Patents

Literature

416 results about "Steel jacket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

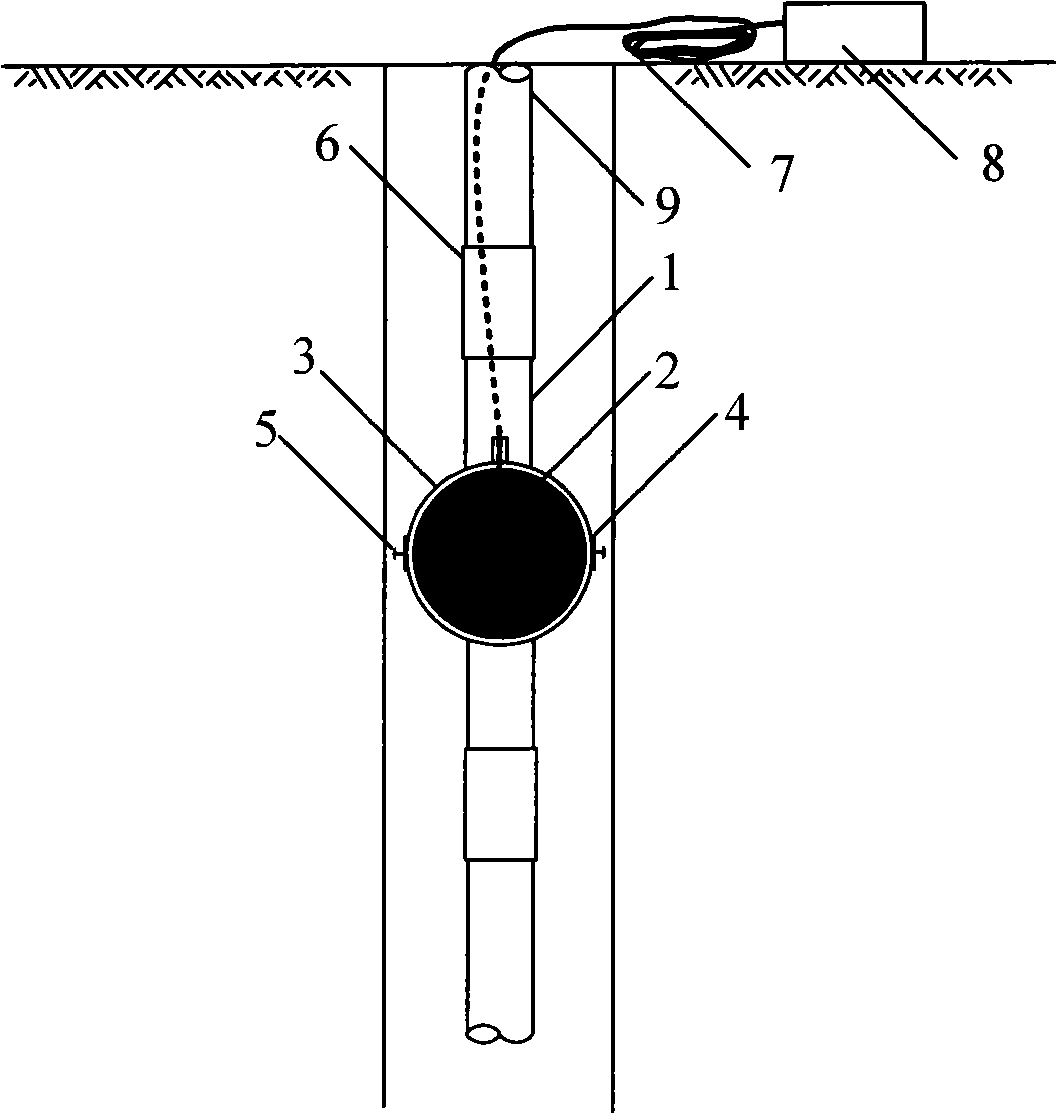

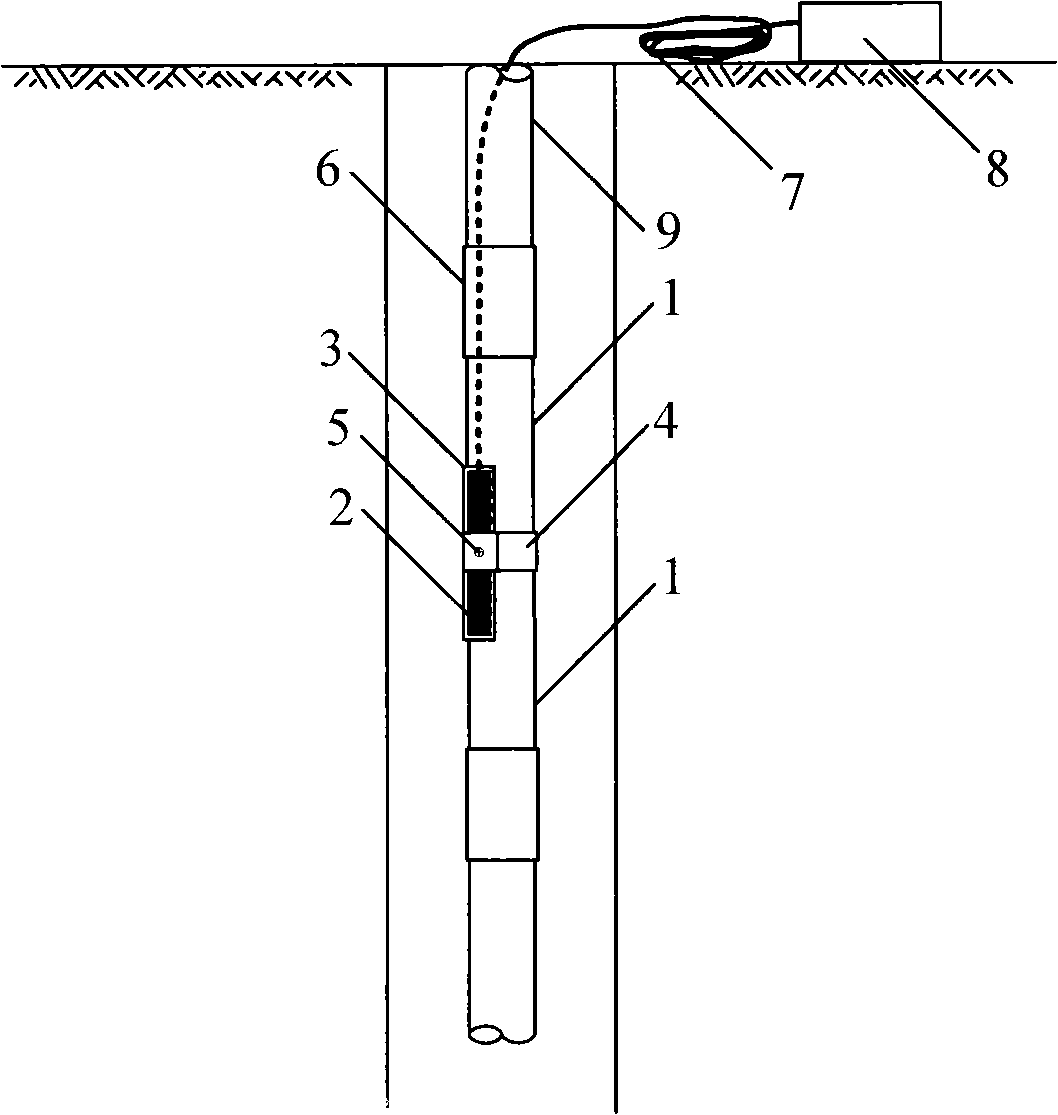

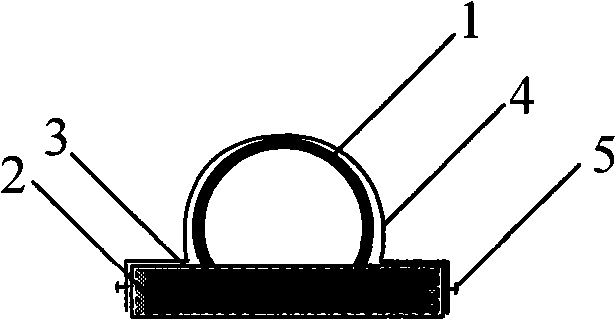

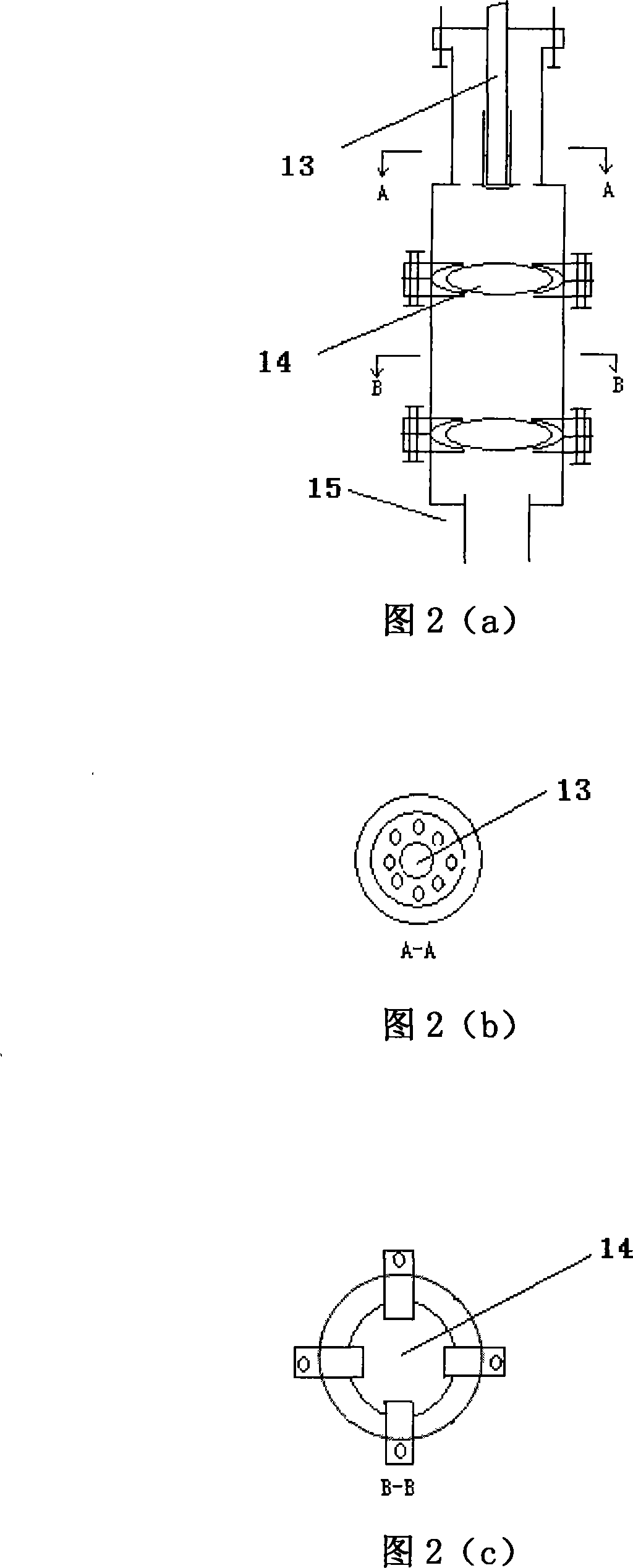

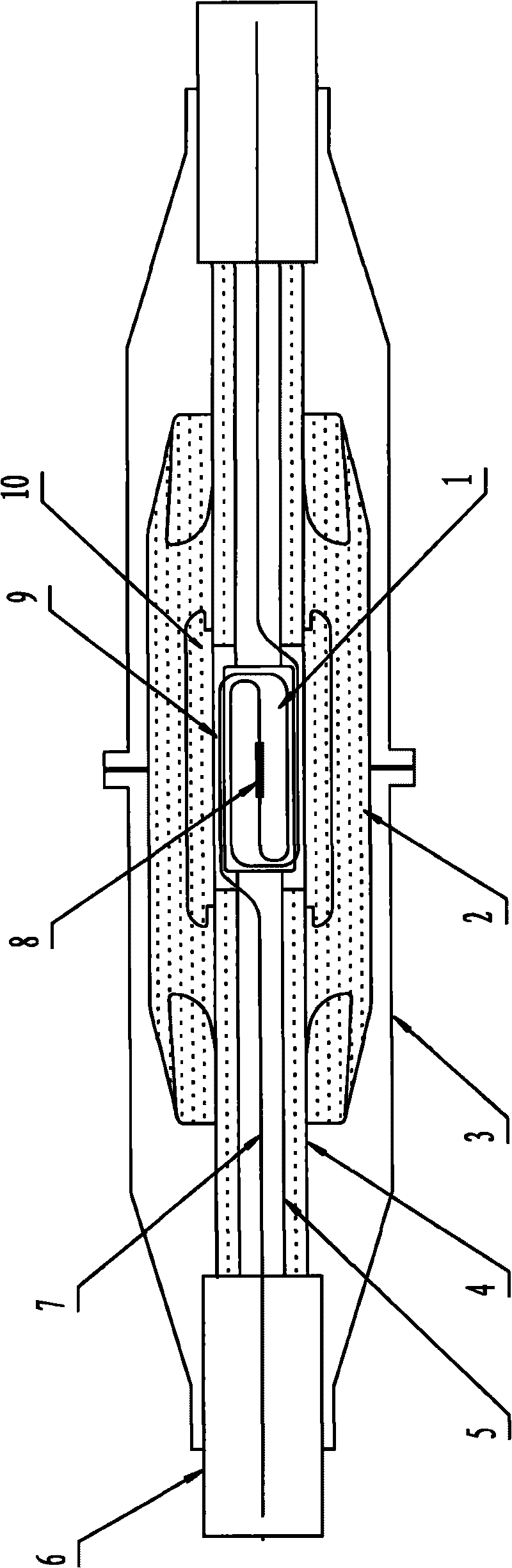

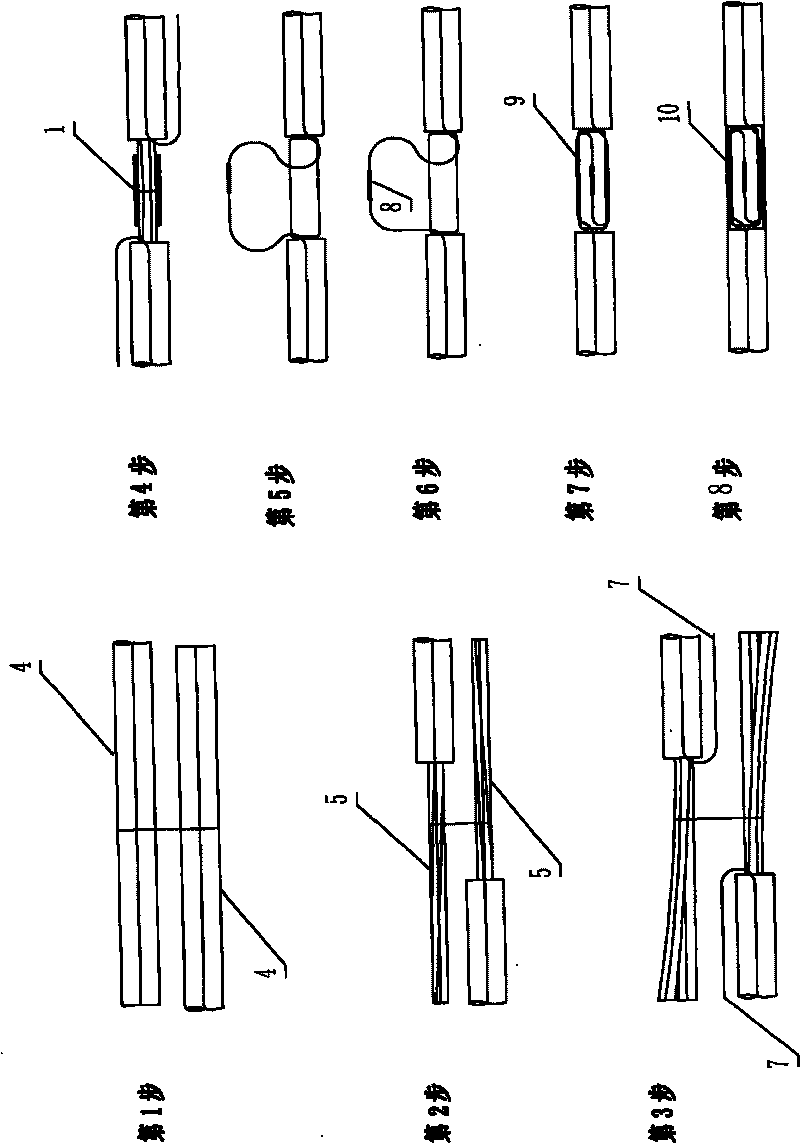

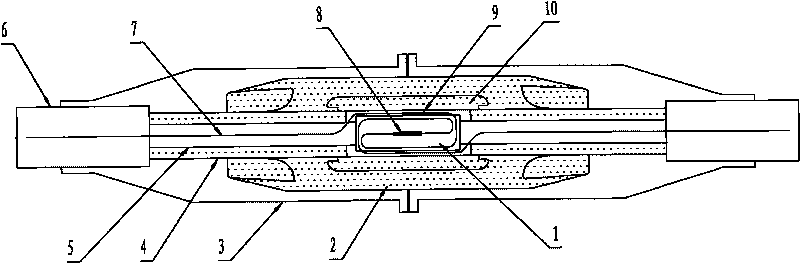

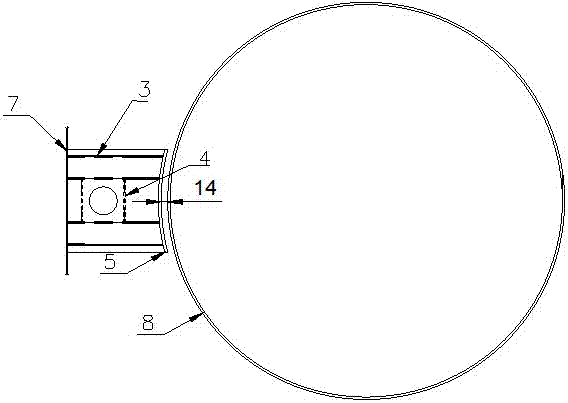

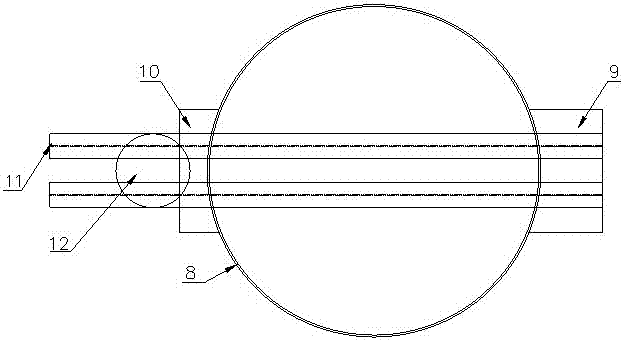

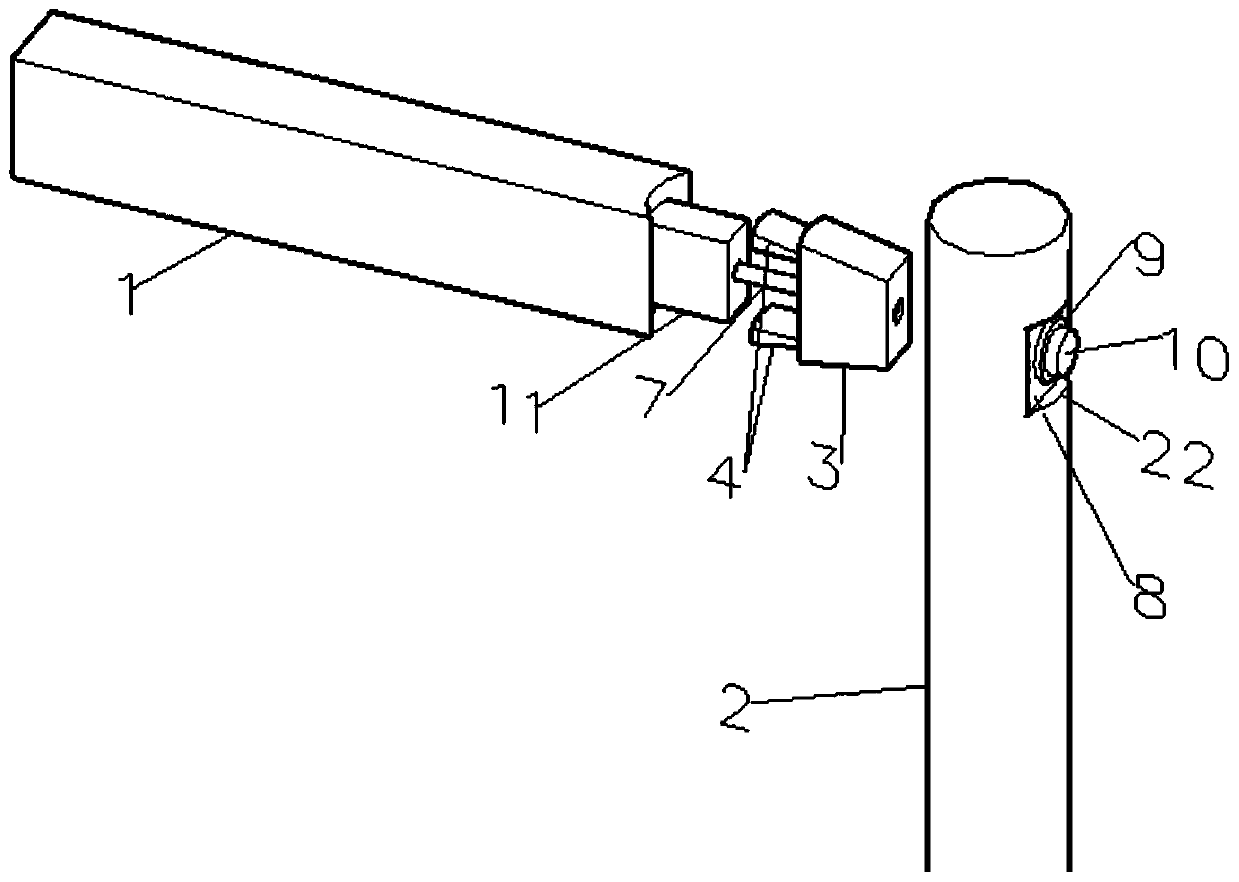

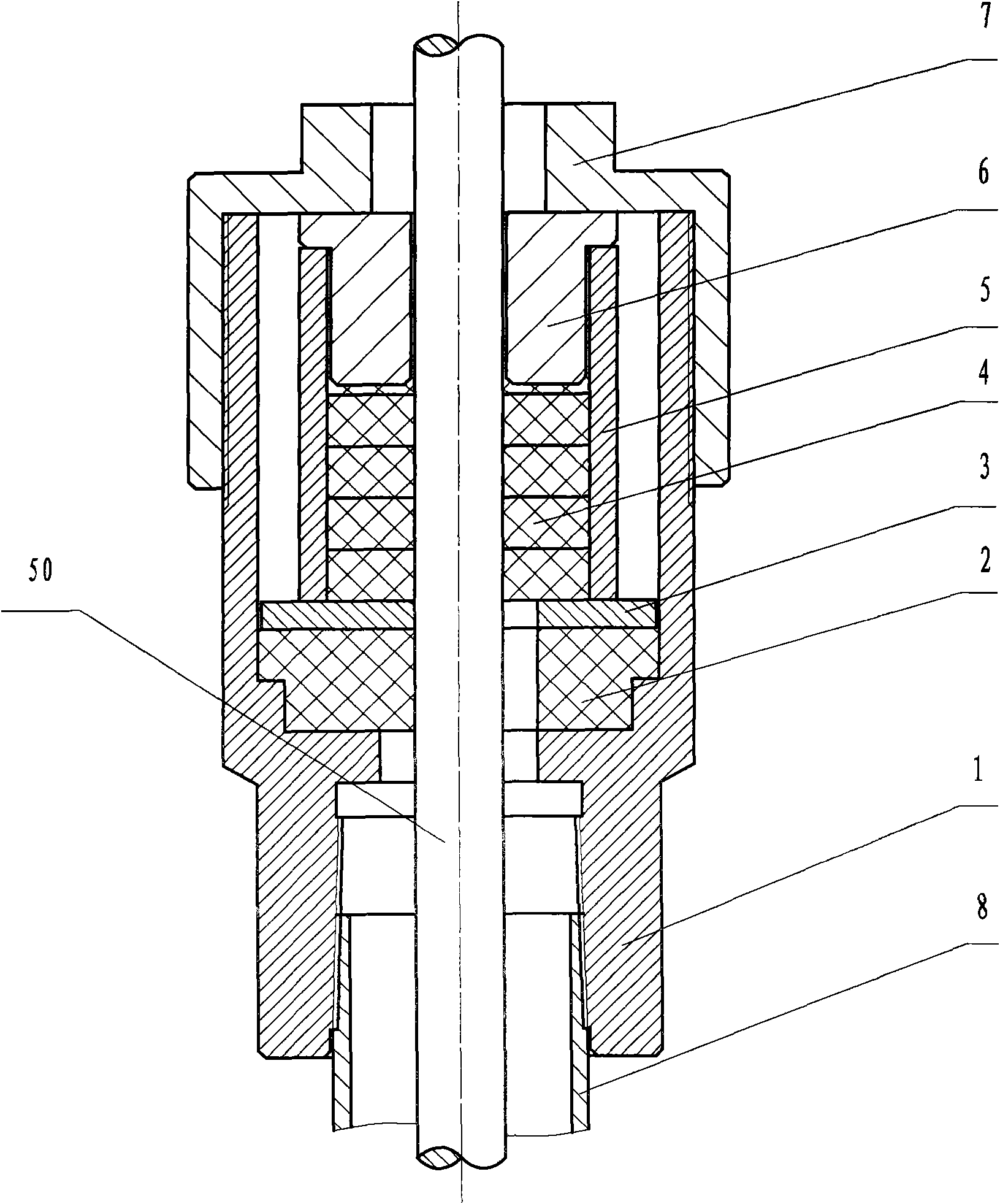

Lateral earth pressure sensor embedment method and device in earth

InactiveCN101358455ALow priceLow bending stiffnessArtificial islandsForce measurementSteel jacketData acquisition

The invention relates to a method for embedding a side-direction soil pressure sensor in the soil and a device thereof, which belongs to the technical field of construction engineering. The device comprises a sensor installation pipe, an extension pipe, a soil pressure sensor, a protective steel jacket, a U-shaped protective steel clip, a rigging screw, a connector pipe, a data transmission guide wire and a data collection instrument. The data transmission guide wire of the soil pressure sensor is connected with the data collection instrument. A notch is arranged in the center of the sensor installation pipe; the soil pressure sensor is put into the protective steel jack and then the soil pressure sensor and the protective steel jack are embedded in the notch; the U-shaped protective steel clip and the rigging screw are used to fix; the connector pipe is used to extend the sensor installation pipe and the extension pie to the design length; the pipes are put into a soil drilling hole; the guide pipes are fixed temporarily, and then fine sand is backfilled into the drilling hole; after the fine sand is consolidated, and the side direction soil pressure test is carried out. The invention has the advantages of convenient installation and operation, economy and practicality, high survival rate of the sensor embedded, capability of quite accurately measuring the side direction soil pressure in the soil, and accurate and reliable test result.

Owner:SHANGHAI JIAO TONG UNIV

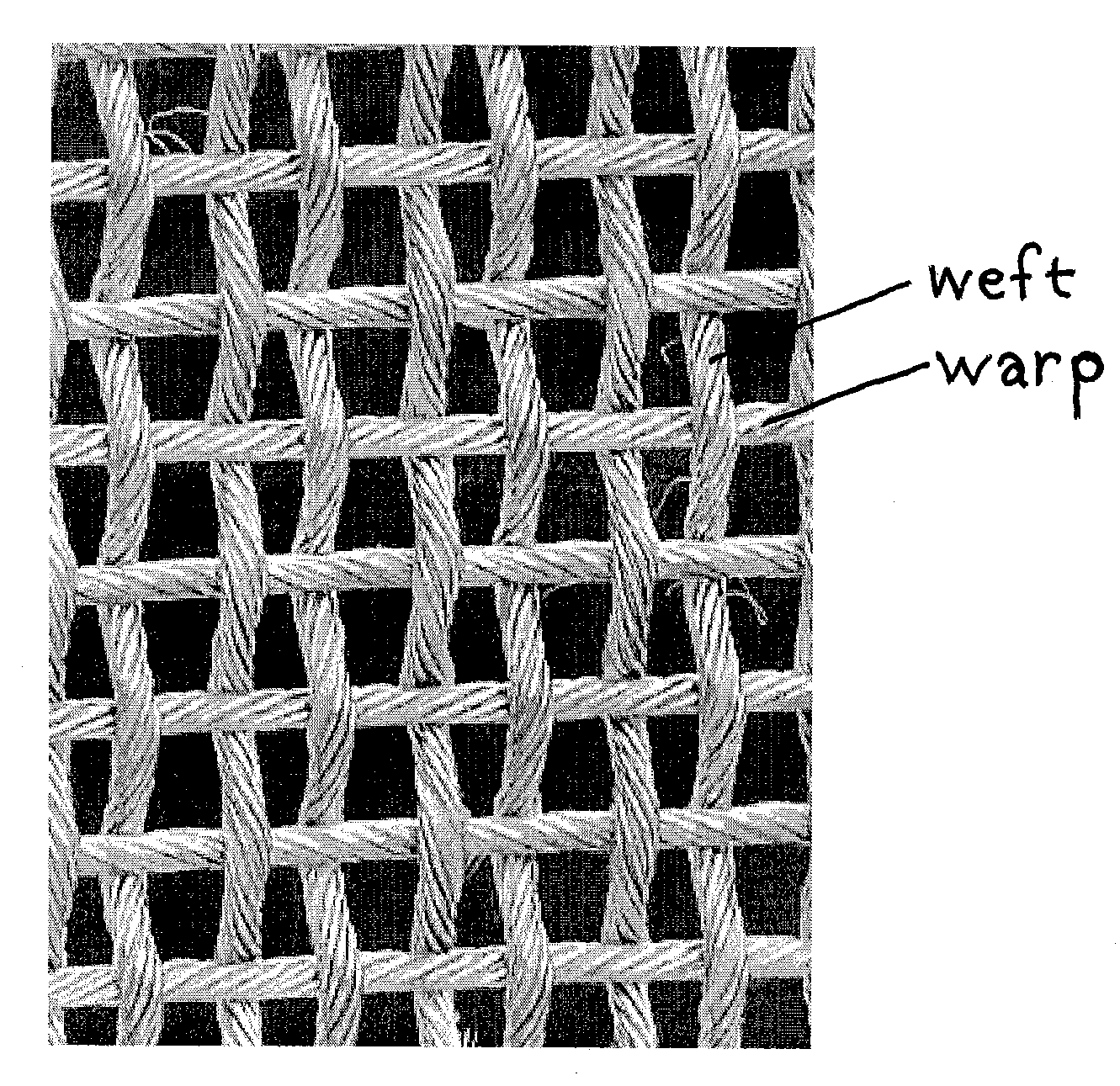

Mesh system

InactiveUS20080127598A1Inhibition releaseSignificant proportionScreensArmourSteel jacketSystems design

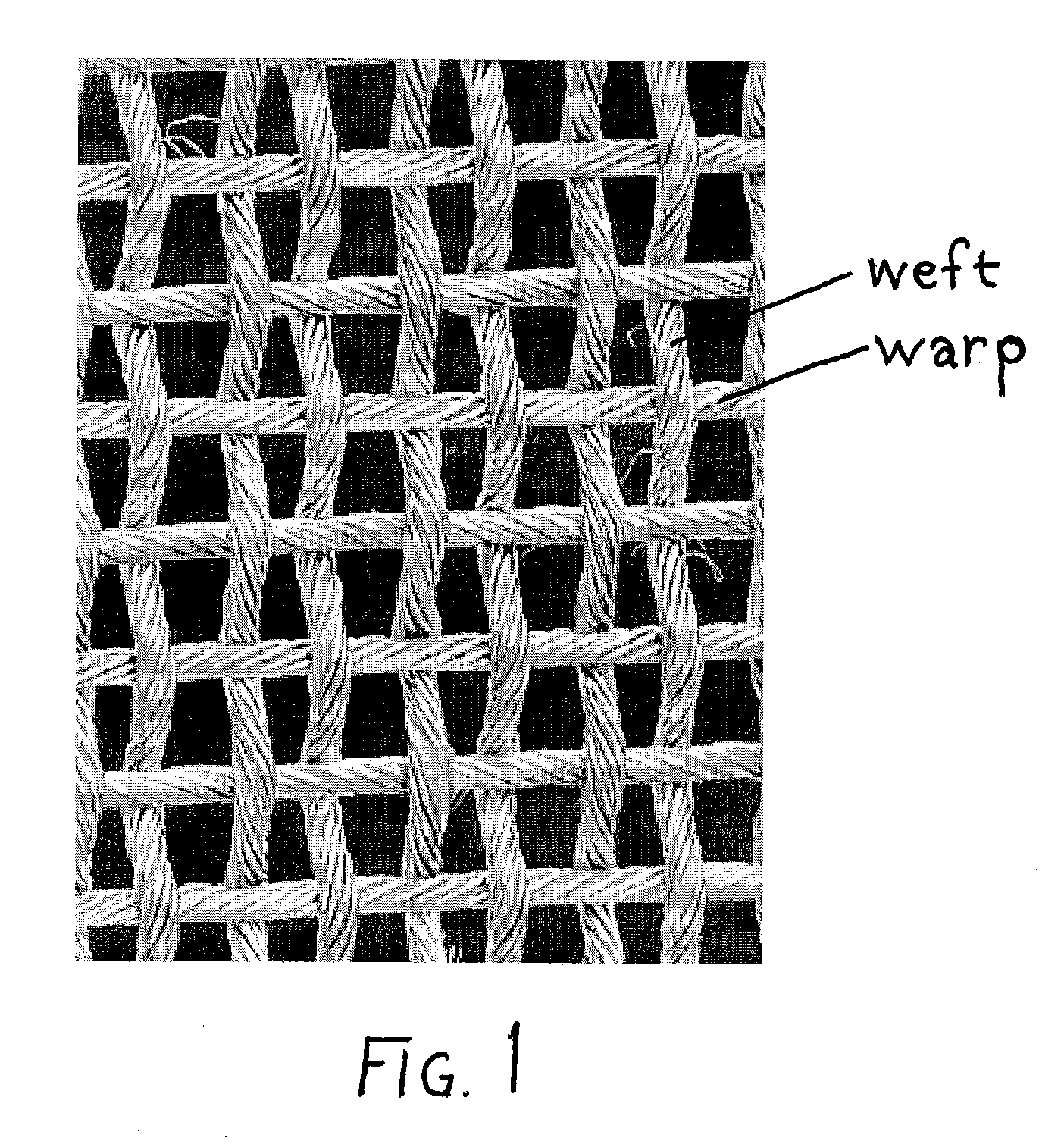

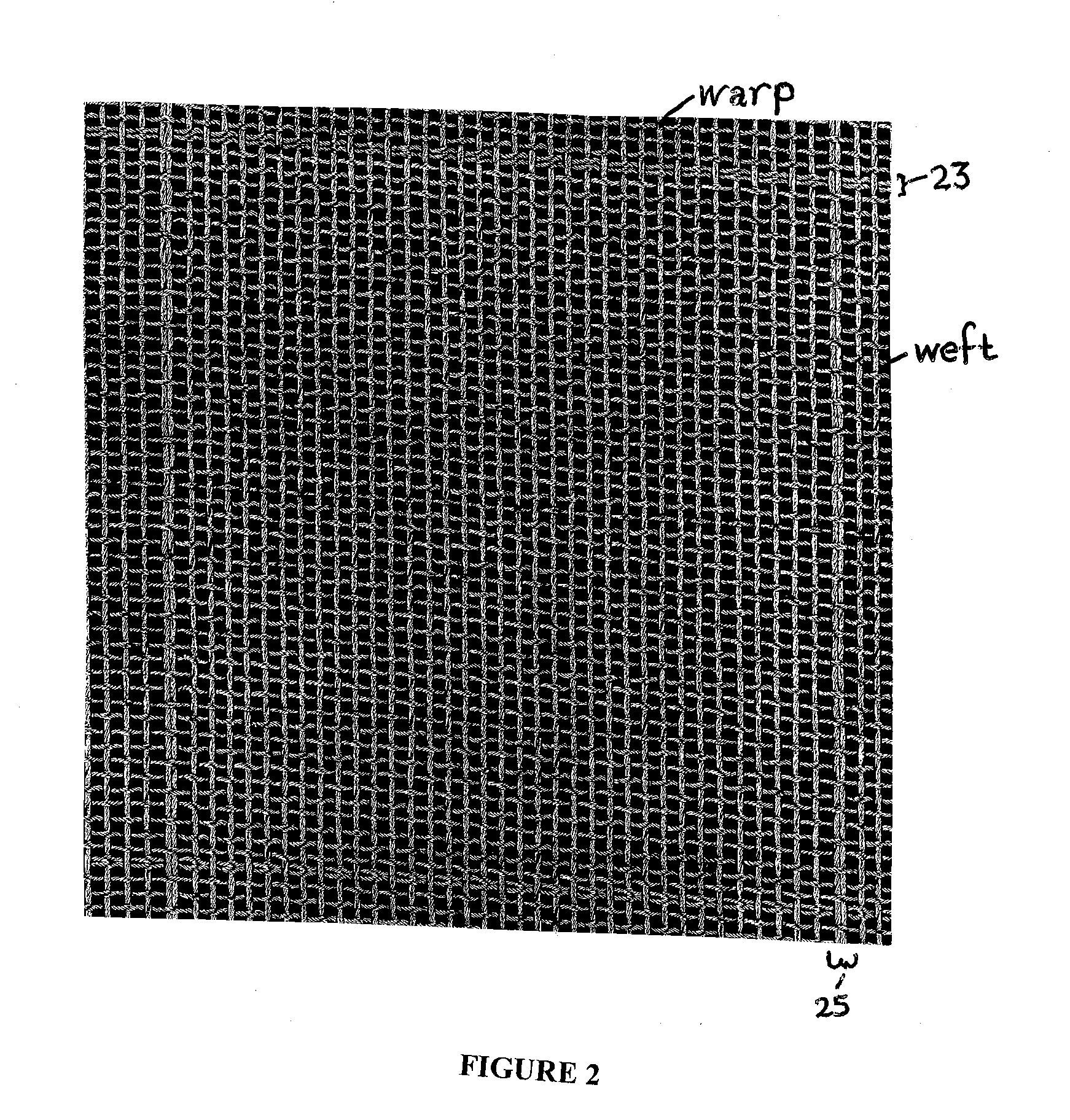

A mesh system for protecting structural openings, such as windows and doors, from storm damage or intrusion is made of a special cable having an aramid core and a twine twisted steel jacket made of a plurality of steel wires spun onto a bundled aramid fiber core. The mesh includes a substantially straight warp and a woven weft. A mesh system designed for limiting the deflection of the mesh under impact and wind load conditions imposed by a hurricane securely fixes and tensions the mesh along at least the direction of the substantially straight warp. A cable construction, cable diameter, mesh weaving loads and percent open area of the mesh are selected such that the mesh system passes a large missile impact test. Security features including periodic use of a plurality of cables and / or sensors may be added to the mesh.

Owner:MAESTROSHIELD IP HLDG

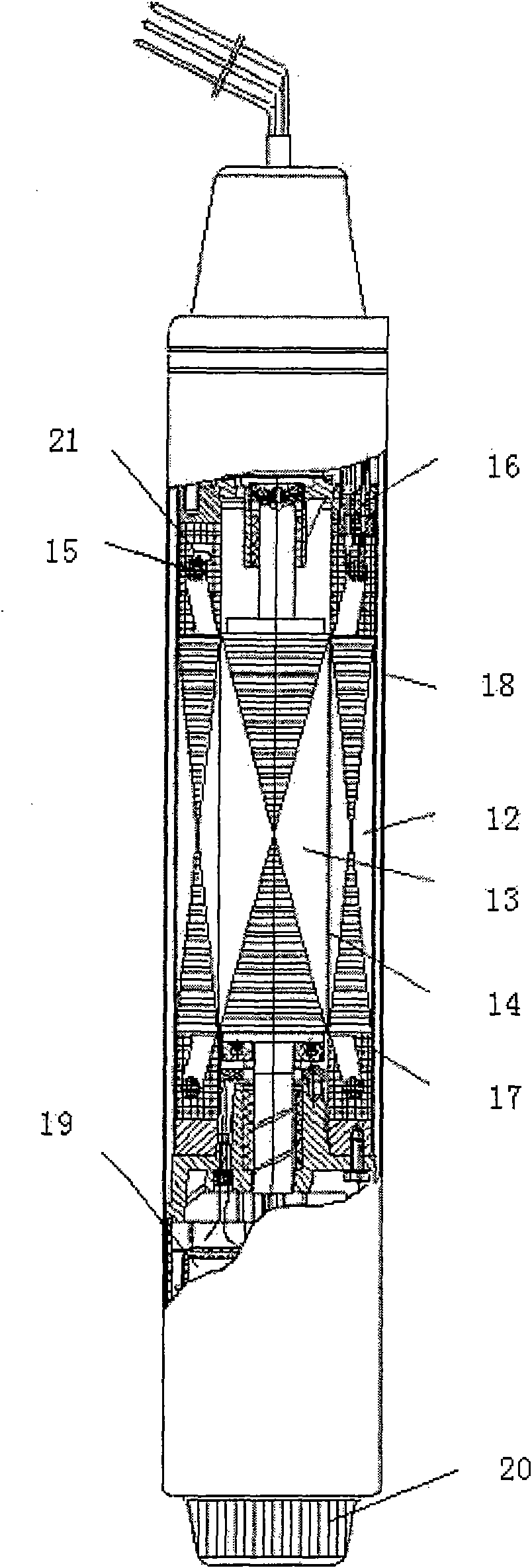

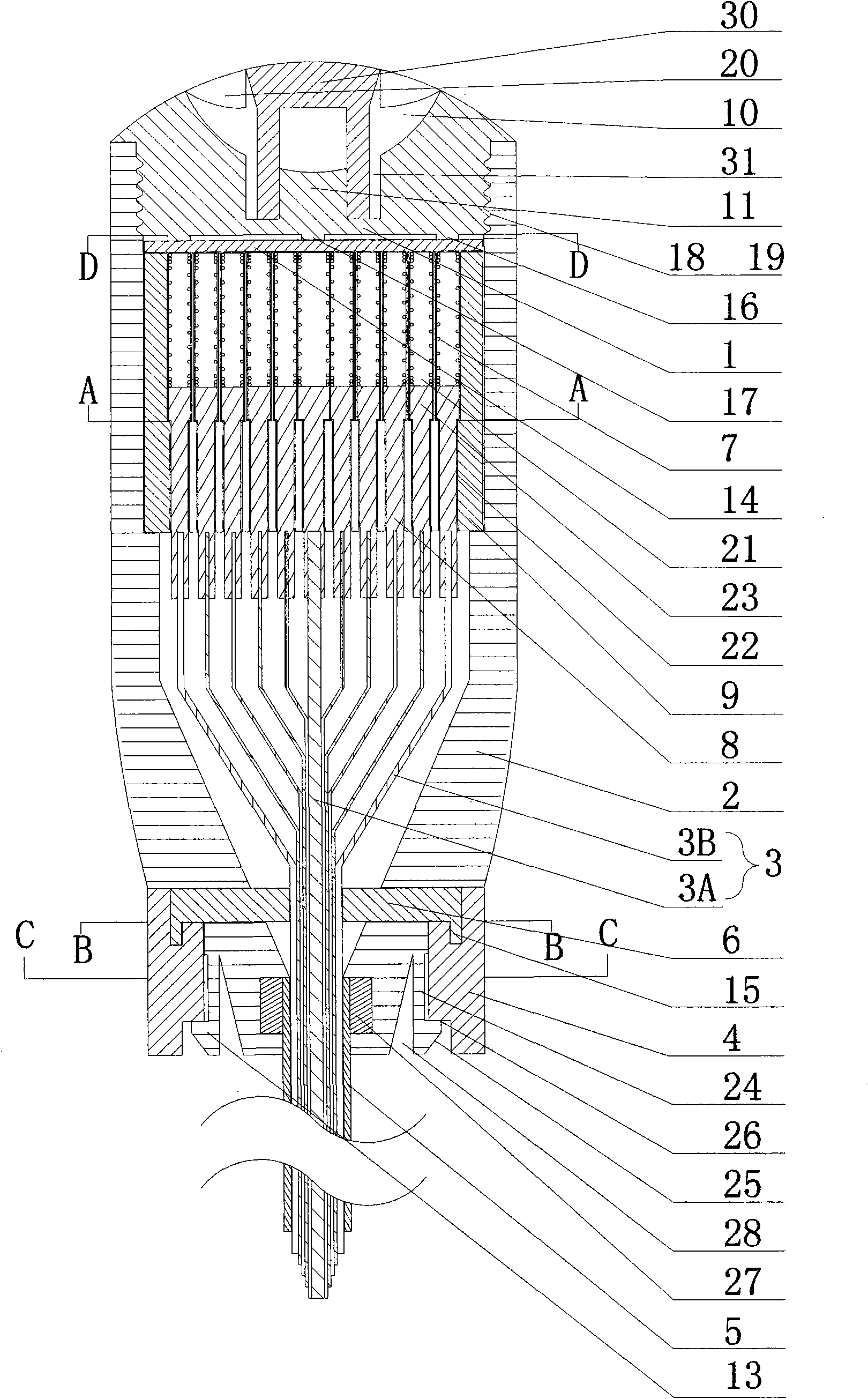

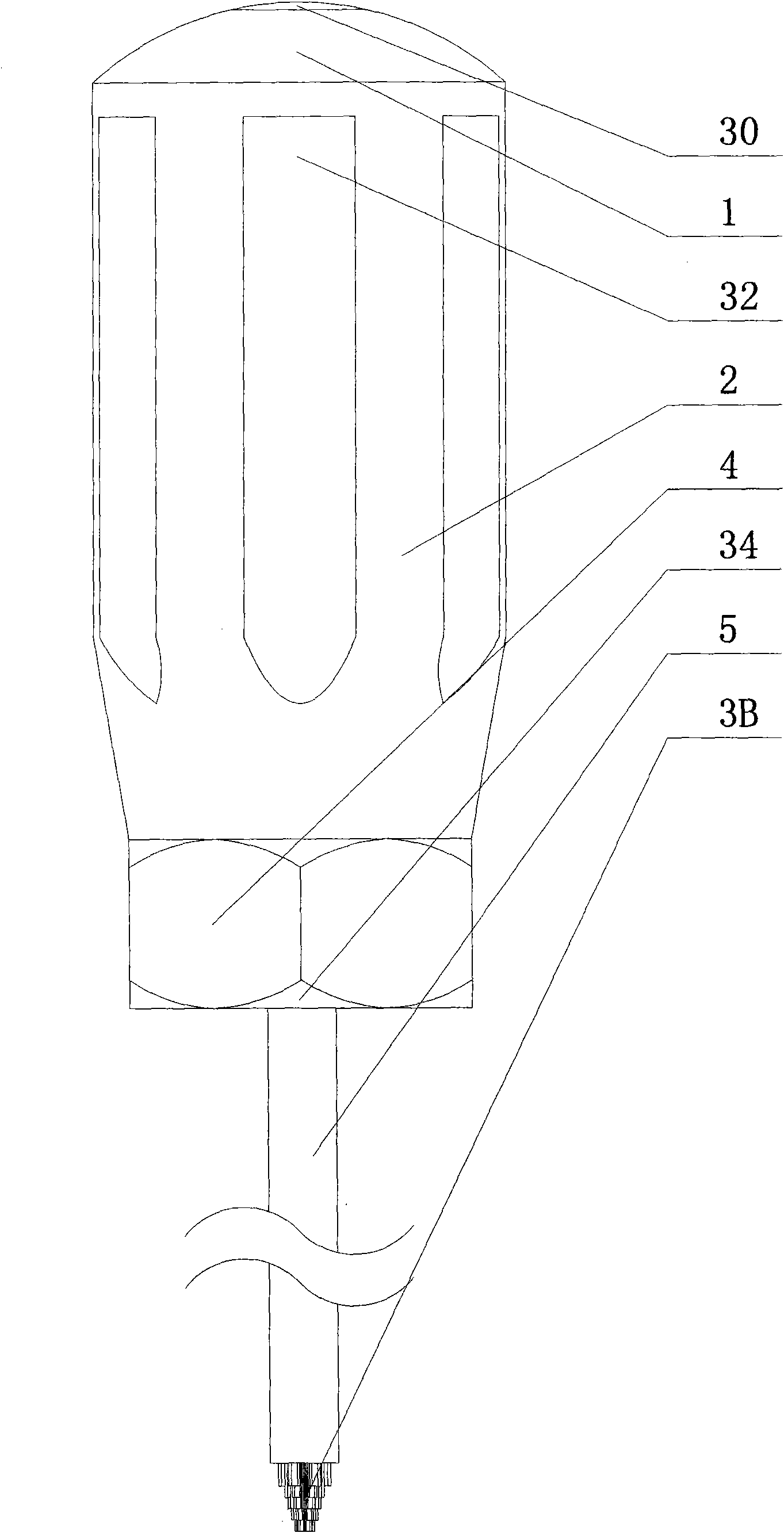

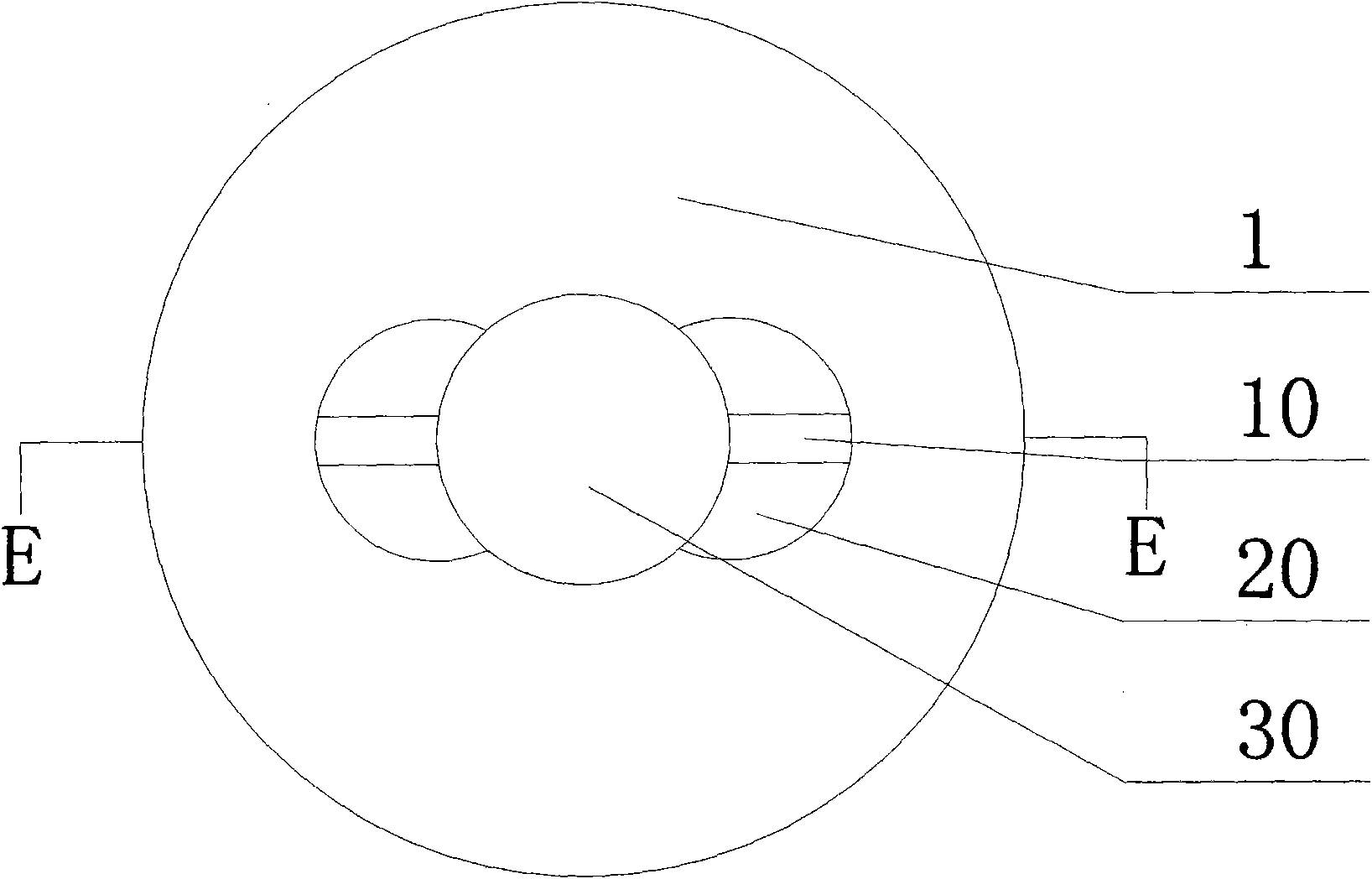

High-frequency pulsed jet flow resonance well drilling device and well drilling method thereof

InactiveCN102493768AIncrease compactionBuried deepLiquid/gas jet drillingMachines/enginesSteel jacketUltrasonic sensor

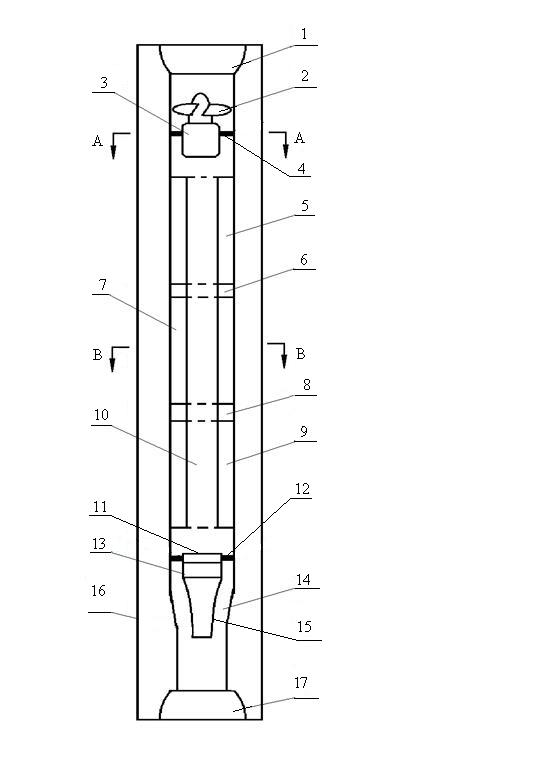

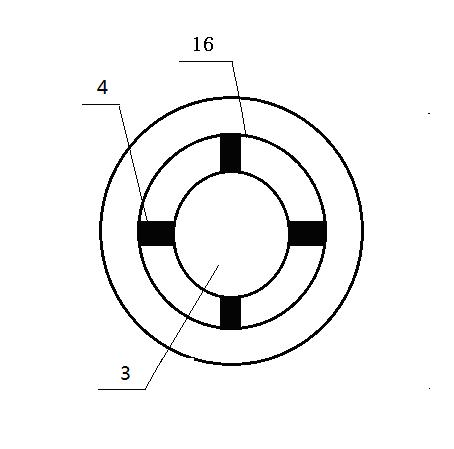

The invention relates to a high-frequency pulsed jet flow resonance well drilling device and a well drilling method thereof. The high-frequency pulsed jet flow resonance well drilling device comprises an outer steel jacket, wherein one end of the outer steel jacket is connected with an upper adapter; the other end of the outer steel jacket is connected with a lower adapter; the upper adapter is connected with a drill collar by a thread; the lower adapter is connected with a drill by the thread; a small hydrogenerator, a density logger, an acoustic logger, a controller and an ultrasonic transducer are successively installed from top to bottom in the outer steel jacket; the small hydrogenerator is composed of a blade and a generator; the blade is installed above the generator; the ultrasonic transducer comprises a fixed end, a transducer and an amplitude transformer; the position on the outer steel jacket, which corresponds to the amplitude transformer, is provided with a necking section; the density logger, the acoustic logger and the controller are mutually separated by cushion blocks; and after the density logger, the acoustic logger and the controller are connected, the inner cavities of the density logger, the acoustic logger and the controller are communicated to form a well drilling fluid path. According to the high-frequency pulsed jet flow resonance well drilling device, the mechanical drilling speed is drastically improved, the improvement amplitude is 1-2 times, and the well drilling cost is effectively lowered.

Owner:NORTHEAST GASOLINEEUM UNIV

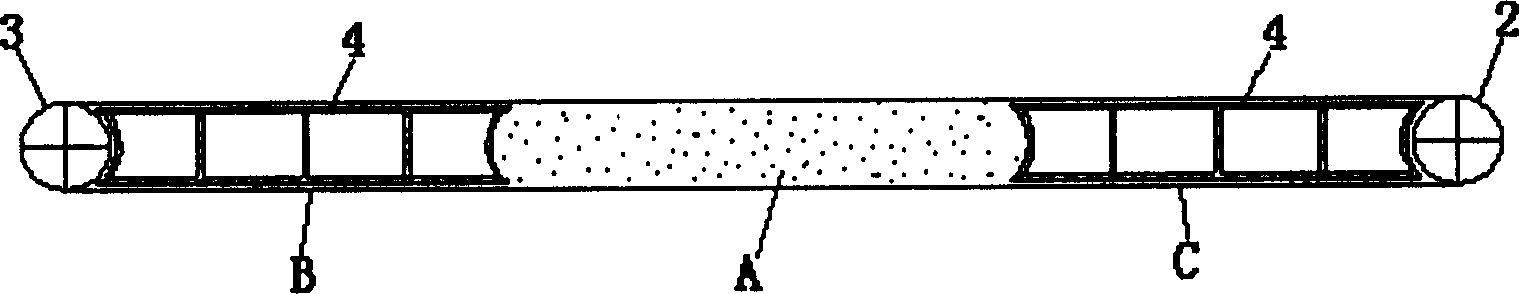

Method for manufacturing solid cored-wires made of high purity calcium metal

A method for manufacturing solid cored-wires made of high purity calcium metal is characterized by comprising the following operating steps: (1) manufacturing calcium metal into calcium metal pumps; (2) processing calcium wires; and (3) synchronously drawing the calcium wires. The invention manufactures the calcium steel common core wires closely integrating inner solid cored-wires made of calcium metal and an outer steel jacket. The calcium steel common core wires do not have the problem of calcium oxidation, thus the shelf life can be prolonged by 3-5 years. The wires are standard in diameter, uniform in density and accurate in measurement. The thickness of the outer steel jacket is 1-2mm which is about 3 times that of the steel strips for the existing products. The outer jacket has high strength, thus avoiding broken wire accidents. The thickness can ensure the product to enter and melt near the ladle bottom plate in the molten steel under the temperature over 1600 DEG C. The calcium reacts in the deep part of the molten steel, the molten steel is fully processed, less calcium is lost and the calcium absorption rate is high. The solid cored-wires are made of electrolytic calcium metal with purity of 99% and have high purity, less impurities and high calcium absorption rate.

Owner:沈阳慧通远达冶金技术研发有限公司

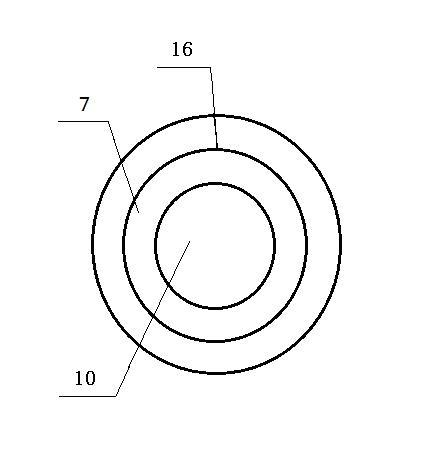

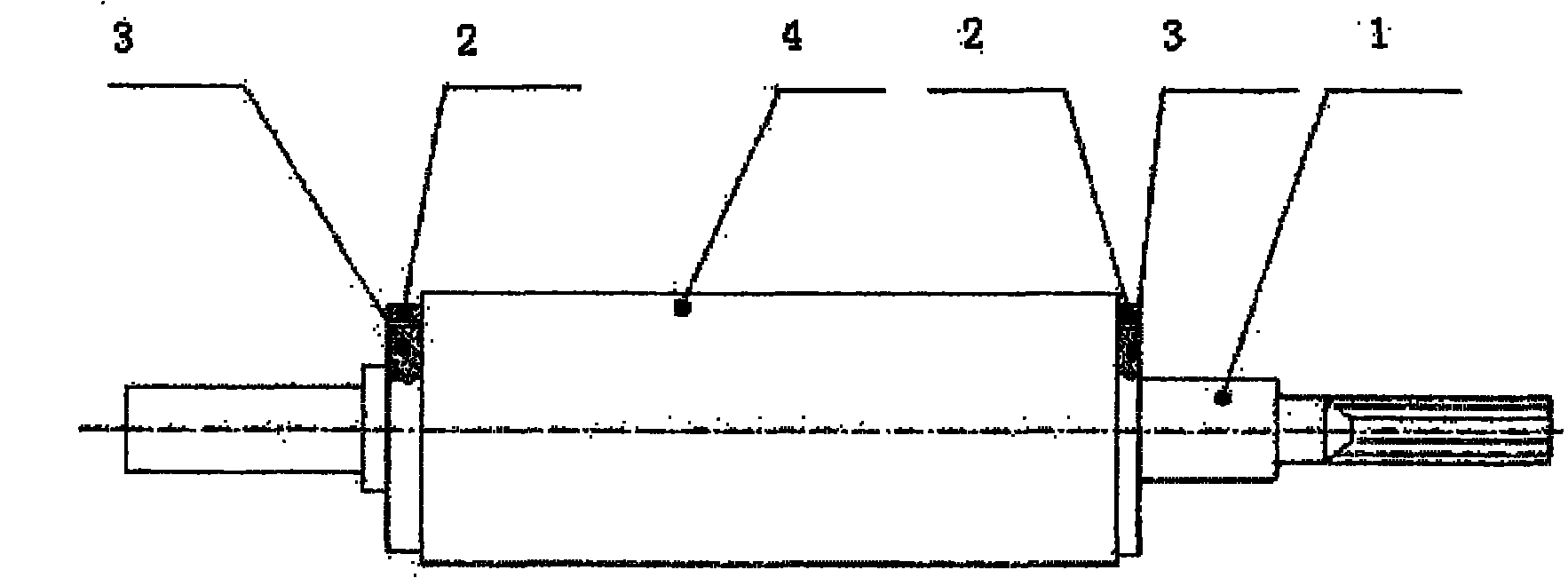

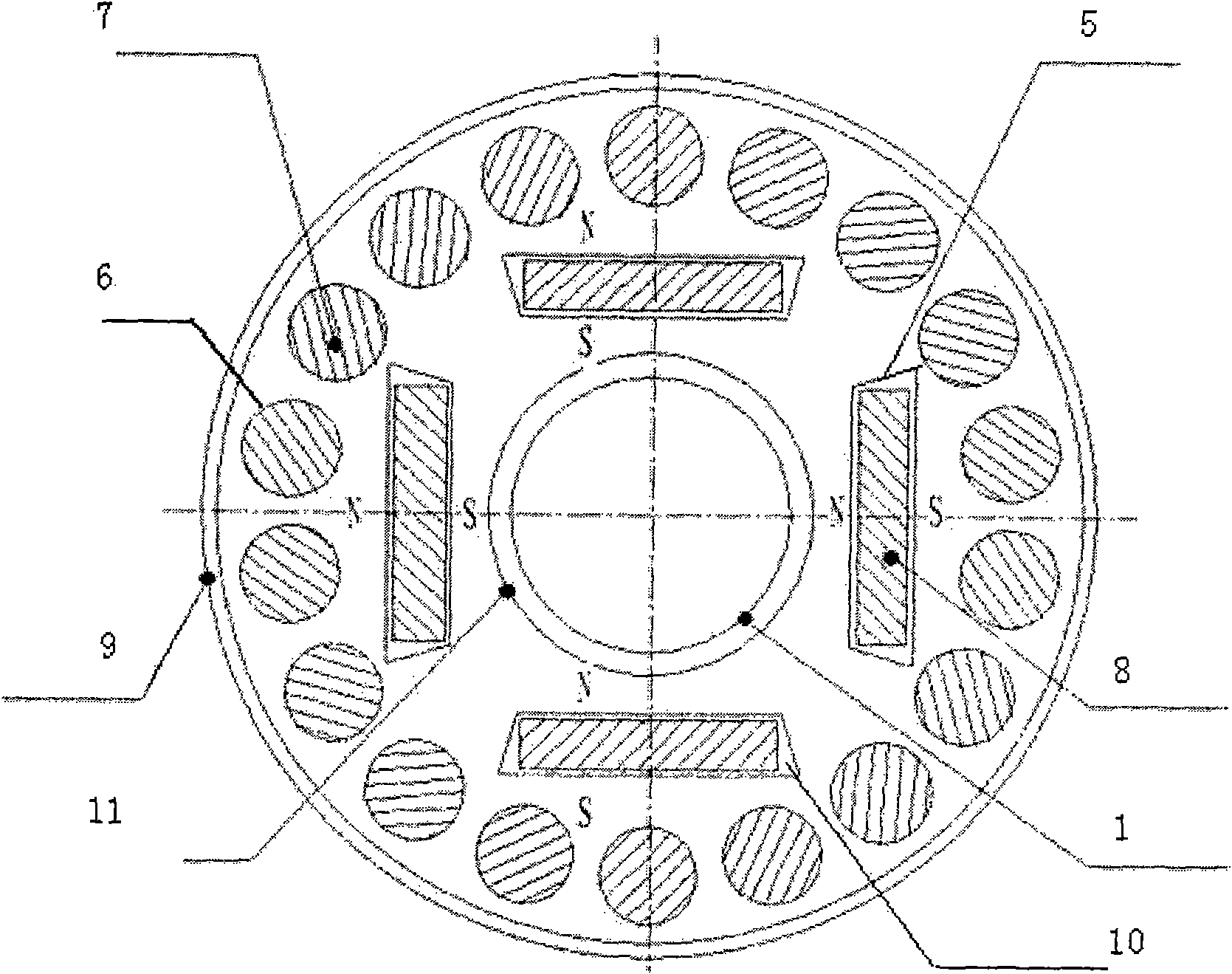

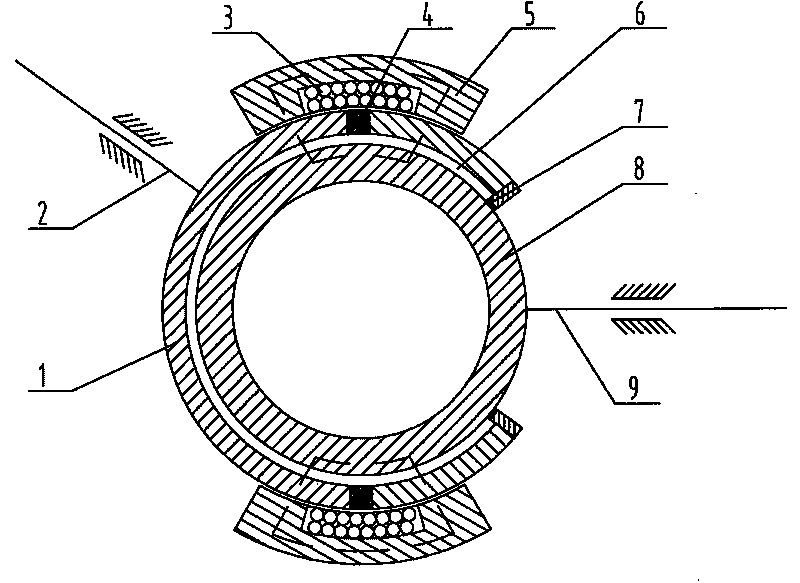

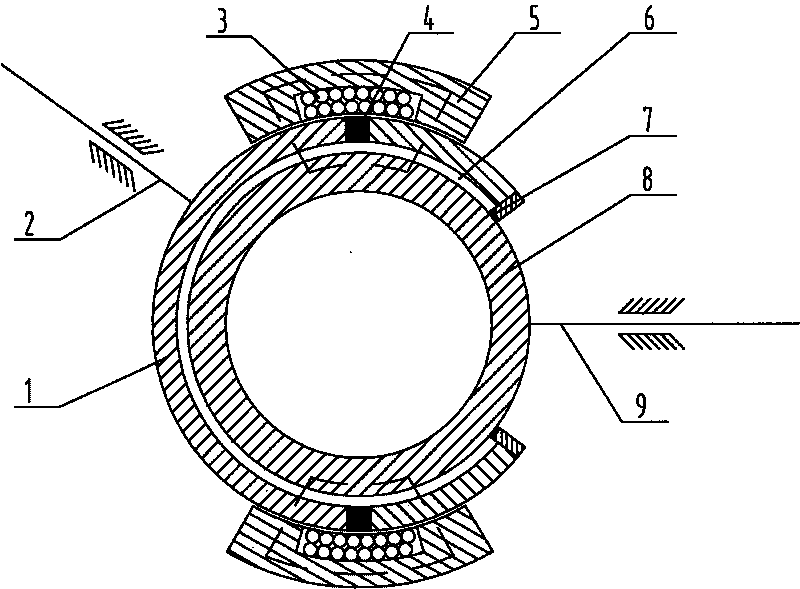

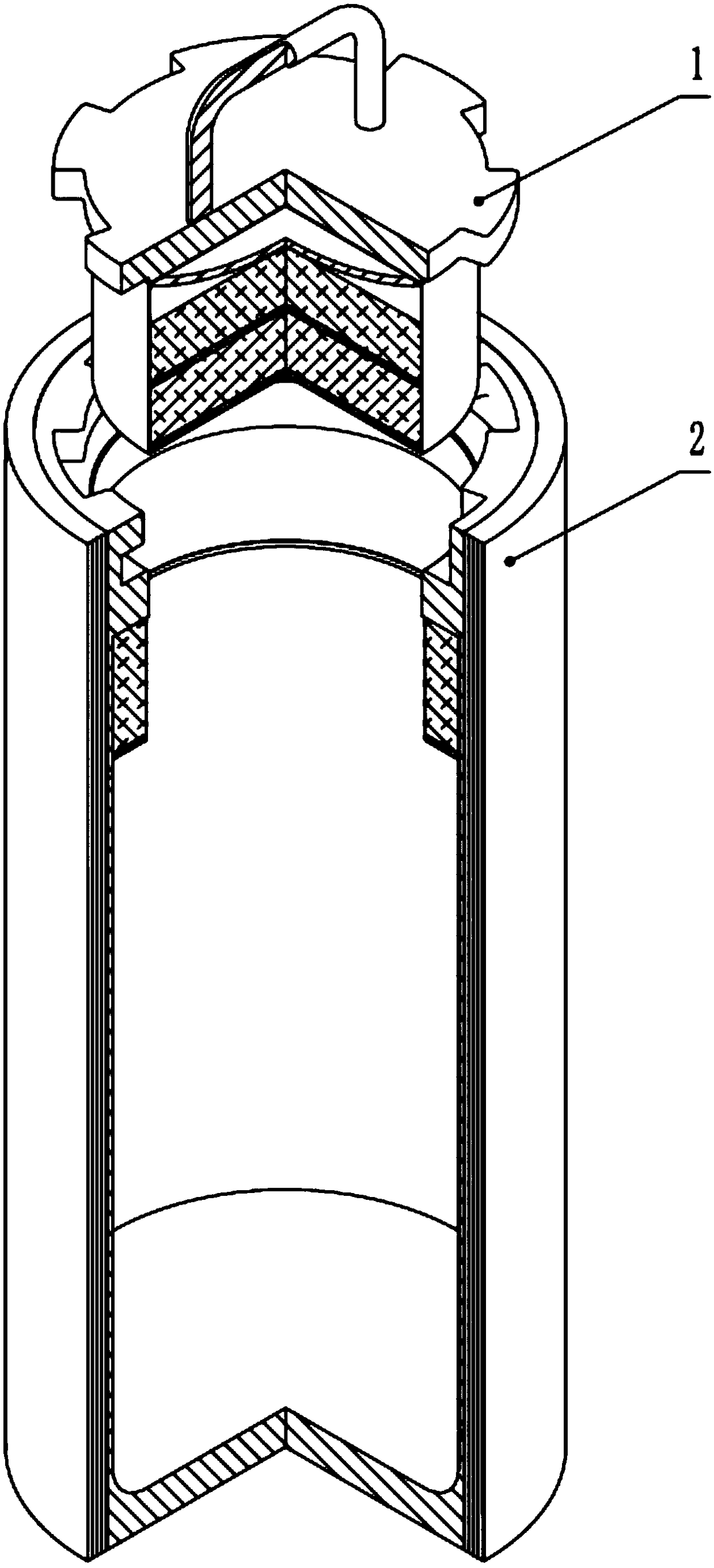

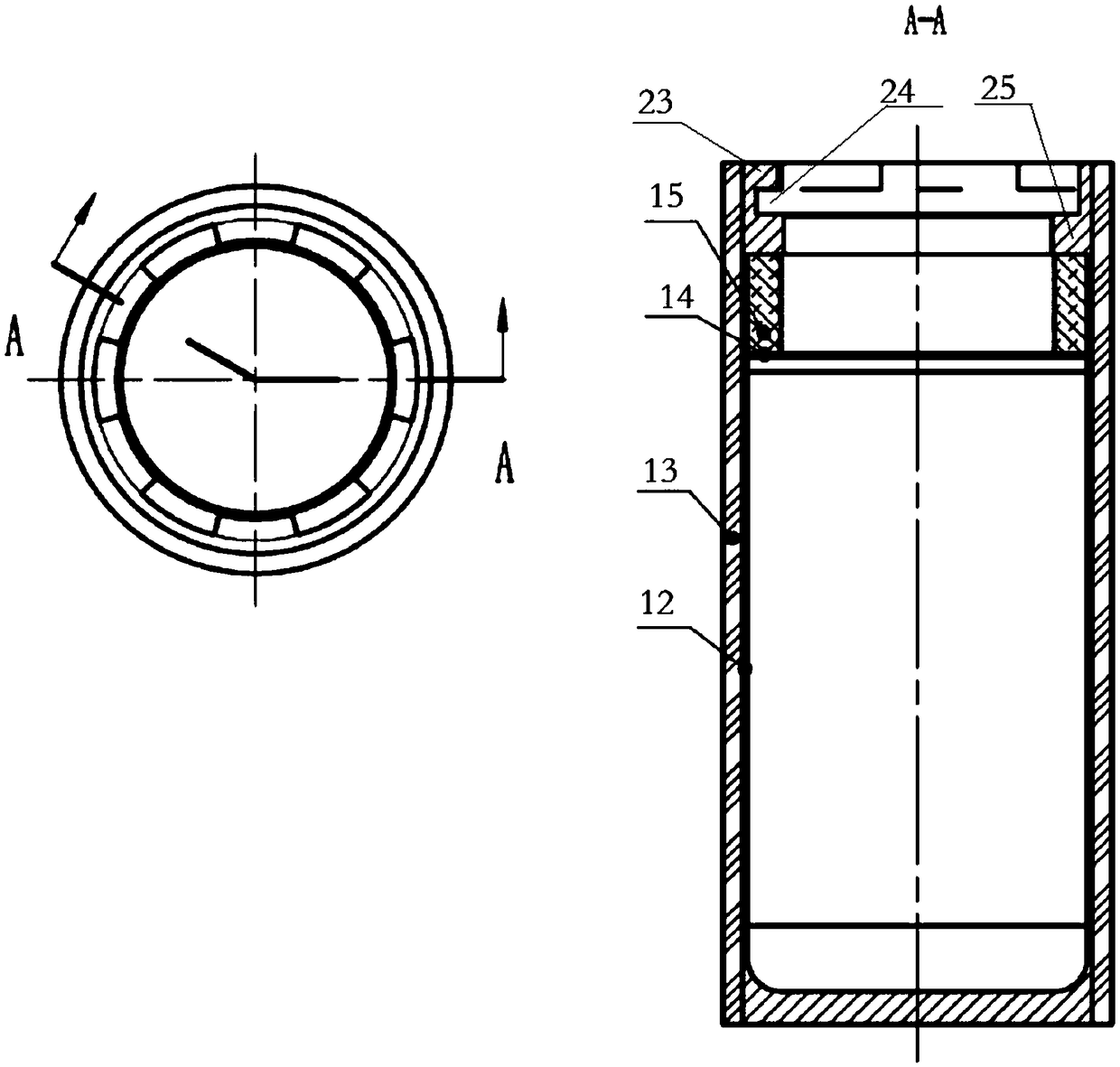

Asynchronous starting and permanent magnet synchronous submersible pump motor

InactiveCN101873043ASignificant advantagesSignificant beneficial effectMagnetic circuit rotating partsSynchronous machinesSynchronous motorSteel jacket

The invention relates to an asynchronous starting and permanent magnet synchronous submersible pump motor. A rotating shaft of a rotor passes through a central hole of a rotor core and is arranged in the rotor core in a penetrating mode; a stainless steel jacket wraps outside the rotor core; a round empty slot is formed along the circumference of the rotor core and passes through the whole rotor core; an aluminum conducting bar is cast in the round empty slot in a penetrating mode; an end ring is cast outside the round empty slot to form a totally closed rotor cage; the inner side of the round empty slot is provided with a trapezoidal empty slot; magnetic steel is embedded into the trapezoidal empty slot and passes through the whole rotor core; the length of the trapezoidal empty slot is more than the width of the magnetic steel; a gap is reserved between two ends of the trapezoidal empty slot in which the magnetic steel is arranged to form a magnetic isolating gap; the rotor at the two ends of the magnetic steel is provided with an arresting device; and a stator is pressed in the shell of a pump body and is opposite to the rotor. The asynchronous starting and permanent magnet synchronous submersible pump motor has the advantages of improving efficiency, reducing volume under the same power, saving materials, overcoming the long-term corrosion of fuel oil on the stator and the rotor by shielding the stator and the rotor with the stainless steel jacket, contributing to pumping various oil bodies, along with asynchronous starting and the function of a synchronous motor.

Owner:天津驰达电机有限公司

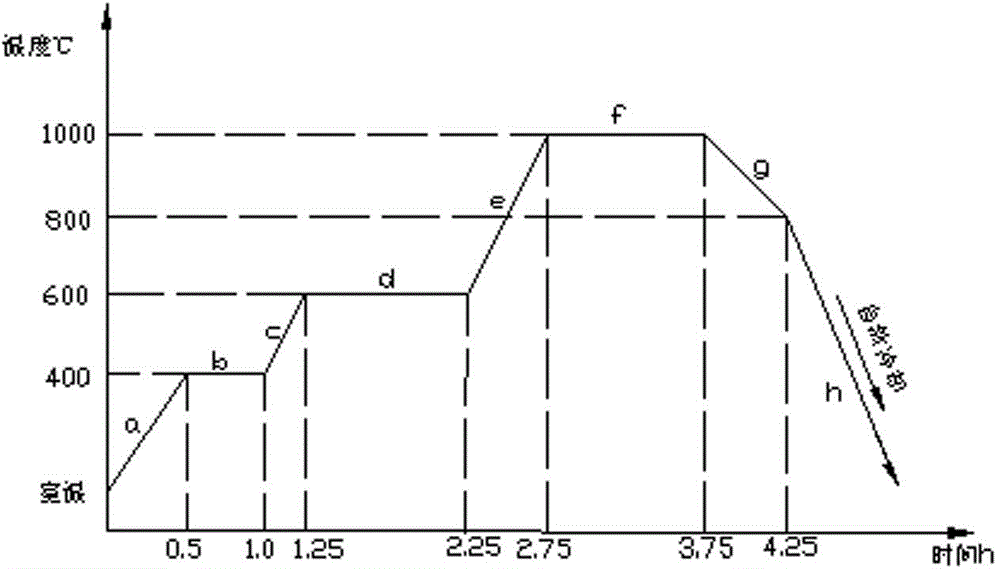

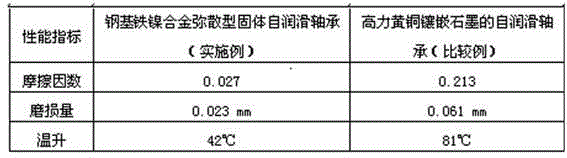

Steel-based iron-nickel alloy diffused-type solid self-lubricating bearing and manufacturing method thereof

The invention discloses a steel-based iron-nickel alloy diffused-type solid self-lubricating bearing and a manufacturing method thereof. The steel-based iron-nickel alloy diffused-type solid self-lubricating bearing is shaft sleeve-shaped; the exterior of the shaft sleeve is a steel jacket; and the inner wall of the shaft sleeve is a wear-resistant layer formed by compacting and sintering iron-nickel alloy mixed powder. The steel-based iron-nickel alloy diffused-type solid self-lubricating bearing is characterized in that the iron-nickel alloy mixed powder comprises 15-20% of nickel, 35-40% of iron, 5-8% of tin, 0.5-1.0% of titanium powder, 1-4% of molybdenum sulfide, 1-3% of aluminum oxide, 1-4% of graphite, 1-2% of zinc stearate and the balance of copper by weight. The manufacturing method of the self-lubricating bearing comprises the following steps of: manufacturing a wear-resistant blank, i.e. blending and stirring the raw materials and carrying out compression molding; manufacturing the steel jacket; and manufacturing the steel-based iron-nickel alloy diffused-type solid self-lubricating bearing, i.e. placing the wear-resistant blank in the steel jacket for vacuum sintering, and carrying out vacuum oil absorption, fine manufacturing and secondary vacuum oil absorption to obtain a finished product. The steel-based iron-nickel alloy diffused-type solid self-lubricating bearing has the characteristics of strong impact resistance, high carrying capacity, wear resistance, low friction coefficients, corrosion resistance and self-lubrication.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

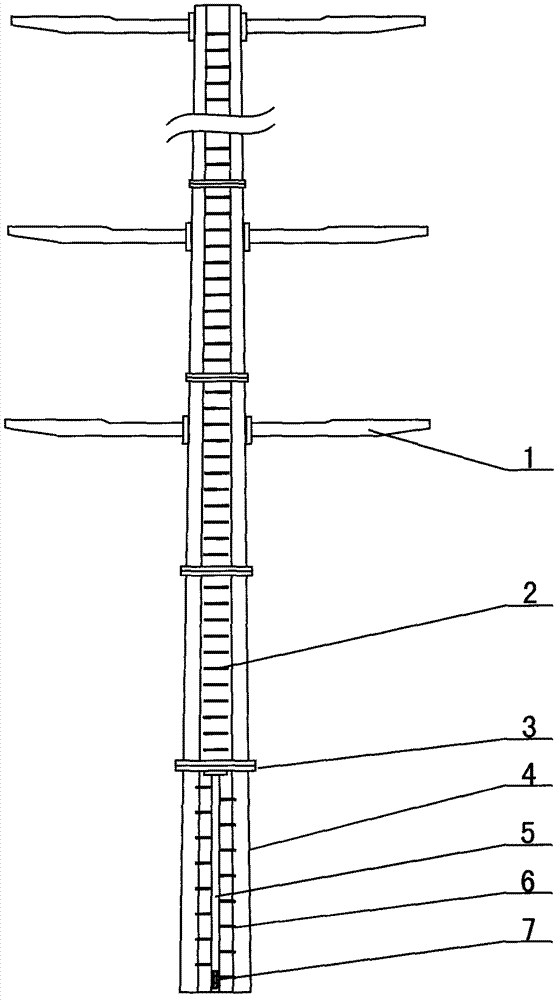

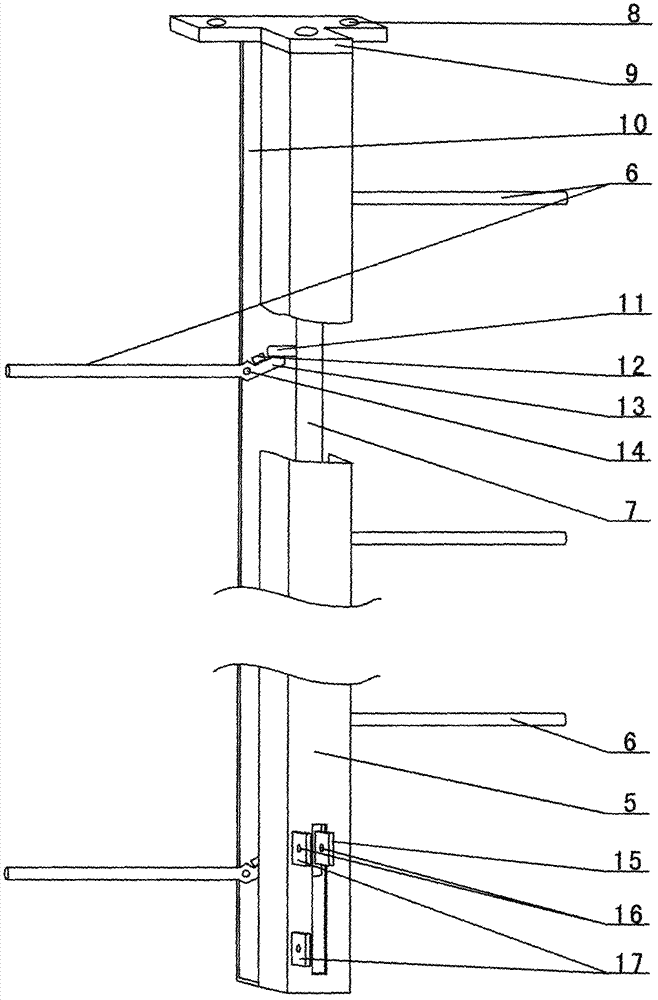

Anti-climbing stair for high-voltage electric wire tower

The invention provides an anti-climbing stair for a high-voltage electric wire tower and relates to a stair. A board shaped like a Chinese character 'Tu' (9) is connected with the face at the lower part of a connection flange (3) at the lowermost part of the high-voltage electric wire tower; the lower part of the convex position of the board shaped like the Chinese character 'Tu' is fixedly connected with the upper end of a channel steel jacket (5); the lower end of the channel jacket is fixedly connected with a forward bending part at the lower end of a back supporting board (10); the both sides of the face at the front part of the back supporting board are movably connected with the inner ends of a plurality of steel roll stairs (6) through a plurality of pin shafts (14); the steel roll stairs are located at a horizontal position, and limiting convex blocks (12) are respectively arranged at each upper part of the steel roll stairs, which is tightly adhered to an upward bending rod (13); splicing rods (11) are respectively arranged at the back part of a connecting rod (7) corresponding to the upper part of the other end of each upward bending rod. The foldable stair arranged at the lower part of the high-voltage electric wire tower disclosed by the invention can be used for effectively preventing children or suicides from climbing the high-voltage electric wire tower.

Owner:国网河南栾川县供电公司

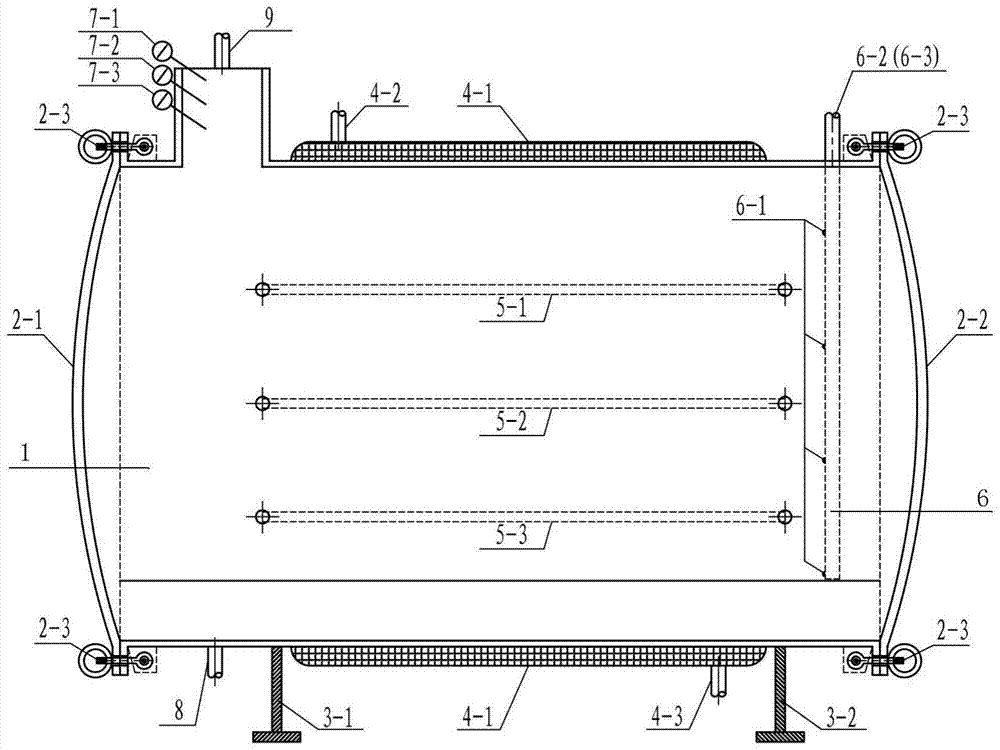

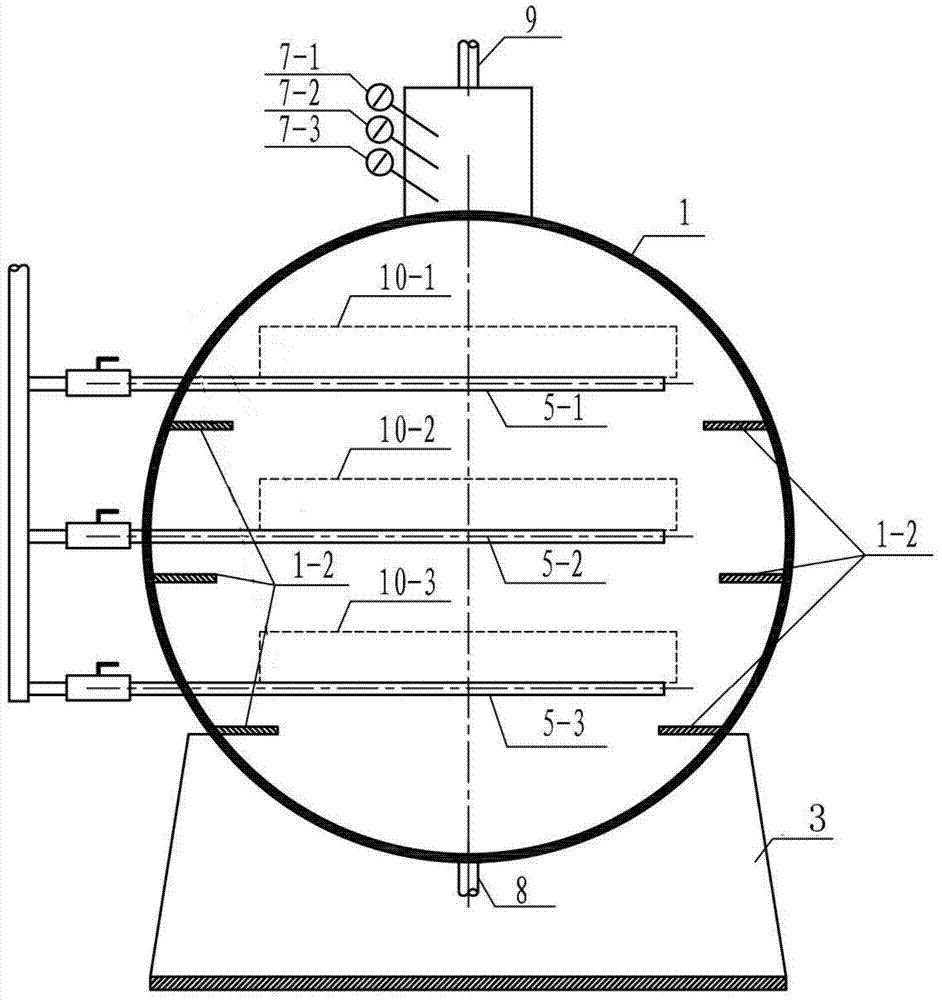

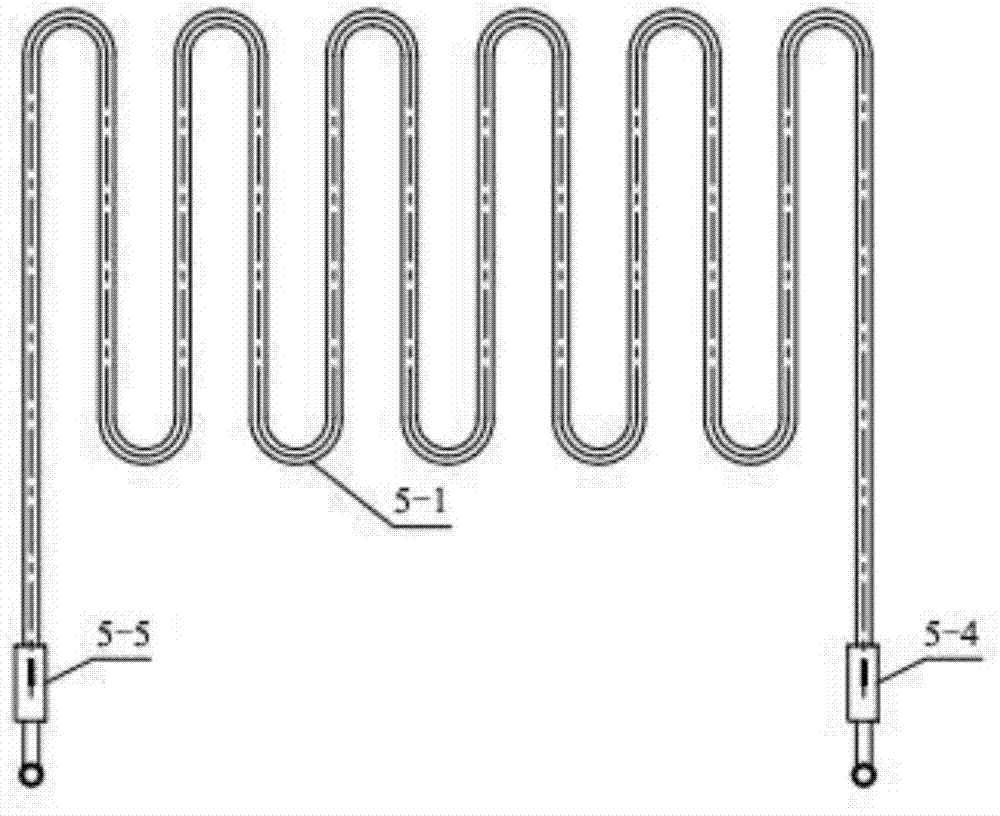

Solid state fermentation reactor and application thereof

InactiveCN104845877AThoroughly sterilizedStable fermentationBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlSteel jacket

The invention discloses a solid state fermentation reactor and an application thereof. The reactor comprises a horizontal cylindrical stainless steel fermentation tank body, a stainless steel jacket is welded on the outer wall of the above tank, and the tank is also provided with a gas outlet, probes, a steam inlet, a steam outlet, a material outlet, movable top covers and a two-fluid spray device; and coil pipes and trays are arranged in the inner cavity of the tank body. The invention also discloses an application of the reactor in cultivation of aerobic, anaerobic and facultative anaerobic microbes. The reactor has the advantages of simple structure, convenience and practicality, can solve the problems of difficult material disinfection, easy bacterial contamination, large labor intensity and low working efficiency of traditional solid state fermentation, realizes automatic control of the solid state fermentation process, and facilitates industrial application of the solid state fermentation.

Owner:NANJING UNIV OF TECH

Thruster of hydrogen-oxygen catalytic ignition mini rocket

The invention provides a thruster of a hydrogen-oxygen catalytic ignition mini rocket, comprising a catalytic ignition device and a combustor device, wherein the catalytic ignition device comprises an end socket, a catalytic cylinder and a catalytic cylinder baseplate; and the combustor device comprises a graphite lining, a graphite precombustion chamber, a precombustion chamber sleeve, a nozzle steel jacket and a tungsten-doped copper nozzle. The thruster is used for realizing hydrogen-oxygen catalytic ignition which can be used for realizing the purpose of repeated ignition. Hydrogen inletsare uniformly distributed at the back semi-section of the combustor in the thruster in the circumferential direction, thus adjusting the hydrogen-oxygen mixing ratio and achieving an afterburning effect. The thruster is simple in structure and ensures that parts can be disassembled and replaced easily.

Owner:BEIHANG UNIV

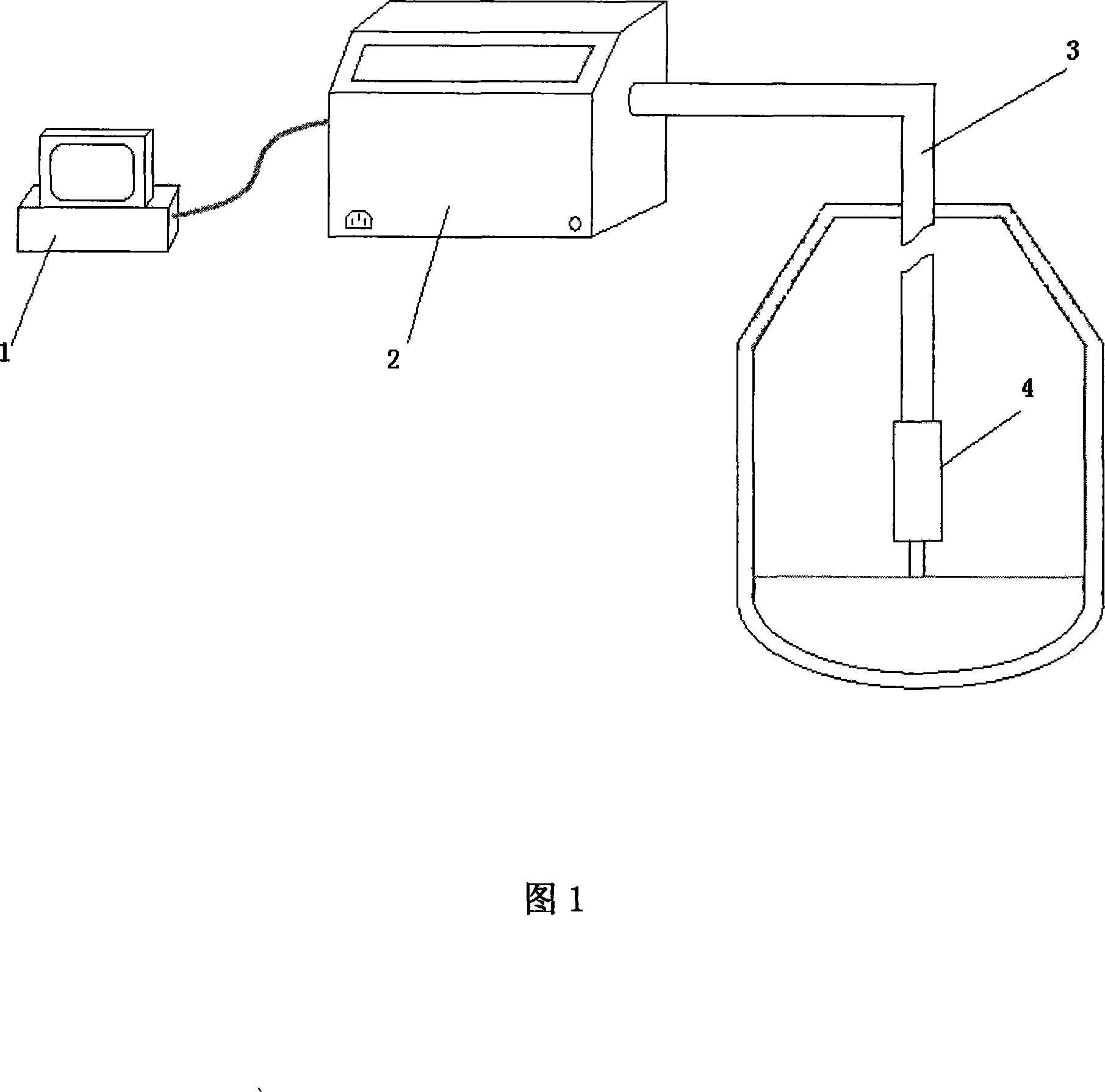

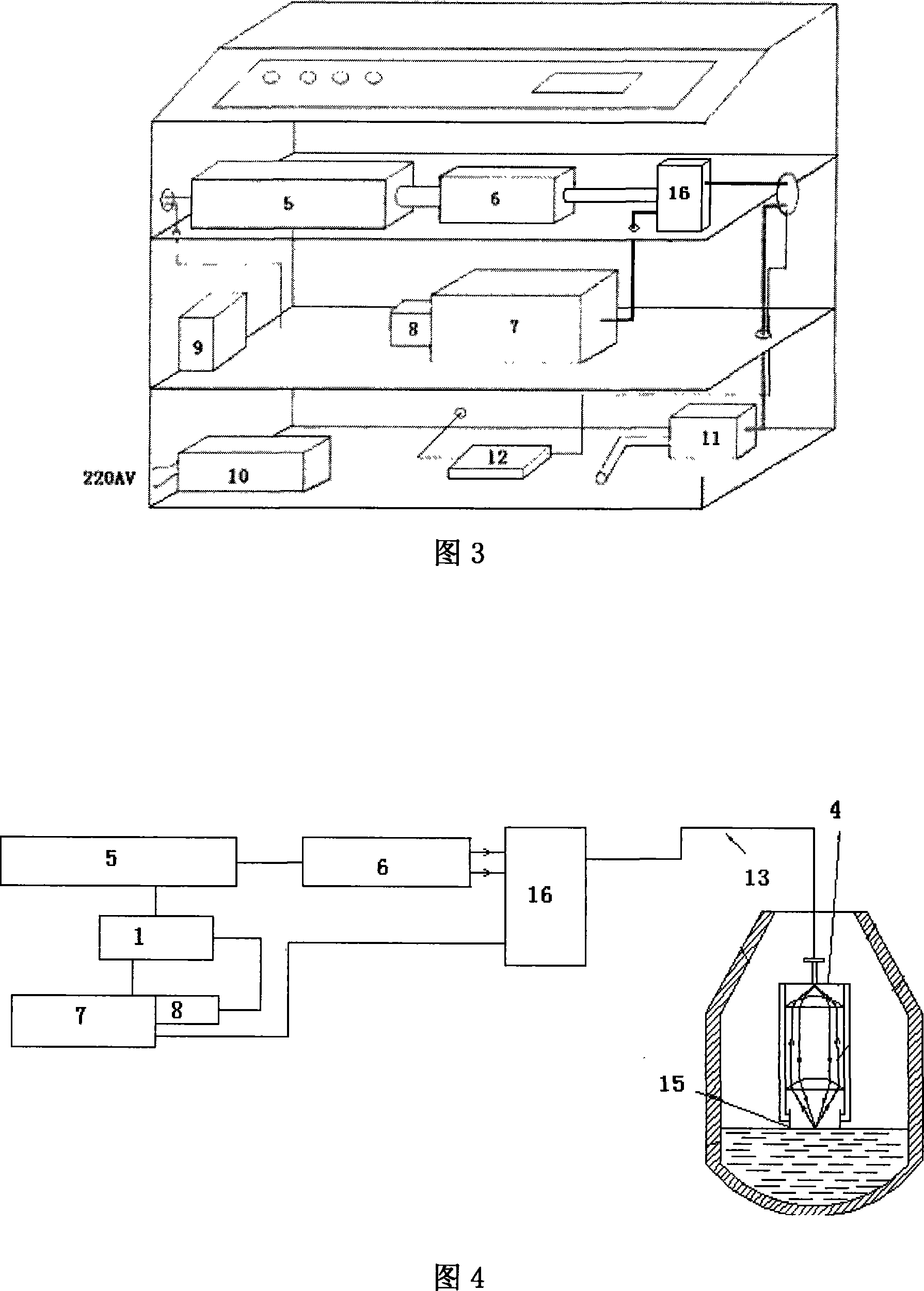

Molten steel component monitoring and analytical equipment

InactiveCN101183074AReduce volumeEasy to install on siteAnalysis by material excitationSteelmakingSteel jacket

The liquid steel component monitoring and analyzing device belongs to the liquid steel analyzing device, and aims at monitoring the steelmaking process on-line, and directly and accurately judges the end point. The invention includes a detection probe, a telescopic tube, a signal generation and acquisition part and a processor. The detection probe structure is: a focusing lens is mounted in the air inside the metal cylinder, and two electrodes are mounted on the front end of the metal cylinder; the telescopic tube adopts a jointed steel pipe jacket, The inner hollow pipe passes through the conductive optical fiber, gas pipe and wire; the signal generation and collection part includes the laser controller, laser generator, optical path coupling components, spectrometer, charge coupled device CCD, blower, detection probe positioning control circuit; the processor receives the charge coupling The electrical signal transmitted by the CCD of the device is A / D converted and processed to analyze the spectral data; the start and stop of the laser generator and the parameter setting of the charge-coupled device CCD are controlled. The invention has the advantages of small volume, convenient on-site installation and fast analysis speed, and is suitable for technological processes such as converters, open hearth furnaces and refining outside furnaces.

Owner:HUAZHONG UNIV OF SCI & TECH

Application of composite power cable connection box with optical fiber arranged in center of conductor

InactiveCN101719651AResolve accuracySolve problems such as easy damage to optical fibersCoupling light guidesCable junctionsSteel jacketPower cable

The invention relates to an application of a composite power cable connection box with an optical fiber arranged in the center of a conductor. The application has the operation steps of: setting the reserved length of a cable, exposing the core of the cable, splitting a round cable split conductor and leading out the optical fiber with a stainless steel jacket from a gap between two fan-shaped conductor units; after cutting off a part of the round cable split conductor, connecting the optical fiber with a cable conductor connecting pipe; carrying out optical fiber welding outside the cable conductor connecting pipe so as to regularly coil and fix the optical fiber in a half-round optical fiber joint box; and then carrying out other operations of the connection box. The invention solves the problems that great effort needs to be taken to move the optical fiber, the temperature measurement of joints is not accurate, and the like of the traditional connecting process; in addition, the invention has reasonable connecting process, easy site construction and simple and quick operation, can meet the automatic monitoring requirements on on-line real-time temperature detection, aging monitoring, and real-time fault monitoring and early warning of the safe operation of a power cable line, can carry out normal cable and optical fiber connecting operations at a construction site, obviously improve the reliability and the efficiency of construction works and reduce the construction cost.

Owner:SHENYANG FURUKAWA CABLE

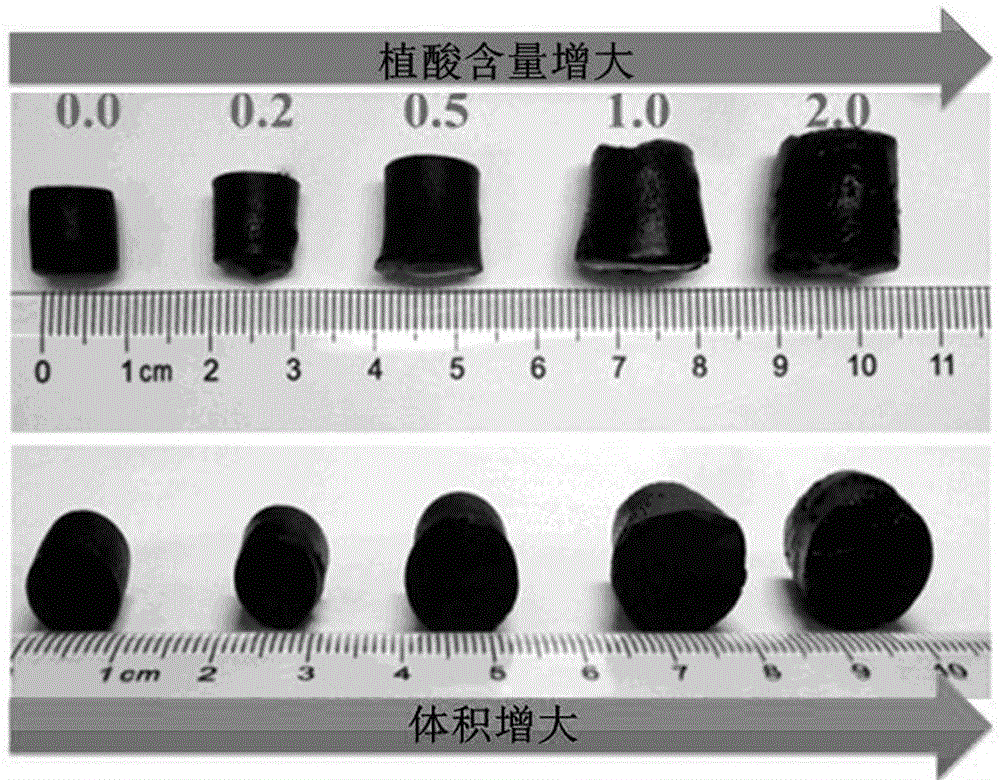

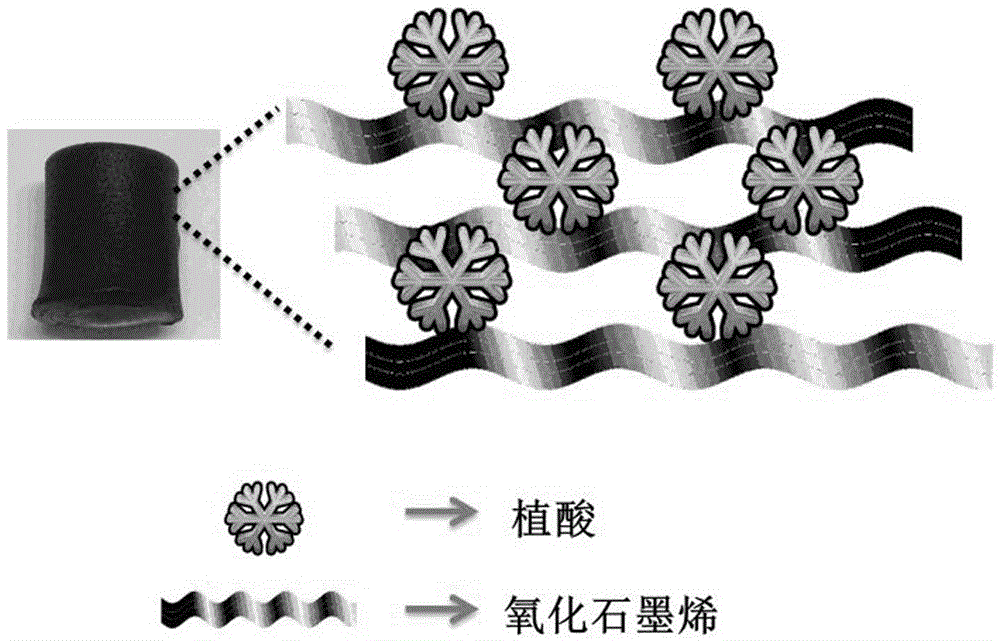

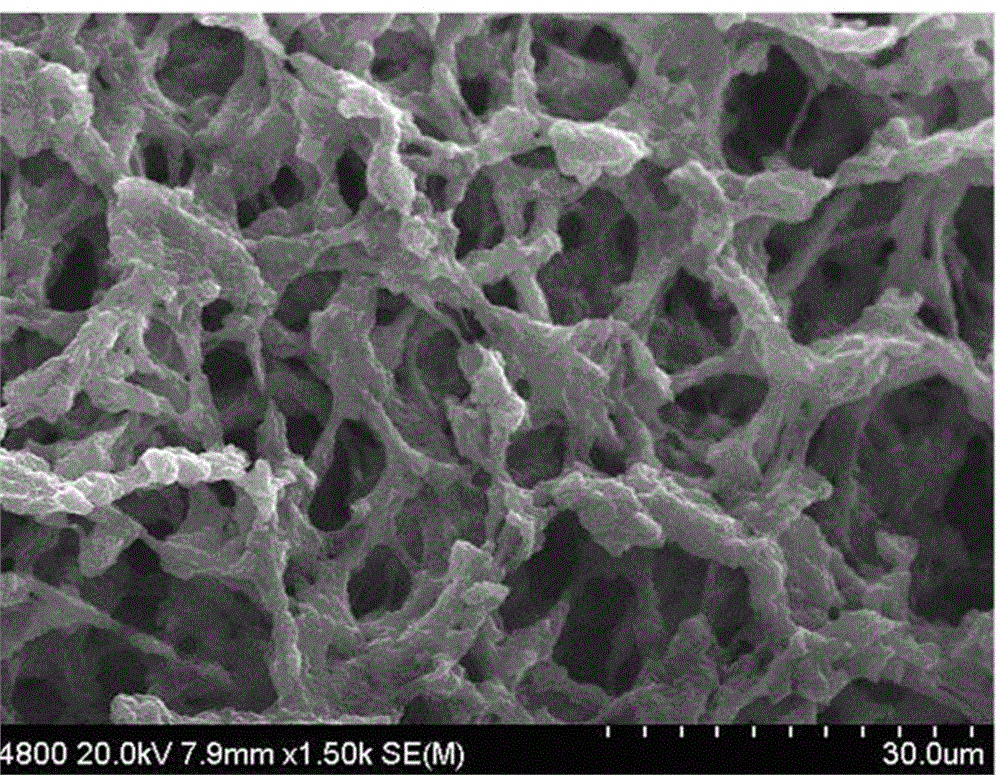

Preparation method of super-hydrophilic super-oleophilic three-dimensional graphene foam material

InactiveCN105753497AOvercoming the deficiency of single invasivenessImprove adsorption capacityCeramicwareSteel jacketFreeze-drying

The invention discloses a preparation method of a super-hydrophilic super-oleophilic three-dimensional graphene foam material.The preparation method includes following steps: 1), adopting a classic Hummers and Offema method to prepare oxidized graphene from natural graphene powder to obtain a dispersive oxidized graphene water solution; 2), placing the oxidized graphene water solution obtained in the step 1) in a reaction kettle, dropwise adding a phytic acid solution in corresponding dosage, embedding the reaction kettle in a stainless steel jacket, disposing the stainless steel jacket in an oven for heating, maintaining 180 DEG C, reacting for 12 h, and naturally cooling to room temperature; freeze-drying a product for 24 h to obtain a cylindrical phytic acid doped super-hydrophilic super-oleophilic three-dimensional graphene foam material.The three-dimensional graphene foam material obtained by the preparation method has special property of zero contact angle to water and oil solutions, is efficient in adsorption and gathering of water, various oil liquids and various organic liquids and can be recycled through simple thermal treatment.

Owner:XIAMEN HUAXIA UNIV

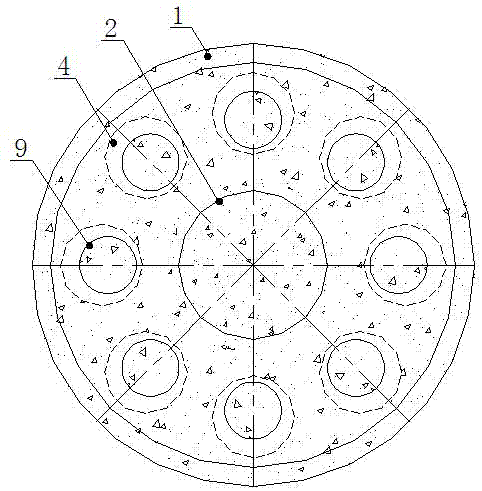

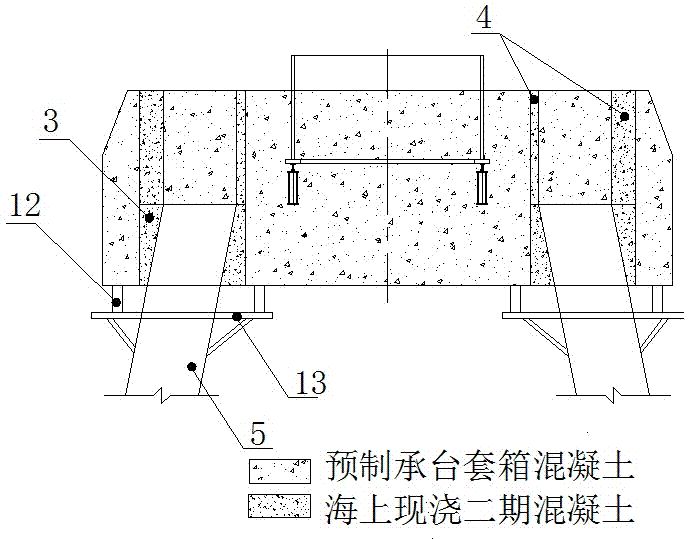

Prefabricated concrete bearing platform with reserved pile nest holes and fabricated multi-pile foundation installation method based on prefabricated concrete bearing platform with reserved pile nest holes

The invention provides a prefabricated concrete bearing platform with reserved pile nest holes and a fabricated multi-pile foundation installation method based on the prefabricated concrete bearing platform with the reserved pile nest holes. A foundation ring is poured at the position in the center of the top face of a concrete body of the prefabricated concrete bearing platform, the multiple annularly-arranged reserved pile nest holes are formed in the positions, corresponding to foundation piles, on the bottom face of the concrete body, and the top of each reserved pile nest hole is provided with a grouting hole way penetrating through the top face of the concrete body. By means of the concrete bearing platform is prefabricated on land, a traditional steel jacket box is replaced by the concrete bearing platform, and a jacket box of the concrete bearing platform serves as a concrete formwork and an important bearing structure; the fabricated multi-pile foundation installation method is adopted, compared with a multi-pile foundation construction scheme used in a sea wind turbine generator at present, sea formwork erecting and disassembling working procedures are omitted, and meanwhile a large amount of sea scene reinforcing steel bar binding can be completed in a prefabrication factory on land; the construction efficiency is greatly improved, the sea bearing platform construction time is saved, and meanwhile the construction cost is reduced.

Owner:POWERCHINA XIBEI ENG

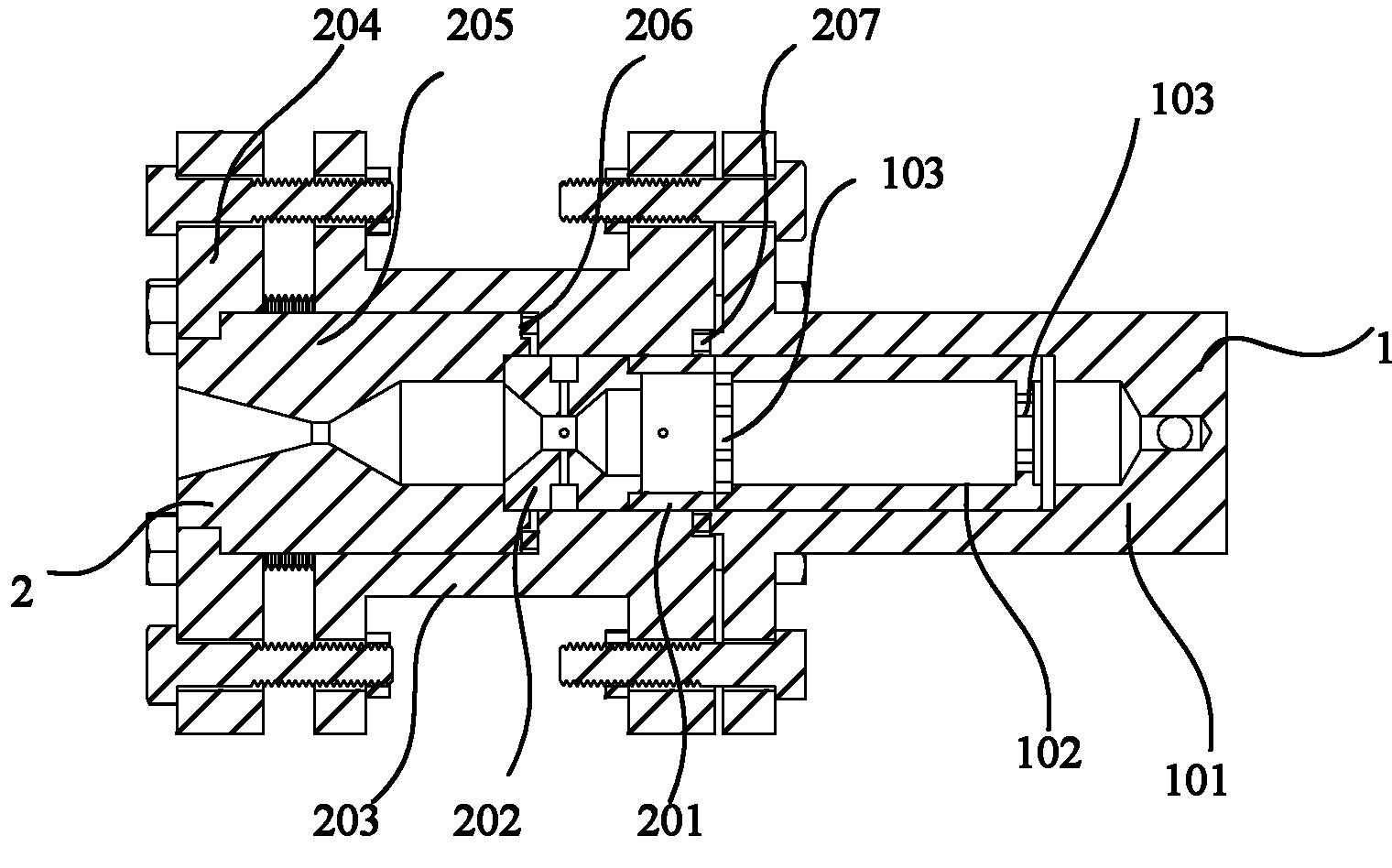

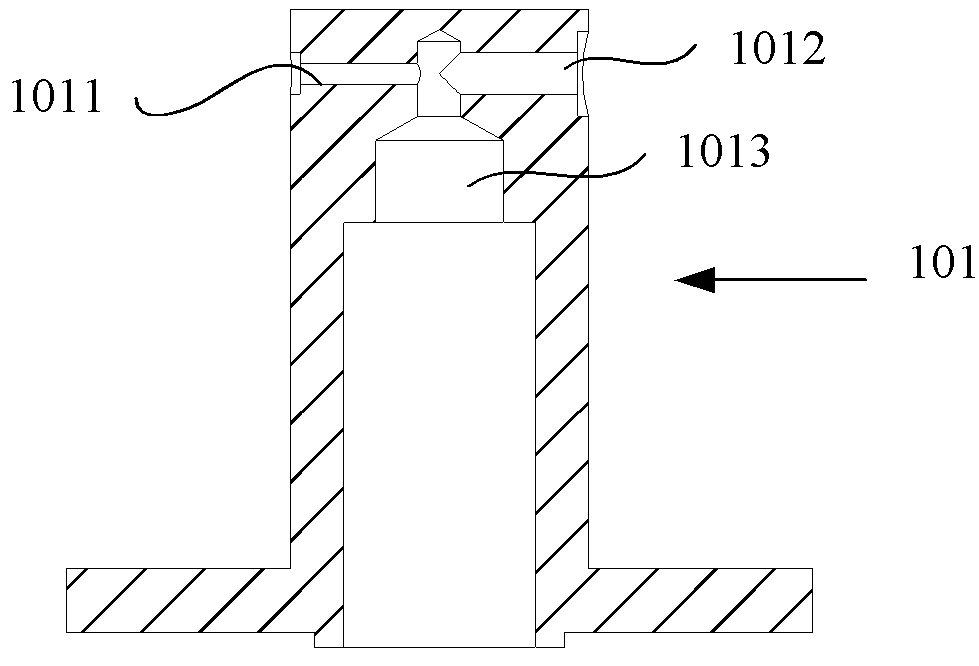

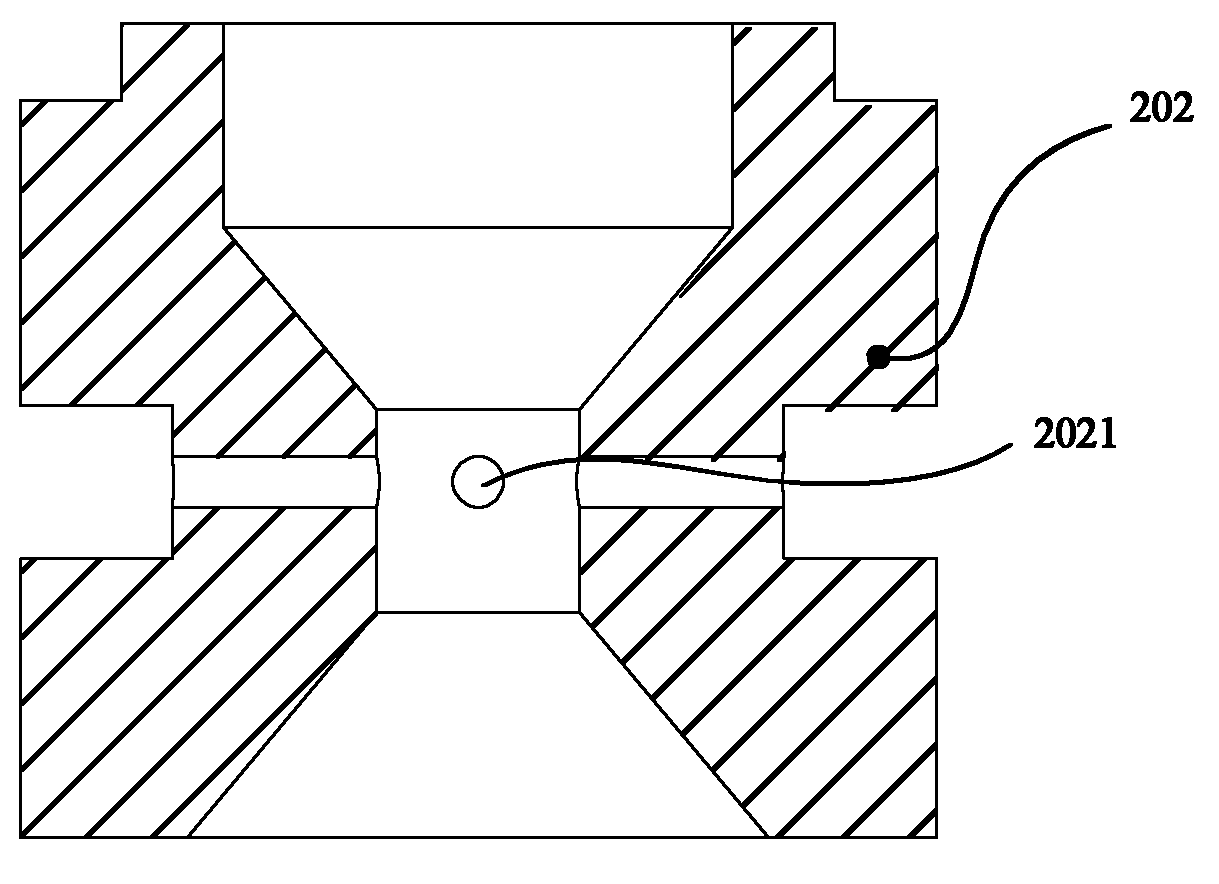

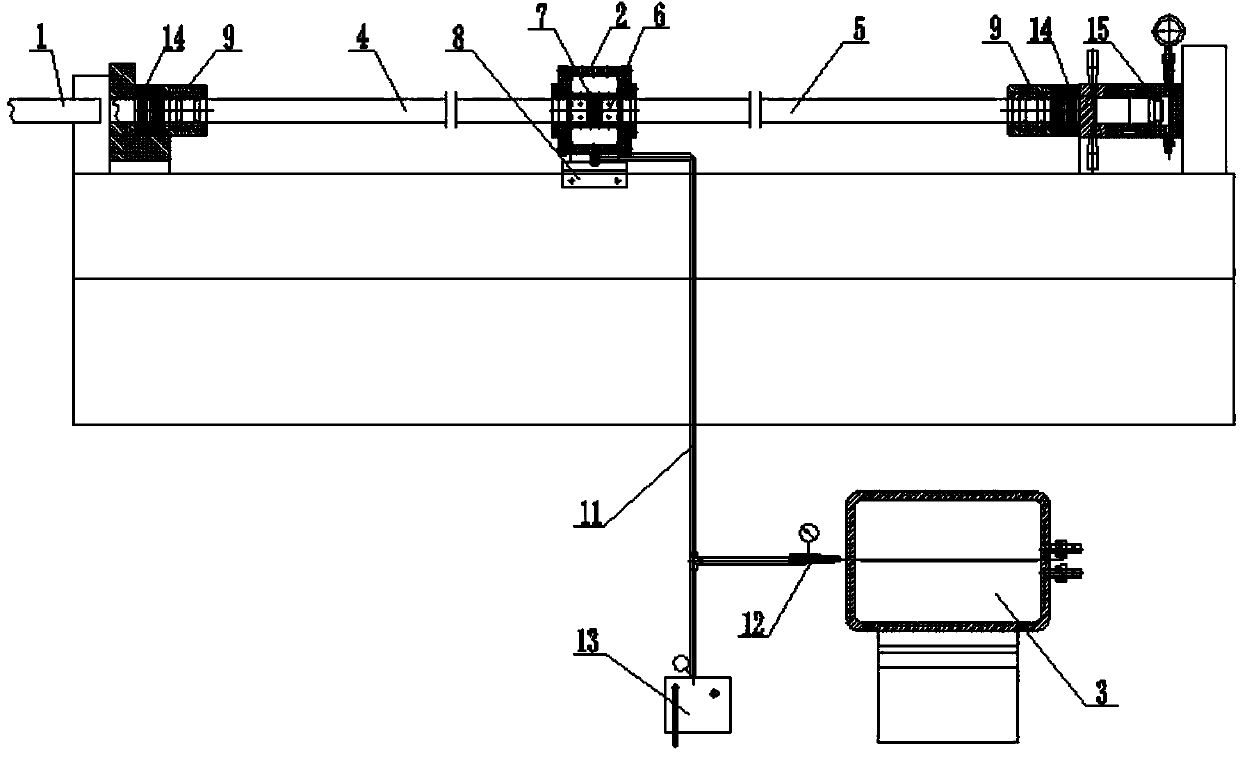

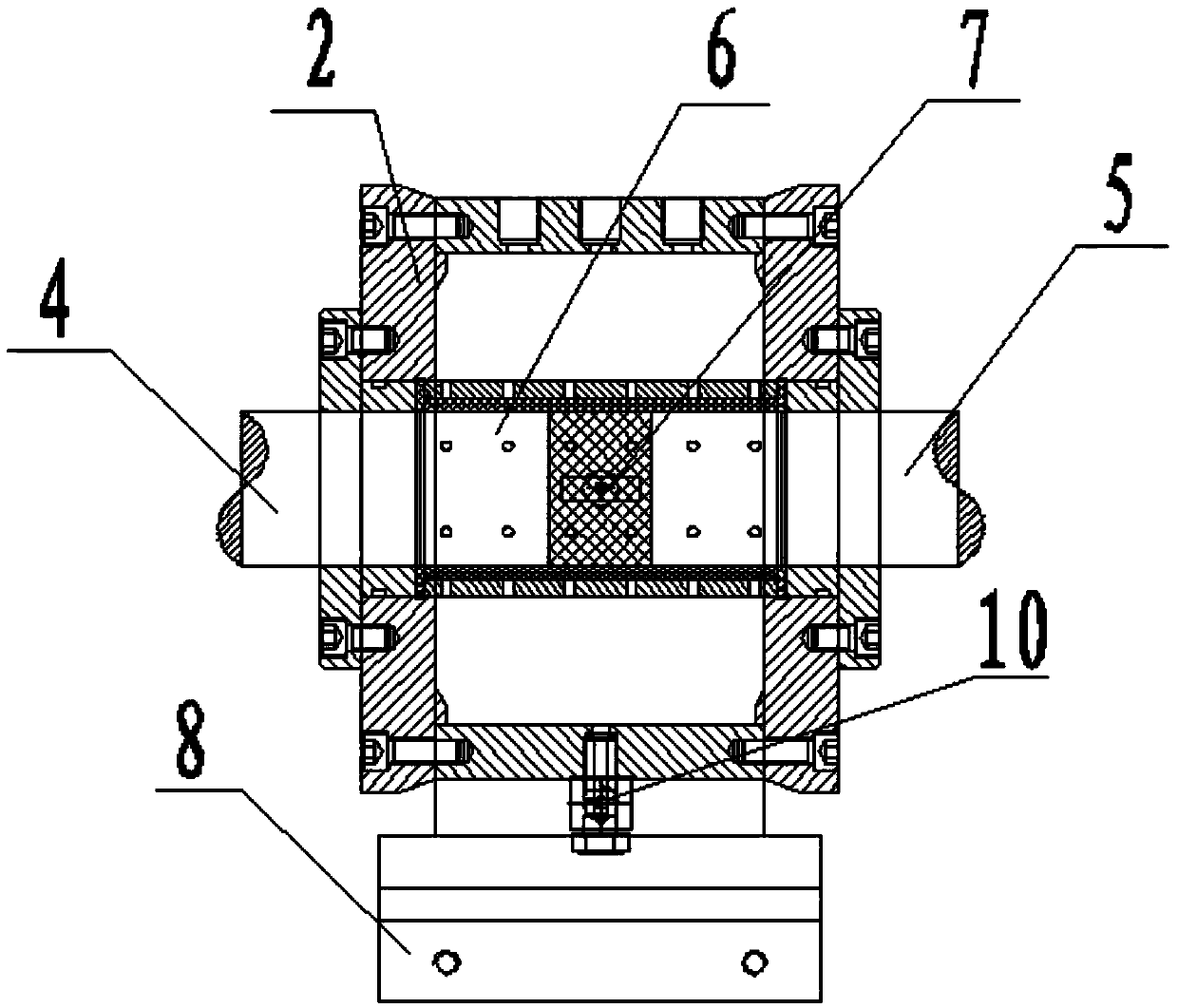

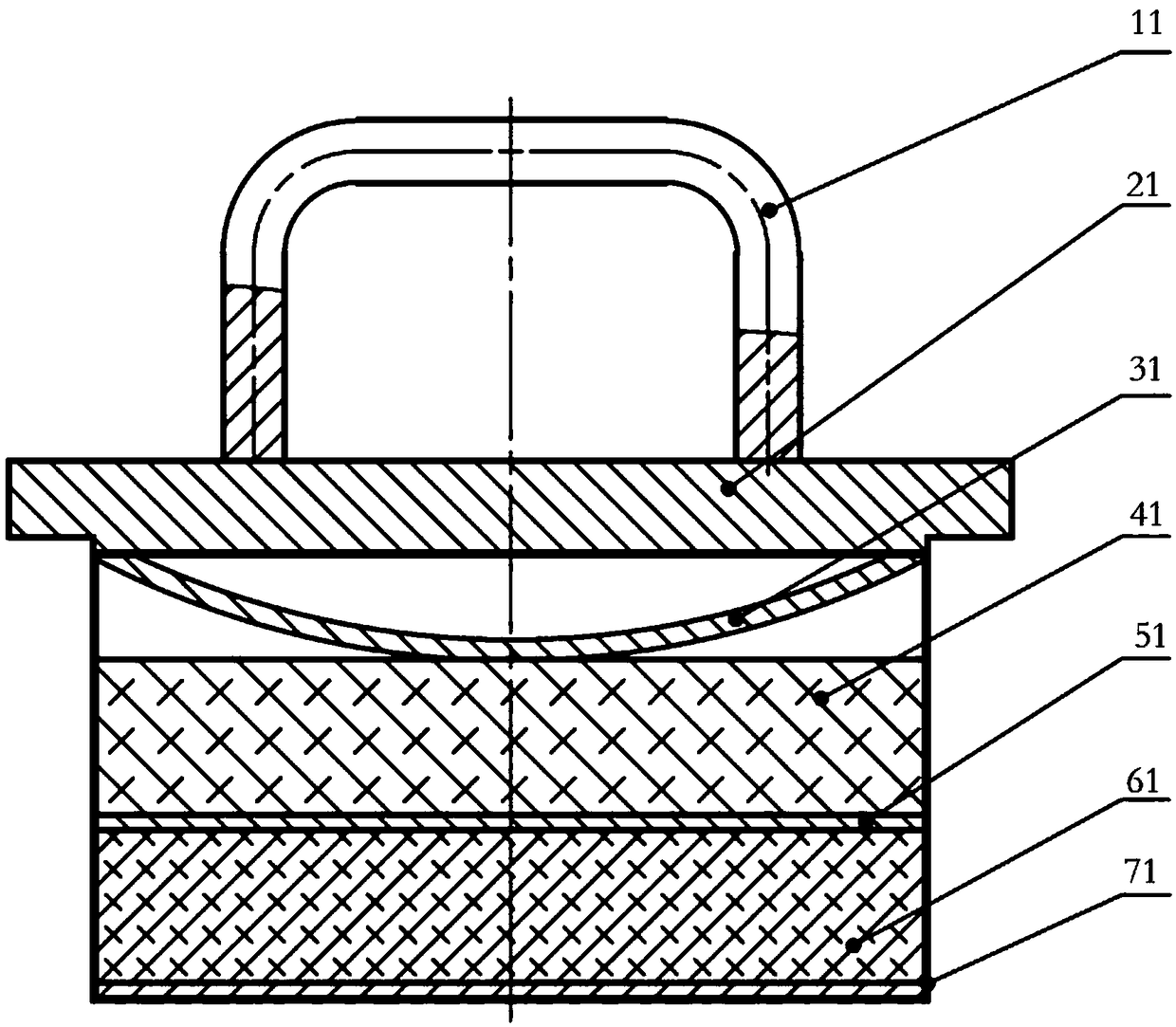

Loading device for simulating stress of coal rock

InactiveCN103743665AAccurate research on performance parametersAccurate researchEarth material testingUsing mechanical meansStress conditionsSteel jacket

The invention discloses a loading device for simulating stress of coal rock. The device comprises a strike bar, a pressurizing oil cylinder, a balancing oil cylinder, an incident rod and a transmitting rod, wherein an oil cylinder support is arranged at the bottom of the pressurizing oil cylinder, a confining pressure chamber is arranged at the center of the pressurizing oil cylinder, a coal rock test piece is placed in the center of the confining pressure chamber, a steel jacket is arranged at the periphery of the coal rock test piece, the incident rod and the transmitting rod clamp the steel jacket on the coal rock test piece, stress pieces are arranged on the incident rod and the transmitting rod or stress pieces are arranged on the coal rock test piece, an oil pipe connector is arranged at the bottom of the pressurizing oil cylinder, the oil pipe connector is connected with an oil pipe which is respectively connected to the balancing oil cylinder and a hydraulic manual pump through a diverter, and a one-way valve is arranged on the oil pipe and close to the balancing oil cylinder. The stress condition of the deep underground coal rock layer is truly restored by means of applying a three-dimensional pressure to the coal rock test pipe through the pressurizing oil cylinder and using the strike rod to strike the incident rod to axially apply a pressure to the coal rock test pipe, so that performance parameters of the deep underground coal rock layer are precisely researched.

Owner:ANHUI UNIV OF SCI & TECH

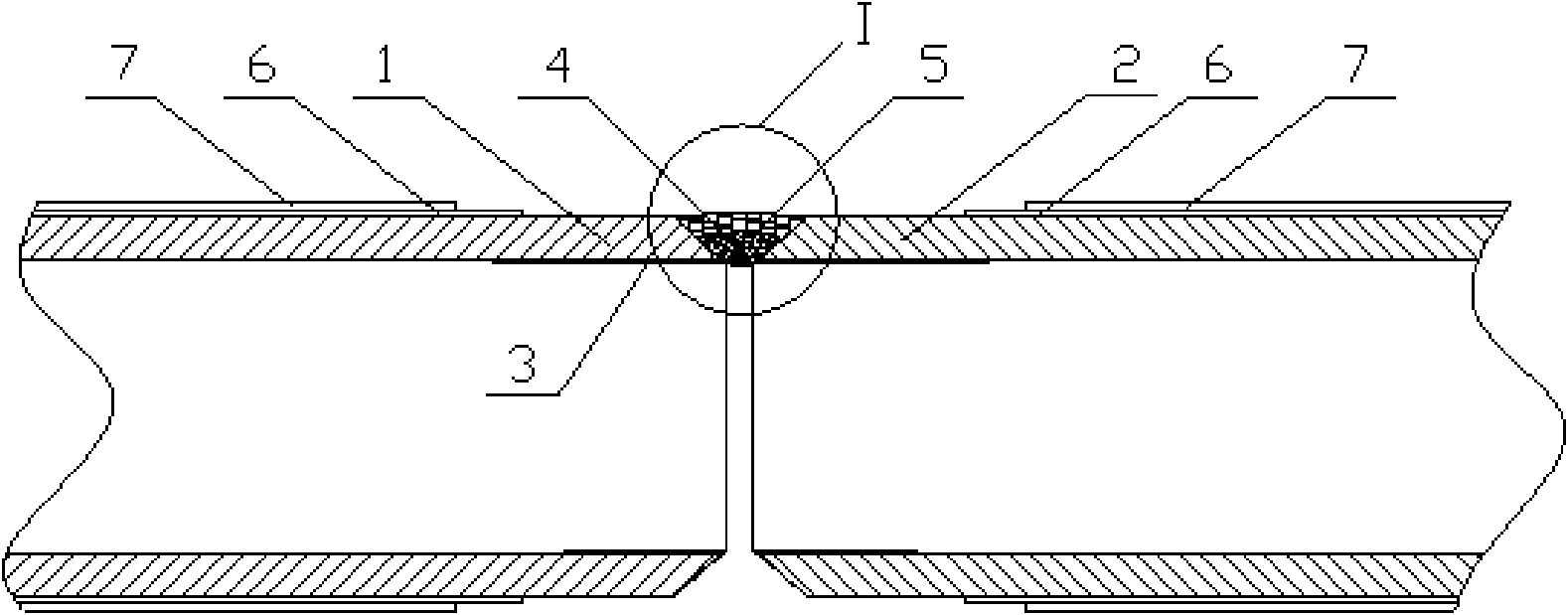

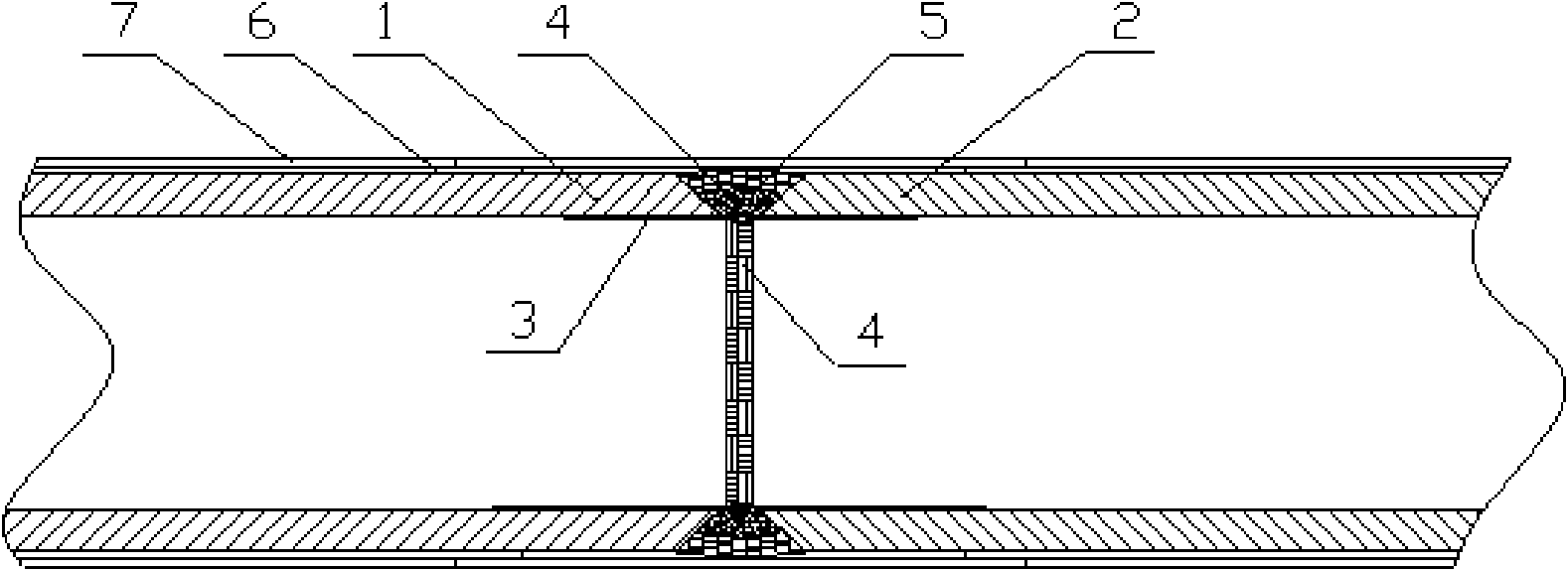

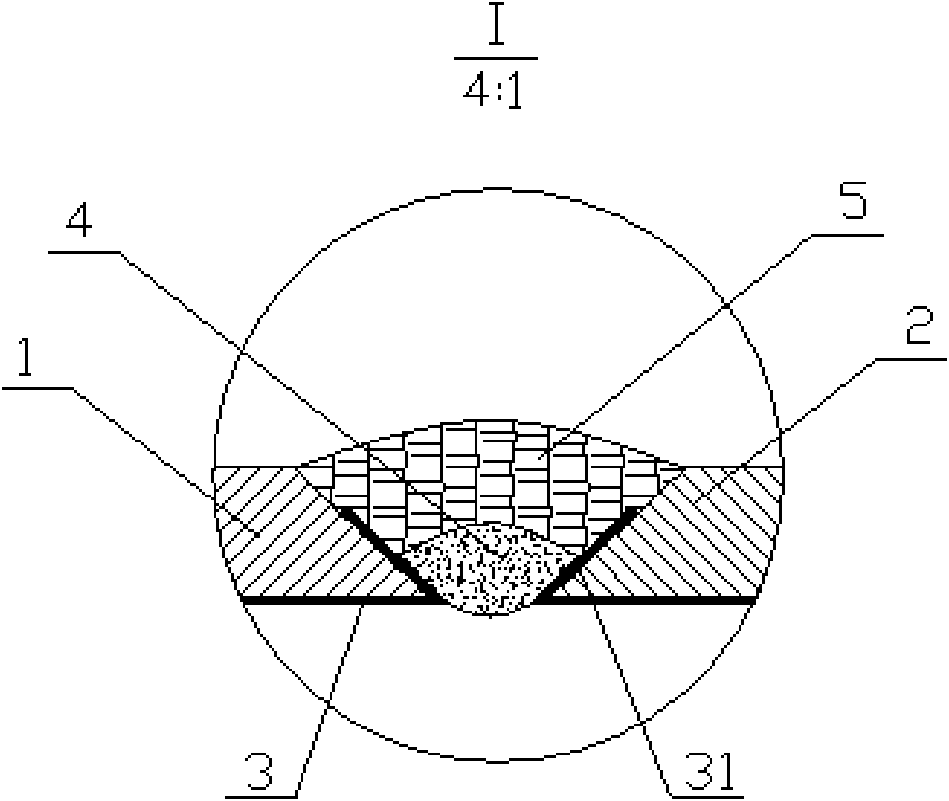

Repair-proof welded connection technology of inner walls of plastic-coated steel tubes

The invention relates to the technical fields of metal surface anti-corrosion and pipe connection and discloses a repair-proof welded connection technology of the inner walls of plastic-coated steel tubes. The welded connection technology comprises the following steps: a. removing rust of the steel tubes; b. spraying metal coating at the ends of the steel tubes through thermal spraying; c. preparing thin-walled stainless steel jackets; d. installing the thin-walled stainless steel jackets in the steel tubes, performing tube expansion to ensure that the thin-walled stainless steel jackets are lined to the inner walls of the steel tubes; e. flanging the ends of the thin-walled stainless steel jackets according to the root shape of the steel tubes to form turnups; f. coating hierarchical coating on the outer walls of the steel tubes; g. transferring the steel tubes with the thin-walled stainless steel jackets to a site; h. welding the thin-walled stainless steel jackets by using stainless steel welding rods; i. welding the steel tubes by using carbon steel welding rods; j. repairing the hierarchical coating on the outer surface of the steel tubes and k. detecting. The invention avoids the repair of the inner wall of the steel tubes, eliminates corrosion blind spots, can not reduce the internal diameter of the steel tubes and flow rate and can greatly improve the installation efficiency of pipes.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

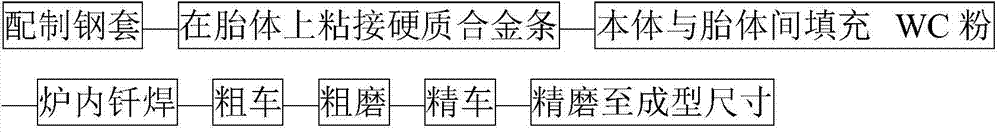

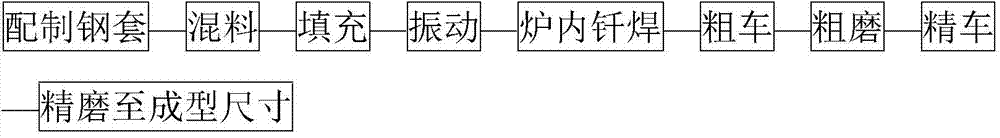

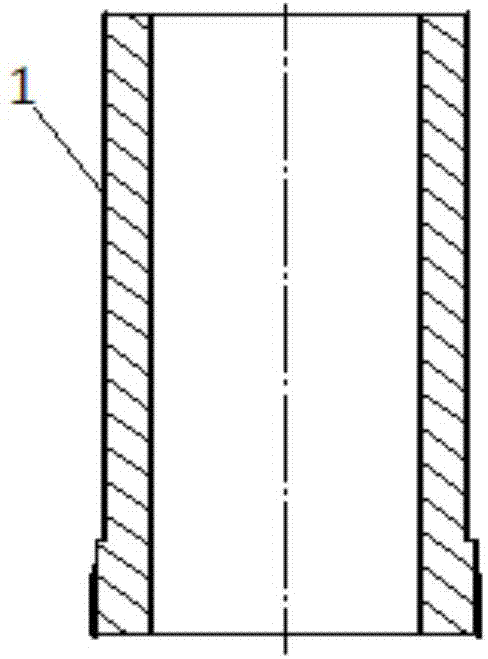

TC bearing and its production method

ActiveCN103711795AIncrease coverageImprove erosion resistanceBearing componentsSteel jacketWear resistant

The invention discloses a TC bearing and its production method. The TC bearing comprises a cylindrical body and a hard alloy wear resistant layer sintered on the inner surface or outer surface of the body. The hard alloy wear resistant layer is formed by sintering of hard alloy pellets, cast tungsten carbide powder and a copper based alloy. The TC bearing can prepared by the processes of steel jacket preparation, mixing, filling, vibration, furnace brazing, rough turning, coarse grinding, finish turning, and accurate grinding. The TC bearing provided by the invention uses hard alloy pellets to replace hard alloy strips, thus enhancing the coverage rate of the wear resistant layer up to more than 90%, greatly improving the erosion resistance of the product, and reducing the friction resistance. The service life of the TC bearing is up to 350-450 hours.

Owner:天津市润博凯特石油机械制造有限公司

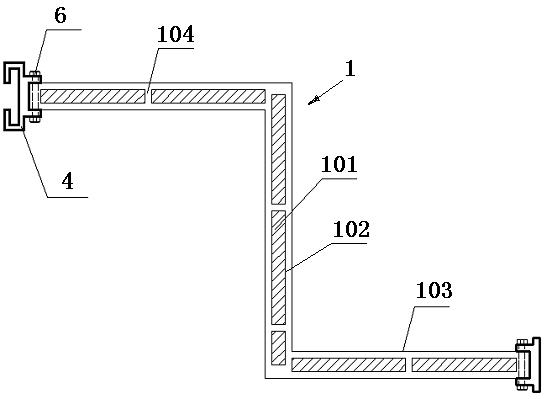

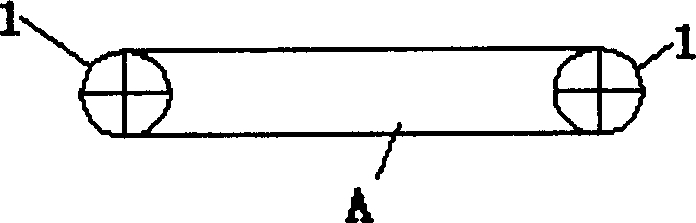

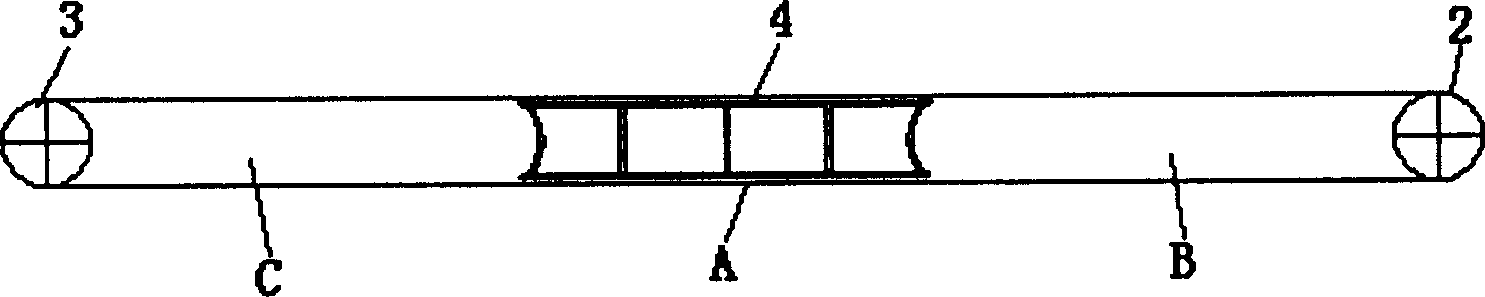

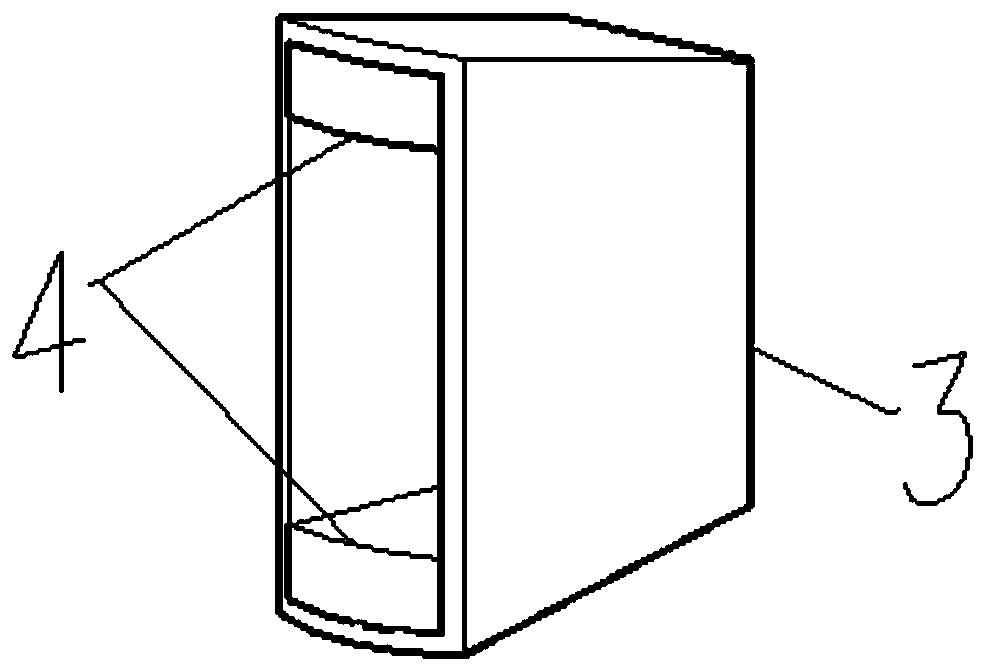

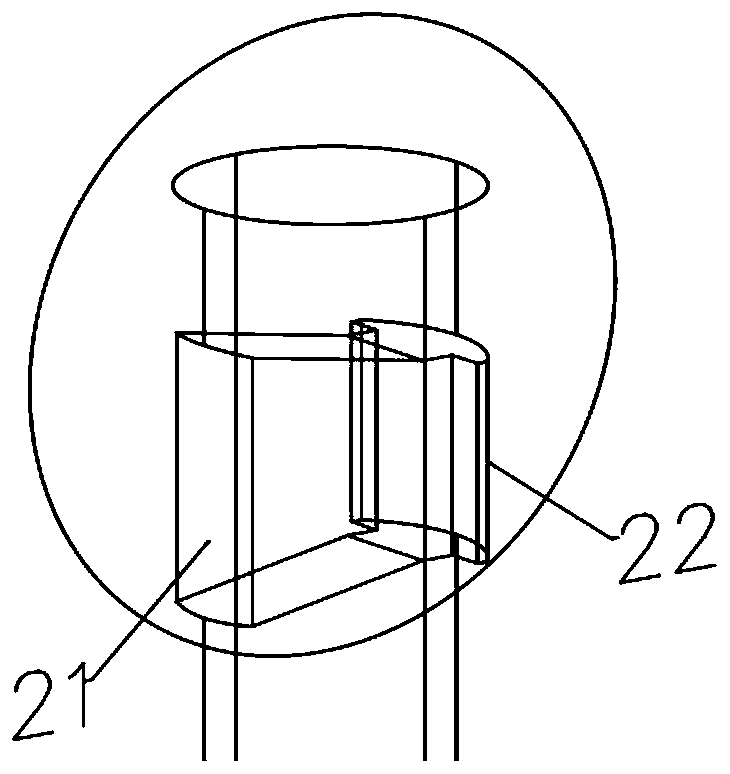

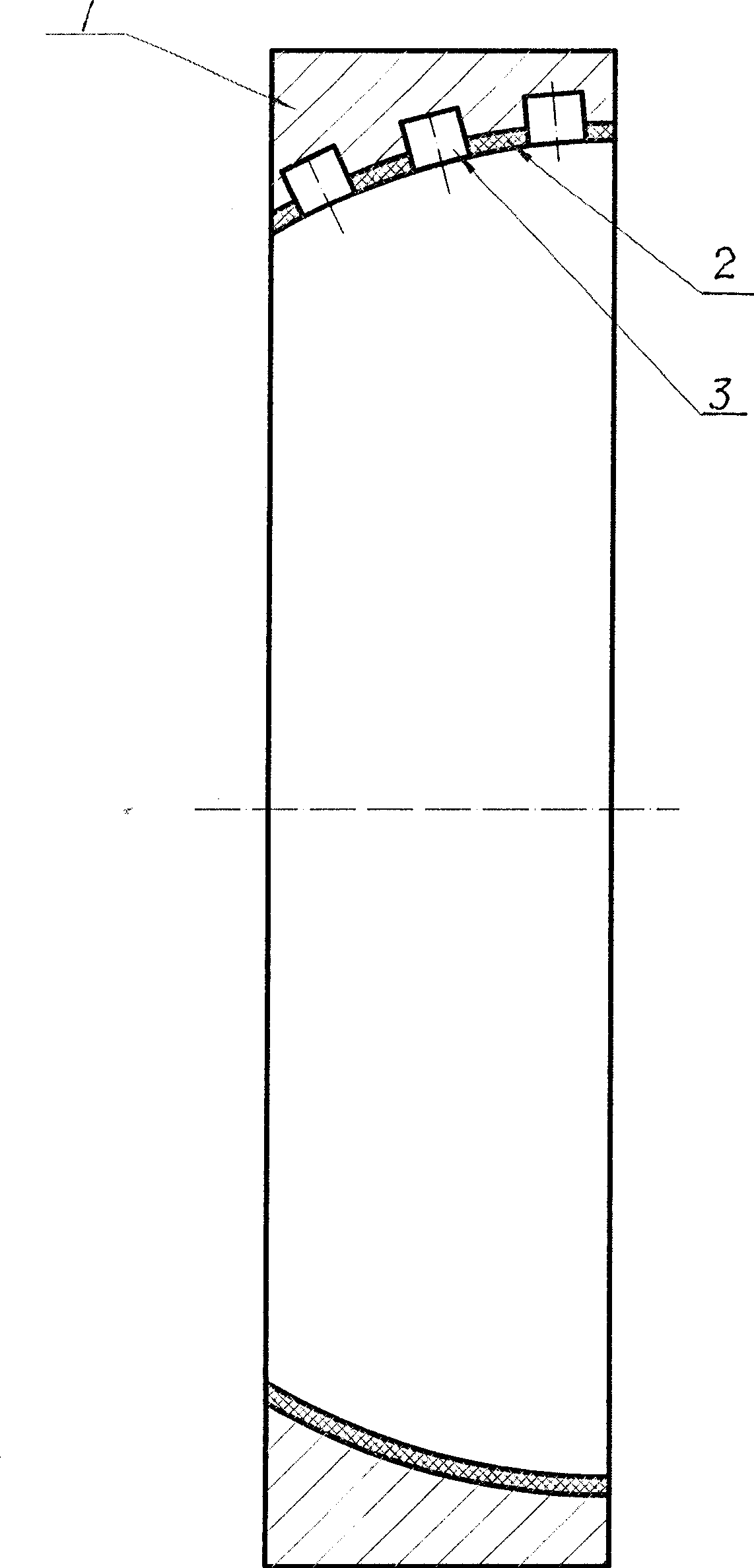

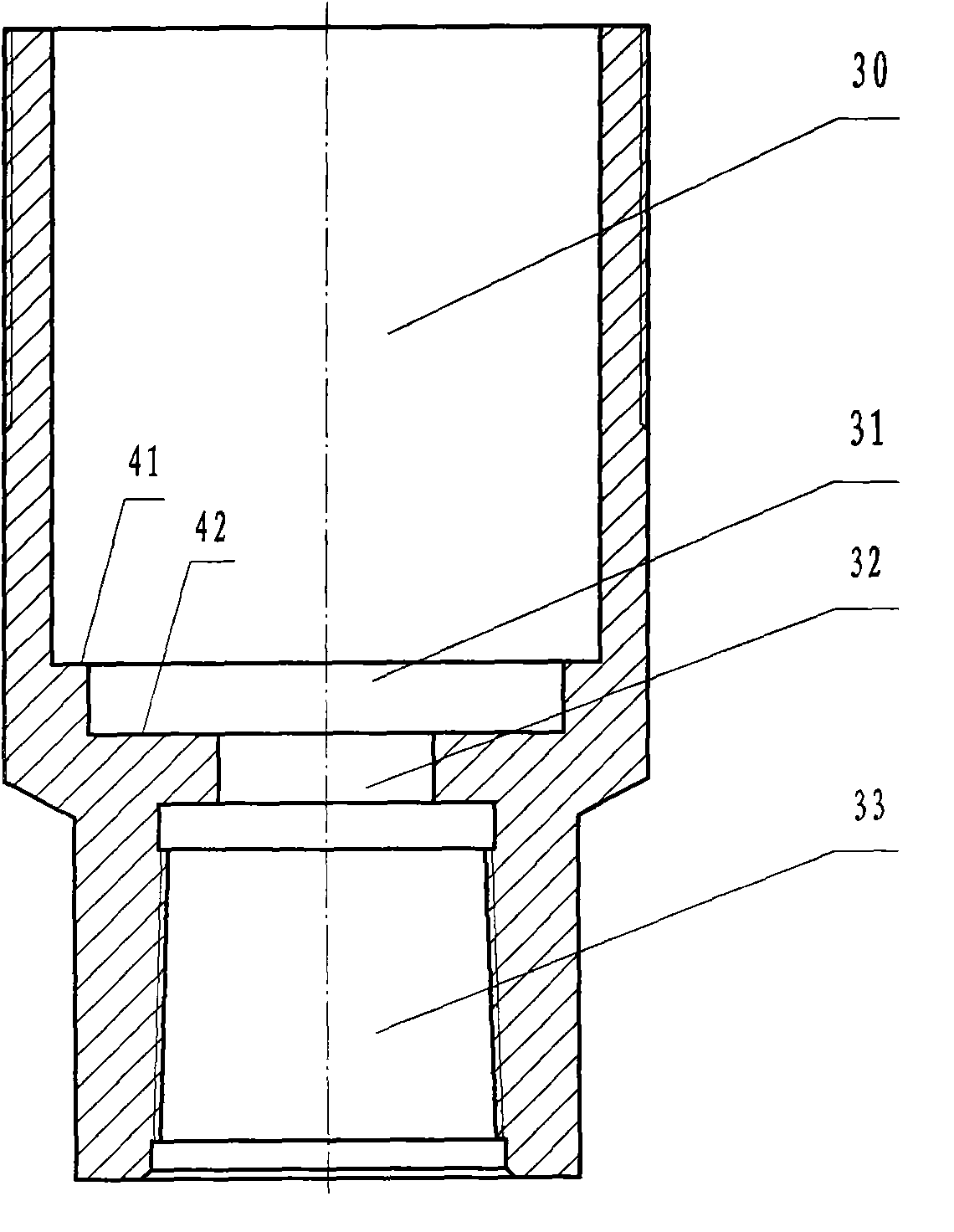

Composite material sheet pile and preparation method thereof

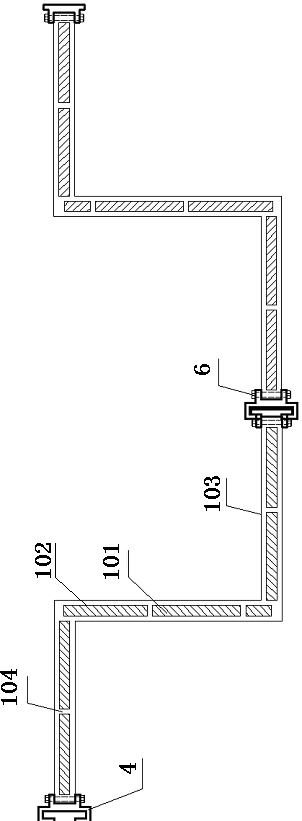

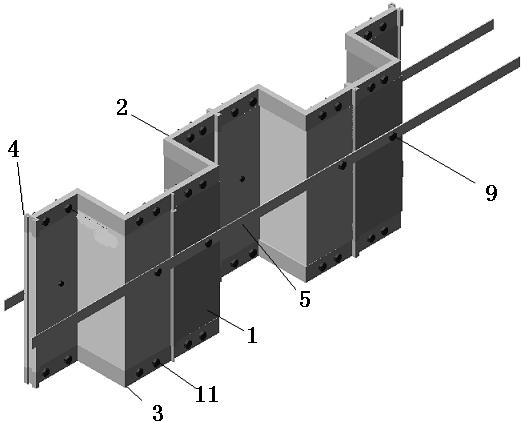

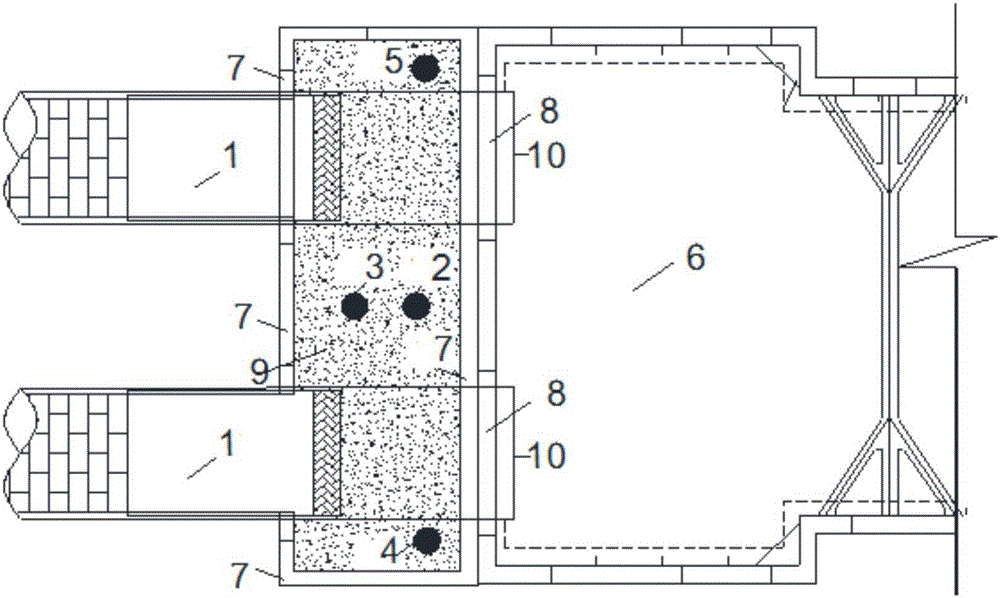

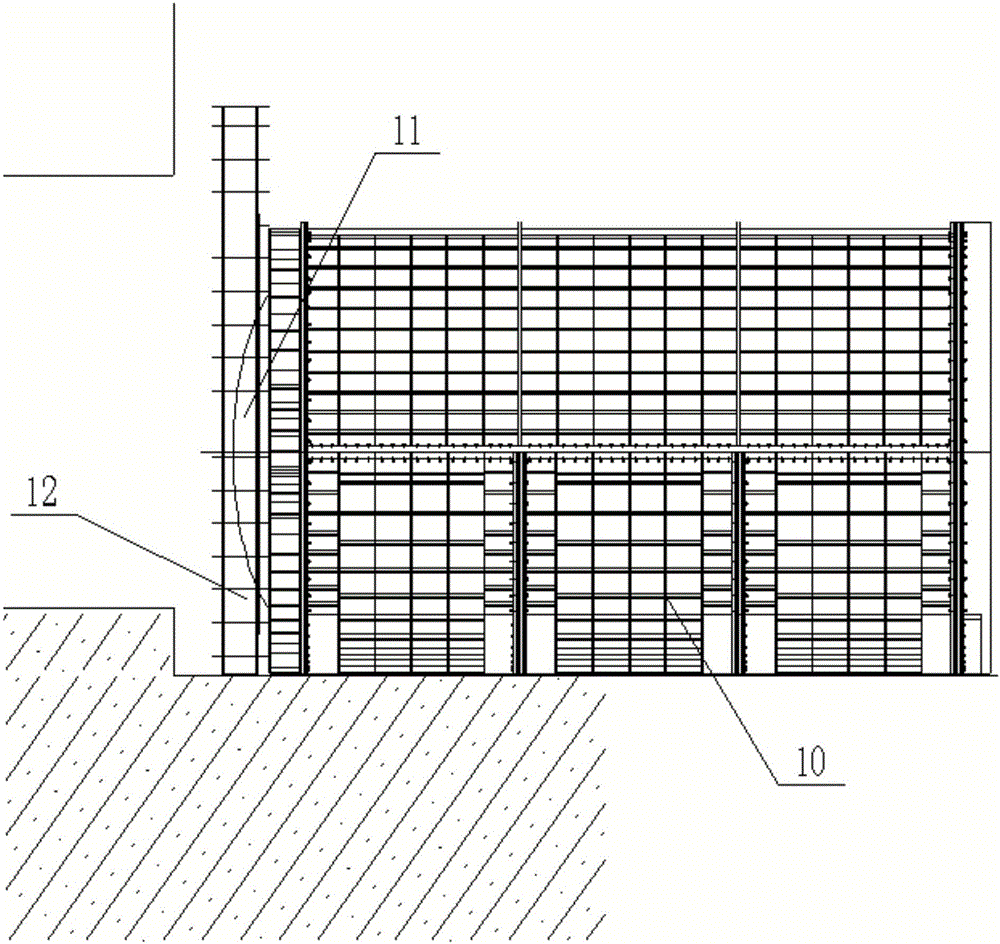

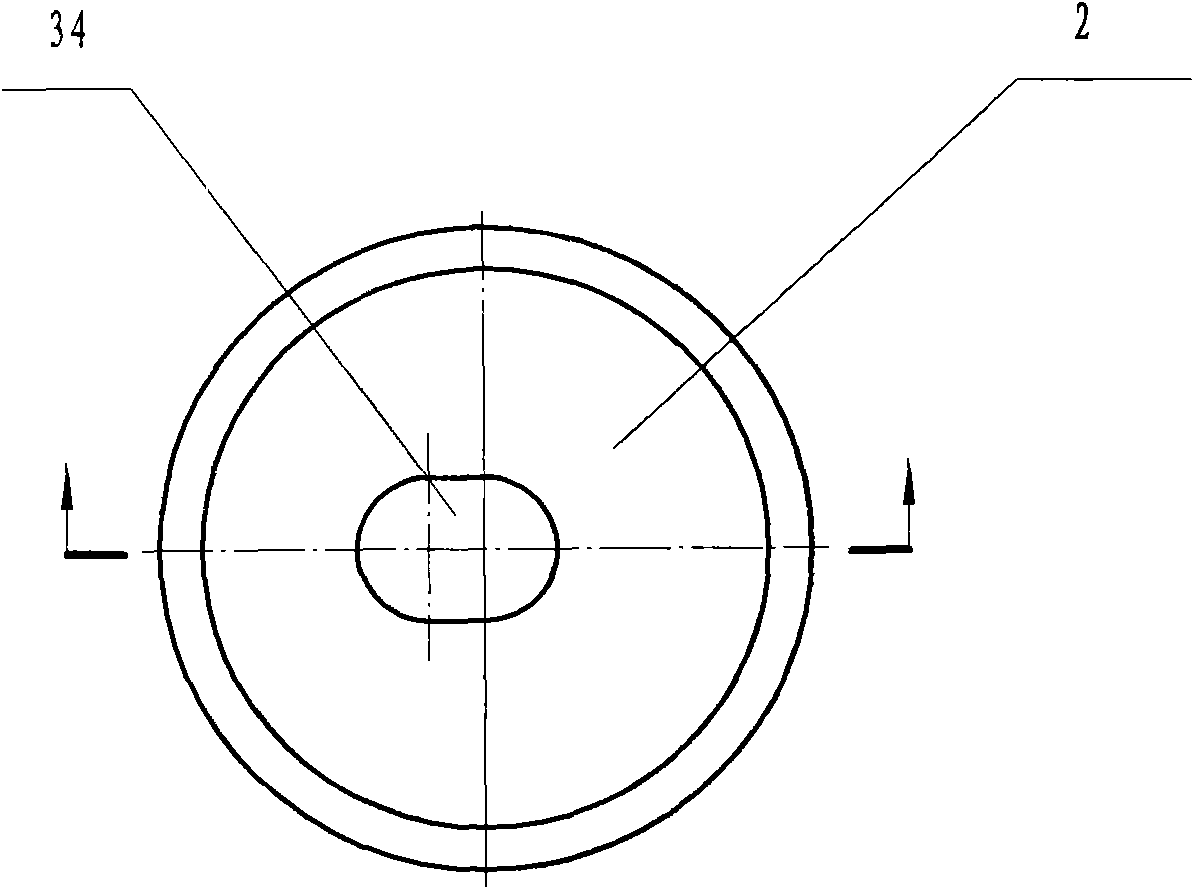

The invention discloses a composite material sheet pile and a preparation method thereof. The composite material sheet pile comprises a pile body (1) and is characterized in that the pile body (1) is the composite material pile body; the upper end of the pile body (1) is covered with a stainless steel jacket head (2), and the lower end of the pile body (1) is connected with a stainless steel pile shoe (3); two side edges of the pile body (1) are respectively connected with a lock catch structure (4) connected with the adjacent pile body (1); the pile body (1) is composed of a core material (101), an inner covering layer (102) and an outer covering layer (103), wherein the inner covering layer (102) covers the inner core (101), and the outer covering layer (103) covers each core material (101) covered with the inner covering layer (102) into the required shape; and a lattice structure (104) is formed between adjacent core materials (101). The composite material sheet pile is characterized by replacing steel with plastics, and has the advantages of light weight, high intensity and long service life and can be reused.

Owner:JIANGSU BOHONG NEW MATERIAL TECH

Airtight receiving construction method for shield steel sleeve

The invention discloses an airtight receiving construction method for a shield steel sleeve. The airtight receiving construction method for the shield steel sleeve includes the following steps that when the shield tail completely enters a reinforcing body, grouting and plugging are conducted on segments disengaging from the shield tail; bentonite slurry is injected to the outer side of a shield body through a radial grouting hole of the shield body; secondary grouting is conducted on the first and second segments disengaging from the shield tail, and thus an external water system is blocked and isolated; dewatering measures are taken inside the reinforcing body, so that the water line in the reinforcing body is lower than the excavation bottom face; the steel sleeve is installed on a pre-buried ring-shaped steel jacket of a tunnel portal, and an end socket and a reaction frame are installed; the steel sleeve is filled with mortar; an underpressure excavation mode is adopted, so that the pressure of muddy water in an excavation bin to the wall of the steel sleeve is reduced; an observation hole is formed in the bottom of the end socket, and the effects of grouting, plugging and dewatering are re-checked; and the end socket and the reaction frame are dismounted, a shield tunneling machine continues to be pushed forward until the shield tunneling machine completely enters a tunnel, grouting and plugging are conducted on the last ring of segments, the tunnel portal is closed, the shield tunneling machine, the steel sleeve, the end socket and the reaction frame are lifted out, and receiving is completed.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR

Fabricated precast concrete box culvert

ActiveCN104912099AHigh strengthQuality is easy to controlArtificial islandsUnderground chambersSteel jacketEngineering

The invention relates to a fabricated precast concrete box culvert. The fabricated precast concrete box culvert comprises a groove-type base paved on the ground horizontally. Bosses are arranged at the middle portions of the upper end faces of stand plates arranged at the two sides of the groove-type base in the length direction of the groove-type base respectively. Multiple long hexagon nuts which are arranged vertically are embedded on the end faces of the bosses in the length direction of the bosses at intervals. Rubber sealing rings are arranged at the outer sides of the bottoms of the bosses in a sleeving mode. Wallboards are vertically arranged above the stand plates arranged at the two sides of the groove-type base. Grooves are formed in the middle portions of the upper surfaces and the lower surfaces of the wallboards in the length direction of the wallboards respectively. Multiple steel jackets which are arranged vertically are arranged at the position, corresponding to the position of each long hexagon nut, of the middle portions of the bottom faces of the grooves in the length direction of the grooves. According to the fabricated precast concrete box culvert, the structure and design are reasonable, the transportation and installation are convenient, four precast concrete plate-shaped components are adopted for assembling, the transportation and installation for the plate-shaped components are convenient, industrialized production is adopted, the concrete strength is high, the quality can be controlled, the composite cost is low, the construction period is short, the quality is good, the application range is wide, and the advantages of being economical and environmental-friendly are possessed.

Owner:南京钜砼建筑工业技术研究所有限公司

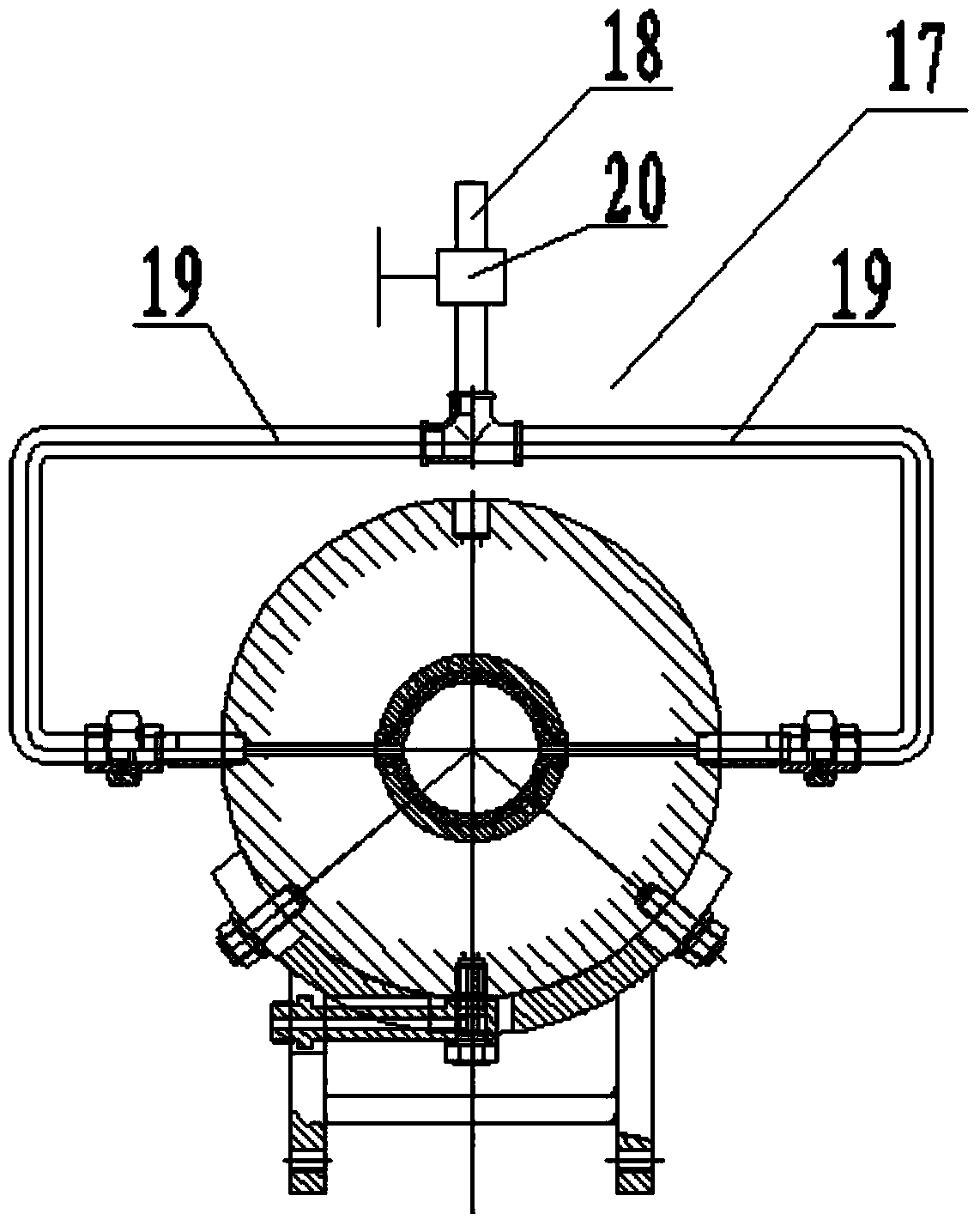

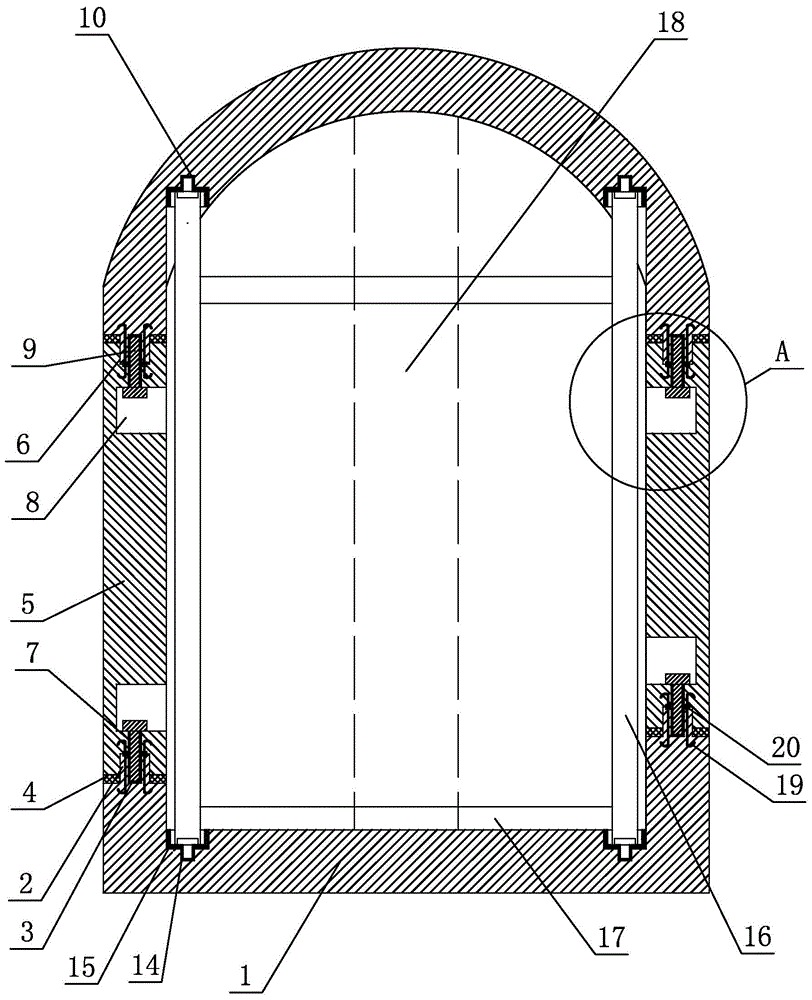

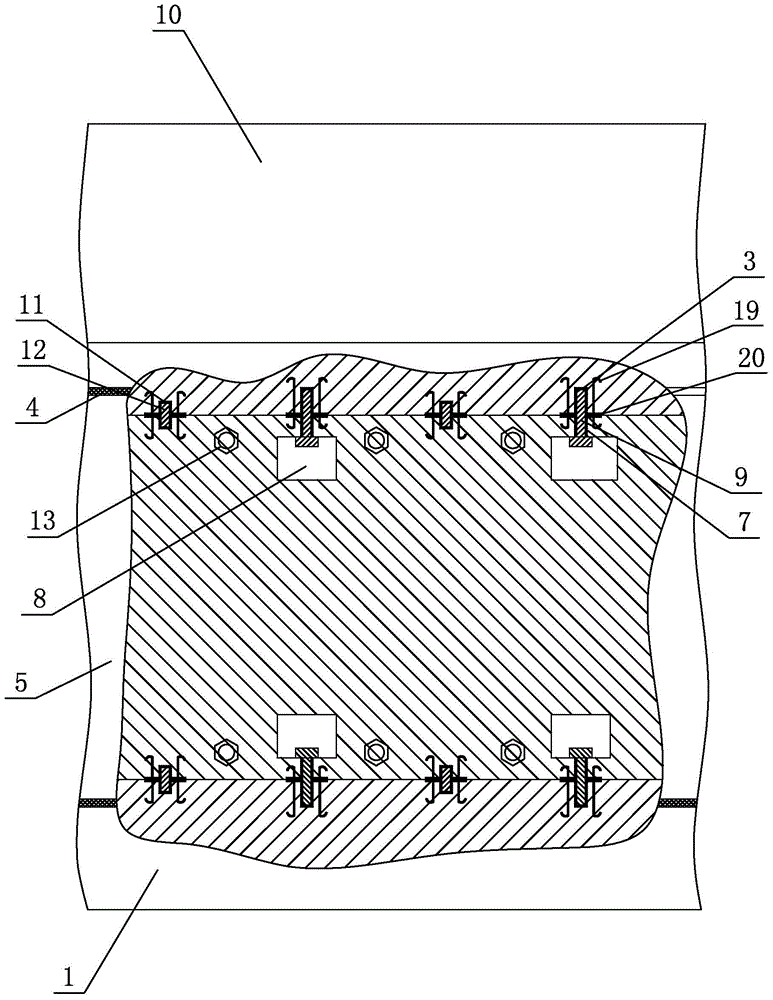

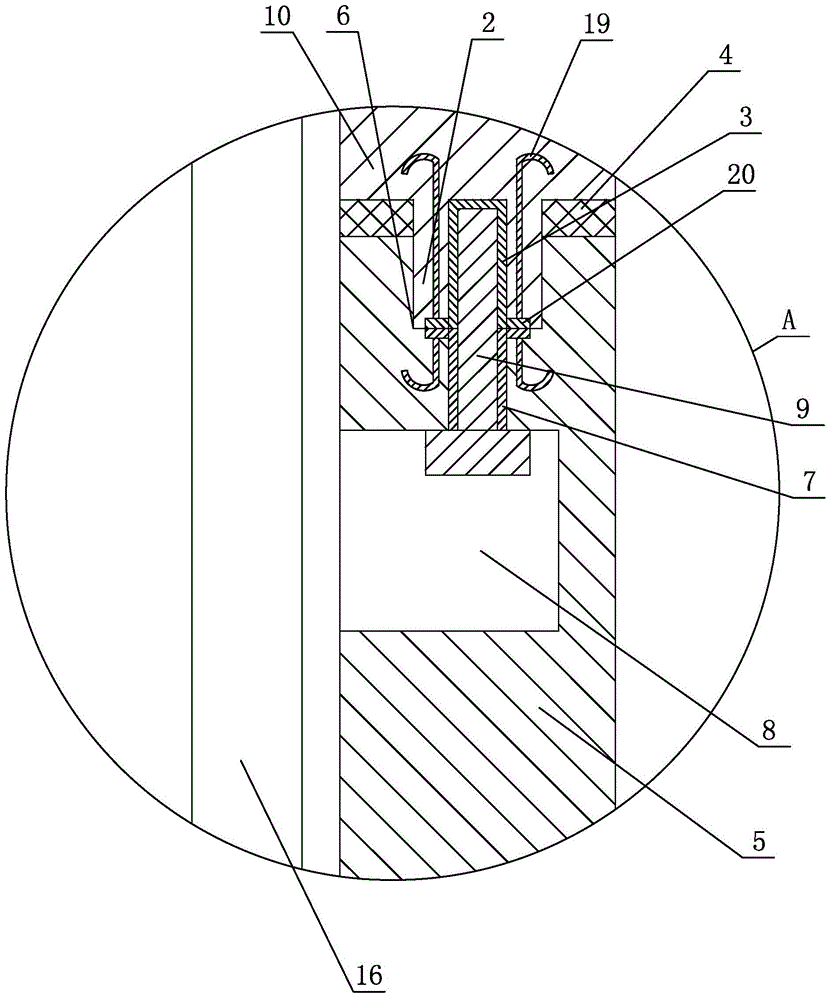

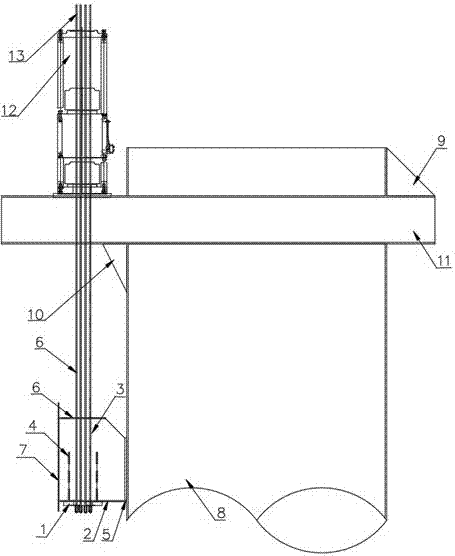

Suspending and guiding device for descending installation of large-scale steel jacket box

InactiveCN107386118AAvoid damageReduce on-site constructionBridge erection/assemblyCaissonsSteel jacketClassical mechanics

The invention relates to the field of descending installation construction of a steel jacket box, in particular to a suspending and guiding device for descending installation of a large-scale steel jacket box. The suspending and guiding device is provided with a suspending device and a guiding device, wherein the suspending device is provided with a continuous jack; suspending steel strands are connected to the continuous jack; bearing beams are arranged at the bottom of the continuous jack; the guiding device comprises a pile foundation steel casing below the bearing beam; a concentric adherent arc-shaped plate is arranged on the left side of the pile foundation steel casing; a concentric interval is formed between the pile foundation steel casing and the concentric adherent arc-shaped plate; the left side of the concentric adherent arc-shaped plate is connected with a baseplate and a top plate which are clung to the inner wall of the steel jacket box; the lower part of the baseplate is connected with an anchor bearing plate; connecting plates arranged on the baseplate are arranged above the anchor bearing plate; and webs are further arranged between the concentric adherent arc-shaped plate and the inner wall of the steel jacket box. The suspending and guiding device has the beneficial effects of simple structure, convenient blanking, high raw material utilization ratio, green and environment-friendly construction and low construction difficulty, and the suspending and guiding device is processed and mounted together with the steel jacket box, so that the construction efficiency is improved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG +1

Method for construction of underground continuous steel jacket box

ActiveCN1793527AReduce sinkingReduce the possibility of collapseArtificial islandsExcavationsSlurry wallSteel jacket

The invention discloses an underground diaphragm wall steel lagging box construction method. It includes the following steps: forming groove segment to groove; cleaning hole; pouring concrete; cutting into steel lagging box; doing as the same for the adjacent; drawing out; cutting it into the second finished groove segment; filling back the first cavity by earthwork. The method adopts í‹one male and one femaleíŒ groove segment jumping type to use steel lagging box to construct. It can reduce the possibility of sinking and collapsing of approach wall, and the influence on groove wall earth from outer loading. It has the advantages of fast construction speed, good foundation ditch lump protection effect, and obvious economic benefit.

Owner:SHANGHAI CONSTR NO 1 GRP

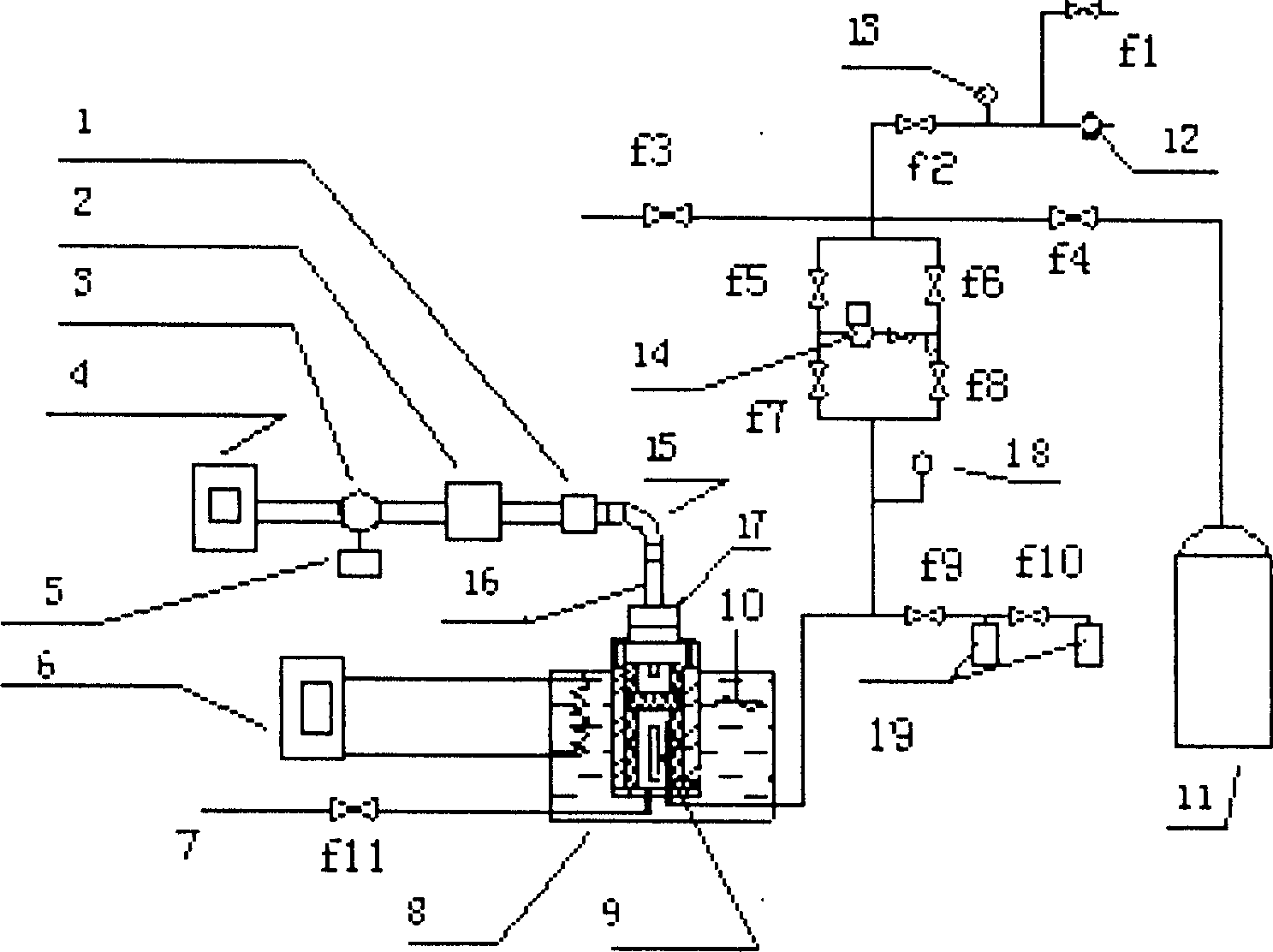

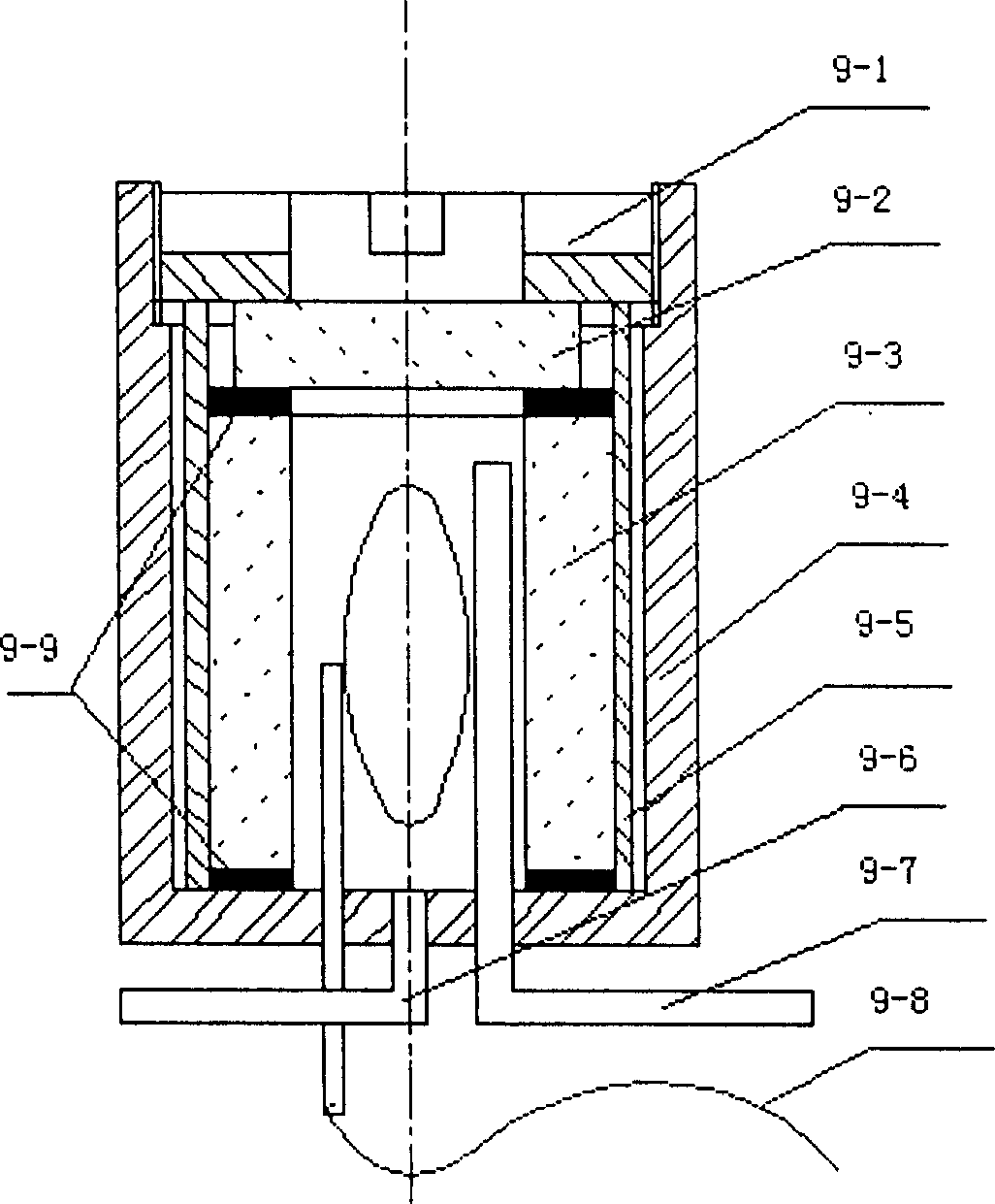

High pressure visible micro wave chemical reaction device

InactiveCN1555912AUnique heating performanceUniform temperature fieldEnergy based chemical/physical/physico-chemical processesChemical reactionSteel jacket

A visual high-pressure microwave heating chemical reactor is composed of microwave generating / controlling / transmitting system, chemical reactor, constant-temp system and reactive gas I / O and metering system. Said chemical reactor consists of stainless steel jacket, protecting stainless steel rings, high pressure resistant glass cylinder, high pressure resistant microwave guide and enclosing head.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Multi-functional screwdriver with transformable head

The invention relates to a multi-functional screwdriver with a transformable head, in particular to a screwdriver which is integrated with different openings such as straight line shape, hexangular shape, triangle shape and concave shape and specifications, and cross-shaped and star-like screws can be assembled and disassembled by the screwdriver, and the head of the screwdriver does not need dismounting and replacement. A set of retractor device is arranged in a handle of the screwdriver, and the retractor device uses at least seven or more than seven steel needles and springs with the corresponding quantity, pistons and piston cylinders of piston cavities, with the corresponding quantity to form a retractable screwdriver body, the outer side of the exposed part of the screwdriver body isprovided with a protective hollow steel jacket, the steel needles at the position of the screwdriver head can contract under the external extrusion action force which is larger than the critical deformation elasticity of the internal spring, at the moment, the spring is compressed and stores energy, when the external extrusion action force disappears, the spring releases energy to push the pistonand the steel needle to be stretched out and reset.

Owner:曾洪峰

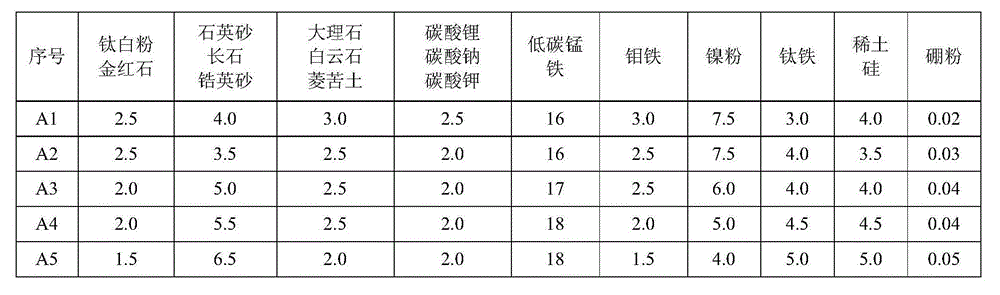

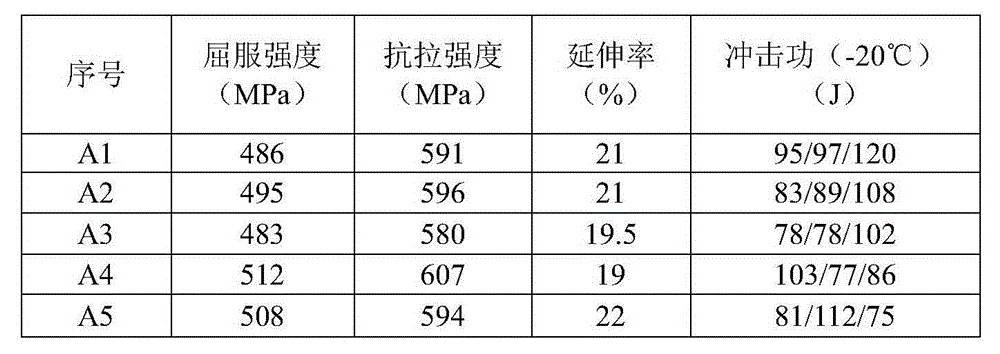

Flux cores for high heat-input electro-gas welding gas protection welding wires and gas protection welding wires

ActiveCN104923989AInhibit growthPromote nucleationArc welding apparatusWelding/cutting media/materialsSteel jacketRare earth

The invention discloses flux cores for high heat-input electro-gas welding gas protection welding wires. The flux cores are prepared, by mass percent, by the chemical constituents of 1-3% of at least one of titanium dioxide and rutile, 3-7% of at least one of quartz sand, feldspar and zircon sand, 1-4% of at least one of marble, dolomite and magnesite, 1-3% of at least one of lithium carbonate, sodium carbonate and potassium carbonate, 14-20% of low-carbon ferromanganese, 1-4% of ferromolybdenum, 4-8% of nickel powder, 2-5% of ferrotitanium, 1-5% of rare-earth silicon, 0.01-0.05% of boron powder and the balance iron powder. The invention further discloses the gas protection welding wires for high heat-input electro-gas welding, each gas protection welding wire comprises a steel jacket and the corresponding flux core which is coated with the steel jacket, and the flux core is any one of the flux cores for the high heat-input electro-gas welding gas protection welding wires. The invention further discloses weld deposited metal which is obtained by adopting any one of the gas protection welding wires to conduct welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Production process of fermented tea beverage

The invention belongs to a production process of a tea beverage, in particular a production process of a fermented tea beverage, and aims to solve the problems that the prepared tea beverage prepared by the existing process contains tea residue solids and the liquid is turbid after being filled. Red tea is placed in a stainless steel cylinder to be subjected to water immersion cleaning and dust cleaning with normal temperature pure water to keep that the red tea contains certain moisture; the clean tea which is subjected to water immersion cleaning is decocted; the decoction utensil is a stainless steel jacketed kettle; the steam decoction temperature is 95 DEG C, and the decoction time is 10 minutes; the tea is filtered and clarified after being decocted, namely the tea is secondarily filtered by using a diatomite filter and a micro-porous membrane filter (200 meshes) respectively and clarified; after tea liquor is obtained, yeast, lactic acid bacteria and acetic acid bacteria strains are added to be subjected to mixed fermentation for 48 hours; anthocyanin powder is mixed to obtain the fermented tea beverage. The fermented tea beverage prepared by using the process does not contain the tea residue solid, the liquid is clear and transparent after being filled, and the color is light brownish.

Owner:HEILONGJIANG LVZHIDU BIOTECH DEV

Spherical magnetorheological fluid clutch

InactiveCN101718314ACompact structurePrevent leakageFluid clutchesSteel jacketMagnetorheological fluid

The invention relates to a spherical magnetorheological fluid clutch, comprising a spherical steel jacket fixed with an input shaft, a steel ball which is fixed with an output shaft and is arranged in the spherical steel jacket, and a magnetorheological fluid working gap filled with magnetorheological fluid is left between the spherical steel jacket and the steel ball, a round hole which leads the output shaft to pass through and is connected with the steel ball is arranged on the spherical steel jacket, a sealing ring is arranged at the periphery of the round hole, a magnetic separation ring is embedded on the spherical steel jacket, a magnetic-conduction ring sheathed on the spherical steel jacket is arranged outside of the embedded magnetic separation ring, and a magnet exciting coil is arranged in the magnetic-conduction ring, corresponding to the magnetic-conduction ring; a main round ball connected with the input shaft drives an output round ball to rotate by the magnetorheological fluid, the current magnitude in the magnet exciting coil is changed, that is, the transmission torque can be changed; the spherical magnetorheological fluid clutch can be used for the occasion that the included angle formed by the input shaft and the output shaft is not in a straight line and the occasion which has high requirements to spark; the structure is compact, the included angle of the input shaft and the output shaft can be changed and the clutch is suitable for small space; the equipment such as an electric brush does not need, and the safety reliability is high.

Owner:XUZHOU WUYANG TECH

Hidden type reinforcing and damping energy dissipation device applicable to sidespan mortise and tenon joints of wood structure

PendingCN110173130APreserve semi-rigid characteristicsAvoid extrusion damageBuilding repairsProtective buildings/sheltersSteel jacketMortise and tenon

The invention provides a hidden type reinforcing and damping energy dissipation device applicable to sidespan mortise and tenon joints of a wood structure. The device is used in the mortise and tenonjoints of the connecting portion of a wood beam and a wood column. The device comprises metal steel jackets arranged on the outer periphery of a tenon and the inner periphery of a mortise. The longitudinal cross section of each metal steel jacket in the length direction of the wood beam is trapezoidal, the upper bottoms face the wood column, and the lower bottoms face the wood beam and are in theopen state. A wedge-shaped viscoelasticity rubber block is arranged on the inner side of each metal steel jacket. A through hidden groove is formed in the wood beam in the length direction. A sleeve in which a shape memory alloy wire is arranged is arranged in the hidden groove. The shape memory alloy wire penetrates through the metal steel jackets and the wood column to be anchored by an anchorage device. The device effectively solves the problems that in a traditional method, the shape structure appearance, the tenon and the mortise are extruded and damaged, tenon pulling damage is caused, and self-resetting is lacked, on the premise of not changing the stress characteristic of the mortise and tenon joints, the bearing capacity of the mortise and tenon joints can be improved, the energydissipation ability is improved, the tenon pulling number is reduced, the self-resetting function after shock is achieved, and the service life of the mortise and tenon joints can be prolonged.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Steel-copper bimetallic axle sleeve and process for producing same

The invention discloses a steel-copper bimetal shaft sleeve, which is provided with a steel sleeve (1), and a copper alloy spray-coated sintered layer (2) is directly connected to the inner side of the steel sleeve (1). The production method is as follows: making a steel sleeve (1) and cleaning its inner surface; directly spraying copper alloy powder on the inner surface of the steel sleeve (1) to form a copper alloy spray coating; The temperature of the melting point sinters the steel sleeve (1) coated with the copper alloy spraying layer, so that the copper alloy spraying layer becomes a copper alloy spraying sintering layer (2) and is closely combined on the inner surface of the steel sleeve (1). The production process is simple, there is no need for the low-carbon cold-rolled steel transition layer of the prior art, a large amount of material can be saved and the weight is light, the copper alloy on the surface layer is dense, the hardness is high, and the porosity is only about 1%. The bonding strength is also much higher than that of the prior art, and has long service life and reliability.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

Fully sealed composite explosion-proof container

The invention discloses a fully sealed composite explosion-proof container comprising an end cover component and a container body. The end cover component is engaged and connected with the container body through a multi-tooth structure, and the end cover component comprises a cover plate of which the lower part is provided with a stainless steel jacket; the stainless steel jacket is internally provided with a high density aluminum foam layer, a separating plate, a low density aluminum foam layer and a spherical film from bottom to top in sequence; and the container body comprises a composite outer layer of which the interior is a metal inner barrel, and the upper part of the metal inner barrel is provided with an annular aluminum foam layer of which the bottom is provided with a separatingplate layer. According to the fully sealed composite explosion-proof container provided by the invention, the barrel is wound by carbon fiber reinforced epoxy resin matrix composites; and the structural strength is high, and the weight is light. The explosion-proof container has the advantages of the simple structure, quick opening and closure, reliable sealing and no fire phenomenon during explosion; the overpressure within the 30cm radius of the opening part is low, and less 20 kPa than the threshold that a human body can bear; and the explosion-proof container is light in weight, and can be handled by one person easily.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Sucker rod deviation-based anti-eccentric wear sealing packing box

The invention discloses a sucker rod deviation-based anti-eccentric wear sealing packing box, which comprises a packing box main body, colloid packing, a steel packing pressure cap and a steel packing pressure cover and is characterized by also comprising a basic rubber cushion, a steel sheet gasket and a steel packing steel jacket. With the unique structure of the packing box main body, eccentric hole structures formed in the middle of the basic rubber cushion and the steel sheet gasket, the matching structure of the steel pacing steel jacket and the steel sheet gasket, the specific structure of the basic rubber cushion and related structures matched with the basic rubber cushion, the whole device enables a deviated sucker rod to drive the circular tube-shaped pacing steel jacket to shift in the derivation direction of an oil-sucking polish rod along the upper surface of the steel sheet gasket so as to drive the round colloid packing placed in the packing steel jacket to shift together, the polish rod is concentric with the packing which penetrates through the polish rod, so that the deviated sucker rod avoids causing eccentric wear of the packing and causing mechanical damage,. Thus, the service life of the packing is prolonged and the packing is intact after being used for one year.

Owner:高洪江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com