A fully-automatic cloth printing machine

A printing machine, fully automatic technology, applied in printing, typewriters, printing devices, etc., can solve the problems of not attracting customers, single color, late start, etc., and achieve the effect of improving inkjet printing efficiency, beautiful patterns, and solid colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

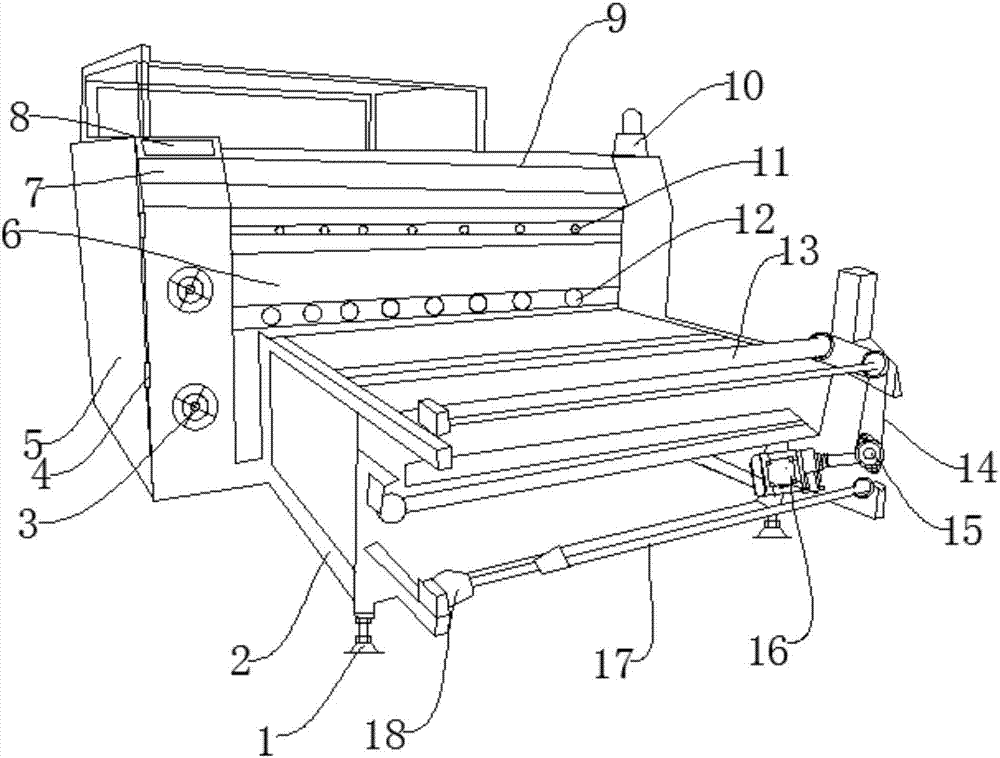

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, a fully automatic cloth printing machine includes a bottom fixed suction cup 1, a frame 2, an exhaust fan 3, an intelligent controller 8, and a drag motor 16. A frame 2 is arranged above the bottom fixed suction cup 1, and the frame 2 acts as For the purpose of stabilizing the fuselage, a bearing 18 is arranged on the top of the frame 2, and the bearing 18 plays a role of rotation, and a cloth roll shaft 17 is arranged beside the bearing 18, and the cloth roll shaft 17 is used for conveying the cloth, and the cloth roll shaft 17 is set beside the There is a drag motor 16, the side of the drag motor 16 is provided with a pulley 15, the top of the pulley 15 is provided with a belt 14, the belt 14 is used to pull the pulley 15, the top of the belt 14 is provided with a rolling shaft 13, and the rolling shaft 13 is used to prevent For the wrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com