Tellurium retort

A distillation furnace and distillation tank technology, applied in distillation separation, selenium/tellurium compounds, inorganic chemistry, etc., can solve the problems of small capacity and low output of tellurium distillation furnaces, achieve improved reflux effect, increase crystal quality, and obvious temperature gradient Effect

Inactive Publication Date: 2007-10-31

成都汉普高新材料有限公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention is to provide a large-capacity tellurium distillation furnace for the shortcomings of the existing tellurium distillation furnace, such as small capacity and low output.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

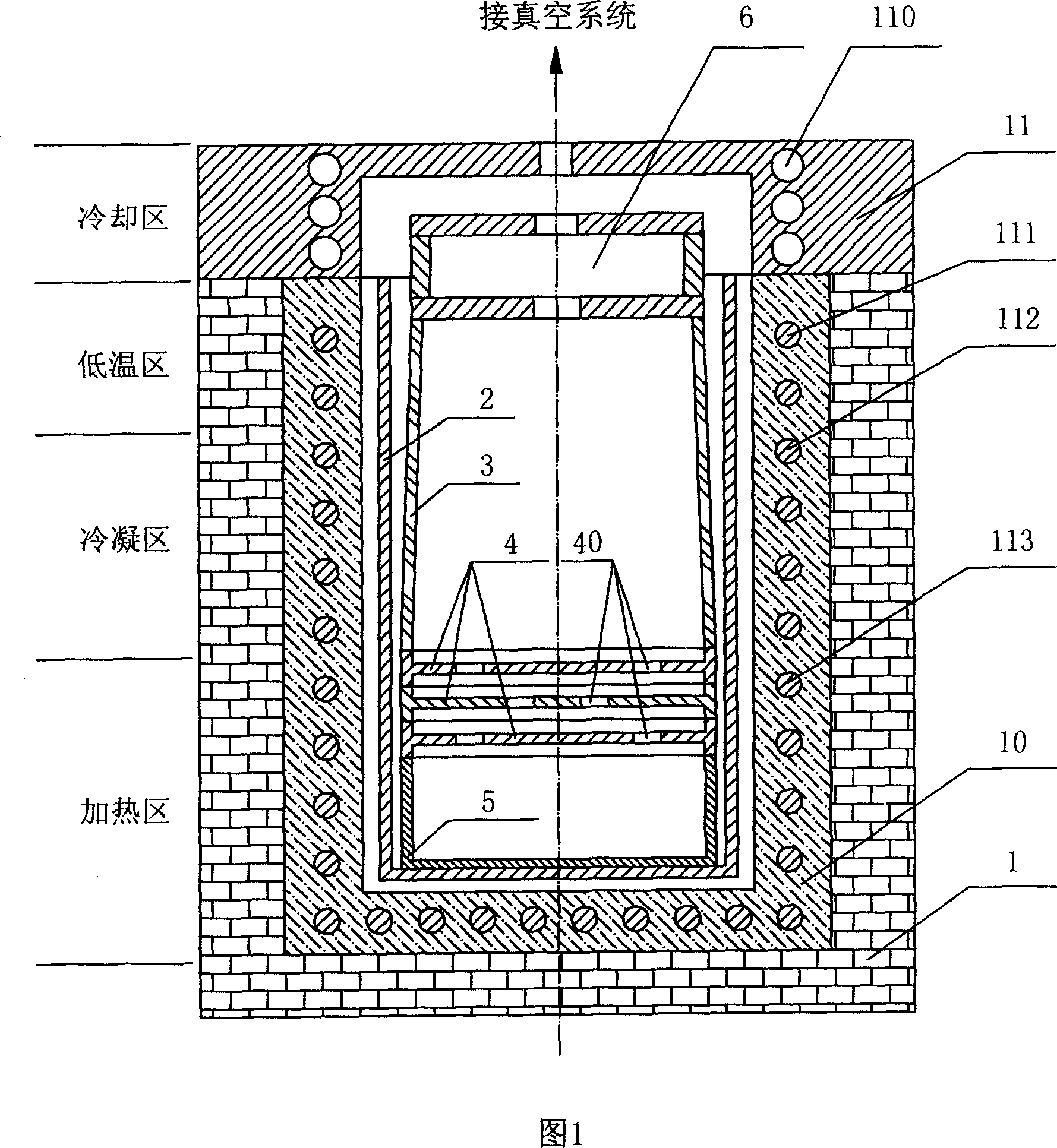

[0036] The distillation furnace structure of this example is referring to Fig. 1.

[0037] 1. Distillation tank

[0038] Material

[0039] 2. Crucible

[0040] Material

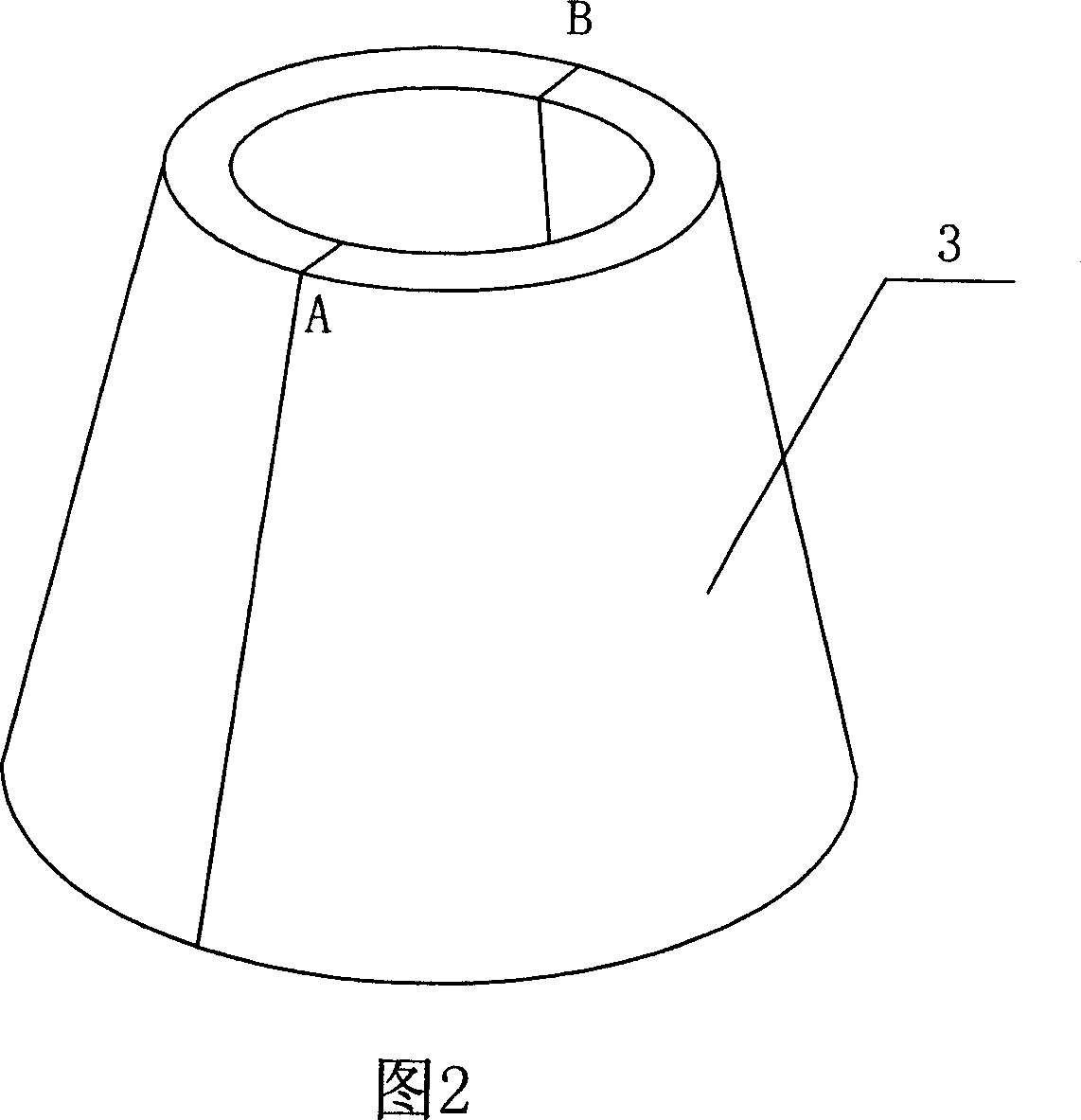

[0041] 3. Condenser

[0042] Material

[0043] 4. Heating and cooling system

[0044] way to heat up

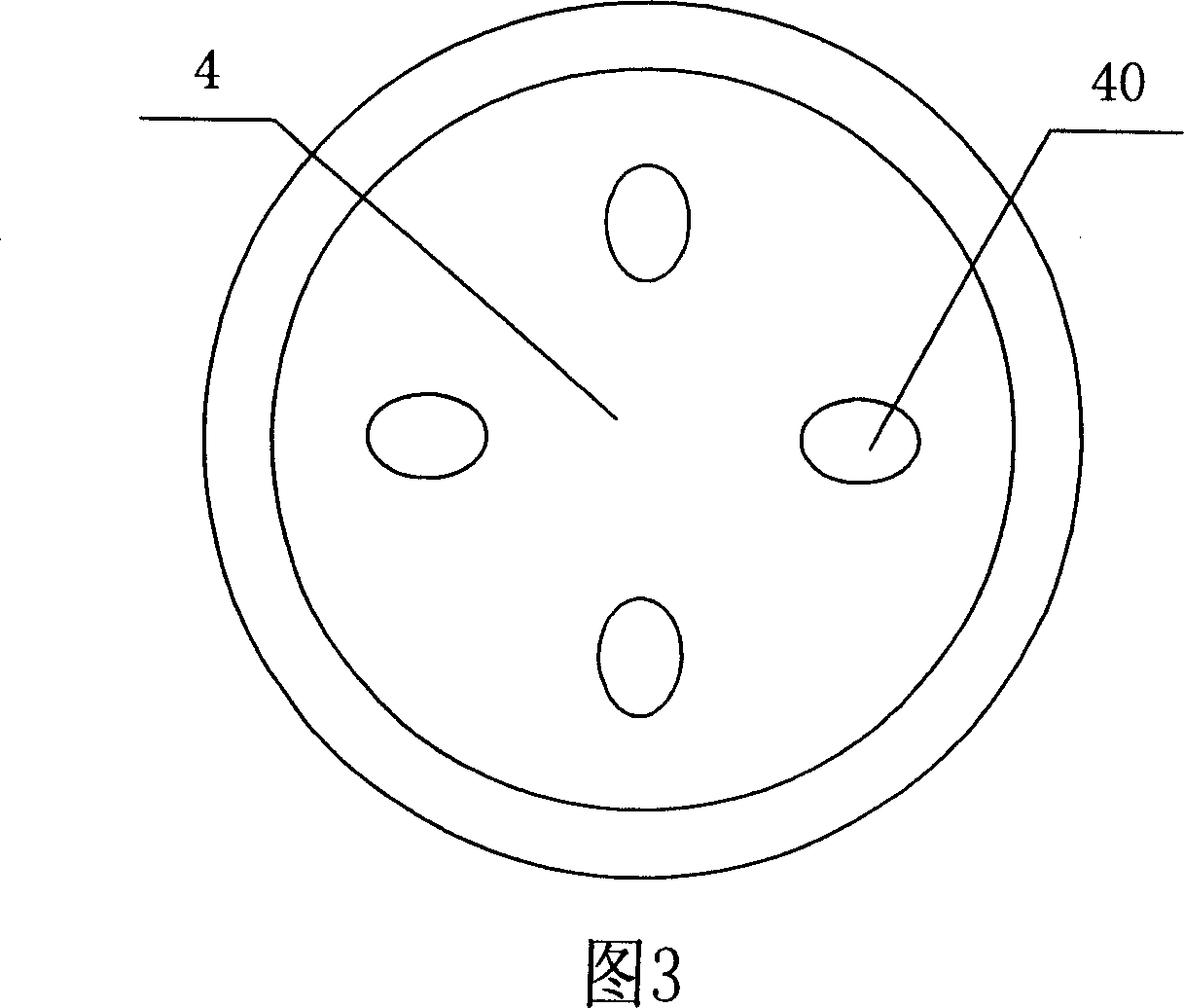

[0045] 5. Tray system

[0046] Number of tray layers

[0047] Indicator name

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a solid fusion distilling technology especially a tellurium retort structure, which comprises the following steps: resolving the problems of small volume and low output; making the tellurium retort comprises distilling pot, copple and condenser; producing the distilling pot with rustless steel; choosing the diameter of distilling pot at 200-300mm, equipping column plate on the lower end of the condenser. This invention increases the output of single furnace and decreases the cost of production.

Description

technical field [0001] The invention relates to solid melting distillation technology, in particular to tellurium distillation furnace structure. Background technique [0002] Vacuum distillation is an important method for preparing high-purity tellurium, which is generally used in the production of 5N high-purity tellurium (99.999% tellurium content). The basic principle of this method is: heat 4N tellurium to the melting point, and the liquid tellurium volatilizes into tellurium vapor in a vacuum state, and the tellurium vapor rises and condenses when it is condensed. Different, condensed in different areas, so that impurity elements can be separated. [0003] The structure of the existing tellurium distillation equipment (distillation furnace) generally includes a distillation tank, a crucible and a condenser. The distillation tank is placed in the heating furnace, the crucible and the condenser are placed in the distillation tank, the lower end of the condenser is conn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B19/00B01D3/00

Inventor 谈逊段威

Owner 成都汉普高新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com