Grinding-in device for new grouped refrigerating compressors

A technology for refrigeration compressors and new machines, applied in compressors, refrigerators, refrigeration components, etc., can solve the problems of poor actual effect, non-sharing of equipment, waste of resources, etc., to increase system reliability, ensure stable operation, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

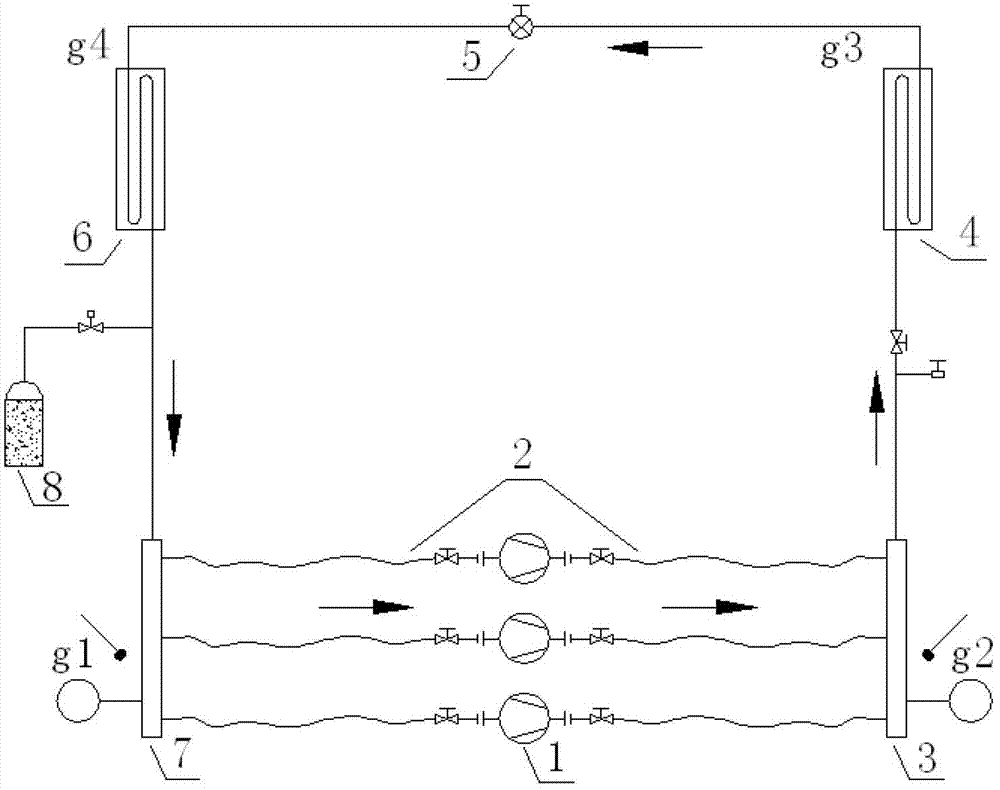

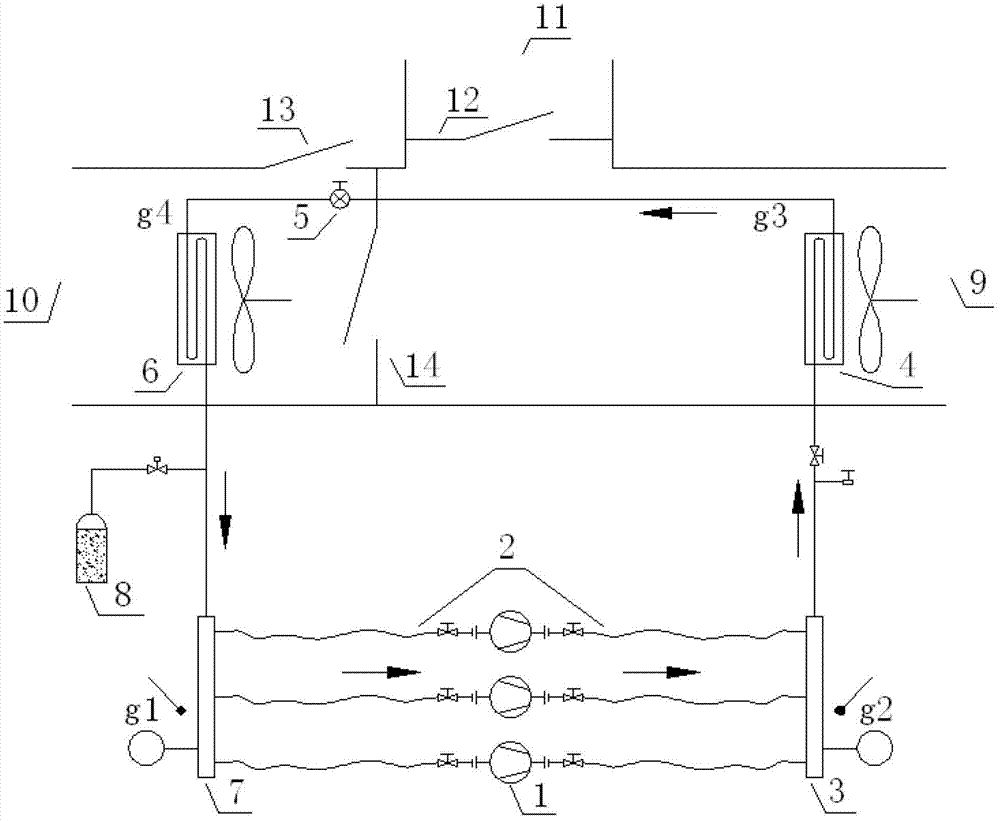

Method used

Image

Examples

Embodiment 2

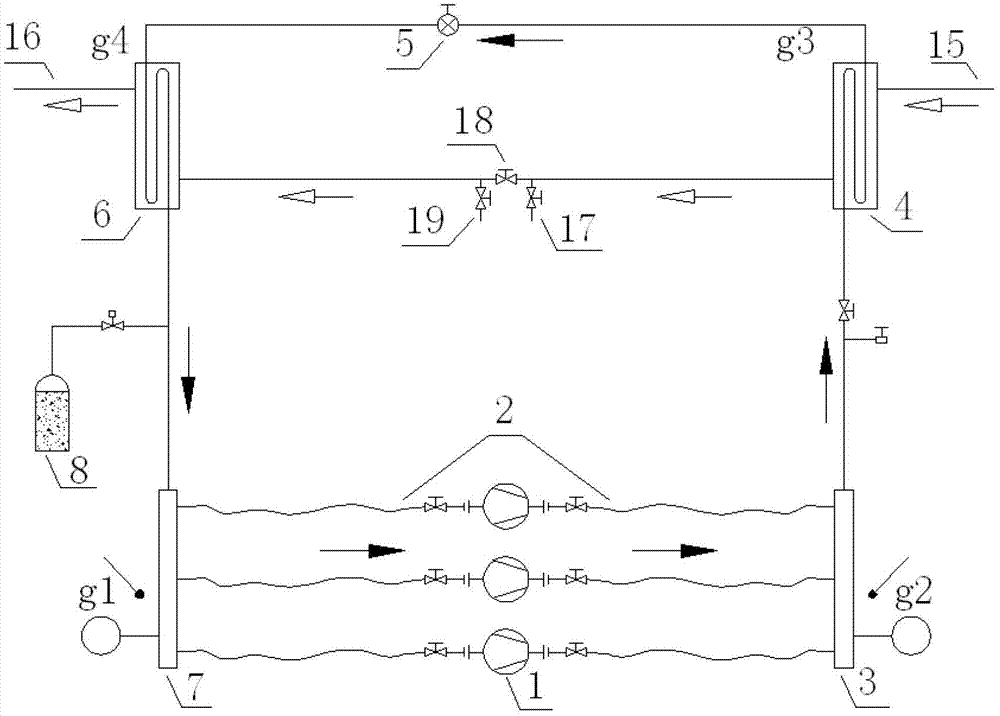

[0028] Such as image 3 As shown, a water-cooled device used for running-in of new compressors in groups. Including hose quick connector 2, air collection bag 3, high-pressure side heat exchanger 4, throttle valve 5, low-pressure side heat exchanger 6, air distribution bag 7, liquid reservoir 8, water inlet and outlet Ⅰ15, water inlet and outlet Ⅱ16, cut-off Valve Ⅰ17, stop valve Ⅱ18, stop valve Ⅲ19. Its features are: between the air distribution bag 7 and the air collection bag 3, there is a hose quick interface 2 for connecting the new compressor 1 to be run-in; the air collection bag 3 is connected to the high-pressure side heat exchanger 4; the throttle valve 5 Set between the high-pressure side heat exchanger 4 and the low-pressure side heat exchanger 6; the low-pressure side heat exchanger 6 is connected to the gas distribution bag 7; the liquid reservoir 8 is connected between the low-pressure side heat exchanger 6 and the gas distribution bag 7 On the pipeline; the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com