Patents

Literature

1395results about "Grinding heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing pads and methods relating thereto

InactiveUS6022268AEnhanced interactionLess-proneRevolution surface grinding machinesOther chemical processesEngineeringTopography

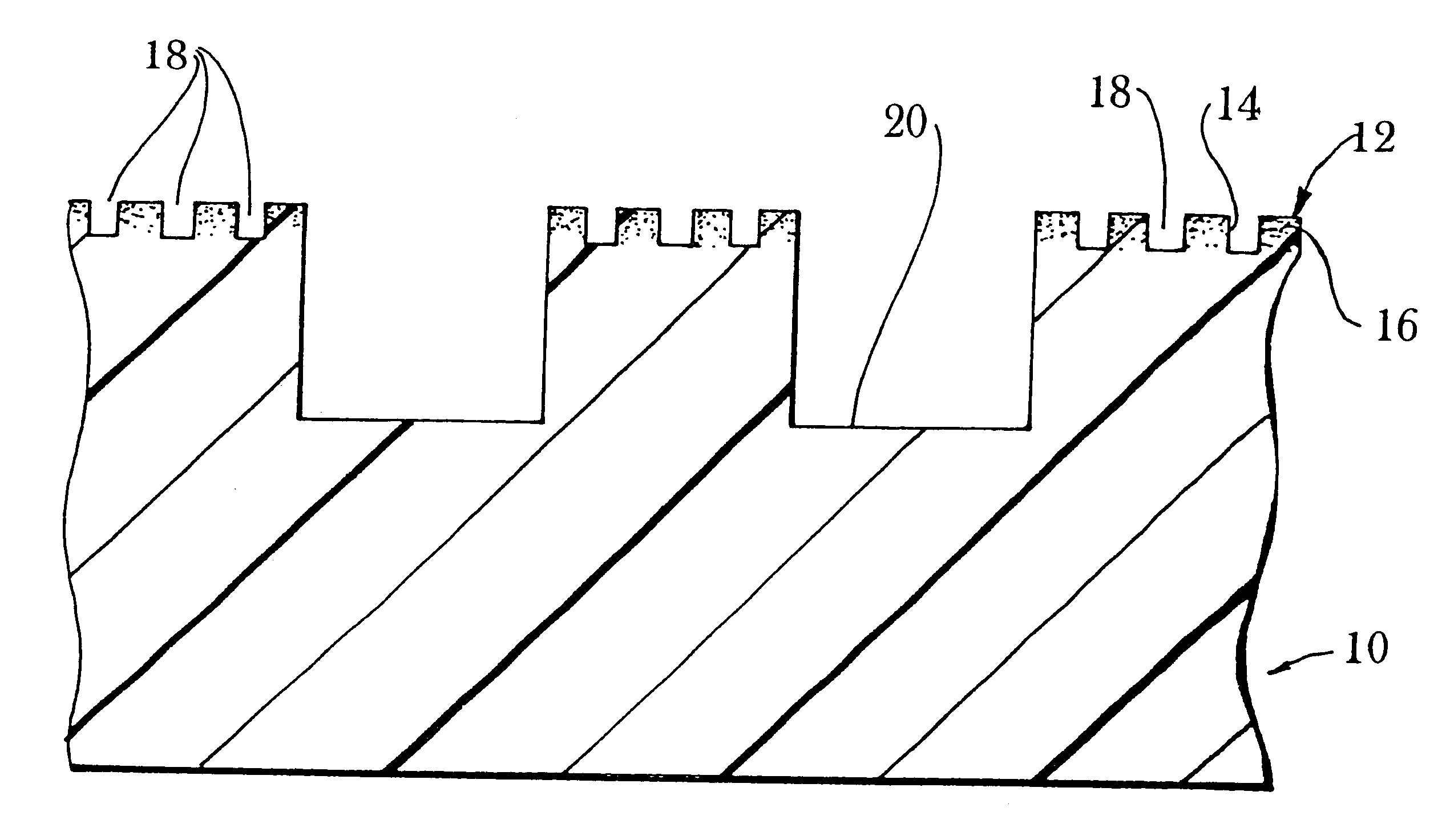

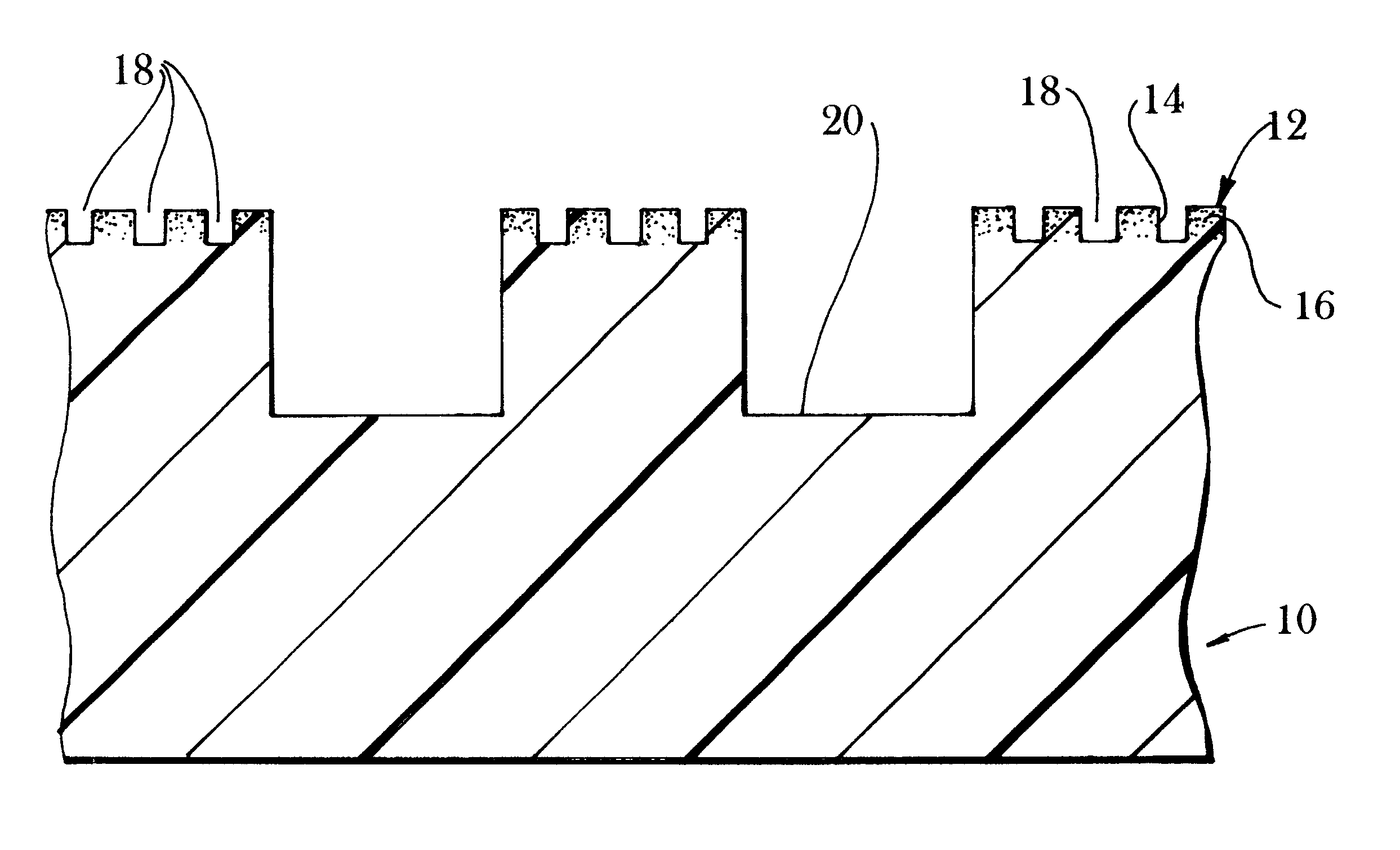

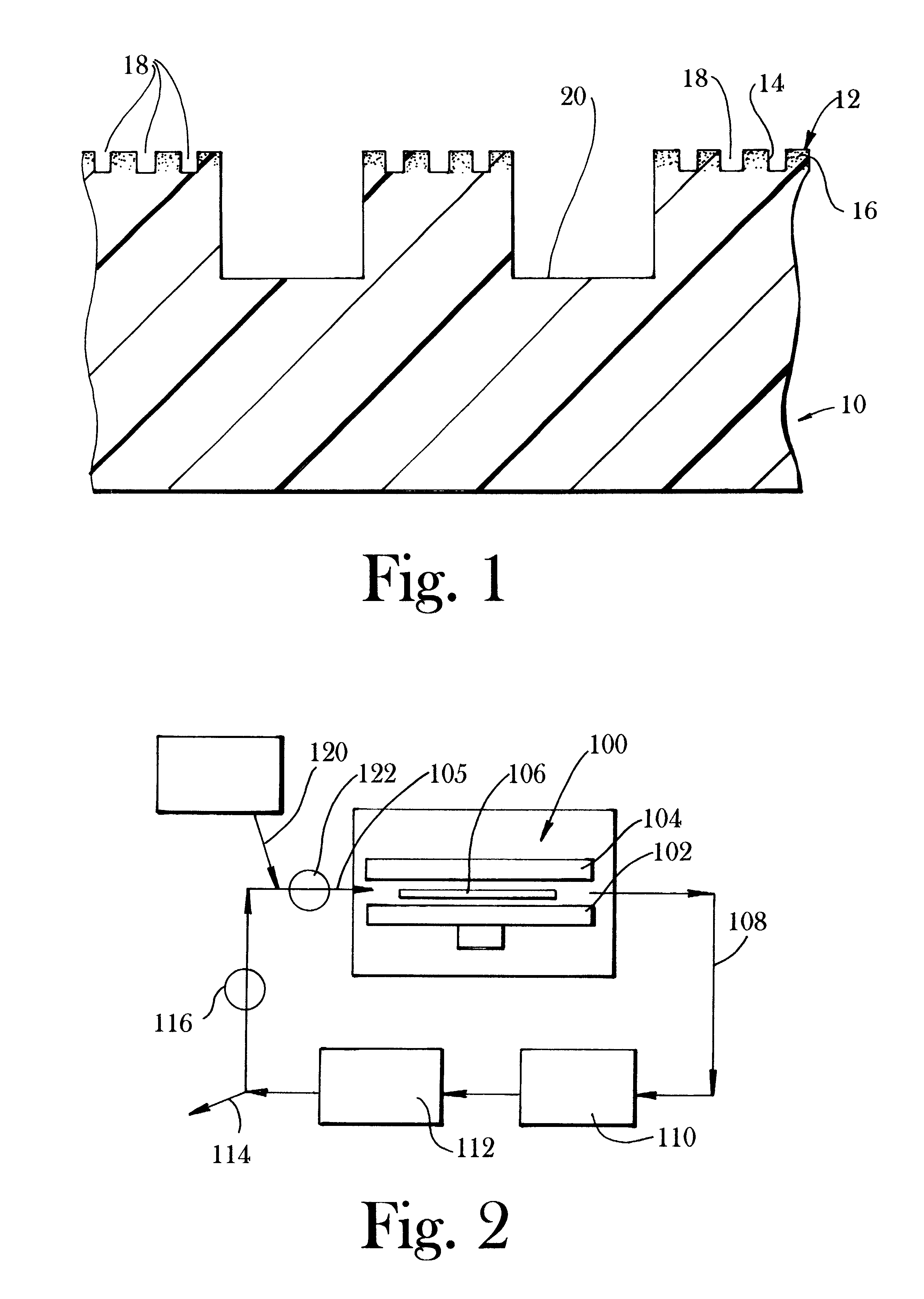

This invention describes improved polishing pads useful in the manufacture of semiconductor devices or the like. The pads of the present invention have an advantageous hydrophilic polishing material and have an innovative surface topography and texture which generally improves predictability and polishing performance.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

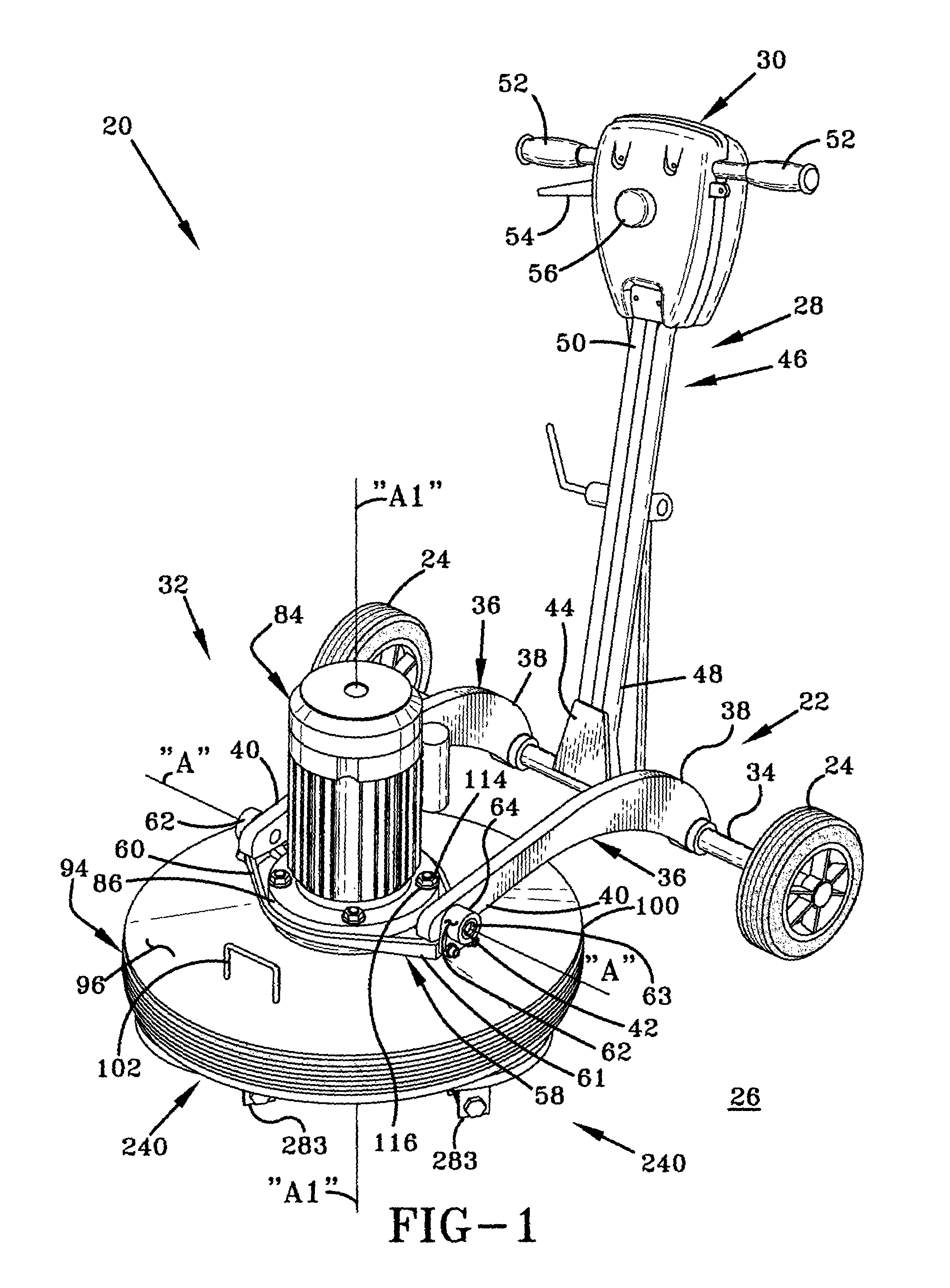

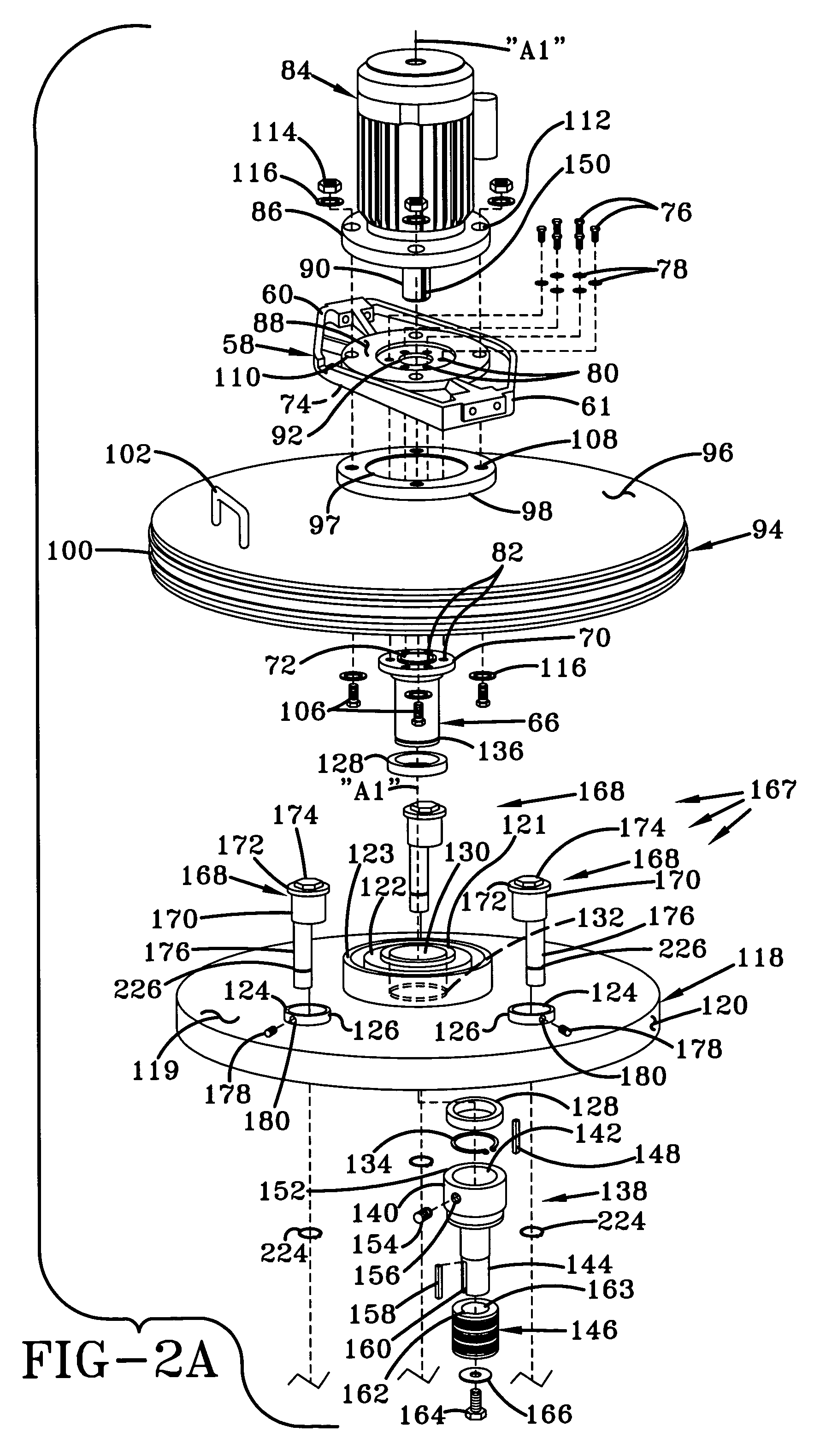

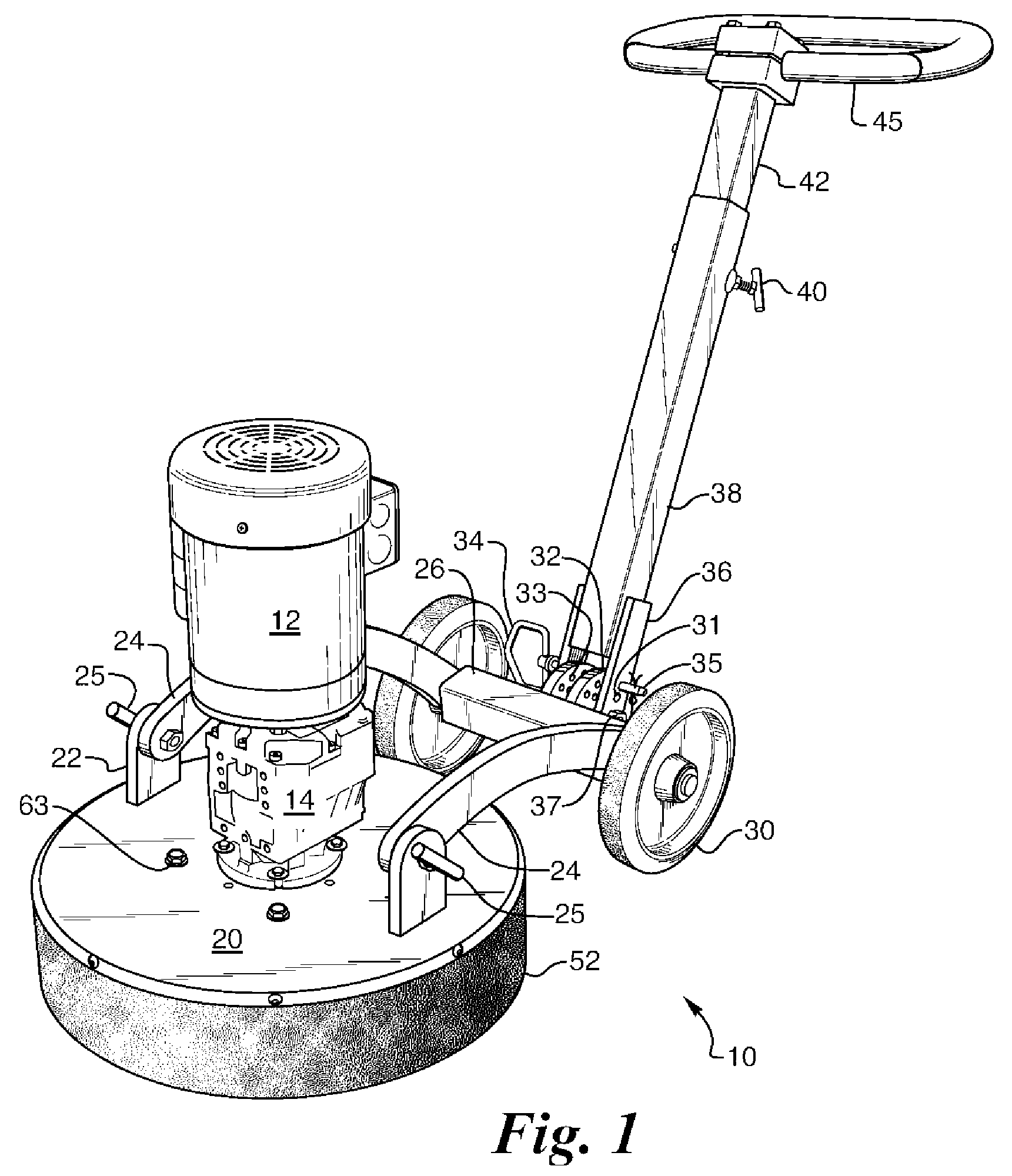

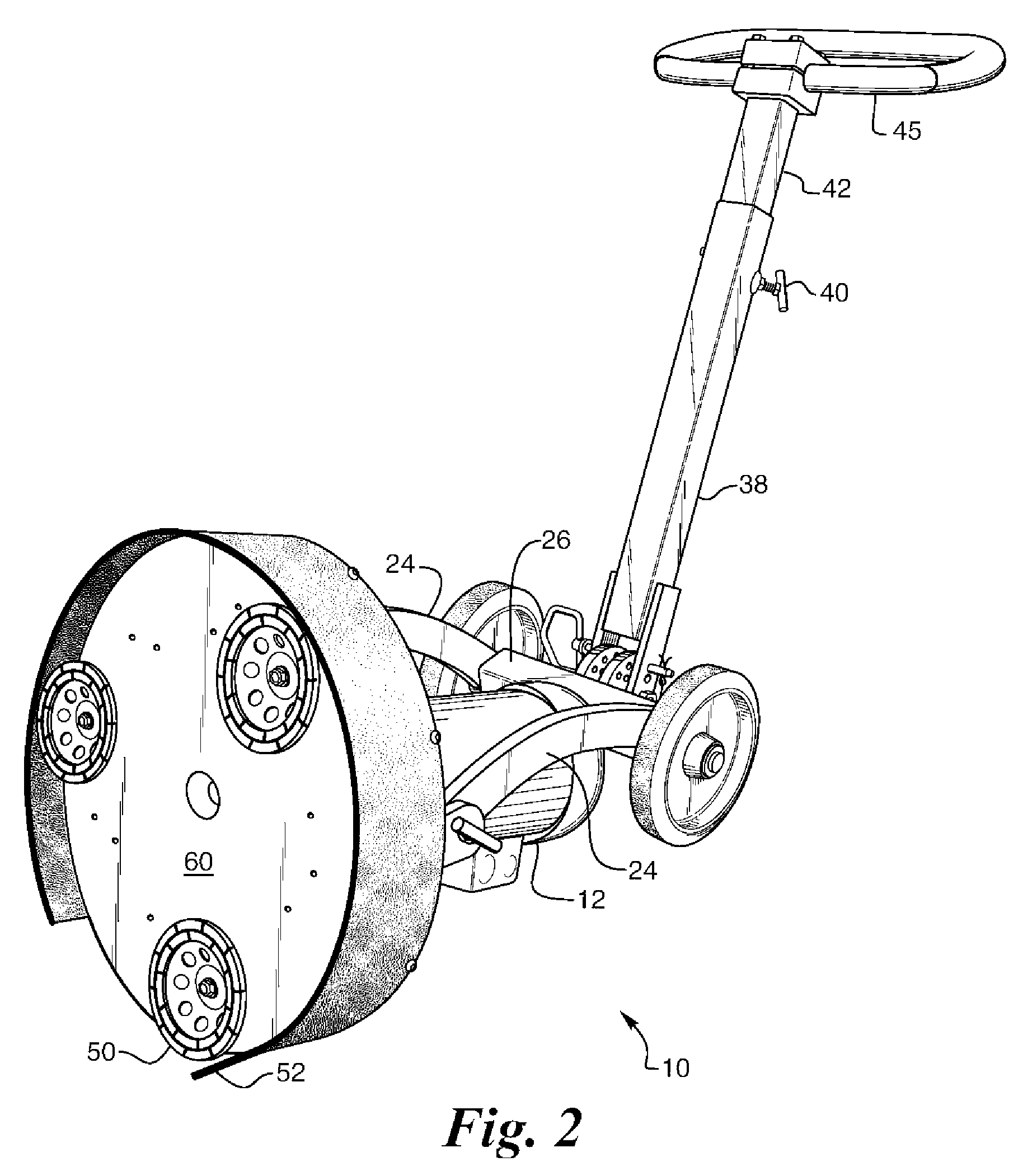

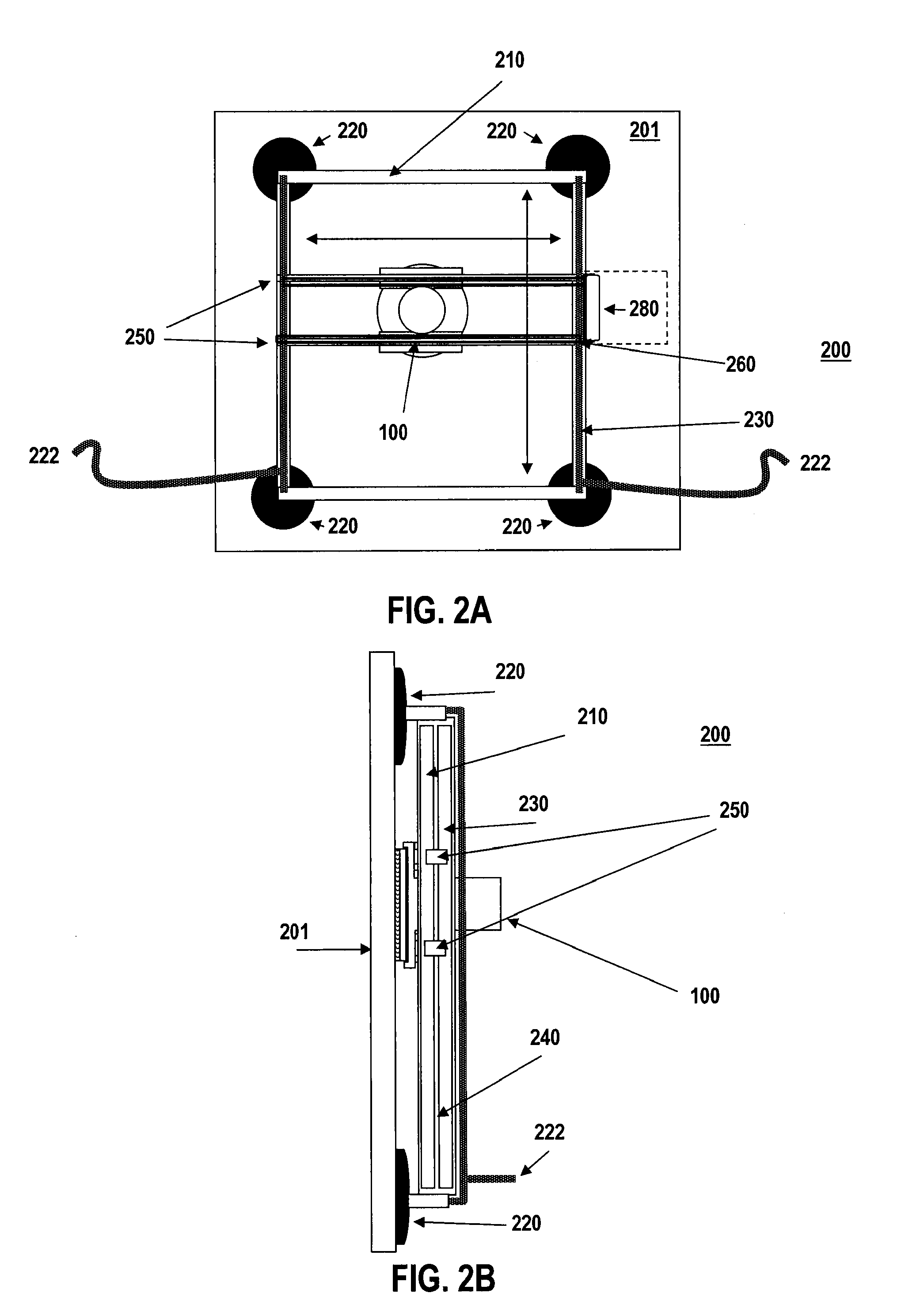

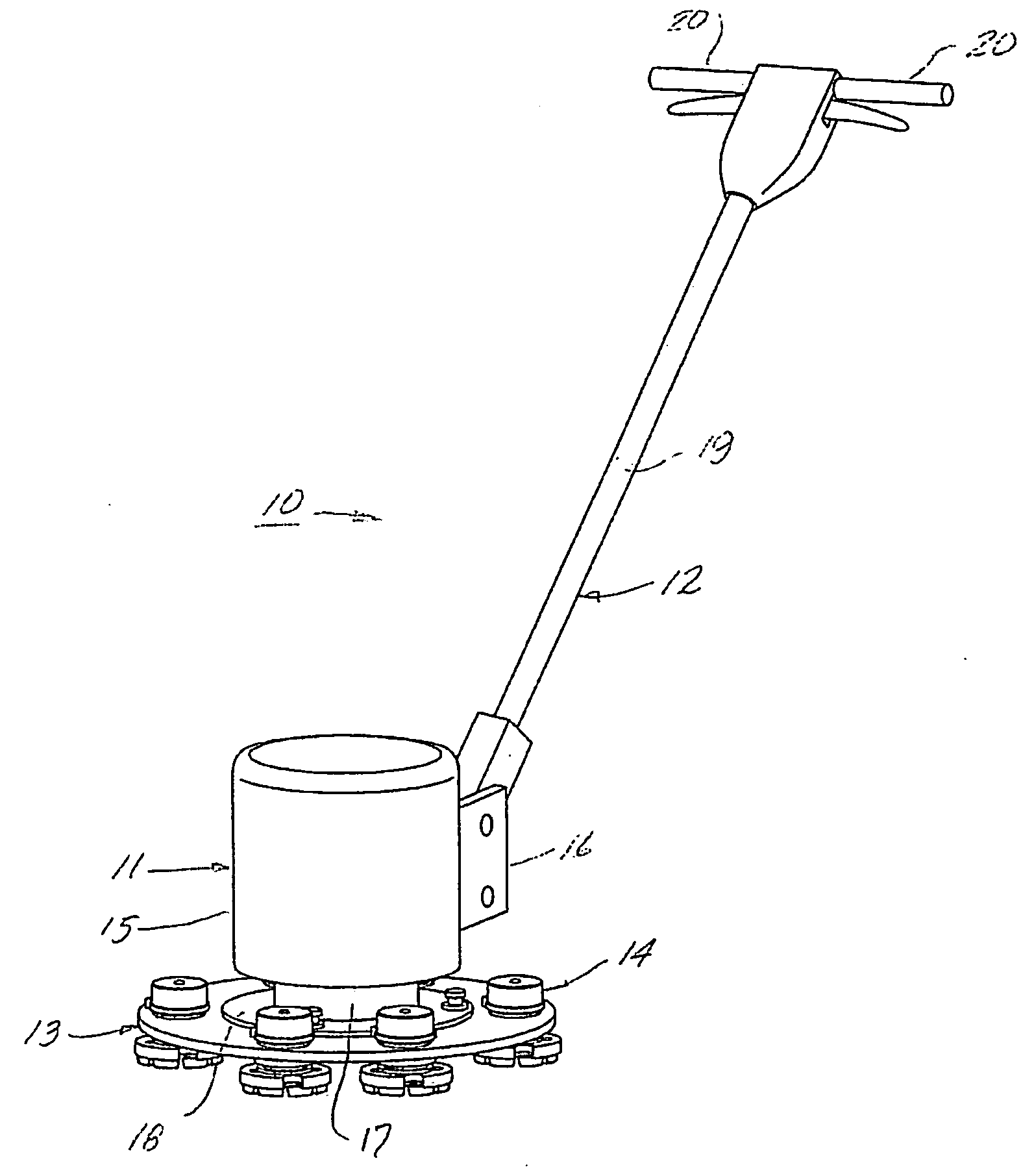

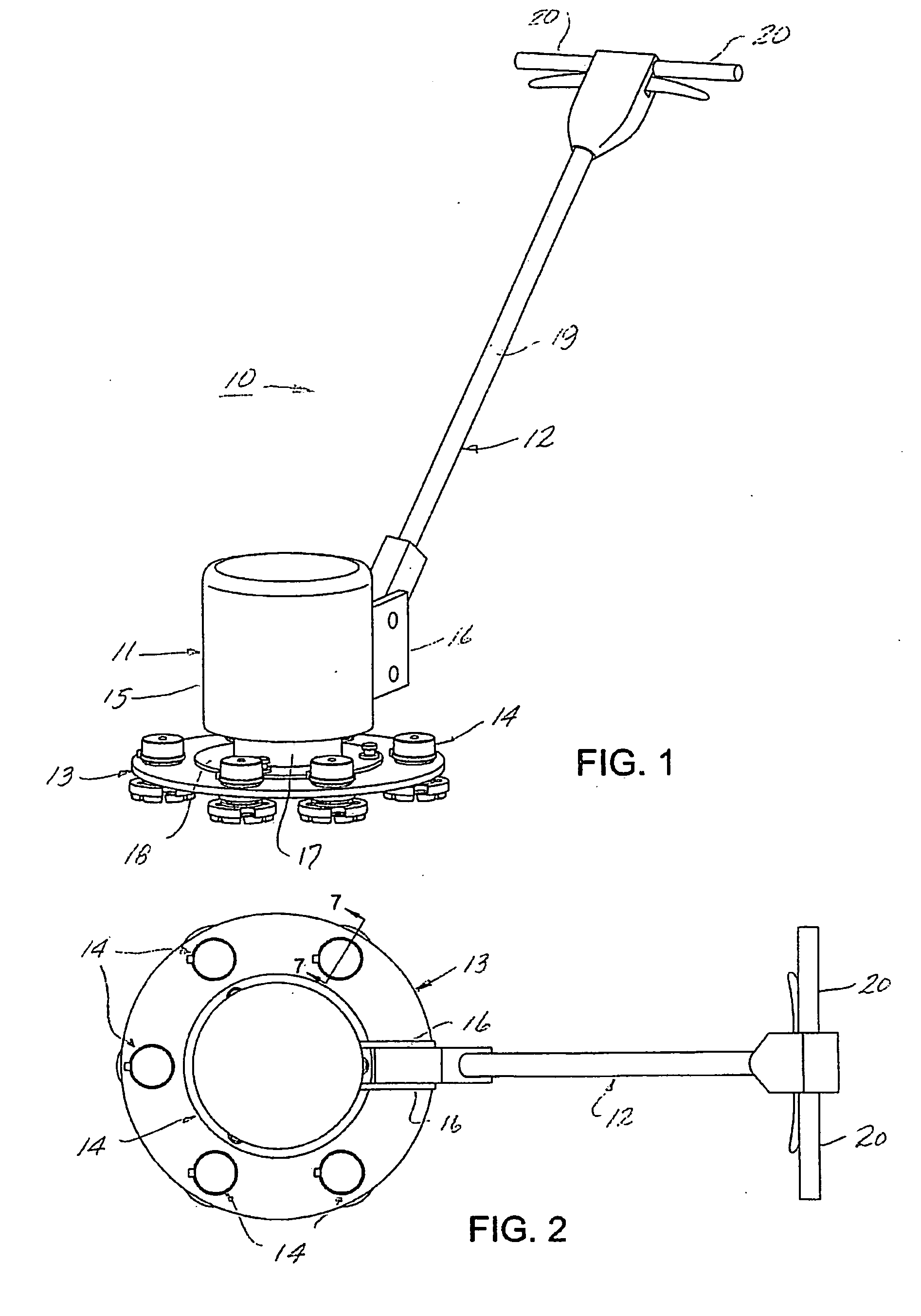

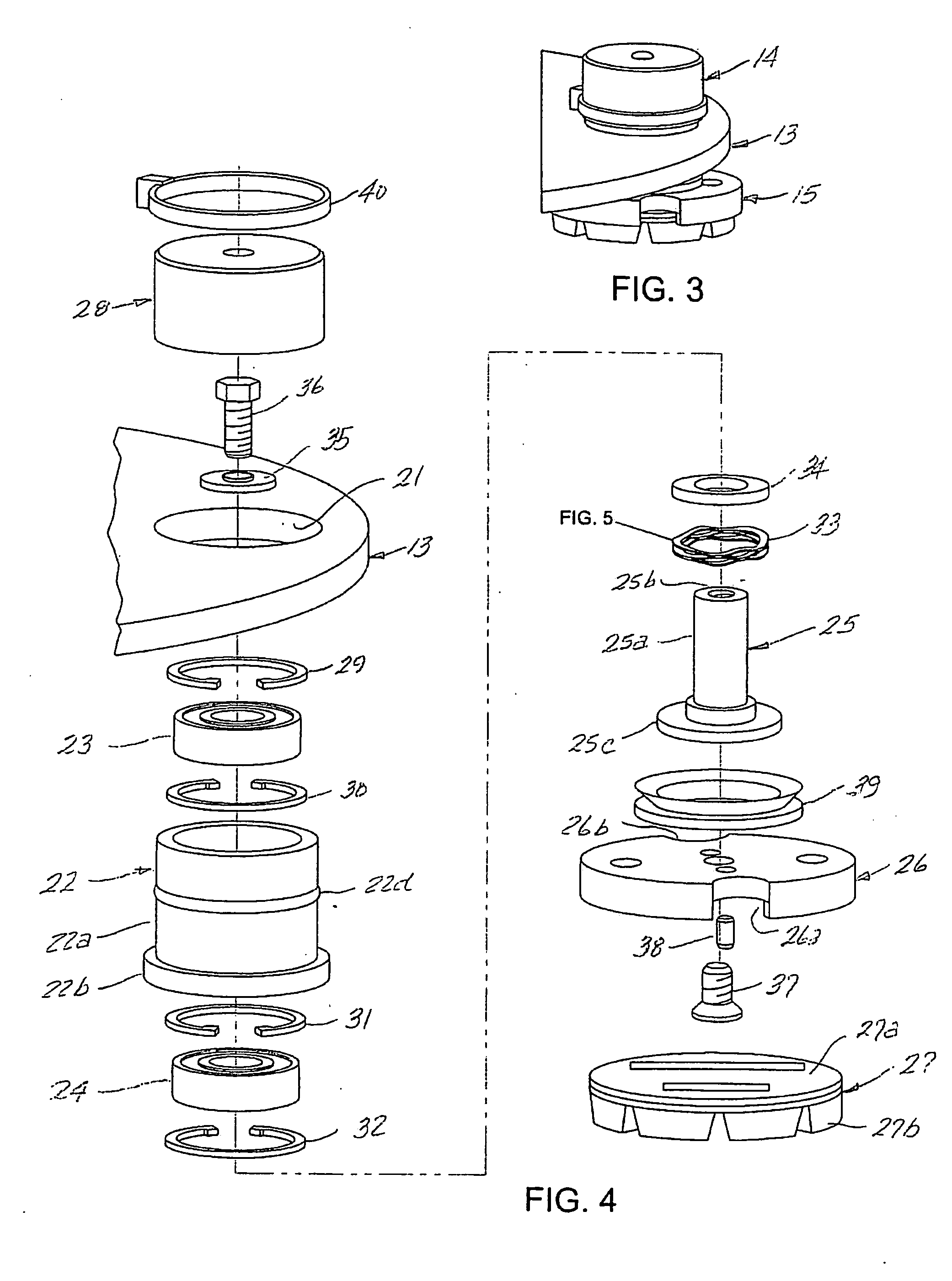

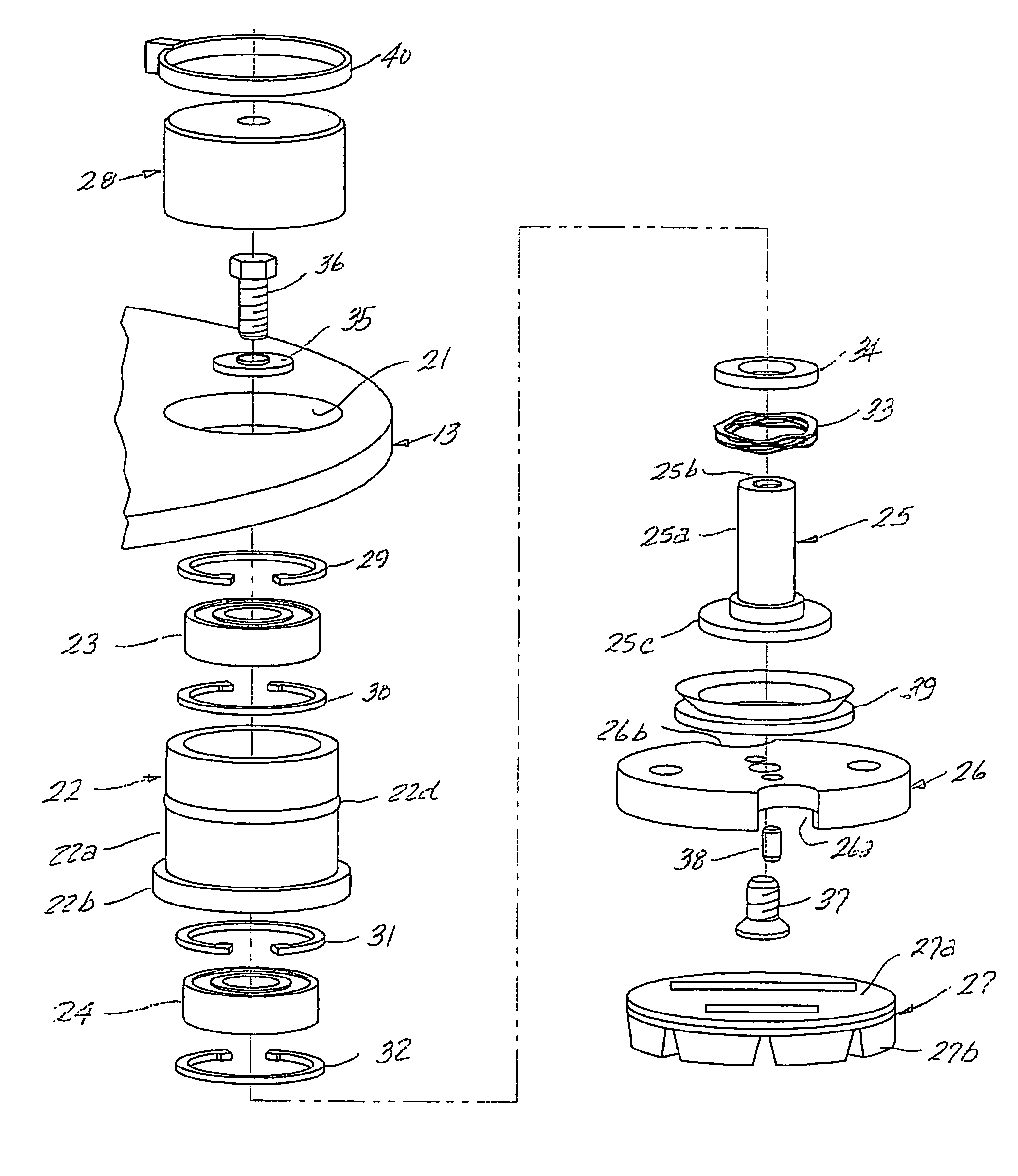

Multidisc floor grinder

A multidisc floor grinder is constructed as a wheeled device that may be moved about the floor by means of a handle. The chassis of the floor grinder supports a bearing housing on gimbals that allow the bearing housing to vary in orientation as the device is moved across an uneven floor. The gimbals are aligned to allow rotation of the bearing housing about a bearing housing axis that is parallel to the floor. The bearing housing supports a main drive shaft which extends downwardly from the bearing housing. The main drive shaft is rotatable relative to the bearing housing within its bearings. A grinder mounting frame is rotatably mounted about the main drive shaft and is supported therefrom. The grinder mounting frame is driven in rotation about the main drive shaft at a greatly reduced speed relative to the rotation of the main drive shaft. The grinder mounting frame carries a plurality of grinding elements which are also driven from the main drive shaft, but at a substantially increased speed of rotation relative thereto. The grinding elements thereby rotate not only about their own axes, but also about the axis of the main drive shaft so as to cover a relatively large floor area with relatively small grinding elements. This arrangement substantially reduces the time required to grind paint or other matter from a floor surface.

Owner:DUNCAN +1

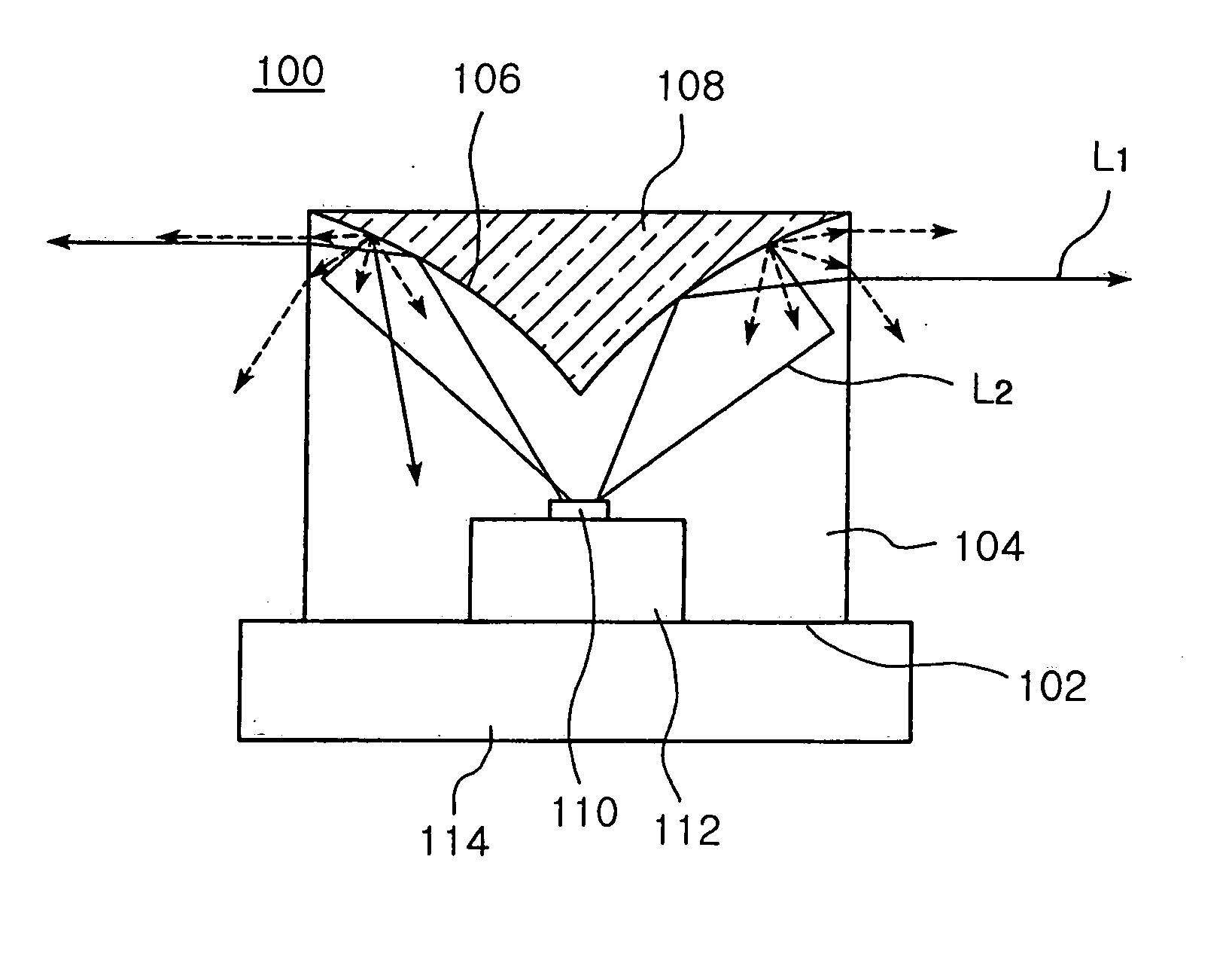

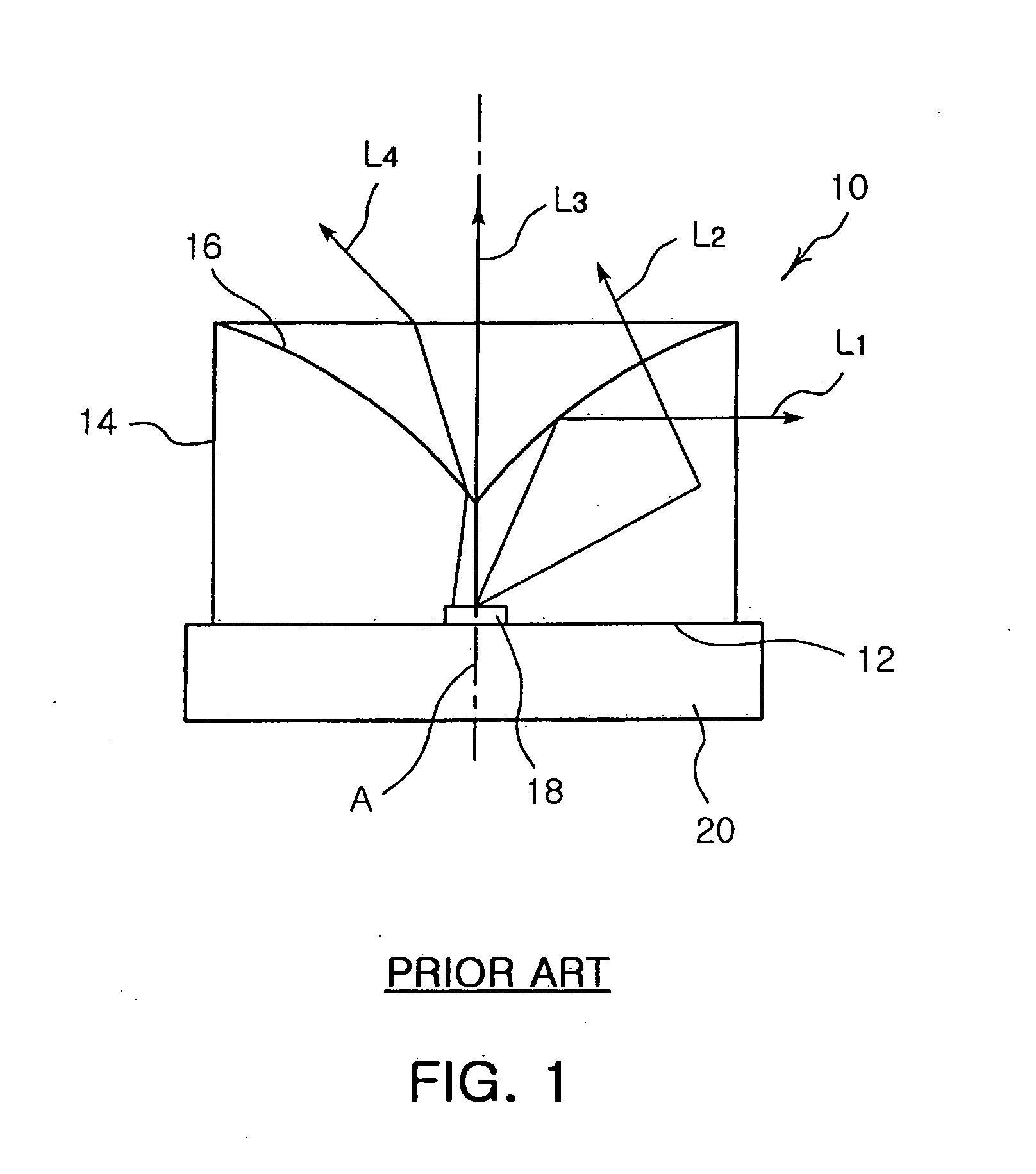

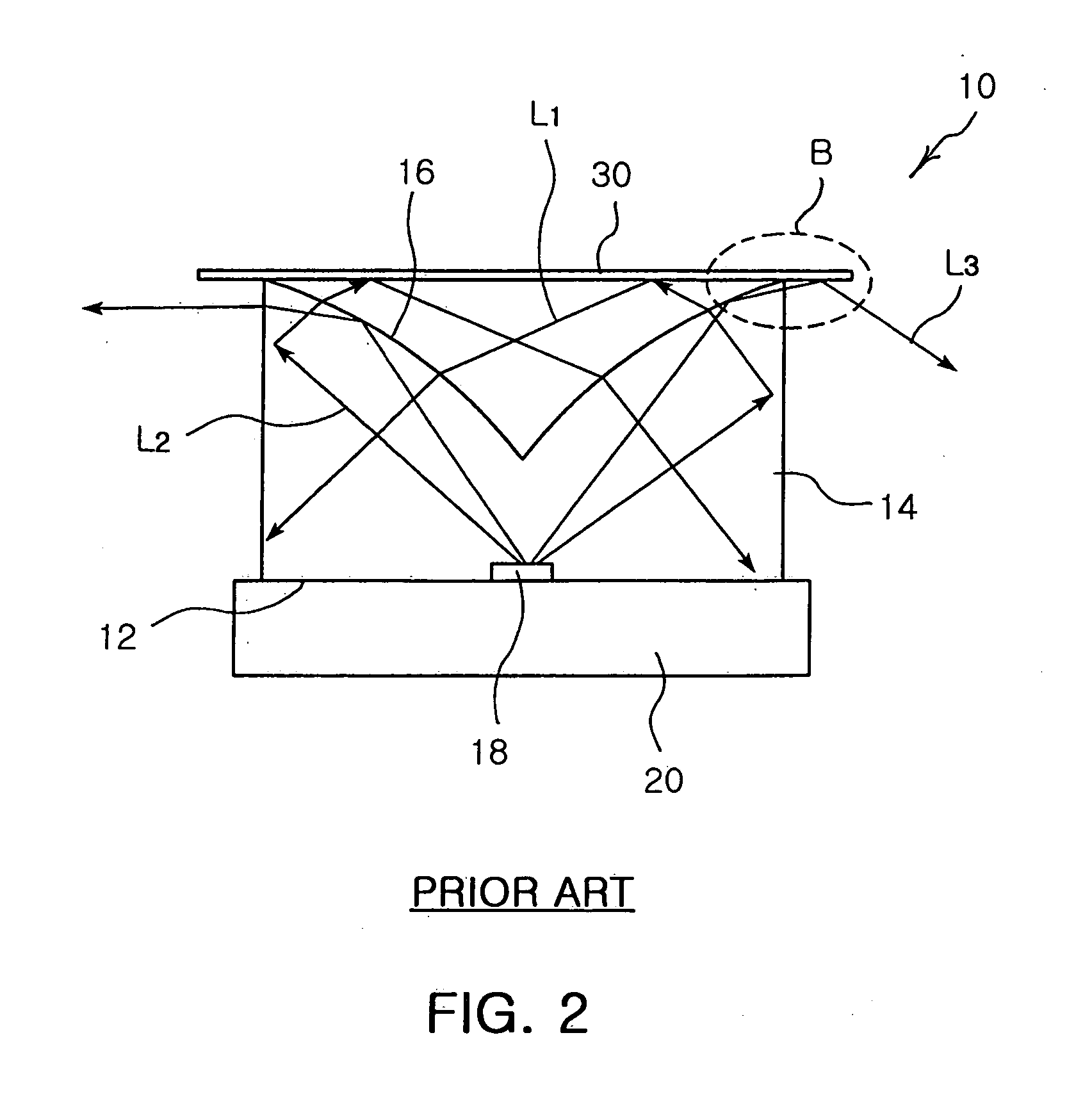

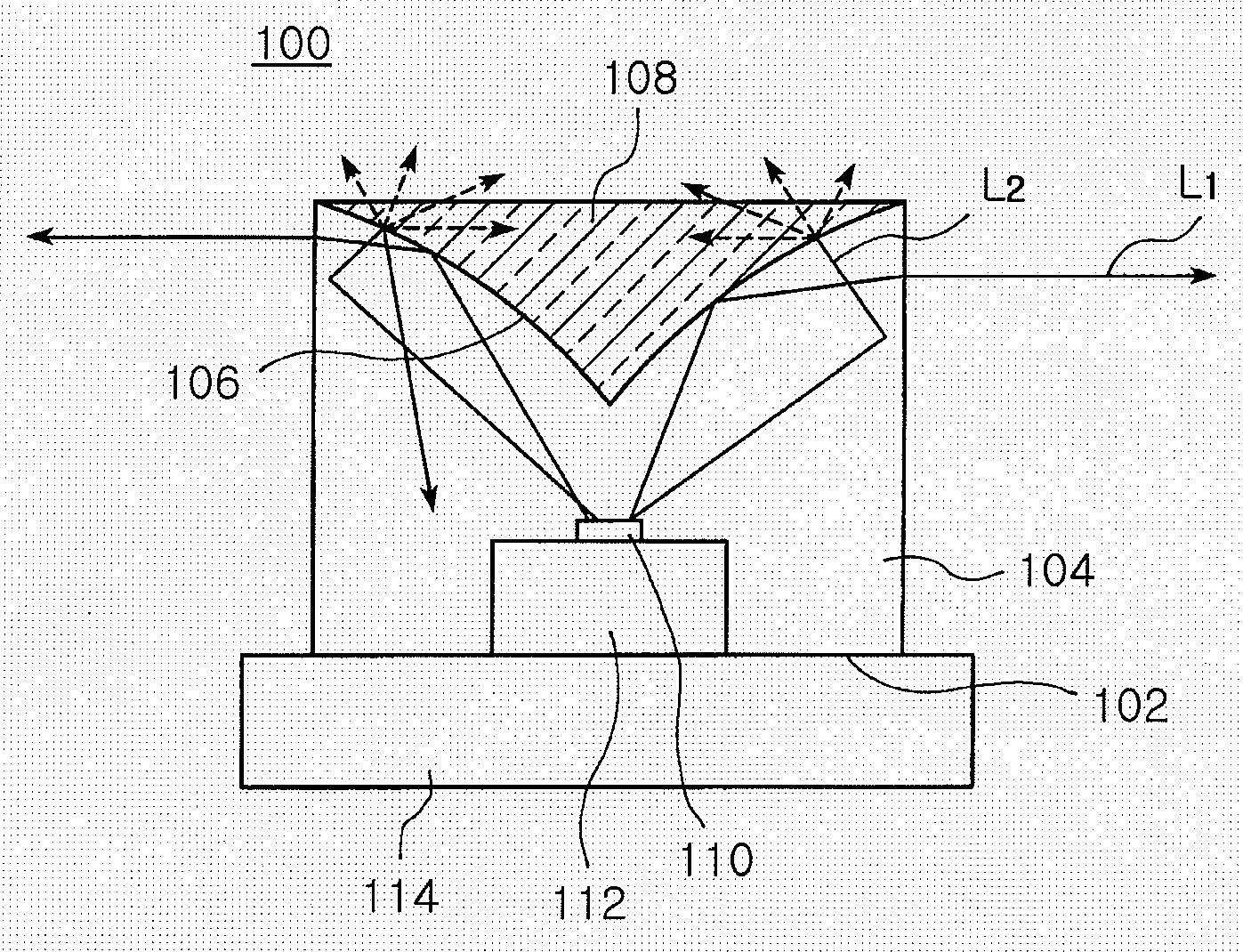

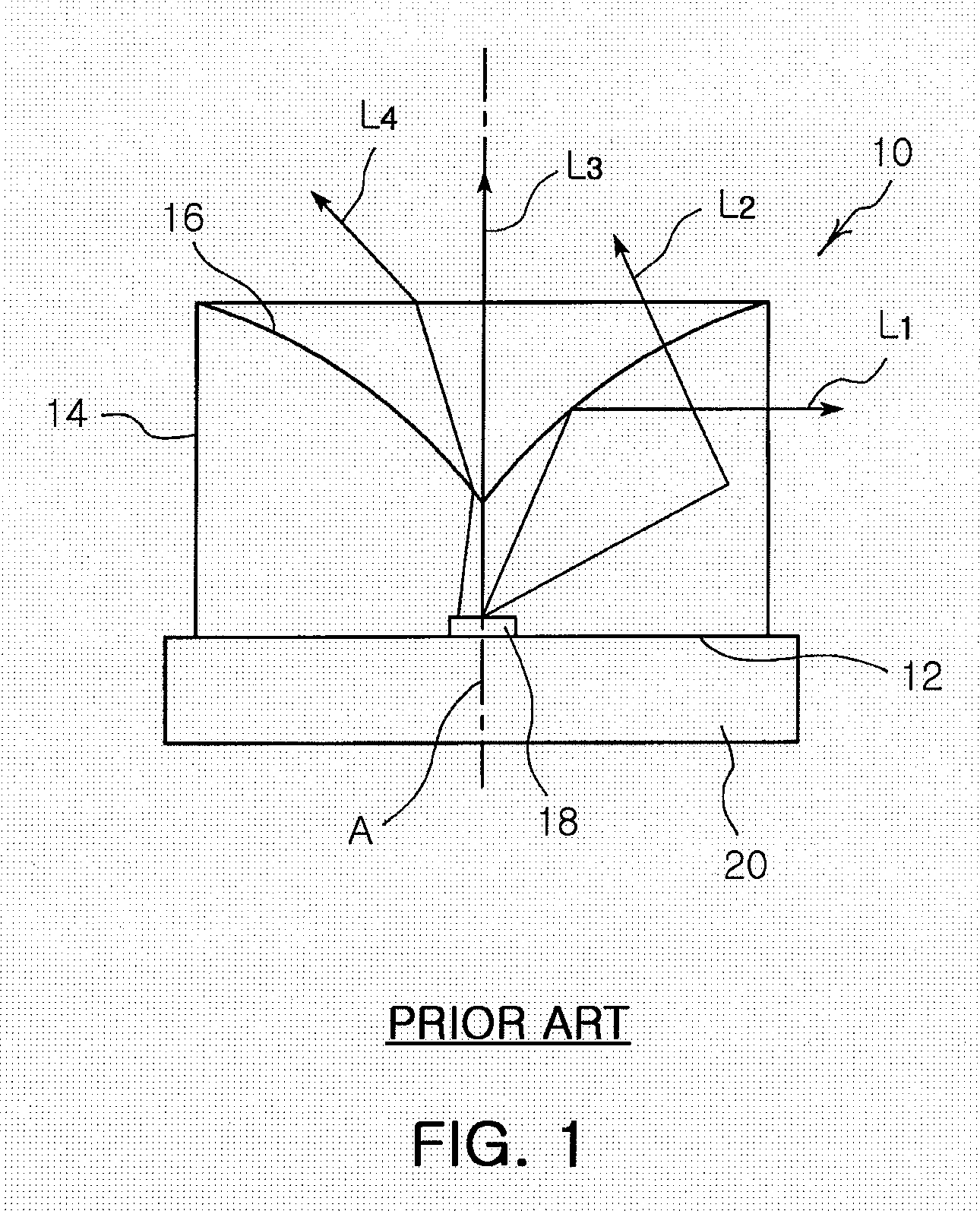

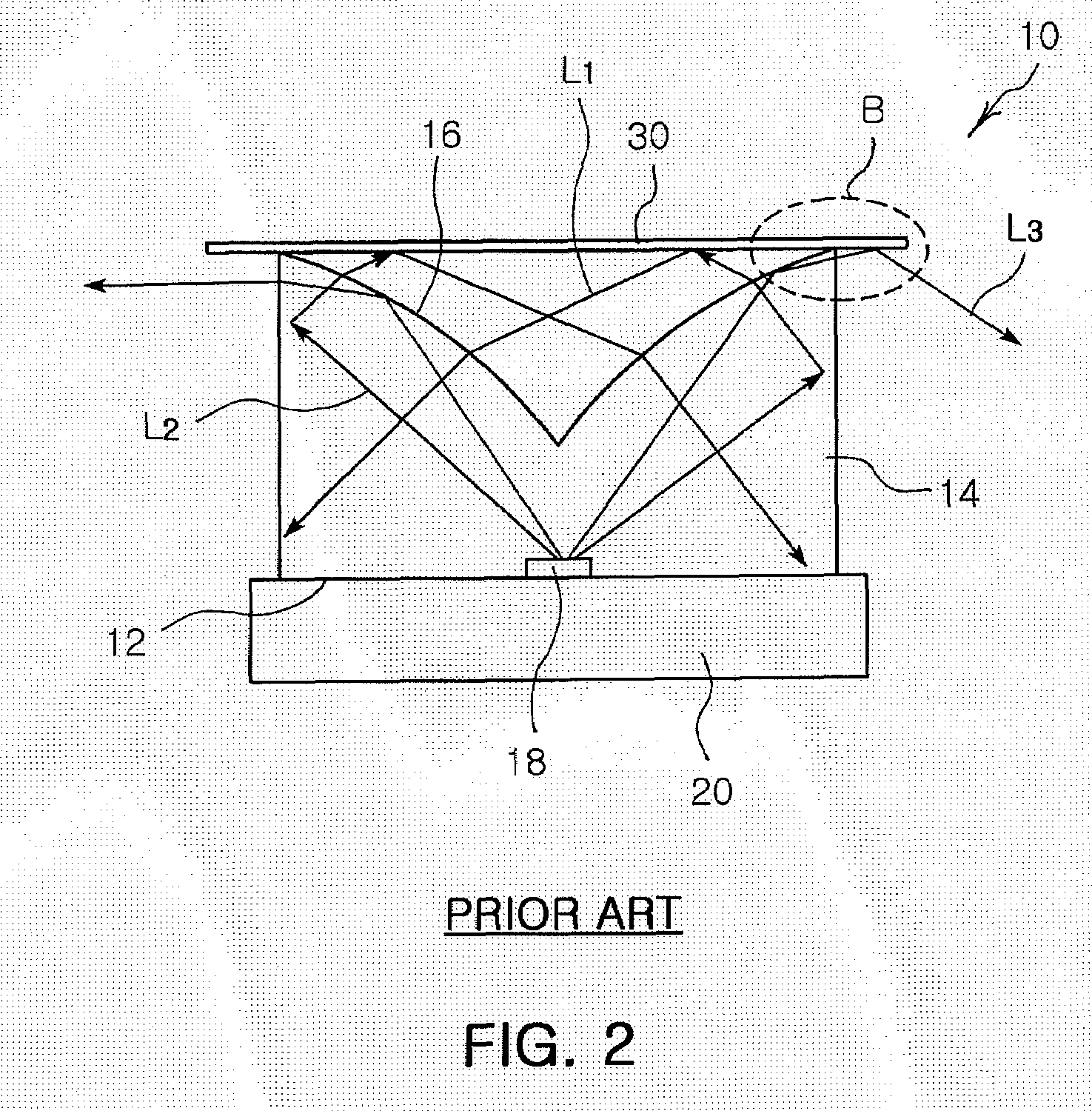

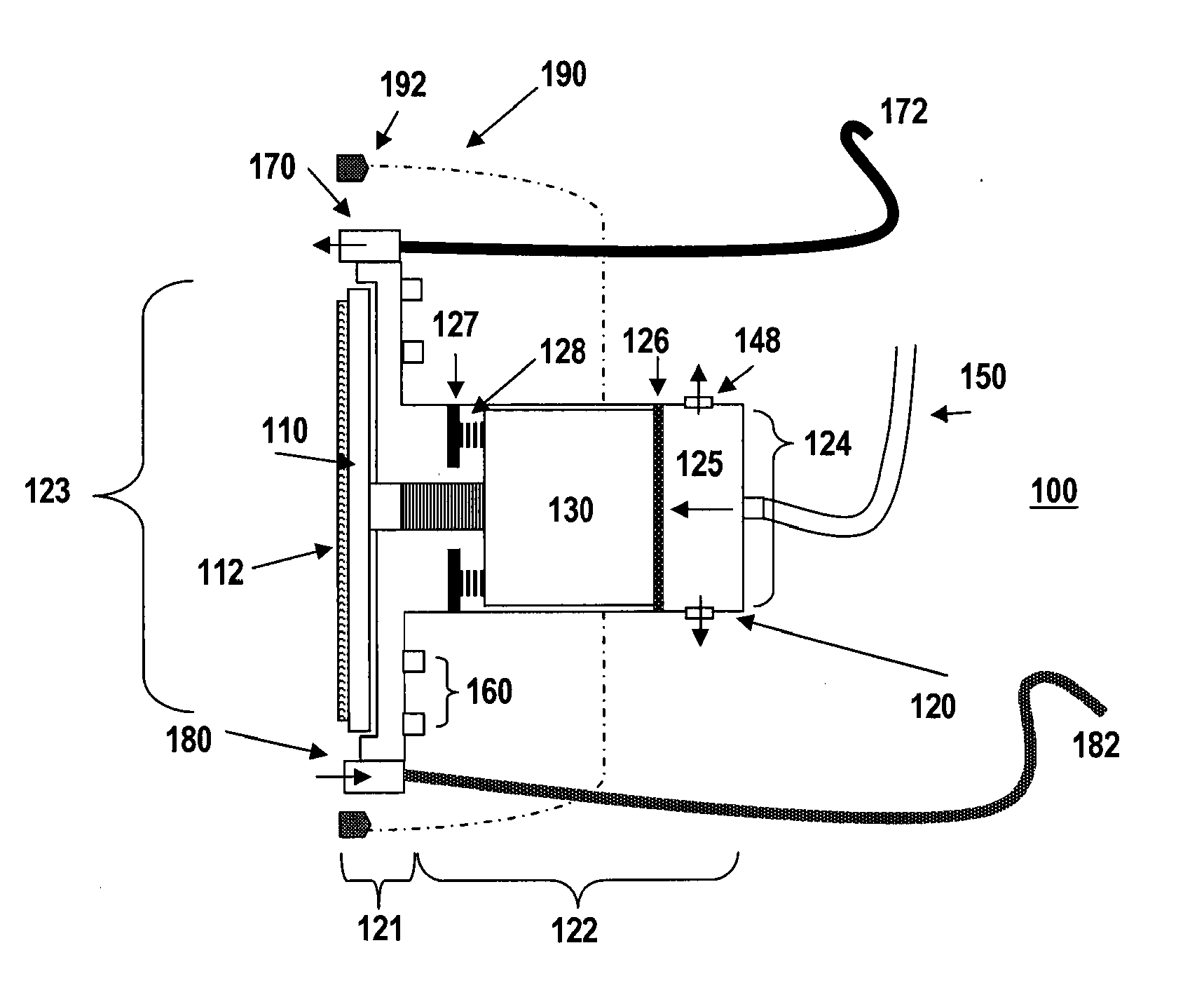

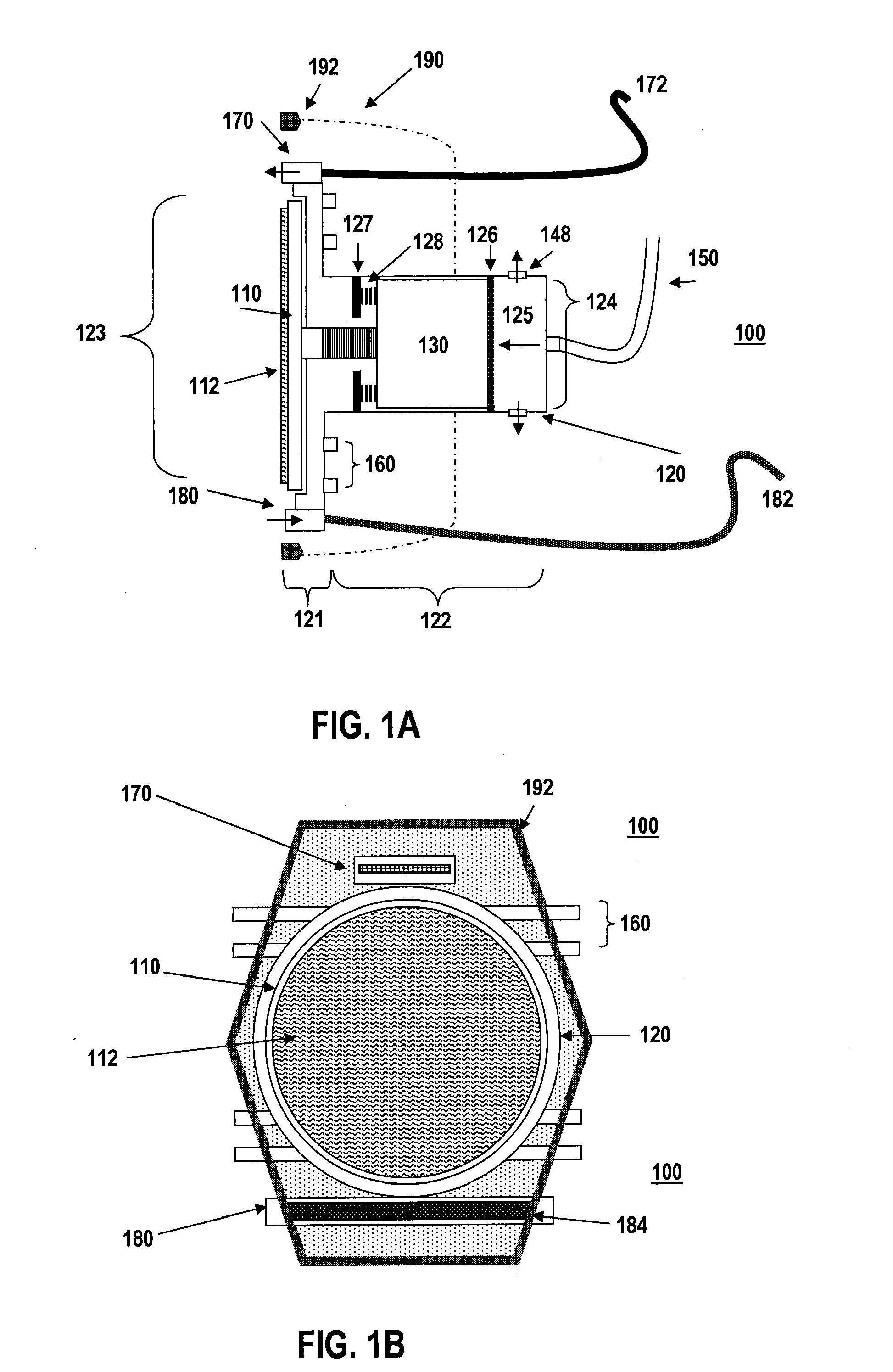

Side-emitting LED package having scattering area and backlight apparatus incorporating the LED lens

ActiveUS20060208269A1Avoid light lossPoint-like light sourceSolid-state devicesOptoelectronicsExit surface

The invention provides an LED package and a backlight device incorporating the LED lens. The LED package has a bottom surface and a light exiting surface cylindrically extended around a central axis of the package from the bottom surface. Also, a reflecting surface is positioned on an opposite side of the bottom surface and symmetrical around the central axis such that light incident from the bottom surface is reflected toward the light exiting surface. Further, a scattering area is formed on the reflecting surface. According to the invention, by applying scattering materials on the reflecting surface of the LED package, a reflecting paper does not need to be attached, thereby simplifying a process and reducing the manufacture time and cost.

Owner:SAMSUNG ELECTRONICS CO LTD

Polishing pads and methods relating thereto

InactiveUS6217434B1Improve the level ofLow levelRevolution surface grinding machinesOther chemical processesTopographySemiconductor

This invention describes improved polishing pads useful in the manufacture of semiconductor devices or the like. The pads of the present invention have an advantageous hydrophilic polishing material and have an innovative surface topography and texture which generally improves predictability and polishing performance.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

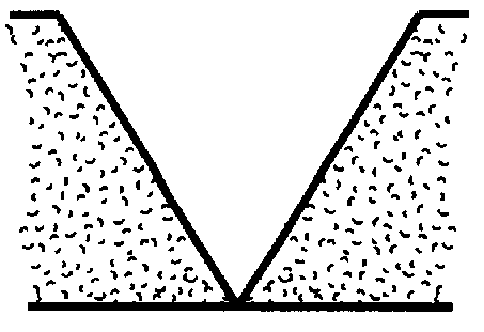

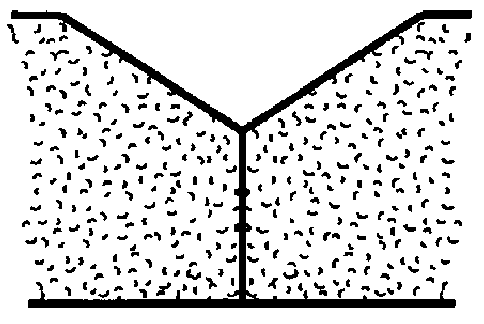

Mosaic polishing pads and methods relating thereto

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Polishing system having a multi-phase polishing substrate and methods relating thereto

InactiveUS6375559B1Semiconductor/solid-state device manufacturingFlexible-parts wheelsEngineeringMulti phase

A chemical-mechanical polishing system which is particularly well suited for use in the manufacture of semiconductor devices or the like. The invention is directed to a polishing pad composition comprising a high modulus phase component and a low modulus phase component. The multi-phase polishing pads are very efficient and effective in providing high performance polishing along an entire polishing surface interface.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Method relating to a polishing system having a multi-phase polishing layer

A method of making a polishing pad composition comprising a high modulus phase component and a low modulus phase component, and a method of polishing a semiconductor substrate by creating nanoasperities at a polishing interface between the polishing layer and the wafer during polishing by providing the high modulus phase component at the polishing interface, either as protrusions from the polishing layer, or by being released from the polishing layer into the polishing interface.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

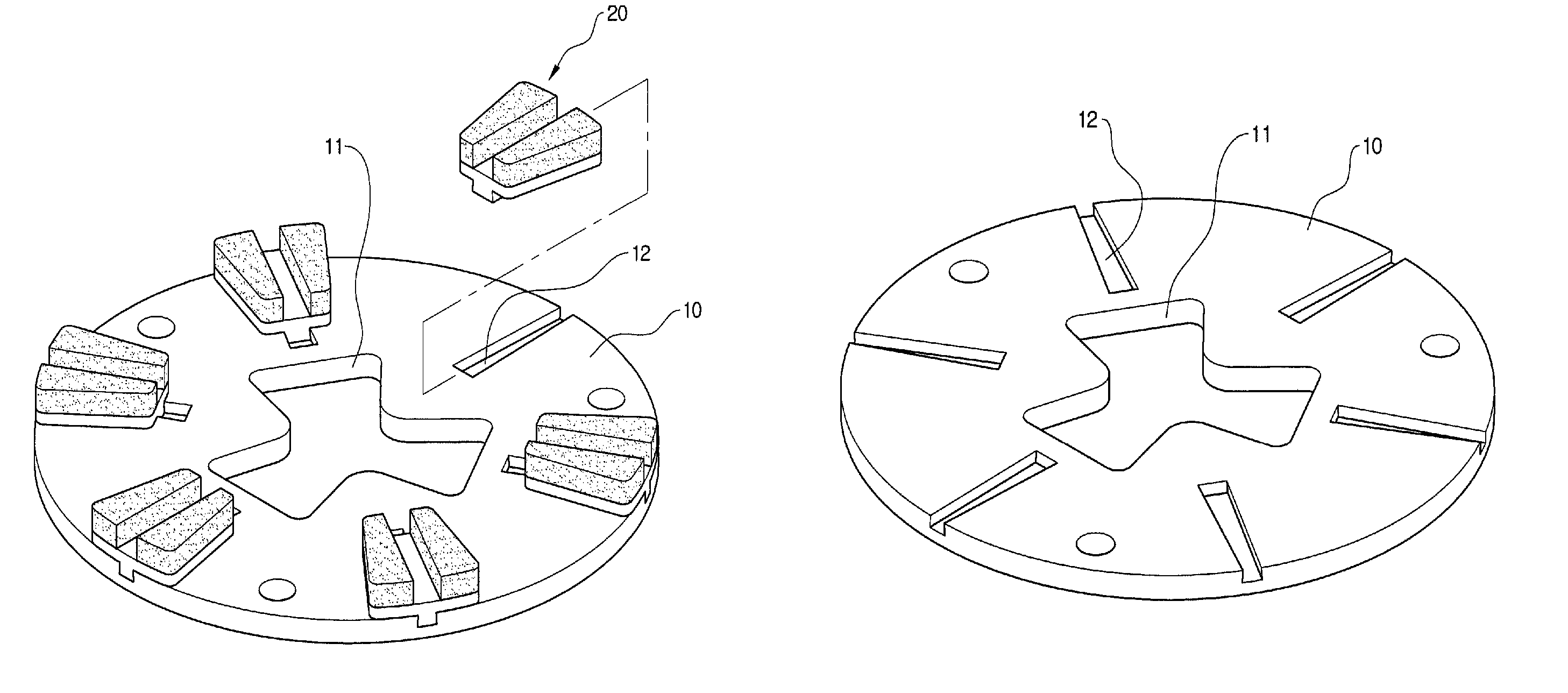

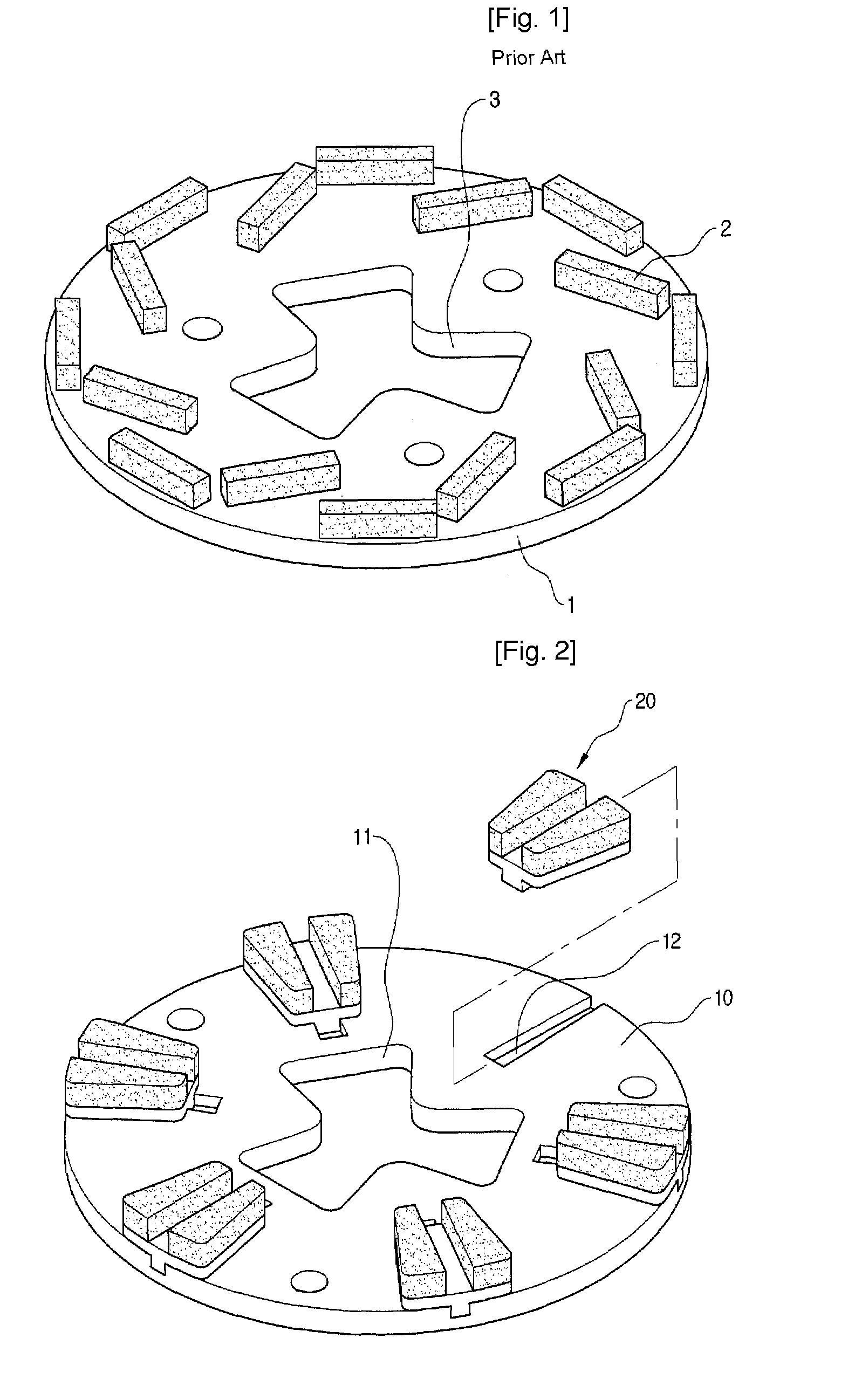

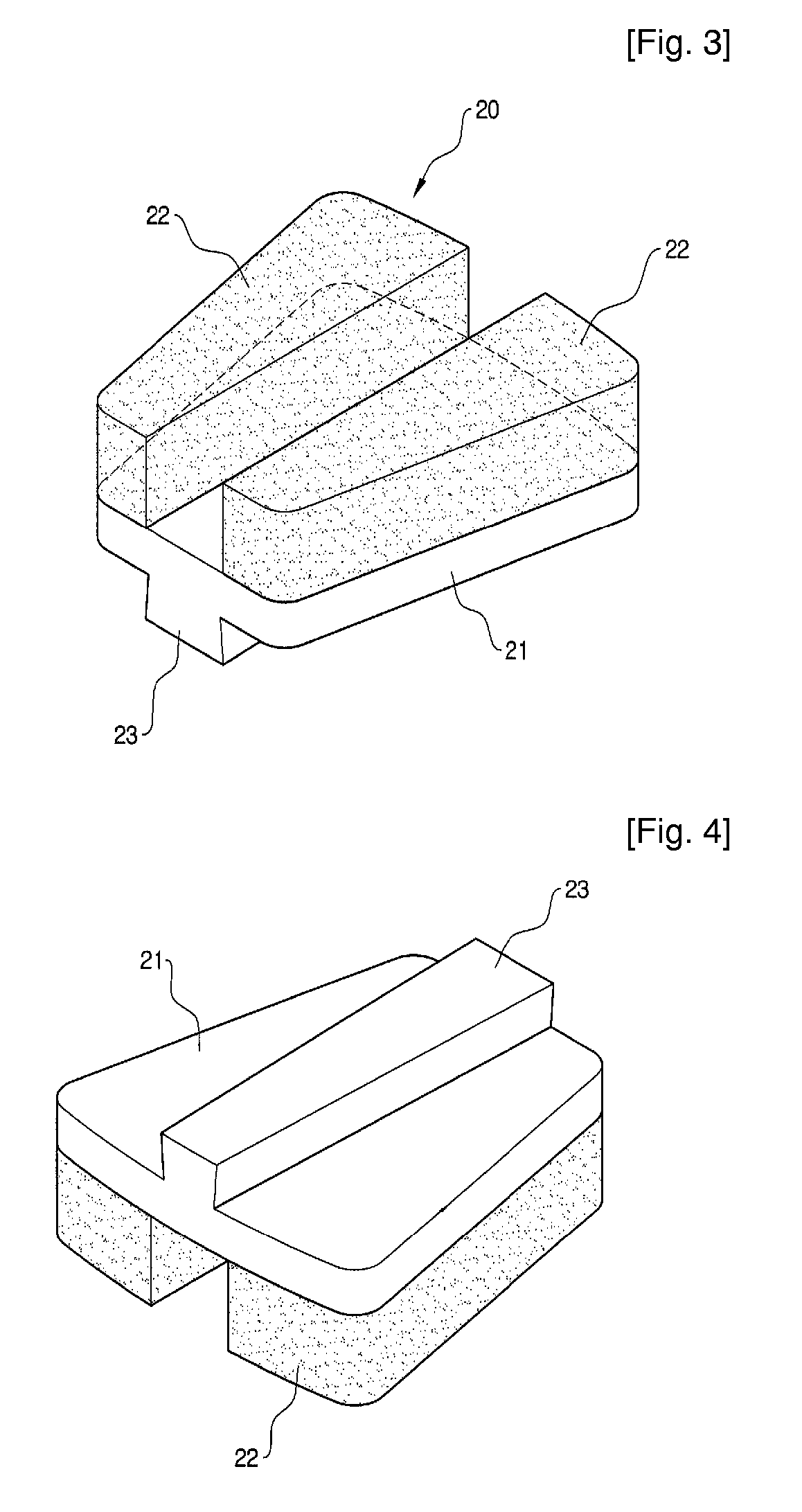

Grinding Wheel

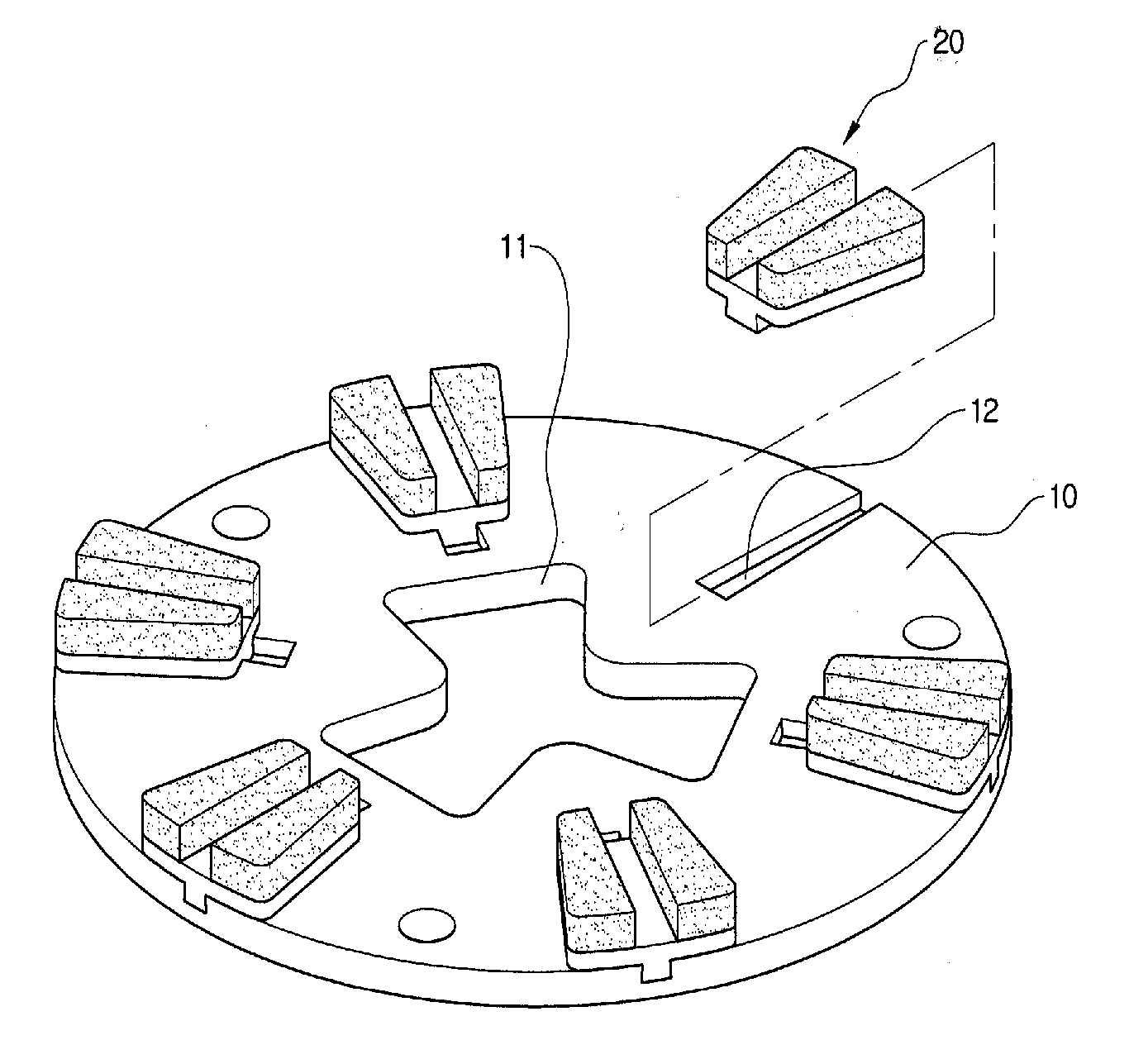

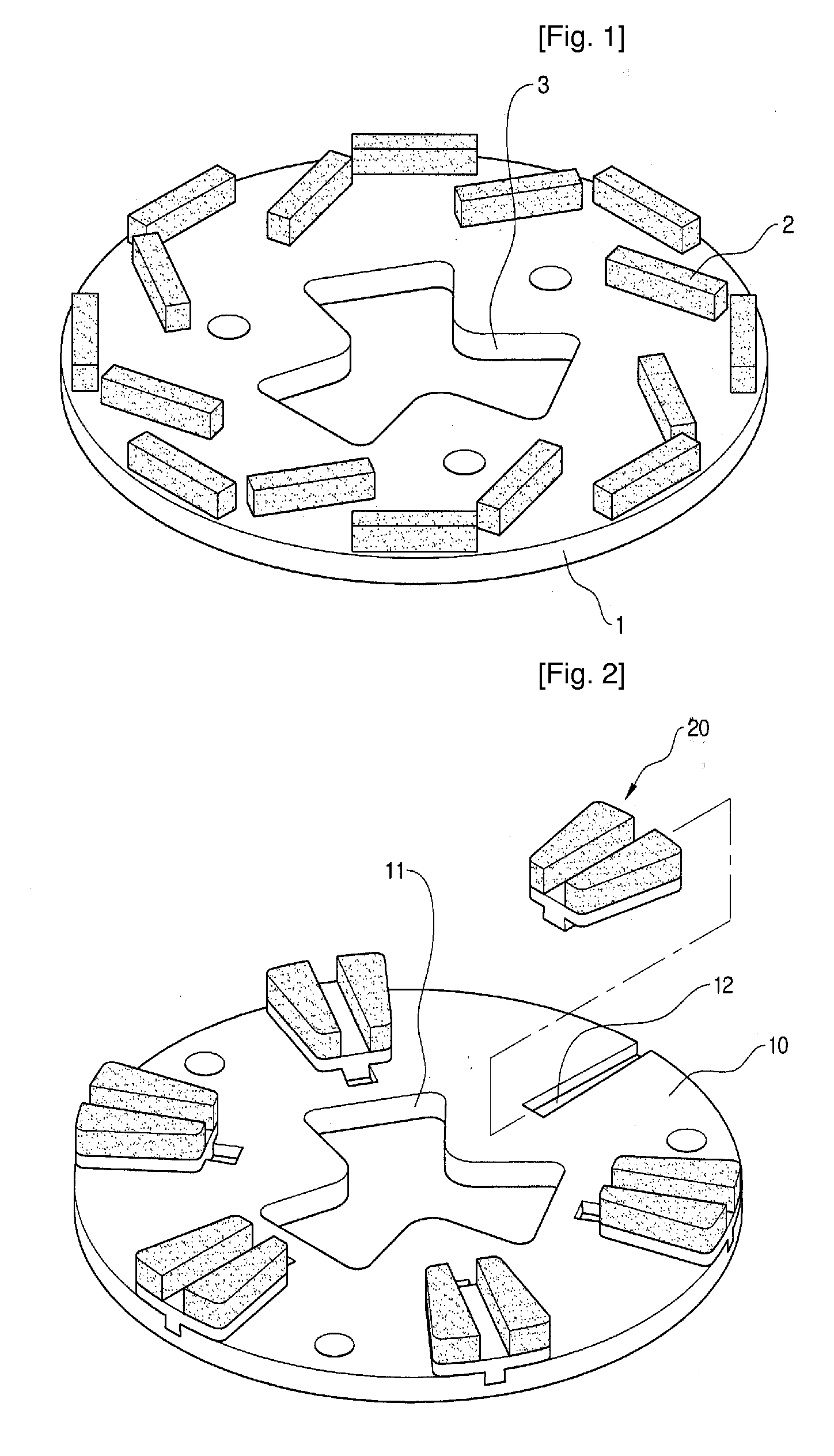

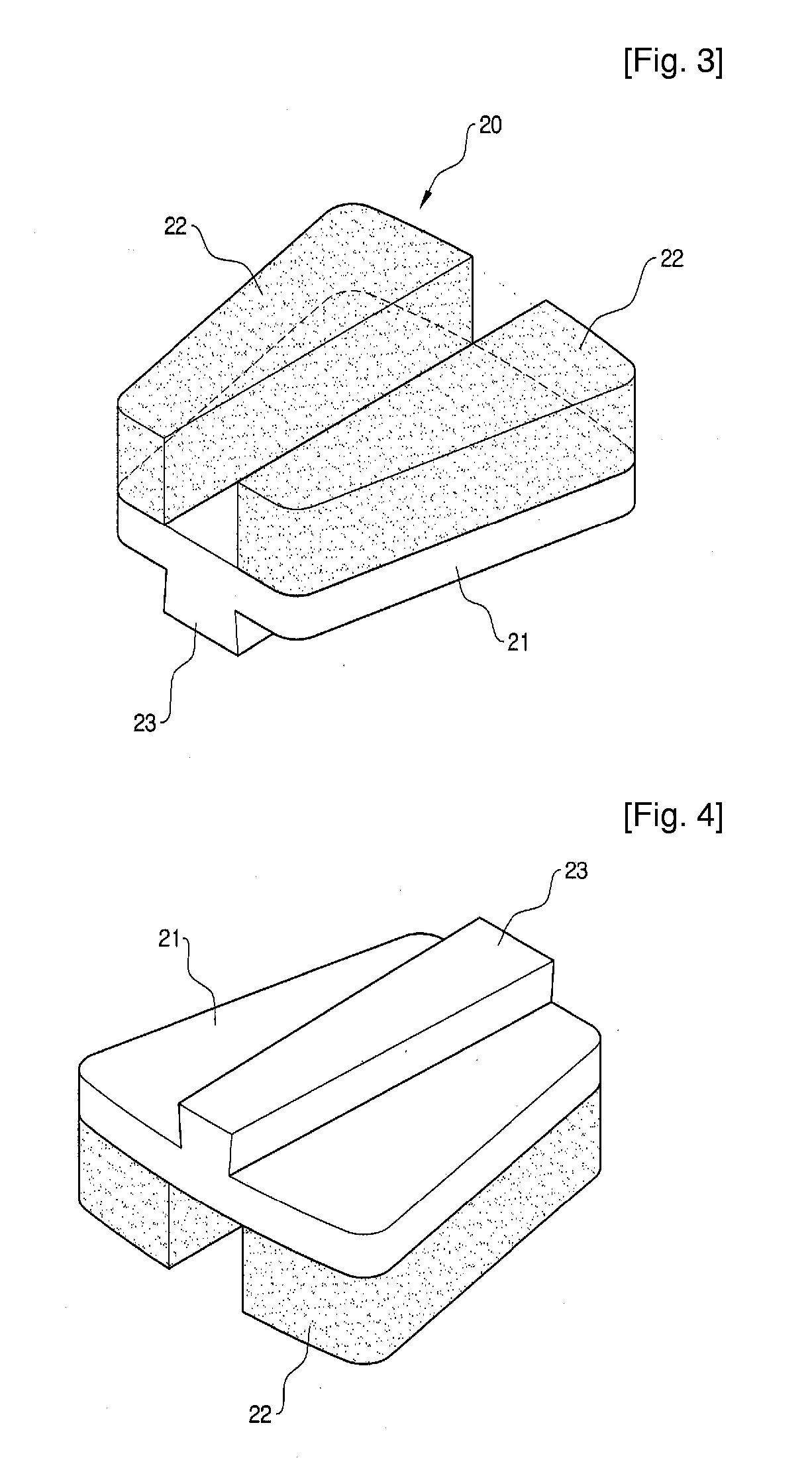

InactiveUS20070254568A1Simple manufacturing processPrevent thermal deformationRevolution surface grinding machinesBonded abrasive wheelsEngineeringGrinding wheel

A grinding wheel has a disc having a connection hole formed at a center thereof, to which a rotation axis of a grinder is connected, and a plurality of abrasive segments detachably connected to a surface of the disc. A plurality of fixing recesses are radially formed on the surface of the disc at an interval and fixing protrusions having a shape corresponding to the fixing recess are formed on bottom surfaces of the abrasive segments, so that the abrasive segments are connected to the disc by inserting the fixing protrusions into the fixing recesses. According to the grinding wheel, when the abrasive segment is worn away or inferior as it is used for a long time, it has only to replace the corresponding abrasive segment only. Accordingly, an economical efficiency is high.

Owner:PARK RIN SOON

Concrete polishing system

InactiveUS20060025059A1Extend your lifeReduce variationPortable grinding machinesBonded abrasive wheelsEngineeringAbrasive

Owner:GUEORGUIEV GUEORGUI D +1

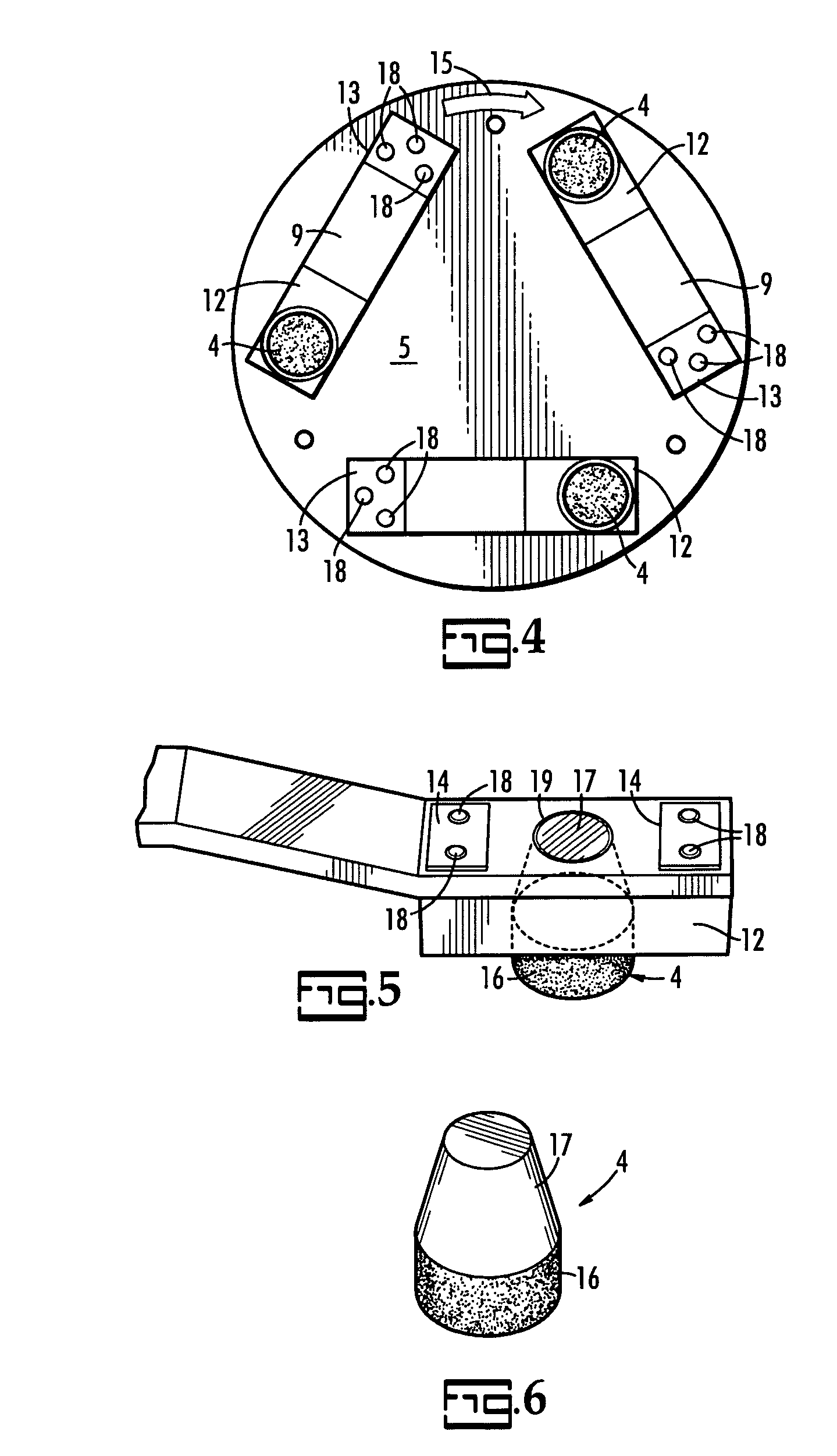

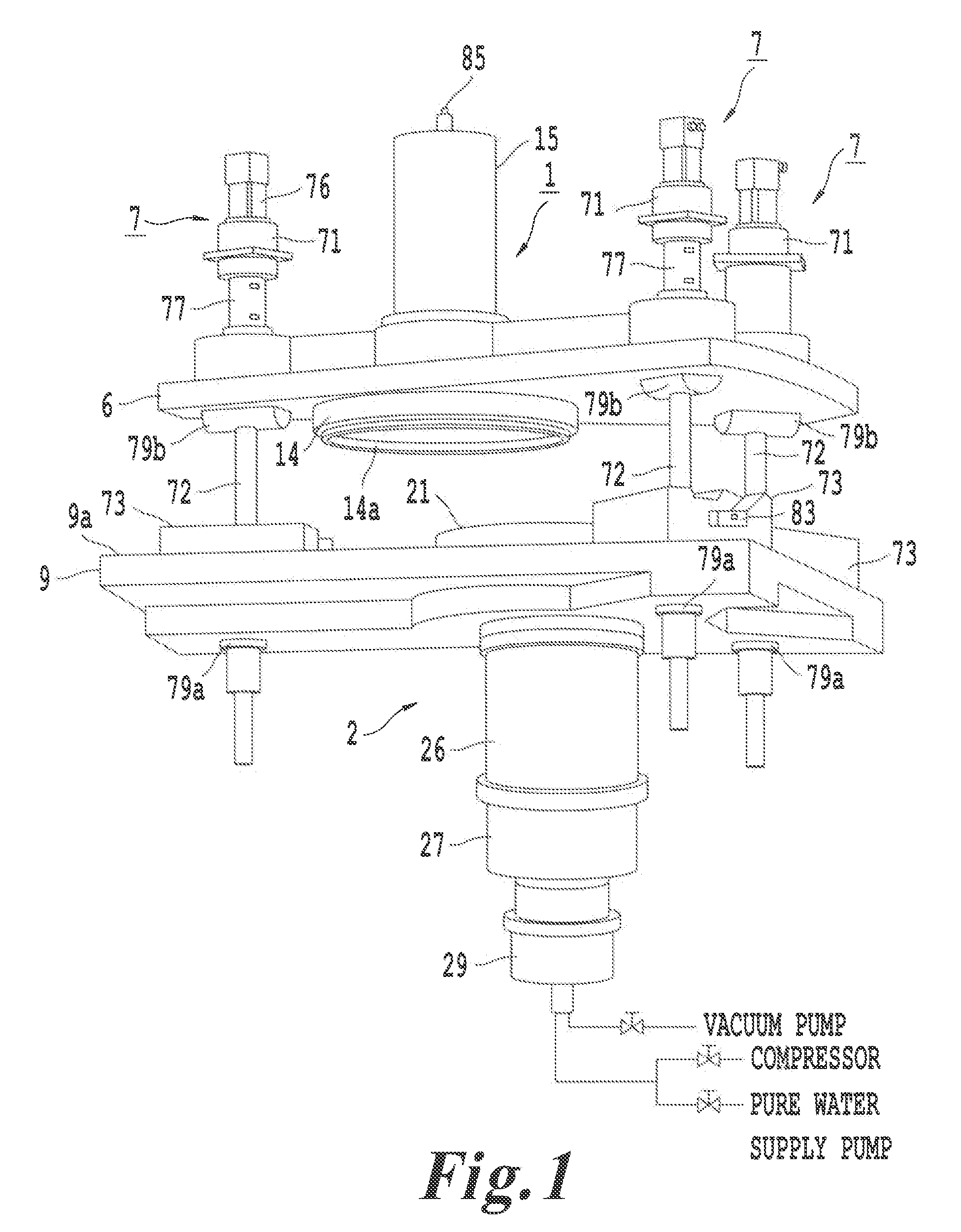

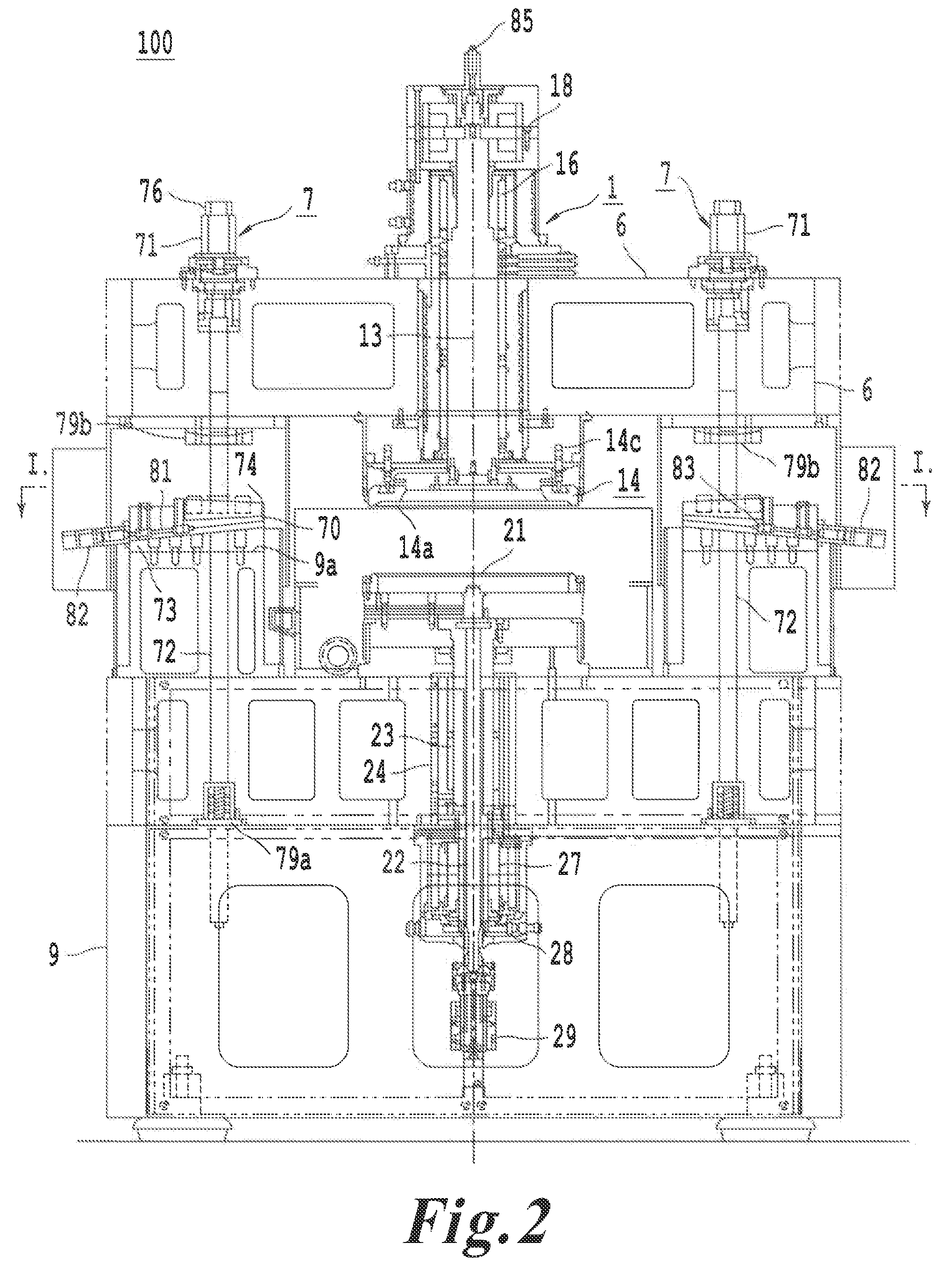

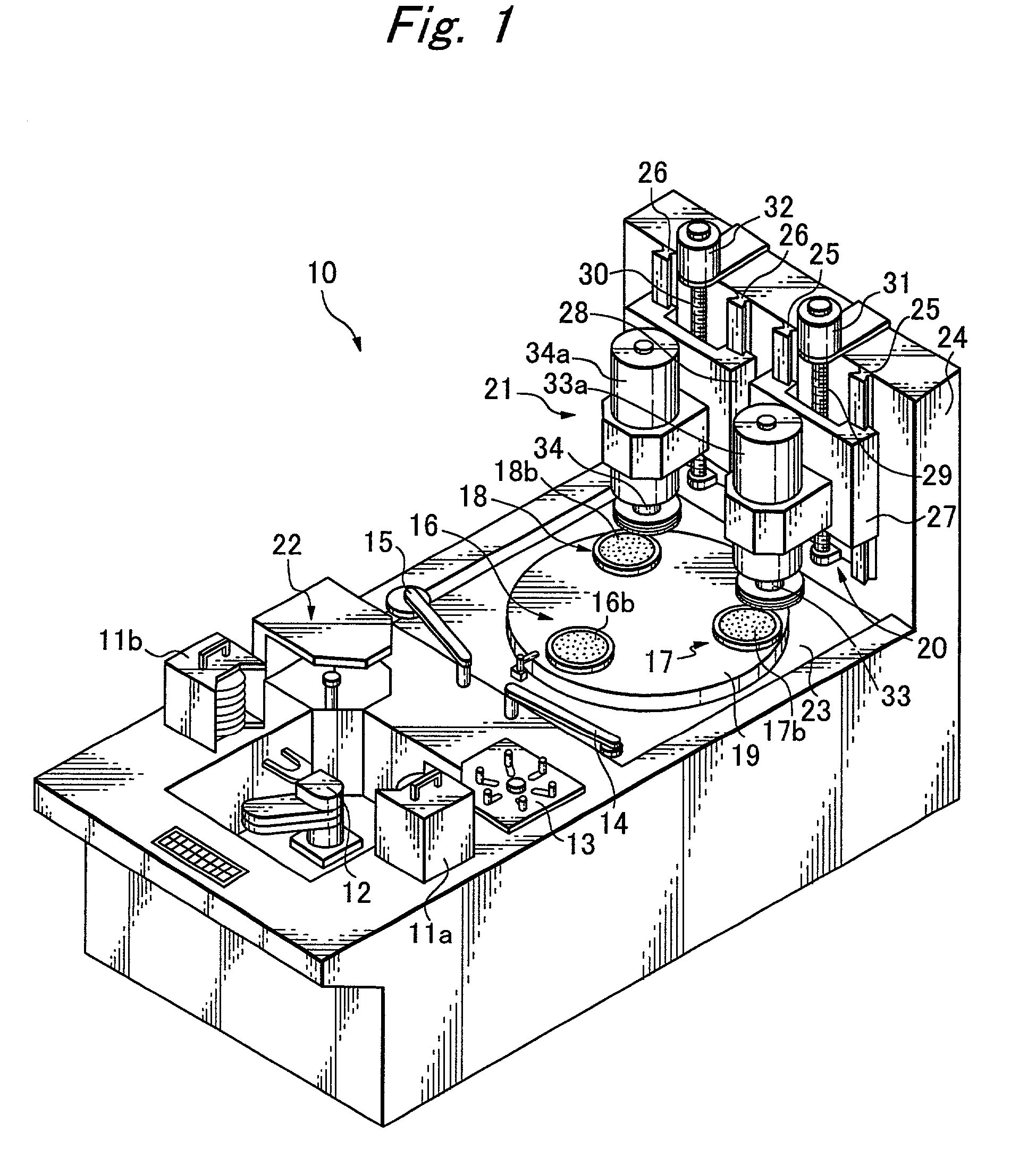

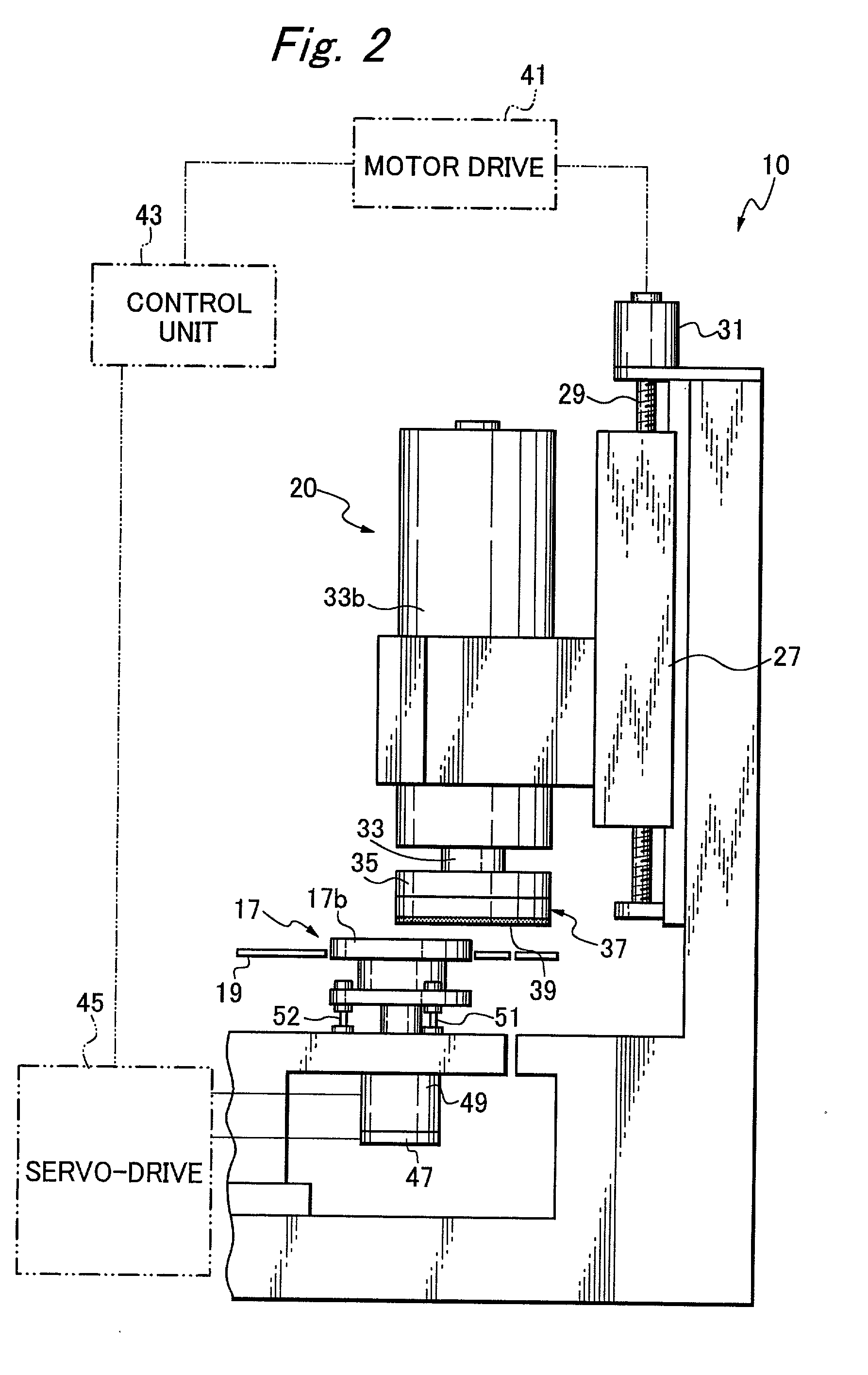

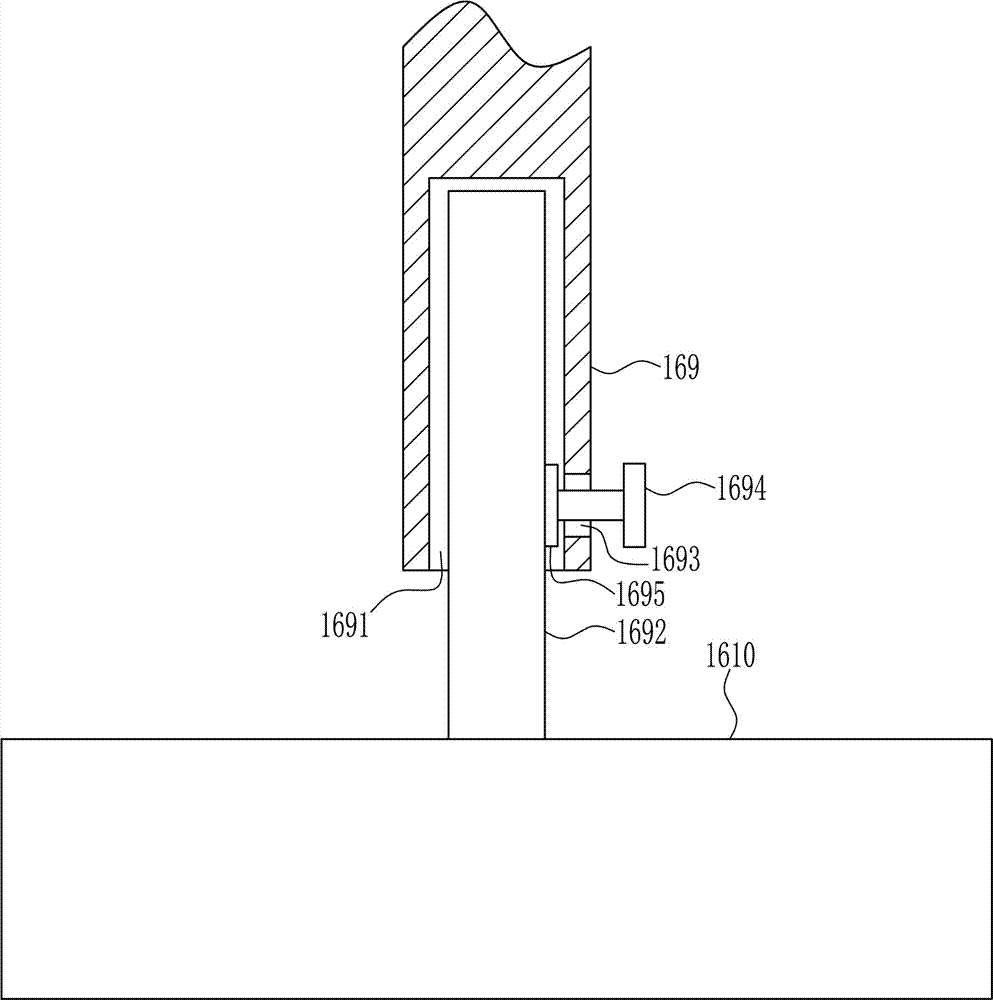

Substrate flat grinding device

InactiveUS20090203299A1Superior flat thickness distributionImprove rigidityEdge grinding machinesPolishing machinesKinematic couplingEngineering

To provide a high-rigidity flat grinding device, a substrate flat grinding device has three fastening plate lifting-and-lowering mechanisms that have kinematic couplings and a cylinder rod that move the fastening plate upward or downward. Being a high-rigidity grinding device in which the load of the fastening plate 6 also is a load on the grindstone 14 that does the grinding, there is little deflection in the thickness distribution of the substrates that are obtained, even if they are semiconductor substrates having a large substrate diameter of 450 mm.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

Side-emitting LED package having scattering area and backlight apparatus incorporating the LED lens

ActiveUS7414270B2Avoid light lossPoint-like light sourceSolid-state devicesOptoelectronicsExit surface

The invention provides an LED package and a backlight device incorporating the LED lens. The LED package has a bottom surface and a light exiting surface cylindrically extended around a central axis of the package from the bottom surface. Also, a reflecting surface is positioned on an opposite side of the bottom surface and symmetrical around the central axis such that light incident from the bottom surface is reflected toward the light exiting surface. Further, a scattering area is formed on the reflecting surface. According to the invention, by applying scattering materials on the reflecting surface of the LED package, a reflecting paper does not need to be attached, thereby simplifying a process and reducing the manufacture time and cost.

Owner:SAMSUNG ELECTRONICS CO LTD

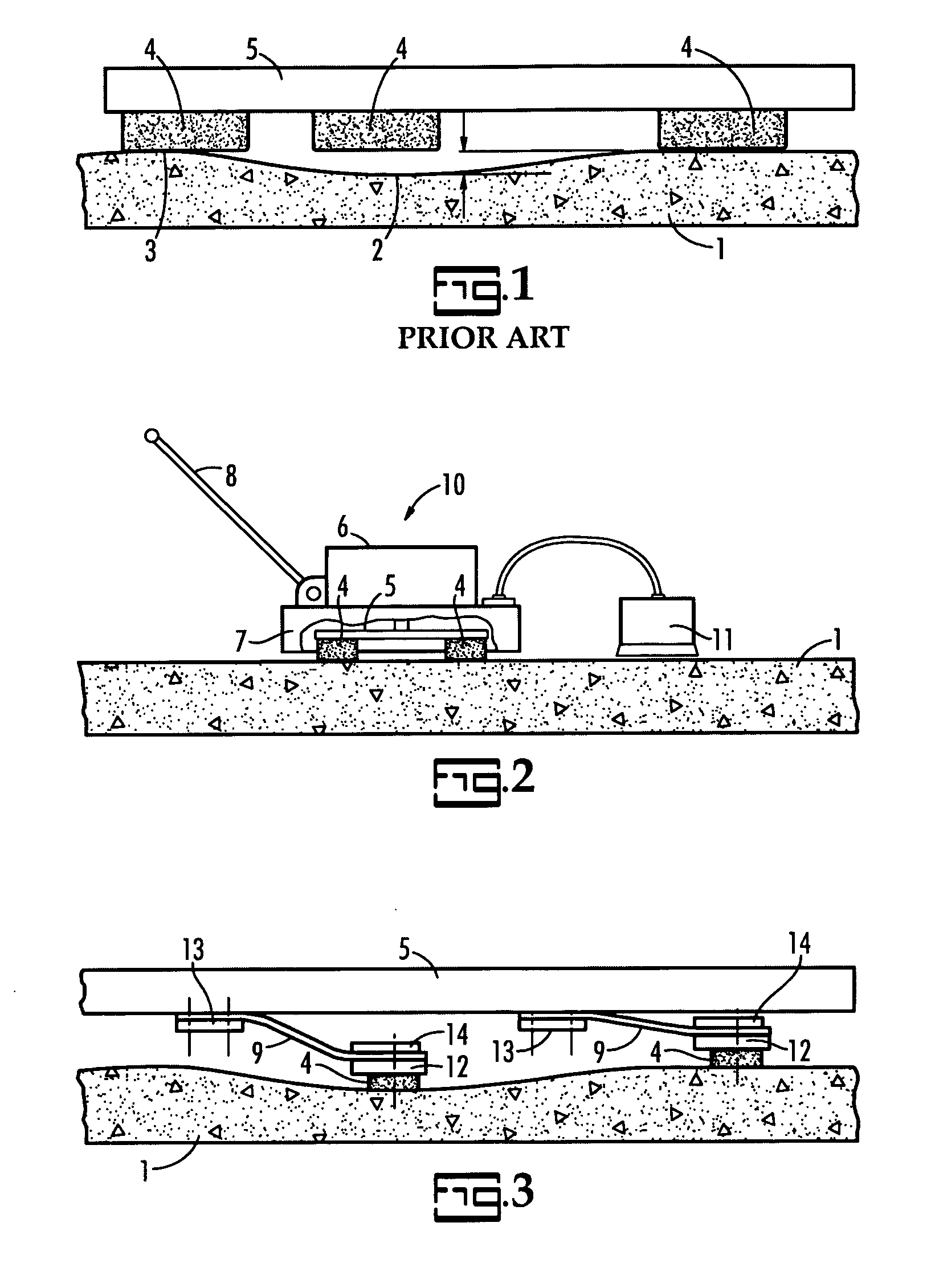

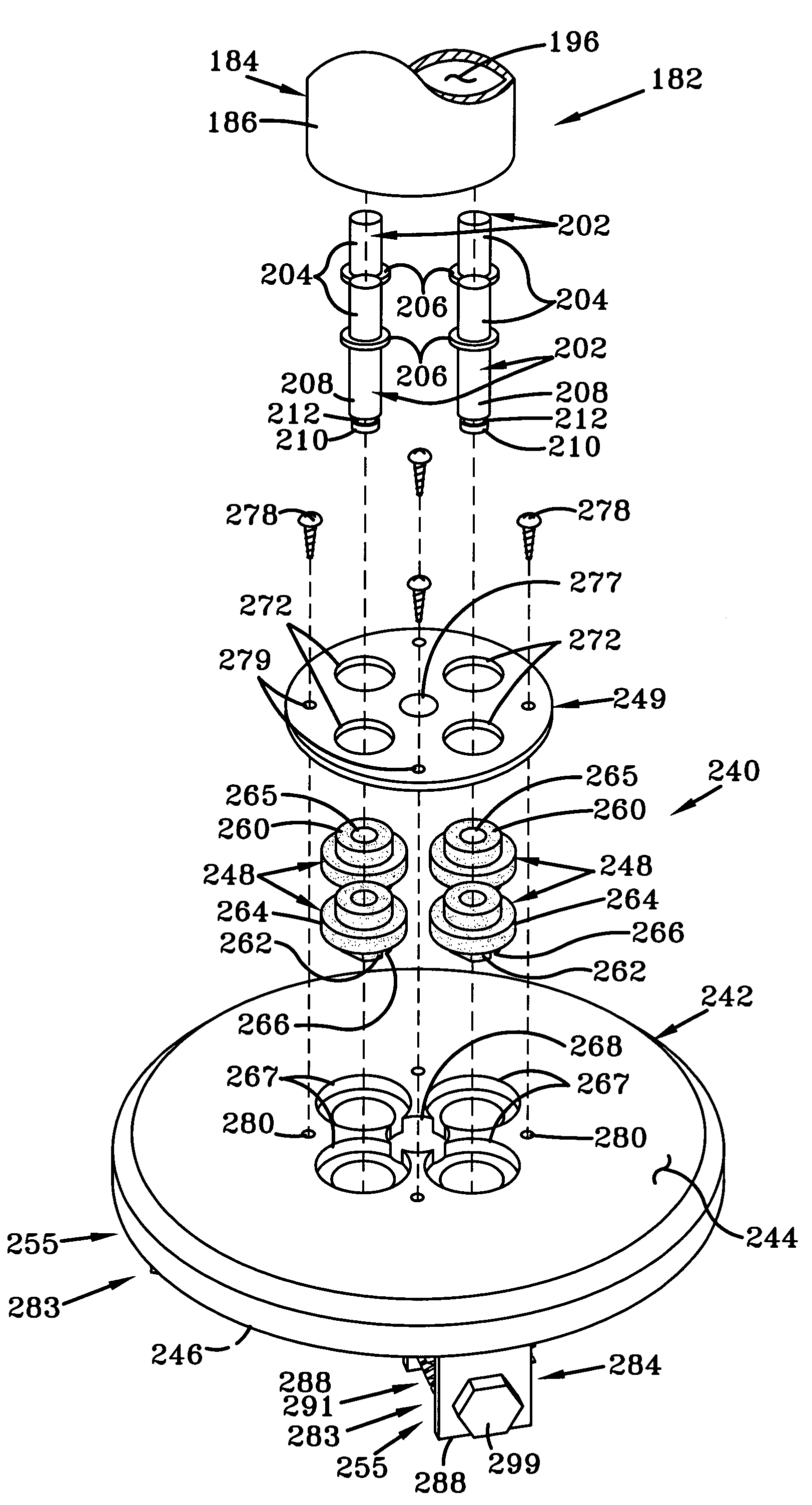

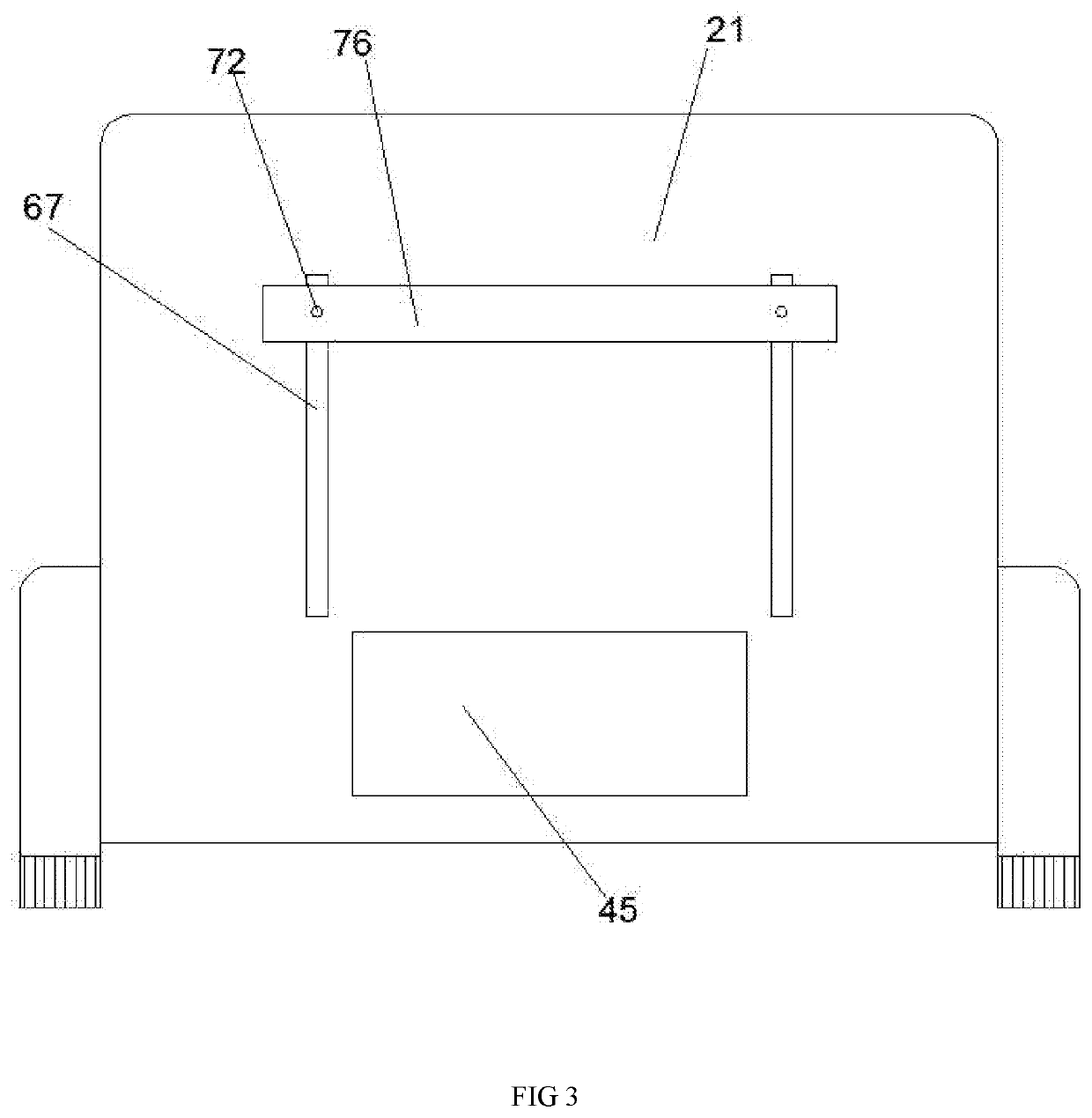

Floor resurfacing disks for rotary floor resurfacing machines

InactiveUS7033258B2Improve consistencyShorten the timePortable grinding machinesGrinding headsEngineeringGrommet

A resurfacing disk which mounts to a rotatable disk mount of a conventional rotary floor resurfacing machine. The resurfacing disk includes a rigid upper disk with four counterbored holes through an upper surface corresponding to four downwardly open holes of each disk mount. A resilient, flanged grommet is retained extending through corresponding holes of a retaining plate mounted to the upper surface. The grommets include respective vertically oriented longitudinal bores closely receive a mounting pin which extends from a corresponding hole of the disk mount. A plurality of rotary cutters each include a bracket which mounts to the upper disk opposite the grommets and an externally toothed cutter rotatably mounted thereto. The rotatable toothed cutters are oriented radially outwardly of the resurfacing disk so as to rotate while engaging the floor as the resurfacing disk spins with the disk mount. A resiliently deformable lower disk may be mounted in place of the rotary cutters and a sandpaper disk is removably affixed thereto using sheets interconnectable hook and a loop fastener material. The grommets and the lower disk deform to permit the floor resurfacing device to more closely follow contours of the floor surface and are easily replaceable if damaged or worn out.

Owner:LITE PREP SURFACE PREPARATION EQUIP

Polishing pads and methods relating thereto

InactiveUS6287185B1Speed up the flowFacilitate smoothing and planarizingRevolution surface grinding machinesFlexible-parts wheelsThermoformingEngineering

Polishing pads are provided having a polishing surface formed from a hydrophilic material. The polishing surface has a topography produced by a thermoforming process. The topography consists of large and small features that facilitate the flow of polishing fluid and facilitate smoothing and planarizing.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

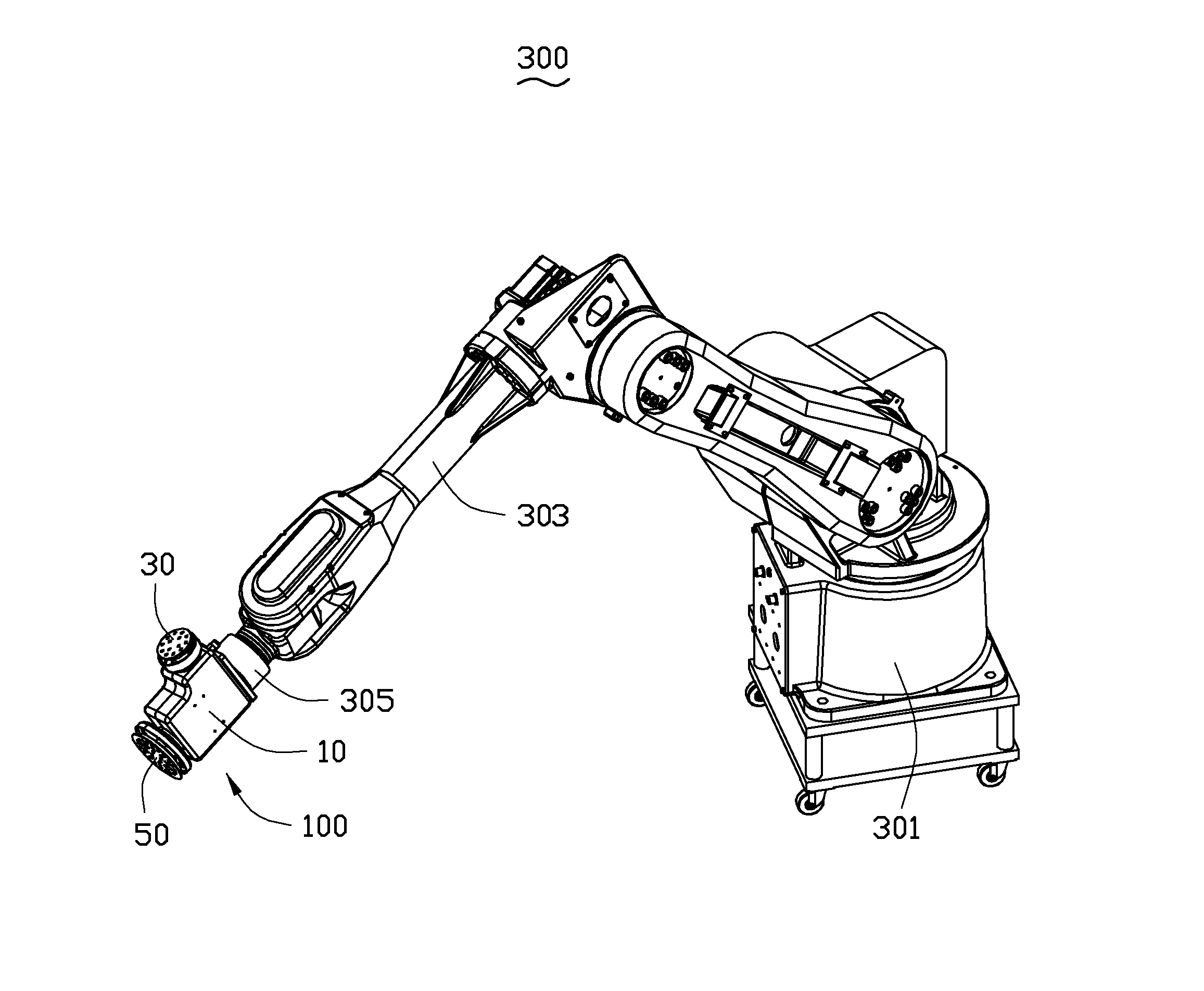

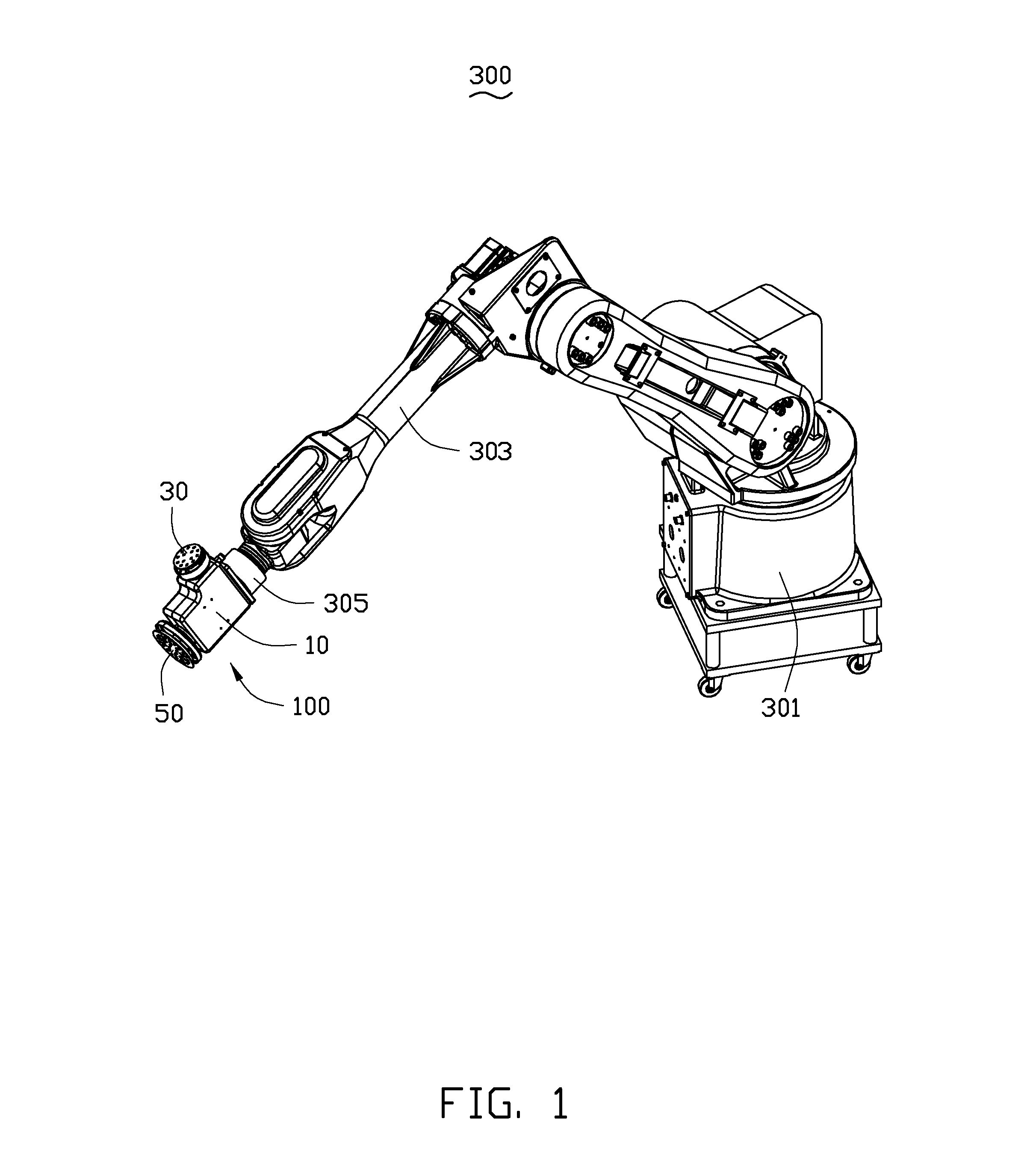

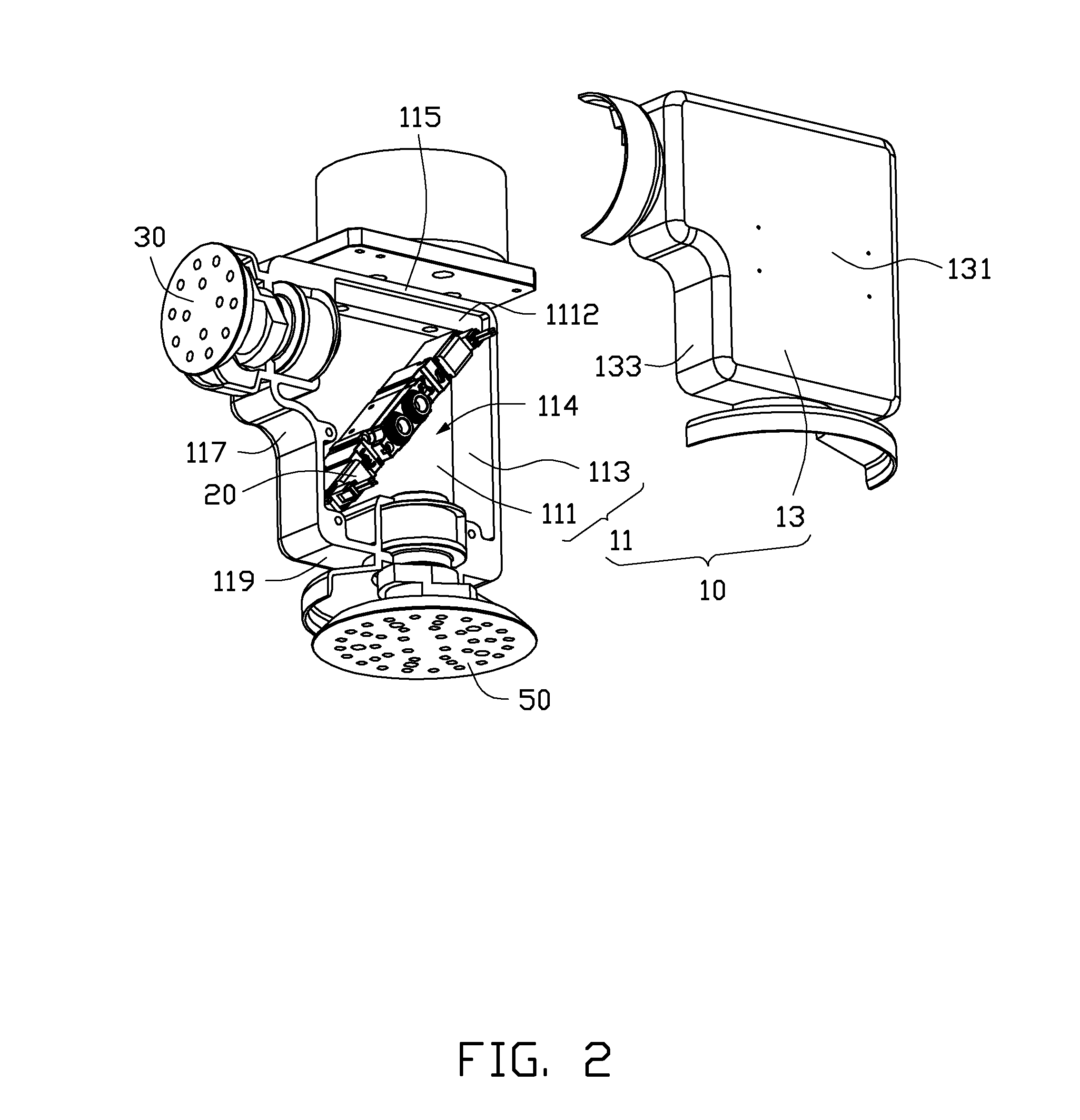

Manipulator and polishing mechanism thereof

A manipulator includes a controlling seat, a robot arm assembly and a polishing mechanism. The robot arm assembly is rotatably connected to the controlling seat; and the polishing mechanism is mounted on the robot arm assembly. The polishing mechanism includes a housing with a first mounting portion and a second mounting portion, a pair of magnetic valves mounted in the housing and electrically connected to the controlling seat, a first polishing assembly partially received in the first mounting portion, and a second polishing assembly partially received in the second mounting portion. The first polishing assembly and the second polishing assembly define an angle therebetween and are respectively connected to the pair of magnetic valves, such that the pair of magnetic valves controls the first and the second polishing assembly respectively to polish one or more workpiece. The present invention further discloses a polishing mechanism of the manipulator.

Owner:FU TAI HUA IND SHENZHEN +1

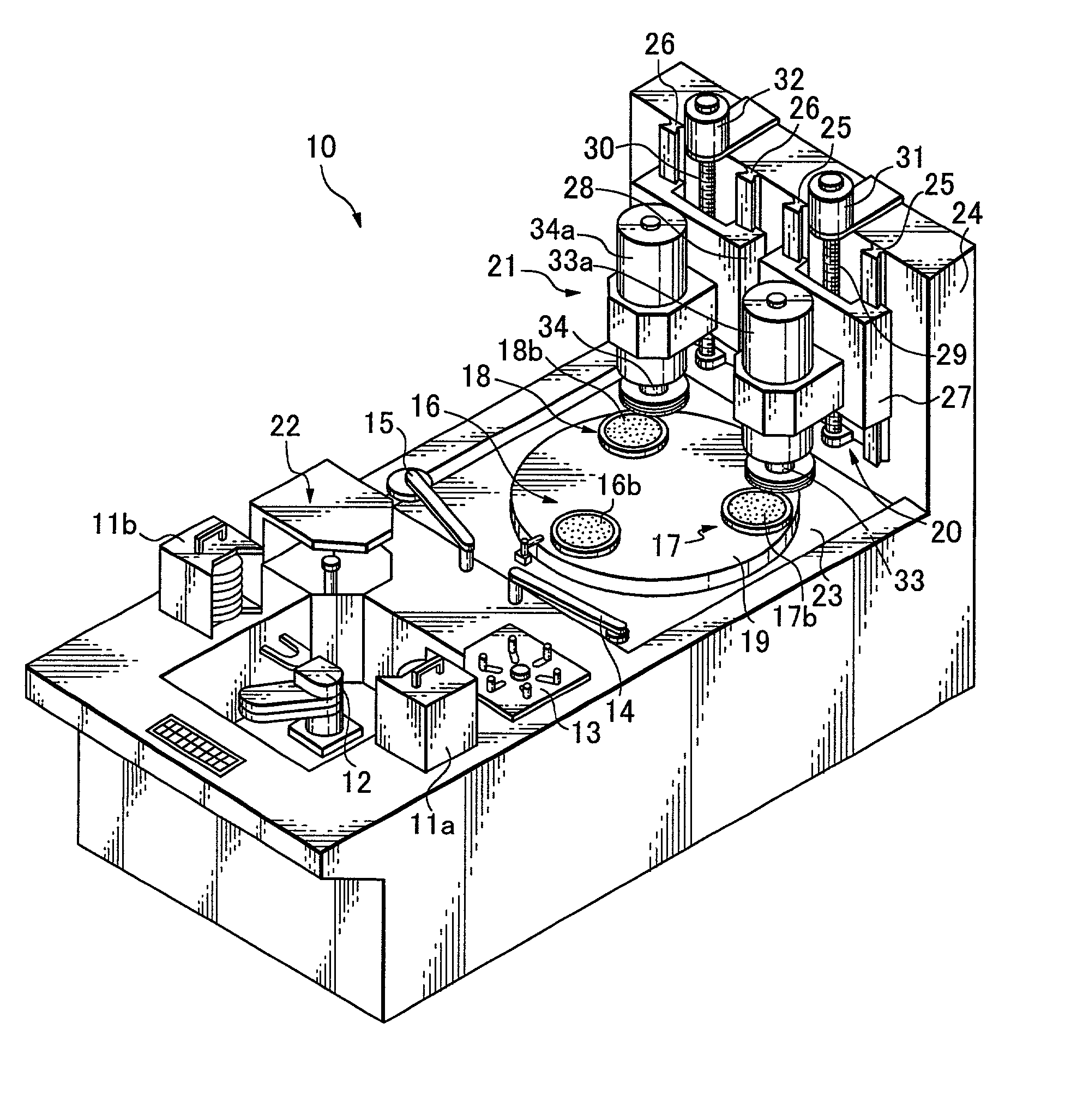

Grinding machine

Disclosed is an improvement in a grinding machine comprising at least a turn table, rotary chuck tables for holding work pieces to be machined, a first grinding means for grinding the work piece held on the chuck table and a second grinding means for grinding the first-ground work piece held on the chuck table. The first grinding means comprises at least a first grinding wheel having pieces of grindstone set so as to define together a first grinding plane, and a first spindle fixed to the first grinding wheel. Likewise, the second grinding means comprises a second grinding wheel having pieces of grindstone set so as to define together a second grinding plane and a second spindle fixed to the second grinding wheel. The first and second grinding means are so arranged that the first angle formed between the linear line connecting from the center of rotation of the turn table to the center of rotation of a selected chuck table and the linear line connecting from the center of rotation of the selected chuck table to the center of rotation of the first spindle is equal to the second angle formed between the linear line connecting from the center of rotation of the turn table to the center of rotation of the selected chuck table and the linear line connecting from the center of rotation of the selected chuck table to the center of rotation of the second spindle. This arrangement assures that all finished work pieces have on and same thickness.

Owner:DISCO CORP

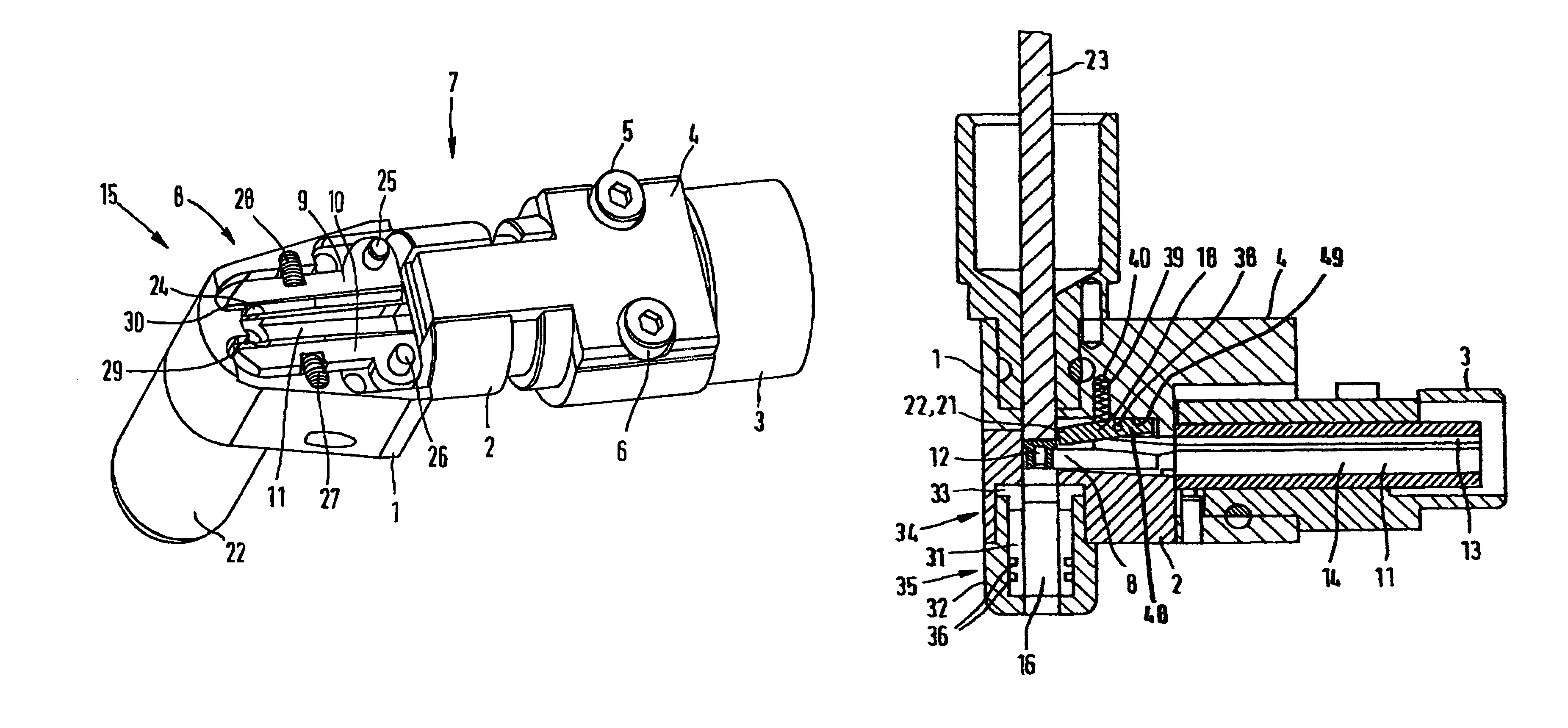

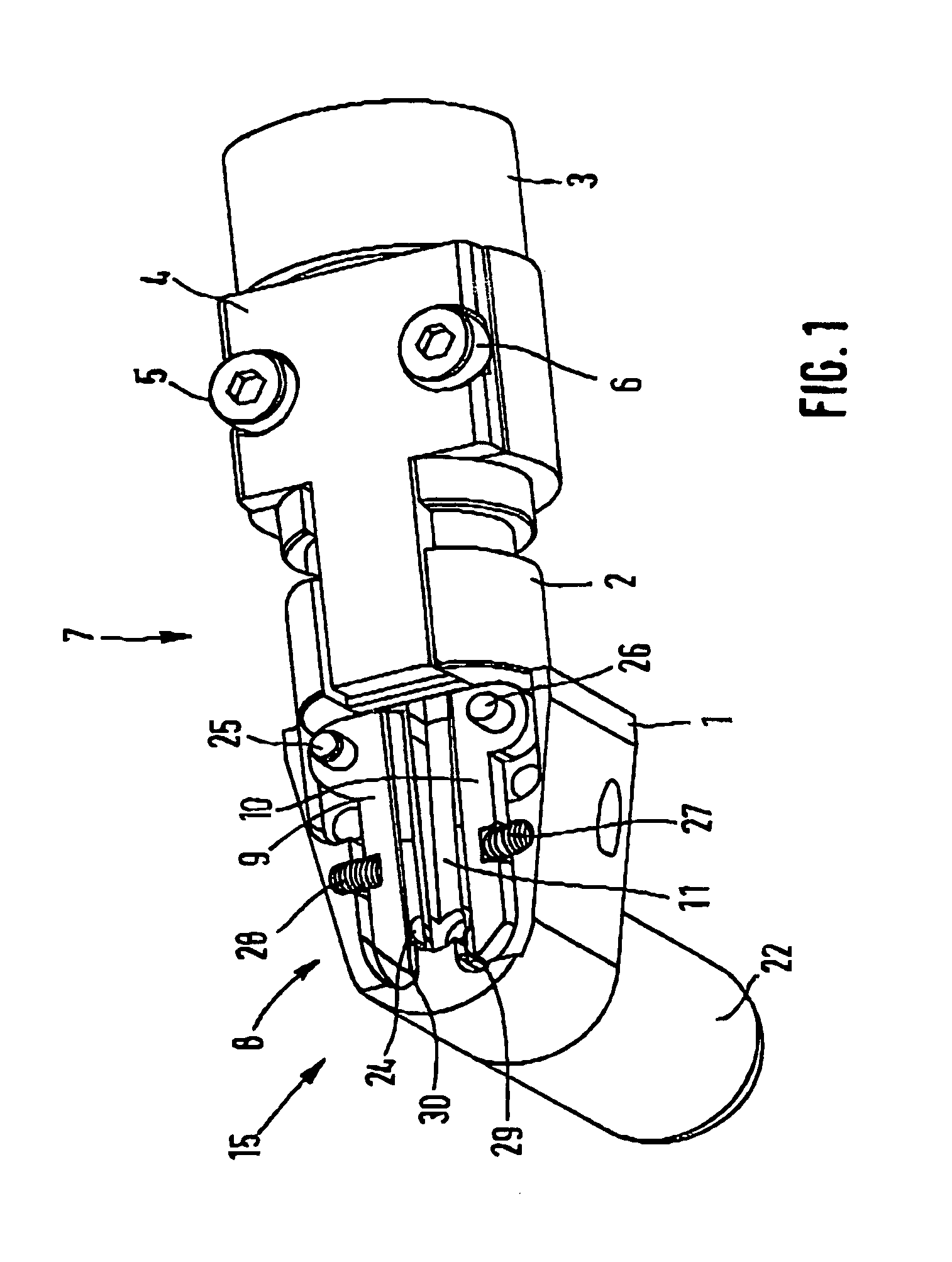

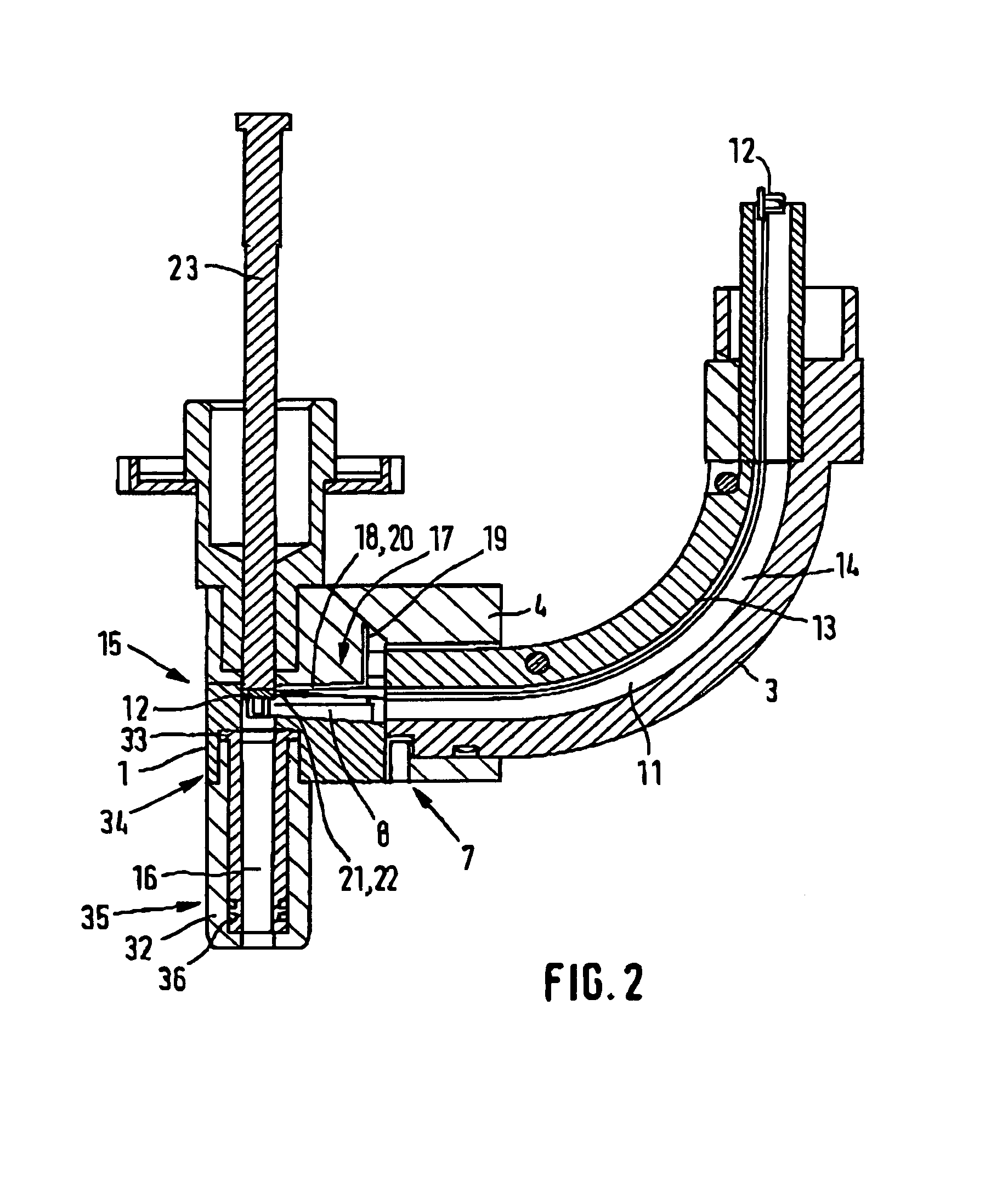

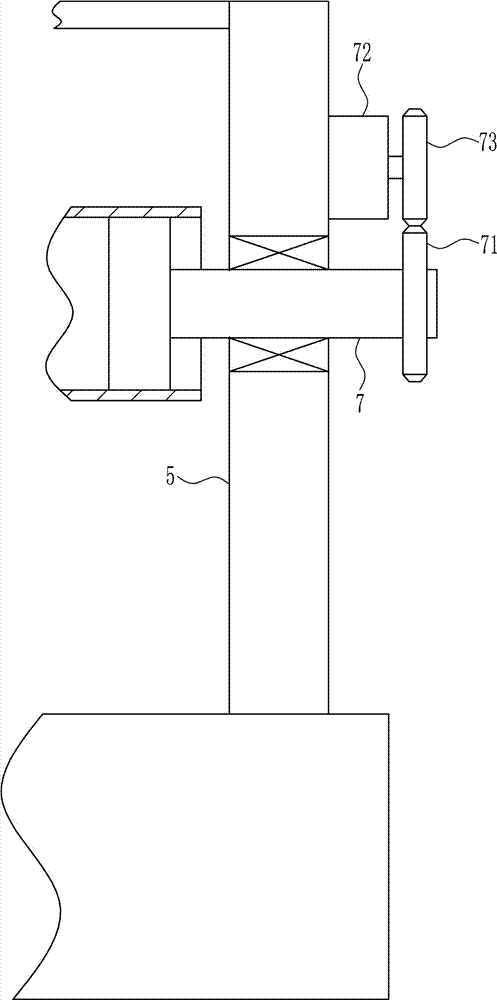

Conveyor for elongate components designed with a head and a shank

InactiveUS6968939B1Reliably into transfer regionPrevent rollingStapling toolsRevolution surface grinding machinesSpring forceEngineering

The invention relates to a conveyor for elongate components (12) designed with a head and a shank. The conveyor comprises a feed arrangement (7). The feed arrangement (7) comprises a transfer arrangement (8) with a transfer region (15) in which a component (12) can be positioned. In the transfer region (15), a feed duct (11) having a head guiding duct (13) and a shank guiding duct (14) passes into a conveying duct (16). The transfer arrangement (8) comprises at least one catch unit (17). The catch unit (17) comprises at least one catch element (18). The catch element (18) is arranged opposite the head guiding duct (13) and penetrates at least partially therein. It can be deflected from the head guiding duct (13) against a spring force.

Owner:NEWFREY

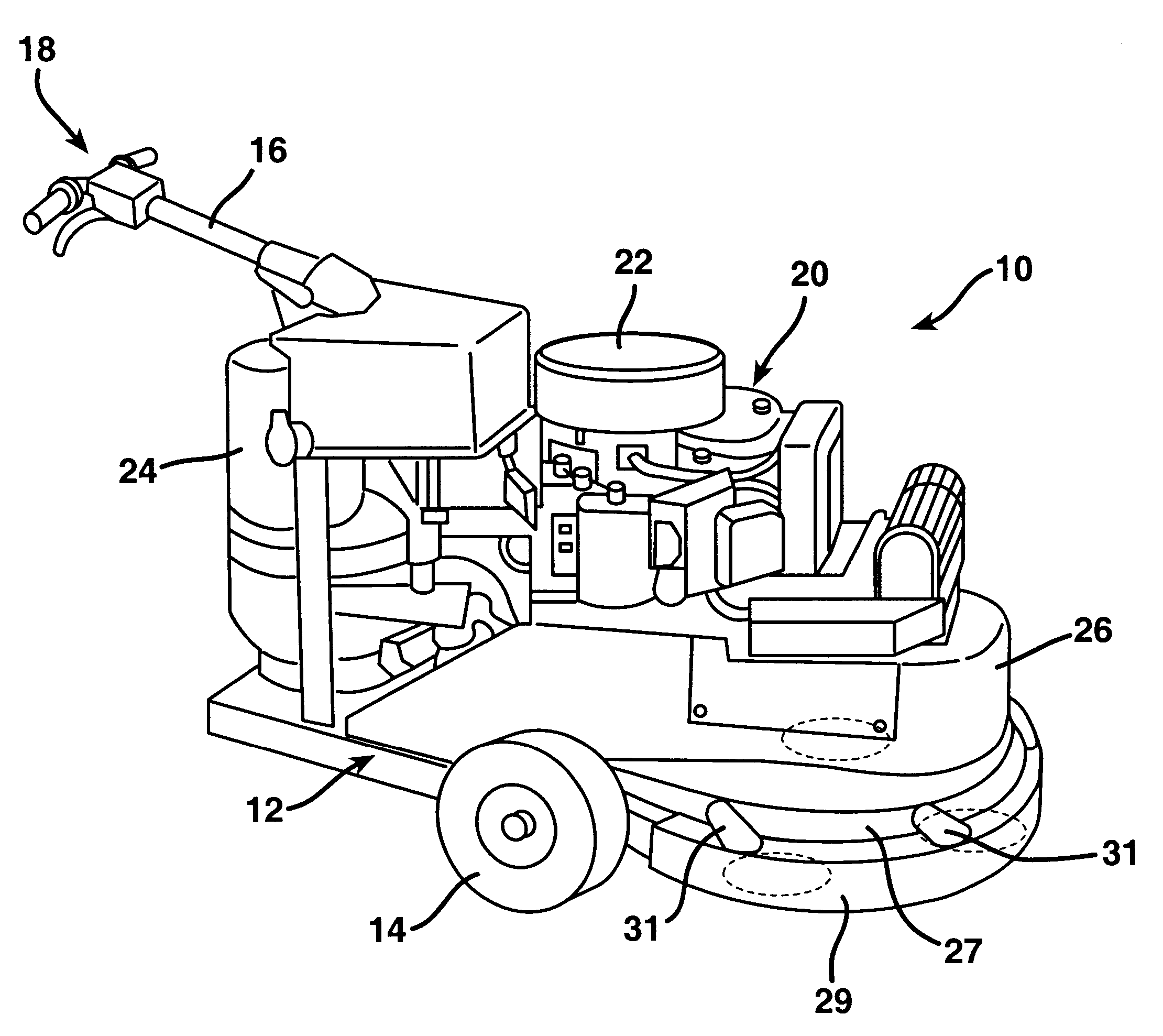

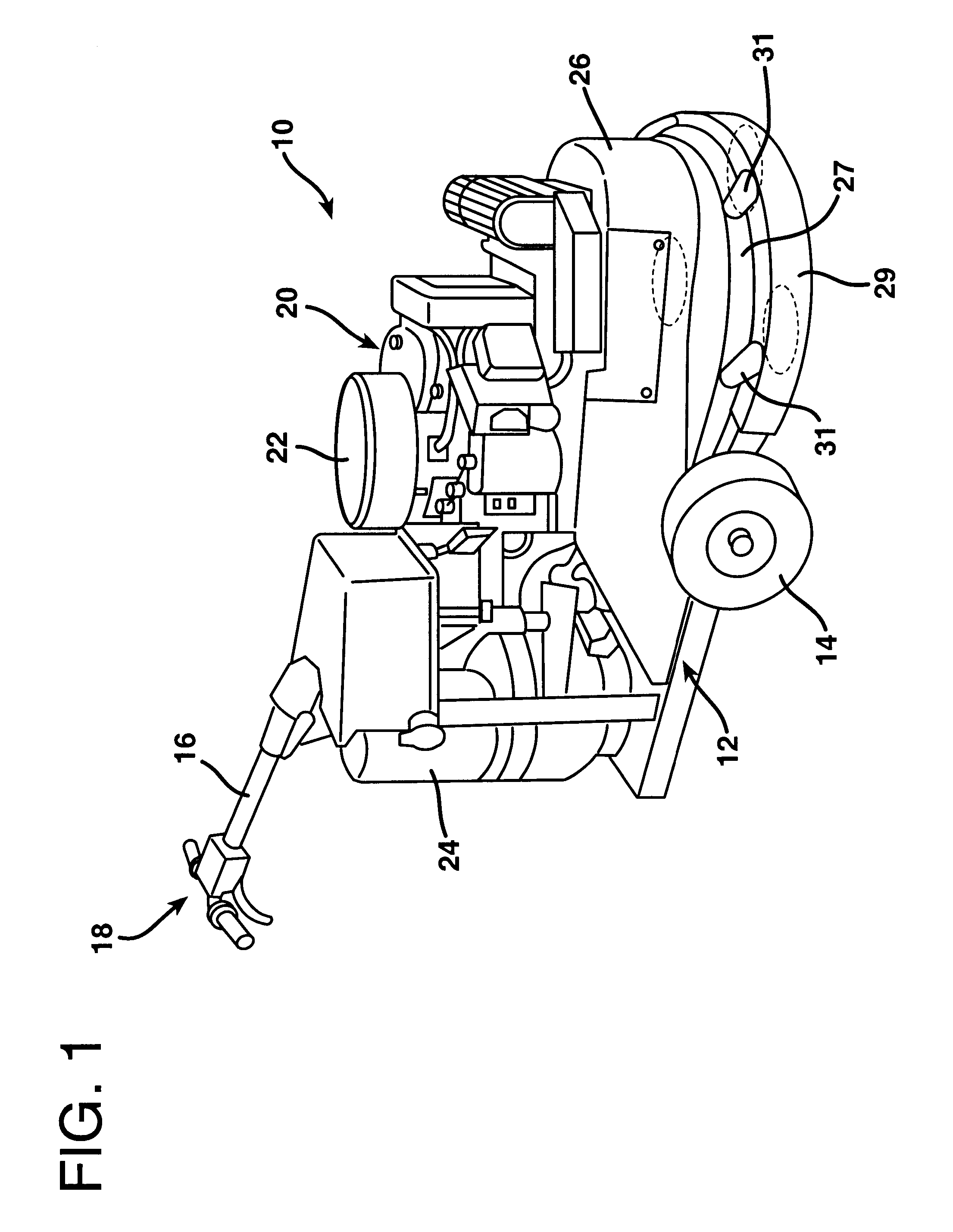

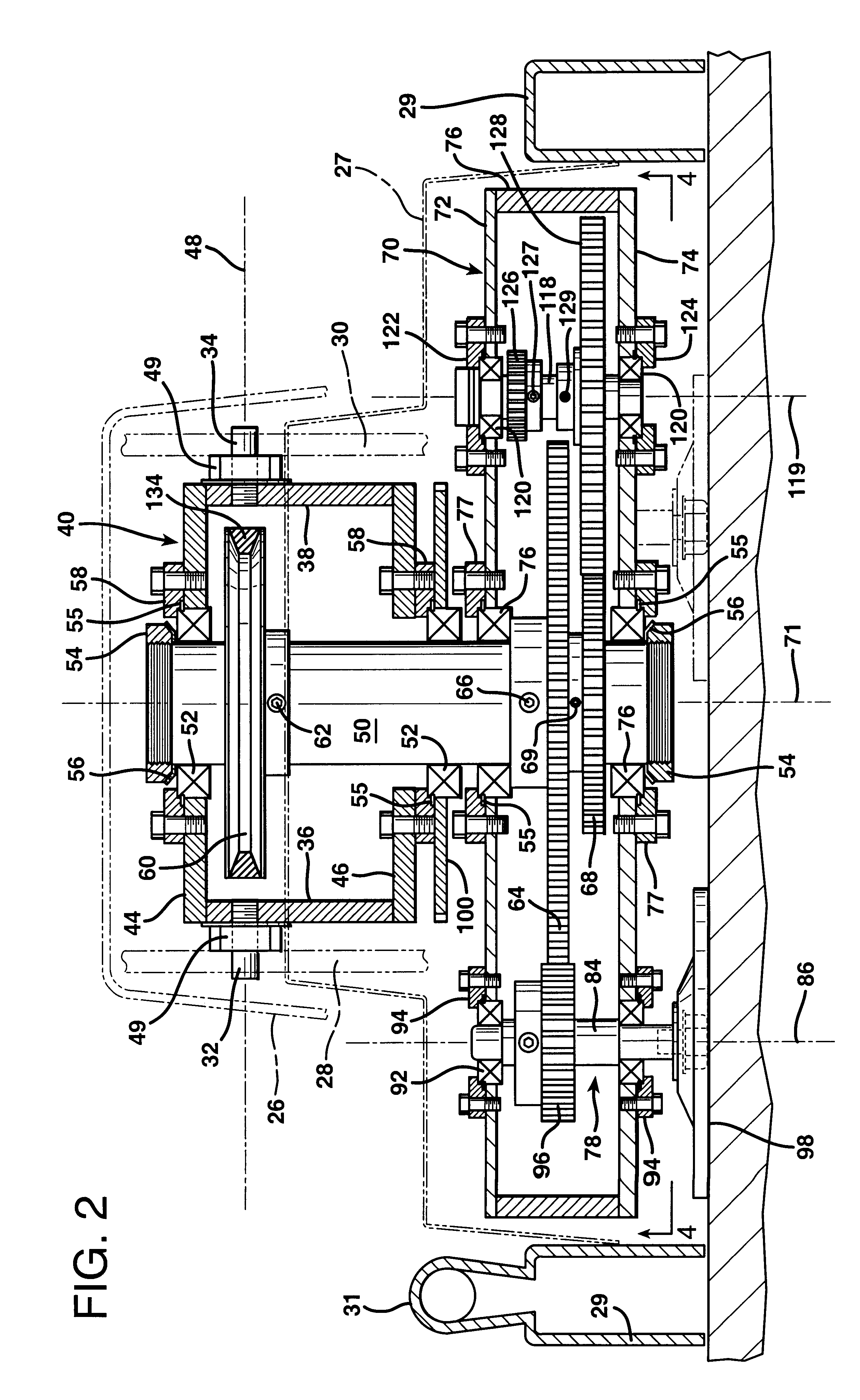

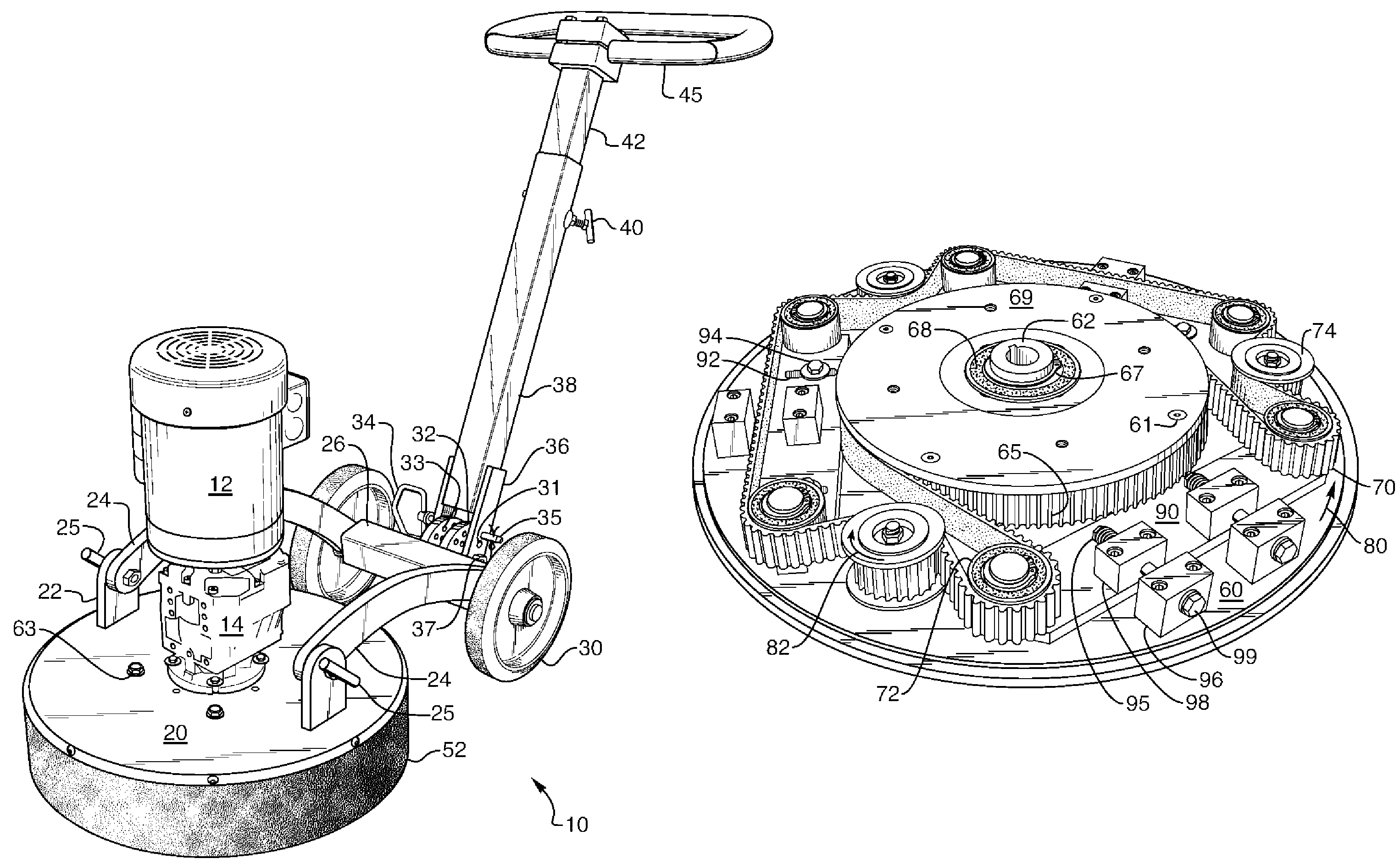

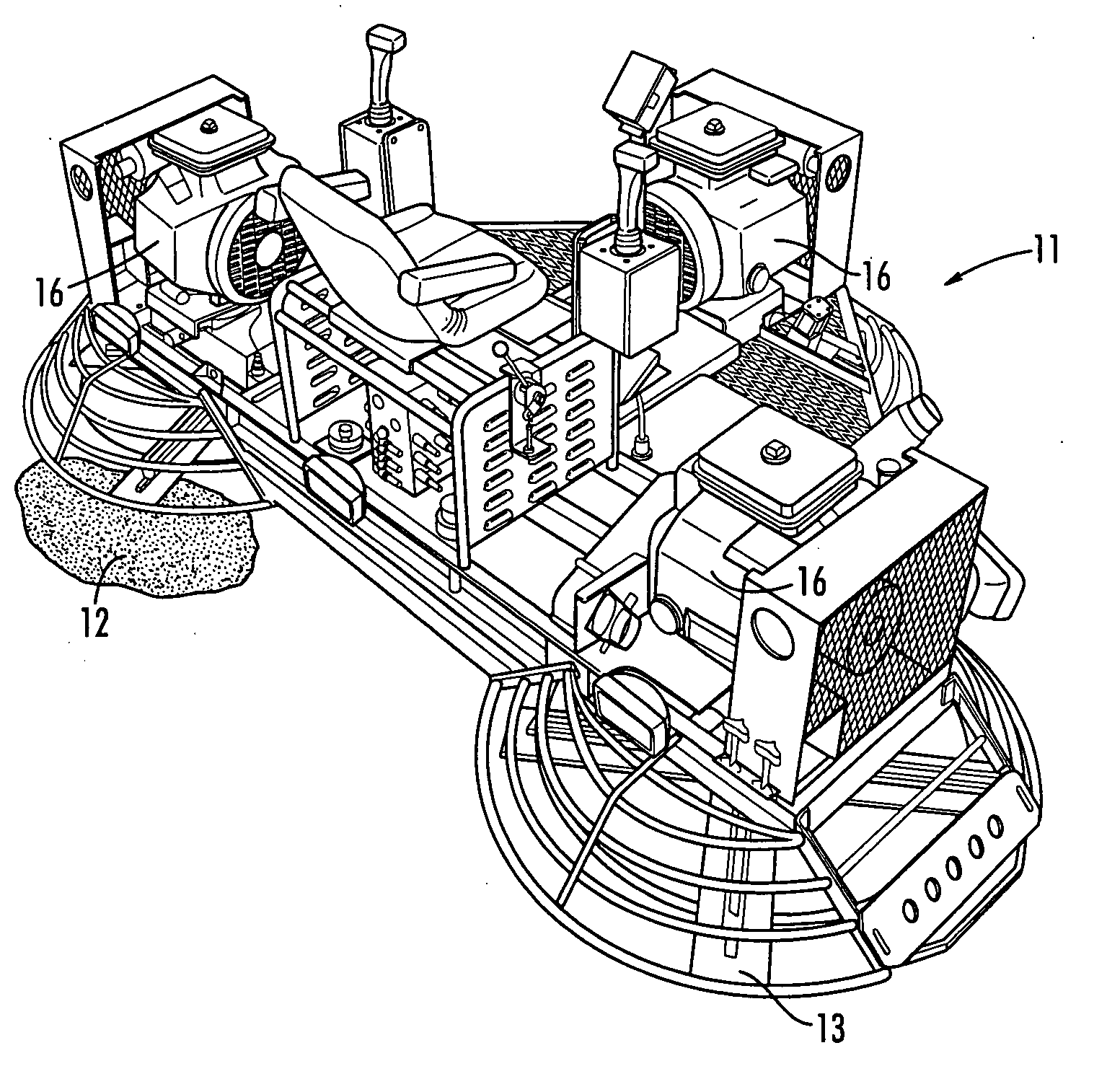

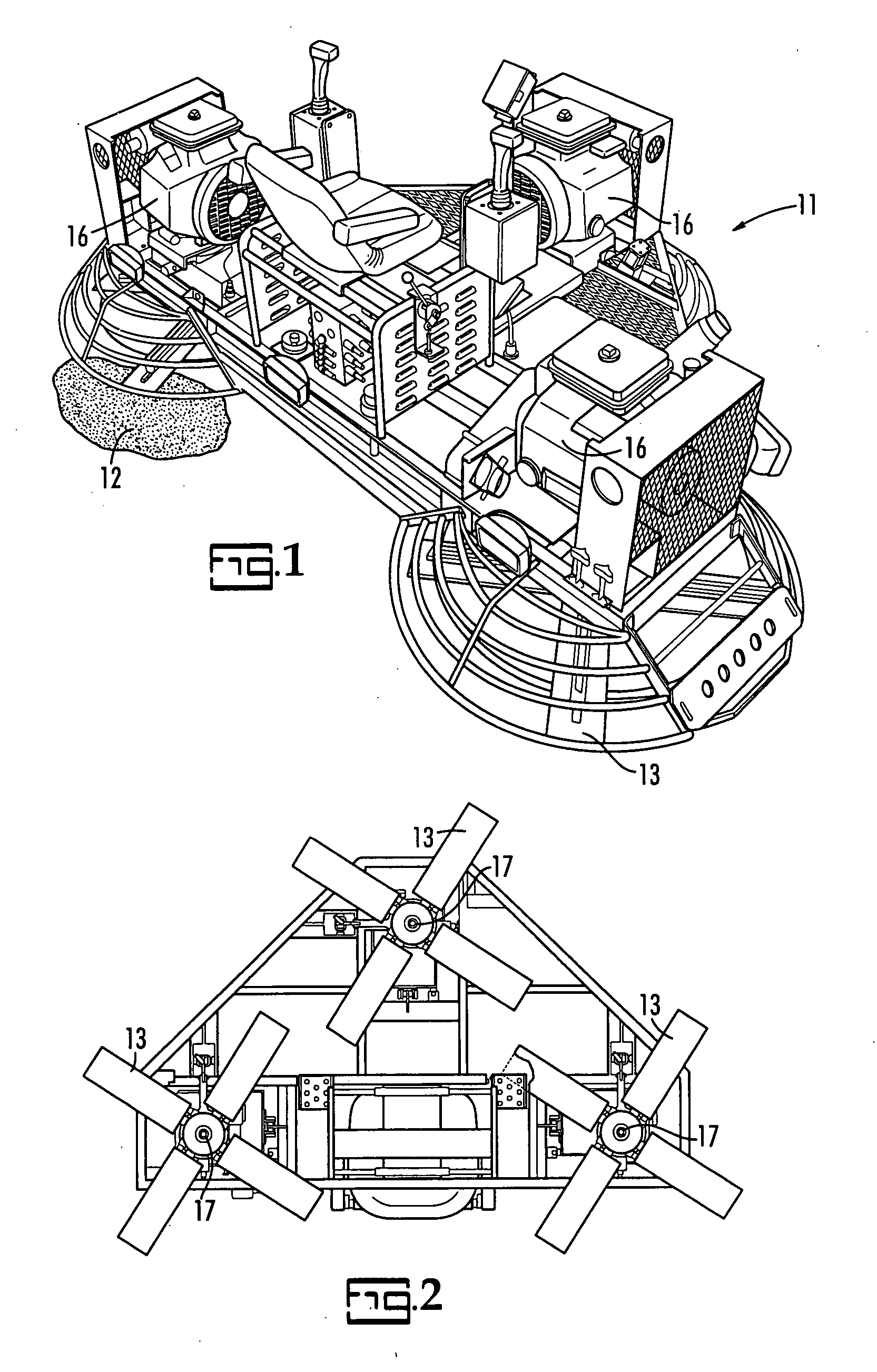

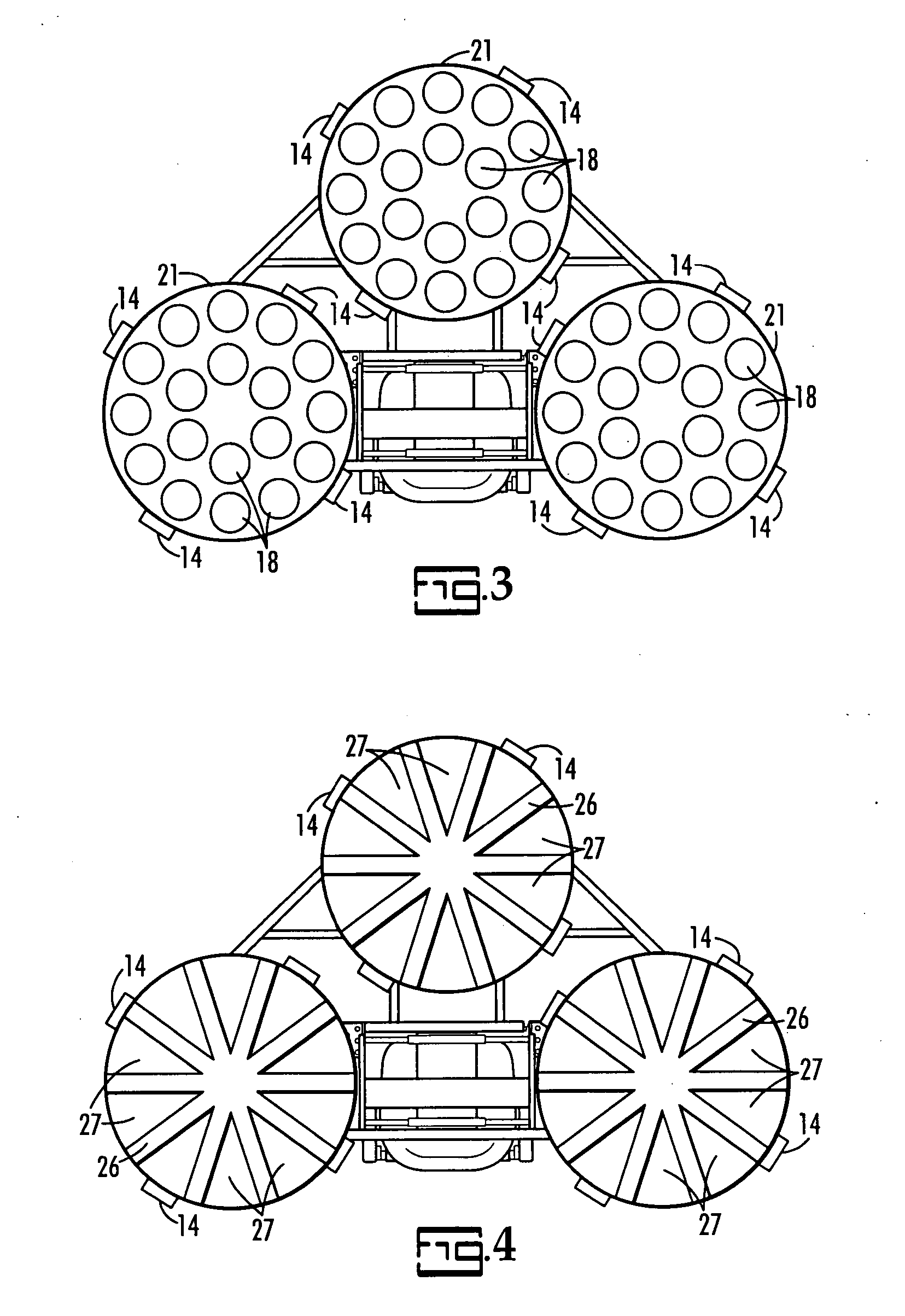

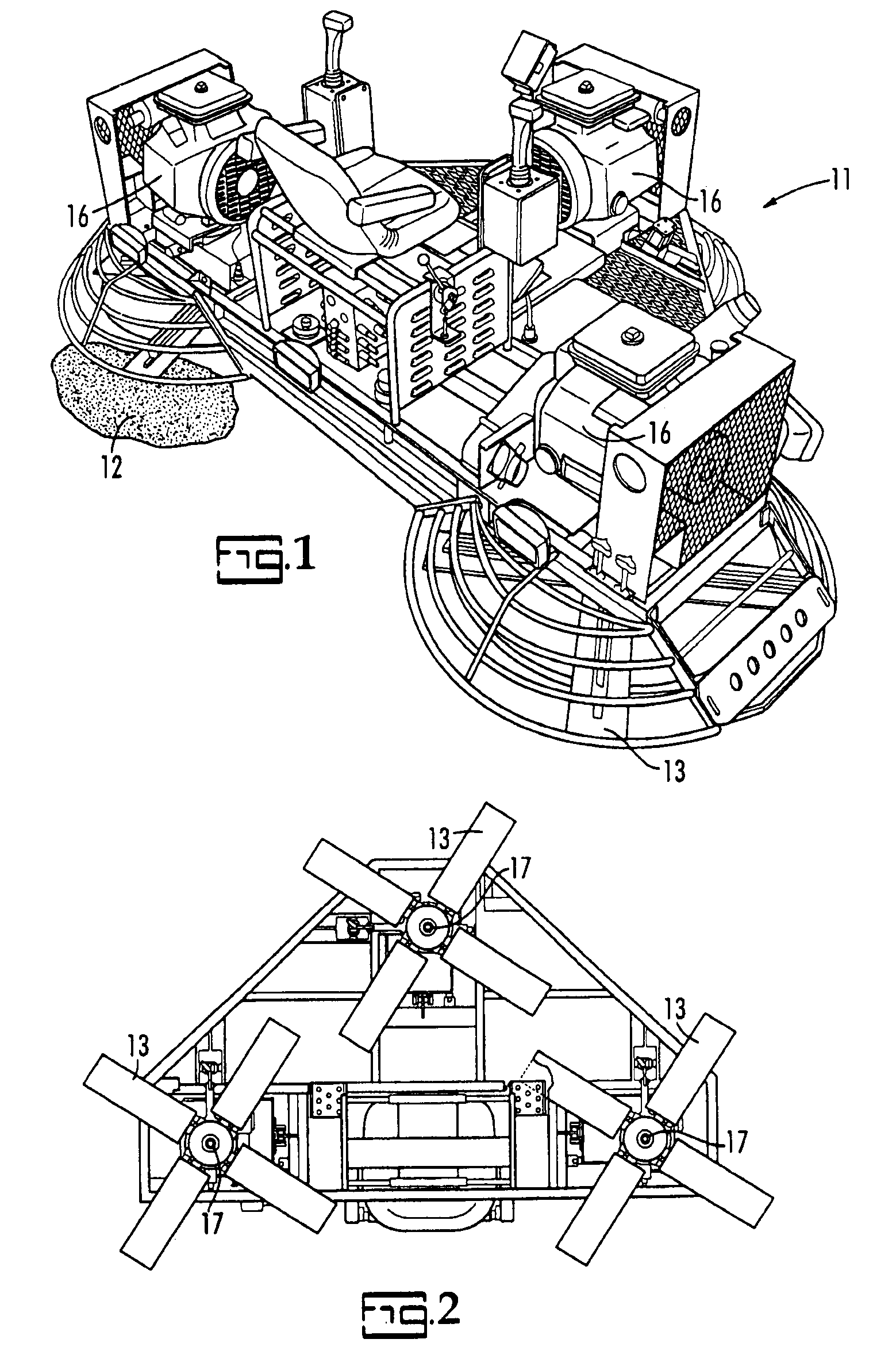

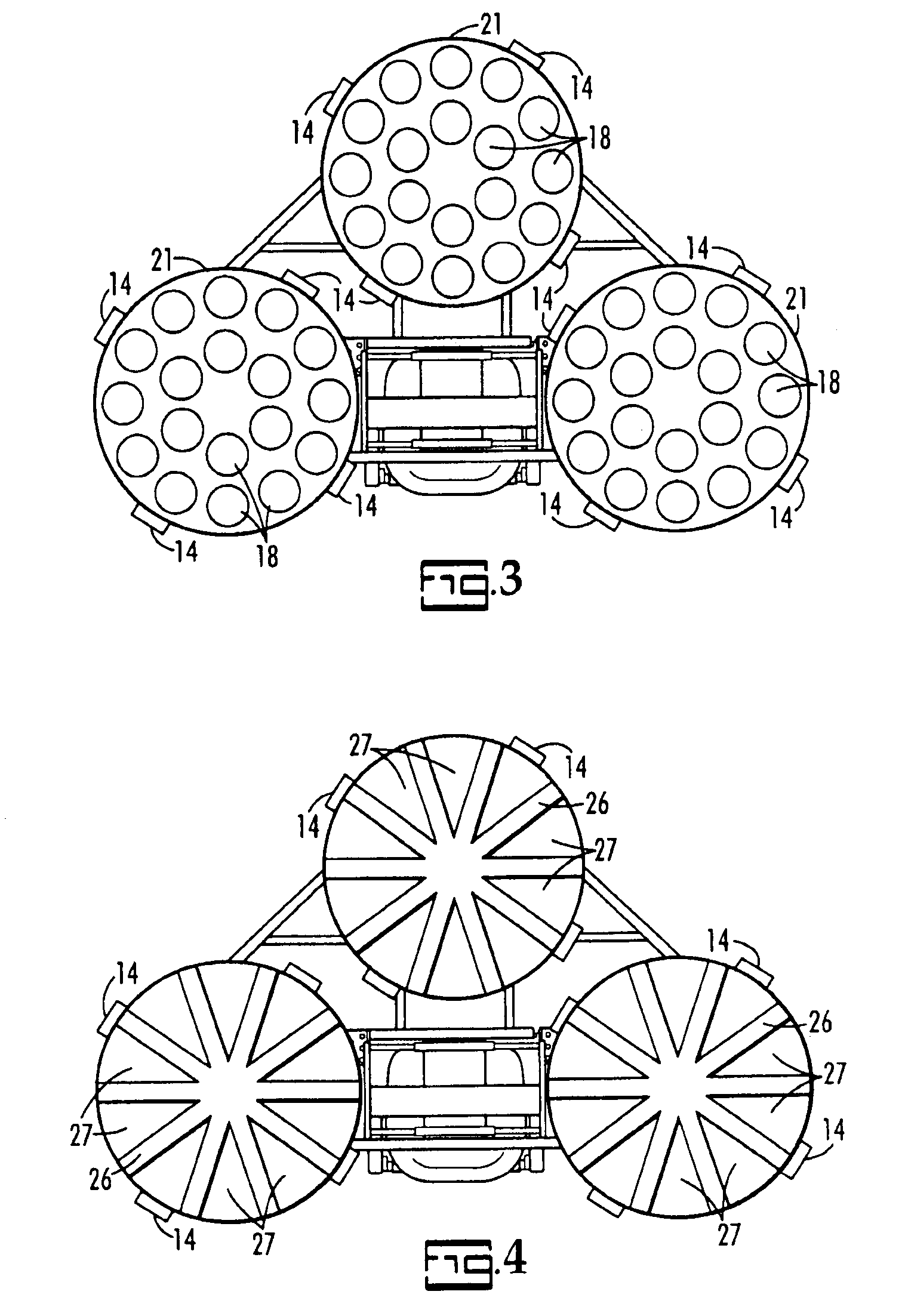

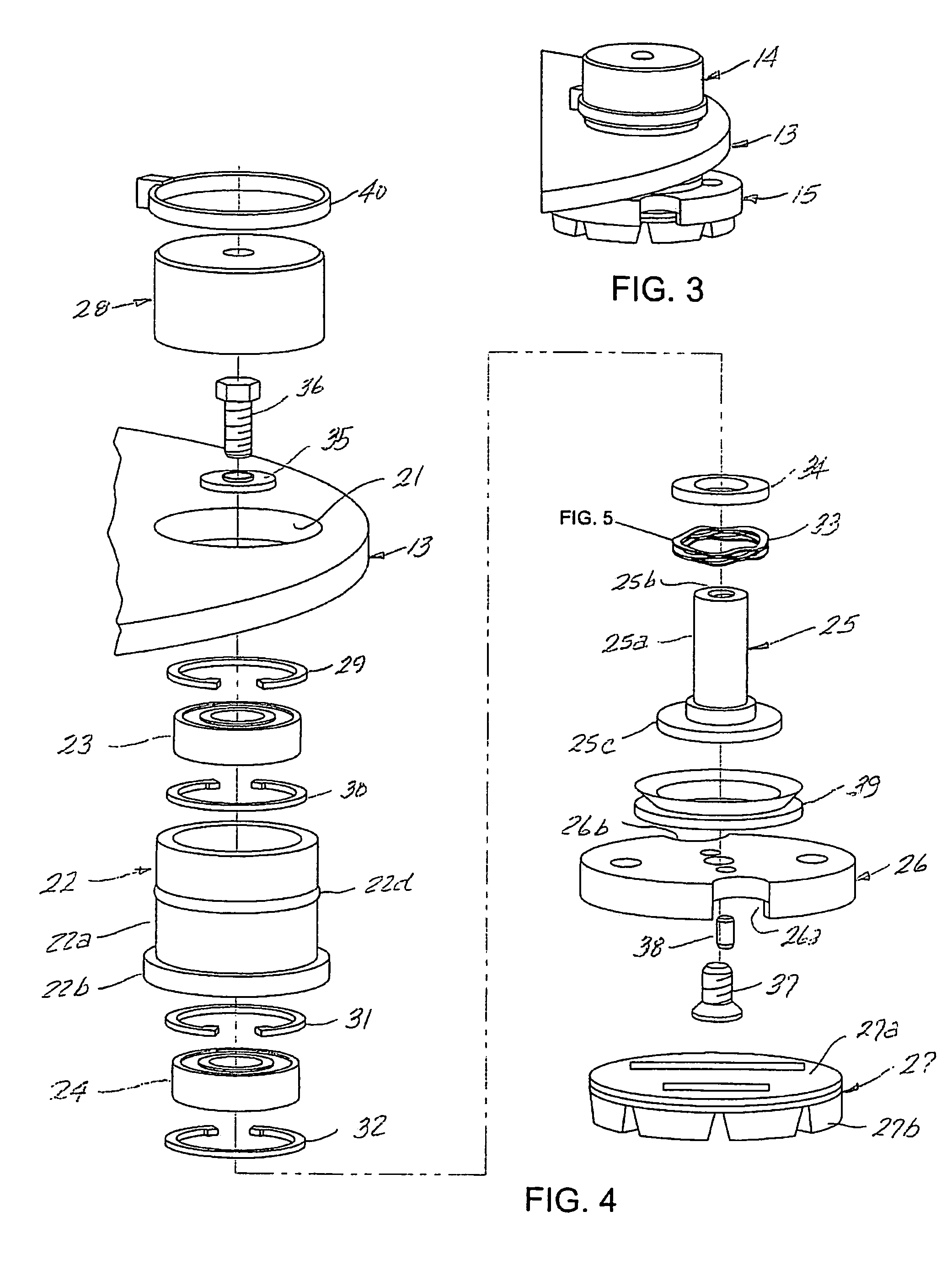

Planetary grinder

ActiveUS7563156B2Easy to controlEasy accessGrinding drivesPortable grinding machinesGear wheelEngineering

Owner:NAT FLOORING EQUIP INC

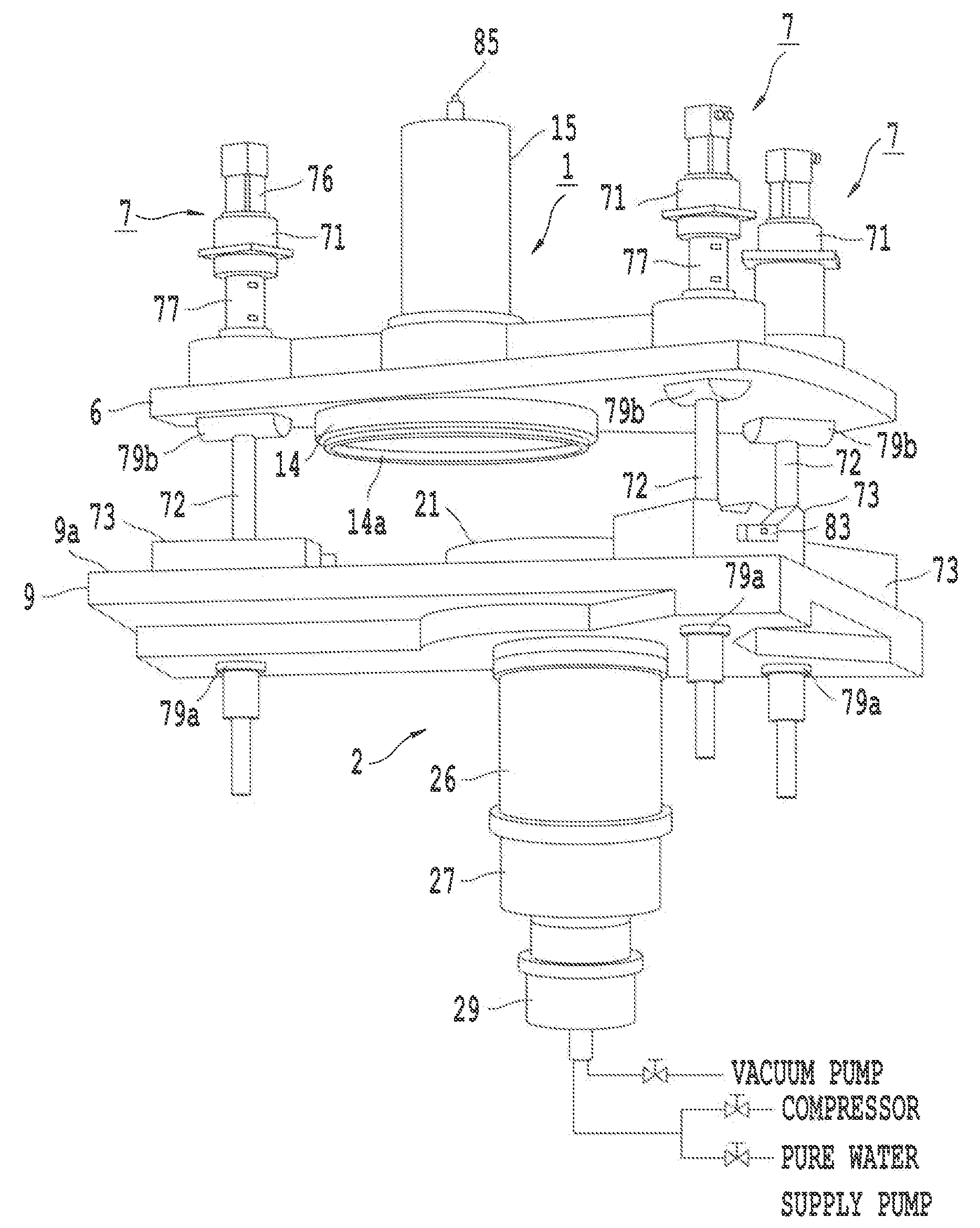

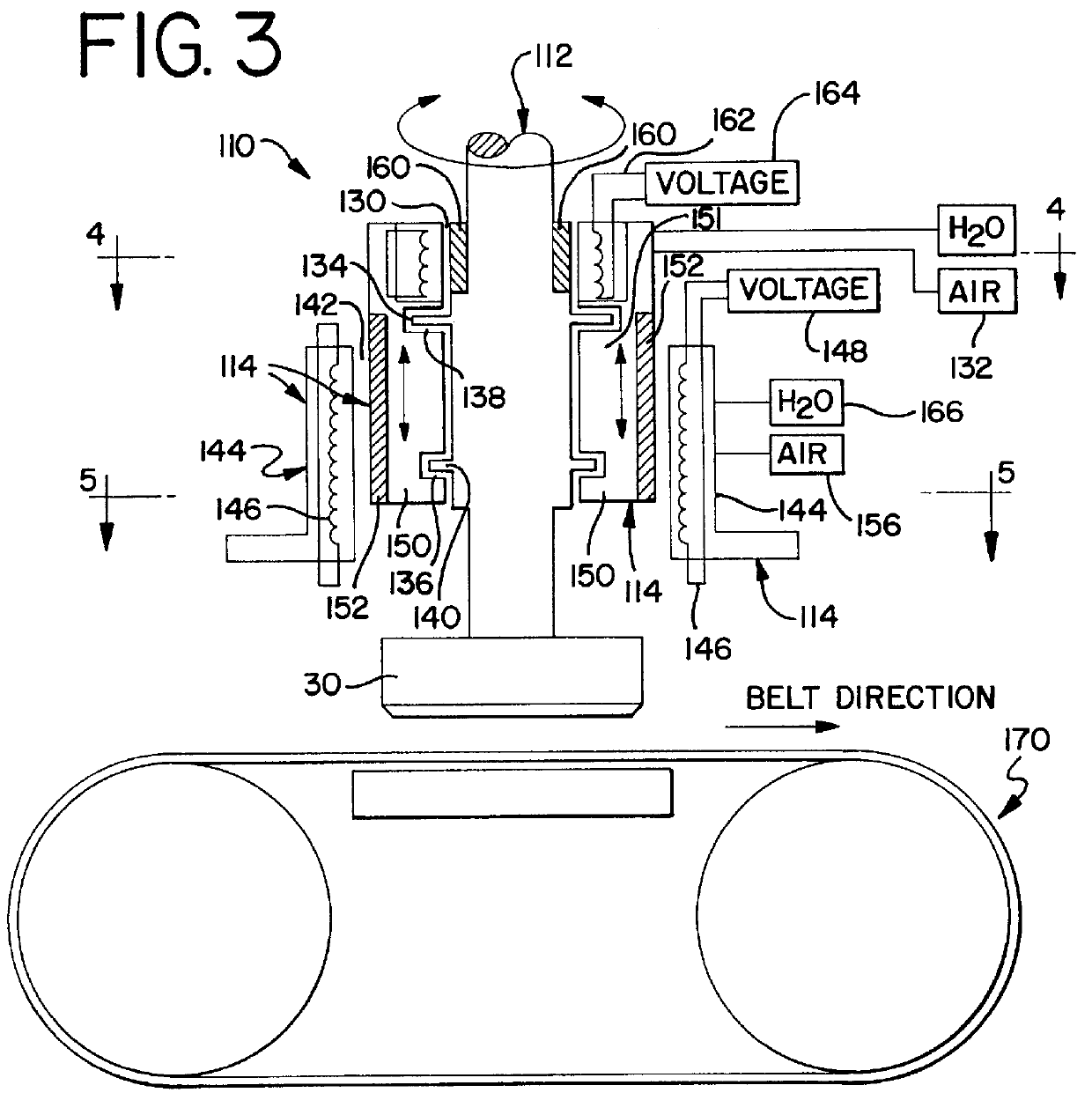

Methods and apparatuses for surface finishing cured concrete

InactiveUS20070292207A1Edge grinding machinesSpherical surface grinding machinesSurface finishCivil engineering

A method and apparatus for finishing cured concrete floors using a riding trowel to which large diameter pans are attached having a balanced distribution of abraders releasably secured to the undersides of the pans. The individual abraders are preferably individually spring biased so as to maintain full contact with the floor when traversing undulations of the floor.

Owner:NEXSEN PRUET

Polishing pads and methods relating thereto

InactiveUS6682402B1Improved flow of polishing fluidEffectively and efficiently performDecorative surface effectsBelt grinding machinesEngineeringTopography

This invention describes improved polishing pads useful in the manufacture of semiconductor devices or the like. The pads of the present invention have an advantageous hydrofoil polishing material and have an innovative surface topography and texture which generally improves predictability and polishing performance.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

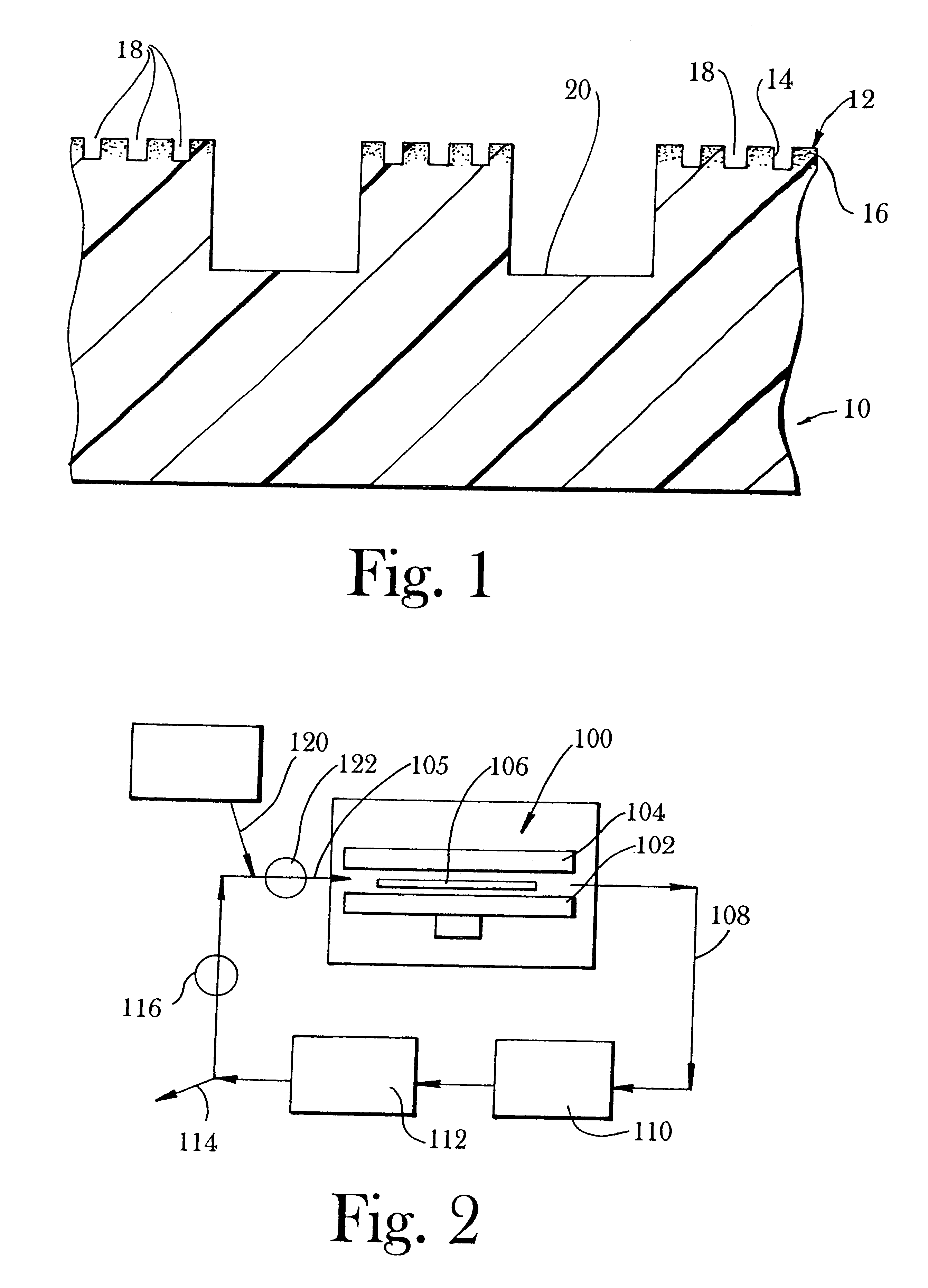

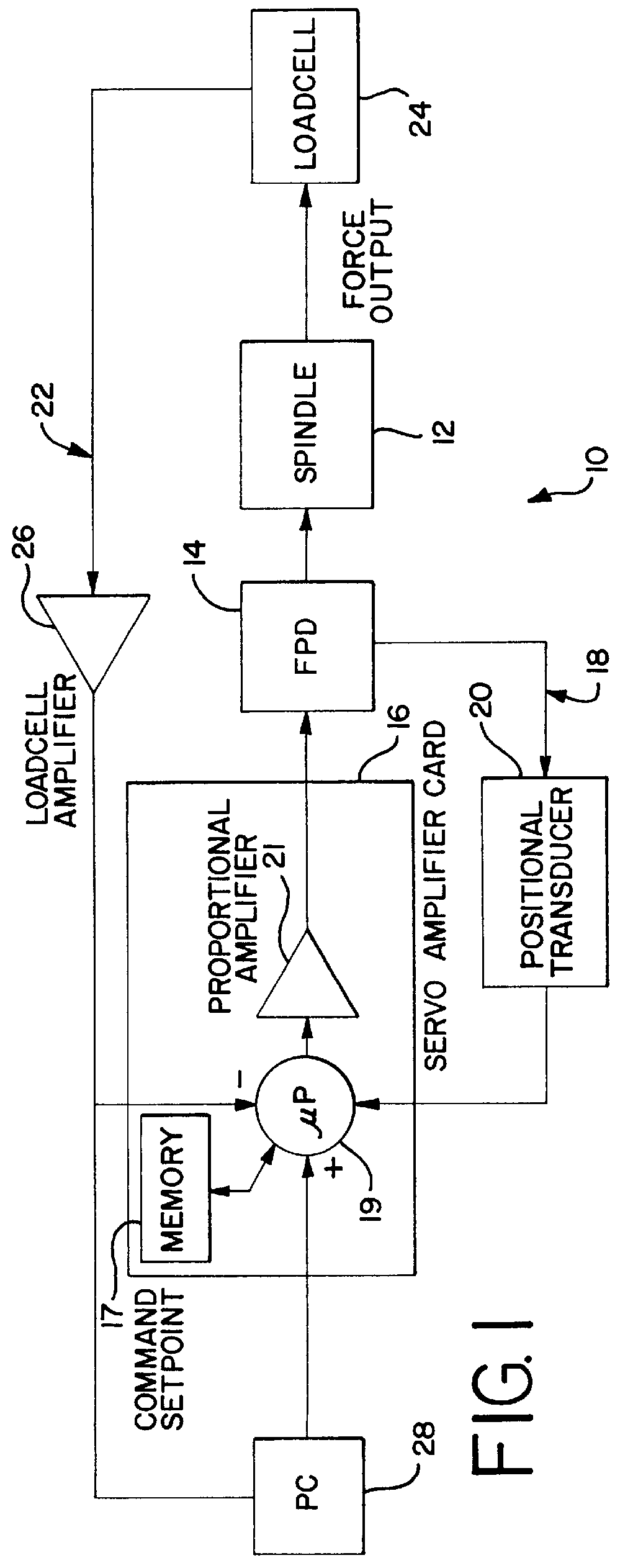

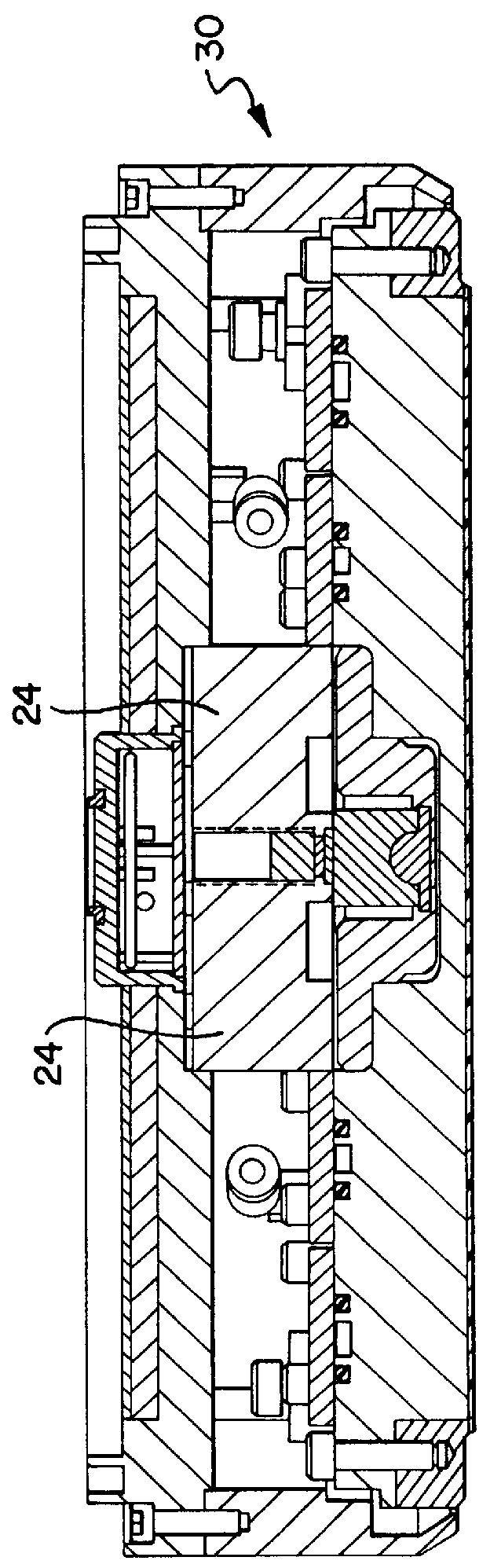

Spindle assembly for force controlled polishing

InactiveUS6083082AReduce frictionHigh polishing precisionSemiconductor/solid-state device manufacturingLapping machinesLoop controlOperation mode

A spindle assembly for force controlled operation in applications such as the chemical mechanical planarization of semiconductor wafers includes an axially and rotatably movable spindle driven by a force producing device. The force producing device is controlled by a position feedback loop in a first mode of operation and a spindle force control feedback loop in a second mode of operation so that the same force producing device controls spindle movement in the first mode of operation and maintains a constant pressure on a workpiece based on the detected applied pressure in the second mode of operation.

Owner:APPLIED MATERIALS INC

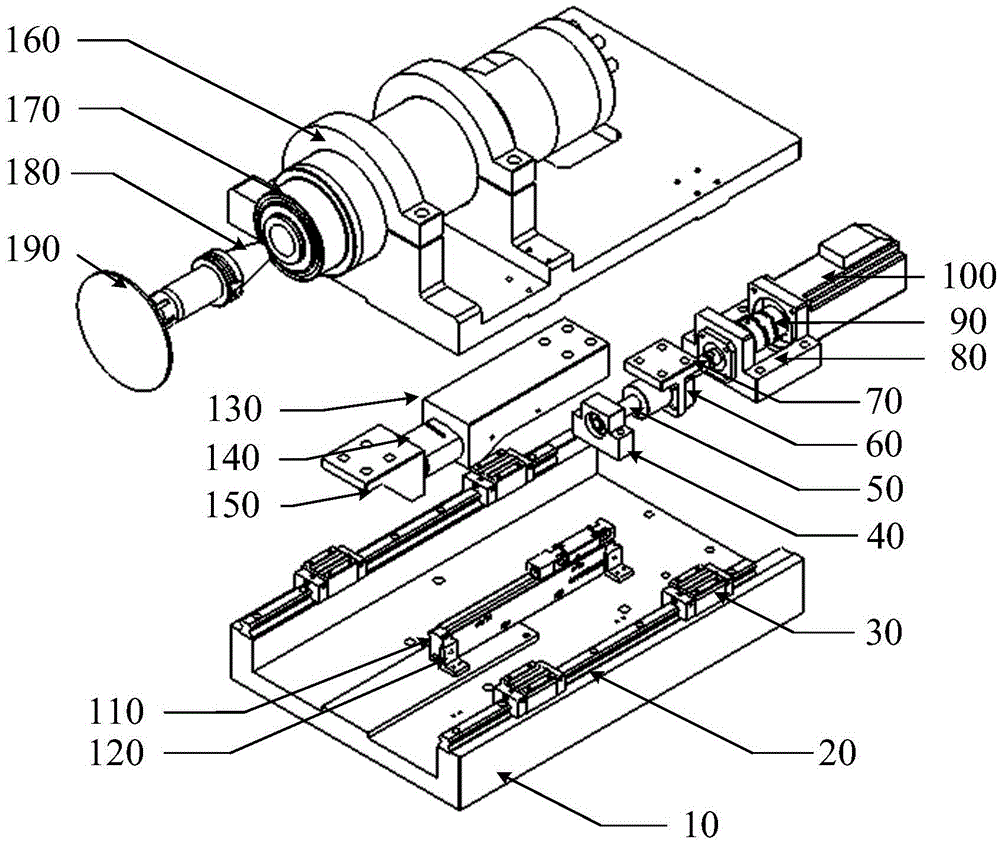

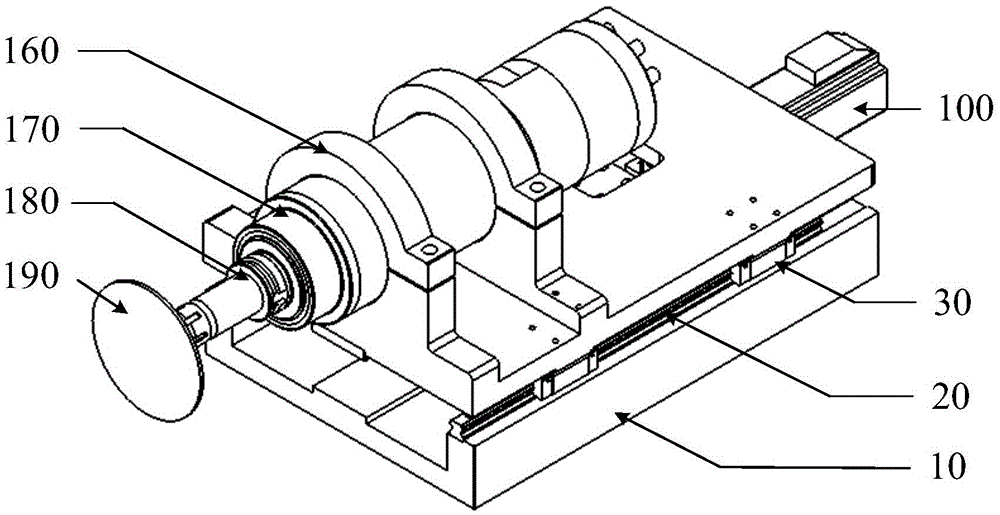

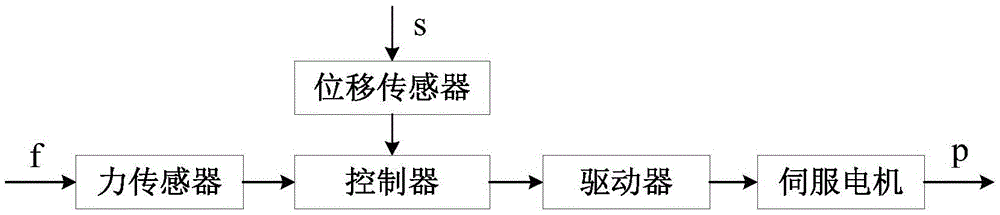

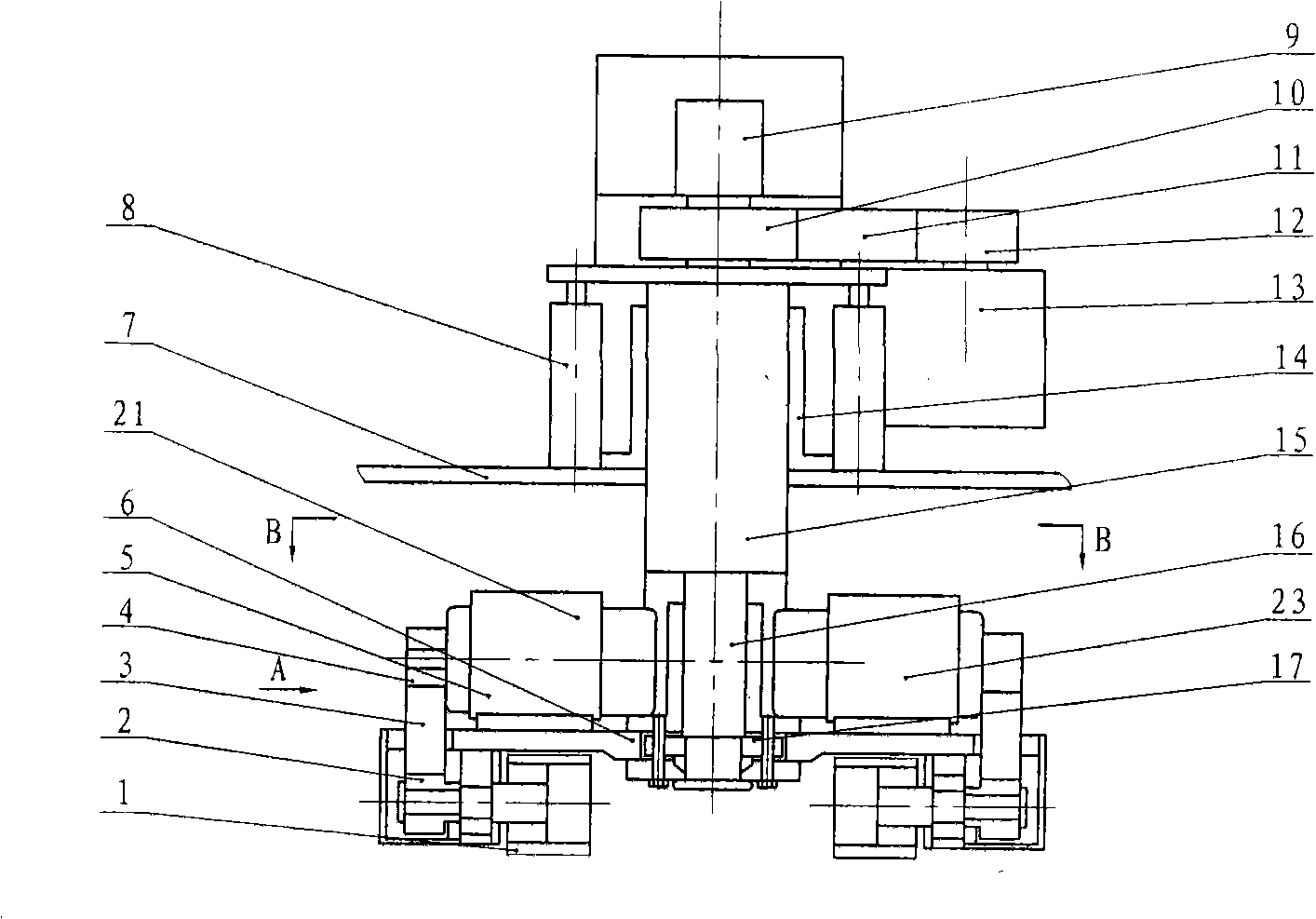

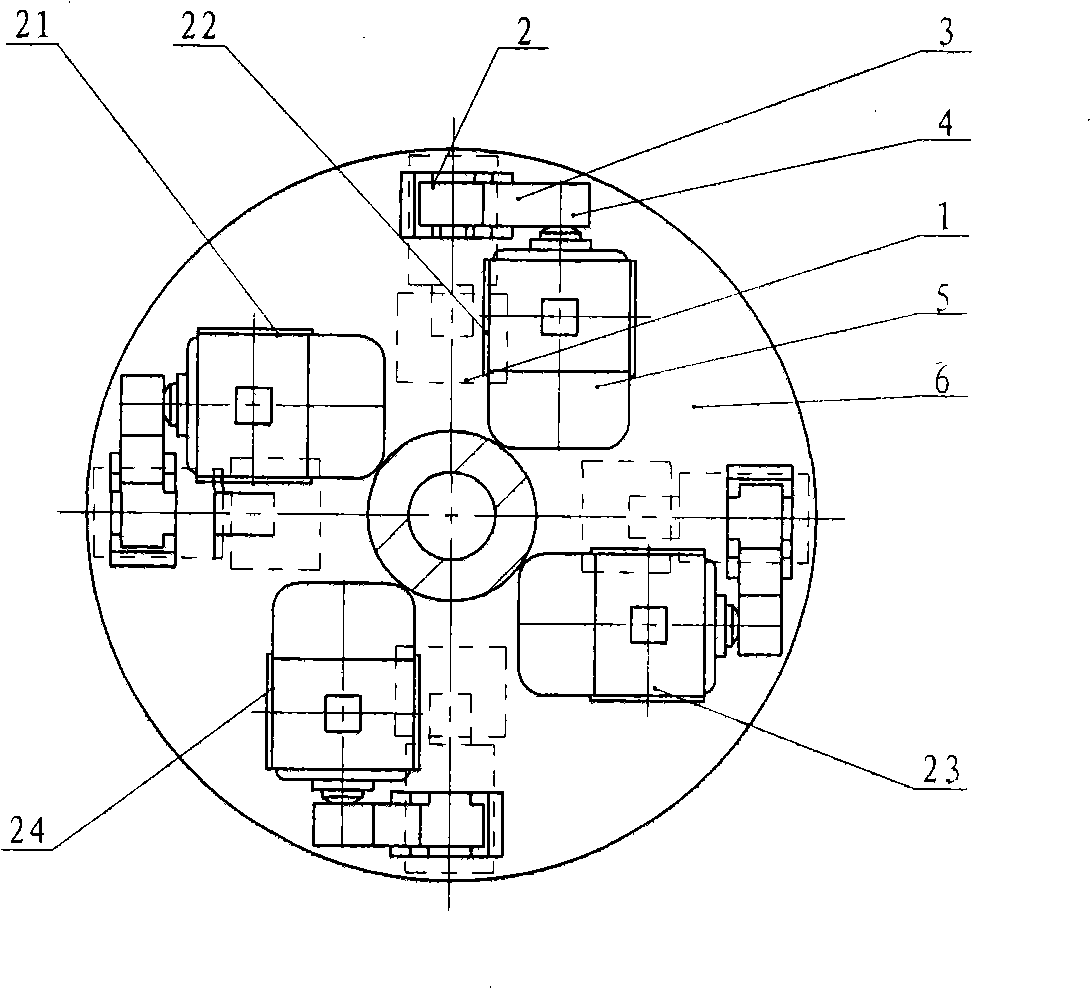

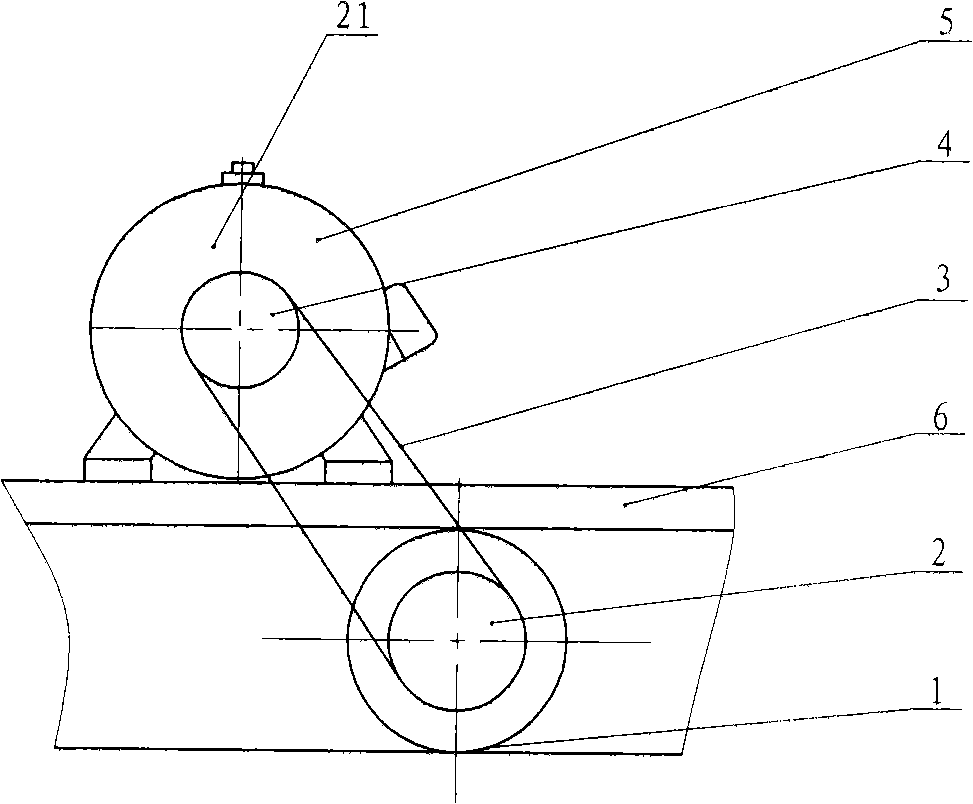

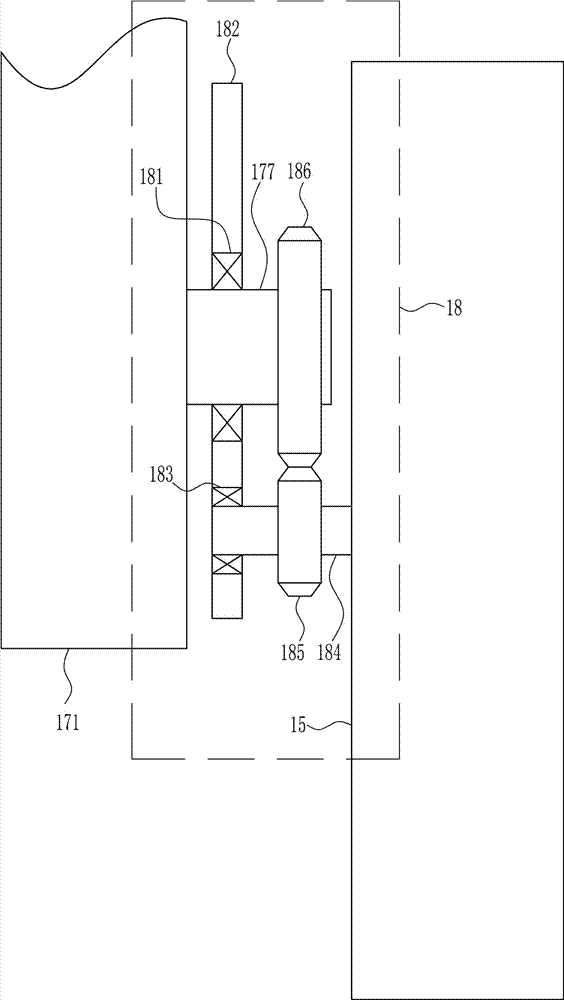

Active compliance end effector for controllable-pitch propeller robot grindingand control method of active compliance end effector

ActiveCN105563309AWith automatic replacementHigh control precisionAutomatic grinding controlGrinding headsEngineeringAlternating current

The invention discloses an active compliance end effector for controllable-pitch propeller robotgrinding and a control method. The active compliance end effector comprises a grinding tool, a BT30 knife handle, a grinding electric spindle, brackets for fixing the grinding electric spindle, a force sensor for detecting a normal grinding force, a support for mounting the force sensor, a displacement sensor for detecting deviation of an end position, a support for fixing the displacement sensor, a ball screw for providing axial movement degree of freedom and transmitting torque, a bearing block for supporting and fixing the ball screw, a ball screw nut, a ball screw nut support, an alternating-current servo motor, a flange support, a coupler, linear guide tracks, sliders, a bottom supporting plate and a control system, wherein the servo motor is connected with the ball screw through the flange support and the coupler; and the control system is used for driving the servo motor. The active compliance end effector has the advantages of simple structure, convenience in assembly, high control precision and high response speed; and meanwhile, the grinding tool can be changed automatically.

Owner:HUAZHONG UNIV OF SCI & TECH

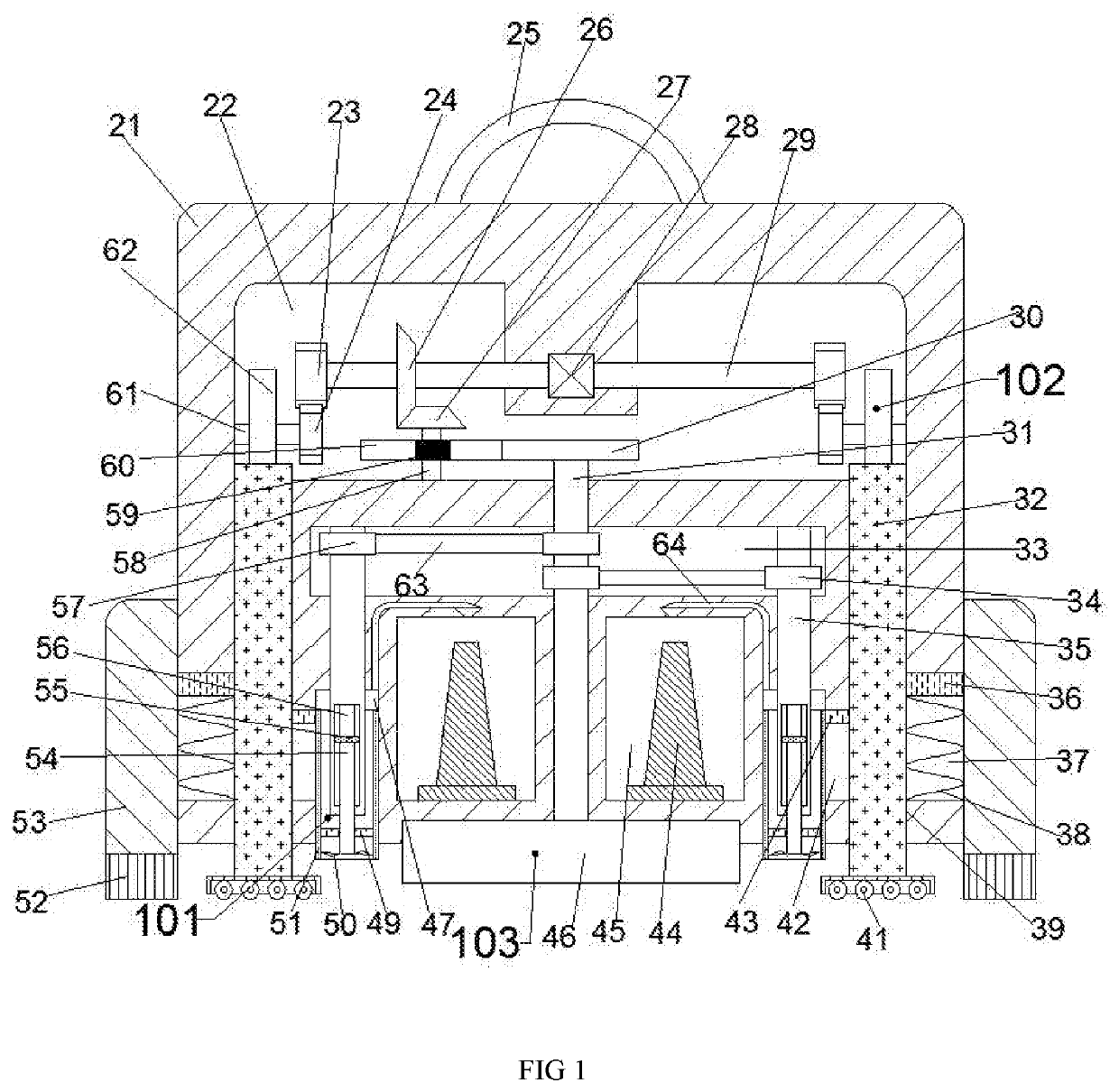

High-efficient stable polishing-grinding apparatus

InactiveCN101327568ASimple structureThe transmission form is simpleGrinding drivesGrinding headsFailure rateMotor drive

The present invention discloses a high-efficiency, stable polishing and grinding device, the transmission system and the lubricating system of which are characterized by simplicity, reliability, convenient maintenance and low failure rate. The polishing and grinding device is composed of a turnplate-revolving mechanism, a turnplate-lifting mechanism and multiple groups of high-speed rotating grinding mechanisms mounted on a turnplate; wherein, each high-speed rotating grinding mechanism is composed of a roller type grinding head, a grinding head motor and driving mechanisms thereof; the roller type grinding head is mounted on the lower side of the turnplate; the grinding head motor is mounted on the upper side of the turnplate; through a group of driving mechanisms, the grinding head motor drives the roller type grinding head to rotate at a high speed. The polishing and grinding device is mainly applied to the polishing and grinding of the surfaces of flat building materials such as polished ceramic tiles and stones.

Owner:佛山市科利得机械有限公司

Quick polishing equipment for steel pipe surfaces for industry

ActiveCN106863102AImprove polishing qualityQuality improvementGrinding carriagesPolishing machinesSteel tubeBolt connection

The invention relates to polishing equipment for steel pipe surfaces, and particularly relates to quick polishing equipment for steel pipe surfaces for industry. The invention aims to provide the quick polishing equipment for the steel pipe surfaces for the industry, which has the advantages of high polishing quality, less polishing risk, time saving and labor saving in polishing. In order to solve the technical problem, the invention provides the quick polishing equipment for the steel pipe surfaces for the industry. The quick polishing equipment comprises a bottom plate, a first sliding rail, a first sliding block, a movable plate, a fixed plate, a first bearing seat, a rotary rod, a fixed block, a cranking bar, a guide rail and a movable block, wherein the first sliding rail is installed in the left side of the bottom plate in a bolt connecting mode, the first sliding block is connected to the interior of the first sliding rail in a sliding mode, the movable plate is installed on the upper end of the first sliding block in a welding mode, and the fixed plate is installed on the upper right part of the bottom plate in a welding mode. The quick polishing equipment has the effects of high polishing quality, less polishing risk, time saving and labor saving in polishing.

Owner:新昌县承慧机电设备有限公司

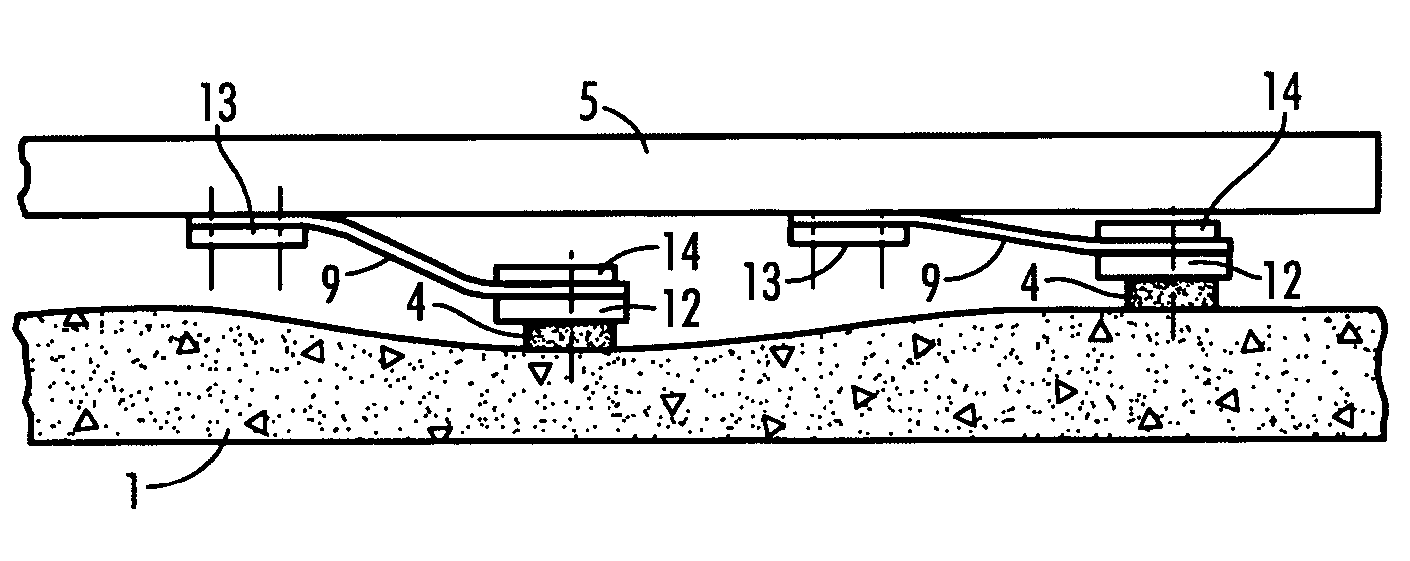

Apparatus and method for surface finishing cured concrete

InactiveUS20090190999A1Easy to installAvoid formingIn situ pavingsBuilding constructionsSurface finishFastener

A method and apparatus for finishing cured concrete floors using a riding trowel to which large diameter pans are rotationally secured, the pans having abraders releasably secured to their undersides. The individual abraders are preferably individually removably secured to the pans by hook-and-loop fasteners, wherein the fasteners are selectively disposed on the flat bottom surfaces of the pans or within shallow depressions in the bottom surfaces of the pans. The riding trowel further comprises a vacuum system in fluid communication with a contained space formed by a shroud having a rigid upper portion and a flexible lower portion where it contacts the finished cured concrete floor surface.

Owner:COPOULOS PAUL

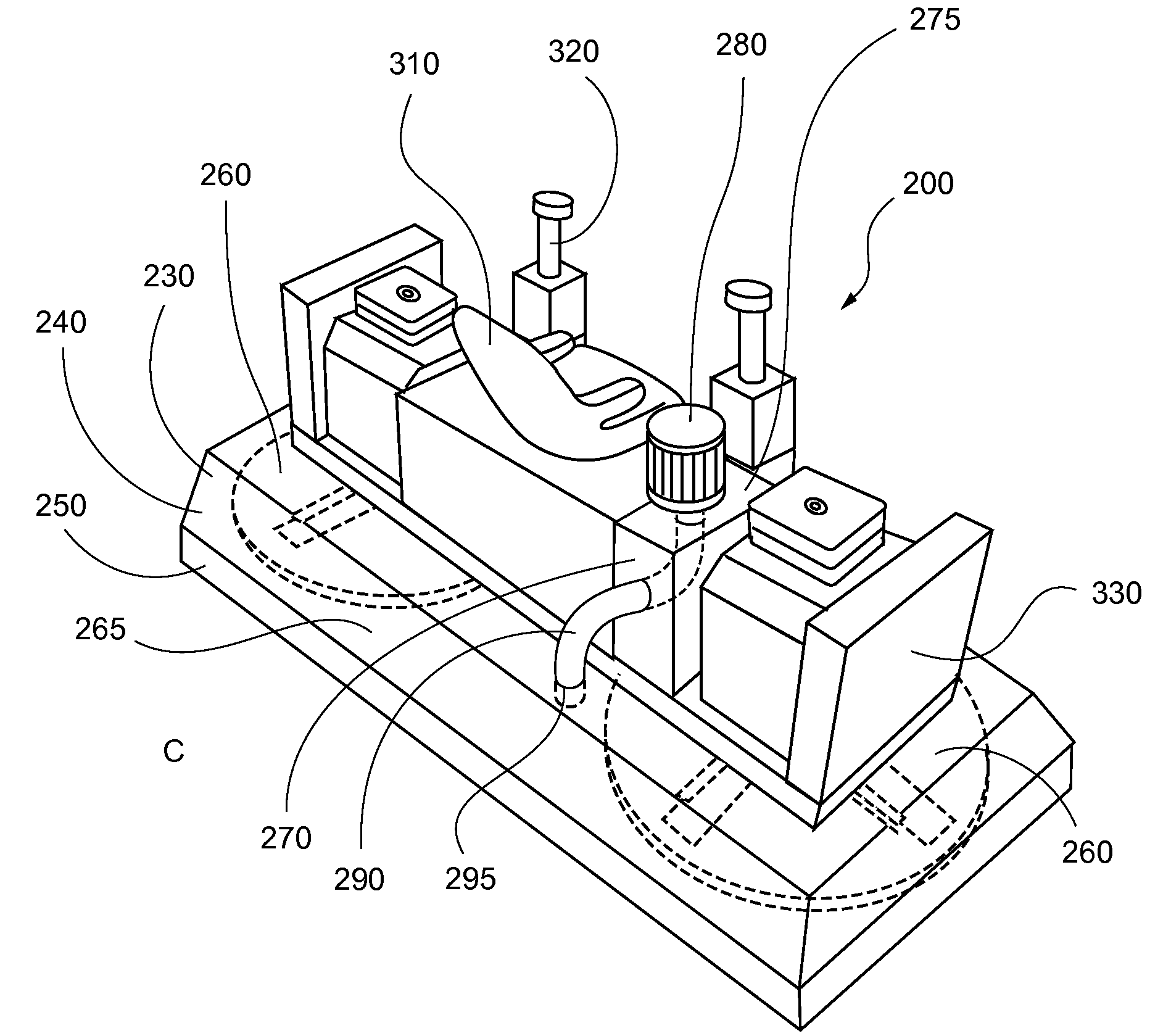

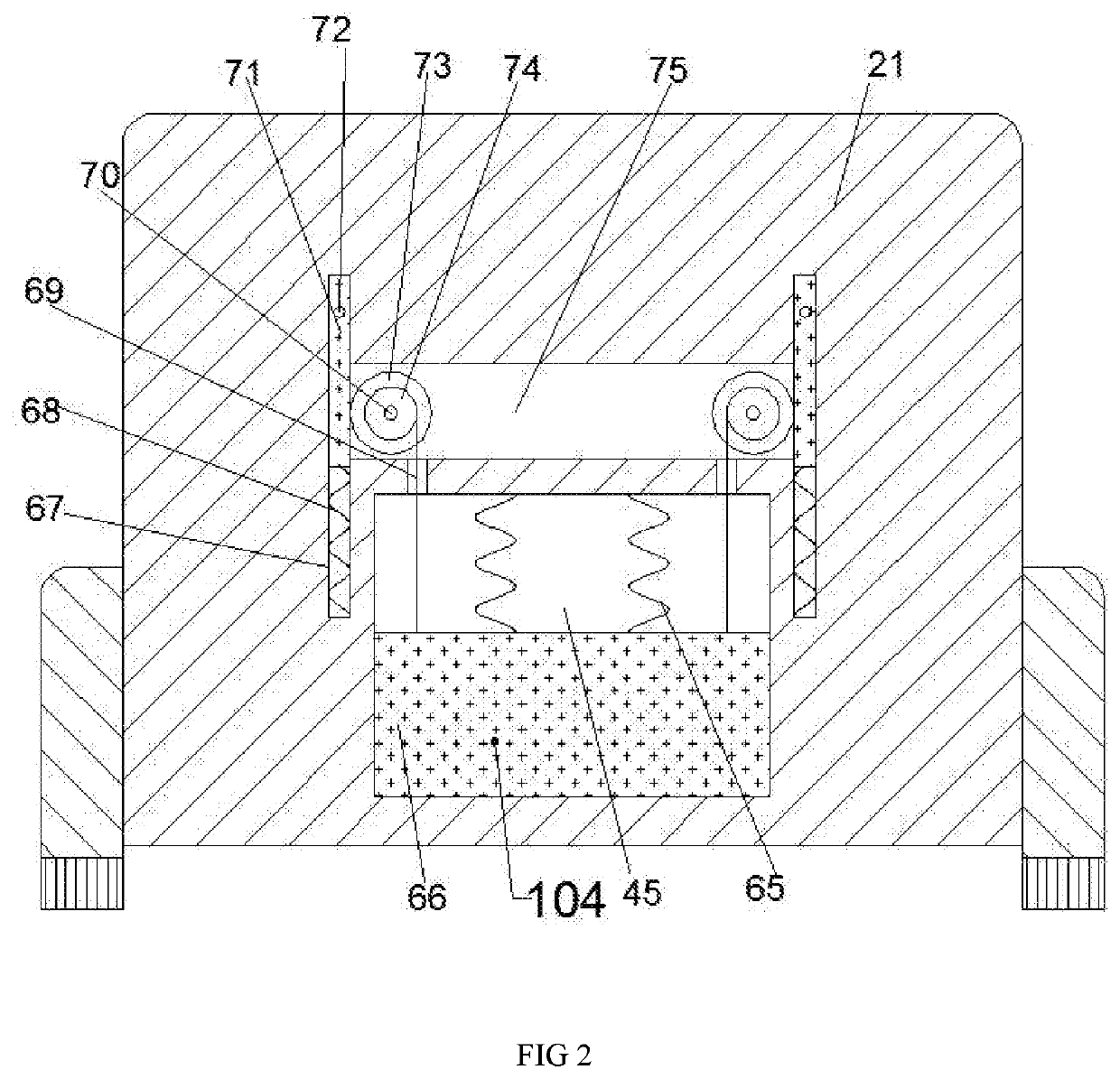

Stone wall grinding and polishing system

A system, apparatus and method capable of grinding and polishing fabricated vertical surfaces of varying shapes and sizes without the use of hand tools. The system comprises a frame which can be affixed to the surface and which supports a grinding and polishing apparatus. The grinding and polishing apparatus uses air pressure to force a rotating grinding or polishing disc against the surface being worked on. The frame is designed so that the grinding and polishing apparatus can be moved (via, e.g., tracking) both vertically and horizontally to any desired point within the frame. The grinding and polishing apparatus optionally includes a water nozzle and vacuum system to spray and recapture water used to cool the surface being operated on.

Owner:PERMASTEELISA NORTH AMERICA

Grinding wheel

InactiveUS7506644B2Highly economicalSimple manufacturing processBonded abrasive wheelsGrinding headsGrinding wheelElectrical and Electronics engineering

A grinding wheel has a disc having a connection hole formed at a center thereof, to which a rotation axis of a grinder is connected, and a plurality of abrasive segments detachably connected to a surface of the disc. A plurality of fixing recesses are radially formed on the surface of the disc at an interval and fixing protrusions having a shape corresponding to the fixing recess are formed on bottom surfaces of the abrasive segments, so that the abrasive segments are connected to the disc by inserting the fixing protrusions into the fixing recesses. According to the grinding wheel, when the abrasive segment is worn away or inferior as it is used for a long time, it has only to replace the corresponding abrasive segment only. Accordingly, an economical efficiency is high.

Owner:PARK RIN SOON

Surface Grinding Machine and Grinding Head Therefor

InactiveUS20100190421A1Edge grinding machinesRevolution surface grinding machinesEngineeringSurface grinding

A surface grinding machine generally consisting of a drive means provided with an output shaft; a planetary disk mounted on the shaft; and at least two grinding head units mounted on the planetary disk, each including a housing mounted on the planetary disk, a shaft having a flange portion, journaled in the unit housing, resilient means interposed between the housing and the flange portion of the unit shaft and a disk provided with a grit surface disposed on an outer side of the flange, portion of the unit shaft.

Owner:AMANO PIONEER ECLIPSE CORP

Environmentally-friendly abrasive grinding tool for grinding stones

InactiveUS20200122293A1Promote sportsImprove applicabilityGrinding drivesGrinding headsDrive wheelDust control

The invention discloses an environmentally-friendly abrasive dusting tool for grinding stones, comprising a machine body, wherein the machine body is provided with a dust removal cavity, and the left and right sides of the dust removal cavity are provided with sliding sleeve grooves symmetrically. The top wall of the sleeve is provided with a ventilation duct communicating with the dust removal chamber. The motor is first turned on in the opposite direction, so that the motor shaft and the main driving wheel are reversed, which drives the horizontal axis and cam to rotate. Compared with the transmission grinding tool, the device collects dust through a fan during the grinding process, which prevents the dust generated by the grinding from causing personal injury to the grinding personnel. At the same time, the device can automatically adjust the grinding height, so that it can adjust the polished stone to have different smoothness.

Owner:YANG CUIFANG

Polishing pads and methods relating thereto

InactiveUS6425816B1Speed up the flowFacilitate smoothing and planarizingPolishing machinesRevolution surface grinding machinesThermoformingEngineering

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Surface grinding machine and grinding head therefor

A surface grinding machine generally consisting of a drive means provided with an output shaft; a planetary disk mounted on the shaft; and at least two grinding head units mounted on the planetary disk, each including a housing mounted on the planetary disk, a shaft having a flange portion, journaled in the unit housing, resilient means interposed between the housing and the flange portion of the unit shaft and a disk provided with a grit surface disposed on an outer side of the flange portion of the unit shaft.

Owner:AMANO PIONEER ECLIPSE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com