Laser scanning processing device

A laser scanning and processing device technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of inability to achieve coaxial air blowing of static focused laser beams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

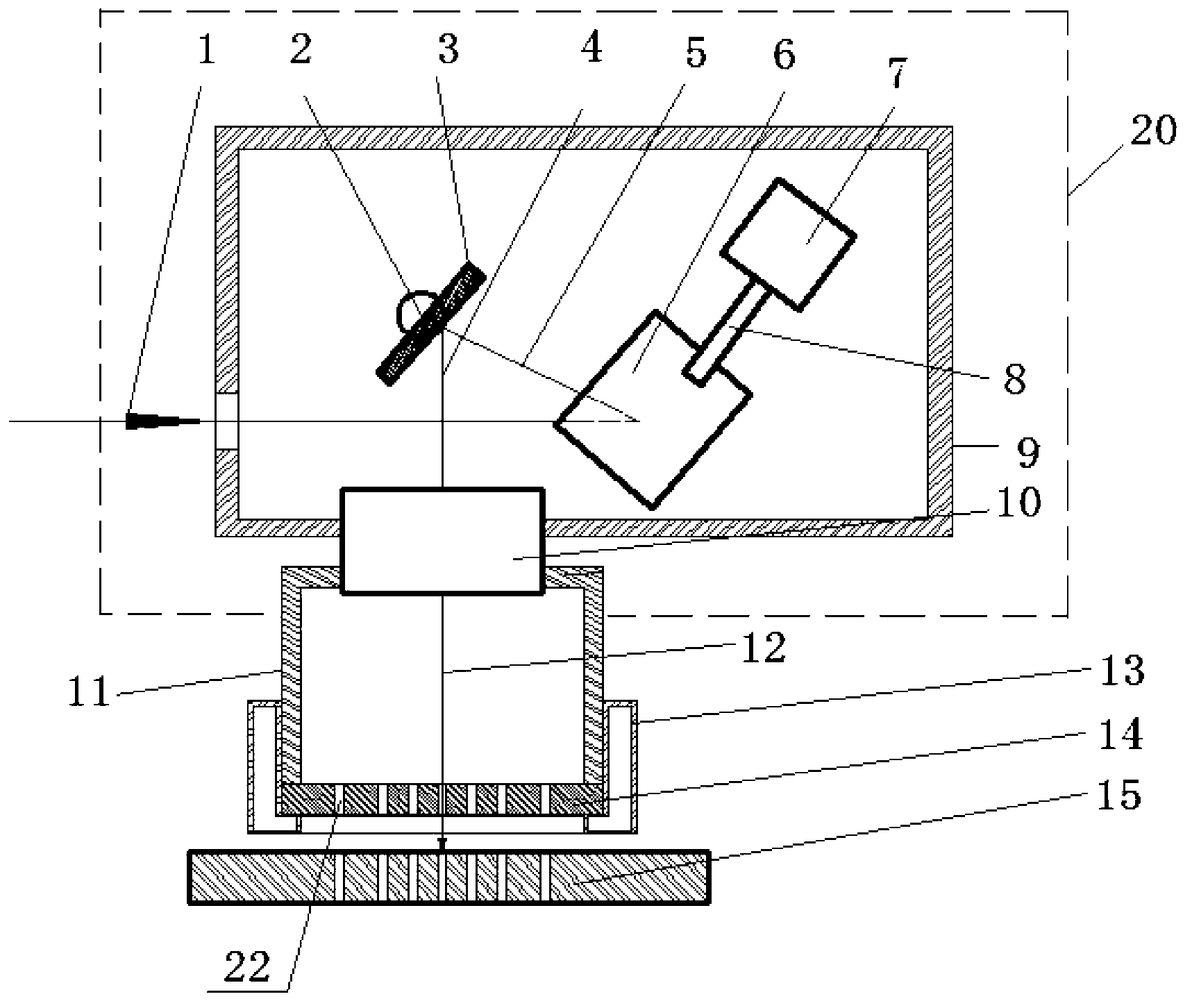

[0043] figure 1 Schematic diagram of the device structure for laser drilling of silicon wafers, such as figure 1 As shown: the silicon wafer laser drilling device includes a galvanometer scanning focusing module 20 , a positive pressure gas chamber 11 , a blowing mask plate 14 , and a negative pressure gas chamber 13 . The galvanometer scanning focusing module 20 includes a scanning galvanometer and a planar scanning focusing mirror 10 .

[0044] The scanning galvanometer includes a first mirror 6, a first motor 7 for driving the first mirror 6, a second mirror 3, a second motor for driving the second mirror 3, and a housing 9 for the scanning galvanometer The side of the scanning galvanometer casing facing the incident laser beam is provided with a laser entrance, and the first reflector 6, the first motor 7, the second reflector 3 and the second motor are located at the scanning oscillator Inside the mirror housing 9. The first mirror 6 of the scanning galvanometer is ins...

Embodiment 2

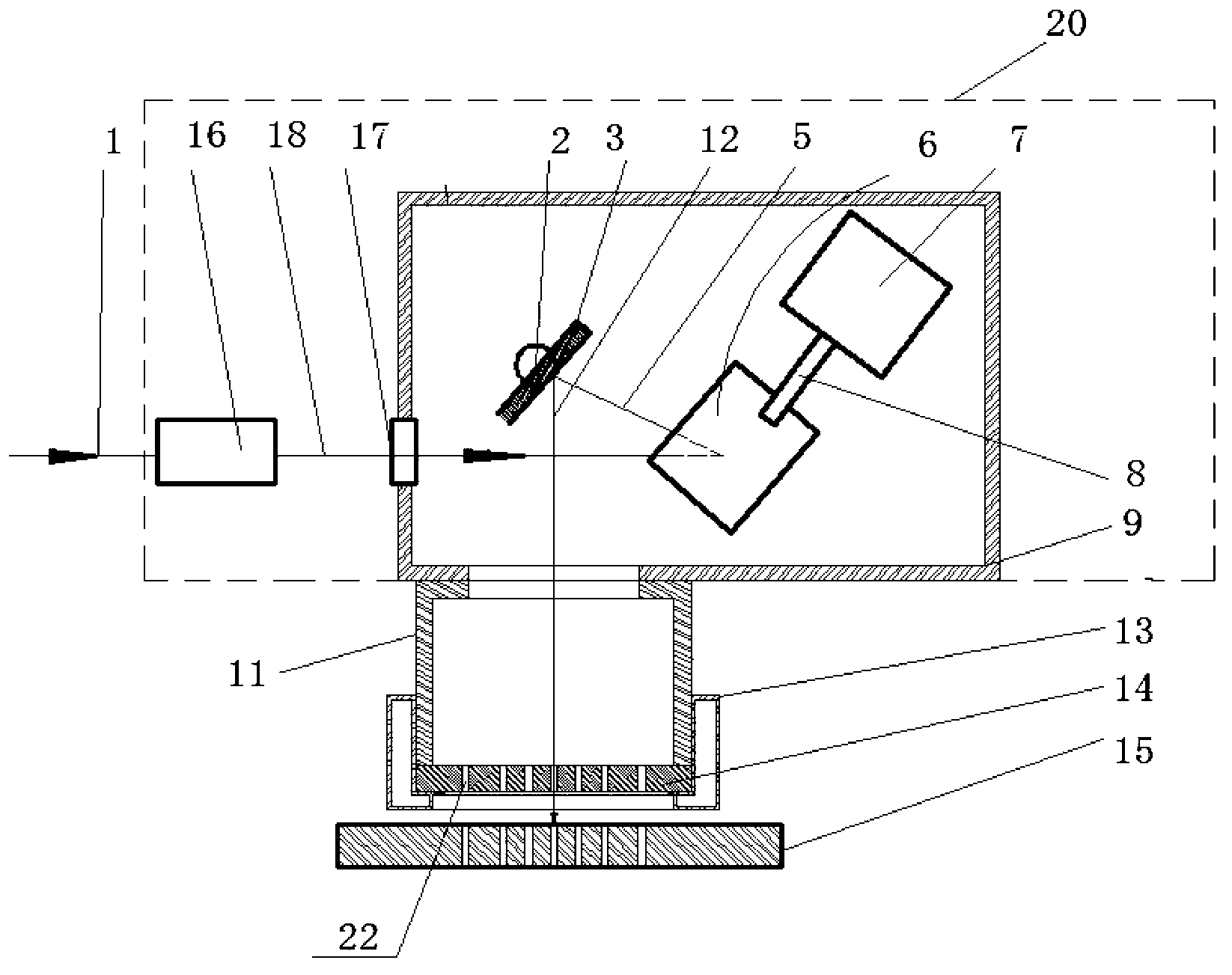

[0057] figure 2 Schematic diagram of the device structure for laser drilling of low-temperature co-fired ceramics, such as figure 2 As shown: the device for laser drilling of low temperature co-fired ceramics includes a galvanometer scanning focusing module 20 , a positive pressure gas cavity 11 , a blowing mask 14 and a negative pressure gas cavity 13 . The galvanometer scanning focusing module 20 includes a dynamic focusing mirror 16 and a scanning galvanometer.

[0058] The dynamic focusing mirror 16 has a wavelength of 1064 nm, a central focal length of 500 mm, and a focusing spot of 50 microns.

[0059] The scanning galvanometer includes a first mirror 6, a first motor 7 for driving the first mirror 6, a second mirror 3, a second motor for driving the second mirror 3, and a housing 9 for the scanning galvanometer . The first reflector 6 , the first motor 7 , the second reflector 3 and the second motor are located in the housing 9 of the scanning galvanometer. A lase...

Embodiment 3

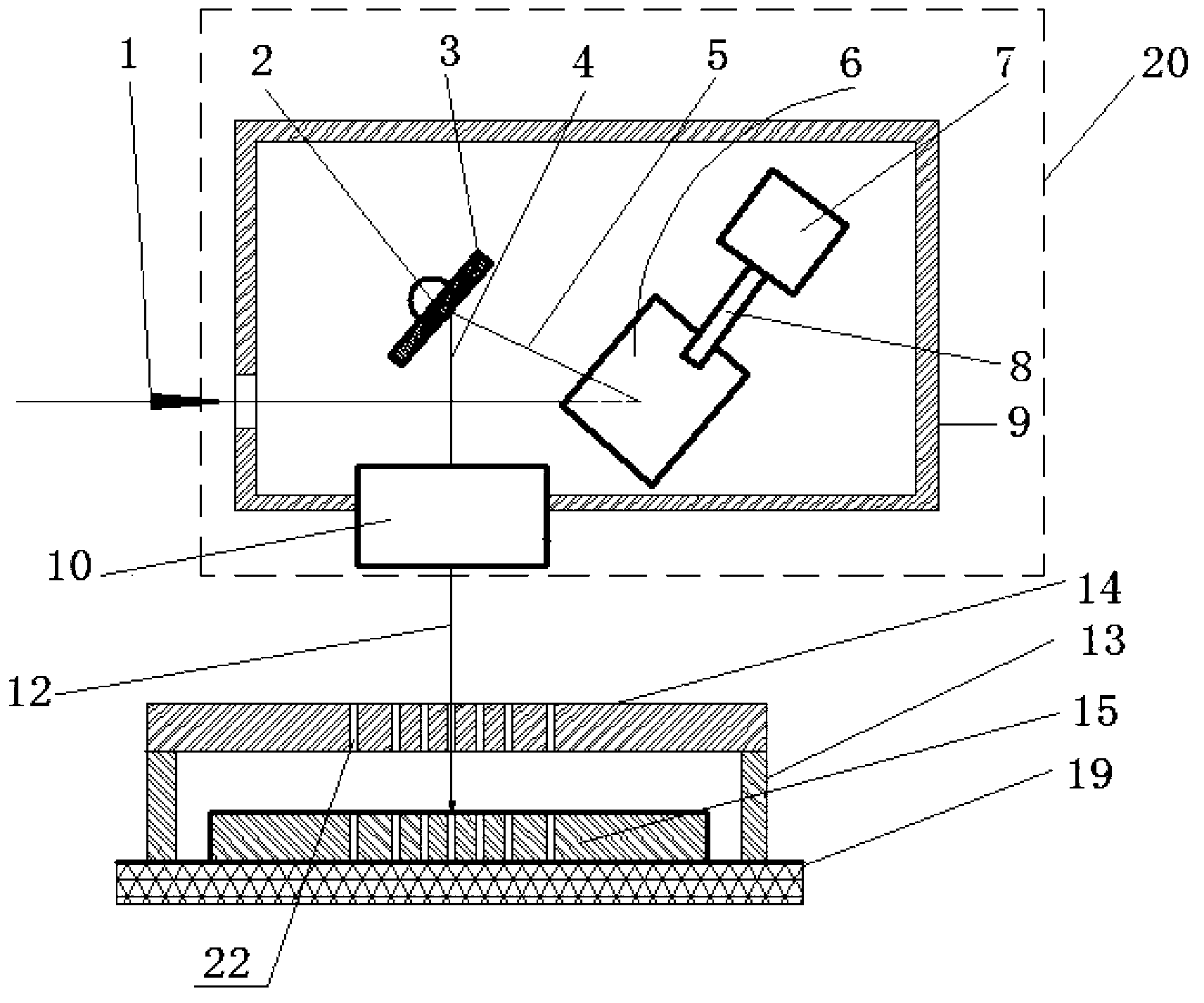

[0071] image 3 Schematic diagram of the device structure for laser drilling of copper sheets, such as image 3 As shown: the copper sheet laser drilling device includes a galvanometer scanning focusing module 20 , an air blowing mask 14 and a negative pressure gas chamber 13 , and the galvanometer scanning focusing module 20 includes a scanning galvanometer and a planar scanning focusing mirror 10 .

[0072] The scanning galvanometer includes a first mirror 6, a first motor 7 for driving the first mirror, a second mirror 3, a second motor for driving the second mirror 3, and a housing 9 for the scanning galvanometer, The first reflector 6, the first motor 7, the second reflector 3 and the second motor are located in the scanning galvanometer housing 9, and the scanning galvanometer housing is provided on the side facing the incident laser beam. The laser entrance, the first motor main shaft and the second motor main shaft are perpendicular to each other. The first mirror 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Laser wavelength | aaaaa | aaaaa |

| Average power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com