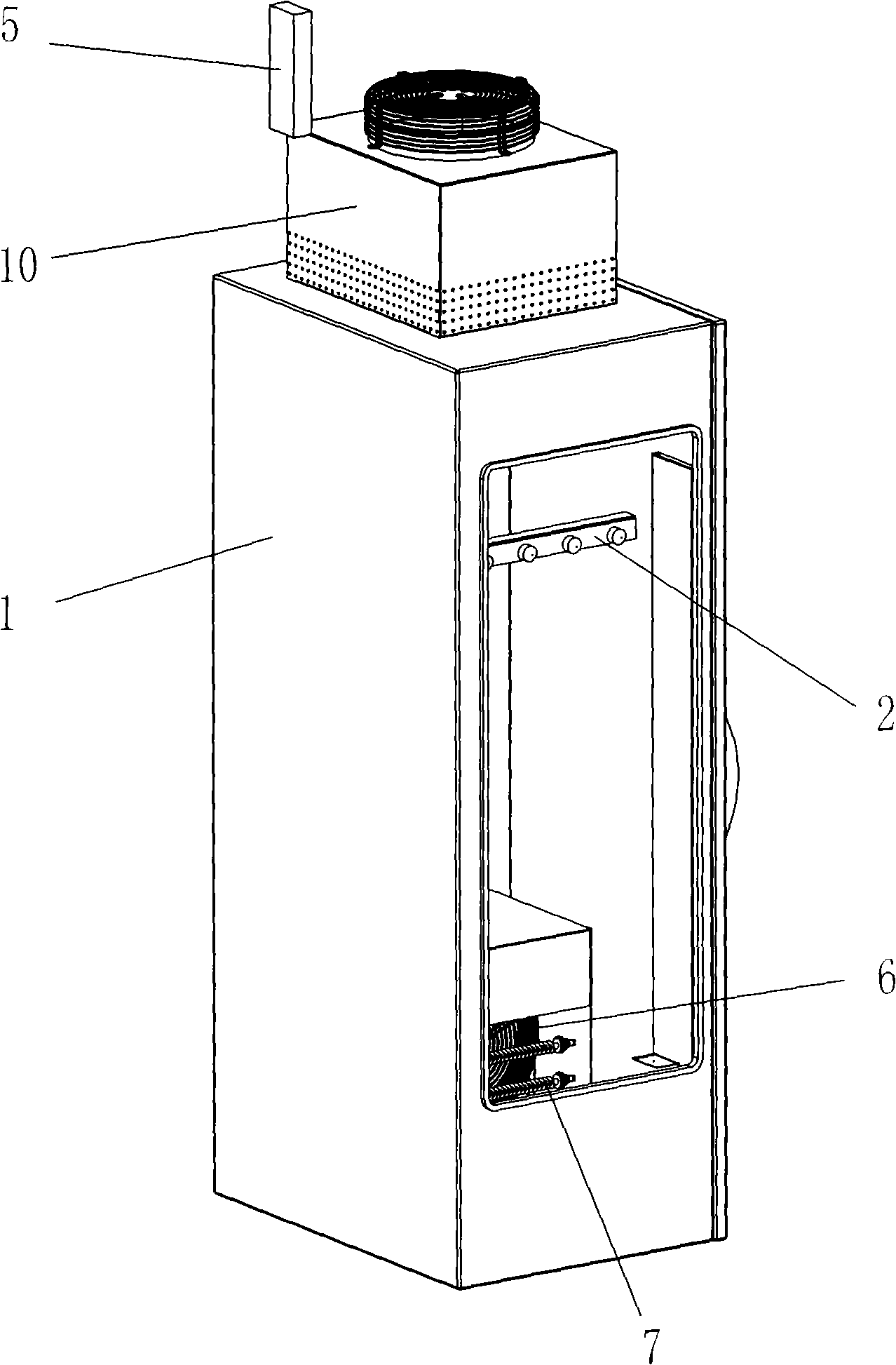

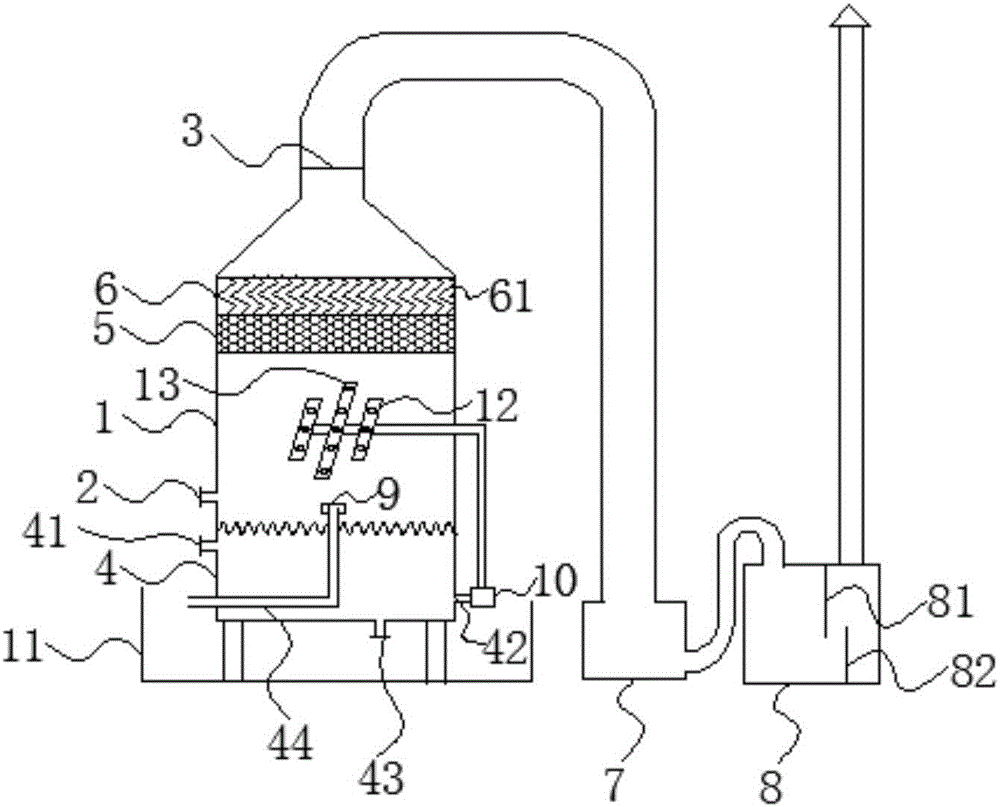

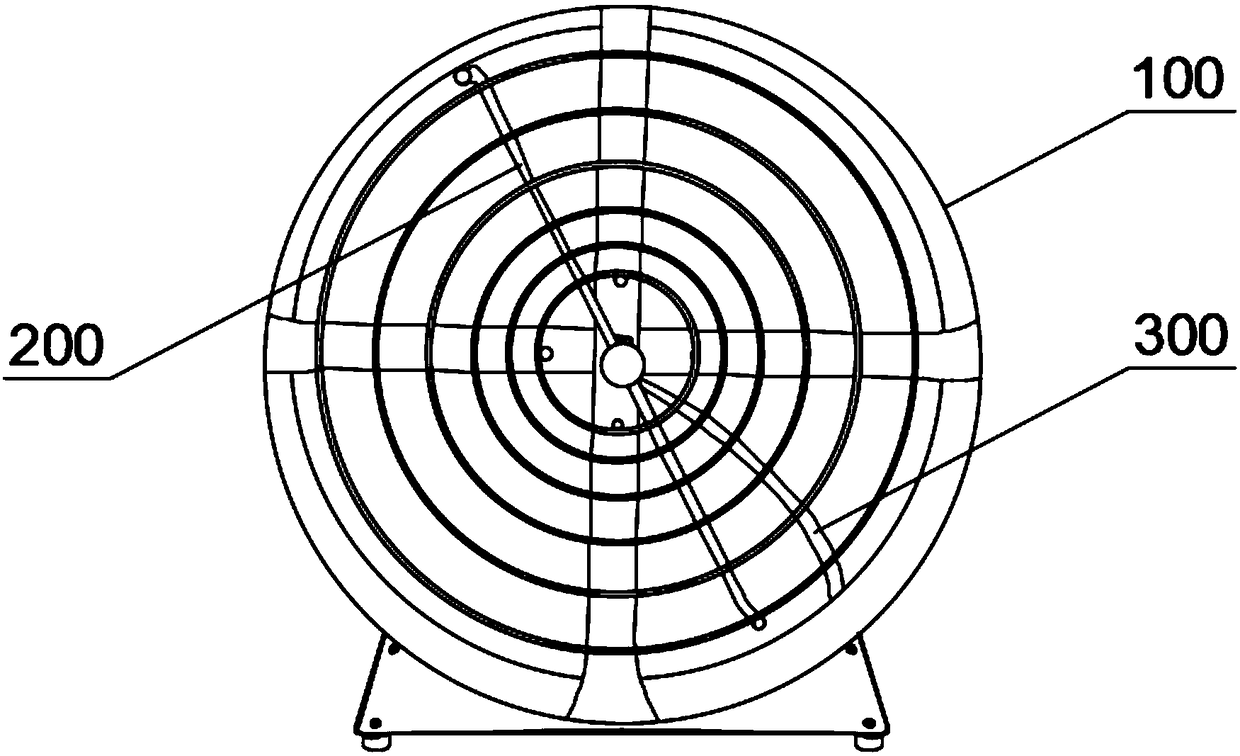

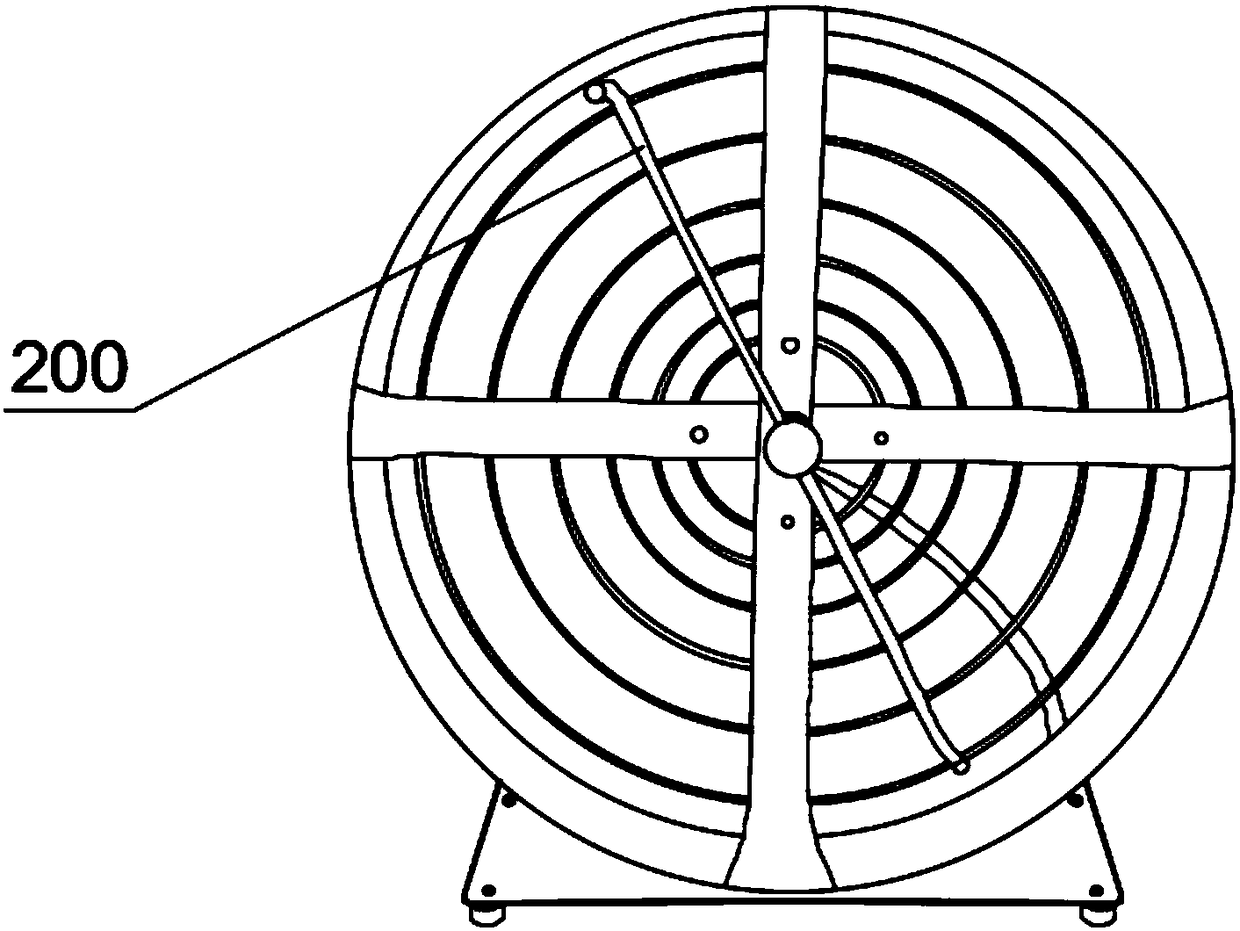

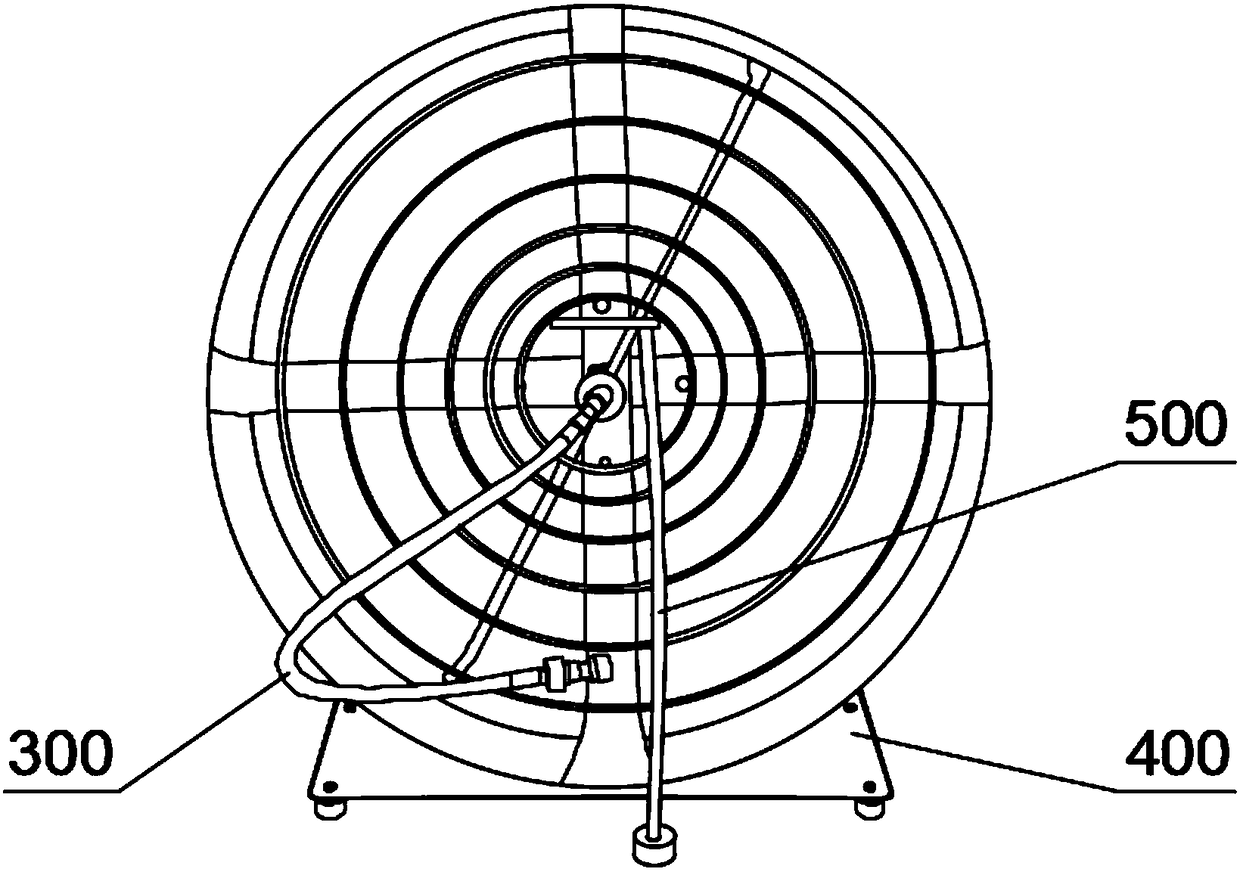

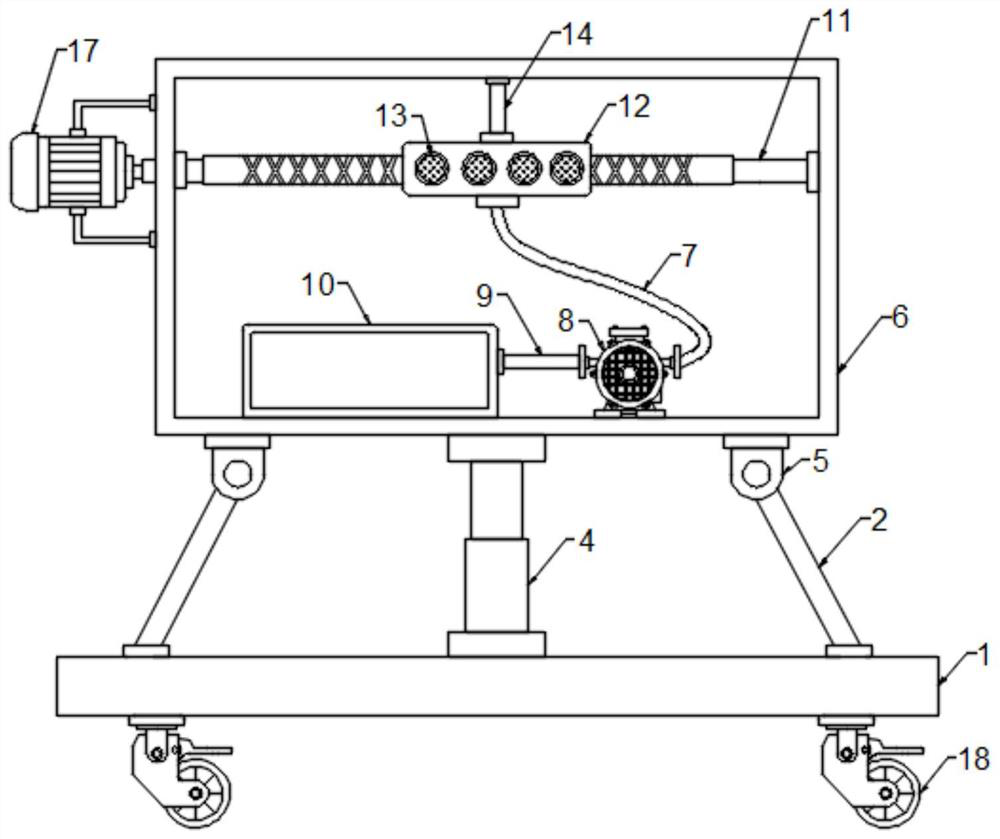

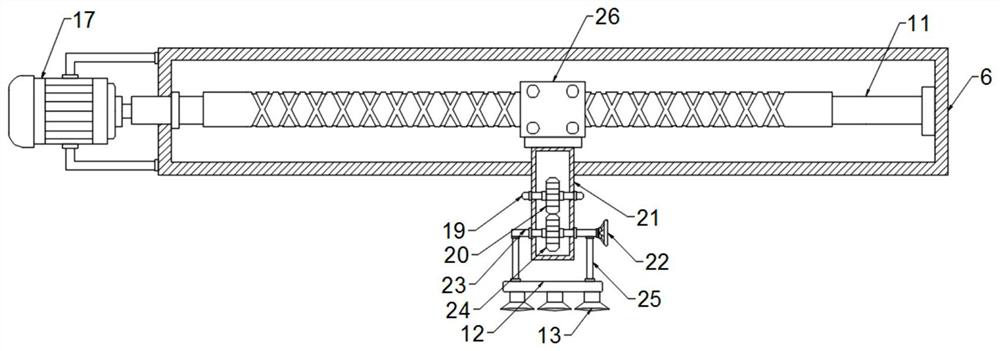

Garden greening seedling watering device

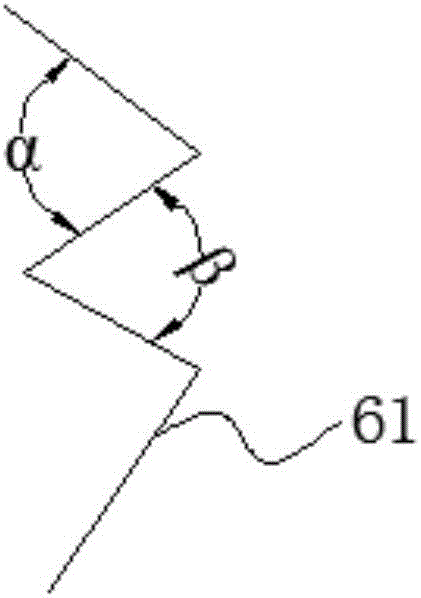

ActiveCN111248062AIncreased spray coverageEven spray irrigation effectClimate change adaptationWatering devicesBiologySeedling

The invention discloses a garden greening seedling watering device. The garden greening seedling watering device comprises a walking unit, a water tank is installed on the walking unit, a water sprinkler seat is installed on one side of the water tank, and a water sprinkler is installed at the top of the water sprinkler seat through support of a plurality of vertical supports. A water supply pipeis further included, the water inlet end of the water supply pipe communicates with the water outlet end of the water tank, and the water outlet end of the water supply pipe communicates with the water inlet end of the water sprinkler. The structure of the garden greening seedling watering device is simple, as a tilt angle of a jet flow guider relative to the horizontal plane becomes periodicallyand continuously larger and smaller, so that the spray coverage of the water sprinkler in the same position is larger, and the sprinkler irrigation effect is better and more uniform; and at this time,some of water jet flow obliquely jetted from the jet flow guider hits on each water cut strip by the sweep of the water cut strips, so that part of water does not shot to the distance smoothly, but sprinkles to areas near the water sprinkler due to the intercept of the water cut strips, and then the drawback that vicinity cannot be irrigated is overcome.

Owner:深圳市方格生态环境有限公司

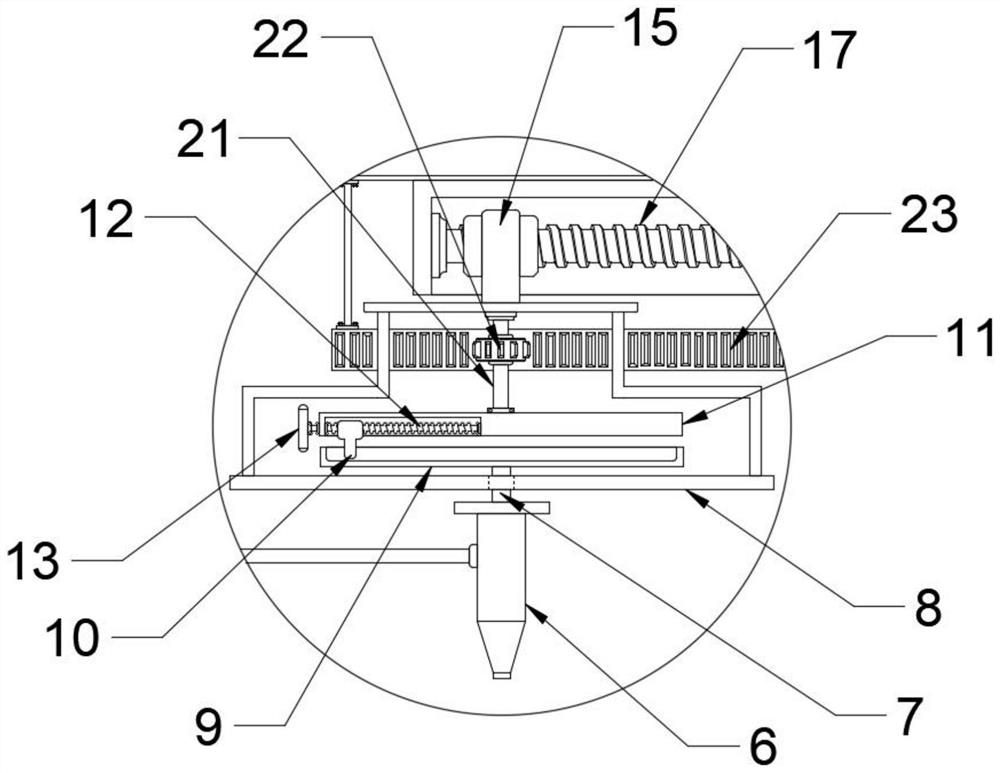

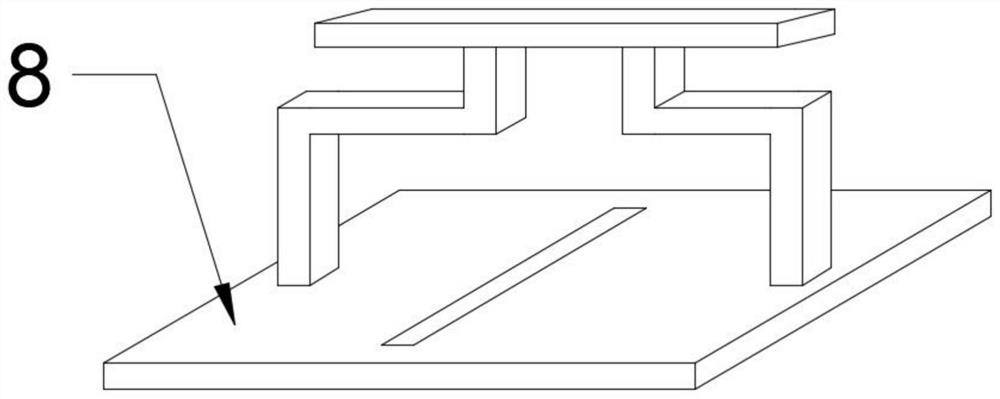

Anti-corrosion treatment device for ventilation fan blade machining

ActiveCN113275304AReduce uncertaintyThe feeding process is stable and effectiveCompression machinesDrying gas arrangementsWater flowEngineering

The invention discloses an anti-corrosion treatment device for ventilation fan blade machining. The anti-corrosion treatment device for ventilation fan blade machining comprises a water tank, wherein a treatment box is fixed to the upper end of the water tank, a building table is fixed to the lower portion of the inner side of the treatment box, a driving mechanism is arranged at the upper end of the building table, and a charging port and a discharging port are formed in the circumferential outer wall of the treatment box in a penetrating mode; and a paint box is fixed to the upper portion of the inner side of the treatment box, a backflow groove is formed in the upper wall of the paint box in a penetrating mode, and a collecting groove communicating with the backflow groove is formed in the inner wall of the treatment box in a penetrating mode. The anti-corrosion treatment device for ventilation fan blade machining has the following advantages: uncertainty caused by manual loading is reduced due to automatic loading and unloading, so that that a stable and effective loading process is ensured, the overall efficiency is effectively increased through circular machining, blades are washed by water flow to be cleaned, dust and stains cannot be carried to enter the subsequent steps, and therefore the overall spraying anti-corrosion treatment quality is improved; and drying treatment can be carried out on the blades sprayed with the paint through circular flowing of the hot air flow, so that subsequent transfer and storage are facilitated.

Owner:南通清风通用机械有限公司

Surface active organosilicone compounds

InactiveUS7872053B2High retention rateEasy to spreadGroup 4/14 element organic compoundsCosmetic preparationsSurface-active agentsMedicinal chemistry

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

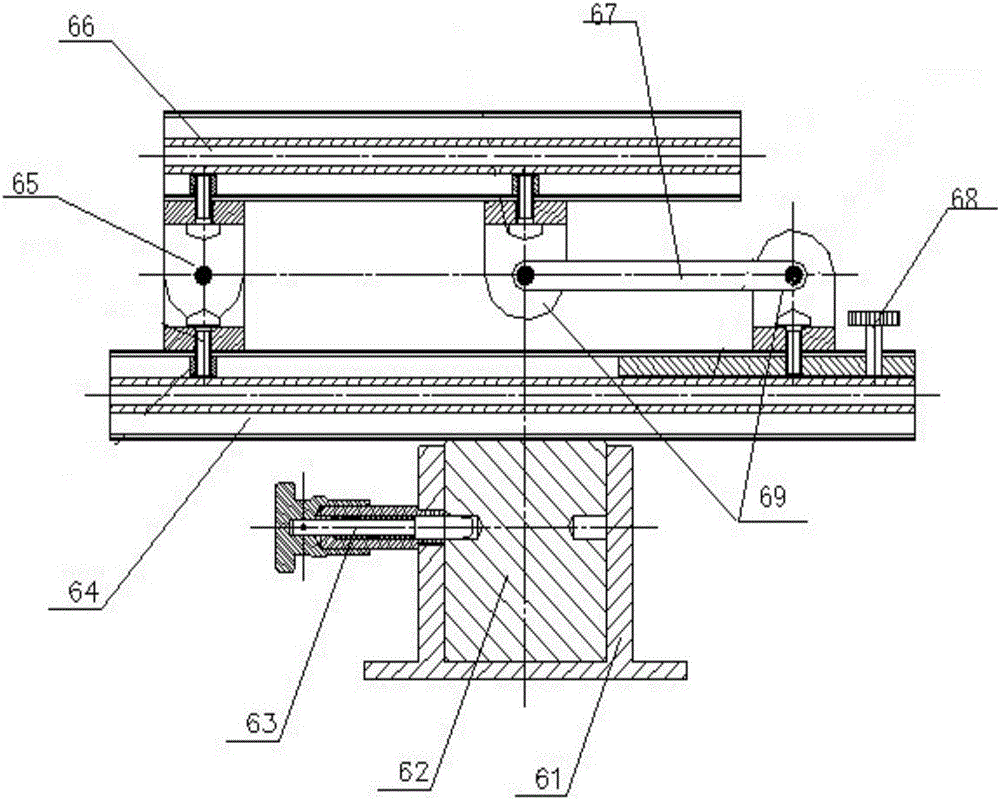

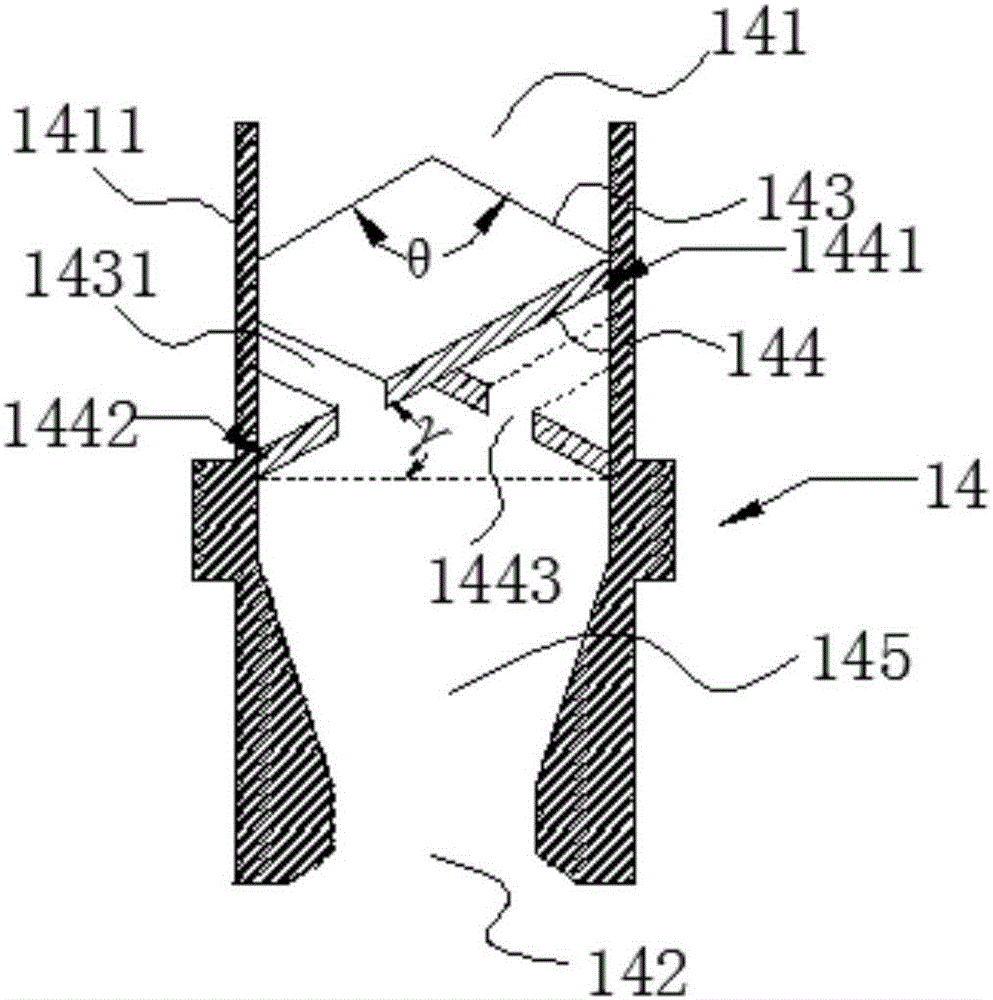

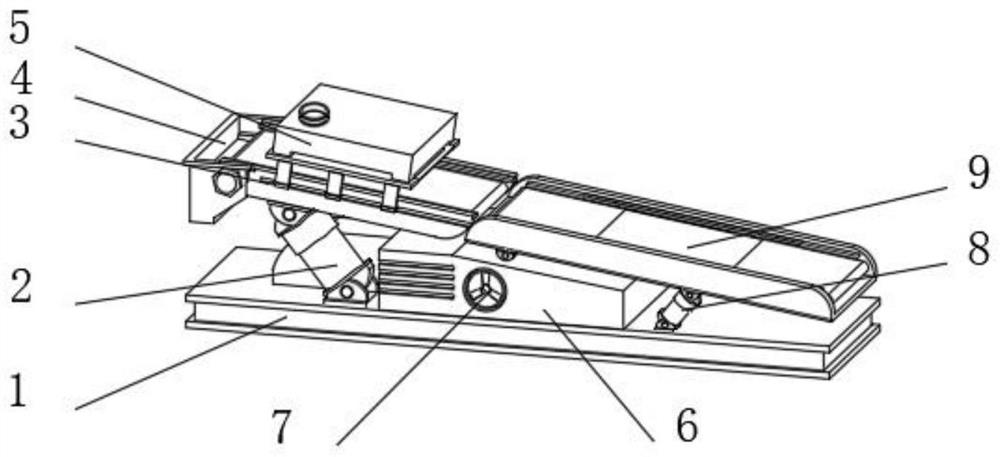

Hand-pushed air-assisted sprayer

InactiveCN104996387AIncreased spray coverageReduce pollutionInsect catchers and killersDiaphragm pumpLow voltage

The invention relates to the technical field of agricultural machinery, and in particular to a hand-pushed air-assisted sprayer. The hand-pushed air-assisted sprayer includes a frame, wheels, a medical kit, an adjustment rack, an axial flow fan and a nozzle assembly; the frame is formed by bending a metal pipe, and the portions which extend to the front constitute hand-pushed rods; a low-voltage electric diaphragm pump powered by batteries is arranged on the frame and acts as a liquid transport pressure source of the nozzle assembly; the adjustment rack includes a horizontal rotation adjustment rack in the lower part or upper part thereof and a vertical rotation adjustment rack in the upper part or lower part thereof; the working direction of the axial flow fan in the horizontal direction can be adjusted by adjusting the horizontal rotation adjustment rack; the working angle of the axial flow fan in the vertical direction can be adjusted by adjusting the vertical rotation adjustment rack, so that the spraying coverage of the nozzle assembly can be expanded and the sprayer is very applicable to spraying pesticides to tea plantations. The batteries are used to replace a traditional diesel engine and serve as the power source, so that the hand-pushed air-assisted sprayer saves energy and is environmentally friendly.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

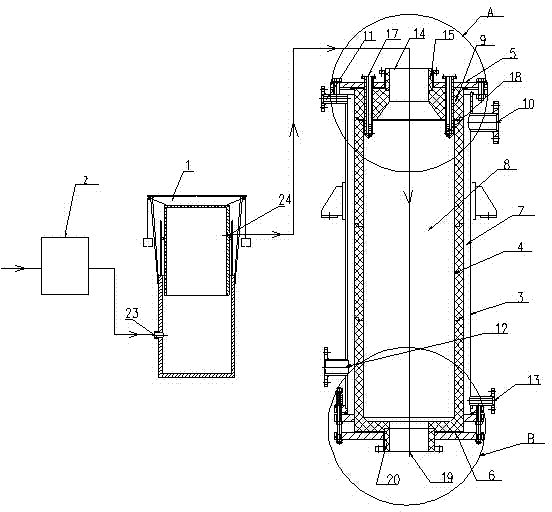

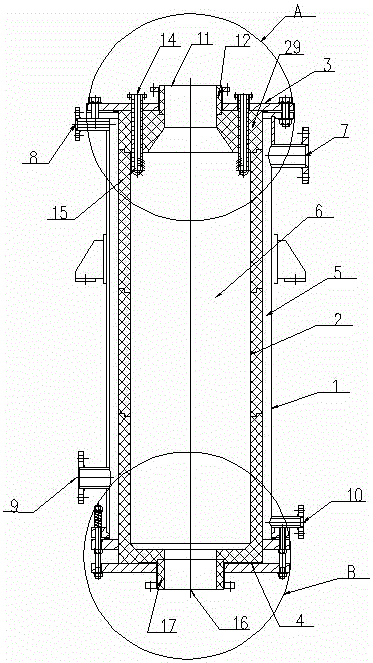

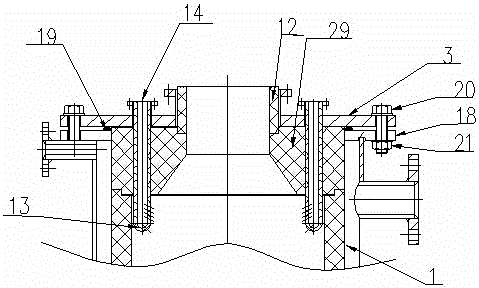

Incineration waste gas quenching treatment system

ActiveCN104329674AEasy to handleSolve pollutionDispersed particle separationIncinerator apparatusGraphiteTower

The invention relates to an incineration waste gas quenching treatment system, which comprises a waste gas buffer device, a quenching tower and an induced draft fan, wherein the induced draft fan, the waste gas buffer device and the quenching tower are sequentially and serially connected by a connecting pipe, the quenching tower comprises an outer steel sleeve and an inner graphite sleeve, an upper spraying cover plate and a lower cover plate respectively covers the upper end and lower end of the outer steel sleeve, the inner graphite sleeve is in a tube shape, and is coaxially arranged in the outer steel sleeve, a cooling water containing cavity for containing cooling water to flow is formed between the inner graphite sleeve and the inner wall of the outer steel sleeve, the inner wall of the inner graphite sleeve is a spraying inner cavity for spraying the waste gas, the upper end of the inner graphite sleeve is communicated with the upper spraying cover plate through an upper sealing head, and the lower end of the inner graphite sleeve is directly communicated with the lower cover plate. The incineration waste gas quenching treatment system has the advantages that the structure is simple, the incineration waste gas is slowly provided for the quenching tower to be treated at uniform speed through the waste gas buffer device, then the waste gas is subject to quenching treatment by the quenching tower, the waste gas produced by incineration at high temperature is effectively treated, and the problems of pollution to environments, energy saving and environment protection are solved.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

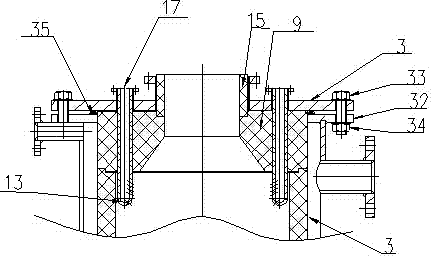

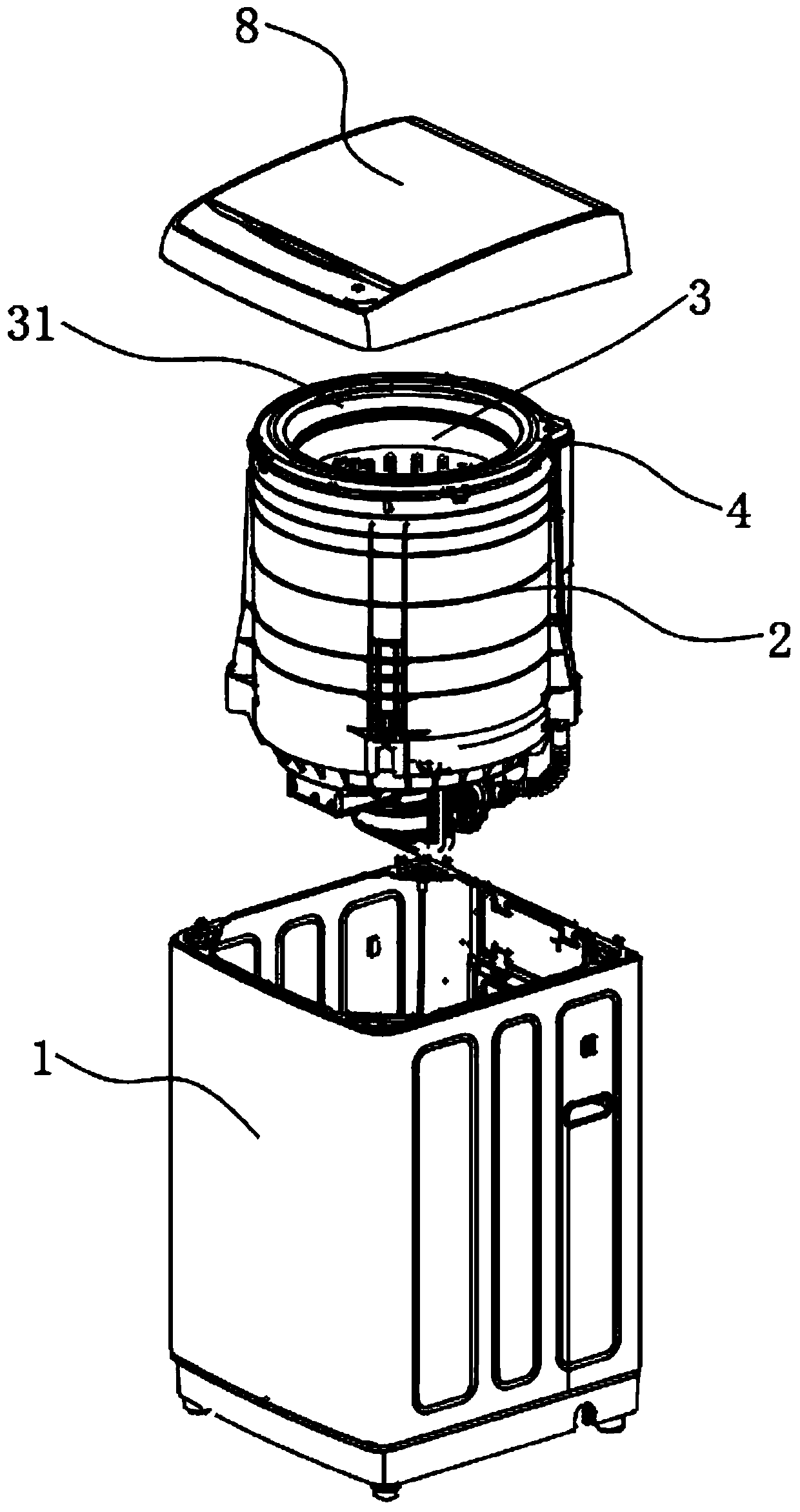

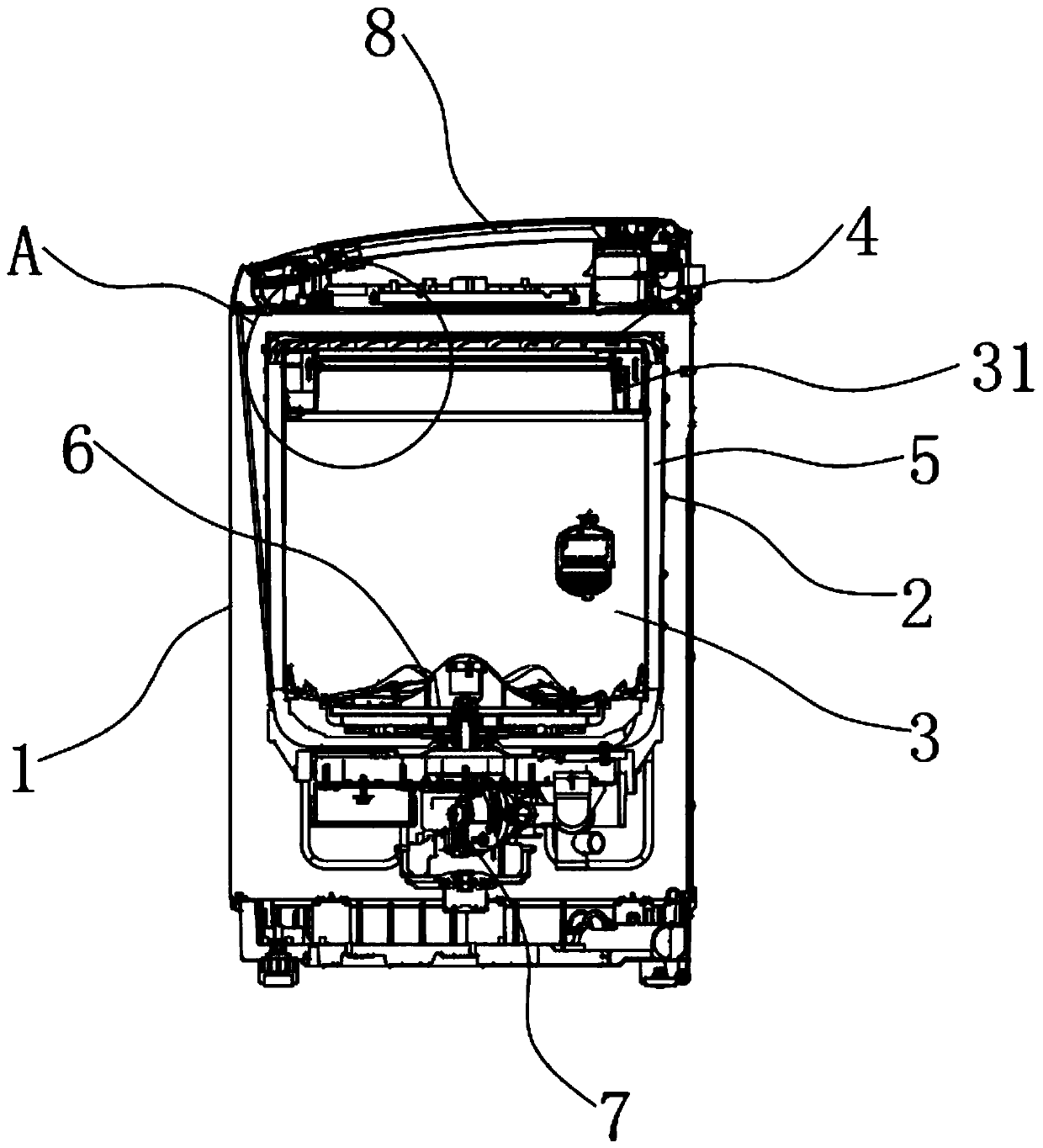

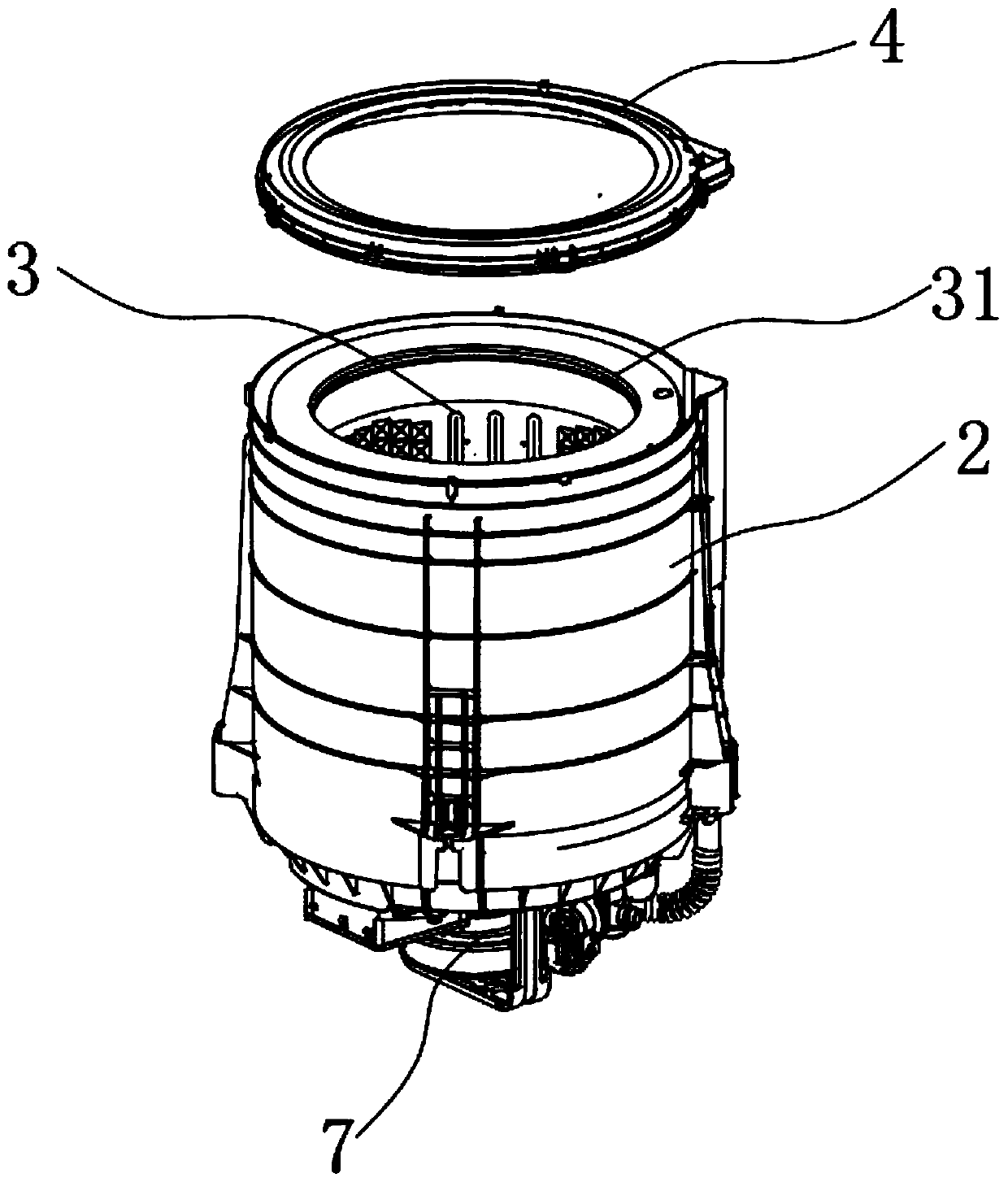

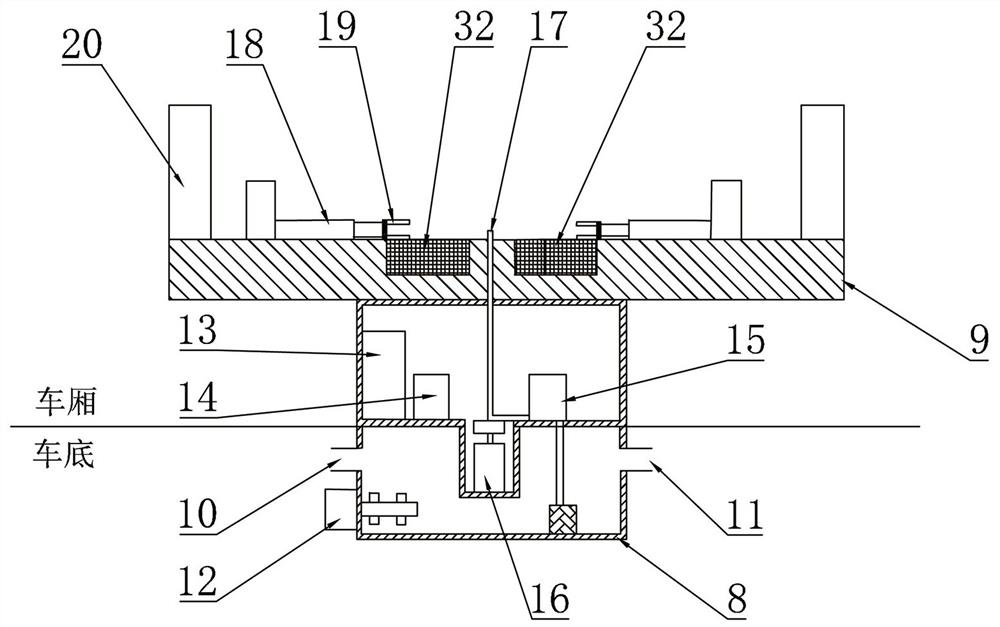

Washing machine

ActiveCN111334993AIncrease the areaWell mixedOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention provides a washing machine. The washing machine comprises a machine body, an outer cylinder, an inner cylinder and a cylinder cover, wherein the outer cylinder is arranged in the machinebody in a connected mode; the inner cylinder is arranged in the outer cylinder in a connected mode, a stream-guiding clearance is arranged between the inner cylinder and the outer cylinder, and the stream-guiding clearance communicates with the inner cylinder; the cylinder cover is arranged on the upper portion of the inner cylinder and the upper portion of the outer cylinder in a covering mode,and multiple stream-guiding ribs are uniformly distributed on the circumferential inner wall of the cylinder cover; when the inner cylinder rotates to drive water in the inner cylinder to generate centrifugal force and climb upwards in the stream-guiding clearance, the stream-guiding ribs guide the water to form first water streams which flow into the inner cylinder; and stop ribs for throttling are arranged at intervals among the stream-guiding ribs, and the stop ribs form occlusion among parts of the stream-guiding ribs to form second water streams which flow into the inner cylinder. According to the washing machine, the sprayed water streams cover the whole inner cylinder through layered spraying, the spraying coverage area is large, spraying and wetting effects are good, detergent andthe water are mixed more uniformly and sufficiently, the washing effect is better, and clothes are not prone to entanglement.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

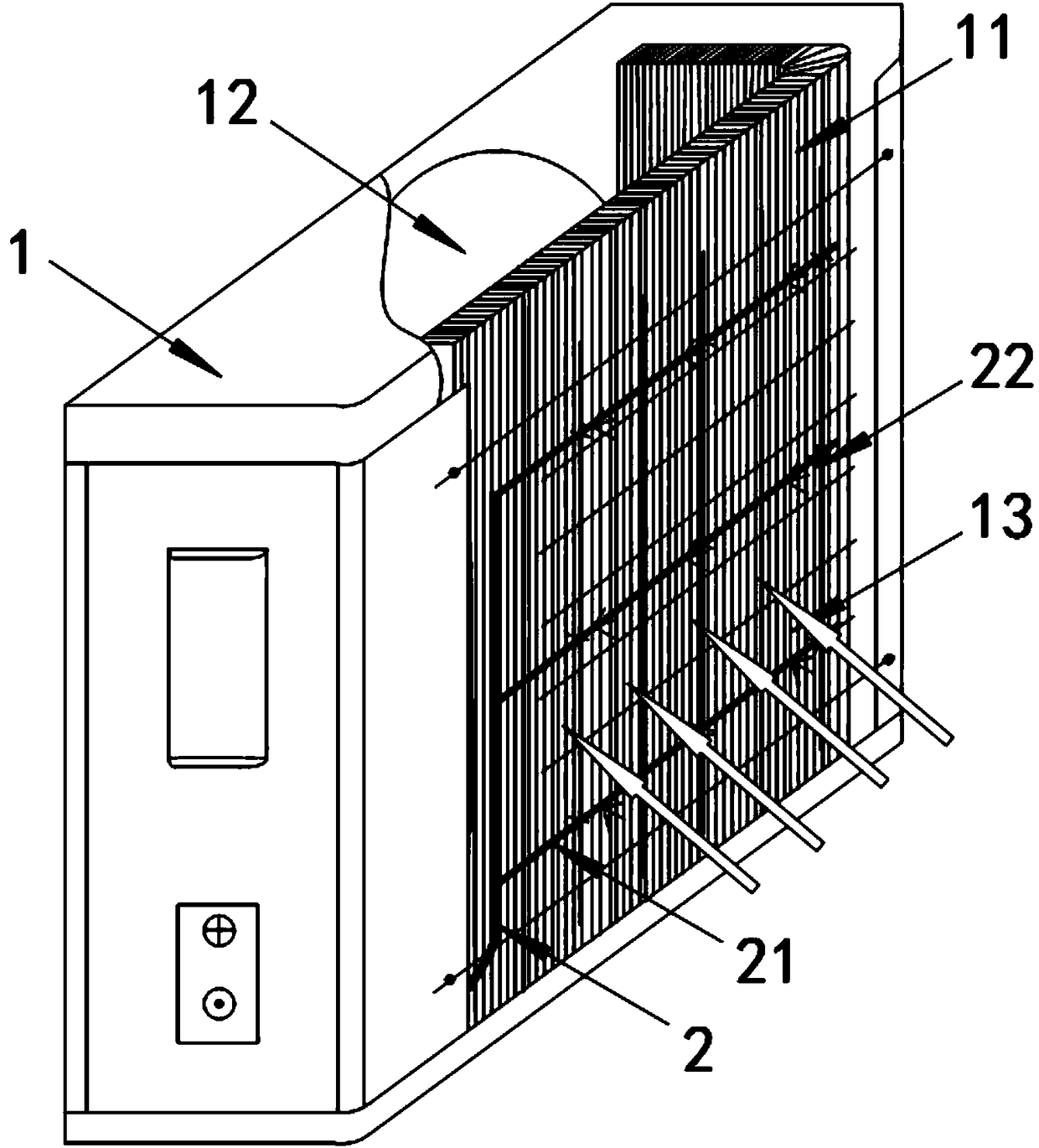

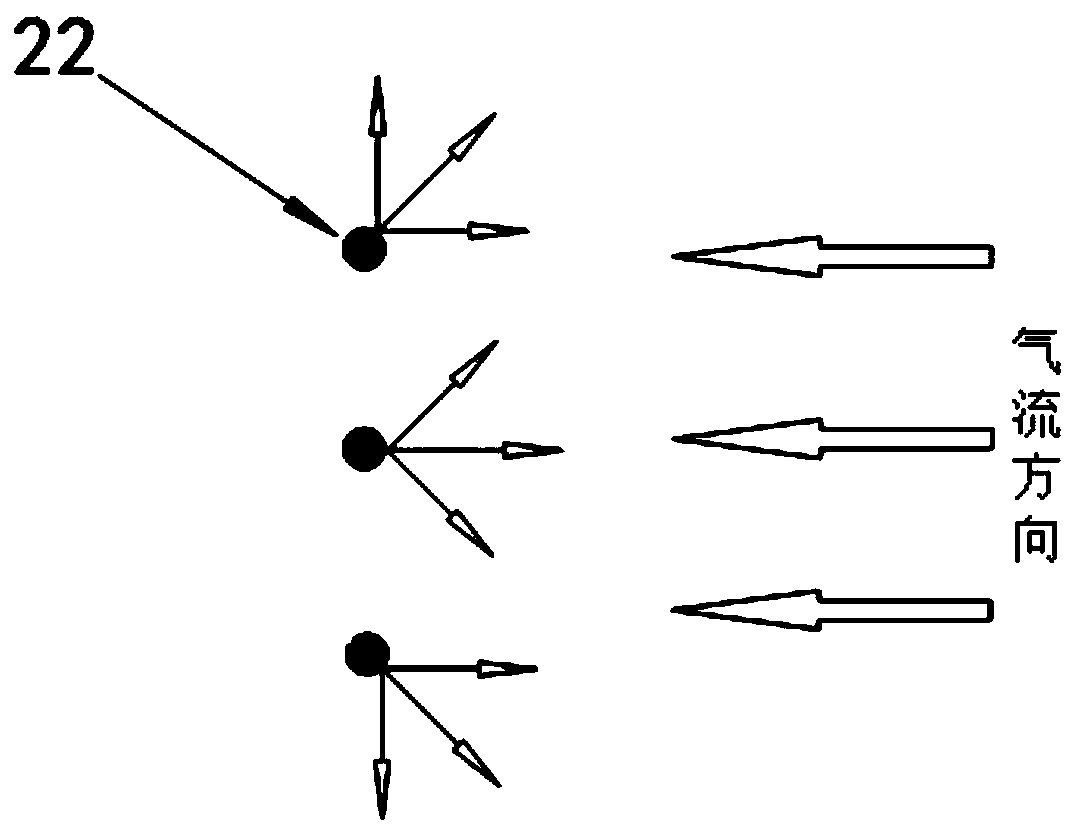

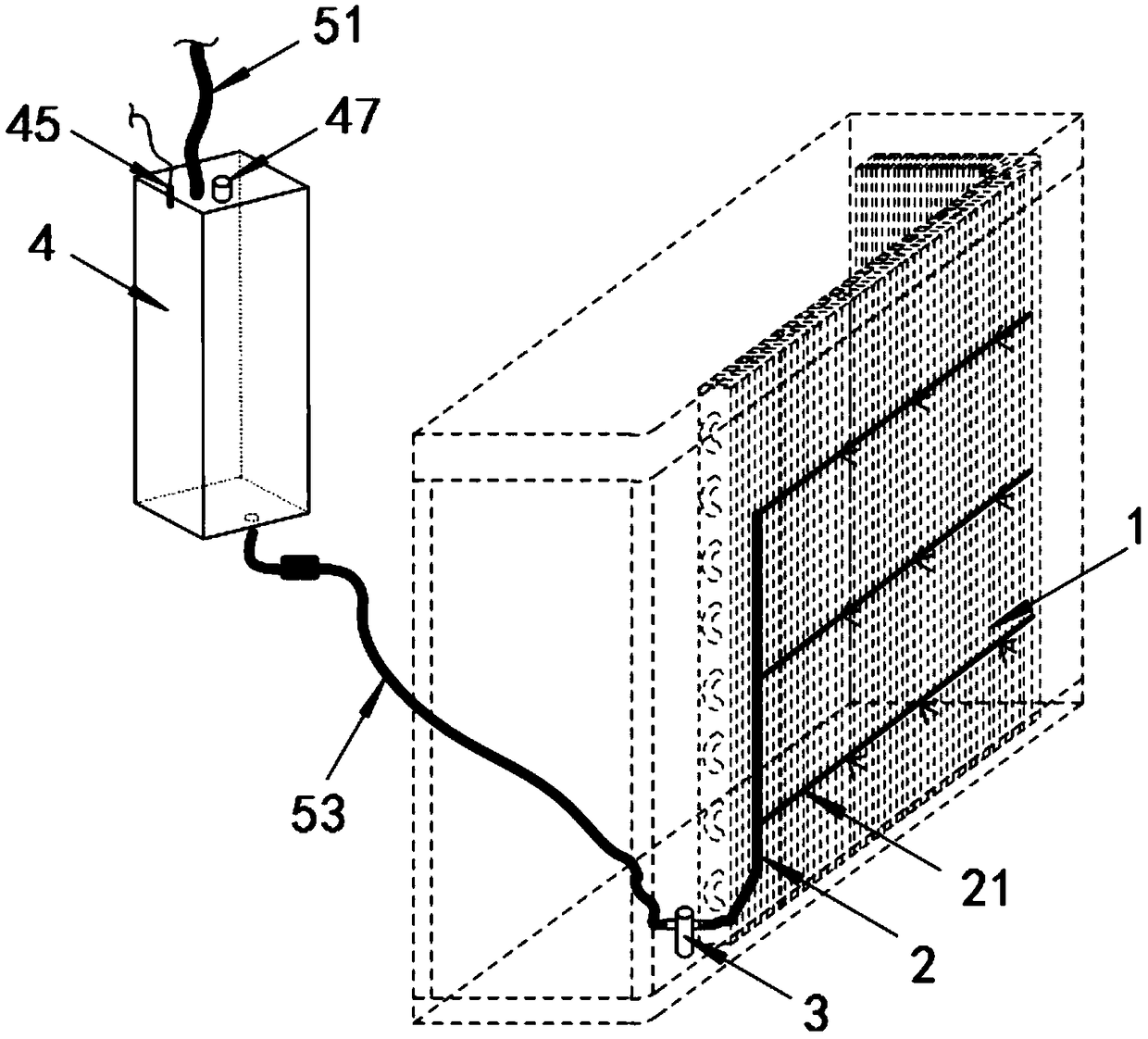

Air conditioner

InactiveCN108194995AIncreased spray coverageImprove cooling efficiencyLighting and heating apparatusAir conditioning systemsElectrical and Electronics engineeringHeat exchanger

The invention discloses an air conditioner and belongs to the technical field of the air conditioner. A spraying device is arranged at an air inlet of an outdoor unit of the air conditioner; and the spraying device comprises spraying holes which are back on to the air inlet. According to the air conditioner disclosed by the invention, the spraying direction of the spraying device is set to be backon to the air inlet of the outdoor unit; sprayed water is conically dispersed, and the spray coverage area is gradually enlarged; meanwhile, the sprayed water is re-sucked into the outdoor unit by negative pressure generated by rotation of an outdoor fan so that the sprayed water can cover a relatively large surface area of an outdoor heat exchanger, the spray coverage area, on the outdoor heat exchanger, of the spraying device is increased, and the heat radiation efficiency of the outdoor heat exchanger is effectively improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Hospital corridor positioning track hidden disinfection machine

InactiveCN112220952ALarge coverage areaReduce work intensityLavatory sanitoryChemicalsElectric machineryProcess engineering

The invention relates to a disinfection machine, in particular to a hospital corridor positioning track hidden disinfection machine. The aim of the invention is to provide the hospital corridor positioning track hidden disinfection machine. According to the hospital corridor positioning track hidden disinfection machine, the water storage capacity is large, workers do not need to bear loads, the spraying area is large, operation is easy, advancing and automatic returning can be conducted according to a designated route, and automatic storage can be achieved. According to the technical scheme,the hospital corridor positioning track hidden disinfection machine comprises a rack sliding groove, a disinfection rack, a motor supporting plate, a power motor and the like, wherein the rack slidinggroove is fixed to a wall body; the rear side of the disinfection rack slides on the rack sliding groove; the motor supporting plate is fixedly connected to the disinfection rack; and the power motoris fixedly connected to the motor supporting plate. According to the invention, the loads can be mechanically borne, the spraying coverage area is large, and a sprayer does not need to be manually carried on the back for disinfection, so that the working intensity of the workers is relieved, and the working efficiency is improved.

Owner:赵荣菊

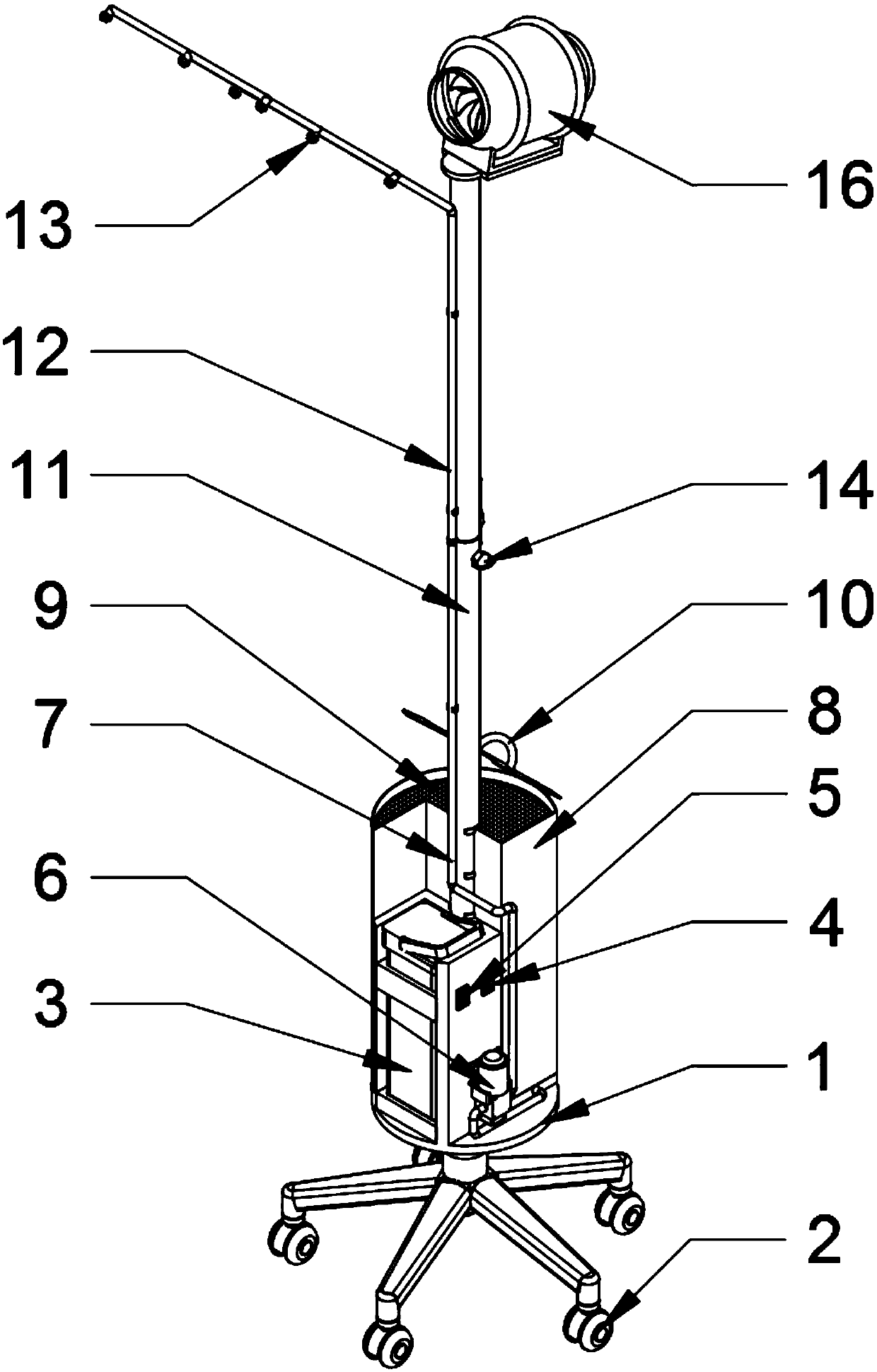

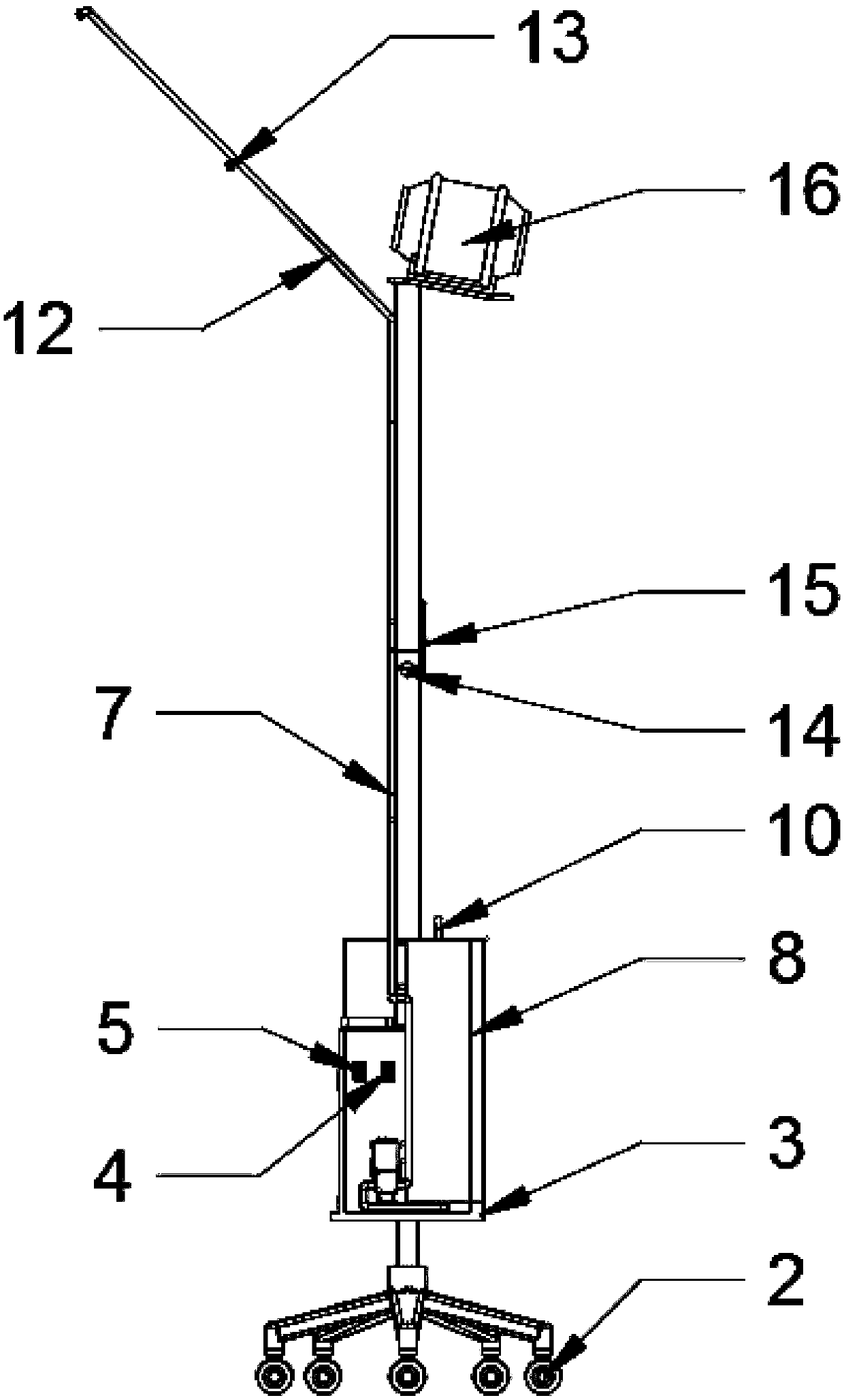

Atomizing, humidifying and dust suppression equipment for environmental engineering site construction

ActiveCN109594772AAvoid affecting the surrounding air qualityIncreased spray coverageRoad cleaningBuilding material handlingWater flowEngineering

The invention provides atomizing, humidifying and dust suppression equipment for environmental engineering site construction. The atomizing, humidifying and dust suppression equipment for environmental engineering site construction comprises a power supply connecting head and a fan; a lithium battery is mounted at the bottom of a pedestal; a power supply plug is arranged at the bottom of the lithium battery; the power supply plug is connected with a water pump control switch and a fan control switch separately through a power supply main jack; the water pump control switch is mounted on the outer end surface of the pedestal; the water pump control switch is electrically connected with a small high-pressure pump through a power line; the fan control switch is mounted on the outer end surface of the pedestal; the small high-pressure pump is fixed on the outer end surface of the pedestal; the small high-pressure pump is communicated with a water supply pipeline; water flow stored in the equipment is atomized, the atomized water drops are sprayed in a construction area at the front end of the equipment slantways, soil in the construction area is humidified, and the influence on the ambient air quality by raise dust generated by the fact that the soil in the dry state is influenced by the external air flow is avoided.

Owner:温州高伟通工业设计有限公司

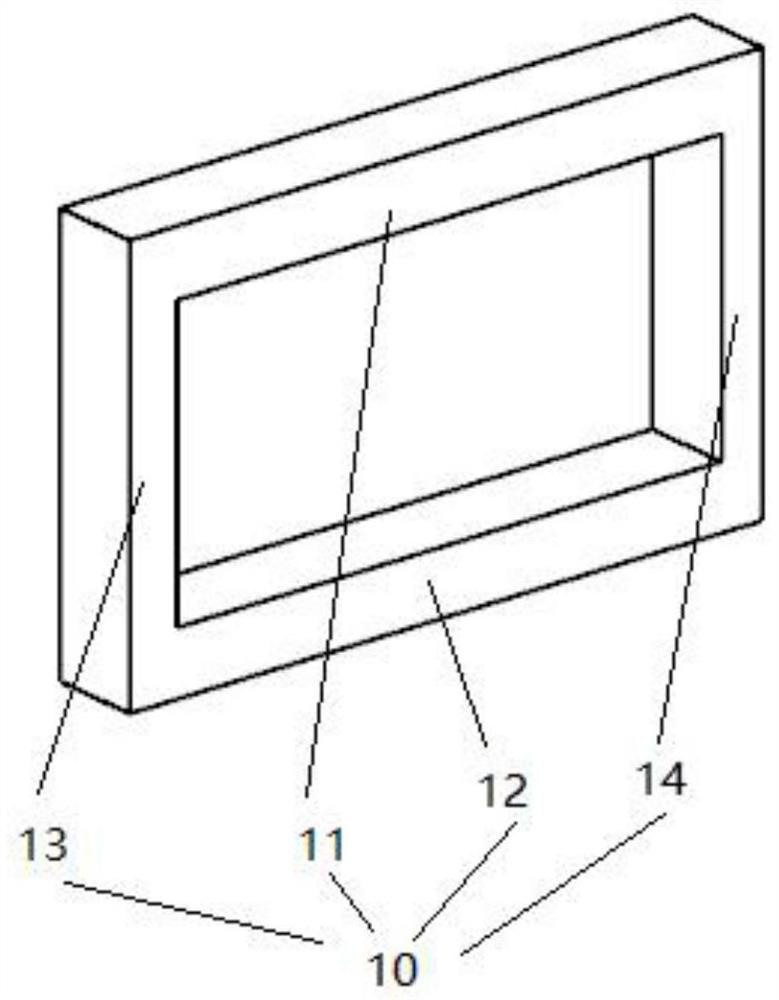

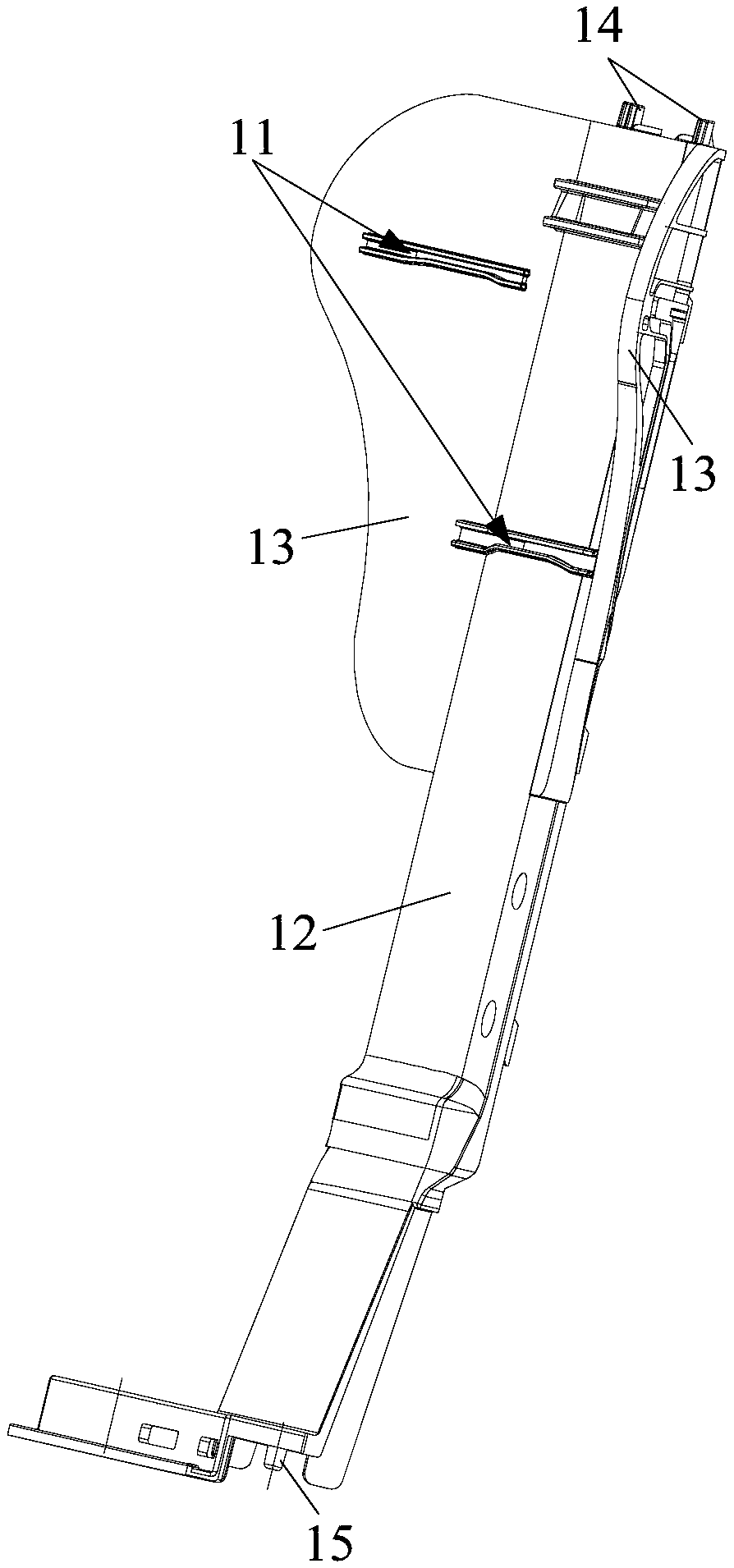

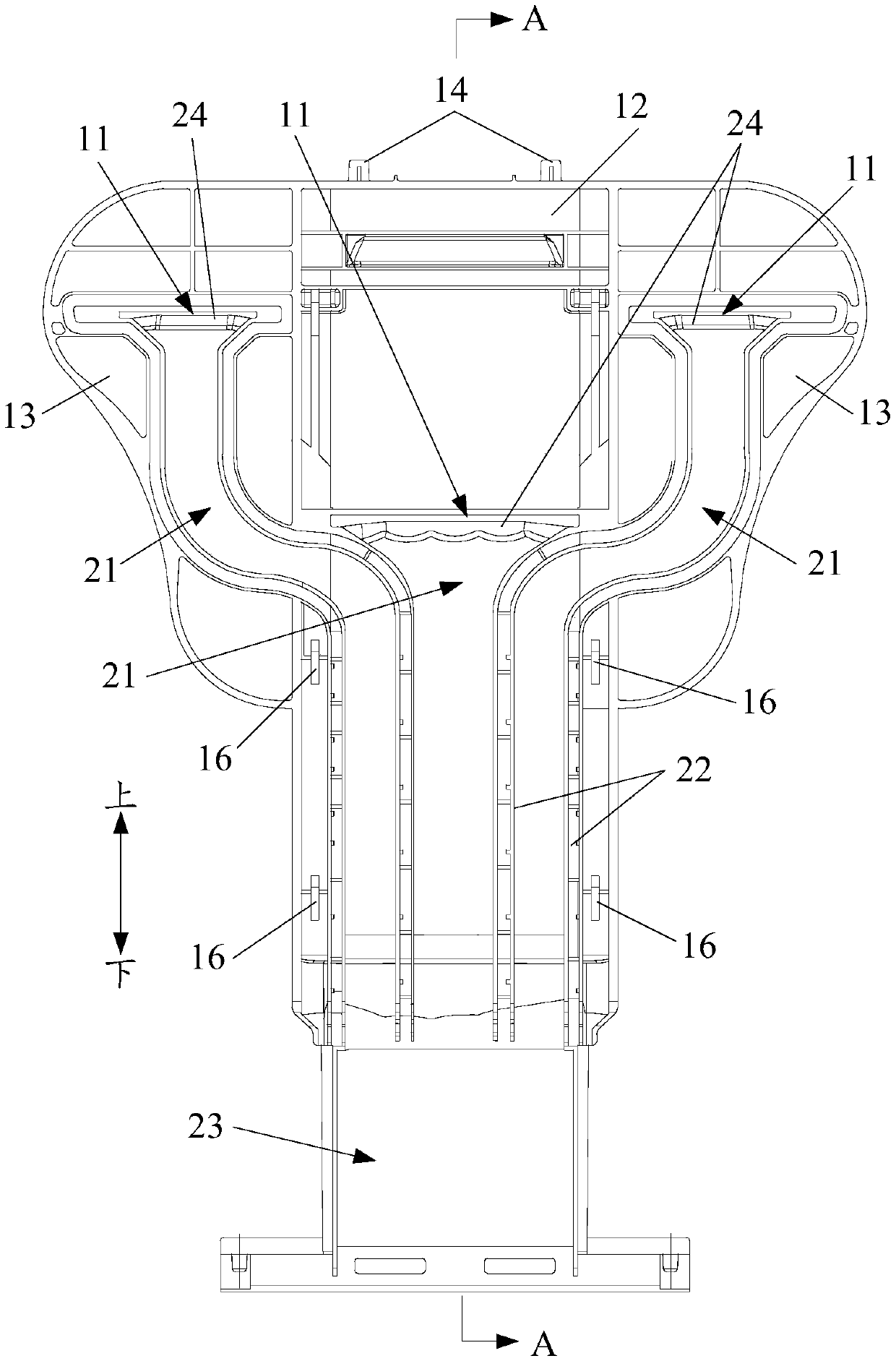

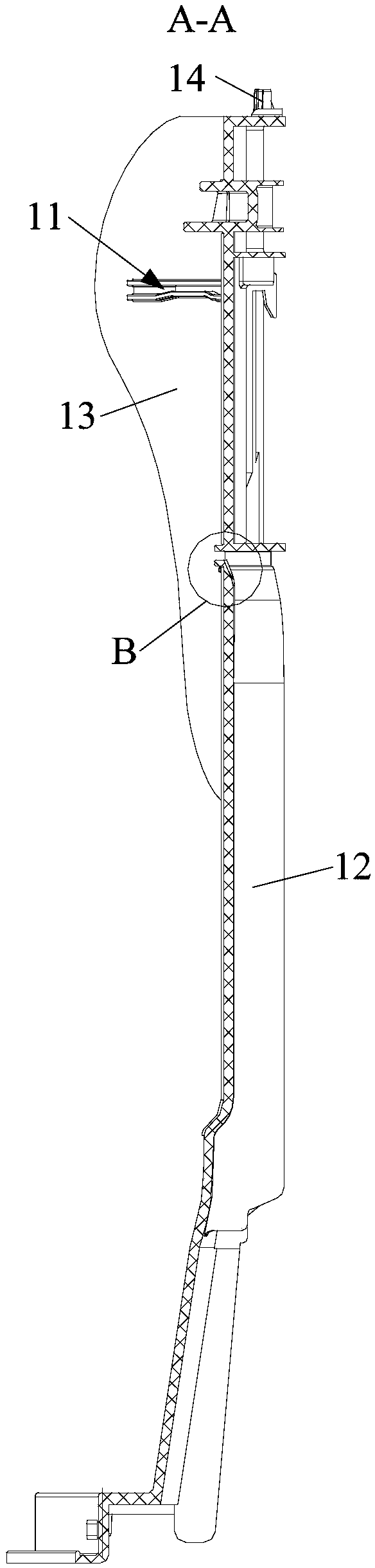

Spray cleaning device

InactiveCN109662669ARealize spin cleaningIncreased spray coverageTableware washing/rinsing machine detailsKitchen equipmentEngineeringMechanical engineering

The invention discloses a spray cleaning device. The device includes a door body, a water tank and a connection pipe are formed / arranged on the door body, the water tank is communicated with the connection pipe, the portion, corresponding to the water tank, of the door body is provided with a support connection disc covering the water tank, a spray element with a hollow structure is arranged on the support connection disc, and the spray element is provided with several spraying holes communicated with the inside of the spray element; the support connection disc is internally provided with a hollow channel communicated with the water tank, and the side, away from the spraying holes, of the spray element extends to the inside of the hollow channel to be communicated with the water tank. Thespray cleaning device achieves the purpose of synchronous cleaning from the upper portion of a washed object on the basis of bottom washing of a traditional washing machine, the coverage area of cleaning is large, the cleaning effect is greatly improved, the cleaning efficiency is effectively improved, and the cleaning needs of multi-layer objects for washing can be met.

Owner:潍坊三亨工贸有限公司

Construction site raise dust treatment device based on environmental protection

PendingCN111957137AProtection against rise and spreadGuaranteed uptimeGeneral water supply conservationUsing liquid separation agentEnvironmental resource managementFunnel shape

The invention discloses a construction site raise dust treatment device based on environmental protection, and belongs to the technical field of environmental protection. The construction site raise dust treatment device based on environmental protection comprises an equipment tank, wherein the equipment tank is a cylindrical tank with a hollow top; a supporting plate is fixedly mounted at the bottom of the equipment tank; the supporting plate is in a circular block shape, a splash-proof plate is fixedly mounted in the center of the bottom wall surface of the supporting plate; the splash-proofplate is in a funnel-shaped plate shape; in the present invention, the invention discloses the construction site raise dust treatment device based on environmental protection. Therefore, a connectingcolumn and a rubber block are driven to descend; therefore, gap seepage grooves are opened; and meanwhile, dust is pressed into the bottom area of the rubber block under the pressure generated by descending of the rubber block and the auxiliary force of rotation of a fan wheel, and when the rubber block is pressed downwards, two closing plates are forced to be opened through the downward pressingpressure of the rubber block, so that the dust is conveyed to the bottom areas of the closing plates, and the effect of treating and collecting the dust is achieved.

Owner:程明兵

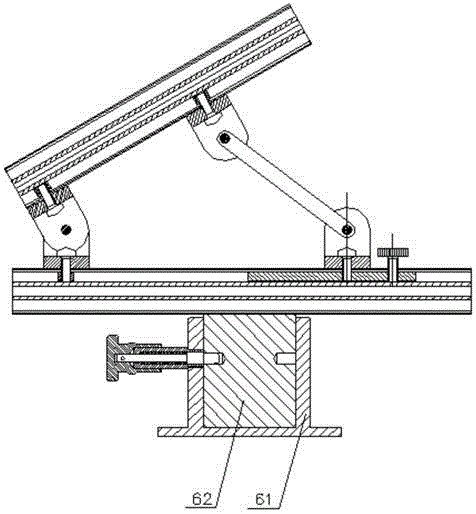

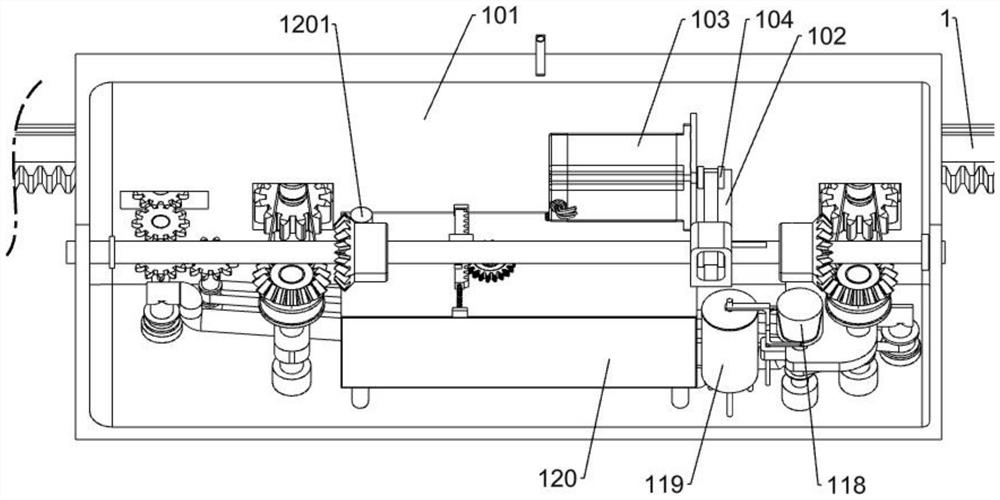

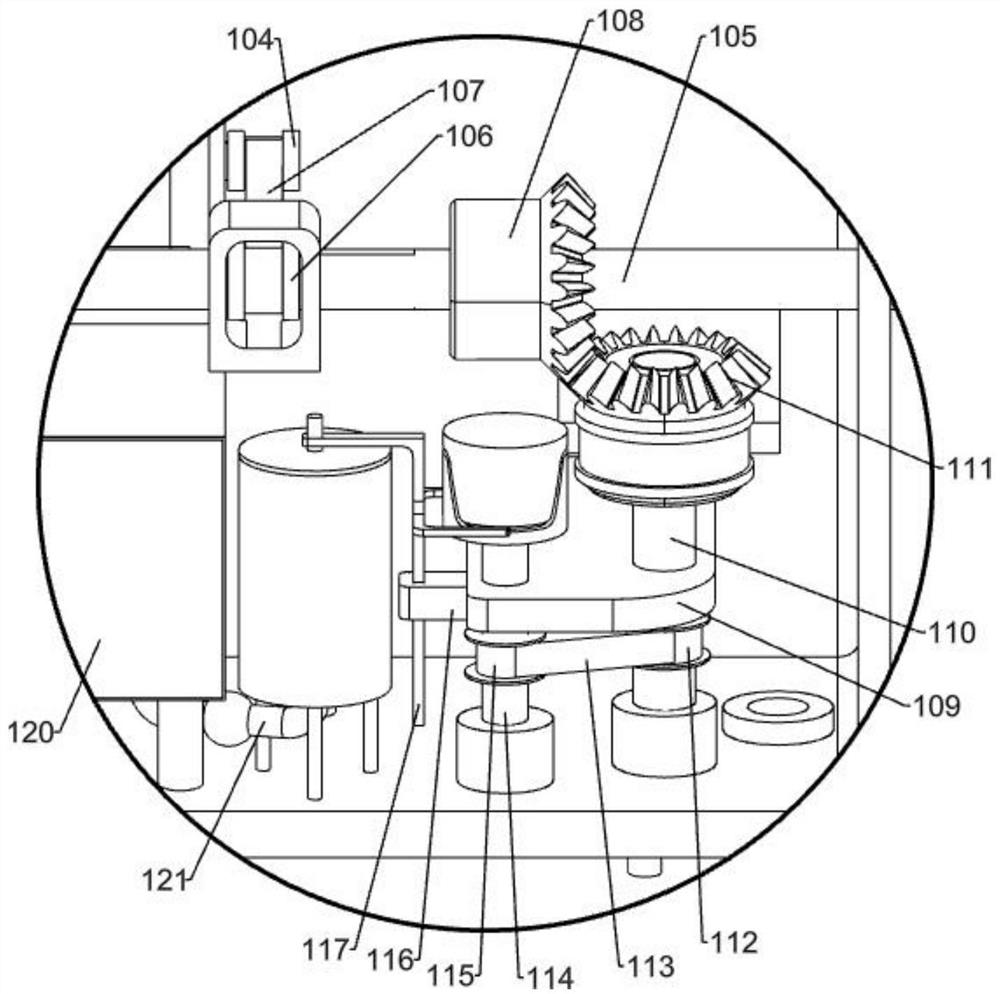

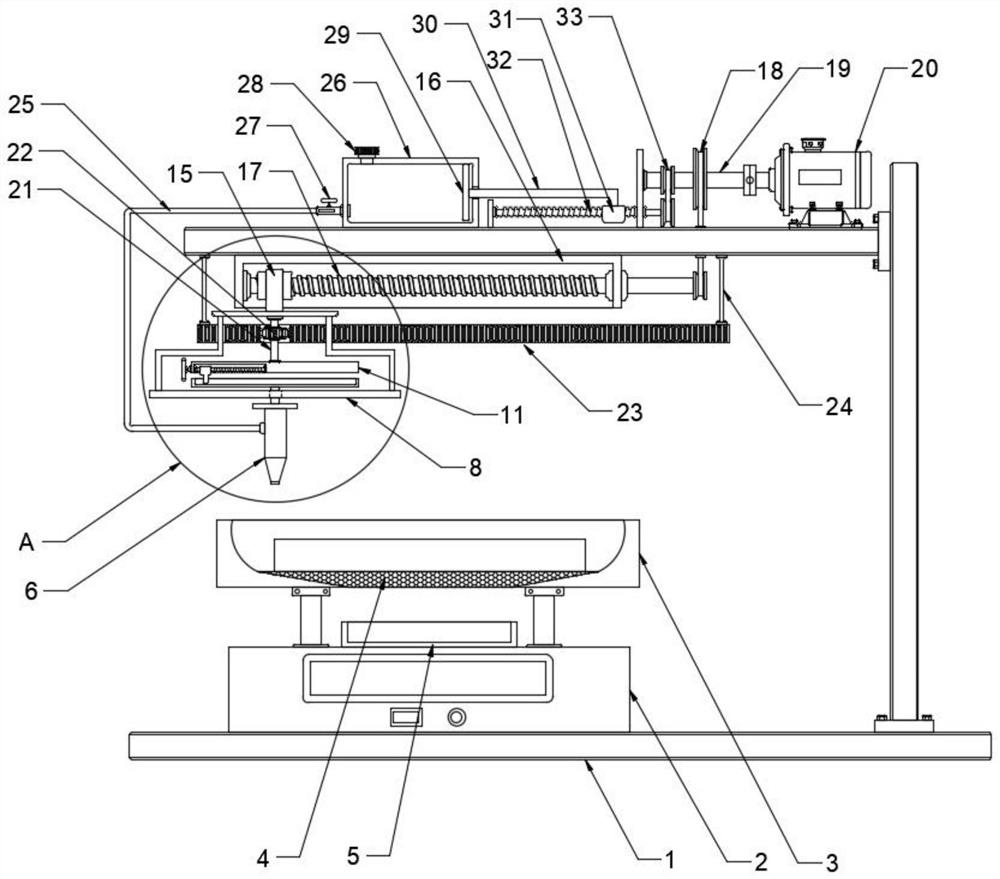

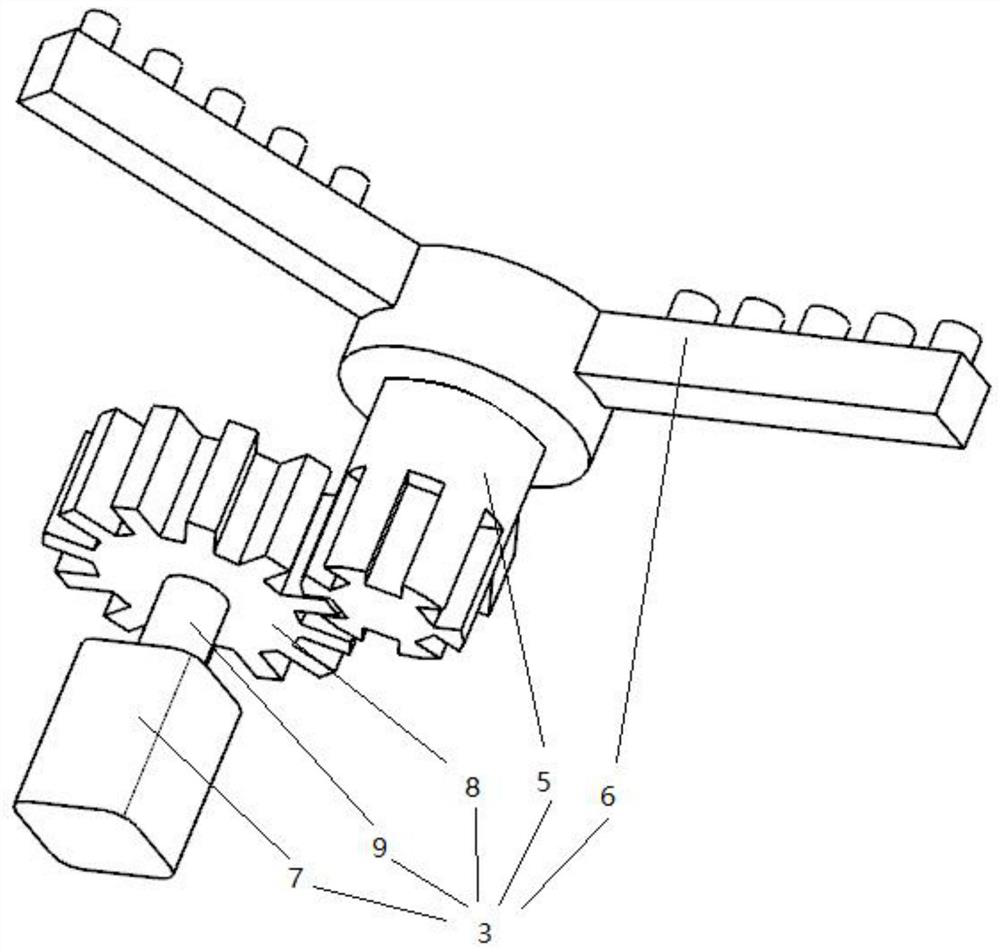

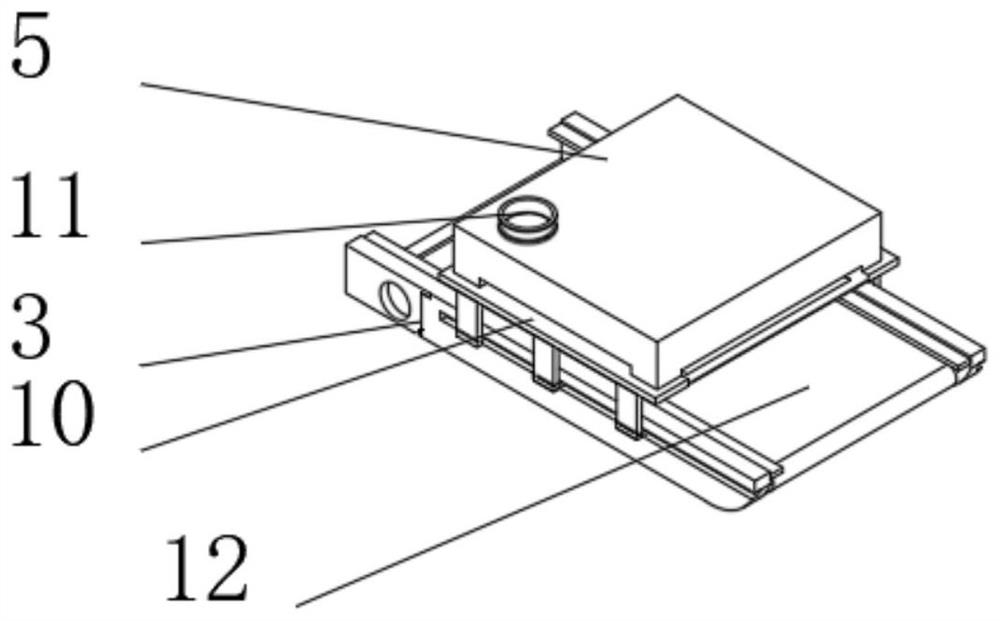

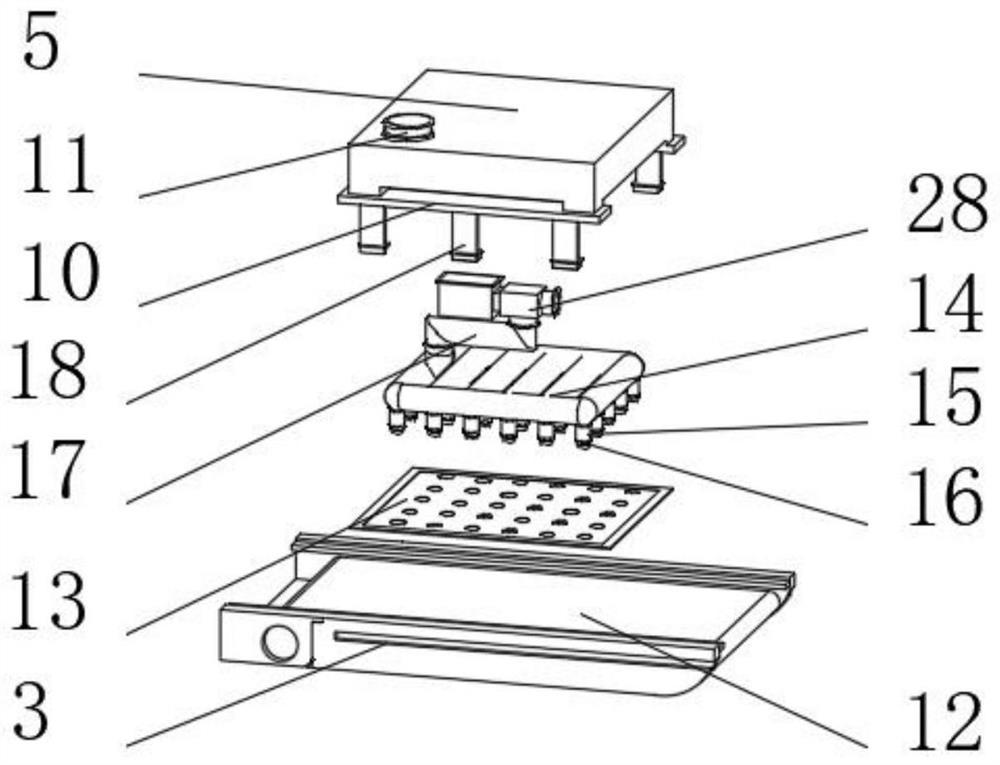

Spraying extrusion structure and water absorption capacity detection equipment for makeup cotton production

PendingCN112666035AIncreased spray coverageEasy to adjustWeighing by absorbing componentCotton padGear wheel

The invention relates to the field of makeup cotton water absorption capacity detection equipment, in particular to a spraying extrusion structure and water absorption capacity detection equipment for makeup cotton production. The spraying extrusion structure comprises a spraying pipe used for uniform spraying, the spraying pipe communicates with an extrusion water supply mechanism, and the spraying pipe is connected with a driving mechanism for driving the spraying pipe to transversely move. By arranging the spraying pipe, the moving frame, the injection pipe, the first moving block, the second lead screw and the extrusion water supply mechanism comprising the injection cylinder, transverse moving spraying of the spray pipe is achieved; by arranging a walking gear, a rotating shaft, an eccentric disc, a traction column, a groove plate, a longitudinal sliding block and a rack plate, the spraying coverage range of the spraying pipe is enlarged, and meanwhile by arranging an adjusting assembly comprising a first lead screw and an adjusting wheel, the spraying pipe coverage range can be adjusted conveniently; and through the electronic weighing platform, the weighing disc, the water seepage plate and the water receiving disc, the water absorption capacity and the water retention capacity of the makeup cotton can be conveniently detected.

Owner:湖南仁瑞无纺制品有限公司

a cooling tower

The invention relates to a quenching tower, comprising an outer steel sleeve and an inner graphite sleeve, the upper and lower ends of the outer steel sleeve are respectively covered with an upper spray cover plate and a lower cover plate; The shaft is installed in the outer steel sleeve, and forms a cooling water cavity with the inner wall of the outer steel sleeve, which can accommodate the circulation of cooling water. The inner wall is a spray inner cavity for gas spraying. The spray cover plate is connected, and its lower end is directly connected with the lower cover plate; the upper part of the outer steel sleeve has a cooling water outlet and a drain port, the cooling water outlet and the drain port are staggered, and the drain port is located at the cooling above the water outlet; the lower part of the outer steel sleeve has a cooling water inlet and a clean discharge port, the cooling water inlet and the clean discharge port are staggered, and the clean discharge port is located below the cooling water inlet. The advantages of the present invention are: adopting the quenching tower, the structure is simple, the manufacture is convenient, and the tail gas produced after high-temperature incineration can be effectively quenched, so as to solve the problems of environmental pollution, energy saving and environmental protection.

Owner:NANTONG STAR GRAPHITE EQUIP CO LTD

PCBA cleaning device

InactiveCN112547637AIncreased spray coverageImprove cleaning efficiencyCleaning using liquidsMotor driveElectric machinery

The invention discloses a PCBA cleaning device. A clearing assembly is rotatably connected to a first frame body, and is positioned on the inner side wall of the first frame body; an adapter head is rotatably connected to the first frame body, and is positioned on the inner side wall of the first frame body; a spray head is detachably connected to the adapter head, and is positioned on the outer surface wall of the adapter head; a plurality of spray heads are arranged on the spray head; a motor is detachably connected to the first frame body, and is positioned inside the first frame body; oneend of a rotary shaft is detachably connected to a gear, and is positioned on the side surface of the rotary shaft; cleanout liquid is sprayed out from the spray head through the spray rod, so that aPCBA board is cleaned without being manually cleaned; and the motor drives the gear to rotate, and the adapter head can rotate along the gear, so that the spray head rotates while spraying out the cleanout liquid, and thus, the spraying coverage area of the cleanout liquid is increased, multiple PCBA boards can be covered, and cleaning efficiency is improved.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

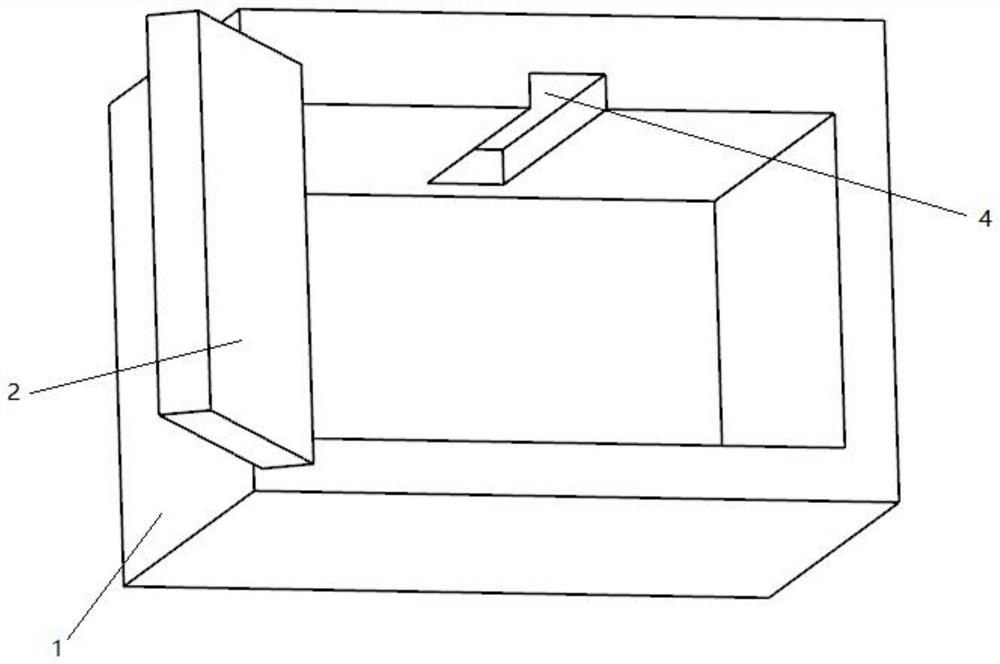

Spray-type flowerpot

ActiveCN105961060AEasy to useIncrease in sizeSelf-acting watering devicesClimate change adaptationEngineeringFlowerpot

The invention discloses spray-type flowerpot comprising a cuboid support plate and a liquid storage box in a hollow cuboid type; the liquid storage box can be detachably fixed on one side of the outer wall surface, facing outer side, of the support plate; the liquid storage box is filled with spray liquid; the longest edge of the liquid storage box is parallel to that of the support plate, and is 2-4 cm shorter than that of the support plate; the area of one side, facing outer side, of the liquid storage box and the area of the outer wall surface, facing outer side, of the support plate are arranged in the following ratio: 1-1.5:2; the spray-type flowerpot also comprises a solar energy water pump arranged in a power room; the solar energy water pump comprises a solar panel, a motor, a miniature water pump and a switch. The spray-type flowerpot uses solar energy power device to spray water, can flexibly control spraying quantity, can save laboring, and can reduce energy consumption.

Owner:林智生

A low-carbon and low-emission sintering method based on multi-type gas coupling injection

The invention discloses a low-carbon low-emission sintering method based on coupled injection of multiple gases. Based on the difference of heat storage capacities of parts at the heights of differentmaterial layers, areas from thermal insulation completion to a waste gas temperature rising point of a material surface of a sintering machine are sequentially divided into a low heat storage capacity area, an intermediate heat storage capacity area and a high heat storage capacity area according to the temperature intervals smaller than 1250 DEG C, 1250-1300 DEG C and 1300-1350 DEG C, and high heating value gas with the injection heating value being larger than 30 MJ / Nm<3>, an intermediate heating value gas with the injection heating value being 15-30 MJ / Nm<3> and low heating value gas withthe injection heating value being smaller than 15 MJ / Nm<3> are separately injected to the three areas. The low-carbon low-emission sintering method effectively couples the differences between the heating capacity requirements and the gas quality of different areas of the sintering material layer, realizes heating capacity balanced distribution of the material layers at different heights, forms a beneficial ore-forming condition, greatly improves the sintering quality and the quality index, meanwhile, effectively expands the coverage area of gas injection, further reduces the solid fuel consumption, increases the emission reduction ratio of pollutants such as NOX, SO2 and COX, and realizes the low-carbon low-emission sintering.

Owner:CENT SOUTH UNIV

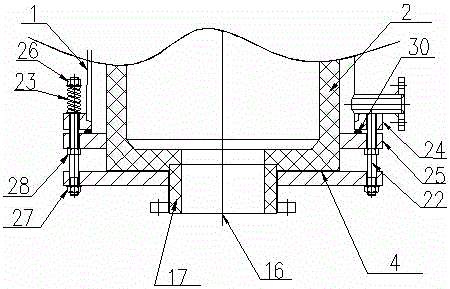

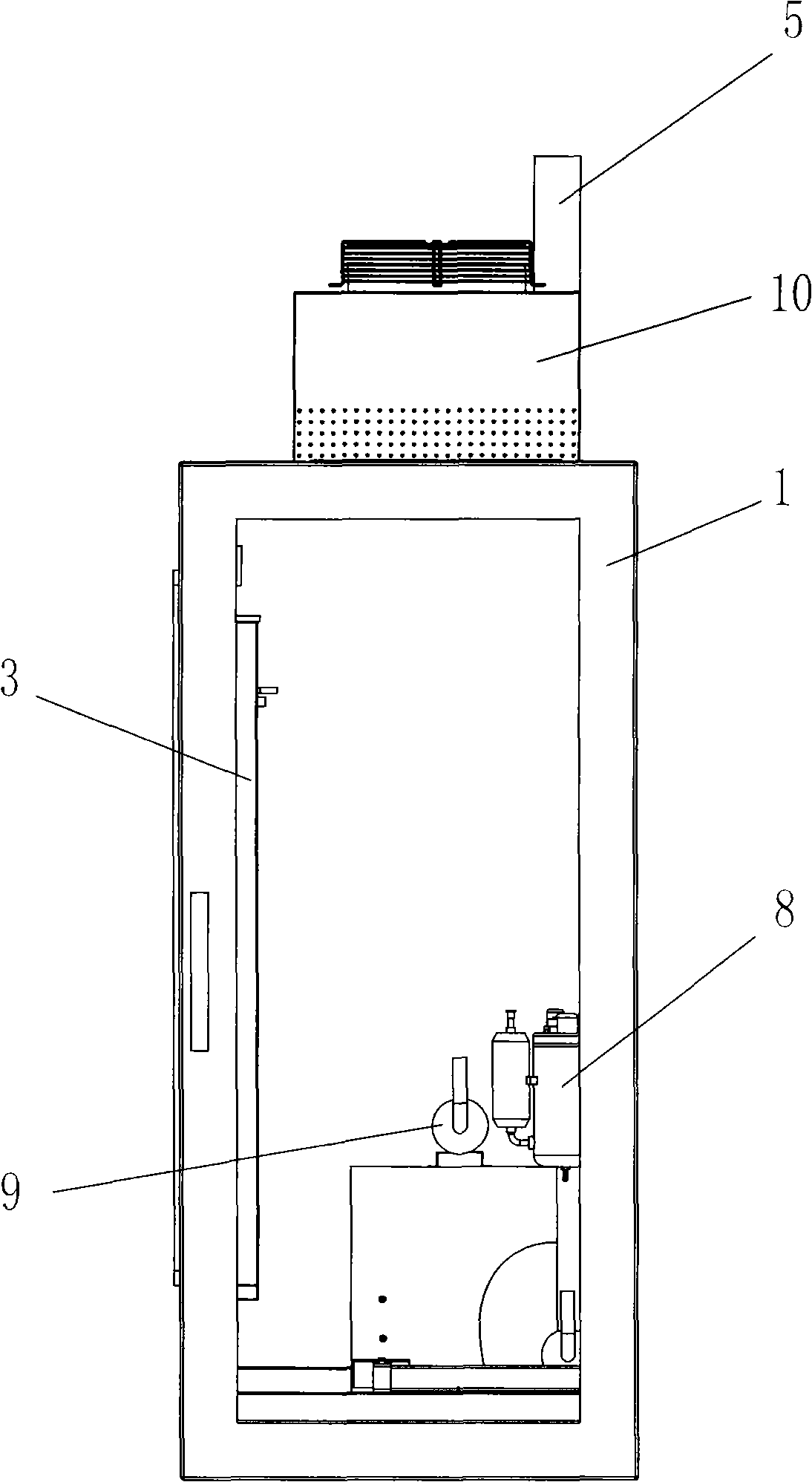

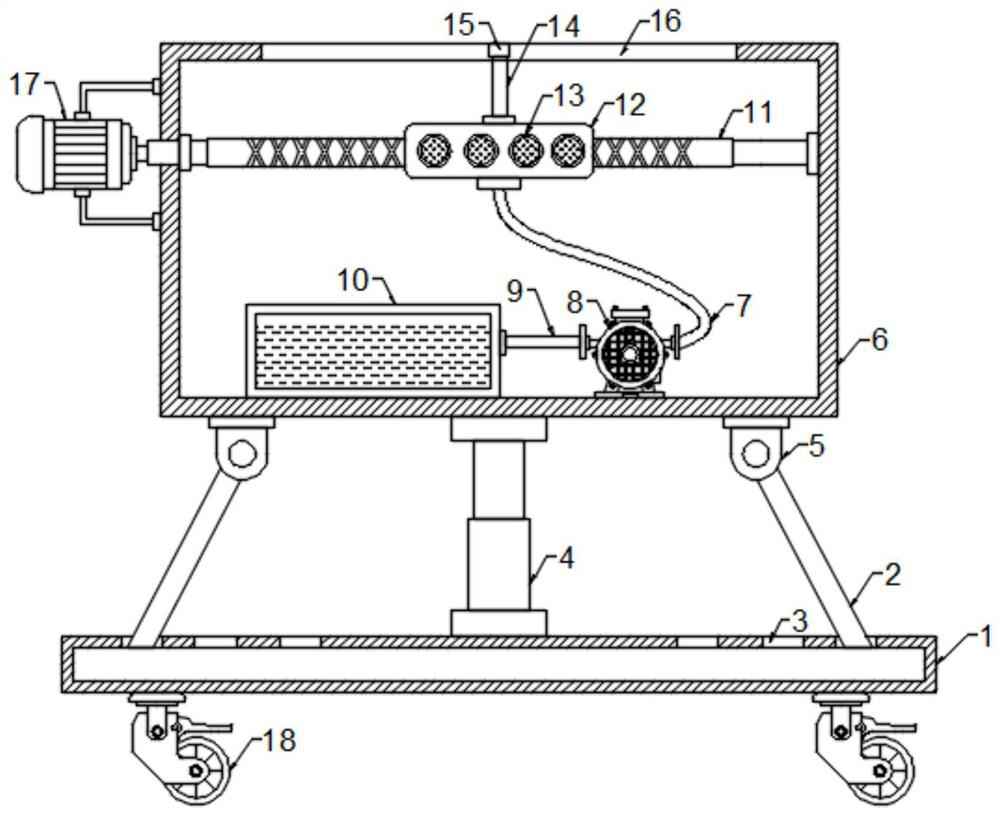

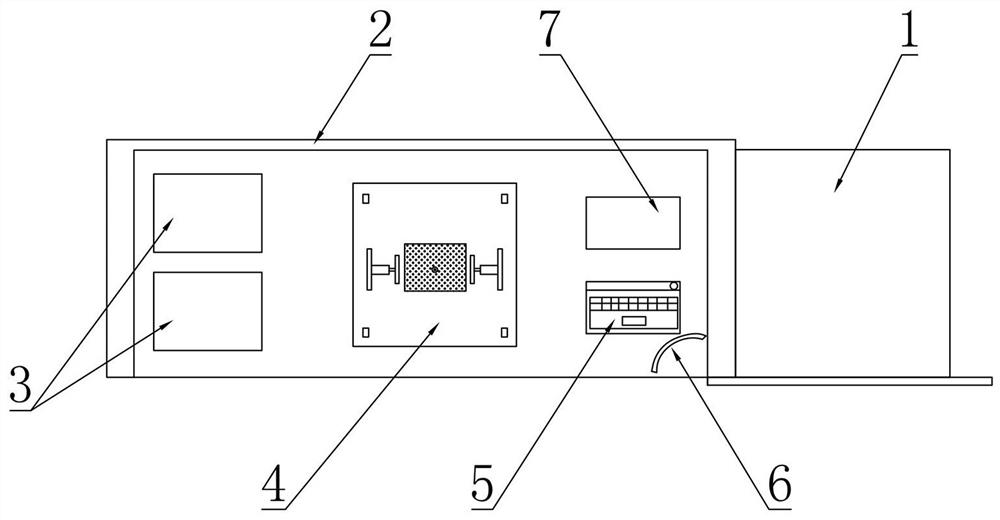

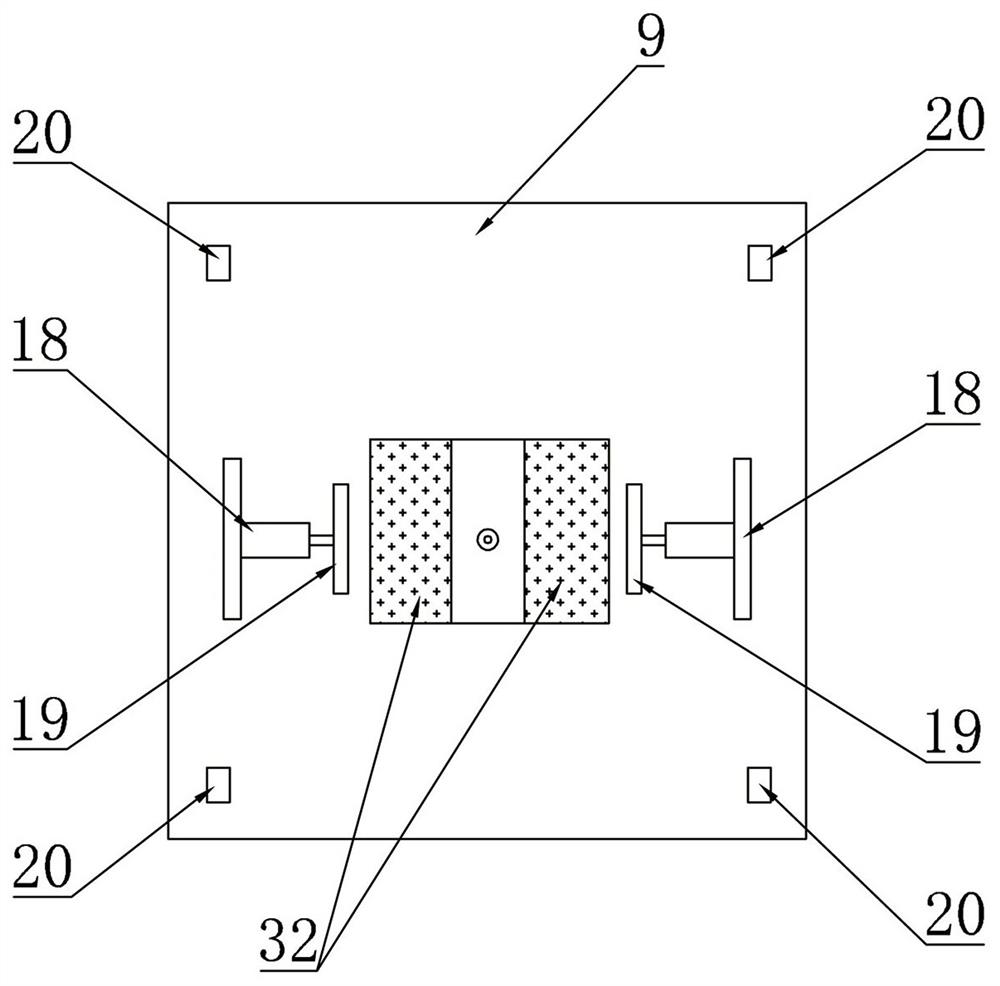

Rain working condition simulation test cabinet device

InactiveCN101782471AMove up and down flexiblyIncreased spray coverageStructural/machines measurementElectricityEngineering

The invention discloses a rain working condition simulation test cabinet device, which comprises a rain working condition simulation cabinet, wherein the inside of the rain working condition simulation cabinet is provided with a horizontally arranged spray system and a longitudinally arranged electrically-driven Y-axis lead screw; the spray system is arranged and fixed on a nut of the electrically-driven Y-axis lead screw; and when a motor works, the spray system moves up and down along with the nut. By means of the electrically-driven Y-axis lead screw, the spray system can flexibly move up and down to increase the spray coverage area and comprehensively actually simulate the rain working condition, so that the rain simulation effect is obvious and the test is accurate.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

Novel wet type dust-removing equipment

InactiveCN106799102AImprove dehydration effectComply with comprehensive atmospheric emission standardsUsing liquid separation agentProduct gasTower

The invention discloses novel wet type dust-removing equipment. The novel wet type dust-removing equipment comprises a tower body with a cylindrical structure; a gas inlet is formed in the side wall of the tower body and a gas outlet is formed in the upper end of the tower body; a water storage device, a spraying device, a water mist-removing filling layer and a dehydrating layer are arranged in the tower body from bottom to top in sequence; the gas inlet is positioned between the water storage device and the spraying device; the dehydrating layer is positioned below the gas outlet; the novel wet type dust-removing equipment also comprises a fan and a buffer box; a gas inlet of the fan is communicated with the gas outlet of the tower body; a gas outlet of the fan is communicated with a gas inlet of the buffer box; a gas outlet of the buffer box is externally connected with a gas discharge pipeline. According to the novel wet type dust-removing equipment, the dust-removing rate reaches 98 percent or above and accords with atmospheric comprehensive discharge standard; in addition, the liquid amount of the discharged gas can be reduced, the dehydrating effect of waste gas is improved, equipment operating power is reduced and equipment operating cost is reduced.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

Water mist fan and water mist condensation system

PendingCN108554062ASimple structureLarge jet cross sectionUsing liquid separation agentEngineeringHigh pressure

The invention discloses a water mist fan and a water mist condensation system and relates to the technical field of water mist condensation. The water mist fan comprises a fan cover, rotation spray pipes and a water inlet pipe. One end of the water inlet pipe is arranged in the middle of the fan cover, and the other end of the water inlet pipe is used for being connected with a high-pressure finewater mist fire extinguishing device; the rotation spray pipes are arranged in the middle of the fan cover through fixed-axis rotation; the rotation spray pipes are communicated with the water inlet pipe. According to the water mist fan, the rotation spray pipes which are arranged in the middle of the fan cover through fixed-axis rotation are communicated with the water inlet pipe, and after beingconnected to the high-pressure fine water mist fire extinguishing device, the rotation spray pipes rotate and spray mist; through cooperation of the fan cover and the rotation spray pipes, the high-pressure fine water mist jet flow with larger cross section can be obtained, the coverage area of water mist is larger, the capacity of condensing poisonous and pernicious gas is higher, the adsorptioneffect on dust is more obvious, and the problem is solved that when a large amount of poisonous and pernicious gas or dust exists, the condensation and adsorption effect of a water mist spray nozzleis not ideal; the water mist fan has high application and popularization value.

Owner:北京金同泰科技有限公司

Semi-fixed type large-volume handpiece station for strip mine

InactiveCN113335833ARealize dust reduction treatmentAchieving superchargingConveyorsOpen-pit miningMining engineeringWater storage tank

The invention discloses a strip mine semi-fixed type large-volume handpiece station which comprises a handpiece station body. An operation machine box is fixedly installed in the handpiece station body. The strip mine semi-fixed type large-volume handpiece station further comprises a spraying device fixedly installed at the top of a conveying plate frame. The spraying device comprises a spraying water storage tank fixedly installed at the top of the conveying plate frame. A water outlet in the bottom of the spraying water storage tank is fixedly connected with spray head assemblies which are distributed right above the conveying plate frame at equal intervals through a booster unit. According to the strip mine semi-fixed type large-volume handpiece station provided in the scheme, through dust falling spray heads distributed at the top of the conveying plate frame at equal intervals, and a diversion guide pipe correspondingly arranged at the bottom of the spraying water storage tank, dust falling treatment on conveyed minerals on the conveying plate frame is achieved, meanwhile, a pressurizing unit arranged on the spraying device is designed, pressurizing treatment on the dust falling part is achieved, and the spraying coverage area and the spraying efficiency of the device are increased.

Owner:王照勇

Dust removal device for coal transportation

PendingCN114073877AAchieve regulationIncreased spray coverageUsing liquid separation agentCastorsDust controlElectric machinery

The invention relates to the technical field of coal, in particular to a dust removal device for coal transportation. The invention aims to solve the problems that manual dust removal is low in working efficiency and low in dust removal speed, and meanwhile, dust and ash can influence human health in the prior art. The dust removal device for coal transportation comprises a base, wherein a working frame is arranged at the top of the base, a driving motor is fixedly connected to one side of the working frame through bolts, a reciprocating screw is arranged on the upper portion of the inner side of the working frame, one end of the reciprocating screw is rotationally connected with one side of the upper portion of the inner side of the working frame through a rotating shaft, a nut seat is connected to the reciprocating screw in a screwed mode through threads, a connecting pipe is arranged on the nut seat, one side of the connecting pipe communicates with an atomizing nozzle, a water pump is fixedly connected to one side of the bottom of the inner side of the working frame through bolts, and a water tank is fixedly connected to the side, away from the water pump, of the bottom of the inner side of the working frame. According to the invention, manual dust falling is replaced, working efficiency is high, a dust falling speed is high, and dust and ash are prevented from influencing human health.

Owner:靖州县绿之嘉实业有限公司

Unmanned aerial vehicle automatic replenishment station and unmanned aerial vehicle intelligent dust falling system applied by same

PendingCN113184183AReduce wasteStrong targetingRotary stirring mixersUsing liquid separation agentUncrewed vehicleElectric devices

The invention discloses an unmanned aerial vehicle automatic replenishment station and an unmanned aerial vehicle intelligent dust falling system applied thereof. The unmanned aerial vehicle automatic replenishment station comprises a replenishment unit used for conducting automatic replenishment on an unmanned aerial vehicle, a ground general control unit used for controlling and deploying the unmanned aerial vehicle and all devices in the unmanned aerial vehicle automatic replenishment station, a parking apron which is used for parking the unmanned aerial vehicle, and a power supply unit which is used for supplying power to all electric devices. The unmanned aerial vehicle intelligent dust falling system comprises the unmanned aerial vehicle automatic replenishment station and at least one unmanned aerial vehicle module matching the unmanned aerial vehicle automatic replenishment station to work. And each unmanned aerial vehicle module is internally provided with a dust suppressant spraying assembly, an information acquisition assembly and a vehicle body control assembly. The unmanned aerial vehicle intelligent dust falling system is high in intelligent degree, good in use simplicity and convenience, low in dust suppression cost and capable of accurately and efficiently performing dust suppression treatment on a construction site. The unmanned aerial vehicle intelligent dust falling system is suitable for being used for treating construction dust on a building construction site.

Owner:XIAN UNIV OF SCI & TECH

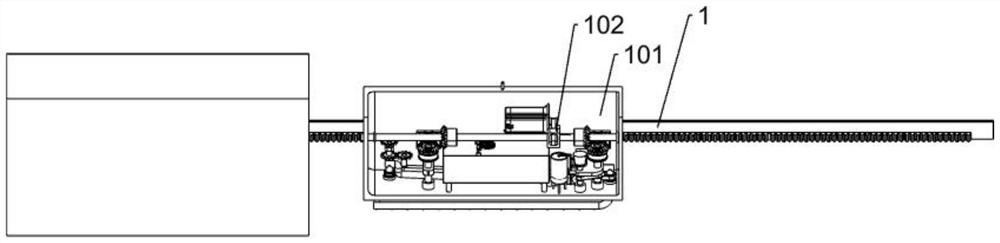

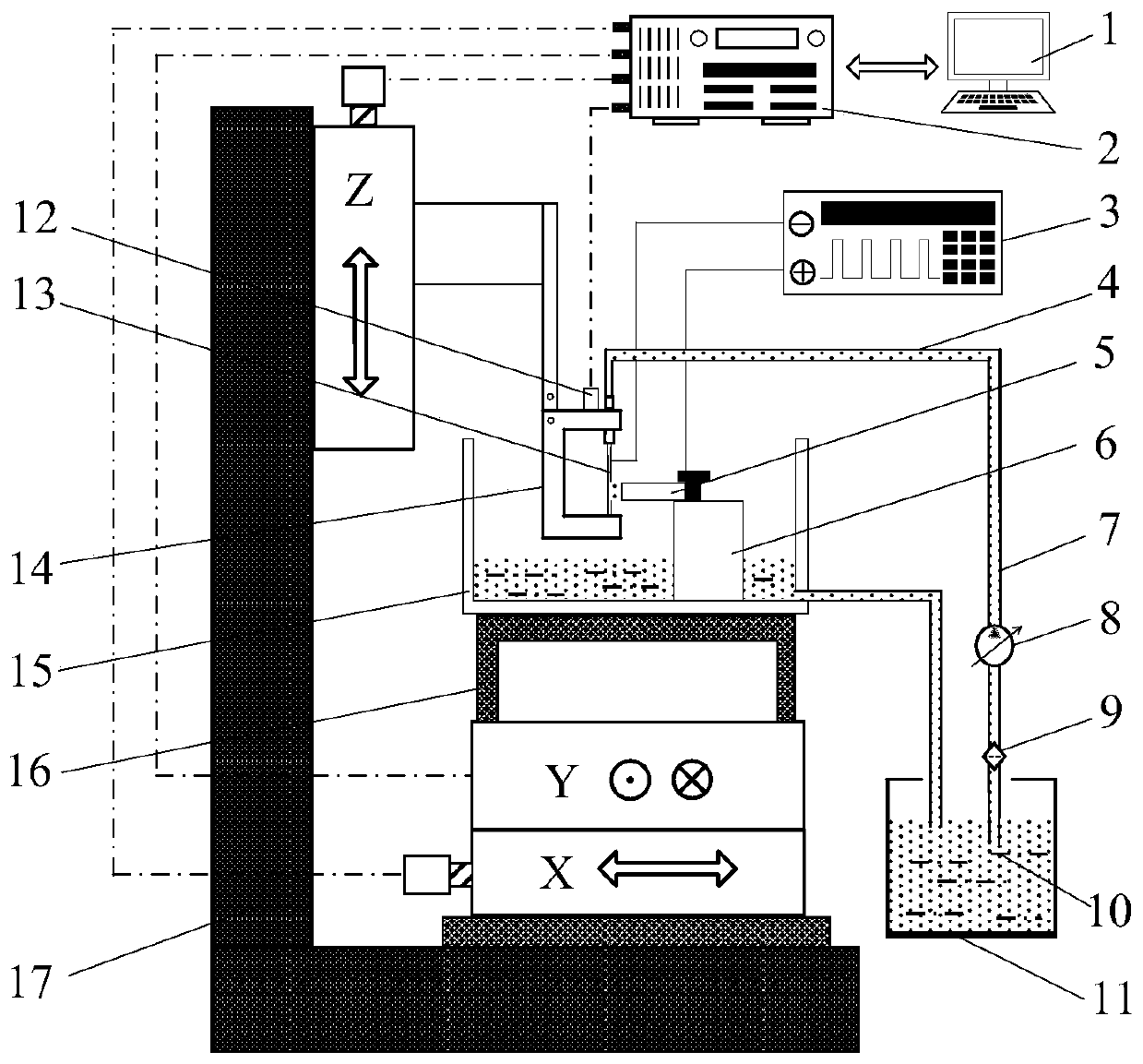

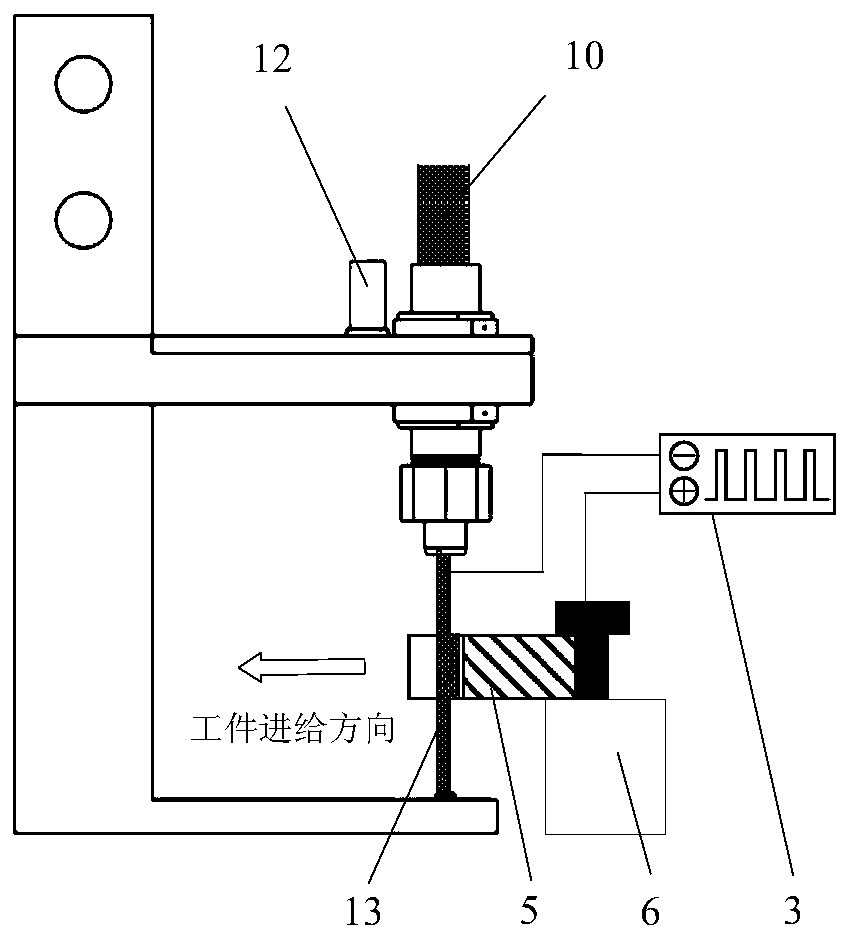

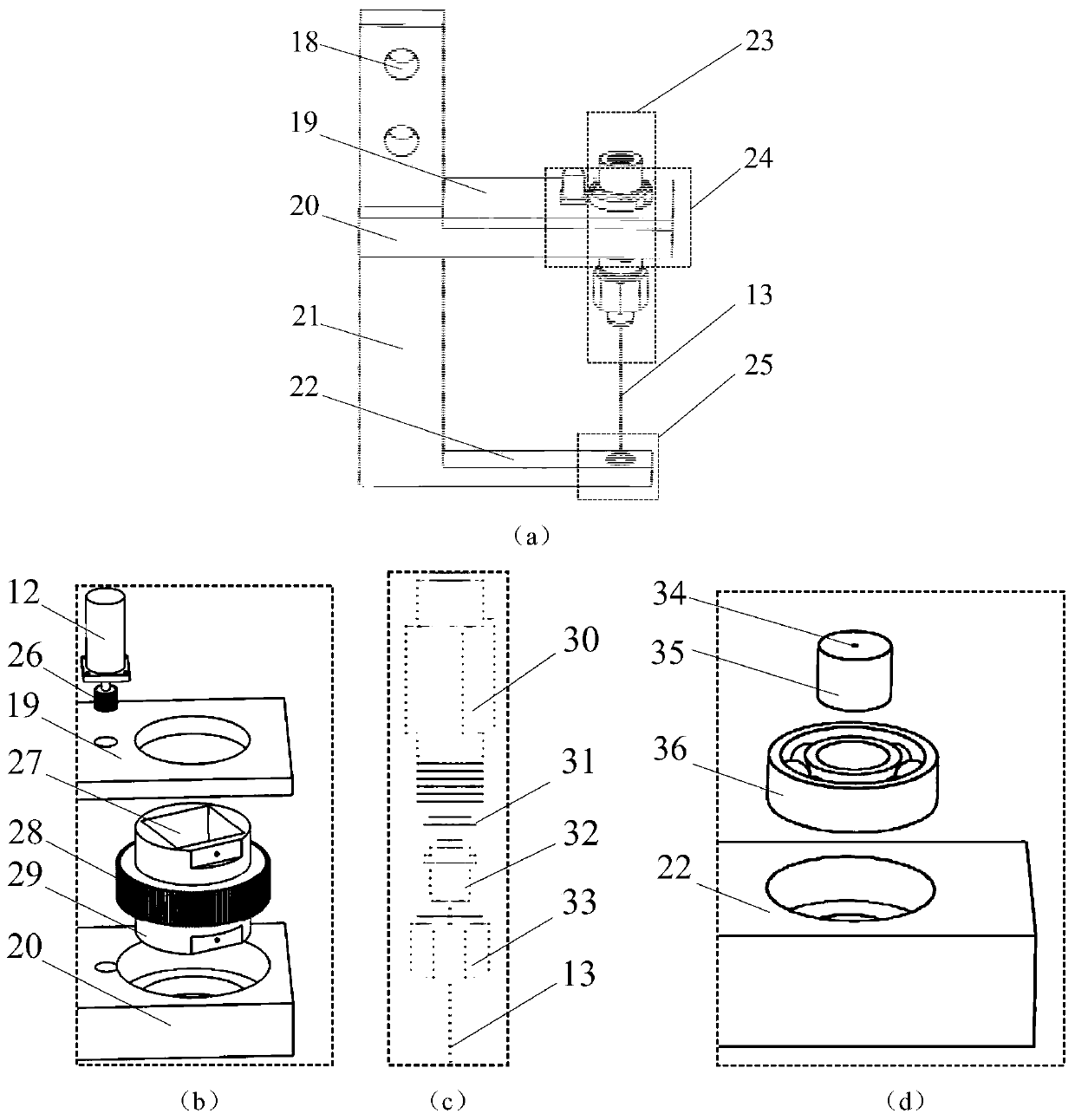

Microtube Electrode System for Electrolytic Cutting of Large Thickness Workpiece Method

ActiveCN108406025BImprove stabilitySpeed up the electrolytic reactionMachining working media supply/regenerationNumerical controlElectrolysis

The invention relates to a method and device for performing electrolytic cutting on a large-thickness workpiece by using a micro tube electrode, and belongs to the technical field of electrochemical machining. The method is mainly characterized in that a micro hollow metal tube with grouped holes or grouped seams or a hollow non-metal tube with a conductive coating is selected to replace an existing metal-wire-shaped electrode to cut the large-thickness workpiece; structures of the grouped holes or the grouped seams are formed in the micro tube electrode with one closed end, an electrolyte with certain pressure is injected from one end of the micro tube electrode and is jetted out from the grouped holes or the grouped seams, the fresh electrolyte flowing at a high speed can directly reacha machining area to perform etching cutting on the workpiece, and electrolysate and bubbles in micro cut seams can be rapidly washed away; and in the machining process, a servo motor drives the microtube electrode to rotate through a steering device so as to change the jetting direction of the electrolyte, and meanwhile, the relative movement of the micro tube electrode to the workpiece can be controlled by utilizing the movement of a numerical control machine tool workbench, so that steering cutting of the workpiece can be realized. The method and the device have the advantages that the update rate of the electrolyte in machining clearances can be increased, the electrolytic reaction speed can be increased, the electrolytic cutting stability can be improved, and meanwhile the electrolytic cutting capacity of the large-thickness workpiece can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

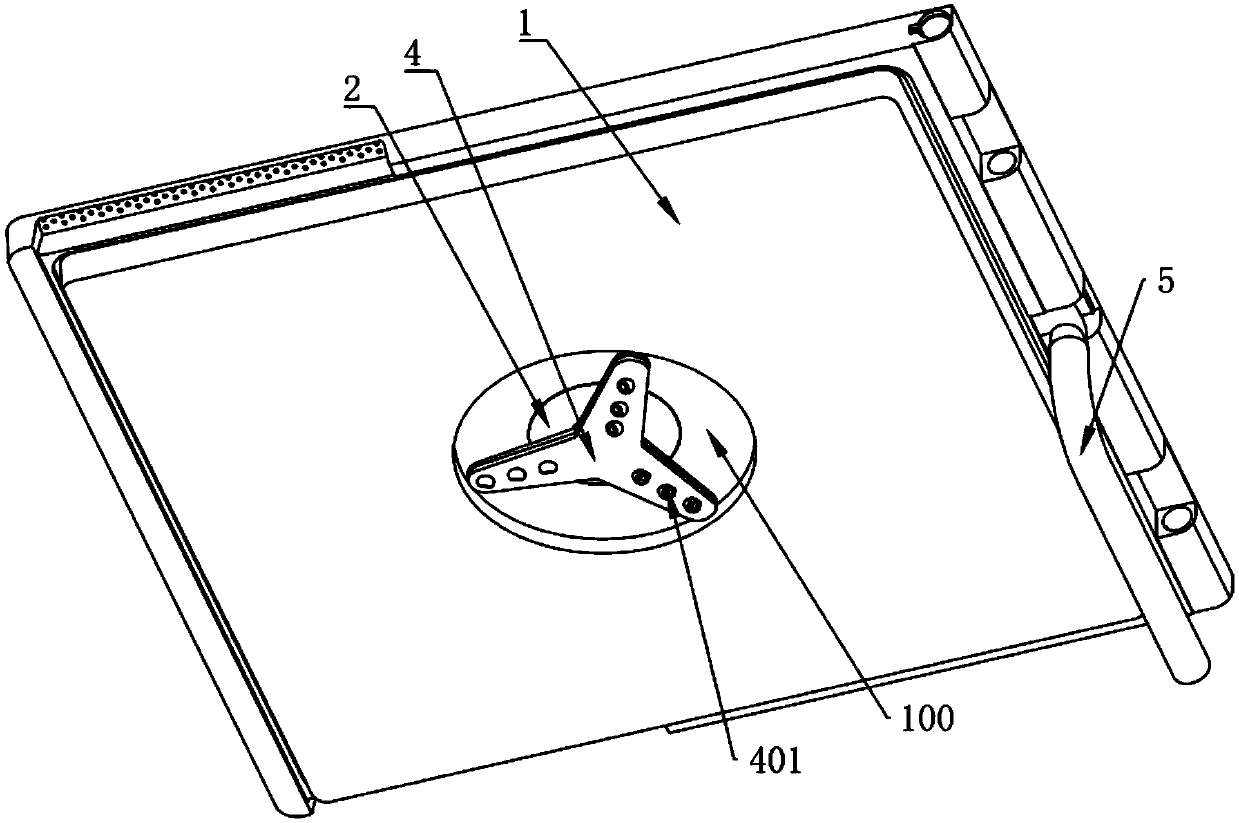

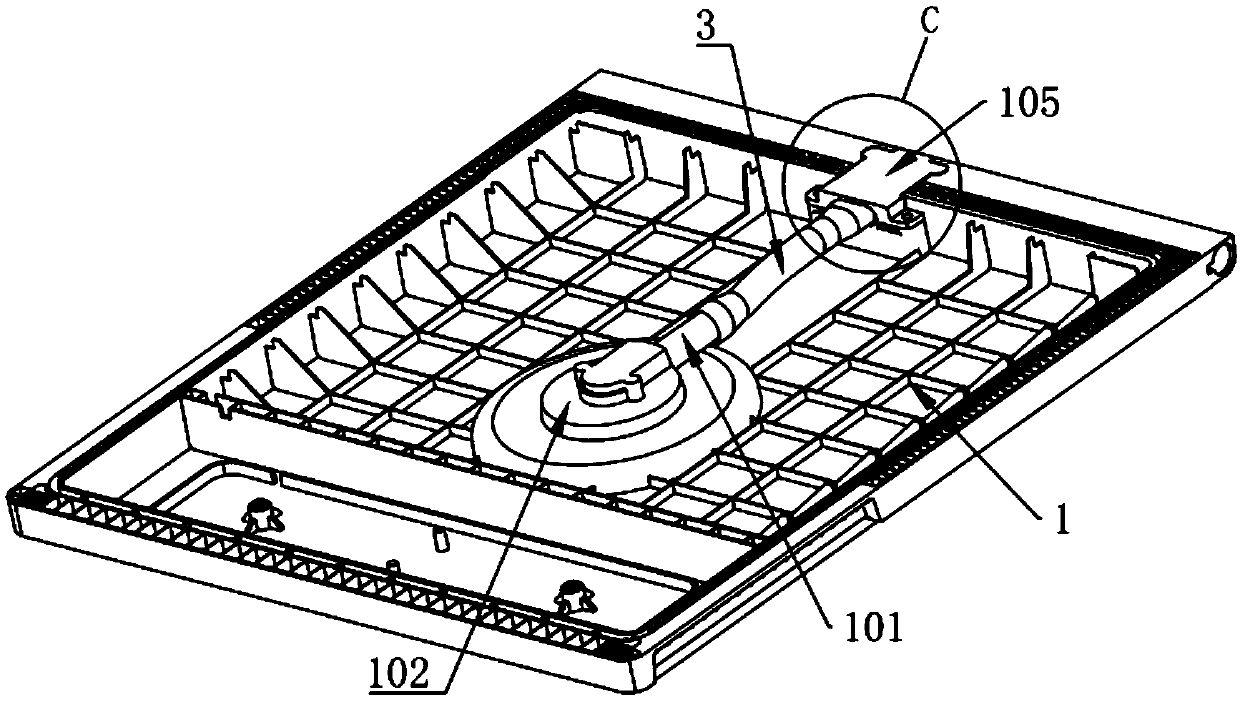

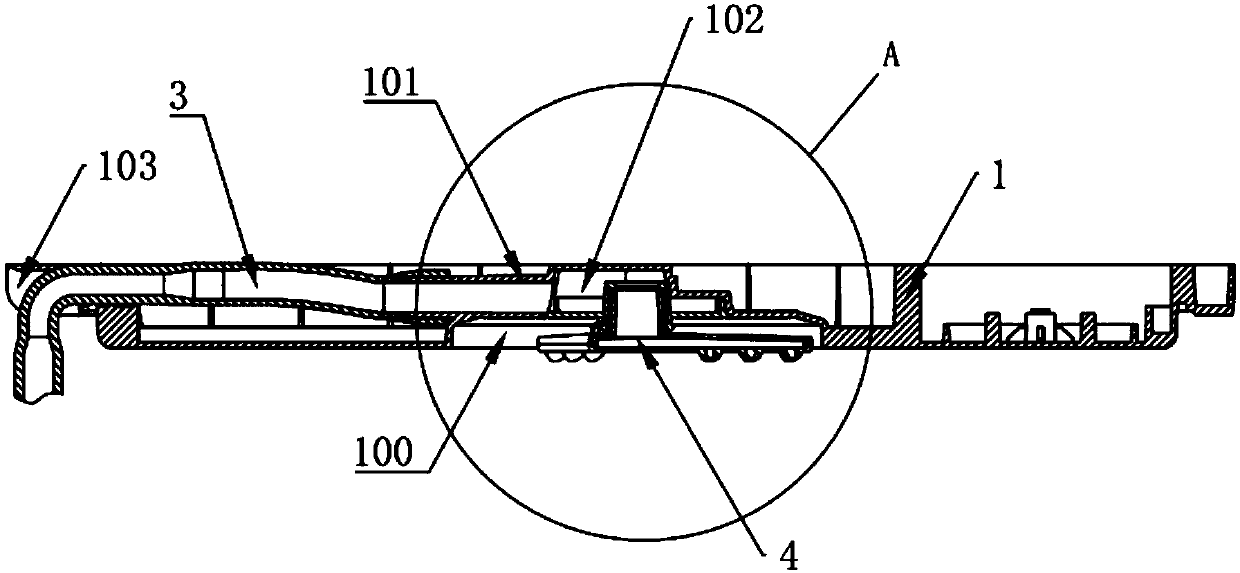

Washing machine, and dehydration barrel assembly and water spraying cover plate

ActiveCN110924085AIncreased spray coverageImprove spray flushing effectOther washing machinesWashing machine with receptaclesLaundry washing machineWater flow

The invention provides a water spraying cover plate, a dehydration barrel assembly and a washing machine. The water spraying cover plate comprises a cover plate body and a flow guide structure, wherein a plurality of water spraying holes distributed at intervals in a circumferential direction of the washing machine are formed in the cover plate body; the flow guide structure is arranged on the cover plate body and comprises a flow guide water passage extending from bottom to top; and the upper end of the flow guide water passage communicates with the plurality of water spraying holes. The water spraying cover plate has the advantages that the plurality of water spraying holes distributed at intervals in the circumferential direction of the washing machine are formed in the cover plate body, so that the spraying coverage range of the waterflow is effectively increased, and the spraying flushing effect on clothes is improved; in a high-speed rotating process of an inner barrel of the washing machine, the waterflow sprayed out from the plurality of water spraying holes in the high-speed rotation process can cover a greater area at the same moment, or even can be connected into a wholeto form 360 degrees, so that the probability of generating a spraying dead corner is greatly reduced; a clothes winding risk in a clothes washing process is further reduced; and the user experience is further improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com