Patents

Literature

545results about How to "Reduce reflection loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

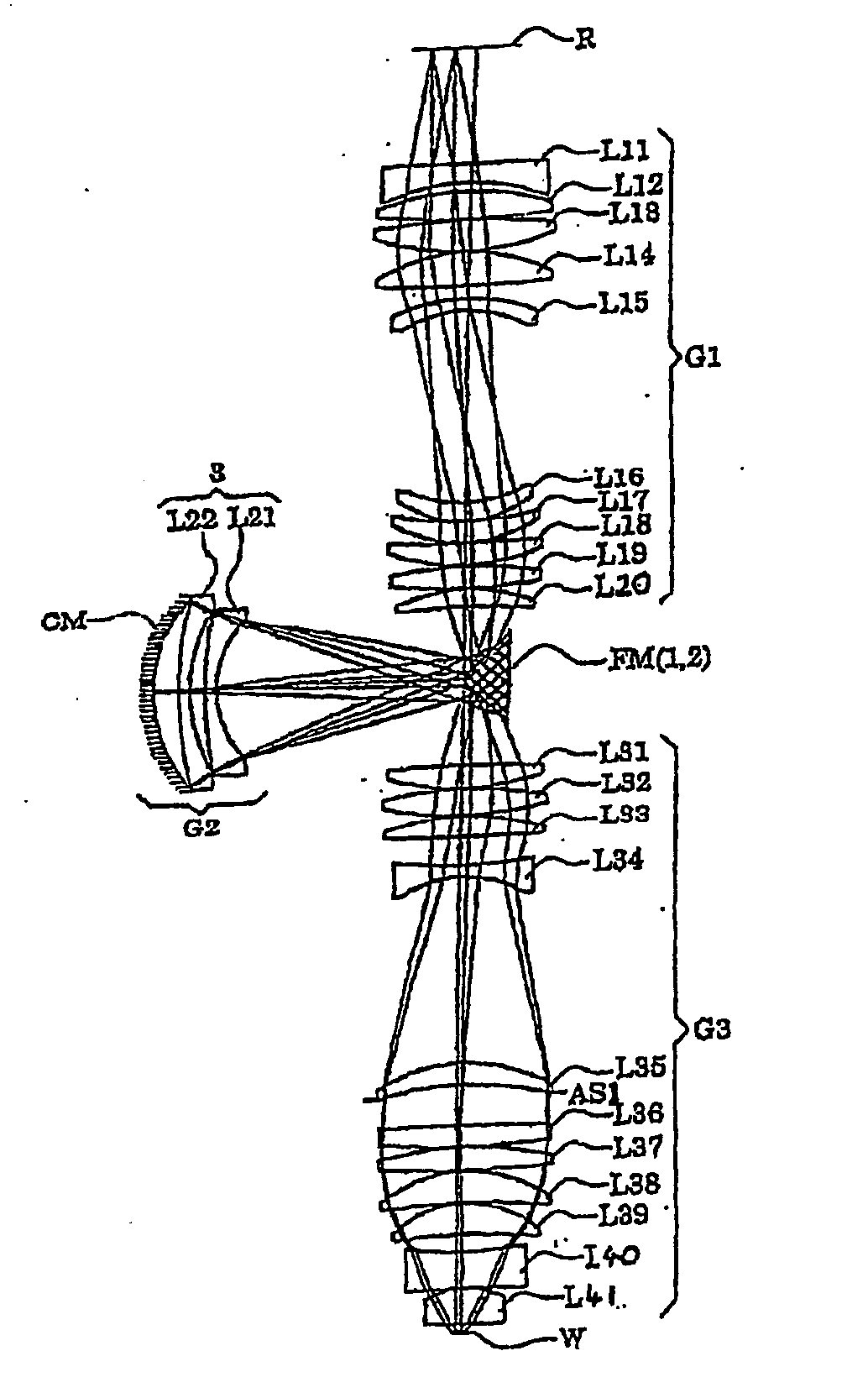

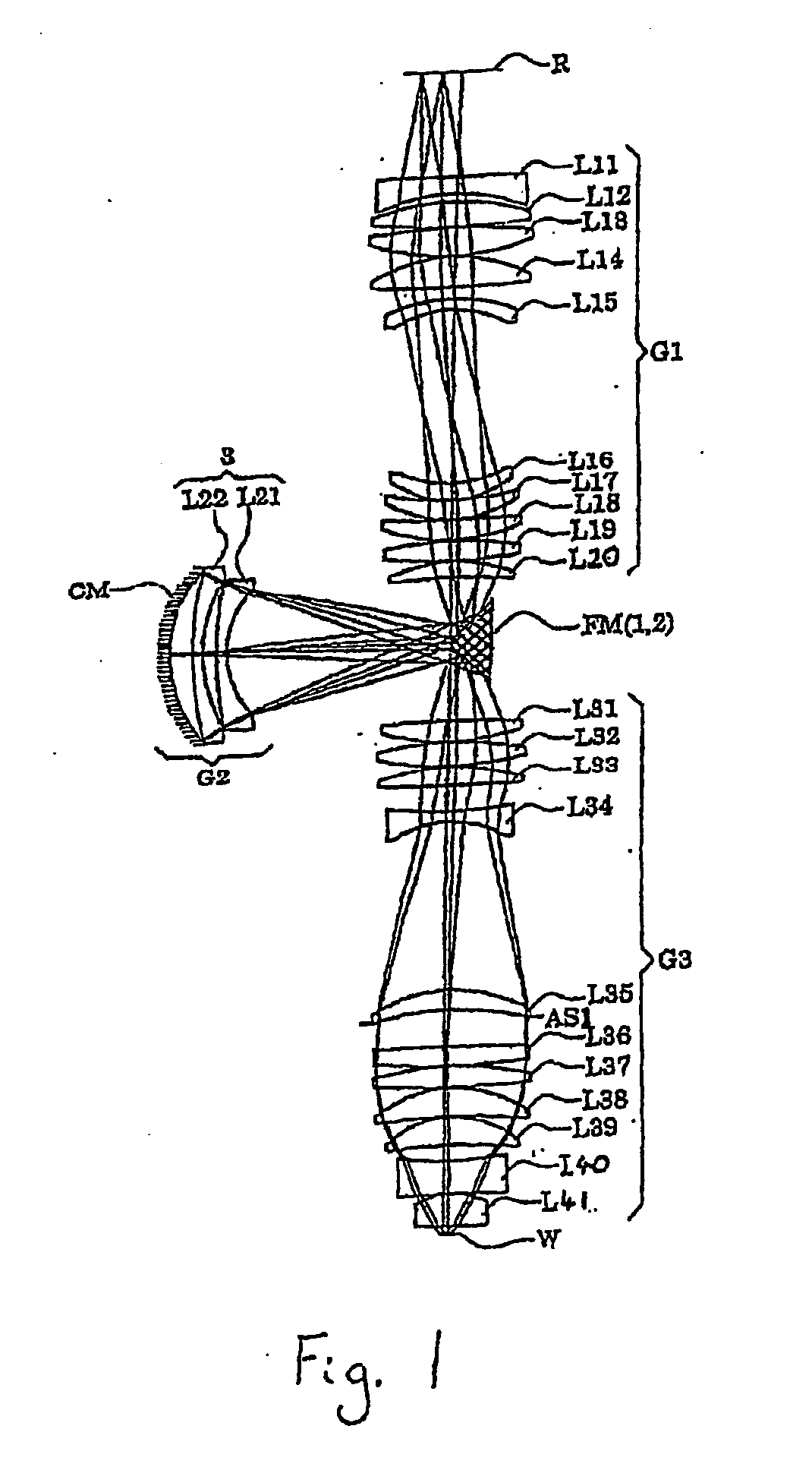

Projection optical system and method for photolithography and exposure apparatus and method using same

InactiveUS20050248856A1Large image-sideWide effective image forming areaSemiconductor/solid-state device manufacturingMicroscopesWide fieldProjection system

Optical Projection System and Method for Photolithography. A lithographic immersion projection system and method for projecting an image at high resolution over a wide field of view. The projection system and method include a final lens which decreases the marginal ray angle of the optical path before light passes into the immersion liquid to impinge on the image plane.

Owner:NIKON CORP

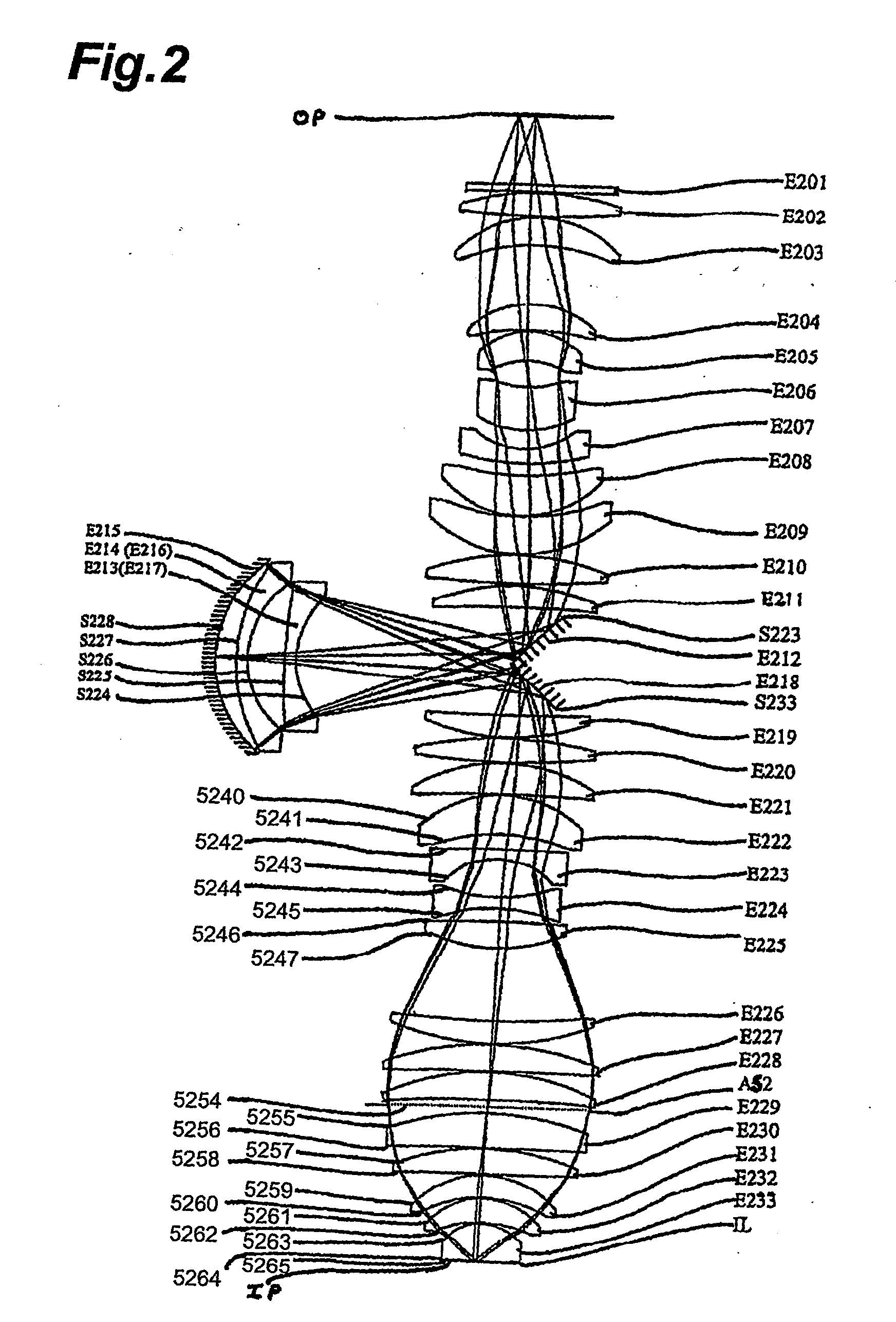

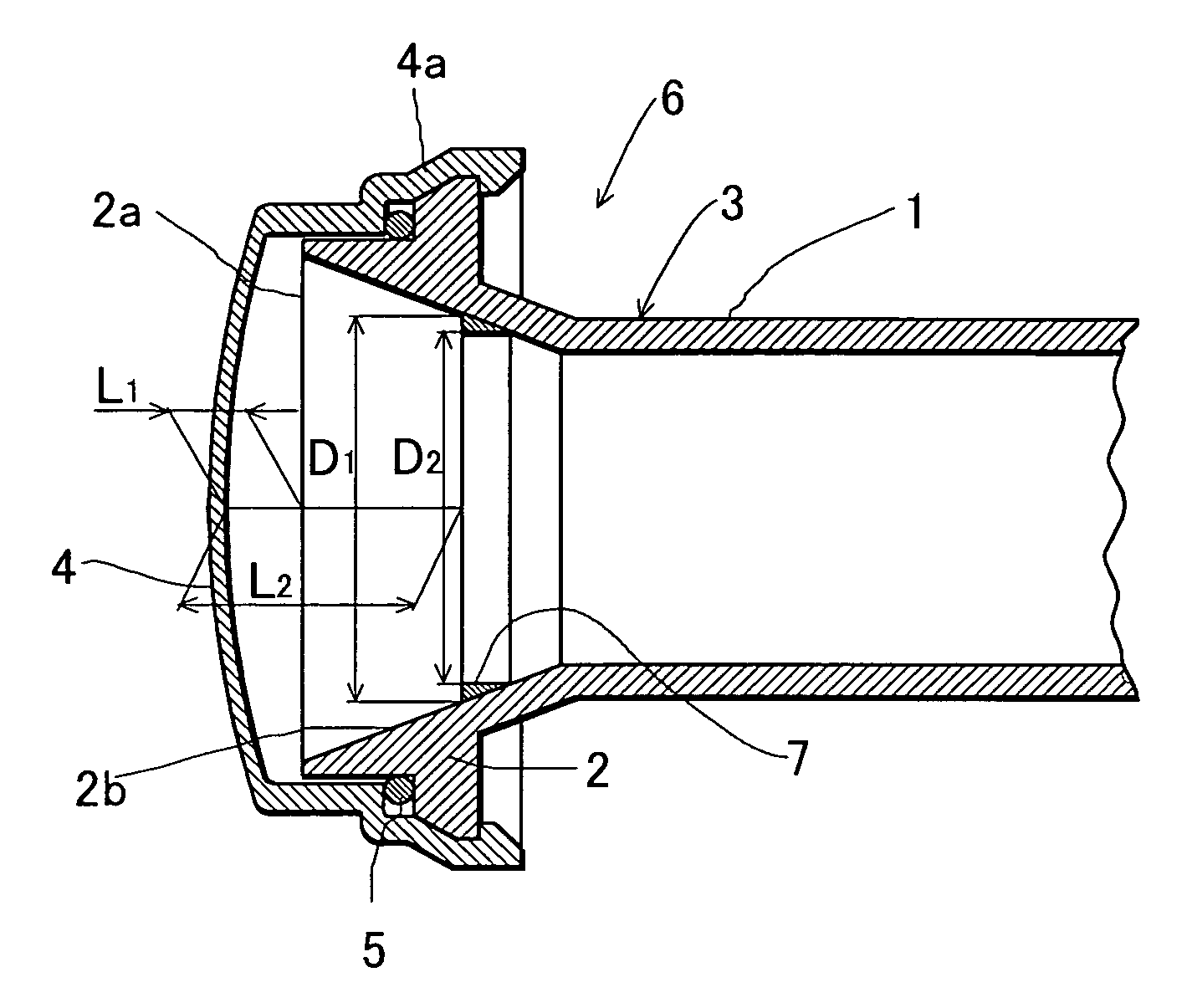

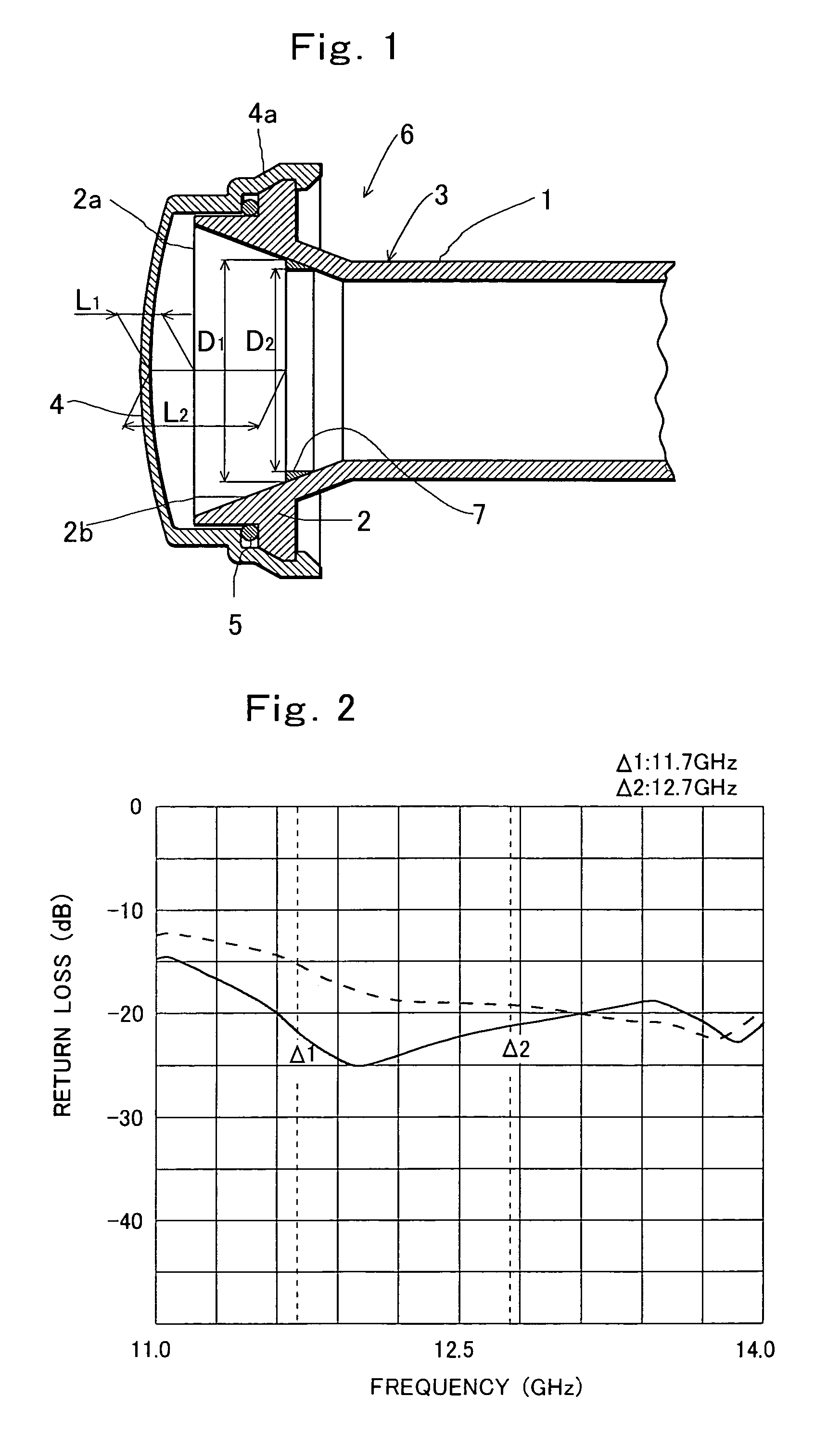

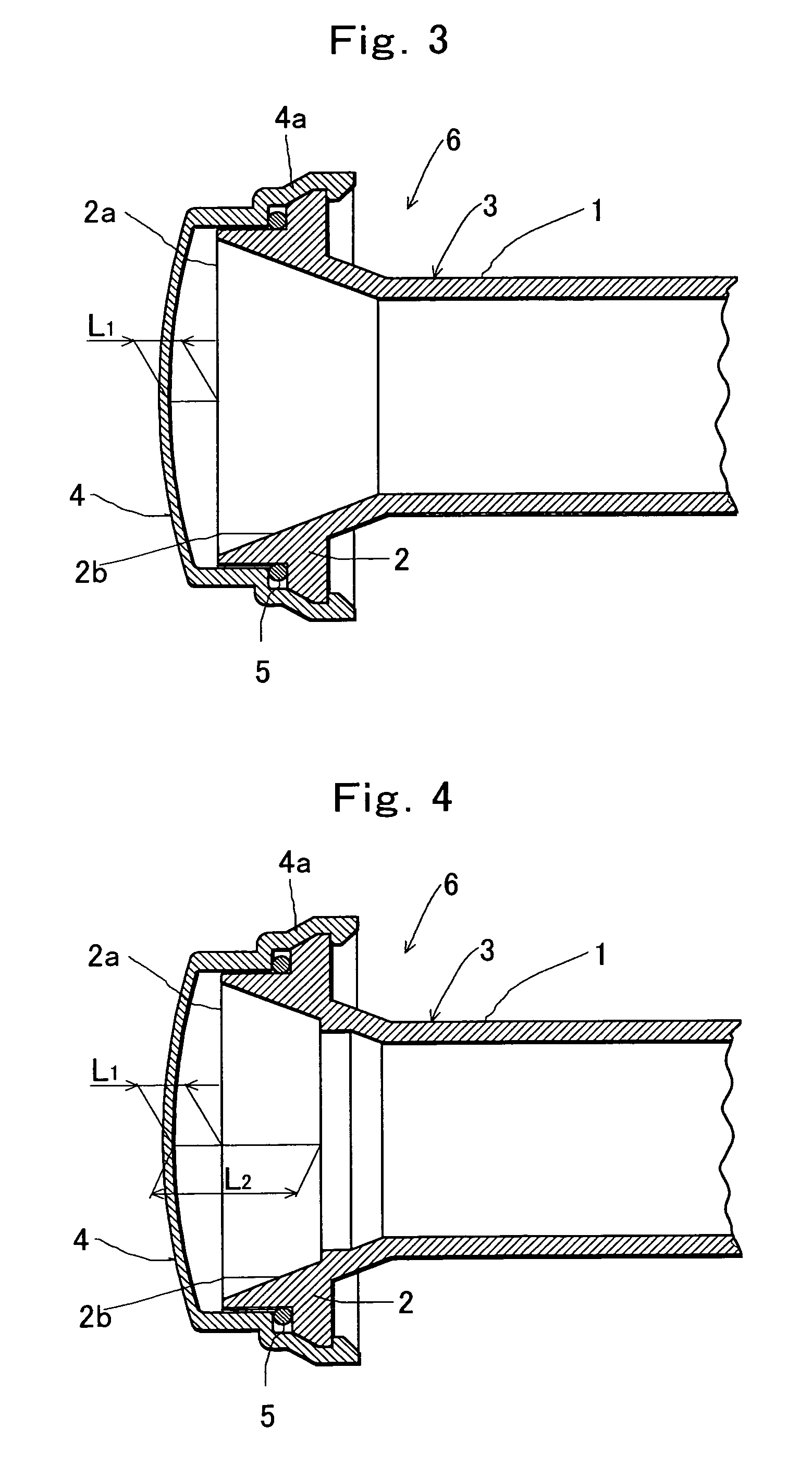

Primary radiator for parabolic antenna

InactiveUS7027003B2Reduce reflection lossWaveguide hornsRadiating element housingsPhysicsParabolic antenna

A primary radiator used for a parabolic antenna including: a radiator body having a horn part provided at one end of a waveguide; and a waterproof cover covering an open end of the horn part of the radiator body, wherein a step is formed on an inner surface of the horn part of the radiator body, and a position of the step is set so that radio waves reflected on the waterproof cover are cancelled out by radio waves reflected on the step to prevent multiple reflection in the radiator body.

Owner:SPC ELECTRONICS +1

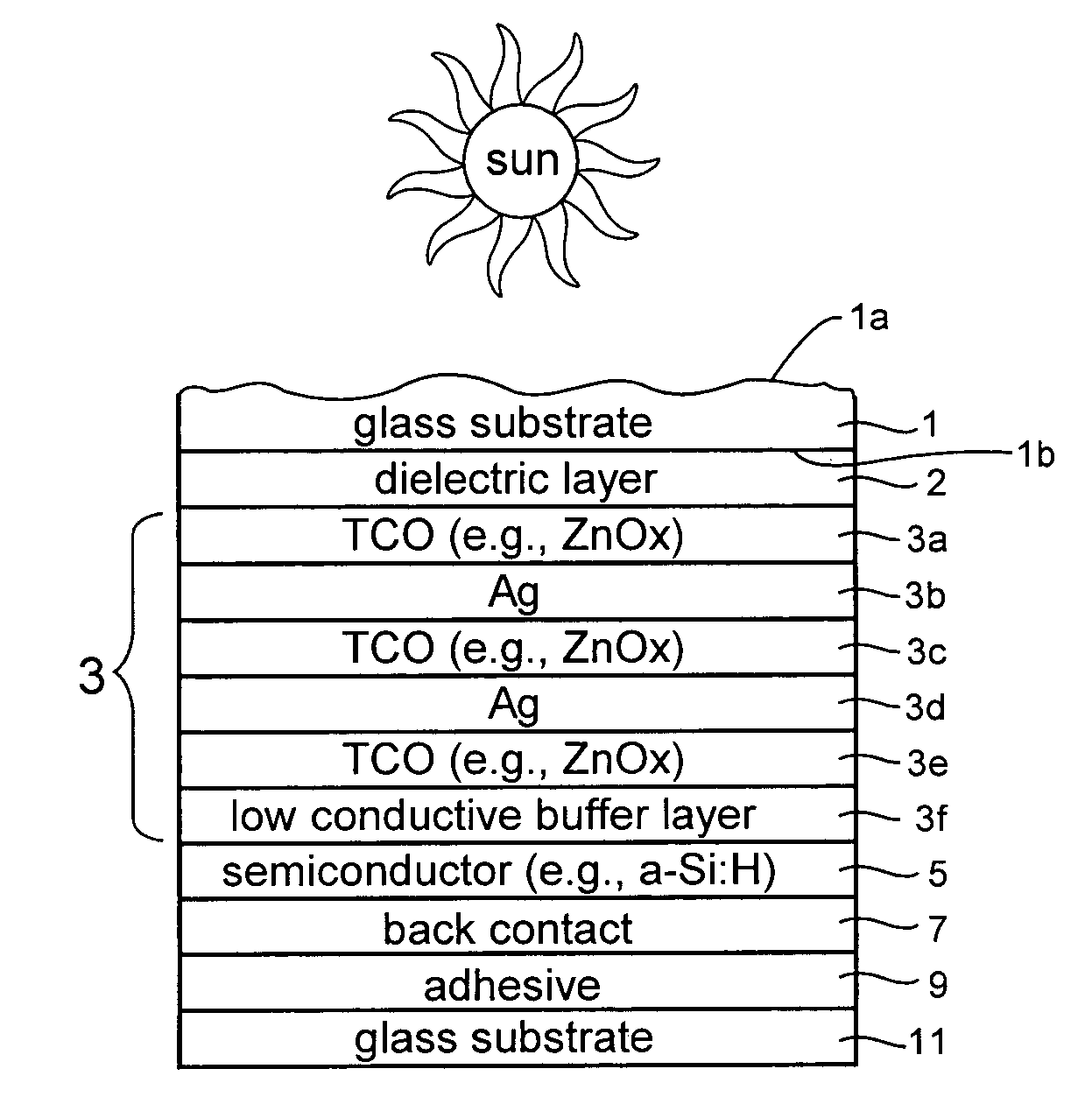

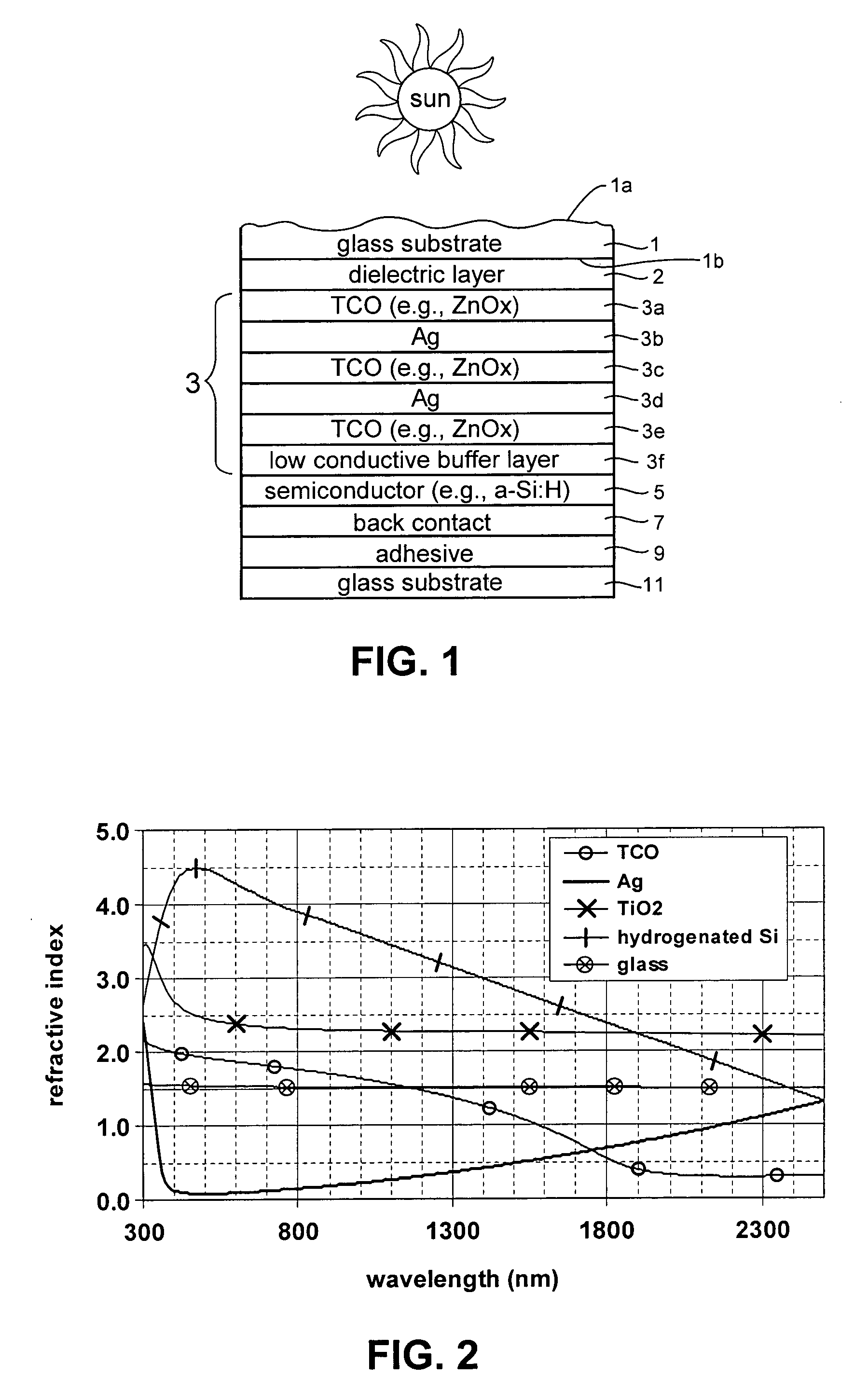

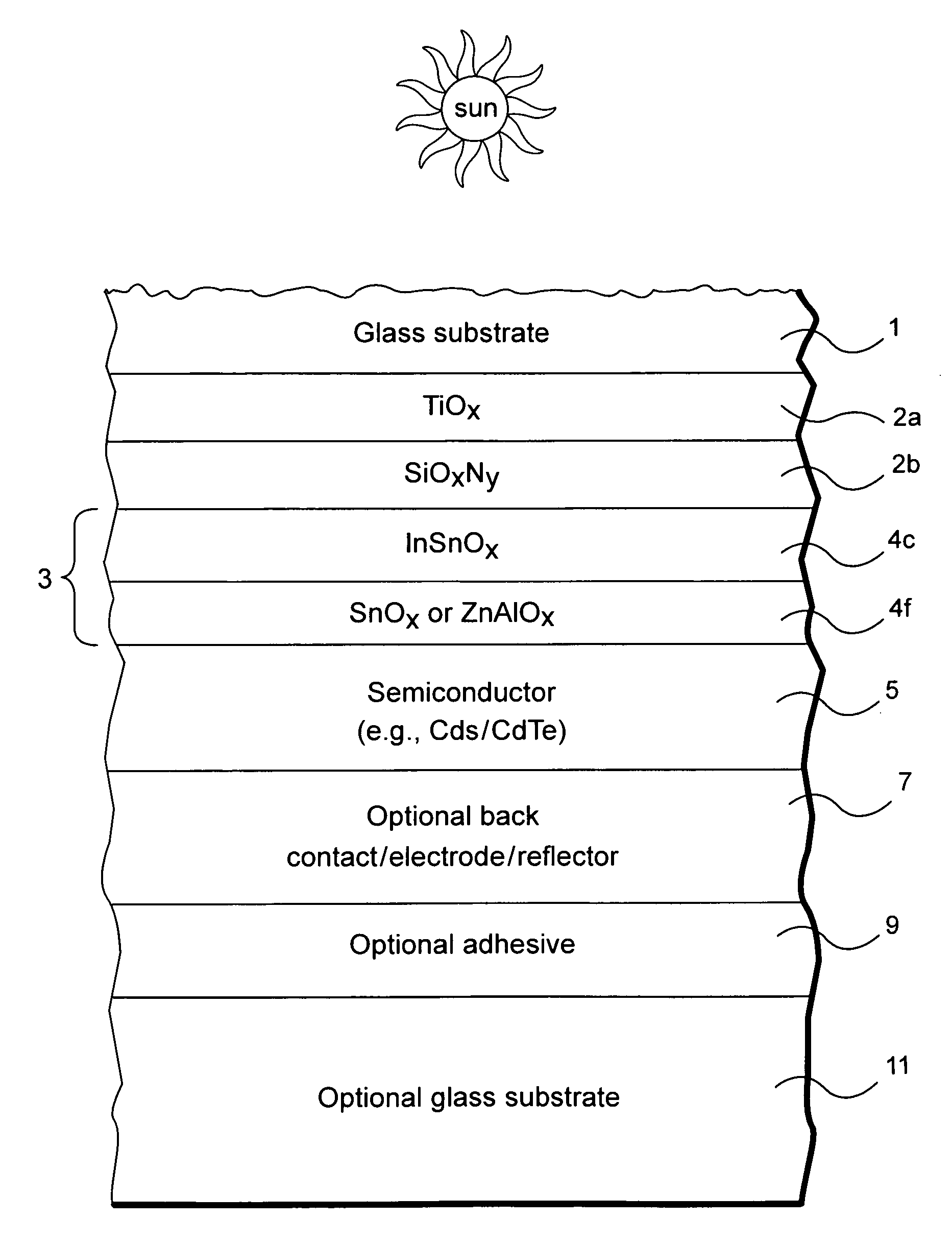

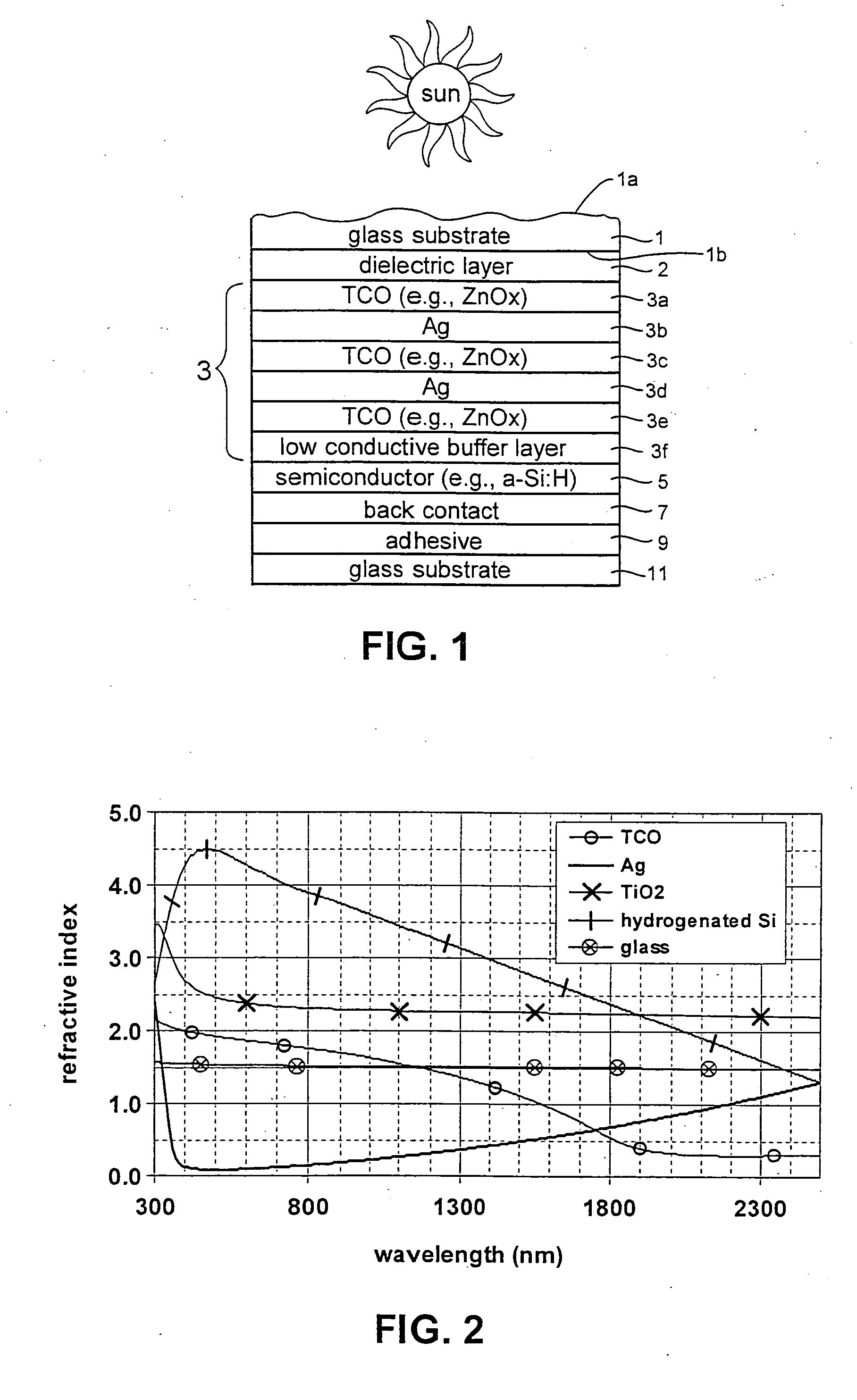

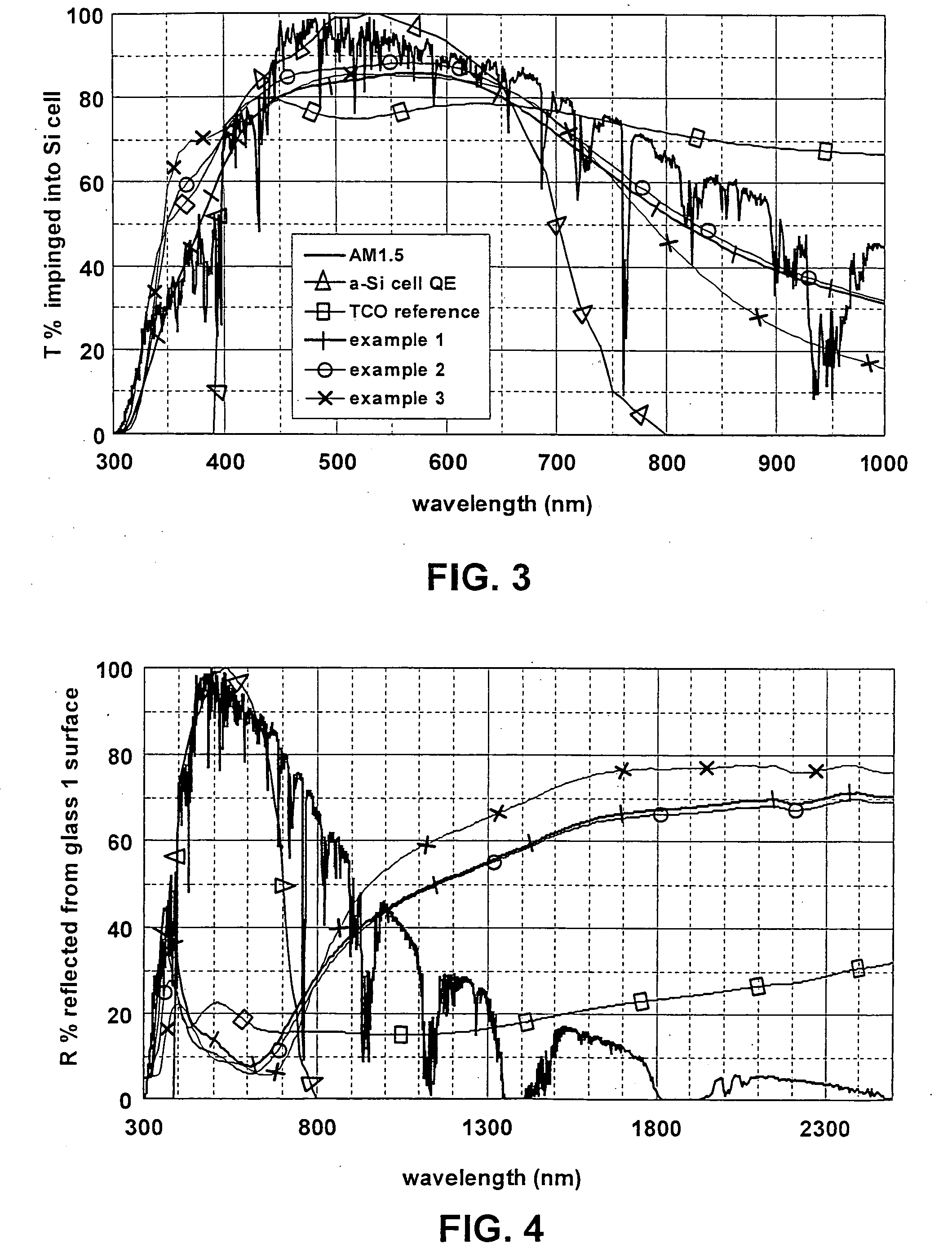

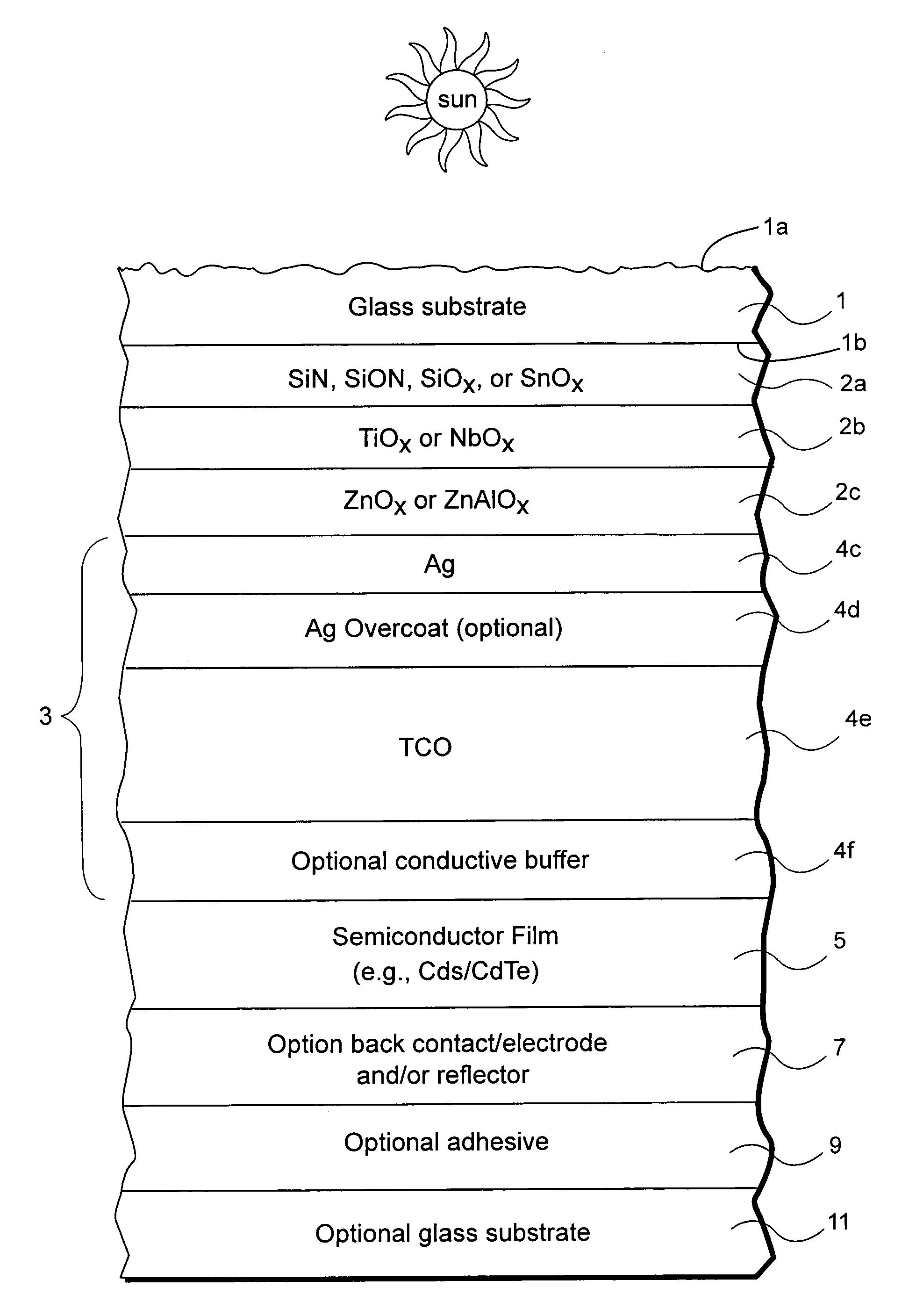

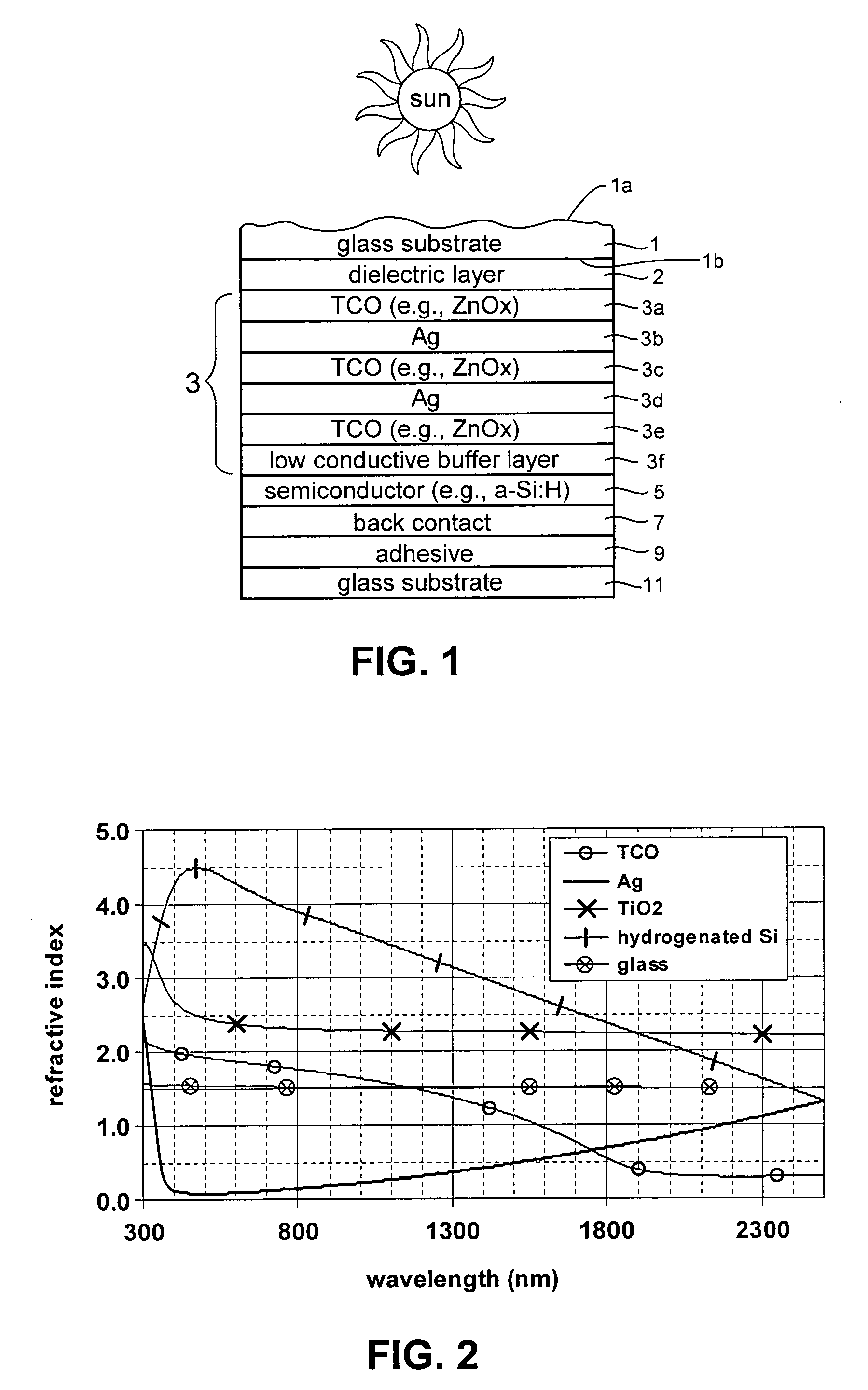

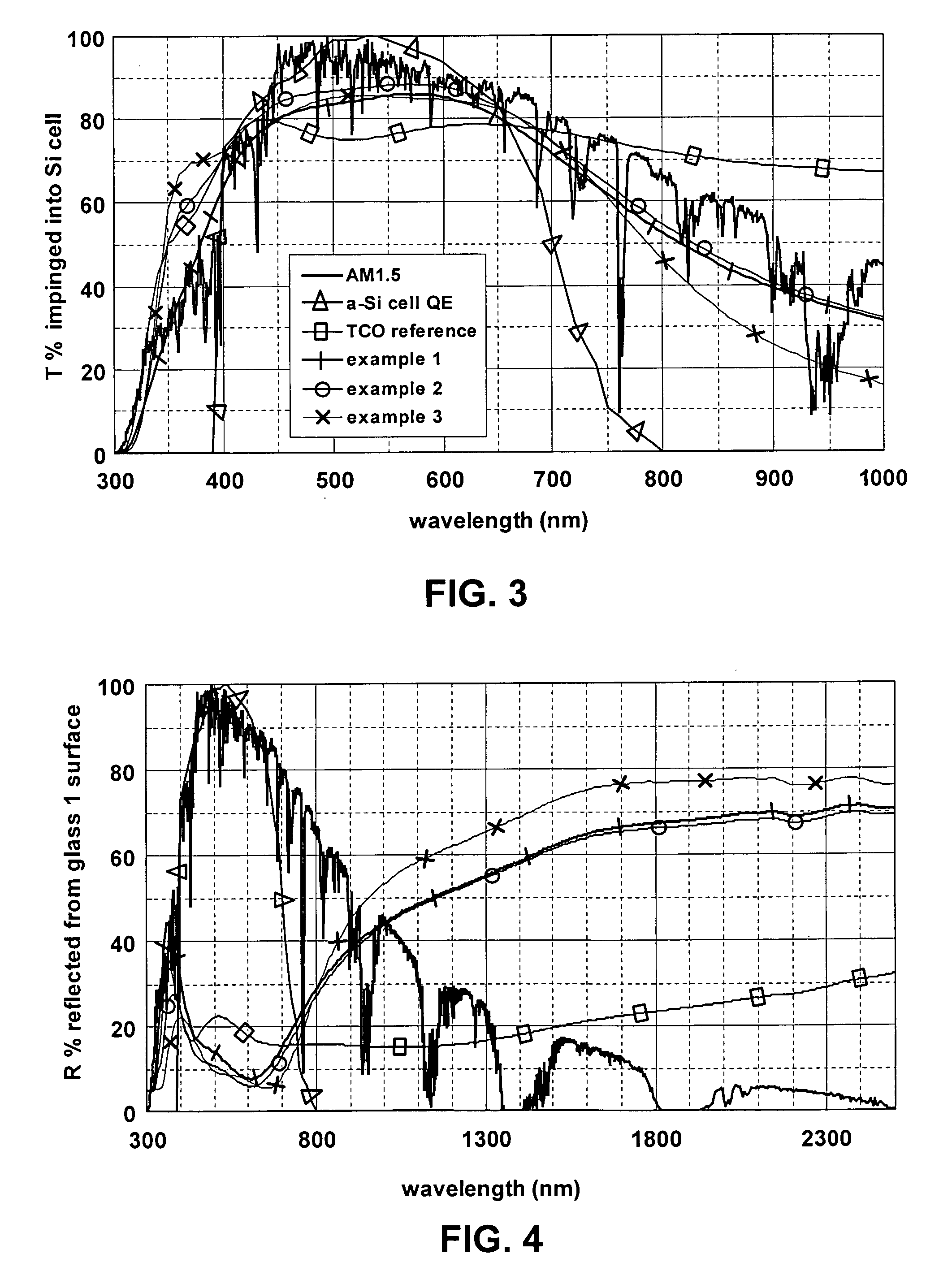

Front electrode for use in photovoltaic device and method of making same

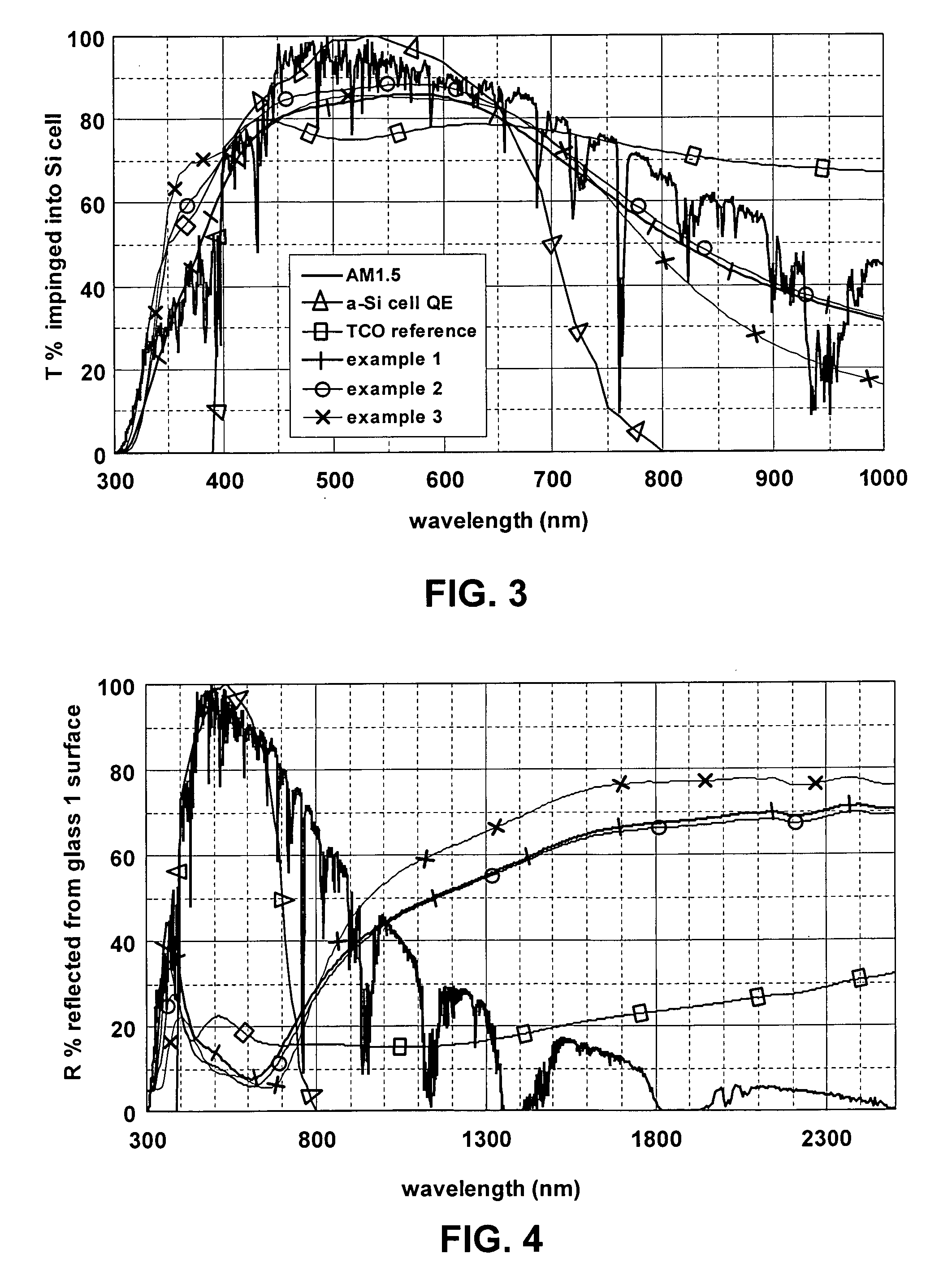

ActiveUS20080210303A1Reduce reflection lossPromote absorptionGlass/slag layered productsCoatingsLight reflectionZinc

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability. At least one of the surfaces of the front glass substrate may be textured in certain example embodiments of this invention.

Owner:GUARDIAN GLASS LLC

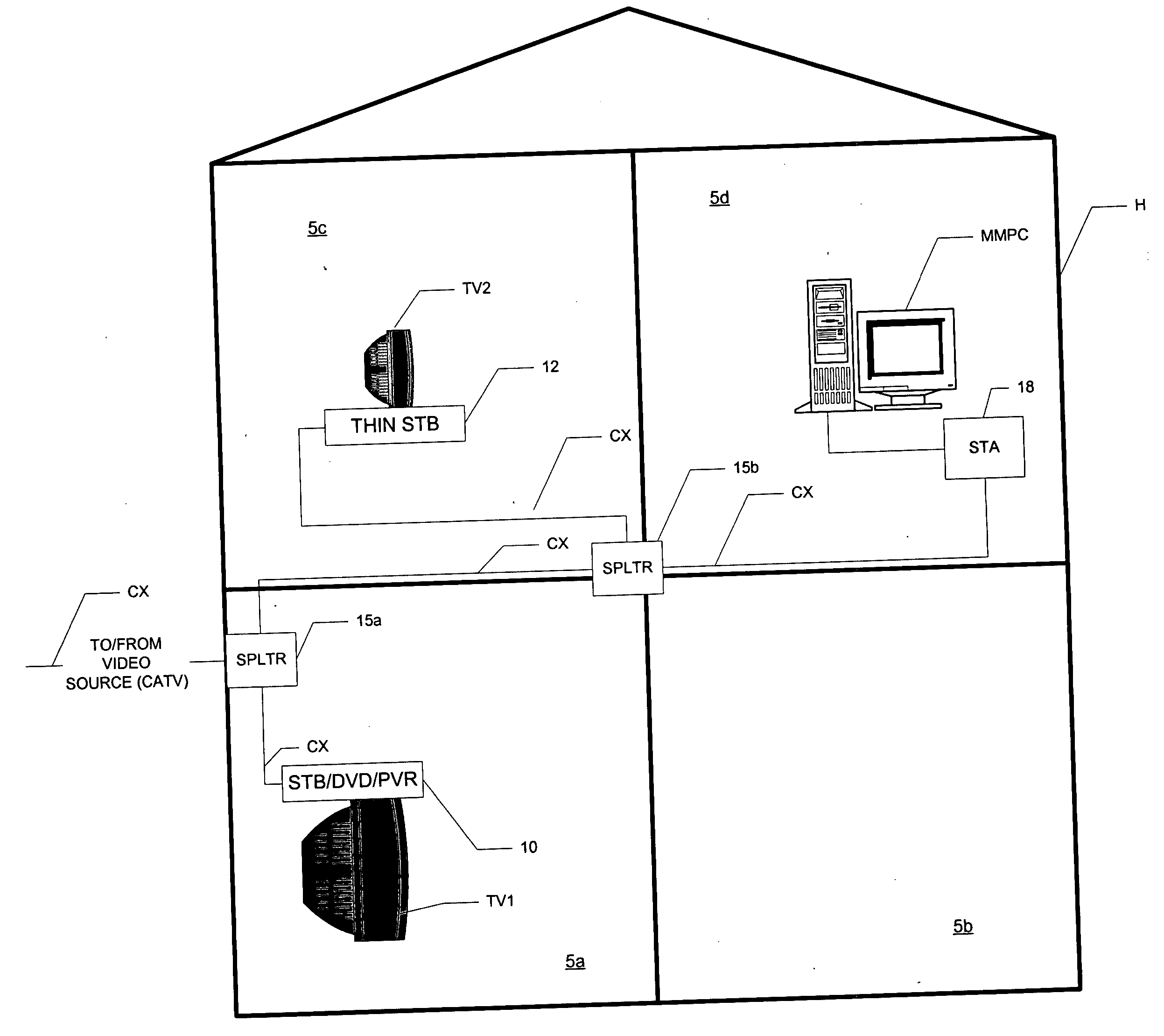

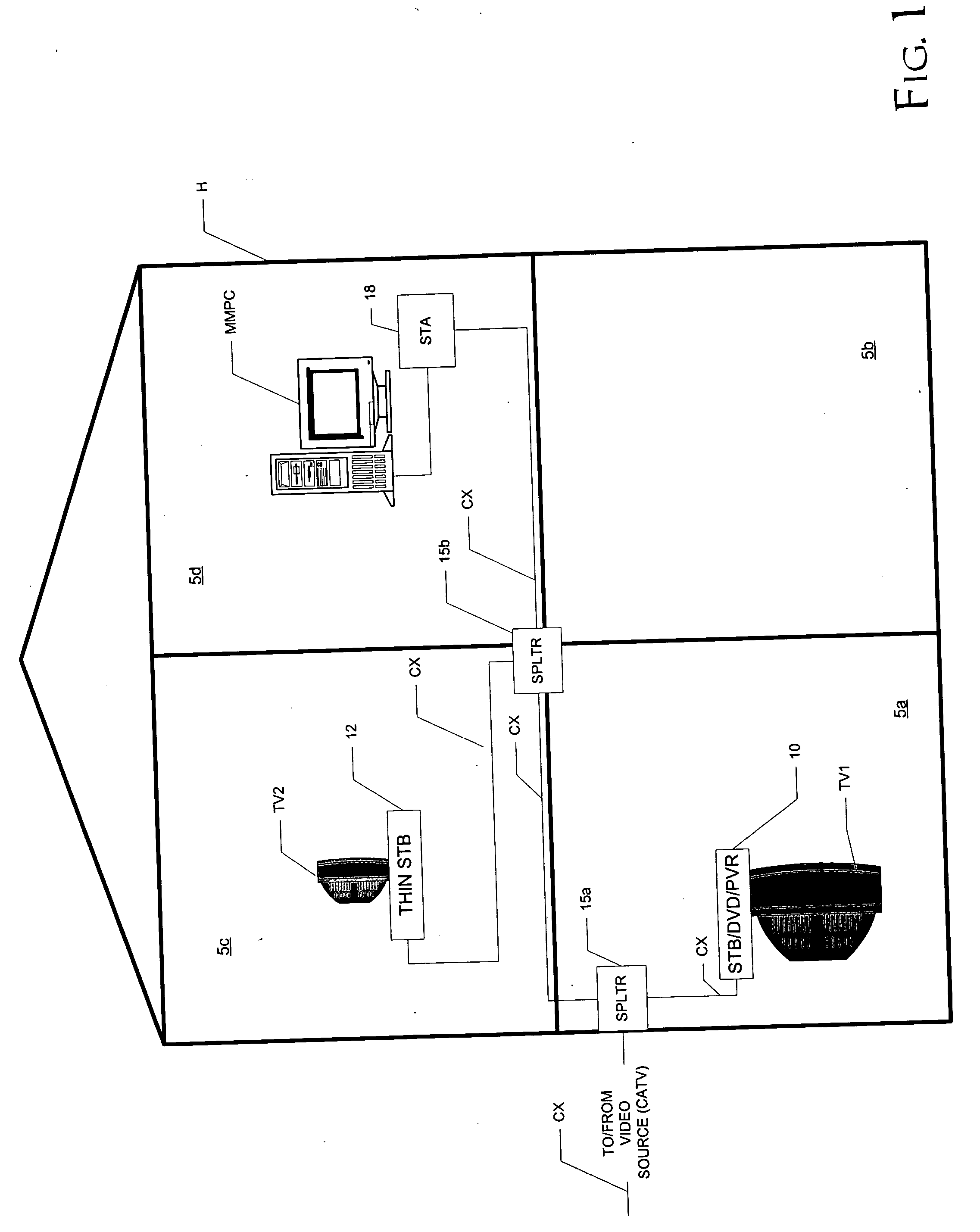

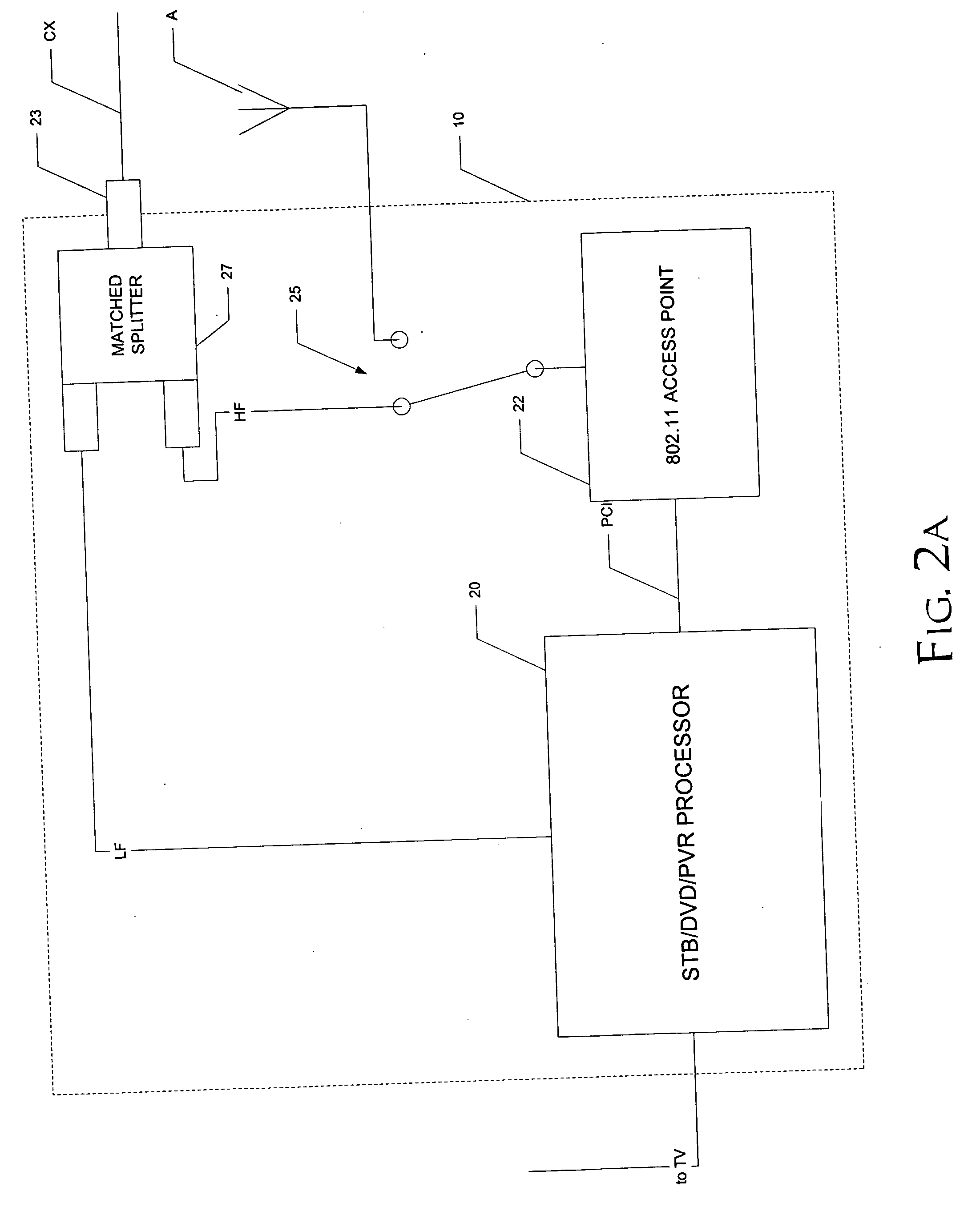

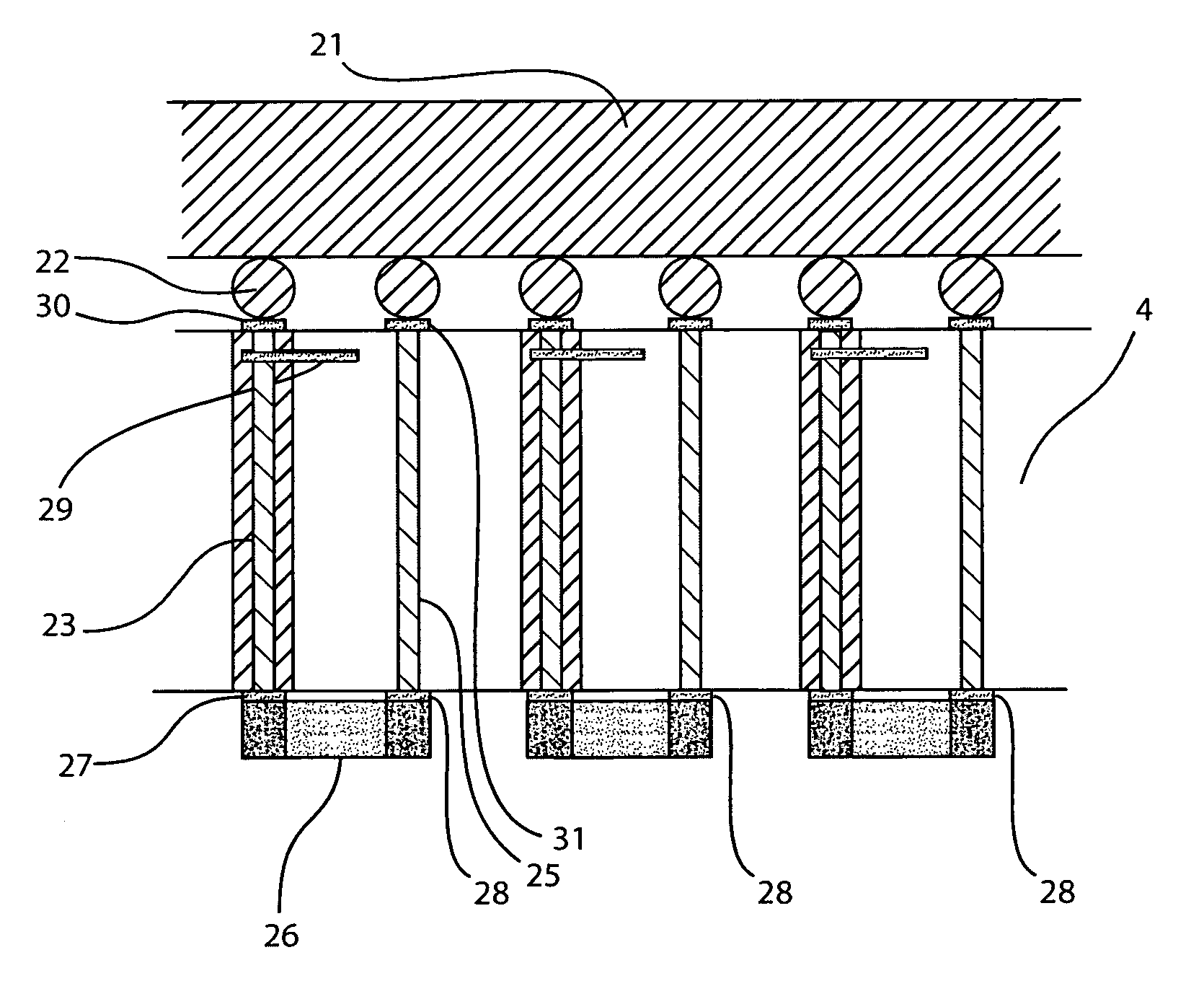

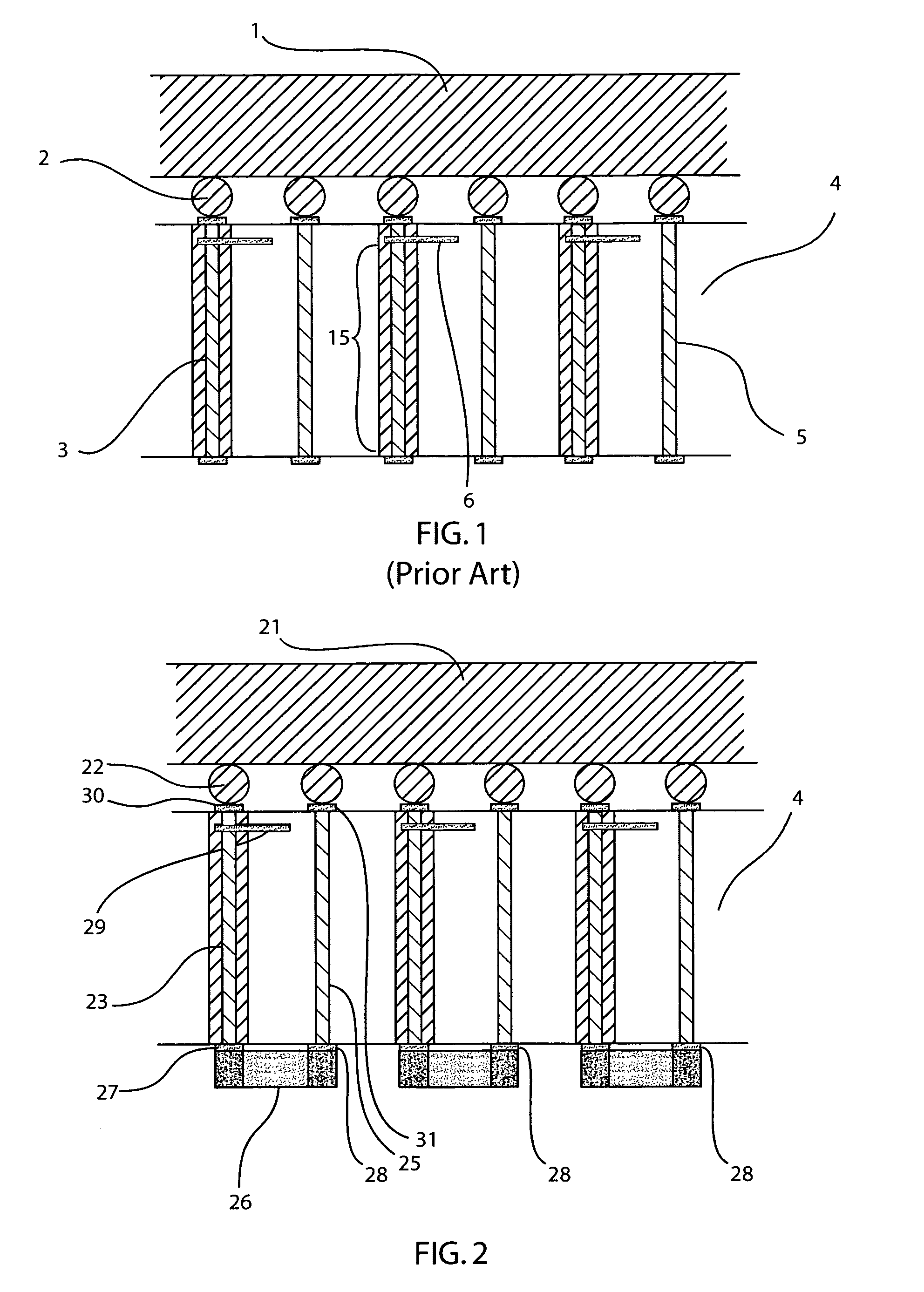

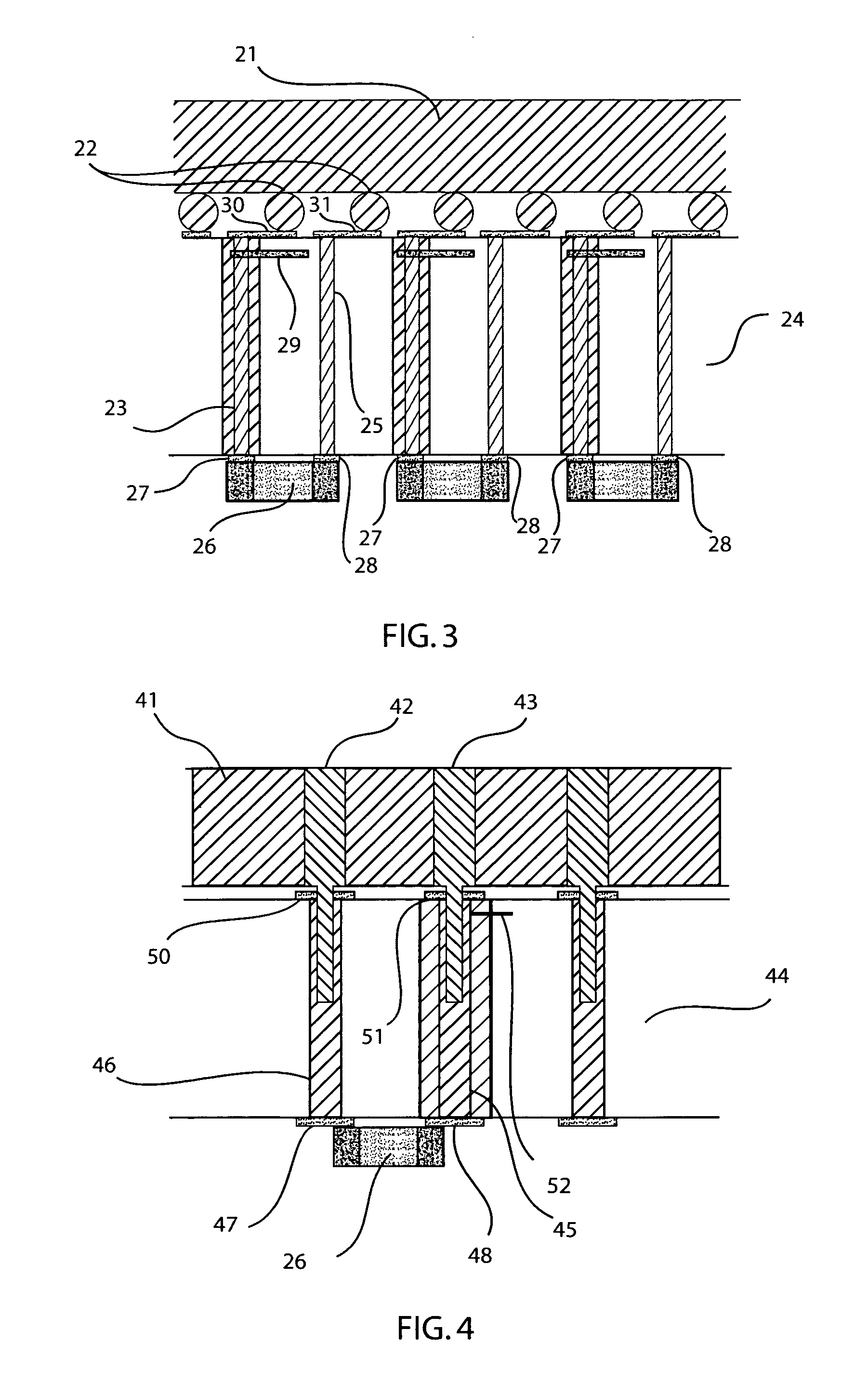

Implementing a hybrid wireless and coaxial cable network

InactiveUS20050034159A1Miniaturized installationIncrease data rateBroadband local area networksClosed circuit television systemsCoaxial cableVideo processing

A home video network, and a home video and data network, utilizing wireless protocol communications over coaxial cable (CX) are disclosed. In the home video network, a main network station (10) includes video processing functionality, such as one or more of a DVD player, personal video recorder (PVR), and a set-top box (STB) for cable or satellite television reception. The main network station (10) also includes a matched splitter (27) that receives coaxial cable (CX) inputs, and provides low-pass filtered and high-pass filtered output. The low-pass filtered output (LF) corresponding to video signals is provided to the video processing functionality (20) and the high-pass filtered output (HF) corresponding to wireless protocol communications is provided to a wireless access point function (22). Other network stations and combinations of functions are also disclosed, including those that utilize a function switch (25) to switch between network communications over coaxial cable (CX) and communications over an antenna (A), in either a single BSS mode or a double BSS mode.

Owner:TEXAS INSTR INC

Front electrode for use in photovoltaic device and method of making same

ActiveUS20090084438A1Reduce reflection lossPromote absorptionPhotovoltaic energy generationSemiconductor devicesIr reflectionLight reflection

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and / or one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability.

Owner:GUARDIAN GLASS LLC

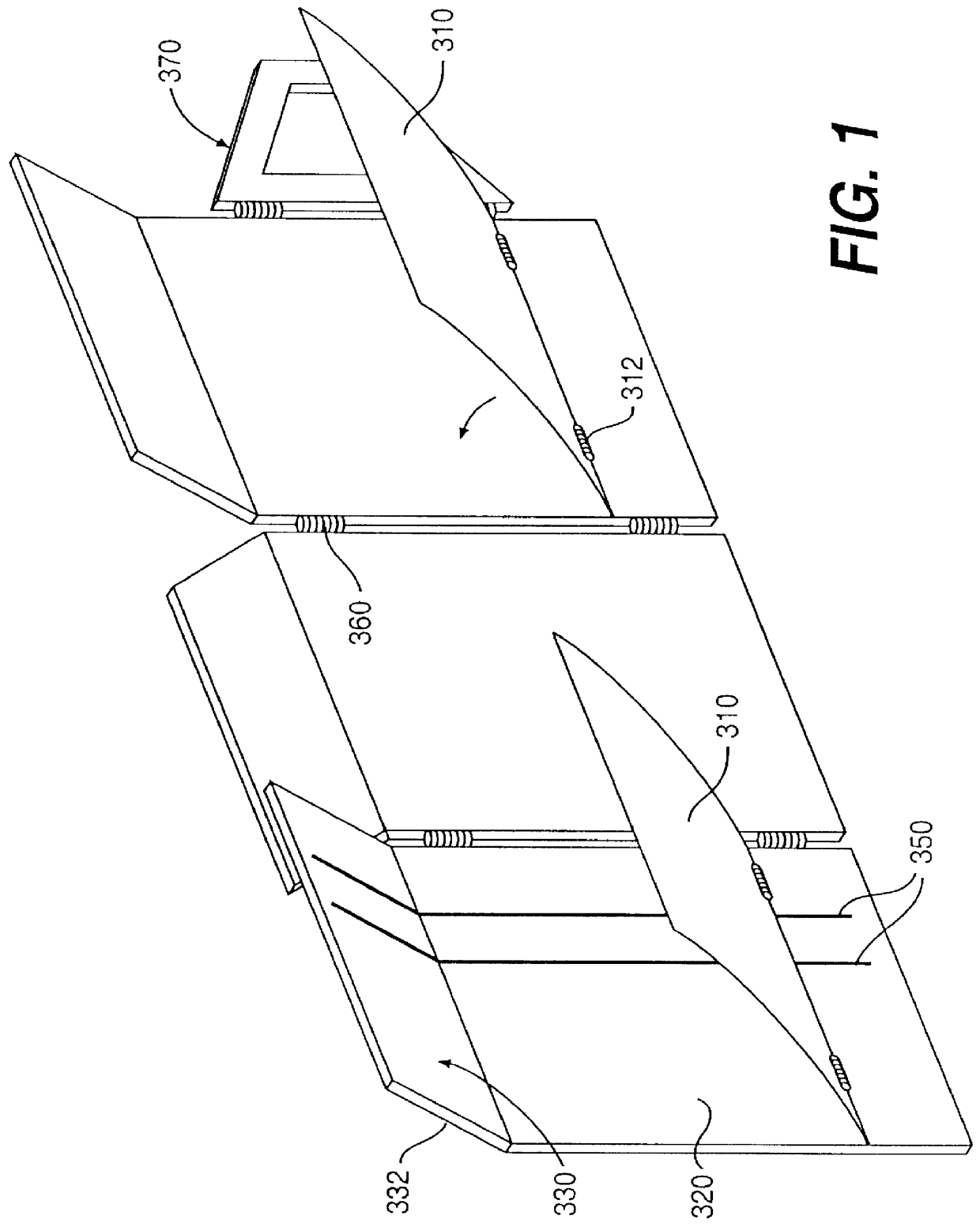

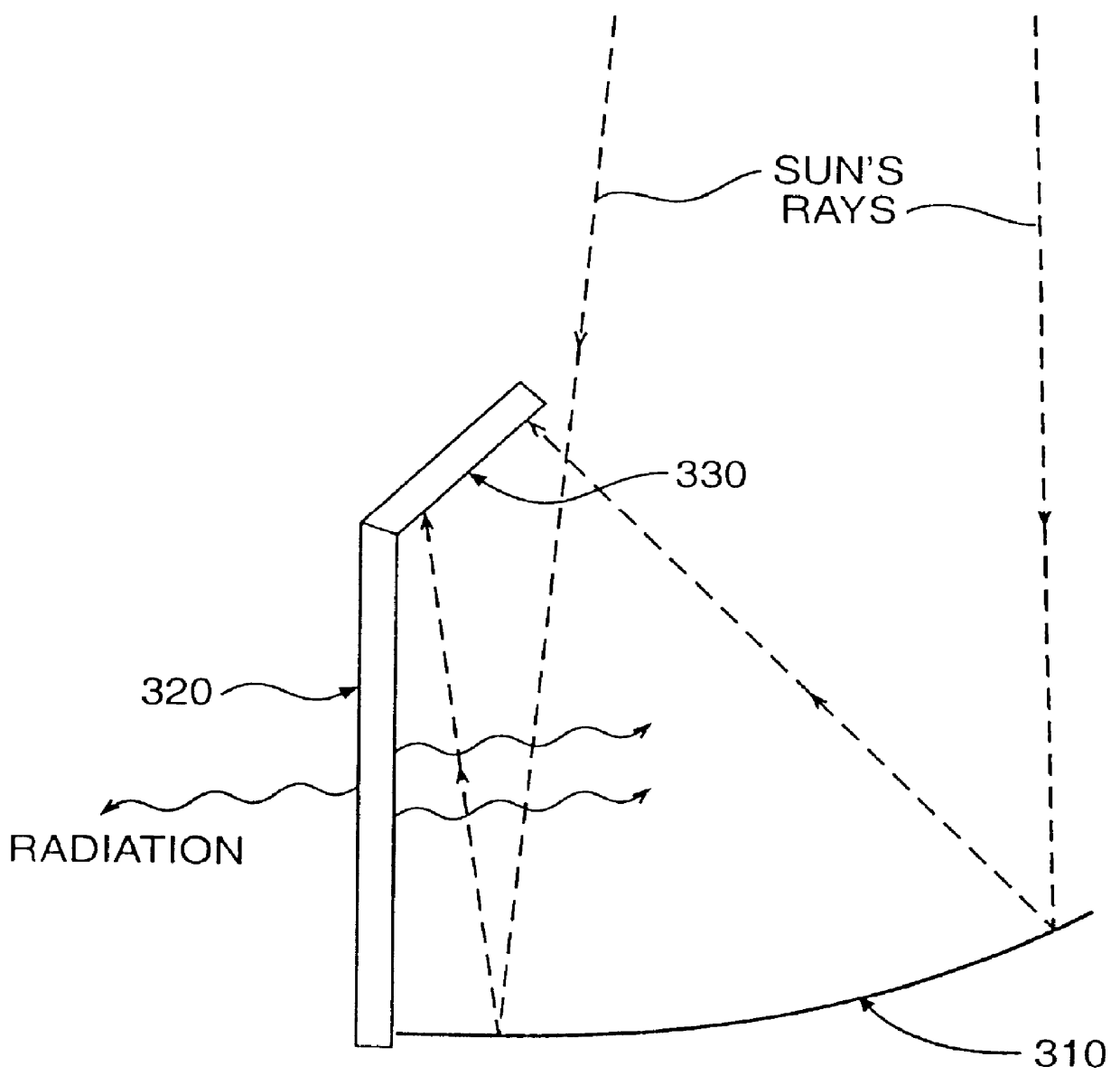

Method and apparatus for improved solar concentration arrays

InactiveUS6118067AIncrease concentrationSimple designSolar heating energyCosmonautic vehiclesCells panelEngineering

A lightweight photovoltaic concentrator is disclosed. The concentrator comprises at least two sections each comprising a cell panel, a radiator panel and a reflector panel. In one embodiment, the concentrator system of the present invention comprises at least two hinged sections each comprising a solar cell panel, a flat radiator panel, and a curved reflective concentrator panel. The solar cell panel comprises at least one photovoltaic cell for generating electrical power in response to radiation. The solar cell panel is aligned with the radiator panel at an angle less than 180 degrees but not less than 90 degrees facing the reflective concentrator panel. In another embodiment, the cell panels on adjoining sections are angled in opposite directions with respect to the radiator panels and wherein the reflective concentrator panels are located on opposite sides of the radiator panels. A heat pipe or loop heat pipe is located in the radiator panel to dissipate heat from the solar cells.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

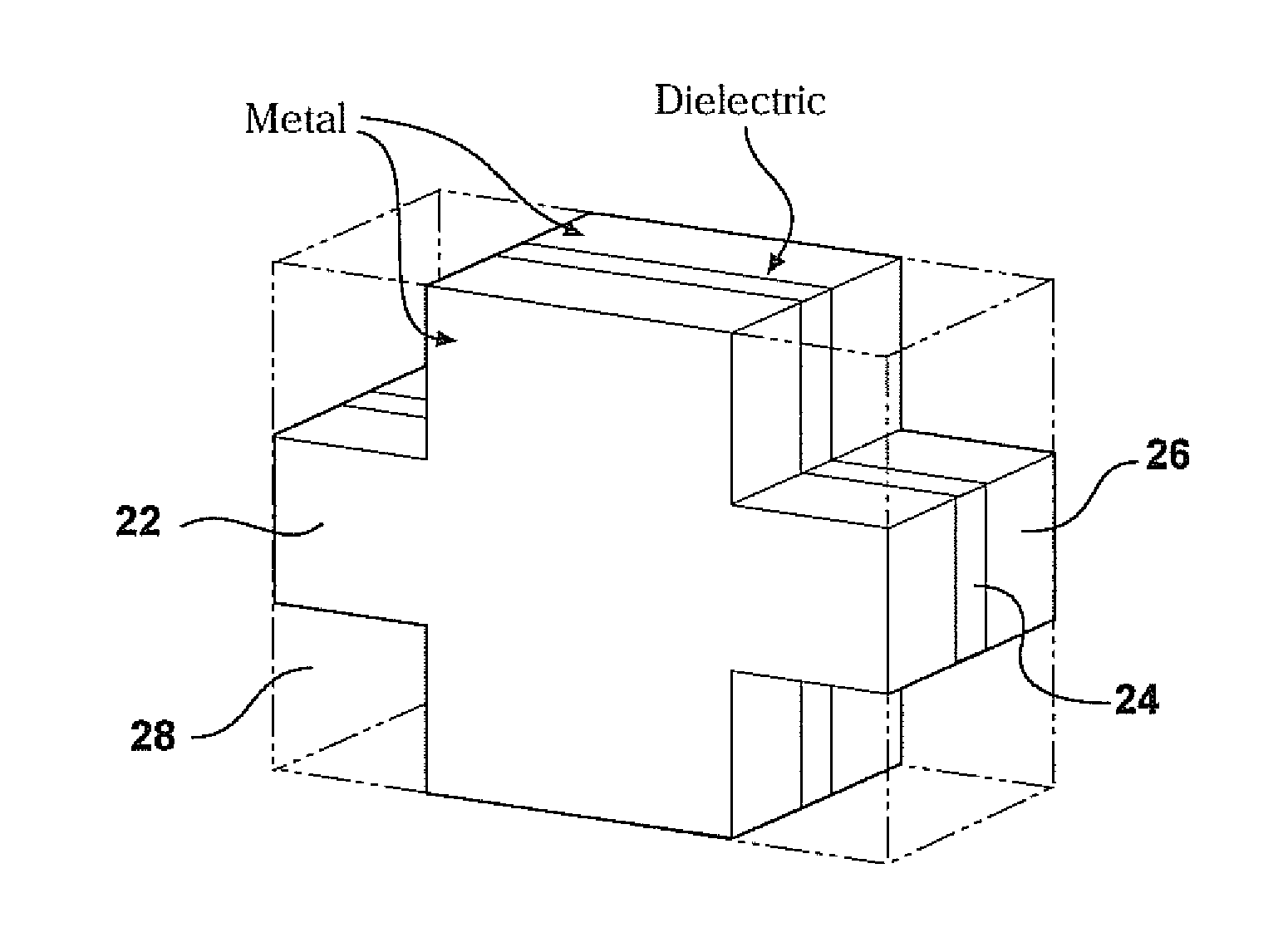

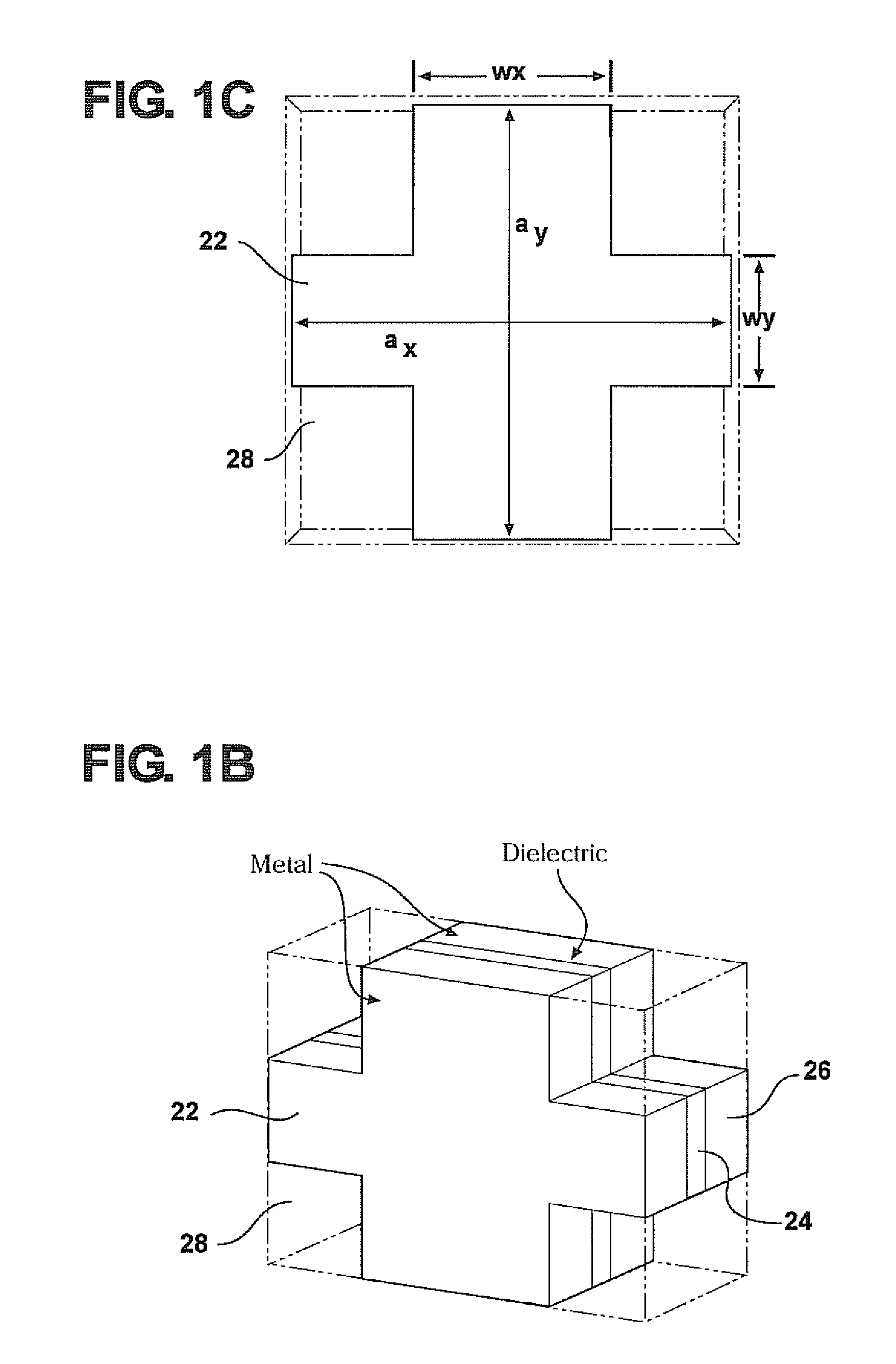

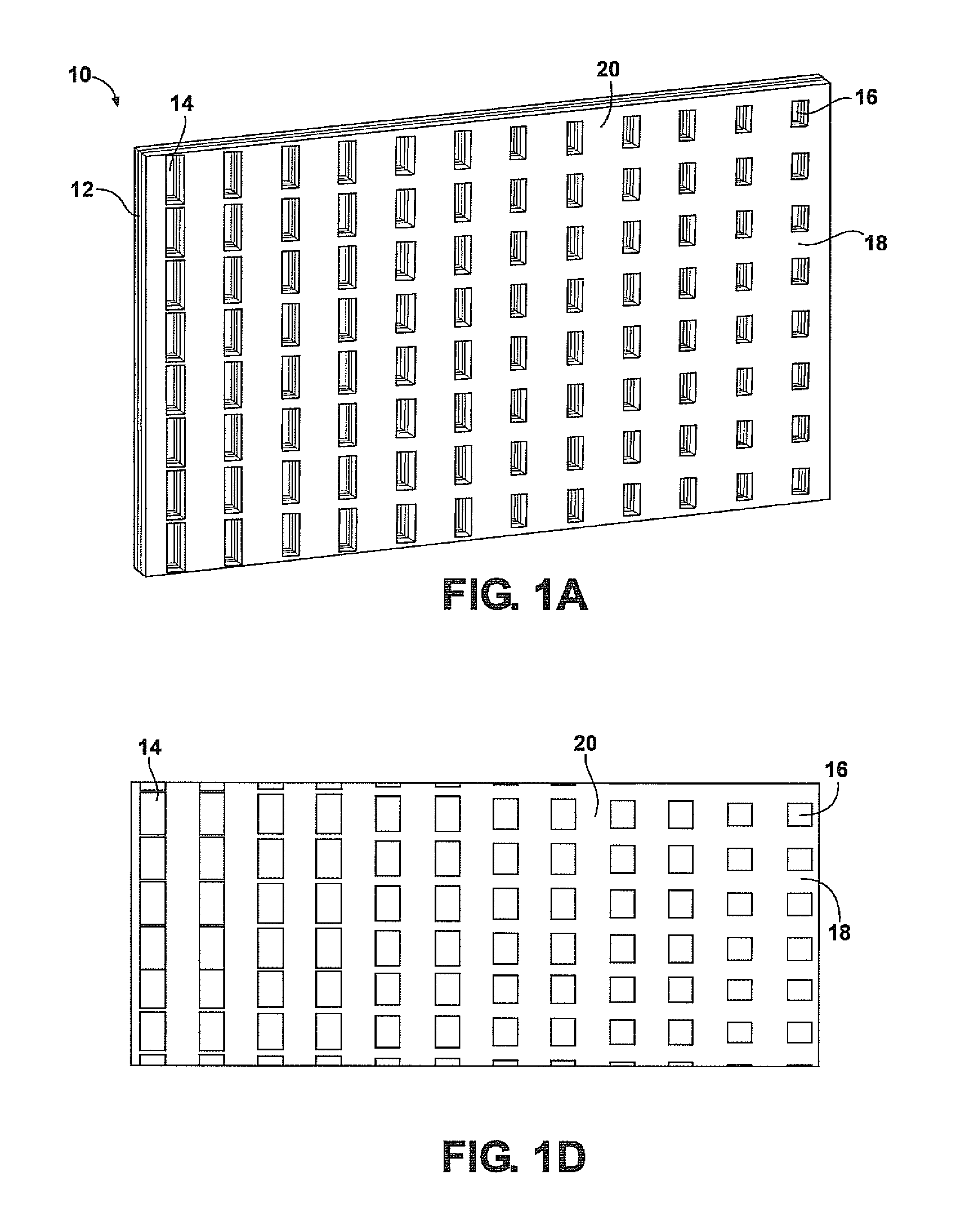

Planar gradient index optical metamaterials

An apparatus comprises a metamaterial including a first conducting layer, a second conducting layer, and a dielectric layer located between the first conducting layer and the second conducting layer. Each conducting layer has holes formed therethrough, for example as an array of holes formed through the metamaterial. The holes are configured so that the metamaterial has a gradient refractive index at an operational wavelength. The operational wavelength may be an IR or visible wavelength. The apparatus may be an optical element, and for example may have the functionality of a lens or prism through the refractive index gradient. Interfaces may be parallel planar interfaces.

Owner:TOYOTA MOTOR CO LTD

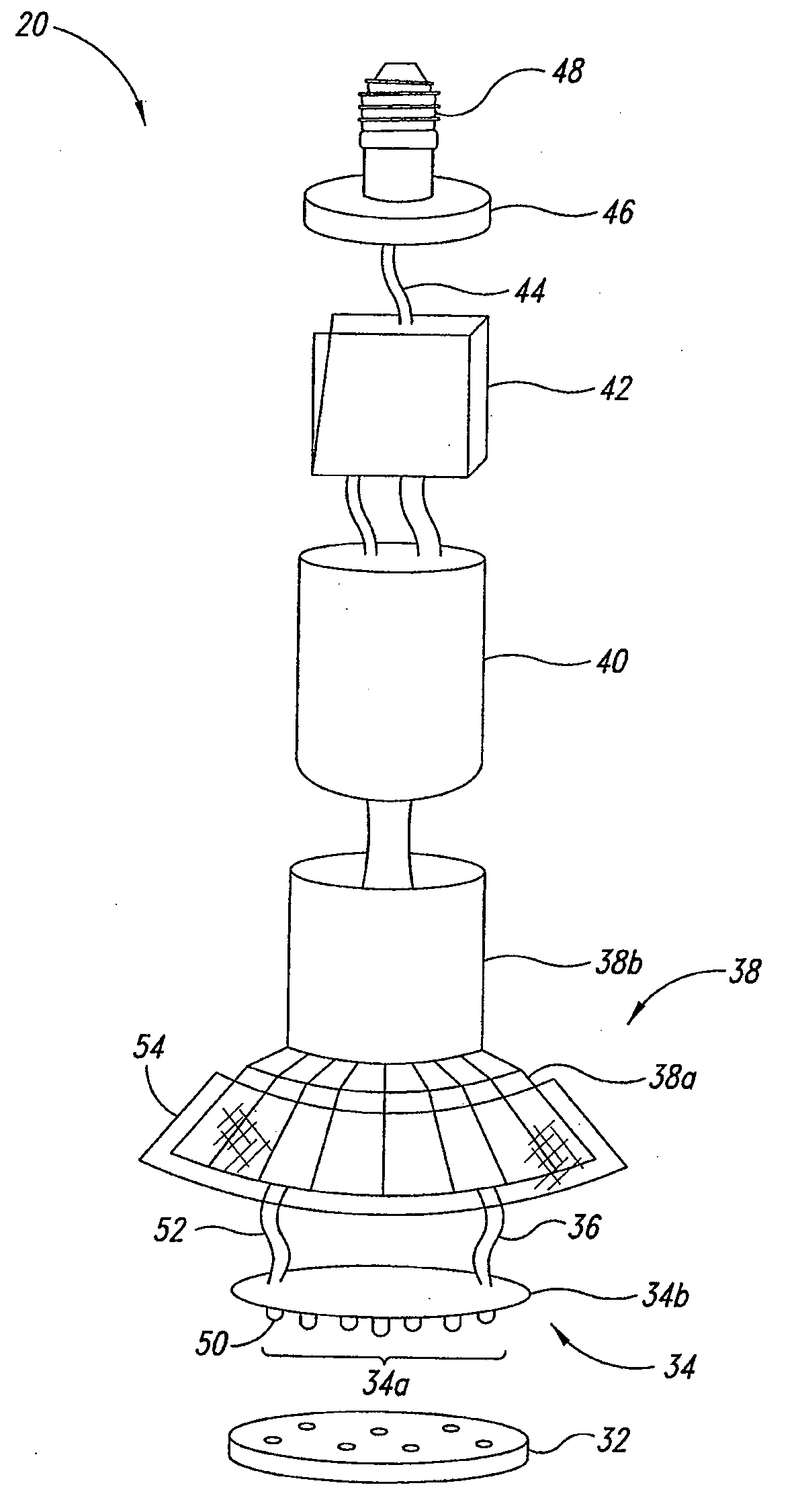

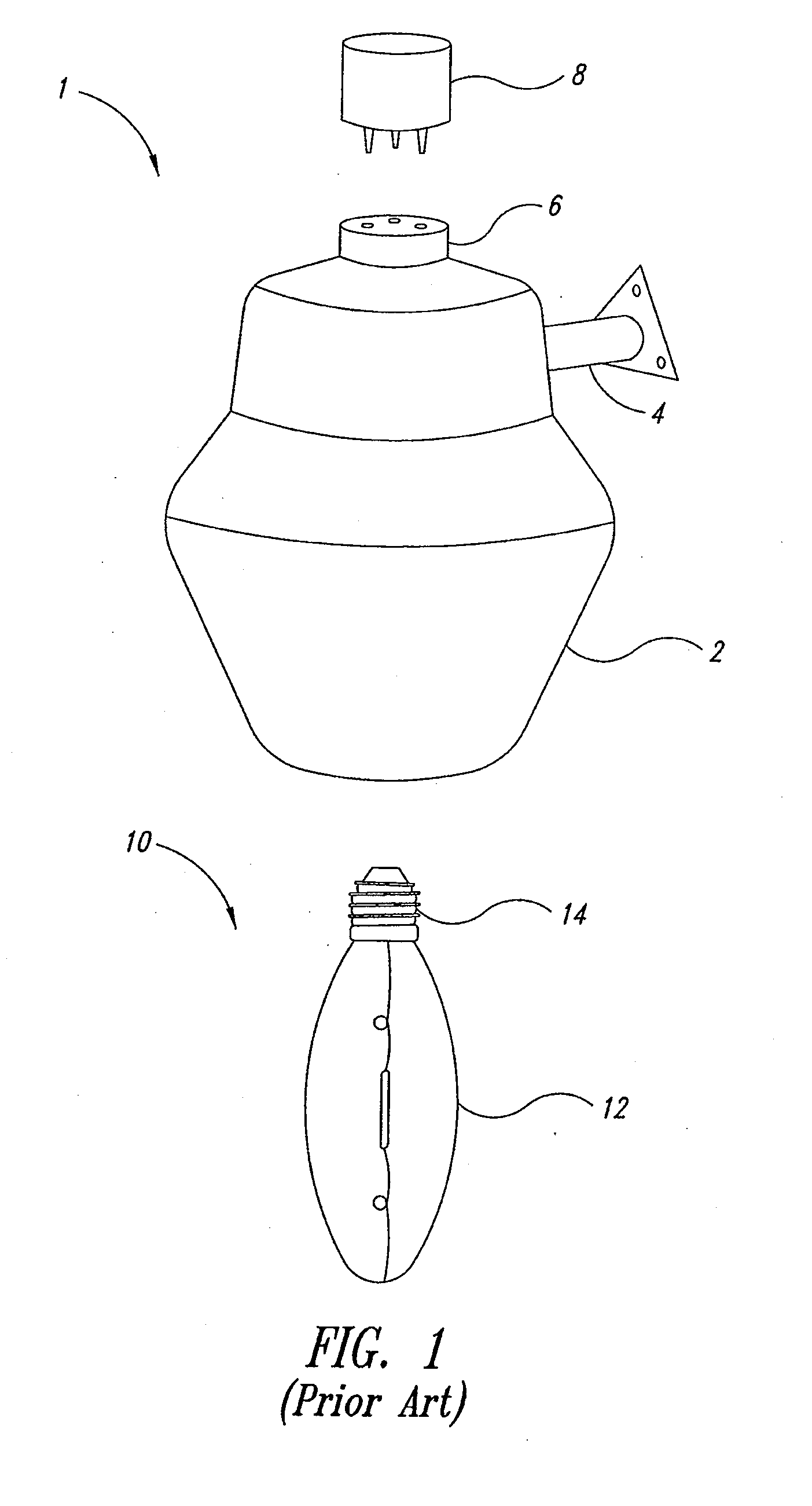

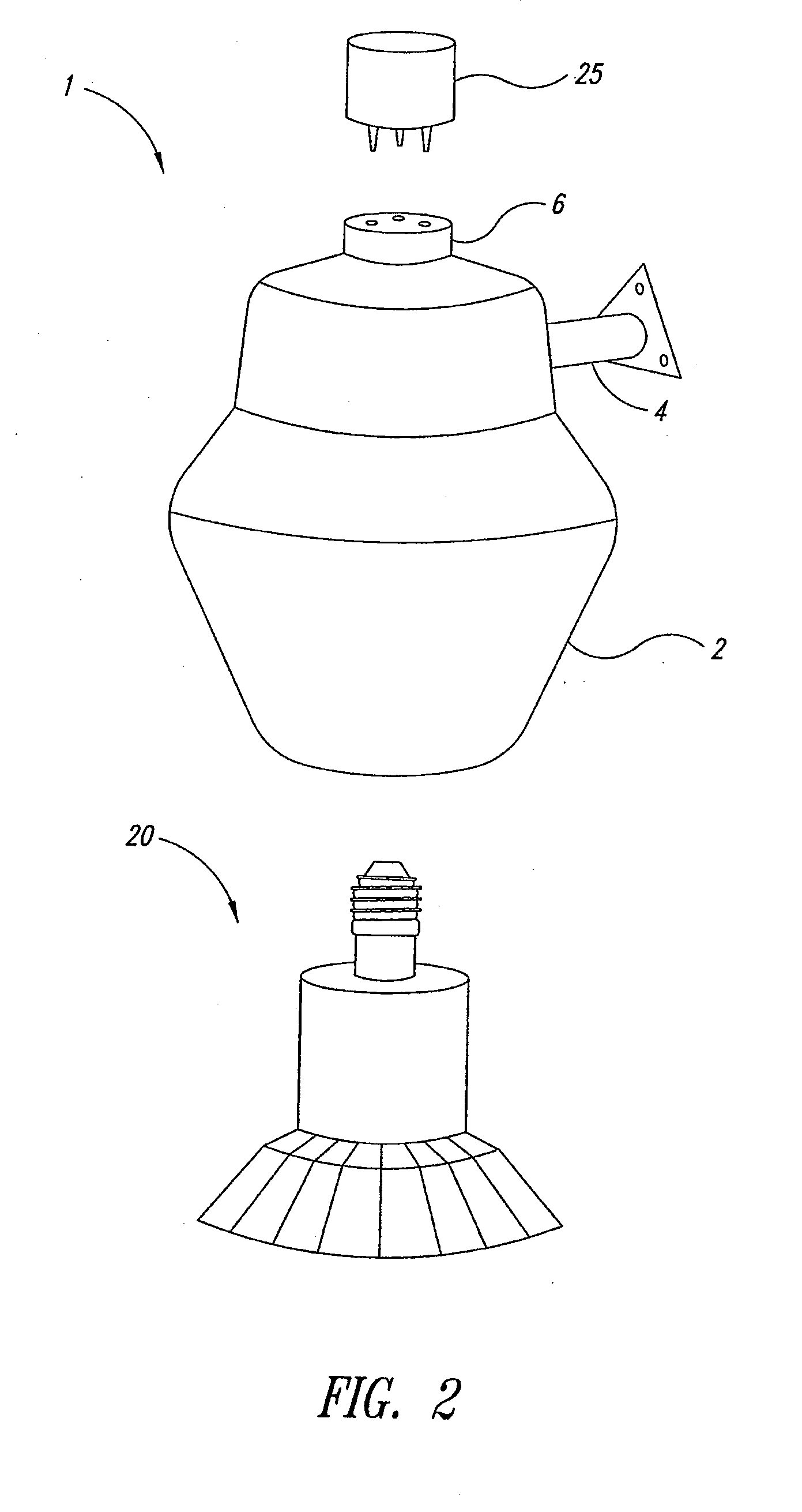

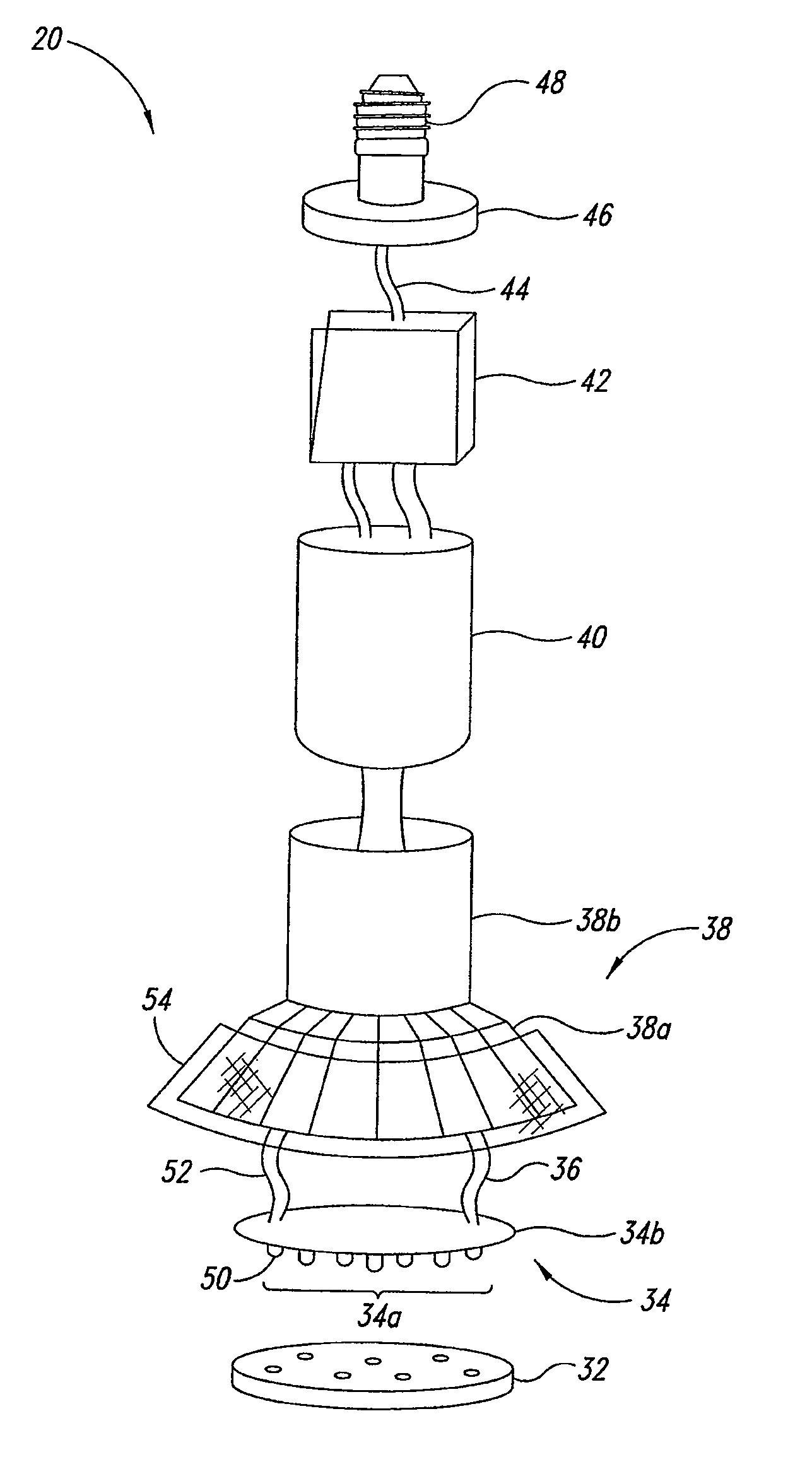

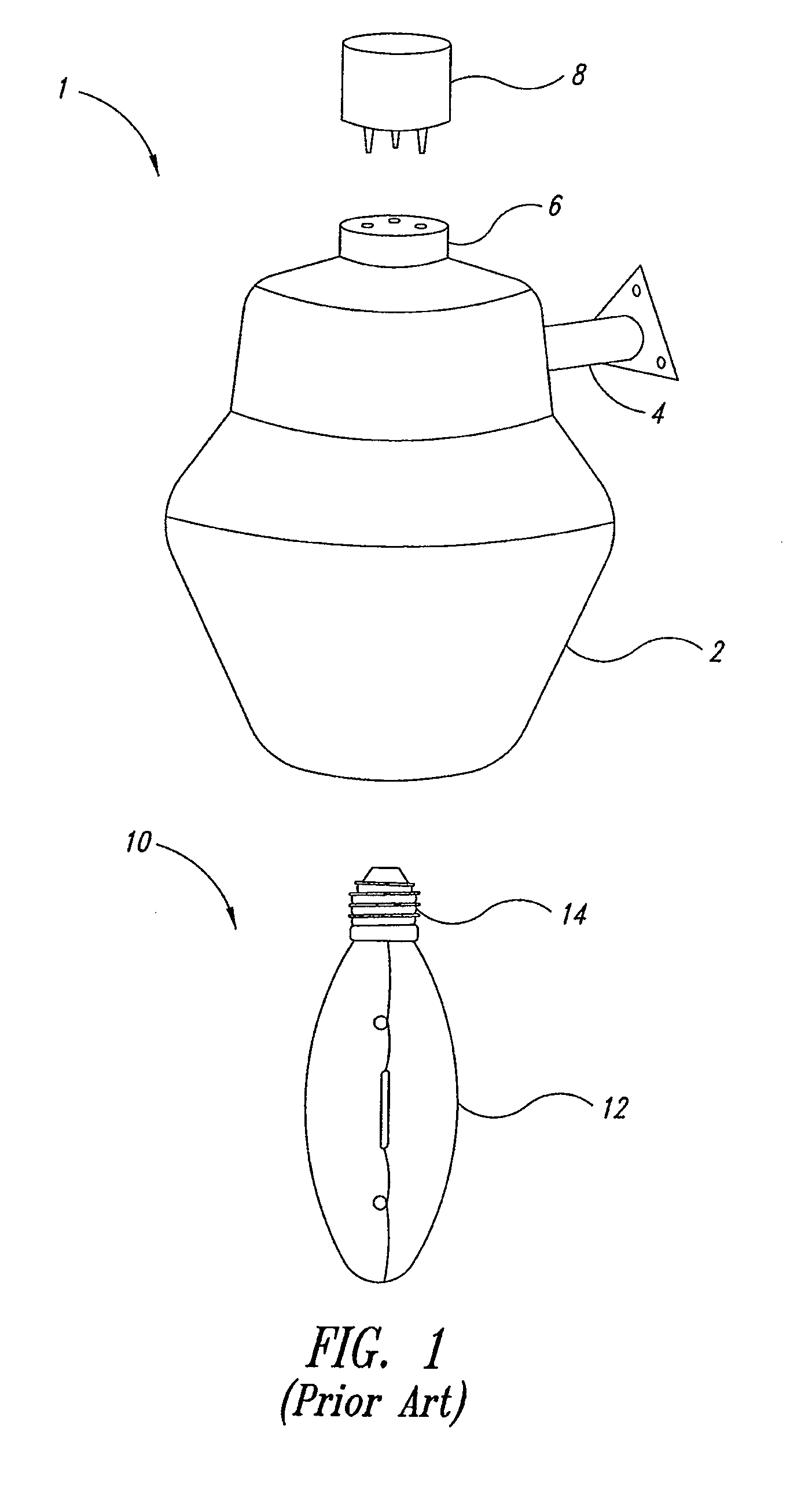

Gas-discharge lamp replacement

ActiveUS20090284155A1Reduce reflection lossReduce lightPoint-like light sourceElectric circuit arrangementsGas-discharge lampColor rendering index

An illumination device comprising a housing fixture, a light source, and an active heat transfer device is provided. The housing fixture includes a base adapted to be receivable in a light fixture receptacle configured to receive a gas-discharge lamp. The light source emits light with a color rendering index higher than a respective color rendering index of at least a type of gas-discharge lamp. The active heat transfer device is physically coupled to the light source and mounted to the housing fixture. The active heat transfer device receives power from a power supply to remove thermal energy from the light source.

Owner:EXPRESS IMAGING SYST

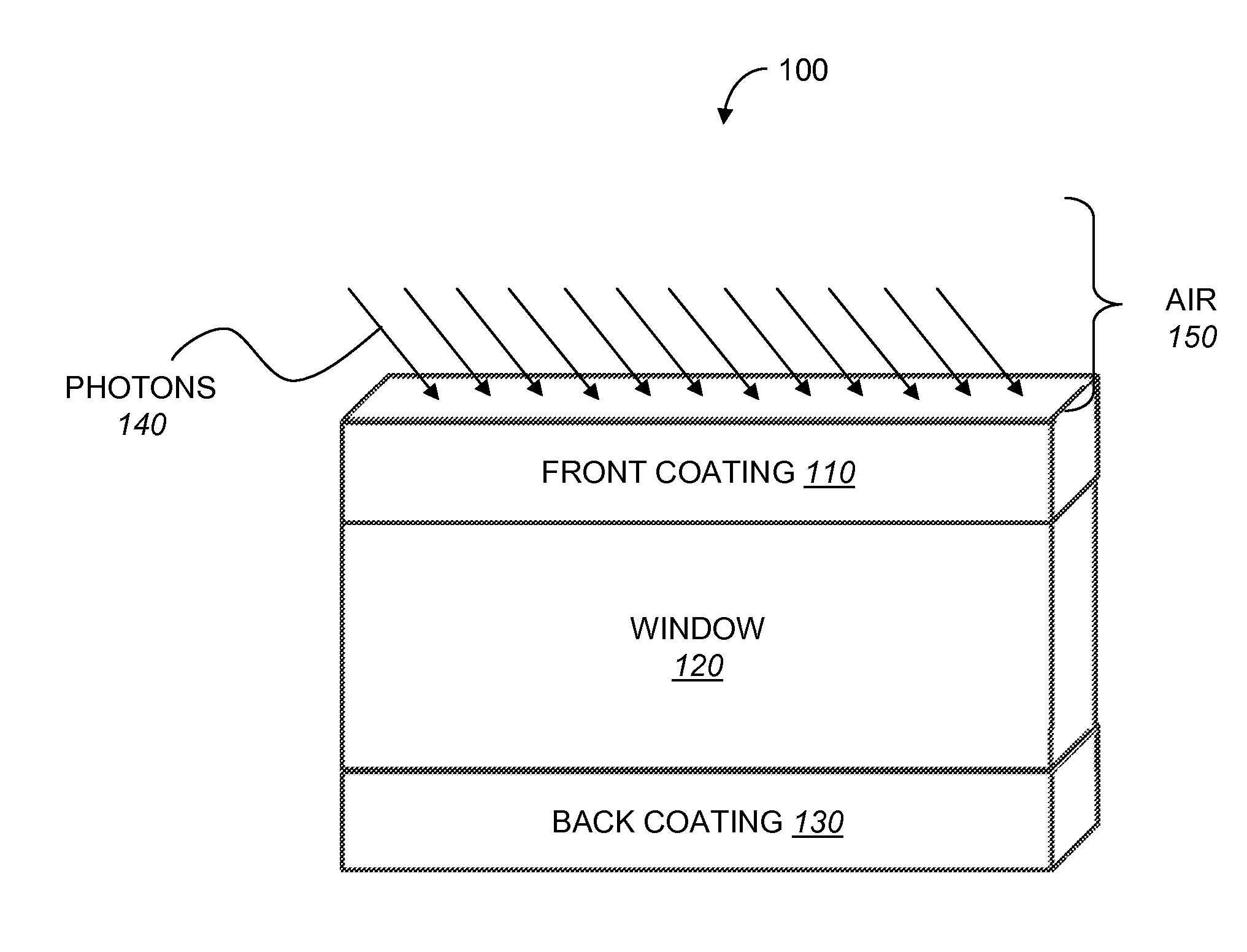

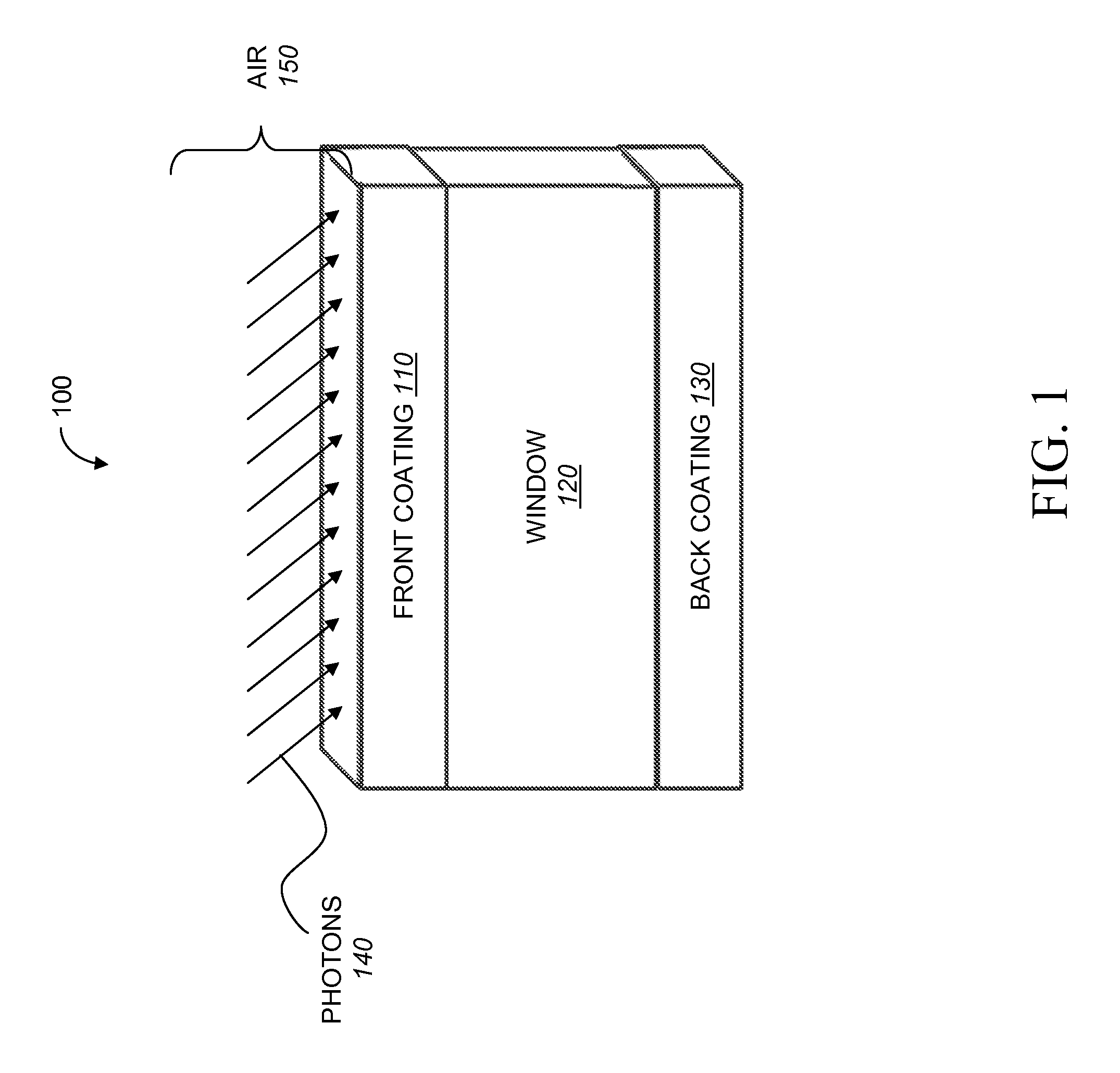

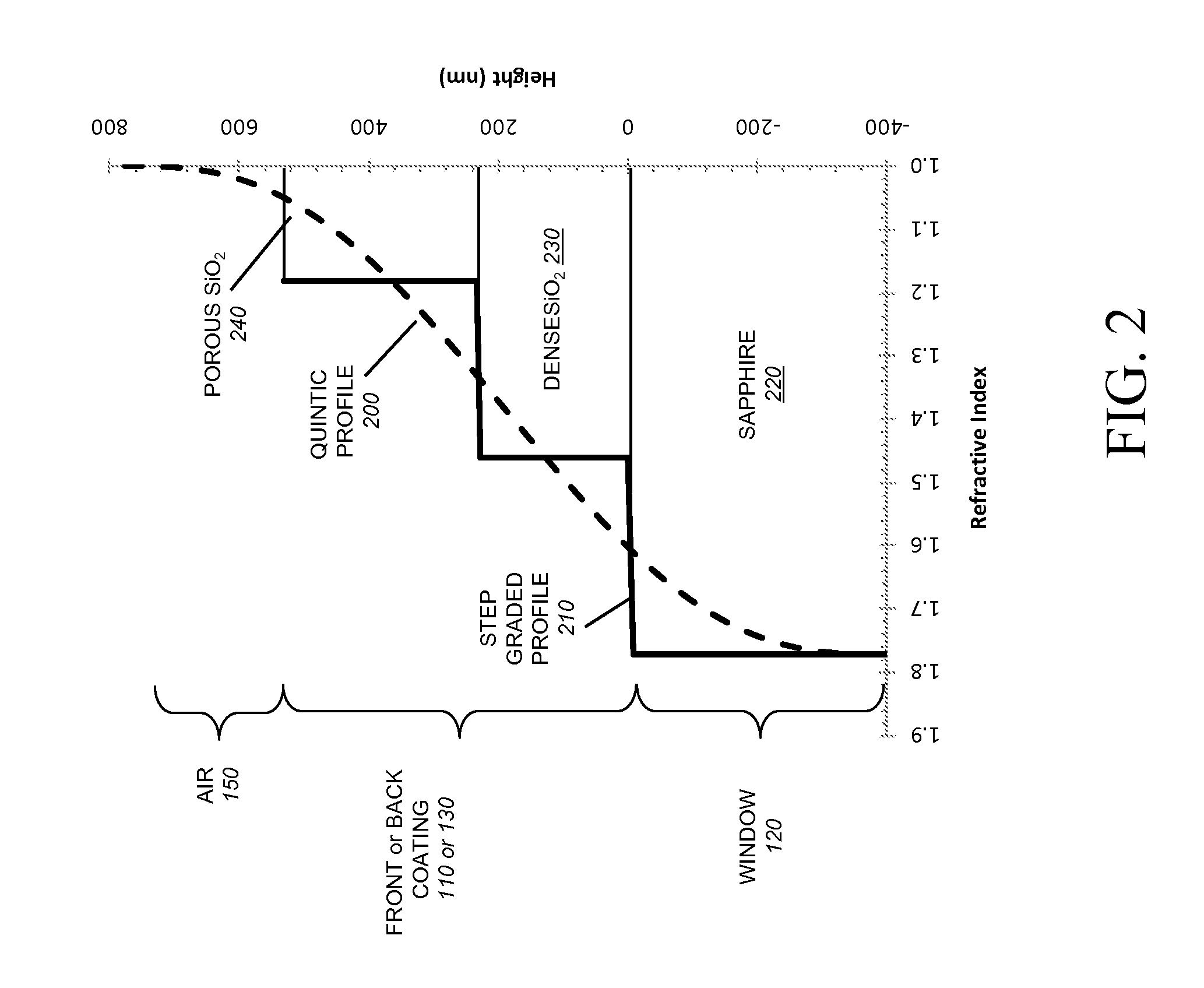

High transmittance optical windows and method of constructing the same

InactiveUS20110168261A1Avoid reflectionsHigh light transmittanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptical coatingMaterial synthesis

Designs for ultra-high, broadband transmittance through windows over a wide range of incident angles are disclosed. The improvements in transmittance result from coating the windows with a new class of materials consisting of porous nanorods. A high transmittance optical window comprises a transparent substrate coated on one or both sides with a multiple layer coating. Each multiple layer coating includes optical films with a refractive index intermediate between the refractive index of the transparent substrate and air. The optical coatings are applied using an oblique-angle deposition material synthesis technique. The coating can be performed by depositing porous SiO2 layers using oblique angle deposition. The high transmittance window coated with the multiple layer coating exhibits reduced reflectance and improved transmittance, as compared to an uncoated transparent substrate.

Owner:MAGNOLIA OPTICAL TECH +1

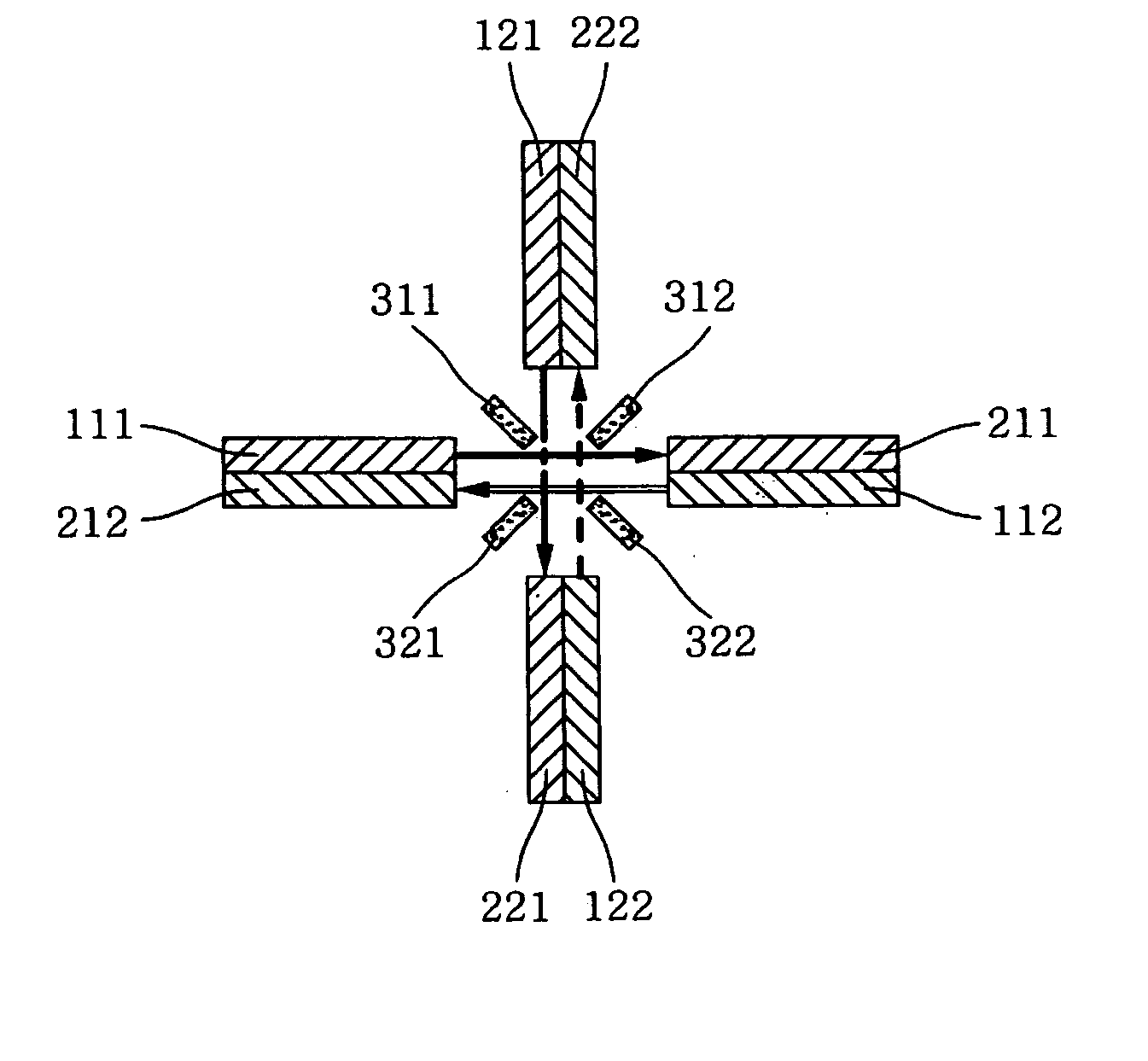

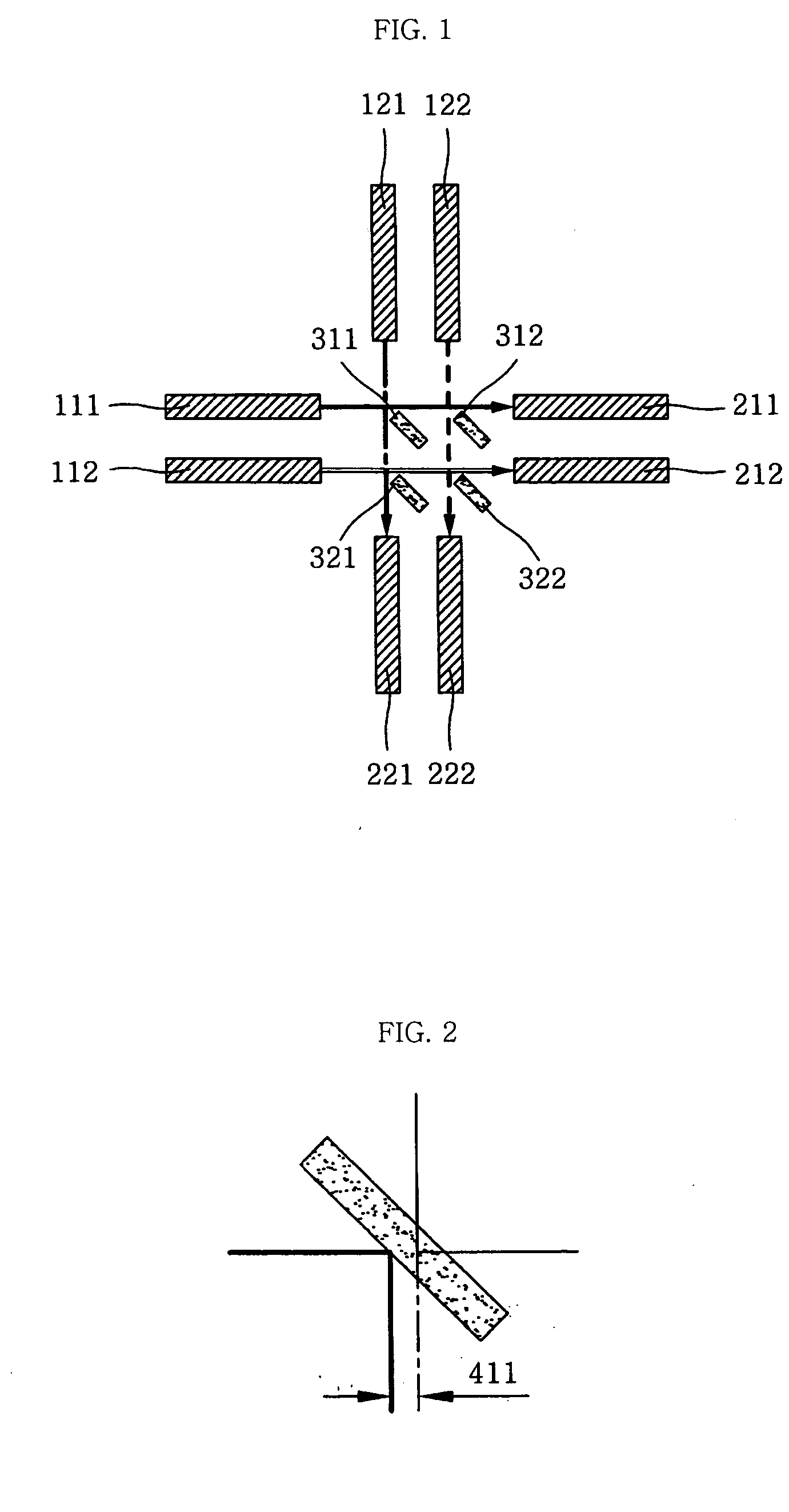

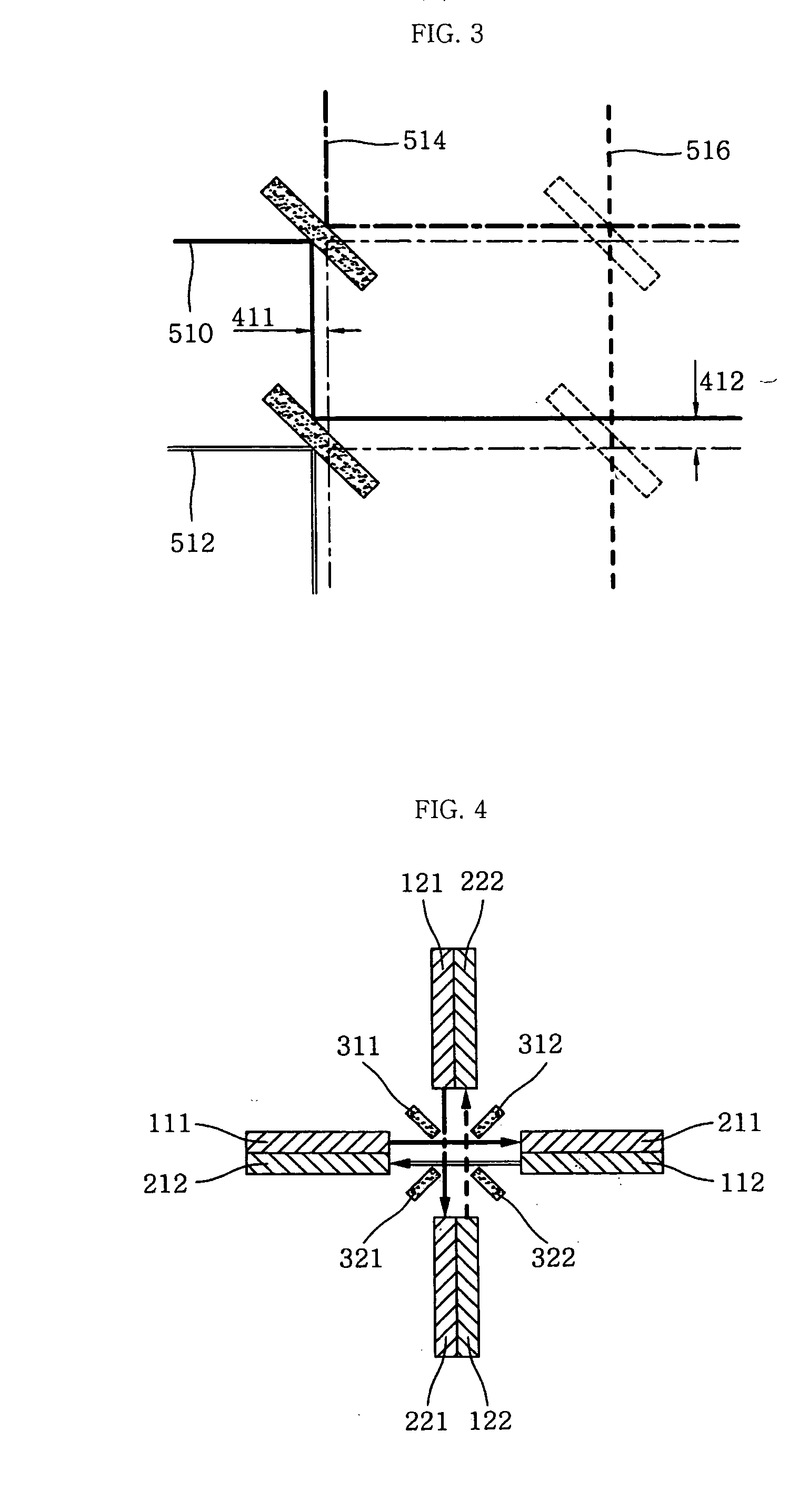

Multi-channel optical switch

InactiveUS20050008285A1Reduced insertion lossReduce reflection lossCoupling light guidesOptical communicationActuator

An optical switch enabling optical communications between an input port and an output port of an optical waveguide by minimizing loss error of an optical signal without using a collimator comprised of a separate mediate optical waveguide, lens or the like is provided. The multi-channel optical switch, which changes optical paths, includes four pairs of input optical waveguides and output optical waveguide arranged in parallel to each other, the first pair of input optical waveguide and output optical waveguide facing the second pair of input optical waveguide and output optical waveguide at an angle of 90 degrees, the first input optical waveguide being installed to correspond to the second output optical waveguide, four mirrors installed to enter in optical path directions between the four pairs of input optical waveguides and output optical waveguides, thereby changing the optical paths, and a mirror actuator for selectively operating the entering of the mirror.

Owner:SAEHYUP +1

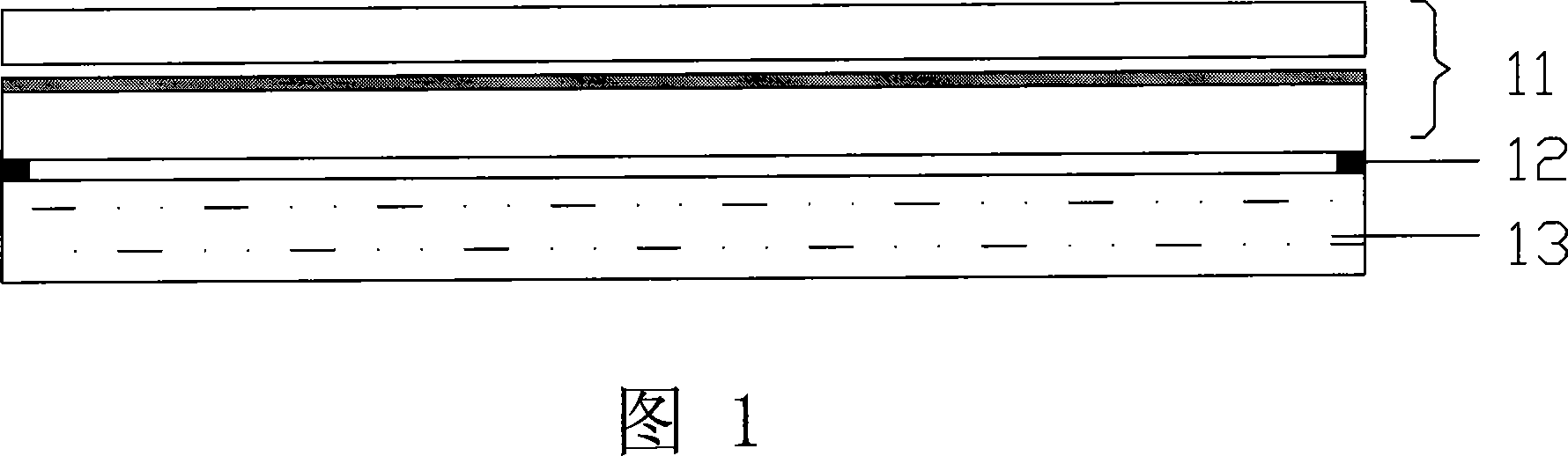

Touching display screen and its making method

InactiveCN101051256AReduce gapReduce reflection lossInput/output processes for data processingHuman–computer interactionElectrode

A display screen of touch type is prepared for using top base plate in display component also as bottom base plate of touch screen, plating conduction layer on external surface of top base plate in display component and arranging electrode used as an operation surface of touch screen on said conduction layer then integrating display component and touch screen to be an unified body.

Owner:TRULY SEMICON

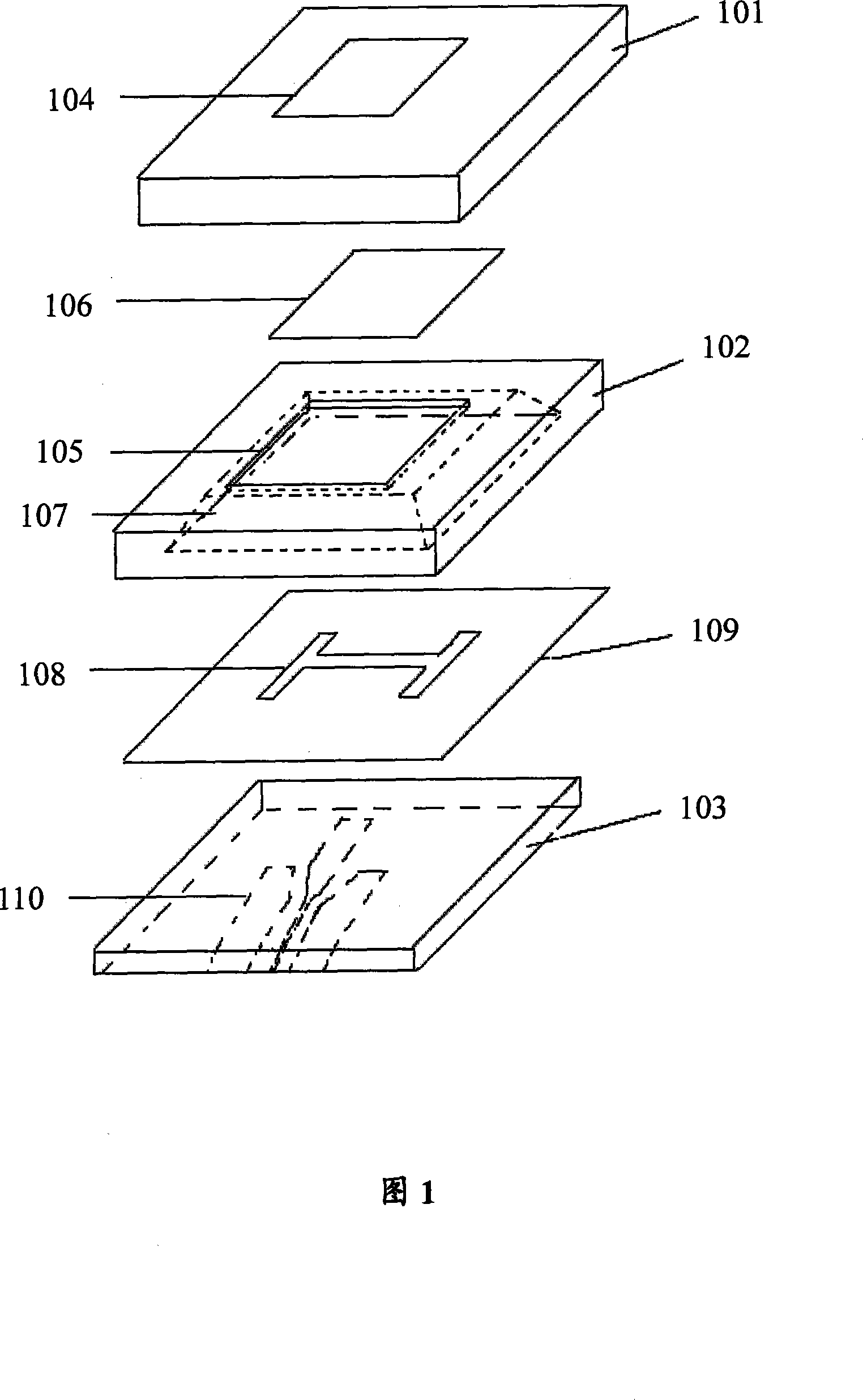

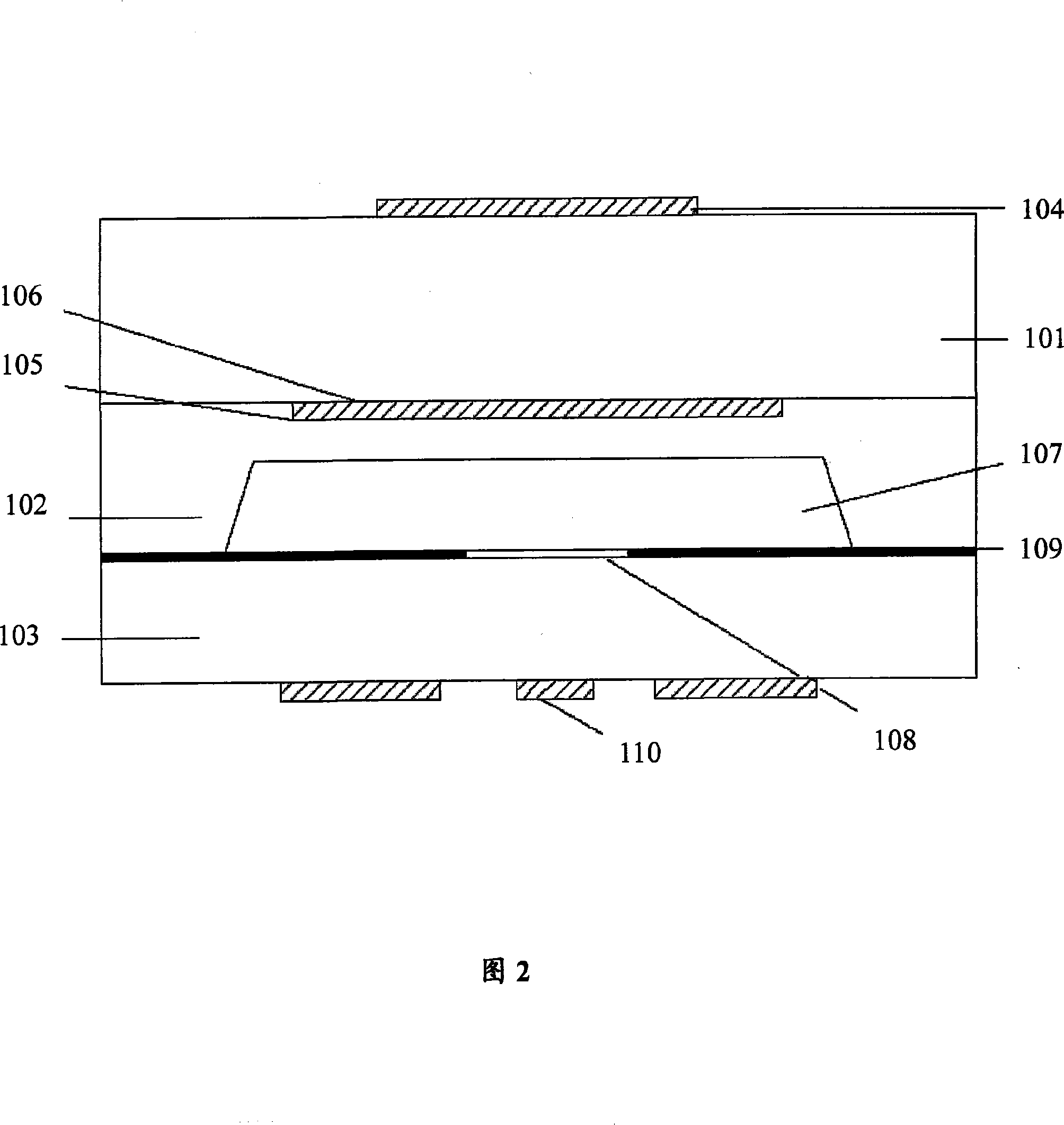

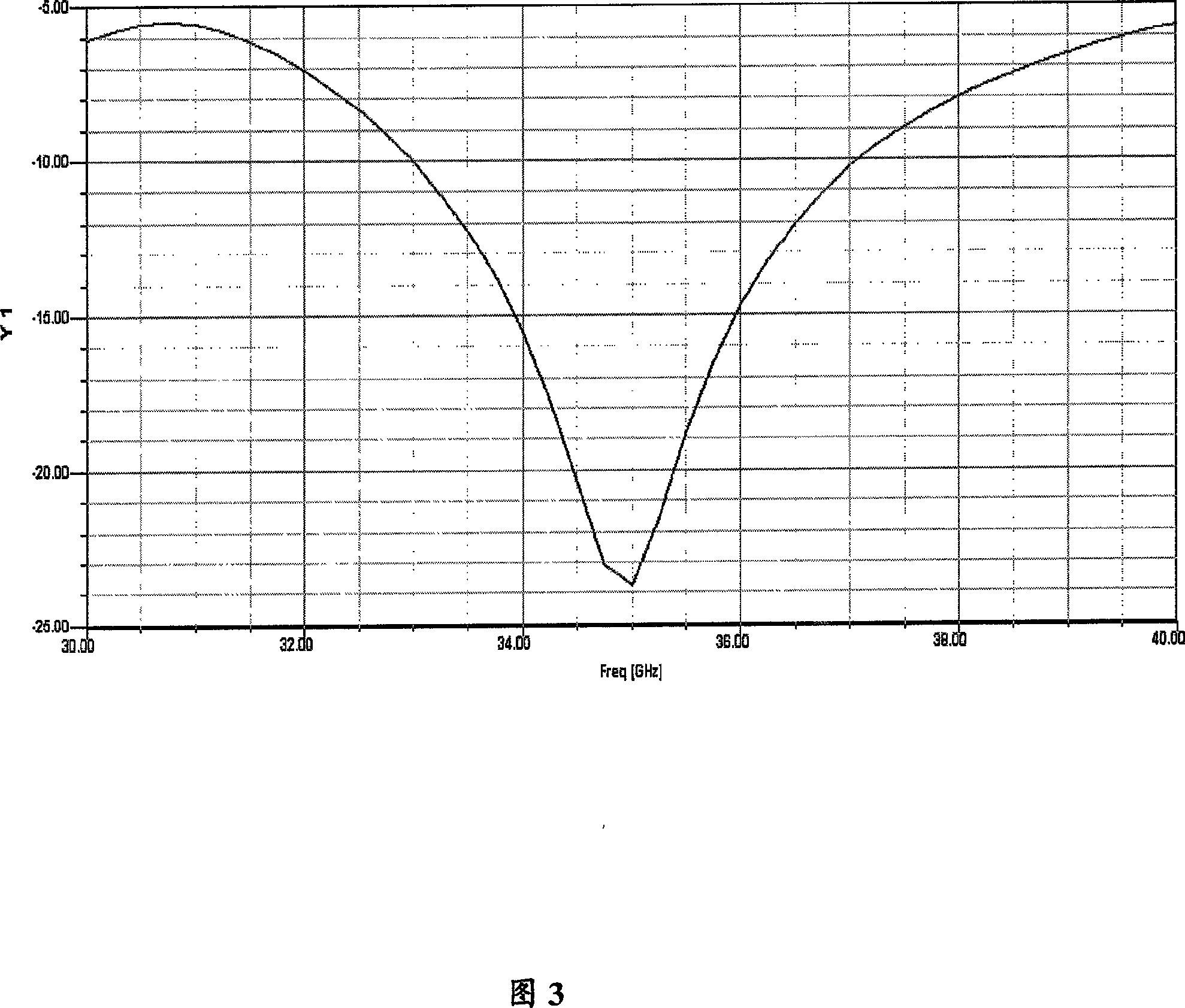

Microcomputer electric stacking type millimeter wave antenna

ActiveCN101141023AReduce distractionsHigh bandwidthDecorative surface effectsRadiating elements structural formsMicrocomputerAnisotropic substrate

The invention provides a micro electromechanical cascade millimeter wave antenna, comprising an upper anisotropic substrate, a middle anisotropic substrate and a lower anisotropic substrate. The upper surface deposit of the upper anisotropic substrate is provided with metal and forms a first metal radiation patch by mechanical erosion. The upper surface deposit of the middle anisotropic substrate is provided with metal and forms a second metal radiation patch by mechanical erosion. The upper surface deposit of the lower anisotropic substrate is provided with metal and forms a FGCPW-MS feeder or a MS feeder by mechanical erosion. The upper anisotropic substrate, the middle anisotropic substrate and the lower anisotropic substrate form a unit by MEMS bonding technology. The antenna has small size and light weight, which is also easy for the further integration.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

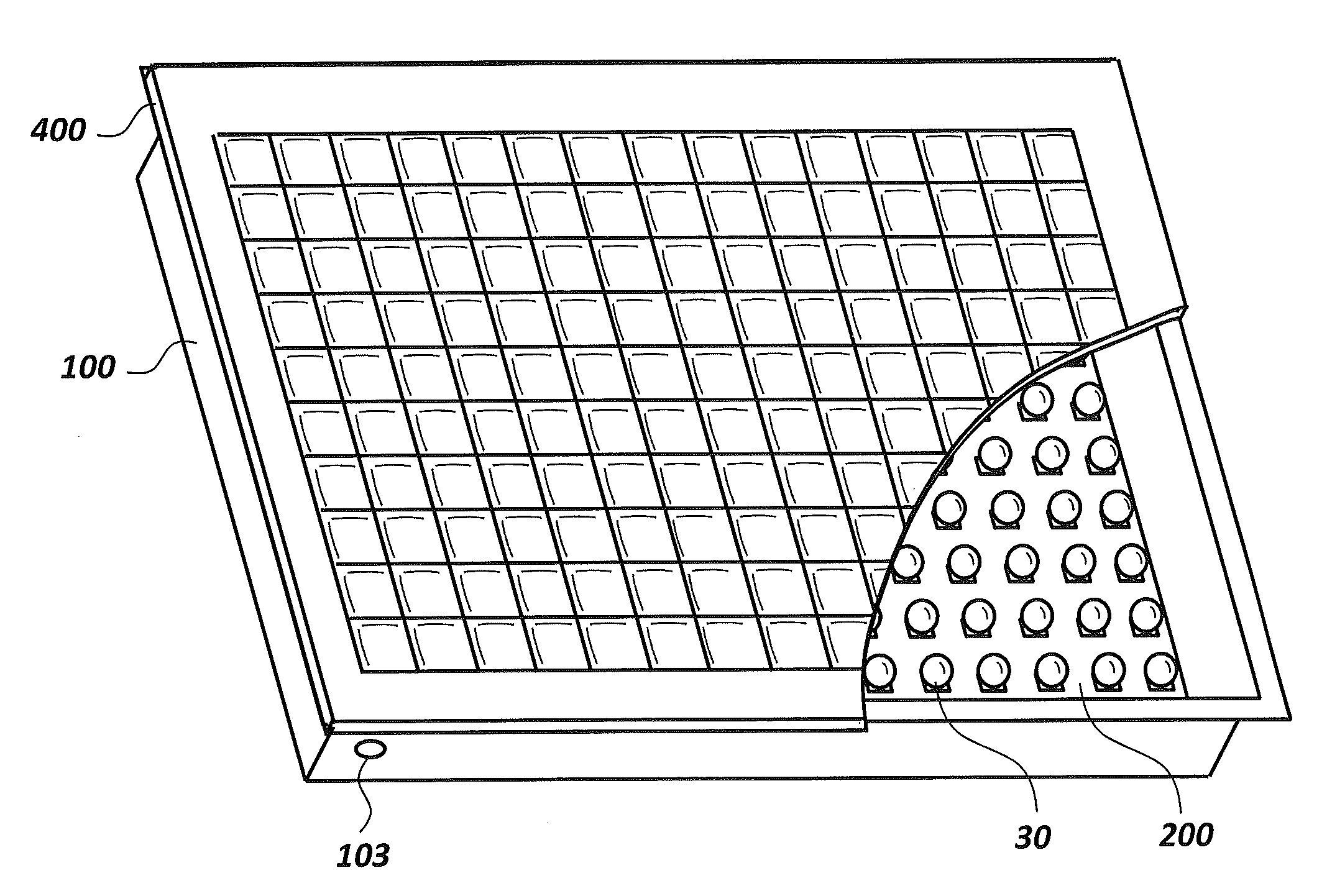

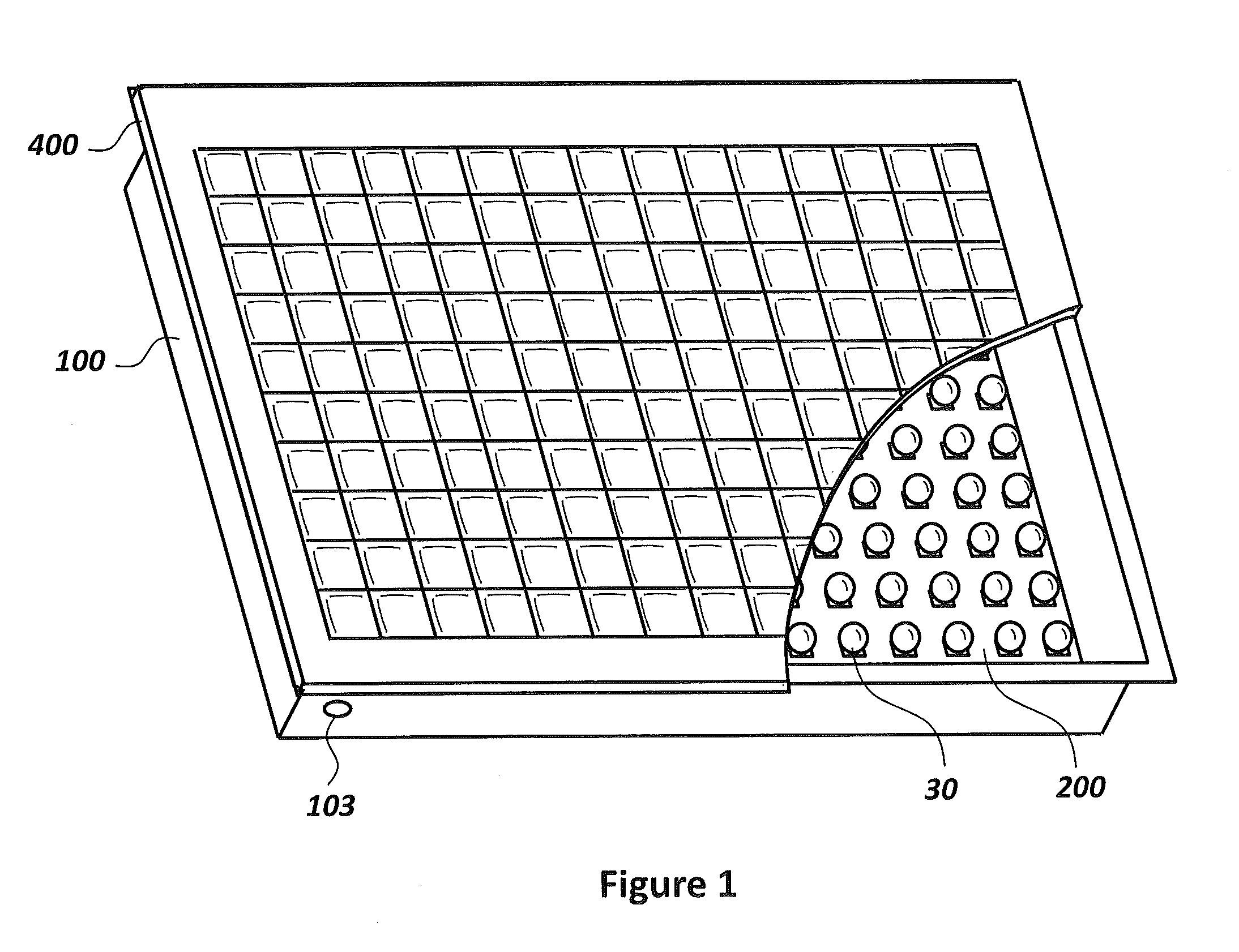

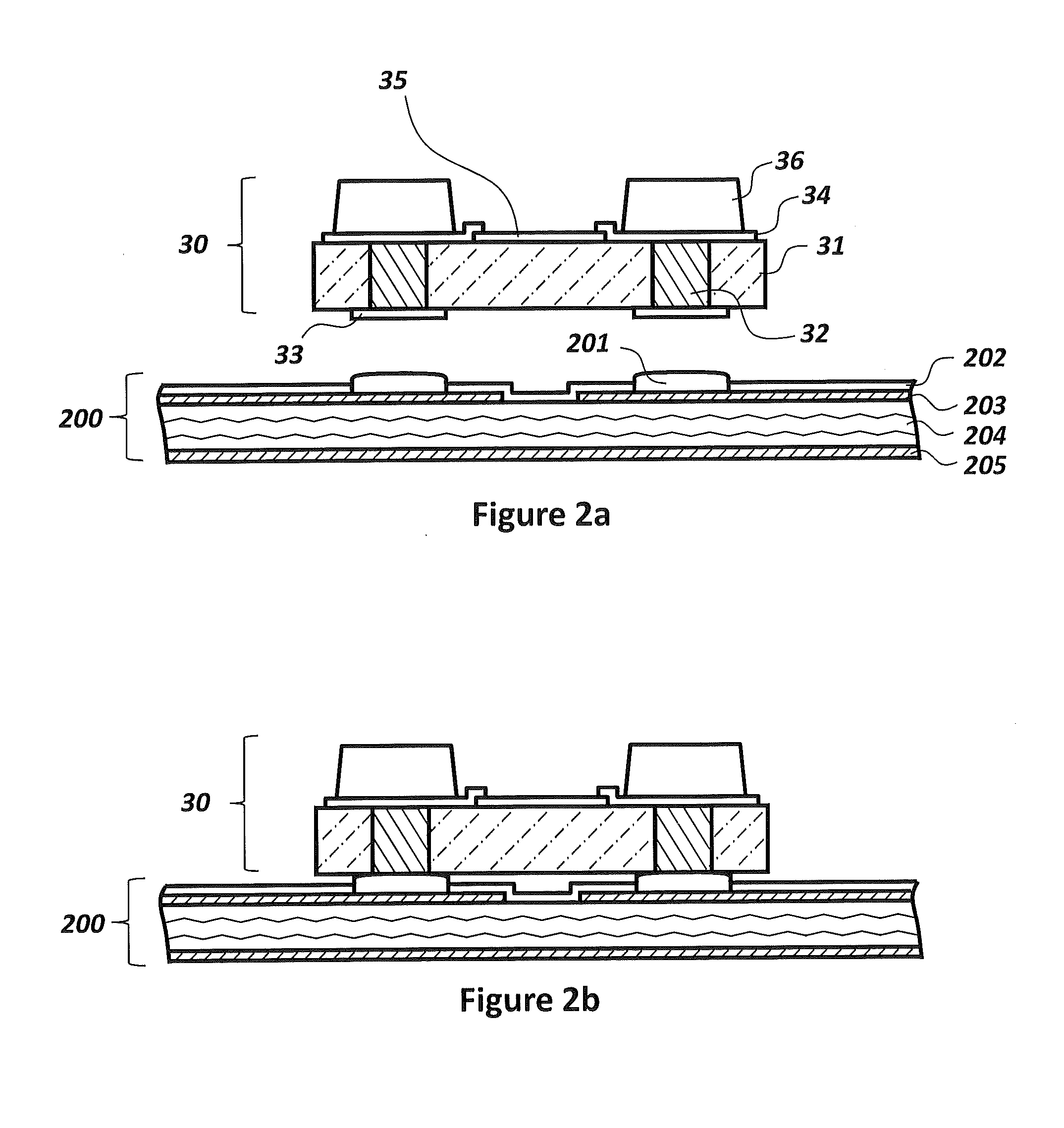

High concentration photovoltaic modules and methods of fabricating the same

InactiveUS20130146120A1Improve efficiencyImprove reliabilityPV power plantsSemiconductor/solid-state device manufacturingHigh concentrationElectrical connection

A concentrator-type photovoltaic module includes a module enclosure having a rigid surface, and a flexible backplane within the enclosure and laminated to the rigid surface by an adhesive layer. The flexible backplane includes an array of interposer substrates having transfer-printed solar cells thereon and an interconnect network that provides electrical connections to the solar cells. A respective secondary spherical lens element is provided on respective ones of the solar cells within the enclosure. An optically transparent encapsulation layer may be provided on the secondary lens element of the respective ones of the solar cells, such that the secondary lens element including the encapsulation layer thereon has a different refractive index. A primary lens element is attached to the enclosure opposite to and spaced-apart from the rigid surface, and is positioned to concentrate light onto the respective ones of the solar cells through the secondary lens element thereon.

Owner:X CELEPRINT LIMITED

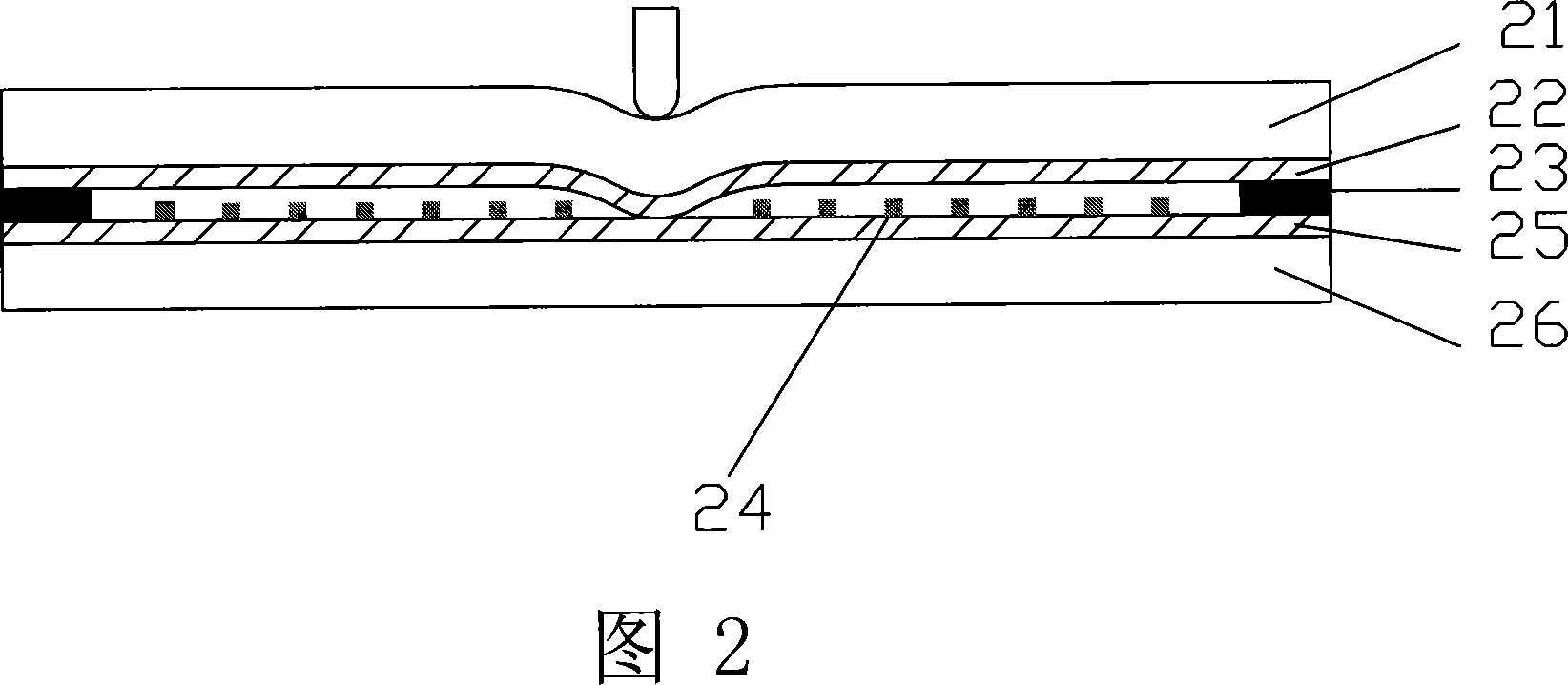

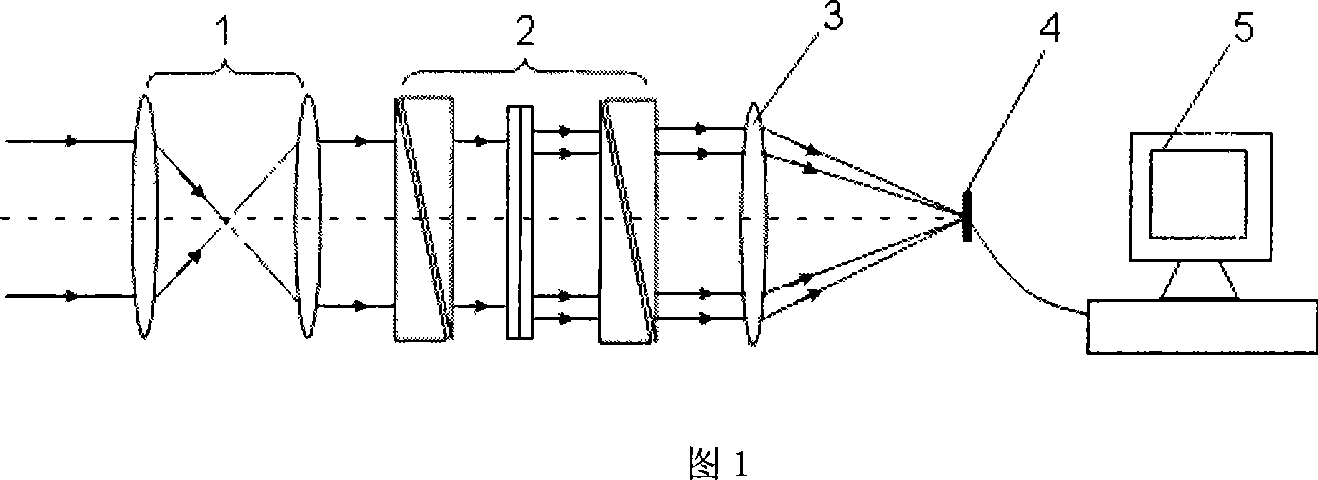

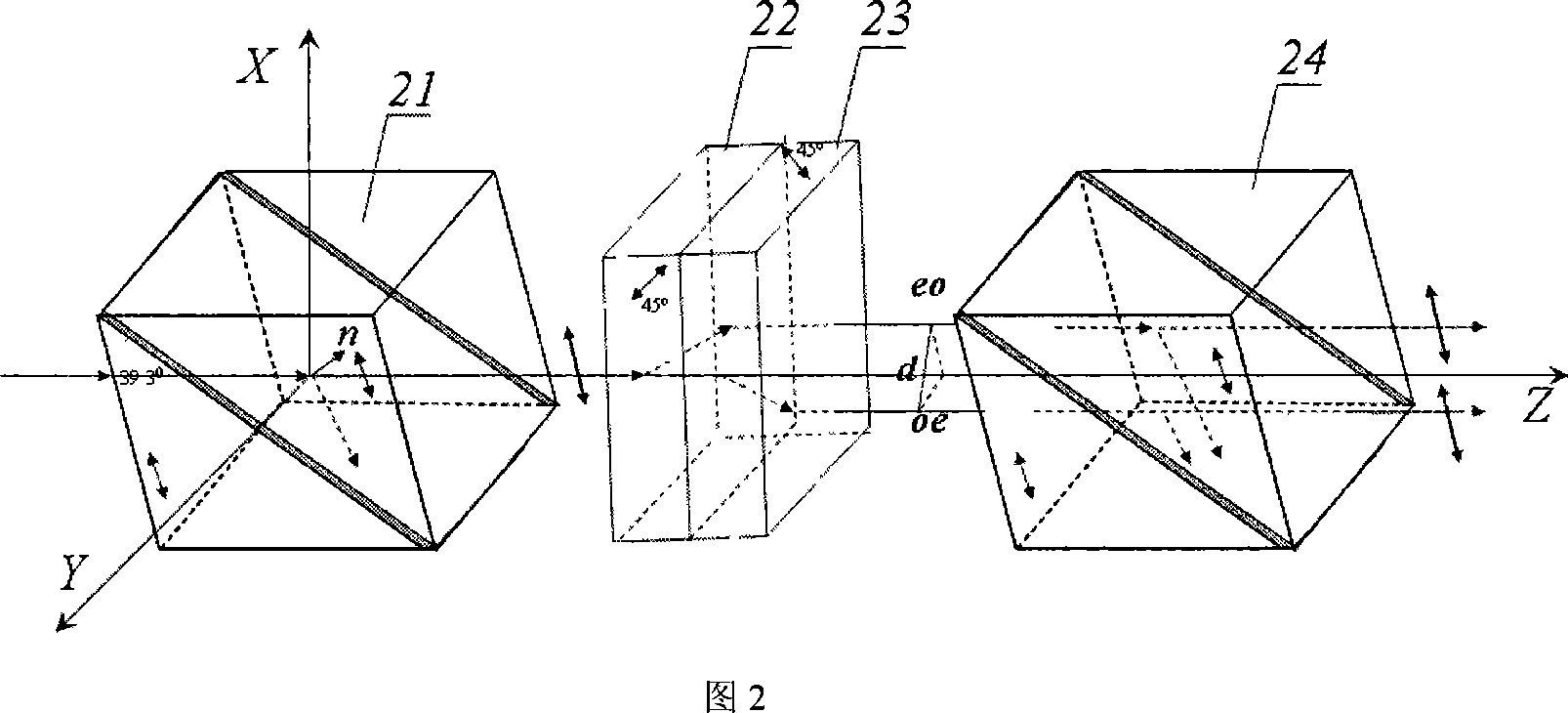

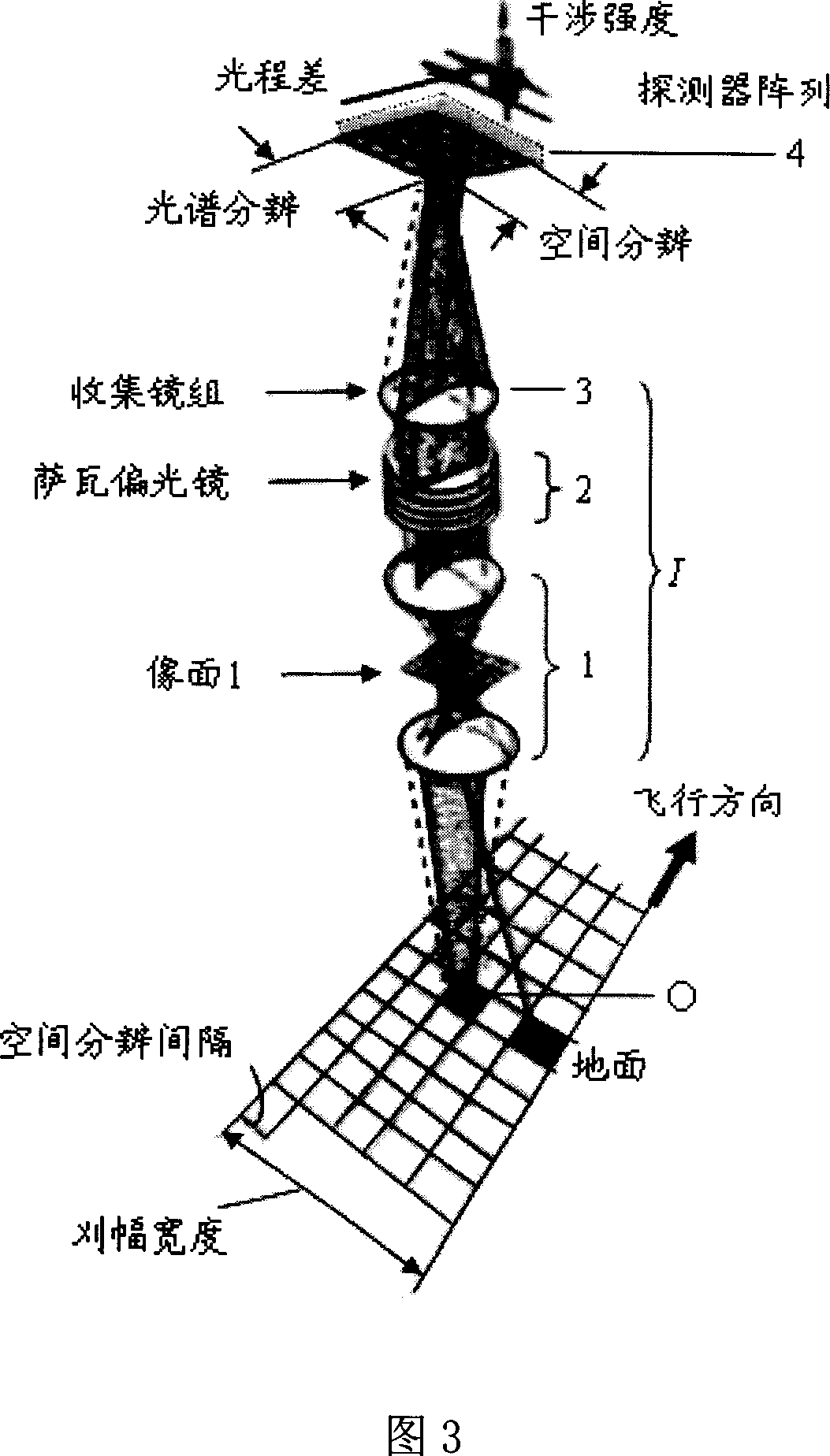

Static birefringent polarizing inteference imaging spectrometer

InactiveCN101046409AIncrease the working bandImprove transmittanceInterferometric spectrometryOptical elementsBeam splitterPrism

The static birefringent polarizing interference imaging spectrometer consists of a pre-telescope system, a polarizing interferometer, an imaging lens set and an area array detector arranged coaxially and successively in the incident light direction, as well as a computerized signal treating system connected to the output of the area array detector. The polarizing interferometer consists of a polarizer, a Savart polariscope and an analyzer. The present invention adopts Savart polariscope as the transverse shearing beam splitter, and the advantages of infinitely far target, linear light path, simple structure, high stability, high S / N ratio, high resolution, etc.

Owner:XI AN JIAOTONG UNIV

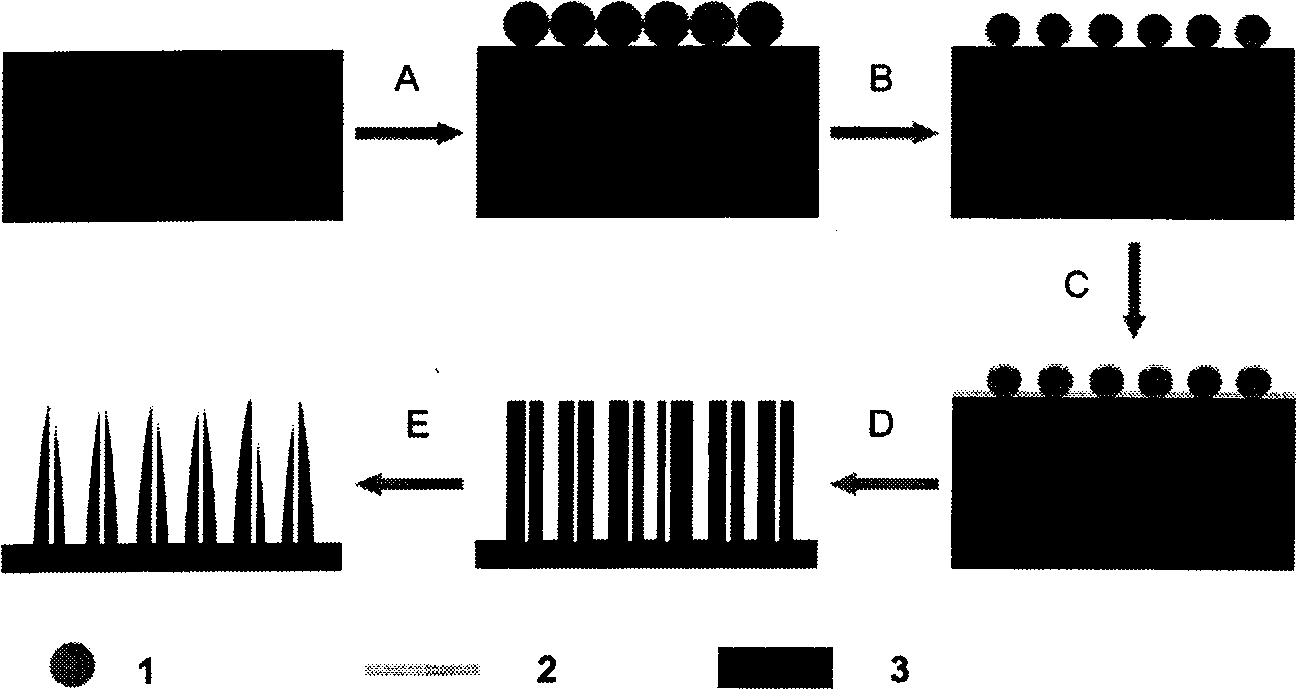

Method for preparing silicon hollow nano-cone array

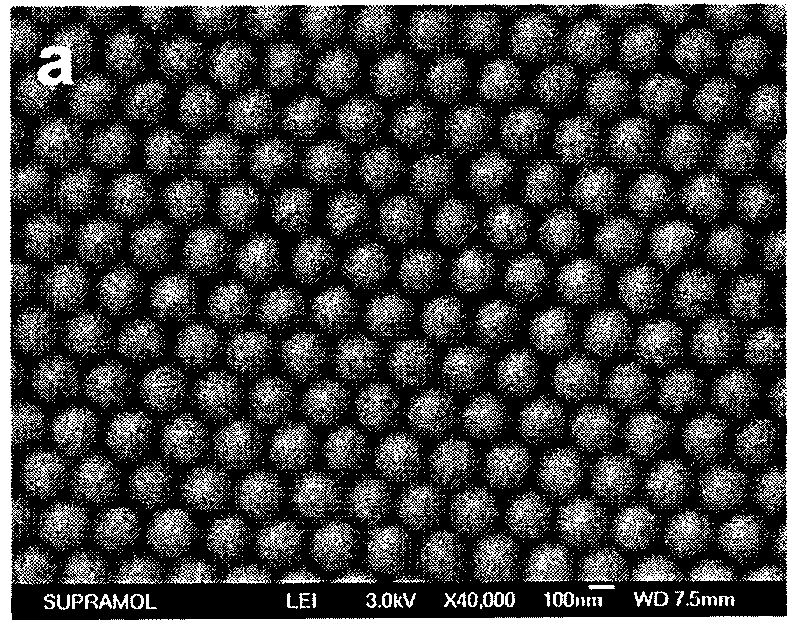

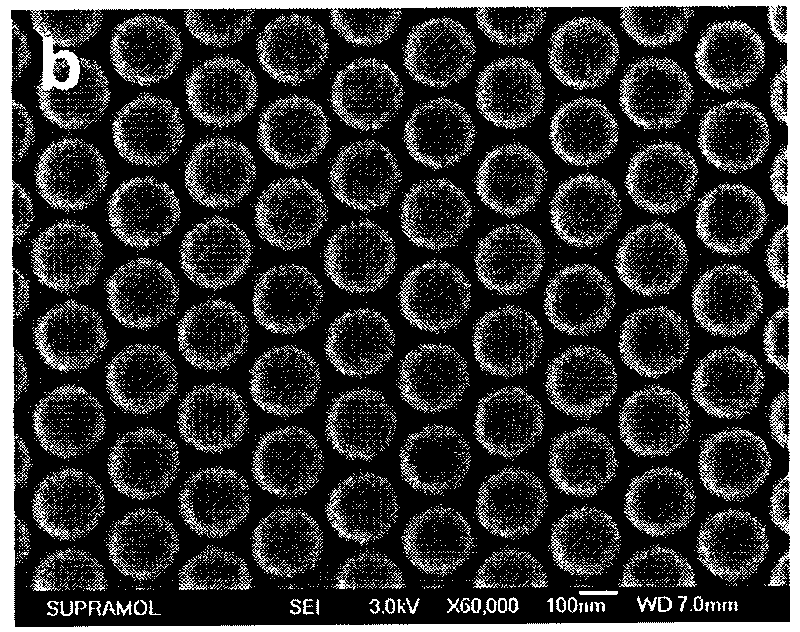

InactiveCN101497429AImprove efficiencyImprove performanceNanostructure manufactureHydrophilizationPolystyrene

The invention relates to a method for preparing a hollow silicon nano conical array, in particular to a method for preparing the hollow silicon nano conical array with large area, uniform bottom diameter length, controllable spacing, controllable period and orderly arrangement. The method comprises the following four steps: washing and surface hydrophilization treatment of a monocrystalline silicon piece, preparation of polystyrene monolayer colloidal crystals, preparation of a hollow silicon nano column array, and construction of a hollow silicon nano conical array. The hollow silicon nano conical array obtained by the method has the advantages of large area, uniform bottom diameter length, controllable spacing, controllable period and orderly arrangement, has extremely superior broad-band dereflection performance, and effectively reduces the surface reflection loss from deep ultraviolet band to medium infrared band (250 nanometers to 15 mu m). The method is simple and controllable, and has wide application prospect on construction of photoelectric devices with low cost and large area and deflection surfaces.

Owner:JILIN UNIV

Process for preparing silicon dioxide nano-cone array

InactiveCN101693519AImprove efficiencyImprove performanceNanostructure manufactureDecorative surface effectsMiddle infraredUltraviolet lights

The invention relates to a process for preparing a silicon dioxide nano-cone array which has large area, controllable interval, controllable cycle and sequential arrangement, and is directly fabricated on a substrate. The process includes three steps: cleaning the quartz plate substrate and performing hydrophilic process on the surface of the quartz plate substrate; preparing polystyrene single-layer colloidal crystals; fabricating the silicon dioxide nano-cone array. The silicon dioxide nano-cone array prepared by the process has extremely excellent wide-band anti-reflection and transmission increasing properties, can realize effectively reducing surface reflection loss and increasing light transmission from ultraviolet light to visible light (350nm to 800 nm) and then to the inside of middle-infrared-band (800nm to 2.5 micrometer) by controlling the cycle. Simultaneously, by changing nature of the surface of nano-cones, antifogging and super-hydrophobic surfaces can be fabricated. The process is simple, comparatively controllable and has wide application prospect on photoelectric devices with low cost and large area and on fabrication of anti-reflection surfaces.

Owner:JILIN UNIV

Efficient solar energy thermal absorber based on optical-thermal absorbing cone structure

ActiveCN103123175AReduce reflection lossProcessing is not difficultSolar heating energySolar heat devicesGlass coverPorous medium

The invention relates to an efficient solar energy thermal absorber based on an optical-thermal absorbing cone structure. The efficient solar energy thermal absorber based on the optical-thermal absorbing cone structure comprises a sealing cover, an insulating tube sleeve, an airflow tube, a thermal absorbing body, a glass cover and a thermal absorbing fastening piece. The efficient solar energy thermal absorber is characterized in that the thermal absorbing body is in a truncated prism structure and each plane can be manufactured separately. Each plane is respectively an optical-thermal absorbing conic board, a plurality of sharp pyramids are distributed on a surface of each plane and each plane is made of a high thermal conductive porous material. The glass cover is in a circular truncated cone shape. A closed containing cavity is formed by the sealing cover, the thermal absorbing body and the glass cover. Air enters into the containing cavity through an air inlet of the sealing cover and is heated through each porous medium optical-thermal absorbing conic board so that solar energy is taken and finally flows out from an outlet end of the thermal absorber along the airflow tube. The efficient solar energy thermal absorber based on the optical-thermal absorbing cone structure has the advantages of solving the problems that an existing thermal absorber is low in thermal absorbing efficiency, difficult to process, large in loss in inner flow and the like, being used independently and in a combined mode through connectors, being mainly applicable to a solar energy thermoelectric conversion system and guaranteeing efficient operation of the system.

Owner:南京凌日星能源科技有限公司

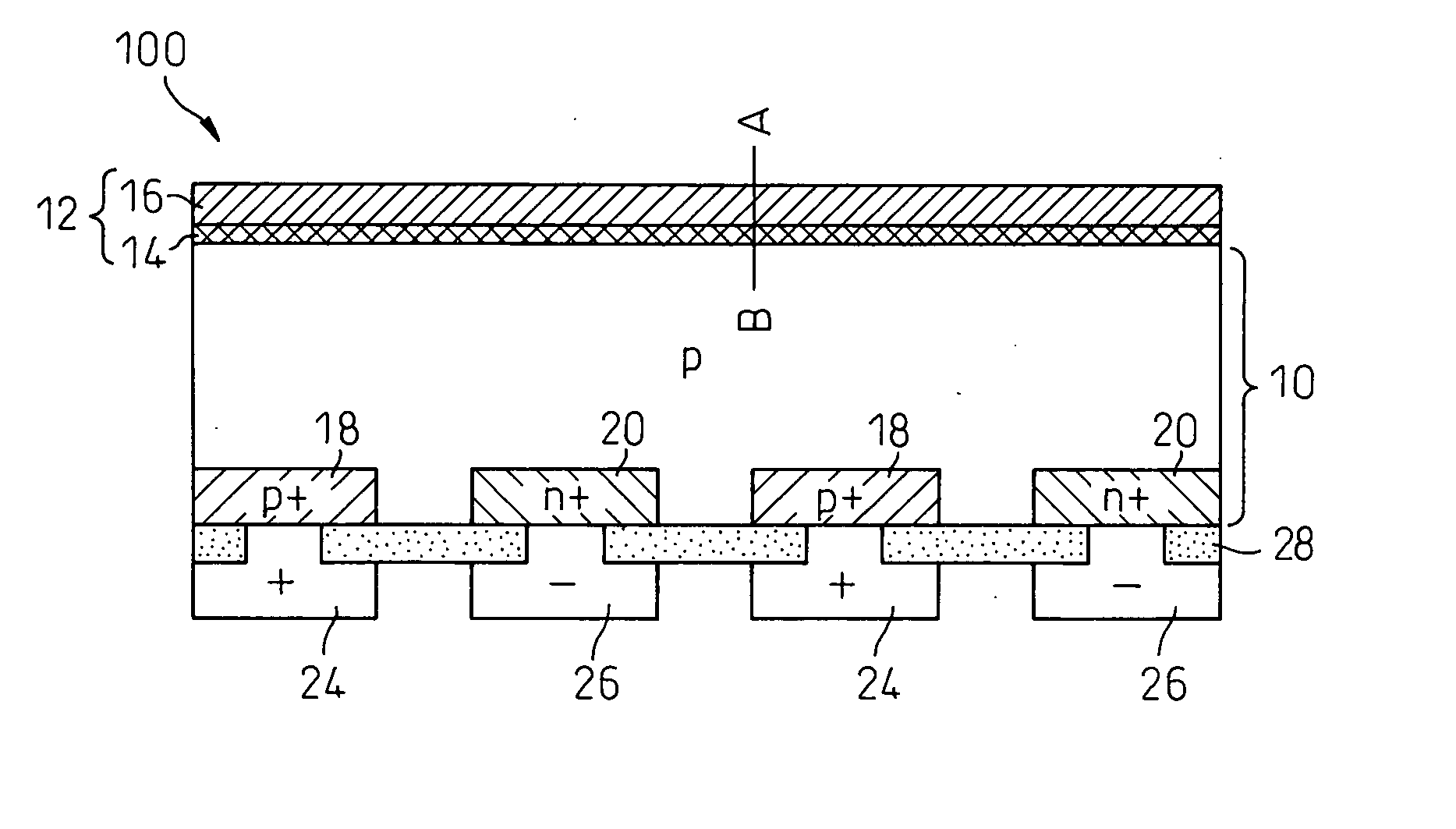

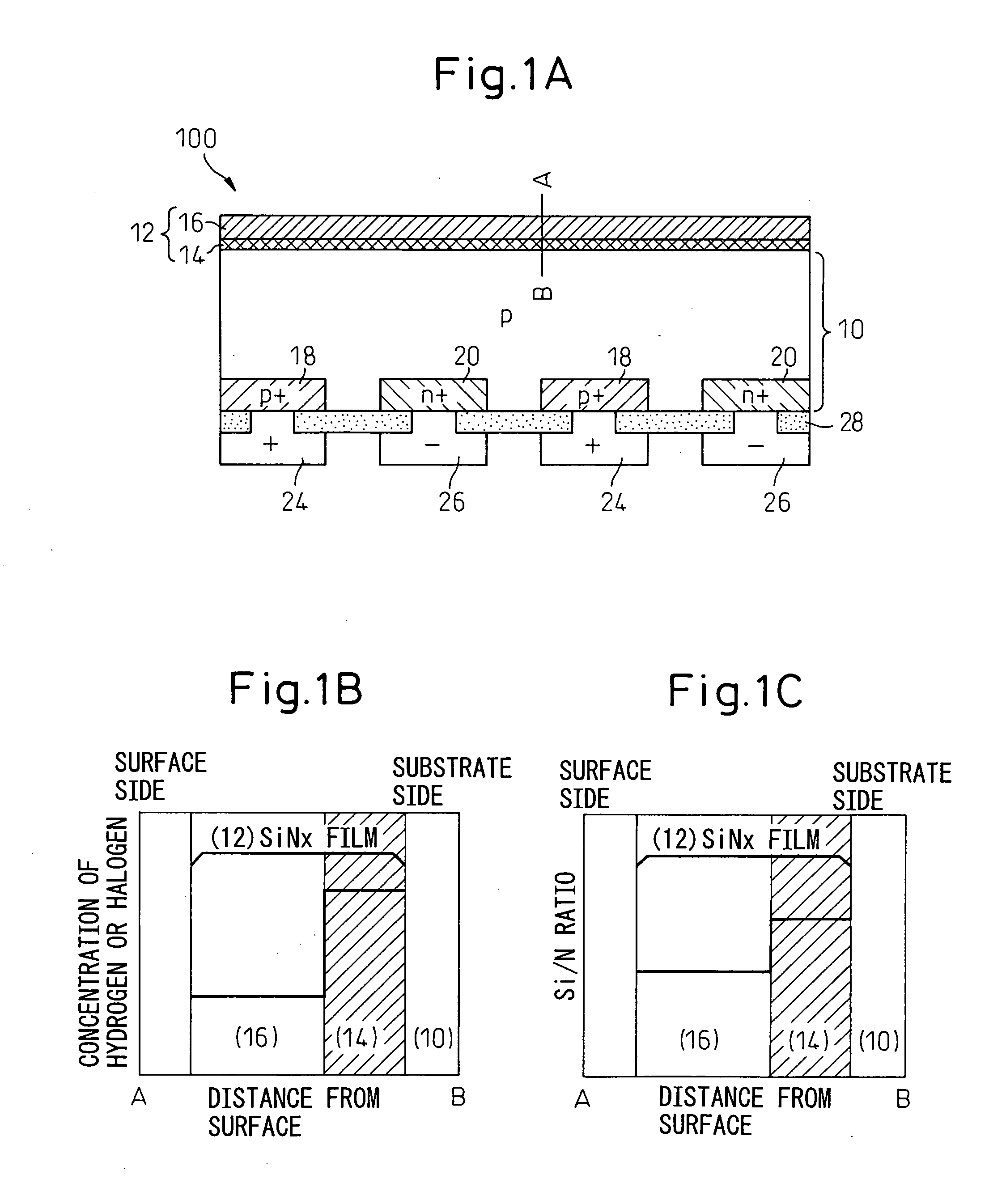

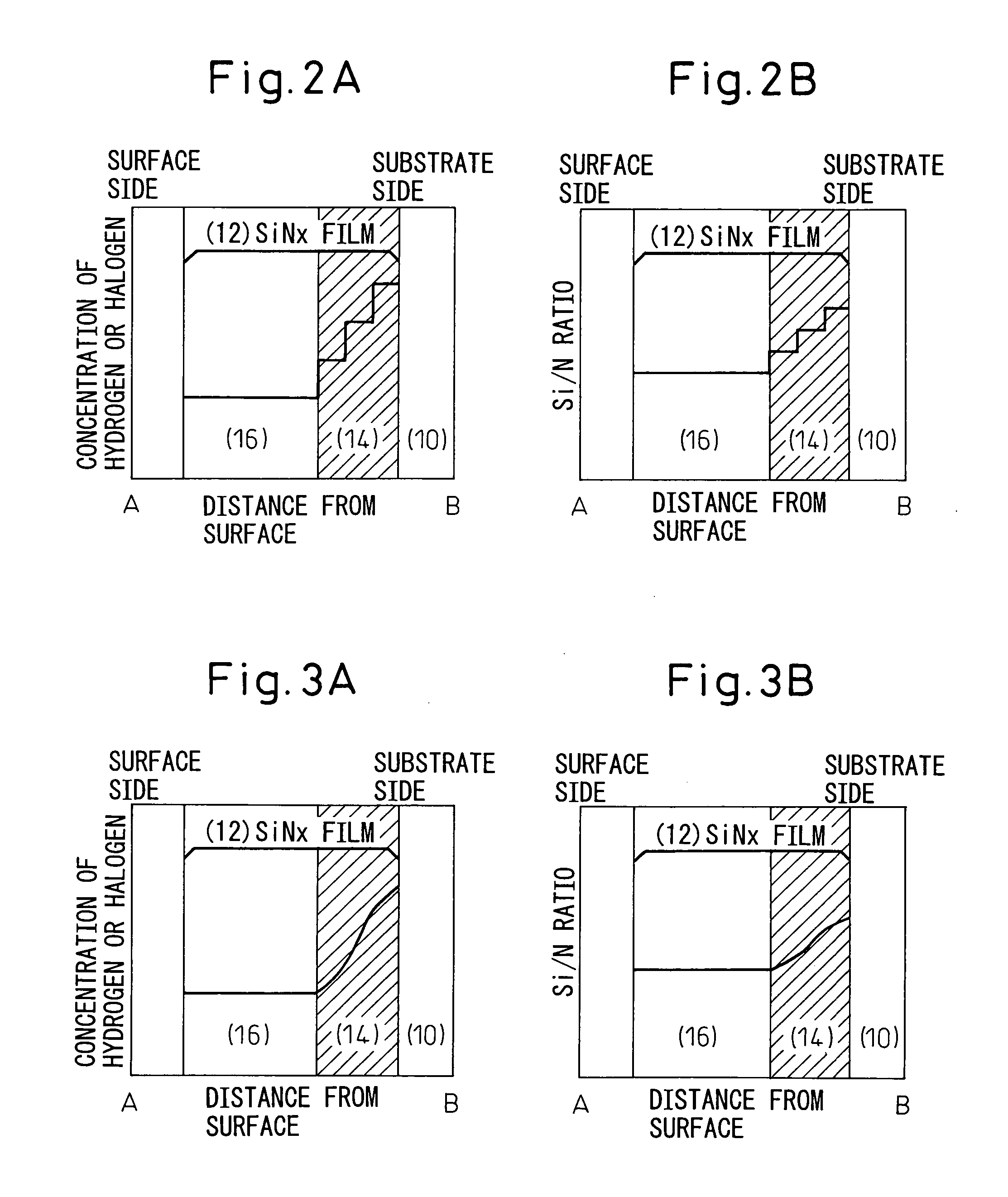

Photovoltaic converter

InactiveUS20050011548A1Reduce reflection lossIncrease power generation ratePV power plantsSolid-state devicesReflection lossHydrogen

A photovoltaic converter, maintaining the function of a protective film, simultaneously reducing the reflection loss and carrier recombination loss, and raising the power generation efficiency, formed on a semiconductor substrate and provided on its light receiving surface with a silicon nitride film as a protective film / antireflection film, wherein a content of hydrogen or a halogen is increased and a ratio of Si content / N content is increased at a boundary region of the silicon nitride film with the semiconductor substrate compared with other portions so as to maintain a refractive index at the boundary region equal to the other portions.

Owner:TOYOTA JIDOSHA KK

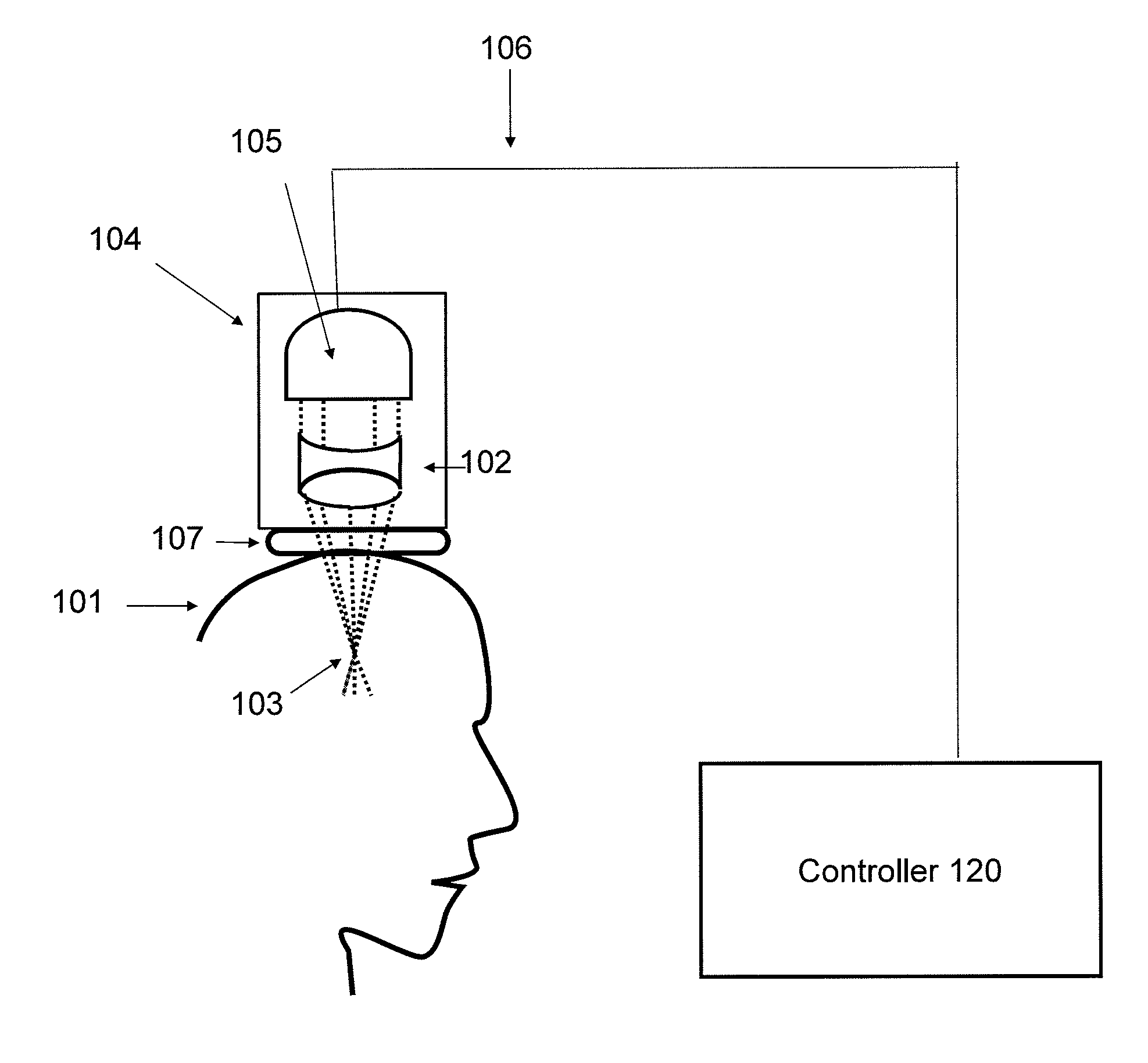

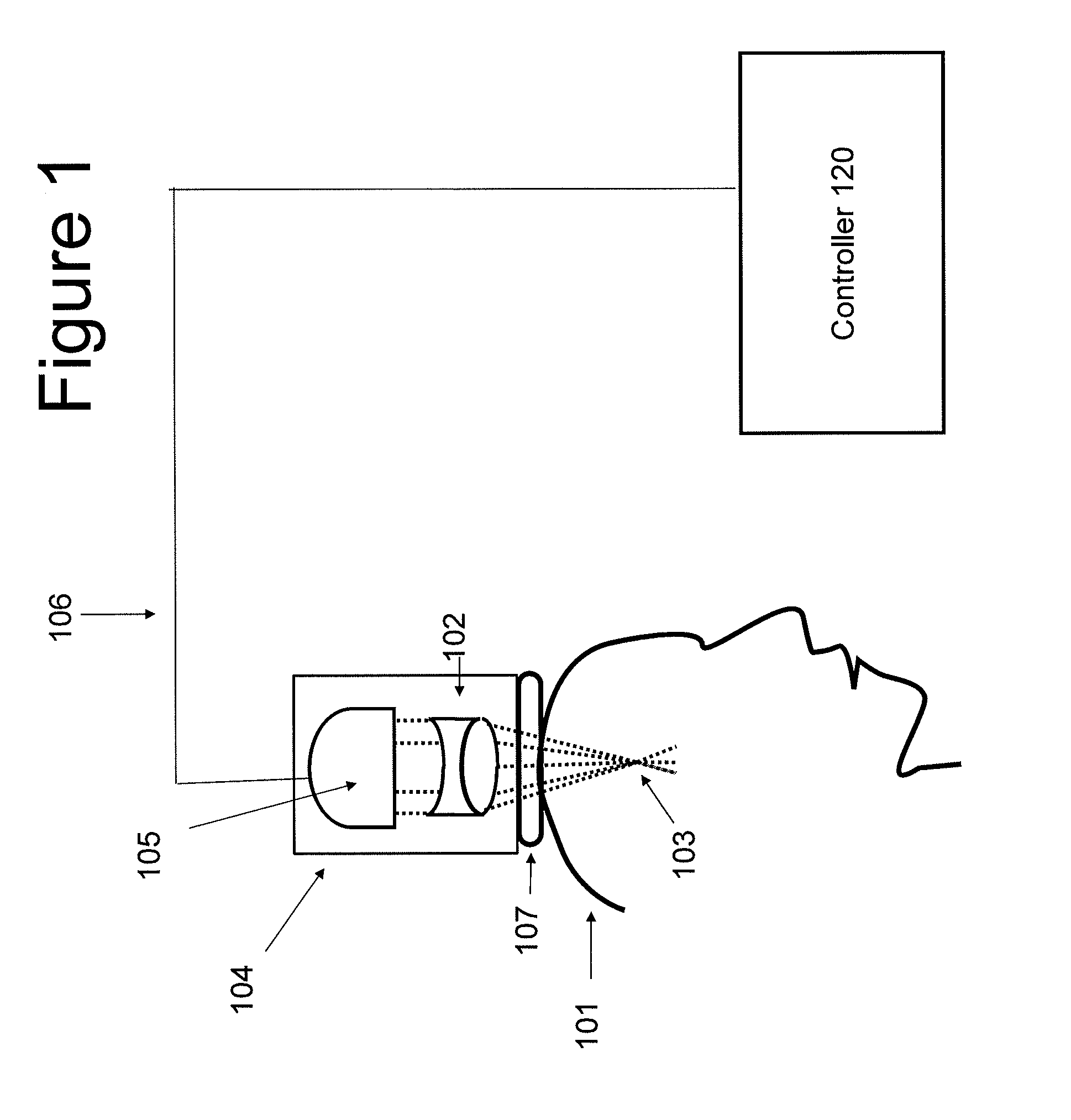

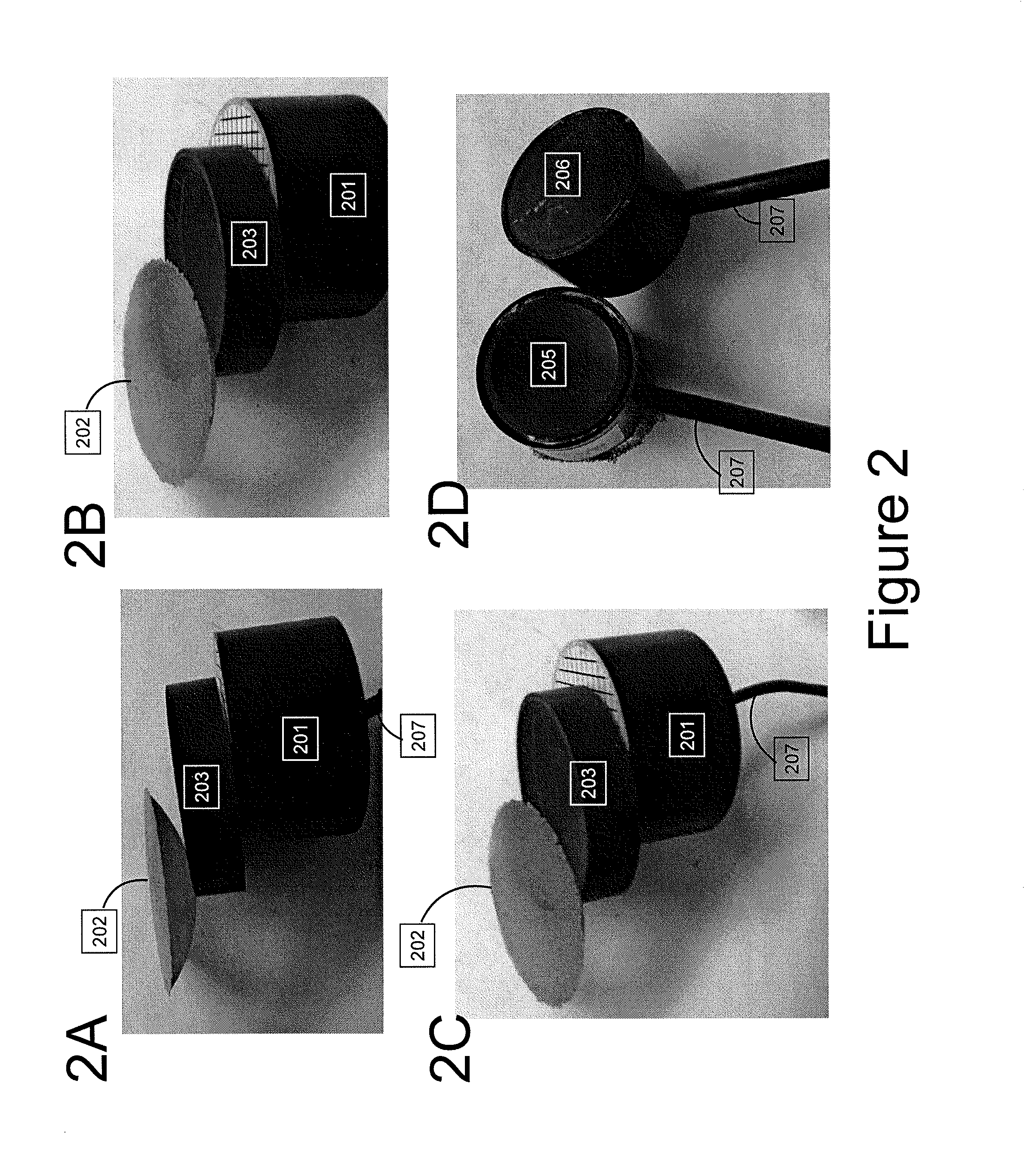

Focused transcranial ultrasound systems and methods for using them

InactiveUS20160038770A1Highly focused ultrasoundMinimizing standing waveUltrasound therapyChiropractic devicesAcoustic energyMedicine

Apparatus and methods for focusing transcranial ultrasound. The systems described herein are advantageous for noninvasive neuromodulation and other transcranial ultrasound applications such as high intensity focused ultrasound (HIFU). In particular, described herein are compound acoustic lens apparatus having a short focal length for use with a transcranial ultrasound system, systems including methods of using them. These compound lens assemblies allow transcranial stimulation of even superficial cortical regions of the brain for ultrasound neuromodulation with a compact, single transducer element system at low (e.g., 0.2 to 1 MHz) frequencies with relatively large diameter (e.g., >15 mm) transducers applying 1 to 10 watts / cm2 of acoustic energy (spatial-peak, temporal-average intensity at the target brain region), and short focal length (e.g., between 15 and 35 mm).

Owner:CEREVAST MEDICAL

Gas-discharge lamp replacement

ActiveUS8926138B2Reduce lightReduce reflection lossLighting support devicesPoint-like light sourceThermal energyGas-discharge lamp

An illumination device comprising a housing fixture, a light source, and an active heat transfer device is provided. The housing fixture includes a base adapted to be receivable in a light fixture receptacle configured to receive a gas-discharge lamp. The light source emits light with a color rendering index higher than a respective color rendering index of at least a type of gas-discharge lamp. The active heat transfer device is physically coupled to the light source and mounted to the housing fixture. The active heat transfer device receives power from a power supply to remove thermal energy from the light source.

Owner:EXPRESS IMAGING SYST

Front electrode for use in photovoltaic device and method of making same

ActiveUS8203073B2Reduce reflection lossPromote absorptionGlass/slag layered productsCoatingsIr reflectionEngineering

This invention relates to a front electrode / contact for use in an electronic device such as a photovoltaic device. In certain example embodiments, the front electrode of a photovoltaic device or the like includes a multilayer coating including at least one transparent conductive oxide (TCO) layer (e.g., of or including a material such as tin oxide, ITO, zinc oxide, or the like) and / or at least one conductive substantially metallic IR reflecting layer (e.g., based on silver, gold, or the like). In certain example instances, the multilayer front electrode coating may include one or more conductive metal(s) oxide layer(s) and one or more conductive substantially metallic IR reflecting layer(s) in order to provide for reduced visible light reflection, increased conductivity, cheaper manufacturability, and / or increased infrared (IR) reflection capability. At least one of the surfaces of the front glass substrate may be textured in certain example embodiments of this invention.

Owner:GUARDIAN GLASS LLC

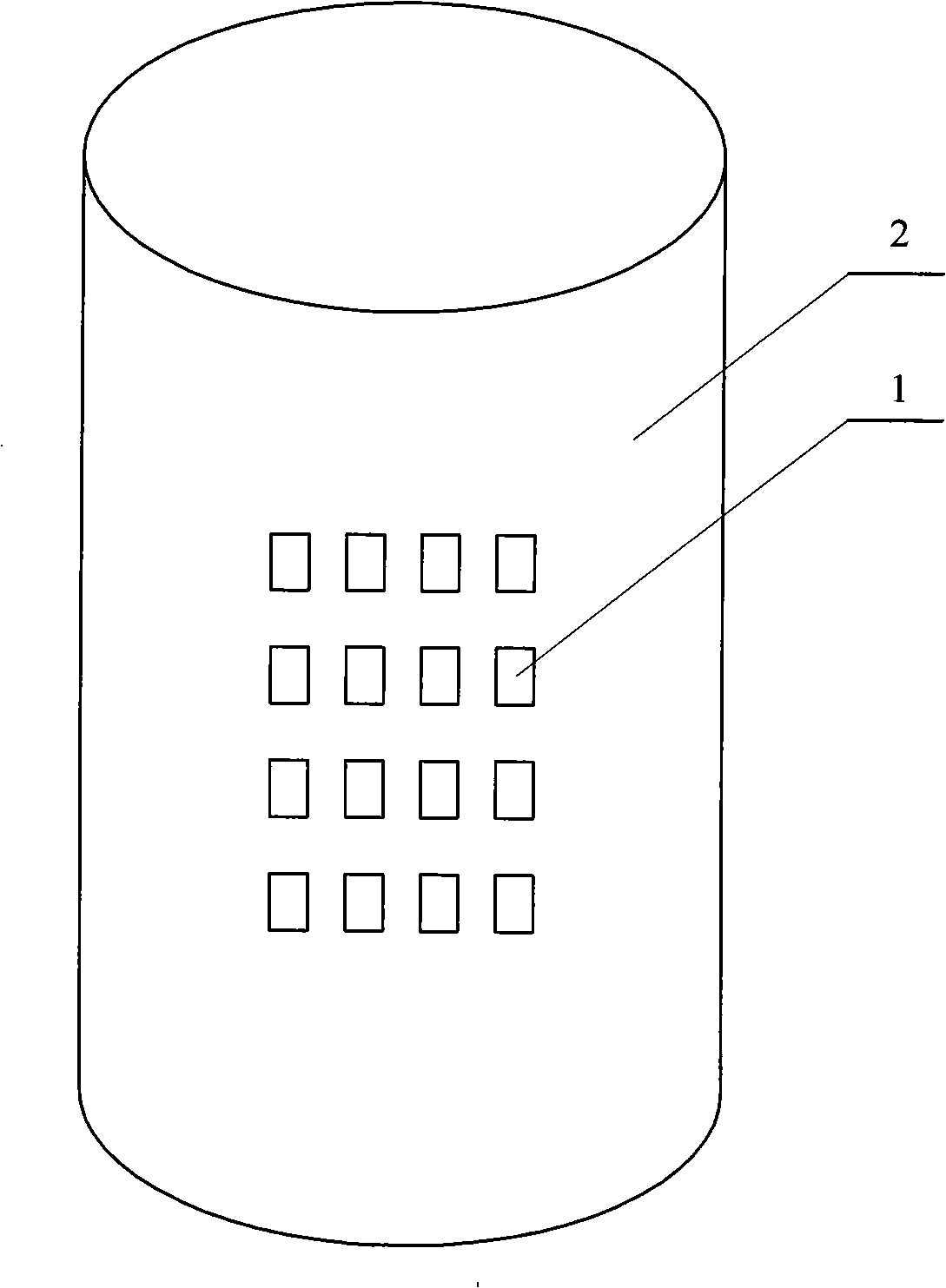

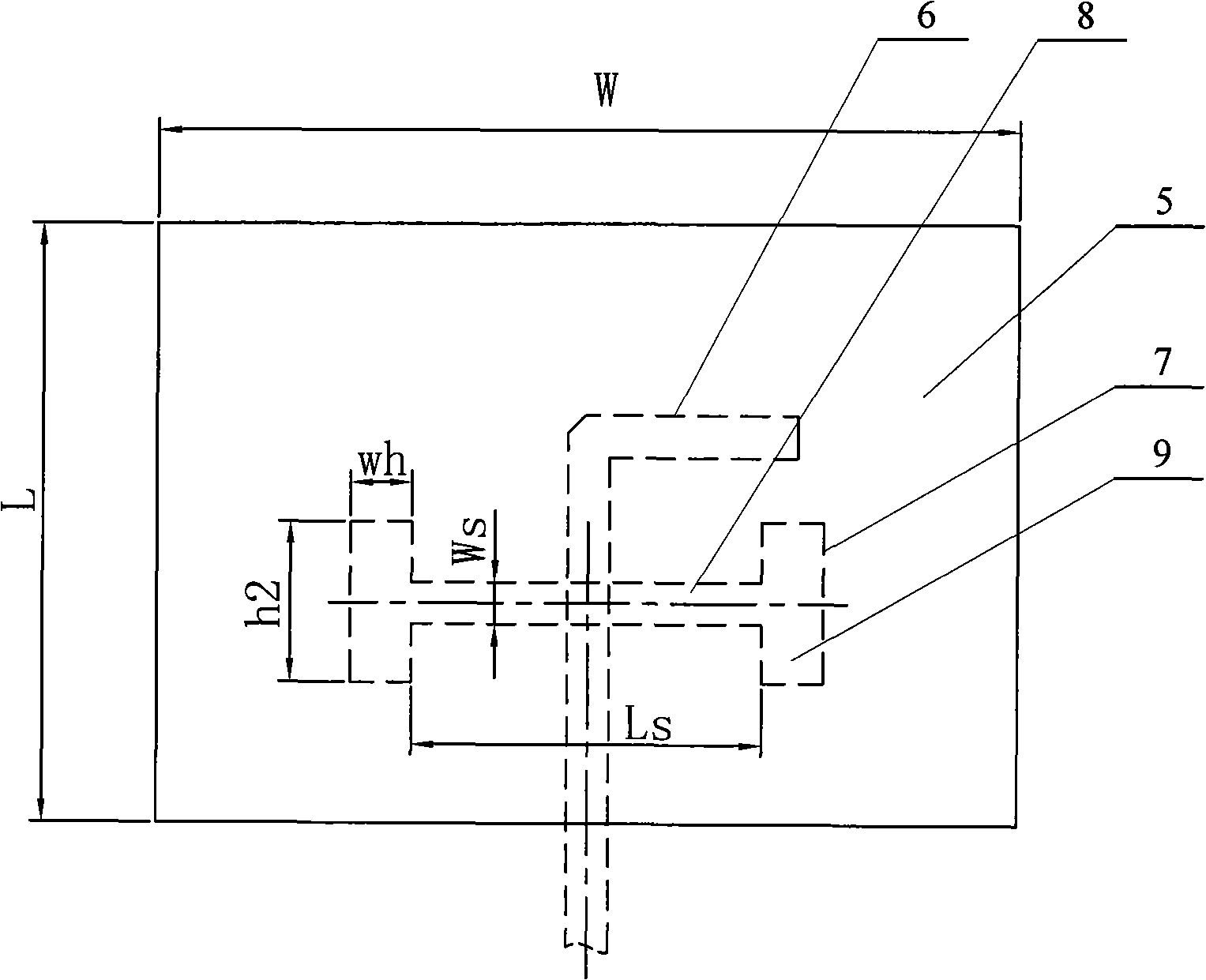

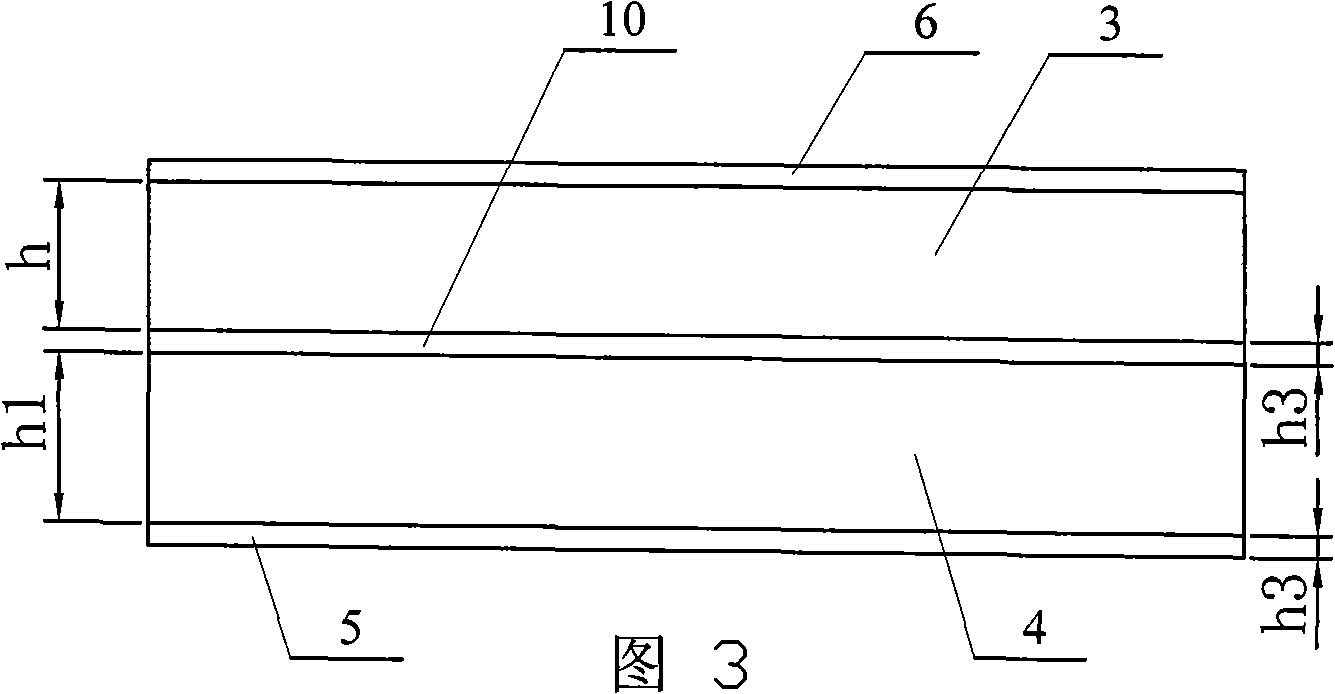

Millimeter wave band broadband cylinder conformal 4*4 microstrip antenna as well as design method thereof

InactiveCN101281998AEasy to installAvoid radiation interferenceAntenna arraysAntenna supports/mountingsAviationSpaceflight

A millimeter wave band broad band column conformal 4*4 micro-band antenna and design method thereof relate to an antenna and design method thereof. For the purpose that the column conformal4 micro-band antenna for aviation, spaceflight, ship and surface car can stably work under frequency of 35GHz, the antenna is equipped with a sheet sticking layer(5), a first medium layer, a second medium layer, a middle floor(10) equipped with a H-shape groove(7), and a feeding network layer(6). The design method includes: designing a planar 4*4 micro-band antenna array with the H-shaped groove (7)in CST through coupling feeding micro-band antenna units by utilizing the H-shaped groove(7), drawing columns with different radius and different material, reducing column type carriers(2) with different thickness by utilizing ''substrate'' function, stretching the two medium layers, the feeding network layer(6), the middle floor(10) and the sheet sticking layer(5) to the column type carriers(2), fetching intersection of the two by utilizing ''intersect'' to conformally arrange the planar array on the column type carriers(2). The micro-band antenna for aviation, spaceflight, ship and surface car can stably work under frequency of 35GHz, and design method is simple.

Owner:HARBIN INST OF TECH

Apparatus and method of via-stub resonance extinction

InactiveUS20070152771A1Reduce reflection lossFlat Frequency ResponseMultiple-port networksFinal product manufactureExtinctionResonance

An apparatus includes a multi-layer printed circuit board having a first through-hole via for a signal connection and a second through hole via for power / ground connections. The printed circuit includes a transmission line connected to at least one through-hole via. A resistor is connected between the first and second through-hole vias to eliminate a resonance notch and achieve a flat frequency response for insertion loss.

Owner:IBM CORP

Coating for Improved Carbon Nanotube Conductivity

ActiveUS20110059317A1Great fiber fiber contactSuperior electrical propertySynthetic resin layered productsNon-conductive material with dispersed conductive materialCarbon nanotubePolymer coating

We discovered that the use of certain dopants or dopant moieties in polymeric coating formulations, that when applied over carbon nanotubes, unexpectedly decrease the measured electrical resistance of the coated carbon nanotubes (CNTs), when measured through the coating, even though the polymer coatings themselves do not have bulk conductivity. CNT compositions with enhanced electrical conductivity and methods of making such compositions are described. The CNTs are preferably coated with a dopant or dopant moiety having a HOMO energy of −7.0 eV or lower.

Owner:BATTELLE MEMORIAL INST

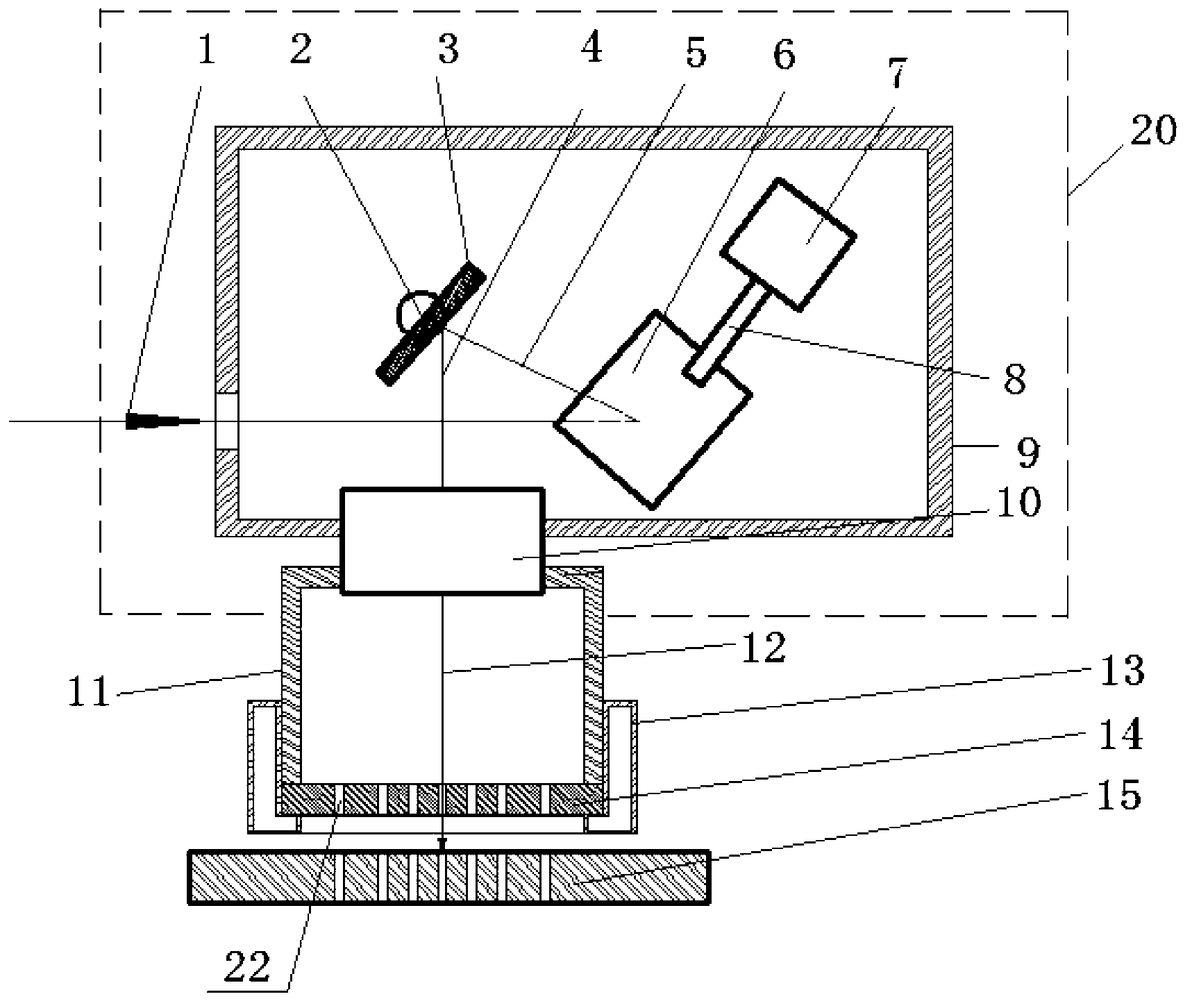

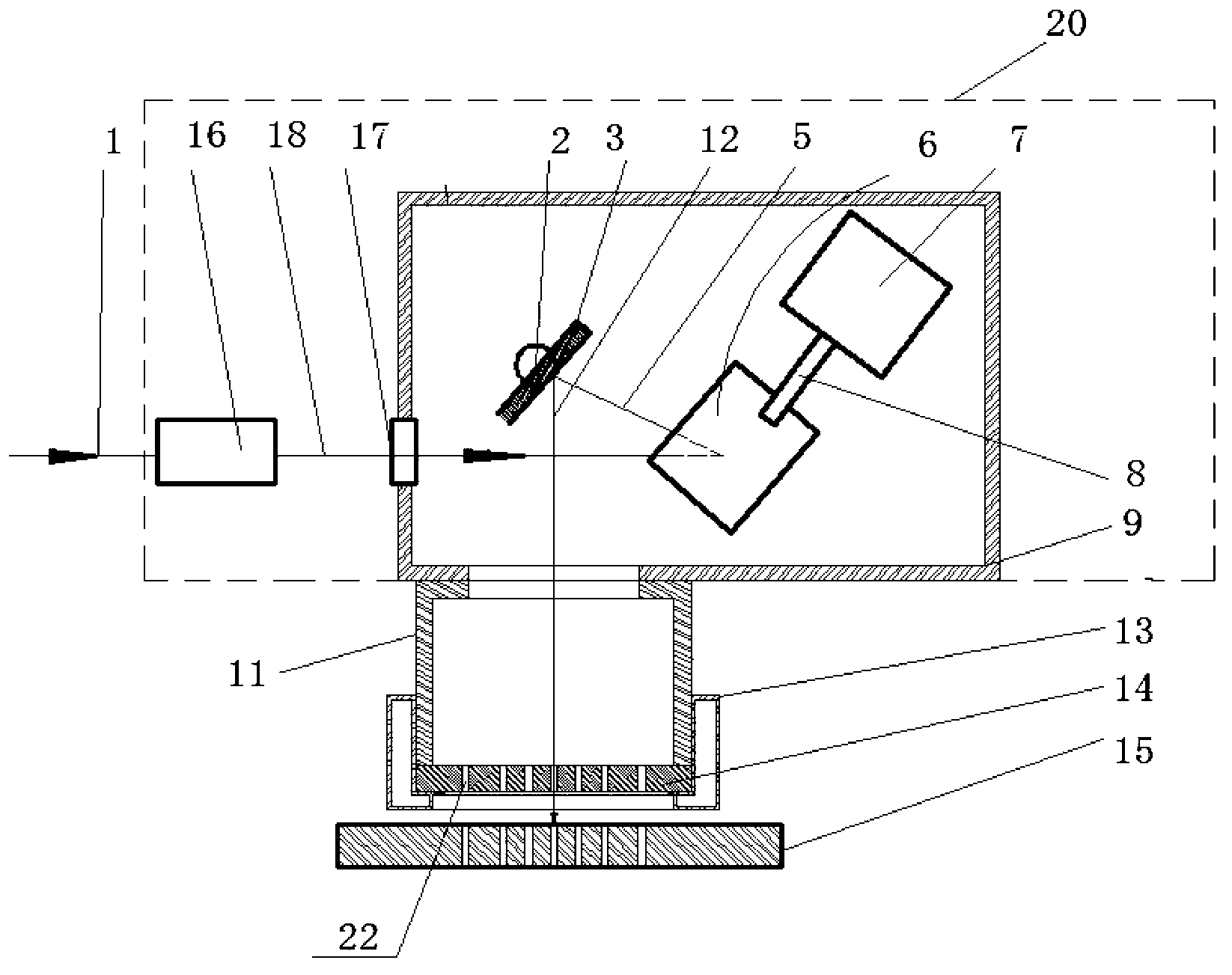

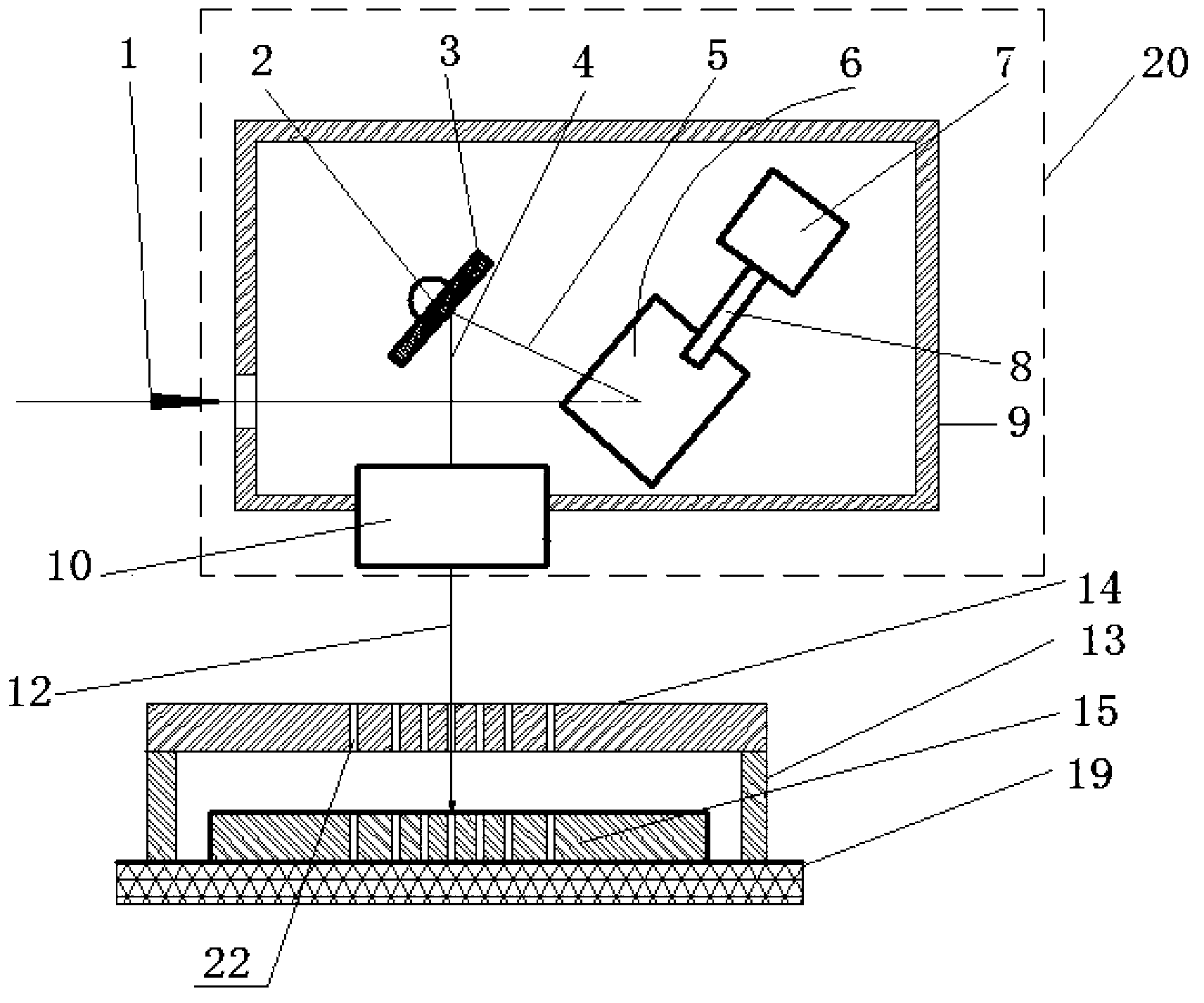

Laser scanning processing device

ActiveCN103182603ASuitable for high-volume industrial productionPromote oxidationLaser beam welding apparatusGalvanometerLaser scanning

The invention relates to a laser scanning processing device which comprises a galvanometer scanning focusing module, a positive pressure gas chamber and / or a negative pressure gas chamber, and an air-blowing mask template, wherein a distributed air-blowing ports are formed by presetting the thickness of the air-blowing mask template, the shapes of air flow windows and the like; and gas, of which the flowing direction is the same as or basically consistent with the transmission directions of lasers transmitting each of air flow windows, is formed by presetting gas pressure difference between a laser incidence surface and a laser emergent surface of the air-blowing mask template. The laser scanning processing device solves a difficult problem in distributed auxiliary air blowing of a galvanometer scanning focusing processing module during large-format laser processing, is a perfect solution of distributed auxiliary air blowing of a laser galvanometer scanning focusing processing method, and is particularly suitable for industrial mass production.

Owner:张立国

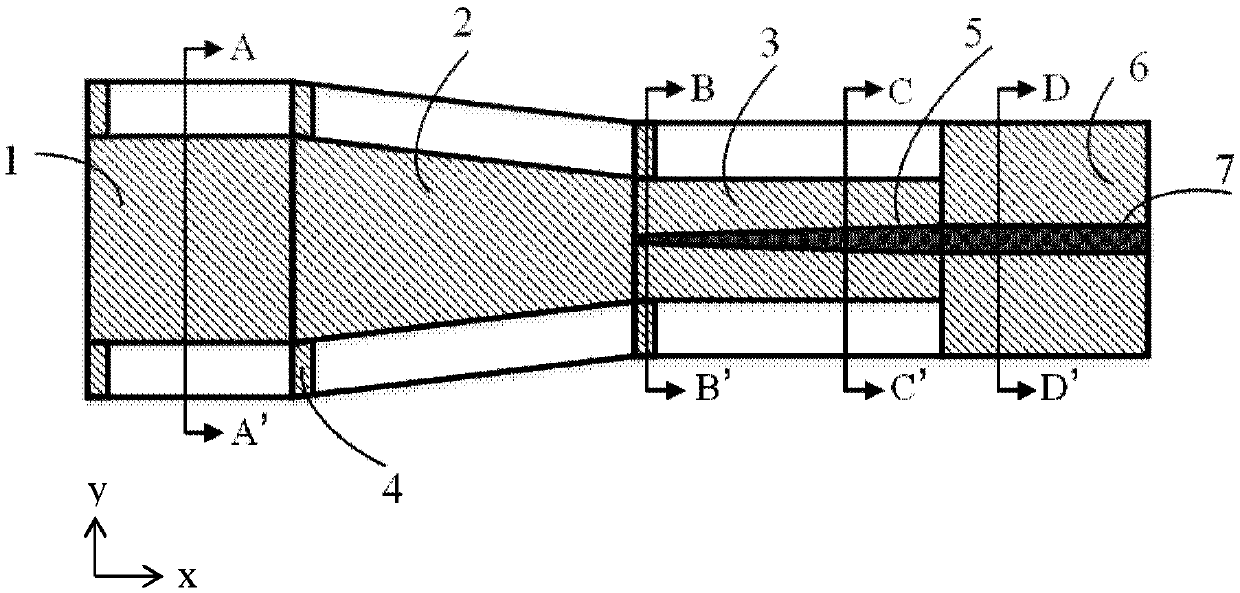

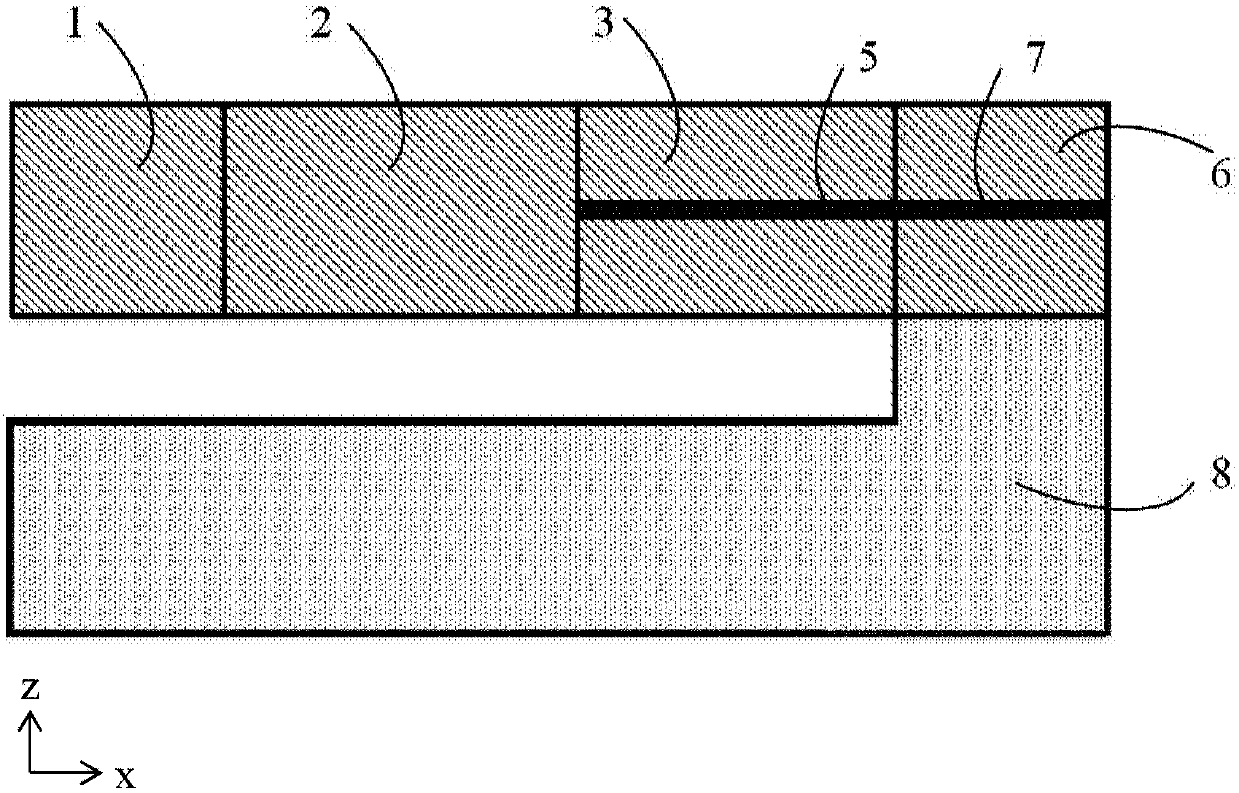

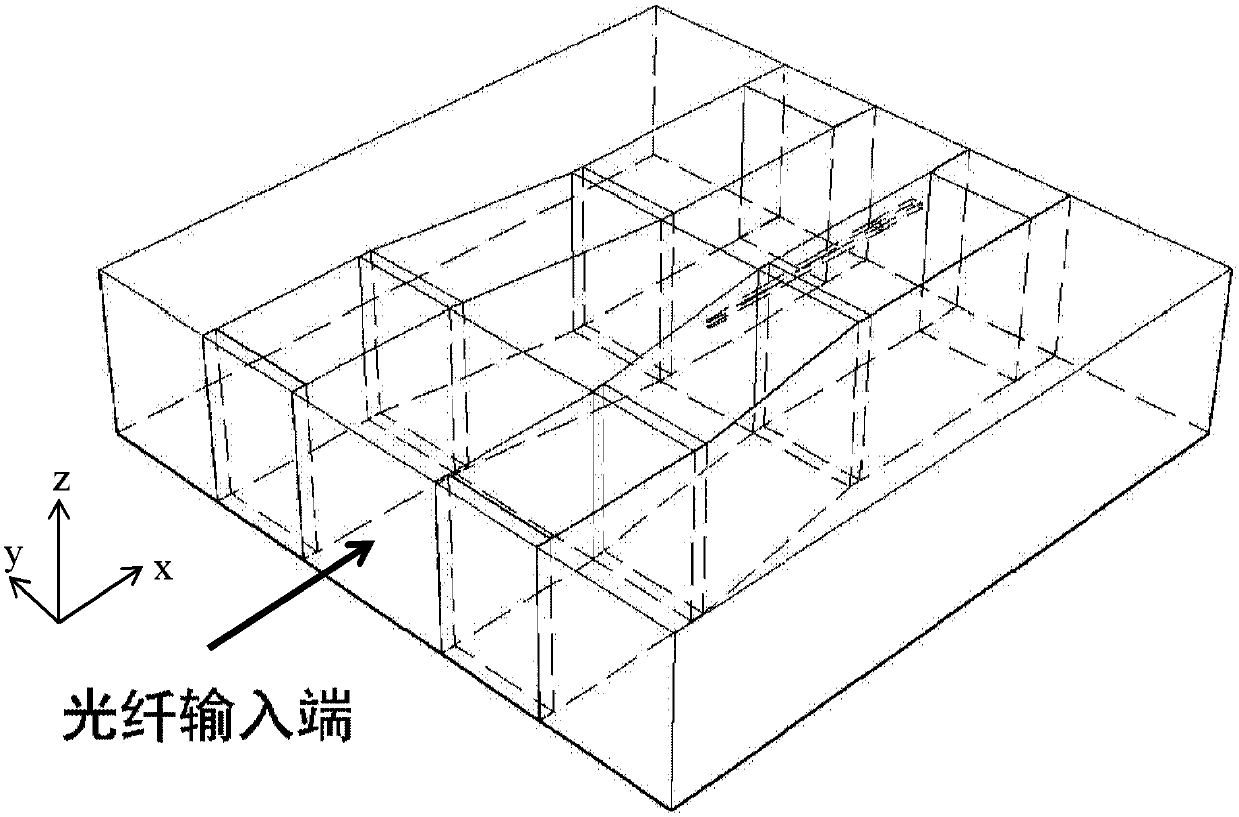

Coupling structure with silicon nanowire waveguide and fiber and manufacturing method thereof

InactiveCN107561640AEliminate leakage lossesIncrease the restrictive effectCoupling light guidesOptical waveguide light guideFiberNanowire

The invention discloses a coupling structure with a silicon nanowire waveguide and a fiber and a manufacturing method thereof. The coupling structure comprises a first silicon dioxide waveguide beingan input waveguide, a tapered silicon dioxide waveguide, a second silicon dioxide waveguide, a silicon dioxide flat-panel structure, a tapered silicon waveguide, and a silicon output waveguide. One side of the tapered silicon dioxide waveguide is connected with the first silicon dioxide waveguide and the dimension of the cross section is reduced gradually along the light transmission direction; the second silicon dioxide waveguide is connected with the other side of the tapered silicon waveguide and the dimension of the cross section of the second silicon dioxide waveguide is smaller than thatof the first silicon dioxide waveguide; the silicon dioxide flat-panel structure is connected with the second silicon dioxide waveguide; the tapered silicon waveguide coated by the second silicon dioxide waveguide is arranged at a symmetric axis of the second silicon dioxide waveguide and has the cross section with the dimension extending gradually along the light transmission direction; and thesilicon output waveguide coated by the silicon dioxide flat-panel structure is arranged at a symmetric axis of the silicon dioxide flat-panel structure and is connected with the tapered silicon waveguide. The simple coupling structure is designed to be convenient and is manufactured easily with low cost; and large-scale production and application of the coupling structure can be realized easily.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

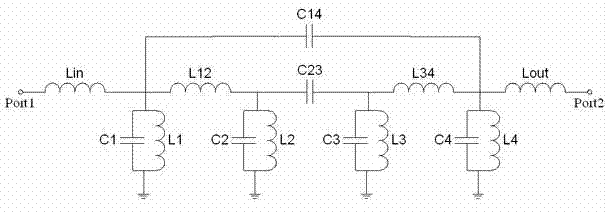

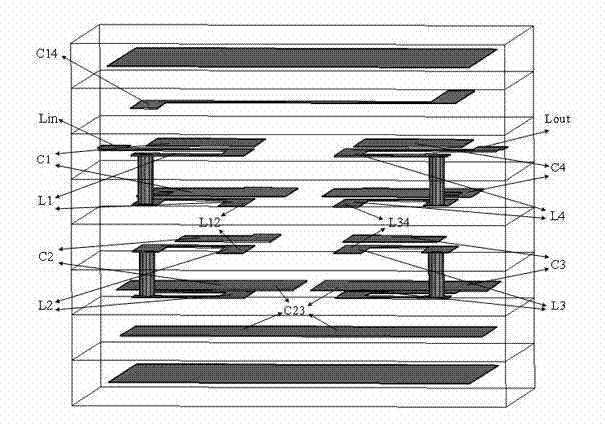

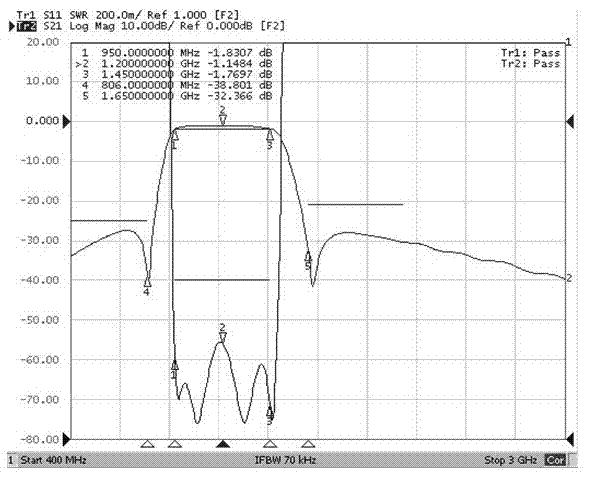

Hybrid lumped distribution miniature band-pass filter

InactiveCN102509824ACompact structureSimple structureMultiple-port networksWaveguide type devicesCapacitanceOut of band rejection

The invention relates to a hybrid lumped distribution miniature band-pass filter. The hybrid lumped distribution miniature band-pass filter comprises a 50-ohmage input-output port installed on the surface, four parallel-connection resonance units, two interstage coupling inductors, a interstage coupling capacitor, a Z-shaped cross coupling capacitor and an input / output inductor which are all achieved through the multilayer low-temperature co-fired ceramic technical skill. The hybrid lumped distribution miniature band-pass filter has the advantages of being good in band-pass selectivity and out of band rejection, low in insertion loss, light in weight, small in volume, high in reliability, good in electric performance, phase-frequency characteristic linearity, temperature stability and electric performance batch uniformity, low in cost, capable of being produced massively and the like, and is especially applicable to radars, communication, rocket carrying, plane carrying, missile carrying, spacecrafts, man-portable mobile communication terminals and other wireless communication handheld and portable terminal products and corresponding frequency range systems with strict requirements for volume, weight, electric performance, reliability and the like.

Owner:WUXI NANLIGONG TECH DEV

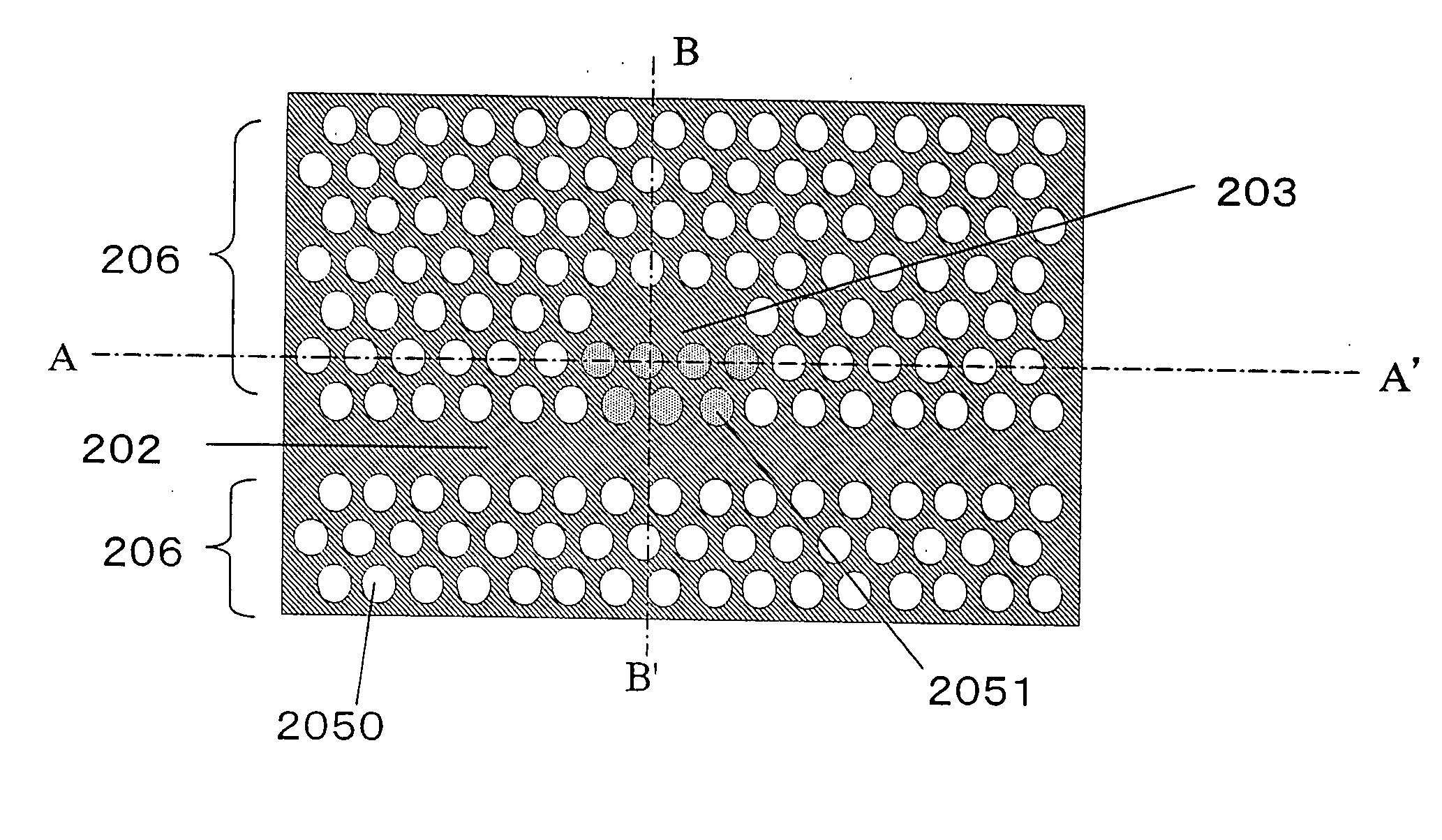

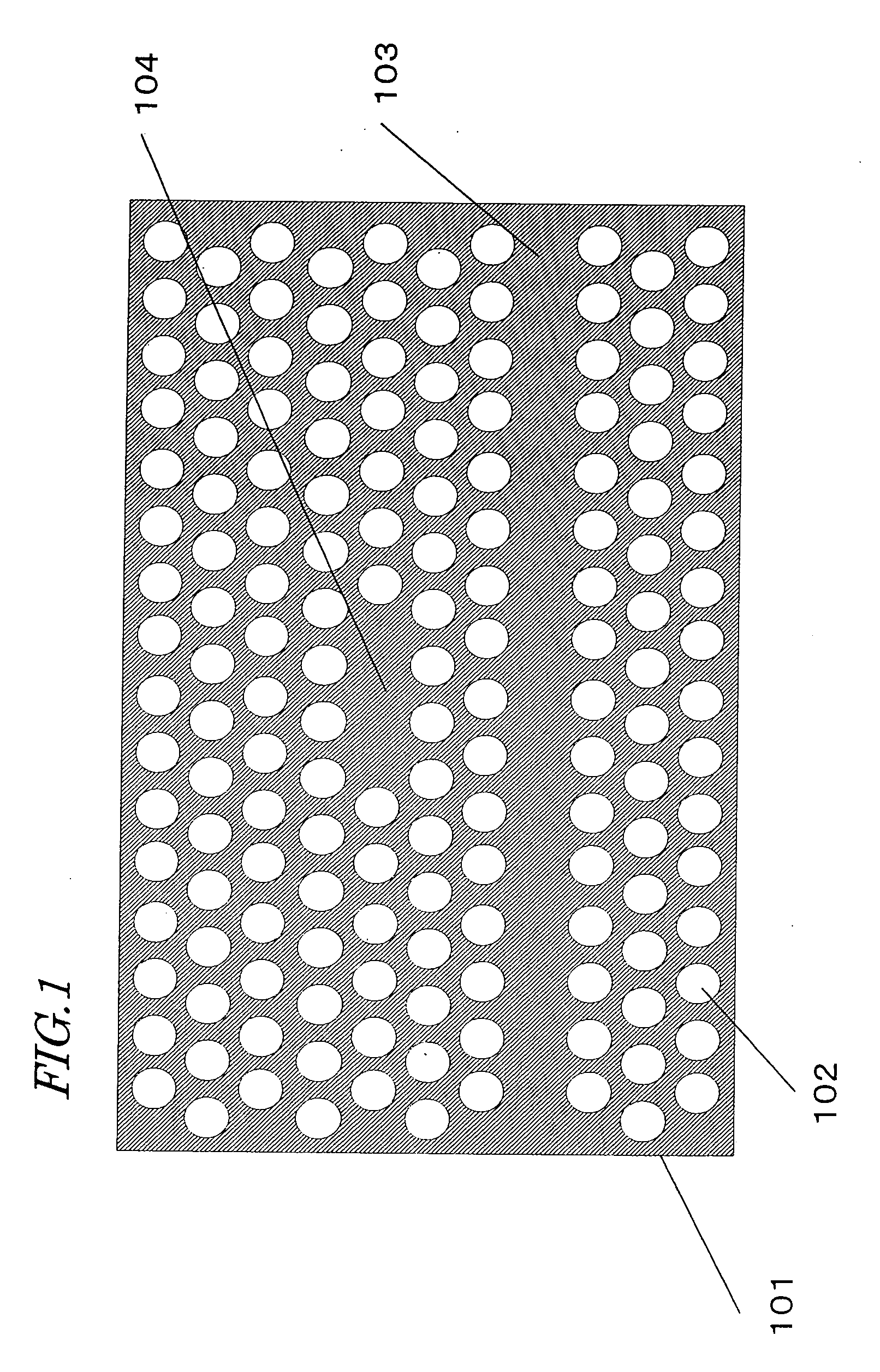

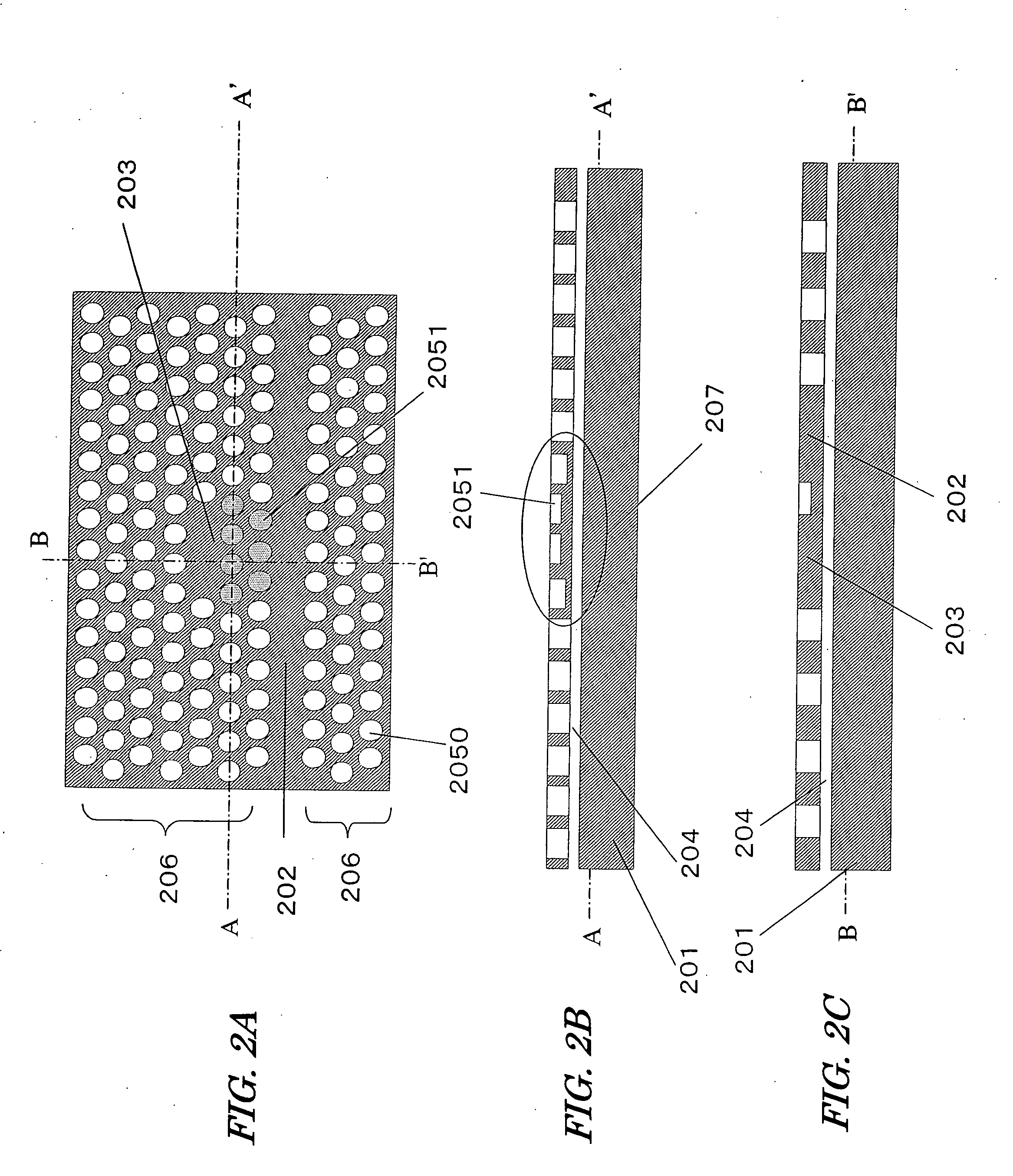

Photonic crystal device

ActiveUS20060034577A1Improve accuracySmall sizeNanoopticsCoupling light guidesPhotonic crystalWaveguide

A photonic crystal device according to the present invention includes: a substrate 201; a periodic structure portion 206 formed in or on the substrate 201, the periodic structure portion 206 having a plurality of holes 2050 and 2051 arranged in a periodic array; at least one optical waveguide 202 formed in or on the substrate 201, the at least one optical waveguide 202 being adjacent to the periodic structure portion 206; and at least one optical resonator 203 formed in or on the substrate 201, the at least one optical resonator 203 being formed in a position away from the optical waveguide 202, with at least one hole 2051 among the plurality of holes 2050 and 2051 of the periodic structure portion 206 being interposed between the optical resonator 203 and the optical waveguide 202. The plurality of holes 2050 and 2051 of the periodic structure portion 206 include a hole 2050 having a depth different from a depth of the at least one hole 2051 interposed between the optical waveguide and 202 the optical resonator 203.

Owner:PANASONIC CORP

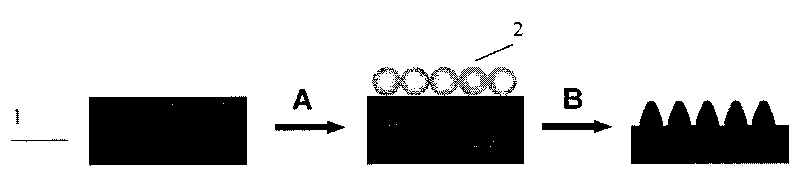

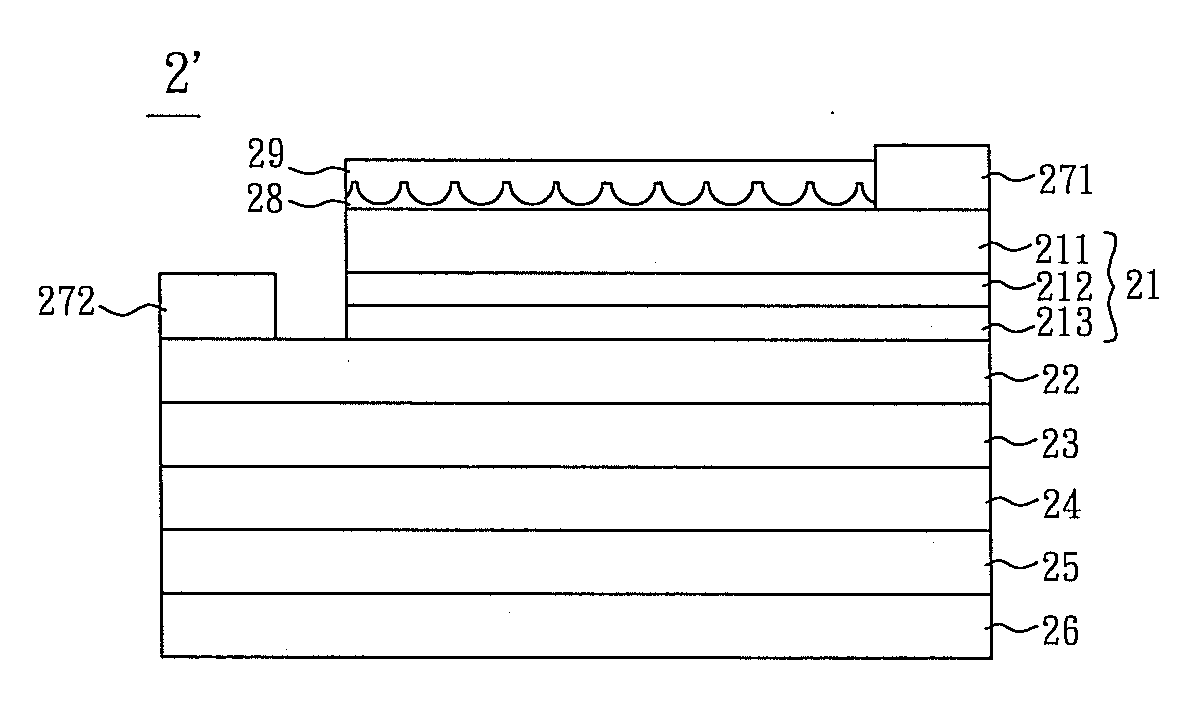

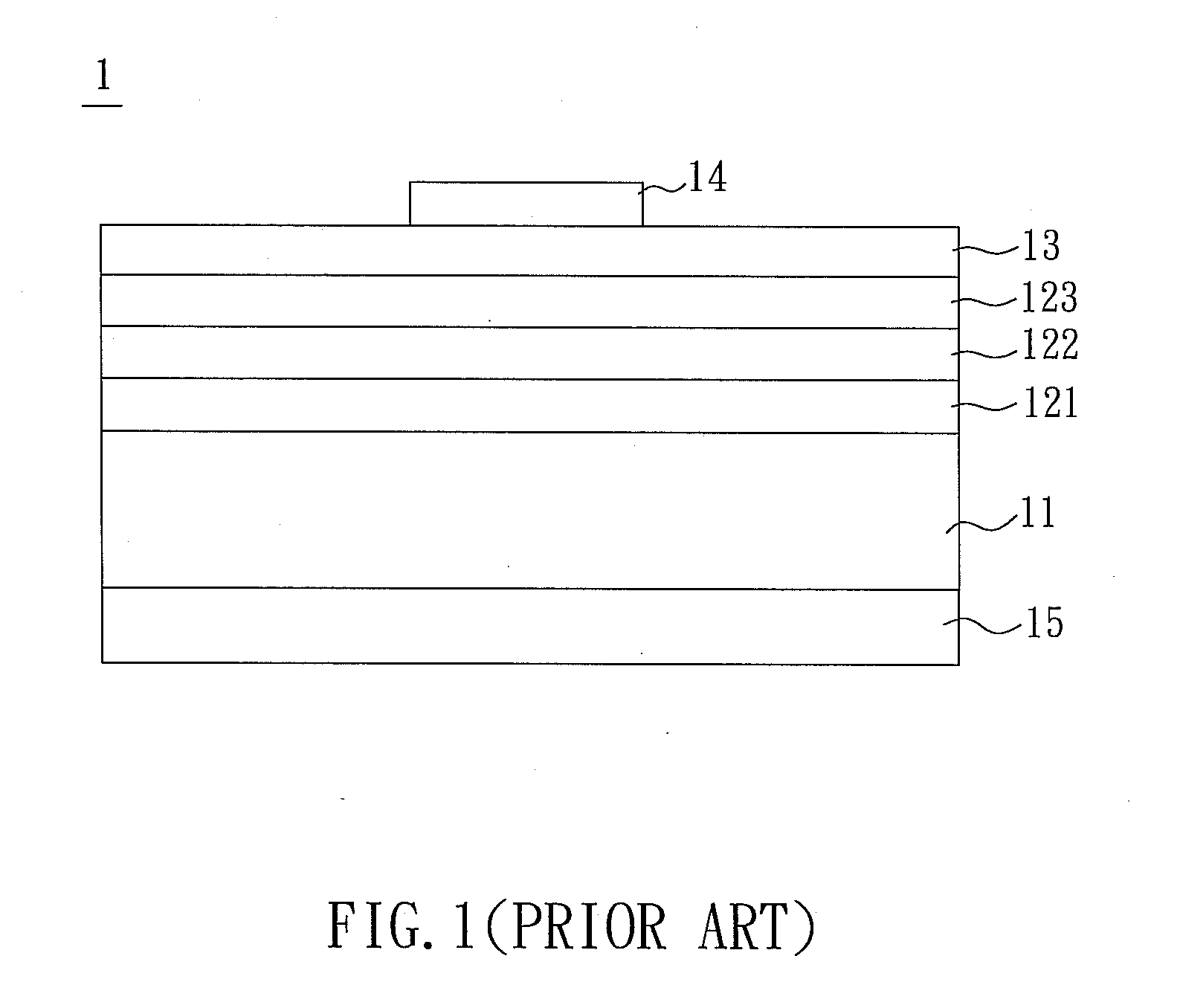

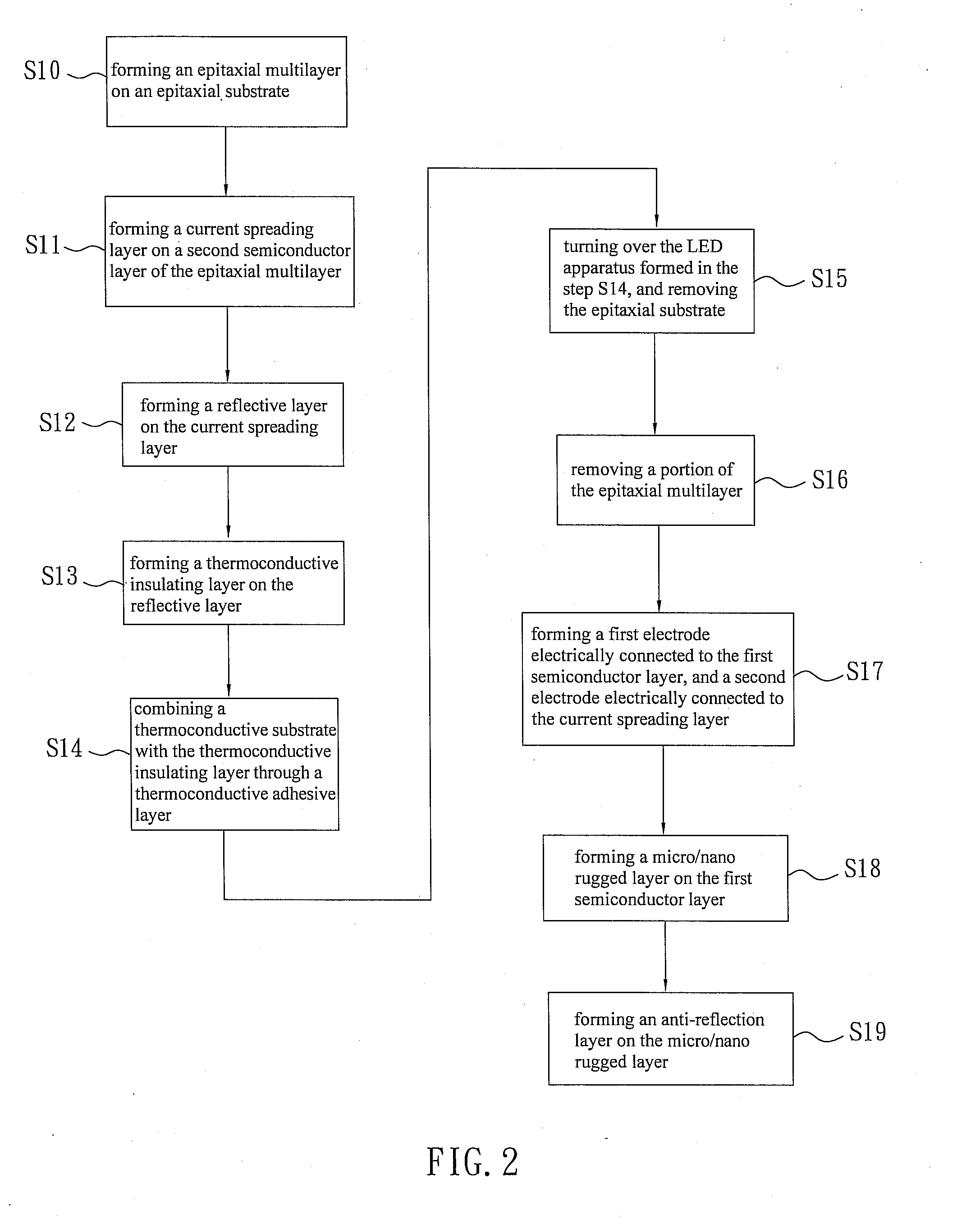

Light-emitting diode apparatus and manufacturing method thereof

ActiveUS20080283859A1Improve luminous efficiencyReduce reflection lossSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringActive layer

A light-emitting diode (LED) apparatus includes an epitaxial multilayer, a micro / nano rugged layer and an anti-reflection layer. The epitaxial multilayer has a first semiconductor layer, an active layer and a second semiconductor layer in sequence. The micro / nano rugged layer is disposed on the first semiconductor layer of the epitaxial multilayer. The anti-reflection layer is disposed on the micro / nano rugged layer. In addition, a manufacturing method of the LED apparatus is also disclosed.

Owner:DELTA ELECTRONICS INC

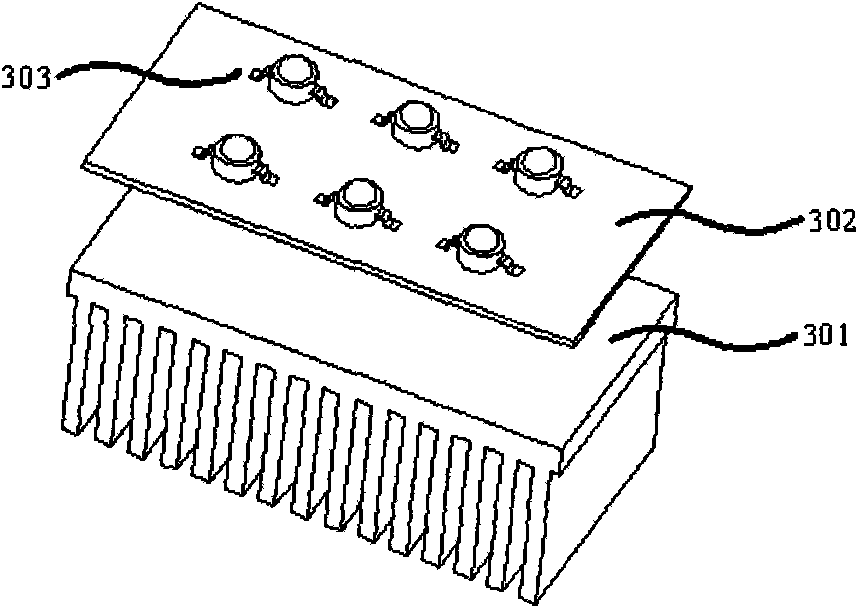

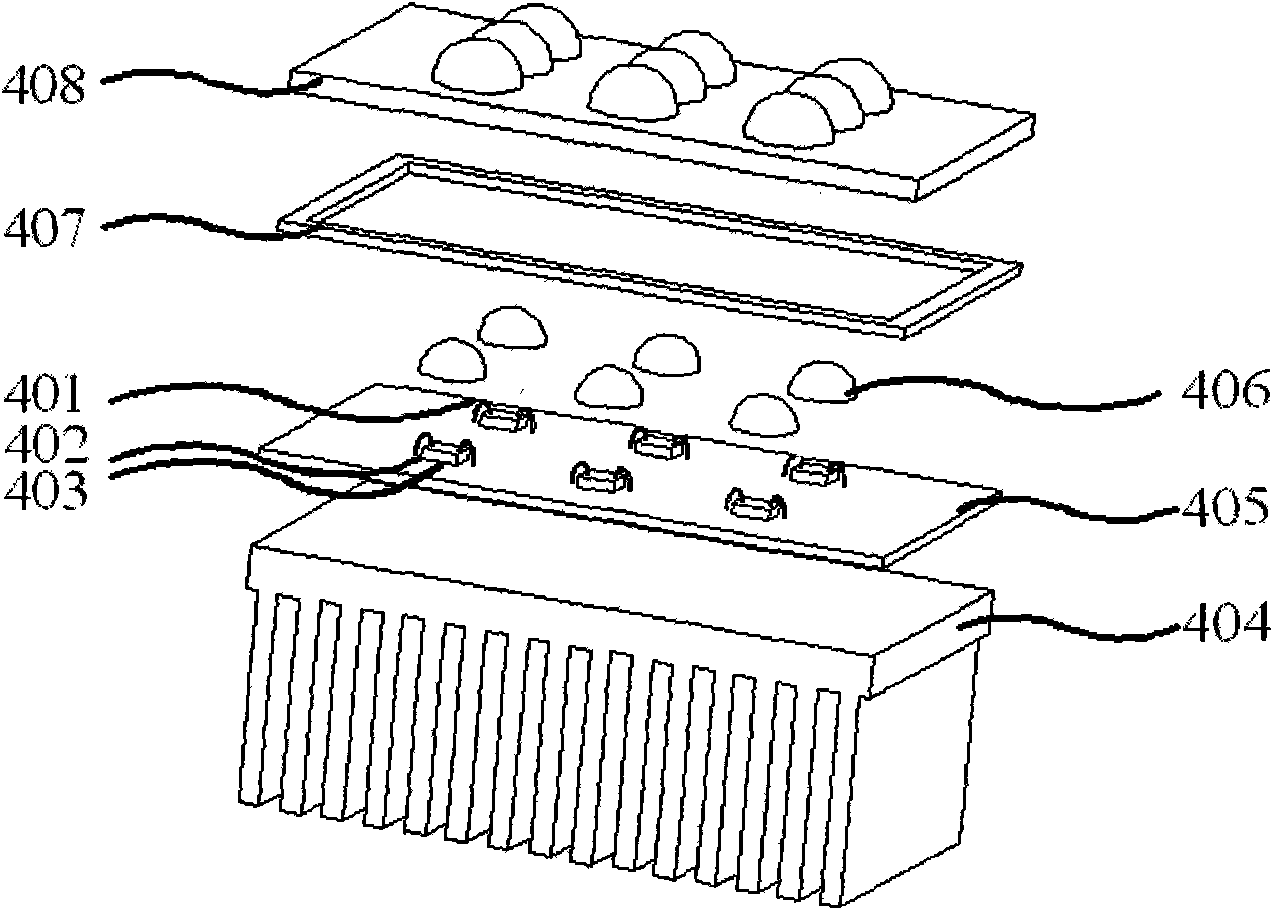

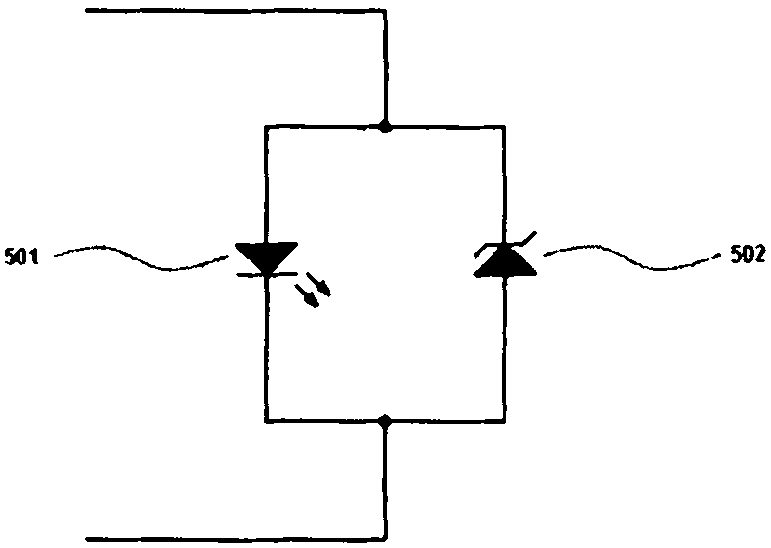

LED module and manufacturing process thereof

InactiveCN101980387AImprove cooling effectIndex matchingSemiconductor devicesReflection lossEngineering

The invention discloses an LED module, which comprises a radiator, a circuit board, an LED chip, an intraconnection track, filling colloid and a lens module, wherein the LED chip is fixed on the circuit board coated with a prime coat; the intraconnection track bridges the LED chip and the pad of the corresponding circuit board; the filling colloid is poured to embed the LED chip and the intraconnection track; the circuit board and the radiator are tightly jointed by faces; and the lens module is covered on the LED chip, the circuit board and the radiator. The LED chip is solidified on the circuit board directly, so the conventional LED packaging process is not used; and a bracket with a heat sink is not used, so that the heat of the LED chip is dissipated to the circuit board and the radiation, which have high heat conductivity, without passing through a heat skink intermediate layer, so the heat dissipation effect is improved. As only the filling colloid is filled between the lens module and the LED chip, light passes through fewer mediums and the transmissivity is high; and the refractive index of the filling colloid and the refractive index of the lens module are matched, so the reflection loss is little and the light rate of the LED module is improved.

Owner:ZHEJIANG XIZI OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com