Patents

Literature

43results about How to "Solid color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PU applying silicone rubber zipper film, coating technology and application thereof

ActiveCN108582928AGood bonding firmnessLow costSlide fastenersSynthetic resin layered productsHydrogenPolymer science

The invention discloses a PU applying silicone rubber zipper film, which comprises a processed PU film and a silicone rubber layer, the PU film is applied on the silicone rubber layer, the silicone rubber layer comprises the following raw materials in parts by mass: 100-120 parts of a vinylsilane rubber component A, 100-120 parts of a vinylsilane rubber component B, 10-30 parts of a color paste pigment, 3-10 parts of a silane coupling agent, 3-10 parts of low-viscosity hydroxyl silicone oil, and 1-3 parts of polyether modified hydrogen silicone oil. The invention also discloses a coating technology of the PU applying silicone rubber zipper film and an application thereof. The coating technology has the advantages that the process is simple, cost is low, the production efficiency is high, the zipper film is easily processed, post-forming is realized, weatherability is good, hydrolysis resistance and high / low temperature resistance are good, color fastness is good, and cleaning is easy,and the PU applying silicone rubber waterproof zipper film has the advantages that the waterproof performance is good, the cost is low, and the usage life is long.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

Low-temperature dyeing method of wool

The invention discloses a low-temperature dyeing method of wool. The low-temperature dyeing method comprises the following steps: (1) wetting; (2) dyeing; (3) carrying out fixation; and (4) drying. With the adoption of the manner, the low-temperature dyeing method of the wool, disclosed by the invention, has the advantages of novel method, quality improvement, safety and environmental friendliness, energy source conservation, firm fixation, time and labor conservation, convenience and practicability, improvement of efficiency and the like; and the low-temperature dyeing method of the wool has a wide market prospect in popularization.

Owner:苏州佳一纺织科技有限公司

Blended yarn spinning technology good in dyeing property

InactiveCN108532060AHas super light fastnessNo discolorationLiquid/gas/vapor removalDyeing processYarnEngineering

The invention discloses a blended yarn spinning technology good in dyeing property. The technology comprises the following steps of blended yarn raw material selection, plasma treatment, bleaching, sizing, modal fiber dyeing, stentering, preshrinking, resultant yarn pretreatment, drafting and sizing. Compared with the prior art, the technology has the advantages that after modal fiber is dyed withdyeing liquor, the yarn has the super light fastness and the property of avoiding color change at high temperature and excellent washing fastness, coloring is easy, and the color is stable. Blended yarn obtained after wool fiber subjected to plasma treatment and the modal fiber are blended can be washed through a washing machine and dried through a roller and is good in fuzzing and pilling resistant property and high in hydrophilia. According to the spinning technology, not only is the dyeing property of the blended yarn improved, but also the blended yarn has the characteristic of the wool fiber, the product quality is improved, and the multi-function use requirements of people are met.

Owner:ANHUI ZHAOBAO TEXTILE TECH CO LTD

Surface smoking and rapid coloring method for sausage type products

InactiveCN105105097AUniform colorSolid colorFood ingredient as colourFood preparationManufacturing cost reductionPhosphate

The invention relates to a surface smoking and rapid coloring method for sausage type products. The method is characterized by comprising the following steps: (1) immersing edible animal sausage casings for filling for 2-12 hours, wherein an immersing solution is prepared from the following components in percentage by mass: 1%-50% of a glucose solution, 0.01%-0.1% of D-sodium isoascorbate, 0.1%-0.5% of phosphate, 0.01%-0.1% of smoking liquid and the balance of water; (2) filling seasoned meat stuffing with the immersed edible animal sausage casings; (3) drying filled sausages; and (4) finally, conveying the dried sausages into a smoking furnace to be smoked. The surface smoking and rapid coloring method for the sausage type products, provided by the invention, has the advantages that the products are colored uniformly, rapidly and stably; the coloring of the products is accelerated and the production cost is reduced; the appearance of the products is greatly improved; the flavor of the products is relatively rich and the color and luster are relatively lasting; and the operation process is simple and convenient so that the method is suitable for large-batch industrial production.

Owner:HENAN ZHONGPIN FOOD IND

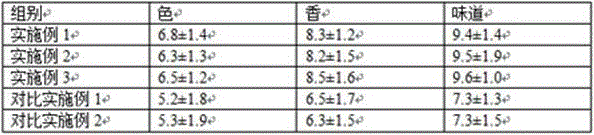

Method for processing Dongpo pork with tea aroma

InactiveCN106805131AReduced availabilityAffects the appearance of bright redsFood ingredient as colourFood ingredient as mouthfeel improving agentHigh concentrationBlack tea

The invention discloses a method for preparing Dongpo pork with tea aroma. The method includes steps of (1) raw material processing working procedures for selecting streaky pork, (2) low-concentration black tea soup and high-concentration black tea soup preparing working procedures, (3) blending working procedures, (4) injection and rolling and rubbing working procedures, (5) blanching, candy frying coloring working procedures and marinating working procedures and (6) sauce reduction working procedures. The method has the advantage that the quality of the Dongpo pork with the tea aroma can be comprehensively enhanced from three aspects of colors, aroma and taste by the injection and rolling and rubbing working procedures and the sauce reduction working procedures.

Owner:ZHEJIANG QINGLIAN FOOD

Fluorescein dyeing method for modified acrylic cotton blended fabric

InactiveCN112663357AEliminate discolorationBase color whiteDry-cleaning apparatus for textilesDyeing processFluoresceinCotton fibre

The invention discloses a fluorescein dyeing method for a modified acrylic cotton blended fabric. The method comprises the following steps of preparing raw materials; blending a desizing solution; desizing the raw materials; preparing a bleaching solution; performing bleaching; washing with water; carrying out re-bleaching and secondary cleaning; performing primary dyeing; preparing a wetting agent and a sodium hydroxide solution; preparing dye liquor; and performing pad dyeing. According to the fluorescein dyeing method for the modified acrylic fiber cotton blended fabric, a bleaching treatment process is adopted, the phenomenon that a base of the bleached fabric changes color before dyeing is eliminated, the ground color of the modified acrylic fiber cotton blended fabric is whiter before dyeing; two different dyeing liquors are used for dyeing during dyeing; the modified acrylic fibers are dyed more uniformly and firmly by using cationic dye liquor; meanwhile, the cotton fibers are dyed by using the reducing dye, so that the soaked colors of the cotton fibers are firmer, color shedding is not easily caused, dyeing is performed in a pad dyeing manner, and redundant dye can be removed in the dyeing process, and the dye can be uniformly distributed on the fabric.

Owner:江苏翔鹰纺织科技有限公司

Multi-color-point and fluorescent color fiber making method

InactiveCN106436369AMeet the requirements of energy saving, emission reduction, health and environmental protectionImprove anti-counterfeitingInksDyeing processEnvironmental resistanceWater based

The invention relates to a multi-color-point and fluorescent color fiber making method. Adopted fibers comprise the plant fiber, the animal fiber and the chemical synthetic fiber. The multi-color-point and fluorescent color fiber making method comprises the steps that 1, the fibers are subjected to pretreatment, wherein the fibers are carded to be fiber rolls; 2, anti-counterfeit patterns needing to be printed are designed on a computer, that is to say, fluorescent colors of all color points are sorted; 3, fluorescent color ink-jet printing ink matched with the adopted fiber is prepared; 4, ink-jet printing dyeing and drying are conducted, and the treated fiber is subjected to finishing and tailoring for use. The method has the advantages that the prepared ink-jet printing ink is a water base, the requirements of energy conservation, emission reduction, health and environmental protection are met, the making method is simple, the plate making process is omitted, a mold for inlaying and containing the fibers is not needed, the ink-jet printing dyeing effect is excellent, it is guaranteed that the pure cotton fiber is bright in color and luster and does not spread, and pure wool, silk fiber and other plastic fiber such as PVC are firm in bonding and bright in color and luster. The fiber has an excellent anti-counterfeit effect by being distributed in security and certificate paper.

Owner:北京优威科技有限公司

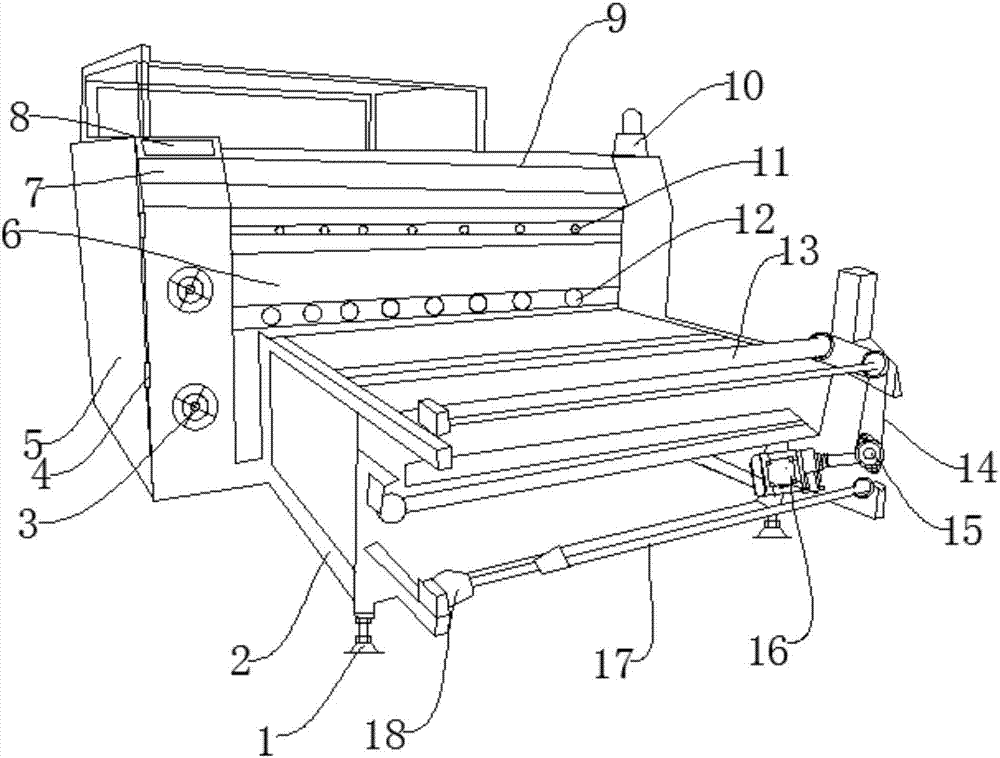

A fully-automatic cloth printing machine

InactiveCN107571627AImprove inkjet efficiencySolid colorTypewritersOther printing apparatusFully automaticConductor Coil

The invention discloses a fully-automatic cloth printing machine which comprises bottom fixed sucking discs, a rack, exhaust fans, an intelligent controller and a drag motor. The rack is arranged above the bottom fixed sucking discs. A bearing is arranged above the frame. A cloth winding shaft is arranged beside the bearing. The drag motor is arranged beside the cloth winding shaft. A pulley is arranged beside the drag motor. A belt is arranged above the pulley. A rolling shaft is arranged above the belt. The exhaust fans are arranged in front of the rolling shaft. Hinges are arranged beside the exhaust fans. Side-opening type protection doors are arranged beside of the hinges. Drying openings are arranged above the side-opening type protection doors; a roller is arranged above the dryingopenings; printing nozzles are arranged above the roller; and an operation table is arranged above the printing nozzles. The beneficial effects are that the painting efficiency is greatly raised; thepatterns are more beautiful; and the colors are firmer and better.

Owner:SHENGZHOU BINGE CLOTHING CO LTD

TPU gluing silicone rubber heat transfer film, coating process and application thereof

ActiveCN108583047AEasy to processGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceWeather resistance

The invention discloses a TPU gluing silicone rubber heat transfer film. The film sequentially comprises a silicone rubber bottom layer, a silicone rubber bonding layer and a TPU thin film; the silicone rubber bonding layer comprises, by mass part, 100 to 120 parts of vinyl silicone rubber based adhesive, 30 to 50 parts of vinyl silicone oil, 3 to 5 parts of polymethylhydrosiloxane, 0.02 to 0.05 part of an inhibitor, 0.05 to 0.2 part of a platinum catalyst, 3 to 5 parts of solid viscosifying powder, 3 to 5 parts of liquid silane coupling agent and 1 to 3 parts of polyether ester modified polysiloxane viscosifier. The invention further discloses a coating process and application of the TPU gluing silicone rubber heat transfer film. The process is simple, the cost is low, the production efficiency is high, the heat transfer film is easily machined, after-forming is achieved, weather resistance is good, hydrolysis resistance is achieved, the film is resistant to high and low temperature,good in color firming, easy to clean, and wide in silicone rubber thickness range, bubbles cannot appear inside, the property and the side effect after engraving of the silicone rubber heat transfer film cannot be affected, the cost is low, and the service life is long.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

Environment-friendly weaving dye printing liquid

InactiveCN104195852AImprove coloring abilityStable storageDyeing processDiphenyl etherSodium chlorate

The invention relates to an environment-friendly weaving dye printing liquid which is prepared by the following components in parts by weight: 15-35 parts of dodecyl diphenyl ether disulfonic sodium, 10-25 parts of waterborne polyurethane, 5-10 parts of alkyl glycoside, 3-15 parts of benzothiazole sulfoacid, 10-50 parts of alcohol alkoxylate, 5-20 parts of dehydrated sorbitol aliphatic ester, 5-10 parts of polyethylene glycol, 2-10 parts of sodium chlorate and 100-200 parts of deionized water. The environment-friendly weaving dye printing liquid has the benefits that (1) the dye liquid is strong in dyeing power, and dyed cloth has good color fastness; (2) the dye liquid can be stably stored for 1 hour and has no sediment; (3) the dye liquid is free of heavy metal, environment-friendly and safe; (4) the product is environment-friendly, and convenient to use.

Owner:艾金富

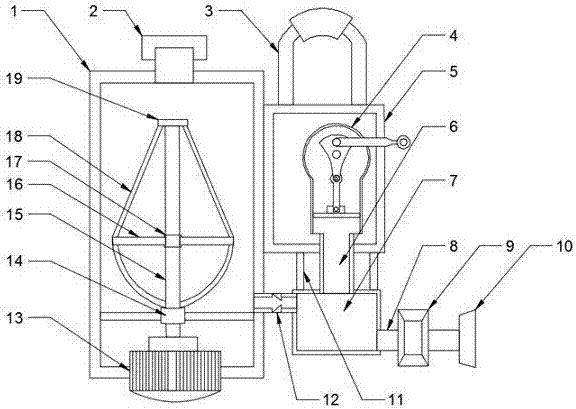

Chemical coating stirring and manual spray-coating machine

InactiveCN107350114AAvoid uneven applicationSpray evenlyLiquid spraying apparatusBiochemical engineeringSpray coating

The invention discloses a chemical coating stirring and manual spray-coating machine. The machine comprises a coating stirring box and a spray-coating box; a motor is arranged at the bottom of the coating stirring box; the upper end of the motor is connected to a rotating rod; the lower end of the rotating rod is fixed to the coating stirring box through a first fixing sleeve; a fixing disc is arranged at the upper end of the rotating rod; a stirring support which is distributed in an array mode is arranged on the lower side of the fixing disc; a fixing cross bar is arranged in the middle of the stirring support; the other end of the fixing cross bar is fixed to the rotating rod in a sleeved mode through a second fixing sleeve; a handle is arranged at the upper end of the spray-coating box; a manual spray-coating device is arranged in the spray-coating box; a suction pipe is arranged at the lower end of the manual spray-coating device; a coating collecting box is fixed to the lower end of the manual spray-coating device through a fixing rod; a feeding pipe is arranged on the left side of the coating collecting box; a spray rod is arranged on the right side of the coating collecting box; an atomizer is arranged in the middle of the spray rod; and a spray head is arranged on the spray rod on the right side of the atomizer. The chemical coating stirring and manual spray-coating machine has the advantages of being uniform in spray-coating and stable in coloring.

Owner:盐城千之诺机械有限公司

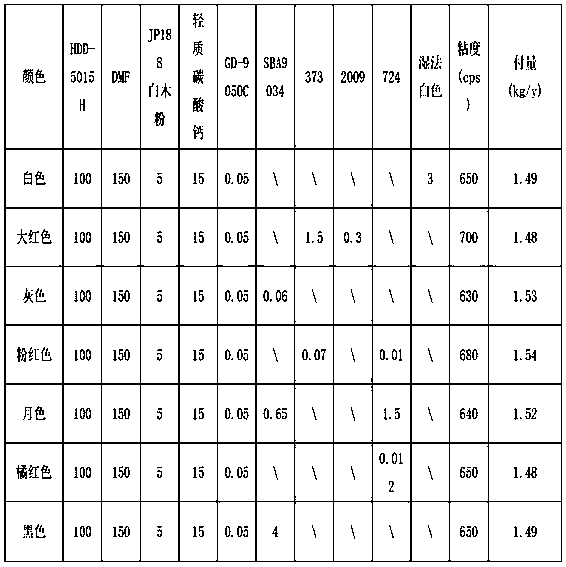

Cashmere wool synthetic leather production method

ActiveCN110886095AAchieve consistencyNo abnormal phenomena such as dead wrinkles and small particlesTextile/flexible product manufactureTextiles and paperPolymer scienceEngineering

The invention discloses a cashmere wool synthetic leather production method. The method includes steps: step 1, base cloth selection and treatment, to be specific, selecting base cloth in thickness of1.40-1.50mm, in gram weight of 400-480g (weight per square meter), in blasting of 15fkg / cm<2> or above, in warp drawing of 150N / 3cm or above, in weft drawing of 500N / 3cm or above, in warp elongationof 30%-90%, in weft elongation of 80%-150% and in warp tear strength of 50N / 3cm or above. By selection of two-sided cashmere wool as the base cloth, due to nonuniformity in wool distribution on the base cloth in a galling process, the cashmere wool is high in requirement on the base cloth, internal deep processing is required, and 240-mesh abrasive paper is adopted for fine grinding of the front face of the two-sided wool to guarantee the surface of a finished product against abnormities such as creases, small particles and the like, and cloth-wool uniformity is realized. By an impregnation process for a wet method, wet-method polyurethane resin is uniformly distributed and permeates into the two-sided cashmere wool, the polyurethane resin permeation quantity is about 1600g / m<2>, and supporting and resilience properties, softness and comfort in hand feeling and breathability of the cashmere wool are achieved.

Owner:ANAN CHINA

Textile pigment

Textile pigment is disclosed. The formula of the textile pigment includes methacrylic acid resin, polyester resin, polyamide resin, glycerol monostearate, potassium sorbate, xylene and corn stigma extract. The textile pigment has the advantages of a reasonable formula, soft color, sound coloring, comfortable hand feeling of a textile after using the textile pigment on the textile, and suitabilityfor coarse fiber fabrics.

Owner:南通森德诺家纺科技有限公司

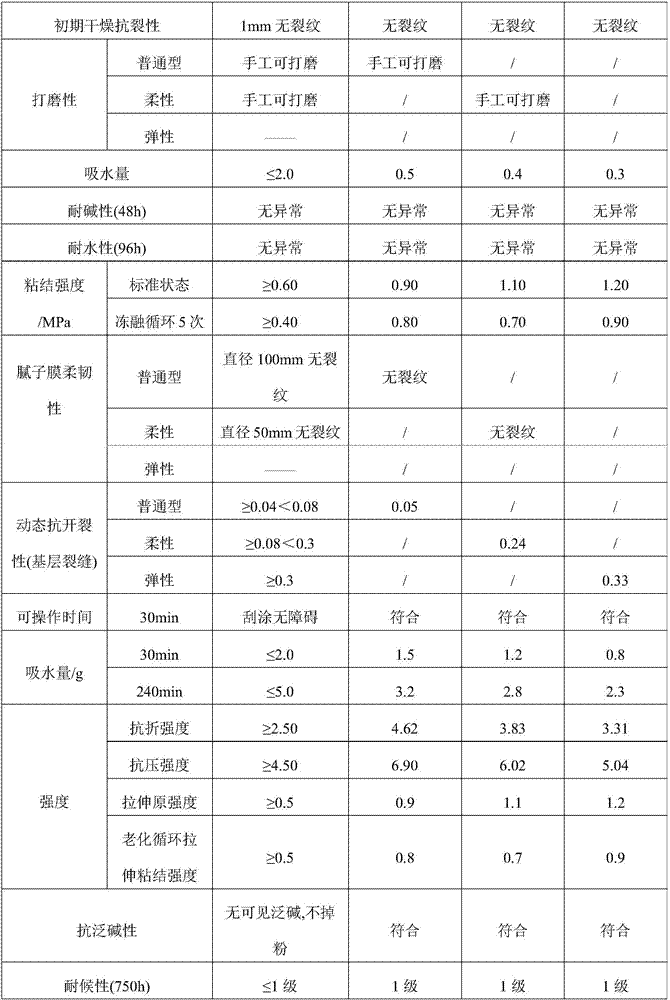

Putty set and preparation method thereof and putty

The invention discloses a putty set and a preparation method thereof. The putty set comprises a first putty component and a second putty component, wherein the first putty component comprises 160-200 weight parts of deionized water, 40-80 weight parts of an emulsion, 6-10 weight parts of a carbon black color paste, and 1-2 weight parts of a preservative; the second putty component comprises 180-240 weight parts of common-silicon low-alkali cement, 500-560 weight parts of white sand, 3-5 weight parts of hydroxypropyl methyl cellulose, 1-4 weight parts of lignocellulose, 1-3 weight parts of a water repellent, 1-3 weight parts of a saltpetering resisting additive, and 1-2 weight parts of a construction modifier. With the adoption of the putty set, high-quality black putty can be prepared; the operation of coating primer on the surface of a wall body in advance during construction is avoided, so that the material cost and the labor cost of construction can be obviously decreased, and a prepared putty coating is outstanding in comprehensive performances.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

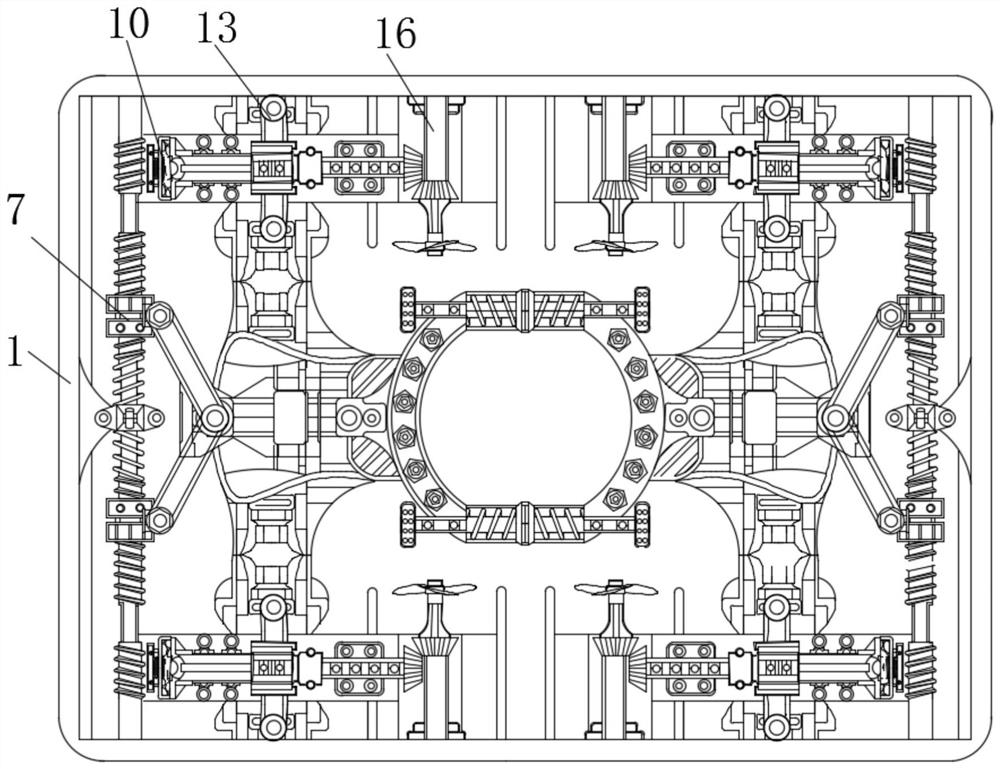

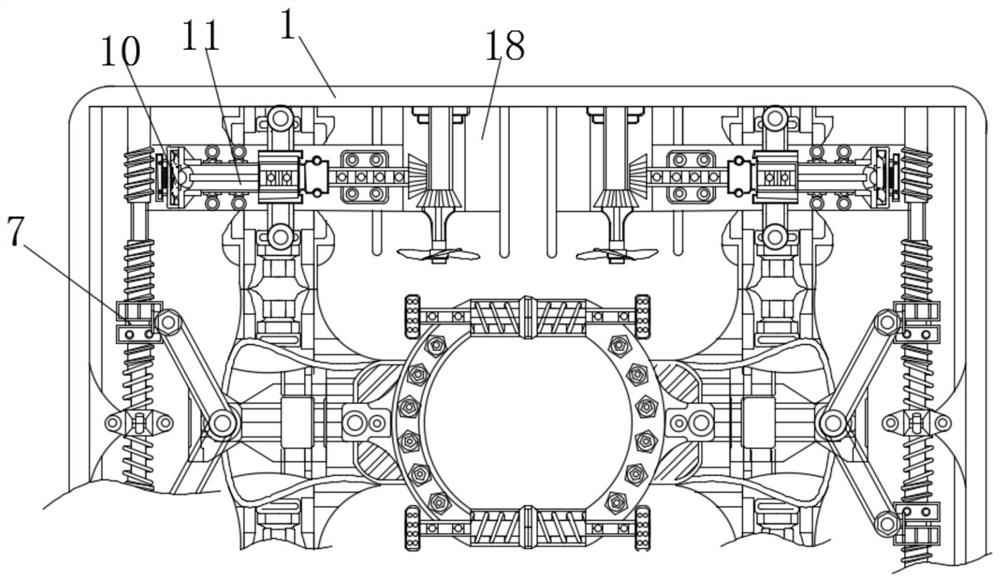

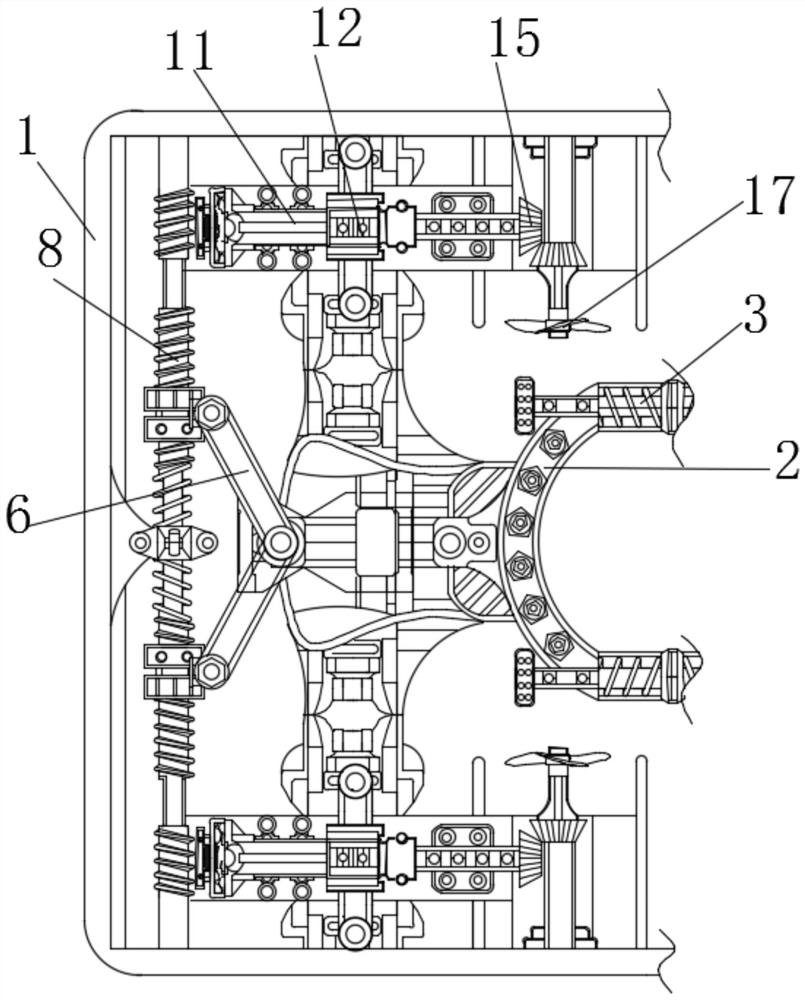

Environment-friendly device for preventing harmful substances from drifting away during coloring of decoration on automobile

InactiveCN112742641ASolid colorTo achieve the protective effectSpraying apparatusDirt cleaningToxic gasHazardous substance

The invention relates to the technical field of automobile decorations, and discloses an environment-friendly device for preventing harmful substances from drifting away during coloring of a decoration on an automobile. The environment-friendly device comprises a shell, a fixing mechanism is movably connected in the shell, a reset mechanism is movably connected to the right end of the fixing mechanism, and a push block is fixedly connected to the left end of the fixing mechanism; and the left end of the push block is fixedly connected with a connecting block, the left end of the connecting block is movably connected with a connecting rod, the left end of the connecting rod is movably connected with a moving block, the axial position of the moving block is movably connected with a worm, and the outer surface of the worm is movably connected with a compression spring. When a limiting block rotates, a driving bevel gear is driven to rotate together, and under the meshing action of a driven bevel gear and the driving bevel gear, the driven bevel gear rotates along with the driving bevel gear, so that a fan is also driven to rotate, poisonous gas is collected through a collection channel during coloring, and the effect of protecting processing personnel is achieved.

Owner:义乌铭富电子商务有限公司

Mildew-proof textile pigment

The present application discloses a mildew-proof textile pigment which comprises the following components: rosin, epoxy resin, polyamide resin, cellulose ether, potassium sorbate, xylene, color paste,isopentyl acetate and 8-hydroxyquinoline copper complex. The mildew-proof textile pigment has the advantages of being reasonable in formula, soft in color, strong in coloring, and capable of giving comfortable hand feeling to a textile using the mildew-proof textile pigment, being applied to a coarse fiber fabric, and effectively reducing late mildew conditions.

Owner:南通森德诺家纺科技有限公司

Fabric pigment

The invention discloses a fabric pigment. The fabric pigment is composed of colophony, polyester resin, polyamide resin, cellulose ether, potassium sorbate, xylene, color paste and vinegar. The fabricpigment has the advantages of being reasonable in composition, flexible in color, firm in coloring, comfortable in hand feeling when applied to fabric, and applicable to coarse fiber fabric.

Owner:南通森德诺家纺科技有限公司

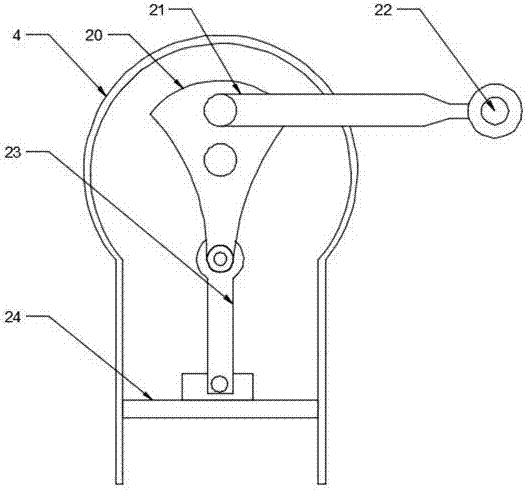

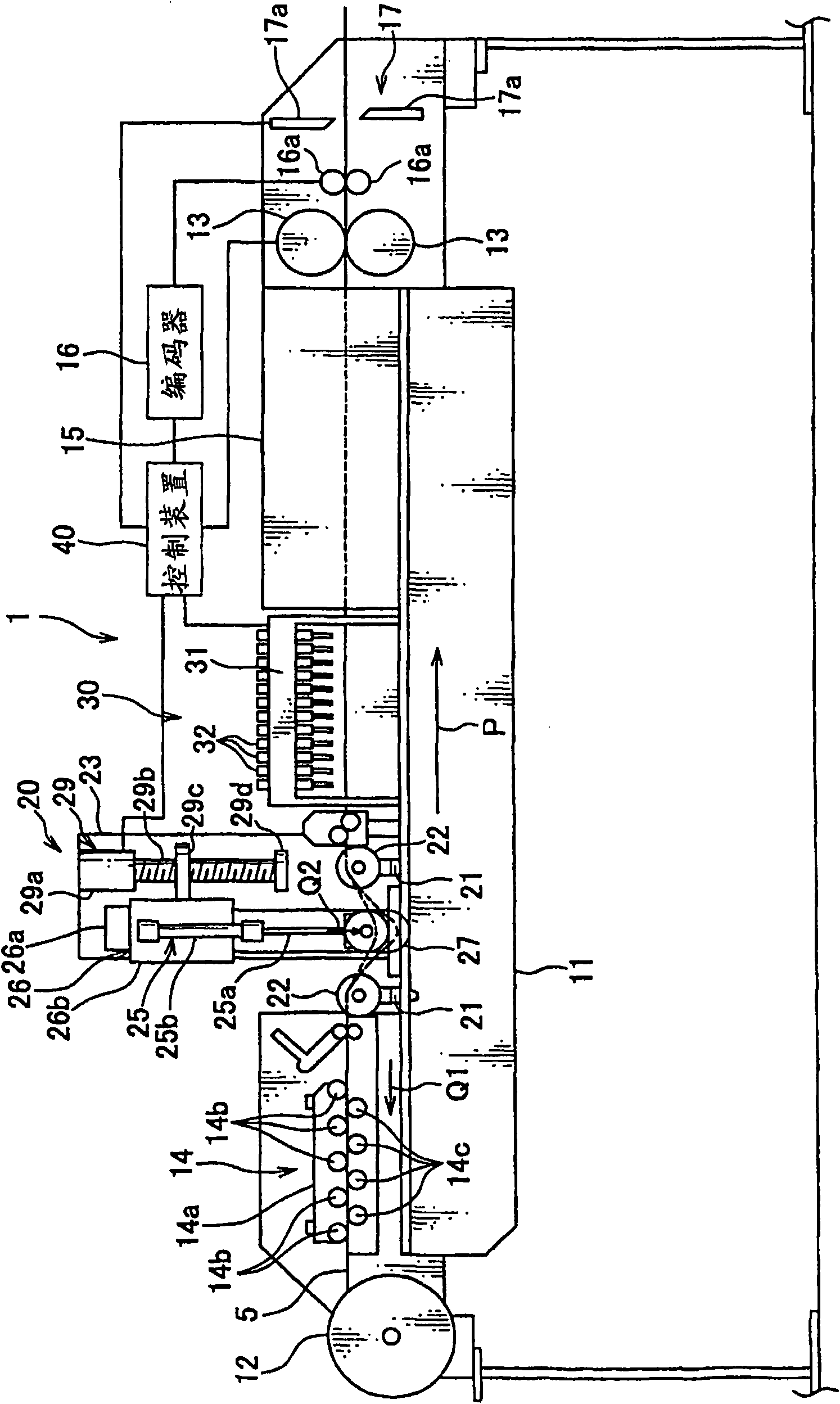

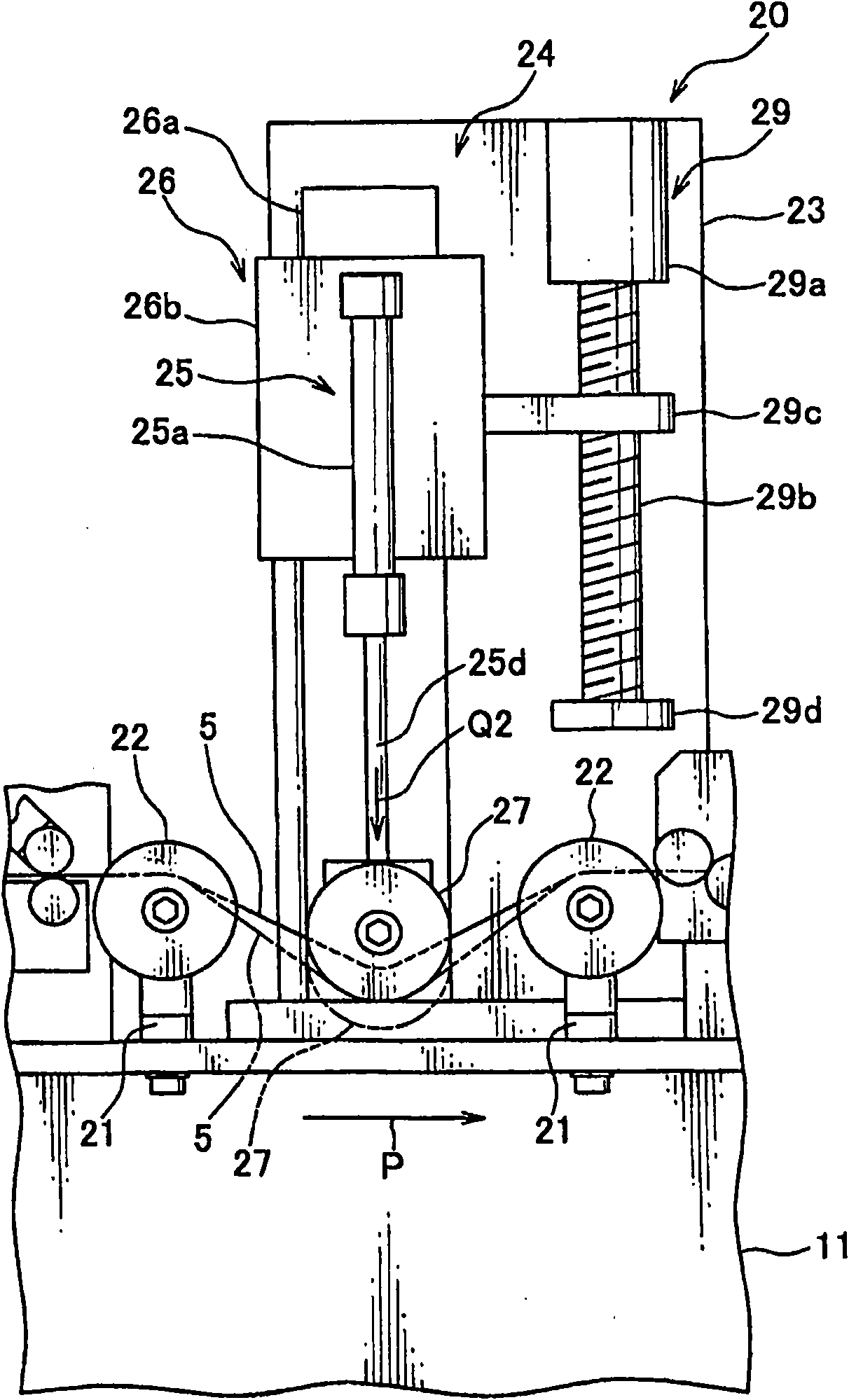

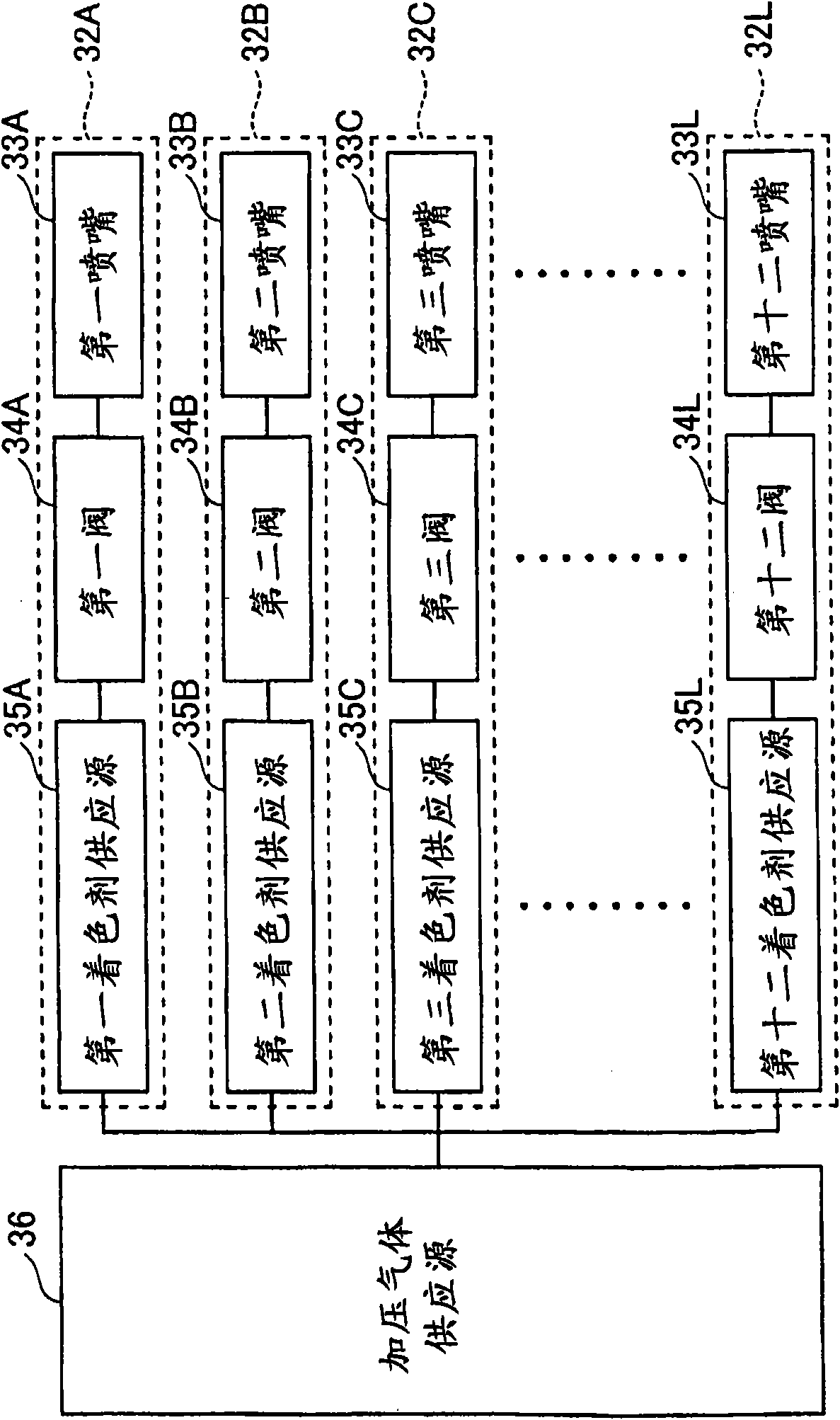

Electric wire slack-absorbing appratus and electric wire slack-absorbing method

InactiveCN101978436BAvoid slackReduce frictionFilament handlingManufacturing wire harnessesControl circuitElectric wire

An electric wire slack-absorbing apparatus and method are provided, by which an electric wire slack can be securely absorbed. The electric wire slack-absorbing apparatus includes a delivery roll, encoder, pressing part, and control device having a control circuit. The delivery roll transfers the electric wire along a longitudinal direction thereof. The encoder detects a transfer length of the electric wire. The pressing part presses the electric wire along a direction crossing a transferring direction of the electric wire. The control circuit makes the delivery roll intermittently transfer the electric wire according to a predetermined pattern. According to the transfer length of the electric wire detected by the encoder, the control circuit makes the pressing part press the electric wire from a time point just before the control circuit makes the delivery roll stop the electric wire to a time point when a predetermined time passes thereafter.

Owner:YAZAKI CORP

Novel textile dye

The invention discloses a novel textile dye. The formula of the novel textile dye includes components as follows: phenolic resin, rosin, polybismaleimide, cellulose ether, citric acid, fluorspar powder, color paste, hydroquinone and abietic acid. The novel textile dye has the advantages that the formula is reasonable, the color is soft, firm coloring is realized, and the color of textile is brightand soft after the novel textile dye is applied to the textile.

Owner:NANTONG SHENGSHI XIANGHE TEXTILE CO LTD

Coating for paper cards and use method thereof

InactiveCN111996835AGood colorSolid colorCoatings with pigmentsPaper/cardboardPolymer scienceColored white

The invention discloses a coating for paper cards. The coating is prepared from the following raw materials in parts by weight: 7000 to 8000 parts of purified water, 140 to 150 parts of pink pigment,150 to 160 parts of yellow pigment, 100 to 120 parts of bright red pigment, 80 to 90 parts of lemon yellow pigment, 50 to 60 parts of white pigment, 10 to 20 parts of black pigment, 10 to 20 parts ofdark blue pigment, 250 to 260 parts of a thickening agent, 260 to 280 parts of mucilage, 1200 to 1230 parts of solid slurry, 5 to 10 parts of melamine, 100 to 200 parts of UV light-cured aromatic urethane acrylate and 100 to 200 parts of salty-fresh water junction oyster shell powder. The invention further provides a use method of the coating. The use method comprises the following steps that during spraying, finished products are cut after cards are printed; every 350 cards are stacked and flatly clamped along a vertical direction through a pneumatic clamp; and a color coating blended in steps is evenly sprayed on the four sides of a pneumatic sprinkling can, wherein spraying time is 60 seconds, so the cards sprayed with the paint are obtained. According to the invention, the problem of low yield caused by non-uniform staining, infirmness and difficulty in spraying of the coating in the prior art is solved, and the technical effect of improving the yield of products is achieved.

Owner:江门市众盛彩印有限公司

A kind of formula for making soft hydrophilic contact lens

ActiveCN103788330BGood flexibilityIncrease elasticityOptical partsOptical elements(Hydroxyethyl)methacrylateIrritation

The invention discloses a soft hydrophilic corneal contact lens manufacturing formula, and relates to the field of production of contact lenses. The soft hydrophilic corneal contact lens manufacturing formula mainly comprises the following components: 500 grams of 2-ethoxyethanol, 25 grams of methyl methacrylate, 20 grams of methacrylic acid, 20 grams of styrene, 800 grams of butyl acetate, 10 grams of 2-mercaptoethanol, 100 grams of propylene glycol, 1,000 grams of hydroxyethyl methacrylate and 5 grams of hexamethylene diisocyanate. A manufactured soft hydrophilic corneal contact lens is high in softness and elasticity and difficult to fade, is stable when being formed and colored, can be more comfortable to wear, and is free of strong irritation effects.

Owner:ZHUHAI SANSHI OPTICAL CO LTD

A kind of tpu laminated silicone rubber lettering film, coating process and application thereof

ActiveCN108583047BEasy to processGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a TPU gluing silicone rubber heat transfer film. The film sequentially comprises a silicone rubber bottom layer, a silicone rubber bonding layer and a TPU thin film; the silicone rubber bonding layer comprises, by mass part, 100 to 120 parts of vinyl silicone rubber based adhesive, 30 to 50 parts of vinyl silicone oil, 3 to 5 parts of polymethylhydrosiloxane, 0.02 to 0.05 part of an inhibitor, 0.05 to 0.2 part of a platinum catalyst, 3 to 5 parts of solid viscosifying powder, 3 to 5 parts of liquid silane coupling agent and 1 to 3 parts of polyether ester modified polysiloxane viscosifier. The invention further discloses a coating process and application of the TPU gluing silicone rubber heat transfer film. The process is simple, the cost is low, the production efficiency is high, the heat transfer film is easily machined, after-forming is achieved, weather resistance is good, hydrolysis resistance is achieved, the film is resistant to high and low temperature,good in color firming, easy to clean, and wide in silicone rubber thickness range, bubbles cannot appear inside, the property and the side effect after engraving of the silicone rubber heat transfer film cannot be affected, the cost is low, and the service life is long.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

Production process for cement colored bricks and tiles

InactiveCN107263696ALabor intensiveReduce labor intensityCeramic shaping plantsBrickUltimate tensile strength

The invention provides a production process for cement colored bricks and tiles and relates to the field of machining equipment for building materials. The production process comprises the steps of the raw material selection, raw material matching, raw material mixing, forming, drying, primary ash removal, position adjustment, coloring, secondary ash removal, roasting, heat reutilization, cooling, quality inspection and finished product storage. The production process solves the problems that by means of an existing production process for the colored bricks and tiles, the manufacturing process is generally poor, the labor intensity of workers is large, meanwhile the strength of products is low, the color is singular, and the production process is not suitable for mass production.

Owner:肥西县碧涛建材有限公司

Rosin type brightening fabric dye

The invention discloses a rosin type brightening fabric dye which comprises the following components in a formula: a polypropylene resin, an epoxy resin, dimethyl formamide, a glass fiber, an abieticacid, pearl powder, green slurry, hydroquinone and pine needle powder. The rosin type brightening fabric dye disclosed by the invention has the advantages of being reasonable in formula, smooth in color and fast in coloring, and a fabric with the rosin type brightening fabric dye has the fragrance of rosin.

Owner:NANTONG SHENGSHI XIANGHE TEXTILE CO LTD

Preparation method of functional hairy crab conditioning tea

The invention relates to a preparation method of functional hairy crab conditioning tea containing ganoderma sinense. The functional hairy crab conditioning tea comprises the following main raw materials and auxiliary materials in parts by weight: 18-22 parts of hairy crab tea, 2-6 parts of ganoderma sinense, 2-6 parts of hawthorn, 2-20 parts of malt and 12-18 parts of xylitol auxiliary materials. The raw materials are baked at a low temperature and then crushed by a superfine crusher, and then are uniformly compounded in proportion, sterilized and packaged in food-grade tea bags. After the functional hairy crab conditioning teabag is brewed with boiled water, the tea soup is bright and transparent in color, soft in taste, harmonious in flavor, free of bitter taste and rich in fragrance, has certain conditioning effects of tonifying spleen and qi, promoting blood circulation, inducing diuresis, eliminating dampness, resisting oxidation, reducing blood sugar and the like, and is particularly suitable for tea drinking requirements of people living in hot and humid climate in the south.

Owner:吴河川

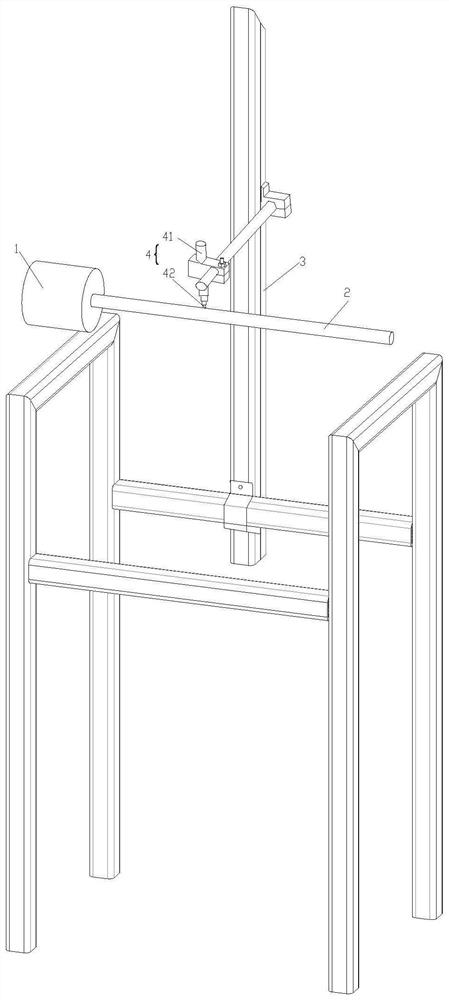

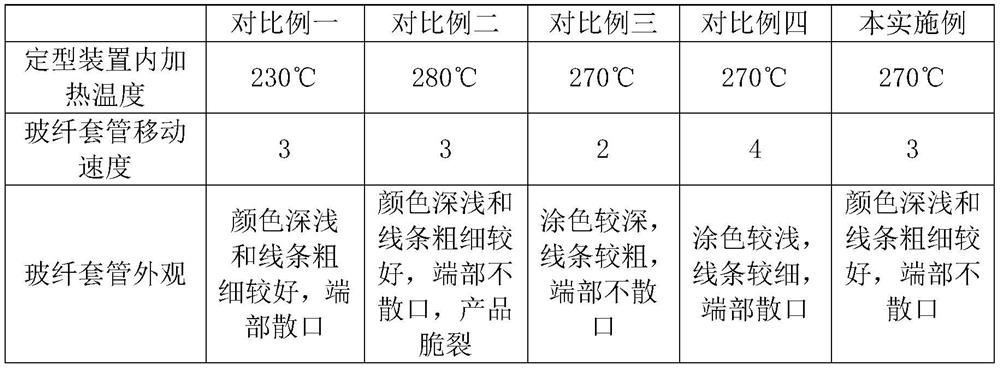

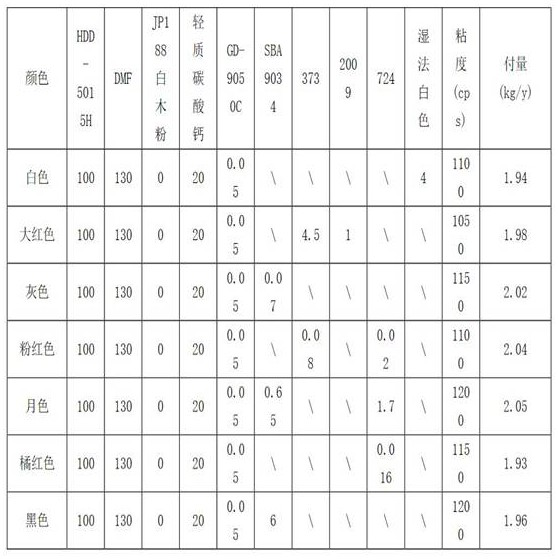

Glass fiber sleeve coloring process and equipment

ActiveCN112474223AGood shaping effectColor stableLiquid surface applicatorsCoatingsMaterials scienceGlass fiber

The invention discloses a glass fiber sleeve coloring process which comprises the following steps: heating and shaping: a glass fiber sleeve is conveyed into a shaping device to be heated and shaped,and the heating and shaping parameters are as follows: the heating temperature range is set to be 265 to 275 DEG C, and the moving speed range of the glass fiber sleeve is set to be 2.5 to 3.5 m / min;and coloring: the glass fiber sleeve heated and shaped in the step S1 is transferred to a coloring device, the coloring device comprises a coloring pipe with a coloring head, color paste is containedin the coloring pipe, and the lower end of the coloring head abuts against the glass fiber sleeve transferred to the position below the coloring head all the time, so that the outer surface of the glass fiber sleeve is coated with the color paste through the coloring head, the color paste is red color paste, blue color paste or yellow color paste. According to the glass fiber sleeve coloring process provided by the invention, the glass fiber sleeve prepared by adopting the process of firstly heating, shaping and then coloring is more stable in coloring and does not fall off, the coloring is more uniform and stable, the shaping effect is good, and an edge line body can be prevented from scattering.

Owner:瑞纳智绝缘材料(苏州)有限公司

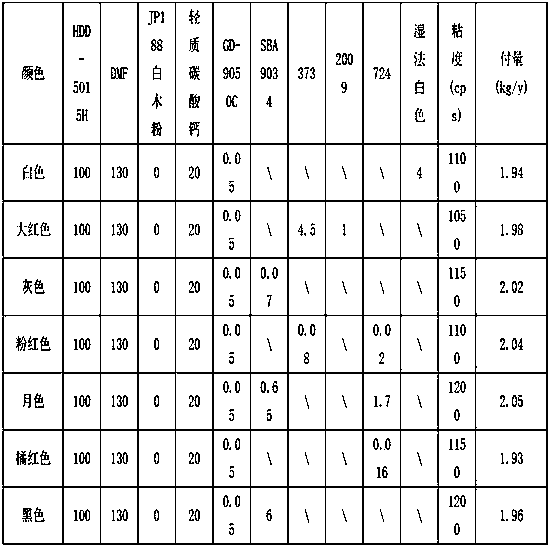

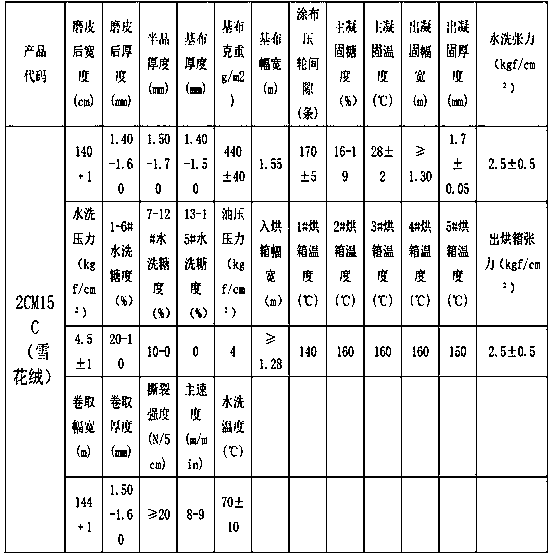

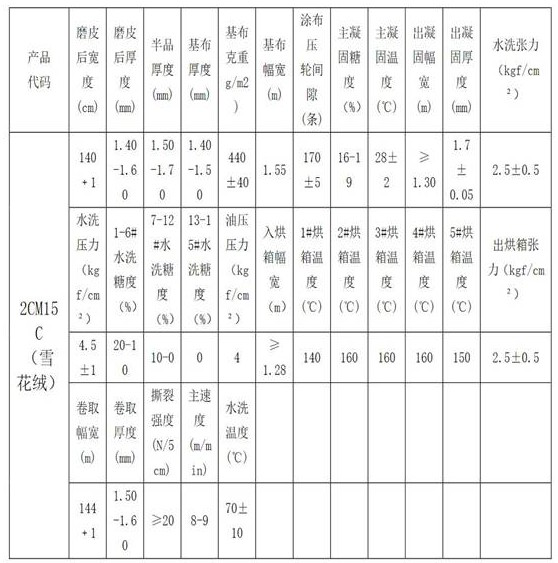

A kind of production method of snow velvet synthetic leather

ActiveCN110886095BAchieve consistencyNo abnormal phenomena such as dead wrinkles and small particlesTextile/flexible product manufactureTextiles and paperPolymer scienceEngineering

The invention discloses a method for producing snowflake synthetic leather. The method comprises the following steps: Step 1: base cloth selection and treatment, selection thickness: 1.40-1.50mm, gram weight 400-480g (weight per square meter), blasting: 15fkg / cm 2 Above, Warp tensile: 150N / 3cm above, Weft tensile: 500N / 3cm above, Warp elongation 30%-90%, Weft elongation 80%-150%, Warp tear strength 50N / 3cm above. The present invention selects the double-sided snowflake velvet as the base fabric. Since the base fabric will have uneven wool during the napping process, the snowflake velvet has high requirements for the base fabric, and deep processing needs to be carried out internally. Fine grinding treatment to ensure that there are no abnormal phenomena such as dead wrinkles and small particles on the surface of the finished product to achieve the consistency of cloth and wool. The wet method uses a large impregnation process to make the wet polyurethane resin evenly distributed and penetrated into the double-sided snowflake fleece. The polyurethane penetration is 1600g / m 2 left and right, so that the double-sided snow fleece has support and resilience, and the hand feels soft and comfortable and has breathability.

Owner:ANAN CHINA

A kind of PU laminated silicone rubber zipper film, coating process and application thereof

ActiveCN108582928BHas anti-agingHas weather resistanceSlide fastenersSynthetic resin layered productsHydrogenPolymer science

The invention discloses a PU applying silicone rubber zipper film, which comprises a processed PU film and a silicone rubber layer, the PU film is applied on the silicone rubber layer, the silicone rubber layer comprises the following raw materials in parts by mass: 100-120 parts of a vinylsilane rubber component A, 100-120 parts of a vinylsilane rubber component B, 10-30 parts of a color paste pigment, 3-10 parts of a silane coupling agent, 3-10 parts of low-viscosity hydroxyl silicone oil, and 1-3 parts of polyether modified hydrogen silicone oil. The invention also discloses a coating technology of the PU applying silicone rubber zipper film and an application thereof. The coating technology has the advantages that the process is simple, cost is low, the production efficiency is high, the zipper film is easily processed, post-forming is realized, weatherability is good, hydrolysis resistance and high / low temperature resistance are good, color fastness is good, and cleaning is easy,and the PU applying silicone rubber waterproof zipper film has the advantages that the waterproof performance is good, the cost is low, and the usage life is long.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

A kind of environment-friendly textile printing and dyeing solution

InactiveCN104195852BImprove coloring abilityStable storageDyeing processTextile printerPolyethylene glycol

The invention relates to an environment-friendly textile printing and dyeing solution, which is composed of the following components by mass: 15-35 parts of sodium dodecyl diphenyl ether disulfonate, 10-25 parts of water-based polyurethane, 5-10 parts of alkyl glycoside, 3-15 parts of benzothiazole sulfonic acid, 10-50 parts of isomeric alcohol polyoxyethylene ether, 5-20 parts of sorbitan fatty acid ester, 5-10 parts of polyethylene glycol, 2-10 parts of sodium chlorate , 100-200 parts of deionized water. The beneficial effects of the present invention are: (1) The dye liquor of the present invention has strong coloring ability, and the colored fabric has good color fastness. (2) The dye solution of the present invention can be stored stably for one month without precipitation. (3) The dye solution of the present invention does not contain heavy metals, and is environmentally safe. (4) The product is environmentally friendly and easy to use.

Owner:艾金富

Dye solution for textile printing and dyeing

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com