Disassembling and assembling equipment for screw of plastic extruder

A screw and plastic technology, applied in the field of screw disassembly and assembly equipment of plastic extruder, can solve the problems of scald caused by human operation, difficult to take out the screw, and high screw temperature, so as to reduce equipment damage and operator safety accidents, and quickly disassemble and replace. , Reduce the effect of screw screw damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through specific implementation modes below in conjunction with the accompanying drawings.

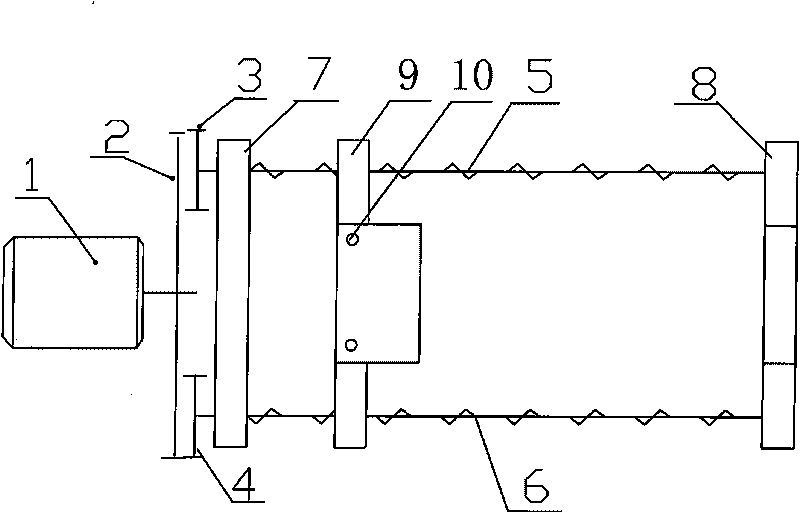

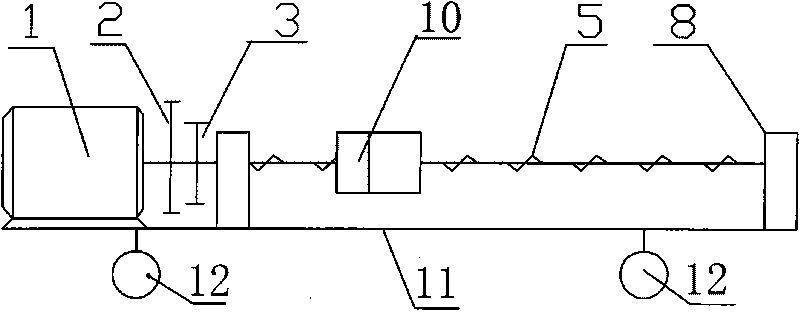

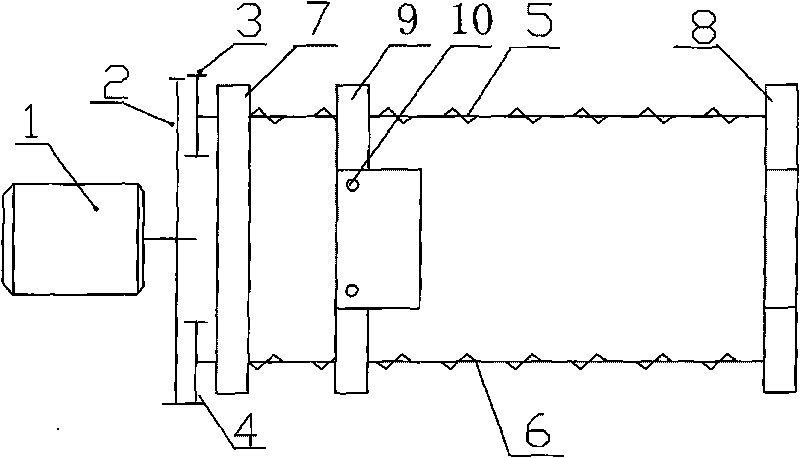

[0019] Plastic extruder screw dismantling equipment, reduction motor (1) is the common reduction motor sold on the market, and gears (2), (3), (4) are involute gears. Gear (2) is installed on the reduction motor (1) through key connection, and gear (3) and gear (4) are respectively fixed on one end of leading screw (5) and (6) through key connection. The reduction motor (1) drives the gear (2), and the gear (2) drives the gear (3) and the gear (4) to rotate. The two ends of leading screw (5), leading screw (6) are connected with bearings respectively, and the bearings at two ends are respectively fixed on the fixed plate (7) and (8). The screw (5) and the screw (6) are provided with a fixed block (9), and the fixed block (9) is provided with two internally threaded holes with the same diameter as the lead screw (5) or (6) (10). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com