Microcomputer electric stacking type millimeter wave antenna

A millimeter-wave antenna and electrical stacking technology, applied in the field of antennas, can solve the problems of deterioration of radiation pattern, degradation of microstrip antenna performance, and large dielectric loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

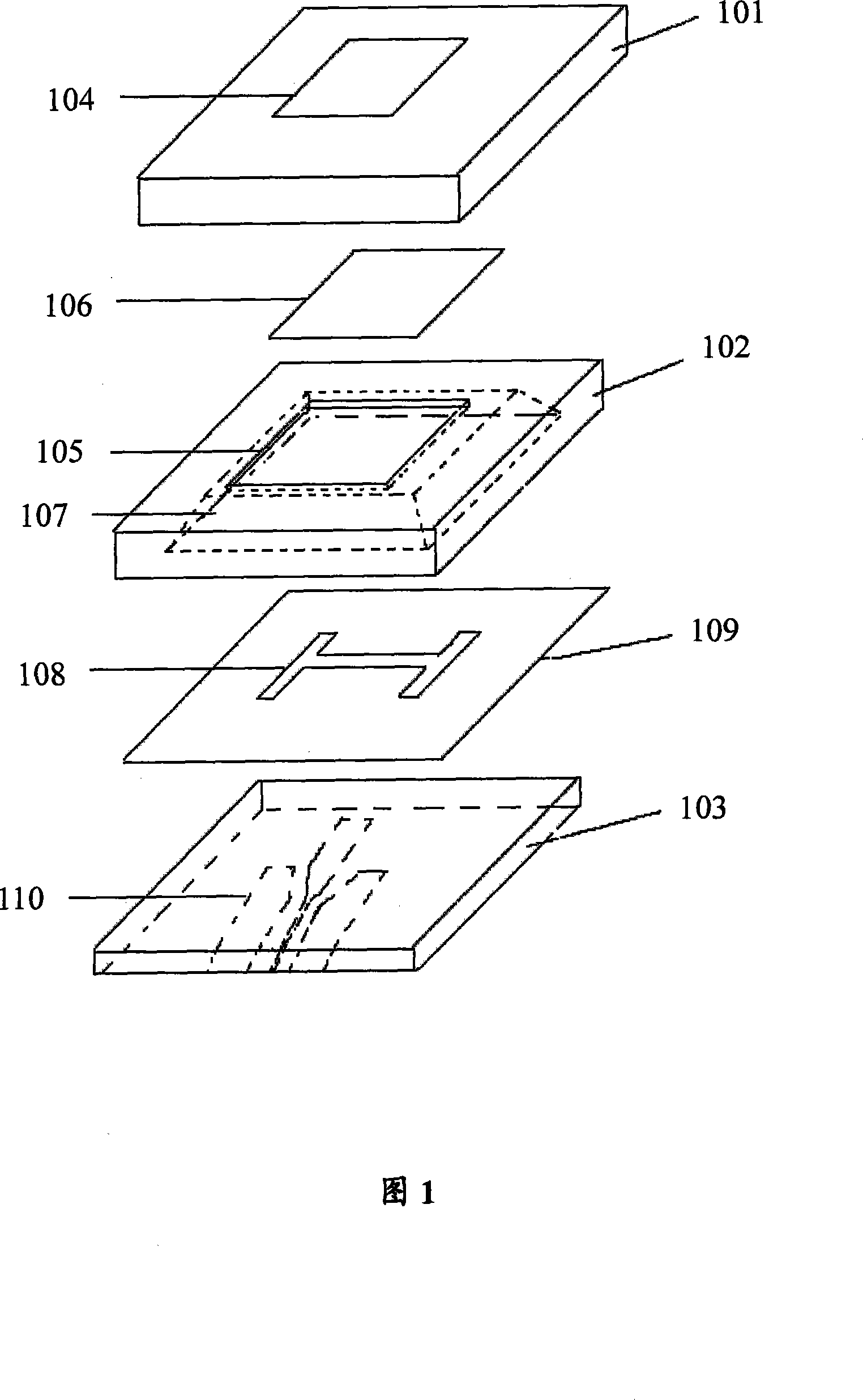

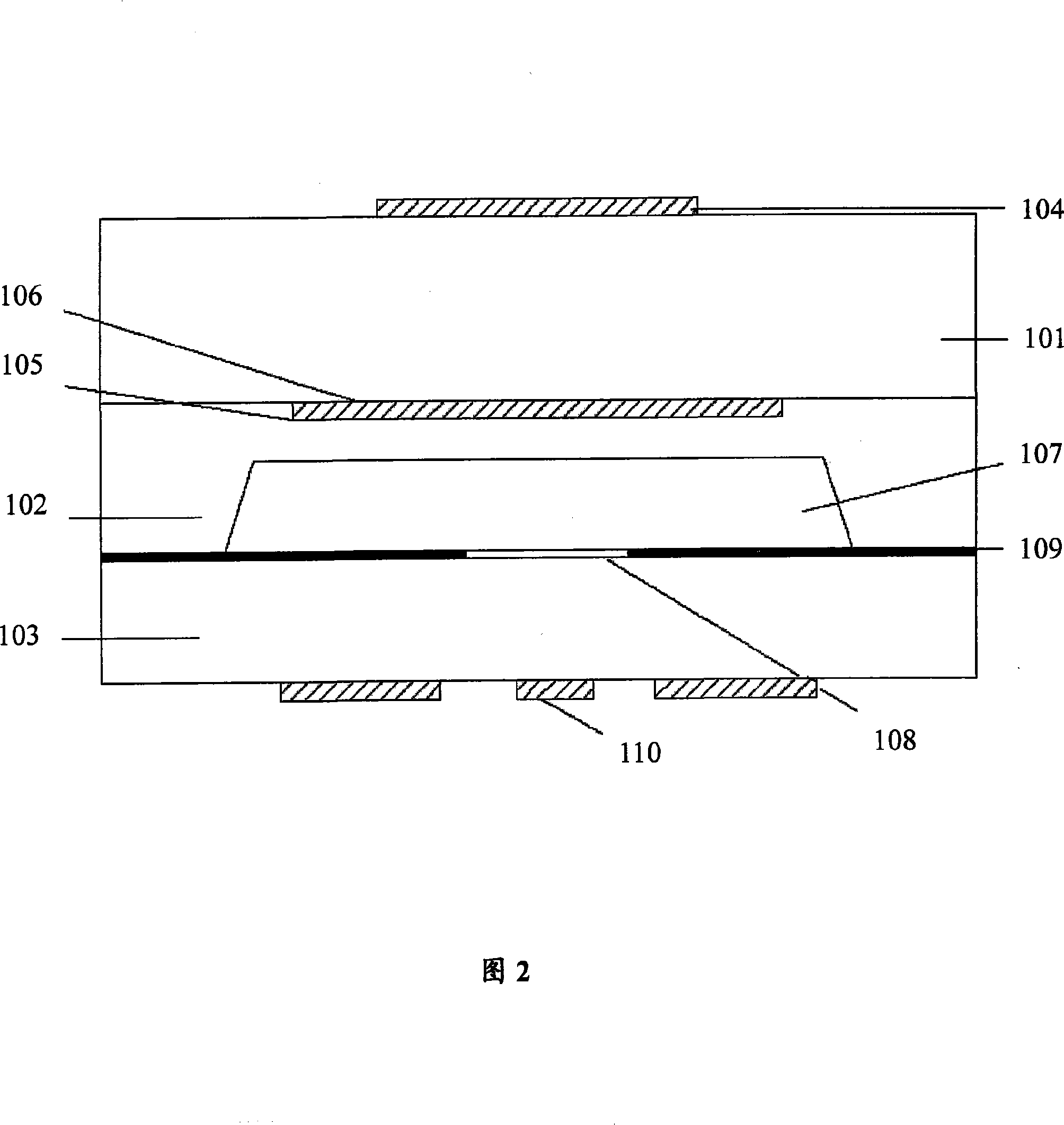

[0038] The following are the embodiments provided by the present invention, which are specifically introduced in conjunction with FIGS. 1 and 2 .

[0039] FIG. 1 is a layered perspective view of an embodiment of the present invention. The MEMS 3-layer stacked millimeter wave antenna provided by the embodiment of the present invention includes an upper dielectric substrate (101), a middle dielectric substrate (102) and a lower dielectric substrate (103), the upper dielectric substrate (101) The material is glass, the material of the middle dielectric substrate (102) is high resistance silicon, the material of the lower dielectric substrate (103) is high resistance silicon, and the upper surface of the upper dielectric substrate (101) is deposited There is metal and is etched to form a first metal radiation patch (104), and the upper surface of the middle layer dielectric substrate (102) is etched with a shallow pool (105) where metal is deposited and etched to form a second met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com