Patents

Literature

88results about How to "Improve reflow effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

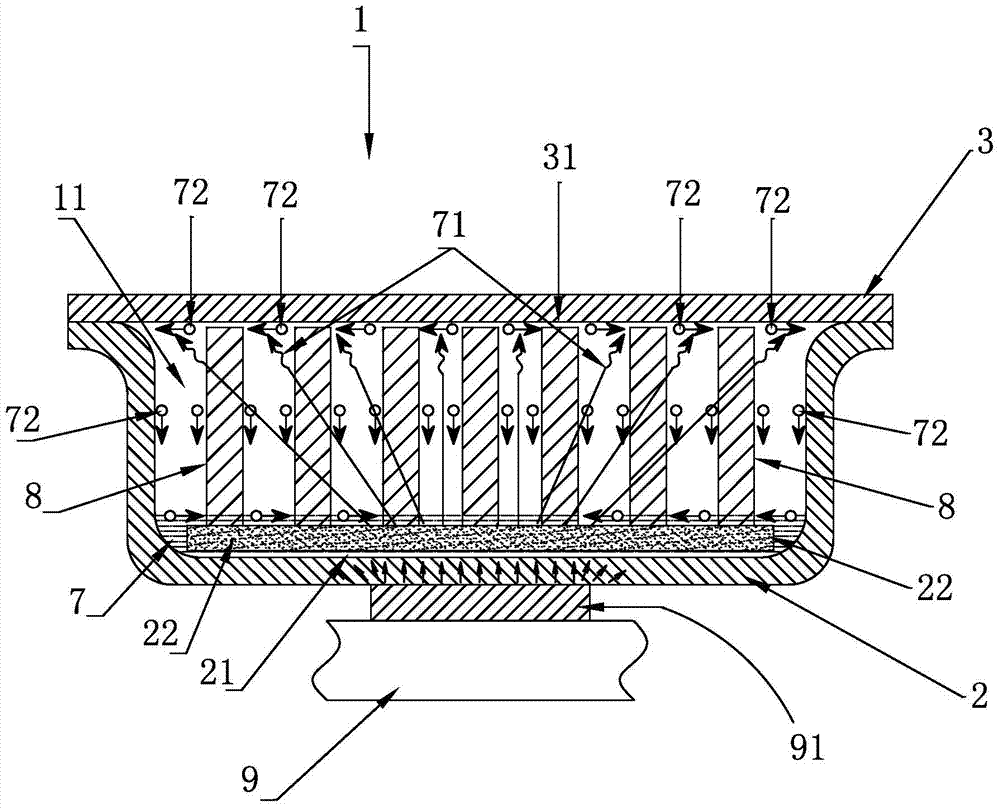

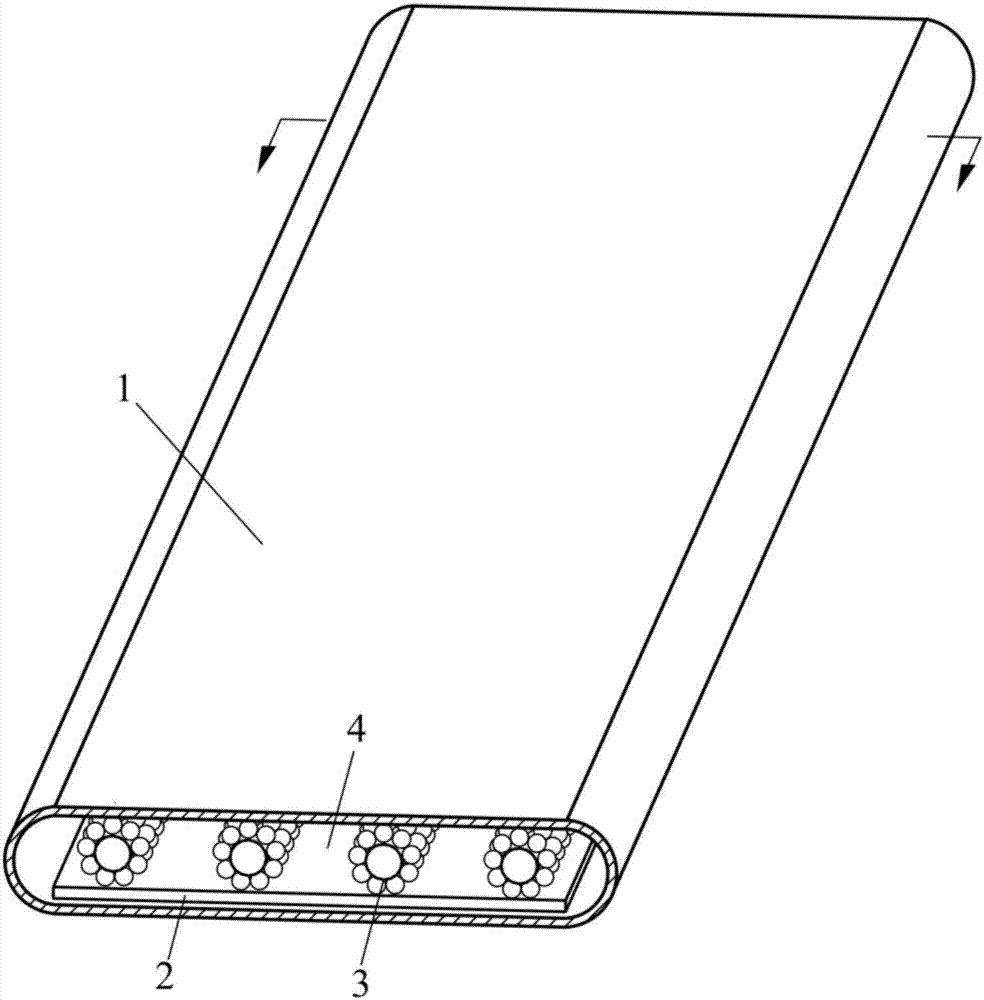

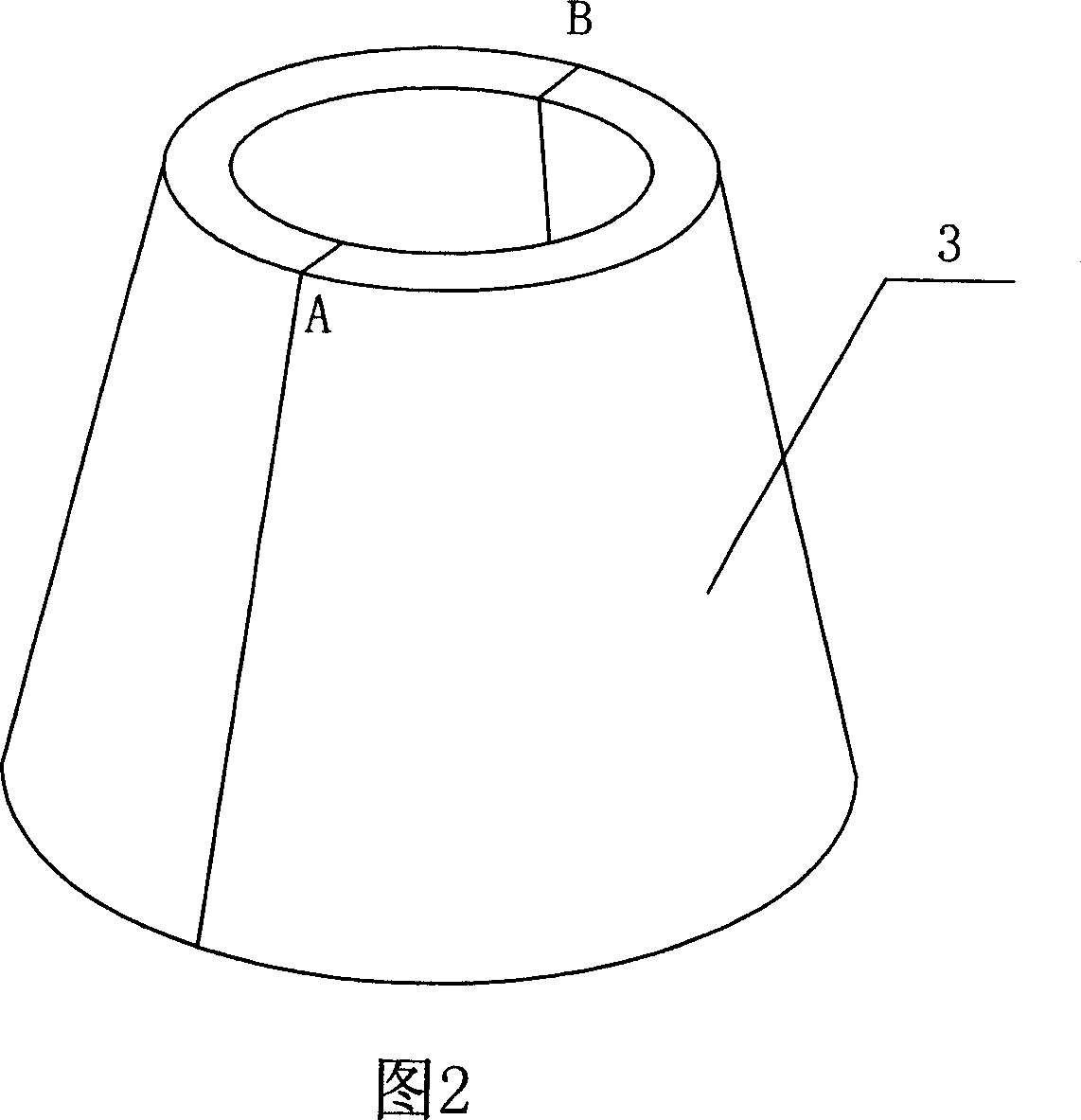

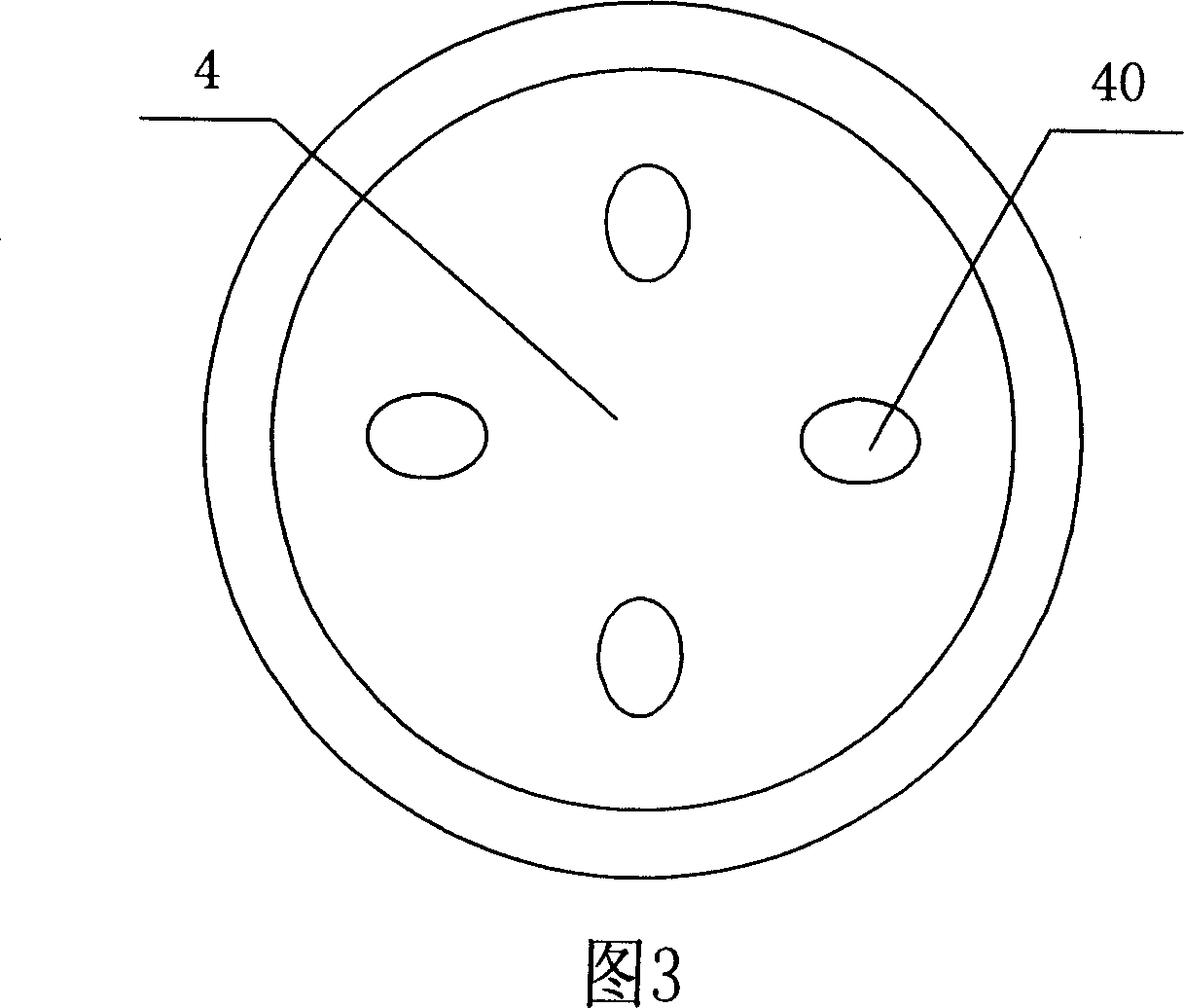

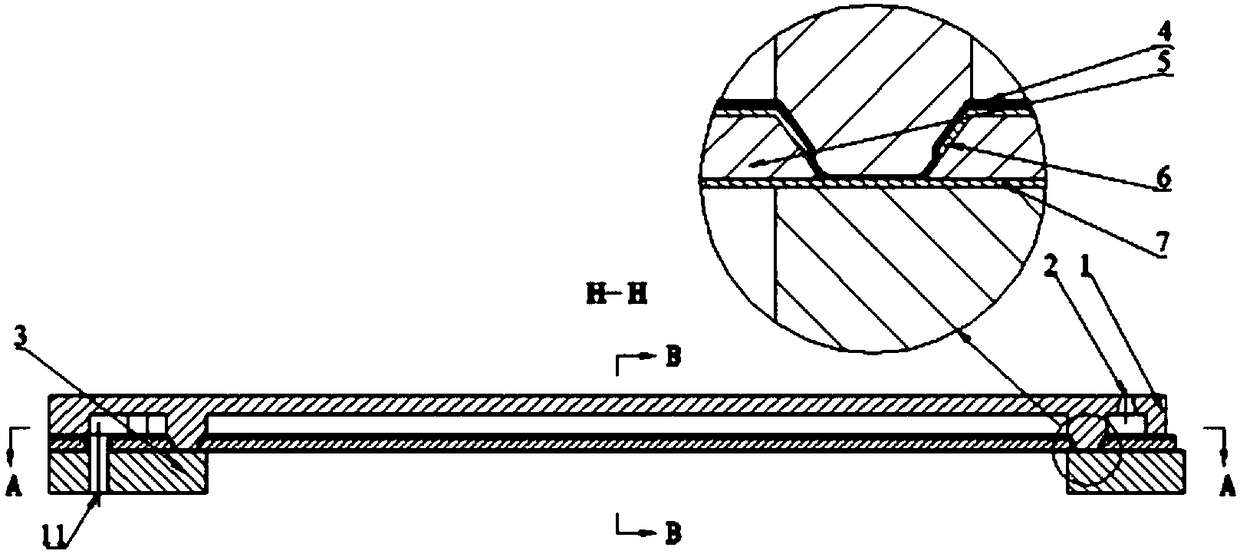

Vapor chamber and method for manufacturing same

ActiveCN103398613AEasy to makeEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceEvaporation

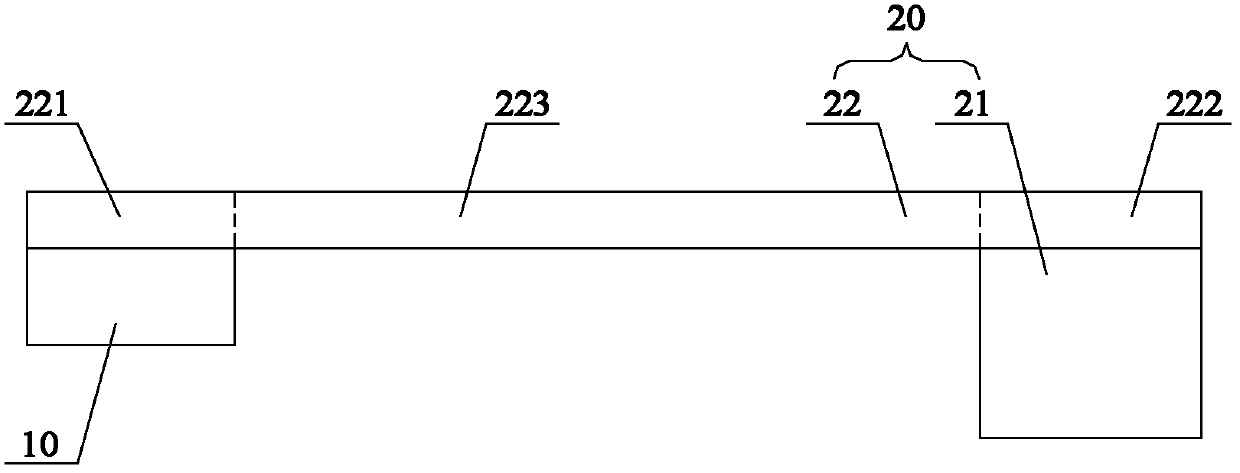

The invention discloses a vapor chamber and a method for manufacturing the same. The vapor chamber is simple in structure, low in cost and good in heat conduction effect and can be manufactured easily and conveniently. The vapor chamber comprises a heated plate and a flat heat dissipation plate. A groove is formed in the inner surface of the heated plate, the flat heat dissipation plate is welded with the heated plate, a vacuum inner cavity is formed between the heat dissipation plate and the groove, working media are filled in the vacuum inner cavity, a part, which is positioned in the vacuum inner cavity, of the heated plate is provided with capillary structure layers, and elemental metal powder is sintered to form each capillary structure layer. The vapor chamber and the method have the advantages that the vapor chamber is simple in manufacture, and the working media on evaporation and condensation zones can be quickly adsorbed by the capillary structure layers, so that high-speed circulation and fast heat conduction effects can be realized; support columns with capillary structures are further arranged in the vacuum inner cavity, accordingly, a condensed vapor backflow effect is obvious, and a sinking or cracking deformation phenomenon of the vapor chamber due to excessively high temperature or external pressure is further prevented; heat can be dissipated evenly by the aid of the vapor chamber, heat resistance of the vapor chamber is reduced, the method for manufacturing the vapor chamber is simple, processes are few, operation is easy, the cost is low, and the vapor chamber and the method are suitable for automatic, intensive and large-scale production.

Owner:东莞维玺温控技术有限公司

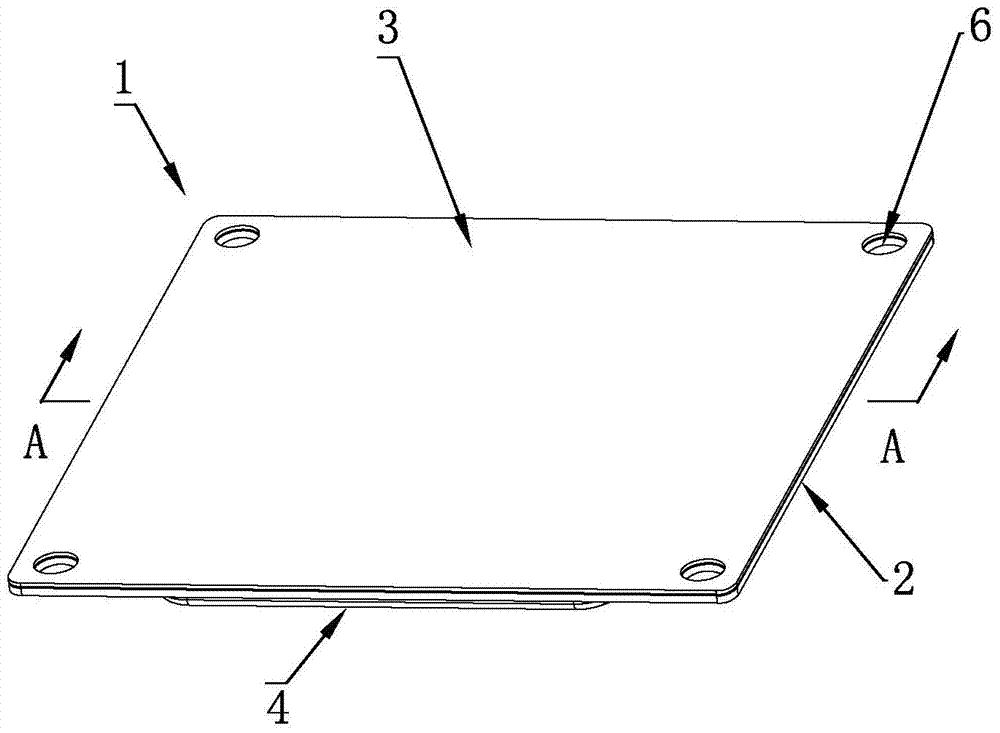

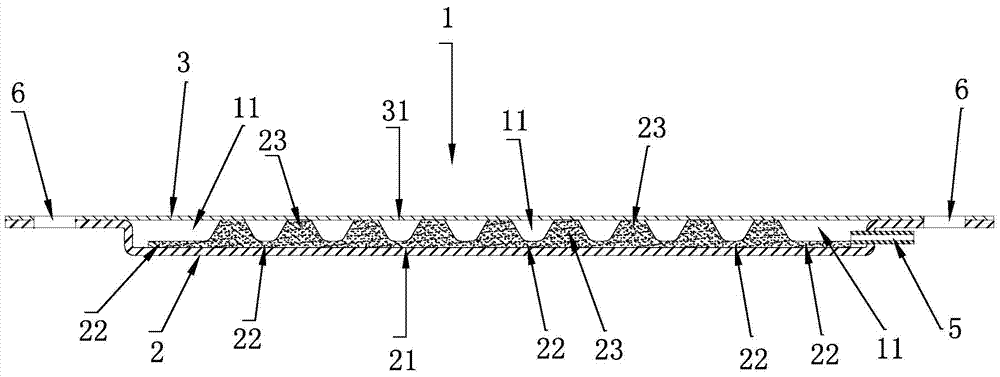

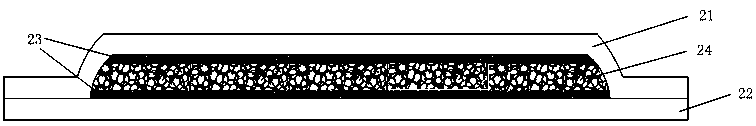

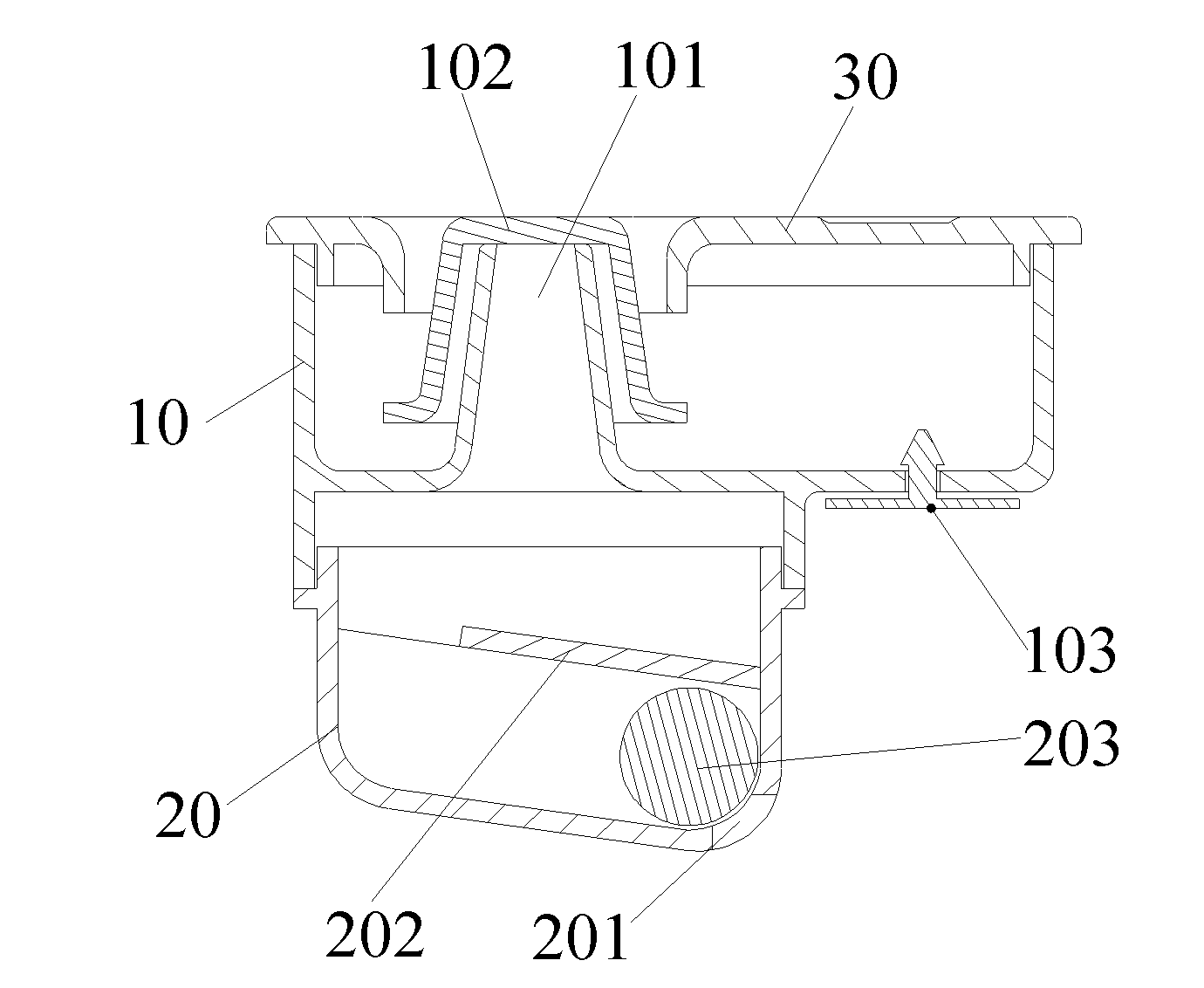

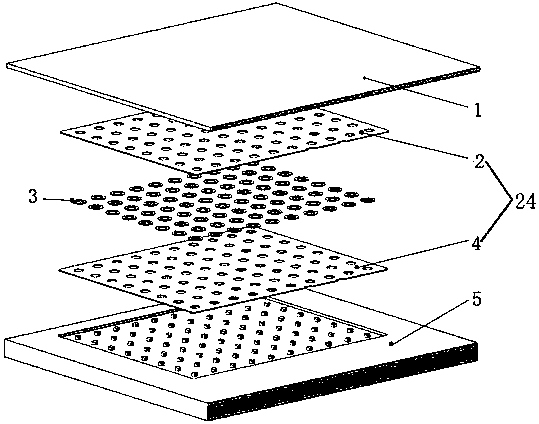

Ultrathin vapor chamber and manufacturing method thereof

PendingCN111465293AImprove structural strengthIncrease productivityCooling/ventilation/heating modificationsHeat flowPorous medium

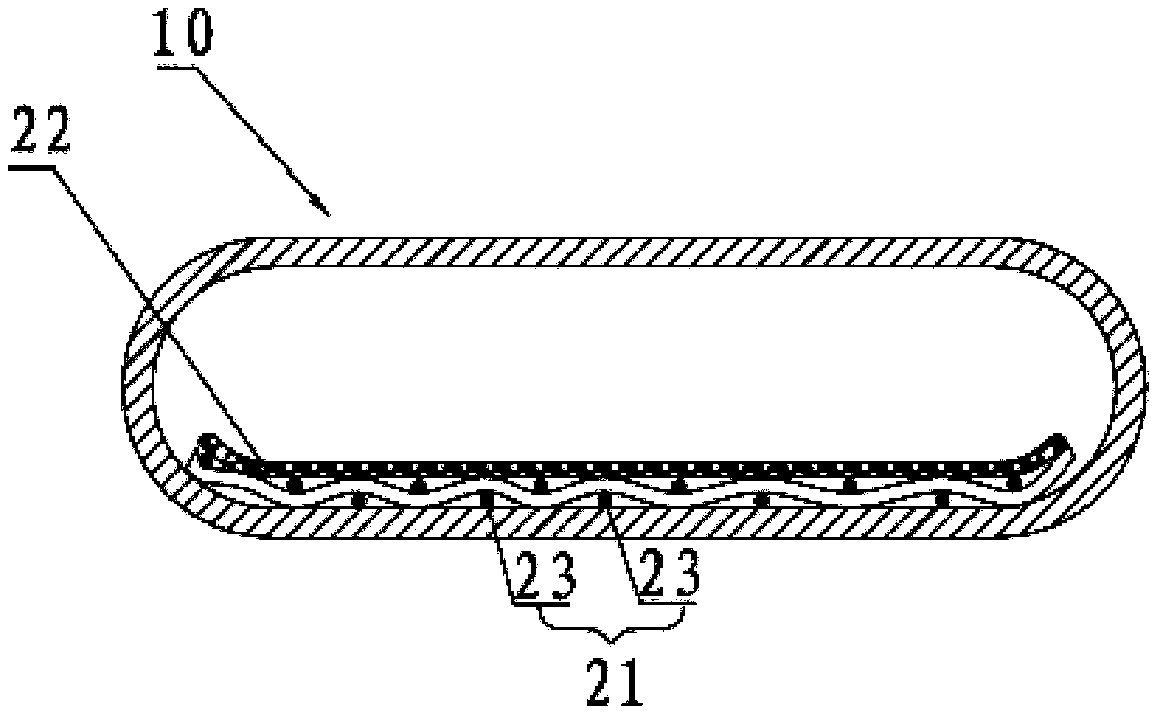

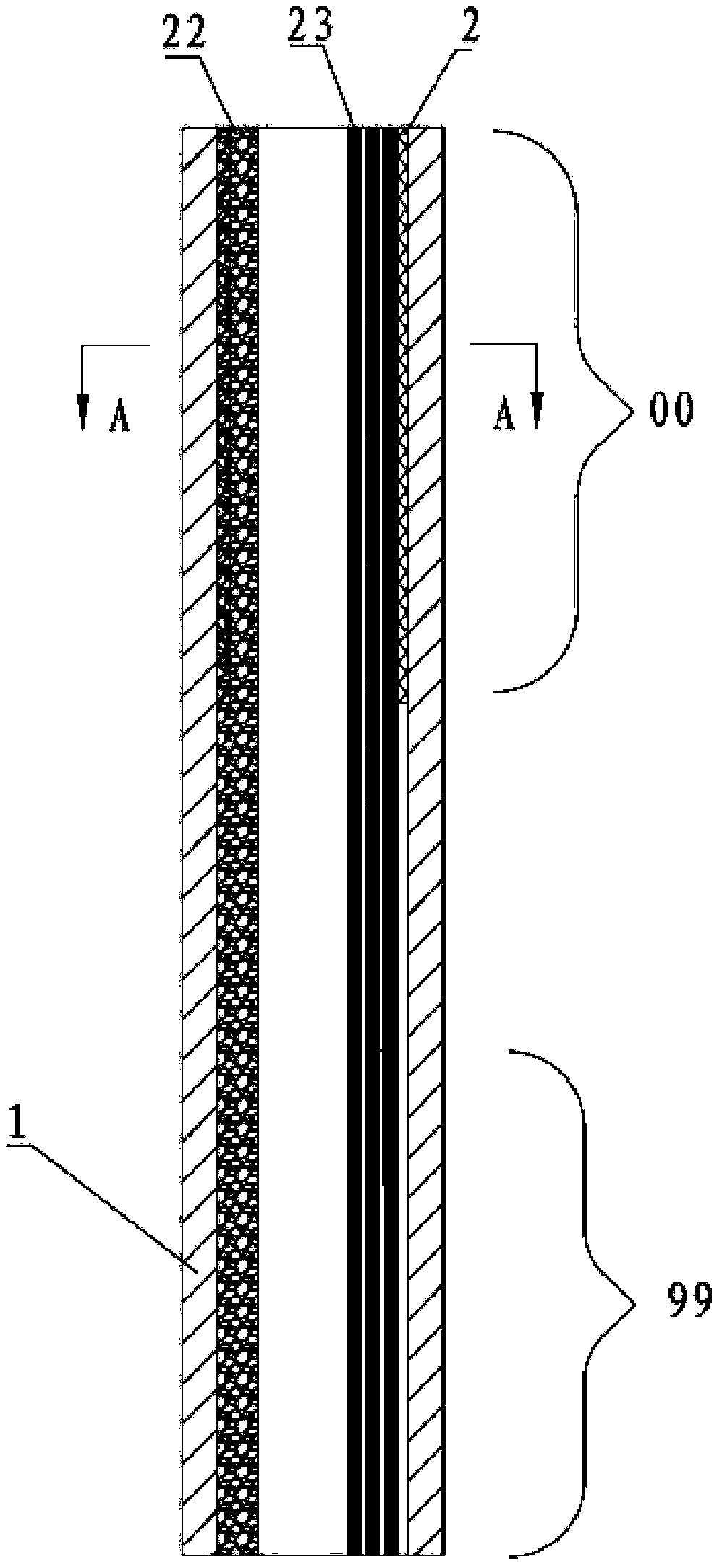

The invention discloses an ultrathin vapor chamber and a manufacturing method thereof. According to the method, porous mediums with different structures, thicknesses and pores are adopted as liquid absorption cores to be connected to the inner surfaces of an upper shell plate and a lower shell plate with different thicknesses, and processes of welding, vacuumizing, liquid injection, packaging andthe like are performed to prepare the ultrathin vapor chamber; and the middle steam cavity of the vapor chamber adopts a porous metal of a single structure or a patterned structure as a supporting layer, so that it is guaranteed that a working medium rapidly flows after being gasified, rapid reflux after gas-to-liquid phase change is promoted, and working medium phase change circulation is accelerated. According to the invention, the structures and the internal gaps of the liquid absorption cores and the porous metal supporting layer are regulated and controlled, so that with a member with good capillary suction and permeability and high thermal conductivity can be prepared, and the vapor chamber manufactured from the member has the advantages of being high in heat dissipation efficiency,light in weight, good in reliability, suitable for manufacturing an ultra-thin structure, capable of meeting the requirements for high heat conduction efficiency and ultra-thinness required by electronic equipment with high heat flux, capable of being manufactured through a reel-to-reel continuous production process, extremely high in production efficiency and quite suitable for large-scale industrial production.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

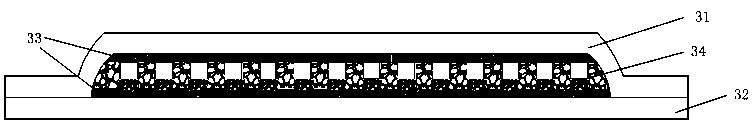

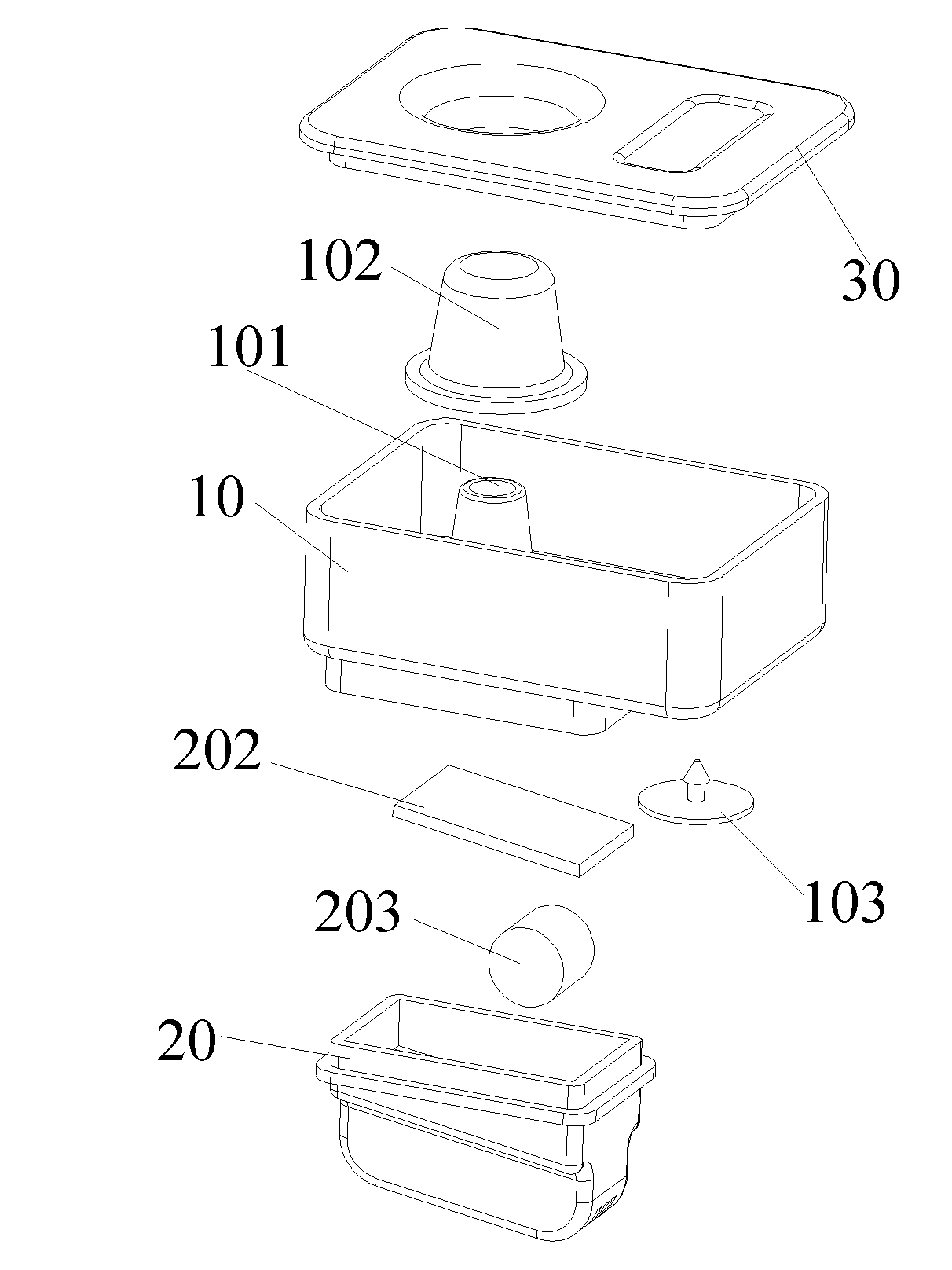

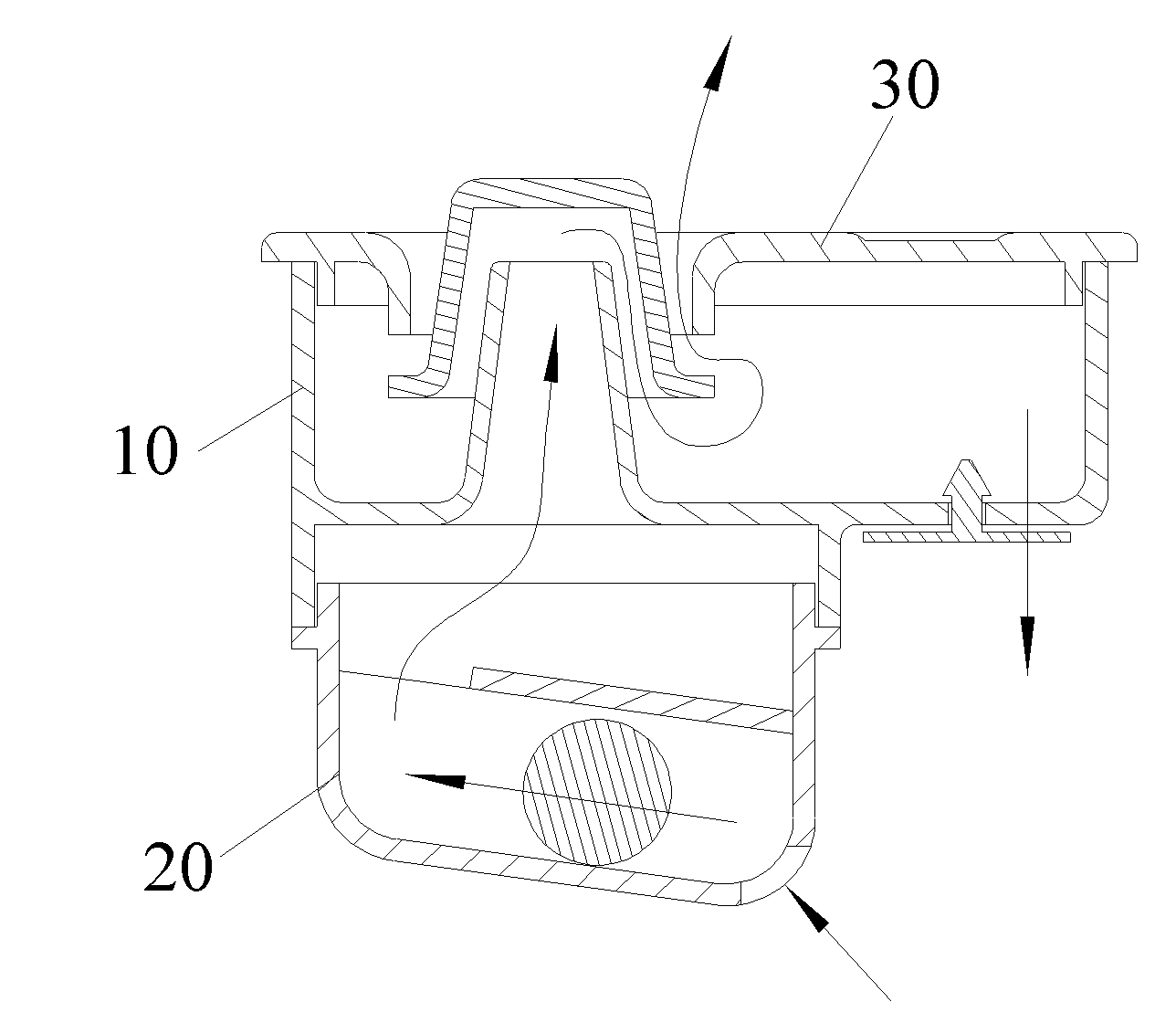

Steam valve and electric cooker comprising the steam valve

ActiveCN102599823AIncrease cooking tasteGuaranteed reflow effectCooking vesselsMultiple way valvesCookerEngineering

The invention provides a steam valve and an electric cooker comprising the steam valve. According to the invention, the steam valve comprises a valve body (10), a valve cap (30) and a valve seat (20), wherein the valve body (10) is provided with an air outlet (101) opening upwards; the valve cap (30) is arranged at the upper end of the valve body (10) and provided with an opening corresponding to the air outlet (101); the valve seat (20) is arranged at the lower end of the valve body (10); the bottom of the valve seat (20) is provided with an air inlet (201); and the air inlet (201) is provided with a returnable air retainer. According to the invention, the steam valve can effectively break foams, has good anti-spilling effect and can allow pressure difference to be generated inside the electric cooker so as to increase the cooking mouthfeel of rice. According to the invention, the electric cooker comprises the steam valve.

Owner:GREE ELECTRIC APPLIANCES INC

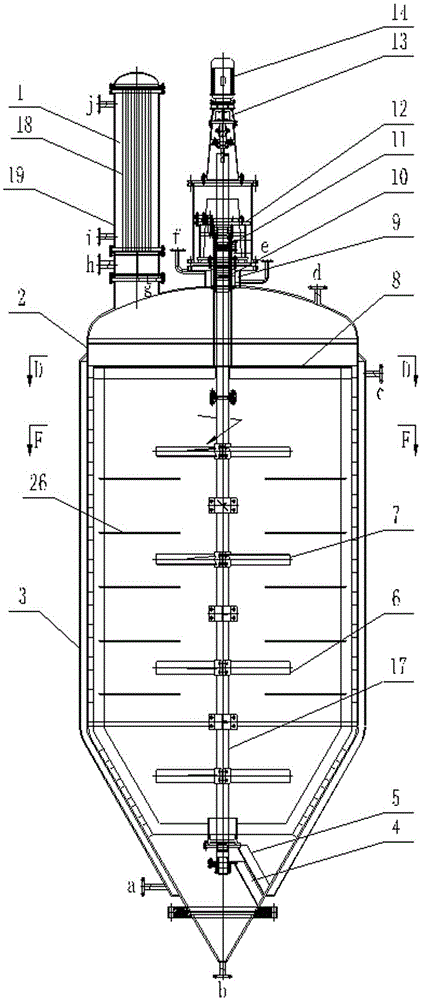

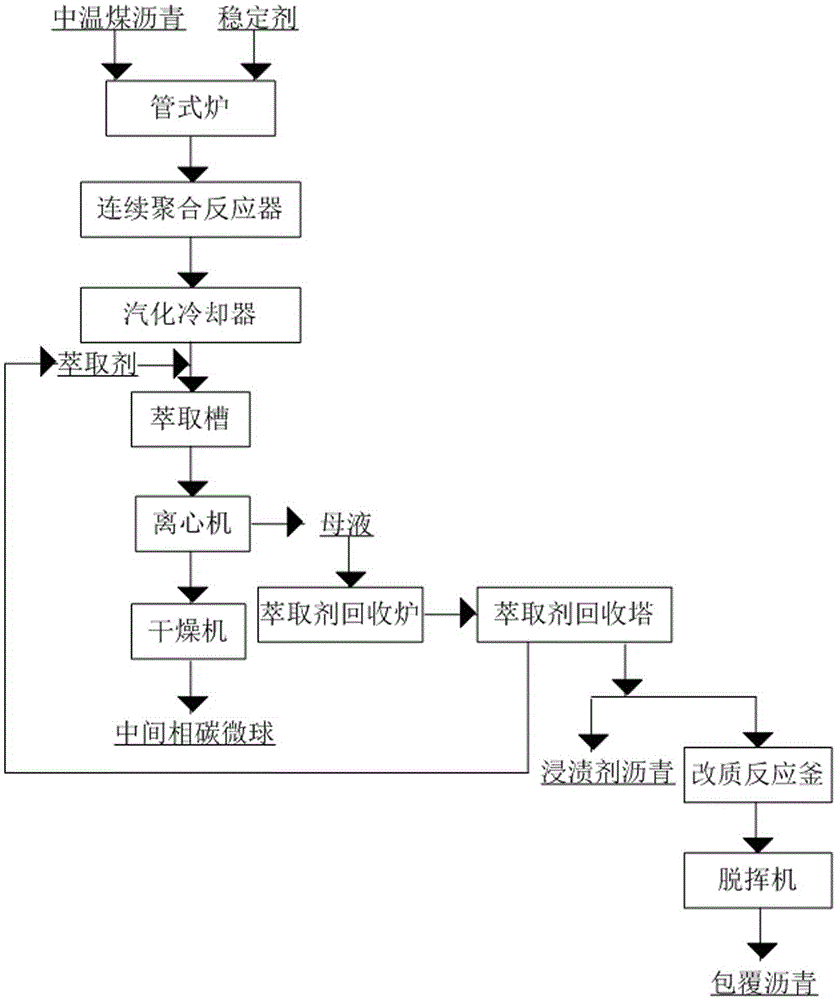

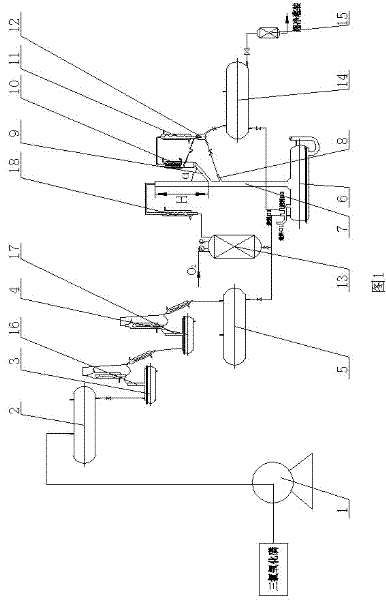

Method for continuously preparing mesocarbon microbeads with co-production of impregnant pitch and coating pitch

ActiveCN105271168AAvoid cokingAvoid hanging on the wallWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereHigh energy

A method for continuously preparing mesocarbon microbeads with co-production of impregnant pitch and coating pitch comprises steps as follows: (1), medium-temperature coal-tar pitch and a stabilizing agent are mixed under the nitrogen atmosphere; (2), a product of the step (1) is heated to 350-380 DEG C, then is sent to a fast heater and is heated to 410-450 DEG C in 1-5 s for a polymerization reaction; (3), a product of the step (2) is cooled to the temperature of 290-340 DEG C and is subjected to mixing extraction with an extracting agent; (4), a mesocarbon microbead product is obtained through centrifugal separation and solid-phase drying; (5), a mother solution is evaporated by a distillation column, the extracting agent is recycled, and the rest of materials at the column bottom is taken as the impregnant pitch or has a modification reaction through a modification reaction kettle. According to the method, the problems of high energy consumption, severe environmental pollution, low product yield, high cost, unstable quality, single variety and the like of a traditional production technology are solved fundamentally.

Owner:ANSHAN XINGDE MATERIAL SCI & TECH

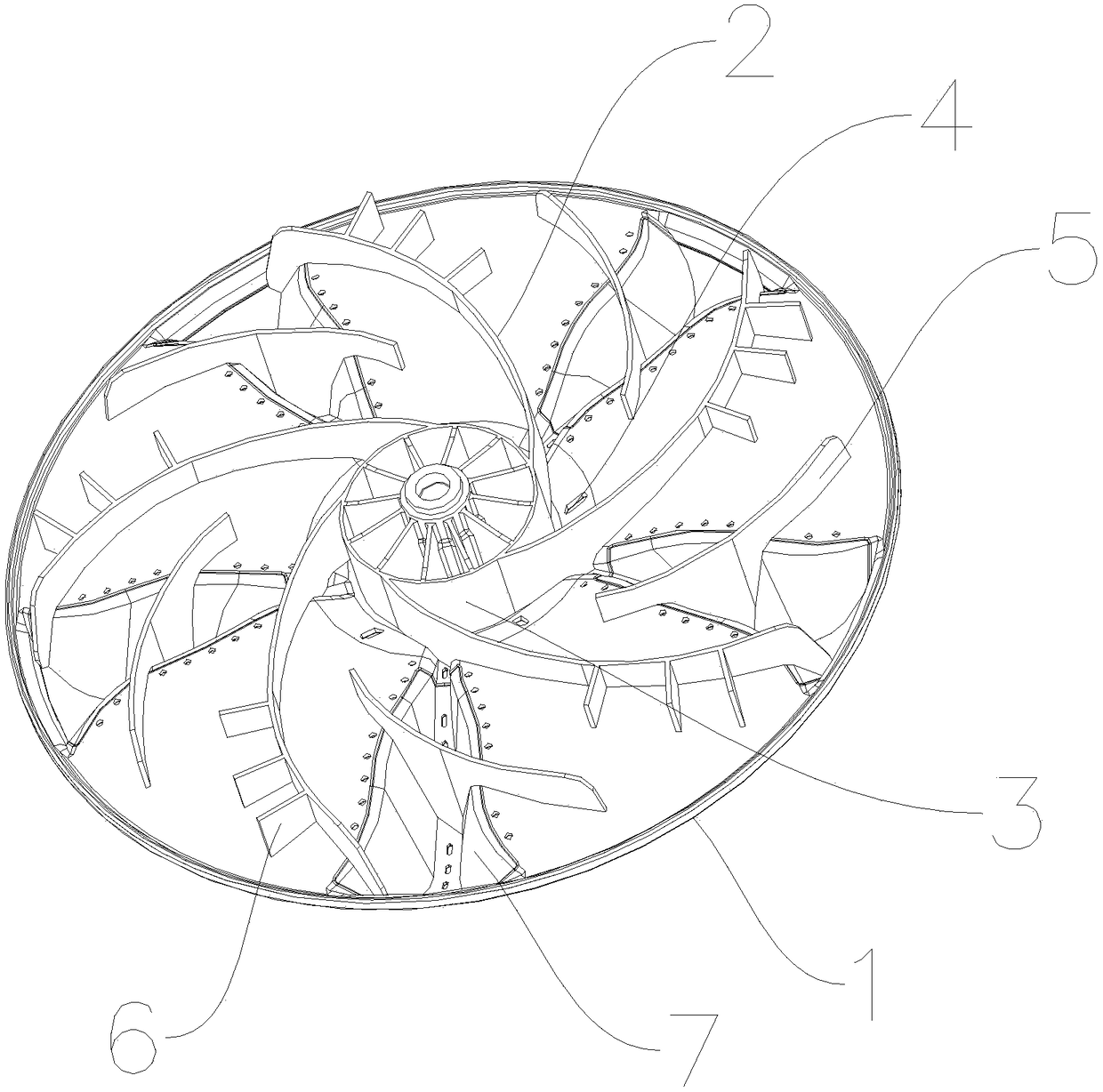

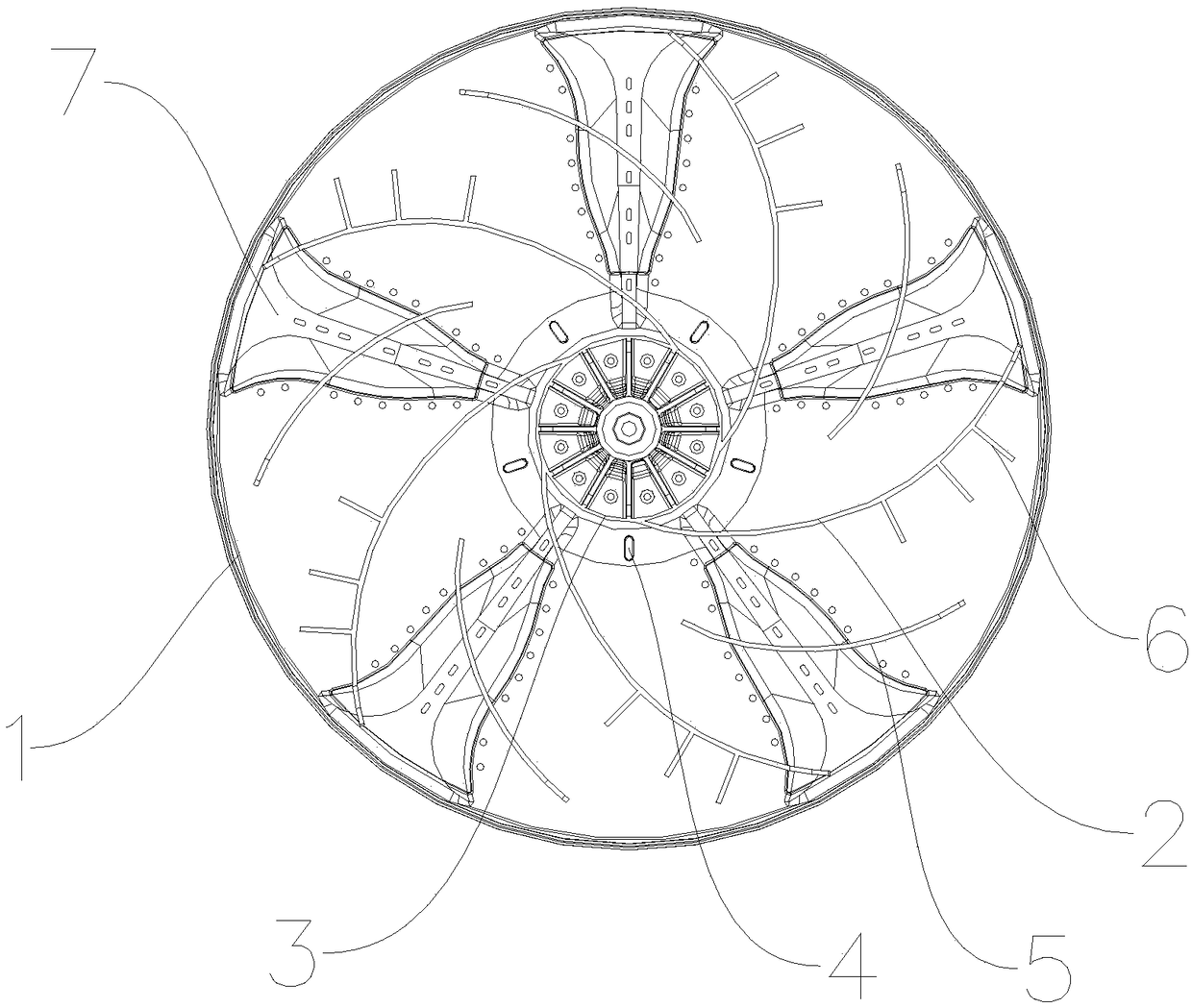

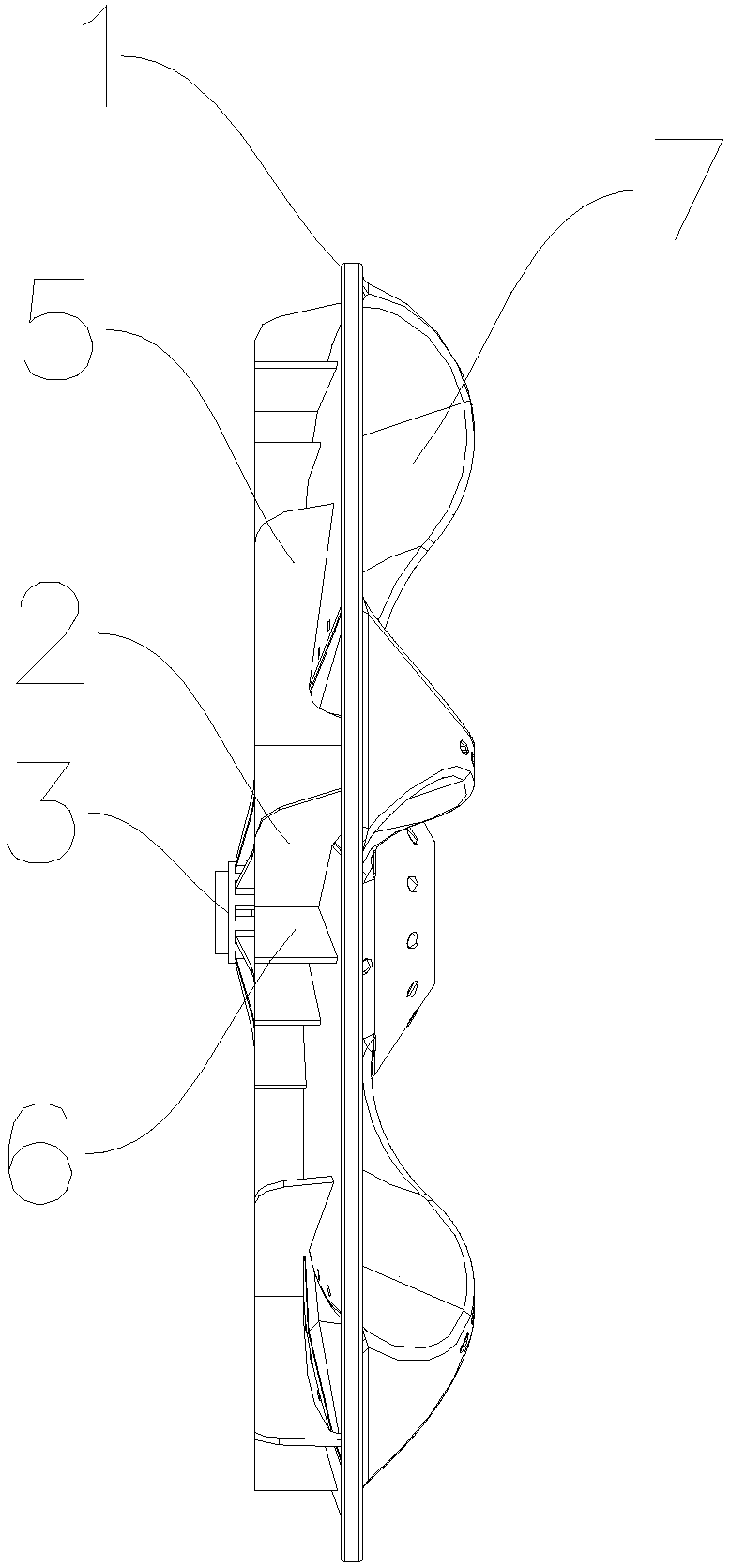

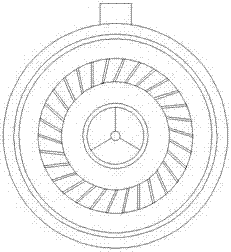

Pulsator mechanism for washing machine and washing machine

ActiveCN108221262AImprove washing effectMeet washing requirementsWashing machine with receptaclesTextiles and paperLaundry washing machineWater flow

The invention belongs to the technical field of washing machines and aims at solving the problem that a pulsator of an existing pulsator washing machine is simple in structure, and accordingly the effect of washing garments is limited. In order to solve the problem, a pulsator mechanism for a washing machine and the washing machine are provided. The washing machine comprises an inner drum, the pulsator mechanism comprises a pulsator at the bottom of the inner drum, one or more spray holes in the pulsator and a water retaining assembly at the bottom of the pulsator, and the water retaining assembly can make water form backflow and spray the water into the inner drum through the spray holes in the pulsator rotation process. Through the water retaining assembly at the bottom of the pulsator,the water can form backflow and is sprayed into the inner drum through the spray holes, the sprayed water flow can generate vertical application force on the garments in the inner drum, then the garments are continuously turned over, under the situation with cooperation of horizontal rotation of the pulsator, the effect of washing the garments can be improved, the washing requirement of a user ismet, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

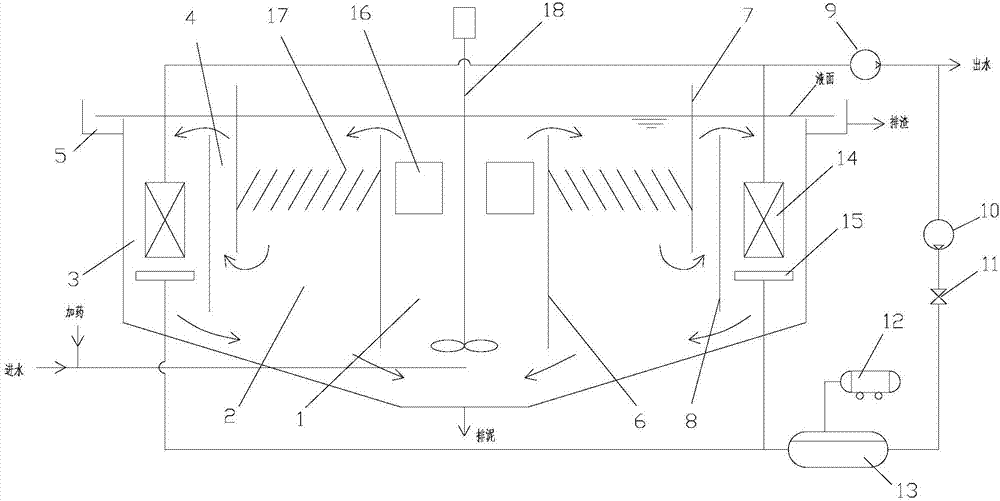

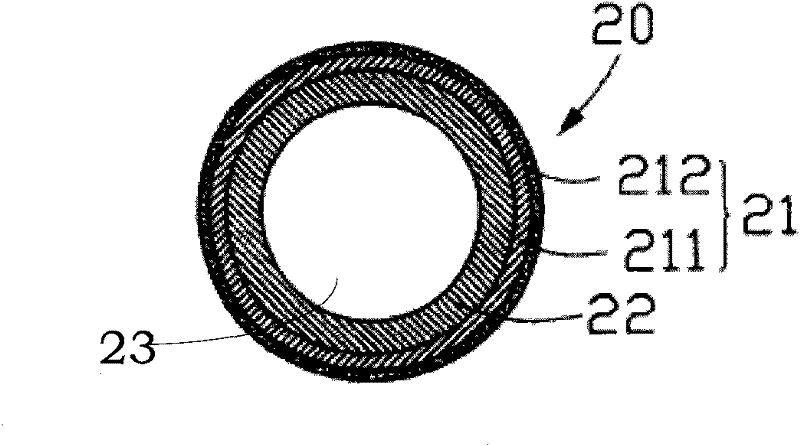

Cylinder type integrated sewage treatment device

InactiveCN107459213AImprove reflow effectAvoid depositionTreatment using aerobic processesSpecific water treatment objectivesOil and greaseSludge

The invention relates to a cylinder type integrated sewage treatment device which comprises a reaction tank, a filtering membrane set, a suction pump, a plurality of bubble releasers, an air dissolving system and a stirrer, wherein the reaction tank has a cylinder structure; the reaction tank is divided into a mixing area, a settling area, a flow guiding area and a filtering reaction area from center to periphery in turn; a stirring blade is arranged in the mixing area; the stirring blade is used for floating the sludge flowing back from the bottom of the settling area and the filtering reaction area; the micro-flocculated grains, which are newly generated in the manner of mixing the colloid, oil, suspended solids and coagulant in sewage, can be quickly adsorbed to the suspending sludge and then enter into the settling area for settling; the sewage treatment device has an excellent sludge refluxing effect and low energy consumption of water flow; the bubble releasers are distributed at the bottom of the filtering reaction area; the filtering membrane set is distributed in the filtering reaction area; the suction pump is connected with a water draining end of the filtering membrane set through a pipeline and is used for pumping the treated water; and the discharged water is high in quality and the effect is excellent.

Owner:湖南美奕机电科技有限公司

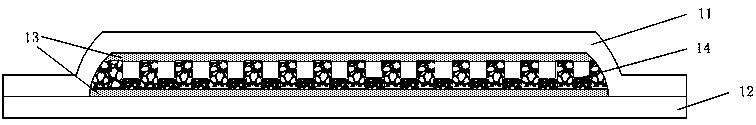

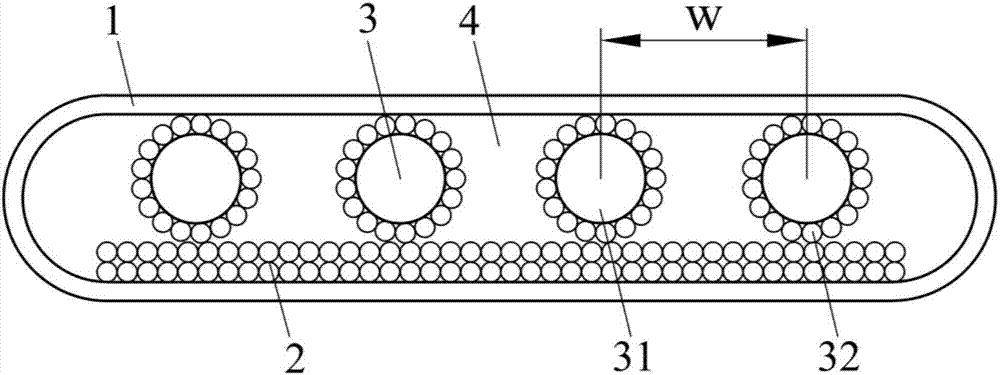

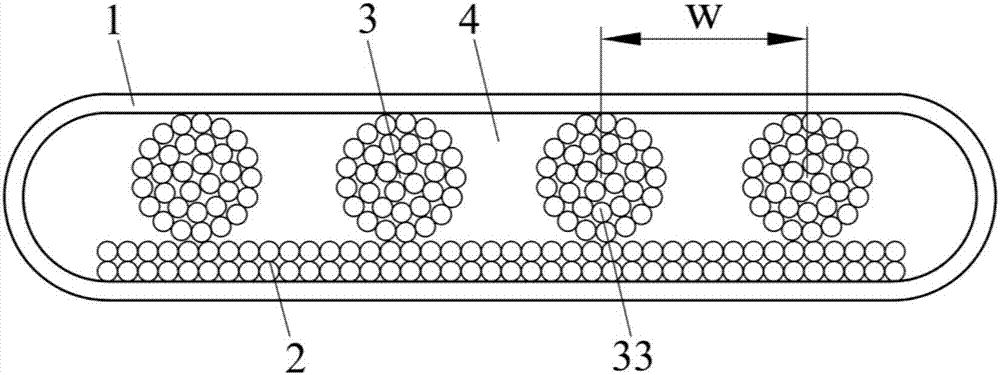

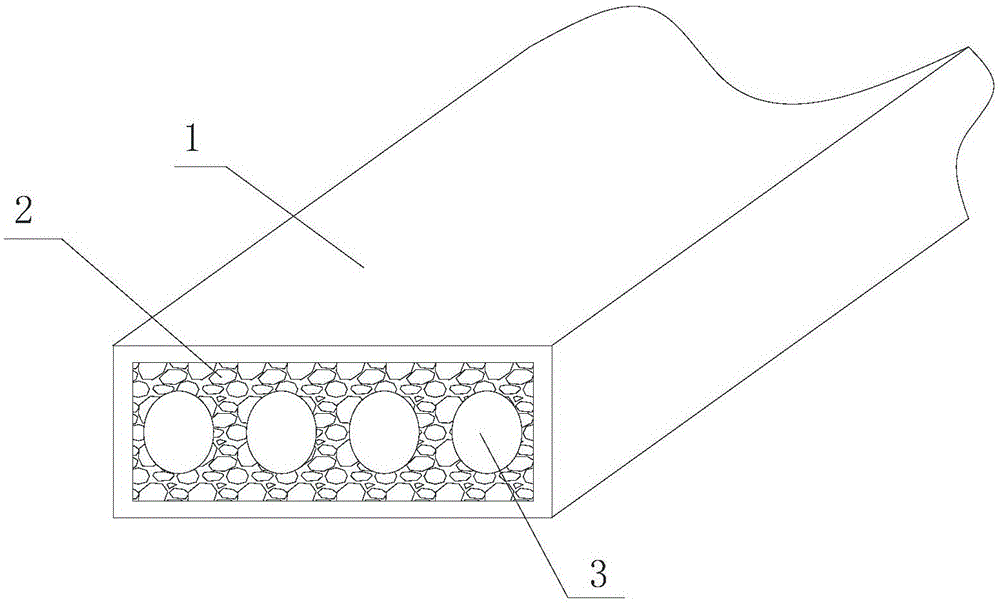

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

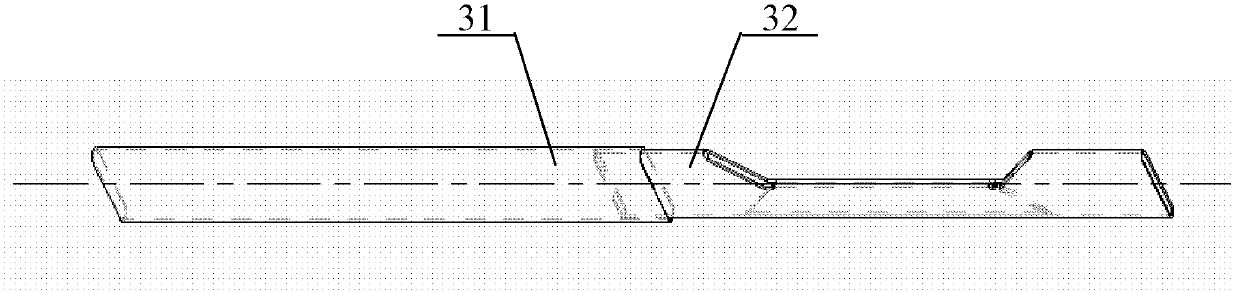

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

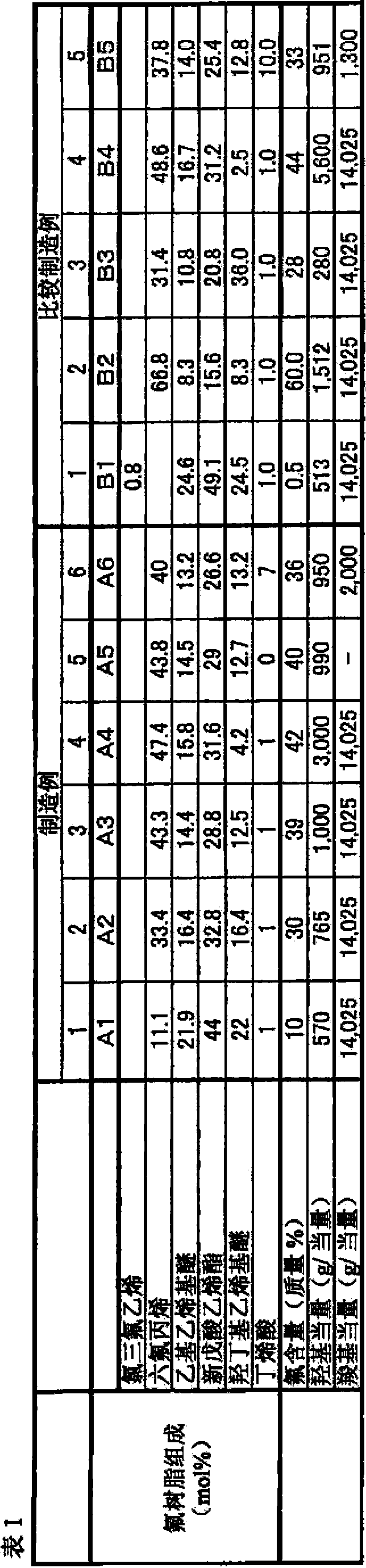

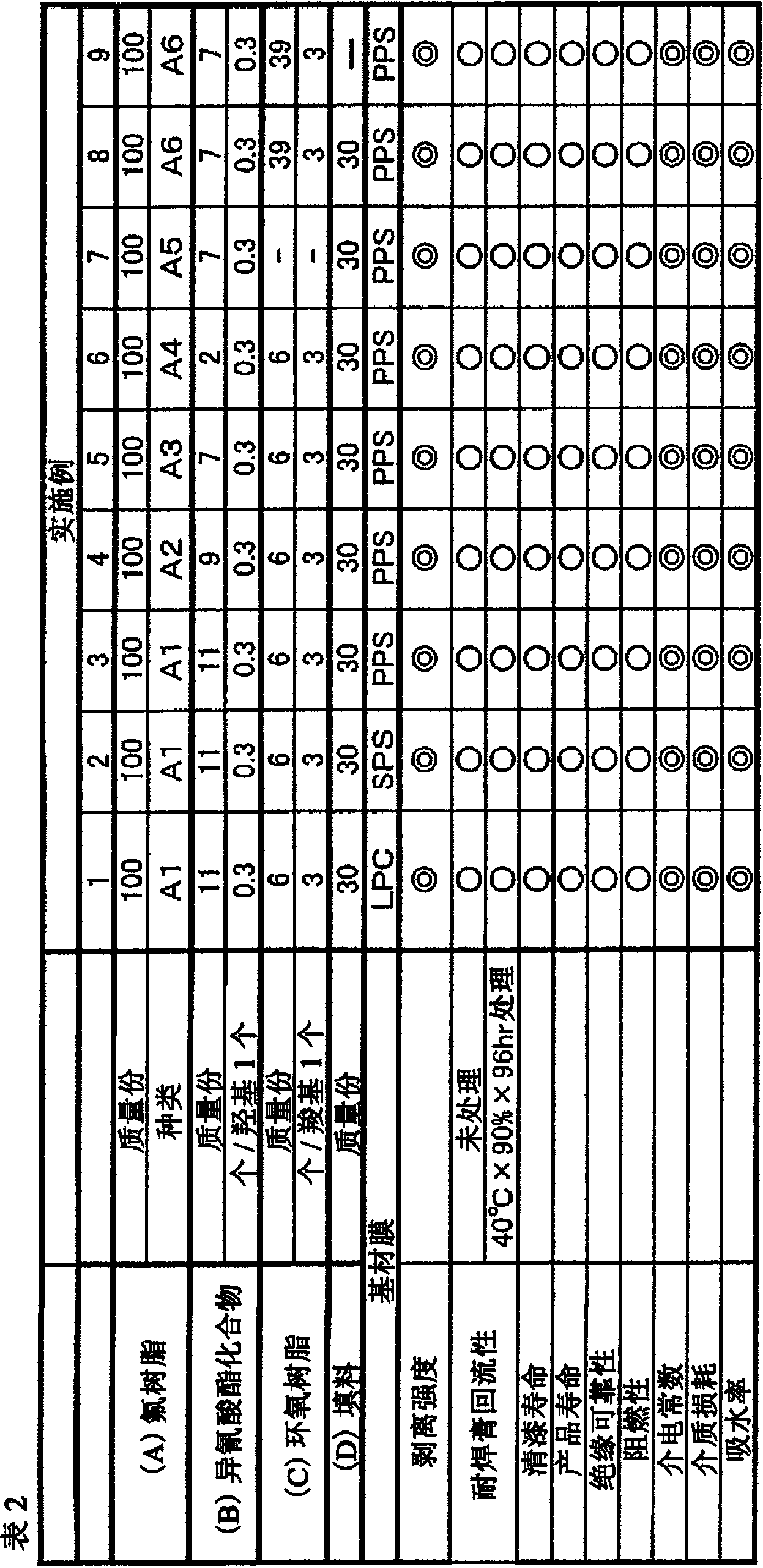

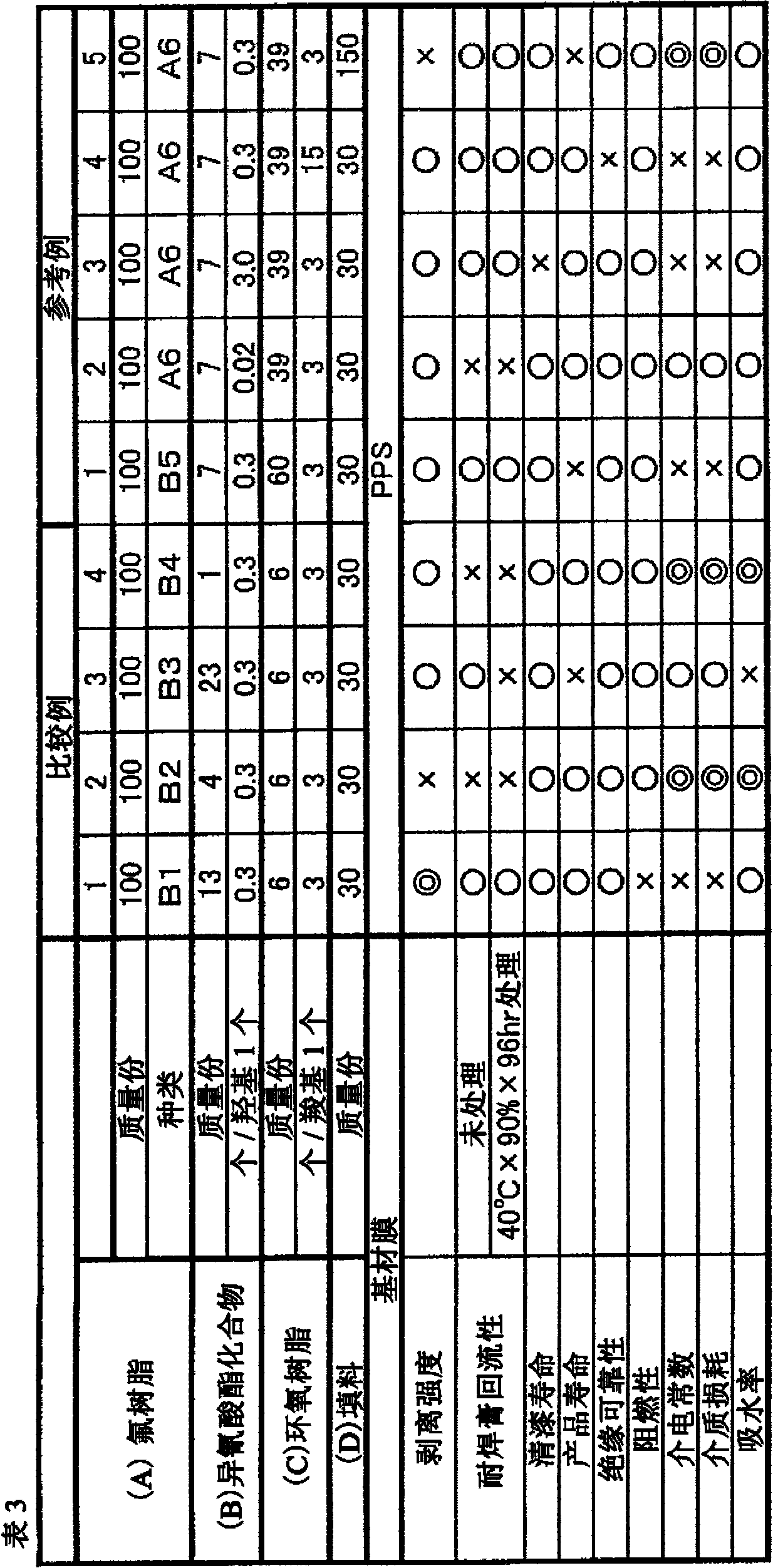

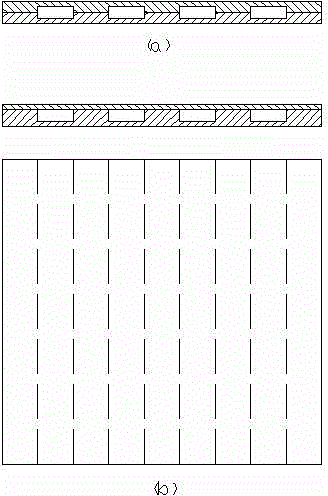

Resin composition, covering film, laminate, resin coated copper foil and binding sheet

ActiveCN103450827AImprove adhesionImprove reflow effectNon-macromolecular adhesive additivesPrinted circuit detailsPolymer scienceCopper foil

The present invention provides a resin composition, a covering film, a laminate, a resin coated copper foil and a binding sheet. Furthermore the invention aims to provide the resin composition for a flexible printed circuit board, which has the advantages of high adhesiveness, high solder reflow resistance and excellent electric characteristic on condition that a substrate film with low dielectric properties is used. The resin composition for the flexible printed circuit board of the invention comprises a fluororesin and an isocyanate compound, and is characterized in that: the fluororesin has a content of 1 to 50% by mass, and a hydroxyl equivalent of 300 to 5500 g / equivalent.

Owner:ARISAWA MFG CO LTD

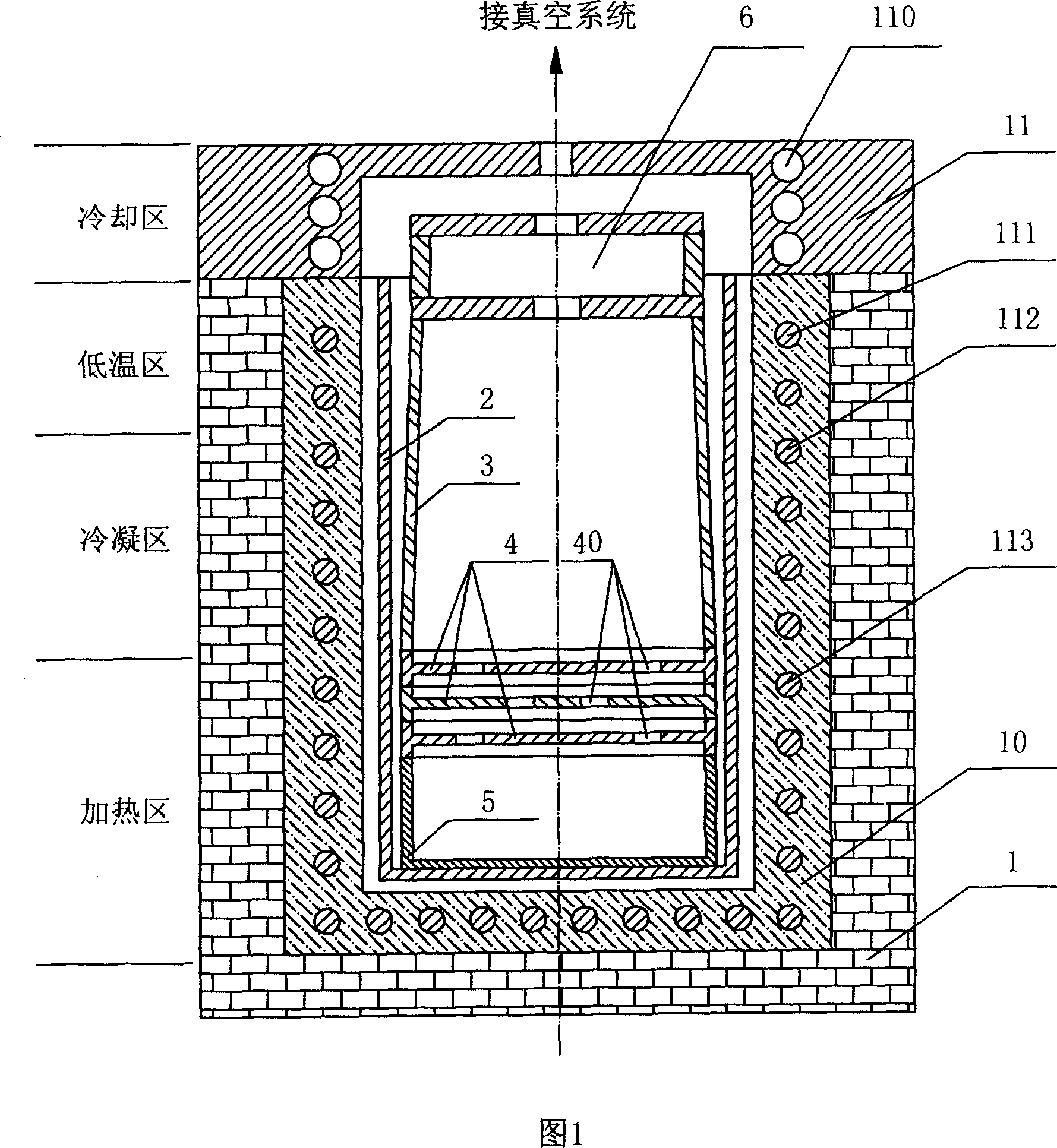

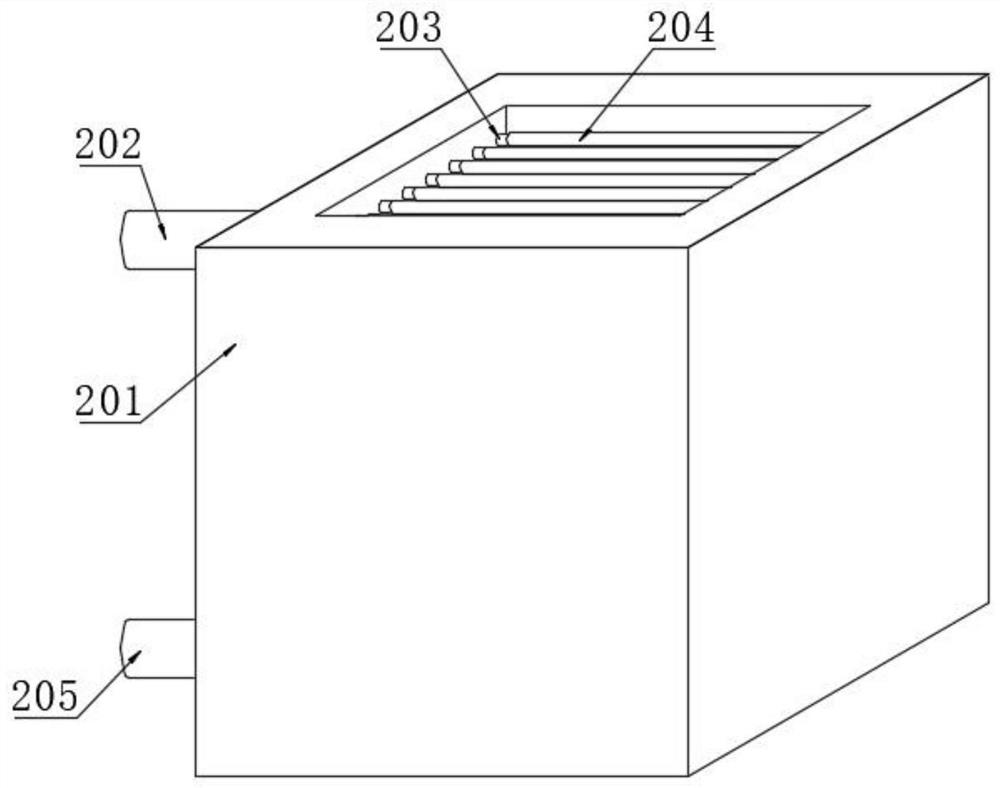

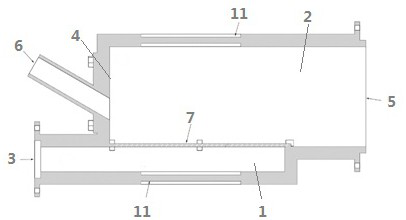

Method for manufacturing heat-pipe-parallel-structure-like foamy copper vapor plate

InactiveCN105841532AReduce thicknessReduce weightIndirect heat exchangersVacuum pumpingSemiconductor

The invention discloses a method for manufacturing a heat-pipe-parallel-structure-like vapor plate by using stepped foamy copper as wicks. The vapor plate is characterized in that an upper copper covering plate, a lower copper covering plate and a stepped or flat foamy copper are sintered, a heat-pipe-structure-like vapor chambers are formed according a geometrical shape, and a liquid phase working medium is injected to the heat-pipe-structure-like vapor chambers; foamy copper steps are rectangle-shaped or trapezoid-shaped, and the foamy copper steps and the flat or stepped foamy copper are sintered on the upper copper covering plate and the lower copper covering plate according to a geometrical structure; a boss portion of the stepped foamy copper has a support effect; after the upper copper covering plate and the lower copper covering plate are combined through copper silver brazing or diffusion welding, vacuum pumping and liquid phase working medium injection are performed. The stepped foamy copper has high porosity and a good capillary character, the vapor chambers mutually communicates, rapid and high-efficient liquid-vapor conversion and gas phase rapid diffusion of in the liquid phase working medium in the vapor end can be ensured, and rapid backflow resistance of a condensation end can be reduced after the liquid-vapor conversion. The manufactured heat-pipe-parallel-structure-like vapor plate can meet the demands of semiconductor electronic devices for rapid and high-efficient heat conduction and heat dissipation.

Owner:JIANGSU GREEN NEW MATERIALS TECH CO LTD

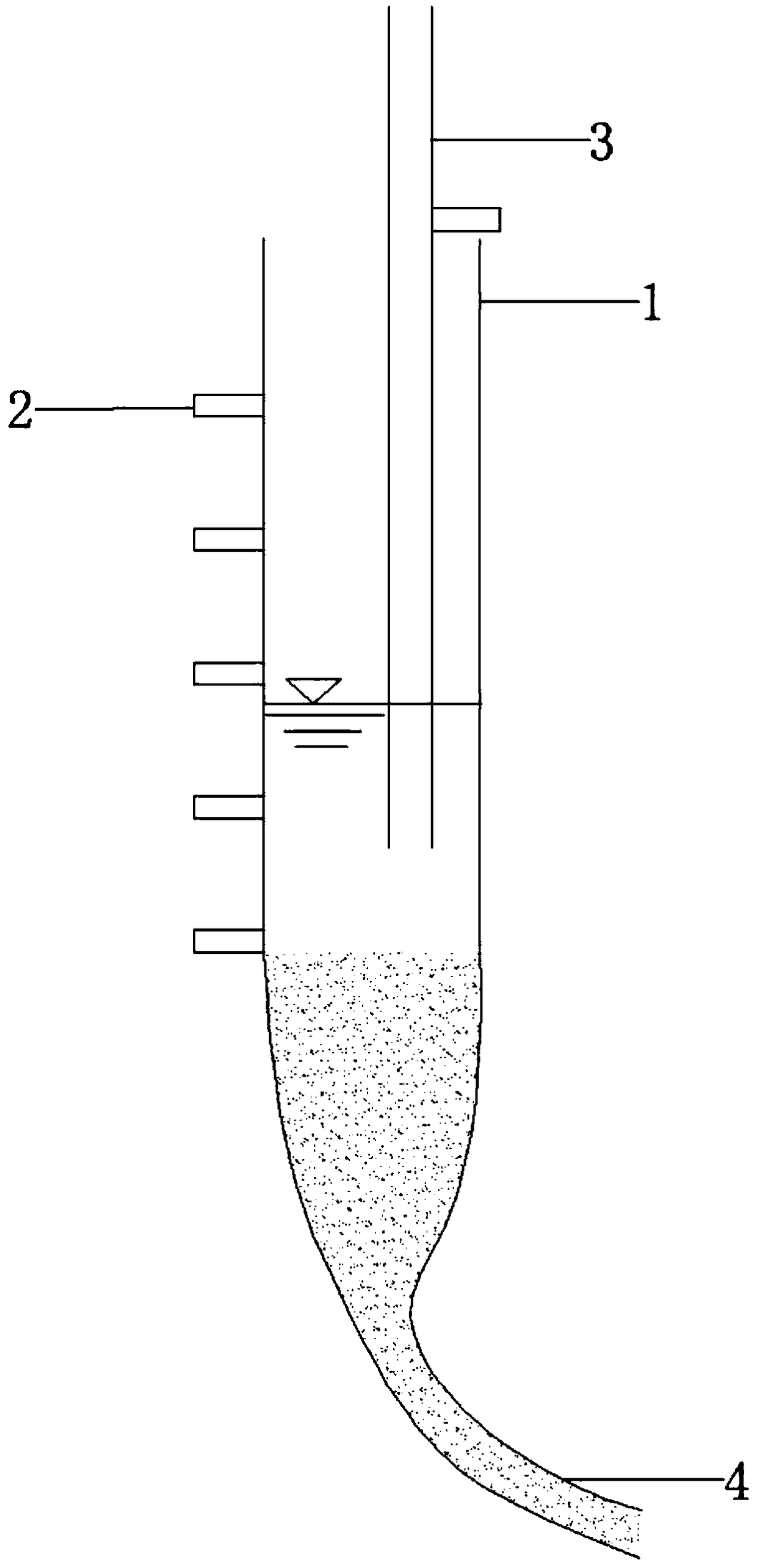

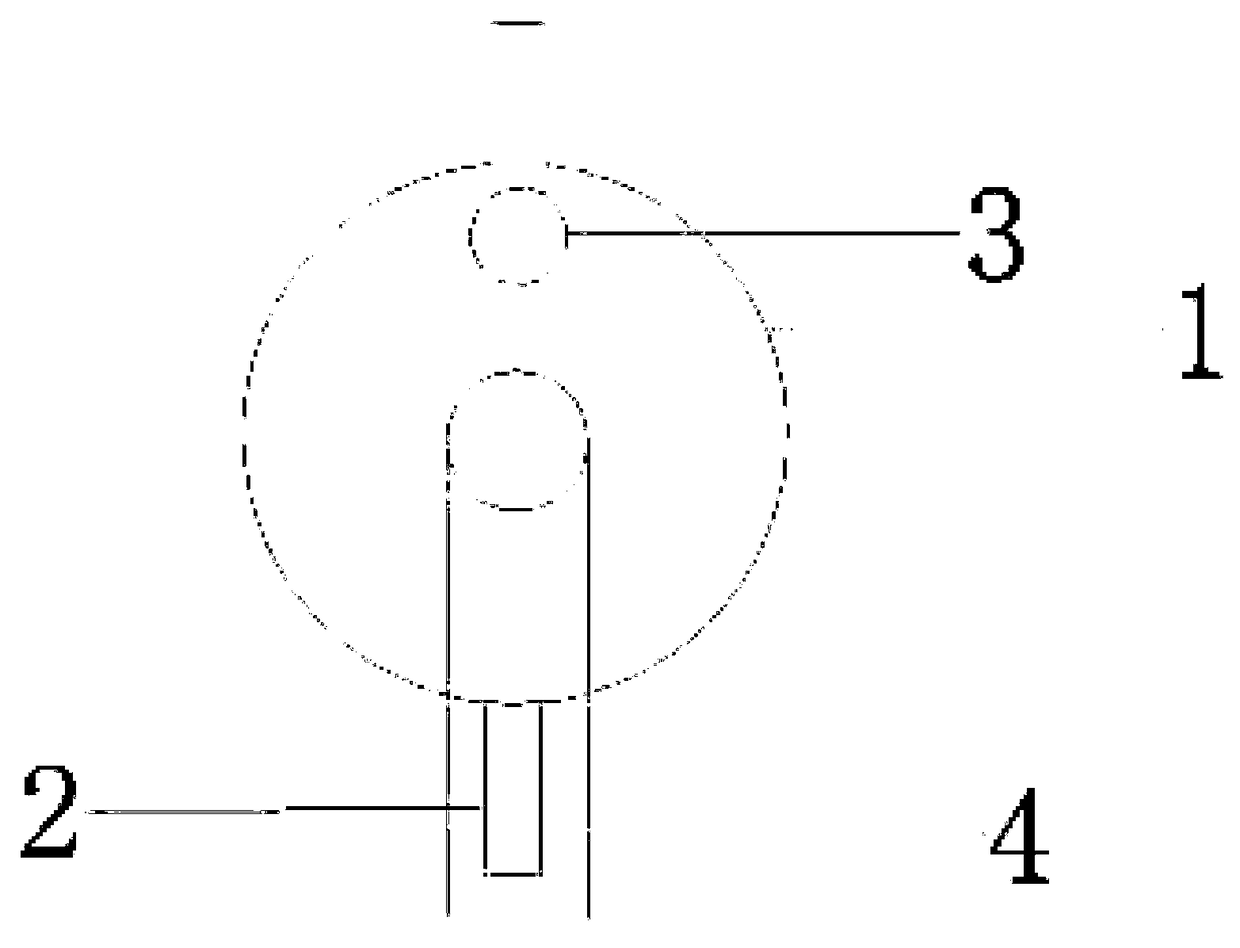

Tellurium retort

InactiveCN101062764AEasy to processIncrease productionSelenium/tellurium compundsDistillation separationTe elementTellurium

The invention discloses a solid fusion distilling technology especially a tellurium retort structure, which comprises the following steps: resolving the problems of small volume and low output; making the tellurium retort comprises distilling pot, copple and condenser; producing the distilling pot with rustless steel; choosing the diameter of distilling pot at 200-300mm, equipping column plate on the lower end of the condenser. This invention increases the output of single furnace and decreases the cost of production.

Owner:成都汉普高新材料有限公司

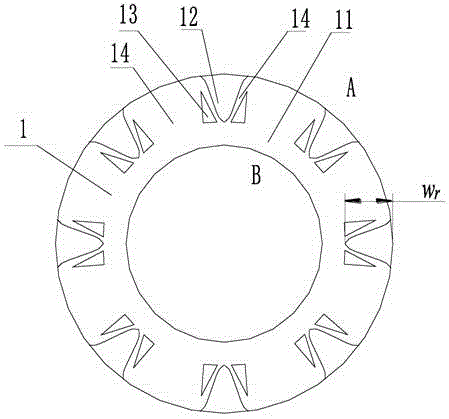

Cosine curve mechanical seal end surface structure

The invention discloses a cosine curve mechanical seal end surface structure. The structure comprises a movable ring and a static ring of a mechanical seal; the outer ends of the sealing end surfaces of the movable ring and the static ring serve as high-pressure sides, namely upstream, and the inner ends of the sealing end surfaces serve as low-pressure sides, namely downstream; smooth and continuous annular sealing dams are arranged on the low-pressure sides of the sealing end surfaces; multiple periodically distributed curve grooves are formed in the high-pressure sides of the sealing end surfaces; openings at one ends of the curve grooves extend to the upstream of the sealing end surfaces, and the other ends of the curve grooves are positioned at the upstream of the annular dams; micro grooves are symmetrically formed in two sides of each curve groove; and the sealing end surfaces are provided with sealing weirs in non-grooving areas between the curve grooves at the upstream of the annular dams. The cosine curve mechanical seal end surface structure has the following beneficial effects: the structure is obvious in reflux effect, low in leakage rate, capable of being applied to various mediums, high in solid particle preventing capacity, excellent in static / dynamic pressure effect and capable of frequently starting and rotating in two directions.

Owner:ZHEJIANG UNIV OF TECH

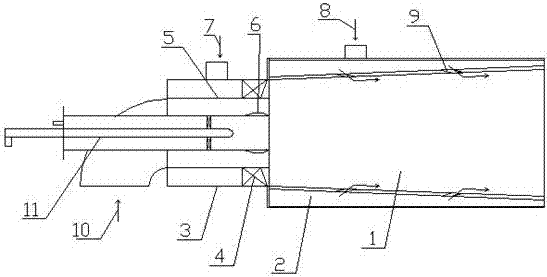

Deep peak-regulating combination type combustion-stabilizing combustor

The invention relates to the technical field of boiler consumption, and in particular discloses a deep peak-regulating combination type combustion-stabilizing combustor. The deep peak-regulating combination type combustion-stabilizing combustor comprises a pulverized coal pre-combustion chamber which is horizontally arranged and communicates with a hearth. The deep peak-regulating combination type combustion-stabilizing combustor is characterized in that a first air chamber is arranged at an end head of the pulverized coal pre-combustion chamber; a first air pipe communicates with the first air chamber, and a first air-pulverized coal mixture inlet is formed in the first air chamber; a secondary air channel is coaxially distributed at the outer side of the first air chamber; an oil combustion cylinder is axially distributed in the first air chamber; a third air chamber which communicates with the hearth is arranged at the outer side of the pulverized coal pre-combustion chamber. The deep peak-regulating combination type combustion-stabilizing combustor is simple in structure, and stable to run; a boil can stably run with low load; the minimum combustion-stabilized composition can be stabilized to reach 0-40% BMCR (Boil Maximum Continuous Rating) when no oil is fed; the deep peak-regulating combination type combustion-stabilizing combustor is free from powder accumulation and coking after long-term running, is maintained a little in later period, and is beneficial for energy conservation and environmental protection.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

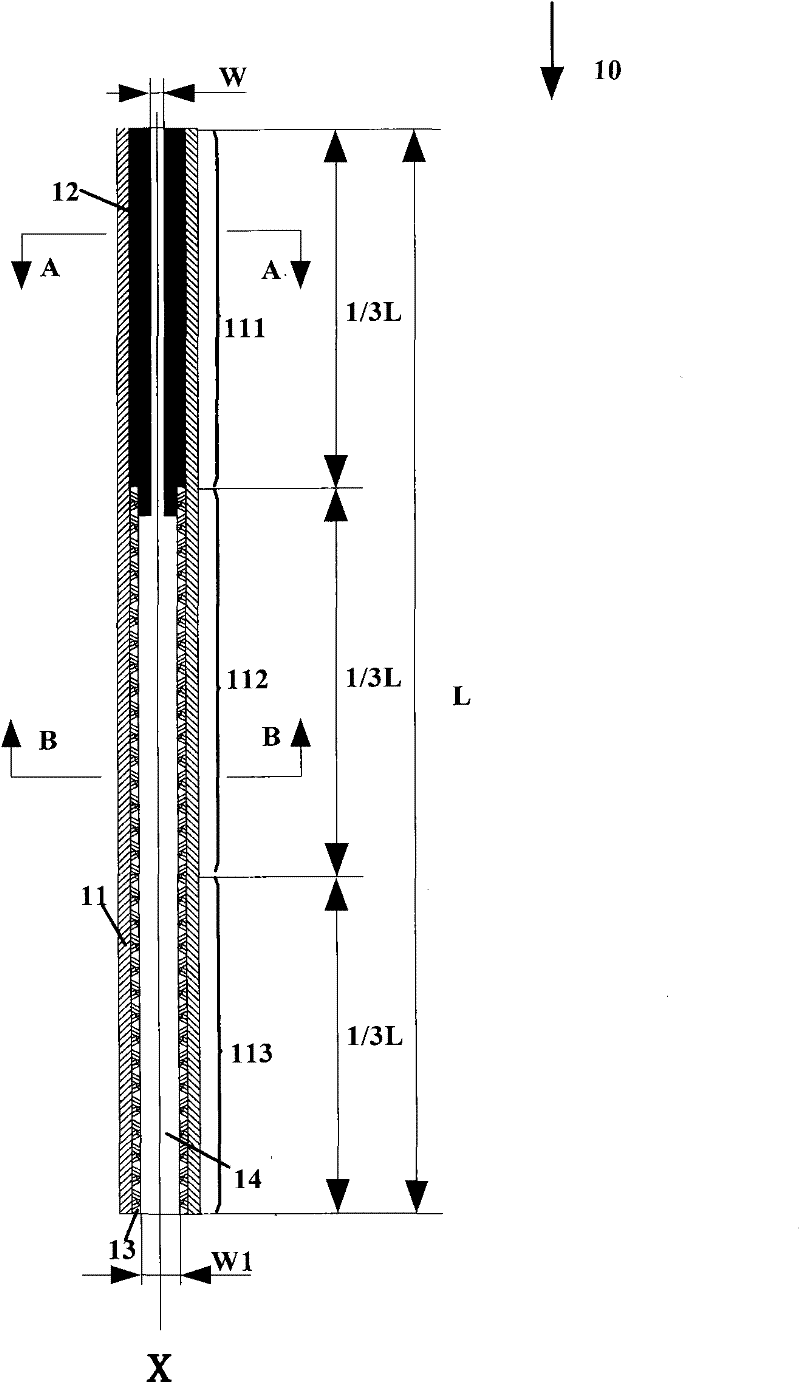

Flat type radiating pipe and manufacturing method thereof

InactiveCN102168931BDecreased maximum heat transferGuaranteed delivery effectIndirect heat exchangersEvaporationHeat transfer efficiency

The invention discloses a flat type radiating pipe and a manufacturing method thereof. The flat type radiating pipe comprises a tube cavity with two closed ends and a tube wall axially surrounding the tube cavity; the tube cavity and the tube wall are axially provided with an evaporation section, a heat insulation section and a condensation section sequentially; the tube cavity is internally provided with a main capillary structure and an auxiliary capillary structure, wherein the main capillary structure contacts with the tube wall of the evaporation section and extends to the heat insulation section of the tube cavity; the auxiliary capillary structure contacts with the tube walls of the heat insulation section and condensation section; in the heat insulation section of the tube cavity,the auxiliary capillary structure is partially covered by the main capillary structure; and a working medium is filled in the tube cavity enclosed by the main capillary structure and the auxiliary capillary structure. The flat type radiator can be used for solving the ponding problem occurring after the radiating pipe is beaten to be very thin; the capillary force of the flat type radiator is improved, the working medium conveying ability is enhanced, and the backflow efficiency of the working medium is improved; and moreover, the composite capillary structure ensures that the heat transfer performance of the radiating pipe is greatly improved, thus the heat transfer efficiency of the flat type radiating pipe is enhanced.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

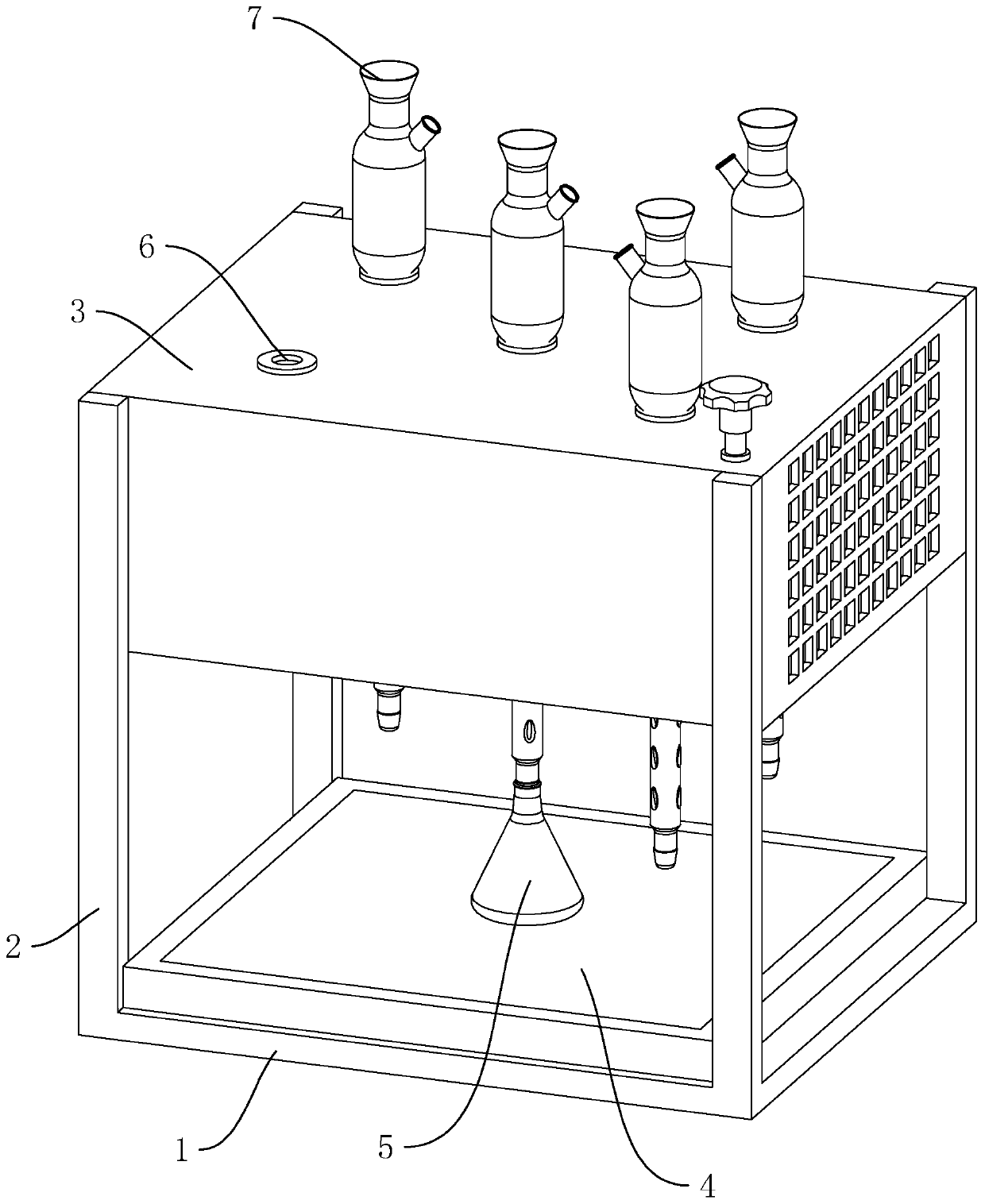

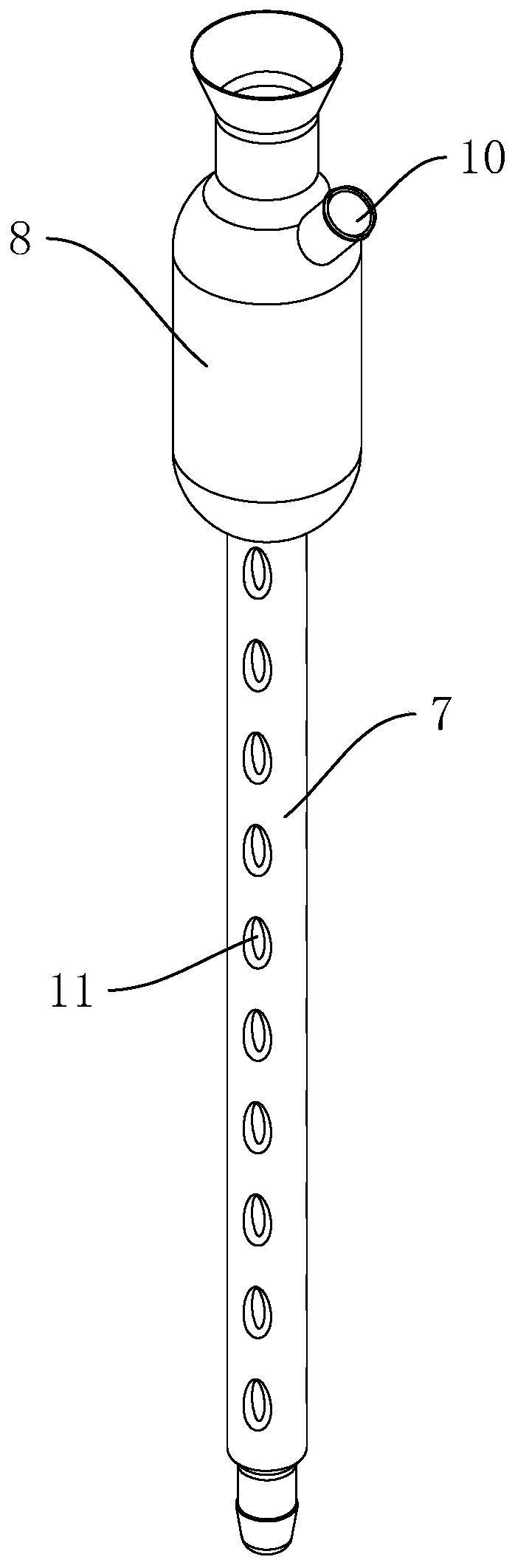

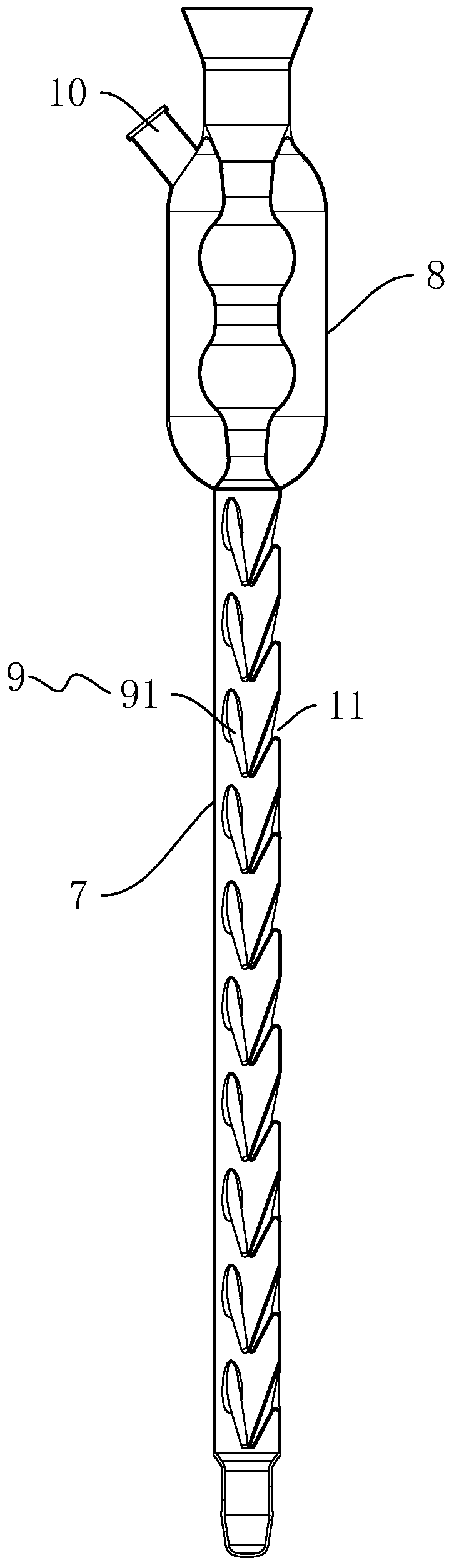

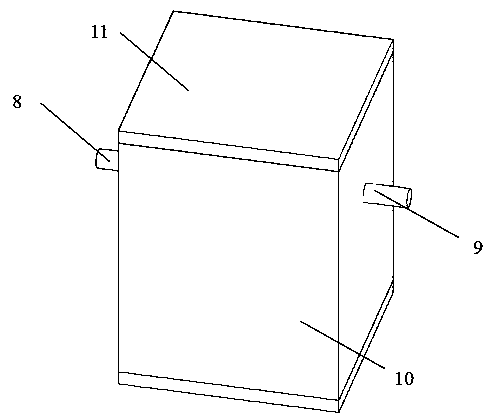

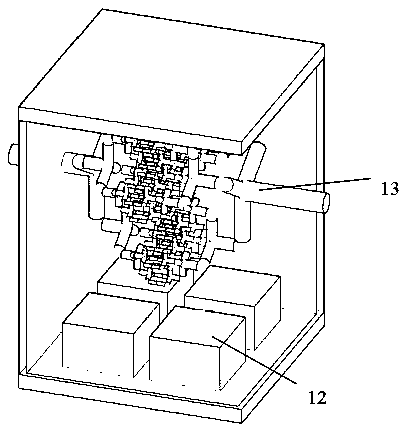

COD digester and application method thereof

ActiveCN110849702ACondensation effect is stableImprove cooling effectPreparing sample for investigationCooling/ventilation/heating modificationsStructural engineeringDigestion

The invention discloses a COD digester, and relates to the field of water sample detection devices. According to the technical scheme, the digester comprises a base, a support arranged on the base anda mounting base arranged at the upper portion of the support; an electric heating furnace plate is arranged on the base; a digestion bottle is placed on the electric heating furnace plate; a plurality of mounting holes are formed in the mounting base in the vertical direction; and reflux condensing pipes are arranged on the mounting holes, the lower ends of the reflux condensing pipes are connected with the digestion bottle, the mounting base is a hollow shell, a cooling fan is arranged in the mounting base and used for blowing air to the reflux condensing pipes for cooling, and vent holes are formed in the two ends, in the air blowing direction of the cooling fan, of the mounting base. Air is blown through the cooling fan to cool the reflux condensing pipes in time, and therefore, the condensation effect of the reflux condensing pipes is more stable.

Owner:台州市绿水青山环境科技有限公司

Daily chemical production device with distillation function and rapid discharging function and daily chemical production method

InactiveCN112675565AImprove discharge efficiencyAvoid condensation and scalingDistillation regulation/controlVapor condensationThermodynamicsDistillation

The invention discloses a daily chemical production device with a distillation function and a rapid discharging function and a daily chemical production method, belonging to the technical field of chemical production. The daily chemical production device comprises a distillation tower body, wherein a condensation mechanism with a fractional condensation function is installed at the middle portion of the distillation tower body; a scraping mechanism used for scraping a discharged material is arranged in and connected with the condensation mechanism; a reflux mechanism for reflux processing of vaporous distillate is arranged at the top of the distillation tower body; a spraying mechanism is further connected to the lower part of the reflux mechanism; a cover plate is arranged on one side of the lower part of the distillation tower body; a heating kettle is in transmission connection with the bottom of the distillation tower body; the cover plate is used for accommodating the heating kettle to feed and discharge materials; and a discharging mechanism is arranged on one side of the distillation tower body and is positioned at the bottom of the condensation mechanism. According to the daily chemical production device disclosed by the invention, the heating kettle is arranged in the distillation tower body, a heat exchange pipe is used for cooling and condensing internal steam, and the condensed distillate is scraped to fall into a discharge box, so distillate discharge efficiency can be remarkably improved, and discharge difficulty is reduced.

Owner:涡阳县华腾日用化学品有限公司

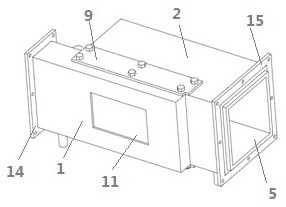

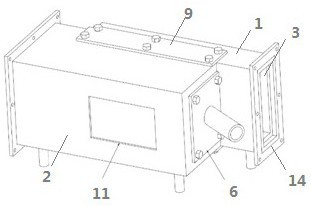

CMC flame tube test box and test method thereof

InactiveCN112903302AHigh simulationIncrease airflowGas-turbine engine testingJet-propulsion engine testingCombustion chamberEngineering

The invention discloses a CMC flame tube test box device, which can well simulate the working conditions in a CMC flame tube: low-temperature and high-temperature air flows, a strong backflow area is formed through a test box body, and the surrounding air flow and temperature distribution condition when the CMC flame tube works can be well simulated; in the invention, various variables can be changed, and gas impact conditions in combustion chambers of different models can be simulated by replacing the detachable high-temperature gas inlet ducts with different angles and calibers. Thus, different working conditions of the CMC flame tube can be simulated by changing parameters such as air inlet temperature, speed and pressure; and the cooling efficiency and the like of the air film holes can be tested by changing the shapes, the distribution and the like of the air film holes in the test piece. According to the invention, various physical quantities can be measured; the temperature distribution on the surface of the flame tube can be measured through the thermal infrared imager; moreover, speckles can be sprayed on the surface of the test piece, strain distribution of the test piece is measured through a DIC measurement system, periodic thermal load can be applied to the test piece, and the damage condition of the test piece is observed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

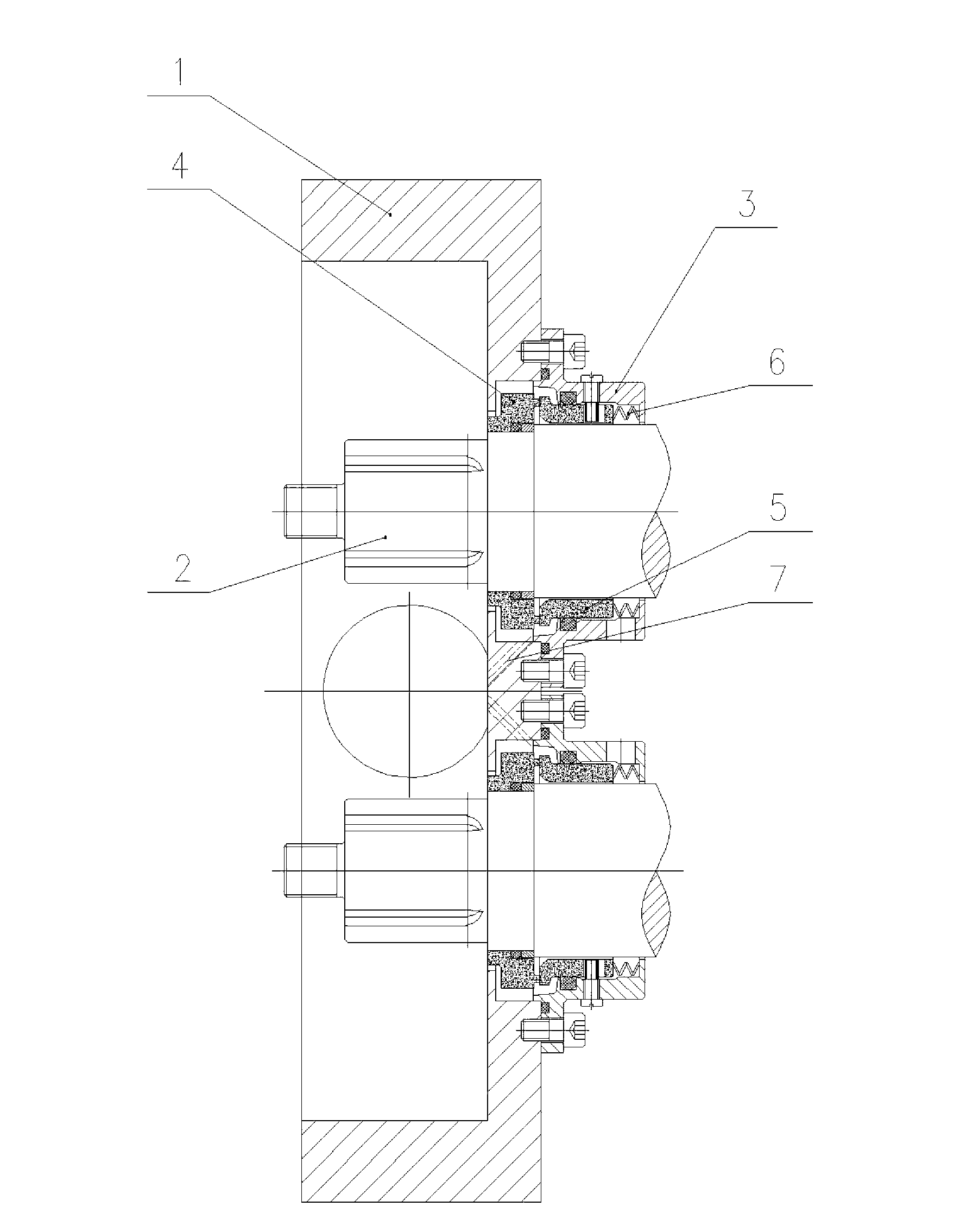

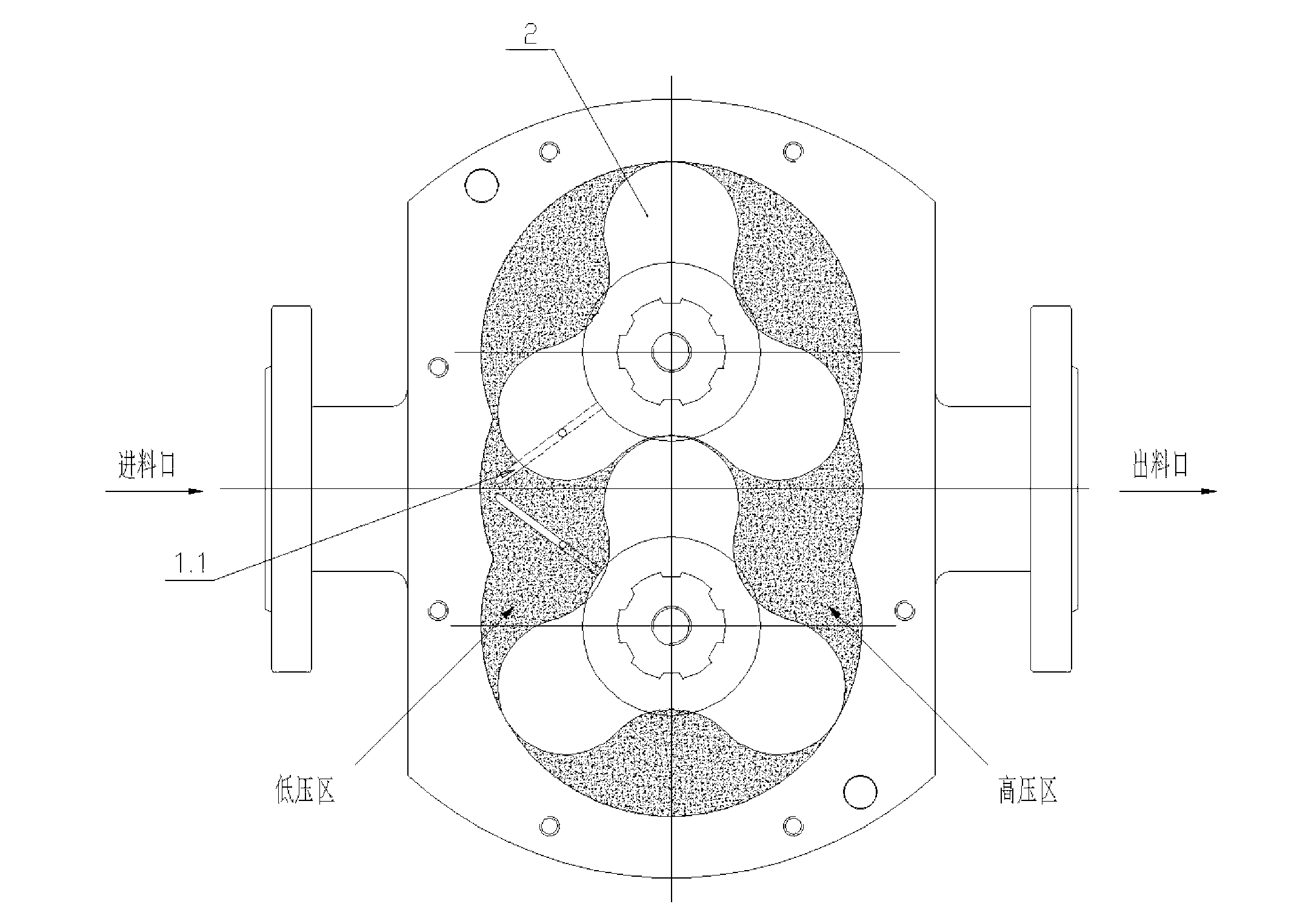

Mechanical seal device of rotor pump

ActiveCN103062049AReduce extrusion pressureImprove sealingMachines/enginesRotary/oscillating piston pump componentsCooling effectLow-pressure area

The invention discloses a mechanical seal device of a rotor pump. The mechanical seal device of the rotor pump comprises a rotary shaft (2), a seal seat (3), a moving ring (4), a static ring (5) and a spring (6), wherein the rotary shaft (2) is arranged on a pump body (1); the seal seat (3) is fixed on the end surface of the pump body (1); the static ring (5) is arranged out of the rotary shaft (2); the static ring (5) is peripherally limited into the seal seat (3); the spring (6) is arranged out of the rotary shaft (2), one end of the spring (6) butts against the static ring (5), and the other end of the spring (6) butts against the inner end surface of the seal seat (3); the end surface of the static ring (5) is pressed and matched on the end surface of the moving ring (4) through the spring (6); and an empty cavity between the moving ring (4) and the pump body (1) is communicated with a low-pressure area of a cavity body of the pump body for containing two rotors through a backflow channel. The mechanical seal device of the rotor pump can increase the seal effect of the moving ring and the static ring and can prolong the service lives, and meanwhile also can increase the cooling effect to the moving ring and the static ring.

Owner:NINGBO DELISHI PUMP IND CO LTD

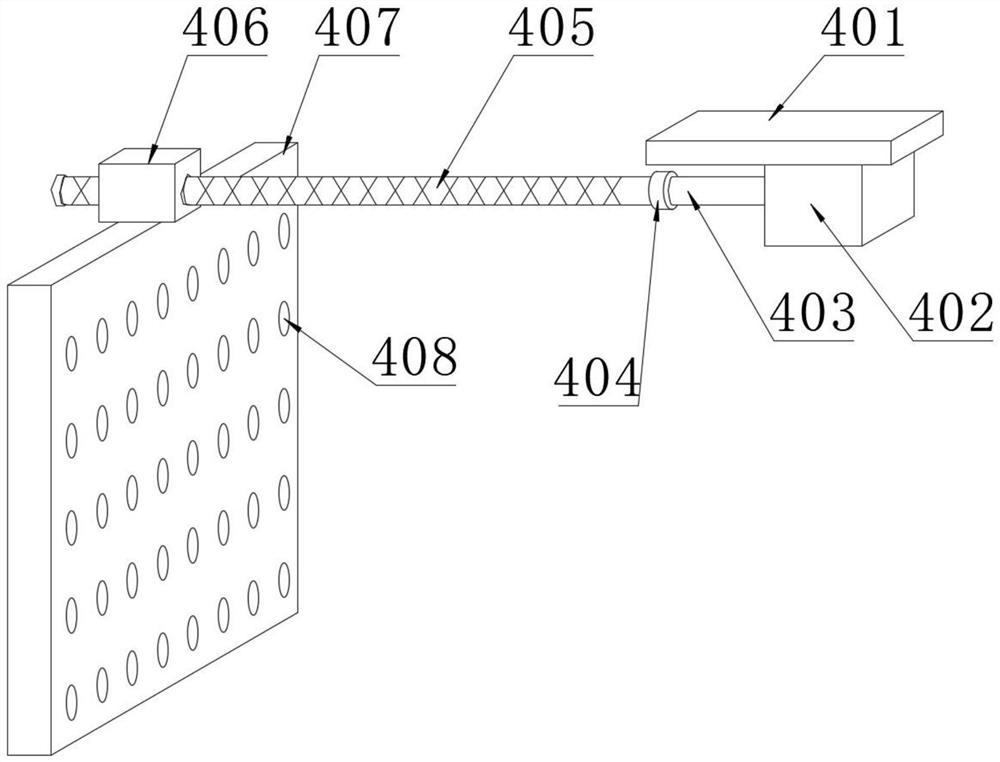

Heat pipe and processing method thereof, and electronic equipment employing heat pipe

ActiveCN103292628ASmall circulation resistanceIncrease flow rateIndirect heat exchangersCooling/ventilation/heating modificationsTablet computerGas phase

The invention discloses a heat pipe. The heat pipe comprises a pipe casing as well as a pipe core composed of first flow channels with liquid phase medium and second flow channels with gas phase medium and arranged in the pipe casing, wherein the pipe core comprises a first pipe section and a second pipe section; in the first pipe section, the second flow channel is wrapped by the first flow channel; and in the second pipe section, the first flow channel and the second flow channel are arranged in parallel. The heat pipe provided by the invention can effectively reduce flow resistance of steam through the improvement of the structure arrangement of the pipe core; an excellent heat dissipation capacity is obtained, while the overall size of the heat pipe can be controlled to the largest extent, so that the possibility for realizing excellent heat dissipation of high-performance notebook computers as well as the application of the heat pipe to tablet computers with smaller space is reliably guaranteed. On the base of the heat pipe, the invention further provides electronic equipment employing the heat pipe and a processing method of the heat pipe.

Owner:LENOVO (BEIJING) CO LTD

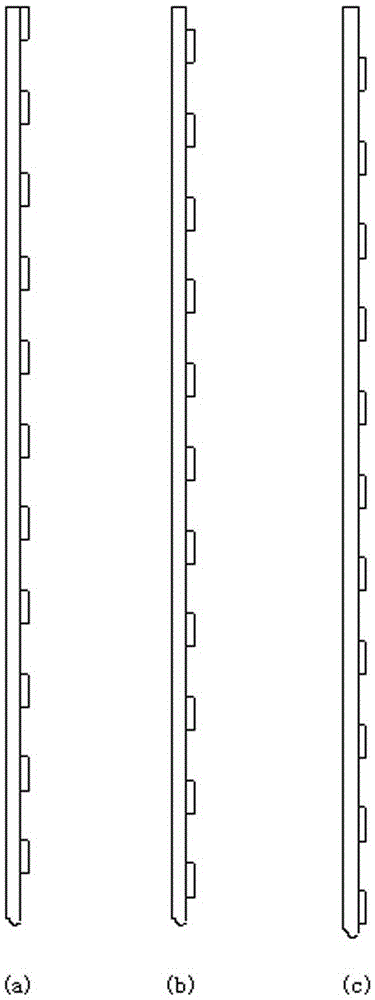

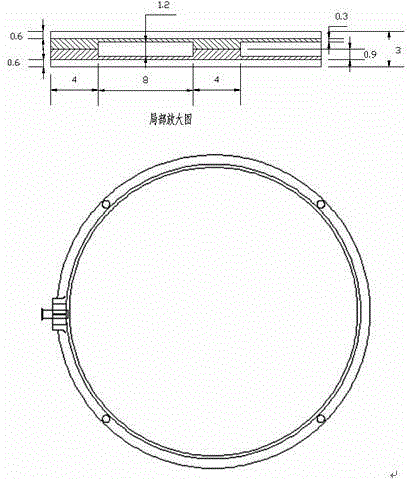

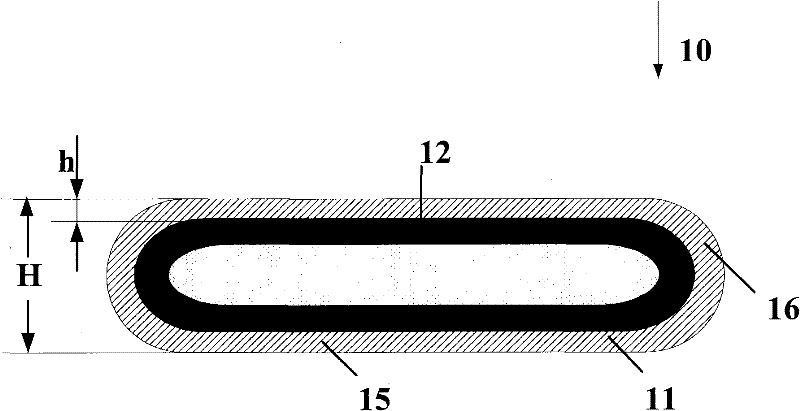

Flat type heat pipe and manufacturing method thereof

The invention discloses a flat type heat pipe and a manufacturing method of the flat type heat pipe. The flat type heat pipe comprises a pipe body, an evaporation section and a condensation section, the evaporation section and the condensation section are arranged at the two ends of the pipe body respectively, a compound sintering capillary structure is arranged in a pipe chamber of the pipe body, the compound sintering capillary structure comprises metal wires and a metal mesh, the metal mesh is arranged on an inner circumferential face of the pipe body of the evaporation section, and the metal wires are arranged along one side face of the axial inner circumferential face of the pipe body in a circumference mode. The flat type heat pipe can effectively ensure the fact that steam flows back to the condensation section when the heat pipe is flattened to be quite thin, can effectively ensure reliability of production of the heat pipe, and further improves efficiency of heat conduction of the heat pipe.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

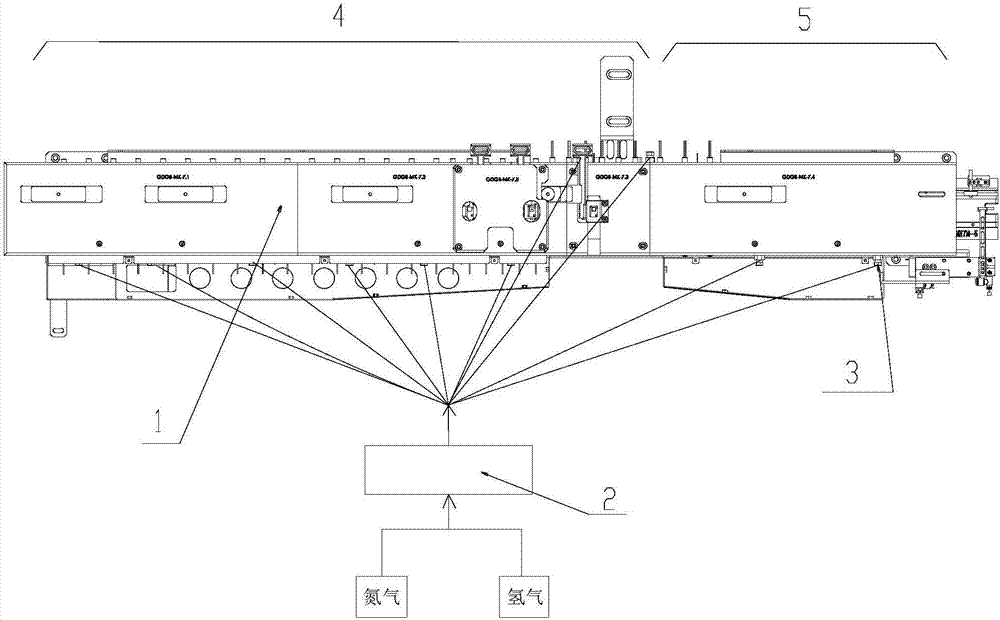

Soft solder mounting rail unit

InactiveCN107309220AImprove cleanlinessImprove reflow effectSemiconductor/solid-state device manufacturingCleaning processes and apparatusHydrogenNitrogen

The invention discloses a soft solder mounting rail unit which comprises a rail body and a plasma cleaning machine. A plurality of hydrogen-nitrogen protecting gas connectors are arranged on the two sides of the rail body. The plasma cleaning machine is provided with a plurality of pipelines. The multiple pipelines communicate with the multiple hydrogen-nitrogen protecting gas connectors correspondingly. Through the structural design, the plasma cleaning machine removes contaminants on the surface of a bare copper framework at the station before the mounting procedure, and conducts reduction and deoxidation on the surface of the bare copper framework containing oxidation elements, the cleanliness of the surface of the bare copper framework is improved in the solder mounting process, and the backflow performance of solder is improved. Meanwhile, through the plasma cleaning machine, the cleanliness of the surface of the bare copper framework is improved, then the requisite amount of hydrogen is decreased, the production cost is reduced, and meanwhile, the safety of the production process is improved.

Owner:大连佳峰自动化股份有限公司

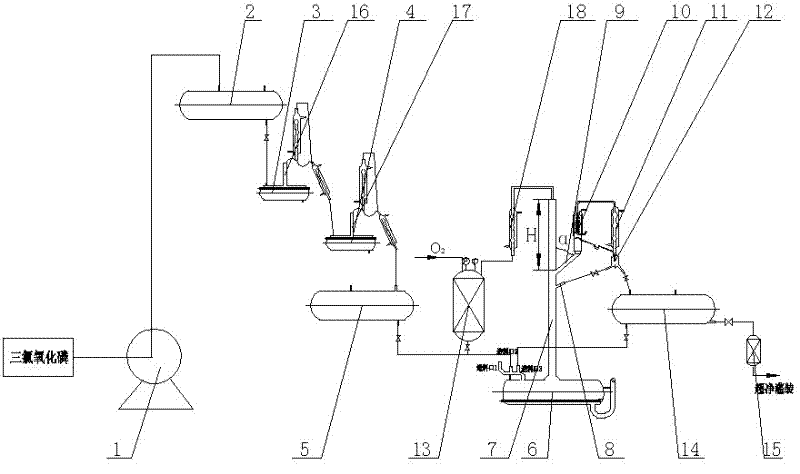

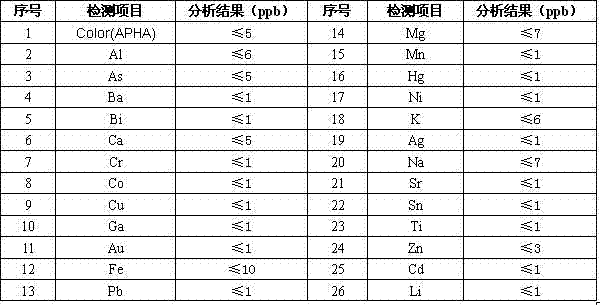

Method and device for producing electronic grade phosphorus oxychloride

ActiveCN102249201AReduce generationLess investmentPhosphorus halides/oxyhalidesState of artBoiling point

The invention discloses a method and device for producing electronic grade phosphorus oxychloride. The method comprises the following steps of: (1) putting technical grade phosphorus oxychloride into a container, adding a sodium bromide or hexadecyl trimethyl ammonium bromide additive into the container, uniformly stirring and conveying the mixture into a high-position storing tank through a conveying pump; (2) introducing the phosphorus oxychloride in the high-position storing tank into a sub-boiling distiller for performing sub-boiling distillation; (3) introducing a distilled product obtained in the step (2) into a half-finished product storing tank; (4) introducing the half-finished product in the storing tank into a rectifying tower; (5) boiling the half-finished product in the rectifying tower in the step (4) and performing total reflux, wherein high-boiling-point impurities are left in the rectifying tower; (6) introducing a phosphorus oxychloride cut fraction into a finished product storing tank, oxidizing, reflowing into the rectifying tower, and performing complete gas-liquid mass transfer separation; and (7) introducing the phosphorus oxychloride product in the finishedproduct storing tank into a filter in a clean room for filtering to obtain the colorless and transparent electronic grade phosphorus oxychloride. According to the method and the device, the defects of the prior art can be overcome.

Owner:徐州市永大化工有限公司

Piezoelectric inkjet printing spray head structure preventing ink backflow

The invention provides a piezoelectric inkjet printing spray head structure preventing ink backflow. An ink supply channel is connected with an ink box. Due to capillary force action, the ink supply channel, a flow limiting part, a pressure generation cavity and a flow guide part are full of ink sequentially, and the ink reaches a nozzle. An upper electrode, piezoelectric ceramics, a lower electrode and a vibration plate form a driving element, when the upper electrode and the lower electrode are electrified simultaneously, the piezoelectric ceramics deform due to an inverse piezoelectric effect, then the vibration plate is driven to deform, the vibration plate deforms to extrude the ink in the pressure generation cavity, the flow limiting part and the flow guide part prevent the ink fromflowing back to the ink supply channel, and the ink is sprayed out from the nozzle. The piezoelectric ceramics are used for the piezoelectric inkjet printing spray head structure, the driving elementgenerate driving force, removing machining is conducted on the base part corresponding to the pressure generation cavity, and the driving element is in a suspension state and is located in the e pressure generation cavity. The piezoelectric inkjet printing spray head structure is simple in manufacture process, low in cost and good in process repeatability and has an ink backflow prevention effect.

Owner:大连瑞林数字印刷技术有限公司

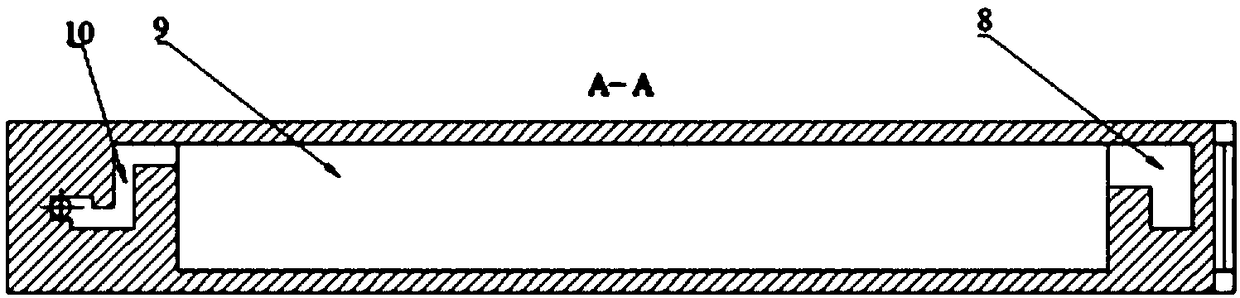

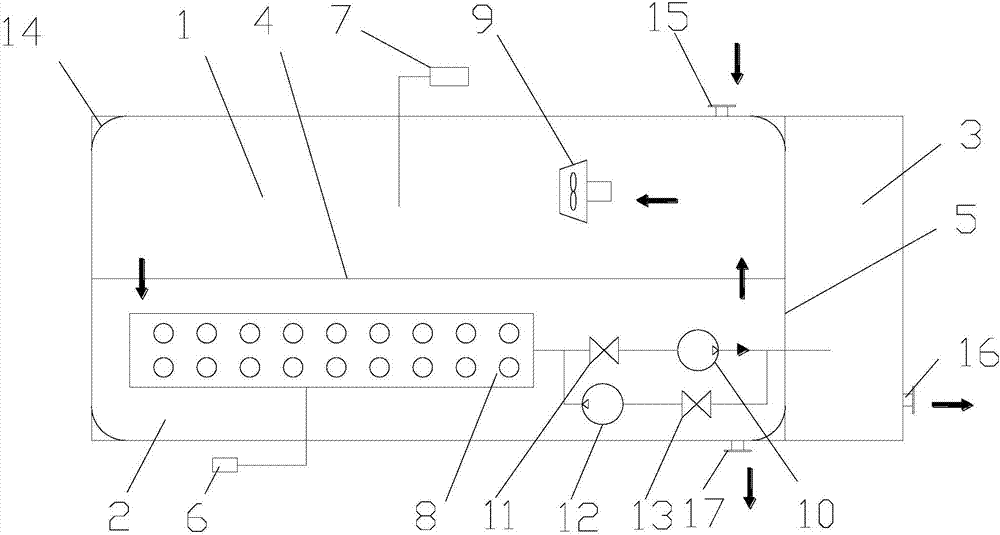

Data center waste heat utilization device

InactiveCN109579100AImprove reflow effectRealize savingsCentral heating with accumulated heatLighting and heating apparatusRefluxData center

The invention discloses a data center waste heat utilization device, which includes a cooling pool, a data center workshop and heat supply network user ends. A heat transfer device is further arrangedin the data center workshop, and the heat transfer device includes an immersion cooling header, a heat load buffer regulating unit, a water pump, and a connecting pipe; the immersion cooling header is composed of a cooling header body, a heat source device and a vertical circulating heat exchange pipe network; and the vertical circulating heat exchange pipe network is of a parting structure and adopts a two-end symmetrical structure, and a water outlet of the vertical circulating heat exchange pipe network is connected with the heat load buffer regulating unit. According to the data center waste heat utilization device, space configuration inside the immersion cooling header and cooling water working medium flow distribution are optimized, favorable conditions are provided for bead condensation, and the condensing heat transfer node condensing droplet reflux capacity of a condensing end is enhanced; storage of excess heat and heat load adjustment are realized by using phase-change materials; and meanwhile, the water temperature is effectively heated to 45 DEG C-60 DEG C, and water loss of an urban heat supply network is supplied as preheating water.

Owner:南京艾科美热能科技有限公司

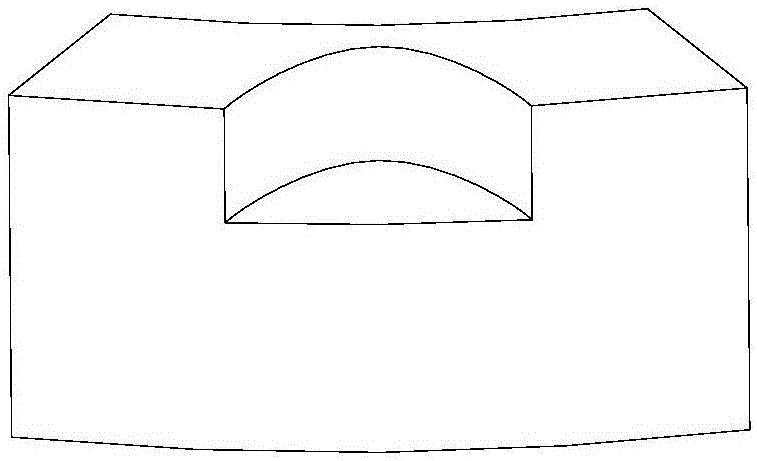

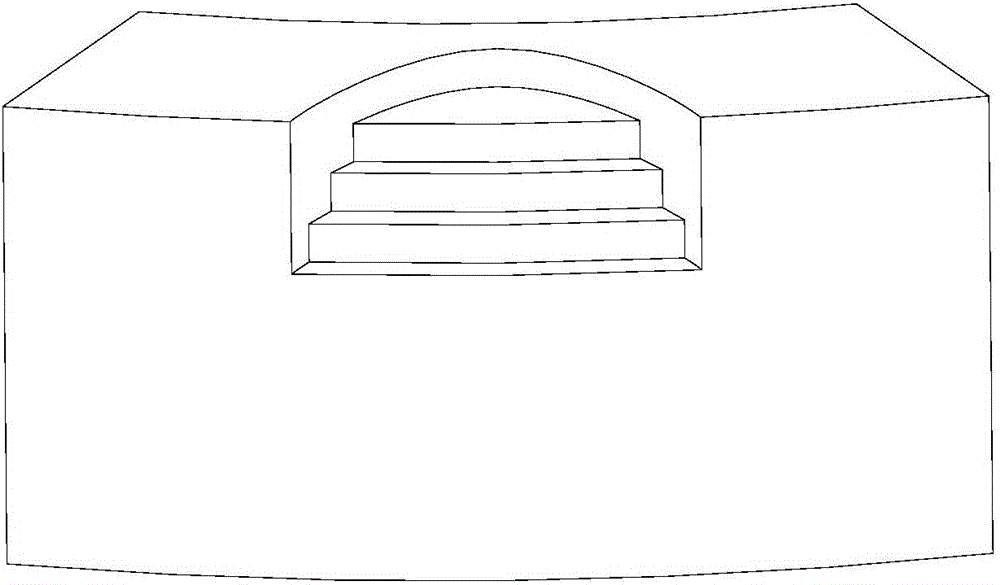

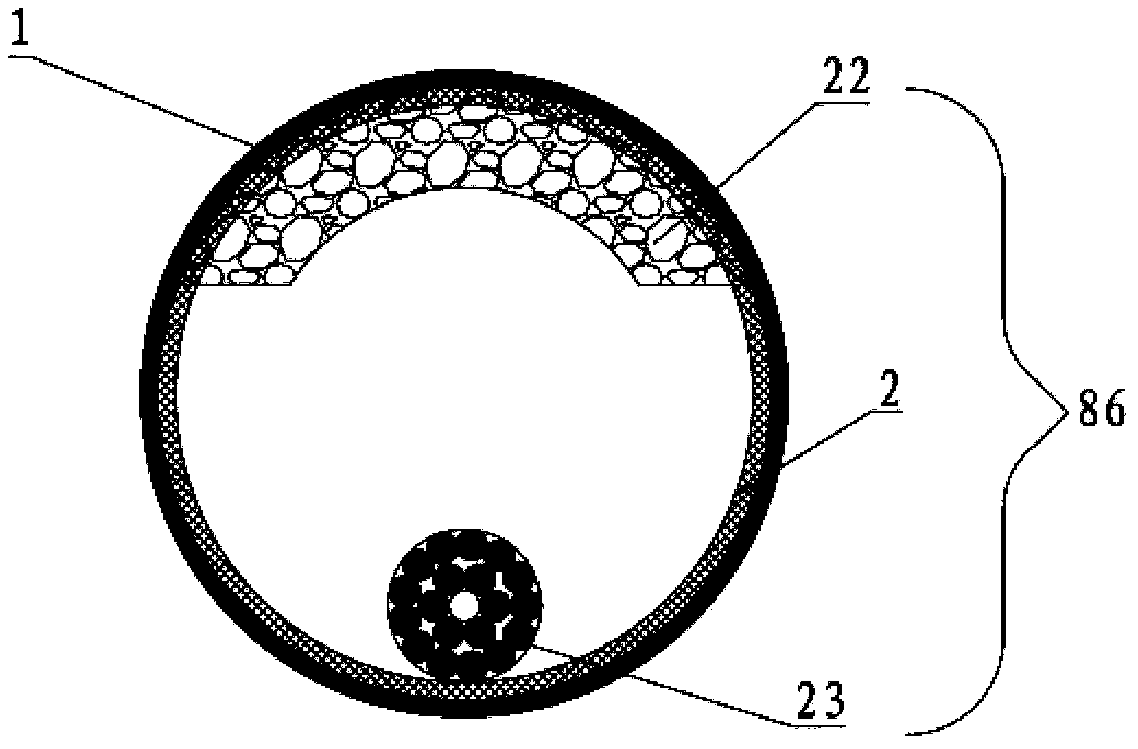

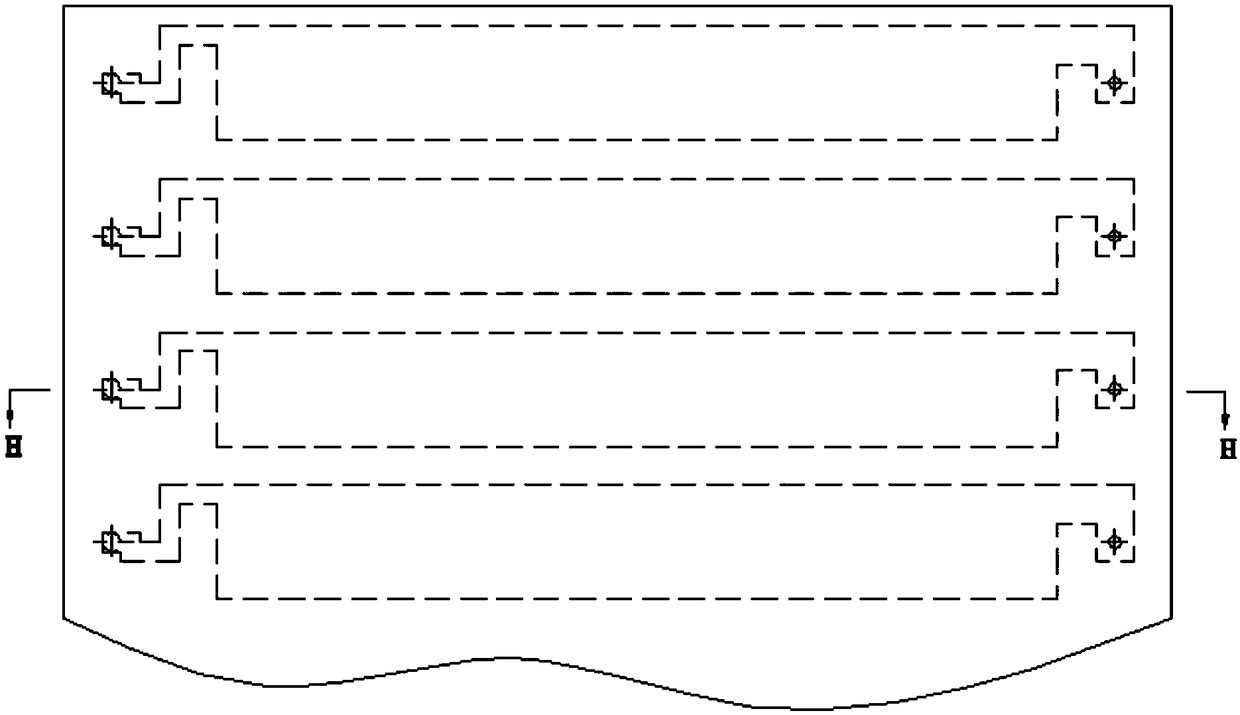

Planar super-conduction heat pipe and preparation method thereof

The invention provides a planar super-conduction heat pipe. The planar super-conduction heat pipe comprises a closed shell, liquid absorption cores formed in the shell, and multiple steam passageways formed in the liquid absorption cores. The planar super-conduction heat pipe is characterized in that each steam passageway is composed of two symmetric arch-bridge-shaped pore ducts. A preparation method specifically includes the steps that 1, brass powder is ultrasonically cleaned at least three times with distilled water or high-purity water, each process is conducted for at least 20 min, chloride ions and sulfate radicals in the brass powder are removed, and the purity of the brass powder is more than 99.9%; 2, the completely-cleaned brass powder is injected into a planar super-conduction heat pipe with a core rod fixed, and even vibration is carried out; 3, the planar super-conduction heat pipe filled with the powder is fixed to a support and placed in a hollow protective sintering furnace to be sintered, and the planar super-conduction heat pipe is sintered for at least 3 hours at the constant temperature of 950 DEG C. Compared with the prior art, the heat conduction capacity is excellent, the super-conduction capacity of the planar super-conduction heat pipe is 5-10 times and even more that of market products, and great market prospects are achieved.

Owner:朱惠冲

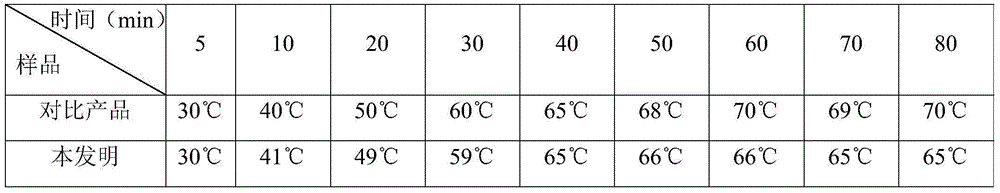

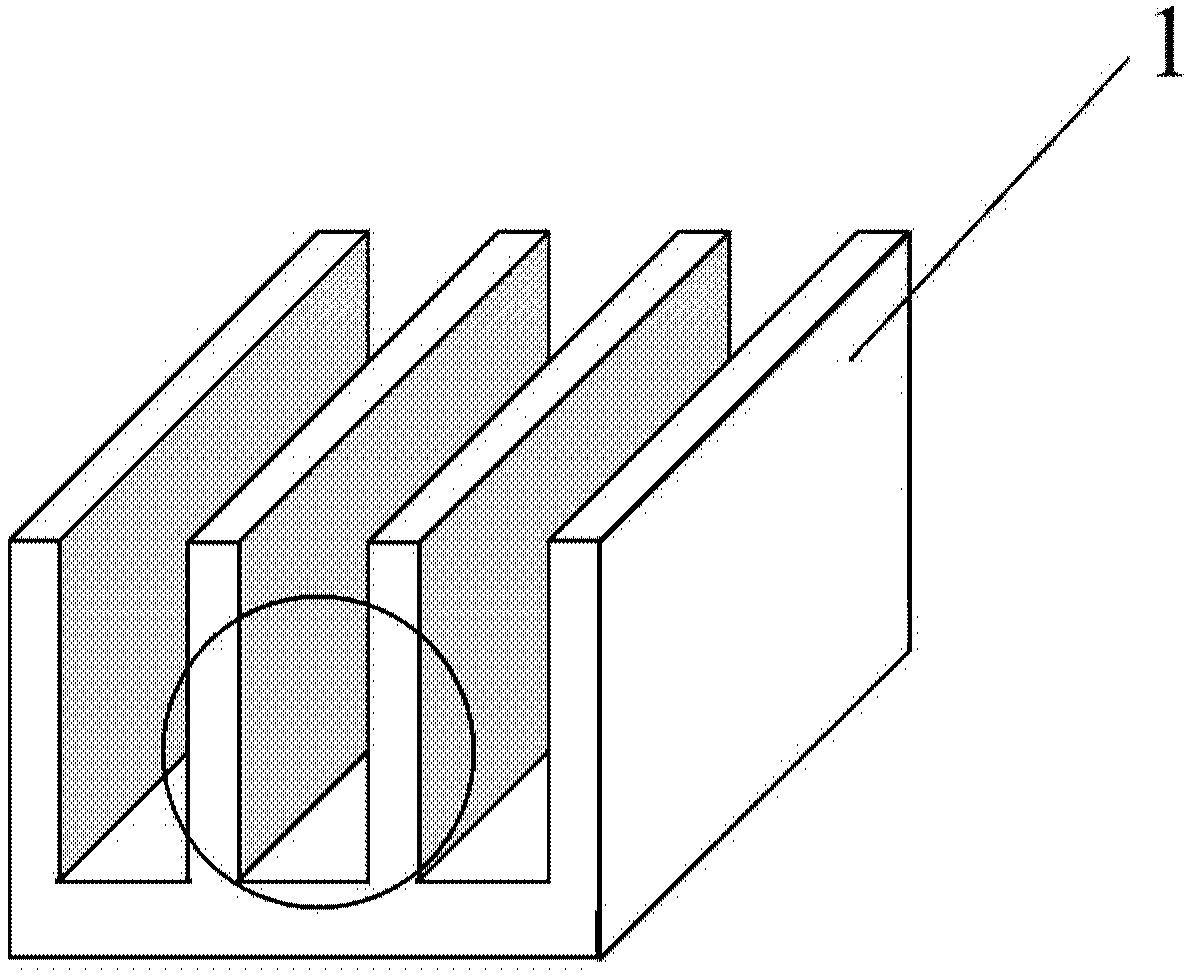

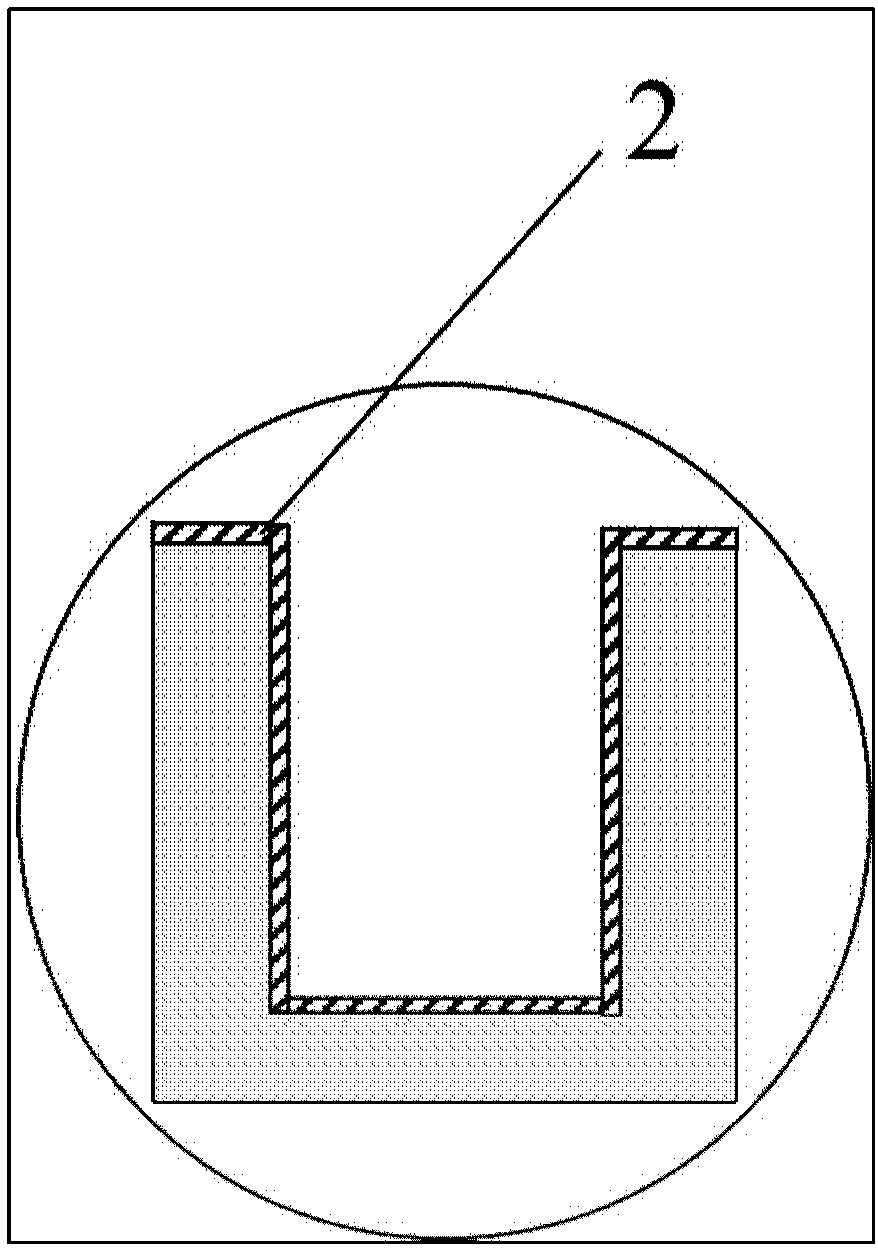

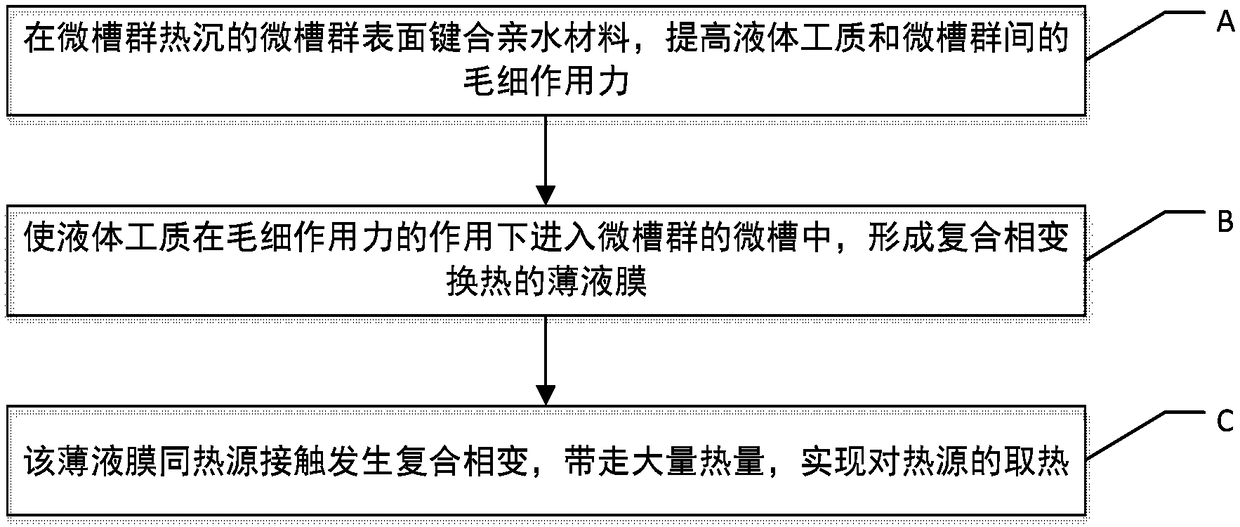

Surface-regulatory flexible microgroove heat sink, heat dissipation device and method

PendingCN108235666AImprove hydrophilicityIncrease capillary forceCooling/ventilation/heating modificationsEngineeringHeat sink

The invention provides a surface-regulatory flexible microgroove heat sink, a heat dissipation device and a method. The flexible microgroove heat sink is prepared from a flexible heat conduction material and has multiple micro-channels in the surface, and the multiple micro-channels form a microgroove group, wherein the surfaces of the microgroove group are hydrophilic surfaces after bonding by ahydrophilic material. Further, the surface-regulatory flexible microgroove heat dissipation device and heat dissipation method are provided on the basis of the flexible microgroove heat sink. The hydrophilic material is bonded on the surfaces of the microgroove group, the capillary force between the surfaces of the microgroove group and liquid work media such as water, methanol, ethanol and otherpolar liquids is increased, the wetting height and the return capability of the liquid work media are increased, the purpose of strengthening heat exchange is achieved, the cost is low, operation is simple and the hydrophilic performance is lasting.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Sludge sedimentation pipe device capable of freely adjusting sedimentation time and using method thereof

InactiveCN109354163AAchieve separationAvoid enteringBiological treatment apparatusSustainable biological treatmentRefluxSludge

The invention discloses a sludge sedimentation pipe device capable of freely adjusting sedimentation time and a using method thereof. The sedimentation pipe device comprises a sedimentation pipe mainbody, a water outlet on the side wall of the sedimentation pipe main body, a water inlet pipe capable of adjusting the water inlet height, and a mud discharge port at the lower part of the sedimentation pipe gradually changes from thick to thin according to a smooth curve. When an amount of deposited sludge is large, the height of the water inlet pipe is increased; when the amount of the sludge tobe precipitated is small, the height of the water inlet pipe is reduced. When the height of the water inlet pipe is adjusted, different sludge sedimentation time can be controlled by draining water from water outlets with different heights, sludge particles with a higher sedimentation speed are retained, the sludge with a poor sedimentation performance is discharged out of the sedimentation pipe,so that the sludge with a good sedimentation performance is obtained.One end of a sludge reflux pipeline is connected with the bottom of the sedimentation pipe, the other end of the sludge reflux pipeline is connected with a water treatment reactor, an inlet of a sludge discharge pipe is positioned at the bottom of the sedimentation pipe, and the sludge is refluxed to a anaerobic zone of a continuous flow reactor, so that the denitrification and dephosphorization effects of the reactor is guaranteed, and the water quality after sewage treatment is improved.

Owner:BEIJING UNIV OF TECH

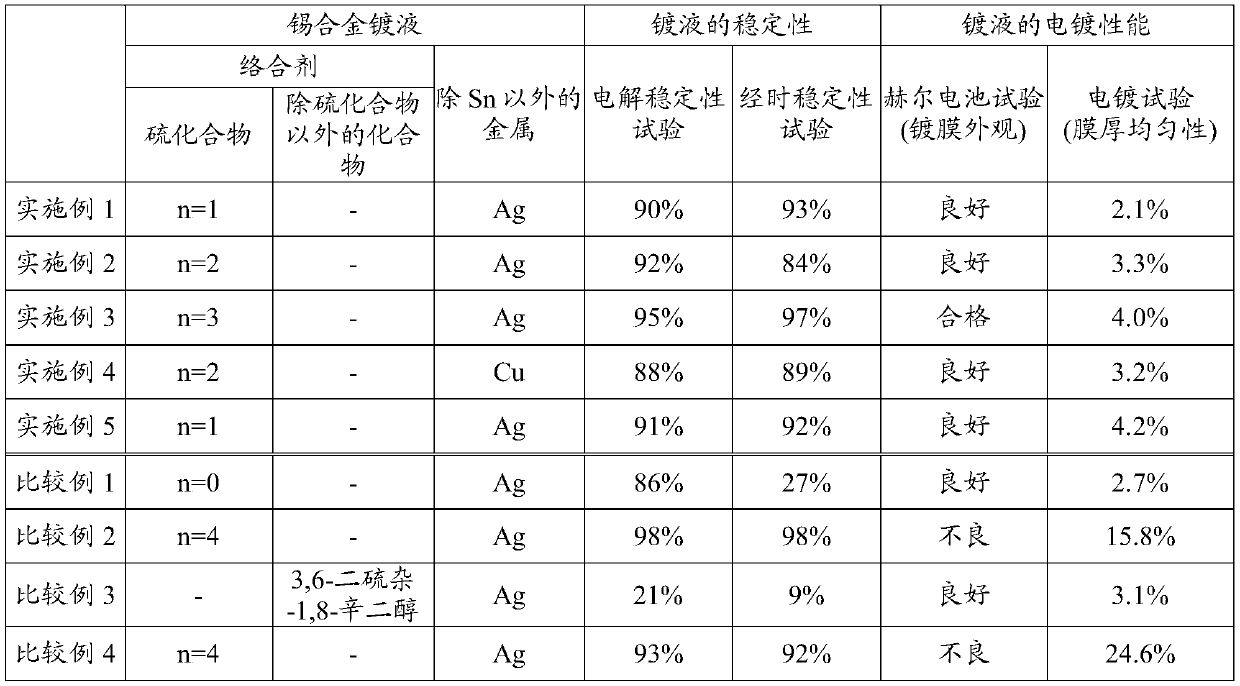

Tin alloy plating solution

A tin alloy plating solution comprising a soluble tin salt, a soluble salt of a metal more precious than tin, and a sulfide compound represented by general formula (1). In formula (1), n is 1 to 3. The metal more precious than tin is preferably silver, copper, gold, or bismuth. HO-CH<2>CH<2>-S-(CH<2>CH<2>-O-CH<2>CH<2>-S)<n>-CH<2>CH<2>-OH (1).

Owner:MITSUBISHI MATERIALS CORP

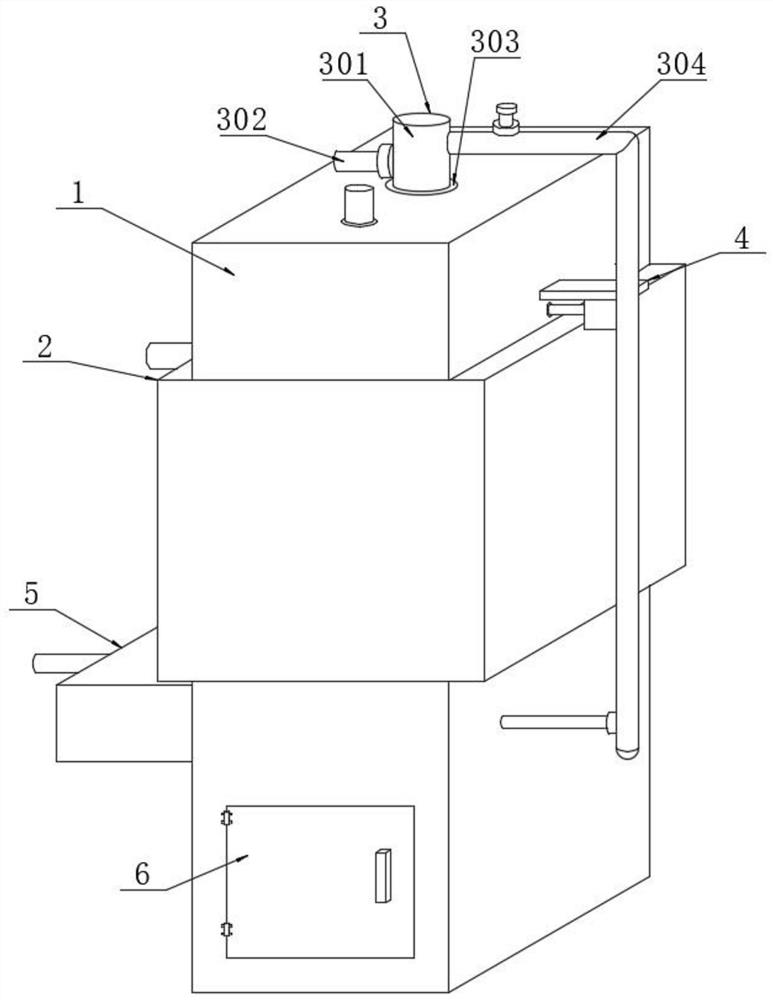

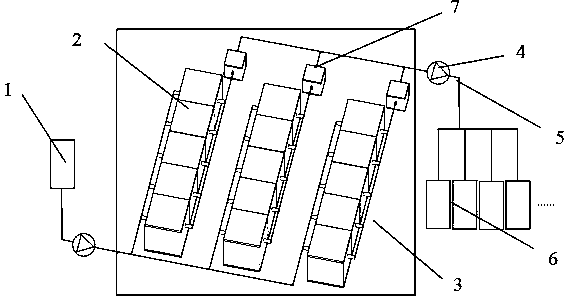

Reflux type ozone MBR (membrane bioreactor) sewage treatment equipment

InactiveCN107129048AImprove processing efficiencySmall footprintSemi-permeable membranesTreatment with aerobic and anaerobic processesOzone generatorReflux

The invention discloses reflux type ozone MBR (membrane bioreactor) sewage treatment equipment. The equipment comprises a reaction tank, an MBR membrane group, an ozone generator, an aeration device, a suction pump and a flow propeller. The reaction tank is partitioned into a biochemical reaction tank, an ozone reaction tank and a clear water tank by a longitudinal partition and a transverse partition, and the flow propeller propels sewage to circulate in the biochemical reaction tank and the ozone reaction tank. The MBR membrane group and the aeration device are arranged in the ozone reaction tank, and the ozone generator is adopted for aeration of the ozone reaction tank through the aeration device. Water treated by the MBR membrane group is pumped into the clear water tank by the suction pump. By high combination of the biochemical technique, the membrane technique and the ozone catalytic oxidation technique, space occupation of the system is reduced, the space utilization rate is increased, and high effluent quality and high treatment efficiency are realized; by ozone aeration for flushing of the MBR membrane group, sludge is prevented from deposition on the surface of the MBR membrane group, and independent arrangement of an aeration system for the MBR membrane group is avoided, so that equipment cost is saved.

Owner:湖南美奕机电科技有限公司

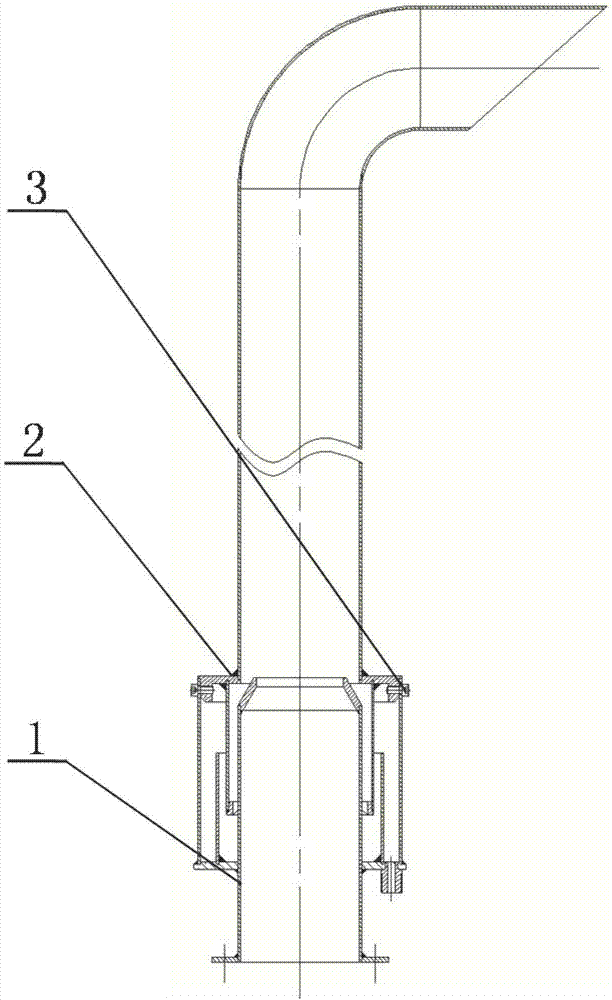

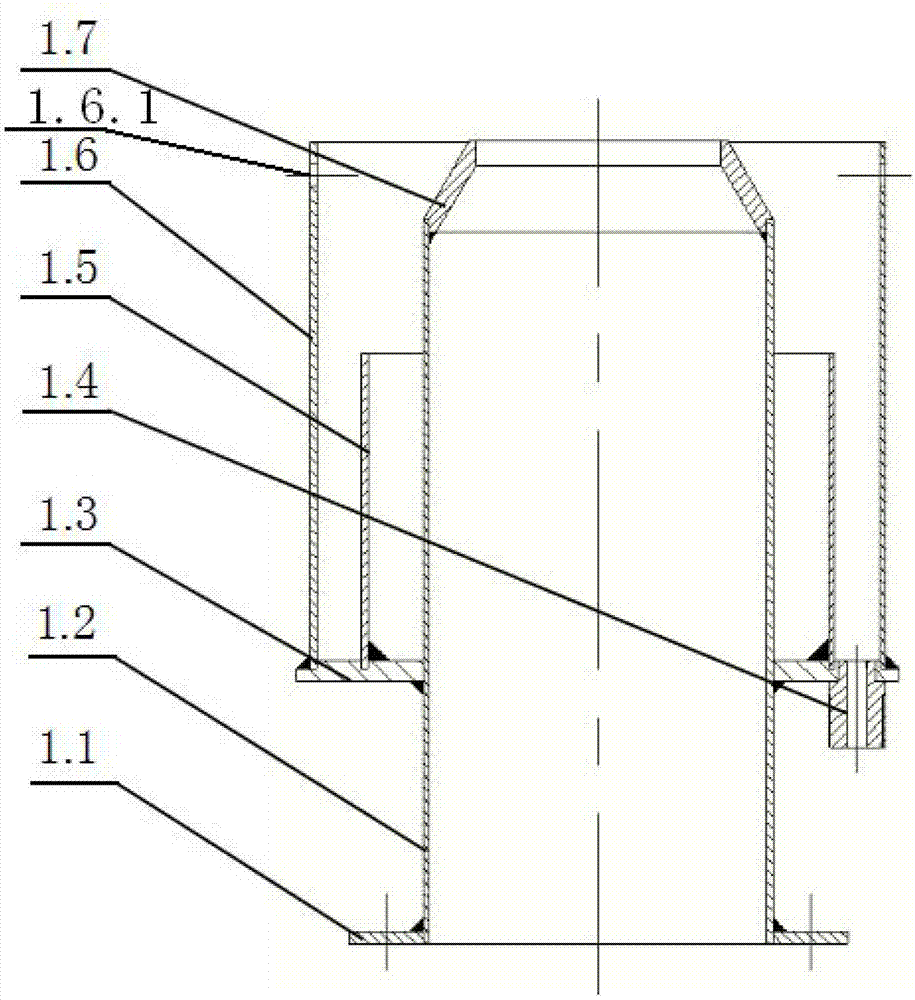

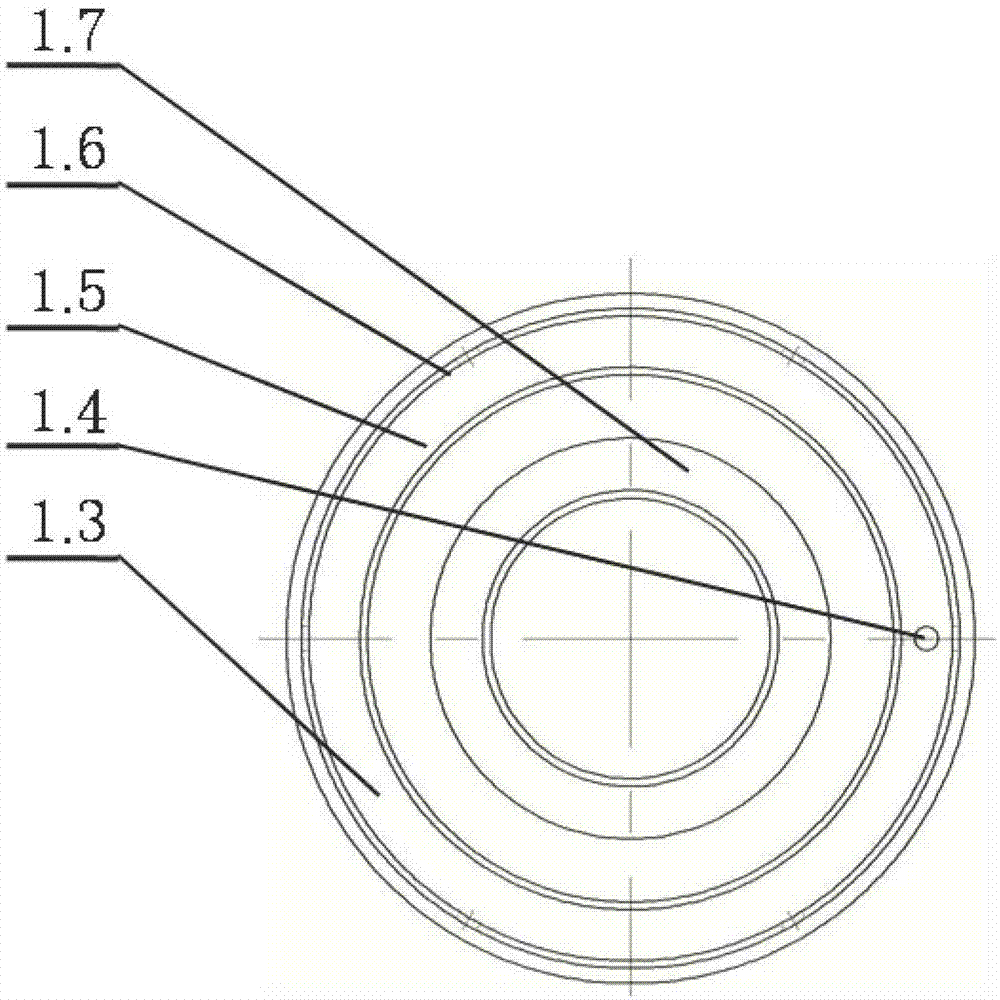

Liquid return preventing chimney

PendingCN107314386AImprove reflow effectEasy to transportDirt cleaningChimneysExhaust gas emissionsEngineering

The invention belongs to the technical field of exhaust gas emission equipment in the field of oil fields, chemical engineering, metallurgy and medicine, and particularly relates to a liquid return preventing chimney. The chimney comprises a chimney fixed part, a chimney detachable part and a fastener. The chimney detachable part is fixed to the upper portion of the chimney fixed part through the fastener. The problems that chimney wall congealed liquid flows back and operation sites are polluted according to a traditional chimney are solved, and the liquid return preventing chimney has the advantages that the effect of preventing chimney wall congealed liquid backflow is achieved, assembly and disassembly are convenient, and conveying is convenient.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

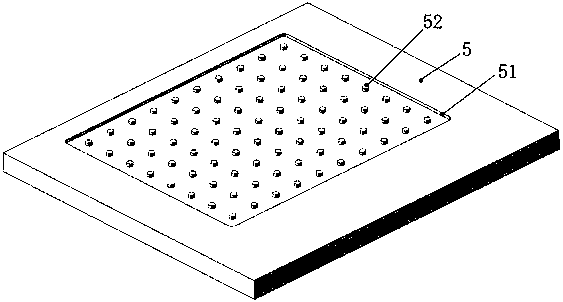

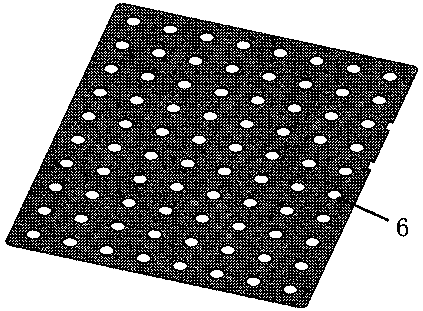

High-performance temperature equalization device

PendingCN109769380AIncrease profitEfficient and stable performance indicatorsCooling/ventilation/heating modificationsSolderingForce function

A high-performance temperature equalization device comprises a bottom plate, a liquid absorption core and a cover plate, wherein the cover plate is fixedly arranged on the bottom plate, a cuboid cavity is formed between the cover plate and the bottom plate, the liquid absorption core is arranged in the cavity, support posts are arranged in the cavity and are arranged on the liquid absorption corein a penetrating way, two ends of the support posts are fixedly connected with the bottom plate and the cover plate, a fixed sleeve fixedly sleeves each support post, an end surface of one end of thefixed sleeve is attached onto the cover plate and is fixedly connected with the cover plate, grooves are formed in an inner wall of the fixed sleeve and the cover plate, the support post is fixedly connected with a side wall and a bottom surface of the groove by vacuum soldering, the bottom plate and the cover plate both are attached onto the liquid absorption core, the groove in the cover plate is assembled with the support post on the bottom plate so that a soldering position is thoroughly separated from the liquid absorption core, and the liquid absorption core is prevented from losing capillary force function; and meanwhile, the welding quality of vacuum soldering is improved to a great extent, a high-efficiency and stable performance index of the temperature equalization device is provided, the upper-layer liquid absorption core and the cover plate can be more closely attached by a diversion ring, and the heat conduction capability and the heat transfer capability of the device are improved.

Owner:XINXIANG TEMEITE HEAT TRASFER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com