Piezoelectric inkjet printing spray head structure preventing ink backflow

An inkjet printing and nozzle technology, which is applied in the field of piezoelectric inkjet printing nozzle structures for preventing ink backflow, can solve problems such as increasing the cost of ink cartridges, and achieve the effects of improving inkjet efficiency, reducing manufacturing costs and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

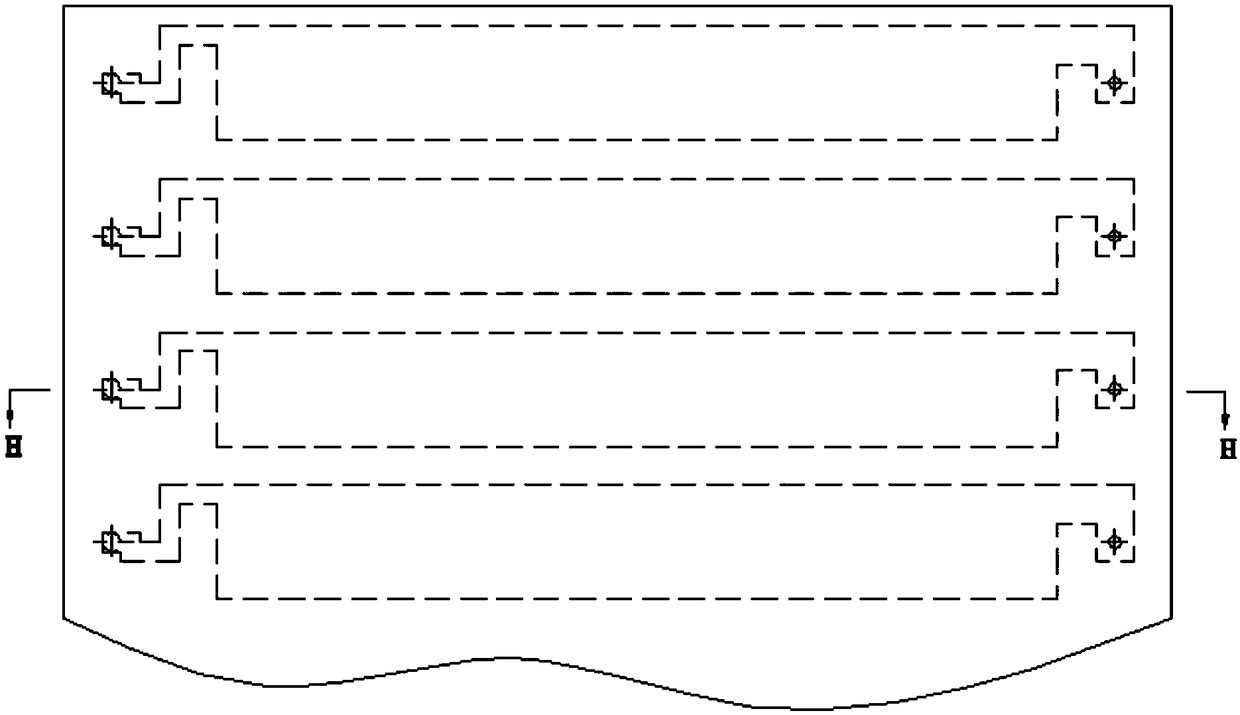

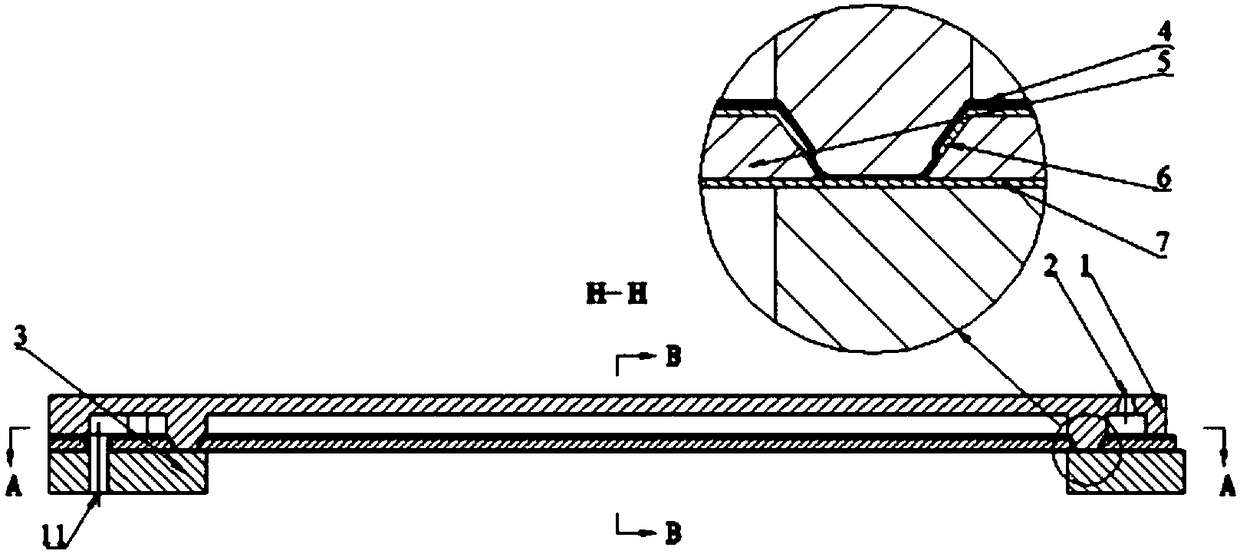

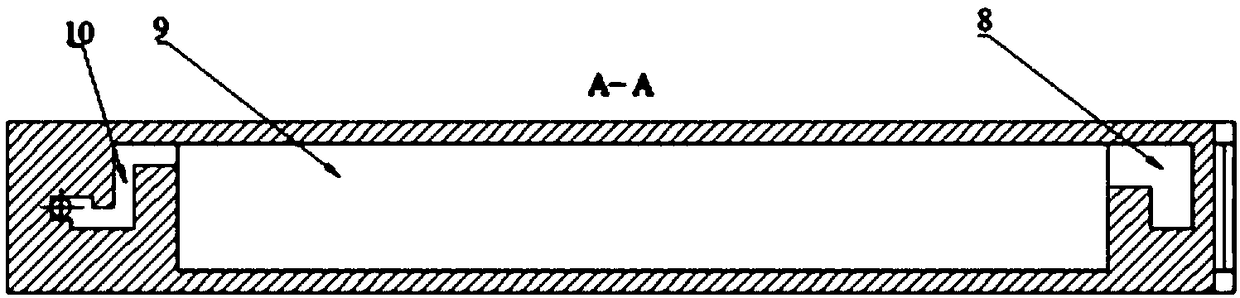

[0062] Such as figure 1 As shown, a piezoelectric inkjet printing head for preventing ink backflow in this embodiment includes a plurality of chambers, such as Figure 2a As shown in -c, each chamber includes: an ink supply channel 11 , a restrictor 10 , a pressure generating chamber 9 , a drain 8 , a nozzle 2 , an upper electrode 6 , a piezoelectric ceramic 5 , a lower electrode 7 , and a vibrating plate 4 .

[0063] Such as image 3 As shown, the structural size of the restrictor in this design is: the length of side a is 50um, the length of side b is 150um, the length of side c is 25um, the length of side d is 50um, the length of side e is 150um, and the length of side f is 150um. The length of side g is 150um, the length of side g is 50um, the length of side h is 100um, the length of side i is 150um, the length of side j is 150um, the length of side k is 25um, and the length of side l is 100um, such as Image 6 As shown, the height of the pressure generating chamber, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com