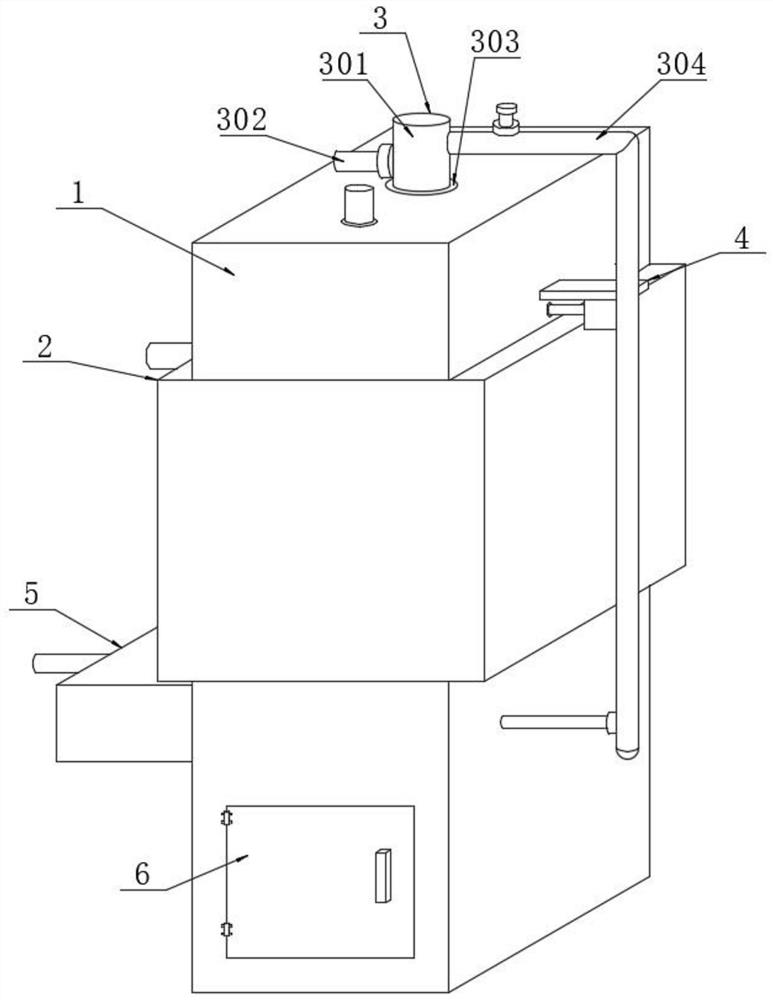

Daily chemical production device with distillation function and rapid discharging function and daily chemical production method

A technology for production equipment and chemicals, which is applied in chemical instruments and methods, separation methods, distillation adjustment/control, etc., can solve the problems of slow discharge efficiency, impact on durable life, low reflux efficiency, etc., and improve condensate output The effect of avoiding condensation and scaling and reducing the difficulty of discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

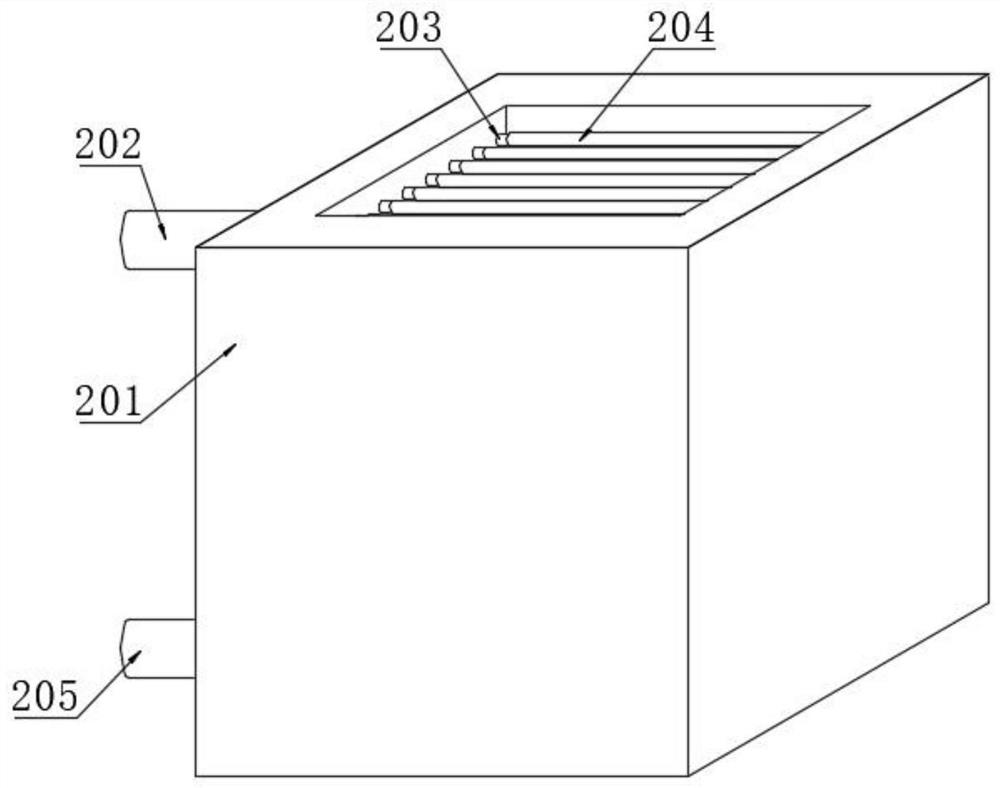

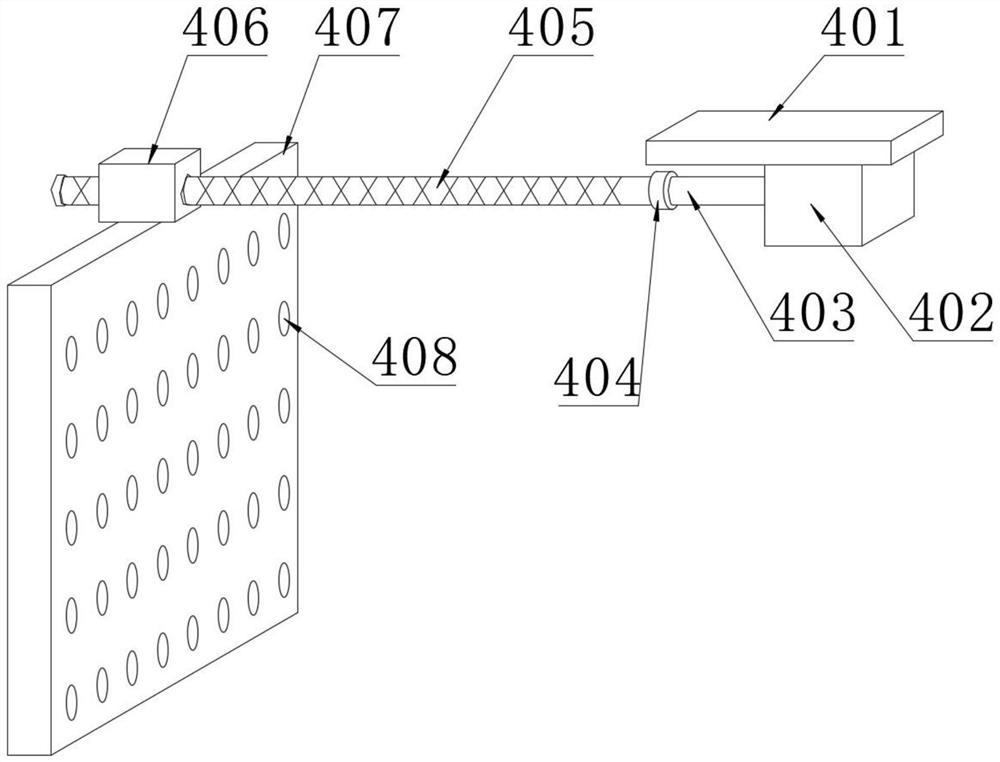

[0047] The implementation method is as follows: when a small amount of steam continues to move upward after the steam is condensed, it can enter the gas collecting hood 301 through the bottom air funnel 305, and when the steam reaches the discharge standard, it can be exhausted through the side suction branch pipe 302 to avoid backflow Affecting the distillation accuracy, when the distillate still exists, after the air pressure is enough to open the valve on one side, it enters the bottom of the distillation tower 1 through the first return pipe 304 connected on one side to reflux and condenses again under the drive of the bottom steam Distillation, so that the distillate can be fully recovered and condensed, effectively increasing the condensed liquid output, and after the condensation is completed, the spray main pipe 306 connected to the side of the external spray pump can be pumped into the spray branch pipe 307 for spray cleaning After the cleaning liquid is sprayed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com