Patents

Literature

332results about How to "Quick disassembly and replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

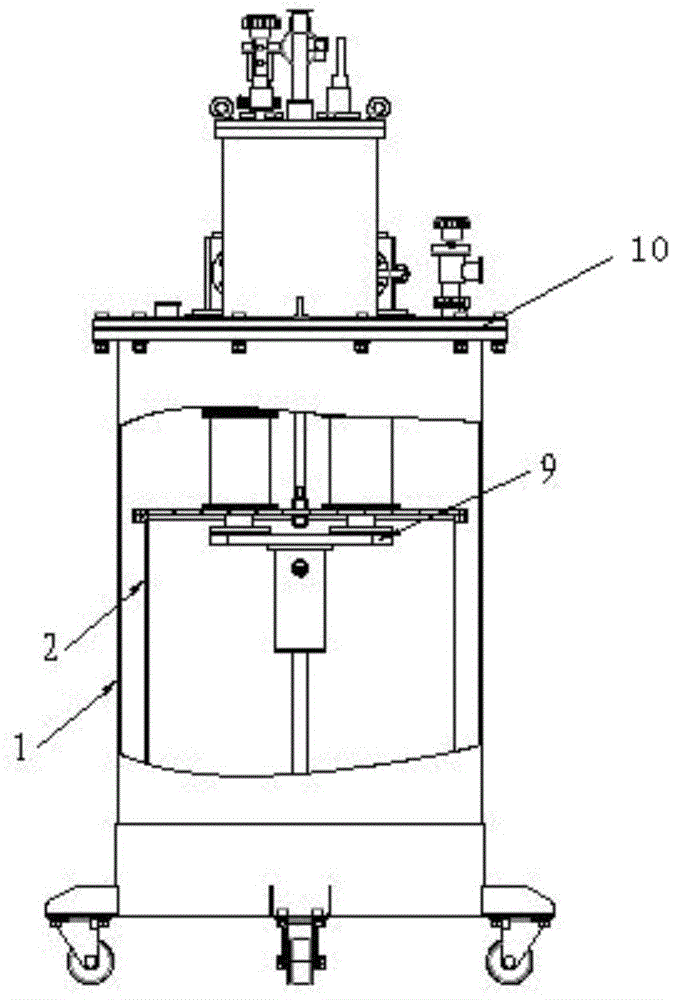

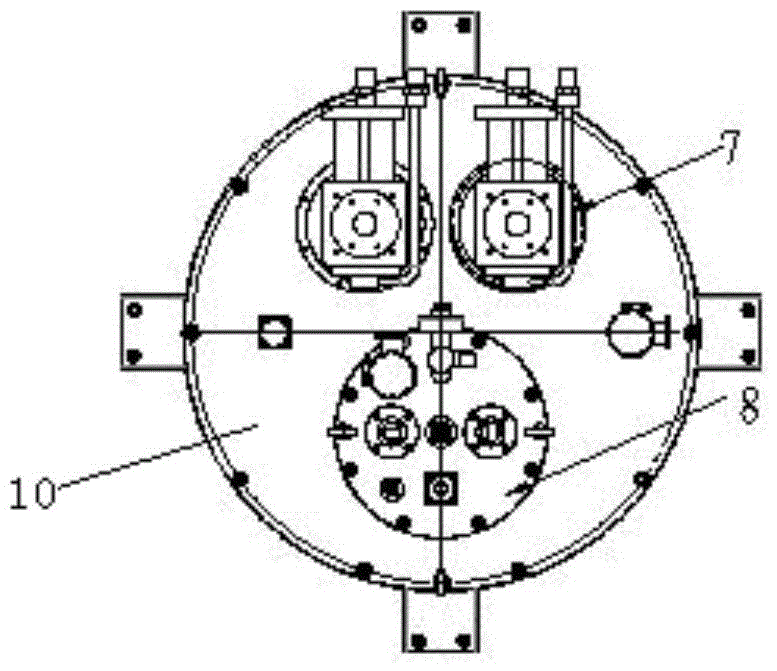

High-temperature superconducting low-temperature helium self-circulation cooling system

ActiveCN103606430ARealize self-circulationSimplify operating proceduresCompression machinesSuperconducting magnets/coilsHigh-temperature superconductivitySuperconducting Coils

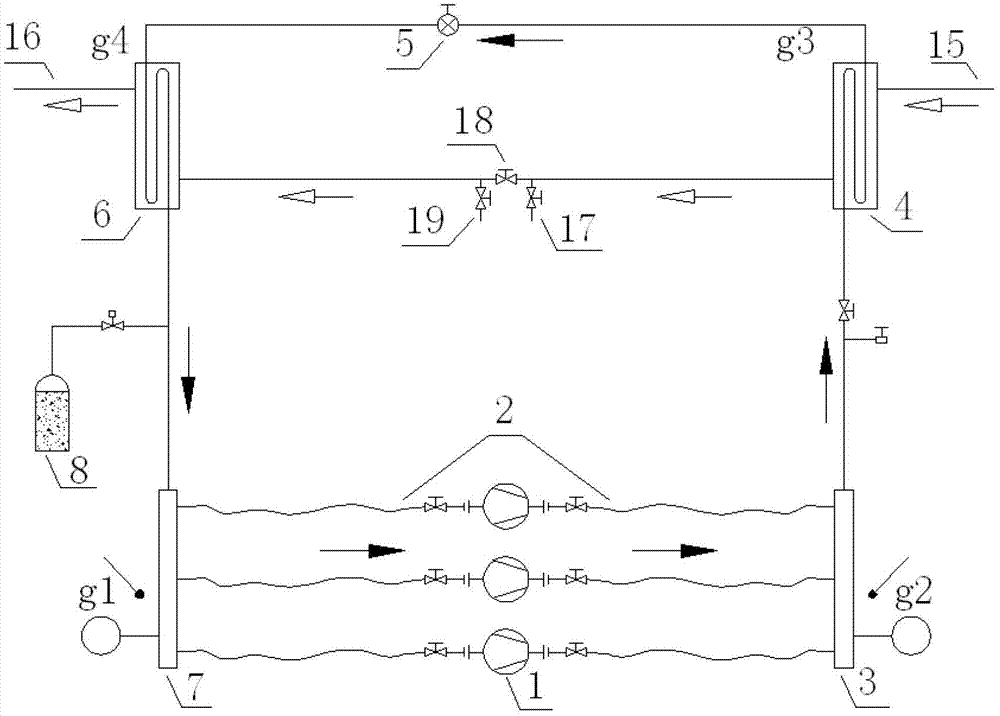

The invention discloses a high-temperature superconducting low-temperature helium self-circulation cooling system. Vertical temperature and density differences of low-temperature helium in the system allow natural convective circulation to form, and the problems that the superconducting magnet used in the direct cooling manner of a small refrigerator is poor in cooling effect and the necessary application of expensive low-temperature helium pumps in forced convective circulation cooling causes high cost are solved. After the system stabilizes, operating pressure is low; the safety problem is solved. A superconducting magnet and a current lead form a whole which can be lifted in or out of magnet mounting space and which is convenient to demount, mount and change; cooling medium helium has controllable temperature, and conditions for the study on performances of high-temperature superconducting magnets at specific temperature are provided.

Owner:VACREE TECH +1

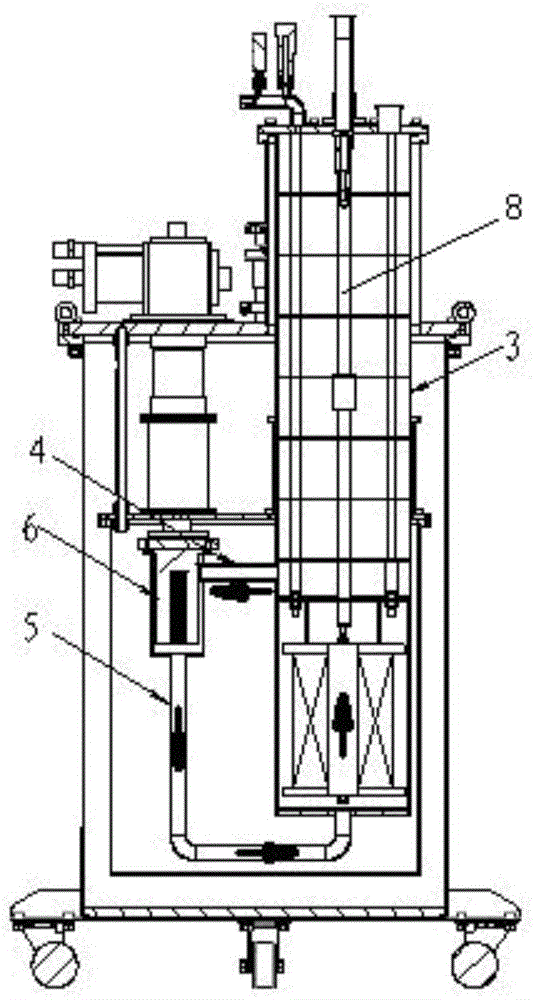

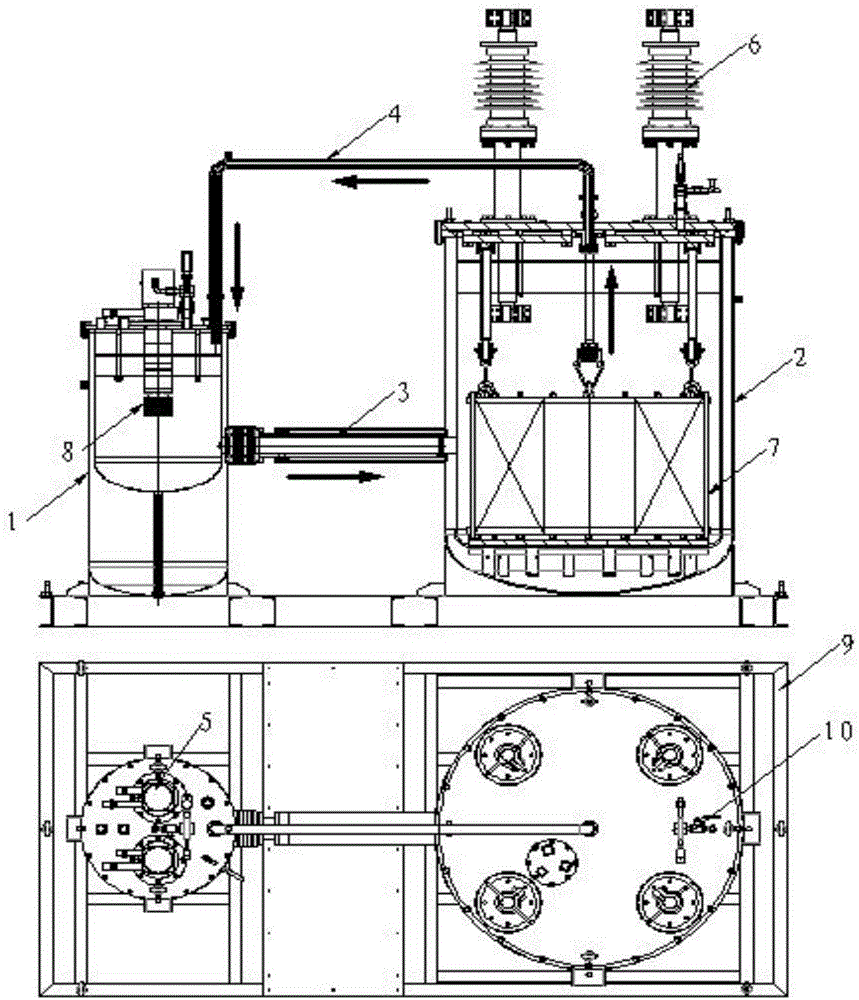

High-temperature superconducting magnet liquid nitrogen zero-evaporation cooling system

ActiveCN103985499AAccelerate evaporationSimplify operating proceduresSuperconducting magnets/coilsWhole bodyCooling effect

The invention discloses a high-temperature superconducting magnet liquid nitrogen zero-evaporation cooling system. Liquid nitrogen is selected to be used as cooling media, a thermosyphon principle is utilized, and in addition, a superconducting magnet is cooled in a way of forming a refrigerating machine installing dewar, a magnet cooling dewar, a liquid nitrogen communication pipeline and an evaporation nitrogen gas communication pipeline into a sealed circulation system. The high-temperature superconducting magnet liquid nitrogen zero-evaporation cooling system solves the problems that in the liquid nitrogen direct soaking cooling mode, liquid nitrogen needs to be regularly supplemented, in the large-cooling-capacity direct cooling mode, the superconducting magnet cooling effect is poor, in the forced convection circulation cooling, a high-price low-temperature nitrogen pump needs to be adopted, and the cost is high. The temperature of cooling media of liquid nitrogen is controllable, conditions are provided for studying the performance of high-temperature superconducting magnets at the specific temperature. The system has the advantages that the refrigerating machine and the superconducting magnet are placed in a separated way, the damage to the refrigerating machine caused by superconducting magnet superconducting loss is avoided, and the safety is improved. The superconducting magnet and a current lead wire form a whole body which can be directly hung out from or hung into the magnet cooling dewar, and the dismounting, the mounting and the replacement are convenient.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

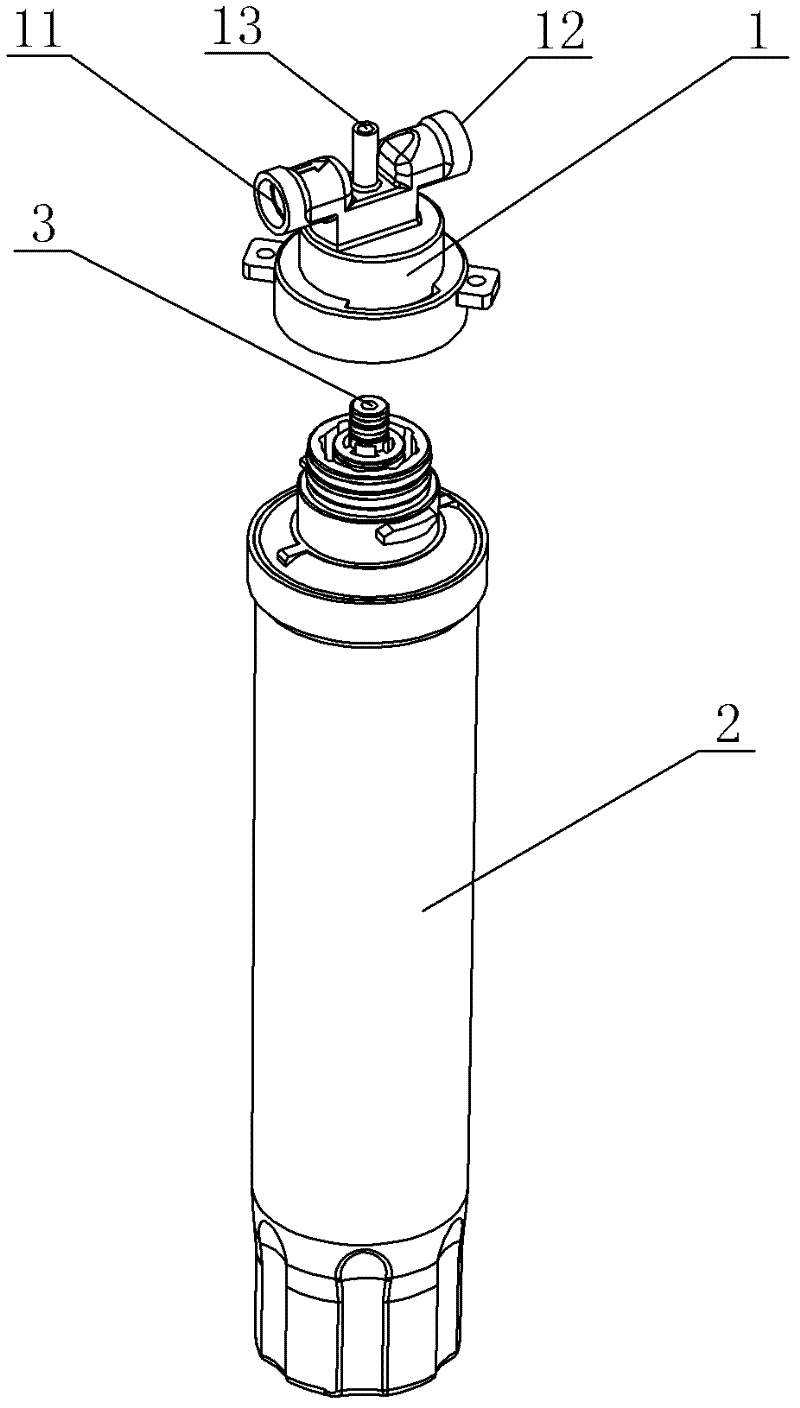

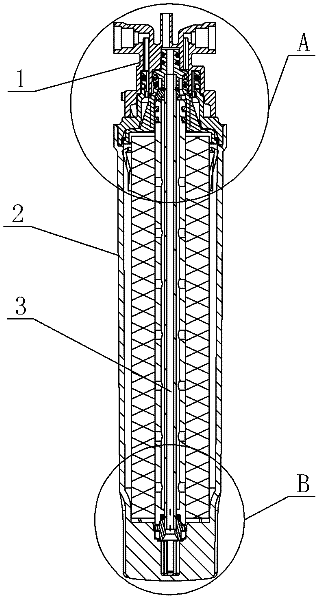

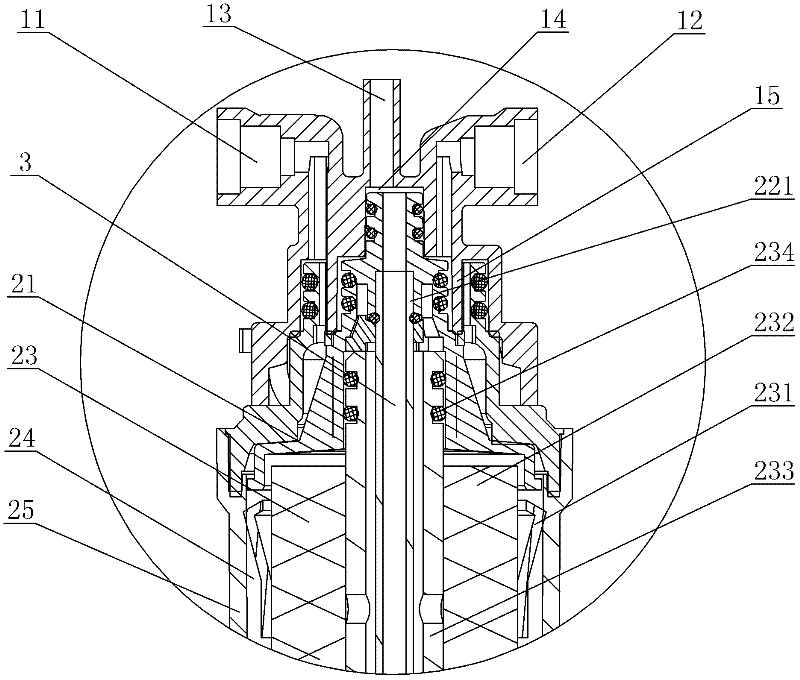

Filter element and joint seat thereof

ActiveCN102407041AQuick disassembly and replacementGood lookingWater/sewage treatment bu osmosis/dialysisStationary filtering element filtersBiochemical engineeringWastewater

The invention discloses a filter element and a joint seat thereof. The filter element comprises a filter element joint seat, a filter element body and a wastewater pipeline, wherein the filter element body is arranged on the filter element joint seat; the filter element joint seat also comprises a water inlet and a water outlet, which are respectively arranged at the two sides of the filter element joint seat, and also is provided with a wastewater port; the wastewater pipeline is arranged in the filter element body; and the wastewater pipeline is communicated with the wastewater port on the filter element joint seat after the filter element body is installed on the filter element joint seat. By adopting the technical scheme in the invention, the filter element with three interfaces on the filter element joint seat can be assembled, disassembled and replaced as rapidly as the filter element with two interfaces, thus being more convenient in use operation. Due to no increase of an additional external wastewater pipe, the filter element and the components of the filter element can be concise in appearance.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

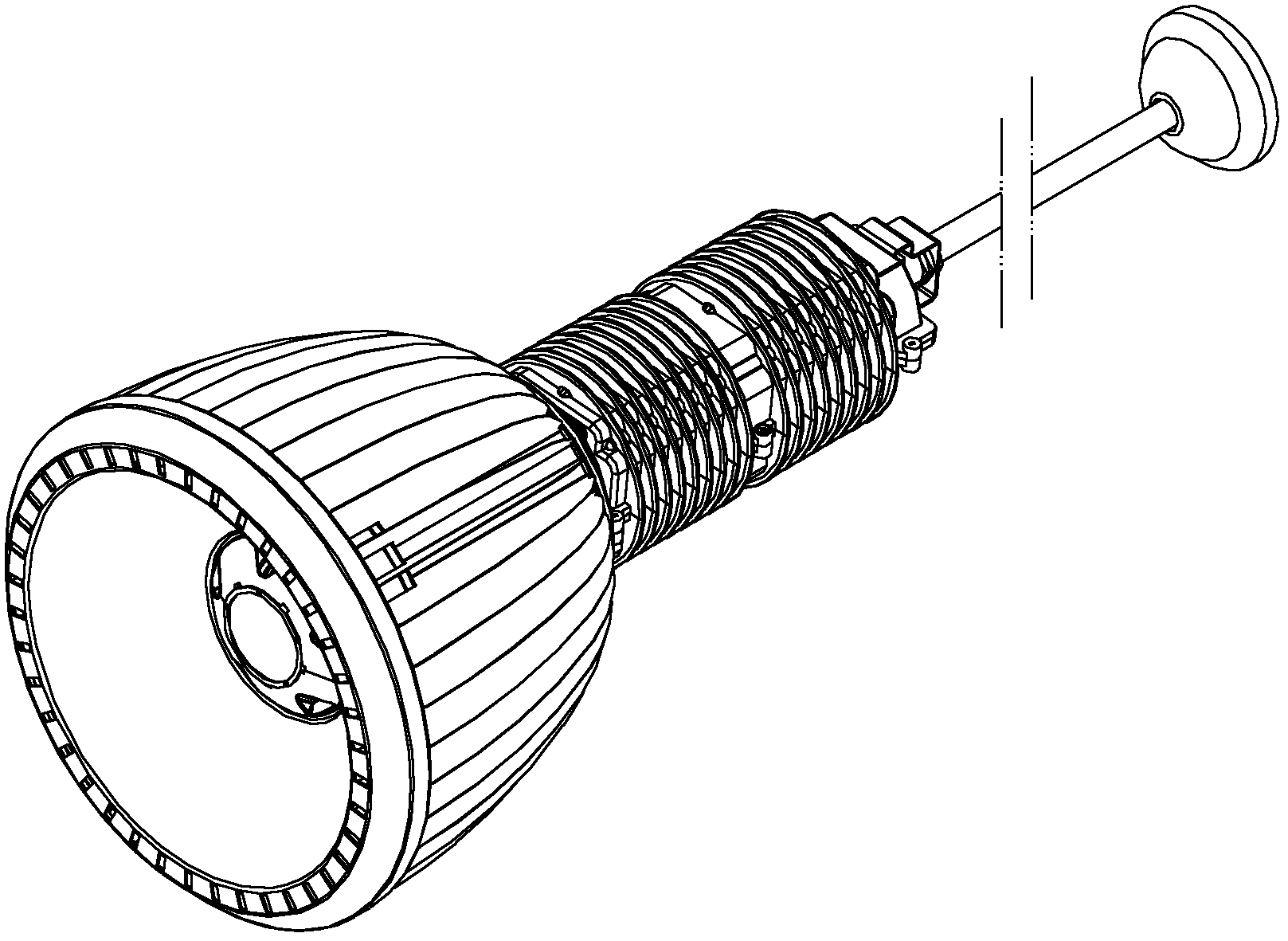

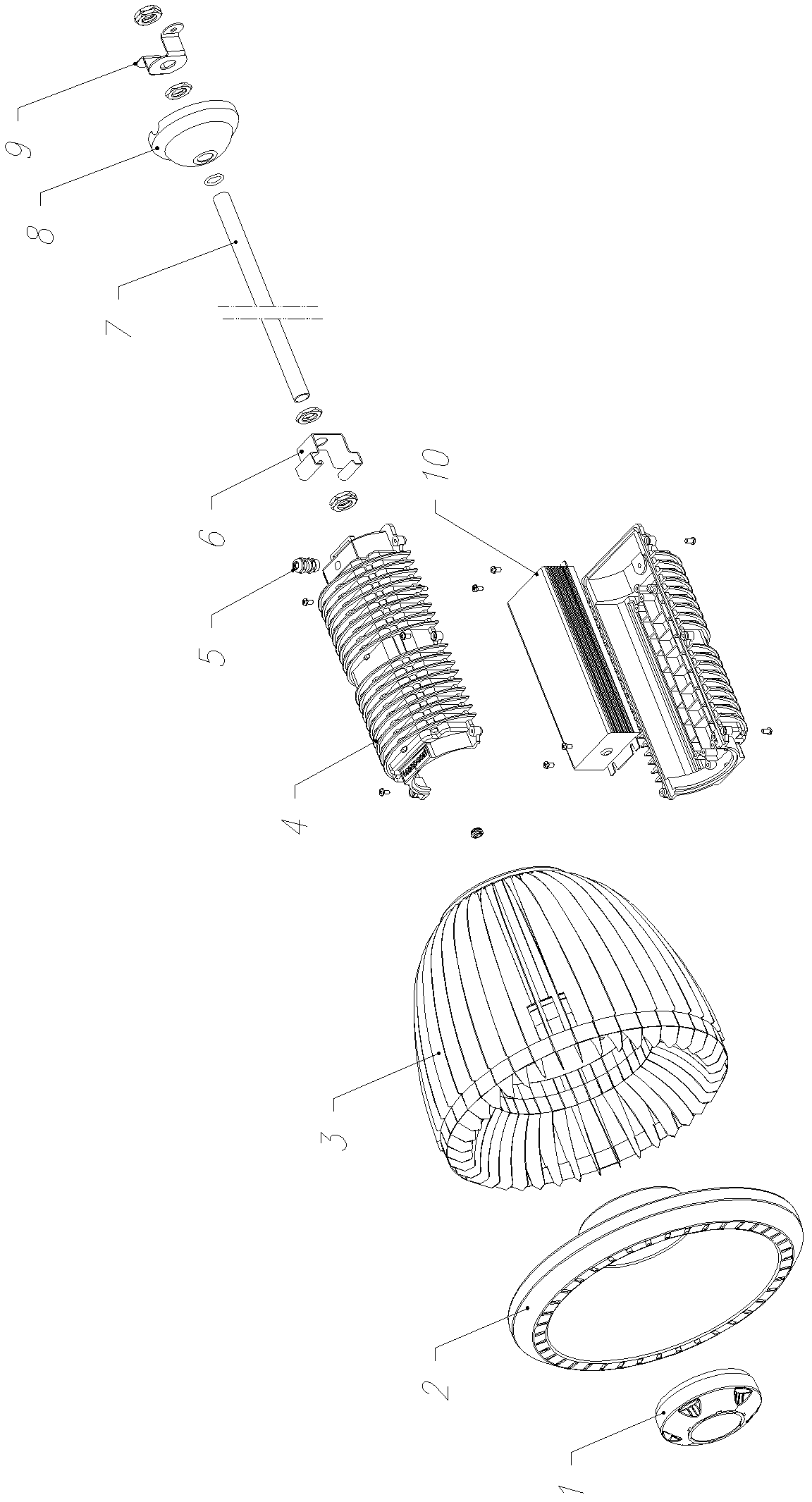

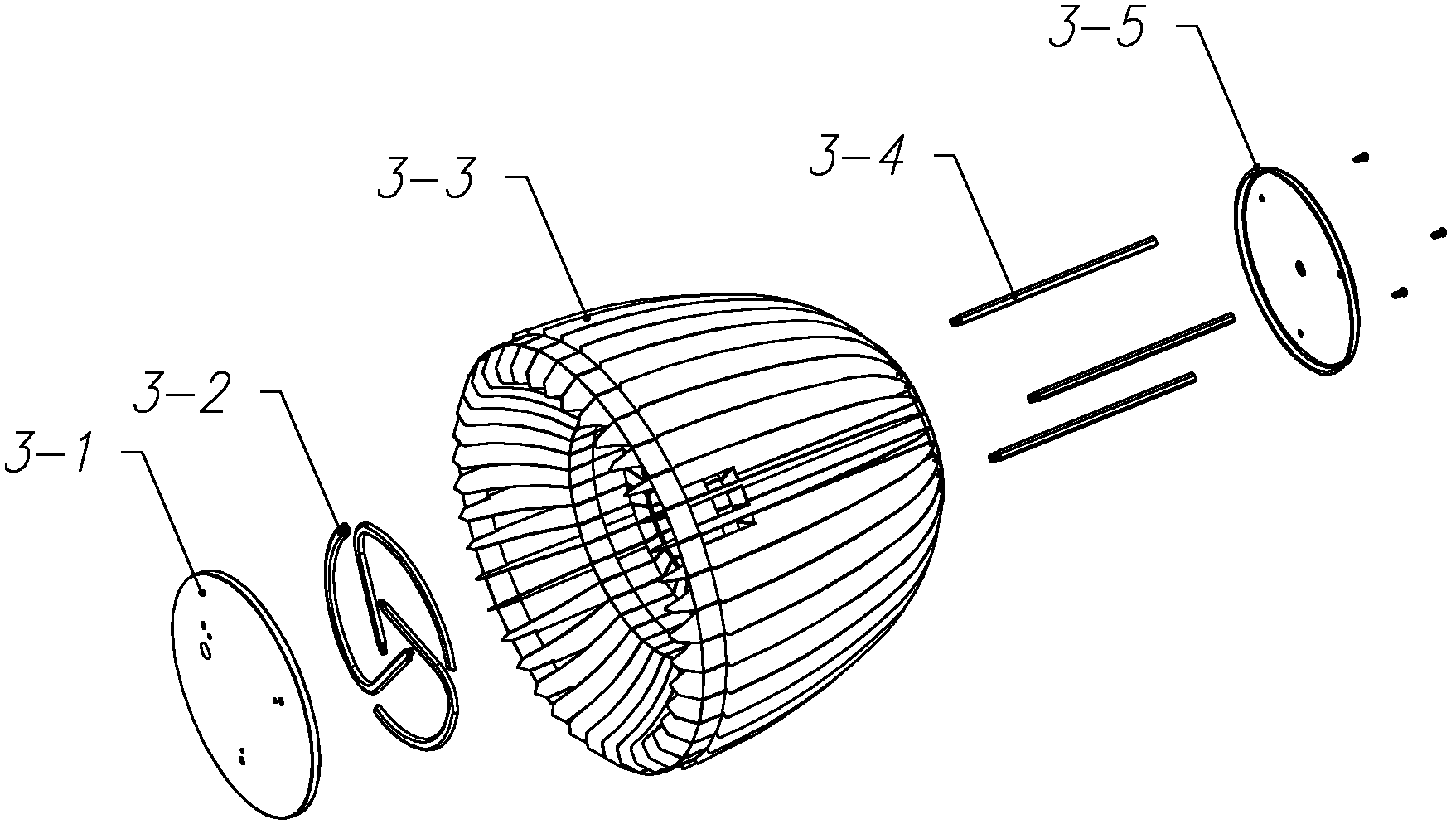

Light-emitting diode (LED) high-roof lamp

InactiveCN102494289AEasy to disassemble and replaceQuick releasePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight-emitting diode

The invention discloses a light-emitting diode (LED) high-roof lamp, which comprises a driver, a radiator assembly and a light source assembly, wherein the radiator assembly has a bowl-shaped structure; radiating fins of the radiator assembly are arranged in a circumferential array and are buckled mutually to form a bowl wall frame; and the light source assembly has an integrally-encapsulated structure, is fixed to a bowl abdomen enclosed by the bowl wall frame and is electrically connected with the driver fixed to the bowl bottom of the bowl-shaped structure in a movable mode. According to the LED high-roof lamp, due to the utilization of a radiating structure of combining a heat conduction pipe and the radiating fins, a good radiating effect is ensured, and both the light source assembly and the radiator assembly are easy to disassemble and replace.

Owner:BEIJING LAMPEARL PHOTOELECTRIC

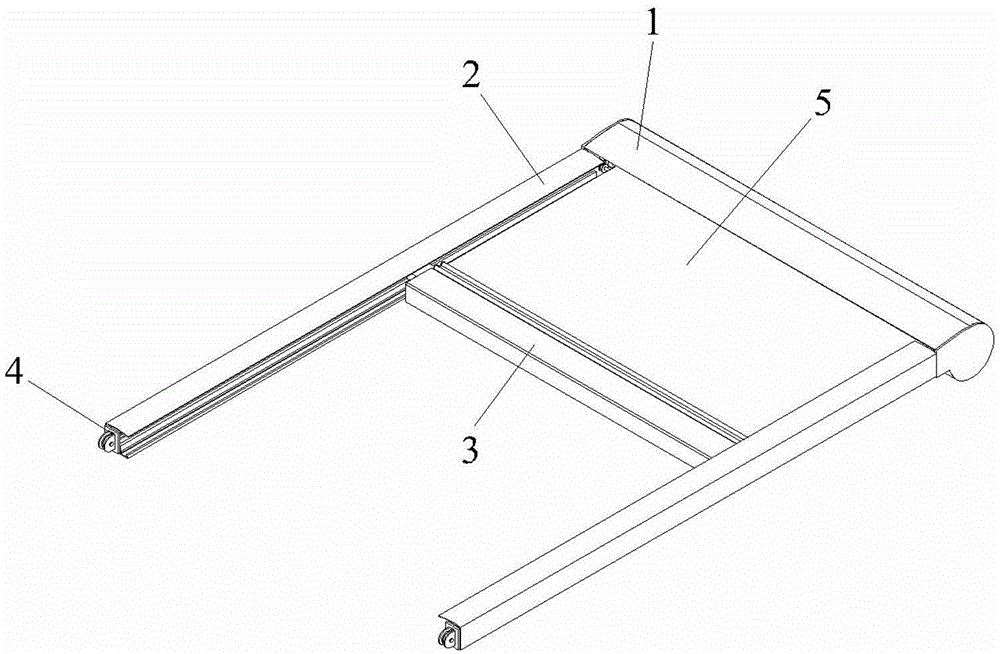

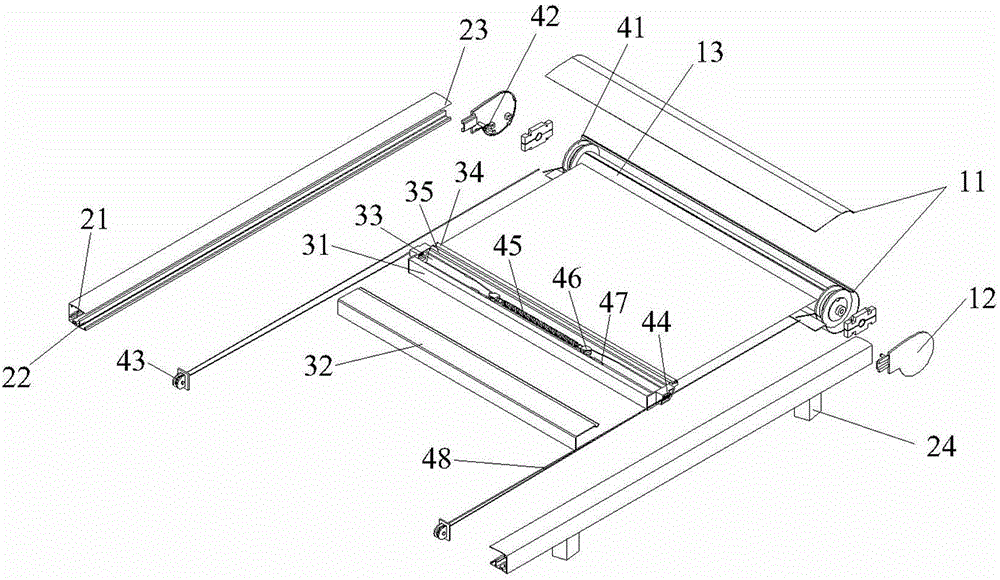

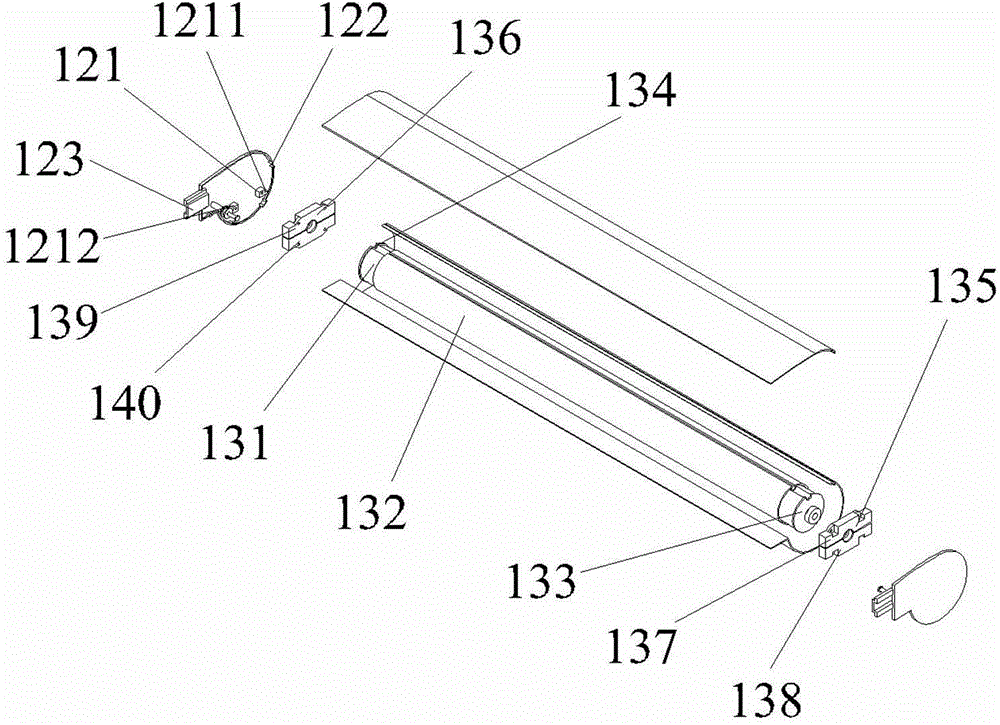

Seamless canopy awning

The invention relates to a seamless canopy awning and belongs to the technical field of outdoor automatic sun-shading. The seamless canopy awning comprises a cloth winding device, a guide rail structure, a sun-shading cloth bottom beam and a traction structure. The cloth winding device is provided with sun-shading cloth. The guide rail structure comprises a traction space containing the traction structure and a bottom beam moving space formed beside the traction space to contain the end of the sun-shading cloth bottom beam. The bottom beam moving space is connected with an extension stop part. According to the scheme, the seamless canopy awning can shade people from sun completely.

Owner:浙江恒红节能科技有限公司

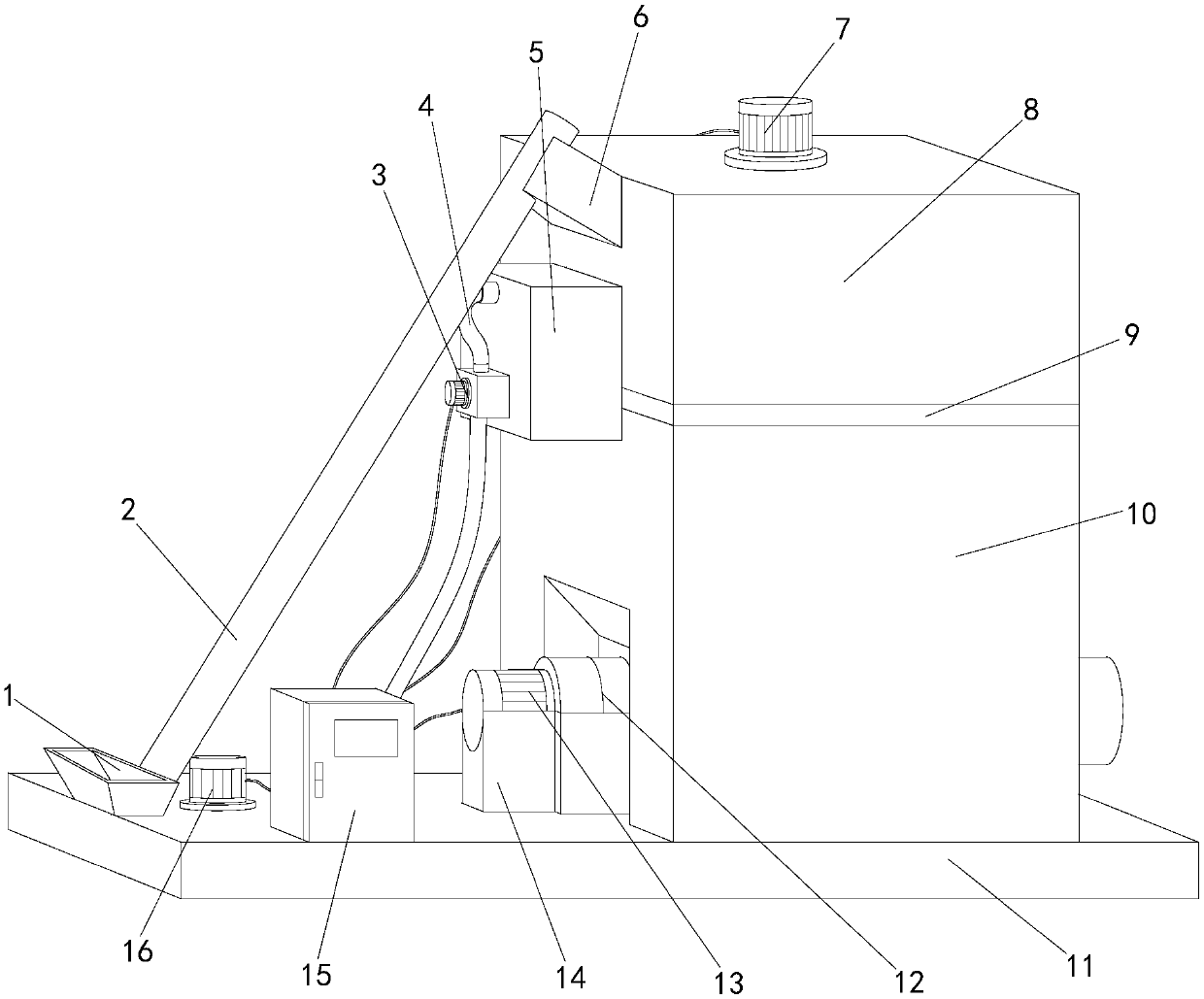

Novel integrated fish forage granule production device

The invention discloses a novel integrated fish forage granule production device. The structure comprises a dry material adding bucket, an elevator, an extraction pump, a feeding tube, a liquid powderadding box, a feed joint, a crushing and stirring motor, a crushing box, a connecting plate, a mixing box, a base, a screw extruder, an extrusion motor, an extrusion assembly seat, a controller, anda lift motor. the base is cuboid; the dry material adding bucket is embedded to a left side of the top end of the base; When the equipment is used, main material and auxiliary materials can be automatically added to the stirring box at ratios by using the ropes, gears, ejector rods, springs and other mechanisms without programming and the main material feeding port is automatically locked when theauxiliary material is used up. automatic control of discharging is also carried out at equal time intervals so that the device can evenly stir so avoid loss and inconvenience caused by mis-programming; the stirring shaft rod of the device is splicing type so that the device can be quickly disassembled or cleaned and is convenient to use.

Owner:JIANGMEN YUEHAI FEED

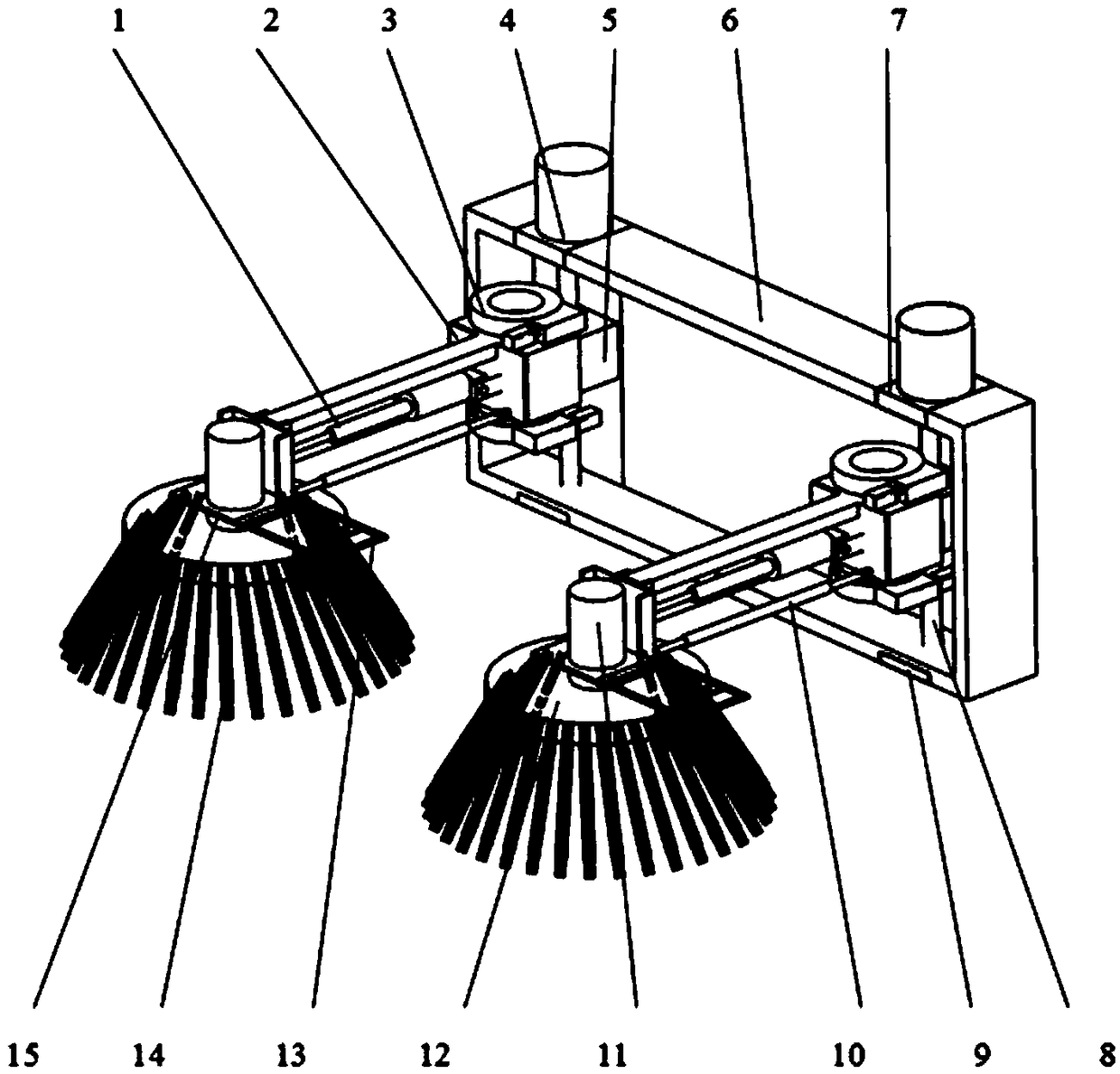

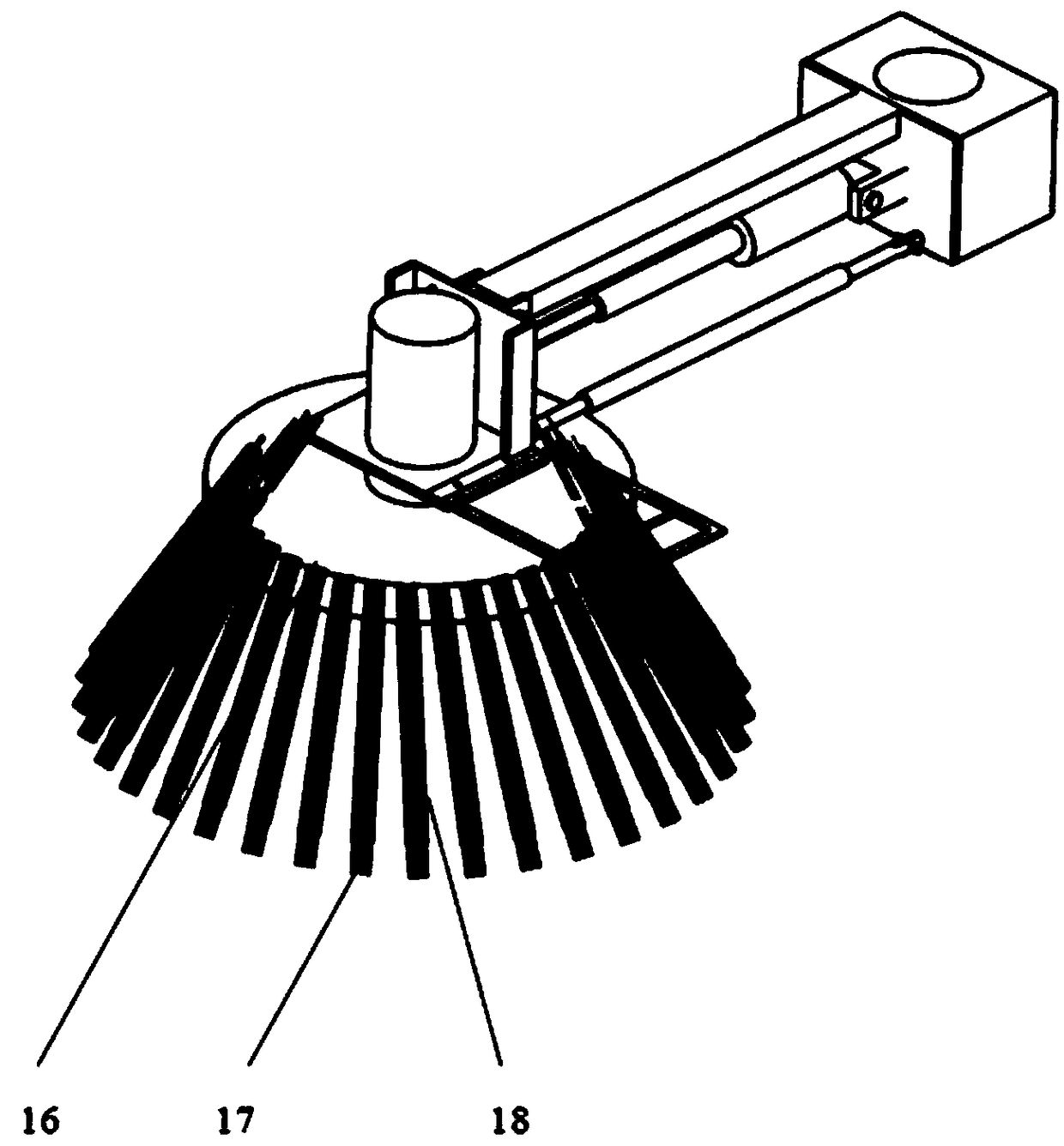

Novel intelligent road cleaning vehicle side brush device

ActiveCN109024408AAutomatically adjust the cleaning range at willAdjustable contact distanceRoad cleaningBristleBrush device

The invention discloses a novel intelligent road cleaning vehicle side brush device. The device comprises a support fixed at the front end of the cleaning vehicle. The support is of a frame-shaped structure. The inside of the support is symmetrically equipped with two edge brush lifting assemblies which are symmetrically arranged, rotary support seats fixedly connected to that two edge brush lifting bearings are arranged at upper and lower ends of the rotary support seats., , A slewing bearing at the upper end is fixedly connected with a connecting rod, A brush bracket is rotatably connected with one end of the connecting rod away from the rotary bearing, the upper end of the brush bracket is fixedly connected with a motor, The end of the output shaft of the motor penetrates the brush bracket and is fixedly connected with a bristle mechanism; an electric push rod is rotatably connected with the side wall of the rotary support seat; the telescopic end of the electric push rod is rotatably connected with the brush bracket; and an air cylinder is rotatably connected with the side wall of the rotary support seat. The novel intelligent road cleaning vehicle edge brush device provided bythe invention has the advantages of simple structure, convenient operation, wide cleaning range and high efficiency.

Owner:HUAIHAI INST OF TECH

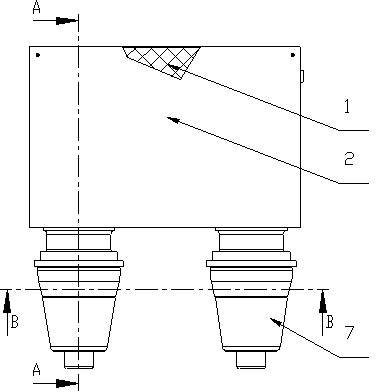

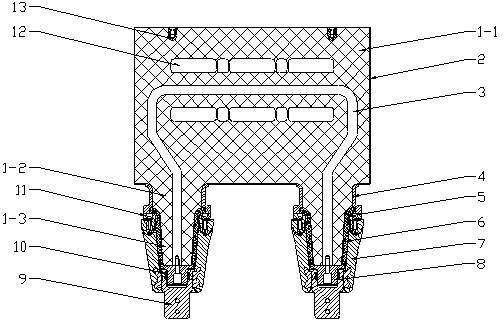

Plug type current transformer

InactiveCN103632827ANo operation involvedQuick disassembly and replacementTransformersTransformers/inductances casingsCopper conductorState of art

The invention discloses a plug type current transformer overcoming the problem that the environment is influenced because the system power failure time is relatively long and a gas filled compartment is needed to be opened for carrying out gas operation when the current transformer is replaced in the prior art. The plug type current transformer is characterized in that a rectangular pouring body, two cylindrical pouring bodies and two conical pouring bodies form an epoxy resin transformer pouring body, wherein a grounded aluminum housing is arranged at the outer surface of the rectangular pouring body, fixed flanges are arranged outside the cylindrical pouring bodies, silicon rubber sleeves are arranged outside the conical pouring bodies, ground potential shielding layers are formed by spraying a conductive adhesive on a contact part of the silicon rubber sleeves and silicon rubber sleeve support rings, and the lower end of a primary copper conductor is fixedly connected with a conducive contact through a screw. The plug type current transformer has the beneficial effects that the plug type current transformer is directly plugged in an inner conical sleeve of a gas-insulated metal-enclosed switchgear to form a plug type connecting structure when being used, the system power failure time is short when the plug type current transformer is replaced, the gas operation is not involved, the safety, energy saving and environment friendliness are achieved, the disassembly, assembly and replacement speeds are high, and the housing can be touched.

Owner:SHENYANG HUADE HIGH TECH ELECTRIC CO LTD

Car stamping device with safety protection function

The invention belongs to the technical field of stamping devices, in particular to a car stamping device with a safety protection function. The car stamping device comprises a box and a supporting table, the box is located on the supporting table, a stamping oil cylinder is arranged on the outer side of the top of the box, and the bottom end of the stamping oil cylinder extends into the box. The bottom end of the stamping oil cylinder is fixedly connected with a mounting plate, an upper mold is arranged on the lower surface of the mounting plate, a base is arranged at the bottom of the box, alower mold is arranged on the upper surface of the base, and vertically arranged protection shafts are arranged on the two sides of the lower mold. The two ends of the two protection shafts are rotationally connected with the top inner wall of the box and the upper surface of the base respectively, the protection shafts are fixedly connected with fixed blocks, and the ends, close to the upper mold, of the fixed blocks are fixedly connected with protection blocks. The defects in the prior art are overcome, the safety protection function is set for the upper mold, it is avoided that the upper mold falls off to case safety accidents, safety of the equipment is improved, equipment damage is avoided, and the service life of the equipment is prolonged.

Owner:ANHUI AOGE AUTOMOTIVE COMPONENTS CO LTD

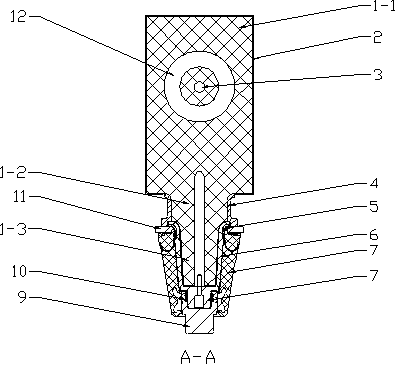

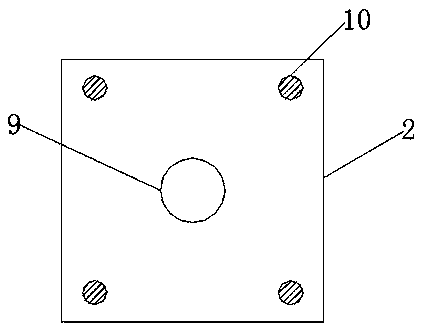

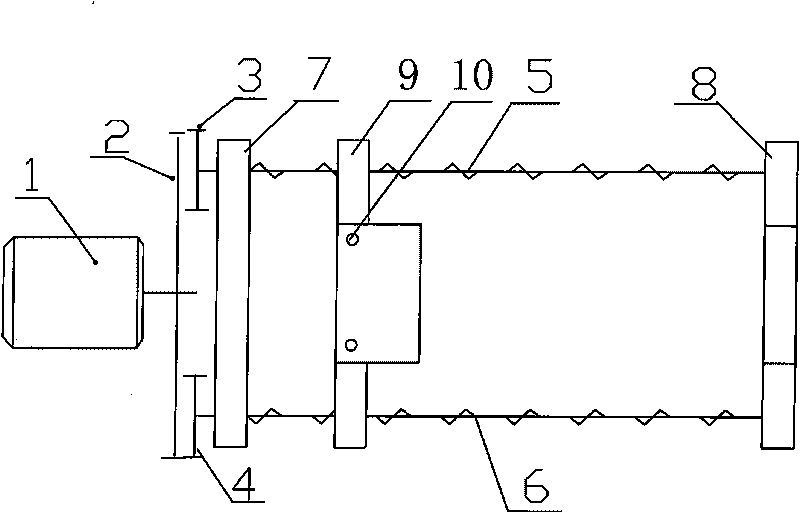

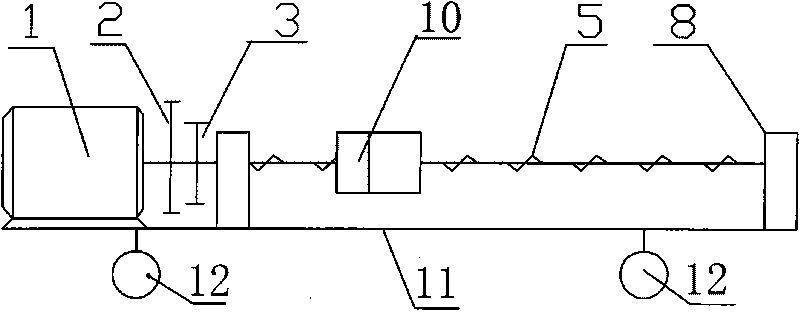

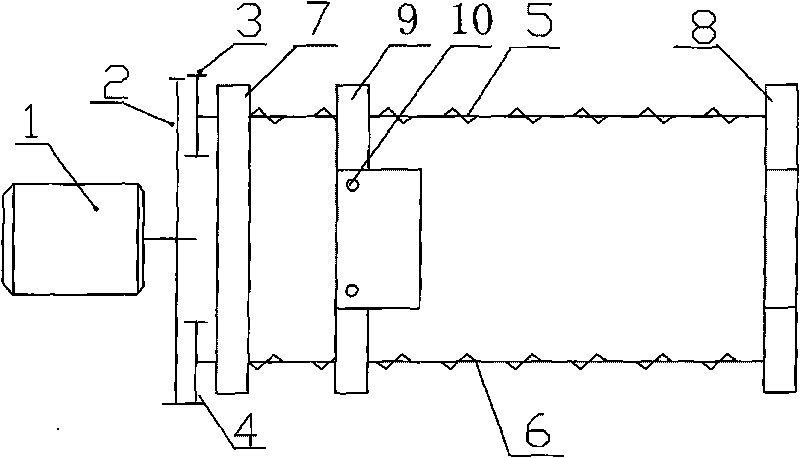

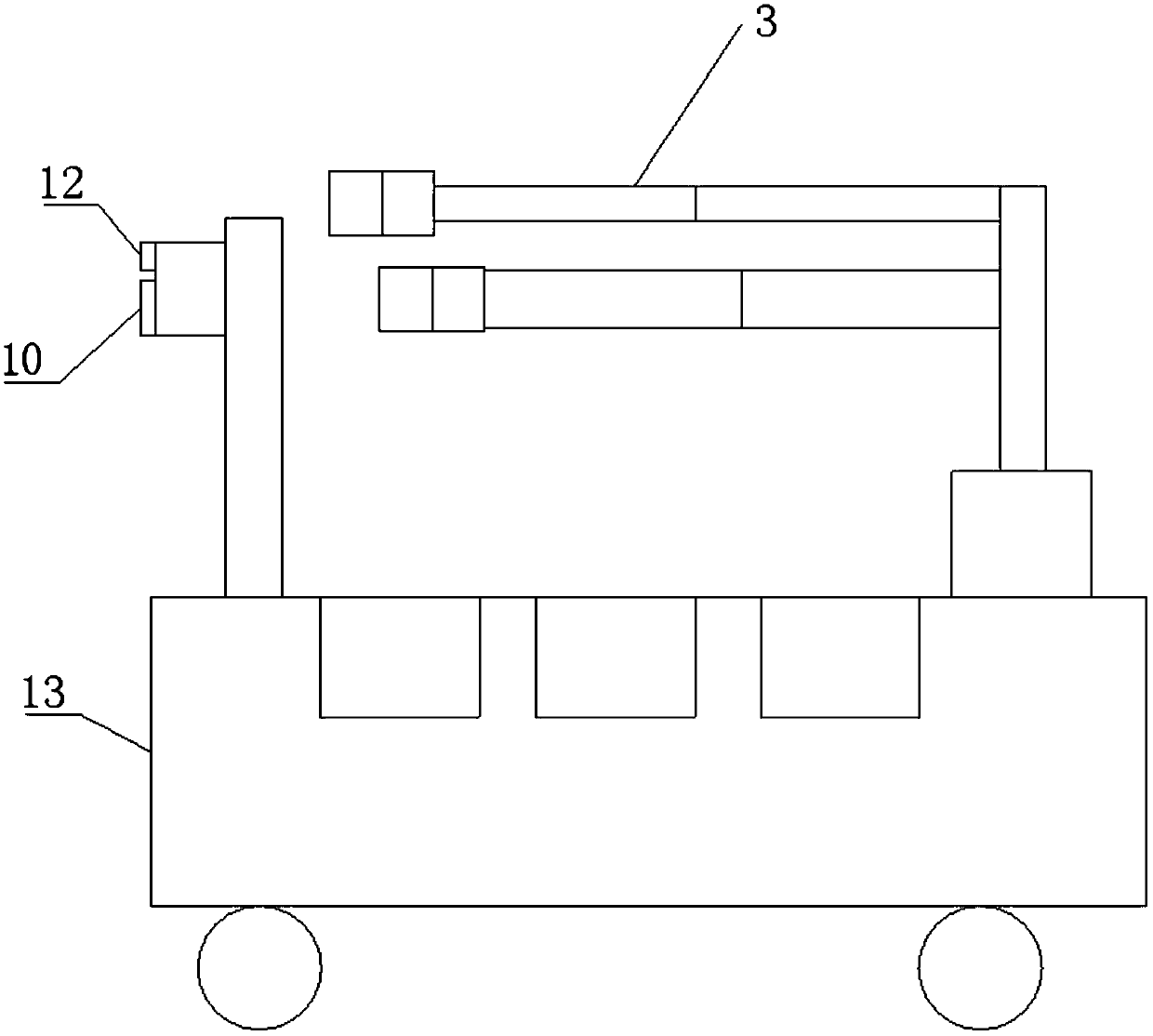

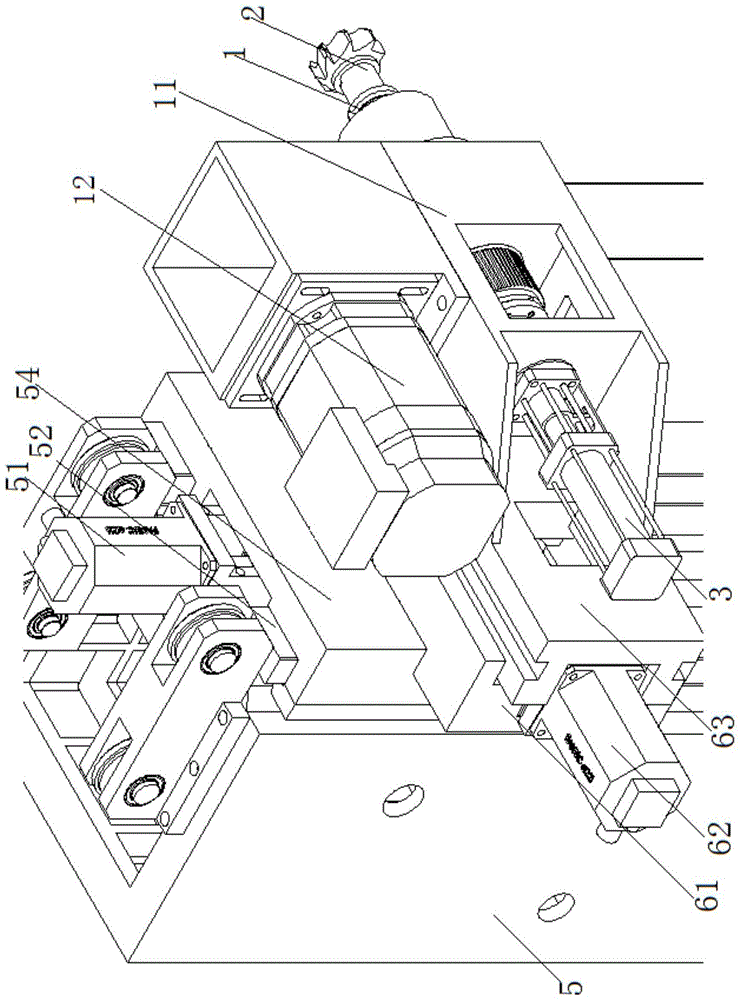

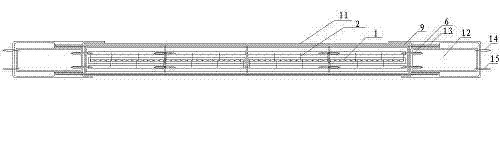

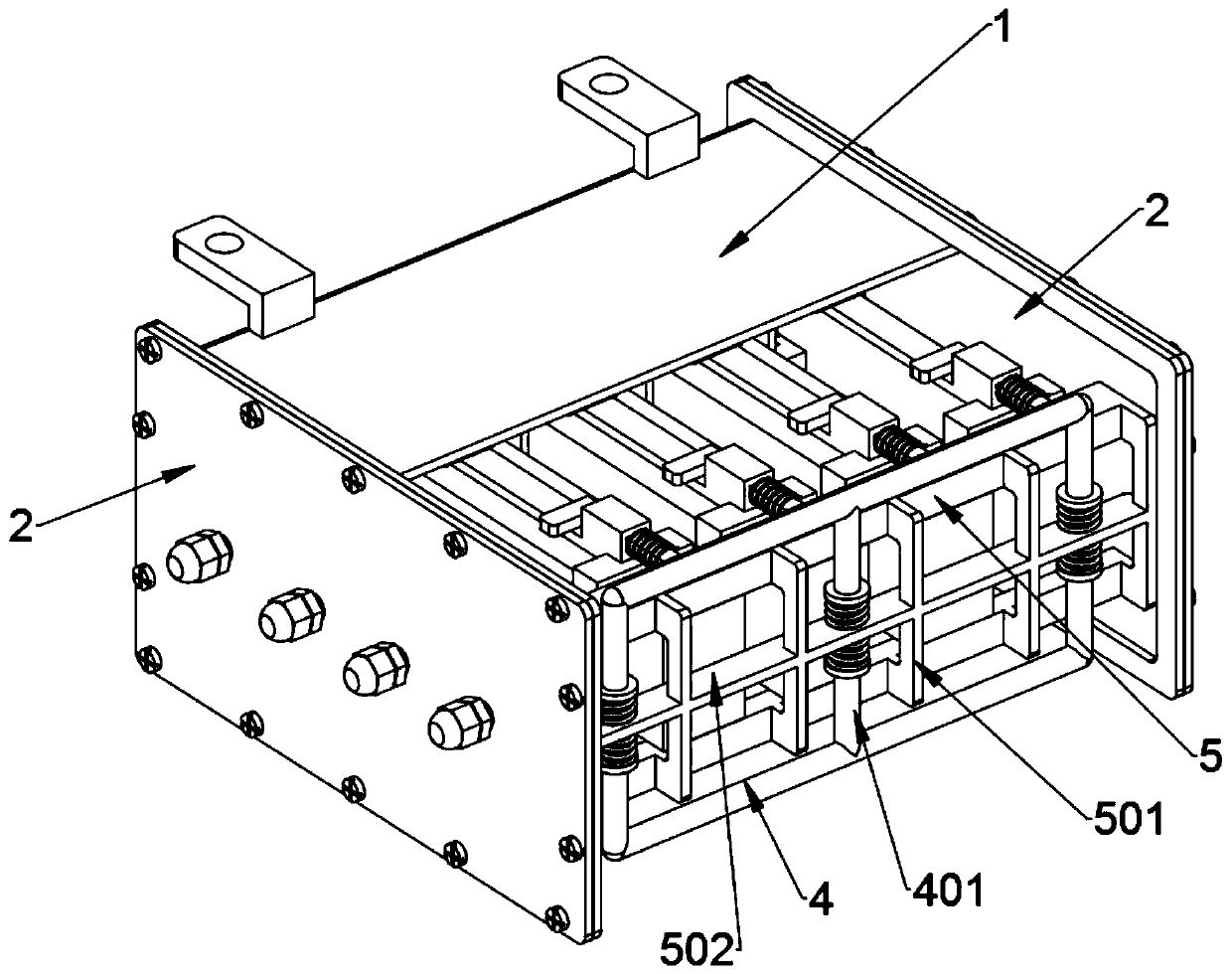

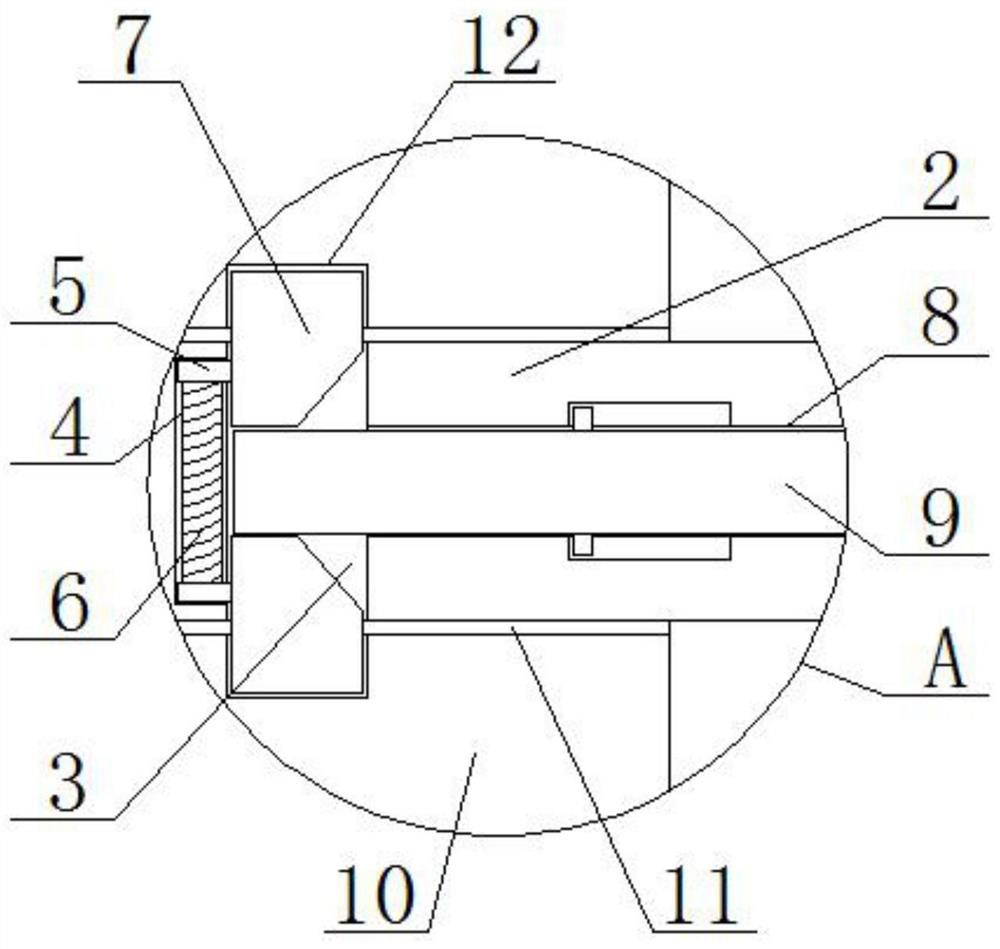

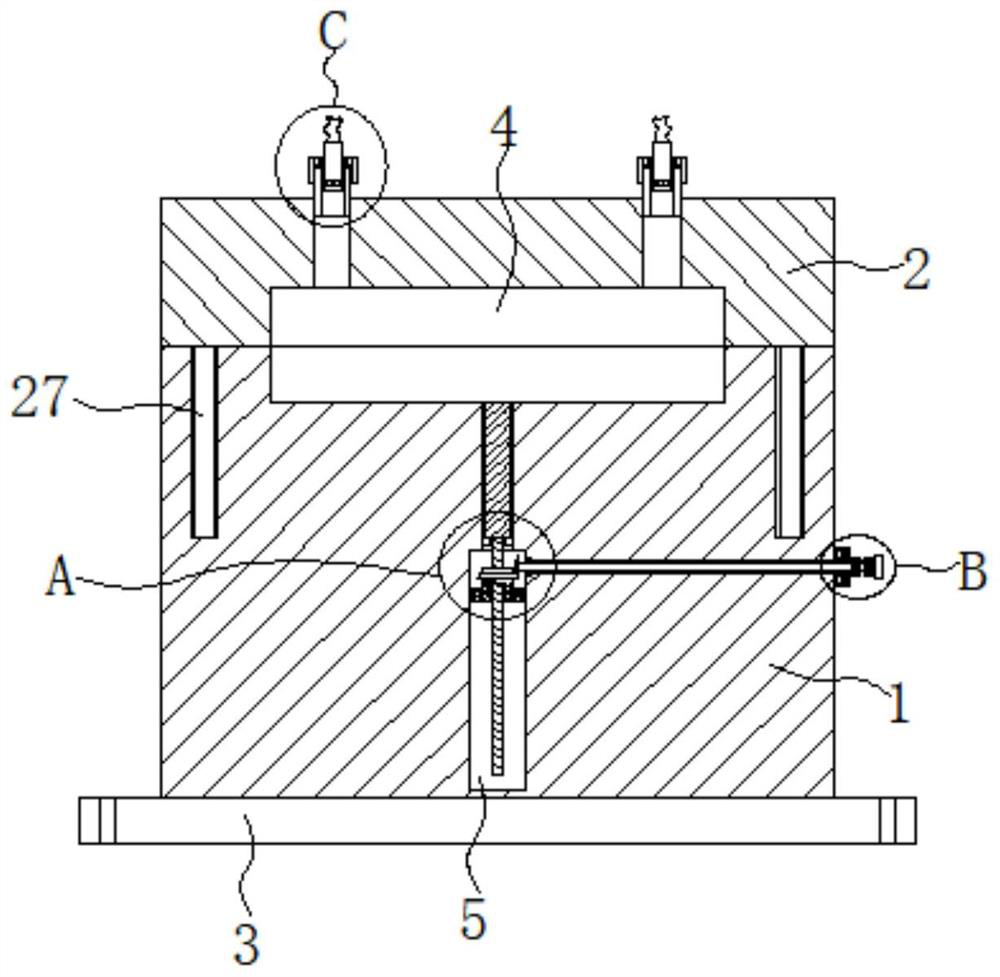

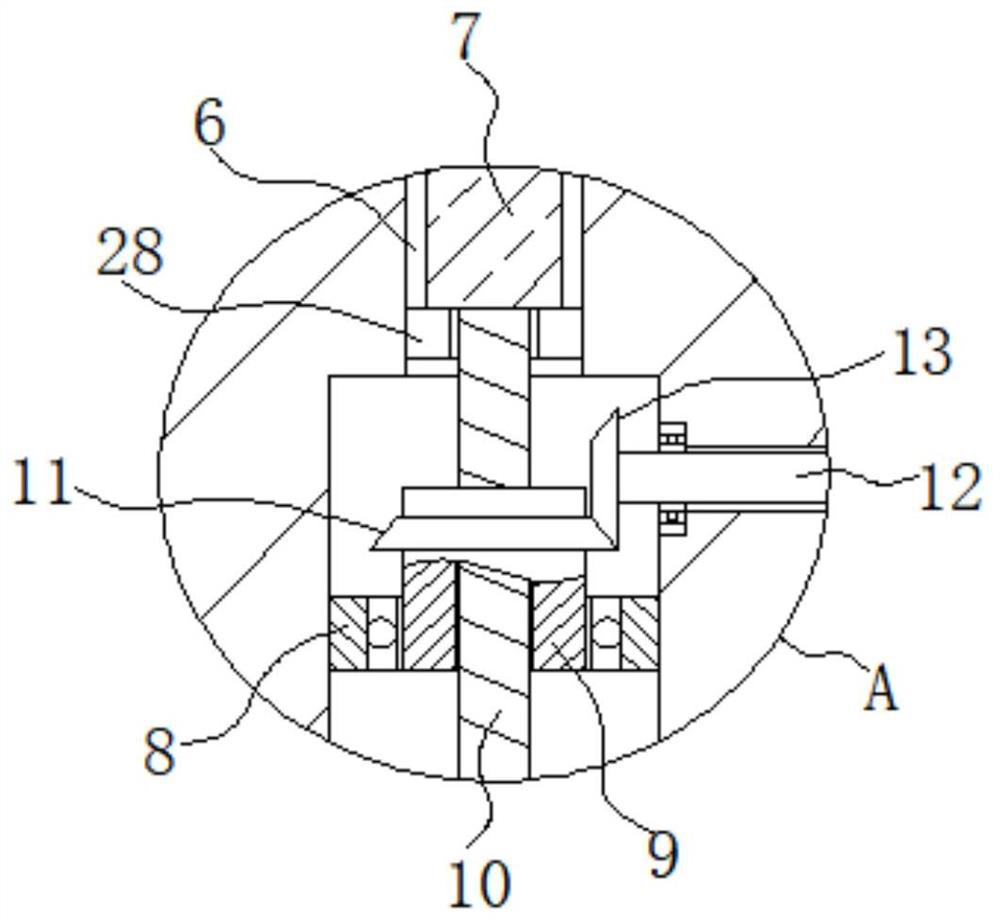

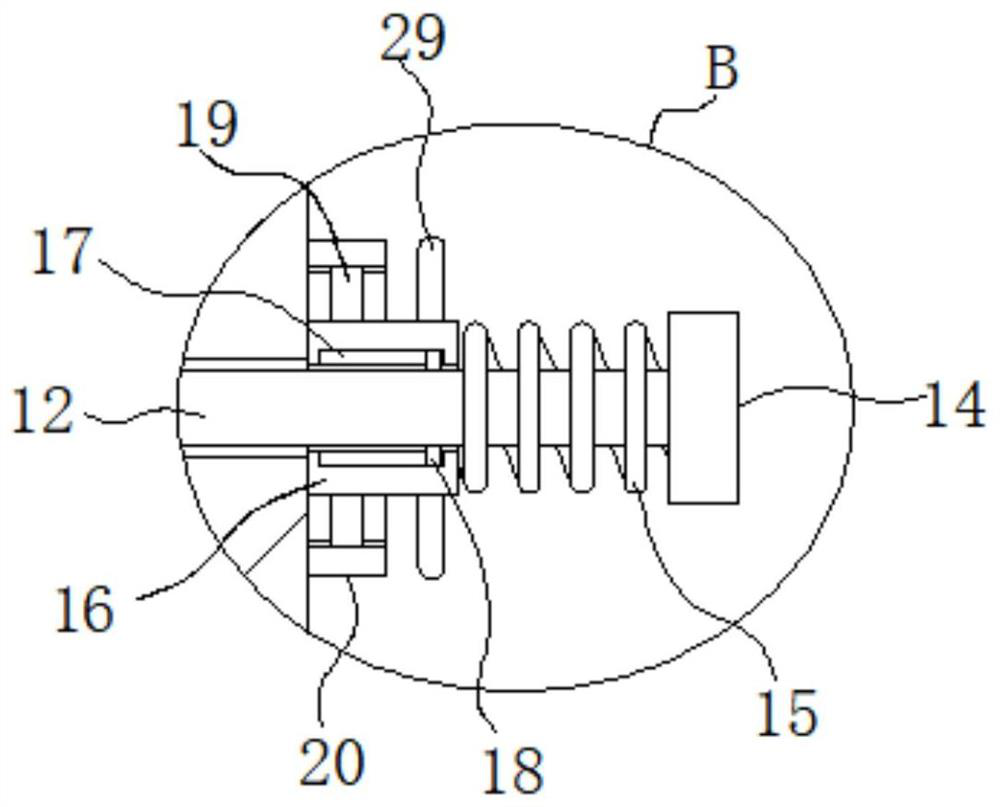

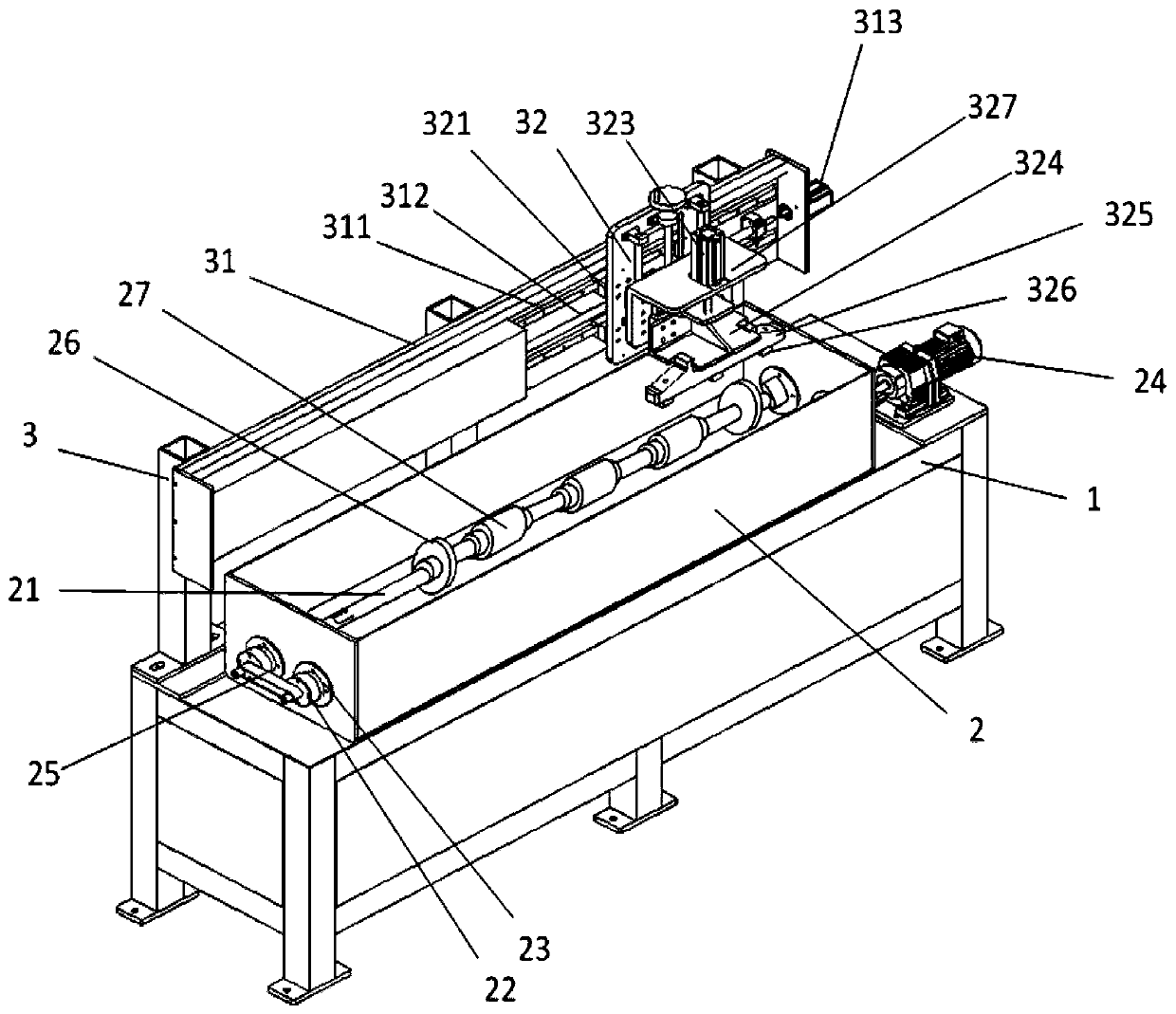

Disassembling and assembling equipment for screw of plastic extruder

InactiveCN101733921AQuick disassembly and replacementIncrease productivityMetal working apparatusLinear motionElectric machinery

The invention belongs to a plastic production machine, in particular to disassembling and assembling equipment for a screw of a plastic extruder. In the prior art, the disassembly and assembly of the screw of the plastic extruder are performed manually by using a raising bar, and therefore have the drawbacks of damaging the screw and scalding operators. In the equipment, a reducer motor (1) drives gears (2), (3) and (4) and threaded rods (5) and (6); the rotation of threaded rods (5) and (6) drives a fixed clamping block (9) to perform a linear motion; the screw, to be disassembled and assembled, of the extruder is fixed by an internally-threaded hole (10) in the fixed clamping block (9) and a bolt; the linear motion of the fixed clamping block (9) drives the screw of the extruder to perform a linear motion; and thus, the disassembly and assembly of the screw of the plastic extruder are completed. The equipment has the advantages that: the disassembly and the assembly of the screw of the extruder is more quick and the production efficiency is high; the manual operation by using the raising bar is changed into mechanical operation, so the damages to the screw are reduced; the production cost is reduced; the use is safe, and the damages to the equipment and the safety accidents of the operators are reduced.

Owner:SHANGHAI KINGFA SCI & TECH

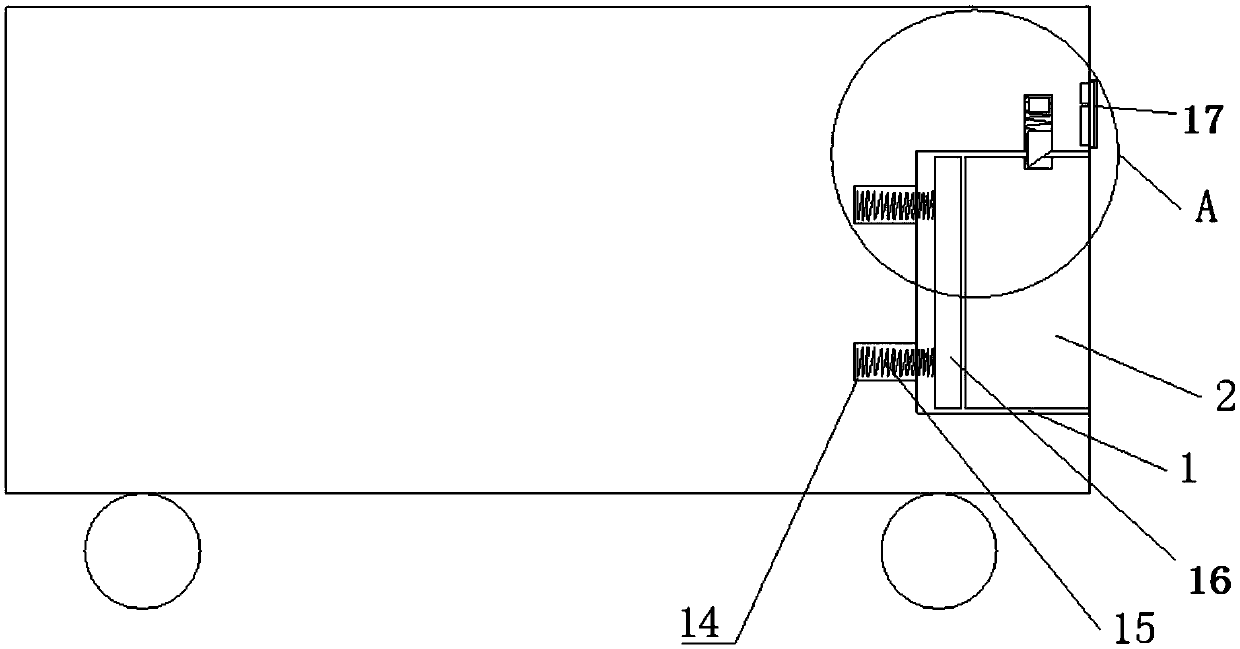

Rapid battery assembling and disassembling device for conveying car

PendingCN109532553AQuick disassembly and replacementIncrease productivityCharging stationsElectric propulsion mountingLocking mechanismEngineering

The invention discloses a rapid battery assembling and disassembling device for a conveying car. The rapid battery assembling and disassembling device comprises a battery locking mechanism, an electromagnetic control assembly, a battery pushing assembly and an electromagnet power supply device. The battery locking mechanism is arranged on the top of a battery installation groove of the conveying car. The electromagnet control assembly is suitable for controlling the battery locking mechanism to lock and unlock batteries. The electromagnet control assembly is arranged on the outer surface of the conveying car. The electromagnet control assembly comprises a wireless charging receiver and an NFC receiving chip. The battery pushing assembly is arranged on the side wall in the battery installation groove of the conveying car. The electromagnet power supply device is arranged on the movable car. By means of the rapid battery assembling and disassembling device, the rapid assembling and disassembling of the batteries of the conveying car can be realized, and the problem that a conveying car is too short in service life, too long in charging time and lower in use efficiency due to the battery technology in the prior art is solved.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

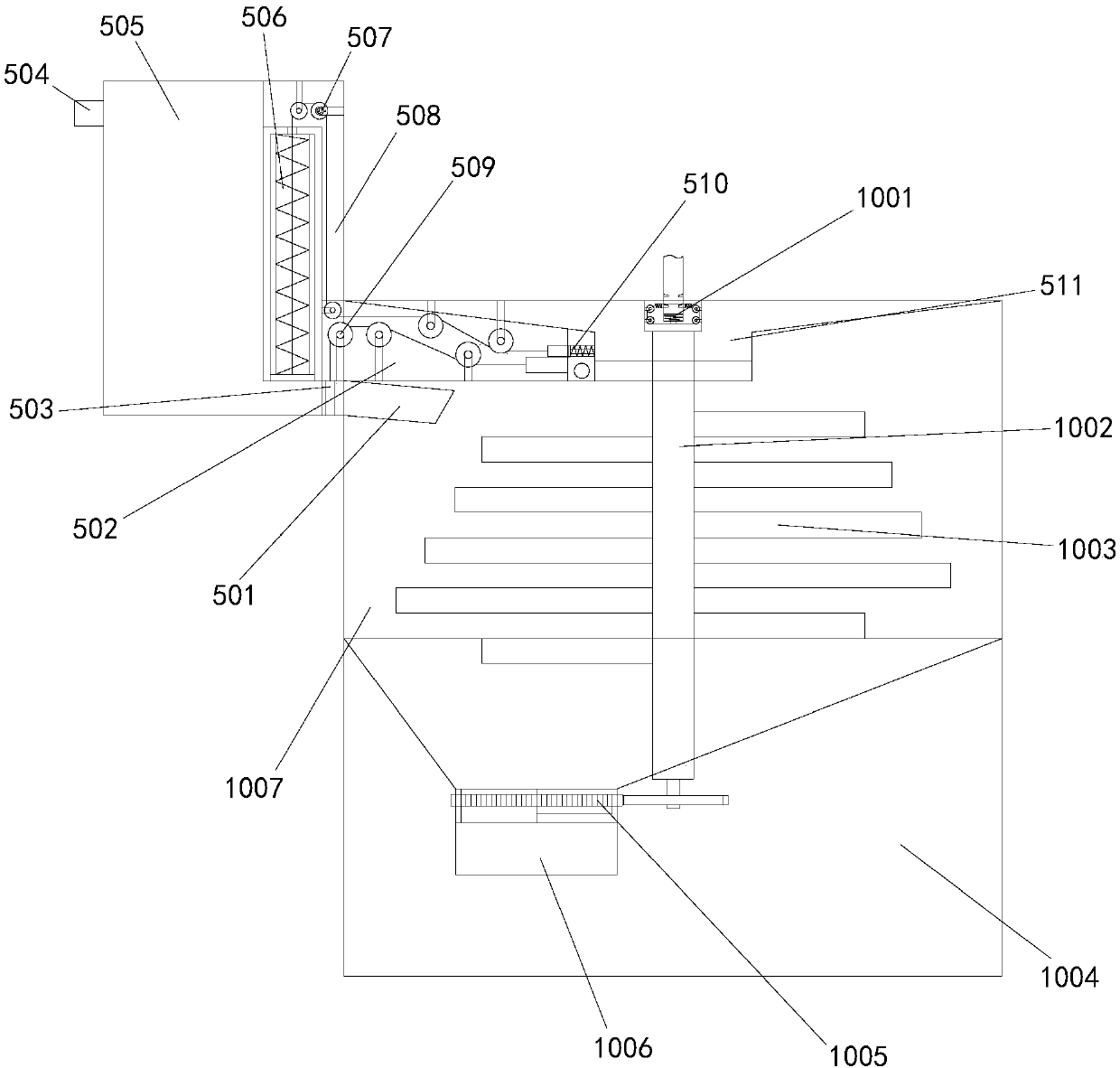

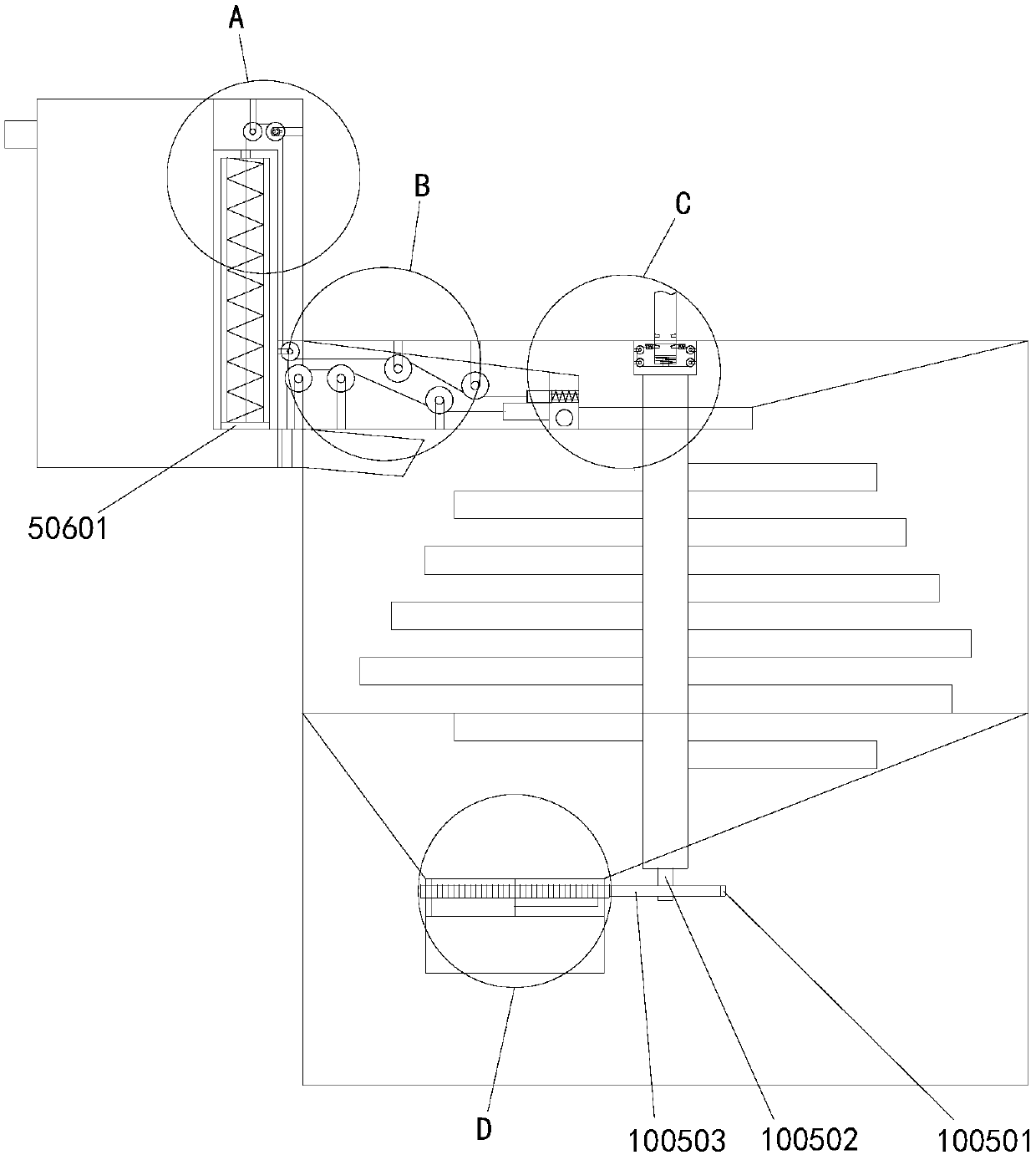

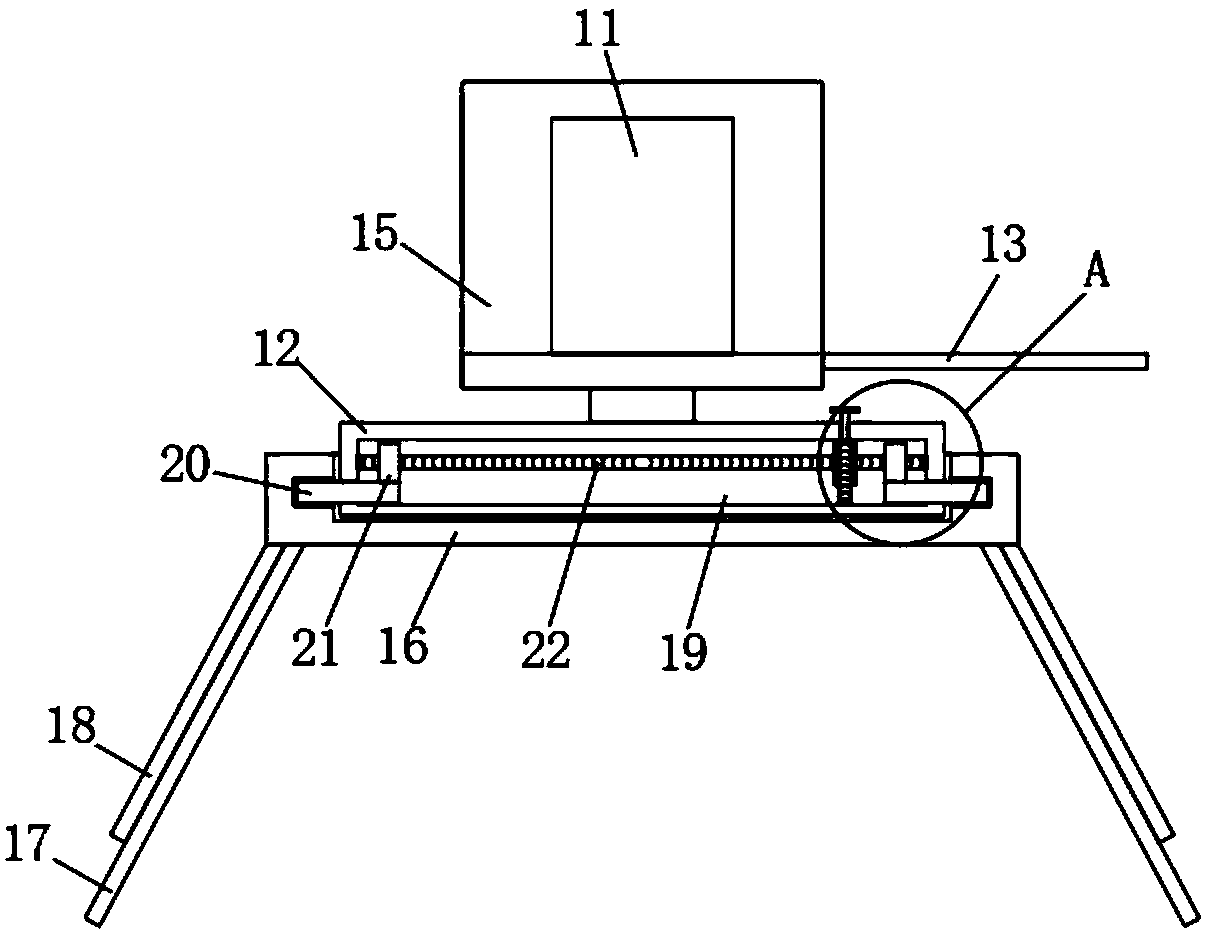

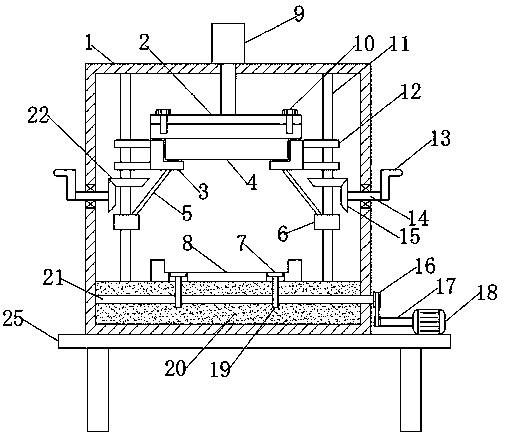

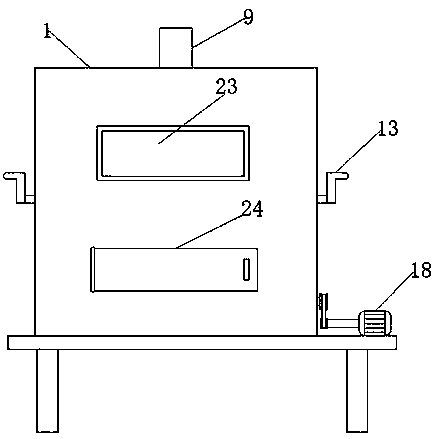

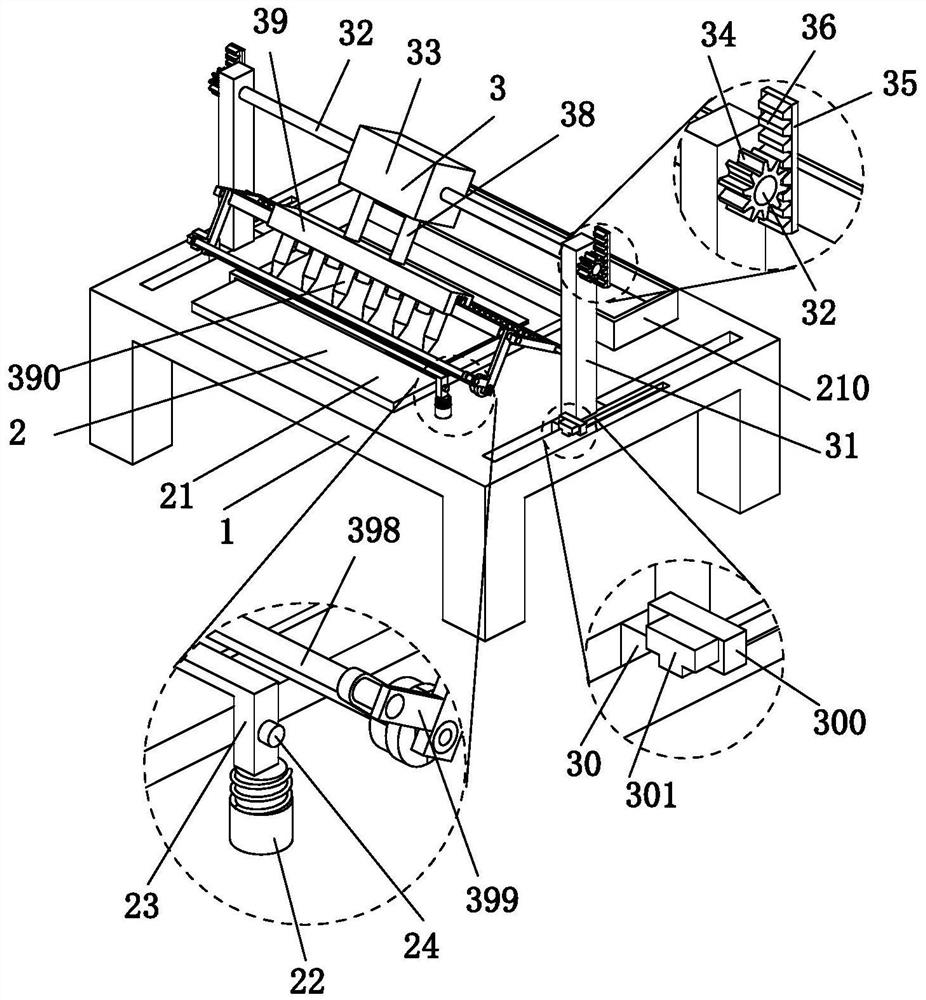

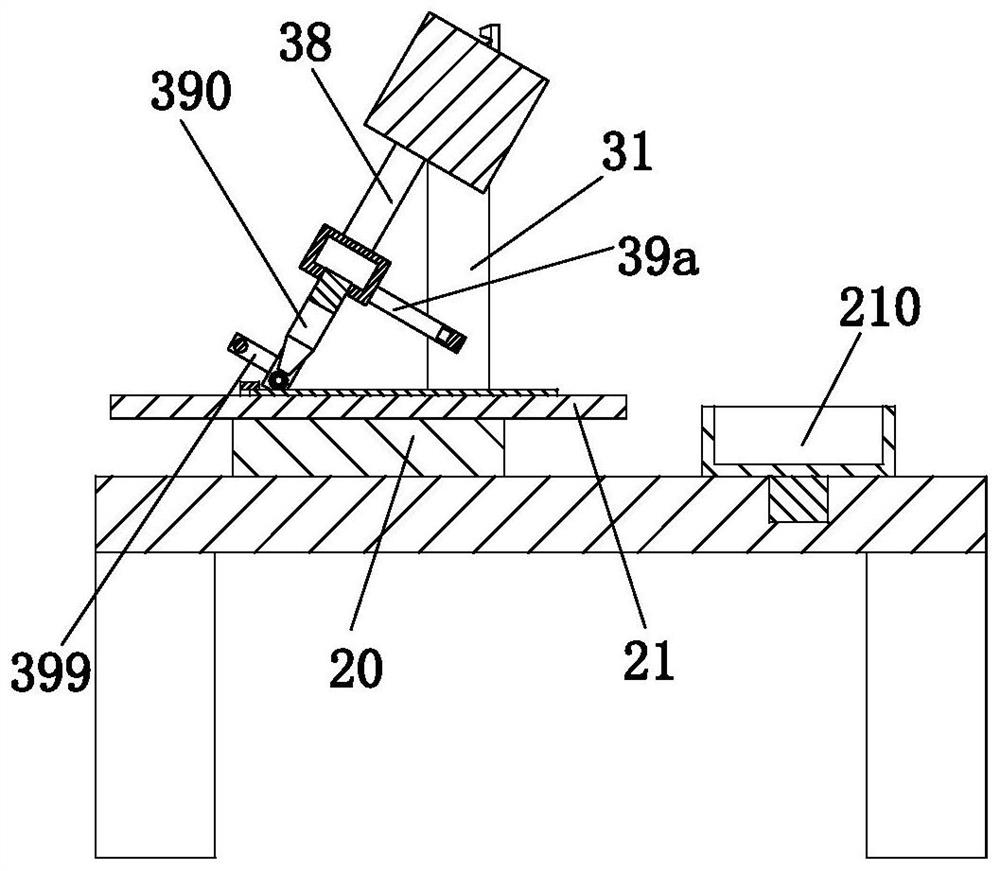

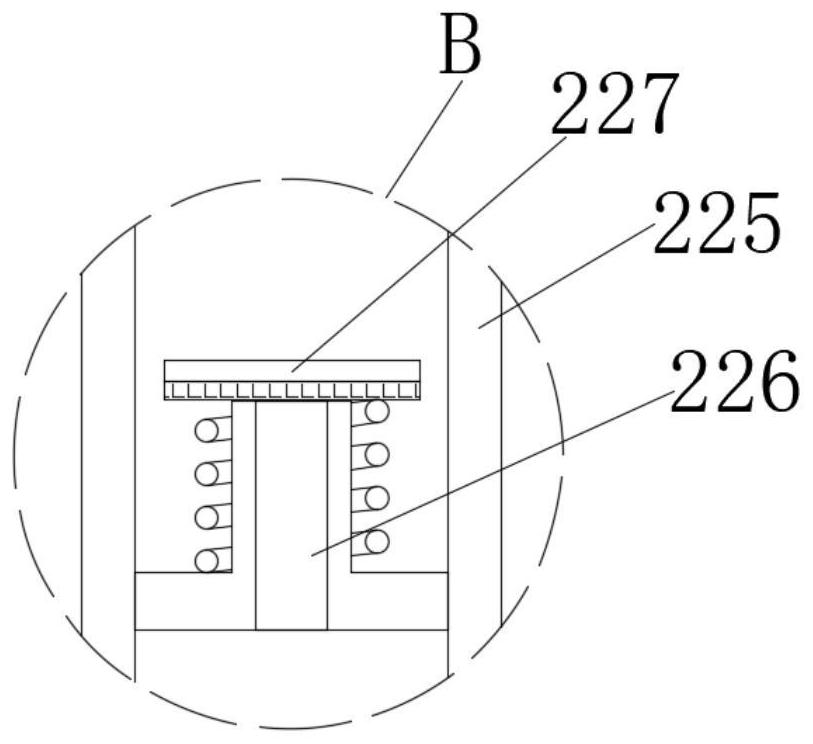

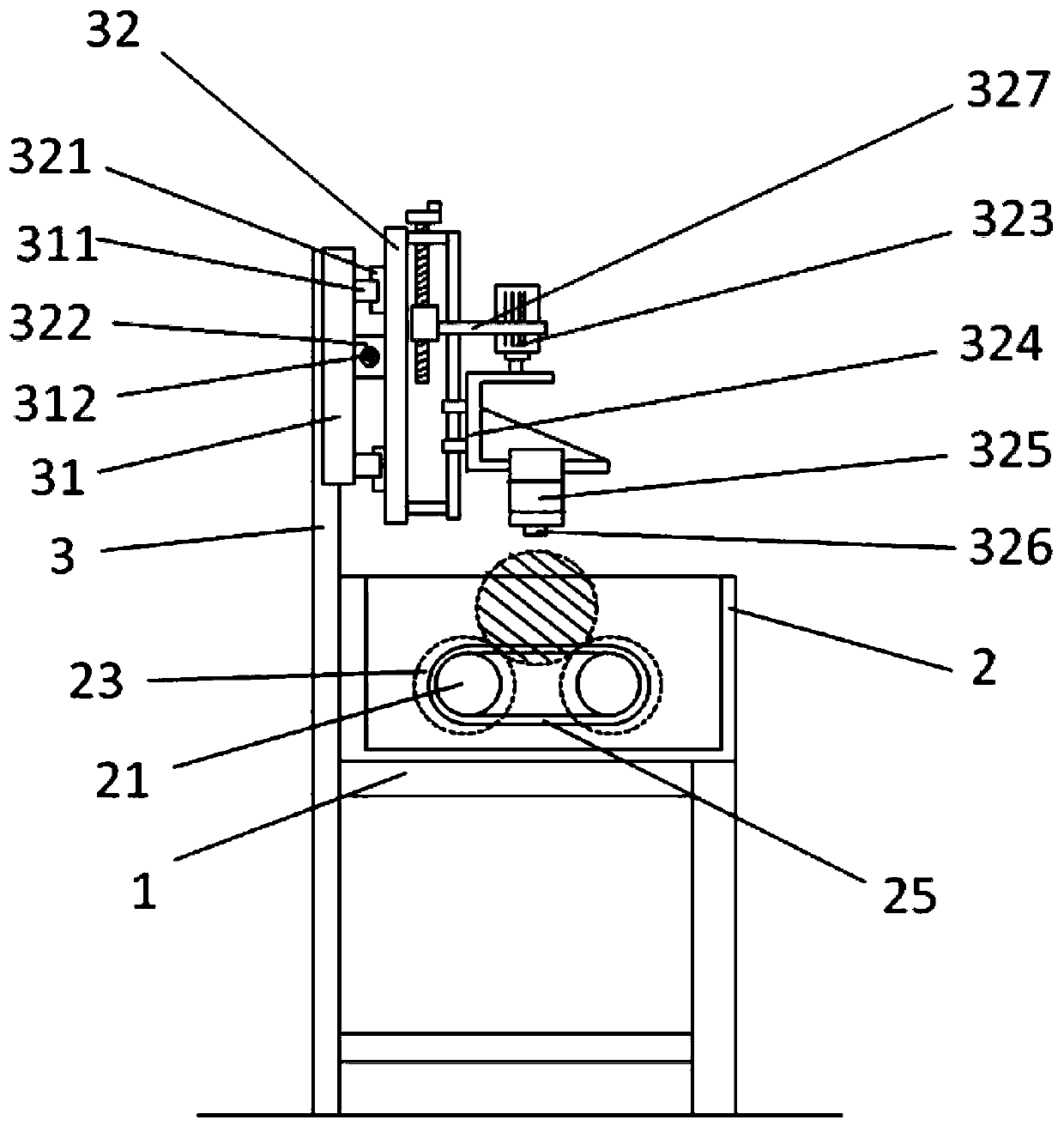

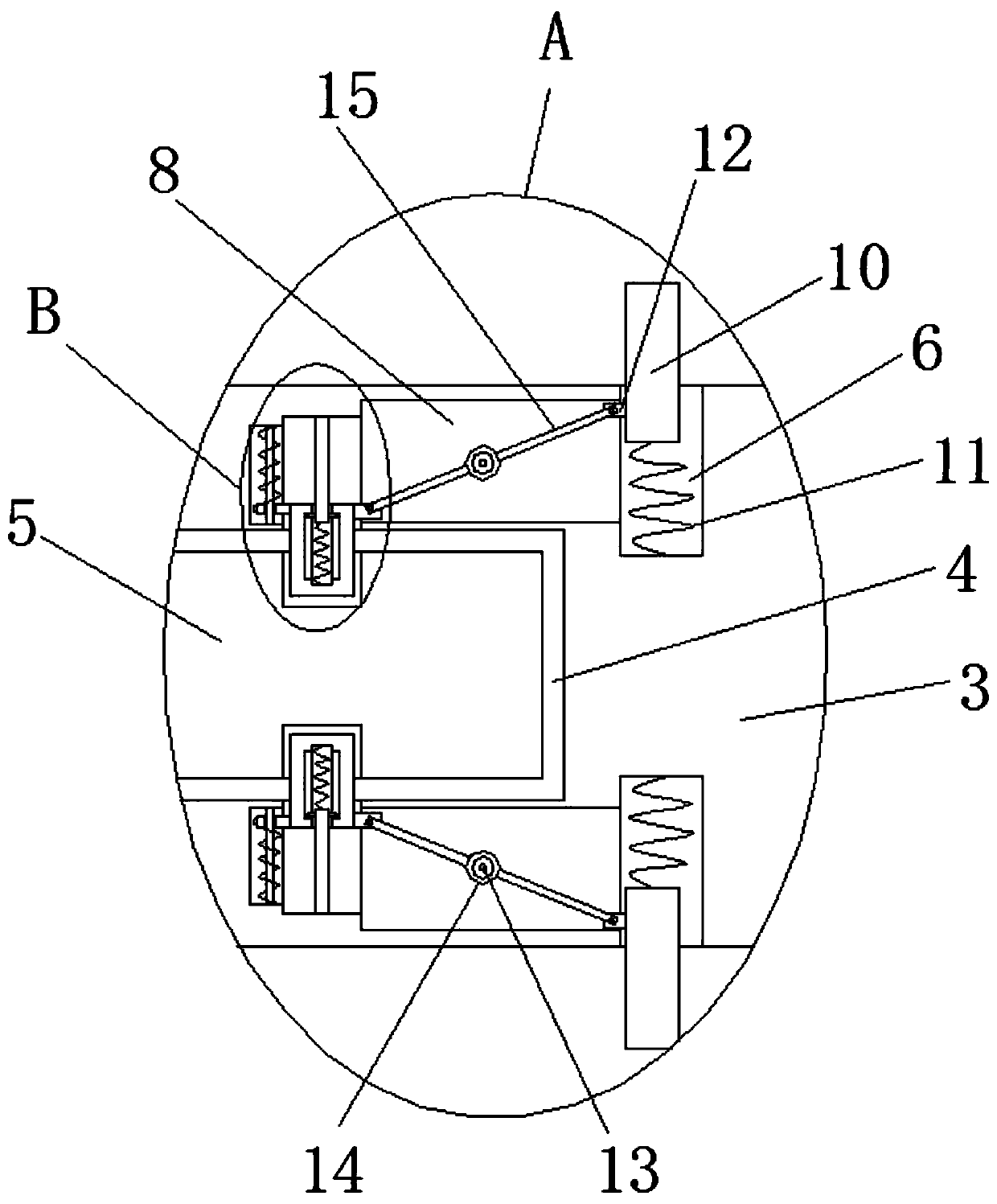

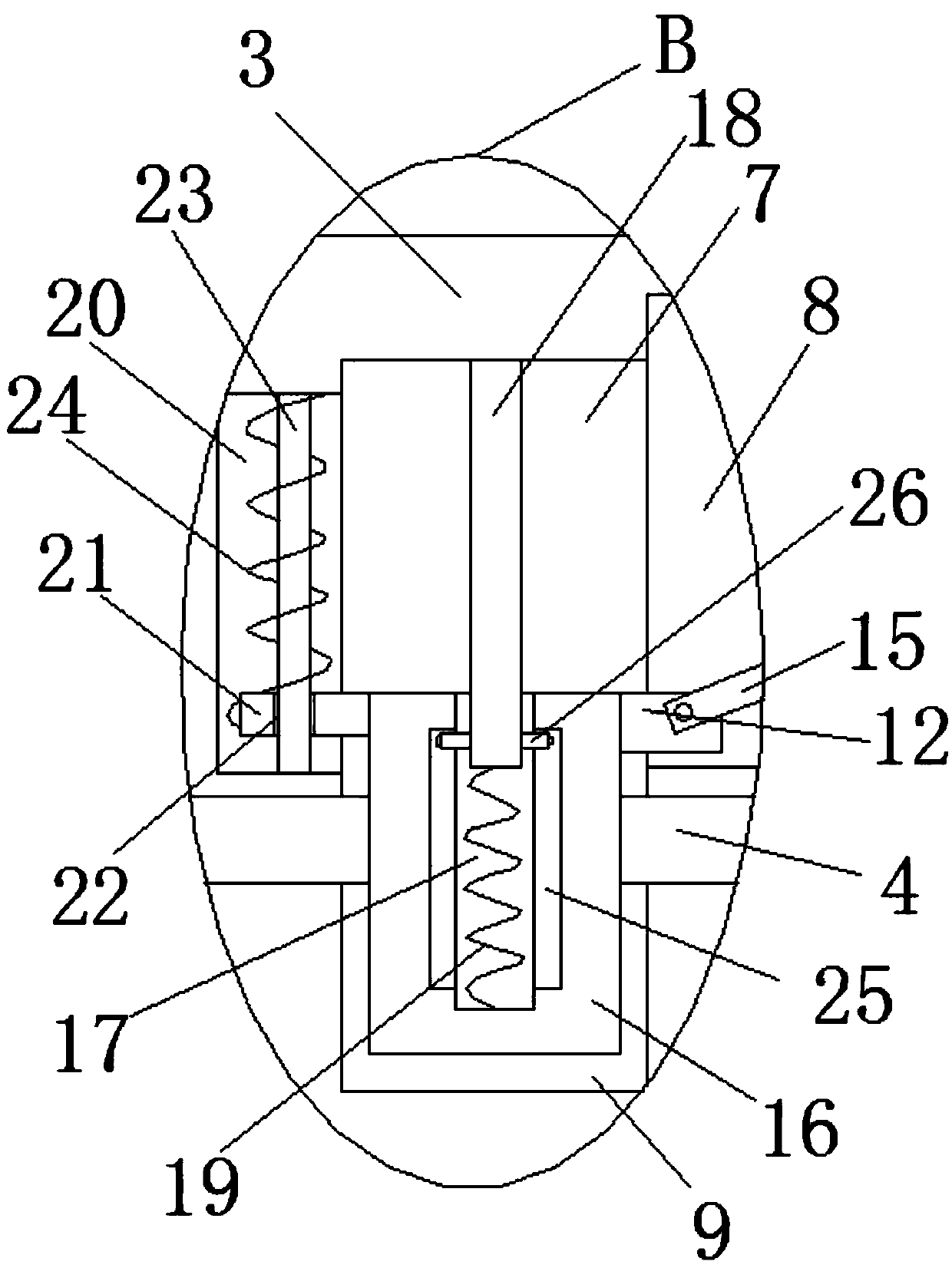

Disposable heating patch gluing processing system

InactiveCN113182113AReduce wasteQuickly adjust the spraying rangeLiquid surface applicatorsSpraying apparatusAdhesiveProcess engineering

The invention relates to a disposable heating paste gluing processing system. The disposable heating paste gluing processing system comprises a workbench, a placement unit and a gluing mechanism, the placement unit is arranged at the upper left end of the workbench, and the gluing mechanism is arranged at the upper right end of the workbench. The disposable heating paste gluing processing is conducted by adoption of a multi-control design concept, the spraying height can be adaptively adjusted through the gluing mechanism according to the thickness size of the middle of the heating patch, the waste rate of an adhesive can be reduced, and meanwhile the spraying range of the adhesive can be rapidly adjusted according to the size of the heating patch due to the movable combination connection mode.

Owner:江苏恬然环保科技发展有限公司

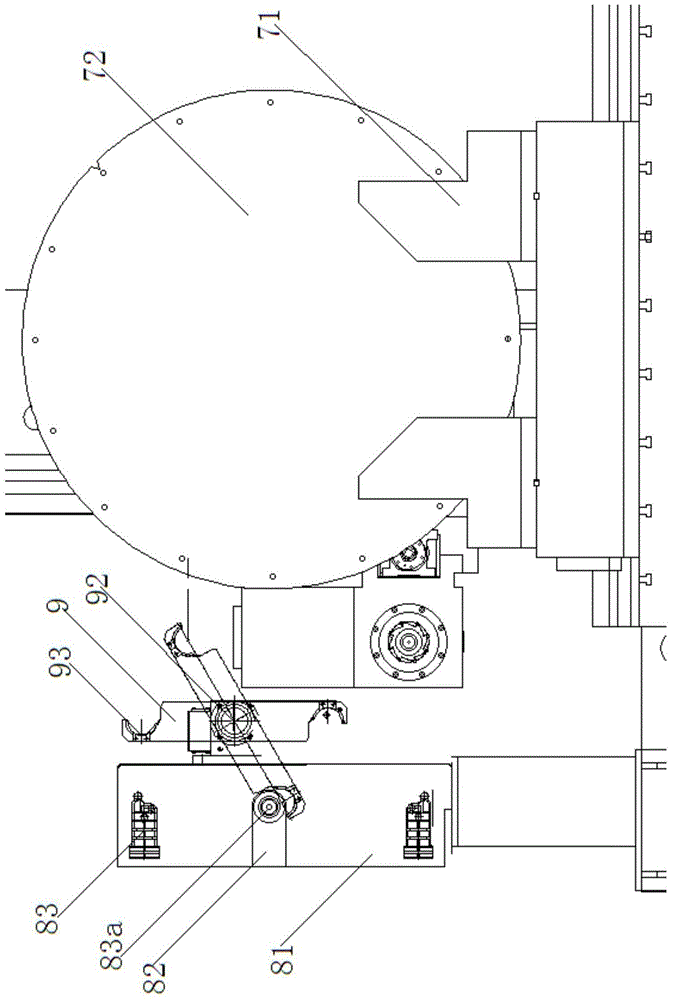

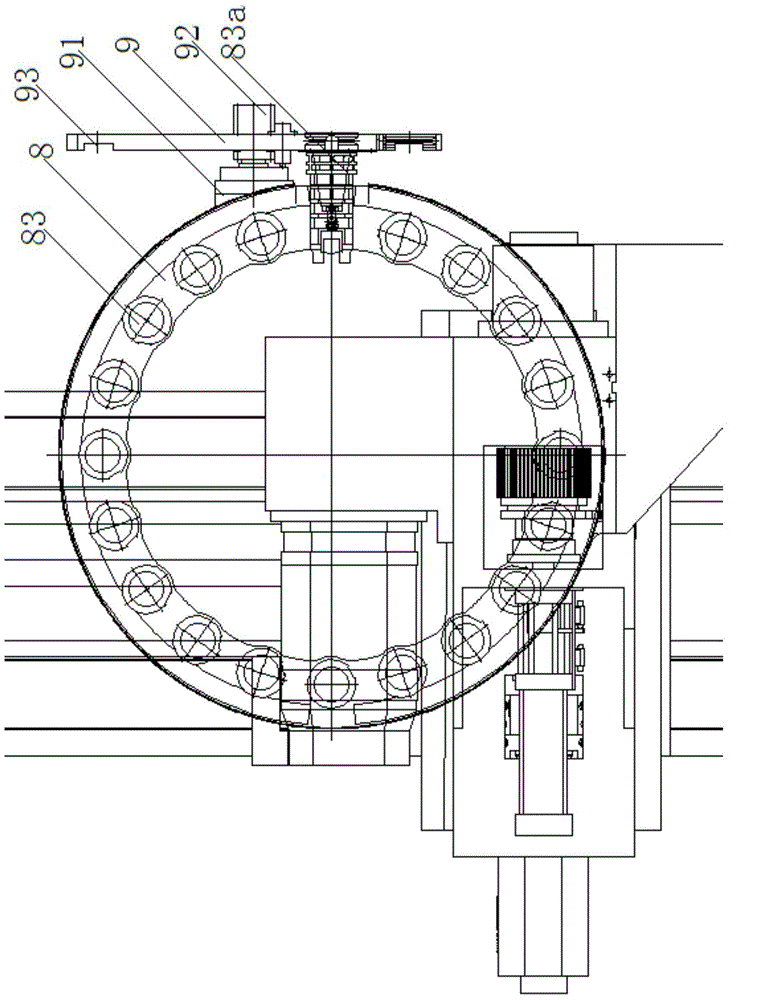

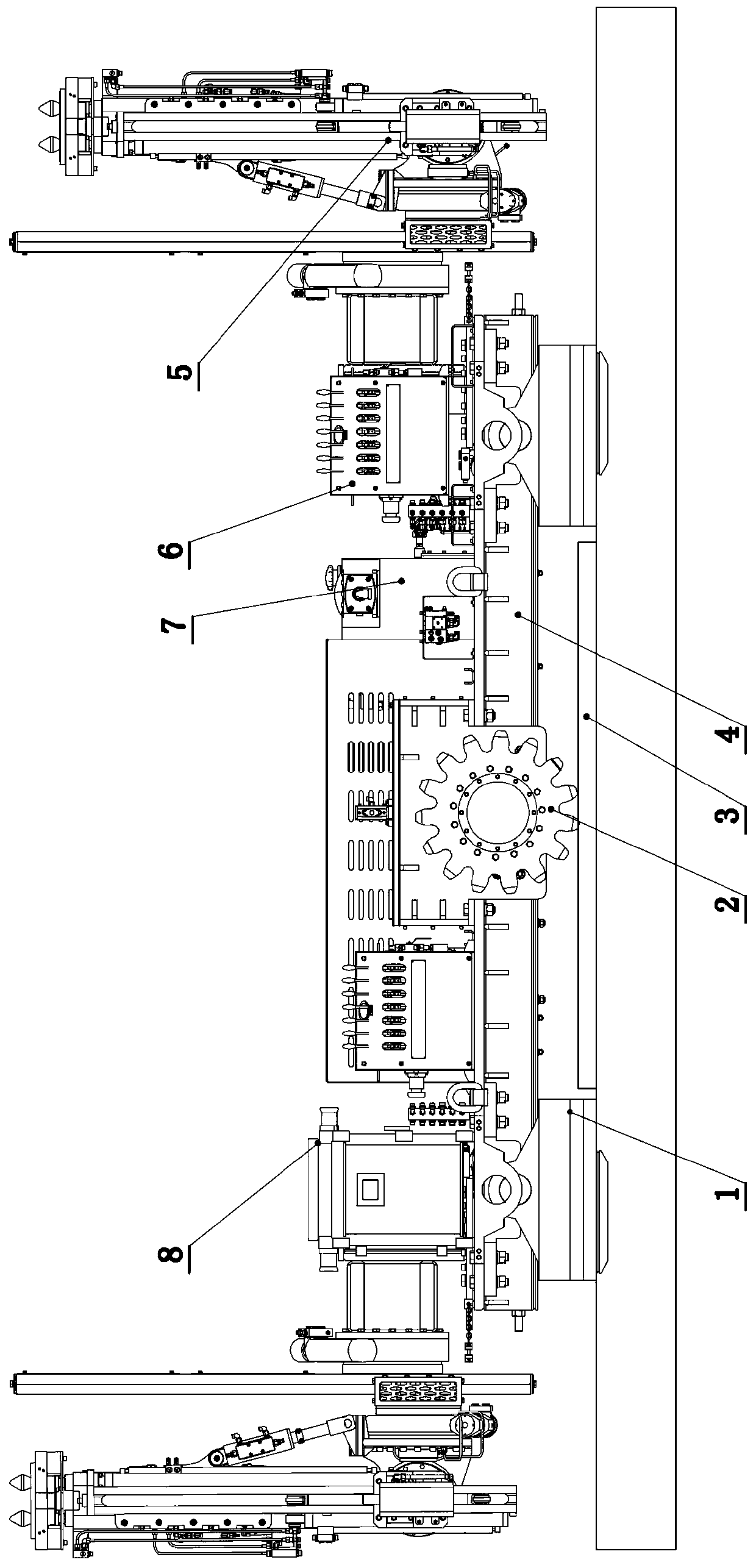

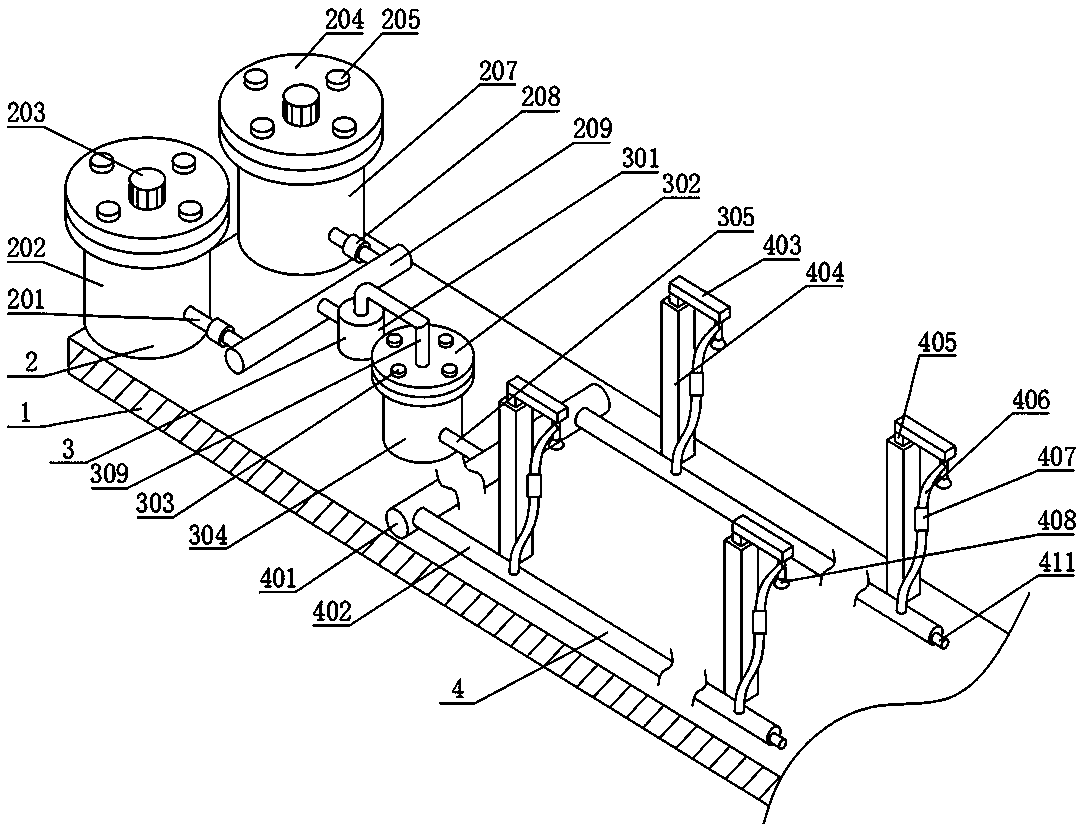

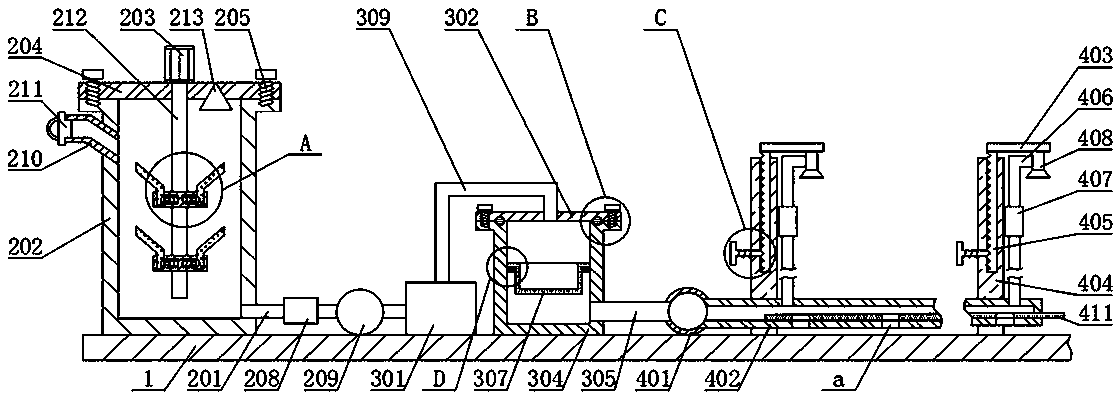

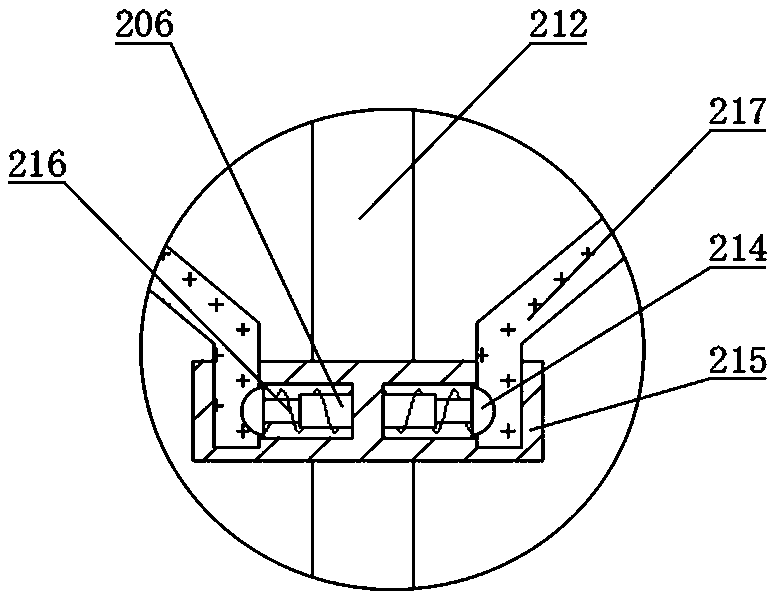

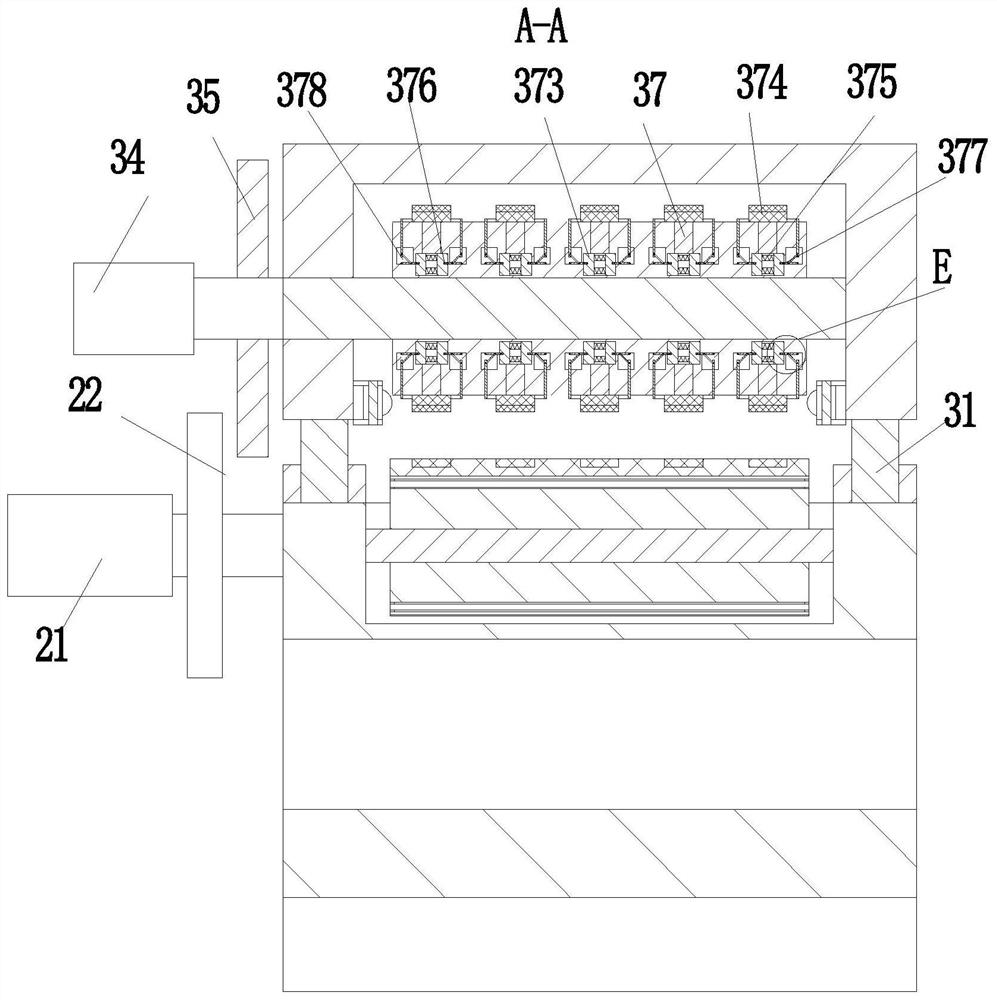

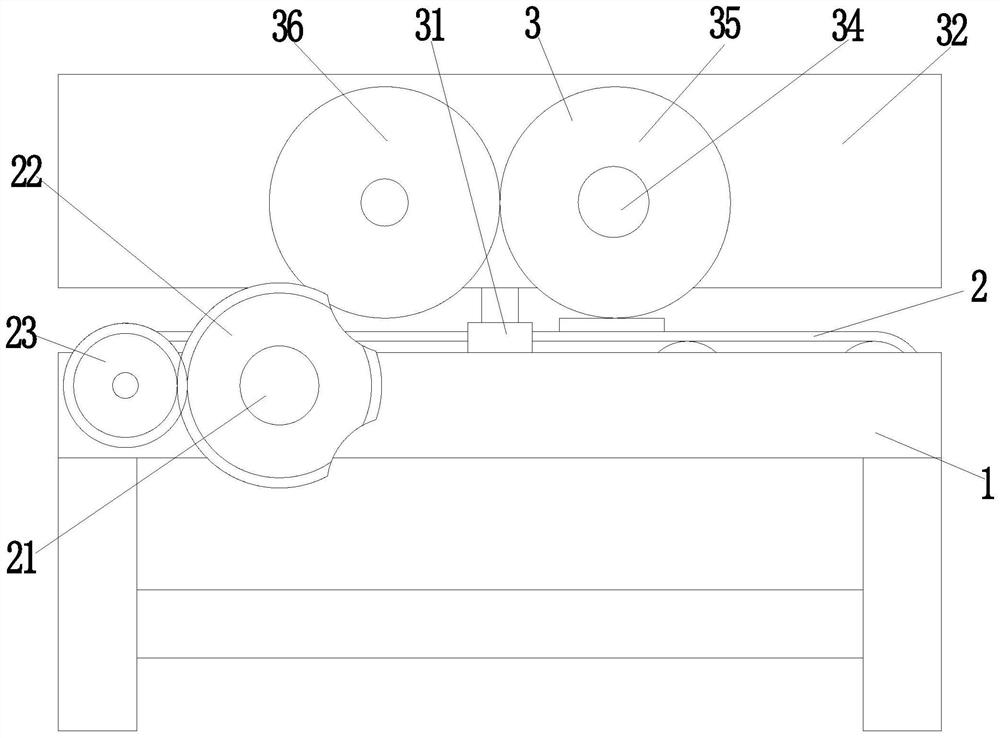

Disc type tool changer system of horizontal numerical-control boring and milling machine

InactiveCN105458805AEasy to grabQuick disassembly and replacementPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a disc type tool changer system of a horizontal numerical-control boring and milling machine. The disc type tool changer system comprises a rotary tool storage disc and a tool changing claw. A plurality of tool installation bases are arranged on the tool storage disc. The tool storage disc drives the tool installation bases to rotate so that all the different tool installation bases can rotate to a tool changing position in a disc type tool changer system shell, and thus tool replacement, dismounting and mounting are facilitated. The tool installation bases can rotate by 90 degrees on the tool storage disc so that the tool changing claw can firmly grab a tool for tool changing work. The tool changing claw is controlled by a tool changing motor to rotate, and a tool changing spindle on the tool changing motor can stretch outwards so as to drive the tool firmly grabbed by the tool changing claw to stretch outwards or retract, and thus the tool is pulled out of or embedded in a spindle or the corresponding tool installation base. In addition, the horizontal numerical-control boring and milling machine further comprises a spindle system and a feeding system. The spindle is controlled through the spindle system to rotate, and feeding of the spindle is controlled through the feeding system.

Owner:SHENYANG NORTH SPECIAL MACHINE TOOL

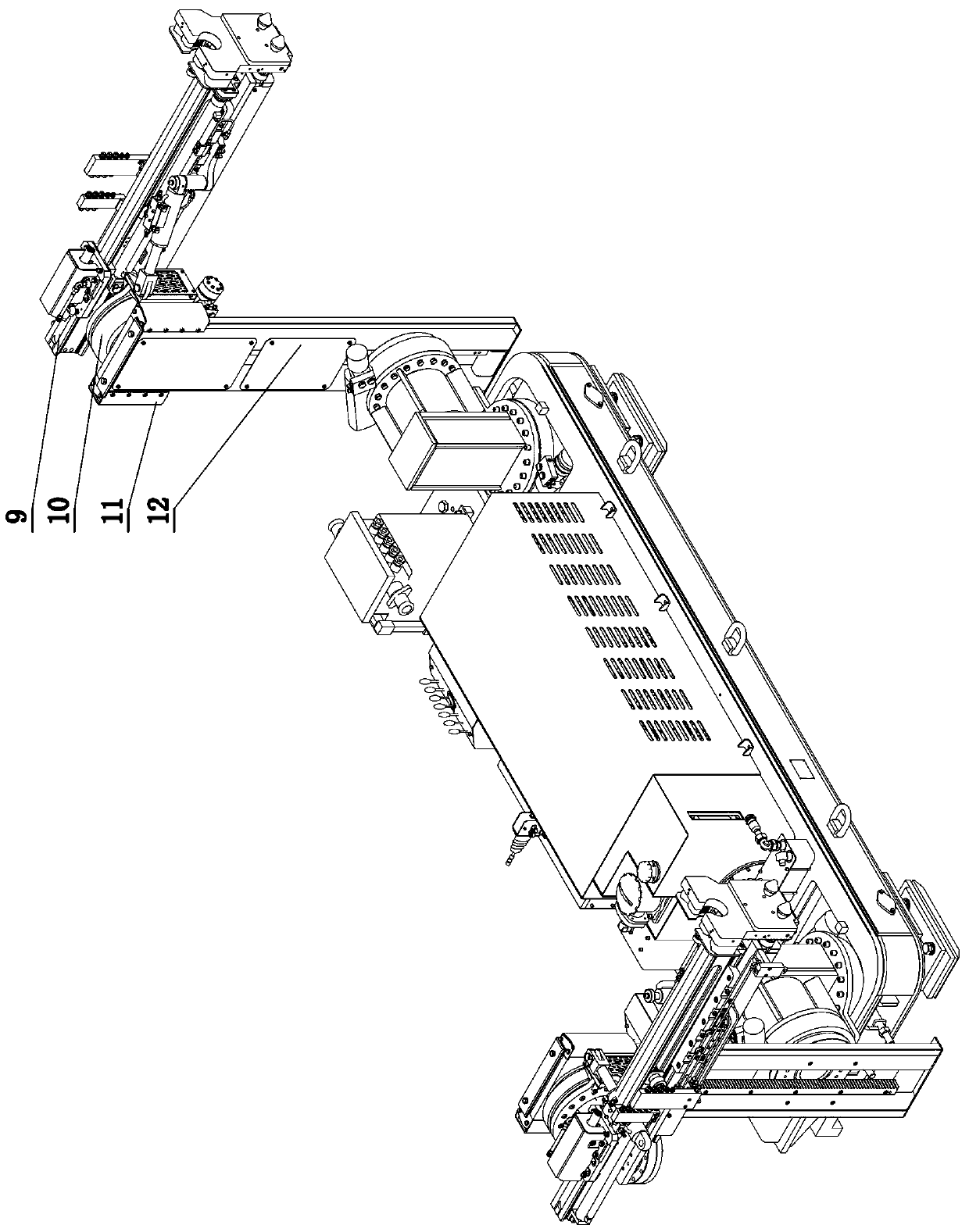

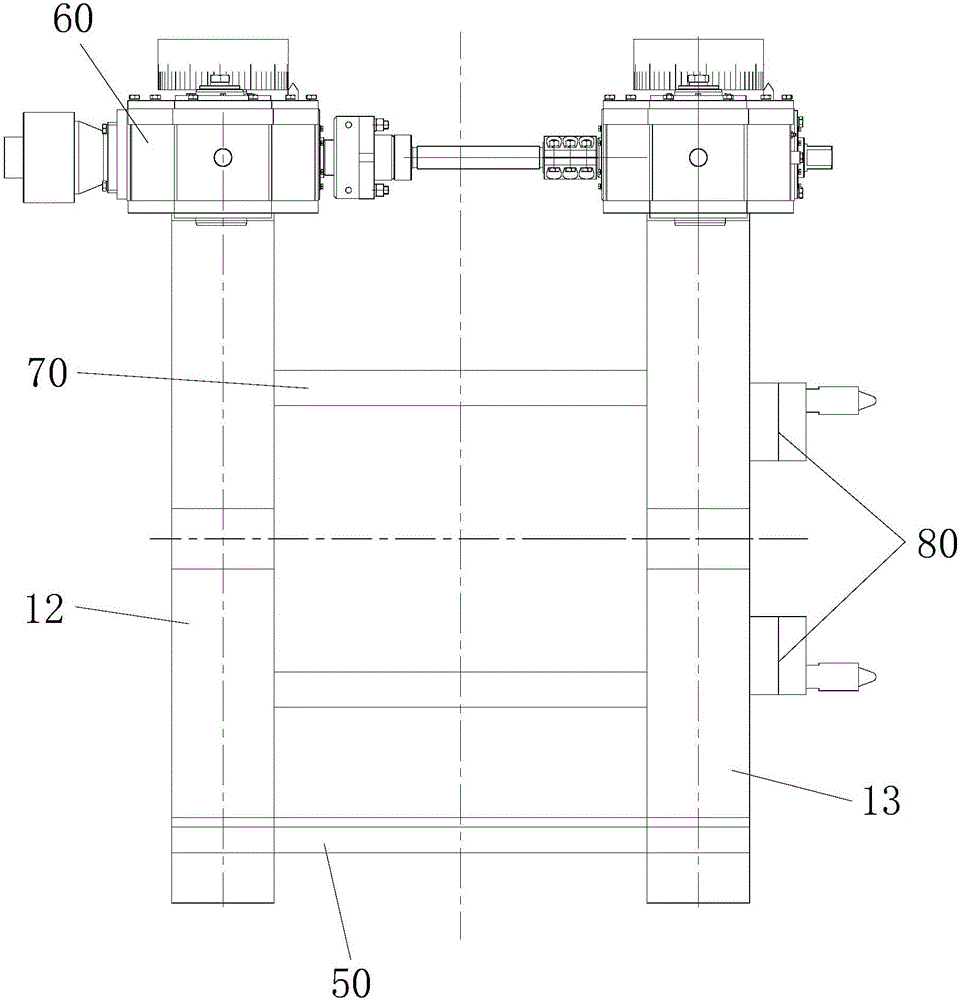

Moving hydraulic anchoring drill rig for coalface

PendingCN109611026ASolve the disadvantages of being heavy and difficult to movePrevent slippingDirectional drillingUnderground transportHydraulic motorDrive wheel

The invention discloses a moving hydraulic anchoring drill rig for a coalface. The moving hydraulic anchoring drill rig comprises a chassis assembly, an operating table, a pump station system and a drill rig assembly, the operating table, the pump station system and the drill rig assembly are all installed on the chassis assembly, a travelling assembly is further installed in the middle of the chassis assembly, and drill rig bodies are installed on the two sides of the chassis assembly through guiding rails correspondingly; the travelling assembly comprises a gear rail driving wheel, a transmission mechanism, and a hydraulic motor, the hydraulic motor is installed in the middle of the chassis assembly, an output shaft of the hydraulic motor is connected with the gear rail driving wheel, the gear rail driving wheel is connected with a scraper gear rail on a scraper in an engaged mode, travelling supporting slipping boots are installed on the two sides of the chassis assembly, and installed on a groove ledge of the scraper; and the drill rig assembly comprises a drill rig body, a sliding seat, a guiding rail and a rotary assembly, a rotary reducer is installed between the guiding rail and a rotary base, the rotary base is connected with the chassis assembly through the rotary reducer, and the drill rig body is connected with the guiding rail through a rotary assembly.

Owner:TIANCHEN COAL MINE OF ZAOZHUANG MINING GRP

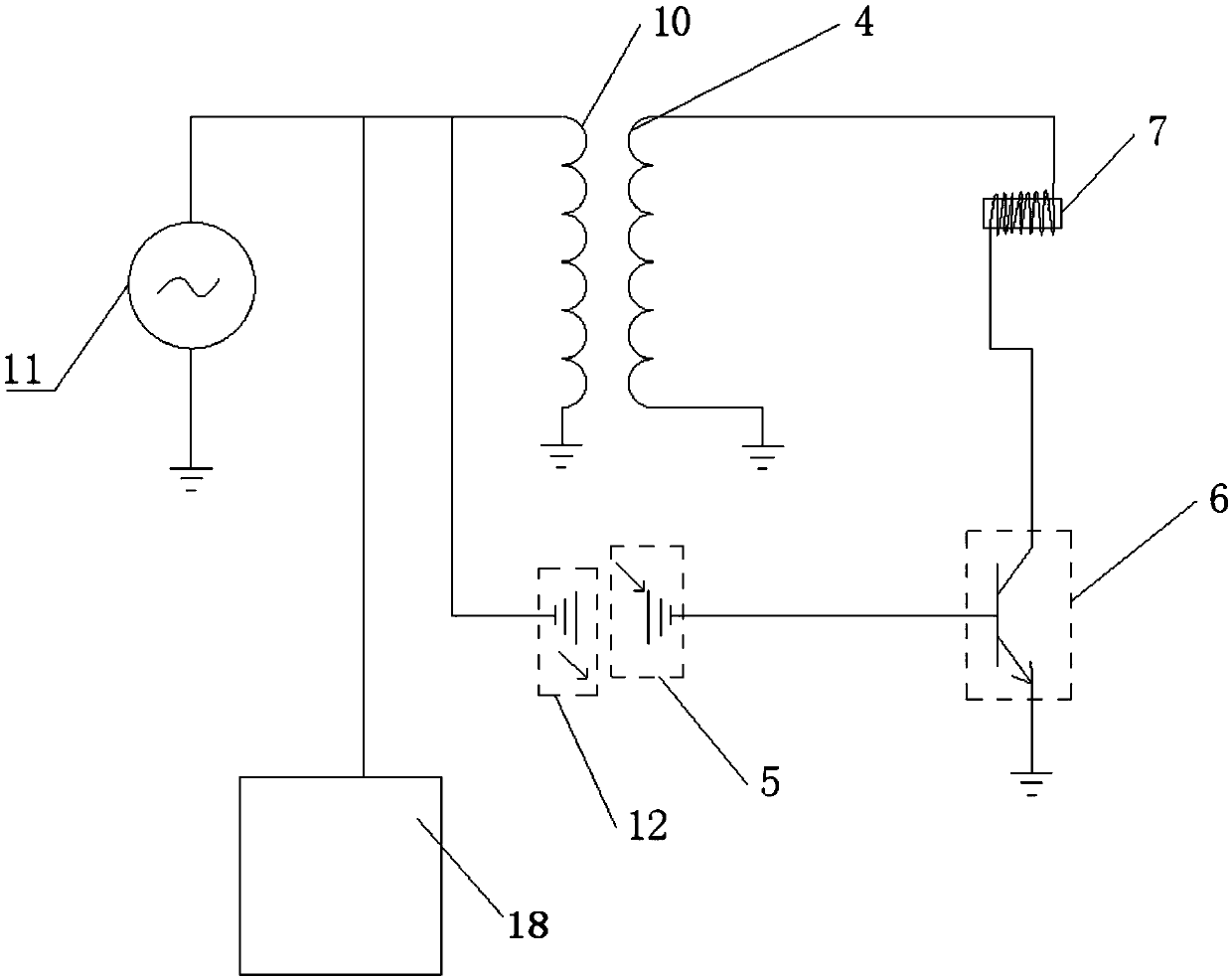

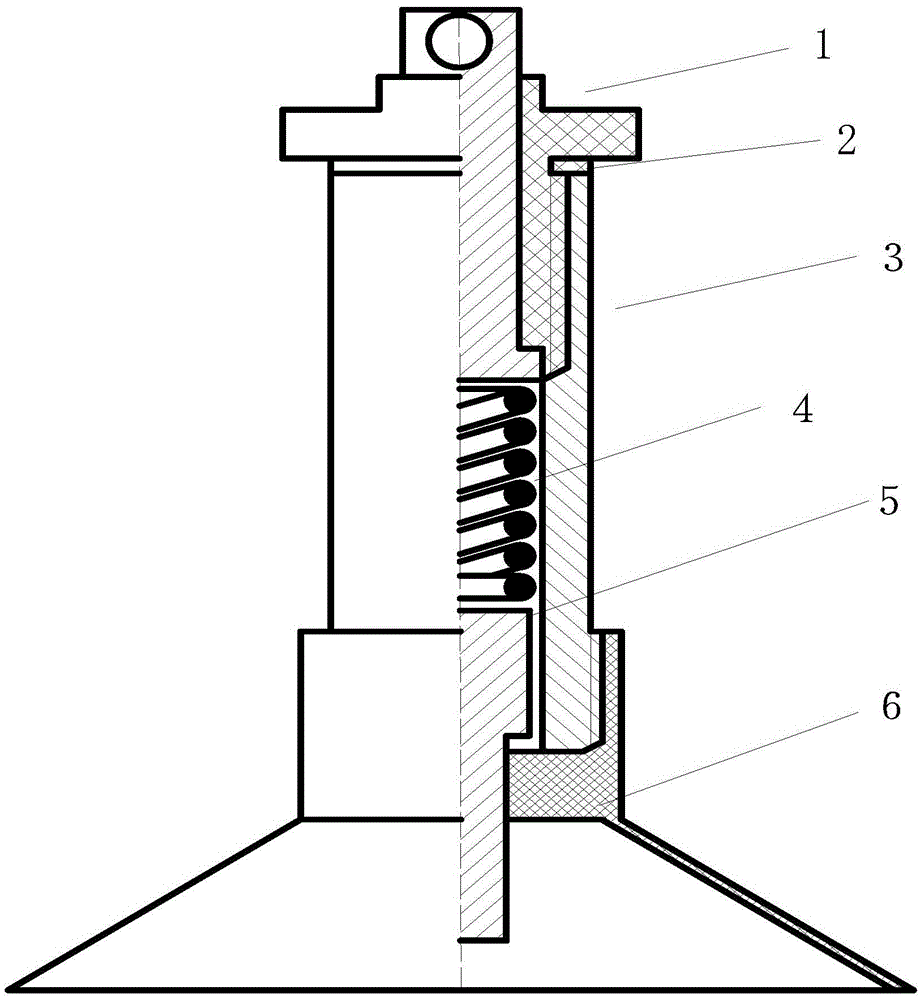

Suction cup type micro-arc oxidation clamp

InactiveCN105671623AConduct electricityWork is not affectedAnodisationElectrolysis componentsMicro arc oxidationAgricultural engineering

The invention discloses a suction cup type micro-arc oxidation clamp. The suction cup type micro-arc oxidation clamp is composed of a conductive nut 1, a sealing washer 2, a PVC pipe 3, a conductive spring 4, an electrode 5 and a suction cup 6, wherein the two ends of the PVC pipe 3 are connected to the conductive nut 1 and the suction cup 6 through threads respectively, the conductive spring 4 and the electrode 5 are arranged inside the PVC pipe 3, the conductive nut 1 is located at the upper part of the PVC pipe 3, and the sealing washer 2 is located between the conductive nut and the PVC pipe; the conductive nut is composed of a nut body and a copper column, and the copper column penetrates through the center of the nut body and is fixed; the copper column of the conductive nut 1 is located above the conductive spring 4, the T-shaped electrode 5 is located below the conductive spring 4, the diameter of the upper part of the electrode is equal to the outer diameter of the conductive spring, and the work end at the lower part of the electrode penetrates through a center hole of the suction cup; the suction cup 6 is located at the lower part of the PVC pipe 3, and a hole with the diameter equal to the diameter of the work end of the T-shaped electrode is formed in the center of the suction cup 6. The suction cup type micro-arc oxidation clamp is simple in structure, low in manufacturing cost, high in universality, reliable in performance, suitable for most work-pieces with planes and electrolytes different in acid-base property and wide in market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

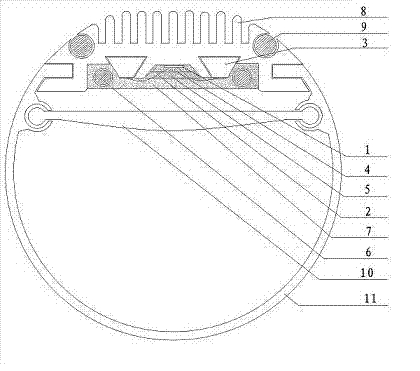

Modular high-definition LED (light emitting diode) daylight lamp

InactiveCN102392948BReduce material costsImprove heat transfer efficiencyPoint-like light sourceElectric circuit arrangementsEpoxyFluorescence

The invention relates to a modular high-definition LED (light emitting diode) daylight lamp, which consists of a lamp carrier, a constant current power supply module, LED light sources and a PC (Polycarbonate) housing, wherein the power supply module is of an external type; the LED light sources are an integrated light source module; the light source module is composed of LED chips, metal wires, a PC circuit board, a transparent silica gel layer, a fluorescent powder layer, a connector assemblies, a transparent epoxy resin layer and a radiator; the radiator is provided with heat dissipating fins, and the bottom of the radiator is provided with a light reflection cup; the LED chips are attached at the bottom of the light reflection cup; the LED chips and the PC circuit board are electrically communicated with each other through the metal wires; the transparent silica gel layer is solidified on the chips; the fluorescent powder layer is arranged on the silica gel layer; the LED chips, the wires, the PC circuit board, the silica gel layer, the fluorescent powder layer, the connector assemblies and the radiator are solidified by the transparent epoxy resin layer to form a whole LED light source module; a plurality of LED light source modules are connected by the connector assemblies to form an integrated LED light source module, and is connected to the PC housing through connectors; and a secondary light distribution lens is arranged in front of the integrated LED light source module and at the inner side of the PC housing.

Owner:罗业富

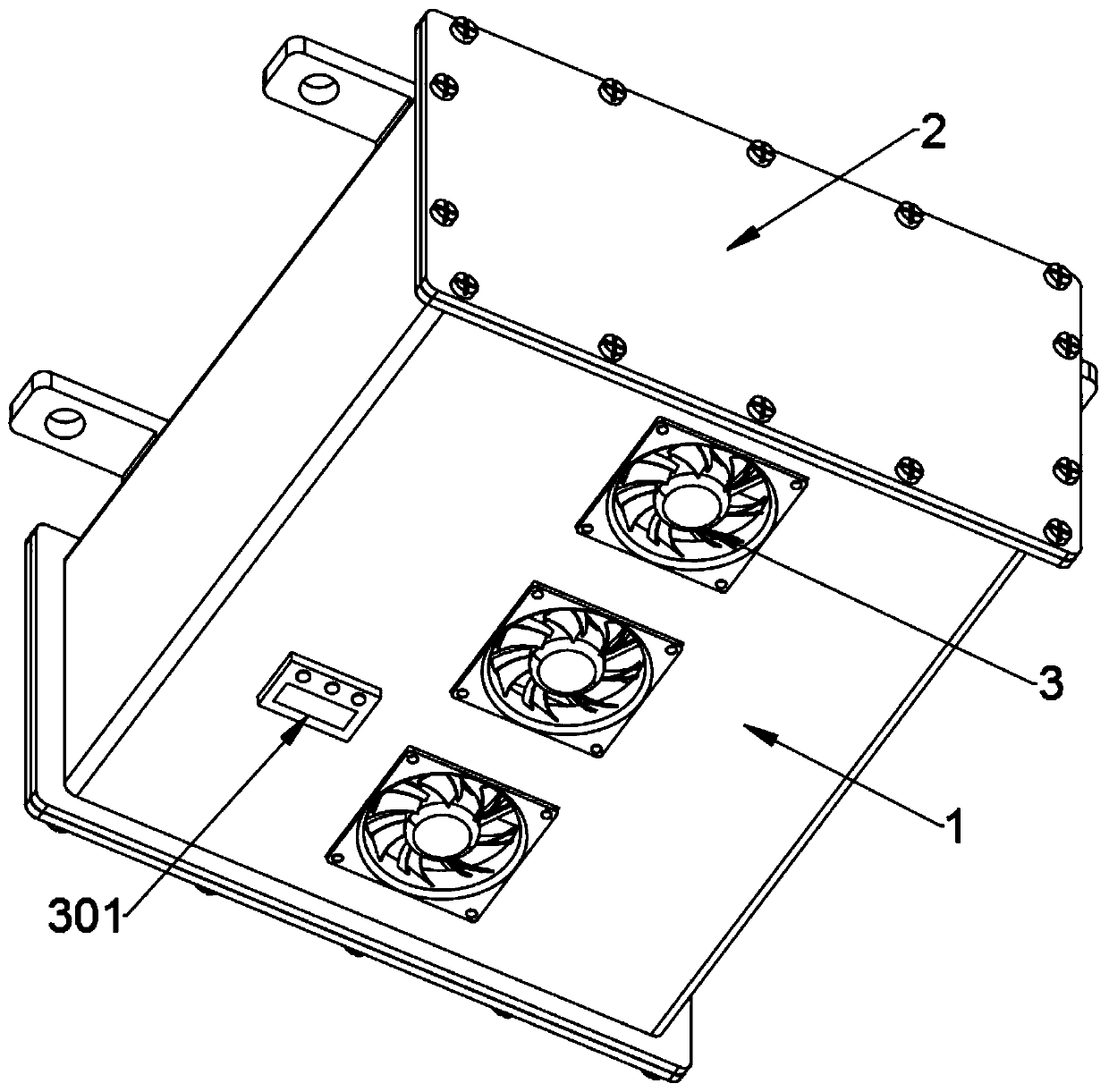

Novel lithium battery receiving box device capable of achieving automatic monitoring and cooling

InactiveCN110311071AQuick disassembly and replacementEasy to disassemble and replaceSecondary cellsCell component detailsEngineeringFront cover

The invention provides a novel lithium battery receiving box device capable of achieving automatic monitoring and cooling. The device includes a box body, a cover plate, cooling fans, a temperature controller, a temperature sensor, positioning frames, positioning sleeves, a sockets, a positioning frame and a lithium battery, wherein the box body is generally rectangular, a rectangular cover plateis disposed on openings of front and rear ends, four cable fixing buckles are arranged in the middle position of the front cover plate in a penetration locking mode, three cooling fans are arranged inthe middle of a bottom plate of the box body in a locking mode, the temperature controller is installed on a bottom plate at one side of the three cooling fans in a penetration locking mode, the square positioning sleeve is welded and fixed to a top end of left and right positioning frames, the two sockets are inserted into the two positioning sleeves under the push action of a spring in a penetration mode, two support frames are sliding support mounting carriers of two clamping frames, and the two clamping frames 5 and the battery can be driven to slidably pull, load and unload in the box body.

Owner:陈明会

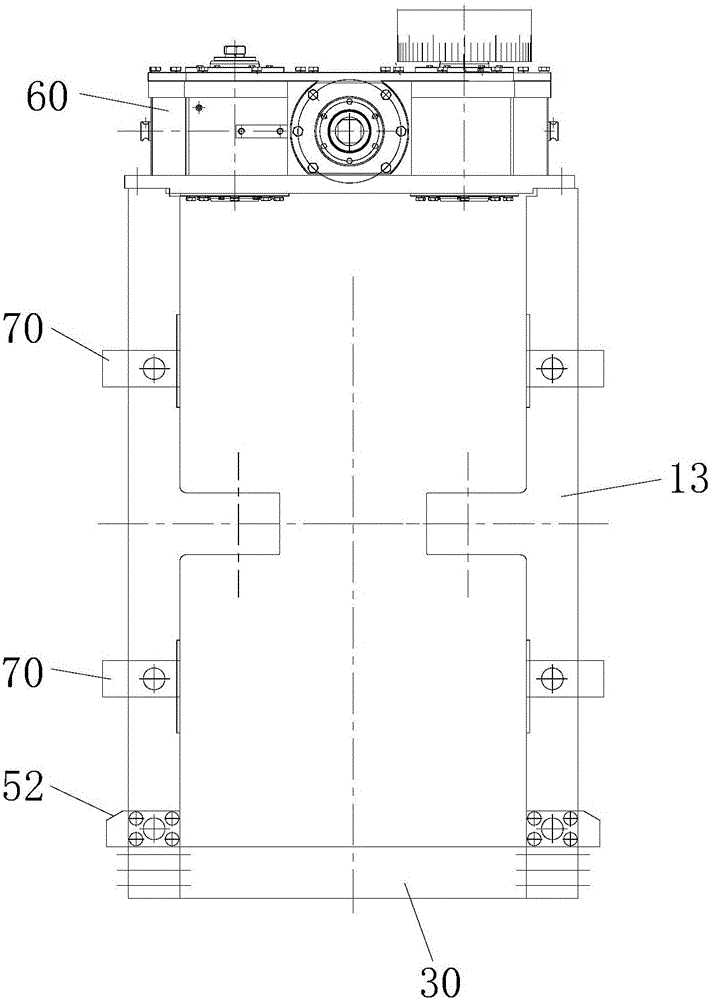

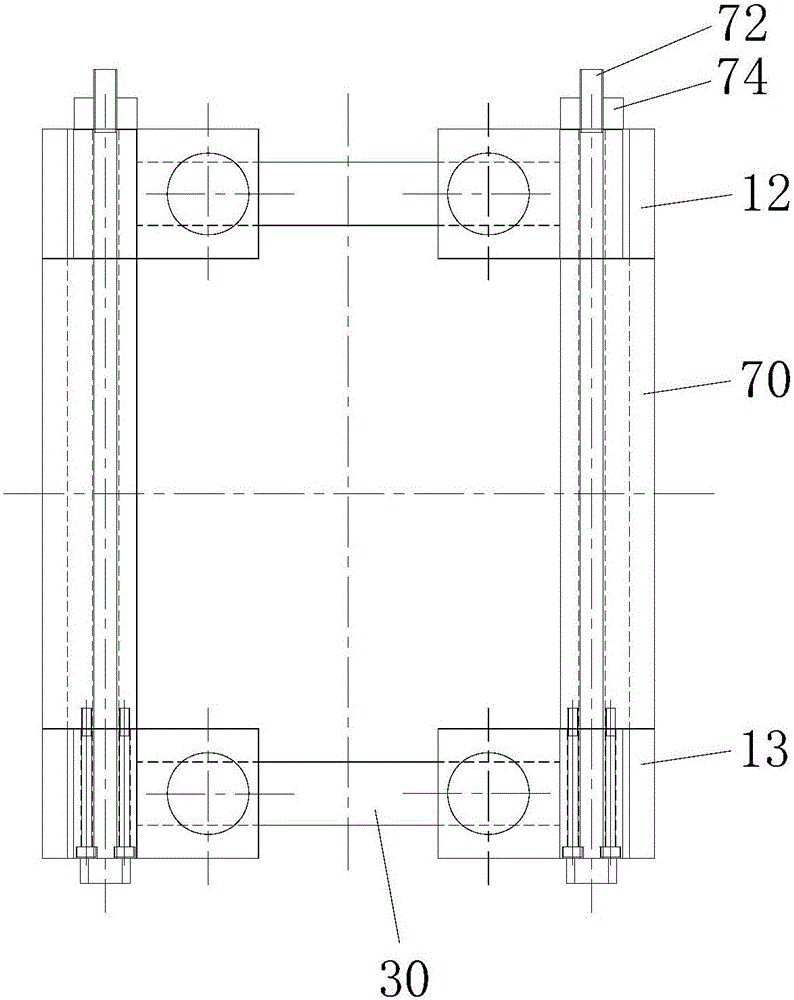

Rolling mill

ActiveCN106040742AEasy to assemble and disassembleQuick disassembly and replacementMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The invention provides a rolling mill. The rolling mill comprises a rack, roller mechanisms and pressing mechanisms. The rack comprises a left archway, a right archway and at least one pair of guide cross beams, wherein the guide cross beams are horizontally connected between the left archway and the right archway. The left archway and the right archway each comprise two stand columns and a connecting cross beam, wherein the two stand columns are arranged oppositely and vertically, and the two ends of the connecting cross beam are detachably connected to the bottoms of the two stand columns correspondingly. The guide cross beams in each pair are arranged between the left archway and the right archway in a front-back symmetry mode, and the two ends of each guide cross beam are detachably connected with the corresponding stand column of the left archway and the corresponding stand column of the right archway correspondingly. Both an upper roller assembly and a lower roller assembly slidably abut against the stand columns. The pressing mechanisms drive the upper roller assembly and the lower roller assembly to slide on the stand columns in a face-to-face mode or oppositely correspondingly, and roller seams are symmetrically decreased or increased through the sliding. According to the rolling mill, a roller system can be disassembled and assembled rapidly, and real-time online symmetrical adjustment of the roller seams is achieved; and since a prestressing mechanism is arranged, on-load pressing can be achieved.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH

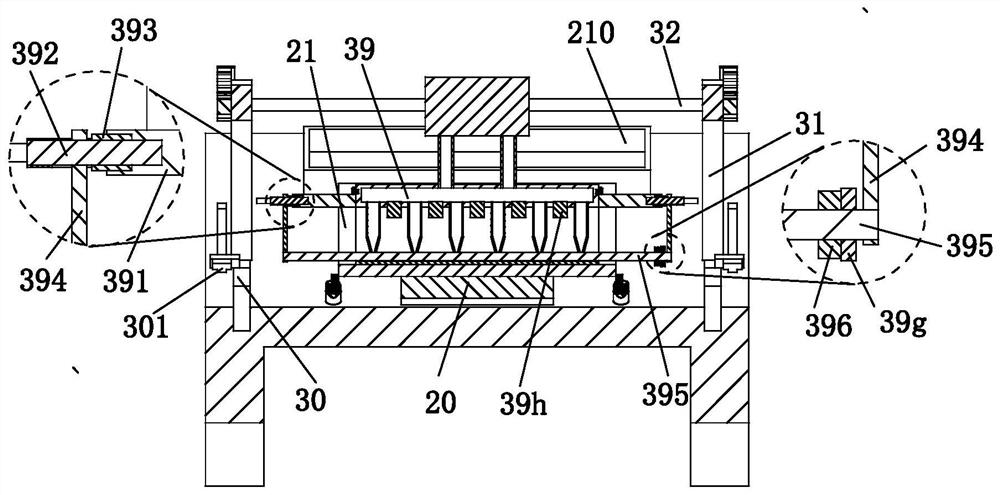

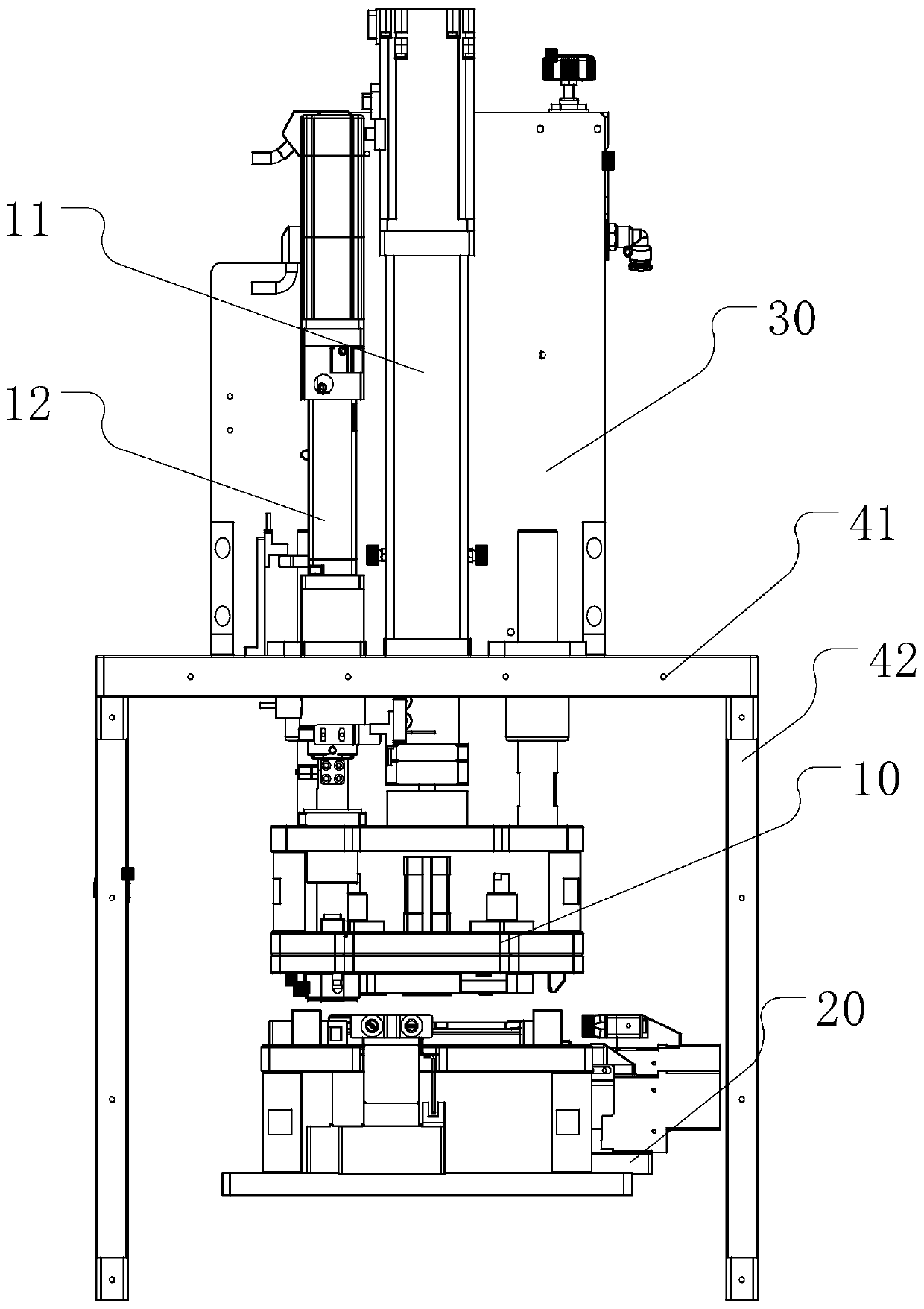

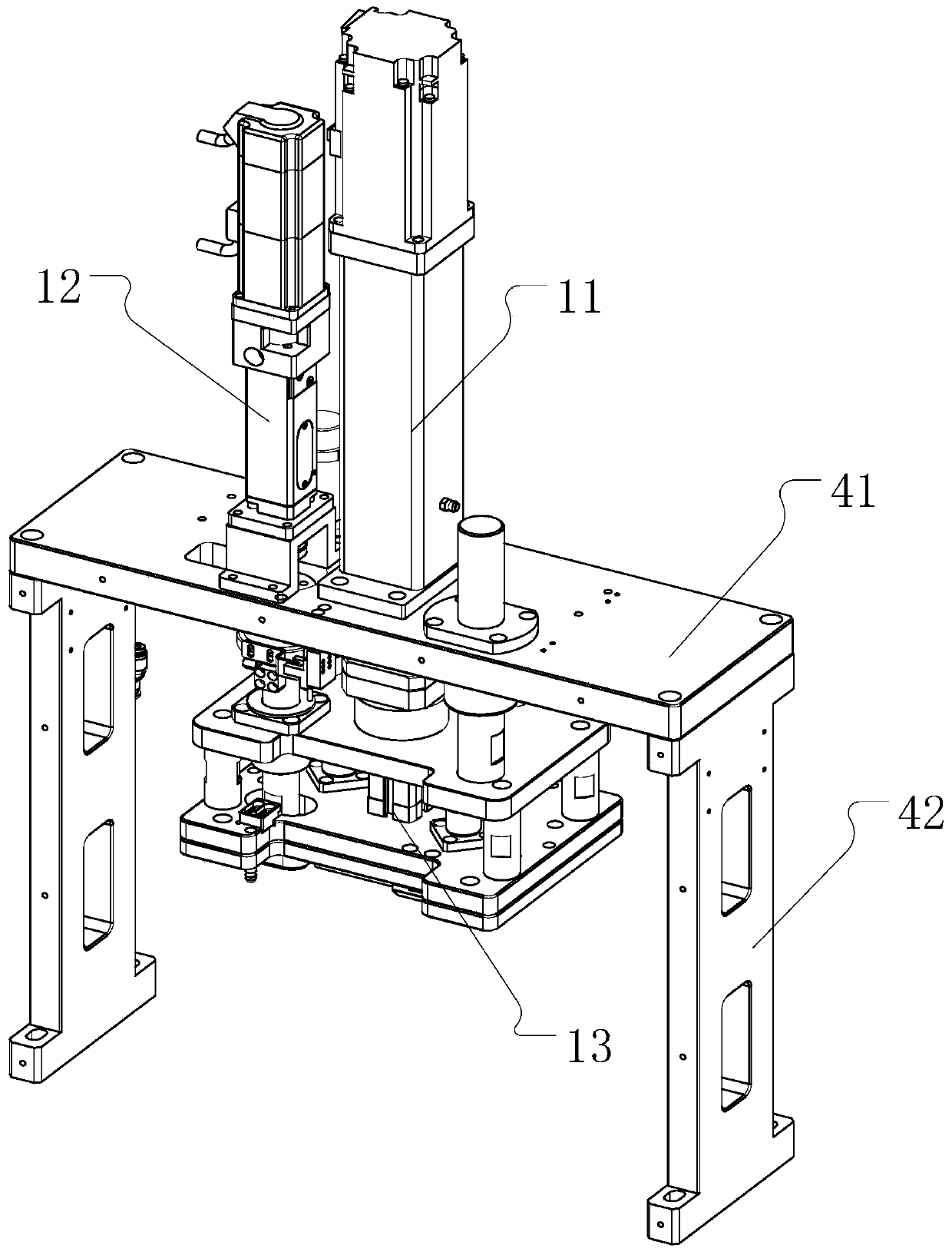

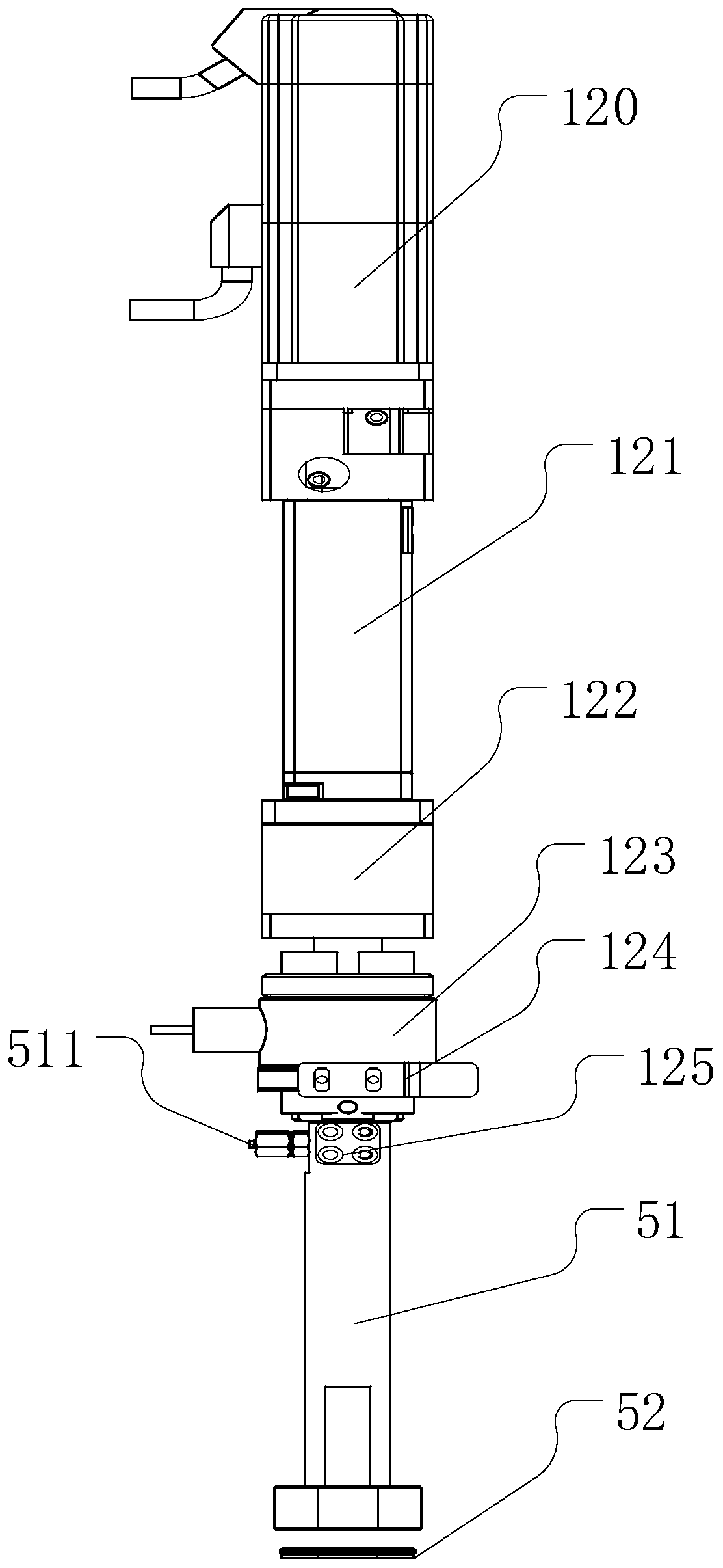

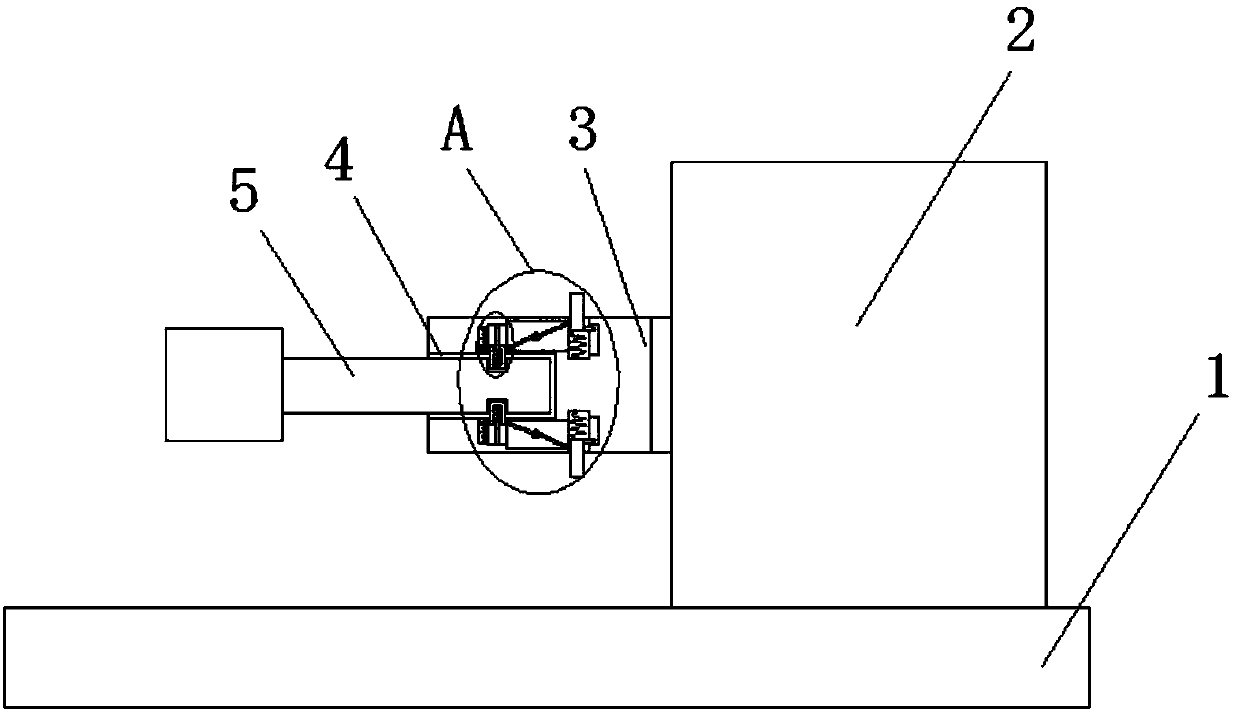

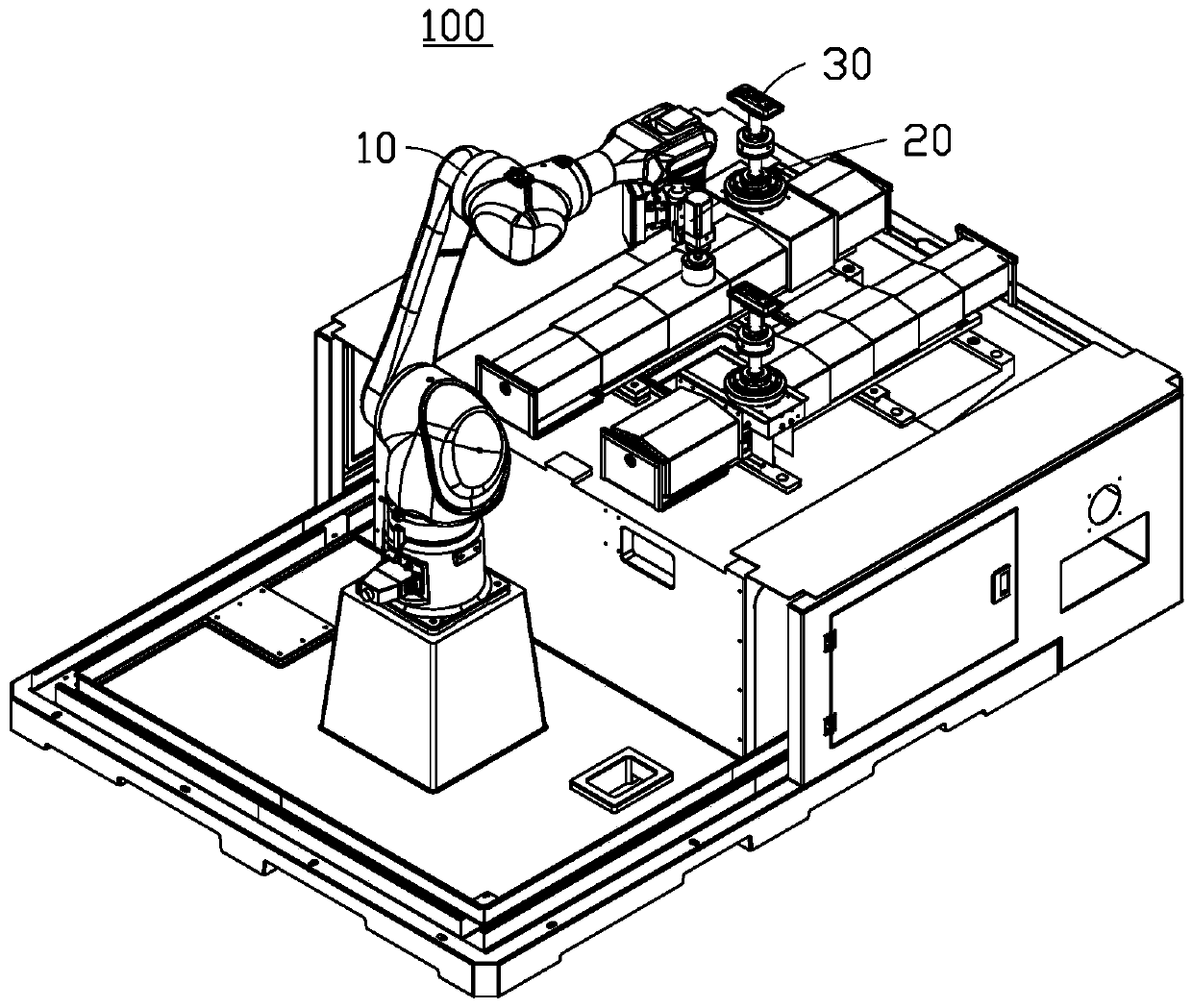

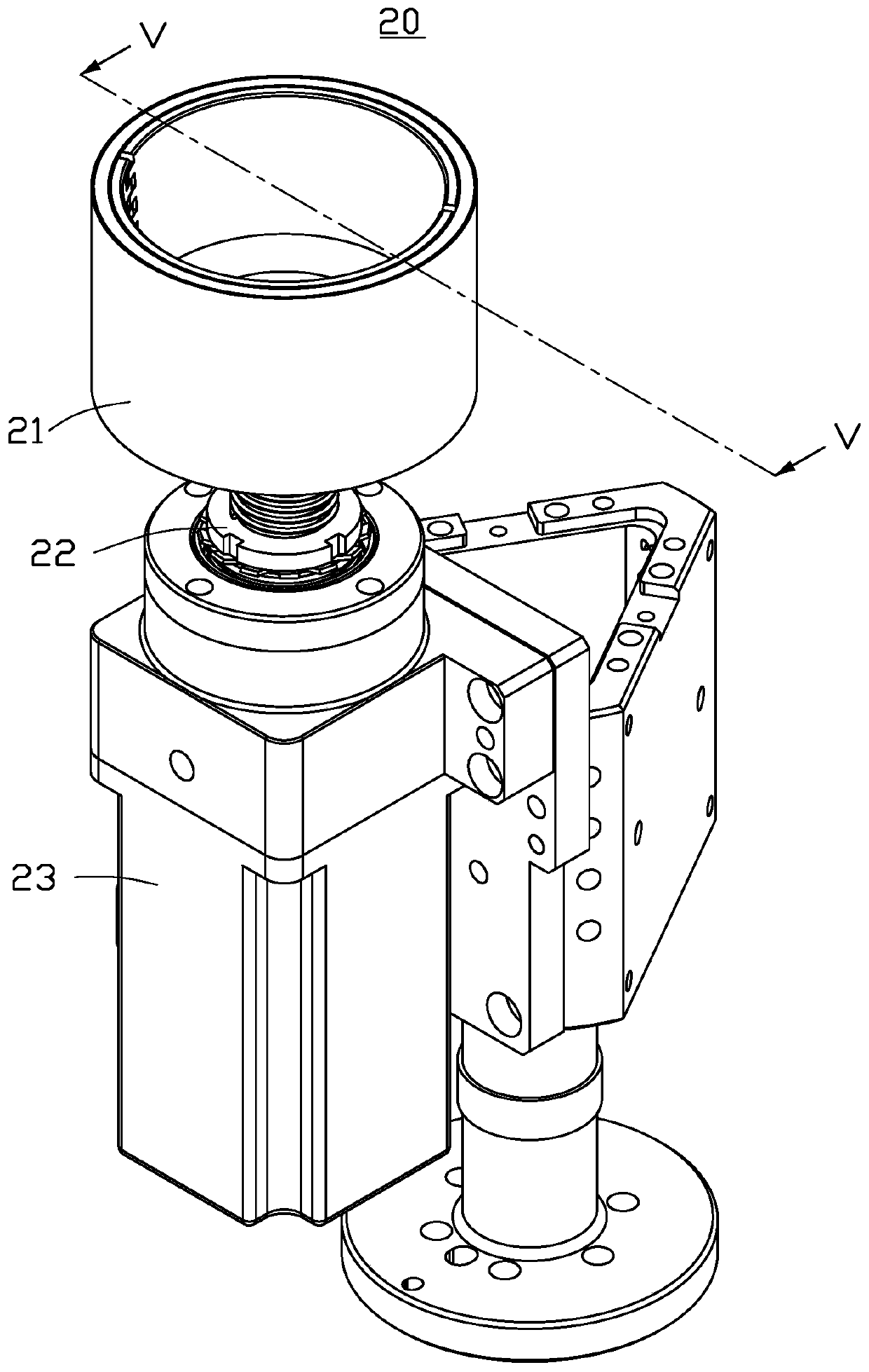

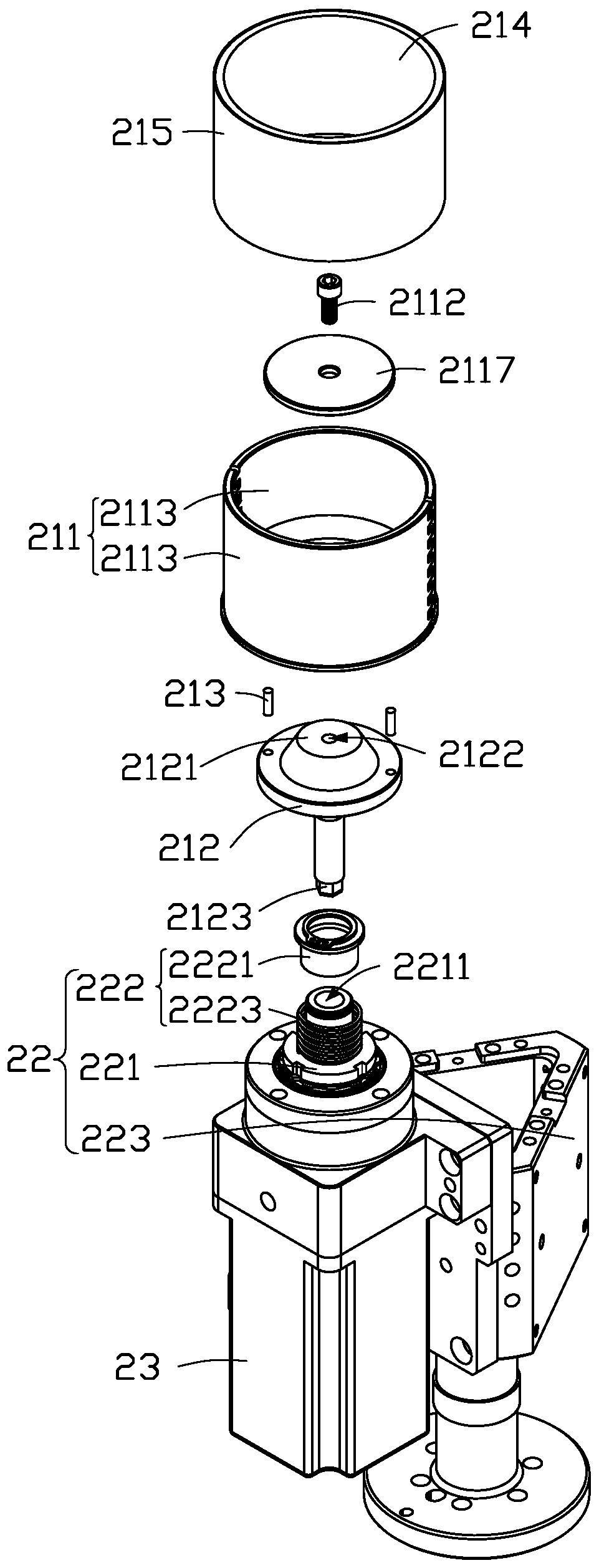

Airtightness test device and method

ActiveCN110132504AImprove test efficiencyRealize visualizationMeasurement of fluid loss/gain rateTest efficiencySoftware engineering

The invention provides an airtightness test device and method. The device comprises an air pressure test assembly, an upper die and a lower die which is arranged opposite to the upper die. The airtightness test device provided by the invention can carry out positive and negative air pressure airtightness tests, and realize the visualization of test results. The upper die and the lower die are aligned in real time, so that high test accuracy and relatively high data repeatability and relevance are achieved. A sealing assembly is in contact with a component to be tested, so that damage to the appearance of the component to be tested is reduced. The sealing assembly can be disassembled and replaced rapidly, so that the test efficiency of the test device is improved. A multi-power sealing structure is used for sealing step by step, so that stress on the component to be tested is reduced, and the process problem in the component to be tested can be debugged and analyzed. A pre-pressing function is realized, so that the stability of airtightness data can be improved effectively.

Owner:HANS LASER TECH IND GRP CO LTD +1

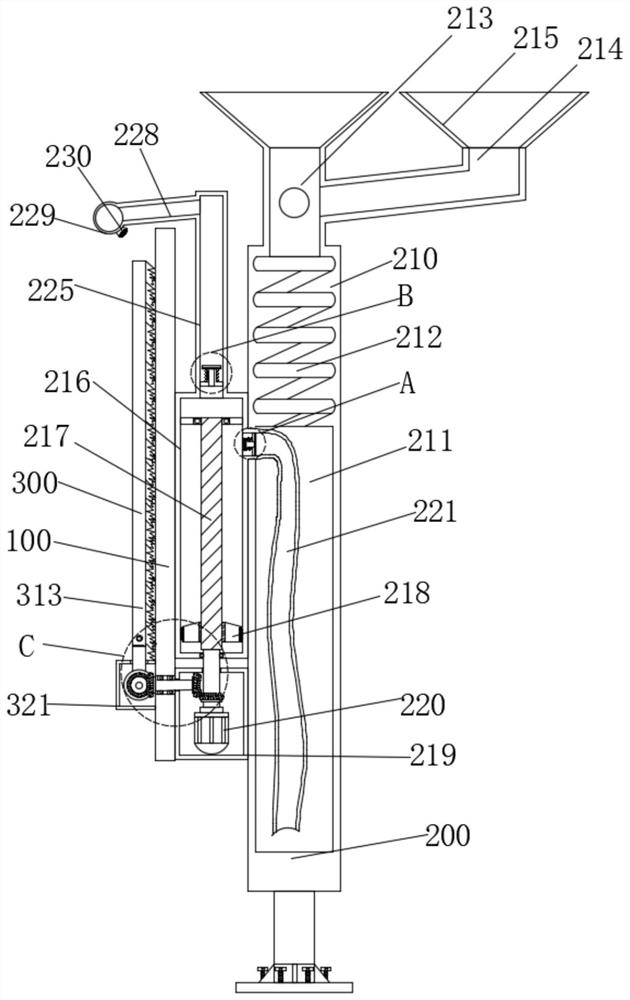

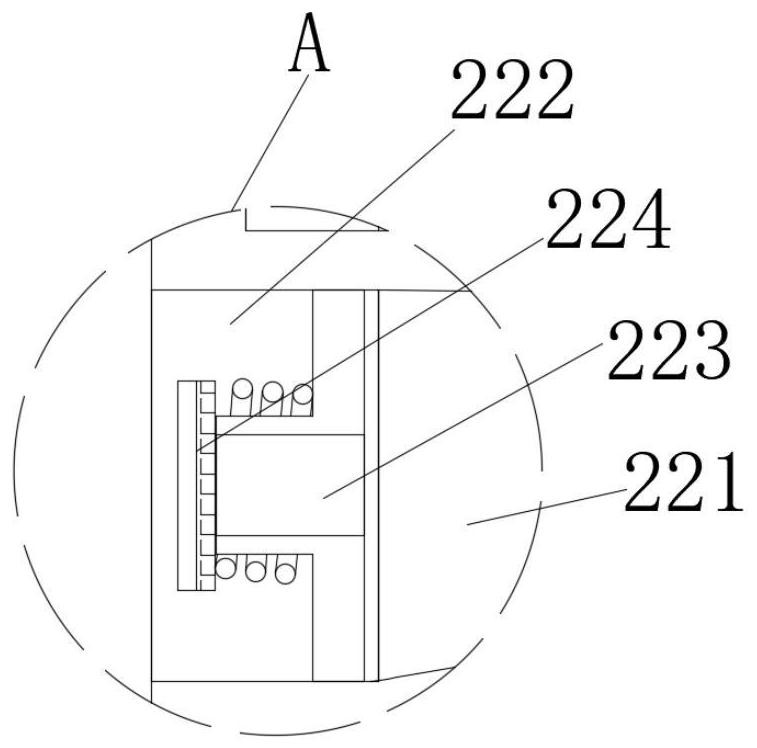

Comprehensive water, fertilizer and pesticide control system for facility agriculture and operation method of system

PendingCN109906741AQuick disassembly and replacementEasy to handleRotary stirring mixersMixer accessoriesSprayerControl system

The invention relates to the technical field of agricultural planting, in particular to a comprehensive water, fertilizer and pesticide control system for facility agriculture and an operation methodof the system. A field, a material mixing device, a filtering device and a spraying device are involved, the material mixing device is arranged on the top left side of the field, the left end of the material mixing device is communicated with the filtering device, and the right end of the filtering device is communicated with the spraying device; according to the system, by arranging a water pump,a sealing plate, a filtering box, a fixed ring, a filtering screen, a water-proof ring and the like, undissolved solid fertilizer particles can be filtered under the effect of the filtering screen, it is avoided that solid particles block a water dripping port, so that the irrigation and fertilizer application efficiency is influenced, and by arranging a spraying pipe, a connecting plate, an adjusting shell, an adjusting rod, a limit rod, a first spring and the like, crops can be sprayed with pesticide through a mist sprayer; the problem that a traditional water and fertilizer spraying devicecannot spray pesticide is solved, and the spraying height of the mist sprayer can be adjusted according to the height of crops.

Owner:祥云泰兴农业科技开发有限责任公司

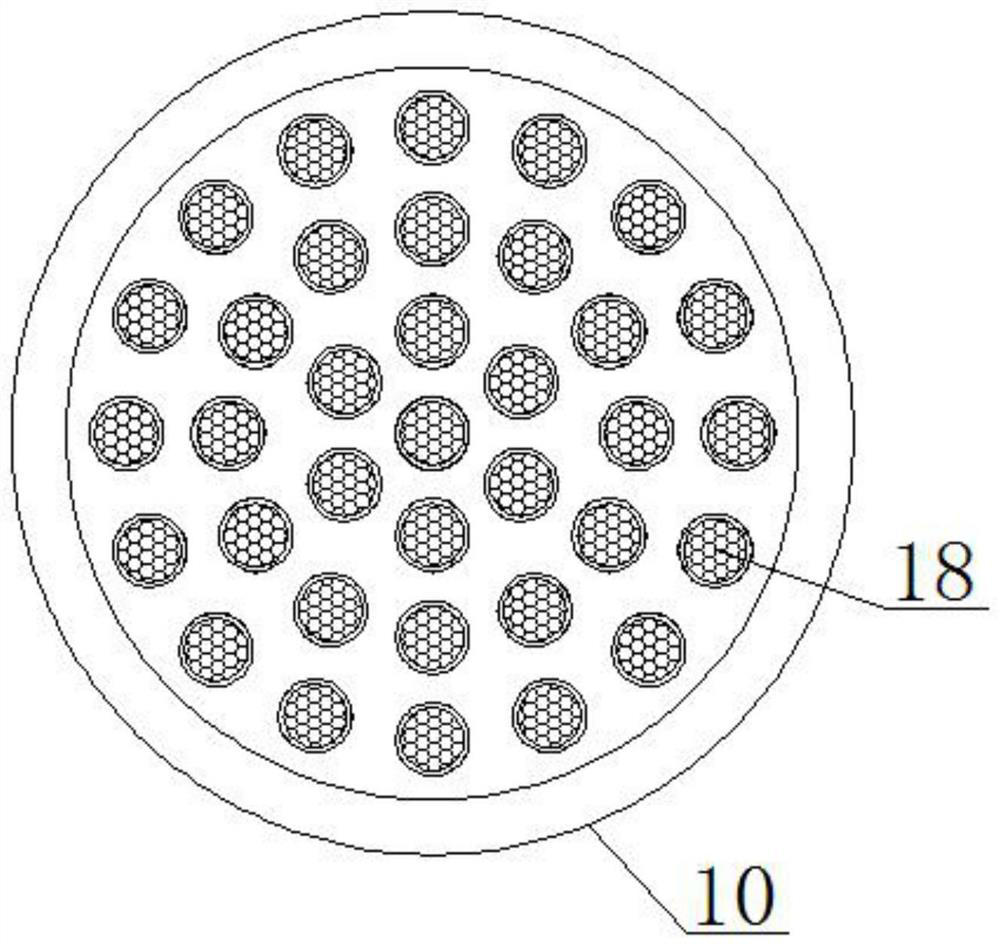

Tail gas purification device with multi-channel structure

ActiveCN112483219AQuick assemblyQuick disassembly and replacementInternal combustion piston enginesExhaust apparatusEngineeringStructural engineering

The invention discloses a tail gas purification device with a multi-channel structure. The tail gas purification device comprises gas outlet pipes and filter layers, wherein a fixing rod is fixed on one sides of the gas outlet pipes; a first connecting groove is formed in one side of the fixing rod; an extrusion groove is formed in one side of the first connecting groove; extrusion blocks are embedded inside the extrusion groove; and a spring is connected between the extrusion blocks. According to the tail gas purification device with the multi-channel structure, a fixing groove is arranged and can be in butt joint with the fixing rod by pulling a filter frame, and thus the filter frame can be pushed to make the fixing groove slide with the fixing rod when the fixing groove is in butt joint with the fixing rod; after the fixing groove slides to one end of the fixing rod, a pressing rod can be pressed to slide with a moving groove; the inclined surface on one side of a clamping block can be extruded when the pressing rod slides; when the clamping block is extruded, the extrusion blocks can be pulled to move so as to stretch the spring; and the clamping block can be inserted into a clamping groove when being extruded, so that the gas outlet pipes and the filter frame are favorably assembled quickly.

Owner:南京瀚深工业部件有限公司

Expressway signboard capable of collecting rainwater for self-cleaning

ActiveCN112411416AEasy to cleanSolve the problem of water fetchingGeneral water supply conservationCleaning using toolsStormwater harvestingPavement maintenance

The invention relates to the technical field of expressway signboards, in particular to an expressway signboard capable of collecting rainwater for self-cleaning. The expressway signboard comprises asignboard body and a servo motor, one side of the signboard body is fixedly connected with a self-cleaning mechanism, and the self-cleaning mechanism comprises a support column; and a rainwater collecting bin is formed in one end of the interior of the supporting stand column, a first circulating bin is formed in one end of the supporting stand column, the interior of a water outlet spray head communicates with the interior of the water flowing bin, and a cleaning mechanism is fixedly connected to the other side of the signboard body. The expressway signboard can effectively collect rainwaterin rainy seasons, can achieve self-cleaning in dry and rain-free seasons, effectively solves the problem that water is difficult to take by pavement maintenance personnel, can quickly rub and clean dust remaining on the surfaces of signboard bodies, is matched with spray washing of the water outlet spray head, and enables the surface of the signboard body to be cleaner.

Owner:江苏鑫瑞交通建设集团有限公司

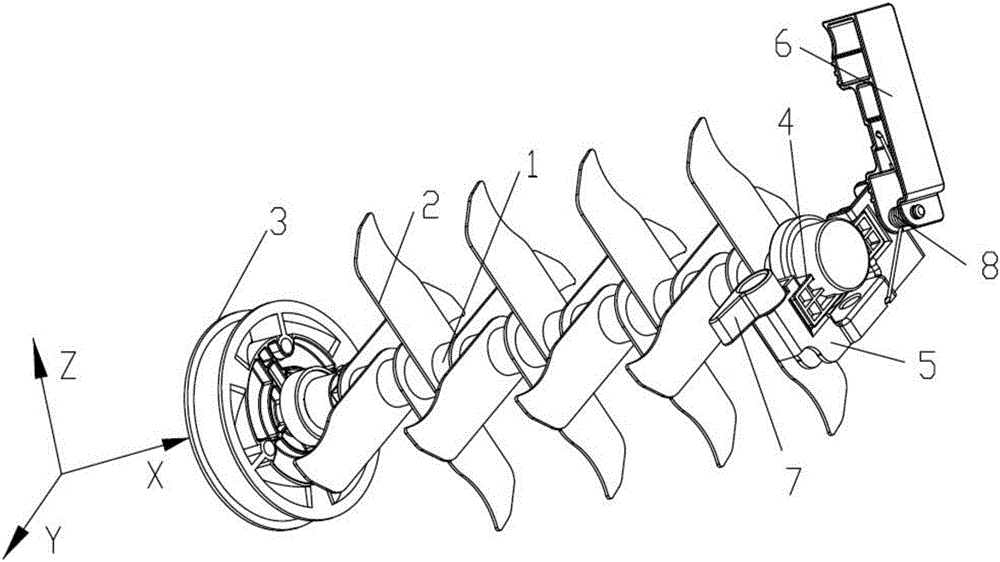

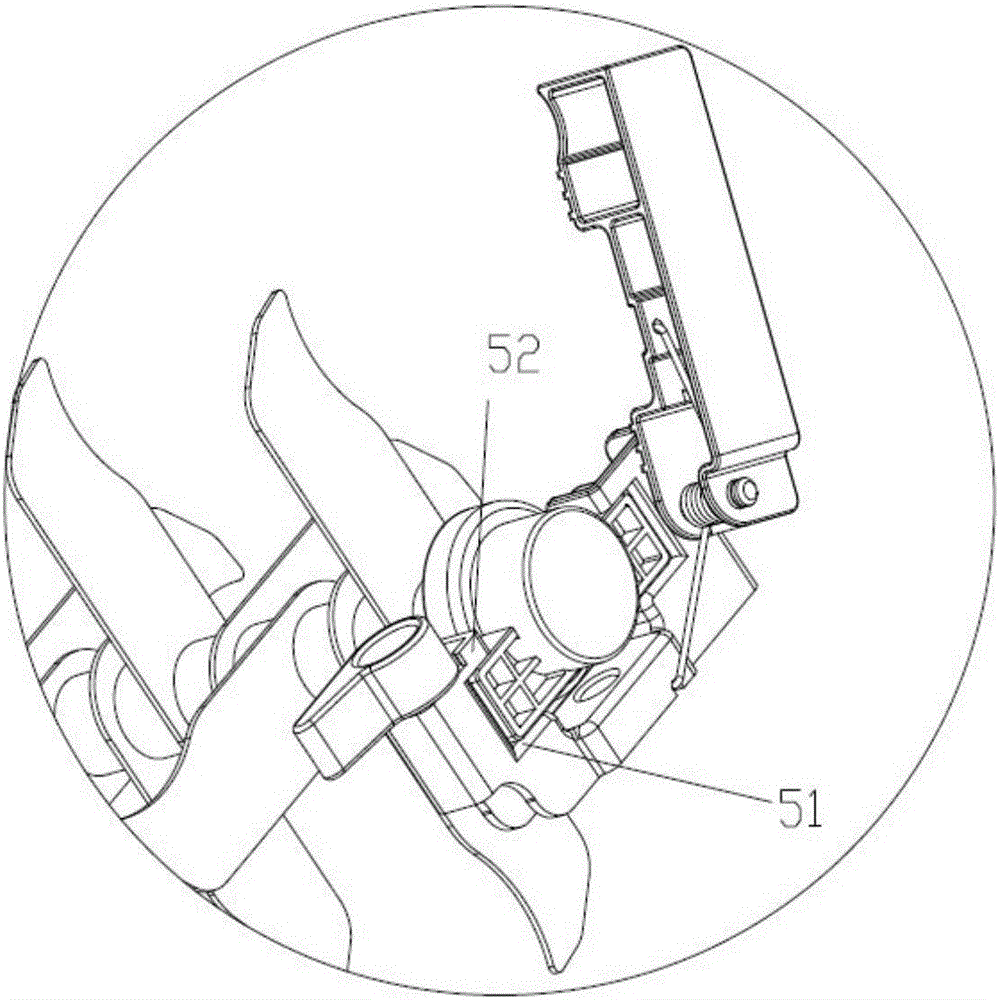

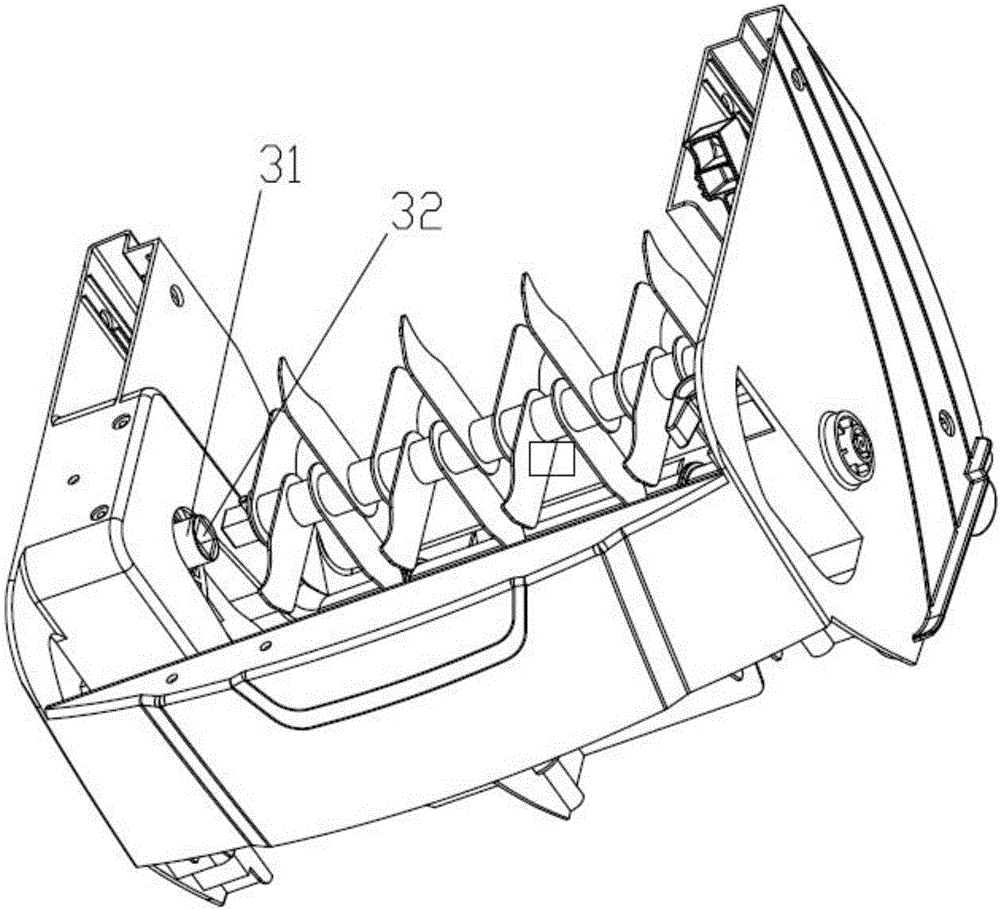

Positioning mechanism and disassembling-and-assembling method for achieving blade-assembly rapid disassembling and assembling and grass thinning machine

The invention discloses a positioning mechanism for achieving blade-assembly rapid disassembling and assembling. When a blade assembly is fixed through the positioning mechanism, one end of a rotating shaft of the blade assembly is inserted into a transmission wheel to be fixed, the other end of the rotating shaft of the blade assembly is clamped on a blade base, movement is limited in cooperation with a limiting block, and assembling is fixedly completed; when disassembling is carried out, limiting of the limiting block is only relieved, the blade assembly is directly, reversely and horizontally pulled and taken out, the disassembling and assembling steps are simplified, rapid disassembling, assembling and replacing of the blade assembly are convenient, and the use comfort is improved when a user uses the product.

Owner:SUZHOU KINGCLEAN PRECISION MACHINERY

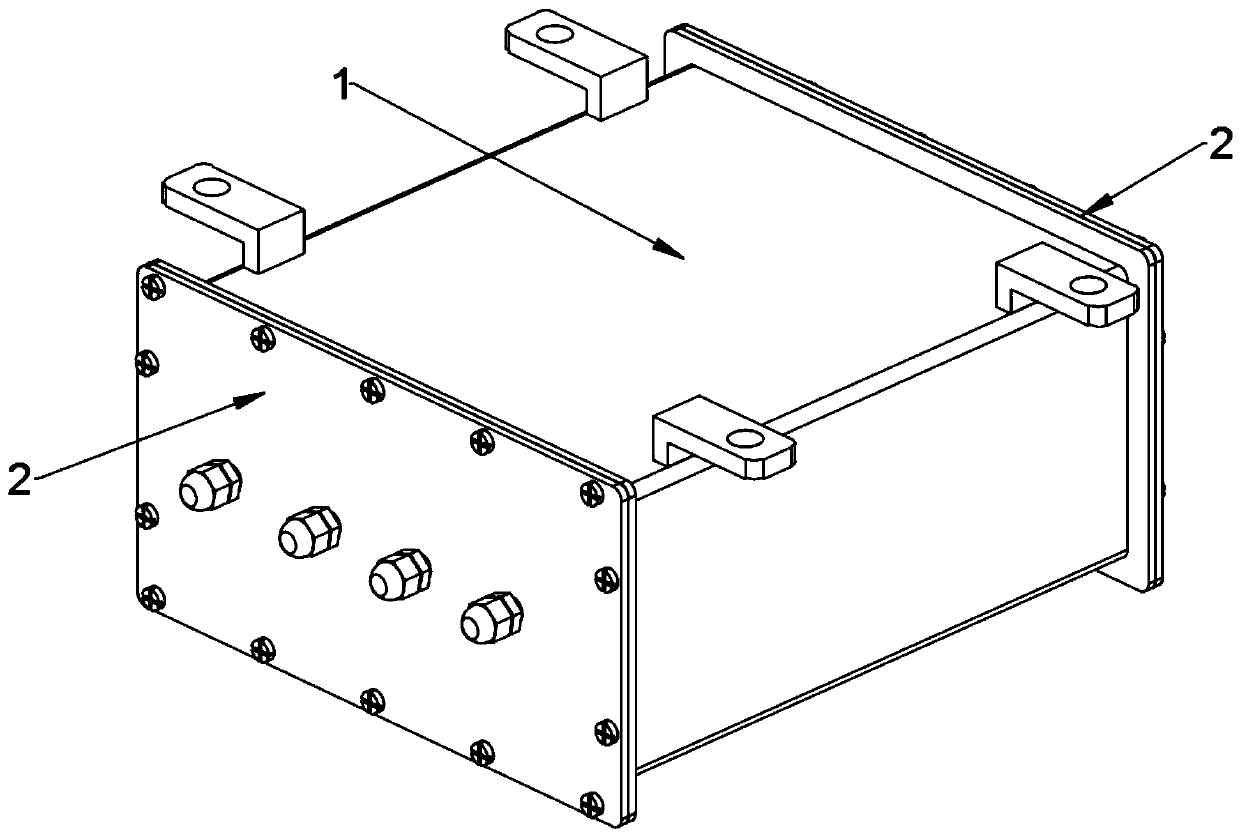

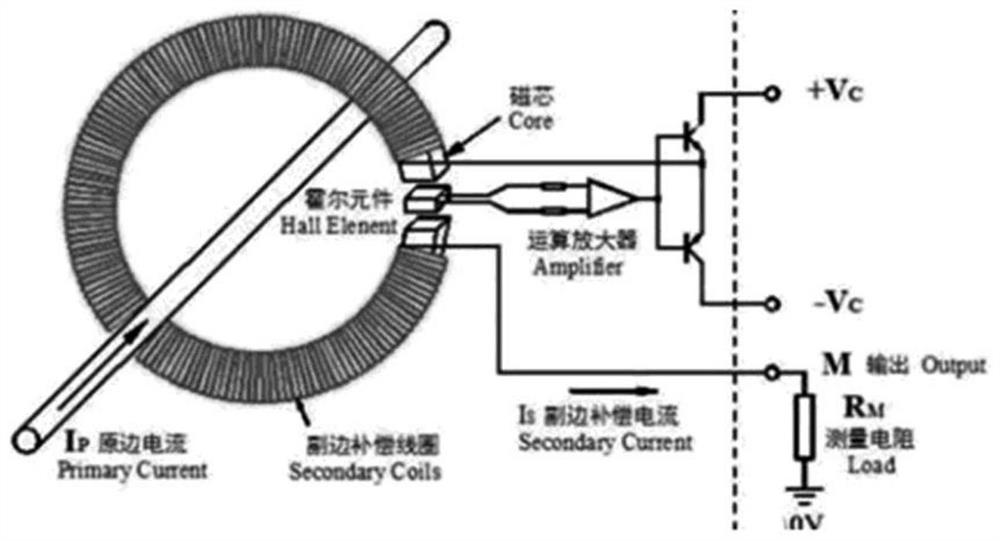

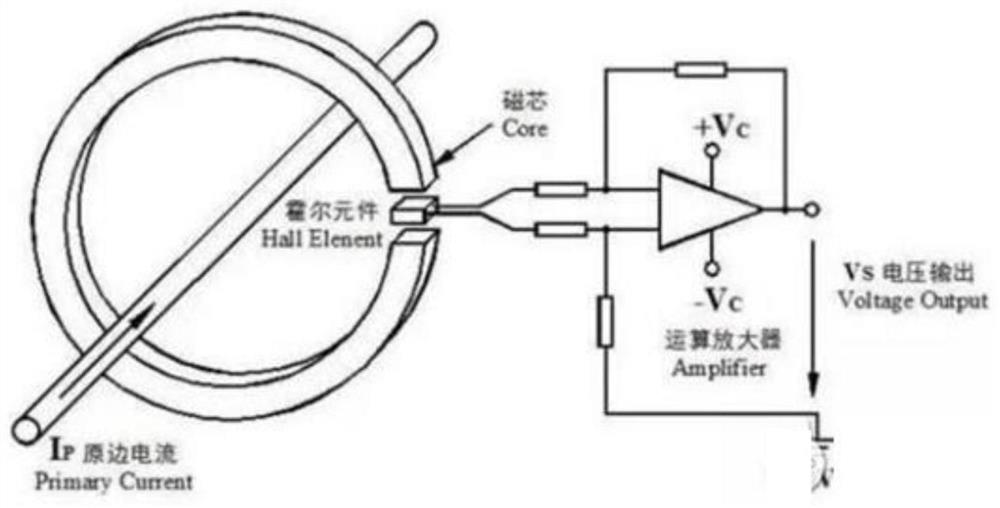

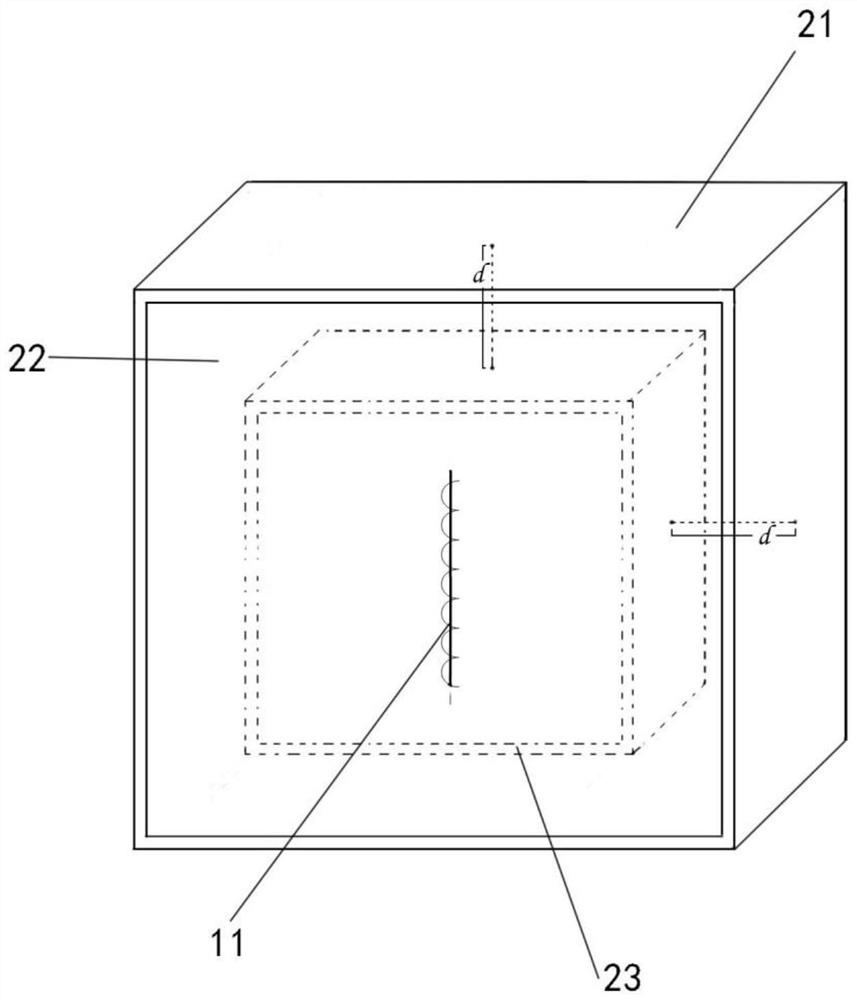

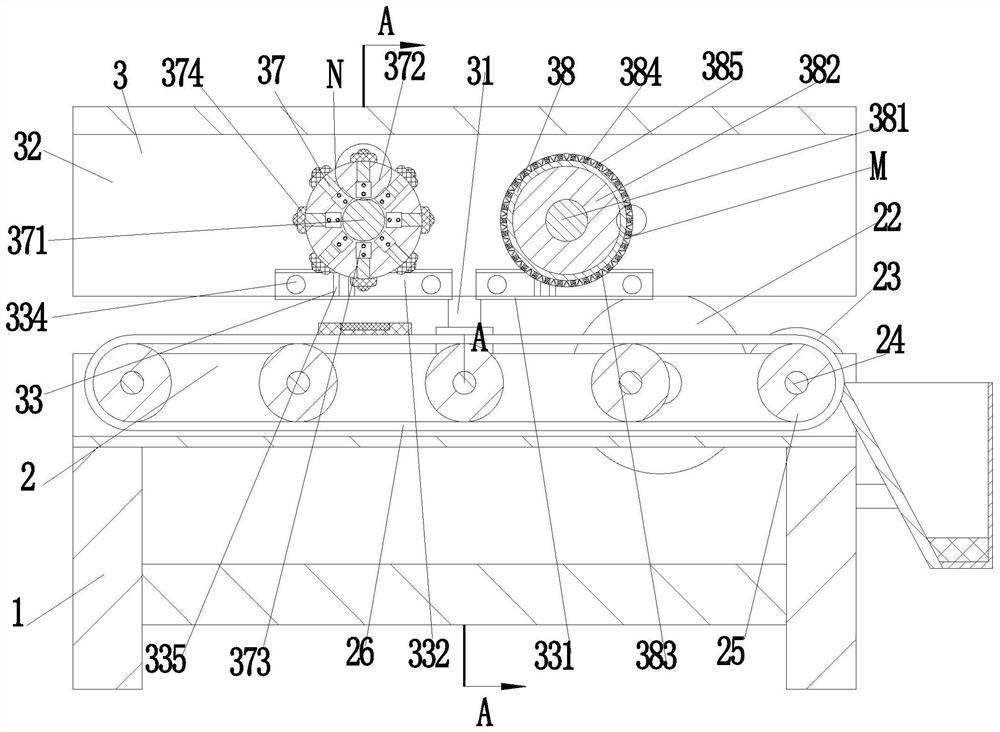

Non-contact current sensor and using method thereof

The invention provides a non-contact current sensor. The non-contact current sensor comprises a GMI magnetic sensor, a shielding body, a circuit processing module and a single-chip microcomputer, theGMI magnetic sensor and the circuit processing module are electrically connected with the single-chip microcomputer. The GMI magnetic sensor is provided with a probe, the probe can detect magnetic field information generated by a detected object, and the circuit processing module and the single-chip microcomputer can convert the magnetic field information into detection values. The probe is arranged in the shielding body, and the shielding body is a metal box body with a certain thickness and high magnetic conductivity. The invention further provides a using method of the non-contact current sensor, and the method comprises the steps: obtaining the shielding body meeting the requirements according to the maximum value of the magnetic field intensity which can be generated by the to-be-measured object; arranging a probe of the GMI magnetic sensor in the shielding body; placing the non-contact current sensor beside an object to be measured; and electrifying the non-contact current sensorto obtain a detection value of the to-be-detected object. The current detection efficiency is improved.

Owner:国创时代(北京)地磁导航通信技术有限公司

Computer memory bank chip coating wiping device

ActiveCN111871905AQuick disassembly and replacementImprove processing efficiencyCleaning using toolsMemory bankGear wheel

The invention relates to a computer memory bank chip coating wiping device. The wiping device comprises a workbench, a conveying device and a cleaning device, wherein the conveying device is arrangedat the upper end of the middle of the workbench, the cleaning device is arranged at the upper end of the conveying device, the cleaning device comprises telescopic supports, a C-shaped plate, positioning frames, a second motor, a first gear, a second gear, a eraser frame and a cleaning brush, and the eraser frame comprises a rotating column, a fixed wheel, rectangular clamping blocks, an eraser block, cylindrical springs, small springs, balls and a control frame. According to the wiping device, through cooperation of the conveying device and the cleaning device, a memory bank is fixed, the surface of the memory bank is cleaned, multiple times of control is not needed in the whole process, and fixing and cleaning can be automatically conducted; and meanwhile, eraser cleaning parts can be rapidly disassembled and replaced, so that the machining efficiency is improved, and the machining cost is reduced.

Owner:ZHONGKAI UNIV OF AGRI & ENG

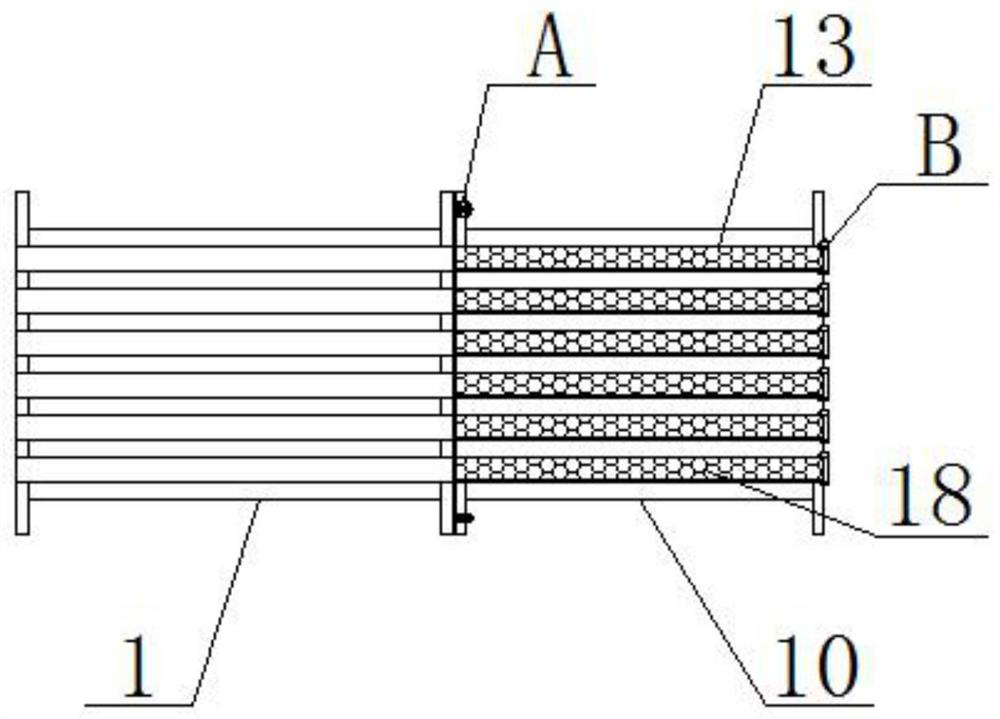

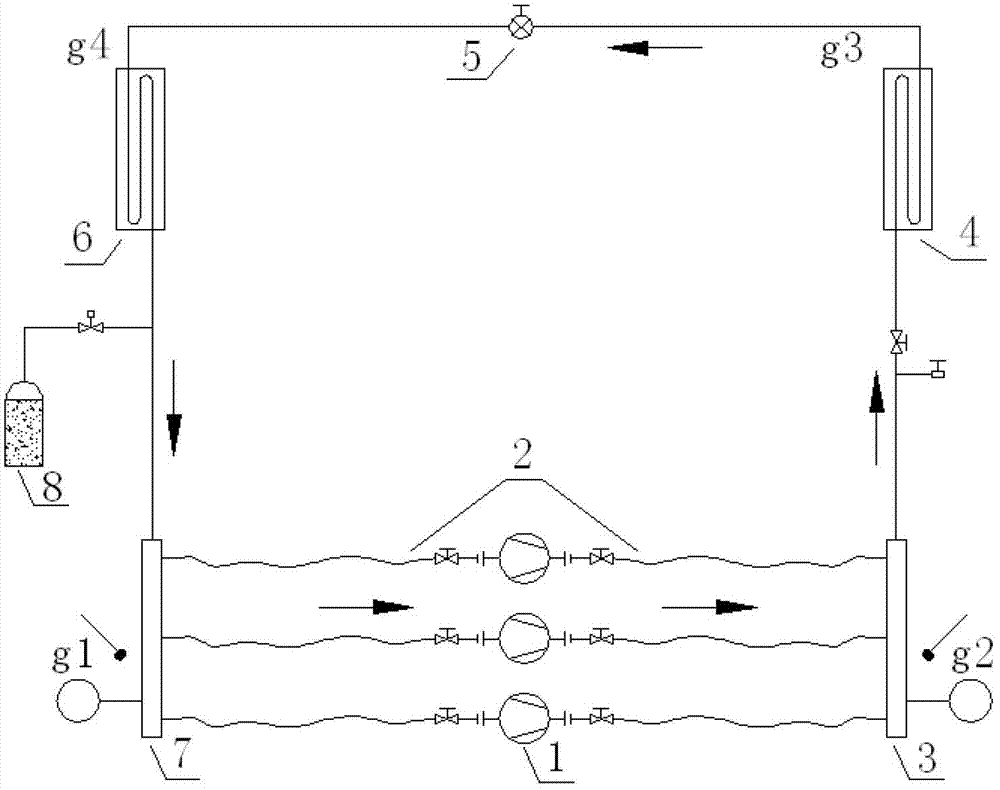

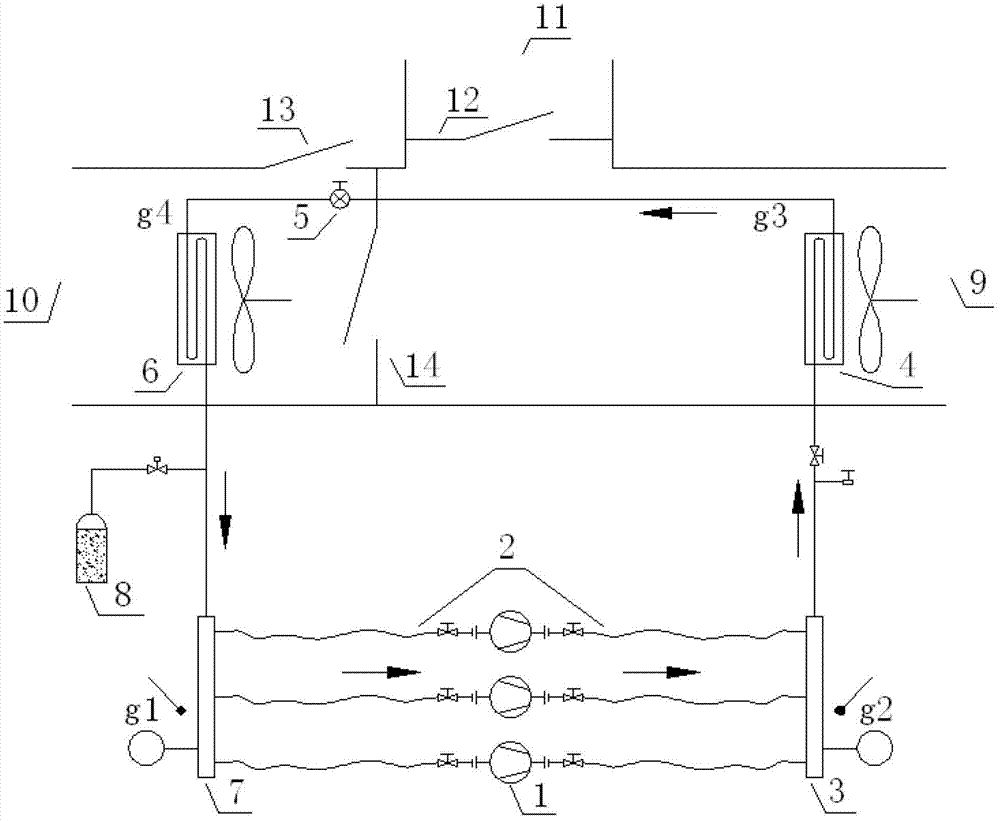

Grinding-in device for new grouped refrigerating compressors

InactiveCN103206808AQuick disassembly and replacementTake advantage ofCompressorPump testingRefrigerantSystem requirements

The invention relates to a grinding-in device for new grouped refrigerating compressors, and belongs to the technical field of refrigerating compressors. Working media flow from a compressor via a high-voltage side heat exchanger (4) and are cooled, pass through an air throttle valve (5), the pressure is lowered; and the working media flow via a low-voltage side heat exchanger (6), and return to the compressor (1) after heat is further absorbed. A reservoir (9) is connected at an outlet of the low-voltage side heat exchanger (6) and refrigerating fluid is replenished or recycled according to system requirements; the high-voltage side heat exchanger (4) and the low-voltage side heat exchanger (6) can be air-cooled or water-cooled; and a single or a plurality of new compressor are connected with an air distribution bag (7) and an air-collecting bag (3) through hose speedy interfaces (2). The grinding-in device has the advantages that production efficiency of a grinding-in process of the new compressors on load is improved; system circulation working media can be nitrogen or refrigerating fluid; enclosed-type grinding-in facilitates cleanness; new compressors are connected rapidly and conveniently by the aid of the air distribution bag, the air-collecting bag and the hose speedy interface, utilization rate of the system is increased; and the heat exchanger can be both water-cooled or air-cooled flexibly.

Owner:BEIJING UNIV OF TECH

Single-cavity molding and secondary seal-off mechanism of injection mold

PendingCN112223637ARealize single-cavity two-color injection moldingEasy to drop and resetBaseboardEngineering

The invention relates to the technical field of injection molds, and discloses a single-cavity molding and secondary seal-off mechanism of an injection mold. The single-cavity molding and secondary seal-off mechanism of the injection mold comprises a fixed half and a moving half, wherein a baseboard is fixedly connected with the bottom of the fixed half, the moving half and the fixed half are arranged in an attached mode, a die cavity is formed after the moving half and the fixed half are closed, a ring cavity is formed in the fixed half, a partition board groove communicates with the top of the ring cavity, and is formed in the top of the ring cavity, the partition board groove communicates with the die cavity, a partition board which matches the interior of the partition board groove isslidingly connected with the interior of the partition board groove, the top end of the partition board is flush with a top groove opening of the partition board groove, a ring block which matches theinterior of the ring cavity is fixedly connected with the interior of the ring cavity, a threaded sleeve is rotatably connected with a center of the ring block through a first bearing, a threaded rodwhich matches the threaded sleeve is fixedly connected with the bottom end of the partition board, and the threaded rod penetrates through the threaded sleeve, and extends downwards. By means of thesingle-cavity molding and secondary seal-off mechanism of the injection mold, single-die-cavity double-color injection molding can be conducted through the injection mold, so that the structure of theinjection mold is greatly simplified, and the injection molding cost is greatly reduced.

Owner:ANHUI ANLAN MOLD

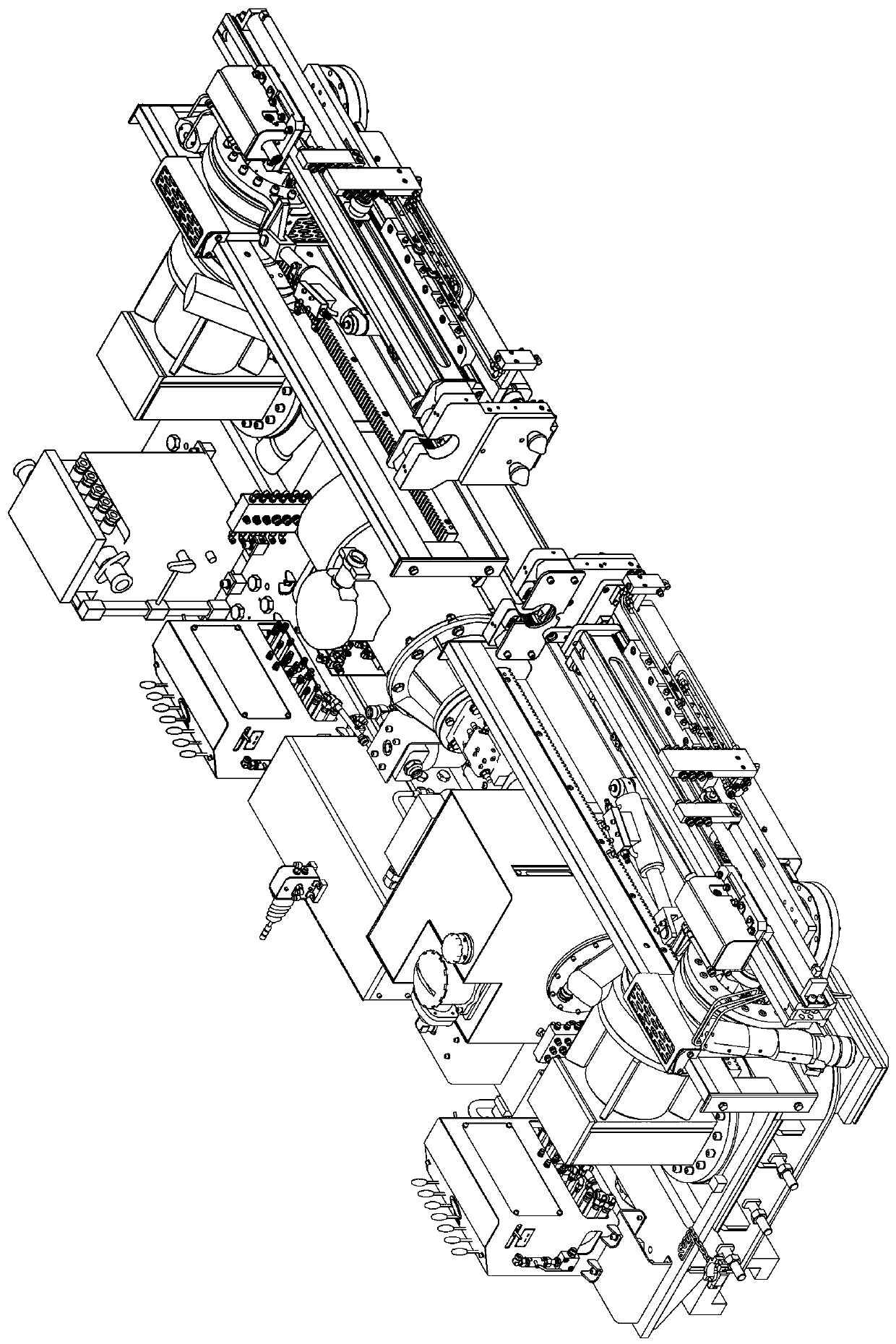

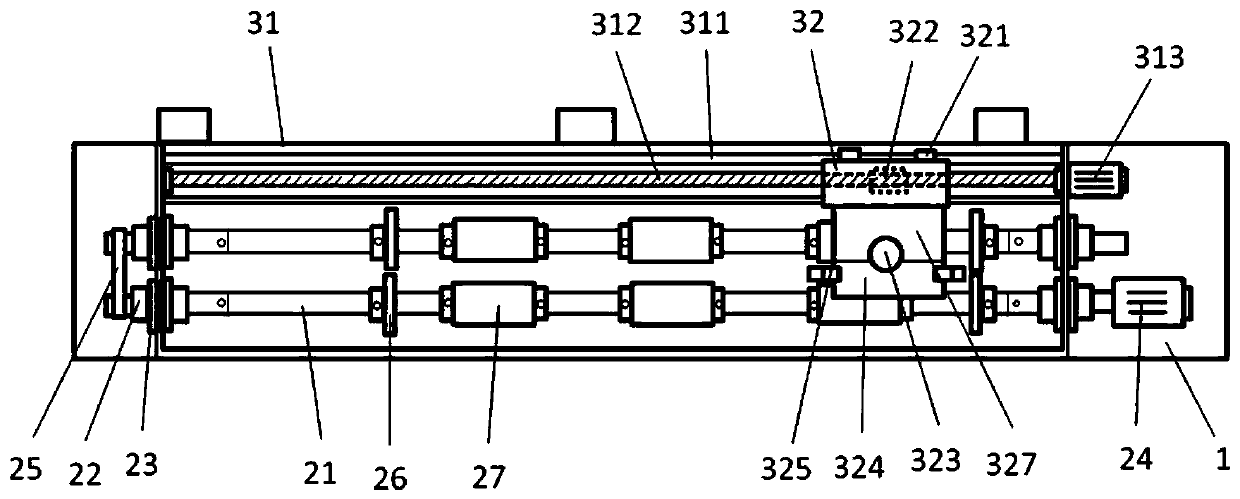

Ultrasonic nondestructive testing device for shaft parts

PendingCN111398423AReduce wearAvoid invalid processingAnalysing solids using sonic/ultrasonic/infrasonic wavesPhysicsElectric machinery

The invention provides an ultrasonic nondestructive testing device for shaft parts. The device comprises a detection workbench and a controller. The detection workbench is provided with a coupling water tank and a cantilever beam unit. A pair of parallel rolling shafts with the same diameter are arranged in the coupling water tank in the horizontal direction, the two ends of each rolling shaft arearranged on the tank wall of the coupling water tank in a penetrating mode through bearings and sealing sleeves, a synchronous belt is connected between the rolling shafts, and the rolling shafts aredriven by a gear motor arranged outside the coupling water tank to rotate in the axial direction. The cantilever beam unit comprises a cross beam arranged above the water tank and parallel to the driving rolling shaft, a probe lifting base capable of moving horizontally is arranged on the cross beam, a probe frame capable of moving up and down is arranged on the probe lifting base, and a plurality of ultrasonic probes are arranged on the probe frame. The flaw detection device is simple in structure, convenient to operate, low in requirement for surface smoothness of a to-be-detected part, notprone to abrasion of the probe, convenient to disassemble, assemble and replace due to the modular design of the probe set and suitable for nondestructive detection application of the shaft parts ofvarious specifications.

Owner:南通银河测控技术开发有限公司

Polishing equipment for machining jewelry box

InactiveCN108044472AQuick disassembly and replacementSimple structureGrinding machinesArchitectural engineering

The invention discloses polishing equipment for machining a jewelry box. The polishing equipment for machining the jewelry box comprises a base, the top of the base is fixedly provided with a servo motor, a fixing block is welded on an output shaft of the servo motor, a first groove is formed in one side, away from the servo motor, of the fixing block, a polishing tool body is arranged in the first groove in a sliding mode, and one end of the polishing tool body extends out of the first groove; and second grooves are formed in the top of the fixing block and the bottom of the fixing block, third grooves are formed in the inner walls of the two sides of the first groove, the two second grooves and the two third grooves are all located on the same horizontal plane, the top of the fixing block and the bottom of the fixing block are both provided with through grooves, and the second groove and the third groove which are located on the same side of the first groove communicate with the corresponding through grooves. According to the polishing equipment for machining the jewelry box, the structure is simple, and the operation is convenient; and moreover, the polishing tool body can be quickly disassembled and replaced through a simple pressing action, so that great convenience is brought to workers, and rapid production is facilitated.

Owner:宁波诚风家居用品有限公司

Polishing head, polishing device and polishing equipment

ActiveCN111451906AImprove grinding efficiencyImprove yieldGrinding wheel securing apparatusGrinding headsPolishingEngineering

The invention provides a polishing head comprising a polishing body and a connection piece, wherein the polishing body and the connection piece are detachably connected. The connection tightness degree between the connection piece and the polishing body is adjusted, so that the diameter of the polishing body is controlled. By adjusting the connection tightness degree between the connection piece and the polishing body, the diameter of the polishing body is controlled, and then detachable rapid installation of the connection piece and the polishing body is achieved. Meanwhile, a polishing belton the polishing body can be rapidly and conveniently replaced. The polishing head is driven by an external drive device to rotate to polish a workpiece, a polishing point of the polishing head achieves the same polishing effect on the whole polished plane of the workpiece, so that the polishing efficiency and yield of the polishing head are improved. The invention also provides a polishing deviceand polishing equipment.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com