High pressure visible micro wave chemical reaction device

A chemical reaction and microwave technology, applied in the field of high-voltage visible microwave chemical reaction device, can solve the problems of high price, low cost, no chemical reaction device, etc., and achieve the effect of wide application range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

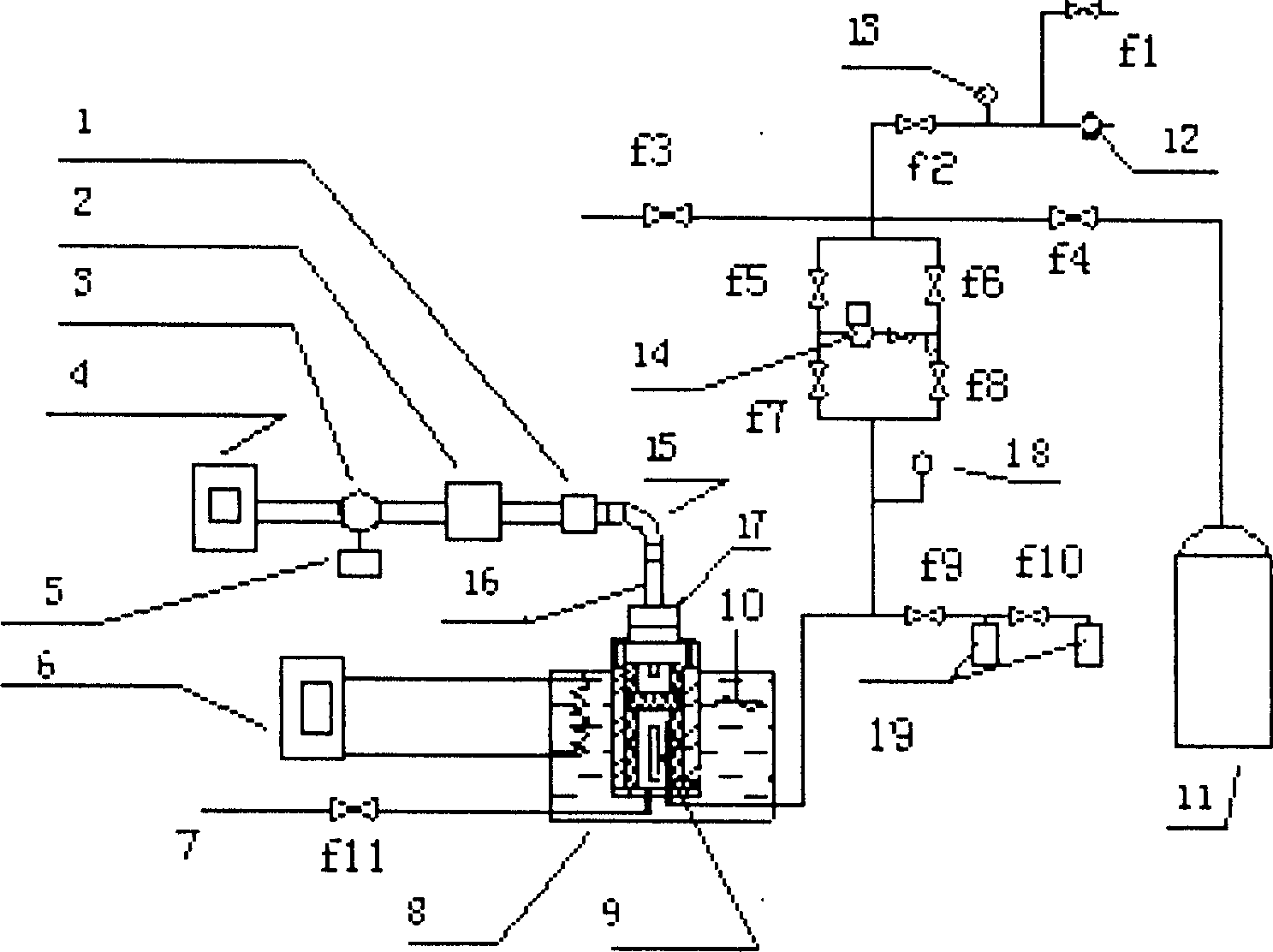

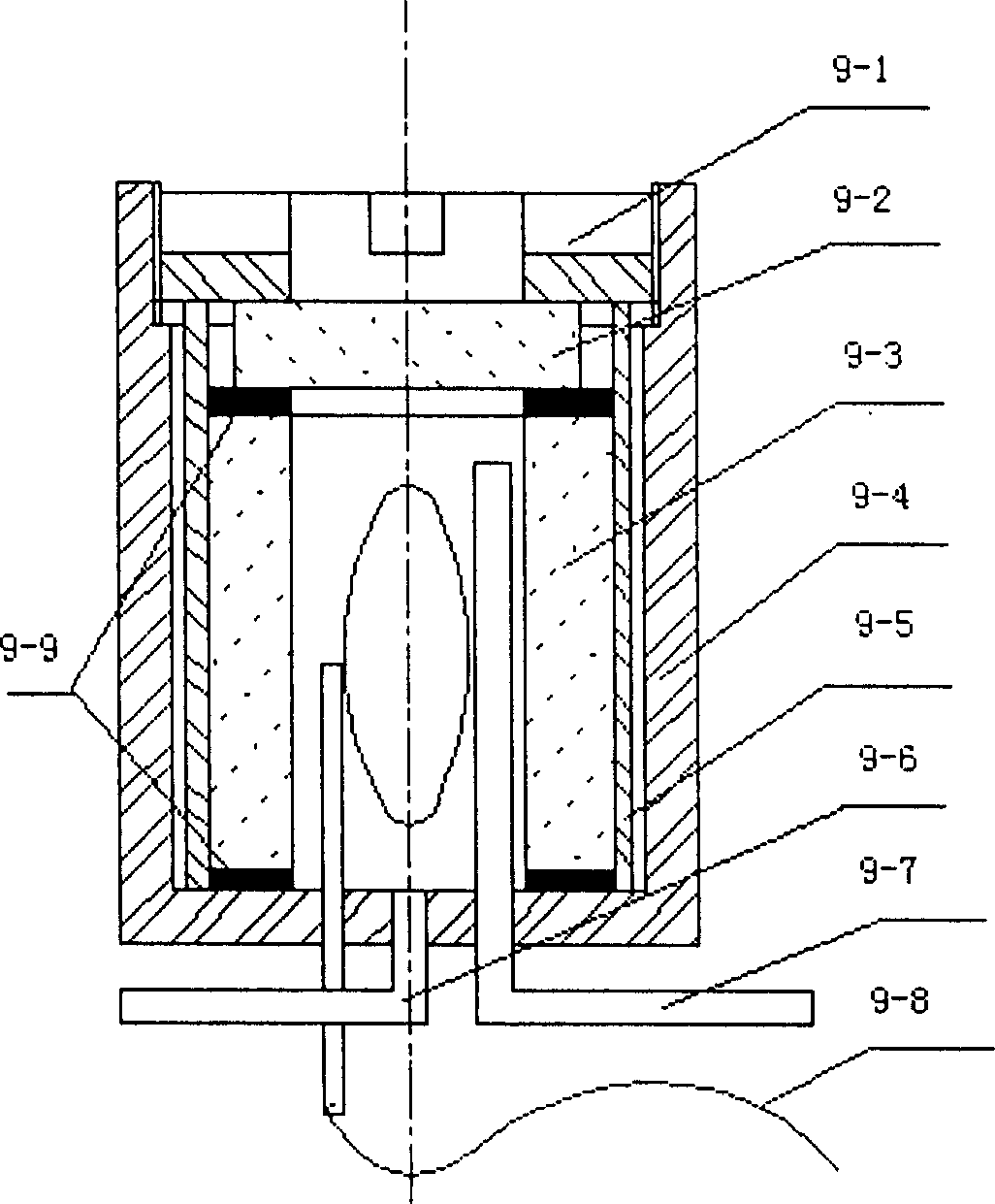

[0029] figure 1 , figure 2 The high-pressure visible microwave chemical reaction device shown includes a microwave generation / control / transmission system, a chemical reaction kettle, a constant temperature system, and a reaction gas inlet and outlet and metering system;

[0030] Microwave generation / control / transmission system consists of microwave source 4, circulator 3, water load 5, directional coupler 2, three-pin adjuster 1, elbow 15, waveguide 16, square-circle transition 17; microwave source 4 and circulator in the system The other two ends of the circulator 3 are connected to the water load 5 and the directional coupler 2; the directional coupler 2 is connected to the three-pin adapter 1; the three-pin adapter 1 is connected to the elbow 15; the elbow 15 is connected to the waveguide 16 Connection; waveguide 16 is connected with square-circle transition 17; square-circle transition 17 is connected with reactor 9; microwave source frequency is 2.45 GHz, maximum output...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com