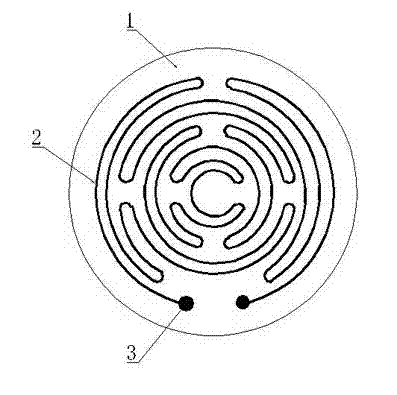

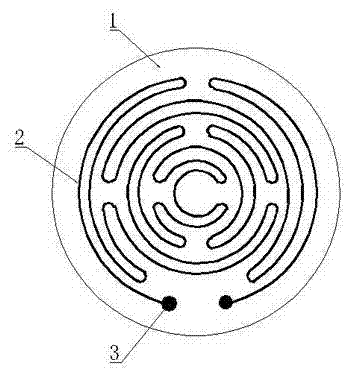

Electric heating element of rare earth thick film circuit based on IR-LED (Infrared Light Emitting Diode) ceramic substrate and preparation method thereof

A rare earth thick film, ceramic substrate technology, applied in the direction of heating element materials, etc., can solve the problems of uneven temperature field, high heat source temperature, inconsistent thermal conductivity and thermal expansion coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] 1. Preparation of quartz ceramic substrate

[0041] The composition of the quartz ceramic substrate material is: high-purity quartz (SiO 2 -Al 2 o 3 -B 2 o 3 -Mg 2 0 3 -ZrO 2 ) ceramics and rare earth oxides, the ratio of each oxide powder of quartz ceramics is: SiO 2 93.5%~96.8%:Al 2 o 3 3~1.5%:B 2 o 3 1~0.5%:Mg 2 0 3 0.5~0.25%: ZrO 2 2~1%: Particle size≤3ηm. It is solidified and prepared by injection molding method, dried and sintered. The rare earth oxide is one or more of lanthanum, cerium, neodymium, promethium, gadolinium, erbium, scandium, yttrium and terbium oxide. Rare earth oxides can be added with different types and proportions of rare earth oxides according to the experimental mathematical model according to the requirements of quartz ceramic substrates with different specifications, different temperatures, and different uses for electrical properties, thermal properties, chemical properties, mechanical properties, and far-infrared functio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com